Page 1

1/32-DIN TEMPERATURE CONTROLLER

INSTALLATION, WIRING AND OPERATION MANUAL

FORM 3882

Page 2

This manual is intended for use in support of installation, commissioning

and configuration of the 1/32-DIN Temperature Controller.

The procedures described in this manual should be undertaken only by

personnel competent and authorized to do so.

Form 2 Edition 1

Page 3

Table of ContentsTable of Contents

Table of Contents

Table of ContentsTable of Contents

PagePage

Page

PagePage

Section 1 - Installation - Panel-MountingSection 1 - Installation - Panel-Mounting

Section 1 - Installation - Panel-Mounting

Section 1 - Installation - Panel-MountingSection 1 - Installation - Panel-Mounting

1.1 Unpacking the Instrument 5

1.2 Installing the Controller in the Mounting Panel 6

Section 2 - Installation - Wiring ConnectionsSection 2 - Installation - Wiring Connections

Section 2 - Installation - Wiring Connections

Section 2 - Installation - Wiring ConnectionsSection 2 - Installation - Wiring Connections

2.1 Mains (Line) Supply 8

2.2 Low V oltage (24V AC/DC) Supply - Option 8

2.3 Thermocouple Input 9

2.4 RTD Inputs 9

2.5 DC Inputs 9

2.6 Relay Outputs (Output 2 & Output 3) 9

2.7 SSR Drive Output (Output 1) 10

2.8 RS485 Communications 10

Section 3 - Front PanelSection 3 - Front Panel

Section 3 - Front Panel

Section 3 - Front PanelSection 3 - Front Panel

3.1 Indicators 11

3.2 Keys 11

Section 4 - Instrument ConfigurationSection 4 - Instrument Configuration

Section 4 - Instrument Configuration

Section 4 - Instrument ConfigurationSection 4 - Instrument Configuration

4.1 Entry into Instrument Configuration Mode 13

4.2 Parameter Sequence 13

4.3 Exit from Instrument Configuration Mode 18

Section 5 - Operation ModeSection 5 - Operation Mode

Section 5 - Operation Mode

Section 5 - Operation ModeSection 5 - Operation Mode

5.1 Normal Operation (Yellow LED OFF) 20

Section 6 - Control Setup (Yellow LED ON)Section 6 - Control Setup (Yellow LED ON)

Section 6 - Control Setup (Yellow LED ON)

Section 6 - Control Setup (Yellow LED ON)Section 6 - Control Setup (Yellow LED ON)

