Panasonic EYFMA1J User Manual [en, es, fr]

Operating Instructions

Instructions d’utilisation

Manual de instrucciones

Destornillador de impacto inalámbrico/Llave de impacto inalámbrica

Perceuse à impact sans l/Clé de serrage à impact sans l

Cordless Impact Driver/Cordless Impact Wrench

Model No: EYFLA4A / EYFLA4AR

EYFLA5A / EYFLA5AR

EYFLA5Q / EYFLA5QR

EYFLA6J / EYFLA6JR

EYFLA6P / EYFLA6PR

EYFMA1P

EYFMA1J

* Pictured: Cordless impact driver

* Image: Perceuse à impact sans l

* En la imagen: Destornillador de impacto inalámbrico

IMPORTANT

This manual contains safety information. Read manual completely before first using this product and save this

manual for future use.

IMPORTANT

Ce mode d’emploi contient des informations sur la sécurité. Lisez-le en entier avant d’utiliser le produit et

conservez-le pour référence.

IMPORTANTE

Este manual contiene información de seguridad. Lea completamente este manual antes de utilizar por primera

vez este producto, y guárdelo para poder consultarlo en el futuro.

Index

English: Page 4

Français: Page

20

Español: Página 38

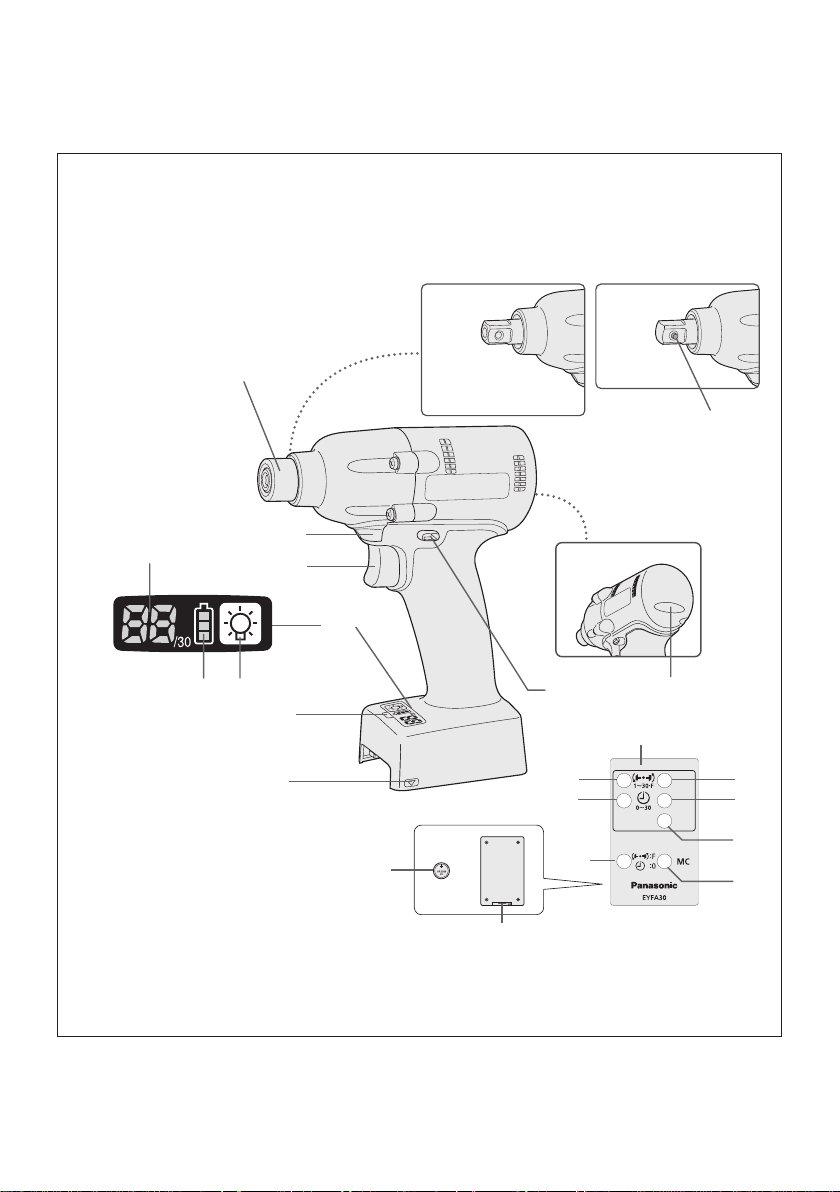

FUNCTIONAL DESCRIPTION

DESCRIPTION DES FONCTIONS

DESCRIPCIÓN FUNCIONAL

EYFLA4A/EYFLA4AR

EYFLA5A/EYFLA5AR

(I)

(G)(H)

(A)

(E)

(D)

(K)

(J)

(F)

(T)

EYFLA5QR

EYFLA5Q

EYFLA6J

EYFLA6JR

EYFMA1J

(C)

(V)

(U)

EYFLA6P

EYFLA6PR

EYFMA1P

(L)

(B)

(M)

(N)

(O)

(P)

(R)

(Q)

Remote control and battery are not included.

La télécommande et la batterie ne sont pas incluses.

El control remoto y la batería no están incluídos.

-

(S)

2 -

6.35 mm - (EYFLA4A, EYFLA4AR/EYFLA5A, EYFLA5AR)/square drive (EYFLA5Q, EYFLA5QR, EYFLA6J,

EYFLA6JR, EYFMA1J/pin type EYFLA6P, EYFLA6PR, EYFMA1P/pin-detent type)

6,35 mm -

(A)

EYFLA6JR, EYFMA1J/type à goujon EYFLA6P, EYFLA6PR, EYFMA1P/type à goupille d'arrêt)

6,35 mm EYFLA6JR, EYFMA1J/tipo pasador EYFLA6P, EYFLA6PR, EYFMA1P/tipo pasador retenedor)

Tightening conrmation lamp

Témoin de conrmation de serrage

(B)

Lámpara de conrmación de apriete

Alignment mark

Marques d’alignement

(D)

Marcas de alineación

Control panel

Panneau de commande

(F)

Panel de control

Battery indication lamp

Témoin indicateur de la batterie

(H)

Lámpara de indicadora de la batería

Variable speed control trigger

Gâchette de commande de vitesse

(J)

Disparador del control de velocidad variable

Pin-detent

Goupille d'arrêt

(L)

Pasador retenedor

+ button

Bouton +

(N)

Botón +

OK button

Bouton OK

(P)

Botón OK (correcto)

Format button

Bouton de format

(R)

Botón de formato

Battery

Batterie

(T)

Batería

Torque set button

Bouton de réglage du couple de serrage

(V)

Botón de ajuste de par de torsión

(EYFLA4A, EYFLA4AR/EYFLA5A, EYFLA5AR)/entraînement carré (EYFLA5Q, EYFLA5QR, EYFLA6J,

(EYFLA4A, EYFLA4AR/EYFLA5A, EYFLA5AR)/excitador cuadrado (EYFLA5Q, EYFLA5QR, EYFLA6J,

Forward/Reverse lever

Levier d’inversion marche avant/marche arrière

(C)

Palanca de avance/marcha atrás

Remote control Assembly Qualier

Véricateur d'assemblage de la télécommande

(E)

Cualicador incorporado con control remoto

LED light on/off button

Bouton Marche/Arrêt de la lumière DEL

(G)

Botón ON/OFF de luz LED

Display

Afchage

(I)

Visor

LED light

Lumière DEL

(K)

Luz indicadora

Remote control

Télécommande

(M)

Control remoto

− button

Bouton −

(O)

Botón −

Torque level button

Bouton de niveau du couple de serrage

(Q)

Botón de palanca de par de torsión

Holder

Support

(S)

Retenedor

Interval set button

Bouton de réglage de l’intervalle

(U)

Botón de ajuste de intervalo

-

3 -

I

.

GENERAL SAFETY

RULES

WARNING! Read all instructions

Failure to follow all instructions listed

below may result in electric shock, fire

and/or serious injury. The term “power

tool” in all of the warnings listed below

refers to your mains operated (corded)

power tool and battery operated

(cordless) power tool.

SAVE THESE INSTRUCTIONS

Work Area Safety

1) Keep work area clean and well lit.

Cluttered or dark areas invite accidents.

2)

Do not operate power tools in explosive

atmospheres, such as in the presence

of flammable liquids, gases or dust.

Power tools create sparks which may

ignite the dust or fumes.

3)

Keep children and bystanders away

while operating a power tool.

Distractions can cause you to lose control.

