Page 1

Service

Manual

-900/16;/56;-966/05

for

Nr.

296-12-1'»

6i6

Pfaff

Series

240

and

1240

Page 2

Service manual for subclass

-*900/.Pfaff

series 240 and 1240

Note:

The adjustments in this service manual apply to Pfaff machine classes 241,

242, 244, 245 and 246 (small vertical hook) and to classes 1241, 1242, 1243,

1244, 1245 and 1246 (large vertical hook).

Deviations

in

the

various

in

such

data

sections.

as

Needle rise positions:

Models

Models B/C and C:

Models C/D:

Thread trim speed: 150

A

and

r.p.m

B:

1.6

2.0

2.2

mm

mm

to

Tools and other equipment for adjustment

Set

of screwdrivers,

Set of

alien

keys

from

blade

2 to 6

width 2 to 10

mm

needle

2.5

mm

mm

rise

and

clearances

are

indicated

as

such

Set of open-ended spanners

Metal

Sewing thread

rule

and

material

from

4 to 14

mm

Page 3

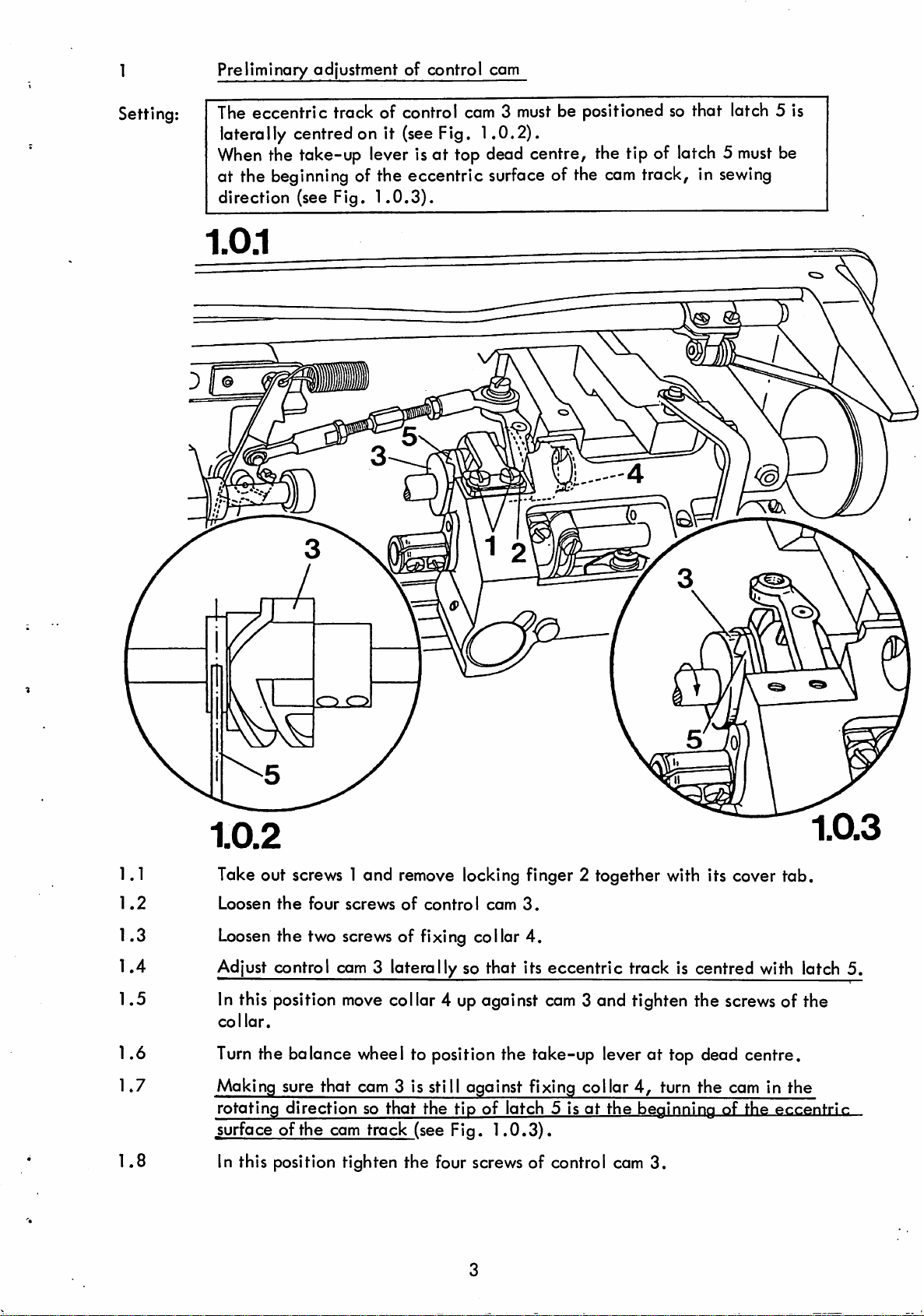

Preliminary adjustment of control cam

Setting;

The eccentric track of control cam 3

laterally centred on it (see Fig.

When

the take-up lever is at top dead centre, the tip of latch 5

must

1.0.2).

be positioned so that latch 5 is

at the beginning of the eccentric surface of the

direction (see Fig.

1

ni

1.0.3).

I)

cam

track, in

o

must

sewing

be

1.1

1.2

1.3

1.4

1.5

1.6

1.7

1.8

1.0.2

Take out screws 1 and remove locking finger 2 together with its cover tab.

Loosen

Loosen

Adjust control cam 3 laterally so that its eccentric track is centred with latch 5.

In this position

collar.

Turn

Making sure that cam 3 is still against fixing

rotating direction so that the tip of latch 5 is at the beginning of the eccentrir

surface of the cam track (see Fig.

In this position tighten the four screws of control com

the

four

screws

the two screws of fixing collar

move

of

control

com

3.

4.

collar 4 up against cam 3 and tighten the

screws

of the

the balance wheel to position the take-up lever at top dead centre.

collar4,turn the cam in the

1.0.3).

3.

