Page 1

ORDER NO. KM40011746C2

Telephone Equipment

PHOENIX100

Digital Cordless Phone

(for Holland)

SPECIFICATIONS

Page 2

1

NOTATION PUBLIC "-//ALDUS//NOTATION TAGGED IMAGE FILE FORMAT//EN"

ENTITY SYSTEM "warning.tif"

1. LOCATION OF CONTROLS

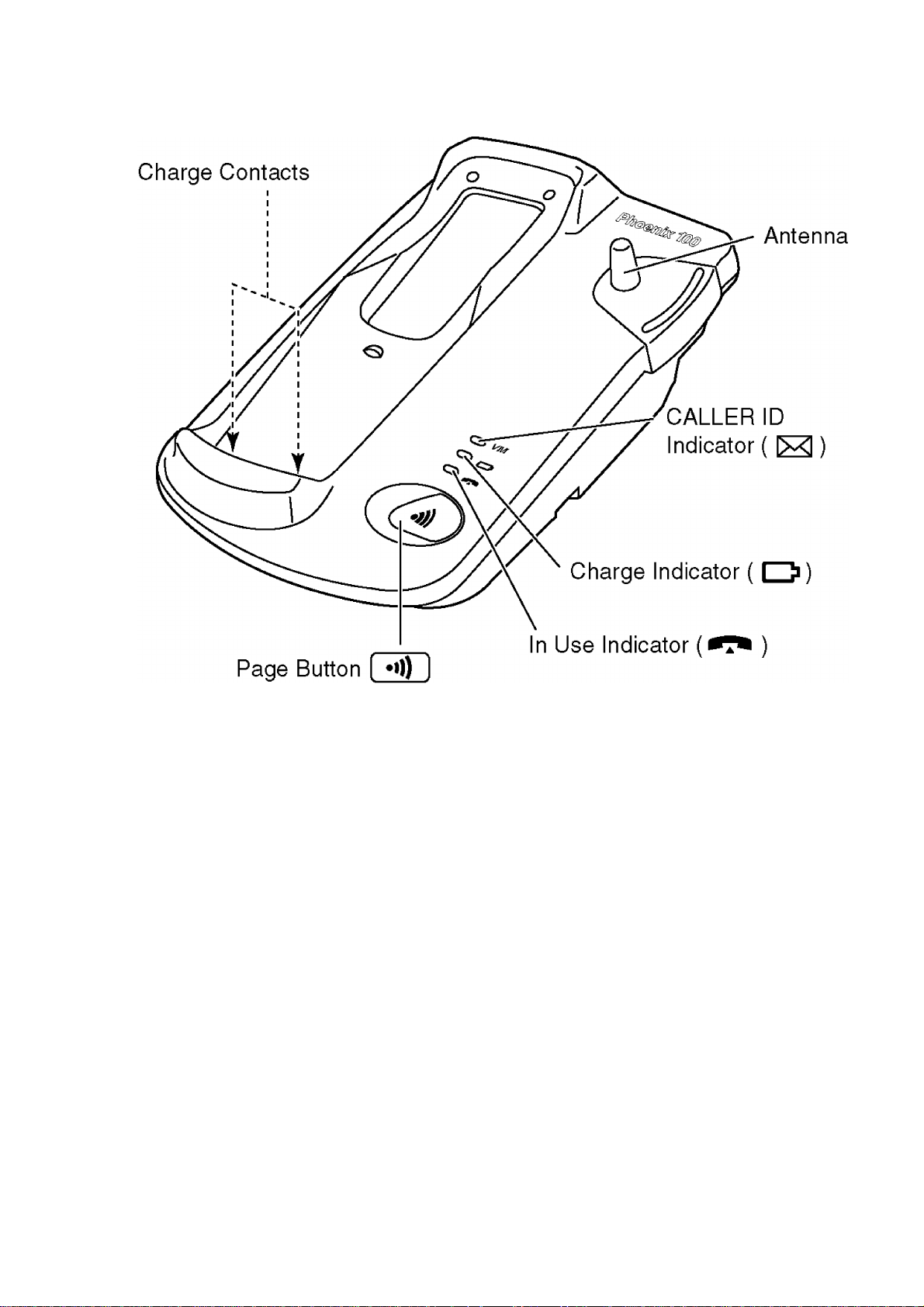

Base Unit

Fig. 1

Page 3

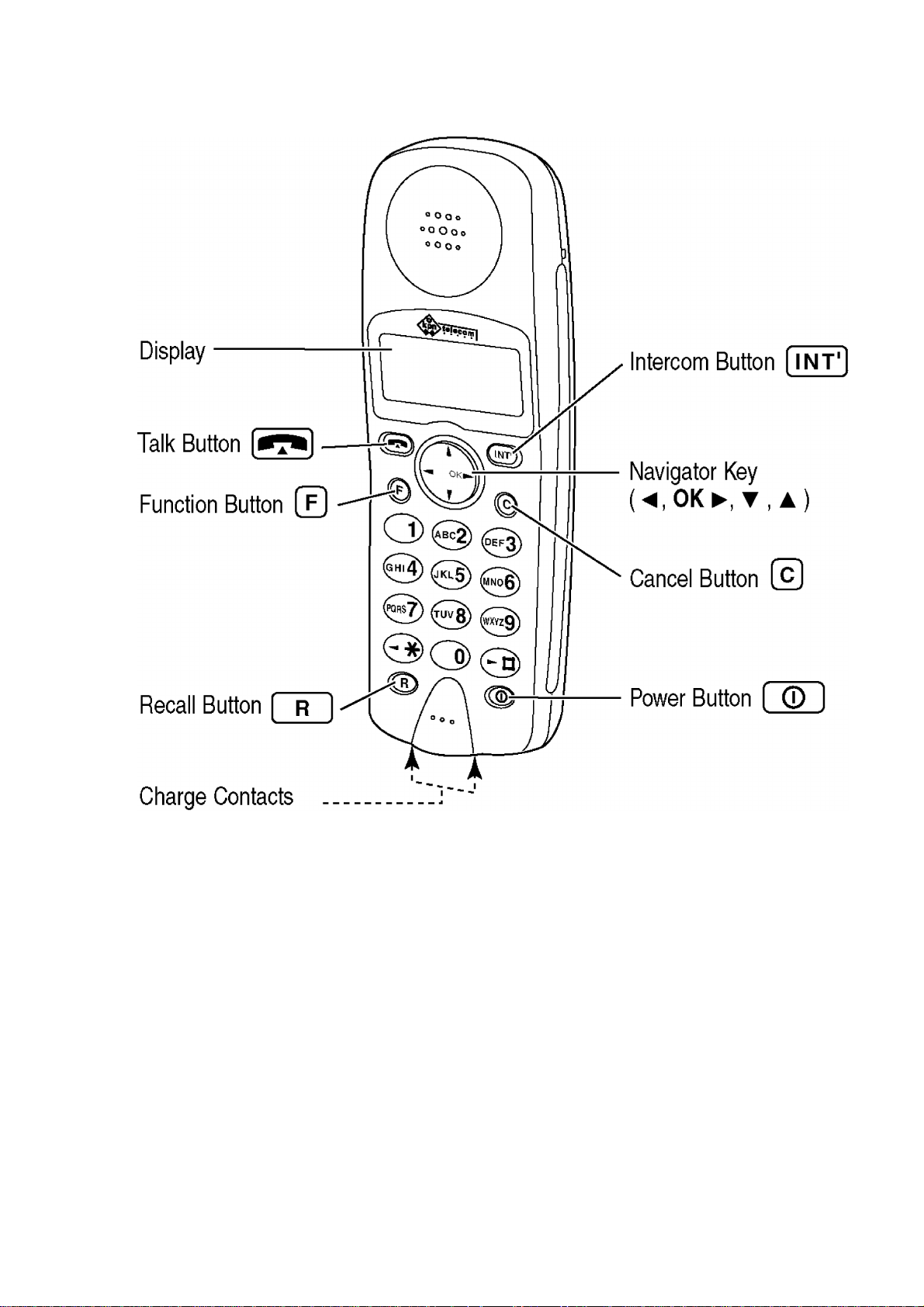

Handset

Fig. 2

Page 4

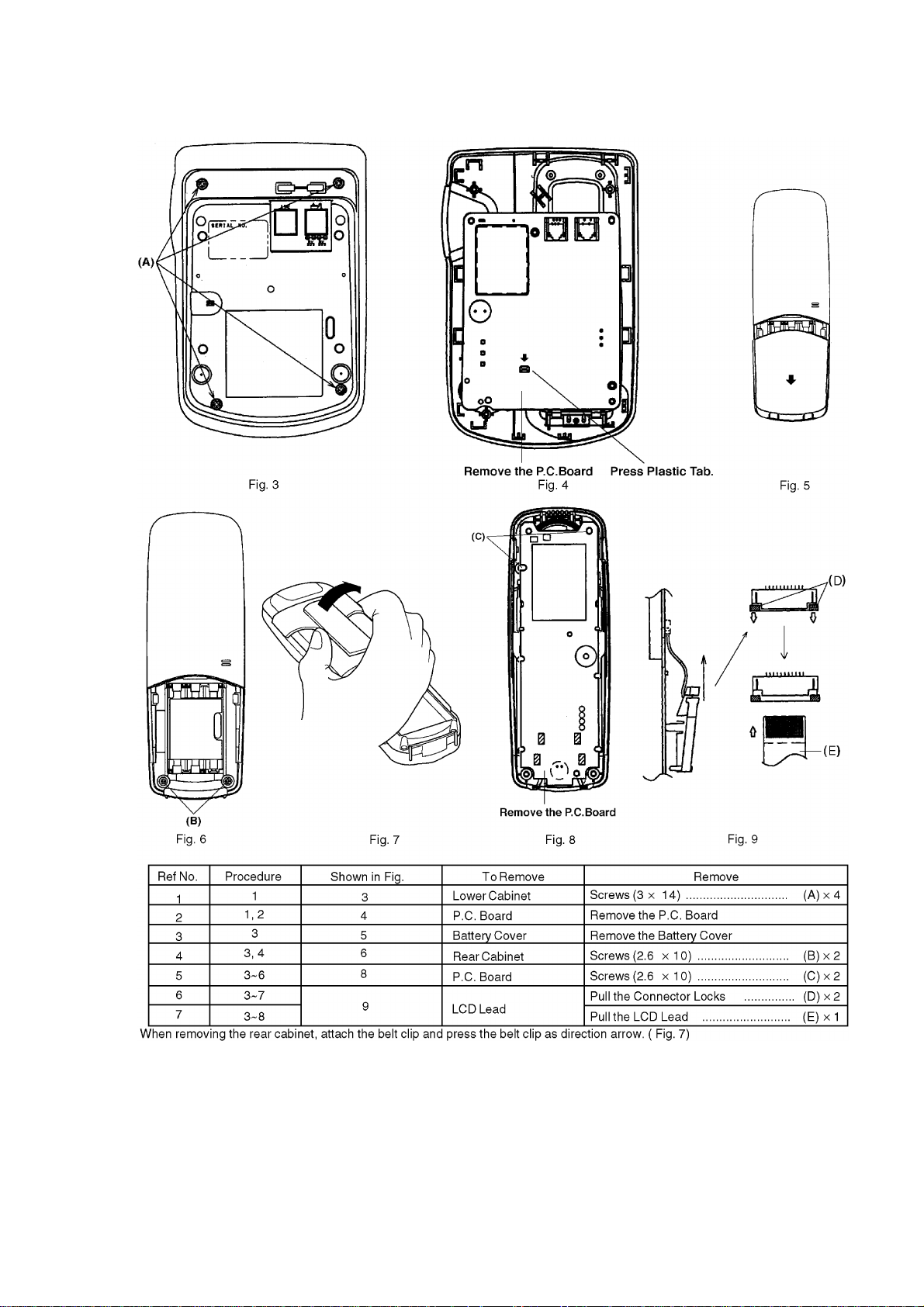

2. DISASSEMBLY INSTRUCUTIONS

Page 5

3. SETTINGS

Page 6

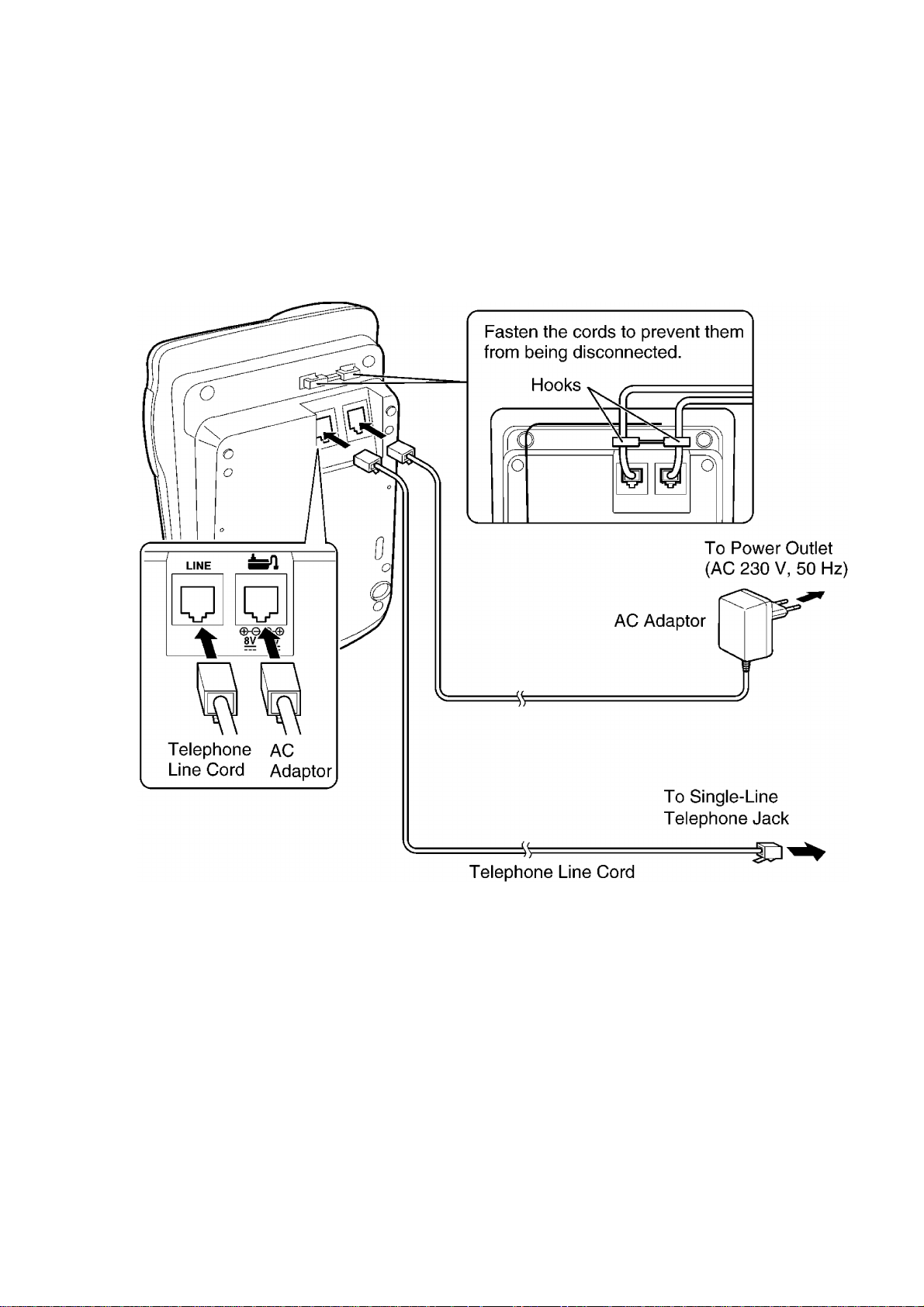

3.1. CONNECTION

Plug in the AC adaptor cord and the telephone line cord to the bottom of the

unit. Then connect the cords as shown.

Fig. 11

- USE ONLY WITH Panasonic AC ADAPTOR KX-TCA11CE.

- Be careful not to confuse the telephone line jack with the AC adaptor jack on

the base unit. If connected improperly, the base unit will not work and

damage may occur.

- The AC adaptor must remain connected at all times. (It is normal for the

adaptor to feel warm during use.)