Electrical Safety

1) Power tool plugs must match the

outlet. Never modify the plug in any

way. Do not use any adapter plugs

with earthed (grounded) power tools.

Unmodified plugs and matching outlets

will reduce risk of electric shock.

2

) Avoid body contact with earthed or

grounded surfaces such as pipes,

radiators, ranges and refrigerators.

There is an increased risk of electric shock

if your body is earthed or grounded.

3) Do not expose power tools to rain or

wet conditions.

Water entering a power tool will increase

the risk of electric shock.

4)

Do not abuse the cord. Never use

the cord for carrying, pulling or

unplugging the power tool. Keep

cord away from heat, oil, sharp edges

or moving parts.

Damaged or entangled cords increase

the risk of electric shock.

5)

When operating a power tool outdoors,

use an extension cord suitable for

outdoor use.

Use of a cord suitable for outdoor use

reduces the risk of electric shock.

Personal Safety

1)

Stay alert, watch what you are doing

and use common sense when operating

a power tool. Do not use a power tool

while you are tired or under the influence

of drugs, alcohol or medication.

A moment of inattention while operating

power tools may result in personal injury.

2

) Use safety equipment. Always wear

eye protection.

Safety equipment such as dust mask,

non-skid safety shoes, hard hat, or

hearing protection used for appropriate

conditions will reduce personal injuries.

3)

Avoid accidental starting. Ensure the

switch is in the off position before

plugging in.

Carrying power tools with your finger on

the switch or plugging in the power tools

that have the switch on invites accidents.

4)

Remove any adjusting key or wrench

before turning the power tool on.

A wrench or a key left attached to a

rotating part of the power tool may result

in personal injury.

5)

Do not overreach. Keep proper

footing and balance at all times.

This enables better control of the power

tool in unexpected situations.

6)

Dress properly. Do not wear loose

clothing or jewellery. Keep your

hair, clothing and gloves away from

moving parts.

Loose clothes, jewellery or long hair can

be caught in moving parts.

7)

If devices are provided for the

connection of dust extraction and

collection facilities, ensure these are

connected and properly used.

Use of these devices can reduce dust

related hazards.

Power Tool Use and Care

1)

Do not force the power tool. Use the

correct power tool for your application.

The correct power tool will do the job

better and safer at the rate for which it

was designed.

2

) Do not use the power tool if the

switch does not turn it on and off.

Any power tool that cannot be controlled

with the switch is dangerous and must

be repaired.

3)

Disconnect the plug from the power

source and/or the battery pack from

-

4 -

the power tool before making any

adjustments, changing accessories,

or storing power tools.

Such preventive safety measures

reduce the risk of starting the power tool

accidentally.

4)

Store idle power tools out of the reach

of children and do not allow persons

unfamiliar with the power tool or these

instructions to operate the power tool.

Power tools are dangerous in the hands

of untrained users.

5)

Maintain power tools. Check for

misalignment or binding of moving

parts, breakage of parts and any other

condition that may affect the power

tools operation. If damaged, have the

power tool repaired before use.

Many accidents are caused by poorly

maintained power tools.

6)

Keep cutting tools sharp and clean.

Properly maintained cutting tools with

sharp cutting edges are less likely to

bind and are easier to control.

7)

Use the power tool, accessories

and tool bits etc. in accordance with

these instructions and in the manner

intended for the particular type of

power tool, taking into account the

working conditions and the work to

be performed.

Use of the power tool for operations

different from those intended could

result in a hazardous situation.

Battery Tool Use and Care

1) Ensure the switch is in the off position

before inserting battery pack.

Inserting battery pack into power tools

that have the switch on invites accidents.

2

) Recharge only with the charger

specified by the manufacturer.

A charger that is suitable for one type

of battery pack may create a risk of fire

when used with another battery pack.

3)

Use power tools only with specifically

designated battery packs.

Use of any other battery packs may

create a risk of injury and fire.

4)

When battery pack is not in use, keep it

away from other metal objects like paper

clips, coins, keys, nails, screws, or other

small metal objects that can make a

connection from one terminal to another.

Shorting the battery terminals together

may cause burns, or a fire.

5)

Under abusive conditions, liquid may

be ejected from battery; avoid contact.

If contact accidentally occurs, flush

with water. If liquid contacts eyes,

additionally seek medical help.

Liquid ejected from the battery may

cause irritation or burns.

Service

1) Have your power tool serviced by a

qualified repair person using only

identical replacement parts.

This will ensure that the safety of power

tool is maintained.

II

. INTENDED USE

This tool is a Cordless Impact Driver/Wrench

and can be used to tighten bolts, nuts, and

screws. Additionally, it provides a torque control

function that automatically stops tool operation

when a preset load is reached to deliver consistent tightening torque. Additionally, a separately

available Assembly Qualier can provide wireless monitoring to determine whether tightening

has been completed properly.

Read “the Safety Instructions” booklet

and the following before using.

III

.

ADDITIONAL SAFETY

RULES

1

) Wear ear protectors when using the

tool for extended periods.

2

) Be aware that this tool is always in an

operating condition, since it does not have

to be plugged into an electrical outlet.

3)

Hold power tools by insulated gripping

surfaces when performing an operation

where the cutting tool may contact hidden wiring or its own cord.

ontact with a “live” wire will make exposed

C

metal parts of the tool “live” and shock the

operator.

4)

Do NOT operate the Forward/Reverse

lever when the main switch is on. The battery will discharge rapidly and damage to

the unit may occur.

5)

During charging, the charger may become

slightly warm. This is normal.

D

o NOT charge the battery for a long period.

6) When storing or carrying the tool, set the

Forward/Reverse lever to the center position (switch lock).

-

5 -

7) Do not strain the tool by holding the speed

control trigger halfway (speed control

mode) so that the motor stops.

