PEERLESS Pinnacle PO-70, Pinnacle PO-70A, Pinnacle PO-84, Pinnacle PO-84A, Pinnacle Installation, Operation & Maintenance Manual

Page 1

Pinnacle

®

Boilers

Peerless

®

Oil

Installation,

Operation &

Maintenance

Manual

As an ENERGY STAR®Partner, PB Heat, LLC has determined that this

product meets the ENERGY STAR

®

guidelines for energy efficiency.

Page 2

USING THIS MANUAL 1

A. INSTALLATION SEQUENCE . . . . . . . . . . . . .1

B. SPECIAL ATTENTION BOXES . . . . . . . . . . . .1

1. PREINSTALLATION 2

A. GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

B. CODES & REGULATIONS . . . . . . . . . . . . . . .2

C. ACCESSIBILITY CLEARANCES . . . . . . . . . . .2

D. COMBUSTION & VENTILATION AIR . . . . . . .2

E. PLANNING THE LAYOUT . . . . . . . . . . . . . . . .3

2. BOILER SET-UP 4

A. GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

3. VENTING, INLET AIR & CONDENSATE 5

A. GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

B. APPROVED MATERIALS FOR EXHAUST

VENT AND INLET AIR PIPING . . . . . . . . . . . .5

C. EXHAUST VENT/INLET AIR LOCATION . . . .5

D. CONCENTRIC VENTING SYSTEM . . . . . . . .6

E. EXHAUST VENT AND AIR INLET PIPE

INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . .6

F. STANDARD VENT KITS . . . . . . . . . . . . . . . . .7

G. CONDENSATE . . . . . . . . . . . . . . . . . . . . . . . .8

4. WATER PIPING 10

A. GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . .10

B. SYSTEM COMPONENTS . . . . . . . . . . . . . . .10

C. SYSTEM PIPING . . . . . . . . . . . . . . . . . . . . . .12

D. FREEZE PROTECTION . . . . . . . . . . . . . . . . .12

E. SPECIAL APPLICATIONS . . . . . . . . . . . . . . .18

5. OIL BURNER INSTALLATION 20

A. GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . .20

B. BURNER INSTALLATION . . . . . . . . . . . . . . .20

6. ELECTRICAL & CONTROLS 21

A. GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . .21

B. BURNER WIRING . . . . . . . . . . . . . . . . . . . . .21

C. BOILER WIRING . . . . . . . . . . . . . . . . . . . . . .21

D. CONTROL TERMS . . . . . . . . . . . . . . . . . . . .22

E. SEQUENCE OF OPERATION . . . . . . . . . . . .23

F. BOILER SAFETY INTERLOCKS . . . . . . . . . .24

G. BOILER TEMPERATURE CONTROL

OPTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . .24

H. CONTROL MODES . . . . . . . . . . . . . . . . . . . .24

I. USER INTERFACE . . . . . . . . . . . . . . . . . . . .24

J. CONTROL ACCESS LEVELS . . . . . . . . . . . .25

K. TROUBLESHOOTING . . . . . . . . . . . . . . . . . .27

L. POC TECHNICAL DATA . . . . . . . . . . . . . . . .28

7. START-UP PROCEDURE 30

A. GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . .30

B. FILL THE SYSTEM WITH WATER . . . . . . . .30

C. CHECK THE ELECTRIC CIRCUITS . . . . . . . .30

D. PRIME THE FUEL UNIT . . . . . . . . . . . . . . . .30

E. SET COMBUSTION . . . . . . . . . . . . . . . . . . .30

F. CHECK BOILER FUNCTION . . . . . . . . . . . . . .31

8. TROUBLESHOOTING 32

A. GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . .32

9. MAINTENANCE 34

A. GENERAL MAINTENANCE (WITH BOILER

IN USE) . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

B. ANNUAL MAINTENANCE (BEFORE THE

START OF HEATING SEASON) . . . . . . . . . .34

10. BOILER DIMENSIONS & RATINGS 37

A. BOILER DIMENSIONS . . . . . . . . . . . . . . . . .37

B. BOILER RATINGS . . . . . . . . . . . . . . . . . . . . .37

11. REPAIR PARTS & OPTIONAL

ACCESSORIES 38

TABLE OF CONTENTS

TABLE OF CONTENTS

Page 3

A. INSTALLATION SEQUENCE

Follow the installation instructions provided in this manual

in the order shown. The order of these instructions has

been set in order to provide the installer with a logical

sequence of steps that will minimize potential

interferences and maximize safety during boiler

installation.

B. SPECIAL ATTENTION BOXES

Throughout this manual special attention boxes are

provided to supplement the instructions and make special

notice of potential hazards. The definition of each of

these categories, in the judgement of PB Heat, LLC

are as follows:

USING THIS MANUAL

Indicates special attention is needed, but not directly

related to potential personal injury or property

damage.

NOTICE

Indicates a condition or hazard which will or can

cause minor personal injury or property damage.

CAUTION

DANGER

Indicates a condition or hazard which will cause

severe personal injury, death or major property

damage.

Indicates a condition or hazard which may cause

severe personal injury, death or major property

damage.

WARNING

1

USING THIS MANUAL

Page 4

2

A. GENERAL

1. Pinnacle Oil boilers are supplied factory assembled

with pressure vessel, base, and jacket panels. A trim

box containing the relief valve, drain valve,

temperature / pressure gauge and associated pipe

fittings is included in the crate.

2. The burner, acoustic shroud and venting are shipped

separately for field assembly. The POC control is

shipped separately for maximum flexibility.

3. The package should be carefully inspected for damage

upon receipt and any damage to the unit should be

reported to the shipping company and wholesale

distributor.

4. The boiler should be stored in a clean, dry location.

5. Carefully read these instructions and be sure to

understand the functions of all mechanical and

electrical connections before beginning the

installation. Contact your PB Heat, LLC

representative for help in answering questions.

6. This boiler must be installed by a qualified contractor.

The boiler warranty may be voided if the boiler is not

installed correctly.

7. This boiler may be installed at high altitudes above

5,000 feet elevation. Consult burner manual

(included) for burner requirements.

B. CODES & REGULATIONS

1. Installation and repairs are to be performed in strict

accordance with the requirements of state and local

regulating agencies and codes dealing with boiler and

appliance installation.

2. In absence of local requirements the following codes

and standards should be followed.

a) ASME Boiler & Pressure Vessel Code, Section IV –

Heating Boilers

b) ASME Boiler & Pressure Vessel Code, Section VI –

Recommended Rules for the Care and Operation

of Heating Boilers.

c) ANSI/NFPA 70 – National Electrical Code

d) NFPA 31 – Standard for the Installation of Oil-

Burning Equipment.

e) ANSI/NFPA 211 – Chimneys, Fireplaces, Vents

and Solid Fuel Burning Appliances.

3. Where required by the authority having jurisdiction,

the installation of this equipment must comply with

ANSI/ASME CSD-1 – Standard for Controls and

Safety Devices for Automatically Fired Boilers.

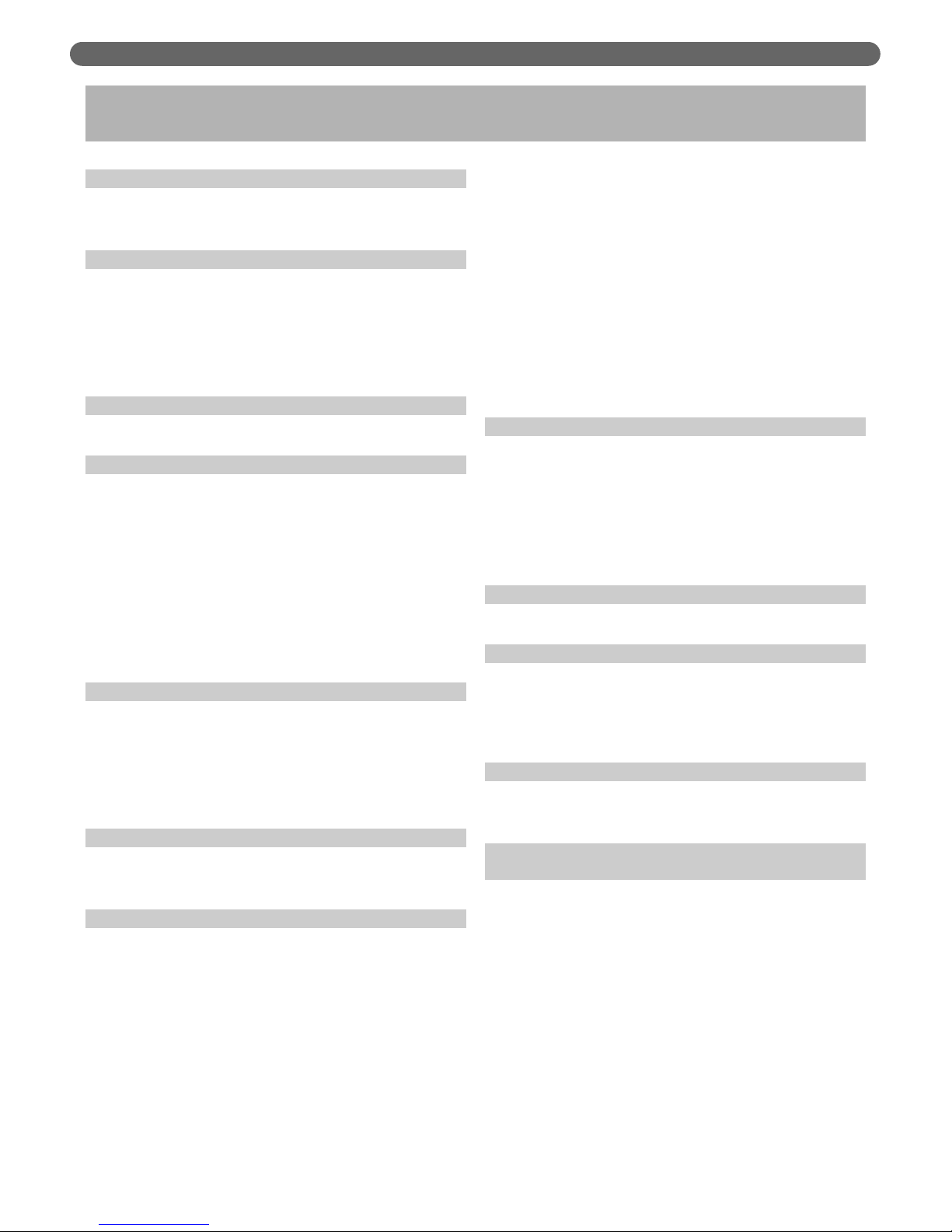

C. ACCESSIBILITY CLEARANCES

1. The Pinnacle Oil boiler is design certified for closet

installations with zero clearance to combustible

construction. In addition, it is certified for use on

combustible floors provided the boiler is not installed

on carpeting.

2. Refer to Figure 1.1 for the recommended clearances

to allow for reasonable access to the boiler. Local

codes or special conditions may require greater

clearances.

D. COMBUSTION & VENTILATION AIR

1. The Pinnacle Oil boiler is designed for several options

for combustion air and venting.

a) Concentric Sidewall Venting

b) Concentric Vertical Chimney Venting

c) Single Wall Vertical Chimney Venting using the

chimney as a chase for inlet air.

d) Concentric Vertical Roof Venting

2. The concentric venting options are designed for

operation with combustion air piped from the outside

(sealed combustion). For these options, no additional

ventilation air is required.

