Page 1

MIC 1460

1/4 DIN SETPOINT PROGRAMMER

OPERATORS MANUAL

FORM 3707

EDITION 1 © MAY 1996

PRICE $10.00

CIRCULAR CHART RECORDERS • STRIP CHART RECORDERS • DATA ACQUISITION SYSTEMS

DATALOGGERS • ANALOG AND MICROBASED CONTROLLERS

MECHANICAL RECORDERS AND CONTROLLERS

PARTLOW CORPORATION • 2 CAMPION ROAD • NEW HARTFORD, NY 13413 USA

1-800-866-6659 • 315-797-2222 • FAX 315-797-0403

Page 2

Information in this installation, wiring, and operation manual is subject to change

without notice. One manual is provided with each instrument at the time of shipment. Extra copies are available at the price published on the front cover.

Copyright © May 1996, The Partlow Corporation, all rights reserved. No part of

this publication may be reproduced, transmitted, transcribed or stored in a retrieval

system, or translated into any language in any form by any means without the

written permission of the Partlow Corporation.

This is the First Edition of the MIC 1460 manual. It was written and produced

entirely on a desk-top-publishing system. Disk versions are available by written

request to the Partlow Publications Department.

We are glad you decided to open this manual. It is written so that you can take full

advantage of the features of your new MIC 1460 setpoint programmer .

NOTE:

It is strongly recommended that Partlow equipped

applications incorporate a high or low limit protective device

which will shut down the equipment at a preset process

condition in order to preclude possible damage to property

or products.

