Panasonic WJHDE-300 Service manual

STANDARD ACCESSORIES

Operating instructions................................................. 1 pc.

The following are for installation.

Power cord ................................................................. 1 pc.

Serial cable ................................................................. 1 pc.

Rack mounting bracket .............................................. 2 pcs.

Bracket fixing screw ................................................... 4 pcs.

HDD fixing screw ...................................................... 16 pcs.

Cable clamp ............................................................. 1 pc.

Clamp fixing screw ................................................... 1 pc.

ORDER NO. AVS0405529C0

S16

Extension Unit

WJ-HDE300

WJ-HDE

300300

Extension Unit

SPECIFICATIONS

Matsushita Electric Industrial Co., Ltd.

All rights reserved. Unauthorized copying and

distribution is a violation of law.

©

2004

The Product with PbF

Required power: 120 V AC 60 Hz for WJ-HDE300

220 V AC - 240 V AC 50 Hz for WJ-HDE300/G

Power consumption: 85 W (including 4 HDDs when installed)

Interface: 2-wire serial, 480 Mbps logical speed

Operating temperature: +5 °C to +45 °C (41 °F to 113 °F)

Operating humidity: Less than 85 %

Dimensions: 420 mm (W) x 88 mm (H) x 350 mm (D), rubber feet exclusive

19-9/16" (W) x 3-7/16" (H) x 13-13/16" (D)

Weight: 7.2 k

g (16 lbs) (not including hard disk drives)

Weight and dimensions indicated are approximate.

Specifications are subject to change without notice.

CAUTION

RISK OF ELECTRIC SHOCK

DO NOT OPEN

CAUTION:

TO REDUCE THE RISK OF ELECTRIC SHOCK,

DO NOT REMOVE COVER (OR BACK). NO USER

SERVICEABLE PARTS INSIDE.

REFER SERVICING TO QUALIFIED SERVICE

PERSONNEL.

This symbol warns the user that uninsulated voltage within

the unit may have sufficient magnitude to cause electric

shock. Therefore, it is dangerous to make any kind of contact

with any inside part of this unit.

This symbol alerts the user that important literature concerning

the operation and maintenance of this has been included.

Therefore, it should be read carefully in order to avoid

any problems.

There are special components used in this equipment which are important for safety. These parts are indicated

by the ” Y ” mark on the schematic diagram and the replacement parts list. It is essential that these critical

parts should be replaced with manufacturer's specified parts to prevent X-radiation, shock, fire, or other hazards.

Do not modify the original design without permission of manufacture.

IMPORTANT SAFETY NOTICE

About Lead Free Solder (PbF)

Distribution of PbF PCB:

PCBs (manufactured) using lead free solder (PbF) will have a stamp on the PCB.

Caution:

8 Lead free solder has a higher melting point than standard solder. Typically the melting points is 35 °C – 40 °C

(95 °F – 104 °F) higher. Please use a soldering iron with temperature control and adjust it to 360 °C – 370 °C

(680 °F – 698 °F). In case of using high temperature soldering iron, please be careful not to heat too long.

8 Lead free solder will tend to splash when heated too high (600 °C / 1112 °F).

8 Lead free solder (Sn - 3.0Ag – 0.5Cu) or equivalents are recommended on repairing our lead free soldered PCB.

Y WARNING

This service information is designed for experienced repair technicians only and is not designed for use by the

general public.

It does not contain warnings or cautions to advise non-technical individuals of potential dangers in attempting to

service a product.

Products powered by electricity should be serviced or repaired only by experienced professional technicians. Any

attempt to service or repair the product or products dealt with in this service information by anyone else could

result in serious injury or death.

SAFETY PRECAUTIONS

GENERAL GUIDELINE

1. When service is required, observe the original lead

dress. Components, wires or cables that indicate

evidence of overheating or other electrical or mechanical

damage should be replaced.

2. After servicing see to that all the protective devices, such

as insulation tape, shields must be properly installed.

3. After servicing, make the following leakage current

checks to prevent the customer from being exposed to

shock hazards.

LEAKAGE CURRENT COLD CHECK

1. Unplug the AC cord and connect a jumper between the

two prongs on the plug.

2. Measure the resistance value, with an ohmmeter,

between the jumpered AC plug and each exposed

metallic cabinet part on the equipment such as

screwheads, connectors, control shafts, etc.

When the exposed metallic part has a return path to the

chassis, the reading should be between 1M Ω and 5.2M

Ω. When the exposed metal does not have a return path

to the chassis, the reading must be ∞ (infinity).

Any resistance value below this range indicates an

abnormality which requires corrective action.

3. Repeat the test with the AC switch in the "OFF" position.

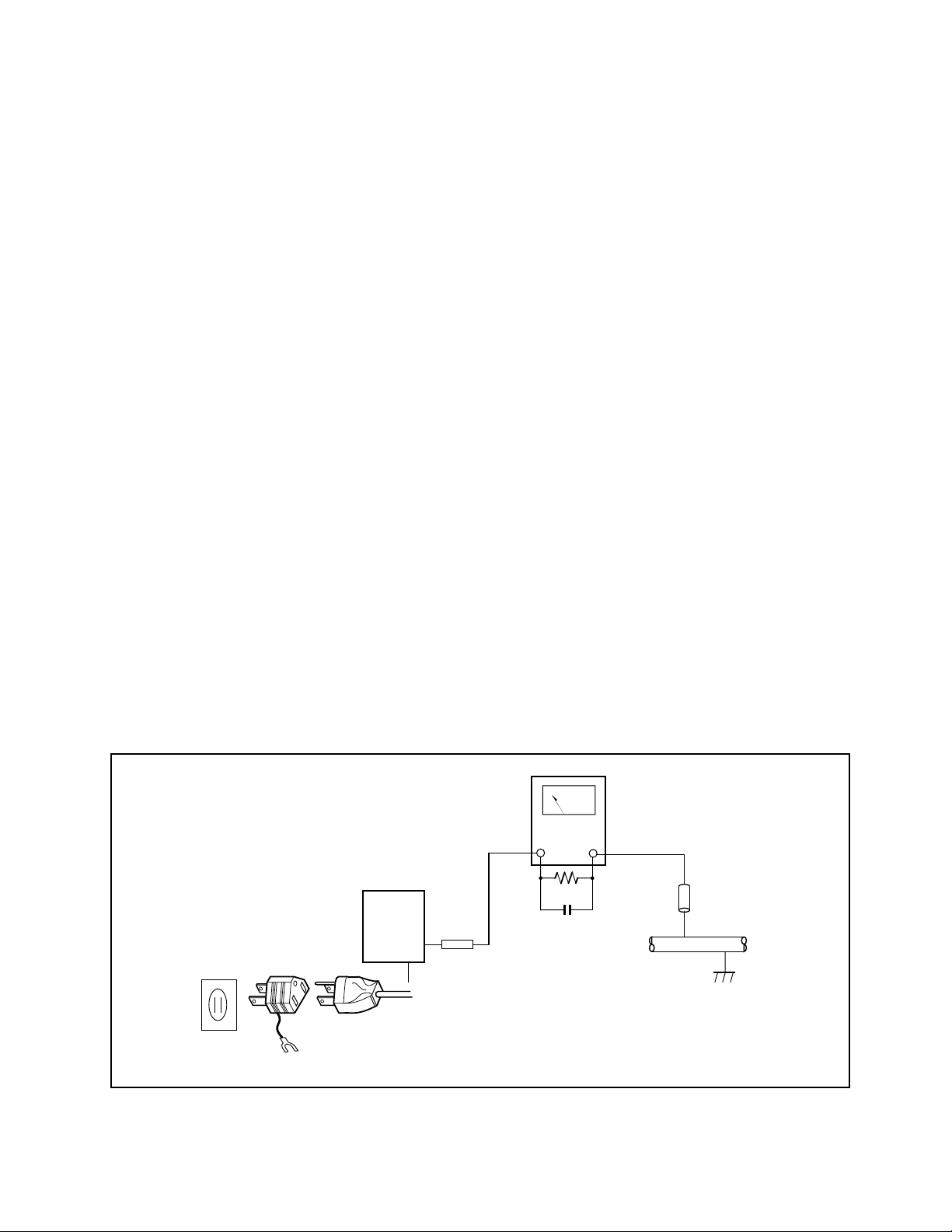

LEAKAGE CURRENT HOT CHECK

1. Plug the AC cord directly into adaptor socket and plug

adaptor into the AC outlet. Do not use an isolation

transformer for this check.

