Page 1

Form 3803 • Price $15.00

Brand

Edition 1 • © Dec. 1997

ONE AND TWO PEN CIRCULAR CHART RECORDING CONTROLLER

MR C 5000

Installation, Wiring, Operation Manual

TWO CAMPION ROAD • NEW HARTFORD, NY 13413 USA

1-800-866-6659 • 1-315-797-2222 • FAX 1-315-797-0403

THE PARTLOW-WEST COMPANY

Page 2

nformation in this installation, wiring, and operation manual is subject to change

without notice. One manual is provided with each instrument at the time of ship-

I

Copyright © December 1997, The Partlow-West Company, all rights reserved. No part of

this publication may be reproduced, transmitted, transcribed or stored in a retrieval system, or translated into any language in any form by any means without the written permission of The Partlow-West Company.

This is the First Edition of the MRC 5000 Recording Controller Manual. It was written and

produced entirely on a desk-top-publishing system. Disk versions are available by written

request to The Partlow-West Company Marketing Communications Department.

We are glad you decided to open this manual. It is written so that you can take full advantage of the features of your new MRC 5000 microbased chart recording controller.

ment. Extra copies are available at the price published on the front cover.

NO TE:

It is strongly recommended that Partlow Brand equipped applications incorporate a high

or low limit protective device which will shut down the equipment at a preset process

condition in order to preclude possible damage to property or products.

