ORDER NO.MAD0503001CE

DVD Player / Video Cassette Recorder

NV-VP23EG / NV-VP23EC / NV-VP23EP / NV-VP28EG / NV-

VP28EC / NV-VP33EG / NV-VP33EC / NV-VP33EB / NV-

VP33EBL / NV-VP33EP /

R4-MECHANISM

Colour

(K).......................Black Type

(S).......................Silver Type

SPECIFICATIONS

2005 Matsushita Electric Industrial CO., Ltd. All rights reserved.

Unauthorized copying and distribution is a violation of law.

1

1. INTRODUCTION

This service manual contains technical information which will allow service personnel to

understand and service this model.

If the circuit is changed or modified, this information will be followed by supplementary service

manual to be filed with original service manual.

Note:

Adjustment procedures, Disassembly Procedures and Assembly Procedures for VCR

Mechanism Chassis are separate volume from this service manual. Please refer to the service

manual for R4 Mechanism Chassis for EURO model (MAD0403002C2).

Model No. Indication Mark

NV-VP23EG 23EG

NV-VP23EC 23EC

NV-VP23EP 23EP

NV-VP28EG 28EG

NV-VP28EC 28EC

NV-VP33EG 33EG

NV-VP33EC 33EC

NV-VP33EB 33EB

NV-VP33EBL 33EBL

NV-VP33EP 33EP

2. SAFETY PRECAUTIONS

2.1. GENERAL GUIDELINES

1. Be careful during removing metal parts, sharp edges.

2. When servicing, observe the original lead dress. If a short circuit

is found, replace all parts which have been overheated or

damaged by the short circuit.

3. After servicing, see to it that all the protective devices such as

insulation barriers, insulation papers shields are properly

installed.

4. After servicing, make the following leakage current checks to

2

prevent the customer from being exposed to shock hazards.

2.1.1. LEAKAGE CURRENT COLD CHECK

1. Unplug the AC cord and connect a jumper between the two

prongs on the plug.

2. Measure the resistance value, with an ohmmeter, between the

jumpered AC plug and each exposed metallic cabinet part on the

equipment such as screwheads, connectors, control shafts, etc.

When the exposed metallic part has a return path to the chassis,

the reading should be between 1M and 5.2M .

When the exposed metal does not have a return path to the

chassis, the reading must be infinity.

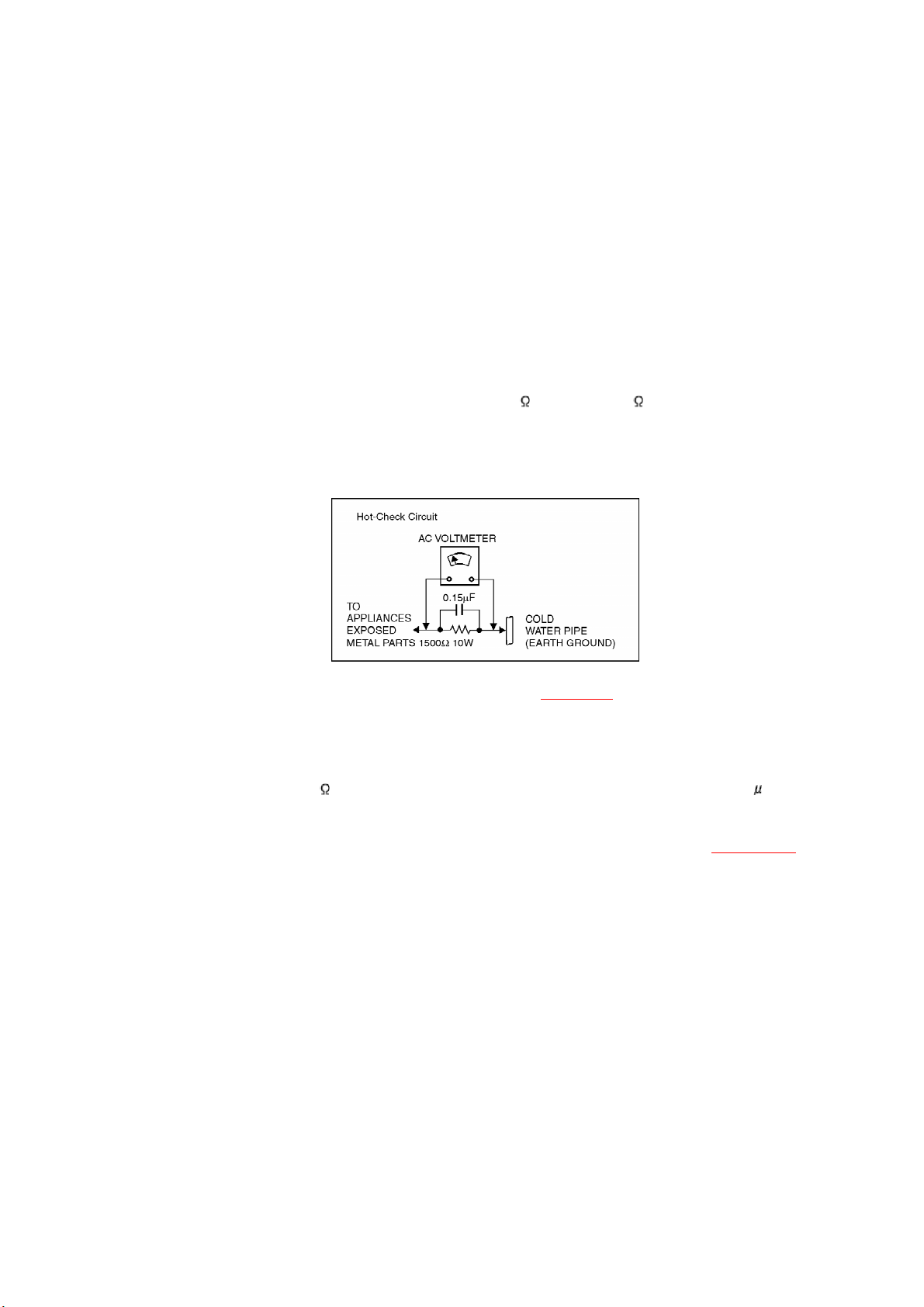

Figure 1

2.1.2. LEAKAGE CURRENT HOT CHECK (See Figure 1)

1. Plug the AC cord directly into the AC outlet. Do not use an

isolation transformer for this check.

2. Connect a 1.5k , 10 watts resistor, in parallel with a 0.15 F

capacitor, between each exposed metallic part on the set and a

good earth ground such as a water pipe, as shown in Figure 1.

3. Use an AC voltmeter, with 1000 ohms/volt or more sensitivity, to

measure the potential across the resistor.

4. Check each exposed metallic part, and measure the voltage at

each point.

5. Reverse the AC plug in the AC outlet and repeat each of the above

measurements.

6. The potential at any point should not exceed 0.75 volts RMS. A

leakage current tester (Simpson Model 229 or equivalent) may be

used to make the hot checks, leakage current must not exceed 1/2

milliamp. In case a measurement is outside of the limits specified,

3

there is a possibility of a shock hazard, and the equipment should

be repaired and rechecked before it is returned to the customer.

3. PREVENTION OF ELECTRO STATIC DISCHARGE

(ESD) TO ELECTROSTATICALLY SENSITIVE (ES)

DEVICES

Some semiconductor (solid state) devices can be damaged easily by static electricity. Such

components commonly are called Electrostatically Sensitive (ES) Devices. Examples of typical

ES devices are integrated circuits and some field-effect transistors and semiconductor "chip"

components. The following techniques should be used to help reduce the incidence of

component damage caused by electro static discharge (ESD).

1. Immediately before handling any semiconductor component or

semiconductor-equipped assembly, drain off any ESD on your

body by touching a known earth ground. Alternatively, obtain and

wear a commercially available discharging ESD wrist strap, which

should be removed for potential shock reasons prior to applying

power to the unit under test.

2. After removing an electrical assembly equipped with ES devices,

place the assembly on a conductive surface such as alminum foil,

to prevent electrostatic charge buildup or exposure of the

assembly.

3. Use only a grounded-tip soldering iron to solder or unsolder ES

devices.

4. Use only an anti-static solder removal device. Some solder

removal devices not classified as "anti-static (ESD protected)"

can generate electrical charge sufficient to damage ES devices.

5. Do not use freon-propelled chemicals. These can generate

electrical charges sufficient to damage ES devices.

6. Do not remove a replacement ES device from its protective

package until immediately before you are ready to install it. (Most

replacement ES devices are packaged with leads electrically

shorted together by conductive foam, aluminium foil or

comparable conductive material).

7. Immediately before removing the protective material from the

leads of a replacement ES device, touch the protective material to

the chassis or circuit assembly into which the device will be

4

installed.

unsichtbare

Lasereinheit

Lasereinheit

Strahlung

der

die

Caution

Be sure no power is applied to the chassis or circuit, and observe

all other safety precautions.

8. Minimize bodily motions when handling unpackaged replacement

ES devices. (Otherwise harmless motion such as the brushing

together of your clothes fabric or the lifting of your foot from a

carpeted floor can generate static electricity (ESD) sufficient to

damage an ES device).

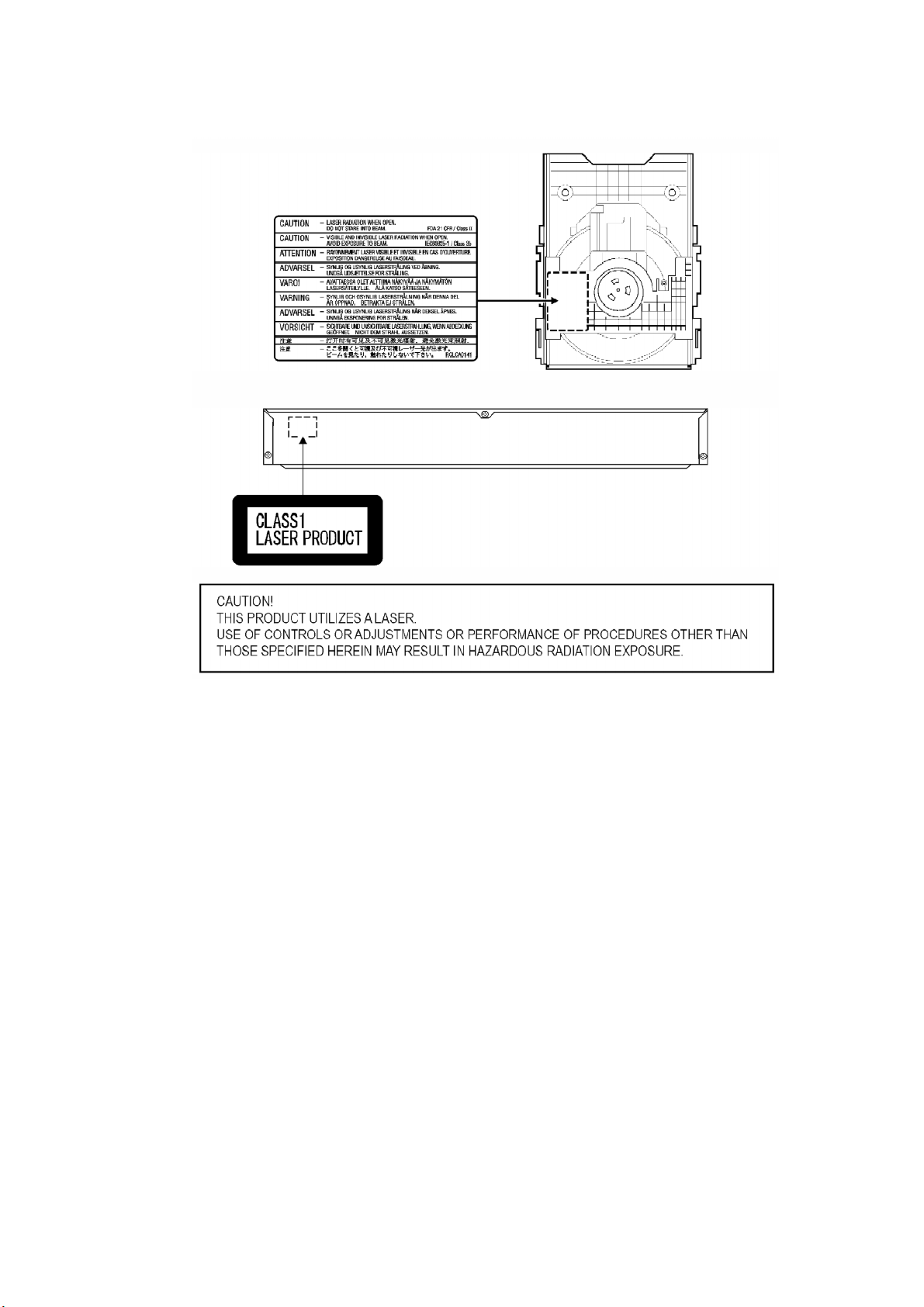

4. PRECAUTION OF LASER DIODE

CAUTION: ACHTUNG:

This product utilizes a laser diode with the unit

turned “on”,

invisible laser radiation is emitted from the pickup

lens.

Wave length: 662 nm/785 nm

Maximum output radiation power from pickup: 100

W/VDE.

Laser radiation from the pickup lens is on a safety

level, if following precautions are followed:

1.Do not disassemble the optical pickup unit,

since radiation

from exposed laser diode is dangerous.

2.Do not adjust the variable resistor on the

pickup unit.

It was already adjusted.

3.Recommend not to look at pickup lens. 3.Nicht in die Fokussierlinse blicken.

4.Do not look at the focus lens using optical

instruments.

Dieses Produkt enthält eine Laserdiode.

Im eingeschalteten Zustand wird

Laserstrahlung von der

Lasereinheit ausgestrahlt.

Wellenlänge: 662 nm/785 nm

Maximale Strahlungsleistung der

/VDE.

Die Strahlung der eingeschalteten

ungefährlich, wenn

folgende Punkte beachtet werden:

1.Die Lasereinheit nicht zerlegen, da die

der freigelegten

Laserdiode gefährlich ist.

2.Den werksseitig justierten Einstellregler

Lasereinheit nicht

verstellen.

4.Auch nicht mit optischen Instrumenten in

Fokussierlinse blicken.

5

4.1. ABOUT LEAD FREE SOLDER (PbF)

This model uses lead free solder (PbF). For repair use only lead free handsolder.

Caution:

Pb free solder has a higher melting point than standard solder; Typically the melting point is 50 70~F (30 - 40~C) higher. Please use a high temperature soldering iron. In case of the soldering

iron with temperature control, please set it to 700 +/-20~F (370 +/-10~C). Pb free solder will tend

to splash when heated too high (about 1100~F/ 600~C). When soldering or unsoldering, please

completely remove all of the solder on the pins or solder area and be sure to heat the soldering

points with the Pb free solder until it melts enough.

5. PREVENTION OF STATIC ELECTRICITY

DISCHARGE

The laser diode in the traverse unit (optical pickup) may brake down due to static electricity of

clothes or human body. Use due caution to electrostatic breakdown when servicing and

handling the laser diode.

5.1. GROUNDING FOR ELECTROSTATIC BREAKDOWN

PREVENTION

Some devices such as the DVD player use the optical pickup (laser diode) and the optical

6

pickup will be damaged by static electricity in the working environment. Proceed servicing

works under the working environment where grounding works is completed.

5.1.1. WORKTABLE GROUNDING

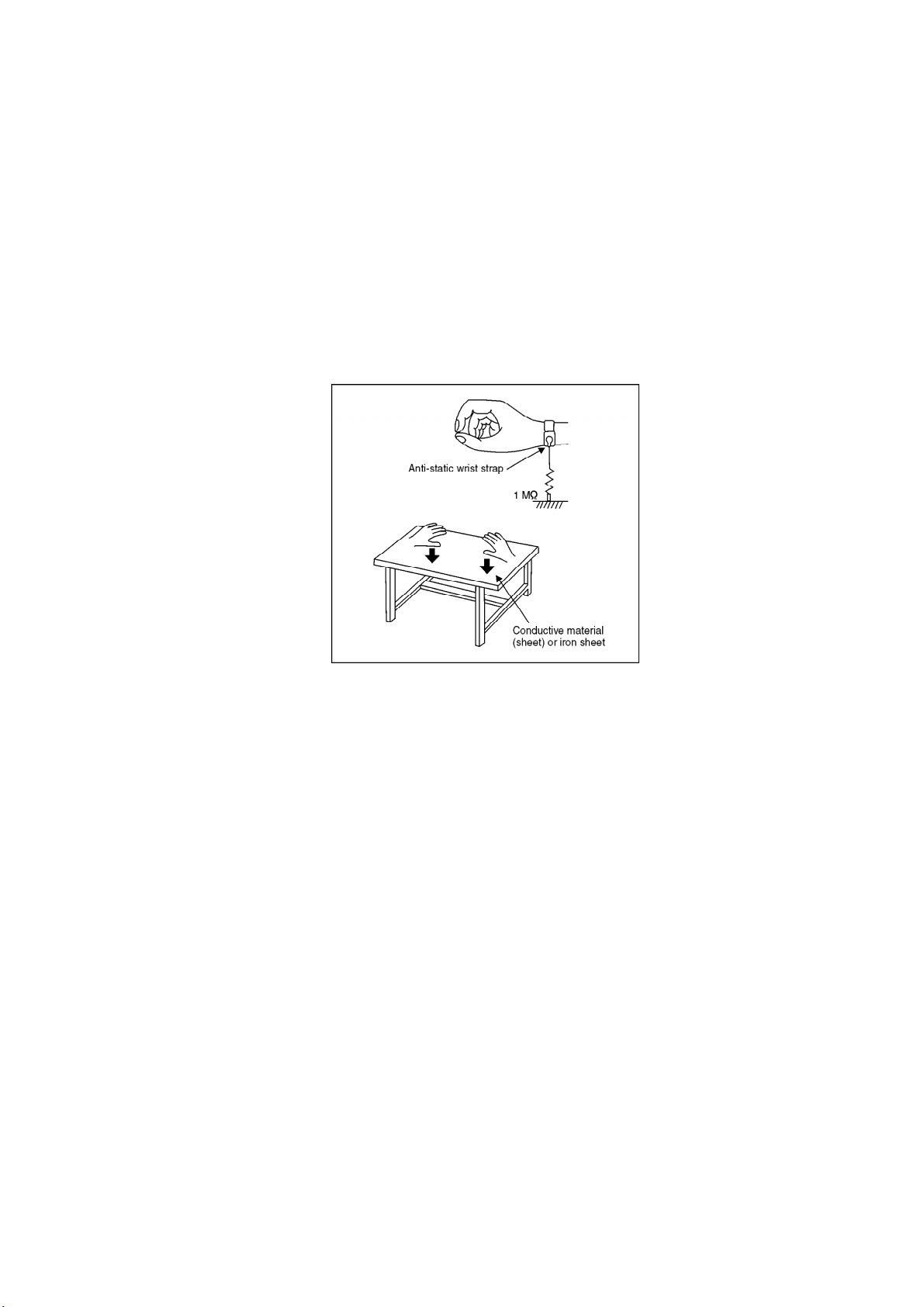

1. Put a conductive material (sheet) or iron sheet on the area where

the optical pickup is placed, and ground the sheet.

5.1.2. HUMAN BODY GROUNDING

1. Use the anti-static wrist strap to discharge the static electricity

form your body.

5.1.3. HANDLING OF OPTICAL PICKUP

1. To keep the good quality of the optical pickup maintenance parts

during transportation and before installation, the both ends of the

laser diode are short-circuited. After replacing the parts with new

ones, remove the short circuit according to the correct procedure.

(See this Technical Guide.)

2. Do not use a tester to check the laser diode for the optical pickup.

Failure to do so will damage the laser diode due to the power

supply in the tester.

6. GENERAL DESCRIPTION

6.1. OPERATING INSTRUCTIONS

6.2. SERVICE CAUTION

6.2.1. REPLACING IC6002/EEPROM

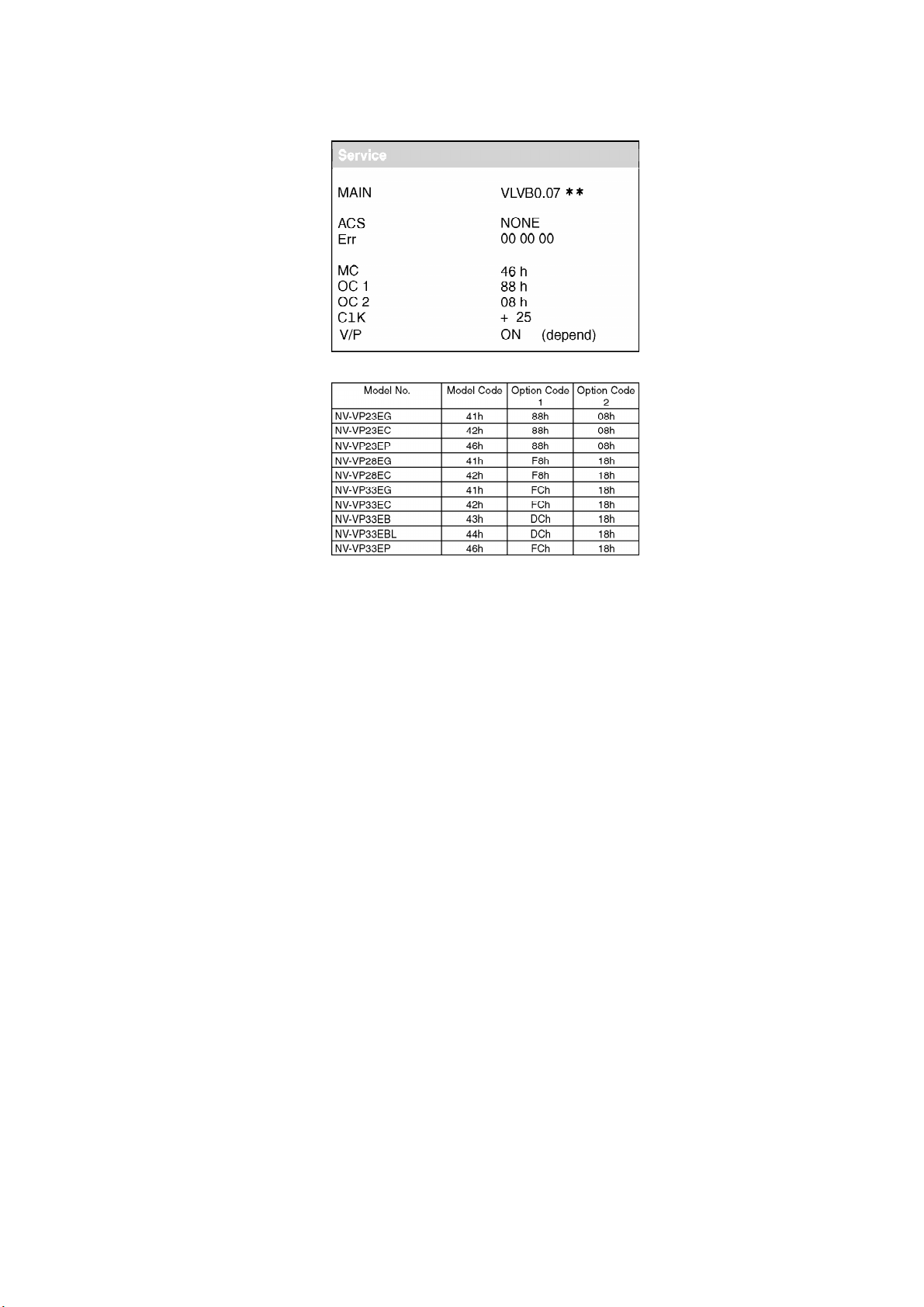

When the EEPROM: IC6002 is replaced, applicable model code, option code and electrical

adjustment data will not be available.