6.1 Adjustment Ranges 23

6.2 Default V alues/Settings 23

Section 7 - Calibration ModeSection 7 - Calibration Mode

Section 7 - Calibration Mode

Section 7 - Calibration ModeSection 7 - Calibration Mode

7.1 Pre-Requisites 24

7.2 Entry into Calibration Mode 25

7.3 Calibration Procedure 26

7.4 Exiting Calibration Mode 27

AppendixAppendix

Appendix

AppendixAppendix

A - Product Specification 28

Edition 1 3 Form

Page 4

Figures & TablesFigures & Tables

Figures & Tables

Figures & TablesFigures & Tables

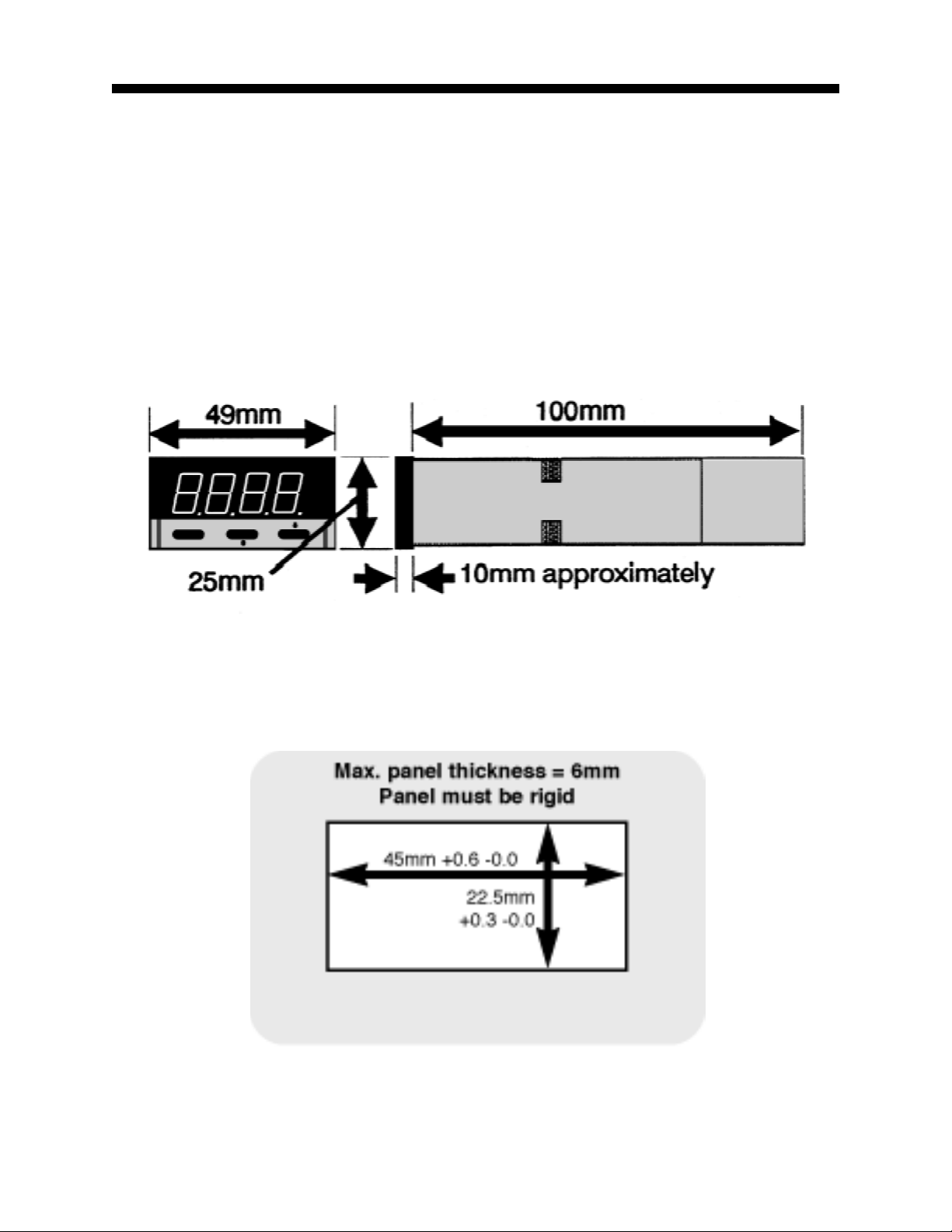

Figure 1-1 Main Dimensions 5

Figure 1-2 Panel Cut-out Dimensions 5

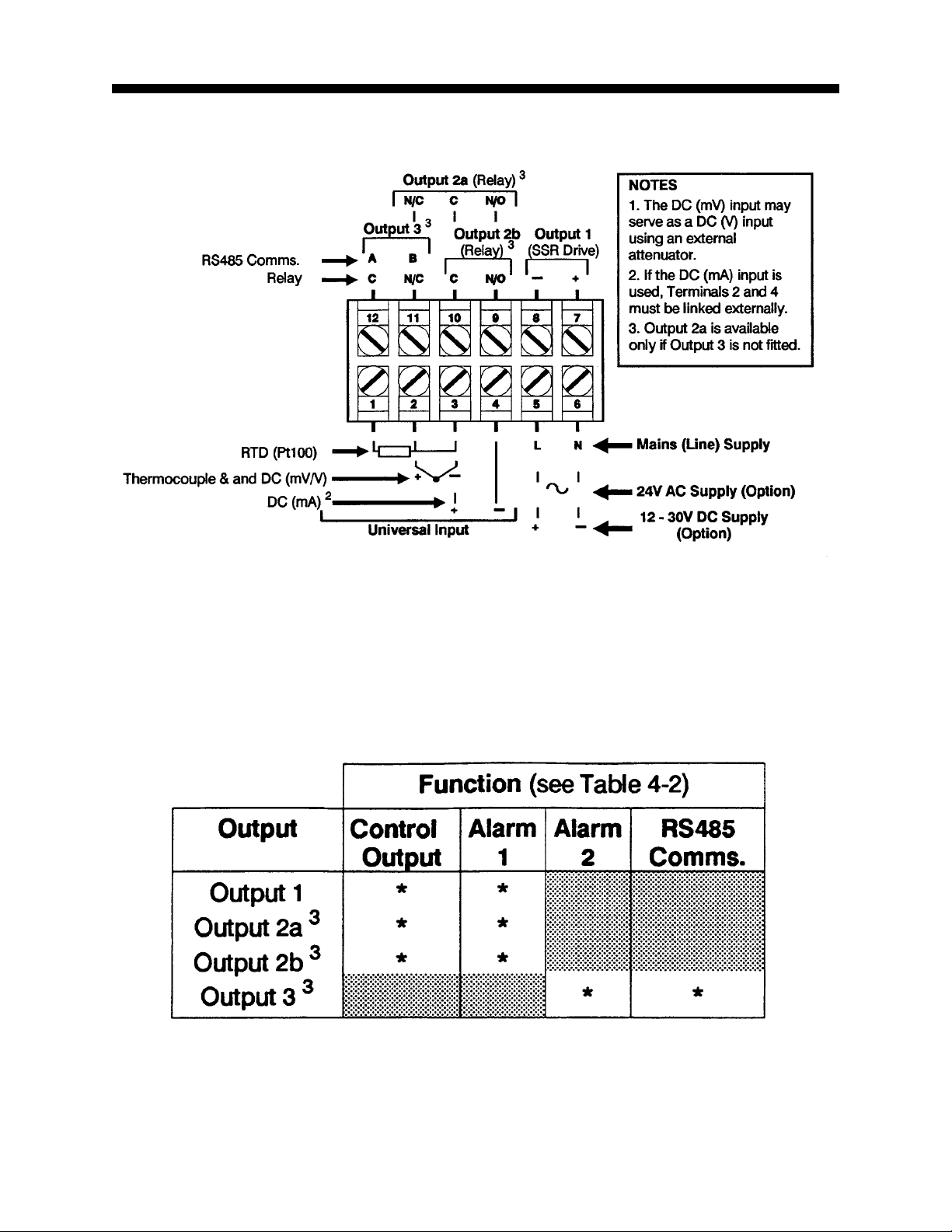

Figure 2-1 Rear Terminal Connections 7

Figure 2-2 Mains (Line) Supply Connections 8

Figure 2-3 Low Voltage AC/DC Supply Connections 9

