Panasonic UF-7000, UF8000, UF-7100, UF-8100 Service Manual

Order Number: MGCS041006C0

H13

Facsimile

UF-7000/8000

UF-7100/8100

[ Version 2.0 ]

WARNING

Thisserviceinformationisdesignedforexperiencedrepairtechniciansonlyandisnotintendedforusebythegeneralpublic.

Itdoesnotcontainwarningsorcautionstoadvisenon-technicalindividualsofpotentialdangersinattemptingtoserviceaproduct.

Productspoweredbyelectricityshouldbeservicedorrepairedonlybyexperiencedprofessionaltechnicians.Anyattempttoservice

orrepairtheproductorproductsdealtwithinthisserviceinformationbyanyoneelsecouldresultinseriousinjuryordeath.

© 2004 Panasonic Communications Co., Ltd.

All rights reserved. Unauthorized copying and distribution is

a violation of law.

This Product Uses Lead (Pb) Free Solder Printed Circuit

Boards (PCBs).

Information regarding Lead-Free (PbF) solder:

Distinction of PbF PCB:

PCBs (manufactured) using lead free solder will have a mark following

the PCB part numbers in a label on the PCB.

Caution:

Pb free solder has a higher melting point than standard solder; typically

the melting point is 50 - 70 F (30 - 40 C) higher. Please use a soldering iron

with temperature control and adjust it to 700 20 F (370 10 C). Exercise care

while using higher temperature soldering irons, do not heat the PCB for too long

to prevent solder splash or damage to the PCB.

Pb free solder will tend to splash when heated too high (about 1100 F/600 C).

ECO SOLDER M705 (available from Senju Metal Industry Co., Ltd.:

URL: http://www.senju-m.co.jp) is recommended when repairing PbF PCBs.

The contents of this Service Manual and the Specifications are subject to change

without notice.

Panasonic Communications Co., Ltd. reserves the right to make improvements in

the product design without reservation and without notice.

Published in Japan.

2

ImportantNotice

PleasereadthisnoticecompletelyBEFOREinstallinganyoptional

accessories.Asfailuretoproperlyinstalltheadditionalboardor

connectorwiththepowerONcoulddamagethemachine'sSDRor

SCboard.

Pleasefollowtheinstructionsbelow:

1. ItisessentialthatyouturnOFFtheMainPowerSwitchlocated

ontheRearSideofthemachine.

2. ItisessentialthatyouunplugtheACPowerCordfromthewall

outlet.(DuringaLightningStorm,topreventelectrocution

disconnecttheTelephoneLineCablefirstbeforeunpluggingthe

ACPowerCord)

3. Pleasereadtheinstallationinstructionscarefullyandfolloweach

step.

<Example:UF-8000>

Note:

O=PowerOFF,l=PowerON

*Thespecificationsaresubjecttochangewithoutnotice.PanasonicCommunicationsCo.,Ltd.reserves

therighttomakeimprovementsintheproductdesignwithoutreservationandwithoutnotice.

3

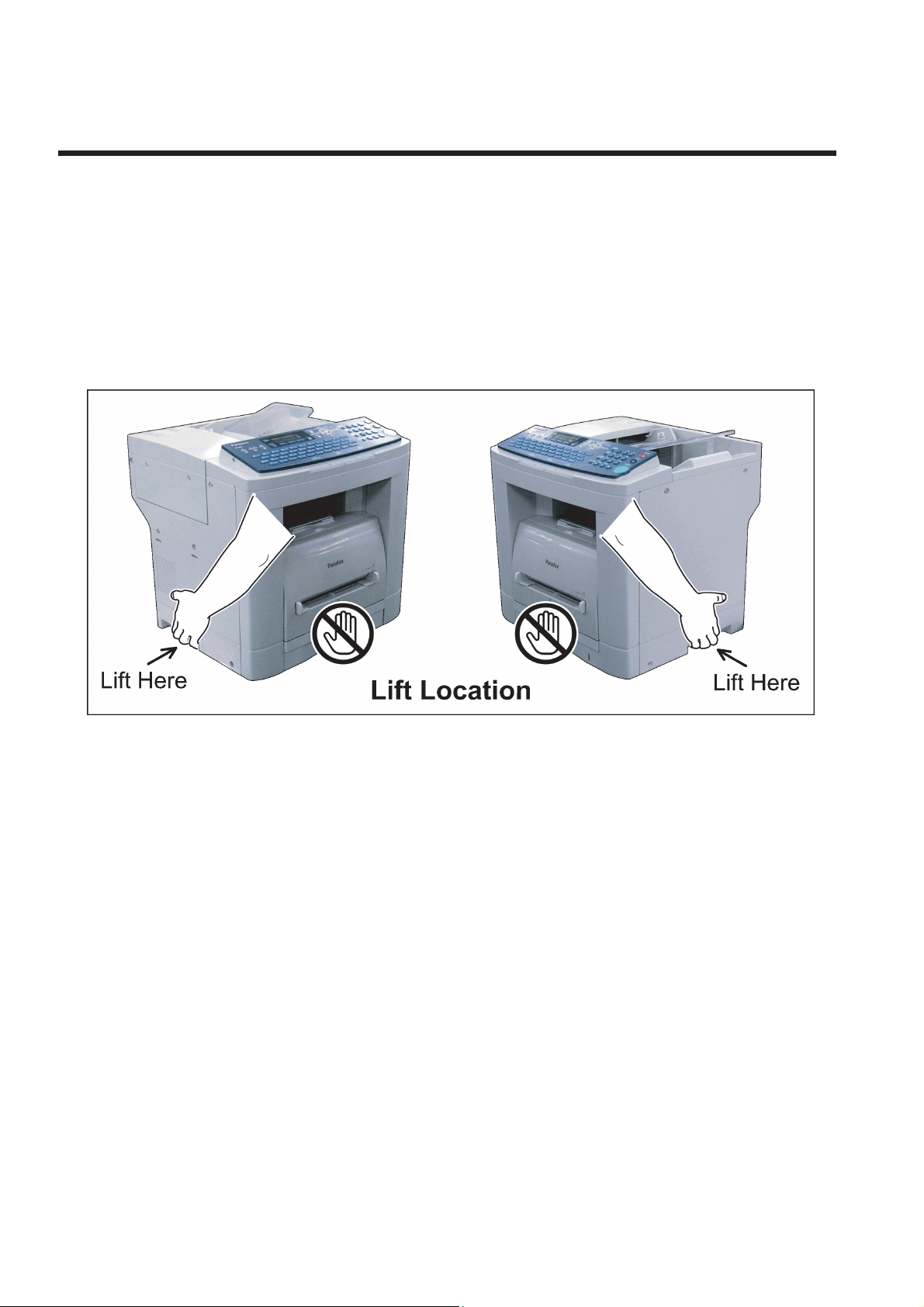

ImportantNoticeforInstallation

Caution:

Dependingonyourmachine'smodel,itmayweightapproximately48.50lb

(22.0kg)withoutanyoptions.

Topreventinjuries,usetheappropriatenumberofpersonnelandliftormove

themachineasillustrated.

DonotliftthemachinebythePaperTrayasitmaycausedamageand/orbodily

injury.

Note:

RefertotheQuickGuidewheninstallingthemachine.

4

e

t

e

Precautions

For Your Safety

To prevent severe injury and loss of life, read this section carefully before servicing the Panasonic

machine to ensure proper and safe operation.

Please ensure that the machine is installed near a wall outlet and is easily accessible.

This section explains the graphic symbols used in the machine and/or this manual.

WARNING:

Denotes a potential hazard that could result in serious injury or death.

CAUTION:

Denotes hazards that could result in minor injury or damage to the machine.

This section also explains the graphic symbols used in the machine and/or this manual.

These symbols are used to alert operators to a specific operating procedure

that must not be performed.

These symbols are used to alert operators to a specific operating procedure

that must be emphasized in order to operate the machine safely.

Installation and Relocation Cautions

CAUTION

Do not place the machine near heaters or volatile, flammable, or combustible materials

such as curtains that may catch fire.

Do not place the machine in a hot, humid, dusty or poorly ventilated environment.

Prolonged exposure to these adverse conditions can cause fire or electric shock.

Place the machine on a level and sturdy surface that can with stand.

If tilted, the machine may tip-over and cause injuries.

When relocating the machine, remove the toner and/or developer, and pack the machin

with proper packing materials for shipping.

When moving the machine, be sure to unplug the power cord from the outlet. If the

machine is moved with the power cord attached, it can cause damage to the cord which

could result in fire or electric shock.

Power and Ground Connection Cautions

WARNING

Ensure that the plug connection is free of dust. In a damp environment, a contaminated

connector can draw a significant amount of current that can generate heat and

eventually cause fire over an extended period of time.

Always use the power cord provided with your machine. When an extension power cord

is required, always use a properly rated cord.

120 V/15 A or AC 220 - 240V/10 A

If you use a cord with an unspecified current rating, the machine or plug may emit smok

or become hot to the touch externally.

Do not attempt to rework, pull, bend, chafe or otherwise damage the power cord. Do no

place a heavy object on the cord. A damaged cord can cause fire or electric shock.

5

Never touch a power cord with wet hands. Danger of electric shock exists.

y.

O

O

If the power cord is broken or insulated wires are exposed, replace immediately with a specified cord onl

Using a damaged cord can cause fire or electric shock.

Stop operation immediately if your machine produces smoke, excessive heat, unusual noise, or smell,

or if water is spilt onto the machine. These conditions can cause fire. Immediately switch Off and

unplug the machine.

Do not disconnect or reconnect the machine while it is on. Disconnecting a live connector can deform

the plug and cause fire.

When disconnecting the machine, grasp the plug instead of the cord. Forcibly pulling on a cord can

damage it and cause fire or electric shock.

When the machine is not used over an extended period of time, switch it Off and unplug it. If an unused

machine is left connected to a power source for a long period, degraded insulation can cause electric

shock, current leakage or fire.

Be sure to switch Off and unplug the machine before accessing the interior of the machine for cleaning,

maintenance or fault clearance. Access to a live machin's interior can cause electric shock.

Be sure to switch Off and unplug the machine before accessing the interior of the machine for

accessing interface cables, maintenance or fault clearance. Access to a live machin's interior can

cause electric shock.

Once a month, unplug the machine and check the power cord for the following. If you notice any

unusual condition, contact your Service Provider.

The power cord is plugged firmly into the receptacle.

The plug is not excessively heated, rusted, or bent.

The plug and receptacle are free of dust.

The cord is not cracked or frayed.

thers

The machine has a built-in circuit for protection against lightning-induced surge current. If lightning strikes in your

neighborhood, switch Off the machine. Disconnect the telephone line cable first, then unplug the power cord from

the machine and reconnect only when the lightning storm has stopped.

If you notice flickering or distorted images or noises on your audio-visual units, your machine may be causing

radio interference. Switch it Off and if the interference disappears, the machine is the cause of the radio interference. Perform the following procedure until the interference is corrected.

Move the machine and the TV and/or radio away from each other.

Reposition or reorient the machine and the TV and/or radio.

Unplug the machine, TV and/or radio, and replug them into outlets that operate on different circuits.

Reorient the TV and/or radio antennas and cables until the interference stops.

For an outdoor antenna, ask your local electrician for support.

Use a coaxial cable antenna.

perating Safeguards

WARNING

Do not touch areas where these caution labels are attached to the surface may be very hot, and cause

server burns.

Do not place any liquid container such as a vase or coffee cup on the machine. Spilt water can cause

fire or shock hazard.

Do not place any metal parts such as staples or clips on the machine. If metal and flammable parts get

into the machine, they can short-circuit internal components, and cause fire or electric shock.

If debris (metal or liquid) gets into the machine, switch Off and unplug the machine.

Operating a debris-contaminated machine can cause fire or electric shock.

Do not try to alter the machine configuration or modify any parts. An unauthorized modification can

cause smoke or fire.

6

is

CAUTION

C

Do not place a magnet near the safety switch of the machine. A magnet can activate the

machine accidentally resulting in injuries.

Do not use a highly flammable spray or solvent near the machine. It can cause a fire.

When copying a thick document, do not use excessive force to press it against the

document glass. The glass may break and cause injuries.

Never touch a labeled area found on or near the heat roller. You can get burnt. If a sheet

of paper is wrapped around the heat roller, do not try to remove it when it is hot, to avoid

injuries or burns. Switch Off the machine immediately, and wait until it cools down.

Do not use conductive paper, e.g. folding paper, carbon paper and coated paper. When

a paper jam occurs, it can cause a short circuit and fire.

Do not place any heavy object on the machine. An off-balance machine can tip-over or

the heavy object can fall, causing damage and/or injuries.

Keep the room ventilated when using the machine for an extended period of time to

minimize the ozone density in the air.

When copying with the document cover open, do not look directly at the exposure lamp.

Direct eye exposure can cause eye fatigue or damage.

Pull out paper trays slowly to prevent injuries.

When removing jammed paper, make sure that no pieces of torn paper are left in the

machine. A piece of paper remaining in the machine can cause a fire. If a sheet of paper

wrapped around the heat roller, or when clearing a jammed paper that is difficult or

impossible to see, do not try to remove it by yourself. Doing so can cause injuries or

burns. Switch Off the machine immediately, and wait until it cools down.

onsumable Safeguards

WARNING

Never throw a toner bottle into an open flame. Toner remaining in the bottle can

cause an explosion and you can get burnt.

Never throw toner or a waste toner container or a toner bottle into an open flame. It

can cause an explosion and you can get burnt.

Keep button batteries out of the reach of children. If a button battery is swallowed

accidentally, get medical treatment immediately.

CAUTION

Never heat the OPC Drum, or scratch its surface. A heated or scratched drum can be

hazardous to your health.

Do not mix new and old batteries together. Otherwise, batteries can burst or leak,

causing a fire or injuries.

Be sure to use the specified type of batteries only.

Ensure that batteries are installed with correct polarity. Incorrectly installed batteries can

burst or leak, resulting in spillage or injuries.