2

Page 3

TABLE OF CONTENTS

SECTION 1 - OVERVIEW 5

1.1 Display 5

1.2 Control 5

1.3 Alarms 5

1.4 Digital Communications 5

1.5 Power Input 5

SECTION 2 - INSTALLATION & WIRING 6

2.1 Unpacking 6

2.2 Location / Mounting 6

2.3 Preparation for Wiring 8

2.4 Wiring Connections 11

SECTION 3 - NORMAL OPERATION 15

3.1 Changing The Chart 15

3.2 Control Output Settings 15

3.3 Alarm Settings 16

3.4 High/Low Limits 16

SECTION 4 - RECORDER SETUP, TEST, AND CALIBRATION 16

4.1 Hardware Selections - Input Jumper Positions 17

4.2 Recorder Programming 17

4.3 Test Mode 20

PAGE NUMBER

SECTION 5 - RECORDER CALIBRATION MODE 21

5.1 Input Calibration 21

5.2 Chart/Pen Calibration 22

SECTION 6 - MODEL NUMBER CHANGES 23

APPENDICES

A - Model Number Hardware Matrix Details 24

B - Specifications 25

Warranty 31

3

Page 4

FIGURES

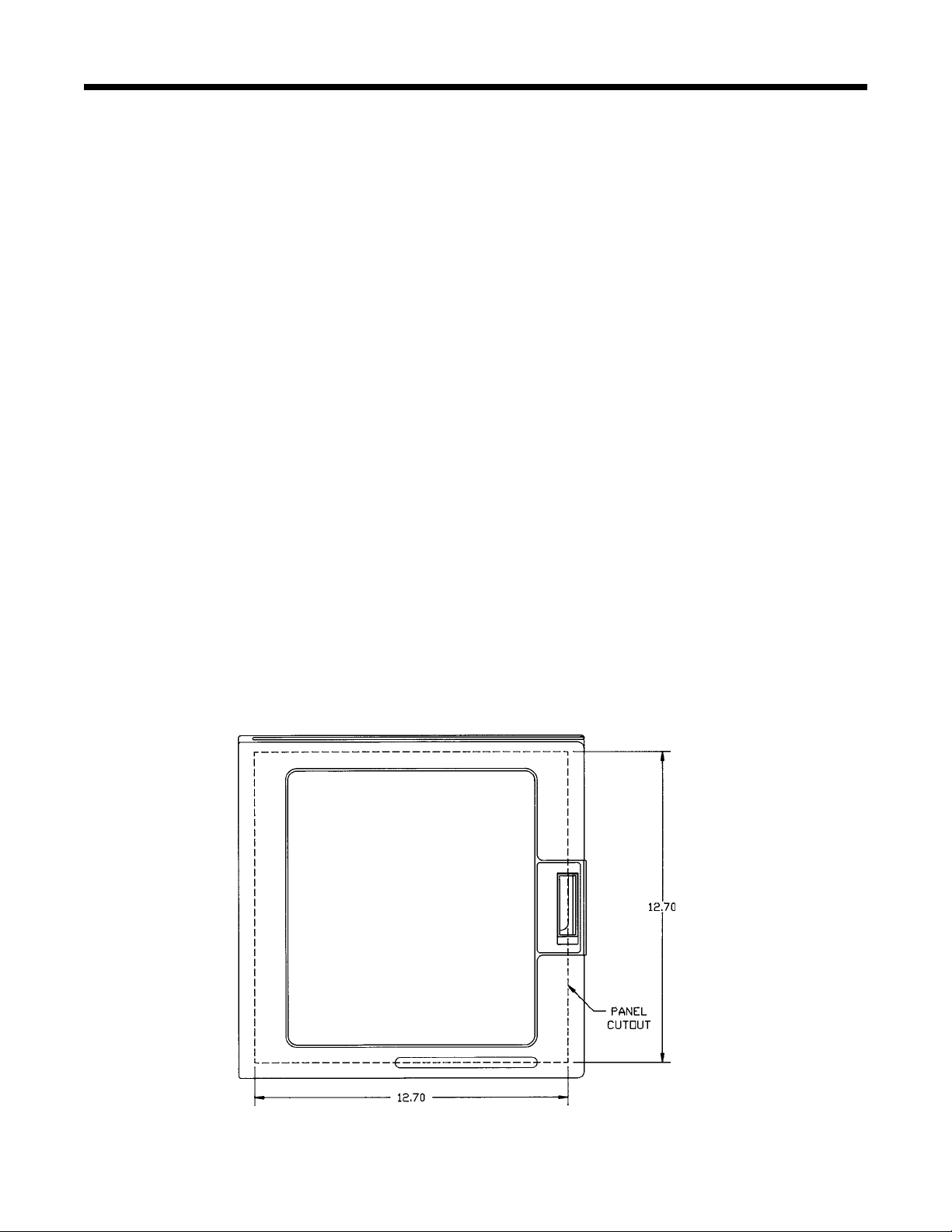

Figure 2-1A Panel Mounting 6

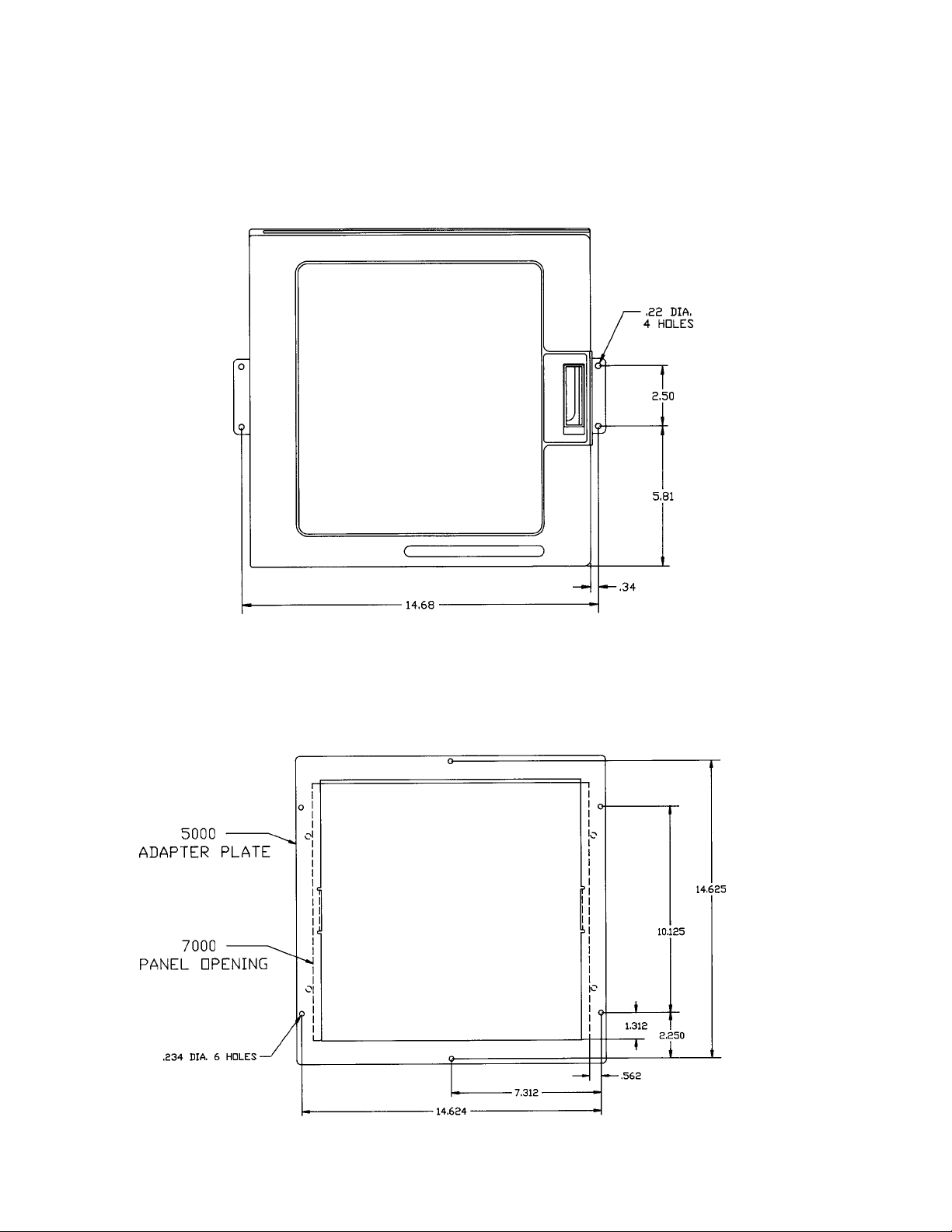

Figure 2-1B Surface Mounting 7

FIgure 2-1C Adaptor Plate 7

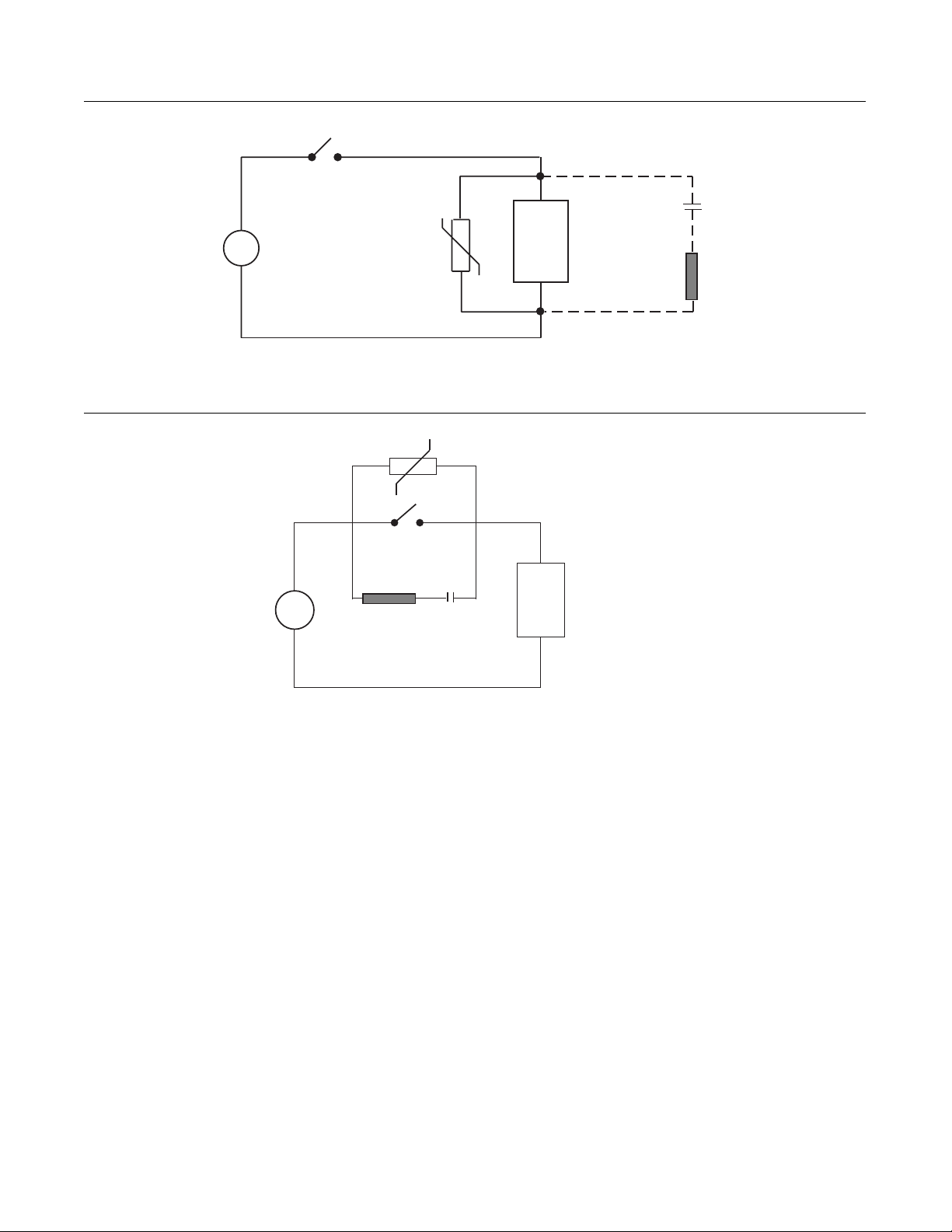

Figure 2-2 Noise Suppression 9

Figure 2-3 Noise Suppression 9

Figure 2-4 Board and Terminal Locations 11

Figure 2-5A AC Power Input Wiring-Standard Voltage 12

Figure 2-5B Power Wiring-Low Voltage 12

Figure 2-6 Input Signal Wiring 12

Figure 2-7 Relay Output Wiring 13

Figure 2-8 Communications Wiring 13

Figure 2-9A Transmitter Power Supply (One Transmitter) 14

Figure 2-9B Transmitter Power Supply (Two Transmitters) 14

4

Page 5

Section 1 Overview

This instrument records process trend lines, one or two pens, on a 10 inch circular chart. As an option, up to two alarm points

are provided for each of the two pens.

This recorder will accept J, K, T, R, and S Thermocouples and RTD inputs, as well as typical Millivolt, Milliamp (4-20mA) and

Volt inputs, (up to 5 volts).

1.1 DISPLAY

Process values for each pen can be displayed on the .56" LED display, or the display can be blanked. In the latter case, the

display is used only for programming and setting alarm points.

1.2 CONTROL

The instrument can be provided with relay control outputs which can be programmed for on-off control capability.

1.3 ALARMS

Two optional alarm output relays, with SPDT contacts, are available for each pen. Each alarm is also configurable as a

latching, limit device. In this case, a manual reset button is required and included when the High/Low Limit option is ordered.

1.4 DIGITAL COMMUNICATIONS

An optional, RS-485 digital communications port is available that utilizes the standard MODBUS RTU protocol.

1.5 POWER INPUT

The standard recorder will operate on input power over the range of 90-264 VAC, 50-60 Hz, without any modifications. A low

power voltage option (20-50 VAC or 22-65 VDC) is also available. All Low Voltage option recorders are clearly identified as

such by a label near the power wiring terminal block.

5

Page 6

Section 2 Installation and Wiring

Read these instructions completely and carefully before proceeding with the installation and operation of this recorder.

Electrical code requirements and safety standards should be observed. Installation should be performed by qualified personnel only.

