Page 1

Model No. KV-S2048C

KV-S2028C

KV-S2046C / S2046CU / S2046CA

KV-S2026C / S2026CU / S2026CA

KV-S2048C

KV-S2028C

KV-S2026C

KV-S2026CU

KV-S2046C

KV-S2046CU

KV-S2046CA

These instructions contain information on operating the scanner. Before reading these

instructions, please read the Installation Guide enclosed with this unit.

Keep the CD-ROM in the protective case. Do not expose the CD-ROM to direct sunlight or

extreme heat and do not scratch or smudge the surface of the CD-ROM.

KV-S2026CA

Page 2

Thank you for purchasing a Panasonic High Speed Color Scanner.

• Panasonic supports your imaging needs with a reliable and easy to use document scanner.

• Panasonic has developed Panasonic Image Enhancement Technology to improve the quality of your scanned

images even beyond the quality of your original document.

Illegal Duplication

It is unlawful to make duplication of certain documents.

Duplicating certain documents may be illegal in your country.

Penalties of fines and/or imprisonment may be imposed on those found guilty. The following are examples of

items that may be illegal to duplicate in your country.

• Currency

• Bank notes and checks

• Bank and government bonds, and securities

• Passports, licenses, official or private documents, identification cards, and the like

• Copyright materials, or trademarks without the consent of the owner

• Postage stamps, and other negotiable instruments

This list is not inclusive, and no liability is assumed for either its completeness or accuracy.

In case of doubt, contact your legal counsel.

Notice:

Install your machine near a supervised area to prevent illegal duplication from being made.

®

As an ENERGY STAR

STAR guidelines for energy efficiency.

However, KV-S2026C and KV-S2046C do not comply with the ENERGY STAR Eligibility Criteria

after April 1, 2007.

• Microsoft, Windows, and Windows Vista are either registered trademarks or trademarks of Microsoft Corporation

in the United States and/or other countries.

• IBM and AT are trademarks of International Business Machines Corporation in the United States, other countries,

or both.

• ISIS, MultiStream, and QuickScan Pro are registered trademarks or trademarks of EMC Corporation.

• Adobe and Reader are registered trademarks of Adobe Systems Incorporated in the United States and/or other

countries.

• Pentium is a trademark or registered trademark of Intel Corporation or its subsidiaries in the United States and

other countries.

• Each company’s name or company product name is each company’s trademark or registered trademark.

Partner, Panasonic has determined that this product meets the ENERGY

The information given in these Operating Instructions is subject to change without notice.

2

Page 3

Before

You Start

Operation

Table of Contents

Page

Notice . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

For Your Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Component Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

• KV-S2048C, KV-S2028C, KV-S2026C / S2026CU / S2026CA. . . . . . . . . . . . . 9

• KV-S2046C / S2046CU / S2046CA. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

• Power turn-on sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

• About LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

• About the SCSI setting (for using SCSI interface only) . . . . . . . . . . . . . . . . . . 12

Installing Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

• System requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

• CD-ROM Contents. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

• Complete installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

• All Drivers & Utilities installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

• Custom installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

• Application installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

• Viewing manuals from the CD-ROM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

• Viewing manuals installed on your computer . . . . . . . . . . . . . . . . . . . . . . . . . 17

Document Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

• Acceptable documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

• Unacceptable documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Loading Documents. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

• When scanning multiple sheets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Care

and

Maintenance

Appendix

Clearing Paper Jams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

• Removing paper jams from the feeding section . . . . . . . . . . . . . . . . . . . . . . . 22

Cleaning the Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

• Outside of the scanner. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

• Inside the scanner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

• Cleaning the reflector sheet for the ending sensor . . . . . . . . . . . . . . . . . . . . . 24

• Cleaning the rollers and sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

• Cleaning the CIS glasses and sensor rollers. . . . . . . . . . . . . . . . . . . . . . . . . . 27

Replacing Consumables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

• Replacing the paper feed roller module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

• Replacing the double-feed prevention roller module . . . . . . . . . . . . . . . . . . . . 32

How to re-attach the sensor rollers . . . . . . . . . . . . . . . . . . . . . . 34

• Re-attach the sensor roller for back scanning to the ADF door. . . . . . . . . . . . 34

• Re-attach the sensor roller for front scanning . . . . . . . . . . . . . . . . . . . . . . . . . 34

Shading Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Repacking Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

• KV-S2048C, KV-S2028C, KV-S2026C / S2026CU / S2026CA. . . . . . . . . . . . 36

• KV-S2046C / S2046CU / S2046CA. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

• Changing the paper feed roller module and double-feed prevention roller . . . 39

Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

3

Page 4

Notice

Federal Communications Commission Requirements

(For United States only)

Note: This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to

part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference

when the equipment is operated in a commercial environment. This equipment generates, uses, and can radiate

radio frequency energy and, if not installed and used in accordance with the instruction manual, may cause harmful

interference to radio communications. Operation of this equipment in a residential area is likely to cause harmful

interference in which case the user will be required to correct the interference at his own expense.

FCC Warning: To assure continued FCC compliance, the user must use only shielded interface cable and the

provided power supply cord. Also, any unauthorized changes or modifications to this equipment would void the

user’s authority to operate this device.

For your safety please read the following text carefully.

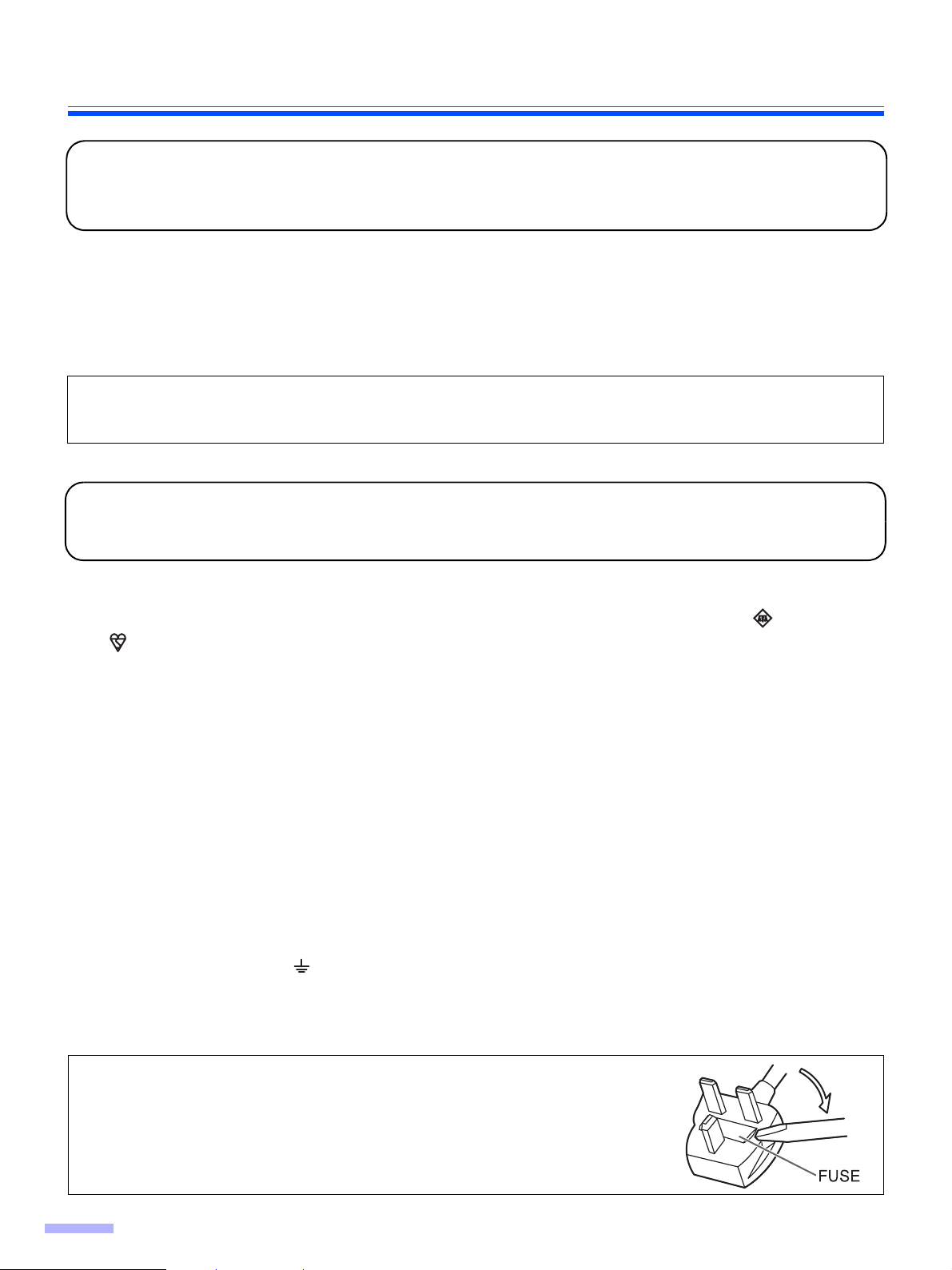

(For United Kingdom only)

This appliance is supplied with a moulded three pin mains plug for your safety and convenience.

A 5 amp. fuse is fitted in this plug. Should the fuse need to be replaced please ensure that the replacement fuse has

a rating of 5 amps. and that it is approved by ASTA or BSI to BS1362. Check for the ASTA mark or the BSI

mark on the body of the fuse. If the plug contains a removable fuse cover you must ensure that it is refitted when

the fuse is replaced. If you lose the fuse cover the plug must not be used until a replacement cover is obtained. A

replacement fuse cover can be purchased from your local Panasonic Dealer.

If the fitted moulded plug is unsuitable for the socket outlet in your home then the fuse should be removed and the

plug cut off and disposed of safely.

There is danger of severe electrical shock if the cut off plug is inserted into any 13 amp. socket.

If a new plug is to be fitted please observe the wiring cord as shown below. If in any doubt please consult a qualified

electrician.

WARNING: This appliance must be earthed.

IMPORTANT: The wires in this mains lead are coloured in accordance with the following cord.

Green-and-Yellow : Earth

Blue : Neutral

Brown : Live

As the colours of the wire in the mains lead of this appliance may not correspond with the coloured markings

identifying the terminals in your plug, proceed as follows.

