Page 1

Page 2

CPFAFD®

Foreword

Automatic

INSTRUCTIONS

262-261

dream

Your

You

ore

now

machine

The

An

exclusive

at

This

Even

Follow

sewing exciting

If

any

instruction

if

you

you

these

have

time.

are

any

has

the

you

feature

book

an

simple

on

sewing

true!

come

proud

have

chosen

will

experienced

instructions

your

problems,

owner

of

easy-to-operate

help

has

Pfaff

you

a

of

a

sewing

understand

seamstress,

and

please

Pfaff 262-261

built-in

vibrator

machines,

you

familiarize

Pfaff-Automatic.

contact

Automatic

machine

the

will

yourself

your

which

the

find this

with

Pfaff

--

the

enables

Stopmatic

and

give

book

the

dealer.

sewing

you

you

valuable

a

exclusive

He will

machine

to

darn

ensures

valuable

automatic

be

guide

glad

with

without

that

tips

to

unlimited

hoops.

your

to

easy

to

features

help

possibilities.

machine

make

sewing

sewing--Pfaff-Automatic

of

your

you

at

any

Karisruhe-Durlach

is

more

machine.

time.

G.

M.

ready

fun

PFAFF

for sewing

for

you.

will

You

AG

Branch

Sewing.

find

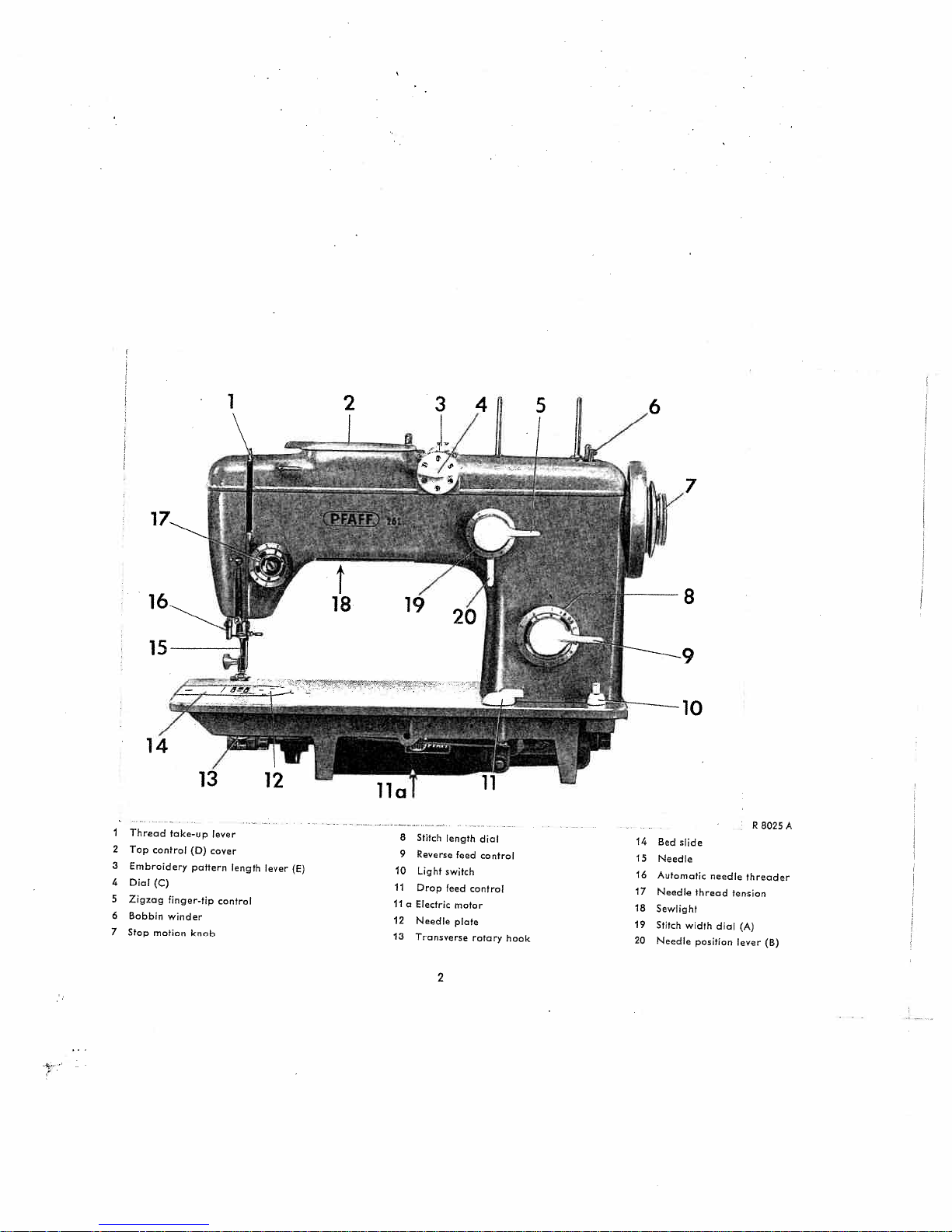

Page 3

Thread

I

2

Top

3

Embroidery

4

Dial

5

Zigzag

6

Bobbin

7

Stop

control

(C)

finger-tip

winder

motion

take-up

(D)

pattern

knob

lever

cover

control

length

lever

(E)

8

9

10

11

11

12

13

Stitch

Reverse

Light

Drop

o

Electric

Needle

Tronuverse

length

feed

switch

feed

motor

plofe

dial

control

control

rotory

hook

rz

6

14

15

16

17

18

19

20

Bed

slide

Needle

Automatic

Needle

Sewlight

Stitch

width

Needle

needle

thread

dial

position

threader

tension

(A)

lever

R

8025

A

(B)

2

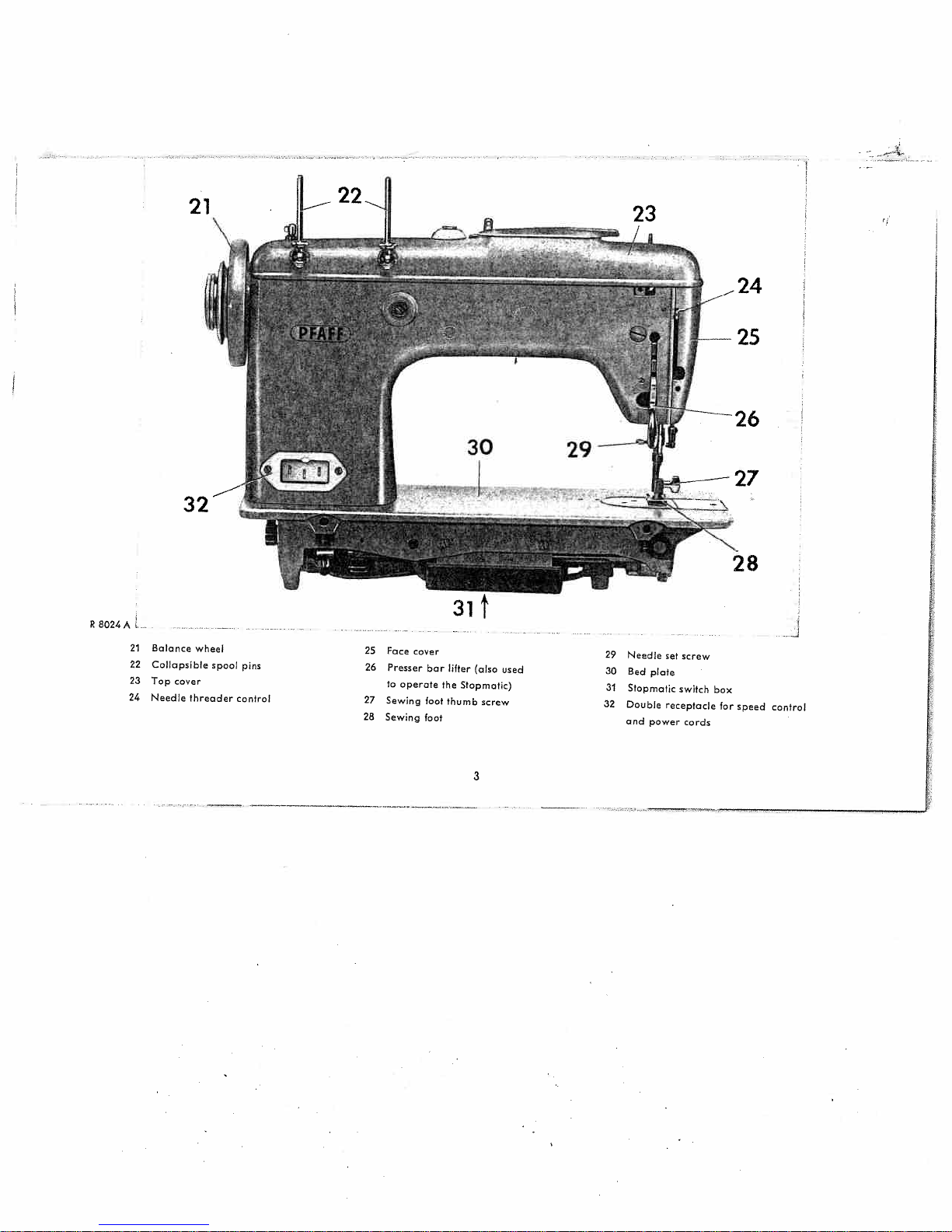

Page 4

R

8024

A

21

22

23

24

Balance

Collapsible

Top

cover

Needle

wheel

threader

spool

pins

control

25

Face

cover

26

Presser

bar

lifter

(also

to

operate

27

Sewing

28

Sewing

fool

foot

the

thumb

used

Stopmatic)

screw

29

30

31

32

Needle

Bed

plate

Stopmatic

Double

and

power

set

screw

switch

receptacle

cords

box

for

speed

control

3

Page 5

688

DR

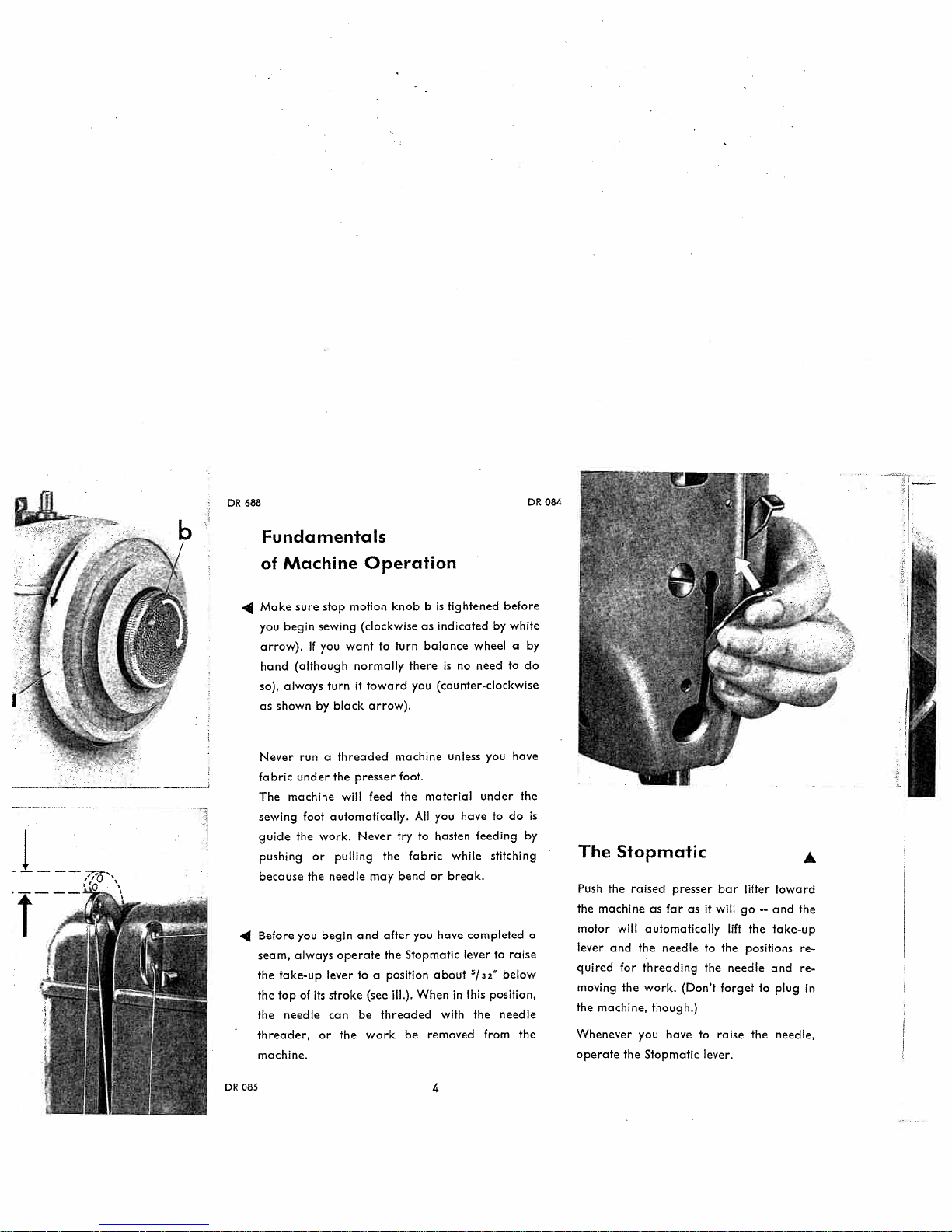

Fundamentals

of

Machine

Operation

DR

.