Caution: The standard recorder will accept a power input over the range of 90-264 VAC. There is a special low power

voltage option that is available. Please verify the AC input power required by the recorder before proceeding with the

installation. The power required is listed in the Model/Serial number label affixed to the platen in the upper left hand

corner.

2.1 UNPACKING

Remove the recorder from the carton and inspect for any damage due to shipment. If any damage is noted, report and file a

claim with the carrier. Write the model number and serial number of the instrument on the inside front cover of this operation

manual for future reference.

2.2 LOCATION / MOUNTING

Locate the instrument away from excessive moisture, oil, dust and vibration. Do not subject the instrument to operating

temperatures outside of the 0 to 55°C (32 to 131°F) range.

The panel where the instrument will be mounted must provide rigid support for the approximate 7 lb. weight of the instrument.

Adjacent instruments may be mounted within a minimum of 2 inches horizontally and 3 inches vertically, providing that proper

panel support is provided.

PANEL MOUNTING:

1. Remove the mounting brackets attached to the recorder upon receipt.

2. Cut panel opening to the dimensions illustrated in Figure 2-1A.

3. Insert the recorder in the panel opening. Reattach the mounting brackets to the side of the recorder with the mounting ears

facing the back of the panel. Adjust the mounting brackets so they fit snugly against the panel, and then tighten.

PANEL MOUNTING HARDWARE REQUIRED: (provided with instrument)

(1) set mounting brackets - mounted to the recorder

(1) set mounting screws - mounted to the recorder

FIGURE 2-1A

±0.06

6

±0.06

Page 7

SURFACE MOUNTING:

1. Loosen the mounting brackets attached to the recorder and flip their position so the ears are flush with the back of he

recorder. Fasten the recorder to the surface using the appropriate fasteners (#10 screws or nuts and bolts) depending on the

surface material.

2. As an alternative, remove the brackets, attach them to the surface, and then attach the recorder to the brackets.

FIGURE 2-1B

RETROFIT:

Note: An Adapter Plate is available (P/N 50033301) that allows the recorder to retrofit with the Partlow MRC 7000 and ARC

4100 recorders. Figure 2-1C shows the adapter plate relative to the MRC 7000/ARC 4100 cutout. The Adapter Plate includes

ears that attach to the sides of the recorder.

FIGURE 2-1C

Use #10 screws

7

Page 8

2.3 PREPARATION FOR WIRING

Electrical noise interference is a phenomenon typical of industrial environments. Use the following guidelines which are

generally used to minimize the effect of electrical noise on instrumentation in general.

2.3.1 WIRING GUIDELINES

Listed below are some of the common sources of electrical noise in the industrial environment:

• Ignition Transformers

• Arc Welders

• Mechanical contact relay(s)

• Solenoids

Before using any instrument near the devices listed, the instructions below should be followed:

1. If the recorder is to be mounted in the same panel as any of the listed devices, separate them by the largest distance

possible.

2. If possible, replace electromechanical relay(s) with solid state relays.

3. Consider using a separate isolation transformer to power the recorder and any other instrumentation in the panel. The

transformer will serve to isolate the recorder from noise found on the AC power lines.

4. If the recorder is being installed on existing equipment, existing wiring should be inspected to insure that good wiring

practices have been followed.

5. Connect a good earth ground to the recorder chassis ground connection. To verify this, take a resistive measurement

from the instrument chassis to the nearest metal water pipe or proven earth ground. The reading should not exceed 100

ohms. Each instrument should have a dedicated earth ground. Do not chain link multiple instrument groundwires.

6. AC neutral should be at or near ground potential. To verify this, measure the AC voltage between neutral and ground.

The reading should be no more than 50 millivolts. If greater, the secondary of the transformer feeding the recorder should be

checked out by an electrician.

7. Wire Isolation/Segregation - this recorder is designed to promote proper separation of the wiring groups that connect to it.

The AC power terminals are located near the top of the instrument. The input signal terminals are located in the middle

section of the main board and the output alarm relay connections are on a separate board in the lower right hand corner of

the instrument.

-

8. Input Signal Wiring

run with shielded cable. Connection lead length should be kept as short as possible. The shield should be grounded at one

end only. The preferred grounding location is at the sensor, transmitter or transducer.

9. For severe levels of electrical noise, it may be necessary to suppress the noise at its source. Many manufacturers of

relays, contractors, etc. supply "surge suppressors" which mount on the noise source. For those devices that do not have

surge suppressors supplied, RC (resistance-capacitance) networks and/or MOVs (metal oxide varistors) may be added.

Inductive Loads - MOVs are recommended for transient suppression for inductive loads, and should be connected in parallel

and as close as possible to the load. See Figure 2-2. Additional protection may be provided by adding an RC network across

the load.

Contacts - Arcing may occur across contacts (relays or switches) when they open and close. This results in electrical noise

as well as damage to the contacts. Connecting an RC network, properly sized, in parallel, can eliminate this problem. See

Figure 2-3.

For circuits up to 3 amps, a combination of a 220 ohm resistor and 0.5 microfarad capacitor (1000 volts) is recommended.

For circuits from 3 to 5 amps, connect two of these in parallel. The resistor should be 1/4 watt or 1 watt for 115 VAC or

230VAC circuits, respectively.

Shielded cable helps eliminate electrical noise being induced on the wires. All input wires should be

8

Page 9

FIGURE 2-2

A.C.

MOV

C

Inductive

Load

R

FIGURE 2-3

MOV

Inductive

A.C.

2.3.1 SENSOR PLACEMENT

If the input probe will be subjected to corrosive or abrasive conditions, it should be protected by the appropriate thermowell.

The probe should be positioned to reflect the true process temperature:

In liquid media - the most agitated area

In air - the best circulated area

For thermocouple sensors, the lead resistance should not exceed 300 ohms. If this is exceeded, recorder accuracy could be

affected. To determine the temperature error caused by lead length resistance, use the following equation:

Terr = TCe x L where; TCe = temperature error in °F or °C per 1000 feet

L = length of lead wire in thousands of feet

R

C

Load

9

Page 10

TABLE 1

Temperature error in °C per 1000 feet of Lead wire

AWG Thermocouple Type:

No. J K T R S

10 0.03 0.09 0.04 0.10 0.11

12 0.05 0.13 0.06 0.16 0.16

14 0.09 0.21 0.10 0.27 0.26

16 0.14 0.34 0.15 0.41 0.42

18 0.22 0.55 0.25 0.68 0.68

20 0.36 0.86 0.39 1.08 1.09

24 0.88 2.19 0.99 2.72 2.73

TABLE 2

Temperature Error in °F per 1000 feet of Lead wire

AWG Thermocouple Type:

No. J K T R S

10 0.06 0.15 0.07 0.18 0.19

12 0.10 0.24 0.11 0.30 0.30

14 0.16 0.39 0.18 0.48 0.48

16 0.25 0.61 0.28 0.75 0.75

18 0.40 0.99 0.45 1.22 1.23

20 0.64 1.55 0.71 1.94 1.96

24 1.58 3.94 1.78 4.89 4.91

For 3 wire RTDs, the instrument can virtually eliminate all lead wire resistance error.

Two wire RTDs should be used only with lead lengths less than 10 feet, unless special input calibration is performed using the

iCor (Input Correction) capability. (See Section 4 for setting iCor.) To determine the temperature error resulting from the lead

length resistance, use the following equation:

Terr = TRe x L where; TRe = temperature error in °C or °F per 1000 feet

L = length of lead wire in thousands of feet

TABLE 3 2 Wire RTD

AWG No. Error °C Error °F

10 +/-5.32 +/-9.31

12 +/-9.31 +/-14.6

14 +/-13.3 +/-23.9

16 +/-21.3 +/-38.6

18 +/-34.6 +/-61.2

20 +/-54.5 +/-97.1

24 +/-86.5 +/-155.6

10

Page 11

2.4 WIRING CONNECTIONS

WARNING: Avoid electrical shock. AC power wiring must not be connected at the source distribution panel until all wiring

connections are completed.