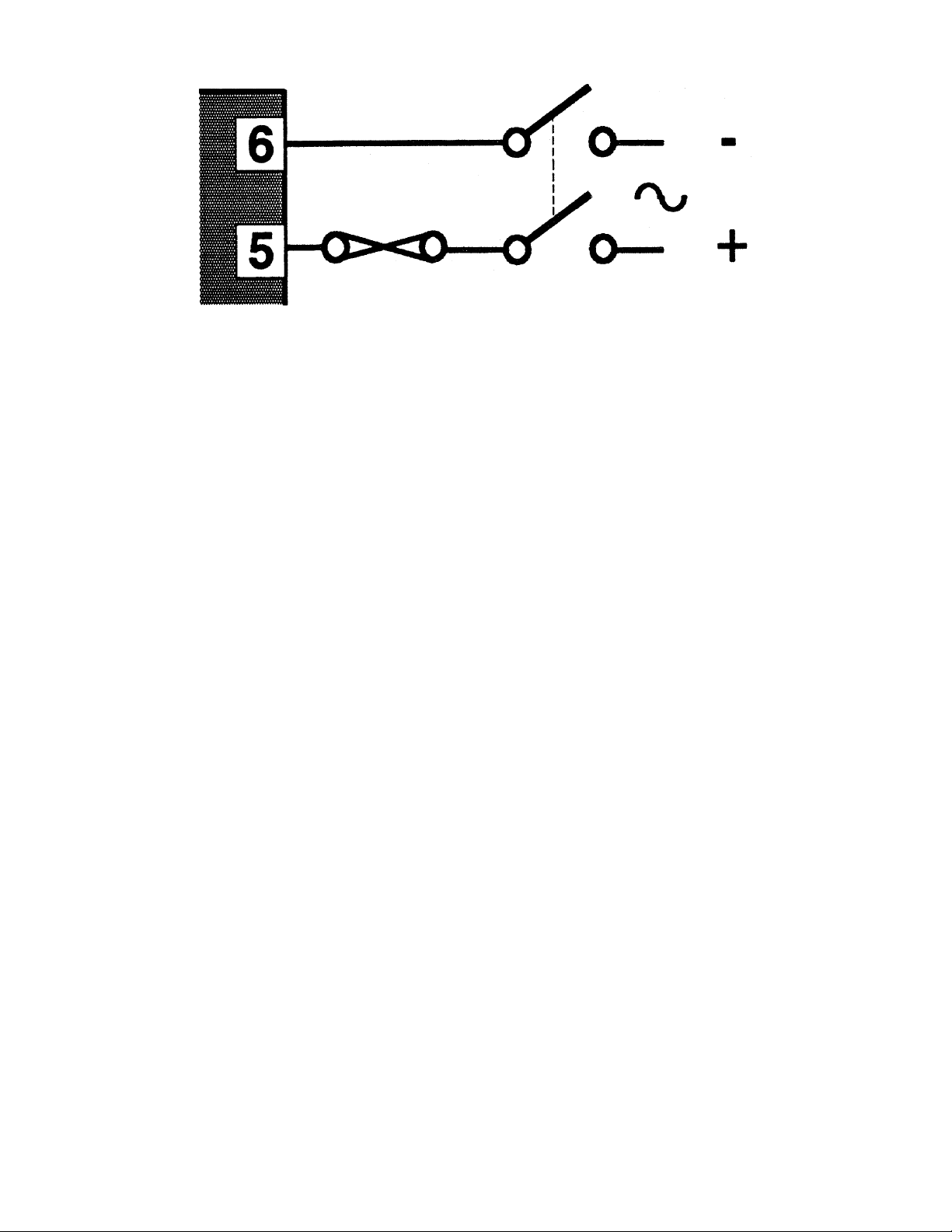

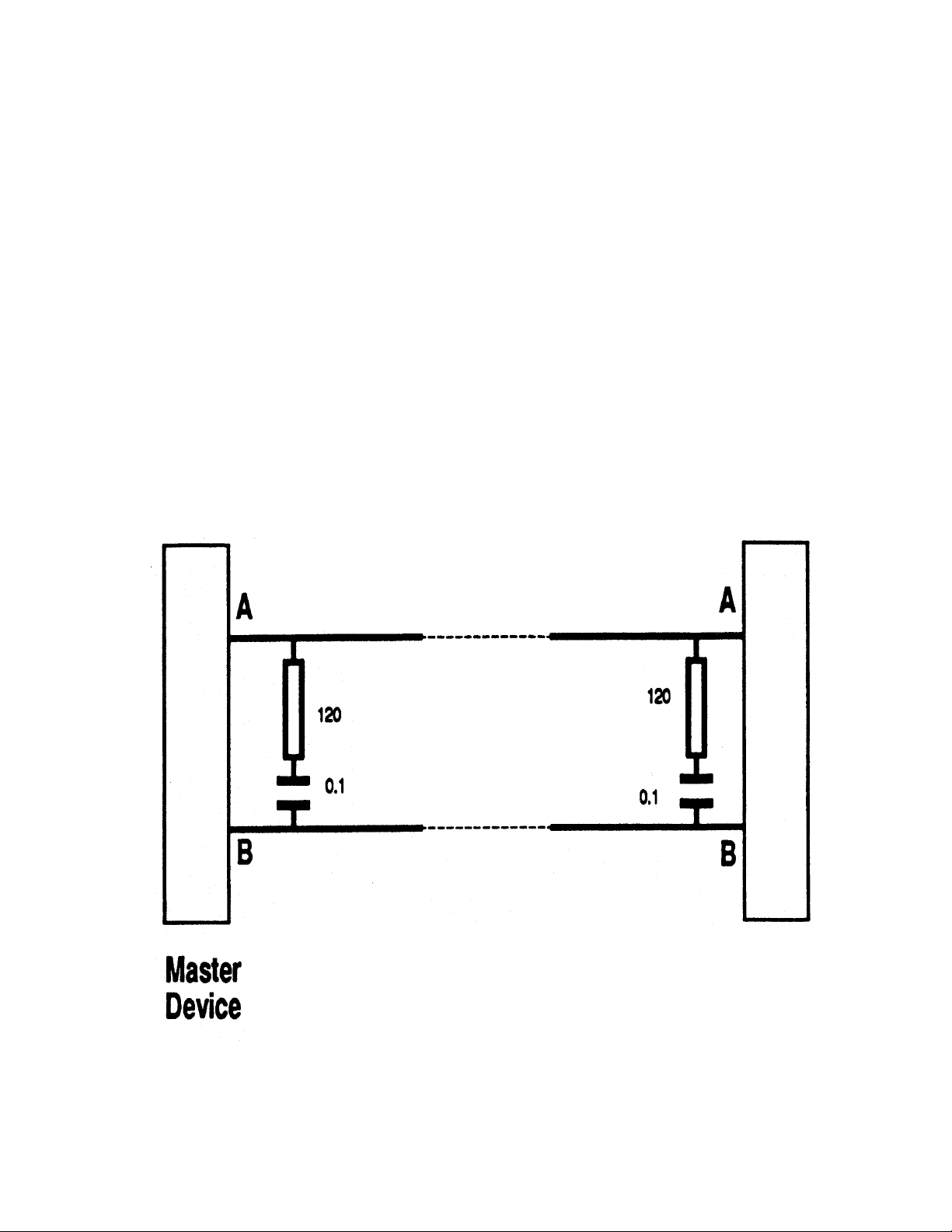

Figure 2-4 RS485 Line Termination 10

Table 4-1 Sensor Selection Codes 17

Table 4-2 Output Selection Codes 17

Form 4 Edition 1

Page 5

Installation - Panel-MountingInstallation - Panel-Mounting

Installation - Panel-Mounting

Installation - Panel-MountingInstallation - Panel-Mounting

1.11.1

1.1

1.11.1

1. Remove the Controller from its packing. A panel gasket and a “no tools

required” fixing strap are supplied. Retain the packing for future use (e.g.

moving the Controller to a different site).

2. Examine the delivered items for damage or deficiencies. If any is found,

notify the carrier immediately. Check that the Product Code on the label

affixed to the Controller housing corresponds to that ordered.

