Page 1

ORDER NO. : PAVCI1206044CE

Service Manual

LCD TV

Model No.

TH-L24C5D

This service information is designed for experienced repair technicians only and is not designed for use by the general public. It does not

contain warnings or cautions to advise non-technical individuals of potential dangers in attempting to service a product. Products powered by

electricity should be serviced or repaired only by experienced professional technicians. Any attempt to service or repair the product or

products dealt with in this service information by anyone else could result in serious injury or death.

There are special components used in this equipment which are important for safety. These are marked by in the Schematic Diagrams,

Circuit Board Diagrams. Exploded Views and Replacement Parts List. It is essential that these critical parts should be replaced with

manufacture’s specified parts to prevent shock, fire or other hazards. Do not modify the original design without permission of manufacturer.

IMPORTANT SAFETY NOTICE

WARNING

© Panasonic Corporation 2012.

1

Unauthorized copying and distribution is a

violation of law.

Page 2

TABLE OF CONTENTS Page

1 Safety Precaution ------------------------------------------------------------------------------------------------ 3

1.1. General Guidelines ---------------------------------------------------------------------------------------- 3

2 Warning ------------------------------------------------------------------------------------------------------------- 4

2.1. Prevention of Electrostatic Discharge(ESD) to Electrostatically Sensitive(ES) Devices 4

2.2. About lead free solder (PbF) ---------------------------------------------------------------------------- 5

3 Service Navigation ----------------------------------------------------------------------------------------------- 6

3.1. Service Hint -------------------------------------------------------------------------------------------------- 6

3.2. Applicable signals ------------------------------------------------------------------------------------------ 7

4 Specifications ----------------------------------------------------------------------------------------------------- 8

5 Troubleshooting Guide ----------------------------------------------------------------------------------------- 9

5.1 No Power ----------------------------------------------------------------------------------------------------- 9

5.2 Abnormal Display ------------------------------------------------------------------------------------------ 10

5.3 No Display --------------------------------------------------------------------------------------------------- 11

5.4 Sound Problem --------------------------------------------------------------------------------------------- 12

5.5 Remote Control Malfunction ---------------------------------------------------------------------------- 13

6 Disassembly and Assembly Instructions --------------------------------------------------------------- 14

7 Block Diagram ---------------------------------------------------------------------------------------------------- 18

8 Wiring Connection Diagram --------------------------------------------------------------------------------- 19

8.1. Caution Statement -------------------------------------------------------------------------------------- 19

8.2. Wiring -------------------------------------------------------------------------------------------------------- 19

9 Exploded View and Replacement Parts List ----------------------------------------------------------- 20

9.1. Exploded View -------------------------------------------------------------------------------------------- 20

9.2. Replacement Parts List ---------------------------------------------------------------------------------- 21

2

Page 3

1 Safety Precautions

1.1. General Guidelines

1. When servicing, observe the original lead dress. If a short circuit is found, replace all parts which have been

overheated or damaged by the short circuit.

2. After servicing, see to it that all the protective devices such as insulation barriers, insulation papers shields are

properly installed.

3. After servicing, make the following leakage current checks to prevent the customer from being exposed to

shock hazards.

4. When conducting repairs and servicing, do not attempt to modify the equipment, its parts or its materials.

5. When wiring units (with cables, flexible cables or lead wires) are supplied as repair parts and only one wire or

some of the wires have been broken or disconnected, do not attempt to repair or re-wire the units. Replace the

entire wiring unit instead.

6. When conducting repairs and servicing, do not twist the Faston connectors but plug them straight in or unplug

them straight out.

1.1.1. Leakage Current Cold Check

1. Unplug the AC cord and connect a jumper between

the two prongs on the plug.

2. Measure the resistance value, with an ohmmeter,

between the jumpered AC plug and each exposed

metallic cabinet part on the equipment such as

screwheads, connectors, control shafts, etc. When

the exposed metallic part has a return path to the

chassis, the reading should be 100 Mohm and

over. When the exposed metal does not have a

return path to the chassis, the reading must be

.

1.1.2. Leakage Current Hot Check (See Figure 1.)

1. Plug the AC cord directly into the AC outlet. Do

not use an isolation transformer for this check.

2. Connect a 1.5kohm, 10 watts resistor, in parallel

with 0.15μF capacitors, between each exposed

metallic part on the set and a good earth ground

such as a water pipe, as shown in Figure 1.