2. Connect a 1.5k Ω/10W resistor, paralleled by 0.15 µF

capacitor, between each exposed metallic part on the

unit and a good earth ground such as a water pipe, as

shown in Figure 1.

3. Use an AC voltmeter, with 1000Ω/volt or more sensitivity,

to measure the potential across the resistor.

4. Check all exposed metallic parts of the cover (BNC

connector, Handle bracket, Metallic cabinet,

Screwheads, Metallic overlays, etc.), and measure the

voltage at each point.

5. Reverse the AC plug in the AC plug adaptor and re-peat

each of the above measurements.

6. The potential at any point should not exceed 0.75 V

RMS.

A leakage current tester (SIMPSON MODEL 229 or

equivalent) may be used to make the hot checks.

Leakage current must not exceed 0.5 milliampere.

In case a measurement is outside of the limits specified,

there is a possibility of a shock hazard, and corrective

action must be taken before returning the instrument to

the customer.

Fig. 1 Leakage Current Hot Check

PRODUCT COMPLIES WITH DHHS RULES 21 CFR SUBCHAPTER J APPLICABLE AT DATE OF MANUFACTURE

AC VOLTMETER

AC OUTLET

DEVICE

UNDER

TEST

ADAPTOR

AC PLUG

Ground Lead Disconnected during safety check.

Test all exposed

metal parts

1.5kΩ

0.15µF

Water Pipe

(Earth Ground)

CONTENTS

MAJOR OPERATING CONTROLS AND THEIR FUNCTIONS .........................................................1-1

WIRING DIAGRAM..............................................................................................................................2-1

SCHEMATIC DIAGRAM

MAIN BOARD (1/5)

PARTITION DIAGRAM..............................................................................................................3-1-1

[1]..............................................................................................................................................3-1-2

[2]..............................................................................................................................................3-1-3

[3]..............................................................................................................................................3-1-4

[4]..............................................................................................................................................3-1-5

MAIN BOARD (2/5)

PARTITION DIAGRAM..............................................................................................................3-2-1

[1]..............................................................................................................................................3-2-2

[2]..............................................................................................................................................3-2-3

[3]..............................................................................................................................................3-2-4

[4]..............................................................................................................................................3-2-5

MAIN BOARD (3/5) ..........................................................................................................................3-3

MAIN BOARD (4/5) ..........................................................................................................................3-4

MAIN BOARD (5/5) ..........................................................................................................................3-5

HDD-DC BOARD .............................................................................................................................3-6

POWER DIVIDER BOARD ..............................................................................................................3-7

FRONT SW BOARD ........................................................................................................................3-8

FRONT LED BOARD .......................................................................................................................3-9

AC/DC BOARD FOR WJ-HDE300.................................................................................................3-10

AC/DC BOARD FOR WJ-HDE300/G.............................................................................................3-11

CONDUCTOR VIEW

MAIN BOARD

(COMPONENT SIDE)...................................................................................................................4-1

(PATTERN SIDE)..........................................................................................................................4-2

HDD-DC BOARD .............................................................................................................................4-3

POWER DIVIDER BOARD / FRONT SW BOARD / FRONT LED BOARD .....................................4-4

AC/DC BOARD ................................................................................................................................4-5

EXPLODED VIEW

(1/6)..................................................................................................................................................5-1

(2/6)..................................................................................................................................................5-2

(3/6)..................................................................................................................................................5-3

(4/6)..................................................................................................................................................5-4

(5/6)..................................................................................................................................................5-5

(6/6)..................................................................................................................................................5-6

REPLACEMENT PARTS LIST............................................................................................................6-1

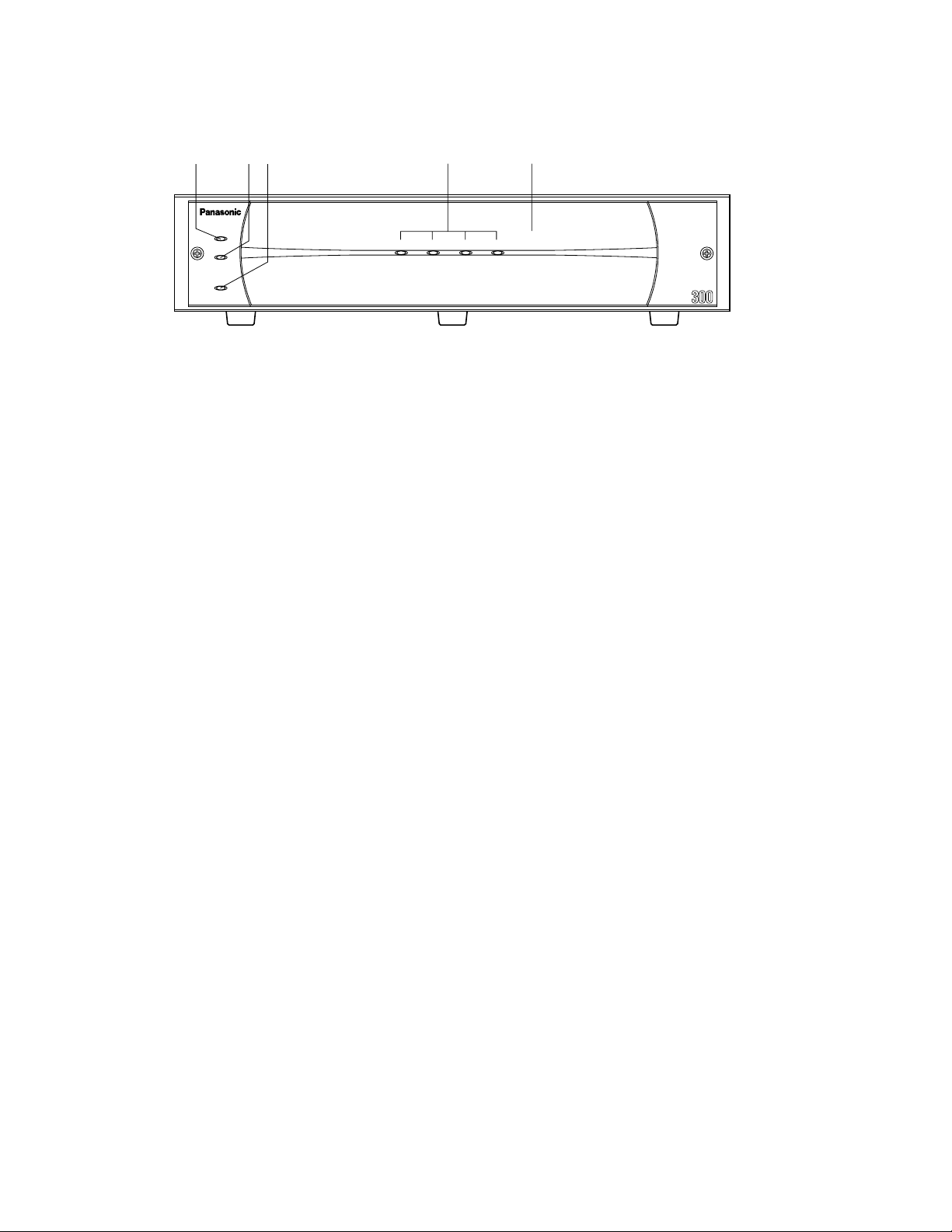

1-1

MAJOR OPERATING CONTROLS AND THEIR FUNCTIONS

■ Front View

ERROR

HDD 1 HDD 2 HDD 3 HDD 4

HDD

POWER

OPERATE

Extension Unit

WJ-HDE

qwe r t

q Error indicator [ERROR]

Lights when an error occurs. Refer to TROUBLESHOOTING for details.

Red: System error

Orange: Thermal error or malfunction of the cooling fan.

w HDD power indicator [HDD POWER]

ON: Indicates that HDDs are powered.

OFF: Indicates that the HDDs are not powered.

Note: Do not move the unit until the motors of the HDDs

stop completely. To stop the motors, turn off the

HDD POWER switch behind the front cover. Move

the unit after confirming that the indicator has gone

out.

e Operate indicator [OPERATE]

Lights green when turning on the power switch on the

rear panel.

r HDD access indicators [HDD 1] [HDD 2] [HDD 3]

[HDD 4]

Each indicator lights to indicate the status of the respective HDD.