UNPACKING THE INSTRUMENTUNPACKING THE INSTRUMENT

UNPACKING THE INSTRUMENT

UNPACKING THE INSTRUMENTUNPACKING THE INSTRUMENT

FIGURE 1-1FIGURE 1-1

FIGURE 1-1 Main Dimensions

FIGURE 1-1FIGURE 1-1

FIGURE 1-2FIGURE 1-2

FIGURE 1-2 Panel Cut-out Dimensions

FIGURE 1-2FIGURE 1-2

Edition 1 5 Form

Page 6

1.21.2

1.2

1.21.2

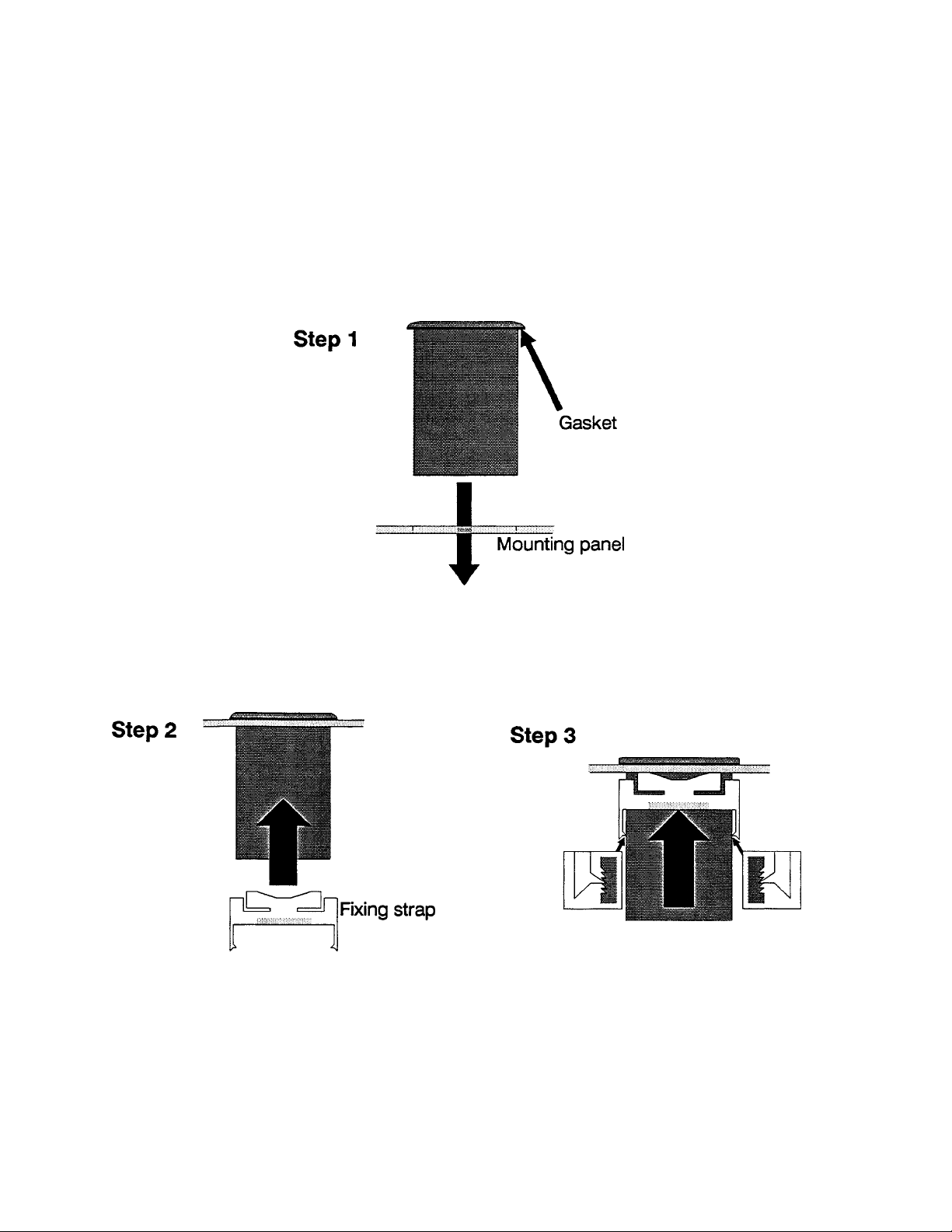

INSTALLING THE CONTROLLER IN THE MOUNTING PANELINSTALLING THE CONTROLLER IN THE MOUNTING PANEL

INSTALLING THE CONTROLLER IN THE MOUNTING PANEL

INSTALLING THE CONTROLLER IN THE MOUNTING PANELINSTALLING THE CONTROLLER IN THE MOUNTING PANEL

CAUTION: Do not remove the front panel gasket from the Controller , as this

may cause inadequate clamping of the Controller to the mounting panel.

Ensure that this gasket is not distorted and that the Controller is positioned

squarely against the mounting panel. Apply pressure to the front panel

bezel only .