7

Table of Contents

Specifications Table ................................ 9

1.1. Fax, Printer, Network Scanner and

Internet Fax Functions ............................. 9

1.2. System Combination.............................. 23

1.3. Options List ............................................ 24

Maintenance, Adjustments and

Check Points ..........................................25

2.1. Preventive Maintenance ........................ 25

2.2. Required Tools....................................... 27

2.3. Preventive Maintenance Points ............. 28

2.4. Preventive Maintenance Check List....... 29

2.5. Updating the Firmware........................... 30

2.6. Adjusting the Printer Registration,

LSU Image Side to Side......................... 39

Troubleshooting ....................................41

3.1. Error Codes (For Copier) ....................... 41

3.2. Information Code Table

(For Facsimile) ....................................... 47

5.19. 2nd Paper Feed Module

Packing and Accessories ..................... 162

5.20. Printer Controller Module

for PCL6 ............................................... 164

5.21. G3 Communication Port Kit

(For UF-8000/8100).............................. 166

5.22. Network Scan / Email /

Internet Fax Kit ..................................... 168

5.23. Hardware Identification Template......... 170

Alphanumerical Parts List .................. 172

Service Modes........................................ 54

4.1. Service Modes (For Copier)................... 54

4.2. Service Modes (For Facsimile) .............. 71

Exploded View & Parts List ................101

5.1. Destination Codes................................ 101

5.2. Control Panel Unit

(For USA and Canada) ........................ 102

5.3. Control Panel Unit

(For Other Destinations) ...................... 104

5.4. ADF...................................................... 106

5.5. Cover Assembly................................... 118

5.6. Right Side Parts ................................... 122

5.7. Motor and Drive Gear Unit ................... 126

5.8. Left Side Parts ..................................... 128

5.9. Rear and Upper Parts .......................... 132

5.10. Fuser Unit ............................................ 134

5.11. Pick Up Roller and Paper

Feed Roller .......................................... 138

5.12. Bottom Parts ........................................ 140

5.13. Mechanical Base.................................. 142

5.14. Paper Tray ........................................... 144

5.15. 2nd Paper Feed Module ...................... 146

5.16. Paper Tray

(2nd Paper Feed Module).................... 150

5.17. PC Boards............................................ 152

5.18. Packing and Accessories..................... 158

8

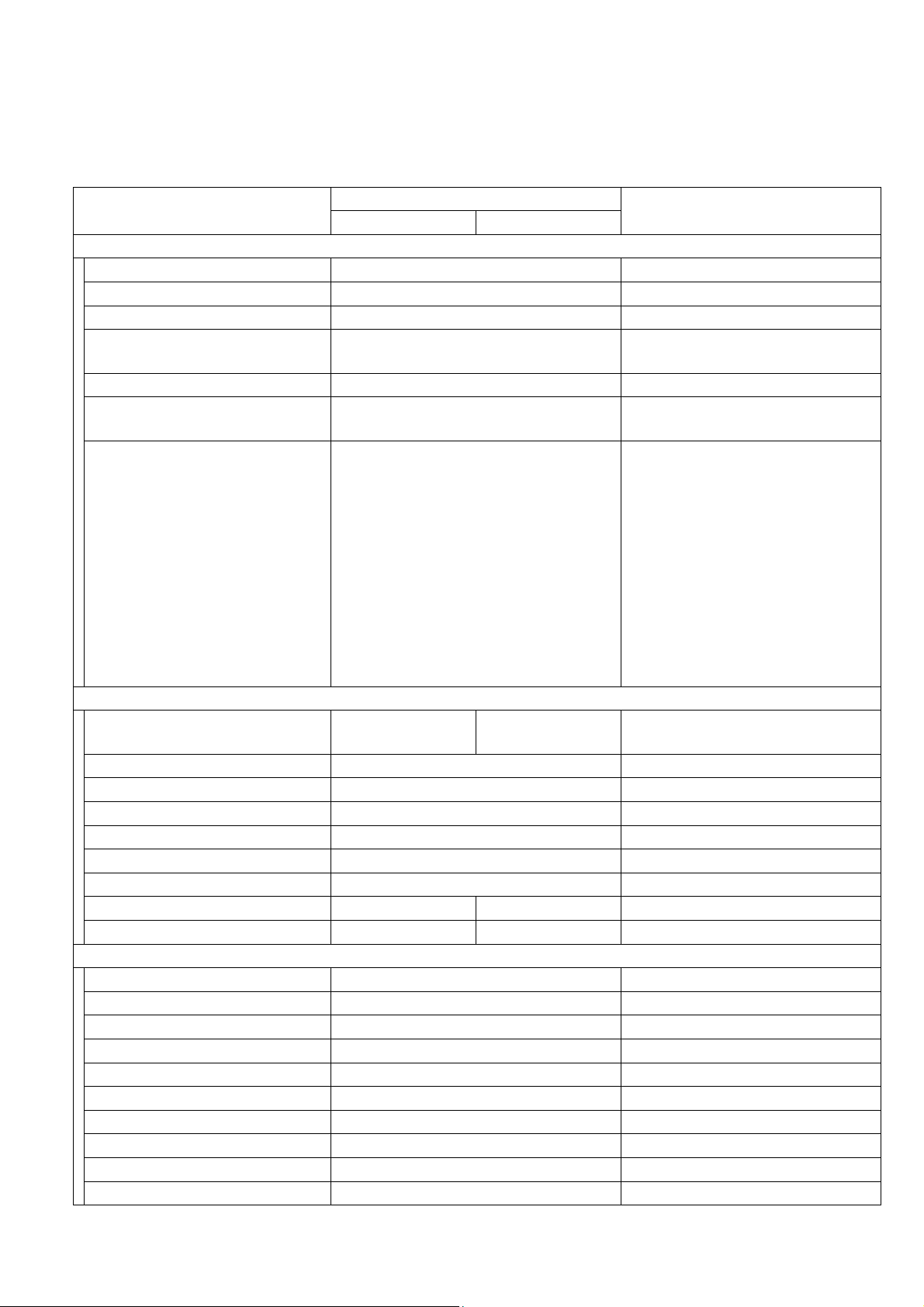

1 Specifications Table

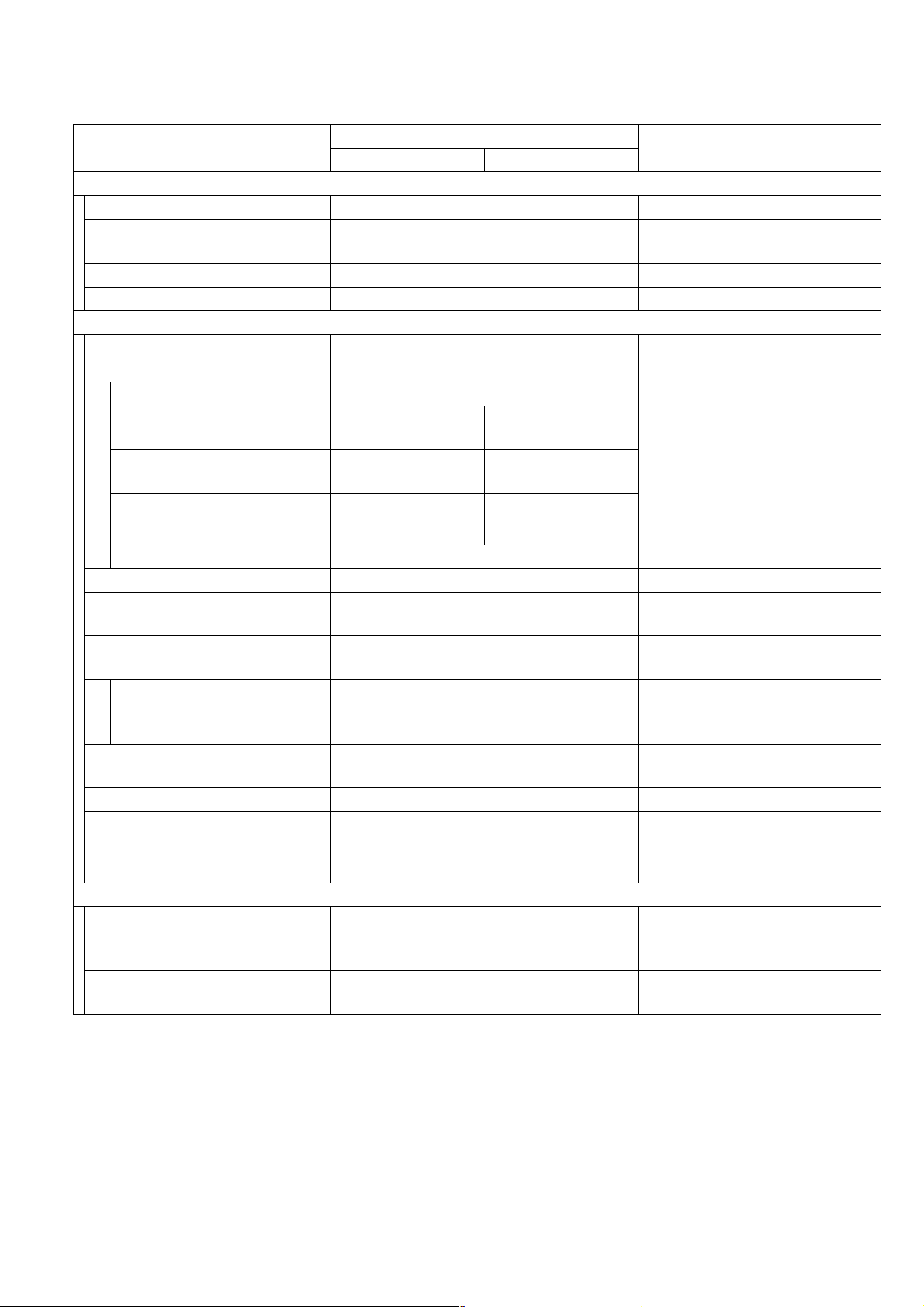

1.1. Fax, Printer, Network Scanner and Internet Fax Functions

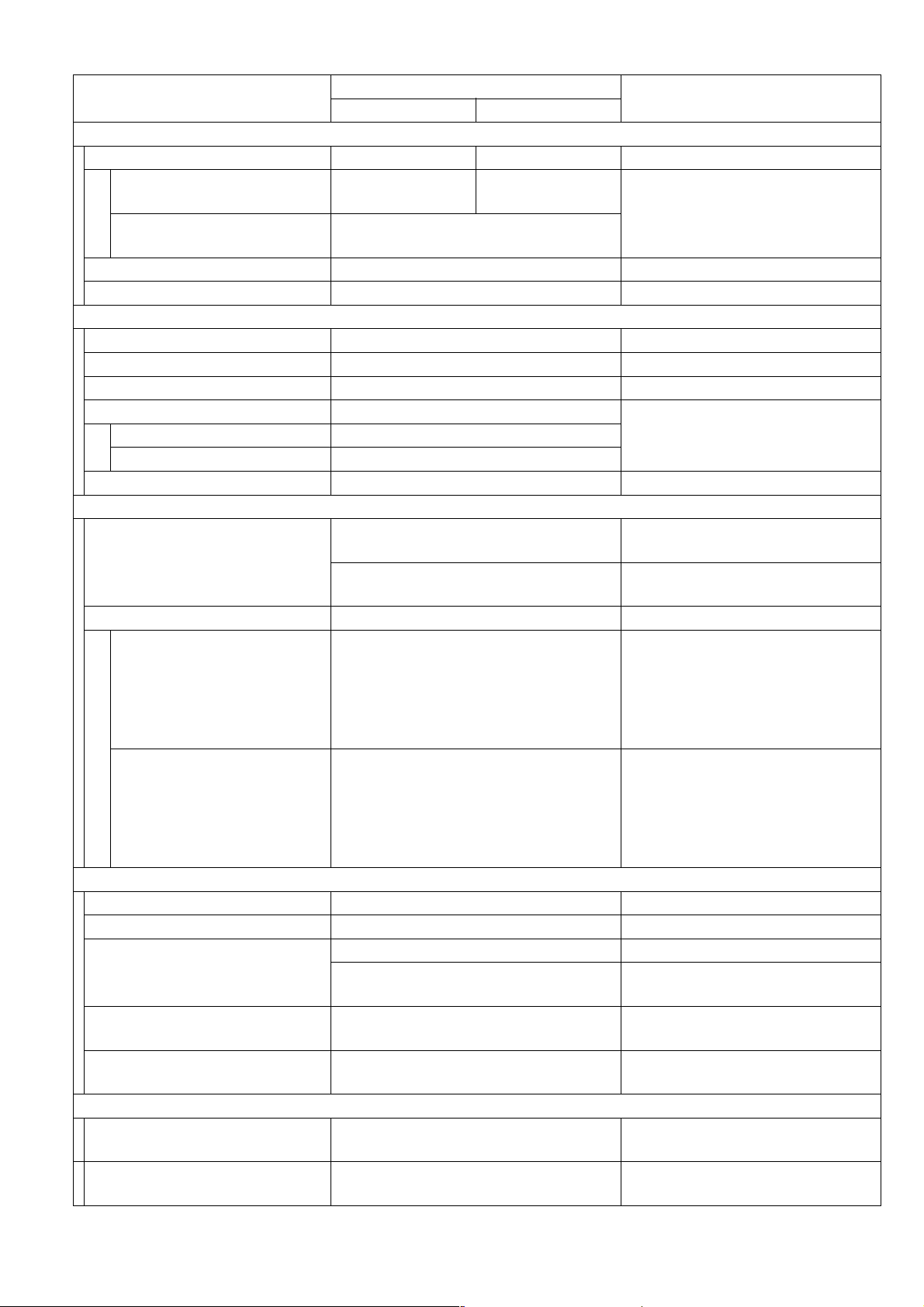

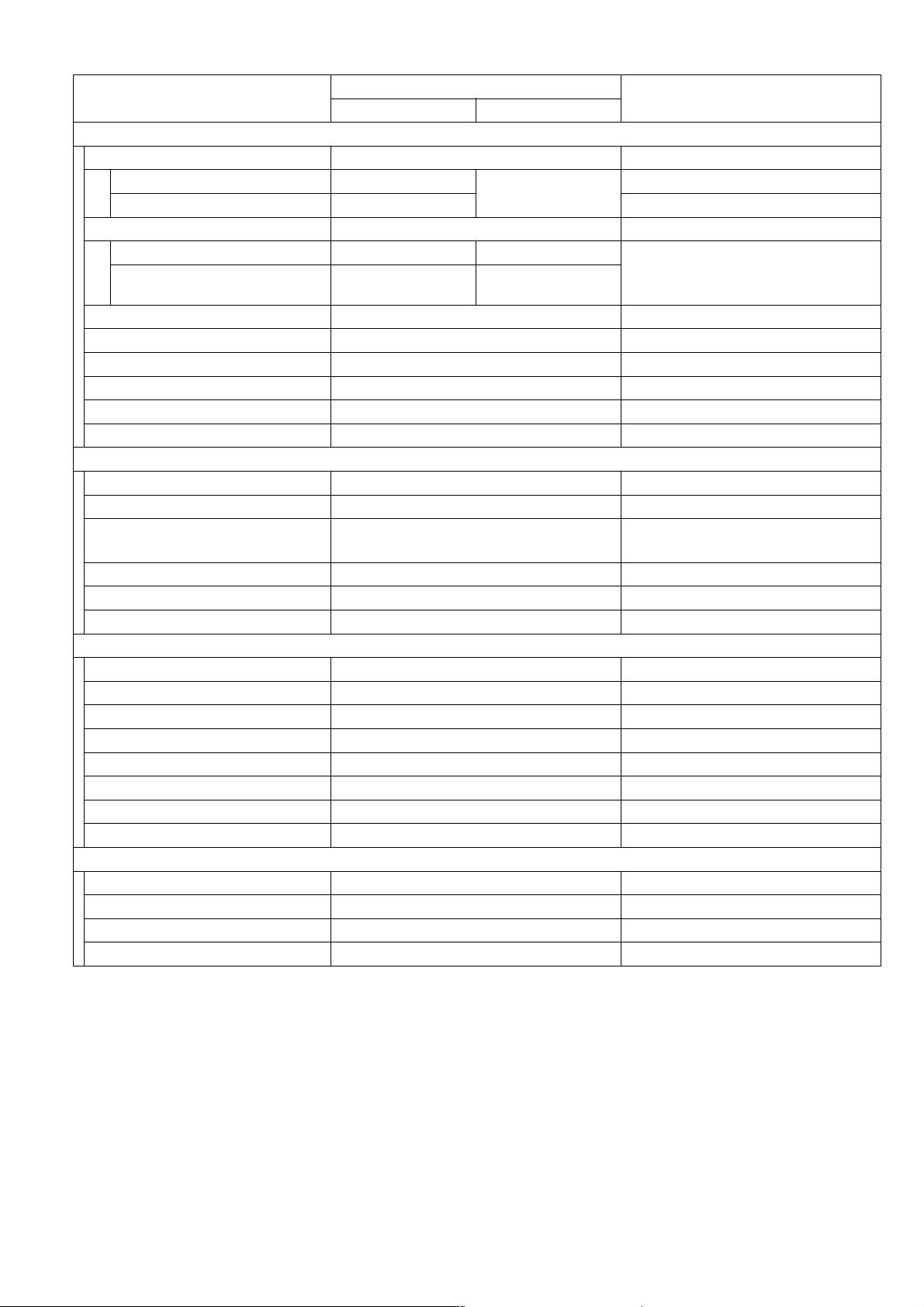

1.1.1. Fax Function

UF-7000/8000

UF-7100/8100

Items

Main Specifications

1 Compatibility Super G3 / G3 ITU-T Std & Non-Std

2 Modem Speed 33.6 - 2.4kbps T.30/V.34/V.17/V.29/V.27ter

3 Coding Scheme JBIG/MMR/MR/MH

4ECM Yes

5 Short Protocol Yes (B, D)

6 Transmission Speed Approx. 2.7 sec

Communication Resolution

7

dpi x lpi (pels/mm x lines/

mm)