Green: Indicates that the respective HDD is running

normally.

Red: Indicates that the respective HDD is the first faulty

drive among the HDDs in the unit.

Red blink: Indicates that the respective HDD is the sec-

ond or subsequent faulty drive among the HDDs in

the unit.

Orange-red alternate blink/Orange: Indicates that the

respective drive is currently being recovered in

RAID level 5 mode.

These indicators normally indicate the status of the

respective drive, but they work as a set when a system

error occurs.

Important

When one of the indicators lights red, replace the

respective HDD immediately. If two or more indicators

light/blink red, it will be impossible to recover data.

There may be cases where it is eventually impossible to

recover data if two drives are coincidentally damaged or

the second drive fails during the data recovery process.

t Front cover

Detach the front cover when it is necessary to install

HDDs or to operate the switches inside the unit.

1-2

y Serial in connector [IN]

Connect the WJ-HD300 series digital disk recorder or

other extension unit with the supplied serial cable.

u Serial out connector [OUT1] [OUT2]

Connect another extension unit with the supplied serial

cable.

i Cooling fan

o Signal GND terminal [SIGNAL GND]

Connect this terminal to the SIGNAL GND terminal of

other equipment to avoid possible grounding loop and

noise if required.

!0 Power switch [POWER]

Turn on the power of the unit with this switch before turning on the power of the digital disk recorder, or turn

them on simultaneously. Otherwise, the HDDs will not be

mounted.

When turning off the power of the unit with this switch,

turn off the power of the digital disk recorder first, and

then turn off the power of this unit after confirming that

all HDD access indicators are not lit or blinking.

!1 AC inlet [AC IN]

Connect the supplied power cord.

!2 Cable clamp fixing hole

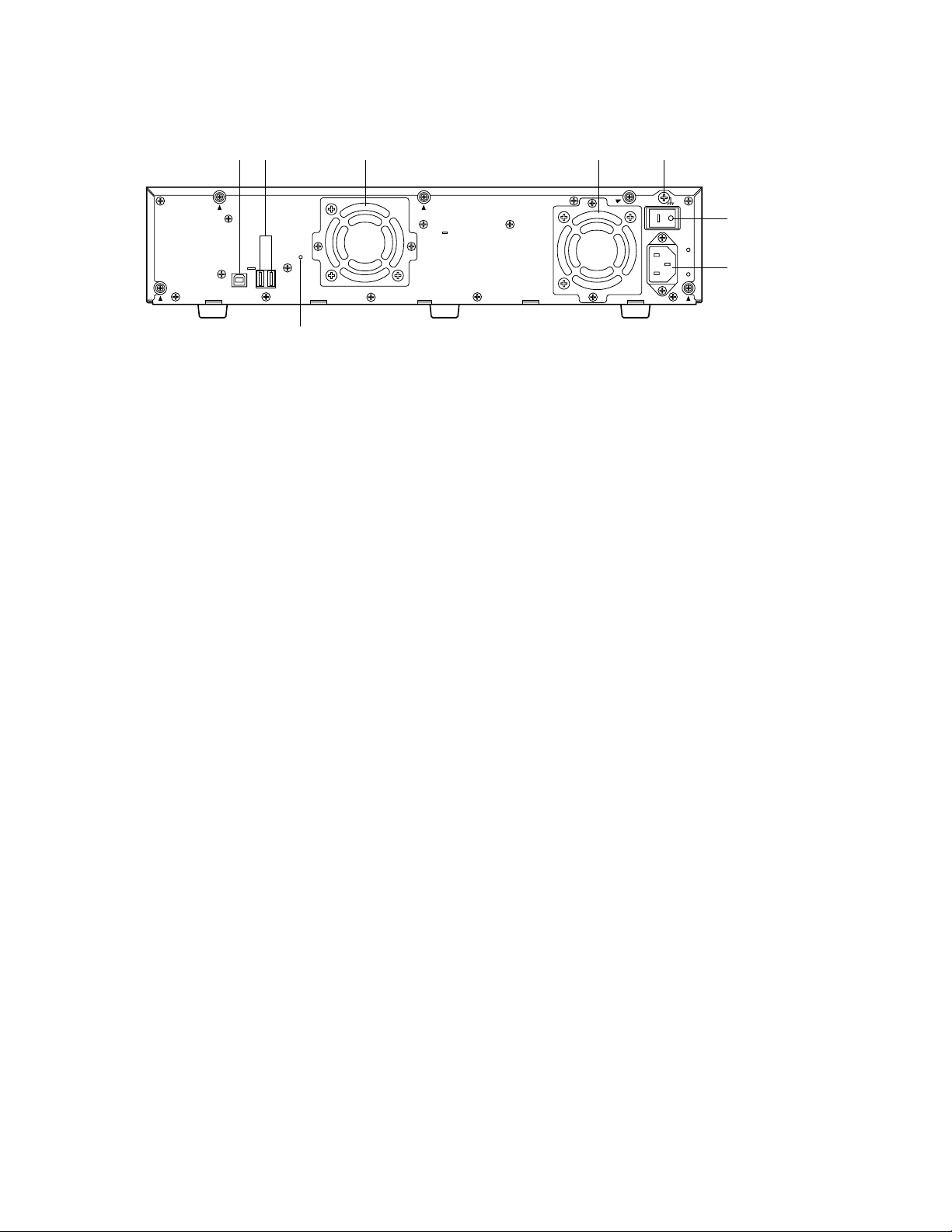

■ Rear View

POWER

AC IN

SIGNAL GND

12

IN OUT

EXT

yu i i

o

!0

!1

!2

1-3

q' Error indicators

Functions as same as that on the front panel.

Red: System error

Orange: Thermal error or malfunction of the cooling fan.

w'HDD power indicator

Functions as same as that on the front panel.

ON: Indicates that HDDs are powered.

OFF: Indicates that the HDDs are not powered.

e'Operate indicator

Functions as same as that on the front panel.

Lights green when turning on the power switch on the

rear panel.

!3 Reset button [RESET]

This button is located inside the unit. To access this button, it is necessary to detach the front cover. Press this

button using a small screw driver (not supplied).

• When SINGLE is selected

After adding or replacing any of the HDDs, press this

button only.

• When RAID 5 is selected

This button is used in combination with the RECOVER

button and MODE switch after adding or replacing any

of the HDDs.

Important

Do not press the RESET button and the RECOVER

button simultaneously when SINGLE is selected.

Otherwise, the setting of the digital disk recorder

may be initialized and it may cause a malfunction.

!4 Mode switch [MODE]

RAID 5: Applies RAID level 5 mode (striping at the byte

level also stripe error correction information).