Therefore, enter and/or adjust the necessary data after replacing IC6002 by referring following

7

procedure.

STEP1.REPLACE THE IC6002

1. Remove the PCB with Mechanism unit by referring the

Disassembly procedure.

2. Disconnect the AC plug and replace the IC6002.

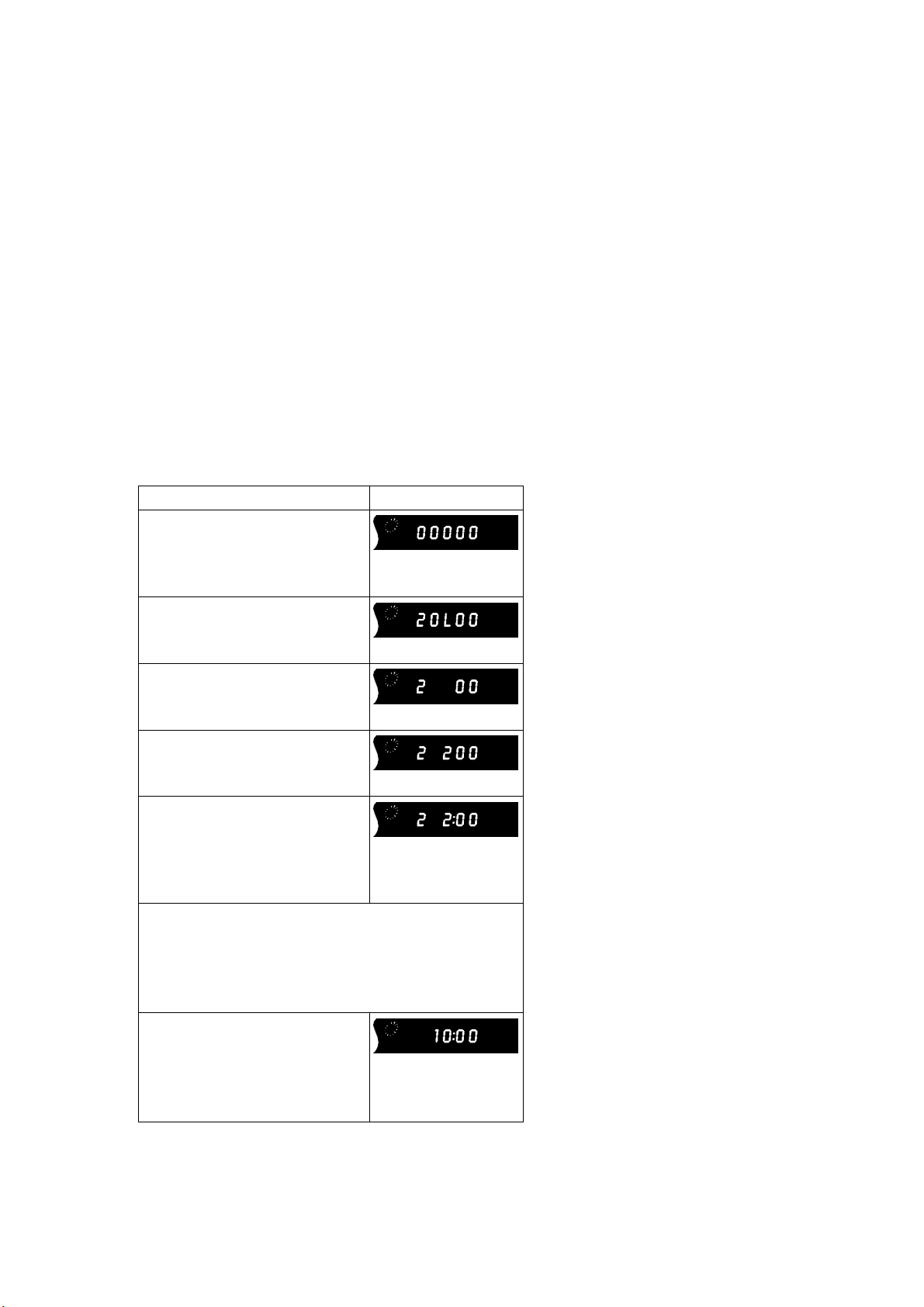

STEP2.INPUT THE MODEL & OPTION CODE

1. Set up the applicable model code and option code by ordering the

following table.

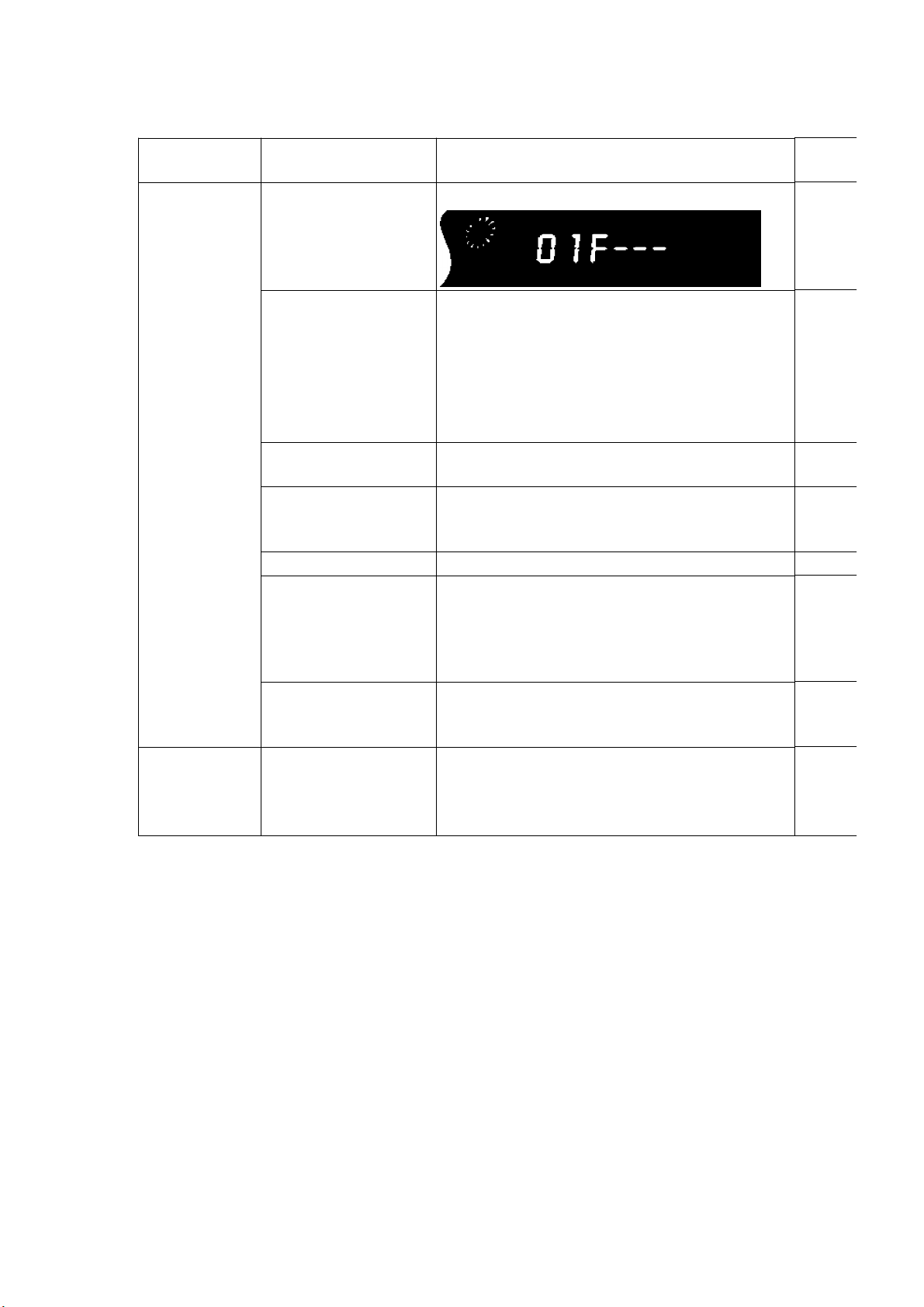

PROCEDURE F.I.P. DISPLAY

Turn on the Service Mode

1.Press the FF key and the

EJECT key simultaneously for

more than 3 seconds.

Activate the Service Mode 2

2.While keep placing FF key,

press the EJECT key in twice.

Activate the Entering Mode.

3.Press the EJECT key for

more than 3 seconds.

Set the Mode 2.

4.Press the CH UP key in

twice.

Display the Setting Code.

5.Press the POWER Button to

turn the power on.

(Colon starts

Enter the Model and Option Code.

6.Service Screen is displayed on the monitor.

7.Set the applicable Model and Option code by

using REW, PLAY, STOP and FF keys on the

Remote Controller. (See Fig.S1 & S2)

Exit from Service Mode.

8.Press the POWER Button to

turn the power off.

9. Press FF and EJECT keys

simultaneously in 6 times.

(Normal Indication)

flashing)

Fig. S1 Service Screen Sample for NV-VP23EP

8

Fig. S2 Model Code & Option Code

NOTE:

Since all electrical adjustments data is still not available, perform the Electrical Adjustment

continuously.

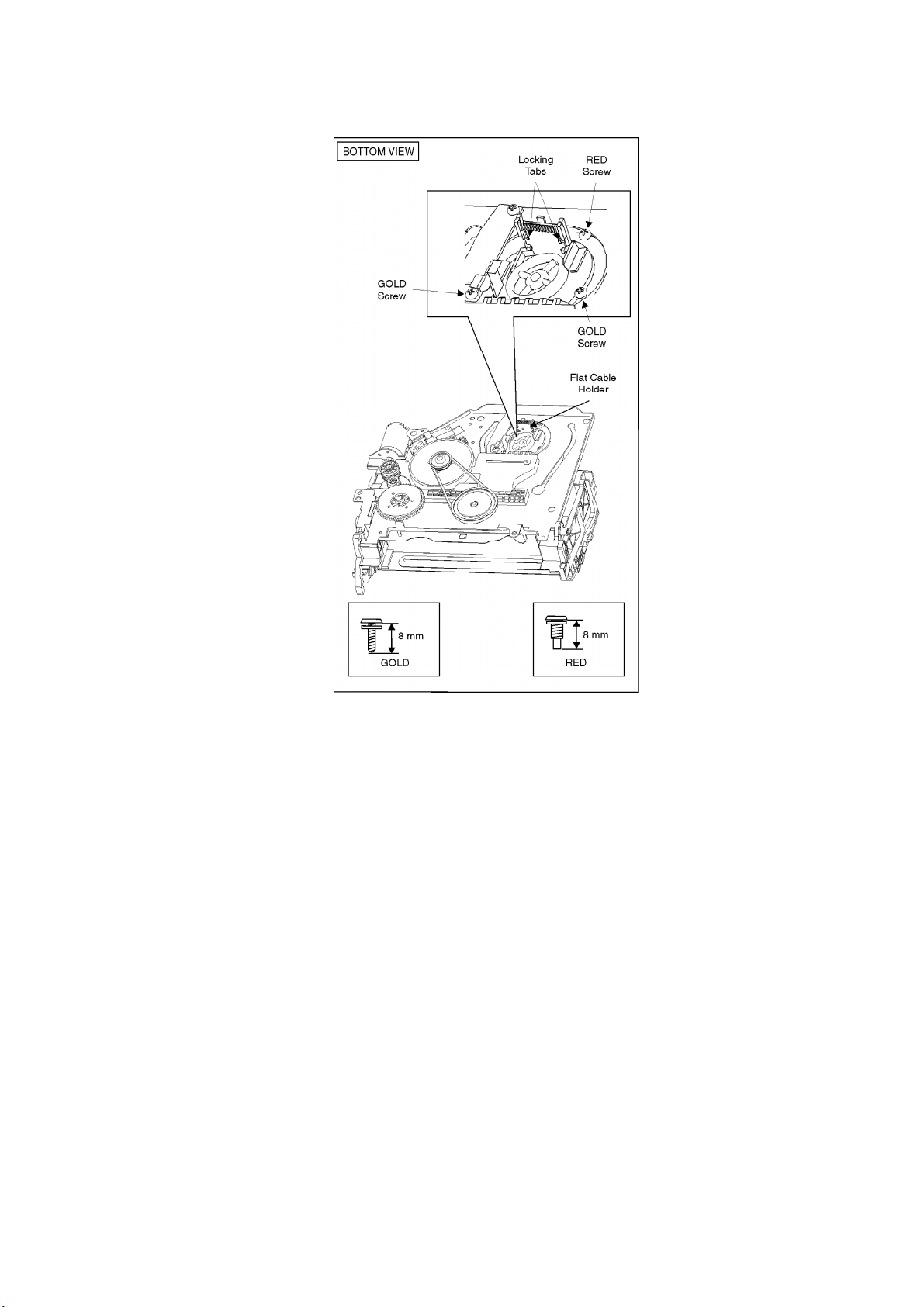

6.2.2. CYLINDER UNIT REPLACEMENT

NOTE:

Replacing only Upper Cylinder unit of R4 Mechanism can not be

performed, as securing of RT gap is impossible out of factory,

please replace the cylinder by whole Cylinder Unit. The

Compatibility Adjustment should be performed after replacement of

the DD Cylinder Unit.

1. Remove the Mechanism Unit from Main PCB / Chassis referring to

"Disassembly Procedure".

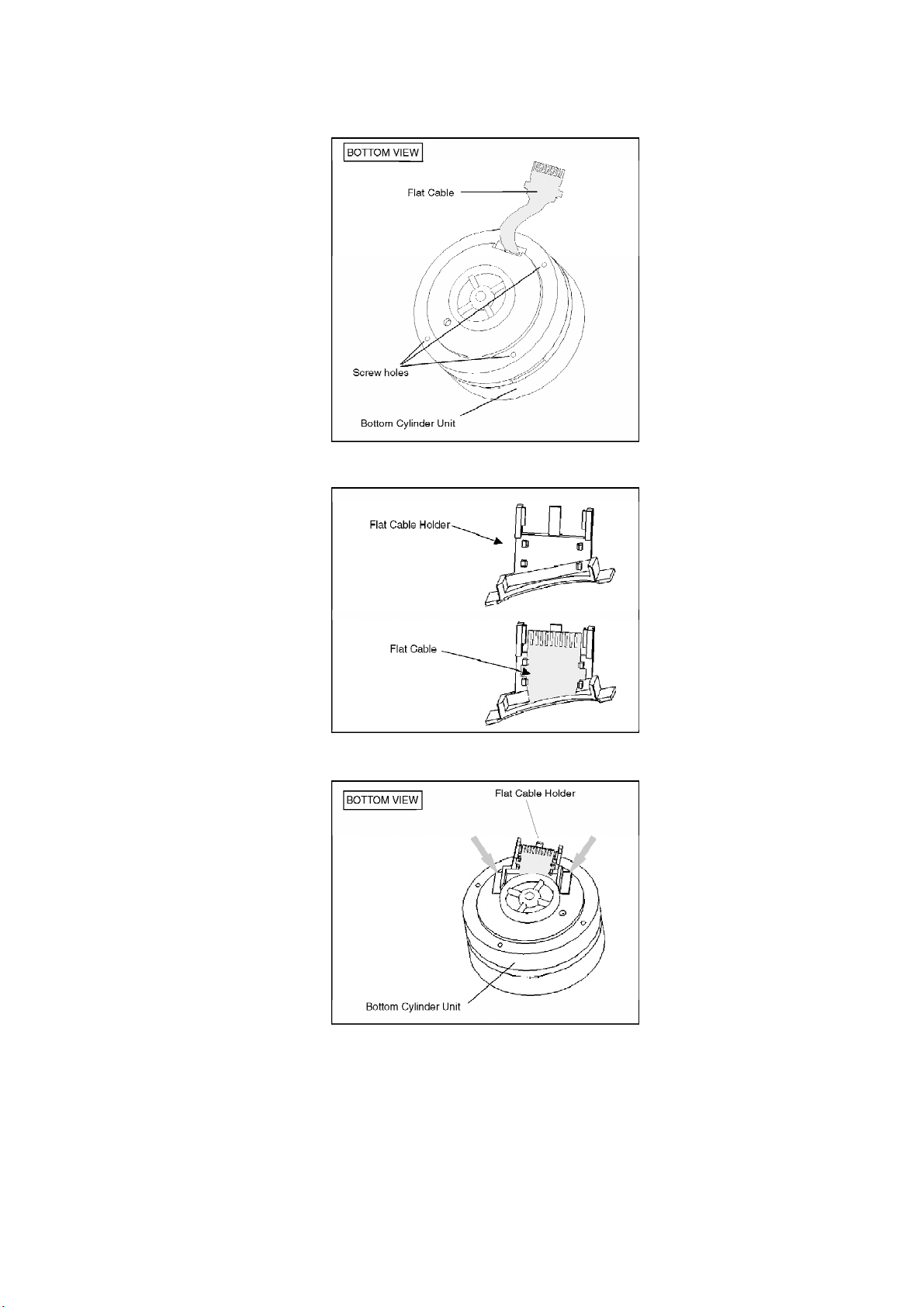

2. Unlock 2 locking tabs on a side to release the Cylinder Flat Cable

as shown.

CAUTION:

Handle the Cylinder Flat Cable with care. When it damaged, you

should replace whole Cylinder unit.

3. Remove the RED screw and GOLD screw to disassemble the

Cylinder Unit.

9

NOTE:

When reassembling, perform the steps in the reverse order, and

perform the COMPATIBILITY ADJUSTMENT certainly after

CYLINDER UNIT REPLACEMENT.

6.2.3. ATTENTION FOR REPLAYING THE DD CYLINDER

1. Put the gloves on your hands.

2. Turn the DD Cylinder Unit over.

10

3. Insert the Flat Cable into the Flat Cable Holder

4. Insert the Flat Cable Holder to the DD Cylinder Unit.

5. The "COMPATIBILITY ADJUSTMENT" should be performed after

the replacement of the DD Cylinder Unit.

NOTE:

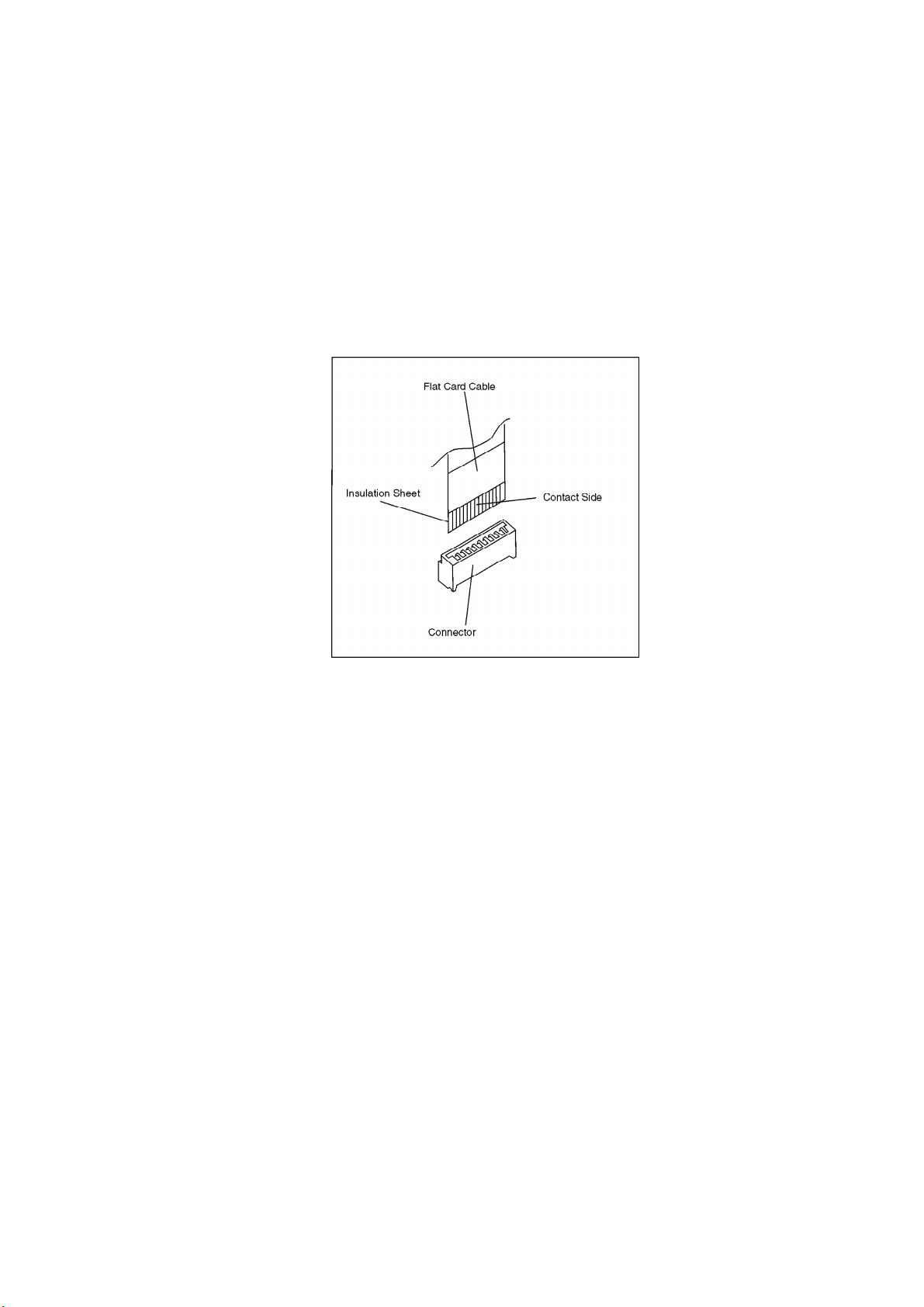

In case that you have inserted the Flat Cable Holder

11

(FPC Holder) to the DD Cylinder Unit before inserting the Flat Cable

(Flexible card) into the Flat Cable Holder. Pushing stopper portion

of the Flat Cable Holder with a small minus screw driver, remove

the Flat Cable Holder while paying attention for not to scratch the

DD Cylinder and not to break the Head Chip as shown below.

