Page 1

SRP

Supplement to the instruction

manual and parts list for the

series 1180, 938 U

296-12-18 748/002

engl. 01.2007

Page 2

Reprinting, copying or translation of PFAFF instruction manuals, whether in whole or in

part, is not permitted without our prior permission and not without written indication of the

source.

PFAFF Industrie Maschinen AG

Postfach 3020

D-67653 Kaiserslautern

Königstr. 154

D-67655 Kaiserslautern

Page 3

Index

Contents ..................................................................................Page

1 Proper use .......................................................................................................................... 4

2 Controls ................................................................................................................................ 5

2.01 Knee switch ..........................................................................................................................5

2.02 Control panel ..........................................................................................................................6

2.02.01 Screen displays ...................................................................................................................... 6

2.02.02 Function keys ......................................................................................................................... 6

2.02.03 Selecting and altering parameters ......................................................................................... 9

2.02.04 Selecting the user level ........................................................................................................ 10

3 Commissioning .................................................................................................................. 11

3.01 Basic position of the machine drive ..................................................................................... 11

3.02 Testing the function of the start inhibitor ............................................................................. 12

4 Setting up ........................................................................................................................... 13

4.01 Entering the maximum speed ............................................................................................. 13

4.02 Setting the presser foot pressure ........................................................................................ 13

4.03 Entering the start and end backtacks ................................................................................... 14

4.04 Setting the stitch counting function for the bobbin thread control ...................................... 15

5 Sewing ................................................................................................................................ 16

5.01 Manual sewing .................................................................................................................... 16

5.02 Programmed sewing ............................................................................................................ 17

5.03 Error messages .................................................................................................................... 18

6 Parameter Settings ............................................................................................................. 19

7 Internet update of the machine software ......................................................................... 20

8 Reset / Cold start ................................................................................................................ 21

9 Parts list ............................................................................................................................. 22

10 Circuit diagrams ................................................................................................................. 23

Page 4

Proper use

1 Proper use

The SRP system uses a linear motor to adjust the presser foot pressure to the actual sewing

speed or workpiece. In addition the presser foot clearance can be adjusted individually.

The adjustments are made by altering parameter values, see Chapter 2.02.03 Selecting/

altering parameters.

Any and all uses of this machine which have not been approved of by the

manufacturer are considered to be inappropriate! The manufacturer cannot be

held liable for any damage caused by the inappropriate use of the machine!

The appropriate use of the machine includes the observance of all operational,

adjustment, maintenance and repair measures required by the manufacturer!