SINGLE: Applies SINGLE mode (no striping across dri-

ves for data or error correction information). Default

position

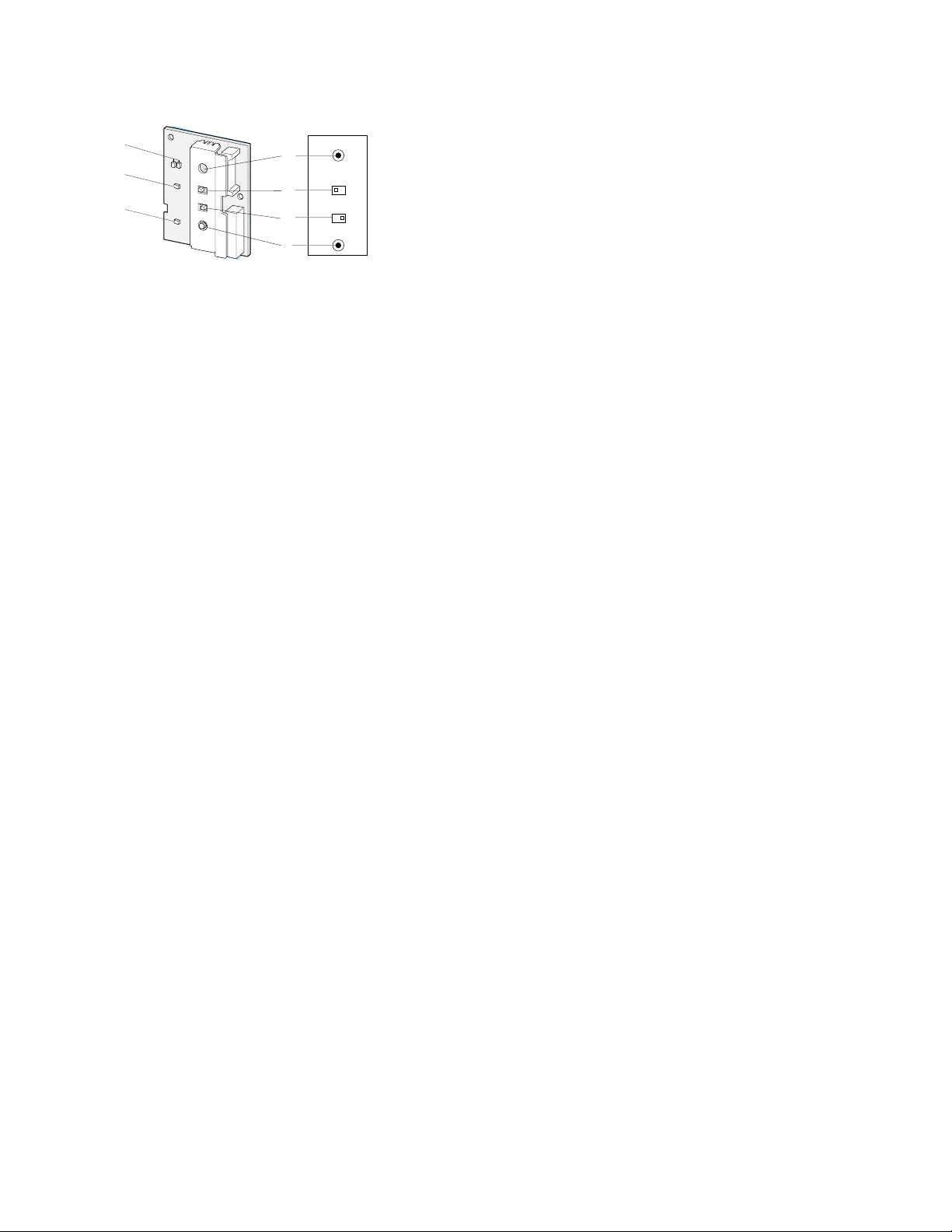

■ Inside the Front Lid

!3

!4

!5

!6

SINGLE RAID5

MODE

RESET

HDD POWER

RECOVER

OFF ON

w’

e’

q’

Important

• Changing the MODE switch will not be accepted when

the ERROR indicator lights red and/or when HDD 1-4

indicate a system error status by lighting red and

orange. When this happens, ask your dealer to solve

the error.

• When set to RAID5, the HDD preinstalled in the digital

disk recorder will not work. Instead, it is applied only to

the HDDs installed in the extension unit and the digital

disk recorder will perform storage and readout of the

image data by accessing the extension unit.

• The position of the MODE switch of all units in a system

must be the same.

• The available disk space of the unit can be logically calculated as follows. The actual space may be several

percent lower than you calculated depending on the

HDD type used and their combination. The most efficient way is to use the same type drives.

When SINGLE is selected, it will be the sum of all

the HDD sizes.

When RAID 5 is selected, it will be as follows.

When 3 HDDs are in the unit: It will be double the

size of the smallest HDD size.

When 4 HDDs are in the unit: It will be triple the size

of the smallest HDD size.

For example, if 4 HDDs of 80 GB, 120 GB, and two

160 GB are mounted, the available disk space will

be 80 G x 3 = 240 GB.

!5 HDD power switch [HDD POWER]

Use this switch in the ON position for normal operation.

ON: Supplies the power to the HDDs and the HDD

power indicators will light. Default position

OFF: Does not supply the power and the HDD power

indicators will go off.

!6 Recover button [RECOVER]

Use this button with the RESET button after replacing

HDDs used in the RAID 5 mode to start data recovery.