PREINSTALLATION

1. PREINSTALLATION

This appliance must be supplied with adequate

combustion air to properly burn the fuel. Failure to

supply an adequate air supply will result in

incomplete combustion resulting in sooting and

carbon monoxide emission. This may result in severe

personal injury, death or major property damage.

WARNING

DANGER

Do not install this boiler on carpeting.

Page 5

3

E. PLANNING THE LAYOUT

1. Prepare sketches and notes showing the layout of the

boiler installation to minimize the possibility of

interferences with new or existing equipment, piping,

venting and wiring.

2. Review the following sections of this manual for

consideration of the limitations with respect to:

a) Venting: Section 3

b) Air Intake Piping: Section 3

c) Condensate Removal: Section 3

d) Water Piping: Section 4

e) Oil Burner & Fuel Piping: Section 5

f) Electric and Controls: Section 6

PREINSTALLATION

This appliance is certified as an indoor appliance. Do

not install this boiler outdoors or locate where it will

be exposed to freezing temperatures.

WARNING

Do not install this boiler where gasoline or other

flammable liquids or vapors are stored or are in use.

WARNING

Service Clearances

Designation Description Dimension

“A” Burner Swing Clearance (Left or Right) 16" [406 mm]

“B” Jet/Acoustic Shroud Removal Clearance 13" [330 mm]

“C” Vent/Air Intake Sampling Clearance 12" [305 mm]

“D” Control Panel Access Clearance 24" [610 mm]

Figure 1.1: Recommended Service Clearances

Page 6

4

A. GENERAL

1. Pinnacle Oil boilers are to be installed in either an

area with a floor drain or in a suitable drain pan.

Do not install any boiler where leaks or relief valve

discharge will cause property damage.

2. This boiler is not intended to support external piping.

All venting and other piping should be supported

independently of the boiler.

3. Provide a level foundation, located as close as

practicable to the center of the heating system.

4. After removing the boiler from the packaging and

setting it on its foundation, open the burner swing

door on the top of the boiler and make sure the jet

inserts are seated properly in the combustion

chamber. Refer to the repair parts in Section 11 to

identify these parts. Close the burner swing door

before continuing.

5. Install the boiler level to prevent condensation from

blocking the vent system.

BOILER SET-UP

2. BOILER SET-UP

Be sure that any packing material that is in the

combustion chamber to protect the Jet Inserts is

removed before firing the appliance. Failure to do

this may result in minor personal injury or property

damage.

CAUTION

Page 7

5

A. GENERAL

1. All venting and air inlet piping is to be installed in

accordance with local building codes, NFPA 31 and

these instructions.

2. This appliance may be vented in any one of the

following three ways. Examples of these systems are

detailed in this section.

a) Concentric Sidewall Venting

b) Concentric Vertical Chimney Venting

c) Single Wall Vertical Chimney Venting using the

chimney as a chase for inlet air

d) Concentric Vertical Roof Venting

B. APPROVED MATERIALS FOR EXHAUST

VENT AND INLET AIR PIPING

1. The venting system for this boiler has been approved

under UL-726 for use with this boiler. No substitutions

are to be made for this material.

2. The venting components shown in Table 3.2 and the

venting kits shown in Figures 3.2 through 3.5 are to

be purchased separately from your distributor.

Questions regarding the proper vent material are to be

directed to your PB Heat, LLC representative.

C. EXHAUST VENT/INLET AIR LOCATION

1. The concentric vent piping for this boiler is approved

for zero clearance to combustible construction.

2. The Pinnacle Oil boiler, like all high efficiency

products, is likely to produce a visible vapor plume

due to condensation. Surfaces near the vent

termination will likely be coated with condensation.

3. Care must be taken to locate the exhaust vent where

the exhaust gas, vapor plume, and condensation do

not cause a hazard or nuisance. For example, do not

locate the exhaust vent termination under a deck

where, under certain conditions, it could form a

coating of ice causing a hazard or reduce the life of

the deck materials.

4. Sidewall Vent System

a) Sidewall vented products are susceptible to wind

conditions that can effect combustion. To minimize

the effects of wind, the exhaust and air inlet

terminations must penetrate the same wall or

vertical surface. In addition, the length of the

exhaust and air inlet pipes must be roughly

equivalent.

b) Condensation from a sidewall vented appliance

may cause paint and other surface coatings to

deteriorate. In addition, soot stains may appear on

surrounding surfaces if the boiler is not properly

maintained.

c) If the boiler is used to heat potable (tap) water, the

boiler will operate year round. The effects of hot

gases and odors must be taken into consideration

during the summer months.

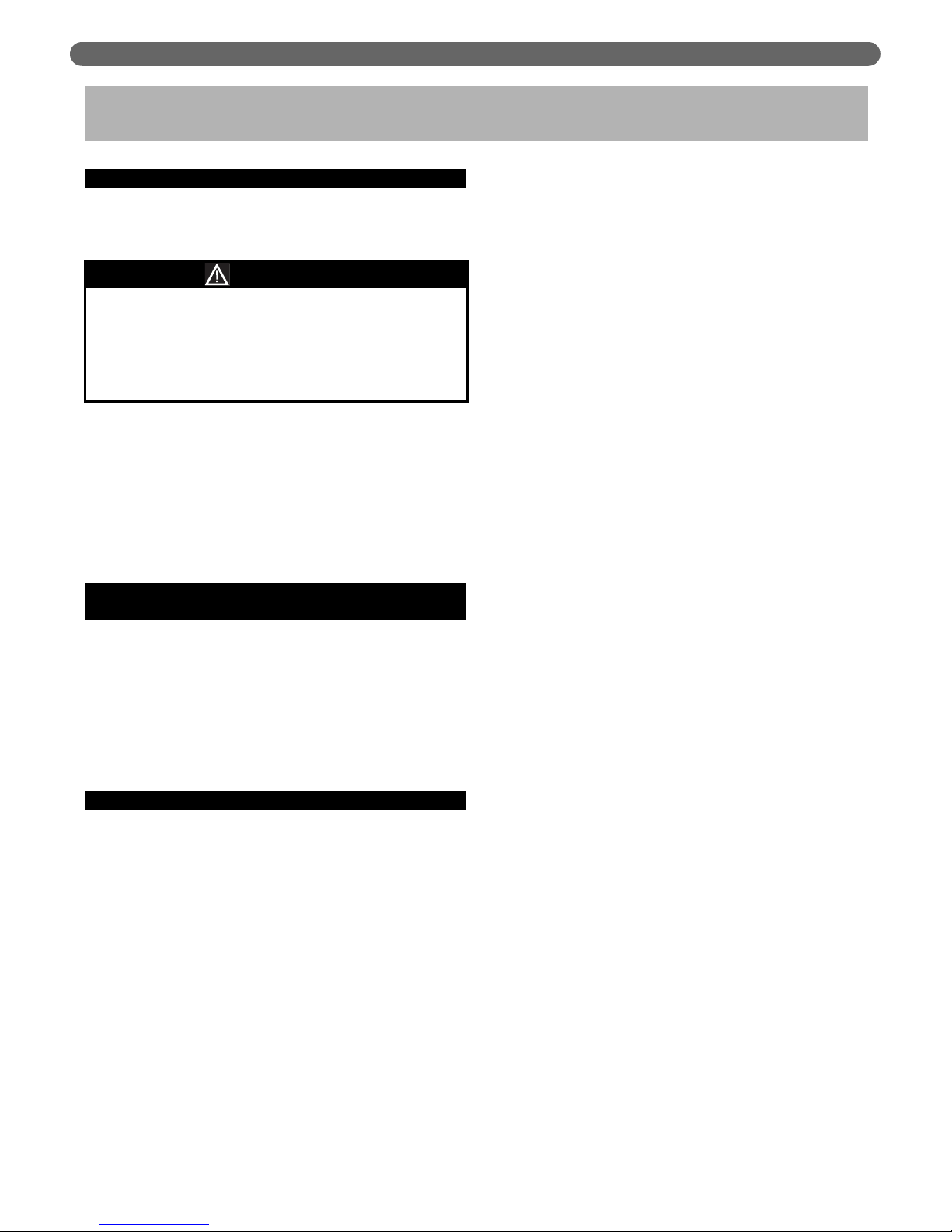

d) See Figure 3.1 for an illustration of clearances for

location of exit terminals for direct-vent, sidewall

venting systems.

e) The boiler vent system shall terminate at least 3

feet (0.9 m) above any forced air inlet located

within 10 feet (3 m). Note: This does not apply to

the combustion air inlet of a direct-vent appliance.

f) Provide a minimum of 1 foot (300 mm) distance

from any door, operable window, or gravity air

inlet into any building.

g) Do not locate the exhaust termination directly

under an operable window.

h) Provide a minimum of 1 foot (300 mm) clearance

from the bottom of the exhaust termination above

the expected snow accumulation level. Snow

removal may be necessary to maintain clearance.

i) Provide 4 feet horizontal clearance from electrical

meters, gas meters, air conditioning condensers or

other external equipment. In no case shall the exit

terminal be above or below the aforementioned

equipment unless a 4 foot horizontal distance is

maintained.

j) Do not locate the exit termination over public

walkways where condensate could drip or freeze,

causing a hazard or nuisance.

k) When the exhaust termination is adjacent to a

public walkway, it is to be located at least 7 feet

(2100 mm) above grade.

l) Do not locate exhaust termination directly under

roof overhangs to prevent icicles from forming.

m) Provide 3 feet (0.9 m) clearance from the inside

corner of adjacent walls.

VENTING, INLET AIR & CONDENSATE

3. VENTING, INLET AIR & CONDENSATE

DANGER

This vent system operates under a positive pressure.

Do not connect vent connectors serving appliances

vented by natural draft into any portion of

mechanical draft systems operating under positive

pressure. Failure to comply will result in severe

personal injury, death or major property damage.

Page 8

6

D. CONCENTRIC VENTING SYSTEM

1. The concentric venting system used with this

appliance consists of an inner pipe constructed of

polypropylene or stainless steel and an outer pipe

made of aluminum.

2. The inner pipe provides a path for the exhaust gases

to exit the boiler to the outdoors while space between

the pipes allows outdoor air to be conveyed to the

boiler.

3. The minimum vent length is 14 equivalent feet for

models PO-70 and PO-84 and 25 feet for models

PO-70A and PO-84A. This minimum length is

required to obtain the efficiency rating of this product.

The maximum vent length is 80 equivalent feet. Since

the air inlet pipe is integral to the vent, the same

minimum and maximum vent lengths apply.

4. The following chart gives equivalent lengths for

several common venting components.

E. EXHAUST VENT AND AIR INLET PIPE

INSTALLATION

1. Only polypropylene vent material supplied by PB

Heat, LLC is to be used with this appliance.

2. Horizontal lengths of vent pipe must slope towards the

boiler at a pitch not less than 1/4" per foot (20 mm

per meter) to allow condensate to drain from the vent

pipe into the boiler. If the vent pipe must be piped

around an obstacle that causes a low point in the

pipe, a drain pipe must be connected to this low point

to provide drainage.

3. All piping must be fully supported. Use pipe hangers

at a minimum of 4 foot (1.2 meter) intervals to

prevent sagging of the vent pipe where condensate

may form.

