Panasonic KX-FP81 Service manual

Compact Plain Paper FAX

KX-FP81

(for U.S.A.)

ORDER NO. KMF0004401C1

F7

© 2000 Kyushu Matsushita Electric Co., Ltd. All

rights reserved. Unauthorized copying and

distribution is a violation of law.

KX-FP81

1 INTRODUCTION

1.1. SAFETY PRECAUTIONS

1. Before servicing, unplug the AC power cord to prevent an electric shock.

2. When replacing parts, use only the manufacturer´s recommended components.

3. Check the condition of the power cord. Replace if wear or damage is evident.

4. After servicing, be sure to restore the lead dress, insulation barriers, insulation papers, shields, etc.

5. Before returning the serviced equipment to the customer, be sure to perform the following insulation resistance test to prevent

the customer from being exposed to shock hazards.

1.2. INSULATION RESISTANCE TEST

1. Unplug the power cord and short the two prongs of the plug with a jumper wire.

2. Turn on the power switch.

3. Measure the resistance value with an ohmmeter between the jumpered AC plug and each exposed metal cabinet part

(screw heads, control shafts, bottom frame, etc.).

Note: Some exposed parts may be isolated from the chassis by design. These will read infinity.

4. If the measurement is outside the specified limits, there is a possibility of a shock hazard.

1.3. FOR SERVICE TECHNICIANS

ICs and LSIs are vulnerable to static electricity.

When repairing, the following precautions will help prevent recurring malfunctions.

1. Cover the plastic part´s boxes with aluminum foil.

2. Ground the soldering irons.

3. Use a conductive mat on the worktable.

4. Do not touch the IC or LSI pins with bare fingers.

1.4. BATTERY CAUTION

CAUTION

Danger of explosion if the battery is replaced incorrectly. Replace only with the same or equivalent type recommended by the

manufacturer. Discard used batteries according to following caution:

Disposal of lithium batteries should be performed by permitted, professional disposal firms knowledgeable in state government

federal and local hazardous materials and hazardous waste transportation and disposal requirements.

A battery continues to have no transportation limitations as long as it is separated to prevent short circuits and packed in strong

packaging.

Commercial firms that dispose of any quantity of lithium cells should have a mechanism in place to account for their ultimate

disposition. This is a good practice for all types of commercial or industrial waste.

Recommend Type Number:

CR2032 (BAT501) Manufactured by MATSUSHITA

CR2032 (BAT501) Manufactured by SONY

2

1.5. AC CAUTION

For safety, before closing the lower cabinet, please make sure of the following precautions.

1. The earth lead is fixed with the screw.

2. The AC connector is connected properly.

3. Wrap the earth lead around the core 3 times.

4. Wrap the AC lead around the core 2 times.

1.6. PERSONAL SAFETY PRECAUTIONS

KX-FP81

1.6.1. MOVING SECTIONS OF THE UNIT

Be careful not to let your hair, clothes, fingers, accessories, etc., become caught in any moving sections of the unit.

The moving sections of the unit are the rollers and a gear. There is a separation roller and a document feed roller which are rotated

by the document feed motor. A gear rotates the two rollers. Be careful not to touch them with your hands, especially when the unit

is operating.

3

KX-FP81

1.6.2. LIVE ELECTRICAL SECTIONS

All the electrical sections of the unit supplied with AC power by the AC power cord are live.

Never disassemble the unit for service with the AC power supply plugged in.

CAUTION:

AC voltage is supplied to the primary side of the power supply unit. Therefore, always unplug the AC power cord before

disassembling for service.

1.7. SERVICE PRECAUTIONS

1.7.1. PRECAUTIONS TO PREVENT DAMAGE FROM STATIC ELECTRICITY

Electrical charges accumulate on a person. For instance, clothes rubbing together can damage electric elements or change their

electrical characteristics. In order to prevent static electricity, touch a metallic part that is grounded to release the static electricity.

Never touch the electrical sections such as the power supply unit, etc.

4

1.8. FEATURES

General

· Help function

Please refer to 2.1.3 WHEN YOU DON'T KNOW HOW TO

OPERATE THE UNIT, USE THE HELP FUNCTION.(P.24)

to print below features.