Page 3

Table of Contents

Section 1 - General Page

1.1 Product Description 1

Section 2 - Installation & Wiring

2.1 Unpacking Procedure 3

2.2 Panel Mounting 3

2.3 Wiring Guidelines 5

2.4 Input Connections 12

2.5 Output Connections 15

Section 3 - Operation

3.1 Power-up Procedure 20

3.2 Keypad Operation 20

3.3 Indicators 22

3.4 Displays 23

3.5 Alarm Status Indication 23

3.6 Viewing Program and Controller Parameters 24

3.7 Adjusting the Setpoint 24

3.8 Manual Control 25

3.9 Using the Pre-Tune Facility 25

3.10 Using the Self-Tune Facility 26

Section 4 - Configuration

4.1 Entry into Configuration 28

4.2 Hardware Definition Mode 29

4.3 Configuration Mode Parameters 31

4.4 Alarm Inhibit Facility 35

4.5 Exit from Configuration Mode 35

Section 5 - Controller Define Mode

5.1 Controller Parameters 37

5.2 Base Mode Displays 52

5.3 Loop Alarm and Loop Alarm Time 52

5.4 Exiting Controller Define Mode 53

MIC 1460 ManualEdition 1 i

Page 4

Section 6 - Program Define Mode

6.1 Entry into Program Define 54

6.2 Paramters Common to All Programs 55

6.3 Parameters which apply to a Specific Program 57

6.4 Parameters in any/each Segment 61

6.5 Using Join, Repeat, and End Segments 64

6.6 Basic Rules to Remember 66

6.7 Exiting Program Define Mode 66

Section 7 - Programs

7.1 Selecting and Running a Program 67

7.2 Changing Timebase 67

7.3 Holding Manually 67

7.4 Jumping to Next Segment 68

7.5 Viewing Program Status 68

7.6 Aborting a Program 69

7.7 End of Progam Indication 69

7.8 Viewing Program/Control Parameters 70

Appendices

A - Input Range Codes 71

B - Board Layout - Jumper positioning 73

Figure B-1 PCB Positions 73

Figure B-2 Output 2/Output 3 Removal 74

Figure B-3 CPU PWA 75

Figure B-4 PSU PWA with Relay or SSR Out.1 76

Figure B-5 PSU PWA with DC Output 1 77

Figure B-6 Option PWA DC Output 2/Output 3 78

C - Specifications 79

D - Model Number Hardware Matrix 87

E - Software Reference Sheet 88

MIC 1460 Manual Edition 1ii

Page 5

Figures

Figure 1-1 Front Panel 2

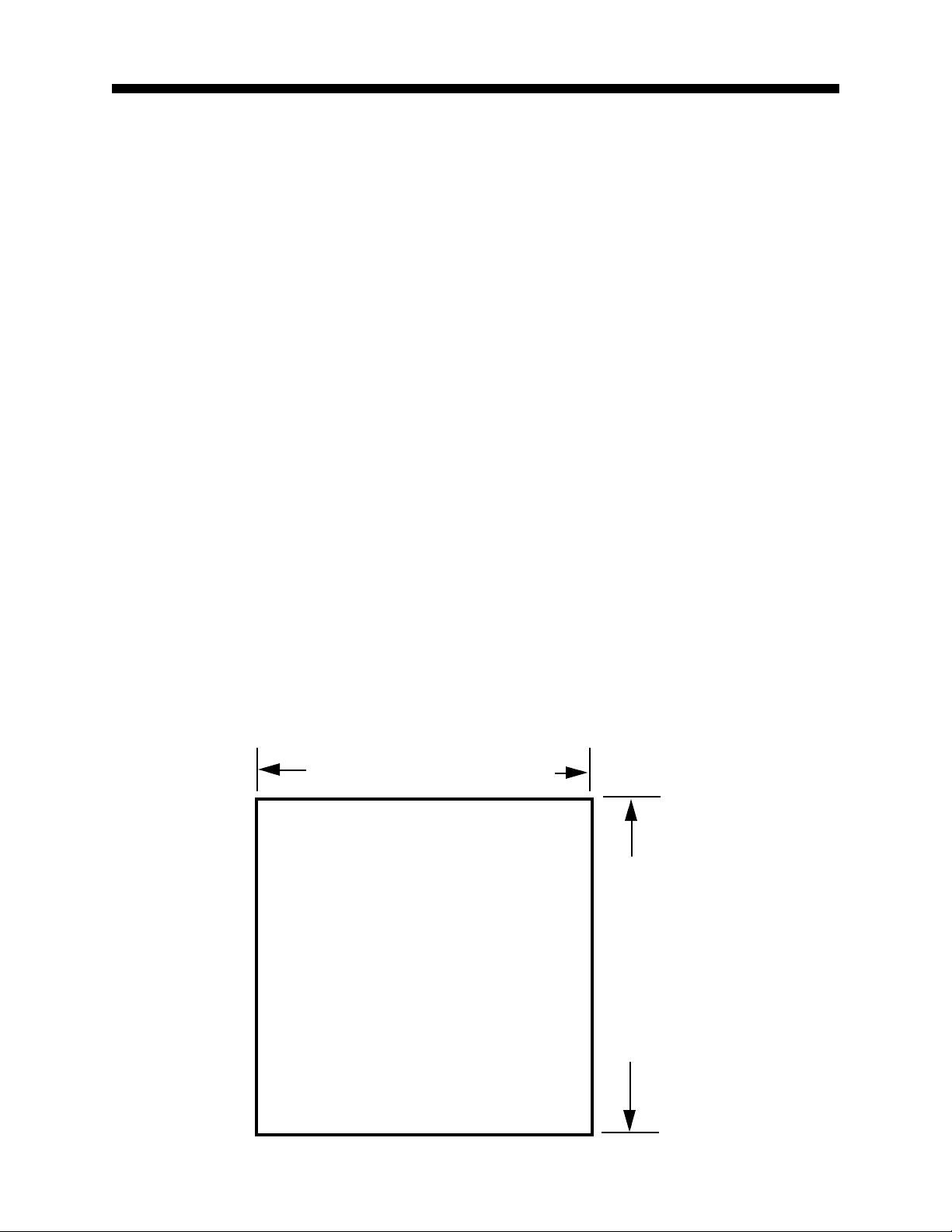

Figure 2-1 Panel Cut-Out Dimensions 3

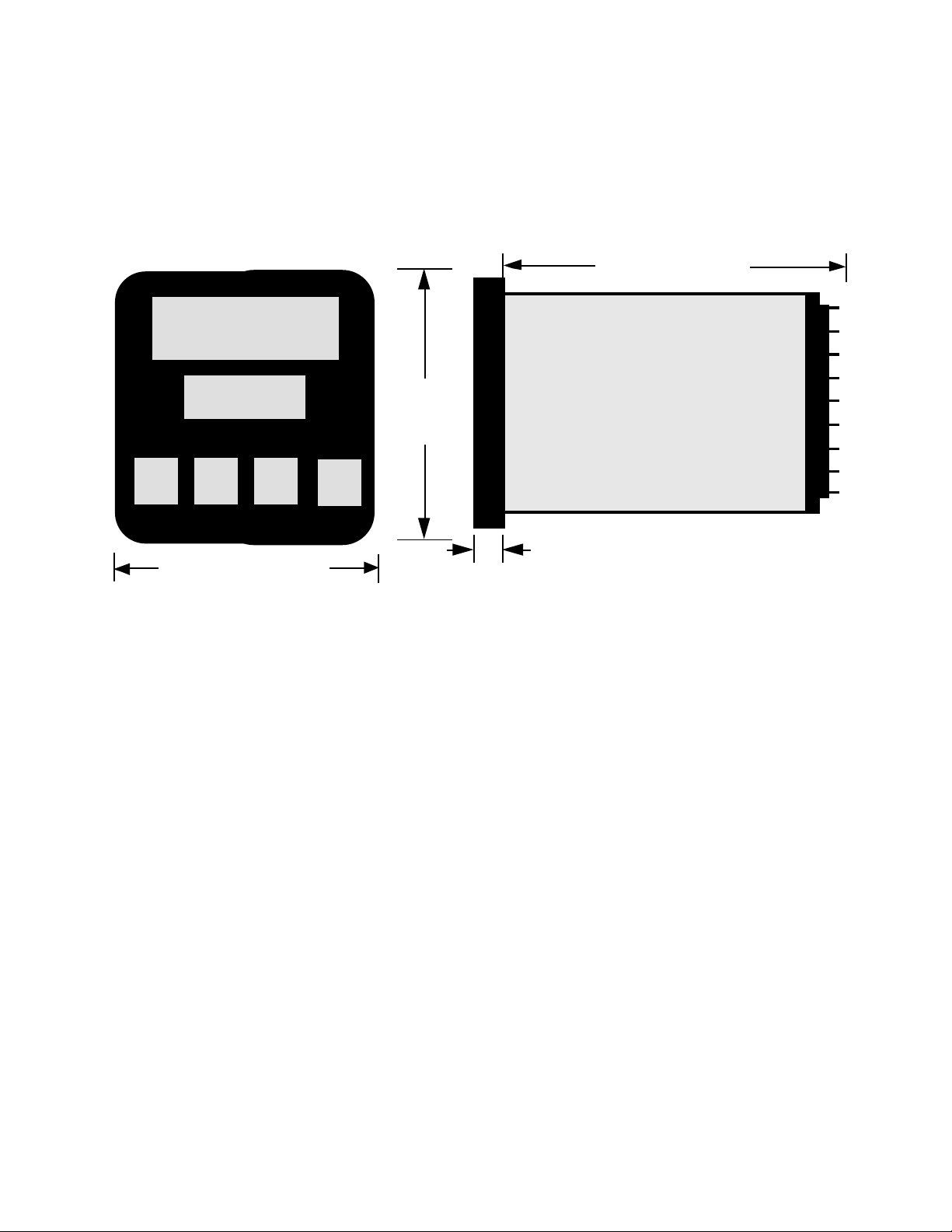

Figure 2-2 Main Dimensions 4

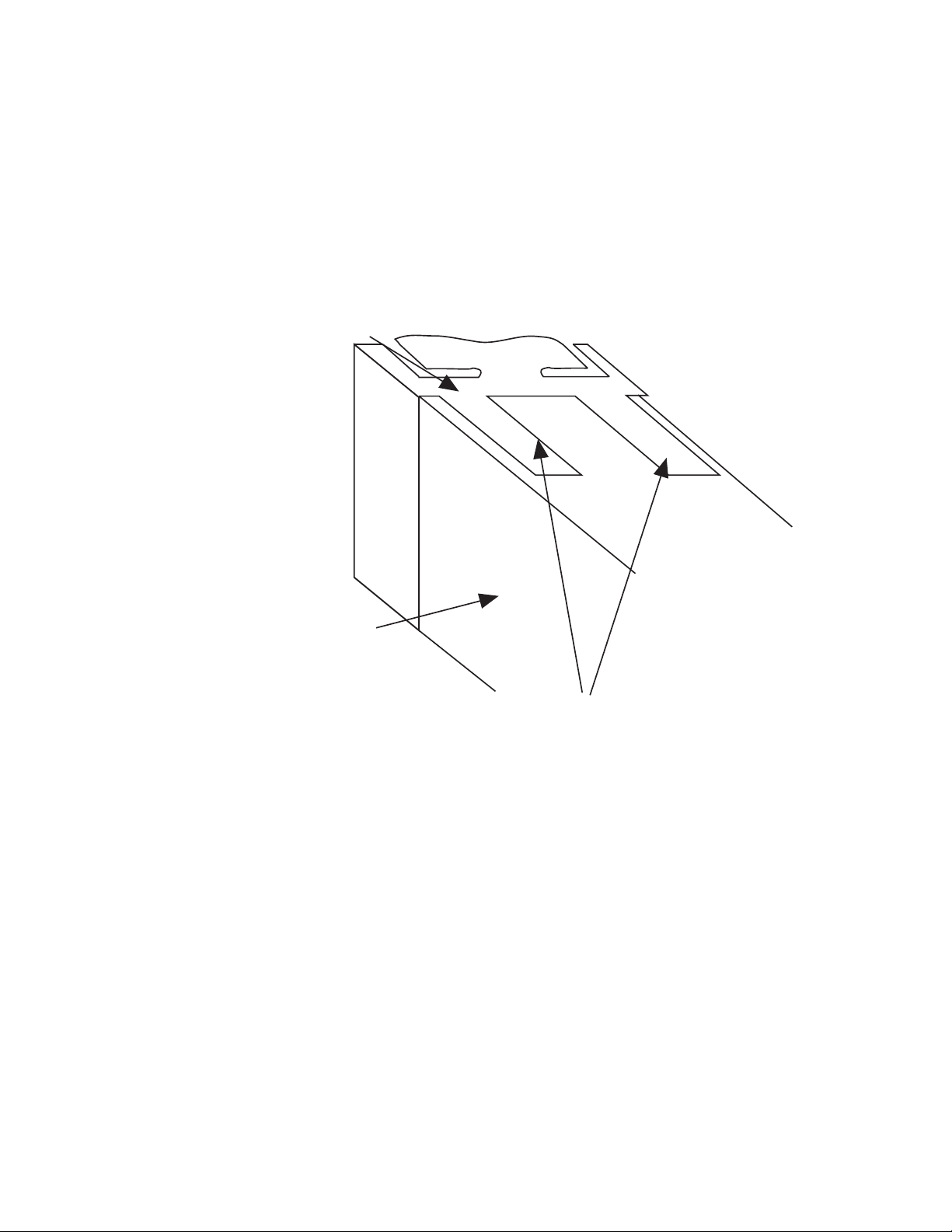

Figure 2-3 Panel Mounting the controller 5

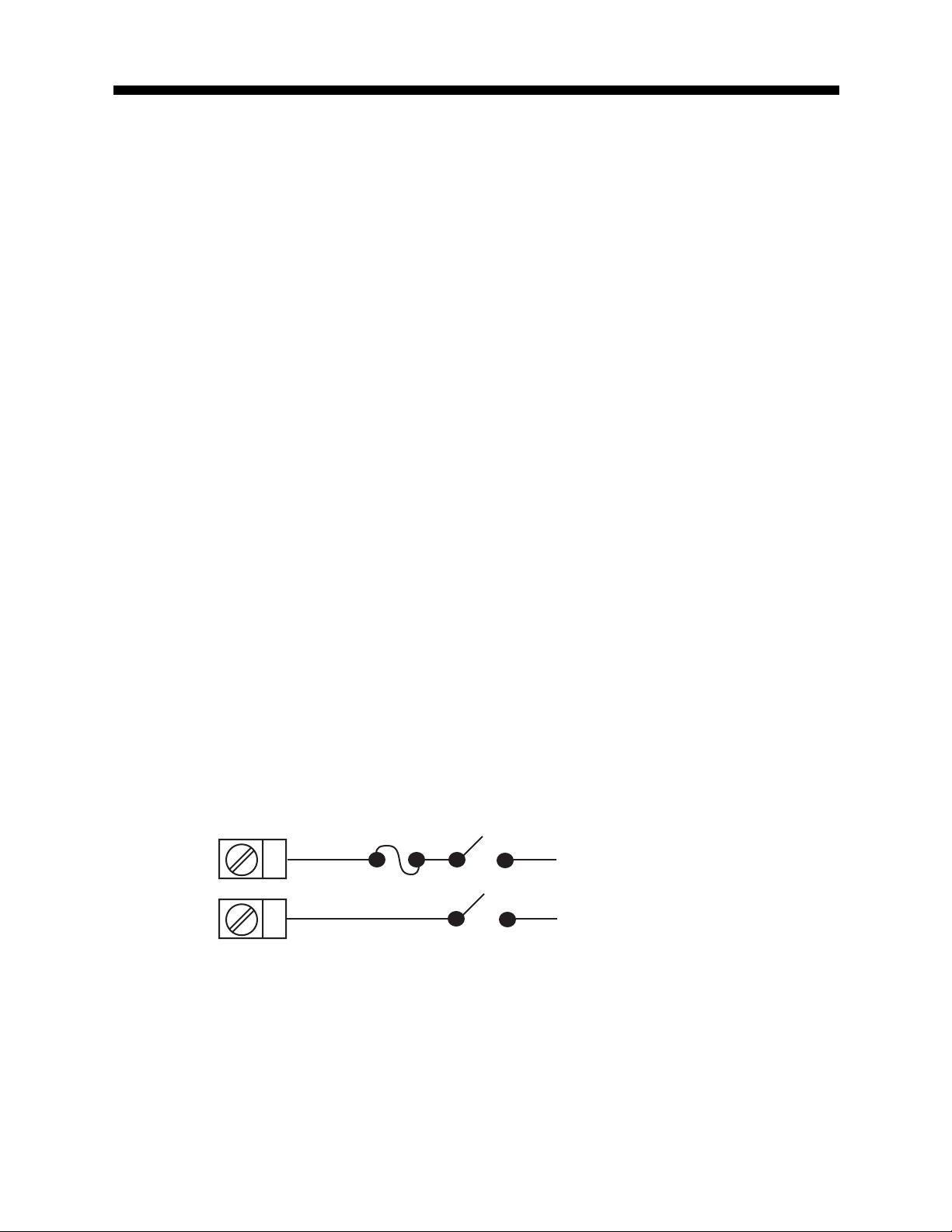

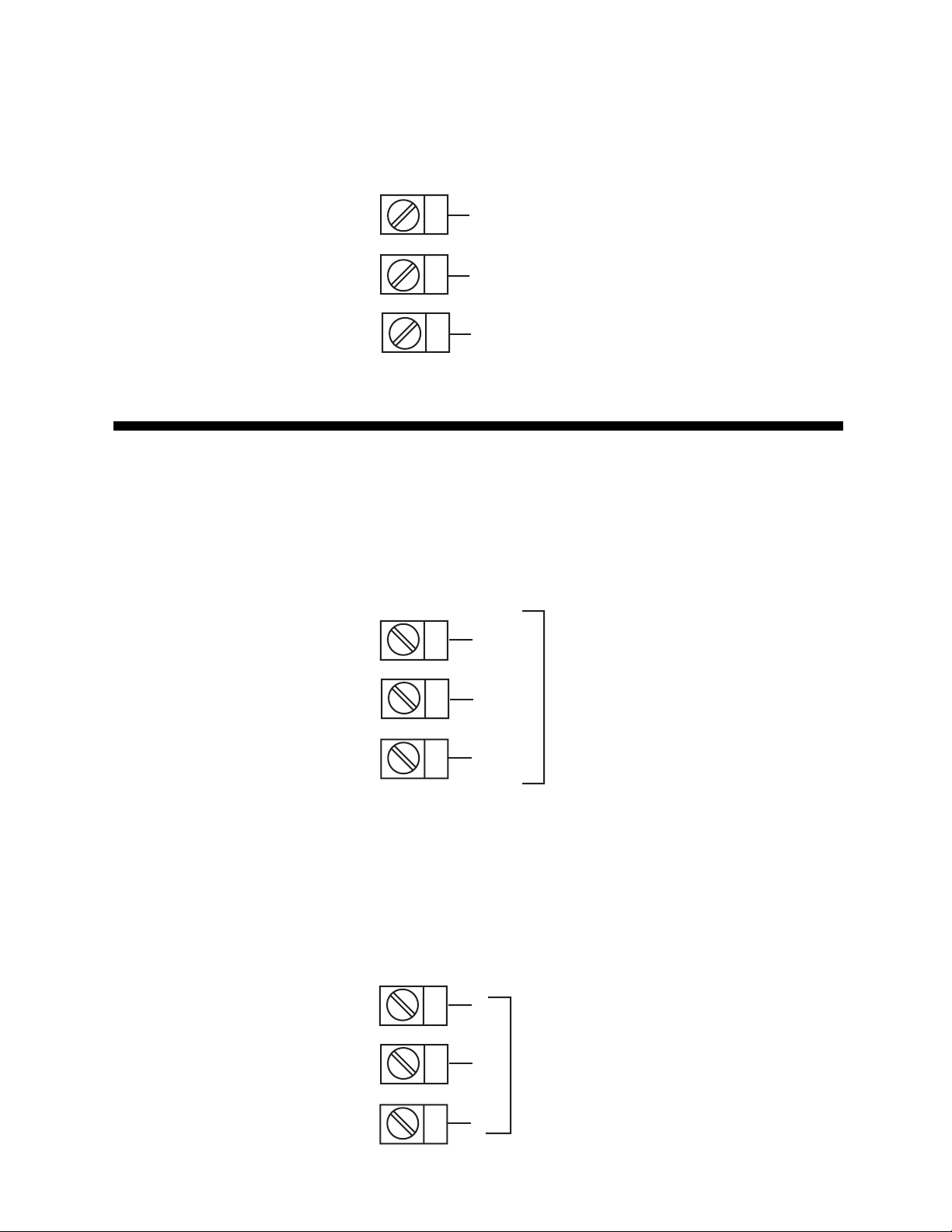

Figure 2-4 Noise Suppression 8

Figure 2-5 Noise Suppression 8

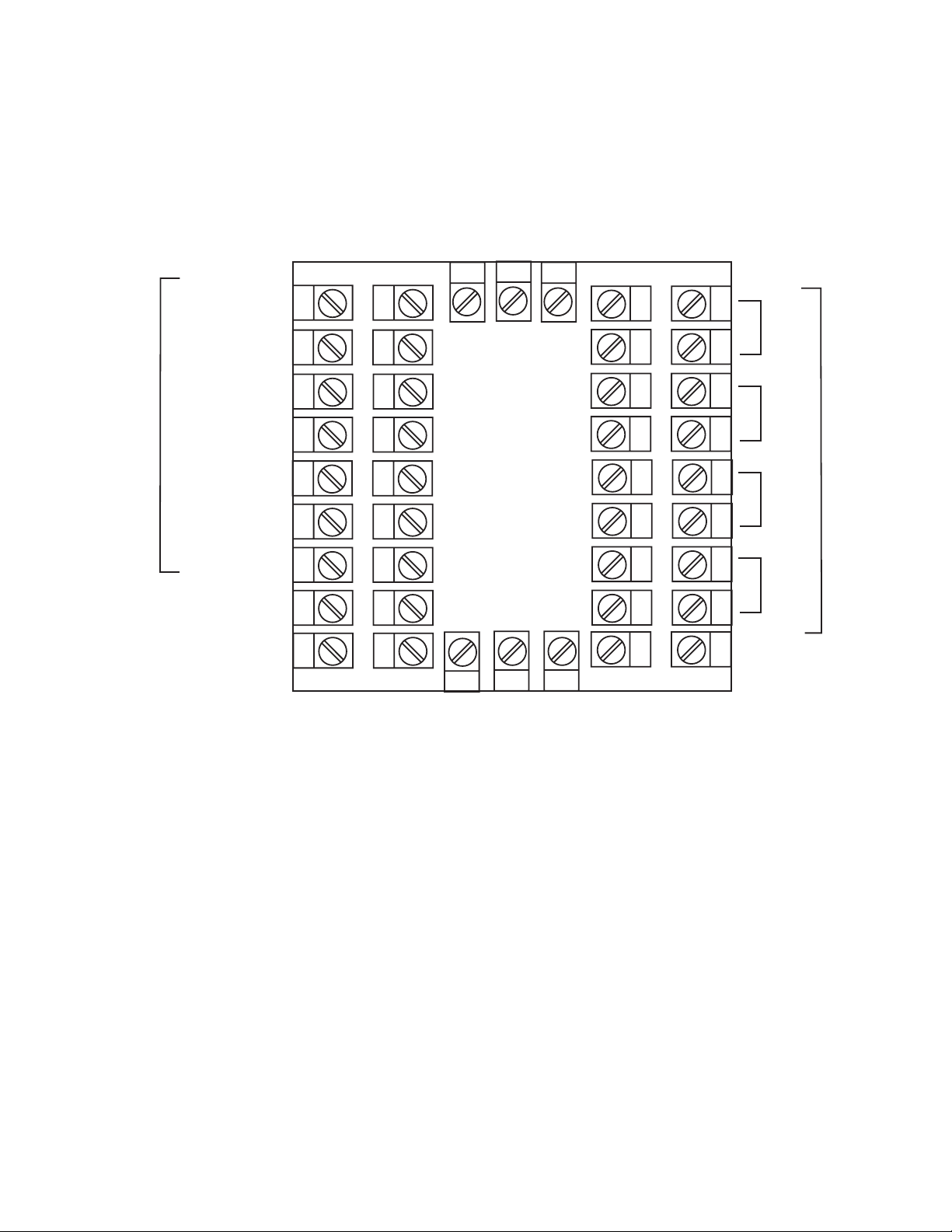

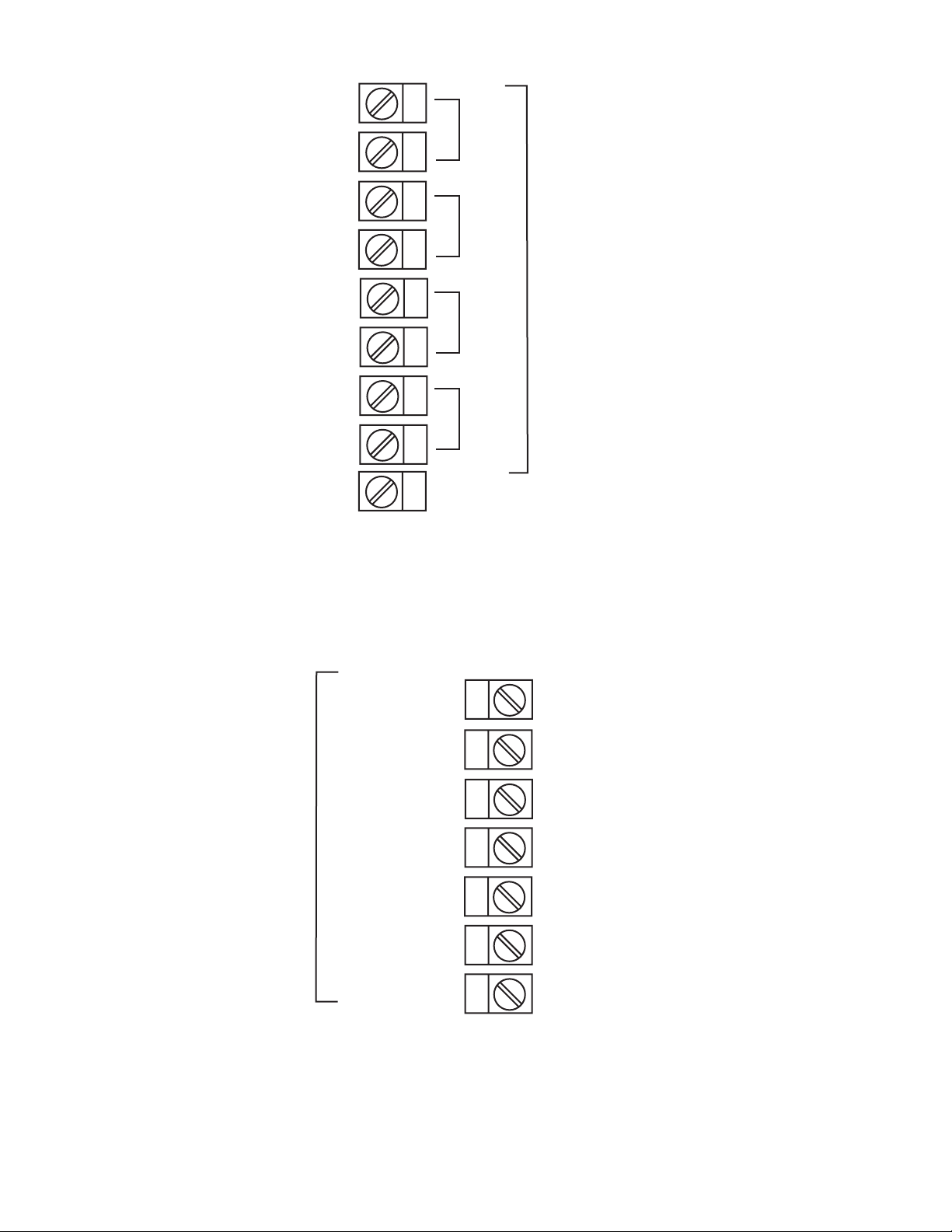

Figure 2-6 Rear Terminal Connections 10

Figure 2-6A Rear Terminal Connections 11

Figure 2-7 Main Supply 12

Figure 2-7A 24V Nominal AC/DC Supply 13

Figure 2-8 Thermocouple (T/C) Input 13

Figure 2-9 RTD Input 14

Figure 2-10 Volt, mV Input 14

Figure 2-11 mA DC Input 14

Figure 2-12 Remote Digital Communications 15

Figure 2-13 Relay Output 1 15

Figure 2-14 SSR Driver Output 1 15

Figure 2-15 mADC Output 1 16

Figure 2-16 Relay Output 2 16

Figure 2-17 SSR Driver Output 2 16

Figure 2-18 mADC Output 2 17

Figure 2-19 Relay Output 3 17

Figure 2-20 SSR Driver Output 3 17

Figure 2-21 mADC Output 3 18

Figure 2-22 End of Program Output 18

Figure 2-23 Event Outputs 18

Figure 2-24 Remote Program Output 19

Figure 5-1 Proportional Band and Deadband/Overlap 48

Figure 5-2 Alarm Operation 49

Figure 5-3 Alarm Hysteresis Operation 51

Figure 6-1 Auto Hold Operation 60

MIC 1460 ManualEdition 1 iii

Page 6

MIC 1460 Manual Edition 1iv

Page 7

Section 1 - General

1.1 PRODUCT DESCRIPTION

This instrument is a powerful, easy-to-use 1/4 DIN setpoint programmer

with full PID control capability (complete with Self-Tune and Pre-T une facilities).

Its standard features include:

• Up to eight programs of up to 16 free-format (e.i. dwell, ramp, join, or

end) segments each.

• Facility to join programs to one another in any sequence (maximum

program length 121 segments)

• User can change currently-running program segment.

• Delayed Start of Program facility

• End of Program relay output

• Universal input-thermocouple, RTD (PT100) or DC linear user-selectable.

• Universal power supply (90 -264V AC 50/60 Hz)

• Configurable from front panel

• Comprehensive front panel displays

• Front panel sealing to NEMA 4 standard

• Behind-panel depth only 100mm (3.94 inchs)

Optional features include:

• Remote control and selection of program (plug-in option)

• Up to four Event relay outputs (plug-in option)

• Second control output

• Recorder output (setpoint or process variable)

• RS-485 serial communications

• User-definable program tag names

• Support software (Off-line Configurator, On-line Graphic Program

Editor) - operates via RS-485 communications link.

MIC 1460 ManualEdition 1 1

Page 8

The Setpoint Programmer has four operating modes:

Base Mode: Day to day PID control operations with no program running.

In this mode, a program may be selected to run.

Program Run Mode: A selected program is running, held or waiting for a

pre-defined delay before starting. In this mode, the operator can view

status and program information.

Program Define Mode:* Used to view/create/edit programs. this mode

is entered either from Base Mode (selected program may be edited/

created) or from Program Run Mode (currently-running program may be

edited).

Controller Define Mode:** Used to define the controller characteristics.

* Entry via Lock Code; also optional Program Lock prevents changing of

program definitions while a program is running.

