Page 1

%

at

1W

\f

‘4

‘I

S

4’

4,-

b

n

SW

4

I

“S

4”

4’

I

Page 2

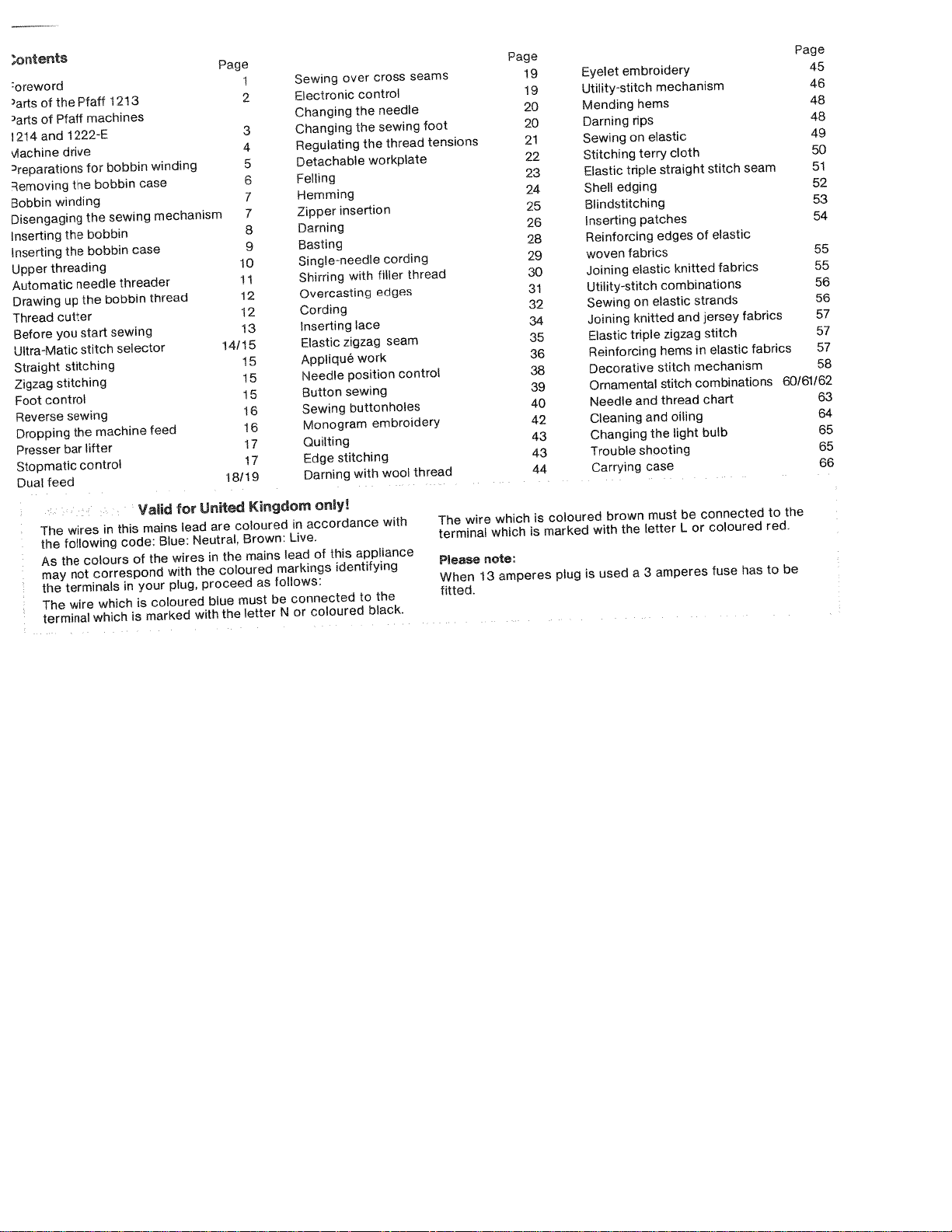

ontentS

:oreword

ofthePfaff

‘arts

Ptaff

of

arts

and

214

winding

threading

control

Dropping

Presser

Stopmatic

feed

Dual

The

the

As

may

the

The

terminal

drive

cutter

you

stitching

the

viachine

3

reparations

Removing

Bobbin

Disengaging

Inserting

Inserting

Upper

Automatic

Drawing

Thread

Before

Ultra-Matic

Straight

Zigzag

Foot

Reverse

machines

1222-E

for

bobbin

the

the

bobbin

the

bobbin

the

needle

the

up

start

stitch

stitching

sewing

machine

the

lifter

bar

control

wires

following

colours

correspond

not

terminals

which

wire

which

1213

bobbin

sewing

threader

bobbin

sewing

selector

in

this

code:

in

winding

case

mechanism

case

thread

feed

V&id

mains

the

of

your

coloured

is

marked

is

Blue:

wires

with

plug,

for

lead

Page

United

are

Neutral,

in

coloured

the

proceed

blue

with

10

11

12

12

13

14/15

18/19

coloured

the

must

the

1

2

3

4

5

6

7

7

8

9

15

15

15

16

16

17

17

Kingdom

Brown:

mains

markings

follows:

as

be

N

letter

Sewing

Electronic

Changing

Changing

Regulating

Detachable

Felling

Hemming

Zipper

Darning

Basting

Single-needle

Shirring

Overcasting

Cording

Inserting

Elastic

Appliqué

Needle

Button

Sewing

Monogram

Quilting

Edge

Darning

ony!

accordance

in

Live.

of

lead

connected

coloured

or

over

control

the

the

the

workplate

insertion

with

lace

zigzag

work

position

sewing

buttonholes

stitching

with

appliance

this

identifying

to

black.

seams

cross

needle

sewing

thread

cording

thread

filler

edges

seam

control

embroidery

thread

wool

with

the

foot

tensions

The

terminal

Please

When

fitted.

wire

note:

13

Page

which

which

amperes

19

19

20

20

21

22

23

24

25

26

28

29

30

31

32

34

35

36

38

39

40

42

43

is

43

44

is

marked

coloured

plug

embroidery

Eyelet

Utility-stitch

Mending

Darning

Sewing

Stitching

Elastic

Shell

Blindstitching

Inserting

Reinforcing

woven

Joining

Utility-stitch

Sewing

Joining

Elastic

Reinforcing

Decorative

Ornamental

Needle

Cleaning

Changing

Trouble

is

edging

Carrying

brown

the

with

used

hems

rips

on

terry

triple

patches

fabrics

elastic

on

knitted

triple

and

shooting

a

mechanism

elastic

cloth

straight

edges

knitted

combinations

elastic

and

zigzag

hems

stitch

stitch

thread

oiling

and

light

the

case

be

must

L

letter

amperes

3

seam

stitch

elastic

of

fabrics

strands

mechanism

combinations

or

jersey

stitch

in

elastic

chart

bulb

connected

coloured

fuse

fabrics

has

fabrics

to

red.

to

Page

45

46

48

48

49

50

51

52

53

54

55

55

56

56

57

57

57

58

60/61/62

63

64

65

65

66

the

be

Page 3

Uz1I®

194

Instruction

for

Pfaff

and

Dear

Welcome

Pfaff

anxious

suggest

this

machine

tell

to

can

We

booklet

and

your

these

familiarize

the

(new)

sewing

instruction

create

suggest

3,

Push-Button

1213,

1222-E

Pfaff

the

to

machine.

try

to

you

that

very

is

about

you

with

first

where

machine

on

parts

yourself

Customer:

modern,

your

out

first

booklet.

versatile,

all

it,

that

and

the

are

your

Book

1214

efficient

You

new

take

wonderful

the

thumb

you

open

then

most

illustrated.

machine,

your

with

are

machine,

the

Your

and

essential

you

Pfaff.

world

probably

time

Pfaff

would

we

things

through

at

it

identifying

By

will

of

but

to

sewing

pages

parts

quickly

the

very

we

read

like

you

the

recommend

We

instructions

your

with

2

of

PFAFF-HANDELSG

Haushaltnähmaschinen

für

Karlsruhe

7500

carefully,

Pfatf

study

you

that

and

always

will

ESELLSCHAFT

West-Germany

41

hope

m.b.H.

be

these

that

a

sewing

sewing

pleasure.

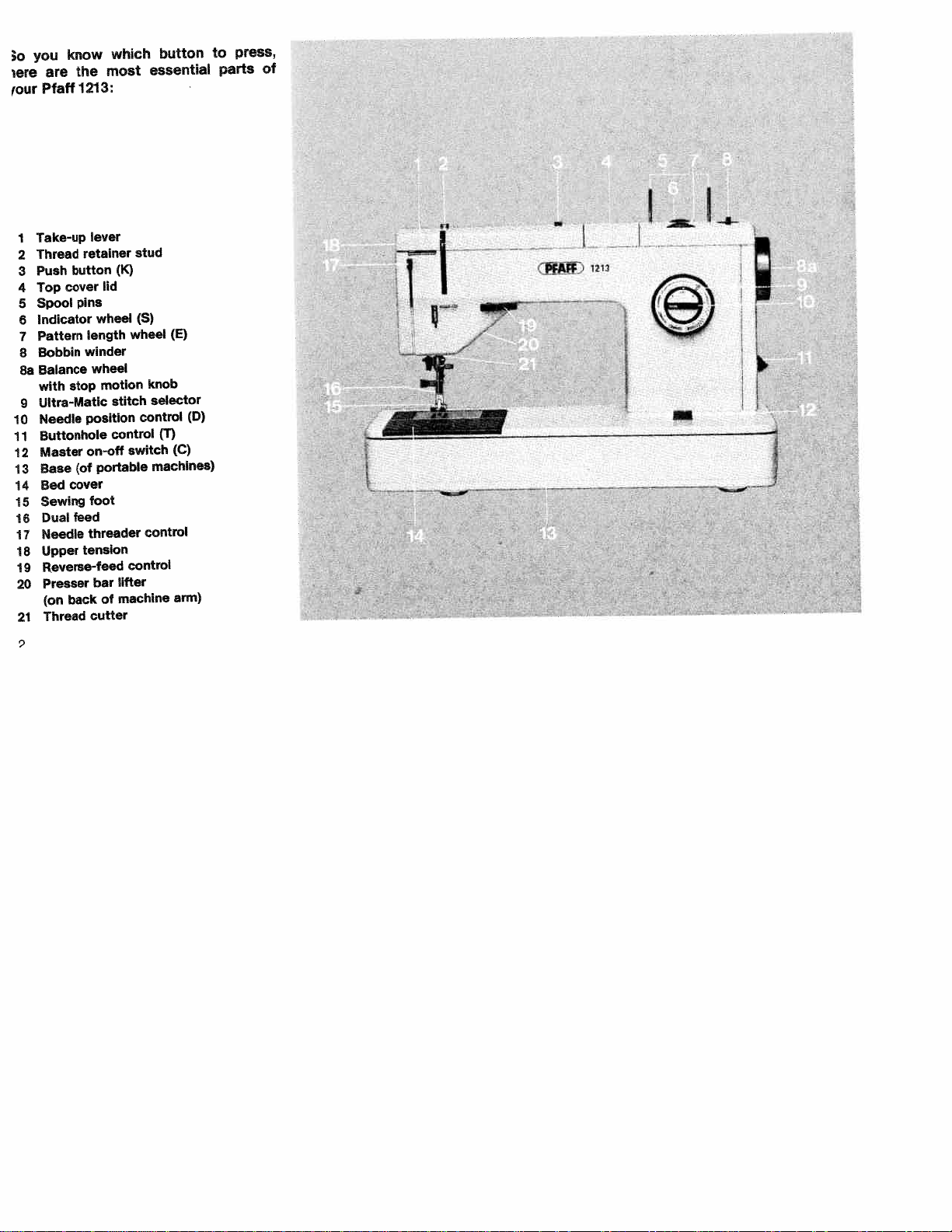

Page 4

o

ere

tour

you

Pfaff

are

know

the

1213:

which

most

button

essential

to

parts

press,

of

Take-up

1

Thread

2

Push

3

Top

4

Spool

5

Indicator

6

Pattern

7

Bobbin

8

Balance

Ba

with

Ultra-Matic

9

Needle

10

Buttonhole

11

Master

12

Base

13

Bed

14

Sewing

15

Dualfeed

16

Needle

17

Upper

18

Reverse-teed

19

Presser

20

21

2

cover

back

(on

Thread

retainer

button

pins

length

winder

stop

position

on-off

(of

cover

threader

tension

lever

lid

wheel

wheel

motion

stitch

control

portable

foot

bar

of

cutter

stud

(K)

(S)

wheel

knob

control

switch

control

control

lifter

machine

(E)

selector

(D)

()

(C)

machInes)

aim)