084

‘I,

I

Make

begin sewing

you

arrow).

hand

so),

alwoys

as

shown

Never

fabric

The

sewing

guide

pushing

because

Before

seam,

take-up

the

the

top

the

needle

threader,

machine.

sure

If

you

(although

by

run

under

machine

foot

the work.

or

the

you

always

its

of

or

motion

stop

(clockwise

want

to

normally

turnittoward

black

arrow).

a

threaded

presser

the

will

feed

automatically.

Never

pulling

may

needle

and

begin

operate

a

lever

to

stroke

(see

be

can

the

work

knob

turn

thereisno

machine

foot.

the

try

the

fabric

bend

after

the

Stopmatic

position

ill.).

threaded

be

is

tightened

b

indicated

as

balance

(counier.clockwise

you

unless

material

All

you

have

to

hasten

while

break.

or

have

about

in

with

removed

completed

levertoraise

this

you

When

wheel

need

you

under

feeding

5/35

the

from

before

white

by

a

to

have

the

todois

stitching

below

position,

needle

the

by

do

by

Stopmcttic

The

the

Push

the

machine

will

a

motor

lever

and

quired

moving

the

machine,

Whenever

operate

for

the

the

raised

far

as

automatically

the

needle

threading

work.

though.)

you

have

Stopmatic

presser

asitwill

(Don’t

to

the

to

lever.

bar

lift

the

needle

forget

raise

lifter

go--and

the

positions

the

take-up

and

to

toward

plug

needle,

A

the

re

re

in

DR

085

4

Page 6

DR

735

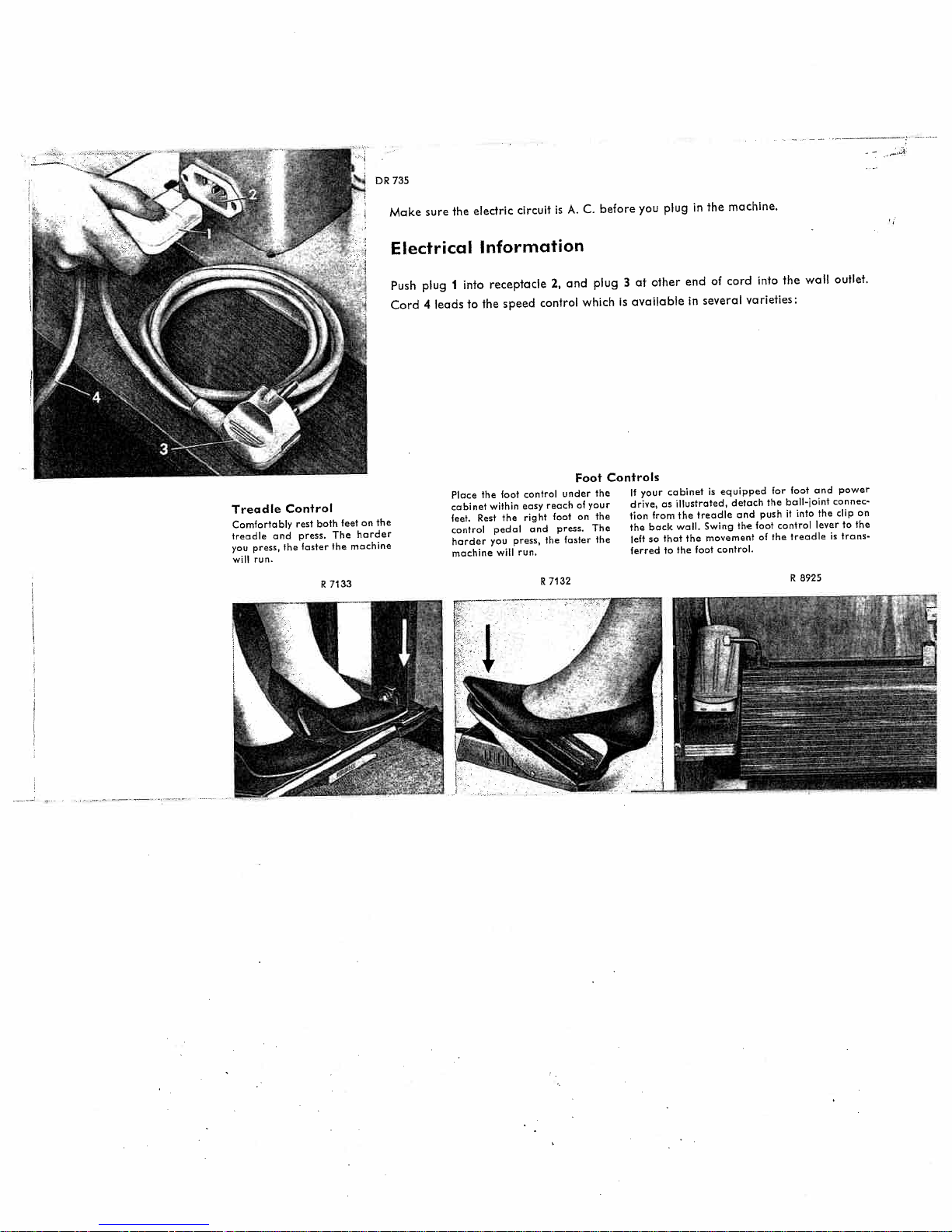

Make

sure

the

electric

circuit

machine.

the

in

plug

you

before

C.

A.

is

Treadle

Comfortably

treadle

press,

you

rue.

will

and

the

Control

rest

press.

foster

both

R

The

the

7133

feet

machine

on

harder

the

Electrical

plug

Push

leads

4

Cord

Information

receptacle

I

into

the

to

the

Place

within

cabinet

Rest

feet.

pedal

control

you

harder

machine

speed

foot

the

wilt

control

easy

right

press,

run.

control

and

R

2,

reach

the

7132

foot

press.

and

under

laster

which

Foot

of

on

plug

the

your

the

The

the

at

3

available

is

Controls

If

drive,

tion

the

left

ferred

your

other

from

bock

so

cabinet

illustrated,

as

the

wall.

that

the

to

end

in

the

foot

of

several

is

treadle

Swing

movement

control.

cord

varieties:

equipped

detach

and

the

into

push

foot

of

the

for

the

the

foot

ball-joint

it

control

treadle

R

into

8925

wall

and

the

lever

outlet.

power

connec

clip

to

trans

is

the

on

Page 7

R

8007

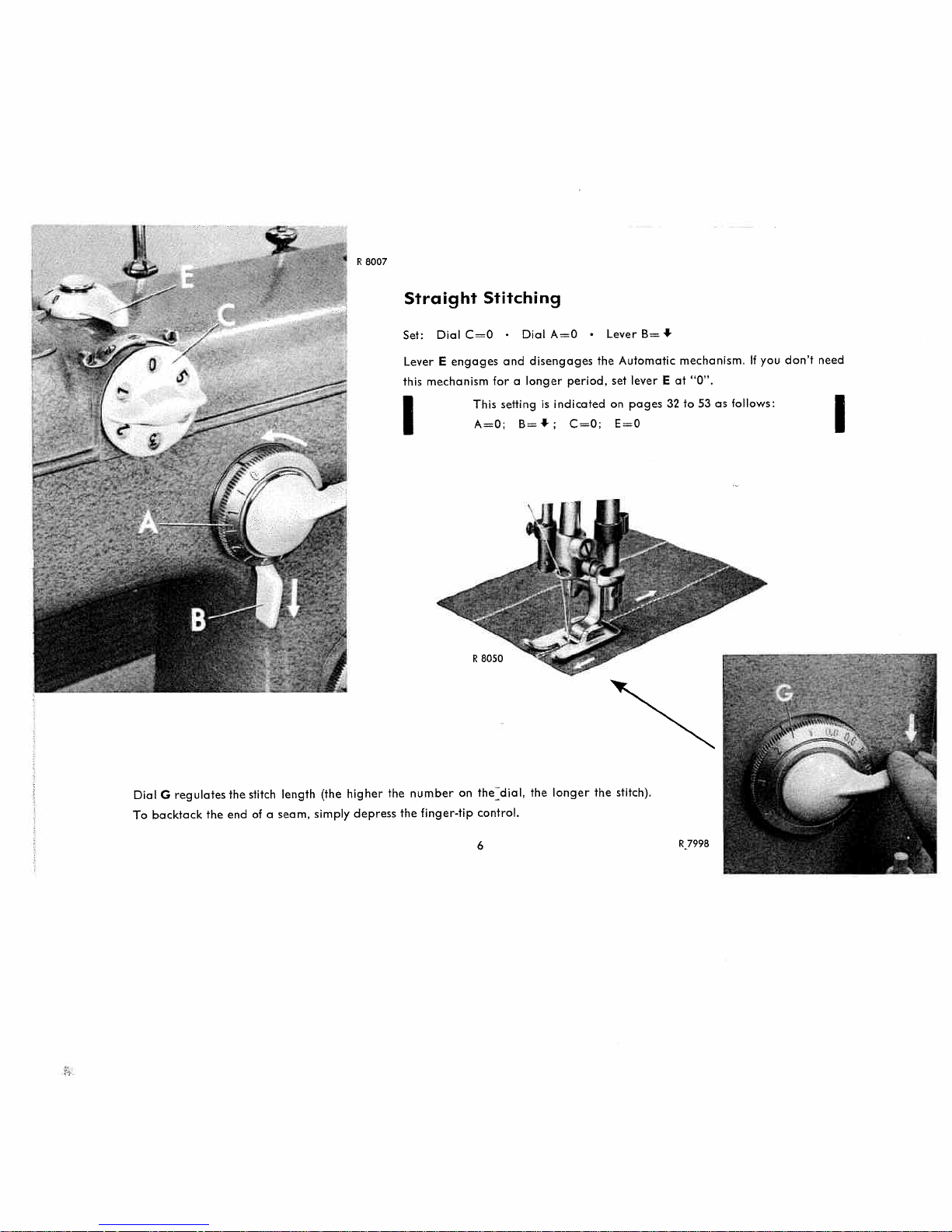

Straight

Dial

Set:

E

Lever

this

mechanism

I

C=O

engages

This

A=0;

Stitching

Dial

disengages

and

for

a

longer

setting

B=4;

w

11

A=O

is

indicated

period,

C=0;

•

Lever

the

on

Automatic

lever

set

pages

E=0

B=

I

mechanism.

Eat“0”.

to

32

need

don’t

you

If

follows:

as

53

I

regulates

Dial

0

backtack

To

the

the end

simply

seam,

of

a

length

stitch

(the

higher

depress

the

the

number

finger-tip

on

thedial,

control.

6

the

longer

the

stitch).

