Page 1

PSG1006004CE

Home Theater Audio System

Model No. SU-HTB500PP

SC-HTB500PP

Product Color: (K)...Black Type

A6

Note: Please refer to the original service manual for:

O Wireless Subwoofer Unit SB-WA500PP-K, Order No. PSG1006031CE

TABLE OF CONTENTS

PAG E PAG E

1 Safety Precautions ----------------------------------------------- 3

1.1. General Guidelines---------------------------------------- 3

1.2. Before Repair and Adjustment ------------------------- 4

1.3. Caution For Fuse Replacement------------------------ 4

1.4. Protection Circuitry ----------------------------------------4

1.5. Safety Part Information -----------------------------------5

1.6. Safety Installation Instructions -------------------------6

2Warning--------------------------------------------------------------7

© Panasonic Corporation 2010. All rights reserved.

Unauthorized copying and distribution is a violation of

law.

Page 2

2.1. Prevention of Electro Static Discharge (ESD)

to Electrostatically Sensitive (ES) Devices ----------7

2.2. Service caution based on Legal restrictions---------8

3 Service Navigation------------------------------------------------9

3.1. Service Information ----------------------------------------9

4 Specifications ---------------------------------------------------- 10

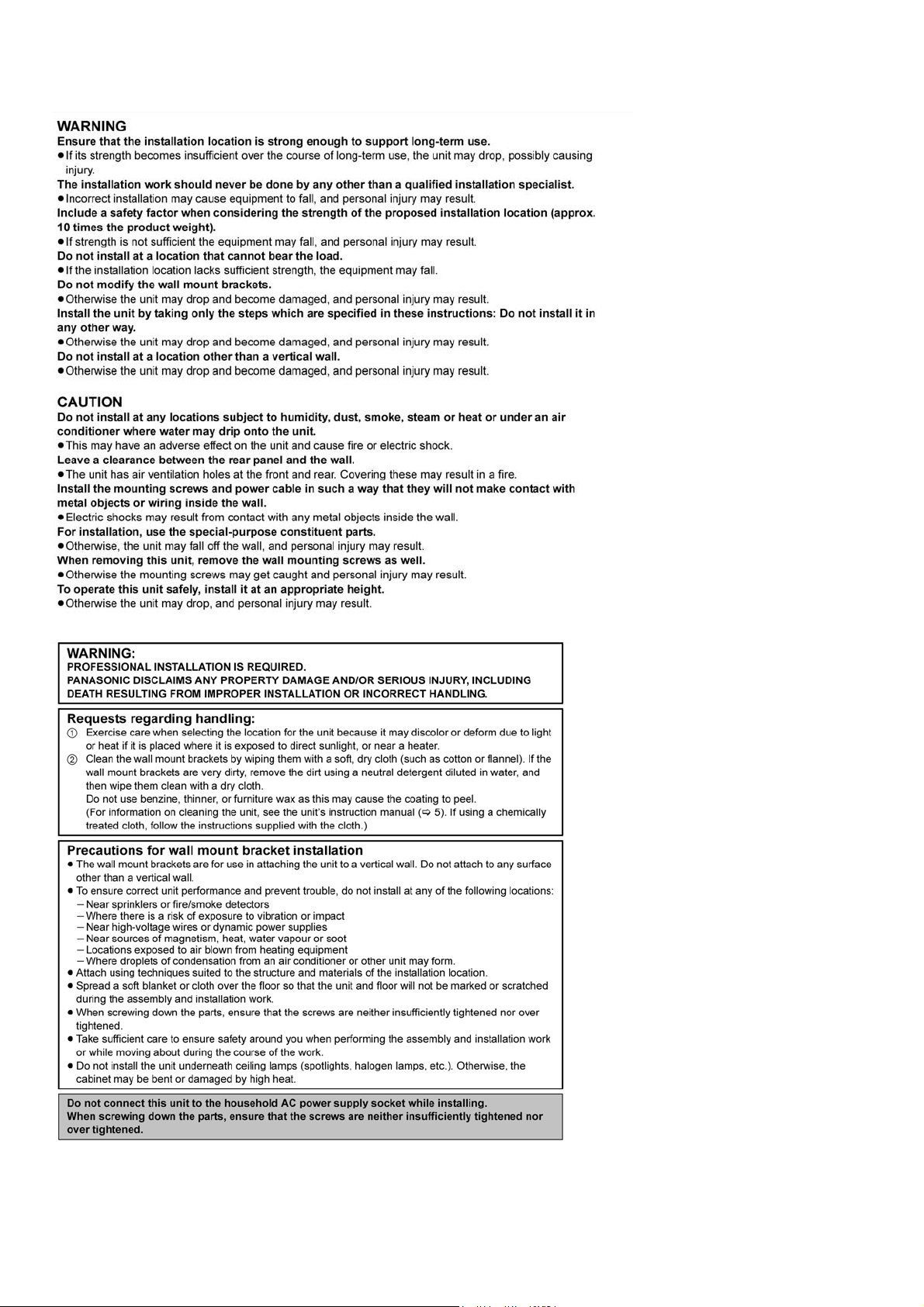

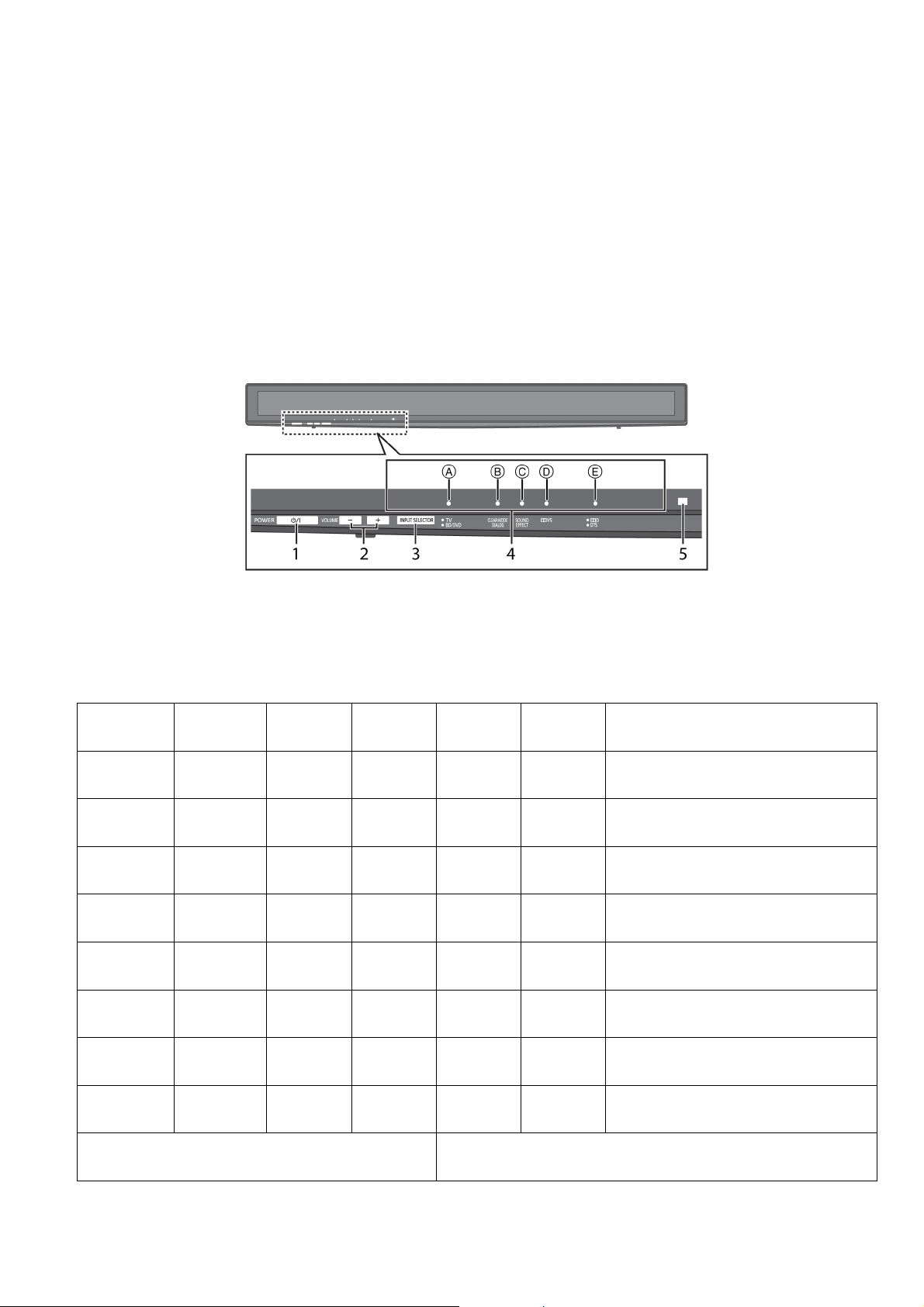

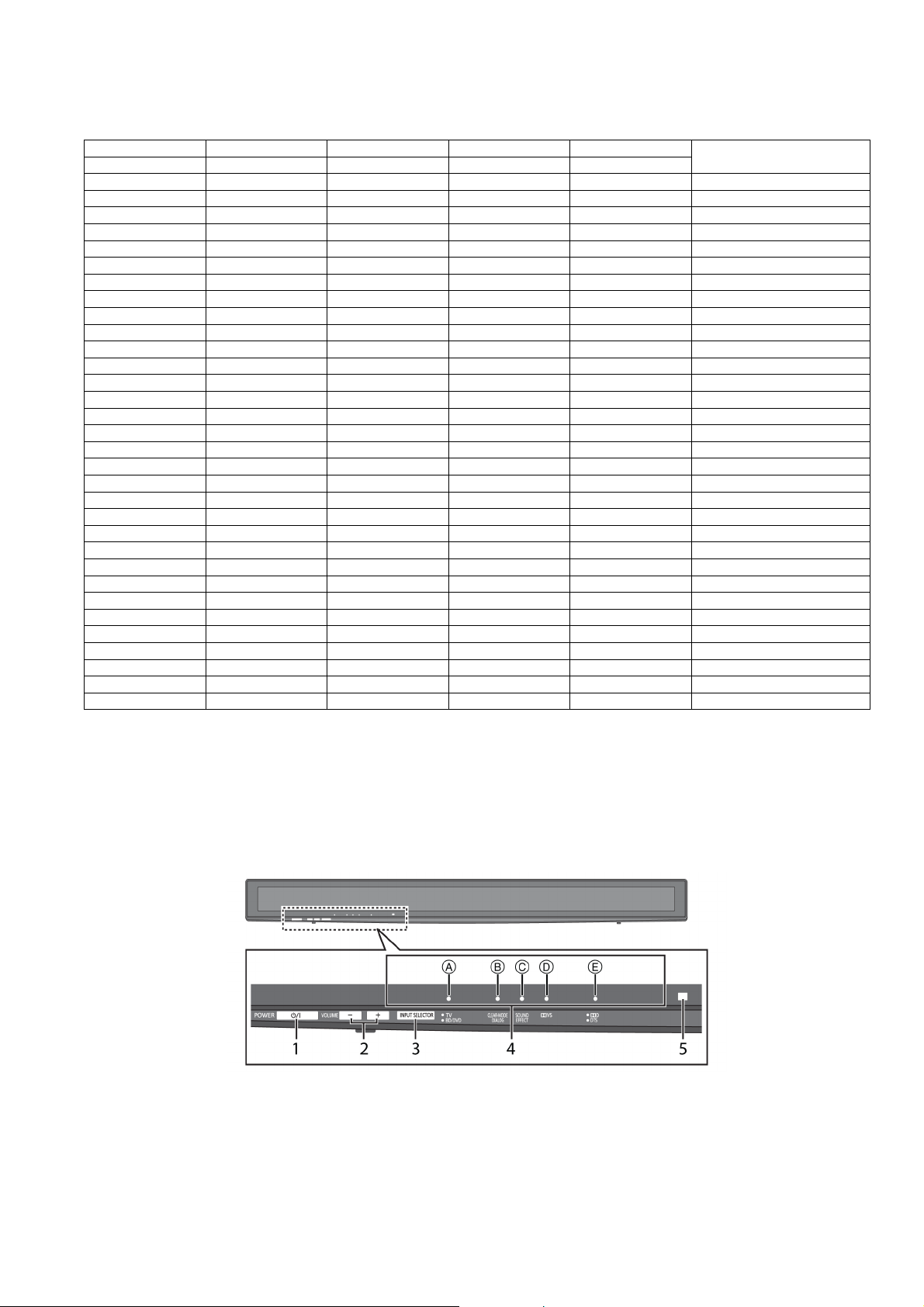

5 Location of Controls and Components------------------ 11

5.1. Main Unit Key Button Operations -------------------- 11

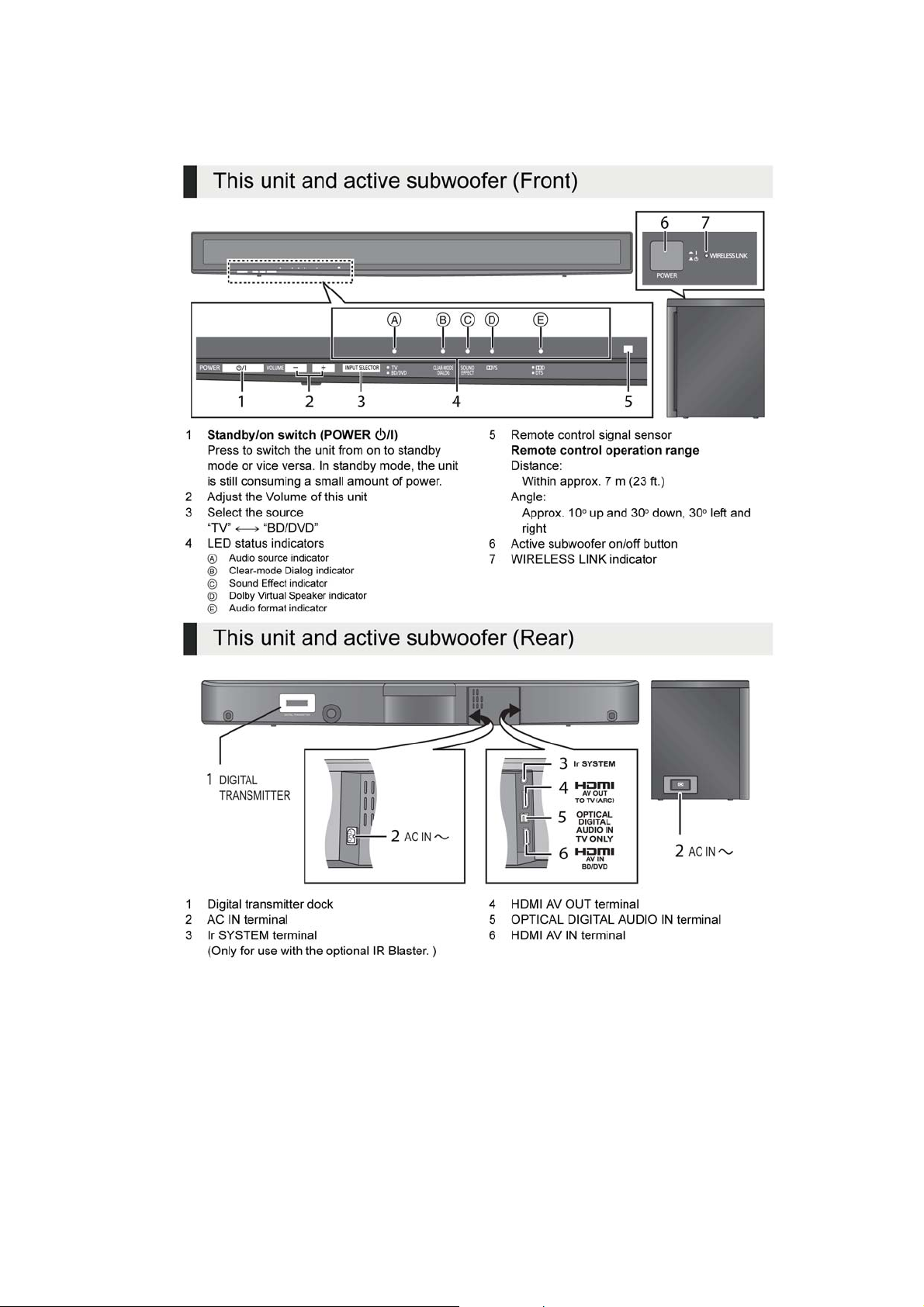

5.2. Remote Control Key Buttons Operation ------------ 12

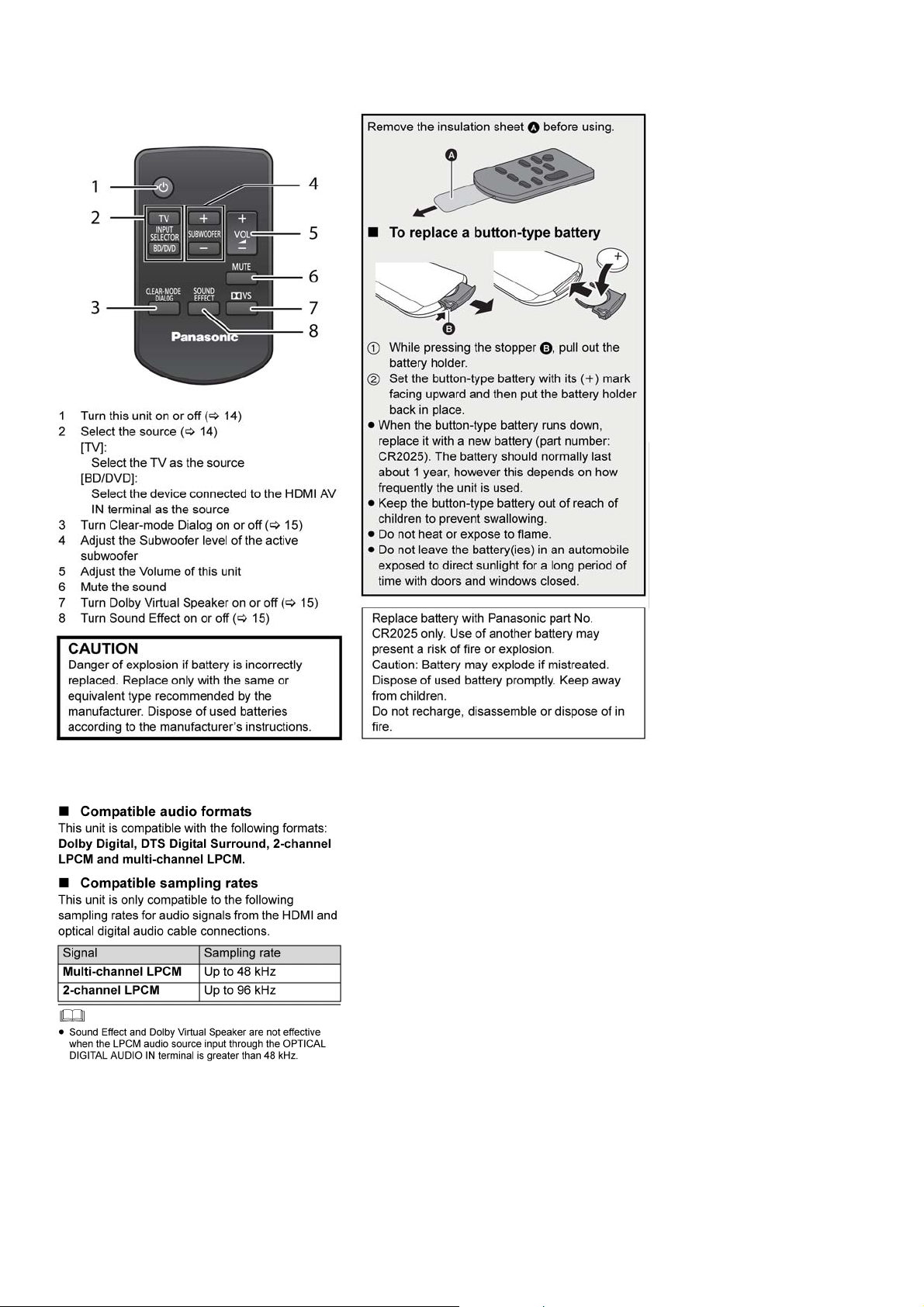

5.3. Audio Information ---------------------------------------- 12

6 Self diagnostic and special mode setting -------------- 13

6.1. Automatically Displayed Error Codes --------------- 13

6.2. Service Mode---------------------------------------------- 14

7 Service Fixture & Tools --------------------------------------- 18

8 Disassembly and Assembly Instructions---------------19

8.1. Disassembly flow chart ---------------------------------20

8.2. Main Parts Location Diagram ------------------------- 20

8.3. Disassembly of Back Cabinet Assembly ----------21

8.4. Disassembly of Wireless Adapter P.C.B. ---------- 26

8.5. Disassembly of Front Speaker L (SP1) ------------ 28

8.6. Disassembly of Front Speaker R (SP2) ----------- 29

8.7. Disassembly of Main Chassis Assembly ---------- 30

8.8. Disassembly of LED P.C.B. and Panel Tact

Switch P.C.B. --------------------------------------------- 33

8.9. Disassembly of AC Inlet P.C.B. ---------------------- 35

8.10. Disassembly of Main P.C.B. -------------------------- 37

8.11. Disassembly of SMPS P.C.B. ------------------------40

8.12. Replacement of Switch Regulator IC (IC5701)

----------------------------------------------------------------43

8.13. Replacement of Rectifier Diode (D5802) ---------- 45

8.14. Disassembly of HDMI P.C.B. ------------------------- 47

9 Service Position ------------------------------------------------- 50

9.1. Checking and Repairing of Main P.C.B. (Side

A) -------------------------------------------------------------50

9.2. Checking and Repairing of Main P.C.B. (Side

B) -------------------------------------------------------------51

9.3. Checking and Repairing of Wireless Adapter

P.C.B. ------------------------------------------------------- 52

9.4. Checking and Repairing of SMPS P.C.B. --------- 53

9.5. Checking and Repairing of HDMI P.C.B. (Side

A) ------------------------------------------------------------55

9.6. Checking and Repairing of HDMI P.C.B. (Side

B) ------------------------------------------------------------56

10 Voltage Measurement & Waveform Chart--------------- 57

10.1. HDMI P.C.B. (1/5) --------------------------------------- 57

10.2. HDMI P.C.B. (2/5) --------------------------------------- 58

10.3. HDMI P.C.B. (3/5) --------------------------------------- 59

10.4. HDMI P.C.B. (4/5) --------------------------------------- 60

10.5. HDMI P.C.B. (5/5) --------------------------------------- 61

10.6. MAIN P.C.B. (1/2) ----------------------------------------62

10.7. MAIN P.C.B. (2/2) ----------------------------------------63

10.8. LED P.C.B. ------------------------------------------------- 63

10.9. SMPS P.C.B. ----------------------------------------------64

10.10. WIRELESS ADAPTER P.C.B. ------------------------ 64

10.11. Waveform Chart (1/2) ----------------------------------- 65

10.12. Waveform Chart (2/2) ----------------------------------- 66

11 Illustration of IC’s, Transistors and Diodes ------------67

12 Overall Simplified Block -------------------------------------- 68

13 Block Diagram --------------------------------------------------- 69

13.1. SYSTEM CONTROL BLOCK DIAGRAM ---------- 69

13.2. HDMI BLOCK DIAGRAM ------------------------------ 70

13.3. AUDIO (1/2) BLOCK DIAGRAM --------------------- 71

13.4. AUDIO (2/2) BLOCK DIAGRAM --------------------- 72

13.5. IC TERMINAL CHART (HDMI/AUDIO) ------------ 73

13.6. POWER SUPPLY (1/2) BLOCK DIAGRAM------- 74

13.7. POWER SUPPLY (2/2) BLOCK DIAGRAM------- 75

14 Wiring Connection Diagram -------------------------------- 77

15 Schematic Diagram Notes ----------------------------------- 79

16 Schematic Diagram -------------------------------------------- 81

16.1. HDMI CIRCUIT (1/6)------------------------------------ 81

16.2. HDMI CIRCUIT (2/6)------------------------------------ 82

16.3. HDMI CIRCUIT (3/6)------------------------------------ 83

16.4. HDMI CIRCUIT (4/6)------------------------------------ 84

16.5. HDMI CIRCUIT (5/6)------------------------------------ 85

16.6. HDMI CIRCUIT (6/6)------------------------------------ 86

16.7. MAIN CIRCUIT (1/4) ------------------------------------ 87

16.8. MAIN CIRCUIT (2/4) ------------------------------------ 88

16.9. MAIN CIRCUIT (3/4) ------------------------------------ 89

16.10. MAIN CIRCUIT (4/4) ------------------------------------ 90

16.11. LED CIRCUIT, PANEL TACT SWITCH

CIRCUIT, AC INLET CIRCUIT ----------------------- 91

16.12. SMPS CIRCUIT (1/2) ----------------------------------- 92

16.13. SMPS CIRCUIT (2/2) ----------------------------------- 93

16.14. WIRELESS ADAPTER CIRCUIT -------------------- 94

17 Printed Circuit Board------------------------------------------ 95

17.1. HDMI P.C.B. (SIDE A) --------------------------------- 95

17.2. HDMI P.C.B. (SIDE B) --------------------------------- 96

17.3. MAIN P.C.B. (SIDE A) ---------------------------------- 97

17.4. MAIN P.C.B. (SIDE B) ---------------------------------- 98

17.5. LED P.C.B., PANEL TACT SWITCH P.C.B.------- 99

17.6. AC INLET P.C.B., SMPS P.C.B., WIRELESS

ADAPTER P.C.B. ---------------------------------------100

18 Terminal Function of IC’s ----------------------------------- 101

18.1. IC604 (RFKWMHTB500P) IC MICRO

PROCESSOR -------------------------------------------101

18.2. IC2002 (RFKWMHTB10PB) IC MICRO

PROCESSOR -------------------------------------------102

19 Exploded View and Replacement Parts List---------- 103

19.1. Exploded View and Mechanical replacement

Parts List--------------------------------------------------103

19.2. Electrical Replacement Parts List ------------------107

2

Page 3

1 Safety Precautions

1.1. General Guidelines

1. When servicing, observe the original lead dress. If a short circuit is found, replace all parts which have been overheated or

damaged by the short circuit.

