Page 1

®

CCC4000 Series

CCD Color Camera

Installation/

Operation Manual

C1925M (3/99)

Pelco • 3500 Pelco Way • Clovis, CA 93612-5699 USA • www.pelco.com

In North America and Canada: Tel (800) 289-9100 or FAX (800) 289-9150

International Customers: Tel (1-559) 292-1981 or FAX (1-559) 348-1120

Page 2

CONTENTS

Section Page

IMPORTANT SAFEGUARDS AND WARNINGS................................................................3

DESCRIPTION................................................................................................................... 3

MODELS ....................................................................................................................3

LOCATION OF PARTS AND CONTROLS .........................................................................4

INSTALLATION .................................................................................................................. 5

CAMERA MOUNTING ...............................................................................................5

POWER REQUIREMENTS........................................................................................6

POWER AND VIDEO CONNECTIONS ............................................................. 6

LENS INSTALLATION................................................................................................7

GENERAL LENS INFORMATION......................................................................7

LENS MOUNTING ............................................................................................. 8

AUTO-IRIS LENSES.......................................................................................... 8

BACK-FOCUS ADJUSTMENT .......................................................................... 8

CAMERA SYNCHRONIZATION AND V-PHASE ....................................................... 9

V-PHASE ADJUSTMENT ..................................................................................9

TROUBLESHOOTING ......................................................................................................10

MAINTENANCE ................................................................................................................10

SPECIFICA TIONS.............................................................................................................1 1

WARRANTY AND RETURN INFORMATION....................................................................12

LIST OF ILLUSTRATIONS

Figure Page

1 Location of Parts and Controls (Front and Rear) ............................................... 4

2 Camera Mounting Screw ...................................................................................5

3 CA1750 Mount Adapter......................................................................................5

4 C-mount Lens with C/CS-Mount Adapter........................................................... 7

LIST OF TABLES

Table Page

A Video Coaxial Cable Requirements ...................................................................6

2 Pelco Manual C1925M (3/99)

Page 3

IMPORTANT SAFEGUARDS AND WARNINGS

Prior to installation and use of this product, the following WARNINGS should be observed.

1. Installation and servicing should only be done by qualified service and installation

personnel.

2. Installation shall be done in accordance with all local and national electrical and

mechanical codes utilizing only approved materials.

3. Use only installation methods and materials capable of supporting four times the

maximum specified load.

The product may bear the following marks:

This symbol indicates that dangerous voltage

constituting a risk of electric shock is present

within this unit.

This symbol indicates that there are important

operating and maintenance instructions in the

literature accompanying this unit.

Please thoroughly familiarize yourself with the information in this manual prior to installation

and operation.

DESCRIPTION

The CCC4000 Series CCD color camera combines high resolution imaging with a very

compact package. This camera features the following:

CAUTION:

RISK OF ELECTRIC SHOCK.

DO NOT OPEN.

1/3-Inch Format Color CCD

This camera uses a 1/3-inch color CCD (charged coupled device) interline transfer sensing

element.

Electronic/Passive Iris Control

Built-in, 4-pole iris drive connector allows this camera to be used with passive (DC

controlled) auto-iris lenses. Video drive auto-iris lenses are not supported.

Lens Compatibility

The standard CS-mount and built-in DC iris control allows this camera to be used with a

wide variety of lenses, including C/CS-mount lenses in the following styles: fixed iris,

manual iris, or passive (DC controlled) auto-iris lenses. C-mount lenses require a C/CSmount adapter. Video drive auto-iris lenses are not supported.

Automatic Gain Control

Automatically adjusts the image to compensate for changes in light levels when using fixed

iris or manual iris lenses.

AC Line Lock

Automatically locks the camera to the AC frequency (60 Hz)–when using AC power

sources–instead of the camera’s internal clock frequency (59.94 Hz) to avoid picture roll

during camera switching operations.

AC or DC Power Compatibility

This camera will automatically adjust to either AC or DC class 2 power supplies.