R7998

Page 8

R

7999

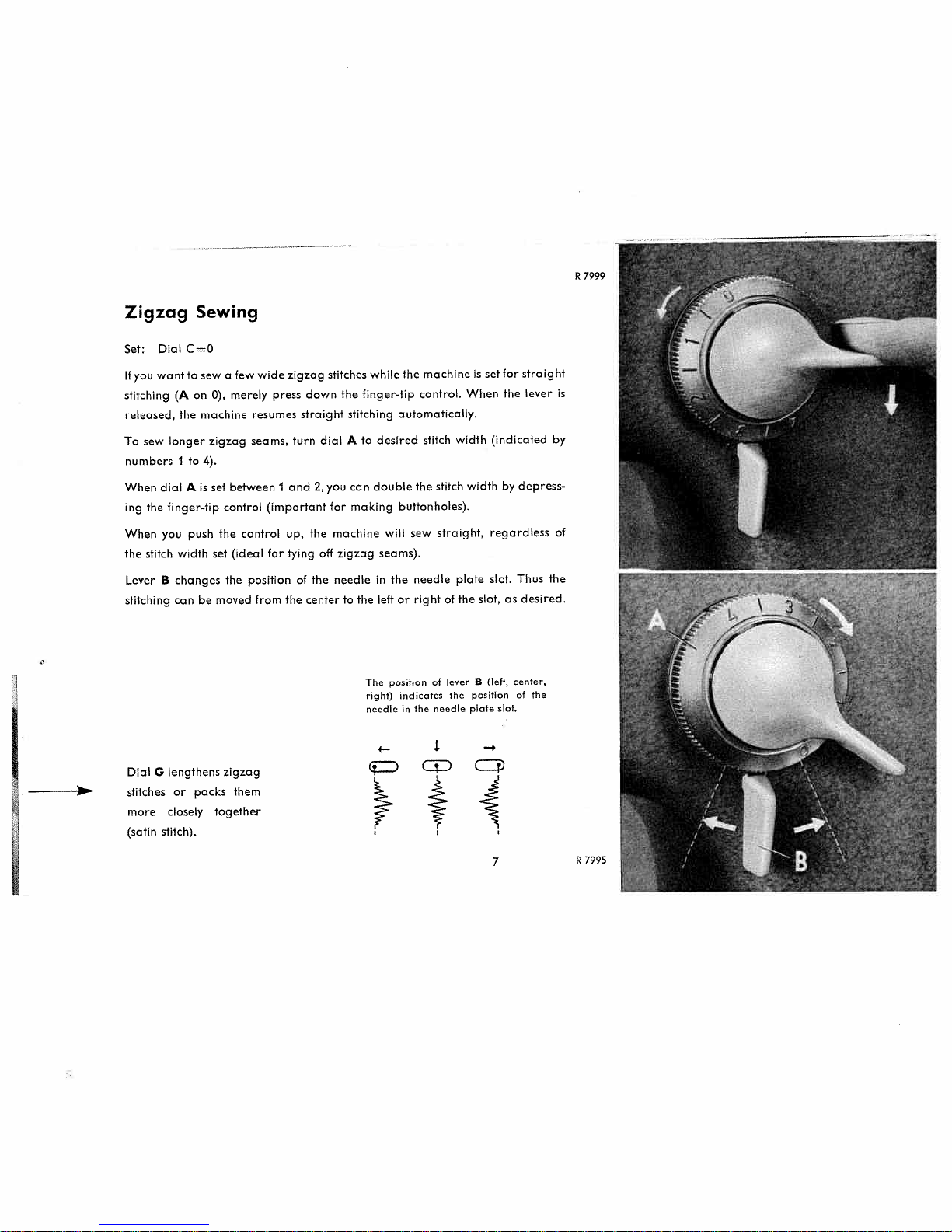

Zigzag

Dial

Set:

want

you

If

stitching

released,

To sew

numbers

When

dial

the

ing

When

you

the

stitch

B

Lever

stitching

G

Dial

stitches

more

stitch).

(satin

Sewing

C=O

to

(Aon0),

the

longer

I

to

Aisset

finger-tip

push

width

changes

can

lengthens

or

packs

closely

sew

mochine

zigzag

4).

the

set

moved

be

zigzag

together

a

few

wide

merely

resumes

seams,

between

(important

control

control

for

(ideal

the position

from

them

zigzag

press down

straight

turn

I

and

2,

the

up,

tying

the

of

the

center

stitches

dial

you

for

machine

off

the

stitching

A

can

making

zigzag

needle

to

while

finger-tip

to

desired

double

seams).

in

left

the

The

right)

needle

4-

machine

the

control.

automatically.

stitch

the

buttonholes).

will

sew

needle

the

right

or

position

indicotes

in

the

cD

When

width

widthbydepress

stitch

straight,

plate

of

the

lever

of

the

plote

needle

is

set

(indicated

regardless

slot.

slot,

(left,

B

position

-+

cEP

7

for

slot.

the

as

straight

lever

Thus

desired.

center,

of

is

by

of

the

the

R7995

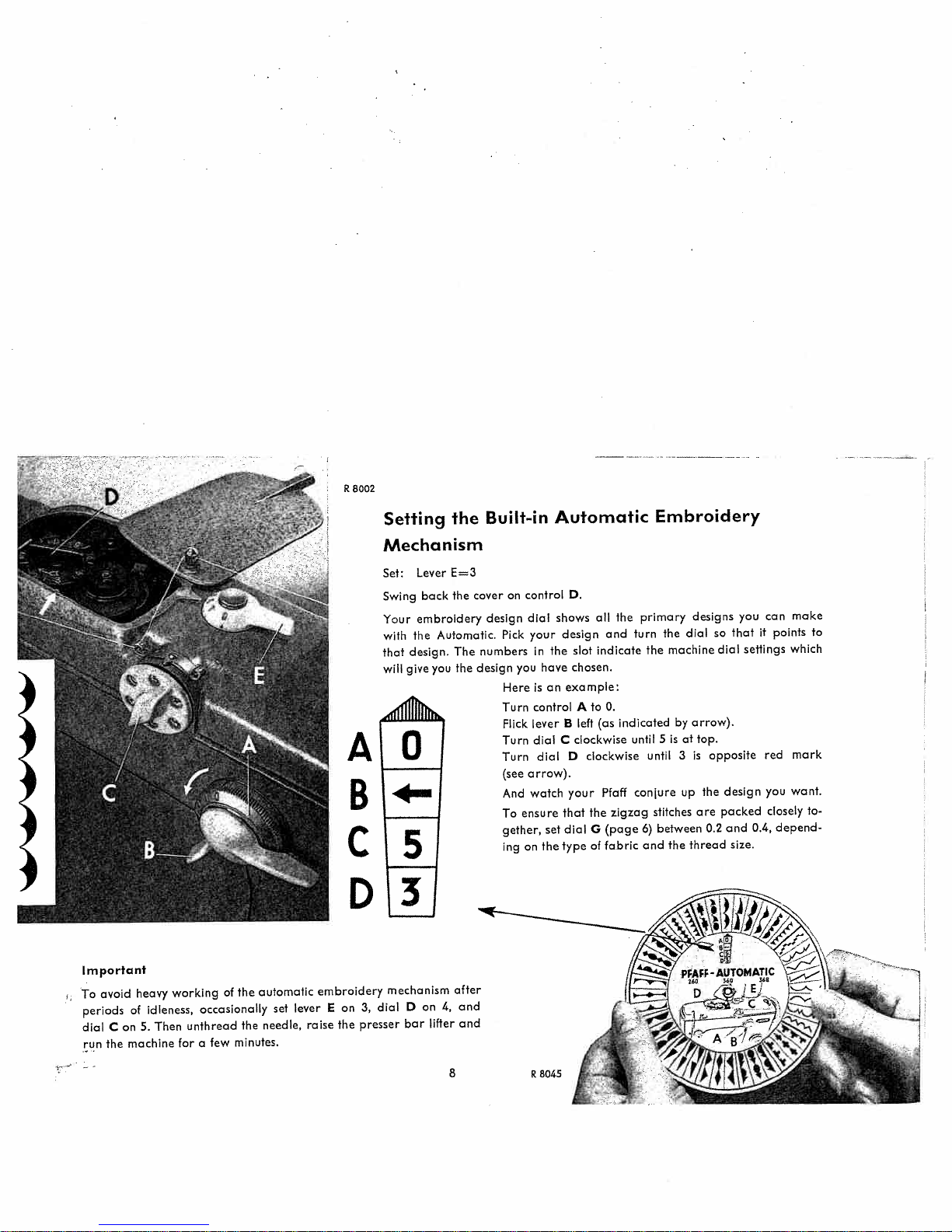

Page 9

‘p

R

)

8002

Setting

the

Built-in

Automatic

Embroidery

Mechanism

E=3

Lever

Set:

0.

control

on

Swing

Your

with

that

give

will

Aj

Bli

C15

back

embroidery

the

design.

the

Automatic.

The

the

you

cover

design

numbers

design

dial

your

Pick

in

have

you

Hereisan

Turn

control

lever

Flick

dial

Turn

Turn

dial

arrow).

(see

watch

And

ensure

To

gether,

the

ing

on

shows

the

set

design

slot

chosen.

example:

A

left

B

clockwise

C

clockwise

D

your

that

dial

type

all

and

indicate

0.

to

(as

Pfaff

the

(page

G

fabric

of

the

turn

indicated

until

zigzag

primary

the

the

5

until3is

conjure

stitches

between

6)

and

designs

dial

machine

arrow).

by

is

at

up

thread

the

so

dial

top.

opposite

the

are

0.2

can

you

thatitpoints

settings

red

you

design

closely

packed

0.4,

and

size.

make

to

which

mark

want.

to

depend

DL3

Important

set

embroidery

lever

raise

automatic

the

occasionally

unthread

for

a

few

of

the

minutes.

needle,

working

heavy

avoid

To

idleness,

C

the

of

5.

on

machine

Then

periods

dial

run

lifter

8

after

and

and

R8045

mechanism

Don4,

dial

3,

E

on

the

presser

bar

Page 10

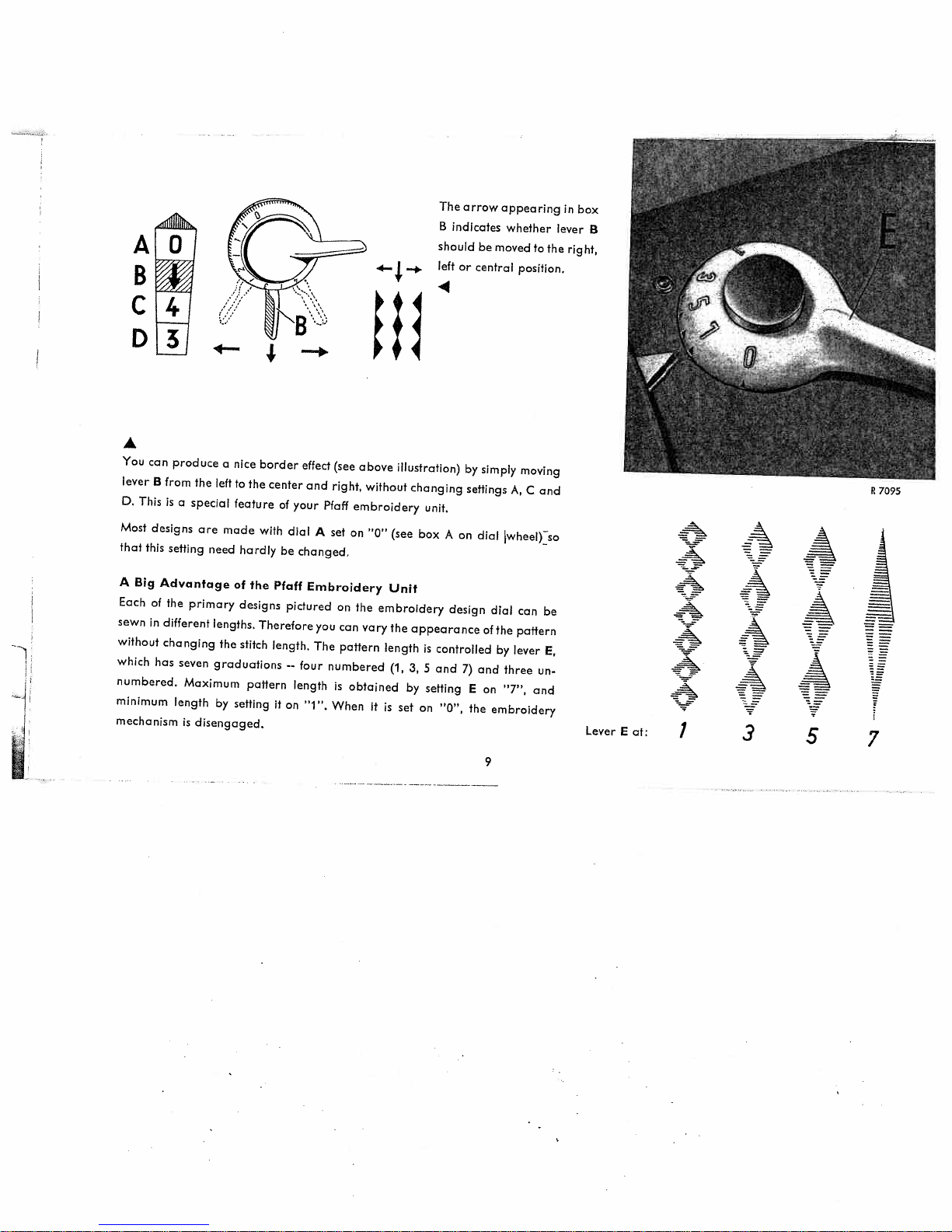

B

c1

The

arrow

appearing

B

indicates whether

should

be

moved

left

or

central

to

the

position.

in

lever

right,

box

B

DJ

A

You

can

lever

B

D.

This

Most

designs

that

this

A

Advantage

Big

Each

of

sewn

in

without

which

has

numbered.

minimum

mechanism

produce

from

is

a

special

setting

the

primary

different

changing

seven

Maximum

length

is

—

nice

a

the

left

to

feature

are

made

need

hardly

of

designs

lengths.

the

stitch

graduations

by

setting

disengaged.

border

the

center

with

the

Therefore

length.

pattern

of

be

Pfaff

pictured

--

it

on

effect

and

your

dial

A

changed.

Embroidery

you

The

four

length

“1”.