H

ErL

I

a

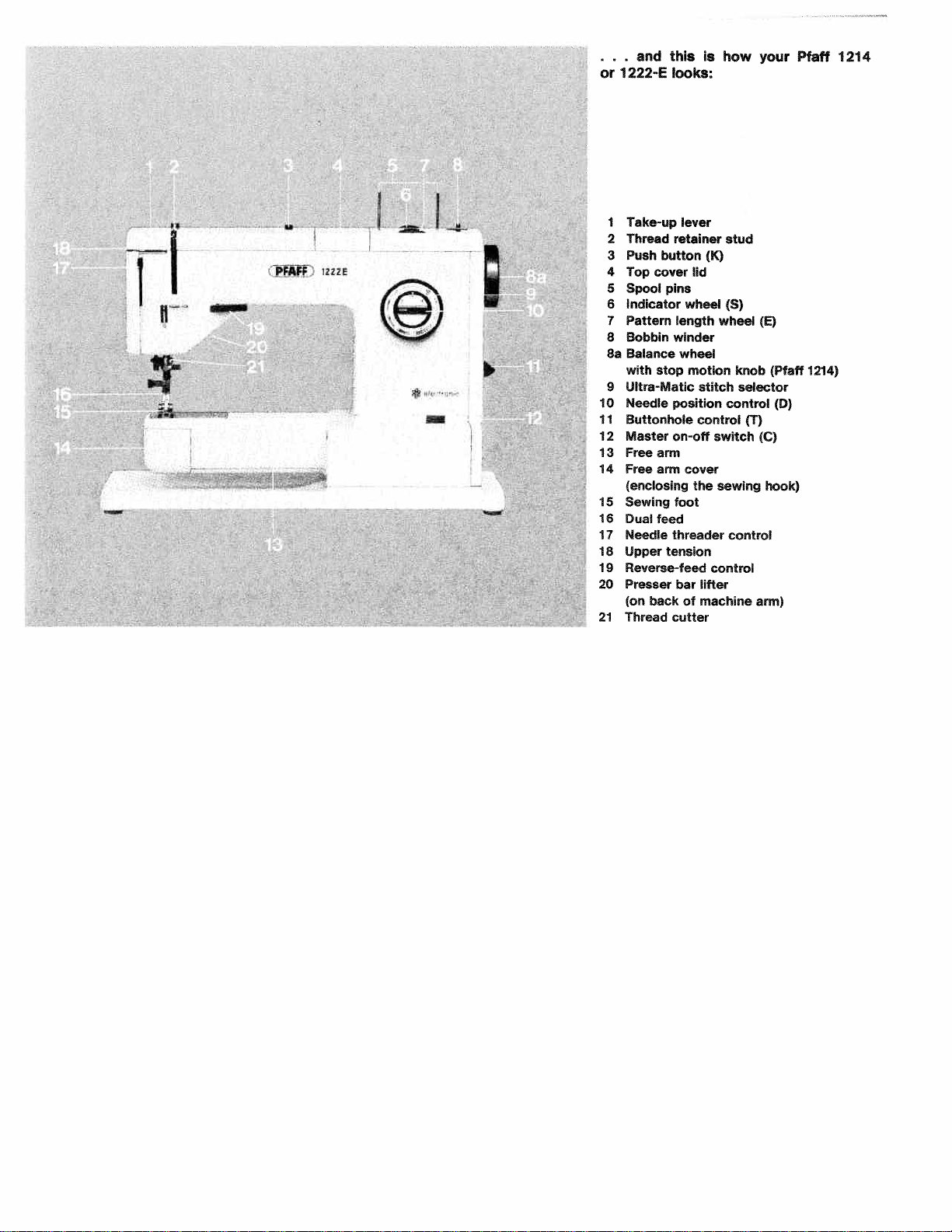

Page 5

_____

•

and

this

is

how

your

Pfaff

1214

1

or

222-E

looks:

1

Take-up

2

Thread

Push

3

•PAFF

•

1222E

4

Topcoverlid

5

Spool

6

Indicator

7

Pattern

8

Bobbin

8a

Balance

with

9

Ultra-Matic

10

Needle

11

Buttonhole

12

Master

13

Free

14

Free

(enclosing

15

Sewing

16

Dualfeed

17

Needle

18

Upper

19

Reverse-feed

20

Presser

(on

21

Thread

button

stop

arm

arm

back

lever

retainer

pins

wheel

length

winder

wheel

motion

position

on-off

cover

foot

threader

tension

bar

of

cutter

(K)

wheel

stitch

control

switch

the

sewing

control

lifter

machine

stud

(S)

knob

selector

control

(1)

control

(E)

(C)

hook)

arm)

(Pfaff

(D)

1214)

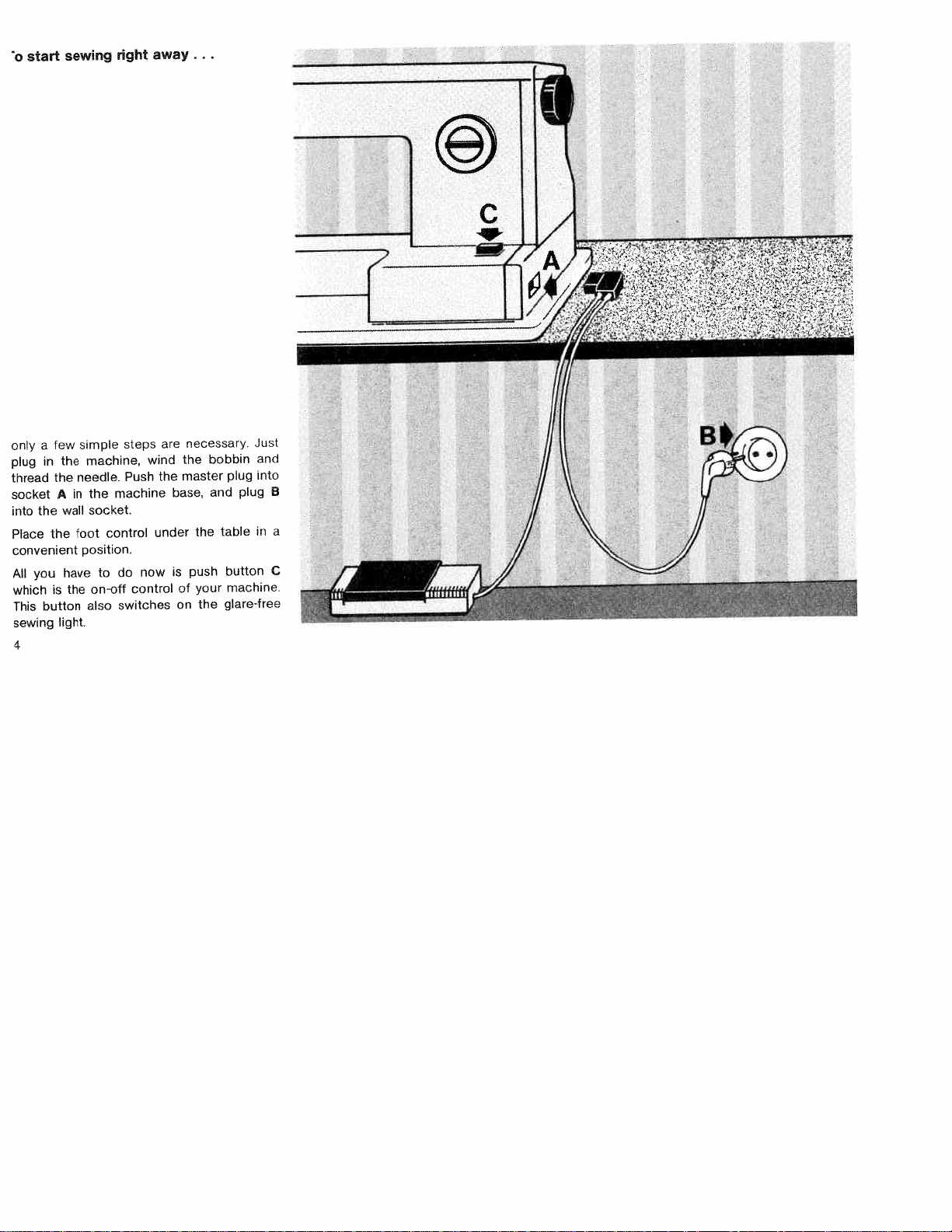

Page 6

away.

sewing

start

o

right

only

a

in

plug

thread

socket

into

the

the

Place

convenient

All

you

is

which

button

This

sewing

4

few

the

the

A

wall

light.

in

have

the

simple

machine,

needle.

the

socket.

foot

position.

to

on-off

also

steps

Push

machine

control

do

switches

wind

under

now

control

are

the

necessary.

the

master

base,

the

push

is

your

of

the

on

bobbin

plug

and

table

button

machine

glare-free

plug

Just

and

into

in

B

a

C

Th.

Page 7

Before

you

start

winding

the

bobbin

remember

a

seam:

two

threads

of

the

fabric

produced

If

your

seam

turn

to

page

To

wind

pushing

mechanism

For

step-by-step

please

refer

that

an

in

the

button

you

upper

are

locked

to

form

this

doesn’t

21.

bobbin,

must be

bobbin

to

page

need

and

a

way

look

turn

C

(page

disengaged

7.

two

a

lower

together

lock

stitch.

is

illustrated

like

the

4).

winding

threads

thread.

in

the

The

the

illustration,

machine

The

(see

instructions

to

These

middle

seam

below.

on

sewing

page

sew

by

7).

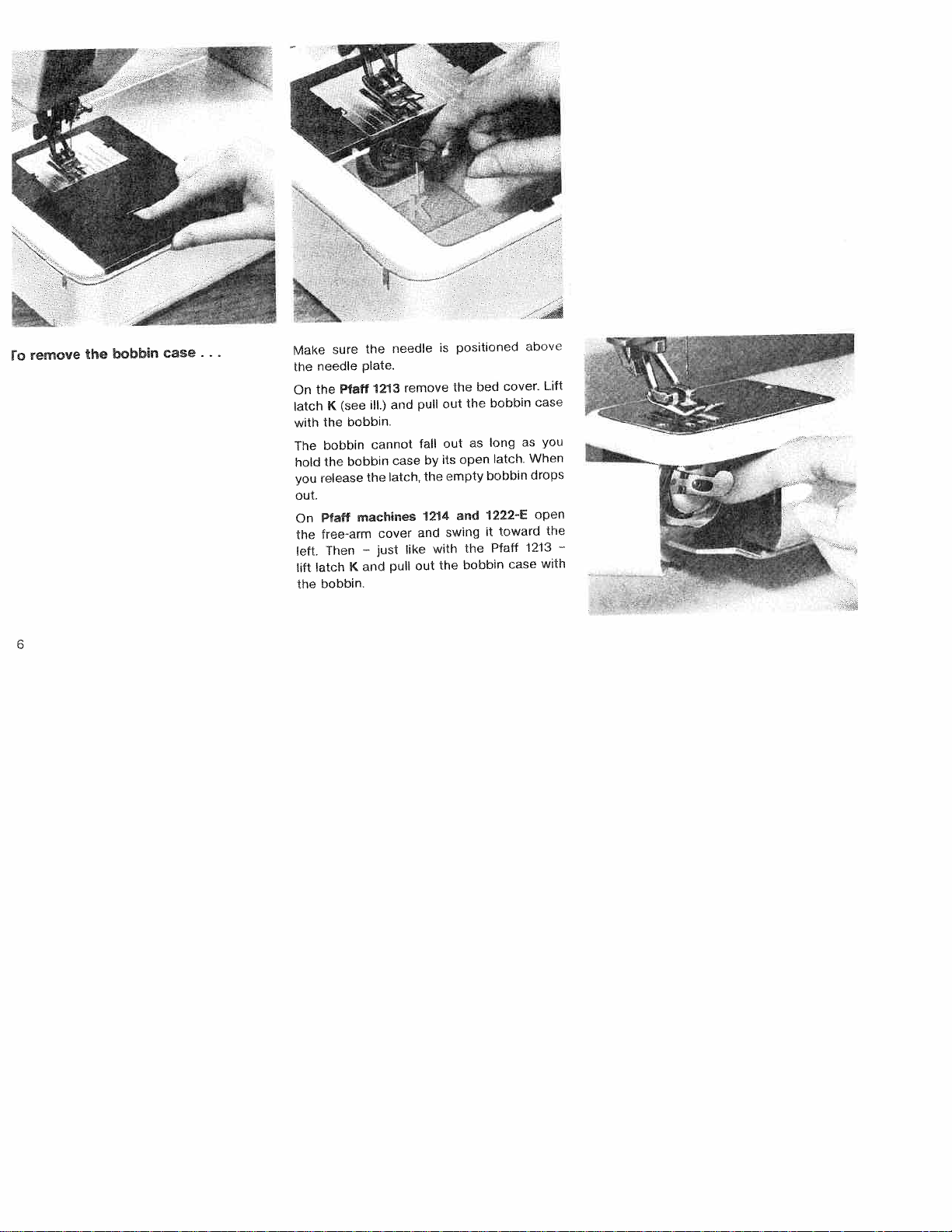

Page 8

\

ro

remove

the

bobbin

case.

Make

the

On

latch

with

The

hold

you

out.

On

the

left.

lift

the

sure

need’e

Pfaff

the

K

(see

the

bobbin

the

release

Ptaff

free-arm

Then

latch

bobbin.

the

plato.