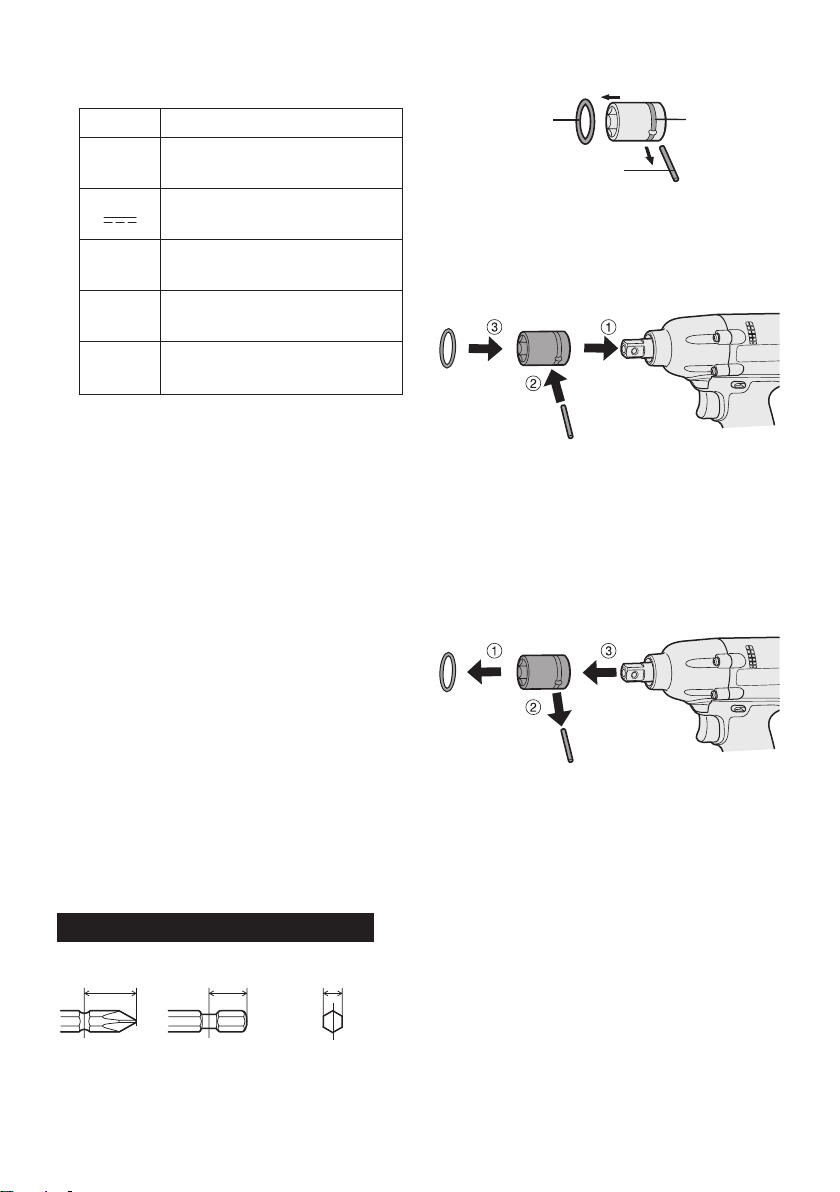

Symbol Meaning

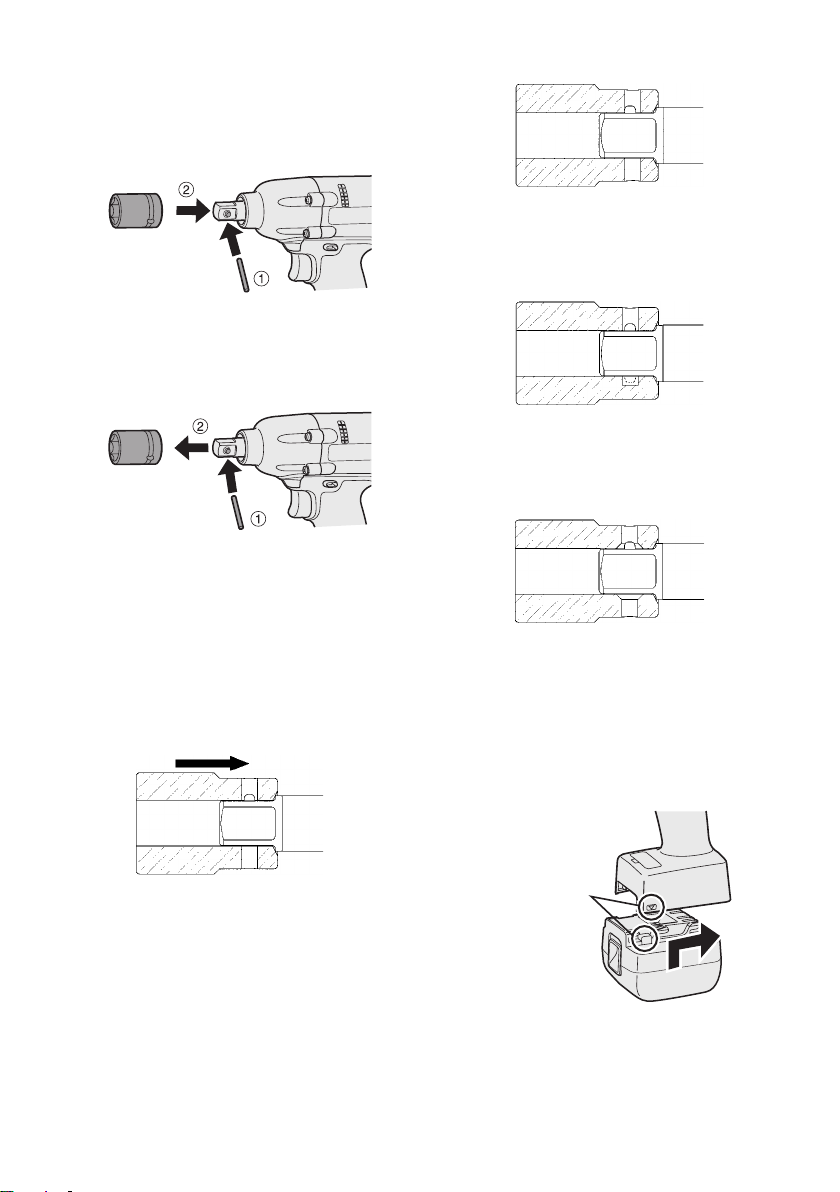

Attaching Socket (Pin type)

• Remove the socket’s rubber ring and pin.

rubber

ring

groove

V

n

0

Revolutions or reciprocations

-1

… min

Ah

IV

. ASSEMBLY

Electrical capacity of battery

Volts

Direct current

No load speed

per minutes

pack

Attaching or Removing Bit

NOTE:

•

When attaching or removing a bit, disconnect battery pack from tool or place the

switch in the center position (switch lock).

1. Hold the collar of quick connect chuck and

pull it out from the tool.

2

. Insert the bit into the chuck. Release the

collar.

The collar will return to its original position

3.

when it is released.

Pull the bit to make sure it does not come out.

4.

5. To remove the bit, pull out the collar in the

same way.

CAUTION:

•

If the collar does not return to its origi-

nal position or the bit comes out when

pulled on, the bit has not been properly

attached. Make sure the bit is properly

attached before use.

EYFLA4A/EYFLA4AR/EYFLA5A/EYFLA5AR

12 mm

(15/32")

9 mm – 9.5 mm

(

23/64" – 3/8")

6.35 mm

(1/4")

pin

1 Attach the socket to the tool.

2 Insert

3 A

the pin. (Taking care to align the pin

holes on the socket and tool.)

ttach the rubber ring by sliding it into place

over the groove.

NOTE:

Be sure to attach the rubber ring to prevent

the pin from falling out.

Removing Socket (Pin type)

1 Remove the rubber ring.

2 Remove the pin.

emove the socket from the tool.

3 R

NOTE:

Keep the temperature of the tool above

the

freezing point (0°C/32°F) when attaching sockets to or detaching them from

the square drive on the tool. Do not use

excessive

ing sockets.

force when attaching or detach-

-

6 -

Attaching Socket (Pin-detent)

1 Depress the pin-detent on the square drive.

2 Attach the socket to square drive.

ake sure the socket is securely attached to

3 M

the square drive.

Removing Socket (Pin-detent)

1 Insert a small rod into the hole on the socket.

Depress the pin-detent, then detach the socket.

2

NOTE:

Keep the temperature of the tool above the

f

reezing point (0°C/32°F) when attaching

sockets to or removing them from the

square drive. Do not use excessive force

when attaching or removing sockets.

CAUTION:

•

When attaching a socket to the driver,

verify that the socket and pin-detent do

not interfere with one another.

T

he pin-detent will be subjected to

excessive force, possibly damaging it.

2 Sockets with a pin hole on one side

only

Y

ou may be unable to remove the

socket if it is attached in the wrong orientation.

3 Sockets whose pin holes have bev-

eled edges

T

he socket will not be held in place

with sufficient force, so that it may

come off during use.

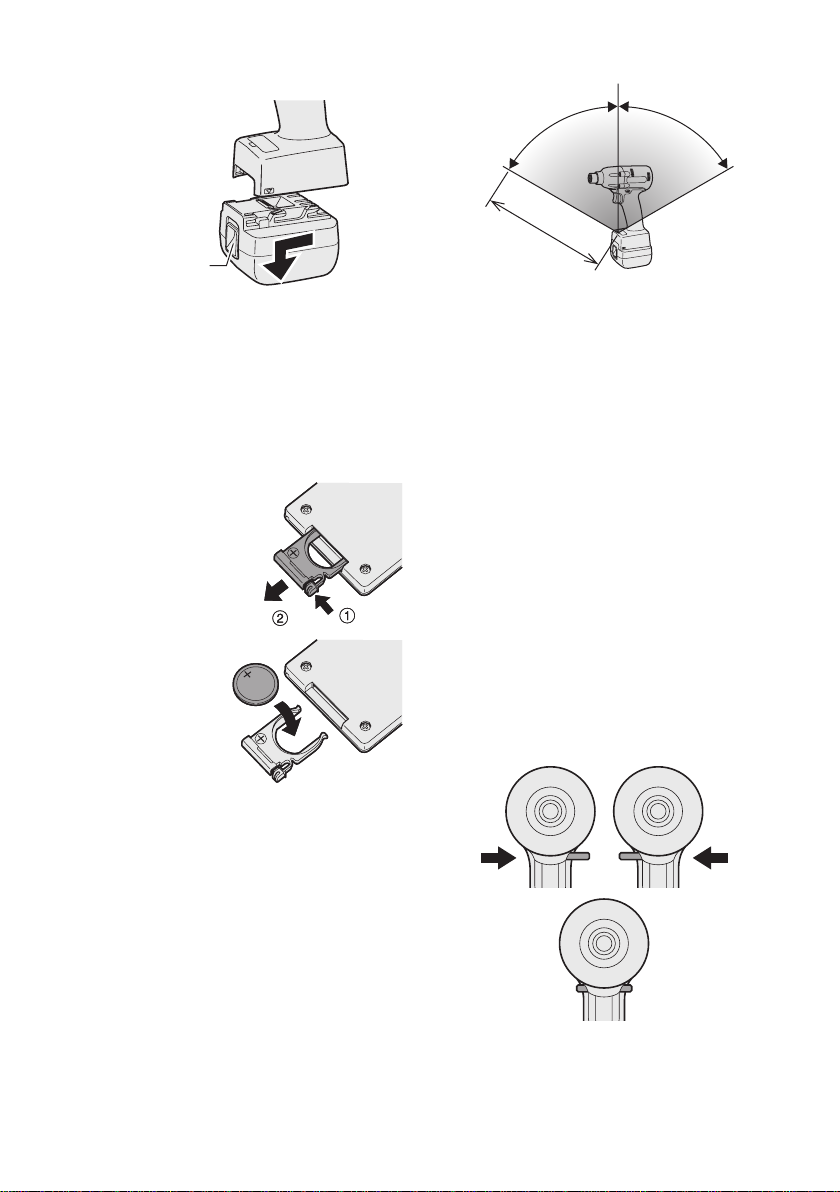

Attaching or Removing Battery Pack

1. To connect the battery pack:

Line up the alignment marks and attach

the battery pack.