All wiring connections are typically made to the instrument at the time of installation. All connections are made behind the

access door on the recorder right side. Loosen the two thumbscrews and open the access door to complete all wiring. Connections should be made at the terminal blocks , two 14 gauge wires maximum, copper conductors only, except thermocouple

inputs. Terminal blocks are designated TB1 through TB4. See Figure 2-4 for the terminal block locations. The number of

terminal blocks present on the instrument depends on the model/hardware configuration.

FIGURE 2-4

Terminals located

TB1

1

behind access door

Pow er Wiring

Recorder

Platen

TB2

TB3

TB4

1

Pen 1 Input

JU1

1

Pen 2 Input

JU2

1

Communications

11

Page 12

2.4.1 ELECTRICAL CONDUIT OPENINGS

The instrument case has 3 conduit openings, all on the right hand side of the case. To minimize the effect of electrical noise,

the following wire groups should be routed through the conduit openings as shown below.

Top Conduit Opening - Power Input - TB1

Middle Conduit Opening - Input Signal Wiring & Communications - TB2, TB3, and TB4

Bottom Conduit Opening - Optional Control/Alarm Outputs - Option Board TB5-TB8

Note: Unused conduit openings should be sealed.

2.4.2.1 AC POWER WIRING - STANDARD VOLTAGE

Connect the AC hot line to terminal 1 of TB1 and the neutral to terminal 2 of TB1.

Connect the AC ground to terminal 3 of TB1. See Figure 2-5A

25A.

FIGURE 2-5A

TB1 - Power Wiring

3

Ground

AC - Neutral

2~

AC - Hot

1~

2.4.2.2 POWER WIRING - LOW VOLTAGE

Connect the AC hot line to terminal 1 of TB1 and the neutral to terminal 2 of TB1.

Connect the AC ground to terminal 3 of TB1. Connrct the DC positive (+) to terminal 1 of TB1 and the negative (-) to terminal

2 of TB2. Connect the ground to terminal 3 of TB1. See Figure 2-5B.

5A

FIGURE 2-5B

TB1 - Power Wiring

3

Ground

AC - Power-Neutral-DC(-)

2

~

AC - Power-Hot-DC(+)

1

~

2.4.3 INPUT SIGNAL WIRING

Pen 1 inputs are connected to TB2 and Pen 2 inputs are connected to TB3. The input wiring for each pen is identical. See

Figure 2-6 for details on wiring various types of inputs to the recorder.

FIGURE 2-6

Millivolt, Volt

TB2/TB3

1

2

+

3

-

4

2 Wire RTD

TB2/TB3

1

2

3

4

mV

V

TC

Install jumper

RTD

TB2/TB3

TB2/TB3

1

2

3

4

Milliamp

1

+

2

-

3

4

3 Wire RTD

mA

Input

RTD

12

Page 13

2.4.4 RELAY OUTPUT WIRING

Relay outputs, up to 2 for each pen, are provided as an option on this instrument with a separate circuit board that is mounted

in the lower right hand corner of the instrument, near the lower electrical conduit hole. Wire up each relay as shown in Figure

2-7.

FIGURE 2-7

TB5 - Pen 1, Alarm 1

1

Normally Closed

Common

2

Normally Open

3

TB6 - Pen 1, Alarm 2

1

Normally Closed

Common

2

Normally Open

3

Alarm Option

Board

TB7 - Pen 2, Alarm 1

1

Normally Closed

Common

2

Normally Open

3

TB8 - Pen 2, Alarm 2

1

Normally Closed

Common

2

Normally Open

3

2.4.5 COMMUNICATIONS WIRING

Connections for the Communications option are made to the Main board via the TB4 connections. See Figure 2-8 for wiring.

FIGURE 2-8

TB4 - Communications

1

2

+

-

3

Shield

13

Page 14

2.4.6 TRANSMITTER POWER SUPPLY WIRING

Connections are made as shown using TB10, terminal 2 as positive (+) and terminal 1 as negative (-). See Figure 2-9A for

one transmitter and Figure 2-9B for two transmitters (40mA DC maximum).

FIGURE 2-9A

FIGURE 2-9B

TB10

- +

1 2

TB2/TB3

+ 1 2 3 4

Shield

Twisted

Pairs

+ -

Two Wire

Transmitters

TB10 TB2

- +

1 2

+ 1 2 3 4

+ -

Two Wire

Transmitters

TB3

+ 1 2 3 4

Shield

Twisted

Pairs

+ -

Two Wire

Transmitters

14

Page 15

Section 3 Normal Operation

Assuming that the MODE switch (discussed later) is in the RUN position, on power up, the recorder will display the software

revision, in the format rX.XX, while the pens move to the home position (toward the center of the chart). Then the instrument

will display the model number. Only the first 8 digits will be displayed, 4 digits at a time, for two seconds each. Then the

display will blank while the recorder is measuring the input(s).

Then the pen(s) will go to their proper positions on the chart and the display will show the process value for pen 1 (if configured to display it) and will alternately show the pen 2 value (if it is present and if configured to display it), indicated by the

green, PEN 2 LED. If any output is active, the appropriate LED will be lit.

Note: Each time power is applied, the pen(s) will move to the home position (toward the center of the chart) and then position

themselves at the proper place on the chart.

The recorder will operate using the Program Parameters that were last stored in memory. The recorder is shipped from the

factory set up for a Type J thermocouple input, range code 1 (0-1400°F) on all pens. To modify the input types and ranges,

see Section 4 for detailed instructions.

Located on the backside of the access door (inside the recorder) is a Short Form Programming Card that summerizes the Run

and Program mode information.

See Appendix A for a complete description of the model number and options. See Section 6 for modifying the recorder model

number.

SENSOR FAULT DETECTION

The recorder will display, record, and act upon normal measured values. If an input is above or below the advertised span, the

display will indicate a Hi or Lo condition, respectively. If the input is disconnected (sensor break) or excessively out of range,

SnSr will be displayed.

Relays, output LED, and pens will react normally when in a Hi or Lo condition, as if the value was high or low, relative to the

setpoint. In a SnSr condition, relays will be de-energized, output LEDs will not be lit, and pens will go upscale.

NOTE: A sensor break can not be detected on zero based Volt and Milliamp inputs (0-5 volts and 0-20mA), as the

divider or shunt resistor, coupled with no input connection, produce a valid input signal of zero.

NOTE: A "Lo" condition can not be detected on zero based Volt, Milliamp, and Millivolt inputs, due to the nature of

the hardware. The instrument will handle slightly negative signals, but more negative inputs will result in the display

indicating a "Hi" condition. Refer to the Specifications section for more details.

3.1 CHANGING THE CHART

To make chart changing easier, the recorder can move the pens to the outside edge of the chart. It is not necessary to use

this capability. Do so only if you find it more convenient.

DO NOT PUSH THE PENS MANUALLY. This could affect mechanical adjustments or bend the pen arms, adversely affecting

accurate operation.

POSITIONING THE PENS FOR CHART CHANGING

While the MODE switch is in the RUN position, press the SCROLL key. CC will appear in the display, designating chart

changing. Press the DOWN arrow key. The recorder will move the pens fully upscale. The display will flash CC. Change the

chart per the instructions that follow and then press the DOWN arrow key again. The recorder will resume normal trend

recording.

CHANGING THE CHART PAPER

To change the chart, pull up on the chart clip located in the center of the chart. Remove the old chart and place the new chart

on the chart hub. DO NOT press down firmly. The UP arrow key can be used to advance the chart. Every time the UP arrow

key is pressed, the chart will advance one step. Line up the current time on the chart with the chart time arrow located to the

right of the display. Then press the chart down on the chart hub and flip the chart clip to the down position.

