Page 1

ORDER NO. MTV1101116CE

Model No. TH-L32C4M

Chassis: KM14

Destination: MIDDLE EAST

LCD TV

TABLE OF CONTENTS

1 Safety Precautions ----------------------------------------------- 3

1.1. General Guidelines---------------------------------------- 3

1.1.1. Leakage Current Cold Check ---------------------- 3

1.1.2. Leakage Current Hot Check (See Figure

1.) --------------------------------------------------------- 3

2 Warning-------------------------------------------------------------- 4

2.1. Prevention of Electrostatic Discharge (ESD)

to Electrostatically Sensitive (ES) Devices---------- 4

2.2. About lead free solder (PbF)---------------------------- 5

3 Service Navigation ----------------------------------------------- 6

3.1. Service Hint ------------------------------------------------- 6

4 Specifications ----------------------------------------------------- 7

5 Service Mode ------------------------------------------------------ 9

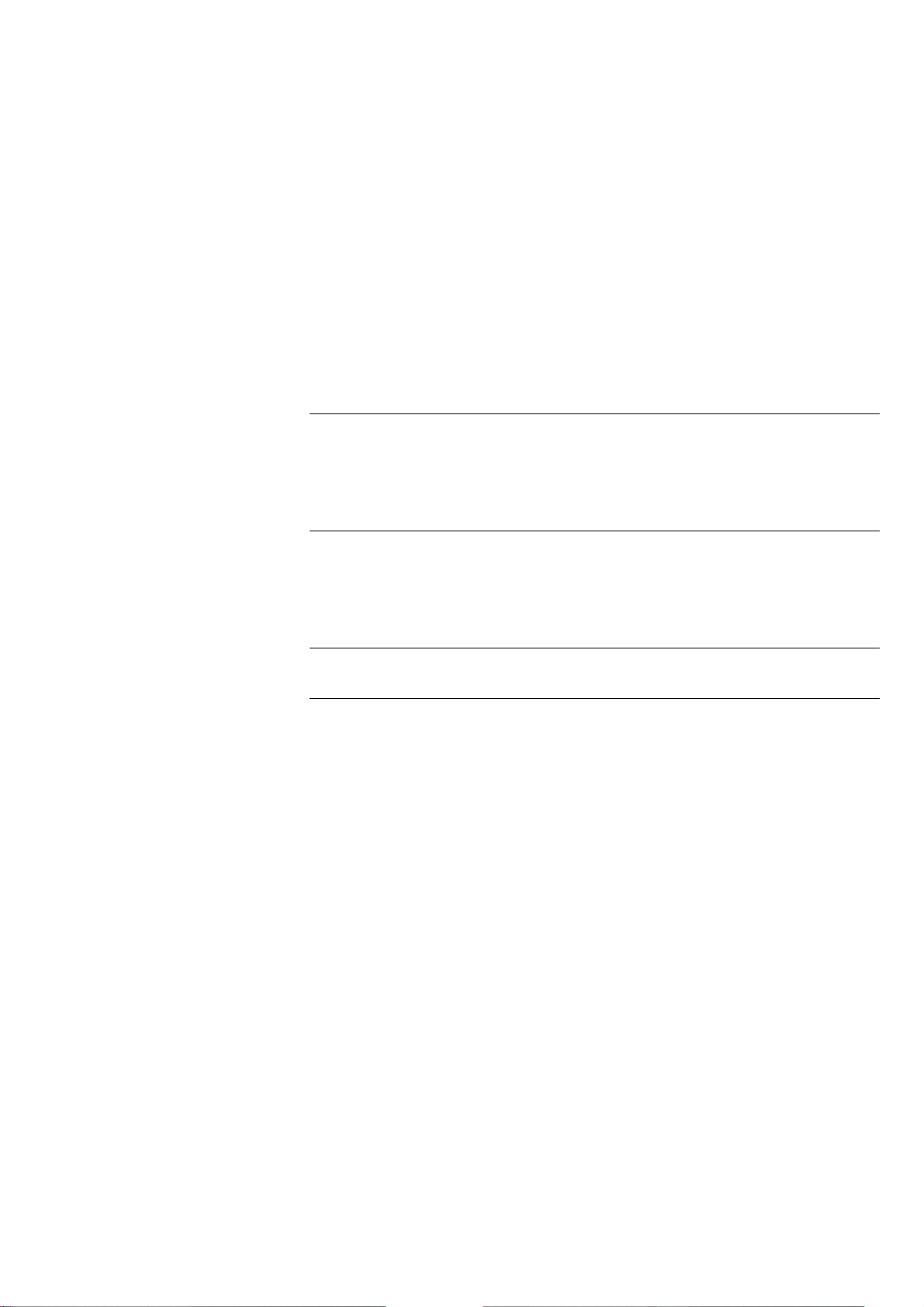

5.1. How to enter into Service Mode ----------------------- 9

5.1.1. Contents of adjustment mode --------------------- 9

5.1.2. How to exit---------------------------------------------- 9

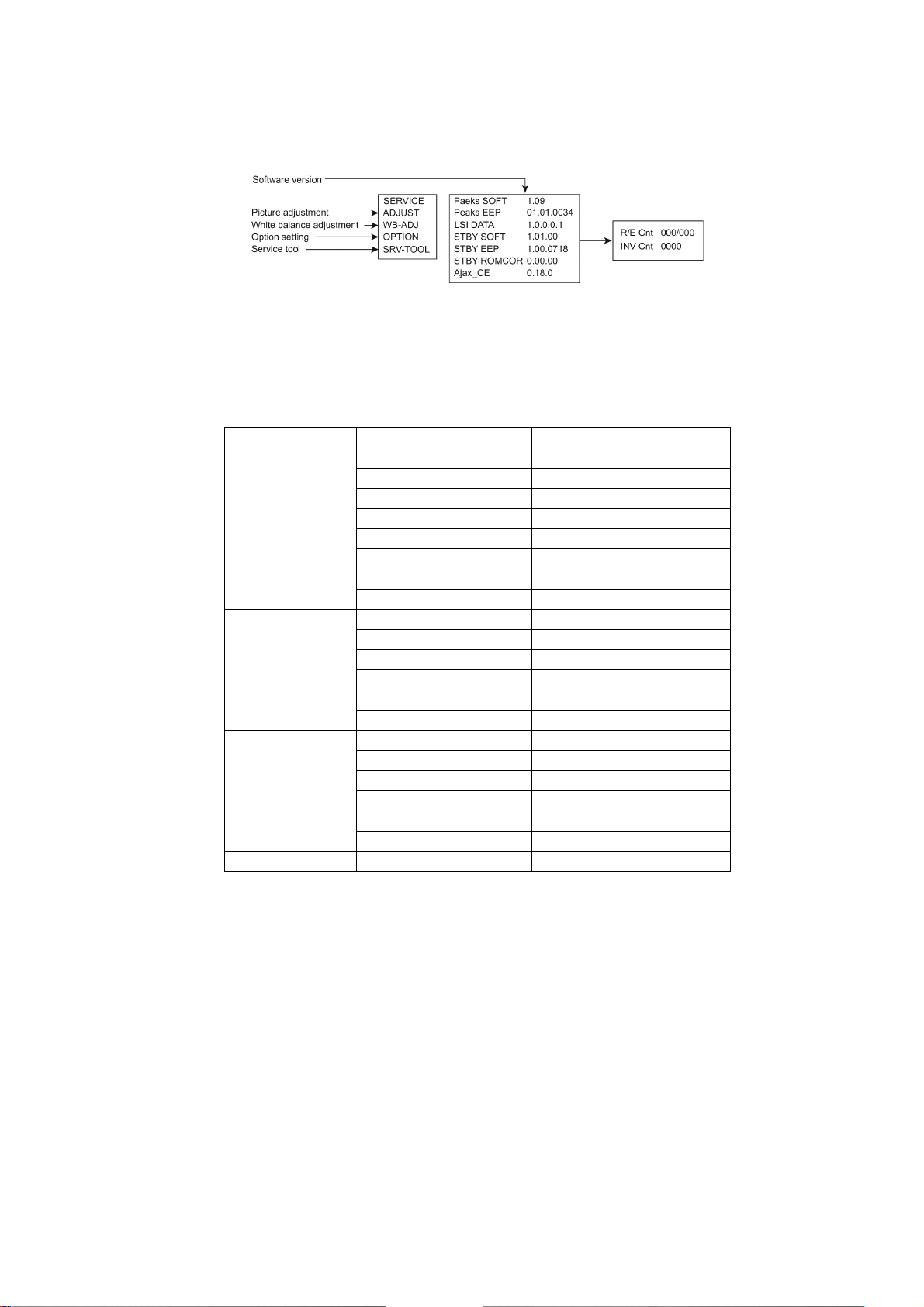

5.2. SRV-TOOL -------------------------------------------------10

5.2.1. How to access ----------------------------------------10

5.2.2. Display of SOS History -----------------------------10

PAG E PAG E

5.2.3. POWER ON TIME/COUNT ----------------------- 10

5.2.4. Exit ------------------------------------------------------ 10

5.2.5. Self Check Mode ------------------------------------ 10

6 Troubleshooting Guide --------------------------------------- 11

6.1. Check of the IIC bus lines------------------------------ 11

6.1.1. How to access --------------------------------------- 11

6.1.2. Exit ------------------------------------------------------ 11

6.1.3. Screen display --------------------------------------- 11

6.2. Power LED Blinking timing chart --------------------- 12

6.3. No Power--------------------------------------------------- 12

7 Disassembly and Assembly Instructions--------------- 13

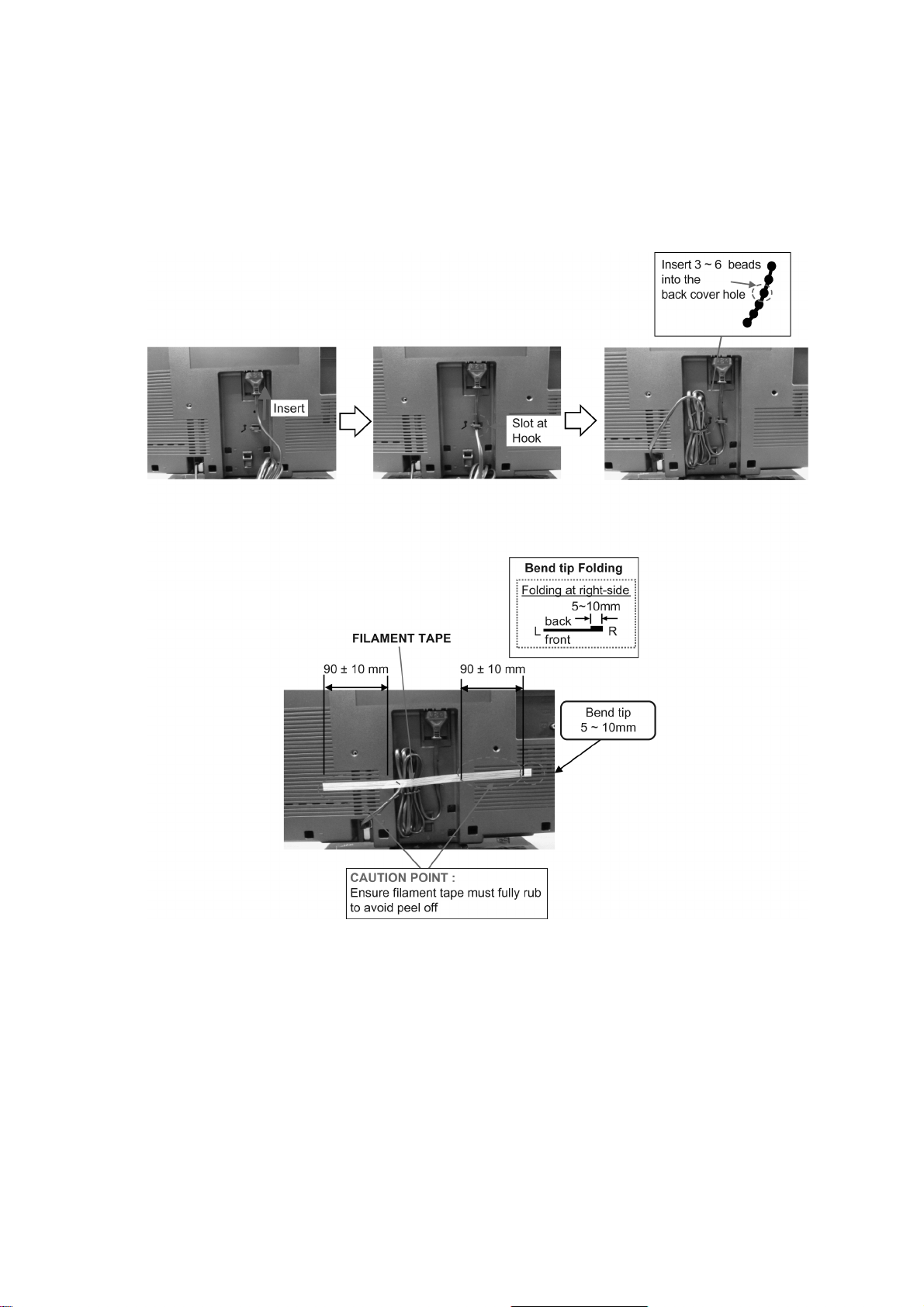

7.1. AC Cord Dressing---------------------------------------- 13

7.2. Speaker Preparation & Installation ------------------ 14

7.3. LCD Panel Fixing & Handling Method -------------- 15

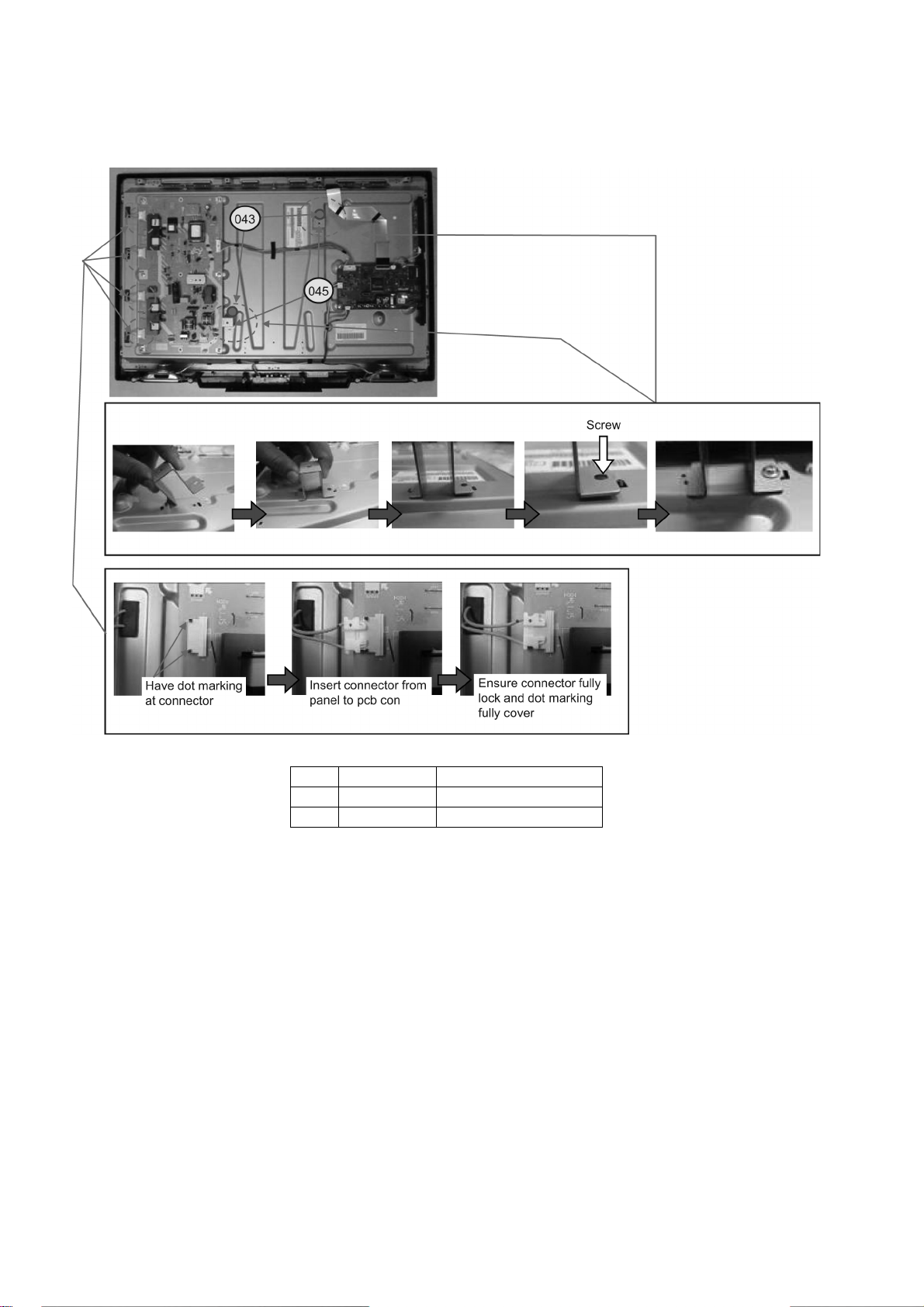

7.4. Installation Panel and PCB ---------------------------- 16

7.5. Speaker Sponge Sticking ------------------------------ 17

7.6. Installation Vesa Metal Top ---------------------------- 18

7.7. LVDS Cable Install--------------------------------------- 19

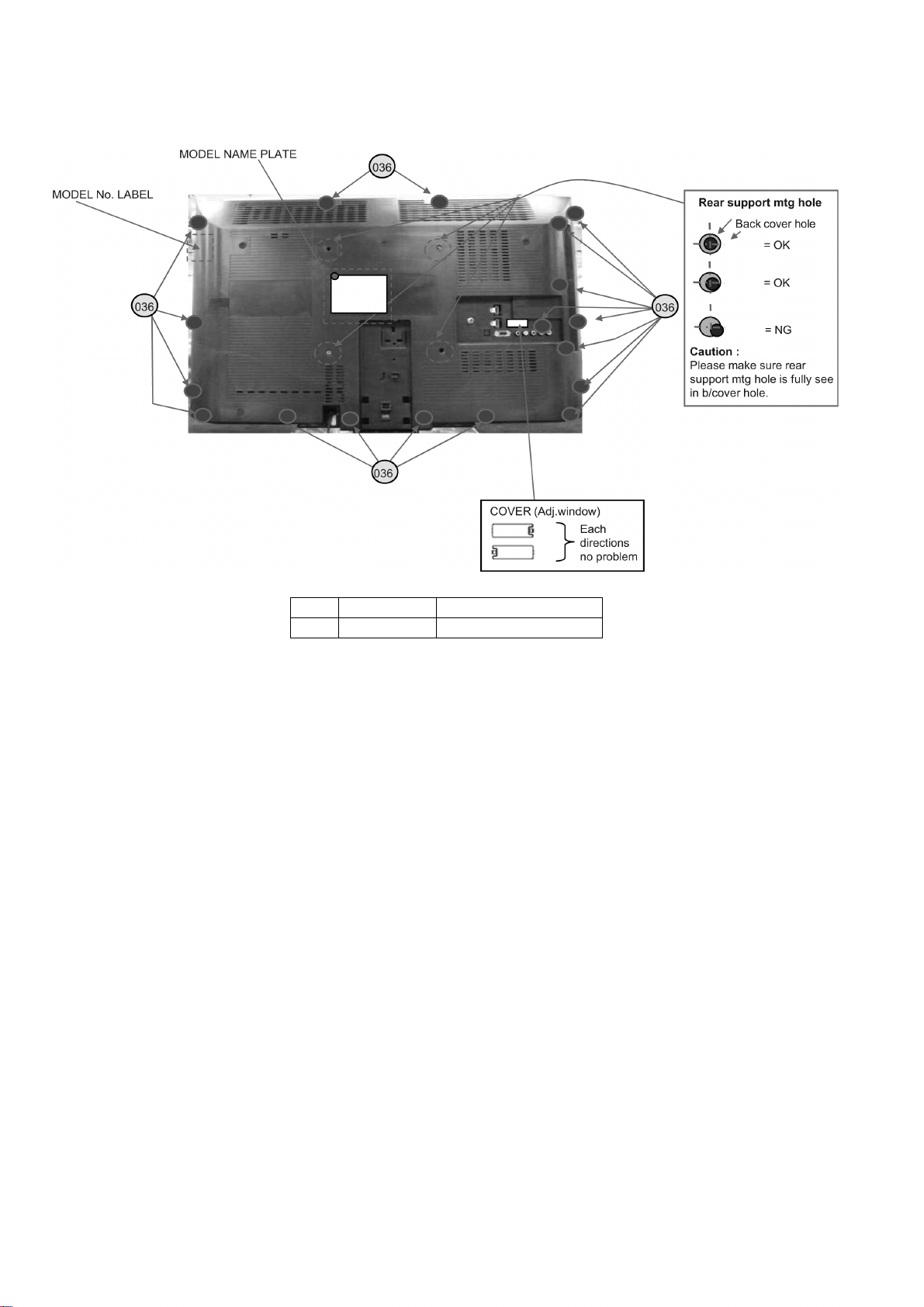

7.8. Back Cover Screw Fixing ------------------------------ 20

© Panasonic Corporation 2011. Unauthorized

copying and distribution is a violation of law.

Page 2

TH-L32C4M

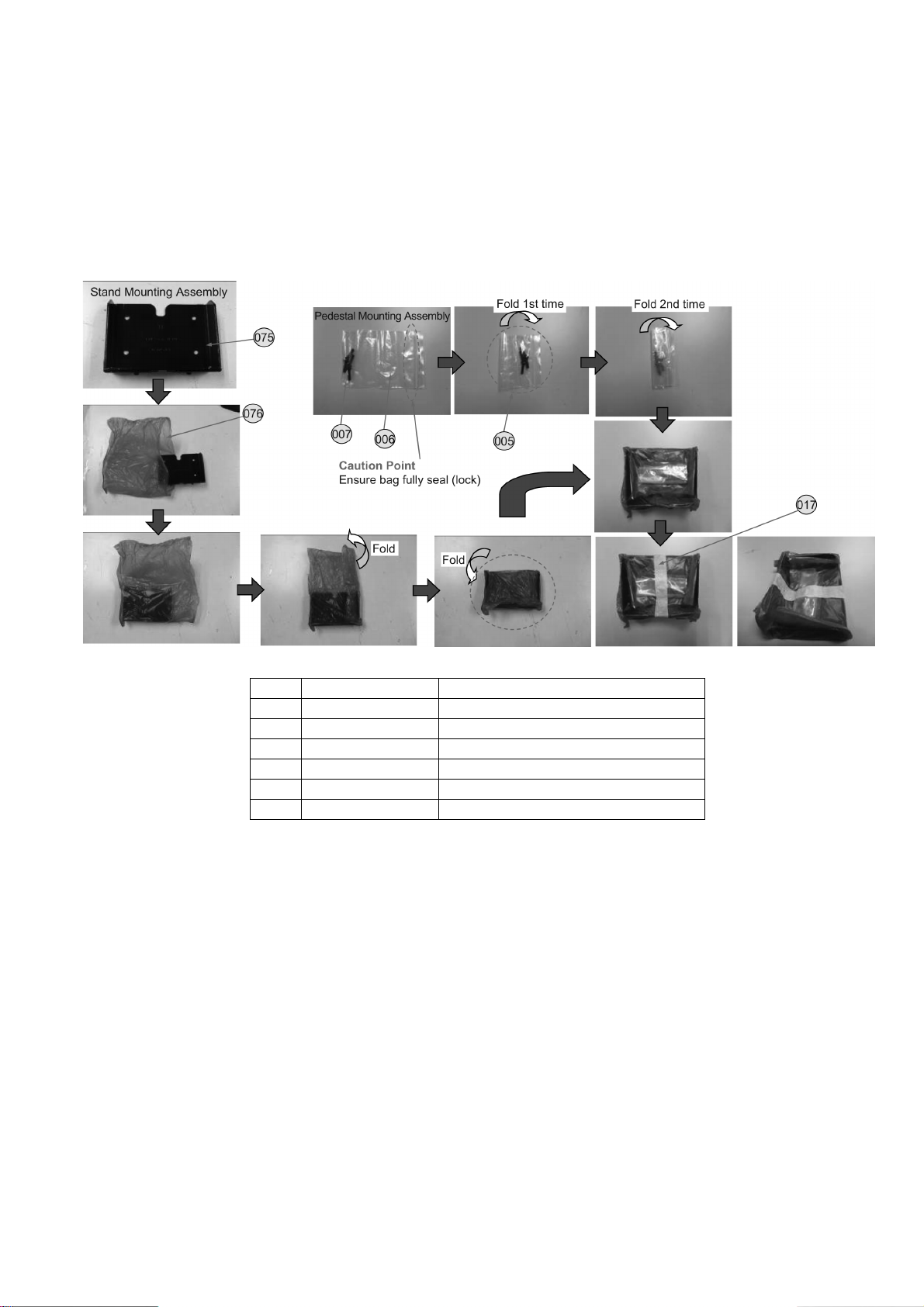

7.9. Stand MTG Preparation --------------------------------21

8 Measurements and Adjustments -------------------------- 22

8.1. Voltage chart of A-board-------------------------------- 22

8.2. Voltage chart of P-board-------------------------------- 22

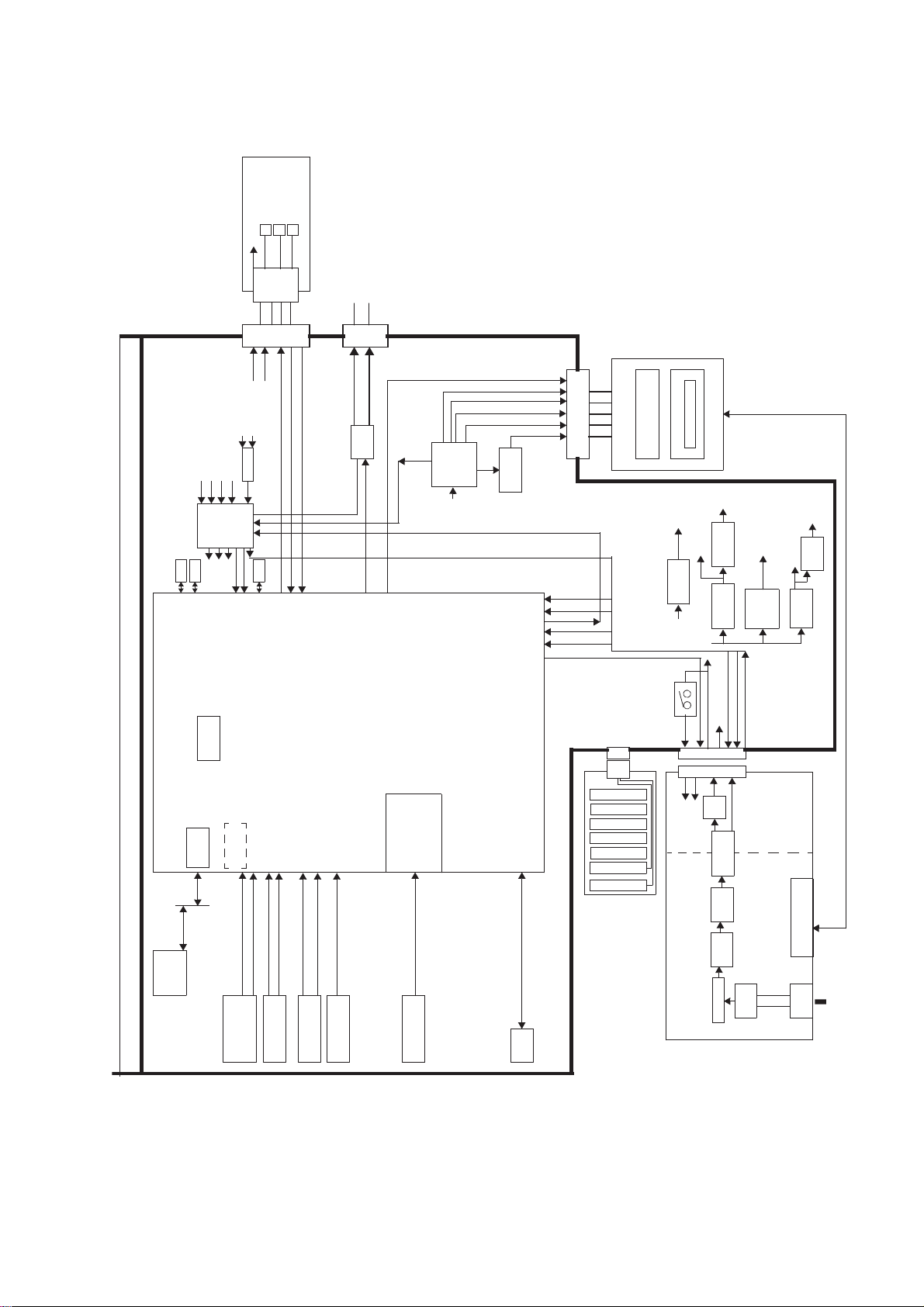

9 Block Diagram --------------------------------------------------- 23

9.1. Main Block Diagram ------------------------------------- 23

10 Wiring Connection Diagram --------------------------------- 24