Display:

1. QUICK SET UP

2. FEATURE LIST

3. JOG-DIAL

4. FAX SND/RCV

5. COPIER

6. Q and A

7. ERRORS

8. REPORTS

· LCD (Liquid Crystal Display) readout

· TAM (Telephone answering machine) interface

TM

· IQ-FAX

This feature can only be used by those who apply to the

FaxSav service.

IQ-FAX is intelligent faxing which allows you to send faxes

via the internet by using the IQ-FAX button.

Behind the IQ-FAX button is the FaxSav Global Fax

Network which manages the delivery of your fax to any fax

machine in the world. It routes your fax via the best and

most time efficient route and will automatically resend your

fax for you, if the receiving fax machine is unavailable.

This "fax-only" network has the added advantage of cost

efficiency due to the internet being integrated into the net

work. Every fax is secure since the FaxSav net work utilizes

the highest encryption legally allowed, ensuring that your

documents stay secure. You get the benefits of carefree

faxing with savings associated with the use of the internet.

It is simple, quick, and secure.

(for U.S.A. only)

KX-FP81

Integrated Telephone System

· On-hook dialing

· Monitor speaker

· Voice muting

· Redialing function

· 50-Station telephone directory with Jog Dial

Enhanced Copier Function

· Multi-copy function (up to 50 copies)

· Enlargement and reduction

· Collate

· 64-Level halftone

Plain Paper Facsimile Machine

· 15 second transmission speed *

· A4/Letter, G3 compatible

· Automatic document feeder (10 sheets)

· Fax pager call

· Quick scan

· Resolution: Standard/Fine/Super fine/Half tone (64 level)

· Broad cast with Jog-Dial

· 50-sheet paper capacity (20 lb.)

· Automatic fax/phone switching

· Distinctive ring detection **

* The speed of 15s/page is based upon the ITU-T No. 1 Test

Chart on the condition t hat memory transmission is performed.

** Subscription to distinctive ring services is required.

Large Memory (24 pages)... Performed by DRAM

Approx. 28 pages of memory reception

Approx. 25 pages of memory transmission

5

KX-FP81

1.9. SPECIFICATIONS

Applicable Lines: Public Switched Telephone Network

Document Size: Max. 216 mm (8 1/2") in width

Max. 600 mm (23 5/8") in length

Effective Scanning Width: 208 mm (8 3/16")

Recording Paper Size: Letter: 216×279 mm (8 1/2"×11")

Legal: 216×356 mm (8 1/2"×14")

A4: 210×297 mm (8 1/4"×11 11/16")

Effective Printing Width: 208 mm (8 3/16")

Transmission Time*: Approx. 15 s/page (Original mode)**

Scanning Density: Horizontal:

8 pels/mm (203 pels/inch)

Vertical:

3.85 lines/mm (98 lines/inch)—STANDARD mode

7.7 lines/mm (196 lines/inch)—FINE/HALF TONE mode

15.4 lines/mm (392 lines/inch)—SUPER FINE Mode

Halftone Level: 64-level

Scanner Type: Contact Image Sensor (CIS)

Printer Type: Thermal Transfer on Plain Paper

Data Compression System: Modified Huffman (MH), Modified READ (MR)

Modem Speed: 9,600/7,200/4,800/2,400 bps; Automatic Fallback

Operating Environment: 5—35°C (41—95°F), 20—80 % RH (Relative Humidity)