- The unit will not work during a power failure. We recommend you connect a

standard telephone on the same line for power protection.

Page 7

- If your unit is connected to a PBX which does not support Caller ID services,

you cannot access those services.

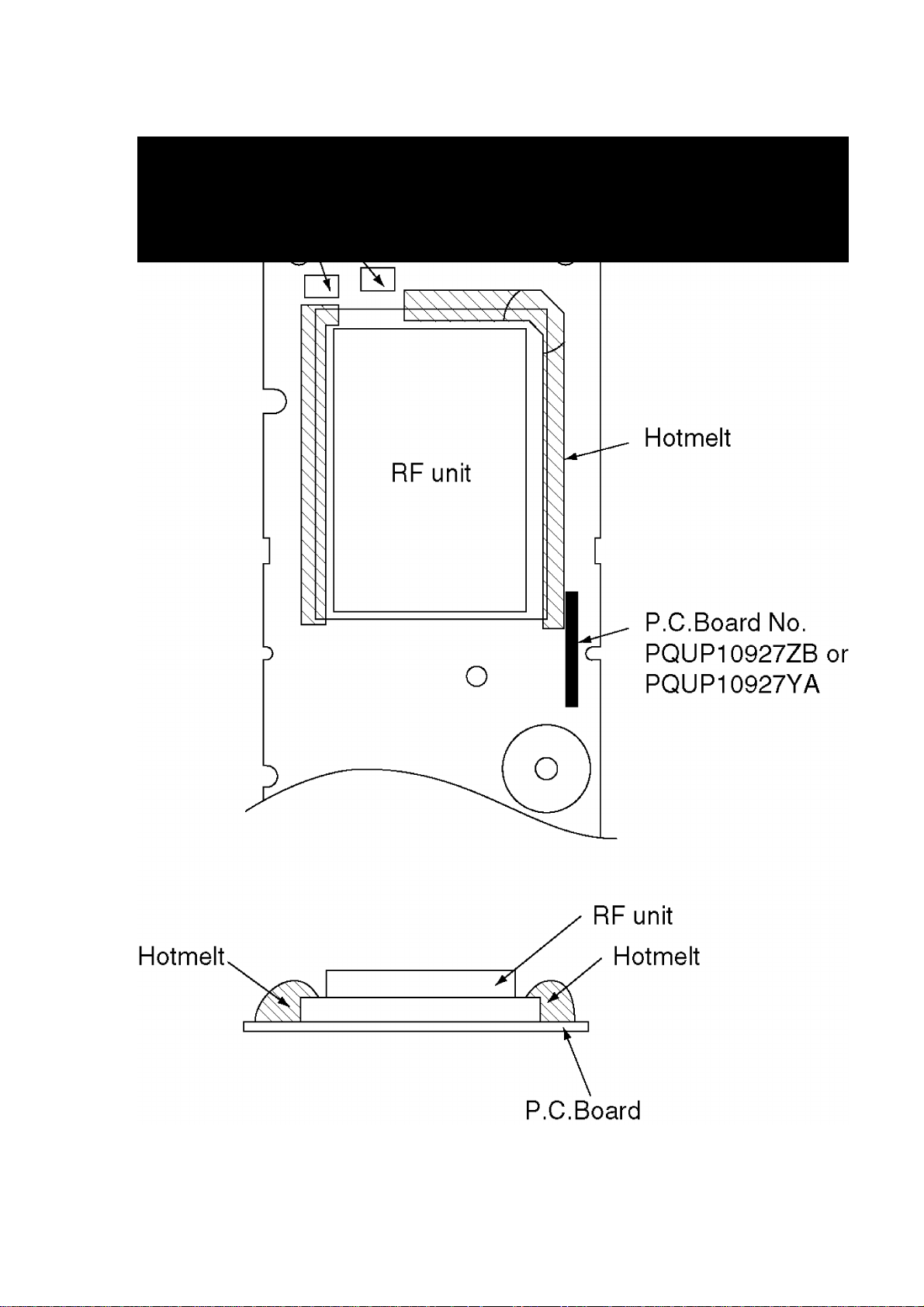

4. HOW TO REPLACE THE RF UNIT OF HANDSET

When replacing the P.C. Board No. PQUP10927ZB and PQUP10927YA, the

hotmelt removing and putting operation is required.

1. Cool the P.C. Board in the freezer for 10 minutes, then remove the hotmelt of

the hatched parts in Fig. 12 with the tip of minus screwdriver.

2. Remove the solder of each pin on RF unit, then remove the RF unit from the

P.C. Board.

3. After soldering the new RF unit on the P.C. Board surely, put the hotmelt on

the hatched part in the Fig. 12.

4. Note:

Above-mentioned hotmelt removing and putting operation is only for the P.C.

Board No. PQUP10927ZB and PQUP10927YA.

5. There is no need of the hotmelt removing and putting operation for the PC

Board No. PQUP10927ZC.