3. Use an AC voltmeter, with 1000 ohms/volt or

more sensitivity, to measure the potential

across the resistor.

4. Check each exposed metallic part, and

measure the voltage at each point.

5. Reverse the AC plug in the AC outlet and

repeat each of the above measurements.

6. The potential at any point should not exceed

0.75 volts RMS. A leakage current tester

(Simpson Model 229 or equivalent) may be

used to make the hot checks, leakage current

must not exceed 1/2 milliamp. In case a

measurement is outside of the limits specified,

there is a possibility of a shock hazard, and the

equipment should be repaired and rechecked

before it is returned to the customer.

Figure 1

3

Page 4

2 Warning

2.1. Prevention of Electrostatic Discharge (ESD) to Electrostatically Sensitive (ES) Devices

Some semiconductor (solid state) devices can be damaged easily by static electricity. Such components commonly

are called Electrostatically Sensitive (ES) Devices. Examples of typical ES devices are integrated circuits and some

field-effect transistors and semiconductor [chip] components. The following techniques should be used to help

reduce the incidence of component damage caused by electrostatic discharge (ESD).

1. Immediately before handling any semiconductor component or semiconductor-equipped assembly, drain off

any ESD on your body by touching a known earth ground. Alternatively, obtain and wear a commercially

available discharging ESD wrist strap, which should be removed for potential shock reasons prior to applying

power to the unit under test.

2. After removing an electrical assembly equipped with ES devices, place the assembly on a conductive surface

such as aluminum foil, to prevent electrostatic charge buildup or exposure of the assembly.

3. Use only a grounded-tip soldering iron to solder or unsolder ES devices.

4. Use only an anti-static solder removal device. Some solder removal devices not classified as [anti-static (ESD

protected)] can generate electrical charge sufficient to damage ES devices.

5. Do not use freon-propelled chemicals. These can generate electrical charges sufficient to damage ES devices.

6. Do not remove a replacement ES device from its protective package until immediately before you are ready to

install it. (Most replacement ES devices are packaged with leads electrically shorted together by conductive

foam, aluminum foil or comparable conductive material).

7. Immediately before removing the protective material from the leads of a replacement ES device, touch the

protective material to the chassis or circuit assembly into which the device will be installed.

Caution

Be sure no power is applied to the chassis or circuit, and observe all other safety precautions.

8. Minimize bodily motions when handling unpackaged replacement ES devices. (Otherwise ham less motion

such as the brushing together of your clothes fabric or the lifting of your foot from a carpeted floor can generate

static electricity (ESD) sufficient to damage an ES device).

4

Page 5

2.2. About lead free solder (PbF)

Note: Lead is listed as (Pb) in the periodic table of elements.

In the information below, Pb will refer to Lead solder, and PbF will refer to Lead Free Solder.

The Lead Free Solder used in our manufacturing process and discussed below is (Sn+Ag+Cu).

That is Tin (Sn), Silver (Ag) and Copper (Cu) although other types are available.

This model uses Pb Free solder in it’s manufacture due to environmental conservation issues. For service and repair

work, we’d suggest the use of Pb free solder as well, although Pb solder may be used.

PCBs manufactured using lead free solder will have the PbF within a leaf Symbol PbF stamped on the back of PCB.

Caution

• Pb free solder has a higher melting point than standard solder. Typically the melting point is 50 ~ 70 °F

(30~40 °C) higher. Please use a high temperature soldering iron and set it to 700 ± 20 °F (370 ± 10 °C).

• Pb free solder will tend to splash when heated too high (about 1100 °F or 600 °C).

If you must use Pb solder, please completely remove all of the Pb free solder on the pins or solder area before

applying Pb solder.If this is not practical, be sure to heat the Pb free solder until it melts, before applying Pb solder.

• After applying PbF solder to double layered boards, please check the component side for excess solder which

may flow onto the opposite side. (see figure below)

Suggested Pb free solder

There are several kinds of Pb free solder available for purchase. This product uses Sn+Ag+Cu (tin, silver, copper)

solder. However, Sn+Cu (tin, copper), Sn+Zn+Bi (tin, zinc, bismuth) solder can also be used.