1213

ill.)

bobbin.

cannot

bobbin

the

machines

—

and

K

and

latch,

cover

just

pull

needle

remove

case

like

pull

faH

and

out

by

the

1214

with

is

posiboned

the

out

out

its

open

empty

and

swing

the

bed

the

as

the

bobbin

cover.

bobbin

long

latch.

bobbin

1222E

it

toward

Pfaff

case

above

case

as

When

drops

open

1213

Lift

you

the

—

with

Page 9

I

to

wind

the

the

sewing

Raise

thread

bobbin

heldinposition

Pass

the

as showninthe above

Wind

the

a

few

Push leverEagainst

balance

knobofPfaft

on

page

winderbypressing

both

on

on

thread

times.

mechanism:

spool

one

bobbin

thread

wheel,

toward

2>

pins

of

winder

magnetically

from

clockwise

and

machines

downonthe

bobbin

and

them.

the

illustration,

the

turn

you.

and

placeaspool

Simply

disc S

(see

spool

to

around

bobbin,

the

stop

1213

and

Start

foot

disengage

place the

whereitis

ill,atleffl.

the

bobbin,

the

bobbin

hold

motion

1214

the

bobbin

control.

the

(8a

of

The

bobbin winder

the bobbin

To

re-engage

bobbin

from

away

re-engaged

machine,

On

the

is

engaged

control.

is

winding,

you.

automatically

Pfaff

1222-E,

or

For

details

stops

full,

the

sewing

turn

The

disengaged

please

automatically

the

stop

sewing

the

sewing

mechanism

motion

mechanism

on

starting

mechanism

the

by

Stopmatic

refertopage

when

after

knob

is

the

17.

Page 10

insert

se.

the

bobbin

into

the

bobbin

Fig.

end

thread

the

down

Pull

.

(as

inches

the

and

.

.

the

indicated

case.

sure

towards

thread

under

bobbin

of

the

by

thread

you.

into

an

the

spring.

should

arrow).

hanging

slot

making

case,

top

the

2:

Fig.

3:

Fig.

thread,

$

the

wise

three

bobbin

drops

As

rotate

Leave

you

from

from

draw

clock

about

the

bobbin

the

into

bobbin

filled

the

Insert

1:

2

Page 11

•

and

in

the

machine

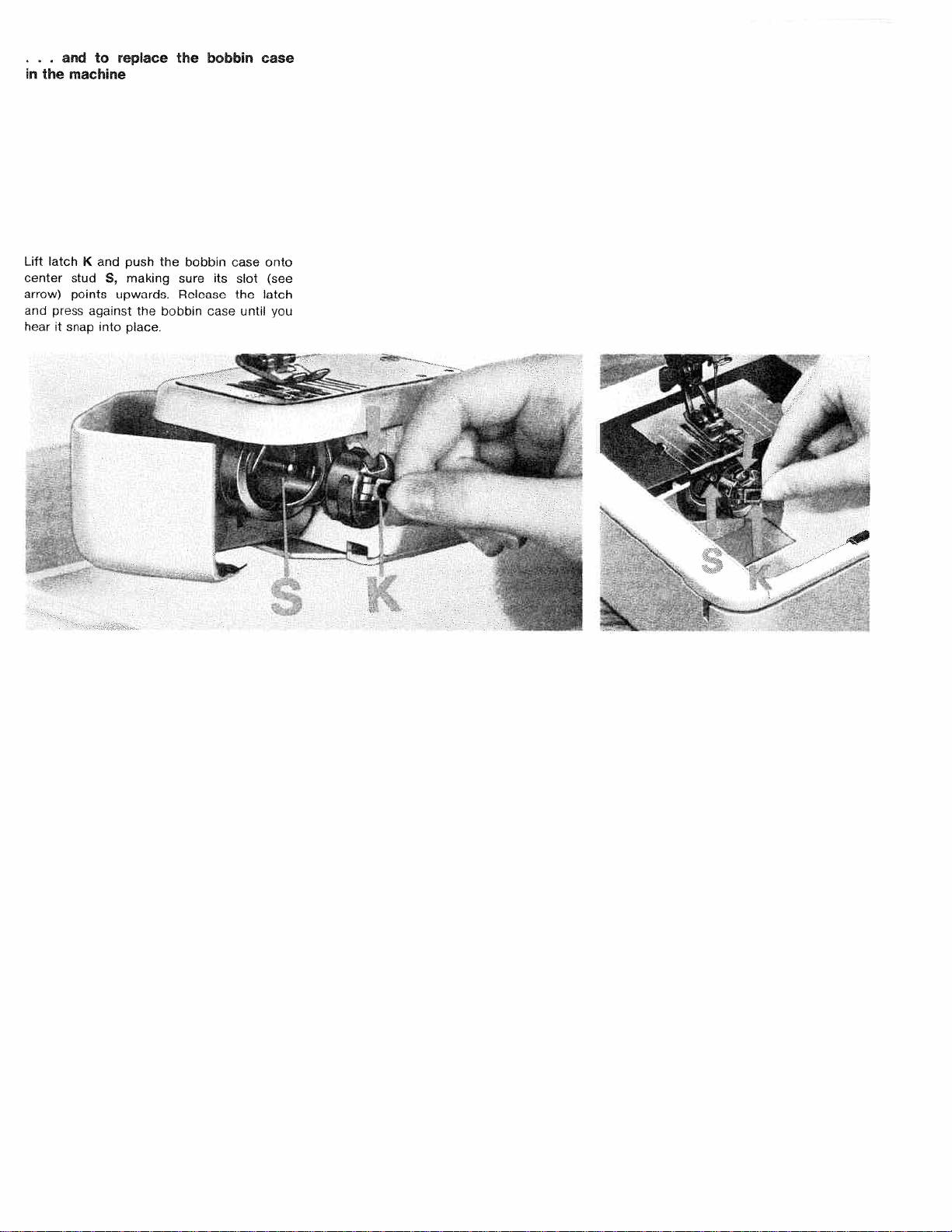

Lift

latch

center

arrow)

and

stud

points

press

hearitsnap

to

K

and

against

into

replace

push

S,

making

upwards.

place.

the

the

the

sure

Release

bobbin

bobbin

bobbin

case

case

onto

case

its

slot

(see

the

latch

until

you

Page 12

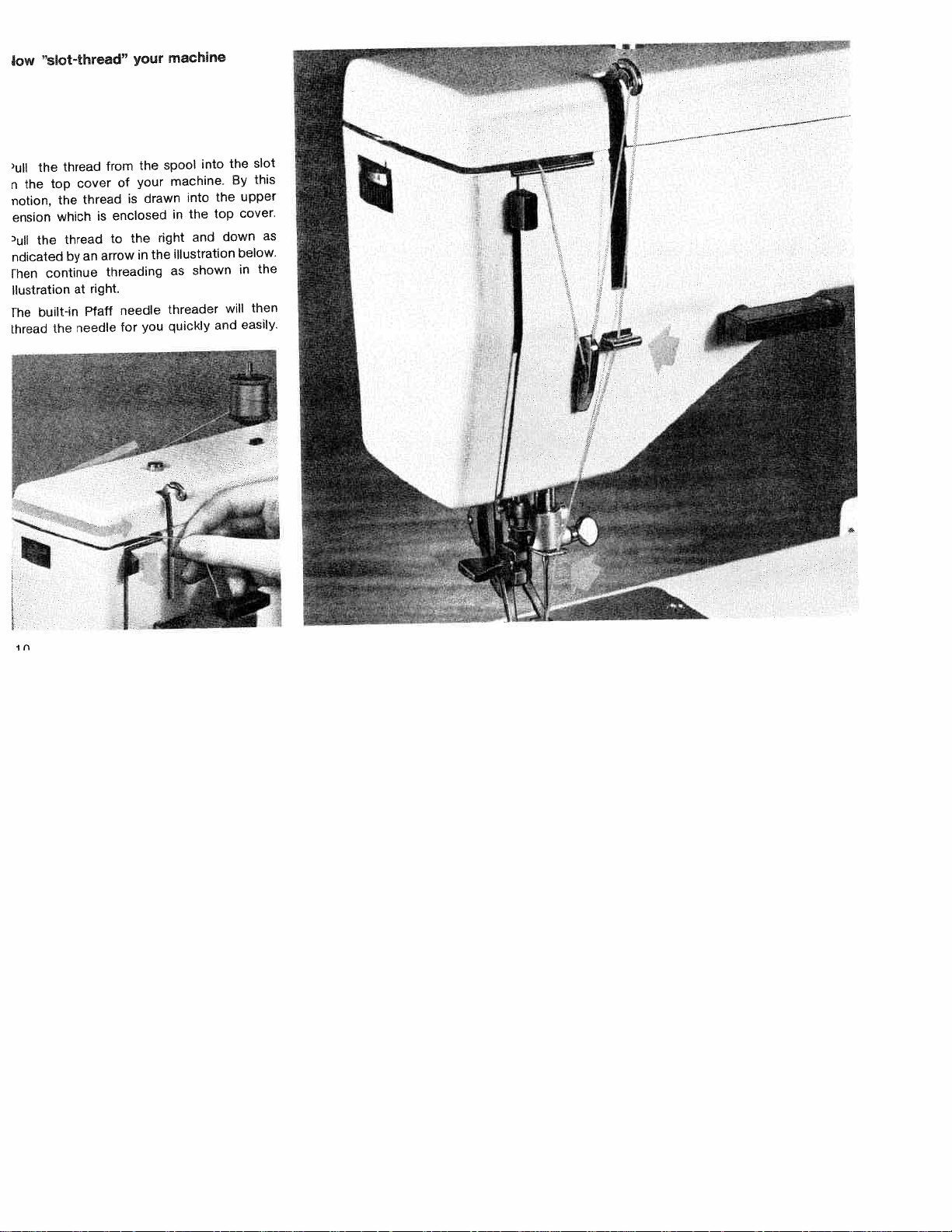

“slot-thread”

ow

the

ull

top

the

n

notion,

ension

the

ulf

ndicated

continue

[hen

Ilustration

built-in

[he

thread

thread

the

which

thread

the

cover

by

at

needle

thread

is

arrow

an

right.

Pfaff

your

the

from

your

of

is

enclosed

the

to

in

threading

needle

for

drawn

right

the

you

machine

spool

machine.

into

the

in

and

illustration

shown

as

threader

quickly

into

the

top

and

the

By

down

will

slot

this

upper

cover.

below.

the

in

then

easily.

as

‘1

Page 13

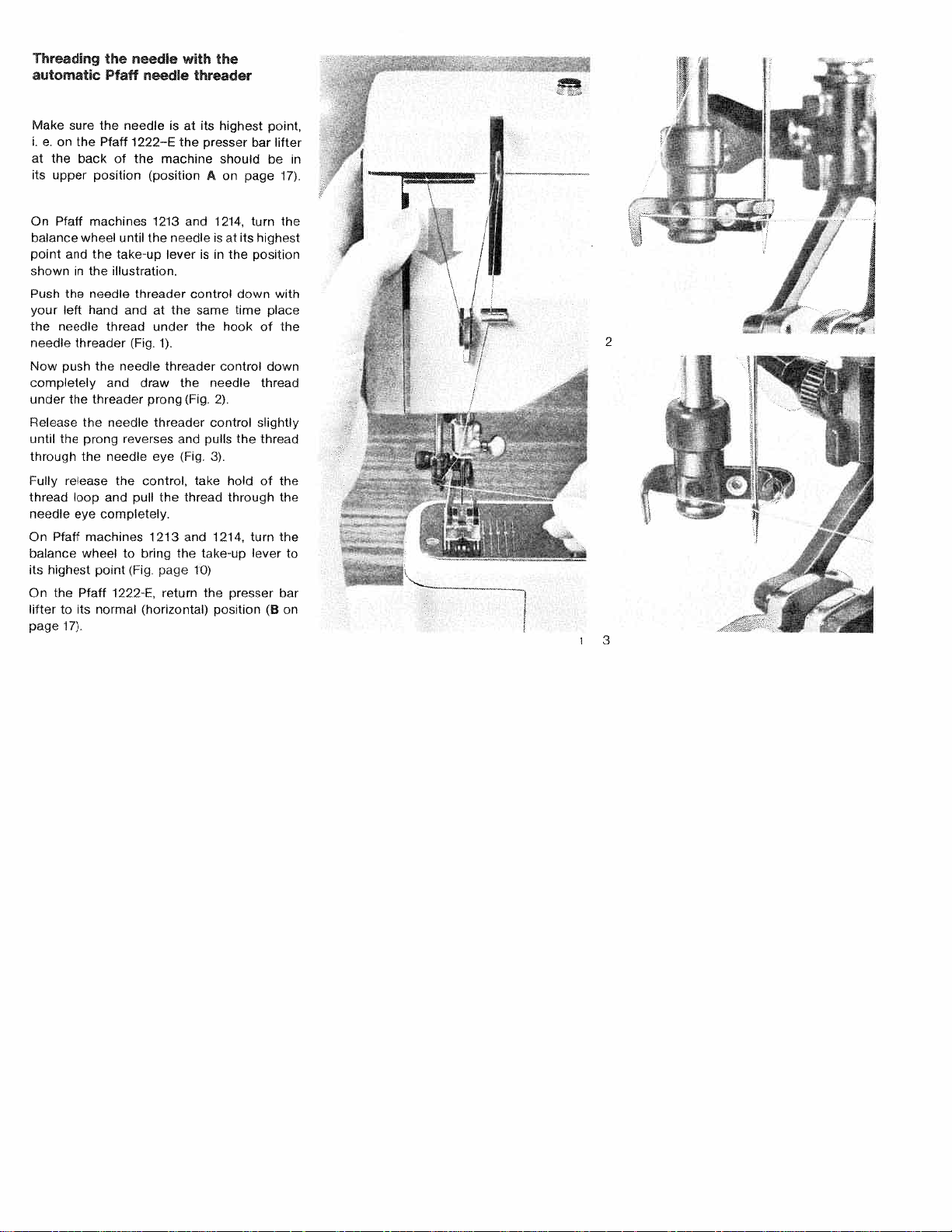

Threading

automatic

Make

sure

i.

e.onthe

at

the

back

its

upper

On

Pfaff

balance

point

shown

Push

your

wheel

and

in

the

left

the needle

needle

threader

Now

push

completely

under

the threader

Release the

until

the

prong

through

Fully

thread

needle

On

balance

its

On

the

release

loop

eye

Pfaff

wheeltobring

highest

the

Pfaff

liftertoits

page

17).

the

Pfaff

the

Pfaff

of

position

machines

until

the

take-up

illustration.

the

needle

hand

thread

the needle

and

needle

needle

the

and

completely.

machines

point

1222—E,

normal

need’e

need’e

needle

is

1222—E

the

machine

(position

1213

the

needle

leverisin

threader

andatthe

under the

(Fig.