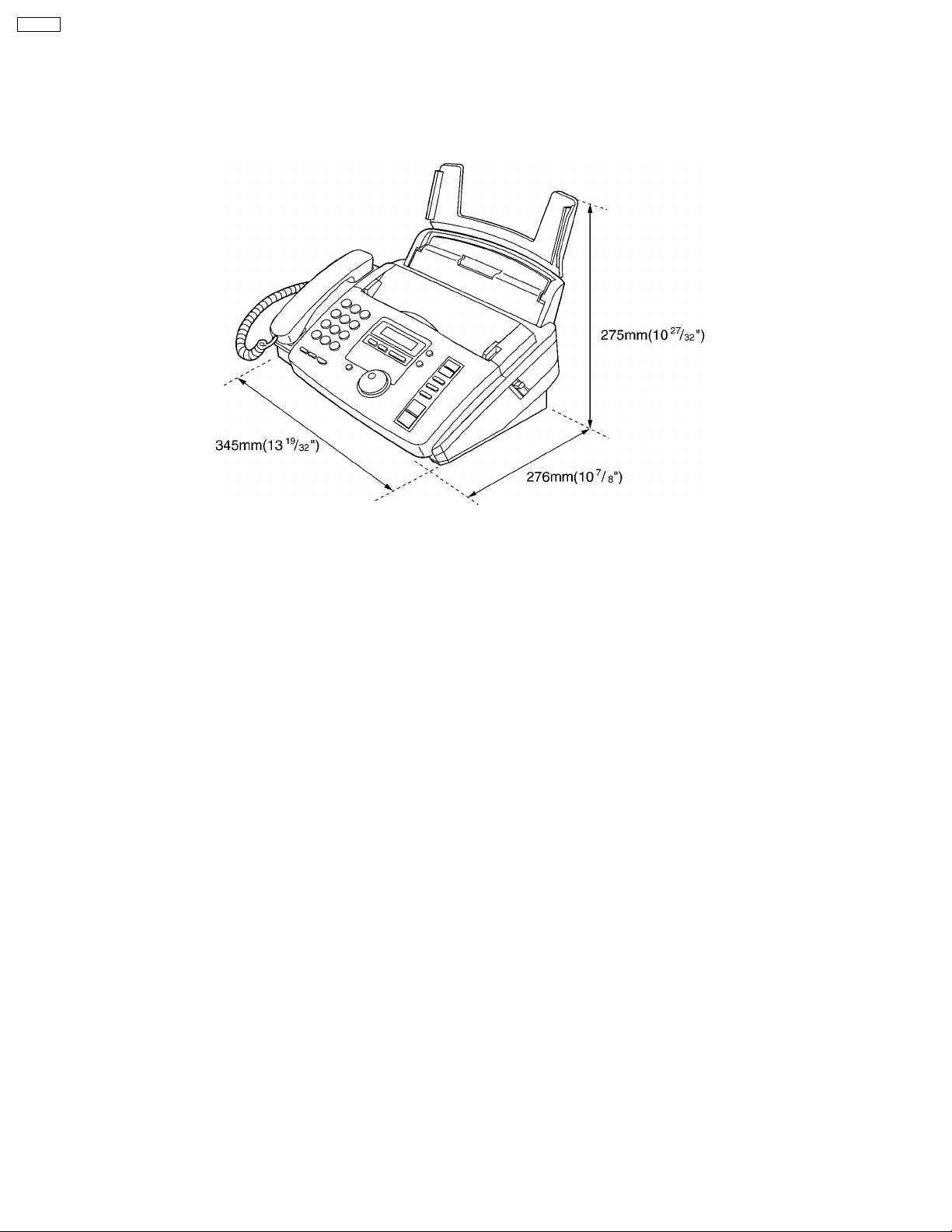

Dimensions (H×W×D): 185×345×276 mm (7 9/32"×13 19/32"×10 7/8")

Mass (Weight): Approx. 3.2 kg (8.5 lb.)

Power Consumption: Standby: Approx. 3.3 W

Transmission: Approx. 16 W

Reception: Approx. 42 W (When receiving a 20% black document)

Copy: Approx. 42 W (When copying a 20% black document)

Maximum: Approx. 135 W (When copying a 100% black document)

Power Supply: 120 V AC, 60 Hz (This unit will not function at 50 Hz.)

Memory Capacity: Approx. 28 pages memory reception

Approx. 25 pages memory transmission

(Based on ITU-T No. 1 Test Chart in standard resolution.)

* Transmission speed depends upon the contents of the pages, resolution, telephone line conditions and capability of the other

party’s machine.

** The 15 second speed is based upon the ITU-T No. 1 Test Chart and original mode. (Refer to "1.11. ITU-T No. 1 Test Chart".)

If the capability of the other party´s machine is inferior to your unit, the transmission time may be longer.

Note:

· Any details given in these instructions are subject to change without notice.

· The pictures and illustrations in these instructions may vary slightly from the actual product.

Design and specifications are subject to change without notice.

1.10. OPTIONAL ACCESSORIES

6

1.11. TEST CHART

1.11.1. ITU-T No.1 TEST CHART

KX-FP81

7

KX-FP81

1.11.2. ITU-T No.2 TEST CHART

8

1.12. LOCATION OF CONTROLS

1.12.1. OVERVIEW

Note:

· The document will be ejected from the front of the unit. Install the unit on a desk or floor with a smooth surface and do not

place anything in front of the unit.