Communication Ports

1 PSTN Line Port 1-Line

2 Leased Line Port No

3 V.24 Line Port No

4 LAN (Network) Yes

5 Centronics Parallel I/F No

6 USB Port Yes USB1.1

7 IEEE-1394 No Firewire

8 Communication Port (Max) 2 Ports 3 Ports

9 Multi Task Operation (Max) 4 Jobs 5 Jobs

Communication Protocols

1 PSTN ITU-T G3 (T.30)

2 Fax over the Internet ITU-T T.37

3 G3 Fax over IP Network ITU-T T.37

4 TCP/IP Yes

5 DHCP Yes

6LDAP Yes

7SMTP Yes

8 LPR/LPD Yes

9SNMP Yes

10 MIB2 Yes

UF-7000/7100 UF-8000/8100

Transmission

Std. : 203 x 98 (8 x 3.85)

Fine : 203 x 196 (8 x 7.7)

S-Fine : 203 x 391 (8 x 15.4)

600dpi : 600 x 600 dpi

Reception

Std. : 203 x 98 (8 x 3.85)

Fine : 203 x 196 (8 x 7.7)

S-Fine : 203 x 391 (8 x 15.4)

600dpi : 600 x 600 dpi

Description

406 x 391 (16 x 15.4)

406 x 391 (16 x 15.4)

Std: 1-Line

Max: 2-Lines

Remarks

Conforms to ITU-T Rec. T.30

ECM

ITU-T Image No. 1

(A4, Std Resolution)

600 dpi communication is only

possible between T.30 Compliant

Panafax, WORKiO, and other

T.30 compliant machines.

2nd G3 Option is available for

UF-8000/8100.

Ethernet 10Base-T/100Base-TX

Ver. 2. 0

9

NOV 2004

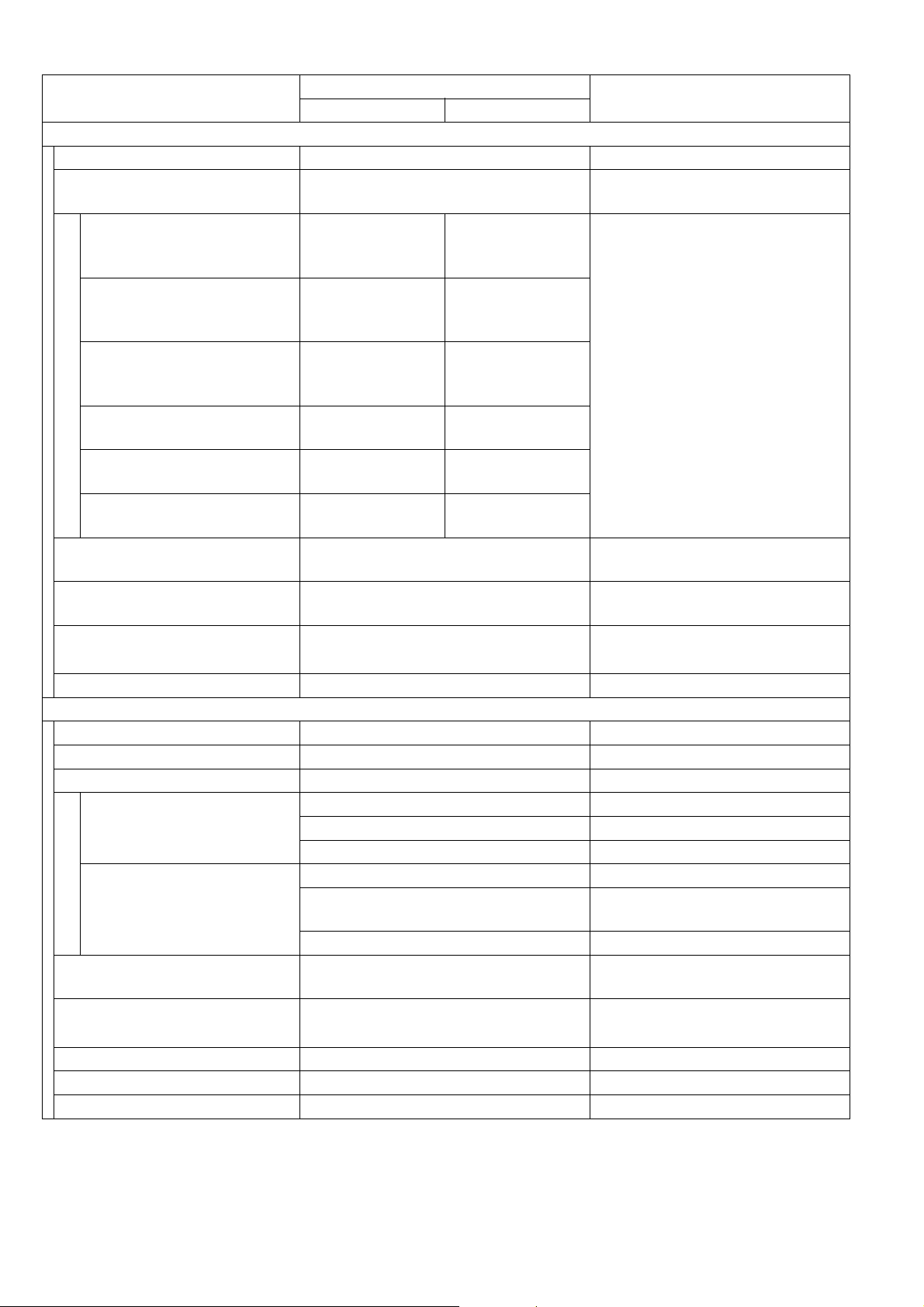

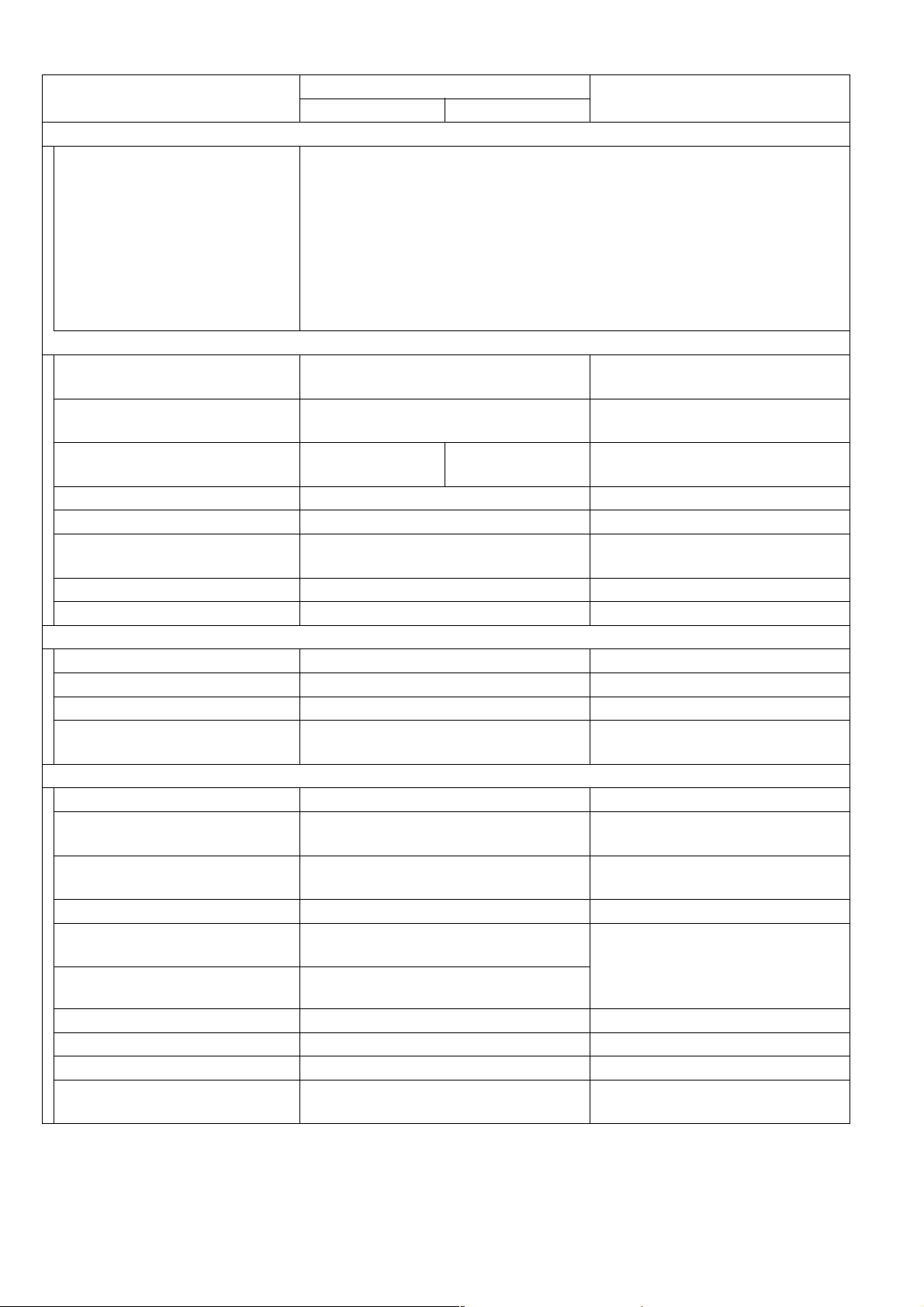

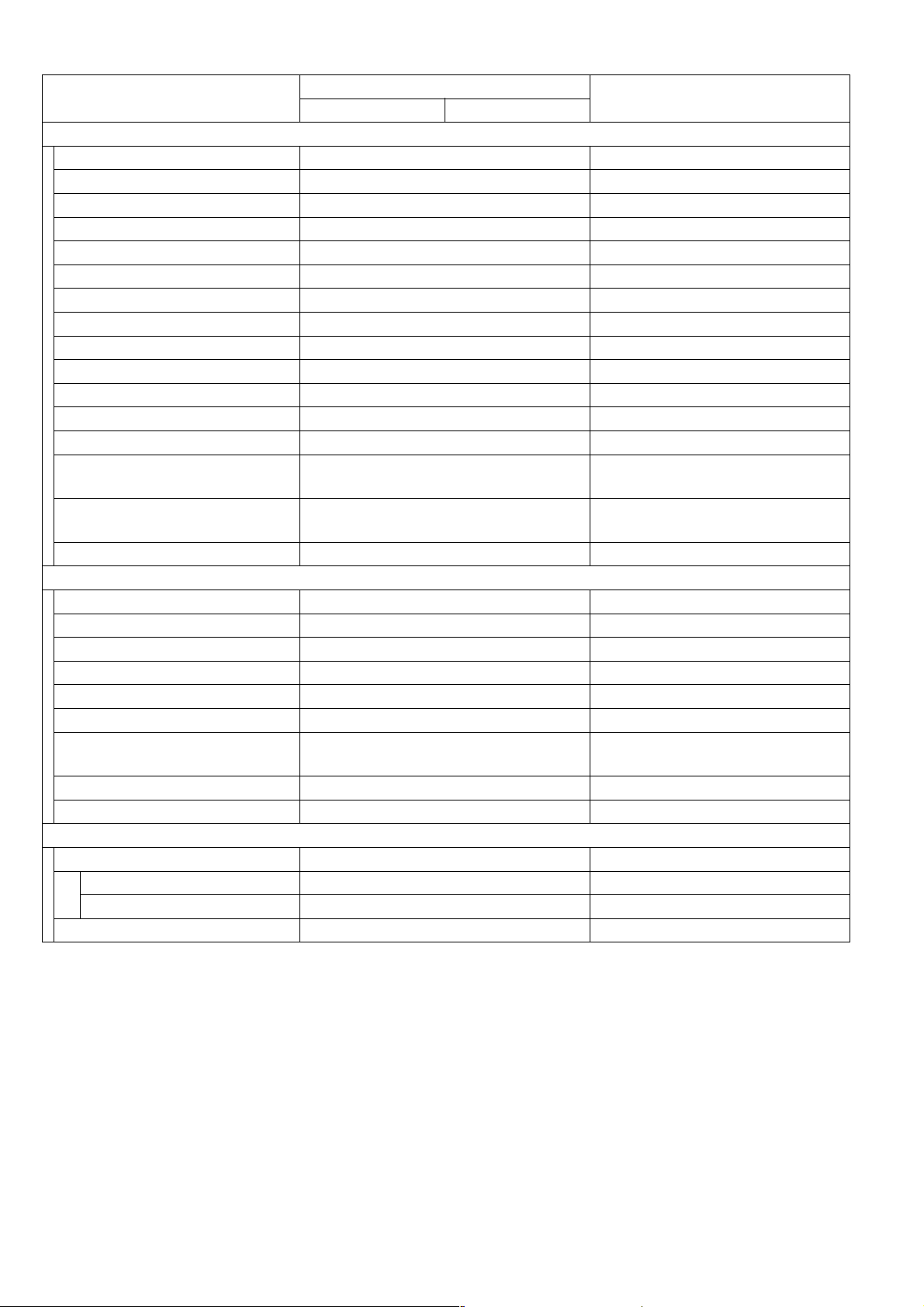

Items

Description

UF-7000/7100 UF-8000/8100

Scanner Mechanism

1 Scanning Device CIS (ADF)

Scanning Resolution /

2

Speed

Std: 203 x 98 (8 x 3.85)

dpi x lpi (pels/mm x lines/

mm)

Fine: 203 x 196 (8 x 7.7)

dpi x lpi (pels/mm x lines/

mm)

S-Fine: 406 x 391 (16 x

15.4) dpi x lpi (pels/mm x

lines/mm)

150dpi: 150 x 150

300dpi: 300 x 300

600dpi: 600 x 600

3 Document Size (Max.)

4 Effective Scanning Width

5 ADF Capacity 100 sheets

LTR : 1.4 sec

A4 : 1.5 sec

LTR : 2.8 sec

A4 : 3.0 sec

LTR : 5.7 sec

A4 : 6.1 sec

LTR : 2.2 sec

A4 : 2.3 sec

LTR : 4.4 sec

A4 : 4.6 sec

LTR : 8.8 sec

A4 : 9.3 sec

LTR : 0.7 sec

A4 : 0.7 sec

LTR : 1.4 sec

A4 : 1.5 sec

LTR : 2.8 sec

A4 : 3.0 sec

LTR : 1.1 sec

A4 : 1.1 sec

LTR : 2.2 sec

A4 : 2.3 sec

LTR : 4.4 sec

A4 : 4.6 sec

Legal

8.5 x 14 in (216 x 2000 mm)

LTR : 8.3 in (212 mm)

A4 : 8.2 in (207 mm)

Excludes: Initializing Time, ADF

slipping factor, and Data XMT

Time.