2. After servicing, ensure that all the protective devices such as insulation barriers, insulation papers shields are properly

installed.

3. After servicing, check for leakage current checks to prevent from being exposed to shock hazards.

1.1.1. Leakage Current Cold Check

1. Unplug the AC cord and connect a jumper between the two prongs on the plug.

2. Using an ohmmeter measure the resistance value, between the jumpered AC plug and each exposed metallic cabinet part on

the equipment such as screwheads, connectors, control shafts, etc. When the exposed metallic part has a return path to the

chassis, the reading should be between 1MΩ and 5.2Ω. When the exposed metal does not have a return path to the chassis,

the reading must be

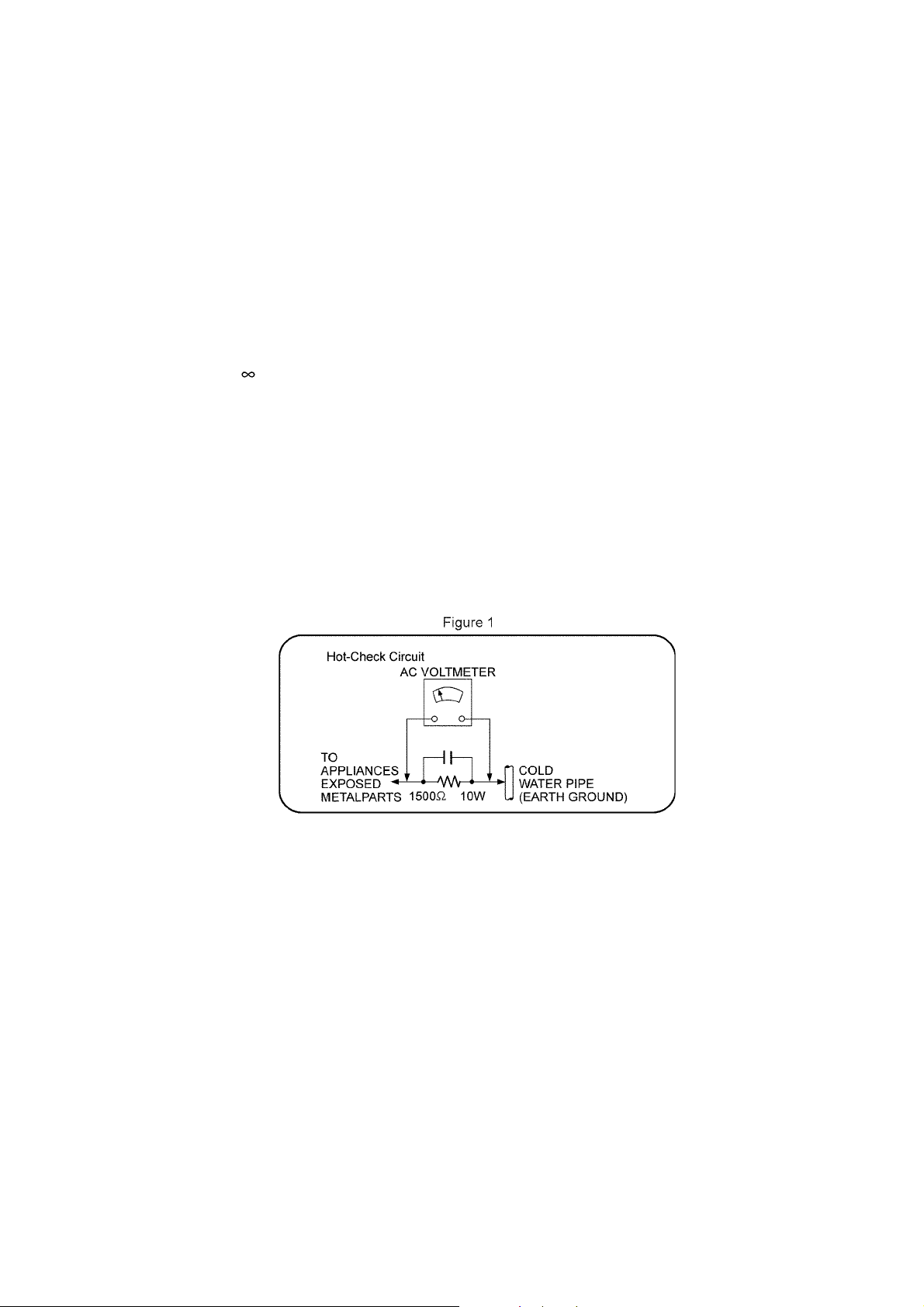

1.1.2. Leakage Current Hot Check

1. Plug the AC cord directly into the AC outlet. Do not use an isolation transformer for this check.

2. Connect a 1.5kΩ, 10 watts resistor, in parallel with a 0.15μF capacitors, between each exposed metallic part on the set and a

good earth ground such as a water pipe, as shown in Figure 1.

3. Use an AC voltmeter, with 1000 ohms/volt or more sensitivity, to measure the potential across the resistor.

4. Check each exposed metallic part, and measure the voltage at each point.

5. Reverse the AC plug in the AC outlet and repeat each of the above measurements.

6. The potential at any point should not exceed 0.75 volts RMS. A leakage current tester (Simpson Model 229 or equivalent)

may be used to make the hot checks, leakage current must not exceed 1/2 milliamp. should the measurement is outside of

the limits specified, there is a possibility of a shock hazard, and the equipment should be repaired and re-checked before it is

returned to the customer.

3

Page 4

1.2. Before Repair and Adjustment

Disconnect AC power, discharge unit AC Capacitors for:

(C5700, C5701, C5702, C5703, C5704, C5706, C5708) through a 10Ω, 1W resistor to ground.

DO NOT SHORT-CIRCUIT DIRECTLY (with a screwdriver blade, for instance), as this may destroy solid state devices.

After repairs are completed, restore power gradually using a variac, to avoid overcurrent.

• Current consumption at AC 120 V, at 60 Hz in NO SIGNAL mode, at volume minimum, SEL: HDMI/D-IN should be ~200 mA.

1.3. Caution For Fuse Replacement

1.4. Protection Circuitry

The protection circuitry may have operated if either of the following conditions are noticed:

• No sound is heard when the power is turned on.

• Sound stops during a performance.

The function of this circuitry is to prevent circuitry damage if, for example, the positive and negative speaker connection wires are

"shorted", or if speaker systems with an impedance less than the indicated rated impedance of the amplifier are used.

If this occurs, follow the procedure outlines below:

1. Turn off the power.

2. Determine the cause of the problem and correct it.

3. Turn on the power once again after one minute.

Note:

When the protection circuitry functions, the unit will not operate unless the power is first turned off and then on again.

4

Page 5

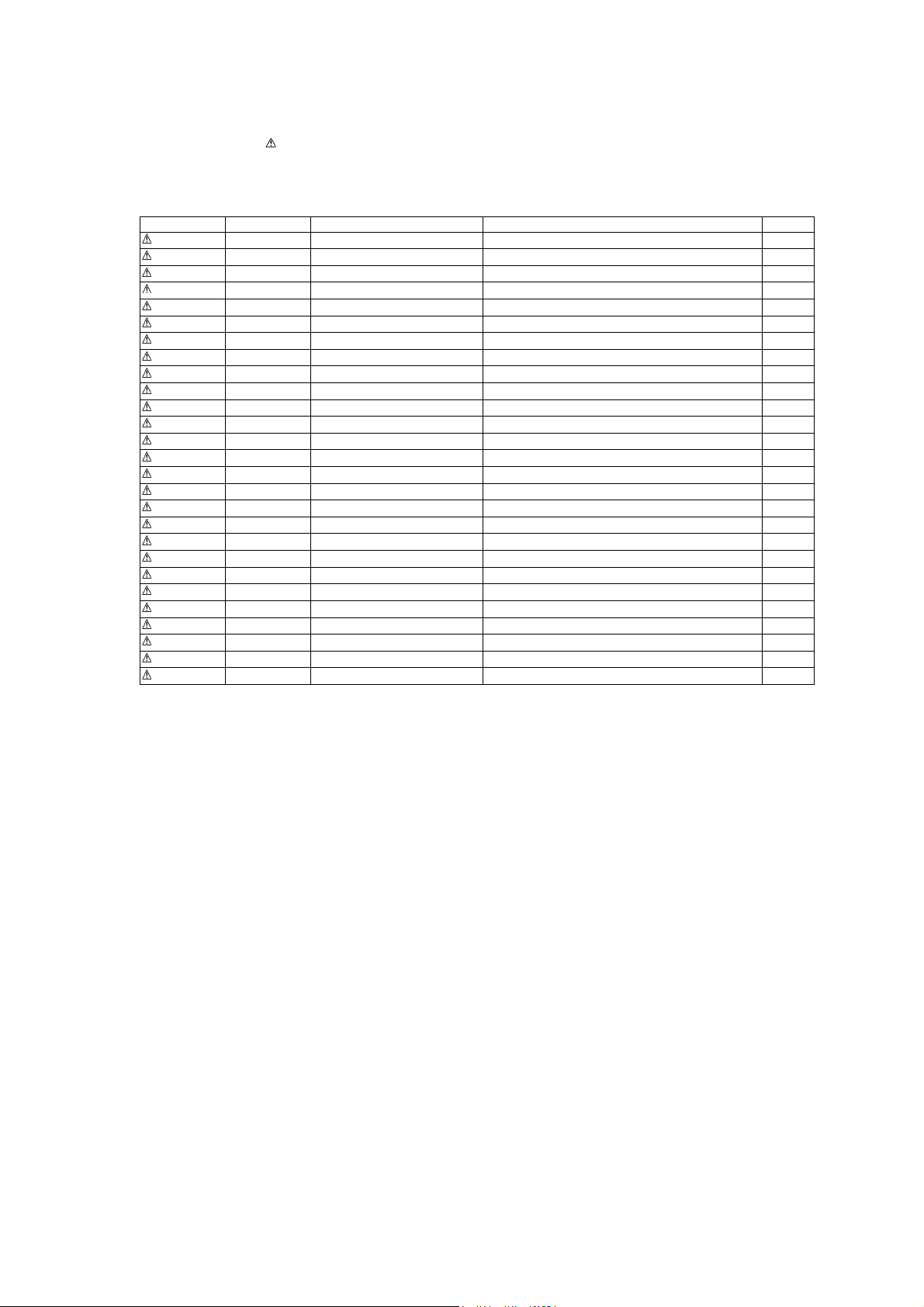

1.5. Safety Part Information

Safety Parts List:

There are special components used in this equipment which are important for safety.

These parts are marked by in the Schematic Diagrams & Replacement Parts List. It is essential that these critical parts should

be replaced with manufacturer’s specified parts to prevent shock, fire or other hazards. Do not modify the original design without

permission of manufacturer.

Safety Ref. No. Part No. Part Name & Description Remarks

2 REXX1104 1P RED/BLACK WIRE (AC INLET-SMPS)

17 RGNX1156-K1 SPEC LABEL

A2 RFAX1027 AC CORD/W FERRITE CORE

A3 RQTX1179-2Y O/I BOOK (En/Cf)

PCB1 REPX0840D HDMI P.C.B. (RTL)

PCB2 REPX0839KA MAIN P.C.B. (RTL)

PCB5 REPX0841BA SMPS P.C.B. (RTL)

PCB6 REPX0841BA AC INLET P.C.B. (RTL)

DZ5701 ERZV10V511CS ZNR

L5701 ELF15N007A FILTER

L5702 ELF19H010A FILTER

T5703 ETS28BH1E5AC TRANSFORMER

T5751 ETS19AB2A6AG SUB TRANSFORMER

PC5720 B3PBA0000402 PHOTO COUPLER

PC5799 B3PBA0000402 PHOTO COUPLER

RY5701 K6B1AEA00003 RELAY

F1 K5D252APA008 FUSE

FP700 K5H302100004 FUSE PROTECTOR

TH5702 D4CAA5R10001 THERMISTOR

P5701 K2ABYA000001 AC INLET

C5700 F1BAF2220023 2200pF

C5701 F0CAF104A105 0.1uF

C5702 F0CAF104A105 0.1uF

C5703 F0CAF104A105 0.1uF

C5704 F1BAF1020020 1000pF

C5706 F1BAF1020020 1000pF

C5708 F1BAF1020020 1000pF

5

Page 6

1.6. Safety Installation Instructions

6

Page 7

2Warning

2.1. Prevention of Electro Static Discharge (ESD) to Electrostatically Sensitive (ES) Devices

Some semiconductor (solid state) devices can be damaged easily by electricity. Such components commonly are called Electrostatically Sensitive (ES) Devices. Examples of typical ES devices are integrated circuits and some field-effect transistors and semiconductor “chip” components. The following techniques should be used to help reduce the incidence of component damage caused by

electro static discharge (ESD).

1. Immediately before handling any semiconductor component or semiconductor-equiped assembly, drain off any ESD on your

body by touching a known earth ground. Alternatively, obtain and wear a commercially available discharging ESD wrist strap,

which should be removed for potential shock reasons prior to applying power to the unit under test.

2. After removing an electrical assembly equiped with ES devices, place the assembly on a conductive surface such as aluminium foil, to prevent electrostatic charge build up or exposure of the assembly.

3. Use only a grounded-tip soldering iron to solder or unsolder ES devices.

4. Use only an anti-static solder remover device. Some solder removal devices not classified as “anti-static (ESD protected)” can

generate electrical charge to damage ES devices.

5. Do not use freon-propelled chemicals. These can generate electrical charges sufficient to damage ES devices.

6. Do not remove a replacement ES device from its protective package until immediately before you are ready to install it. (Most

replacement ES devices are packaged with leads electrically shorted together by conductive foam, aluminium foil or comparable conductive material).

7. Immediately before removing the protective material from the leads of a replacement ES device, touch the protective material

to the chassis or circuit assembly into which the device will be installed.

Caution

Be sure no power is applied to the chassis or circuit, and observe all other safety precautions.

8. Minimize body motions when handling unpackaged replacement ES devices. (Otherwise harmless motion such as the brushing together of your clothes fabric or the lifting of your foot from a carpeted floor can generate static electricity (ESD) sufficient

to damage an ES device).

7

Page 8

2.2. Service caution based on Legal restrictions

2.2.1. General description about Lead Free Solder (PbF)

The lead free solder has been used in the mounting process of all electrical components on the printed circuit boards used for this

equipment in considering the globally environmental conservation.

The normal solder is the alloy of tin (Sn) and lead (Pb). On the other hand, the lead free solder is the alloy mainly consists of tin

(Sn), silver (Ag) and Copper (Cu), and the melting point of the lead free solder is higher approx.30 degrees C (86°F) more than that

of the normal solder.

Definition of PCB Lead Free Solder being used

The letter of “PbF” is printed either foil side or components side on the PCB using the lead free solder.

(See right figure)

Service caution for repair work using Lead Free Solder (PbF)

• The lead free solder has to be used when repairing the equipment for which the lead free solder is used.

(Definition: The letter of “PbF” is printed on the PCB using the lead free solder.)

• To put lead free solder, it should be well molten and mixed with the original lead free solder.

• Remove the remaining lead free solder on the PCB cleanly for soldering of the new IC.

• Since the melting point of the lead free solder is higher than that of the normal lead solder, it takes the longer time to melt the

lead free solder.

• Use the soldering iron (more than 70W) equipped with the temperature control after setting the temperature at 350±30 degrees

C (662±86°F).

Recommended Lead Free Solder (Service Parts Route.)

• The following 3 types of lead free solder are available through the service parts route.

RFKZ03D01K-----------(0.3mm 100g Reel)

RFKZ06D01K-----------(0.6mm 100g Reel)

RFKZ10D01K-----------(1.0mm 100g Reel)

Note

* Ingredient: Tin (Sn), 96.5%, Silver (Ag) 3.0%, Copper (Cu) 0.5%, Cobalt (Co) / Germanium (Ge) 0.1 to 0.3%

8

Page 9

3 Service Navigation

3.1. Service Information

This service manual contains technical information which will allow service perssonnel’s to understand and service this model.

Please place orders using the parts list and not the drawing reference numbers.

If the circuit is changed or modified, this information will be followed by supplement service manual to be filed with original service

manual.

• Micro-processor :

1. The following components are supplied as an assembled part.

• Micro-processor IC, IC604 (RFKWMHTB500P).

• Micro-processor IC, IC2002 (RFKWMHTB10PB).

9

Page 10

4 Specifications

Q GENERAL

Power consumption: Main unit : 27 W

Digital transmitter : 1.2 W

Power consumption in standby mode: Main unit : Approx. 0.1 W

Power supply: AC 120 V, 60 Hz

Dimensions (W x H x D):

Main unit :

(Without wall mount bracket) 1029 mm x 108 mm x 58 mm (10 1/2” x 4 1/4” x 2 9/32”)

(With wall mount bracket) 1029 mm x 108 mm x 80 mm (10 1/2” x 4 1/4” x 3 5/32”)

Digital transmitter : 43.5 mm x 37.3 mm x 8.2 mm (1 23/32” x 1 15/32” x 5/16”)

Mass:

Main unit :

(Without wall mount bracket) Approx. 2.8 kg (6.2 lbs)

(With wall mount bracket) Approx. 2.9 kg (6.4 lbs)

Digital transmitter : Approx. 0.0095 kg (0.0209 lbs)

Operating temperature range: 0°C to +40°C (+32°F to +104°F)

Operating humidity range: 20% to 80% RH (no condensation)

Q AMPLIFIER SECTION

RMS Output Power

Front ch: 60 W per channel (4 Ω), 1 kHz, 10% THD

Total RMS Dolby Digital mode power: 240 W

FTC Output Power

Front ch: 25 W per channel (4 Ω), 120 Hz to 20 kHz, 1% THD

Total FTC Dolby Digital mode power: 87 W

Q SPEAKER SECTION

FRONT SPEAKERS (BUILT-IN)

Type: 1 way 1 speaker system (Bass Reflex)

Full range: 6.5 cm (2 1/2”) Cone type x 2

Output sound pressure: 78 dB/W(1m)

Frequency range: 35 Hz to 180 Hz (-16dB)

40 Hz to 160 Hz (-10dB)

Q TERMINAL SECTION

HDMI This unit supports “HDAVI Control 5” function.

HDMI input

Input Connector: Type A (19 pin)

HDMI AV output

Output Connector: Type A (19 pin)

Digital Audio Input (TV only)

Optical digital input: Optical terminal

Sampling frequency: 32 kHz, 44.1 kHz, 48 kHz

Audio Format: LPCM, Dolby Digital

IR Blaster

Terminal 1: 3.5 mm (1/8”) jack

Q WIRELESS SECTION

Wireless module

Frequency range: 2.4 GHz to 2.4835 GHz

Number of channels: 3

Note:

1. Specifications are subject to change without notice.

2. Total harmonic distortion is measured by the digital spectrum analyzer.

10

Page 11

5 Location of Controls and Components

5.1. Main Unit Key Button Operations

11

Page 12

5.2. Remote Control Key Buttons Operation

5.3. Audio Information

12

Page 13

6 Self diagnostic and special mode setting

This unit is equipped with features of self-diagnostic & special mode setting for checking the functions & reliability.

Special Note : Checking of the reliability (ageing) & changer operation must be carry out to ensure good working condi-

tion in unit.