The wire which is coloured Green-and-Yellow must be connected to the terminal in the plug which is marked with the

letter E or by the Earth symbol or coloured Green-and-Yellow.

The wire which is coloured Blue must be connected to the terminal in the plug which is marked with the letter N or

coloured Black.

The wire which is coloured Brown must be connected to the terminal in the plug which is marked with the letter L or

coloured Red.

How to replace the fuse :

Open the fuse compartment with a screwdriver and replace

the fuse.

4

Page 5

For Your Safety

To prevent severe injury and loss of life, read this section

carefully before using the unit to ensure proper and safe

operation of your unit.

This section explains the graphic symbols used

in this manual

Denotes a potential

hazard that could

W ARNING

CAUTION

These symbols are used to

alert operators to a specific

operating procedure that must

not be performed.

These symbols are used to

alert operators to a specific

operating procedure that must

be emphasized in order to

operate the unit safely.

result in serious injury

or death.

Denotes hazards that

could result in minor

injury or damage to

the unit.

W ARNING

Power and Ground Connection

The power source voltage of this unit is

listed on the nameplate.

Only plug the unit into an AC outlet with the

proper voltage.

If you use a cord with an unspecified current

rating, the unit or plug may emit smoke or

become hot to the touch.

The fact that the equipment operates

satisfactorily does not imply that the power

point is grounded (earthed) and that the

installation is completely safe. For your

safety, if in any doubt about the effective

grounding (earthing) of the power point,

consult a qualified electrician.

If the plug cannot be inserted into the AC

outlet, contact a licensed electrician to

replace the AC outlet with a properly

grounded (earthed) one.

Do not defeat the purpose of the grounding

(earthing) plug (ex. do not use a conversion

plug).

Plug the power cord firmly into an AC outlet.

Otherwise, it can cause fire or electric

shock.

Do not pull, bend, rest objects on, or chafe

the power cord, and plug.

Damage to the power cord or plug can

cause fire or electric shock.

Do not attempt to repair the power cord, or

plug. If the power cord or plug is damaged

or frayed, contact an authorized service

representative for a replacement.

Ensure that the plug connection is free of

dust. In a damp environment, a

contaminated connector can draw a

significant amount of current that can

generate heat, and eventually cause fire if

left unattended over an extended period of

time.

Never touch the plug with wet hands.

Danger of electric shock exists.

When you operate this product, the power

outlet should be near the product and easily

accessible.

To ensure safe operation the power cord

supplied must be inserted into a standard

three-prong AC outlet which is effectively

grounded (earthed) through the normal

wiring.

Stop operation immediately if the unit emits

smoke, excessive heat, abnormal smell, or

unusual noise. These conditions can cause

fire or electric shock. Immediately turn the

unit off, and unplug the power cord, and

contact your dealer for service.

When disconnecting the unit, grasp the plug

instead of the cord. Pulling on a cord forcibly

can damage it, and cause fire or electric

shock.

5

Page 6

For Your Safety

Operating Safeguards

If metal fragments or water gets into the

unit, turn the unit off, and unplug the unit

immediately. Contact your dealer for

service. Operating the contaminated unit

can cause fire or electric shock.

Do not open covers, and do not attempt to

repair the unit yourself. Contact your dealer

for service.

Do not alter the unit or modify any parts.

Alteration or modification can cause fire or

electric shock.

During thunderstorms, do not touch the unit

and plug. It may cause an electric shock.

Roller Cleaning Paper

Do not drink or inhale the roller cleaning

paper fluid including isopropyl alcohol.

The roller cleaning paper may be harmful to

sensitive skin. Please use protective gloves.

Do not use the roller cleaning paper near a

heater or open flame.

Installation and Relocation

Do not position the unit in a location where

it is unstable.

To prevent fire or shock hazard, do not

expose this unit to rain or any type of

moisture.

Do not place the unit in a hot humid or

dusty environment.

Prolonged exposure to these adverse

conditions may cause fire or electric shock.

When moving the unit, be sure to unplug

the power cord from the AC outlet. If the

unit is moved with the power cord attached,

it can cause damage to the cord which

could result in fire or electric shock.

Do not use the tray hanging out of a table.

When carrying the unit, do not use the trays

as handles.

When carrying the unit, hold the both side

grips.

Power

6

CAUTION

The unit should be used only with the power

cord enclosed with the unit.

When the unit is not used over an extended

period of time, switch it off, and unplug it. If

an unused unit is left connected to a power

source for a long period, degraded insulation

may cause electric shock, current leakage,

or fire.

Operating Safeguards

If the unit falls down or gets damaged, turn

the unit off, and unplug the power cord.

Otherwise, it may cause fire or electric

shock.

Do not place any liquids or heavy items on

the unit.

Accidental spillage of liquid into the unit

may cause severe damage. If this occurs,

turn the unit off, unplug the power cord,

and contact your dealer for service.

Page 7

Caution Labels

KV-S2048C, KV-S2028C, KV-S2026C / S2026CU / S2026CA

For Your Safety

KV-S2046C / S2046CU / S2046CA

7

Page 8

For Your Safety

Precautions

Installation

• Do not place the scanner in direct sunlight, in a cold draft, or near heating apparatus.

• Do not place the scanner near apparatus which generate electronic or magnetic noise.

• Protect the scanner from static electricity.

• Do not move the scanner immediately from a cold place to a warm place. It may cause dew.

CD-ROM

• Handle a CD-ROM carefully.

• Prevent a CD-ROM from damage, and keep clean.

Roller Cleaning Paper

• Do not store the roller cleaning paper in direct sunlight or in a place with temperature over 40 °C (104 °F).

• Only use the roller cleaning paper to clean the rollers and scanning area.

• If you need more information about the roller cleaning paper, please refer to the Material Safety Data Sheet

(MSDS).

• Please ask your Panasonic sales company about obtaining the Material Safety Data Sheet.

KEEP AWAY FROM FIRE.

Others

• Remove all staples from the document before scanning.

• Do not use thinner, benzine, or cleaners containing abrasives or surfactants, for cleaning the outside of

scanner.