Controller

Form 6 Edition 1

Page 7

Installation - Wiring ConnectionsInstallation - Wiring Connections

Installation - Wiring Connections

Installation - Wiring ConnectionsInstallation - Wiring Connections

FIGURE 2-1FIGURE 2-1

FIGURE 2-1 Rear Terminal Connections

FIGURE 2-1FIGURE 2-1

Edition 1 7 Form

Page 8

2.12.1

2.1

2.12.1

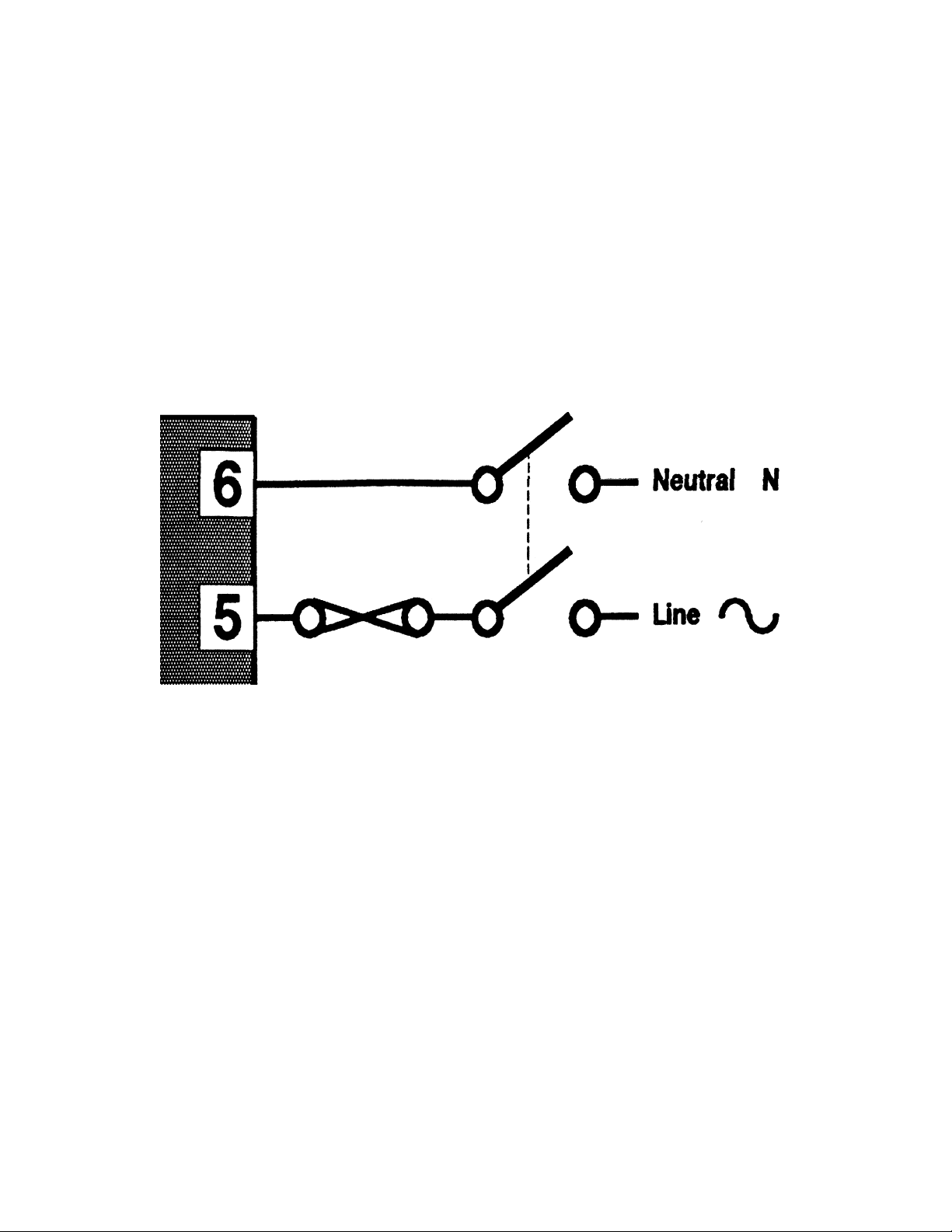

MAINS (LINE) SUPPLYMAINS (LINE) SUPPLY

MAINS (LINE) SUPPLY

MAINS (LINE) SUPPLYMAINS (LINE) SUPPLY

This version of the Controller will operate on a 96 - 264V AC 50/60Hz mains

(line) supply. The power consumption is approximately 4W.

CAUTION: This equipment is designed for installation in an enclosure

which provides adequate protection against electric shock. Local

regulations regarding electrical installation should be rigidly observed.

Consideration should be given to prevention of access to the power

terminations by unauthorized personnel. Power should be connected via a

two-pole isolating switch (preferably situated near the Controller) and a 1A

fuse, as shown in Figure 2-2.

FIGURE 2-2FIGURE 2-2

FIGURE 2-2 Mains (Line) Supply Connections

FIGURE 2-2FIGURE 2-2

If the contacts of the relay output(s) are used to carry mains (line) voltage, it

is recommended that the relay contacts mains (line) supply should be

switched and fused in a similar manner but should be separate from the

Controller mains (line) supply.

2.22.2

2.2

2.22.2

LOW VOLTAGE (24V AC/DC) SUPPLY - OPTIONLOW VOLTAGE (24V AC/DC) SUPPLY - OPTION

LOW VOLTAGE (24V AC/DC) SUPPLY - OPTION

LOW VOLTAGE (24V AC/DC) SUPPLY - OPTIONLOW VOLTAGE (24V AC/DC) SUPPLY - OPTION

This version of the Controller will operate on 12 - 24V AC 50/60Hz or 12 30V DC supply . The power consumption is approximately 4W. The

connections are shown in Figure 2-3; these should be made via a two-pole

isolating switch and a 315mA slow-blow (anti-surge Type T) fuse.

Form 8 Edition 1

Page 9

FIGURE 2-3FIGURE 2-3

FIGURE 2-3 Low Voltage AC/DC Supply Connections

FIGURE 2-3FIGURE 2-3

2.32.3

2.3

2.32.3

THERMOCOUPLE INPUTTHERMOCOUPLE INPUT

THERMOCOUPLE INPUT

THERMOCOUPLE INPUTTHERMOCOUPLE INPUT

The correct type of thermocouple extension leadwire or compensating cable

must be used for the full distance between the Controller and the thermocouple, ensuring that the correct polarity is observed throughout. Joints in

the cable should be avoided, if possible.

NOTE: Do not run the thermocouple cables adjacent to power-carrying

conductors. If the wiring is run in a conduit, use a separate conduit for the

thermocouple wiring. If the thermocouple is grounded, this must be done at

one point only. If the thermocouple extension lead is shielded, the shield

must be grounded at one point only.

2.42.4

2.4

2.42.4

RTD INPUTSRTD INPUTS

RTD INPUTS

RTD INPUTSRTD INPUTS

The compensating lead should be connected to Terminal 3. For two-wire

RTD inputs, Terminals 2 and 3 should be linked. The extension leads should

be of copper and the resistance of the wires connecting the resistance

element should not exceed 5 ohms per lead (the leads should be of equal

length).

2.52.5

2.5

2.52.5

DC INPUTSDC INPUTS

DC INPUTS

DC INPUTSDC INPUTS

DC (mV) inputs are connected to Terminals 2 and 3 in the polarity shown in

Figure 2-1; DC (V) inputs are connected to the same terminals with the

same polarity but require an external attenuator. DC (mA) inputs are connected to Terminals 3 and 4 in the polarity shown in Figure 2-1 with Terminals 2 and 4 linked externally.

2.62.6

2.6

2.62.6

RELAY OUTPUTS (OUTPUT 2 & OUTPUT 3)RELAY OUTPUTS (OUTPUT 2 & OUTPUT 3)

RELAY OUTPUTS (OUTPUT 2 & OUTPUT 3)

RELAY OUTPUTS (OUTPUT 2 & OUTPUT 3)RELAY OUTPUTS (OUTPUT 2 & OUTPUT 3)

The contacts are rated at 2A resistive at 120/240V AC.

Edition 1 9 Form

Page 10

2.72.7

2.7

2.72.7

This output produces a time-proportioned non-isolated DC signal (0 - 10V

nominal, into 500Ω minimum).

SSR DRIVE OUTPUT (OUTPUT 1)SSR DRIVE OUTPUT (OUTPUT 1)

SSR DRIVE OUTPUT (OUTPUT 1)

SSR DRIVE OUTPUT (OUTPUT 1)SSR DRIVE OUTPUT (OUTPUT 1)

2.82.8

2.8

2.82.8

The “A” terminal (Terminal 12) on the Controller should be connected to the

“A” terminal on the master device; the “B” terminal (Terminal 11) on the

Controller should be connected to the “B” terminal on the master device.

