Panasonic KX-FT21RS User Manual

PARSONAL FACSIMILE

KX-FT21RS

(Russia)

ORDER NO. KM79911336C3

© 1999 Kyushu Matsushita Electric Co., Ltd. All

rights reserved. Unauthorized copying and

distribution is a violation of law.

KX-FT21RS

CONTENTS

Page Page

1 INTRODUCTION 3

1.1. SAFETY PRECAUTIONS

1.2. INSULATION RESISTANCE TEST

1.3. FOR SERVICE TECHNICIANS

1.4. BATTERY CAUTION

1.5. AC CAUTION

1.6. PERSONAL SAFETY PRECAUTIONS

1.7. FEATURES

1.8. SPECIFICATIONS

1.9. OPTIONAL ACCESSORIES

1.10. CCITT No. 1 TEST CHART

1.11. LOCATION OF CONTROLS

1.12. CONNECTIONS

1.13. INSTALLATION

1.14. MAINTENANCE ITEMS AND COMPONENT LOCATIONS

2 TROUBLESHOOTING GUIDE

2.1. TROUBLESHOOTING SUMMARY

2.2. USER RECOVERABLE ERRORS

2.3. TROUBLESHOOTING DETAILS

2.4. PROGRAMMING AND LISTS

2.5. TEST FUNCTIONS

2.6. JOURNAL 3

3 ADJUSTMENTS

3.1. ADJUSTING THE FEED PRESSURE

4 DISASSEMBLY INSTRUCTIONS

5 HOW TO REPLACE THE FLAT PACKAGE IC

5.1. PREPARATION

5.2. FLAT PACKAGE IC REMOVAL PROCEDURE

5.3. FLAT PACKAGE IC INSTALLATION PROCEDURE

5.4. BRIDGE MODIFICATION PROCEDURE

6 CIRCUIT OPERATIONS

6.1. CONNECTION DIAGRAM

6.2. GENERAL BLOCK DIAGRAM

6.3. CONTROL SECTION

6.4. FACSIMILE SECTION

6.5. SENSORS AND SWITCHES

6.6. MODEM SECTION

6.7. Analog Unit Block Diagram

6.8. NCU SECTION

6.9. ITS (Integrated telephone System) and MONITOR

SECTION

10

11

14

18

18

19

21

74

79

81

83

83

84

95

95

95

96

96

97

97

98

100

109

119

122

129

130

132

3

3

3

3

4

5

6

7

7

8

9

6.10. EXT. TEL

6.11. OPERATION PANEL

6.12. POWER SUPPLY BOARD SECTION

7 FOR THE SCHEMATIC DIAGRAMS

8 PRINTED CIRCUIT BOARD

8.1. PRINTED CIRCUIT BOARD (DIGITAL BOARD):

COMPONENT VIEW

8.2. PRINTED CIRCUIT BOARD (DIGITAL BOARD): BOTTOM

VIEW

8.3. PRINTED CIRCUIT BOARD (ANALOG BOARD):

COMPONENT VIEW

8.4. PRINTED CIRCUIT BOARD (ANALOG BOARD):

BOTTOM VIEW

8.5. PRINTED CIRCUIT BOARD (SWITCHING POWER

SUPPLY)

8.6. PRINTED CIRCUIT BOARD (OPERATION BOARD)

9 SCHEMATIC DIAGRAM

9.1. SCHEMATIC DIAGRAM (DIGITAL CIRCUIT)

9.2. SCHEMATIC DIAGRAM (ANALOG CIRCUIT)

9.3. SCHEMATIC DIAGRAM (SWITCHING POWER SUPPLY)

9.4. SCHEMATIC DIAGRAM (OPERATION CIRCUIT)

10 TERMINAL GUIDE OF THE IC·S TRANSISTORS AND DIODES

11 FIXTURES AND TOOLS

12 CABINET, MECHANICAL AND ELECTRICAL PARTS

LOCATION

12.1. OPERATION PANEL SECTION

12.2. UPPER CABINET SECTION

12.3. LOWER CABINET/P.C.B. SECTION

12.4. MOTOR SECTION

12.5. ACTUAL SIZE OF SCREWS AND WASHER

13 ACCESSORIES AND PACKING MATERIALS

14 REPLACEMENT PARTS LIST

14.1. CABINET AND ELECTRICAL PARTS

14.2. DIGITAL BOARD PARTS

14.3. ANALOG BOARD PARTS

14.4. OPERATION BOARD PARTS

14.5. POWER SUPPLY BOARD PARTS

14.6. FIXTURES AND TOOLS

133

135

137

140

141

141

142

143

144

145

146

147

147

148

149

150

151

152

153

153

154

155

156

157

158

159

159

160

162

164

165

166

2

KX-FT21RS

1 INTRODUCTION

1.1. SAFETY PRECAUTIONS

1. Before servicing, unplug the AC power cord to prevent an electric shock.

2. When replacing parts, use only the manufacturer´s recommended components.

3. Check the condition of the power cord. Replace if wear or damage is evident.

4. After servicing, be sure to restore the lead dress, insulation barriers, insulation papers, shields, etc.

5. Before returning the serviced equipment to the customer, be sure to perform the following insulation resistance test to prevent

the customer from being exposed to shock hazards.

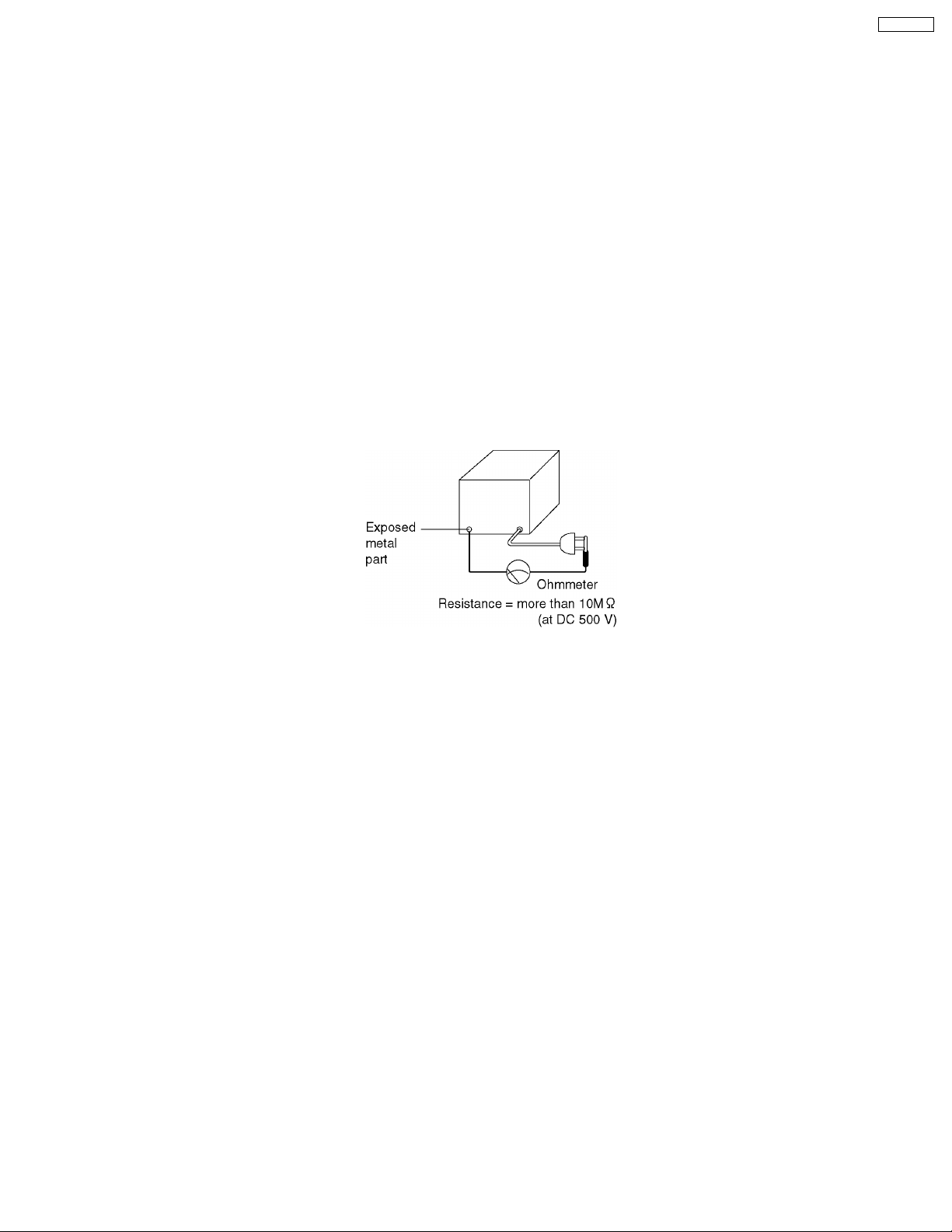

1.2. INSULATION RESISTANCE TEST

1. Unplug the power cord and short the two prongs of the plug with a jumper wire.

2. Turn on the power switch.

3. Measure the resistance value with an ohmmeter between the jumpered AC plug and each exposed metal cabinet part (screw

heads, control shafts, bottom frame, etc.).

Note: Some exposed parts may be isolated from the chassis by design. These will read infinity.

4. If the measurement is outside the specified limits, there is a possibility of a shock hazard.

The equipment should be repaired and rechecked before it is returned to the customer.

1.3. FOR SERVICE TECHNICIANS

ICs and LSIs are vulnerable to static electricity.

When repairing, the following precautions will help prevent recurring malfunctions.

1. Cover the plastic part´s boxes with aluminum foil.

2. Ground the soldering irons.

3. Use a conductive mat on the worktable.

4. Do not touch the IC or LSI pins with bare fingers.

1.4. BATTERY CAUTION

CAUTION

Danger of explosion if battery is incorrectly replaced.

Replace only with the same or equivalent type recommended by the manufacture. Dispose of used batteries according to the

manufacturer´s instructions.