15

Page 16

3.2 CONTROL OUTPUT SETTINGS

3.2.1 SINGLE OUTPUT

When Single Output On/Off control is configured as CH (Control Heat), the relay will turn OFF when the process value is

greater than the setpoint by one-half the hysteresis value and turn ON when the process value is less than the setpoint by

one-half the hysteresis value.

When Single Output On/Off control is configured as CC (Control Cool), the relay will turn ON when the process value is

greater than the setpoint by one-half the hysteresis value and turn OFF when the process value is less than the setpoint by

one-half the hysteresis value.

3.2.2 DUAL OUTPUT - HEAT/COOL

When Dual Output On/Off control is configured as CH (Control Heat) for Output 1 and CC (Control Cool) for Output 2, Output 1

relay will turn OFF when the process value is greater than the setpoint plus one-half the hysteresis value and turn ON when

the process value is less than the setpoint minus one-half the hysteresis value. Output 2 relay will turn ON when the process

value is greater than the setpoint plus one and one-half the hysteresis value and turn OFF when the process value is less than

the setpoint plus one-half the hysteresis value.

3.2.3 DUAL OUTPUT - HEAT/HEAT

When Dual Output On/Off control is configured as CH (Control Heat) for Output 1 and CH for Output 2, Output 1 relay will turn

OFF when the process value is greater than the setpoint plus one-half the hysteresis and turn ON when the process value is

less than the setpoint minus one-half the hysteresis value. Output 2 relay will turn OFF when the process value is equal to the

setpoint minus one-half the hysteresis and turn ON when the process value is equal to the setpoint minus one and one-half the

hysteresis value.

3.2.4 DUAL OUTPUT - COOL/COOL

When Dual Output On/Off control is configured as CC (Control Cool) for Output 1 and CC for Output 2, Output 1 relay will turn

OFF when the process value is equal to the setpoint minus one-half the hysteresis and turn ON when the process value is

equal to the setpoint plus one-half the hysteresis value. Output 2 relay will turn OFF when the process value is equal to the

setpoint plus one-half the hysteresis value and turn ON when the process value is equal to the setpoint plus one and one-half

the hysteresis value.

3.2.5 TO REVIEW/MODIFY CONTROL SETTINGS

Repeatedly depress the SCROLL key. If any control outputs exist, the OUT LED (OUT 1/1, OUT2/1, etc.) for the first existing

control will flash along with its current control setpoint in the order shown below. Note that CC (for chart changing) will also

appear in the sequence when the SCROLL key is repeatedly depressed.

OUT 1/1 LED flashes Display shows Pen 1/Control setpoint

value

OUT 2/1 LED flashes Display shows Pen 2/Control setpoint

value

If Control Changes are allowed/enabled, use the UP/DOWN keys to change the setting. All control settings are defaulted to 0

and are adjustable from -9999 to 9999 (assuming no decimal positions).

If Control Changes are disabled, the settings cannot be changed, only viewed.

16

Page 17

3.3 ALARM SETTINGS

There are two possible alarm set point values for each of the two possible inputs/pens. They will be displayed only if the alarm

options are present and configured. The types of alarms and the ability to make alarm set point changes, is defined during

configuration. See Section 4 to select the types of alarms and to allow/disable alarm changes.

TO REVIEW/MODIFY ALARM SETTINGS

Repeatedly depress the SCROLL key. If any alarms exist, the alarm LED (ALRM 1/1, ALRM 1/2, etc.) for the first existing

alarm will flash along with its current alarm set point in the order shown below. Note that CC (for chart changing) will also

appear in the sequence when the SCROLL key is repeatedly depressed.

OUT 1/1 LED flashes Display shows Pen 1/Alarm 1 setpoint value

OUT 1/2 LED flashes Display shows Pen 1/Alarm 2 setpoint value

OUT 2/1 LED flashes Display shows Pen 2/Alarm 1 setpoint value

OUT 2/2 LED flashes Display shows Pen 2/Alarm 2 setpoint value

If Alarm Changes are allowed/enabled, use the UP/DOWN keys to change the setting. All alarm settings are defaulted to 0

and are adjustable from -9999 to 9999 (assuming no decimal positions).

If Alarm Changes are disabled, the settings cannot be changed, only viewed.

3.4 HIGH/LOW LIMITS

High or Low Limits are latching alarms. Once an alarm is engaged, it will remain active until BOTH of the following occur:

1) The alarm condition no longer exists (i.e. for a high limit the process value has fallen below the alarm

setpoint), and,

2) The alarm condition is acknowledged by depressing the red reset button to right of the display, on the platen.

The button will reset any limit alarms that can be reset.

If power is cycled and the alarm condition no longer exists, the corresponding limit will be reset.

Section 4 - Recorder Setup, Test, and Calibration

Because the MODE switch protects the configuration as well as the calibration of the recorder, "calibration seal" labels are

provided to cover up the switch, if desired, to secure the configuration and calibration, as well as record the date of the

calibration. The label looks like this:

MODE

CAL

DATE

/

/

If necessary, remove the label or "seal" to access the MODE switch.

The instrument has two basic "modes" of operation. The Run mode (as addressed in Section 3) is the normal operating

mode. The other basic mode is the Program/Test/Calibration mode, which is used only for setup, troubleshooting, and

calibration. The Program/Test/Calibration mode, accessed by having the MODE switch in the PROG/TEST/CAL position, is

further divided into the three respective modes of Program, Test, and Calibration. Each of these modes is divided into

sections corresponding to a portion of the programming parameters, or individual test or calibration functions.

The availability of various options (i.e. alarms, communications, etc.), as defined by the model number shown by the recorder

on power-up, will determine the selections offered in the Program, Test, and Cal mode. For example, if no alarm options exist,

then the alarm types do not need to be configured.

Located on the back of the access panel (inside the recorder) is a Short Form Programming Card that can be used as a

reference for selecting all program parameters.

17

Page 18

4.1 HARDWARE SELECTIONS - INPUT JUMPER POSITIONS

Hardware jumpers JU1 and JU2 are used to select the input type for Pen 1 and Pen 2 respectively. The jumper positions are

shown on the main wiring label on the recorder as well as on the Short Form Programming Card. See below:

JU1 and JU2 Positions - JU1 is located between wiring terminals TB2 and TB3 on the edge of the main board. JU2 is located

between wiring terminals TB3 and TB4 on the same board.

RTD and Millivolt 5 VDC Milliamp Thermocouple

4.2 RECORDER PROGRAMMING

The recorder setup programming can only be accomplished when the MODE slide switch is placed in the PROG/TEST/CAL

position. This switch is located to the left of the display. The Program mode is used to select: chart rotation speed, input

types/ranges, display scaling, and display options, chart scaling, and relay operation.

In the Program/Test/Calibration mode, the keys will function as follows:

SCROLL When a mode or section designation is displayed, SCROLL steps to the next mode or section.

When a parameter code is displayed, SCROLL will display the corresponding parameter value.

When a parameter value setting is displayed, SCROLL will display the next parameter code.

DOWN ARROW When a mode or section designation is displayed, DOWN will enter that mode or section.

When a parameter code is displayed, DOWN will display the next parameter code.

When a parameter setting is displayed, the setting will be decremented or changed, unless it is at its limit.

UP ARROW When a mode designation is displayed, the UP key will have no effect, as the instrument is at the initial level.

Use the MODE switch to return to normal operation.

When a section designation is displayed, the UP key will revert to the mode designation.

When a parameter code is displayed, UP will revert back to the section designation.

When a parameter setting is displayed, the setting will be incremented or changed, unless it is at its limit.

To enter the Program/Test/Cal mode, position the MODE switch accordingly. The unit will display Prog. Subsequent

depressions of the SCROLL key will cause the unit to display tESt, and then CAL, and back to Prog.

NOTE: When the MODE switch is placed in the PROG/TEST/CAL position, all output LEDs will be turned off and all

relays will be deenergized.

To enter the Program mode, press the DOWN arrow key when Prog is displayed.