MODELS

CCC4000-2 NTSC format camera

CCC4000-2X PAL format camera

CCC4001-2 Same as CCC4000-2, except electronic shutter disabled

Pelco Manual C1925M (3/99) 3

Page 4

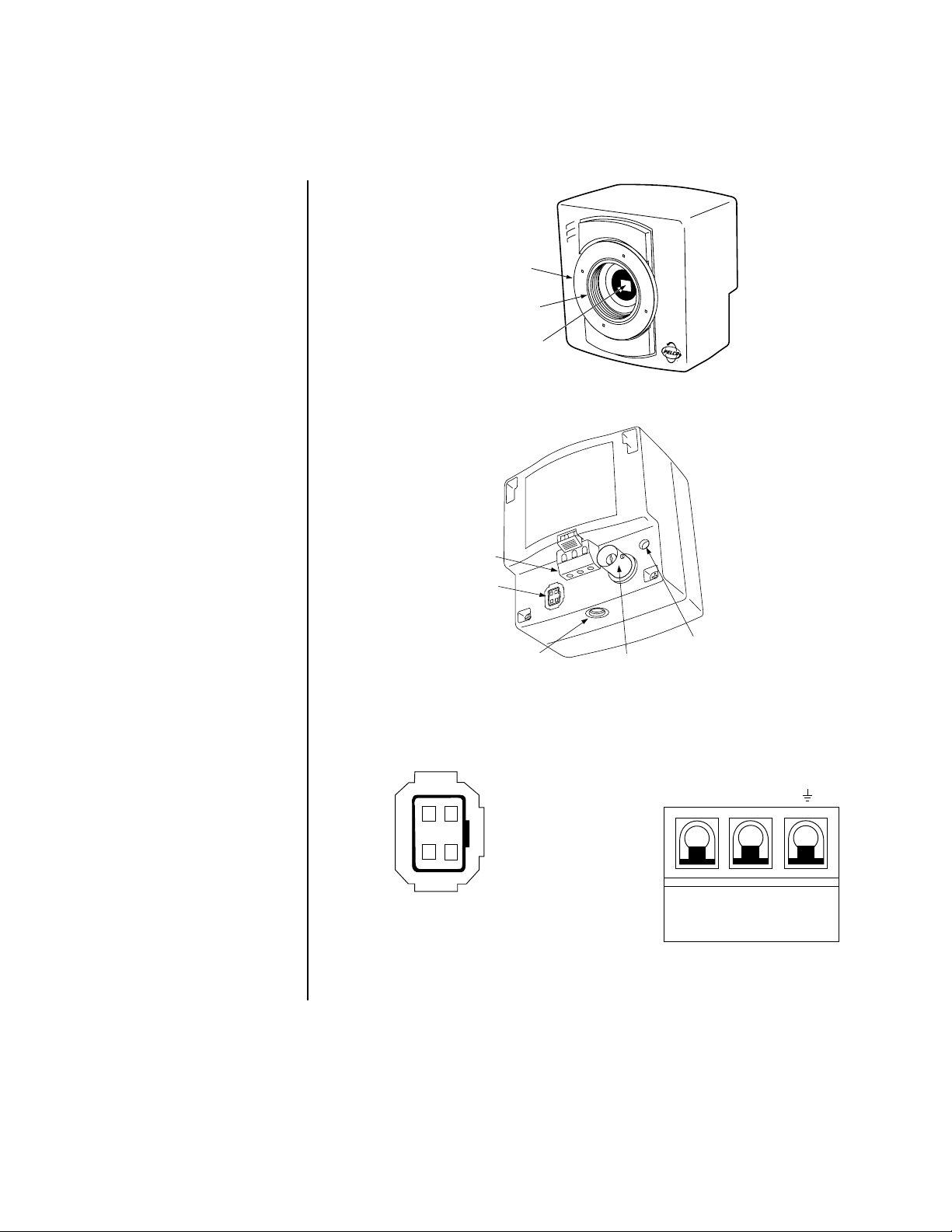

LOCATION OF PARTS AND CONTROLS

AC

DC–

AC

DC+

GND

FRONT VIEW

BACK-FOCUS

LOCKING RING

CS-MOUNT RING

1/3-INCH

CCD ELEMENT

REAR VIEW

POWER

CONNECTOR

IRIS

CONNECTOR

CAMERA MOUNT

(1/4-20 UNC)

VIDEO OUTPUT

(BNC)

V-PHASE

ADJUSTMENT

IRIS CONNECTOR PINOUTS POWER CONNECTOR PINOUTS

4

2

31

PIN 1 = CONTROL COIL + (DAMPING COIL –)

PIN 2 = CONTROL COIL – (DAMPING COIL +)

PIN 3 = DRIVE COIL +

PIN 4 = DRIVE COIL –

Figure 1. Location of Parts and Controls (Front and Rear)

4 Pelco Manual C1925M (3/99)

Page 5

INSTALLATION

CAMERA MOUNTING

Mount the camera using a 1/4–20 mounting screw that does not exceed .197" (4.5 mm ±.2

mm) in length (refer to Figure 2).