3

KX-FT21RS

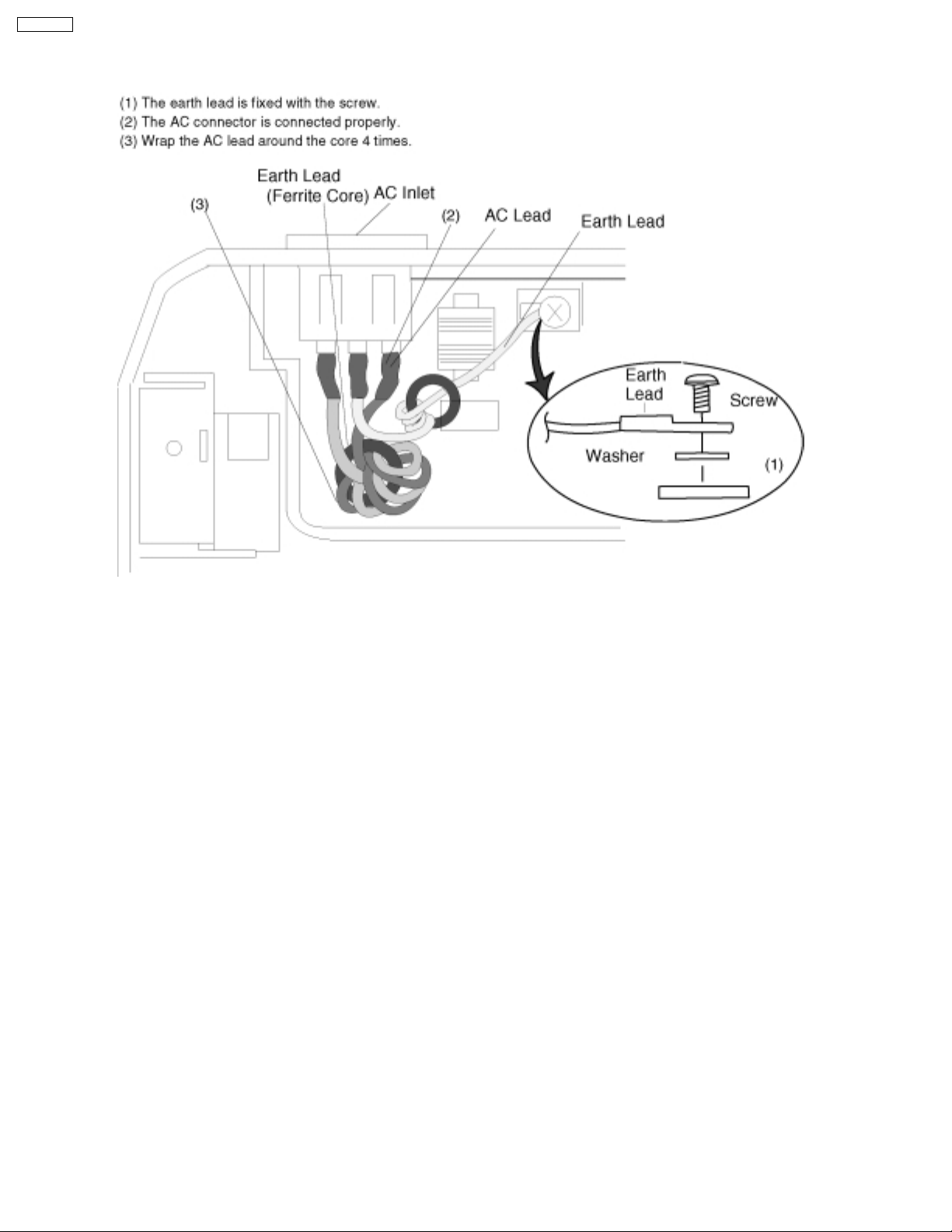

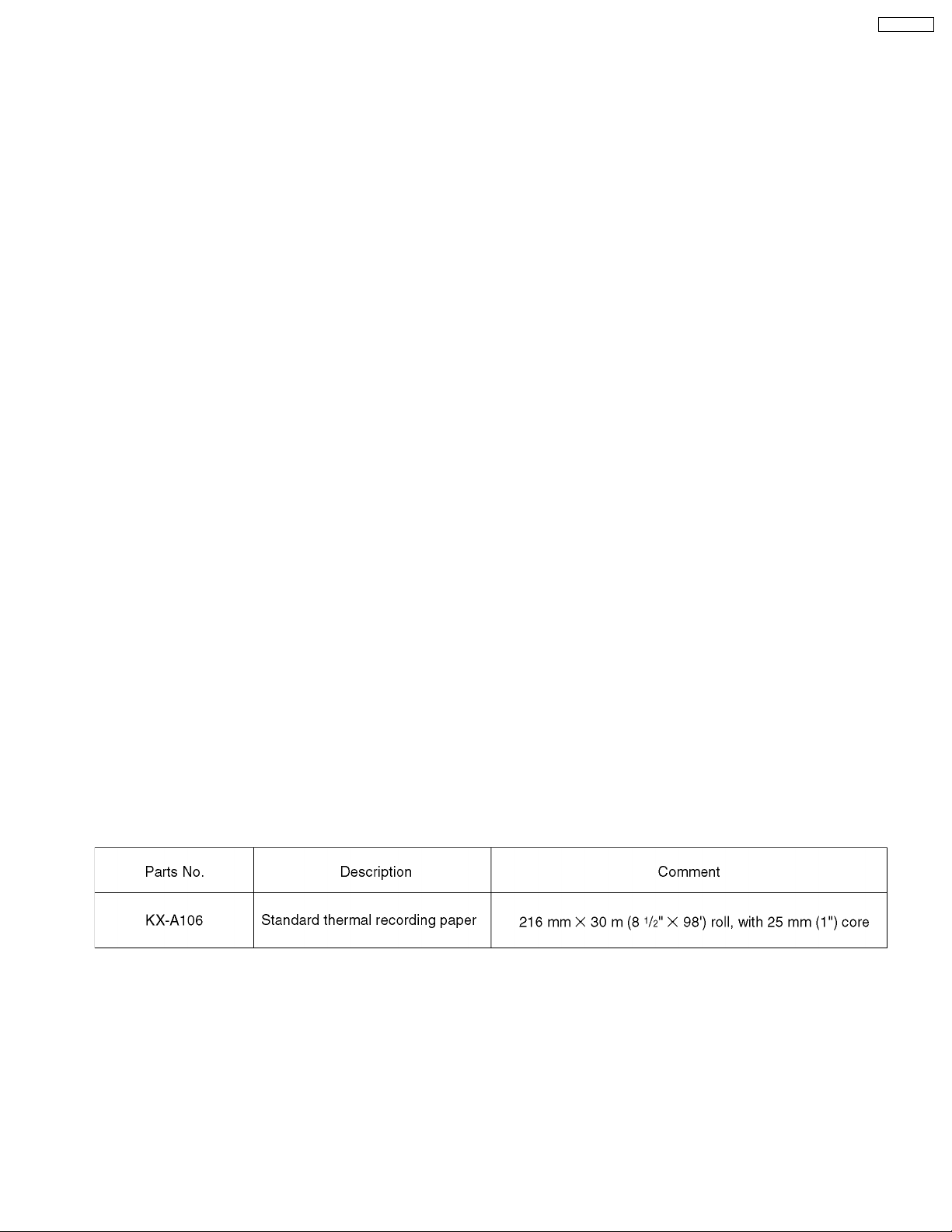

1.5. AC CAUTION

For safety, before closing the lower cabinet, please make sure of the following precautions.

4

KX-FT21RS

1.6. PERSONAL SAFETY PRECAUTIONS

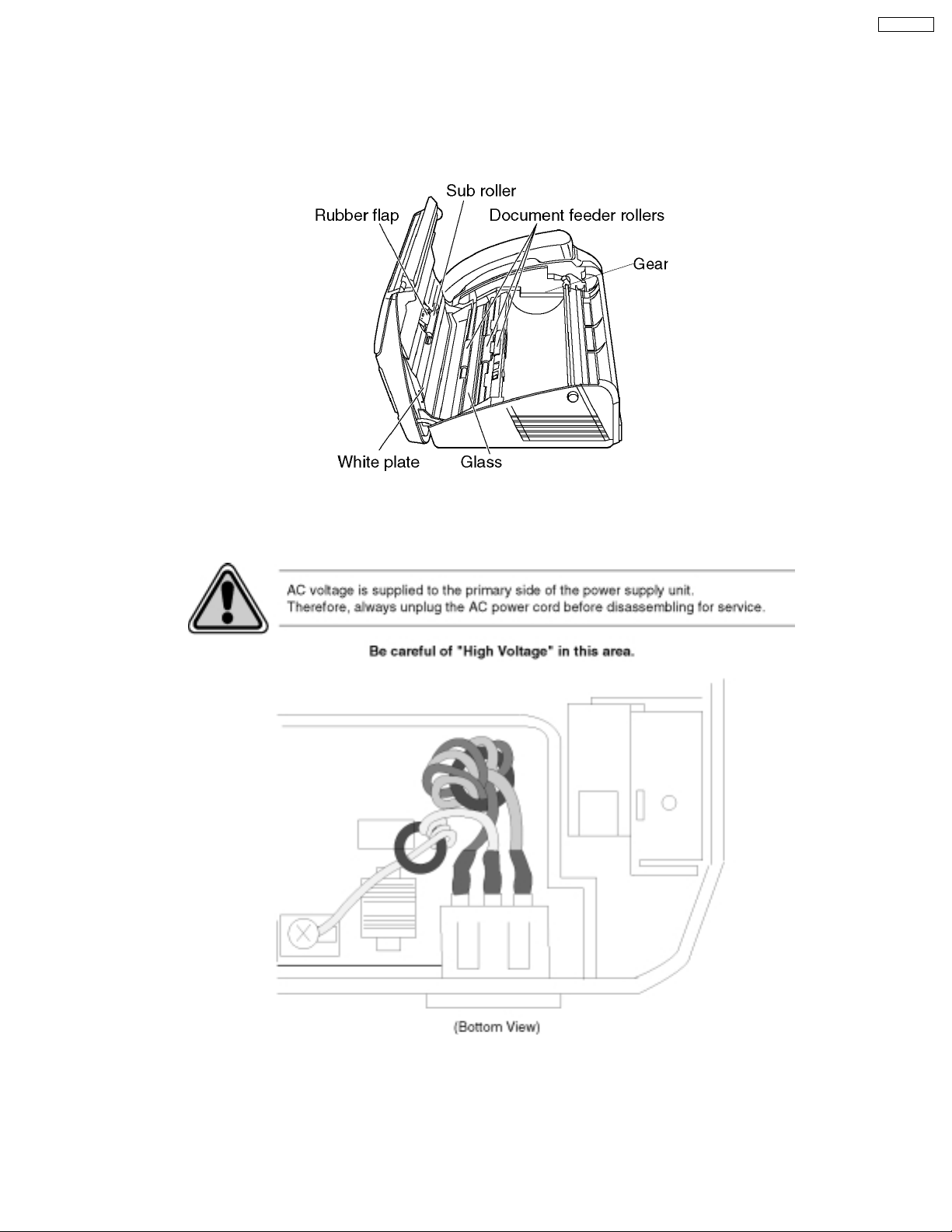

1.6.1. MOVING SECTIONS OF THE UNIT

Be careful not to let your hair, clothes, fingers, accessories, etc., become caught in any moving sections of the unit.

The moving sections of the unit are the rollers and a gear. There is a separation roller and a document feed roller which are rotated

by the document feed motor. A gear rotates the two rollers. Be careful not to touch them with your hands, especially when the unit

is operating.

1.6.2. LIVE ELECTRICAL SECTIONS

All the electrical sections of the unit supplied with AC power by the AC power cord are live.

Never disassemble the unit for service with the AC power supply plugged in.

(Bottom view)

5

KX-FT21RS

1.7. FEATURES

General

· Desktop type

· LCD (Liquid Crystal Display) readout

· Help function

· Copier function

Facsimile

· Space Saving Compact Design

· Resolution: standard/fine/super fine/halftone

· Copier Function

· Automatic Document Feeder (10 Sheets)

· Help Printout

· Easy-to-view LCD (15 Characters)

Integrated telephone system

· Electric Volume Control

· On-hook dialing

· Redialing function

· Temporary tone dialing

· Electric telephone directory

6

KX-FT21RS

1.8. SPECIFICATIONS

Applicable Lines: Public Switched Telephone Network

Document Size: Max. 216 mm (8 1/2”) in width

Max. 600 mm (23 5/8”) in length

Effective Scanning Width: 208mm (8 3/16”)

Recording Paper Size: 216 mm max. 30 m (8 1/2”×98”) roll

Effective Printing Width: 208 mm (8 3/16”)

Transmission Time*: Approx. 15 s/page (Original mode)**

Approx. 30 s/page (G3 Normal mode)

Scanning Density: Horizontal:

8 pels/mm (203 pels/inch)

Vertical:

3.85 lines/mm (98 lines/inch)—STANDARD mode

7.7 lines/mm (196 lines/inch)—FINE/HALF TONE mode

15.4 lines/mm (392 lines/inch)—SUPER FINE mode

Halftone Level: 64-level

Scanner Type: Contact Image Sensor (CIS)

Printer Type: Thermal Printing

Data Compression System: Modified Huffman (MH), Modified READ (MR)

Modem Speed: 9,600 / 7,200 / 4,800 / 2,400 bps; Automatic Fallback

Operating Environment: 5°C—35°C (41°F—95°F), 45 %—85 % RH (Relative Humidity)

Dimensions (H×W×D): 122 mm × 338 mm × 240 mm (4 13/16” × 13 5/16” × 9 7/16”)

Mass (Weight): Approx. 2.5 kg (5.5 lb.)

Power Consumption: Standby: Approx. 5.5 W

Transmission: Approx. 17 W

Reception: Approx. 30 W (When receiving the CCITT No. 1 Test Chart)

Copy: Approx. 30 W (When copying the CCITT No. 1 Test Chart)

Maximum: Approx. 120 W (When copying a 100 % black document)

Power Supply: 220—240 V AC, 50/60 Hz

* Transmission speed depends upon the contents of the pages, resolution, telephone line conditions and capability of the other

party´s machine.

** The 15 second speed is based upon the CCITT No. 1 Test Chart.

Note:

· Any details given in these instructions are subject to change without notice.

· The pictures and illustrations in these instructions may vary slightly from the actual product.