Fig. 12

Page 8

Page 9

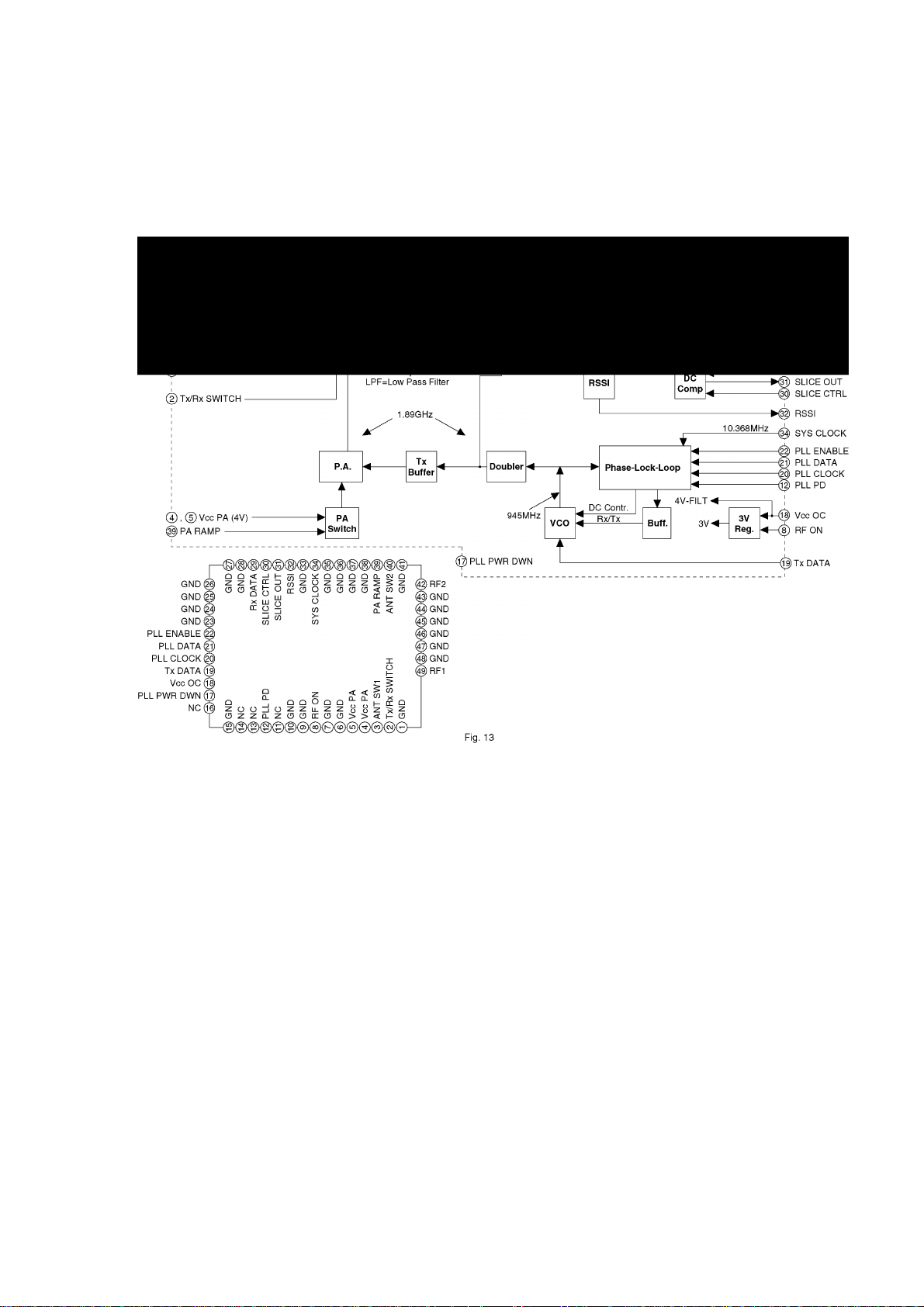

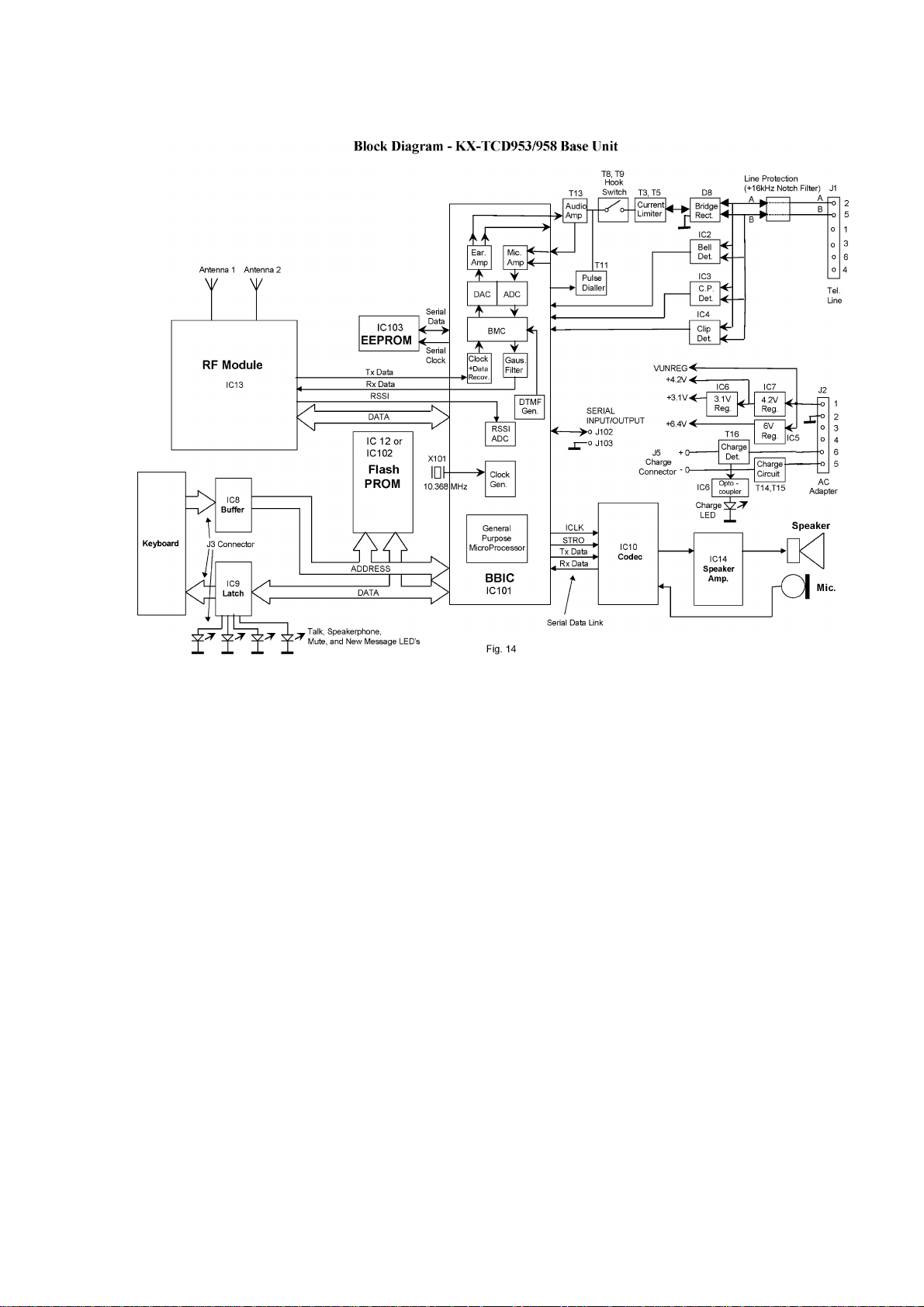

5. BLOCK DIAGRAM RF UNIT (BASE UNIT)

6. BLOCK DIAGRAM BASEBAND SECTION AND LINE

INTERFACE (BASE UNIT)

Page 10

7. CIRCUIT OPERATION (BASE UNIT)

7.1. R.F. SECTION (SEE BLOCK DIAGRAM Fig. 13)

7.2. THE BASE-BAND SECTION (SEE BLOCK DIAGRAM Fig.

14)

7.2.1. INTRODUCTION

The base-band section consists of a base-band integrated circuit (BBIC), a Flash

PROM, an EEPROM, and an AND Gate.

7.2.2. THE BASE-BAND INTEGRATED CIRCUIT (BBIC)

The PQVINSC14424 (IC101) is a CMOS device designed to handle all the audio,

signal and data processing needed in a DECT base unit. It contains a "burst

mode controller” microprocessor which takes care of DECT specific physical

layer and radio section control. It also contains two ADPCM transcoders, a low

Page 11

power 14 bit codec (ADC/DAC), various other ADC´s, DAC´s and timers, a

gaussian filter for the DECT GFSK modulation method, clock and data recovery

circuits, a clock oscillator circuit, a DTMF generator (DSP), an echo suppression

circuit (DSP), and a pair of gain controllable audio amplifiers for line input and

line output and a general purpose microcontroller.

The IC101 interfaces to its external PROM (IC102) via a data/address/control

bus. It connects to the EEPROM via a serial interface, and a second serial

interface is used during manufacture and service to connect to an external

computer.

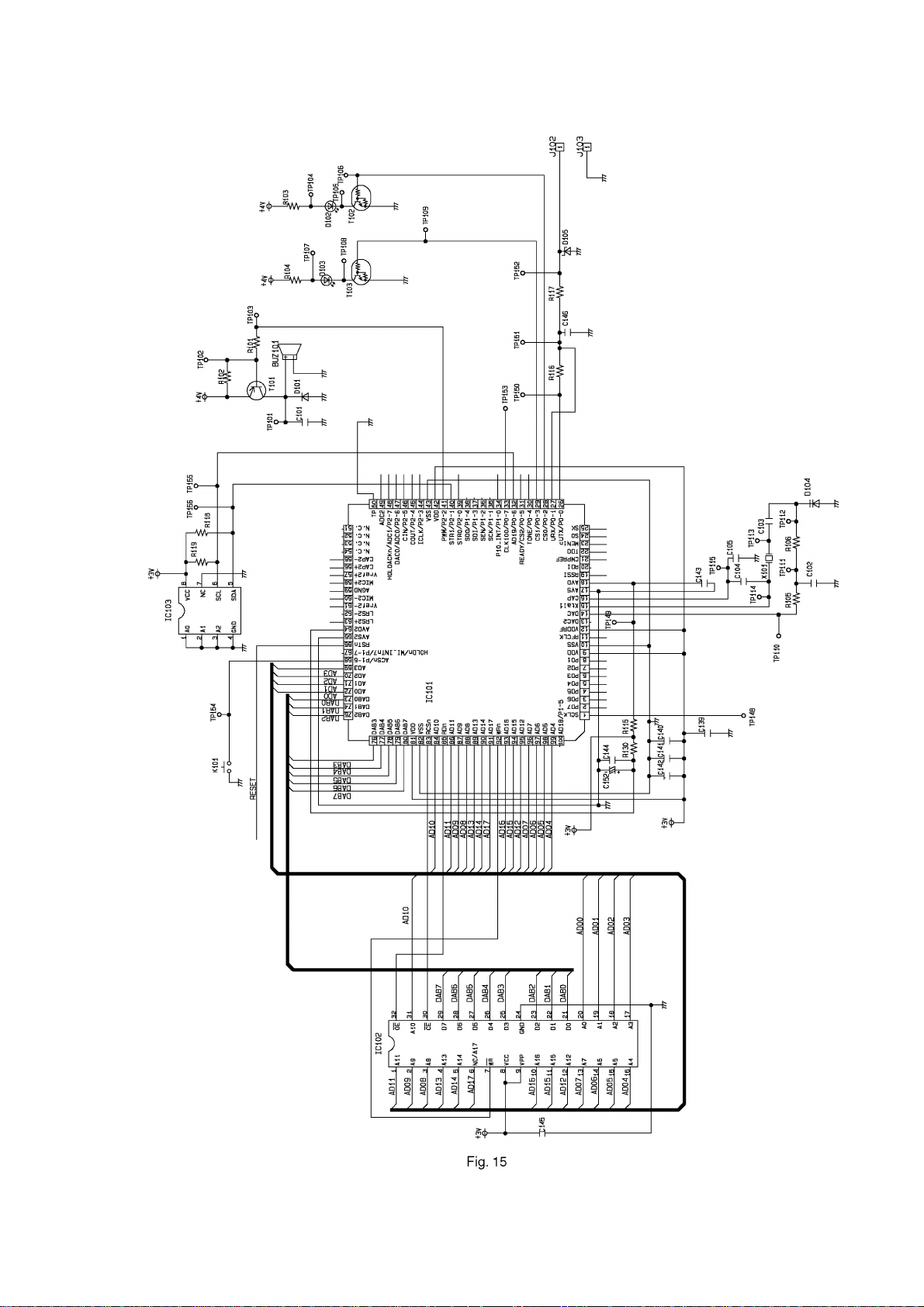

7.2.3. FLASH PROM (SEE Fig. 15)

The 1 Mbit (IC102) Flash PROM contains the operational firmware for the

microcontroller. It is interfaced to the data/address/control bus using address

lines A0 to A16, data lines D0 to D7, and chip select (pin 30), output enable (pin

32), and write (pin 7).