Page 4

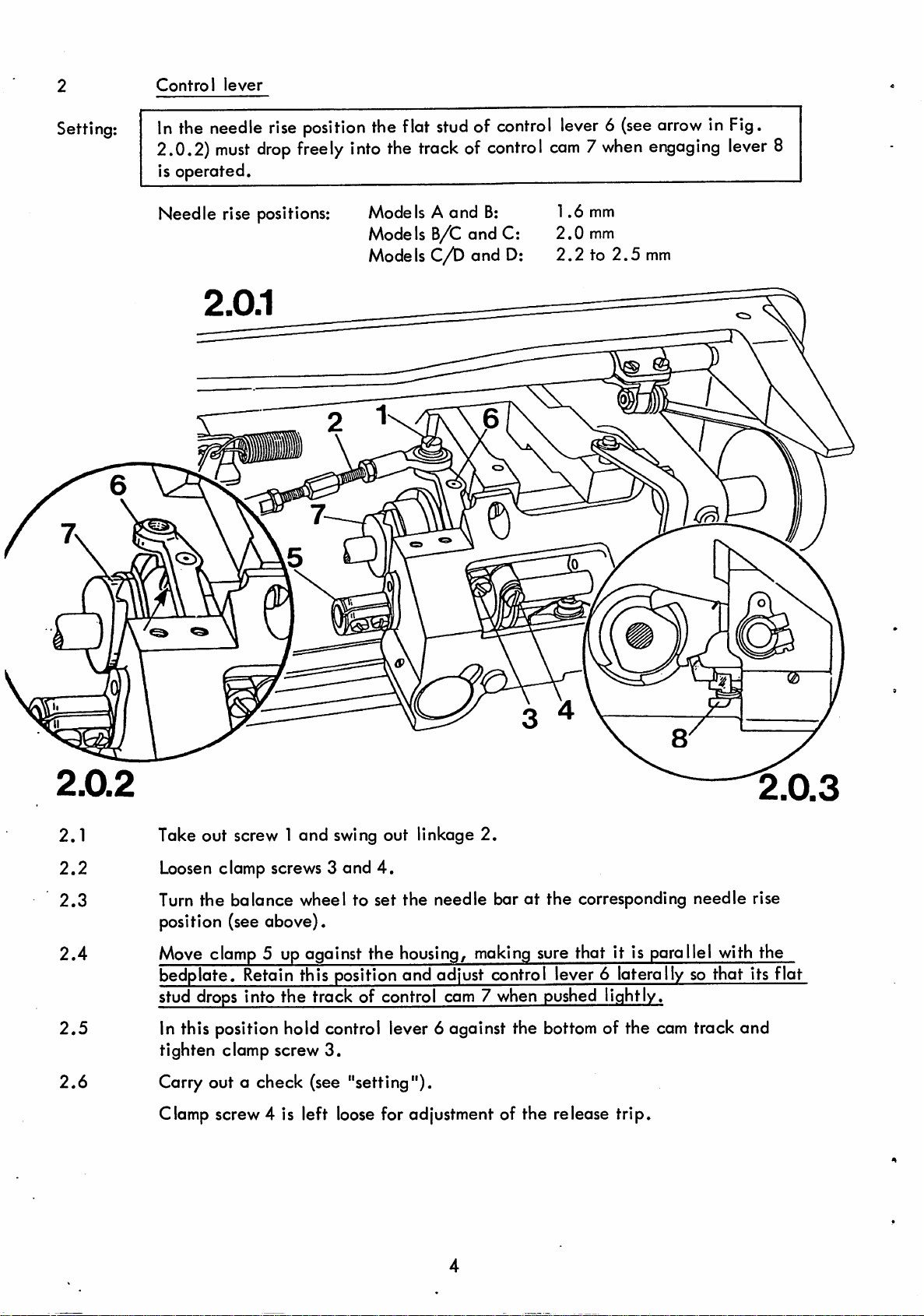

2

Control

lever

Setting:

In

the needle

2.0.2)

must

is operated.

Needle

rise positions:

rise

drop

position

freely

the flat

into

Models

the

studofcontrol

trackofcontrol

A

and

Models B/C and C:

Models C/D and D:

B:

lever6(see

com7when

1.6

mm

2.0

mm

2.2

to

2.5

arrow

engaging

mm

in Fig.

lever

8

2.0.2

2.1

2.2

2.3

2.4

2.5

2.6

2.0.3

Take out screw 1 and swing out linkage 2.

Loosen

Turn the balance wheel to set the needle baratthe corresponding needle rise

position (see above).

Move clomp 5 up against the housing, making sure that it is parallel with the

bedplate. Retain this position and adjust control lever 6 laterally so that its flat

stud drops into the track of control cam 7 when pushed lightly.

In this position hold control lever 6 against the bottom of the cam track and

tighten clamp screw

Carry out a check (see "setting").

Clamp screw 4 is left loose for adjustment of the release trip.

clomp screws 3 and

3.

4.