The display will show PEn1 (Pen 1 parameters). Subsequent depressions of the SCROLL key will show PEn2 (Pen 2

parameters, if Pen 2 exists), CHAr (Chart operation), CP (Comms parameters, if optional communications is installed) and

then back to PEn1.

To enter the desired section of the Program mode, press the DOWN arrow key when the desired section is displayed.

Use the keys as defined previously to enter modes and sections, move around, and modify parameter settings. The parameters, their definitions, and range of adjustment, are as follows:

PEN 1 AND PEN 2 SECTIONS OF PROGRAM MODE

(Pen 2 will appear only if present in the recorder.)

18

- PEn1 and PEn2

Page 19

These parameters apply to each pen, assuming pen 2 is present, and are configured in each respective section.

PARAMETER PARAMETER DEFAULT

CODE DESCRIPTION SETTINGS OR RANGE SETTING

InPS Input Selection 0 - 18 1

0 = J T/C 0 to 760°C

1 = J T/C 0 to 1400°F

2 = K T/C 0 to 1360°C

3 = K T/C 0 to 2500°F

4 = T T/C -200 to 400°C

5 = T T/C -330 to 750°F

6 = R T/C 200 to 1650°C

7 = R T/C 400 to 3000°F

8 = S T/C 200 to 1650°C

9 = S T/C 400 to 3000°F

10 = RTD 100 ohm -140 to 400°C

11 = RTD 100 ohm -200 to 750°F

12 = 0-20mA

13 = 4-20mA

14 = 0-50mV

15 = 10-50mV

16 = 0-25mV

17 = 0-5VDC

18 = 1-5VDC

ICor Input Correction -999 to 999* 0

(calibrates sensor to

recorder)

A1 Output Type OFF = none OFF

(will show only if present) Hi = High Alarm

Lo = Low Alarm

HL = High Limit

LL = Low Limit

CH= Control Heat

CC= Control Cool

A2 Output Type OFF = none OFF

(will show only if present) Hi = High Alarm

Lo = Low Alarm

HL = High Limit

LL = Low Limit

CH= Control Heat

CC= Control Cool

dISP Display Input/Pen Value On = Display value On

during normal operation, OFF = Do not display value

RUN mode

dPOS Decimal Point Position 0 = nnnn 0

1 = nnn.n

2 = nn.nn

EUU Engineering Units that -9999 to 9999* 5000

equate to upper

transducer input

(will show only for Volt

or Milliamp Input types)

EUL Engineering Units that -9999 to 9999* 0

equate to lower

transducer input

(will show only for Volt

or Milliamp Input types)

19

Page 20

ChUP Value that equates to -9999 to 9999* 100

upper chart division

ChLO Value that equates to -9999 to 9999 0

Lower chart division

HySt Hysteresis or Switch 0 to 200* 3

differential for outputs

in units, not percent

(will show only if outputs present)

dFF Display Filter Factor 1 to 10 1

Filters display for input

noise. Higher number

means more filtering.

ALC Alarm Changes On = Allowed/Enable On

Determines if output OFF = Disable

setpoints can be changed

in the RUN mode

* The range shown corresponds to no decimal position. If dPOS is 1, 9999 becomes 999.9, 200 becomes 20.0, etc.

CHART SECTION OF PROGRAM MODE

(There is only one parameter in this section)

- CHAr

PARAMETER PARAMETER DEFAULT

CODE DESCRIPTION SETTINGS OR RANGE SETTING

ChSP Chart Speed OFF = off - don't rotate 24Hr

8Hr = 8 hours

12Hr = 12 hours

24Hr = 24 hours

48Hr = 48 hours

7dAy = 7 days

**COMMUNICATION PARAMETER - CP

(There is only one parameter in this section) Only seen if optional communications is ordered.

PARAMETER PARAMETER DEFAULT

CODE DESCRIPTION SETTINGS OR RANGE SETTING

CAd Communication Address 0 to 247 0

NOTE: Communications Bit Rate is fixed at 9600 baud.

20

Page 21

4.3 TEST MODE - TEST

To enter the Test mode, press SCROLL until tESt shows on the display. Press DOWN to enter the Test mode. Press

SCROLL to display the various tests (diSP and Chrt). Press DOWN to enter a test section.

4.3.1 Display, Keypad, and Relay Test

Once you enter the Display/Keypad/Relay test by depressing DOWN, the display should first show all 8s with decimal points

and all status LEDs lit for about 5 seconds. Then the display will go blank for 5 seconds.

Then the display will show SCrL. Depress the SCROLL key to proceed with the keypad test.

The display will show UAro. Depress the UP arrow key to proceed with the keypad test.

The display will show dAro. Depress the DOWN arrow key to complete the keypad test.

The display will show rLy while the instrument does the relay test. Each output relay will be energized in sequence for about 4

seconds while its status LED (OUT 1/1, OUT 1/2, OUT 2/1, or OUT 2/2) is lit. When complete, rLy will be displayed for 4

seconds and then diSP will be displayed.

4.3.2 Chart Test -

Running the Chart Test will produce a test pattern drawn by the pens on the chart with the chart advancing.

After entering the test by pressing DOWN, the green pen will go toward the home position and the red pen will go toward the

outside of the chart. The chart will rotate at roughly 1 revolution every 1.5 minutes. Both pens will travel about 80% of the

chart in about 15 seconds, and then reverse their travel, and return to their initial position. This process will continue to be

repeated.

Depress any key to terminate the Chart test. The pen(s) will go to the home position and then Chrt will be displayed.

Chrt

- diSP

21

Page 22

Section 5 Recorder Calibration Mode - CAL

As covered in Section 4, the "calibration seal" may need to be removed to access the MODE switch to gain access to the

calibration section. The MODE switch must be positioned to the PROG/TEST/CAL position.

CAUTION: DO NOT ATTEMPT ANY CALIBRATIONS WITHOUT THE PROPER TEST EQUIPMENT THAT MEETS OR

EXCEEDS THE SPECIFICATIONS LISTED.

The Calibration mode provides for the calibration of all the input types for each input as well as the calibration of each pen to

the chart.

The Input Calibration can be performed for

ONLY the Input Type selected in the Program Mode Input Selection code InPS. See below:

Input Type JU1 JU2 InPS

Thermocouple DOWN DOWN "1"

RTD PARK PARK "11"

mV PARK PARK "14"

mA MIDDLE MIDDLE "12"

V UP UP "17"

ONLY the Input Type selected bt the hardware jumpers JU1 and/or JU2 AND

5.1 INPUT CALIBRATION - inP

EQUIPMENT REQUIRED:

Input source with accuracy better than±0.05% of reading.

Thermoucouple: 1 J type

1 mercury thermometer ±.25ºF or equivalent

Allow 30 minutes of warm up time for the instrument with the T/C connected before

proceeding with calibration

DC: 0 to 50mV or

0 to 5V or

0 to 20mA

RTD: Decade resistance box with .01% resolution or equivalent.

PROCEDURE:

Position the input conditioning jumpers (JU1 for Pen 1 and JU2 for Pen 2) for the proper input (T/C, RTD, mV, mA or V). Be

sure that the Input Selection parameter InPS in Program Mode has been set correctly.

To enter the Calibration mode, depress SCROLL until CAL appears on the display. Press DOWN to enter the Calibration

mode. Depressing SCROLL will display the following Calibration sections: inP and Chrt. inP is the input calibration section

and Chrt is the Chart calibration section. Press DOWN to enter the desired section when it is displayed.

The Input Calibration section is divided into four sections: PEn, rAng, rEF, and SCAn. PEn selects the pen/input to be

calibrated, rAng selec!ts the input type (T/C, RTD, etc.) to be calibrated, rEF defines the source value to be applied, and

SCAn performs the actual calibration.

A 50mV Input calibration must be performed before the Cold Junction Compensation Calibration can be performed.

With PEn displayed, depress the SCROLL key to display the pen/input selected. Use the UP or DOWN keys to select 1 or 2,

then depress the SCROLL key and rAng should be displayed.