4

Page 5

Controls

2 Controls

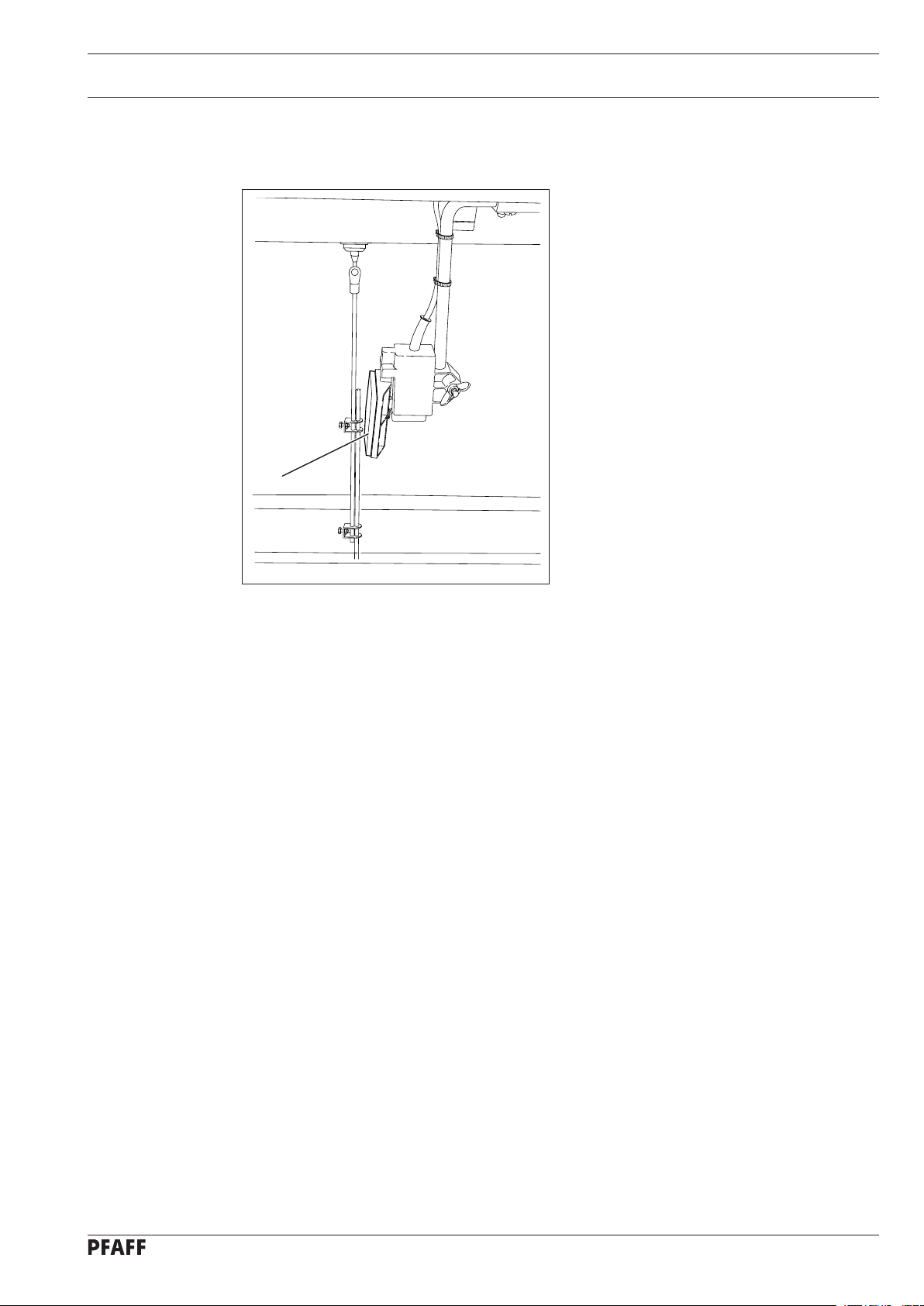

2.01 Knee switch

By operating knee switch 1, the presser

●

foot can be raised when sewing is inter-

rupted.

1

Fig. 2 - 01

5

Page 6

Controls

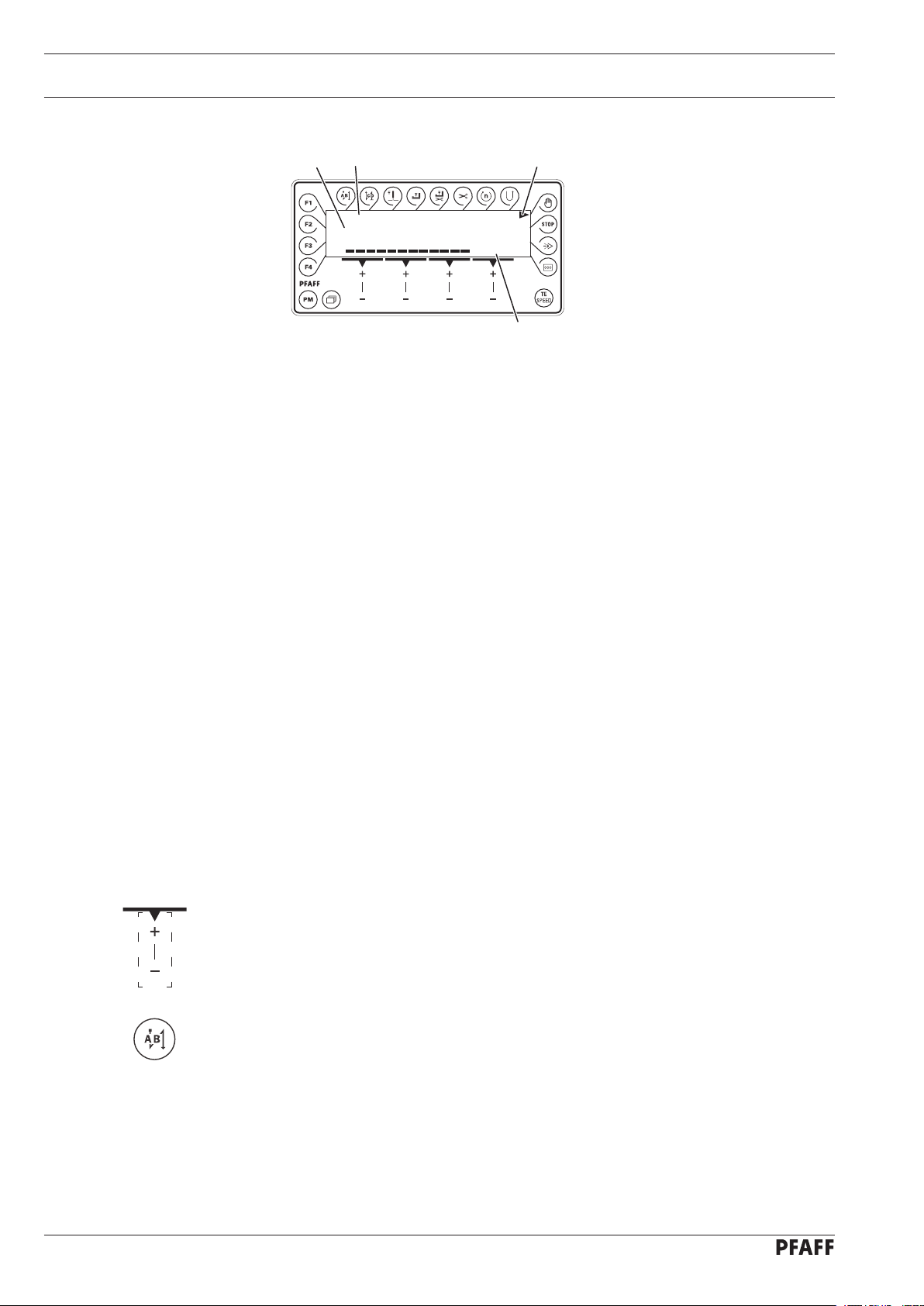

2.02 Control panel

1

The control panel consists of display 1 and the function keys described below. The display

1 consists of a two-line alpha-numerical LCD display with 16 symbols per line. The texts 3

show the respective status of the function keys and the operating status of the machine.