(see

right,

Pfaff

embroidery

set

on

on

can

pattern

numbered

is

obtained

When

above

wiihout

“0”

the

embroidery

vary

it

illustration)

changing

(see

Unit

the

appearance

length

(1,

3,

by

is

set

unit.

box

is

controlled

5

and

setting

on

A

design

‘0”,

by

settings

on

7)

E

the

simply

dial

wheelrso

dial

of

the

by

and

three

on

“7”,

embroidery

9

moving

A,

can

pattern

lever

C

and

be

E,

un

and

LeverEat:

7

3

5

7

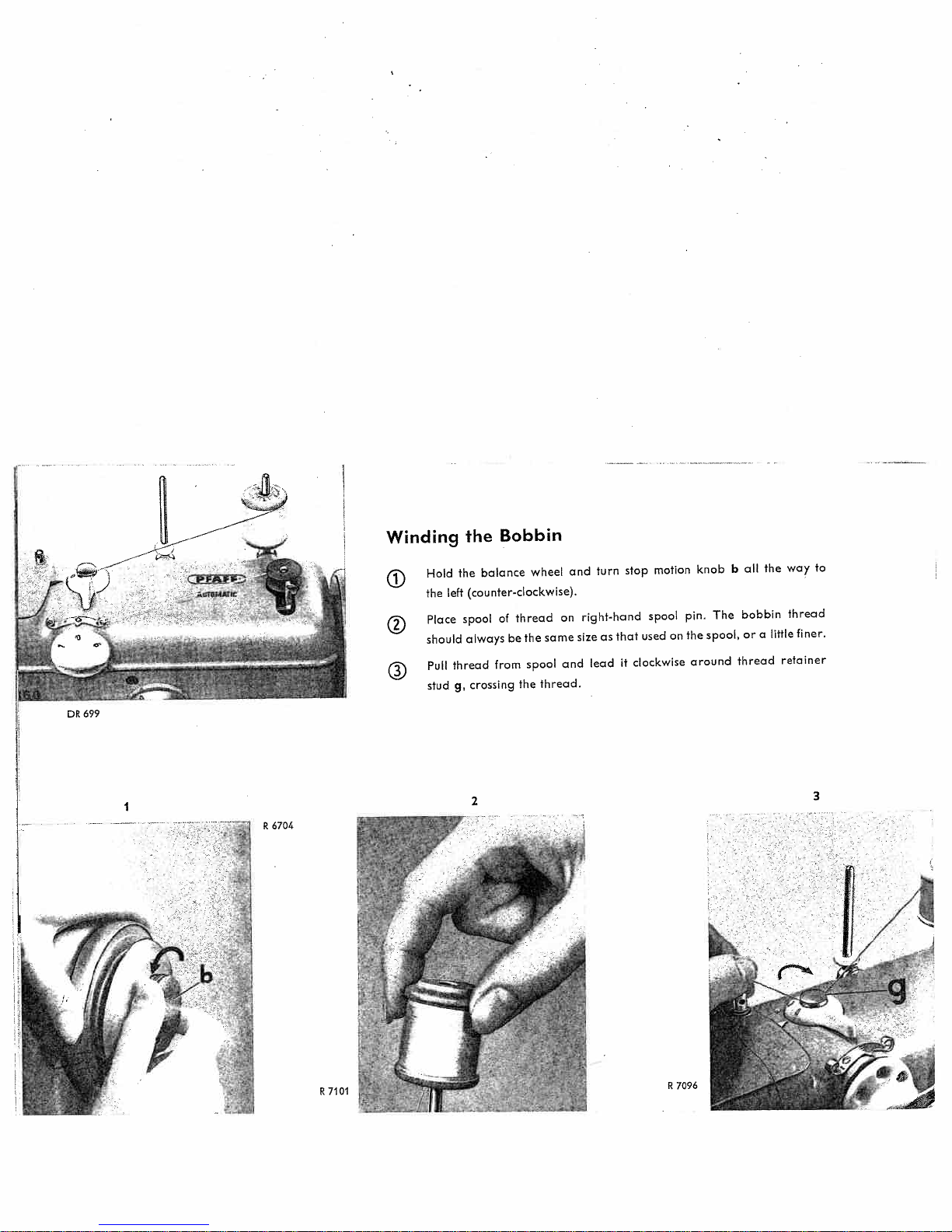

Page 11

DR

699

Winding

Hold

the

Place

should

Pull

stud

Bobbin

the

blonce

the

(counter-clockwise).

left

threod

of

spool

be

always

from

thread

crossing

g,

the

wheel

the

spool

on

some

thread.

and

size

and

turn

right-hand

that

as

it

lead

stop

spool

used

clockwise

motion

on

knob

pin.

the

around

The

spooi,

b

bobbin

thread

to

way

the

all

thread

finer.

little

a

or

retainer

6704

R

R7101

2

3

I

R7096

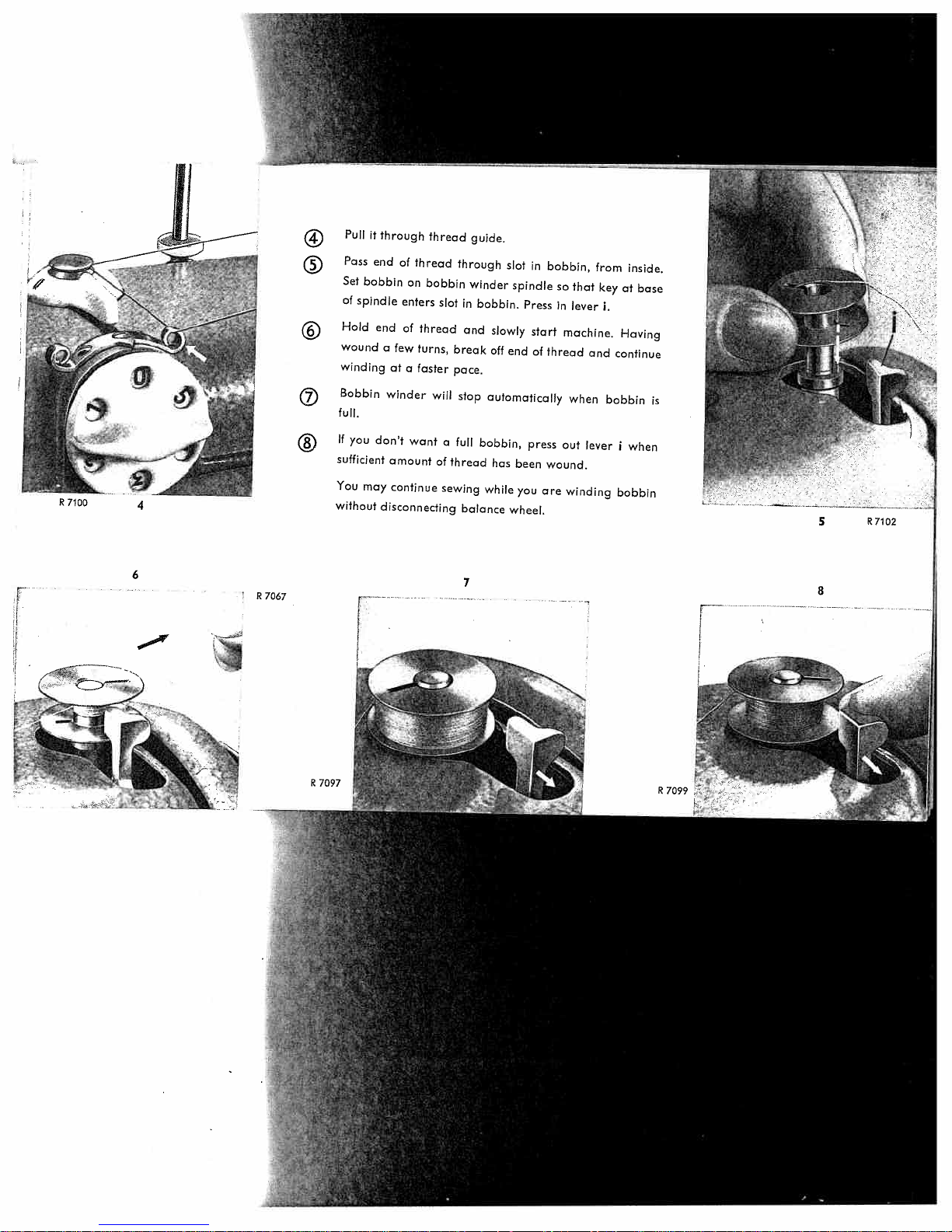

Page 12

R

7100

Pull

Pass

Set

bobbin

of

spindle

Hold

wound

winding

Bobbin

full.

If

you

sufficient

You

may

without

it

through

end

of

thread

on

enters

end

of

few

a

at

a

winder

don’t

want

amount

continue

disconnecting

thread

bobbin

thread

turns,

faster

slot

will

a

of

sewing

through

in

and

break

pace.

stop

full

thread

balance

guide.

winder

bobbin.

slowly

off

automatically

bobbin,

has

while

slot

spindle

Press

end

been

you

wheel.

in

start

of

press

bobbin,

so

in

thread

wound.

are

that

lever

machine.

and

when

out

lever

winding

from

key

i.

bobbin

inside.

at

base

Having

continue

when

bobbin

is

R7102

6

R7067

7

8

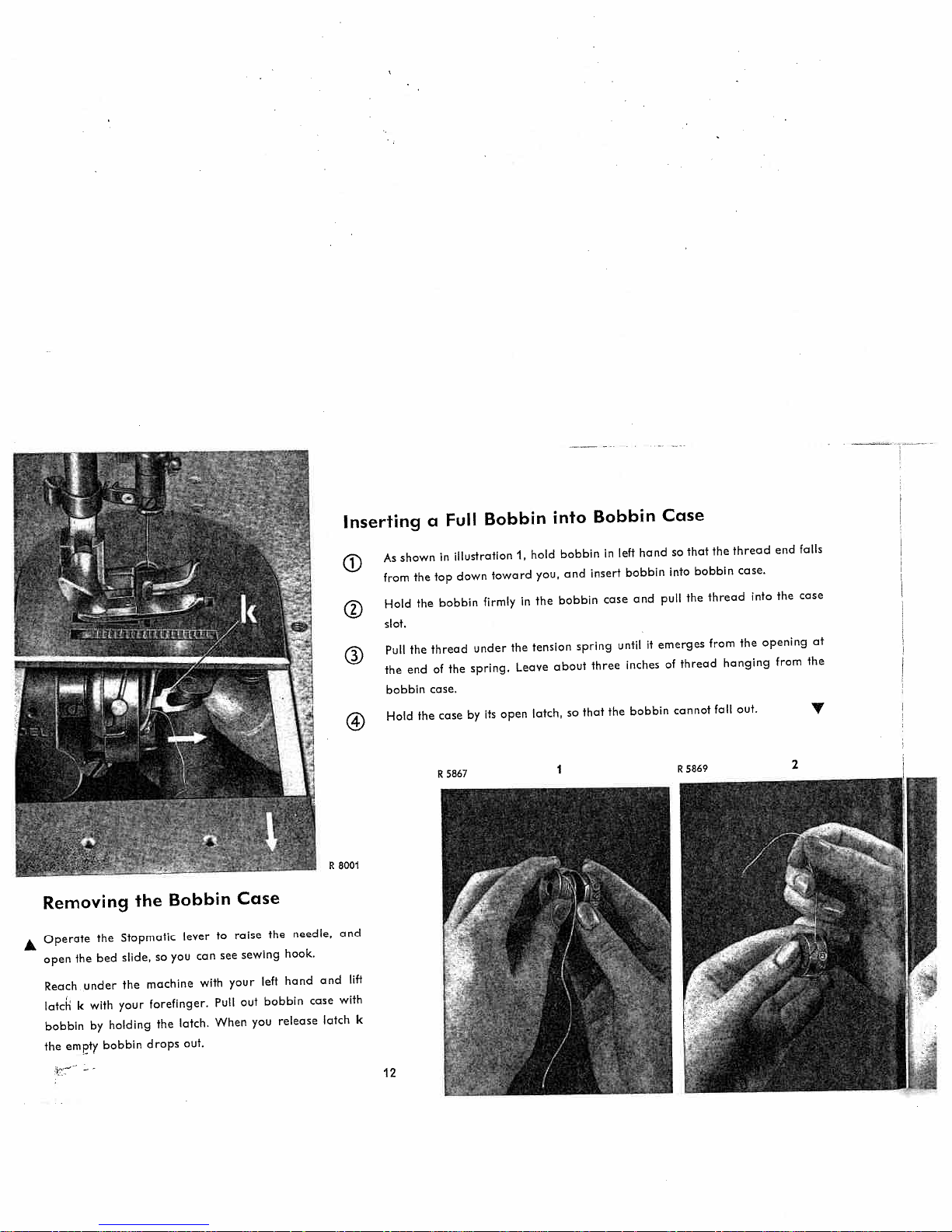

Page 13

Inserting

©

8001

R

shown

As

from

Hold

slot.