5

Page 6

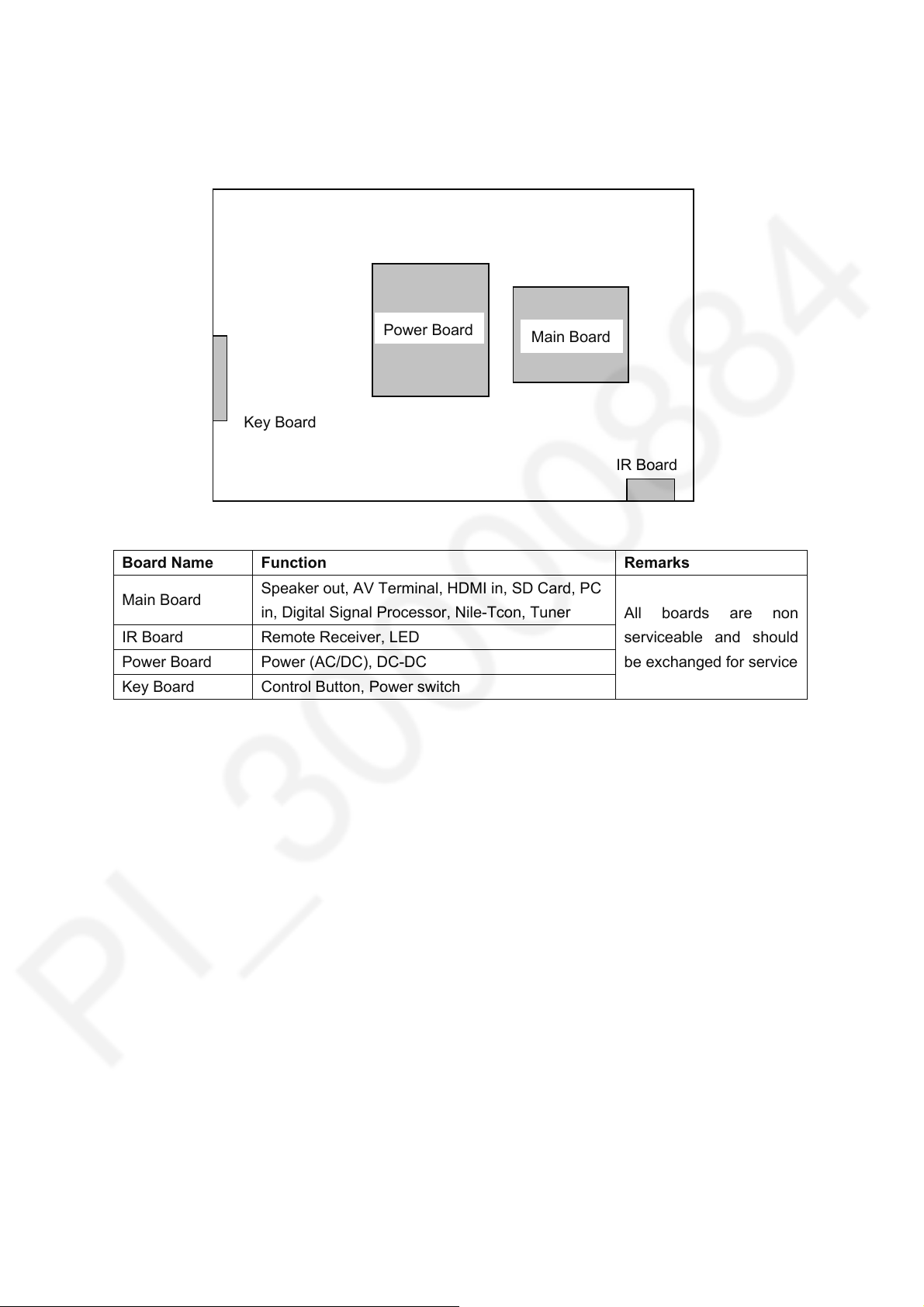

3 Service Navigation

3.1 Service Hint

Board Name Function Remarks

Main Board

IR Board Remote Receiver, LED

Power Board Power (AC/DC), DC-DC

Key Board Control Button, Power switch

Key Board

Speaker out, AV Terminal, HDMI in, SD Card, PC

in, Digital Signal Processor, Nile-Tcon, Tuner

Power Board

Main Board

IR Board

All boards are non

serviceable and should

be exchanged for service

6

Page 7

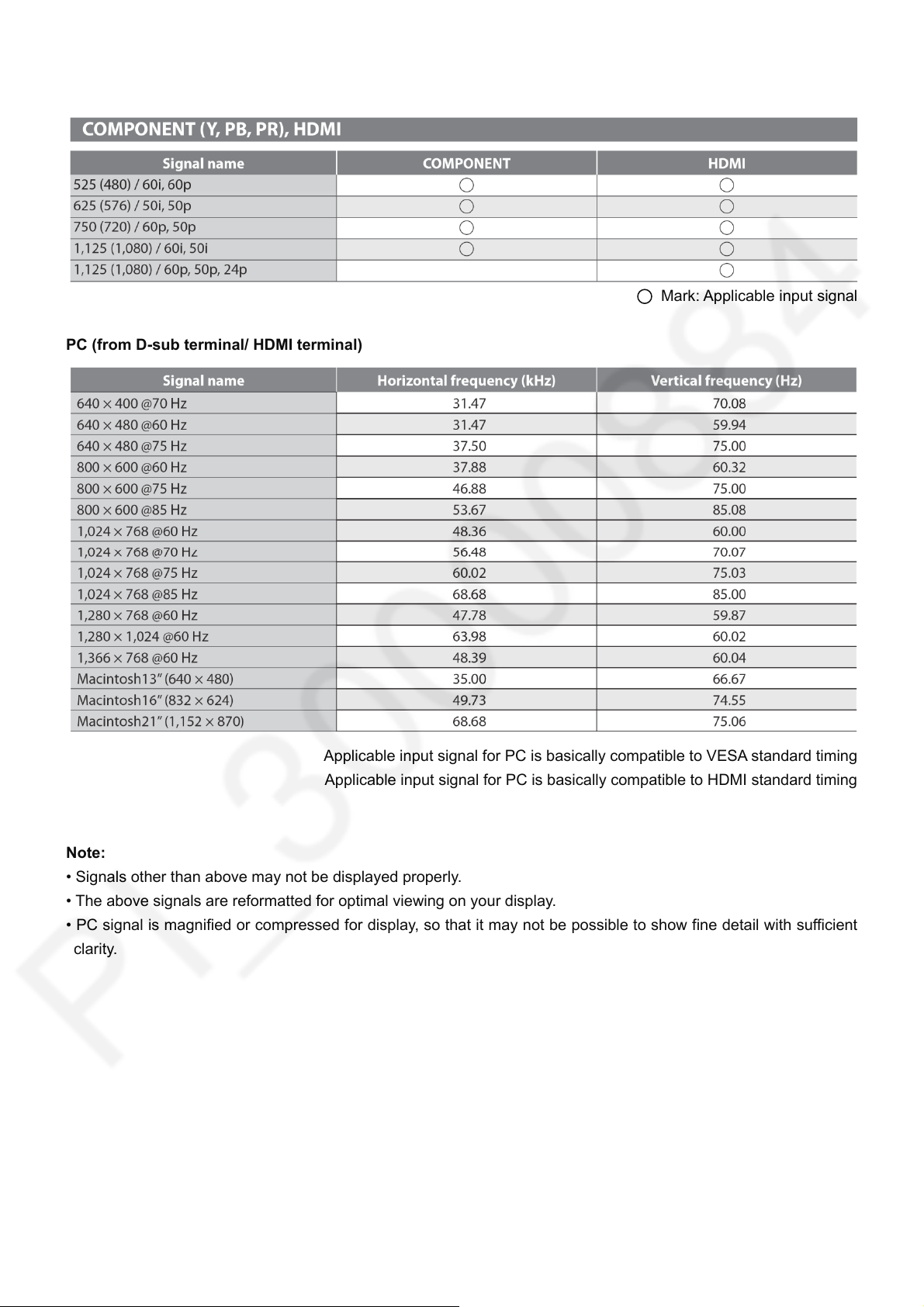

3.2. Applicable signals

COMPONENT (Y, PB, PR), HDMI

PC (from D-sub terminal/ HDMI terminal)

Mark: Applicable input signal

Applicable input signal for PC is basically compatible to VESA standard timing

Applicable input signal for PC is basically compatible to HDMI standard timing

Note:

• Signals other than above may not be displayed properly.

• The above signals are reformatted for optimal viewing on your display.

• PC signal is magnified or compressed for display, so that it may not be possible to show fine detail with sufficient

clarity.

7

Page 8

4 Specifications

8

Page 9

5. Troubleshooting Guide

p

5.1 No Power

No power (LED “Off”)

Check the AC input and

the power is “ON”?