1).

threader

draw

prong

threader

reverses

eye

control,

pull

the

1213

(Fig

page

return

(horizontal)

with

threader

at

the

and

control

the

(Fig.

and

(Fig.

take

thread

and

the

10)

its

presser

Aonpage

same

control

pulls

take-up

the

the

highest

should

1214,

isatits

control

needle

the

time

hook

bar

turn

position

down

point,

lifter

be

highest

with

place

of

down

thread

2).

slightly

the

thread

3).

hold

of

through

1214,

turn

lever

presser

position(Bon

in

17).

the

the

2

the

the

the

to

bar

3

Page 14

eW4M

Pew

1HOlVB

oiS9B

weas

fteZB!Z

r

A

.7

—

,—.

/

/

$

p

/

a

6

0

N

N

/

V

0

Ok

MM

‘p

I.

qoU)1

Page 15

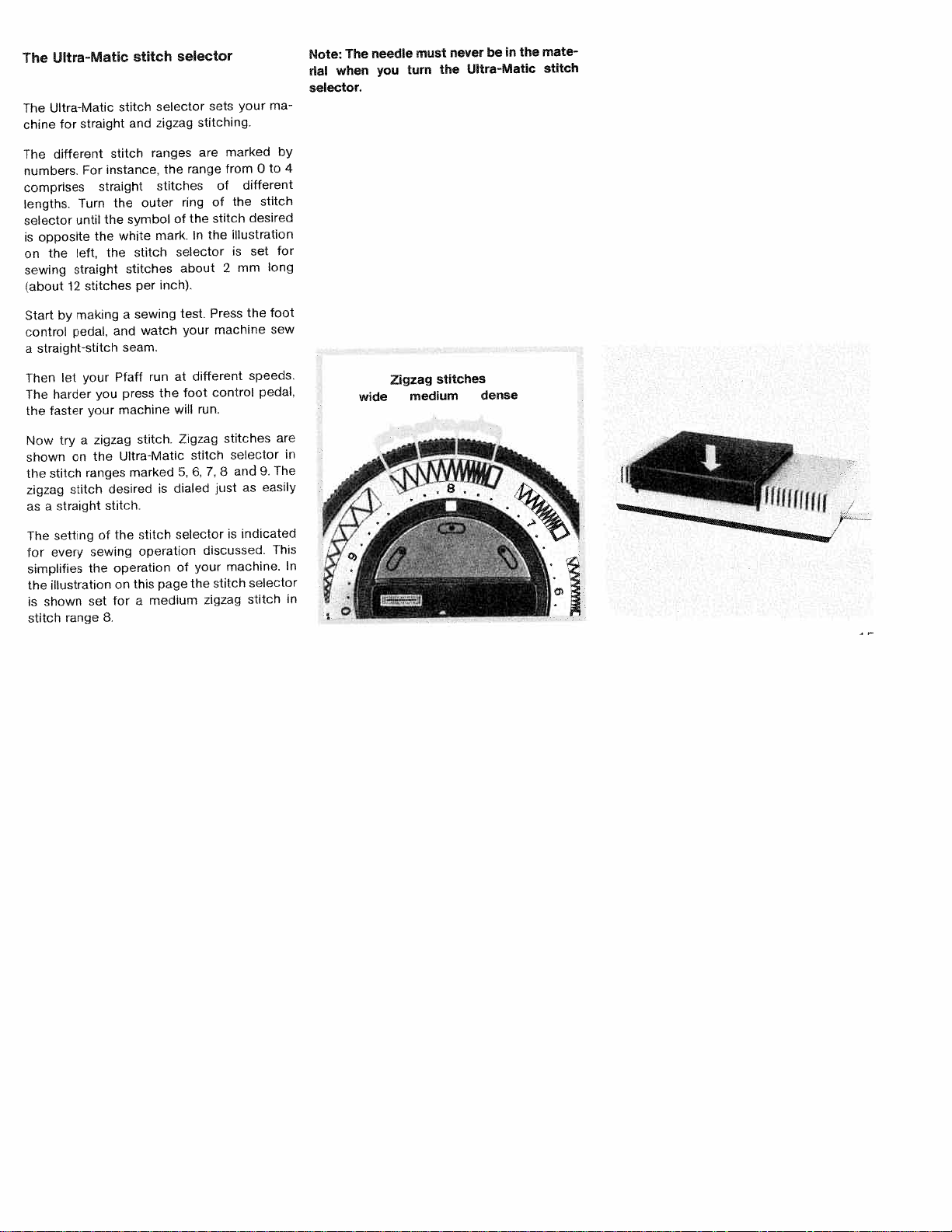

The

The

chine

Ultra-Matic

Ultra-Matic

straight

for

stitch

stitch

and

selector

selector

zigzag

sets

stitching.

your

ma

Note

when

rial

selector.

The

needle

you

must

turn

never

the

the

in

be

Liltra-Matic

mate

stitch

different

The

numbers.

comprises

lengths.

selector

opposite

is

the

on

sewing

(about

by

Start

control

straight-stitch

a

let

Then

The

harder

the

faster

try

Now

shown

the

stitch

zigzag

straight

a

as

setting

The

every

for

simplifies

the

illustration

shown

is

range

stitch

For

Turn

until

left,

straight

stitches

12

making

pedal,

your

your

a

on

ranges

stitch

stitch

instance,

straight

the

the

the

you

zigzag

the

desired

stitch

of

sewing

the

set

8.

ranges

outer

the

symbol

white

stitch

stitches

per

sewing

a

watch

and

seam.

run

Pfaff

press

machine

stitch.

Ultra-Matic

marked

stitch

the

operation

operation

this

on

medium

a

for

the

stitches

of

mark.

selector

inch).

at

the

will

Zigzag

5,

dialed

is

selector

of

page

range

ring

the

In

about

test.

your

different

foot

stitch

6,

your

the

marked

are

from

of

the

of

stitch

illustration

the

is

2

Press

machine

control

run.

stitches

selector

8

7,

just

is

discussed.

machine.

stitch

zigzag

0

different

stitch

desired

set

mm

the

speeds.

pedal,

and

9.

easily

as

indicated

selector

stitch

by

to

for

long

foot

sew

are

The

This

4

stitches

Zigzag

wide

in

In

in

medium

dense

-U.

Page 16

Darning

page

26.

with

your

Pfaff

discussed

is

on

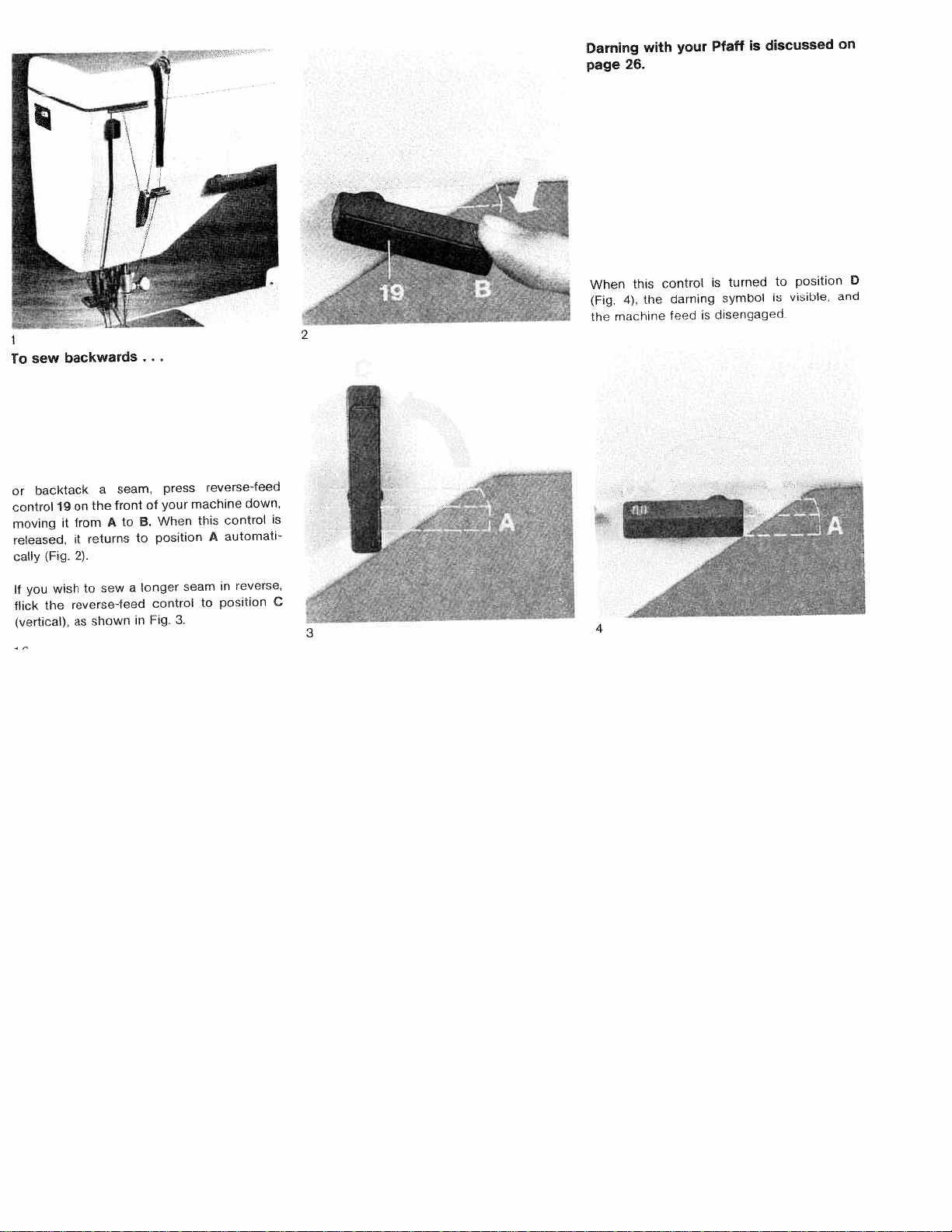

sew

ro

backtack

or

control

moving

released,

cally

you

If

flick

(vertical),

backwards

19

it

(Fig.

wish

the

seam,

a

front

the

on

A

from

returns

it

2).

sew

to

reverse-feed

shown

as

turned

to

is

visible,

darning

teed

is

symbol

disengaged

is

control

this

When

4),

(Fig.

the

reverse-feed

press

machine

your

of

When

to

B.

position

to

seam

longer

a

control

Fig.

3.

in

this

to

control

automati

A

in

position

down,

reverse,

is

C

;

‘

3

.2

4

the

machine

position

0

and

Page 17

When

1222E.

Pfaff

the

flick

tion.