10.1. Wire Dressing 1------------------------------------------- 24

10.2. Wire Dressing 2 ------------------------------------------26

11 Schematic Diagram--------------------------------------------- 27

11.1. Schematic Diagram Notes ----------------------------- 27

11.2. A Board ----------------------------------------------------- 28

11.2.1. A Board - Sheet : 002 (1 / 2)---------------------- 28

11.2.2. A Board - Sheet : 002 (2 / 2)---------------------- 29

11.2.3. A Board - Sheet : 003 (1 / 3)---------------------- 30

11.2.4. A Board - Sheet : 003 (2 / 3)---------------------- 31

11.2.5. A Board - Sheet : 003 (3 / 3)---------------------- 32

11.2.6. A Board - Sheet : 004 (1 / 2)---------------------- 33

11.2.7. A Board - Sheet : 004 (2 / 2)---------------------- 34

11.2.8. A Board - Sheet : 009 (1 / 2)---------------------- 35

11.2.9. A Board - Sheet : 009 (2 / 2)---------------------- 36

11.2.10. A Board - Sheet : 100 (1 / 2)---------------------- 37

11.2.11. A Board - Sheet : 100 (2 / 2)---------------------- 38

11.2.12. A Board - Sheet : 101 (1 / 4)---------------------- 39

11.2.13. A Board - Sheet : 101 (2 / 4)---------------------- 40

11.2.14. A Board - Sheet : 101 (3 / 4)---------------------- 41

11.2.15. A Board - Sheet : 101 (4 / 4)---------------------- 42

11.2.16. A Board - Sheet : 300 (1 / 1)---------------------- 43

11.2.17. A Board - Sheet : 301 (1 / 2)---------------------- 44

11.2.18. A Board - Sheet : 301 (2 / 2)---------------------- 45

11.2.19. A Board - Sheet : 302 (1 / 2)---------------------- 46

11.2.20. A Board - Sheet : 302 (2 / 2)---------------------- 47

11.2.21. A Board - Sheet : 701 (1 / 2)---------------------- 48

11.2.22. A Board - Sheet : 701 (2 / 2)---------------------- 49

11.2.23. A Board - Sheet : 703 (1 / 1)---------------------- 50

11.2.24. A Board - Sheet : 800 (1 / 1)---------------------- 51

11.3. GK Board---------------------------------------------------52

11.3.1. GK Board (1 / 1) ------------------------------------- 52

11.4. KA Board --------------------------------------------------- 53

11.4.1. KA Board (1 / 2)-------------------------------------- 53

11.4.2. KA Board (2 / 2)-------------------------------------- 54

11.5. P Board ----------------------------------------------------- 55

11.5.1. P Board (1 / 4)---------------------------------------- 55

11.5.2. P Board (2 / 4)---------------------------------------- 56

11.5.3. P Board (3 / 4)---------------------------------------- 57

11.5.4. P Board (4 / 4)---------------------------------------- 58

12 Printed Circuit Board ------------------------------------------ 59

12.1. A-BOARD -------------------------------------------------- 59

12.2. GK-BOARD ------------------------------------------------ 61

12.3. KA-BOARD ------------------------------------------------ 62

12.4. P-BOARD -------------------------------------------------- 63

13 Exploded View and Replacement Parts List -----------65

13.1. Exploded View and Mechanical Replacement

Parts List --------------------------------------------------- 65

13.2. Electrical Replacement Parts List -------------------- 65

13.2.1. Replacement Parts List Notes ------------------- 65

13.2.2. Electrical Replacement Parts List ---------------66

2

Page 3

TH-L32C4M

1 Safety Precautions

1.1. General Guidelines

1. When servicing, observe the original lead dress. If a short circuit is found, replace all parts which have been overheated or

damaged by the short circuit.