6.2.4. FLAT CARD CABLE INSTALLATION

When installing the Flat Card Cable on the connector, install the Flat Card Cable with the cable

contacts facing the connector contacts.

6.3. REMOVAL OF CASSETTE TAPE

When the cassette tape could not be uninstalled from an electrical malfunction, there are two

ways to remove a cassette tape.

1. Removal by compulsory unloading.

A. Press FF and EJECT button simultaneously for more than 3

seconds and set the Service Mode to 7.

B. Press STOP button in order to unload the mechanism.

(Pay attention to tape slack)

Service Mode Indication:

7 0L 00 (STOP) 7 0L A2 (EJECT)

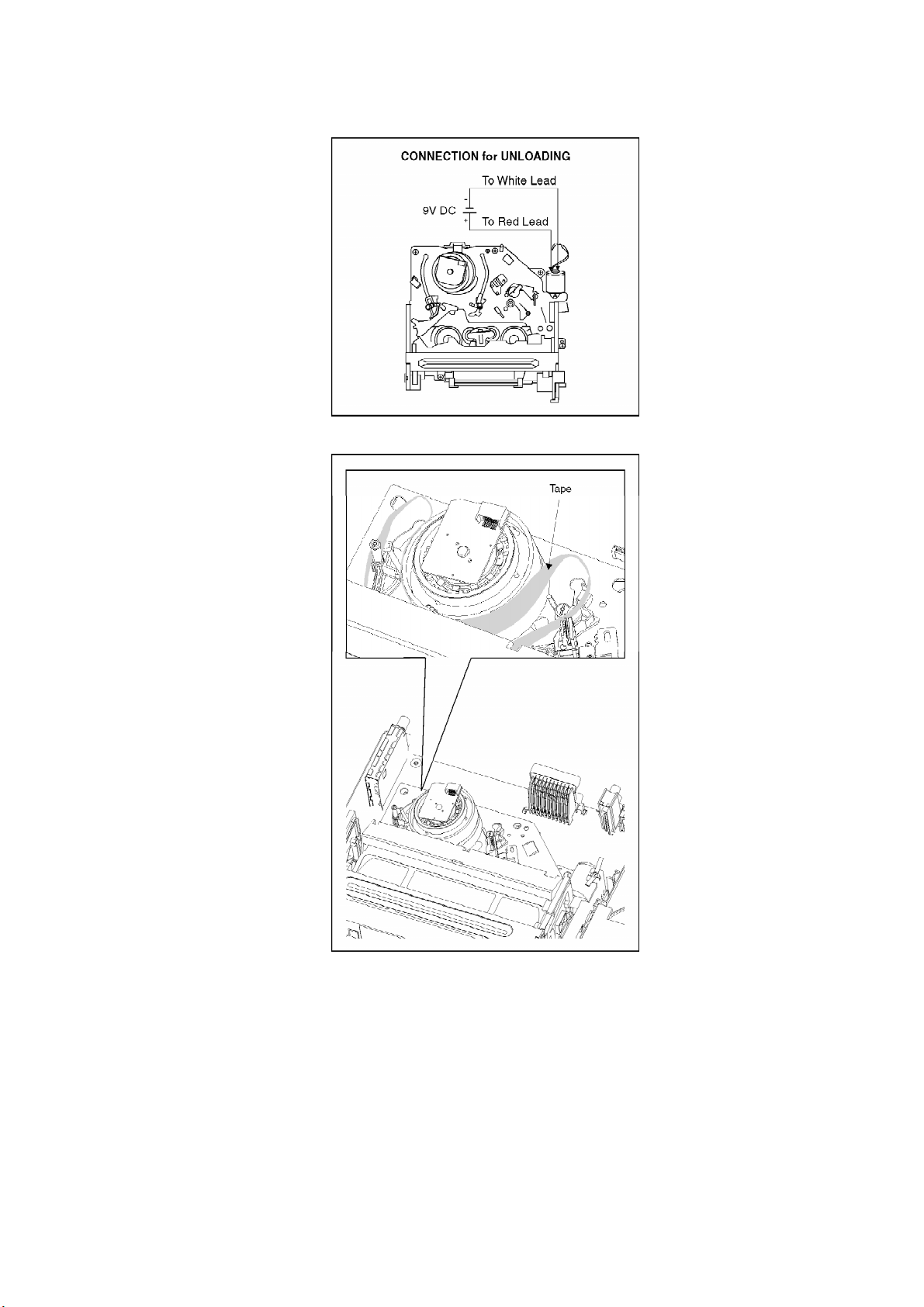

2. Removal by manual operation by rotating the Loading Motor with

the batteries.

A. Disconnect the AC plug, and remove the Top Panel and the

Front Panel by referring to the Disassembly Procedures.

B. Connect one batterie (9V spec.) to the Loading Motor in series

for supplying 9V to rotate the Loading Motor.

12

C. Stop unloading just before unloading would be completed.

D. Then the tape becomes slack.

13

E. Rotate the S-Reel by a small minus screwdriver to remove the

slack tape.

F. Then unload again to remove the cassette tape.

14

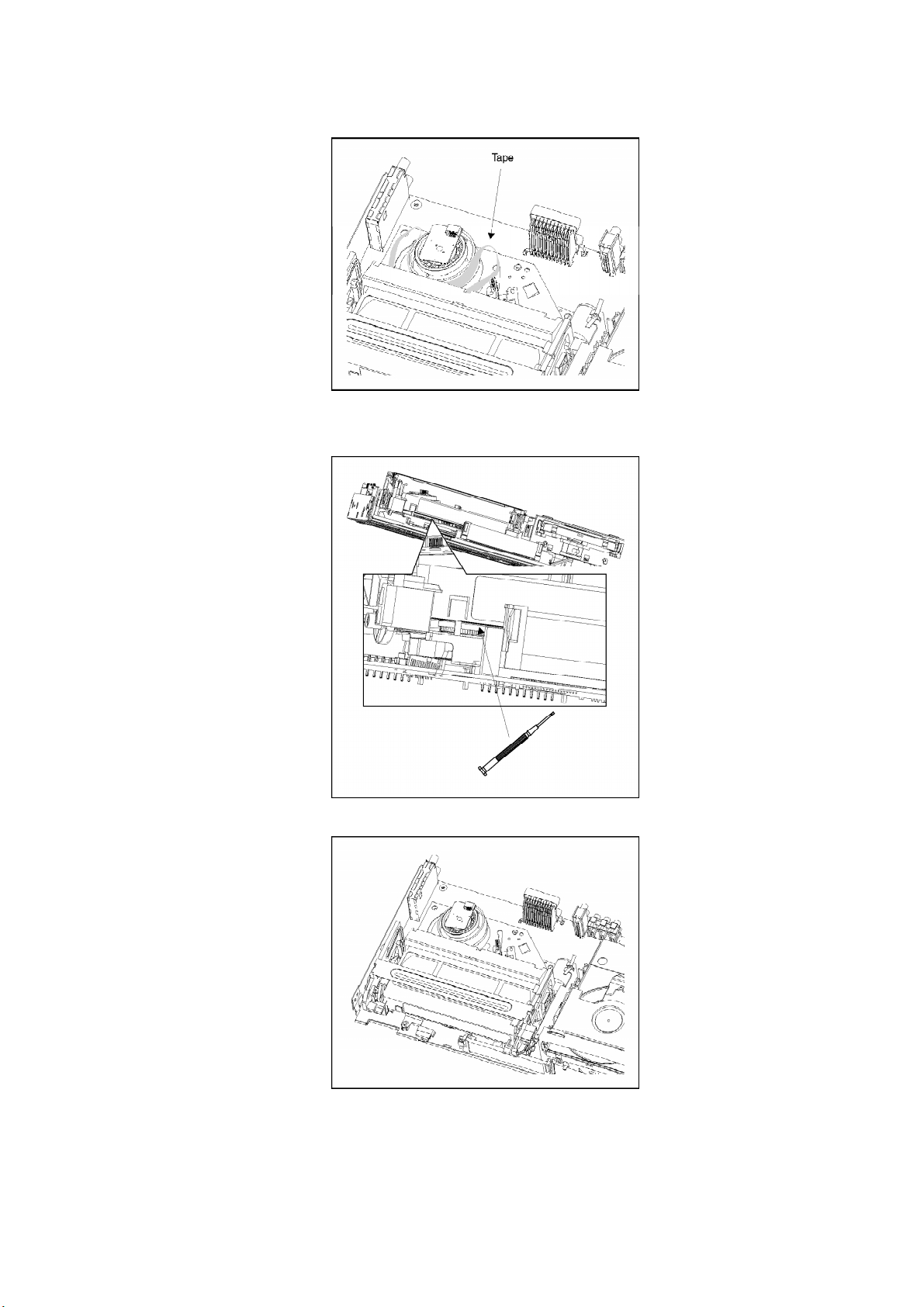

3. Removal by manual operations after uninstalling the mechanism.

A. Disconnect the AC plug remove the Top Panel, Front Panel and

the Mechanism by referring to the Disassembly Procedures.

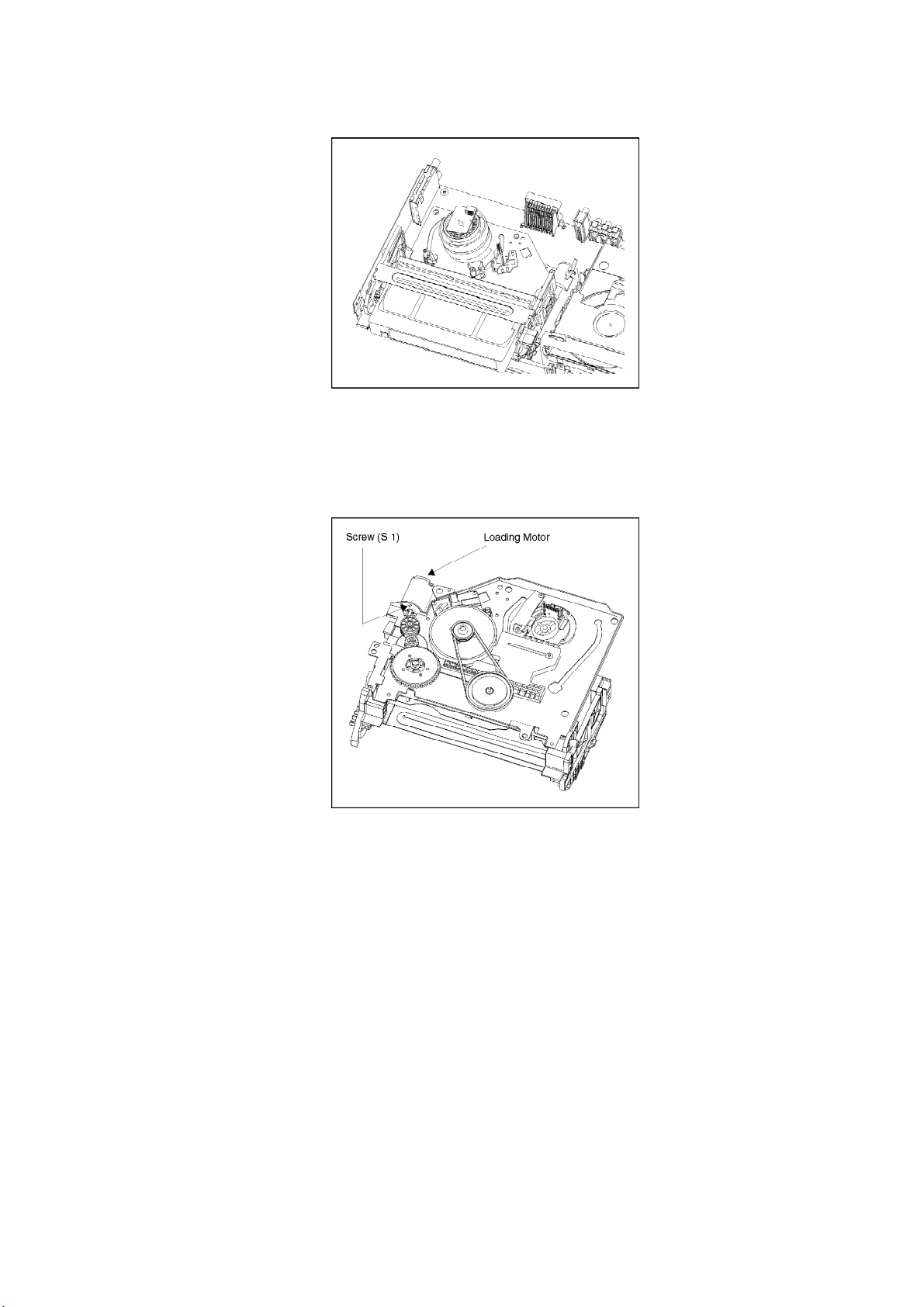

B. Remove the Screw (S1) and remove the Loading Motor both.

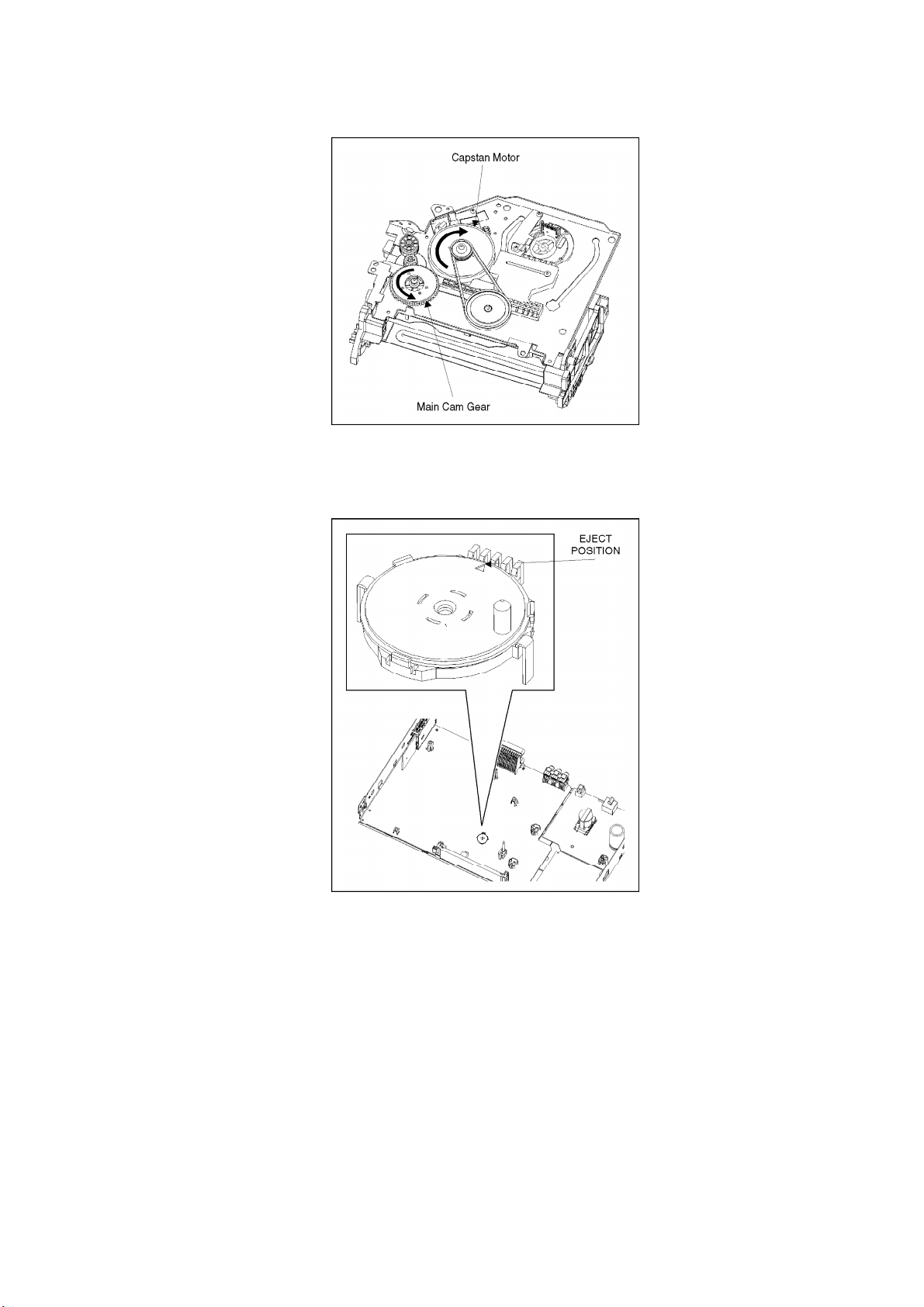

C. Rotate the Main Cam Gear counter-clockwise until just before

the unloading would be completed.

D. Rotate the Capstan Motor clockwise to remove the slack tape.

15

E. Rotate the Main Cam Gear counter-clockwise again to remove

the cassette-tape.

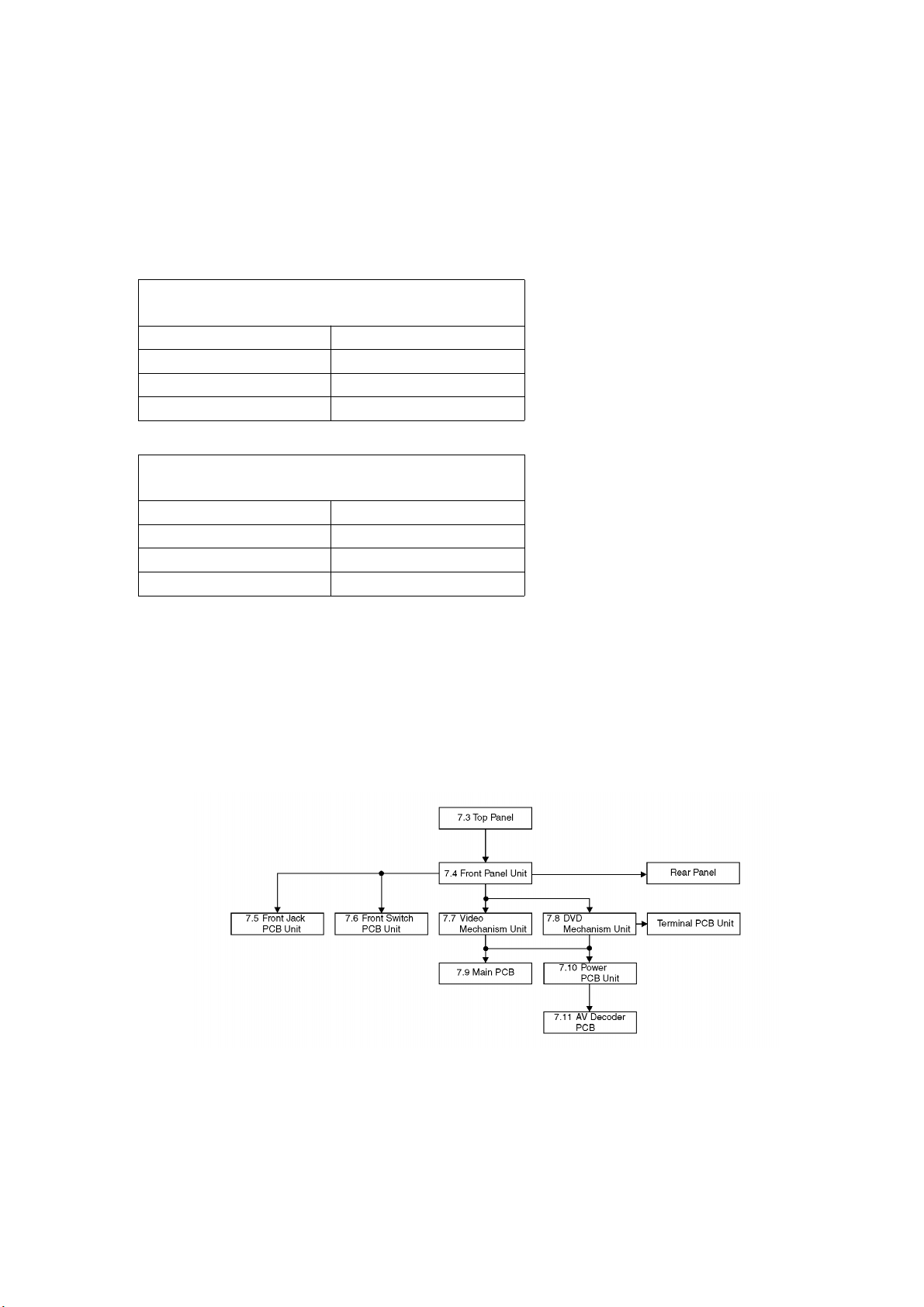

F. Set the Position Switch to EJECT POSITION certainly.

G. Install the Loading Motor and tighten screw (S1).

6.4. SELF-DIAGNOSIS & SERVICE INFORMATION DISPLAY

Refer to the Service Manual for R4 Mechanism Chassis for EURO model (MAD0403002C2).

6.5. INTRODUCTION OF VIDEO / HEAD CLEANING CASSETTE /

(POLISHING TYPE)

1. We are pleased to introduce Panasonic Video Head Cleaning

Cassette, VFK0923FT [for service purposes] and VFK0923FSE [

for end users] for all VHS/SVHS VCP and VCR.

16

2. These cleaning cassettes are exclusive removing the hard and

sticky clogging on video heads.