7.2.4. EEPROM (SEE Fig. 15)

The electrically erasable PROM PQVINM4C32L (IC103) is used to store all the

temporary operating parameters for the base (see EEPROM LAYOUT). It uses a

two-line serial data interface with the BBIC, with bi-directional data on pin 5

(TP94), and clock on pin 6 (TP93).

7.2.5. CLOCK GENERATION (SEE Fig. 15)

A single clock generator in the BBIC uses an external crystal X101 to derive all

clock frequencies used in the base. The crystal is tuned to the exact frequency

of 10.368 MHz during manufacture by feeding a DC voltage from a DAC in the

microcontroller (from pin 14 of IC101) to the varicap diode D104 (TP112).

The BBIC provide buffered clock signals RFCLK (pin 11, TP139) at 10.368 MHZ

for the Frequency Synthesizer, which is only active during the PLL lock period.

Other clock is SCLK on pin 1 (3.456MHz). The basic data rate for TRADAT and

RECDAT is 1.152 Mbits/s, which is 10.368 MHs divided by 9. The data rate for the

serial interface to the phase-lock-loop is also 1.152 Mbits/s.

Circuit Diagram

Page 12

Page 13

7.2.6. LOCATOR KEY (SEE Fig. 15)

The keyboard “Locator (Page)” button is connected to pin 68 (TP154) of the

IC101. When pressed the base transmits a message to the handset, which then

beeps.

7.2.7. FACTORY SERIAL PORT (SEE Fig. 15)

In order to communicate with the handset during manufacture and servicing

(using a PC) a serial data link has been provided. Serial data input/output is

provided on J102 (TP151), and a ground is provided on J103. The bi-directional

serial data line is split into two at IC101 pin 27 (input) and pin 26 (output). Data

rate is 9600 baud J103. D105provides ESD protection, and R117 and C146

provide RF de-coupling.

7.2.8. BUZZER CIRCUIT (SEE Fig. 15)

A square-wave signal from IC101 pin 41 (TP103) is used to sound the buzzer via

switching transistor T101 (TP101). Various tones and cadences are used

dependent on function. Buzzer volume is varied by changing the duty cycle of

the drive waveform. D101 provides quenching of back-emf generated when T101

turns off.

7.2.9. OFF HOOK AND CALLER LED´S (SEE Fig. 15)

When the Handset is in “Talk” mode, the Off-Hook LED D102 is switched on by

transistor T102 (on), using a control line from pin 28 of IC101 (TP106). “On the

TCD952 the caller” LED is switched via T103.

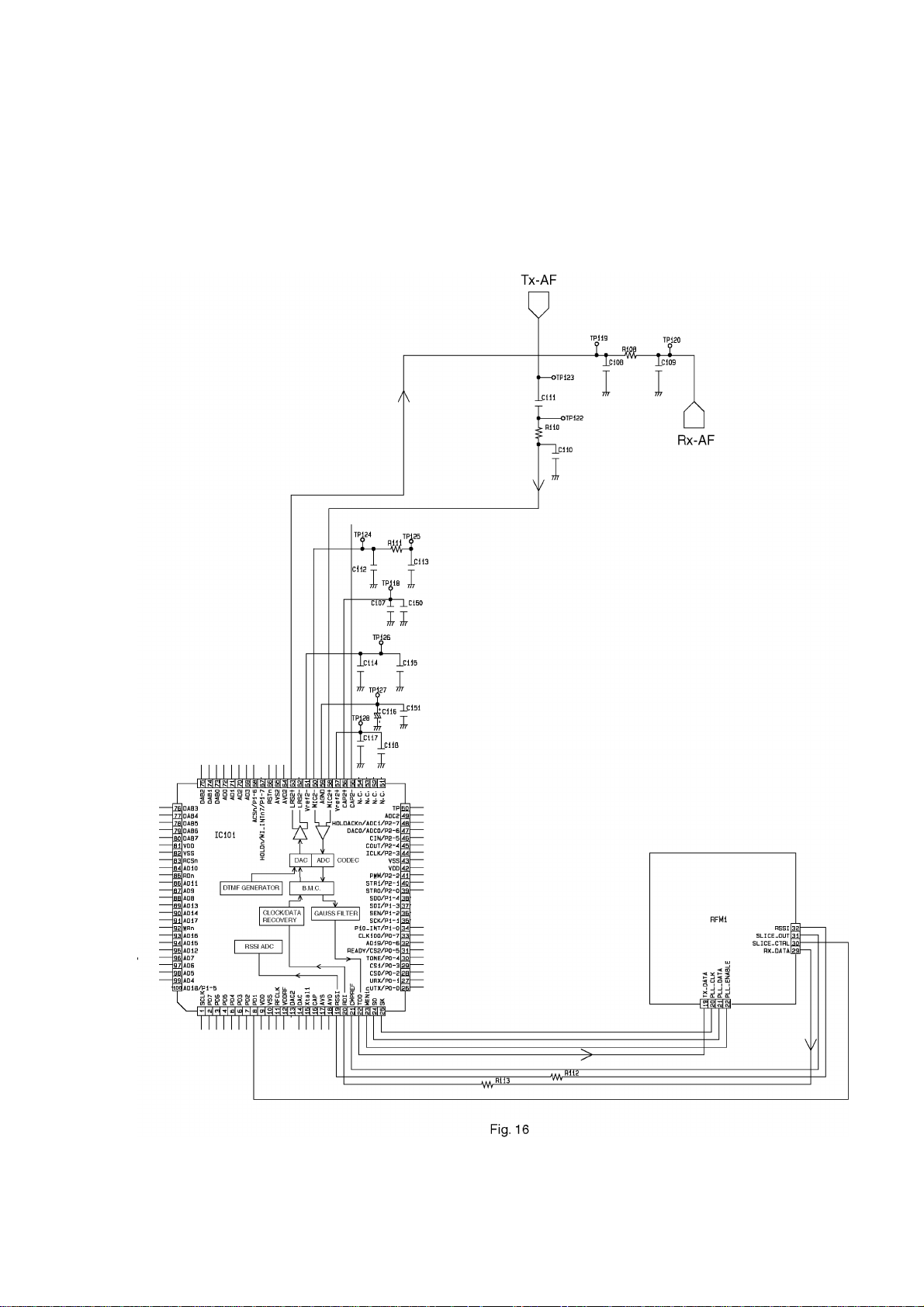

7.2.10. AUDIO PATH-RX AUDIO-LINE INPUT (SEE Fig. 16)

Audio from the Line Interface TXAF (TP123) enters the BBIC on pin 58. R111 and

C113 are to balance the line input amplifier, into the ADC part of the codec,

where it is sampled and turned into digital data. The burst mode controller then

processes this raw data (called the B-field) performing encryption and

scrambling, adding the various other fields that go together to produce the GAP

standard DECT frame, assigning to a time slot and channel etc. The data then

passes through the gaussian filter to emerge on pin 22 as TRADAT, (TP132).

7.2.11. AUDIO PATH - TX AUDIO - LINE OUTPUT (SEE Fig. 16)

Audio from the receiver RECDAT enters the BBIC on pin 20 and passes through

the clock recovery circuit. The burst mode controller separates out the B-field

data, and performs de-encryption and de-scrambling as required. It then goes to

Page 14

the DAC part of the codec where data is turned back into analogue audio. The

audio signal is amplified by the gain-controlled line output amplifier, and

balanced audio is output on pin 63, and fed as RXAF (TP120) to the Line

Interface.

Circuit Diagram

Page 15

7.3. THE LINE INTERFACE SECTION (SEE BLOCK

DIAGRAM Fig. 15)

7.3.1. INTRODUCTION

This section consists of the telephone line interface, bell detector, hookswitch,

pulse dialing circuits, audio circuits, DC mask & line impedance circuits, power

supplies, and battery charger circuits.

7.3.2. TELEPHONE LINE INTERFACE (SEE Fig. 17)

The telephone line is connected (via 2 or 3 jumpers selected for country of

destination) to a bridge rectifier D8. Surge suppressor SA3 protects against

excessive line voltages. Test points are TP14 (A), TP13 (B), TP21 (S) and TP15

(E). Bridge rectifier D8 provides for lines of either polarity. The output of D8 is

“Line +” (TP50) and “Line -” which is ground.

7.3.3. EARTH RECALL (SEE Fig. 17)

For countries that require Earth Recall facilities, relay RLY1 is provided to short

the E line to the A or B lines. The relay is energised when transistor T2 is

switched on by a high level on the EARTH control line (TP77) from the BB-IC

IC101. D1 will quench the large back-emf voltage that would otherwise occur

across the relay coil when T2 turns off.

7.3.4. BELL DETECTOR (SEE Fig. 17)

The AC ringing signal is detected by optocoupler IC2, using its internal diode in

conjunction with D4. DC from the line is blocked by the wall plug inside. The

other components D2, D3, and R3 reduce current and increase the circuit

impedance in line with national requirements. When ringing is detected IC2 will

turn on, and the RING line (TP76) will be dragged to a low voltage.

Circuit Diagram

Page 16

7.3.5. CLIP CIRCUITS (SEE Fig. 17)

The caller ID signal is detected by IC4.

7.3.6. HOOKSWITCH (AND PULSE DIALING) (SEE Fig. 18)

T8 is the hookswitch, driven by T9. When the phone is “off-hook”, the HOOK

control signal from the BBIC will be a high logic level (+3V), and all both

transistors will be on, thus T8 will “loop” the line. The zenner diode D10

protects transistors T11 to T13 against transient line voltages.

7.3.7. PULSE DIALING (SEE Fig. 18)

During pulse dialing the hookswitch (T8, T9) is used to generate the pulses

using the HOOK control signal, which is set high during pulses. To force the line

impedance low during the “pause” intervals between dial pulses, the

PAUSE-DIAL signal turns on T11, which turns on T12 harder (increases current),

thus reducing line impedance (see 7.3.10. BATTERY CHARGER (SEE Fig. 19))

Page 17

7.3.8. AUDIO CIRCUITS (SEE Fig. 18)

The line output signal from the BBIC RXAF (TP120) is amplified by T13. The

RXAF line is DC coupled to T13 thus making it work as a current limiter (typically

< 8mA). The emitter load of T13 is complex to achieved the correct frequency

response, since the line load (for UK) is also complex. The line input signal

TXAF (TP123) is taken from the junction of R41 and R70. Phase cancellation of

the line output audio occurs at this point, so that only incoming line audio

should be passed to the BBIC on TXAF.