** Enry via a Lock Code.

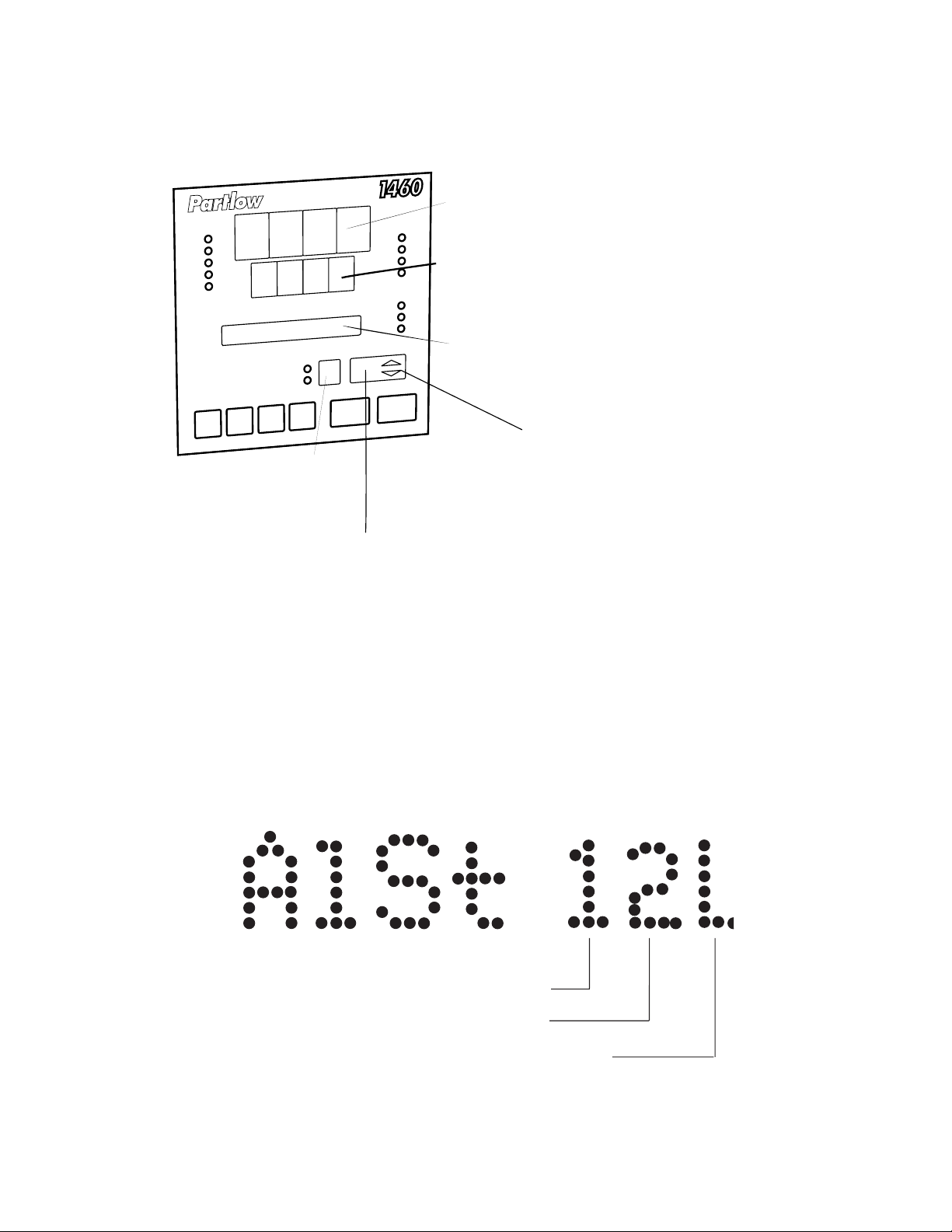

FIGURE 1-1

Front Panel

MIC 1460 Manual Edition 12

Page 9

Section 2 - Installation & Wiring

2.1 UNPACKING PROCEDURE

1. Remove the instrument from its packing. The instrument is supplied

with a panel gasket and push-fit strap. Retain the packing for future use,

should it be necessary to transport the instrument to a different site or

return it to the factory for repair/testing.

2. Examine the delivered items for damage or deficiencies. If any is

found, notify the carrier immediately. Check that the model number

shown on the label affixed to the instrument housing corresponds to that

ordered (see Appendix D).

2.2 PANEL-MOUNTING THE SETPOINT PROGRAMMER

The panel on which the instrument is to be mounted must be rigid and may

be up to 6.0 mm (.25 inches ) thick. The cutout required for a single instrument is shown in Figure 2-1.

FIGURE 2-1

Cut-Out Dimensions

92 mm +0.5 - 0.00

(3.62”+.020 - .000)

PANEL

CUTOUT

SIZE

92 mm + 0.5 - 0.0

(3.62” + .020 - .000)

MIC 1460 ManualEdition 1 3

Page 10

The main dimensions of the instrument are shown below.

FIGURE 2-2

Main Dimensions

100 mm (3.94 in.)

96 mm

(3.78 in)

Side View

96 mm

(3.78 in.)

Max. Panel Thickness 6.0mm (.25 inches)

10 mm (0.39 in.)

To panel-mount the instrument:

1. Insert the rear of the instrument housing through the cutout (from the

front of the mounting panel) and hold the instrument lightly in position

against the panel. Ensure that the panel gasket is not distorted and that

the instrument is positioned squarely against the mounting panel. Apply

pressure to the front panel bezel only.

Caution: Do not remove the panel gasket, as this may result

in inadequate clamping of the instrument in the panel.

2. Slide the fixing strap in place (Figure 2-3) and push it forward until it

is firmly in contact with the rear face of the mounting panel (the tongues

on the strap should have engaged in matching rachet positions on the

instrument housing and the fixing strap springs should be pushing firmly

against the mounting panel rear face).

MIC 1460 Manual Edition 14

Page 11

Once the instrument is installed in its mounting panel, it may be subsequently removed from its housing, if necessary, as described in Appendix

B.

FIGURE 2-3

Panel-Mounting the Instrument

Mounting Clamp

Controller Housing

Tongues on mounting clamp engage in

ratchet slots on controller housing

2.3 PREPARATION FOR WIRING

Electrical noise is a phenomenon typical of industrial environments. The

following are guidelines that must be followed to minimize the effect of

noise upon any instrumentation.

2.3.1 INST ALLATION CONSIDERA TIONS

Listed below are some of the common sources of electrical noise in the

industrial environment:

• Ignition T ransformers

• Arc Welders

• Mechanical contact relay(s)

• Solenoids

MIC 1460 ManualEdition 1 5

Page 12

Before using any instrument near the device listed, the instructions below

should be followed:

1. If the instrument is to be mounted in the same panel as any of the

listed devices, separate them by the largest distance possible. For maximum electrical noise reduction, the noise generating devices should be

mounted in a separate enclosure.

2. If possible, eliminate mechanical contact relay(s) and replace with

solid state relays. If a mechanical relay being powered by an instrument

output device cannot be replaced, a solid state relay can be used to

isolate the instrument.

3. A separate isolation transformer to feed only instrumentation should

be considered. The transformer can isolate the instrument from noise

found on the AC power input.

4. If the instrument is being installed on existing equipment, the wiring in

the area should be checked to insure that good wiring practices have

been followed.

2.3.2 AC POWER WIRING

Neutral (For 1 15 VAC)

It is good practice to assure that the AC neutral is at or near ground potential. To verify this, a voltmeter check between neutral and ground should be

done. On the AC range, the reading should not be more than 50 millivolts.

If it is greater than this amount, the secondary of this AC transformer supplying the instrument should be checked by an electrician. A proper neutral

will help ensure maximum performance from the instrument.

2.3.3 WIRE ISOLA TION

Four voltage levels of input and output wiring may be used with the unit:

• Analog input or output (i.e. thermocouple, R TD, VDC, mVDC, or

mADC)

• SPDT Relays

• SSR driver outputs

• AC power

MIC 1460 Manual Edition 16

Page 13

The only wires that should run together are those of the same category. If

they need to be run parallel with any of the other lines, maintain a minimum

6 inch space between wires. If wires must cross each other , do so at 90

degrees. This will minimize the contact with each other and reduces "cross

talk". "Cross Talk" is due to the EMF (Electro Magnetic Flux) emitted by a

wire as current passes through it. This EMF can be picked up by other

wires running in the same bundle or conduit.

In applications where a High Voltage Transformer is used (i.e. ignition systems) the secondary of the transformer should be isolated from all other

cables.

This instrument has been designed to operate in noisy environments, however , in some cases even with proper wiring it may be necessary to suppress the noise at the source.

2.3.4 USE OF SHIELDED CABLE

Shielded cable helps eliminate electrical noise being induced on the wires.

All analog signals should be run with shielded cable. Connection lead

length should be kept as short as possible, keeping the wires protected by

the shielding. The shield should be grounded at one end only. The preferred grounding location is the sensor, transmitter, or transducer .

2.3.5 NOISE SUPPRESSION AT THE SOURCE

Usually when good wiring practices are followed no further noise protection

is necessary. Sometimes in severe electrical environments, the amount of

noise is so great that it has to be suppressed at the source. Many manufacturers of relays, contactors, etc. supply "surge suppressors" which

mount on the noise source.

For those devices that do not have surge suppressors supplied. RC (resistance-capacitance) networks and/or MOV (metal oxide varistors) may be

added.

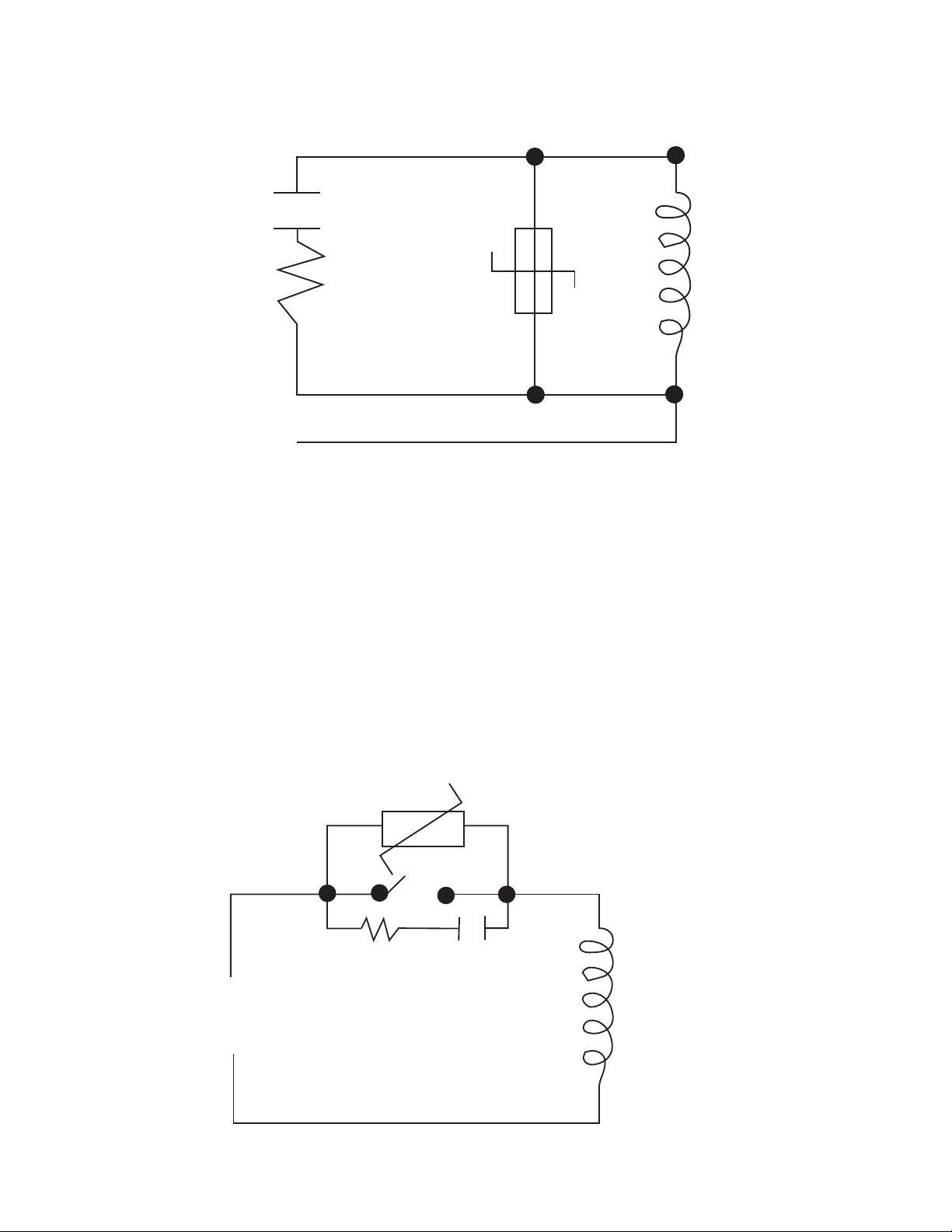

Inductive Coils - MOV's are recommended for transient suppression in

inductive coils connected in parallel and as close as possible to the coil.

See Figure 2-4. Additional protection may be provided by adding an RC

network across the MOV.

MIC 1460 ManualEdition 1 7

Page 14

FIGURE 2-4

0.5

mfd

1000V

220

ohms

115V 1/4W

230V 1W

Coil

Contacts - Arcing may occur across contacts when the contact opens and

closes. This results in electrical noise as well as damage to the contacts.

Connecting a RC network properly sized can eliminate this arc.

For circuits up to 3 amps, a combination of a 47 ohm resistor and 0.1 microfarad capacitor (1000 volts) is recommended. For circuits from 3 to 5

amps, connect 2 of these in parallel. See Figure 2-5, below.

FIGURE 2-5

MOV

R C

Inductive

Coil

MIC 1460 Manual Edition 18

Page 15

2.3.5 SENSOR PLACEMENT (THERMOCOUPLE OR RTD)

Two wire RTD's should be used only with lead lengths less than 10 feet.

If the temperature probe is to be subjected to corrosive or abrasive condi-

tions, it should be protected by the appropriate thermowell. The probe

should be positioned to reflect true process temperature:

In liquid media - the most agitated area

In air - the best circulated area

MIC 1460 ManualEdition 1 9

Page 16

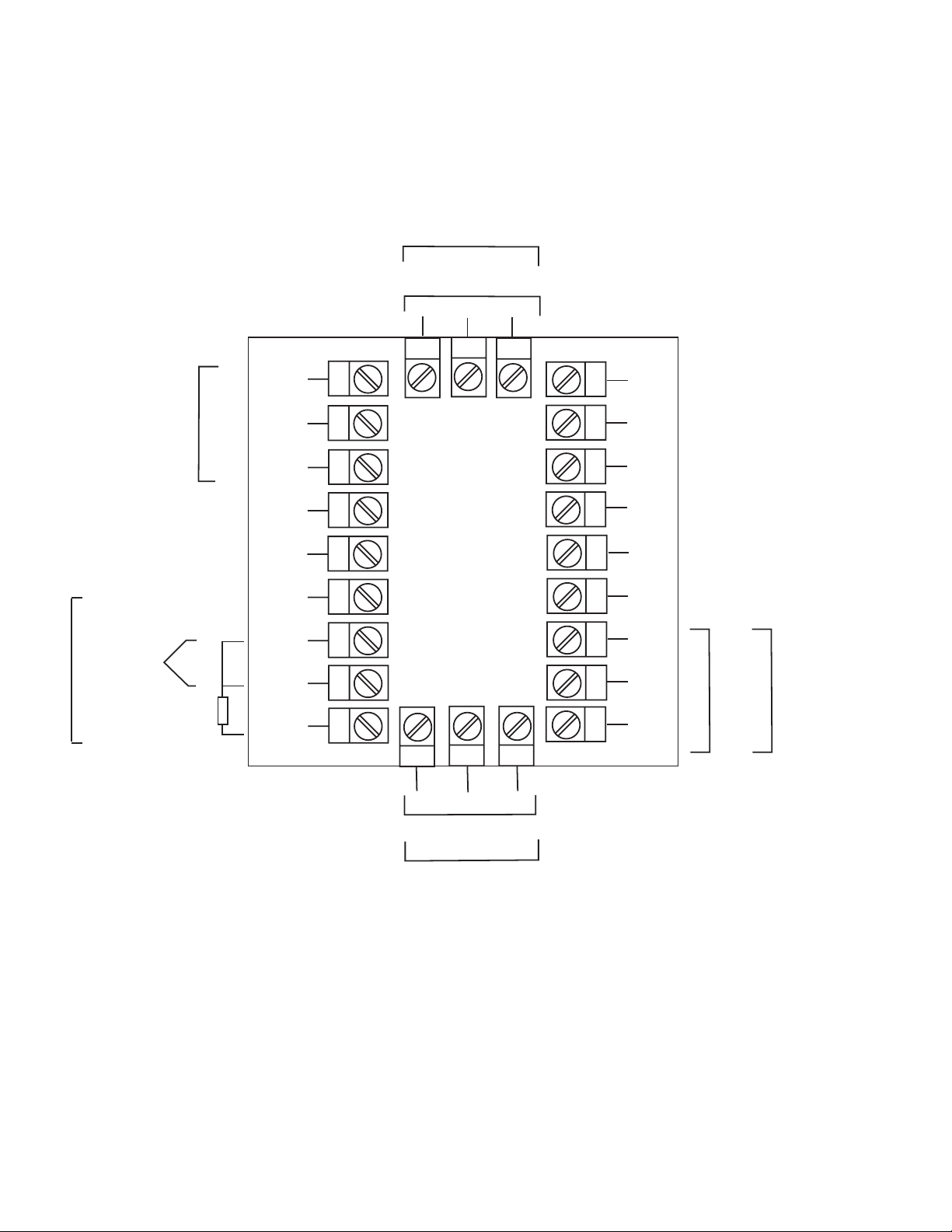

FIGURE 2-6

Rear Terminal Connections

OUTPUT 3

Relay

END OF

PROGRAM

OUTPUT

+

INPUT

Linear (mA)

-

N/O

N/C

-

+

+

RTD

Linear (V/mV)

Thermocouple

C

N/C

SSR/DC

-

9

8

7

6

5

4

3

2

1

24

N/OC

+

11

1210

23 22

13

14

15

16

17

18

19

20

21

MAINS (LINE)

SUPPLY

24V 24V

L

AC DC

N

B

RS485

A

COM

-

+

SERIAL

COMMS.

N/C

C

SSR/DC

N/O

-

+

Relay

OUTPUT 1

+

SSR/DC

N/O

MIC 1460 Manual Edition 110

C

Relay

OUTPUT 2

-

N/C

Page 17

FIGURE 2-6A

RESET

RUN/HOLD

REMOTE INPUTS

X60 (FAST)

R0

R1

R2

C

33

32

31

30

29

28

27

26

25

34

#1

35

36

#2

37

38

#3

39

EVENT OUTPUTS

40

#4

41

42

MIC 1460 ManualEdition 1 11

Page 18

2.4 Input Connections

In general, all wiring connections are made to the instrument after it is installed. Avoid electrical shock. AC power wiring must not be connected to

the source distribution panel until all wiring connection procedures are

completed.