(Letter size for USA and Canada;

A4 size for Other Destinations)

(Letter size for USA and Canada;

A4 size for Other Destinations)

Face Up, top feed

LTR / A4 (20 lb / 75 g/m

6 Collation Stack Yes Face Down

Printer Mechanism

1 Recording Method LP

2

Recording Resolution Fax 600 x 600 dpi

3 Recording Paper Size

Letter / Legal For USA and Canada

Paper Tray

A4 / A5 For EU

A4 / A5 / B5 For Other Destinations

Letter / Legal / Invoice For USA and Canada

Bypass

A4, FLS, A5

For EU

FLS = 8 x 13 in, 8.5 x 13 in

A4 / A5 / B5 For Other Destinations

Effective Printing Width

4

LTR : 8.1 in (207mm)

A4 : 7.9 in (201 mm)

5 Recording Paper Capacity 250 sheets

Letter : USA and Canada

A4 : Other Destinations

Tray 1 + 2 : Max. 800 sheets

LTR / A4: 20 lb (75 g/m

6

Collation Stack Yes Face Down

7 Consumable All in One Cartridge

8 Low Toner Warning Yes

Remarks

UF-7000/8000

UF-7100/8100

2

)

2

)

Ver. 2. 0

10

NOV 2004

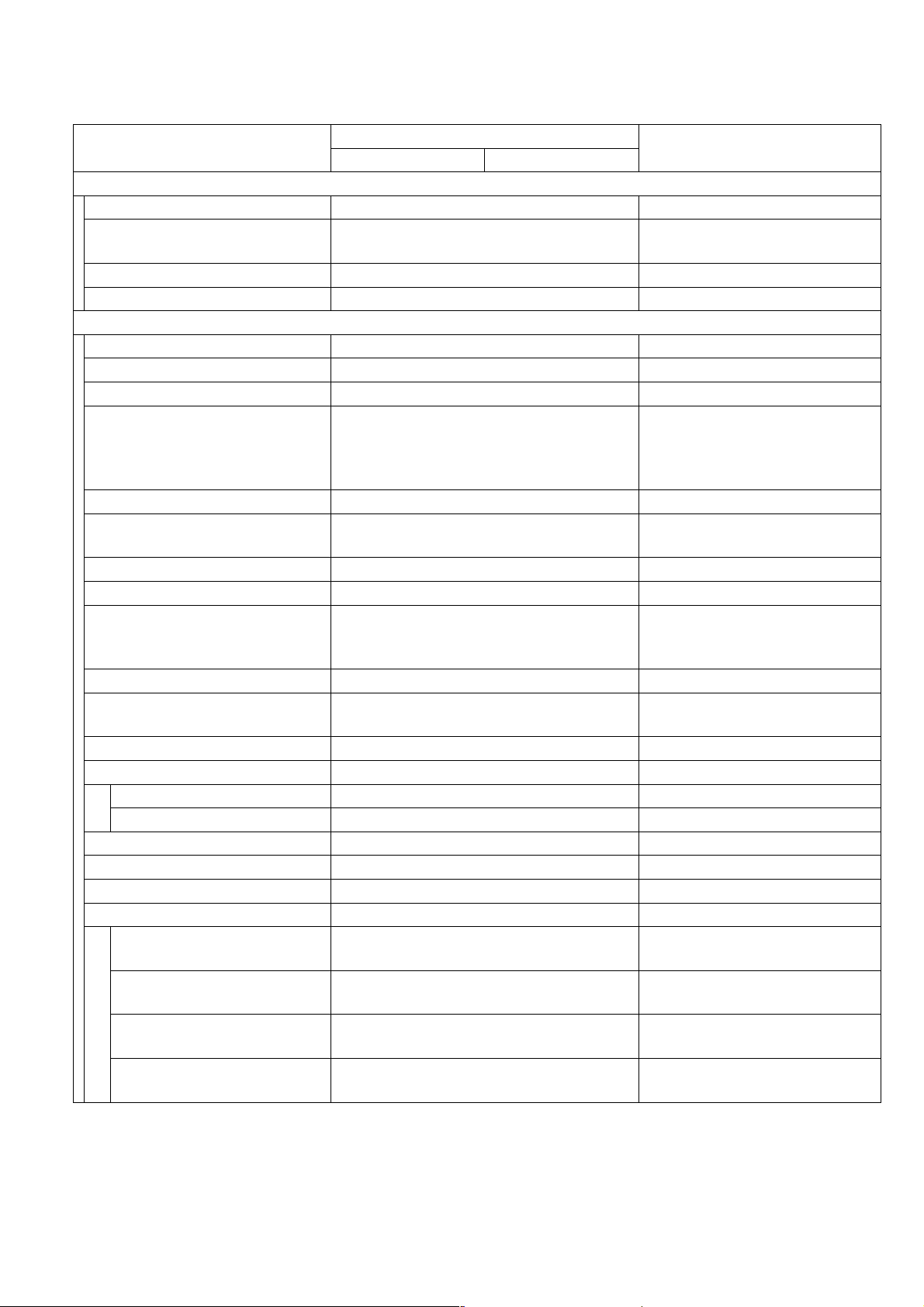

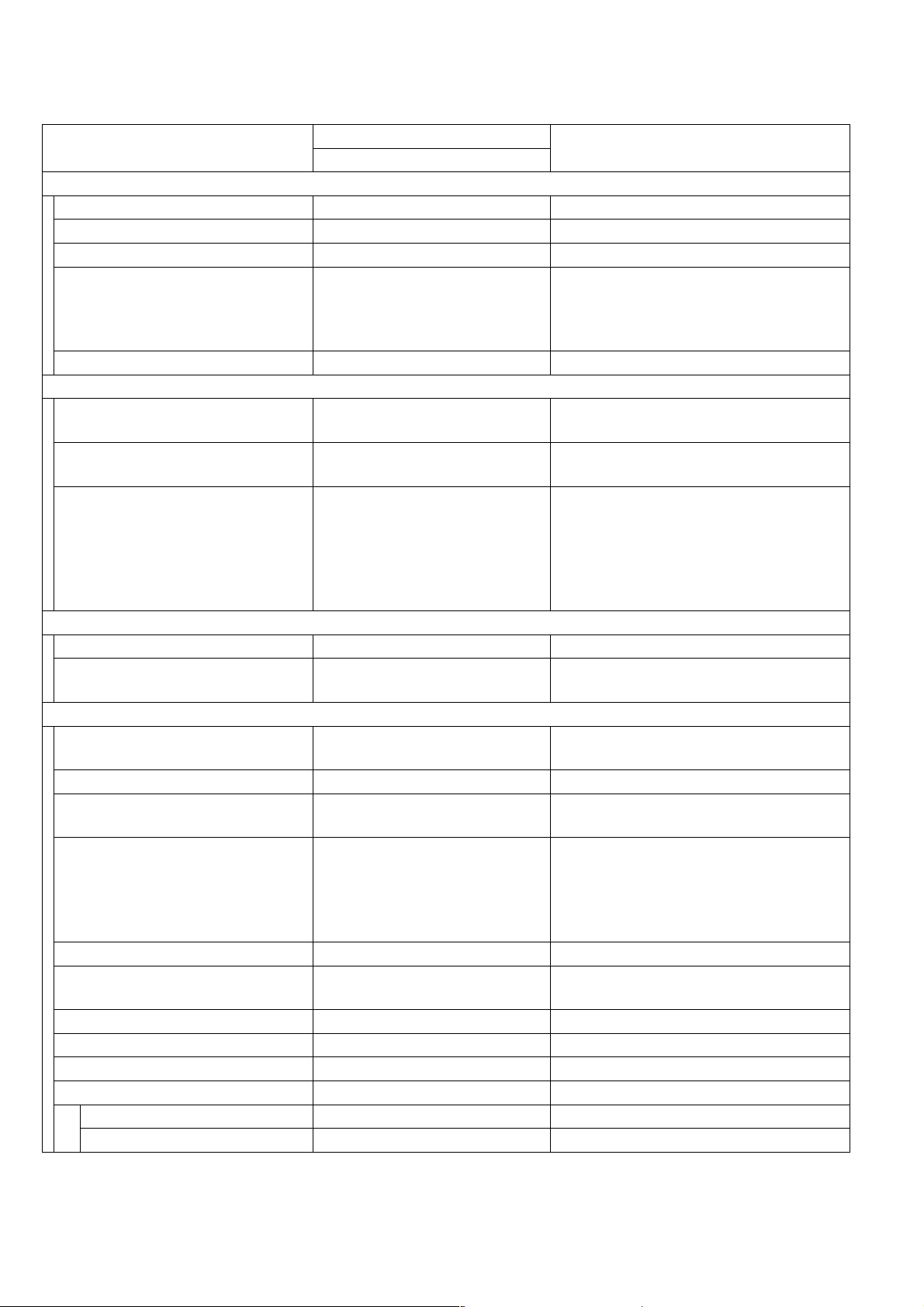

Items

Description

Remarks

UF-7000/7100 UF-8000/8100

Memory

1Fax Memory

Standard Memory

(Flash)

Optional Memory

(SD Memory Card)

3 MB

(180 pages)

12 MB

(720 pages)

32 MB to 512 MB

(Max. 1,020 to 12,750 pages)

ITU-T Image No.1 (A4, Std

Resolution)

(Refer to 1.1.5.)

2 Printer Page Memory 32 MB

3 Sort Memory 16 MB

Copy Quality

1 Halftone Yes 256-Level Error Diffusion

2 Resolution 600 x 600 dpi

3 Original Contrast Selection Yes 5-Levels

4 Smoothing (Rx)

Fax, Copy Yes

With Auto Picture / Text

Recognition

PC Printing Data No

5 2-Sided Copy Yes Scan twice

Power Supply

1 Power Requirement

99 - 132 VAC 47 - 63 Hz

Single phase

180 - 264 VAC 47 - 63 Hz

Single phase

120 VAC

220 - 240 VAC

2 Power Consumption

Standby 13 W

Transmission 21 W

Reception 860 W

120 VAC Power Supply

Copy 860 W

Maximum 1000 W

Standby 14 W

Transmission 23 W

Reception 850 W

220 - 240 VAC Power Supply

Copy 850 W

Maximum 1000 W

Ambient Conditions

1 Temperature 50 - 80 °F / 10 - 30 °C

2 Relative Humidity 30 - 80%RH

UL60950-1 / CSA C22.2 No.60950-1 For USA and Canada

3Safety

4EMI

5 Lead Free Solder (PbF)

EN60950-1

Class B computing device peripheral

in FCC Rules Part 15

This Product uses Lead Free (PbF)

PCBs

For EU and

Other Destinations

For USA and Canada

Refer to the inner Front Cover

and the Parts Manual for details

Construction

1 Dimensions (W x D x H)

2 Weight (Excluding paper)

17.7 x 17.9 x 18.0 in

(450 x 454 x 448 mm)

48.5 lb

(22.0 kg)

Excluding projections

Excluding consumable supplies

and options

UF-7000/8000

UF-7100/8100

Ver. 2. 0

11

NOV 2004

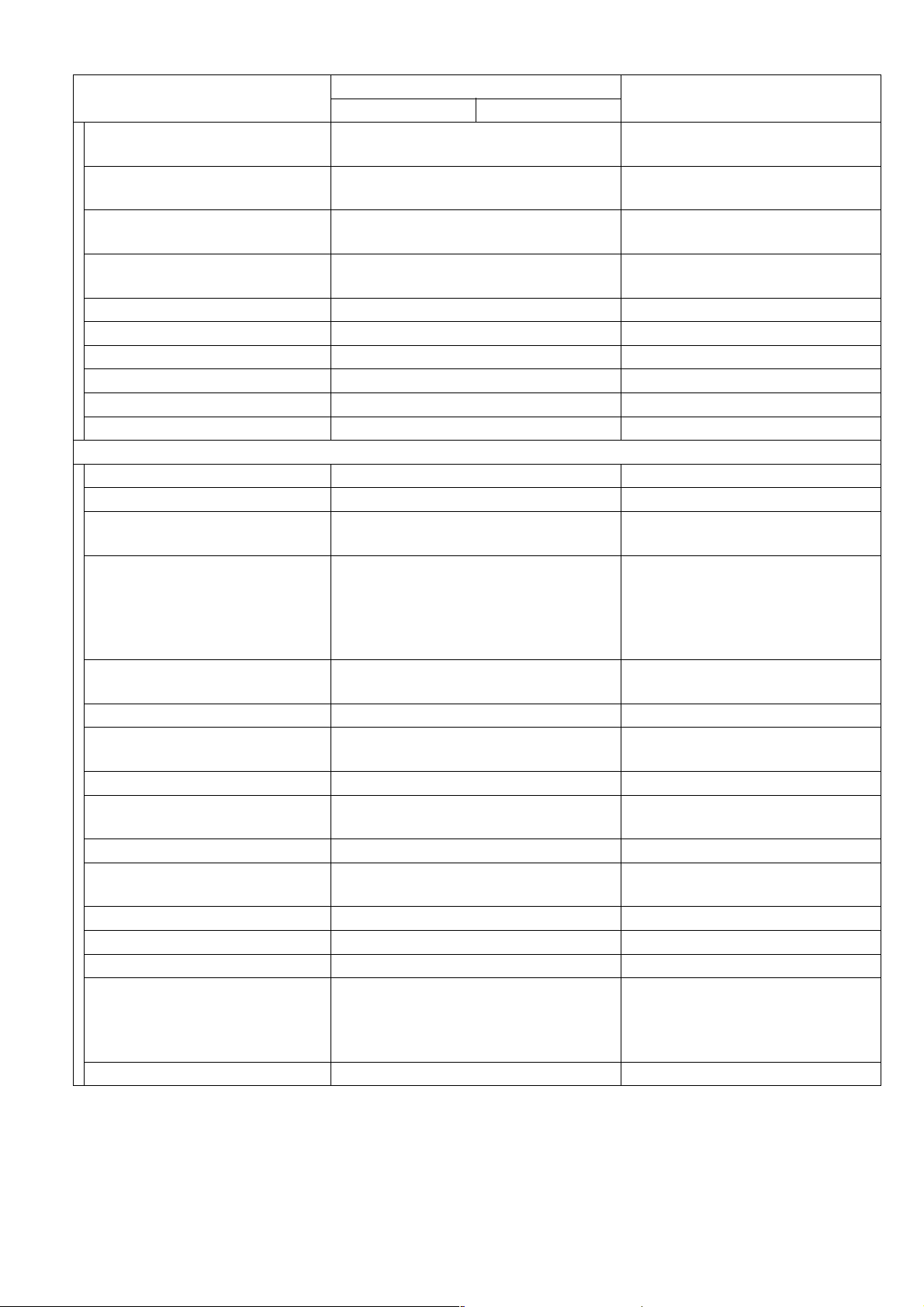

Items

Description

Remarks

UF-7000/7100 UF-8000/8100

Consumables

Yield: 5 K (5% coverage), 6 K Max

Average yield is based on 5% coverage of the printable area with

repetitive printing of 10 pages (Letter/A4 size, single side printing,

default density). The yield of a Toner Cartridge varies depending on the

1 Toner Cartridge

coverage, temperature, humidity, media, etc. Therefore, the average

yield cannot be guaranteed. Continuously printing 10% coverage of

printable area will reduce the yield of the Toner Cartridge to about half as

compared to 5% coverage printing. The maximum yield of the Toner

Cartridge will not exceed 6,000 pages by way of Digital Counter.