KX-FP81

9

KX-FP81

1.12.2. CONTROL PANEL

10

1.13. CONNECTIONS

(1) Connect the handset cord.

(2) Connect the telephone line cord.

(3) Connect the power cord.

· When the power is turned on for the first time, the unit will print some basic information.

KX-FP81

Note:

· For additional equipment protection, we recommend the use of a surge protector. The following types are available;

TELESPIKE BLOK MODEL TSB (TRIPPE MFG. CO.), SPIKE BLOK MODEL SK6-0 (TRIPPE MFG. CO.), SUPER MAX

(PANAMAX) or MP1 (ITW LINX).

The warranty does not cover damage due to power line surges or lightning.

· When you operate this product, the power outlet should be near the product and easily accessible.

· If you want to connect an answering machine to the unit you will remove the stopper with your finger and connect the cord

to the EXT jack.

11

KX-FP81

1.14. INSTALLATION

1.14.1. INSTALLATION SPACE

The space required to install the unit is shown below.

The dimensions given are necessary for the unit to operate efficiently.

Note:

· Avoid excessive heat or humidity.

· Use the unit within the following ranges of temperature and humidity.

· Ambient temperature: 5°C to 35°C

· Relative humidity: 20% to 80% (without condensation)

· Power cord length should be less than 5 meters (16.4 feet). Using a longer cord may reduce the voltage or cause

malfunctions.

· Avoid direct sunlight.

· Do not install near devices which contain magnets or generate magnetic fields.

· Do not subject the unit to strong physical shock or vibration.

· Keep the unit clean. Dust accumulation can prevent the unit from functioning properly.

· To protect the unit from damage, hold both sides when you move it.

12

1.14.2. INSTALLING THE PAPER TRAY

Insert one tab on the paper tray into one slot on the back of the unit

) and then insert the other tab into the other slot ( ).

(

Note:

· Do not place the unit in areas where the paper tray may be

obstructed by a wall, etc.

To use legal size paper

Please purchase a legal paper tray Model No. KX-FA50 and install as

shown above.

KX-FP81

To use A4l size paper

You need to install the A4 paper guide to the right side of the paper tray.

1. Insert the bottom tab on the A4 paper guide into the lower slot.

2. Push the guide into the upper slot.

13

KX-FP81

1.14.3. INSTALLING THE RECORDING PAPER

Letter* or legal** size recording paper can be loaded. The unit can hold up to 50 sheets of 60 g/m2to 75 g/m2(16 lb. to 20lb.) paper

or 30 sheets of 90 g/m

2

(24 lb.) paper.

*Letter=216 mm × 279 mm (8 1/2” × 11”)

**Legal=216 mm × 356 mm (8 1/2" × 14")

***A4=210 mm × 297 mm (8 1/4" × 11 11/16")

If you use legal size paper, please purchase a legal paper tray, Model No. KX-FA50 and install it.

For best results, only use inkjet paper such as Hammermill® Jet Print. If you use other types of paper, the print quality may

be affected.

(1) Fan the stack of paper to prevent a paper jam.

(2) Pull the tension bar forward and hold open while inserting

the paper.

· The paper should not be over the tab.

· If the paper is not inserted correctly, readjust the paper

or the paper may jam.

Note for recording paper:

· Avoid paper with a cotton and/or fiber content that is over 20%, such as letterhead paper or paper used for

resumes.

· Do not use different types or thicknesses of paper at the same time. This may cause a paper jam.

· Avoid extremely smooth or shiny paper that is highly textured.

· Avoid paper that is coated, damaged or wrinkled.

Note:

· Avoid double-sided printing

· Do not use paper printed from this unit for double-sided printing with other copiers or printers, or the paper may jam.

· Some paper only accepts print on one side. Try using the other side of paper if you are not happy with the print quality.

Trademarks:

· Hammermill® is a registered trademark of INTERNATIONAL PAPER in the United States and/or other countries.

14

1.14.4. ADDING PAPER TO THE PAPER TRAY

(1) Pull the cassette open lever forward and remove all of the

installed paper.

(2) Add paper to the removed paper and straighten.