•

Slide the battery pack until it locks into

position.

Proper socket attachment

• Some sockets may not function well with

the driver due to their shape. Avoid use

of sockets such as the following:

1 Sockets

makes contact with the side of the

socket’s pin hole when the socket is

attached to the driver.

shaped so that the pin-detent

-

7 -

Alignment

marks

2. To remove the battery pack:

Approx. 50 cm

Vertically

A

p

p

r

o

x

.

6

0

°

A

p

p

r

o

x

.

6

0

°

Forward Reverse

Switch lock

Push up on the button from the front to release the battery pack.

Wireless remote control range

Button

V

. OPERATION

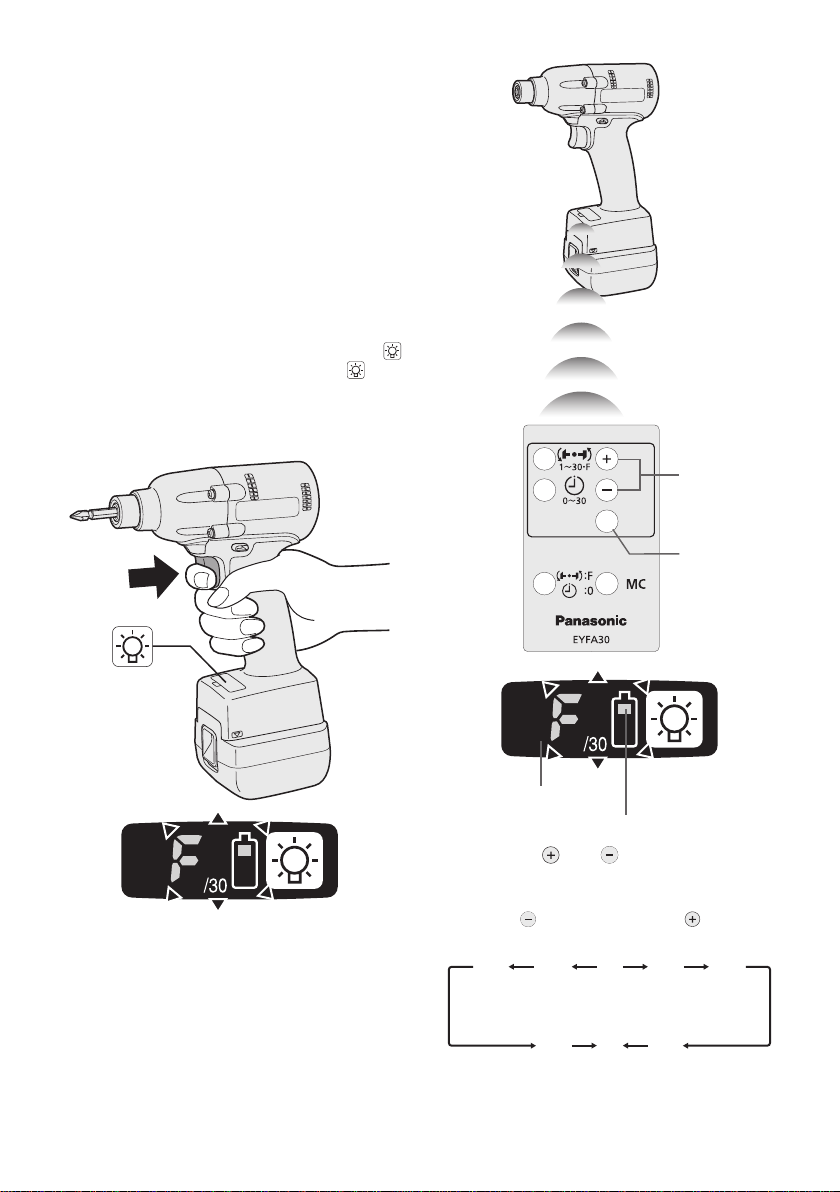

Before Using the Remote

Control (Available as an

optional accessory)

Insert the battery

1. Pull out the battery holder.

1 P

ush in on the fastener as indicated by

the arrow.

2 Pull out the holder

2. Insert the battery and

push the holder

back in.

NOTE:

•

If the tool does not respond to the wire-

less remote control even when the remote

control is operated close to the tool, the

attery (CR2025) is dead. Replace it with

b

a fresh battery.

•

The included battery is provided for sample

use and may not last as long as commercially available batteries.

.

The remote control should be operated within

approximately 50 cm and approximately 60°

vertically and horizontally of the perpendicular

relative to the infrared Assembly Qualier on

the tool.

Under the following circumstances, you may

•

not be able to operate the tool, even within

this range.

If there is an object between the remote

•

control’s transmitter and the tool’s Assembly Qualifier.

Use outdoors or in other environments

•

where the remote control Assembly Qualifier

is exposed to a strong light source, or when

the remote control transmitter or Assembly

Qualifier is dirty may cause the tool to fail to

respond, even when the remote control is

used within the operating range.

[Main Body]

Switch and Forward/Reverse

Lever Operation

-

CAUTION:

To prevent damage, do not operate

Forward/Reverse lever until the bit comes

to a complete stop.

8 -

Forward Rotation Switch

Operation

1. Push the lever for forward rotation.

2. Depress the trigger switch slightly to start

the tool slowly.

The speed increases with the amount of

3.

depression of the trigger for efficient tightening of screws. The brake operates and

the bit stops immediately when the trigger

is released.

4.

After use, set the lever to its center posi-

tion (switch lock).

Reverse Rotation Switch

Operation

1.

Push the lever for reverse rotation. Check

direction of rotation before use.

Depress the trigger switch slightly to start the

2

.

tool slowly.

3. After use, set the lever to its center position (switch lock).

CAUTION:

•

To eliminate excessive temperature

increase of the tool surface, do not

operate the tool continuously using two

or more battery packs. Tool needs cool

off time before switching to another

pack.

Tightening confirmation lamp

• The tightening confirmation lamp can be

used to check whether the torque control

function was activated.

the

CAUTION:

When the tool stops automatically after

•

the switch is released during impactmode tightening and then re-engaged

within 1 second, the red lamp will light up

to indicate the risk of excessive torque

application as a result of re-tightening.

NOTE

•

The tightening confirmation lamp will

not turn on under the following conditions:

•

When the torque clutch is set to “F”

• During reverse rotation operation

• The lamp turns off when the tool is in

operation.