Page 5

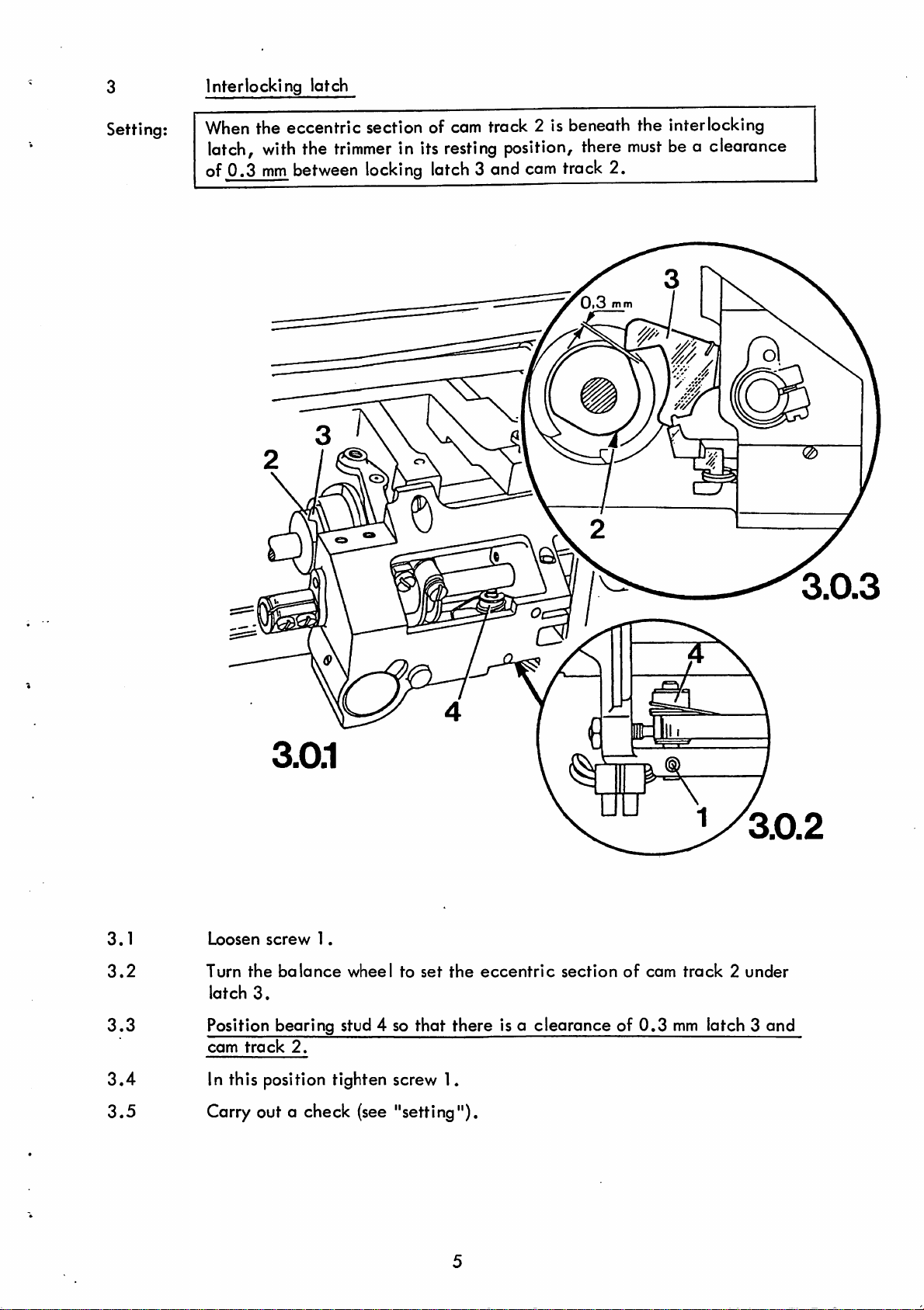

3

Interlocking latch

Setting:

When the

latch,

of 0.3

with

mm

eccentric

the

trimmer

between

section of cam track 2 is beneath

in its

locking

resting

latch

position,

3 and

cam

o

there

track

2.

the

interlocking

must

bea clearance

3.1

3.2

3.3

3.4

3.5

Loosen

Turn

latch

Position bearing stud 4 so

cam

In this position tighten screw 1.

Carry out a check (see "setting").

the

3.

track

screw

balance

2.

1.

wheel

to

set

that

the

eccentric

there is a

section

of

clearanceof0.3

com

track2under

mm

latch 3

and

Page 6

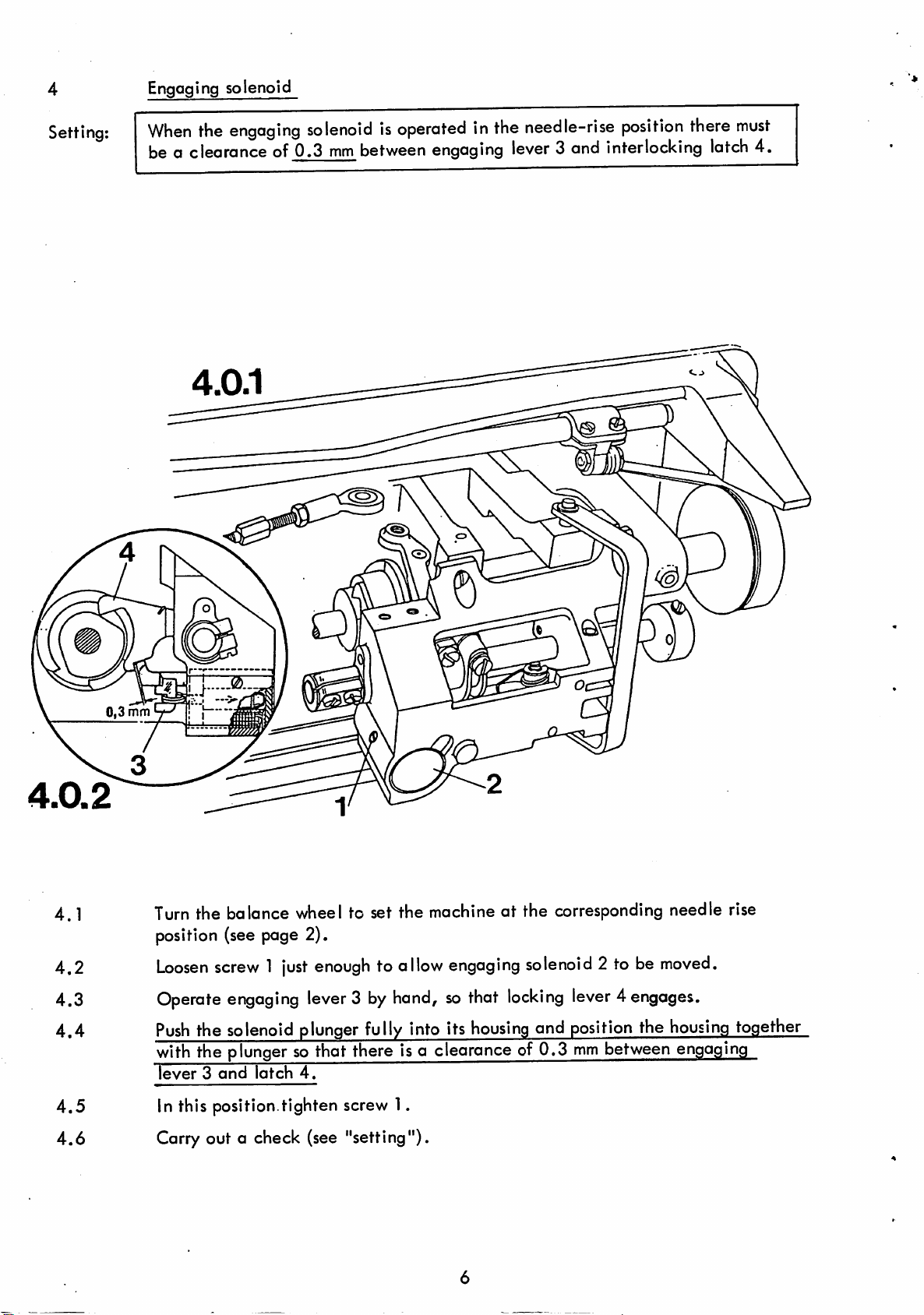

4

Engaging solenoid

Setting:

When

the

engaging

solenoidisoperatedinthe

be a clearance of 0.3

mm

between

engaging

needle-rise

lever

3 and interlocking

position

there

latch

must

4.

4.1

4.2

4.3

4.4

o

Turn

the balance wheel to set the machine at the corresponding needle rise

position (see page 2).

Loosen

Operate

Push

with

lever3and

screw1just

engaging

the

solenoid

the

plungersothat there isa clearanceof 0.3

latch

enoughtoallow

lever3by

plunger

4.

hand,sothat

fully

engaging

into its

housing

solenoid

locking

and

2 to be

moved.

lever4engages.

position

mm

the

between

housing

engaging

together

4.5

4.6

In this position.tighten screw 1.

Carry out a check (see "setting").