Pull

the

bobbin

Hold

the

end

the

the

the

a

in

top

bobbin

thread

of

case.

case

Full

illustration

down

under

spring.

the

by

Bobbin

1,

toward

in

firmly

the

Leave

its

open

hold

you,

the

tension

latch,

into

bobbin

and

bobbin

about

so

Bobbin

insert

spring

three

that

in

case

the

left

bobbin

until

inches

bobbin

and

hand

it

Case

sa

into

the

pull

emerges

thread

of

cannot

that

bobbin

the

thread

from

hanging

fall

thread

case.

the

out.

into

opening

end

the

from

falls

case

at

the

‘F

can

with

to

see

your

Pull

When

Case

raise

sewing

out

you

the

left

bobbin

release

needle,

hook.

hand

case

Bobbin

the

bed

with

by

Stopmatic

slide,

the

your

holding

bobbin

the

so

machine

forefinger.

the

drops

lever

you

latch.

out.

Removing

Operate

A

open

Reach

latci

bobbin

the

the

under

k

empty

and

latch

and

lift

with

k

12

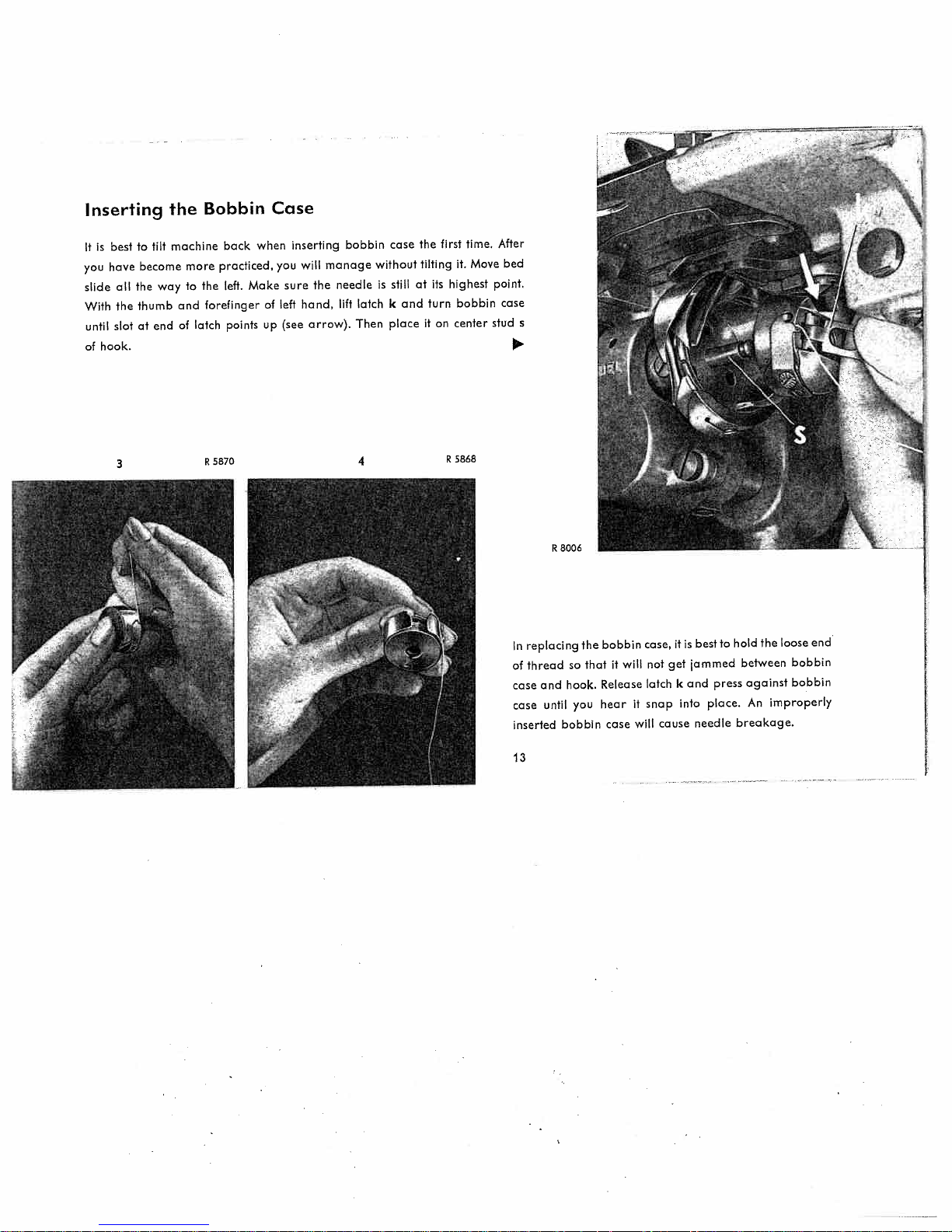

Page 14

Inserting

best

It

is

have

you

all

slide

the

With

slotatend

until

hook.

of

3

tilt

to

become

way

the

thumb

the

machine

more

to

ond

latch

of

Bobbin

bock

practiced,

left.

the

forefinger

points

5870

R

when

Make

Case

you

of

up

inserting

will

sure

left

(see

the

hand,

arrow).

bobbin

manage

needle

lift

latch

Then

4

case

without

still

is

k

place

the

tilting

at

turn

and

itoncenter

its

first

highest

5868

R

time.

Move

it.

bobbin

After

bed

point.

case

stud

s

8006

R

replacing

In

thread

of

case

case

inserted

13

and

until

the

so

hook.

you

bobbin

that

bobbin

will

it

Release

hear

case

it

will

case,

not

latch

snap

get

cause

it

is

k

into

best

jammed

and

place.

needle

to

press

hold

the

between

against

An

breakage.

end

loose

bobbin

bobbin

improperly

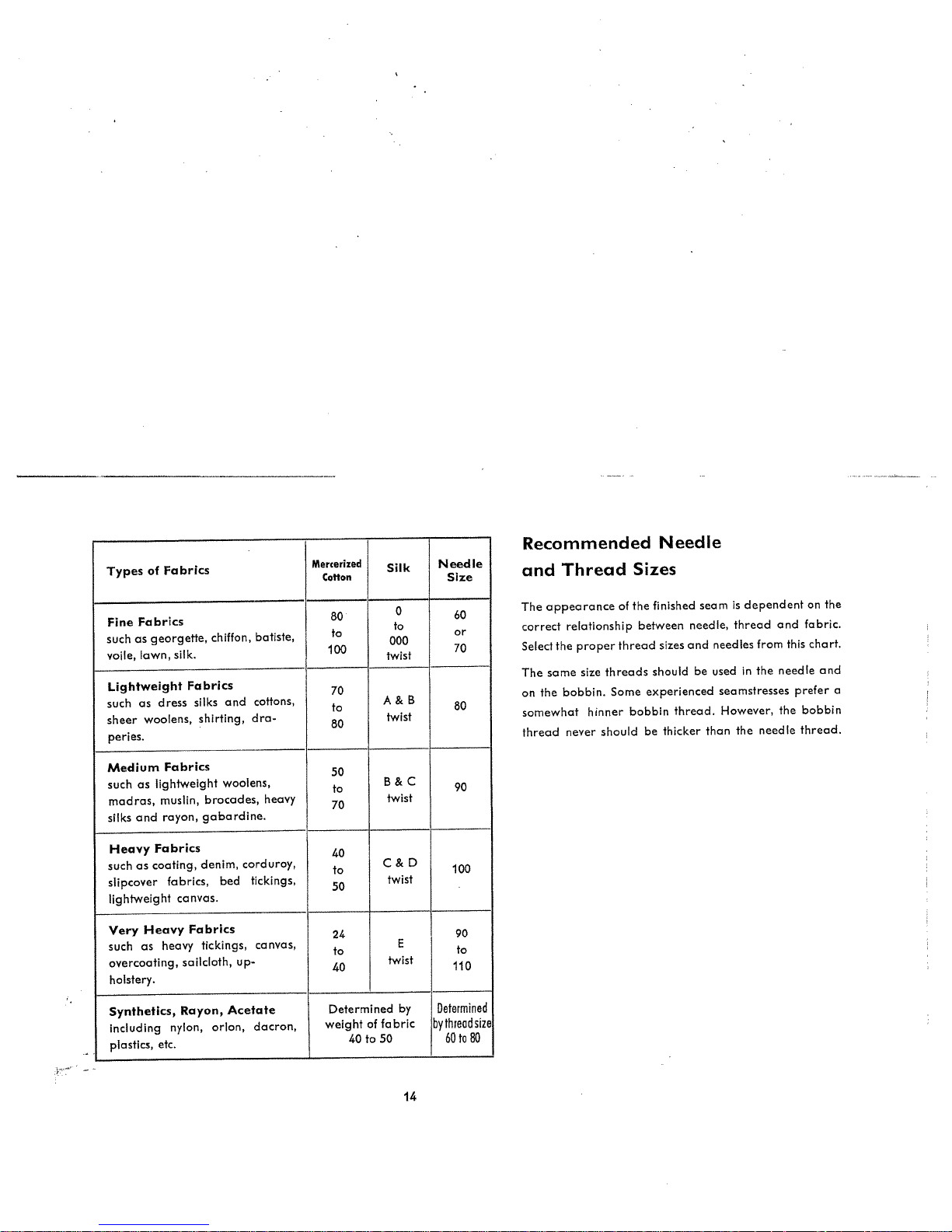

Page 15

of

Types

Fabrics

Fine

georgette.

as

such

lawn,

voile,

Lightweight

such

as

woolens,

sheer

peries.

Fabrics

silk.

dress

Fabrics

silks

shining,

chiffon,

and

batiste,

cottons,

dra-

Mercerized

Cotton

80

to

100

70

to

Silk

000

twist

A

twist

Sizes

the

of

thread

bobbin

between

Needle

finished

needle,

and

sizes

should

experienced

thread.

thicker

be

seam

needles

used

be

seamstresses

than

is

dependent

thread

from

the

in

However,

the

and

needle

needle

the

this

prefer

on

fabric.

chart.

and

bobbin

thread.

the

a

Recommended

Needle

Size

0

to

&

60

or

70

B

80

and

appearance

The

correct

Select

same

The

the

on

somewhat

thread

Thread

relationship

the

proper

size

bobbin.

hinner

never

fhreads

Some

should

Medium

lightweight

as

such

madras,

and

silks

Fabrics

Heavy

coating,

as

such

slipcover

lightweight

Heavy

Very

as

such

overcoating,

holstery.

Synthetics,

including

plastics,

Fabrics

muslin,

rayon,

fabrics,

canvas.

heavy

nylon,

etc.

brocades,

gabardine.