8

Page 9

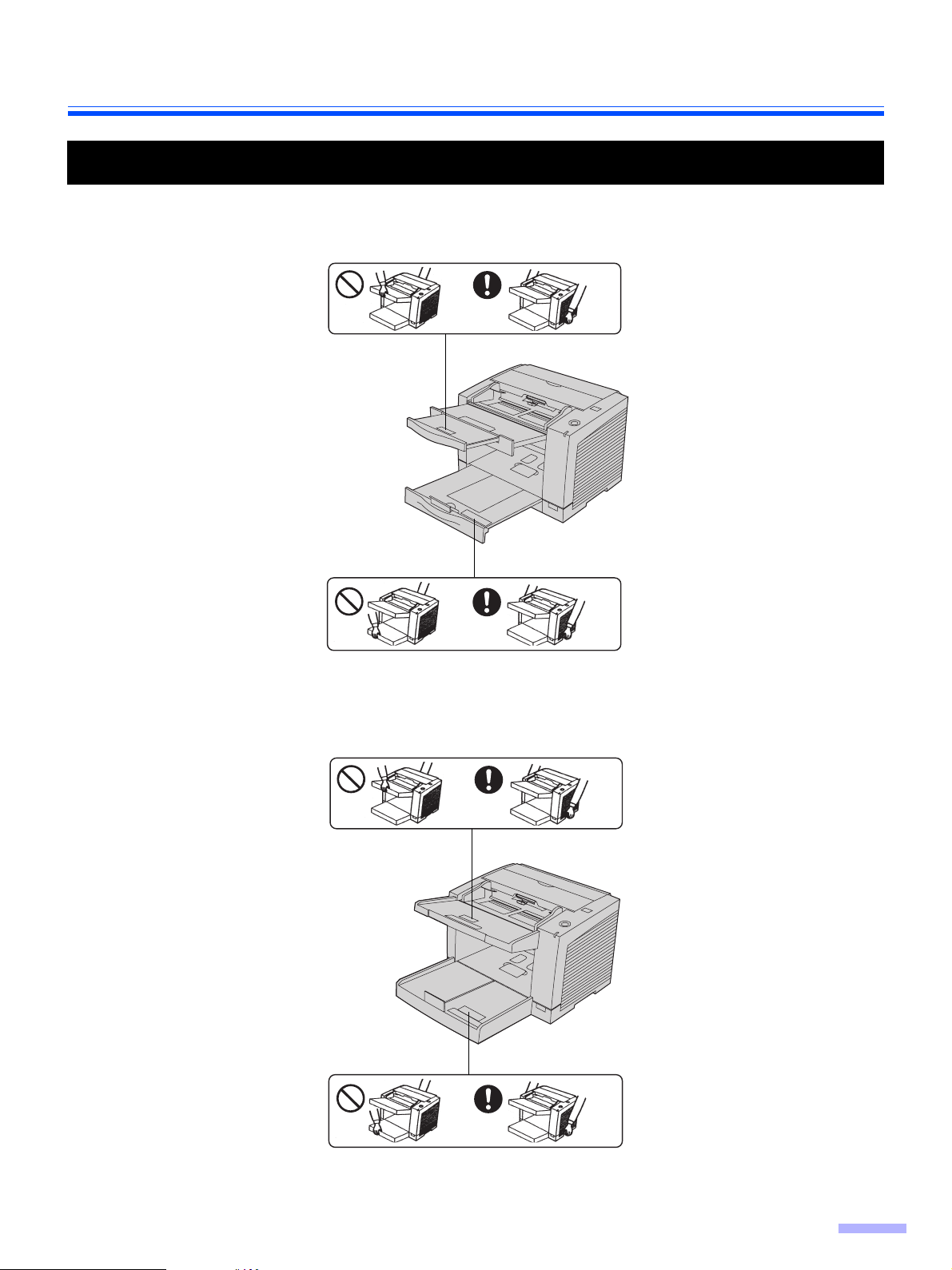

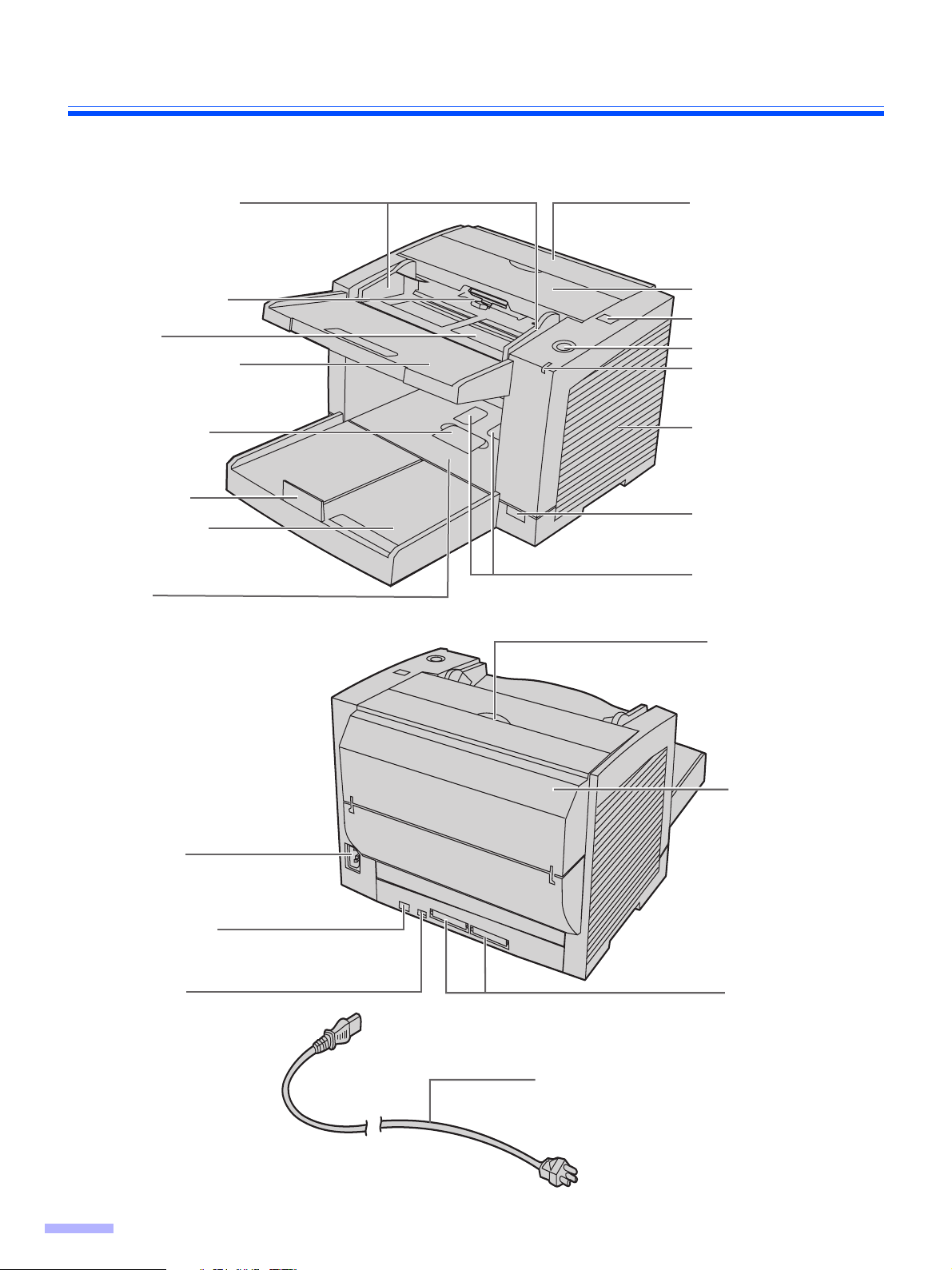

Component Identification

KV-S2048C, KV-S2028C, KV-S2026C / S2026CU / S2026CA

Document guides

Paper feed roller

Feed tray

Feed extension

tray

Business card stopper

Exit extension

tray

Exit stopper

Exit tray

Imprinter door

(for KV-S2048C only)

ADF door

ADF door release

STOP/START button

LED

Radiation vent

Power switch

Business card guides

Imprinter door pull

(for KV-S2048C only)

AC inlet

USB connector

DIP switch

(for KV-S2026C / S2026CU

/ S2026CA only)

Note:

≥ KV-S2048C and KV-S2028C have only USB interface.

Imprinter door

(for KV-S2048C only)

SCSI connectors

(for KV-S2026C / S2026CU

/ S2026CA only)

Power cord

Plugs vary in shape among countries.

9

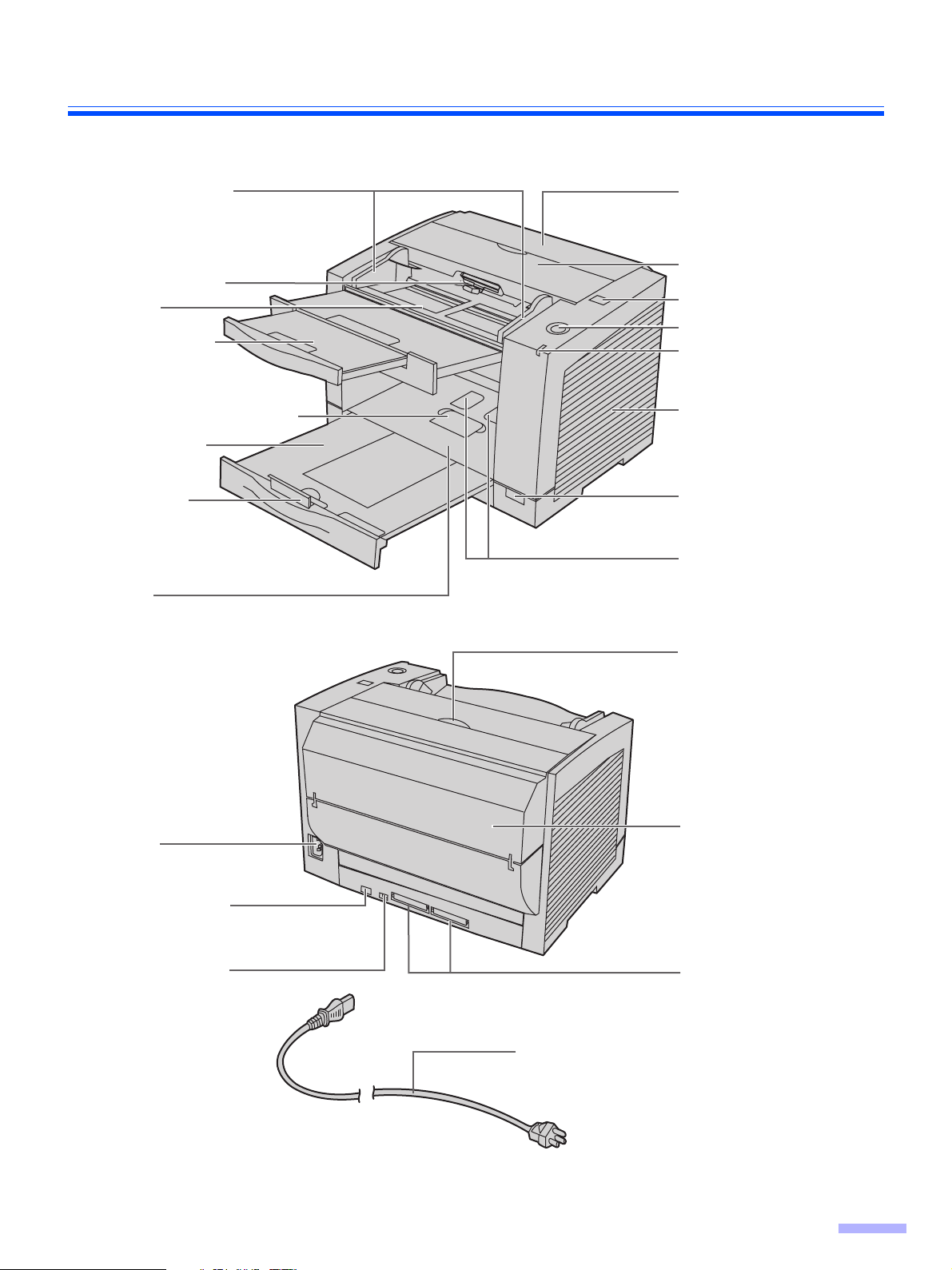

Page 10

Component Identification

KV-S2046C / S2046CU / S2046CA

Document guides

Paper feed roller

Feed tray

Feed extension

tray

Business card

stopper

Exit stopper

Exit extension

tray

Exit tray

Imprinter door

ADF door

ADF door release

STOP/START button

LED

Radiation vent

Power switch

Business card

guides

Imprinter door pull

AC inlet

USB connector

DIP switch

10

Imprinter door

SCSI connectors

Power cord

Plugs vary in shape among countries.