Caution: This equipment is designed for installation in an

enclosure which provide adequate protection against electric shock. Local regulations regarding electrical installation should be rigidly observed. Consideration should be

given to prevention of access to the power terminations by

unauthorized personnel. Power should be connected via a

two pole isolating switch (preferably situated near the equipment) and a 1 A fuse, as shown in Figure 2-7.

FIGURE 2-7

Main Supply

The instrument will operate on 90-264V AC 50/60 Hz mains (line) supply.

The power consumption is approximately 4 VA. If the instrument has relay

outputs in which the contacts are to carry mains (line) voltage, it is recommended that the relay contact mains (line) supply should be switched and

fused in a similar manner but should be separate from the instrument

mains (line) supply.

L

13

N

14

MIC 1460 Manual Edition 112

Line

Neutral

Page 19

FIGURE 2-7A

24V Nominal AC/DC Supply

The supply connection for the 24V AC/DC option of the instrument are as

shown below . Power should be connected via a two pole isolating switch

and a 315 mA slow -blow (anti-surge type T) fuse. With the 24V AC/DC

supply option fitted, these terminals will accept the following supply voltage

ranges:

24V (nominal) AC 50/60Hz - 20-50V

24V (nominal) DC - 22-65V

L

13

14

N

24V AC

50/60Hz

-

24V DC

+

FIGURE 2-8

Thermocouple (T/C) Input

Make the thermocouple connections as illustrated below. Connect the

positive leg of the thermocouple to terminal 2 and the negative leg to

terminal 3.

-

+

Thermocouple

FIGURE 2-9

RTD Input

Make RTD connections as illustrated below. For a three wire RTD, connect

the resistive leg of the RTD to terminal 1 and the common legs to terminals

2 and 3. For a two wire RTD, connect one leg to terminal 2 and the other

leg to terminal 3 as shown below. A jumper wire supplied by the customer

must be installed between terminals 2 and 3. (Continued on next page)

3

2

MIC 1460 ManualEdition 1 13

Page 20

Input conditioning jumper must be positioned correctly (see Appendix B)

and Hardware Definition Code must be correct (see Appendix C).

3

2

RTD

1

FIGURE 2-10

V olt, mV Input

Make volt and millivolt connections as shown below . Terminal 2 is positive

and terminal 3 is negative. Input conditioning jumper must be positioned

correctly (see Appendix B) and Hardware Definition Code must be correct

(see Appendix C).

-

+

Linear (V/mV)

FIGURE 2-11

mADC Input

Make mADC connections as shown below. Terminal 4 is positive and terminal 1 is negative Input conditioning jumper must be positioned correctly

(see Appendix B) and Hardware Definition Code must be correct (see Appendix C).

+

3

2

1

4

3

Linear (mA)

-

MIC 1460 Manual Edition 114

2

1

Page 21

FIGURE 2-12

Remote Digital Communications - RS485

Make digital communication connections as illustrated below .

16

17

18

B

A

COM

Output Connections 2.5

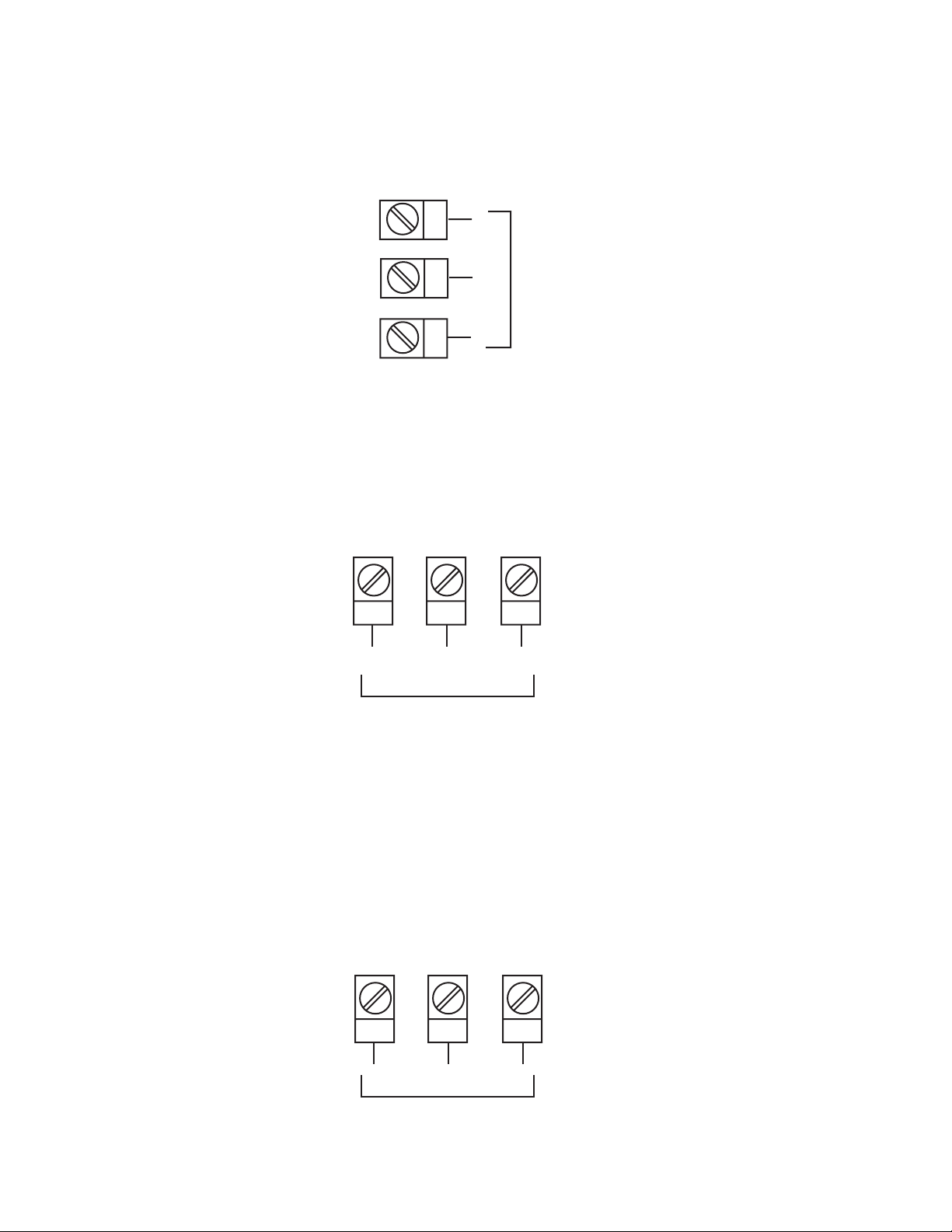

FIGURE 2-13

Relay Output 1 (Control Output 1)

Connections are made to Output 1 relay as illustrated below. The contacts

are rated at 2 amp resistive, 120/240 VAC .

19

N/C

20

21

FIGURE 2-14

SSR Driver Output 1 (Control Output 1)

Connections are made to Output 1 SSR Driver as illustrated below. The

solid state relay driver is a non-isolated 0-4 VDC nominal signal. Output

impedance is 250 ohms.

19

20

21

C

Relay

N/O

-

SSR

+

MIC 1460 ManualEdition 1 15

Page 22

FIGURE 2-15

mADC Output 1 (Control Output 1)

Make connections for DC Output 1 as illustrated below.

19

20

21

FIGURE 2-16

Relay Output 2 (Control Output 2 OR Alarm 2)

Connections are made to Output 2 relay as illustrated below. The contacts

are rated at 2 amp resistive, 120/240 VAC.

24 23 22

-

DC

+

N/O

FIGURE 2-17

SSR Driver Output 2 (Control Output 2 OR Alarm 2)

Connections are made to Output 2 SSR Driver as illustrated below. The

solid state relay driver is a non-isolated 0-4 VDC nominal signal. Output

impedance is 250 ohms.

24 23 22

+

C

Relay

SSR

N/C

-

MIC 1460 Manual Edition 116

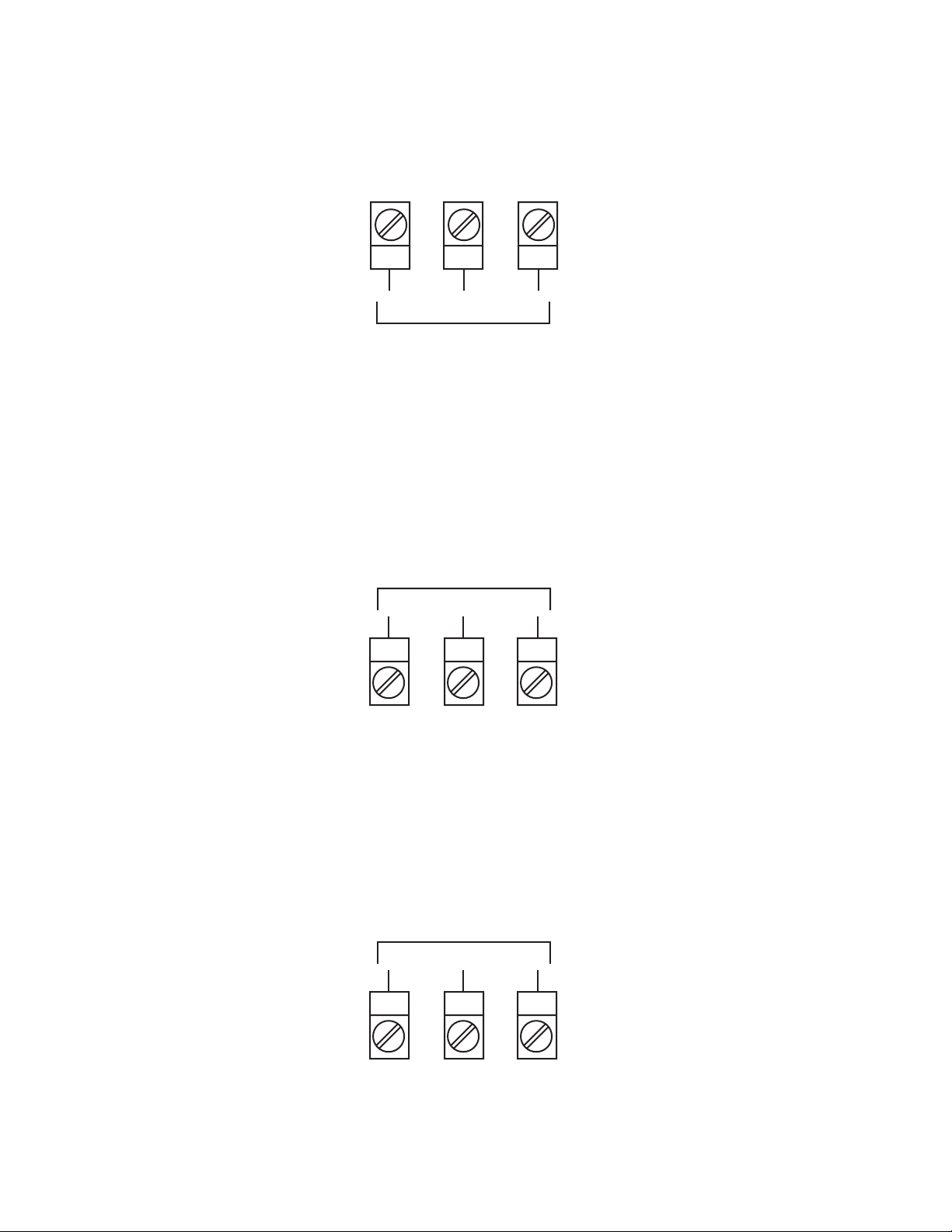

Page 23

FIGURE 2-18

mADC Output 2 (Control Output 2)

Make connections for DC Output 2 as illustrated below.

24 23 22

+

DC

FIGURE 2-19

Relay Output 3 (Alarm 1)

Connections are made to Output 3 relay as illustrated below. The contacts

are rated at 2 amp resistive, 120/240 VAC.

Relay

10 11 12

FIGURE 2-20

SSR Driver Output 3 (Alarm 1)

Connections are made to Output 3 SSR Driver as illustrated below. The

solid state relay driver is a non-isolated 0-4 VDC nominal signal. Output

impedance is 250 ohms.

-

N/OCN/C

SSR

-

10 11 12

+

MIC 1460 ManualEdition 1 17

Page 24

FIGURE 2-21

mADC Output 3 (Recorder Output Only)

Make connections for DC output 3 as illustrated below.

DC

-

10 11 12

FIGURE 2-22

End of Program Output

Connections are made to End of Program Output as shown below. The

contacts are rated at 5 amp resistive, 120/240 V AC.

N/O

END OF

PROGRAM

OUTPUT

C

N/C

+

9

8

7

FIGURE 2-23

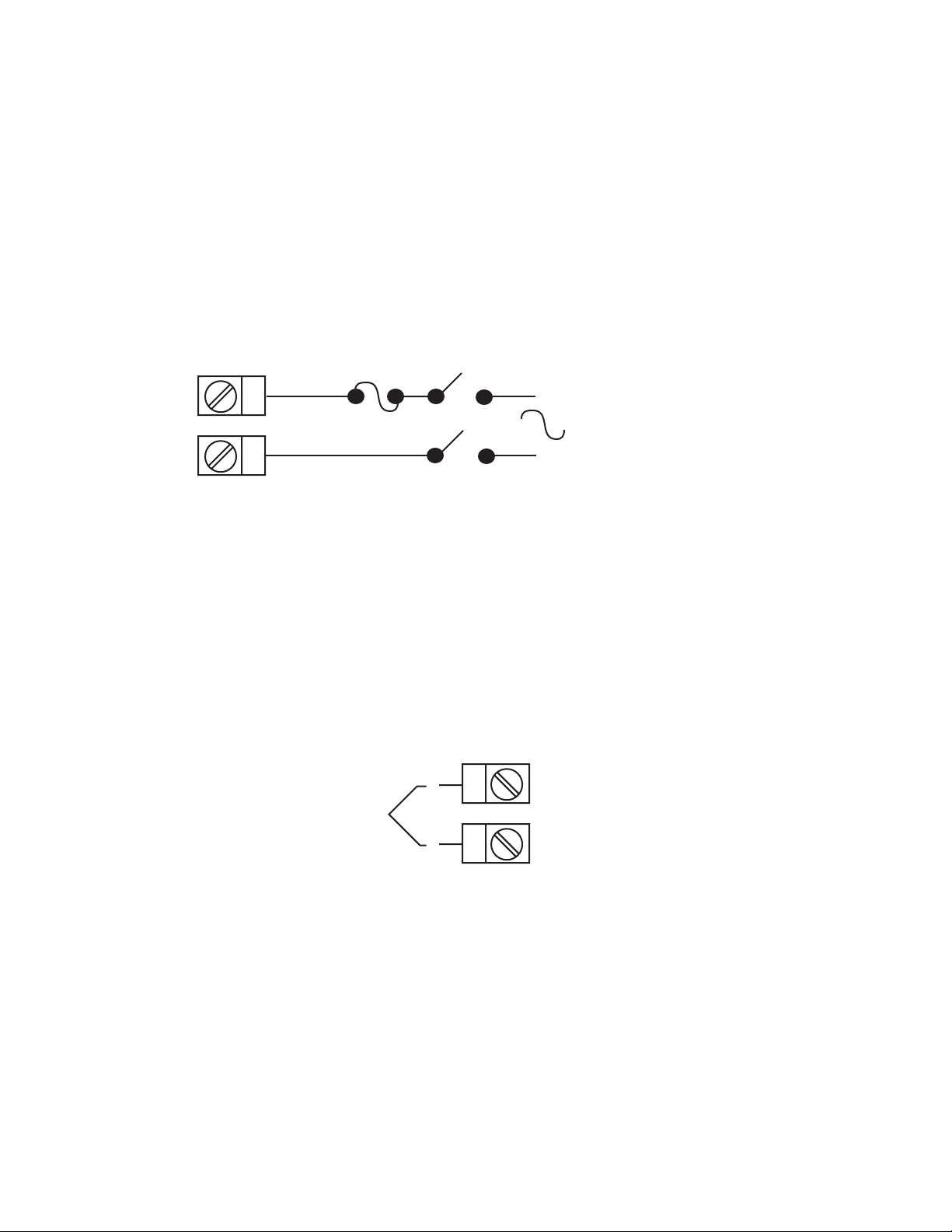

Event Outputs (optional)

If the Event Outputs have been specified, make connections as shown on

top of next page. The contacts are rated at 5 amps, 120/240 VAC.

MIC 1460 Manual Edition 118

Page 25

34

35

36

37

38

39

40

41

42

#1

#2

#3

EVENT OUTPUTS

#4

FIGURE 2-24

Remote Program Inputs (optional)

If the Remote Program Control Inputs has been specified, make connections as shown.

33

R0

32

R1

31

R2

RESET

RUN/HOLD

30

29

REMOTE INPUTS

C

28

27

X60 (FAST)

Note: Only one remote connection shown for clarity.