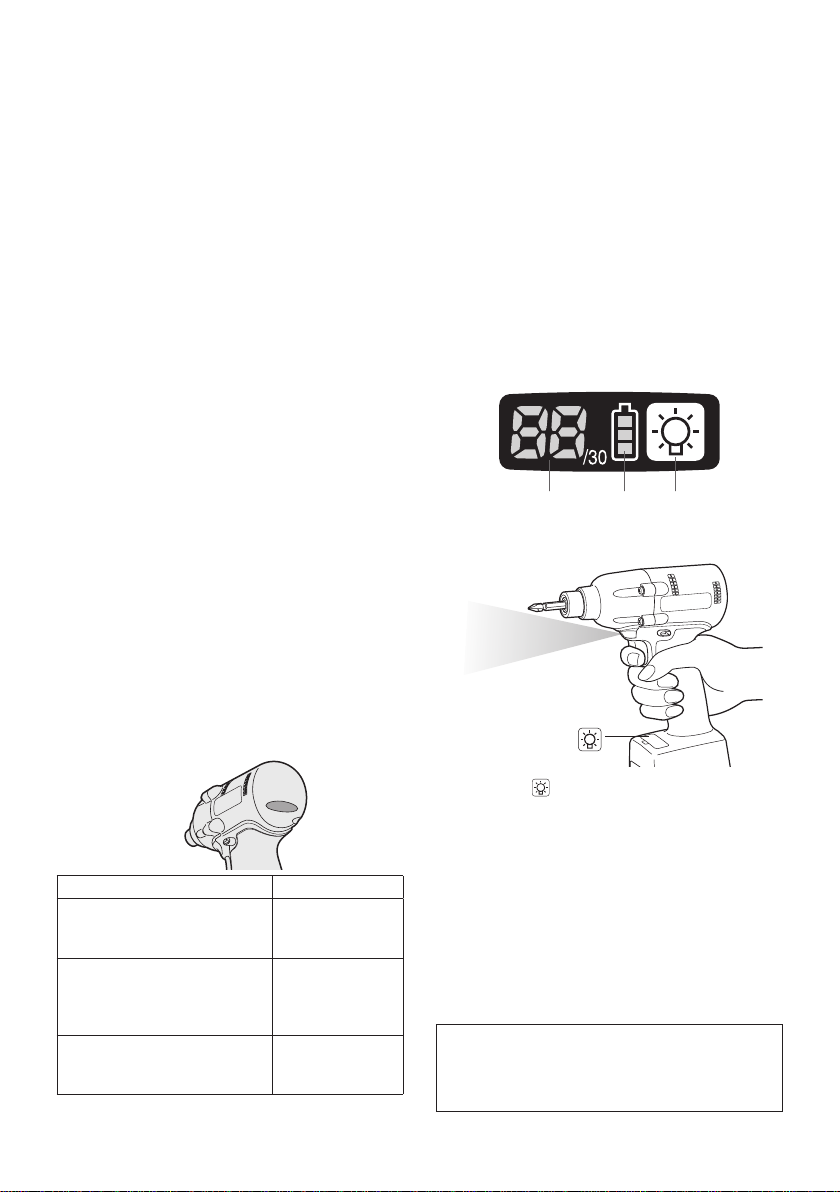

Control Panel

(1) (2) (3)

(1) LED light

Tool status Lamp display

Tightening complete

(with torque control

function operation)

Tightening not complete

•

• Tightening complete

with retightening within 1

second

The automatic stop

function has been

activated.

Green

(For approx.

seconds)

Red

(For approx.

seconds)

Red

(For approx. 5

minutes)

Pressing the button toggles the LED light on

and off.

The light illuminates with very low current, and

it does not adversely affect the performance

tool during use or its battery capacity.

the

CAUTION:

The built-in LED light is designed to illu-

2

2

-

9 -

•

minate the small work area temporarily.

•

Do not use it as a substitute for a regular

flashlight, since it does not have

enough brightness

This tool has the built-in LED light.

Caution: DO NOT STARE INTO BEAM.

Use of controls or adjustments or performance

of procedures other than those specied herein

may result in hazardous radiation exposure.

.

of

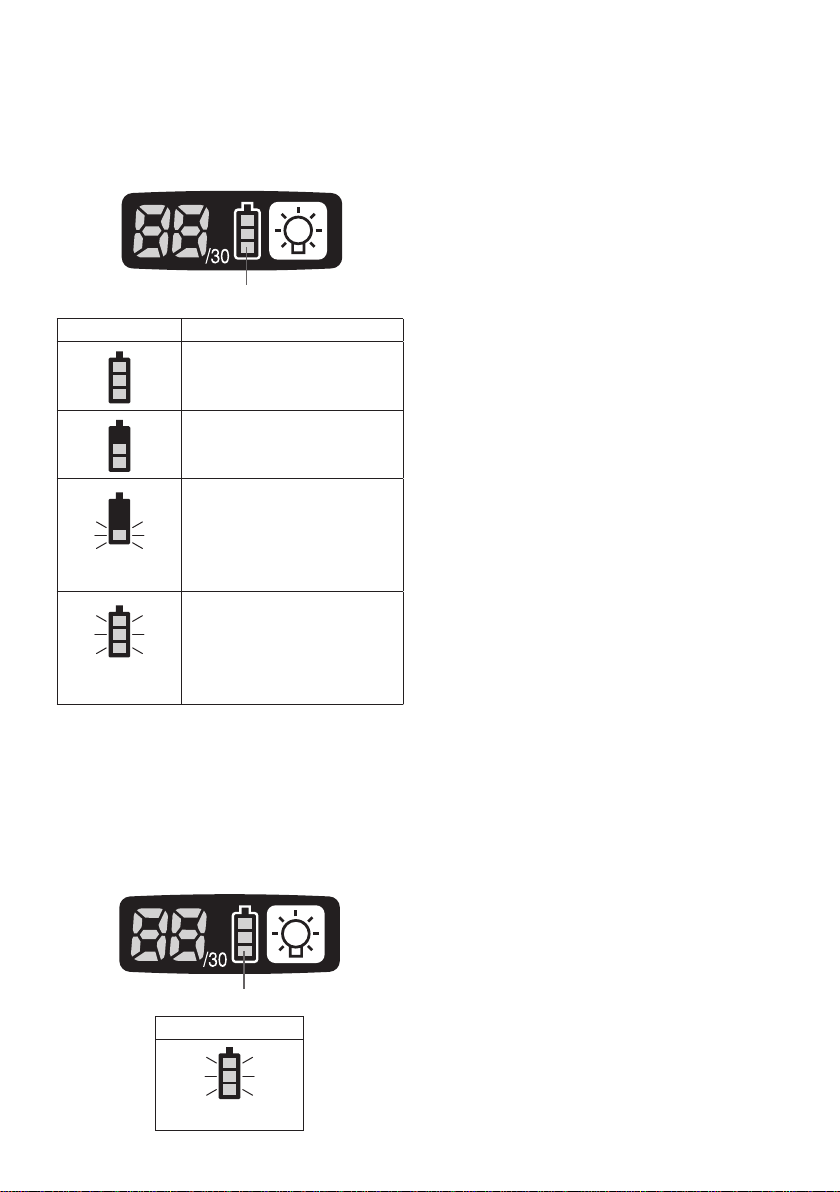

(2) The battery indication lamp

• Use the battery indication lamp to check

how much power is left in the battery.

Battery life varies slightly with ambient tem-

•

perature and battery characteristics. The

lamp is designed to provide a rough indication of remaining battery life.

Battery indication lamp

Indicator Battery status

Fully charged

Approx. 40% or less

remaining

Flashing

Approx. 20% or less

remaining (indicates need

to recharge battery)

Flashing

Flashing

The battery pack will need

to be charged soon.

No charge

The battery pack needs to

be charged.

(The tool’s automatic

power-off function will

activate at this stage.)

Automatic power-off function

• The automatic power-off function is designed

to prevent a loss of tightening torque due to

reduced battery voltage. Once it has been

activated, the tool will not operate until the

battery pack has been charged (or replaced

with a fresh unit), even if the trigger is

depressed.

Battery indication lamp

Indicator

Flashing

NOTE:

• All 3 bars on the battery indication lamp

will flash when the automatic power-off

function is activated.

When the battery indication lamp begins

•

flashing, the battery pack should be

charged (or replaced with a fresh unit)

immediately.

Be sure to fully charge the battery pack

•

in question after activation of the automatic power-off function. Failure to do

so may prevent the automatic power-off

function from being properly deactivated.

(3) The torque control function

• The torque control function calculates the

load from the motor’s rotational angle during

the hammer impact and determines that the

bolt has been properly seated when a preset load value is exceeded. Driving is then

automatically stopped after a preset number

of impacts have been delivered to the bolt.

CAUTION:

Always check the tool’s tightening

•

torque before use. Improper tool operation may result in excessive or inadequate tightening.

CAUTION:

•

Always operate the tool with the switch

fully engaged. The torque control function will not operate when the switch is

not sufficiently engaged, preventing the

tool from stopping automatically.

In work where a heavy load comes to

•

bear during tightening, the load may be

interpreted as the seating of the bolt,

preventing the bolt from being completely tightened.

Repeated tightening of the same bolt

•

may break the bolt or deform the material into which the bolt is being driven as

a result of excessive tightening.

The tightening torque value and preci-

•

sion vary with factors such as the material into which the bolt is being driven

and the condition of the socket being

used. Adjust the torque as necessary

for the work being performed. Bolt tightening torque varies due to the factors

described below.