Page 11

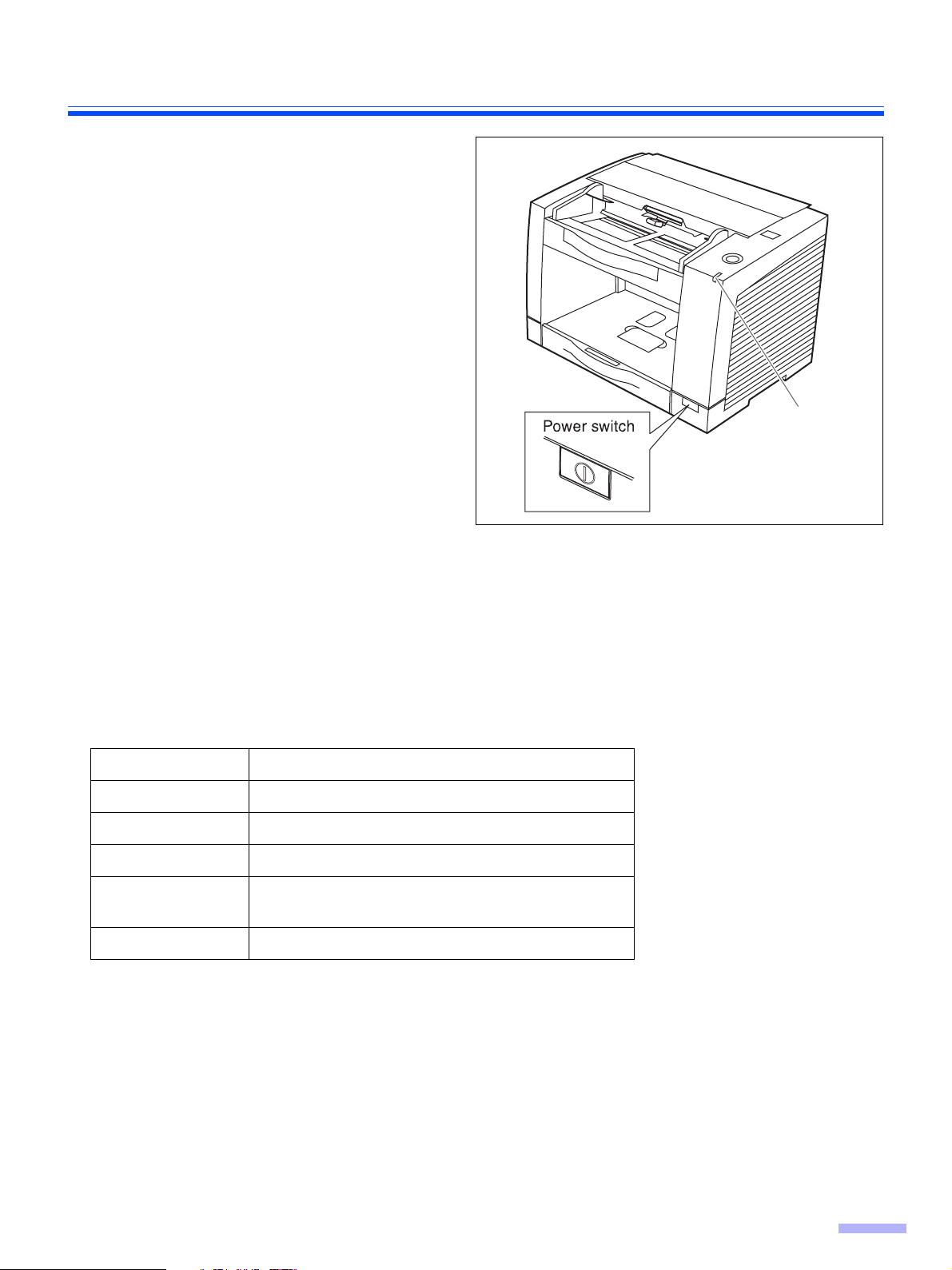

Power turn-on sequence

Turn on the power of the scanner.

1

• Press the power switch.

(The LED will now light.)

Turn on the power of the host

2

computer after scanner’s LED lights

.

green

• In case of the USB connection, the host

computer recognizes the scanner automatically when the scanner is powered on

even after the host computer is powered

on.

Component Identification

LED

About LED

LED indicates the status of the scanner as follows:

LED light Status

Green Ready to scan or scanning

Green (Blink) Sleep mode

Orange Ready to scan or scanning with warning *

Orange (Blink) Initializing

Sleeping with warning *

Red An error occurred *

1

*

The rollers need to be cleaned or replaced.

*1*2Check the status of the scanner using the User utility.

The User utility is included in the CD-ROM.

3

*

With KV-S2048C and KV-S2028C, the LED blinks in green.

1 *3

2

1

11

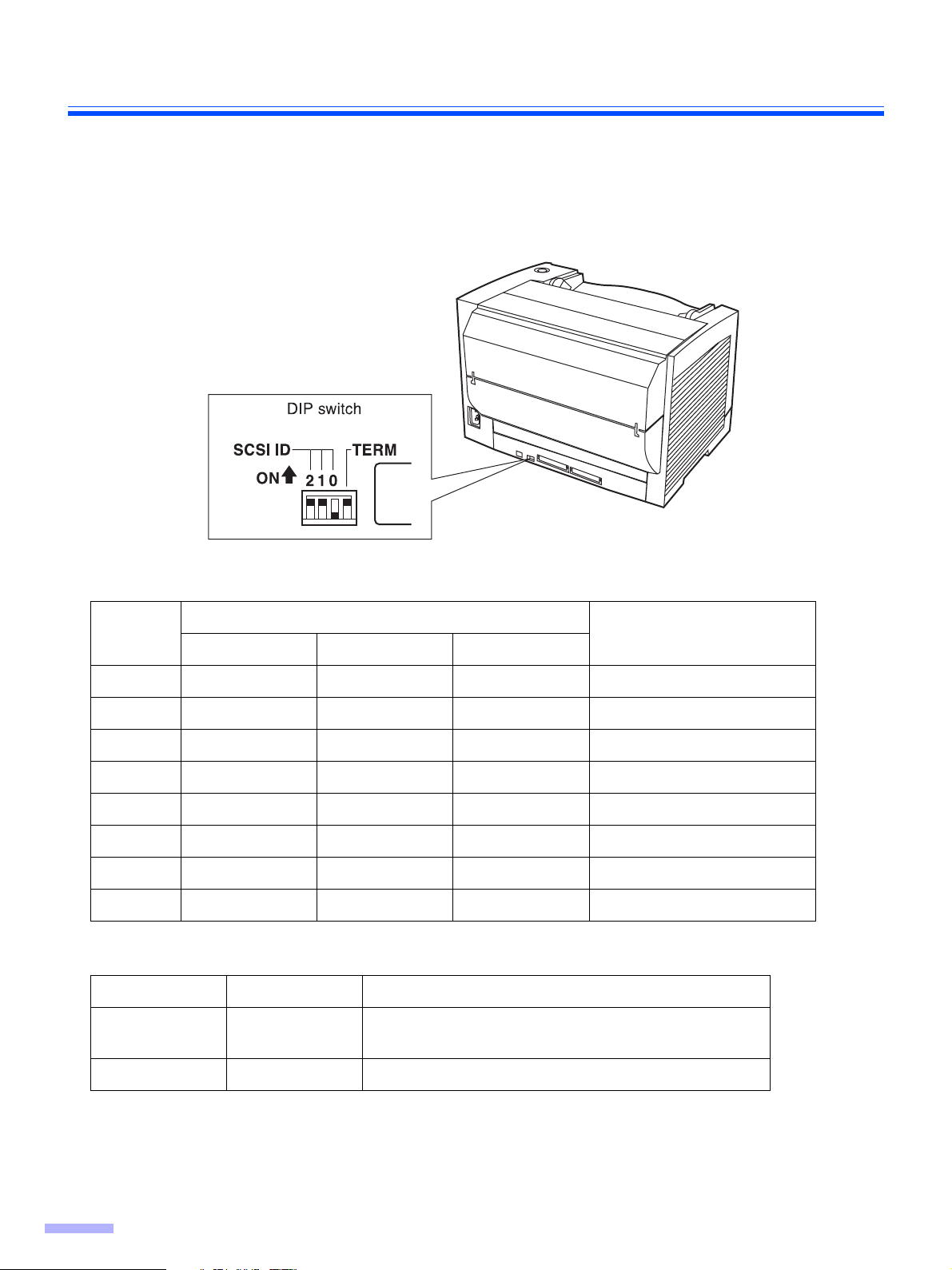

Page 12

Component Identification

About the SCSI setting (for using SCSI interface only)

(For KV-S2046C / S2046CU / S2046CA / S2026C / S2026CU / S2026CA)

When connecting the scanner to a SCSI chain using a SCSI cable, perform the SCSI ID setting correctly.

The scanner is provided with a DIP switch for the SCSI ID No. setting and the terminator setting.

SCSI ID Setting

Switch

ID No.