2. After servicing, see to it that all the protective devices such as insulation barriers, insulation papers shields are properly

installed.

3. After servicing, make the following leakage current checks to prevent the customer from being exposed to shock hazards.

4. When conducting repairs and servicing, do not attempt to modify the equipment, its parts or its materials.

5. When wiring units (with cables, flexible cables or lead wires) are supplied as repair parts and only one wire or some of the

wires have been broken or disconnected, do not attempt to repair or re-wire the units. Replace the entire wiring unit instead.

6. When conducting repairs and servicing, do not twist the Faston connectors but plug them straight in or unplug them straight

out.

1.1.1. Leakage Current Cold Check

1. Unplug the AC cord and connect a jumper between the

two prongs on the plug.

2. Measure the resistance value, with an ohmmeter,

between the jumpered AC plug and each exposed

metallic cabinet part on the equipment such as

screwheads, connectors, control shafts, etc. When the

exposed metallic part has a return path to the chassis, the

reading should be 100 Mohm and over.

When the exposed metal does not have a return path to

the chassis, the reading must be .

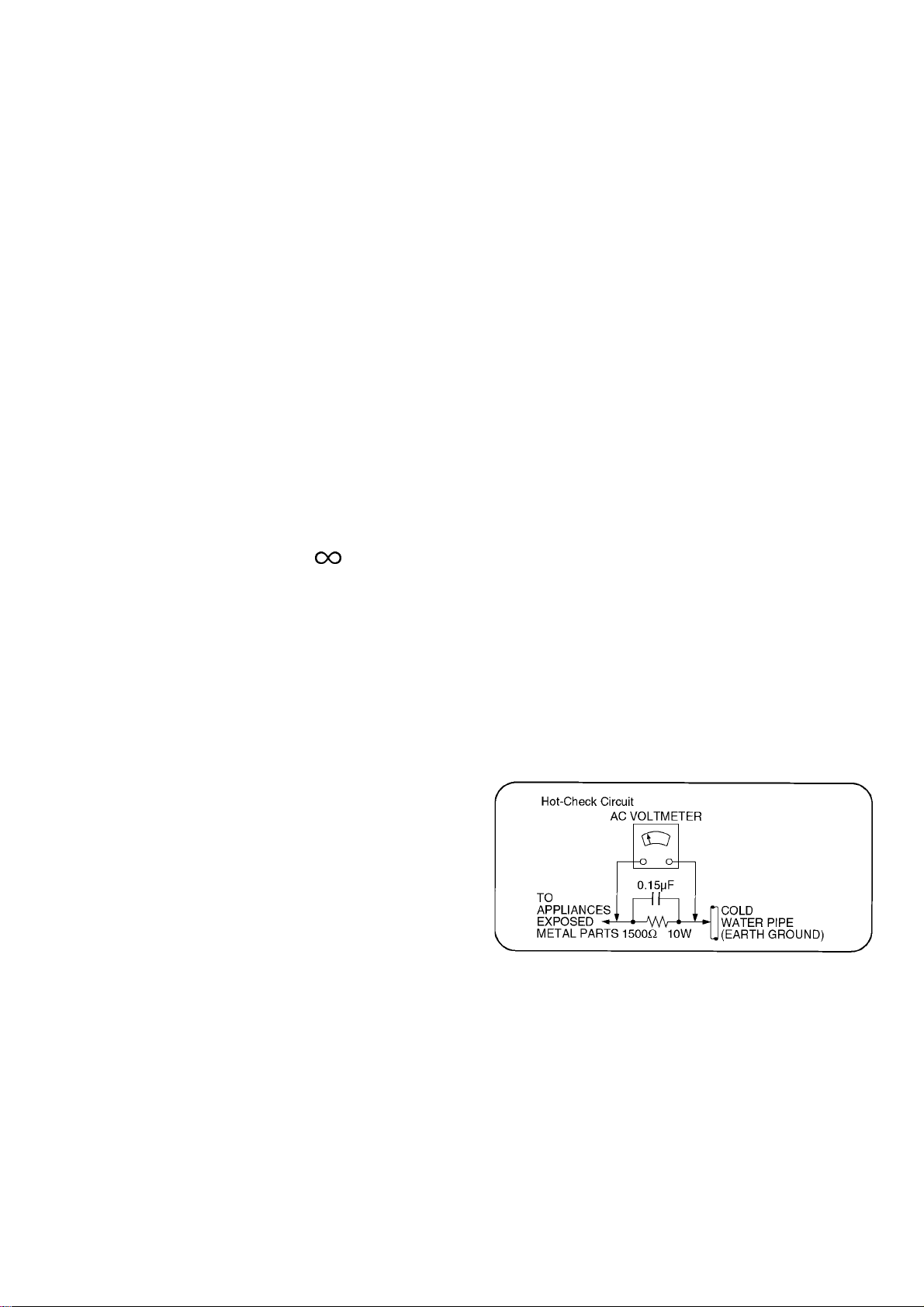

1.1.2. Leakage Current Hot Check (See

Figure 1.)

1. Plug the AC cord directly into the AC outlet. Do not use

an isolation transformer for this check.

2. Connect a 1.5kohm, 10 watts resistor, in parallel with a

0.15μF capacitors, between each exposed metallic part

on the set and a good earth ground such as a water pipe,

as shown in Figure 1.

3. Use an AC voltmeter, with 1000 ohms/volt or more

sensitivity, to measure the potential across the resistor.

4. Check each exposed metallic part, and measure the

voltage at each point.

5. Reverse the AC plug in the AC outlet and repeat each of

the above measurements.

6. The potential at any point should not exceed 0.75 volts

RMS. A leakage current tester (Simpson Model 229 or

equivalent) may be used to make the hot checks, leakage

current must not exceed 1/2 milliamp. In case a

measurement is outside of the limits specified, there is a

possibility of a shock hazard, and the equipment should

be repaired and rechecked before it is returned to the

customer.

Figure 1

3

Page 4

TH-L32C4M

2Warning

2.1. Prevention of Electrostatic Discharge (ESD) to Electrostatically

Sensitive (ES) Devices

Some semiconductor (solid state) devices can be damaged easily by static electricity. Such components commonly are called

Electrostatically Sensitive (ES) Devices. Examples of typical ES devices are integrated circuits and some field-effect transistors and

semiconductor [chip] components. The following techniques should be used to help reduce the incidence of component damage

caused by electrostatic discharge (ESD).

1. Immediately before handling any semiconductor component or semiconductor-equipped assembly, drain off any ESD on your

body by touching a known earth ground. Alternatively, obtain and wear a commercially available discharging ESD wrist strap,

which should be removed for potential shock reasons prior to applying power to the unit under test.

2. After removing an electrical assembly equipped with ES devices, place the assembly on a conductive surface such as

aluminum foil, to prevent electrostatic charge buildup or exposure of the assembly.

3. Use only a grounded-tip soldering iron to solder or unsolder ES devices.

4. Use only an anti-static solder removal device. Some solder removal devices not classified as [anti-static (ESD protected)] can

generate electrical charge sufficient to damage ES devices.

5. Do not use freon-propelled chemicals. These can generate electrical charges sufficient to damage ES devices.

6. Do not remove a replacement ES device from its protective package until immediately before you are ready to install it. (Most

replacement ES devices are packaged with leads electrically shorted together by conductive foam, aluminum foil or

comparable conductive material).

7. Immediately before removing the protective material from the leads of a replacement ES device, touch the protective material

to the chassis or circuit assembly into which the device will be installed.

Caution

Be sure no power is applied to the chassis or circuit, and observe all other safety precautions.

8. Minimize bodily motions when handling unpackaged replacement ES devices. (Otherwise ham less motion such as the

brushing together of your clothes fabric or the lifting of your foot from a carpeted floor can generate static electricity (ESD)

sufficient to damage an ES device).

4

Page 5

TH-L32C4M

2.2. About lead free solder (PbF)

Note: Lead is listed as (Pb) in the periodic table of elements.

In the information below, Pb will refer to Lead solder, and PbF will refer to Lead Free Solder.

The Lead Free Solder used in our manufacturing process and discussed below is (Sn+Ag+Cu).

That is Tin (Sn), Silver (Ag) and Copper (Cu) although other types are available.

This model uses Pb Free solder in it’s manufacture due to environmental conservation issues. For service and repair work, we’d

suggest the use of Pb free solder as well, although Pb solder may be used.

PCBs manufactured using lead free solder will have the PbF within a leaf Symbol PbF stamped on the back of PCB.

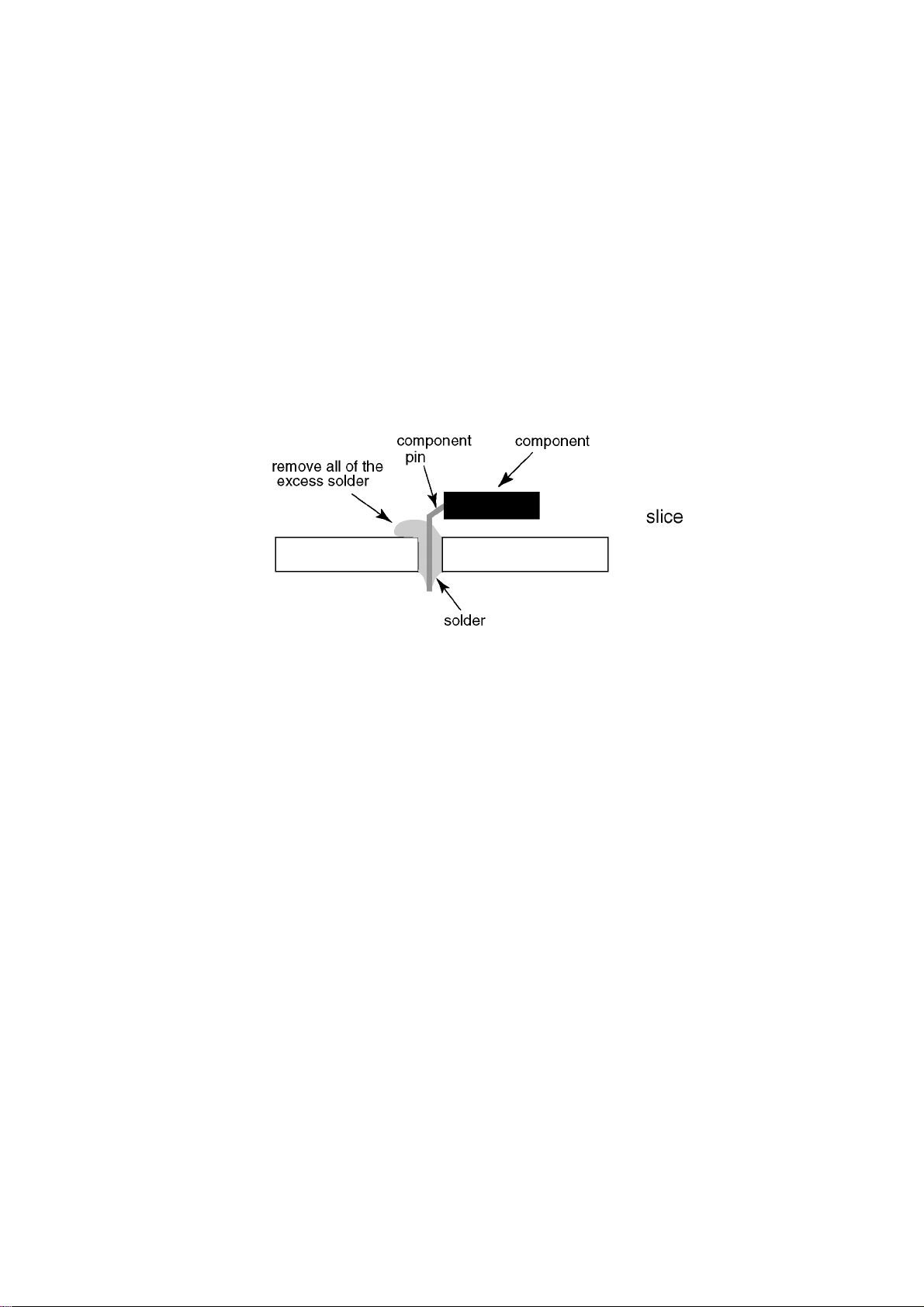

Caution

• Pb free solder has a higher melting point than standard solder. Typically the melting point is 50 ~ 70 °F (30~40 °C) higher. Please

use a high temperature soldering iron and set it to 700 ± 20 °F (370 ± 10 °C).

• Pb free solder will tend to splash when heated too high (about 1100 °F or 600 °C).

If you must use Pb solder, please completely remove all of the Pb free solder on the pins or solder area before applying Pb

solder. If this is not practical, be sure to heat the Pb free solder until it melts, before applying Pb solder.

