Page 1

Recorders

Data Sheet

Recording Controller/Profiler

DESCRIPTION

The VersaChart is perfect for demanding applications

requiring a high performance recorder/controller with

custom ramp/soak capability. The Versachart provides powerful true time based profile capability and

exceptional value per data. Using advanced printing

technology, the Versachart produces a circle chart in

four colors with alpha/ numeric chart characters for

clear, accurate and readable charts that can be

archived.

MRC 9000™ VersaChart

Versatile Recorder,

Powerful Controller!

APPLICATIONS:

• Demanding Process Validation

• Trend Analysis

• Regulatory Compliance

• Product Safety

Applications:

- Temperature, Pressure and Relative Humidity

INDUSTRIES

Oven, chamber, furnaces, heat treating, food

processing, harsh water environments

™

It is the only circle chart recorder to deliver up to 16

Profiles with up to 8 segments per profile. The profiling feature provides closed loop PID process control

with the added capability of configurable setpoints as

a function of time. Additionally, the profile feature

includes actuators, parameters and a function block

feature permitting logic equations. The entire recorder (recorder, controller and profile feature) is

easy to setup with its innovative PC configuration port

and available PC configuration software with security

and single point data access features. A recovery

feature is also part of the profile option which enables

users to choose a course of action in the advent of

power loss, preventing unnecessary process cycling.

Finally, a guaranteed soak feature assures that the

actual process variable during soak is within a preselected tolerance for the soak time to increase

product quality and prevent waste/loss.

Process Automation Worldwide Brands: LFETM • PartlowTM • PMATM • RustrakTM • West

FEA TURES/BENEFITS

• Micro-based recorder/controller with profile

• Four Pens and Four Colors

• Flexible chart sizes–Choose from 10–12˝ diameter

• Two displays–allowing you to see critical process

• Easy, straightforward PC programming–allows you

• True time based profiling capability (including Four

• Reliability—maintenance free recording for years

• Excellent features/reasonable price

www.partlow.com • www.danaherindustrialcontrols.com

capability

values at the same time

to configure your recorder with a logical step-bystep process using a simple keypad

Process PID Loops, Recovery Action, Guaranteed

Soak)—and up to 16 profiles— puts you in control

of your process

to come

Customer Service +1 800.390.6405

Technical Support +1 800.866.6659

TM

Page 2

Recorders

Hollowshaft, Incremental EncodersRecording Controller/Profiler

SPECIFICATIONS

STANDARD FEATURES

Modes: Digital; record, controller or profile

functionality.

Display: Two line, 40 character vacuum

fluorescent display with 0.21˝ (5mm) high

characters; 15 keys for programming and unit

operation; display modes; automatic or

manual sequencing; 3 display formats.

Programmable Profiles: Up to 8 user program-

mable profiles.

Status Indicators: 8 user-configurable red LED

status indicators; real time clock for time and

date stamping on chart output.

Chart: 10–12˝ circular chart; 100 charts

furnished with each instrument.

Chart Drive: DC stepper motor.

Chart Rotation: User-configurable from 6 to 9999

hours per revolution.

Chart Range: Bottom and top of span –999999 to

999999 units.

Pen Type: Four disposable fiber tip pens.

Pen Color: Pen 1 (red); Pen 2 (green); Pen 3

(blue); Pen 4 (black).

Memory Backup: EEPROM and battery backed

SRAM; 5 year minimum life.

Construction/Enclosure: Gasketed, cover, case

and windows. Structural foam case and

cover; optional door lock or glass window

option.

OPERATING CHARACTERISTICS

Operating Temp: 32° to 122°F (0° to 50°C).

Storage Temp: –40° to 149°F (–40° to 65°C).

Ambient Temp.: 0.04% of span per degree C

deviation from 25°C.

Humidity: 0% to 90% non–condensing R.H.

Vibration: 0.5 to 100Hz @ 0.2g.

Electro Static Discharge: N/A

ELECTRICAL

Power Consumption: 60VA max.

Line Voltage: 90–264VAC 50/60Hz..

MRC 9000™ VersaChart

Versatile Recorder,

Powerful Controller!

INPUTS

Thermocouple: J, K, T, R, S, E, B, N, G, D, C, Ni/

Ni-Moly and Platinel II.