Options

Printer Controller Module

1

(PCL6*)

Network Scan / Email /

2

Internet Fax Kit

2nd G3 Communication

3

Port Kit

No Yes

Yes

Yes

4 Accounting Software Yes

5 Expansion Board Yes

6 SD Memory Card

Yes

32 MB - 512 MB

Use Genuine SD Memory Cards

only.

7 2nd Paper Feed Module Yes

8 Handset Kit Yes Specific Destinations only.

Multi-Task Operation

1 Multi Task Operation Yes

2 Direct XMT Reserve Yes

3 Memory XMT Reserve Yes

Number of Memory Job

4

Files

Yes Max. 50 files

Dialing/Telephone Features

1 Directory Search Dialing Yes

Directory Search

2

(LDAP Email)

Directory Search

3

(LDAP Fax)

Yes

Yes

4 One-Touch Auto Dialers 80 (40 x2: Upper/Lower)

5 Abbr. Auto Dialers

6 Total Auto Dialers

200

(max. 920)

280

(Max. 1,000)

Plus an additional 720 stations

available to select from, when the

optional SD Memory Card

(Minimum 32 MB) is installed.

7 Program Dials 80

8 Max. Number Digits (Fax) 36

9 Max. Number Digits (Email) 60

Max. Station Name

10

Characters

15

UF-7000/8000

UF-7100/8100

Ver. 2. 0

12

NOV 2004

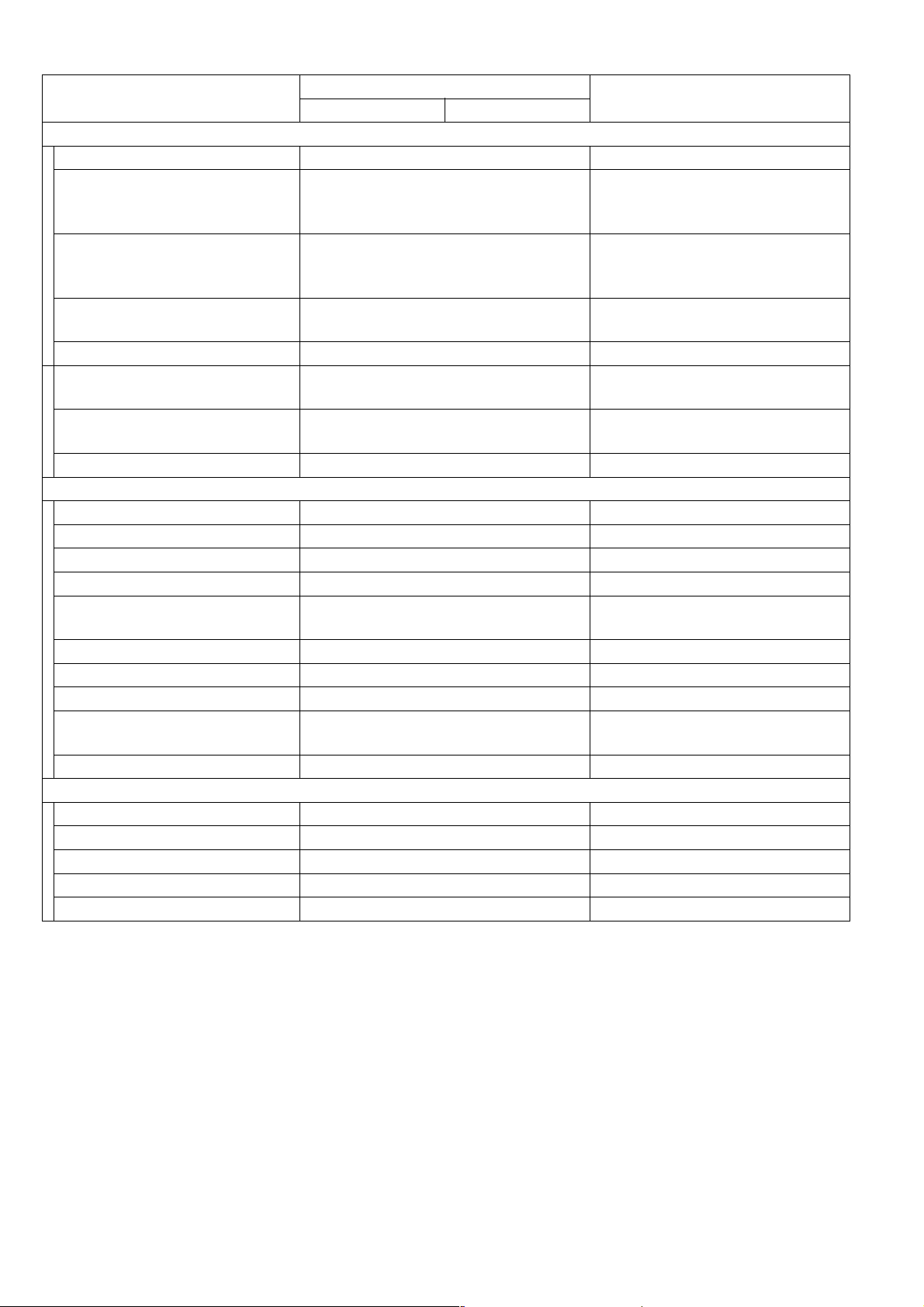

UF-7000/8000

UF-7100/8100

Items

Description

Remarks

UF-7000/7100 UF-8000/8100

Full Number Dialing

11

(Buffered Dialing)

Direct Dialing

12

(Monitor Dialing)

13 Automatic Redialing Yes

14 Manual Redialing Yes

Yes Max. 50 stations

Yes Voice mode

Up to 15 times at 0 to 15 min.

intervals

Pressing the REDIAL/PAUSE

button

15 Line Monitor Speaker Yes 1st Line only

16 Chain Dialing (Hybrid Dial) Yes In Monitor Dialing mode only

17 Pulse / Tone Dialing Yes 10 pps / DTMF

18 Pulse to Tone Change Yes

19 Flash Key Yes

20 Handset Option

Transmission Features

1 Direct Transmission Yes

2 Memory Transmission Yes Page Retransmission

Quick Memory

3

Transmission

Yes

Max. 330 stations

Multi-Station Transmission

4

(Sequential Broadcasting)

Yes

(280 One-Touch / Abbr. + 50 Full

Number Dialing)

Max.1000 stations when the SD

Memory Card is installed

Direct Deferred

5

Transmission

No ADF Deferred Transmission

6 Deferred Transmission Yes Max. 50 timers

Deferred Multi-Station

7

Transmission

Yes

8 Priority Direct Transmission Yes Priority ADF Transmission

Priority Memory

9

Transmission

No

10 Batch Transmission Yes Real Time (up to 5 Files)

90 Degree Rotation

11

Transmission

No

12 Cover Sheet Yes

13 Confidential Mail Box No

14 Multi-Copy Transmission No

FAX: Back-up with Flash

15 Memory Back-Up Yes

Memory.

Copy / Printer: No Back-up with

D-RAM

16 Duplex Scanning Yes Scan twice, Fax once

Ver. 2. 0

13

NOV 2004

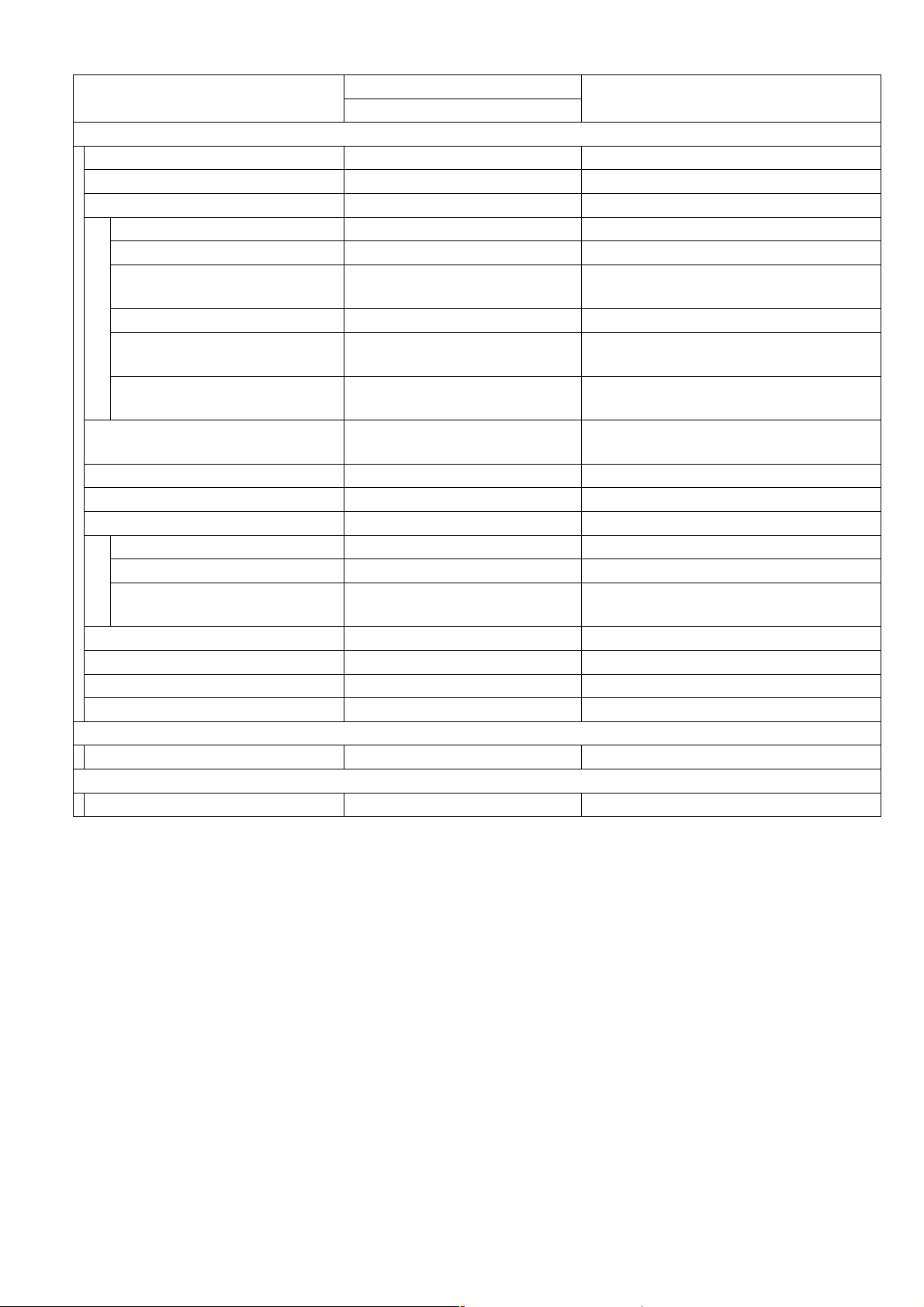

Items

Description

UF-7000/7100 UF-8000/8100

Reception Features

1 Substitute Reception Yes

LTR/A4/LGL: 70 - 100%

2 Fixed Reduction Yes

(in 1% Steps), Top & Left

Alignment

LTR/A4/LGL: 70 - 100%

3 Auto Reduction Yes

(in 1% Steps), Top & Left

Alignment

4 Overlap Printing Yes

Page End Approx. 0.51 in (13

mm)

5 Receive to Memory Yes

Distinctive Ring Detector

6

(DRD)

90 Degree Rotation

7

Reception

Yes Specified Destinations only

No

8 Duplex Printing Yes

Polling

1 Polling Yes

2 Turnaround Polling No

3 Multi-Station Polling Yes

4 Deferred Polling Yes

Deferred Multi-Station

5

Polling

Yes

6 Direct Polling Tx No

7 Memory Polling Tx Yes 1 File

8 Preset Polling Password Yes

Temporary Polling

9

Password

Yes

10 Continuous Polling Yes

Convenience

1 Panel Display Yes

2 Voice Contact No

3 Edit File Mode Yes With View Mode

4 Incomplete File Save Yes With View Mode

5 Automatic Fax Cover Sheet Yes

UF-7000/8000

UF-7100/8100

Remarks

Ver. 2. 0

14

NOV 2004

Items

Description

UF-7000/7100 UF-8000/8100

Copy Features

1First Copy Time

Letter 25 sec.

A4 26 sec.

19 sec.

2 Copy Speed

Letter Approx. 15 cpm Approx. 19 cpm Paper Feed: 1st Paper Tray;

A4 Approx. 14 cpm Approx. 18 cpm

Paper Exit: to Exit Tray;

Continuous Copy Mode.

3 Single Copy Yes

4 Multiple Copy Yes

5 Sort Copy only Yes

6 Enlargement Yes

7 Reduction Yes

8 Zoom Yes 71% - 141%

Certainty

1 Verification Stamp Yes

2 Header / Total Page Print Yes

3 Transaction Journal Yes

200 Transactions /

with View Mode

4 Comm. Journal Yes With Image

5 Last Ind. XMT Journal Yes

6 Power Failure Report No

Printout Lists

1 One-Touch List Yes

2 ABBR. No. List Yes

3 Program List Yes

4 Address Book Search List Yes Auto Dialer List

5 Fax Parameter List Yes

6 File List Yes With View Mode

7 Ind. XMT Journal Yes

8 Directory Sheet Yes

Identifications

1 Logo Yes 25 Characters

2 Multiple Logo No

3 Character ID Yes 16 Characters

4 Numeric ID Yes 20 Digits

UF-7000/8000

UF-7100/8100

Remarks

Ver. 2. 0

15

NOV 2004

Items

Description

Remarks

UF-7000/7100 UF-8000/8100

Special Communications

1 Password XMT / RCV No

2 Selective Reception No TSI Check

3 Relay XMT Request No

4 Relay XMT Center No

5 Confidential XMT / Polling No

6 Confidential Center No

7 Mailbox XMT / Polling No

8 Mailbox Center No

9File XMT No

10 Received Fax Forward Yes Received File Transfer

11 Sub-address XMT Yes T. Routing

12 Sub-address Auto Routing Yes

13 NYSE Yes For USA and Canada only

14 Internet Fax Relay XMT Yes

15 Email Relay XMT Yes

Internet Fax → Internet Fax →

G3FAX

PC → Internet Fax→ Internet Fax

→ G3FAX

16 Panafax Desktop Yes

Others

1 Fax Access Code Yes

2 PIN Code Access Yes For USA and Canada only

3 Intelligent Redial (AI) Yes 5 Files

4 Department Code Yes 50 Departmental Codes

5 Power Saver Mode Yes

6 Self Diagnostic Function Yes

Remote Diagnostic

7

Function

Yes Specific Destinations only

8 Check & Call Function Yes

9 V.24 / Encryption Interface No

Firmware Update

1 Local Update

SD Memory Card Yes

USB Port Yes

2 LAN (Network) Yes

UF-7000/8000

UF-7100/8100

Ver. 2. 0

16

NOV 2004

1.1.2. Printer Function

UF-7000/8000

UF-7100/8100

Items

Description

UF-7000/7100 UF-8000/8100

Interface

1 Centronics Parallel I/F No

2 LAN (Network) Yes

Ethernet 10Base-T/100Base-

TX

3 USB Port Yes USB1.1

4 IEEE-1394 No Firewire

Printer Function

1 Printing Size LGL / LTR / A4 / A5

2Bypass Yes

3 Stapling No

Selectable 600 dpi, with

4 Printing Resolution (dpi) Max. 1200 (Interpolated) x 600 dpi

Smoothing, the results are

similar to PCL6 Printers (1200

dpi Interpolated).

