Page 1

Panasonic Service and Technology Company

SA-

Technical Guide

Home Theater Products Repair

60

For 2008-9 models:

PT7

SA-PT660

SA-PT760 / 954 / 956

SA-PT960

SH-FX65, 67, FX85

(wireless)

Contents

Hints / Layout / Reset 4

Wireless Section 8

Power On Sequence 14

5 Disc Mechanism (

CR-14)

o Operation 15

o Alignment 16

o Troubleshooting 21

o Laser replacement 25

Power Supply, 31

Herb Chin

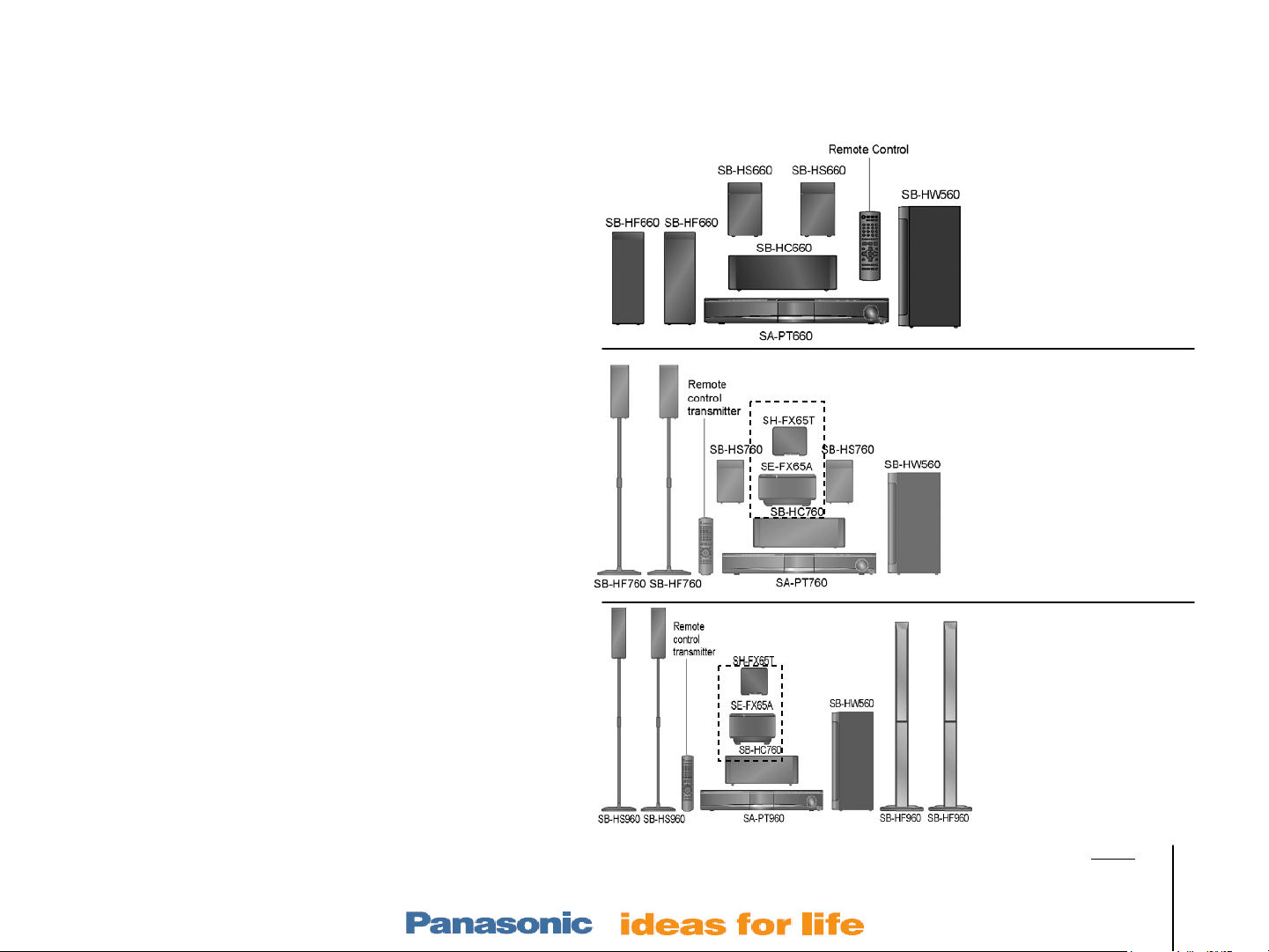

Sample Model SC-PT760 Home Theater System

National Training

Protection Troubleshooting

(F61 or F76 Error Code) 34

No Audio (main unit) 39

Outline

Wireless

Mech

Pwr Supply

Protection

Audio

Models:

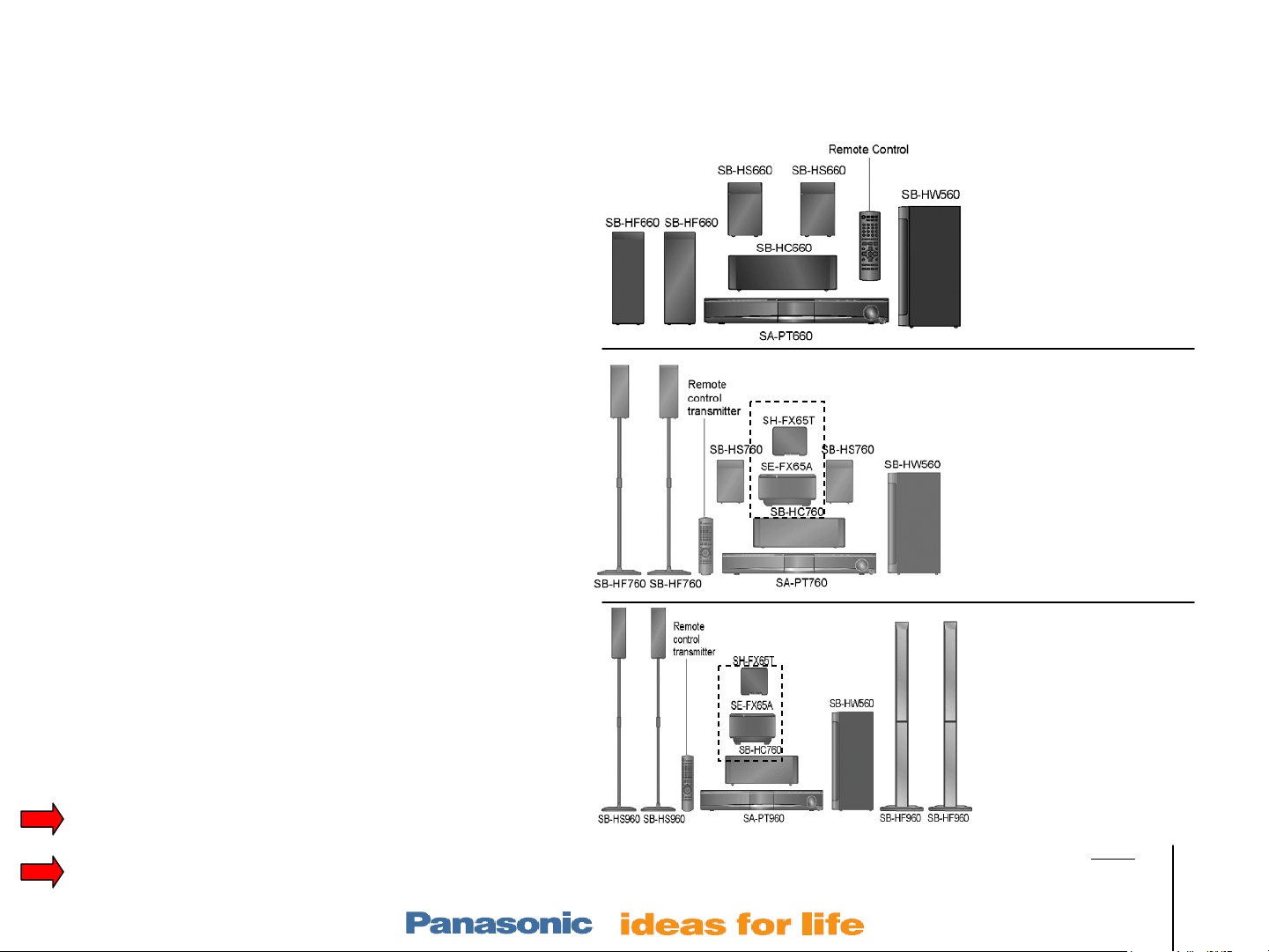

SA-PT660

SA-PT760

SA-PT960

SA-PT1060

SH-FX67, 85

Page 2

Panasonic Service and Technology Company

Produced by

Panasonic Services and Technology Company

National Training Department

Secaucus, NJ

Copyright © 2008 by Panasonic Services Company

All rights reserved. Unauthorized copying and distribution is a violation of law

Warning

This service information is designed for experienced repair technicians only and is not designed for use by

the general public. It does not contain warnings or cautions to advise non-technical individuals of potential

dangers in attempting to service a product. Products powered by electricity should be serviced or repaired

only by experienced professional technicians. Any attempt to service or repair the product or products dealt

with in this service information by anyone el se coul d result in seri o us injury or death.

Outline

Wireless

Mech

Pwr Supply

Protection

Audio

Models:

SA-PT660

SA-PT760

SA-PT960

SA-PT1060

SH-FX67, 85

Page 3

Table of Contents

Electronics –Layouts / Hints

Hints – p/n, New codes, Tests, Reset 4

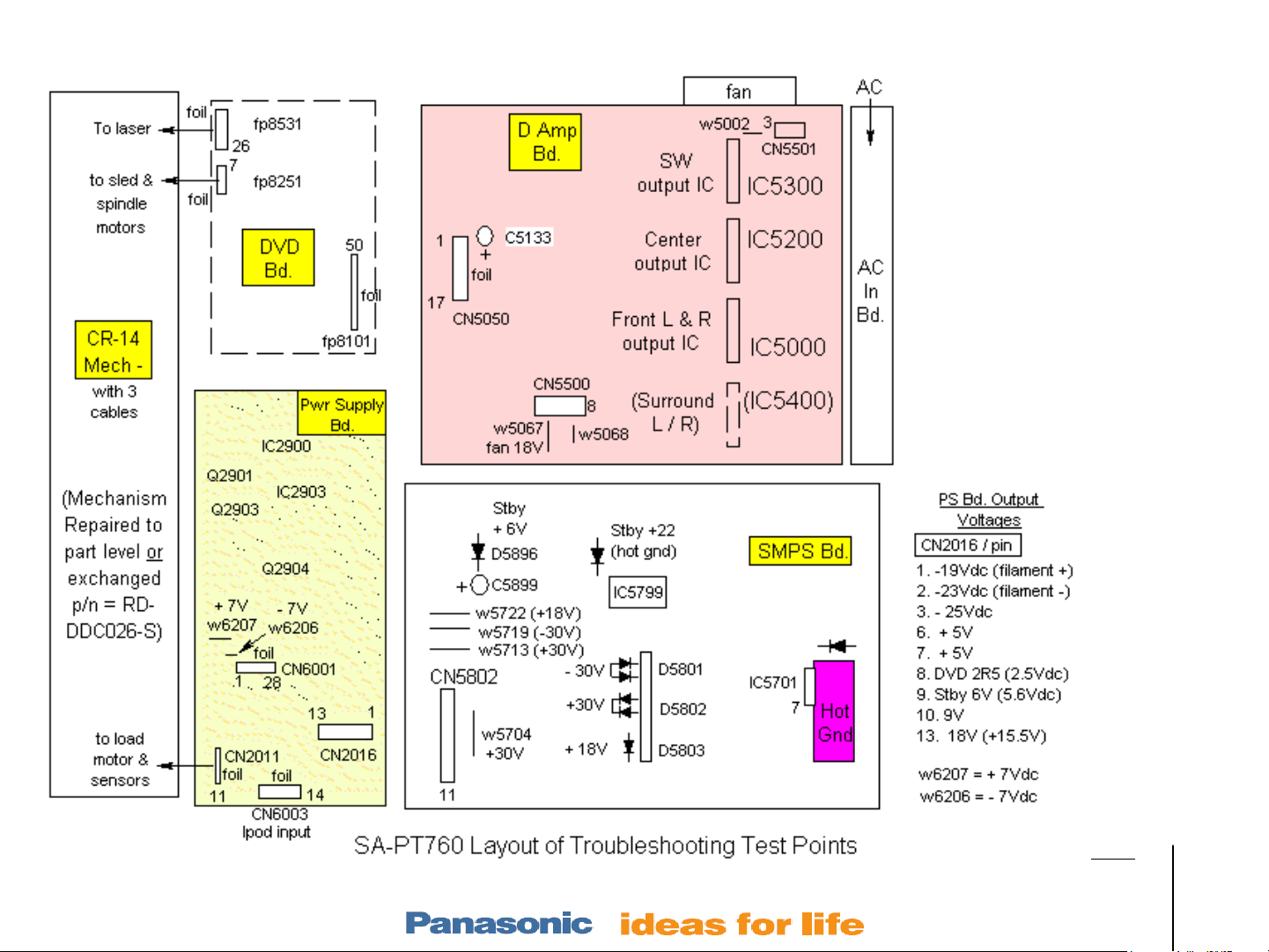

Layout w test points and PS voltages 5

Wireless

SH-FX65/66 Rear Receiver Setup 8

Wireless Troubleshooting Plan 9

Testing & Paring Trans & Rec 10

Transmitter / Receiver Repair Info 11

Power ON

Power On Sequence 14

Mechanism – stacked 5 Disc model CR-14

Operation 15

Alignment 16

Troubleshooting 21

Laser Replacement (removal & install) 25

Power Supply

PS Block with isolation strategy 31

Home Theater Products Repair

center SW

T

R

SW

center

SA-PT660

SA-PT760

PS Circuit with ref voltages 32

Protection

Protection Concept (F61 & F76 codes) 34

Protection Circuitry 35

Protection Repair Procedure 36

Audio

Concept 39

Speaker Output Waveform 40

Sample Problems & Repair Methods 41

Slide # 3

T

R

center

SW

SA-PT960

Outline

Wireless

Mech

Pwr Supply

Protection

Audio

Models:

SA-PT660

SA-PT760

SA-PT960

SA-PT1060

SH-FX67, 85

Page 4

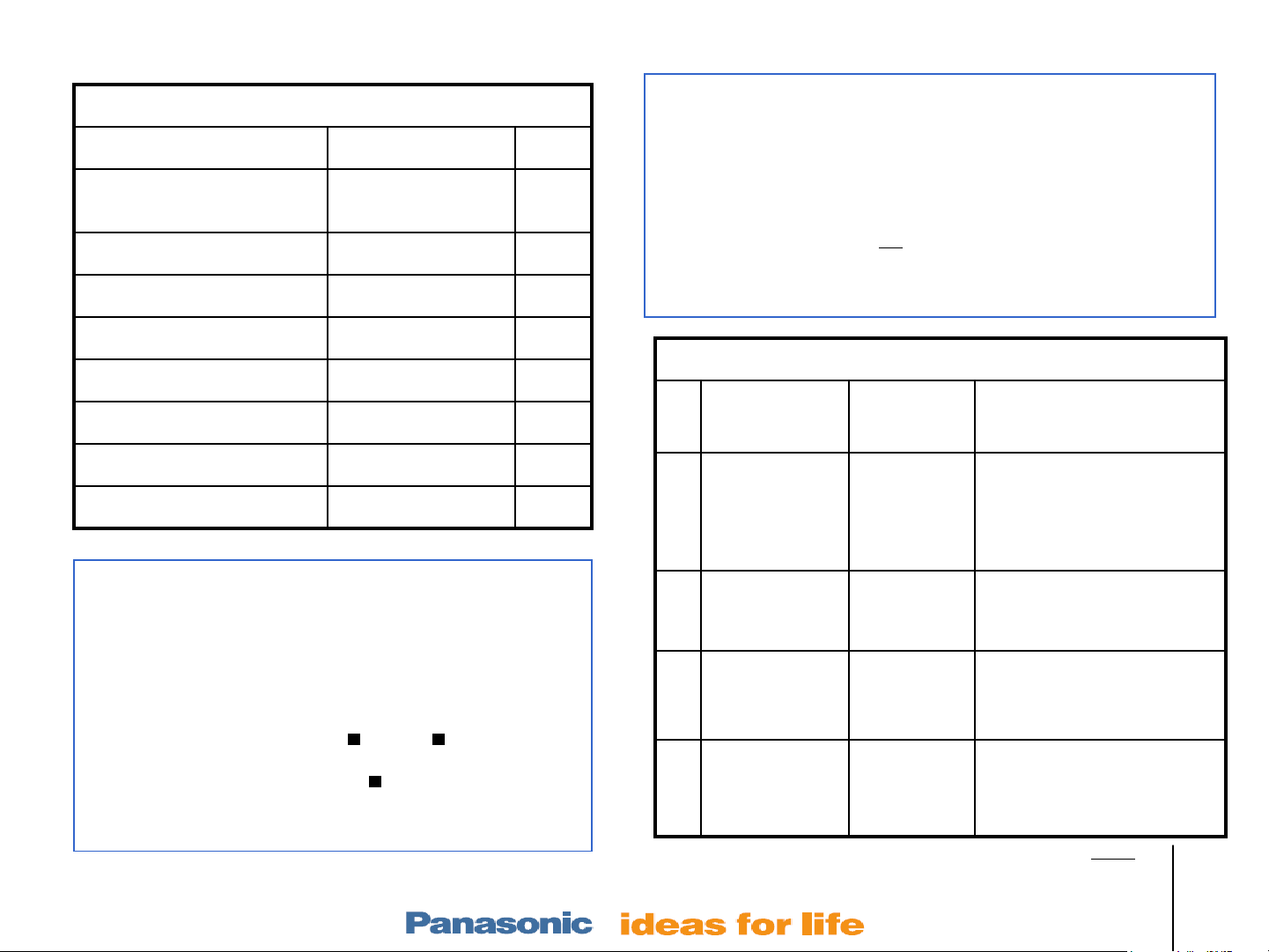

Hints – I Common P/N, II Missing error codes, III Unplugged cable symptoms, IV Reset

Remote SA-PT760,

PT960

Remote SA-PT660 N2QAyb 000 210

Fan L6FAJCCH 0007

Output ICs C1bA 00000 487

Transmit Card Repx 0644b

Receiver card Repx 0645b

CR-14 Mechanism RD-DDC026-S Exch

Traverse / Laser Assem RR-DDtx002-V

IV Reset after DVD Board replacement

1. After replacing the DVD board Play recovery disc

2. Reset –

Slide # 4

I Popular Part Numbers

Description P/N Note

N2QAyb 000 214

(p/n = RFKZD 03r005) containing firmware +

update. Select yes or no for update.

1. Select DVD mode & wait for “1 No Disc” display.

2. Press >10 (remote) and (panel). = Stop.

3. Until the display = “INIT”.

4. While still pressing STOP , also press the remote

OK button until the word “RESET” appears.

5. Power off the unit and unplug for 1 min.

II Error Codes not in the Service Manual:

Changer Error – appears when a button is pressed and the

mechanism is not responding. Go to the mechanism troubleshooting of

this book to determine if it is mechanical.

Sum Error – Incorrect communications with DVD board micro.

Transport is dead, DVD can not

cable or DVD bd.

be selected. Replace 50 pin ribbon

F897 – Play the recovery disc and reset the unit. (see IV at left)

III Troubleshooting by cable Removal

Cable

Removed

1 Large 50 pin

DVD cable

CN2001 off

2 2 rear mech

cables off

(fp8531,fp8251)

3 Main Bd.

CN2007 off

4 PS Bd /

mech

CN2011 off

Display Symptom

Hello, Aux

(last input),

Close,

“change

error”

Hello, Din.

None

Hello,

Change,

Open.

Fan on, No AM/FM mode,

No audio. Unit remains on.

Vol level # changes w knob

but no audio.

Fan on, Mech motor buzzes,

display skips DVD when

press Sel button, No audio.

CN2007 is only for the

display. No display. Unit

works OK otherwise.

Fan on, locked on last input

mode used but that audio

works fine with volume

control.

Outline

Wireless

Mech

Pwr Supply

Protection

Audio

Models:

SA-PT660

SA-PT760

SA-PT960

SA-PT1060

SH-FX67, 85

Page 5

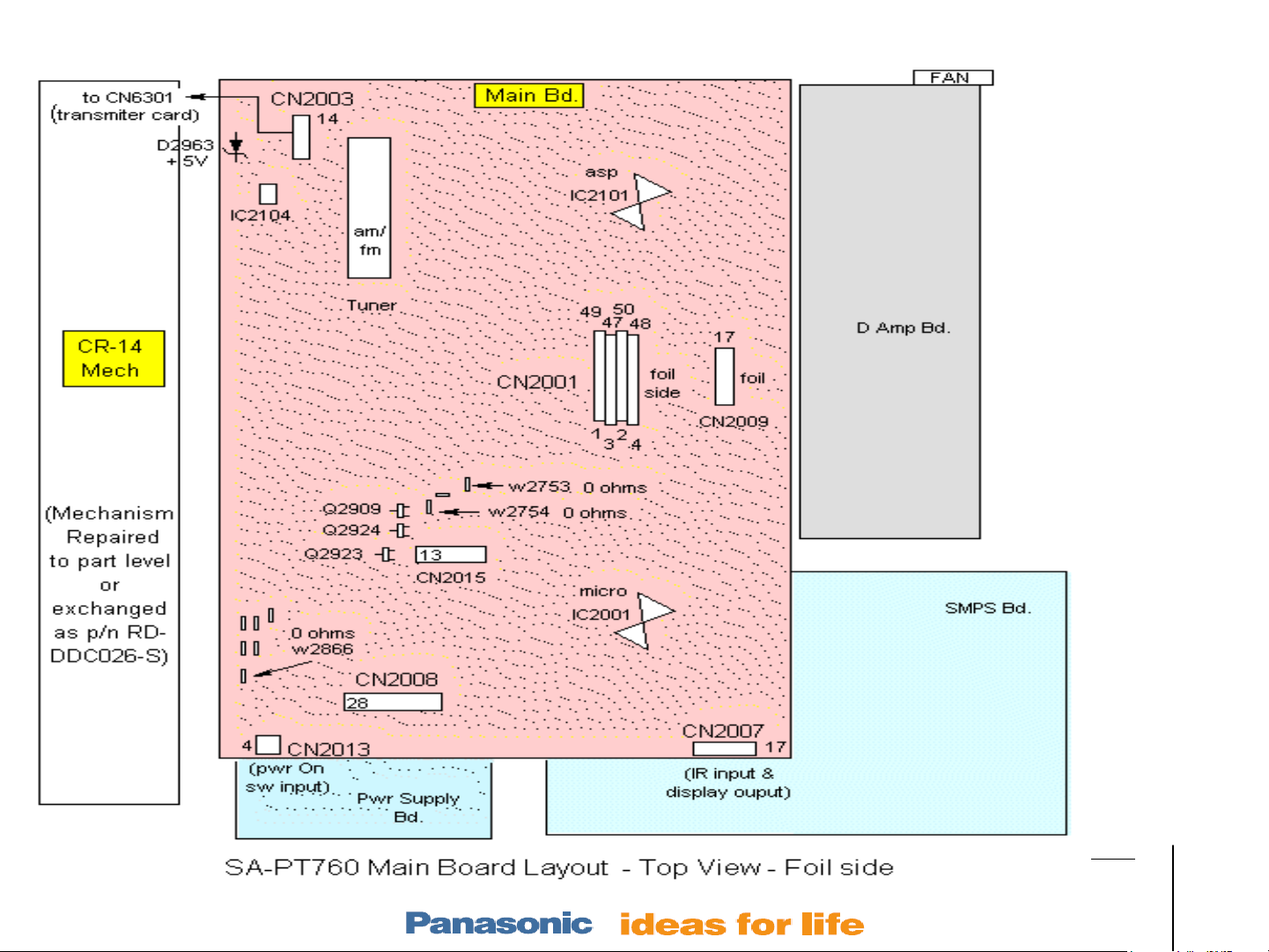

PT760 Layout 1 – Top Level

Slide # 5

Outline

Wireless

Mech

Pwr Supply

Protection

Audio

Models:

SA-PT660

SA-PT760

SA-PT960

SA-PT1060

SH-FX67, 85

Page 6

PT760 Layout – Bottom Level

Slide # 6

Outline

Wireless

Mech

Pwr Supply

Protection

Audio

Models:

SA-PT660

SA-PT760

SA-PT960

SA-PT1060

SH-FX67, 85

Page 7

Table of Contents

Electronics –Layouts / Hints

Hints – p/n, New codes, Tests, Reset 4

Layout w test points and PS voltages 5

Wireless

SH-FX65/66 Rear Receiver Setup 8

Wireless Troubleshooting Plan 9

Testing & Paring Trans & Rec 10

Transmitter / Receiver Repair Info 11

Power ON

Power On Sequence 14

Mechanism – stacked 5 Disc model CR-14

Operation 15

Alignment 16

Troubleshooting 21

Laser Replacement (removal & install) 25

Power Supply

PS Block with isolation strategy 31

Home Theater Products Repair

center SW

T

R

SW

center

SA-PT660

SA-PT760

PS Circuit with ref voltages 32

Protection

Protection Concept (F61 & F76 codes) 34

Protection Circuitry 35

Protection Repair Procedure 36

Audio

Concept 39

Speaker Output Waveform 40

Sample Problems & Repair Methods 41

Slide # 7

T

R

center

SW

SA-PT960

Outline

Wireless

Mech

Pwr Supply

Protection

Audio

Models:

SA-PT660

SA-PT760

SA-PT960

SA-PT1060

SH-FX67, 85

Page 8

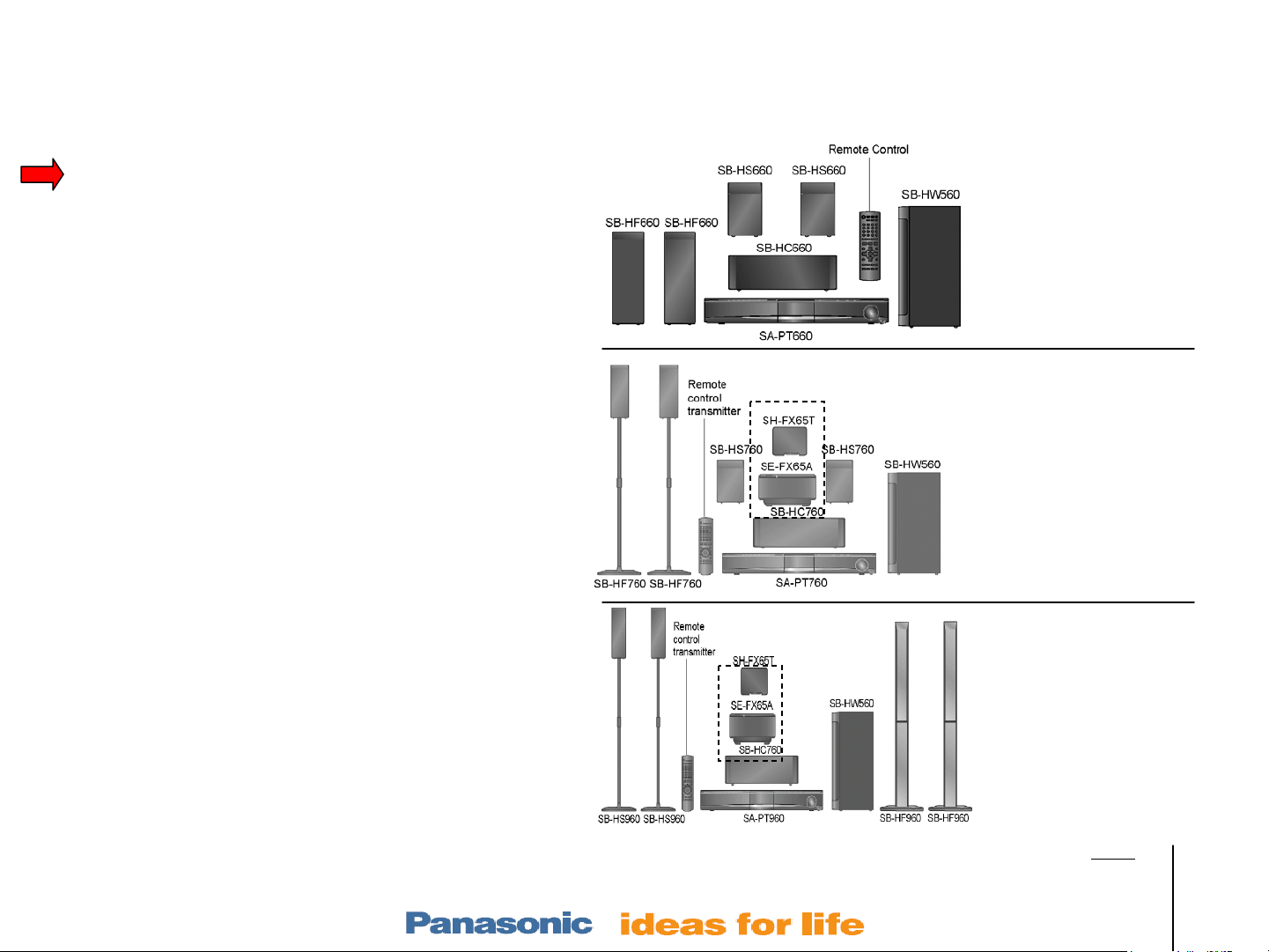

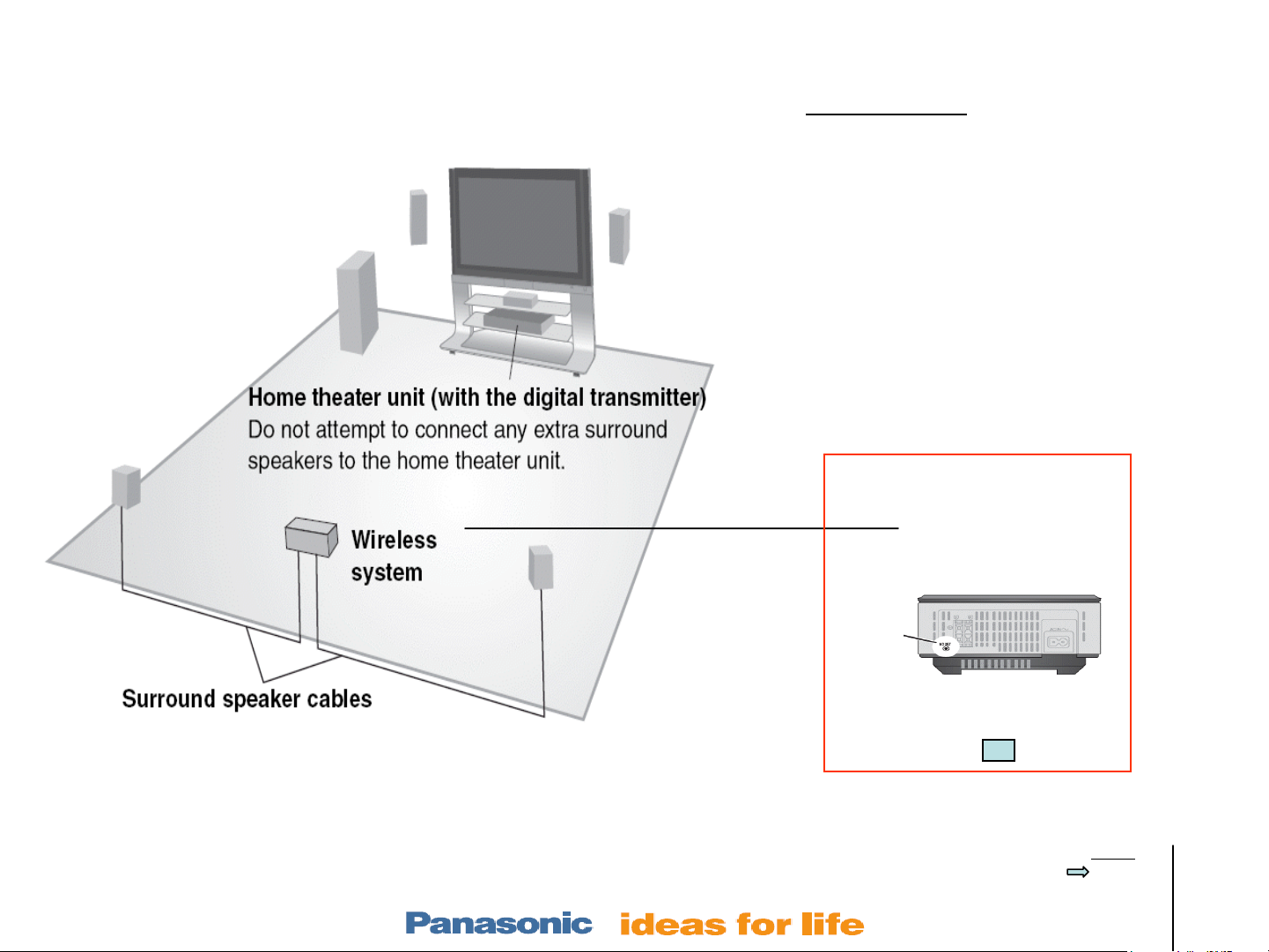

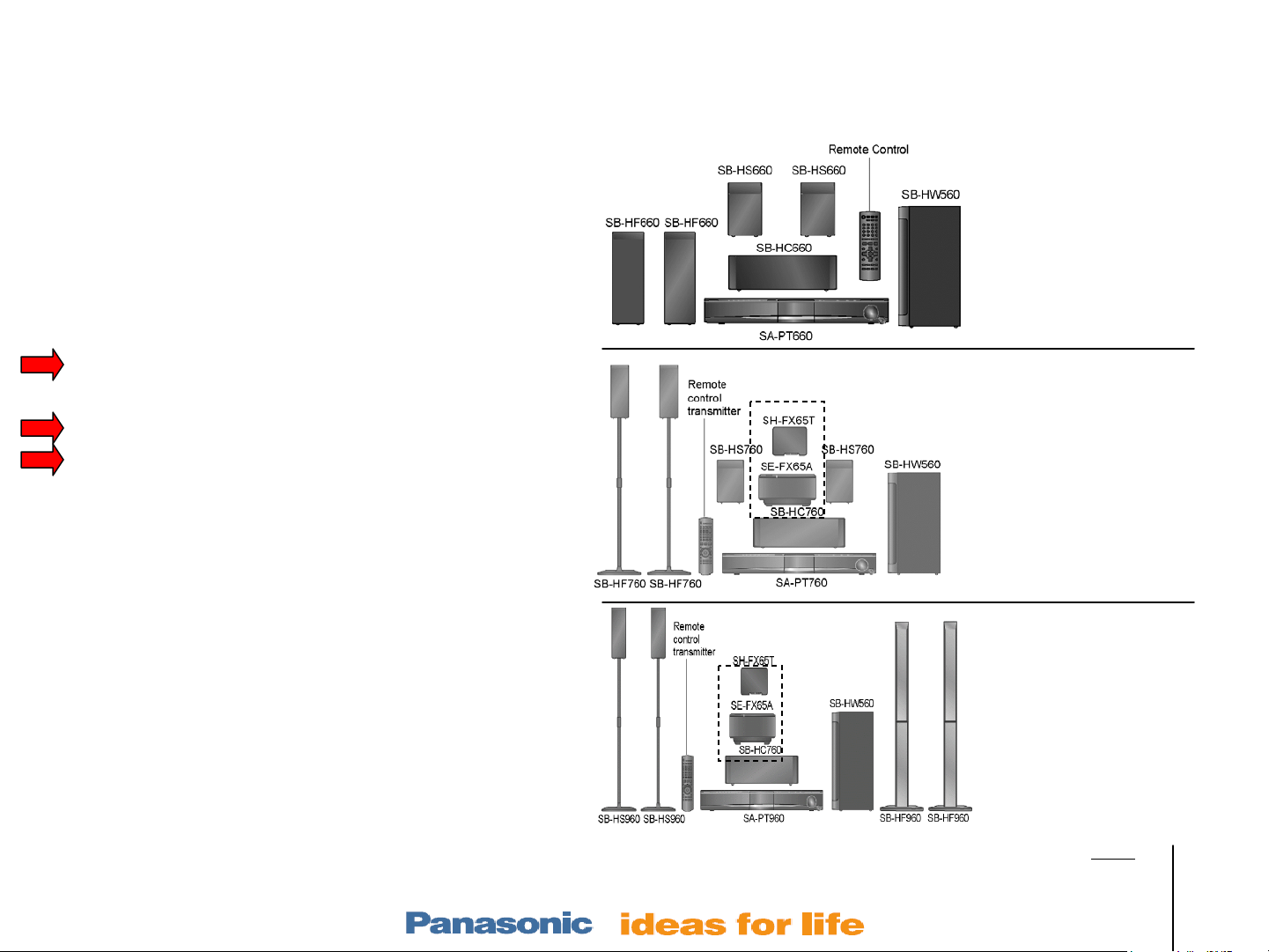

Home Theater Wireless Products

Panasonic Model

SA-PT660 – no wireless spks.

(optional FX67 or / & FX85)

SA-PT760 – wireless rear spks.

SA-PT960 – wireless rear spks + more pwr

Need a manual for the wireless

portions of the above units? Try a

model below.

SH-FX65 – takes spk wires.

SH-FX67 – takes spk plug.

Wireless rear receiver

Optional for the ‘PT660

SH-FX65/67

max range = 49’

Slide # 8

Transmitter card – REPX 0644b

Receiver card - REPX 0645b

ID set

button

(back)

Receiver

Transmitter card

Outline

Wireless

Mech

Pwr Supply

Protection

Audio

Models:

SA-PT660

SA-PT760

SA-PT960

SA-PT1060

SH-FX67, 85

Page 9

SA-PT760 Wireless Troubleshooting Plan

Wireless rear does not work – W1 or W2 display icons do blink at power on.

1. RF connection has not been made. Go to slide 6 to pair the transmitter and receiver.

Steps 1-6.

2. Go to slide 8 to troubleshoot the receiver. Make sure there is standby voltage input the

receiver and the pair button is working (pin 9 grounds when the button is pressed.

3. Go to slide 7 to check the transmitter card Sw +5V voltage at the main board (CN2003)

or at the card socket itself CN6301).

Wireless rear does not work – W1 or W2 display icons do NOT blink at power on.

1. The RF connection is OK. No audio is the problem. Replace the transmitter card if

hot (damaged when plugged in while the unit was powered on).

2. Go to slide 6 and follow steps 7 to turn on “S Music” mode (surround music). This

makes the rear surround speaker sound the same as main L & R.

Slide # 9

3. Input an audio source (play some music).

4. Disconnect the speakers and turn the volume control to max (level number 50 is

displayed).

5. Go to slide 8. Check for audio at the receiver card CN1100/pins 2 & 4.

6. If there was no audio present at CN1100 (receiver), Go to slide 7. Check for audio at

the transmitter socket CN6301/pins 10 & 12.

Outline

Wireless

Mech

Pwr Supply

Protection

Audio

Models:

SA-PT660

SA-PT760

SA-PT960

SA-PT1060

SH-FX67, 85

Page 10

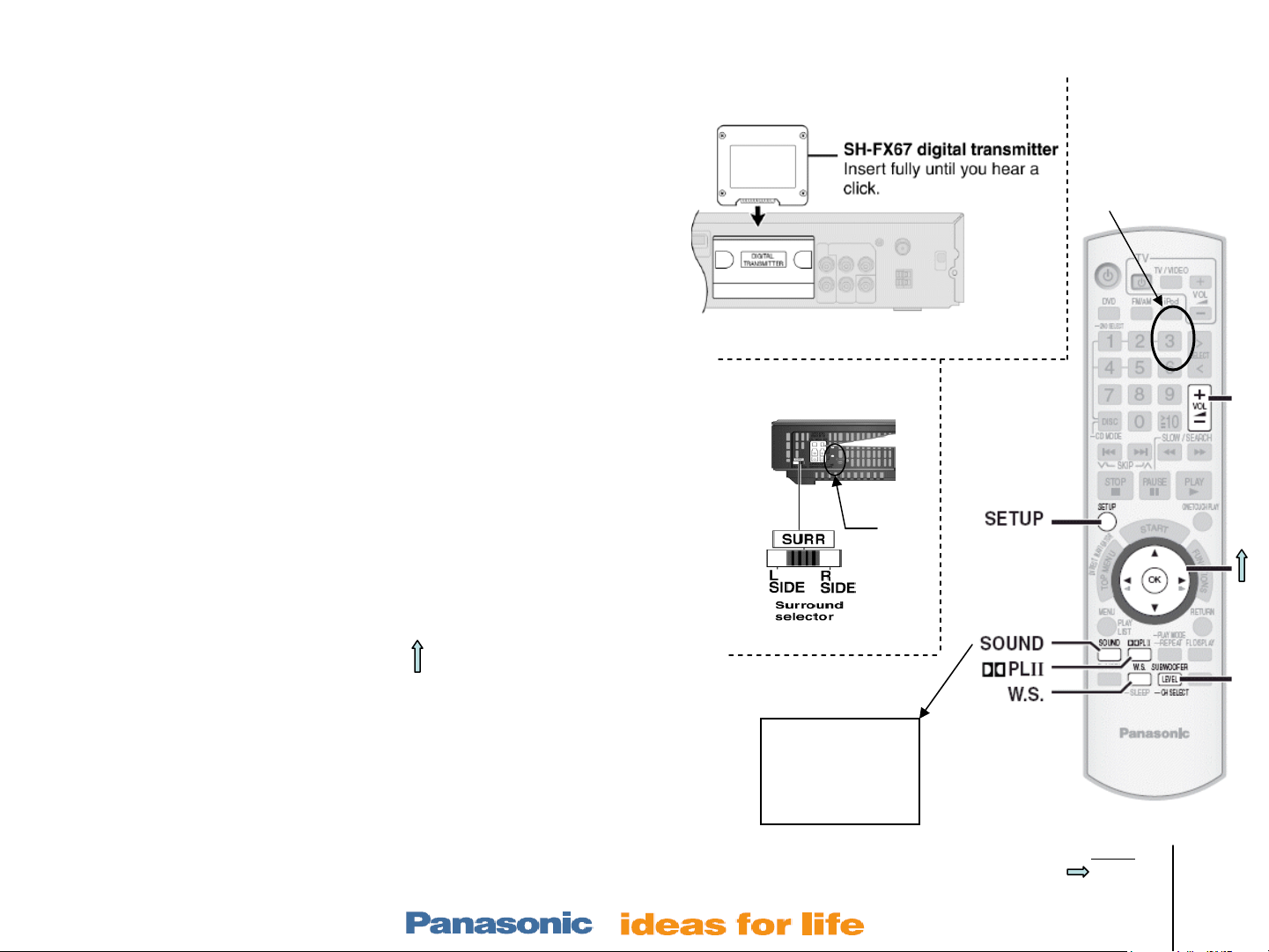

Wireless Information – RF Pairing / Matching T & R

RF Pairing

1. Proximity – Bring the wireless receiver to the transmitter.

2. Power ON – Plug the transmitter card in. Turn everything on

and press the selector button for DVD mode. (Do not plug

the card in with the unit on. A damaged card will get hot.)

3. Setup – While the W1 / W2 icon is blinking in the unit’s

display, hold down the front panel FF button and the

remote’s “3” Button.

4. Indicators – a) W1 / W2 will blink on the main unit’s display

if the transmitter card is inserted. b) “P” icon will be

displayed when the pairing process is started.

5. Mating – While the “P” is present, press the rear receiver

recessed “ID Set” button.

6. Indicator – The W1 / W2 will stop blinking proving an RF

match has been made.

2. Transmitter card

5. ID Set button

ID

Set

3. Press

panel FF &

3 buttons

On

7. Audio Test – Repeatedly press the remote’s SOUND button until the

panel displays “S.Music”. Then press the arrow button to turn ON “S.

Music”. The rear speakers will have the same music as the front L & R.