• After applying PbF solder to double layered boards, please check the component side for excess solder which may flow onto the

opposite side. (see figure below)

5

Page 6

TH-L32C4M

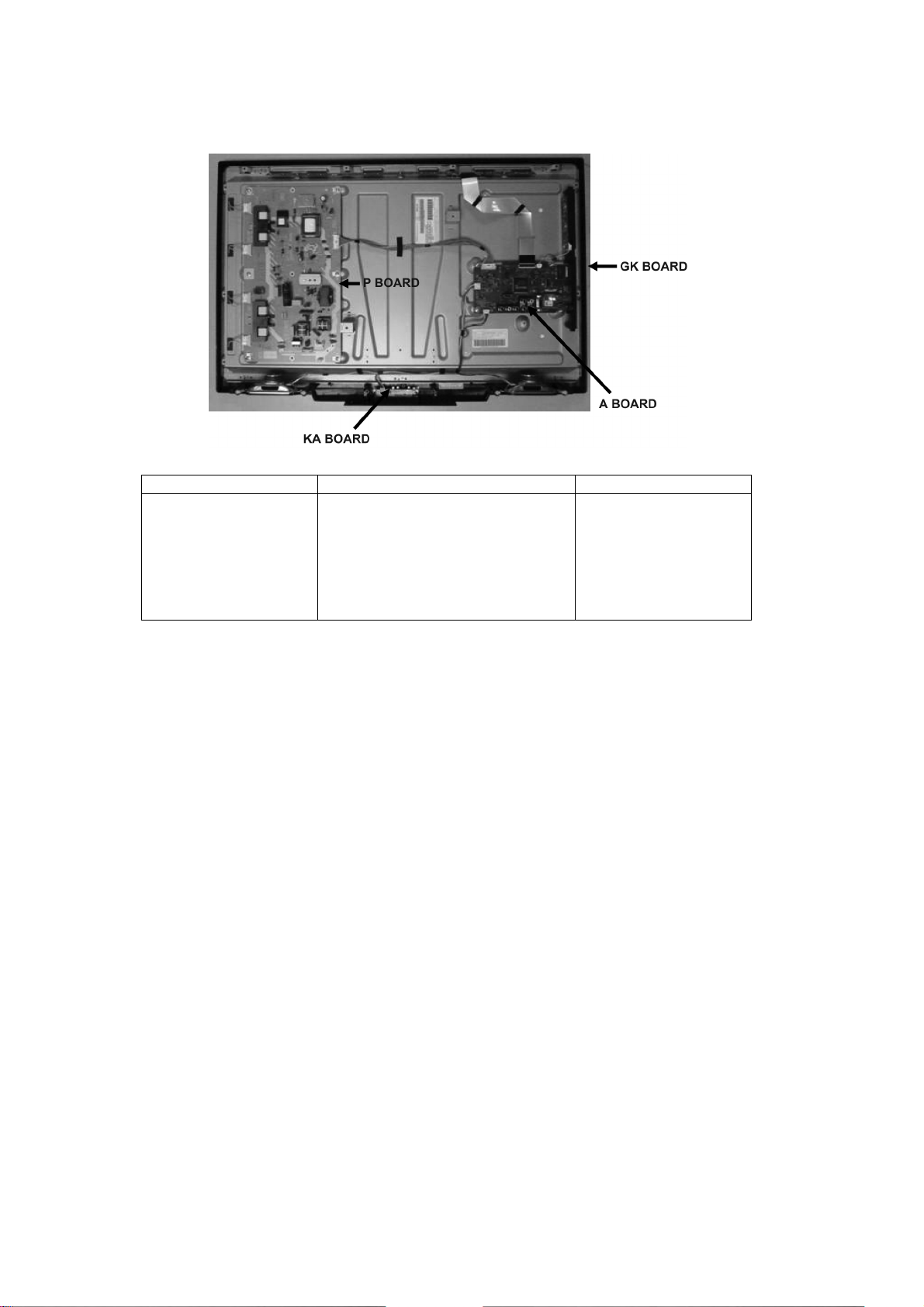

3 Service Navigation

3.1. Service Hint

Board Name Main Device Remarks

A BOARD AVSW, TUN, EEP, SPI, MTK IC Repairable

P BOARD Power Supply and Inverter Repairable

KA BOARD Remote, LED, Luminunce Sensor Repairable

GK BOARD Power Switch, Keyscan Repairable

6

Page 7

4 Specifications

Power Source AC Auto 110 - 240 V, 50 / 60 Hz

Power Consumption

Power Rating 88 W

Standby Condition 0.3 W

Display panel

Aspect Ratio 16:9

Visible screen size 80 cm (diagonal)

698 mm (W) × 393 mm (H)

Number of pixels 1,049,088 (1,366 (W) × 768 (H))

Sound

Speaker (108 mm × 42 mm) × 2pcs, 8 Ω

Audio Output 10 W (5 W + 5 W), 10% THD

PC signals VGA, SVGA, WVGA, XGA

SXGA, WXGA ...... (compressed)

Horizontal scanning frequency 31 - 69 kHz

Vertical scanning frequency 59 - 86 Hz

Receiving Systems / Band name 17 SYSTEMS FUNCTIONS

1 PAL B, G, H

2 PAL I

3 PAL D, K

4 SECAM B, G

5 SECAM D, K

6 SECAM K1

7 NTSC M (NTSC 3.58 / 4.5MHz)

8 NTSC 4.43 / 5.5 MHz

9 NTSC 4.43 / 6.0 MHz

10 NTSC 4.43 / 6.5 MHz

11 NTSC 3.58 / 5.5 MHz

12 NTSC 3.58 / 6.0 MHz

13 NTSC 3.58 / 6.5 MHz

14 SECAM I

15 PAL 60 Hz / 5.5 MHz Playback from Special Disc Players and

16 PAL 60 Hz / 6.0 MHz

17 PAL 60 Hz / 6.5 MHz

Receiving Channels (Regular TV)

VHF BAND 2 - 12 (PAL / SECAM B, K1)

0 - 12 (PAL B AUST.)

1 - 9 (PAL B N.Z.)

1 - 12 (PAL / SECAM D)

1 - 12 (NTSC M JAPAN)

2 - 13 (NTSC M USA)

UHF BAND 21 - 69 (PAL G, H, I / SECAM G, K, K1)

28 - 69 (PAL B AUST.)

13 - 57 (PAL D, K)

13 - 62 (NTSC M JAPAN)

14 - 69 (NTSC M USA)

CATV S1 - S20 (OSCAR)

1 - 125 (USA CATV)

C13 - C49 (JAPAN)

S21 - S41 (HYPER)

Z1 - Z37 (CHINA)

5A, 9A (AUST.)

Aerial - Rear VHF / UHF

Operating Conditions Temperature : 0°C - 40°C

Humidity : 20 % - 80 % RH (non-condensing)

Connection Terminals

AV1 Input AUDIO L-R RCA PIN Type × 2 0.5 V [rms]

VIDEO RCA PIN Type × 1 1.0 V [p-p] (75 Ω)

COMPONENT Y 1.0 V [p-p] (including synchronization)

, PR/C

P

B/CB

AV2 Input AUDIO L-R RCA PIN Type × 2 0.5 V [rms]

VIDEO RCA PIN Type × 1 1.0 V [p-p] (75 Ω)

Audio Output AUDIO L-R RCA PIN Type × 2 0.5 V [rms]

R

Reception of broadcast transmission and

playback from video cassette tape recorders.

Playback from special VCR’s or DVD.

Special VCR’s or DVD.

± 0.35 V [p-p]

TH-L32C4M

7

Page 8

TH-L32C4M

Others HDMI Input TYPE A Connectors

PC Input HIGH-DENSITY D-SUB 15 PIN R, G, B/0.7 V[p-p] (75 Ω)

HD, VD/TTL LEVEL 2.0-5.0 V [p-p] (high impedance)

Card Slot SD Card slot × 1

USB

Dimension (W x H x D) 763 mm × 510 mm × 196 mm (With Pedestal)

Mass 8.0 kg Net (With Pedestal)

USB 2.0 TYPE A Connectors × 1

763 mm × 478 mm × 85 mm (TV only)

7.5 kg Net (TV only)

DC 5 V, Max. 500 mA

Note

• Design and Specifications are subject to change without notice. Mass and Dimensions shown are approximate.

8

Page 9

TH-L32C4M

5 Service Mode

5.1. How to enter into Service Mode

While pressing [VOLUME ( - )] button of the main unit, press [INFO] button of the remote control three times within 2 seconds.

5.1.1. Contents of adjustment mode

• Value is shown as a hexadecimal number.

• Preset value differs depending on models.

• After entering the adjustment mode, take note of the value in each item before starting adjustment.

Main item Sub item Sample Data

ADJUST CONTRAST 000

COLOR 59

TINT FE

SUB-BRT 800

BACKLGT 20D

B-Y-G 40

R-Y-A 0

VCOM 189

WB-ADJ R-GAIN 75

G-GAIN 80

B-GAIN 65

R-CENT 80

G-CENT 80

B-CENT 9B

OPTION Boot ROM

STBY-SET 00

EMERGENCY ON

CLK MODE 00

CLOCK FC7

EDID-CLK HIGH

SRV-TOOL 00

5.1.2. How to exit

Switch off the power with the [POWER] button on the main unit or the [POWER] button on the remote control.

9

Page 10

TH-L32C4M

5.2. SRV-TOOL

5.2.1. How to access

1. Select [SRV-TOOL] in Service Mode.

2. Press [OK] button on the remote control.

5.2.2. Display of SOS History

SOS History (Number of LED blinking ) indication.

From left side; Last SOS, before Last, three occurrence before, 2nd occurrence after shipment, 1st occurrence after shipment.

This indication except 2nd and 1st occurrence after shipment will be cleared by [Self-check indication and forced to factory

shipment setting].

5.2.3. POWER ON TIME/COUNT

Note : To display TIME/COUNT menu, highlight position, then press MUTE for 3sec.

Time : Cumulative power on time, indicated hour : minute by decimal

Count : Number of ON times by decimal

Note : This indication will not be cleared by either of the self-checks or any other command.

5.2.4. Exit

1. Disconnect the AC cord from wall outlet.

5.2.5. Self Check Mode

1. Press the ‘MENU’ button (on the remote control) and the ‘VOL DOWN’ button on the LCD panel.

2. Press ON/OFF button on the panel to Exit.

10

Page 11

TH-L32C4M

6 Troubleshooting Guide

Use the self-check function to test the unit.

1. Checking the IIC bus lines

2. Power LED Blinking timing

6.1. Check of the IIC bus lines

6.1.1. How to access

Self-check indication only:

Produce TV reception screen, and while pressing [VOLUME ( - )] button on the main unit, press [OK] button on the remote control

for more than 3 seconds.

Self-check indication and forced to factory shipment setting:

Produce TV reception screen, and while pressing [VOLUME ( - )] button on the main unit, press [MENU] button on the remote

control for more than 3 seconds.

6.1.2. Exit

Disconnect the AC cord from wall outlet.

6.1.3. Screen display

11

Page 12

TH-L32C4M

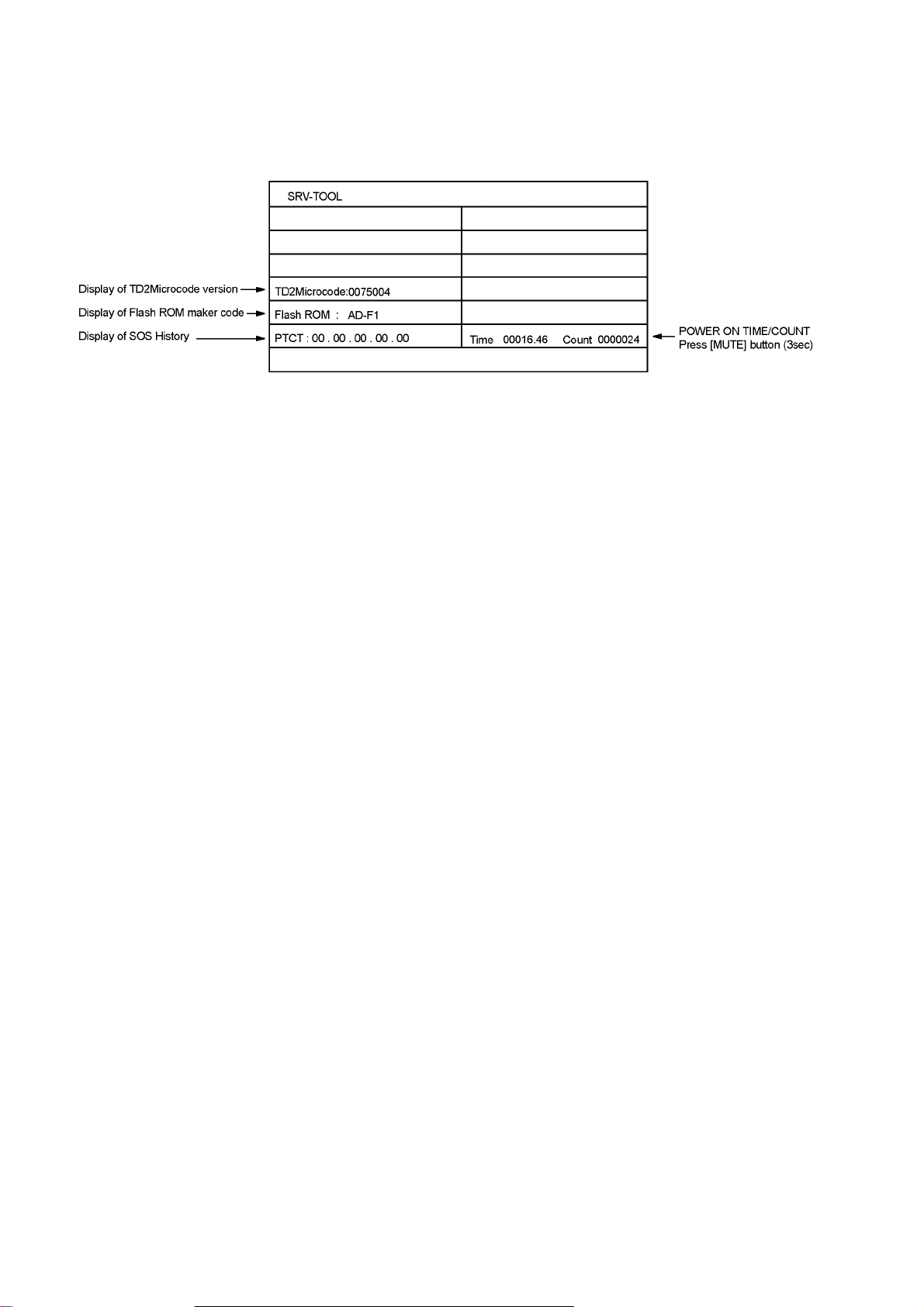

6.2. Power LED Blinking timing chart

1. Subject

Information of LED Flashing timing chart.

2. Contents

When an abnormality occurs, the protection circuit will operate and reset the unit to stand by mode. During this time, the

defective block can be identified by the number of blinking times of the Power LED on the front panel of the unit as follow:

No Name Factor R_LED Blink PCB NAME

A-Board

1 BL_SOS SOS from PANEL inverter 1

2 TV_SOS TCON power down 3

3 SOUND_SOS SOS from audio AMP 9 A-Board

P-Board

LCD Panel

A-Board

TCON-Board

6.3. No Power

First check point

There are following 2 states of No Power indication by power LED.

1. No lit

2. Red is lit then turns red blinking a few seconds later. (See 6.2.)

12

Page 13

7 Disassembly and Assembly Instructions

7.1. AC Cord Dressing

1. Insert AC-Cord head into back cover.

2. Slot AC-Cord wire at back cover hook.

3. Slot AC-Cord bead core at back cover.

4. Tapping AC-Cord wire with filament tape.

TH-L32C4M

13

Page 14

TH-L32C4M

7.2. Speaker Preparation & Installation

1. Fix sp rubber bush to speaker unit.

2. Fix speaker with sp rubber bush to cabinet.

No. Part no. Description

048 L0AA10B00003 SPEAKER UNIT

057 TMM4GJ004 SP RUBBER BUSH

14

Page 15

7.3. LCD Panel Fixing & Handling Method

1. Place down the cabinet as shown below.

2. Fix LCD panel into the cabinet by taking below precautions.

TH-L32C4M

Other general precautions

1. Do not press panel surface to avoid blue spot on the panel display.

2. Do not use hard cloth or rub the surface too hard. This may cause scratches on the surface.

3. Take care not to subject the TV’s surface to water or detergent. Any liquid (including pets urine) if enters the product could

lead to TV failure.

4. Take care not to subject the surface to insect repellent, solvent, thiner or other voiltile substances. This may degrade surface

quality or cause peeling of the paint.

5. The surface of the display panel is specially treated and may be easily damaged. Take care not to tap or scratch with your

fingernail or other hard objects.