The control panels switches on all LCD-segments and the horn automatically for a short time

during the power-on phase, after which the lettering PFAFF appears on the display, until the

higher-ranking control unit sends commands to the control panel.

2.02.01 Screen displays

3

Speed

4000 SRP

2

30%

4

Activated functions are displayed with a triangular marking 2 below or next to the respec-

●

tive function key.

●

In the sewing mode all relevant sewing data is displayed and these can be changed di

rectly, depending on the status of the machine, see also Chapter 5 Sewing.

●

During the parameter input the selected parameter number with the corresponding value

is displayed, see Chapter 2.02.03 Selecting/changing parameters.

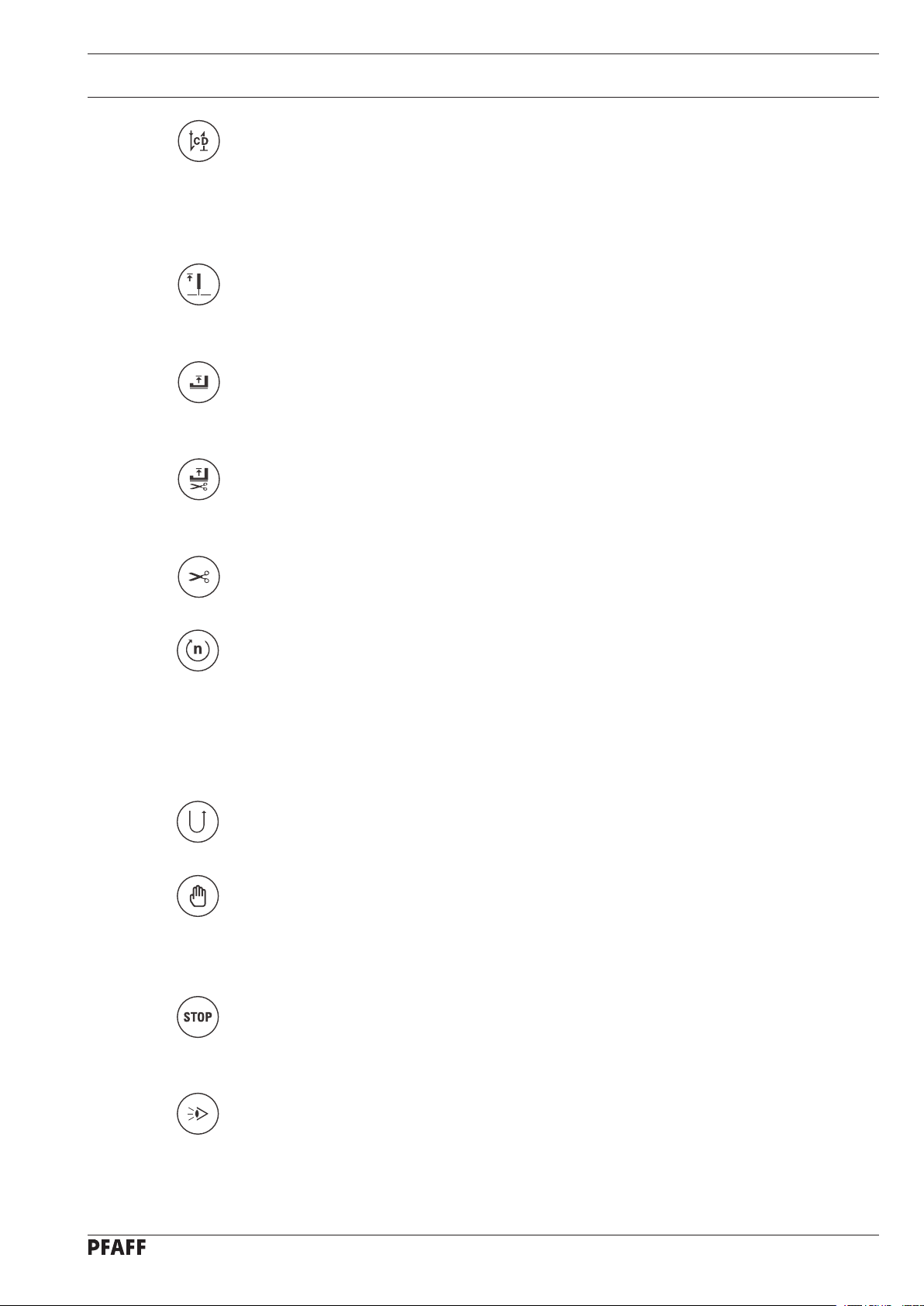

2.02.02 Function keys

The function keys described below are used basically to switch machine functions on and

off.

If a corresponding value has to be set for the activated function, this is carried out with the

corresponding +/- key. By pressing and holding the corresponding +/- key, the appropriate

numerical value 4 is changed slowly to begin with. If the corresponding +/- key is held down

longer, the values change more quickly.

Start backtacks

If this key is pressed, the backtacks at the beginning of the seam (start backtacks) are

●

switched on or off. The number of forward stitches (A) or reverse stitches (B) for the start

backtacks can be changed by pressing the +/- key underneath. To convert from double

backtack to single backtack set the corresponding number of stitches at zero.