8. W1 / W2 still blinking? – Use the troubleshooting info in the next pages.

Slide # 10

7. Rear Audio Test

1. H. Bass

2. R.C. FCS

3. SRD Enh(ance)

4. S.Music

Outline

Wireless

Mech

Pwr Supply

Protection

Audio

Models:

SA-PT660

SA-PT760

SA-PT960

SA-PT1060

SH-FX67, 85

Page 11

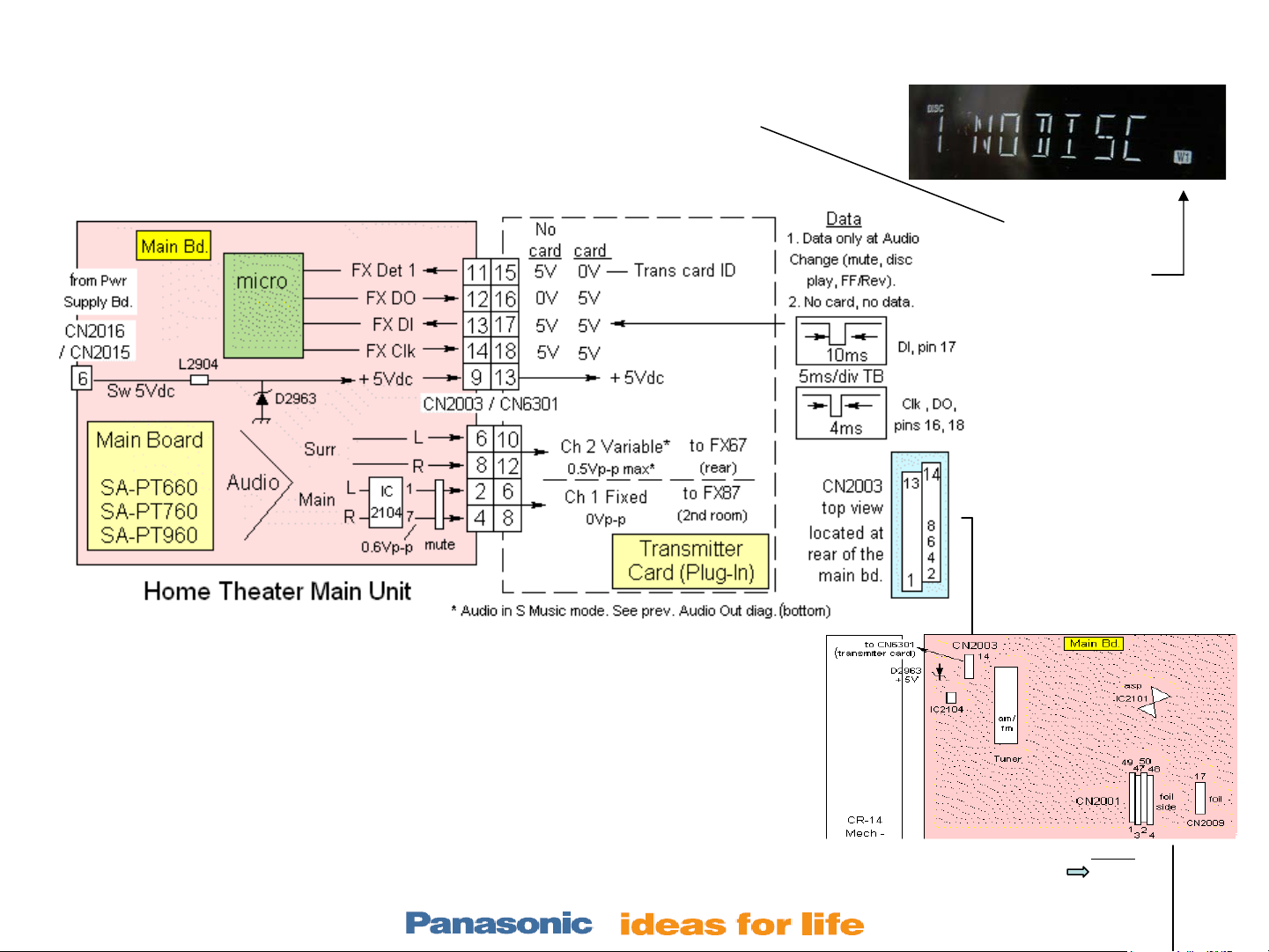

Wireless - Troubleshooting Information ½ - Transmitter part

Use this diagram to:

Prove that the T card is recognized (CN2003/pin 11).

Power is getting to the T card (CN2003/pin 9).

Audio is getting to the T card (CN2003/ pin 2-8).

When the T card is

inserted, the micro

blinks a W1 icon

Transmitter card – REPX 0644b

Receiver card - REPX 0645b

Notes:

1. Measure the voltages at the CN2003 main board with the Transmitter

card / Bd. plugged in.

2. Channel 2 audio is present with a surround sound DVD or if the S

Music is turned ON. See the previous slide, step 7 for access S Music.

nd

3. Channel 1 audio is only present when its 2

room accessory

transmitter card is plugged in. Otherwise channel 1 is muted.

4. Data is only present when the T card is in.

Slide # 11

Rear of Main Unit

Outline

Wireless

Mech

Pwr Supply

Protection

Audio

Models:

SA-PT660

SA-PT760

SA-PT960

SA-PT1060

SH-FX67, 85

Page 12

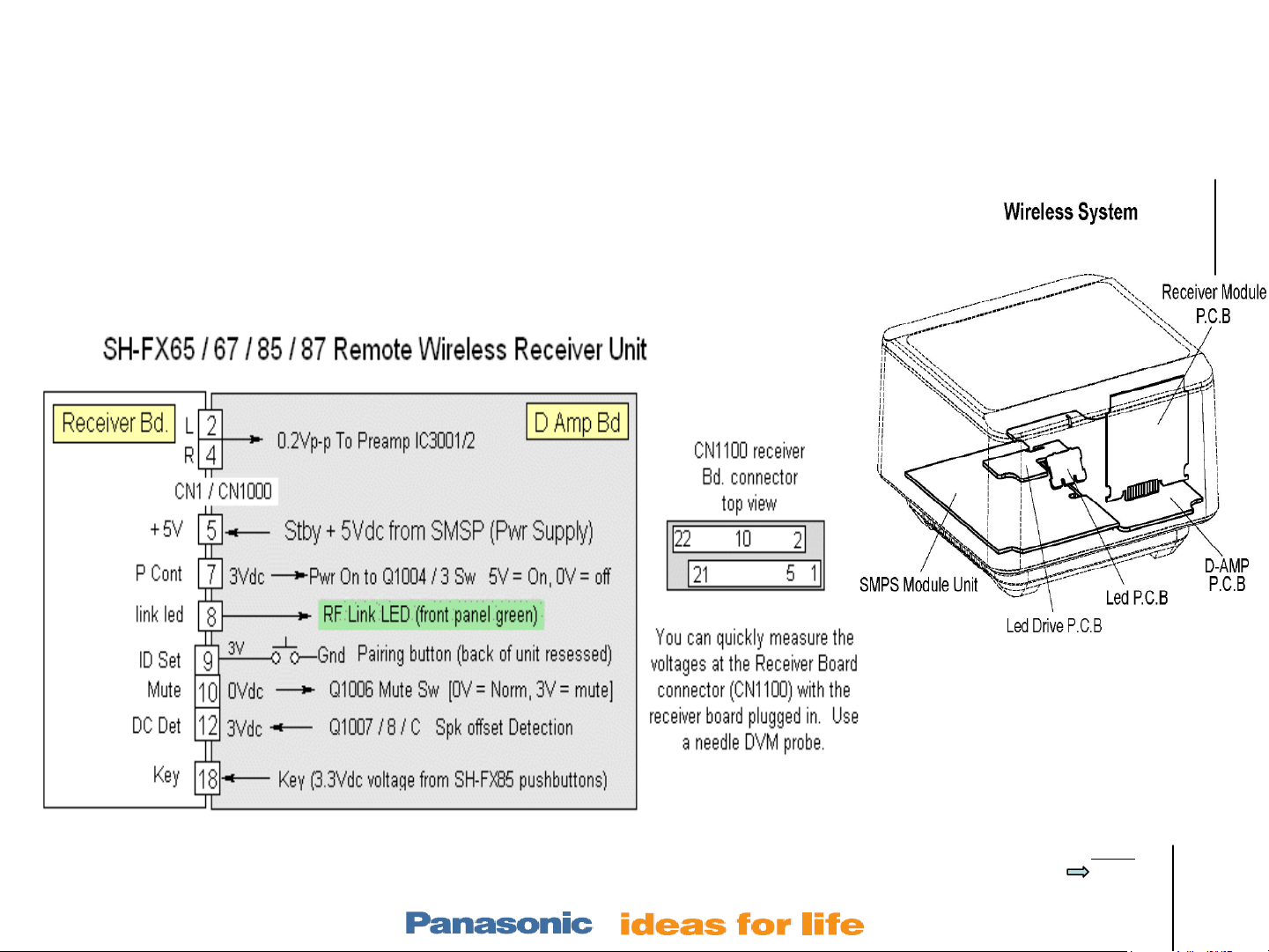

Wireless - Troubleshooting Information 2/2 – Receiver part

Use this diagram to:

Receiver card is getting power (CN1100/pin 5).

Receiver card is outputting Audio (CN1100/ pin 2).

Receiver card is not muting the audio (CN1100/ pin 10).

Transmitter card – REPX 0644b

Receiver card - REPX 0645b

SH-FX67

receiver / amp

Slide # 12

Outline

Wireless

Mech

Pwr Supply

Protection

Audio

Models:

SA-PT660

SA-PT760

SA-PT960

SA-PT1060

SH-FX67, 85

Page 13

Table of Contents

Electronics –Layouts / Hints

Hints – p/n, New codes, Tests, Reset 4

Layout w test points and PS voltages 5

Wireless

SH-FX65/66 Rear Receiver Setup 8

Wireless Troubleshooting Plan 9

Testing & Paring Trans & Rec 10

Transmitter / Receiver Repair Info 11

Power ON

Power On Sequence 14

Mechanism – stacked 5 Disc model CR-14

Operation 15

Alignment 16

Troubleshooting 21

Laser Replacement (removal & install) 25

Power Supply

PS Block with isolation strategy 31

Home Theater Products Repair

center SW

T

R

SW

center

SA-PT660

SA-PT760

PS Circuit with ref voltages 32

Protection

Protection Concept (F61 & F76 codes) 34

Protection Circuitry 35

Protection Repair Procedure 36

Audio

Concept 39

Speaker Output Waveform 40

Sample Problems & Repair Methods 41

Slide # 13

T

R

center

SW

SA-PT960

Outline

Wireless

Mech

Pwr Supply

Protection

Audio

Models:

SA-PT660

SA-PT760

SA-PT960

SA-PT1060

SH-FX67, 85

Page 14

Unit Operation - Plug in, Power On Sequence

1. Plug In, Press Power On

Fan

2. Fan turns on - starts noisy (high speed)

3. Hello is displayed

4. Last Mode used is displayed

(DVD, Aux, D-in, Am, FM, or IPod)

DVD Mode

5. Micro checks “Top” & “Home” mech

switches to ID tray 1 (SW3 & Q3 = 0Vdc =

tray 1 loaded in the laser).