Since

repeatedly

it

how

tions:

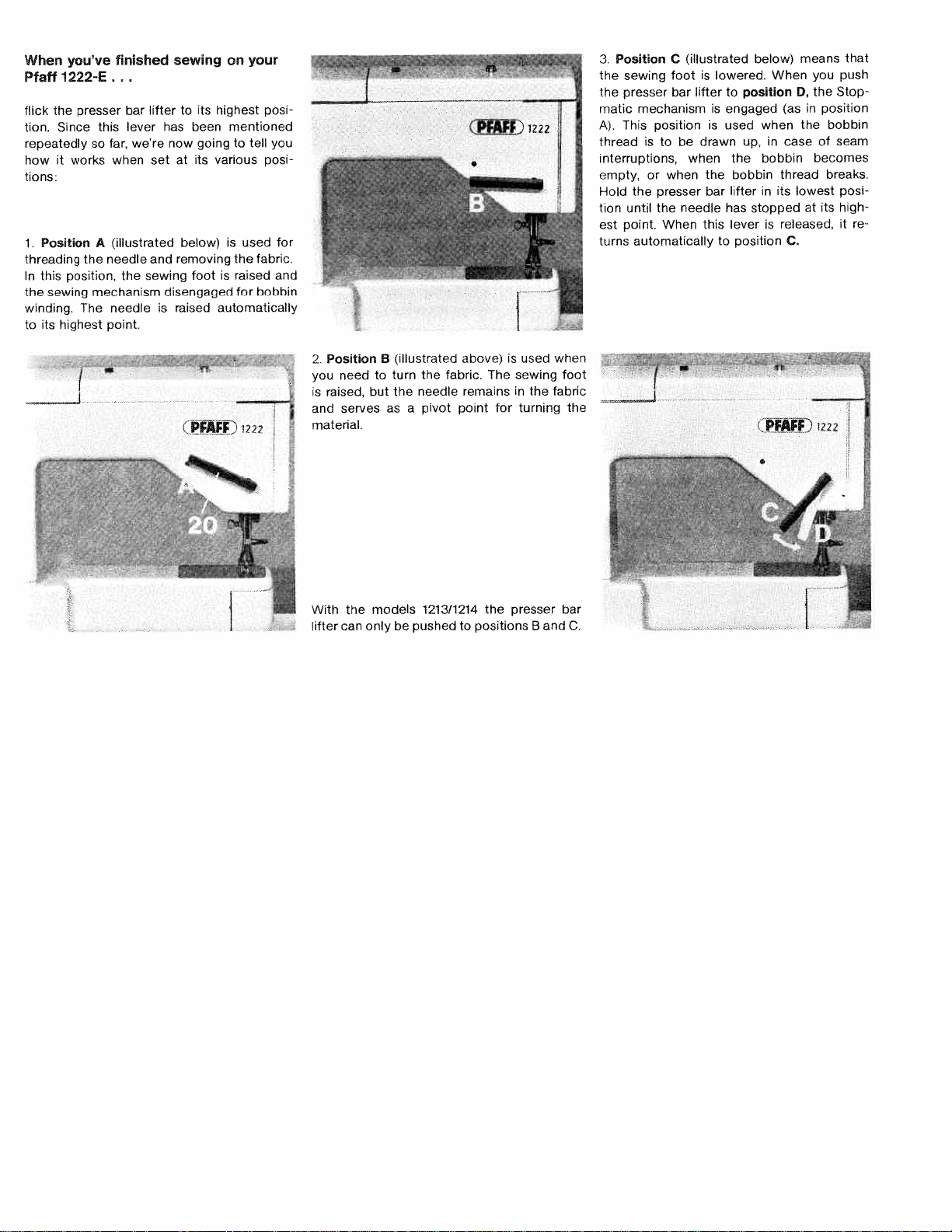

Position

1.

threading

In

this

the

sewing

winding

highest

to

its

you’ve

presser

this

so

works

A

the

position,

mechanism

The

finished

bar

lever

we’re

far,

when

(illustrated

needle

the

needle

point.

lifter

has

now

set

and

sewing

disengaged

is

sewing

its

to

been

going

at

its

below)

removing

foot

raised

your

on

mentioned

to

tell

is

used

the

is

raised

for

posi

posi

fabric.

bobbin

highest

various

automatically

you

for

and

3.

Position

the

sewing

presser

the

mechanism

matic

A).

This

thread

is

interruptions,

empty,

Hold

tion

est

turns

or

the

until

point.

automatically

C

foot

bar

position

be

to

when

presser

needle

the

When

(illustrated

lowered.

is

to

lifter

is

engaged

is

used

drawn

when

the

bar

has

this

to

below)

When

position

when

in

up,

bobbin

the

bobbin

lifterinits

stopped

lever

is

position

means

you

D,

in

(as

the

case

thread

lowest

at

released,

C

that

push

the

Stop

position

bobbin

of

seam

becomes

breaks.

posi

its

high

it

re

--I

PMF)

1222

2

Position

need

you

raised,

is

and

serves

material.

With

can

lifter

the

B

to

but

models

only

(illustrated

turn

needle

the

a

as

pushed

be

fabric.

the

pivot

point

1213/1214

to

above)

The

remains

the

positions

for

is

used

sewing

in

the

turning

presser

when

foot

fabric

the

bar

and

C.

B

--

Page 18

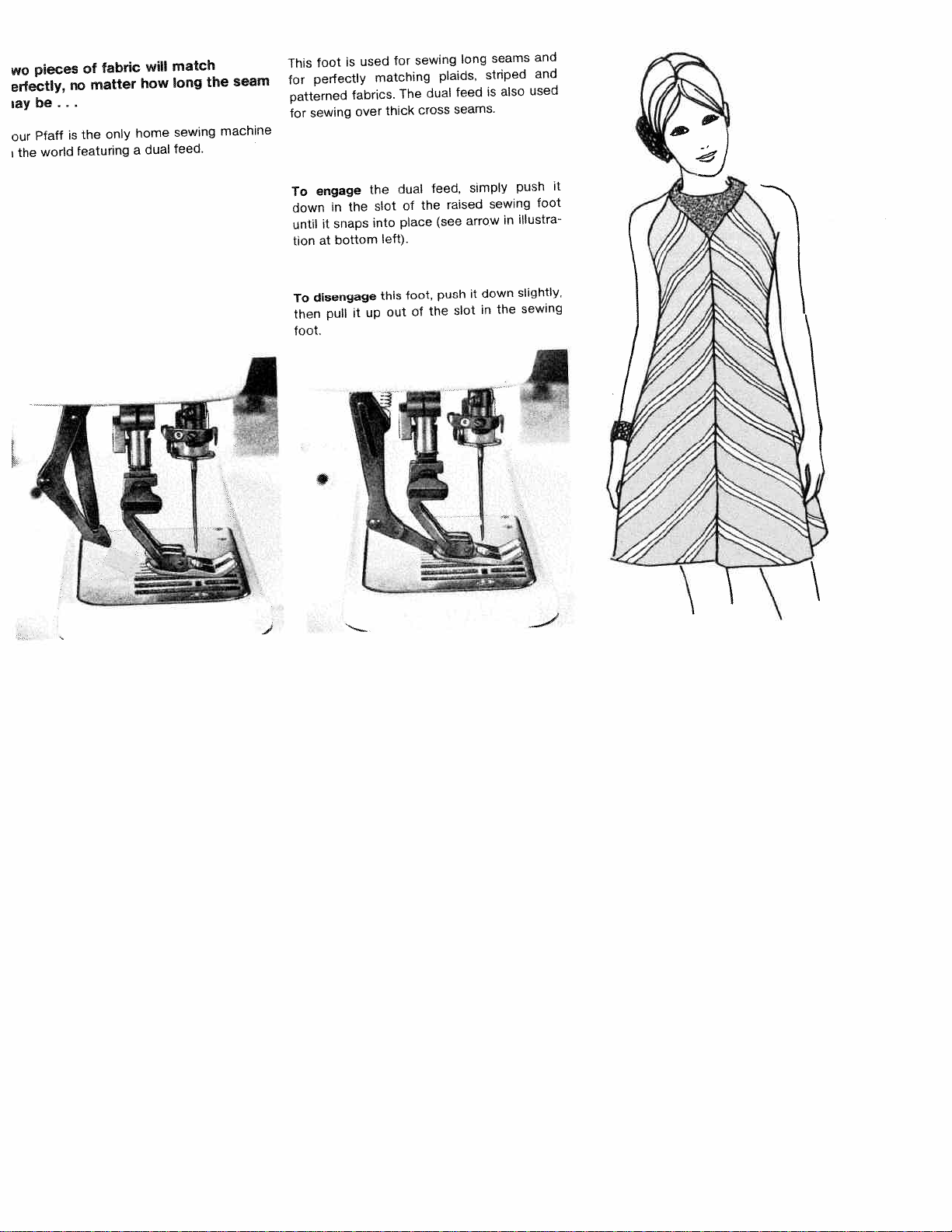

pieces

wo

erfectly,

be.

iay

Ptaff

our

world

the

of

matter

no

is

the

featuring

fabric

only

wiH

how

home

dual

a

match

long

sewing

feed.

the

machine

seam

foot

This

perfectly

for

patterned

sewing

for

engage

To

down

until

at

tion

disengage

To

then

foot.

it

pull

in

snaps

is

fabrics.

over

the

bottom

it

used

matching

the

slot

into

up

thick

left).

this

out

for

The

dual

of

place

sewing

cross

foot,

of

the

dual

feed,

the

plaids,

seams.

raised

(see

push

slot

long

feed

arrow

seams

striped

is

simply

sewing

down

it

in

also

in

the

and

and

used

push

foot

illustra

slightly,

sewing

it

Page 19

Other

feed

foot

No

squares

similar

(below)

feet

include

and

matter

felling

or

to

when

which

how

other

that

the

foot.

shown

you

be

can

hemmer

carefully

patterns,

sew

used

the

in

without

foot,

you

the

with

result

top

the

the

blindstitch

match

will

illustration

feed,

dual

dual

Whenyoujointwopiecesofcheckedmaterial

the

the

will

aid

of

match

exactly.

with

stripes

of

pagel

the

be

dual

feed

(See

the

squares

ill,

at

bottom

or

Even

no

of

the

obstade

the

Pfaff

thickest

for

1222-E.

cross

the

seams

dectronic

are

Control

electronic

The

scenes”

the

whenever

several

or

pressure

electronic

your

of

sewing

the

in

you

layers

on

control

machine

stitching

for

material.

control

comes

have

the

which

sew

to

fabric.

of

foot

instantly

to

through

to

control

reduces

slow

operates’

assistance

your

thick

over

relieve

Just

. .

stitchbystitch

thickest

the

.

the

behind

seams

and

speed

the

the

spots

19

Page 20

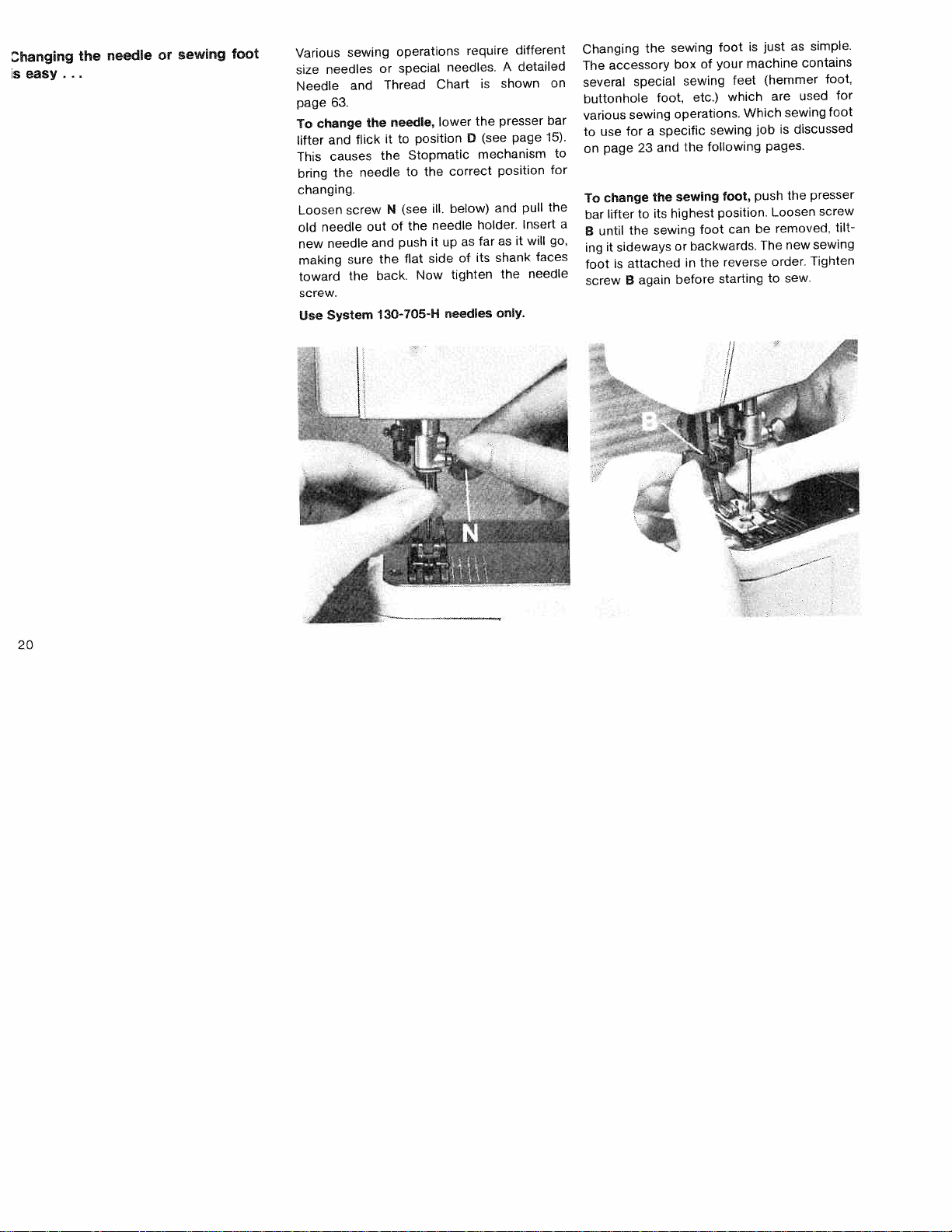

Dhangng

easy.

s

the

neede

or

sewing

foot

Various

needles

size

Needle

page

change

To

and

lifter

This

bring

changing.

Loosen

needle

old

needle

new

making

toward

screw.

System

Use

sewing

and

63.

causes

the

screw

sure

the

or

the

flick

the

needle

out

and

the

back.

130-705-H

operations

special

Thread

needle,

to

it

Stopmatic

to

(see

N

the

of

push

flat

Chart

lower

position

the

ill,

needle

up

it

side

Now

require

needles.

