Panasonic KX-FT57E Service manual

ORDER NO. KM79905280C2

KX-FT57E

INTRODUCTION

PERSONAL FACSIMILE

KX-FT57E

(for United Kingdom)

WARNING

This service information is designed for experienced repair technicians only and is not designed for use by the general public.

It does not contain warnings or cautions to advise non-technical individuals of potential dangers in attempting to service a product.

Products powered by electricity should be serviced or repaired only by experienced professional technicians.

Any attempt to service or repair the product or products dealt with in this service information by anyone else could result in serious

injury or death.

C

1999 Kyushu Matsushita Electric Co., Ltd.

All rights reserved. Unauthorized copying and distribution is a violation of law.

|1 |

KX-FT57E

The serial number contents of 11 digits. The serial number may be found on the bottom of the unit.

INTRODUCTION

TABLE OF CONTENTS

Page

SAFETY PRECAUTIONS.......................................................................................................................................5

INSULATION RESISTANCE TEST ........................................................................................................................5

FOR SERVICE TECHNICIANS ..............................................................................................................................5

BATTERY CAUTION ..............................................................................................................................................6

FITTING CAUTION.................................................................................................................................................6

AC CAUTION..........................................................................................................................................................7

PERSONAL SAFETY PRECAUTIONS ..................................................................................................................8

SPECIFICATIONS..................................................................................................................................................9

CCITT NO.1 TEST CHART ..................................................................................................................................10

LOCATION OF CONTROLS ................................................................................................................................11

FEATURES...........................................................................................................................................................12

CONNECTION......................................................................................................................................................13

INSTALLATION ..............................................................................................................................................14~17

COMPONENT LOCATIONS.................................................................................................................................18

MAINTENANCE ITEMS..................................................................................................................................18, 19

CLEANING THE INSIDE OF THE UNIT...............................................................................................................20

TROUBLESHOOTING GUIDE

TROUBLESHOOTING SUMMARY ......................................................................................................................22

USER RECEIVERABLE ERRORS.......................................................................................................................23

TROUBLESHOOTING DETAILS................................................................................................................... 24~91

PROGRAMMING AND LISTS ....................................................................................................................... 92~97

TEST FUNCTIONS.........................................................................................................................................98, 99

ADJUSTMENTS

TABLE OF TEST EQUIPMENTS AND TOOLS ................................................................................................101

ADJUSTING THE FEEDER PRESSURE...........................................................................................................101

CCD ADJUSTMENTS ............................................................................................................................... 102~104

DOCUMENT READ START POSITION ADJUSTMENT............................................................................104, 105

|2 |

DISASSEMBLY INSTRUCTIONS

DISASSEMBLY INSTRUCTIONS ............................................................................................................. 108~116

HOW TO REPLACE THE FLAT PACKAGE IC ..................................................................................................117

CIRCUIT OPERATIONS

CONNECTION DIAGRAM..................................................................................................................................119

GENERAL BLOCK DIAGRAM ...................................................................................................................120, 121

CONTROL SECTION ................................................................................................................................ 122~127

FACSIMILE SECTION............................................................................................................................... 127~135

DIGITAL SPEAKER PHONE CIRCUIT ..............................................................................................................136

MODEM SECTION .................................................................................................................................... 137~143

EXPLANATION OF ANALOG SECTION BLOCK DIAGRAM.....................................................................144, 145

NCU SECTION ...........................................................................................................................................146~149

KX-FT57E

INTRODUCTION

ANALOG GATE ARRAY.............................................................................................................................150, 151

OPERATION PANEL..........................................................................................................................................152

LCD COG TYPE .................................................................................................................................................153

POWER SUPPLY BOARD SWITCHING SECTION...................................................................................154~156

FOR THE SCHEMATIC DIAGRAMS..................................................................................................................157

PRINTED CIRCUIT BOARD (DIGITAL BOARD) ................................................................................................159, 160

SCHEMATIC DIAGRAM (DIGITAL CIRCUIT).............................................................................................................161

SCHEMATIC DIAGRAM (ANALOG CIRCUIT)............................................................................................................162

PRINTED CIRCUIT BOARD (ANALOG BOARD) ...............................................................................................163, 164

SCHEMATIC DIAGRAM (CCD)...................................................................................................................................165

PRINTED CIRCUIT BOARD (CCD) ............................................................................................................................165

PRINTED CIRCUIT BOARD (SWITCHING POWER SUPPLY BOARD) ....................................................................166

SCHEMATIC DIAGRAM (SWITCHING POWER SUPPLY CIRCUIT) ........................................................................167

PRINTED CIRCUIT BOARD (OPERATION PANEL BOARD) ....................................................................................168

SCHEMATIC DIAGRAM (OPERATION PANEL CIRCUIT).........................................................................................169

TERMINAL GUIDE OF IC'S TRANSISTOR AND DIODES .........................................................................................170

TOOLS........................................................................................................................................................................ 171

CABINET, MECHANICAL AND ELECTRICAL PARTS LOCATION ...................................................................172~177

ACCESSORIES AND PACKING MATERIALS............................................................................................................178

REPLACEMENT PARTS LIST ........................................................................................................................... 179~189

|3 |

KX-FT57E

INTRODUCTION

Page

Safety Precautions ................................................................................... 5

Insulation Resistance Test ....................................................................... 5

For Service Technicians........................................................................... 5

Battery Caution......................................................................................... 6

Fitting a Plag to the Mains Lead............................................................... 6

AC Caution ............................................................................................... 7

Personal Safety Precautions .................................................................... 8

Specifications ........................................................................................... 9

ITU-T Test Chart No. 1........................................................................... 10

Location of Controls ............................................................................... 11

Features ................................................................................................. 12

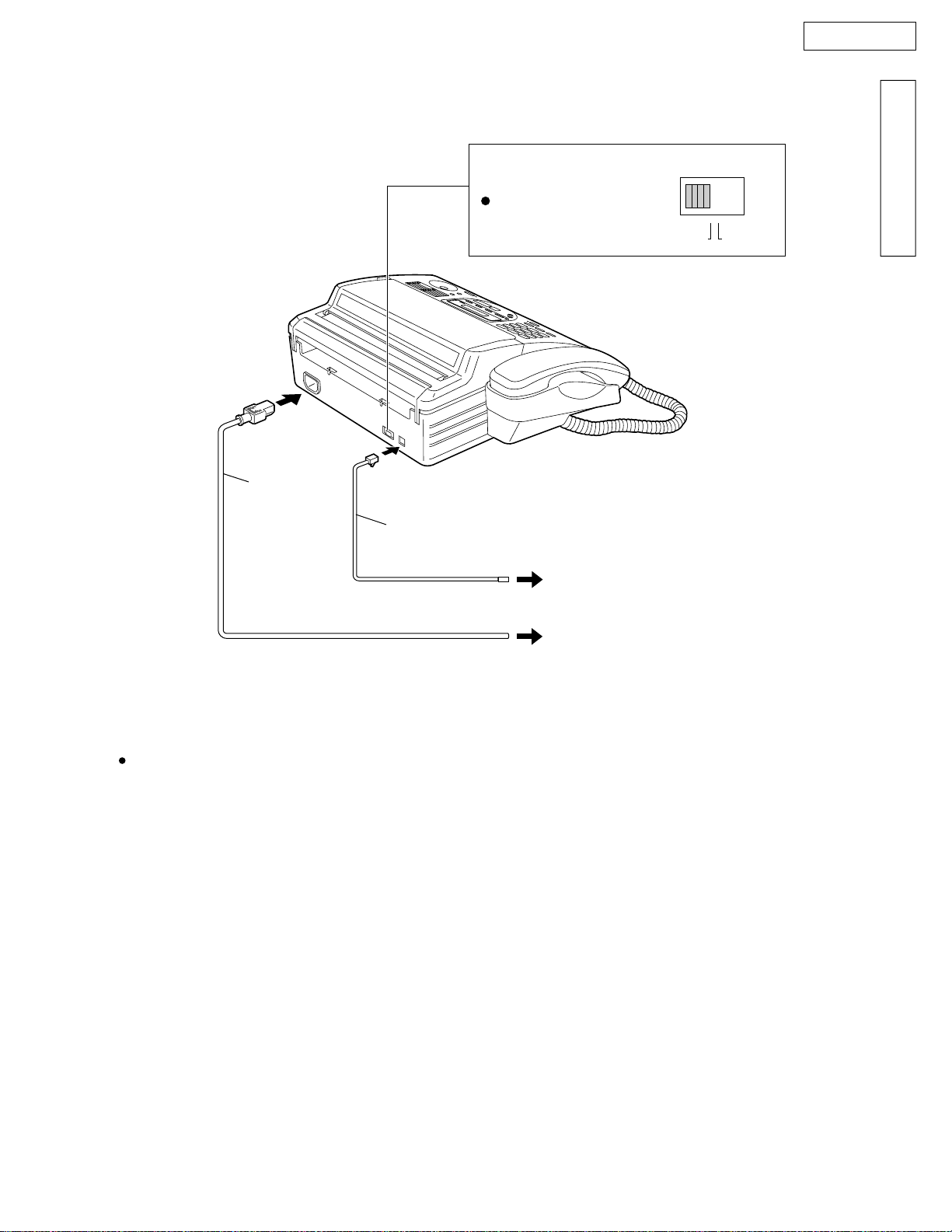

Connection ............................................................................................. 13

Installation ........................................................................................ 14~17

Component Locations ............................................................................ 18

Maintenance Items ........................................................................... 18, 19

Cleaning the Inside of the Unit ............................................................... 20

|4 |

KX-FT57E

SAFETY PRECAUTIONS

1. Before servicing, unplug the power cord to prevent an electric shock.

2. When replacing parts, use only the manufacturer’s recommended components.

3. Check the condition of the power cord. Replace if wear or damage is evident.

4. After servicing, be sure to restore the lead dress, insulation barriers, insulation papers, shields, etc.

5. Before returning the serviced equipment to the customer, be sure to perform the following insulation resistance

test to prevent the customer from being exposed to shock hazards.

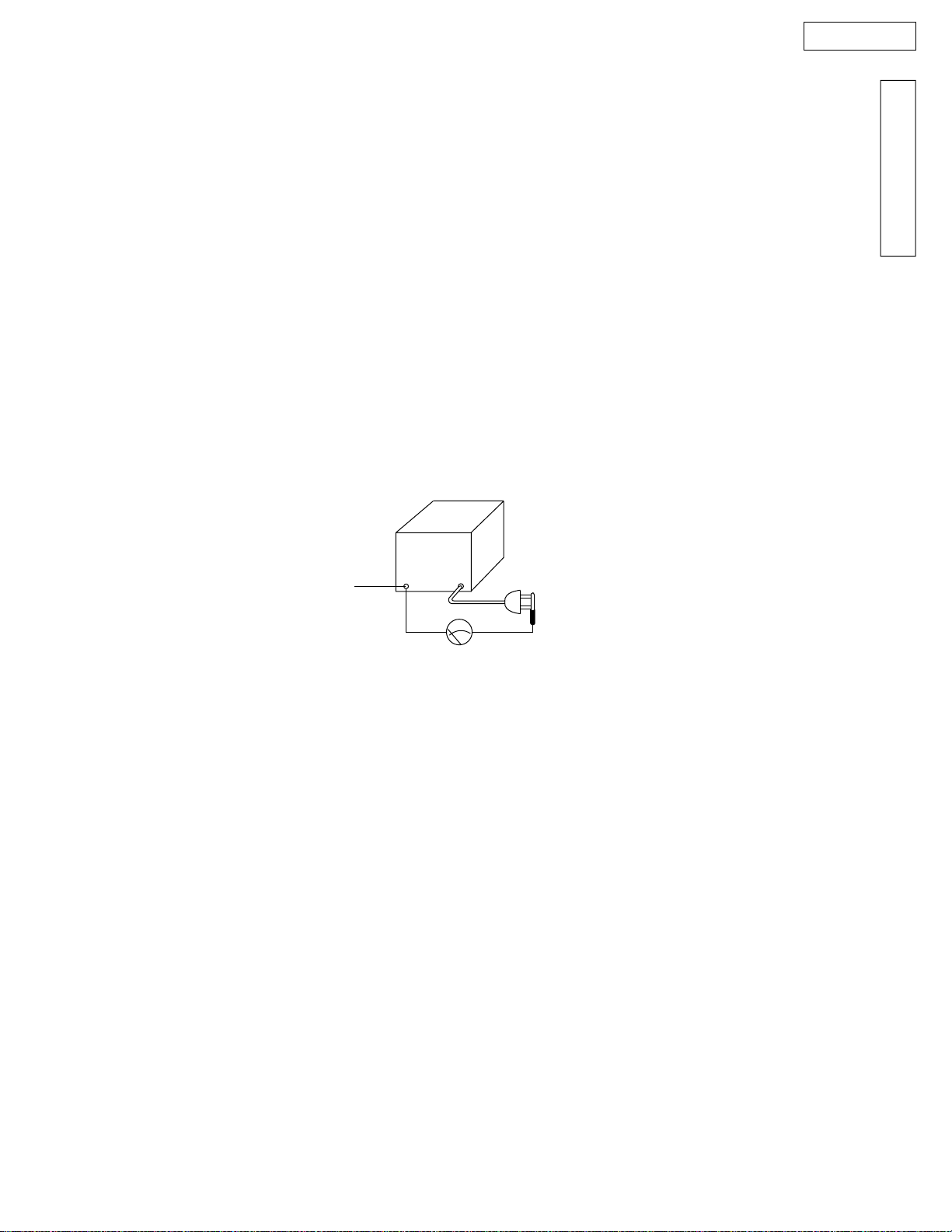

INSULATION RESISTANCE TEST

1. Unplug the power cord and short the two prongs of the plug with a jumper wire.

2. Turn on the power switch.

3. Measure the resistance value with an ohmmeter between the jumpered AC plug and each exposed metal cabinet part.

(screwheads, control shafts, handle brackets, etc.)