-

6

Page 7

Controls

End backtacks

If this key is pressed, the backtacks at the end of the seam (end backtacks) are switched

●

on or off. The number of reverse stitches (C) or forward stitches (D) can be changed by

pressing the +/- key underneath. To convert from double backtack to single backtack set

the corresponding number of stitches at zero.

Needle position

If this key is pressed the corresponding function is switched on or off. When the function

●

is switched on, the needle positions at t.d.c. after sewing stops.

Foot position after stop

●

If this key is pressed the corresponding function is switched on or off. When the function

is switched on, the presser foot is raised after sewing stops.

Foot position after trimming

●

If this key is pressed the corresponding function is switched on or off. When the function

is switched on, the presser foot is raised after thread trimming.

Thread trimmer

If this key is pressed the thread trimming function is switched on or off.

●

Speed (only in programmed sewing)

If this key is pressed the corresponding function is switched on or off. In the seam pro-

●

gram the speed is not dependent on the pedal. When the function is switched on, the

speed cannot be adjusted by pedal. Sewing can only be carried out at the set maximum

speed.

●

If the function is switched off, the speed up to maximum speed is adjusted by the pedal.

Reverse sewing

●

If this key is pressed the reverse sewing function is switched on or off.

Manual seam (only in programmed sewing)

If this key is pressed the machine switches to manual sewing. When the function is swit-

●

ched on, the move to the next seam section is not carried out by stitch counting or sensor, but manually with the use of the pedal (position "-2").

Stop

If this key is pressed the corresponding function is switched on or off. When the function

●

is switched on, the machine stops automatically at the end of a seam section.

Sensor

●

In manual sewing the number of compensating stitches from the point where the photo

cell is light to the end of the seam can be set under parameter 111, and in programmed

sewing directly.

7

-

Page 8

Controls

Stitch counting

If this key is pressed the corresponding function is switched on or off. The value for the

●

compensating stitches can be changed immediately with the corresponding +/- key.

When the function is switched on, the machine moves to the next seam section after se-

wing the number of stitches entered.

TE/Speed

In the programmed sewing mode, the number of stitches is entered by stitching them

●

off.

●

If this key is pressed once, the machine changes to parameter input.

●

If this key is pressed twice (within

Scrolling

●

If this key is pressed in the programmed sewing mode, the machine scrolls through the

input menus on the display.

PM

If this key is pressed the programmed sewing function is switched on or off. When the

●

function is switched on, the letters "PM" appear on the display of the control panel. The

parameters related to the program are shown in the alpha-numerical part of the display.

F1

No function assigned

●

F2

No function assigned

●

F3

No function assigned

●

5 seconds) the machine changes to stitch input.