RTD: 100 ohm, platinum 100 or nickel 100,1–2

wire; 0.00385 ohms or 0.00392/ohm/°C; –94°

to 300°F (–70° to 150°C).

RDT Excitation Current: 1mA.

DC Voltage: 0 to 25mV, 0 to 100mV, 0 to 1V,

0 to 10V.

DC Current: 0–20mA or 4–20mA.

OUTPUTS

CONTROL OUTPUTS:

Relay: SPST; 5.0A resistive @ 115VAC; 2.5A

resistive, 1/8HP @ 230VAC.

SSR Driver: Open collector output; short

circuit protected @ 100mA max; provides

4VDC @ 20mA or 3VDC @ 40mA.

Current: 0–20mA or 4–20mA; 650 ohm

maximum load.

ALARM/EVENT OUTPUTS (Options):

Number: Up to four alarms for each of four

process variables. Type: Process high/low

and rate/rising and falling.

Relay: SPST/SPDT; 5.0A resistive @ 115VAC;

2.5A resistive @ 230VAC.

SSR Driver: Open collector output; short

circuit protected @ 100mA max; provides

4VDC @ 20mA or 3VDC @ 40mA.

Process Alarm: Direct (High) or Reverse (Low)

–999999 to 999999 units.

Deviation Alarm: Direct (deviation above

setpoint) or Reverse (deviation below

setpoint) –3000 to 3000 units.

Deviation Band Alarm: Open or closed 1 to

3000 units.

Alarm Hysteresis: Fully adjustable.

™

PERFORMANCE

GENERAL:

Input Measurement Error: ±0.25% of measure-

ment span reference accuracy.

Ambient Temperature Error: 0.01% of span per

degree C deviation from 25°C.

Cold Junction Compensation Error: ±0.2% @

25°C.

Cold Junction Compensation Rejection:

0 ±0.4°C from 25°C.

Linearization Error: TCs: ±0.25°C typical; ±0.5°C

worst case with exceptions. RTDs: ±0.1°C

typical; ±0.3°C worst case.

Isolation: 500VDC/350VAC.

Chart Accuracy: Recording: 0.3% of span. Chart

Rotation: ±0.2 minutes for a 24 hour rotation,

assuming all backlash removed, 6–9999 hours

per revolution.

PROCESS

CONTROL

www.partlow.com • www.danaherindustrialcontrols.com

Process Automation Worldwide Brands: LFETM • PartlowTM • PMATM • RustrakTM • West

U

L

®

LISTED

88BO

Customer Service +1 800.390.6405

Technical Support +1 800.866.6659

TM

Page 3

Recorders

MRC 9000™ VersaChart

Versatile Recorder,

™

Hollowshaft, Incremental EncodersRecording Controller/Profiler

SPECIFICATIONS

PERFORMANCE (cont’d)

Algorithm Accuracy: N/A.

Scan Rate: 2 scans/second; scan rate is

programmable for each input with the

limitation that a total of 16 measurements

can be made in one second.

Noise Rejection: Normal mode: 100dB

minimum at 60Hz or greater. Common mode:

120dB minimum at 115VAC maximum.

Process Value Output Error Limit: N/A.

Record Error Limit: N/A.

Sensor Fault Detection: Sensor break on all

temperature controls, RTUs, 1 to 5 volt and

4–20mA inputs.

Transmitter Power Supply: Up to 4 isolated

25mA @ 24VDC supplies available.

Data Backup: EEPROM for input board and

motherboard calibration data; battery

backed SRAM for configuration data.

DIMENSIONS

Powerful Controller!

COMMUNICATIONS INTERFACES

Communications Port: RS-232/485 serial, half

duplex.

Protocol: Modbus RTU.

Bit Rate: User-configurable 1200, 2400, 4800,

9600 baud.

Address: User-configurable, 1–247.

RATINGS/AGENCY APPROVALS

Safety: UL 1092 File E67237; CSA Spec 142 File

67237; CE EN60010-1 1193/1995.

Immunity: CE compliance EN50082-2.

Emissions: CE compliance EN550081-1:1992;

EN55022 Class A.

Hazardous Location: ETL Listed Class 1 & II

Division 2 and Class III, Division 1 & 2 Ref

56042.

Other: ISO 9002 registered.

PROTECTION

NEMA 3 standard; NEMA 4 optional.