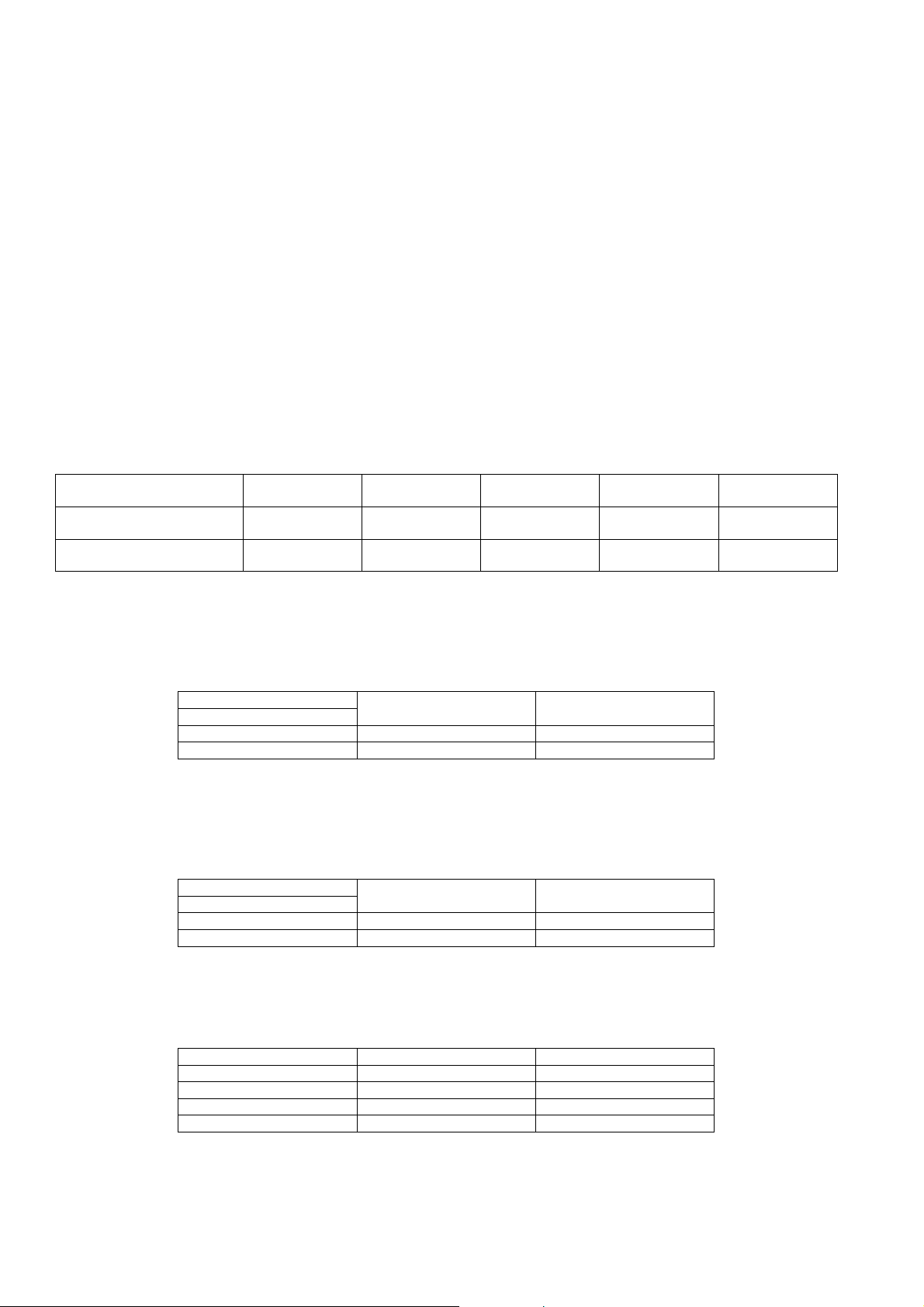

6.1. Automatically Displayed Error Codes

This model does not have a display unit hence error code (when a fault condition occurs) is represented by the LED status indicators. Refer to Fig 6.1

Here is the description of the LED status indicators:

LED 1 Audio source Indicator (TV, BD/DVD)

LED 2 Clear-mode Dialog indicator (Clear-Mode)

LED 3 Sound Effect Indicator (Sound-Effect)

LED 4 Dolby Virtual Sound Indicator (DVS)

LED 5 Audio Format Indicator (DD/DTS)

Fig 6.1

6.1.1. Error Code Display Details by LED Blinking Indicators

This section describes the LED status indicators by its blinking to represent the error codes.

Caution: The LED blinking process will stop only when the unit is power-off completely.

Error Code LED 1 (TV/BD/

DVD)

OVERLOAD

(F61) X XXX *

F76

* XXXX

F70 DSP

X XXX*2

F70 DAP

X XXX*3

F70 HDMI

X XXX*4

U701

*2 XXXX

U703

*3 XXXX

U704

*4 XXXX

“X” means LED off.

“*” means LED blink (RED) 1 time, then off.

“*2” means LED blink (RED) 2 times, then off.

LED 2

(CLEAR-

MODE)

LED 3

(SOUNDEFFECT)

LED 4 (DVS) LED 5 (DD/

DTS)

Speaker protection, D-AMP IC or Fan abnormality. Check for faulty parts and replace with

new parts if necessary.

DC Power/Voltage Supply abnormality. Check

for faulty parts and replace with new parts if

necessary.

DSP - Main Micro-p IC communication failure/

abnormality. Check for faulty parts and replace

with new parts if necessary.

DAP - Main Micro- P IC communication failure /

abnormality. Check for faulty parts and replace

with new parts if necessary.

HDMI to Main Micro-P IC communication error.

Check for faulty parts and replace with new

parts if necessary.

Connected devices error (HDCP non-compliance). Check for faulty parts and replace with

new parts if necessary.

HDMI connectionabnormality (cable damage,

HDCP non-complianceetc). Check for faulty

parts and replace with new parts if necessary.

HDMI image format incompatibility. Check for

faulty parts and replace with new parts if neces-

sary.

“*3” means LED blink (RED) 3 times, then off.

“*4” means LED blink (RED) 4 times, then off.

Table 6-1

Cause and Problem

13

Page 14

6.2. Service Mode

This mode can be used during servicing.

Here are the procedures to enter into service mode:

Step 1 : Power-up the main unit.

Step 2 : Press & hold [VOL+] button, [VOL-] button and [POWER] button on main unit.

This unit is equipped with service mode function for:

Step 1 : Checking the region/model and generation no.

Step 2 : Checking the Main micro-p & HDMI micro-p firmware version.

Legend:

“O” means LED ON

“X” means LED OFF

6.2.1. Checking of Main Micro-p Firmware version

Here are the procedures to check the region/model, generation no. and main firmware version:

Step 1 : Power-up the main unit.

Step 2 : Enter into service mode. (Refer to Section 6.2 for the procedures).

Step 3 : Press [VOL+] to check for the region/model & generation no. (Refer to table 6-2 for information on the LED indication).

Step 4 : Press [VOL+] to check for the main micro-p firmware version no. (Refer to table 6-2 for information on the LED indication).

Key Operation LED 1 (TV/BD/DVD) LED 2 (CLEAR-

Press [VOL+] button on main

unit for one time

Press [VOL+] button on main

unit for two times

Generation Bit No. Model Bit No. Region Bit 1 Region bit 0 O

Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

MODE)

LED 3 (SOUND-

EFFECT)

LED 4 (DVS) LED 5 (DD/DTS)

Table 6-2

6.2.1.1. Generation Bit No.

The generation bit no. is used for indication of the Model Year. (Refer to table 6-3 for more information).

Generation Bit Number Model By Year

(TV/BD/DVD) LED

X 0 2010

O 1 2011

Table 6-3

6.2.1.2. Model Bit No.

The model bit no. is to indicate the software for the specific model. (base on chip-select detection).

(Refer to table 6-4 for more information)

Model Bit Number Model No.

CLEAR-MODE LED

X 0 HTB500

O 1 HTB10/50

Table 6-4

(Green)

6.2.1.3. Region Bit No.

The region bit no. is to indicate the destination for model. (Refer to table 6-5 for more information).

Region Bit 1 Region Bit 0 Main Software

SOUND EFFECT DVS By Destination

X X 0 : Japan

X O 1 : US

O X 2 : Europe/Asia

Table 6-5

14

Page 15

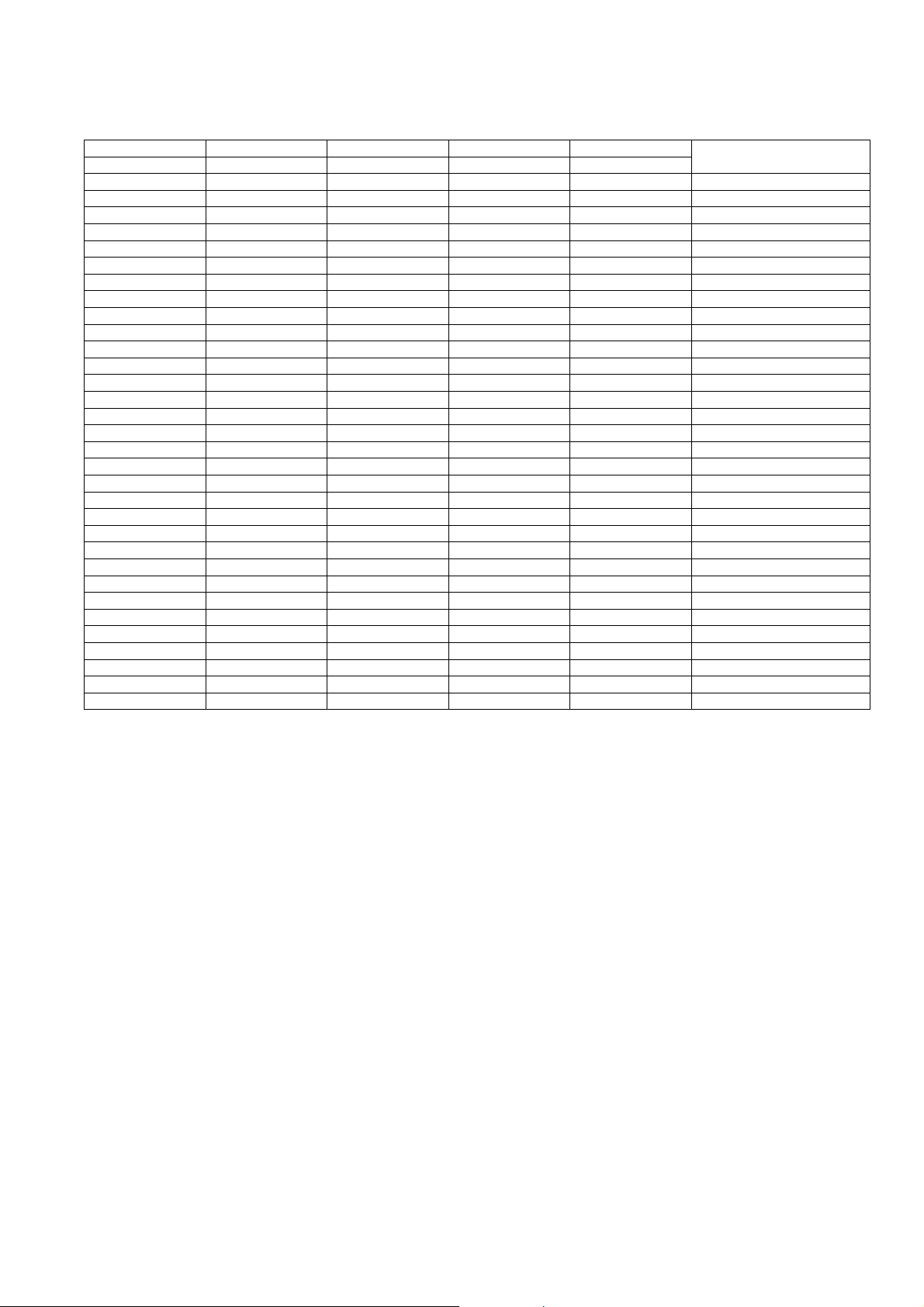

6.2.1.4. Firmware version Bit No. (Bit 0~4)

It is to indicate the firmware version no. (Bit 0 ~4). (Refer to table 6-6 for more information).

Bit 4 Bit 3 Bit 2 Bit 1 Bit 0 Version No

DVS DPLII DOLBY DTS PCM/AAC

XXXXX 00

XXXXO 01

XXXOX 02

XXXOO 03

XXOXX 04

XXOXO 05

XXOOX 06

XXOOO 07

XOXXX 08

XOXXO 09

XOXOX 10

XOXOO 11

XOOXX 12

XOOXO 13

XOOOX 14

XOOOO 15

OXXXX 16

OXXXO 17

OXXOX 18

OXXOO 19

OXOXX 20

OXOXO 21

OXOOX 22

OXOOO 23

OOX X X 24

OOX XO 25

OOX OX 26

OOX OO 27

OOOX X 28

OOOX O 29

OOOOX 30

OOOOO 31

Table 6-6

15

Page 16

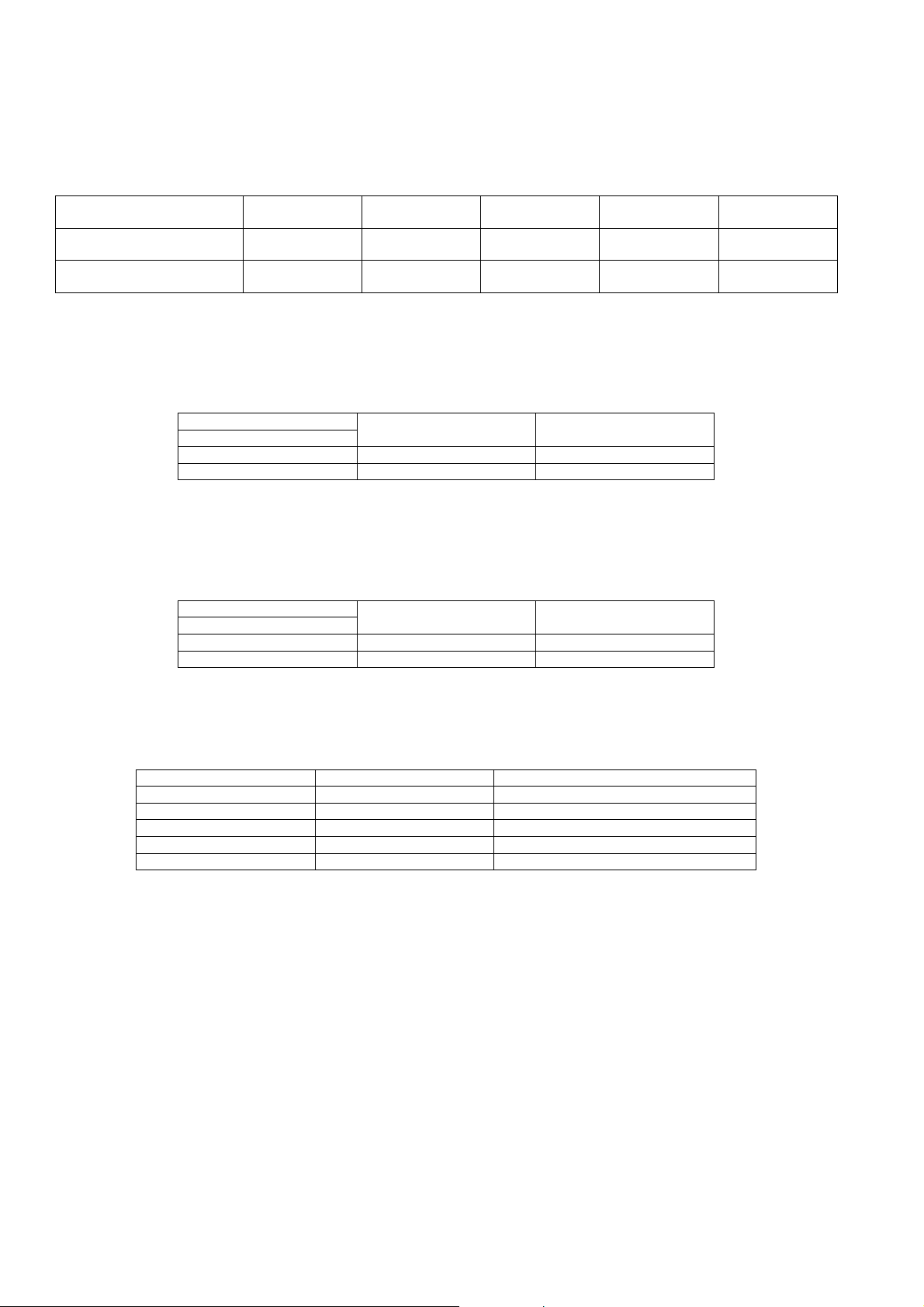

6.2.2. Checking of HDMI Micro-p Firmware version

Here are the procedures for checking the HDMI micro-p firmware version no:

Step 1 : Enter into service mode. (Refer to Section 6.2 for the procedures)

Step 2 : Press [VOL-] to check the region no. (Refer to table 6-7 for information).

Step 3 : Press [VOL-] to check the HDMI micro-p firmware version no. (Refer to table 6-7 for information).

Key Operation LED 1 (TV/BD/DVD) LED 2 (CLEAR-

Press [VOL-] button on main

unit

Press [VOL-] button on main

unit

Generation Bit No. Model Bit No. Region Bit 1 Region bit 0 O

Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

MODE)

LED 3 (SOUND-

EFFECT)

LED 4 (DVS) LED 5 (DD/DTS)

Table 6-7

6.2.2.1. Generation Bit No.

The generation bit no. is used for indication of the Model Year. (Refer to table 6-8 for more information).

Generation Bit Number Model By Year

(TV/BD/DVD) LED

X 0 2010

O 1 2011

Table 6-8

6.2.2.2. Model Bit No.

The model bit no. is to indicate the software for the specific model. (base on chip-select detection).

(Refer to table 6-9 for more information)

Model Bit Number Model No.

CLEAR-MODE LED

X 0 HTB500

O 1 HTB10/50

Table 6-9

(Green)

6.2.2.3. Region Bit No.

The region bit no. is to indicate the destination for model. (Refer to table 6-10 for more information).

Region Bit 1 Region Bit 0 HDMI Software

SOUND EFFECT DVS By last 2 digit

XX Invalid

XO For Japan

O X For Others

OO Invalid

Table 6-10

16

Page 17

6.2.2.4. Firmware version Bit No. (Bit 0~4)

It is to indicate the firmware version no. (Bit 0 ~4). (Refer to table 6-9 for more information).

Bit 4 Bit 3 Bit 2 Bit 1 Bit 0 Version No

DVS DPLII DOLBY DTS PCM/AAC

XXXXX 00

XXXXO 01

XXXOX 02

XXXOO 03

XXOXX 04

XXOXO 05

XXOOX 06

XXOOO 07

XOXXX 08

XOXXO 09

XOXOX 10

XOXOO 11

XOOXX 12

XOOXO 13

XOOOX 14

XOOOO 15

OXXXX 16

OXXXO 17

OXXOX 18

OXXOO 19

OXOXX 20

OXOXO 21

OXOOX 22

OXOOO 23

OOX X X 24

OOX XO 25

OOX OX 26

OOX OO 27

OOOX X 28

OOOX O 29

OOOOX 30

OOOOO 31

Table 6-11

6.2.3. Cold start

Here are the procedures to do a reset for the main unit.

Step 1 : Power-up the main unit.

Step 2 : Press & hold [POWER] button on main unit for 4s or more.

All LED will light-up and blink for 2 times (at frequency of 4Hz)

17

Page 18

7 Service Fixture & Tools

Prepare service tools before proccess service position.

Ref. No. Service Tools Remarks

SFT1 Main P.C.B. (CN700) - SMPS P.C.B. (H2016) REXX1103 (10P Cable Wire)

18

Page 19

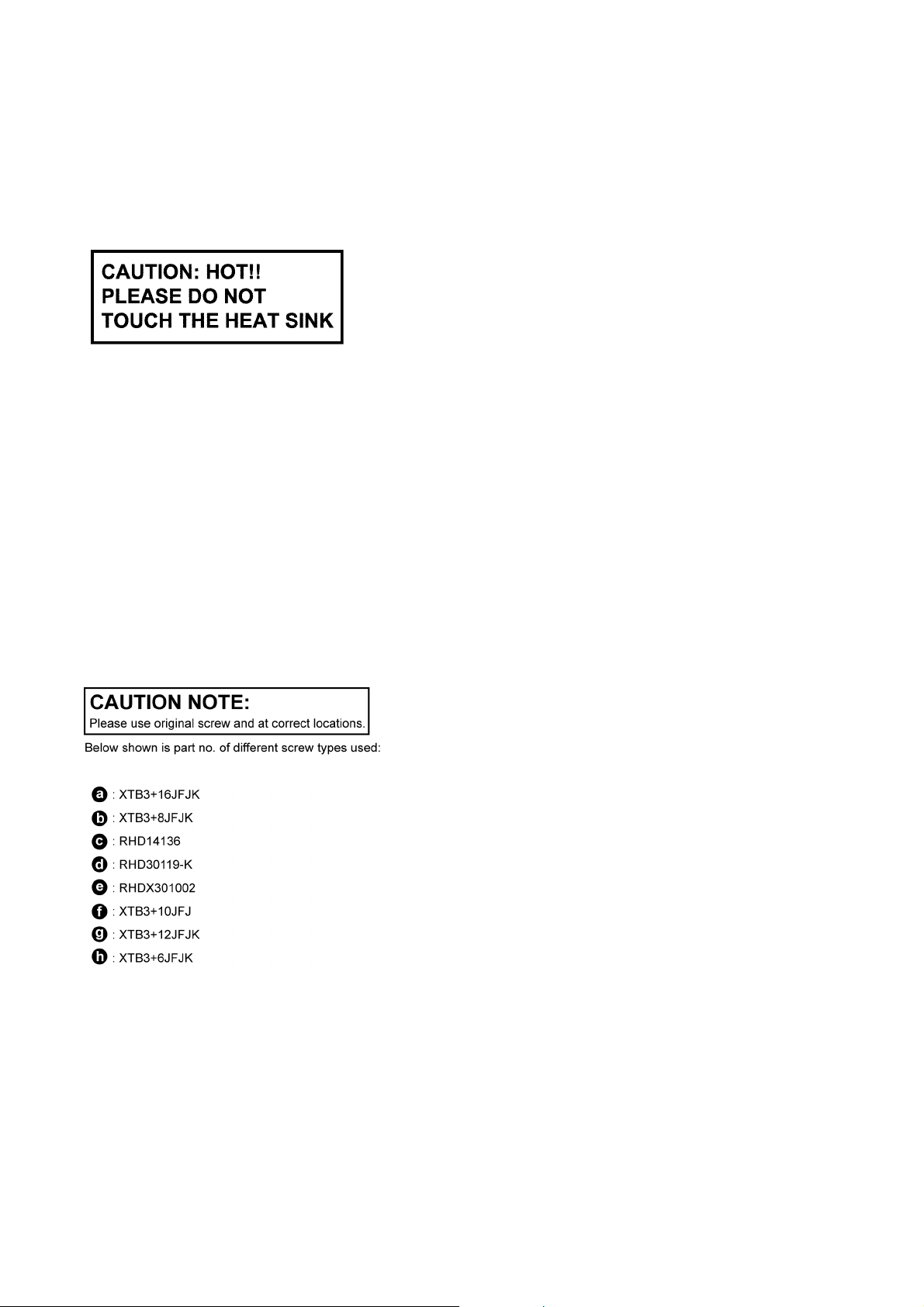

8 Disassembly and Assembly Instructions

Caution Note:

• This section describes the disassembly and/or assembly procedures for all major printed circuit boards & main components for

the unit. (You may refer to the section of “Main components and P.C.B Locations” as described in the service manual)

• Before carrying out the disassembly process, please ensure all the safety precautions & procedures are followed.

• During the disassembly and/or assembly process, please handle with care as there may be chassis components with

sharp edges.

• Avoid touching heatsinks due to its high temperature after prolong use. (See caution as described below)

• During disassembly and assembly, please ensure proper service tools, equipments or jigs is being used.

• During replacement of component parts, please refer to the section of “Replacement Parts List” as described in the

service manual.

• Select items from the following indexes when disassembly or replacement are required.

• Disassembly of Back Cabinet Assembly

• Disassembly of Wireless Adapter P.C.B.

• Disassembly of Front Speaker L (SP1)

• Disassembly of Front Speaker R (SP2)

• Disassembly of Main Chassis Assembly

• Disassembly of LED P.C.B. and Panel Tact Switch P.C.B.

• Disassembly of AC Inlet P.C.B.

• Disassembly of Main P.C.B.

• Disassembly of SMPS P.C.B.

• Replacement of Switch Regulator IC (IC5701)

• Replacement of Rectifier Diode (D5802)

• Disassembly of HDMI P.C.B.