F4

No function assigned

●

8

Page 9

Controls

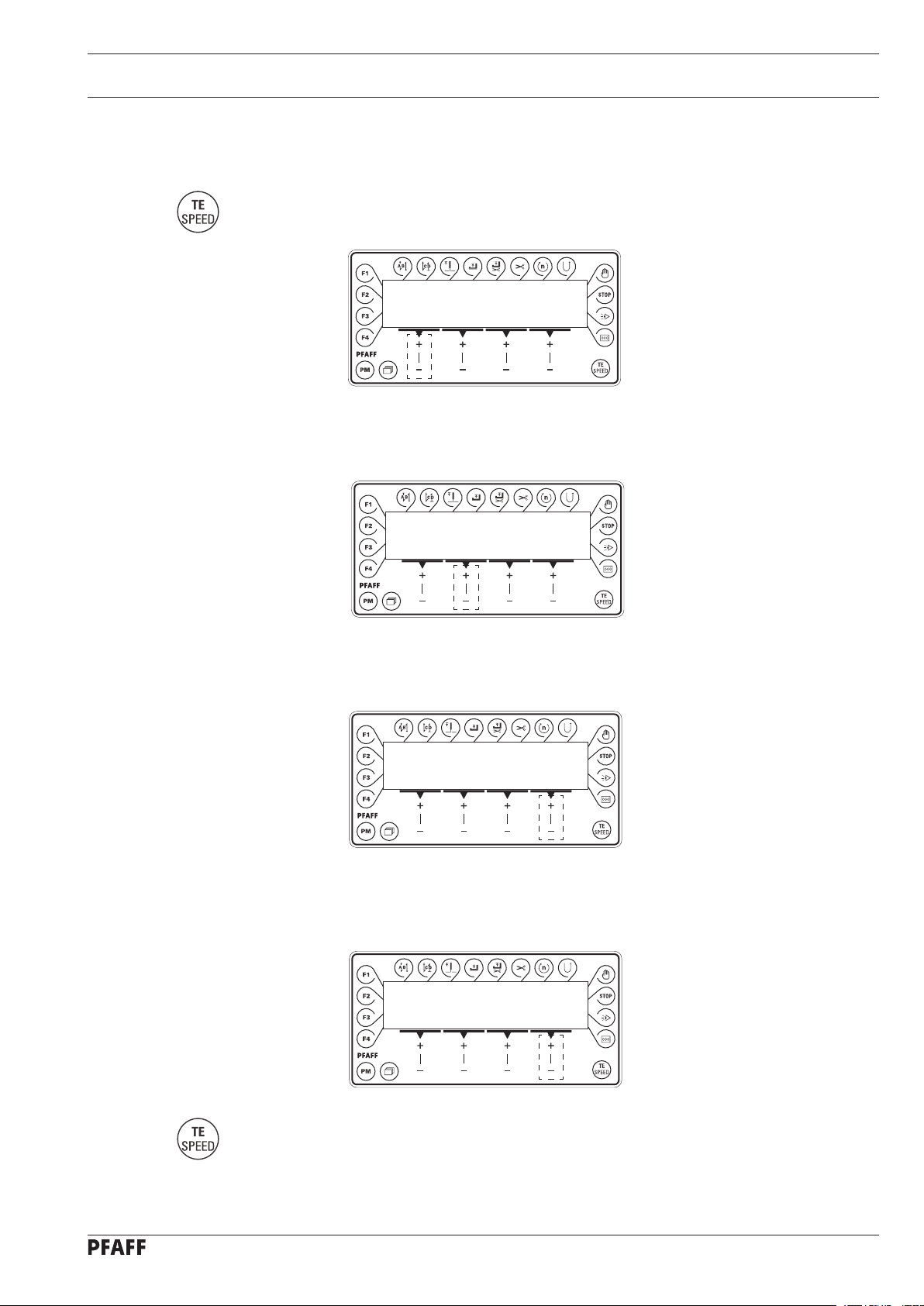

2.02.03 Selecting and altering parameters

Switch on the machine.

●

No

No

●

Press the

By pressing the corresponding +/- key select the desired parameter group, e.g. "600".●

By pressing the corresponding +/- key select the desired parameter, e.g. "660" for the

●

bobbin thread monitoring function.

TE/Speed key to call up the parameter input function.

TE

No

200

TE

No

600

VAL

TE

No VAL

660 1

By pressing the corresponding +/- key set the desired value for the parameter selected,

●

e.g. "

2" for the "bobbin rest thread counter on" function..

TE

No VAL

660 2

Press the TE/Speed key to take over the value and change to the sewing mode.●

9

Page 10

Controls

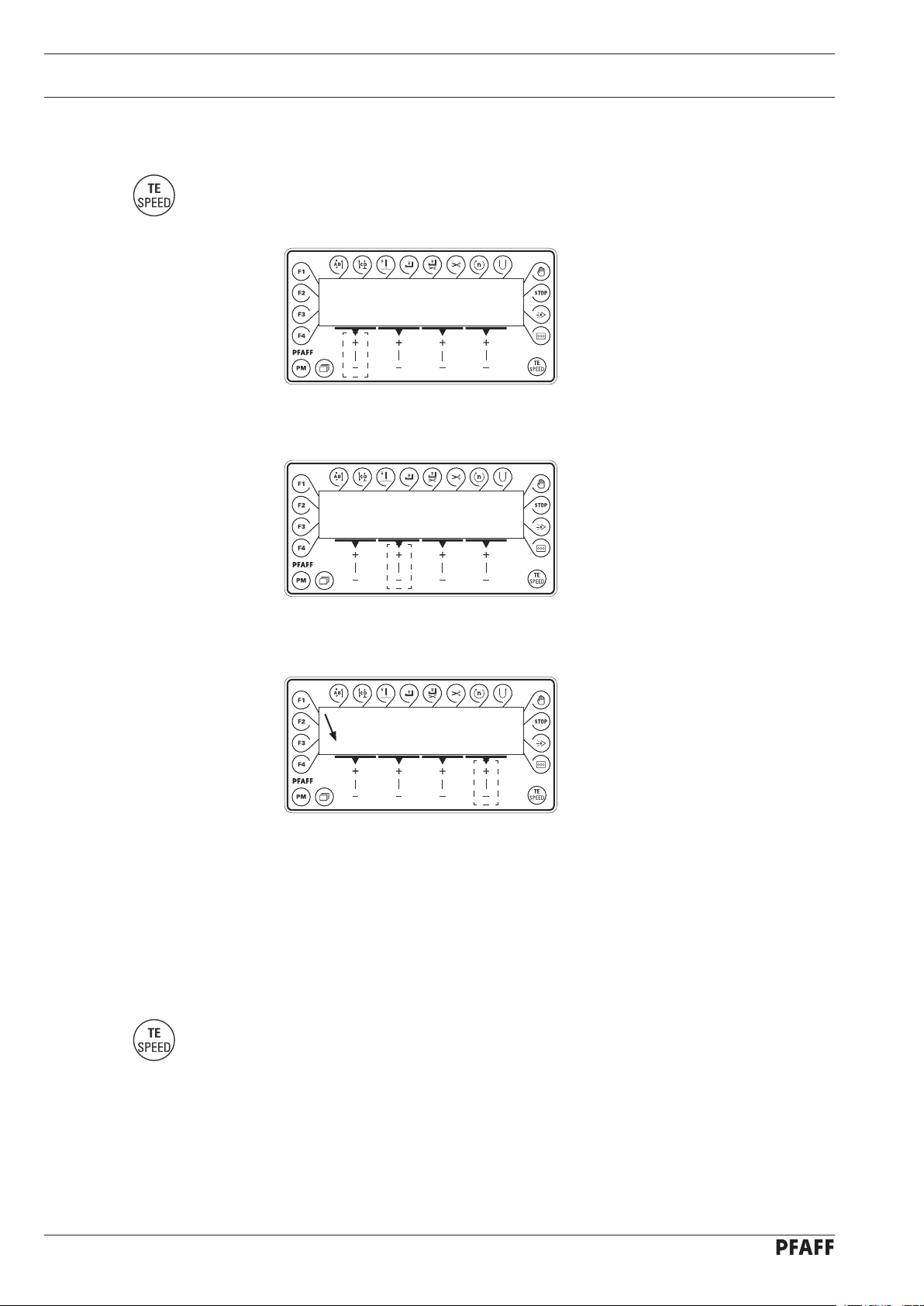

2.02.04 Selecting the user level

Switch on the machine.