1.9. OPTIONAL ACCESSORIES

7

KX-FT21RS

1.10. CCITT No. 1 TEST CHART

8

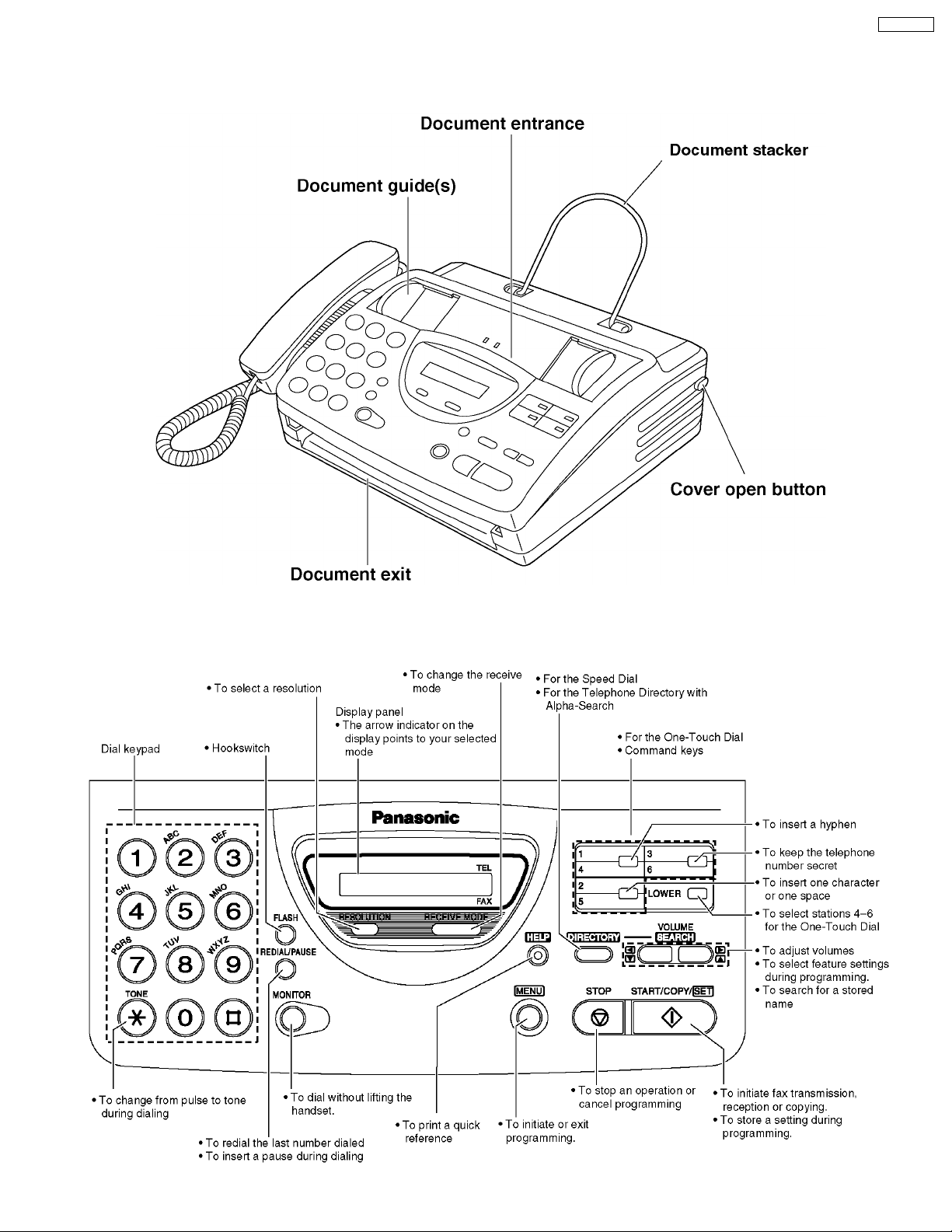

1.11. LOCATION OF CONTROLS

1.11.1. OVERVIEW

KX-FT21RS

1.11.2. CONTROL PANEL

9

KX-FT21RS

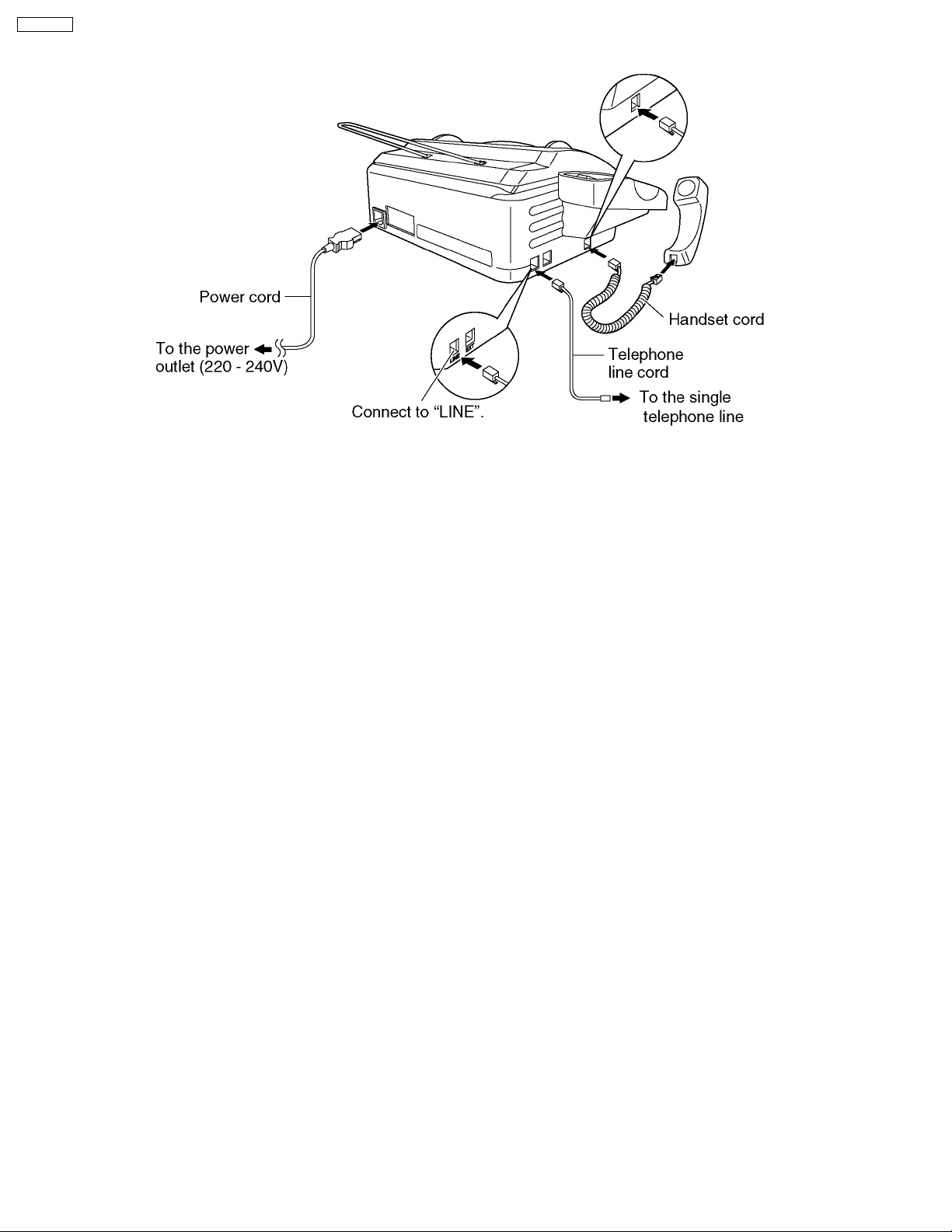

1.12. CONNECTIONS

NOTE

When you operate this products, the power outlet should be near the product and easily accessible.

10

1.13. INSTALLATION

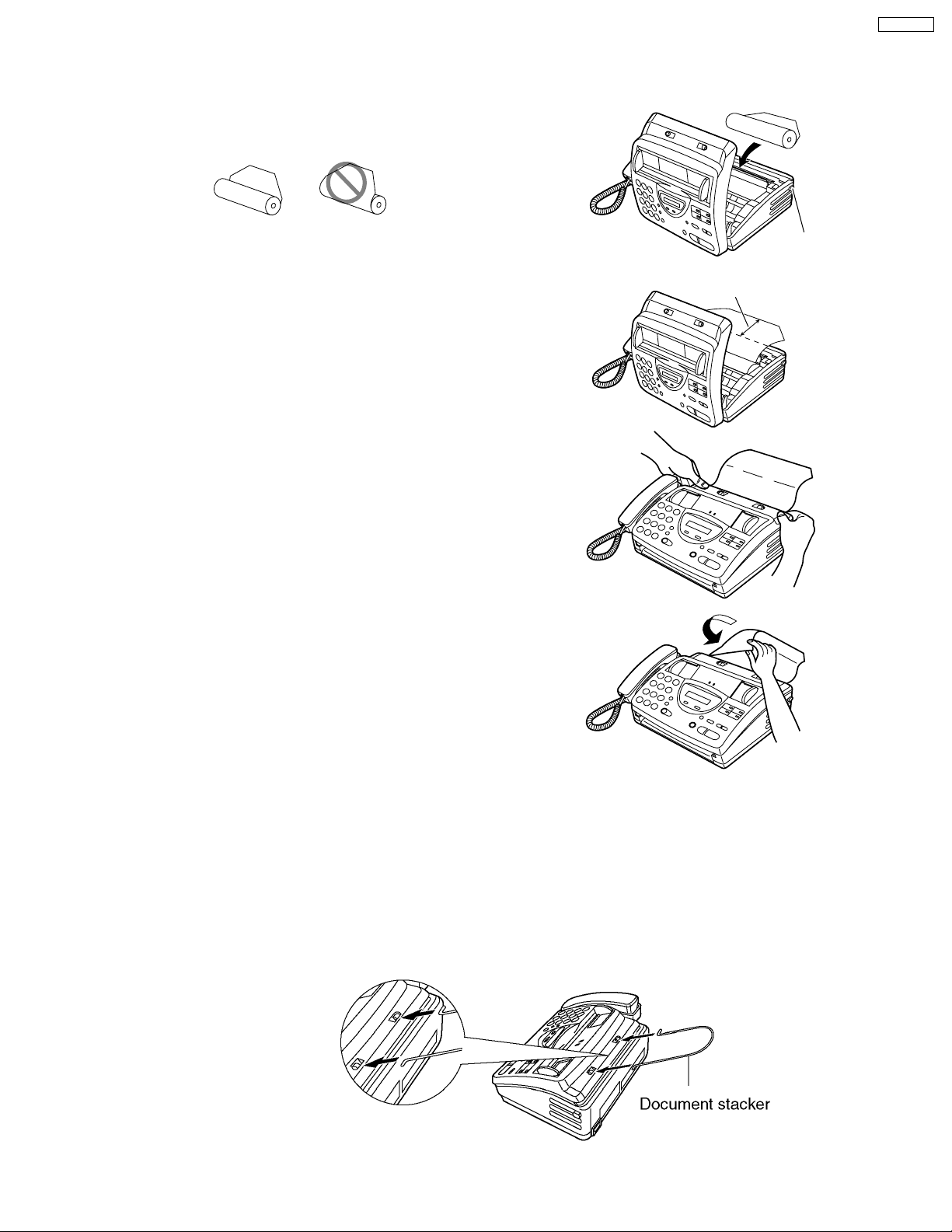

1.13.1. INSTALLING THE RECORDING PAPER

Open the cover by pressing the cover open button

1

and install the recording paper roll.

KX-FT21RS

correct

If the paper is secured with glue or tape, cut

approximately 15 cm (6 inches) from the

beginning.

Pull the leading edge of the paper approximately

10 cm (4 inches) out of the unit.

2

Make sure that there is no slack in the

paper roll.

Close the cover securely by pushing down on

3

4

both ends.

Tear off the excess paper by pulling it

towards you.

incorrect

Cover open

button

10 cm

Note:

Only use the included roll of paper or specified recording paper, or else the print quality may be affected and/or excessive

thermal head wear may occur.

For accessory order information.

When the power cord is connected, every time you close the cover a message will be printed. If the recording paper is set to

the wrong side, the message will not be printed. Install the paper correctly.

1.13.2. Document Stacker

Install the document stacker.

11

KX-FT21RS

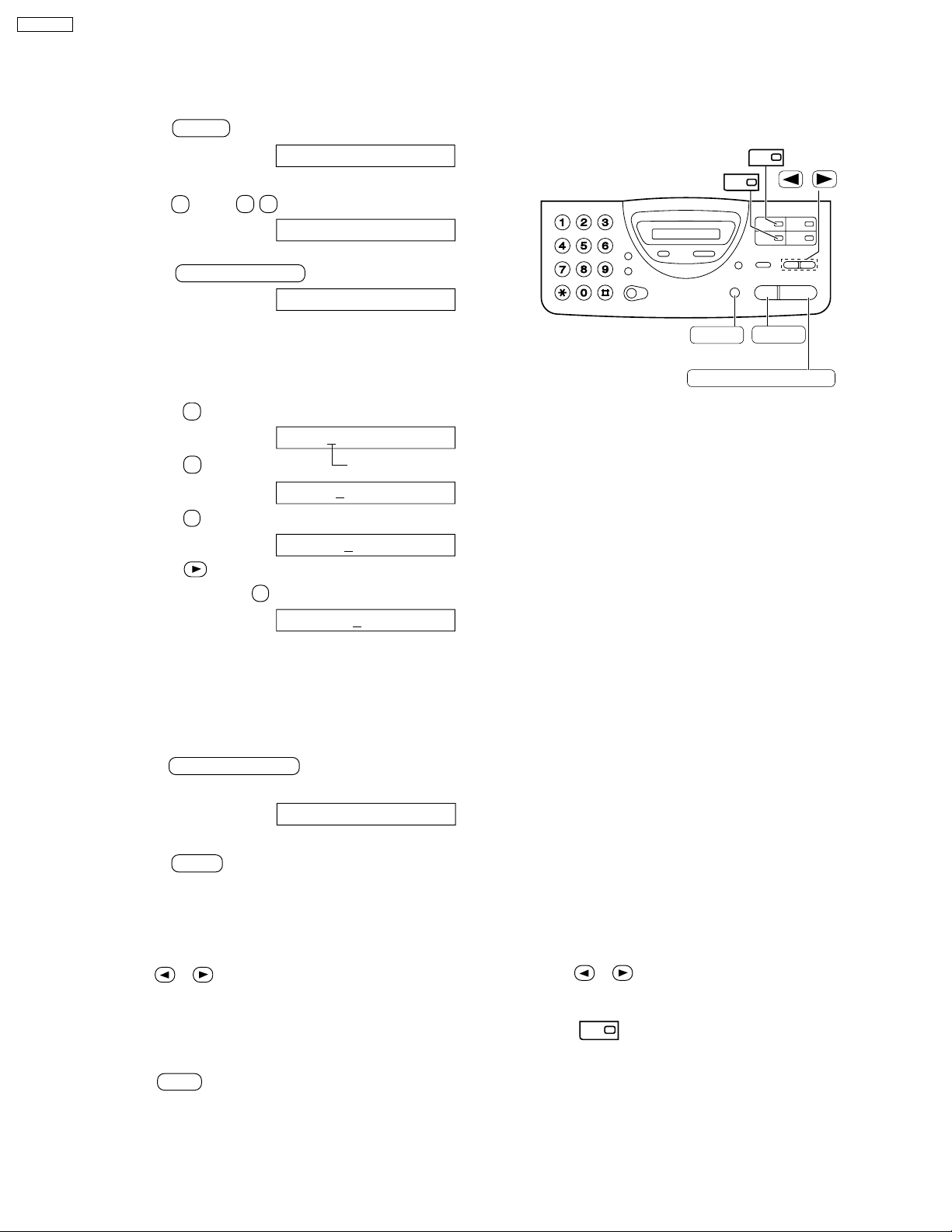

1.13.3. SETTING YOUR LOGO

The logo can be your company, division or name.