4. Do not use the boiler to support any piping. All piping

is to be supported externally.

VENTING, INLET AIR & CONDENSATE

Fitting Description Equivalent Length

Elbow, 90° 5

Cleanout Tee 5

Elbow, 45° 3

Vertical Vent Termination 0

Sidewall Vent Termination 0

Figure 3.1: Location of Exit Terminals of Mechanical Draft and Direct-Venting Systems

Page 9

7

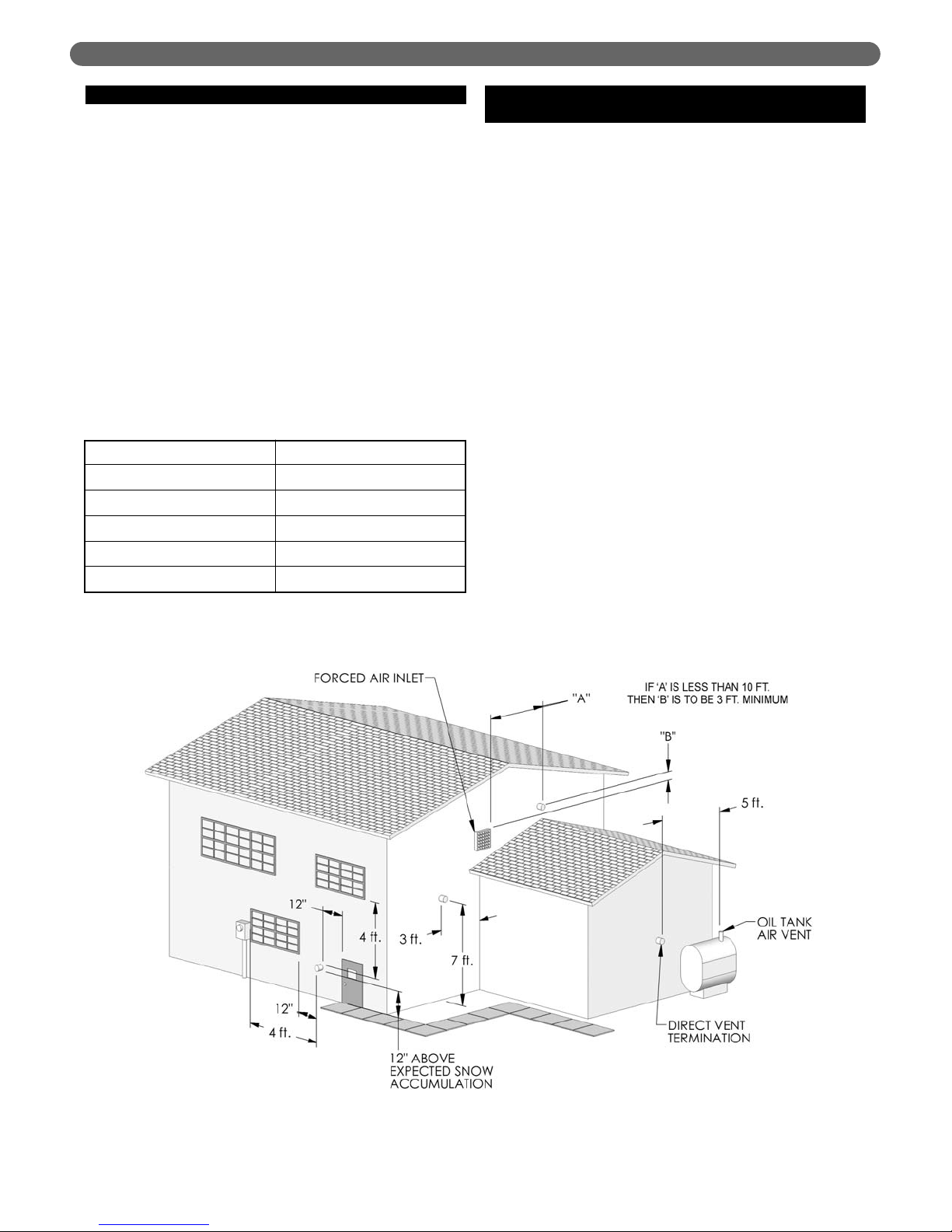

F. STANDARD VENT KITS

1. Common Vent Kit (54044): The common vent kit

is required for each Pinnacle Oil Boiler. This includes:

a) (54000) Concentric Sample Port Adapter

b) (54001) Concentric Clean-out Tee

c) (54006) Adjustable Length Vent Pipe - 19-1/2"

Max.

d) (54002) Concentric 90° Support Elbow

e) (54048) Vent Pipe Support

2. Concentric Sidewall Vent Kit (54045): A

concentric sidewall vent kit is used for boilers that are

vented through a building wall. This type of

installation is shown in Figure 3.2. This kit includes:

a) (54029) Concentric Sidewall Termination

b) (54003) Concentric 90° Elbow

c) (54007) Concentric Wall Plate

Additional vent pipe and fittings may be required to

complete the installation. Refer to the component list

for vent pipe in Table 3.2.

3. Concentric Vertical Chimney Vent Kit (54047):

A concentric vertical chimney vent kit is used to pipe

both the exhaust vent and the inlet air through an

existing chimney. An example of this type of

installation is shown in Figure 3.3. This kit includes:

a) (54012) Aluminum Shaft Cover Assembly

b) (54015) Vertical Vent Termination

Additional concentric vent pipe components may be

required to complete the installation. Refer to the

component list for vent pipe in Table 3.2.

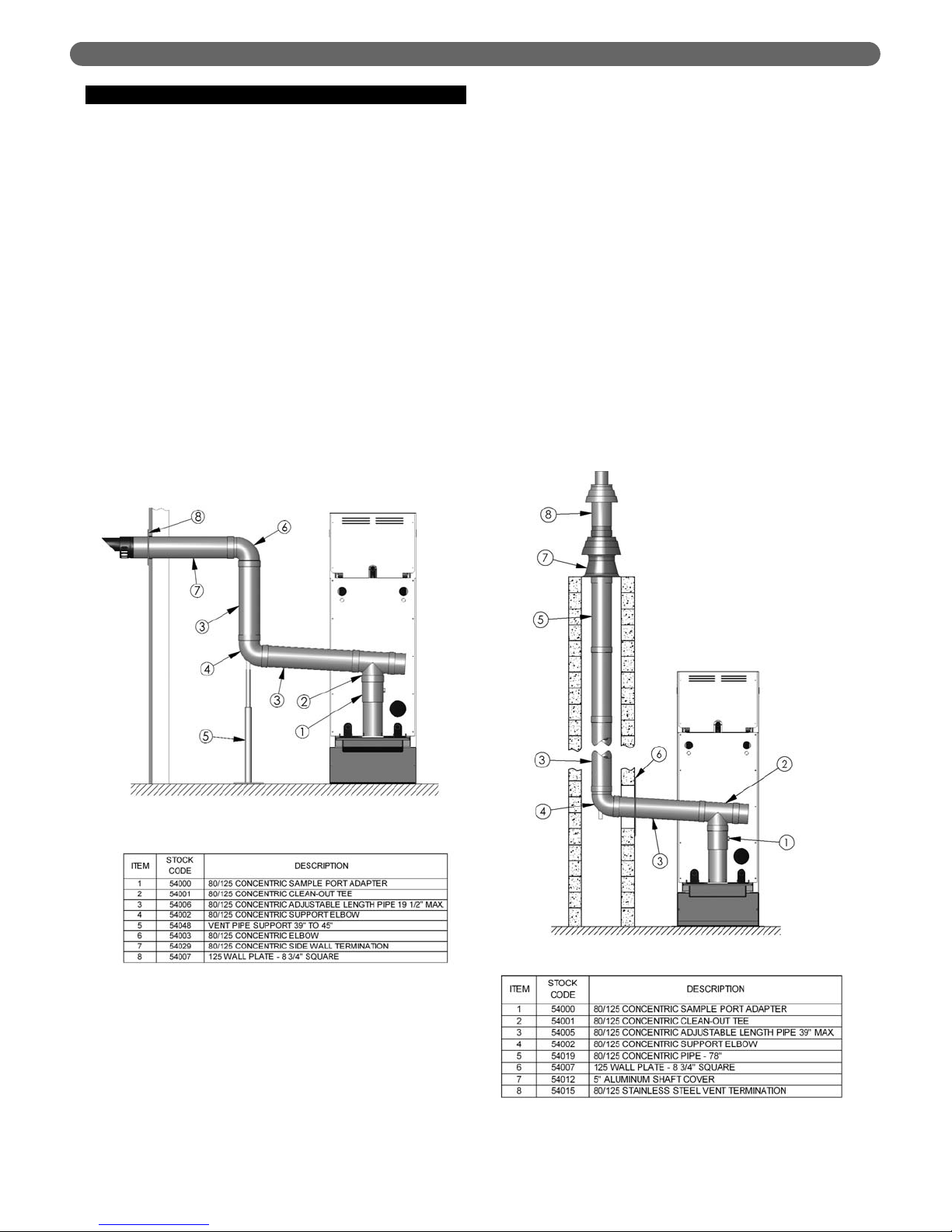

4. Single Wall Vertical Chimney Vent Kit (54046):

A single wall vertical chimney vent kit is used to pipe

the exhaust vent through an existing chimney while

drawing the inlet air down through the chimney

around the exhaust vent pipe. An example of this type

of installation is shown in Figure 3.4. This kit includes:

a) (54036) Stainless Steel End Pipe

b) (54013) Aluminum Shaft Cover

Additional vent pipe components may be required to

complete the installation. Refer to the component list

for vent pipe in Table 3.2.

VENTING, INLET AIR & CONDENSATE

Figure 3.2: Sidewall Venting

Figure 3.3: Concentric Vertical Chimney Venting

Page 10

5. Concentric Vertical Roof Vent Kit (54049): The

concentric vertical roof vent kit is used without a

chimney to vent through the building roof. This type

of installation is shown in Figure 3.5. Additional

concentric vent pipe components may be required to

complete the installation. Refer to the component list

for vent pipe in Table 3.2.