MIC 1460 ManualEdition 1 19

Page 26

Section 3 - Operation

3.1 POWER UP PROCEDURE

Verify all electrical connections have been properly made before applying

power to the instrument.

If the instrument is being powered for the first time, it may be desirable to

disconnect the controller output connections. The instrument will be into

control following the power up sequence and the output(s) may turn ON .

During Power up, a self-test procedure is initiated during which all LED

segments in the two front panel displays appear and all LED indicators are

ON . When the self-test procedure is complete, the instrument reverts to

normal operation.

Note: When power is first applied, a delay of approx. 3 seconds will be

seen before the displays light up.

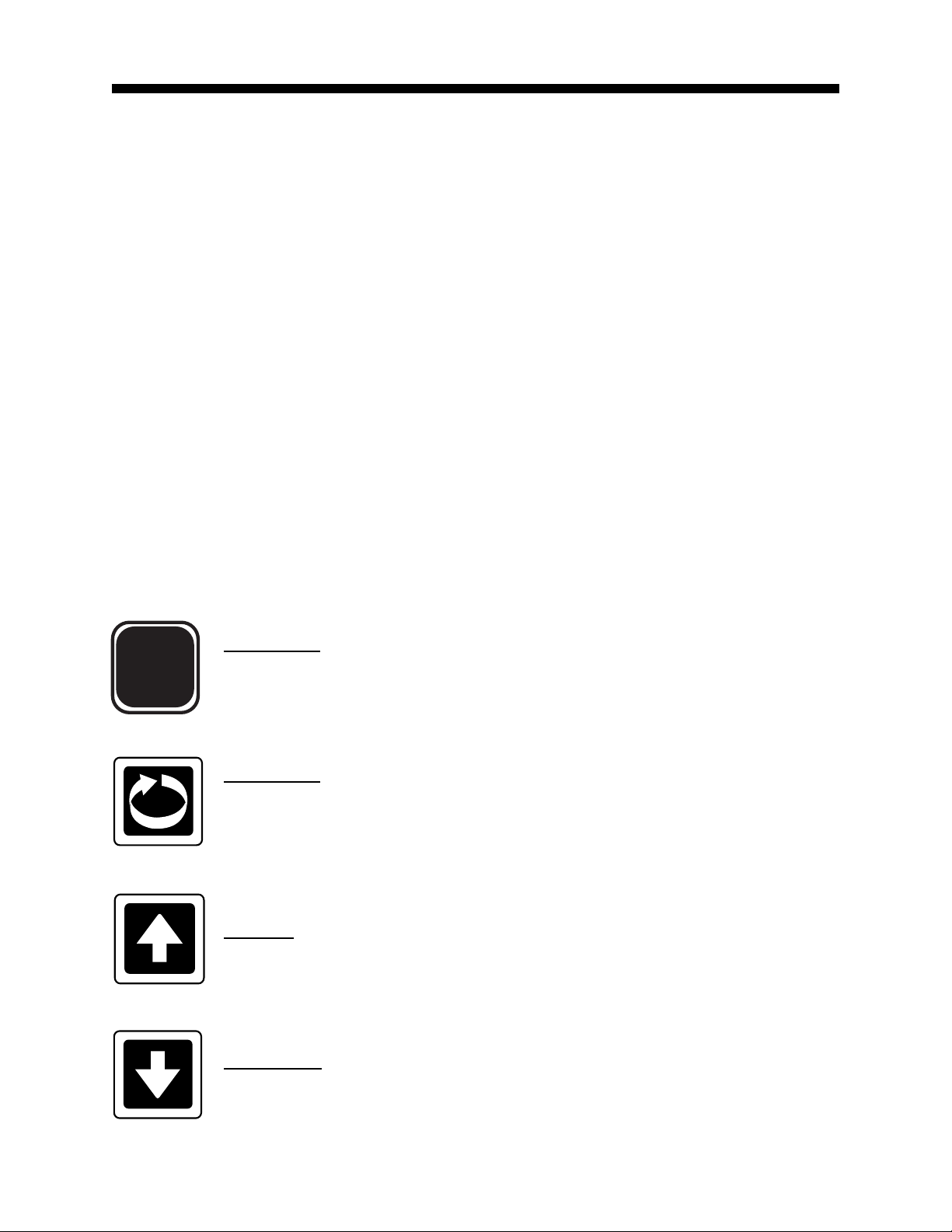

3.2 KEYPAD OPERATION

Mode Key

MODE

Changes mode of instrument.

Scroll Key

Displays the next parameter in sequence (indicated by Message display).

Up Key

Increments displayed parameter value/cycles through options.

Down Key

Decrements displayed parameter value/cycles through options.

MIC 1460 Manual Edition 120

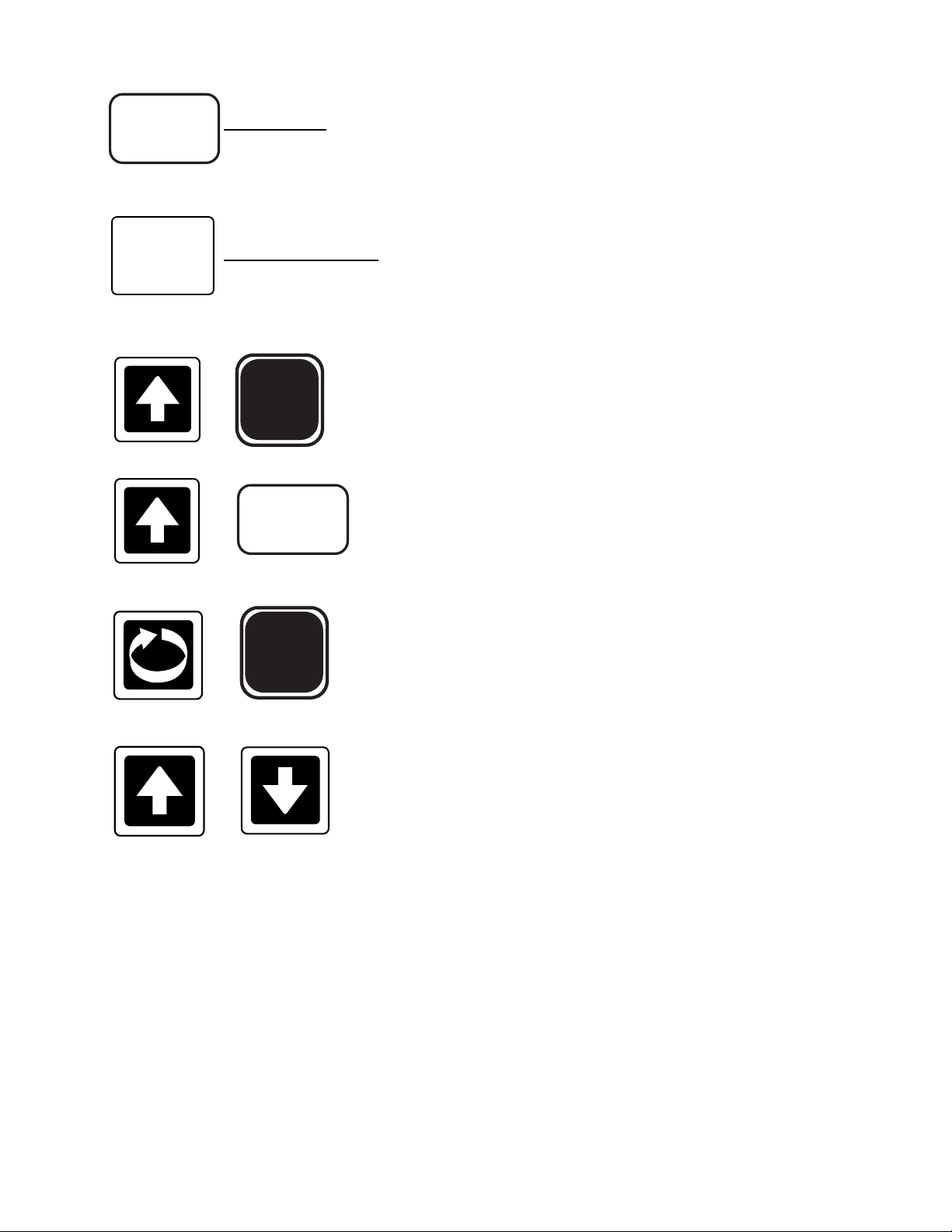

Page 27

PROF

PROF Key

Cycles through Program (profile) numbers.

RUN/HOLD

RUN/HOLD Key

Runs, holds or aborts current program (profile).

Selects/de-selects Self-T une and Pre-Tune (when

MODE

+

+

+

PROF

MODE

message display shows appropriate message).

Jumps to next segment, when program is

running.

Selects/de-selects Manual Control

+

Sets a segment to Dwell when defining a

program.

MIC 1460 ManualEdition 1 21

Page 28

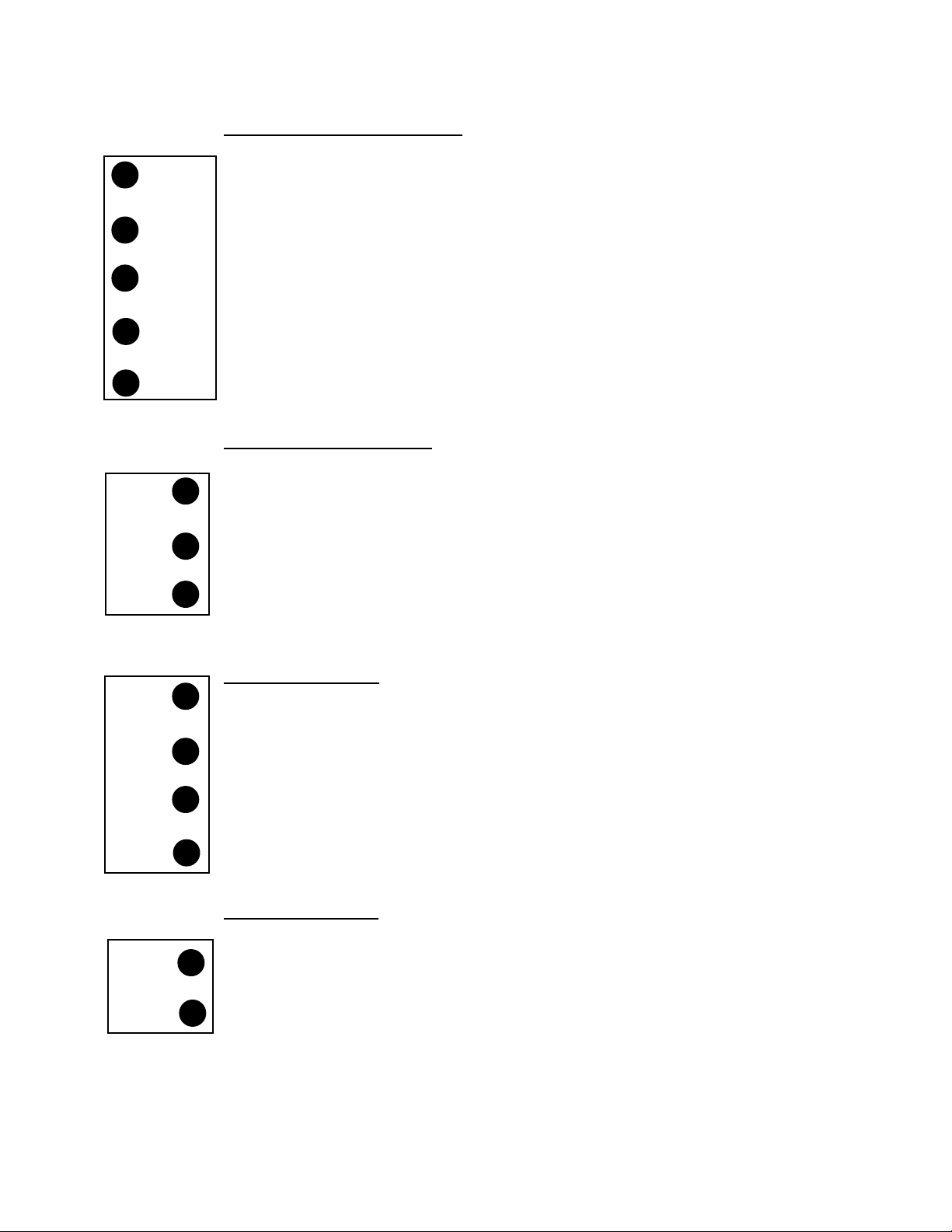

3.3 INDICATORS

Control Status Indicators

AT

ALM

OP1

OP2

MAN

RUN

HLD

x60

A T - ON when Self-Tune is active; flashes when Pre-

Tune is active.

ALM - Flashes when any alarm is active.

OP1 - ON when primary control output is active.

OP2 - ON when secondary control output (if fitted) is

active.

MAN - ON when Manual Control is selected.

Run Status Indicators

RUN - ON - Program running or (if HLD ON also) held

Flashing - Program in Delayed state

HLD - ON - Program held

Flashing - Program in Auto-Hold

x60 - OFF - timebase = hours/minutes

ON - timebase = minutes/seconds

EV1

EV2

EV3

EV4

SET

PRG

Event Indicators

Each indicates the status (active or inactive) of a user-defined

event (OFF = inactive, ON = active)

Mode Indicators

SET - ON when Controller Define Mode or Program

Define Mode is entered; flashes when viewing

parameters in Controller Define Mode or Program

Define Mode after entry from Base Mode.

PRG - ON when Program Define Mode is entered.

MIC 1460 Manual Edition 122

Page 29

3.4 DISPLAYS

PROGRAM NUMBER

Number of currentlyselected program

UPPER DISPLAY

Process Variable value

LOWER DISPLAY

Setpoint value or value/setting

of parameter being viewed/edited.

MESSAGE DISPLAY

CURRENT RAMP STATE

= UP Ramp

= DOWN Ramp

BOTH ON = Dwell

Both flashing = In Manual Control while

program is running

SEGMENT NUMBER

Number of current segment

3.5 ALARM STATUS INDICATION

When any alarm is active, the ALM indicator will flash. To view the main

status in the Message Display, press the SCROLL key until a display appears in the form:

Appears only if Alarm 1 is active

Appears only if Alarm 2 is active

Appears only if the Loop Alarm is active

MIC 1460 ManualEdition 1 23

Page 30

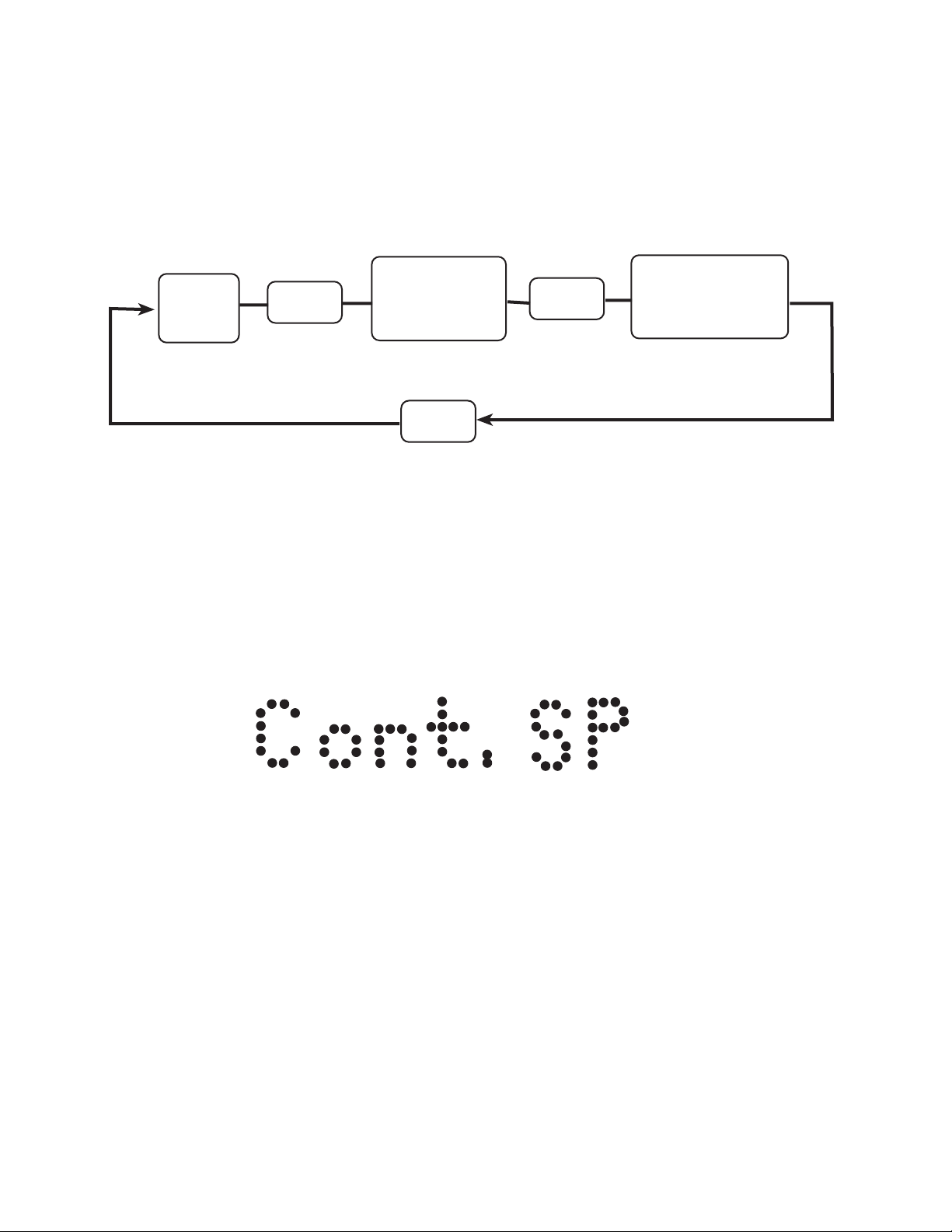

3.6 VIEWING PROGRAM AND CONTROLLER PARAMETERS

In Base Mode (i.e. with no program currently running or held), the MODE

key gives "view only" access to Program Define Mode and Controller Define Mode.