D

correct

below)

as

of

tighten

needles

different

A

shown

is

presser

the

page

(see

mechanism

position

and

holder.

it

far

as

shank

its

the

only.

detailed

pull

Insert

will

faces

needle

on

bar

15).

to

for

the

go,

a

Changing

accessory

The

several

buttonhole

various

to

use

on

page

change

To

lifter

bar

until

B

it

sideways

ing

is

foot

screw

the

special

sewing

a

for

23

the

to

the

attached

again

B

sewing

box

foot,

operations.

specific

and

sewing

highest

its

sewing

or

before

foot

your

of

sewing

etc.)

sewing

following

the

position.

foot

backwards.

the

in

starting

feet

which

Which

foot,

can

reverse

just

is

machine

(hemmer

are

job

pages.

push

Loosen

removed.

be

The

order.

to

as

used

sewing

discussed

is

the

new

sew.

simple.

contains

foot,

for

foot

presser

screw

tilt

sewing

Tighten

Page 21

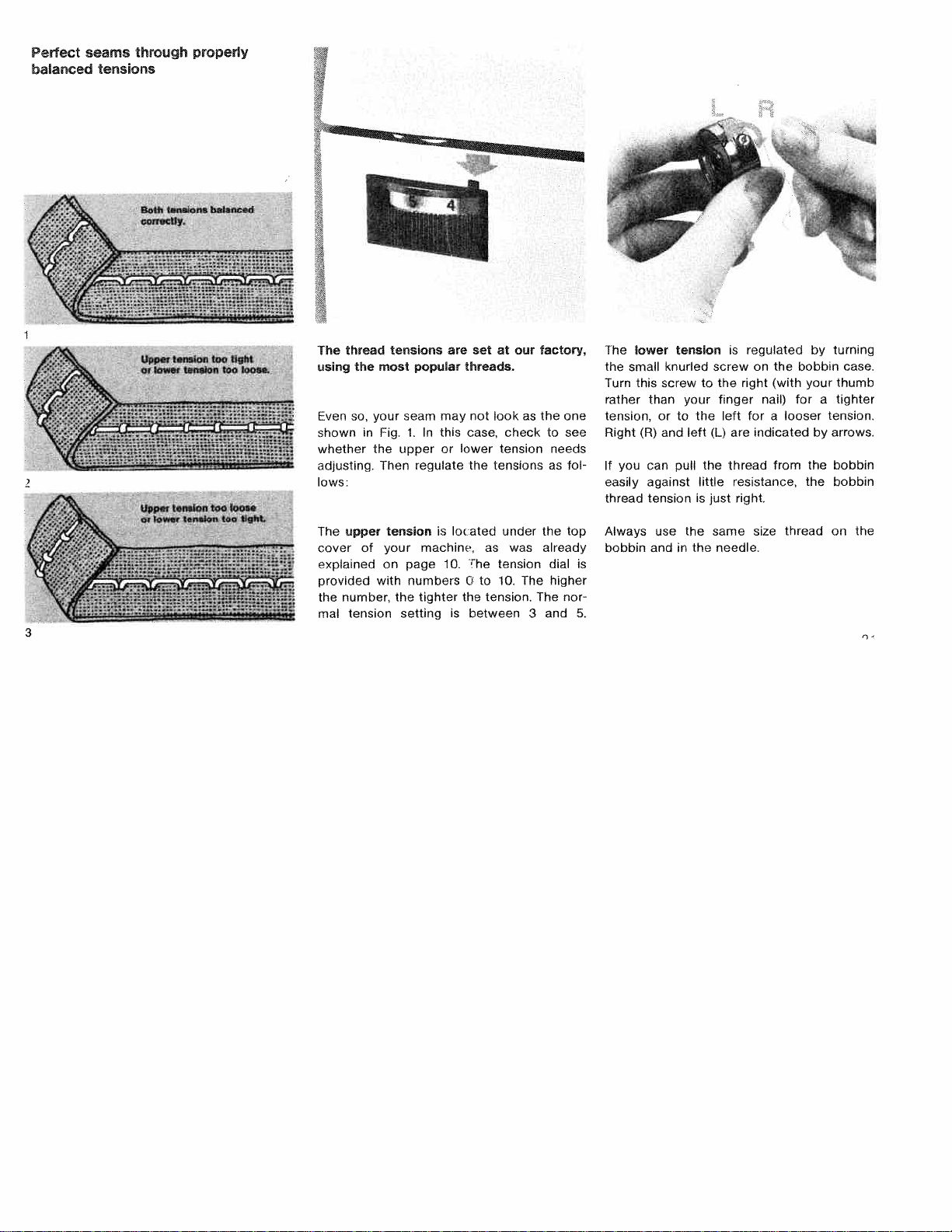

Perfect

balanced

seams

tensions

through

ten&ons

Both

properly

V

btanced

The

thread

using

the

Even

so,

shown

whether

adjusting.

lows;

The

upper

cover

explained

provided

number,

the

tension

mal

tensions

most

popular

your

seam

in

the

of

with

In

Fig.

1.

upper

Then

regulate

tensionislocated

your

machine’,

on

page

numbers

tighter

the

setting

may

this

or

10.

are

is

set

threads.

not

case,

lower

the

‘The

to

0

the

between

at

look

check

tension

tensions

under

as

was

tension

10.

tension.

our factory,

the

one

as

to

needs

as

the

already

dial

higher

The

nor

The

3

and

see

fol

top

is

5.

The

the

small

Turn

rather

tension,

Right

If

you

easily

thread

Always

bobbin

lower

this

screw

than

ortothe

(R)

and

can

against

tension

use

andinthe

tension

knurled

your

left

pull

the

to

the

little

is

screw

the

finger

left

(L)

just

same

needle.

regulated

is

on

right

nail)

foralooser

indicated

are

thread

resistance,

right.

size

the

(with

from

thread

by

bobbin

your

for a

by

the

the

turning

case.

thumb

tighter

tension.

arrows.

bobbin

bobbin

the

on

‘11

Page 22

detachab’e

vorking

surface...

workplate

increases

your

Straightstitch

and

zigzag

Pfaffmachines

detachable

a

with

illustration

pushed

pins

over

enter

machine.

below.

the

the

and

1214

workplate,

This

free

appropriate

1222-E

workplate

arm

until

as

are

shown

its

holes

I

supplied

simply

is

two

in

the

in

guide

the

increase

To

Portable,

1213

illustrated

the

below.

sewing

attach

the

area

bedplate

of

your

extension

sewing

Pfaff

work

Page 23

see

Now

advantage

lake

machine

stitching.

for

offers

yourself

of

you

the

what

many

in

your

possibilities

straight

Pfaff

and

can

zigzag

do.

this

FeHing

Ultra-Matic

straight

length:

Stitch

Engage

material

felling

Attach

93-040

No.

obtained

Felled

seams

They

fabric.

childrens

tions:

seam:

First

with

gether

bottom

Make

sure

evenly.

the

over

must

edge

pieces.

Second

foot.

felling

same

the

at

the

pull

sewing.

while

stitch

stitch

dual

requires

938-31

from

wear

piece

the

The

edge

seam:

fabric

1.5—2

feed

toot

your

are

are

Lay

their

protruding

fabric

bottom

of

not

Insert

Stitch

end

selector:

if

it.

(can

Pfaff

used

often

and

are

the

right

the

be

down

it

as

sideways

to

used

two

sides

enters

fabric

top

folded.

the

the

be

dealer)

join

made

pieces

about

should

piece,

seam

to

first

on

facing

the

Open

the

to

two

bed

in

ridge

seam.

keep

two

of

4

felling

be

but

left,

.

#

1))

pieces

linen

opera

fabric

and

mm

folded

the

the

into

starting

Lightly

it

the

(‘).

foot

top

two

taut

to

the

c-i

rj

J

of

or

:I

r-

23

Page 24

Hemming

Ultra-Matic

straight

length:

Stitch

Engage

Attach

93-040

No.

stitch

stitch

dual

hemmer

934-31.

selector:

‘

2

feed

foot

When

against

neat,

a

the

Fold

making

several

hemmer

the

folded

Draw

both

ing

illustration

the

into

hand

Make

under

should

fabric

toe.

left

produce

To

zigzag

use

the

to

proceed,

you

fraying

durable

beginning

a

inches

edge

fabric

the

threads

hemmer

(see

sure

the

be

edge

maximum

hem

hem

foot

down

at

ill,

the

right

well

is

stitches.

as

fabric

a

and

edge

about

long.

and

with

into

backwards,

top.

the

foot

the

at

fabric

half

filled

line

in

elastic

an

stitch

instructed

the

at

finish.

the

of

Place

lower

the

bottom).

does

of

with

with

Turn

edge,

same

mm

3

or

3

hemmer

Feed

scroll

the

hem

length

above.

fabric

the

same,

4

not

fabric

the

on

the

you

time

edge

(“)

material

straight

shown

as

the

with

slip

foot.

right

soft

stitch

in

protect

produce

wide

Stitch

foot

fabric

your

sideways

The

so

side

materials,

range

twice,

and

under

stitches.

pull

by

in

edge

right

scroll

that

of

selector

6

it

the

the

the

the

and

2

Page 25

No.

Dual

insertion

lengt:

93-040

or

feed

Zipper

Ultra-Matic

straight

Stitch

Attach

With

stitch

zipper

without

stitch

15—2

foot

927-31.

selector:

Baste

open

zipper

edge

1).

(Fig.

raise

Then

Continue

zipper,

the

other

the

zipper

Stop

seam,

zipper.

zipper.

finished

The

the

Stitch

it.

for

of

Leave

the

lower

(Fig.

about

raise

Continue

closed

close

about

foot

the

zipper

the

stitching

then

close

side

3).

cm

5

the

zipper

zipper

5

the

foot

zipper

stitch

(2”)

zipper

sewing

to

cm

along

needle

until

across

to

short

closure

the

(2”),

and

you

the

on

foot

foot

the

left

guiding

the

in

close

reach

this

right

of

the

to

is

fabric,

edge

zipper

the

again

edge

the

and

shown

the

material,

the

(Fig.

the

end

end

open

end

in

then

the

of

right

teeth

zipper.

end

and

the

of

the

of

the

the

of

Fig.

2).

of

up

4.

25

Page 26

Darning

Ultra-Matic

straight

length:

Stitch

darning

Attach

93-040

No.

stitch

stitch

1—4

foot

960-91.

selector:

3

darning,

For

this,

do

horizontal

left

symbol

darning

ing.

vibrator.

darning

the

plate,

foot

material

the

When

length.

material

depress

This

and

rises

darning

swing

is

foot

motion

When

when

depends

It

under

the

the

visible

moves

foot

too,

under

foot

machine

reverse-feed

the

position

is

the

presses

the

so

hole,

a

the

control

on

and

up

controlled

needle

needle

that

needle

the

you

how

on

needle

feed

so

upper

its

down

enters

against

it

you

determine

fast

pedal.

that

rises,

can

and

dropped.

is

control

the

while

by

the

freely

by

you

how

side.

a

the

the

hand.

the

move

to

darning

The

darn

built-in

fabric,

needle

darning

move

stitch

far

To

its

the

you

Page 27

the

Hold

and

back

the

with

the

sure

the

turn

forth

and

stitches.

area

worn

Tubular

stockings,

and

free

arm

across

forth

lengthwise.

Triangular

close

with

material

forth

machine

stitches

fabric

over

This

around

articles,

of

tears

across

at

the

anchors

such

can

the

the

stitches

flat

running

are

right

preceding

the

be

Pfaff

hole,

and

across

with

closely

angles

the

hole.

as

easily

1222.

rips

both

the

at

threads

sleeves,

first

hands.

hole

high

spaced.

and

work

darned

Stitch

crosswise,

best

are

and

Stitch

lengthwise,

speed.

Then

back

sew

short

with

the

in

trouser

on

back

then

darned

lengthwise.

Be

un

legs

the

and

you

After

reverse-feed

position.

ing

have

finished

control

back

darning,

its

to

swing

regular

the

sew

27

Page 28

hirring

Itra-Matic

zigzag

idest

range

itch

cording

ttach

93-040

0.

wfth

stitch

91

5

fiUer

stitch

or

foot

5-35.

thread

selector:

in

6.

produce

To

thread

cording,

pose

thread

sew

and

When

slide

distribute

inserting

it

more

is

under

you

the

a

needed.

is

thread

the

cotton

a

on

have

material

its

filler

a

durable.

durable

the

the

fullness

thread

As

best

thread.

groove

wrong

finished

along

evenly.

shirring

with

suited

of

side

the

the

in

the

effect,

single-needle

for

Place

cording

the

of

zigzag

filler

shirring

this

the

the

thread

filler

a

pur

filler

foot

fabric.

seam,

makes

to

S

S

—

.S

Page 29

ON

jqwnu

O6U3

qo4p’

6useawaO

qo4I3s

Oi4A1eJ4Ifl

04

Aje4eipoUiwi

UI

IEflP

mo

Si

Aulpo

OIO-6

qos

PJ

uO

6-O6

fl

!

se6pe

J9I

q4

uMes

:J0400105

JO

9

6ui

:s8iq

oo

sy

0144

pus

nbA

0144

MOS

OIPOSU

abp

SONS4

ieqo

14S!U!4

6uOs

JSAO

St

e

0uO

s4!

pq

1404145

e6pe

peonpoid

u:

‘06P0

04U!