An optional CA1750 Mount Adapter is supplied to attach the camera to a ceiling mount.

CAUTION:

Be

careful not to damage the camera by

screwing the adapter too far

onto the threaded stud. As

soon as the stud threads appear through the adapter

captive nut, tighten the

knurled nut.

To install the adapter (refer to Figure 3):

1. Place the camera inside the adapter and align the camera mount boss with the

elongated hole in the adapter.

2. Attach the camera to the adapter with the provided 1/4-20 bolt and washers.

3. Attach the adapter with camera to the 1/4-20 threaded stud on the installed mount

swivel head. Tighten the knurled nut on the mount against the adapter.

-inch UNC (20 pitch)

7 in. (ASA standard)

Figure 2. Camera Mounting Screw

Figure 3. CA1750 Mount Adapter

Pelco Manual C1925M (3/99) 5

Page 6

POWER REQUIREMENTS

An external power supply (not provided) is required when using CCC4000 Series cameras.

This camera will accept either AC or DC power in accordance with the chart immediately

below. A safety ground terminal ( ) is provided on the connector block to connect the

camera to ground potential. Maximum voltage between the supply inputs and the safety

ground must be less than 50 volts. Camera electronics are galvanically insulated from the

camera supply, which protects a system with more than one camera from ground loop

problems. The power connector block can be removed from the camera to ease mounting

and/or installation.

Model AC Power DC Power

CCC4000-2, CCC4001-2 12–27.6 VAC @ 60 Hz 10.8–39 VDC (2.7 W)

CCC4000-2X 12–24 VAC @ 50 Hz 10.8–34 VDC (2.7 W)

POWER AND VIDEO CONNECTIONS

WARNING:

Be

sure to connect the

power and ground

leads to the appropriate terminals. Wrong connections

may cause malfunction and/

or damage to the video

camera.

If you are using AC power and are wiring more than one camera to the same transformer,

connect one side of the transformer to the same terminal on all cameras, and connect the

other side of the transformer to the remaining terminal on all cameras. Failure to connect all

of the cameras the same will cause the cameras to be out of phase with each other and

may produce what appears to be vertical roll when switching between cameras.

Connect a video cable to the SIGNAL OUT connector (BNC) on the rear of the camera

(refer to Figure 1). Refer to Table A for the type of video coaxial cable to use.

Table A. Video Coaxial Cable Requirements

Cable Type* Maximum Distance

RG59/U 750 ft (229m)

RG6/U 1,000 ft (305m)

RG11/U 1,500 ft (457m)

* Minimum cable requirements:

75 ohms

All-copper center conductor

All-copper braided shield with 95% braid coverage

6 Pelco Manual C1925M (3/99)

Page 7

LENS INSTALLATION

GENERAL LENS INFORMATION

CCC4000 Series cameras are factory adjusted to the CS-mount standard. Fixed iris,

manual iris, or passive (DC controlled) auto-iris lenses may be used. Passive (DC

controlled) auto-iris lenses require a standard 4-pin square connector (type D4-152N, not

supplied) that is standard on all Pelco lenses.

C-mount lenses are also compatible by using a Pelco PCMA40 C/CS-mount adapter. Refer

to Figure 4.

Important Lens Notes:

Passive (DC controlled) auto-iris lenses are recommended in outdoor applications to

control lighting changes and prevent picture smear.

This camera will not support active (video controlled) auto-iris lenses (having a built-in

electronic circuit for driving the iris).

C-MOUNT

LENS

C/CS-MOUNT

ADAPTER

CAMERA

Figure 4. C-mount Lens with C/CS-Mount Adapter

Pelco Manual C1925M (3/99) 7

Page 8

LENS MOUNTING

Do not release the back-focus locking ring unnecessarily. Back-focus adjustment has

been set at the factory to the standard CS-mount back-focus distance.

To mount a lens:

1. Remove the black protection cover from the CS-mounting ring.

2. If using a C-mount lens, mount a C/CS-mount adapter between lens and camera.

Refer to Figure 4.

3. Screw the lens on the camera. Be careful to prevent dust from entering the space

between the lens and the CCD element. If necessary, use clean, compressed air to

remove any foreign matter.