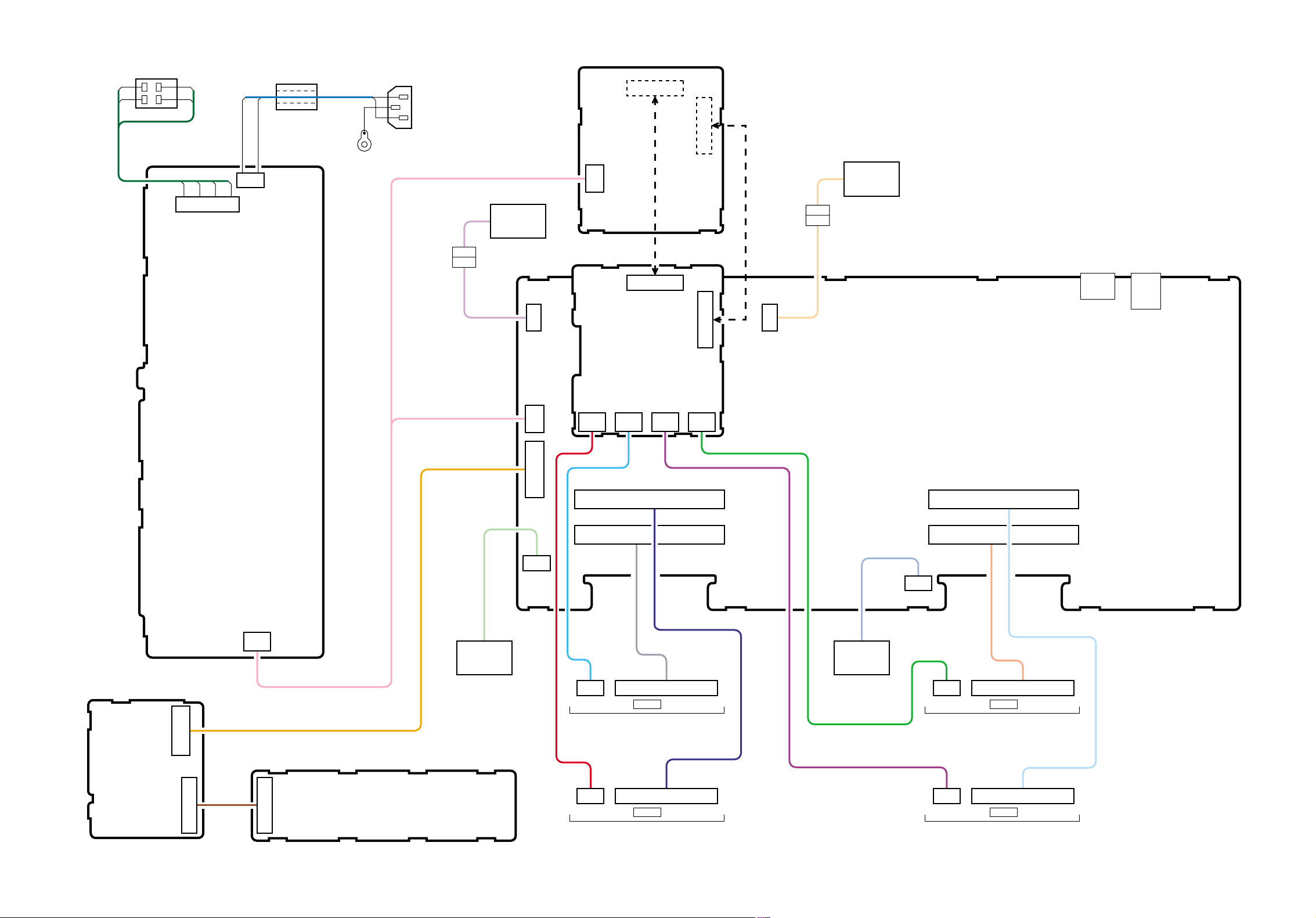

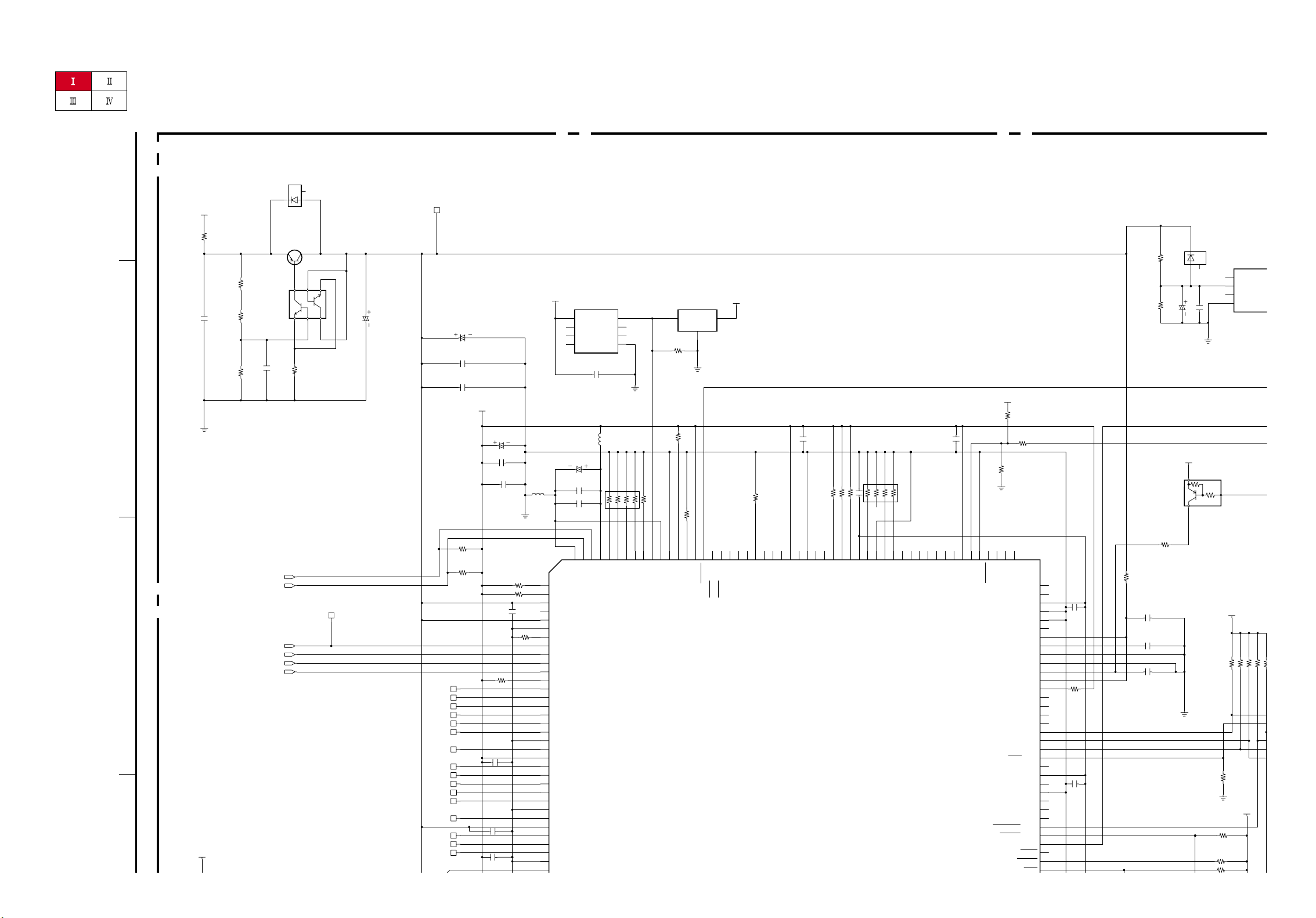

2-1

WIRING DIAGRAM

MO3

COOLING

FAN-3

SW11

POWER SWITCH

L11

FERRITE CLAMP

CN11

AC INLET

MO4

COOLING

FAN-4

MO2

COOLING

FAN-2

MO1

COOLING

FAN-1

TO HDD

HDD 2

TO HDD

HDD 1

TO HDD

HDD 4

TO HDD

HDD 3

113

3

3

1

5

7

57

13

CN1

CN2

E13

E14

E15

E26

E11

E20 E23

E21

E17

E16

E19

E18

E22

E24

E25

E12

19

210

CN3

13

CN520

119

110

10 1

220

CN100

119

220

9

10

1

2

CN550

CN500

31

CN522

10 1

10

1

1

2

1

2

39

40

39

40

414 14

1

CN101

CN100

CN102

CN201

CN202

1

2

1

2

39

40

39

31

40

CN203

CN521

CN200

CN103 CN104

14

CN105

111

122

101

CN100

CN102

101

13

CN101

CN523

CN101

CN100

MAIN BOARD

AC/DC

BOARD

HDD-DC

BOARD

POWER

DIVIDER

BOARD

FRONT LED BOARDFRONT SW BOARD

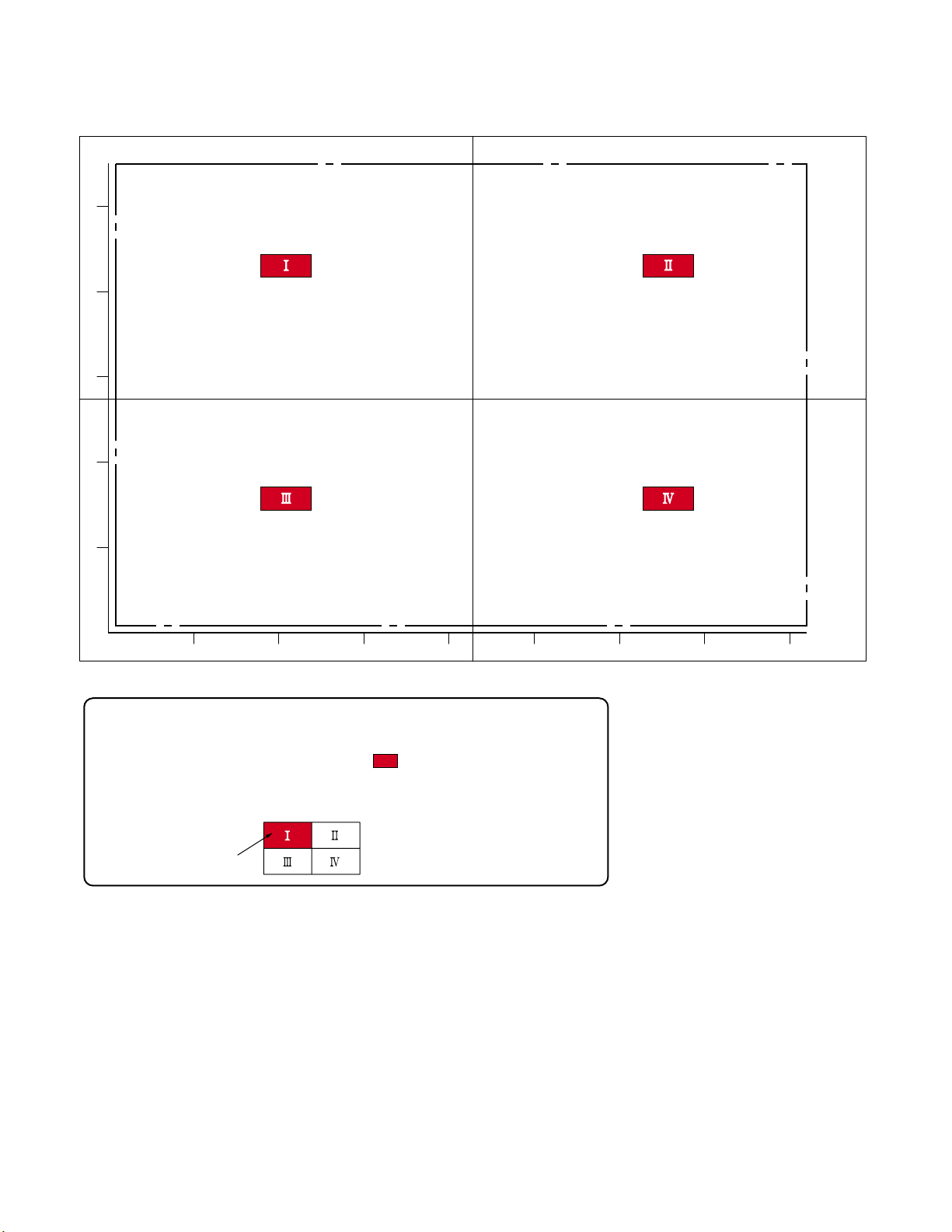

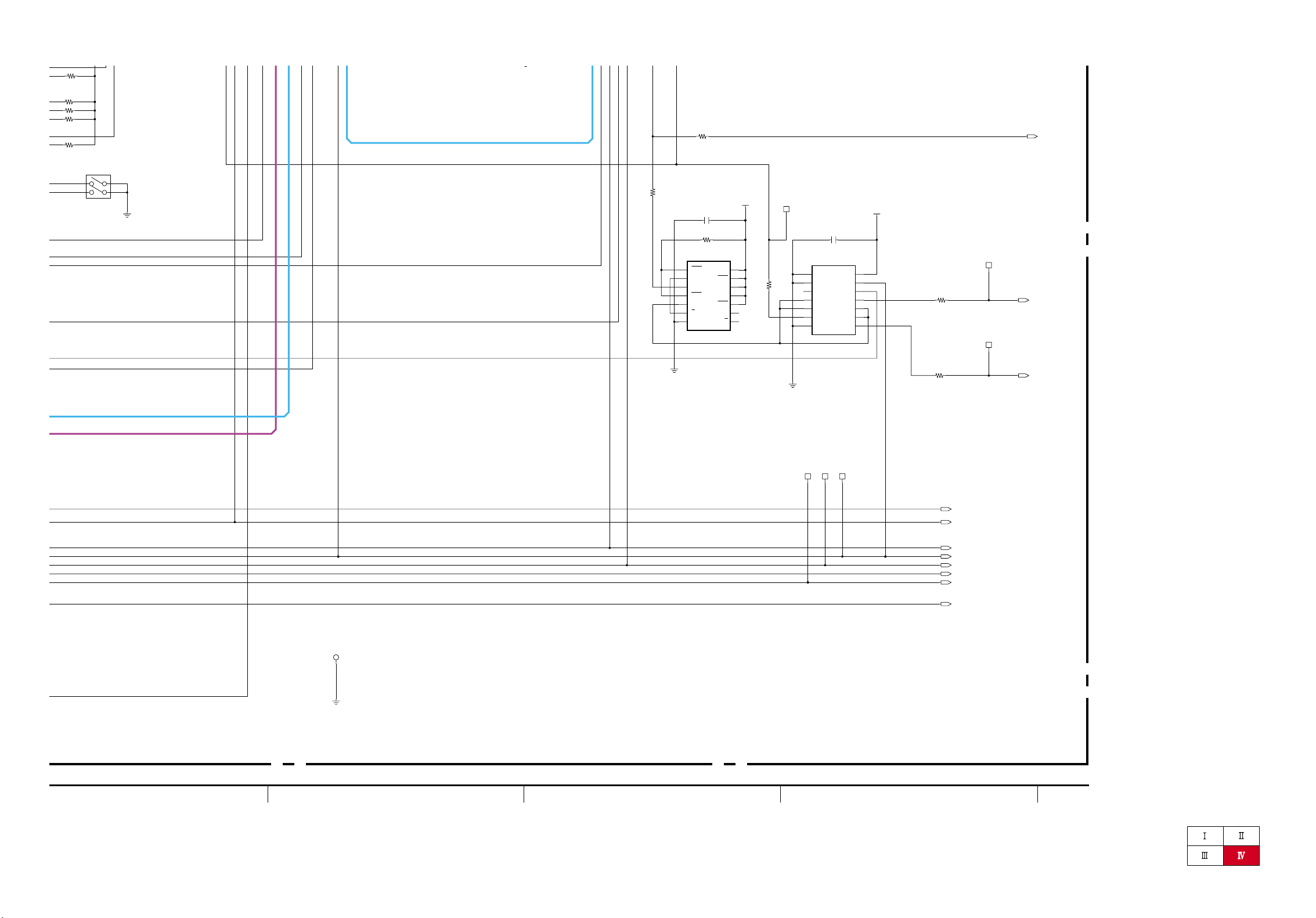

3-1-1

PARTITION DIAGRAM FOR SCHEMATIC DIAGRAM

OF MAIN BOARD (1/5)

<LOCATION MARK>

(Refer to the page 3-1-2.)

(Refer to the page 3-1-4.)

(Refer to the page 3-1-3.)

(Refer to the page 3-1-5.)

• The Location Mark indicated in each Schematic Diagram of Main Board (1/5) is as follows.

<Example>

For Schematic Diagram

of Main Board (1/5) [1] :

• The Schematic Diagram of Main Board (1/5) is described by 4 partitions.

• When connecting all the Schematic diagram, refer to this Partition Diagram.

Location of each Schemaitc diagram is marked ( ) in the diagram.

Location Mark

MAIN BOARD (1/5)

1

A

B

C

D

E

F

2345678

3-1-2

SCHEMATIC DIAGRAM OF MAIN BOARD (1/5) [1]

<LOCATION MARK>

D[15]

R111 10k

R133 10k

TD116

Q100

D101

TD104

R103

470

C156 0.1

TD107

R104

330

1/4W

XINIT

Q101

1

25

34

6

R110

10k

V5D

TD100

C133

0.1

XDONE

R101

330

IC

1

NC_1

2

INPUT

3

NC_2

4

GND

SU

TD115

TD113

IRQ1

V3D

IC102

OPEN

1

+VS

2

VOUT

3

GND

R102

15

TD117

R112 10k

IRQ3

V3D

Q102