With rAng displayed, depress the SCROLL key to show the range code of the input type to be calibrated. The range codes

are shown below. Use the UP or DOWN keys to select the range to be calibrated:

0=None, means no calibration will be performed.

1=50 millivolts for all millivolt and thermocouple ranges.

2=5 volts for all volt ranges.

22

Page 23

3=Milliamp for all milliamp ranges.

4=RTD for all RTD ranges.

5=Cold Junction Compensation for all T/C ranges.

After selecting the proper range code, depress the SCROLL key and rEF should be displayed.

With rEF displayed, depress the SCROLL key to display the value for the source to be connected. Connect the input source

set for this value to the selected input terminals. After connecting the source, depress the SCROLL key and SCAn should be

displayed. When rAng selected is 5, connect the J type thermocouple to the input terminals. Position the "HOT" junction

outside the enclosure with the mercury thermometer position along side. Using the UP or DOWN keys, make the display

match the reading seen on the mercury thermometer.

With SCAn displayed, depress the SCROLL key. The display will count up in seconds, denoting that it is proceeding with the

calibration. When the calibration is complete, the display will show PEn.

With PEn displayed, depress the SCROLL key to select another pen, or UP to return to inP.

If something fails in the process, FAIL will be displayed. Depress any key to return to the inP display.

The reference values needed to calibrate each input type are as follows:

CODE REFERENCE VALUE

1-millivolt/TC 50.00mV ±0.01mV

2-volt 5.00 Volts ±0.01V

3-milliamp 20.00mA ±0.01mA

4-RTD 200.0ohms ±0.01%

5-T/C AMBIENT

5.2 CHART/PEN CALIBRATION - Chrt

This Cal section calibrates the pens to the chart, and is divided into two additional sections: PEn and ArC. PEn calibrates the

pen spans to the chart. ArC provides a capability to make the pens sweep the chart to facilitate mechanical adjustments of

pen arms.

PEN SPAN CALIBRATION

With Chrt in the display, press DOWN to enter the Chart calibration section and PEn will be displayed. Depressing the

SCROLL key will toggle between PEn and ArC. With PEn in the display, press DOWN to enter the Pen Span calibration

section. Each pen will home (move downscale), and the display will blank (this could take as long as 20 seconds). The

display will show P1Lo.

With P1Lo displayed, Pen 1 will be positioned at the low end of the chart. Use UP or DOWN to position Pen 1, the red pen, on

the inner ring of the chart. Press SCROLL when done.

The display will now show P1Hi and the red pen will go to the outer ring of the chart. Again, use UP or DOWN to adjust the

pen. Press SCROLL when done.

If Pen 2 is included, the same process must be repeated for Pen 2, the green pen. After P2Hi is completed, depressing

SCROLL will return to PEn.

If Pen 2 is not included, press SCROLL twice to skip P2Lo and P2Hi calibration, and return to PEn.

- PEn

23

Page 24

PEN ARC MECHANICAL ADJUSTMENTS

Important Note:

Pen arc adjustments have been done at the factory and should not need to be done in the field, unless the pen arm

adjustments (mechanical) have been compromised. (This can happen if the pens are forcibly moved.)

Adjustments can be made at the bottom or top of span. In either position, the arm "length" can be adjusted by moving the pen

blade toward or away from the pivot point, but the pen tip should also line up with the inner or outer ring of the chart. The

latter is referred to as "position". Only the red pen can be adjusted to draw the correct arc. It is not mechanically possible for

the green pen to draw the correct arc if the red pen is adjusted to do so.

With Chrt in the display, press DOWN to enter the Chart calibration section and PEn will be displayed.

With PEn displayed, depressing the SCROLL key will toggle between PEn and ArC. With ArC in the display, press DOWN to

enter the Pen Arc adjustment section. During arc calibration/adjustment, ArC will remain in the display. The pens will move to

the home position and the red pen will then draw an arc upscale.

If the pen is upscale, pressing the DOWN key will cause the selected pen to move downscale. If it is already downscale, the

DOWN key will cause the chart to advance. If the pen is downscale, pressing the UP key will cause it to move upscale. If it is

already upscale, the UP key will cause the chart to advance. Adjust the red pen's "length" and "position" on the inner/outer

ring as needed. Repeat this sequence until the red pen is properly adjusted.

When finished with the red pen, press SCROLL to adjust the green pen. For the green pen, the "length" should be adjusted

so that it almost touches the red pen when they pass each other. Adjust the "position" to align with the inner/outer ring. When

finished with the green pen, press SCROLL to exit. P1Lo will be displayed, as the Pen Span calibration must now be done.

- ArC

Section 6 Model Number Changes

When adding options to the recorder in the field, it is necessary to change the model number contained within the memory of

the recorder.

The model number is displayed during the power up sequence. The first 8 digits of the model number are displayed in two 4

digit steps. The first displayed value will be the prefix 5, the first pen option, second pen option, and pen 1 output (the first 4

digits of the model number). The next display will show the pen 2 output, communications, case, and voltage options present

on the recorder.

To change the model number, set the MODE switch to the PROG/TEST/CAL position, and power down and power up the

recorder. After the software revision is displayed while the pen(s) go to the home position, the first 4 digits of the model

number will be displayed. Use UP or DOWN to change the number. Press SCROLL and the next 4 digits of the model

number will be shown. Again use UP or DOWN to change the number. Make sure the model number is correct for the

hardware options present.

When complete, depress SCROLL. Refer to section 4.2 to make any programming changes required by the change in

hardware options.

24

Page 25

Appendix A - Model Number Matrix

5

FIRST PEN OPTION

1 Recorder Only

2 Controller

4 High/Low Limit*

SECOND PEN OPTION

0 None

1 Recorder Only

2 Controller

4 High/Low Limit*

PEN 1 OUTPUTS

0 None

1 One Alarm Relay

2 Two Alarm Relays

PEN 2 OUTPUTS

0 None

1 One Alarm Relay

2 Two Alarm Relays

COMMUNICATIONS

0 None

1 Configurator Port

2 RS-485 Coms

3 Configurator Port &

RS-485 Coms

SUFFIX

Blank None

AA Alarms And Communications

Connectivity Option

(Allows for later field installation

of both options)

VOLTAGE

1 Standard (90-264 VAC)

2 Low Voltage**

3 Standard Voltage Operation

and Transmitter Power Supply

4 Low Voltage Operation

and Transmitter Power Supply

* Does not include a relay. Order relays in output options.

** Low Voltage is 20-50 VAC or 22-65 VDC

† Consult factory for availability

CASE

1 Standard - NEMA 3

2 Door Lock

3 NEMA 4X

†

25

Page 26

Appendix B - Specifications

INPUTS

Input Types/Range Type Range

Thermocouple J 0°C to 760°C0°F to 1400°F

K0°C to 1360°C0°F to 2500°F

T -200°C to 400°C -330°F to 750°F

R 200°C to 1650°C 400°F to 3000°F

S 200°C to 1650°C 400°F to 3000°F

RTD 100 ohm Platinum -140°C to 400°C -220°F to 750°F

.00385 ohms/ohm/°C

Current DC 0 to 20mA, 4 to 20mA

Internal 4.7 ohm Shunt Resistor

Voltage DC 0 to 25mV, 0 to 50mV, 10 to 50mV, 0 to 5 V, 1 to 5 V

Impedance > 100M ohm for TC and mV inputs

100K ohms for 5V inputs

4.7 ohms for mA inputs

RTD Excitation Current 150 microamps, typical

Input Scan Rate 1 scan per second for non-RTD inputs

1 scan per 1.2 seconds for RTD inputs

Input Correction Offset Adjustment, -999 to 999 units

Sensor Fault Detection Display goes to "SnSr" and pen goes upscale if a sensor break is detected

No sensor break can be detected for zero based Volt and Milliamp ranges

Display goes to "Hi" 10% above span.

Display goes "Lo" 10% below span or zero, whichever is higher.