1) Bolt

Bolt diameter: Tightening torque gener-

•

ally increases with bolt diameter.

•

Torque coefficient (indicated by the bolt

manufacturer), grade, length, etc.

-

10 -

2) Other

3…28

1F30 229

• Bit and socket condition: Material,

amount of play, etc.

•

Use of a universal joint or socket

adapter

•

User: Manner in which the tool is

applied to the bolt, strength with which

the tool is held, manner in which the

tool’s switch is engaged

Condition of object being tightened: Ma-

•

terial, seating surface finish

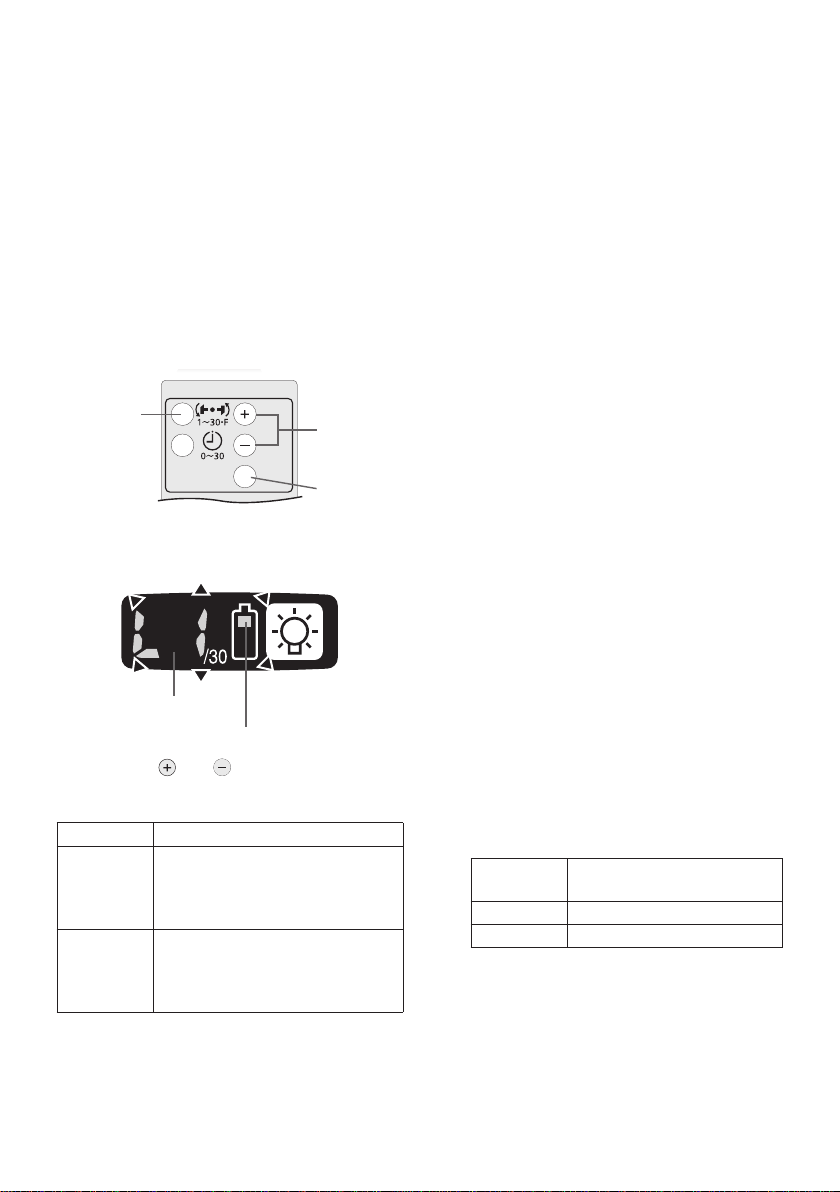

Setting the tool to configuration mode

1.

Turn off the control panel.

• If the control panel is on, remove and

then reinsert the battery pack.

. Engage the switch while pushing the

2

button and then release both the

ton and the switch.

After all the LED lamps have turned off,

•

the control panel will flash and change

to configuration mode.

Configuring the torque clutch setting

but-

(1)

(2)

NOTE:

• Tools ship from the factory set to “F”

mode (torque control function off).

•

The control panel will turn off if the tool

is not operated for a period of 5 minutes.

Display

Battery indication lamp

1. Press the and buttons to select the

clutch setting that is appropriate for the

work being performed.

-

11 -

As the button

is pressed

• “F” indicates that the torque control function is off.

As the button

is pressed

• You can select from 30 torque clutch

settings (1 to 30).

Use figures from the Tightening Torque

•

Chart to guide your selection of torque

clutch setting. (See the following tightening torque chart)

. Press the OK button to accept the select-

2

ed torque clutch setting.

•

The control panel will stop flashing and

light up.

CAUTION:

•

You must press the OK button in order

for the selected setting to take effect.

•

Be sure to verify the new value after

changing the setting. (See page 14.)

Setting the snug point detection level

(1)

1. Press the torque setting mode button.

• The snug point detection level setting

value will be displayed.

Display

Battery indication lamp

2. Press the and buttons to set the best

snug point detection level for the work

you’re performing.

Display Snug point detection level

L1

L

(Use for work characterized by

low loads before the snug point

(Use for work characterized by

2

high loads before the snug point

is reached.)

is reached.)

(2)

(3)

Low

High

3.

Press the OK button to accept the number

of torque stages and the snug point detection level.

The tool’s panel will flash and then light

•

up continuously.

CAUTION:

• Set the snug point detection level from

“L1.” Setting the snug point detection level

rom “L2” may result in cracking or defor-

f

mation of the target material.

f the tool stops before the snug point at

• I

snug point detection level “L1,” set the

nug point detection level to “L2.”

s

• Changing the snug point detection level

from “L1” to “L2” may increase the torque.

Set the number of torque stages again

after making this change.

• The setting will not be changed until

you press the OK button.

• After changing the setting, be sure to check

the new setting value. (See page 14.)

IMPORTANT INFORMATION:

• You can set the snug point detection

level and retightening prevention time at

the same time by changing the retightening prevention time (see page 13)

before pressing the OK button and then

pressing the OK button.

Pressing the torque setting mode but-

•

ton toggles the display between the

snug point detection level setting value

and the number of torque stages setting value.

The tool ships with the snug point

•

detection level set to “L1.”

When the number of torque stages has

•

been set as shown below, the snug

point detection level cannot be switched

from “L1” to “L

Model

EZFLA4 1 to 8

EZFLA5 1 to 3

2.”