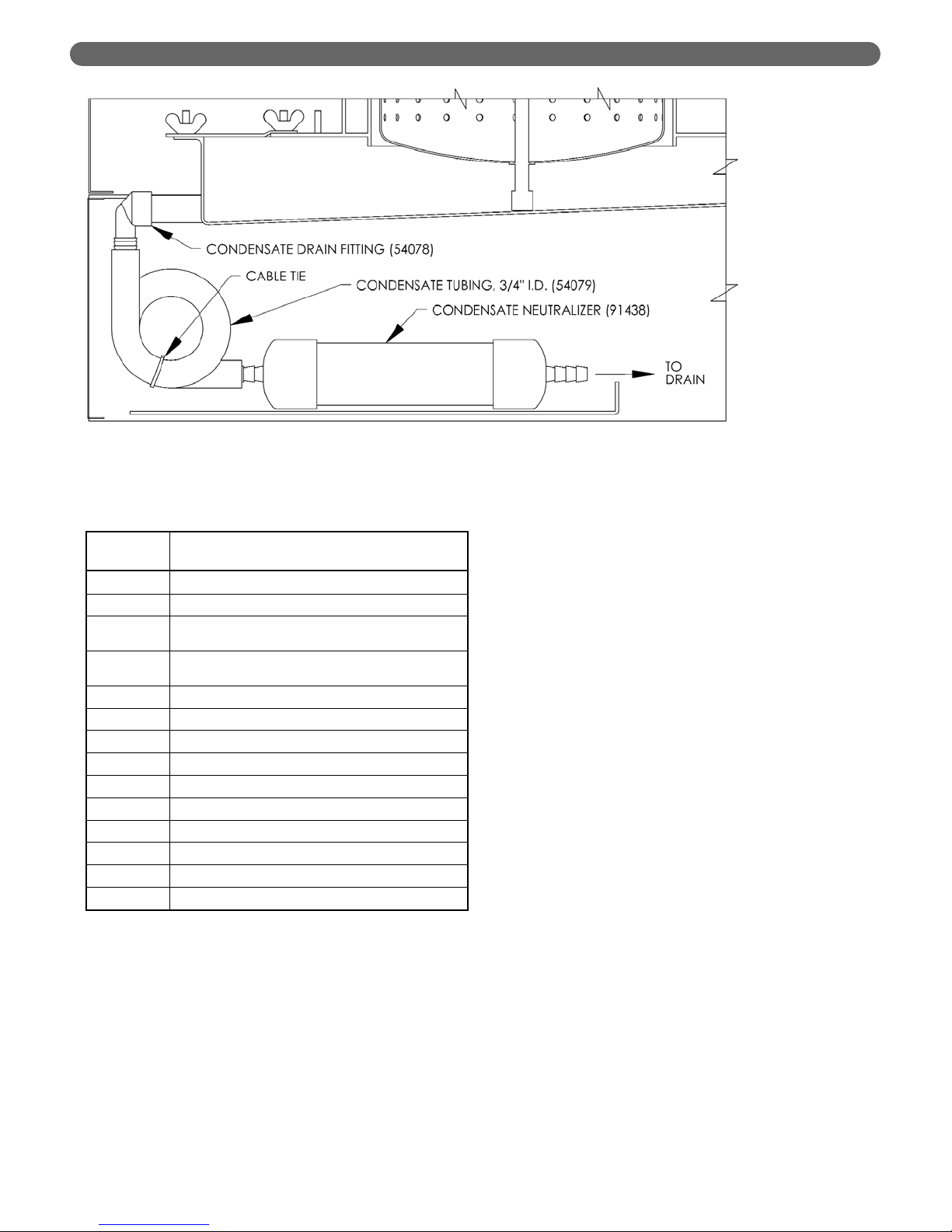

G. CONDENSATE

1. The disposal of all condensate into public sewage

systems is to be in accordance with local codes and

regulations. In the absence of such codes, follow these

instructions.

2. The condensate from oil-fired condensing appliances

may have a pH value as low as 2. Some local codes

require the use of neutralization equipment to treat the

condensate.

3. A condensate neutralizer (91438), available from your

distributor is recommended to reduce the acidity of

the condensate before it is piped to a drain.

4. This appliance must be fitted with a condensate trap

to prevent flue gas leakage.

5. Figure 3.6 shows a simple condensate trap that can

be utilized with this equipment. A 3/4" Female NPT x

3/4" O.D. Barb Adapter is used to attach a 3/4" ID

PVC (Tygon) Hose.

6. If the condensate outlet of the Pinnacle boiler is below

the drain level, a condensate pump must be used.

7. All piping for the condensate drain should be

corrosion resistant material such as PVC or

polypropylene. Do not use galvanized, aluminized, or

materials containing copper (such as brass or bronze)

for pipe or fittings.

8

VENTING, INLET AIR & CONDENSATE

Figure 3.4: Single Wall Vertical Chimney Venting

Figure 3.5: Concentric Vertical Roof Venting

Page 11

9

VENTING, INLET AIR & CONDENSATE

Figure 3.6: Condensate Trap & Neutralization

Table 3.2: Vent Pipe Component List

Stock

Code

Description

54017 Concentric Vent Pipe 19" Long

54018 Concentric Vent Pipe 39" Long

54006

Adjustable Length Concentric Vent Pipe - 19-1/2"

Maximum Length

54005

Adjustable Length Concentric Vent Pipe - 39"

Maximum Length

54003 90° Concentric Elbow

54062 Wall Clamp for Concentric Vent Pipe

54063 Universal Lead Tile for Vertical Vent Termination

54064 Flat Roof Flashing for Vertical Vent Termination

54024 9" Polypropylene Vent Pipe

54025 19" Polypropylene Vent Pipe

54026 39" Polypropylene Vent Pipe

54027 78" Polypropylene Vent Pipe

54023 90° Polypropylene Elbow

54058 45° Polypropylene Elbow

Page 12

10

A. GENERAL

1. All boiler piping is to be installed in accordance with

local building codes and these instructions.

2. This appliance is to be installed so that the electrical

components of the burner and ignition system are

protected from water (dripping, spraying, etc.) during

operation and service. Service includes circulator

replacement, condensate system cleaning, control

replacement and other general maintenance

procedures.

B. SYSTEM COMPONENTS

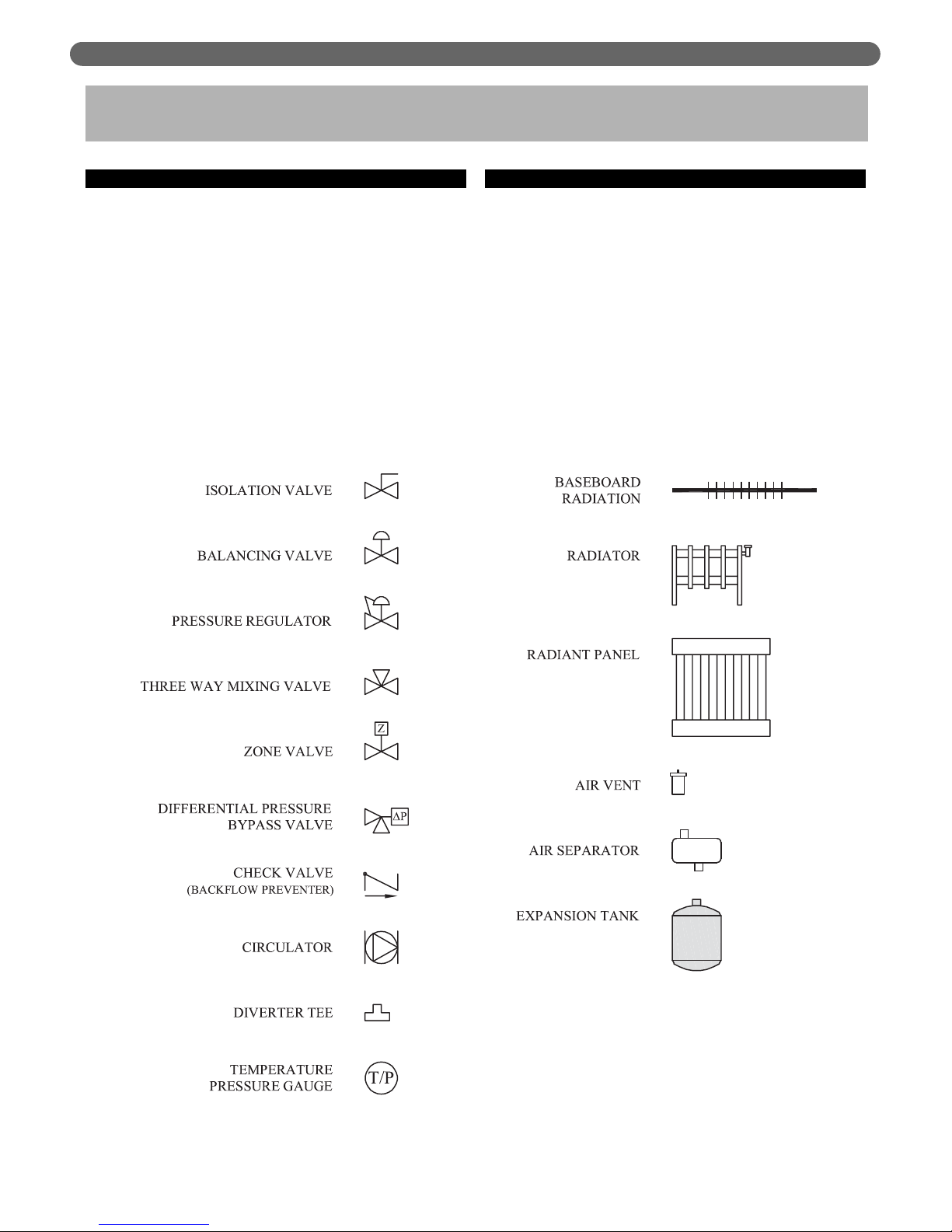

Figure 4.1 shows the symbol key for piping diagrams in

this section. The following are brief descriptions of system

components.

1. Pressure/Temperature Gauge: A combination

pressure/temperature gauge is provided with the unit

to be mounted in the piping from the boiler supply to

the system. Installation of this gauge is required by

most local codes.

WATER PIPING

4. WATER PIPING

Figure 4.1

Page 13

11

2. Air Elimination: Any closed-loop hydronic system in

which a Pinnacle Oil boiler is installed must have an

air elimination device. As the system water is heated,

dissolved oxygen, carbon dioxide and nitrogen gases

will separate from the liquid. An air elimination device

(such as a TACO 430 Series Air Scoop with an

automatic air vent) is required to remove the dissolved

gasses from the system preventing corrosion in the

piping system and eliminating system noise.

3. Expansion Tank: An expansion tank (such as a Bell &

Gossett Series HFT) is required to provide room for

expansion of the heating medium (water or glycol

solution). Consult expansion tank manufacturer’s

instructions for specific information regarding

installation. The expansion tank is to be sized for the

required system volume and capacity. In addition, be

sure that the expansion tank is sized for the proper

heating medium. Glycol solutions may expand more

than water for a given temperature rise.

4. Y-Type Strainer: In older heating systems where a

significant amount of sediment may be present, it may

be necessary to install a Y-type strainer. The strainer

should be checked and cleaned often in the first few

months of operation to assure that sediment does not

build up in the heat exchanger.

5. Flow Control Valve: Flow control valves such as the

Taco Flo-Check or Bell & Gossett Flo-Control are

used to prevent gravity circulation by incorporating a

check valve with a weighted disc.

6. Pressure Reducing Valve: A pressure reducing valve

such as the Bell & Gossett B-38 or Taco #329 is used

in a hydronic system to automatically feed water to

the system whenever pressure in the system drops

below the pressure setting of the valve. These valves

should not be used in glycol solution systems unless

the glycol concentration is closely monitored.

7. Back Flow Preventer: A back flow preventer is

required in some jurisdictions to prevent hydronic

system water from backing up into the potable water

supply. This is especially important on systems in

which glycol solution is used as the heating medium.