Note: Some exposed parts may be isolated from the chassis by design. These will read infinity.

4. If the measurement is outside the specified limits, there is a possibility of a shock hazard.

The equipment should be repaired and rechecked before it is returned to the customer.

INTRODUCTION

Exposed

metal

part

Ohmmeter

Resistance = more than 5M ¶

(at DC 500 V)

FOR SERVICE TECHNICIANS

ICs and LSIs are vulnerable to static electricity.

When repairing, the following precautions will help prevent recurring malfunctions.

1) Cover the plastic parts boxes with aluminum foil.

2) Ground the soldering irons.

3) Use a conductive mat on the worktable.

4) Do not touch the IC or LSI pins with bare fingers.

|5 |

KX-FT57E

BATTERY CAUTION

SAFETY CAUTIONS FOR LITHIUM BATTERY

(FOR UNITED KINGDOM)

THE LITHIUM BATTERY IS A CRITICAL COMPONENT

TYPE NUMBER CR2032 (BATT) MANUFACTURED BY MATSUSHITA

CR2032 (BATT) SONY

IT MUST NEVER BE SUBJECTED TO EXCESSIVE HEAT OR DISCHARGE. IT MUST THEREFORE ONLY BE FITTED

IN EQUIPMENT DESIGNED SPECIFICALLY FOR ITS USE.

REPLACEMENT BATTERIES MUST BE OF AN APPROVED TYPE AND MANUFACTURER AS INDICATED ABOVE.

THEY MUST BE FITTED IN THE SAME MANNER AND LOCATION AS THE ORIGINAL BATTERY, WITH THE CORRECT

POLARITY CONNECTIONS OBSERVED.

DO NOT ATTEMPT TO RE-CHARGE THE OLD BATTERY OR RE-USE IT FOR ANY OTHER PURPOSE. IT SHOULD BE

DISPOSED OF IN WASTE PRODUCTS DESTINED FOR BURIAL RATHER THAN INCINERATION.

WARNING

THE LITHIUM BATTERY IN THIS EQUIPMENT MUST ONLY BE REPLACED BY QUALIFIED PERSONNEL. WHEN

NECESSARY, CONTACT YOUR LOCAL PANASONIC SUPPLIER.

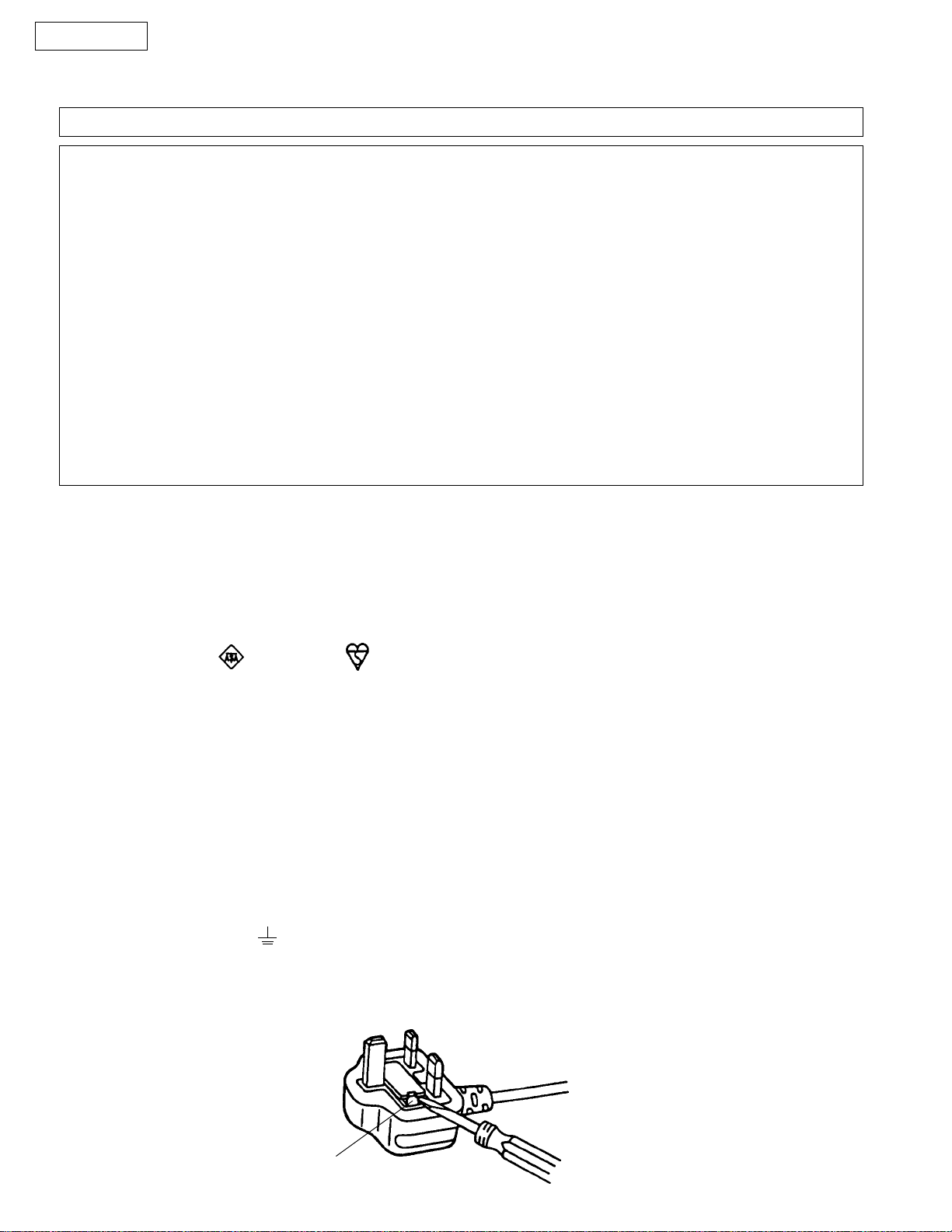

FITTING A PLUG TO THE MAINS LEAD

This appliance is supplied with a moulded three pin mains plug for your safety and convenience.

A5 amp fuse is fitted in this plug. Should the fuse need to be replaced please ensure that the replacement fuse has rating of

5 amps and that it is approved by ASTA or BSI to BS1362.

Check for the ASTA mark or the BSI mark on the body of the fuse.

If the plug contains a removable fuse cover you must ensure that it is refitted when the fuse is replaced. If you lose the fuse cover

the plug must not be used until a replacement cover is obtained. A replacement fuse cover can be purchased from your local

Panasonic Dealer.

IF THE FITTED MOULDED PLUG IS UNSUITABLE FOR THE SOCKET OUTLET IN YOUR HOME THEN THE FUSE SHOULD

BE REMOVED AND THE PLUG CUT OFF AND DISPOSED OF SAFELY.

THERE IS A DANGER OF SEVERE ELECTRICAL SHOCK IF THE CUT OFF PLUG IS INSERTED INTO ANY 13 AMP SOCKET.

If a new plug is to be fitted please observe the wiring code as shown below.

WARNING : THIS APPLIANCE MUST BE EARTHED.

IMPORTANT : The wires in this mains leads are colored in accordance with the following code:

Green-and-yellow: Earth

Blue: Neutral

Brown: Live

As the colors of the wires in the mains lead of this appliance may not correspond with the colored markings identifying the

terminals in your plug, proceed as follows.

The wire which is colored GREEN-AND-YELLOW must be connected to the terminal in the plug which is marked with the letter

E or by the safety earth symbol or colored GREEN or GREEN-AND-YELLOW.

The wire which is colored BLUE must be connected to the terminal in the plug which is marked with the letter N or colored

BLACK. The wire which is colored BROWN must be connected to the terminal in the plug which is marked with the letter L or

colored RED.

How to replace the fuse : Open the-fuse compartment with a screwdriver and replace the fuse and fuse cover.

FUSE

|6 |

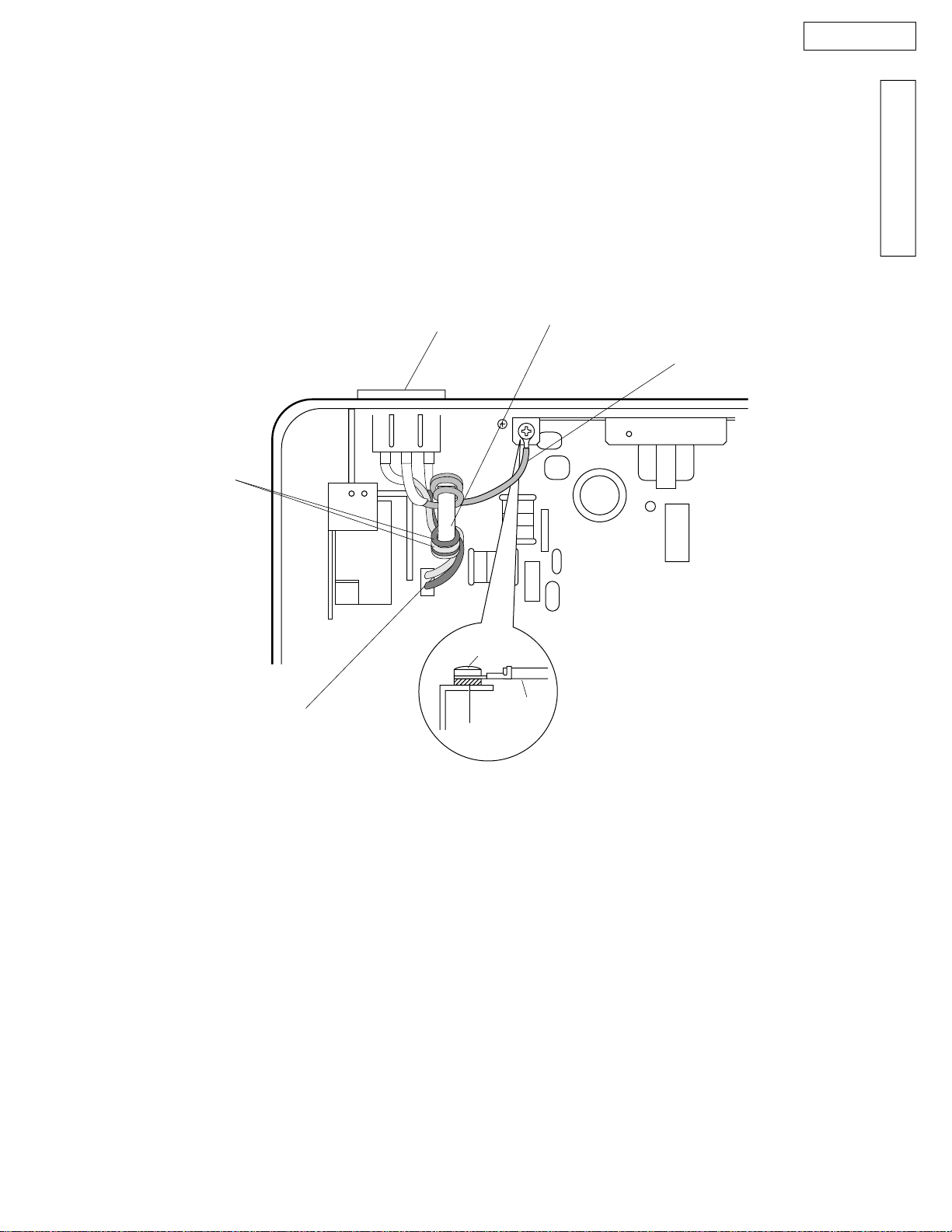

AC CAUTION

For your safety, before closing the lower cabinet , please check the following precautions.

The earth lead is fixed by the screw.

The AC connector is connected properly.

Wrap the AC leads around the core 2 times.

Wrap the Earth lead around the core 3 times.

(BOTTOM VIEW)

Earth Lead

AC lnlet

AC Lead

(Ferrite Core)