Press MENU .

1

Display: SYSTEM SET UP

Press # , then 0 2 .

2

Press START/COPY/SET .

3

YOUR LOGO

LOGO=

1

2

/

Enter your logo, up to 30 characters, by using

4

the dial keypad. See the next page for details.

Example: Bill

1. Press 2 twice.

LOGO=

2. Press 4 six times.

LOGO=B

3. Press 5 six times.

LOGO=Bi

4. Press to move the cursor to the next

space and press 5 six times.

LOGO=Bil

To enter the same number key continuously ,

move the cursor to the next space.

Press START/COPY/SET .

5

B

i

Cursor

l

l

MENU

START/COPY/SET

STOP

(Delete)

SETUP ITEM [ ]

Press MENU .

6

T o correct a mistake

Press or to move the cursor to the incorrect

character, then make the correction.

T o delete a character

Move the cursor to the character you want to delete and

press STOP .

Note:

Words in blankets ( ) are Spanish. A translated version for each market is available with this

model series.

12

To insert a character

1. Press or to move the cursor to the

position to the right of where you want to

insert the character.

2. Press (One-Touch Dial key 2) to insert a

2

space and enter the character.

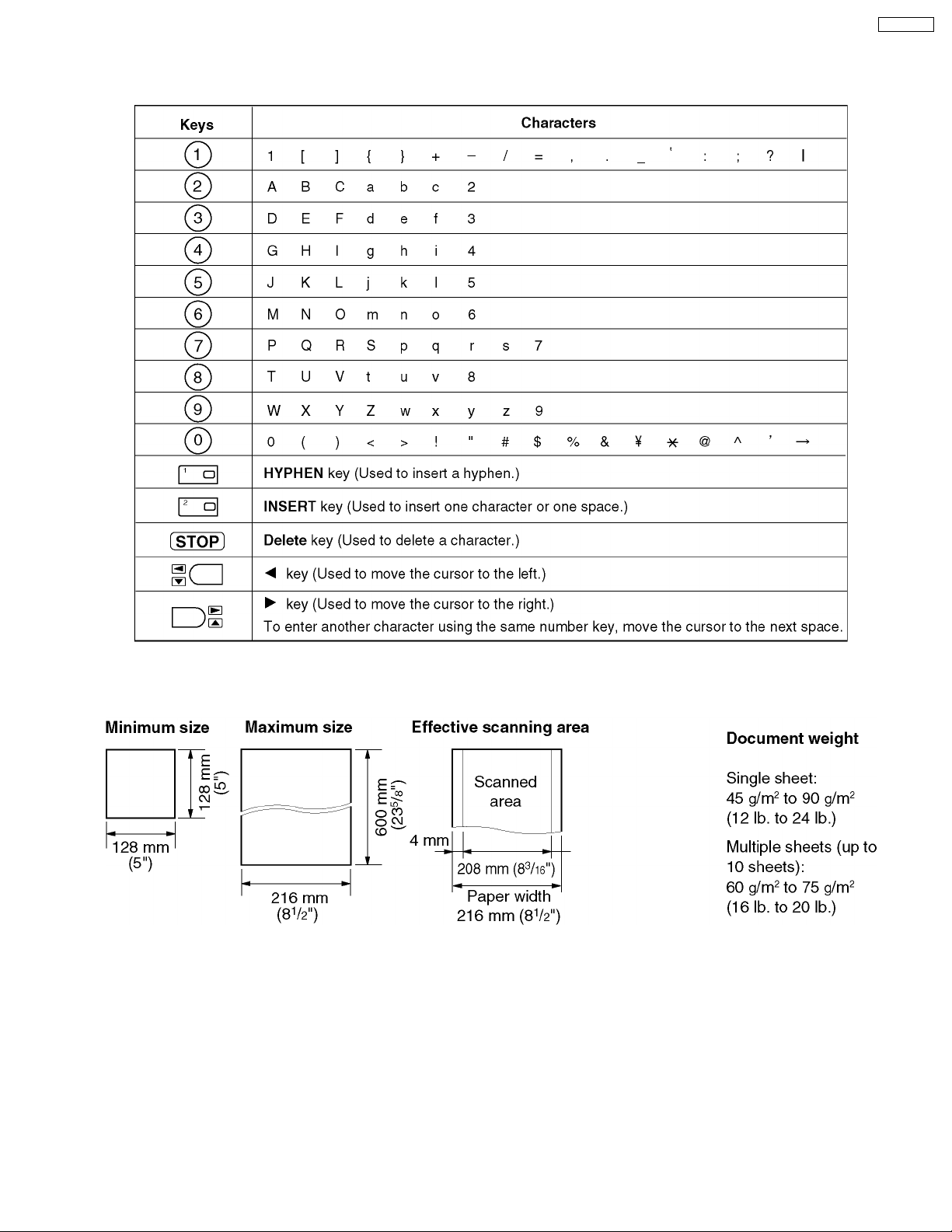

1.13.4. To select characters with the dial keypad

Pressing the dial keys will select a character as shown below.

KX-FT21RS

1.13.5. Documents you can send

Note:

Remove clips, staples or other similar fastening objects.

Check that ink, paste or correction fluid has dried.

Do not send the following types of documents. Use copies for fax transmission.

· Chemically treated paper such as carbon or carbonless duplicating paper

· Electrostatically charged paper

· Heavily curled, creased or torn paper

· Paper with a coated surface

· Paper with a faint image

· Paper with printing on the opposite side that can be seen through the front (e.g. newspaper)

13

KX-FT21RS

1.14. MAINTENANCE ITEMS AND COMPONENT LOCATIONS

1.14.1. OUTLINE

MAINTENANCE AND REPAIRS ARE PERFORMED USING THE FOLLOWING STEPS.

1. Periodic maintenance

Inspect the equipment periodically and if necessary, clean any contaminated parts.

2. Check for breakdowns

Look for problems and consider how they arose.

If the equipment can be still used, perform copying, self testing or communication testing.

3. Check equipment

Perform copying, self testing and communication testing to determine if the problem origina tes from the transmitter, receiver or

the telephone line.

4. Determine causes

Determine the causes of equipment problem by troubleshooting.

5. Equipment repairs

Repair or replace the defective parts and take appropriate measures at this stage to ensure that the problem will not recur.

6. Confirm normal operation of the equipment

After completing the repairs, conduct copying, self testing and communication testing to confirm that the equipment operates

normally.

7. Record keeping

Make a record of the measures taken to rectify the problem for future reference.

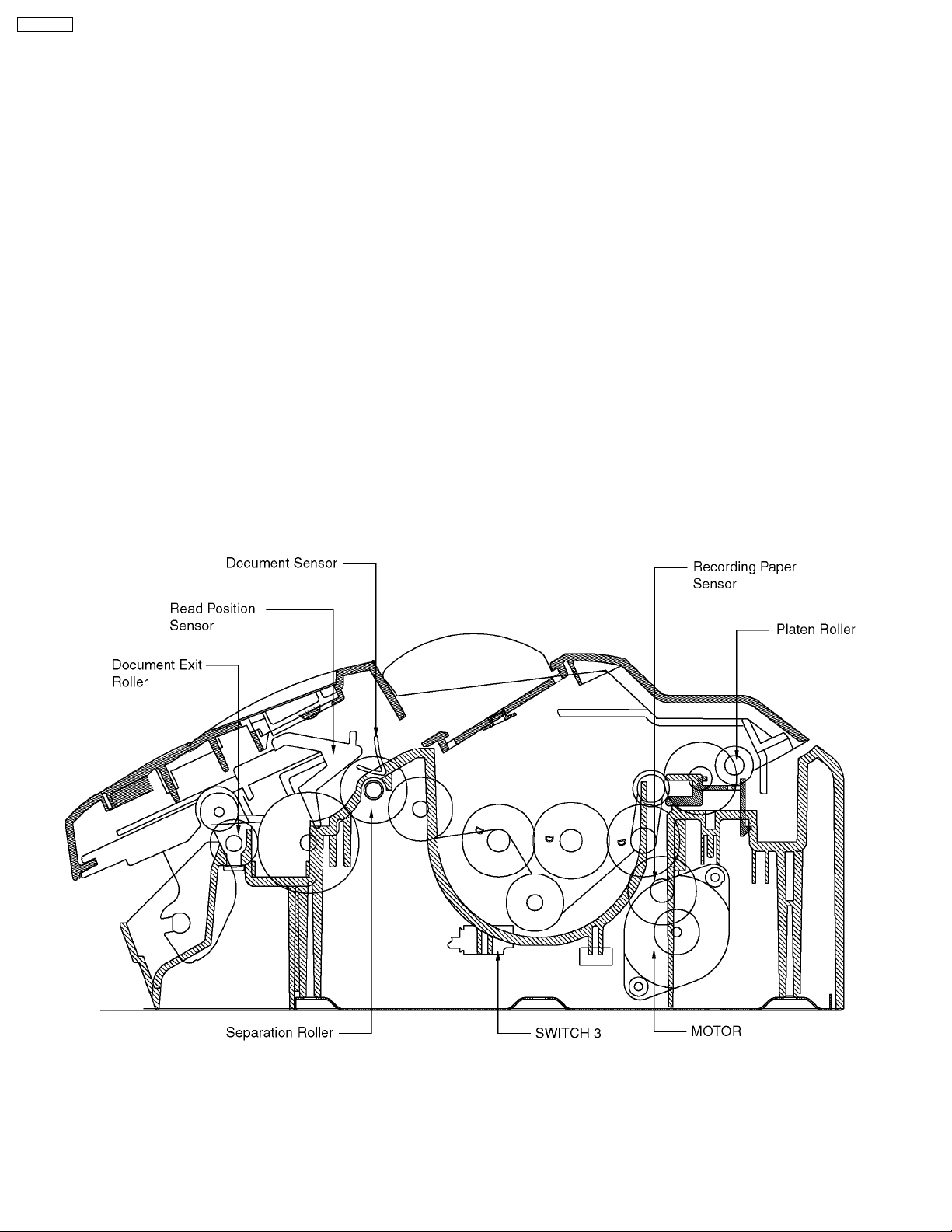

1.14.2. MAINTENANCE CHECK ITEMS/COMPONENT LOCATIONS

14

1.14.2.1. MAINTENANCE LIST

1.14.2.2. MAINTENANCE CYCLE

KX-FT21RS

15

KX-FT21RS

1.14.3. MAINTENANCE

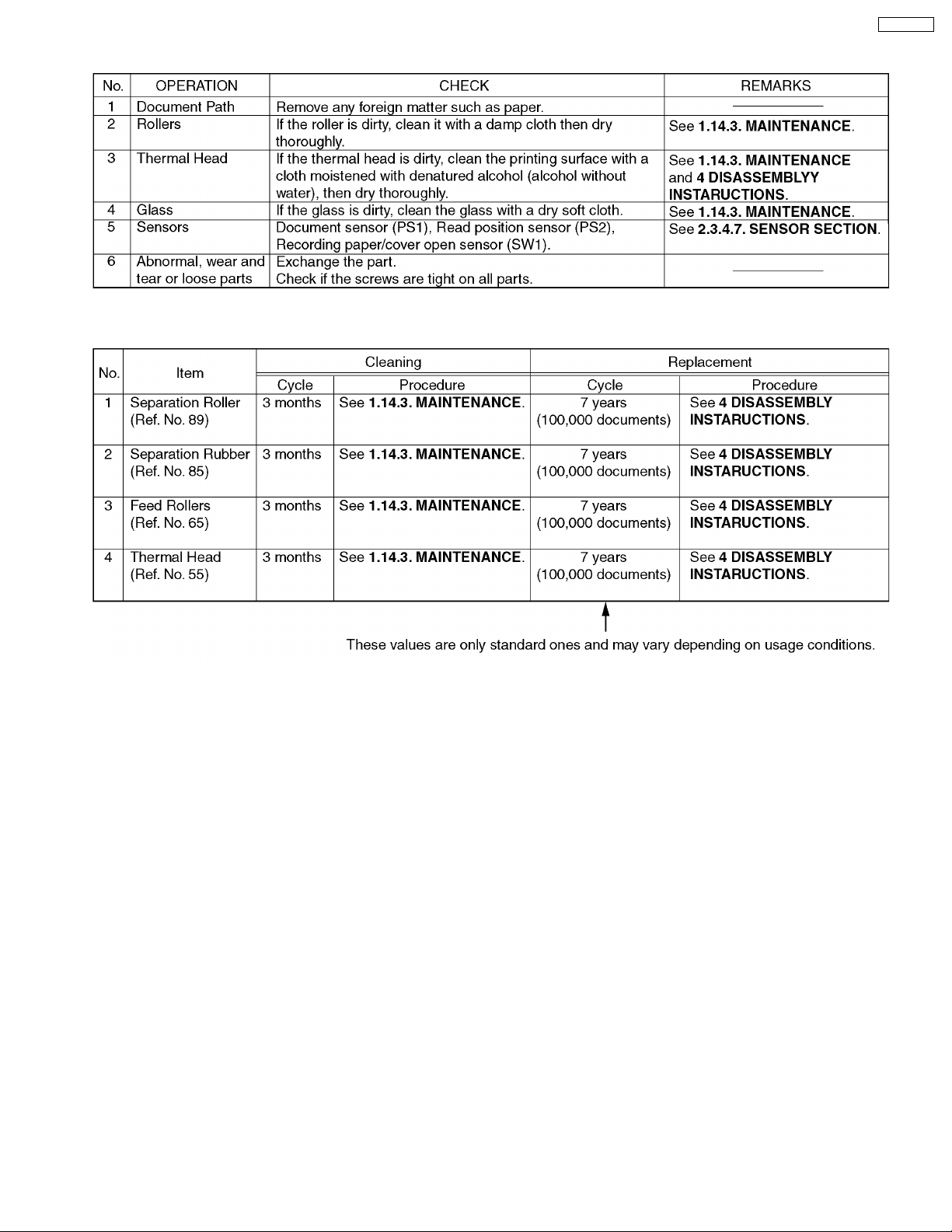

1.14.3.1. CLEANING THE DOCUMENT FEEDER UNIT

If misfeeding occurs frequently or if dirty patterns or black bands appear on a copied or transmitted document, clean the document

feeder.