●

No

No

●

Press the

By pressing the corresponding +/- key select the parameter group "700".●

By pressing the corresponding +/- key

TE/Speed key to call up the parameter input function.

TE

No

101

TE

No

A 798 0

select the parameter "798".●

VAL

TE

No VAL

B 798 1

By pressing the corresponding +/- key select the desired user level:

●

0" = operator level A

"

"1" = technician level B

"11" = service level C

The respective level is displayed on the screen. (see arrow)

Press the TE/Speed key to take over the value and change to the sewing mode.

●

10

Page 11

Commissioning

3 Commissioning

3.01 Basic position of the machine drive

Switch on the machine.●

Speed

4000 SRP

30%

No

Press the

●

●

Select the technician level B (value "

TE/Speed key to call up the parameter input function.

Selecting the user level.

TE

No VAL

B 798 1

By pressing the corresponding +/- key

TE

No

B 700 0

1") with parameter "798", see Chapter 2.02.04

select the parameter group "700".●

Sew a stitch by operating the pedal.

●

●

Turn the balance wheel in the direction of sewing until the needle point is level with the

top edge of the needle plate.

●

Press the TE/Speed key to take over the setting and to conclude the input.

11

Page 12

Commissioning

3.02 Testing the function of the start inhibitor

●

ERROR

9

PRESS TE-SPEED

Switch the machine on at the main switch and tilt back the sewing head.

The error message "ERROR 9" must appear on the control panel.

●

If the message does not appear, check the setting of the safety switch

(in the machine instruction manual).

●

Set the sewing head upright again and acknowledge the error message by pressing the

TE/Speed key. The machine is ready for operation again.

12

Page 13

Setting up

4 Setting up

.01 Entering the maximum speed

4

Switch on the machine.●

Speed

4000 SRP

30%

Enter the maximum speed by pressing the corresponding +/- key.●

4.02 Setting the presser foot pressure

Speed

4000 SRP

30%

The presser foot pressure is adjusted with the sewing speed. The greater the sewing speed,

the higher the pressure foot pressure. By altering the percent increase of the presser foot

pressure, the increase of the presser foot pressure can be infl uenced by an increased sew-

ing speed. The current pressure foot pressure can be seen on the bar graph display.

Switch on the machine.

●

Set the desired percent increase of the presser foot pressure by pressing the correspon-

●

ding +/- key.

13

Page 14

Setting up

4.03 Entering the start and end backtacks

Switch on the machine.

●

2x

A

●

Select the manual sewing mode by pressing the "

●

Press the

By pressing the corresponding +/- key select the desired value for the number of forward

●

stitches (A) of the start backtack.

TE/Speed key twice to select the input menu for start and end backtacks.

In the programmed sewing mode it is possible to call up the input menu for

start and end backtacks by pressing the scroll key, see Chapter

med sewing.

PM

A B C C

3 3 3 3

PM" key.

5.02 Program-

B

C

D

●

By pressing the corresponding +/- key select the desired value for the number of reverse

stitches (B) of the start backtack.

●

By pressing the corresponding +/- key select the desired value for the number of reverse

stitches (C) of the end backtack.

●

By pressing the corresponding +/- key select the desired value for the number of forward

stitches (D) of the end backtack.

14

Page 15

Setting up

4.04 Setting the stitch counting function for the bobbin thread control

Switch on the machine.

●

2x

No

VAL

●

Press the

By pressing the corresponding +/- key select the parameter "760".●

Press the corresponding +/- key to set the number of remaining stitches, which can still be

sewn after recognition by the bobbin thread control function.

The selected value is multiplied by 10*

Example display 5 x 200** = 1000 stitches. The setting depends among other things on the

thread strength.

TE/Speed key to call up the parameter input function.

TE

No VAL

A 101 ON

TE

No VAL

A 760 5

or 200** and the result is the number of stitches.

If the TE/Speed key is pressed, the value is taken over and the machine changes into the

●

sewing mode.

The bobbin thread rest counter can only be used, if parameter "

lue "1" or "2".

* If for parameter

** If for parameter

660 the value is "1", the multiplier is 10

660 the value is "2", the multiplier is 200

660" is set at va-

15

Page 16

Sewing

5 Sewing

5.01 Manual sewing

In the sewing mode all relevant adjustments for the sewing operation are shown on the dis-

play and can be altered directly. Functions can be switched on and off by pressing the key.

In this mode a difference is made between manual sewing and programmed sewing. To

change from manual to programmed sewing, press the PM key. In programmed sewing the

text "PM" appears on the display.

After the machine has been switched on, the max. speed and presser foot pressure can be

adjusted with the corresponding +/- keys.