6. If tray 1 is not in the laser compartment

(default), the mech will load tray 1 in:

• Not tray 1 moves to stock (center) position. (Q1 UD

sensor = 0Vdc to stop rear traverse motor)

• Elevator moves laser assembly up to tray 1 level (SW 3

= 0Vdc at top level to stop the stock/elevator motor @

tray 1)

• Tray 1 is pulled into the laser assembly

Tray 1

laser

Trays

stocked

mech

SA-PT760

Top view

mech

Aux, D-in, Am, FM, or IPod Mode

5. Use the panel “Select” button to

change modes or the < or >

buttons to change stations.

6. Tray 1 status is displayed (disc

tracks or time or No disc)

Tray

release

7. With Tray 1 in the laser compartment, Disc

Detection occurs

laser on, focus searches. Disc spins if a disc is found.

8. Tray 1 status (contents if any) is displayed.

Slide # 14

• Mech clamps the disc

– Laser moves away from home,

Tray out

position

Outline

Wireless

Mech

Pwr Supply

Protection

Audio

Models:

SA-PT660

SA-PT760

SA-PT960

SA-PT1060

SH-FX67, 85

Page 15

5 Disc Mechanism - Operation

Default position = Tray 1 is loaded into the laser assembly at plug-in, power-on when the DVD

function is selected. The remaining 4 trays are in the middle “stock” area.

laser

Trays 2-5rear

Side View

Stock

location

Tray 5 selection

– (button 5 is pressed)

a) Press 5 button – Display = “Disc 5”

b) Laser unclamps and the tray returns to middle stock location (TRV motor).

c) Display = “Change”

d) Laser assembly lowers to tray 5 location (Stocker motor).

e) TRV motor pulls tray 5 into the laser assembly.

f) TRV motor clamps the disc if any.

g) TRV motor moves the sled away from home position to begin disc readout for play.

All Trays out – (Close / Open button is pressed)

a) Laser drops down (unclamps) and tray returns to middle stock location (TRV motor).

b) Stocker motor continues to turn to internally catch all 5 gears of the #328 “OC” gear. When the last gear is

caught, all the trays are moved to the end of the stock area almost out of the mechanism (for disc insertion)

Slide # 15

Outline

Wireless

Mech

Pwr Supply

Protection

Audio

Models:

SA-PT660

SA-PT760

SA-PT960

SA-PT1060

SH-FX67, 85

Page 16

5 Disc Mechanism - Concept & Transfer Alignment 1/4

Operational Concept:

There are 2 motors and 8 sensors in the CR-14 mech.

laser

Figure 1a – Default position

side view

Figure 1b – mech components

Mech

p/n = RD-ddc 026-S

Stock

area

rear

I. The traverse motor moves:

Trays 2-5rear

• Laser back & forth

• Clamps disc

• Pulls trays into the laser assembly

traverse

motor

Tray 1

laser

II. The stocker motor moves

• Tray(s) between the middle stocker

area and out of the assembly

(for disc insertion)

• Traverse / laser platform up/dwn,

III. Trays moved from the stock area must be

Stock

motor

Top

view

transferred to the laser area.

1) Tray transfer is made after the traverse assembly

elevators to the desired tray level. The following

occurs in the rear traverse assembly:

2) The traverse motor uses arms to pull the tray into

gear #331. Pictures in the fourth slide 4/4.

3) SW4 opens (fp 8251) to tell the micro the tray is in.

4) The traverse motor continues to turn, bringing the tray

in, then clamps the disc

5) SW5 opens (fp 8251) at clamp end and sled moves

away from home.

Traverse

assembly p/n =

RD-DDtx002-V

6) The sled moves the laser to the approx TOC disc

area & stops. The laser comes on, lens focus

searches and if a disc is found, spins it.

7) SW4 and SW5 are both inside the Traverse

assembly.

Slide # 16

Outline

Wireless

Mech

Pwr Supply

Protection

Audio

Models:

SA-PT660

SA-PT760

SA-PT960

SA-PT1060

SH-FX67, 85

Page 17

5 Disc Mechanism - Assembly Transfer Alignment – Trays Out 2/4

Preparing the Traverse unit

for docking:

1. Trays Out (laser down)

2. Rotate the black gears so

the white slider and laser

are forward, as shown.

Next page is a close up

picture.

Rear

Slide # 17

Figure 2

Outline

Wireless

Mech

Pwr Supply

Protection

Audio

Models:

SA-PT660

SA-PT760

SA-PT960

SA-PT1060

SH-FX67, 85

Page 18

5 Disc Mechanism Assembly Transfer Alignment – Trays Out 3/4

#331 gear

Preparing the Traverse unit for docking:

3. Slide the top #336 sub slide plate inside the

cutout to the left or as far as it will go without

force (pictured down).

4. This permits the other end of the #336 slide

plate to engage gear #331.

5. Rotate the #331 gear (cw) so the plastic arm

of the sub plate points past the triangle cutout, all

the way left as shown. This is the elev ator position.

6. The rear Traverse portion of the mech is ready

for docking with the front tray assembly.

7. Optional - At the middle tray area (fig 4), you may

manually rotate the stocking motor gear so the black gear

hole lines up here. It will pwr to this position anyway.

8. Plug in the mech’s 3 ribbon cables and test

.

rear

Slide # 18

cutout

left

front

Figure 3

Figure 4

Outline

Wireless

Mech

Pwr Supply

Protection

Audio

Models:

SA-PT660

SA-PT760

SA-PT960

SA-PT1060

SH-FX67, 85

Page 19

5 Disc Mechanism Assembly Transfer Alignment – Tray In 4/4

rear

Laser

area

Lever

#333

Gear #331

Stock

area

Fig 5 – Traverse assembly elevatored

up to tray level. Note position of #333

tray load lever for elevator operation.

Operational Concept Conclusion

III. Trays moved from the middle stock area

must be transferred to the laser area.

• Tray transfer is made after the traverse

assembly elevators to the desired tray level.

• The traverse motor uses arms to pull the tray

into gear #331. Details in slide 4/4, above.

• SW4 opens (fp 8251) to tell the micro the tray is

in.

Fig 6 – Traverse

motor moves #333

lever to pull tray 1 in.

Fig 7 - #333 lever

slips under tray 1.

Fig 8 - #333 lever pulls tray

1 into gear #331 on the

other side (not shown).

Gear #331 grabs the tray

teeth and pulls the tray into

the laser assembly.

Slide # 19

Outline

Wireless

Mech

Pwr Supply

Protection

Audio

Models:

SA-PT660

SA-PT760

SA-PT960

SA-PT1060

SH-FX67, 85

Page 20

Table of Contents

Electronics –Layouts / Hints

Hints – p/n, New codes, Tests, Reset 4

Layout w test points and PS voltages 5

Wireless

SH-FX65/66 Rear Receiver Setup 8

Wireless Troubleshooting Plan 9

Testing & Paring Trans & Rec 10

Transmitter / Receiver Repair Info 11

Power ON

Power On Sequence 14

Mechanism – stacked 5 Disc model CR-14

Operation 15

Alignment 16

Troubleshooting 21

Laser Replacement (removal & install) 25

Power Supply

PS Block with isolation strategy 31

Home Theater Products Repair

center SW

T

R

SW

center

SA-PT660

SA-PT760

PS Circuit with ref voltages 32

Protection

Protection Concept (F61 & F76 codes) 34

Protection Circuitry 35

Protection Repair Procedure 36

Audio

Concept 39

Speaker Output Waveform 40

Sample Problems & Repair Methods 41

Slide # 20

T

R

center

SW

SA-PT960

Outline

Wireless

Mech

Pwr Supply

Protection

Audio

Models:

SA-PT660

SA-PT760

SA-PT960

SA-PT1060

SH-FX67, 85

Page 21

Mechanism Access for Troubleshooting

Access - Cover removal

to view the mechanism

1. Left fig 9 - Push

down on the 2

plastic catches and

slide the top plastic

cover ¼” rearwards

to unlock.

2. Lift up the top plastic

cover about ¼” for

clearance and slide

out toward the front

to unhook the 2 tray

stop arms.

¼”

Slide # 21

3. Right fig 10 –

up

¼”

Remove the spindle

magnet plate by

pulling in on the 2

out

plastic catches, then

lift the plate up and

out.

Outline

Fig 9 – cover removal Fig 10 – spindle magnet plate

Wireless

Mech

Pwr Supply

Protection

Audio

Models:

SA-PT660

SA-PT760

SA-PT960

SA-PT1060

SH-FX67, 85

Page 22

Mech Troubleshooting. Is it the Mech or the Circuitry?

Troubleshooting concept: The fastest way to find out if the circuitry is causing the mech problem is to

check the sensors. When they turn on, they ground out the micro input lines, proving each sensor is OK.

Default

tray 1

position

Fig

11

rear

Fig

12

Isolation

Procedure:

1a. Note the

position of the

tray in the

jammed

mechanism

(pictured left).

1b. Unplug the

ribbon cable

from socket

CN2011.

2. Measure the

voltage at each

of the CN2011

socket pins.

The voltages

should be

identical to the

ones listed on

the next page.

Fig

13

Default = Tray 1 loaded

Slide # 22

(shown is tray 3 loaded)

Defect - All or some trays OutDefect -Trays 2-5 loaded

Outline

Wireless

Mech

Pwr Supply

Protection

Audio

Models:

SA-PT660

SA-PT760

SA-PT960

SA-PT1060

SH-FX67, 85

Page 23

Slide # 23

Mech Troubleshooting. Is it the Mech or the Circuitry?

When the mechanism does not work correctly, is the problem mechanical? Is it

a sensor under the mech? Is it on the main board by the microprocessor?

Isolation Procedure:

1. Note which tray is in the laser assembly. Unplug the ribbon cable at CN2011.

2. Compare the dc voltages at the 11 pin connector (without the cable inserted) to the

“No cable” column voltages shown below. If any are different, the main board is at fault.

Check the pull up resistors and check the main board for cracks.

3. Note the position of the trays in the mechanism. Reconnect CN2011.

4. Compare the dc voltages at the same CN2011 connector to the corresponding

column in the chart below (cable inserted). Pictures are on the previous page.

If any of the voltages do not agree with the chart below, the corresponding sensor (Q1-5, Sw3,4) is

bad. If the voltages all agree, the mechanical assembly is defective or out of alignment. Replace

the assembly, or do the prev. transfer alignment.