Circuit Diagram

7.3.9. POWER SUPPLIES (SEE Fig. 19)

The AC Adaptor for the KX-TCD952PDB consists of two separate isolated DC

supplies providing a +8 V supply for the base circuitry, and a 9 V supply only for

the charger circuit. The isolation is because the main base circuitry is

connected to the telephone line, so potentially hazardous voltages may be

present, while the charger circuitry has charge contacts that could be touched

by the operator, so the two supplies must be kept separate. The 8 V supply from

the AC Adaptor is connected via J2 pin 1 (TP90) +8 V, and J2 pin 2 (TP89)

ground. The unregulated +8 V supply is fed to the first regulator.This regulator

IC7 provides a regulated output pin 2 (TP91) of +4.0 V (called +4V). The second

regulator IC6 is fed with +4V and provides the stable +3.0V supply (TP95).

During power-up this regulator generates a RESET signal (TP94) which is used

to reset the microcontroller and BBIC.

7.3.10. BATTERY CHARGER (SEE Fig. 19)

The 9 V supply from the AC Adaptor is connected via J2 pin 6 (TP82) positive,

Page 18

and J2 pin 5 (TP78) negative. The constant current battery charger circuit is

made up of T14 and T15 (series pass transistor) and associated components.

Charging detector circuit T16 switches on when a charging current flows

through R64 and D11, and turns on the “Charging” LED D12. The charge

contacts are J5. Charge current flows in via J5 (negative), through T15, R63, AC

Adaptor 9 V supply, R64, D11, and out via J5 (positive).

Circuit Diagram

8. BLOCK DIAGRAM RF UNIT (HANDSET)

Page 19

9. BLOCK DIAGRAM BASE-BAND SECTION

(HANDSET)

Page 20

10. CIRCUIT OPERATION (HANDSET)

10.1. THE BASE-BAND SECTION (SEE BLOCK DIAGRAM

Fig. 21)

10.1.1. INTRODUCTION

The base-band section consists of a base-band integrated circuit (BBIC), a Flash

PROM, an EEPROM, an LCD Display, a Microphone, an Earpiece, and power

supply/battery management circuits.

10.1.2. THE BASE-BAND INTEGRATED CIRCUIT (BBIC)

The National SC14405 BBIC (IC1) is a CMOS device designed to handle all the

audio, signal and data processing needed in a DECT handset. It contains two

microprocessors - one general purpose - while the other ìburst mode controllerî

takes care of DECT specific physical layer and radio section control.The BBIC

also contains the ADPCM transcoders, a low power 14 bit codec (ADC/DAC),

various other ADCís, DACís and timers, a UART for data communication with RF

Page 21

unit, a gaussian filter for the DECT GFSK modulation method, clock and data

recovery circuits, a clock oscillator circuit, a battery management circuit, and a

pair of gaincontrollable amplifiers for the microphone and earpiece.

10.1.3. FLASH PROM (SEE Fig. 22)

The 2 Mbit Flash PROM IC2 contains the operational firmware for the BBIC’s

general purpose microprocessor. It is interfaced to the BBIC using address lines

AD0 to AD17, data lines DAB0 to DAB7, and the chip select (IC1 pin 84), read (IC1

pin 86), and write (IC1 pin 93) control lines.

Fig. 22

Circuit Diagram

10.1.4. LCD DISPLAY, AND DISPLAY DRIVER (SEE Fig. 23)

The LCD display also receives data via a serial interface. Serial data is sent to

LCD display on pin 3 (TP70). The RS signal (pin 1, TP67) is used by the BBIC to

send either commands or data.

Fig. 23

Circuit Diagram

Page 22

10.1.5. AUDIO PATH - TX AUDIO (SEE Fig. 24)

Balanced audio from the microphone (TP40 and TP41) enters the BBIC at pins

61 and 63. A balanced bias voltage for the (“electret” type) microphone is

supplied by the BBIC from pins 60 and 64 via R31 and R32. This supply is

de-coupled by R22, R27, C21, C28, and C22. RF de-coupling of the microphone

signal is provided by R27, C25, R28, C26, R24, R25, and C20. The microphone

audio signals are coupled to the BBIC via C22 and C23, which provide some

high pass filtering.

In the BBIC audio passes through the gain-controlled microphone amplifier, into

the ADC part of the codec, where it is sampled and turned into digital data. The

burst mode controller then processes this raw data (called the B-field)

performing encryption and scrambling, adding the various other fields that go

together to produce the GAP standard DECT frame, assigning to a time slot and

channel etc. The data then passes through the gaussian filter to emerge on pin

20 as TRADAT.

10.1.6. AUDIO PATH - RX AUDIO (SEE Fig. 24)

Audio from the receiver RECDAT (TP54) enters the BBIC on pin 18 and passes

through the clock recovery circuit. The burst mode controller separates out the

B-field data, and performs de-encryption and de-scrambling as required. It then

Page 23

goes to the DAC part of the codec where data is turned back into analogue

audio. The audio signal is amplified by the gain-controlled earpiece amplifier,

and balanced audio is output on pins 65 and 66, and fed to the earpiece (TP31

and TP32). The leads feeding the earpiece are RF de-coupled by C15 to R22,

C17, C16, R23, and C18. C19 provides low pass filtering.

Fig. 24

Circuit Diagram

10.1.7. CLOCK GENERATION (SEE Fig. 25)

A single clock generator in the BBIC uses an external crystal X1 to derive all

clock frequencies used in the handset. The crystal is tuned to the exact

frequency of 10.368 MHz during manufacture by feeding a DC voltage from an

internal DAC (from pin 12) to the varicap diode D12 (TP25). The RFCLK output

(pin 10, TP56) is a buffered clock signal at 10.368 MHz for the Frequency

Synthesizer, that is only active during the PLL lock period (see section 1.3). The

basic data rate for TX-DATA and RX-DATA is 1.152 Mbits/s, which is divided by

9. The data rate for the serial interface to the phase-lock-loop is also 1.152

Mbits/s.

10.1.8. KEYBOARD (SEE Fig. 25)

Page 24

The keyboard “On” button is connected directly to pin 41 of the BBIC (TP10).

When pressed it turns the handset on and off (must be held for off). All other

keys are connected in a row/column matrix. They are scanned in six rows using

scan pulses (only active when keys are pressed) from IC1 pins 28 to 33. The four

key matrix columns are input to the BBIC on pins 31 to 34.

Fig. 25

Circuit Diagram

10.1.9. FACTORY SERIAL PORT (SEE Fig. 21)

Page 25

In order to communicate with the handset during manufacture and servicing

(using a PC) a serial data link has been provided. Serial data input/output is

provided on J6 (TP65), and a ground is provided on J7. The bi-directional serial

data line is split into two at IC1 pin 27 (input) and pin 26 (output). Data rate is

9600 baud or 115.2 kBaud. D13 provides ESD protection, and R37 and C56

provide RF de-coupling.

10.1.10. BUZZER CIRCUIT (SEE Fig. 26)

A square-wave signal from IC1 pin 45 is used to sound the buzzer via switching

transistor T5 (TP22). Various tones and cadences are used dependent on

function. Buzzer volume is varied by changing the duty cycle of the drive

waveform. D11 provides quenching of back-emf generated when T5 turns off.

10.1.11. BATTERY SUPPLY (SEE Fig. 26)

The three cell NiCd/NiMH rechargeable battery supplies the handset via 2A fuse

(actually a coil), and is de-coupled by C3 and C4. It directly supplies T3 in the

baseband section, and also the Tx PA in the RF Section. It also supplies IC1

(de-coupled by C9), and most of the RF Section (VCC-OC) (decupled by R35 and

C47, C48 and VCC-PA).

10.1.12. MAIN 3V REGULATOR (SEE Fig. 26)

The BBIC measures the battery voltage on pins 58 using an internal ADC. If the

battery voltage is below 3.36 V, TC3 is switched to power off mode. R7 and C5

provide a reset pulse (TP84) used for resetting the BBIC when power on. The +3

V supply (TP10) is fed to the BBIC, Flash PROM, EEPROM, and Display Driver.

10.1.13. BATTERY CHARGING CIRCUIT (SEE Fig. 26)

The charge circuit is designed to operate with a constant current charger in the

base. L1, L2, D2 and D4 protect against electro-static discharge (ESD). The

charging current from the base is turned on and off by T1 using a control signal

from the BBIC (pin 39, TP6) via T2. R3 provides initial current in the event of a

totally flat battery, and D6 protects against the high voltage present on the

charge contacts if there is no battery in the handset. R4 and R5 provide a signal

for the BBIC to detect (pin 40) that the handset had been placed on the base

charger. If the handset is off, it will be switched on, and charging will start.

Fig. 26

Circuit Diagram

Page 26

11. ADJUSTMENT (BASE UNIT)

Adjustment objectives

item Symptom Remedy

frequency Synchronization with the portable handset is lost

immediately.

No link is established.

Perform the adjustments

described in item(1).

Page 27

Tools required for adjustments

- Frequency counter

- Personal computer

- Serial communication tool

- Test software (batch files)

- Line simulator

- Oscillator

- Audio level meter

Item(1)

1. Connect the serial link to test computer to J102 (serial data) and J103 (GND).

2. Connect the AC adaptor.

3. Connect the frequency counter to TP148 (SCLK) and J103 (GND).

4. Send batch file “FIXFREQ.BAT”

5. Send “SETFREQ.BAT” to set the clock frequency. The default value is 80.

Increase the value to increase the frequency. The clock frequency must be

3,456 kHz ± 0.007 kHz.

12. ADJUSTMENT (HANDSET)

Adjustment objectives

item Symptom Remedy

frequency Synchronization with the portable handset is lost

immediately.

No link is established.

battery The communication (standby) times is short. Perform the adjustments

The low battery display period is too long or too

short.

Perform the adjustments

described in item(1).

described in item(2).

Tools required for adjustments

Page 28

- Frequency counter

- Power supply unit (DC 3V~5V, 1A)

- Personal computer

- Serial communication tool

- Test software (batch files)

Item(1)

1. Connect the serial link to test computer to J6 (serial data) and J8 (GND).

2. Turn off power for the base unit.

3. Input a 3.9V supply to the handset J5 (+) and J8 (GND).

4. Connect the frequency counter to TP56 and J8 (GND).

5. Press the “power on” button.

6. Send batch file “FIXFREQ.BAT”.

7. Use batch file “SETFREQ.BAT” to set the clock frequency. The default value

is 80. Increase the value to increase the frequency and vice-versa. The clock

frequency must be 10,368.000 kHz ± 0.02 kHz.

Item(2)

1. Connect the serial link to test computer for J6 (serial data) and J8 (GND).

2. Set the battery voltage to 4.6V at J1 and J2.

3. Press the “power on” button.

4. Send batch file “READBATT.BAT”. The returned hex value is M2.

5. Send batch file “WRTBATT.BAT M2”.

6. Set the battery voltage to 3.5V at J5 (+).

7. Send batch file “READBATT.BAT”. The returned hex value is M1.

8. Send batch file “WRTBATT.BAT M1”.

9. Calculate the low value 2 level:

10. Send “WRTBATT.BAT M3”.

Page 29

13. CHECK PROCEDURE (BASE UNIT)

13.1. TEST EQUIPMENT REQUIRED AND EQUIPMENT

SETUP

13.2. INITIAL POWER + BBIC TESTS

1. Turn on the 10V supply.

2. Check for approx. 70 mA current on the 10V supply.

3. Check the 4V supply voltage (TP91). It must be 3.88 ±0.2V.

4. Check the 3.3V supply voltage (TP95). It must be 3.0 ±0.2V.

5. Connect SCLK (TP148) to CH.1 on the scope.

6. Check if the clock waveform is 3,456 kHz.

7. Send batch file “SELF TEST”.

13.3. SET THE CLOCK FREQUENCY

Page 30

1. Send batch file “FIX FREQ”.

2. Check for approx. 90 mA current on the 8V supply.

3. Transfer SCLK (TP148) to the frequency counter.

4. Send batch file “SETFREQ nn” to set the clock frequency. The default value of

nn is 80. Increase the value to increase the frequency and vice-versa. The

clock frequency must be 3,456 kHz ( ± 0.007 kHz).