3. These improve the efficiency of video head cleaning service and

shortening cleaning time for end users.

VFK0923FT

(For Service usage)

Type of Cassette Full VHS Cassette

Cleaning Time 10 Seconds/Time

Tape Length 20 m

Usability in a Path 180 Times

VFK0823FSE

(For end users)

Type of Cassette Full VHS Cassette

Cleaning Time 10 Seconds/Time

Tape Length 3.34 m

Usability in a Path 30 Times

Note:

The tape material itself is the same in both types.

7. DISASSEMBLING THE CASING AND CHECKING

PCBs

7.1. DISASSEMBLY PROCEDURE

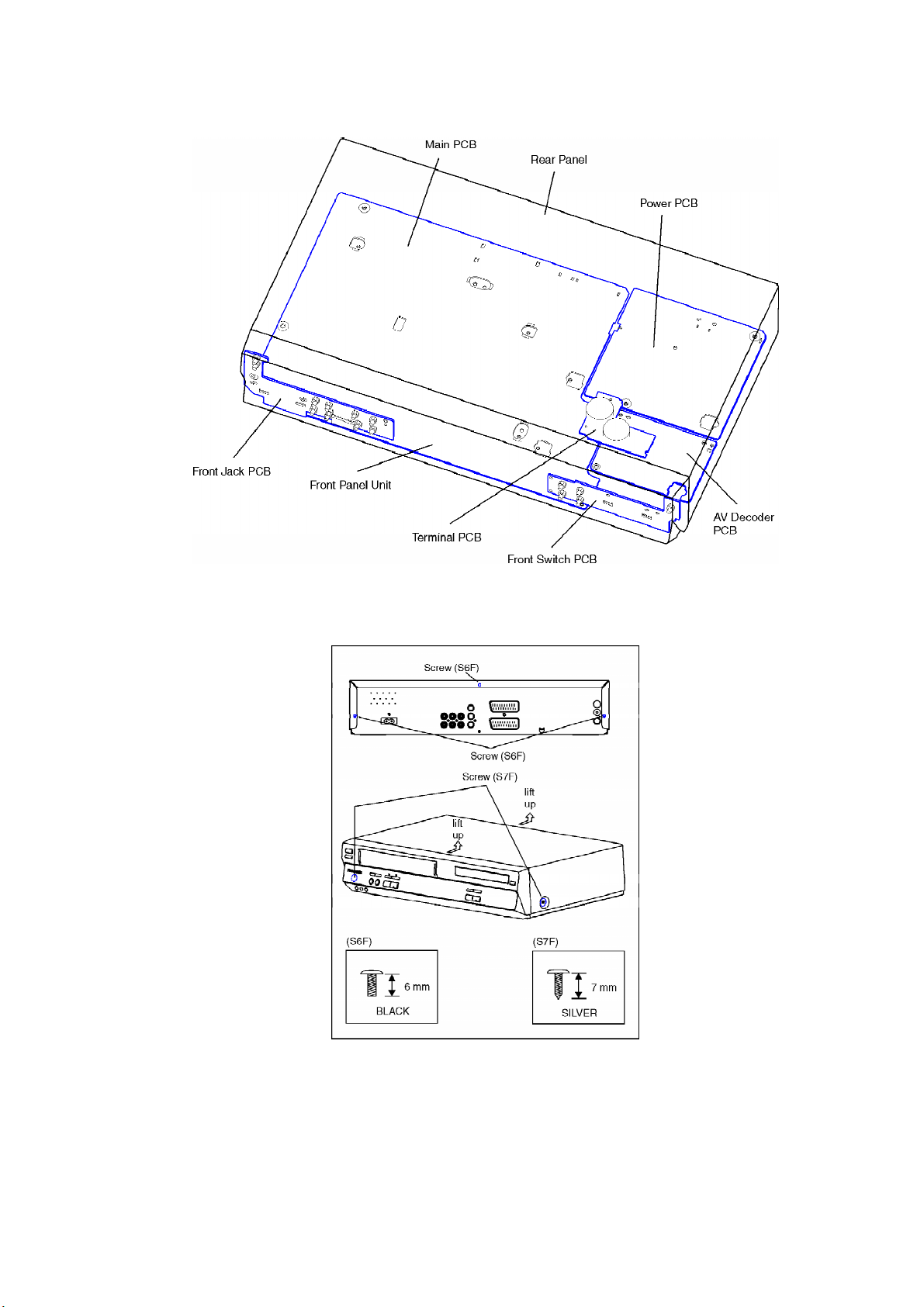

7.2. CASING PARTS AND PCB POSITIONS

17

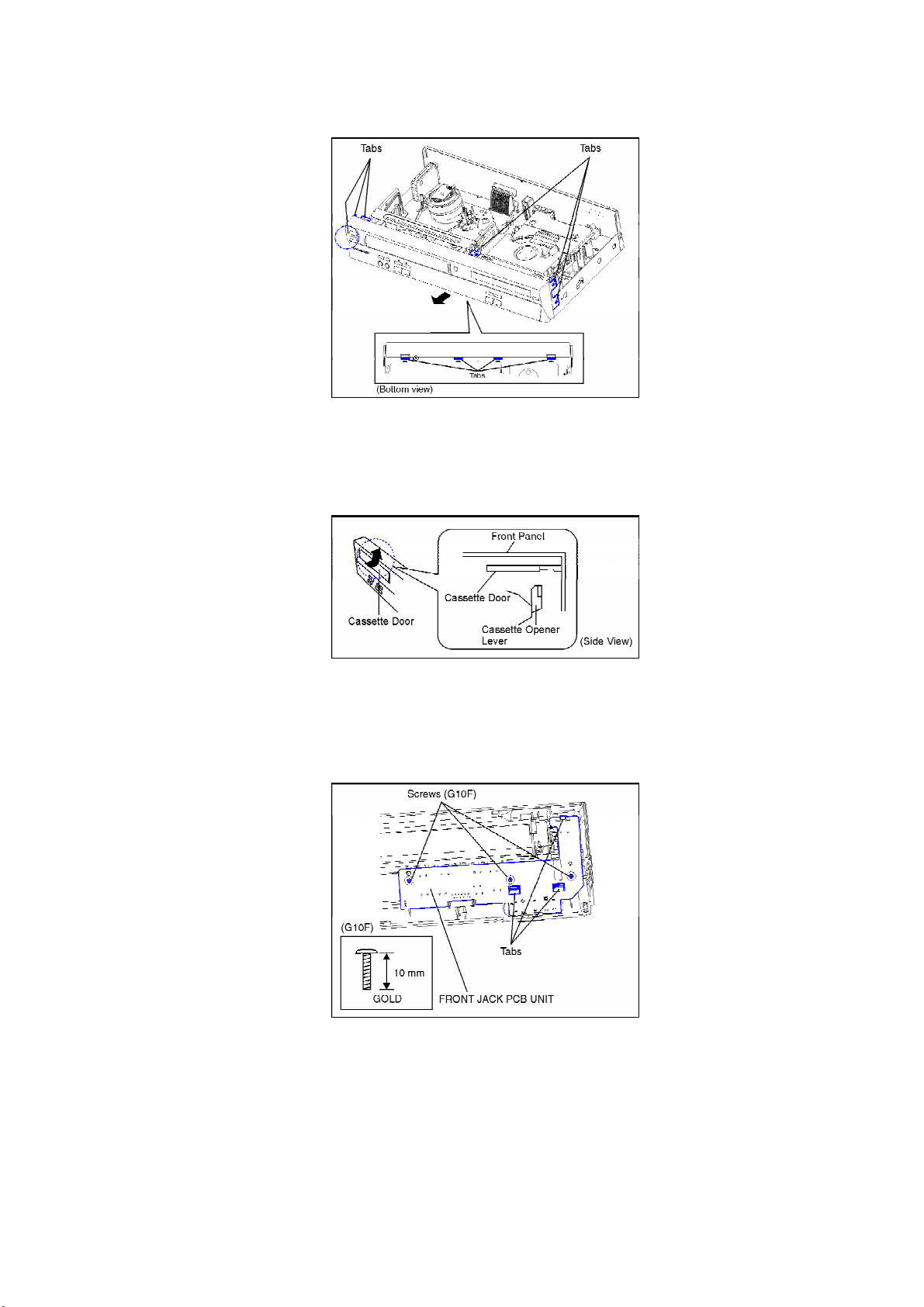

7.3. TOP PANEL

1. Unscrew the Screws.

7.4. FRONT PANEL UNIT

1. Unscrew the Screw.

2. Remove the Tabs.

18

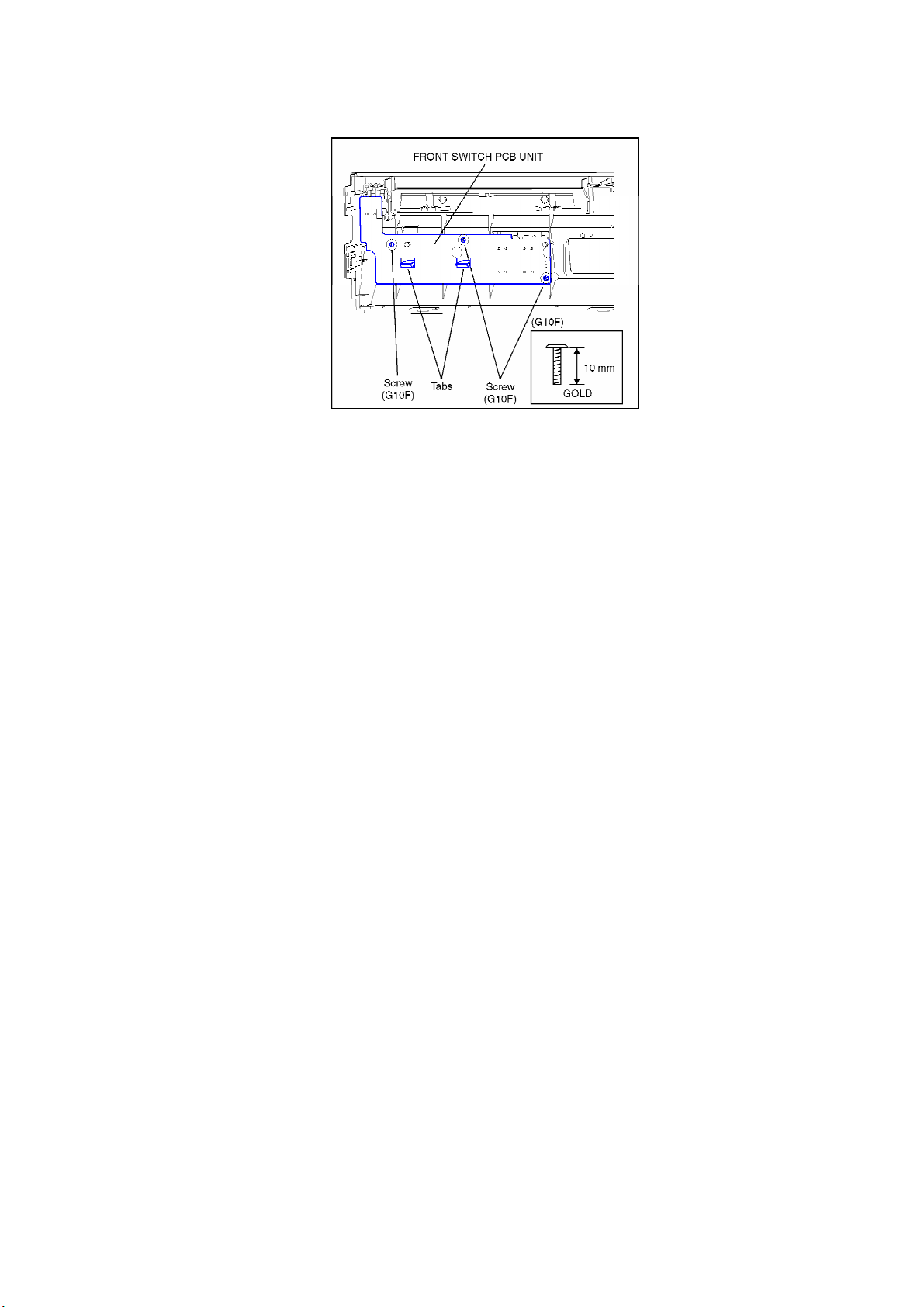

Note:

When attaching Front Panel, in order to hook Cassette Door

Opener Lever to Cassette Door, push up cassette door in the

direction of arrow and insert a front panel.