4. When using a passive (DC controlled) auto-iris lens, connect the iris cable to the iris

connector on the back of the camera. Refer to the

5. Aim the camera and focus the lens to the object or area to be observed.

6. If a manual-iris lens is used, adjust the iris for the best picture quality. The largest

aperture gives the best light sensitivity, the smallest aperture the greatest depth of

field.

Auto-Iris Lenses

section.

AUTO-IRIS LENSES

Passive auto-iris lenses are DC controlled via the 4-pin iris drive connector (type D4-152N)

located on the back of the camera (refer to Figure 1). When an auto-iris lens is used the

electronic shutter speed is fixed at 1/60th of a second for EIA-standard cameras or 1/50th

of a second for CCIR-standard cameras. The electronic shutter speed feature does not

apply to the CCC4001-2 model since this function has been disabled.

NOTE:

The iris cable of a

(passive) auto-iris lens prevents the lens being rotated

more than 180 degrees. In

this case, disconnect the iris

cable, rotate the lens a full

turn, reconnect the iris cable

and continue the adjustment.

NOTE:

When adjusting

back-focus with an auto-iris

lens, the iris cable must be

plugged into the iris drive

connector; otherwise, the

iris will not open.

Pin connections for the iris drive connector are as follows (refer to Figure 1):

pin 1 control coil + (damping coil -)

pin 2 control coil - (damping coil +)

pin 3 drive coil +

pin 4 drive coil -

BACK-FOCUS ADJUSTMENT

Do not release the back-focus locking ring unnecessarily. Back-focus adjustment has

been set at the factory to the standard CS-mount back-focus distance.

Back-focus is defined as the distance between the lens optics and the camera’s CCD

sensing element.

Accurate back-focus becomes most critical when tracking stationary objects with a

motorized zoom lens. In rare cases, however, a camera that gives an unsharp picture using

a particular lens may require back-focus adjustment.

Fixed Focal Length Lenses

1. With the camera operating, position the camera to view the intended object.

2. Set the focus ring, if present, to infinity (∞).

3. Set the lens iris to its widest usable opening. Use a neutral density filter with auto-iris

lenses in outdoor or bright light settings to ensure maximum iris opening during backfocus adjustment. When a neutral density filter is not available, point the camera to a

relatively dark area to obtain the greatest iris opening.

4. Adjust the back-focus.

a. Turn the back-focus locking ring counterclockwise to loosen the CS-mount ring.

8 Pelco Manual C1925M (3/99)

Page 9

b. Adjust the lens and the CS-mount ring together until picture is sharpest.

c. Hold the lens and CS-mount ring in place and turn the back-focus locking

ring clockwise to tighten.

Motorized Zoom Lenses

1. With the camera operating, position the camera to view an object at a distance not

less than 45 feet (15 meters) away.

2. Using the camera controller, set the lens in the following manner:

a. Zoom out as far as possible (zoom wide).

b. Focus on the distant object (focus far).

c. Open the iris as wide as possible (iris open). Use a neutral density filter with

auto-iris lenses in outdoor or bright light settings to ensure maximum iris opening

during back-focus adjustment. When a neutral density filter is not available, point

the camera to a relatively dark area to obtain the greatest iris opening.

3. Adjust back-focus until the object is in sharpest focus.

a. Turn the back-focus locking ring counterclockwise to loosen the CS-mount ring.

b. Adjust the lens and the CS-mount ring together until picture is sharpest.

c. Hold the lens and CS-mount ring in place and turn the back-focus locking ring

clockwise to tighten.

4. Zoom in all the way on the distant object, then focus the lens for best picture.

5. Zoom out all the way while observing the focus on the monitor (known as “tracking”). If

the image stays in focus throughout the entire zoom range, the back-focus is correct.

Otherwise repeat the process beginning with step 1.

CAMERA SYNCHRONIZATION AND V-PHASE

When using a DC power supply, synchronization is internally locked and V-phase control is

inoperative.

V-phase adjustment is unnecessary when using AC power with a single camera.

When powering more than one camera with AC, phase differences may occur as a result of

being connected to different power groups. These phase differences become apparent as a

brief rolling of the picture each time cameras are switched, known as vertical roll.

Vertical roll can be corrected by synchronizing the cameras using the V-phase control

button inside the opening on the back of the camera (refer to Figure 1). Each time the

V-phase button is pressed, the line lock position shifts by 60 degrees.