13.4. QUICK Tx CHECK

1. Set the CMD60 to MODULE TEST.

2. Send batch file “H”.

3. Confidence check of Power (NTP): it must be +20 to +25 dBm.

4. Confidence check of Frequency Offset: it must be 0 ± 40 kHz.

5. Confidence check of Deviation of B field Data Type 01010101: it must be 207

to 270 kHz.

13.5. LOOPBACK TEST

1. Set the CMD60 to MANUAL TEST.

2. Set the CMD60 TRAFFIC CARRIER to 5.

3. Send batch file “TESTMODE”.

4. On the CMD60, press “SETUP CONNECT”.

5. Check the Power (NTP): It must be +20 to +25 dBm.

6. Press MODULATION.

7. Set Data Type to “Fig. 27”.

8. Check the Frequency Drift: it must be 0 ± 45 kHz/ms.

9. Check the Frequency Offset: it must be 0 ± 40 kHz.

10. Send batch file ìWREE 00 16 nmî to adjust the Deviation (Max. B Field) with

Data Type: 01010101. Increase the value nm to increase the Deviation and

vice-versa. The least significant digit (m) of the value must be 1 (i.e. only the

values 31, 41, 51, 61 etc. are allowed). The Deviation must be 207 to 270 kHz.

11. Check the Deviation (Max. ± B Field) with Data Type “Fig. 27”: it must be 202

to 404 kHz.

12. Press MENU UP.

13. Press POWER RAMP.

Page 31

14. Check the Burst fits mask.

15. Press MENU UP.

16. Press BER.

17. Note the Sensitivity (reduce RF LEVEL for a BER of approx. 1000ppm) : the

RF LEVEL must be < - 90 dBm.

18. Press MENU UP.

19. Press BEARER RELEASE.

Note:

These tests can be repeated on Traffic Carriers 5 and 9.

13.6. TELEPHONE LINE TESTS

1. Connect the tel line from the base under test to the line simulator.

2. Send batch file “OFFHOOK”.

3. Check if the green “In-Use” LED is on.

4. Set the line current to 40 mA on the line simulator.

5. Send batch file “ONHOOK”.

6. Check that the line current is 0 ± 0.5 mA.

7. Check if the green “In-Use” LED is off.

8. Send batch file “OFFHOOK”.

9. Check the DC Voltage on TP45. It must be 9.5 ± 0.5V.

10. Send batch file “LINIMP 1”.

11. Check the DC Voltage on TP45. It must be < 3.5V.

12. Send batch file “LINIMP 0”.

13. Send batch file “PULDIAL”.

14. Observe on the line simulator current meter that 5 dial pulses are output

causing the current to reduce to approx. 20mA.

15. Send batch file “STRTDTMF”.

16. Check on the scope that a DTMF waveform is output on that tel line.

17. Send batch file “STOPDTMF”.

18. Disconnect the tel line from the base under test to the line simulator.nm

19. Connect the “Bell” Oscillator to the tel line.

20. Set the “Bell” Oscillator voltage to 32V RMS 23Hz.

Page 32

21. Send batch file “RINGDET”.

22. Check that the ringing voltage has been detected (1 = detected).

13.7. CHARGE CURRENT TEST

1. Connect the 11V supply to J2 pin 6 (+) and J2 pin 5 (-).

2. Connect the ammeter with a series load resistor of 56ΩΩ/2 W to J3 (+) and J4 (-).

3. Switch on the 11V supply.

4. Check the Charge Voltage to J3 and J4 9.5 ± 0.5 V.

5. Switch off the 11V supply.

6. Connect the 11V supply to the “11V Supply” sockets on the test jig.

14. CHECK PROCEDURE (HANDSET)

14.1. TEST EQUIPMENT REQUIRED AND EQUIPMENT

SETUP

NOTATION PUBLIC "-//ALDUS//NOTATION TAGGED IMAGE FILE FORMAT//EN"

ENTITY SYSTEM "14_01_01.tif"

14.2. INITIAL POWER + BBIC TESTS

1. Turn on the 3.9V supply.

2. Press the “Power-on” button.

3. Check for a “beep” and approx 80 mA current on the 3.9V supply.

4. Check the 3.0V supply voltage (TP10). It must be 2.85 +/- 0.3.

5. Connect RFCLK (TP56) to CH.1 on the scope. Send batch file RFCLK1.

6. Check if the clock waveform is 10,368.000 kHz, +/- 40Hz.

7. Send batch file ”SELF TEST”. The first 4 digits are FLASH ROM checksum,

the next 2 digits are RAM test, and must be 00.

14.3. SET CLOCK FREQUENCY

1. Send batch file “RFCLK1”.

2. Connect RFCLK (TP56) to the frequency counter.

Page 33

3. Send batch file “SET FREQ nn” to set the clock frequency. The default value

of nn is 80. Increase the value to increase the frequency. The clock frequency

must be 10,368.000 kHz ± 0.04 kHz.

14.4. QUICK Tx CHECK

1. Set the CMD60 to MODULE TEST.

2. Send batch file “H”.

3. Confidence check of Power (NTP): must be +20 to +25 dBm.

4. Confidence check of Frequency Offset: must be 0 ± 40 kHz.

5. Confidence check of Deviation of B field Data Type 01010101: must be 207 to

270 kHz.

14.5. LOOPBACK TEST

1. Set the CMD60 to MANUAL TEST.

2. Set the CMD60 TRAFFIC CARRIER to 5.

3. Send batch file “TESTMODE”.

4. On the CMD60 press “SETUP CONNECT”.

5. Check Power (NTP): must be +20 to +25 dBm.

6. Press MODULATION.

7. Set Data Type to “Fig. 27”.

8. Check the Frequency Drift: must be 0 ± 45 kHz/ms.

9. Check the Frequency Offset: must be 0 ± 40 kHz.

10. Send batch file ìWREE 00 16 nmî to adjust the Deviation (Max. B Field) with

Data Type: 01010101. Increase the value nm to increase the Deviation and

vice-versa. The least significant digit (m) of the value must be 1 (i.e. only the

values 31, 41, 51, 61 etc. are allowed). The Deviation must be 207 to 270 kHz

11. Check the Deviation (Max. ± B Field) with Data Type “Fig. 27”: must be 201 to

404 kHz.

12. Press MENU UP.

13. Press POWER RAMP

14. Check the Burst fits mask.

15. Press MENU UP.

16. Press BER.

Page 34

17. Note the Sensitivity (reduce the RF LEVEL for a BER of approx. 1000ppm) :

RF LEVEL must be < - 90 dBm

18. Press MENU UP.

19. Press BEARER RELEASE.

Note:

These tests can be repeated on Traffic Carriers 0 and 9.

15. TROUBLESHOOTING GUIDE

15.1. HANDSET: DOES NOT OPERATE

NOTATION PUBLIC "-//ALDUS//NOTATION TAGGED IMAGE FILE FORMAT//EN"

ENTITY SYSTEM "15_01_01.tif"

NOTATION PUBLIC "-//ALDUS//NOTATION TAGGED IMAGE FILE FORMAT//EN"

ENTITY SYSTEM "15_01_02.tif"

15.2. HANDSET: LINK

NOTATION PUBLIC "-//ALDUS//NOTATION TAGGED IMAGE FILE FORMAT//EN"

ENTITY SYSTEM "15_02_01.tif"

NOTATION PUBLIC "-//ALDUS//NOTATION TAGGED IMAGE FILE FORMAT//EN"

ENTITY SYSTEM "15_02_02.tif"

NOTATION PUBLIC "-//ALDUS//NOTATION TAGGED IMAGE FILE FORMAT//EN"

ENTITY SYSTEM "15_02_03.tif"

15.3. HANDSET: DOES NOT LINK

NOTATION PUBLIC "-//ALDUS//NOTATION TAGGED IMAGE FILE FORMAT//EN"

ENTITY SYSTEM "15_03_01.tif"

15.4. BASE UNIT: DOES NOT CHARGE

NOTATION PUBLIC "-//ALDUS//NOTATION TAGGED IMAGE FILE FORMAT//EN"

ENTITY SYSTEM "15_04_01.tif"

15.5. HANDSET: DOES NOT CHARGE

Page 35

Refer to the simplified manual (cover) for other areas.

Notes:

1. The marking (RTL) indicates that the Retention Time is limited for this item.

After the discontinuation of this assembly in production, the item will

continue to be available for a specific period of time. The retention period of

availability is dependent on the type of assembly, and in accordance with the

laws governing parts and product retention.

After the end of this period, the assembly will no longer be available.

2. Important safety notice

Components identified by mark have special characteristics important for

safety. When replacing any of these components, use only manufacture´s

specified parts.

3. The S mark indicates service standard parts and may differ from production

parts.

4. RESISTORS & CAPACITORS

Unless otherwise specified;

All resistors are in ohms (ΩΩ) k = 1000 ΩΩ, M = 1000kΩΩ

All capacitors are in MICRO FARADS (µµF) P=µµµµF

*Type & Wattage of Resistor

Page 36

19.1. Base Unit

19.1.1. CABINET AND ELECTRICAL PARTS

Ref. No. Part No. Part Name & Description Remarks

1 PQBC10270Z1 PAGE BUTTON S

2 PQHR10648Y LED LENDS

3 PQJT10165Z BATTERY TERMINAL

4 PQKM10369T1 UPPER CABINET S

5 PQSA10078Z ANTENNA

6 PQSA10079Z ANTENNA

7 PQSX10099Z RUBBER SWITCH

8 PQYF10146Z2 LOWER CABINET S

9 PQGT14464Z NAME PLATE

19.1.2. MAIN P.C.BOARD PARTS

Page 37

Ref. No. Part No. Part Name & Description Remarks

PCB1 PQWPCDPX100H MAIN P. C. BOARD ASS´Y (RTL)

(ICS)

IC2 PQVIPC357CN IC

IC4 PQVILMV321M5 IC

IC6 PQVIMC295130 IC

IC7 PQVILM1117MP IC

IC101 PQVINS14424V IC

IC102 PQWICDPX100H IC

IC103 PQVIT2432WM6 IC

(TRANSISTORS)

T4 PQVTBF822T7 TRANSISTOR(SI)

T6 2SA1037K TRANSISTOR(SI)

T7 PQVTBCP5216T TRAMSISTOR(SI)

T8 2SA1807NT TRANSISTOR(SI)

T9 PQVTBF822T7 TRANSISTOR(SI)

T13 2SD1994A TRANSISTOR(SI)

T14 2SD601A TRANSISTOR(SI)

T15 2SD1664Q TRANSISTOR(SI)

T16 2SA1037K TRANSISTOR(SI)