15

Page 16

TH-L32C4M

7.4. Installation Panel and PCB

1. Fix LCD panel into cabinet and screw.

2. Fix PCB at Panel and screw.

3. Fix KA board at led panel.

4. Fix connector wire to KA board.

5. Fix Led panel at cabinet and screw.

No. Part no. Description

039 VVX32H121G00 LCD PANEL

040 XTV3+12JFJ SCREW(PANEL2/V1)

043 THEJ036J SCREW (A4/P6/VM2/BTM2)

16

Page 17

7.5. Speaker Sponge Sticking

1. Insert vesa metal (bc) at back cover.

2. Stick speaker sponge at back cover.

TH-L32C4M

Planning No. No. Part no. Description

KX-L32C4K/X/RA/G/T/M

030 TKZ4GX5034 VESA METAL(BC)

035 TMK4GG040 SP. SPONGE

17

Page 18

TH-L32C4M

7.6. Installation Vesa Metal Top

1. Fix vesa metal top at lcd panel and screw.

2. Fix lcd panel wire to pcb, ensure connector fully lock.

No. Part no. Description

043 THEJ036J SCREW (A4/P6/VM2/BTM2)

045 TKZ4GX5056 VESA METAL (TOP)

18

Page 19

7.7. LVDS Cable Install

1. Fix LVDS cable at PCB and lcd panel.

2. Stick felt at LVDS cable.

TH-L32C4M

19

Page 20

TH-L32C4M

7.8. Back Cover Screw Fixing

Fix back cover and 18 screws.

No. Part no. Description

036 XTV3+12JFJ SCREW (Back Cover 18pcs)

20

Page 21

7.9. Stand MTG Preparation

(Stand Mounting)

1. Insert stand mtg into bag.

2. Fold bag follow sequence.

(Pedestal Mounting Assembly)

1. Insert screw into bag and ensure bag fully seal (lock).

2. Fold bag follow sequence (2 time).

3. Put Pedestal Mounting assembly at stand mtg assembly and tape with yellow tape.

TH-L32C4M

No. Part no. Description

005 TXFPE01LUUK PEDESTAL MTG ACCESSORIES

006 TPE4GX001 BAG FOR STAND MTG SCREW

007 XSS4+16FJK SCREW

017 T5E4G62400 YELLOW TAPE

075 TBL5ZA3140 STAND MTG

076 TPE4GH040 BAG FOR STAND MTG RED

21

Page 22

TH-L32C4M

8 Measurements and Adjustments

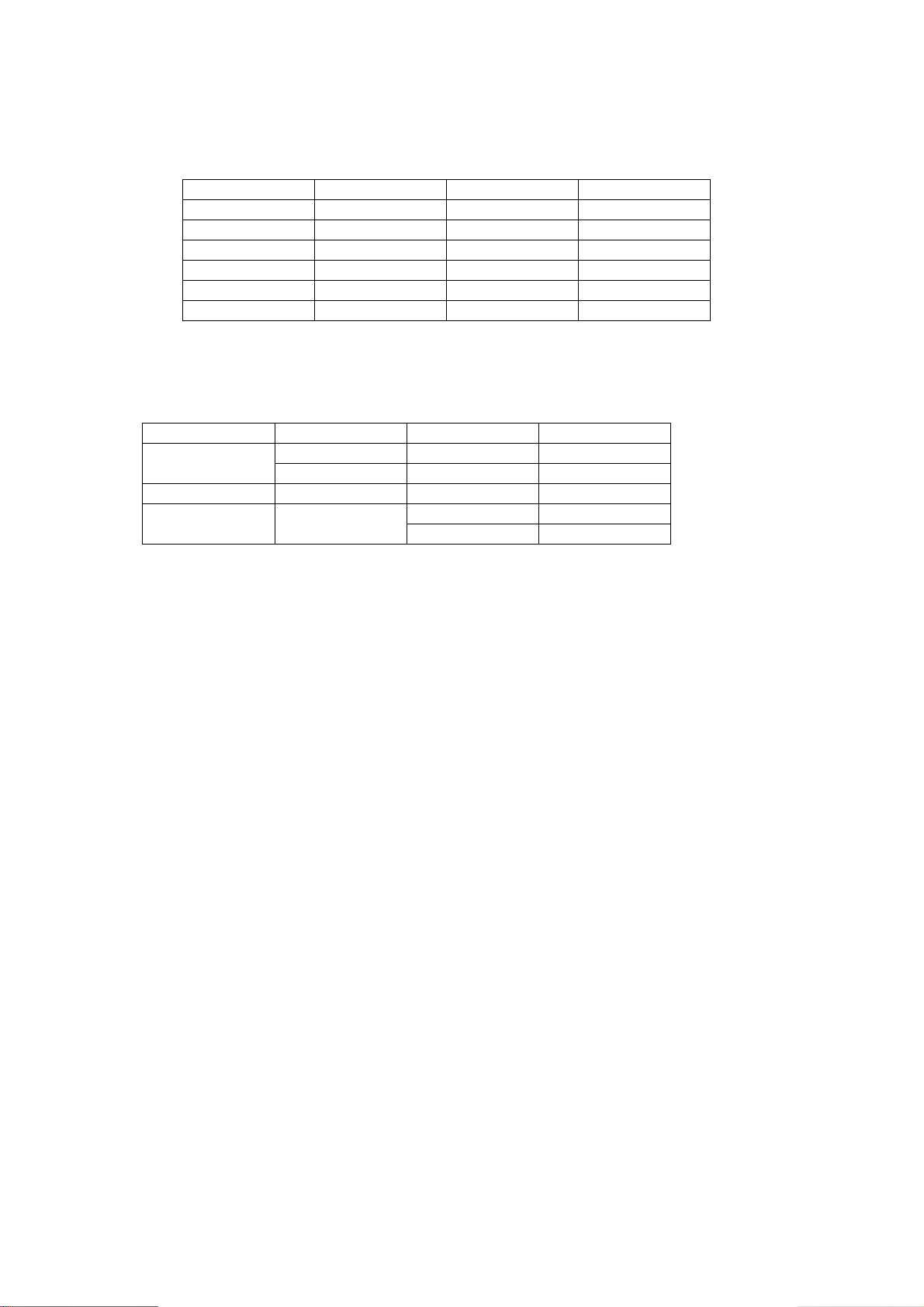

8.1. Voltage chart of A-board

Set A-Board to a dummy set and check the satisfaction with the specified voltage as following table.

Power Supply Name Measurement Point Specification (V) Remark

SUB1.8V TP8700 1.74 - 1.90 -

SUB1.2V TP8000 1.18 - 1.32 -

SUB3.3V TP8701 3.19 - 3.46 -

SUB5V TP8702 4.9 - 5.1 -

STB5V TP5400 4.9 - 5.1 -

PNL5V TP8307 4.9 - 5.3 TNP4G515 only

8.2. Voltage chart of P-board

Set IP-Board to a dummy set and check the satisfaction with the specified voltage as following table.

VOLTAGE TEST POINT SPECIFICATION (V) STATE

PFC390V

DTV16V TP7503, TP7505 15.6 ± 1.5 Reception

STBY6V TP7506

+TP7201, TP7202 390 ± 15 Reception * HOT

-TP7203, TP7204 - Reception * HOT

5.8 ± 0.8 Reception

5.8 ± 0.8 Stand By

22

Page 23

9 Block Diagram

SP7

FLASH

CPU BUS

I/F

CPU BUS

SIF_OUT

TUNER

VIDEO

VIDEO_OUT

V

L/

R

TU

COMP

Y/PB/PR

L/R

PC

R/G/B/H/V

HDMI 1

HDMI I/F

RECEIVER

USB

USB I/F

P

O

W

E

R

LINE

FILTER

RECTIFIER

PFC

CIRCUIT

PWM

CONTROL

PROCESS

VOLTAGE

CONVERTER

DCDC

+6V

SUB_ON

RELAY

5.8VS

F 16V

P1

L

N

AC CORD

GK BOARD

P BOARD

KEY 2

KEY 1

RELAY

SUB_ON

KEY 1

KEY 3

DDR

2

EEPROM

SUB9V

STB 1.2V

STB 3.3V

SOUND SOS

(LED 9 TIMES)

T CON SOS

(LED 3 TIMES)

EEPROM

ANALOG-ASIA

P 15V

STB 5V

SUB 5V

STB 5V

OVP DET

P15V

STB 5.8V

P 15V

5.8VS

PWM

BL_ON

BL_SOS

BL_SOS (LED 1 TIM ES)

PWM

BL_ON

PWM

PWM

AUDIO

AMP

L

R

A12

SUB 3.3V

STB 3.3V

POWER LED (R)

REMOTE IN

C.A.T.S SENSOR

AUDIO OUT

T CON

DCDC

SPEAKER (L)

SPEAKER (R)

SND SOS

SOS SENCE

P 15V

GAMMA

DAC

LVDS-TX

AVDD 12.6V

DVDD 2.5V

VOFF 2.5V

VON 31V

LVDS DATA

DCDC

STB 5V

DCDC

SUB 3.3V

DCDC

SUB 3.3V

SUB 3.3V

SUB 1.8V

DCDC

SUB 1-1

2

V

SU

B 1.12V

DCDC

SUB 5V

P 15V

V

5B

T

SV

8

.

5BT

S

DCDC

HDMI 3.3V

HDMI 3.3V

SUB 5V

MTK

INV

MAIN

LCD DRIVER

BACK LIGHT

PANEL

A04

GK04

P2 A02

A10

V10

POWER LED

REMOTE RECEIVER

C.A.T.S SENCOR

STB +3.3V

V-BOARD

POWER LED

REMOTE RECEIVER

C.A.T.S SENSOR

9.1. Main Block Diagram

TH-L32C4M

23

Page 24

TH-L32C4M

10 Wiring Connection Diagram

10.1. Wire Dressing 1

1. Fix all connector at PCB.

2. Stick felt at LCD panel for wire dressing.

Wire

No.1 P2 ~ A09

No.2 A12 + A10 ~ Speaker Left

No.3 A12 + A10 ~ KA10

Clamper

123

24

Page 25

1. Fix wire to pcb (unsure fully lock).

2. Fix pcb with wire to side av bracket and screw.

TH-L32C4M

25

Page 26

TH-L32C4M

10.2. Wire Dressing 2

1. Fix all connector at PCB.

2. Fix AC-cord at PCB.

3. Slot Ac cord at bottom panel.

4. Stick control key sheet and side label ind. sheet.

5. Slot side av bracket at PCB.

No. Part no. Description

043 THEJ036J SCREW (A4/P6/VM2/BTM2)

046 TKZ4GX5105 METAL BRACKET BOTTOM

049 TMME268 CLAMPER

26

Page 27

11 Schematic Diagram

11.1. Schematic Diagram Notes

TH-L32C4M

27

Page 28

TH-L32C4M

<1A>

<3A>

<2A>

11.2. A Board

11.2.1. A Board - Sheet : 002 (1 / 2)

28

Page 29

<1A>

<3A>

<2A>

TH-L32C4M

11.2.2. A Board - Sheet : 002 (2 / 2)

29

Page 30

TH-L32C4M

<1A>

11.2.3. A Board - Sheet : 003 (1 / 3)

30

Page 31

11.2.4. A Board - Sheet : 003 (2 / 3)

<1A>

<1B>

TH-L32C4M

31

Page 32

TH-L32C4M

<1B>

11.2.5. A Board - Sheet : 003 (3 / 3)

32

Page 33

11.2.6. A Board - Sheet : 004 (1 / 2)

<1A>

<2A>

<3A>

<4A>

TH-L32C4M

33

Page 34

TH-L32C4M

<1A>

<2A>

<3A>

<4A>

11.2.7. A Board - Sheet : 004 (2 / 2)

34

Page 35

11.2.8. A Board - Sheet : 009 (1 / 2)

<1A>

<2A>

TH-L32C4M

35

Page 36

TH-L32C4M

<1A>

<2A>

11.2.9. A Board - Sheet : 009 (2 / 2)

36

Page 37

11.2.10. A Board - Sheet : 100 (1 / 2)

<1A>

<2A>

TH-L32C4M

37

Page 38

TH-L32C4M

<1A>

<2A>

11.2.11. A Board - Sheet : 100 (2 / 2)

38

Page 39

11.2.12. A Board - Sheet : 101 (1 / 4)

TH-L32C4M

<1A>

<2A>

39

Page 40

TH-L32C4M

<1B>

<2B>

<3B>

<4B>

<1A>

<2A>

11.2.13. A Board - Sheet : 101 (2 / 4)

40

Page 41

11.2.14. A Board - Sheet : 101 (3 / 4)

<1C>

<2C>

<1B>

<2B>

<3B>

<4B>

TH-L32C4M

41

Page 42

TH-L32C4M

<1C>

<2C>

11.2.15. A Board - Sheet : 101 (4 / 4)

42

Page 43

11.2.16. A Board - Sheet : 300 (1 / 1)

TH-L32C4M

43

Page 44

TH-L32C4M

<1A>

<2A>

11.2.17. A Board - Sheet : 301 (1 / 2)

44

Page 45

11.2.18. A Board - Sheet : 301 (2 / 2)

<1A>

TH-L32C4M

<2A>

45

Page 46

TH-L32C4M

<1A>

<2A>

<4A>

<3A>

11.2.19. A Board - Sheet : 302 (1 / 2)

46

Page 47

<1A>

<2A>

<4A>

<3A>

TH-L32C4M

11.2.20. A Board - Sheet : 302 (2 / 2)

47

Page 48

TH-L32C4M

11.2.21. A Board - Sheet : 701 (1 / 2)

<1A>

<2A>

<3A>

48

Page 49

<1A>

<3A>

<2A>

TH-L32C4M

11.2.22. A Board - Sheet : 701 (2 / 2)

49

Page 50

TH-L32C4M

11.2.23. A Board - Sheet : 703 (1 / 1)

50

Page 51

11.2.24. A Board - Sheet : 800 (1 / 1)

TH-L32C4M

51

Page 52

TH-L32C4M

11.3. GK Board

11.3.1. GK Board (1 / 1)

52

Page 53

11.4. KA Board

11.4.1. KA Board (1 / 2)

TH-L32C4M

<1A>

<2A>

53

Page 54

TH-L32C4M

11.4.2. KA Board (2 / 2)

<1A>

<2A>

54

Page 55

11.5. P Board

11.5.1. P Board (1 / 4)

TH-L32C4M

<1A>

<2A>

<3A>

55

Page 56

TH-L32C4M

<1B>

<3B>

<2B>

<1A>

<3A>

<2A>

11.5.2. P Board (2 / 4)

56

Page 57

11.5.3. P Board (3 / 4)

<1C>

<3C>

<2C>

<1B>

<3B>

<2B>

TH-L32C4M

57

Page 58

TH-L32C4M

<1C>

<3C>

<2C>

11.5.4. P Board (4 / 4)

58

Page 59

TH-L32C4M

IJHGFE

DCBA

1

2

3

4

5

6

A-BOARD (TOP COMPONENT SIDE)

TNP4G506

A

1

11

21

40 31

1

A

6

11

10

15

5

1

19

1

1

16

17

32

1111

1

4

1

3

4

5

SUFFIX.