Earth Lead

KX-FT57E

INTRODUCTION

AC Connector

Screw

Washer

Earth

Lead

|7 |

KX-FT57E

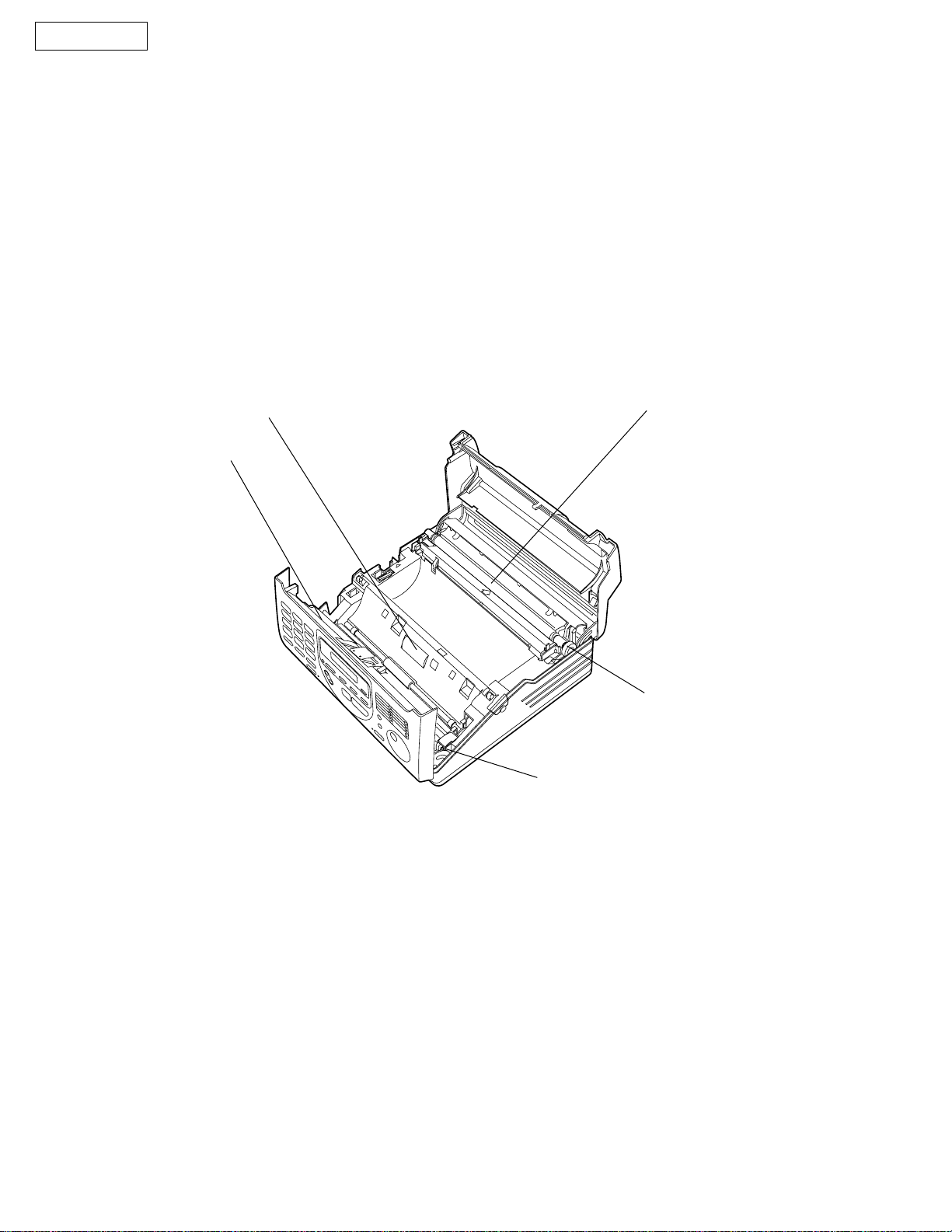

PERSONAL SAFETY PRECAUTIONS

Be careful not to let your hair, clothes, fingers, accessories, etc., become caught in any of the moving sections of the unit. These

are driven by the carriage gear, paper feed roller, pressure roller, eject roller, spur, pick-up roller, etc., which are driven by the

paper feed motor. The separation roller and document feed roller are rotated by the document feed motor via a gear. Also, the

spurs are metal and sharply pointed. Be careful not to touch them with your hands.

Separation roller

Document rollers

Recording paper roller

Recording paper gear

Document feed gear

|8 |

Applicable Lines:

KX-FT57E

SPECIFICATIONS

INTRODUCTION

Public Switched Telephone Network

Document Size:

Effective Scanning Width:

Printing Paper Size:

Effective Printing Width:

Transmission Time*:

Scanning Density:

Halftone Level:

Scanner Type:

Printer Type:

Data Compression System:

Modem Speed:

Operating Environment:

Dimensions (H ~W ~D):

Mass (Weight):

Max. 216 mm in width

Max. 600 mm in length

208 mm

216 mm ~ max. 50 m roll

208 mm

Approx.15 s/page (Original mode)

Approx.30 s/page (G3 Normal mode)

Horizontal : 8 pels/mm

Vertical : 3.85 lines/mm–Standard mode

7.7 lines/mm–Fine/Half tone mode

15.4 lines/mm–Super fine mode

64-level

CCD image sensor

Thermal printing

Modified Huffman (MH), Modified READ (MR)

9,600/7,200/4,800/2,400 bps; Automatic Fallback

5–35 , 45–85 % RH (Relative Humidity)

118 ~351 ~265 mm

Approx. 3.7 kg

Power Consumption:

Power Supply:

Memory Capacity:

* Transmission speed depends upon the contents of the pages,

resolution, telephone line conditions and capability of the other

party's machine.

The 15 second speed is based upon the CCITT No. 1 Test

Chart on the condition that memory transmission is performed.

** If both fax documents nad voice messages are recorded in

memory, the corresponding capacities above will be shortened.

*** Recording time may be reduced by the calling party's

background noise.

Standby: Approx. 6.5 W

Transmission: Approx. 16 W

Reception: Approx. 23 W (When receiving the CCITT No. 1 Test Chart)

Copy: Approx. 32 W (When copying the CCITT No. 1 Test Chart)

Maximum: Approx. 120 W

220–240 V AC, 50 Hz

Voice memory: Approx. 18 minutes of recording time including the greeting

message***

Fax memory: Approx. 13 pages of memory reception

(Based on the CCITT No. 1 Test Chart in standard resolution)

Note:

• Any details given in these instructions are subject to change without notice.

• The pictures and illustrations in these instructions may vary slightly from the actual product.

|9 |

KX-FT57E

CCITT NO.1 TEST CHART (Actual size)

|10 |

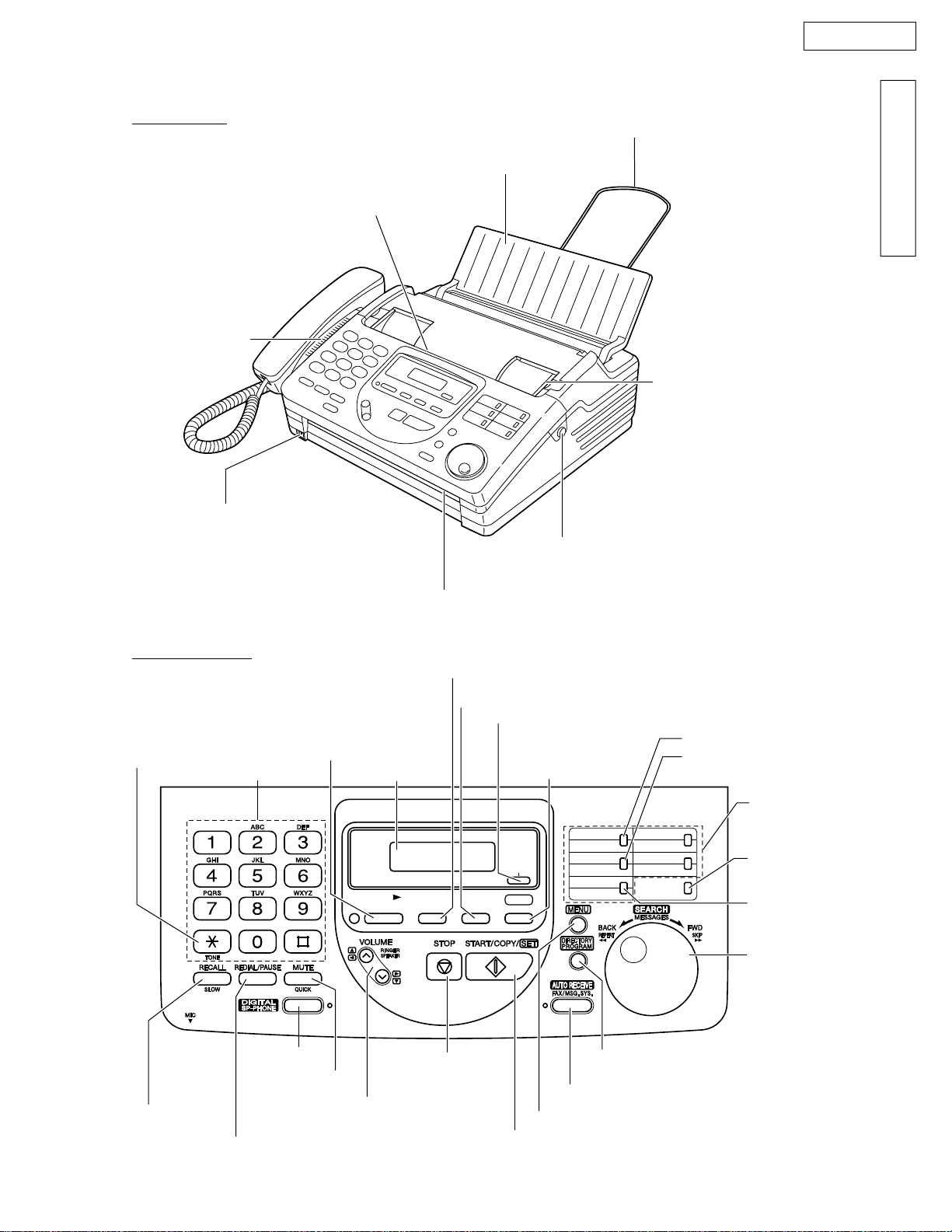

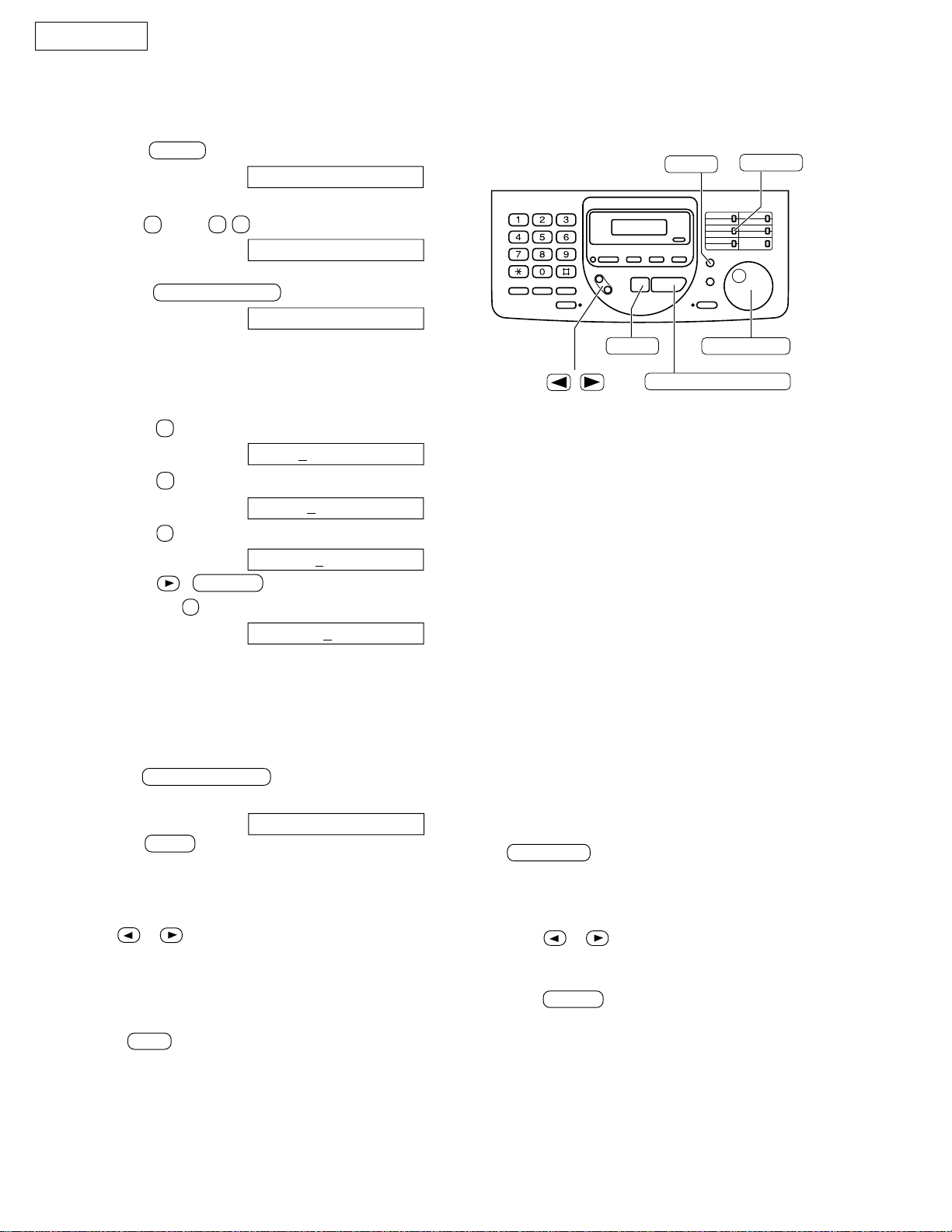

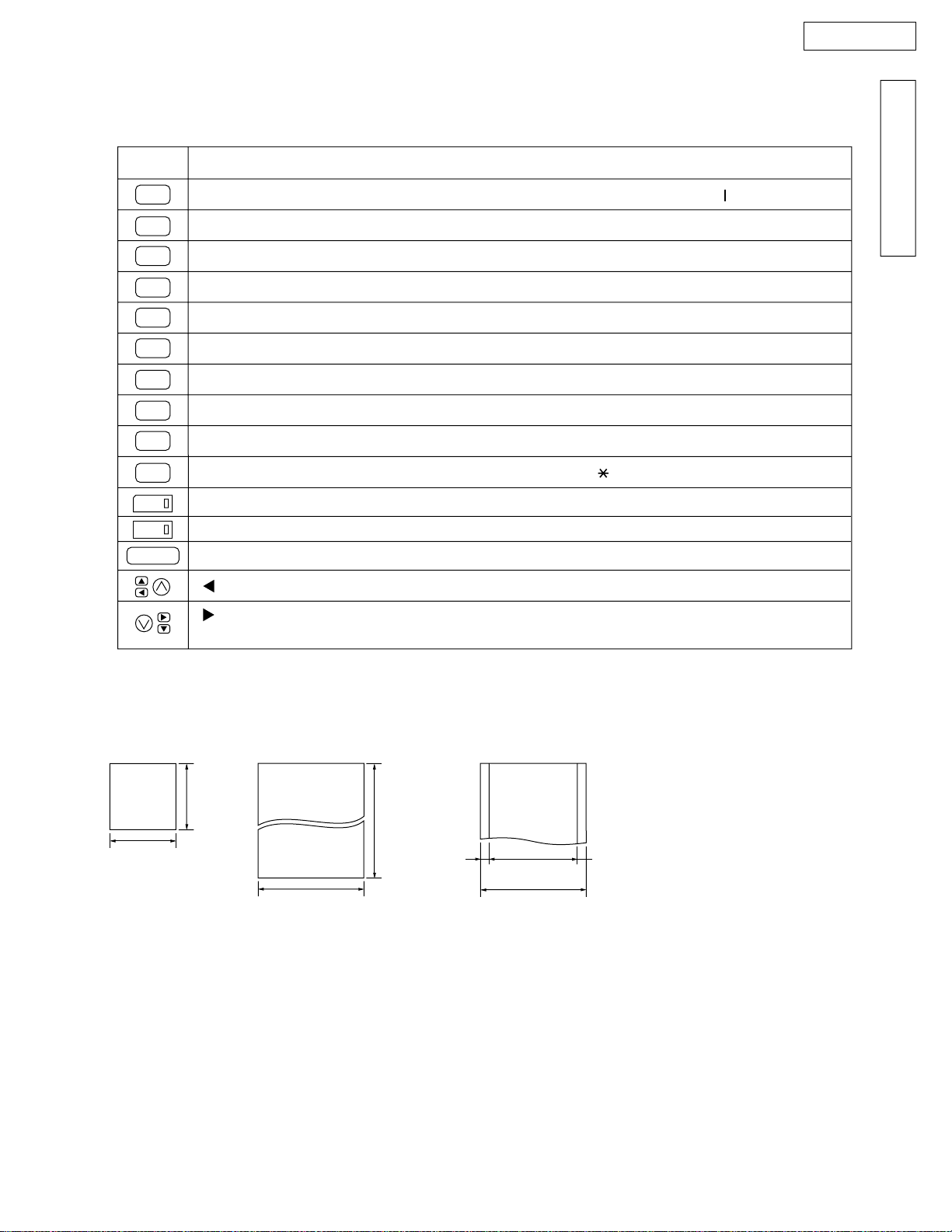

Front View

Speaker

KX-FT57E

LOCATION OF CONTROLS

INTRODUCTION

Paper stacker

Document feeder tray

Document entrance

Document guides

Microphone

Control panel

l

Used to change from pulse

to tone during dialing.