denim,

Fabrics

tickings,

sailcloth,

Rayon,

orion,

woolens,

corduroy,

bed

up-

Acetate

heavy

tickings,

canvas,

dacron,

I

Determined

weight

50

to

70

40

to

50

24

to

40

40

to

of

&

B

twist

&

C

twist

twist

fabric

50

C

D

E

by

14

90

100

90

to

110

Determined

byfhreadsize

80

to

60

Page 16

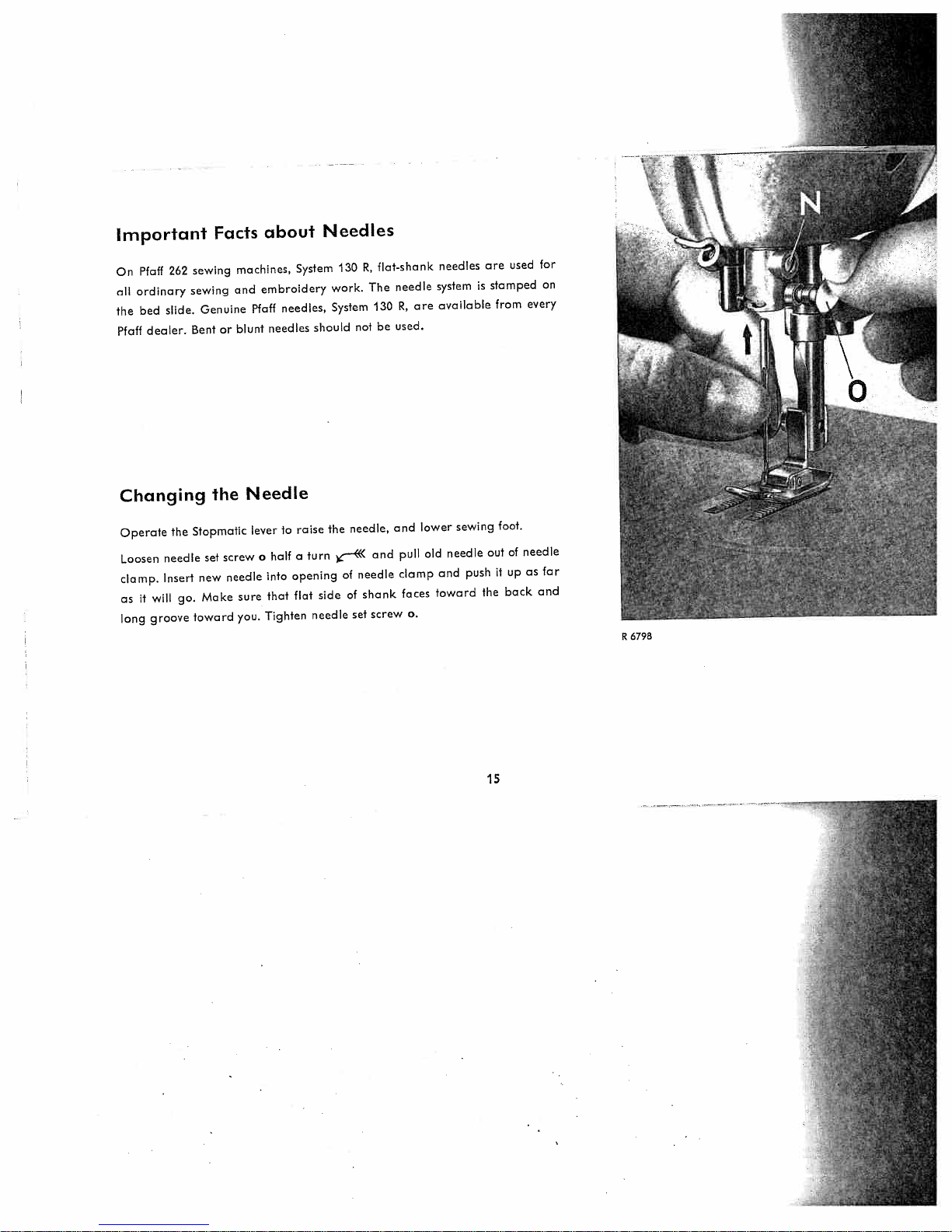

Important

262

Pfaff

On

ordinary

all

slide.

bed

the

dealer.

Pfaff

Changing

it

groove

the

needle

Insert

will

Operate

Loosen

clamp.

as

long

sewing

sewing

Genuine

Bent

Stopmatic

new

go.

toward

Facts

the

set

Make

machines,

and

blunt

or

screw

needle

sure

you.

about

embroidery

needles,

Pfaff

needles

Needle

to

lever

half

o

into

that

Tighten

System

should

raise

turn

a

opening

side

flat

needle

Needles

R,

130

The

work.

System

not

needle,

the

g—€(

needle

of

shank

of

set

flat-shank

needle

130

R,

used.

be

and

pull

and

clamp

screw

are

faces

o.

lower

old

needles

system

available

sewing

needle

push

and

toward

are

stamped

is

out

the

from

foot.

it

back

used

of

up

for

every

needle

as

and

on

far

R

6798

15

Page 17

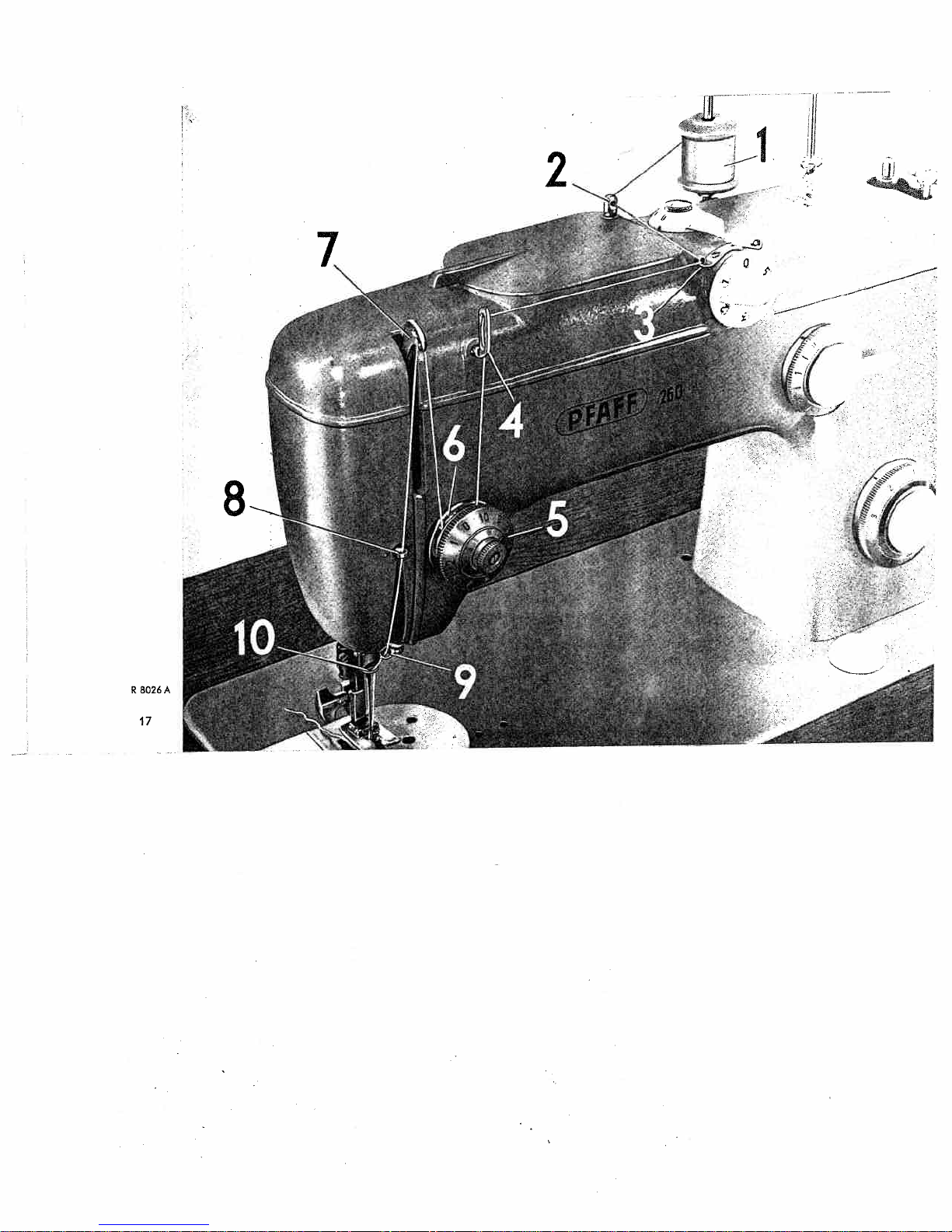

Upper

Threading

Place

thread

in

(see

Pull

it

thread

to

Bring

to

of

Then

spool

illustration

thread

over

far

check

tension

the

take-up

left

thread

thread

oihis

of

guides

between

to

through

guides

for

thread

2

opposite).

the

spring

against

lever

one

needle,

easily

you

and

right

8

and

on

ony

6.

7

of

3

so

At

the

as

the

front

and

spool

and

two

that

the

top

and

9

through

some

high

holes

to

quickly.

pin

of

it

cover

as

then

back.

and

I

tension

slips

time,

of

it

at

into

both

properly

the

will

arid.

its

the

The

thread

lead

thread

discs

press

machine.

and

go

Pull

slot

automatic

5,

the

of

retainer

illustrated,

as

into

thread

pass

thread

left

end

the

thread

of

needle

through

slot

passing

into

needle

openings

and

and

from

slots

clamp

threader

holes

jerk

under

down

right

ot

16

4

left

10.

will

0

:

.1”..-

I

I

‘-—

‘.-—

-

l.

I,.—’

‘

‘,

I

/

—-\

/

Page 18

V

9109

N

Page 19

Operating

the

Needle

Threader

DR

086

Operate

about

is

Now

1

lower

With

eye.

Hold

Release

Jerk

the

/32”

Stopmaiic

below

sewing

the

your

Keep

thread

control

control

the

left

control

loosely

down

R8013

Ieer

top

foot

hand

in

slightly

of

and

push

this

and

again

lift

to

its

position.

until

stroke,

--

needle

lead

so

the

it

prong

the

needle

os

threader

from

thread

2

to

illustrated

left

reverses

w

loop

raised

its

control

around

will

on

and

position

page

down

the

pulls

fall

small

off

R8009

4).

until

pin,

thread

the

(which

threader

then

through

prong.

been

reached

has

prong

placeitbehind

needle

Pull

thread

3

(see

w

eye.

through

when

opposite

hook

the

of

needle

ascending

page)

threader

eye

R8010

penetrates

prong.

and

takeup

release

lever

needle

control.

4

Page 20

When

shorten

Push

so

w

lease

loop

Since

the

needle,

through

V

you

the

needle

that

control.

--

through

the

its

take-up

the

have

had

procedure

threader

end

is

Prong

needle

lever

sufficient

it

is

needle

about

eye.

sufficient

as

control

w

now

eye.

is

follows:

down.

/s

inch

pulls

almost

to

pull

w

needle

Place

to

end

at

only

the

its

threading

thread

right

of

the

highest

about

behind

of

the

thread

point

three

practice,

hook

prong.

--

instead

when

inches

you

Slowly

you

of

of

may

prong

of

thread

thread

the

R

8458

re

Drawing

Hold

needle

the

needle

Lightly

pull

both

threads

thread

moves

needle

back

19

Up

down

thread

under

the

Bobbin

lightlyinyour

and

up

to

draw

sewing

again

foot

left

bobbin

before

Thread

hand.

and

take-up

thread

you

Turn

put

up

balance

lever

through

fabric

wheel

reaches

needle

into

toward

its

highest

plate

machine.

you

position.

slat.

A

until

Place

Page 21

R

8004

A

check

take

few

zigs

whether

a

stroighi

are

(see

surest way

The

wide

thatisif

ond

correct.

is

closely

tightly

seam

on

zagsofthe

To

ed,

a

stitches

fabric

rect.

aminingazigzag

equally

fabric,

the

ment

the

tensions

woven

and

zigzag

drawninon

sketch

to

seam,Ifthe

surface

threads

the

ore

pieceoffabric

seams.Ifthe

the

tensions

Ill),

double-check

underside

and

are

locked

seam,

the

correctly

both

balanc

and

straight

sidesofthe

are

this

is

zigzag seam

exactly

tension

sew

cor

by

of

adlust

ex

is

the

at

Correct

Balanced

have

perfect

Ca

use:

Ca use:

Tension

tensions

seams as

Sketch

Upper

Sketch

Upper

are

sketched

I—The

tension

II—The

tension

essential for

Regulation

sewing.Ifyour

below

(Ill).

threads

too

threads

too tightorlower

interlock

looseorlower

interlockonthe

on

tension

tension

the

tensioniscorrect,

underside

tight.

too

surfaceofthe

too

loose.

of

the

fabric.

you

fabric.

will

20

Page 22

DR

079

Regulating

bobbin

The

be

should

it

knurled

small

Determine

forefinger

and

enough

strong

weight.

gradually

However,

slide

V

thread

little

a

screw

correct

the

and

to

down.

tension

tighter

on

Turn

Turn

bobbin

letting

keep

you

as

Thread

rarely

than

bobbin

the

left

it

right

it

tension

the

bobbin

the

jerk

needs

for

case

bobbin

your

Tension

adjusting,

ordinary

which

c4<

holding

by

case

from

case

hand

for

for

hang

sewing.

can

looser

tighter

the

being

slightly,

except

Adjustment

turned

be

tension.

tension.

thread

freely.

the

for

The

pulled

embroidery

with

between

end

tension

down

bobbin

the

is

mode

thumb

should

by

case

when

by

thumb

own

its

should

The

upper

The

sion

turn

a

tip.

be

final

upper

--

of

indicate

ber,

be

it

upper

the

Your

needle

stitch

tension

Turn

Turn

loose

the

different

greater

the

necessary

upper

work.

dial,

tension

to

tension

tension

tension

appearance

as

left

right

so

is

--

tight

dial.

degrees

tension.

the

reset

to

should

follows:

)-

designed

be

can

The

of

the

be

a

has

can

for

for

covered

numbers

tension.

Only

tension.

set

third

be

looser

tighter

that

in

about

at

regulated

tension.

tension.

all

with

on

The

very

For

tension

grades

one

tension

the

higher

rare

ordinary

5.

disc

by

of

complete

num

the

cases

sewing,

for

the

ten

dial

will

two

A

R8029

21

Page 23

Stitch

Length

Regulation

dial

Turn

on

mork

regulate

facilitate

To

section.