Disconnect the power cord and the telephone

1

line cord.

Open the cover by pressing the cover open button.

2

Clean the document feeder rollers, sub roller and

3

rubber flap with a cloth moistened with isopropyl

rubbing alcohol, and let all parts dry thoroughly.

Clean the white plate and glass with a soft dry cloth.

4

Close the cover securely by pushing down on both

5

6

Caution:

or tissues, to clean the inside of the unit.

ends.

Connect the power cord and the telephone line

cord.

Do not use paper products, such as paper towels

Separation roller

Cover

Cover open button

Telephone

line code

Power cord

Sub roller

Document

feeder rollers

16

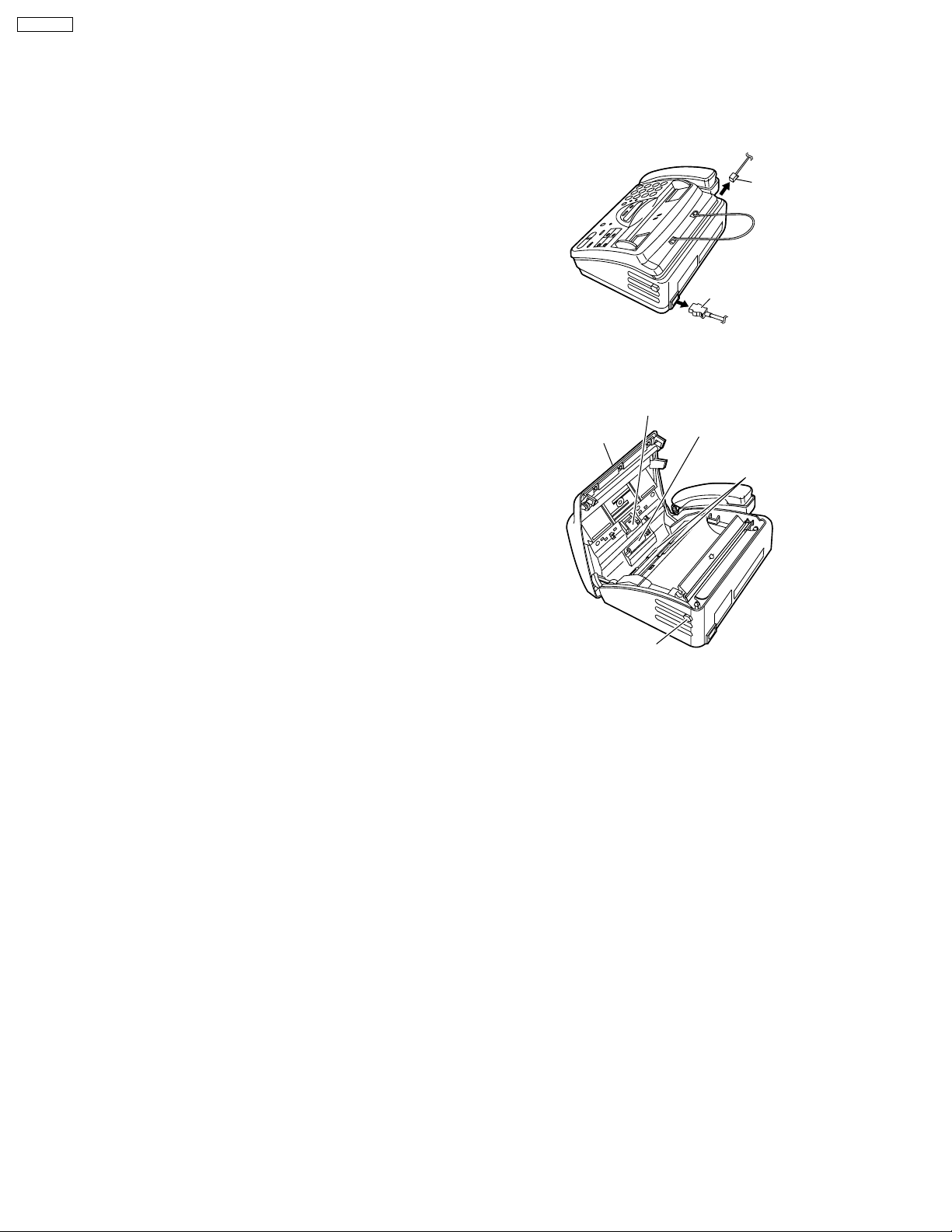

1.14.3.2. CLEANING THE THERMAL HEAD

If dirty patterns or black bands appear on a copied or received document, clean the thermal head.

Disconnect the power cord and the telephone

1

line cord.

KX-FT21RS

Open the cover by pressing the cover open button.

Thermal head

2

Clean the thermal head with a cloth moistened with

3

4

5

Caution:

a dry cloth and do not touch the thermal head directly with

your fingers.

1.14.3.3. CLEANING THE PICK UP ROLLER........Refer to 4 DISASSEMBLY INSTRUCTION

isopropyl rubbing alcohol, and let it dry thoroughly.

Close the cover securely by pushing down on both

ends.

Connect the power cord and the telephone line

cord.

To prevent a malfunction due to static electricity , do not use

Cover open

button

Caution:

Do not push on

the black cover

17

KX-FT21RS

2 TROUBLESHOOTING GUIDE

2.1. TROUBLESHOOTING SUMMARY

2.1.1. TROUBLESHOOTING

After confirming the problem by asking the user, troubleshoot according to the instructions and observe the following precautions.

2.1.2. PRECAUTIONS

1. If there is a problem with the print quality or the paper feed, first check if the installation space and the print paper meets the

specifications, the paper selection lever/paper thickness lever is set correctly, and the paper is set correctly without any slack.

2. Before troubleshooting, first check that the connectors and cables are connected correctly (not loose).

If the problem occurs randomly, check it very carefully.

3. When connecting the AC power cord with the unit case and checking the operation, exercise utmost care when handling electric

parts in order to avoid electric shocks and short-circuits.

4. After troubleshooting, double check that you have not forgotten any connectors, left any loose screws, etc.

5. Always test to verify that the unit is working normally.

2.1.3. WHEN YOU DON´T KNOW HOW TO OPERATE THE UNIT, USE THE HELP

FUNCTION

18

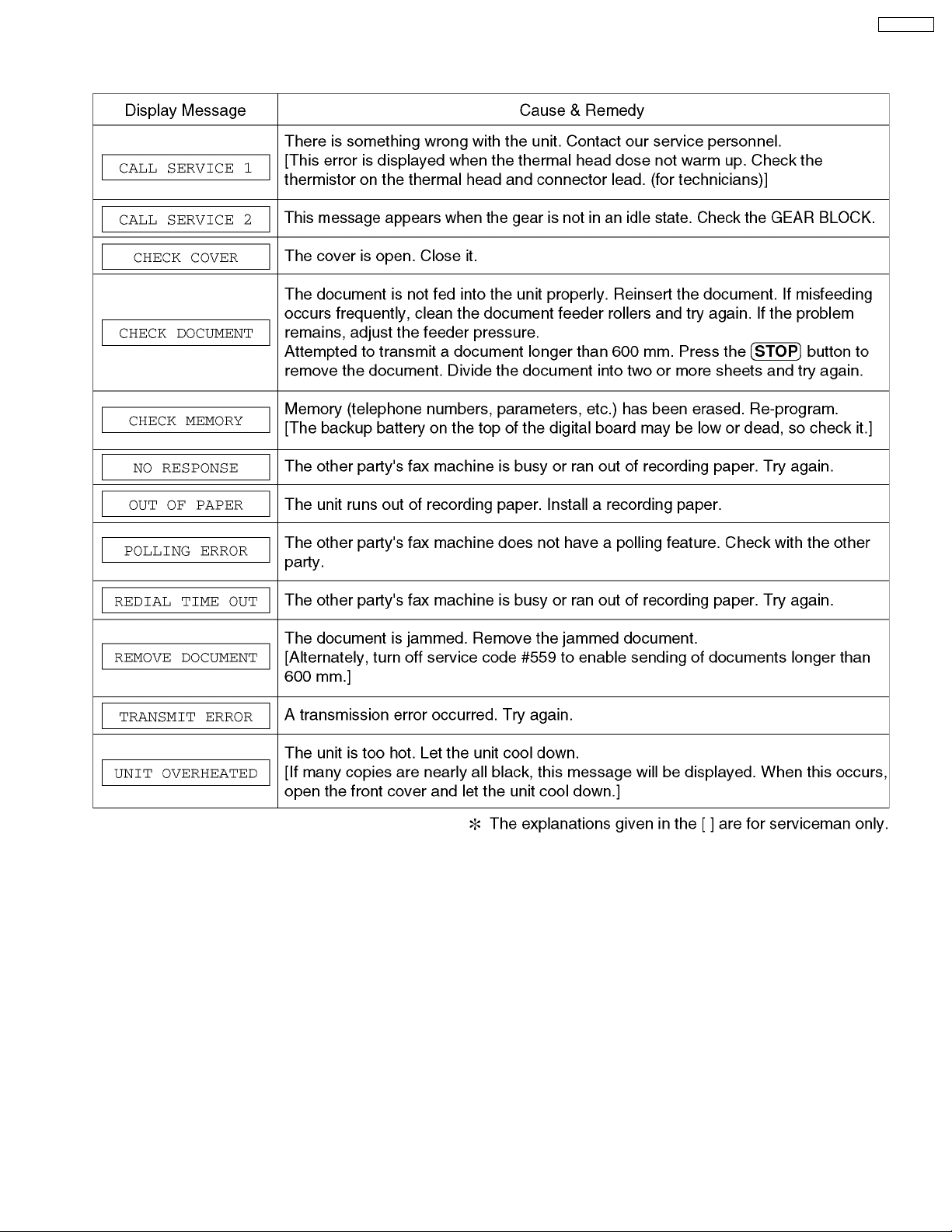

2.2. USER RECOVERABLE ERRORS

If the unit detects a problem, the following messages will appear on the display.

KX-FT21RS

Note:

The explanations given in the [ ] are for servicemen only.

19

KX-FT21RS

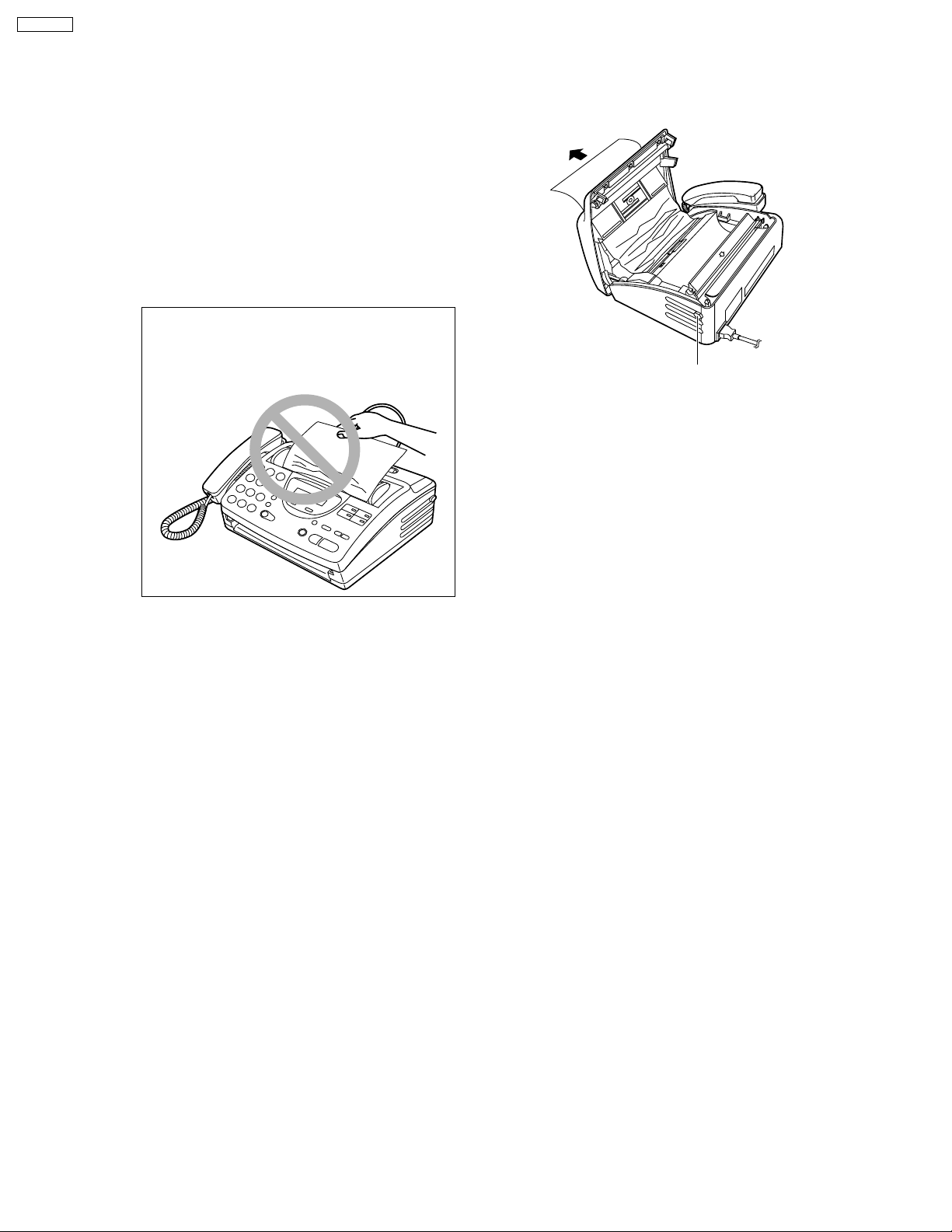

2.2.1. Document Jam

If the unit does not release the document during feeding, remove the jammed document as follows.