l

Used as a hook switch.

l

Used for slow play back.

l

Used to redial the last number dialed.

l

Used to insert a pause during dialing.

l

Used to play recorded

messages.

Dial keypad

l

Used for speaker

operation.

l

Used for voice muting.

l

Used for quick playback.

l

Used to adjust volumes.

l

Used to select feature

settings during programming.

Document exit

Display panel

PLAY

MESSAGES

Front lid open button

l

Used to record greeting messages.

l

Used to record memo messages and

a telephone conversation.

l

Used to erase recorded messages.

l

Used to erase your own recorded greeting messages.

l

Used to select a resolution.

l

Used to print a quick

reference.

l

Used to confirm a stored

telephone number.

RESOLUTION

CALLS

HELPERASERECORD

l

Used to stop an

operation or cancel

programming.

l

Used to initiate or exit programming.

l

Used to initiate fax transmission, reception or copying.

l

Used to store a setting during programming.

l

Used to insert a hyphen.

l

Used to insert one character or one

space.

1

HYPHEN

6

2

7

INSERT

3

8

SECRET

l

Used to store or edit names and

4

9

5

10

NAME/ TEL NO.

LOWER

telephone numbers.

l

Used to turn on/off the auto answer mode.

l

Used for the One-Touch Dial.

l

Used as command keys.

l

Used to confirm a stored

telephone number.

l

Used to select stations 6-10

for the One-Touch Dial.

l

Used to keep the telephone

number secret.

l

Used to search for a stored

name.

l

Used to select characters

during programming.

l

Used to select the basic features

during programming.

l

Used to skip and/or repeat the

recorded messages in the

answering device.

|11 |

KX-FT57E

FEATURES

General

Desktop type

LCD (Liquid Crystal Display) readout

Automatic paper cutter

Silent ring fax recognition system

Help function

Copier function

Facsimile

Automatic document feeder (up to 15 sheets)

64-level halftones

Resolution: standard/fine/super fine/halftone

Delayed transmission

Overseas transmission mode

Remote fax receiving using an extension phone

Junk mail prohibitor

Digital answering system

Voice mailbox

Tone remote control system

Integrated telephone system

One-touch dialer (10 phone number)

50-station speed dialer

Electronic telephone directory

Digital Hands-free speaker phone

|12 |

CONNECTION

KX-FT57E

INTRODUCTION

Power cord

Dialing mode switch:

Set to TONE.

If you cannot dial,

set to PULSE.

Telephone line cord

DIALING MODE

PULSETONE

To a single telephone line socket

To the power outlet

(220-240V)

Note:

This machine should be connected to a nearby power outlet that is easily accessible.

|13 |

KX-FT57E

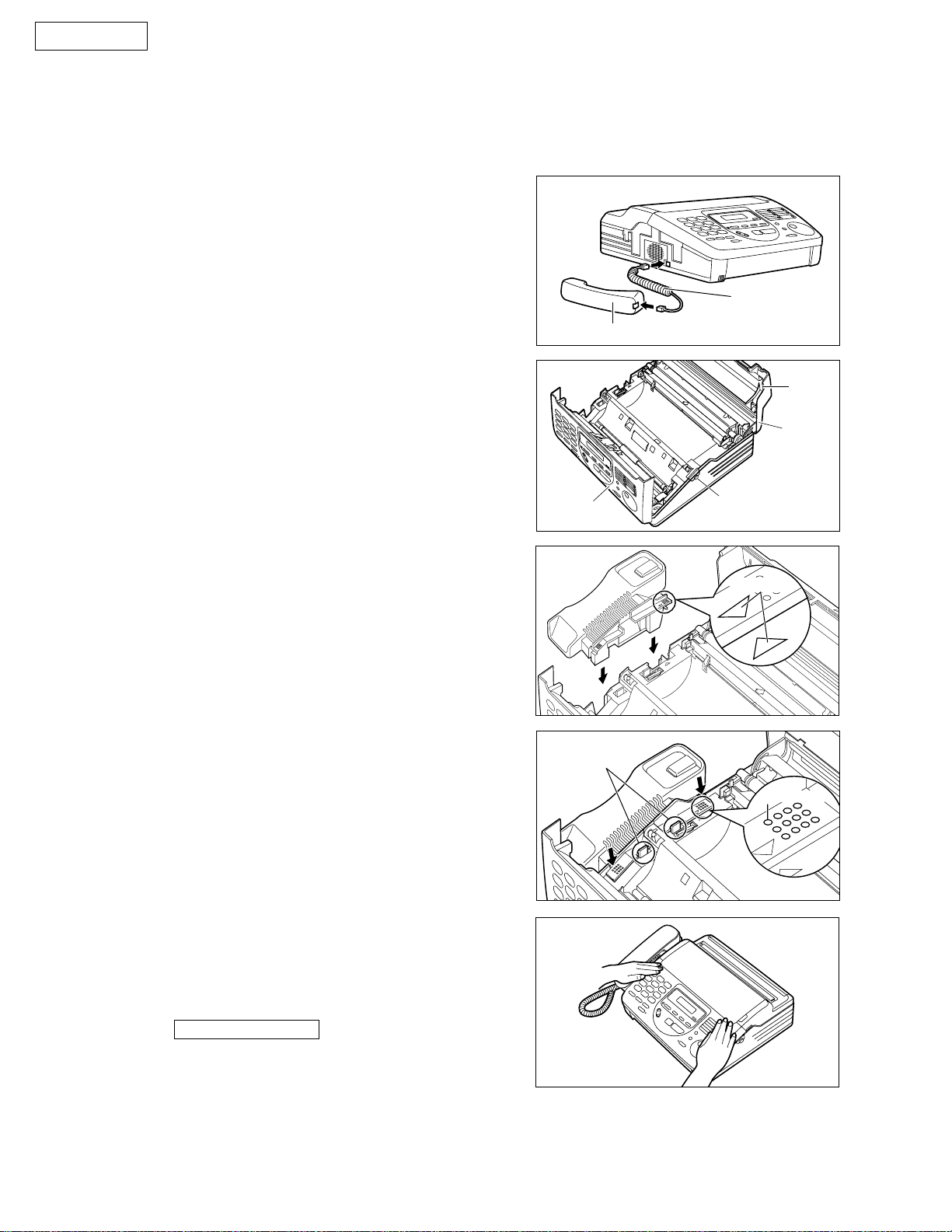

1. Installing the handset cradle

Connect the handset cord.

1

Open the front lid by pressing the front lid open

2

3

button.

Open the back lid by lifting up the tabs located

on the both side.

INSTALLATION

Handset

Front lid

Handset cord

Tab

Black lid

Front lid open

button

4

5

6

Insert the handset cradle by matching the triangles.

Press down on the dotted mark on the handset

cradle until it clicks into place.

Make sure the two hooks lock the handset

•

cradle firmly.

Place the handset on the handset cradle and close

the lids securely.

If the handset cradle is not installed correctly, the

•

unit will show the following message when the

power is switched on.

CHECK CRADLE

Check steps 4 and 5 again.

Triangles

Hooks

Dotted mark

Note:

To save space or when using the unit mainly for faxes, you can use the DIGITAL SP-PHONE button on the

•

unit without the handset and cradle.

|14 |

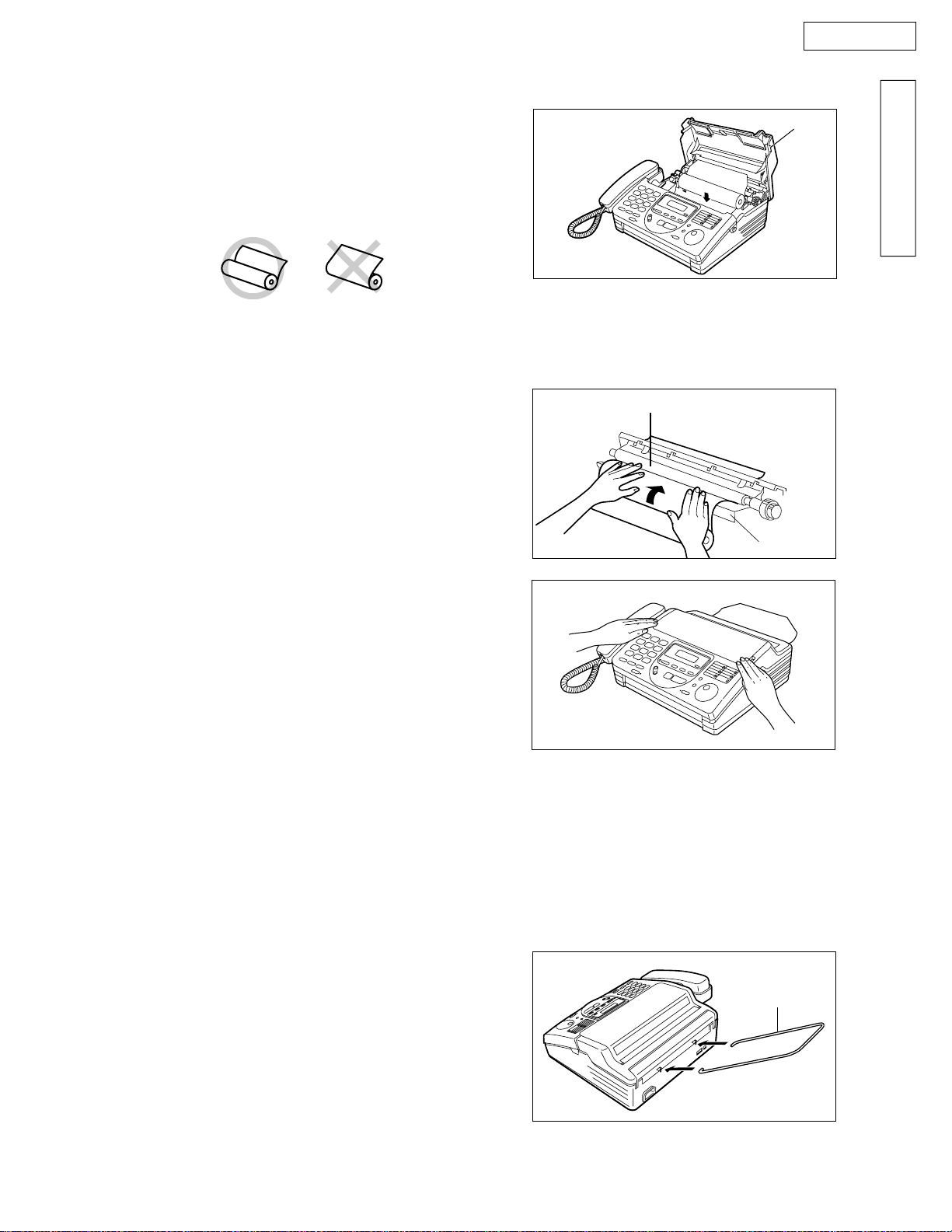

2. Installing the recording paper

KX-FT57E

1

2

3

Open the back lid by lifting up the tabs located

on the both sides.

Install a recording paper roll.

Make sure that the shiny side of the paper is

•

facing down.

incorrectcorrect

If the paper is secured with glue or tape, cut

•

approx. 150 mm from the beginning of the roll.

Insert the leading edge of the recording paper

between the recording paper roller and the silver

plate, then pull it a few centimeters out of the unit.

Make sure that there is no slack in the paper roll.

•

INTRODUCTION

Tab

Recording paper roller

Silver plate

Close the back lid by gently pressing down on both

4

Note:

•

excessive thermal head wear may occur.

ends.

Only use the included roll of paper or specified recording paper, or the print quality may be affected and/or

3. Installing the paper stacker

Install the paper stacker.

Paper stacker

|15 |

KX-FT57E

4. SETTING YOUR LOGO

The logo can be a company, division or name.

(1) Press MENU .

Display: 1. SYSTEM SET UP

(2) Press # , then 0 2 .

YOUR LOGO

(3) Press START/COPY/SET .

LOGO=

(4) Enter your logo, up to 30 characters, by following the

instructions on the next page.