PHYSICAL DIMENSIONS

Width: 14.12˝ (359mm).

Depth: 7.75˝ (197mm).

Height: 16.77˝ (426mm).

Weight: 25 lbs (9.1kg).

Mounting/Mounting Position: Panel or wall.

OPTIONS/ACCESSORIES

Diverse pen options (see config.matrix for

details).

Choose from up to 8 input options (see

config.matrix for details).

Optional profiling feature—up to four loops in a

single package.

NEMA 4 protection optional.

Diverse window and door lock options.

RS-232/485 communication option.

17.04"

(432.82mm)

EC1

EC5

EC2 EC3

12.600"

(320.04mm)

14.12"

(358.65mm)

EC6

EC4

7.747"

(196.77mm)

WARRANTY

2.12"

(53.85mm)

12.60"

(320.04mm)

2.044"

(58.93mm)

5.24"

(133.10mm)

Made in USA.

* Specifications subject to change without notice in accordance with

our DBS policy of continuous improvement. All product and brand

names are trademarks of their respective companies. All rights

reserved.

Partlow™ brand and MRC 9000™ are trademarks of Danaher Industrial

Controls Group. All rights reserved.

© 2005 DICG Corp.

Partlow Brand MRC 9000 Data Sheet (5/05)

2 years.

+1 800.873.8731 • www.partlow.com • www.danaherindustrialcontrols.com

Worldwide Brands: AndersonTM • DynaparTM • Eagle SignalTM • HaroweTM • HengstlerTM • NegeleTM • NorthStarTM • PartlowTM • Veeder-RootTM • West