Number of torque stages

setting

-

12 -

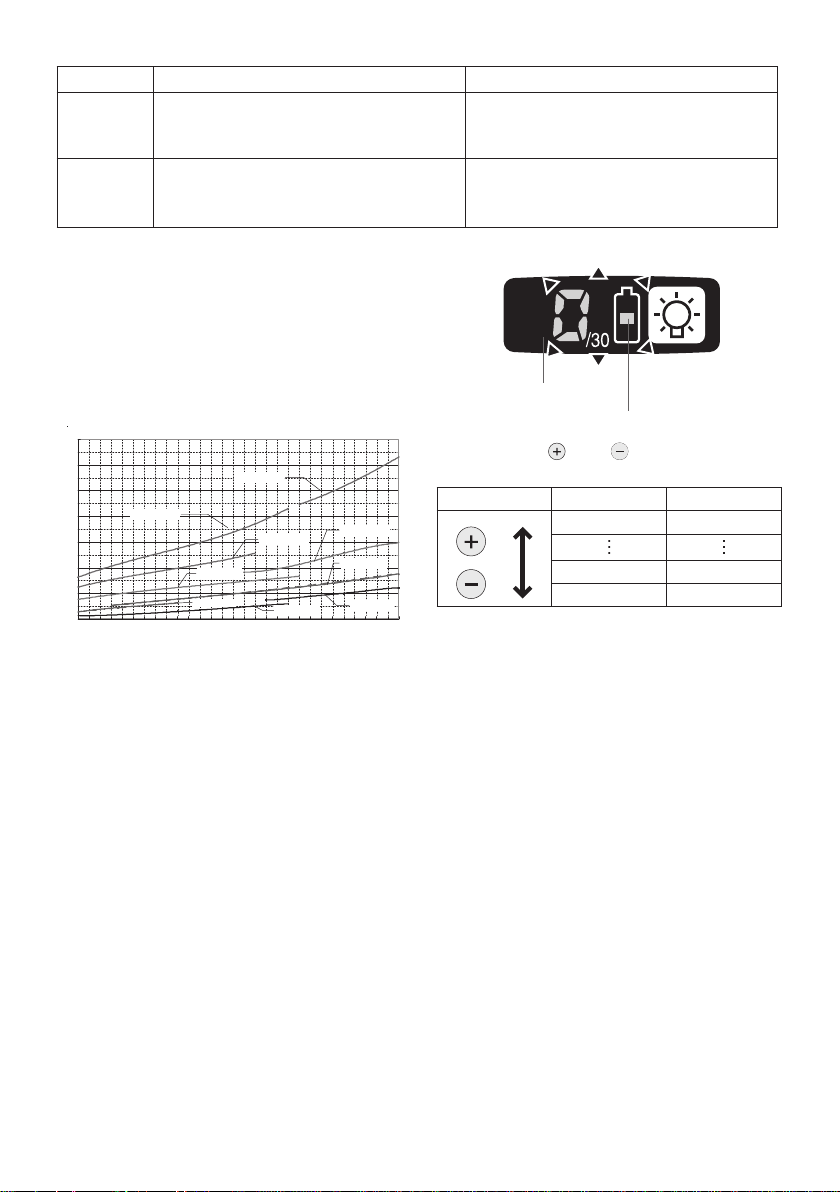

Snug point detection level guidelines

0

20

40

60

80

100

120

140

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30

N

m

EYFLA4(M6)

EYFLA6(M8)

EYFLA4(M8)

EYFLA5(M8)

EYFLA6(M10)

EYFMA1(M10)

EYFMA1(M12)

EYFMA1(M14)

EYFLA5(M6)

Display Snug point detection level Applications (reference)

L1

L

(Use for work characterized by low loads

Low

before the snug point is reached.)

High

2

(Use for work characterized by high

loads before the snug point is reached.)

•

Tightening bolts in materials that are

easily cracked or deformed, etc.

•

Tightening bolts in materials with mis-

aligned holes, etc.

Tightening self-tapping screws, etc.

•

Tightening Torque Chart (for Reference Use)

The values illustrated on this chart were measured under the conditions described below

and are provided for reference purposes.

Actual tightening torque varies with ambient

conditions (the particular bolt being tightened,

hardware being used, method of holding the

bolt in place, etc.).

Display

Battery indication lamp

3. Press the and buttons to set the

desired time.

Buttons Display Seconds

30 3

1 0.1

0 Off

Measurement conditions

• Temperature: Room temperature (20°C/68°F)

Using the Interval Set

•

The interval set operates to prevent the tool

from operating after it automatically stops as

a result of the torque control function, even if

the switch is engaged.

1.

Set the tool to configuration mode.

(See page 11.)

2. Press the interval set button.

• The control panel will begin flashing.

Display: The number 0 ashes on and off.

Battery indication lamp: The middle bar

of the battery ashes on and off.

4.

Press the OK button to accept the select-

ed setting.

The control panel will stop flashing and

•

light up, and the torque clutch setting

will be displayed.

CAUTION:

Be sure to verify the new value after

•

changing the setting.

13 -

-

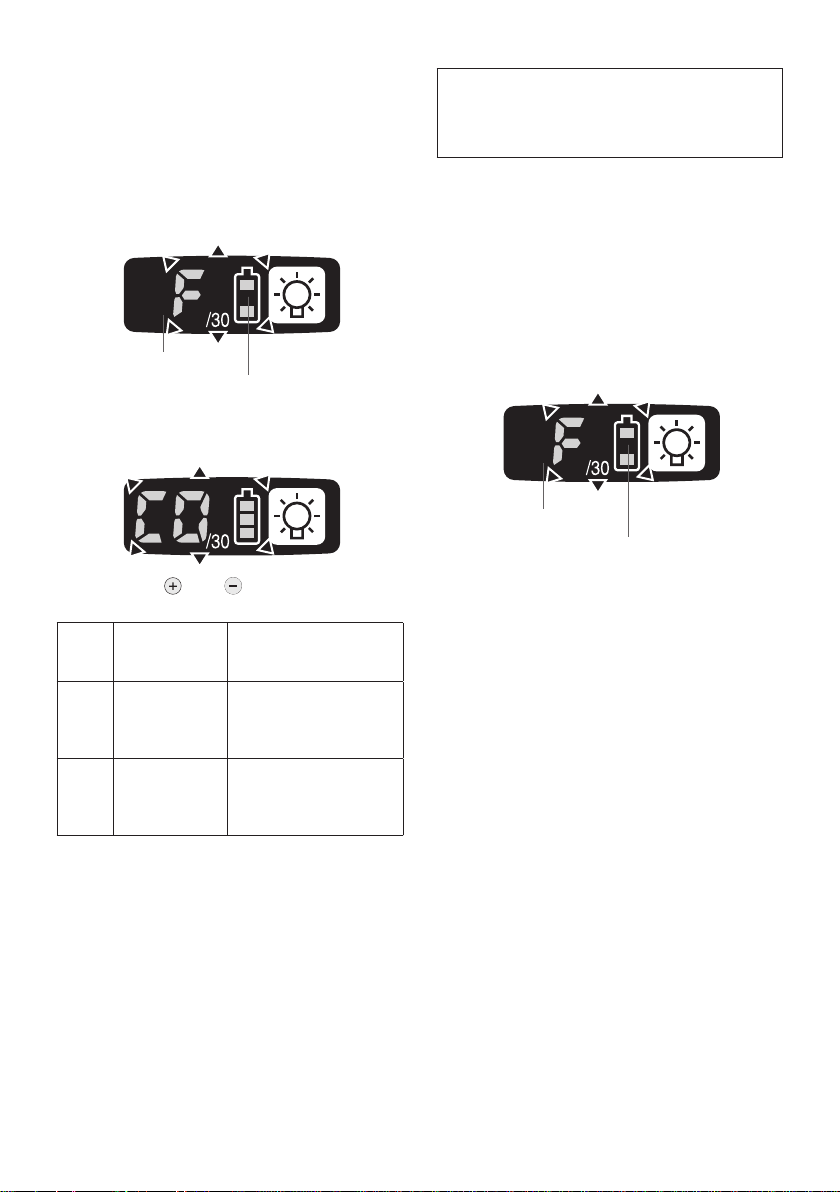

Radio signal range limitation function

on/off setting (EYFLA4AR, EYFLA5AR,

EYFLA5QR, EYFLA6PR)

1.

Set the tool to configuration mode.

(See page 11.)

2. Press the format button.

• The control panel will begin flashing.

Display: The letter “F” ashes on and off.

Battery indication lamp: The upper and

lower bars of the battery ash on and off.

Display

Battery indication lamp

3. Press the format button again.

• Radio signal range limitation function

on/off setting value will be displayed.

4. Press the and buttons to set radio

signal range limitation function on/off.

Display

Factory settings

Radio signal

range limitation

function mode

Tool is operational in the

C0 OFF

C1 ON

• Radio signal range limitation function

setting: C0 (OFF)

NOTE:

•

For more information about how to register

the tool and assembly qualifier, see the

assembly qualifier instruction manual.

absence of communications with the Assembly

Qualier.

Tool is not operational

in the absence of communications with the As-

sembly Qualier.

Status

Initializing All Settings

Factory settings

• Torque clutch setting: “F” (torque control function off)

•

Interval setting: 0 (off)

• This section explains how to revert all tool

settings to their default values at the time of

shipment from the factory.

•

The error display will be turned off.

1. Set the tool to configuration mode.

(See page 11.)

2. Press the format button.

• The control panel will begin flashing.

Display: The letter “F” ashes on and off.

Battery indication lamp: The upper and

lower bars of the battery ash on and off.

Display

Battery indication lamp

3. Press the OK button to accept the select-

ed setting.

The control panel will stop flashing and

•

light up.

Checking Tool Settings

•

This section describes how to have the

tool display current settings for approximately 3 seconds when the tool is

stopped.

You cannot check tool settings when the

•

control panel is turned off. First, engage

the switch briefly to reactivate the display.

Checking the sung point detection setting

Press the torque set button.

1.

• Control panel display

Display: The torque set lights up.

Battery indication lamp: The upper and mid-

dle bars of the battery ash on and off.

Checking the interval

1. Press the interval set button.

• Control panel display

Display: The interval set lights up.

Battery indication lamp: The middle bar

of the battery ashes on and off.

-

14 -

Checking tool circuits

1. Press the torque level button.

• Control panel display

Display: The torque set display lights up.

Battery indication lamp: The middle and

lower bars of the battery ash on and off.