19

Page 20

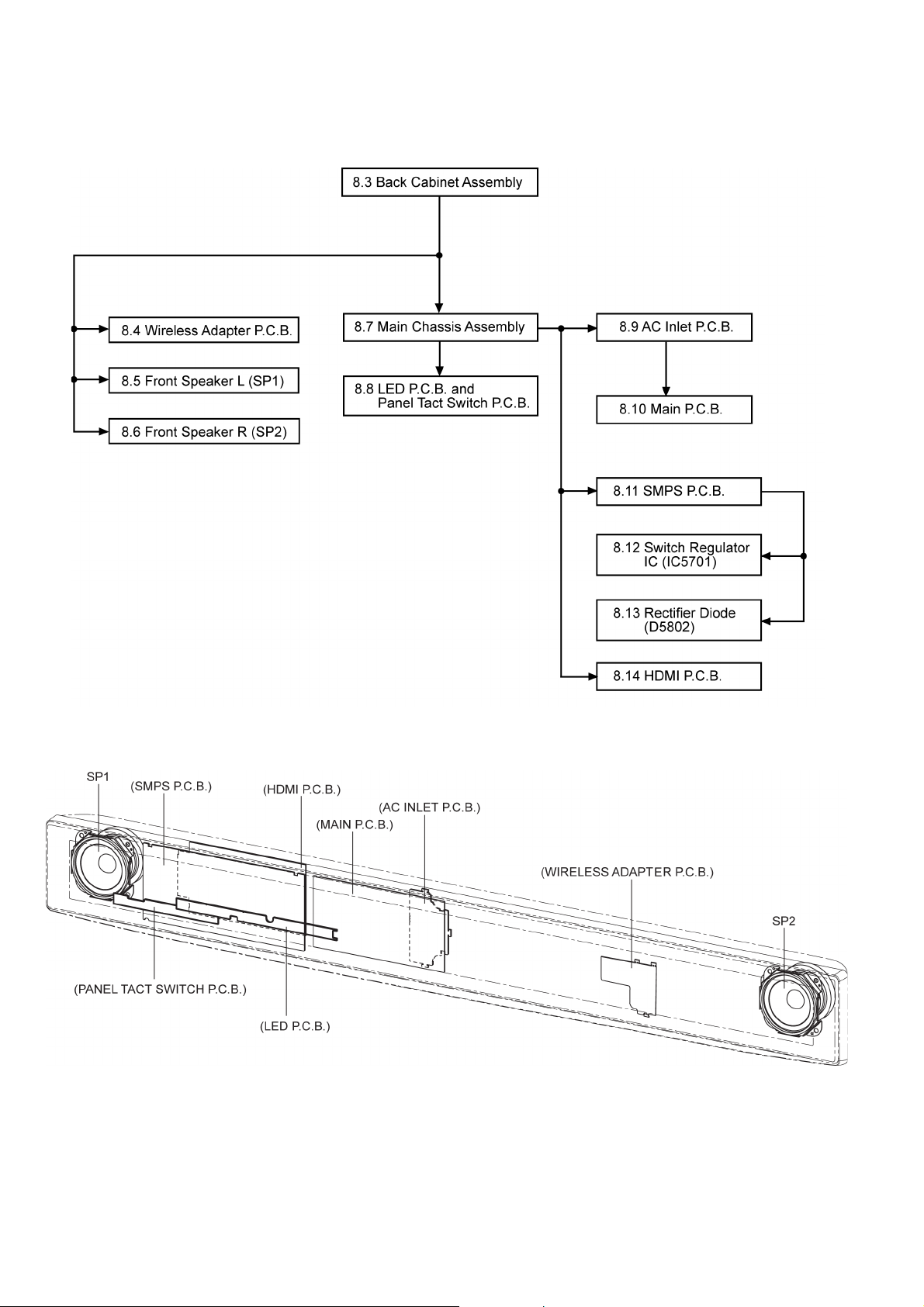

8.1. Disassembly flow chart

The following chart is the procedure for disassembling the casing and inside parts for internal inspection when carrying out the servicing.

To assemble the unit, reverse the steps shown in the chart below.

8.2. Main Parts Location Diagram

20

Page 21

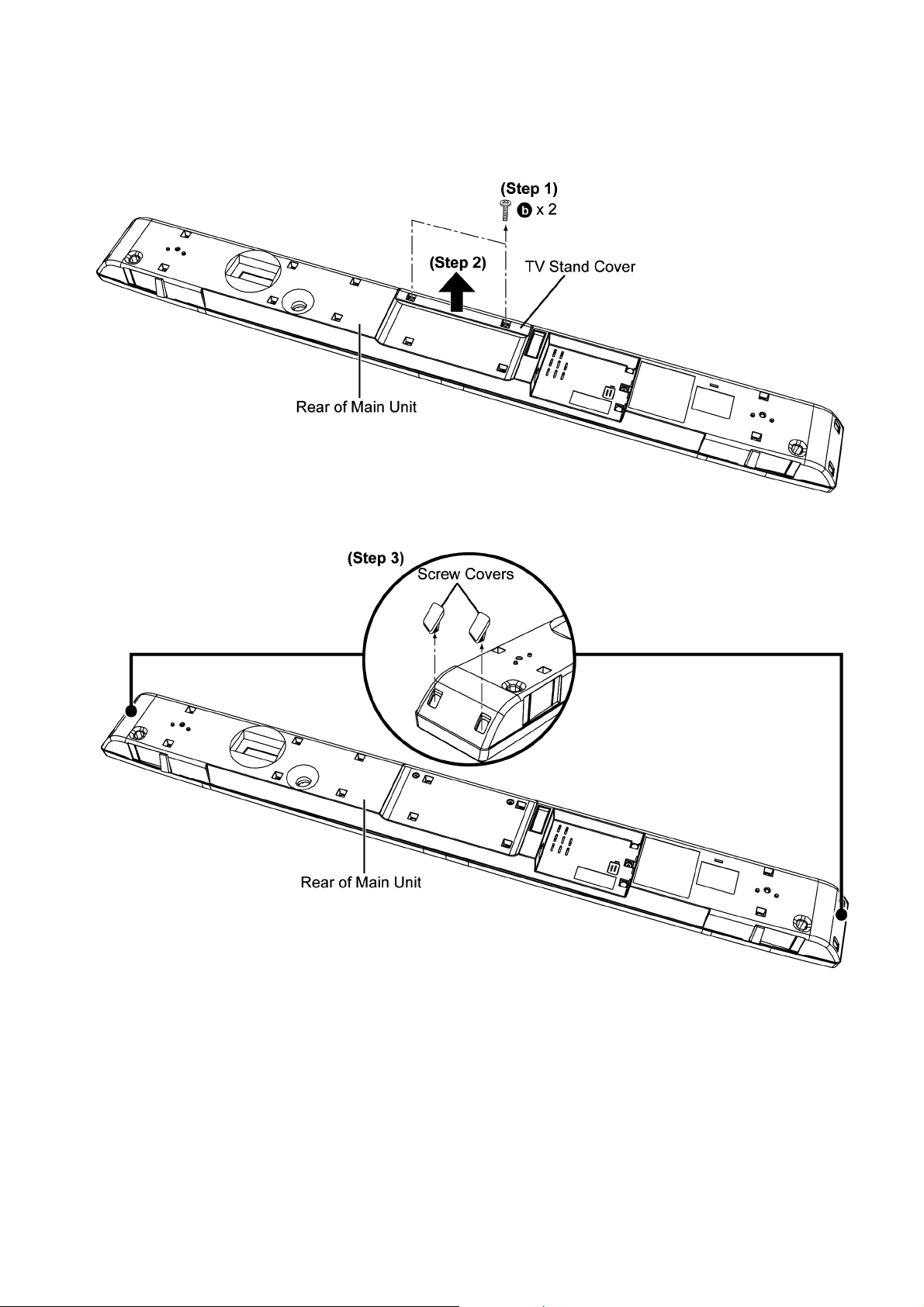

8.3. Disassembly of Back Cabinet Assembly

Step 1 : Remove 2 screws.

Step 2 : Remove the TV Stand Cover as arrow shown.

Step 3 : Remove 4 Screw Covers.

21

Page 22

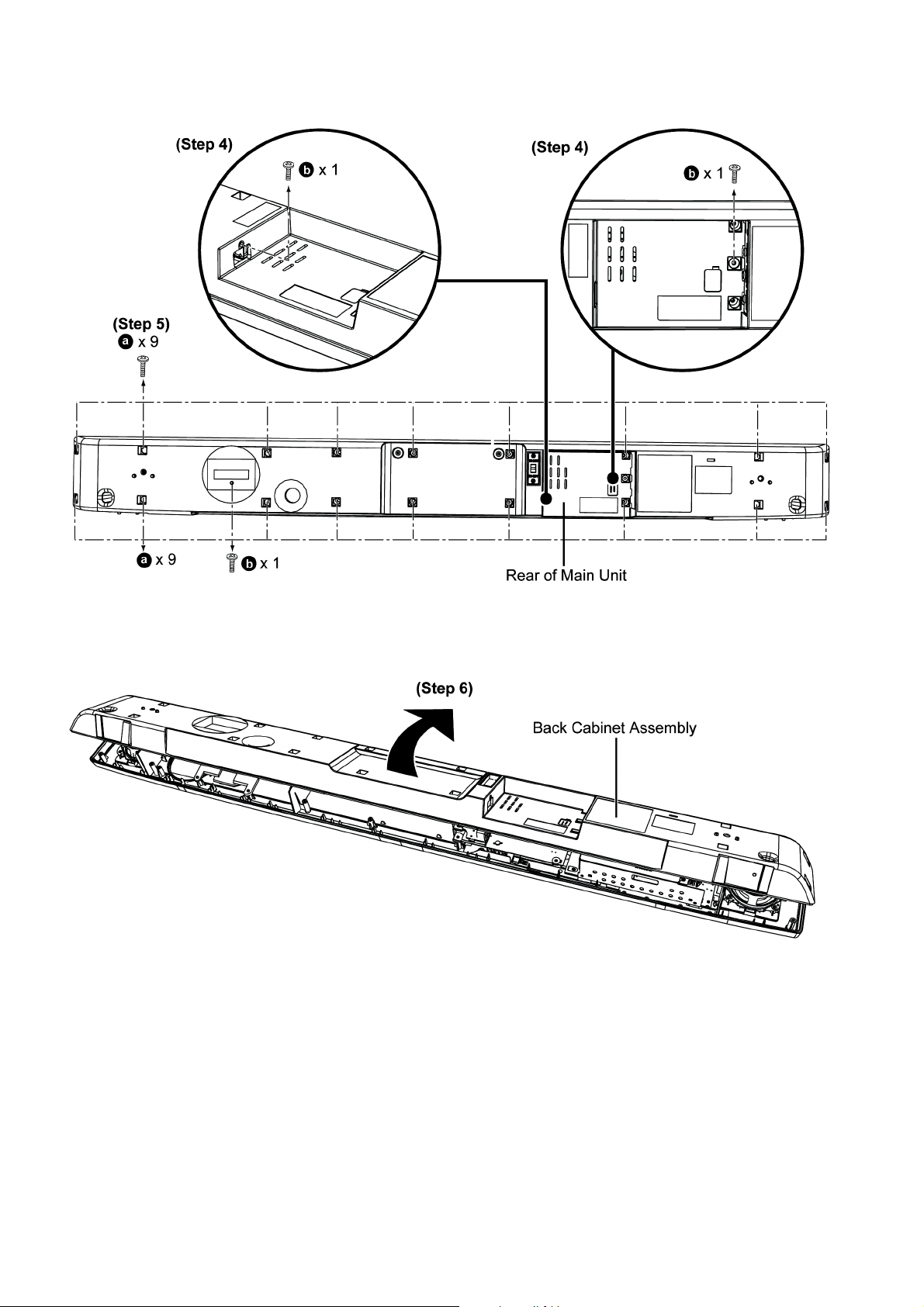

Step 4 : Remove 3 screws.

Step 5 : Remove 18 screws.

Step 6 : Lift up and flip over the Back Cabinet Assembly as arrow shown.

Caution : Do not exert too much force as it may damage the wiring within.

22

Page 23

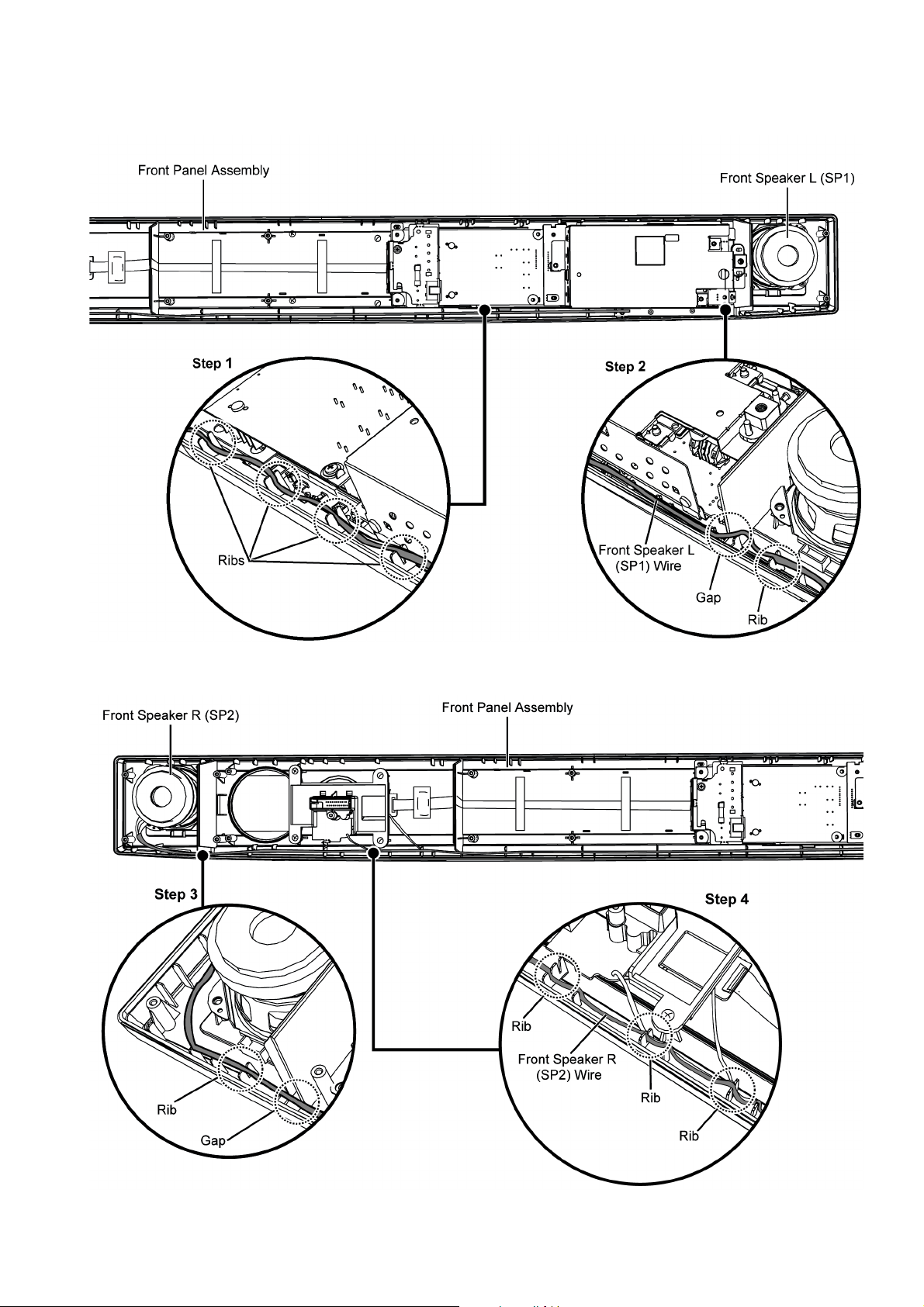

8.3.1. Wire Dressing for assembling

Step 1 : Ensure Front Speaker L (SP1) wire is properly dressed into the Front Panel Assembly ribs.

Step 2 : Ensure Front Speaker L (SP1) wire is properly dressed into the Front Panel Assembly gap and rib.

Step 3 : Ensure Front Speaker R (SP2) wire is properly dressed into the Front Panel Assembly rib and gap.

Step 4 : Ensure Front Speaker R (SP2) wire is properly dressed into the Front Panel Assembly ribs.

23

Page 24

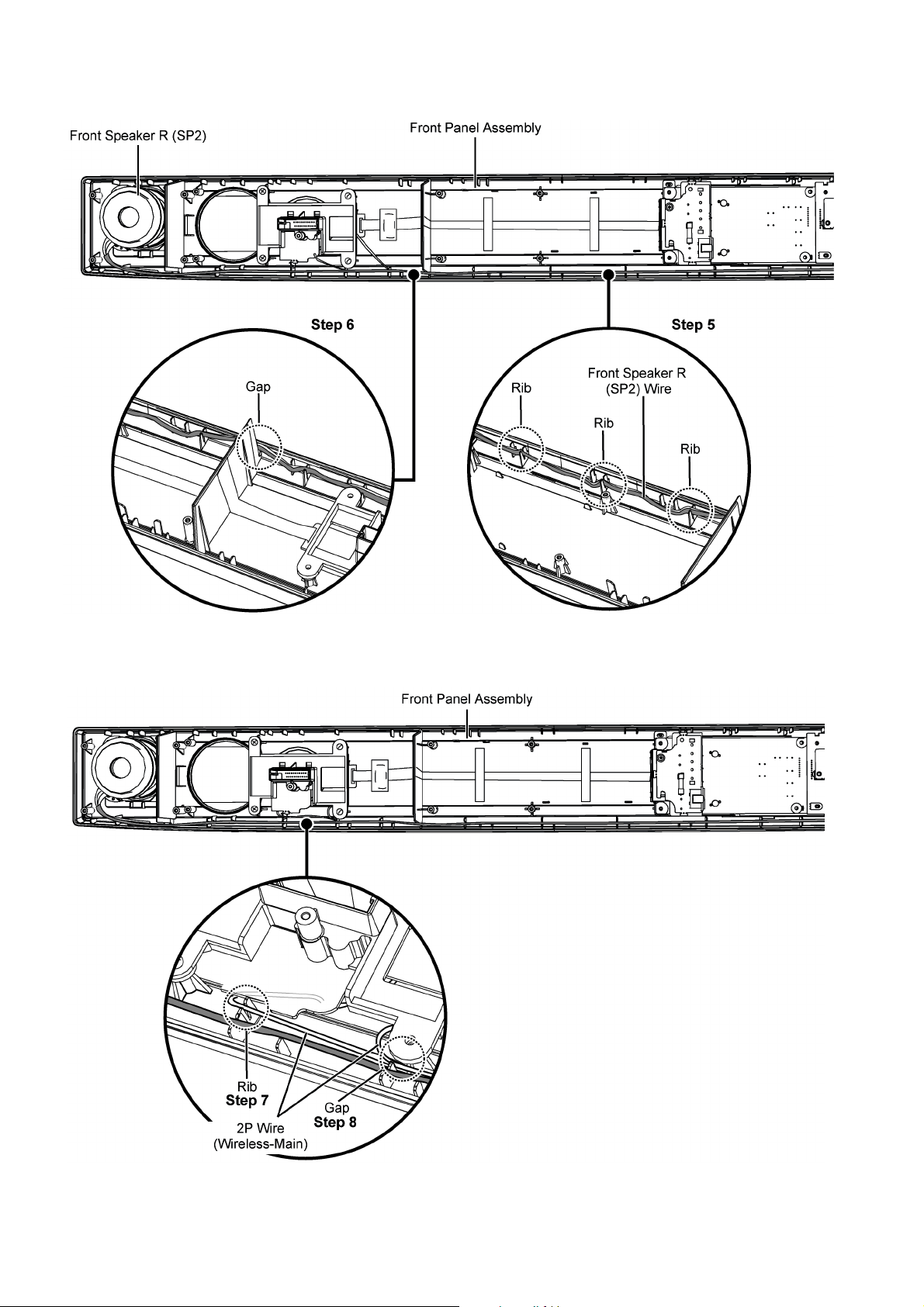

Step 5 : Ensure Front Speaker R (SP2) wire is properly dressed into the Front Panel Assembly ribs.

Step 6 : Ensure Front Speaker R (SP2) wire is properly dressed into the Front Panel Assembly gap.

Step 7 : Ensure 2P Wire (Wireless-Main) is properly dressed into the Front Panel Assembly rib.

Step 8 : Ensure 2P Wire (Wireless-Main) is properly dressed into the Front Panel Assembly gab.

24

Page 25

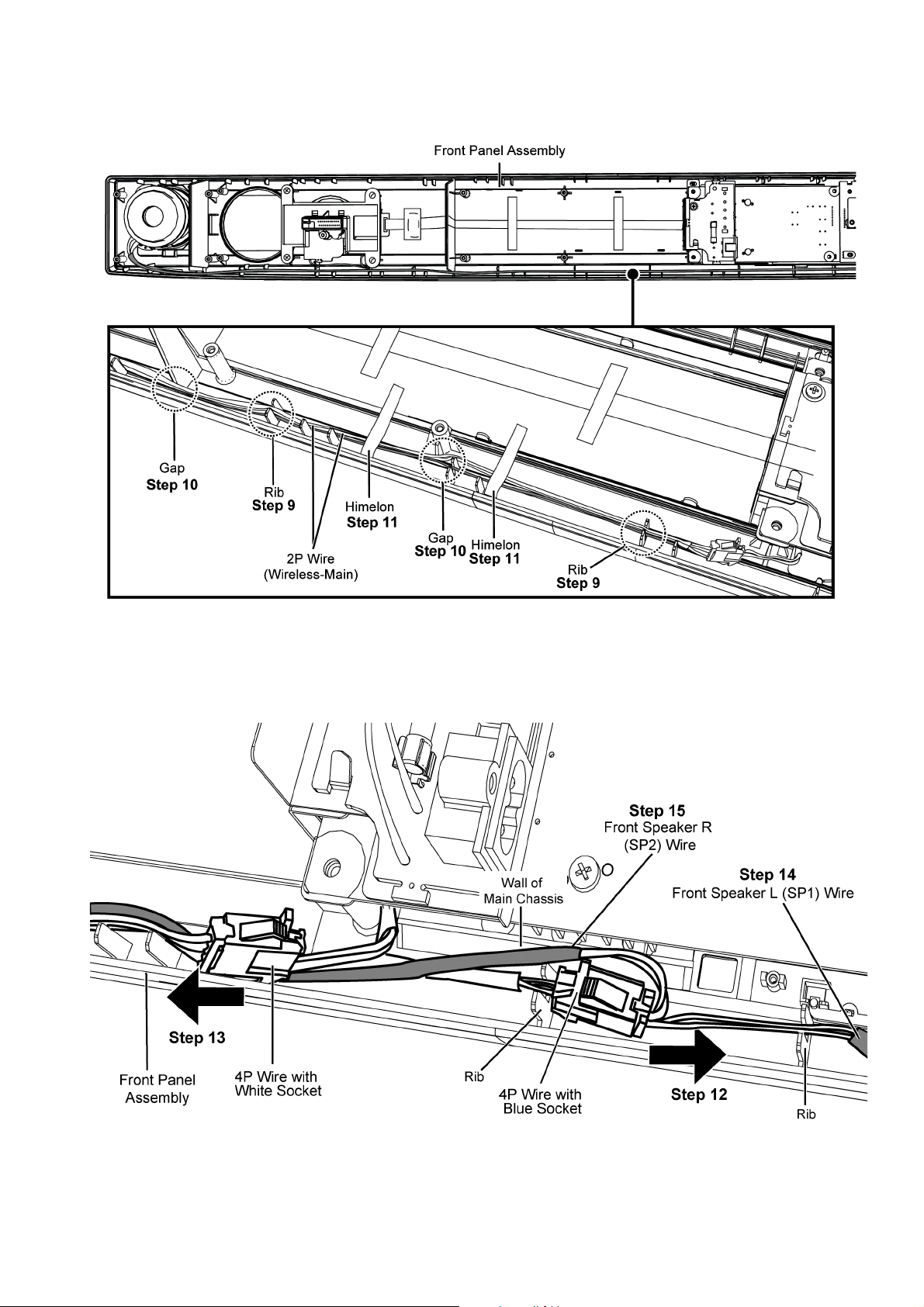

Step 9 : Ensure 2P Wire (Wireless-Main) is properly dressed into the Front Panel Assembly ribs.

Step 10 : Ensure 2P Wire (Wireless-Main) is properly dressed into the Front Panel Assembly gaps.

Step 11 : Paste 2 pieces of himelons over the wires.