INPUT PERFORMANCE

Performance Under Reference Condition:

Measurement Error Type J, K, T, R, S, and RTD: ±0.25% of span ±1 degree

mA, mV, and VDC: ±0.25% of scaled span plus 1 least significant digit

Cold Junction Compensation Error ±0.2°C @ 25°C

Cold Junction Compensation Rejection 0.04°/°C deviation from 25°C

Linearization Error TCs: ±0.25°C typical, ±0.5°C worst case with expectations

RTDs: ±0.1°C typical, ±0.3°C worst case

Ambient Temperature Error ±0.01% of span per°C deviation from 25°C

Common Mode Rejection >120 dB at 50/60 Hz, 260 VAC max.

Normal Mode Rejection 85 dB minimum @60Hz or greater

Isolation Universal input isolated from all outputs at 240VAC

Inputs share a common signal ground

Reference Conditions

Ambient Temperature 25°C

Relative Humidity 60 - 70%

Supply Voltage 115 VAC, 60 Hz

Source Resistance < 10 ohms for TC input

Lead Resistance < 0.1 ohm/lead balanced (Pt100)

.

26

Page 27

RECORDING

Pen Type Disposable fiber tip

Pen Color Pen 1 - Red

Pen 2 - Green

Chart Size 10 inch

Chart Drive Stepper motor

Chart Rotation User configurable: 8 hours, 12 hours, 24 hours, 48 hours, or 7 days

Chart Span Bottom and top of span, -9999 to 9999 units

RECORDING PERFORMANCE

Chart Recording Accuracy 0.5% of chart span reference accuracy

Chart Rotation Accuracy ± 0.5% of rotation time, assuming all backlash removed

OPERATOR INTERFACE

Display Four digit, 0.56" high, red, seven segment, LED display

Status Indicators Four red LED alarm status indicators, One green LED Pen 2 indicator

Keypad Three keys for programming and unit operation

Display Modes Normal: Process value(s) or blank

CONTROL OUTPUTS

Number Up to two control outputs for each of two inputs

Type On/Off, Reverse or Direct Acting

Hysteresis Fully adjustable, 0 to 200 units, First output straddles setpoint, second output

setpoint plus or minus 1/2 hysteresis and setpoint plus or minus 11/2 hysteresis

ALARMS

Number Up to two process alarms for each of two inputs

Type Process high or low

Limit Device Optional high/low limits for each input with latching output

Normally open output latches open

Red reset button included to the right of the display

Hysteresis Fully adjustable, 0 to 200 units, single sided

Security Alarm setpoint changes can be prohibited

Sensor Fault Action Alarms work normally in "Hi" and "Lo" conditions

Alarm relays are deenergized in a "SnSr" sensor break condition

RELAY OUTPUTS

Relays SPDT, contacts rated 5 amps resistive at 115 VAC,

2.5 amps resistive at 230 VAC, 1/8 HP at 230 VAC (single phase),

250 VA at 115/230

POWER REQUIREMENTS

Line Voltage 90-264 VAC, 50/60 Hz

Optional: 20-50 VAC, 50/60 Hz or 22-65 VDC

Power Consumption: 18 VA Maximum

27

Page 28

TRANSMITTER POWER SUPPLY

Transmitter Power Supply Provides up to 40mA of current at 24VDC

CONSTRUCTION

Enclosure Injection molded Noryl case and cover with acrylic window

NEMA Rating NEMA 3 standard, NEMA 4X future option

Conduit Openings Three openings on the right side

Mounting Panel or wall

Overall Dimensions 14" wide X 14" high X 3.8" deep.

(355.6mm X 355.6mm X 96.5mm)

Panel Cutout 12.7" wide X 12.7" high

(322.58mm X 322.58mm)

Panel Depth 2.5" (63.5mm)

Panel Protrusion 1.3" (33.0mm)

Weight 7 lbs maximum

Retrofit With adaptor plate, will fit Partlow MRC 7000/ARC 4100 cutout

EVIRONMENTAL AND OPERATING CONDITIONS

Operating Temperature 0°C to 55°C (32°F to 122°F)

Storage Temperature -40°C to 65°C (-4°F to 149°F)

Humidity 10 to 90% RH, non-condensing

Vibration 0.3 to 100 Hz @ 0.2g

Mounting Position Up to 30° forward or backward tilt from vertical

Up to 10° side tilt from vertical

DIGITAL COMMUNICATONS

Configuration Port TTL levels

Communications Port RS-485 serial communications, Half-duplex

Protocol MODBUS RTU

Bit Rate 9600 bits per second

Parity Odd

Address User configurable - 0 to 247

GENERAL REFERENCE DATA

Data Backup EEPROM for configuration parameters and calibration data

EEPROM for alarm setpoints

Warranty Two years

APPROVALS AND COMPLIANCE

Safety UL Approved for USA - UL 1092, UL 916, and QUXY - File E67237

UL Certified for Canada - CSA Spec 142 - File E67237

CE - Complies with EN 61010-1:1993: Pending

Immunity/Susceptability CE - Complies with EN50082-1992: Pending

Emissions CE - Complies with EN50081-1: 1992 and EN50081-2:1994: Pending

Limit Device FM: Pending

28

Page 29

NOTES

1. Linearization accuracy is based on conformance to NIST Monograph 175 (based on the ITS-90) for letter-designated

thermocouple types, or other industry standards for RTDs.

2. Factory Calibration is defined by limits of repeatability in a manufacturing environment and ± 0.15°C for thermocouple

29

Page 30

NOTES

Page 31

Warranty and Return Statement

These products are sold by The Partlow-West Company under the warranties set forth in the following paragraphs. Such

warranties are extended only with respect to a purchase of these products, as new merchandise, directly from The PartlowWest Company or from a Partlow Brand distributor, representative or reseller, and are extended only to the first buyer thereof

who purchases them other than for the purpose of resale.

Warranty

These products are warranted to be free from functional defects in materials and workmanship at the time the products leave

the The Partlow-West Company factory and to conform at that time to the specifications set forth in the relevant Partlow Brand

instruction manual or manuals, sheet or sheets, for such products for a period of two years.

THERE ARE NO EXPRESSED OR IMPLIED WARRANTIES WHICH EXTEND BEYOND THE WARRANTIES HEREIN AND

ABOVE SET FORTH. THE PARTLOW-WEST COMPANY MAKES NO WARRANTY OF MERCHANTABILITY OR FITNESS

FOR A PARTICULAR PURPOSE WITH RESPECT TO THE PRODUCTS.

Limitations

The Partlow-West Company shall not be liable for any incidental damages, consequential damages, special damages, or any

other damages, costs or expenses excepting only the cost or expense of repair or replacement as described above.

Products must be installed and maintained in accordance with The Partlow-West Company instructions. Users are responsible for the suitability of the products to their application. There is no warranty against damage resulting from corrosion,

misapplication, improper specifications or other operating condition beyond our control. Claims against carriers for damage in

transit must be filed by the buyer.

This warranty is void if the purchaser uses non-factory approved replacement parts and supplies or if the purchaser attempts

to repair the product themselves or through a third party without ThePartlow-West Company authorization.

Returns

The Partlow-West Company’s sole and exclusive obligation and buyer’s sole and exclusive remedy under the above warranty

is limited to repairing or replacing, free of charge, the products which are reported in writing to ThePartlow-West Company at

its main office indicated below.

The Partlow-West Company is to be advised of return requests during normal business hours and such returns are to include

a statement of the observed deficiency. The buyer shall pre-pay shipping charges for products returned and The PartlowWest Company or its representative shall pay for the return of the products to the buyer.

Approved returns should be sent to: THE PARTLOW-WEST COMPANY

2 CAMPION ROAD

NEW HARTFORD, NY 13413 USA

Page 32

THE PARTLOW-WEST COMPANY

2 CAMPION ROAD • NEW HARTFORD, NY 13413 USA

1-800-866-6659 • 315-797-2222 • FAX 315-797-0403

Loading...

Loading...