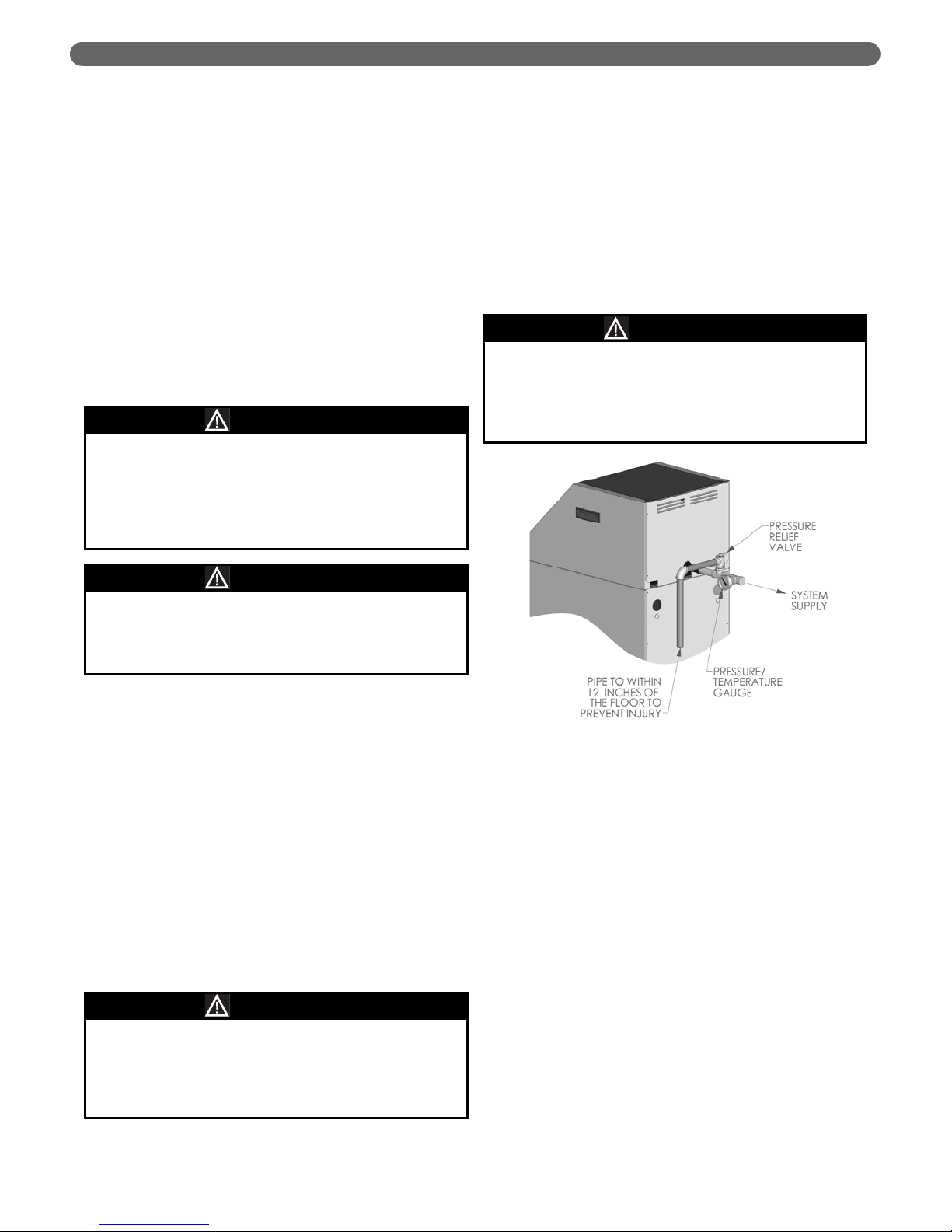

8. Pressure Relief Valve: A pressure relief valve is

supplied with each boiler for installation in the supply

piping. Figure 4.2 shows the installation of the

pressure relief valve and the temperature/pressure

gauge. The relief valve discharge is to be piped within

12” (305mm) of the floor and close to a floor drain.

Provide piping that is the same size or larger than the

relief valve outlet.

9. Isolation Valve: Isolation valves are intended to

provide a positive shut-off for isolating sections of

system piping. Ball valves and gate valves are

examples of valves for this purpose. These types of

valves are not intended for throttling flow.

10. Balancing Valve: Balancing valves are intended to

throttle water flow. Examples of this type of valve are

globe and needle valves.

11. Zone Valve: Zone valves are electronically activated

valves intended for use with zone thermostats to

provide heat only in the zone in which it is required.

12. Differential Bypass Valve: A differential bypass valve is

used to allow minimum circulation in a system

employing zone valves if all the zone valves close

before the circulator stops. This prevents the circulator

from “dead heading.”

13. Circulator: The boiler circulator is to be sized to

overcome the pressure drop of the system while

providing the flow required by the boiler.

WATER PIPING

Use only inhibited propylene glycol solutions which

are specifically formulated for hydronic systems.

Unlike automotive antifreeze, solutions for hydronic

applications contain corrosion inhibitors that will

protect the system components from premature

failure due to corrosion.

CAUTION

Pipe the discharge of the relief valve as close as

possible to the floor and away from high traffic areas.

Pipe the discharge close to a floor drain. Failure to

do so may result in serious personal injury and/or

property damage.

CAUTION

Use only inhibited propylene glycol solutions which

are specifically formulated for hydronic systems.

Ethylene glycol is toxic and may cause an

environmental hazard if a leak or spill occurs.

WARNING

Figure 4.2

Valves which automatically feed water under low

water conditions can allow leaks to go unnoticed.

This may allow large amounts of fresh water to be

added to the system resulting in scaling in the boiler

heat exchanger or dilution of glycol solutions.

NOTICE

Page 14

12

a) If the boiler is piped in a secondary loop of a

primary/secondary heating system, the circulator

will need only to overcome the resistance of the

boiler and any fittings in that loop. In the case of

the Pinnacle Oil boiler, the pressure drop through

the boiler is nearly negligible.

b) The circulator should be sized based on the boiler

net output. The boiler “Net I=B=R Output” for

each Pinnacle Oil Model is listed in the chart

below. This value includes a piping pickup factor

of 1.15.

c) The required flow rate can be calculated based on

the design temperature difference from the return

to the supply of the boiler. For a PO-50 with a

design water temperature rise of 20°F the

calculation is as follows:

d) The pressure drop of the system then determines

the circulator that should be used.

e) Special consideration must be given if propylene

glycol solution is to be used as a heating medium.

- Propylene glycol has a higher viscosity than

water; therefore the system pressure drop will

be higher.

- Propylene glycol has a lower heating capacity

than water and therefore requires a higher flow

rate (14% for a 50% glycol solution) to transfer

heat similar to water.

14. Indirect Water Heater: An indirect water heater,

such as the Peerless Partner, should be piped into

a dedicated zone. It consists of a water tank that

is heated by boiler water passing through an

internal coil.

C. SYSTEM PIPING

1. Figure 4.3: This illustration shows a single Pinnacle Oil

Boiler, a Peerless Partner Indirect Water Heater, and a

single heating zone.

a) The standard POC #1 control will accept separate

inputs for heating and hot water. This will allow

the heating zone to be supplied with a variable

temperature depending on outdoor temperature

(outdoor reset) while the domestic hot water zone

will have a pre-designated set point. A complete

description of this control will be given in Section

6 of this manual, Electrical & Controls. Note:

Outdoor reset operation requires an optional

Outdoor Sensor (54034).

b) By upgrading to the POC #2 control (54031), the

boiler may give domestic hot water full priority

over the heat load.

2. Figure 4.4: This diagram shows an additional zone in

which baseboard radiation is the heat load. Baseboard

radiation can be operated using the outdoor reset

function to maximize the boiler efficiency.

3. Figure 4.5: This figure shows diverter tees used in

combination with conventional hydronic radiators on

an additional zone.

a) Also, a second boiler is shown piped in parallel

with the first. It is important that the common

headers are sized to match the system piping.

Smaller headers may result in flow fluctuations

through the boilers.

b) An upgrade to the POC #3 control (54032) allows

a second boiler with a POC #1 conrol to act as a

second stage, firing only when the first boiler fails

to meet the load demand.

4. Figure 4.6: This illustration shows two boilers piped in

parallel feeding a primary/secondary system with 5

zones using zone circulators. In this configuration, the

supply water temperatures become increasingly cooler

when all zones are calling. Therefore, the hottest and

smallest zones should be piped closest to the boiler for

best results.

5. Figure 4.7: This illustration shows a system in which

zone valves are used in place of zone circulators.

Notice that this system utilizes reverse return piping

(where the first zone supplied is the last zone on the

return), which makes it easier to balance the system. If

the heating loops are very different in length,

balancing valves, shown on the return side of each

loop, are required.

D. FREEZE PROTECTION

1. Propylene glycol for hydronic heat transfer

applications is specially formulated for this purpose. It

includes inhibitors which prevent the glycol from

attacking metallic system components. Make certain

that the system fluid is checked for the correct

concentration and inhibitor level.

2. Do not used galvanized pipe in systems using

propylene glycol solutions.

3. Use water low in mineral content and make sure there

is no petroleum based solution in the mixture.

4. Make sure the heating system is clean.

5. Mix propylene glycol solution at room temperature.

6. Do not use a chromate treatment.

7. Do not use automotive type glycol. Use an inhibited

propylene glycol specifically formulated for hydronic

heat transfer.

WATER PIPING

Do not use more than 50% propylene glycol.This

provides freeze protection to -28°F. Higher

concentrations will inhibit heat transfer and reduce

the system flow rate.

NOTICE

Output 56,000

= = 5.6 GPM

(

'

T x 500) 20 x 500

Required Flow =

Boiler

Model

Boiler Input

Net I=B=R

Output (Btu/hr)(gph) (Btu/hr)

PO-70 &

PO-70A

0.50 70,000 56,000

PO-84 &

PO-84A

0.60 84,000 67,000

Page 15

Figure 4.3: One Boiler with Two Zones using Zone Circulators

13

WATER PIPING

Page 16

14

WATER PIPING

Figure 4.4: One Boiler with Three Zones using Zone Circulators

Page 17

15

WATER PIPING

Figure 4.5: Two Boilers with Four Zones using Zone Circulators

Page 18

16

WATER PIPING

Figure 4.6: Two Boilers with Five Primary/Secondary Zones using Zone Circulators

Page 19

17

WATER PIPING

Figure 4.7: Two Boilers with Five Reverse Return Zones using Zone Valves

Page 20

8. Propylene glycol solution is expensive and is more

prone to leaks than water. Use welded or sweat joints

where possible to minimize leaks. Where threaded

joints must be used, inspect them regularly for leaks.

9. The propylene glycol solution must be checked at

least once per year as recommended by the propylene

glycol supplier. It includes a corrosion inhibitor that

can diminish over time causing the solution to

become corrosive.

10. Check local regulations to see if a system containing

propylene glycol solutions must include a back-flow

preventer or require that the glycol system be isolated

from the water supply.

E. SPECIAL APPLICATIONS

1. Boilers used in conjunction with a chiller.

a) If the boiler is used in conjunction with a chilled

water system, pipe the chiller in a separate parallel

loop.

b) Assure that the boiler circulator is disabled during

chiller operation so chilled water does not enter

the boiler.

c) Install a flow control valve (spring check) to

prevent gravity flow through the boiler.

d) See figure 4.8 for recommended system piping.

2. Boilers connected to heating coils in a forced air system:

a) If the heating coil is exposed to chilled air

circulation, install flow control valves or other

automatic means to prevent gravity circulation of

the water during cooling cycles.

b) See figure 4.9 for recommended system piping.