#2 #1 #0

0 OFF OFF OFF

1OFF OFF ON

2 OFF ON OFF

3 OFF ON ON

4ON OFF OFF

5ON OFF ON

6 ON ON OFF Default setting

7ON ON ON

SCSI Terminator Setting

Function Switch Description

Enable ON • The last device in the SCSI chain

• Default setting

Remarks

12

Disable OFF Not the last device in the SCSI chain

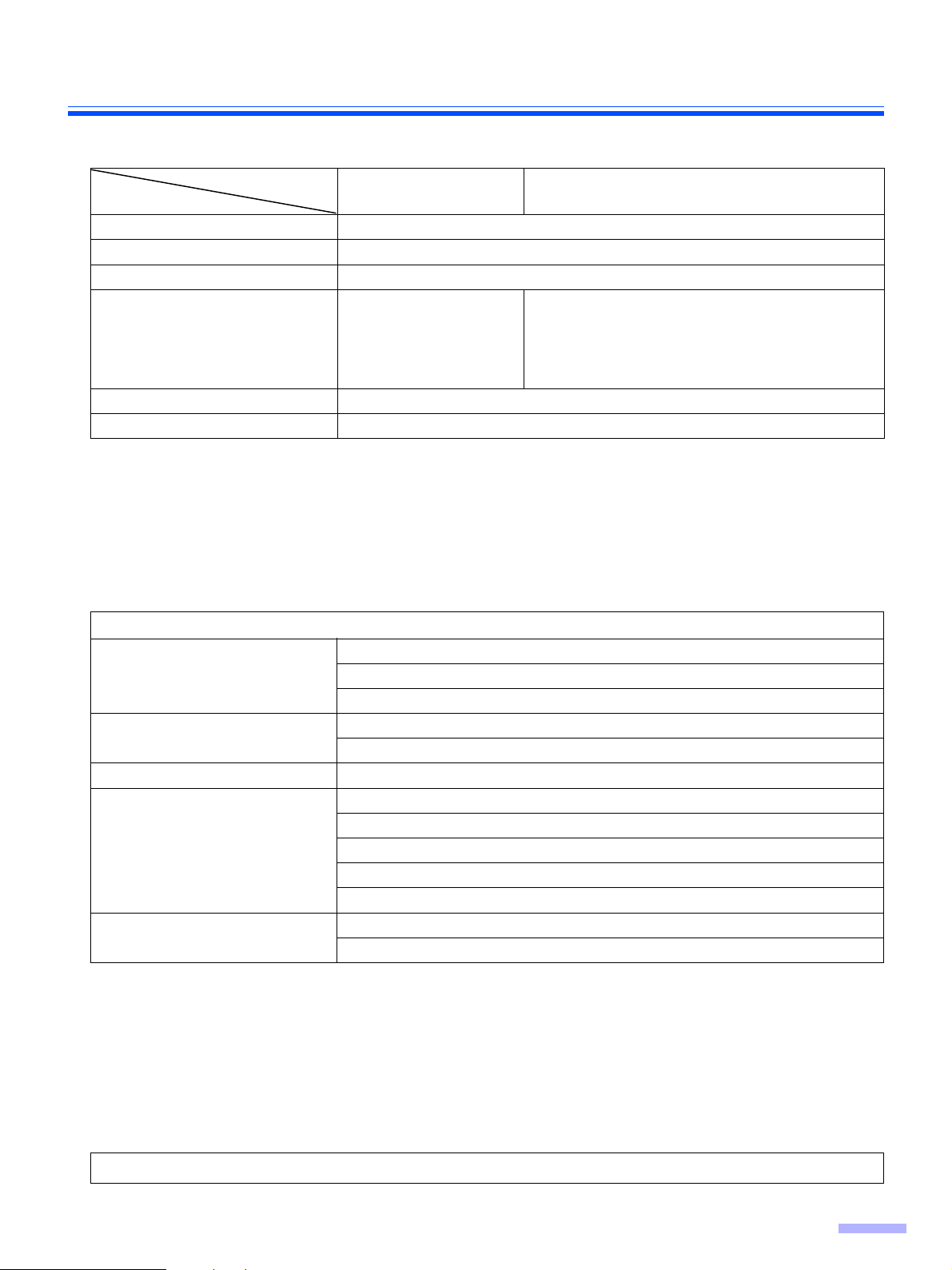

Page 13

Installing Software

System requirements

KV-S2048C

KV-S2028C

Computer

CPU

OS

IBM® PC/AT® or compatible machine with a CD-ROM drive

Pentium® III, 1GHz or higher

Windows® 2000*1, Windows® XP*2, Windows Vista

USB 2.0 USB 2.0

Interface

Memory

HDD

*1

Microsoft® Windows® 2000 operating system (hereafter Windows 2000)

*2

Microsoft® Windows® XP operating system (hereafter Windows XP)

*3

Microsoft® Windows VistaTM operating system (hereafter Windows Vista)

256 MB or higher

1 GB or more free space is required.

SCSI

Recommended SCSI board

KV-S2046C / S2046CU / S2046CA

KV-S2026C / S2026CU / S2026CA

TM *3

(64 bit is not available.)

III

Adaptec SCSI 2930U / 2940U / 29160N / 19160

With Windows Vista: Adaptec 29160N / 19160

• The above system requirements may not satisfy recommendation of all operating system and bundled

application softwares.

CD-ROM Contents

Contents

Device Driver

Drivers

Applications

Utilities

Manuals

Others

TWAIN

ISIS

RTIV

QuickScan Pro

User Utility

Installation Guide

Operating Instructions

PIE Reference Manual

RTIV Reference Manual

User Utility Reference Manual

Control Sheet

Warranty Information (U.S.A. Only)

TM

Demo

• RTIV (Reliable Throughput Imaging Viewer) is a Panasonic original application software, and does not require

either TWAIN driver nor ISIS driver.

• PIE is an acronym for Panasonic Image Enhancement Technology.

®

• To view manuals, Adobe

• If the CD-ROM does not automatically start, please run

Reader® must be installed.

“CDRun.exe” on the CD-ROM.

• There are some restrictions for QuickScan Pro due to being a trial version.

• When using QuickScan Pro, the ISIS driver is required.

• The control sheets are stored as PDF files in the CD-ROM provided with the scanner. For use them, print the

control sheets in the same size as the document pages to be scanned.

Make sure to login to Windows 2000 / Windows XP / Windows Vista as an administrator.

13

Page 14

Installing Software

Complete installation

All drivers, applications, utilities, and manuals can be installed at the same time using the Complete installation.

Turn off the power of the scanner.

1

Insert the CD-ROM into your CD/DVD drive on your computer.

2

If you have a feature called ’Autorun’ activated, this will start the installation process

3

automatically.

Note:

• If the AutoPlay dialog box is displayed in Windows Vista, select ’CDRun.exe’.

• If the program does not automatically start, click [Start], click [Run...], click [Browse...], and select the CD/

DVD drive containing the installation software, double-click on “CDRun.exe” in the root directory to

manually start the installation routine, then click [OK].

Select your scanner.

4

Select the [Complete] from the [Installation] list.

5

Follow the instructions on the screen.

6

If the screen 'Windows* can't verify the publisher of this driver software' appears,

continue with the installation by selecting 'Install this driver software anyway'.

Turn on the power of the scanner.

7

Follow the instructions of the hardware wizard to complete the installation.

8

The installation process is performed automatically in Windows Vista.

Even if the screen

appears, continue with the installation.

*Microsoft® Windows® operating system (hereafter Windows)

‘Digital Signature was not found for this driver’ or ‘has not passed Windows Logo testing···’

14

Page 15

Installing Software

All Drivers & Utilities installation

All drivers, utilities, and manuals can be installed at the same time using the All Drivers & Utilities installation.

Turn off the power of the scanner.

1

Insert the CD-ROM into your CD/DVD drive on your computer.

2

If you have a feature called ’Autorun’ activated, this will start the installation process

3

automatically.

Note:

• If the AutoPlay dialog box is displayed in Windows Vista, select ’CDRun.exe’.

• If the program does not automatically start, click [Start], click [Run...], click [Browse...], and select the CD/

DVD drive containing the installation software, double-click on “CDRun.exe” in the root directory to

manually start the installation routine, then click [OK].

Select your scanner.

4

Select the [All Drivers & Utilities] from the [Installation] list.

5

Follow the instructions on the screen.

6

If the screen 'Windows can't verify the publisher of this driver software' appears, continue

with the installation by selecting 'Install this driver software anyway'.

Turn on the power of the scanner.

7

Follow the instructions of the hardware wizard to complete the installation.

8

The installation process is performed automatically in Windows Vista.

Even if the screen ‘Digital Signature was not found for this driver’ or ‘has not passed Windows Logo testing···’

appears, continue with the installation.

15

Page 16

Installing Software

Custom installation

Each driver, utility, and manual can be installed using the Custom installation selection, as required.

Turn off the power of the scanner (only when installing Device Driver).

1

Insert the CD-ROM into your CD/DVD drive on your computer.

2

If you have a feature called ’Autorun’ activated, this will start the installation process

3

automatically.

Note:

• If the AutoPlay dialog box is displayed in Windows Vista, select ’CDRun.exe’.

• If the program does not automatically start, click [Start], click [Run...], click [Browse...], and select the CD/

DVD drive containing the installation software, double-click on “CDRun.exe” in the root directory to

manually start the installation routine, then click [OK].

Select your scanner.

4

Select the [Custom] from the [Installation] list.

5

Select a driver, an utility, or a manual.

6

If the screen 'Windows can't verify the publisher of this driver software' appears, continue

with the installation by selecting 'Install this driver software anyway'.

Follow the instructions on the screen.

7

When installing device driver, proceed following steps.

Turn on the power of the scanner.

8

Follow the instructions of the hardware wizard to complete the installation.

9

The installation process is performed automatically in Windows Vista.

Even if the screen ‘Digital Signature was not found for this driver’ or ‘has not passed Windows Logo testing···’

appears, continue with the installation.

16

Page 17

Application installation

RTIV and/or QuickScan Pro Demo can be installed as follows.

Insert the CD-ROM into your CD/DVD drive on your computer.

1

If you have a feature called ’Autorun’ activated, this will start the installation process

2

automatically.

Note:

• If the AutoPlay dialog box is displayed in Windows Vista, select ’CDRun.exe’.

• If the program does not automatically start, click [Start], click [Run...], click [Browse...], and select the CD/

DVD drive containing the installation software, double-click on “CDRun.exe” in the root directory to

manually start the installation routine, then click [OK].

Select your scanner.

3

Select the [RTIV] or the [Quick Scan Pro Demo] from the [Installation] list.

4

Follow the instructions on the screen.

5

The installation process is performed automatically in Windows Vista.

Installing Software

Even if the screen ‘Digital Signature was not found for this driver’ or ‘has not passed Windows Logo testing···’

appears, continue with the installation.

Viewing manuals from the CD-ROM

All manuals on the CD-ROM can be viewed using the Adobe Reader.

Insert the CD-ROM into your CD/DVD drive on your computer.

1

If you have a feature called ’Autorun’ activated, this will start the installation process

2

automatically.

Note:

• If the AutoPlay dialog box is displayed in Windows Vista, select ’CDRun.exe’.

• If the program does not automatically start, click [Start], click [Run...], click [Browse...], and select the CD/

DVD drive containing the installation software, double-click on “CDRun.exe” in the root directory to

manually start the installation routine, then click [OK].

Select your scanner.

3

Select a manual from the list.

4

Viewing manuals installed on your computer

All manuals installed on your computer can be viewed as follows.

Click [Start], and then click [All Programs] - [Panasonic] - [Scanner Manuals].

1

• For Windows 2000, click [Program] instead of [All Programs].

Note:

• To install manuals on your computer, see page 16.

Select the desired manual.

2

17

Page 18

Document Specifications

Acceptable documents

Document size:

Paper thickness:

50.8~216 mm (2.0~8.5 in.)

The height of all the documents on the tray should not

70~635 mm (2.76~25 in.)

Unacceptable documents

The following types of documents may not scan properly:

• Curled, wrinkled, or folded documents

exceed the limit mark on the document guide.

Single paper feeding is recommended for papers

exceeding the legal size length.

Single paper feeding 40~127 g/m

Continuous paper feeding 50~127 g/m

2

(10.7~33.9 lb.)

2

(13.3~33.9 lb.)

Curl: Fold:Feeding direction Feeding direction

Less than

5 mm (0.2 in.)