This instrument uses standard RS485 devices, isolated from all other inputs

and outputs. The devices present a 1/4-unit load to the RS485 line. Generally, termination will not be required but may be necessary for line lengths

greater than 100 metres. Where termination is necessary, it is recommended that a 120Ω resistance in series with a 0.1µF capacitor be used at

each end of the line (see Figure 2-4).

RS485 COMMUNICATIONSRS485 COMMUNICATIONS

RS485 COMMUNICATIONS

RS485 COMMUNICATIONSRS485 COMMUNICATIONS

Controller

FIGURE 2-4FIGURE 2-4

FIGURE 2-4 RS485 Line Termination

FIGURE 2-4FIGURE 2-4

Form 10 Edition 1

Page 11

Front PanelFront Panel

Front Panel

Front PanelFront Panel

3.13.1

3.1

3.13.1

3.23.2

3.2

3.23.2

INDICATORSINDICATORS

INDICATORS

INDICATORSINDICATORS

KEYSKEYS

KEYS

KEYSKEYS

Green: OFF - PV < SP

ON - PV = SP

Flashing - PV > SP

Yellow: OFF - Normal Operation

ON - Control Setup

Flashing - Instrument Configuration

Red: Flashes when alarm(s) active

Scroll key

All Modes except Calibration:

If parameter value displayed, shows parameter

legend (for 1.5 seconds). If legend displayed,

shows value of next parameter.

Calibration:

Starts calibration phase.

Down key

Normal Operation:

Decrements parameter value. With process variable

displayed, dis-engages Pre-Tune*. Also confirms

request for entry into

Control Setup/Instrument Configuration:

Decrements parameter value.

Calibration:

Steps to previous calibration phase.

Edition 1 11 Form

Instrument Configuration

.

Page 12

Up key

Normal Operation:

Decrements parameter value. With process variable

displayed, requests Pre-Tune*.

Control Setup/Instrument Configuration:

Decrements parameter value.

Calibration:

Steps to next calibration phase.

Scroll & Down keys

Normal Operation:

Enters

Calibration

.

Scroll & Up keys

Normal Operation:

Requests entry into

Normal Operation:

Control Setup

Enters

Control Setup/Instrument

Configuration/Calibration:

Returns to

Normal Operation

Instrument Configuration

Down & Up keys

.

.

.

Form 12 Edition 1

Page 13

Instrument ConfigurationInstrument Configuration

Instrument Configuration

Instrument ConfigurationInstrument Configuration

4.14.1

4.1

4.14.1

ENTRY INTO INSTRUMENT CONFIGURATION MODEENTRY INTO INSTRUMENT CONFIGURATION MODE

ENTRY INTO INSTRUMENT CONFIGURATION MODE

ENTRY INTO INSTRUMENT CONFIGURATION MODEENTRY INTO INSTRUMENT CONFIGURATION MODE

1. Hold down Scroll and Up keys

simultaneously until the display begins to flash.

2. When display begins to flash, release the

Scroll and up keys and press the Down key.

4.24.2

4.2

4.24.2

The Scroll key is used to step through the parameters in the following

manner:

Edition 1 13 Form

PARAMETER SEQUENCEPARAMETER SEQUENCE

PARAMETER SEQUENCE

PARAMETER SEQUENCEPARAMETER SEQUENCE

Page 14

The parameter sequence is as follows:

Scroll key steps through displays; Up/Down keys adjust displayed values.

1. Appears only if sensor selected is DC (mA, Mv or V).

2. Appears only if Comms. configured and fitted.

3. Appears only if Output 3 configured and fitted.

4. Appears only if PID control is configured.

Form 14 Edition 1

Page 15

4.2.14.2.1

4.2.1

4.2.14.2.1

Adjustment RangesAdjustment Ranges

Adjustment Ranges

Adjustment RangesAdjustment Ranges

Continued on next page

Edition 1 15 Form

Page 16

Continued from previous page

Form 16 Edition 1

Page 17

TABLE 4-1TABLE 4-1

TABLE 4-1 Sensor Selection Codes

TABLE 4-1TABLE 4-1

TABLE 4-2TABLE 4-2

TABLE 4-2 Output Selection Codes

TABLE 4-2TABLE 4-2

Edition 1 17 Form

Page 18

4.2.24.2.2

4.2.2

4.2.24.2.2

DEFAULT VALUESDEFAULT VALUES

DEFAULT VALUES

DEFAULT VALUESDEFAULT VALUES

4.34.3

4.3

4.34.3

EXIT FROM INSTRUMENT CONFIGURATION MODEEXIT FROM INSTRUMENT CONFIGURATION MODE

EXIT FROM INSTRUMENT CONFIGURATION MODE

EXIT FROM INSTRUMENT CONFIGURATION MODEEXIT FROM INSTRUMENT CONFIGURATION MODE

To exit from Instrument Configuration Mode:

Hold down the Up and Down keys

for three seconds

The instrument will then return to Normal Operation Mode via an instrument

reset and self-test sequence.

NOTE: If there is no key activity for five minutes in Instrument Configuration

Mode, an automatic return is made to Normal Operation Mode (via an instrument reset and self-test sequence).

Form 18 Edition 1

Page 19

Operation ModeOperation Mode

Operation Mode

Operation ModeOperation Mode

Scroll Key

Down Key

Up Key

INDICATORS

Green:

Yellow:

Red:

Edition 1 19 Form

OFF – Process Variable less than Setpoint

ON – Process Variable equals Setpoint

Flashing – Process Varible greater than Setpoint

OFF – Normal Operation

ON – Control Setup

Flashing – Alarm(s) active

Page 20

5.15.1

5.1

5.15.1

NORMAL OPERATION (Yellow LED OFF)NORMAL OPERATION (Yellow LED OFF)

NORMAL OPERATION (Yellow LED OFF)

NORMAL OPERATION (Yellow LED OFF)NORMAL OPERATION (Yellow LED OFF)

In this mode, the display normally shows the process variable value. Use

the Scroll key to step through a sequence of parameters as follows:

The following parameters are available in Normal Operation.

Form 20 Edition 1

Page 21

5.1.15.1.1

5.1.1

5.1.15.1.1

EASY TUNEEASY TUNE

EASY TUNE

EASY TUNEEASY TUNE

If the Controller has been configured for Easy T une operation, all tuning is

executed automatically; no operator action is required.