Display Tool circuit

H6 EYFLA4

H7 EYFLA5

H8 EYFLA6

H9 EYFMA1

NOTE:

•

If you engage the switch while a setting

is being displayed, the control panel will

revert to the torque clutch setting display.

CAUTION:

The torque set display is not intended

•

to be used to identify the type of drive

component parts (hammer, etc.) used

in a particular tool.

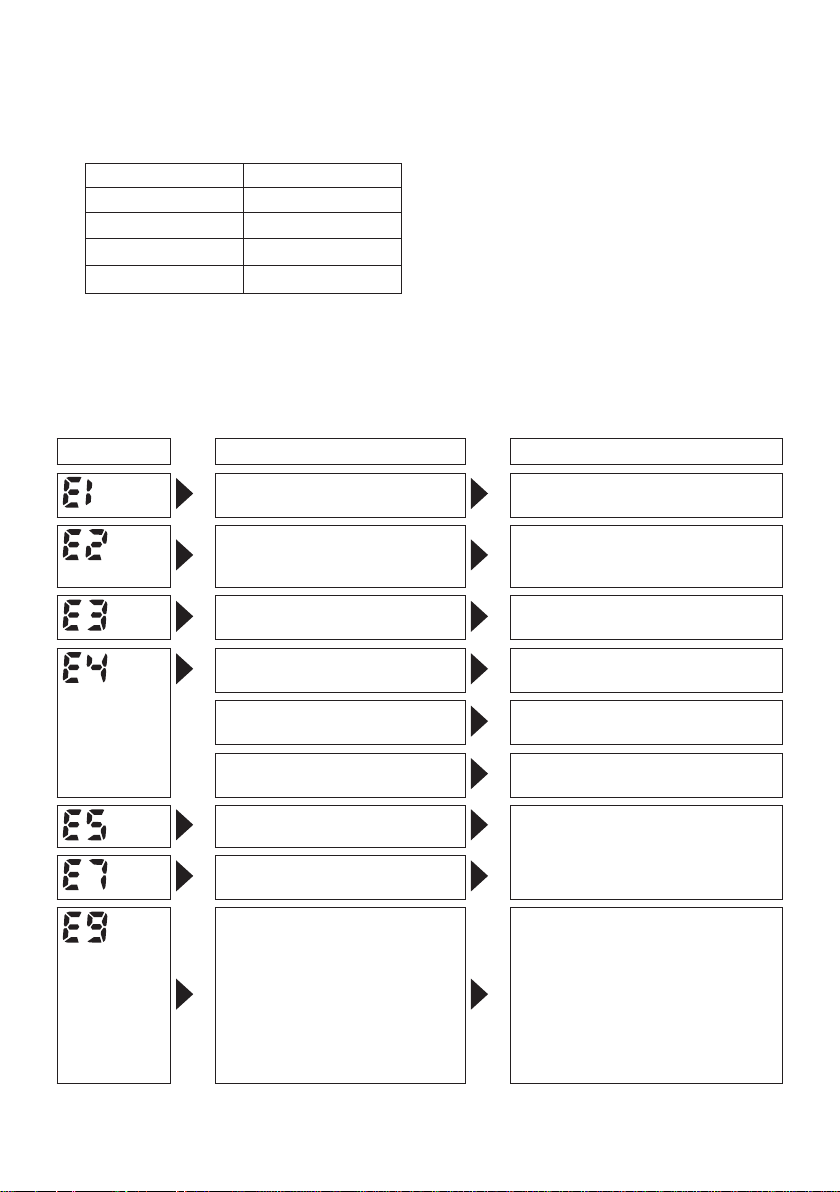

Error Display

In the event of a tool or battery pack malfunction, the control panel will display an error message.

Please check the tool or battery pack as described in the following chart before having them

serviced.

Display Likely cause Corrective action

Setting error Re-initialize the tool using the

The battery pack is too hot. Stop work and allow the battery

The tool is too hot to operate. Stop work and allow the tool to

The contacts that connect the

battery pack and tool are dirty.

The battery pack has not been

properly inserted into the tool.

The pins on either the tool or

battery pack have worn down.

Motor failure, etc. Stop using the tool immediately.

Tool circuit malfunction, failure,

etc.

The tool is unable to communicate with the Assembly Quali-

er while the radio signal range

limitation function is on.

remote control. (See page 14.)

pack to cool before resuming use

of the tool.

cool before resuming use.

Remove any dirt.

Insert the battery pack rmly into

the tool.

Replace the battery pack.

• Verify that the tool has been

properly registered to the Assembly Qualifier.

Verify that the Assembly Qualifi-

•

er’s group setting has been configured correctly.

Improve the reception state, for

•

example by moving the Assembly Qualifier closer to the tool.

-

15 -

-

16 -

[Battery Pack]

For Appropriate Use of Bat-

tery Pack

Li-ion Battery Pack

• For optimum battery life, store the Li-ion battery pack following use without charging it.

• When charging the battery pack, confirm

that the terminals on the battery charger

are free of foreign substances such as dust

and water etc. Clean the terminals before

charging the battery pack if any foreign substances are found on the terminals.

The life of the battery pack terminals may be

affected by foreign substances such as dust

and water etc. during operation.

• When battery pack is not in use, keep it

away from other metal objects like: paper

clips, coins, keys, nails, screws, or other

small metal objects that can make a connection from one terminal to another.

Shorting the battery terminals together may

cause sparks, burns or a fire.

• When operating the battery pack, make sure

the work place is well ventilated.

• When the battery pack is removed from the

main body of the tool, replace the battery

pack cover immediately in order to prevent

dust or dirt from contaminating the battery

terminals and causing a short circuit.

Battery Pack Life

The rechargeable batteries have a limited life.

If the operation time becomes extremely short

after recharging, replace the battery pack with

a new one.

Battery Recycling

ATTENTION:

A Li-ion battery that is recyclable powers

the product you have purchased.

Please call 1-800-8-BATTERY for information on how to recycle this battery.

[Battery Charger]

Charging

Read the operating manual for Panasonic battery charger for the battery pack before charging.

Before charging the battery

Charge the battery at a temperature of 5°C

(41°F) to 40°C (104°F).

The battery pack cannot be charged at a temperature of less than 5°C (41°F). If the temperature of the battery pack is less than 5°C

(41°F), rst remove the battery pack from

the charger and allow it to sit for an hour in a

location where the temperature is 5°C (41°F) or

warmer. Then charge the battery pack again.

VI.

MAINTENANCE

Use only a dry, soft cloth for wiping the unit.

Do not use a damp cloth, thinner, benzine, or

other volatile solvents for cleaning.

VII

. ACCESSORIES

Charger

• EY0L80

• EY0L81

Battery pack

•

EYFB30

• EYFB40

Remote control

•

EYFA30

Protector for tool

EYFA01-A (Blue)

•

• EYFA01-Y (Yellow)

• EYFA01-H (Gray)

• EYFA01-G (Green)

Protector for battery

•

EYFA02-H

• EYFA04-H

Assembly Qualier

•

EYFRZ01

• EYFR02

Federal Communications Commission Interference

Statement

This equipment has been tested and found to comply with the limits for a Class B digital device,

pursuant to part 15 of the FCC Rules. These limits are designed to provide reasonable protection

against harmful interference in a residential installation. This equipment generates, uses and can

radiate radio frequency energy and, if not installed and used in accordance with the instructions,

may cause harmful interference to radio communications. However, there is no guarantee that

interference will not occur in a particular installation. If this equipment does cause harmful interference to radio or television reception, which can be determined by turning the equipment off

and on, the user is encouraged to try to correct the interference by one or more of the following

measures:

Reorient or relocate the receiving antenna.

•

•

Increase the separation between the equipment and receiver.

•

Connect the equipment into an outlet on a circuit different from that to which the receiver is

connected.

Consult the dealer or an experienced radio/TV technician for help.

•

FCC Caution: To assume continued compliance, install and use in accordance with provided

instructions. Use only the battery pack specied in the instructions. Any changes or modications

not expressly approved by the party responsible for compliance could void the user’s authority to

operate this equipment.

FCC ID: O4O-EYFLA IC : 8507A-EYFLA

The enclosed device complies with Part 15 of the FCC Rules. Operation is subject to the following

two conditions: (i.) this device may not cause harmful interference and (ii.) this device must accept

any interference received, including interference that may cause undesired operation.

This Class B digital apparatus complies with Canadian ICES-003.

Panasonic Electric Works Power Tools Co., Ltd.

33, Okamachi, Hikone, Shiga, Japan

17 -

-

Loading...

Loading...