SW

0144

siq

9)j

IcSM

BinS

opqeJ

S

Page 30

Cording

Ultra-Matic

straight

length:

Stitch

Central

twin

Insert

Attach

grooves.

stitch

stitch

needle

needle.

cording

2

position

foot

selector:

with

Twin

be

can

Cording

linen

Cording

bobbin

ing

thread

slot

the

The

minent

pearl

Cording

thread.

needle,

obtained

goods,

thread

the

above

filler

thread

very

is

dresses,

made

is

needles,

the

of

thread

Unless

woollens

on

If

you

cording

from

popular

with

and

and

face

makes

you

can

want

a

make

the

cover

be

to

foot

your

blouses,

two

filler

other

the

prefer

used

is

best

apply

and

Pfaff

as

needle

cord.

sure

(see

cording

cording

a

etc.

When

to

below

Fig.

special

a

for

made

cording

J

dealer.

trimming

threads,

thread

draw

the

1).

more

purpose.

this

with

to

plate

on

one

disc

pro

thread,

wool

a

trans

a

in

parent

matching

Select

the

and

material

of

Hold

the

On

thread

machine

(Fig.

materials,

the

size

filler

the

Pfaff

through

3).

color.

distance

of

used.

base

the

cord

1213

after

the

take

between

filler

as

Portable,

slot

removing

a

cord

shown

at

filler

the

the

I

to

in

pull

bottom

the

thread

twin

suit

Fig.

bed

needles

the

2.

the

of

cover

in

type

filler

a

the

1

3

Page 31

To

twin

tained

make

needles

from

different

and

any

size

Pfaff

cording,

cording

dealer:

feet

the

can

tollowng

be

ob

Three-row

is

which

mm

to

2.8

Five-row

which

to

1.8

Seven-row

which

to

1.8

is

2.4

is

mm

cording

used

(approx,

cording

used

mm

cording

used

(approx.

with

with

(approx.

with

foot

twin

foot

twin

/

twin

foot

No.

needles

7/)

to

No.

needles

/,

No.

needles

to

‘16”)

93-040

set

apart.

93-040

to

93-040

set

apart.

948-31

2.4

from

950-31

from

set

3/)

apart.

952-31

1.2

from

33

Page 32

hiserting

Ultra-Matic

straight

length:

Stitch

ordinary

Attach

93-040

No.

the

Place

and

terial

both

on

the

Cut

fold

(2),

turn

Now

zigzag

wide

the

over

stitch

sides

fabric

the

ace

stitch

(initially)

1

910-91.

lace

sew

fabric

the

stitch

edges

selector:

sewing

on

down

it

(1).

open

stitch

of

the

under

edges

in

the

foot

right

with

selector

stitch

lace

side

straight

the

back

range

on

lace

to

the

of

and

the

stitches

insertion

iron

medium-

a

and

6

right

ma

(3).

sew

side.

-.

-“

ç:;;

j

-:

4_

the

to

close

the

material

wrong

the

Trim

seams

34

excess

on

side

away

(4).

3

Page 33

ON

s

Wfl!

LO4i4S

al4J

IlM

/SOsi1

MOS

1ISeI3

3!4eV4-eJ4lfl

04

6sz6iz

IBJ4uOD

OIO-C6

868U3

pu

SP.fl

6ez6iz

3!4SI

O4t4S

S08UJ

apaeu

Aeuipio

enp

peo-os

P4P

pooru4sui

q34!4S

L6-O6

pej

JO4

4°°!4

DI4S89

oqwAs

pU

eAoq

9

wees

:Jo4DeIOs

U014!SOd

4004

6U1M05

udo-ssid

O!4SjO

wees

q4!M

uq

I

uaaM4eq

si

wes

91J4

sswd

SIJ84OW

t4OflS

8U!I4DW

uedo

AfJJn3:3Jd

S

40S

Page 34

Appliqué

Ultra—Matic

straight

Stitch

Attach

No.

stitch

length:

cording

93-040

work

stitch

91

selector:

(initially)

1

foot

5-35.

‘1

4

4

Page 35

Regardless

designs

appliquéing

articles,

napkins

cloths,

beachwear,

and

es

things.

the

Trace

fabric.

Turn

1.

stitch

zigzag

appliqué

that

so

covered

is

Turn

2.

stitch

zigzag

edges

the

Undo

3.

the

trim

right

the

on

Turn

4.

in

stitch

edges

raw

design

the

cord.

filler

a

or

such

the

the

the

excess

the

use

design

on

of

the

stitch

whether

motifs

a

adds

wall

as

and

cushions

on

stitch

stitch

in

right

the

design

completely.

selector

stitch

stitch

in

the

appliqué

zigzag

first

material

(Fig.

side

selector

stitch

range

the

of

raised

a

you

that

beautiful

hangings

aprons,

the

selector

range

side

traced

Then

range

3).

6

appliqué

effect,

create

ready-made..

are

fashion

children’s

and

wrong

to

of

its

on

stitch

not-too-dense

a

to

and

5

the

on

seam

close

a

to

sew

and

again,

satin-stitch

many

side

the

9,

the

wrong

wrong

(Fig.

to

dense

your

and

place

it

sew

the

over

own

trim

table

dress

other

the

of

largest

the

material

side

down.

over

side.

and

1)

seam

zigzag

give

To

over

to

the

37

Page 36

Where

hole:

most

For

enters

achieved

selector

position,

this

the

on

For

buttons

seams,

needle

the

enters

This

into

be

changed

indicated

does

in

the

the

to

left.

other

and

however,

the

done

is

position.

sewing

needle

by

the

the

sewing

hole

needle

in

the

the

middle,

turning

position

buttonhole

sewing

the

must

turning

by

the

If

a

for

instructions.

needle

at

operations,

hole

knob

jobs,

various

position

be

hole

needle

certain

enter

the

the

in

D

shown

symbol

e.

g.

functional-stitch

of

changed

the

on

knob

0

position

sewing

the

right

the

middle.

in

in

sewing

the

right

until

job,

needle

or

the

Fig.

is

needle

so

left?

needle

This

stitch

1.

located

that

or

snaps

it

has

this

is

In

on

in

it

left.

to

is

38

Right

needle

the

on

needie

enters

right.

position:

needle

the

the

hole

Page 37

Button

Ultra-Matic

straight

the

Drop

(see

pp.

needle

Right

38).

p.

(see

clear-view

Attach

93-040

No.

the

Place

sewing

enter

will

correct

the

needle

the

two

or

again.

the

Turn

range

stitch

distance

the

selector

This

enters

left

its

as

Sew

necessary

stitch

the

a

sew

threads.

When

above

sewing

stitch

stitch

machine

and

16

920-91

material

and

foot

tfte

stitch

tying

stitch

left

the

stitch.

many

to

selector

few

sewing

process.

selector:

26).

position

align

right

position

stitches,

selector

which

9

between

is

hole

zigzag

fasten

tying

on

feed

sewing

and

them

hole

of

through

corresponds

the

correctly

set

exactly

the

to

stitches.

four-hole

foot

the

so

in

the

the

the

then

the

to

holes

stitches

button

straight

buttons,

button

that

button.

button

hole.

raise

it

as

Then

under

the

by

Sew

the

stitch

exactly

the

in

the

if

descends

you

as

securely.

stitching

repeat

needle

Check

letting

needle

width

button.

needle

trim

the

one

for

deem

Turn

and

the

to

the

in

-

.

-

-

—---

-

•

—

IL

Page 38

ewhig

Mtach

\Io.

93—040

nachine

-ieedle

Oneck

jecorative

outtons

the

Mark

fabric.

set

To

sewing,

hole

clockwise

sewing

clockwise

Turn

symbol

turn

Now

that

so

setting

machine

The

density

buttonhoes

buttonhole

924—91.

embroidery

bobbin

and

make

to

and

are

out

buttonhole

machine

the

interrupted,

is

only.

D

knob

positioned

is

the

buttonhole

its

mark.

(see

too

Use

thread

thread

that

sure

functional-stitch

page

(see

on

for

make

Even

only.

clockwise

ring

outer

thus

is

above,

ill.

No.

all

13).

the

programmed

you

sure

when

knob

until

below

the

of

symbol

for

set

center).

50

as

D

the

must

its

stitch

medium

a

turn

buttonhole

be

buttonhole

setting

above

is

button

knob

turned

mark.

selector

stitch

the

D

recommend

We

the

out

in

ted

thread

selector

further

are

they

above,

ill

Place

the

pull

the

of

grooves

two

Lower

you

Now

tinuous

Begin

1.

the

to

Push

2.

above,

zigzag

control

The

3.

seam.

left

long

Then

4.

again

Release

5,

is

it

machine

the

the

completely

Cut

6.

ripper.

stitch

accordance

being

toward

apart;

packed

center).

fabric

the

filler

and

foot,

foot.

the

can

operation,

by

buttonhole

buttonhole

left)

stitches

again.

T

machine

Now

the

as

press

sew

to

positioned

cord

filler

the

sewing

density

used.

±,

when

together

under

cord

place

in

its

sew

sewing

the

until

for

sew

seam.

first

buttonhole

the

control

vertically.

makes

trim

and

buttonhole

which

with

When

the

over

sole

the

as

the

length

control

machine

the

thus

is

second

T.

a

into

buttonhole

a

the

you

stitches

turn

you

more

the

the

strands

both

(see

buttonhole

follows

right

marked.

first

set

seam,

this

bartack.

Knob

During

few

the

ends.

both

open

should

fabric

turn

are

it

closely

buttonhole

at

lug

above,

ill,

seam

down

T

has

Then

bar.

for

making

control

now

D

stitches.

tying

buttonhole

with

be

and

the

spaced

toward

the

under

one

in

according

(see

made

release

sewing

T

turns

this

your

to

selec

the

stitch

(see

foot,

back

the

right>.

con

a

it

down

until

phase,

seam

seam

try

—

ill.

few

the

as

Pull

For

sewing

clockwise

buttonhole

its

mark.

setting

buttonhole.

you

After

D

knob

central

white

the

the

until

Repeat

have

clockwise

needie

mark

next

snaps

it

symbol

sewn

position

(normal

buttonhole,

into

positioned

for

this

all

the

until

is

position)

turn

again

place

under

subsequent

each

buttonhoies,

symbol

positioned

knob

for

under

D

with

the

turn

the

Page 39

aew!

uo4!Sod

Page 40

Monogram

Ultra-Matic

stitch

zigzag

size

of

monogram

the

Drop

darning

Attach

93-040

No.

the

Trace

then

and

darning

a

and

lifter

embroêdery

stitch

(depending

machine

foot

960-91.

monogram

the

on

hoop

draw

up

selector:

desired).

feed.

first

fabric.

and

the

on

on

Place

lower

bobbin

piece

a

the

the

thread.

3

of

material

presser

paper

bar

slowly

as

your

give

embroider

closely

acquired

to

embroider

too

not

/

and

if

or

a

flimsy

were

you

monogram

outlines

the

together.

can

be

clear-view

practice,

little

monograms

without

-

writing.

dimen

twice,

embroider

sewing

you

in

using

hoop

the

Move

traced

want

quality,

you

be

the

able

that

outlines

to

stitches

the

have

are

hoop.

monograms

cording

the

you

If

sional

packing

Straight-lined

with

ed

foot.

Once

will

fabrics

darning

a

in

follow

and

evenly,

42

:1

r

Page 41

Quilting

Ultra-Matic

stitch

straigh

zigzag

small

zipper

Attach

93-040

No.

quilting

the

the

Set

spacing

attach

To

shank

the

on

are

holes

be

can

quilting

have

which

stitch

927-31

gauge

gauge

between

the

in

easily

gauge

(2>

stitch.

foot

for

quilting

of

line.

pushed

hole

a

selector:

or

and

to

the

seams.

zipper

the

Compress

be

can

in

apply

the

desired

gauge

through

attached

their

foot.

shank,

place

foot

it

until

the

so

the

that

the

holes.

to

spring

gauge

all

both

This

feet

the

Mark

quilting

the

the

of

Having

material

gauge

previously

sequent

the

preceding

first

gauge

material.

completed

under

finger

sewn

seam,

seam

the

now

guide

line

finger

the

(or

of

the

on

along

first

zipper

runs

marked>.

the

stitches.

seam,

foot

along

gauge

fabric

the

For

raw

move

so

the

any

finger

or

that

guide

edge

the

the

seam

sub

along

stitching

Edge

Ultra-Matic

straight

length:

Stitch

zipper

Attach

93-040

No.

foot

sewing

the

Guide

marking

needle

stitch

the

plate.

stitch

2

foot

927-31

No.

edge

desired

selector:

or

93-040

the

of

ordinary

910-91.

material

stitching

along

margin

the

on

line

the

I

43

Page 42

Darning

Ultra-Matic

zigzag

stitch

6or7.

Drop

the

Attach

darning

No.