5.2.25.2.2

5.2.2

5.2.25.2.2

MANUAL TUNING WITH PRE-TUNEMANUAL TUNING WITH PRE-TUNE

MANUAL TUNING WITH PRE-TUNE

MANUAL TUNING WITH PRE-TUNEMANUAL TUNING WITH PRE-TUNE

When the Controller is configured for Manual T uning, the Pre-T une facility is

available. Pre-T une is used to optimise system start-up (normally after

power-up or after a major change to the process being controlled). To activate Pre-T une:

NOTE: Pre-Tune cannot be activated if the Process Variable is within 5% of

input span from the setpoint.

To dis-engage Pre-Tune:

NOTE: Pre-Tune is a single-shot operation and, therefore, when it is completed, Pre-Tune will dis-engage itself automatically.

Edition 1 21 Form

Page 22

Control Setup (Yellow LED ON)Control Setup (Yellow LED ON)

Control Setup (Yellow LED ON)

Control Setup (Yellow LED ON)Control Setup (Yellow LED ON)

To enter Control Setup mode, press the Up and Down keys simultaneously

for more than three seconds. The same key action exits this mode. The

parameters are as follows:

Form 22 Edition 1

Page 23

6.16.1

6.1

6.16.1

ADJUSTMENT RANGESADJUSTMENT RANGES

ADJUSTMENT RANGES

ADJUSTMENT RANGESADJUSTMENT RANGES

6.26.2

6.2

6.26.2

DEFAULT VALUES/SETTINGSDEFAULT VALUES/SETTINGS

DEFAULT VALUES/SETTINGS

DEFAULT VALUES/SETTINGSDEFAULT VALUES/SETTINGS

Edition 1 23 Form

Page 24

Calibration ModeCalibration Mode

Calibration Mode

Calibration ModeCalibration Mode

The Controller is shipped from the factory ready-calibrated and normally

does not need further calibration. However, some users may have a legal

requirement for annual calibration. The procedures set out in this Section

serve that purpose.

7.17.1

7.1

7.17.1

PRE-REQUISITESPRE-REQUISITES

PRE-REQUISITES

PRE-REQUISITESPRE-REQUISITES

The Calibration Mode has four phases. In addition to the Controller to be

calibrated, each phase requires the appropriate input to be fitted before that

phase is executed. These pre-requisites are shown in the box below.

NOTE: These procedures should be implemented only by personnel competent and authorized to do so.

CALIBRATION PRE-REQUISITES

Phase 1 - DC mV Linear Input: 50mV DC across Terminals 2 & 3 in the

polarity shown in Figure 2-1.

Phase 2 - RTD Input: 200W across Terminals 1 & 2 with com-

pensating lead connected to Terminal 3.

Phase 3 - DC mA Input: 20mA current source connected to Termi-

nals 3 & 4 in the polarity shown in Figure

2-1.

Phase 4 - Thermocouple Input/CJC: 0

Form 24 Edition 1

o

C reference facility , Type K thermocouple leads (or equivalent) connected to

Terminals 2 & 3.

Page 25

7.27.2

7.2

7.27.2

Entry into Calibration ModeEntry into Calibration Mode

Entry into Calibration Mode

Entry into Calibration ModeEntry into Calibration Mode

To enter Calibration Mode:

1. Power-down

the Controller.

3. As the first key action after power-up, hold

down the Scroll and Down keys for at least six

seconds.

2. Power-up the

Controller .

The Controller will then enter the Calibration Mode and will display:

indicating that the first calibration phase is ready to be executed.

Edition 1 25 Form

Page 26

7.37.3

7.3

7.37.3

Calibration ProcedureCalibration Procedure

Calibration Procedure

Calibration ProcedureCalibration Procedure

n Use Up key (step forward) or Down key (step backward) to select required phase.

n Use Scroll key to start selected phase.

n If FAIL displayed, use Up or Down key to return to start of failed phase.

Form 26 Edition 1

Page 27

7.47.4

7.4

7.47.4

EXITING CALIBRATION MODEEXITING CALIBRATION MODE

EXITING CALIBRATION MODE

EXITING CALIBRATION MODEEXITING CALIBRATION MODE

To exit Calibration Mode:

Hold down the Up and Down keys for three

seconds.

The Controller will then return to Normal Operation Mode

NOTE: If there is no key activity for five minutes in Calibration Mode, an

automatic return is made to Normal Operation Mode.

Edition 1 27 Form

Page 28

Appendix AAppendix A

Appendix A

Appendix AAppendix A

Product SpecificationProduct Specification

Product Specification

Product SpecificationProduct Specification

UNIVERSAL INPUTUNIVERSAL INPUT

UNIVERSAL INPUT

UNIVERSAL INPUTUNIVERSAL INPUT

Sample Rate: 4 samples/second

Digital Filter: Filter time constant selectable from front panel. Adjust-

ment range 0.0 to 100.0 seconds in 0.5 second

increments.

Input Resolution: 14-bit resolution approximately. Always at least four

times better than the display resolution.

Input Impedance: >10MΩ resistive.

Isolation: 240V ac isolation from all outputs except SSR Drive.

Input Offset: Adjustable ± input span, subject to display limit on

negative values (-1999).

Thermocouple InputThermocouple Input

Thermocouple Input

Thermocouple InputThermocouple Input

Ranges selectable from the front panel are:

Calibration: Complies with BS4937, NBS125 and IEC584.

Sensor Break Detection: Break detected within two seconds.

Form 28 Edition 1

Page 29

RTD InputRTD Input

RTD Input

RTD InputRTD Input

Ranges selectable from the front panel are:

Type and Connection: Three-wire Pt100.

Calibration: Complies with BS1904 and DIN43760.

Lead Compensation: Automatic scheme.

RTD Sensor Current: 150µA approximately.

Sensor Break detection: Break detected within two seconds.

DC InputDC Input

DC Input

DC InputDC Input

Ranges selectable from the front panel are:

OUTPUTSOUTPUTS

OUTPUTS

OUTPUTSOUTPUTS

Output 1 - SSR Drive (Standard)

Usage: Selectable - may be used as Control Output

or Alarm 1 Output.

Drive Capability: >10Vdc into 500Ω minimum (50mA

maximum).

Isolation: Not isolated from input.

Output 2 - Relay (Standard)Output 2 - Relay (Standard)

Output 2 - Relay (Standard)

Output 2 - Relay (Standard)Output 2 - Relay (Standard)

Usage: Selectable - may be used as Control Output

or Alarm 1 Output.

Contact Type: Single pole, single throw (SPST).

Edition 1 29 Form

Page 30

Rating: 2A resistive at 120/240V ac.