Example (using the dial keypad): Bill

1. Press 2 twice.

LOGO=

B

2. Press 4 six times.

LOGO=B

3. Press 5 six times.

LOGO=Bi

4. Press ( VOLUME ) to remove the cursor

and press 5 six times.

LOGO=Bil

i

l

l

/

MENU

STOP

(Delete)

START/COPY/SET

INSERT

EASY DIAL

• To enter the same number key continuously,

move the cursor to the next space.

(5) Press START/COPY/SET .

SYSTEM SET UP [ ]

(6) Press MENU .

To correct a mistake

• Use or to move the cursor to the incorrect

character, then make the corrections.

To delete a character

• Move the cursor to the character you want to delete and

press STOP .

Note:

• You can enter your logo by rotating

EASY DIAL (See next page).

To insert a character

1. Press or to move the cursor to the

position to the right of where you want to

insert the character.

2. Press INSERT to insert a space and enter

the character.

|16 |

Selecting characters with the dial keypad

Pressing the dial keys will select a character as shown below.

KX-FT57E

INTRODUCTION

Keys

1

2

3

4

5

6

7

8

9

0

1

2

STOP

Characters

1

[

]

{

}

+

–/=, .

A

B

C

a

b

D

E

F

d

e

G

H

I

g

h

J

K

L

j

k

M

P

T

W

O

N

Q

U

X

m

n

R

S

p

V

t

u

Y

Z

w

0()<>!"#$%

2

c

3

f

4

i

5

l

6

o

rs7

q

8

v

yz9

x

&

HYPHEN key (To insert a hyphen.)

INSERT key (To insert a one character or one space.)

Delete key (To delete a character.)

key (To move the cursor to the left.)

,

–

\

:

@

;

?

^

f

¤

key (To move the cursor to the right.)

To enter the another character using the same number key, move the cursor to the next space.

Documents you can send

Minimum size Maximum size Effective scanning area Document weight

Scanned

128 mm

128 mm

216 mm

Note:

Remove clips, staples or other similar fastening objects.

Check that ink, paste or correction fluid has dried.

Do not send the following types of documents. Use copies for fax transmission.

– Chemically treated paper such as carbon or carbonless duplicating paper

– Electrostatically charged paper

– Heavily curled, creased or torn paper

– Paper with a coated surface

– Paper with a faint image

– Paper with printing on the opposite side that can be seen through the front (e.g. newspaper)

600 mm

4 mm

area

208 mm

Paper width

216 mm

Single sheet:

45 to 90 g/m

Multiple sheets:

60 to 80 g/m

2

2

|17 |

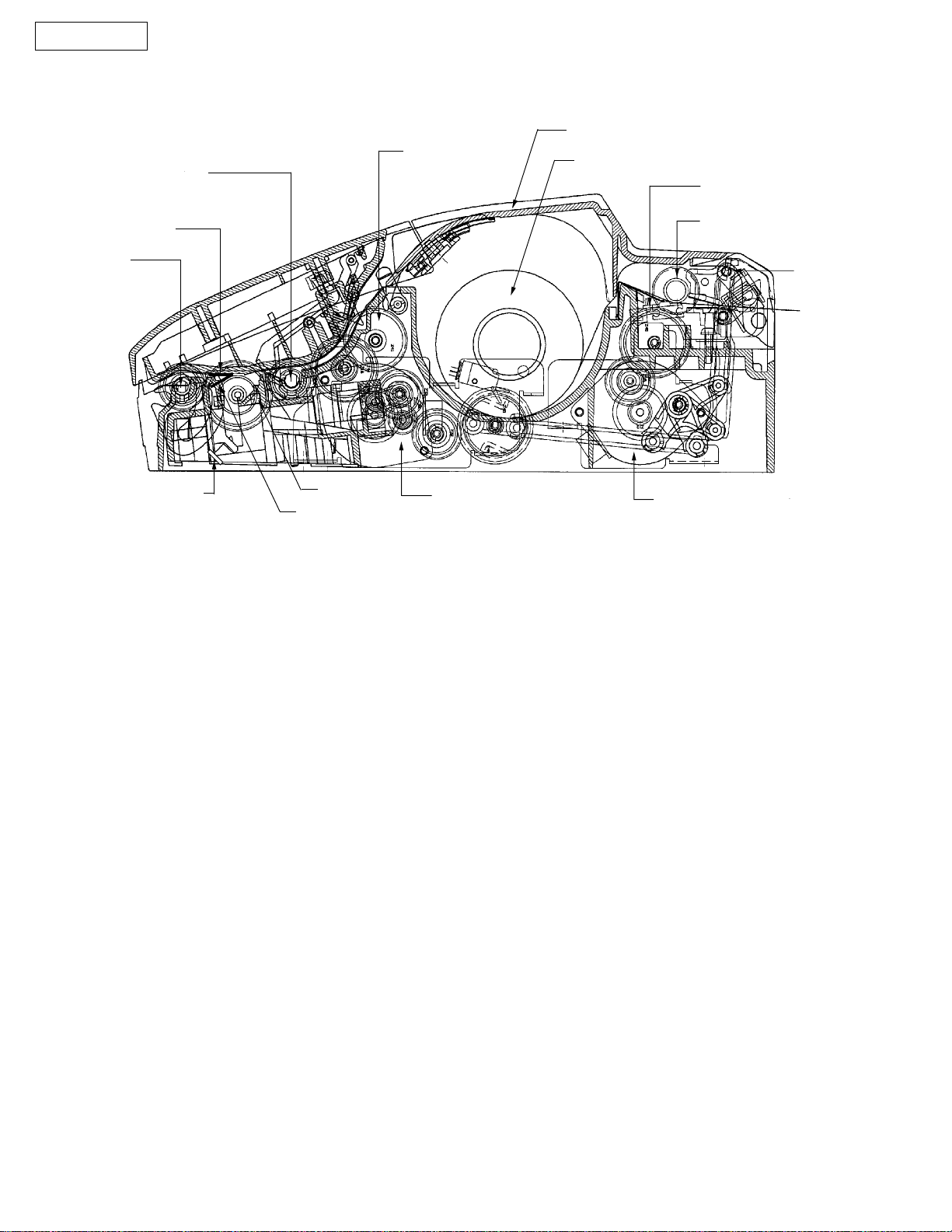

KX-FT57E

Document

Feed Roller

COMPONENT LOCATIONS

Recording Paper Cover

Separation Roller

Recording Paper

Thermal Head

Target Glass

Document

Feed Roller

Mirror

Lens

LED Array

Transmission Motor

MAINTENANCE ITEMS

1. OUTLINE

MAINTENANCE AND REPAIRS ARE PERFORMED USING THE FOLLOWING STEPS.

Recording Paper Roller

Cutter

Reception Motor

1) Periodic maintenance

Inspect the equipment periodically and if necessary, clean as required.

2) Check for breakdowns

Look for signs of trouble and consider how the problems arose.

If the equipment can still be used, perform copying, self -testing or communications testing.

3) Check equipment

Perform copying, self testing and communications testing to determine if the problem originates from the transmitter,

receiver or telephone line.

4) Determine causes

Determine the causes of the equipment problem by troubleshooting.

5) Equipment repairs

Repair or replace the defective parts and take appropriate measures at this stage to ensure that the problem does

not recur.

6) Confirm normal operation of the equipment

After completing the repairs, conduct copying, self testing and communications testing to confirm that the equipment

operates normally.

7) Record keeping

Make a record of the measures taken to rectify the problem for future reference.

|18 |

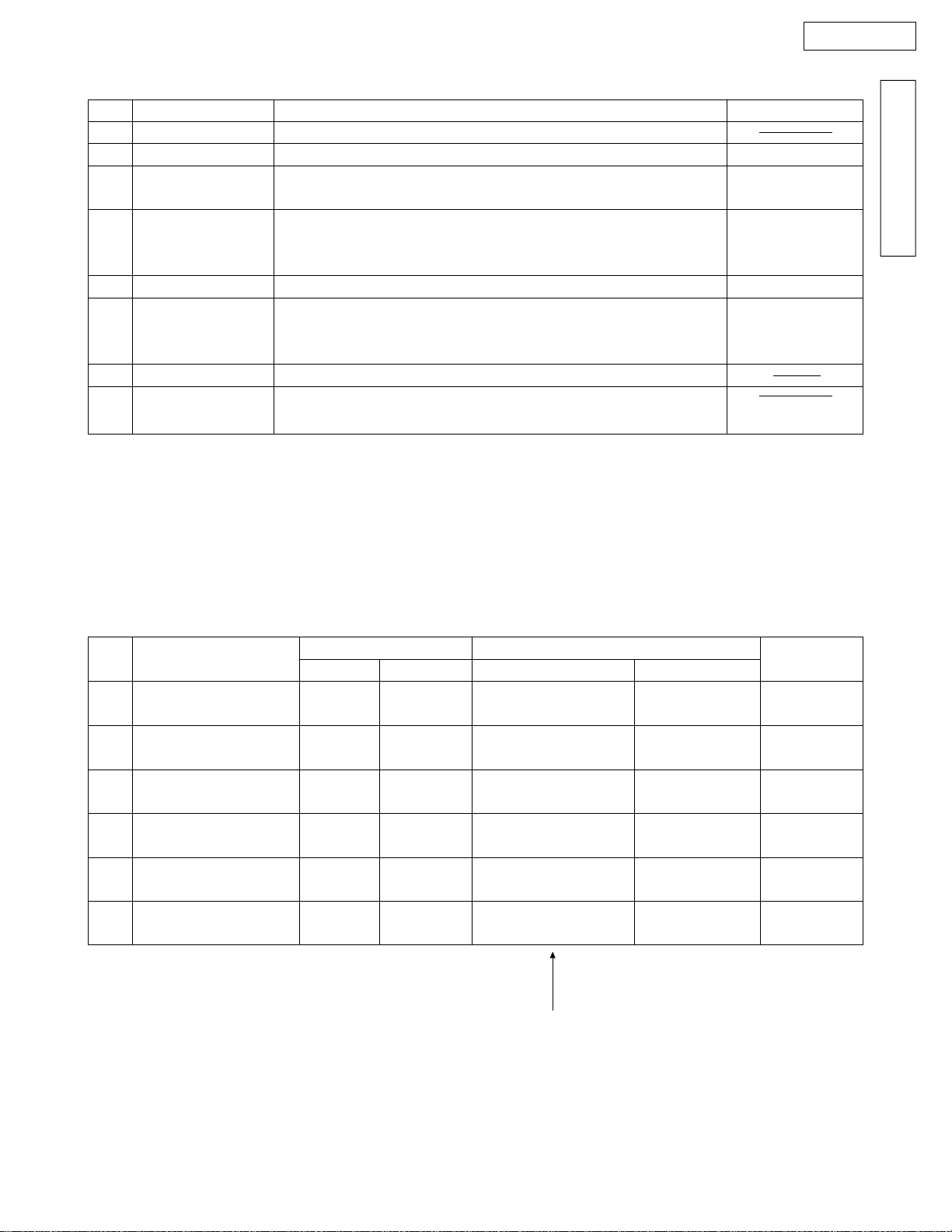

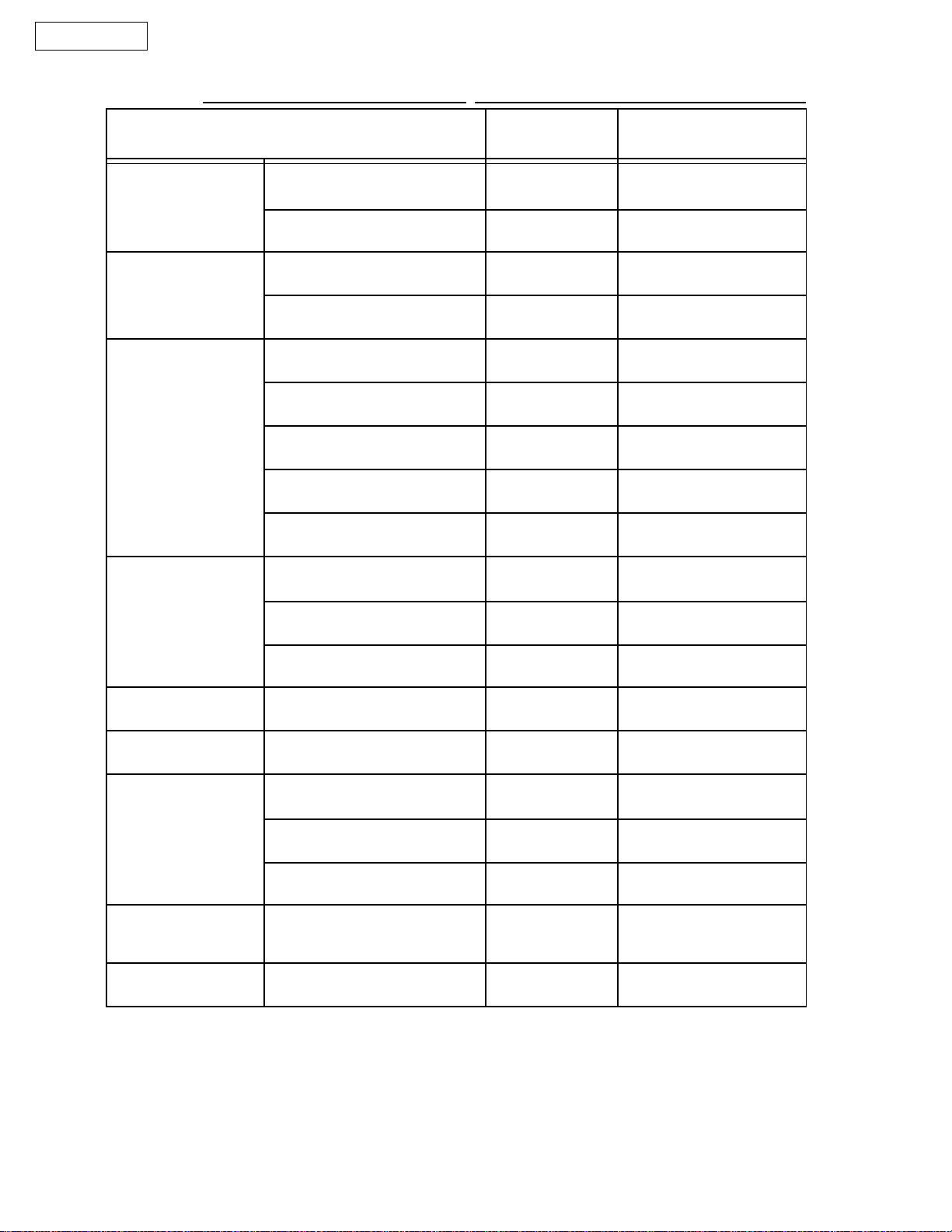

2-1. MAINTENANCE LIST

KX-FT57E

NO.