• Perforated or punched documents

• Not rectangular or irregularly shaped documents like documents with tags

• Thermal or photosensitive paper

• Extremely smooth, shiny paper, or paper that is highly textured

• Carbonless paper

• Creased or ripped paper

• Coated paper

When documents cannot be scanned properly, try to change the resolution or the number of documents scanned.

The following types of documents must

• Irregular document thickness, such as envelopes

• Damaged or notched document

• Documents out of specified size, thickness, and weight

• Documents containing hard attachments such as metal or plastic (ex. Clips or staples)

• Bound or glued documents

• Document with wet ink or cinnabar seal ink

• Paper with carbon

• Cloths and plastic films

• Light penetrating documents such as OHP sheet and tracing paper

be avoided:

Less than

5 mm (0.2 in.)

18

Page 19

Loading Documents

When scanning multiple sheets

• Remove all staples from the document before scanning.

• Curled documents may cause a paper jam or damaging the document, therefore, set the document flat before

scanning.

• When scanning very important documents, confirm that the number of scanned images matches the number of

actual pages.

Documents that have been stapled

1

together or stacked together (as in a

file folder) will need to be separated.

(1)Fan the stack of documents to sepa-

rate all the edges.

(2)Hold both ends and bend the docu-

ments as shown in the illustration.

(3)To flatten the documents, hold firmly

and pull them apart as shown in the

illustration.

Repeat these steps as necessary.

Carefully align the documents.

2

Prior to scanning, remove, all staples and paper clips

from pages.

1

2

3

Adjust the document guides slightly

3

larger than the actual size of the documents.

Document guides

19

Page 20

Loading Documents

When scanning paper longer than the

4

feed tray, pull out the feed extension

tray from the feed tray and the exit

extension tray as shown in the figure

on the right.

• The exit extension tray of KV-S2046C,

KV-S2046CU and KV-S2046CA is fixed.

Adjust the position of the exit stopper.

• When using small sized documents like

business cards, raise the business card

guides and the business card stopper.

Caution:

Do not use the business card guides and the

business card stopper for larger documents

than their acceptable size. It will cause paper

jams.

Feed extension tray

Exit stopper

Exit extension tray

A

Place the documents on the feed tray

5

with the side to be scanned facing up.

• Be sure to place the documents on the

feed tray as shown in the figure on the

right.

• The amount of documents should not

exceed the limit mark on the document

guide. This may cause a paper jam or

skew.

Business card guides Business card stopper

Paper feed roller

Feed tray

20

Page 21

Loading Documents

Adjust the document guides to the size

6

of the documents.

Set documents under the paper feed

7

roller.

(1)Lift the lever of the paper feed roller

as shown in the figure.

(2)Push documents in the direction of

the arrow until they stop under the

paper feed roller.

Document guides

Paper feed roller

1

2

21

Page 22

Clearing Paper Jams

Torn documents, thin documents or documents that are creased on the top edge may cause paper jams. If a paper

jam occurs, remove the jammed sheet according to the following procedure.

Removing paper jams from the feeding section

Remove all documents from the feed

1

tray.

Push the ADF door release to open the

2

ADF door.

Remove the jammed document.

3

• If the jammed document remains at the

feed tray side, pull it up.

22

• If the jammed document appears at the

exit tray side, remove it from the exit side.

Page 23

Make sure that the sensor rollers are

4

installed properly, before closing the

ADF door.

• If the sensor rollers are removed, re-

attach them. (Refer to page 34.)

Clearing Paper Jams

Sensor roller (front)

Close the ADF door.

5

• When you close the ADF door, close it

securely until the door is locked.

Sensor roller (back)

23

Page 24

Cleaning the Unit

Outside of the scanner

Clean the unit at least once a month.

Turn the power off.

1

Clean the cover with a soft cloth.

2

• Please use a water-dampened cloth that

has been throughly wrung.

• Do not use thinner, benzine, or cleaners

containing abrasives or surfactants.

Remove dirt and dust from the radia-

3

tion vent with a brush.

Radiation vent

Inside the scanner

Clean the unit at least once a week or when 20,000 sheets have been scanned, whichever comes first.

•

• Clean the rollers and sensors if paper jamming or multiple-sheet feeding occurs frequently.

(Refer to pages 25-26.)

• Clean the CIS glasses and sensor rollers when lines appear on the scanned images. (Refer to pages 27-28.)

• If the documents you scan are dirty, then the scanner components will also become dirty. To maintain proper

scanning, clean the scanner components frequently.

Cleaning the reflector sheet for the ending sensor

Remove dust on the reflector sheet of the

•

ending sensor with a cotton swab.

• The reflector sheet is behind the center of

the paper release rollers.

Reflector sheet

for ending sensor

24

Paper release roller

Cotton swab

Page 25

Cleaning the Unit

Cleaning the rollers and sensors

Roller cleaning paper:

Open the bag on the dotted line and take out

the roller cleaning paper.

• If the roller cleaning paper bag is left opened for

a long period of time before using it, the alcohol

will evaporate. Please use the roller cleaning

paper immediately after opening the bag.

Dotted line

• Before using the roller cleaning paper, please

read the safety information on the Operation

Manual enclosed with the roller cleaning paper.

The roller cleaning paper (Model No. KV-SS03) is available from the dealer where you

purchased your scanner.

For supplies and accessories: Call 1-866-823-0002 (U.S.A. only) or your dealer.

Turn the power off.

1

Push the ADF door release to open the

2

ADF door.

25

Page 26

Cleaning the Unit

Use the roller cleaning paper (KV-SS03)

3

to remove the dirt from the surfaces of

the double-feed prevention roller, paper

feed roller, separation roller, 6 drive

rollers, and 6 free rollers.

Remove dust on the paper sensors

(Paper detector, Double feed detectors,

Waiting sensor, and Starting position

sensor) and reflector sheets with a

cotton swab.

• When wiping off the dirt on the roller sur-

faces, hold the rollers to prevent them

from rotating, and wipe the rollers all the

way around them proceeding from one

end to the other in the directions of the

arrows shown in the figure on the right.

Double-feed

prevention roller

Drive rollers

Double feed detector (KV-S2048C and KV-S2028C only)

Waiting sensor

Paper detector

Reflector sheets

Drive rollers

Paper feed roller

Separation roller

26

Free rollers

Double feed detector (KV-S2048C and KV-S2028C only)

Make sure that the sensor rollers are installed properly, before closing the ADF door.

Starting position sensor

Free rollers

4

• If the sensor rollers are removed, re-attach them. (Refer to page 34.)

Close the ADF door.

5

• When you close the ADF door, close it securely until the door is locked.

Clear the roller cleaning counter with the User Utility.

6

• After the rollers have been cleaned, press the [Clear Counter] button in the “User Utility” to clear

the [After Clean Roller] counter to zero.

• Refer to the User Utility Reference Manual.

Page 27

Cleaning the CIS glasses and sensor rollers

Turn the power off.

1

Push the ADF door release to open the

2

ADF door.

Cleaning the Unit

27

Page 28

Cleaning the Unit

Clean the CIS glasses and sensor roll-

3

ers using the roller cleaning paper.

• If the sensor rollers are removed while

cleaning, re-attach them after cleaning.

Sensor roller (front)

CIS glass (front)

Sensor roller (back)

28

Sensor roller (front)

CIS glass (back)

Close the ADF door.

4

• When you close the ADF door, close it

securely until the door is locked.

Page 29

Replacing Consumables

Replacing the paper feed roller module

Turn the power off.

1

Push the ADF door release to open the

2

ADF door.

Push the two green levers down at

3

both ends of the paper feed roller module to unlock the paper feed rollers.

• When moving the green levers, do not

apply pressure in any other direction

other than in the direction shown by the

arrows. Otherwise the levers may break.

29

Page 30

Replacing Consumables

Remove the paper feed roller module

4

straightly, holding up the paper feed

case along the groove of the feed

cover to pull out the claw out of the

case.

Claw

Groove

Paper feed case

Install the new paper feed roller mod-

5

ule with its gear on the right.

1 Hang both ends of the paper feed

roller module.

2 While slightly lifting the paper feed

roller module, pass the claw along

the groove of the feed cover.

3 Attach the bearings at both ends of

the paper feed roller module into the

guide grooves of the chassis in the

.

scanner.

Chassis

Bearings

30

Green levers

Page 31

Push up the green levers at both ends

6

in the direction of the arrows until they

click into place.

• After installing the paper feed roller mod-

ule, confirm that the feed rollers can be

moved lightly in vertical direction.

Replacing Consumables

Close the ADF door.

7

• When you close the ADF door, close it

securely until the door is locked.

31

Page 32

Replacing Consumables

Replacing the double-feed prevention roller module

Turn the power off.

1

Push the ADF door release to open the

2

ADF door.

Remove the double-feed prevention

3

roller cover.

Remove the double-feed prevention

4

roller module in the direction of the

arrow.

Double-feed prevention roller cover

32

Double-feed prevention roller module

Page 33

Replacing Consumables

Install the new double-feed prevention

5

roller module by matching the groove

of its shaft with the groove of the metal

holder.

Make sure that both ends of the shaft

reach the springs of the holder.

Close the double-feed prevention roller

6

cover.

Wider groove

Metal holder

Close the ADF door.

7

• When you close the ADF door, close it

securely until the door is locked.

Clear the roller replacing counter with the User Utility.

8

• After the rollers have been replaced, press the [Clear Counter] button in the “User Utility” to clear

the [After Replace Roller] counter to zero.

• Refer to the User Utility Reference Manual.

33

Page 34

How to re-attach the sensor rollers

If the sensor rollers are removed, re-attach them.

Re-attach the sensor roller for back scanning to the ADF door

Attach the shorter sensor roller to the ADF door

by placing the non-gear side to the ADF door

release.

• Match the groove to the guide.

• Push the roller, and confirm the sensor is locked

by the springs on both sides.

Springs

Re-attach the sensor roller for front scanning

Attach the longer roller to the unit by placing

the non-gear side to the ADF door release.

• Match the groove to the guide.

• Attach the side of the ADF door release first, and

attach the other side.

Confirm both rollers move slightly.

• Press down on the sensor rollers and rotate them.

34

Page 35

Shading Adjustment

(For KV-S2048C and KV-S2028C only)

z What is the purpose of the shading adjustment?