Step 12 : Ensure 4P Wire Blue Socket must be dressed facing toward right direction as shown.

Step 13 : Ensure 4P Wire White Socket must be dressed facing toward left direction as shown.

Step 14 : Ensure Front Speaker L (SP1) wire is properly dressed into the Front Panel Assembly rib.

Step 15 : Ensure Front Speaker R (SP2) wire is properly dressed into the Front Panel Assembly between rib and wall of Main Chas-

sis.

25

Page 26

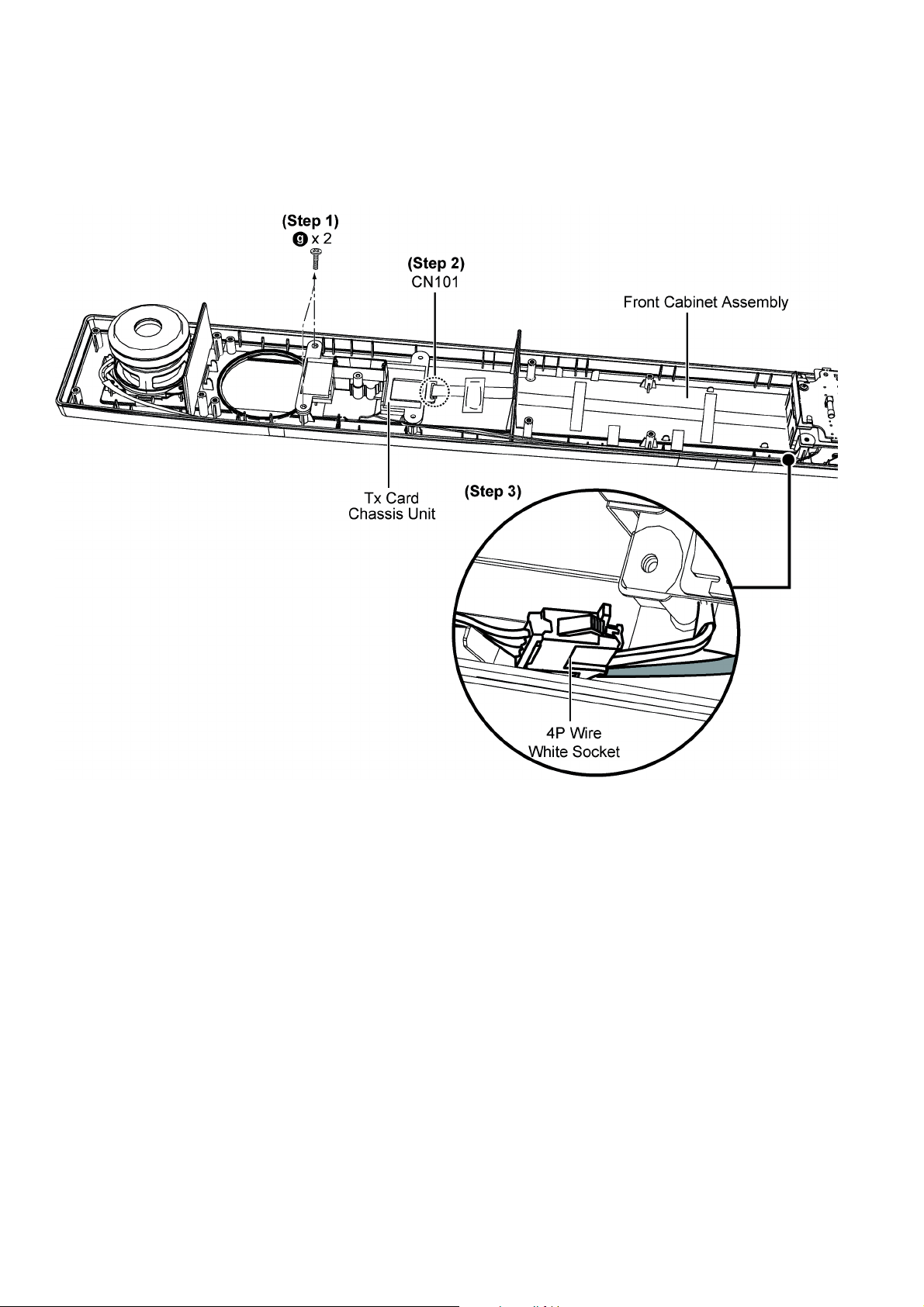

8.4. Disassembly of Wireless Adapter P.C.B.

• Refer to “Disassembly of Back Cabinet Assembly”.

Step 1 : Remove 2 screws.

Step 2 : Detach 14P FFC of connector (CN101) on Tx Card Chassis Unit.

Step 3 : Disconnect the 4P Wire White Socket.

26

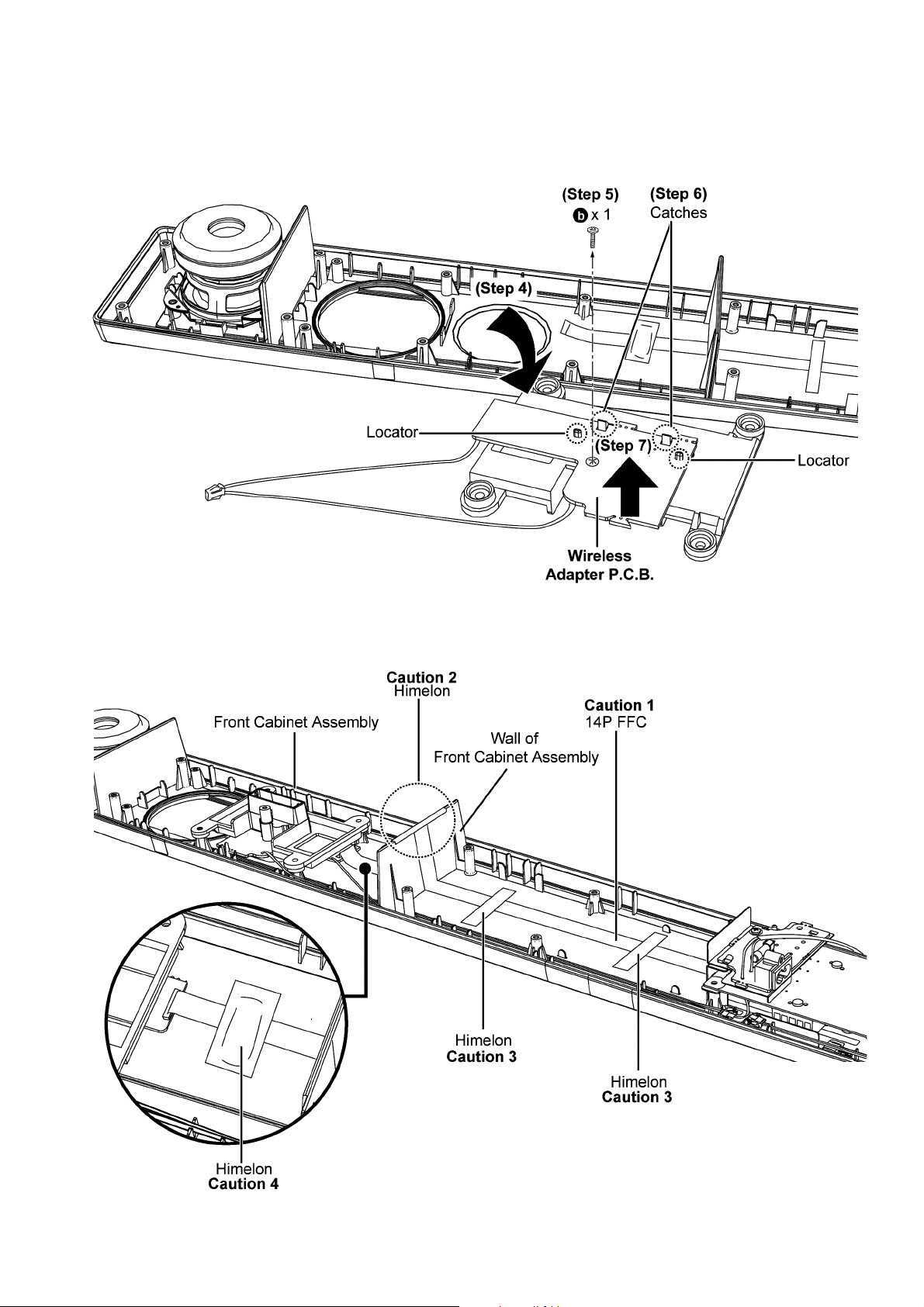

Page 27

Step 4 : Flip over the Tx Card Chassis Unit as arrow shown.

Step 5 : Remove 1 screw.

Step 6 : Release the catches.

Step 7 : Remove the Wireless Adapter P.C.B. as arrow shown.

Caution : During assembling, ensure the Wireless Adapter P.C.B. is properly seated onto the locators.

Caution 1 : During assembling, ensure the 14P FFC must be dressed flatly onto the Front Cabinet Assembly.

Caution 2 : During assembling, ensure to paste the himelon over the 14P FFC onto wall of the Front Cabinet Assembly.

Caution 3 : During assembling, ensure to paste the himelon over the 14P FFC onto the Front Cabinet Assembly.

Caution 4 : During assembling, ensure to paste the himelon over ferrite core onto the Front Cabinet Assembly.

27

Page 28

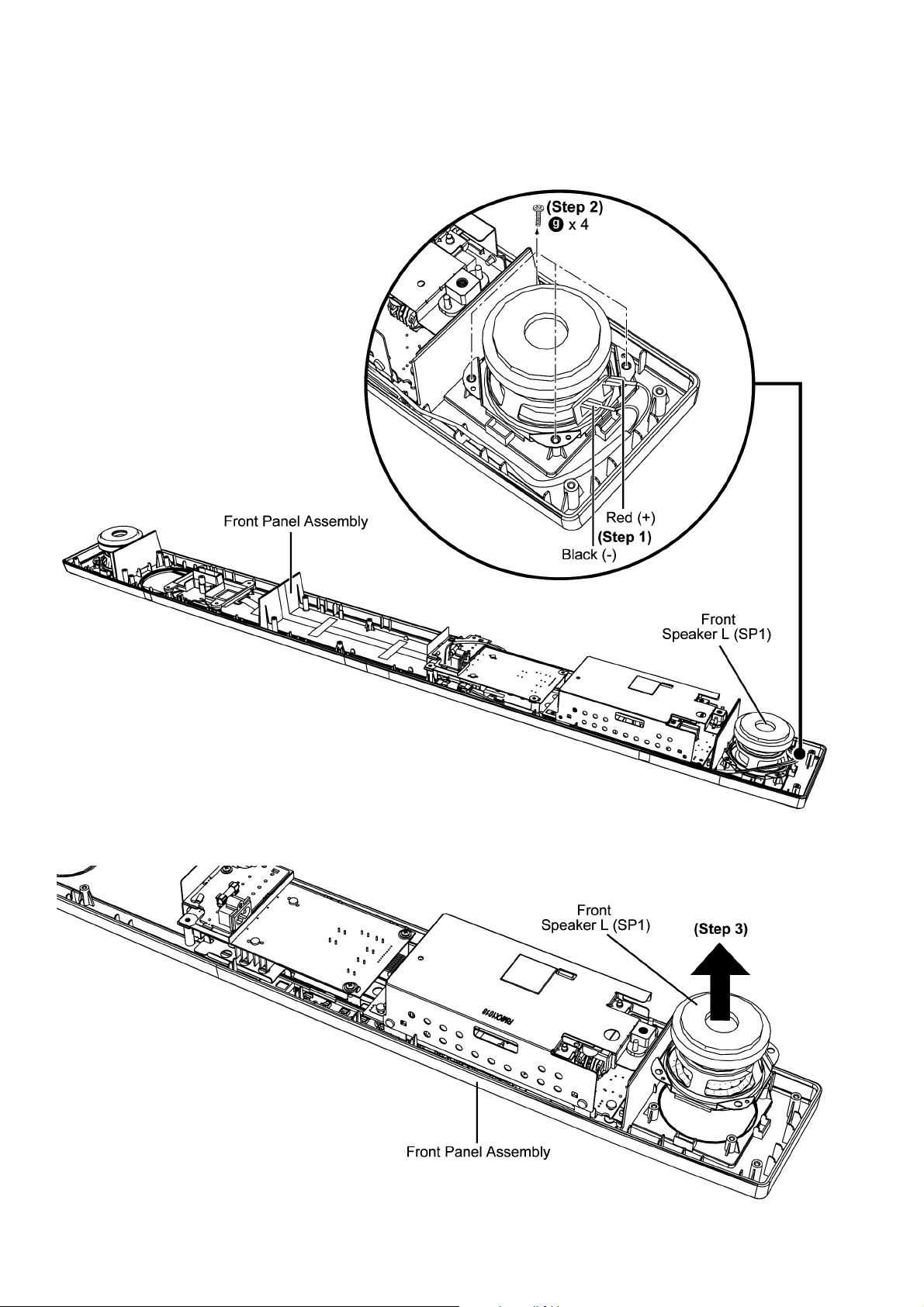

8.5. Disassembly of Front Speaker L (SP1)

• Refer to “Disassembly of Back Cabinet Assembly”.

Step 1 : Detach the Red (+) and Black (-) speaker wires.

Step 2 : Remove 4 screws.

Step 3 : Remove the Front Speaker L (SP1).

28

Page 29

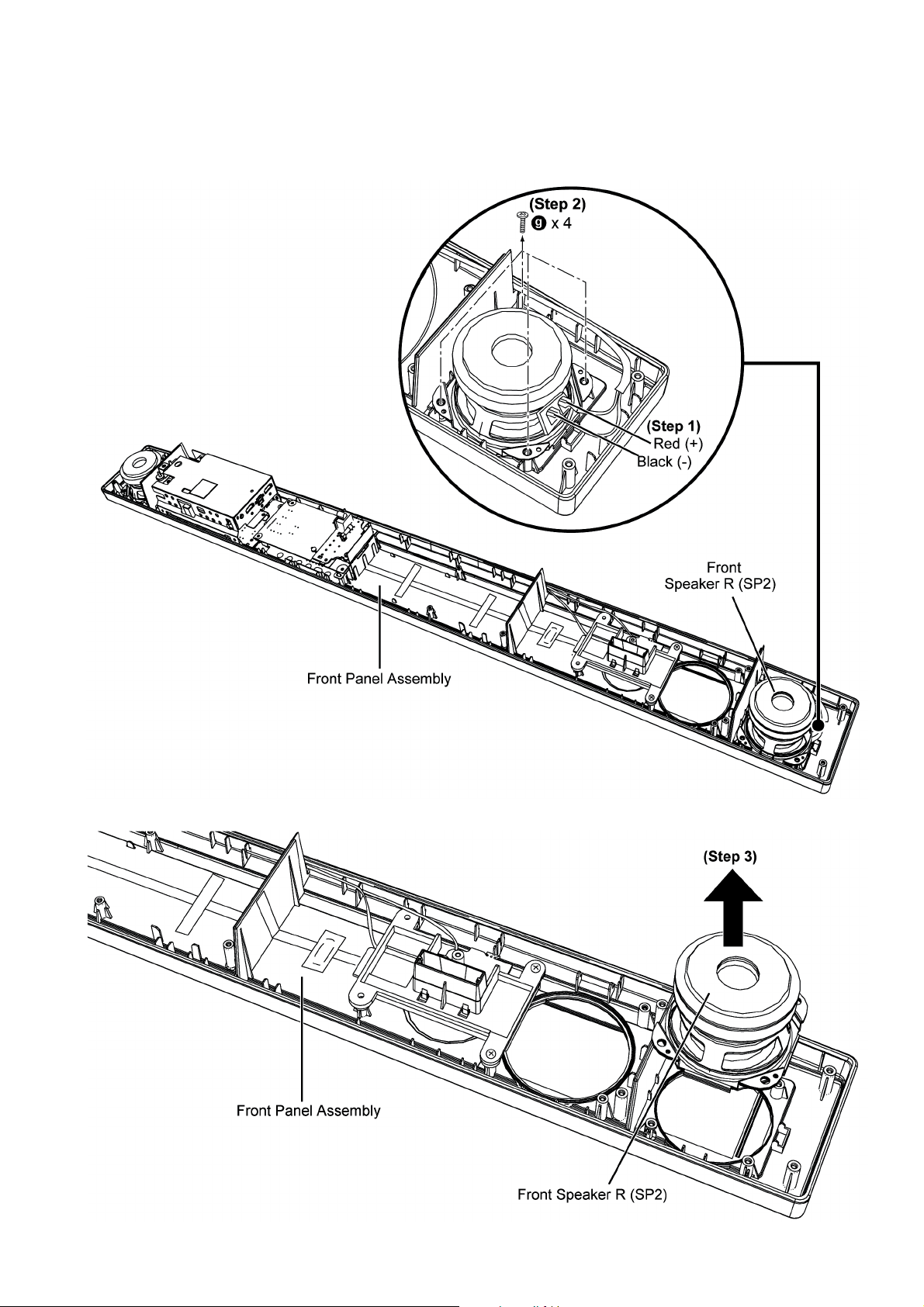

8.6. Disassembly of Front Speaker R (SP2)

• Refer to “Disassembly of Back Cabinet Assembly”.

Step 1 : Detach the Red (+) and Black (-) speaker wires.

Step 2 : Remove 4 screws.

Step 3 : Remove the Front Speaker R (SP2).

29

Page 30

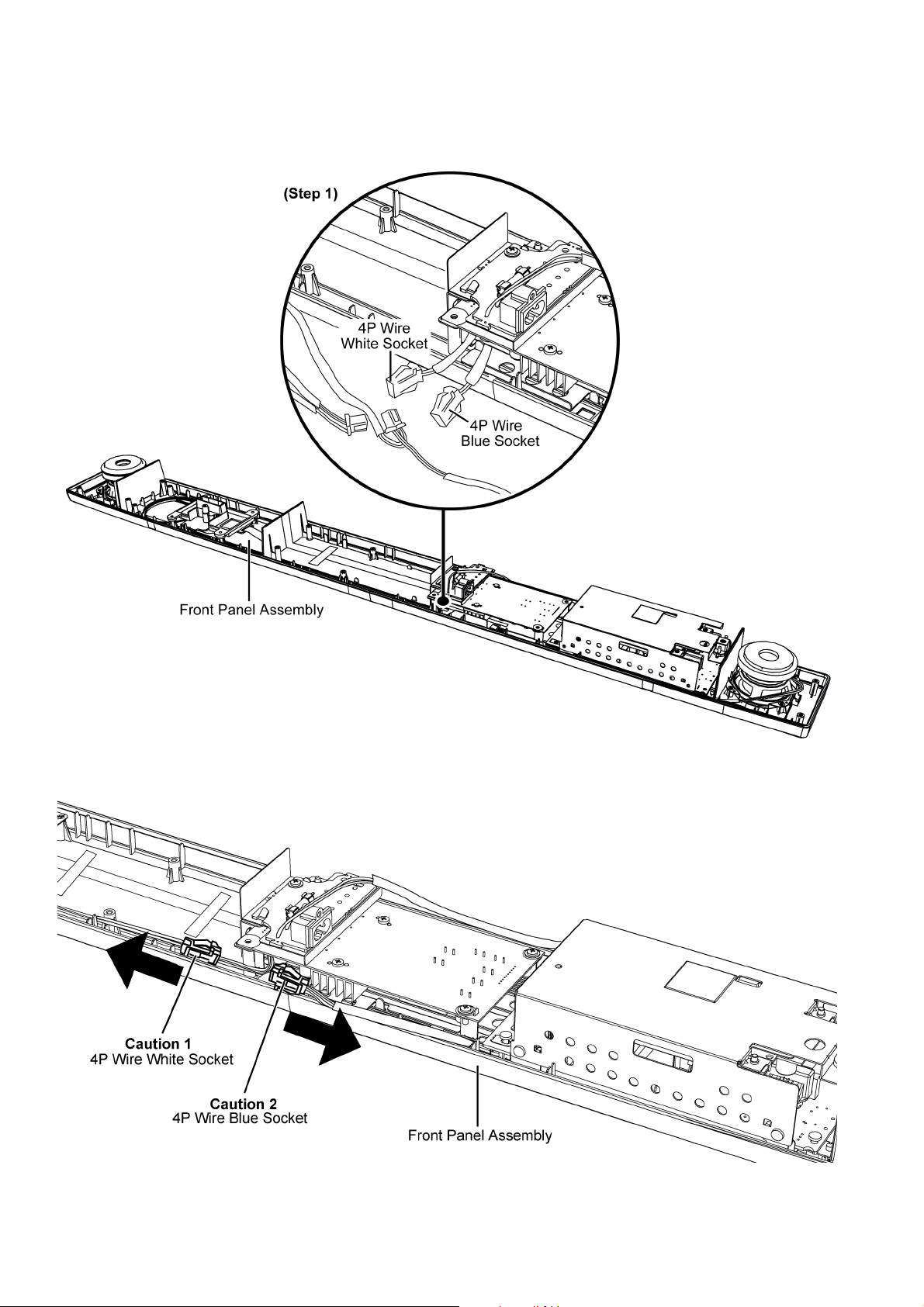

8.7. Disassembly of Main Chassis Assembly

• Refer to “Disassembly of Back Cabinet Assembly”.

Step 1 : Disconnect the 4P Wire Blue Socket and 4P Wire White Socket.

Caution 1 : During assembling, ensure 4P Wire White Socket must be dressed facing toward left direction as shown.

Caution 2 : During assembling, ensure 4P Wire Blue Socket must be dressed facing toward right direction as shown.

30

Page 31

Step 2 : Place the Main Chassis Assembly beside the Front Panel Assembly as arrow shown.

Step 3 : Detach 12P FFC of the connector (CN300) on Main P.C.B.

Step 4 : Detach 14P FFC of the connector (CN100) on Main P.C.B.

Step 5 : Remove Main Chassis Assembly.

31

Page 32

Caution 1 : Before assembling the Main Chassis Assembly, ensure the FFC of the connector (CN350) is properly bend at

supporting tape area.

Caution 2 : During assembling, ensure the Main Chassis Assembly is seated properly onto the locators.

32

Page 33

8.8. Disassembly of LED P.C.B. and Panel Tact Switch P.C.B.

• Refer to “Disassembly of Back Cabinet Assembly”.

• Refer to “Disassembly of Main Chassis Assembly”.

Step 1 : Remove 4 screws and detach Panel Tact Switch P.C.B..

Step 2 : Slightly detach the Panel Tact Switch P.C.B. from Front Panel Assembly.

Step 3 : Remove 3 screws.

Step 4 : Remove the PC Sheet.

Step 5 : Remove the LED P.C.B. together with Panel Tact Switch P.C.B. as arrow shown.

33

Page 34

Caution 1 : During assembling, ensure the LED P.C.B. is seated properly onto the locator.

Caution 2 : During assembling, ensure the 3P Cable Wire is properly dressed behind Front Panel Assembly rib.

34

Page 35

8.9. Disassembly of AC Inlet P.C.B.

• Refer to “Disassembly of Back Cabinet Assembly”.

• Refer to “Disassembly of Main Chassis Assembly”.

Step 1 : Cut off the Cable Tie.

Caution : During assembling, ensure the head of cable tie must be facing inward and tail of cable tie must be properly cut

with remaining 1mm away from the head.

Step 2 : Remove 1 screw.

Step 3 : Slightly lift up the AC Inlet P.C.B. as arrow shown.

Caution : During assembling, ensure the AC Inlet P.C.B. is properly seated onto the locators.

35

Page 36

Step 4 : Desolder the wires, black (TL20) and red (TL10).

Step 5 : Remove the AC Inlet P.C.B. as arrow shown.

Caution : During assembling, ensure the cable wire is properly seated onto the hook.

36

Page 37

8.10. Disassembly of Main P.C.B.

• Refer to “Disassembly of Back Cabinet Assembly”.