7.5. FRONT JACK PCB UNIT

1. Unscrew the Screws.

2. Remove the Tabs.

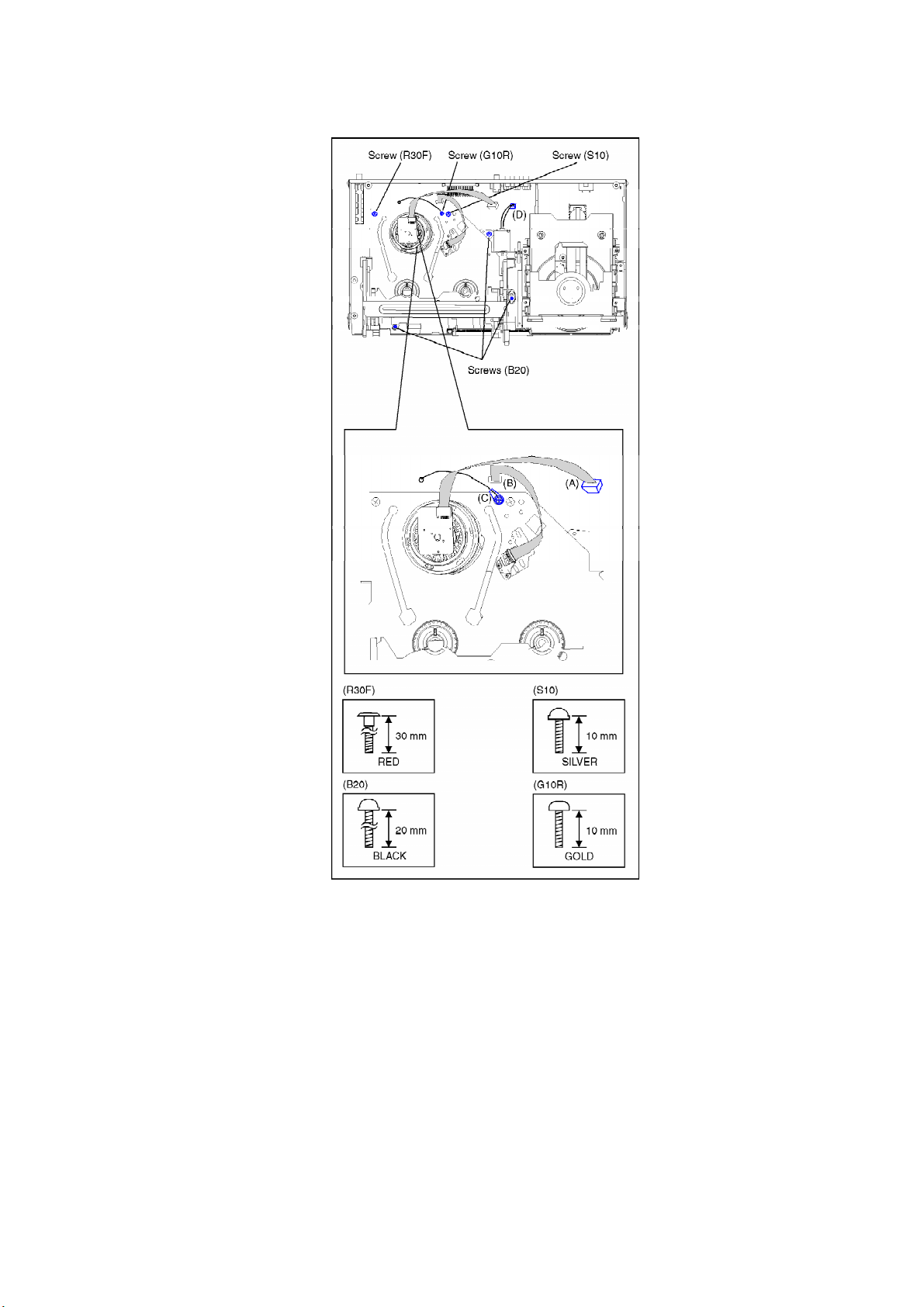

7.6. FRONT SWITCH PCB UNIT

1. Release the Screws.

2. Remove the Tabs.

19

7.7. VIDEO MECHANISM UNIT

1. Unscrew the Screws.

2. Disconnect the Cylinder Connector (A).

3. Disconnect the A/C Head Connector (B).

4. Disconnect the Connector (C).

5. Disconnect the Loading Motor Connector (D).

6. Remove the VHS Mechansim Unit.

20

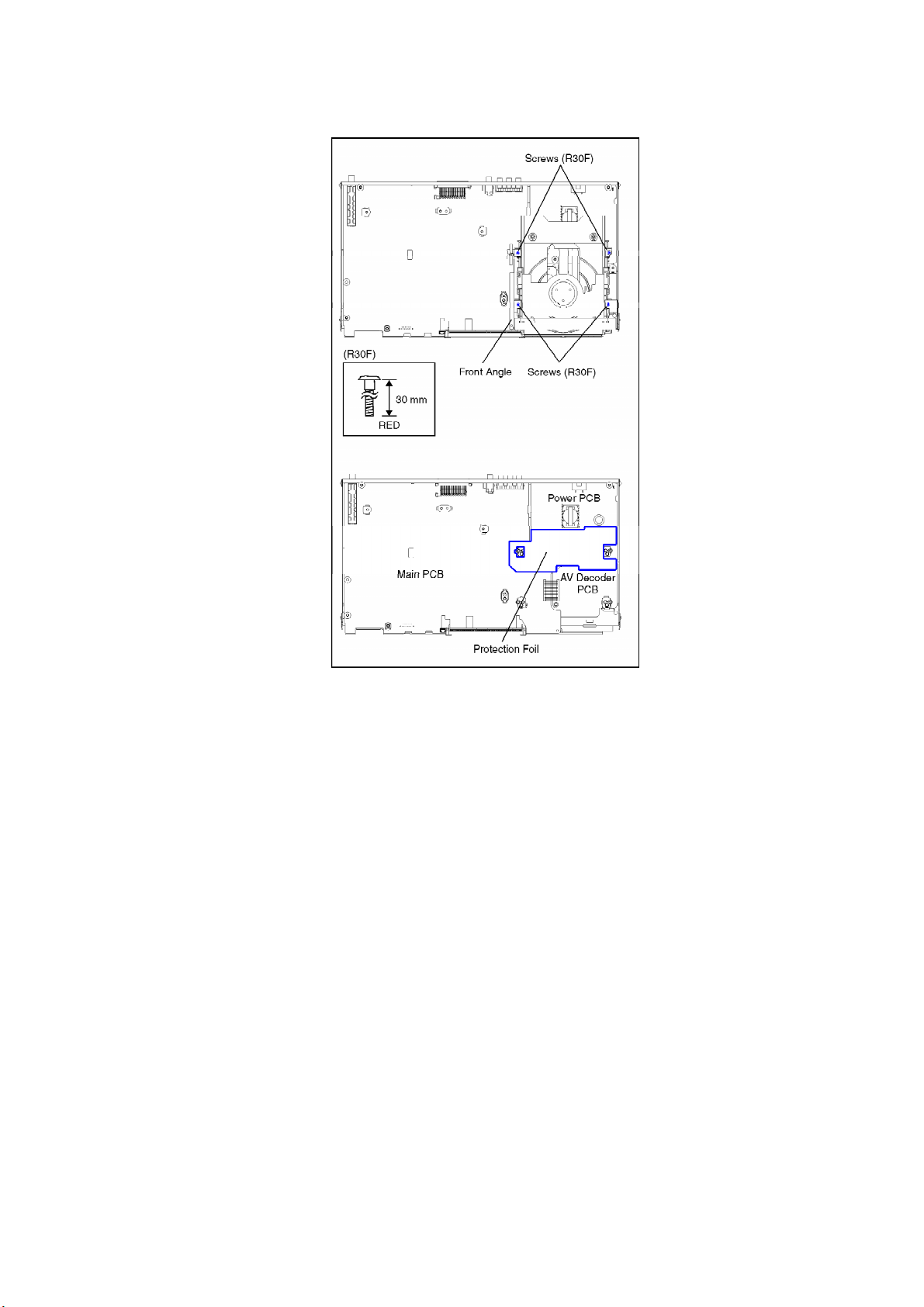

7.8. DVD MECHANISM UNIT

1. Unscrew the Screws.

2. Lift up the DVD Mechanism Unit.

3. Remove the Cables.

4. Remove the DVD Mechanism Unit.

5. Remove the Protection Foil.

21

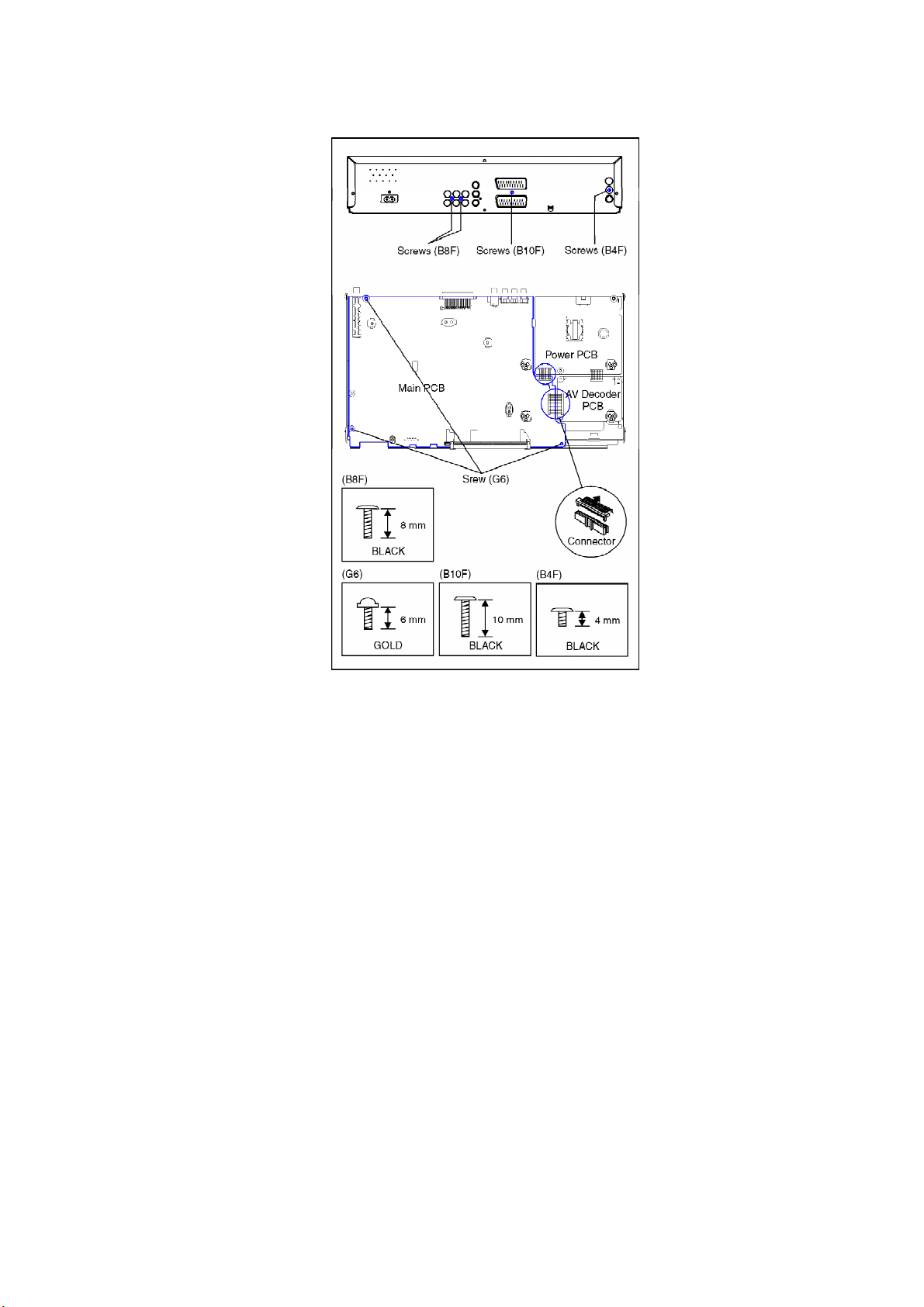

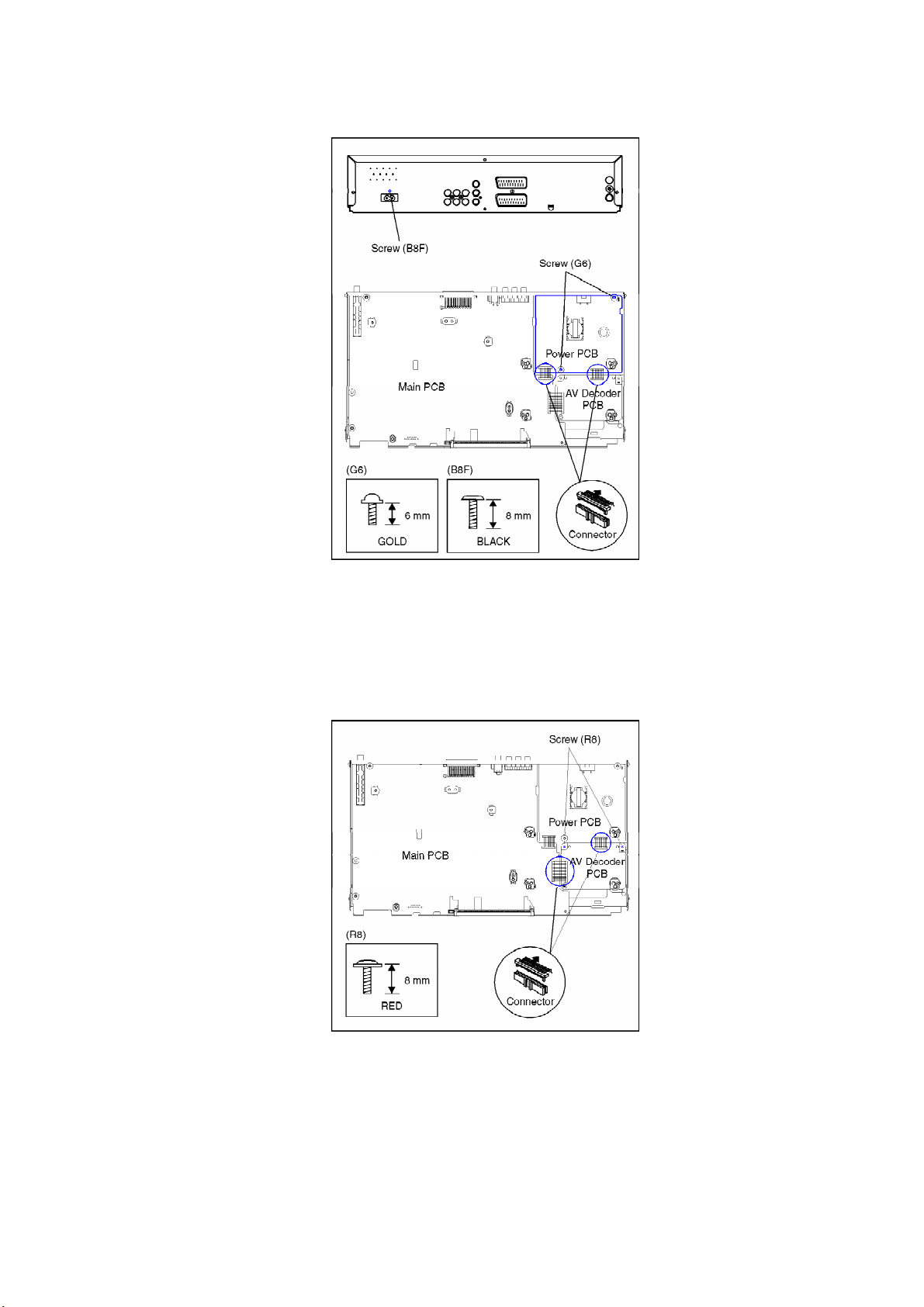

7.9. MAIN PCB UNIT

1. Unscrew the Screws.

2. Release the Connectors.

3. Remove the Main PCB Unit.

22

7.10. POWER PCB UNIT

1. Unscrew the Screws.

2. Release the Connectors.

3. Remove the Power PCB Unit.

23

7.11. AV DECODER PCB UNIT

1. Unscrew the Screws.

2. Release the Connectors.

3. Remove the AV Decoder PCB Unit.

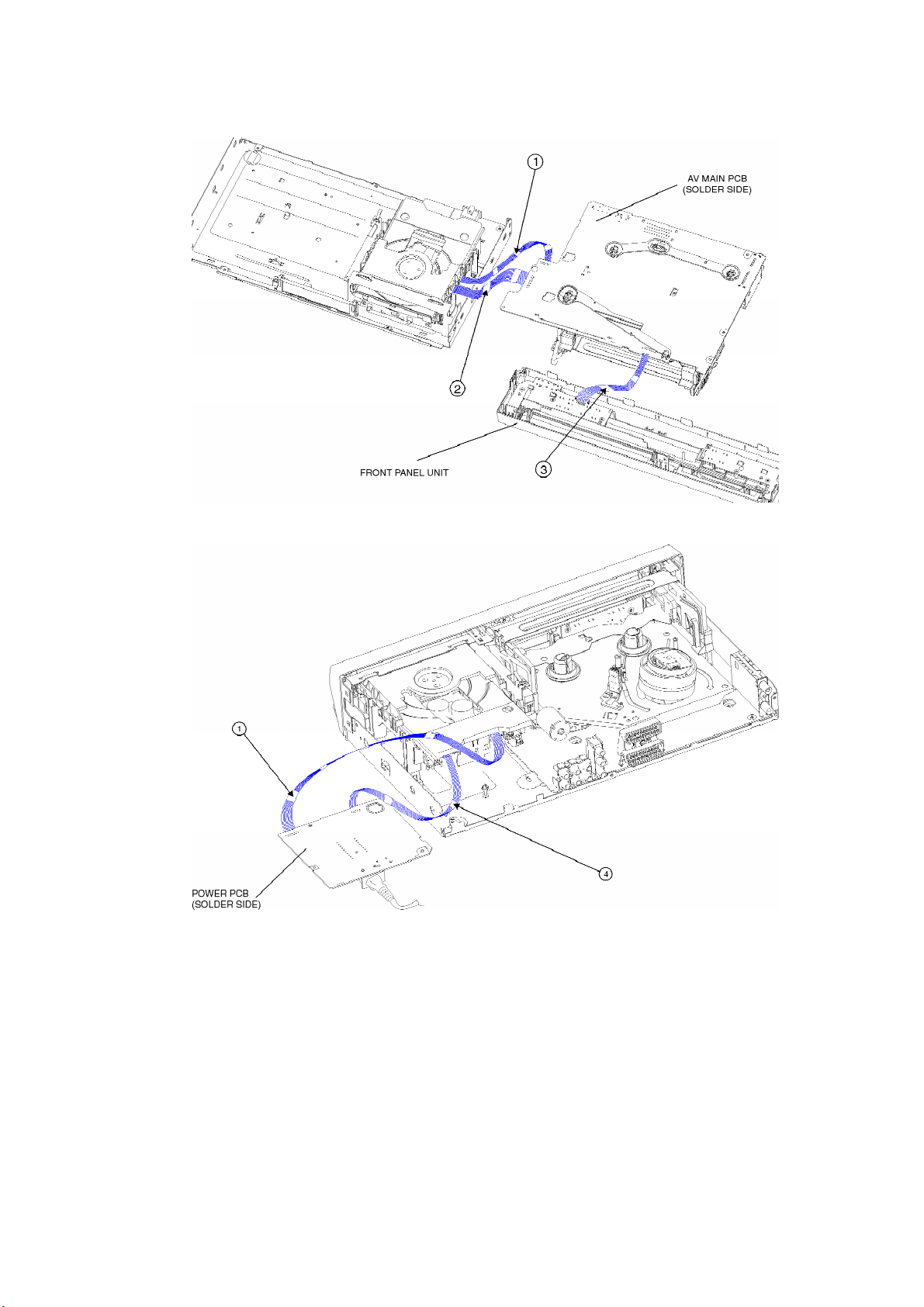

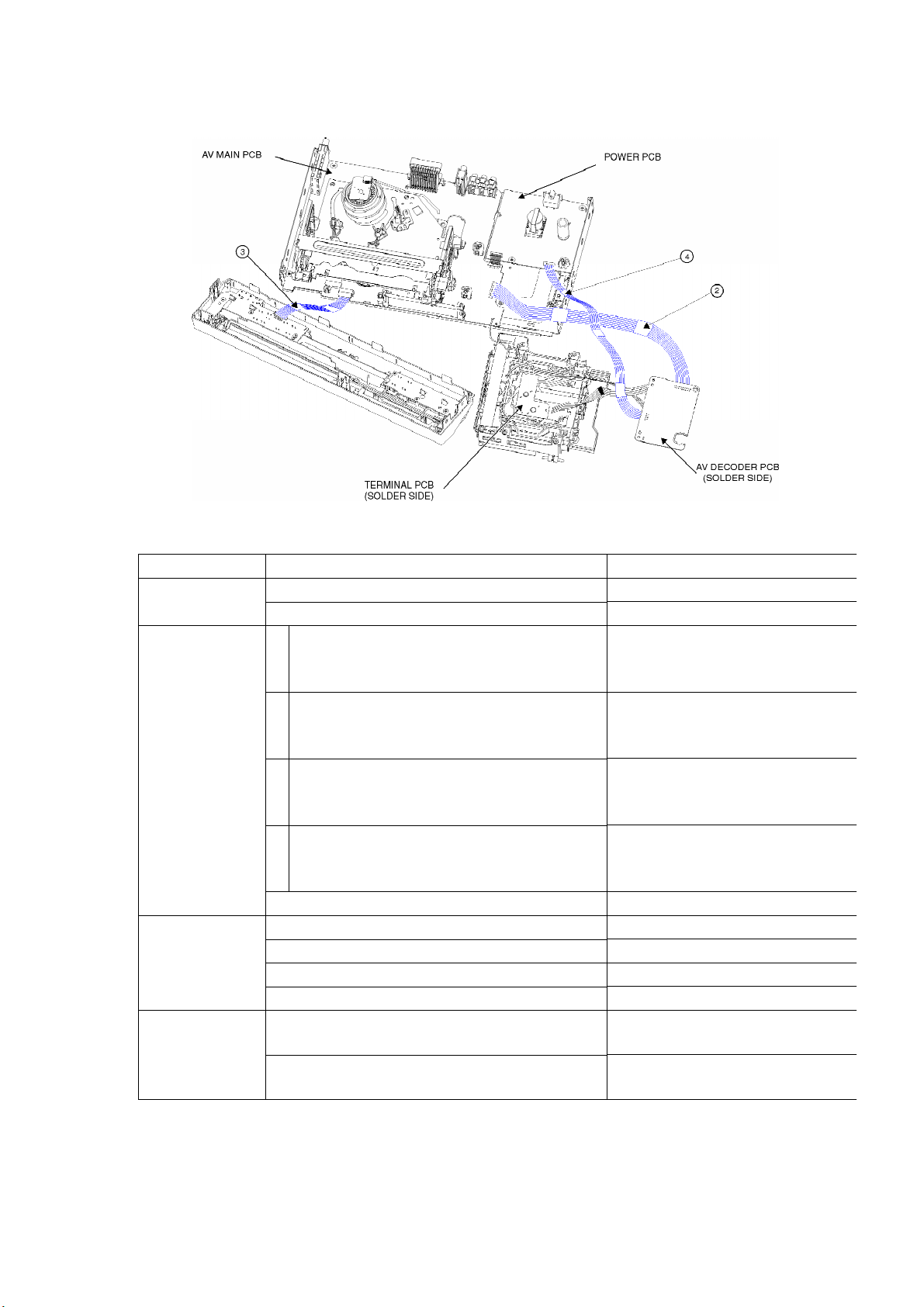

7.12. SERVICE POSITION

7.12.1. SERVICE POSITION OF THE AV MAIN PCB

24

7.12.2. SERVICE POSITION OF THE POWER SUPPLY PCB

7.12.3. SERVICE POSITION OF THE DECODER PCB AND TERMINAL PCB

25

7.12.4. SERVICE TOOLS AND EQUIPMENT

commercially

commercially

Application Name Number

Tilt adjustment DVD test disc DVDT-S15 or DVDT-S01

Hex wrench Available on sales route.

Inspection 1 Extension cable (13pins)

PS1301 (Power PCB) - P1001 (AV Main

PCB)

2 Extension cable (19pins)

P8003 (AV Decoder PCB) - PS4301 (AV

Main PCB)

3 Extension cable (12pins)

PP4801 (Front Jack PCB) - PS7501 (AV

Main PCB)

4 Extension cable (9pins)

P8002 (AV Decoder PCB) - PS1302 (Power

PCB)

DVD unit adjustment stand 1 VFK1727

Others Screw lock RZZ0L01

Grease 1 RFKXGAK152

Grease 2 RFKXPG641

Oil (1) RFKXGA1280

Confirmation CD test disc PVCD-K06 or any other

VCD test disc PVCD-K06 or any other

VFK1876

RFKZ0170

RFKZ0215

RFKZ0288

available disc

available disc

8. OPTICAL PICKUP SELF-DIAGNOSIS AND /

26

REPLACEMENT PROCEDURE

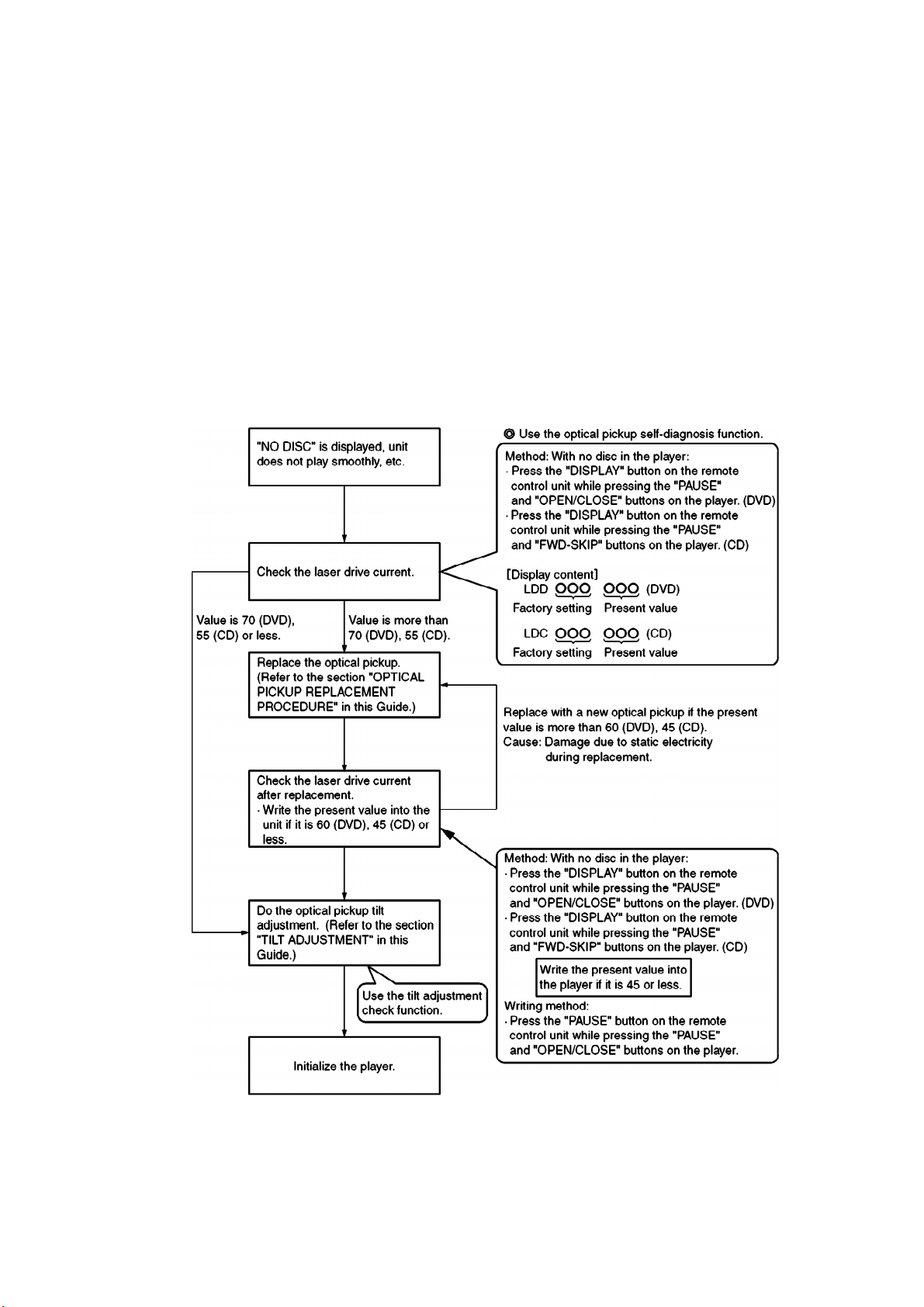

8.1. SELF-DIAGNOSIS

The optical pickup self-diagnosis function and tilt adjustment check function have been

included in this unit. When repairing, use the following procedure for effective Self-diagnosis

and tilt adjustment. Be sure to use the self-diagnosis function before replacing the optical

pickup when "NO DISC" is displayed. As a guideline, you should replace the optical pickup

when the value of the laser drive current is more than 55.

Note:

Press the power button to turn on the power, and check the value within three minutes before

the unit warms up. (Otherwise, the result will be incorrect.)

8.2. CAUTIONS TO BE USED BEFORE REPLACING THE OPTICAL

PICKUP UNIT AND SPINDLE MOTOR ASSEMBLY

27

Before replacing the optical pickup unit and spindle motor assembly, check the total using

Display

hours

4

10

hours

4

10

hours

4

10

hours for each of them. The checking method is as follows:

Operating state & Key operation

Using hours of CD laser Press “PAUSE”, “FWD-SKIP” and “5” on the remote

control in this order while the unit is stopped

Using hours of DVD laser Press “PAUSE”, “FWD-SKIP” and “5” on the remote

control in this order while the unit is stopped

Using hours of SP motor

Resetting using hours of CD

and DVD lasers

(Simultaneous resetting)

Resetting using hours of

the motor

Press “PAUSE”, “FWD-SKIP and “6” on the remote

control in this order while the unit is stopped

Press “STOP”, “FWD-SKIP” and “5” on the remote

control in this order while displaying Timer 1 data

Press “STOP”, “FWD-SKIP” and “6” on the remote

control in this order while displaying Timer 2 data

T1_xxxx_yyyy

yyyy: total

displayed by

figures (unit:

T1_xxxx_yyyy

xxxx: total

displayed by

figures (unit:

T2_xxxx

xxxx: total

displayed by

figures (unit:

T1_0000_0000

T2_0000

Cautions to be taken when replacing the optical pickup

The optical pickup may break down due to the static electricity of human body. Take proper

protection measures against static electricity before repairing the parts around the optical

pickup. (See the page describing the PREVENTION OF STATIC ELECTRICITYDISCHARGE.)

1. Do not touch the areas around the laser diode and actuator.

2. Do not judge the laser diode with a tester. (The tester will be

damaged easily.)

9. SELF-DIAGNOSIS FUNCTION AND SERVICE

MODES

9.1. SERVICE MODE TABLE 1

The service modes can be activated by pressing various button combination on the player and

remote control unit.

28

Player buttons Remote control unit

Note

to

-

Diagnosis

Function

Display).

to

Optical

Tilt

Adjustment

the

ROM

program.

to

Optical

Replacement

Procedure.

to

Initializing

player.

buttons

PLAY (DVD)

+

OPEN/CLOSE

0 Displaying the UHF display Refer

Application

9.1. Self

PAUSE

SKIP/

SEARCH<<

OPEN/CLOSE

5 Jitter check, tilt adjustment

*Display shows J_xxx_yyy_zz

"yyy" and "zz" shown to the right have nothing

to do with the jitter value. "yyy" is the error

counter, while "zz" is the focusdrive value.

Refer to section 11.3. for Optical Pickup Tilt

Adjustment Procedure.