(3) Fan the stack of paper.

(4) Pull the tension bar forward and hold open while inserting

the paper.

1.14.5. DOCUMENTS THE UNIT CAN FEED

KX-FP81

Note:

· Remove chips, staples or other similar fastening objects.

· Check that ink, paste or correction fluid has dried.

· Do not send the following types of documents. Use copies for fax transmission.

— Chemically treated paper such as carbon or carbon less duplicating paper

— Electrostatically charged paper

— Heavily curled, creased or torn paper

— Paper with a coated surface

— Paper with a faint image

— Paper with printing on the opposite side that can be seen through the front (e.q. newspaper)

15

KX-FP81

1.14.6. SETTING YOUR LOGO

The logo can be your company, division or name.

(1) Press

Display:

(2) Press , then .

(3) Press .

(4) Enter your logo, up to 30 characters, by using the dial

keypad.

Example: Bill

.

a. Press

twice.

b. Press six times.

c. Press six times.

d. Press to move the cursor to the next space and

press

six times.

(5) Press .

(6) Press .

Note:

· You can enter your logo by rotating

To correct a mistake

· Press

then make the correction.

To delete a character

· Move the cursor to the character you want to delete and press

or to move the cursor to the incorrect character,

.

.

To insert a character

1. Press

where you want to insert the character.

2. Press

or to move the cursor to the position to the right of

(Insert) to insert a space and enter the character.

16

1.14.7. TO SELECT CHARACTERS WITH THE DIAL KEYPAD

KX-FP81

1.14.8. TO SELECT CHARACTERS USING THE JOG DIAL

Instead of pressing the dial keys, you can select characters using the JOG DIAL.

(1) Rotate

(2) Press

· The character displayed in step 1 is inserted.

(3) Return to step 1 to enter the next character.

Display order of characters

to move the cursor to the next space.

unit the desired character is displayed.

17

KX-FP81

1.14.9. REPLACING THE FILM CARTRIDGE

When the unit runs out of ink film, the following message will be displayed.

Display:

Install a new ink film. The following ink films are available for replacement. Each roll prints about 150 letter size pages.

Refer to 1.10 OPTIONAL ACCESSORIES.(P.6)

Model No. KX-FA53: Replacement film (1 roll)

Model No. KX-FA55: Replacement film (2 rolls)

(1) Open the front cover by pulling up the center part.

(2) Push the back cover open button ( ) and open the back

cover (

).

(3) Pull up the blue gear side and remove the used ink film.

Remove the used core.

18

(4) Remove the stoppers and tags from the new ink film. Find

the “T” shaped gear (blue).

(5) Insert the blue core of the front ink film roll into the right slot

of the unit (

left slot of the unit (

Insert the back ink film roll (

). Insert the “T” shaped gear (blue) into the

).

).

KX-FP81

(6) If the ink film is slack, tighten it by winding the gear.

(7) Close the back cover securely by pushing down on the

dotted area at both ends (

Close the front cover securely (

).

).

· The following message will be displayed while the unit is

checking that there is no slack on the ink film.

Display:

Note:

· The ink film is completely safe to touch, and will not

rub off on your hands like carbon paper.

19

KX-FP81

1.15. MAINTENANCE ITEMS AND COMPONENT LOCATIONS

1.15.1. OUTLINE

MAINTENANCE AND REPAIRS ARE PERFORMED USING THE FOLLOWING STEPS.

1. Periodic maintenance

Inspect the equipment periodically and if necessary, clean any contaminated parts.

2. Check for breakdowns

Look for problems and consider how they arose.

If the equipment can be still used, perform copying, self testing or communication testing.

3. Check equipment

Perform copying, self testing and communication testing to determine if the problem originates from the transmitter, receiver or

the telephone line.

4. Determine causes

Determine the causes of the equipment problem by troubleshooting.

5. Equipment repairs

Repair or replace the defective parts and take appropriate measures at this stage to ensure that the problem will not recur.

6. Confirm normal operation of the equipment

After completing the repairs, conduct copying, self testing and communication testing to confirm that the equipment operates

normally.

7. Record keeping

Make a record of the measures taken to rectify the problem for future reference.