• Refer to “Disassembly of Main Chassis Assembly”.

• Refer to (Step 1) to (Step 3) of “Disassembly of AC Inlet P.C.B.”.

Step 1 : Remove the PC Sheet Assembly as arrow shown.

Step 2 : Remove 2 screws.

37

Page 38

Step 3 : Detach the 50P FFC of the connector (CN200) on Main P.C.B..

Step 4 : Detach the 12P FFC of the connector (CN300) on Main P.C.B..

Step 5 : Detach the 14P FFC of the connector (CN100) on Main P.C.B..

Step 6 : Slightly push forward the Main P.C.B. to avoid touching the Main Chassis Unit and lift it up as arrow shown.

Step 7 : Flip the Main P.C.B. to top of the Main Chassis Assembly.

38

Page 39

Step 8 : Detach the 10P Cable Wire of the connector (CN700) on Main P.C.B..

Step 9 : Remove the Main P.C.B..

Caution : During assembling, ensure the 10P wire must be properly dressing as diagram shown.

39

Page 40

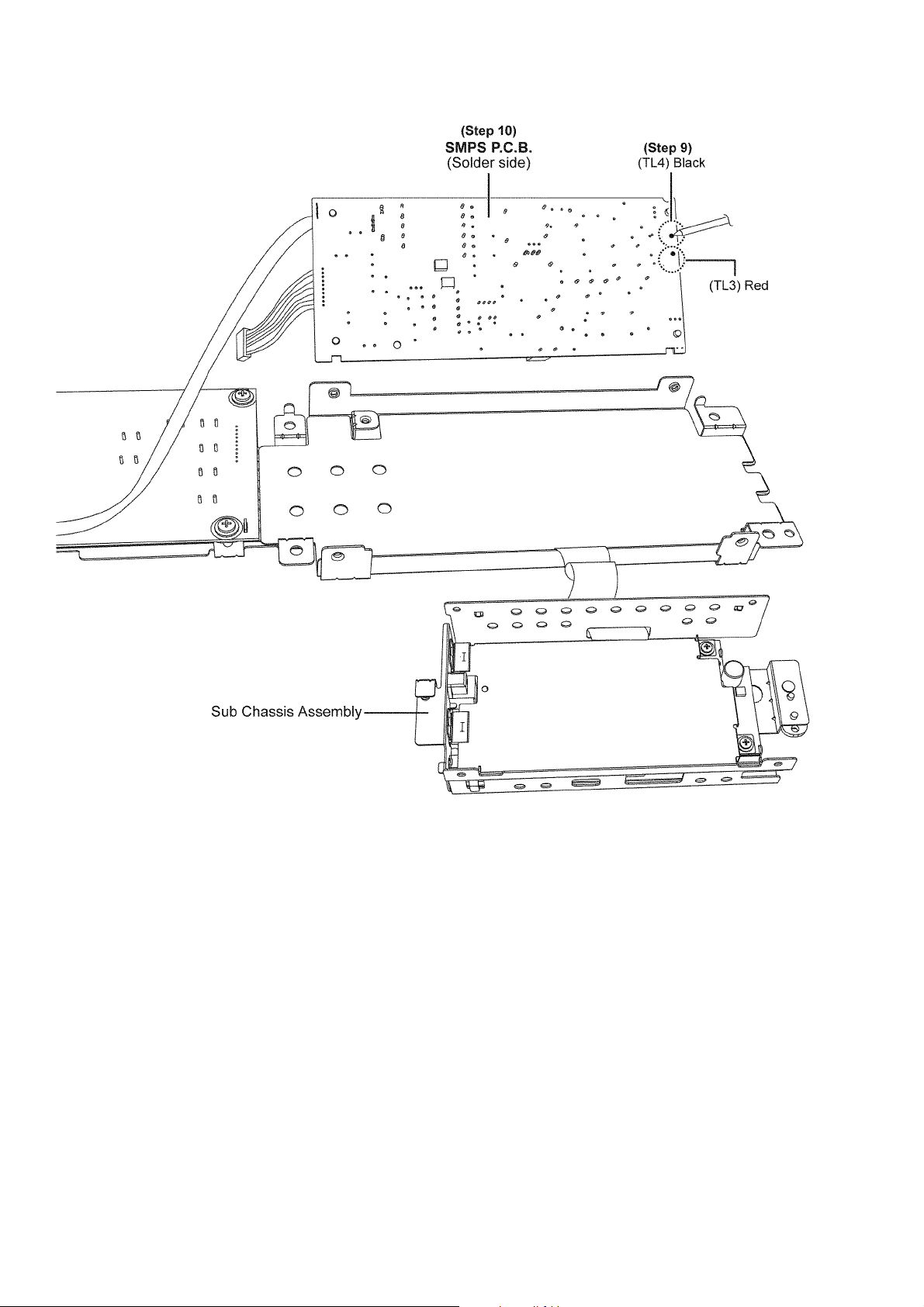

8.11. Disassembly of SMPS P.C.B.

• Refer to “Disassembly of Back Cabinet Assembly”.

• Refer to “Disassembly of Main Chassis Assembly”.

Step 1 : Release the Wire from the hook.

Caution : During assembling, ensure the cable wire is properly slot into the hook.

Step 2 : Remove 2 screws.

Step 3 : Remove 2 screws.

Step 4 : Release the Himelon from Sub Chassis Assembly.

Step 5 : Slightly lift up the Sub Chassis Assembly and place at the side as arrow shown.

Caution : Do not exert too much force as it may damage the FFC.

40

Page 41

Step 6 : Remove 1 screw.

Step 7 : Detach the 10P Cable Wire of the connector (CN700) on Main P.C.B..

Step 8 : Lift up the SMPS P.C.B..

Caution : During assembling, ensure the SMPS P.C.B. is properly seated onto the locators.

41

Page 42

Step 9 : Desolder the wires, black (TL4) and red (TL3).

Step 10 : Remove the SMPS P.C.B..

42

Page 43

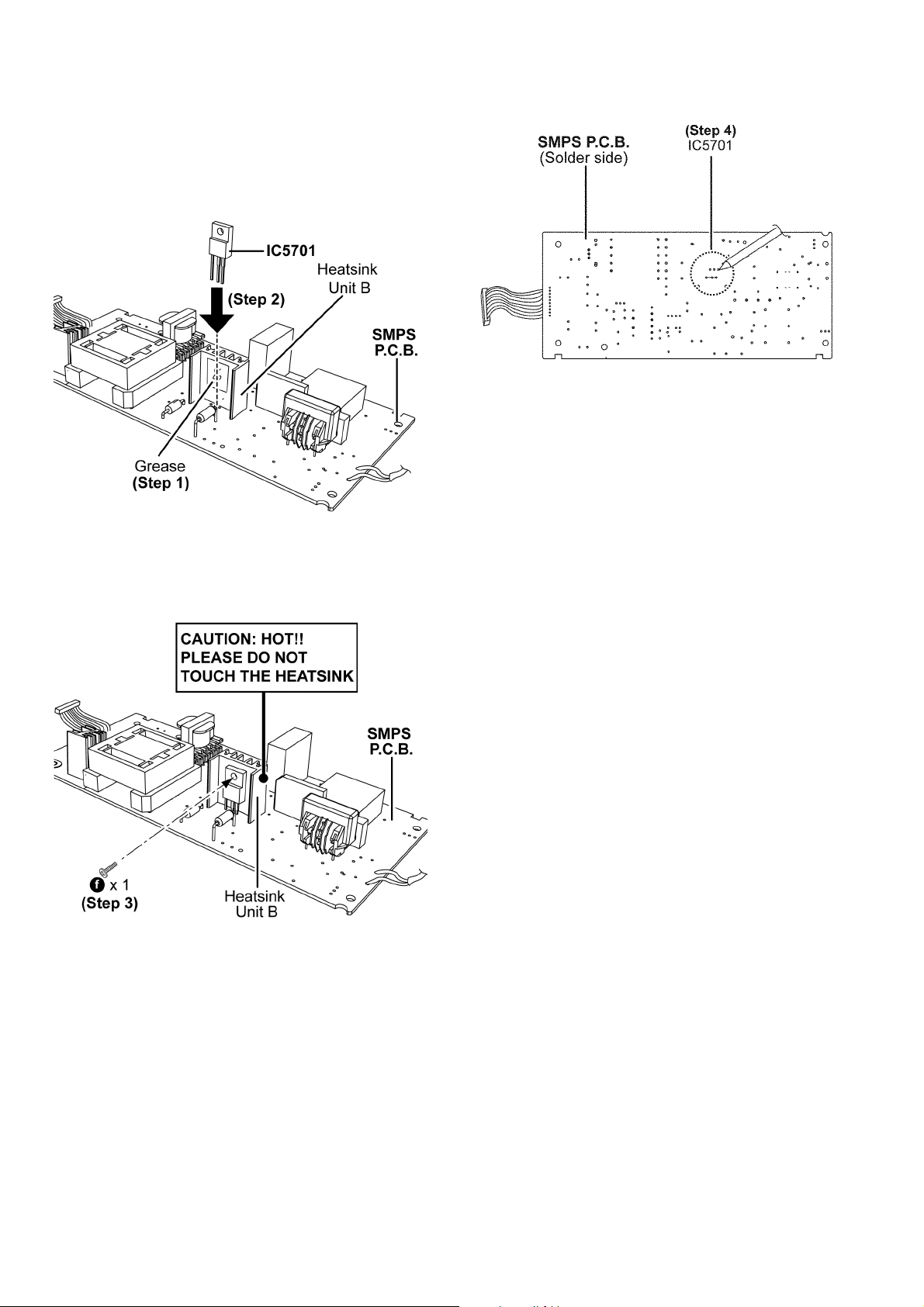

8.12. Replacement of Switch Regulator IC (IC5701)

• Refer to “Disassembly of SMPS P.C.B.”.

8.12.1. Disassembly of Switch Regulator IC (IC5701)

Step 1 : Desolder pins of the Switch Regulator IC (IC5701) on

the solder side of SMPS P.C.B..

Step 2 : Remove 1 screw.

Caution : Avoid touching the Heatsink Unit B due to its

high temperature after prolonged use. Touching it may

lead to injuries.

Step 3 : Remove the Switch Regulator IC (IC5701).

43

Page 44

8.12.2. Assembly of Switch Regulator IC (IC5701)

Step 1 : Apply Grease on the Heatsink Unit B.

Step 2 : Mount the Switch Regulator IC (IC5701) onto the

SMPS P.C.B..

Caution : Ensure the pins of Switch Regulator IC (IC5701)

are properly seated on the SMPS P.C.B..

Step 4 : Solder pins of Switch Regulator IC (IC5701) on the sol-

der side of SMPS P.C.B..

Step 3 : Screw the Switch Regulator IC (IC5701) to the Heatsink Unit B.

Caution : Ensure the Switch Regulator IC (IC5701) is tightly

screwed to the Heatsink Unit B.

44

Page 45

8.13. Replacement of Rectifier Diode (D5802)

• Refer to “Disassembly of SMPS P.C.B.”.

8.13.1. Disassembly of Rectifier Diode (D5802)

Step 1 : Desolder pins of the Rectifier Diode (D5802) on the

solder side of SMPS P.C.B..

Step 2 : Remove 1 screw.

Caution : Avoid touching the Heatsink Unit A due to its

high temperature after prolonged use. Touching it may

lead to injuries.

Step 3 : Remove the Rectifier Diode (D5802) from the Heatsink

Unit A.

45

Page 46

8.13.2. Assembly of Rectifier Diode (D5802)

Step 1 : Apply Grease on the Heatsink Unit A.

Step 2 : Mount the Rectifier Diode (D5802) onto the SMPS

P. C .B . .

Caution : Ensure the pins of Rectifier Diode (D5802) are

properly seated on the SMPS P.C.B..

Step 4 : Solder pins of the Rectifier Diode (D5802) on the sol-

der side of SMPS P.C.B..

Step 3 : Screw the Rectifier Diode (D5802) to the Heatsink Unit

A .

Caution : Ensure the Rectifier Diode (D5802) is tightly

screwed to the Heatsink Unit A.

46

Page 47

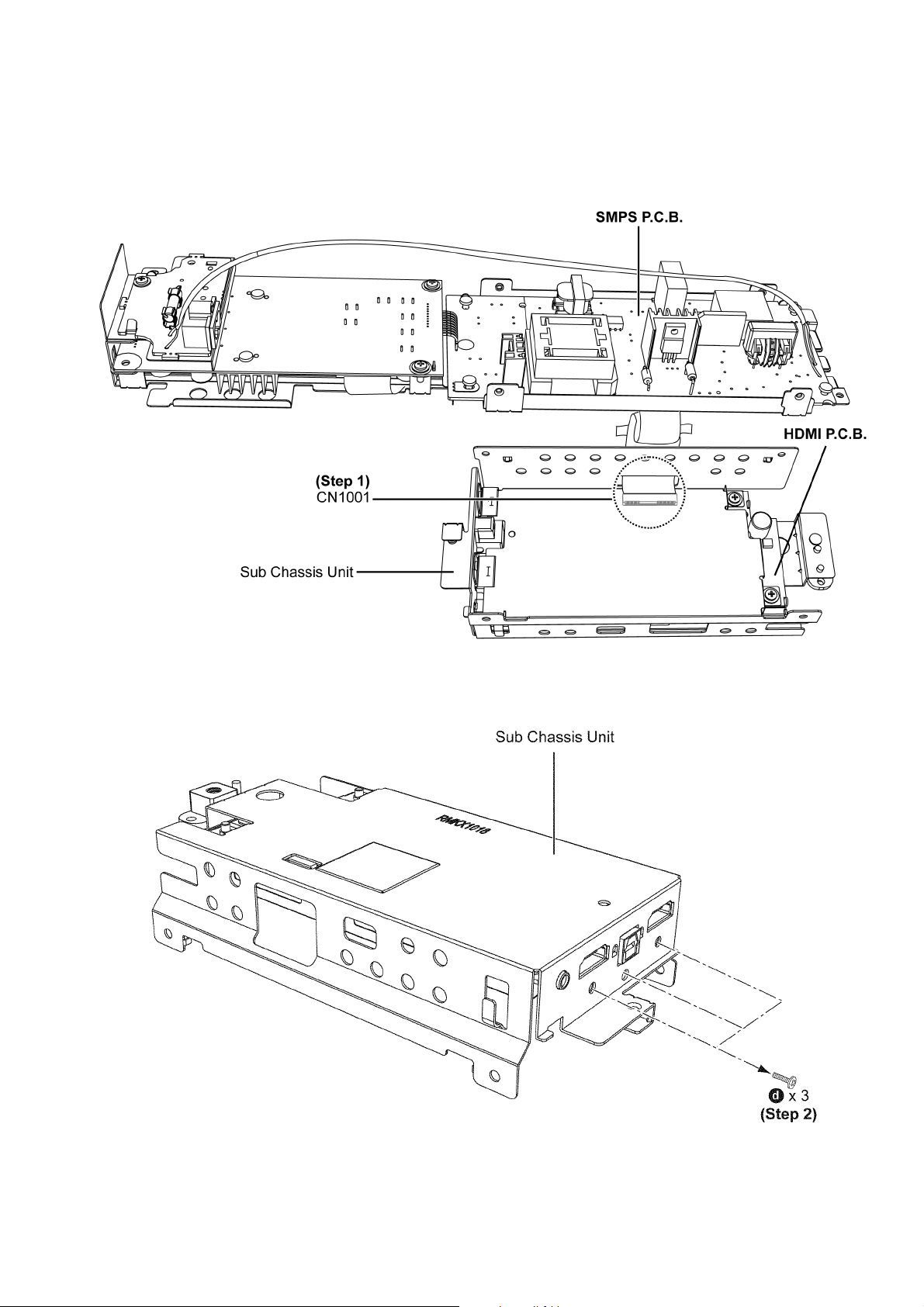

8.14. Disassembly of HDMI P.C.B.

• Refer to “Disassembly of Back Cabinet Assembly”.

• Refer to “Disassembly of Main Chassis Assembly”.

• Refer to (Step 1) - (Step 5) of “Disassembly of SMPS P.C.B.”.

Step 1 : Detach the 50P FFC of the connector (CN1001) on HDMI P.C.B..

Step 2 : Remove 3 screws.

47

Page 48

Step 3 : Remove 2 screws.

Step 4 : Lift up the HDMI P.C.B. Unit as arrow shown.

Caution : During assembling, ensure the HDMI P.C.B. Unit is properly seated onto the locators.

48

Page 49

Step 5 : Desolder the 2 legs of Shield Plate Unit.

Step 6 : Desolder the 2 legs of Shield Plate Unit.

Step 7 : Remove the HDMI P.C.B. Chassis as arrow shown.

49

Page 50

9 Service Position

Note: For description of the disassembly procedures, see the Section 8.

9.1. Checking and Repairing of Main P.C.B. (Side A)

Step 1 : Remove Back Cabinet Assembly.

Step 2 : Remove AC Inlet P.C.B..

Step 3 : Remove the PC Sheet Assembly.

Step 4 : Main P.C.B. (Side A) can be checked and repaired as diagram shown.

50

Page 51

9.2. Checking and Repairing of Main P.C.B. (Side B)

Step 1 : Remove Back Cabinet Assembly.

Step 2 : Remove Main Chassis Assembly.

Step 3 : Remove AC Inlet P.C.B..

Step 4 : Remove the PC Sheet Assembly.

Step 5 : Remove Main P.C.B..

Step 6 : Connect 10P Cable Wire of connector (CN700) on Main P.C.B..

Step 7 : Connect 50P FFC of connector (CN200) on Main P.C.B..

Step 8 : Connect 14P FFC of connector (CN100) on Main P.C.B..

Step 9 : Connect 12P FFC of connector (CN300) on Main P.C.B..

Step 10 : Connect 4P Wire Blue Socket and 4P Wire Blue Socket.

Step 11 : Connect 4P Wire White Socket and 4P Wire White Socket.

Step 12 : Main P.C.B. (Side B) can be checked and repaired as diagram shown.

51

Page 52

9.3. Checking and Repairing of Wireless Adapter P.C.B.

Step 1 : Remove Back Cabinet Assembly.

Step 2 : Remove 2 screws.

Step 3 : Flip over the Tx Card Chassis Unit as arrow shown.

Step 4 : Wireless Adapter P.C.B. can be checked and repaired as diagram shown.

52

Page 53

9.4. Checking and Repairing of SMPS P.C.B.

Step 1 : Remove Back Cabinet Assembly.

Step 2 : Remove Main Chassis Assembly.

Step 3 : Remove SMPS P.C.B..

Step 4 : Connect 4P Wire Blue Socket.

Step 5 : Connect 4P Wire White Socket.

53

Page 54

Step 6 : Flip the SMPS P.C.B. as arrow shown.

Step 7 : Connect 10P Cable Wire to connector (CN700) with 10P Extension Cable Wire (SFT1).

Step 8 : SMPS P.C.B. can be checked and repaired as diagram shown.

54

Page 55

9.5. Checking and Repairing of HDMI P.C.B. (Side A)

Step 1 : Remove Back Cabinet Assembly.

Step 2 : Remove Main Chassis Assembly.

Step 3 : Remove the HDMI P.C.B..

Step 4 : Attach the 50P FFC of the connector (CN1001) on HDMI P.C.B..

Step 5 : Connect 10P Cable Wire to connector (CN700) with 10P Extension Cable Wire (SFT1).

Step 6 : Connect 4P Wire Blue Socket.

Step 7 : Connect 4P Wire White Socket.

Step 8 : HDMI P.C.B. (Side A) can be checked and repaired as diagram shown.

55

Page 56

9.6. Checking and Repairing of HDMI P.C.B. (Side B)

• Refer to (Step 1) to (Step 7) of “Checking and Repairing of HDMI P.C.B. (Side A)”.

Step 1 : Flip the HDMI P.C.B. as arrow shown.

Step 2 : HDMI P.C.B. (Side B) can be checked and repaired as diagram shown.

56

Page 57

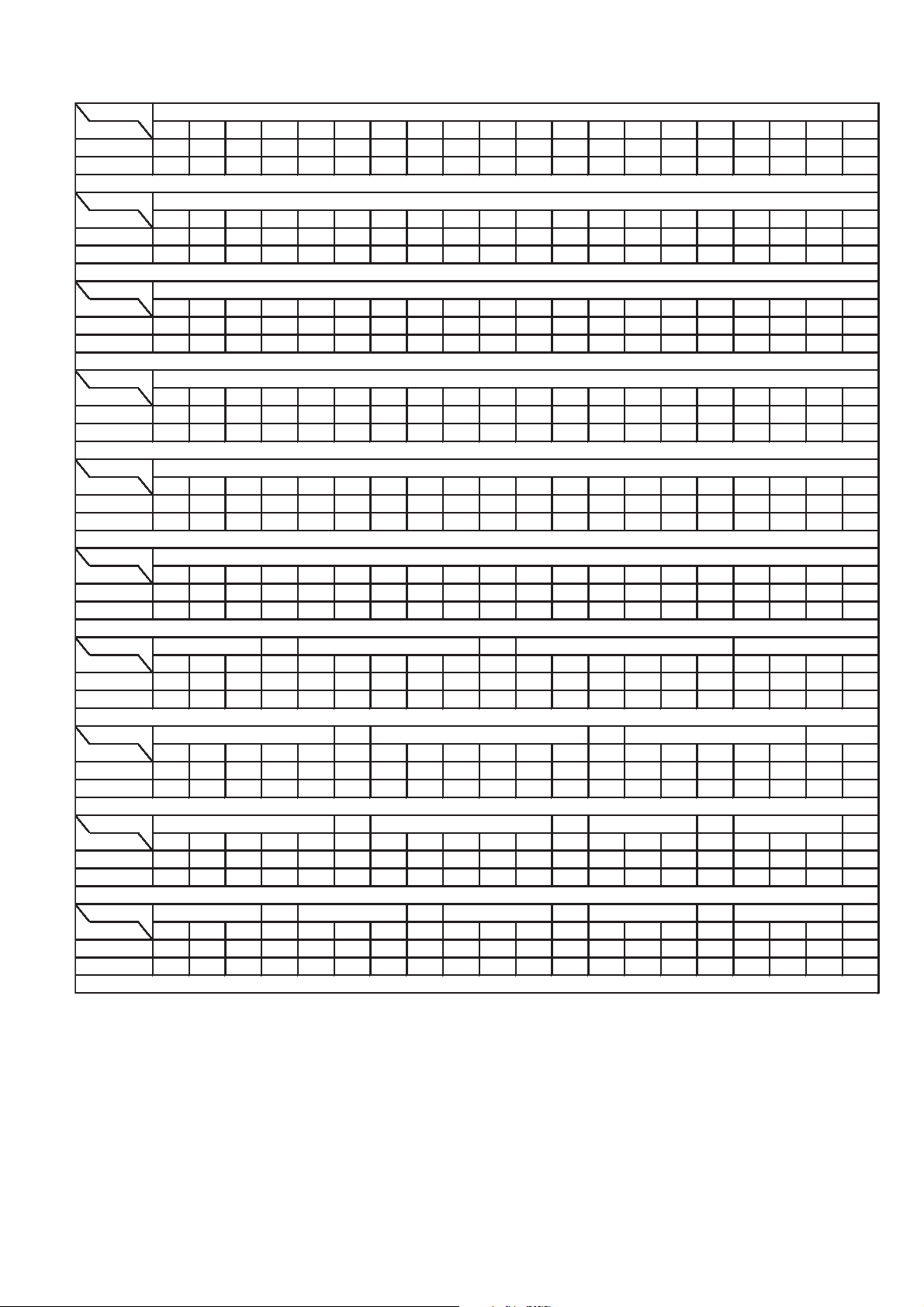

10 Voltage Measurement & Waveform Chart

REF NO.