The CCC4000 Series cameras generate a video signal with synchronization pulses

corresponding to the following:

CCC4000-2 NTSC Standard

CCC4000-2X PAL Standard

CCC4001-2 NTSC Standard

V-PHASE ADJUSTMENT

Generally, it is necessary to have two people in communication when cameras are

synchronized: one person at the camera to be synchronized and a person at the monitor to

observe the vertical “roll” and the effect of any adjustments made at the camera.

1. Choose a camera to which all of the other cameras will be synchronized. Go through

the available cameras and determine the best camera to which the others should be

synchronized.

Pelco Manual C1925M (3/99) 9

Page 10

2. Select a second camera that is out of synchronization with the first camera.

3. To shift the V-phase, use a sharp pencil, a toothpick, or some other pointed device

capable of being inserted into the V-phase adjustment opening. Each press of the Vphase button will shift the AC linelock by 60 degrees.

4. Switch the cameras back and forth, observing the “roll” between the cameras when

they are switched.

5. If “roll” is present, press the V-phase button again, observing the “roll” each time an

adjustment is made.

6. Repeat this process as many times as necessary and for each of the other cameras in

the system.

TROUBLESHOOTING

The following conditions may be observed when using a CCD camera and are not

necessarily a fault of the camera.

Vertical smear This may occur when viewing a bright object or an intense

reflection.

Patterned noise and blemish A fixed pattern may appear over the entire monitor screen

Jagged picture Becomes noticeable when viewing stripes, straight lines, or

Camera does not operate There are no serviceable parts on CCC4000 Series

MAINTENANCE

Be careful not to spill water or other liquids on the unit.

Avoid operating or storing the unit in the following locations:

Extremely hot or cold places. The operating temperature of CCC4000 Series cameras

is 14° to 122°F (10° to 50°C).

Damp or dusty places

Where it may become exposed to rain

Locations subject to strong vibrations

Near generators of powerful electromagnetic radiation such as radio or television

transmitters

Remove dust or dirt on the surface of the lens or optical filter with a blower.

when the camera is operated at a high temperature.

similar patterns.

cameras. If a camera fails to function properly, confirm that

all necessary connections are in order and that lens

adjustments are correct for the application.

Clean the body with a dry cloth. If it is very dirty, use a cloth dampened with a small quantity

of neutral detergent, then wipe dry. Avoid the use of volatile solvents such as thinners,

benzene, alcohol, and insecticides. They may damage the surface finish, or impair the

operation of the cameras.

10 Pelco Manual C1925M (3/99)

Page 11

SPECIFICATIONS

CCD Sensor: Color 1/3-inch interline transfer

Pixels

NTSC: 512 H x 492 V

PAL: 512 H x 582 V

Sensing Area: 4.7 x 3.5 mm (3/16 x 1/8 in.)

Sync System: Free running/line lock (when AC powered)

Horizontal

Resolution: 400 TV lines

Lens Mount: CS mount

Light Sensitivity: 3.5 lux (≥ 50 ire/-6 dB) at f/1.2

Electronic Shutter

Speed (N/A for the CCC4001-2 model)

NTSC: 1/60-1/50,000 sec

PAL: 1/50-1/50,000 sec

Signal to

Noise Ratio: > 50 dB

Gain Control: Automatic

Power

Requirements

PAL: 12–24 VAC, 10.8–34 VDC

NTSC: 12–27.6 VAC, 10.8–39 VDC

Video Output: CVBS, 1 Vp-p, 75 ohms

Lens Jack: 4-pin connector (type D4-152N)

Power

Consumption

(camera only): 2.7 watts maximum

Operating

Temperature: 14° to 122°F (-10° to 50°C)

Humidity: 20–95% relative humidity

Construction: Conductive-coated ABS

Mounting Threads: 1/4-20 UNC

Dimensions: 2.75 in. W x 2.88 in. H x 2.38 in. D (70 x 72.5 x 60 mm)

Weight

(without lens): 0.45 lb (200g)

(Design and product specifications subject to change without notice.)

Pelco Manual C1925M (3/99) 11

Page 12

REGULATORY NOTICES

NOTE: This equipment has been tested and found to comply with the limits of a Class A

digital device, pursuant to part 15 of the FCC rules. These limits are designed to provide

reasonable protection against harmful interference when the equipment is operated in a

commercial environment. This equipment generates, uses, and can radiate radio frequency

energy and, if not installed and used in accordance with the instruction manual, may cause

harmful interference to radio communications. Operation of this equipment in a residential

area is likely to cause harmful interference in which case the user will be required to correct

the interference at his own expense.