Figure 4.8: Boiler in conjunction with a Chilled Water System

18

WATER PIPING

Page 21

19

Figure 4.9: Boiler Connected to a Heating Coil in a Forced Air System

WATER PIPING

Page 22

20

A. GENERAL

1. The oil burner for this appliance is supplied separately

but must be as specified for this equipment. At the

time of this printing, the following burners are Listed

in accordance with UL-726, Oil Fired Boiler

Assemblies:

a) Beckett AFG

b) Heat Wise Pioneer I (Not Yet Available)

2. Check for concealed damage to the burner or controls

when it is unpacked. If concealed damage is found,

notify the carrier and/or wholesale distributor at once.

3. Install the burner in accordance with instructions given

in this section and with those provided by the burner

manufacturer.

B. BURNER INSTALLATION

1. The burner is supplied with a mounting flange fixed in

position to provide the proper insertion depth.

2. Be sure that a high temperature gasket is installed

between the burner mounting flange and the

combustion chamber cover plate.

3. Care must be taken when routing the oil lines so they

do not interfere with opening and closing the

combustion chamber cover plate. Flexible oil lines

may be installed to allow opening the cover plate for

servicing.

4. Oil Burner Specifications: The following charts

indicate the nozzle specification, fuel pressure and

initial air settings for firing the burner. Final

adjustments shall be made using combustion analysis

equipment and a smoke spot tester.

5. Refer to Section 7, Start-Up Procedure, for

information on proper CO²and smoke levels.

OIL BURNER INSTALLATION

5. OIL BURNER INSTALLATION

DANGER

This appliance is intended for use with Commercial

Standard #2 Oil fuel as specified in ASTM D396. Use

with other fuels, including gasoline and crankcase

oil, will void the appliance warranty.

Since the burner on this appliance is located at the

top of the appliance in a down-fired configuration,

disconnecting the oil lines while the burner door is

closed will allow oil to drip into the combustion

chamber.To avoid this, install the burner with flexible

oil lines and only disconnect the lines after the

combustion chamber cover plate is swung open.

NOTICE

Boiler

Model

Danfoss Nozzle

Specification

Pump Pressure

(psig)

Air Damper

Setting

PO-70 &

PO-70A

0.45 gph 60° AS 130 1.5

PO-84 &

PO-84A

0.55 gph 60° AS 130 2.5

This combustion equipment must be installed by

qualified service person who is responsible for the

correct installation and adjustment of this equipment.

Failure to comply with this may cause a condition

which may cause severe personal injury, death, or

major property damage.

WARNING

Table 5.1: Beckett Burner Specification

Page 23

21

A. GENERAL

1. This appliance is to be wired in accordance with local

codes and regulations as defined by the Authority

having jurisdiction. In the absence of such local codes,

it shall be wired in accordance with the latest edition

of the National Electrical Code, ANSI/NFPA 70.

B. BURNER WIRING

1. Burners intended for use with this boiler will come

equipped with a wiring harness that terminates in a

quick-disconnect style connector that mates with the

connector supplied with the boiler.

2. If the burner supplied does not have such a harness

and connector, contact your boiler/burner supplier

and/or your PB Heat, LLC representative.

3. Refer to the wiring diagram shown in Figure 6.1 for

reference and further details.

C. BOILER WIRING

1. To open the boiler control panel the two screws at the

top of the upper front panel must be removed. The

burner cover must be removed to access these screws.

2. Figure 6.2 shows the customer connections to the

boiler control terminals. All customer connections are

to be made to the labeled screw terminations in the

electrical control panel.

ELECTRICAL & CONTROLS

6. ELECTRICAL & CONTROLS

The wiring diagrams in this manual are for general

reference only and apply only to the appliance as it is

specified from the factory which includes a burner

primary control and a boiler temperature control

(POC#1, POC#2, or POC#3).

WARNING

Do not bypass the wiring harness provided with this

boiler or burner. Failure to apply the correct harness

can result in severe personal injury, death or

substantial property damage.

WARNING

Figure 6.1: Boiler Wiring Diagram

Page 24

22

D. CONTROL TERMS

To describe the operation of this appliance, there are

several terms that must be defined. The following is a

short glossary of terms.

1. Parallel Piping: In parallel piping applications the

boiler outlet goes directly to the system. In these

cases, only one sensor, the boiler supply sensor, is

required to control the boiler target temperature.

2. Primary/Secondary Piping: In primary/secondary

piping applications, the system supply temperature

may be lower than the boiler outlet temperature. An

additional sensor (54033) is required to control the

boiler based on the system supply, while the boiler

supply sensor continues to limit the boiler target based

on the programmed values.

3. Setpoint demand: A setpoint demand is a fixed target

temperature that is programmed into the control by

the installer. For example, if the system requires 180°F

water when a call for heat is initiated, the control

targets that temperature.

4. Outdoor Reset: Outdoor reset describes a system

where the boiler target temperature is calculated

based on outdoor temperature. As the outdoor

temperature increases, the system requirement

decreases. This allows the boiler to operate at a lower,

more efficient temperature.

5. Reset Override: Reset override occurs when a boiler is

operating on an outdoor reset temperature and a

setpoint demand is introduced. Reset override

changes the target temperature to the setpoint target,

overriding the outdoor reset temperature.

6. Domestic Hot Water Priority: Domestic hot water

(DHW) priority is when a system uses reset override

and controls circulators to provide a higher

temperature water to a DHW tank while preventing

this high temperature water from circulating to the

heating zones. To provide control of the DHW

circulator the POC #2 (54031) or POC #3 (54032) is

required.

7. Boiler Differential: In order to operate a boiler without

frequent cycling on and off a boiler differential is used.

All POC controls work on an automatic differential

that will change between 2°F and 42°F based on the

system response. The differential is split across the

target temperature. For example, if the target

temperature is 160°F and the differential is at 10°F, the

boiler will shut down at 165°F and turn on at 155°F.

ELECTRICAL & CONTROLS

Figure 6.2: Customer Electrical Connections

Figure 6.3: Parallel Piping

Figure 6.6: Boiler Differential

Figure 6.4: Primary/Secondary Piping

Figure 6.5: Outdoor Reset Ratio

(Boiler Design - Boiler Start)

(Outdoor Start - Outdoor Design)

Boiler Target = Boiler Start + RR (Outdoor Start - Actual Outdoor)

RR =

Page 25

23

ELECTRICAL & CONTROLS

E. SEQUENCE OF OPERATION

1. System Power-up:

a) When power is first applied the control turns on all

segments in the display for 2 seconds.

b) Next, the software version is displayed for 2

seconds.

c) Finally the control enters the normal operating

mode.

2. Heating Cycle:

a) On a call for heat (or DHW), the boiler runs

according to the control modes listed in Section 6H.

b) The boiler continues to run until either the call for

heat (or DHW) is satisfied or the boiler reaches the

target temperature plus half of the differential.

c) When the boiler turns off, a 2 minute post-purge

(air evacuation of the combustion chamber) is

initiated.

d) If the boiler cycles off on temperature, it will allow

the temperature to drop to the target temperature

minus half of the differential before cycling back on.

e) When the boiler satisfies the load, the control will

go into a standby mode and the target

temperature is displayed as “- - -“.

Circulator: Displays when a

circulator is in operation.

ºF, ºC: Units of

Measurement

Burner: Displays when the burner is

operating. When the POC #3

Control is used it will display either

1 or 2 to show what stage of the

boiler is on.

Pointer: Displays the

operation as indicated

by the text

Figure 6.7: Control Display

Symbol Description

Page 26

24

ELECTRICAL & CONTROLS

F. BOILER SAFETY INTERLOCKS

1. High Water Temperature Limit Switch: This boiler has

a maximum operating temperature of 210°F. If the

boiler water temperature reaches 210°F, the high

temperature limit will interrupt the heating cycle and

begin a post-purge. After the temperature drops 10°F,

the switch will automatically reset and allow the boiler

to reinitiate.

2. High Vent Temperature Limit Switch: The vent system

for this boiler has a maximum temperature limit of

210°F. If the exhaust vent temperature reaches or

exceeds 210°F (120°C), the limit will interrupt the

heating cycle and initiate a post-purge. The limit will

not reset until the red button under the burner hood is

pressed.

G. BOILER TEMPERATURE CONTROL

OPTIONS

The Pinnacle Oil boiler is offered with the POC #1

control board as standard. This boiler may be ordered

with the POC #2 or POC#3 control upgrades. The

features of each of these are as follows:

1. POC #1 Control: This control is factory set for on/off

operation. It can be easily programmed to provide

outdoor reset with reset override (requires Outdoor

Sensor #54034). This control can be used with an

external zone control that controls a DHW circulator

for DHW priority. It will provide a fixed setpoint water

temperature on a call for DHW.

2. POC #2 Control: This control offers the same

features of POC #1 with the added benefit of a DHW

circulator relay to provide full domestic hot water

priority without relying on an external zone control.

3. POC #3 Control: This control offers the same

features of POC #2 while allowing a second boiler

with a POC #1 control to be added to provide a

second stage of heating. If the first boiler does not

meet the demand in a reasonable time, the second

boiler will be started.

H. CONTROL MODES

The POC control allows 6 modes of operation.

1. Mode 1: This is designed to operate the boiler at a

fixed set point for systems which use parallel piping.

Once a heat demand signal is present, the control

operates the boiler to maintain a fixed temperature at

the boiler outlet. This is the default control mode and

requires no additional sensors.

2. Mode 2: This is designed to operate the boiler at a

fixed set point for systems using primary/secondary

piping. Once a heat demand is present, the control

operates the boiler to maintain a fixed temperature at

the system supply. This mode requires an additional

system supply sensor (54033).

3. Mode 3: This is designed to operate a parallel-piped

boiler with outdoor reset when a heat demand signal

is introduced. This requires an outdoor sensor

(54034). A setpoint demand (such as domestic hot

water) will override (reset override) the heat demand

and change the target temperature to the setpoint

value. For full DHW priority, control of the system and

DHW circulators is required. This can be

accomplished using the POC #2 or POC#3 control

from PB Heat. This can also be accomplished using

an external zone relay as shown later in this section.

4. Mode 4: This is designed to operate a primary/

secondary-piped boiler with outdoor reset when a

heat demand signal is introduced. This requires an

outdoor sensor (54034) in addition to a system supply

sensor (54033). A setpoint demand (such as domestic

hot water) will override (reset override) the heat

demand and change the target temperature to the

setpoint value. For full DHW priority, control of the

system and DHW circulators is required. This can be

accomplished using the POC #2 or POC#3 control

from PB Heat. This can also be accomplished using

an external zone relay as shown later in this section.

5. Mode 5: Mode 5 is designed for external boiler

control for multiple boiler installations. In this case, the

POC #1 control is used to provide boiler circulator

control only. The staging and sequencing is controlled

by the external control. This can be used in a two

boiler system to provide 2-stage operation as we will

show later in this section.

I. USER INTERFACE

1. The POC controls offer status display of the boiler

circulator, burner, and heat or DHW demand.

2. It also displays the boiler supply temperature (°F or

°C) as standard while allowing the user to scroll

through 6 other temperature displays as well as a

display of the overall run time on the boiler.

3. The three push buttons on the face of the POC

Controls are labeled “Item”, “i” and “j” are used

for selecting and adjusting settings.