CN2011 Connector Voltage

CN2011/

pin

1 8.2V 7.5V 7.5Vdc 7.5Vdc Motor driver Vcc

2 gnd No change

3 5Vdc 5Vdc 5Vdc 5Vdc Q4 Mode sensor Elevator dwn

4 gnd

5 5Vdc 0Vdc 5Vdc 0Vdc SW3 Top sw

6 5Vdc 0Vdc 0Vdc 0Vdc Q1 UD (lever

7 0Vdc 0Vdc 0Vdc 0Vdc Motor fwd

8 0Vdc 0Vdc 0Vdc 0Vdc Motor rev

9 5Vdc 0Vdc 0Vdc 0Vdc Q2 close (gear

10 5Vdc 0Vdc 0Vdc 5Vdc Q3 home (gear

11 5Vdc 0Vdc 0Vdc 0Vdc Q5 open (lever

No CN2011

cable

Tray

1 in

Trays

2-5 in

All trays

out

CN2011/pin

corresponds to:

sensor)

sens)

sens)

sens)

Changes

during

Trays

stocked

Tray moves

back / forth

H at tray out

Outline

Wireless

Mech

Pwr Supply

Protection

Audio

Models:

SA-PT660

SA-PT760

SA-PT960

SA-PT1060

SH-FX67, 85

Page 24

Table of Contents

Electronics –Layouts / Hints

Hints – p/n, New codes, Tests, Reset 4

Layout w test points and PS voltages 5

Wireless

SH-FX65/66 Rear Receiver Setup 8

Wireless Troubleshooting Plan 9

Testing & Paring Trans & Rec 10

Transmitter / Receiver Repair Info 11

Power ON

Power On Sequence 14

Mechanism – stacked 5 Disc model CR-14

Operation 15

Alignment 16

Troubleshooting 21

Laser Replacement (removal & install) 25

Power Supply

PS Block with isolation strategy 31

Home Theater Products Repair

center SW

T

R

SW

center

SA-PT660

SA-PT760

PS Circuit with ref voltages 32

Protection

Protection Concept (F61 & F76 codes) 34

Protection Circuitry 35

Protection Repair Procedure 36

Audio

Concept 39

Speaker Output Waveform 40

Sample Problems & Repair Methods 41

Slide # 24

T

R

center

SW

SA-PT960

Outline

Wireless

Mech

Pwr Supply

Protection

Audio

Models:

SA-PT660

SA-PT760

SA-PT960

SA-PT1060

SH-FX67, 85

Page 25

5 Disc Mechanism Laser Replacement 1/5 – Removed from any play position

If the mechanism is replaced, The TRV / laser assembly is transplanted to the new mechanism.

Mech p/n = RD-DDC026-S

Traverse/Laser p/n = RD-DDtx002-V

Setup –

Move Mech to PLAY position:

A. Power the unit on, select

DVD and let the micro

back

automatically move the

mechanism to load tray 1,

play position

position is shown at left for

understanding only *).

(the default PLAY

B. Unplug the 3 cables and

Remove the mechanism.

Mech p/n = RD-DDC026-S

Traverse/Laser p/n = RD-DDtx002-V

Fig 14

Slide # 25

front

Panasonic CR-14

Mechanism -

Default Position

(no discs)

C. Turn the mech over.

Go to the next page.

* Verification is from the front panel tray

compartment. Trays 2-5 are seen below

but tray 1 is recessed (loaded).

Tray 1 inside

Trays 2-5

Front view

Outline

Wireless

Mech

Pwr Supply

Protection

Audio

Models:

SA-PT660

SA-PT760

SA-PT960

SA-PT1060

SH-FX67, 85

Page 26

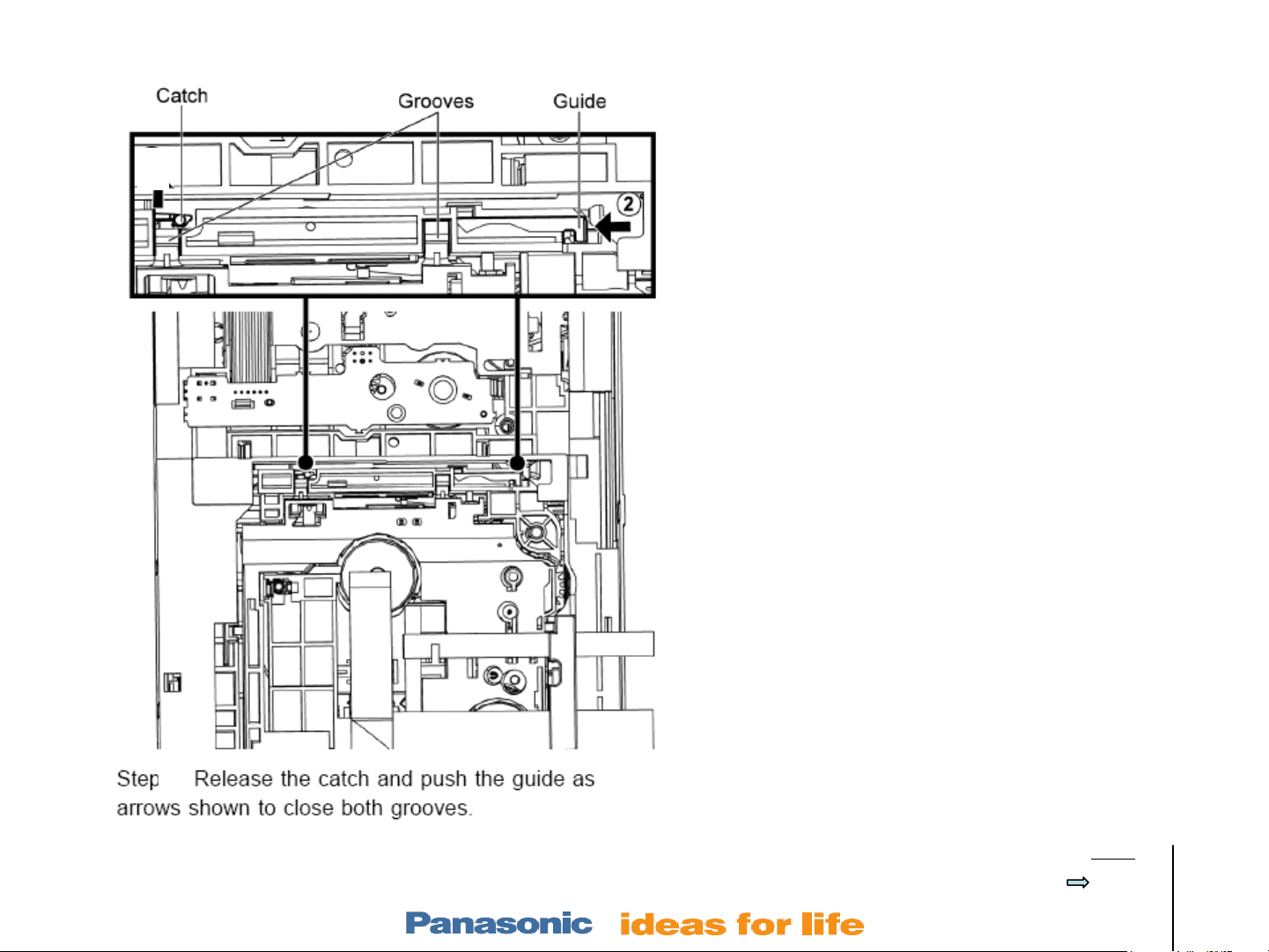

5 Disc Mechanism Laser Replacement 2/5 – Removed from play position

front

# 336

# 335

back

D. Removing the Laser assembly

from the bottom in play position:

1. Locate the bottom of #335 TRV

slide plate and move the catch

up as shown.

2. Slide #336 sub slide plate to the

right as shown until the grooves

in the slot are revealed

(permitting the traverse

assembly to lift out).

3.

Go to the next page.

Fig 15

Slide # 26

Outline

Wireless

Mech

Pwr Supply

Protection

Audio

Models:

SA-PT660

SA-PT760

SA-PT960

SA-PT1060

SH-FX67, 85

Page 27

5 Disc Mechanism Laser Replacement 3/5 – Removed from play position

front

Removing the Laser assembly:

3. Lift up the TRV assembly in

the direction of the two

arrows shown.

Go to the next page.

Fig

16

Slide # 27

back

Outline

Wireless

Mech

Pwr Supply

Protection

Audio

Models:

SA-PT660

SA-PT760

SA-PT960

SA-PT1060

SH-FX67, 85

Page 28

5 Disc Mechanism Laser Replacement 4/5 – Installation

B A

Reinstalling the Laser

assembly:

4. Before dropping the laser

assembly into the TRV

assembly observe the two

areas (A & B) outlined.

5. During the insertion, mate

the pin of the laser slider

(A) to the mechanism’s

corresponding groove (B).

Slide # 28

Go to the next page.

Fig

17

Outline

Wireless

Mech

Pwr Supply

Protection

Audio

Models:

SA-PT660

SA-PT760

SA-PT960

SA-PT1060

SH-FX67, 85

Page 29

5 Disc Mechanism Laser Replacement 5/5 – Installation

Reinstalling the Laser assembly:

6. Drop the laser assembly in.

7. Slide the lever to the left as

shown in arrow 2.

8. Make sure the catch is back

down.

9. Finished. Turn the mechanism

over and connect the mech’s 3

ribbon cables to the remainder

of the unit.

Slide # 29

Fig 18

4

Outline

Wireless

Mech

Pwr Supply

Protection

Audio

Models:

SA-PT660

SA-PT760

SA-PT960

SA-PT1060

SH-FX67, 85

Page 30

Table of Contents

Electronics –Layouts / Hints

Hints – p/n, New codes, Tests, Reset 4

Layout w test points and PS voltages 5

Wireless

SH-FX65/66 Rear Receiver Setup 8

Wireless Troubleshooting Plan 9

Testing & Paring Trans & Rec 10

Transmitter / Receiver Repair Info 11

Power ON

Power On Sequence 14

Mechanism – stacked 5 Disc model CR-14

General Operation 15

Concept & Alignment 16

Failure? Mech or circuitry? Access 21

Laser Replacement (removal & install) 25

Power Supply

PS Block with isolation strategy 31

Home Theater Products Repair

center SW

T

R

SW

center

SA-PT660

SA-PT760

PS Circuit with ref voltages 32

Protection

Protection Concept (F61 & F76 codes) 34

Protection Circuitry 35

Protection Repair Procedure 36

Audio

Concept 39

Speaker Output Waveform 40

Sample Problems & Repair Methods 41

Slide # 30

T

R

center

SW

SA-PT960

Outline

Wireless

Mech

Pwr Supply

Protection

Audio

Models:

SA-PT660

SA-PT760

SA-PT960

SA-PT1060

SH-FX67, 85

Page 31

Dividing a PS problem to the

output or regulation stage

with 2 voltages.

Measure voltages. Look up voltages

on chart below for the defect area.

1

2

Power Supply Block for Stby, Pwr On, Isolation.