93-040

Knitted

cloth

are best

spots

darned

with

stitch

in

machine

960-91.

garments

wool

selector:

stitch

foot

and articles

darned

with

feed.

this

thread

range

with

thread

wool

are

made

of

thread since

not as

terry

stiff

as

those

darned

darning

Draw

hole

this

under

Run

back

individual

down

area.

thread,

the

darning

linesofstitching

make

thread.

the

of

the

foot.

the

the

and

on

Once

trim

darned

the

wool

darning

The

darning

machine

forth

strands

the

the

it.

thread.

darn

wool

right

Then

area

too

with

thread

foot

and place

across

closely

and

hole

lengthwise,

Do

too

hard.

foot

thread

(ill,

the

is

covered

sew

not

closely

thin

through

and

right).

hole,

together.

left

back

space

embroidery

the

into

the

must

be

the

wool

packing

the

defective

of

with

forth

and

using

the

since

this

needle

slot

placed

thread

Stitch

the

a

various

would

and

of

the

it

wool

over

thin

44

Page 43

Eyelet

eyelet

For

cover

need

93-040

No.

inserted

adjoining

plate

Pfaff

your

Drop

Remove

Lower

bobbin

the

embroidery

embroidery

plate

946-45

the

in

drawing).

be

can

dealer.

machine

the

the

presser

the

thread.

feed

obtained

sewing

which

slot

This

feed.

foot.

bar

you

cover

from

lifter

is

(see

and

draw

up

Mark

with

make

and

your

scissors.

Push

the

of

stitch

stitch

Now

hand

by

portant

Sew

the

dots.

seam

the

little

selector

range

sew

around

position

Place

crosswise

a

ripper

stud

holes

around

at

obtain

to

of

or

5

uniform

a

every

of

the

the

in

to

6.

the

beautiful

the

fabric

or

a

hole

eyelets

cut

a

cover

the

narrow

hole,

rate.

in

at

pointed

plate

fabric

turning

eyelets.

twice.

on

darning

a

each

and

zigzag

This

fabric

the

hoop

using

dot,

embroidery

through

turn

stitch

the

very

is

one

the

in

hoop

im

45

Page 44

built-in

The

built-in

possible

of

elastic

set

your

the

buttons.

functional

makes

The

it

kinds

are

stretch

machine

pushing

To

open

utility-stitch

of

utility-stitch

to

materials,

(e.g.

fabrics)

for

button.

a

machine

lidinthe

symbols

utility-stitch

sewing

sew

functional

no

tricot,

or

not.

the

utility-stitch

for

top

appear

mechanism

mechanism

matter

jersey,

Simply

functional

cover.

simple

seams

whether

Helanca

desired

The

the

on

makes

on

they

and

set

the

stitching,

different

row

left

all

by

Simply

to

set

button

Each

tive

utility-stitch,

length

position

illustration

The

howtoset

you

To

sew

identified

D

knob

cated

the

dial.

pushabutton

your

machine

shows

recommended

is

which

on

your

elastic

an

the elastic-stitch

by

until

the

needle

the

on

button

for

the

and

as

tobeset

the

opposite

machine.

seam, push

is

the

symbol

indicates

wellasthe

by

position

opposite

desired

the

of

turning

page

the button

symbol,

symbol

the

the

stitch.

respec

needle

knob

shows

mark

stitch

0.

Turn

indi

on

46

D

,

ns5dgaeof

Special

cheted

stitches.

edge

For

seams

are

exposed

and

for

For

shell

For

darning

elastic,

and

for

elastic

fabrics

that are

to

utility-stitch

edging

rips

sewing

utility-stitch

terry

S.

seam

on

which

pressed

great

stress

combinations.

blindstrichmg

and

worn

cloth,

combinations.

knitted

secures

areas,

inserting

open

(e.g.

and

the

ski

and

sewing

patches

fabric

later

pants),

utity

crot

or

on

—

—

/\

A

/

——

\

\/

X>,X,XyX

‘

‘

\‘

/\

A

A

/

\

/

V

//X,x

\ç\ç\ç--

‘ ‘

——

*

A

I

,‘

‘

\

\/

\\

\\

‘

—

\

‘

/\

v

/

/

Cross

Ovedock

Eastc

straIght

Bhnd

stItch

Eastc

.

stItch

StItCh

tripe

StItCh

stitch

-

Page 45

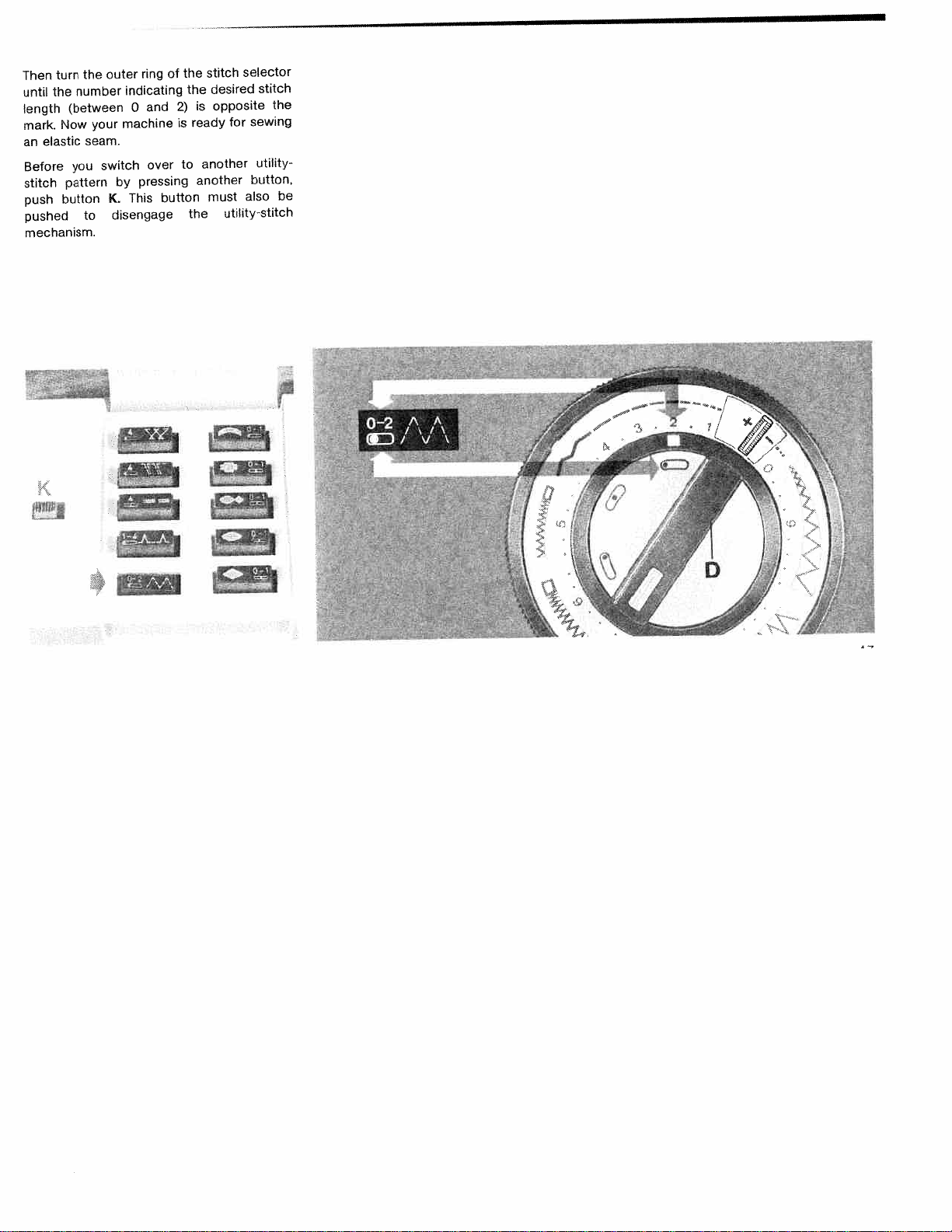

turn

Then

the

until

(between

length

Now

mark.

elastic

an

Before

pattern

stitch

button

push

pushed

mechanism.

the

number

your

seam.

you

to

outer

indicating

machine

switch

by

This

K.

disengage

ring

and

0

over

pressing

of

2)

is

button

the

the

to

the

stitch

desired

opposite

is

ready

another

another

must

selector

stitch

the

sewing

for

utility-

button,

also

utility-stitch

be

Page 46

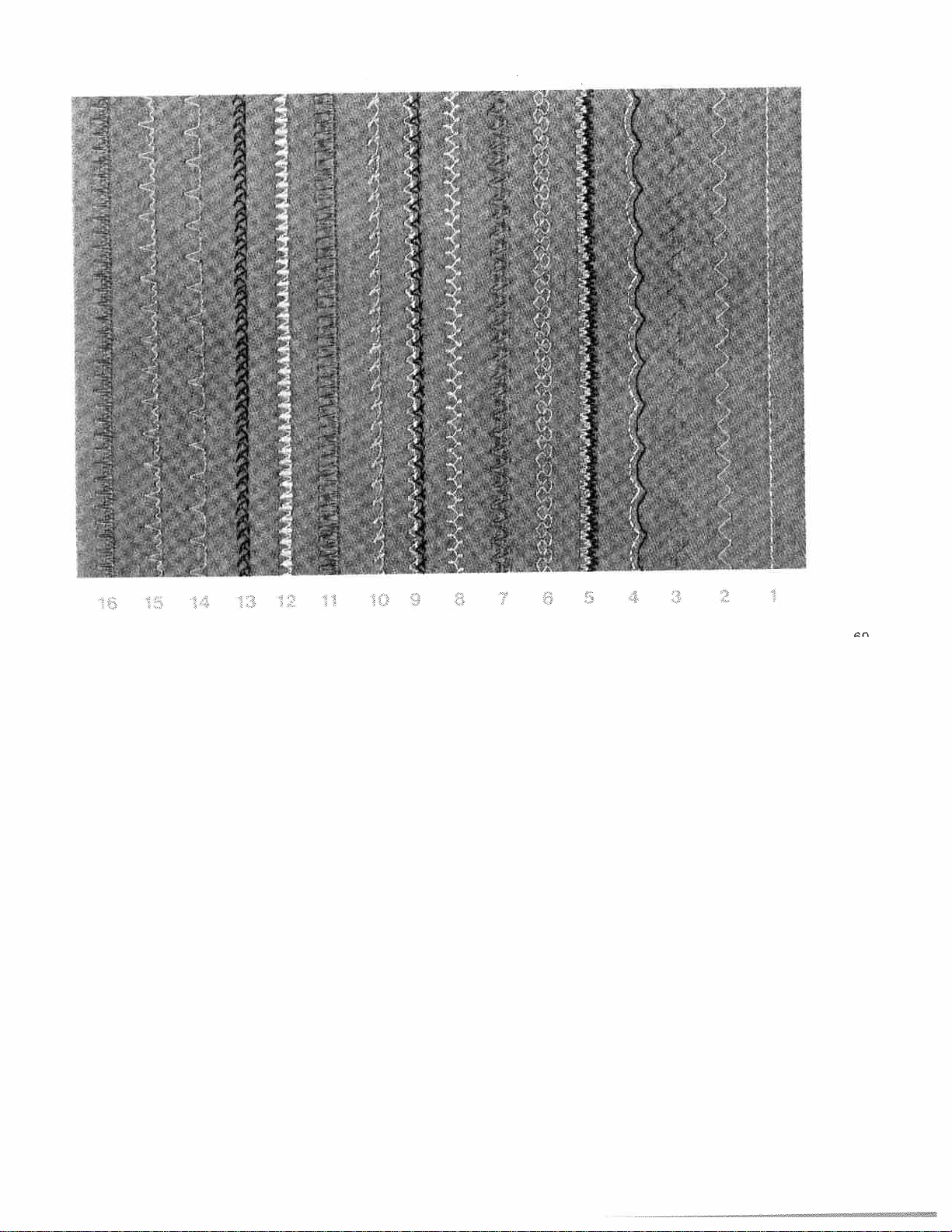

These

stitches

sewing

utiIity

make

Mending

Elastic

Stitch

needle

Left

Ordinary

No.

93-040

Engage

stitch

length:

sewing

dual

hems

between

position

91

feed

0-91

and

foot

darning

0

and

rips

%_

—

•%

_%

—

—

_%.

1

_%

_%_%

>>>>>>>

—

—

—

—

>>>>>>>

>>>>>>>

easy

for

you

-—-—

—“

Rip

damaged

terial

press.

that

edgeofthe

Sewitdown

individual

To

material

the

the

open

in

the

Then

its

folded

mend

under

individual

sectionofthe

Take

area,

right

insert

edge

hem.

with

an

patterns

rip,

placeapiece

a

and

it

elastic-stitch

hem

pieceofsuitable

a

size,

fold

this

pieceinthe

isinline with

elastic

seam,

overlap

join

(see

both

patterns

opposite

it

in

ill.).

plies

the

so

of

half

hem

folded

that

suitable

so

overlap.

the

ma

and

so

the

that

Page 47

Sewing

Elastic

Stitch

needle

Left

Ordinary

93-040

No.

Engage

the

Lay

it

with

Then

elastic

more

The

fabric

the

stitch

length:

elastic

both

sew

seam.

on

sewing

910-91

dual

the

you

will

eIastc

1

position

foot

feed

on

hands

stretched

stretch

be

fabric

the

far

as

gathered.

as

elastic

the

edge,

possible

down

elastic,

stretching

(see

with

more

the

ill.).

an

49

Page 48

Stitching

Elastic

length:

Stitch

needle

Left