MODE 1234567891011121314151617181920

CD PLAY 0 0 0 3.4 0 3.2 0 3.4 0 0 0 1.8 0 0 0 1.7 1.7 0.9 0 1.7

STANDBY 0 0 0 3.4 0 3.2 0 3.4 0 0 0 1.8 0 0 0 1.7 1.7 0.9 0 1.7

REF NO.

MODE 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40

CD PLAY 3.3 1.8 0.2 0.2 0 0.2 0.2 3.4 1.6 1.6 0 1.7 1.7 1.7 0 3.4 3.4 0 0 1.7

STANDBY 3.3 1.8 0.2 0.2 0 0.2 0.2 3.4 1.6 1.6 0 1.7 1.7 1.7 0 3.4 3.4 0 0 1.7

REF NO.

MODE 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 57 58 59 60

CD PLAY 0 1.8 0 0 0 0 0.1 0 0.1 3.3 1.7 1.7 0 1.7 1.8 0 3.3 3.2 3.2 3.2

STANDBY 0 1.8 0 0 0 0 0.1 0 0.1 3.3 1.7 1.7 0 1.7 1.8 0 3.3 3.2 3.2 3.2

REF NO.

MODE 61 62 63 64 65 66 67 68 69 70 71 72 73 74 75 76 77 78 79 80

CD PLAY 3.2 3.4 3.2 3.2 1.8 3.4 0 3.2 3.2 3.2 3.2 3.2 3.4 3.2 3.1 0 3.2 3.2 3.3 1.9

STANDBY 3.2 3.4 3.2 3.2 1.8 3.4 0 3.2 3.2 3.2 3.2 3.2 3.4 3.2 3.1 0 3.2 3.2 3.3 1.9

REF NO.

MODE 81 82 83 84 85 86 87 88 89 90 91 92 93 94 95 96 97 98 99 100

CD PLAY1.93.41.8000003.4000001.800003.4

STANDBY1.93.41.8000003.4000001.800003.4

REF NO.

MODE 101 102 103 104 105 106 107 108 109 110 111 112 113 114 115 116 117 118 119 120

CD PLAY0000003.43.43.43.401.800000003.3

STANDBY0000003.43.43.43.401.800000003.3

REF NO.

MODE 121 122 123 124 125 126 127 128

CD PLAY 3.2 0 0.6 3.4 1.8 0.6 0 3.4

STANDBY 3.2 0 0.6 3.4 1.8 0.6 0 3.4

REF NO.

MODE 1234567891011121314151617181920

CD PLAY 0 1.7 1.7 3.3 0 3.3 2.0 2.0 2.0 2.0 3.4 3.2 0 0 0 0 2.8 2.8 0 0

STANDBY 0 1.7 1.7 3.3 0 3.3 2.0 2.0 2.0 2.0 3.4 3.2 0 0 0 0 2.8 2.8 0 0

REF NO.

MODE 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40

CD PLAY0005.0000000000000002.00

STANDBY0005.0000000000000002.00

REF NO.

MODE 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 57 58 59 60

CD PLAY 5.0 1.0 0 2.5 0 1.0 0 0 0 0 3.3 0 3.3 0.2 1.7 0 0 0 1.7 1.6

STANDBY 5.0 1.5 0 2.5 0 1.4 0 0 0 0 3.3 0 3.3 0 1.7 0 0 0 1.7 1.7

IC1001

IC1002

SU-HTB500PP HDMI P.C.B.

IC1001

IC1002

IC1001

IC1001

IC1002

IC1001

IC1001

IC1001

Note:

• Indicated voltage values are the standard values for the unit measured by the DC electronic circuit tester (high-impedance) with

the chassis taken as standard.

Therefore, there may exist some errors in the voltage values, depending on the internal impedance of the DC circuit tester.

• Circuit voltage and waveform described herein shall be regarded as reference information when probing defect point because it

may differ from actual measuring value due to difference of Measuring instrument and its measuring condition and product itself.

10.1. HDMI P.C.B. (1/5)

57

Page 58

10.2. HDMI P.C.B. (2/5)

REF NO.

MODE 61 62 63 64

CD PLAY 1.7 0.1 0 0.1

STANDBY 1.7 0 0 0

REF NO.

MODE 12345

CD PLAY 3.4 3.4 0 0 0

STANDBY 3.4 3.4 0 0 0

REF NO.

MODE 12345

CD PLAY 5.0 0 4.9 0 3.3

STANDBY 5.0 0 5.0 0 3.3

REF NO.

MODE 123456

CD PLAY 1.7 0 1.7 1.7 3.4 0

STANDBY 1.7 0 1.7 1.7 3.4 0

REF NO.

MODE 1234567891011121314151617181920

CD PLAY 3.3 3.0 1.7 0 3.3 3.3 3.3 3.3 3.3 0 3.3 3.3 3.3 3.2 3.2 3.4 3.4 3.4 0 0

STANDBY 3.3 3.3 2.6 0 3.3 3.3 3.3 3.3 3.3 0 3.3 3.3 3.3 3.4 3.4 3.4 3.4 3.4 0 0

REF NO.

MODE 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40

CD PLAY 0 0 0 0 3.3 3.3 0 0 0 0 0 0 0 3.4 1.9 3.4 0 3.3 3.3 3.3

STANDBY 0 0 0 0 3.3 3.3 0 0 0 0 0 0 0 3.4 1.9 3.4 0 3.3 3.3 3.3

REF NO.

MODE 41 42 43 44 45 46 47 48 49 50

CD PLAY 0 3.2 3.3 3.3 3.3 3.3 0 3.3 3.3 0

STANDBY 0 3.2 3.3 3.3 3.3 3.3 0 3.3 3.3 0

REF NO.

MODE 1234567891011121314151617181920

CD PLAY 3.3 0 3.3 0 0 3.3 3.3 0 0 0 0 0 3.3 0 0 0 0 0 0 0

STANDBY 3.3 0 3.3 0 0 3.3 3.3 0 0 0 0 0 3.3 0 0 0 0 0 0 0

REF NO.

MODE 1234567891011121314151617181920

CD PLAY 1.2 1.2 0 2.1 3.4 3.3 0 0 0 1.1 1.5 3.2 1.6 0 1.4 3.2 3.2 3.3 3.3 3.3

STANDBY 1.2 1.2 0 2.1 3.4 3.3 0 0 0 1.1 1.5 3.2 1.6 0 1.3 3.2 3.2 3.3 3.3 3.3

REF NO.

MODE 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40

CD PLAY 3.2 3.2 0 0 0 3.2 3.2 0.7 0.2 0.6 3.2 3.2 0 0 3.1 3.1 0 3.2 3.2 0

STANDBY 3.2 3.2 0 0 0 3.2 3.2 0.7 0.2 0.6 3.2 3.2 0 0 3.1 3.1 0 3.2 3.2 0

IC1005

IC1006

IC2002

SU-HTB500PP HDMI P.C.B.

IC1002

IC2002

IC1006

IC1006

IC1008

IC1003

IC1004

58

Page 59

10.3. HDMI P.C.B. (3/5)

REF NO.

MODE 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 57 58 59 60

CD PLAY03.23.21.33.2000000000000000

STANDBY03.23.21.33.2000000000000000

REF NO.

MODE 61 62 63 64 65 66 67 68 69 70 71 72 73 74 75 76 77 78 79 80

CD PLAY 0 3.2 0 0 0 0 3.0 2.9 3.3 3.3 3.4 0 0 3.3 0 0 3.2 3.3 0 0

STANDBY 0 3.2 0 0 0 0 3.0 2.9 3.3 3.3 3.4 0 0 3.3 0 0 3.2 3.3 0 0

REF NO.

MODE 81 82 83 84 85 86 87 88 89 90 91 92 93 94 95 96 97 98 99 100

CD PLAY000000003.43.40001.82.1003.23.20

STANDBY000000003.43.40001.82.1003.23.20

REF NO.

MODE 12345678

CD PLAY 0 0 3.2 0 3.2 3.2 0 3.2

STANDBY 0 0 3.2 0 3.2 3.2 0 3.2

REF NO.

MODE 12345

CD PLAY 3.9 3.2 3.3 0 0

STANDBY 3.9 3.2 3.3 0 0

REF NO.

MODE 1234567891011121314151617181920

CD PLAY 0 1.7 1.7 1.6 0 1.7 0 0.2 0 0 0 0.2 0 1.7 0 1.6 1.6 1.7 0 3.3

STANDBY 0 1.7 1.7 1.6 0 1.7 0 0 0 0 0 0 0 1.7 0 1.6 1.6 1.7 0 3.3

REF NO.

MODE 123456

CD PLAY 1.6 0 1.6 1.6 3.3 1.6

STANDBY 1.6 0 1.6 1.6 3.3 1.6

REF NO.

MODE 1234567891011121314151617181920

CD PLAY1.100000000001.803.3000000

STANDBY1.200000000001.803.3000000

REF NO.

MODE 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40

CD PLAY 0 0 0 3.3 3.3 0 1.8 1.8 0 1.1 1.1 1.8 1.1 1.1 0 1.1 1.1 1.8 1.1 1.1

STANDBY 0 0 0 3.3 3.3 0 1.8 1.8 0 1.1 1.1 1.8 1.1 1.1 0 1.1 1.1 1.8 1.1 1.1

REF NO.

MODE 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 57 58 59 60

CD PLAY 0 1.8 0 3.3 5 5 5 3.3 3.3 0.3 3.3 3.3 3.3 0 1.8 2.5 2.5 2.5 2.5 2.5

STANDBY 0 1.8 0 3.3 5 5 5 3.3 3.3 0.3 3.3 3.3 3.3 0 1.8 2.5 2.5 2.5 2.5 2.5

IC2003

IC2004

IC2101

SU-HTB500PP HDMI P.C.B.

IC2002

IC2101

IC2006

IC2081

IC2101

IC2002

IC2002

59

Page 60

10.4. HDMI P.C.B. (4/5)

REF NO.

MODE 61 62 63 64 65 66 67 68 69 70 71 72 73 74 75 76 77 78 79 80

CD PLAY 2.6 2.6 2.6 1.8 0 3.3 2.6 2.6 2.6 2.6 2.6 2.6 2.6 2.6 2.6 1.8 2.4 1.2 1.3 1.3

STANDBY 2.6 2.6 2.6 1.8 0 3.3 2.6 2.6 2.6 2.6 2.6 2.6 2.6 2.6 2.6 1.8 2.4 1.2 1.3 1.3

REF NO.

MODE 81 82 83 84 85 86 87 88 89 90 91 92 93 94 95 96 97 98 99 100

CD PLAY

1.2 1.3 1.3 1.3

1.3 1.2 0 0 3.3

1.3

1.3 1.3 1.3 1.3 1.3 1.3 1.3 1.3 1.8 0

STANDBY

1.2 1.3 1.3 1.3

1.3 1.2 0 0 3.3

1.3

1.3 1.3 1.3 1.3 1.3 1.3 1.3 1.3 1.8 0

REF NO.

MODE 12345

CD PLAY 2.5 3.2 1.8 0 0

STANDBY 2.5 3.2 1.8 0 0

REF NO.

MODE 12345678

CD PLAY 0 0 0 0 5.0 5.0 5.0 5.0

STANDBY 0 0 0 0 5.0 5.0 5.0 5.0

REF NO.

MODE 1234567891011121314151617181920

CD PLAY 1.3 1.2 1.3 0 0 3.3 1.3

1.3

1.3 1.3 0

1.8

1.3 1.3 1.3 1.3 0 3.3 1.0 0.5

STANDBY 1.3 1.2 1.3 0 0 3.3 1.3

1.3

1.3 1.3 0

1.8

1.3 1.3 1.3 1.3 0 3.3 1.0 0.5

REF NO.

MODE 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40

CD PLAY 0.5 0 0 1.8 1.8 0 0

0

000

3.3

3.3 3.3 0 0 1.8 3.3 0 0

STANDBY 0.5 0 0 1.8 1.8 0 0

0

000

3.3

3.3 3.3 0 0 1.8 3.3 0 0

REF NO.

MODE 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 57 58 59 60

CD PLAY 0 3.3 0 0 0 3.3 0

0

03.30

0

0 1.8 0 3.3 3.3 3.3 0 3.3

STANDBY 0 3.3 0 0 0 3.3 0

0

03.30

0

0 1.8 0 3.3 3.3 3.3 0 3.3

REF NO.

MODE 61 62 63 64 65 66 67 68 69 70 71 72 73 74 75 76 77 78 79 80

CD PLAY 3.3 3.3 0 3.3 3.3 3.3 0 3.3 3.3 3.3 0 1.8 0 3.3 0 0 0 0 0 1.8

STANDBY 3.3 3.3 0 3.3 3.3 3.3 0 3.3 3.3 3.3 0 1.8 0 3.3 0 0 0 0 0 1.8

REF NO.

MODE 81 82 83 84 85 86 87 88 89 90 91 92 93 94 95 96 97 98 99 100

CD PLAY00000003.33.301.81.801.61.63.33.3003.3

STANDBY00000003.33.301.81.801.61.63.33.3003.3

REF NO.

MODE 101 102 103 104 105 106 107 108 109 110 111 112 113 114 115 116 117 118 119 120

CD PLAY 0 3.3 0 3.3 0 0 1.8 2.8 2.8 2.8 2.8 0 3.3 2.8 2.8 2.8 2.8 0 1.8 2.8

STANDBY 0 3.3 0 3.3 0 0 1.8 2.7 2.7 2.7 2.7 0 3.3 2.7 2.7 2.6 2.7 0 1.8 2.7

IC2232

IC2232

SU-HTB500PP HDMI P.C.B.

IC2101

IC2232

IC2232

IC2232

IC2232

IC2101

IC2102

IC2231

60

Page 61

10.5. HDMI P.C.B. (5/5)

REF NO.

MODE 121 122 123 124 125 126 127 128 129 130 131 132 133 134 135 136 137 138 139 140

CD PLAY 2.8 2.8 2.8 0 3.3 2.8 2.8 2.8 2.8 0 1.8 2.8 2.8 1.2 1.3 0 3.3 1.3 1.2 1.3

STANDBY 2.7 2.7 2.7 0 3.3 2.7 2.7 2.7 2.7 0 1.8 2.8 2.7 2.7 1.3 0 3.3 1.3 1.2 1.3

REF NO.

MODE 141 142 143 144

CD PLAY 1.3 0 1.8 1.3

STANDBY 1.3 0 1.8 1.3

REF NO.

MODE 12345

CD PLAY 2.5 3.2 1.8 0 0

STANDBY 2.5 3.2 1.8 0 0

REF NO.

MODE 12345

CD PLAY 6.0 2.5 0 1.2 2.1

STANDBY 6.0 2.5 0 1.2 2.1

REF NO.

MODE 12345

CD PLAY 18.0 3.1 0 1.2 2.1

STANDBY 18.0 3.1 0 1.2 2.1

REF NO.

MODE 12345

CD PLAY 6.0 0 6.0 0 5.2

STANDBY 6.0 0 6.0 0 5.3

REF NO.

MODE ECB 12345 123456

CD PLAY 0 3.4 0 3.1 3.1 3.2

3.5

3.5 5.0 0 0 5.2 5.0 5.2

STANDBY 0 3.4 0 3.2 3.2 3.2

3.5

3.5 5.0 0 0 5.2 5.0 5.2

REF NO.

MODE 12345 123456 12345

CD PLAY

4.8 5.0 4.8 5.0

5.0 5.0 0 0

4.8

5.0 4.8 4.8 5.0 4.8 5.0 5.0

STANDBY

4.8 5.0 4.8 5.0

5.0 5.0 0 0

4.8

5.0 4.8 4.8 5.0 4.8 5.0 5.0

REF NO.

MODE 12345 12345 ECB ECB

CD PLAY 0 0.5 0 3.1 5.0 0 0.5 0 5.0 3.1 0 1.2 0 0 3.3 0

STANDBY 0 0.5 0 3.1 5.0 0 0.5 0 5.0 3.1 0 1.3 0 0 3.3 0

REF NO.

MODE ECB ECB ECB ECB ECB

CD PLAY

000

04.80 0

5.0

002.10

003.1

STANDBY

000

04.80 0

5.0

002.10

003.1

Q2231

Q2232

Q2233

Q2234

Q2103

Q2108

IC2232

IC4793

IC2232

IC2233

IC4722

IC4724

SU-HTB500PP HDMI P.C.B.

QR2001

QR2002

QR2004

QR2231

QR4704

Q2235

Q2236

QR2232

QR4703

61

Page 62

10.6. MAIN P.C.B. (1/2)

REF NO.

MODE 1 2 3

CD PLAY

3.3 0 5.0

STANDBY

3.3 0 5.0

REF NO.

MODE 1 2 3 4 5 6 7 8 9 1011121314151617181920

CD PLAY 1.8 0.1 0.8 0.9 0.1 0.1 2.0 0.1 3.3 1.3 3.3 3.3 3.3 3.3 3.3 0 1.9 0 0.5 0.8

STANDBY 1.8 0.1 0.8 0.9 0.1 0.1 1.9 0.1 3.3 1.3 3.3 3.3 3.3 3.3 3.3 0 1.9 0 0 0.9

REF NO.

MODE 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40

CD PLAY0003.33.31.70000001.8003.33.2000

STANDBY 0 0 0 3.3 3.3 1.7 0 0 0 0 0 0 1.8 0 0 3.3 3.2 0 0 0

REF NO.

MODE 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 57 58 59 60

CD PLAY00000001.800003.33.300001.31.3

STANDBY00000001.800003.33.300001.31.4

REF NO.

MODE 61 62 63 64

CD PLAY 1.3 1.3 1.6 0.1

STANDBY 1.3 1.3 1.6 0.1

REF NO.

MODE 1 2 3 4 5 6 7 8 9 1011121314151617181920

CD PLAY3.33.3003.303.30000000003.3000

STANDBY 3.3 3.3 0 0 3.3 0 3.3 0 0 0 0 0 0 0 0 0 3.3 0 0 0

REF NO.

MODE 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40

CD PLAY 3.3 3.3 3.3 10.1 0 20.3 20.3 10.1 0 0 10.2 20.3 10.2 10.2 20.3 10.2 0 0 10.2 20.3

STANDBY 3.3 3.3 3.3 10.1 0 20.3 20.3 10.1 0 0 10.2 20.3 10.2 10.2 20.3 10.2 0 0 10.2 20.3

REF NO.

MODE 41 42 43 44

CD PLAY 20.3 0 10.2 3.3

STANDBY 20.3 0 10.2 3.3

REF NO.

MODE 1 2 3 4 5 6 7 8 9 1011121314151617181920

CD PLAY 3.2 3.2 1.2 0.1 3.4 0.1 1.2 0 0 0 0 3.2 1.6 0 1.6 3.2 3.2 0 3.4 3.2

STANDBY 3.1 3.1 1.2 0.1 3.4 0.1 1.2 0 0 0 0 3.2 1.6 0 1.6 3.2 3.2 0 3.4 3.2

REF NO.

MODE 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40

CD PLAY 0 3.4 3.2 3.4 0 3.2 0 3.2 3.2 3.2 3.2 3.2 0.4 0 0.2 0.6 0.7 0 0 0

STANDBY 3.2 3.4 0 3.4 0 3.2 0 3.2 3.2 3.2 3.2 3.2 0.4 0 0.2 0.6 0.7 0 0 0

IC401

IC401

IC604

SU-HTB500PP MAIN P.C.B.

IC107

IC604

IC405

IC405

IC405

IC401

IC401

62

Page 63

10.7. MAIN P.C.B. (2/2)

REF NO.

MODE 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 57 58 59 60

CD PLAY 0 0 3.2 2.1 0 0 0 0.8 2.0 0 0 0 0 3.2 0 0 0 0 0 0

STANDBY 0 0 3.2 2.1 0 0 0 1.2 2.0 0 0 0 0 3.2 0 0 0 0 0 0

REF NO.

MODE 61 62 63 64 65 66 67 68 69 70 71 72 73 74 75 76 77 78 79 80

CD PLAY 0 3.2 3.2 0 0 0 0 0 0.6 3.4 3.4 3.2 3.2 0 3.4 3.2 3.4 3.2 3.2 0

STANDBY 0 3.2 3.2 0 0 0 0 0 0.6 3.4 3.4 3.2 3.2 0 3.4 3.2 3.4 3.2 3.2 0

REF NO.

MODE 81 82 83 84 85 86 87 88 89 90 91 92 93 94 95 96 97 98 99 100

CD PLAY 3.2 0 3.4 0.3 0 0 0 0 3.2 3.1 3.5 3.5 0 3.4 3.4 0 0 3.3 3.2 0

STANDBY 3.2 0 3.4 0.3 0 0 0 0 3.2 3.1 3.5 3.5 0 3.4 3.4 0 0 3.3 3.2 0

REF NO.

MODE 12345678

CD PLAY 3.0 3.0 0 0 3.2 3.2 0 3.2

STANDBY 3.1 3.0 0 0 3.1 3.1 0 3.1

REF NO.

MODE 1234

CD PLAY 4.0 6.0 0 0

STANDBY 3.9 6.0 0 0

REF NO.

MODE 123

CD PLAY 3.3 0 6.0

STANDBY 3.3 0 6.0

REF NO.

MODE 12345

CD PLAY 20.0 12.0 0 1.1 2.0

STANDBY 20.0 12.0 0 1.1 2.0

REF NO.

MODE 12345

CD PLAY 20.0 5.0 0 1.2 1.9

STANDBY 20.0 5.0 0 1.2 1.9

REF NO.

MODE ECB ECB ECB ECB ECB

CD PLAY

000

16 -0.1 0 10.0 0 10.0 10.0 0 10.0 0 0 0

STANDBY

000

16 -0.1 0 0.3 0 0.3 0.3 0 0.3 0 0 0

REF NO.

MODE ECB ECB ECB

CD PLAY

000

3.2 0 3.2 0 0 0

STANDBY

000

3.2 0 3.2 0 0 0

QR600

QR601

QR602

Q500

Q501

Q704

IC606

SU-HTB500PP MAIN P.C.B.

IC604

IC700

IC701

IC702

IC604

IC604

IC605

Q114

Q116

REF NO.

MODE 123456789101112131415161718

CD PLAY

003.10

0.5 0.6 0.6 0.1 0.6

4.6

4.6 0.6 0.6 2.0 0 0 0 4.4

STANDBY

003.10

0.5 0.6 0.6 0.1 0.6

4.6

4.6 0.6 0.6 2.0 0 0 0 4.4

SU-HTB500PP LED P.C.B.

IC300

10.8. LED P.C.B.

63

Page 64

10.9. SMPS P.C.B.

REF NO.

MODE 1234567

CD PLAY 159.3 0 0 17.5 0.1 1.3 0.6

STANDBY 159.3 0 0 17.5 0.1 1.3 0.6

REF NO.

MODE 12345678

CD PLAY 6.0 0.8 2.4 12.3 165.0 0 0 0

STANDBY 6.0 0.8 2.4 12.3 165.0 0 0 0

REF NO.

MODE 123

CD PLAY 18.3 2.5 0

STANDBY 18.3 2.5 0

REF NO.

MODE 123

CD PLAY 4.8 2.5 0

STANDBY 4.8 2.5 0

REF NO.

MODE E C B E C B E C B

CD PLAY 6.9 7.8 6.9 0 3.3 0 0 0.1 0.7

STANDBY 6.9 7.8 6.9 0 3.3 0 0 0.1 0.7

SU-HTB500PP SMPS P.C.B.

Q5720

Q5841

Q5899

IC5701

IC5799

IC5801

IC5899

REF NO.

MODE 12345

CD PLAY 6.0 2.5 0 1.2 2.1

STANDBY 6.0 2.5 0 1.2 2.1

IC100

SU-HTB500PP WIRELESS ADAPTER P.C.B.