Speed

4000 SRP

30%

Further functions in manual sewing, also see Chapter 2.02.02Function keys:

Start backtacks on/off

End backtacks on/off Thread trimming on/off

Needle position raised on/off Sensor on/off

Presser foot raised on/off

Presser foot raised after

thread trimming on/off

16

Page 17

Sewing

5.02 Programmed sewing

In the programmed sewing mode 99 programs, each with 9 seam sections and 999 stitches,

can be programmed.

The fixed programs are used for the quick and easy production of seams with different

numbers of stitches. The pedal setting "0" is used to switch to the next seam section.

After the machine has been switched on and the programmed sewing mode has been

selected with the PM key, the display appears for selecting the program number, seam

section and number of stitches.

PM

current

program number

1 1 13

current seam segment

number of stitches

With the scroll key other menus can be selected for entering the values for start and end

backtacks and the maximum speed in the corresponding seam section.

PM

speed in current

seam segment

1000 5 0

program number

of linked program

number of seam segments

Further functions in programmed sewing, also see Chapter 2.02.02 Function keys:

Start backtacks on/off Seam section speed on/off

End backtacks on/off

Reverse sewing direction on/

off

Needle position raised on/off Manual sewing on/off

Presser foot raised on/off Stop on/off

Presser foot raised after

thread trimming on/off

Sensor on/off

Thread trimming on/off Stitch count on/off

17

Page 18

Sewing

5.03 Error messages

If a fault occurs, the text "ERROR" appears on the display, together with an error code and

short instructions. An error message is caused by incorrect settings, faulty elements or

seam programs as well as by overload conditions.

ERROR

9

PRESS TE-SPEED

Correct the error.

●

●

Acknowledge error correction by pressing the TE/Speed key

.

18

Page 19

Parameter Settings

6 Parameter Settings

Group

Parameter

Description

2

251 Presser foot clearance when raised

by pedal (pedal position –2)

Access level

Adjustment

range

B, C 0 - 255 160

Standard value

252 Presser foot clearance when raised

B, C 0 - 255 150

by knee switch

256 Min. presser foot pressure during sewing B, C 0 - 32 10

258 Machine feed type

B, C 0 - 1 0

1 = needle feed, 0 = bottom feed

287 Presser foot clearance when raised

B, C 0 - 255 150

by pedal (pedal position –1)

288 Presser foot holding pressure while the

B, C 0 - 255 80

M/C is stoped

6

607 Maximum speed B, C 300 - 5500

660 Bobbin thread monitoring

B, C 0 - 2

0 = off

1 = by sensor (-926/06)

2 = by stitch counting

7

Needle position 0

700

B, C 0 - 255

(needle reference position

702 Needle position 1 (needle lowered) B, C 0 - 255 90

703 Needle position 2 (take-up lever raised) B, C 0 - 255 236

4000

1180

= 1

938 U

= 0

*

760 Multiplier for the fixed value (200) for

A,B, C

0 - 250 5

stitch count

799 Selected machine class C 1 - 2 1

8

800 Rotating direction of the motor

9

985 Switch on angle for thread trapper B,C 0 - 255 67

C 0 - 1 0

986 Switch off angle for thread trapper B,C 0 - 255 206

989 Thread trapper at beginning of seam

B,C 0 - 2 0

1 = yes, 0 = no

*

Adjustment see Chapter 3.01 Basic position of the machine drive unit.

The standard values listed in the table are basic settings, which can be altered if

necessary.

For more displays and information see the motor instruction manual.

19

Page 20

Software-Update

7 Internet update of the machine software

The machine software can be updated with PFAFF flash programming. For this purpose the

PFP boot program and the appropriate control software for the machine type must be in-

stalled on a PC. To transfer the data to the machine, the PC and the machine control unit

must be connected with an appropriate null modem cable (part no. 91-291 998-91).

The PFP boot program and the control software of the machine type

can be downloaded from the PFAFF-homepage using the following path:

www.pfaff-industrial.com/pfaff/de/service/downloads

To update the machine software carry out the following steps:

While the machine software is being updated, no setting up, maintenance or

adjustment work may be carried out on the machine!

Switch off the machine.

●

Connect the PC (serial interface or appropriate USB-adapter) and the machine control unit

●

(RS232).

Switch on the PC and start the PFP boot program.

●

Select the machine type.

●

Press the "programming" button.

●

An auxiliary program (Quickloader) is started.

●

Switch on the machine within

●

The software update is carried out, the updating status is shown on the bar display.

●

60 seconds.

After the update has been completed, the message "Software updated successfully

●

completed" appears.

If this message does not appear, the entire procedure must be repeated!

The operational reliability of the machine is not restored until the programming

has been carried out successfully and without errors.

Switch off the machine, end the quickloader and PFP-boot program.

●

End the connection between the PC and the machine control unit.

●

Switch on the machine.

●

A plausibility control is carried out and, if necessary, a cold start.

More information and assistance is at your disposal in the file "PFPHILFE.TXT",

which can be called up from the PFP boot program by pressing the "help"

button.

20

Page 21

Reset / Cold start

8 Reset / Cold start

After selecting the reset menu, by pressing the corresponding key it is possible to delete

seam parameters, to delete seam programs or to carry out a cold start.

A

Press and hold "+" on keys A and D and switch on the machine.

●

Select Reset

1 2 3

A

B

1 = Resetting the seam parameters

●

Press "+" on key A.