1

2

3

4

5

6

7

8

OPERATION

Document Path

Rollers

Recording Paper

Roller

Thermal Head

LED Array

Sensors

Mirrors and Lens

Abnormal, wear and

tear or loose parts

CHECK ITEM

Remove any foreign matter such as a scrap of paper.

If a roller is dirty, clean it with a damp cloth, then let it dry thoroughly.

If the platen is dirty, clean it with a damp cloth, then let it dry thoroughly.

Remove the paper before cleaning.

If the thermal head is dirty, clean the printing surface with a cloth

moistened with denatured alcohol (alcohol without water), then let it dry

thoroughly.

If the LED array is dirty, clean the glass with a dry soft cloth.

Confirm the operation of the following sensors: recording paper sensor

(SW2), document sensor (PI302), read position sensor (PI301), cover

open sensor (SW5), and JAM sensor (SW3).

If the mirror and lens are dirty, clean them with a dry soft cloth.

Replace the part. Be sure that all of the part's screws are tightened.

REMARKS

See page 20.

See page 114.

See page 116.

See page 20.

See pages 84, 85.

INTRODUCTION

2-2. MAINTENANCE CYCLE

No.

Separation Roller

1

(Ref. No. 58)

Separation Rubber

2

(Ref. No. 23)

Feed Roller

3

(Ref. No. 49, 53)

Target Glass

4

(Ref. No. 171)

Thermal Head

5

(Ref. No. 59)

Recording Paper Roller

6

(Ref. No. 112)

Items

3 months

3 months

3 months

3 months

3 months

3 months

Cycle

Cleaning

Procedure

See page. 20.

––––

See page. 20.

See page. 20.

See page. 116.

See page. 114

Replacement

Cycle

7 years

(63,000 documents)

7 years

(63,000 documents)

7 years

(63,000 documents)

7 years

(63,000 documents)

7 years

(63,000 documents)

7 years

.

(63,000 documents)

These values are only an indication and may vary depending on

actual usage conditions.

Procedure

See page 113.

––––

See page 113.

––––

See page 116.

See page 114.

Remarks

|19 |

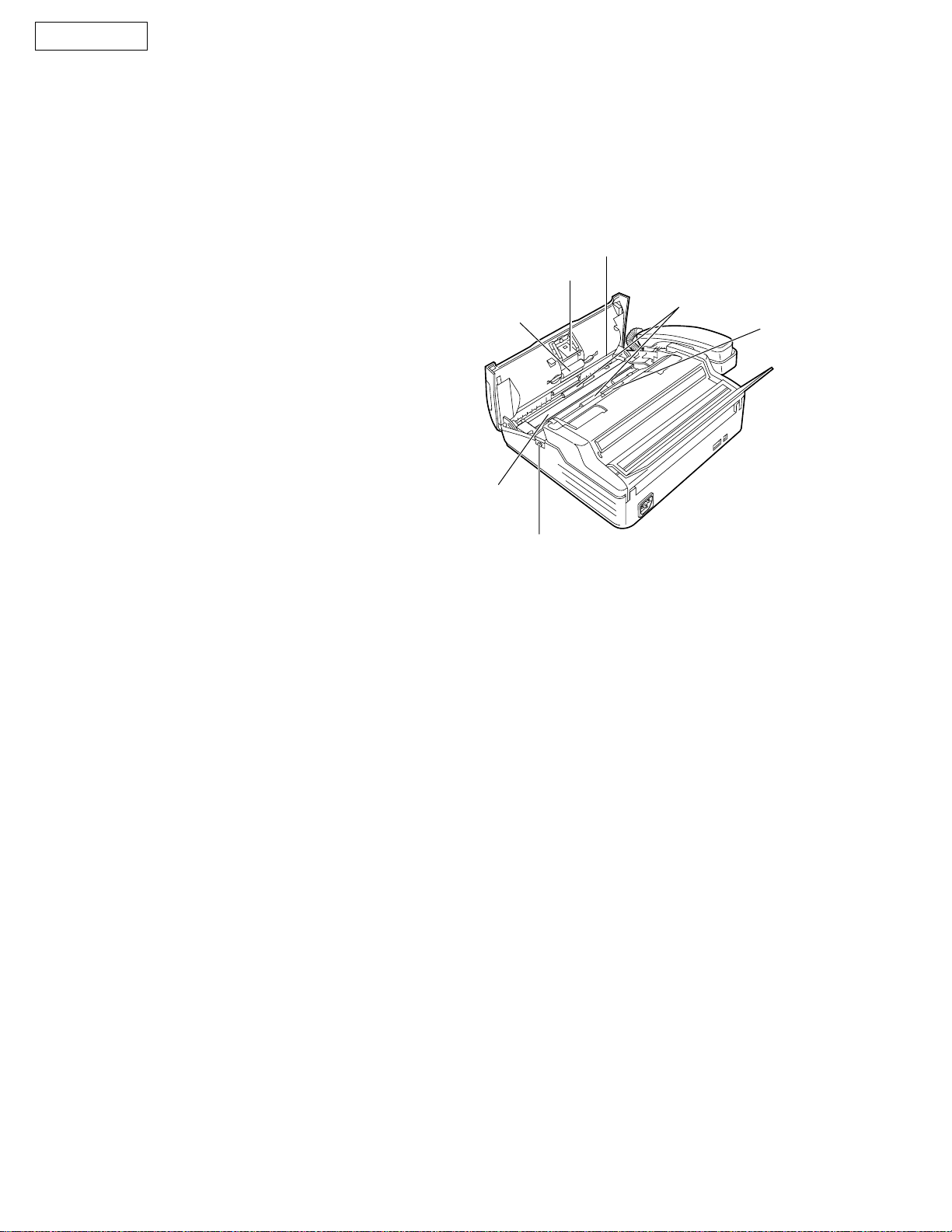

KX-FT57E

CLEANING THE INSIDE OF THE UNIT

If misfeeding occurs frequently, or dirty patterns or black bands appear on a copied or transmitted document,

clean the document feeder rollers, separation roller, sub roller, rubber flap, white plate and glass.

Disconnect the power cord and the telephone line

1

2

3

4

5

6

cord.

Open the front lid by pressing the front lid open

button.

Clean the document feeder rollers and roller with a

cloth moistened with isopropyl rubbing alcohol, and

let dry thoroughly.

Clean the white plate and glass with a soft dry

cloth.

Clean the front lid by gently pressing down on both

ends.

Connect the power cord and the telephone line

cord.

Rubber flap

Sub roller

Glass

White plate

Document

feeder rollers

Separation roller

Caution:

Do not use paper products (such as paper towels or

•

tissues) to clean the inside of the unit.

Front lid open button

|20 |

TROUBLESHOOTING GUIDE

Page

1. Troubleshooting Summary .................................................................... 22

1-1. Troubleshooting..................................................................... 22

1-2. Precautions............................................................................ 22

2. User Recoverable Errors....................................................................... 23

3. Troubleshooting Details................................................................... 24~91

KX-FT57E

TROUBLESHOOTING GUIDE

3-1. Outline ................................................................................... 24

3-2. Starting troubleshooting......................................................... 24

3-3. Troubleshooting items table .................................................. 25

3-4. Simple check-list.................................................................... 26

3-5. ADF section ..................................................................... 27~36

3-6. Communication section ................................................... 37~57

3-7. Digital board section ........................................................ 58~72

3-8. Analog board section....................................................... 73~76

3-9. Digital Speaker phone section......................................... 77, 78

3-10.Power supply section....................................................... 79~82

3-11.Operation board section ........................................................ 83

3-12.Sensor section ................................................................. 84, 85

3-13.Read section.................................................................... 86~90

3-14.Thermal head section ............................................................ 91

4. Programming and Lists ................................................................... 92~97

5. Test Functions................................................................................. 98, 99

|21 |

KX-FT57E

1. TROUBLESHOOTING SUMMARY

1-1. Troubleshooting

After having confirmed the abnormal condition by asking the user, troubleshoot according to the instructions in

Observe the following precautions when troubleshooting.

1-2. Precautions

1) If there is trouble with the print quality or the paper feed, first check that the installation space and print

paper meets the specifications. Then check that the paper selection lever/paper thickness lever is set

correctly and the paper is set correctly without any slack.

2) Before troubleshooting, first check that the connectors and cables are connected correctly and securely.

Moreover, if the abnormality occurs randomly, check very carefully.

3) When testing with the AC power connected to the unit, exercise utmost care when handling the electric parts

in order to avoid electric shock and short-circuits.

4) After troubleshooting, double check that you have not forgotten any connectors, left any loose screws, etc.

5) Always test to verify that the unit is working normally.

|22 |

2. USER RECOVERABLE ERRORS

If the unit detects a problems, the following messages will appear on the display.

DISPLAY MESSAGE CAUSE AND REMEDY

There is something wrong with the unit. Contact your service personnel.

CALL SERVICE

CHECK COVER

CHECK CRADLE

CHECK DOCUMENT

•

[Check the thermistor on the thermal head and connector lead. (for technicians)]

[This error is displayed when the thermal head does not warm up.]

The back lid is open. Close it.

•

The handset and handset cradle have been removed when you connect the power

•

cord.

--- When you want to use the handset and handset cradle, install the handset cradle

correctly.

--- When you do not use the handset and handset cradle, set the handset switch to

NO HANDSET. Then, disconnect and connect the power cord again.

The document is not fed into the unit properly. Reinsert the document.

•

If the misfeeding occurs frequently, clean the document feeder rollers inside the unit.

If the problem remains, adjust the feeder pressure.

Attempted to transmit a document longer than 600 mm (23

•

and remove the document. Divide the document into two or more sheets and try again.

[If you do wish to devide the document, change the service code #559 to "OFF". Refer

to page 94.]

5

/8"). Pres the STOP button

KX-FT57E

TROUBLESHOOTING GUIDE

CHECK MEMORY

DIRECTORY FULL

FAX IN MEMORY

MEMORY FULL

NO RESPONSE

NO TEL GREETING

OUT OF PAPER

PAPER JAMMED

POLLING ERROR

REDIAL TIME OUT

Memory (phone numbers, parameters, etc.) has been erased. Re-program.

•

There is no space to store new stations in the EASY DIAL directory. Edit or erase

•

unnecessary stations.

The unit has documents in memory. Install a new recording paper roll or clear the

•

jammed paper.

There is no room left in memory to record a message. Erase some or all of the

•

messages.

The memory is full of received documents. Install a new recording paper roll or clear

•

the jammed paper.

The receiving unit is busy or ran out of recording paper. Try again.

•

The TEL/FAX greeting message has not been recorded. Record a greeting message.

•

The unit ran out of recording paper. Install a new recording paper roll.

•

A recording paper jam occurred. Clear the jammed paper.

•

The other fax machine does not provide the polling function. Check with the other

•

party.

The receiving unit is busy or ran out of recording paper. Try again.

•

REMOVE DOCUMENT

TRANSMIT ERROR

UNIT OVERHEATED

The document is jammed. Remove the jammed document.

•

Attempted to transmit a document longer than 600 mm (23

•

and remove the document. Divide the document into two or more sheets and try again.

A transmission error occurred. Try again.

•

The unit is too hot. Let the unit cool down.

•

[If many copies are nearly all black, this message will be displayed.]