6 Checking the region numbers and broadcast

system

7 Checking the program version Check

9 Lighting Confirmation Function of Display Tube

FUNCTIONS Checking the laser drive current Refer

PAUSE Writing the laser drive current value after

replacing the optical pickup (do not use for

anything other than optical pickup replacement)

Initializing the DVD player

(restoring factory preset settings)

Refer

11.3.

Pickup

FLASH

10.8.

Pickup

Refer

9.5.

DVD

9.2. DVD SELF DIAGNOSTIC FUNCTION-ERROR CODE

29

Error Code Error Content Additional error explanation

error)

the

error

violation

(

error

of

occured

incompatible

data

defect

to

series

by

U11 Focus error

H01 Tray loading error

H02 Spindle servo error (Spindle servo, DSC SP motor, CLV servo

H03 Traverse servo error

H04 Tracking servo error

H05 Seek error

H06 Power error Cannot switch off the power because of

and system computer communication

H07 Spindle motor drive error

F103 Illegal highlight Position Big possibility of disc specification

highlight display

F498 No communication between Front

Micro Computer and Main Micro

Computer after power on

F499 No response from Main Micro

Main Micro Computer hangs up

Computer when key code is sent from

Front Micro Computer to Main Micro

Computer

F4FF Force initialize failure (time out)

F500 DSC error DSC stops in the occurence of servo error

focus error, etc)

F501 DSC not Ready DSC-system computer communication

(Communication failure caused by idling

F502 DSC Time out error Similar disposal as F500

F503 DSC communication Failure Communication error (result error

communication command was sent)

F505 DSC Attention error Similar disposal as F500

F506 Invalid media Disc is flipped over, TOC unreadable,

disc

F600 Access failure to management

information caused by demodulation

Operation stopped because navigation

accessible caused by the demodulation

error

F601 Indeterminate sector ID requested Operation stopped caused by the request

abnormal ID data

F602 Access failure to LEAD-IN caused by

LEAD IN data unreadable

demodulation error

F603 Access failure to KEYDET caused by

Access failure to CSS data of disc

demodulation error

F610 ODC abnormality No permission for command execution

F611 6626 QCODE don’t read Error Access failure to seek address in CD

F612 No CRC OK for a specific time Access failure to ID data in DVD series

F630 No reply to KEY DET enquiry (for internal use only)

F631 CPPM KEY DET is not available till the

FILE terminal

(CPPM file system is unreadable caused

scratches)

30

Error Code Error Content Additional error explanation

violation

disc

reply

preset

preset

preset

F632 CPPM KEY DET is not available Been revoked or falsified

F103 Illegal highlight Position Big possibility of disc specification

highlight display

F700 MBX overflow When replying message to disc manager

F701 Message command does not end Next message is sent before replying to

manager

F702 Message command changes Message is changed before it is sent as a

disc manager

F880 Task number is not appropriate Message coming from a non-existing task

F890 Sending message when message is

being sent to AV task

F891 Message couldn’t be sent to AV task Begin sending message to AV task

F893 FROM falsification

F894 EEPROM abnormality

F895 Language area abnormality Firm version agreement check for factory

F896 No existence model Firm version agreement check for factory

F897 Initialize is not completed Initialize completion check for factory

F8A0 Message command is not appropriate Begin sending message to AV task

Sending message to AV task

setting failure prevention

setting failure

prevention

failure prevention

Note:

An error code will be canceled if a power supply is turned OFF.

*1: CPPM is the copy guard function beforehand written in the disk

for protection of copyrights.

9.3. LAST ERROR CODE SAVED DURING NO PLAY

31

Error

computer

code

0xDOBF

0xDOC0

0xDOC1

0xDOC2

0xDOC3

0xDOC4

0xDOC5

code

F0BF 6) Cannot playback

because physical layer is

not recoginizable

F0C0 8) DVD: Cannot playback

because it is not DVD Video

/Audio/VR

F0C1 9) DVD: Prohibited by the

restricted region code

F0C2 A) DVD: PAL restricted

playback

F0C3 B) DVD: Parental lock

setting prohibits the

playback of the entire title

F0C4 C) VCD: Prohibited

because it is in PHOTO CD

format

F0C5 VCD/CD: Prohibited

because it is CDROM

without CD-DA

Error Content System computer Setting task System

PCND_NOPLAY

PHYSICAL 0x50

PCND_NOPLAY VIDEO

0x70

PCND_NOPLAY RCD

0x80

PCND_NOPLAY PAL

0x90

PCND_NOPLAY PTL

0xA0

PCND_NOPLAY PHOTO

CD 0xB0

PCND_NOPLAY

CDROM 0xC0

error

DiscManager

DiscManager

DiscManager

DiscManager

DiscManager

DiscManager

DiscManager

9.4. SERVICE MODE TABLE 2

Pressing various button combinations on the player and remote control unit can activate the

service modes.

9.5. SERVO PROCESS FLOW

32

9.6. DVD SERVO PROCESS DISPLAY MODE

Process

50~7F

80~9F

A0~BF

In starting operation of the player, a number is allotted to each servo process so that the

operation of each step can be seen. The relation between the process and the displayed number

are as follows:

Number allotment to the servo process.

Process

classification

Initial start process Initial start The process starts after the tray is loaded.

Restart process Restart When a user operates in the “READY” state,

Seek process Seek The optical pickup is moved to the disc

Each processing item Description

(The state

is changed to “READY” or “PREPARE”.)

Secondary learning Servos for the DVD-DL 1st layer and the CD-

DA double

speed are learned in this step.

each servo is

turned on.

destination in this

process.

0~40

33

Process

Process

C1~C3

C4~C6

C7~C9

F0~FF

classification

Repair process Recover

Stop process Stop A servo is controlled in response to the

Each processing item Description

(Error check) An error is searched in the PLAY/SEEK state.

(Attention) An error is recovered following the attention

error

interrupt from the S-ODC.

(Q code read) If any Q code is improperly read, reset and

retry.

user~s operation

to stop the disc completely.

9.7. OVERVIEW OF EACH FUNCTION

9.7.1. CUMULATIVE OPERATION TIME DISPLAY

1. Operation/display

DVD/CD laser operation

time

Unit: 120 hours in decimal

notation

Spindle motor operation

time

Unit: 1230 hours in decimal

notation

Key operations are as follows.

Laser operation time ............. In STOP mode,

main unit PAUSE+FWD-SKIP+ remote controller [5]

Spindle motor operation time ..... In STOP mode,

main unit PAUSE+FWD-SKIP+ remote controller [6]

To reset the timer, perform the following while

displaying the time with above key operation.

Laser operation time ............. In STOP mode,

main unit STOP+FWD-SKIP+ remote controller [5]

Spindle motor operation time ..... In STOP mode,

main unit STOP+FWD-SKIP+ remote controller [6]

2. How to utilize

Reference information in fault diagnosis of laser or

spindle motor system.

Review of faulty point in repeated repair

34

9.7.2. SERVO PROCESS DISPLAY

1. Operation/display

While the player is in STOP mode, perform the specified key

operation to display the servo process number on FL.

When the display does not change from the error

indication, press Open/Close key to show

the servo process number.

Key operation: In STOP mode,

main unit PAUSE+FWD- SKIP+ remote controller [7]

Number to the left ...

... Process number when

halted

Number to the right ...

... Process number in

progress

9.8. SALES DEMONSTRATION LOCK FUNCTION

This function prevents discs from being lost

when the unit is used for sales demonstrations

by disabling the disc eject function.

"LOCK" is displayed on the unit and

ordinary operation is disabled.

9.8.1. SETTING

The sales demonstration lock is set by simultaneously pressing STOP button on the player and

POWER button on the remote control unit.

9.8.2. CANCELLATION

The lock can be cancelled by the same procedure as used

in setting. ("UNLOCK" is displayed on cancellation.

Disconnecting the power cable from power outlet does

not cancel the lock.)

9.9. HANDLING AFTER COMPLETING REPAIRS

Use the following procedure after completing repairs.

9.9.1. PRECAUTIONS

Do not disconnect the power plug from the outlet with the tray still open, then close the tray

manually.

9.9.2. METHOD

Confirm that the power is turned on:

1. Press the "OPEN/CLOSE" button to close the tray.

2. Press the "POWER" button to turn off the power.

35

3. Disconnect the power plug from the outlet.

9.10. SERVICE PRECAUTIONS

9.10.1. RECOVERY AFTER THE DVD PLAYER IS REPAIRED

When an FROM or an EEPROM on the decoder PCB has replaced, carry out the recovery disc

processing to optimize the drive. Playback the disk to process the recovery automatically.

Note:

This unit requires no initialization process carried out after the traditional DVD players were

repaired.

When the recovery measures are taken, the customer setting will return to the factory setting as

same as the procedure described in item of "Initialization". Write down the contents of the

setting before recovery processing and reset the player.

9.10.2. FIRMWARE VERSION-UP OF THE DVD PLAYER

The firmware of the DVD player may be renewed to improve the quality including

operationability and playability to the substandard discs processing to optimize the drive.

Note:

If the AC power supply is shut down during version-up due to a power failure, the version-up is

improperly carried out. In such a case, replace the FROM and carry out the version-up again.

The product number of the version-up disc will be noticed when it is supplied.

9.10.3. FIRMWARE VERSION-UP AND RECOVERY WITH DISC

- Recovery

- Firmware updating

Simply run the recovery disc. Then both of the above

operations are automatically performed.

Commercially available CD-R can now perform updating

and recovery process, making it easier to update the

version.

Recovery process: Optimization of player after replacement

of FROM and Decoder PCB.

Version updating: Firmware updating for improved

operability and performance.

9.10.4. HOW TO USE RECOVERY DISC

9.10.4.1. PERFORMIG RECOVERY

1. Load the recovery disc RFKZD03R005 on to the player and run it.

2. Recovery is performed automatically. When it is finished,

a message appears on the screen.

36

3. Remove the recovery disc.

4. Turn off the power.

9.10.4.2. UPDATING FIRMWARE

1. Load the recovery disc RFKZD03R005

on to the player and run it.

2. Firmware version of the player is automatically checked.

Appropriate message appears whenever necessary.

3. Using remote controllers cursor key,

select whether version updating is to be done or not

(Selection of Yes/No).

4. a. If Yes is selected, version updating is performed.

b. If No is selected, only recovery is performed.

5. a. When updating is finished, remove the disc

according to the message appearing on the screen.

b. Remove the disc according to the message

appearing on the screen.

6. Turn off the power.

9.11. VCR SELF-DIAGNOSIS RESULT DISPLAY

The "SELF-DIAGNOSIS RESULT DISPLAY & MEMORY

function is built in this VTR.

It means that when the VCR detects undesirable condition,

it can be displayed a “Error code (Two numbers from the right)” with Service Mode 2.

Since the "Error code" is stored in the EEPROM,

it can be displayed although after disconnected the AC leads.

It can be displayed with Service Mode 2.

(If a second error had been detected,

only the most recent error is displayed.)

For more details, refer to the Service Manual

for R4 Mechanism Chassis for EURO model

(MAD0403002C2).

9.12. CAUTION FOR AC MAINS LEAD (NV-VP33EB/EBL)

10. ASSEMBLING AND / DISASSEMBLING / THE

MECHANISM UNIT

10.1. DISASSEMBLY PROCEDURE

37

10.2. TERMINAL PCB UNIT

1. Unscrew the Screw.

2. Remove the Solder.

3. Remove the Cable.

4. Remove the Terminal PCB Unit.

38

10.3. FRONT HOLDER

1. Remove the Front Holder

10.4. CLAMP PLATE UNIT

39

1. Push the stopper with hand to slide the tabs and remove the

clamp plate unit.

10.5. TRAY

1. Lift the tray.

<Precautions in reassembling the tray>

Reassemble the tray so that it is in the backmost position.

1. Turn traverse gear until cam gear leaver comes to the lever

adjusting position at the end of mechanical chassis unit.

40

2. Check the position of convex phase on back of the tray, and that

of concave phase on drive gear.

A. Place the tray on the unit from rearward.

41

B. Inch the tray frontward until convex phase and concave phase

mate.

Caution:

Make sure to mate convex phase and concave phase properly, so

that the gap between turntable and tray becomes 5mm or less.

42

10.6. TRAVERSE BLOCK

1. Lift the traverse block while spreading the hook of the mechanical

chassis unit.

2. Disengage the tabs from the holes of the mechanical chassis unit.

10.7. TRAVERSE GEAR

1. Disengage the tabs from the traverse gear.

2. Remove the traverse gears B and C.

43

<Precautions in reassembling the traverse block>

Take the following precautions when reassembling the traverse block.

1. Turn traverse gear on the traverse block to let trigger lever turn

rightward (Front view).

2. Bring cam gear lever to the lever adjusting position at the end of

mechanical chassis unit.

3. Put tabs A and B into slots A and B respectively.

Place tabs C into hooks to mount the traverse block on

mechanical chassis unit (Slot A... Mechanical chassis unit, Slot

B... Cam gear).

44

10.8. OPTICAL PICKUP UNIT

1. Unscrew the screws.

2. Remove the spring holders and the springs.

3. Pull out the drive shaft and guide shaft.

45

10.8.1. DISASSEMBLING THE OPTICAL PICKUP UNIT

1. Remove the two screws and remove the TRV feed rack.

2. Remove the FFC cable.

3. Remove the optical pickup.

Fig. 1

10.8.2. CAUTIONS TO BE TAKEN WHEN REPLACING THE OPTICAL PICKUP

- Replace the optical pickup according to the following procedure.

1. Install the TRV feed rack on the optical pickup (see Fig. 1).

2. Install the Optical Pickup Unit, Spring, Drive shaft, Guide shaft

and Spring holder on the Traverse block.

Cautions to be taken when assembling the unit: Install the Pickup

Unit so that it is located at the rear end of the Guide shaft.

3. Install the FFCable (see Fig. 1).

Fig. 2

46

Fig. 3

10.9. DISASSEMBLING THE / MIDDLE CHASSIS

1. Remove the holder pins.

2. Remove the tab.

3. It lifts while pulling it in the direction of the arrow.

47

10.10. DISASSEMBLING THE / TRAVERSE

1. Unscrew the screw.

2. Remove the traverse gear A.

10.11. DISASSEMBLING THE / SPINDLE MOTOR UNIT /

1. Remove the floating rubbers.

48

11. ADJUSTMENT PROCEDURES

11.1. IMPORTANT POINTS IN ADJUSTMENT

11.1.1. IMPORTANT POINTS IN OPTICAL ADJUSTMENT

- Before starting optical adjustment be sure to take anti-static

measures.

- Optical pickup tilt adjustment is needed after replacement of the

following components.

1. Optical pickup unit

2. Spindle motor unit

3. Optical pickup peripheral parts (such as rail)

Notes

Adjustment is generally unnecessary after replacing other parts of the traverse unit. However,

make adjustment if there is a noticeable degradation in picture quality. Optical adjustments

cannot be made inside the optical pickup. Adjustment is generally unnecessary after replacing

the traverse unit.

11.1.2. IMPORTANT POINTS IN ELECTRICAL ADJUSTMENT

- Follow the adjustment procedures described in this Manual.

11.2. STORING AND HANDLING TEST DISCS

- Surface precision is vital for DVD test discs. Be sure to store and

handle them carefully.

1. Do not place discs directly onto the workbench, etc., after use.

2. Handle discs carefully in order to maintain their flatness. Place

them into their case after use and store them vertically. Store

discs in a cool place where they are not exposed to direct sunlight

or air from air conditioners.

3. Accurate adjustment will not be possible if the disc is warped

when placed on a surface made of glass, etc. If this happens, use

a new test disc to make optical adjustments.

4. If adjustment is done using a warped disc, the adjustment will be

incorrect and some discs will not be playable.

11.3. OPTICAL ADJUSTMENT

11.3.1. OPTICAL PICKUP TILT ADJUSTMENT

49

Measurement

point

Measuring equipment Adjustment value

None (Main unit display

for servicing is used.)

11.3.1.1. ADJUSTMENT PROCEDURE

Adjustment

point

Tangential

adjustment

screw

Tilt

adjustment

screw

Mode Disc

T01 (inner

periphery)

play

T43 (outer

periphery)

play

Adjust to the minimum

jitter value.

DVDR-S15

or DVDTS01

1. While pressing PAUSE and OPEN/CLOSE buttons on the main

unit, press "5" on the remote control unit.

2. Confirm that "J_xxx_yyy_zz" is shown on the front display.

For your information:

"yyy" and "zz" shown to the right have nothing to do with the jitter value. "yyy" is the error

counter, while "zz" is the focus drive value.

Note:

Jitter value appears on the front display.

3. Play test disc T01 (inner periphery).

4. Adjust tangential adjustment screw so that the jitter value is

minimized.

5. Play test disc T43 (outer periphery).

6. Adjust tilt adjustment screw 1 so that the jitter value is minimized.

7. Play test disc T43 (outer periphery).

8. Adjust tilt adjustment screw 2 so that the jitter value is minimized.

9. Repeat adjusting tilt adjustment screws 1 and 2 alternately until

the jitter value is minimized.

11.3.1.2. IMPORTANT POINTS

1. Make tangential adjustment first and then make tilt adjustment.

2. Repeat adjusting two or three times to find the optimum point.

50

3. Finish the procedure with tilt adjustment.

Note:

When adjust Tilt adjustment screw 2, turn the DVD unit slightly so that the Tilt adjustment screw

2 could be adjusted.

51

11.3.1.3. CHECK AFTER ADJUSTMENT

Play test disc or any other disc to make sure there is no picture degradation in the inner, middle

and outer peripheries and no audio skipping. After adjustment is finished, lock each adjustment

screw in position using screw lock.

11.3.1.4. PROCEDURE FOR SCREW LOCK

1. After adjustment, remove top panel, tray, clamper base and

traverse unit in this sequence.

2. Lay the traverse unit upside down and fix adjustment screw with

screw lock.

3. After fixing, reassemble traverse unit, clamper base, tray and top

panel.

11.4. VCR ELECTRICAL ADJUSTMENT PROCEDURES

11.4.1. TEST EQUIPMENT

The following equipments are required for Electrical

Adjustments.

1. Dual-Trace Oscilloscope

- Voltage Range: 0.005-5V/div

- Frequency Range: DC-35MHz

- Probes: 10:1 / 1:1

2. Frequency Counter

- Frequency Range: 0-10MHz

- Probes: 1:1

3. Universal Counter

4. Digital Volt Meter (D.V.M.)

52

5. Video Sweep Generator

REMARKS

procedure

ADJUSTMENT

Fig.

of

FREQUENCY

RESPONCE

ADJUSTMENT

in

6. Sinewave Generator

7. Video Pattern Generator

8. Monitor TV

9. DC Power Supply

10. VHS Blank Tape

11. VHS Alignment Tape

- Parts No.: VFJ8125H3F(PAL)

11.4.2. VCR SETTING

When no indication in the procedure, set each selector as follows.

1. TAPE SPEED: SP

2. CHANNEL: AV1/AV2

(Set to signal input terminal number)

11.4.3. ADJUSTMENTS

ITEM TP ADJ. MODE INPUT TAPE M. EQ. SPEC

PG

SHIFTER

ADJUSTMENT

VIDEO

FREQUENCY

RESPONSE

ADJUSTMENT

--- ---

VIDEO

OUT

--- SP/LP/EP

PLAYBACK

PLAYBACK

(SELFREC)

---

VIDEO

SWEEP

(See

Fig. E1

)

ALIGNMENT

TAPE

(PAL)

BLANK

TAPE

--- --- Refer to

OSCILLO

SCOPE/

VIDEO

SWEEP

GENERAT

OR

SP: 0+-1

(dB)

(90~110%)

LP: 0+-1

(dB)

(90~110%)

EP: 0+-3

(dB)

(70~140%)

(See Fig.

E2)

PG

SHIFTER

shown in

Refer to the

procedure

VIDEO

as shown

53

CONDITION:

BURST SIGNAL OFF / 75 ohm

TERMINATED

Fig. E1 Fig. E2

11.4.4. PG SHIFTER ADJUSTMENT / (AUTOMATIC)

Fig. E3

PROCEDURES FIP DISPLAY

Press the FF and EJECT Keys

simultaneously for 3 seconds.

Press the FF and EJECT Keys

simultaneously twice.

Press the EJECT key for 3

seconds.

Press the CH UP key once.

Insert the Alignment cassette

tape. (PAL:VFJ8125H3F)

When the sequence of the automatical adjustment

has been terminated, the following action has been

made.

*SUCCEED: The cassette tape is ejected.

*ERROR : The "F2"is displayed on the FIP.

(Check the Servo/Syscon circuit and

Cylinder unit.)

Release the Service mode by pressing the EJECT

and FF keys simultaneously in 6 times until the FIP

becomes normal indication.

11.4.5. VIDEO FREQUENCY RESPONSE ADJUSTMENT

Fig. E4

54

PROCEDURES FIP DISPLAY

Input the Video sweep signal.

(See Fig.E1)

Press the FF and EJECT Keys

simultaneously for 3 seconds.

Press the FF and EJECT Keys

simultaneously twice.

Press the EJECT key for 3

seconds.

Press the CH UP key until

"11" is displayed on FIP.

Insert the Self-recorded tape

and playback it. (SP/LP/EP

mode)

Connect the Oscilloscope to:

*CH1....Video Out (TW3002).

Press the "4" key on the remote controller.

(Confirm that TW6002 becomes high(5V)).

Adjust the Frequency response by pressing the

"2"(increase) and/or "8"(decrease) key on the

Remote Controller. (See Fig.E2)

Store the Adjusted value by pressing the "5" key

on the Remote

Controller.

Release the Service mode by pressing the EJECT

and FF keys

simultaneously in 6 times until the FIP becomes

normal indication.