TM

Page 4

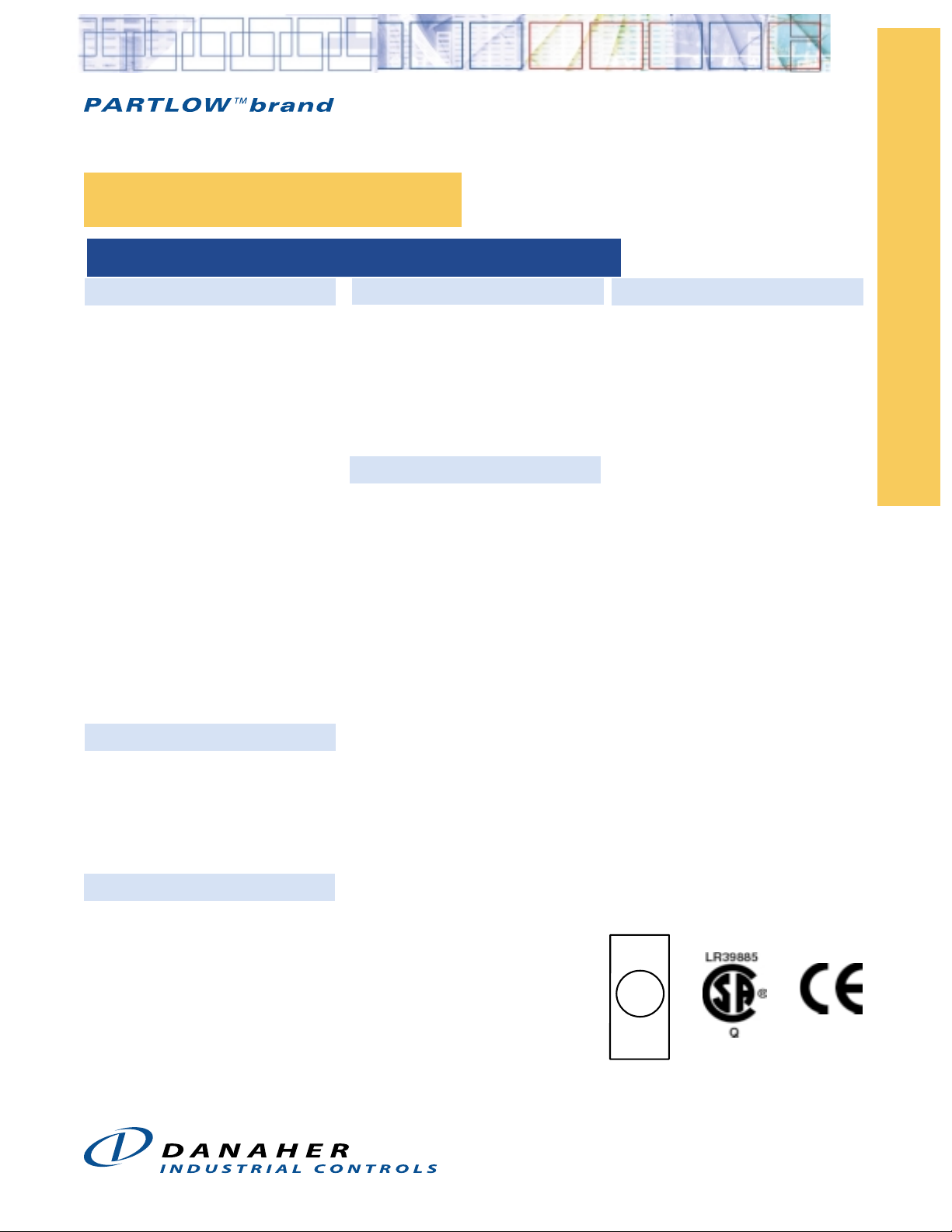

MRC9000

VersaChart

4 Color

Recorder /

Controller/

Profiler

* Total quantity of SPDT Relays and SSR Drivers must be less than or equal to eight.

** Pens/colors are added to the instrument in the following order: red, then green, then blue, and then black.

*** Door Lock N/A with NEMA 4

7 Three Trend

Pens, Four

Colors

Pens, Four

Colors

6 Two Trend

Pen, Four

Colors

5 One T rend

Pens, Four

Colors

Inputs

4 Four Trend

4 Four

3 Three Trend

Pens, Three

Colors**

3 Three

Inputs

2

3 Profiler

Controller

Two

Colors**

2 Two

Inputs

Only

2 Two Trend,

One Color**

Input

9

1

Recorder

1 One T rend,

1 One

0

0 None

2 Two

4 Four

6 Six

8 Eight

0 None

2

4 Four

6 Six

8 Eight

Two

SSR Drivers

SSR Drivers

SSR Drivers

SSR Drivers

Model

Code 2:

Type

Code 3:

Pens/Colors

Code 4:

Universal

Inputs

Code 5:

Required

Zero

Code 6:

Relay

Outputs*

Code 7:

SSRD

Outputs

MODELS

Code 1:

Flow Controller

Recorders

6 Four 4-20mA

Isolated

5

Isolated

Three 4-20mA

Isolated

Supplies

Window

w/Door

Lock ***

4 Two 4-20mA

Isolated

4 Four

Supplies

3 Plastic

4 Plastic

Window

2 Two 4-20mA

3 One 4-20mA

Non-Isolated

2 Two

3 Three

Supplies

1 Math &

Totalizer

Window

w/Door

Lock ***

Panel Mount

1 One 4-20mA

Non-Isolated

1 One

Supply

1 Math

2 Totalizer

1 RS-232

/RS-485

2 Glass

Window

2 NEMA 4

Panel Mount

0 None

0 None

0 None

0 None

1 Glass

1 NEMA 3

Code 8:

4-20mA

Outputs

Code 9:

Transmitter

Power Supply

Code 10:

Math/

Totalizer

Code 11:

Digital

Communications

Code 12:

Enclosure

Options

Code 13:

Case Type and

Mounting

MRC 9000

Versatile Recorder,

Powerful Controller!

™

VersaChart

™

Headquarters: 1675 Delany Road • Gurnee, IL 60031-1282 • USA

Phone: +1 847.662.2666 • Fax: +1 847.662.6633

Satellite Locations:

North America: North Carolina, South Carolina, Connecticut, Massachusetts, New York,

Canada, British Virgin Islands • Europe: United Kingdom, Italy, France, Germany, Spain,

Slovakia • Latin America: Brazil • Asia: China, Japan, Korea, Singapore

www.partlow.com • www.danaherindustrialcontrols.com

Process Automation Worldwide Brands: LFETM • PartlowTM • PMATM • RustrakTM • West

Customer Service:

Tel.: +1.800.390.6405

Fax: +1.910.879.5486

partlow.custserv@dancon.com

TM

Technical Support:

Tel.: +1.800.866.6659

Fax: +1.847.782.5277

partlow.techsupport@dancon.com

Loading...

Loading...