5 Interface USB / Ethernet

6OS

Win 98 / Win Me / Win NT 4.0 /

Win 2000 / Win XP

7 Printer Work Memory Size 20 MB Not expandable

8GDI Yes

Requires Optional PCL6

9 PDL (PCL6) Yes

Emulation Kit and Optional

Expansion Board.

10 PDL (PS3) No

11 Duplex Printing Yes

Custom Size/Postcard Size is

not available.

12 Collation Stack Yes

13 Status Monitor

Network Yes

USB No

14 Network Status Monitor Yes

15 Smoothing Yes

16 Applicable PC IBM PC, AT or Compatible

17 Multi-Task Operation

Printing while Fax-XMT

from Memory

Printing while Fax-RCV into

Memory

Fax-XMT from Memory

while Printing

Fax-RCV into Memory while

Printing

Yes

Yes

Yes

Yes

Remarks

Ver. 2. 0

17

NOV 2004

Items

Description

UF-7000/7100 UF-8000/8100

Output to separate tray for

18

Printing, Fax, Copy

No

19 Font Yes

20 Secure Mailbox Yes

UF-7000/8000

UF-7100/8100

Remarks

Requires Optional PCL6

Emulation Kit

Requires Optional SD Memory

Card (256 MB or 512 MB).

Max. 10 mailboxes.

Ver. 2. 0

18

NOV 2004

1.1.3. Network Scanner Function

UF-7000/8000

UF-7100/8100

Items

Description

Remarks

UF-7000/7100 UF-8000/8100

Interface

1 Centronics Parallel I/F No

2 LAN (Network) Yes

Ethernet 10Base-T/100Base-

TX

3 USB Port No

4 IEEE-1394 No Firewire

Network Scanning Function

1 Scanning Device CIS

2 Scanning Speed (ADF)

Mono

150dpi: 150 x 150

300dpi: 300 x 300

600dpi: 600 x 600

LTR : 2.2 sec

A4 : 2.3 sec

LTR : 4.4 sec

A4 : 4.6 sec

LTR : 8.8 sec

A4 : 9.3 sec

LTR : 1.1 sec

A4 : 1.1 sec

LTR : 2.2 sec

A4 : 2.3 sec

LTR : 4.4 sec

A4 : 4.6 sec

Excludes: Initializing Time,

ADF slipping factor, and Data

XMT Time.

Letter size: for USA and

Canada

A4 size : for Other

Destinations

Color No

3 Halftone 256 Halftone shades With Error Diffusion

4 Max. Document Size

Scanning Resolution

5

(dpi)

8.5 x 14 in (216 x 2000 mm)

Legal

600 x 600

Mono

300 x 300

Default: 300 dpi

150 x 150

6OS

Win NT 4.0 / Win 2000 / XP

Win 98 / Me /

7 2-Sided Scanning No

8 File Format Multi-page TIFF / PDF

9 Completion Notice Yes

Auto Pop-up on the PC Screen

10 Protocol TCP/IP / Non-Std

Network Address Features

Shared with Fax/Internet Fax

1 One Touch Address Keys 80

One-Touch Address, 80 in

To ta l

2 Abbr. Address Numbers 20

Independent for Network

Scanner

Ver. 2. 0

19

NOV 2004

1.1.4. Internet Fax Function

UF-7000/8000

UF-7100/8100

Items

Description

Remarks

UF-7000/7100/8000/8100

Main Specifications

1 Communication Protocols SMTP / POP3 / MIME

2 Max. Modem Speed NA

3 Coding Scheme JBIG/MMR/MR/MH

Selectable

4 File Format TIFF / PDF

(PDF formats are used for Scan-toEmail, current Internet Fax standards

do not support these file formats)

5 Line Interface RJ-45 Ethernet LAN

Scanner Mechanism

1 Max. Document Size

2 Effective Scanning Width

LTR : 8.3 in (212 mm)

A4 : 8.2 in (207 mm)

Legal

216 x 2000 mm

Letter size: for USA and Canada

A4 size : for Other Destinations

Std : 203 x 98 (8 x 3.85)

Fine : 203 x 196 (8 x 7.7)

Scanning Resolution

3

dpi x lpi (pel/mm x lines/mm)

S-Fine : 203 x 391 (8 x 15.4)

: 406 x 391

LAN: 600 dpi, 16 x 15.4 Scanning

Resolution is available.

(16 x 15.4)

600dpi : 600 x 600 dpi

Printer Mechanism

1 Printing Resolution 600 dpi

2 Effective Recording Width

LTR : 8.1 in (207 mm)

A4 : 7.9 in (201 mm)

Transmission Features

1 Multi-Task Operation Yes

Convenient simultaneous G3 Fax and

LAN operation.

2 Memory Transmission Yes

Sequential Multi-Station

3

Transmission

Yes

Max. 330 stations

Simultaneous Multi-Station

4

Transmission

Yes

(280 One-Touch / Abbr. + 50 Full

Number Dialing)

Max.1000 stations when the SD

Memory Card is installed

5 Sender Selection Yes

G3 / Email Mixed

6

Broadcasting

Yes

7 Deferred Transmission Yes

8 Fax Forward Yes Received File Transfer

9 Sub-address RCV Yes Inbound Routing

10 Mail Header

Email Header Print Selection Yes All or From / To / Subject only

Subject Line Random Entry

Ver. 2. 0

20

NOV 2004

UF-7000/8000

UF-7100/8100

Items

Description

Remarks

UF-7000/7100/8000/8100

LAN Features

1 Internet Fax Communication Yes

2 Internet Mail Reception Yes

3 Internet Fax Server Features

Internet Fax Relay XMT Yes Internet Fax → Internet Fax → G3FAX

Email Relay XMT Yes PC → Internet Fax → G3FAX

Received Fax / Email

Forward

Yes Local print available

PC FAX Transmission Yes Panafax Desktop Only (Network)

Inbound Routing

Phone Book Registration from

PC

Internet Fax Parameters

4

Registration via Email

Yes Using Sub-Address.

Local print available

Yes Via Email or Network Address Editor

Yes

5 Internet Delivery Confirmation Yes With MDN

6 Network Scanning Yes 600 dpi

7 Network Printing

LPR / LPD Yes 600 dpi

GDI Yes 600 dpi

PDL Yes

Requires Optional PCL6 Emulation Kit

and Optional Expansion Board.

8 DHCP Client Yes

9 LDAP Yes Lightweight Directory Access Protocol

10 TIFF Viewer Yes Selectable, PDMS / TIFF Viewer

11 NYSE Yes For USA and Canada only

Certainty

1 Comm. Journal (w / Image) Yes

ID

1 Email Address Yes

Ver. 2. 0

21

NOV 2004

UF-7000/8000

UF-7100/8100

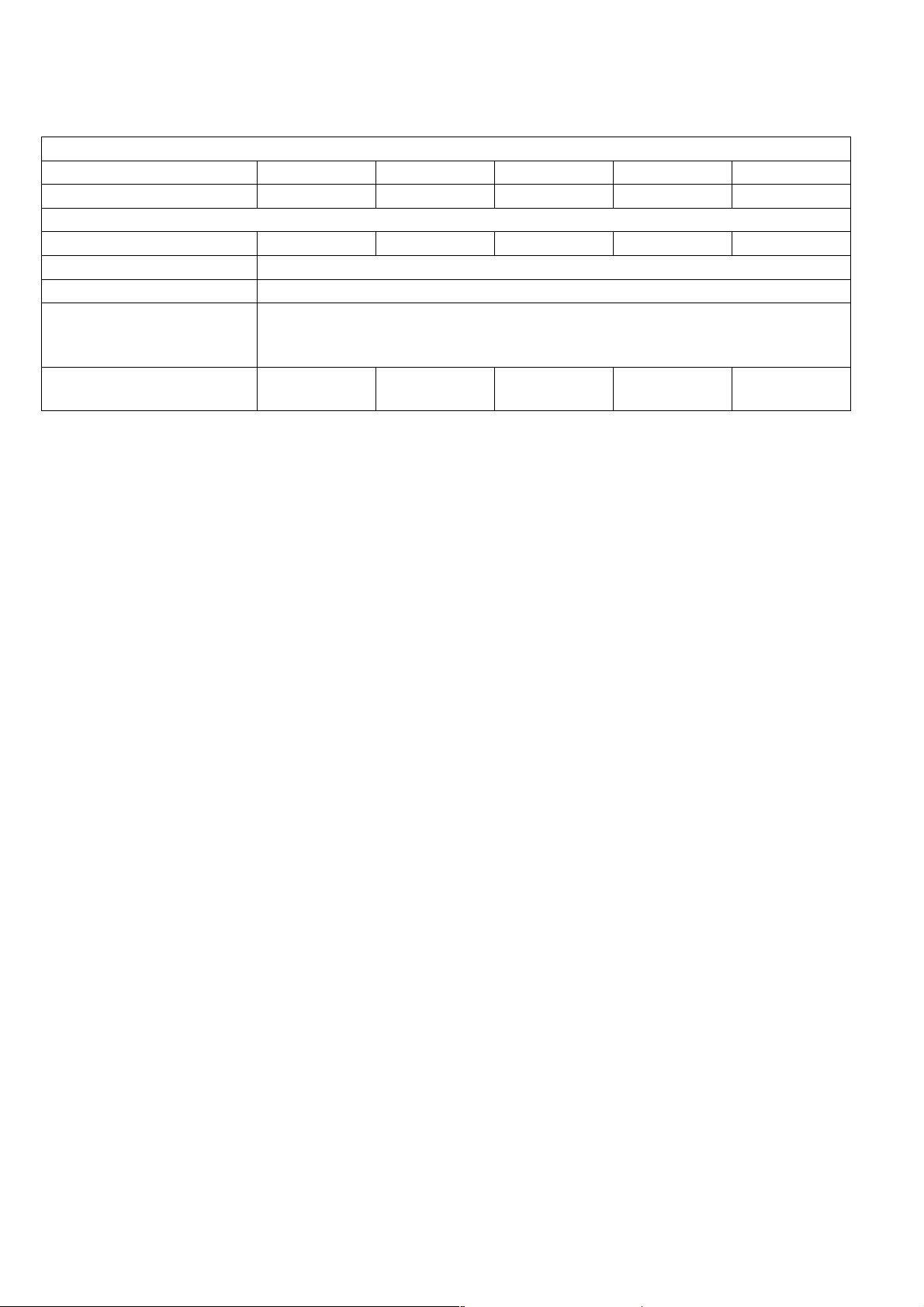

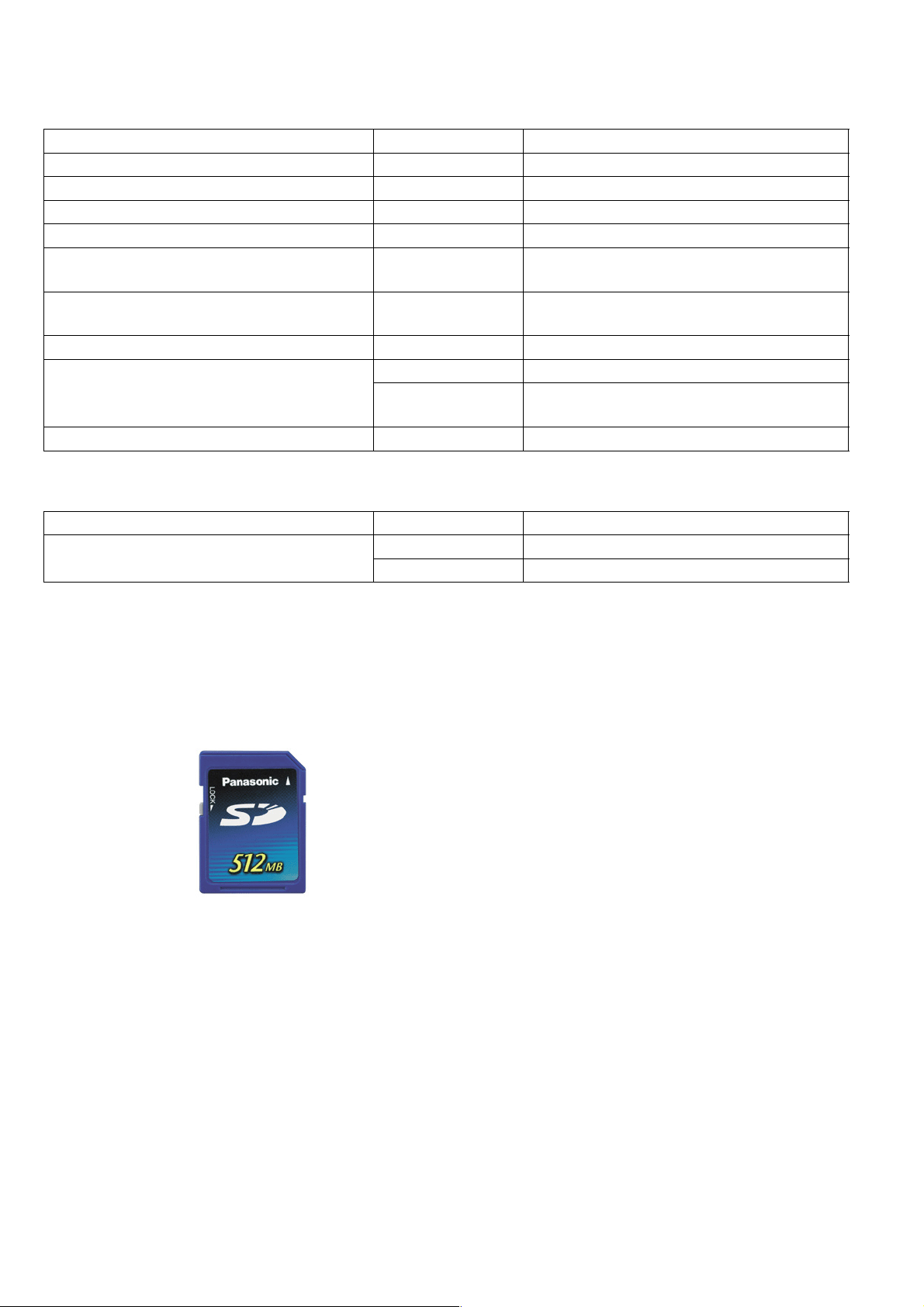

1.1.5. SD Memory Card

SD Memory Card Format Structure and Allocation by Function

SD Memory Card Format Structure

SD Memory Size (n MB) 32 MB 64 MB 128 MB 256 MB 512 MB

Max. Number of Pages 1,020 2,900 6,800 12,750 12,750

Memory Allocation Usage by Function

Function 32 MB 64 MB 128 MB 256 MB 512 MB

1000-Station Auto-Dialer Yes

Job MIB Data Yes

G3 Fax/Internet Fax

Scan-to-Email

Scan-to-PC/File

Mailbox/Secure Mailbox

Print (See Note 5)

N/A N/A N/A

Note:

1. This function is available only when an SD Memory Card is installed.

2. Max. Number of Pages is based on ITU-T Image No.1 (A4, Standard Resolution).

3. Fax/Internet Fax XMT memory storage = Max. 255 pages/file, Max 50 Files; Scan to PC/File = Max.

999 pages.

4. Fax/Internet Fax RCV memory storage = Max. 999 pages.

With 2nd G3 Option installed = Max. 999 pages/Channel.