10.10. WIRELESS ADAPTER P.C.B.

64

Page 65

10.11. Waveform Chart (1/2)

WF No. IC401-19 (PLAY)

2Vp-p(20nsec/div)

WF No. IC401-20 (PLAY)

1Vp-p(20nsec/div)

WF No. IC401-42,43,44,45,46,

47 (PLAY)

6Vp-p(1usec/div)

WF No. IC401-29,31 (PLAY)

3.2Vp-p(500nsec/div)

WF No. IC401-40,41 (PLAY)

6Vp-p(1usec/div)

WF No. IC405-6,8,16,18 (PLAY)

6Vp-p(1usec/div)

WF No. IC405-28,31,36,39 (PLAY)

32Vp-p(1usec/div)

WF No. IC604-13 (PLAY)

2.6Vp-p(50nsec/div)

WF No. IC604-15 (PLAY)

2Vp-p(50nsec/div)

WF No. IC1001-17 (PLAY)

2Vp-p(20nsec/div)

WF No. IC1001-18 (PLAY)

1.7Vp-p(20nsec/div)

WF No. IC1001-23,24,26,27,

34 (PLAY)

3.4Vp-p(5usec/div)

WF No. IC1001-48 (PLAY)

3.6Vp-p(10usec/div)

WF No. IC1001-49 (PLAY)

6Vp-p(2usec/div)

WF No. IC1001-51 (PLAY)

6.4Vp-p(2usec/div)

WF No. IC1002-44 (PLAY)

8Vp-p(1usec/div)

WF No. IC1002-47 (PLAY)

0.2Vp-p(5msec/div)

WF No. IC1002-54 (PLAY)

6.4Vp-p(2usec/div)

WF No. IC1002-64 (PLAY)

4Vp-p(2nsec/div)

WF No. IC1008-4 (PLAY)

2.4Vp-p(200nsec/div)

65

Page 66

10.12. Waveform Chart (2/2)

WF No. IC2002-10 (PLAY)

0.5Vp-p(10usec/div)

WF No. IC2002-11 (PLAY)

3Vp-p(20usec/div)

WF No. IC2002-13 (PLAY)

3.8Vp-p(100nsec/div)

WF No. IC2002-15 (PLAY)

2.6Vp-p(100nsec/div)

WF No. IC1008-6 (PLAY)

3Vp-p(200nsec/div)

WF No. IC2101-4,6,7 (PLAY)

5.2Vp-p(500nsec/div)

WF No. IC2101-8 (PLAY)

3.6Vp-p(5usec/div)

WF No. IC2101-9 (PLAY)

5Vp-p(5usec/div)

WF No. IC2006-3 (PLAY)

6.8Vp-p(1usec/div)

WF No. IC2006-8,12 (PLAY)

3.4Vp-p(5usec/div)

WF No. IC2006-17 (PLAY)

5.2Vp-p(1usec/div)

WF No. IC2232-78 (PLAY)

6Vp-p(1usec/div)

WF No. IC2232-81,82,83,84

(PLAY)

3.4Vp-p(5usec/div)

WF No. IC2232-94 (PLAY)

3Vp-p(20nsec/div)

WF No. IC2232-95 (PLAY)

1Vp-p(20nsec/div)

66

Page 67

11 Illustration of IC’s, Transistors and Diodes

No.1

No.1

MIP2F20MSSCF

1

4

5

2

3

C0JBAQ000073 (18P)

C0JBAZ001466 (20P)

C1AB00003217 (44P)

C3ABMG000238 (50P)

C0FBZK000013 (64P)

C1AB00002975 (100P)

C1AB00003216 (64P)

C2HBCY000030 (128P)

C0CBCAG00015

C0CBCBG00013

C0DBAYH00005

C0CBABC00117

RFKWMHTB10PB

RFKWMHTB500P

C3EBEC000047

C3EBEC000060

C0DAEMZ00001

1

3

2

B1ABCF000011

B1ABCF000079

B1ABMF000020

B1ADBL000010

B1GBCFGG0030

B1GBCFJJ0007

B1GBCFNN0004

B1GDCFJJ0008

B0BC010A0007

B0BC012A0264

B0BC018A0267

B0BC030A0264

B0BC5R600003

B0BC6R2A0266

Cathode

Anode

A

Ca

A

Ca

Cathode

Anode

B0EAKT000061

B0EAKT000062

B0EAMM000057

B0HAMP000094

B0JAMF000011

B0HBSM000054

B0EDKT000009

B3AGB0000037

Ca

A

A

Ca

A

A

C0JBAR000396

C0JBAB000986

C0CBCBC00049

C0CBCDC00014

C0EBG0000107

B0JCME000012

B0JCPG000005

Cathode

Anode

A

Ca

2SC3940ARA

C0DAAMH00013

C2CBDD000001

B1CFGD000002

1

7

5

3

B0ACCK000005

B0JCAE000001

B0EBNR000015

A

Ca

Cathode

Anode

Anode

Anode

Anode

Cathode

C1AB00002989 (144P)

No.1

1

38

39

64

65

102

103

128

1

30

31

50

51

80

81

100

1

4

5

2

3

B1HBCFA00003

1

4

6

5

2

3

Cathode

Anode

A

Ca

1

10

11

20

MA2J1110GL

MAZ8300GML

8

4

67

Page 68

12 Overall Simplified Block

68

Page 69

13 Block Diagram

SU-HTB500PP SYSTEM CONTROL BLOCK DIAGRAM

D600

D602

D601

85

CN350CN300

6 SCL

5 SDA

MICRO PROCESSOR

RFKWMHTB500P

IC604

EEPROM

C3EBEC000060

X600

IC605

LED DI 80

LED DATA

76

CN350CN300

LED CLK 81

LED CLK

67

CN350CN300

LED CS 82

LED DRIVER

C0JBAQ000073

IC300

SCL 29

SDA 30

1 OUT

RESET

C0EBG0000107

IC606

AC SYNC 20

XIN 15

XOUT 13

LED LCK

LED DI

LED CLK

LED CS

94

CN350CN300

LED OE 85

LED OELED OE

KEY2 91

KEY2

INPUT SELECTOR

KEY2

S303

VOLUME-

S304

6V

11

CN352*CN351*

58

CN350CN300

KEY1 92

KEY1

POWER

KEY1

S300

VOLUME+

S301

22

CN352*CN351*

49

CN350CN300

REMOTE 19

REMOTE 5

REMOTE REMOCON

310

CN350CN300

83

CN700H2016*

VREF

5V

3.3V

REMOTE

CONTROL SENSOR

Z300

VDD 2

DAP SCL22

DAP SCL

DAP SCL

ECO DAMP93

ECO DAMP

ECO DAMP

DAP RESET26

DAP RESET

DAP RESET

DAP PDN63

DAP PDN

DAP PDN

DAP MUTE23

DAP MUTE

DAP MUTE

SD53

SD

DC DET94

DATA2

CLK3

LCK4

OE17

DCDET

DCDET

S DET95

SDET

PCONT90

PCONT

MUTE ALL21

MUTE ALL

DT OUT CODEC79

RESET CODEC78

CLK DSP69

MOSI DSP74

RESET DSP72

MISO DSP77

SDET

SD

DAP SDA24

DAP SDA

DAP SDA

VALID18

VALID

VALID

Q6 11

D305

Q5 10

D304

Q4 9

D303

Q2 7

Q1 6

D301

Q8 13

Q7 12

D307

LED P.C.B.

PANEL TACT SWITCH P.C.B.

MAIN P.C.B.

HDMI P.C.B.

SMPS P.C.B.

3912

CN200CN1001

465

CN200CN1001

3615

CN200CN1001

483

CN200CN1001

474

CN200CN1001

4110

CN200CN1001

RESET CODEC

M RESET43

2625

CN200CN1001

3417

CN200CN1001

2922

CN200CN1001

M RESET

REMOTE

H SO36

H SO

2724

CN200CN1001

M CLK37

M CLK

RESET DSP

MOSI DSP

MISO DSP

DT OUT CODEC

HDMI MUTE48

501

CN200CN1001

HDMI MUTE

M SI35

2823

CN200CN1001

M SI

PWR CTRL89

3219

CN200CN1001

PWR CTRL

CLK DSP

FROM/TO

AUDIO

FROM/TO

HDMI

TO

POWER SUPPLY

FROM/TO

AUDIO

FROM

POWER SUPPLY

QR600

MUTING

CONTROL

HDMIMUTE DIS27

HDMIMUTE DIS

QR602

MUTING

QR601

MUTING

NOTE: “ * ” REF IS FOR INDICATION ONLY

W-SDO

W-SDI

W-SCL

W SCL

W SDO

W SDI

DIGITAL

TRANSMITTER

WIRELESS ADAPTER P.C.B.

CN101

8

CN100 CN100

513

CN101

10

CN100 CN100

612

CN101

9

CN100 CN100

711

6

7

4

13.1. SYSTEM CONTROL BLOCK DIAGRAM

69

Page 70

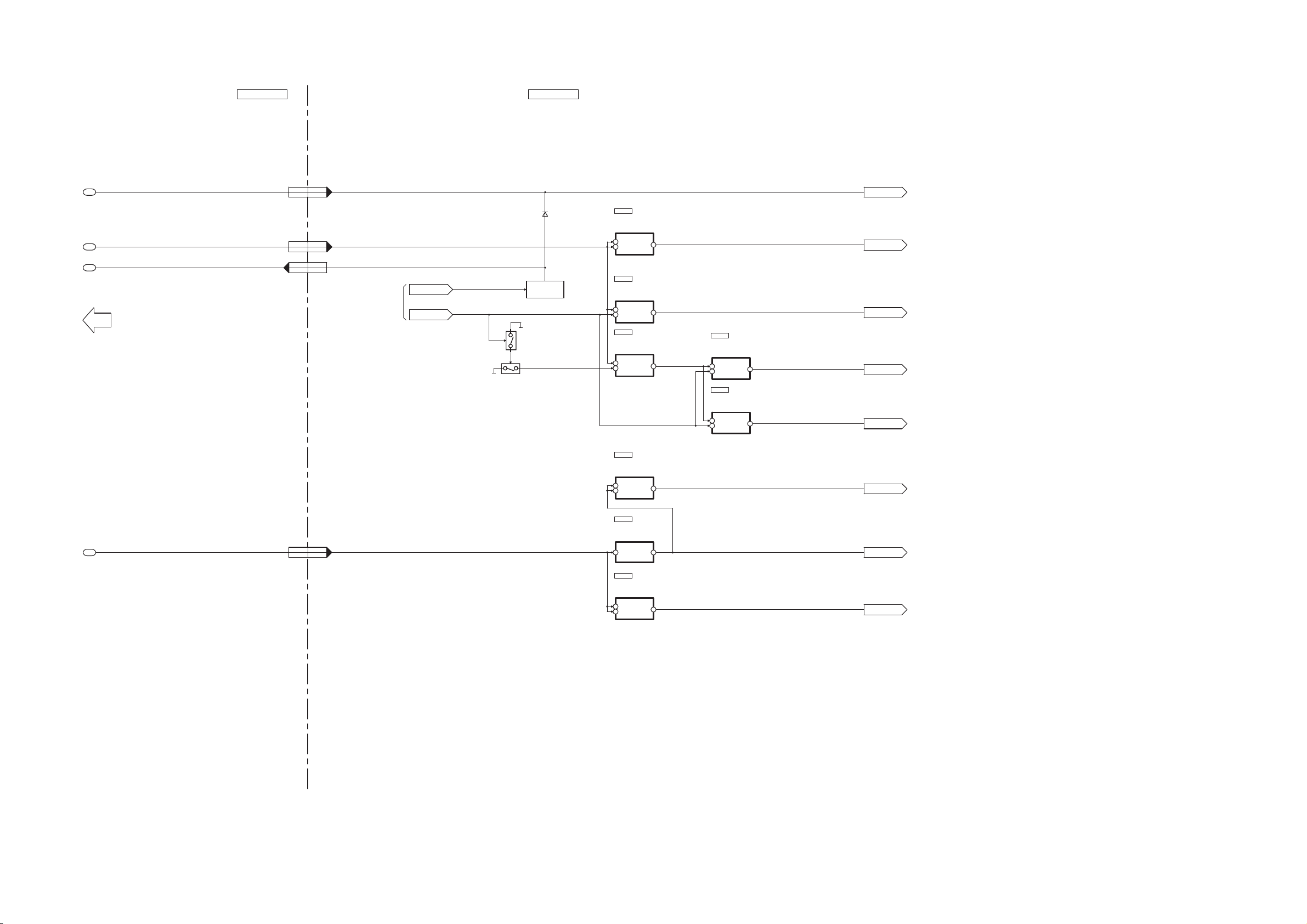

13.2. HDMI BLOCK DIAGRAM

: HDMI AUDIO INPUT SIGNAL LINE : HDMI VIDEO INPUT SIGNAL LINE : AUDIO OUTPUT SIGNAL LINE : VIDEO OUTPUT SIGNAL LINE

HDMI P.C.B.

JK2203

HDMI AV IN

(BD/DVD)

HOTPLUG

DDC SDA

DDC SCL

IC2003

C3EBEC000047

EEPROM

SCL 6

SDA 5

Q2108

LEVEL SHIFTER

IC2232

C1AB00002989

HDMI RECEIVER

X2002

RESET 100

SCDT 101

IC2231

TC - 2

C3EBEC000047

EEPROM

QR2231,QR2232

Q2231,Q2232

Q2233,Q2234

Q2235,Q2236

DSDA128

DSCL129

19

16

15

HDMI SWITCHING

CIRCUIT

R1X0- ~ R1X2R1X0+ ~ R1X2+

INT 102

XTALIN 95

XTALOUT 96

CSDA

CSCL

MUTEOUT

X2231 X2001

26

27

73

IC2002

RFKWMHTB10PB

MICRO PROCESSOR

IDROM CK22

IDROM DT21

CEC I/O17

RX1 HPD76

WRITESEL25

RX1 SCL26

RX1 SDA27

XCOUT

11

XCIN10

RX RESET39

RX SCDT74

RX INT20

XOUT13

XIN15

D0 ~ D35 TC - 1

HDMI POWER 42

MAIN POWER 43

I2C SCL

I2C SDA

36

35

DCDET 54

M RST 68

SO 30

CLK 28

REM 5

AMUTE 53

TX HPD 75

TX RESET 38

TX INT 19

SI 29

D2003

D2004

QR2001

MUTING

IC2101

C1AB00002975

HDMI TRANSMITTER

RESET25

INT24

HPD 51

CSDA49

CSCL48

47

DSDA

46 DDC SCL15

DSCL

Q2103

SWITCH

3.3V

X2003

25

P1 7

XCOUT4

XCIN6

IC1008

C2CBDD000001

MICRO CONTROLLER

TX0- ~

TX0+ ~

P1 3 17

TX2-

TC - 3

TX2+

QR2004

SWITCH

DCDET

HDMI POWER

H POWER

M SI

M RESET

H SO

M CLK

REMOTE

HDMI MUTE

3.3V

DCDET

HDMI POWER

CN200CN1001

3219

CN200CN1001

2823

CN200CN1001

2625

CN200CN1001

2922

CN200CN1001

2724

CN200CN1001

3417

CN200CN1001

501

JK4001

Ir SYSTEM

1

3

4

2

JK2101

HDMI AV OUT

(TO TV(ARC))

HOTPLUG19

DDC SDA16

TO

POWER SUPPLY

MAIN P.C.B.

FROM/TO

SYSTEM CONTROL

10

TMDS CLK+

TMDS CLK- 12 R1XC-57

13

CEC

MCLK

LRCK

IEC958

TMDS CLK+10

CEC13

HEAC+(ARC)14

ARC

ARC

MCLK

BCK

BCK

LRCK

I2S0

I2S0

I2S1

I2S1

I2S2

I2S2

I2S3

I2S3

TO AUDIO

IEC958

R1XC+58

ODCK 5 IDCK88

MCLK 89 MCLK5

SCK 86 SCK11

WS 85 WS10

SD0 81

SD1 82 SD18

SD2 83 SD27

SD3 84 SD36

SPDIF 78 SPDIF4

SD09

IC2006

C0JBAZ001466

LOGIC

1A12

1A24

1A36

1A48

2A111

2A213

2A315

2A417

31

TXC+

TXC- 30 TMDS CLK-12

IC2081

C0JBAB000986

INVERTER

3

2A

2Y4

1Y1 18

1Y2 16

14

1Y3

12

1Y4

2Y1 9

7

2Y2

2Y3 5

2Y4 3

SU-HTB500PP HDMI BLOCK DIAGRAM

70

Page 71

13.3. AUDIO (1/2) BLOCK DIAGRAM

TO AUDIO

SECTION (2/2)

SU-HTB500PP AUDIO(1/2) BLOCK DIAGRAM

1

2

3

4

5

CODEC

C0FBZK000013

IC1002

DSP

C2HBCY000030

IC1001

SDRAM

C3ABMG000238

IC1006

MULTIPLEXER

C0JBAR000396

IC1005

CDOUT 8

/RST 12

RESET

A6

ARC

MCLK

RXP7

JK4101

INPUT 3 42

RXP247

BCK

DAI SCLK129

LRCK

DAI LRCLK130

I2S2

DAI DATA224

I2S3

DAI DATA323

I2S0

DAI DATA027

IEC958

IEC 95844

XTAL OUT16

I2S1

DAI DATA126

DAO LRCLK1

54

DAO SCLK1

52

CX LRCLK

DAO MCLK

40

RMCK

355

CX SCLK

2

DAO DATA149DAO DATA2

48

CX SDIN2

DAO DATA0

51

64

DAI LRCLK2

32

DAI SCLK2

33

SAI LRCLK

DAI DATA4

34

SAI SDOUT

60

SCP1 CLK

126

121

SCP1 MISO 124

CCLK

7

SCP1 MOSI

123

CDIN

954

SAI SCCLK

61

CH11

COM 4CH03

RXP148

OMCK59

A0 - A10 TC - 4

DQ0 - DQ15 TC - 5

X1000

XTI17

XTO18

1932

CN200CN1001

3912

CN200CN1001

465

CN200CN1001

3615

CN200CN1001

483

CN200CN1001

474

CN200CN1001

4110

CN200CN1001

1833

CN200CN1001

DSP SD1

DSP SD3

DSP MCLK

DSP LRCLK

DSP SCLK

DSP SD1

DSP SD3

DSP MCLK

DSP LRCLK

DSP SCLK

1536

CN200CN1001

1635

CN200CN1001

1338

CN200CN1001

RESET CODEC

RESET DSP

MOSI DSP

MISO DSP

MCLK

ARC

IEC958

I2S0

I2S1

I2S2

I2S3

BCK

LRCK

DT OUT CODEC

CLK DSP

FROM/TO

SYSTEM CONTROL

FROM/TO

SYSTEM CONTROL

FROM HDMI

MAIN P.C.B.

OPTICAL

DIGITAL AUDIO IN

(TV)

: OPTICAL/HDMI AUDIO INPUT SIGNAL LINE : AUDIO OUTPUT SIGNAL LINE

HDMI P.C.B.

NOTE: “ * ” REF IS FOR INDICATION ONLY

71

Page 72

13.4. AUDIO (2/2) BLOCK DIAGRAM

: OPTICAL/HDMI AUDIO INPUT SIGNAL LINE : AUDIO OUTPUT SIGNAL LINE

2

5

4

3

1

DSP SD3

DSP MCLK

DSP LRCLK

DSP SCLK

DSP SD1

TO AUDIO

SECTION (1/2)

DAP SDA

DAP SCL

DAP RESET

DAP PDN

DAP MUTE

DAP SDA

DAP SCL

DAP RESET

DAP PDN

DAP MUTE

IC401

C1AB00003216

DIGITAL AUDIO PWM PROCESSOR

XTL OUT

19

X400

XTL IN

20

MCLK

63

LRCLK

26

SCLK

27

SDIN3

29

SDA

24

SCL

25

RESET

11

PDN

13

MUTE

14

CLOCK, PLL &

SERIAL DATAI/F

IIC SERIAL

CONTROL I/F

MAIN P.C.B.

DIGITAL AUDIO

PROCESSOR

DAP CONTROL PWM CONTROL

SYSTEM CONTROL

PWM SECTION

DEVICE CONTROL

VALID VALID

39

PWM P 4

47

PWM M 4

46

PWM P 3

45

PWM M 3

44

PWM FL+

PWM FL-

PWM FR+

PWM FR-

PWM FL+

PWM FL-

PWM FR+

PWM FR-

IC405

C1AB00003217

DIGITAL AMPLIFIER

5 SD(L)

6 PWM A

8 PWM B

16 PWM C

18 PWM D

7 RST AB(L)

17 RST CD(L)

BST A 43

OUT A

OUT B 36

BST B 34

BST C 33

OUT C 31

OUT D 28

BST D 24

WIRELESS ADAPTER P.C.B.

DIGITAL

TRANSMITTER

WCLK

BCLK

ADAT0

Q500,Q501

SWITCH

SP FL-

39

SP FL+

SP FR-

SP FR+

CN1019CN100CN100

114

CN1017CN100CN100

132

CN1015CN100CN100

141

CN401*

-

+

-

+

FRONT

(LEFT)

FRONT

(RIGHT)

4

CN401*

3

CN401*

2

CN401*

1

FROM/TO

SYSTEM CONTROL

SD

SD

VALID

VALID

ECO DAMP

ECO DAMP

DC DET

DC DET

NOTE: “ * ” REF IS FOR INDICATION ONLY

72

SD

VALID

ECO SUPLLY

CIRCUIT

Q114,Q116

DC DETECT

SP PROTCT

SU-HTB500PP AUDIO(2/2) BLOCK DIAGRAM

Page 73

13.5. IC TERMINAL CHART (HDMI/AUDIO)

Q0 16 D0 98

Q1 15 D1 97

Q2 14 D2 96

Q3 13 D3 95

Q4 10 D4 94

Q5 9 D5 93

Q6 8 D6 92

Q7 7 D7 91

Q8 3 D8 90

Q9 2 D9 86

Q10 1 D10 85

Q11 144 D11 84

Q12 141 D12 83

Q13 140 D13 82

Q14 139 D14 81

Q15 138 D15 80

Q16 135 D16 79

Q17 134 D17 78

Q18 133 D18 77

Q19 132 D19 75

Q20 129 D20 74

Q21 128 D21 73

Q22 127 D22 72

Q23 126 D23 71

Q24 123 D24 70

Q25 122 D25 69

Q26 121 D26 68

Q27 120 D27 67

Q28 117 D28 63

Q29 116 D29 62

Q30 115 D30 61

Q31 114 D31 60

Q32 111 D32 59

Q33 110 D33 58

Q34 109 D34 57

Q35 108 D35

D0

D1

D2

D3

D4

D5

D6

D7

D8

D9

D10

D11

D12

D13

D14

D15

D16

D17

D18

D19

D20

D21

D22

D23

D24

D25

D26

D27

D28

D29

D30

D31

D32

D33

D34

D3556

IC2101

HDMI TRANSMITTER

IC2232

HDMI RECEIVER

SIGNAL NAMETC

1

Pin NoPort Name Pin No Port Name

TX0- 33 9

TX0+ 34 7

TX1- 36 6

TX1+ 37 4

TX2- 39 3

TX2+

TX0-

TX0+

TX1-

TX1+

TX2-

TX2+40

TMDS D0-

TMDS D0+

TMDS D1-

TMDS D1+

TMDS D2-

TMDS D2+1

IC2101

HDMI TRANSMITTER

SIGNAL NAMETC

3

Pin NoPort Name Pin No Port Name

SU-HTB500PP IC TERMINAL CHART (HDMI/AUDIO)

JK2201

HDMI AV OUT (TO TV(ARC))

TMDS D0- 9 R1X0- 61

TMDS D0+ 7 R1X0+ 62

TMDS D1- 6 R1X1- 65