1—4

normal

Far

Reverse

backtack

To

When

down.

automatically.

foot.

this,

do

To

way,

this

In

Thereverse

until

the

stitch

the

dial

length

satin

setting

The

stitching,

satin

Sewing

beginning

the

the

This

operate

seam

one

stitches

number

housing

as

stitching,

control

feature

the

is

will

indicating

(see

required.

the

depends

set

or

is

is

control

placed

about

be

straight

0—I

on

on

dial

of

end

released,

ideal

rhythm

in

neatly

the

the

range

the

0.2.

a

for

desired

arrow).

type

seam,

the

darning

and

beside

same

the

on

of

simply

machine

move

length

the

stitch

Or

scale

fabric

rips

other.

sew

press

resumes

with

the

forward

as

length

just

is

ond

fabric

a

the

the

few

thread

opposite

is

stitches

large

as

finger-tip

forward

ordinary

slightly

stitches.

as

used.

size

control

sewing

sewing

sideways.

the

and

the

22

Page 24

Dropping

the

Machine

Feed

The

hoop

machine

embroidery

To

lower

wise.

When

fabric

feed

feed

Fabric

control

resumes

dropped

is

button

and

below

will

is

v

automatically

cease

turned

for

sewing.

the

feeding.

darning

needle

to

the right

when

with

plate, turn

farasitwill

as

you

startZsewing.

aid

the

drop

feed

of

the

control

vibrator,

v

for

clock

1

of

go,

feeding

the

23

R6705

Page 25

R

7086

R

7085

Darning

Attach

darning

As

machine

the

is

thus

held

risen

clear

needle.

(Only

down

again.

delicate

Foot

foot

sews,

No.

when

Hold

and

53670,

the

it

the

fabrics

Vibrator

as

vibrator

is

entered

fabric

should

instructed

moves

by

taut

with

clamped

be

presser

the

above.

needle,

both

Drop

bar

hands

into

and

hoops.)

and

can

machine

darning

be

as

you

feed

moved

move

foot

and

freely

it

lower

up

back

Changing

Raise

lift

left.

foot

presser

and

down.

when

and

the

Tilt

and

the

forth

the

needle,

the

The

needle

presser

foot

tighten

bar

fabric

under

the

Turn

sideways

the

lifter.

has

the

bar

the

screw

Sewing

and

operate

sewing

and

securely.

pull

Foot

foot

the

it

thumb

down.

Stopmatic

screw

Slip

lever

to

on

to

the

new

.2

24

DR

082

Page 26

R

8035

Care

Longevity

proper

Use

Pfaff

vegetable

All

moving

establish

principal

and

and

cleaning

sewing

oils.

and

a

pattern

oiling

Maintenance

smooth

machine

and

oiling.

machine

Remove

rotating

points

when

all

are

oil

lint

parts

oiling

marked

performance

only.

Never

before

require

your

by

oiling.

regular

machine.

arrows.

are

lubricate

lubrication.

Begin

dependent

machine

under

It

the

on

regular

with

is

advisable

bedplate.

animal

The

oiling

day

Don’t

short

and

or

to

The

raceway

point.

you

forget

hook

sew.

shaft.

Put

to

in

A

the

sewing

hook

the

is

most

important

one

drop

of

oil

into

the

oil

raceway

dry

A

the

raceway

bearings

will

and

cause

bevel

rapid

gears

each

wear.

of

the

R

8036

25

Page 27

R

8065

reached

be

can

cover.

cover,

and

arm

applied

be

should

Oil

work

the

soil

may

oil

of

two

or

One

between

E

lever

set

lift.

drops

R

of

5

8460

machine

the

in

points

oiling

The

top

machine

suffice.

remove

up,

the

quantities

sluggishness.

top

the

back

it

jilt

removing

by

easily

cause

usually

you

7.

pull

Excessive

will

cover

sparingly.

and

oil

Before

and

To

A

points

Oiling

machine

head

the

in

Page 28

8

8030

Regular

Accumulations

operation

plate

ond

remove

To

machine

To

feed,

replace,

V

Machine

of

the

clean

the

turn

reverse

of

lint

machine.

the

needle

8

8454

feed

the

the

packed

with

plate,

needle

above

Care

between

Therefore,

a

toothpick

turn

plate

procedure.

out

half

the

from

the

tooth

or

thumb

a

turn

time

similar

rows

to

nut

(Fig.

of

time,

wooden

(Fig.

8455),

R

the

remove

R

R

feed

obect.

8654),

and

8455

cause

noisy

the

needle

drop

lift

it

Tilt

bobbin.

accumulated

Onceina

checkup

out.

the

the

machine

With

while

by

your

back

and

take

out

bobbin

case

and

a

soft

brush

remove

the

lint

which

the

vicinity

in

your

Pfaff

Pfaff

dealer.

of

the

should

sewing

be

given

hook.

a

thorough

A

has

27

Page 29

Sewlight

15-watt

The

change

To

bulb

Push

inserting

When

bulb

Press

Facts

sewlight

the

into

and

in

light

socket,

new

turn

recessed

is

turn

Pfaff

right.

bulb:

light

Ieft

under

and

bulb,

Close

pull

be

grille.

the

sure

machine

out.

Note

to

arm

slide

voltage

bulb

and

of

can

pins

electric

into

swung

be

bayonet

circuit.

out

socket

by

pulling

slats.

down

the

grille.

DR626

extra

No

needed

Press

sewlight

.4

this

for

on

sewlight

your

button

and

card

machine.

switch

ta

off.

R8066A

is

28

R8067A

Page 30

Trouble

Shooting

Machine

1.

Ca

Needle

Wrong

Needle

Machine

Needle

2.

Needle

use:

Ca

The

Thread

Poor,

Hook

oiling.

Burrs

use:

above

knotty

raceway

or

Skips

incorrectly

needle,

bent.

threaded

fine

too

Thread

mentioned

tension

or

sharp

or

too

rotten

is

edges

jammed

Stitches

inserted.

improperly.

too

thick

Breaks

cause

may

tight.

thread

on

needle

for

with

used.

the

read

th

thread

plate

thread.

breakage.

slot.

Remedy:

Push

needleupas

faces

toward

The

correct

sewing,

use

Insert

Check

Use

Remedy:

See

Adjust

Use

needs

or

Clean

Polish

new

and

correct

remedies

tensions

good

and

needle

needle.

quality

oil

you,

needle

System

correct

needle

listed

as

hook

plate

far

and

flat

system

130R

threading

and

under

instructed.

threads

raceway.

slat

with

as

it

side

needles.)

thread.

1.

only.

will

is

as

above.

fine

go

of

shank

stamped

instructed

emery

and

be

away

an

cloth.

sure

that

the

long

groove

from

you.

bed

slide.

(For

ordinary

on

pages

16

and

17.

29

Page 31

Needle

3.

Ca

use:

needle

Bent

too

Needle

pulls

Fabric

plate.

case

Bobbin

Faulty

4.

Cause:

Improper

Bobbin

Pieces

Machine

5.

too

unevenly

of

Thread

Cause:

dog

Feed

needle

above

Accumulations

Breaks

strikes

thin

needle

inserted

Stitch

tension.

heavy,

thread

set

or

Feeds

too

plate

of

point

thread

it

so

incorrectly.

Formation

knotty

wound.

between

Improperly

low,

level.

packed

lint

sewing

of

too

bends

or

tension

does

heavy.

and

hard.

nat

between

hook.

strikes

discs.

rise

up

feed

needle

enough

teeth.

Remedy:

Replace

correct

Use

Don’t

Push

Remedy:

Adjust

only

Use

Don’t

around

Raise

Remedy:

Hove

Take

needle

force

bobbin

tensions

run

thread

presser

your

off

needle

the

case

first-rate

thread

bar

Pfaff

needle

once

at

and

feeding

until

instructed.

as

thread

over

retainer

lifter

dealer

plate

prevent

to

thread

motion.

you

--

finger

stud

and

make

and

hear

the

on

remove

the

remove

further

sizes.

Guide

it

correct

when

top

necessary

snap

lint

the

into

winding

cover

thread.

with

damage.

material

size

and

adjustment.

a

place.

for

the

stiff

lightly.

needle

the

bobbin,

through

brush.

and

but

thread

fabric.

lead

guide.

it

30

Page 32

6.

Machine

Cause:

beltistoo

Motor

excessive

raceway

Hook

of

thread.

Mechanism

Machine

mechanism

dery

Bobbin

bobbin

pressure

works

winder

is

not

Works

lacks

clogged

heavily

working

being

loose,

on

is

engaged.

filled).

Heavily

or

bearings.

oil

or

inferior

by

when

has

obstructed

is

while

shrunk

oil.

automatic

sewing

and

causes

by

pieces

embrol-

(when

Remedy:

dealer

your

and

only

note

bobbin

Pfaff

on

Pfaff

oil

hook

sewing

page

winder.

Have

Clean

Use

See

a

Stop

adjust

raceway.

machine

8.

the

oil

belt

--

tension.

never

salad

oil

or

glycerine.

Stopmatic

7.

Cause:

After

happen

you

Take-up

rise

not

Thread

The

thread

If

sufficient

be

this

If

wheel

Thread

frequent

push

when

new

action

back,

that

the

the

lever

Jamming

Pfaff

should

jamming

Works

operation

take-up

presser

strikes

Stopmatic

rotary

happen

overcome

to

should

then

Incorrectly

bar

hard

not

jerk

can

of

lever

lifter

lever

hook

it

be

the

does

up

against

is

will

jaminthe

to

hard

free

back

avoided,

Stopmaiic

not

all

the

stop

its

operated.

Note

not

working

the

jammed

and

forth.

however,

it

move

when

way.

does

or

“Fundamentals

the

normally

raceway

of

may

the

thread,

jam,

of

mechanism.

if

you

Remedy:

The

built-in

Waitafew

cooled

Have

your

of

Machine

if

even

sewing

the

drop

put

a

the

follow

down

the

instructions

31

thermal

minutes

and

Pfaff

dealer

Operation”

machine

hook,

kerosene

of

until

the

the

switch

electric

adjust

should

power

on

both

on

into

may

page

be

page

the

circuit

the

handled

of

the

interrupted

have

motor

has

Stopmatic.

4.

the

motor

hook

4.

and

the

been

improperly.

in

raceway,

the

thermal

closed

most

jerk

electric

circuit.

switch

automatically.

instances

balance

the

have

will

Page 33

Using

Zipper

Machine

DiaIA=O

C=0

Dial

or

Pin

Position

the

want

fabric

Turn

left

to

other

edge

insertion,

V

Insertion

Setting:

baste

of

edge

side

foot

of

Sewing

Lever

Lever

closed

zipper

of

edge

right

to

of

zipper,

one

in

a

as

follow

Feet

E=0

zipper

depends

fabric

the

side.

stitch

continuous

guide.

directions

on

Run

For

in

and

wrong

whether

on

overlap

to

straight

a

across

operation.

other

your

Attachments

fabric.

of

side

not

or

zipper.

the

seam

up

and

end

Use

of

zipper

types

package.

zipper

you

close

the

right

(for

parallel

Sew

various

adlustable

stitcher

fastened

is

thumb

edge

guide.

fabric

sewing

of

settings

distances

(without

screw.

guide

Ta

edge

foot,

Edge

Machine

rows

seam

to

Far

half

sew

or

page

see

Stitching

DialA=Oto4

C=O

Dial

straigt

of

the

from

No.

guide

quilting

machine

the

wider

a

turn

narrow

preceding

no

using

6)

Setting:

or

fabric

53077

gauge).

marginal

and

parallel

seam

edge

Lever

zigzag

bed

use

guide.

Lever

edge

The

with

along

E=0

stitches

the

and

seam

stitching,

end

low

seams,

right

by

the

using

edge

guide

long

turn

as

guide

edge

7153A

R

at

a

41

R

8033

Quilting

Machine

DialA=O

C=0

Dial

Edge

gauge

entire

gauge

Attractive

covers

Setting:

stitcher

sews

surface

finger

can

.

.

parallel

along

tea

be

LeverB=’

Lever

41350

No.

the

of

the

cosies,

quilted.

32

E=0

rows

fabric.

slippers,

used

of

preceding

with

stitching

Always

row

seat

the

over

guide

of

pads

quilting

the

stitches.

and

the

8032

R

Page 34

41242

Flat

Felled

Seams

7171

R

Second

Open

into

placed

The

the

felling

close

felling

Seam

two

foot

foot

pieces,

to

opening,

edge

the

a

has

place

but

needle

and

them

stitch

not

slot,

under

down

beyond

rather

the

it.

than

to

4

needle

the

a

needle

Machine

A=O

Dial

felled

Flot

operations.

felled

Flat

felling

Seam

First

pieces

Lay

1/

inch.

folded

stitched

truding

twice.

ed

right

Make

left.

hole,

Setting

or

seoms

seams

elosilcized

on

Feed

over

down.

seam

side

sure

(optional)

2

together

both

edge

Make

allowance

up,

that

permit

to

33

ore

usually

pieces

of

insert

used

fabrics

with

top

sure

seam

second

zigzag

to

ore

into

piece

that

is

durably

only.

the

not

seam

felling.