5. One Mailbox accepts a maximum of 20 print jobs. A 512 MB SD Memory Card stores approximately

105 pages of PCL bitmap print data, whereas a 256 MB SD Memory Card stores approximately 50

pages.

6. Once the SD Memory Card is installed, the standard Fax & Internet Fax Flash Memory and the

Network Scanning D-RAM is no longer used.

7. Max. page number may differ depending on the manufacturer of the SD Memory Card.

Yes

Yes

(50 pages)

Yes

(105 pages)

Ver. 2. 0

22

NOV 2004

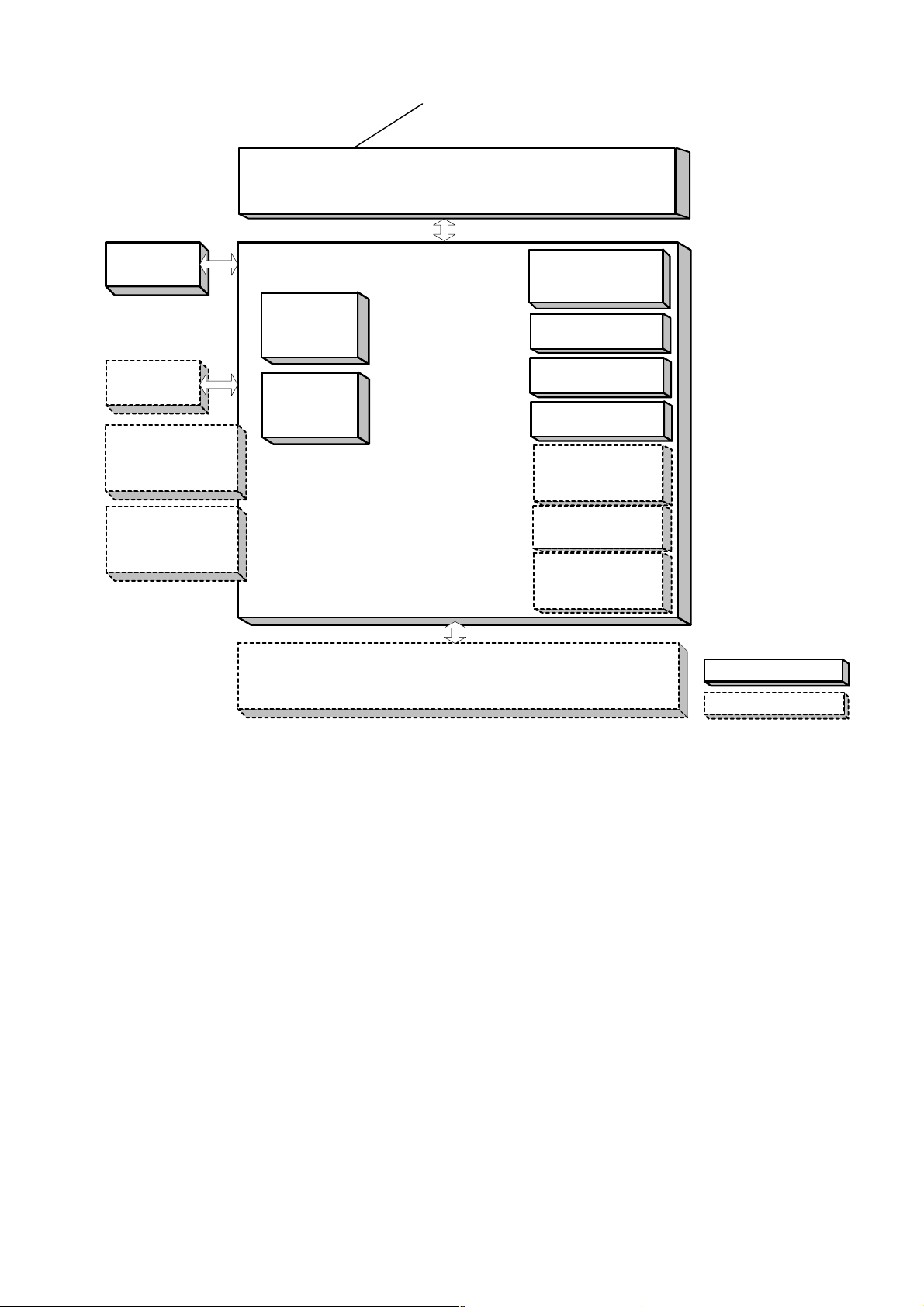

1.2. System Combination

UF-7000/8000

UF-7100/8100

Panel

(PNL PC Board)

Handset Kit

Option

Program

Expansion Board

8MB

SD Memory Card

(32 MB - 512 MB)

Automatic Document Feeder (ADF)

Main PC Board (SC)

Automatic

Duplex Unit

Electronic

Sorting

Memory

(SDR PC Board)

Super G3 Fax

Communication

(FXB PC Board)

GDI Printer

USB Interface

10/100 Ethernet

Interface

2nd Super G3 Fax

Communication

Option

PCL6

Emulation Option

Network Scanner

Email / Internet Fax

Option

2nd Paper Feed Module Option

Standard Configuration

Option

Ver. 2. 0

23

NOV 2004

1.3. Options List

■ Options

Option Name Option Number Remarks

Printer Controller Module (PCL6*) UE-404091

Network Scan / Email / Internet Fax Kit UE-404090

2nd G3 Communication Port Kit UE-407026 For UF-8000/8100 only

Accounting Software DA-WA10 For Accounting Function

Expansion Board DA-EM600

SD Memory Card

---- 32 MB up to 512 MB

2nd Paper Feed Module DA-DS188

UE-403171 For USA and Canada

Handset Kit

UE-403172

Deluxe Stand DA1D190 For USA and Canada only

■ Supplies

F-ROM Board (8 MB) is required for PCL

printing.

Use Genuine SD Memory Cards only

For Other Destinations

Available in Specified Destinations

UF-7000/8000

UF-7100/8100

Part Name Part Number Remarks

All in One Cartridge

UG-5530 For USA and Canada

UG-5535 For Other Destinations

Note:

1. PCL6 is a Page Description Language of the Hewlett-Packard Company.

2. The Part Name(s) / Part Number(s) differ depending on the Models and the Destinations.

3. Genuine SD Memory Cards depict an SD Logo on their label.

(Panasonic's 512 MB Sample is shown below).

Ver. 2. 0

24

NOV 2004

2 Maintenance, Adjustments and Check Points

2.1. Preventive Maintenance

Preventive maintenance is performed at specific intervals and consists of machine

cleaning and parts replacement.

It is essential to perform these service activities properly and at the specified intervals

for customer satisfaction.

The purpose of this service is to maintain machine performance and image quality.

- You should prepare the replacement parts, and cleaning tools beforehand.

- After completing the preventive maintenance, discard the used parts and

packaging in accordance with local regulations and clean the surrounding

area.

- Before servicing the equipment, disconnect the power cord from the wall outlet.

- Before using solvents such as IPA (Isopropyl alcohol), put on rubber gloves

and eye protection.

1 Timing

- Perform the preventive maintenance in accordance with the Preventive

Maintenance Check List (refer to 3.4) in the service manual.

UF-7000/8000

UF-7100/8100

2 Cleaning the Rollers

- Rollers should be cleaned with water and cloth.

- Use the IPA (Isopropyl Alcohol) sparingly.

3 Disassembly and Adjustment Precautions

CAUTION!

Turn the Power Switch on the Rear Side of the machine to the OFF

position, and then unplug the AC Power Cord from the wall outlet

before disassembling the machine. (During a Lightning Storm, to

prevent electrocution disconnect the Telephone Line Cable first

before unplugging the AC Power Cord.)

- After taking the unit apart, do not attempt to operate the machine.

- When operating the machine with covers removed, be careful and avoid clothing

from being caught by moving components.

-

While the electricity is applied to the unit, do not connect nor disconnect the

connectors on any PC Board.

- Ensure to use correct screws.

- Use toothed lock washers for the installation of ground wires to ensure electrical

continuity.

- To reassemble, reverse the sequence of disassembly, unless otherwise specified.

- Blown fuses should only be replaced with fuses of the same specified rating.

Ver. 2. 0

25

NOV 2004

4 Laser Handling Precautions

The optical laser system employed by this photocopier is completely sealed by

a protective housing and an external cover. Therefore, the laser beam will not

stray or leak during photocopying operation.

However, when servicing the photocopier, take the following precautions:

1. Do not insert any screwdrivers or other tools that have high reflective

properties into the laser's path.

.

2. Before servicing the machine, remove watches, rings, or other metallic

objects that you may be wearing. (This is to avoid the danger of the laser

striking the eye by reflecting off the metallic objects being worn.)

Since the laser beam cannot be seen with the naked eye, for maximum

safety, please follow the above precautions.

5 Safety Interlock Switches

- The service technician may defeat the safety interlock switches by inserting a

interlock cheater into the opening of the switch cover.

- Ensure to remove the interlock cheater from the switch cover after completion

of service.

UF-7000/8000

UF-7100/8100

Ver. 2. 0

26

NOV 2004

2.2. Required Tools

No. Tools No. Tools

1 Soft Cloth 7 Pliers

2 Isopropyl Alcohol 8 Cotton Swab

3 Phillips Screwdriver (#2) 9 Brush

KS-660 - Conductive Grease

4 Stubby Phillips Screwdriver (#2) 10

5 Slotted Screwdriver (3/32 in) 11

6 Tweezer

2.2.1. Preventive Maintenance Method

(Available from Shin-Etsu Silicones of America, Inc.

URL: http://www.shinetsusilicones.com)

Molykote EM-50L Grease

(Available from Dow Corning,

URL: http://www.dowcorning.com)

UF-7000/8000

UF-7100/8100

No. Part Description

Important

Action

1 Memory Data Check

Auto Document

2

Feeder (ADF)

3 Scanner Unit

4 Transmitter Unit

Check &

Clean

Check &

Clean

Check &

Clean

5 Inspection Items Check

6 Gears, Rollers Shafts

7 Timing Belts

Check &

Grease

Check &

Clean

Comments

1. Print the RAM DATA for reference and as a precaution.

2. After completing the task(s), print and compare the RAM

DATA with the previously printed one.

1. Clean the Rollers with Wet soft cloth (Water).

Note:

For stubborn toner accumulation, wipe with a soft cloth

saturated with Isopropyl Alcohol first, then follow up with

a soft cloth saturated with water.

1. Clean the Scanning Glass or White Reference Sheet with

Isopropyl Alcohol when required.

2. Clean it with Wet soft cloth.

1. Remove any foreign obstacles.

2. Clean the Rollers with Wet soft cloth (Water).

1. Check the Harnesses.

2. Check the Connectors.

3. Check the Screws. If required, replace consumable parts.

1. Check and grease the required Gears and Shafts.

1. Check for belt looseness or abrasion.

2. Adjust the Idle Pulley.

Ver. 2. 0

27

NOV 2004

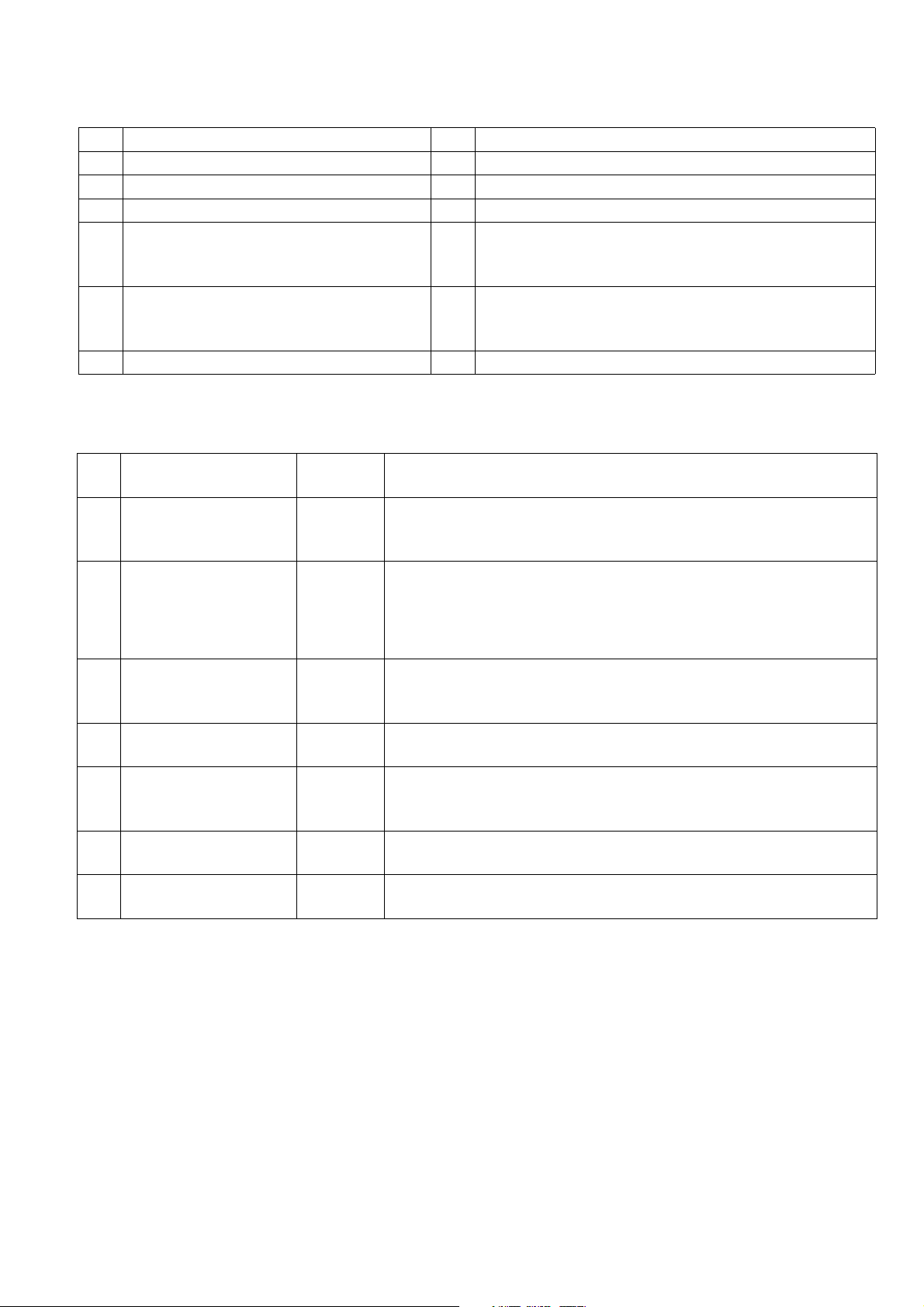

2.3. Preventive Maintenance Points

ADF & Scanner: Front View

Separation Roller

3

2

Feed Roller

1

Pick Up Roller

ADF Pad

4

White Sheet

CIS (Contact Image Sensor)