20

1.15.2. MAINTENANCE CHECK ITEMS/COMPONENT LOCATIONS

KX-FP81

21

KX-FP81

1.15.2.1. MAINTENANCE LIST

NO. OPERATION CHECK REMARKS

1 Document Path Remove any foreign matter such as paper. —

2 Rollers If the roller is dirty, clean it with a damp cloth then dry

3 Platen Roller If the platen is dirty, clean it with a damp cloth then dry

4 Thermal Head If the thermal head is dirty, clean the printing surface with a

5 Sensors Document sensor (PI302), Read position sensor (PI301),

6 Glass If the glass is dirty, clean them with a dry soft cloth. Refer to 1.15.3

7 Abnormal, wear and tear

or loose parts

thoroughly.

thoroughly. Remove the paper and film cartridge before

cleaning.

cloth moistened with denatured alcohol (alcohol without

water), then dry thoroughly.

Hook switch (SW101), Paper top sensor (PI501), Film end

(SW501), Cover open sensor (PI303), Document top switch

(SW353), Document set switch (SW352) and Confirm the

operation of the sensors.

Replace the part. Check if the screws are tight on all parts. —

1.15.2.2. MAINTENANCE CYCLE

No. Item Cleaning Cycle Replacement

1 Separation Roller (Ref. No. 117) 3 months 7 years*

2 Separation Rubber (Ref. No. 5) 3 months 7 years (100,000 documents) Refer to 1.15.2 MAINTENANCE

3 Feed Rollers (Ref. No. 4) 3 months 7 years (100,000 documents) Refer to 4 DISASSEMBLY

4 Thermal Head (Ref. No. 33) 3 months 7 years (100,000 documents) Refer to 4.8 HOW TO REMOVE

5 Platen Roller (Ref. No. 93) 3 months 7 years (100,000 documents) Refer to 4.9 HOW TO REMOVE

6 Pickup Roller (Ref. No. 72) 3 months 7 years (100,000 documents) Refer to 4.10 HOW TO REMOVE

* These values are standard and may vary depending on usage conditions.

Cycle Procedure

(100,000 documents)

Refer to 1.15.3

MAINTENANCE(P.23).

—

Refer to 1.15.3

MAINTENANCE(P.23).

See 1.15.2 MAINTENANCE CHECK

ITEMS/COMPONENT

LOCATIONS(P.21) and 4.4 HOW TO

REMOVE THE ANALOG, DIGITAL

AND POWER BOARDS AND AC

INLET(P.109).

MAINTENANCE(P.23).

Refer to 4.6 HOW TO REMOVE

THE SEPARATION

ROLLER(P.112).

CHECK ITEMS/COMPONENT

LOCATIONS(P.21).

INSTRUCTIONS(P.106).

THE TERMAL HEAD(P.114).

THE PLATEN ROLLER, BACK

COVER(P.115).

THE PICKUP ROLLER(P.116).

22

1.15.3. MAINTENANCE

1.15.3.1. CLEANING THE DOCUMENT FEEDER UNIT

If misfeeding occurs frequently or if dirty patterns or bands appear on a transmitted document or on the original of a copied

document, clean the document feeder.

1. Disconnect the power cord and the telephone line cord.

2. Open the front cover by pulling up the center part.

3. Clean the document feed rollers and rubber flap with a cloth

moistened with isopropyl rubbing alcohol, and let all parts dry

thoroughly.

4. Clean the glass with a soft dry cloth.

5. Close the front cover securely.

6. Connect the power cord and the telephone line cord.

Caution:

· Do not use paper products, such as paper towels

or tissues, to clean the inside of the unit.

KX-FP81

1.15.3.2. CLEANING THE THERMAL HEAD AND BLACK BAR

If dirty patterns or black or white bands appear on a copied or received document, clean the thermal head.

1. Disconnect the power cord and the telephone line cord.

2. Open the front cover by pulling up the center part.

3. Open the back cover by pushing the back cover open button.

4. Clean the thermal head with a cloth moistened with isopropyl

rubbing alcohol, and let it dry thoroughly.

5. Close the back cover securely by pushing down on the dotted

area at both ends. Close the front cover securely.

6. Connect the power cord and the telephone line cord.

Caution:

· To prevent a malfunction due to static electricity,

do not use a dry cloth and do not touch the thermal

head directly with your fingers.