4

5

8

1

4

1

8

5

1

3

4

6

4

5

8

1

4

58

1

IN

OUT

17

10

1

32

26

OUT

IN

411

7

1

3

1

2

4

5

9

6

7

8

10

11

12

65

256

193

129

1

1

4

5

8

1

4

5

8

1

4

1

12

1

7

1

55

1

3

45

32

1

24

1

1

4

IC4004

TU4800

JK3300

JK3703

JK1000

IC5000

Q3104

Q3105

JK1031

IC5416

IC8700

IC8701

IC8702

IC8704

IC8705

Q4702

JK3000

Q4154

IC4900

CN0100

CN8000

JK8850

IC8001

IC8004

IC8007

A02

A09

JK4800

A10

A14

THERMAL PAD

A

THERMAL PAD

THERMAL PAD

L

NR

UWY

PS

V

X

QTFC

M

K

H

EB

J

G

DA

D

L

E

M

F

A

G

J

B

H

K

C

THERMAL PAD

THERMAL PAD

THERMAL PAD

THERMAL PAD

TNP4G506

3

THERMAL PAD

UPPER

LOWER

IC5602

IC4150

IC4120

IC8200

A12

R4910

R3190

C3174

R8127

D1953

D5180

L8703

C8062

ZA0055

R3193

JS0014

C4904

C3110

D3055

C8064

A09

JS0020

R8705

R8111

R1958

C5020

R0966

JS0000

C8730

FL4003

L2001

C4816

IC8200

JK3000A

JS0006

R8122

R3104

R4823

C5004

IC4150

JS0023

JS0002

C4121

R3101

C4075

R4021

R3210

D4703

R8737

C5476

C8722

TD006

R1957

R4048

VJ4902

CN8000

JS0027

C4917

R8732

R8138

C8733

C0064

C3121

C8703

C5615

R1955

R4046

R3092

R3205

C8203

C8000

JS0001

R3118

C8710

TD001

R4020

C4801

L8700

ZA0065

R2030

JS0040

C8769

R2752

R8109

IC1951

C4812

C8060

JS0013

R8703

C3097

R4178

R4126

Q4702

C3172

C8737

IC4004

L8702

C4173

JS0026

JS0009

R8137

C8731

C3138

C5613

D4044

JK3300

ZA0058

IC8001

R4171

R2018

L4020

R4121

R8734

D2765

R3111

C3131

R1961

R1956

R4047

JS0031

C4910

L4151

L4703

C5001

R8098

R4919

R4715

JS0008

L4900

C5006

R8224

ZA0050

C2013

D2764

C3142

R3110

C3130

R8106

R5606

R1960

R1954

R4815

R4172

JS0039

R8738

R8125

C8723

C8714

C8900

C5625

R1962

R4819

R4907

JS0015

C3134

R8115

C8112

C4074

C5000

R4724

JS0007

C8140

C3102

R4824

C1954

R3204

R4181

C2008

R8708

L4904

C4815

D0901

C4906

R8740

C4080

R0967

R3192

IC4120

C4903

R8704

R0907

CN0100

R4131

C4901

C0083

R8134

D5004

R4909

C2010

R8119

R4827

C1955

TU4800

C4181

R4721

JS0024

JS0017

JS0004

D3107

C4077

L4800

C2014

R8733

R3124

C8721

C8712

C3108

TD005

R4817

R3093

R3207

A02

C4915

R8730

D2763

R8709

C8728

C8143

R4859

D4045

R4030

R2029

JS0029

Q4154

R4125

R4101

C4804

R0933

ZA0060

A14

C4187

R3191

C4902

C3175

C0085

C8739

R3242

L4019

C4908

R8741

FL4001

L4901

R0947

R4184

R3175

IC8701

C4802

R2012

IC4900

JS0005

C8773

R8117

C3101

R4820

C5002

D4171

C8726

R8118

L4153

R4826

Q1951

R0909

R8151

C8727

C8142

R8104

TD002

C1956

C5171

C0070

R8701

C3132

C3113

R5012

R4818

C8061

L4805

R4911

R4128

C0086

D4834

ZA0059

R0906

L4021

JS0011

C3171

L3010

D1952

C4803

R0932

L8701

JK4800

R4742

JS0022

JK3000

IC8700

R3100

R8103

C4817

JK8850

C8200

R3195

C3127

IC5416

IC5602

L4902

R8225

L4801

R2009

JS0010

C5477

IC8705

C3133

C8715

R8108

R8100

R1963

FL4000

R4049

R3097

A10

C4174

C4916

IC8702

R8700

C8711

C5624

R5010

R1953

R4814

R3091

R2026

JS0032

JS0018

R4119

L4704

C5003

R4025

R3178

R3102

C5016

R3099

C8065

L5601

R4923

R3194

C4907

C0069

C8716

R8101

R5009

C4081

R0900

D4169

R8707

R4866

FL4002

L4903

A12

R4130

JS0012

C4900

L3011

D5003

R0934

C4002

C8063

R4922

L4018

C4905

C3177

R8150

D2762

R1951

R4740

JS0021

C4909

D2756

C8717

R1959

C4082

R8025

C4180

C2009

D3105

R4867

D1951

C4818

C8059

D4704

R8739

C8741

C8736

C3093

R5175

R0908

C4179

R4132

C4150

R8135

D1954

Q4806

C4004

R3209

X8301

JS0028

R4122

R8735

R8139

IC8704

C3139

C8713

R8107

R5607

Q3105

C5616

JK3703

R3094

R0901

JK3000B

C2011

R8152

R3119

R8123

R3106

R4868

R4860

C3111

TD003

C1957

R4029

R2027

JS0025

JS0019

C0062

C0058

C3103

JK1000

R4026

C4911

C8725

C4078

C1952

R8099

C4188

C4151

C3176

X4000

R8136

Q4808

D3056

R4920

C3173

C0082

D2760

R3113

JK1031

C3095

R0935

ZA0067

IC8004

D5480

R8113

R8102

C4083

C4814

D4000

C3178

R5055

C3126

C8705

C5021

IC8007

JS0030

R3197

JS0016

JS0003

C3182

R8120

C8114

C4076

VJ4905

D4170

C4182

C4912

D8702

D3108

C4079

C1953

IC8200-A

ZA0057

R2006

C2012

C8720

C8709

Q3104

C5614

C5009

C8740

C8735

C8724

C3125

C2751

IC5000

C5012

Parts Location

IC1951

Ref.No Location Ref.No Location Ref.No Location

IC4004

IC4120

IC4150

IC4900

E2

E2

D3

E3

B2

D0901

D1951

D1952

D1953

D1954

E2

E2

E2

E2

E2

D4045

D4169

D4170

D4171

D4044 E2

E2

D3

E3

E3

IC5000

IC5416

IC8001

IC8004

IC8007

E2

B3

IC5602 F2

D2

D2

C2

D2756

D2760

D2762

D2763

D2764

A1

A1

B1

B1

A1

D4703

D4704

D4834

D5003

D5004

E2

E2

E3

E2

B3

IC8200

IC8200A

C3

C3

D2765

D3055

D3056

D3105

A1

D1

C1

C1IC8700

IC8701

A2

B1

D5180

D5480

D8702

E2

B3

B1

IC8702 F1

D3107

D3108

D4000

D1

D1

D3IC8704

IC8705

B3

A3

12 Printed Circuit Board

12.1. A-BOARD

59

Page 60

TH-L32C4M

6

5

A

4

A-BOARD (BOTTOM COMPONENT SIDE)

TNP4G506

JS0036

JS0034

JS0038

TP0003

TP0005

TP0001

JS0033

JS0035

JS0037

TP0006

ZA0052

JK8850

3

JK1031

ZA0062

2

JK3300

JK3300

1

TP5601

D3053

D3054

L3004

L3005

R3059

C3183

L3003

D3052

ZA0051

R3060

TP0004

R3063

R3064

TP5602

TP2021

TP0002

TP5012

TP5007

TP5008

TP5011

R5038

C5027

TP5010

R5056

R5051

C5028

R5050

R5052

TP5009

R5041

TP5005

R5039

C5031

TP5006

R5054

R5053

C5035

R5040

R5037

R5036

R5032

C5032

C5033

C5030

C5029

C5034

L4802

C4805

C4806

R3061

R3062

D5173

D5172

D5174

R5003

R5002

R5007

R5006

C5026

R0962

D0904

D0905

D0912

D0911

D0913

R0971

D0910

R0970

C0078

TP0900

TP0903

TP0911

TP0920

TP4802

TP0901

BB

TP0912

TU4800

JK4800

TP4801

TP0904

D0914

Q4153

D5175

R0963

VB1

C0071

D0907

TP0905

RESET

D2001

R2001

C2001

R2004

R2025

TP2001

ZA0066

Q4151

Q4152

C4167

C4165

C4166

D4167

R4167

R4168

D4168

R4166

R4170

Q4153

R4169

L4150

PA4150

D4175

R4173

C0077

TP0910

C5022

D0909

D0906

D0908

D0902

TP0906

TP0909

R0944

TP0908

TP0907

VIDEOOUT

TU4800

JK4800

VB2

SDA

SIFOUT

SCL

TP4800

TP8700

C4168

R4156

D4159

C4153

D4160

C4154

D4161

D4162

C4160

D4166

D4172

L4152

C4175

C0057

D4174

C0067

C0065

TP5002

C0061

R0911

R0965

R0964

JK3703

TP4804

TP2008

R4033

R2003

TP2022

C2005

C2007

R2005

Q4151

R4161

Q4152

R4159

R4158

D4163

R4157

C4158

C4159

C4157

C4155

C4156

C4178

C4176

C4177

R0920

R0921

C1951

R1952

R0977

R0976

R0978

R0979

11

6

JK3703

15

10

R4032

C2003

TP4053

TP4054

D2005

TP2010

TP4004

R0918

TP4005

R0919

D4151

C4170

R4162

D4165

R4160

C0089

R4155

R4154

C4164

D4158

C4169

C4163

R4150

D4154

D4156

C4161

D4153

Q4150

R4151

C4162

D4155

R4153

D4152

D4150

Q4150

C4152

D4173

TP4151

R8241

R8240

R5049

IC8706

4

5

C8776

IC8706

C8774

3

1

C8777

C8775

R8019

1

5

C4123

R4031

TP4023

TP4042

TP4043

TP4055

TP4038

TP4052

C0088

TP4035

TP4039

TP4050

TP4037

TP4041

TP4051

TP4036

TP4027

TP4040

TP4150

D4157

TP4003

R4152

TD004

C0081

R5033

R5034

R5035

D1955

C0080

C8118

C8116

C8049

R8016

ZA0061

D3100

C3179

R3116

R3103

D3102

C3181

R3114

R3105

D3101

C3180

OUTINOUT

R3115

C3112

R3203

C3104

C3141

R3107

R3112

C3140

IN

C4129

C4124

C4122

C4126

TP4022

TP4024

TP4026

TP4045

TP4025

TP4034

TP4030

TP4046

C4125

TP4031

TP4048

TP4044

C4127

R4124

C4130

TP4029

TP4033

R4127

TP4020

TP4032

TP4028

R4024

C8027

C8028

R8015

C8023

C8002

C8006

L8039

R8002

C8037

C8036

L8006

C8035

R5177

C8034

L4907

R4913

R4912

L4906

L4908

R4914

L4909

R4915

R8011

C8032

C8025

R8005

C8051

C8004

C8117

C8040

R8001

R8013

C8031

C8127

R8009

R8010

R8012

C0063

Q3002

8

Q3002

L3012

IC3001

C3137

R3096

R3098

C3136

R3095

C3135

C3143

1

JK3000

C0056

C4131

C4133

TP4049

TP4047

TP4006

TP4021

L4000

C4003

C4001

C4132

C4134

C4120

R4123

C4128

4

3

C8135

IC8703

C8129

C8133

1

5

TP8000

L8037

C8131

IC8703

C8005

R8003

C8053

C8113

R8006

R8017

IC3001

5

Q3001

R3120

R3108

C3116

C3117

R3176

D3106

4

C8054

C8106

C8213

R8204

R8207

C8021

C8016

C8055

C8052

C8014

C8020

C8013

C8056

C8033

L5605

C8057

R8014

C8026

C8041

R8007

C8115

R8004

C8058

C8103

R8018

C8050

R3123

R3122

C3109

R4741

L8046

D4722

R0974

R0975

R0945

R0973

R0972

TP8003

R3121

C0084

Q3001

C3105

C3106

C3107

JK3000

16

R3196

R8038

R4739

IC3000

JK3000A

C8732

ZA0053

ZA0054

C8219

C8218

C8226

C8110

C8225

C8217

C8222

C8220

C8221

C8019

C8108

C8224

C8223

C8228

C8216

C8227

Q4501

C0068

R4571

R4573

Q4501

C4552

JK1000

IC3000

89

C3169

R3109

C3170

R3201

L3122

R3199

R3200

L3123

R3202

D3104

1

D3103

ZA0063

TP5400

R8124

R8121

R8110

R8126

R8128

TP4503

R4718

TP4701

TP4502

R4719

R4574

R4562

C0066

R4578

C4547

D4721

R4575

Q4500

R4577

R4576

R4572

C4551

TP8703

Q2001

R2024

Q2002

R2022

R2021

R2023

R2016

TP2012

TP2013

TP2011

C8738

R8736

Q5000

R2019

C0079

Q5000

R5001

R5000

C4913

VJ4904

C4914

L4905

R4908

TP2016

TP2017

TP2014

TP2002

R4921

TP2015

TP8704

R8731

C8734

TNP4G506

REVERSE FOR SUFFIX.SEE

4

TP4062

TP8701

TP4063

TP4064

TP4065

A12

1

3

A

R4917

R4916

Ref.No Location Ref.No Location Ref.No Location Ref.No Location

IC3000

IC3001

IC8703

IC8706

D1

D1

D3

C2

D0902

D0904

D0905

D0906

D0907

D0908

D0909

D0910

D0911

D0912

D0913

R8702

C8700

D8700

D0914

D1955

TP8702

Q2751

R2772

R2789

C2755

L2752

L2754

R2751

R2788

R2791

C2750

L2750

C2752

L2751

C2775

C2754

C2753

R8706

D8701

TP2771

C8707

TP2773

TP2769

TP2775

TP2774

TP2772

TP2770

D2001

D2005

D3052

D3053

D3054

Parts Location

B2

B2

B2

B2

B2

B2

B2

B2

B2

B2

B2

B2

C2

B3

C3

A1

A1

A1

D3100

D3101

D3102

D3103

D3104

D3106

D4150

D4151

D4152

D4153

D4154

D4155

D4156

D4157

D4158

D4159

D4160

D4161

C1

C1

C1

E1

D4162

D4163

D4165

D4166

C3

C3

C3

B3

E1 D4167 B3

D1

C3

C3

C3

C3

C3

C3

D4168

D4172

D4173

D4174

D4175

D4721

D4722

B3

C3

C3

B3

B3

E2

D2

C3 D5172 B3

C3 D5173 B3

C3

B3

D5174

D5175

B3

B3

B3 D8700 F1

C3 D8701 F1

60

IJHGFEDCBA

Page 61

TH-L32C4M

IJHGFEDCBA

1

2

3

4

5

6

GK-BOARD (BOTTOM COMPONENT SIDE)

TNP4G514

GK-BOARD (TOP COMPONENT SIDE)

TNP4G514

Parts Location

Ref.No Location

D2600

D2601

C2

C2

GK

AV

TV

-/V+/

F

V

SW2600

SW2601SW2602SW2603SW2604SW2605SW2606

GK1

POWER

TNP4G514

TUPNI-

LOV

+

L

OV-HC

MENU

CH+

GK

1

1

SEE REVERSE FOR ORDER NO.

13

C2601

C2604

SW2600

SW2601

SW2602

SW2603

SW2604

SW2605

SW2606

D2600

D2601

R2601

R2602

R2603

R2604

R2605

GK1

TNP4G514

GK1

ORDER

NO.

3

1

12.2. GK-BOARD

61

Page 62

TH-L32C4M

IJHGFEDCBA

1

2

3

4

5

6

KA-BOARD (TOP COMPONENT SIDE)

TNPA5378

KA-BOARD (BOTTOM COMPONENT SIDE)

TNPA5378

TP2800

TP2801

TP2802

TP2803

TP2804

TP2806

TP2807

TP2808

TP2809

RM2800

1

TNPA5378

KA

13

REVERSE FOR SUFFIX.