4. Menus: All of the selectable items displayed by the

control are organized into two menus designated

and . Advanced options in both

menus are accessible by switching the

Installer/Advanced dip switch located behind the lower

control cover.

a) This is the default menu for all three POC

controls and is displayed in the Menu Field above

the Number Field when accessing the View menu.

Table 6.1 shows the View Menu for the POC

controls.

- The first column shows the item field with the

default values (where applicable) for the

control.

- The next two columns show the access level at

which these items are available.

- The fourth column shows the description of

the item field and if the item is only available

in certain control modes, the modes in which it

is shown are listed.

- The fifth column shows the range of values

that may be displayed on this screen.

VIEW

ADJUSTVIEW

Page 27

25

b) To enter the Adjust Menu press the

“Item”, “i” and “j” keys simultaneously for

1 second.

- The Items in this menu allow the installer to set

up the control for a particular installation.

- Once in the ADJUST menu, use the “Item”

key to scroll through the parameters listed in

Table 6.2.

- Use the “i” and “j” keys to change the

values. A blank column entitled, “Actual

Setting” allows the installer to record the

settings for reference.

J. CONTROL ACCESS LEVELS

1. Each POC control has an “Advanced” and “Installer”

Access level. These are selectable by the control dip

switch.

a) The “Advanced” access level includes all the

settings and displays available in the control.

b) The “Installer” access level includes only the

settings and displays that are required for

system setup.

2. To access the control dip switch:

a) Remove the snap-on outer cover.

b) Remove the screw and lower cover plate on the

control.

c) The dip switch is located under this panel and

may be switched between “Advanced” and

“Installer”. The dip switch is shown in Figure 6.8.

ADJUST

ELECTRICAL & CONTROLS

Item Field

Access Level

Description Range

INSTALLER ADVANCED

• •

Current outdoor air temperature as measured by outdoor

sensor. This is the default display for the control.

MODE = 3, 4

-60 to 190°F

(-51 to 88°C)

• •

Target boiler supply is the temperature the control is currently

trying to maintain at the boiler or system supply temperature

MODE = 1, 2, 3, 4

---, 35 to 226°F

(2 to 108°C)

• •

Current boiler supply water temperature as measured by the

boiler supply sensor.

MODE = 2, 4

14 to 266°F

(-10 to 130°C)

• •

Current system supply water temperature as measured by the

system supply sensor.

MODE = 1, 3, 5 (Installer Level)

MODE = 2, 4 (Advanced Level)

14 to 266°F

(-10 to 130°C)

• •

Current boiler inlet water temperature as measured by the

optional boiler inlet sensor. This value will be displayed if the

optional boiler return sensor is connected.

MODE = ALL

14 to 266°F

(-10 to 130°C)

•

Current difference in temperature between the boiler supply

and the boiler return sensors. This value will be displayed if

the optional boiler return sensor is connected.

MODE = ALL

0 to 252°F

(0 to 140°C)

•

The total number of running hours of the boiler since this

item was last cleared.

MODE = ALL

0 to 999

Table 6.1: View Menu

Figure 6.8: Control Dip Switch

Page 28

26

ELECTRICAL & CONTROLS

Item Field

Access Level

Description Range

Actual

Setting

INSTALLER ADVANCED

• •

Sets the operating mode for the control 1, 2, 3, 4 or 5

Default (1)

________

• •

Minimum boiler target temperature

during setpoint operation

MODE = 1, 2, 3, 4

OFF, 70 to 220°F

(OFF, 21 to 104°C)

Default

(180°F)

________

• •

The outdoor temperature used to

calculate the reset ratio and the boiler

target temperature.

MODE = 3, 4

35 to 85°F

(2 to 29°C)

Default

(70°F)

________

• •

The design outdoor temperature used to

calculate the reset ratio.

MODE = 3, 4

-60 to 32°F

(-51 to 0°C)

Default

(10°F)

________

• •

The starting water temperature used to

calculate the reset ratio and the boiler

target temperature.

MODE = 3, 4

14 to 266°F

(-10 to 130°C)

Default

(70°F)

________

• •

The design boiler water Temperature

used in the reset ratio calculation.

MODE = 3, 4

0 to 252°F

(0 to 140°C)

Default

(180°F)

________

•

The maximum boiler water temperature.

This maximum supersedes any

differential or outdoor reset targets.

120 to 210ºF

(49 to 99ºC)

Default

(200°F)

________

•

The minimum temperature allowed for

the boiler target temperature.

MODE = 1, 2, 3, 4

OFF, 80 to 180ºF

(27 to 82ºF)

Default

(OFF)

________

•

The differential that the control is to use

when it is operating the boiler.

MODE = 1, 2, 3, 4

AUTO, 2 to 42ºF

(1 to 23ºC)

Default

(AU)

________

•

Determines when to stop pump purging.

MODE = ALL

OFF, 0:20 to 9:55

min, ON

Default

(0:20)

________

• •

System warm weather shutdown temperature.

MODE = 3, 4

35 to 100ºF, OFF

(2 to 38ºC)

Default

(70°F)

________

• •

Units of measurement

MODE = ALL

ºF or ºC

Default (°F)

________

Table 6.2: Adjust Menu

Page 29

27

K. TROUBLESHOOTING

1. Table 6.3 shows Error Codes that may be

encountered with the POC series controls.

a) The first column shows error code display screen.

b) The next column shows descriptions of error codes.

c) The last column shows several steps to be taken to

correct the error code.

2. To test control functions, first turn off the service

switch on the boiler control bezel. Then, the harness

may be disconnected by pushing down on the tab on

the side of the harness connector and gently removing

the harness.

a) A good quality electrical multimeter capable of

reading 0-300V as a minimum and at least 02,000,000 Ohms is required to test the control.

b) Testing the Sensors: To test the sensors, the actual

temperature at each sensor location must be

measured. If a temperature gauge is not mounted

in the boiler piping near the sensor to be tested, a

good quality digital thermometer with a surface

temperature probe is recommended for the best

accuracy.

- Measure the temperature at the location of the

sensor.

- Measure the resistance through the sensor.

ELECTRICAL & CONTROLS

Service and maintenance must be performed by

properly trained and experienced personnel. Failure

to comply with this requirement may cause severe

personal injury, death or major property damage.

WARNING

Table 6.3: Error Code Menu

Item Field Description Required Action

The control was unable to read an item from its read-only

memory (ROM).

Check that all settings in the

adjust menu are correct.

The control is no longer able to read the boiler supply sensor due to

a short circuit. If the boiler inlet sensor is present and operational,

the boiler will continue to operate using the boiler inlet sensor.

Check the wiring to the boiler

supply sensor. If no problem is

found, replace the sensor.

The control is no longer able to read the boiler supply sensor due to

an open circuit. If the boiler inlet sensor is present and operational,

the boiler will continue to operate using the boiler inlet sensor.

Check the wiring to the boiler

supply sensor. If no problem is

found, replace the sensor.

The control is no longer able to read the boiler return sensor due to

a short circuit. The boiler will continue to operate.

Check the wiring to the boiler

supply sensor. If no problem is

found, replace the sensor.

The control is no longer able to read the boiler return sensor due to

an open circuit. The boiler will continue to operate.

Check the wiring to the boiler

supply sensor. If no problem is

found, replace the sensor.

The control is no longer able to read the system supply sensor due

to a short circuit. If the boiler outlet sensor is present and operational, the control will operate based on the boiler outlet sensor.

Check the wiring to the boiler

supply sensor. If no problem is

found, replace the sensor.

The control is no longer able to read the system supply sensor due

to an open circuit. If the boiler outlet sensor is present and operational, the control will operate based on the boiler outlet sensor.

Check the wiring to the boiler

supply sensor. If no problem is

found, replace the sensor.

The control is no longer able to read the outdoor sensor due to

a short circuit. The boiler will continue to operate based on an

assumed outdoor temperature of 32ºF (0ºC).

Check the wiring to the boiler

supply sensor. If no problem is

found, replace the sensor.

The control is no longer able to read the outdoor sensor due to

an open circuit. The boiler will continue to operate based on an

assumed outdoor temperature of 32ºF (0ºC).

Check the wiring to the boiler

supply sensor. If no problem is

found, replace the sensor.

Page 30

28

ELECTRICAL & CONTROLS

- Using table 6.4, estimate the temperature at

the sensor.

- If the resistance is much higher than expected,

there may be a broken wire, a poor

connection, or a defective sensor.

- If the resistance is much lower than expected,

there may be a short in the wiring, moisture in

the sensor, or a defective sensor.

c) Test the Power Supply: Make sure exposed

wires and bare terminals are not in contact

with other wires or grounded surfaces

- Turn on the power using the boiler service

switch located on the control bezel.

- Measure the voltage between terminals 12 and

24 on the harness connector (These are the top

two connections on the control and are labeled

on the back of the control) (See Figure 6.2).

- The voltage should be between 22 and 26 VAC.

- Turn off the boiler service switch before reconnecting the harness to the control.

d) Test the Heat Demand: Turn on the boiler service

switch, located on the control bezel.

- Measure the voltage between terminal (2) Ht D

(Heat Demand) and terminal (1) CD

(Common Demand).

- When there is a heat demand signal, the

voltage across these terminals should read

between 20 and 260 VAC. When no call for

heat is expected, the voltage should be less

than 5 VAC.

- Turn off the boiler service switch before reconnecting the harness to the control.

e) Test the Setpoint Demand: Turn on the boiler

service switch, located on the control bezel.

- Measure the voltage between terminal (3) Set

D (Setpoint Demand) and terminal (1) CD

(Common Demand).

- When there is a setpoint demand signal, the

voltage across these terminals should read

between 20 and 260 VAC. When no call for

heat is expected, the voltage should be less

than 5 VAC.

- Turn off the boiler service switch before reconnecting the harness to the control.

f) Test the Control’s Output Functions: All POC

controls feature a built-in test routine for testing

the control outputs. The test routine is initiated

when the “i” button is pressed in and held in

while in the view menu. The outputs are tested in

the following sequence:

- Step 1: After 1 second, the boiler circulator is

turned on.

- Step 2: After 4 seconds, the DHW circulator is

turned on (POC #2 & POC#3 Only).

- Step 3: After 7 seconds the burner demand is

activated.

- Step 4: After 10 seconds the second stage

burner is activated (POC #3 Only)

- Step 5: After 13 seconds, the Alarm terminal is

activated.

- After the “i” button is released, the control

continues normal operation.

L. POC TECHNICAL DATA

Control: Microprocessor based PI control.

Enclosure Material: Black Noryl plastic

Dimensions: 4-3/4 x 2-7/8 x 1-7/8 inches

(120 x 74 x 48 mm)

Approvals: CSA C US, meets ICES & FCC regulations

for EMI/RFI

Ambient Conditions: Indoor use only, -40 to 140°F (-40

to 60°C), <90% Relative Humidity

Power Supply: 24V ±10% 50/60Hz 75 VA

Stage 1 Relay: 120 VAC, 5A 1/6 hp, pilot duty

Circulator Relays: 120 VAC, 5 A 1/6 hp, pilot duty

Stage 2* Relay: 120 VAC, 3 A, 1/6 hp

Alarm** Relay: 24 VAC, 3 A, 1/6 hp

Sensors included – NTC thermistor, 10 k: @ 77°F

(25°C), E = 3892

* POC #3 Control Only

** POC #2 & #3 Controls Only

Temperature Resistance Temperature Resistance Temperature Resistance Temperature Resistance

ºF ºC

:

ºF ºC

:

ºF ºC

:

ºF ºC

:

-50 -46 490,813 20 -7 46,218 90 32 7,334 160 71 1,689

-40 -40 336,606 30 -1 34,558 100 38 5,828 170 77 1,403

-30 -34 234,196 40 4 26,099 110 43 4,665 180 82 1,172

-20 -29 165,180 50 10 19,900 120 49 3,760 190 88 983

-10 -23 118,018 60 16 15,311 130 54 3,050 200 93 829

0 -18 85,362 70 21 11,883 140 60 2,490 210 99 703

10 -12 62,465 80 27 9,299 150 66 2,045 220 104 598

Table 6.4: Sensor Resistance Tables

Page 31

29

This page intentionally left blank.