Yes

No

Power “On”

Power board output=5V?

Yes

Use RC or Key to turn on

the TV

No

Replace the Main board

No

Yes

Replace the Power board

1. RC can turn on the TV and Key can’t,

replace the key board.

2. Key can turn on the TV and RC can’t,

lace the RC.

re

9

Page 10

5.2 Abnormal Display

t

Abnormal Display

Check the OSD is

No

Replace LVDS Cable

No

Replace the main board

No

Replace the panel

normal?

Yes

Enter factory mode

to Reset

No

Replace the main board

Yes

Rese

10

Page 11

5.3 No Display

g

No display (LED No

power (LED “Off”)

Check TV is under control and power

on/off by remote control and

power key?

Yes

Check the backlight is

“On”?

No

Replace the main board

Yes

Check the LVDS cable

Yes

Panel Vcc = 5V?

Yes

Replace the Panel

No

Reinsert or replace the

LVDS cable

No

Replace the main board

No

Check the P/S and

ON/OFF

nal is available?

si

Yes

Power board output=12/16V?

Yes

Replace the Panel

Replace main board

Replace the power board

No

No

11

Page 12

5.4 Sound Problem

No sound or sound abnormal

Check the TV is muted, adjust the

volume or enter the menu to reset?

Check the audio source connection

and the TV system are correct?

No

Replace the speaker

No

Yes

Replace the main board

Replace the main board

12

Page 13

5.5 Remote Control Malfunction

Remote Control malfunction

Check the remote control battery is

not properly placed or no power?

No

Use the other remote controls

No

Whether the IR board is

abnormal?

Yes

Replace the battery

Yes

Replace the remote control

Yes

Replace the IR board

No

Replace the main board

13

Page 14

6. Disassembly and Assembly Instructions

1. Remove the screws to remove the stand.

2. Remove the screws to remove the rear cover.

Rear cover is jointed with front cabinet by several hooks at top and both side.

After remove the screws, take rear cover at bottom side and pull up it forcibly just like tearing rear cover from front

cabinet.

14

Page 15

3. Unplug these connectors and cable clip on the main board and power board.

4. Remove the speakers

15

Page 16

5. Remove the screws to remove the Main board and Power Board.

6. Remove the screws to remove the SKT.

16

Page 17

7. Remove the panel and LVDS .

8. Remove the Key board and IR board.

17

Page 18

7 Block Diagram

Main Board

Power Board

18

Page 19

8 Wiring Connection Diagram

8.1. Caution statement.

Caution:

Please confirm that all flexible cables are assembled correctly.

Also make sure that they are locked in the connectors.

Verify by giving the flexible cables a very slight pull.

8.2. Wiring

1

3

2

4

① ② ③ ④

MBTOPA N E L

MBTOKBTOIRBOARD

MBTOSPEAKER

●

● ● ●

● ●

19

Page 20

9 Exploded View and Replacement Parts List

9.1. Exploded View

20

Page 21

9.2 Replacement Parts List

Note: All parts aresupplied by PAVCI.

for TH-L24C5D

Safety Ref.No. Part No. Part Name & Description Pcs Remarks

1 TZZ00000257A Bezel 1

2 TZZ00000185A Speaker 1

3 TZZ00000359A IR Board 1

4 L5EDDYY00393 LCD Panel 1

5 TZZ00000404A Power Board 1

6 TZZ00000330A Main Board-CBPFB6QCA3Q 1

7 TZZ00000424A IO Label 1

8 TZZ00000259A Stand 1

9 TZZ00000390A Rear Cover 1

10 TZZ00000368A Key Cover 1

11 TZZ00000371A Key Pad 1

12 TZZ00000366A Key Board 1

13 TZZ00000392A Base 1

TZZ00000189A Power Cord 1

TZZ00000001A Remote Controller 1

TZZ00000458A Manual 1

TZZ00000539A Rating Label 1

TZZ00000586A Cushion-T 1

TZZ00000587A Cushion-B 1

TZZ00000588A Carton 1

TZZ00000500A PE Bag For Set 1

TZZ00000223A Cable 1 MB TO KB TO IR BOARD

TZZ00000200A Cable 1 MB TO SPEAKER

TZZ00000193A LVDS Cable 1 MB TO PANEL

21

Loading...

Loading...