Page 7

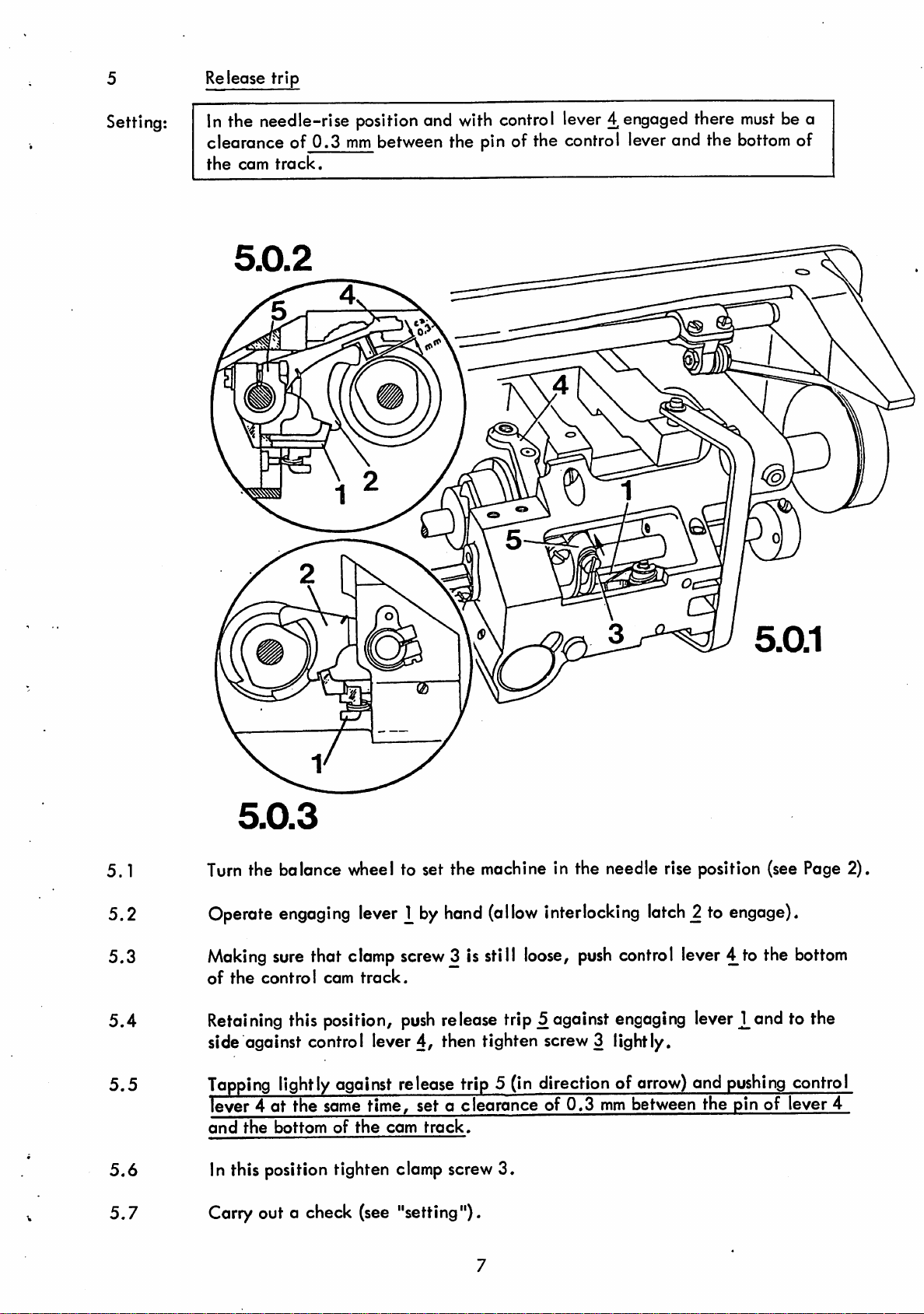

5 Release trip

Setting:

in the needle-rise

clearance of

the

cam

0.3

track.

position

mm

between the pin of the control lever and the

and

with

control

lever4engaged

there

o

must

bottom

bea

of

5.1

5.2

5.3

5.4

5.5

5.6

5.7

5.0.3

Turn

the balance wheel to set the machine in the needle rise position (see Page 2)

Operate

Making

of

the

Retaining

side against control lever 4, then tighten screw3 lightly.

Tapping

lever 4 at the same time, set a clearance of

and

In this position tighten clamp screw

Carry out a check (see "setting").

engaging

sure

that clamp screw3 is still

control

this position,

cam

lever

track.

by

hand

(allow

interlocking

loose,

push

release trip 5 against engaging lever

lightlyagainst release trip 5 (in direction of

the

bottom

of

the

cam

track.

3.

push

0.3

latch

2 to engage).

control lever 4 to the

J_and

arrow)