Life: >500,000 operations at rated voltage &

current.

Isolation: Inherent.

Output 3 - Relay or Communications (Options)Output 3 - Relay or Communications (Options)

Output 3 - Relay or Communications (Options)

Output 3 - Relay or Communications (Options)Output 3 - Relay or Communications (Options)

Relay Output

Usage: Selectable - may be used as Alarm 2.

Contact Type: Single pole, single throw (SPST).

Rating: 2A resistive at 120/240V ac.

Life: >500,000 operations at rated voltage &

current.

Isolation: Inherent.

Communications Port

T ype: Serial Asynchronous UAR T -to-UART link.

Data Format: 1 start bit, selectable parity (odd, even or

none), 8 data bits, 1 stop bit.

Physical Layer: RS485 (two-wire).

Transmitter Drive Capability: 32 standard RS485 unit loads.

Receiver Bus Loading: 0.25 standard RS485 unit load.

Presentation Layer: MODBUS RTU protocol.

Maximum Number of Zones: 128.

Baud Rate: Selectable from front panel in the range

9600, 4800, 2400 and 1200.

Zone Address Range: 1 to 128.

LOOP CONTROLLOOP CONTROL

LOOP CONTROL

LOOP CONTROLLOOP CONTROL

Control Algorithms: Direct/reverse-acting PID or On/Off.

Automatic Tuning Types: Pre-Tune or Hands-OFF EASY TUNE.

Proportional Band: 0.5% to 999.9% at 0.1% resolution.

Reset

(Integral Time Constant): 1 second to 99 minutes 59 seconds and OFF

(greater than 99 minutes 59 seconds).

Form 30 Edition 1

Page 31

Rate

(Derivative Time Constant: 0 (OFF) to 9 minutes 59 seconds.

Bias (Manual Reset): 0 to 100%.

On/Off Hysteresis: 0.1% to 10.0% of input span.

Output Cycle Time: Selectable from 0.5sec. (SSR Drive only), 1,

2, 4, 8, 16, 32, 64, 128, 256, 512 secs.

Setpoint Range: Bounded by Input Range Maximum and Input

Range Minimum. Setpoint lockable.

ALARM CONTROLALARM CONTROL

ALARM CONTROL

ALARM CONTROLALARM CONTROL

Max. Number of Alarms: Two, if two physical outputs are available.

Alarm TypesProcess High: Input Range Minimum to Input Range

Maximum.

Process Low: Input Range Minimum to Input Range

Maximum.

Deviation (High/Low): ±input span (negative values limited by dis-

play to -1999).

Band: 1 LSD to input span.

PERFORMANCEPERFORMANCE

PERFORMANCE

PERFORMANCEPERFORMANCE

Reference ConditionsReference Conditions

Reference Conditions

Reference ConditionsReference Conditions

Generally as BS5558.

Ambient Temperature: 20

o

C±2oC.

Relative Humidity: 60 to 70% non-condensing.

Supply Voltage: 90 to 254V ac 50Hz æ 1%.

Source Resistance: <10Ω for thermocouple.

Lead Resistance: <0.1Ω/lead balanced (Pt100).

Performance Under Reference ConditionsPerformance Under Reference Conditions

Performance Under Reference Conditions

Performance Under Reference ConditionsPerformance Under Reference Conditions

Common Mode Rejection: >120dB @ 50/60Hz giving negligible effect at

up to 264V at 50/60Hz.

Series Mode Rejection: >500% of input span at 50/60Hz giving negli-

gible effect.

Edition 1 31 Form

Page 32

Thermocouple Inputs

Measurement Accuracy: 0.1% of input span ±1 LSD typical (0.25% for

T ypes J and T). NOTE: Reduced performance

for Type B 100 to 600

Linearisation Accuracy: Better than ±0.2

o

range (±0.05

C typical).

Better than ±0.5

o

o

o

C (and oF equivalent).

C at any point for any 0.1oC

C at any point for any 1oC

range.

o

Cold Junction Compensation: Better than ±0.7

C.

RTD Inputs

Measurement Accuracy: ±0.1% of input span ±1 LSD.

Linearisation Accuracy: Better than ±0.2

range (±0.05

Better than ±0.5

o

C at any point for any 0.1oC

o

C typical).

o

C at any point for any 1oC

range.

DC mA/mV Inputs

Measurement Accuracy: ±0.1% of input span ±1 LSD.

Operating ConditionsOperating Conditions

Operating Conditions

Operating ConditionsOperating Conditions

Ambient T emperature

o

(Operating): 0

C to 55oC.

Ambient T emperature

(Storage): -20

o

C to 80oC.

Relative Humidity: 20% to 95% non-condensing.

Supply Voltage: 90 to 264V ac 50/60Hz.

Source Resistance: 1000Ω maximum (thermocouple).

Lead Resistance: 50Ω/lead maximum (Pt100).

Performance Under Operating Conditions:Performance Under Operating Conditions:

Performance Under Operating Conditions:

Performance Under Operating Conditions:Performance Under Operating Conditions:

Temperature Stability: 0.01% on input span/

o

C change in ambient

temperature (RTD and DC mA/mV 0.005% of

o

span/

C).

Form 32 Edition 1

Page 33

Cold Junction Compensation: Better than ±1oC.

Supply voltage Influence: Negligible.

Relative Humidity Influence: Negligible.

Sensor Resistance Influence: Thermocouple 1000Ω <0.1% of span error.

RTD Pt100 50Ω/lead <0.25% of span error.

ENVIRONMENTALENVIRONMENTAL

ENVIRONMENTAL

ENVIRONMENTALENVIRONMENTAL

Operating Conditions: See PERFORMANCE.

EMI Immunity: Complies with BS EN 50082 Parts 1 (1992)

and 2 (1995).

EMI Emissions: Complies with BS EN 50081 Parts 1 (1992)

and 2 (1994).

Safety Considerations: Complies with BS EN 61010 Part 1 (1993) in

so far as it applies.

Supply Voltage: 90 - 264V ac 50/60Hz (standard);

12 - 24V ac 50/60Hz or 12 - 30V dc (option).

Power Consumption: 4W maximum.

Front Panel Sealing: To IP66 (similar to NEMA4).

PHYSICALPHYSICAL

PHYSICAL

PHYSICALPHYSICAL

Dimensions: Behind-panel depth 100mm. Front face

25mm high x 49 mm wide.

Mounting: Plug-in with panel-mounting sleeve. Panel

cutout 45mm x 22.5mm.

Terminals: Screw type.

Weight: 100g.

Edition 1 33 Form

Loading...

Loading...