PRODUCT WARRANTY AND RETURN INFORMATION

WARRANTY

Pelco will repair or replace, without charge, any merchandise proved defective in material or

workmanship for a period of one year after the date of shipment.

Exceptions to this warranty are as noted below:

• Five years on FT/FR8000 Series fiber optic products.

®

• Three years on Genex

• Three years on Camclosure

CC3701H-2X, CC3751H-2, CC3651H-2X, MC3651H-2, and MC3651H-2X camera models,

which have a five-year warranty.

•Two years on standard motorized or fixed focal length lenses.

•Two years on Legacy

fixed dome products.

•Two years on Spectra

continuous motion applications.

•Two years on Esprit

• Eighteen months on DX Series digital video recorders, NVR300 Series network video

recorders, and Endura

• One year (except video heads) on video cassette recorders (VCRs). Video heads will be

covered for a period of six months.

• Six months on all pan and tilts, scanners or preset lenses used in continuous motion

applications (that is, preset scan, tour and auto scan modes).

Pelco will warrant all replacement parts and repairs for 90 days from the date of Pelco

shipment. All goods requiring warranty repair shall be sent freight prepaid to Pelco, Clovis,

California. Repairs made necessary by reason of misuse, alteration, normal wear, or accident

are not covered under this warranty.

Pelco assumes no risk and shall be subject to no liability for damages or loss resulting from

the specific use or application made of the Products. Pelco’s liability for any claim, whether

based on breach of contract, negligence, infringement of any rights of any party or product

liability, relating to the Products shall not exceed the price paid by the Dealer to Pelco for

such Products. In no event will Pelco be liable for any special, incidental or consequential

damages (including loss of use, loss of profit and claims of third parties) however caused,

whether by the negligence of Pelco or otherwise.

The above warranty provides the Dealer with specific legal rights. The Dealer may also have

additional rights, which are subject to variation from state to state.

Series products (multiplexers, server, and keyboard).

®

and fixed camera models, except the CC3701H-2,

®

, CM6700/CM6800/CM9700 Series matrix, and DF5/DF8 Series

®

, Esprit®, ExSite™, and PS20 scanners, including when used in

®

and WW5700 Series window wiper (excluding wiper blades).

™

Series distributed network-based video products.

If a warranty repair is required, the Dealer must contact Pelco at (800) 289-9100 or

(559) 292-1981 to obtain a Repair Authorization number (RA), and provide the following

information:

1. Model and serial number

2. Date of shipment, P.O. number, Sales Order number, or Pelco invoice number

3. Details of the defect or problem

If there is a dispute regarding the warranty of a product which does not fall under the

warranty conditions stated above, please include a written explanation with the product

when returned.

Method of return shipment shall be the same or equal to the method by which the item was

received by Pelco.

RETURNS

In order to expedite parts returned to the factory for repair or credit, please call the factory at

(800) 289-9100 or (559) 292-1981 to obtain an authorization number (CA number if returned

for credit, and RA number if returned for repair).

All merchandise returned for credit may be subject to a 20% restocking and refurbishing

charge.

Goods returned for repair or credit should be clearly identified with the assigned CA or RA

number and freight should be prepaid. Ship to the appropriate address below.

If you are located within the continental U.S., Alaska, Hawaii or Puerto Rico, send goods to:

Service Department

Pelco

3500 Pelco Way

Clovis, CA 93612-5699

If you are located outside the continental U.S., Alaska, Hawaii or Puerto Rico and are

instructed to return goods to the USA, you may do one of the following:

If the goods are to be sent by a COURIER SERVICE, send the goods to:

Pelco

3500 Pelco Way

Clovis, CA 93612-5699 USA

If the goods are to be sent by a FREIGHT FORWARDER, send the goods to:

Pelco c/o Expeditors

473 Eccles Avenue

South San Francisco, CA 94080 USA

Phone: 650-737-1700

Fax: 650-737-0933

REVISION HISTORY

Manual # Date Comments

C1925M 1/98 Original version.

3/99 Added CCC4001-2 model. Revised manual format.

Pelco, the Pelco logo, Camclosure, Esprit, Genex, Legacy, and Spectra are registered trademarks of Pelco. ©Copyright 1999, Pelco.

Endura and ExSite are trademarks of Pelco. All rights reserved.

12 Pelco Manual C1925M (3/99)

Loading...

Loading...