mm

between the pin of lever 4

and

pushing

bottom

to the

control

Page 8

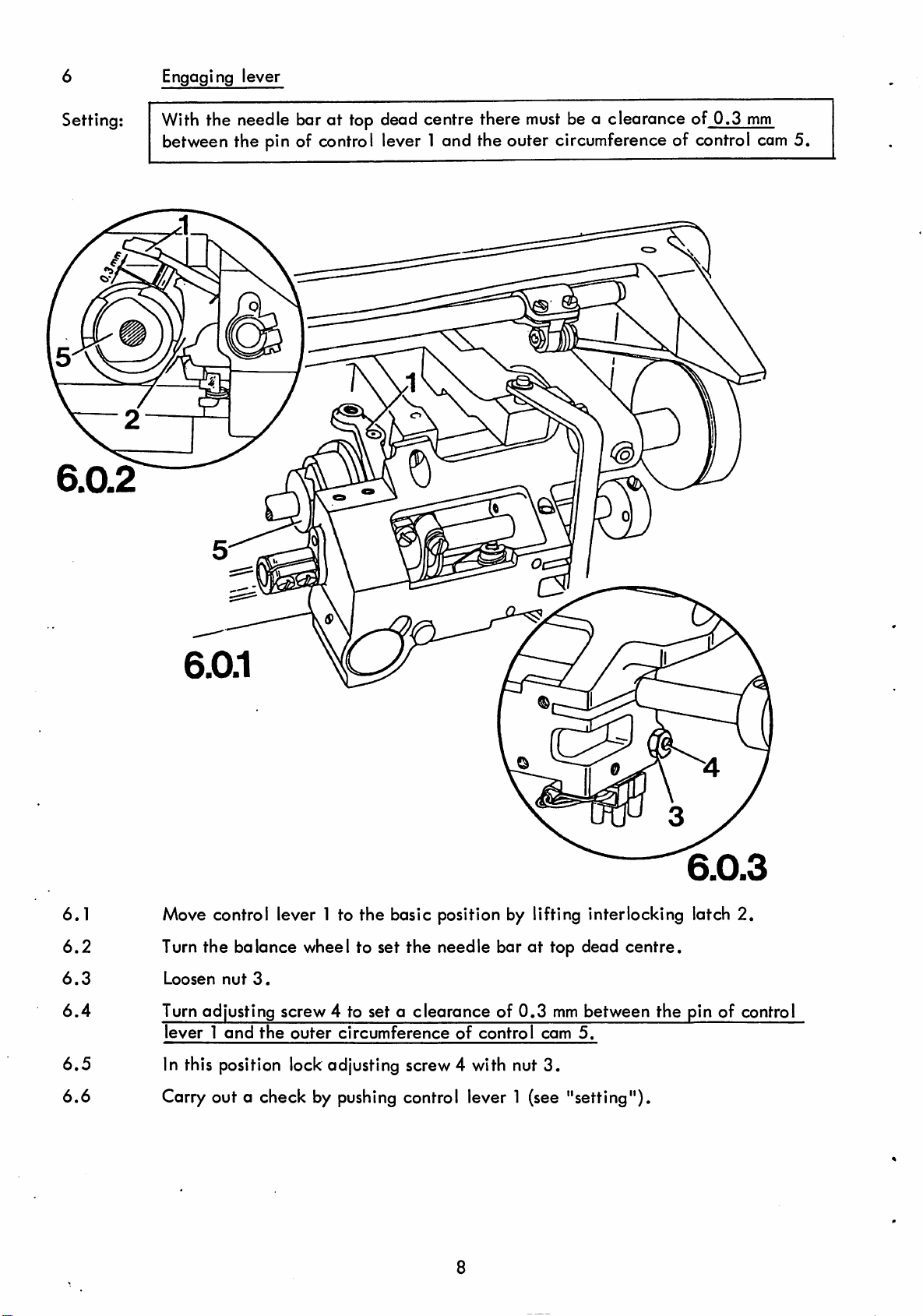

6

Engaging lever

Setting:

With

the needle bar at top dead centre there

must

be a clearance of 0.3

between the pin of control lever 1 and the outer circumference of control

mm

com

5.

6.1

6.2

6.3

6.4

6.5

6.6

Move control lever 1 to the basic position by lifting interlocking latch 2,

Turn the balance wheel to set the needle barattop dead centre.

Loosen

Turn adjusting screw 4 to set a

lever1and

In this position lock adjusting screw 4 with nut

nut

3.

the

outer

clearanceof0.3

circumference

of

control

mm

com

3.

between

5.

Carry out a check by pushing control lever 1 (see "setting").

6.0.3

the

pinofcontrol

Page 9

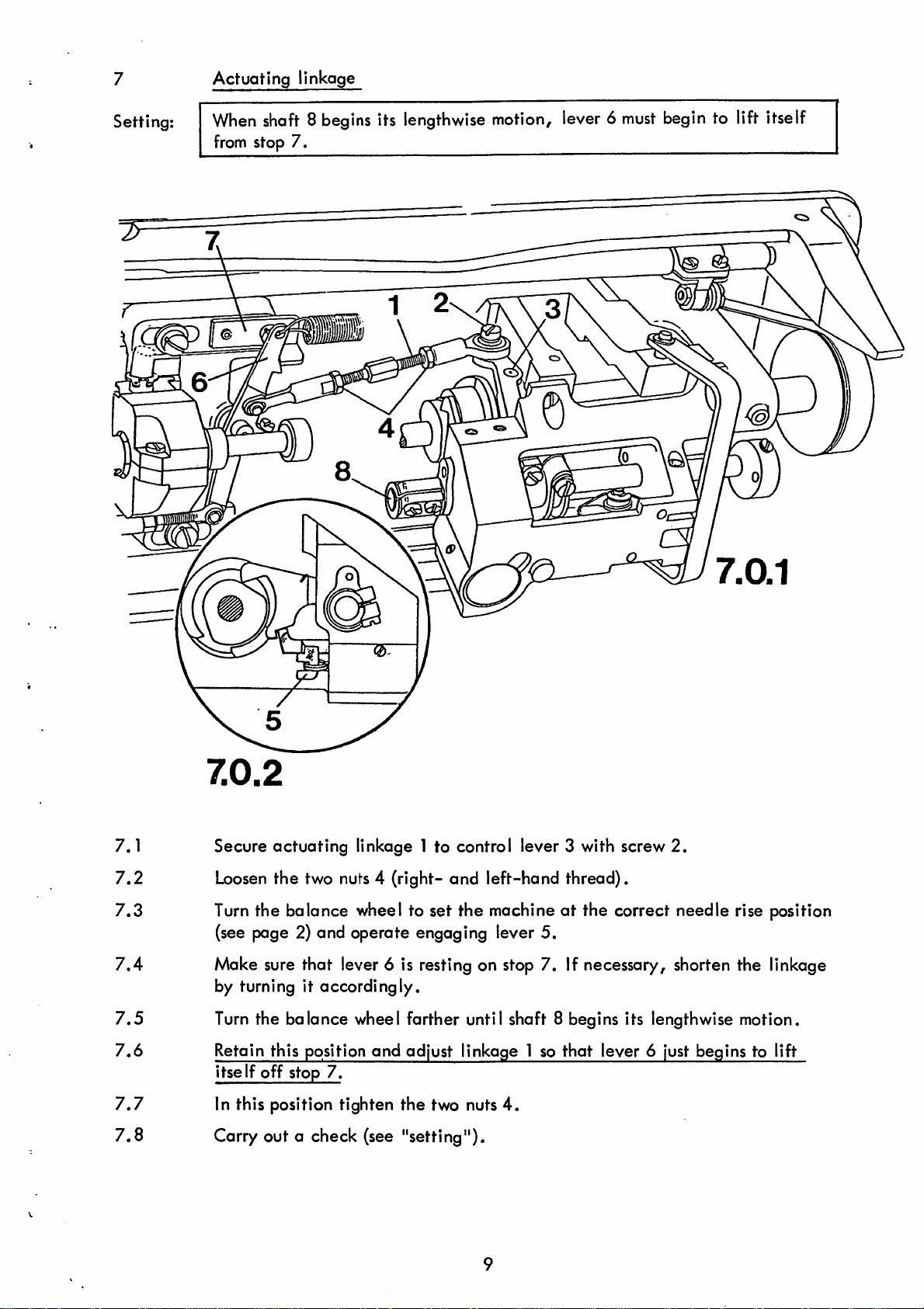

Actuating linkage

Setting:

When

from

shaft8begins

stop 7.

its

lengthwise

motion,

lever6must

begintolift

&

itself

7.1

7.2

7.3

7.4

7.5

7.6

7.7

7.8

7.0.2

Secure actuating linkage 1 to control lever 3 with screw

Loosen

Turn

the two nuts 4 (right- and left-hand thread).

the balance wheel to set the machineatthe correct needle rise position

(see page 2) and operate engaging lever 5.

Make sure that lever 6 is resting on stop 7. If necessary, shorten the linkage

by turning it accordingly.

Turn the balance wheel farther until shaft 8 begins its lengthwise motion.

Retain this position

itself

off

stop

In this position tighten the two nuts

7.

and

adjust

linkage 1 so

4.

that

lever 6 just begins to lift

Carry out a check (see "setting").

2.