C113

0.1

V3D

R108

10k

C117

47/6.3

V5D

C120

0.1

R163

OPEN

OPEN

C100

1

DGND

C135 0.1

C131

0.1

C121

0.1

DGND

R113

10k

R109

10k

R116

10k

10k

10k

R125

OPEN

TD103

TD110

C110

0.01

V3D

IRQ0

R118

10k

IRQ2

V3D

TD105

Z110

123

45

678

DGND

C137 470p

R123 10k

C108

OPEN

R119 10k

C126

0.1

DGND

R161

0

R138

10k

C119

0.01

V3D

R137

10k

TD106

TD111

R164

51k

C136 470p

IC101

1

MD1

2

MD2

3

Vcc_1

4

NC

5

Vcc_2

6

Vss_1

7

NMI

8

IRQ0/PTH[0]

9

IRQ1/PTH[1]

10

IRQ2/PTH[2]

11

IRQ3/PTH[3]

12

IRQ4/PTH[4]

13

D31/PTB[7]

14

D30/PTB[6]

15

D29/PTB[5]

16

D28/PTB[4]

17

D27/PTB[3]

18

D26/PTB[2]

19

VssQ_1

20

D25/PTB[1]

21

VccQ_1

22

D24/PTB[0]

23

D23/PTA[7]

24

D22/PTA[6]

25

D21/PTA[5]

26

D20/PTA[4]

27

Vss_2

28

D19/PTA[3]

29

Vcc_3

30

D18/PTA[2]

31

D17/PTA[1]

32

D16/PTA[0]

33

VssQ_2

34

D15

123

124

RESETM

125

PTH[5]/ADTRG

126

PTG[7]

127

ASEMD0/PTG[6]

128

ASEBRKAK/PTG[5]

129

UCLK/PTG[4]

130

AUDATA[3]/PTG[3]

131

AUDATA[2]/PTG[2]

132

Vss_4

133

AUDATA[1]/PTG[1]

134

Vcc_5

135

AUDATA[0]/PTG[0]

136

TRST/PTF[7]

137

TMS/PTF[6]

138

TDI/PTF[5]

139

TCK/PTF[4]

140

DMNS/PTF[3]

141

DPLS/PTF[2]

142

TXDPLS/PTF[1]

143

TXDMNS/PTF[0]

144

MD0

145

Vcc-PLL1

146

CAP1

147

Vss-PLL1

148

Vss-PLL2

149

CAP2

150

Vcc-PLL2

151

AUDCK/PTH[6]

152

Vss_5

153

Vss_6

154

Vcc_6

155

XTAL

156

EXTAL

157

STATUS0/PTJ[6]

158

STATUS1/PTJ[7]

159

TCLK/PTH[7]

160

IRQOUT

161

VssQ_9

162

CKIO

163

VccQ_9

164

TXD0/SCPT[0]

165

SCK0/SCPT[1]

166

TXD1/SCPT[2]

167

SCK1/SCPT[3]

168

TXD2/SCPT[4]

169

SCK2/SCPT[5]

170

SCPT[6]

171

RXD0/SCPT[0]

172

RXD1/SCPT[2]

173

Vss_7

174

RXD2/SCPT[4]

175

Vcc_7

176

IRQ5/SCPT[7]

177

IRQ6/PTC[7]

178

IRQ7/PTC[6]

179

XVDATA/PTC[5]

180

TXENL/PTC[4]

181

VssQ_10

182

VBUS/PTD[3]

183

VccQ_10

184

SUSPND/PTD[2]

185

NF/PTC[3]

186

NF/PTC[2]

187

NF/PTC[1]