All seam parameters are deleted, "MASTER-RESET 1" is displayed for a short time on the

screen.

2 = Resetting the seam programs

Press "+" on key

●

All seam programs are deleted, "MASTER-RESET 2" is displayed for a short time on

the screen.

B.

D

D

3 = Cold start

Press "+" on key

●

The values of the machine control unit are set back to their basic values, except the value

for the machine class. "COLD START" is displayed for a short time on the screen.

After a cold start, all programmed values are reset to their state at the time of

delivery. For this reason, after a cold start, the parameters 799, 800

must be checked and reset if necessary.

D.

and 700

21

Page 22

Parts list

91-262 908-05

X 8

91-262 893-91

91-264 156-05

12-360 063-05 (2x)

91-262 900-05 (2x)

11-130 233-15 (4x)

11-130 203-15

12-640 130-55

91-262 931-05

91-118 711-05

91-262 770-05

91-264 769-92

11

-132 223-15

11

-330 955-15

99-137 341-01

91-262 926-11

91-264 186-91

40/3

12-360 043-05 (3x)

12-610 190-45

11-225 220-15 (3x)

91-264 187-91

12-640 130-55 (2x)

91-262 931-05 (2x)

91-262 929-15

99-137 341-0

1

91-262 930-05

12-024 191-15

71-170 002-20

11-130 086-15 (2x)

91-262 962-91

91-262 958-15

Y 8

12-005 154-15 (3x)

9 Parts list

Only on the

PFAFF 1181, 1183)

22

Page 23

Circuit diagrams

14 Stromlaufpläne

10 Circuit diagrams

.01 Reference lists for the circuit diagrams of the 938 U

10

(Connection diagram 91-191 478-95)

A1 Controller Quick P50 ED

A2 Control panel BDF S2

A14 Sewing head recognition unit (OTE)

B1 Initiator zig-zag stitch control

H1 Sewing lamp

H10 LED Stitch counter

M1 Sewing motor

M2 Linear motor SRP

Q1 Main switch

S1 Pedal set value transmitter

S2 SRP knee switch

S6 Start inhibitor key

S41 Manual backtacking key

S42 Needle position change key (threading key)

S43 Single stitch switch

X0 PC-interface (RS 232)

X1 M1 Sewing motor

X2 M1 Incremental transmitter

X3 S1 Speed control unit

X4 Control panelBDF S2

X5 Outputs-Inputs

X6 Bobbin thread monitor (optional)

X7 Light barrier (optional)

X8 M2 SRP

X12 S2 SRP knee switch

X22 Y2 -900/.. Thread trimmer (FS)

X24 Y4 -910/.. Automatic foot lift

X25 Y5 -911/.. Backtacking

X28 Y8 Thread tension release (FSL)

X40 S4. Keyboard

X46 S6 Start inhibitor

X50 A14 Sewing head recognition unit (OTE)

Y2 -900/.. Thread trimmer

Y4 -910/.. Automatic foot lift

Y5 -911/.. Backtacking

Y8 Thread tension release (FSL)

23

Page 24

Circuit diagrams Version 05.11.03 91-191 478-95 Part1

24

Page 25

91-191 478-95 Part 2 Version 05.11.03 Circuit diagrams

25

Page 26

Circuit diagrams Version 05.11.03 91-191 478-95 Part3

26

Page 27

10.02 Reference lists for the circuit diagrams of the 1181 and 1183

(Connection diagram 91-191 517-95)

A1 Controller Quick P50 ED

A2 Control panel BDF S2

A14 Sewing head recognition unit (OTE)

H1 Sewing lamp

H10 LED Stitch counter

M1 Sewing motor

M2 Linear motor SRP

Q1 Main switch

S1 Pedal set value transmitter

S2 SRP knee switch

S6 Start inhibitor key

S41 Manual backtacking key

S42 Needle position change key (threading key)

S43 Single stitch switch

Circuit diagrams

X0 PC-interface (RS

X1 M1 Sewing motor

X2 M1Incremental transmitter

X3 S1 Speed control unit

X4 A2 Control panel BDF S2

X5 Outputs-Inputs

X6 Bobbin thread monitor (optional)

X7 Light barrier (optional)

X8 M2 SRP

X12 S2 SRP knee switch

X22 Y2 -900/.. Thread trimmer (FS)

X24 Y4 -910/.. Automatic foot lift

X25 Y5 -911/..Backtacking

X28 Y8 Thread tension release (FSL)

X40 S4. Keyboard

X46 S6 Start inhibitor

X50 A 14 Sewing head recognition unit (OTE)

Y2 -900/..Thread trimmer

Y4 -910/.. Automatic foot lift

Y5 -911/.. Backtacking

Y8 Thread tension release (FSL)

232)

27

Page 28

Circuit diagrams Version 12.01.07 91-191 517-95 Part1

28

Page 29

91-191 517-95 Part 2 Version 12.01.07 Circuit diagrams

29

Page 30

Circuit diagrams Version 12.01.07 91-191 517-95 Part 3

30

Page 31

Notes

Page 32

PFAFF Industrie Maschinen AG

Postfach 3020

D-67653 Kaiserslautern

Königstr. 154

D-67655 Kaiserslautern

Telefon: (0631) 200-0

Telefax: (0631) 17202

E-Mail: info@pfaff-industrial.com

Loading...

Loading...