UF-7000/8000

UF-7100/8100

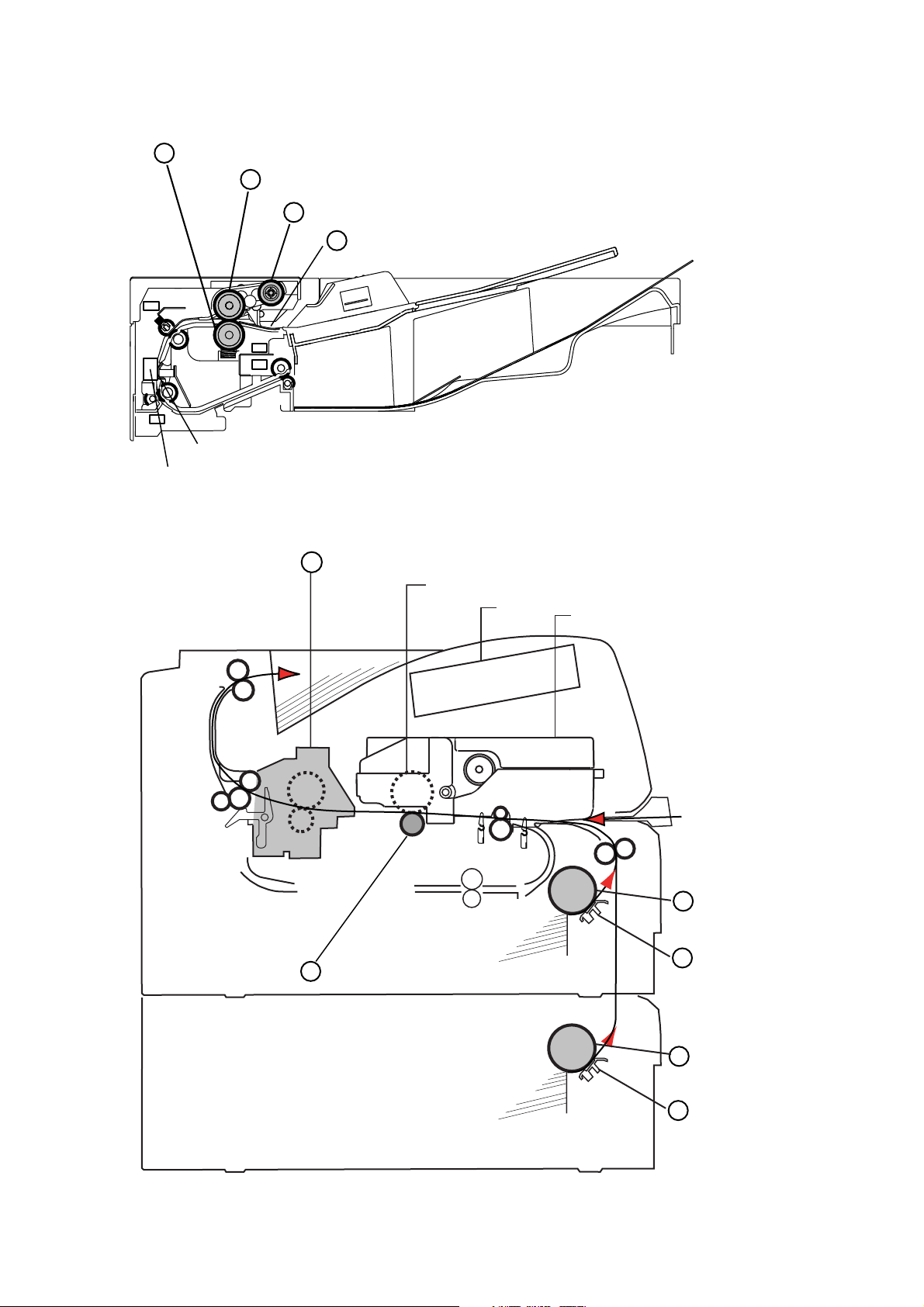

Printer: Left Side View

Fuser Unit

10

OPC Drum

Bias Transfer Roller (BTR)

7

LSU

Toner Cartridge

5

Pick Up Roller

Separation Pad

6

Ver. 2. 0

28

8

Pick Up Roller

Separation Pad

9

NOV 2004

UF-7000/8000

UF-7100/8100

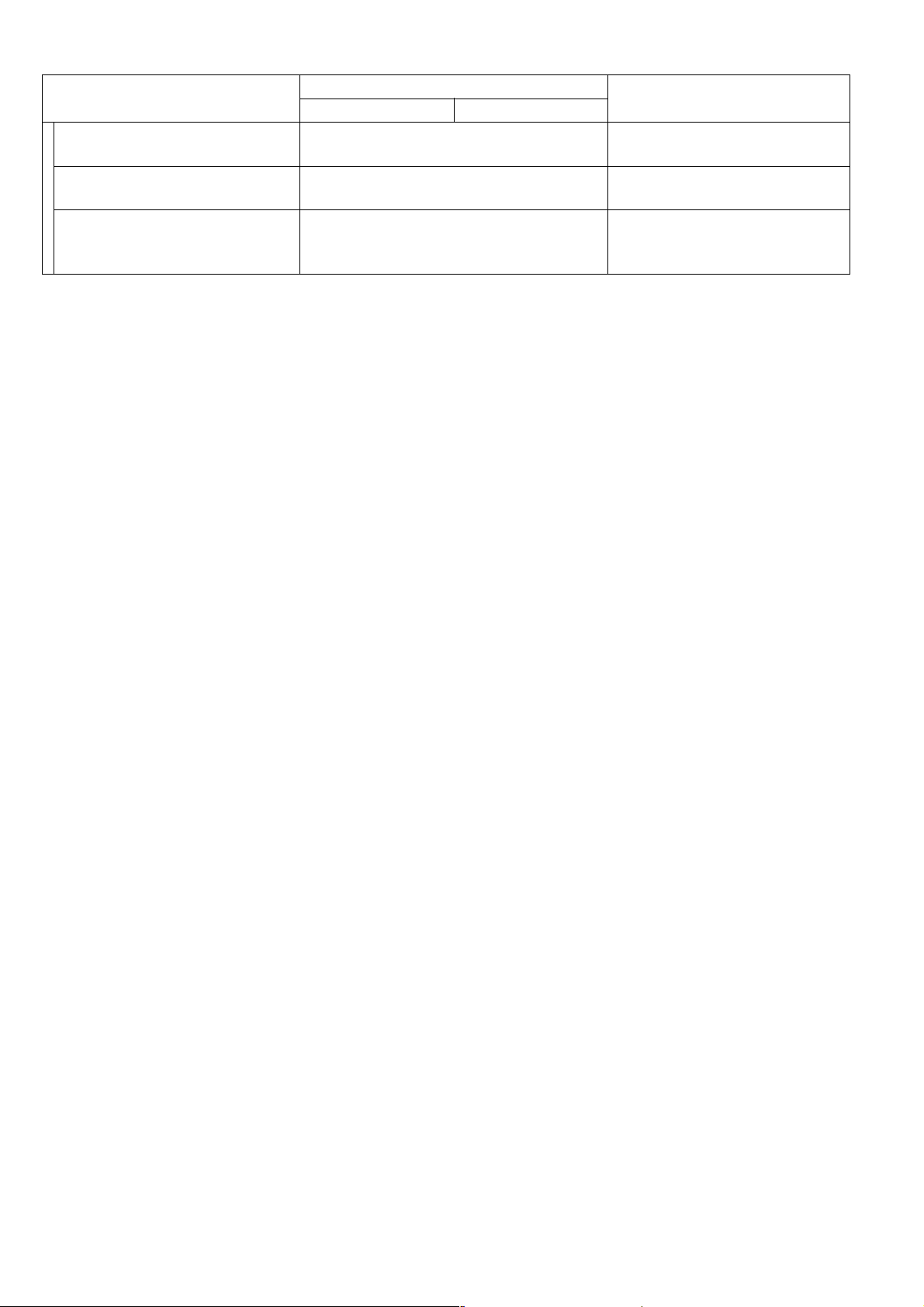

2.4. Preventive Maintenance Check List

The chart outlined below is a general guideline for maintenance. The list is for an average usage of 50

transmitted and received documents per day. Needless to say, the environmental conditions and actual use

will vary these factors. The chart below is for reference only.

No.

Preventive

Maintenance

Parts

Ref.

No.

(Sheet)

Cleaning Replacement/Adjustment

Cycle

Method

Cycle

(Sheet)

ADF Unit

1 Pick Up Roller 416 10K Wet soft cloth 85K

2 Feed Roller 419 10K Wet soft cloth 85K

3 Separation Roller 403 10K Wet soft cloth 85K

4 ADF Pad 401 10K Dry soft cloth -

Paper Feed Module

5 Pick Up Roller 1416 10K Wet soft cloth 85K

6 Separation Pad 1715 10K Wet soft cloth 85K

Bias Transfer Roller

7

(BTR)

1603 10K Dry soft cloth 85K

2nd Paper Feed Module

8 Pick Up Roller 1833 10K Wet soft cloth 85K

9 Separation Pad 1912 10K Wet soft cloth 85K

Procedure

Refer to

2.2.1. of the

Service

Manual

Refer to

2.2.8. of the

Service

Manual

Refer to

2.2.9. of the

Service

Manual

Refer to

2.2.11. of the

Service

Manual

Ref.

Counter

F7-08

F7-12

F7-13

Fuser Unit

Refer to

10 Fuser Unit 1330 - - 85K

2.2.7. of the

Service

F7-02

Manual

Note:

1. Wet Cloth represents a soft cloth saturated with water.

For stubborn toner accumulation, wipe with a soft cloth saturated with Isopropyl Alcohol first, then

follow up with a soft cloth saturated with water.

2. The Maintenance Cycle is based on the Counter Information for each individual module.

To verify the counter information, print the Total Counter List using the Service Mode: F7 - Electronic

Counter - 00 (List Print).

3. Cleaning, Replacement and Adjustment Cycle (Sheet) are based on using Panasonic's recommended

standard paper and supplies. These cycles may vary with the kind of paper used, Paper size,

orientation, print duty, continuous/interval print and/or ambient conditions.

Ver. 2. 0

29

NOV 2004

UF-7000/8000

UF-7100/8100

2.5. Updating the Firmware

The Quick and Easy Methods of Updating the Firmware are to use the Network Firmware Program

Tool (FUP) using Ethernet LAN Port and a Crossover Cable or to use a Master SD Memory Card.

The Network FUP Tool version must be 3.XX or higher, and it can be found on the Panasonic Document

Management System CD-ROM included with the main unit or on the CD-ROM included with the PCL

option.

Refer to the Firmware Update Operation Instructions, Service Notes (8.1.) for additional details.

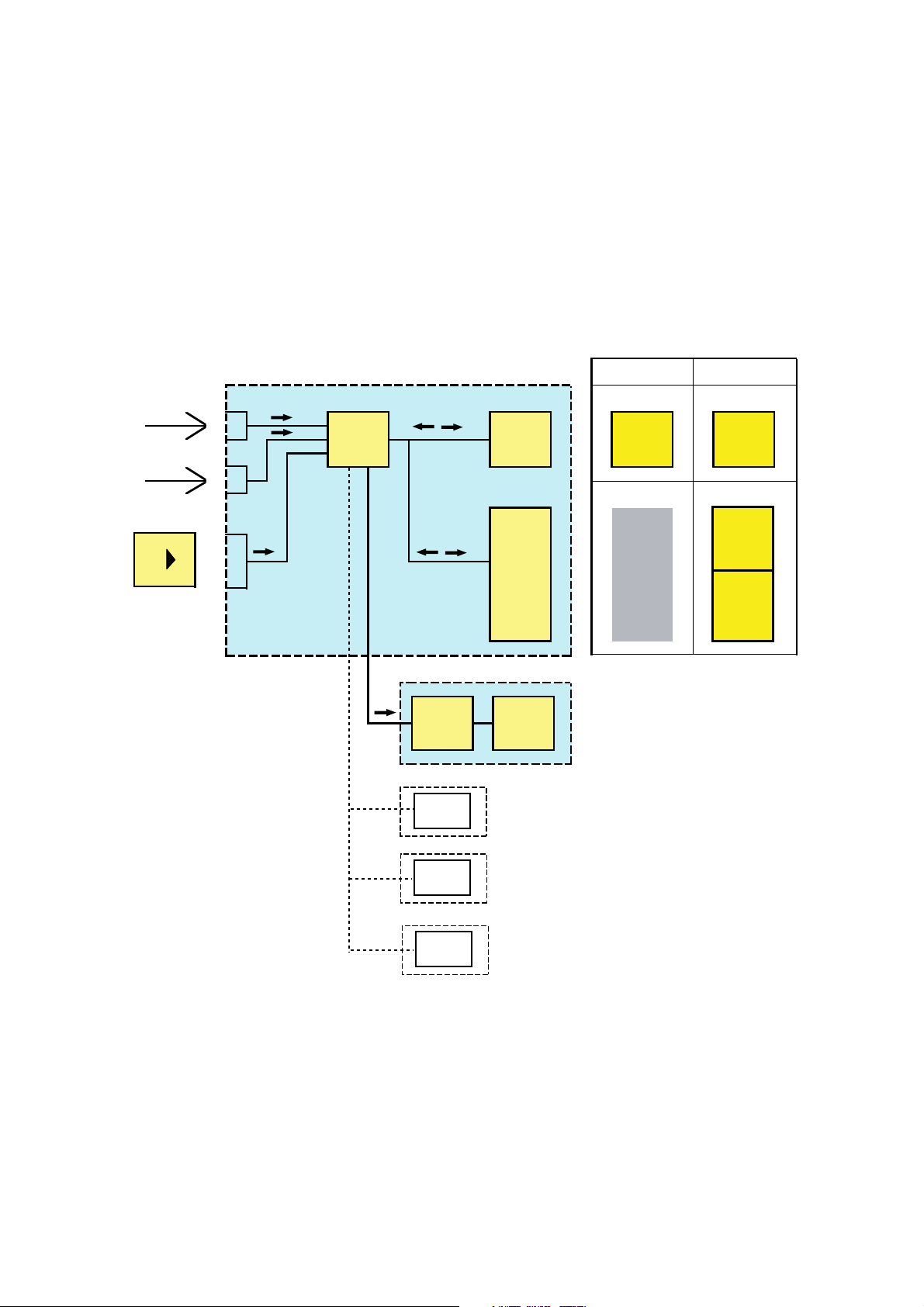

2.5.1. Firmware Configuration

A. Hardware Configuration

This machine is controlled by a Main CPU which is located on the System Control (SC) PC Board and

other sub CPUs on the PCBs. The Firmware of SC PCB and 2nd G3 PCB can be updated using a PC

or an SD Memory Card.

EthernetPort

PC

USBPort

PC

SDMemoryCardPort

SDMemoryCard

(32MBupto512MB)

SCPCBoard

CPU

2ndG3PCBoard

CPU

PanelPCBoard

CPU

Standard

Configuration

OnBoard (A)

F-ROM

4MB

Slot1(CN515)

FRM8PCB

8MB

F-ROM

4MB

PanelControlProgram

(1) (2)

Program Program

4MB

WithPCLOption

Configuration

(B)

4MB

(C)

8MB

(3)

Program

4MB

(4)

Font

4MB

SDRPCBoard

CPU

PrinterEnginePCBoard

CPU

ScannerControlProgram

PrinterControlProgram

B. SC PC Board Firmware

The 4 MB Program Memory (F-ROM) is integrated on the SC PCB. An Optional Expansion 8 MB

Program Memory (FRM8 PCB) can be installed into SLOT 1.

The Firmware to be written into the 4 MB onboard and the 8 MB of SLOT 1 depends upon Standard or

PCL Option.

(1) Standard

The Standard Program (1) is only written into the 4 MB onboard, which is assigned as ROM

Code (A).

(2) For PCL Option

The PCL Control Program (2) must be written into the 4 MB onboard, which is assigned as ROM

Code (B). The PCL Control Program (3) and PCL Font data (4) are written into the 8 MB in the

30

Ver. 2. 0

NOV 2004

Loading...

Loading...