1.15.3.3. CLEANING THE PICKUP ROLLER

Refer to 4.10 HOW TO REMOVE THE PICKUP ROLLER.(P.116)

23

KX-FP81

2 TROUBLESHOOTING GUIDE

2.1. TROUBLESHOOTING SUMMARY

2.1.1. TROUBLESHOOTING

After confirming the problem by asking the user, troubleshoot according to the instructions and observe the following precautions.

2.1.2. PRECAUTIONS

1. If there is a problem with the print quality or the paper feed, first check if the installation space and the print paper meets the

specifications, the paper selection lever/paper thickness lever is set correctly, and the paper is set correctly without any slack.

2. Before troubleshooting, first check that the connectors and cables are connected correctly (not loose).

If the problem occurs randomly, check it very carefully.

3. When connecting the AC power cord with the unit and checking the operation, exercise utmost care when handling electric

parts in order to avoid electric shocks and short-circuits.

4. After troubleshooting, double check that you have not forgotten any connectors, left any loose screws, etc.

5. Always test to verify that the unit is working normally.

2.1.3. WHEN YOU DON´T KNOW HOW TO OPERATE THE UNIT, USE THE HELP

FUNCTION

· How to use:

1. press

2. press

3. press

.

until the desired item is displayed.

.

24

2.2. USER RECOVERABLE ERRORS

If the unit detects a problem, one or more of the following messages will appear on the display.

KX-FP81

Note:

The explanations given in the [ ] are for servicemen only.

CROSS REFERENCE:

1.8 FEATURES(P.5)

2.2.1 DOCUMENT JAMS(P.26)

2.2.2 RECORDING PAPER JAMS(P.27)

3 ADJUSTMENTS(P.105)

25

KX-FP81

CROSS REFERENCE:

2.2.1 DOCUMENT JAMS(P.26)

Note:

The explanations given in the [ ] are for servicemen only.

2.2.1. DOCUMENT JAMS

If the unit does not release the document during feeding, remove the jammed document as follows.

(1) Open the front cover by pulling up the center part.

(2) Remove the jammed document carefully.

(3) Close the front cover securely.

Note:

· Do not pull out the jammed paper forcibly before opening the front cover.

26

2.2.2. RECORDING PAPER JAMS

If the unit does not eject any recording paper during reception or copying, the recording paper has jammed and the display will

show the following massage.

When paper has jammed under the film cartridge

Display:

Remove the jammed paper as follows.

(1) Open the front cover by pulling up the center part.

KX-FP81

(2) Push the back cover open button ( ) and open the back

cover (

).

(3) Remove the jammed recording paper.

27

KX-FP81

(4) If the ink film is slack, tighten it by winding the gears.

(5) Close the back cover securely by pushing down on the

dotted area at both ends (

Close the front cover securely (

).

).

28

2.3. TROUBLESHOOTING DETAILS

2.3.1. OUTLINE

Troubleshooting is for recovering quality and reliability by determining the broken component and replacing, adjusting or cleaning

it as required. First, determine the problem then decide the troubleshooting method. If you have difficulty finding the broken part,

determine which board is broken. (For example: the Digital PCB, Analog PCB, etc.) The claim tag from a customer or dealer may

use different expressions for the same problem, as they are not a technician nor engineer. Using your experience, test the problem

area corresponding to the claim. Also, returns from a customer or dealer often have a claim tag. For these cases as well, you need

to determine the problem. Test the unit using the simple check list on 2.3.3.1 SIMPLE CHECK LIST(P.31). Difficult problems may

be hard to determine, so repeated testing is necessary.

2.3.2. STARTING TROUBLESHOOTING

Determine the symptom and the troubleshooting method.

KX-FP81

CROSS REFERENCE:

2.3.3.1 SIMPLE CHECK LIST(P.31)

2.3.6 DIGITAL BOARD SECTION(P.64)

2.3.8 POWER SUPPLY BOARD SECTION(P.76)

29

KX-FP81

2.3.3. TROUBLESHOOTING ITEMS TABLE

CROSS REFERENCE:

2.3.4 ADF (Auto Document Feed) SECTION(P.32)

2.3.5 COMMUNICATION SECTION(P.45)

2.3.7 ANALOG BOARD SECTION(P.73)

2.3.9 OPERATION PANEL SECTION(P.79)

2.3.10 SENSOR SECTION(P.80)

30

Loading...

Loading...