VIEW ONLY

CONTROLLER

DEFINE

MODE

BASE

MODE

MODE

VIEW ONLY

PROGRAM

DEFINE

MODE

MODE

MODE

3.7 ADJUSTING THE CONTROLLER SETPOINT

With the Setpoint Programmer in Base Mode (i.e. with the RUN, HLD, SET,

and PRG indicators OFF), the two main displays will show the process

variable value (upper display) and the setpoint value (lower display - Read

Only). To change the setpoint value:

1. Press the SCROLL key, the Message Area will display:

2. Use the UP and DOWN keys to change the setpoint value (in the

lower display) as required.

3. When the setpoint value is set as desired, press the SCROLL key

again to return to the initial display.

MIC 1460 Manual Edition 124

Page 31

3.8 MANUAL CONTROL

In any mode except Configuration Mode, the operator may select manual

control of the process by simultaneously pressing the SCROLL and MODE

keys, provided Manual Mode is enabled in Controller Define Mode. The

instrument will then enter Base Mode or (if a program is currently running)

Program Run Mode with the program held. The Message Display will

show:

and the lower Main Display will show the power output value, which may

then be adjusted using the UP and DOWN keys. While manual control is

being used, the power output display is included in the displays available in

Base Mode and Program Run Mode.

To cancel manual control, press the SCROLL and MODE keys simultaneously, wereupon the power out value display and the Power message

display will disappear and the Setpoint Controller will remain in whatever

mode prevailed when manual control was cancelled (if this is Program Run

Mode, the currently-running program will be resumed from the point at

which it was held).

3.9 USING THE PRE-TUNE FACILITY

The Pre-Tune facility is used to set the instrument's PID control parameters

to values which are approximately correct in order to provide a base from

which the Self-Tune facility may subsequently optimize tuning. Pre-T une

may be activated as follows:

1. With the instrument in Base mode (with the RUN and HLD indicators

OFF), press the SCROLL key until the Message Display shows:

MIC 1460 ManualEdition 1 25

Page 32

and the lower Main Display shows:

2. Press the MODE and UP keys to change the lower Main Display to:

indicating that the Pre-Tune facility is now activated. The AT indicator

will flash.

NOTES:

1. If the process variable is within 5% of the input span from the

setpoint, the Pre-Tune facility cannot be activated and any attempt

to do so will have no effect.

2. Since the Pre-Tune facility is a single-shot operation, it will automatically de-activate itself once the operation is complete.

To de-activate the Pre-Tune facility manually (with the instrument in Base

Mode), press the SCROLL key to obtain the same Message Displays

above; then press the MODE and UP keys simultaneously to change the

lower Main display from ON to OFF.

3.10 USING THE SELF-TUNE FACILITY

The Self-T une facility is used to optimize tuning while the Controller part of

the instrument is operating. Self Tune may be activated as follows:

1. With the instrument in Base Mode (with RUN and HLD indicators

OFF), press the SCROLL key until the Message Display shows:

MIC 1460 Manual Edition 126

Page 33

and the lower Main Display shows:

2. Press the MODE and UP keys to change the lower Main Display to:

indicating that the Self-T une facility is now activated. The AT indicator is

on continuously.

To de-activate the Self-Tune facility, press the SCROLL key to obtain the

same Message Display as above; then press the MODE and UP keys simultaneously to change the lower Main Display from ON to OFF.

MIC 1460 ManualEdition 1 27

Page 34

Section 4 - Configuration

4.1 ENTRY INTO CONFIGURATION MODE

To enter Configuration Mode:

1. Ensure that the instrument is powered down.

2. Power-up the instrument and within 30 seconds of power-up, hold

down the UP and SCROLL keys simultaneously for approximately five

seconds.

NOTE: This must be the first key action after power-up.

The instrument will then enter Configuration Mode, whereupon the upper

and lower main displays will initially be of the form:

showing the current input code selected, and the Message Display will

show:

The user may then step through the Configuration Mode parameters using

the SCROLL key. For each parameter, the Message Display will show a

legend identifying that parameter and the lower main display will show the

current setting of that parameter. The setting may be adjusted using the

UP/DOWN keys. As soon as the setting is changed, the lower main display

will flash, indicating that the new setting has yet to be confirmed. When the

setting is as required, it may be confirmed by pressing the MODE key,

whereupon the upper display will stop flashing.

MIC 1460 Manual Edition 128

Page 35

NOTE: Changes to the setting of certain Configuration Mode parameters (i.e. input range, output use and type) will cause the Program Define Mode and Controller Define Mode parameters to be

automatically set to their default values.

4.2 HARDWARE DEFINITION CODE

This parameter is a special facility in Configuration Mode, which is used to

specify the hardware fitted (input type, output types, etc); this must be compatible with the hardware actually fitted. It can be accessed, with the instrument in Configuration Mode, by simultaneously pressing the DOWN

and SCROLL keys. The Message Display will then show:

and lower main display will be of the form:

Input Type

1 RTD/Linear (mV)

2 Thermocouple

3 Linear DC (mA)

4 Linear DC (V)

Output 1 Type

1 Relay Output

2 SSR Output

3 DC Output (0-10V)

4 DC Output (0-20mA)

5 DC Output (0-5V)

7 DC Output (4-20mA)

Output 3 Type

0 None

1 Relay Output (Alarm Output Only)

2 SSR Output (Alarm Output Only)

3 DC Output 0-10V (Recorder Output Only)

4 DC Output 0-20mA (Recorder Output Only)

5 DC Output 0-5V (Recorder Output Only)

7 DC Output 4-20mA (Recorder Output Only)

Output 2 Type

0 None

1 Relay Output (Control or Alarm Output)

2 SSR Output (Control or Alarm Output)

3 DC Output 0-10V (Control Output Only)

4 DC Output 0-20mA (Control Output Only)

5 DC Output 0-5V (Control Output Only)

7 DC Output 4-20mA (Control Output Only)

MIC 1460 ManualEdition 1 29

Page 36

The displayed code may be incremented/decremented using the UP/

Event Output

Option PCB

fitted

DOWN keys as required. The maximum setting available for this code is

4777. For example, the code for a thermocouple input, 4-20mA DC primary

output (Output 1) and relay Output 3 would be 2701. When the code is first

altered, the code display will flash, until the desired value is displayed and

confirmed by pressing the MODE key.

NOTE: It is essential that this code is changed promptly whenever

there is a change to the instrument's hardware configuration

(change of input/output type, alarm/recorder output added/removed

etc.). The instrument software depends upon this code to operate

correctly.

Hardware Definitions may be viewed as Read Only displays in Base Mode

by pressing the SCROLL and DOWN keys simultaneously.

While the Hardware Definition Code is displayed, pressing the SCROLL key

will cause the Message Display to change to:

and the lower main display to change to one of:

No option PCB

fitted

Both Option

PCBs fitted

Digital Input

Option PCB

fitted

The desired setting can be achieved using the UP/DOWN keys.

MIC 1460 Manual Edition 130

Page 37

Press the SCROLL key to change the Message Display to:

and the lower main display to one of:

RS485

Communications

Option PCB not

fitted

RS485

Communications

Option PCB fitted -

Programmer acting as

slave device

Option PCB fitted -

Programmer acting as

RS485

Communications

master device

The desired setting can be achieved using the UP/DOWN keys.

To exit from the Hardware Definition Code facility, press the DOWN and

SCROLL keys simultaneously (which will cause a return to the normal Configuration Mode). Alternatively, either of the methods of exit from Configuration Mode may be used here.

4.3 CONFIGURATION MODE PARAMETERS

The Configuration Mode parameters are presented for view/edit in the following sequence:

MESSAGE AVAILABLE

STEP DESCRIPTION DISPLAY FUNCTION SETTING

1 Primary Input Input Code display- See App. A

Range

5

ed defines

input type/

range (see

App. A)

2 Control Action Control Specifies dir - Direct

control Acting

action of rEu- Reverse

Output 1

1

Acting

MIC 1460 ManualEdition 1 31

Page 38

MESSAGE AVAILABLE

STEP DESCRIPTION DISPLAY FUNCTION SETTINGS

3 Alarm 1 T ype Alarm 1 Specifies P_hi- Process

Alarm 1 High

Operation P_Lo-Process

Low

dE-Deviation

bAnd-Band

nonE-None

4 Alarm 2 T ype Alarm 2 Specifies P_hi-Process

Alarm 2 High

Operation P_Lo-Process

Low

dE-Deviation

bAnd-Band

nonE-None

5 Alarm Inhibit Inhibit Specifies nonE-No

which alarms inhibit

are inhibited ALA1-Alarm1

ALA2-Alarm 2

both-Both

Alarms

6 Output 2 Usage Out2 Use Specifies out2-Control

use of Output

Output 2

2

A2_d-Alarm 1

(direct)

A2_r-Alarm 2

(reverse)

Or_d-Alarm 1

OR 2

(direct)

(Continued on next page)

MIC 1460 Manual Edition 132

Page 39

MESSAGE AVAILABLE

STEP DESCRIPTION DISPLAY FUNCTION SETTINGS

Or_r-Alarm 1

OR 2

(reverse)

Ad_d-Alarm 1

AND 2

(direct)

Ad_r-Alarm 1

AND 2

(reverse)

LP_d-Loop

Alarm

(direct)

LP_r-Loop

Alarm

(reverse)

7 Output 3 Useage Out3 Use Specifies Al_d-Alarm 1

use of (direct)

Output 3

3

Al_r-Alarm 1

(reverse)

Or_d-Alarm 1

OR 2

(direct)

Or_r-Alarm 1

OR 2

(reverse)

Ad_d-Alarm 1

AND 2

(direct)

Ad_r-Alarm 1

AND 2

(reverse)

LP_d-Loop

Alarm

(direct)

(Continued on the next page)

MIC 1460 ManualEdition 1 33

Page 40

MESSAGE AVAILABLE

STEP DESCRIPTION DISPLAY FUNCTION SETTINGS

LP_r-Loop

Alarm

(reverse)

rEcS-Rcdr

Output

(SP)

rEcP-Rcdr

Output

(PV)

8 Segment Mode Seg Mode Defines para- ti- Time

meter used to rA-Ramp Rate

specify duration

of each segment

(along with final

SP value)

9 Baud Rate

6

Baud Rate Selects Baud Numeric

Rate for RS485 value: 1200,

Comms. 2400, 4800 or

9600

10 Address

6,7

Address Selects RS485 Numeric

comm. address value in range

1-32

11 CJC

4

Enable/ CJC Enables/ EnAb-enabled

Disabled disables cold diSA-disabled

junction comp.

12 Lock Code Lock Displays Read Only-

Code current lock no adjustment

code value in Conf. Mode

For Notes on Configuration Mode Parameters, see next page.

MIC 1460 Manual Edition 134

Page 41

Notes on Configuration Mode Parameters

1. If the secondary output is chosen as Output 2 (COOL) control output, its

action is always the compliment of the action of Output 1.

2. The default setting for Output 2 Usage is Alarm 2 hardware output,

direct-acting (if relay/SSR output) or Output 2 - COOL (if DC output).

3. The default setting for Output 3 Usage is Alarm 1 hardware output,

direct-acting (if relay/SSR output) or Process Variable Recorder Output

(if DC output)

4. This parameter does not appear in the sequence if the input type

selected is not thermocouple. If the CJC is disabled, the initial display in

Operator Mode will show horizontal bars flashing in the lower display.

5. The primary input default setting is dependent upon the hardware fitted,

as indicated in the Hardware Definition Code.

6. These parameters do not appear if the Hardware Definition Comms

parameters is set to nonE.

7. This parameter does not appear if the Programmer communications

option is set to operate in Master mode.

4.4 ALARM INHIBIT FACILITY

On power-up, an "alarm" condition may occur, based on the alarm value,

the process value and, if appropriate to the alarm type, the setpoint value.

This would normally activate an alarm; however, if the pertinent alarm is

inhibited, the alarm indication is suppressed and the alarm will remain inactive. This will prevail until the "alarm" condition returns to the "inactive"

state, whereafter the alarm will operate normally.

4.5 EXIT FROM CONFIGURATION MODE

To leave Configuration Mode, depress the UP and SCROLL keys simultaneously.

Note: An automatic exit to Base Mode will be made if, in Configuration Mode, there is no front panel key activity for five minutes.

The exit is made via the power-up self-test routines which includes a lamp

test.

MIC 1460 ManualEdition 1 35

Page 42

Section 5 - Defining The Controller Parameters

(Controller Define Mode)

Entry can be made into this mode from Program Define Mode, Program

Run Mode or Base Mode.

To enter from Base Mode or Program Run Mode:

1. Press the SCROLL and UP keys simultaneously. The lower display

will show 0 and the Message Display will show:

2. Use the UP and DOWN keys to set the value in the lower Main Display to the correct Lock Value (defined by the user in Controller Define

Mode) and press the SCROLL key. The Setpoint Programmer is now in

Program Define Mode.

Note: If an incorrect Lock Code value is entered, the instrument will

return to the original mode (i.e. Base Mode or Program Run Mode)

3. Press the MODE key.

The instrument is now in the Controller Define Mode.

Upon entry into the Controller Define Mode, the SET indicator will then

come ON and the first of the Controller parameters (Input Filter Time Constant) will be presented for editing/viewing. Using the SCROLL key, step

through the sequence of Controller parameters, editing as required (using

the UP/DOWN keys).

MIC 1460 Manual Edition 136

Page 43

5.1 CONTROLLER PARAMETERS

The Controller parameters appear in the following sequence:

MESSAGE AVAILABLE

STEP DESCRIPTION DISPLAY FUNCTION SETTING

1 Input Filter Time Filter Defines time 0.0 seconds

Constant constant for (filter OFF) to

input filter 100.0 sec(removes onds in 0.5

extraneous increments.

impulse from Default =

the process 2.0 seconds.

variable input.

2 Process V ariable Offset Modifies actual For linear

Offset

1

PV value: input, limited

Offset PV + by Scale

Actual PV = Range Max.

PV value used and Scale

Range Min.

Default=0.

3 Output 1 Power Out1 Indicates Not adjustable

current Output1 "Read Only"

power level

4 Output 2 Power

2

Out2 Indicates No adjustable

current Output2 "Read Only"

power level

5 Proportional P.Band 1 Defines portion 0.0% (ON/

Band 1 (PB1) of input span OFF control)

in which the to 999.9%

Output 1 power of input span.

level is propor- Default =

tional to the 10.0%

(offset) process

variable value

MIC 1460 ManualEdition 1 37

Page 44

MESSAGE AVAILABLE

STEP DESCRIPTION DISPLAY FUNCTION SETTING

6 Proportional P.Band 2 Defines portion 0.0% (ON/

Band 2

2

(PB2) of input span OFF control)

in which the to 999.9%

Output 2 power of input span.

level is propor- Default =

tional to the 10.0%

(offset) process

variable value

7 Reset

3

Reset Integral Time 1 second to

Constant 99 minutes

59 seconds

per repeat

8 Rate

3

Rate Derivative 00 seconds to

Time Constant 99 minutes

59 seconds

9 Overlap or Overlap Defines the -20% to +20%

Deadband

4

portion of the (negative

proportional band value =

(PB1 + PB2) deadband,

over which both positive

outputs are value =

active (overlap) overlap)

or neither output Default = 0%

is active

(deadband)

10 Bias Bias Bias applied to 0% to 100%

(Manual Reset)

3

output power, (Output1 only)

expressed as -100% to

a percentage +100%

of output power (Output 1 &

Output 2)

Default=25%

MIC 1460 Manual Edition 138

Page 45

MESSAGE AVAILABLE

STEP DESCRIPTION DISPLAY FUNCTION SETTING

11 ON/OFF Diff 1 Switching 0.1% to 10%

Differential

5

Diff 2 differential for of input span

Diff 1 output (Diff 1 Default=0.5%

or Diff 2) or both

outputs (Diff) set

to ON/OFF

control

(PB1, PB2 or

both = 0%)

12 Setpoint SP High The maximum Current

High Limit

6

limit for setpoint setpoint value

adjustment. to input

Should be set Range Max.

to a value which Default =

prevents Input Range

setpoint values Max.

causing damage

to the process.

13 Setpoint SP Low The minimum Input Range

Low Limit

6

limit for setpoint Min. to current

adjustment. setpoint

Should be set value.

to a value which Default =

prevents Input Range

setpoint values Minimum.

causing damage

to the process.