T101 PQVTBC80725T TRANSISTOR(SI) S

T102 UN521 TRANSISTOR(SI) S

T103 UN521 TRANSISTOR(SI) S

(DIODES)

D2 PQVDBZV55C02 DIODE(SI)

D3 PQVDBZV55C02 DIODE(SI)

D4 MA110 DIODE(SI)

D8 PQVDS1ZB60F1 DIODE(SI)

D10 MA1Z300 DIODE(SI)

D11 MA112 DIODE(SI)

D13 MA8180 DIODE(SI)

D101 MA110 DIODE(SI)

D104 PQVDHVU359 DIODE(SI)

D105 MA8047 DIODE(SI)

(LEDS)

D12 LNJ211R8ARU LED

D102 LNJ311G8TRU LED

D103 LNJ311G8TRU LED

(JACKS)

J1 PQJJ1T018Z JACK/SOCKET

J2 PQJJ1T019Z JACK/SOCKET

(OTHERS)

BUZ1 PQEFBC1211B BUZZER S

SA3 PQVDDSS301L VARISTOR

X101 PQVCF1036N4Z CRYSTAL OSCILLATOR

J5 PQJP02A85Z CONNECTOR

(RESISTORS)

R3 PQ4R18XJ472 4.7k

R4 ERJ3GEYJ103 10k

R5 PQ4R18XJ565 5.6M

R6 ERJ3GEYJ334 330k

R7 PQ4R18XJ565 5.6M

R8 ERJ3GEYJ334 330k

R13 ERJ3GEYJ223 22k

R14 ERJ3GEYJ223 22k

Page 38

Ref. No. Part No. Part Name & Description Remarks

R19 ERJ3GEYJ394 390k

R20 ERJ3GEYJ393 39k

R21 ERJ3GEYJ394 390k

R22 ERJ3GEYJ104 100k

R23 PQ4R18XJ104 100k

R24 PQ4R10XJ202 2k

R25 PQ4R10XJ000 0

R26 ERJ3GEYJ103 10k

R27 ERJ3GEYJ222 2.2k

R31 ERJ3GEYJ130 13

R32 PQ4R18XJ562 5.6k

R33 ERJ1WYJ152 1.5k

R34 ERJ1WYJ152 1.5k

R35 ERJ3GEYJ104 100k

R36 PQ4R18XJ272 2.7k

R39 ERJ3GEYJ103 10k

R40 ERJ3GEYJ222 2.2k

R41 ERJ3GEYJ333 33k

R43 ERJ3GEYJ560 56

R53 ERJ3GEY0R00 0

R54 ERJ3GEYJ273 27k

R55 ERJ3GEYJ223 22k

R56 ERJ12YJ390 39

R57 ERJ14YJ8R2 8.2

R58 ERJ3GEYJ473 47k

R59 ERJ3GEYJ331 330

R60 ERJ3GEYJ152

R61 ERJ3GEYJ102 1k

R62 ERJ3GEYJ101 100

R63 PQ4R10XJ8R2 8.2

R64 PQ4R10XJ1R5 1.5

R65 ERJ3GEYJ101 100

R66 PQ4R10XJ122 1.2k

R67 ERJ3GEYJ102 1k

R68 ERJ3GEYJ202 2k

R69 ERJ3GEYJ224 220k

R70 ERJ3GEYJ332 3.3k

R101 ERJ3GEYJ102 1k

R102 ERJ3GEYJ103 10k

R103 ERJ3GEYJ151 150

R104 ERJ3GEYJ151 150

R105 ERJ3GEYJ105 1M

R106 ERJ3GEYJ105 1M

R107 ERJ3GEYJ101 100

R108 ERJ3GEYJ560 56

R110 ERJ3GEYJ101 100

R111 ERJ3GEYJ101 100

R112 ERJ3GEYJ273 27k

R113 ERJ3GEYJ332 3.3k

R114 ERJ3GEYJ1R0 1

R115 ERJ3GEYJ100 10

R116 ERJ3GEYJ102 1k

R117 ERJ3GEYJ101 100

R118 ERJ3GEYJ103 10k

1.5k

Page 39

Ref. No. Part No. Part Name & Description Remarks

R119 ERJ3GEYJ103 10k

R120 ERJ3GEYJ103 10k

R121 ERJ3GEYJ222 2.2k

R122 ERJ3GEYJ100 10

R130 ERJ3GEYJ100 10

R135 ERJ3GEYJ0R00 0

R136 ERJ3GEYJ222 2.2k

R422 ERDS1VJ000 0

R519 ERDS1VJ000 0

JMP5 PQ4R10XJ000 0

JMP8 PQ4R10XJ000 0

JMP19 PQ4R10XJ000 0

JMP20 PQ4R10XJ000 0

JMP22 PQ4R10XJ000 0

JMP204 ERJ3GEY0R00 0

JMP205 ERJ3GEY0R00 0

JMP206 ERJ3GEY0R00 0

(CAPACITORS)

C1 ECUV1C104KBV 0.1

C2 ECQE2474KF 0.47

C3 ECUV1H102KBV 0.001

C4 ECUV1H102KBV 0.001

C10 PQCUV1C105ZF 1

C12 ECUV2H102KB 0.001

C13 ECUV1H102KBV 0.001

C14 ECUV2H102KB 0.001

C15 ECUV1H102KBV 0.001

C16 ECUV2H681KB 680P

C17 ECUV2H681KB 680P

C18 ECUV2H681KB 680P

C19 ECEA2EUR47 0.47

C21 ECEA1HKS100 10

C22

C25 ECUV1H100DCV 10P

C27 ECUV1H472KBV 0.0047

C29 PQCUV1C224KB 0.22

C33 ECUV1C104KBV 0.1

C34 PQCUV1H104ZT 0.1 S

C35 PQCUV1H683KB 0.068

C36 ECEA1HKS2R2 2.2

C38 ECUV1H103KBV 0.01

C39 ECUV1C105KB 1

C40 ECEA1CK101 100 S

C41 ECUV1H100DCV 10P

C42 ECEA1CK101 100 S

C43 PQCUV1C224KB 0.22

C44 ECUV1H100DCV 10P

C45 ECEA0JK221 220 S

C47 ECUV1C225ZF 2.2

C48 ECUV1C225ZF 2.2

C101 ECUV1H101JCV 100P

C102 ECUV1H103KBV 0.01

C103 ECUV1H102KBV 0.001

C104 ECUV1H390JCV 39P

ECUV1H103KBV 0.01

Page 40

Ref. No. Part No. Part Name & Description Remarks

C105 ECUV1H390JCV 39P

C106 PQCUV1C224KB 0.22

C107 PQCUV1C105ZF 1

C108 ECUV1H100DCV 10P

C109 PQCUV1C224KB 0.22

C110 ECUV1H100DCV 10P

C111 ECUV1C104KBV 0.1

C112 ECUV1H100DCV 10P

C113 ECUV1C104KBV 0.1

C114 PQCUV1C105ZF 1

C115 ECUV1H100DCV 10P

C116 ECST0JY106 10

C117 PQCUV1C105ZF 1

C118 ECUV1H100DCV 10P

C123 ECUV1H102KBV 0.001

C125 PQCUV1H681JC 680P

C136 PQCUV1C224KB 0.22

C137 ECUV1H100DCV 10P

C139 ECUV1C104KBV 0.1

C140 ECUV1C104KBV 0.1

C141 ECUV1C104KBV 0.1

C142 ECUV1C104KBV 0.1

C143 ECUV1C104KBV 0.1

C144 ECUV1C104KBV 0.1

C145 ECUV1C104KBV 0.1

C146 ECUV1H101JCV 100P

C147 ECUV1H220JCV 22P

C148 ECUV1H220JCV 22P

C150 ECUV1H100DCV 10P

C151 ECUV1H100DCV 10P

C152 ECST0JY106 10

C156 PQCUV1H683KB 0.068

C160 ECUV1H100DCV 10P

C161 ECUV1H100DCV 10P

C162 ECUV1H100DCV 10P

R49 ECUV1H100DCV 10P

RF UNIT PARTS

RFM1 PQLZ10008Z RF BLOCK

19.2. Handset

19.2.1. CABINET AND ELECTRICAL PARTS

Page 41

Ref. No. Part No. Part Name & Description Remarks

101 PQAX3P25Z SPEAKER

102 PQBX10324Y2 PUSH BUTTON S

103 PQGT14463Z NAME PLATE

104 PQGP10145X2 LCD PANEL S

105 PQHG10486Z RINGER RUBBER

106 PQHR10693Z LCD REFLECTOR

107 PQHR10649Y LCD HOLDER

108 PQHR10651Z LCD SPONGE

109 PQHS10342Z SPEAKER NET

110 PQHX10861Z REFLECTOR SHEET

111 PQHX10862Z LCD COVER SHEET

112 PQJC10035Z BATTERY TERMINAL

113 PQJC10036Z BATTERY TERMINAL

114 PQJC10037Z BATTERY TERMINAL

115 PQJC904Y BATTERY TERMINAL

116 PQJT10143Z BATTERY TERMINAL

117 PQKM10370W2 FRONT CABINET S

118 PQSA10085Y ANTENNA

119 PQSX10100Y KEYBOARD SWITCH

120 PQYF10186Z1 REAR CABINET S

19.2.2. MAIN P.C.BOARD PARTS

Ref. No. Part No. Part Name & Description Remarks

PCB100 PQWPTCD955GR MAIN P. C. BOARD ASS´Y (RTL)

(ICS)

IC1 PQVI14405AKS IC

IC2 PQWITCD955GR IC

(TRANSISTORS)

T1 PQVTBC80825T TRANSISTOR(SI) S

T2 UN521 TRANSISTOR(SI) S

T3 PQVTBC80825T TRANSISTOR(SI) S

T4 2SC2412K TRANSISTOR(SI)

T5 PQVTBC81825T TRANSISTOR(SI) S

(DIODES)

D1 PQVDBYD17D DIODE(SI)

D2 PQVDBZD27C18 DIODE(SI) S

D3 MA112 DIODE(SI)

D4 PQVDBZD27C18 DIODE(SI) S

D5 MA112 DIODE(SI)

D6 PQVDBZD27C56 DIODE(SI) S

D7 PQVDHRU0203A DIODE(SI) S

D8 PQVDSML310MT DIODE(SI) S

D9 PQVDSML310MT DIODE(SI) S

D10 PQVDSML310MT DIODE(SI) S

D11 MA110 DIODE(SI)

D12 PQVDHVU359 DIODE(SI)

D13 MA8047 DIODE(SI)

(COILS)

F1 PQLQR2M5N6K COIL

L1 ELJPA100KF COIL

L2 ELJPA100KF COIL

Page 42

Ref. No. Part No. Part Name & Description Remarks

(OTHERS)

A101(+) PQJT10152Y ANTENNA

A101(-) PQJT10152Y ANTENNA

LS2(+) PQJT10161Z SPEAKER TERMIANL

LS2(-) PQJT10161Z SPEAKER TERMIANL

J1 PQJT10090Z BATTERY TERMINAL S

J2 PQJT10090Z BATTERY TERMINAL S

J3 PQJT10090Z BATTERY TERMINAL S

J4 PQJT10090Z BATTERY TERMINAL S

BZ1 PQEFBDB111GP BUZZER

J10 PQJS18A96Z CONNECTOR

X1 PQVCF1036N3Z CRYSTAL OSCILLATOR

M1 PQJM146Z MICROPHONE

LCD LNY163C01 LIQUID CRYSTAL DISPLAY

(RESISTORS)