11.4.6. LOCATION OF TEST POINTS & CONTROLS (MAIN PCB)

55

12. ABBREVIATIONS

56

INITIAL/LOGO ABBREVIATIONS

A A0~UP

ACLK

AD0~UP

ADATA

ALE

AMUTE

AREQ

ARF

ASI

ASO

ASYNC

ADDRESS

AUDIO CLOCK

ADDRESS BUS

AUDIO PES PACKET DATA

ADDRESS LATCH ENABLE

AUDIO MUTE

AUDIO PES PACKET REQUEST

AUDIO RF

SERVO AMP INVERTED INPUT

SERVO AMPOUTPUT

AUDIO WORD DISTINCTION

SYNC

B BCK

BCKIN

BDO

BLKCK

BOTTOM

BYP

BYTCK

C CAV

CBDO

CD

CDSCK

CDSRDATA

CDRF

CDV

CHNDATA

CKSL

CLV

COFTR

CPA

CPCS

CPDT

CPUADR

CPUADT

CPUIRQ

CPRD

CPWR

CS

CSYNCIN

CSYNCOUT

BIT CLOCK (PCM)

BIT CLOCK INPUT

BLACK DROP OUT

SUB CODE BLOCK CLOCK

CAP. FOR BOTTOM HOLD

BYPATH

BYTE CLOCK

CONSTANT ANGULAR

VELOCITY

CAP. BLACK DROP OUT

COMPACT DISC

CD SERIAL DATA CLOCK

CD SERIAL DATA

CD RF (EFM) SIGNAL

COMPACT DISC-VIDEO

CHANNEL DATA

SYSTEM CLOCKSELECT

CONSTANT LINEAR VELOCITY

CAP. OFF TRACK

CPU ADDRESS

CPU CHIP SELECT

CPU DATA

CPU ADDRESS LATCH

CPU ADDRESS DATA BUS

CPU INTERRUPT REQUEST

CPU READ ENABLE

CPU WRITE ENABLE

CHIPSELECT

COMPOSITE SYNC IN

COMPOSITE SYNC OUT

57

INITIAL/LOGO ABBREVIATIONS

D DACCK

DEEMP

DEMPH

DIG0~UP

DIN

DMSRCK

DMUTE

DO

DOUT0~UP

DRF

DRPOUT

DREQ

DRESP

DSC

DSLF

DVD

D/A CONVERTER CLOCK

DEEMPHASIS BIT ON/OFF

DEEMPHASIS SWITCHING

FL DIGIT OUTPUT

DATA INPUT

DM SERIAL DATA READ

CLOCK

DIGITAL MUTE CONTROL

DROP OUT

DATAOUTPUT

DATA SLICE RF (BIAS)

DROP OUT SIGNAL

DATA REQUEST

DATA RESPONSE

DIGITAL SERVO CONTROLLER

DATA SLICE LOOP FILTER

DIGITAL VIDEO DISC

E EC

ECR

ENCSEL

ETMCLK

ETSCLK

ERROR TORQUE CONTROL

ERROR TORQUE CONTROL

REFERENCE

ENCODER SELECT

EXTERNAL M CLOCK (81MHz/

40.5MHz)

EXTERNAL S CLOCK (54MHz)

F FBAL

FCLK

FE

FFI

FEO

FG

FSC

FSCK

FOCUS BALANCE

FRAME CLOCK

FOCUS ERROR

FOCUS ERROR AMP

INVERTED INPUT

FOCUS ERROR AMP OUTPUT

FREQUENCY GENERATOR

FREQUENCY SUB CARRIER

FS (384 OVER SAMPLING)

CLOCK

G GND COMMON GROUNDING

(EARTH)

H HA0~UP

HD0~UP

HINT

HRXW

HOST ADDRESS

HOST DATA

HOST INTERRUPT

HOST READ/WRITE

58

INITIAL/LOGO ABBREVIATIONS

I IECOUT

IPFRAG

IREF

ISEL

IEC958 FORMAT DATA

OUTPUT

INTERPOLATION FLAG

I (CURRENT) REFERENCE

INTERFACE MODE SELECT

L LDON

LPC

LRCK

LASER DIODE CONTROL

LASER POWER CONTROL

L CH/R CH DISTINCTION

CLOCK

M MA0~UP

MCK

MCKI

MCLK

MDATA

MDQ0~UP

MDQM

MLD

MPEG

MEMORY ADDRESS

MEMORY CLOCK

MEMORY CLOCK INPUT

MEMORY SERIAL COMMAND

CLOCK

MEMORY SERIAL COMMAND

DATA

MEMORY DATA INPUT/OUTPUT

MEMORY DATA I/O MASK

MEMORYSERIAL COMMAND

LOAD

MOVING PICTURE EXPERTS

GROUP

O ODC

OFTR

OSCI

OSCO

OSD

P P1~UP

PCD

PCK

PDVD

PEAK

PLLCLK

PLLOK

PWMCTL

PWMDA

PWMOA, B

OPTICAL DISC CONTROLLER

OFF TRACKING

OSCILLATOR INPUT

OSCILLATOR OUTPUT

ON SCREEN DISPLAY

PORT

CD TRACKING PHASE

DIFFERENCE

PLL CLOCK

DVD TRACKING PHASE

DIFFERENCE

CAP. FOR PEAK HOLD

CHANNEL PLL CLOCK

PLL LOCK

PWM OUTPUT CONTROL

PULSE WAVE MOTOR DRIVEA

PULSE WAVE MOTOR OUT A,

B

59

INITIAL/LOGO ABBREVIATIONS

R RE

RFENV

RFO

RS

RSEL

RST

RSV

READ ENABLE

RF ENVELOPE

RF PHASE DIFFERENCE

OUTPUT

(CD-ROM) REGISTER SELECT

RF POLARITY SELECT

RESET

RESERVE

S SBI0, 1

SBO0

SBT0, 1

SCK

SCKR

SCL

SCLK

SDA

SEG0~UP

SELCLK

SEN

SIN1, 2

SOUT1, 2

SPDI

SPDO

SPEN

SPRCLK

SPWCLK

SQCK

SQCX

SRDATA

SRMADR

SRMDT0~7

SS

STAT

STCLK

STD0~UP

STENABLE

STSEL

STVALID

SUBC

SBCK

SUBQ

SYSCLK

SERIAL DATA INPUT

SERIAL DATA OUTPUT

SERIAL CLOCK

SERIAL DATA CLOCK

AUDIO SERIAL CLOCK

RECEIVER

SERIAL CLOCK

SERIAL CLOCK

SERIAL DATA

FL SEGMENT OUTPUT

SELECTCLOCK

SERIAL PORT ENABLE

SERIAL DATA IN

SERIAL DATA OUT

SERIAL PORT DATA INPUT

SERIAL PORT DATA OUTPUT

SERIAL PORT R/W ENABLE

SERIAL PORT READ CLOCK

SERIAL PORT WRITE CLOCK

SUB CODE Q CLOCK

SUBCODE Q DATA READ

CLOCK

SERIAL DATA

SRAM ADDRESS BUS

SRAM DATA BUS 0~7

START/STOP

STATUS

STREAM DATA CLOCK

STREAM DATA

STREAM DATA INPUT ENABLE

STREAM DATA POLARITY

SELECT

STREAM DATAVALIDITY

SUB CODE SERIAL

SUB CODE CLOCK

SUB CODE Q DATA

SYSTEM CLOCK

60

INITIAL/LOGO ABBREVIATIONS

T TE

TIBAL

TID

TIN

TIP

TIS

TPSN

TPSO

TPSP

TRCRS

TRON

TRSON

V VBLANK

VCC

VCDCONT

VDD

VFB

VREF

VSS

TRACKING ERROR

BALANCE CONTROL

BALANCE OUTPUT 1

BALANCE INPUT

BALANCE INPUT

BALANCE OUTPUT 2

OP AMP INPUT

OP AMP OUTPUT

OP AMP INVERTED INPUT

TRACK CROSSSIGNAL

TRACKING ON

TRAVERSE SERVO ON

V BLANKING

COLLECTOR POWER SUPPLY

VOLTAGE

VIDEO CD CONTROL

(TRACKING

BALANCE)

DRAIN POWER SUPPLY

VOLTAGE

VIDEO FEED BACK

VOLTAGE REFERENCE

SOURCE POWER

SUPPLYVOLTAGE

W WAIT

WDCK

WEH

WSR

BUS CYCLE WAIT

WORD CLOCK

WRITE ENABLE HIGH

WORD SELECT RECEIVER

61

INITIAL/LOGO ABBREVIATIONS

X X

XALE

XAREQ

XCDROM

XCS

XCSYNC

XDS

XHSYNCO

XHINT

XI

XINT

XMW

XO

XRE

XSRMCE

XSRMOE

XSRMWE

XVCS

XVDS

XVSYNCO

X' TAL

X ADDRESS LATCH ENABLE

X AUDIO DATA REQUEST

X CD ROM CHIP SELECT

X CHIP SELECT

X COMPOSITE SYNC

X DATA STROBE

X HORIZONTAL SYNC OUTPUT

XH INTERRUPTREQUEST

X' TAL OSCILLATOR INPUT

X INTERRUPT

X MEMORY WRITE ENABLE

X' TAL OSCILLATOR OUTPUT

X READ ENABLE

X SRAM CHIP ENABLE

X SRAM OUTPUT ENABLE

X SRAM WRITE ENABLE

X V-DEC CHIPSELECT

X V-DEC CONTROL BUS

STROBE

X VERTICAL SYNC OUTPUT

13. INPUT / OUTPUT CHART

13.1. INPUT / OUTPUT CHART FOR IC6001

13.2. TRUTH TABLE (EC/EP MODEL)

13.3. TRUTH TABLE (EB/EBL MODEL)

14. WAVEFORM TABLE

14.1. WAVEFORM

15. VOLTAGE CHART

16. INTERCONNECTION DIAGRAM

17. BLOCK DIAGRAM

17.1. POWER SUPPLY BLOCK DIAGRAM

17.2. VCR LUMINANCE & CHROMINANCE BLOCK DIAGRAM

17.3. VCR AUDIO BLOCK DIAGRAM

62

17.4. SYSCON & SERVO BLOCK DIAGRAM

17.5. DVD VIDEO BLOCK DIAGRAM

17.6. DVD OVERALL BLOCK DIAGRAM

17.7. DVD SERVO BLOCK DIAGRAM

17.8. DVD AUDIO BLOCK DIAGRAM

18. SCHEMATIC DIAGRAM

18.1. POWER PCB

18.2. MAIN PCB - AUDIO/VIDEO

18.3. MAIN PCB - I/O SECTION

18.4. MAIN PCB - SYSCON & SERVO

18.5. MAIN PCB - SYSCON & SERVO (ONLY REPD0024x)

18.6. AV DECODER PCB

18.7. FRONT PANEL PCB

18.8. TERMINAL PCB

19. PRINTED CIRCUIT BOARD

19.1. MAIN PCB (COMPONENT SIDE)

19.2. MAIN PCB (SOLDER SIDE)

19.3. MAIN PCB (COMPONENT SIDE - ONLY REPD0024x)

19.4. MAIN PCB (SOLDER SIDE - ONLY REPD0024x)

19.5. DECODER PCB (COMPONENT SIDE)

19.6. DECODER PCB (SOLDER SIDE)

19.7. POWER PCB

19.8. FRONT PCB

19.9. TERMINAL PCB

20. EXPLODED VIEWS

63

20.1. VCR CHASSIS PARTS SECTION

20.2. DVD CHASSIS PARTS SECTION

64

20.3. CASING PARTS SECTION

65

66

20.4. PACKING PARTS SECTION

67

21. REPLACEMENT PARTS LIST

Notes:

*Important safety notice:

Components identified by ; mark have special

characteristics important for safety.

Furthermore, special parts which have purposes of

fireretardant (resistors), high-quality sound (capacitors),

lownoise (resistors), etc. are used.

68

When replacing any of components, be sure to use only

manufactures specified parts shown in the parts list.

Do not use any part number shown on the Schematic

Diagramm for ordering. When you order a part,

please refer only to the PARTS LIST.

*Warning:

This product uses a laser diode.

Refer to caution statements.

*The marking (RTL) indicates the retention time is limited

for this item. After the discontinuation of this assembly in

production, it will no longer be available.

*PCB’s are identified by “ ” character.

Note: The *1, *2, *3, *4, *5, *6, *7, *8, *9, *10, *11, *12

in the Remarks column shows the models as

follows:

*1=NV-VP33EP-S

*2=NV-VP33EG-S

*3=NV-VP33EG-K

*4=NV-VP33EC-S

*5=NV-VP33EC-K

*6=NV-VP33EB-S

*7=NV-VP33EBL-S

*8=NV-VP28EC-S

*9=NV-VP28EG-S

*10=NV-VP23EP-S

*11=NV-VP23EC-S

*12=NV-VP23EG-S

No indication = all models

21.1. VIDEO MECHA CHASSIS UNIT

69

Ref. No. Part No. Part Name & Description Pcs Remarks

1 VEG1642-DKIT RDD CYLINDER 1

2 VEM0750 CAPSTAN UNIT 1

3 L1AZ00000004 FE HEAD UNIT 1

4 VDG1510 INTERMEDIATE GEAR 1

5 VDG1511-4 MAIN CAM GEAR 1

6 VDG1512 IDLER GEAR 1

7 VDG1512 IDLER GEAR 1

8 VDG1514-1 CHANGE GEAR 1

9 VDR0372 REEL TABLE 1

10 VDR0372 REEL TABLE 1

11 VDV0391-2 CAPSTAN BELT 1

12 VMB3550 CHANGE GEAR SPRING 1

14 VMD4252 OPENER PIECE 1

15 VMD4253 LED PRISM 1

17 VML3624-1 MAIN LEVER 1

18 VML3626-1 PINCH CHARGE ARM 1

19 VML3632 IDLER ARM 1

20 VMX3092 P4 CAP 1

21 VDB1431 TENSION ARM BOSH 1

22 VEM0796 LOADING MOTOR UNIT 1

23 VDG1637 WORM GEAR 1

24 VMD4987 WORM BEARING 1

25 VXA7105-2 SUPPLY SHAFT HOLDER UNIT 1

26 VXA7106-2 TAKE UP SHAFT HOLDER UNIT 1

27 L1AE00000036 AC HEAD UNIT 1

28 VXA7311 SECTOR GEAR UNIT 1

29 VXL3107 SUPPLY LOADING ARM UNIT 1

30 VXL3108 TAKE UP LOADING ARM UNIT 1

31 VXL3109-4 PINCH ARM UNIT 1

32 VXL3110 P5 ARM UNIT 1

33 VXL3111-1 TENSION ARM UNIT 1

34 VMB3547-3 TENSION SPRING 1

35 VXL3112 SUPPLY BRAKE ARM UNIT 1

36 VXL3113 TAKE UP BRAKE ARM UNIT 1

37 VMB3548-2 TAKE UP BRAKE SPRING 1

38 VXL3124-2 CHANGE LEVER UNIT 1

39 VXP2133-1 CENTRE CLUTCH UNIT 1

40 VXP2168 TORQUE CLUTCH UNIT 1

41 VMD4983 FPC HOLDER 1

50 VMA0L25 TOP PLATE 1

51 VMD4255-4 SIDE PLATE (L) 1

52 VMD4254-4 SIDE PLATE (R) UNIT 1

53 VML3706-1 OPENER LEVER 1

54 VXA7110-3 CASSETTE HOLDER UNIT 1

55 VXL3160 MAIN SHAFT UNIT 1

B1 VHD1044 SCREW 1

B2 XSN3+35 SCREW 1

B3 XTN26+7J SCREW 1

B4 XTN26+7J SCREW 1

B5 XTN26+7J SCREW 1

B6 XTV26+5F SCREW 1

B7 XTV26+5F SCREW 1

B8 XTV26+8FR SCREW 1

B9 XTV26+8FR SCREW 1

70

Ref. No. Part No. Part Name & Description Pcs Remarks

B10 VHD1066 SCREW 1

B11 VHD1066 SCREW 1

B12 VHD1185 SCREW 1

B13 VHD1095 SCREW 1

B14 VHD1117 SCREW 1

B15 VHD1117 SCREW 1

W1 VMX2208 WASHER 1

W2 VMX3196 WASHER 1

W3 VMX2699 WASHER 1

W4 VMX3196 WASHER 1

21.2. DVD MECHA CHASSIS UNIT

Ref. No. Part No. Part Name & Description Pcs Remarks

101 RXQ1241 TRV MOTOR UNIT 1

102 RMR1654-K MIDDLE CHASSIS 1

103 RMS0712-1 FIXED PIN 2

105 RMN0771 FFC HOLDER 1

108 RMG0545-A1 FLOATING RUBBER 4

112 RDG0499 TRV GEAR(A) 1

113 RMC0415 ADJUST SP. HOLDER(A) 3

116 RMEC0320 ADJUST SPRING 3

119 RMM0260 TRV DRIVE RACK 1

120 RMSC0710 DRIVE SHAFT 1

121 RMSC0711 GUIDE SHAFT 1

122 RHD17045 SCREW 2

123 VHD1224-C SCREW 3

124 RDG0500 TRV GEAR(B) 1

125 RDG0501 TRV GEAR(C) 1

126 RMEC0319 TRV GEAR SPRING 1

128 RGQ0280-K4 TRAY 1

129 RXQ0748 MECHA CHASSIS UNIT 1

129-1 XTW3+12S SCREW 1

129-2 KDF111E00093 OPEN SW 1

130 JSMC0048 MAGNET HOLDER 1

131 RMR1445-K CLAMP PLATE 1

132 RMR1447-X MAGNET HOLDER 1

133 XWG6FFY WASHER 1

134 RMR1446-X CLAMPER 1

138 RAF3113A-C OPU(4.16H) 1

139 REZ1616-2 INTERFACE FFC 26P 1

140 RQLCA0141 LASER CAUTION LABEL 1

141 RMG0561-T CUSHION RUBBER 1

143 REZ1615 MOTOR DRIVE FFC 1

21.3. CASING PARTS

71

Ref. No. Part No. Part Name & Description Pcs Remarks

201 TOP PANEL VP31ECS VGM2029-1 1 *1,*2,*4,*6,*7,*8,*9,*10,

*11,*12

201 TOP PANEL VGM2079-1 1 *3,*5

202 FRONT PANEL RYPD0021A-S 1 *1

202 FRONT PANEL RYPD0018A-S 1 *2

202 FRONT PANEL RYPD0018A-K 1 *3

202 FRONT PANEL RYPD0019A-S 1 *4

202 FRONT PANEL RYPD0019A-K 1 *5

202 FRONT PANEL RYPD0020A-S 1 *6,*7

202 FRONT PANEL RYPD0024A-S 1 *12

202 FRONT PANEL RYPD0025A-S 1 *11

202 FRONT PANEL RYPD0027A-S 1 *10

202 FRONT PANEL RYPD0022A-S 1 *9

202 FRONT PANEL RYPD0023A-S 1 *8

203 BOTTOM CHASSIS RMKD0005 1

204 BLINDER PANEL RGKD0013-S 1 *1,*2,*4,*6,*7,*8,*9,*10,

*11,*12

204 BLINDER PANEL RGKD0013-K 1 *3,*5

205 POWER BUTTON RGUD0012-S 1 *1,*2,*4,*6,*7,*8,*9,*10,

*11,*12

205 POWER BUTTON RGUD0012-K 1 *3,*5

206 DVD OC BUTTON RGUD0013-S 1 *1,*2,*4,*6,*7,*8,*9,*10,

*11,*12

206 DVD OC BUTTON RGUD0013-K 1 *3,*5

207 TIMER REC. CAP RGZD0001-Q 1

208 REAR PANEL RGRD0007A-A 1 *1,*2,*3,*4,*5

208 REAR PANEL RGRD0007A-B 1 *6,*7

208 REAR PANEL RGRD0007A-D 1 *10,*11,

*12

208 REAR PANEL RGRD0007A-C 1 *8,*9

210 FRONT ANGLE VMP7683 1

211 DVD SPACER(L) RMRD0002 1

212 DVD SPACER (R) RMRD0001 1

213 MECHA SPACER(R) VMX3229 1

214 MECHA SPACER(F) VMX3398 1

217 WIRE CABLE 2PIN REXD0001 1

218 FFC (7P) (CYLINDER) REZD0012 1

220 FFC (6P AC-HEAD) REZD0016 1

221 TRAY ORNAMENT RGKD0012-S 1 *1,*2,*4,*6,*7,*8,*9,*10,

*11,*12

221 TRAY ORNAMENT RGKD0012-K 1 *3,*5

222 FOOT VKA0364 2

223 FL HOLDER RMND0005 1

224 EARTH SPRING (T) VMC1534 2

228 PCB SUPPORT (POW) RMXD0005 1

229 PCB SPACER (MDL) RMXD0004 1

230 BARRIER(U) RMZD0002 1

232 PCB SPACER (POW) RMXD0003 1

B105 SCREW(R4MECH L) VHD1452-2 1

B201 SCREW VHD1094 2 *1,*2,*4,*6,*7,*8,*9,*10,

*11,*12

B201 SCREW VHD1041-1 2 *3,*5

B209 SCREW(R4MECH S) VHD1453-2 3

72

Ref. No. Part No. Part Name & Description Pcs Remarks

B217 SCREW (DECODER) RHD30090-1 7

B221 SCREW (DVD) VHD1770 4

B222 SCREW (TUNER) XSN3+4FJK 1

B223 SCREW (SCART) XTB4+10GFJK 1

B225 SCREW XTV26+6FFJ 1

B230 SCREW VHD0690-1 5

B230 SCREW VHD0690-1 3

B238 SCREW (MECHA) XTW3+10PN 1

B239 SCREW (SPRING) XTV26+6FFJ 1

B240 SCREW (FRONT PCB) RHD26046 6

21.4. PACKING PARTS

Ref. No. Part No. Part Name & Description Pcs Remarks

PC1 PACKING CASE RPGD0022-1 1 *1,*2,*4,*6,*7,*8,*9,*10,

*11,*12

PC1 PACKING CASE RPGD0023-1 1 *3,*5

PC2 MIRAMAT BAG RPFD0004 1

PC3 CUSHION L RPND0007A 1

PC4 CUSHION R RPND0007B 1

A1 REMOTE EUR7720X50 1 *1,*2,*3,*4,*5,*8,*9

A1 REMOTE EUR7720X60 1 *6,*7

A1 REMOTE EUR7720X70 1 *10,*11,

*12

A2 BATTERY COVER UR77EC2003 1

A3 POWERCORD RJA0043-1C 1

A3 POWERCORD RJA0044-3C 1

A4 PE-BAG RPFD0001 1 *1,*2,*3,*4,*5,*8,*9,*10,

A4 PAPER BAG RPFD0003 1 *6,*7

A5 O/I BOOK ENG CONT RQTD0138-A 1 *1,*2,*3,*4,*5,*8,*9,*10,

A5 O/I BOOK RUS RQTD0145-R 1 *1,*10

A5 O/I BOOK POL RQTD0146-Q 1 *1,*10

A5 O/I BOOK CZE RQTD0147-S 1 *1,*10

A5 O/I BOOK HUN RQTD0148-T 1 *1,*10

A5 O/I BOOK GER RQTD0134-D 1 *2,*3,*4,*5,*8,*9,*11,*12

A5 O/I BOOK ITA RQTD0135-V 1 *2,*3,*4,*5,*8,*9,*11,*12

A5 O/I BOOK DUT RQTD0136-H 1 *2,*3,*4,*5,*8,*9,*11,*12

A5 O/I BOOK FRE PAL RQTD0137-C 1 *4,*5,*8,*11

A5 O/I BOOK SPA RQTD0139-M 1 *4,*5,*8,*11

A5 O/I BOOK POR RQTD0140-U 1 *4,*5,*8,*11

A5 O/I BOOK ENG CONT RQTD0138-A 1 *1,*2,*3,*4,*5,*8,*9,*10,*

A5 O/I BOOK FIN RQTD0141-K 1 *4,*5,*8,*11

A5 O/I BOOK SWE RQTD0142-Z 1 *4,*5,*8,*11

A5 O/I BOOK DAN RQTD0143-J 1 *4,*5,*8,*11

A5 O/I BOOK ENG UK RQTD0144-B 1 *6,*7

A6 RF CABLE K1TWACC00001 1

*1,*2,*3,*4,*5,*8,*9,*10,

*11,*12

*6,*7

*11,*12

*11,*12

11,*12

73

Ref. No. Part No. Part Name & Description Pcs Remarks

A7 AV CORD K2KA6CA00001 1 *1,*2,*3,*4,*5,*8,*9,*10,

*11,*12

A8 ACC.BOX VPK2246 1

21.5. PRINTED CIRCUIT BOARD

Ref. No. Part No. Part Name & Description Pcs Remarks

TU7601 TUNER ENGF7501GF 1 *2,*3,*4,*5,*8,*9,*11,*12

TU7601 TUNER ENGF7502GF 1 *1,*10

TU7601 TUNER ENG57D02G1F 1 *6

TU7601 TUNER ENG57D03G1F 1 *7

MAIN PCB REPD0010A 1 (RTL)