Page 10

8

Final adjustment of the control cam

Setting:

When control lever 3 is engaged and the needle, moving up

centre, has reached a position 12

of

catcher

4 must

begin.

mm

above the needle plate, the movement

from

bottom dead

12mm

8.0.4

8.1

8.2

Turn the balance wheel to set the take-up lever a little past top dead centre.

Loosen

the

two

screws

in

control

cam1which

are

now

accessible.

Turn the balance wheel farther to set the machine at the needle rise position

(see page 2). Operate engaging lever 2.

8.3

8.4

8.5

8.6

8.7

8.8

Make sure the control lever is engaged, then

control

Turn

12

Retain this position

feelaresistance.

cam

1.

the balance wheel farther in sewing direction until the needle point is

mm

above the needle

plate.

and

turn control cam 1 in its rotating direction until you

loosen

the remaining

In this position tighten the accessible screws in control cam 1.

Turn

the balance wheel to gain access to the remaining

and

tighten these,

too.

screws

Carry out a check (see "setting").

10

screws

of control

of

cam

1

Page 11

9

Locking finger

Setting:

With the thread

mm

about 5

between

9.0.1

trimmer

locking

in its resting position there

finger 1 and control lever 3.

must

be a clearance of

9.1

9.2

9.3

9.4

—

9.0.2

Fit locking finger 1 with its tab and tighten screws 2 just a

Push

locking finger 1 fully in the direction of the arrow, then position it

laterallysothat

finger

and

control lever

In this position fully tighten screws 2.

Carry out a check (see "setting").

there

is a

clearanceofabout5mm

3.

between

little.

the

locking

11

Page 12

10 Secondary actuating linkage (only on two-needle machines)

Setting:

With

the thread

trimmer

centre to hole centre)

shafts

2.

in its resting position the

must

correspond with the distance between the centres of

length

of linkage 3

(from

hole

10.1

10.2

10.3

10.4

10.5

e

10.0.1

Make sure the trimming mechanism is in its resting position, then loosen the

two nuts 1 (right- and left-hand thread).

Measure

Adjust the length of linkage 3 so that the distance between levers 4 and 5

(measured

the

In this position lock the two nuts 1.

Carry out a check (see "setting").

centres

the

distance

between

of

shafts

between

the

2.

hole

the

centres)

centres

corresponds

of

shafts

2.

with

the

distance

between

12

Page 13

11

Catcher

height

Setting;

Adjustment

When

operating

sewing hook 4 by 0.1

3

to be

mode

the

take-up

positionbyhand,

2

leverisat

11

twice

mm.

on

two-needle

top

dead

the

lower

centre

catcher

ro^

machines

and

catcher2is

point

must

pushedtoits

clear

the

back

of

11.0.1

(S)

11.0.2

11.1

11.2

11.3

11.4

11.5

11.6 Carry out a check (see "setting").

Loosen

Loosen

Turn the balance wheel to set the take-up leverattop dead centre.

Set

hook

In this position, fully tighten the screws of fixing collar

that the latter is resting on the shaft bearing.

Clamp screw 1 is left

clamp screw 1 just enough to allow catcher 2 to turn.

the two screws in fixing collar

catcher

4.

2 so that its lower point is

loose

for the following adjustment.

3.

0.1

mm

above

the back of sewing

3,

making sure

13

Page 14

12

Trimmer

knife

Setting:

Adjustment

The

elongated

the knife

When

knife 3 must rest lightly on the catcher.

the

to be

made

twice

holeofthe

must

not touch the casting (see arrow).

point

of catcher 4

on two-needle

knife

mustbeparallel

has

passed

12.0.1

mm

machines.

with

about3mm

V

.

knife

beyond

bracket5,but

the

knife

edge,

7^

12.1 Make sure that clamp screw 1 is loose, then

12.2

First

position knife 3 so that it cannot collide

12.3 Position catcher 4 by hand so that its point protrudes

by

about

12.4

12.5

12.6 Carry out check (see "setting").

Push

touch the casting (see arrow) and its elongated hole is parallel with knife

bracket

In this position tighten the screws 2.

3 mm.

the knife lightly against the catcher and position it so that it does not

5.

14

loosen

with

the two screws 2.

catcher 4.

beyond

the knife edge

Page 15

13 Catcher reversal position

Setting:

Note:

13.0.1

Adjustment

in

the

reversal

cutting

When

in order to

edgeofknife4(see

clomp

to be

made

twice

on

positionofcatcher3its

arrowinFig.

screw

check

1 is

the

loosened,

"setting".

<S)

two-needle

the

following

%

back

13.0.2).

machines.

edge

mustbeflush

adjustments

have

with

to be

the

made

13.0.3

13.1

13.2

13.3 Retain this position and set catcher 3 so that its back edge is

13.4

13.5 Carry out a check (see "setting").

Make

rise

Continue

position.

cutting edge of knife 4

In

sure

position

this

position

that

clamp

andoperate the

turning

the balance

tighten

screw

(see

clamp

1 is

loose,

engaging

wheeltomove

arrow in Fig. 13.0.2).

screw1,making

15

then

lever.

set the

engaging

sure

machine

thereisno

shaft

at the

2 to its

flush

vertical

13.0.2

needle

for

left

with the

play,

Page 16

14 Bobbin

thread

trapper spring

Adjustment to be

Setting; Between the underside of catcher 4 and trapper spring 5 there

clearance of

position the end of the trapper

the

catcher

distanceof10

from

the inside of spring 5 to hollow stud 7 (see Fig.

be possible to

mode

0.3

mm

(see Fig.

(see arrow in

mm

on series 240 machines (12

remove

and replace the bobbin cose without hindrance.

twice on two-needle machines.

14.0.2).

spring

14.0.3).

When catcher 4 is in its reversal

mustbeflush

The trapper spring must be setata

with the back edge of

mm

on series 1240), measured

14.0.4).

14.0.2

(S

must

Also it

be a

must

rp

0

V.

14.0.4

2)

%

14.0.1

16

Page 17

14.1

Loosen

the

two

screws

1.

14.2

14.3

14.4

14.5

14.6

14.7 Re-connect spring 3 (Fig.

Position

of its elongated holes.

In

Disconnect spring 3 (Fig.

Swing

Retain

0.3

bracket 2 parallel

this

position

catcher 4

tighten the

across

this position and bend trapper

mm

between

the

catcher

with

two

14.0.5).

trapper

14.0.5).

the bedplateof the

screws

spring

1a little.

5 by hand.

spring5so

and

the

spring (see

machine

and at the

middle

that there is a clearance of

Fig.

14.0.2).

14.8 Set the machineat the needle rise position, operate the engaging lever, then

14.9

14.10

turn the balance wheel to set

Loosen

Position trapper spring

that the tips of the

screws

6.