R1 ERJ3GEYJ103 10K

R2 PQ4R10XJ122 1.2K

R3 PQ4R18XJ471 470

R4 ERJ3GEYJ682 6.8K

R5 ERJ3GEYJ103 10K

R6 ERJ3GEYJ153 15K

R7 ERJ3GEYJ104 100K

R8 ERJ3GEYJ270 27

R9 ERJ3GEYJ270 27

R10 ERJ3GEYJ270 27

R11 ERJ3GEYJ682 6.8K

R12 ERJ3GEYJ103 10K

R13 PQ4R10XJ100 10

R14 ERJ3GEYJ563 56K

R15 ERJ3GEYJ104 100K

R16 ERJ3GEYJ563 56K

R17 ERJ3GEYJ104 100K

R18 ERJ3GEYJ102 1K

R19 ERJ3GEYJ102 1K

R20 ERJ3GEYJ105 1M

R21 ERJ3GEYJ105 1M

R22 ERJ3GEYJ100 10

R23 ERJ3GEYJ100 10

R24 ERJ3GEYJ101 100

R25 ERJ3GEYJ101 100

R27 ERJ3GEYJ101 100

R28 ERJ3GEYJ101 100

R29 ERJ3GEYJ471 470

R30 ERJ3GEYJ471 470

R31 ERJ3GEYJ102 1K

R32 ERJ3GEYJ102 1K

R33 ERJ3GEYJ822 8.2K

R34 ERJ3GEYJ332 3.3K

R35 ERJ3GEYJ1R0 1

R36 ERJ3GEYJ100 10

R37 ERJ3GEYJ102 1K

R38 ERJ3GEYJ101 100

R39 ERJ3GEYF824 820K

R40 ERJ3GEYF434 430K

Page 43

Ref. No. Part No. Part Name & Description Remarks

R44 ERJ3GEYJ103 10K

R46 ERJ3GEYJ224 220K

R49 ERJ3GEYJ104 100K

R50 ERJ3GEYJ563 56K

R51 ERJ3GEYJ104 100K

(CAPACITORS)

C1 PQCUV1E104MD 0.1

C2 ECUV1C104KBV 0.1

C3 ECEV1AA101 100

C4 ECUV1H100DCV 10P

C5 PQCUV1C224KB 0.22

C6 ECUV1H100DCV 10P

C7 PQCUV1C105ZF 1

C9 ECUV1C104KBV 0.1

C10 ECUV1H100DCV 10P

C11 ECUV1H103KBV 0.01

C12 ECUV1H102KBV 0.001

C13 ECUV1H390JCV 39P

C14 ECUV1H390JCV 39P

C15 ECUV1H100DCV 10P

C16 ECUV1H100DCV 10P

C17 ECUV1H100DCV 10P

C18 ECUV1H100DCV 10P

C19 PQCUV1A105KB 1

C20 ECUV1H100DCV 10P

C22 ECUV1H472KBV 0.0047

C23 ECUV1H472KBV 0.0047

C24 PQCUV1H563KB 0.056

C25 ECUV1H100DCV 10P

C26 ECUV1H100DCV 10P

C27 PQCUV1C105ZF 1

C28 ECST0JY106 10

C29 PQCUV1C105ZF 1

C30 ECST0JY106 10

C35 ECUV1H102KBV 0.001

C37 PQCUV1H681JC 680K

C47 PQCUV1C224KB 0.22

C48 ECUV1H100DCV 10P

C50 ECUV1C104KBV 0.1

C51 ECUV1C104KBV 0.1

C52 ECUV1C104KBV 0.1

C53 ECUV1C104KBV 0.1

C54 ECUV1C104KBV 0.1

C55 ECUV1C104KBV 0.1

C56 ECUV1H101JCV 100P

C57 PQCUV1C224KB 0.22

C58 PQCUV1C224KB 0.22

C59 PQCUV1C224KB 0.22

C60 ECUV1C104KBV 0.1

C61 ECUV1C104KBV 0.1

C62 ECUV1C104KBV 0.1

C63 ECUV1C104KBV 0.1

C64 ECUV1C104KBV 0.1

C65 ECUV1H100DCV 10P

Page 44

16

16

49 42

1

IC201

R114

15

C136

BUZ101

18

IC103

T103

R104

T102

D103

D12

D102

R103

JMP206

JMP205

JMP204

JMP203

JMP202

JMP201

R117

R118

C137

R119

D101

C101

C146

C151

C116

R102

T101

C141

R101

R116

C106

R107

C125

C118

C117

C110

R109

R110

C111

C105

C143

R49

R115

C104 C102

C150

C115

C107

C114

R111

C27

R70

C50

PQUP10924XA

41

JMP1

RL1

T2

R69

C43

27

2616

C45

X101

D104

C139

C103

R105

R106

C140

1

IC101 IC102

C144

R121

C104

C152

C154

C113

R131

8

C108

IC104

1

R41

C147

100

C109

C28

R122

C127

C148

R113

16 1

R112

C142

R73

T11

T12

R52 R51

R72

C29

R43

IC6

C156

R74

JMP3

D1

C47

JMP16

1

C44

R4

R136

32

T13

R66

JMP4

1

R54

SA3

IC1

R55

R53

R71

JMP12

L1

T1

R1

R2

IC2C145

C25

D10

C48

R56

T16

J1

JMP21

SA2SA1

1

T8

R36

R57

C32

ICT

JMP7

JMP18

JMP17

C2

C1

T9

R58

C33

R65

J2

SA4

JMP6

JMP10

JMP5

L2

JMP19

JMP20

R7

R8C4

C17

R5

R6

C18

C3

D2

R24

R3

D3D4

R30

R35

R39

R40

L5

C26

R62

D11

D13

J5

R64

JMP13 JMP14

JMP8 JMP9 JMP15

L3

C5

JMP22

C16

D6 D7

R9

C19

R59

D8

C10

R13

R23

C20

R25

D9

C36

R60

C34

T14

R63

R17

C35

R34

R33

R15

R18

R61

T4

T5

R31

C37

T15

C7

R10

IC3

1

R26

R28

R29

C21

T6

R32

DL

C38

DE

C8C6

R11

R16

C22

C39

R27

R120

T7

C9

R12

C11

C15

R21 R19

R22

R20

PWR

GND

I/O

LI

C40

IC7

C41

C42

C12C14

IC4

C13

D105

R68R67

1

1

Page 45

J5J4

K101

Page 46

M1

K22

K1 K19 K16 K13 K10

K21 K18 K15 K12

K20 K17 K14 K11

K8 K4

K9

K7

K5

K6 K2

K3

D8

D9

D10

C57

TP66

J9 J10

TP68

TP69

TP70

TP67

R46

C69

TP81

C61

C62

C63

C64

R43

JMP2

C59

JMP1

C58

R41

C60

TP76

C70

TP74

TP73

TP80

TP79

TP78

TP77

LS12 LS11

JMP3

R42

TP72

TP71

TP75

R40

R39

PQUP10927Z

LS22 LS21

TP101

Page 47

C75

C74

D3

D5

D4

D2

R16

R17

J4

J2

L2

R1

T1

D6 D7

T2

R50

R2

J1

R5

C25

R27

C24

R28

C68

C26

C1

R3

L1

J3

IC3

C73

D14

C4

R31

C65

C68

C67

C30

R32

D15

D1

D13

C2

F1

J5 J7 J6 J8

R48

C22

C21

R47

R6

C18

R29

R26

C16

T3

R30

C19

C8

R14

R15

C27

C9

R25

R24

C29

R22R4

C7

C17

C6

C20

C52

C15

R23

R38

C54

C28

R18

R19

T5

R7

C5

C10

R37

C56

R49

D11

IC1

C55

C37

IC2

R36

C51

C50

C53

R20

C13C14

C11

R21

BZ1

D 12

C12

C71

C3

X1

C35

R51

R33

R9

R44

C39

R11

R34

R13

PQUP10927Z

C47

C48

T4

R10

R35

R12

R8

A102

A101

RFM1

Page 48

( )

( )

LINE VOLTAGE 48V DC

0

W

0

W

N.M.

()

N.M.

N.M.

( )

()

()

()

)

N.M.

N.M.

0

W

0

W

( )

)

N.M.

+3V

PULSE TO 0V

DURING RINGING

( )

48V DC

( )

5.6M

W

m

330k

0.001

+2.5V (ON-HOOK)

5.6M

W

0

W

10

m

5.6k

W

0

W

0

W

1.5V

CLIP

(Caller ID)

1.5V

IC4

100k

CHARGE

PULSE

m

0.47

N.M

IC2

1.5V

1.5V

1.5V

0.1V

IC3

13

W

m

0.47

W

2k

W

W

0

100k

T4

m

0.01

1.5k

W

1.5k

W

0

W

W

W

10k

2.2k

m

+48V ON-HOOK

330k

0.001

+10.2V OFF-HOOK

+46V ON-HOOK

+48V OFF-HOOK

+0V ON-HOOK

+0.7V OFF-HOOK

+0.1V ON-HOOK

+10.0V OFF-HOOK

N.M.

( )

3.3k

W

2.2

56W

27k

N.M.

22k

W

0

2.2

m

W

8.2

W

+2.5V (ON-HOOK)

W

m

56

+1.9V (ON-HOOK)

IC104

+9.9V (ON-HOOK)

+9.9V (ON-HOOK)

W

)

( )

N.M.

N.M.

m

47k

W

0.1

( )

( )

NM

( )

( )

( )

( )

( )

( )

N.M.

( )

N.M.

N.M.

( )

330

W

m

W

0.1

1.5k

0.0.68

m

( )

0V

( )

)

N.M.

N.M.

( )

1.5V

Bell

1.5V

TX · AF

11.5V

(ON-CHARGE)

+11.8V

()

1.3V

(ON-CHARGE)

J5

1

2

10.8V

(ON-CHARGE)

HAND SET 6V

(ON-CHARGE)

IC102

IC7 IC6

+3.9V

2.2k

W

IC103

+3V

POWER

ON

0

+3V

t

60msec 200msec

RX · AF

IC101

+3.9V

0V

+0.05V

(LED ON)

+2V

+3V

+0.05V

+2V

+3V

TX-DATA

N.M.

0R0

0R0

FREQ 3.456MHz

+3V

0V

1.7V

0.1V

10.368MHz

39P

39P

1.7V

0.6V

10.368MHz

RX-DATA

Page 49

3.9V

3.9V

2.9V

IC3

0V

2.9V

+3V TO +8V WHEN

ON CHARGE

3.9V

0V

3.3V

700mV

0V

LED-ON 1.4V

LED-OFF 2.5V

LED-ON 1.1V

LED-OFF 0V

2.9V

0V

0V

ANALOG RX

ANALOG TX

2.3V (WHEN TALK MODE)

2.5V

(WHEN TALK MODE)

2.5V

(WHEN TALK MODE)

0V

0V

0V

0V

2.9V

IC1

0.4V

2.9V

0.4V

2.9V

2.9V

IC2

2.9V

0V

10.368MHz

5msec

2.9V

0V

2.9V

10.368MHz

1.6Vp-p

+3.9V

TX-DATA

0V

RX-DATA

Loading...

Loading...