*2,*3,*9

MAIN PCB REPD0024A 1 (RTL)

*2,*3,*9

MAIN PCB REPD0010B 1 (RTL)

*4,*5,*8

MAIN PCB REPD0024B 1 (RTL)

*4,*5,*8

MAIN PCB REPD0010C 1 (RTL)

*6

MAIN PCB REPD0024C 1 (RTL)

*6

MAIN PCB REPD0010D 1 (RTL)

*7

MAIN PCB REPD0024D 1 (RTL)

*7

MAIN PCB REPD0010E 1 (RTL)

*1

MAIN PCB REPD0024E 1 (RTL)

*1

MAIN PCB REPD0010F 1 (RTL)

*12

MAIN PCB REPD0010G 1 (RTL)

*11

MAIN PCB REPD0010J 1 (RTL)

*10

DECODER PCB REPD0011A 1 (RTL)

POWER PCB REPD0012A 1 (RTL)

FRONT SWITCH PCB REPD0013A 1 (RTL)

FRONT JACK PCB REPD0014A 1 (RTL)

TERMINAL PCB REP3606A-C 1 (RTL)

21.6. ELECTRICAL PARTS

74

Ref. No. Part No. Part Name & Description Pcs Remarks

C1001 CHIP CAPACITOR F1H1H1030007 1

C1003 CHIP CAPACITOR F1H1H1030007 1

C1004 ALU ELEC CAPACITOR ECEA1CKA470B 1

C1005 ALU ELEC CAPACITOR ECEA1CKA470B 1

C1107 ALU ELEC CAPACITOR F2A1V3300027 1

C1108 CHIP CAPACITOR F1H1A2240004 1

C1109 CHIP CAPACITOR F1H1H1030006 1

C1112 CAPACITOR F0C2G473A022 1

C1121 CERAMIC CAPACITOR F1BAF101A013 1

C1122 CERAMIC CAPACITOR ECKWNA102MEV 1

C1123 CERAMIC CAPACITOR F1BAF101A013 1

C1124 CERAMIC CAPACITOR F1BAF101A013 1

C1125 X2 CAPACITOR ECQU2A683MVA 1

C1126 X2 CAPACITOR ECQU2A683MVA 1

C1142 ALU ELEC CAPACITOR EEUEB2G330E 1

C1200 CHIP CAPACITOR F1H1C104A008 1

C1220 CAPACITOR EEUFM1A471B 1

C1221 ALU ELEC CAPACITOR ECA1AHG221B 1

C1230 CAPACITOR EEUFM1H220B 1

C1240 CAPACITOR EEUFM1A681B 1

C1241 ALU ELEC CAPACITOR ECA1AHG221B 1

C1250 CAPACITOR EEUFM1E471B 1

C1251 ALU ELEC CAPACITOR ECA1EHG101B 1

C1260 CAPACITOR EEUFM1A122B 1

C1261 ALU ELEC CAPACITOR F2A1A2210012 1

C1270 CAPACITOR EEUFM1H220B 1

C1280 CAPACITOR EEUFM1A471B 1

C1290 ALU ELEC CAPACITOR EEUFM1E221B 1

C1291 ALU ELEC CAPACITOR ECA1EHG101B 1

C1320 ALU ELEC CAPACITOR ECEA0JKA221B 1

C1321 CHIP CAPACITOR F1H1C104A008 1

C1340 ALU ELEC CAPACITOR ECEA0JKA221B 1

C1341 CHIP CAPACITOR F1H1C104A008 1

C1360 ALU ELEC CAPACITOR ECEA0JKA221B 1

C1362 ALU ELEC CAPACITOR ECEA1AKA470B 1

C1364 CHIP CAPACITOR F1H1H1030007 1

C1390 ALU ELEC CAPACITOR F2A1C221A019 1

C1501 CHIP CAPACITOR F1H1H1030007 1

C1602 ALU ELEC CAPACITOR ECEA0JKA101B 1

C1604 ALU ELEC CAPACITOR ECEA1AKA220B 1

C1606 CHIP CAPACITOR F1H1H1030007 1

C1607 ALU ELEC CAPACITOR ECEA0JKA470B 1

C1608 CHIP CAPACITOR F1H1E104A030 1

C2501 CHIP CAPACITOR F1H1H1030007 1

C2504 CHIP CAPACITOR ECJ1VB1C563K 1

C2505 CHIP CAPACITOR ECJ1VB1C563K 1

C2506 CHIP CAPACITOR ECJ1VB1C563K 1

C2507 CHIP CAPACITOR ECJ1VB1C563K 1

C2508 CHIP CAPACITOR F1H1C104A042 1

C2509 CHIP CAPACITOR F1H1A105A004 1

C2510 CHIP CAPACITOR F1H1H330A736 1

C2511 ALU ELEC CAPACITOR ECEA0JKN220B 1

C2512 ALU ELEC CAPACITOR ECEA1EKA4R7B 1

75

Ref. No. Part No. Part Name & Description Pcs Remarks

C2513 CHIP CAPACITOR ECJ1VB1H392K 1

C2514 CHIP CAPACITOR F1H1E104A030 1

C2515 CHIP CAPACITOR F1H1C104A042 1

C2516 CHIP CAPACITOR F1H1A2240004 1

C2517 CHIP CAPACITOR F1H1E223A029 1

C2518 CHIP CAPACITOR F1H1E223A029 1

C2519 CHIP CAPACITOR F1H1C104A042 1

C2520 CHIP CAPACITOR F1H1H1020005 1

C2521 ALU ELEC CAPACITOR ECEA1CKA220B 1

C2522 ALU ELEC CAPACITOR F2A0J471A016 1

C2523 CHIP CAPACITOR F1H1C104A042 1

C2524 CHIP CAPACITOR F1H1C104A042 1

C2525 CHIP CAPACITOR F1H1C104A042 1

C2526 CHIP CAPACITOR F1H1E104A030 1

C2527 CHIP CAPACITOR F1H1H182A219 1

C2529 CHIP CAPACITOR F1H1A105A004 1

C2530 ALU ELEC CAPACITOR EEUFM1E221B 1

C3001 CHIP CAPACITOR F1H1H1510001 1

C3002 CHIP CAPACITOR F1H0J1050012 1

C3003 CHIP CAPACITOR F1H1C104A042 1

C3005 CHIP CAPACITOR F1H1H2700003 1

C3006 CHIP CAPACITOR F1H1C104A042 1

C3007 CHIP CAPACITOR F1J1A105A003 1

C3008 ALU ELEC CAPACITOR ECEA1EKA4R7B 1

C3010 CHIP CAPACITOR F1J1A105A003 1

C3011 CHIP CAPACITOR F1H1H1030007 1

C3012 ALU ELEC CAPACITOR ECEA0JKA470B 1

C3014 CHIP CAPACITOR F1H1A105A004 1

C3015 CHIP CAPACITOR F1H0J1050012 1

C3017 CHIP CAPACITOR F1H1C104A042 1

C3019 CHIP CAPACITOR F1H1C104A042 1

C3020 ALU ELEC CAPACITOR ECEA1HKA3R3B 1

C3021 ALU ELEC CAPACITOR ECEA1CKA100B 1

C3023 CHIP CAPACITOR F1H1H1030006 1

C3024 CHIP CAPACITOR ECJ1VB1H331K 1

C3025 CHIP CAPACITOR F1H1C104A042 1

C3026 ALU ELEC CAPACITOR ECEA0JKA470B 1

C3027 ALU ELEC CAPACITOR ECEA1HKA010B 1

C3028 ALU ELEC CAPACITOR ECEA1HKA4R7B 1

C3029 ALU ELEC CAPACITOR ECEA1HKAR47B 1

C3030 CHIP CAPACITOR F1H1E223A029 1

C3031 CHIP CAPACITOR F1H1C333A041 1

C3032 ALU ELEC CAPACITOR ECEA1HKA3R3B 1

C3033 CHIP CAPACITOR F1H1C104A042 1

C3034 ALU ELEC CAPACITOR ECEA1HKA2R2B 1

C3035 CHIP CAPACITOR F1H1E223A029 1

C3036 ALU ELEC CAPACITOR ECEA0JKA470B 1

C3037 CHIP CAPACITOR F1H1H1030007 1

C3038 CHIP CAPACITOR ECJ1VC1H030C 1

C3039 CHIP CAPACITOR F1H0J1050012 1

C3040 CHIP CAPACITOR F1H1H1030007 1

C3041 CHIP CAPACITOR F1H1H1030007 1

C3042 CHIP CAPACITOR F1H1E104A030 1

C3053 CHIP CAPACITOR F1H1H1030007 1

76

Ref. No. Part No. Part Name & Description Pcs Remarks

C3054 CHIP CAPACITOR F1H1H4700004 1

C3058 CHIP CAPACITOR F1H1C104A042 1

C3070 CHIP CAPACITOR F1H1C104A042 1

C4001 ALU ELEC CAPACITOR ECEA0JKA101B 1

C4003 CHIP CAPACITOR F1H1H472A219 1

C4004 CHIP CAPACITOR ECJ1VB1H122K 1

C4005 ALU ELEC CAPACITOR ECEA0JKA220B 1

C4006 ALU ELEC CAPACITOR ECEA1EKA4R7B 1

C4009 ALU ELEC CAPACITOR ECEA0JKA220B 1

C4011 CHIP CAPACITOR ECJ1VB1H822K 1

C4012 ALU ELEC CAPACITOR ECEA1HKA4R7B 1

C4013 CHIP CAPACITOR F1H1H1030007 1

C4016 CHIP CAPACITOR F1H1C104A042 1

C4017 ALU ELEC CAPACITOR ECEA1CKA100B 1

C4018 CHIP CAPACITOR F1J1A105A003 1

C4019 ALU ELEC CAPACITOR ECEA1CKA100B 1

C4020 CHIP CAPACITOR ECJ1VC1H221J 1

C4021 PLAST FILM CAPACITOR ECQB1H223JF3 1

C4022 CHIP CAPACITOR ECJ1VB1H152K 1

C4023 ALU ELEC CAPACITOR ECEA0JKA470B 1

C4024 CHIP CAPACITOR F1H1E223A029 1

C4026 ALU ELEC CAPACITOR ECEA0JKA470B 1

C4027 ALU ELEC CAPACITOR ECEA1HKA3R3B 1

C4301 ALU ELEC CAPACITOR ECEA1CKA101B 1

C4302 ALU ELEC CAPACITOR ECA1CAK470XB 1

C4303 ALU ELEC CAPACITOR ECA1CAK470XB 1

C4304 CHIP CAPACITOR F1H1E104A030 1

C4305 CHIP CAPACITOR F1H1H4700004 1

C4306 CHIP CAPACITOR ECJ1VC1H471J 1

C4307 CHIP CAPACITOR F1H1E104A030 1

C4308 CHIP CAPACITOR F1H1H4700004 1

C4309 CHIP CAPACITOR ECJ1VC1H471J 1

C4310 ALU ELEC CAPACITOR ECEA1CKA101B 1

C4311 ALU ELEC CAPACITOR ECEA0JKA470B 1

C4501 ALU ELEC CAPACITOR ECEA1CKA100B 1

C4502 ALU ELEC CAPACITOR ECEA1CKA100B 1

C4503 ALU ELEC CAPACITOR ECEA1CKA100B 1

C4504 PLAST FILM CAPACITOR ECQB1H473JF3 1

C4505 ALU ELEC CAPACITOR ECEA1AKA330B 1

C4506 ALU ELEC CAPACITOR ECEA1CKA100B 1

C4507 ALU ELEC CAPACITOR ECEA1CKA220B 1

C4508 PLAST FILM CAPACITOR ECQB1H153JF3 1

C4509 CHIP CAPACITOR F1H1C333A041 1

C4511 CHIP CAPACITOR F1H1H1030007 1

C4514 CHIP CAPACITOR F1H1H1030007 1

C4515 ALU ELEC CAPACITOR ECEA0JKA101B 1

C4516 CHIP CAPACITOR F1H1H1030007 1

C4517 CHIP CAPACITOR F1H1E104A030 1

C4519 CHIP CAPACITOR F1H1A2240004 1

C4520 PLAST FILM CAPACITOR ECQB1H153JF3 1

C4521 ALU ELEC CAPACITOR ECEA1CKA220B 1

C4522 ALU ELEC CAPACITOR ECEA1CKA100B 1

C4523 ALU ELEC CAPACITOR ECEA1AKA330B 1

C4524 PLAST FILM CAPACITOR ECQB1H473JF3 1

77

Ref. No. Part No. Part Name & Description Pcs Remarks

C4525 ALU ELEC CAPACITOR ECEA0JKA101B 1

C4526 CHIP CAPACITOR F1H1H1030006 1

C4527 CHIP CAPACITOR F1H1C104A042 1

C4528 CHIP CAPACITOR F1H1C104A042 1

C4529 ALU ELEC CAPACITOR ECEA1CKA100B 1

C4530 CHIP CAPACITOR ECJ2FB0J225K 1 *1,*2,*3,*4,*5,*6,*7

C4530 CHIP CAPACITOR F1J0J2250003 1 *8,*9,*10,*11,*12

C4531 CHIP CAPACITOR ECJ2FB0J225K 1 *1,*2,*3,*4,*5,*6,*7

C4531 CHIP CAPACITOR F1J0J2250003 1 *8,*9,*10,*11,*12

C4532 ALU ELEC CAPACITOR ECEA1CKA100B 1

C4533 ALU ELEC CAPACITOR ECEA1CKA100B 1

C4534 ALU ELEC CAPACITOR ECEA1CKA470B 1

C4535 CHIP CAPACITOR F1J1A105A003 1

C4536 ALU ELEC CAPACITOR ECEA1AKA220B 1

C4537 CHIP CAPACITOR F1H1E104A030 1

C4538 CHIP CAPACITOR F1H1C104A042 1

C4539 CHIP CAPACITOR F1H1H1030006 1

C4540 CHIP CAPACITOR F1H1C104A042 1

C4541 CHIP CAPACITOR F1H1C104A042 1

C4801 CHIP CAPACITOR F1H1H1010005 1

C4802 CHIP CAPACITOR F1H1H1010005 1

C4901 CHIP CAPACITOR ECJ1VB1H471K 1

C4902 CHIP CAPACITOR ECJ1VB1H471K 1

C4903 ALU ELEC CAPACITOR ECEA0JKA220B 1

C4904 CHIP CAPACITOR F1H1H4700004 1

C4905 CHIP CAPACITOR F1H1H4700004 1

C4906 CHIP CAPACITOR ECJ1VB1H471K 1

C4907 CHIP CAPACITOR ECJ1VB1H471K 1

C4908 CHIP CAPACITOR ECJ1VB1H471K 1

C4909 CHIP CAPACITOR ECJ1VB1H471K 1

C4910 CHIP CAPACITOR F1H1C104A042 1

C4911 CHIP CAPACITOR ECJ1VB1H471K 1

C4912 CHIP CAPACITOR F1H1H4700004 1

C4913 CHIP CAPACITOR F1H1H4700004 1

C4914 CHIP CAPACITOR ECJ1VB1H471K 1

C4915 CHIP CAPACITOR ECJ1VB1H471K 1

C4916 CHIP CAPACITOR ECJ1VB1H471K 1

C4917 CHIP CAPACITOR F1H1A105A004 1

C4918 CHIP CAPACITOR F1H1E104A030 1

C4919 CHIP CAPACITOR F1H1C104A042 1

C4920 CHIP CAPACITOR F1H1A105A004 1

C4921 ALU ELEC CAPACITOR ECEA0JKA221B 1

C4922 CHIP CAPACITOR F1H1A105A004 1

C4923 CHIP CAPACITOR F1H1E104A030 1

C4924 CHIP CAPACITOR F1H1A105A004 1

C4925 CHIP CAPACITOR F1H1E104A030 1

C4926 CHIP CAPACITOR F1H1A105A004 1

C4927 ALU ELEC CAPACITOR ECEA0JKA221B 1

C4928 CHIP CAPACITOR F1H1C104A042 1

C4929 CHIP CAPACITOR F1H1C104A042 1

C4930 CHIP CAPACITOR F1H1A105A004 1

C4931 CHIP CAPACITOR F1H1A105A004 1

C4932 CHIP CAPACITOR F1H1A105A004 1

C4933 CHIP CAPACITOR F1H1A105A004 1

78

Ref. No. Part No. Part Name & Description Pcs Remarks

C4934 ALU ELEC CAPACITOR F2A0J102A016 1

C4935 CHIP CAPACITOR F1H1E104A030 1

C4936 ALU ELEC CAPACITOR ECEA0JKA101B 1

C4937 CHIP CAPACITOR F1H1C104A042 1

C4938 ALU ELEC CAPACITOR ECEA0JKA331B 1

C4939 ALU ELEC CAPACITOR ECEA0JKA331B 1

C4940 ALU ELEC CAPACITOR ECEA0JKA470B 1

C4941 ALU ELEC CAPACITOR ECEA1AKA220B 1

C4942 CHIP CAPACITOR F1H1E104A030 1

C4943 CHIP CAPACITOR F1H1E104A030 1

C4944 CHIP CAPACITOR F1H1E104A030 1

C4945 CHIP CAPACITOR F1H1H1030007 1

C4946 CHIP CAPACITOR ECJ1VB1H471K 1

C4947 CHIP CAPACITOR ECJ1VB1H471K 1

C4948 CHIP CAPACITOR F1H1A105A004 1

C4949 CHIP CAPACITOR F1H1A105A004 1

C4951 CHIP CAPACITOR F1H1H4700004 1

C4972 ALU ELEC CAPACITOR ECEA0JKA470B 1

C4974 ALU ELEC CAPACITOR ECEA0JKA470B 1

C4975 CHIP CAPACITOR F1H1E104A030 1

C5001 CHIP CAPACITOR F1H1H1030006 1

C5002 CHIP CAPACITOR F1H1H1030006 1

C5003 CHIP CAPACITOR F1H1H1030006 1

C5004 CHIP CAPACITOR F1H1H1030006 1

C5005 CHIP CAPACITOR F1H1C104A042 1

C5006 ALU ELEC CAPACITOR ECEA0JKA470B 1

C5007 CHIP CAPACITOR F1H1E104A030 1

C6003 CHIP CAPACITOR ECJ1VB1H471K 1

C6004 CHIP CAPACITOR F1H1H1030007 1

C6005 CHIP CAPACITOR F1H1H1030007 1

C6006 CHIP CAPACITOR F1H1H330A736 1

C6007 CHIP CAPACITOR F1H1H1030007 1

C6008 ALU ELEC CAPACITOR F2A0J471A016 1

C6009 CHIP CAPACITOR ECJ1VC1H180J 1

C6010 CHIP CAPACITOR ECJ1VC1H180J 1

C6011 CHIP CAPACITOR ECJ1VC1H180J 1

C6012 CHIP CAPACITOR F1H1H1500009 1

C6015 ALU ELEC CAPACITOR ECEA1CKA100B 1

C6016 CHIP CAPACITOR F1H1H1030007 1

C6017 CHIP CAPACITOR ECJ1VB1H681K 1

C6022 CHIP CAPACITOR ECJ1VB1H221K 1

C6023 CHIP CAPACITOR F1H1A105A004 1

C6024 ALU ELEC CAPACITOR ECEA0JKA470B 1

C6025 CHIP CAPACITOR F1H1E104A030 1

C6029 CHIP CAPACITOR F1H1A105A004 1

C6032 ALU ELEC CAPACITOR ECEA0JKA470B 1

C6035 CHIP CAPACITOR F1H0J1050012 1

C6036 CHIP CAPACITOR ECJ1VB1H561K 1

C6037 CHIP CAPACITOR F1H1H330A736 1

C6038 CHIP CAPACITOR F1H1E104A030 1

C6039 CHIP CAPACITOR F1J1A105A003 1

C6040 CHIP CAPACITOR F1H1E104A030 1

C6041 CHIP CAPACITOR ECJ2YB0J475K 1 *1,*2,*3,*4,*5,*6,*7,*8,*9

C6042 CHIP CAPACITOR ECJ1VB1C563K 1

79

Ref. No. Part No. Part Name & Description Pcs Remarks

C6101 CHIP CAPACITOR F1H1E104A030 1

C6103 CHIP CAPACITOR F1H1E104A030 1