5,

spring

catcher4at

and if necessary bracket 2, in the elongated hole so

are

flush

with

its reversal position.

the

bock

edge of catcher 4 (see

arrow

in Fig. 14.0.3) and the distance between the inside of the spring and hollow

stud 7 is about 10

14.11 In this position, tighten

mm

on Series 240 and 12

screws

1and 6 securely,

mm

on Series 1240 (see Fig.

making

sure that bracket 2

14.0.4)

is still parallel with the machine bedplate.

14.12 Carry out a check (see "setting").

17

14.0.5

Page 18

15

Tension

release

bracket

Setting;

With the

be a clearance of 7

With

the

trimmer

presser

in its resting position and th presser foot raised there

mm

between release bracket

foot

lowered

and the

edge of the rear positioning stop

discs

must

be released

just

enough

15.0.1

^and

(see

point

arrow

of catcher 6

in fig. 15.0.3) the

to allow the thread to

casting 4.

level

with

pass

through

must

the

tension

freely.

15.1

15.2

15.3

15.4

15.5

15.6

15.7

15.8

15.9

15.0.2

Check that the trimmer is in its resting position and the presser foot is raised,

then

loosen

Adjust

and

the

In this position, tighten the two screws 1.

Loosen

Turn

the balance wheel to set the machine in the needle rise position and

operate the engaging lever by hand.

Lower

Turn the balance wheel farther to set the point of catcher 6 level with

the back edge of the rear positioning stop.

Retain

the

two

screws

1.

the height of linkage rod 2 so that the clearance between release bracket 3

housing is

screw

about

5.

7 mm.

the presser foot onto the needle plate.

this position and

push

eccentric 7 (eccentric

15.0.3

lobe

facing

downwards)

towards the left together with release bracket 3 until the needle thread can

be easily pulled

In this position tighten screws

through

the

discs

of the thread tension.

5.

18

Page 19

16 Adjusting the synchronizer

16.1 On single-needle

Setting:

Adjustment

ha

Ives

On

sewing

also

(-720/02).

stops,

dead centre. After thread

leverattop dead

machines

with

Quick lever-operated

appliestotwo-needle

the

machine

centre.

must

trimming

halt

the machine

6!

machines

with

the

stop

motor^

with

disengageable

needle

must

bar4

mm

past

position with the take-up

type "700".

needle-bar

bottom

16.1.1

16.1.2

16.1.3

16.1.4

16.1.5

16.1.6

16.0.2

16.0.1

Remove

Loosen

Turn

Retain

switch-off

Turn

dead

Retain

switch-off

cap 1 and loosen cap screw 2 of synchronizer

the two retaining screws

4.

the balance wheel to set the needle bar 4

this

position

track

and

exactly

set

over

the

middle

the

carbon

of

the

brush,

insulated

mm

then

3.

past bottom dead centre.

segmentofthe

tighten

screws

the balance wheel (in sewing direction) to set the take-up lever at top

centre.

this

position

track

and

exactly

set

over

the

the

middle of

carbon

the

brush,

insulated

then

segmentofthe

tighten

cap

4.

screw

inner

outer

2.

16.1.7

16.1.8

Switch on the machine, check the positioning accuracy and re-adjust if

necessary.

Replace cap. 1.

19

Page 20

16.2

On

two-needle

machines with

Quick

lever-operated

Stop motor,

type

"700"

Setting: On

take-up

sewing

stops

leverattop dead

16.0.4

and after thread

centre.

trimming

the

machine

must

halt

with

the

16.2.1

16.2.2

16.2.3

16.2.4

16.2.5

16.2.6

16.2.7

16.2.8

16.0.3

Remove

Also loosen the two retaining screws

Turn

Retain this position and set the end of the insulated segment of the inner

gwitch-off track over the front end of the carbon brush holder (in sewing

direction) (see arrow in Fig.

(This

Turn the balance wheel to set the

Retain this position and set the middle of the insulated segment of the outer

switch-off track exactly over the carbon brush, then tighten cap screw

Switch on the machine and carry out a check (see "setting") and readjust

if necessary.

Replace cap 1.

cap 1 and

the balance wheel to set the needle barattop dead centre.

loosen

cop screw 2 of synchronizer 3.

4.

16.0.4),

then tighten retaining screws

adjustment does not set a stopping position.)

take-up

leverattop dead centre.

4.

2.

20

Page 21

16.3 On

single-

and

two-needle

machines

with

Quick

electronic

stop

motor,type

"800"

Setting:

On

sewing

stops

the

machine

dead centre. After thread

lever at top dead centre.

must

trimming

holt

the

with

the

machine

needle

must

bar4mm

position

past

with

bottom

the take-up

16.3.1

16.3.2

16.3.3

16.3.4

16.3.5

16.3.6

16.3.7

16.3.8

16.3.9

16.3.10

16.0.5

Remove

Loosen retaining screw 2.

Set the take-up lever at top dead centre.

Set

Set the needle bar 4

Set inner magnet tab 4 with the red magnet alsoatits opposite poleatthe bottom,

In this position tighten retaining screw 2.

Switch

Check the two positions by operating the pedal, and re-adjust if necessary.

Replace the cap on synchronizer 1.

the cap of synchronizer 1 on the balance wheel.

outer

magnet

on

the

tab

machine.

3 with the yellow magnetatits opposite poleatthe bottom.

mm

past bottom dead centre.

16.0.6

Note: A toggle switch makes it possible to switch off the function "4

of needle bar (two-needle machines); the machine will then only position with

the take-up lever

at

t.d.c.

21

mm

past

b.d.c.

Page 22

16.4

On

single-

and two-needle machines with Efka Variostop motor^type

"V".

Setting:

Note:

On sewing stops the machine

dead

centre.

After thread

dead

centre.

trimming

the machine

must

holt with the needle bar 4

must

position the take-up lever at top

mm

past bottom

If fitted, set the toggle switch on the motor, for selecting needle position

"4

mm

post

b.d.c."

at

"unten" (= down).

16.0.9

4

16.4.1

16.4.2

16.4.3

16.4.4

16.4.5

16.4.6

16.4.7

16.4.8

Note:

16.0.7

16.0.8

Loosen

Turn the balance wheel to set the take-up leverattop dead centre.

In this position turn the outer control disc 3 so that its slot isatthe bottom

between

Set the needle bar 4

In

the

Switch

Check the

Replace cover 1.

A toggle switch

of

the take-up leveratt.d.c.

the two retaining screws 2 and remove cover 1 of the synchronizer.

the

two

this

position

two

on

needle

projectionsofthe

mm

turn

inner

switch

projections.

the

machine.

two

positions by operating the pedal, and re-adjust if necessary.

makes

bar"(two-needle

past bottom dead

control

it possible to switch off the function "4

machines);

switch.

disc

the

22

centre.