SEE

RM2800A

RM2800

TP2800 TP2801TP2802

TP2803

TP2804

TP2806

TP2807

TP2808

TP2809

KA

KA10

RM2800

AB AD

AE

AF

AA AC

AG

TNPA5378

1

3

KA

1

Q2800

Q2802

Q2801

1

SUFFIX.

1

7

SN2800

KA10

C2801

C2802

C2803

Q2800

C2804

Q2801

C2805

Q2802

C2806

C2807

C2809

C2811

D2800

D2801

D2802

D2803

R2800

D2804

R2801

D2805

R2802

R2803

R2804

R2805

R2806

R2807 R2808

R2809

R2810

R2811

R2815

R2817

R2825

R2826

R2827

R2828

R2829

R2830

R2831

D2800A

D2800B

RM2800A

RM2800

Parts Location

D2800A

Ref.No Location

D2800B

D2801

D2802

D2803

D2804

D2805

D4

D4

C4

C4

D4

D4

D4

12.3. KA-BOARD

62

Page 63

TH-L32C4M

IJHGFEDCBA

1

2

3

4

5

6

P-BOARD (TOP COMPONENT SIDE)

TNP4G508

P

AQS LABEL

JS7201

JS7202

JS7801

JS7802

JS7803

JS7808

JS7809

C7102C7103

C7104

C7105

C7106

C7107

C7108

JS7811

C7109

C7301

ZA7001ZA7002

ZA7003

C7110

ZA7005

C7307

C7308

C7309

JS7822

C7508

D7101

D7103

C7511 C7513

C7514

R7104

C7515

D7302

D7303

IC7301

D7503

JS7850

S7100

L7201

L7202

L7203

R7323

R7324

PC7301

PC7302

PC7303

F7101

L7801

L7802

L7803

L7804

L7805

L7806

R7346

L7808

L7809

T7302

J201

J202

J203

J204

J205

J206

J207

J208

J209

J211

J212

CF7102

JS7104

JS7105

JS7301

JS7308

JS7309

JS7310

JS7311

C7202

Q7201

C7210

C7211

C7213

P1

P2

C7217

P5

P6

P7P8

C7801

D7205

R7201

D7206

R7202

JS7551

R7210

L7104

L7105

C7827

C7828

L7301

L7303

L7304

L7305

C7832

L7308

T7201

C7850

LF7101

LF7102

LF7103

T7801

T7802

T7803

T7804

J101

J102

J103

J104

J105

J107

J108

J109

J301

J302

J303

J304

J110

J305

J306

J112

J307

J113

J114

J309

J115

J117

J118

54

COLD

COLD

COLD

HOT

LIVE CIRCUIT

HOT

54

1

2

3

FOR CONTINUED PROTECTION AGAINST RISK OF FIRE,

REPLACE ONLY WITH SAME TYPE AND RATING OF FUSE.

CAUTION

1

2

2

1

2

21

1

3

4

2

1

1

2

3

4

14

3

2

2

1

4

L

N

TNP4G508 P

CAUTION

HIGH VOLTAGE

DIP

2

CAUTION

HIGH VOLTAGE

3

1

T5AH 250V

J210

D7102

1

2

1

J310

J111

J213

J120

J119

R7335

J001

D7506

C7214

C7509

D7505

C7101

CF7101

C7804

ZA7004

AQS LABEL

JS7302

L7302

JS7101

L7101

JS7102

L7102

C7212

D7315

1

4

5

8

ORDER

NO.

1

6

712

D

S

G

2

1

21

1

1

2

1

2

1212

1

3

8

4

1

6

711

12

3

6

12

3

6

54

13

+

-

Parts Location

IC7301

Ref.No Location Ref.No Location Ref.No Location Ref.No Location

D2 D7101

D7102

D7103

D7205

A2

B2

C2

C2

D7206

D7302

D7303

D7315

C2

B1

B1

E2

D7503

D7505

D7506

F2

F1

F1

12.4. P-BOARD

63

Page 64

IJHGFEDCBA

1

2

3

4

5

6

P-BOARD (BOTTOM COMPONENT SIDE)

TNP4G508

P

JA1

JA2

JA3

JA4

JA5

JA6

JA7

JA8

JA9

C7102

C7103

C7104

C7105

C7106

C7107

C7108

C7109

C7301

ZA7001

C7302

ZA7002

C7303

ZA7003

C7304

C7110

C7305

ZA7005

Q7301

Q7302

C7307

Q7303

C7308

C7309

Q7306

JA10

C7501

JA11

C7502

JA12

C7503

JA13

C7504

JA14

C7505

Q7501

C7506

Q7502

C7507

Q7503

C7508

Q7504

C7509

Q7505

D7101

D7103

C7510

C7511

R7101

C7512

R7102

C7513

R7103

C7514

R7104

C7515

D7302

D7303

D7304

R7301

R7302

R7303

C7520

C7521

D7309

R7305

R7306

R7308

D7501

IC7301

D7502

D7503

D7310

D7504

R7501

R7502

D7507

R7503

D7508

D7314

R7310

R7504 R7505

R7506

D7317

R7313

R7507

JS7850

D7318

R7314

R7508

IC7501

D7319

R7315

R7509

R7316

R7317

R7318

S7100

D7320

R7510

R7511

L7201

R7512

L7202

R7513

L7203

R7514

R7515

R7322

R7516

R7323

R7517

R7324

R7518

R7519

R7328

PC7301

R7329

PC7302

PC7303

R7520

R7330

F7101

TP7201

TP7202

TP7203

TP7204

PA7551

R7341

L7801

L7802

L7803

L7804

R7344

L7805

R7345

L7806

R7346

L7808

L7809

T7302

TP7801

TP7802

TP7803

TP7804

TP7805

TP7806

TP7807

TP7808

TP7809

TP7810

TP7811

TP7812

TP7813 TP7814

TP7815 TP7816

TP7817

TP7818

TP7819

TP7820

TP7821TP7822

CF7102

TP7851

TP7852

TP7853

TP7854

TP7855

C7201

C7202

C7203

C7204

C7205

Q7201

C7206

Q7202

C7207

C7208

C7210

C7211

C7213

P1

P2

C7216

C7217

C7218

C7219

P5 P6

P7

P8

C7220

C7801

D7201

C7802

D7202

D7203

D7204

D7205

Q7801

R7201

C7806

D7206

Q7802

R7202

Q7803

R7203

C7808

D7208

Q7804

R7204

C7809

R7205

R7206

R7207

R7208

R7209

IC7201

C7810

C7811

C7812

C7813

C7814

R7210

C7815

R7211

C7816

C7817

R7213

C7818

C7819

R7215 R7216

R7217

R7219

C7820

C7821

C7822

C7823

C7824

L7104

C7825

R7221

L7105

D7801

C7826

C7827

R7223

C7828

R7224

C7829

R7801

R7226

D7806

R7802

D7807

R7803

D7808

R7804

R7229

D7809

R7805

L7301

R7806

R7807

L7303

C7830

R7808

L7304

L7305

C7831

R7809

IC7801

C7832

C7833

C7834

R7230

D7810

L7308

C7835

R7231

D7811

R7232

D7812

R7233

D7813

R7234

D7814

R7810

R7811

D7816

R7812

D7817

R7813

D7818

R7814

D7819

R7815

TP7101

R7816

TP7102

R7817

TP7103

R7818

TP7104

R7819

TP7105

C7842

C7843

C7844

C7845

C7846

C7847

R7820

R7821

R7822

R7823

R7824

R7825

T7201

R7826

C7850

R7828

C7851

R7829

C7852

TP7501

TP7502

TP7503

R7830

TP7504

R7831

TP7505

R7832

TP7506

R7833

R7834

R7835

LF7101

R7836

LF7102

R7837

LF7103

R7838

C7861

R7839

C7862C7863

C7864

C7865

C7866C7867

C7868

R7840

R7841

R7842

R7843

R7844

T7801

T7802

T7803

T7804

N

L

CAUTION HIGH VOLTAGE CAUTION HIGH VOLTAGE

COLD

LIVE CIRCUIT

HOT

HOT

HOT

TNP4G508

P

COLD

T5AH 250V

COLD

D7207

Q7203

C7221

D7102

D7209

R7335

D7506

C7214

R7342

D7505

C7101

CF7101

C7804

1

ZA7004

L7102

L7101

L7302

C7212

D7315

8

5

4

1

SEE REVERSE FOR ORDER NO.

12

7

6

1

D

G

S

1

2

1

12

21 21 21 21

D

G

S

D

G

S

1

45

8

1

9

18

10

4

8

3

1

7

16

11

6

3

21

6

3

12

54

31

+

-

Parts Location

IC7201

Ref.No Location Ref.No Location Ref.No Location Ref.No Location

IC7501

IC7801

D1

B1

A3

D7101

D7102

D7103

D7201

D7202

F2

E2

E2

C1

D1

D7310

D7314

D7315

D7317

D7318

C2

C2

B2

C2

C1 D7809 A3

D7801

D7806

D7807

D7808

B3

F3

D4

C4

D7203

D7204

D7205

D7206

D7208

D2

E2

D2

D2

D1

D7319

D7320

D7501

D7502

D7503

C2

C2

C1

C1

A2 D7814 C2

D7810

D7811

D7812

D7813

D3

C3

B3

C3

D7209

D7302

D7303

D7304

D7309

C1

E1

E1

C1

C2

D7504

D7505

D7506

D7507

D7508

B1

A1

A1

C1

C1

D7816

D7817

D7818

D7819

B3

A3

A3

C3

TH-L32C4M

64

Page 65

13 Exploded View and Replacement Parts List

13.1. Exploded View and Mechanical Replacement Parts List

Please click the radio button for ‘Diagrams ll/Parts List’ on the menu bar.

13.2. Electrical Replacement Parts List

13.2.1. Replacement Parts List Notes

TH-L32C4M

65

Page 66

TH-L32C4M

13.2.2. Electrical Replacement Parts List

Note: All part will be supplied by PAVCKM.

Safety Ref.

No.

C1951 F1H1H102A831 C 1000PF , 50V

C1953 F1J0J106A004 C 10UF , 6.3V

C1954 F1J0J106A004 C 10UF , 6.3V

C1955 F1G1H101A565 C 100PF , 50V

C2001 F1G1E1030005 C 0.01UF , 25V

C2003 F1G1H1020008 C 1000PF , 50V

C2008 F1K1E106A136 C 10UF , 25V

C2009 F1G1C104A077 C 0.1UF , 16V

C2010 F1G1C1030008 C 0.01UF , 16V

C2011 F1G1C104A077 C 0.1UF , 16V

C2012 F1J1A106A087 C 10UF , 10V

C2751 F1G1H1020008 C 1000PF , 50V

C2752 F1G1H1020008 C 1000PF , 50V

C2753 F1G1H1020008 C 1000PF , 50V

C2754 F1G1H1020008 C 1000PF , 50V

C2755 F1G1H1020008 C 1000PF , 50V

C2775 F1G1H101A565 C 100PF , 50V

C2801 F2G0J470A019 C 10UF , 10V

C2802 F1G1C1030008 C 0.01UF , 16V

C2805 F1H1C104A041 C 0.1UF , 16V

C3093 F1G1C1030008 C 0.01UF , 16V

C3095 F1G1C1030008 C 0.01UF , 16V

C3097 F1G1C1030008 C 0.01UF , 16V

C3101 F1J1A106A043 C 10UF , 10V

C3102 F1J1A106A043 C 10UF , 10V

C3105 F1G1A105A047 C 1UF , 10V

C3106 F1G1C104A077 C 0.1UF , 16V

C3107 F1J1A106A087 C 10UF , 10V

C3108 F1G1C470A117 C 47PF , 16V

C3109 F1G1C470A117 C 47PF , 16V

C3110 F1G1C470A117 C 47PF , 16V

C3111 F1G1A473A053 C 0.047UF , 10V

C3113 F1K1E106A136 C 10UF , 25V

C3116 F1J1A106A043 C 10UF , 10V

C3117 F1J1A106A043 C 10UF , 10V

C3121 F1H1C105A145 C 1UF , 16V

C3125 F1G1A473A053 C 0.047UF , 10V

C3130 F1J1A106A087 C 10UF , 10V

C3131 F1J1A106A087 C 10UF , 10V

C3132 F1J1A106A087 C 10UF , 10V

C3133 F1J1A106A087 C 10UF , 10V

C3134 F1J1A106A087 C 10UF , 10V

C3135 F1J1A106A087 C 10UF , 10V

C3136 F1J1A106A087 C 10UF , 10V

C3137 F1H1C105A145 C 1UF , 16V

C3138 F1G1H220A565 C 22PF , 50V

C3139 F1G1H220A565 C 22PF , 50V

C3142 F1G1H3310003 C 330PF , 50V

C3143 F1G1H3310003 C 330PF , 50V

C3169 F1J1A106A043 C 10UF , 10V

C3170 F1J1A106A043 C 10UF , 10V

C3171 F1G1C1030008 C 0.01UF , 16V

C3172 F1G1C1030008 C 0.01UF , 16V

C3173 F1G1H152A571 C 1500PF , 50V

C3174 F1G1C1030008 C 0.01UF , 16V

C3175 F1G1H152A571 C 1500PF , 50V

C3176 F1G1C1030008 C 0.01UF , 16V

C3177 F1G1C1030008 C 0.01UF , 16V

C3179 F1G1C470A117 C 47PF , 16V

C3180 F1G1C470A117 C 47PF , 16V

C3181 F1G1C470A117 C 47PF , 16V

C3182 F1H1C105A145 C 1UF , 16V

C3183 F1G1C470A117 C 47PF , 16V

C4001 F1J1C475A217 C 4.7UF , 16V

C4002 F1J1A106A087 C 10UF , 10V

C4003 F1G1C1030008 C 0.01UF , 16V

Part No. Part Name & Description Remarks

CAPACITORS

Safety Ref.

No.