Open the cover by pressing the cover open

1

button.

Remove the jammed document carefully.

2

Close the cover securely by pushing down

3

on both ends.

Note:

• Do not pull out the jammed paper forcibly.

before opening the cover.

Cover open button

20

KX-FT21RS

2.3. TROUBLESHOOTING DETAILS

2.3.1. OUTLINE

Troubleshooting guide provides a logical path of deduction to assist in locating a fault and suggests methods of restoring the unit

to full working condition. Use the reported symptoms of the fault to determine the best troubleshooting method. Even difficult faults

can be tracked to a specific block or area, for example, the "Digital Board" or "Image Sensor".

A variety of fault descriptions from customers often point to the same area and, for this reason, careful analysis of the reported

symptoms is required. After every repair, test all functions to ensure no problems are evident.

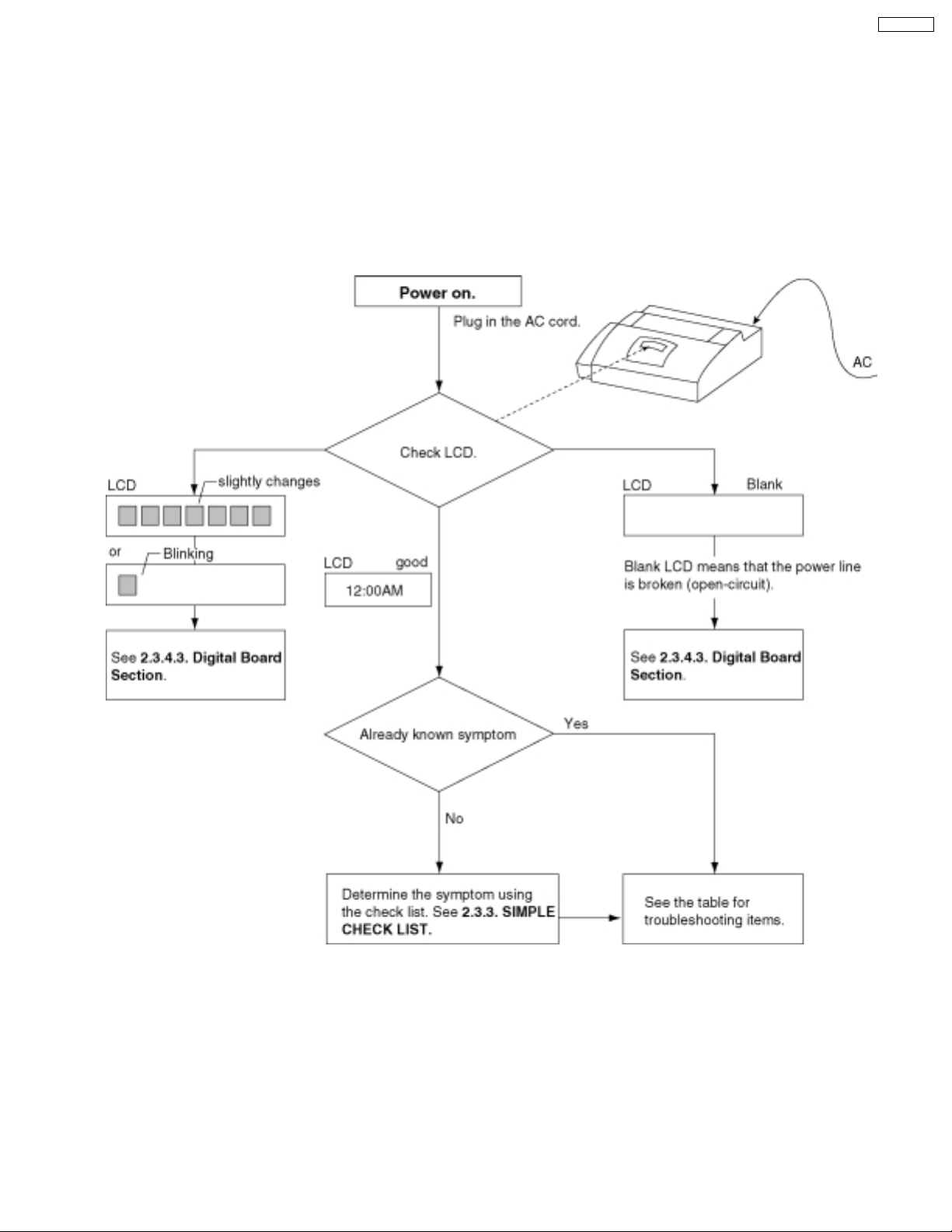

2.3.2. STARTING TROUBLESHOOTING

Select the appropriate troubleshooting method according to the symptoms.