4 so

machine

that

its

slotisat

will

then

the

mm

only

bottom

post

position

between

b.d.c.

with

Page 23

16.5

Setting:

On single- and two-needle

On

sewing

dead

After

dead

centre.

thread

centre.

stops

the

trimming

machine

the

machines

must

machine

with

Posistop

holt

with

the

must

position the take-up

motor,

needle

type

bar 4

"PQK"

mm

lever

past

at top

bottom

Note:

if fitted, set the

"4

mm

16.0.10

past

b.d.c."

toggle

switch

on the

at "unten"(=down).

motor,

for

selecting needle

position

16.5.1

16.5.2

16.5.3

16.5.4

16.5.5

16.5.6

16.5.7

16.5.8

16.5.9

Note:

16.0.11

Loosen

Loosen

Turn

In this position hold

disc

Turn the balance wheel to set the take-up leverattop dead centre.

In

so

Tighten alien screw

the

two

screws1and

alien

screw

the balance wheel to set the needle bar 4

4 so

that

this

position

that

the

middle

the

middle

hold

of

3.

the

the

its

3.

remove

balance

of

its

balance

slotispositioned

cover

wheel firmly

slotispositioned

wheel

firmly

at

2.

mm

past bottom dead centre.

and

turn the large control

at

and

diode

diode

turn

5.

5.

the

small

control

16.0.12

disc

6

Switch on the machine and check the two positions (see "setting"), by operating

the pedal, and re-adjust if necessary.

Replace cover 2 and secure it with screws 1.

A

toggle

of

needle

switch

bar

(two-needle

makesitpossibletoswitch

machines);

the

off

the

machine

function"4mm

will

then

only

post

b.d.c.

position

with

the take-up leveratt.d.c.

23

Page 24

16.6

On

one-

and

two-needle

machines

with

Posistop

rnotorf

type

880

Setting:

Note:

When

bar 4

sewing

mm

past

is

interrupted,

bottom dead

the

centre.

should stop with the takeup lever

If

applicable, turn

ing

the

needle

position,

down

the toggle switch on the

i.e.

4

machine should

stop

After thread trimming

at

top

dead

centre.

mm

past

bottom dead

with

motor

centre.

the

the

for

needle

machine

select

16.6.1

16.6.2

16.6.3

16.6.4

16.6.5

16.6.6

16.6.7

16.6.8

Remove

diode

On

machines

the

motor

Turn

centre.

In

this

its

edge2is

Turn

In

this

edge

Tighten

Switch

pedal

3

the

the

4

cover

is

on

(see

of

is

not

with

control

balance

position,

balance

position,

positioned

screw

_1.

the

"Setting");

16.0.13

synchronizer

influenced

automatic

box.

wheel

turn

positioned

wheel

turn

behind

machine

by

to

set

the

behind

to

set

outer

and

check

re-adjust,

and

loosen

sunlight.

backtacking,

the

needle

inner

the

control

diode

control

diode

takeup

3.

both

if

screw

switch

bar

disc

3.

lever

disc

positions

in

necessary.

off

4

mm

in

at

such

by

Make

sure

"backtacking"

past

such

a way

means

top

top

a way

dead

that

of

that

on

dead

that

centre.

its

the

16.6.9

Note:

Replace

By means

centre

that

the

cover

of

ofatoggle

of

needle

machine

synchronizer.

switch

bar"

always

(on

stops

the

position

two-needle

with

24

machines)

the

takeup

"4

mm

past

can

lever

be

bottom

eliminated

raised.

dead

so

Page 25

Appendix

for

machines

with

pneumatic

sorvo

Unit —966/05

25

Page 26

17

Piston

starting

position

Correct

setting:

With

the thread

there

should

and stop 5 on piston rod 3

trimmer

beaclearance

at rest and the

of

abt.

0.5

(Fig.l7.0.2).

3

piston

mm

of cylinder 1 fully retracted

between

castellated

screw

2

To

adjust,

After

"Correct setting").

loosen

the

adjustment,

nut

4 and

lock-tighten

turn

26

stop

5 accordingly.

nut4and

check

this

adjustment

o

(see

Page 27

18

"On"

positionofswitch

and

actuating

lever

Correct

setting;

18.0.1

With the thread

retracted there should be a clearance of

lever ^ and

When

needle bar is at

should be in line with the center line of switch roller 2 (Fig. 18.0.3).

When

depress

(toward switch housing 5). (See Fig.18.0.4).

control

lever2 has fully operated

plunger

Furthermore,

lever^when

trimmer

switch

lever3contacts

bottom

6 another 0.2 to 0.3

switch

shaft7has

at rest and the piston of the cylinder fully

roller 2 (Fig. 18.0.2).

dead center, the inner edge of actuating lever 1

roller 2

moved

the

switch

should

abt.

0.2

mm

bottomofthe

roller 2, it

mm

when

reliably

10

mm

drop

(switch

between actuating

com

track

while

should

roller carrier 4 is operated

down

be

overactuating

the

possible

inoperative).

to

18.0.2

Q

18.0.4

To

adjust,

adjust the

After

"Correct setting").

loosen

positionofswitch

the

adjustment,

screws8and9and

housing

tighten

screws8and9and

27

turn

5.

collar

_10

(do

check

not

move

this

adjustment

18.0.3

it!),

then

(see

Page 28

19

"Off" position of switch and actuating lever

Correct

setting:

When shaft 1 has moved

actuating

Furthermore

sleeve2should

when

operating roller carrier 4 with shaft ^ at its point of

reversal (after having

abt.

begintopress

moved

plunger5 another 0.2 to 0.3

10

mm

abt. 14

mm

(Fig.19.0.3).

in the direction

against

switch

mm),itshould

indicated

by an arrow,

roller3 (Fig.19.0.2)

be possible to

depress

5

1

©

19.0.

To

adjust, loosen screws 6 and adjust the position of switch carrier 7

accordingly.

After the adjustment, tighten screws 6 and check this adjustment (see

"Correct

setting").

28

Page 29

Contents

1 Preliminary adjustment of control

2

Control

lever

com

3 Interlocking latch 5

4 Engaging solenoid 6

5 Release trip 7

6 Engaging lever 8

7 Actuating linkage 9

8 Final adjustment of the control cam 10

9 Locking finger

11

3

4

10 Secondary actuating linkage (only on two-needle machines) 12

11

12

Catcher

Trimmer

height 13

knife

14

13 Catcher reversal position 15

14 Bobbin thread trapper spring 16

15

16 Synchronizer

Tension

release

bracket

18

19-23

Appendix for machines with pneumatic servo unit -966/05

17 Piston starting position 26

18 "On" position of switch and octuorting lever 27

19 "Off" position of switch

and

actuarting lever 28

Page 30

Pfaff, D

6750

Kalserslautern, Postfach

3020/3040,

PrintedinWest

Telex:

045753,

Gedfuckt in der Bundesrepublik Deutschland

Germany•ImpritneenR.F.A. •

Telefax(0631)

Impresoenla R.F.A.

17202

Loading...

Loading...