The process whereby the variations in the distribution of the lamp’s light quantity are transformed into a fixed output

within the scanning range is known as shading adjustment. It can be carried out by means of the User Utility using

the special shading paper which is provided with this scanner.

z When shading adjustment is required

Proceed with the compensation when the colors in some parts of the scanned images differ in the extreme, or when

the image quality fails to be improved even after the inside the scanner is cleaned.

z Before proceeding with the shading adjustment

Before proceeding, be absolutely sure to thoroughly clean the CIS glasses, transport path, drive rollers, free rollers,

and sensor rollers using the roller cleaning paper.

If the shading adjustment is carried out while these parts are still dirty, it will not be possible to eliminate the lines that

form on the scanned images.

z Shading adjustment procedure

1. Start the User Utility.

2. Click “User Shading” on the main menu, and operate as the image display dictates. For further details, refer to

"User Shading" section in the User Utility Reference Manual.

z Caution

If the scanned images are still lined after the shading adjustment has been performed and if these lines are not eliminated even after the ADF glass areas have been cleaned, it means that the shading has not been compensated

properly. Clean the parts again, and then proceed with the shading adjustment.

35

Page 36

Repacking Instructions

KV-S2048C, KV-S2028C, KV-S2026C / S2026CU / S2026CA

It is highly recommended that you keep the original carton and ALL packing materials. If you need to transport or

ship your scanner, please follow these instructions.

Please Note:

• Please use the original carton and all of the original packing materials.

• Improper repacking of the scanner may result in a service charge to repair the unit.

• The scanner should be handled in the correct (horizontal) position.

Materials Required:

• Original Scanner Carton & Packing Materials

• Shipping Tape and Scissors

Turn the power switch off and disconnect your scanner from the electrical outlet and the

1

interface cable.

Return the feed extension tray, exit stopper and exit extension tray to their original posi-

2

tions.

Pack the scanner.

3

Power cord

• Be sure to use a

power cord whose

shape matches the

shape of the electric

outlet.

USB cable (KV-S2048C and KV-S2028C only)

CD-ROM

KV-S2048C, KV-S2028C: 1 piece

KV-S2026C / S2026CU / S2026CA: 2 pieces

36

Page 37

Repacking Instructions

KV-S2046C / S2046CU / S2046CA

It is highly recommended that you keep the original carton and ALL packing materials. If you need to transport or

ship your scanner, please follow these instructions.

Please Note:

• Please use the original carton and all of the original packing materials.

• Improper repacking of the scanner may result in a service charge to repair the unit.

• The scanner should be handled in the correct (horizontal) position.

Materials Required:

• Original Scanner Carton & Packing Materials

• Shipping Tape and Scissors

Turn the power switch off and disconnect your scanner from the electrical outlet and the

1

interface cable.

Remove the feed extension tray and exit extension tray.

2

Pack the scanner.

3

Power cord

• Be sure to use a

power cord whose

shape matches the

shape of the electric

outlet.

Tray

CD-ROM

Note: How to remove the feed extension tray

1 Pull up the tray.

2 With pressing down the center of the tray,

3 pull out the tray.

Feed extension tray

37

Page 38

Specifications

Items

Scanner

KV-S2046C

Model No. KV-S2048C

Scanning face Duplex

Scanning method

*

*

1

1

Binary

200 dpi

Color

150 dpi

Binary

200 dpi

Color

150 dpi

Scanning

speed

Letter size

portrait

Scanning

speed

A4 size

portrait

Resolution

Tonal gradation

Image control

SimplexApprox. 43 pages/min.

DuplexApprox. 76 images/min.

SimplexApprox. 19 pages/min.

DuplexApprox. 34 images/min.

SimplexApprox. 41 pages/min.

DuplexApprox. 72 images/min.

SimplexApprox. 18 pages/min.

DuplexApprox. 32 images/min.

100-600 dpi (10 dpi step)

Optical: 600 dpi (Main and Sub scanning directions)

Binary mode, Gray scale mode (4/8 bit), Dither mode (16/256 step), Error diffusion

Note: Dither and Error diffusion are executed by driver software or RTIV.

Image emphasis (5 step), Dynamic threshold, Automatic separation, Noise reduction,

Deskew, Cropping, Mirror image, Monochrome reversing, Gamma correction

Note: These all functions are executed by driver software or RTIV.

CIS (Contact-type color image sensor) Front & Back sides

KV-S2046CU

KV-S2046CA

Background: Black sensor roller

SimplexApprox. 23 pages/min.

Duplex Approx. 42 images/min.

SimplexApprox. 10 pages/min.

Duplex Approx. 18 images/min.

SimplexApprox. 22 pages/min.

Duplex Approx. 40 images/min.

SimplexApprox. 9 pages/min.

Duplex Approx. 16 images/min.

KV-S2028C

KV-S2026C

KV-S2026CU

KV-S2026CA

Other function

Size

Paper

Double feed detection Ultrasonic Document length Ultrasonic Document length

Interface (Transfer rate) USB 2.0

Feed tray capacity 120 sheets [64 g/m

Thickness

Weight

Patch code detection (Kodak patch 2, 3, T)

Note: 1 portion both side each executed only by ISIS driver.

50.8 x 70 mm (2.0 x 2.8 in.) to 216 x 356 mm (8.5 x 14 in.)

Note: The setting of the paper length is possible to 25 inches in TWAIN, ISIS and RTIV.

In case of a paper beyond legal size, 1 by 1 paper scanning in the resolution

under 300 dpi is recommended.

Single paper feeding: 0.05 to 0.15 mm (2.0 to 5.9 mils)

Continuous paper feeding: 0.06 to 0.15 mm (2.36 to 5.9 mils)

Note: 1 mil = 1/1000 in.

Single paper feeding: 40 to 127 g/m

Continuous paper feeding: 50 to 127 g/m

Note: 1 lbs = 3.75 g/m

2

SCSI III (20 MB/sec)

2

(10.7 to 33.9 lbs.)

2

(13.3 to 33.9 lbs.)

USB 2.0

2

(17 lbs.)], 100 sheets [75 g/m2 (20 lbs.)]

USB 2.0

SCSI III (20 MB/sec)

USB 2.0

38

Page 39

Specifications

Items

Unit

Environment

KV-S2046C

Model No. KV-S2048C

External dimensions

(Width x Depth x

Height)

Weight 9.1 kg (20.1 lbs.) 8.6 kg (19.0 lbs.) 8.5 kg (18.7 lbs.)

Power requirement

Maximum

(Scanning)

Power

consumption

Operating temperature

and humidity

Storage temperature

and humidity

Minimum

(Standby)

Sleep mode

343 x 487 x 269 mm

(13.5 x 19.2 x 10.6 in.)

Note: When tray is

pulled

0.3 A (AC100 – 1

0.2 A (AC220

(AC100 – 120 V)

3.5 W

6 W

(AC220 –

–

240 V)

20 V)

240 V)

KV-S2046CU

KV-S2046CA

343 x 487 x 239 mm

(13.5 x 19.2 x 9.4 in.)

Note: When tray is

installed

–

AC100

AC220

1 A (AC100 –

0.5 A

0.35 A (AC100

0.2 A (AC220

6 W (AC100

8 W

Temperature: 15 °C to 30 °C (59 °F to 86 °F)

Temperature: 0 °C to 35 °C (32 °F to 95 °F)

120 V 50/60 Hz

–

240 V 50/60 Hz

(AC220 –

– 1 20 V)

–

240 V)

–

120 V)

(AC220 –

240 V)

Humidity: 30 % to 80 % RH

Humidity: 10 % to 80 % RH

KV-S2028C

120 V)

240 V)

3.5 W

(AC100 – 120 V)

6 W

(AC220 –

343 x 487 x 269 mm

(13.5 x 19.2 x 10.6 in.)

Note: When tray is pulled

0.3 A (AC100 – 120 V)

0.2 A

(AC220 – 240 V)

240 V)

KV-S2026C

KV-S2026CU

KV-S2026CA

6 W (AC100

8 W (AC220

–

120 V)

– 240 V)

CD-ROM(s)

Printed documents (Safety and Installation guide)

Accessories

Option/Consumables

2

*

Imprinter Unit

(KV-SS032)

Power cord

Roller cleaning paper

USB cable (For

Shading paper (For KV-S2048C

White roller kit (KV-SS023)

Roller Exchange Kit with Black Sensor Roller (KV-SS024)

Roller Exchange Kit with White Sensor Roller (KV-SS025)

Roller cleaning paper (KV-SS03)

Ink cartridge (KV-SS021) -

KV-S2048C and KV-S2028C only)

and KV-S2028C

Imprinter Unit

(KV-SS020)

only)

-

*1The scanning speed depends on the test environment.

The scanning speed differs depending on the host computer operating environment or application.

2

To change the paper feed roller module and double-feed prevention roller, see below.

*

Changing the paper feed roller module and double-feed prevention roller

To ensure long performance, Panasonic recommends changing the paper feed roller module and double-feed

prevention roller after 300, 000 sheets have been scanned.

If double feeding or paper jamming occurs frequently even after roller cleaning, please call your dealer, and order

a "Roller Excahnge Kit".

• Before replacing each roller, refer to

“Replacing Consumables” on page 29.

39

Page 40

Troubleshooting

If a problem occurs while the unit is being used, check the following items and check the scanner status by User Utility.

If the unit still malfunctions, turn it OFF, unplug the power cord and call for service.

Symptom Possible Cause Remedy

Problem with the AC outlet. Check and reset the circuit breaker.

The LED does not light when the power

switch is turned ON.

The computer does not recognize the

scanner.

SCSI connection

The power cord is not plugged in. Insert the power plug firmly.

Problem with power supply.

The scanner is not connected to the

computer correctly.

The scanner is not registered correctly.

The computer cannot recognize the

SCSI card.

The same ID number is used for the

scanner and the other device.

The terminator is not set correctly.

The scanner was turned on after the

computer was turned on.

Disconnect the scanner from the electric outlet and call for service.

Connect the cables correctly.

Uninstall the scanner from PC.

Register the scanner hardware again.

(See page 14.)

Check your computer whether the SCSI

card is installed correctly using the

device manager’s property.