MIC 1460 ManualEdition 1 39

Page 46

MESSAGE AVAILABLE

STEP DESCRIPTION DISPLAY FUNCTION SETTING

14 Recorder Output Rec High The value of -1999 to 9999

Scale Maximum

7

the process (decimal point

variable or as for the

setpoint (as process

applicable) variable

for which the input range).

recorder output Default =

is a minimum. Input Range

Max.

15 Recorder Output Rec Low The value of -1999 to 9999

Scale Minimum

7

the process (decimal point

variable or as for the

setpoint (as process

applicable) variable

for which the input range).

recorder output Default =

is a minimum. Input Range

Min.

16 Output Power Out High Limits the 0% to 100%

Limit

3

power level of

Output 1 (used

to protect the

process).

17 Output 1 CycTime1 Limits 0.5, 1, 2, 4,

Cycle Time

8

frequency of 8, 16, 32, 64,

operation of 128, 256 or

output relay 512 seconds.

to maximize Default =

relay life. 32 seconds.

MIC 1460 Manual Edition 140

Page 47

MESSAGE AVAILABLE

STEP DESCRIPTION DISPLAY FUNCTION SETTING

18 Output 2 CycTime2 Limits 0.5, 1, 2, 4,

Cycle Time

8

frequency of 8, 16, 32, 64,

operation of 128, 256 or

output relay 512 seconds.

to maximize Default =

relay life. 32 seconds.

19 Process High HiAlarm1 If Alarm 1 is Input Range

Alarm 1 value a Process High Max. to Input

Alarm, the Range Min.

value of Default =

process Input Range

variable at or Max.

above which

Alarm 1 will

be active.

20 Process Low LoAlarm1 If Alarm 1 is Input Range

Alarm 1 value a Process Low Max. to Input

Alarm, the Range Min.

value of Default =

process Input Range

variable at or Min.

below which

Alarm 1 will

be active.

21 Band Alarm 1 BaAlarm1 If Alarm 1 is ± (input span)

value a Band Alarm, from setpoint.

the band of Default = five

process input units.

variable values

(centered on

the setpoint)

outside which

the process

variable will

cause this alarm

to be active.

MIC 1460 ManualEdition 1 41

Page 48

MESSAGE AVAILABLE

STEP DESCRIPTION DISPLAY FUNCTION SETTING

22 Deviation DeAlarm1 If Alarm 1 is ± (input

(High/Low) a Deviation range)

Alarm 1 High/Low from setpoint

value Alarm, gives Default =

a value above five input

(positive value) range units.

or below

(negative value)

the setpoint.

If the process

variable deviates

from the setpoint

by a margin

greater than this

value, the alarm

becomes active

23 Alarm 1 Al1 Hyst Value defines 1 LSD to 10%

Hysteresis a hysteresis of input span

value band on the (0 is an

"safe" side invalid value)

of the Alarm 1

value

24 Process High HiAlarm2 If Alarm 2 is Input Range

Alarm 2 value a Process High Max. to Input

Alarm, the Range Min.

value of Default =

process Input Range

variable at or Max.

above which

Alarm 2 will

be active

MIC 1460 Manual Edition 142

Page 49

MESSAGE AVAILABLE

STEP DESCRIPTION DISPLAY FUNCTION SETTING

25 Process Low LoAlarm2 If Alarm 2 is Input Range

Alarm 2 value Process Low Max. to Input

Alarm, the Range Min.

value of Default =

process Input Range

variable at or Min.

below which

Alarm 2 will

be active

26 Band Alarm 2 BaAlarm2 If Alarm 2 is ± (input span)

value a Band Alarm, from setpoint.

the band of Default =

process five input

variable units.

values

(centered on

the setpoint)

outside which

the process

variable will

cause this

alarm to be

active.

MIC 1460 ManualEdition 1 43

Page 50

MESSAGE AVAILABLE

STEP DESCRIPTION DISPLAY FUNCTION SETTING

27 Deviation DeAlarm2 If Alarm 2 is a ± (input

(High/Low) Deviation range)

Alarm 2 value High/Low from setpoint.

Alarm, gives Default =

a value above five input

(positive value) range units

or below

(negative value)

the setpoint.

If the process

variable deviates

from the setpoint

by a margin

greater than this

value, the alarm

becomes active.

28 Alarm 2 Al2 Hyst A non-zero 1 LSD to 10%

Hysteresis value value defines of input span

a hysteresis

band on the

"safe" side of

the Alarm 2

value

29 Loop Alarm Loop Alm Enables/ 0 (disabled)/

Enable disables Loop 1 (enabled)

Alarm Default =

0 (disabled)

MIC 1460 Manual Edition 144

Page 51

MESSAGE AVAILABLE

STEP DESCRIPTION DISPLAY FUNCTION SETTING

30 Loop AlarmTime LpAtime If ON/OFF 1 second to

control is 99 minutes

selected 59 seconds.

(i.e. PB1=0) Default =

and Loop 99 minutes

Alarm is 59 seconds

enabled, this

defines the

duration of the

saturation

condition

after which the

Loop Alarm

is activated

31 Scale Range Range Pt For linear 0 XXXX

Decimal Point

9

inputs, defines 1 XXX.X

the decimal (default)

point position 2 XX.XX

3 X.XXX

32 Scale Range Range Hi For linear -1999 to 9999

Maximum

9

inputs, defines (decimal point

the scaled as defined

input value by Scale

when the Range

process Decimal

variable input Point

is at its parameter).

maximum Default =

value. 100.0

MIC 1460 ManualEdition 1 45

Page 52

MESSAGE AVAILABLE

STEP DESCRIPTION DISPLAY FUNCTION SETTING

33 Scale Range Range Lo For linear -1999 to 9999

Minimum

9

inputs, defines (decimal point

the scaled as defined

input value by Scale

when the Range

process Decimal

variable input Point

is at its parameter).

minimum Default = 0.0

value.

34 Auto Pre-Tune Auto PT Determines OFF =

Enable/Disable whether the Disabled

Pre-Tune ON = Enabled

facility is Default = OFF

automatically

activated on

power-up

35 Manual Control A/M Enab Enables/ OFF =

Enable/Disable disables Disabled

operator ON = Enabled

selection of Default = Off

manual control

36 Communications ComWrite Enables/ OFF =

Write Enable/ disables Disabled

Disable

10

changing of ON = Enabled

parameter Default = Off

values or

settings via the

RSs485

communications

link.

MIC 1460 Manual Edition 146

Page 53

MESSAGE AVAILABLE

STEP DESCRIPTION DISPLAY FUNCTION SETTING

37 Lock value Lock Defines the 0 to 9999

four-digit code Default = 10

required to

enter Program

define Mode or

Controller

Define Mode

Notes on Configuration Define Mode Parameters

1. The Process Variable Offset value should be chosen with care. Any

adjustment to this parameter is, in effect, a calibration adjustment.

Injudicious application of values to this parameter could lead to the dis

played process variable value bearing no meaningful relationship to the

actual process variable value. There is no front panel indication when

this parameter is in effect (i.e. has been set to a non-zero value).

2. These parameters are applicable only if the secondary control (COOL)

output is fitted.

3. These parameters are not applicable if Proportional band 1 is set to 0

(i.e. ON/OFF control).

4. This parameter is not applicable if Proportional band 1 is set to 0 or if

Output 2 (COOL) is not fitted.

5. The message Display will show Diff1 for ON/OFF control on Output 1

only, Diff 2 for ON/OFF control on Output 2 only or Diff for ON/OFF

control on both Output 1 and Output 2.

6. Internal software prevents (a) the Setpoint High Limit being given a

value less than any setpoint value contained in currently-resident

programs, and (b) the Setpoint Low Limit being given a value greater

than any setpoint value contained in currently-resident programs.

7. These parameters are not applicable if the Recorder Output option is not

fitted.

8. Output 1 cycle Time is not applicable if Proportional Band 1 is set to 0 or

if Output 1 is a DC linear output. Output 2 cycle Time is not applicable if

Proportional Band 1 is set to 0, if Output 2 is not fitted or if Output 2 is a

DC linear output.

MIC 1460 ManualEdition 1 47

Page 54

9. These parameters are applicable only if a linear input is fitted.

10. Applicable only if the RS485 Communications option is fitted.

FIGURE 5-1

Proportional Band 1

Pb1

Output 1

Output 2

Setpoint

Output Power (%)

Proportional

Band 1

Pb1

Output 1

Output 2

Output Power (%)

Setpoint

Proportional Band 2

Pb2

Overlap

(Positive value)

SPrd

Deadband

(negative value)

SPrd

Output 2

Output 1

Process Variable

Proportional

Band 2

Pb2

Output 2

Output 1

Process Variable

Proportional

Band 1

Output 1

Output 2

Output Power (%)

Pb1

Output 2 OFF

Setpoint

Positive values Negative values

Overlap/Deadband

Sprd

MIC 1460 Manual Edition 148

Proportional Band 2

Pb2 = 0

Output 2 ON

Process Variable

ON/OFF

Differential

HyS2

Output 2

Output 1

Page 55

FIGURE 5-2

Process High Alarm

direct-acting

Process High Alarm

reverse-acting

Process Low Alarm

direct-acting

Process Low Alarm

reverse-acting

"ALM" Off

Relay Off

"ALM" Off

Relay On

"ALM" flashes

Relay On

"ALM" flashes

Relay Off

"ALM" flashes

Relay On

PV

ALARM POINT

"ALM" flashes

Relay Off

PV

ALARM POINT

"ALM" Off

Relay Off

PV

ALARM POINT

"ALM" Off

Relay On

PV

ALARM POINT

Band Alarm

direct-acting

open within band

Band Alarm

reverse-acting

closed within band

"ALM" flashes

"ALM" flashes

(Continued on next page)

Relay On

Relay Off

ALARM VALUE

"ALM" Off

Relay Off

SP

ALARM VALUE

"ALM" Off

Relay On

SP

"ALM" flashes

Relay On

PV

"ALM" flashes

Relay Off

PV

MIC 1460 ManualEdition 1 49

Page 56

Deviation High Alarm

direct-acting

(positive value)

Deviation Low Alarm

direct-acting

(negative value)

"ALM" Off

Relay Off

"ALM" flashes

Relay On

SP

"ALM" flashes

Relay On

PV

ALARM

POINT

"ALM" Off

Relay Off

PV

Deviation High Alarm

reverse-acting

(positive value)

Deviation Low Alarm

reverse-acting

(negative value)

"ALM" Off

Relay Off

"ALM" flashes

Relay On

ALARM

POINT

ALARM

POINT

SP

SP

"ALM" flashes

Relay Off

PV

ALARM

POINT

"ALM" Off

Relay Off

PV

SP

MIC 1460 Manual Edition 150

Page 57

FIGURE 5-3

PROCESS

HIGH

ALARM

PROCESS

LOW

ALARM

DEVIATION

HIGH

ALARM

DEVIATION

LOW

ALARM

Alarm Hysteresis

Alarm Inactive

Process Variab le

Alarm Hysteresis

Alarm Inactive

Alarm Hysteresis

Alarm Inactive

Alarm Hysteresis

Process

Variable

Alarm Active

Alarm Active

Alarm Value

Alarm Active

Setpoint

Setpoint

Alarm Value

Process Variab le

Alarm Inactive

Alarm Inactive

Alarm

Value

Alarm Inactive

Process Variab le

BAND

ALARM

Alarm Inactive

Alarm

Inactive

Setpoint

Alarm Value

Alarm Hysteresis

Alarm Active

Alarm Active

Alarm Hysteresis

Alarm

Inactive

Alarm Inactive

Alarm Value

Alarm

Active

Alarm

Inactive

Process

Variab le

MIC 1460 ManualEdition 1 51

Page 58

5.2 BASE MODE DISPLAYS

Once the complete cycle of Controller Define Mode parameters has been

displayed, the user may then step through the Base Mode displays (controller setpoint - alarm status - Self Tune - Pre-Tune), making adjustments

where required, before re-starting the Controller Define Mode parameter

cycle.

5.3 LOOP ALARM AND LOOP ALARM TIME

The Loop Alarm is a special alarm which detects faults in the control feedback loop by continuously monitoring process variable response to the

control output(s).

The Loop Alarm facility, when enabled, repeatedly checks the control

output(s) for saturation i.e. either or both outputs being at the maximum or

minimum limit. If an output is found to be in saturation, the Loop Alarm

facility starts a timer; thereafter, if the saturated output has not caused the

process variable to be corrected by a pre-determined amount V after a time

T has elapsed, the Loop Alarm goes active. Subsequently, the Loop Alarm

facility repeatedly checks the process variable and the control output(s).

When the process variable starts to change value in the correct sense or

when the saturated output comes out of saturation, the Loop Alarm is deactivated.

For PID control, the Loop Alarm Time T is always set to twice the value of

the Reset (Integral Time Constant) parameter. For On/Off control, the user

defined value of the Loop Alarm Time parameter is used.

The value of V is dependent upon the input type:

°C ranges: 2°C or 2.0°C

°F ranges: 3°F or 3.0°F

Linear ranges: 10 least significant display units

For single output controllers, the saturation limits are 0% and Output Power

Limit. For dual output controllers, the saturation limits are -100% and Output Power Limit.

MIC 1460 Manual Edition 152

Page 59

Notes:

1. Correct operation of the Loop Alarm depends upon reasonably accurate

PID tuning.

2. The Loop Alarm is automatically disabled during Manual Control Mode

and during execution of the Pre-T une facility. Upon exit from Manual

Control Mode or after completion of the Pre-Tune routine, the Loop

Alarm is automatically re-enabled.

When full ON/OFF control is selected (i.e. Proportional Band 1 is set to 0)

and Loop Alarm is enabled, the Loop Alarm Time parameter determines

the duration of the saturation condition after which the Loop alarm will be

activated. It may be adjusted within the range 1 second to 99 minutes 59

seconds. This parameter is omitted from the display sequence if ON/OFF

control is not selected or Loop Alarm is disabled. The default setting is

99:59.

5.4 EXITING CONTROLLER DEFINE MODE

The operator may exit from Controller Define Mode by pressing the MODE

key until the Exit ? prompt appears in the Message Display, then pressing

the SCROLL key, which will cause a return to the mode from which entry

was made.

Note: An automatic return is made if there is no key activity in Controller Define Mode for five minutes.

MIC 1460 ManualEdition 1 53

Page 60

Section 6 - Defining and Viewing a Program

(Program Define Mode)

The instrument may be put into Program Define Mode from either Base

Mode or Program Run Mode (i.e. with a program currently running).

6.1 ENTRY INTO PROGRAM DEFINE MODE

1. Press the SCROLL and UP keys simultaneously. The lower Main Display will show 0 and the Message Display will show:

2. Use the UP and DOWN keys to set the value in the lower Main Display

to the correct Lock Value (defined by the user in Controller Define Mode)

and press the SCROLL key.

The instrument will enter Program Define Mode, the SET and PRG indicators will go ON and the operator will be able to edit programs and segments. The MODE key can then be used (a) to switch to Controller Define

Mode , and then (b) to show a Message display:

To return to Program Define Mode (and re-start the Program Define/Controller Define/Exit? display cycle), press the MODE key; to return to Base

Mode, press the SCROLL key.

If an incorrect Lock Value is entered, the instrument will return to Base

Mode.

Program parameters are divided into three categories:

(a) Those common to all programs - global parameters

(b) Those which apply to a specific program as a whole

(c) Those relevant to a specific segment in a specific program

MIC 1460 Manual Edition 154

Page 61

In Program Define mode, the operator will be presented with the first of a

sequence of parameter displays. The operator may then step through the

sequence, using the SCROLL key. The parameter setting (in the lower

Main Display) may be changed using the UP/DOWN keys. The displayed

Program Number may be changed using the PROF key and the displayed

Segment Number may be changed using the RUN/HOLD key.

Note: If entry is made from Program Run Mode and the Program Lock

is ON, only Controller Define Mode will be accessible.

6.2 PARAMETERS COMMON TO ALL PROGRAMS

(Program Number = A, Segment Number = Blank)

The parameters common to all programs (global parameters) are presented

for edit/viewing in the following sequence:

MESSAGE AVAILABLE

STEP DESCRIPTION DISPLAY FUNCTION SETTING

1 Start On Start on Defines SEtP-Current

setpoint value Controller

at start of setpoint value

each program

Proc-Current

Process

variable value

2 End On End on Defines F_SP-End on

setpoint value Final SP value

at end of value*

each program

SEtP-End on

Controller SP

value

MIC 1460 ManualEdition 1 55

Page 62

MESSAGE AVAILABLE

STEP DESCRIPTION DISPLAY FUNCTION SETTING

3 Delay Time Delay Defines delay Numerical

(in hours/min) value, with the

between decimal point

initiating the acting as the

program and delimiter

actually starting between the

two units

(hours/min)

4 Program Lock LockProg Defines On - No

whether the changes

operator is permitted

permitted to

change program OFF- changes

definitions while permitted

a program is

running/held

5 Power Fail Recovery Defines 0 or 1

Recovery response to 0=Cold Start

restoration of (entry into

power after Base

Mode with

Program

No. set as

when

power

failed and

Segment

Number

blank.

1 = W arm

Start (pro gram re sumed

from point

when

power

failed

MIC 1460 Manual Edition 156

Page 63

6 External Selection Ext. Sel Defines nonE = No

functions external

which may be selection

controlled

externally SEL=Program

selection only

run = Only

Run, Hold,

Abort, and

x60 functions

both = All

program

selection and

run control

functions

* The Final Setpoint value for the End Segment of each program.