Page 32

30

A. GENERAL

1. Confirm that all electricity is turned off and that valves

for water and oil supply are closed.

2. Inspect the water piping, venting, oil piping, and

electrical wiring. Be sure that all components are

installed properly and, where applicable, in

accordance with the manufacturer’s instructions.

3. Be sure that this boiler is installed as instructed in this

manual and in accordance with good engineering

practice.

B. FILL THE SYSTEM WITH WATER

1. Fill the boiler and system with water, making certain

to vent all air from each high point in the system.

Open each manual air vent in the system until all air

is released and water begins to be discharged. Close

the manual air vents.

2. The pressure reducing valve on the cold water inlet

will allow the system to be pressurized to the required

system pressure. This pressure is not to exceed 30 psig.

3. Check piping joints and fittings throughout the system

and repair leaks as required.

C. CHECK ELECTRIC CIRCUITS

1. Inspect the electrical system to make sure all

connections are made.

2. Disconnect the jumper on the t-t terminals of the

burner primary control.

3. Turn on any boiler disconnect switches that are

connected to the incoming power.

4. Turn on the boiler service switch.

5. The POC Control will go through the start-up

sequence as indicated in section 6.

6. Once the control is on and the default display (no

error codes) is shown, turn off the electrical power

and replace the jumper on the t-t terminals of the

boiler primary control.

D. PRIME THE FUEL UNIT

1. Since the oil pump on this boiler is located at the top

of the unit, particular attention must be paid to

assuring that the oil line to the boiler is filled.

2. Bleed air from the fuel unit as soon as the burner

motor begins rotating. Follow the burner

manufacturer’s instructions, included with the burner,

to bleed the air.

E. SET COMBUSTION

1. Instruments Required:

a) Combustion analysis instrument that reads O²or

CO²such as the Testo 325M. An absorption type

analyzer such as the Bacharach Fyrite analyzer

may also be used.

b) Draft gauge or inclined manometer such as a

Dwyer 1227 Flextube or a digital manometer such

as the Testo 506.

c) Smoke spot tester such as the Testo 0554.1317 or

Bacharach True Spot.

2. Adjust the burner air settings in accordance with the

burner manufacturer’s instructions to obtain a clean

flame with no smoke. A value of 12% to 12.5% CO

²

should be achievable without a smoke spot.

3. The following steps are to properly adjust the burner:

a) Decrease the burner air until a trace of smoke is

obtained.

b) Measure the CO²(or O²) and record the reading.

START-UP PROCEDURE

7. START-UP PROCEDURE

This boiler is equipped with a pressure relief valve

that is set at 30 psi. If the system is pressurized to

above 30 psi, the relief valve will activate and allow

water to flow from the boiler.

CAUTION

Blocking or restricting the pressure relief valve will

cause a condition that may cause severe personal

injury, death and/or severe property damage.

WARNING

Do not attempt to start this appliance when excess fuel

or vapor has accumulated in the combustion chamber.

Starting the burner under these conditions may result

in hazardous operation and may cause severe personal

injury, death or major property damage.

WARNING

The burner combustion must be adjusted using

appropriate test instruments to measure carbon

dioxide (CO²), over-fire pressure and smoke.

Failure to do so may result in hazardous operation

and may cause severe personal injury, death or major

property damage.

WARNING

Page 33

c) Increase air to reduce CO²(or increase O²) by

about 1%.

d) Re-check the smoke level. It should be zero.

4. Install the sound absorbing burner cover.

5. After about 15 minutes of operation, check the smoke

level and CO²level. If the CO²level has increased

significantly, re-adjust the air damper.

F. CHECK BOILER FUNCTION

1. Start and stop the burner several times to assure

satisfactory operation.

2. Observe boiler operation under normal operation for

a short time. Assure that the boiler temperature is not

increasing too rapidly.

3. Check the system to assure that there are no leaks or

overfilling problems which may cause excessive make

up water to be added. Make up water may cause

liming in the boiler and corrosion in ferrous system

parts.

31

START-UP PROCEDURE

Page 34

32

TROUBLESHOOTING

A. GENERAL

The following table shows conditions that may possibly occur with the Pinnacle Oil Boiler and instructions on how to

troubleshoot these conditions.

8. TROUBLESHOOTING

Condition Remedy

The boiler does not run and the

control screen is blank.

1. Make sure that 120 VAC power is present at Terminals L & N in the control panel.

2. Make sure the boiler service switch is switched on.

The boiler does not run and the

control screen is on.

1. Check if the “Dem” segment is visible on the control display. This indicates that the

control is getting a demand from either the thermostat or the DHW tank.

2. Check for the burner symbol on the control display. This symbol indicates that the

temperature control is calling for the burner to operate.

3. Check indicator light on the Burner Primary control.

a. If it is on, it is detecting light, connections are shorted or the cad cell or control is

defective. Shield cad cell from light source.

i. If the indicator light goes off, eliminate the external light source or permanently

shield the cad cell.

ii. If the indicator light stays on, replace cad cell. If indicator light does not turn off,

remove cad cell lead wires. If light goes off replace cad cell bracket assembly. If

indicator light does not turn off, replace controller.

b. If it is off, jumper the limit terminal and L1.

i. If the burner starts, check the limit circuit (See Step 4).

ii. If the burner doesn’t start, disconnect line voltage power by turning off the

service switch. Check all wiring connections. Tighten any loose connections and

recheck. If burner still doesn’t start, replace the primary control

4. Check the boiler water temperature gauge. If the boiler water is above 210°F check

boiler circulator operation. Be sure that all air is purged from the system.

5. Depress the vent temperature limit reset button. Check all wiring in the limit circuit.

The burner starts, and then locks

out on safety with indicator light

flashing.

1. Check that limit switches are closed and contacts are clean.

2. Check for line voltage power at the oil primary control. Voltage should be 110 VAC to

130 VAC.

3. Reset primary control by pushing in and releasing the red reset button.

a. If the indicator light stops flashing go to step (4).

b. If the indicator light continues to flash, verify that the primary control is not in

restricted mode. If not in restricted mode, replace primary control.

4. Burner will re-try for ignition. Listen for spark after burner turns on (after 2 second

delay).

a. If there is no spark, check for line voltage at the igniter terminals, if line voltage is

present, replace the igniter.

b. If there is a spark, check to see if oil is being sprayed into the combustion chamber.

If there is no oil, check oil valve, oil valve wiring, pump and oil supply.

5. Check indicator light after the flame is established but before the oil primary control

locks out.

a. If the indicator light is on until the control locks out and starts flashing during

lockout, replace the primary control.

b. If the indicator light stays off, go to step (6).

Page 35

Bleeding the fuel unit:

In order to assure a good stream of incoming fuel, it is a

good idea to bleed fuel from the bleed port on the fuel

unit.

1) Attach a 36” clear plastic tube to the “bleed”

connection on the burner fuel unit.

2) Position a fuel oil safe container near the boiler

with the end of the bleed hose in the container.

3) Turn on the burner, open the bleed port, and

observe the fuel in the bleed hose for evidence of

air bubbles or water.

Isolating F

uel System Problems:

To isolate problems originating in the fuel supply system

from those originating in the burner, the boiler may be

run using flexible rubber hose and a clean bucket of

commercial standard #2 fuel oil.

1) Connect the rubber hose to the fuel inlet

connection on the fuel unit.

2) Be sure that the hose is filled before starting the

burner.

3) Run the burner from the clean bucket and check

CO²and Smoke levels.

4) If the combustion is clean with this set-up then the

problem is most likely in the fuel supply system.

33

TROUBLESHOOTING

Condition Remedy

(Cont’d from previous page)

The burner starts, and then locks

out on safety with indicator light

flashing.

6. Check cad cell sighting for view of the flame.

a. Turn off the service switch on the front of the boiler

b. Unplug cad cell and clean the face with a soft cloth. Check the sighting of the cad

cell for a view of the flame.

c. Re-install cad cell and turn on the service switch.

d. Re-start burner.

7. If the burner locks out, check the cad cell.

a. Turn off the service switch on the front of the boiler.

b. Replace cad cell and disconnect jumper from t-t terminals on primary control to

assure that no call for heat is present.

c. Turn on the service switch. Expose the cad cell to a bright light such as a flashlight.

i. If the indicator light is on, re-install control and go back to step 3.

ii. If the indicator light is off, go to step 8

8. Check the cad cell bracket assembly

a. Turn off the service switch on the front of the boiler

b. Remove cad cell leads from the primary control and leave the control lead wires

open. Turn on the service switch. Place a jumper across the cad cell terminals after

the burner motor turns on.

i. If the indicator light is on, replace the cad cell bracket assembly.

ii. If the indicator light is off, replace the primary control.

Burner runs with poor combustion,

#1 or higher smoke spot.

1. Check CO²Level. If the CO²has increased or decreased beyond the recommended

11.0% to 13.0% CO²then adjust the air damper to correct the problem.

2. Check the oil supply piping for leaks.

a. Air leaks can cause excessive smoke and poor combustion. These may or may not

be made evident by fuel leakage. Assure that all joints have been properly sealed.

b. Check the fuel filter fittings and gaskets for proper sealing.

3. Connect a clear polycarbonate hose to the fuel unit’s bleed connection. Position a

container to receive the fuel at the end of the bleed hose. Observe the oil in the

container for air bubbles or evidence of water. If there is evidence of air bubbles,

re-check the supply piping for leaks.

4. If there is no evidence of air or water in the fuel line, replace the oil nozzle. The nozzle

is to be replaced only with the nozzle recommended in Section 5, Oil Burner

Installation or as recommended by the Factory.

Oil nozzles are inexpensive; however they are critical to the operation of the boiler.

They should be kept in their protective sleeve, away from dirt and debris until ready

to install. It is a good idea to have an extra nozzle in case of problems.

Page 36

34

A. GENERAL MAINTENANCE (WITH BOILER

IN USE)

All boilers require periodic inspection and maintenance.

General boiler inspection can be performed by a

homeowner. However, if any potential problems are

found, a qualified installer or service technician/agency

must be notified.

1. Remove any combustible materials, gasoline and

other flammable liquids and substances that generate

flammable vapors from the area where the boiler is

installed.

2. Observe general boiler conditions (unusual noises,

vibrations, etc.)

3. Observe operating temperature and pressure on the

combination gauge located in the supply piping at the

rear of the boiler.

a) Boiler pressure should never be higher than 25

psig.

b) Boiler temperature should never be higher than

210°F.

4. Check for water leaks in the boiler and system piping.