Use the different SCSI ID numbers for

each devices.

If the scanner is the last device in the

SCSI chain, set the DIP switch of SCSI

terminator to Enable.

If the scanner is not the last device in

the SCSI chain, set the DIP switch of

SCSI terminator to Disable.

Turn the computer OFF. Turn the scanner ON, and then turn the computer ON

again.

USB connection

Scan speed is slow at USB connection.

The ADF does not open when the ADF

door release is pushed.

The document has been loaded on the

feed tray. But the scanner does not start

scanning.

40

The USB interface of the computer is

not installed correctly.

The scanner is connected via USB hub. Do not connect via USB hub.

The cable without High-Seed logo is

used.

The scanner is connected with USB

1.1.

The ADF door is not closed properly.

The document is not loaded properly.

The sensor cannot detect the document

as the edge of the document is curled.

The sensors or reflector sheets are

dirty.

Check the computer whether the USB

interface of your computer is correctly

using the device manager’s property.

Use the cable with High-Speed logo.

Connect with USB 2.0.

Push the ADF door release again after

you close the ADF door until it is locked.

Load the document correctly.

(See page 19.)

Flatten the document and load it again.

Clean the sensors and reflector sheets.

(See page 24.)

Page 41

Troubleshooting

Symptom Possible Cause Remedy

Double feeding or skewing problems

occur frequently or the scanner stops

loading while scanning.

The scanned document is blank.

Vertical lines appear on the scanned

document.

The scanning density is uneven.

The rollers are dirty.

The rollers have reached their life

expectancy.

The document is curled or folded.

The irregular type document is to be

scanned.

The document has a length of less than

70 mm (2.75z).

The document to be scanned was

loaded face down (upside down).

The CIS glasses are dirty.

The sensor rollers are dirty.

The CIS glasses or the sensor rollers

are dirty.

Clean all of the rollers.

(See page 25.)

Replace the paper feed roller module

and the double-feed prevention roller

module.

(See page 29 and page 32.)

Flatten the document and load it again

after reducing the pages.

Make a copy of the document on specified paper (see page 38) and scan the

copy.

Make a copy of the document on paper

of the specified size and scan the copy.

Load the document correctly.

(See page 19.)

Clean the CIS glasses.

(See page 27.)

Clean the sensor rollers.

(See page 27.)

Clean the CIS glasses and the sensor

rollers.

(See page 27.)

The color of the scanned document is

extremely different from the original

document.

Dark spots or noise appear on the

scanned documents.

Scanned image has moire fringes such

as stripe or wavy pattern noise.

Portions of the edge of the scanned

document are dark.

The setting of the monitor is wrong. Adjust the monitor setting.

The CIS glasses or the sensor rollers

are dirty.

It is caused by printing pattern of the

document and the congeniality of the

scanning resolution.

The edge of document is folded or

wrinkled.

Clean the CIS glasses and the sensor

rollers.

(See page 27.)

Please change the resolution and try to

scan.

Flatten the document.

The Remove Shadow or Border

Removal functions may also correct the

problem.

Refer to the PIE Reference Manual or

the RTIV Reference Manual when using

these functions.

If you still experience problems after following these suggestions, please contact our Technical Support Department at

1-800-726-2797 for further assistance. (U.S.A. only)

41

Page 42

Index

Page Page

A

AC inlet . . . . . . . . . . . . . . . . . . . . . . . . . 9, 10

Acceptable documents . . . . . . . . . . . . . . . 18

Accessories . . . . . . . . . . . . . . . . . . . . . . . 39

ADF door . . . . . . . . . . . . . . . . . . . . . . . 9, 10

ADF door release . . . . . . . . . . . . . . . . . 9, 10

All Drivers & Utilities installation . . . . . . . . 15

Application installation . . . . . . . . . . . . . . . 17

B

Business card guides . . . . . . . . . . . 9, 10, 20

Business card stopper . . . . . . . . . . 9, 10, 20

C

Caution labels. . . . . . . . . . . . . . . . . . . . . . . 7

CIS glasses. . . . . . . . . . . . . . . . . . . . . . . . 28

Cleaning the CIS glasses . . . . . . . . . . . . . 27

Cleaning the rollers. . . . . . . . . . . . . . . . . . 25

Cleaning the sensor rollers. . . . . . . . . . . . 27

Cleaning the sensors . . . . . . . . . . . . . . . . 25

Cleaning the unit. . . . . . . . . . . . . . . . . . . . 24

Clearing paper jams . . . . . . . . . . . . . . . . . 22

Complete installation . . . . . . . . . . . . . . . . 14

Component identification . . . . . . . . . . . . . . 9

Custom installation . . . . . . . . . . . . . . . . . . 16

E

ENERGY STAR . . . . . . . . . . . . . . . . . . . . . 2

Exit extension tray . . . . . . . . . . . . . 9, 10, 20

Exit stopper . . . . . . . . . . . . . . . . . . 9, 10, 20

Exit tray . . . . . . . . . . . . . . . . . . . . . . . . 9, 10

External dimensions. . . . . . . . . . . . . . . . . 39

F

Feed extension tray . . . . . . . . . . . . 9, 10, 20

Feed tray . . . . . . . . . . . . . . . . . . . . 9, 10, 20

Feed tray capacity . . . . . . . . . . . . . . . . . . 38

For Your Safety . . . . . . . . . . . . . . . . . . . . . 5

Free rollers. . . . . . . . . . . . . . . . . . . . . . . . 26

G

Green levers . . . . . . . . . . . . . . . . . . . . . . 29

I

Image control . . . . . . . . . . . . . . . . . . . . . . 38

Imprinter door. . . . . . . . . . . . . . . . . . . . 9, 10

Imprinter door pull . . . . . . . . . . . . . . . . 9, 10

Interface. . . . . . . . . . . . . . . . . . . . . . . . . . 38

L

D

DIP switch. . . . . . . . . . . . . . . . . . . . 9, 10, 12

Document guides . . . . . . . . . . . . . . 9, 10, 19

Double feed detection. . . . . . . . . . . . . . . . 38

Double feed detector . . . . . . . . . . . . . . . . 26

Double-feed prevention roller . . . . . . . . . . 26

Double-feed prevention roller cover . . . . . 32

Double-feed prevention roller module. . . . 32

Drive rollers. . . . . . . . . . . . . . . . . . . . . . . . 26

42

LED . . . . . . . . . . . . . . . . . . . . . . . . 9, 10, 11

Limit mark . . . . . . . . . . . . . . . . . . . . . . . . 20

Loading documents . . . . . . . . . . . . . . . . . 19

O

Operating temperature and humidity . . . . 39

Option/Consumables . . . . . . . . . . . . . . . . 39

Page 43

Page Page

P

Paper . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Paper detector . . . . . . . . . . . . . . . . . . . . . 26

Paper feed roller . . . . . . . . . . . . . . . 9, 10, 26

Paper feed roller module . . . . . . . . . . . . . 29

Power consumption . . . . . . . . . . . . . . . . . 39

Power cord . . . . . . . . . . . . . . . . . . . . . . 9, 10

Power requirement . . . . . . . . . . . . . . . . . . 39

Power switch. . . . . . . . . . . . . . . . . . . . . 9, 10

Precautions. . . . . . . . . . . . . . . . . . . . . . . . . 8

R

Radiation vent. . . . . . . . . . . . . . . . . 9, 10, 24

Reflector sheets . . . . . . . . . . . . . . . . . . . . 26

Repacking. . . . . . . . . . . . . . . . . . . . . . . . . 36

Replacing consumables . . . . . . . . . . . . . . 29

Replacing the double-feed prevention

roller module. . . . . . . . . . . . . . . . . . . . . . . 32

Resolution. . . . . . . . . . . . . . . . . . . . . . . . . 38

Roller cleaning paper . . . . . . . . . . . . . 25, 28

Roller exchange kit . . . . . . . . . . . . . . . . . . 39

U

Unacceptable document . . . . . . . . . . . . . 18

USB cable . . . . . . . . . . . . . . . . . . . . . 36, 39

USB connector. . . . . . . . . . . . . . . . . . . 9, 10

User Utility . . . . . . . . . . . . . . . . . . . . . 26, 33

W

Waiting sensor . . . . . . . . . . . . . . . . . . . . . 26

Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

S

Scanning face. . . . . . . . . . . . . . . . . . . . . . 38

Scanning method . . . . . . . . . . . . . . . . . . . 38

Scanning speed . . . . . . . . . . . . . . . . . . . . 38

SCSI connectors. . . . . . . . . . . . . . . . . . 9, 10

SCSI setting . . . . . . . . . . . . . . . . . . . . . . . 12

SCSI terminator . . . . . . . . . . . . . . . . . . . . 12

Sensor rollers . . . . . . . . . . . . . . . . 23, 28, 34

Separation roller . . . . . . . . . . . . . . . . . . . . 26

Shading adjustment . . . . . . . . . . . . . . . . . 35

Specifications . . . . . . . . . . . . . . . . . . . . . . 38

Starting position sensor . . . . . . . . . . . . . . 26

STOP/START button . . . . . . . . . . . . . . 9, 10

Storage temperature and humidity . . . . . . 39

T

Tonal gradation. . . . . . . . . . . . . . . . . . . . . 38

Troubleshooting . . . . . . . . . . . . . . . . . . . . 40

43

Page 44

Panasonic Communications Company of North America

Unit of Panasonic Corporation of North America

One Panasonic Way, Secaucus, New Jersey 07094

Panasonic Canada Inc.

5770 Ambler Drive, Mississauga, Ontario, L4W 2T3

Panasonic Business Systems U.K.

A Division of Panasonic U.K. Ltd.

Willoughby Road, Bracknell, Berkshire, RG12 8FP

Panasonic Marketing Europe GmbH

Hagenauer Strasse 43, 65203 Wiesbaden, Germany

For information of Compliance with EU relevant Regulatory

Directives, Contact to Authorised Representative:

Panasonic Testing Centre

Panasonic Marketing Europe GmbH

Winsbergring 15, 22525 Hamburg, Germany

Panasonic Corporation

Web Site: http://panasonic.net

© Panasonic Communications Co., Ltd. 2007

F1108FS0

Loading...

Loading...