[When this occurs, open the front cover and let the unit cool down.]

|23 |

5

/8"). Press the STOP button

KX-FT57E

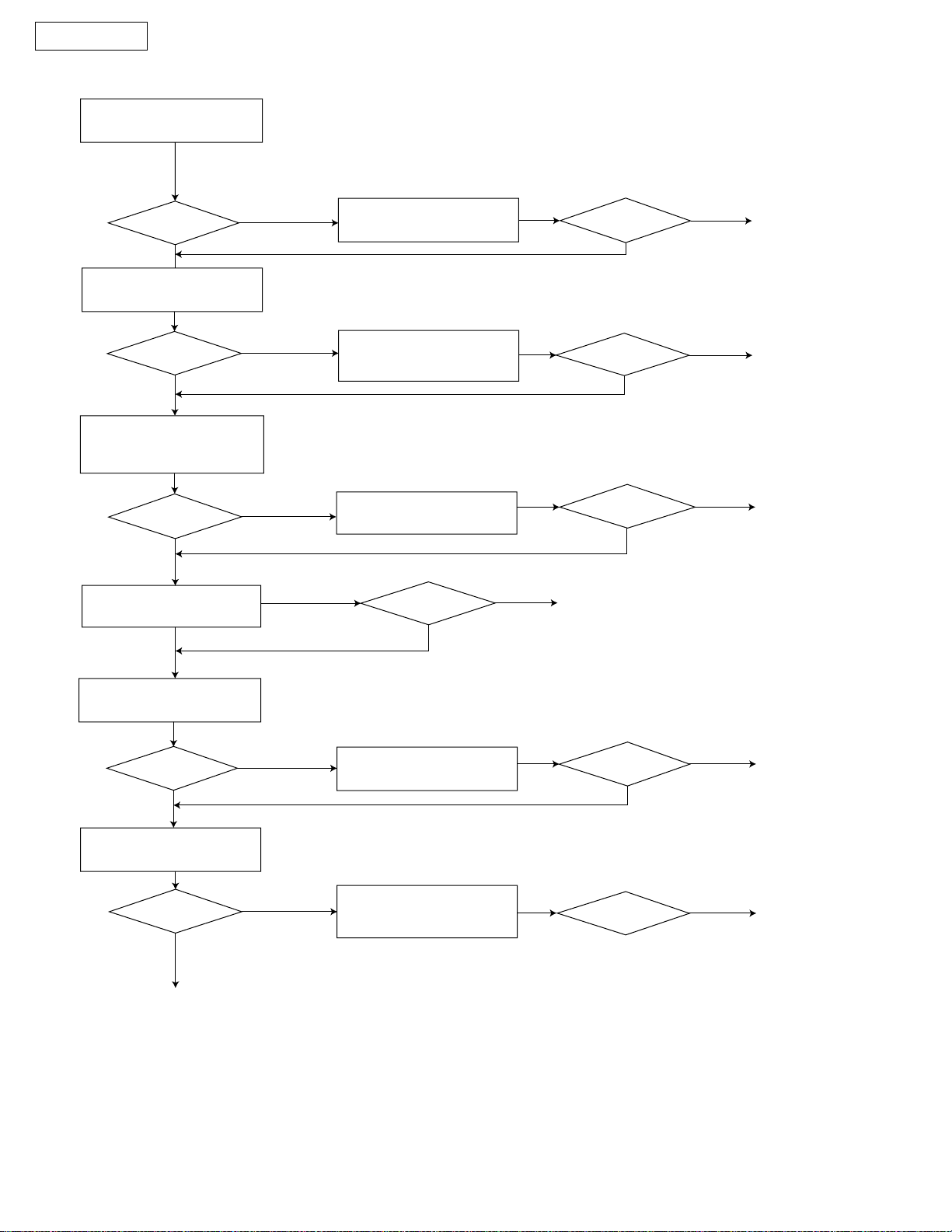

3. TROUBLESHOOTING OF DETAILS

3-1. OUTLINE

The troubleshooting guide provides a logical path of deduction to assist in locating a fault and suggests methods of restoring

the unit to full working condition. Use the reported symptoms of the fault to determine the best troubleshooting method.Even

difficult faults can be tracad to a specific block or area, for example, the "Digital Board"or "Image Sensor".

A variety of fault descriptions from customers often point to the same area and, for this reason, careful analysis of the

reported symptoms is required. After every repair, test all functions to ensure no problems are evident.

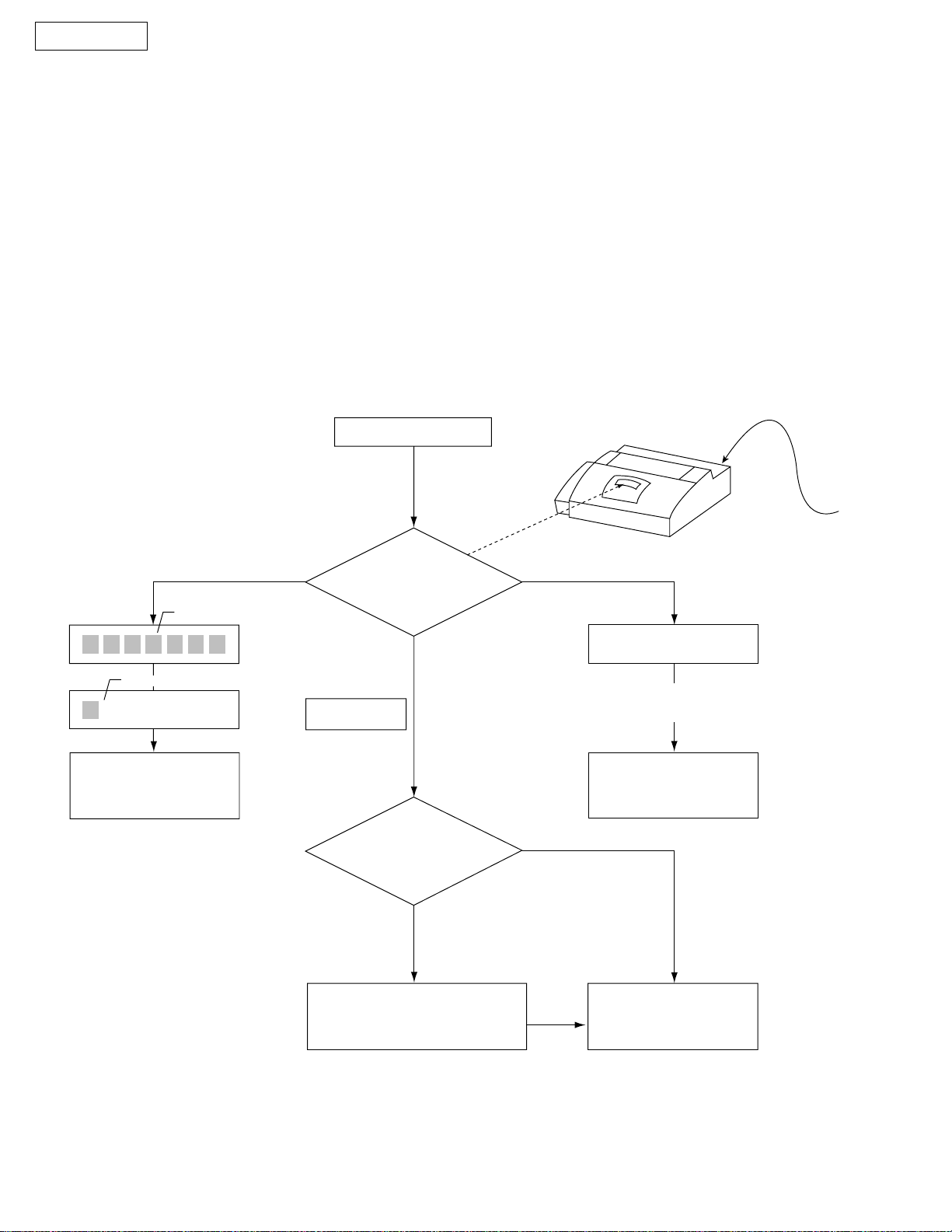

3-2. STARTING TROUBLESHOOTING

• Select the appropriate troubleshooting method according to the symptoms.

Power on.

Plug in the AC cord.

LCD

or

Blinking

See the digital board

section.

(See page 58.)

slightly changes

Check LCD.

LCD

12:00AM

good

Already known symptom

No

Yes

LCD

Blank LCD means that the power line

is broken (open-circuit).

See the digital board

section.

(See page 58.)

Blank

AC

Determine the symptom using

the check list. (See page 25.)

|24 |

See the table for

troubleshooting items.

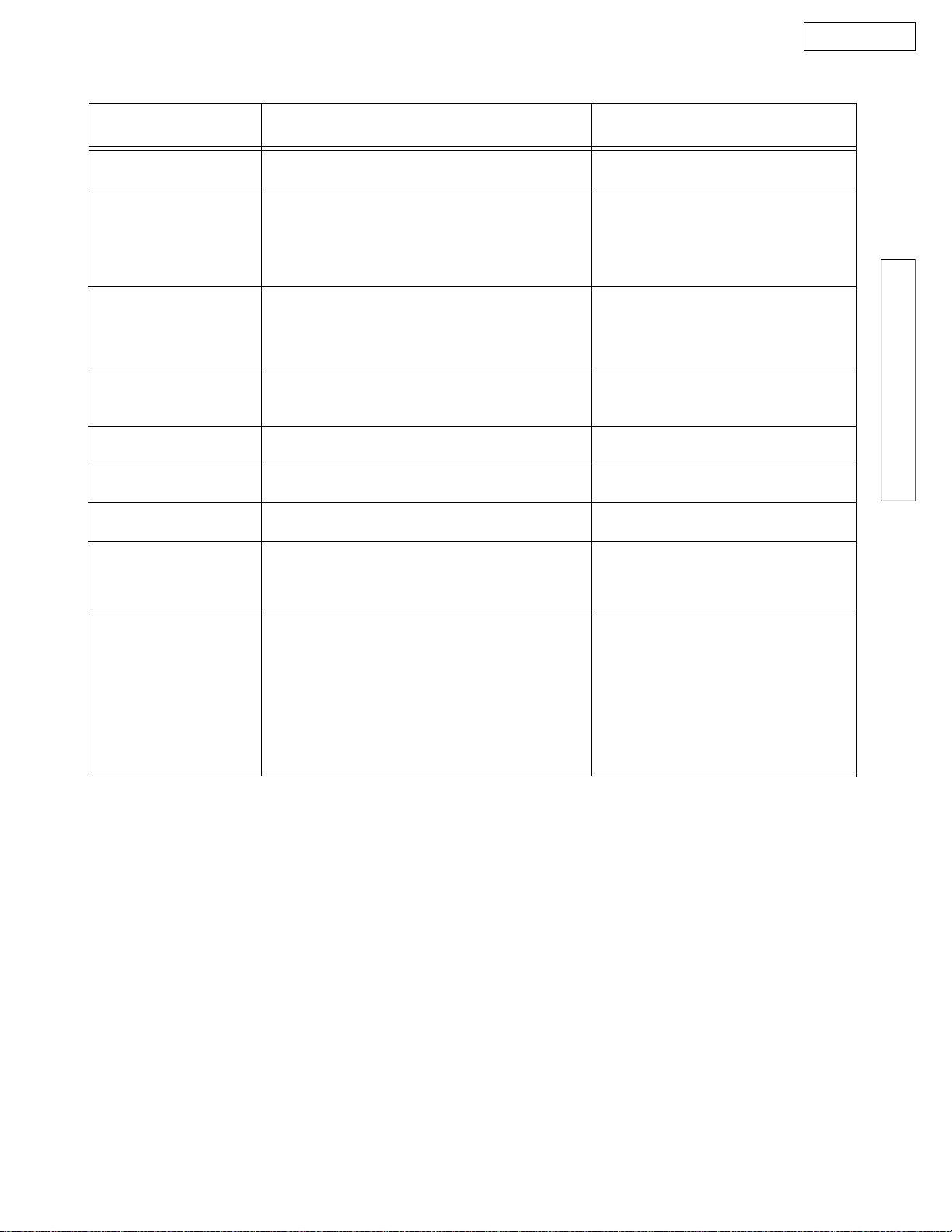

3-3. TROUBLESHOOTING ITEMS TABLE

FUNCTION SYMPTOM PAGE

KX-FT57E

The unit doesn't work at all.

Printing

Paper paths section

Abnormal

mechanical sound

Cutter

Power supply

Operation panel

Sensor

No character or faint response in the LCD

Skewed sending image

Expanded printing

Image is distorted.

Black or White lateral lines on the printed copy.

No feed

Paper jam

Multiple feed

Skewed

Abnormal sound from the product

Can not cut the recording paper.

Voltage output is abnormal.

Keys are not accepted.

"PAPER JAMMED" is displayed.

"CHECK COVER" is displayed.

"CHECK DOCUMENT" is displayed.

Page 34

Page 34

Page 31

Page 32

Page 27

Page 28

Page 29

Page 30

Page 35

Page 33

Page 79

Page 83

Page 84

TROUBLESHOOTING GUIDE

Communication

FAX, TEL

(Analog board)

Can not communicate by fax.

An error code is displayed.

Can't talk.

DTMF tone doesn't work.

Handset/Monitor sound, volume

TAM doesn't work.

Digital speaker phone

Page 37

Page 37

Page 73

Page 73

Page 73

Page 73

Page 77

|25 |

KX-FT57E

3-4. SIMPLE CHECK LIST

SERIAL NO.

DATE

FAX operaton

Copy operation

Telephone operation

FUNCTION JUDGEMENT

Transmission

Receiving

FINE mode

HALF TONE mode

Handset transceiver/ receiver

Ringer sound

Dial operation

Volume operation

VOX detection

Key check

OK / NG

OK / NG

OK / NG

OK / NG

OK / NG

OK / NG

OK / NG

OK / NG

OK / NG

OK / NG

REFERENCE

Service code 815

ƒ

(Digital SP-Phone LED)

Service code 561

ƒ

Operation panel

Sensor

Digital speaker

phone

Digital TAM

LED check

LCD check

Sensor check

Greeting Rec/Play

Incoming message Rec/Play

Memo Rec/Play

OK / NG

OK / NG

OK / NG

OK / NG

OK / NG

OK / NG

OK / NG

Voice prompt OK / NG

Clock

OK / NG

ƒ

Check according to the service code referring

to the Test function on page 98.

Service code 557

Service code 558

Service code 815

ƒ

ƒ

ƒ

Service code 784

Check whether voice

prompt is played or not.