C4004 F1J1A106A087 C 10UF , 10V

C4120 F1G1C104A077 C 0.1UF , 16V

C4121 F1G1C104A077 C 0.1UF , 16V

C4122 F1G1C104A077 C 0.1UF , 16V

C4123 F1G1C104A077 C 0.1UF , 16V

C4124 F1G1C104A077 C 0.1UF , 16V

C4125 F1G1C104A077 C 0.1UF , 16V

C4126 F1G1C104A077 C 0.1UF , 16V

C4127 F1G1C104A077 C 0.1UF , 16V

C4128 F1J1A106A087 C 10UF , 10V

C4129 F1G1C104A077 C 0.1UF , 16V

C4130 F1G1C104A077 C 0.1UF , 16V

C4131 F1G1C104A077 C 0.1UF , 16V

C4132 F1G1C104A077 C 0.1UF , 16V

C4133 F1G1C104A077 C 0.1UF , 16V

C4134 F1H1C105A145 C 1UF , 16V

C4150 F1J1E475A267 C 4.7UF , 25V

C4151 F1G1C104A077 C 0.1UF , 16V

C4152 F1J1E105A231 C 1UF , 25V

C4153 F1H1H104A970 C 0.1UF , 50V

C4154 F1H1H104A970 C 0.1UF , 50V

C4155 F1H1H473A918 C 0.047UF , 50V

C4156 F1H1H473A918 C 0.047UF , 50V

C4157 F1H1H473A918 C 0.047UF , 50V

C4158 F1H1H104A970 C 0.1UF , 50V

C4159 F1H1H473A918 C 0.047UF , 50V

C4160 F1H1H104A970 C 0.1UF , 50V

C4161 F1J1E105A231 C 1UF , 25V

C4162 F1H1H104A970 C 0.1UF , 50V

C4163 F1K1E106A136 C 10UF , 25V

C4164 F1K1E106A136 C 10UF , 25V

C4165 F1K1E225A085 C 2.2UF , 25V

C4166 F1K1E225A085 C 2.2UF , 25V

C4167 F1K1E225A085 C 2.2UF , 25V

C4168 F1K1E225A085 C 2.2UF , 25V

C4169 F1H1H104A970 C 0.1UF , 50V

C4170 F1G1A105A047 C 1UF , 50V

C4173 F1G1E472A086 C 4700PF , 25V

C4174 F1G1H560A565 C 56PF , 50V

C4175 F1J1C475A170 C 4.7UF , 16V

C4176 F1J1C475A170 C 4.7UF , 16V

C4177 F1J1C475A170 C 4.7UF , 16V

C4178 F1J1C475A170 C 4.7UF , 16V

C4179 F1G1E472A086 C 4700PF , 25V

C4180 F1G1A105A047 C 1UF , 50V

C4181 F1J1E475A267 C 4.7UF , 25V

C4182 F1J1E475A267 C 4.7UF , 25V

C4187 F1K0J1060017 C 10UF , 6.3V

C4188 F1K0J1060017 C 10UF , 6.3V

C4801 F1G1H1020008 C 1000PF , 50V

C4802 F1J1A106A087 C 10UF , 10V

C4803 F1G1H1020008 C 1000PF , 50V

C4804 F1J1A106A087 C 10UF , 10V

C4805 F1G1H1020008 C 1000PF , 50V

C4806 F1J1A106A087 C 10UF , 10V

C4812 F1G1A105A047 C 1UF , 10V

C4814 F1G1A2240008 C 0.22UF , 10V

C4817 F1G1H100A565 C 10PF , 50V

C4818 F1G1A473A053 C 0.047UF , 10V

C4900 F1G1C104A077 C 0.1UF , 16V

C4901 F1G1A105A047 C 1UF , 10V

C4902 F1H1E104A029 C 0.1UF , 25V

C4903 F1H1E104A029 C 0.1UF , 25V

C4904 F1G1E104A087 C 0.1UF , 25V

C4905 F1G1E104A087 C 0.1UF , 25V

C4906 F1H1E104A029 C 0.1UF , 25V

C4907 F1H1E104A029 C 0.1UF , 25V

C4908 F1G1E104A087 C 0.1UF , 25V

C4909 F1G1E104A087 C 0.1UF , 25V

Part No. Part Name & Description Remarks

66

Page 67

TH-L32C4M

Safety Ref.

No.

C4910 F1K1E106A136 C 10UF , 25V

C4911 F1K1E106A136 C 10UF , 25V

C4912 F1J1A106A087 C 10UF , 10V

C4915 F1G1C104A077 C 0.1UF , 16V

C4916 F1H1E224A123 C 0.22UF , 25V

C4917 F1H1E224A123 C 0.22UF , 25V

C5000 F1G1A105A047 C 1UF , 10V

C5001 F2H0J1010009 C 100UF , 6.3V

C5002 F1G1A105A047 C 1UF , 10V

C5004 F1G1A105A047 C 1UF , 10V

C5006 F1J1E105A231 C 1UF , 25V

C5012 F1G1A105A047 C 1UF , 10V

C5020 F1H1A4740009 C 0.47UF , 10V

C5021 F1G1A105A047 C 1UF , 10V

C5022 F1G1A105A047 C 1UF , 10V

C5026 F1H1C105A145 C 1UF , 16V

C5027 F1G1C104A077 C 0.1UF , 16V

C5028 F1G1C104A077 C 0.1UF , 16V

C5035 F1G1C104A077 C 0.1UF , 16V

C5171 F1G1C1030008 C 0.01UF , 16V

C5476 F1G1A105A047 C 1UF , 10V

C5477 F1G1A105A047 C 1UF , 10V

C5613 EEEHB0J221UP C 220UF , 6.3V

C5616 F1G1C104A077 C 0.1UF , 16V

C5624 F1J1A106A087 C 10UF , 10V

C5625 F1G1C104A077 C 0.1UF , 16V

C7102 F1A2E471A003 C 470PF , 250V

C7103 F1A2E471A003 C 470PF , 250V

C7104 F0CAF224A124 C 0.22UF , 250V

C7105 F0CAF224A124 C 0.22UF , 250V

C7201 F1J1H222A721 C 2200PF , 50V

C7202 F1A3A221A060 C 220PF , 1kV

C7203 F1J1H102A721 C 1000PF , 50V

C7204 F1J1H104A717 C 0.1UF , 50V

C7205 F1J1H2240009 C 0.22UF , 50V

C7206 F1J1H1030007 C 0.01UF , 50V

C7207 F1J1H1030007 C 0.01UF , 50V

C7208 F1J1H474A757 C 0.47UF , 50V

C7210 F1A3A221A060 C 220PF , 1kV

C7212 F2A2W1010011 C 100UF , 450V

C7214 F0C2H105A019 C 1UF , 500V

C7218 F1J1H2240009 C 0.22UF , 50V

C7219 F1J1H2240009 C 0.22UF , 50V

C7220 F1J1H1030007 C 0.01UF , 50V

C7221 F1J1H1030007 C 0.01UF , 50V

C7301 F1B3D470A099 C 47PF , 2kV

C7302 F1J1H102A721 C 1000PF , 50V

C7303 F1J1H472A702 C 47000PF , 50V

C7304 F1J1E105A231 C 1UF , 25V

C7305 F1J1H101A709 C 100PF , 50V

C7307 F2A1H330A122 E 33UF , 50V

C7308 F1A2E471A003 C 470PF , 250V

C7309 F2A1H330A122 E 33UF , 50V

C7501 F1J1H104A717 C 0.1UF , 50V

C7502 F1J1H2240009 C 1UF , 25V

C7503 F1J1E105A231 C 1UF , 25V

C7505 F1J1H1030007 C 0.01UF , 50V

C7508 F1A3A471A060 C 470PF , 1kV

C7509 F1A3A471A060 C 470PF , 1kV

C7512 F1J1H104A717 C 0.1UF , 50V

C7513 F2A1E6810034 C 680UF , 25V

C7514 F2A1E101A089 E 100UF , 25V

C7520 F1J1H104A717 C 0.1UF , 50V

C7521 F1J1H104A717 C 0.1UF , 50V

C7802 F1J1H474A757 C 1UF , 25V

C7804 F0C2H105A019 C 1UF , 500V

C7806 F1J1H152A721 C 1500PF , 50V

C7808 F1J1H152A721 C 1500PF , 50V

C7809 F1J1H101A709 C 100PF , 50V

C7810 F1J1H101A709 C 100PF , 50V

C7811 F1J1H101A709 C 100PF , 50V

C7812 F1J1H101A709 C 100PF , 50V

Part No. Part Name & Description Remarks

Safety Ref.

No.

C7813 F1J1H101A709 C 100PF , 50V

C7814 F1J1H101A709 C 100PF , 50V

C7815 F1J1H101A709 C 100PF , 50V

C7816 F1J1E105A231 C 1UF , 25V

C7817 F1J1H1030007 C 0.01UF , 50V

C7818 F1J1H1030007 C 0.01UF , 50V

C7819 F1J1H104A717 C 0.1UF , 50V

C7820 F1J1H474A757 C 0.47UF , 50V

C7821 F1J1H1030007 C 0.01UF , 50V

C7822 F1J1H474A757 C 0.47UF , 50V

C7826 F1J1H1030007 C 0.01UF , 50V

C7827 F1A3A471A060 C 470PF , 1kV

C7828 F1A3A471A060 C 470PF , 1kV

C7831 F1J1H1030007 C 0.01UF , 50V

C7832 F1A3A222A060 C 2200PF , 1kV

C7833 F1J1H101A709 C 100PF , 50V

C7834 F1J1H472A702 C 4700PF , 50V

C7835 F1J1H472A702 C 4700PF , 50V

C7842 F1J1H152A721 C 1500PF , 50V

C7843 F1J1H152A721 C 1500PF , 50V

C7844 F1J1H152A721 C 1500PF , 50V

C7845 F1J1H152A721 C 1500PF , 50V

C7846 F1J1H152A721 C 1500PF , 50V

C7847 F1J1H152A721 C 1500PF , 50V

C7850 F1A2E471A003 C 470PF , 250V

C7861 ECCT3G150JGV C 15PF , 4kV

C7862 ECCT3G150JGV C 15PF , 4kV

C7863 ECCT3G150JGV C 15PF , 4kV

C7864 ECCT3G150JGV C 15PF , 4kV

C7865 ECCT3G150JGV C 15PF , 4kV

C7866 ECCT3G150JGV C 15PF , 4kV

C7867 ECCT3G150JGV C 15PF , 4kV

C7868 ECCT3G150JGV C 15PF , 4kV

C8000 F1J1A475A087 C 4.7UF , 10V

C8004 F1G1C104A077 C 0.1UF , 16V

C8005 F1G1C104A077 C 0.1UF , 16V

C8006 F1G1C104A077 C 0.1UF , 16V

C8013 F1G1C104A077 C 0.1UF , 16V

C8014 F1G1A105A047 C 1UF , 10V

C8016 F1G1C104A077 C 0.1UF , 16V

C8019 F1J1A106A087 C 10UF , 10V

C8020 F1G1C104A077 C 0.1UF , 16V

C8021 F1G1C104A077 C 0.1UF , 16V

C8023 F1G1C104A077 C 0.1UF , 16V

C8025 F1G1C104A077 C 0.1UF , 16V

C8026 F1G1C104A077 C 0.1UF , 16V

C8027 F1G1C104A077 C 0.1UF , 16V

C8031 F1G1C104A077 C 0.1UF , 16V

C8032 F1G1C104A077 C 0.1UF , 16V

C8033 F1G1C104A077 C 0.1UF , 16V

C8034 F1G1C104A077 C 0.1UF , 16V

C8035 F1G1C104A077 C 0.1UF , 16V

C8036 F1J1A475A087 C 4.7UF , 10V

C8037 F1G1C104A077 C 0.1UF , 16V

C8040 F1G1C104A077 C 0.1UF , 16V

C8041 F1G1C104A077 C 0.1UF , 16V

C8049 F1J1A106A087 C 10UF , 10V

C8050 F1G1C104A077 C 0.1UF , 16V

C8052 F1J1A106A087 C 10UF , 10V

C8053 F1G1C104A077 C 0.1UF , 16V

C8054 F1G1C104A077 C 0.1UF , 16V

C8055 F1G1C104A077 C 0.1UF , 16V

C8056 F1G1C104A077 C 0.1UF , 16V

C8057 F1G1C104A077 C 0.1UF , 16V

C8058 F1G1C104A077 C 0.1UF , 16V

C8059 F1G1C104A077 C 0.1UF , 16V

C8060 F1G1C104A077 C 0.1UF , 16V

C8061 F1G1C104A077 C 0.1UF , 16V

C8062 F1G1C104A077 C 0.1UF , 16V

C8063 F1J1A106A087 C 10UF , 10V

C8064 F2G0J470A019 E 47UF , 6.3V

C8065 F1G1C104A077 C 0.1UF , 16V

C8103 F1G1C104A077 C 0.1UF , 16V

Part No. Part Name & Description Remarks

67

Page 68

TH-L32C4M

Safety Ref.

No.

C8106 F1G1C104A077 C 0.1UF , 16V

C8108 F1G1C104A077 C 0.1UF , 16V

C8110 F1G1C104A077 C 0.1UF , 16V

C8112 F1G1C104A077 C 0.1UF , 16V

C8113 F1G1C104A077 C 0.1UF , 16V

C8114 F1G1C104A077 C 0.1UF , 16V

C8115 F1G1C104A077 C 0.1UF , 16V

C8116 F1G1A105A047 C 1UF , 10V

C8117 F1G1C104A077 C 0.1UF , 16V

C8118 F1G1C104A077 C 0.1UF , 16V

C8127 F1G1C104A077 C 0.1UF , 16V

C8129 F1J1A475A087 C 4.7UF , 10V

C8131 F1J1A106A087 C 10UF , 10V

C8133 F1G1C104A077 C 0.1UF , 16V

C8135 F1G1C104A077 C 0.1UF , 16V

C8140 F1G1H6R0A732 C 6PF , 50V

C8142 F1G1H5R0A732 C 6PF , 50V

C8143 F1G1A105A047 C 1UF , 10V

C8200 F1G1C104A077 C 0.1UF , 16V

C8203 F1G1C104A077 C 0.1UF , 16V

C8213 F1G1C104A077 C 0.1UF , 16V

C8216 F1G1C104A077 C 0.1UF , 16V

C8217 F1G1C104A077 C 0.1UF , 16V

C8218 F1G1C104A077 C 0.1UF , 16V

C8219 F1G1C104A077 C 0.1UF , 16V

C8220 F1G1C104A077 C 0.1UF , 16V

C8221 F1G1C104A077 C 0.1UF , 16V

C8222 F1G1C104A077 C 0.1UF , 16V

C8223 F1G1C104A077 C 0.1UF , 16V

C8224 F1G1C104A077 C 0.1UF , 16V

C8225 F1G1C104A077 C 0.1UF , 16V

C8226 F1G1C104A077 C 0.1UF , 16V

C8227 F1G1C104A077 C 0.1UF , 16V

C8228 F1G1C104A077 C 0.1UF , 16V

C8700 F1G1E1030005 C 0.01UF , 25V

C8703 F1J1A106A087 C 10UF , 10V

C8705 F1G1H1020008 C 1000PF , 50V

C8707 F1G1C223A081 C 0.022UF , 16V

C8709 F1J1A106A087 C 10UF , 10V

C8710 F1J1A106A087 C 10UF , 10V

C8711 F1G1C223A081 C 0.022UF , 16V

C8712 F1G1H1020008 C 1000PF , 50V

C8714 F1J1A475A087 C 4.7UF , 10V

C8715 F1J1A106A087 C 10UF , 10V

C8716 F1G1C104A077 C 0.1UF , 16V

C8717 F1G1C104A077 C 0.1UF , 16V

C8720 F1K1E106A136 C 10UF , 25V

C8721 F1K1E106A136 C 10UF , 25V

C8722 F1K1E106A136 C 10UF , 25V

C8723 F1K1E106A136 C 10UF , 25V

C8724 F1K1E106A136 C 10UF , 25V

C8726 F1J0G2260001 C 22UF , 4V

C8727 F1J0G2260001 C 22UF , 4V

C8728 F1K1E106A136 C 10UF , 25V

C8730 F1K1E106A136 C 10UF , 25V

C8731 F1K1E106A136 C 10UF , 25V

C8732 F1J0G2260001 C 22UF , 4V

C8733 F1J0G2260001 C 22UF , 4V

C8734 F1G1C1030008 C 0.01UF , 16V

C8736 F1G1C1030008 C 0.01UF , 16V

C8737 F1G1E472A086 C 4700PF , 25V

C8738 F1G1C1030008 C 0.01UF , 16V

C8740 F1G1C1030008 C 0.01UF , 16V

C8741 F1G1E472A086 C 4700PF , 25V

C8769 F1G1C223A081 C 0.022UF , 16V

C8773 F1J1A106A087 C 10UF , 10V

C8774 F1G1C104A077 C 0.1UF , 16V

C8775 F1J1A475A087 C 4.7UF , 10V

C8776 F1J1A106A087 C 10UF , 10V

C8777 F1G1C104A077 C 0.1UF , 16V

C8900 F1G1C104A077 C 0.1UF , 16V

D0901 EZJZ0V120JA VARISTOR

Part No. Part Name & Description Remarks

DIODES

Safety Ref.

No.

D0902 EZJZ0V120JA VARISTOR

D0904 EZAEG2A50AX FILTER

D0905 EZAEG2A50AX FILTER

D0910 EZAEG2A50AX FILTER

D0911 EZAEG2A50AX FILTER

D0912 EZAEG2A50AX FILTER

D0913 EZAEG2A50AX FILTER