21

KX-FT21RS

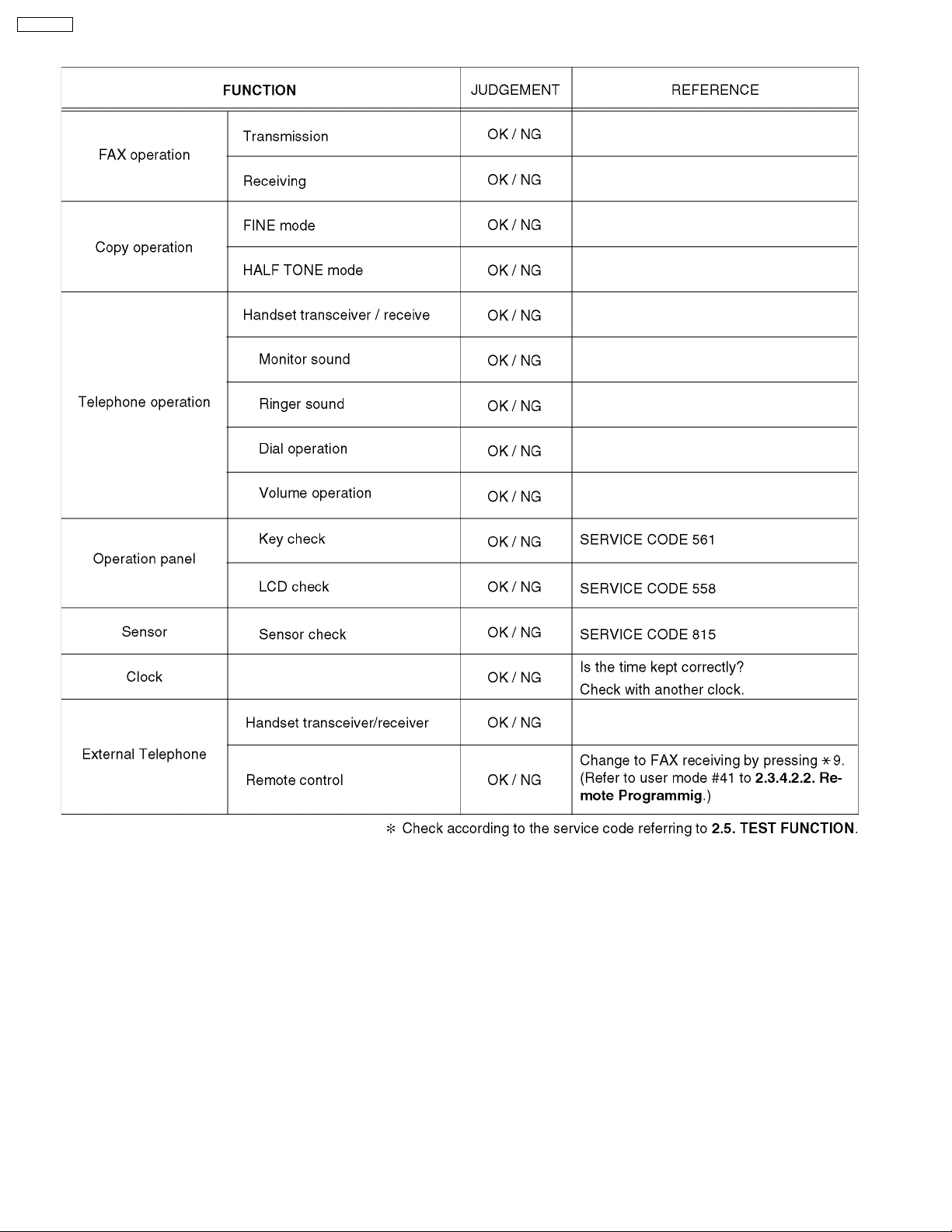

2.3.3. Simple Check List

22

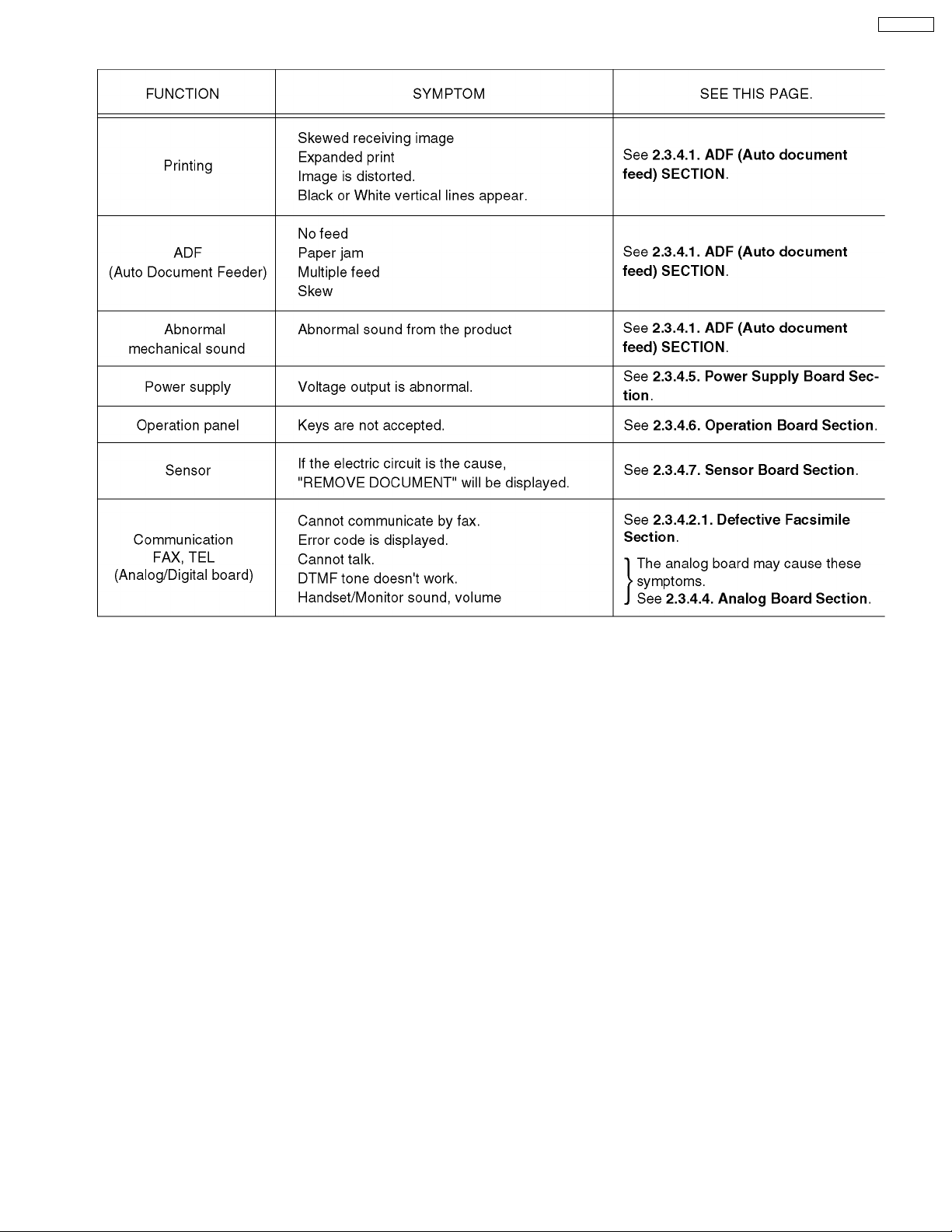

2.3.4. TROUBLESHOOTING ITEMS TABLE

KX-FT21RS

23

KX-FT21RS

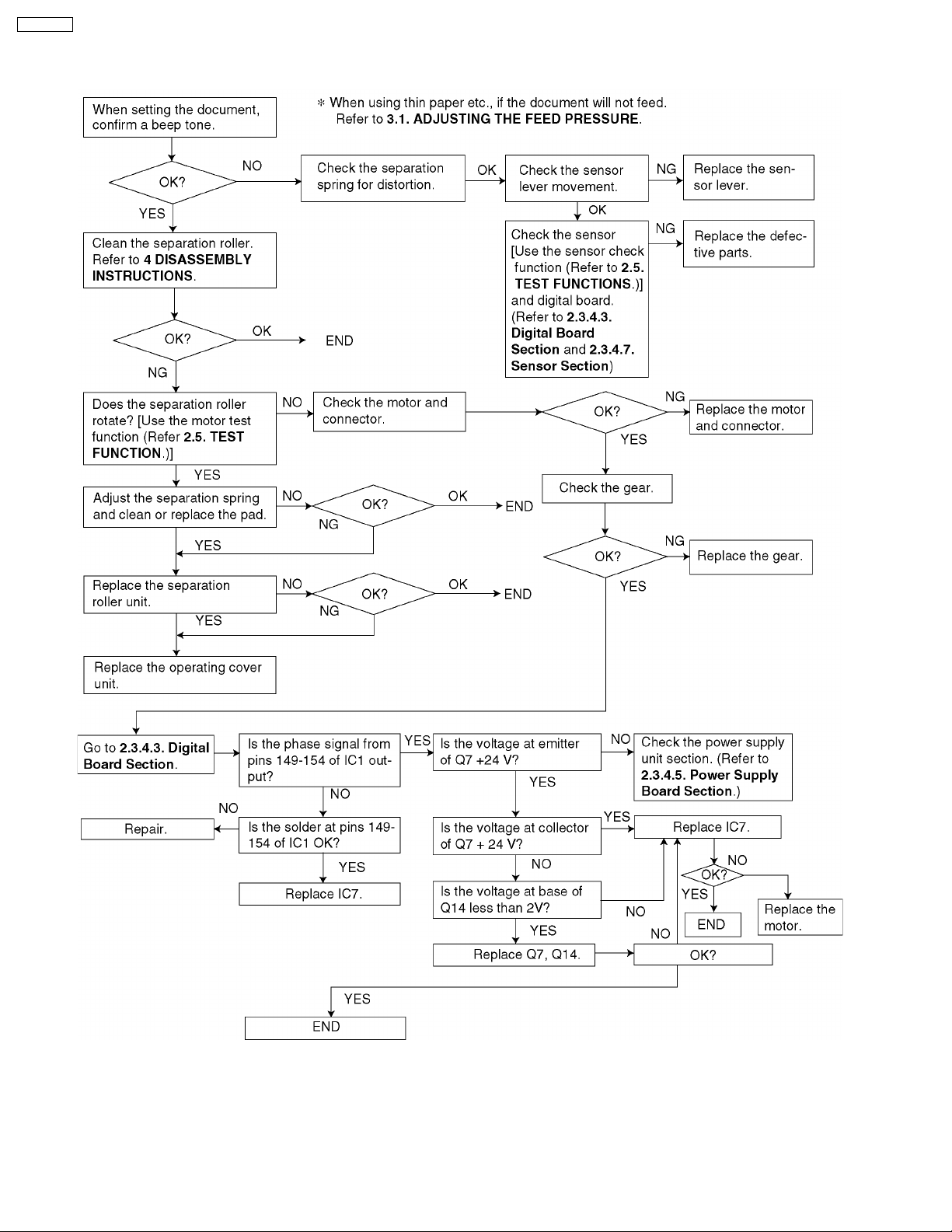

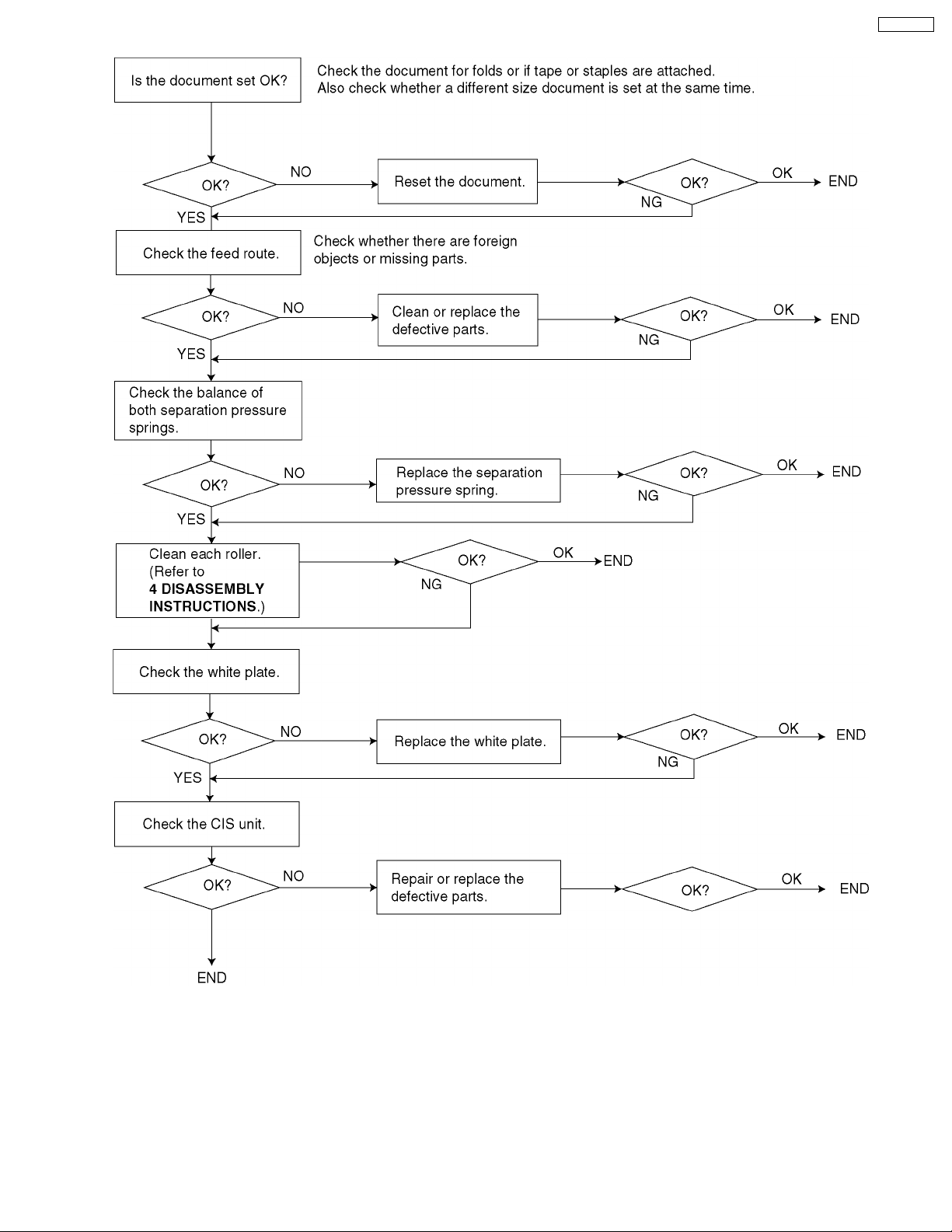

2.3.4.1. ADF (Auto Document Feed) Section

1. No document feed

24

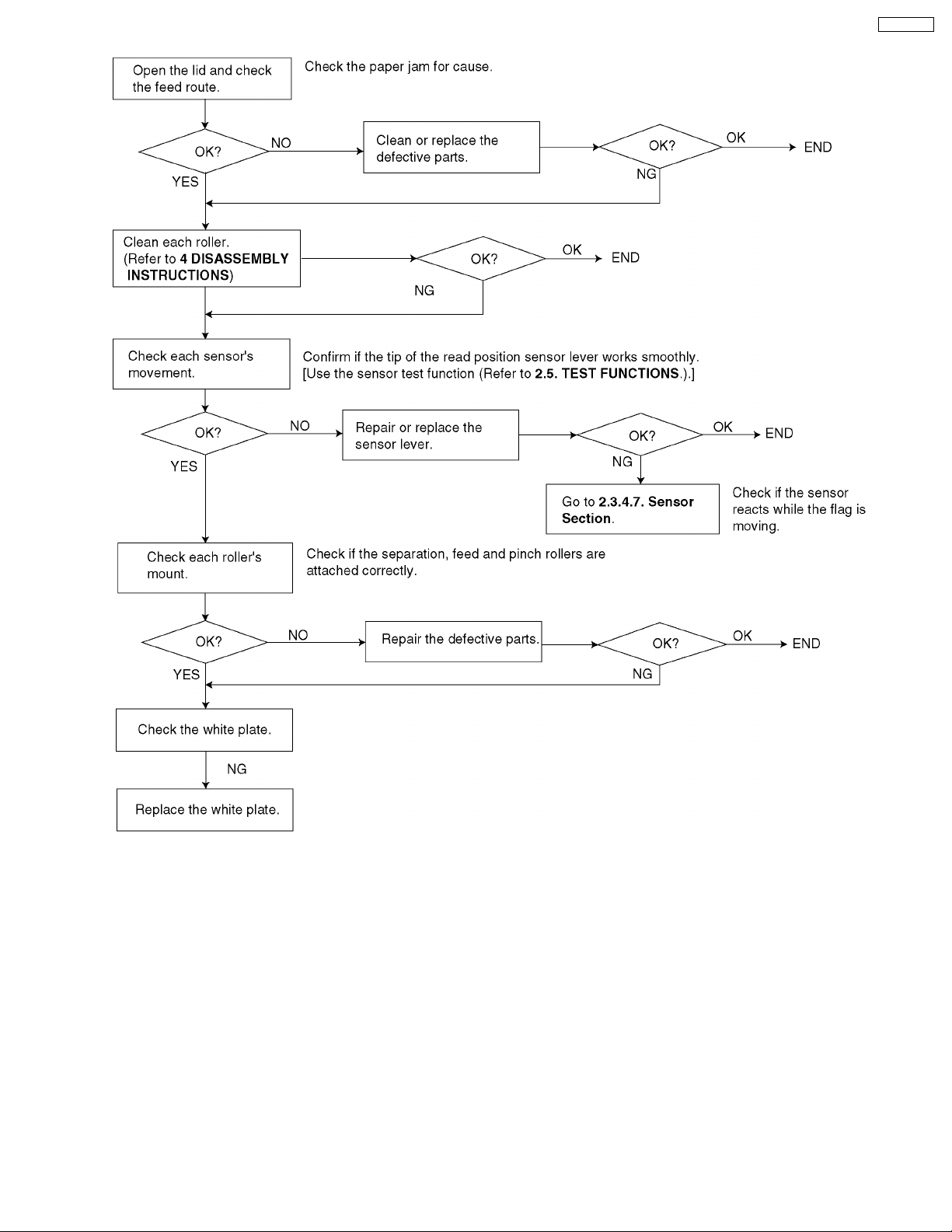

2. Paper JAM

KX-FT21RS

25

KX-FT21RS

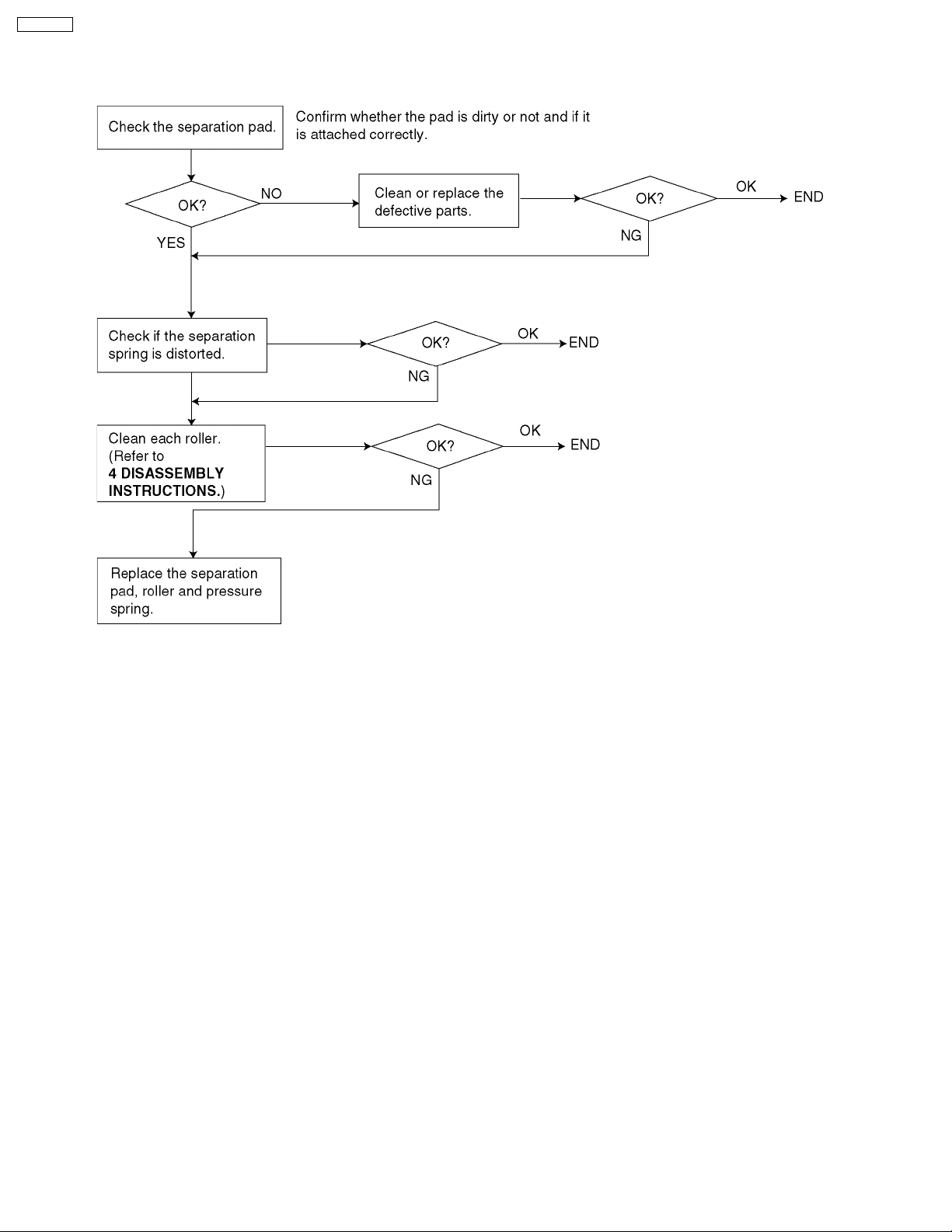

3. Multiple feed

When using thick paper etc., If the document will not feed.