Lever

straight

right

felling

and

pro

fold

ridge

is

R7154

B=

join

sides

foot,

4

two

stitched.

facing

as

C=O

Dial

pieces

of

Norrow

and

illustrated,

fabric.

zigzag

the

so

Lever

They

bottom

that

E=O

are

stitches

piece

the

made

ore

bottom

in

used

protruding

fabric

two

for

is

Page 35

46281

Machine

DialA=2to4

Dial

C=O

Rolled

delicate

hem,

ease

dial

A

increase

zigzag

stitch

effect.

Setting:

hems

fabrics.

on

the

.

are

thread

2

or

tension

so

Rolled

‘

Lever

For

3.

the

Hems

LeverB=+

E=O

used

to

a

smooth,

tension

To

hem

and

hem

slightly

has

finish

unpuckered

tricot

use

the

a

rolled

sheer

and

fabrics,

widest

shell

set

41248

R

5912

Hemming

Machine

DialA=eOor2to4

Dial

or

The

hem.

on

Fold

the

needle

and

fabric

forward.

Draw

threads

will

so

scroll.

filled

Avoid

fabric

you

If

you

‘/,“

sketch

Before

sewn

hemmer

the

hemmer

close

ensure

that

come

of

first,

C=O

You

type

over

stitches

edge.

the

backwards,

the

Don’t

with

ugly

against

want

corner,

2.

Then

you

Setting:

can

of

edge

to

Don’t

fabric

a

hem

fabric

ends

to

the

to

hem

as

Lever

foot

is

hem

fabric

of

foot.

in

the

the

folded

Take

trim

into

neat

edge

crowd

at

by

the

needle

end

hem

severol

cut

away

hem

the

illustrated

E=O

indispensable

with

straight

you

are

fabric

Place

fabric

material

edge.

the

work

the

threads

the

scroll

Inserting

hem

right

is

in

fabric

all

times

slowing

plate

of

the

remaining

the

second

last

edge,

in

sketch

LeverB=’I

using.

about

under

about

Sew

out

of

the

from

line

with

into

the

(see

down

an

hem

(see

edges,

edge,

cut

you

if

or

‘Is”

backwards

of

the

(sketch

the

fabric

the

the

scroll,

ill,

at

feeding.

the

ill,

hem

portion

on

away

3.

zigzag

to

hemmer

‘/s”

hemmer

beginning.

left

top).

left

at

first

instructed

about

want

stitches,

facilitate

short

machine

1).

into

the

edge

but

To

side

of

bottom).

edge

hem,

of

as

do

to

of

by

keep

to

‘J.”

sew

foot

far

scroll

of

this,

the

above.

a

depending

insertion

so

its

rear

as

pulling

by

pulling

Feed

hemmer

the

scroll

press

foot

within

as

shown

of

the

uniform

that

edge

the

like

fabric

before

about

hem

into

the

rear

it

both

this

well

the

in

R

7172

34

R5915

Page 36

—

44088

44088

Machine

similar

Two

loined

center

foot

so

wide

with

strip.

that

zigzag

Setting:

pieces

zigzag

Place

the

stitches.

Butt

Seaming

Dial

of

stitches.

the

abutted

A=3

fabric

selvaged

edges

Hem

4.Lever

or

which

Worn

edges

are

edgesofsheet.

raw

do

bed

of

centered

not

sheets

the

4

R

5925

+

B=

ravel

may

remaining

under

Machine

Overcasting

needle

the

edges

cast

Dial

easily

may

be

mended

pieces

needle,

the

Setting:

prevents

taking

after

C=O

be

this

sheet

of

Overcasting

Dial

frayed

one

fabric

.

Lever

together

butted

Cut

way.

under

them

Join

A=2to4

stitch

cut

is

E=O

out

the

with

Edges

edges.

into

and

and

worn

sewing

close,

‘

Usealong,

fabric

the

before

Lever

the

and

B=

the

pieces

wide

other

are

Dial

zigzag

over

oined.

C=O

stitch

its

and

edge.

Lever

sew

You

edge

may

7169

R

E=O

with

over

F’

P

‘

r

A

35

Page 37

Attaching

Lace

44088

—

Machine

A=1

Dial

C=O

Dial

con

You

First

tion.

grain.

Sew

excess

‘V

Setting:

attach

fold

Press

together

fabric

LeverB=’l

desired

line

a

of

the

rows

E=O

two

of

the

fabric

of

of

material

Lace

operations.

of

area

straight

lace.

about

stitching

fabric

the

stitching

Turn

halfway

under

back

Place

the

the

and

both

over

Setting:

job

over

with

and

the

Fold

Inserting

Lever

takes

the

edges

slit

two

edges

Lever

E=O

edging

down

Overlap

narrow

B=

side

in

/e

lace

zigzag

close

one

inch

with

on

to

simple

folded

stitches.

seam.

the

opera

fabric

edge.

Trim

Machine

DialA=lto3

C=O

Dial

sewing

This

lace

the

attach

and

3

to

Lever

lace

fabric

fold.

with

wrong

on

I

along

work

between

insertion.

press.

a

length,

firm,

for

elastic

as

and

out.

Turn

narrow

overcast

seam.

lined

work

Trim

in

to

zigzag

edges,

the

right

stitch

making

away

preceding

side,

of

excess

set

medium

a

material

section.

machine

R7170

36

R7161

Page 38

44088

Seam

Elastic

the

elastic

with

materials)

Inserting

‘?

(especially

Patches

on

7156

R

Large

the

Now

For

Also

hales

fabric.

you

additional

zigzag

the

can

Place

begin

be

the

oversew

to

strength

seam

patched

patch

stitch

forms

quickly.

over

the

over

an

the

raw

elastic

Cut

damaged

edges

corners

patch

with

twice.

juncture

Machine

Dial

Stitch

Machine

so

area.

the

between

Dial

Stitch

that

Turn

A=0

length

A==4

length

its

elastic

over

Setting:

Setting:

grain

seam

and

material

the

Lever

control

Inserting

(especially

Lever

control

will

or

trim

37

B=

between

B=+

about

match

zigzag

the

close

and

Patches

non-elastic

on

0.5

the

to

the

Dial

and

0.2

Dial

rest

seam.

seams.

patch.

with

of

R7157

C=3

0.6

Zigzag

materials)

C=O

(see

Dial

also

Lever

D=8

page

Stitches

E=0

53)

Lever

E=1

Page 39

Single-Needle

Cording

46121

R7162

Machine

DiolA=2

Dial

Trace

thread

foot.

hold

used

over

stitch

V

-%

b—.

Setting:

C=O

cording

through

Follow

the

filler

for

many

embroidery

length

between

your

Lever

Lever

pattern

the

pattern

thread

sewing

B=4

E=O

groove

with

/2

on

fabric

in

with

lightly.

lobs.

contrasting

and

For

1.

the

sole

a

The

added

and

satin

of

satin

thread.

r

r

pull

the

stitch

effects

a

sewing

stitch

filler

and

sew

Set

Shirrirsg

Machine

Dial

Dial

Filler

is

Follow

place

top

both

Width

filler

When

slide

distribute

o

line

Leave

it

out,

depending

will

of

are

thread

moterial

of

piece

be

Setting:

A=2

C=O

thread:

above

filler

the

fabric.

guided

of

zigzag

you

have

fullness.

straight

filler

on

exposed.

to

2’/2

cotton

thread

used.

along

thread

by

piece,

thestress

.

Lever

(pearl

directions

under

Fabric

in

the

depends

finished

Finish

stitching.

in

the

as

to

Lever

E=O

the

you

which

for

ond

groove

the

filler

the

shirring

8=4

thread)

shirring,

rather

than

filler

thread

of

the

on

thickness

zigzog

seam,

thread

shirring

or

straight-stitch,

the

shirring

‘

but

on

foot.

of

to

with

pull

:..

_%.

.

R7159

38

R752

Page 40

k

7163

of

line

a

Lever

Dial

Lever

Dial

below

D=3

D=4

with

B=+

were

sewn

V

the

accentuate

6121

LeverB=+

Lever

easy

the

on

of

contrasting

with

and

fabric.

the

satin

run

stitching.

Work

E=O

and

narrow

the

edges

stitches.

filler

a

modern.

wrong

motif

close

side

material

zigzag

will

the

to

the

of

To

thread

of

appear

line

applique

make

(pearl

fabric

right

to

stitches

of

the

and

side.

the

on

the

on

stitching

with

design

thread)

Applique

C=O

design

a

side

excess

go

Setting:

piece

design

side,

of

over

is

the

material

Machine

DialA==1

1

/s

Dial

I.

Appliqueing

Trace

baste

Outline

wrong

right

Trim

and

medium-wide

visible,

more

satin

the

under

Or

Automatic

embroidery

The

the

with

the

And

embroidery.

following

Dial

Dial

Lever

stems:

Dial

Dial

Lever

applique

outlines

settings:

A=O

C=4

E=1

A=O

C=1

E=1

7167

R

39

R7155

Page 41

46721

R7166

There

appearance

in

25-square

the

stitches.

that

your

are

Then

Openwork

Machine

Dial

hundreds

to

box

sew

rows

A=O

applique,

illustrated.

over

satin

of

Embroidery

Setting:

and

patterns

of

straight-stitch

stitching

2/2

excellent

openwork

sew

First,

are

Lever

for

embroidery

over

with

lines

even

B=

openwork

traced

ciii

a

the

so

.4

Dial

4

embroidery.

much

is

lines

medium-wide

corners

When

the

seams.

make

To

design

dery

you

C=O

simpler.

twice,

of

your

finish

an

using

satin

squares

sewing,

attractive

instead

Lever

Although

embroider

Let’s

short

stitch.

modern

satin

of

E=O

straight

Make

look

cut

similar

sure

neat.

every

out

design,

stitching.

other

outline

square.

flowers

Be

careful

or

free

that

forms

you

with

don’t

an

injure

embroi

R7179

40

Page 42

R

7158

—

44088

4612?

Machine

Dial

A=2

Dial

D=5

Scalloping

Automatic.

as

trimming

illustrations

The

sparkle

J

\

J

(

I

J

I

I

Setting:

canbedone

Scalloped

on

toachild’s

First,

trace

piece

of

above,

guide

scallops

may

vary

sketch)

When

you

along

scalloped

ScaHoping

Lever

B=

Lever

E=1

edges

numerous

(left)

collar.

the

fabric.

place

fabric

needle

produced

are

the

changing

by

have

4.

in

show

collar

Set

along

length

finished,

edge.

to

7

a

jiffy

can

articles.

how

Here’s

pattern

machine

under

traced

automatically.

of

the

setting

trim

Dial

C=3

on

your

used

be

scalloping

how

on

as

sewing

scallops

the

excess

Pfaff

effectively

todoit.

doubled

a

indicated

foot

line.

lever

of

fabric

adds

and

The

You

(see

262

E.

Machine

DialA=2to4

Dial

C=O

Draw

designs

broidery

work

outline

right,

then

direction

be

added

Setting:

hoops.

with

left,

your

of

using

by

Scroliwork

‘

Lever

Lever

E=O

fabric.

on

you

As

wide

alternating

movements.

variegated

B=+

are

satin

Clamp

following

stitches,

the

An

work

rhythm

exciting

thread.

the

move

into

and

note

em

scrollhoops

the

may

41

R7150

Page 43

44088

J

Beautiful

with

Ploff’s

fabrics,

such

fabrics

are

needle

has

insertion.

Hemstitching

I

Sew

first

2

Stop

machine

3

Lift

sewing

4

Sew

second

needle

S

If

you

ore

right

at

Imitation

Machine

Stitch

hemstitching

System

as

batiste,

not

recommended

a

slightly

The

hemstitching

very

is

row

on

when

foot,

turn

row,

holes

of

previous

making

turning

points,

Length:

130

simple

the

needle

as

more

Setting:

effects

(wing)

organdy,

thicker

left

fabric

shown

than

pivot

(see

of

zigzag

Hemstitching

Dial

1_li/s

on

handkerchiefs,

needle

georgette,

because

shank,

needle

sketch).

the

area

to

is

fabric

in

direction

in

the

in

sketch,

stitches

lines

two

fabric

on

A=21/s

available

the

cannot

be

on

guiding

as

of

hemstiiching,

needle,

Increase

etc.,

needle

needle

be

threaded

hemstitched.

right.

the

of

arrow,

material

it

descends

and

Lever

Tension

blouses,

Pfaff

at

well

are

penetrations

set

screw

lower

and

parallel

on

the

alternotely

proceed

as

Hemstitching

4

Hemstitching

rics.

Draw

machine

along

“zigs”

opposite

to

thread

Draw

the

length

you

will

B=

dresses,

stores

suited

must

with

foot

to

right4

directed

For

several

both

and

threads

‘4

close

be

the

first

leave

this

for

each

bar

you

have

Dial

and

so

at

extra