1. Output volt

@ w5713

2. FdBk volt

at w5711

Defect area

30Vdc 1.5Vdc Normal Operation

Lower than 30V Higher than 1.5V Reg circuit (IC5801, Q5802)

Lower than 30V Lower than 1.5V Output Stage (IC5701,

T5701, D5702)

Higher than 30V Higher than 1.5V Output Stage (IC5701,

T5701, D5702)

Higher than 30V Lower than 1.5V Reg circuit (IC5801, Q5802)

Slide # 31

Plug In, Power ON Sequence

1. Press Power ON

2. Fan turns on - Starts Noisy

3. Hello is displayed

4. Last Mode used is displayed.

Outline

Wireless

Mech

Pwr Supply

Protection

Audio

Models:

SA-PT660

SA-PT760

SA-PT960

SA-PT1060

SH-FX67, 85

Page 32

Power Supply Circuit

Slide # 32

Outline

Wireless

Mech

Pwr Supply

Protection

Audio

Models:

SA-PT660

SA-PT760

SA-PT960

SA-PT1060

SH-FX67, 85

Page 33

Table of Contents

Electronics –Layouts / Hints

Hints – p/n, New codes, Tests, Reset 4

Layout w test points and PS voltages 5

Wireless

SH-FX65/66 Rear Receiver Setup 8

Wireless Troubleshooting Plan 9

Testing & Paring Trans & Rec 10

Transmitter / Receiver Repair Info 11

Power ON

Power On Sequence 14

Mechanism – stacked 5 Disc model CR-14

Operation 15

Alignment 16

Troubleshooting 21

Laser Replacement (removal & install) 25

Power Supply

PS Block with isolation strategy 31

Home Theater Products Repair

center SW

T

R

SW

center

SA-PT660

SA-PT760

PS Circuit with ref voltages 32

Protection

Protection Concept (F61 & F76 codes) 34

Protection Circuitry 35

Protection Repair Procedure 36

Audio

Concept 39

Speaker Output Waveform 40

Sample Problems & Repair Methods 41

Slide # 33

T

R

center

SW

SA-PT960

Outline

Wireless

Mech

Pwr Supply

Protection

Audio

Models:

SA-PT660

SA-PT760

SA-PT960

SA-PT1060

SH-FX67, 85

Page 34

PT760 Protection Troubleshooting Concept

Slide # 34

Outline

Wireless

Mech

Pwr Supply

Protection

Audio

Models:

SA-PT660

SA-PT760

SA-PT960

SA-PT1060

SH-FX67, 85

Page 35

PT760 Protection Circuit

Slide # 35

Outline

Wireless

Mech

Pwr Supply

Protection

Audio

Models:

SA-PT660

SA-PT760

SA-PT960

SA-PT1060

SH-FX67, 85

Page 36

F61 / F76 error code Repair procedure (1/2)

Use the protection diagrams for strategy information (p32-33) and the layout diagram (p25-26) to

locate test points. The main strategy below is to first isolate the problem to one of 5 boards.

Board Isolation:

F61 Error Code

1. Even if the fan blades were spinning, replace the fan if the 3 pin CN5501 fan connector

voltages are 7vdc, 0V, and 0.6Vdc (normal = 7V, 0V, 0V) at power on.

2. Isolate the problem to the D Amp board – The problem is on the D Amp board if the unit

remains powered on (no F61 error code) with CN5050 unplugged (disconnected).

3. Isolate the problem to the SMPS board – The problem is on the SMPS board if the unit

remains powered on (no F61 error code) with CN5802/pin 4 removed from the plug and the

connector plugged back into the socket (with wire 4 missing).

Go to B, next page.

See Protect diagrams.

Go to A.

F76 Error Code

1. On the Main board, unsolder CN2008/pin 21 OR remove jumper w2866 (layout diagram page 25).

2. Turn the unit ON. Does the Unit shut down with an F76 error code?

Slide # 36

a) The unit remains ON (no F76 error code). The problem is on the power supply board or DVD module. Go to C,

next page.

b) The unit still shuts off with an F76 error code. The problem is on the main board or power supply bd. Go to D,

next page.

Outline

Wireless

Mech

Pwr Supply

Protection

Audio

Models:

SA-PT660

SA-PT760

SA-PT960

SA-PT1060

SH-FX67, 85

Page 37

F61 / F76 error code Repair procedure (2/2)

F61 Error Code F76 Error Code

A) D Amp Board

1. If the voltage at +

C5133 is 0.6Vdc, one

of the output ICs is

bad. Check the speaker

terminal voltages to find out

which +/- pair is more than

0.6Vdc at power on. The

terminal that is 0.6V or

more has a bad output IC.

+C5133 = 0Vdc means

the output ICs are all

good.

2. If the voltage at fan

CN5501/pin 3 = 0.6Vdc,

replace the fan. 0 V = norm.

3. If this CN5501/pin 3 fan

voltage is normal at 0Vdc

before shutdown, cut

jumper W5002. Reconnect

CN5050 & power On. Unit

stops shutting down?

Replace Q5640 & Q5641.

4. If cutting W5002 does not

stop the shutdown F61

error code, replace SMD

Q5101,Q5102.

Slide # 37

B) SMPS Board

1. Keep CN5802/pin

4 disconnected.

2. Use the layout

diagram to locate

and measure the

+30V and -30V

and fan 18V

(CN5500/pin1) .

Missing? Trace it

to its source using

the simplified PS

diagrams.

3. If the voltages are

all present,

replace TH5860,

Q5861,2 and

QR5802.

Use the layout diagrams

(slide 25-26) to locate

jumpers and key parts.

C) Power Board

1. Resolder

CN2008/pin 21 or

reconnect jumper

w2866 (removed

previously).

2. Unplug 50 pin

ribbon cable at

main board

CN2001 and power

on the unit. No

more F76 error

code? Replace the

DVD module

3. If F76 still appears,

replace Q2921,

Q2922 and R2913.

D) Main or Pwr Board

1. Resolder CN2008/pin 21 or

reconnect jumper w2866

(removed previously).

2. Remove jumper w2753 so

the unit will not shutdown.

a) If the unit still shuts

down with an F76 error

code, - replace the pull

up resistor (R2051) at

IC2001/pin 43 and then

the micro IC2001.

b) If the unit stops shutting

down, Check all the 11

power supply voltages

listed on the layout

diagram.

• If one is missing or

excessive, trace it to its

source.

• If the voltages are all normal,

check the main bd.

protection parts (D2945,

Q2919, Q2909, Q2923,4 and

related zeners.

Outline

Wireless

Mech

Pwr Supply

Protection

Audio

Models:

SA-PT660

SA-PT760

SA-PT960

SA-PT1060

SH-FX67, 85

Page 38

Table of Contents

Electronics –Layouts / Hints

Hints – p/n, New codes, Tests, Reset 4

Layout w test points and PS voltages 5

Wireless

SH-FX65/66 Rear Receiver Setup 8

Wireless Troubleshooting Plan 9

Testing & Paring Trans & Rec 10

Transmitter / Receiver Repair Info 11

Power ON

Power On Sequence 14

Mechanism – stacked 5 Disc model CR-14

Operation 15

Alignment 16

Troubleshooting 21

Laser Replacement (removal & install) 25

Power Supply

PS Block with isolation strategy 31

Home Theater Products Repair

center SW

T

R

SW

center

SA-PT660

SA-PT760

PS Circuit with ref voltages 32

Protection

Protection Concept (F61 & F76 codes) 34

Protection Circuitry 35

Protection Repair Procedure 36

Audio

Concept 39

Speaker Output Waveform 40

Sample Problems & Repair Methods 41

Slide # 38

T

R

center

SW

SA-PT960

Outline

Wireless

Mech

Pwr Supply

Protection

Audio

Models:

SA-PT660

SA-PT760

SA-PT960

SA-PT1060

SH-FX67, 85

Page 39

Audio Processing Concepts

Slide # 39

Outline

Wireless

Mech

Pwr Supply

Protection

Audio

Models:

SA-PT660

SA-PT760

SA-PT960

SA-PT1060

SH-FX67, 85

Page 40

Audio – Speaker Output Waveforms

Units with a digital power output IC always outputs a sine wave at the speaker terminals

Digital Scope snapshot at the Speaker Terminals

Normal “RF” waveform at the speaker

terminals even when there is no sound!

No Audio @ spk term Music or Voice Audio @ spk term

Output IC is ON * but may be muted or

no audio is input.

Spk Terminal Output = background sine wave at

1.4Vp-p @ 375kHz. Duty cycle = 50%

Average spk DC voltage = 0Vdc

Typical voice waveform

at the speaker terminals

There is a constant 1.4Vp-p minimum signal

with the digital (PAM) audio.

Background sine wave is modulated with

voice audio that averages above and

below the 0V center line (PAM).

Slide # 40

Same output with or without speakers.

* Output ICs can be turned off from the mute

input. 5V = norm, 3V = mute, 0V = Off.

PAM = Pulse Amplitude Modulation

Outline

Wireless

Mech

Pwr Supply

Protection

Audio

Models:

SA-PT660

SA-PT760

SA-PT960

SA-PT1060

SH-FX67, 85

Page 41

Sample Audio Problems – Troubleshooting Methods

Refer to the Audio simplified diagram and layout

Audio Troubleshooting Isolation Methods

1. No Audio Causes (all inputs dead)

a) Pwr Supply loss – check for + 30Vdc at pwr on. (see layout diagram)

b) No Osc input – check for 4.5Vp-p (375kHz) at pin 1 of each output IC5000-5400/pin 1.

c) Mute input – check for normal (unmute) 5Vdc at CN2009/pins 12, 13, 17.

d) Mute input – check for broken headphone jack Sw at CN2007/pin 11 [5V = hp in, 3.5V = hp out]

2. Missing 1 or more channels (remote is needed)

a) Mute – check for normal 5Vdc at each output IC5000-5400/pin 23 (last pin).

b) No Osc – check for 4.5Vp-p (375kHz) at each output IC5000-5400/pin 1.

c) Use the Audio Process diagram info to select “S Music” then scope the audio at CN2003 pins.

3. Hum - Unplug CN5050 and power the unit on.

a) Hum still present? – “Damp” board problem. The board’s gnd should not touch the chassis.

PT760/960 remote

N2QAYB 000 214

b) Hum gone? – SMPS or Main board problem. (Main transformer T5701 if lightning damage)

4. Mute Causes

a) Headphone plugged in instructs the micro t o mute the spk output (ck sw at CN2007/pin 11) .

b) Unplug the tuner (from the main board) to see if it is killing data communications.

c) Check the mute voltages at CN2009/pins 17(all spk mute), pin 13 (frt & Sw mute), pin 12 (cent

d) DVD board no communications or its 50 pin cable is defective / damaged.

5. Low volume

Normal signal levels when the volume control is max at 50 are at the audio processing concepts

diagram, lower left corner box. Vp-p Levels are with the “S Music” On and Off.

Slide # 41

& Surr mute). Normal voltage = 5Vdc. 0V = mute.

PT660 remote

N2QAYB 000 210

Outline

Wireless

Mech

Pwr Supply

Protection

Audio

Models:

SA-PT660

SA-PT760

SA-PT960

SA-PT1060

SH-FX67, 85

Page 42

Table of Contents

Electronics –Layouts / Hints

Hints – p/n, New codes, Tests, Reset 4

Layout w test points and PS voltages 5

Wireless

SH-FX65/66 Rear Receiver Setup 8

Wireless Troubleshooting Plan 9

Testing & Paring Trans & Rec 10

Transmitter / Receiver Repair Info 11

Power ON

Power On Sequence 14

Mechanism – stacked 5 Disc model CR-14

Operation 15

Alignment 16

Troubleshooting 21

Laser Replacement (removal & install) 25

Power Supply

PS Block with isolation strategy 31

Home Theater Products Repair

center SW

T

R

SW

center

SA-PT660

SA-PT760

PS Circuit with ref voltages 32

Protection

Protection Concept (F61 & F76 codes) 34

Protection Circuitry 35

Protection Repair Procedure 36

Audio

Concept 39

Speaker Output Waveform 40

Sample Problems & Repair Methods 41

Slide # 42

T

R

center

SW

SA-PT960

Outline

Wireless

Mech

Pwr Supply

Protection

Audio

Models:

SA-PT660

SA-PT760

SA-PT960

SA-PT1060

SH-FX67, 85

Loading...

Loading...