Refer to 3.1. ADJUSTING THE FEED PRESSURE.

26

4. Skew

KX-FT21RS

27

KX-FT21RS

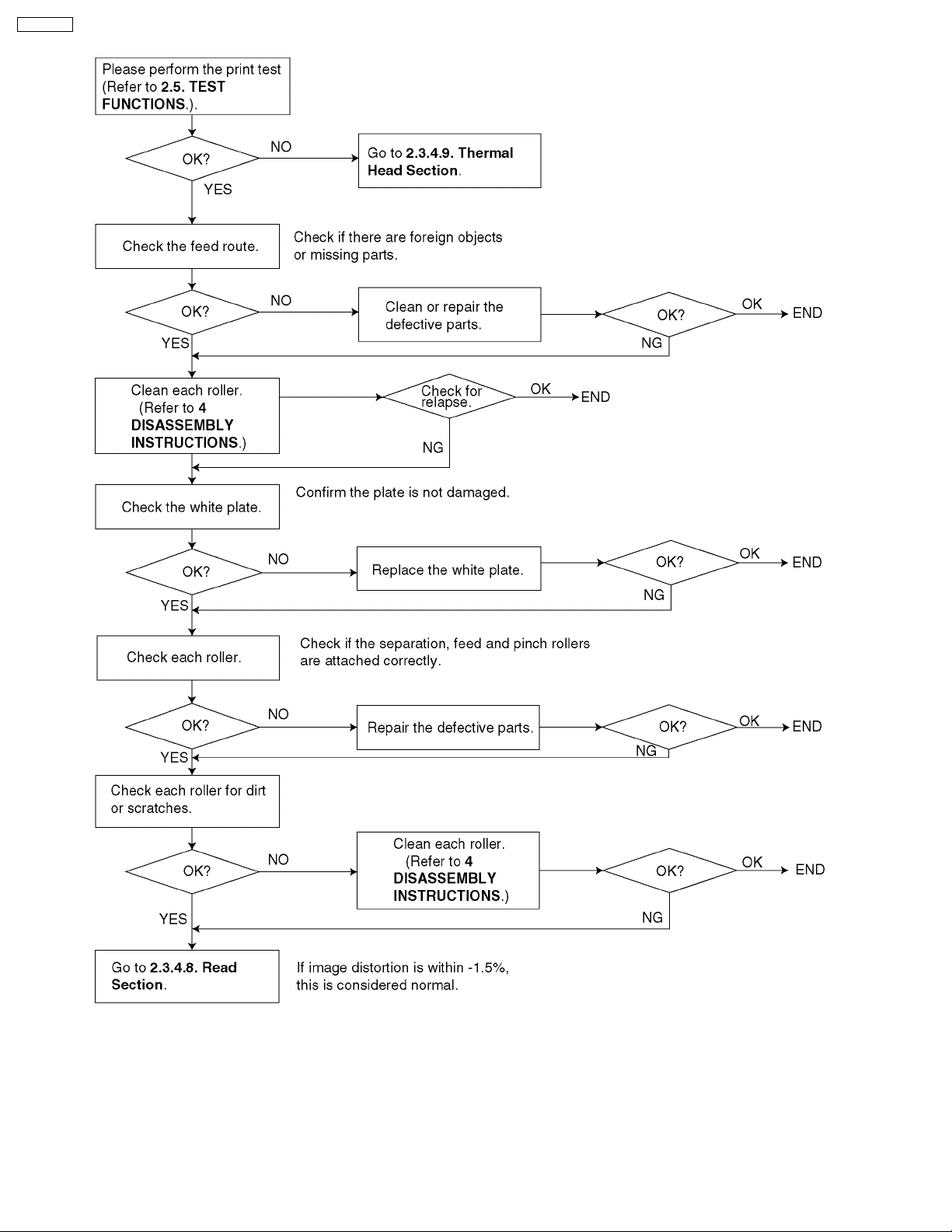

5. Image is distorted (When printing)

28

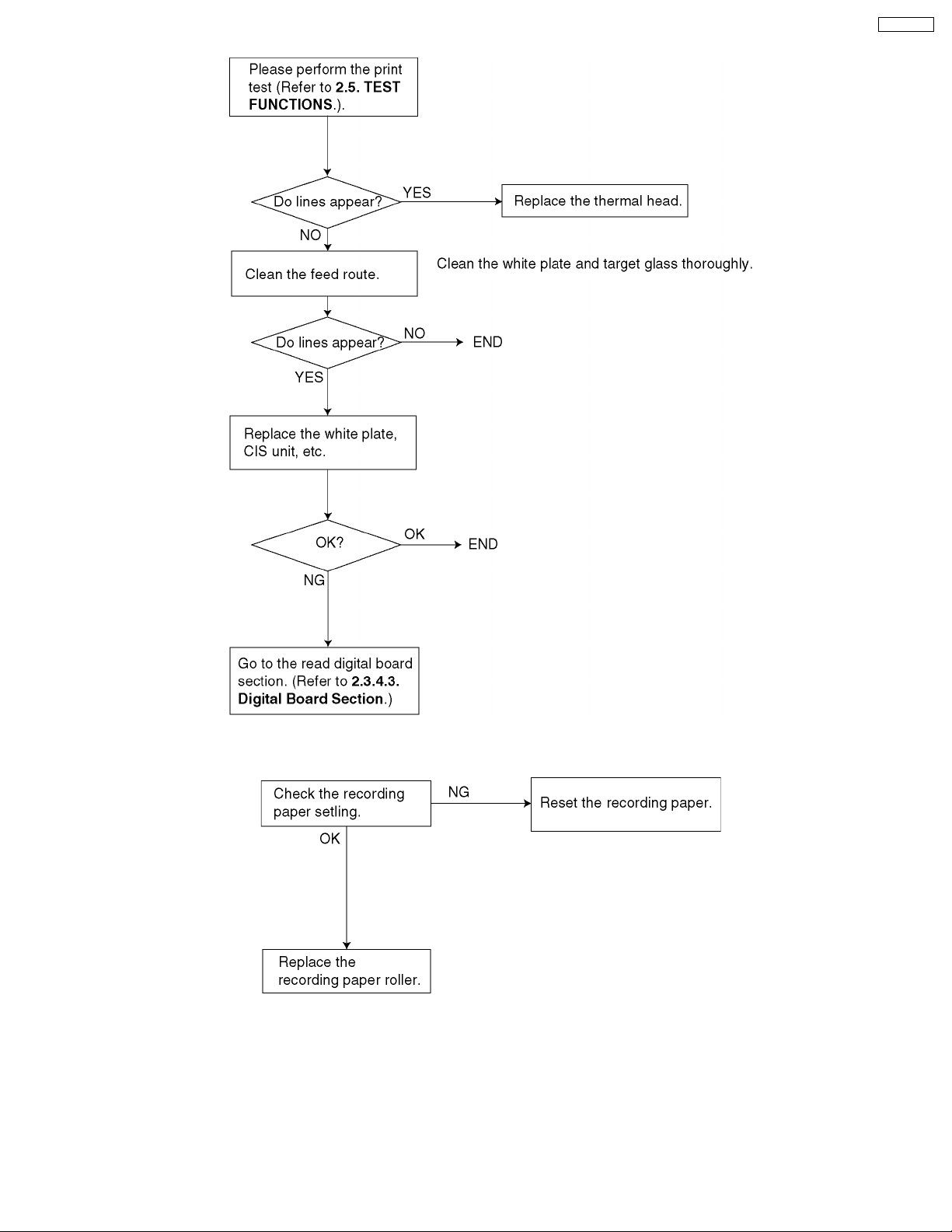

6. Black or white vertical lines appear

KX-FT21RS

7. Skewed receiving image

29

KX-FT21RS

8. Expander print (When printing)

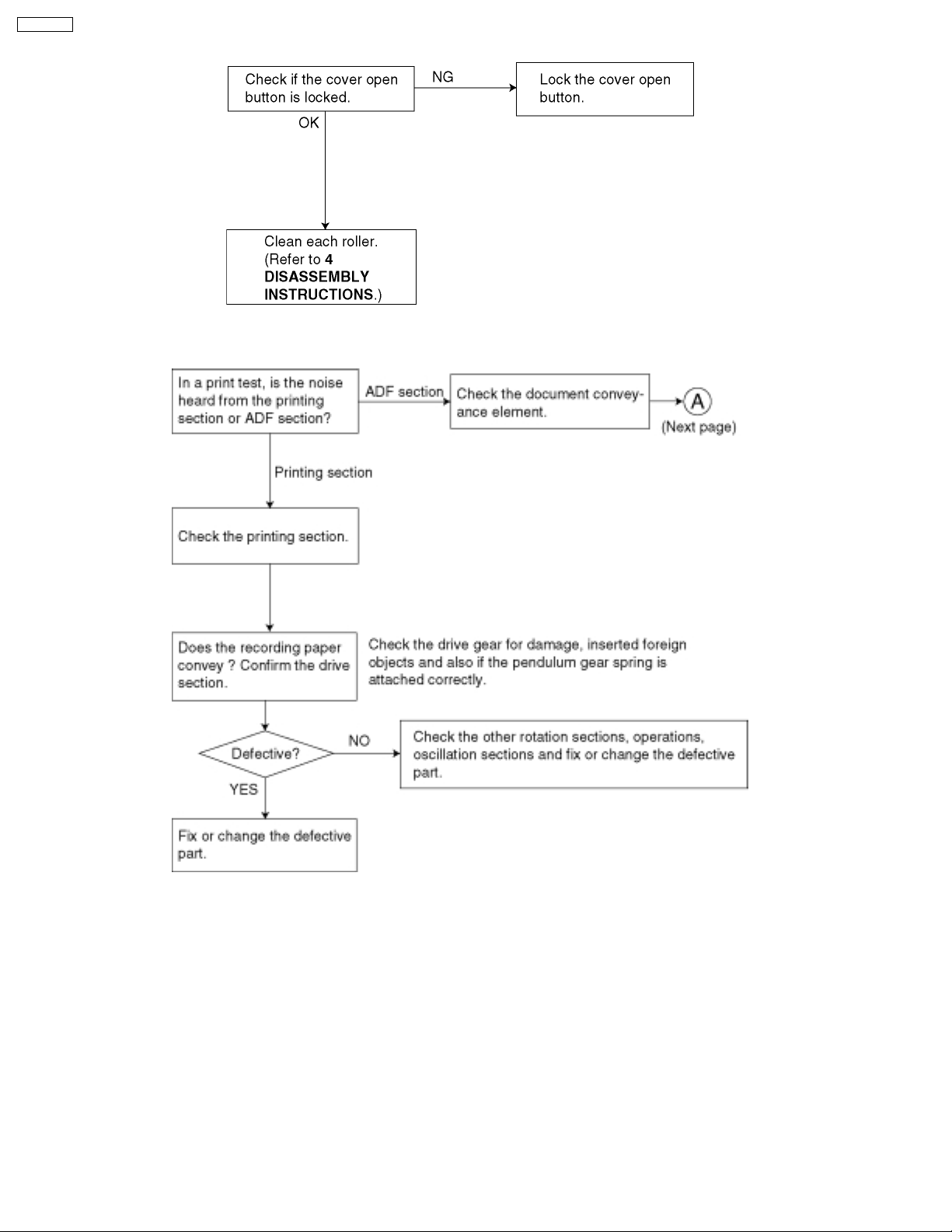

9. When copying or printing, an abnormal sound is heard from the unit

30

Loading...

Loading...