Check accuracy.

|26 |

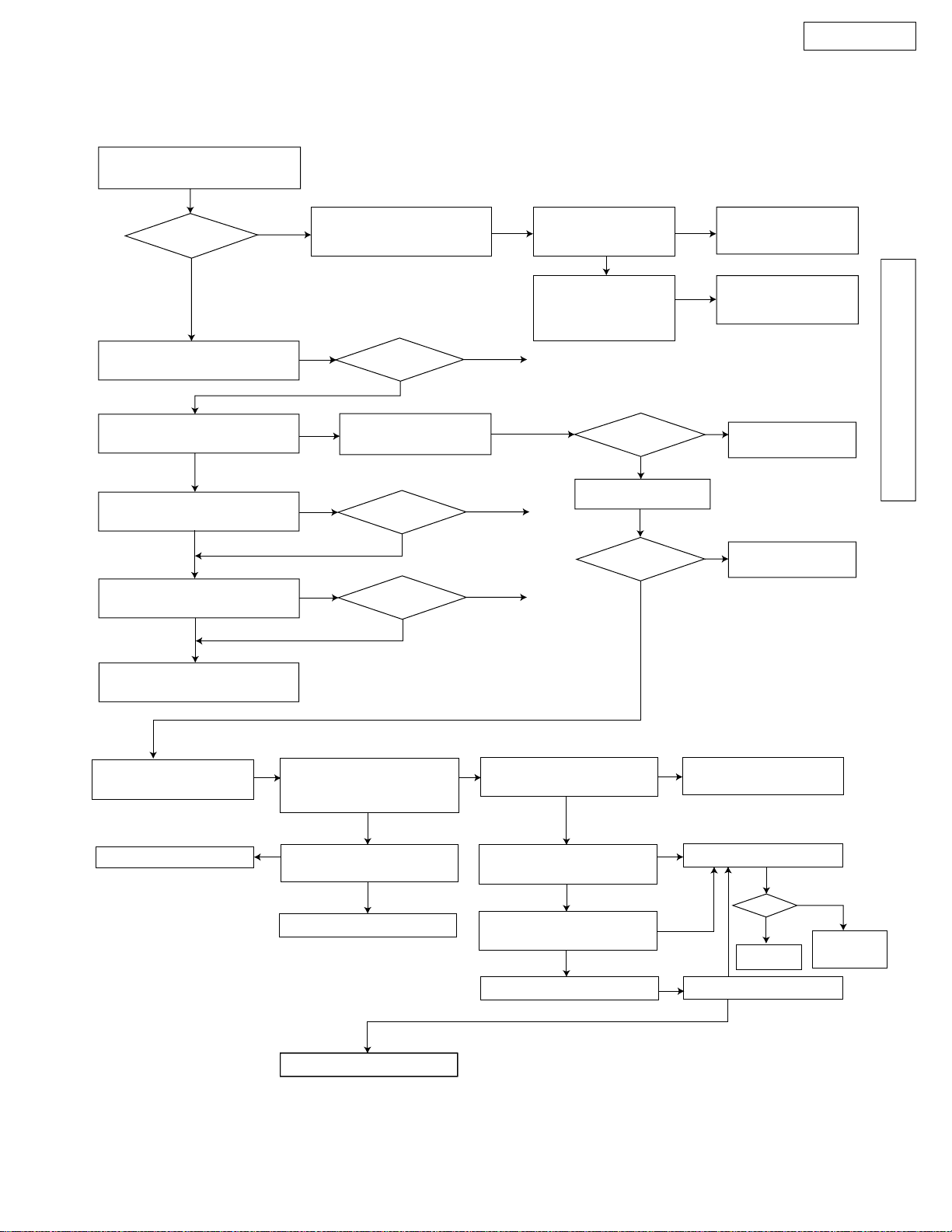

3-5. ADF (Auto document feed) SECTION

KX-FT57E

(1) No document feed

When setting a document,

confirm the beep tone.

OK?

YES

Clean the separation roller.

( page 114 )

Does the separation roller

rotate?

YES

Check the separation spring

and pad?

YES

NO

ƒ

When using thin paper etc., if the document will not feed,

refer to the feed pressure adjustment (page 101).

Check if separation

spring is distorted.

OK?

NG

Check the motor and

NO

connector.

NO

OK?

NG

OK

OK

NG

Check the sensor

lever movement.

Check the sensor

and digital board.

(pages 58 and 84)

END

END

OK

OK?

YES

Check the gear.

OK?

Replace the sensor

NG

lever.

NG

Replace the defective parts.

NG

Replace the motor

and connector.

NG

Replace the gear.

TROUBLESHOOTING GUIDE

Replace the separation

roller unit.

YES

Replace the operation cover

unit.

Go to the digital board

section. (page 58)

NO

Repair.

NO

Is the phase signal from

pins 73-77 of IC1 output?

Is the solder at pins 7377 of IC1 OK?

Replace IC7.

OK?

NG

YES

YES

OK

END

Is the voltage at emitter

of Q1 +24 V?

YES

Is the voltage at collector

of Q1 +24 V?

NO

Is the voltage at pin 11 of

IC7 less than 2V?

YES

Replace Q1.

YES

Check the power supply

unit section. (page 79)

Replace IC7.

OK?

YES

NO

NO

END

OK?

NO

Replace

the motor.

END

|27 |

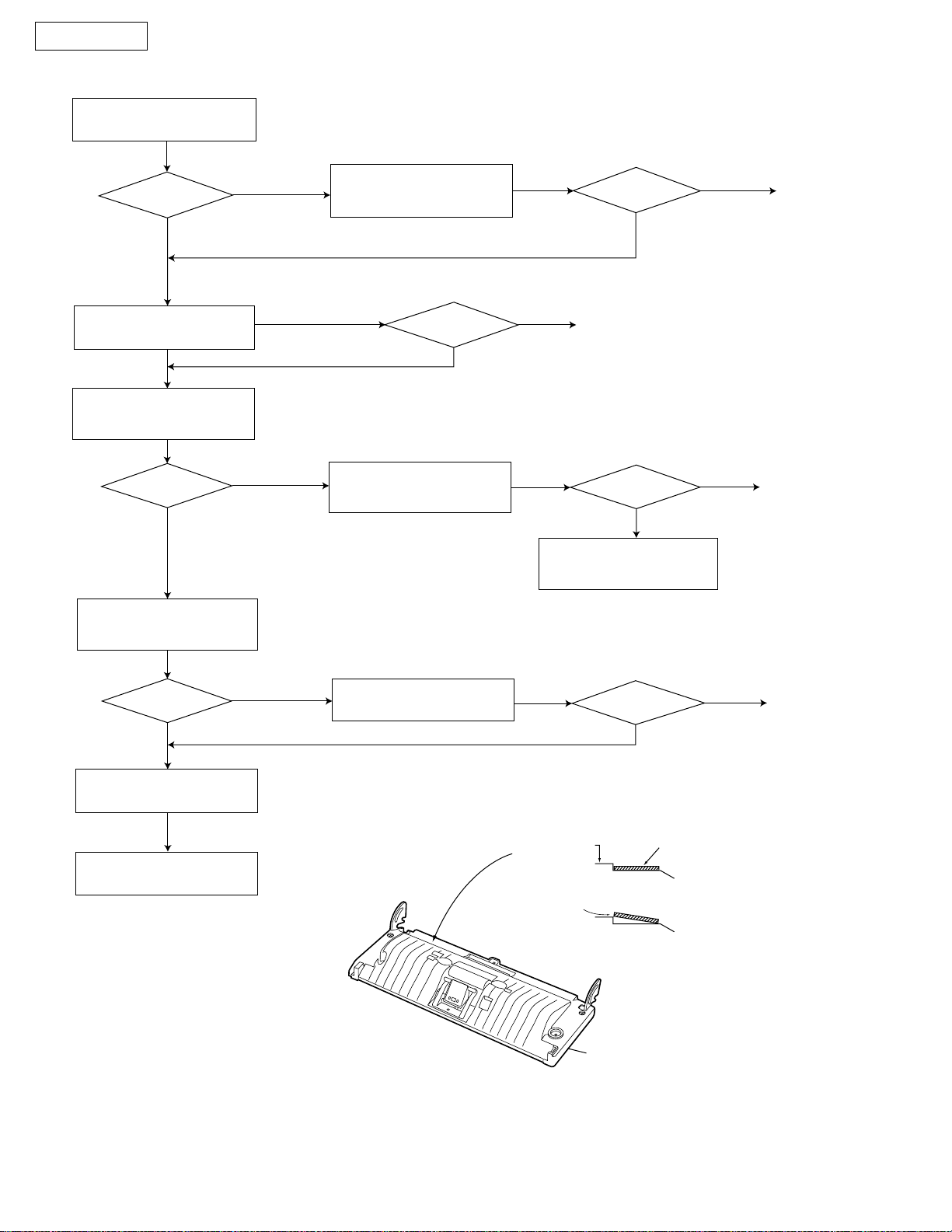

KX-FT57E

(2) Paper JAM

Check the feed route.

OK?

YES

Clean each of the rollers.

(pages 113 and 114 )

Check each of the

sensors movement.

OK?

YES

Check the paper jam for markings or objects stuck on the sheet.

NO

Confirm that the location tip of the read position

sensor lever works smoothly. [Use the sensor test function (page 98)]

NO

Clean or replace the

defective parts.

OK?

NG

Repair or replace the

sensor lever.

NG

OK

END

NG

Go to the sensor section.

(page 84)

OK?

OK?

OK

OK

Check if the sensor

reacts while the flag is

moving.

END

END

Check each roller

mount.

OK?

YES

Check the white plate.

NG

Replace the white plate.

Check that the separation, feed and pinch

rollers are attached correctly.

NO

Repair the defective parts.

Operation

cover

Document

OK?

NG

White Plate

Operation Board Cover

OK

OK

NG

END

|28 |

Fig. A

(3) Multiple feed

Check the separation pad.

ƒ

When using thin paper etc., if the document will not feed,

refer to the feed pressure adjustment (page 101).

Confirm whether the pad is dirty or not and

is attached correctly.

KX-FT57E

OK?

YES

Check if the separation

spring is distorted.

Clean each of the rollers.

(pages 113 and 114)

Replace the separation

pad, roller and pressure

spring.

NO

Clean or replace the

defective parts.

OK?

NG

OK?

NG

OK

OK

END

END

NG

OK?

OK

END

TROUBLESHOOTING GUIDE

|29 |

KX-FT57E

(4) Skew

Is the document setting

OK?

Check whether the document is folded and if

tape or staples are attached. Also check

if a different size document is set at

the same time.

OK?

YES

Check the feed route.

OK?

YES

Check the balance of

both separation pressure

springs.

OK?

YES

Clean each of the rollers.

(pages 113 and 114 )

NO

Check whether there are foreign

objects or missing parts.

NO

NO

Reset the document.

Clean or replace the

defective parts.

Replace the separation

pressure spring.

NG

OK?

OK

NG

NG

NG

END

OK?

OK?

OK?

OK

OK

OK

END

END

END

Check the white plate.

(Refer to Fig. A of page 28)

OK?

YES

Check the CCD unit.

OK?

END

NO

NO

Replace the white plate.

Repair or replace the

defective parts.

NG

OK?

OK?

OK

OK

END

END

|30 |

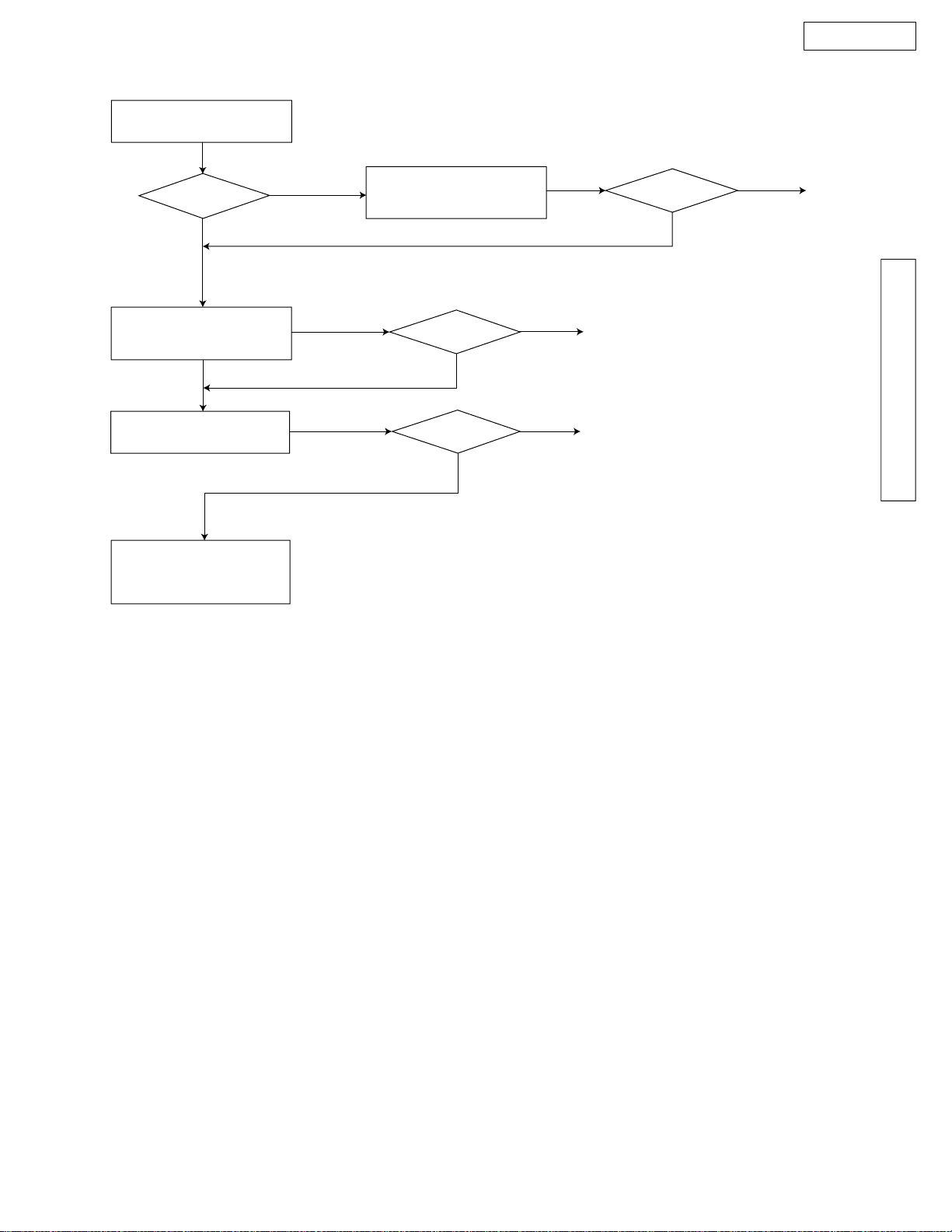

Loading...

Loading...