188

PTC[0]

189

DRAK0/PTD[1]

190

DRAK1/PTD[0]

191

DREQ0/PTD[4]

192

DREQ1/PTD[6]

193

RESETP

194

VccQ_11

195

MD3

196

MD4

197

Vss_8

198

Avss_1

199

AN[0]/PTL[0]

200

AN[1]/PTL[1]

201

AN[2]/PTL[2]

202

AN[3]/PTL[3]

203

PTL[4]

204

PTL[5]

205

AVcc

206

PTL[6]

207

PTL[7]

208

Avss_2

C118

0.1

TD112

C114

0.1

C152

0.1

Z111

123

45

678

R132

10k

C105

47/6.3

C129 0.1

L101

R162

100

C109

0.1

R117

10k

C132

0.1

C122

0.01

D100

C155

33/6.3

R136

10k

R124

OPEN

R131 10k

R121 10k

L100

R122 10k

DGND

DGND

DGND

C115

0.1

DGND

R140

10k

R139

10k

C102

0.47

TD114

TD108

TD102

TD101

R127

10k

R120

10k

C123

100/6.3

R100

0

TD109

R126

0

R134 470

V3D

IC108

1

VOUT

2

N.C._1

3

N.C._2

4

GND

5

N.C._3

6

N.C._4

7

N.C._5

8

+VS

+1.9V

MAIN BOARD (1/5)

D

E

F

3-1-3

SCHEMATIC DIAGRAM OF MAIN BOARD (1/5) [2]

<LOCATION MARK>

A[16]

A[9]

A[10]

A[11]

A[12]

A[13]

A[14]

A[15]

A[18]

A[8]

A[7]

A[6]

A[5]

A[4]

A[3]

A[2]

D[15]

D[7]

D[14]

D[6]

D[13]

D[5]

D[12]

D[4]

D[11]

D[3]

D[2]

D[9]

D[1]

D[8]

A[1]

D[10]

D[0]

A[17]

D[1]

D[2]

D[3]

D[0]

D[7]

D[6]

D[5]

D[4]

A[13]

A[14]

A[11]

A[1]

A[2]

A[3]

A[4]

A[12]

A[10]

A[9]

A[8]

A[7]

A[6]

A[5]

D[8]

D[12]

D[13]

D[14]

D[15]

D[11]

D[10]

D[9]

R141

10k

C147

0.1

IC107

1

NC

2

IN_A

3

GND

4

OUT_Y

5

VCC

A[1-25]

C156 0.1

V3D

C145

0.1

C157 0.1

C149

0.1

R155

OPEN

IC111

1

NC_1

2

INPUT

3

NC_2

4

GND

5

NC_3

6

OUTPUT

7

SUPPLY_VOLTAGE

8

NC_4

Z119

1

2

3

45

6

7

8

DGND

Z112

22 22

22

22

22

22

22

1

2

3

45

6

7

8

R143

OPEN

R152

47

R142

22

R149

0

V3D

V3D

OPEN

Z118

1

2

3

45

6

7

8

V3D

R146

33

C141

0.1

R151

OPEN

DGND

V3D

DGND

C143

33/6.3

IC103

1

A15

2

A14

3

A13

4

A12

5

A11

6

A10

7

A9

8

A8

9

N.C._1

10

N.C._2

11

WE

12

RESET

13

N.C._3

14

N.C._4

15

RY/BY

16

N.C._5

17

A17

18

A7

19

A6

20

A5

21

A4

22

A3

23

A2

24

A1

25

A0

26

CE

27

VSS_1

28

OE

29

DQ0

30

DQ8

31

DQ1

32

DQ9

33

DQ2

34

DQ10

35

DQ3

36

DQ11

37

VCC

38

DQ4

39

DQ12

40

DQ5

41

DQ13

42

DQ6

43

DQ14

44

DQ7

45

DQ15/A-1

46

VSS_2

47

BYTE

48

A16

C144

0.1

Z113

1

2

3

45

6

7

8

TD120

C158 0.1

R138

10k

R137

10k

DGND

DGND

C138

0.1

X100

(66.666MHz)

1

CONT

2

GND

3

OUT

4

VDD

V3D

C142

0.1

C151

0.1

R144

OPEN

R132

10k

Z114

22

Z115

22

Z116

1

2

3

45

6

7

8

CN100

OPEN

1

3

5

7

910

8

6

4

2

11 12

13 14

V3D

C140

0.1

R136

10k

DGND

R131 10k

Z117

1

2

3

45

6

7

8

IC104

1

VDD_1

2

DQ0

3

VDDQ_1

4

DQ1

5

DQ2

6

VSSQ_1

7

DQ3

8

DQ4

9

VDDQ_2

10

DQ5

11

DQ6

12

VSSQ_2

13

DQ7

14

VDD_2

15

LDQM

16

WE

17

CAS

18

RAS

19

CS

20

BA0

21

BA1

22

A10/AP

23

A0

24

A1

25

A2

26

A3

27

VDD_328VSS_1

29

A4

30

A5

31

A6

32

A7

33

A8

34

A9

35

A11

36

NC_1

37

CKE

38

CLK

39

UDQM

40

NC_2

41

VSS_2

42

DQ8

43

VDDQ_3

44

DQ9

45

DQ10

46

VSSQ_3

47

DQ11

48

DQ12

49

VDDQ_4

50

DQ13

51

DQ14

52

VSSQ_4

53

DQ15

54

VSS_3

C139

0.1

DGND

DGND

R140

10k

C146

33/6.3

R139

10k

1

2

3

45

6

7

8

Z120

1

2

3

45

6

7

8

V3D

V3D

1

2

3

45

6

7

8

D[0-15]

66.666MHz

<INDEX>

IC100 A2

IC101 B2,B3,B4,

C2,C3,C4,

D2,D3,D4

IC103 E6,F6

IC104 C6,D6

IC105 B7,C7

IC106 B8,C8

IC107 C8,D8

IC108 E2

IC109 A3,A4

IC110 A4

IC111 E5,F5

Q100 E1,F1

Q101 E1

Q102 E5

D100 F1

MAIN BOARD (1/5)

3-1-4

SCHEMATIC DIAGRAM OF MAIN BOARD (1/5) [3]

<LOCATION MARK>

A[1]

A[2]

A[3]

A[4]

A[5]

A[6]

A[7]

A[8]

A[9]

A[10]

A[11]

A[12]

A[13]

A[14]

A[15]

A[16]

A[17]

A[19]

A[20]

A[21]

A[22]

A[23]

A[24]

D[0]

D[1]

D[2]

D[3]

D[4]

D[5]

D[6]

D[7]

D[8]

D[9]

D[10]

D[11]

D[12]

D[13]

D[14]

D[15]

A[25]

A[1]

A[2]

A[3]

A[4]

A[5]

A[6]

A[7]

A[8]

A[9]

A[10]

A[11]

A[12]

A[13]

A[14]

A[15]

A[16]

A[17]

A[18]

A[19]

A[20]

A[21]

A[22]

A[23]

A[24]

A[25]

A[18]

D[15]

D[14]

D[13]

D[12]

D[11]

D[10]

D[9]

D[8]

D[7]

D[6]

D[5]

D[4]

D[3]

D[2]

D[1]

D[0]

XCSZ

Z106

1

2

3

45

6

7

8

R133 10k

TD116

C130

0.1

Z107

1

2

3

45

6

7

8

R115

33

Z100

OPEN

1

2

36

45

45

45

45

7

8

IC110

1

IN_B

2

IN_A

3

GND4OUT_Y

5

VCC

C111

0.1

TD115

C124

0.1

CSRZ

DGND

TD117

R106

10k

0.1

DGND

DGND

R158

10

C154 0.1

C116

0.1

V12D

SW101

OPEN

24

13

Z108

1

2

3

45

6

7

8

Z109

1

2

3

45

6

7

8

V5D

IC109

1

NC_1

2

INPUT

3

NC_2

4

GND

5

NC_3

6

OUTPUT

7

SUPPLY_VOLTAGE

8

NC_4

DGND

C112

10/16

R130

OPEN

R129

OPEN

R128

470

XWRTZ

C127

0.1

R160

1k

C134

0.1

R165

OPEN

V3D

Z102

1

2

36

7

8

SW100

OPEN

1

2

3

4

5

V3D

C103

0.1

C128

0.1

R107

10k

R166

OPEN

C101

0.1

V3D

C104

0.1

Vcc_3

30

D18/PTA[2]