6.3 PARAMETERS WHICH APPLY TO A SPECIFIC PROGRAM

AS A WHOLE

(Program Number = 1 to 9, Segment = Blank)

Only the parameters relevant to the displayed program number (which can

be changed using the PROG key) are presented. The parameter sequence

is as follows:

MESSAGE AVAILABLE

STEP DESCRIPTION DISPLAY FUNCTION SETTING

1 Cycle Count Cycles Defines the 1 - 9999

number of Program will

times the repeat the set

program will number of

be repeated of times

inF = Program

will repeat

indefinitely

MIC 1460 ManualEdition 1 57

Page 64

MESSAGE AVAILABLE

STEP DESCRIPTION DISPLAY FUNCTION SETTING

2 Auto Hold AutoHold Selects OFF = No

operation of Auto Hold

Auto Hold

facility H_SP = Auto

(relative to Hold above

setpoint) setpoint only

L_SP = Auto

Hold below

setpoint only

both = Auto

Hold above

and below

setpoint

3 Hold Band HoldBand Defines the Numerical

width of the value

Hold Band (0.0 to span)

4 Hold On Hold on Defines d_r = Auto

whether the Hold on

Auto Hold ramps and

facility is dwells

used on

ramps only , ___d = Auto

dwells only Hold on

or both dwells only

___r = Auto

Hold on

ramps only

MIC 1460 Manual Edition 158

Page 65

MESSAGE AVAILABLE

STEP DESCRIPTION DISPLAY FUNCTION SETTING

5 Pre-x60 Pre-x60 Determines nonE = No

whether the pre-selection

timebase for

the program ON

is pre-selected

to be hours/ OFF

minutes or

minutes/

seconds

This parameter sequence may be viewed/edited for any program by simply

changing the Program Number as required, using the PROF key, then stepping through the parameters with the SCROLL key.

MIC 1460 ManualEdition 1 59

Page 66

FIGURE 6-1

HOLD on DWELL

Setpoint

HOLD on RAMP

(Positive Ramp)

Hold Band

Hold Band

Program held

if Auto Hold is

set to L_SP or

both

Process V ariable

Program held

if Auto Hold is

set to H_SP or

both

Setpoint

HOLD on RAMP

(Negative Ramp)

Hold Band

Program held

if Auto Hold is

set to L_SP or

both

Setpoint

Program held

if Auto Hold is

set to H_SP or

both

Process

Variable

Program held

if Auto Hold is

set to H_SP or

both

Program held

if Auto Hold is

set to L_SP or

both

MIC 1460 Manual Edition 160

Page 67

6.4 EDITING/VIEWING PARAMETERS IN ANY/EACH

SEGMENT IN A SPECIFIC PROGRAM

(Program Number = 1 to 9, Segment Number = 1-16)

Adjust the Program Number (using the PROF key) and the Segment Number (using the RUN/HOLD key) as required. The parameters presented will

be these relevant to the program and segment whose numbers are displayed. The parameters sequence for each segment is as follows:

MESSAGE AVAILABLE

STEP DESCRIPTION DISPLAY FUNCTION SETTING

1 Final Setpoint V alue Final SP Defines the Numeric value

final value of (limited by

the setpoint SPHi and

for this SPLo) or

segment, (by pressing

selects a the UP/

dwell segment DOWN keys

or indicates simultanea Join, Repeat, ously)

or End Program indicates a

segment dwell with:

_ _ _ _

or, if the

segment is

already a

Join, Repeat,

or End

Program

segment,

as shown

below

MIC 1460 ManualEdition 1 61

Page 68

MESSAGE AVAILABLE

STEP DESCRIPTION DISPLAY FUNCTION SETTING

2 Segment Time Time Defines the Four-digit

or or duration/ramp number in the

Ramp Rate RampRate rate of the form nn.nn

as selected of the segment (hours.

in Configuration or whether minutes or

Mode this is a Join, seconds) or

Repeat or negative

End Program values as

segment* follows:

J01 - Join to

Program 1

J02 - Join to

Program 2

J03 - Join to

Program 3

J04 - Join to

Program 4

J05 - Join to

Program 5

J06 - Join to

Program 6

J07 - Join to

Program 7

J08 - Join to

Program 8

rEP - Repeat

Segment

End - End

Program

MIC 1460 Manual Edition 162

Page 69

MESSAGE AVAILABLE

STEP DESCRIPTION DISPLAY FUNCTION SETTING

3 Event † Event Defines the Four-bit

states of binary

the four number

event outputs (0=inactive,

for this segment 1=active)

* If a segment is set to be a Join segment, a repeat segment or an End

Program segment, the next depression of the SCROLL key will set the

Segment Number to A and the parameter displayed will be the first in the

sequence of parameters common to the whole program - Cycle Count.

Otherwise, the next depression of the SCROLL key will display the next

segment parameter - Event (for the current segment) if the Event Output

hardware is fitted.

† This parameter appears in the sequence only if the Event Output hardware is fitted, in which case this parameter will be followed by the Final

Setpoint Value parameter for the next segment. If this hardware is not

fitted, this parameter will be omitted from the sequence and the segment

number will be advanced, causing the Final Setpoint Value parameter for

the next segment to appear immediately.

CANCELLING JOIN, REPEAT OR END PROGRAM SEGMENTS

This can be achieved:

(a) at the Final Setpoint Value parameter, by simultaneously pressing the

UP/DOWN keys to produce a Dwell segment, or

(b) at the Segment Time/Ramp Rate parameter, by incrementing the value

to 0 or a positive value.

MIC 1460 ManualEdition 1 63

Page 70

6.5 USING JOIN, REPEAT AND END SEGMENTS AND

CYCLING PROGRAMS

By default, the instrument has eight programs, each 16 segments long (all

16 segments are active and, at the end of Segment 16 is an implicit End

Segment). These programs can be made shorter (using End segments) or

longer (by creating program sequences with Join, Repeat and End segments). The only limit to the size of a program sequence is a maximum

length of 121 active segments plus seven Join segments plus one End

segment (i.e. all eight programs joined to make one program sequence).

Segments follow a free format in that ramp or dwell can be followed by

dwell or ramp, completely as desired.

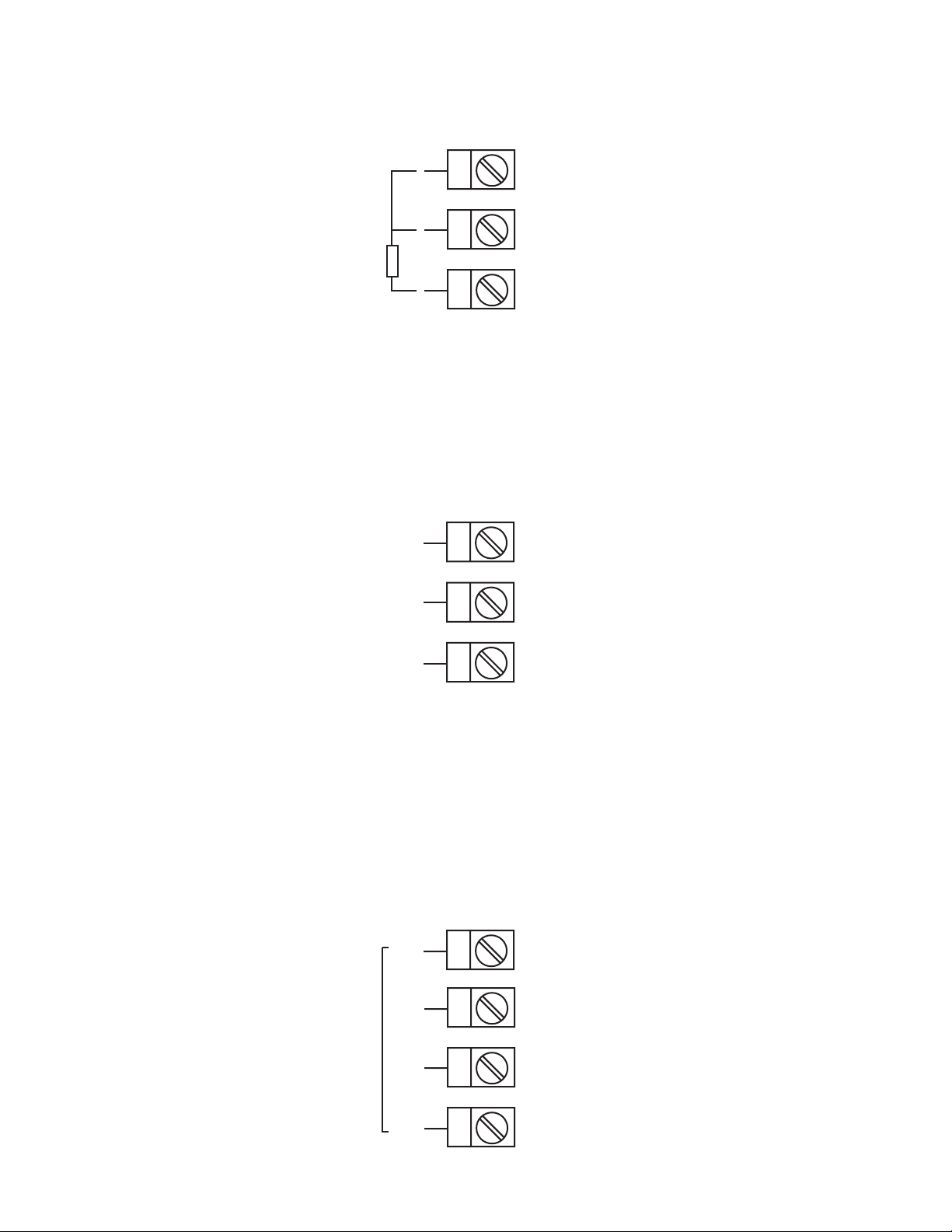

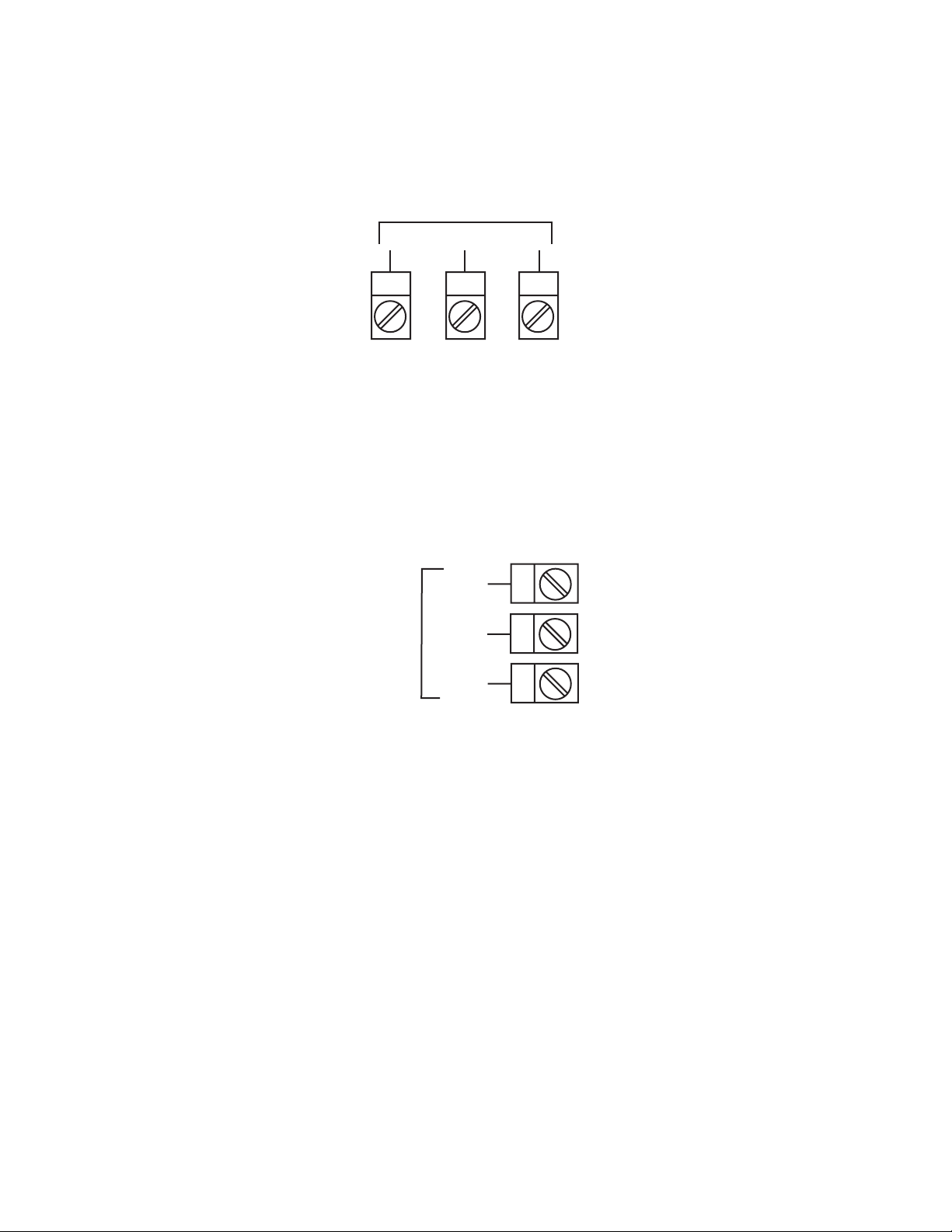

Consider two example programs:

PROGRAM 1

(5 active segments, 1 End segment)

2

1

3

4

End

Segment

(3 active segments, 1 End segment)

5

PROGRAM 2

2

1

3

End

Segment

To join the two programs to form a program sequence, change the End

segment of Program 1 to a Join segment (Segment Time or Ramp Rate set

to J02 - Join Program 2):

PROGRAM 1

(5 active segments, 1 Join segment)

2

1

3

4

Join

Segment

(3 active segments, 1 End segment)

1

5

PROGRAM 2

2

3

End

Segment

There are no restrictions on joining programs; several programs can be

joined to one program (i.e.to prove user-selectable warm-up programs,

depending upon which program is run first).

MIC 1460 Manual Edition 164

Page 71

The Cycle feature can be used to make more complex program sequences.

n

Consider the two simple example programs previously described:

PROGRAM 1

(5 active segments, 1 End segment)

2

1

3

4

End

Segment

(3 active segments, 1 End segment)

5

PROGRAM 2

2

1

3

End

Segment

and consider the case where Program 1 is set to perform two cycles and

Program 1 is joined to Program 2. When Program 1 is run, the result would

be:

PROGRAM 1

2

1

PROGRAM 1

2

3

4

5

1

3

4

5

Join

Segment

PROGRAM 2

1

2

3

End

Segme

If Program 2 were now set to perform ten cycles, the result would be:

PROGRAM 1

2

1

PROGRAM 1

2

3

4

5

1

3

10 Cycles

4

5

Join

Segment

PROGRAM 2

2

1

End

Segment

3

MIC 1460 ManualEdition 1 65

Page 72

Now, with Program 2 set to perform 10 cycles, change its last segment to a

Repeat segment (Segment Time or Ramp Rate set to REP); the result

would be:

PROGRAM 1

2

1

PROGRAM 1

2

3

4

1

5

3

4

5

Join

Segment

PROGRAM 2

1

10 Cycles

2

3

Repeat

Segment

At the end of the tenth cycle of Program 2, the program sequence would

end.

6.6 BASIC RULES TO REMEMBER

In any program sequence:

• A program ending in a Join segment will perform the required number

of cycles of

itself

before joining the new program.

• A program ending in a Repeat segment (hence, by definition, the last

program in the sequence) will perform the required number of cycles of

itself

before ending the sequence.

• A program ending in an End segment (hence, by definition, the last

program in the sequence) will perform its cycle on the

sequence

before ending that sequence.

entire program

6.7 EXITING PROGRAM DEFINE MODE

The operator may exit from Program Define Mode by pressing the MODE

key until the Exit ? prompt appears in the Message Display, then pressing

the SCROLL key, which will cause a return to the mode from which entry

was made.

Note: An automatic return is made if there is no key activity in Program Define Mode for five minutes.

MIC 1460 Manual Edition 166

Page 73

Section 7 - Programs

7.1 SELECTING AND RUNNING A PROGRAM

When no program is running, the instrument is in Base Mode and the RUN

and HLD indicators are OFF. In this mode, select a program as follows:

1. Hold down the PROF key until the required program number is dis-

played.

2. Press the RUN/HOLD key once to start the program. The RUN indi-

cator will then go ON; the instrument is now in Program Run Mode.

7.2 CHANGING THE PROGRAM TIMEBASE

While a program is running, the normal timebase is hours/minutes. To

change to a timebase of minutes/seconds (i.e. select the x60 facility) press

the UP key for more than five seconds, whereupon the x60 indicator will go

ON. To cancel operation on the x60 timebase, press the DOWN key for

more than five seconds, whereupon the x60 indicator will go OFF.

7.3 HOLDING A PROGRAM MANUALLY

The operator may hold or freeze a program by momentarily pressing the

RUN/HOLD key. The HLD indicator will then go ON (the RUN indicator

staying ON) and the program will stop execution. The program may subsequently be restarted by momentarily pressing the RUN/HOLD key again.