31

D17/PTA[1]

32

D16/PTA[0]

33

VssQ_2

34

D15

35

VccQ_2

36

D14

37

D13

38

D12

39

D11

40

D10

41

D9

42

D8

43

D7

44

D6

45

VssQ_3

46

D5

47

VccQ_3

48

D4

49

D3

50

D2

51

D1

52

D0

53A054A155A256A357

VssQ_458A459VccQ_460A561A662A763A864A965A1066A1167A1268A1369VssQ_570A1471VccQ_572A1573A1674A1775A1876A1977A2078A2179Vss_380A2281Vcc_482A2383VssQ_684A2485VccQ_686A2587BS/PTK[4]88RD89WE0/DQMLL

90

WE1/DQMLU

91

WE2/DQMUL/PTK[6]

92

WE3/DQMUU/PTK[7]

93

RD/WR94AUDSYNC/PTE[7]

95

VssQ_796CS097VccQ_798CS2/PTK[0]

99

CS3/PTK[1]

100

CS4/PTK[2]

101

CS5/PTK[3]

102

CS6

103

PTE[4]

104

PTE[5]

105

CKE/PTK[5]

106

RAS3L/PTJ[0]

107

NF/PTJ[1]

108

CASL/PTJ[2]

109

VssQ_8

110

CASU/PTJ[3]

111

VccQ_8

112

NF/PTJ[4]

113

NF/PTJ[5]

114

DACK0/PTD[5]

115

DACK1/PTD[7]

116

PTE[6]

117

PTE[3]

118

RAS3U/PTE[2]

119

PTE[1]

120

TDO/PTE[0]

121

BACK

122

BREQ

123

WAIT

124

RESETM

125

PTH[5]/ADTRG

126

PTG[7]

127

ASEMD0/PTG[6]

ASEBRKAK/PTG[5]

C114

0.1

Z105

1

2

3

45

6

7

8

RSTI

R105

100

R114

470

XPRGZ

V3D

R135 10k

R131 10k

IC100

1

VREF

2

RESIN

3

CT

4

GND5RESET

6

RESET

7

VSSENSE

8

VCC

V3D

Z103

OPEN

OPEN

OPEN

1

2

36

7

8

C125

0.1

R157

1k

R159

OPEN

C107

0.1

TD118

C153

0.1

R156

1k

Z104

1

2

3

45

6

710k

10k

10k

10k

10k

10k

8

Z101

1

2

36

7

8

TD119

R134 470

DGND

C106

2.2/50

1

A

B

C

234

3-1-5

SCHEMATIC DIAGRAM OF MAIN BOARD (1/5) [4]

<LOCATION MARK>

R133 10k

TD125

R145

56

TP100

OPEN

WAITZ

CPUCLK

PORSTN

DGND

IC106

1

1A

2

1B

3

1Y

4

2A

5

2B

6

2Y

7

GND83Y

9

3A

10

3B

11

4Y

12

4A

13

4B

14

VCC

XCLK

DGND

CSZ

V3D

SW101

OPEN

24

13

R148

22

R130

OPEN

DGND

TD124

BSZ

R154

68

WRZ

R150

68

TD121

TD122

C148

0.1

TD123

R153

68

DGND

RDZ

WE1Z

IC105

1

1CLR

2

1D

3

1CLK

4

1PRE

5

1Q

6

1Q

7

GND82Q

9

2Q

10

2PRE

11

2CLK

12

2D

13

2CLR

14

VCC

V3D

R135 10k

TD126

DCLK

R131 10k

DGND

C150

0.1

R147

10k

R134 470

WE0Z

33.333MHz

33.333MHz

5678

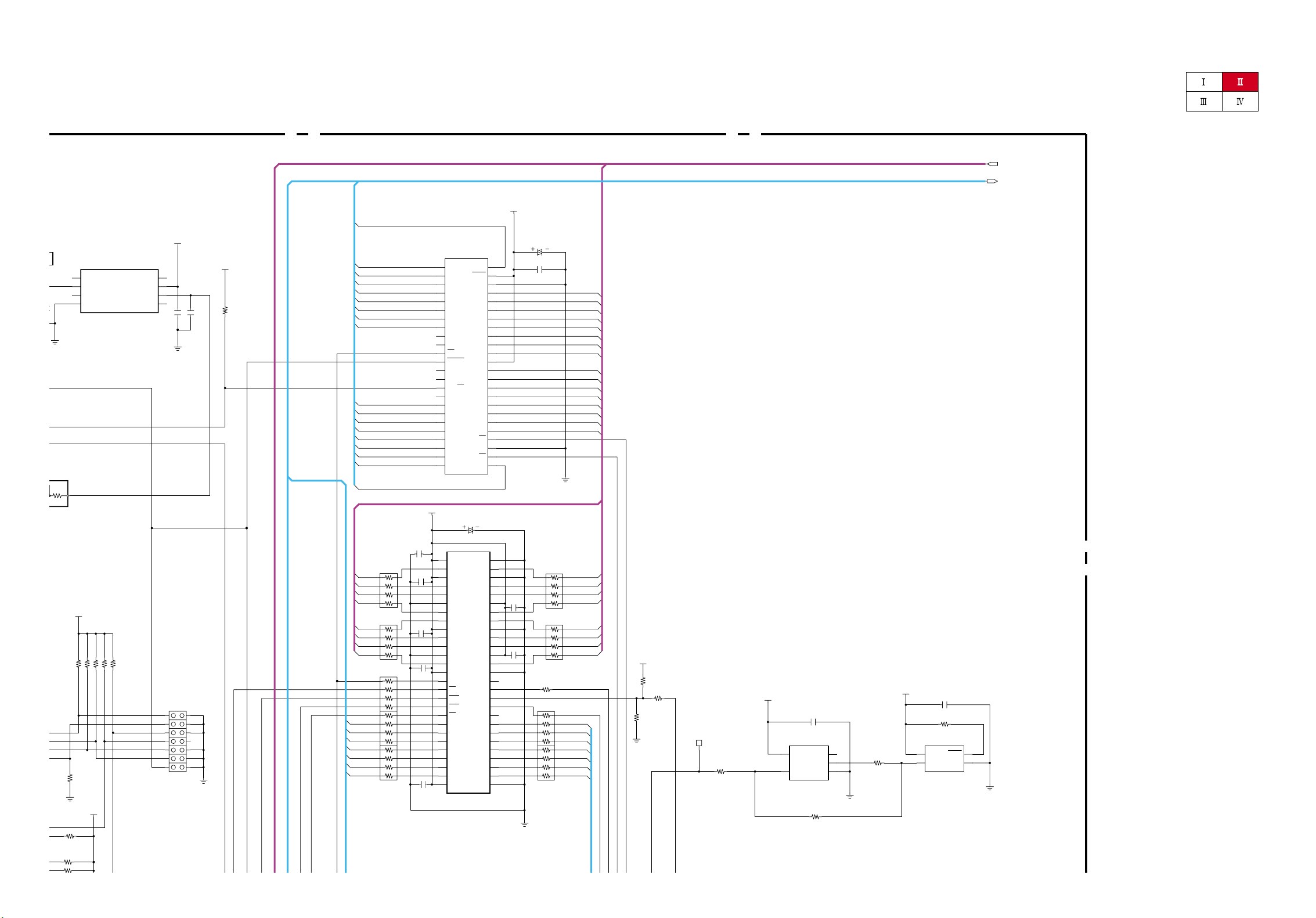

3-2-1

PARTITION DIAGRAM FOR SCHEMATIC DIAGRAM

OF MAIN BOARD (2/5)

<LOCATION MARK>

(Refer to the page 3-2-2.)

(Refer to the page 3-2-4.)

(Refer to the page 3-2-3.)

(Refer to the page 3-2-5.)

• The Location Mark indicated in each Schematic Diagram of Main Board (2/5) is as follows.

<Example>

For Schematic Diagram

of Main Board (2/5) [1] :

• The Schematic Diagram of Main Board (2/5) is described by 4 partitions.

• When connecting all the Schematic diagram, refer to this Partition Diagram.

Location of each Schemaitc diagram is marked ( ) in the diagram.

Location Mark

9

A

B

C

D

E

F

G

H

MAIN BOARD (2/5)

10 11 12 13 14 15 16 17 18 19

Loading...

Loading...