Page 1

ORDER NO.MAD0608024CE

DVD Recorder

DMR-EX95VEG

DMR-EX95VEB

Vol. 1

Colour

(S).......................Silver Type

© 2006 Matsushita Electric Industrial CO., Ltd. All

rights reserved. Unauthorized copying and

distribution is a violation of law.

Page 2

DMR-EX95VEG / DMR-EX95VEB

CONTENTS

Page Page

1 SAFETY PRECAUTIONS 4

1.1. GENERAL GUIDELINES

2 WARNING

2.1. PREVENTION OF ELECTROSTATIC DISCHARGE (ESD)

TO ELECTROSTATIC SENSITIVE (ES) DEVICES

2.2. PRECAUTION OF LASER DIODE

2.3. SERVICE CAUTION BASED ON LEGAL RESTRICTIONS

3 SERVICE NAVIGATION

3.1. SERVICE INFORMATION

3.2. CAUTION FOR DivX (For EG only)

4 SPECIFICATION

5 NEW FEATURE

5.1. ABOUT DivX (EXCEPT EB)

5.2. HDAVI CONTROL (HDMI LINK)

6 LOCATION OF CONTROLS AND COMPONENTS

7 OPERATING INTRUCTIONS

7.1. (DVD) TAKING OUT THE DISC FROM RAM-DRIVE UNIT

WHEN THE DISC CANNOT BE EJECTED BY

OPEN/CLOSE BUTTON

7.2. (VHS) REMOVING OF CASSETTE TAPE

8 SERVICE MODE

8.1. (DVD) SELF-DIAGNOSIS AND SPECIAL MODE

SETTING

8.2. (VHS) SELF-DIAGNOSIS AND SPECIAL MODE

SETTING

9 SERVICE FIXTURE AND TOOLS

10 ASSEMBLING AND DISASSEM BLING

10.1. DISASSEMBLY FLOW CHART

10.2. P.C.B. POSITIONS

10.3. CAUTION WHILE INSERTING CASSETTE TAPE WHEN

DISASSEMBLING THE UNIT

10.4. TOP CASE

10.5. FRONT PANEL

10.6. FRONT JACK P.C.B. &FL DRIVE P.C.B.

10.7. REAR PANEL

10.8. HARD DISC DRIVE

10.9. FAN MOTOR

10.10. VCR MECHANISM UNIT

10.11. MAIN P.C.B.

10.12. TUNER

10.13. DVD-RAM DRIVE / DIGITAL P.C.B. MODULE

10.14. SD/DV IN P.C.B.

10.15. POWER & DIGITAL I/F P.C.B.

10.16. BACK END P.C.B.

10

10

15

17

18

18

19

21

21

32

34

35

35

35

35

36

36

37

37

38

38

38

39

39

39

40

41

42

4

5

5

6

7

8

8

8

9

10.17. HDMI P.C.B.

11 MEASUREMENTS AND ADJUSTMENTS

11.1. SERVICE POSITIONS

11.2. CAUTION FOR REPLACING PARTS

11.3. (DVD) STANDARD INSPECTION SPECIFICATION

AFTER MAKING REPAIRS

12 MISCELLANEOUS

12.1. ABBREVIATIONS

13 BLOCK DIAGRAM

13.1. POWER SUPPLY BLOCK DIAGRAM

13.2. SYSTEM CONTROL, SERVO & TIMER BLOCK

DIAGRAM

13.3. AUDIO BLOCK DIAGRAM

13.4. VIDEO BLOCK DIAGRAM

13.5. DIGITAL I/F P.C.B. BLOCK DIAGRAM

13.6. HDMI BLOCK DIAGRAM

14 SCHEMATIC DIAGRAM

14.1. INTERCONNECTION DIAGRAM

14.2. POWER SUPPLY

14.3. DIGITAL I/F

14.4. IO / TUNER

14.5. SYSCON / SERVO / TIMER MAIN

14.6. VIDEO

14.7. AUDIO NICAM

14.8. FRONT JACK

14.9. FL DRIVE

14.10. SD/DV IN

14.11. HDMI

15 PRINTED CIRCUIT BOARD

15.1. POWER & DIGITAL I/F P.C.B. (COMPONENT SIDE)

15.2. POWER & DIGITAL I/F P.C.B. (SOLDER SIDE)

15.3. MAIN P.C.B. (COMPONENT SIDE)

15.4. MAIN P.C.B. (SOLDER SIDE)

15.5. FRONT JACK P.C.B.

15.6. FL DRIVE P.C.B.

15.7. DV IN P.C.B.

15.8. HDMI P.C.B.

16 APPENDIX FOR SCHEMATIC DIAGRAM

16.1. VOLTAGE AND WAVEFORM CHART

17 EXPLODED VIEWS

17.1. MECHANISM & CASING PARTS

17.2. FRONT PANEL PARTS

17.3. VHS MECHANISM PARTS

17.4. PACKING & ACCESSORIES SECTION

18 REPLACEMENT PARTS LIST

42

43

43

46

52

53

53

59

59

60

61

62

64

65

67

67

68

69

70

71

72

73

74

75

76

77

79

79

80

81

82

83

84

85

86

87

87

99

99

100

101

102

103

2

Page 3

DMR-EX95VEG / DMR-EX95VEB

18.1. CASING PARTS & PRINTED CIRCUIT BOARDS 103

18.2. VHS MECHANISM PARTS

18.3. PACKING & ACCESSORIES PARTS

18.4. ELECTRICAL PARTS

18.5. SERVICE FIXTURE AND TOOLS

19 DIAGRAMS FOR PRINTING A4 SIZE

103

104

104

117

118

19.1. BLOCK DIAGRAM FOR PRINTING A4 SIZE

19.2. SCHEMATIC DIAGRAMS FOR PRINTING A4 SIZE

19.3. POWER DIGITAL I/F P.C.B. FOR PRINTING A4 SIZE

19.4. MAIN P.C.B. FOR PRINTING A4 SIZE

158

19.5. OTHER P.C.B. FOR PRINTING A4 SIZE

118

132

154

162

3

Page 4

DMR-EX95VEG / DMR-EX95VEB

1 SAFETY PRECAUTIONS

1.1. GENERAL GUIDELINES

1. Be careful during removing metal parts, sharp edges.

2. When servicing, observe the original lead dress. If a short

circuit is found, replace all parts which have been

overheated or damaged by the short circuit.

3. After servicing, see to it that all the protective devices such

as insulation barriers, insulation papers shields are properly

installed.

4. After servicing, make the following leakage current checks

to prevent the customer from being exposed to shock

hazards.

1.1.1. LEAKAGE CURRENT COLD

CHECK

1. Unplug the AC cord and connect a jumper between the two

prongs on the plug.

2. Measure the resistance value, with an ohmmeter, between

the jumpered AC plug and each exposed metallic cabinet

part on the equipment such as screw heads, connectors,

control shafts, etc. When the exposed metallic part has a

return path to the chassis, the reading should be between

1MΩ and 5.2MΩ.

When the exposed metal does not have a return path to

the chassis, the reading must be infinity.

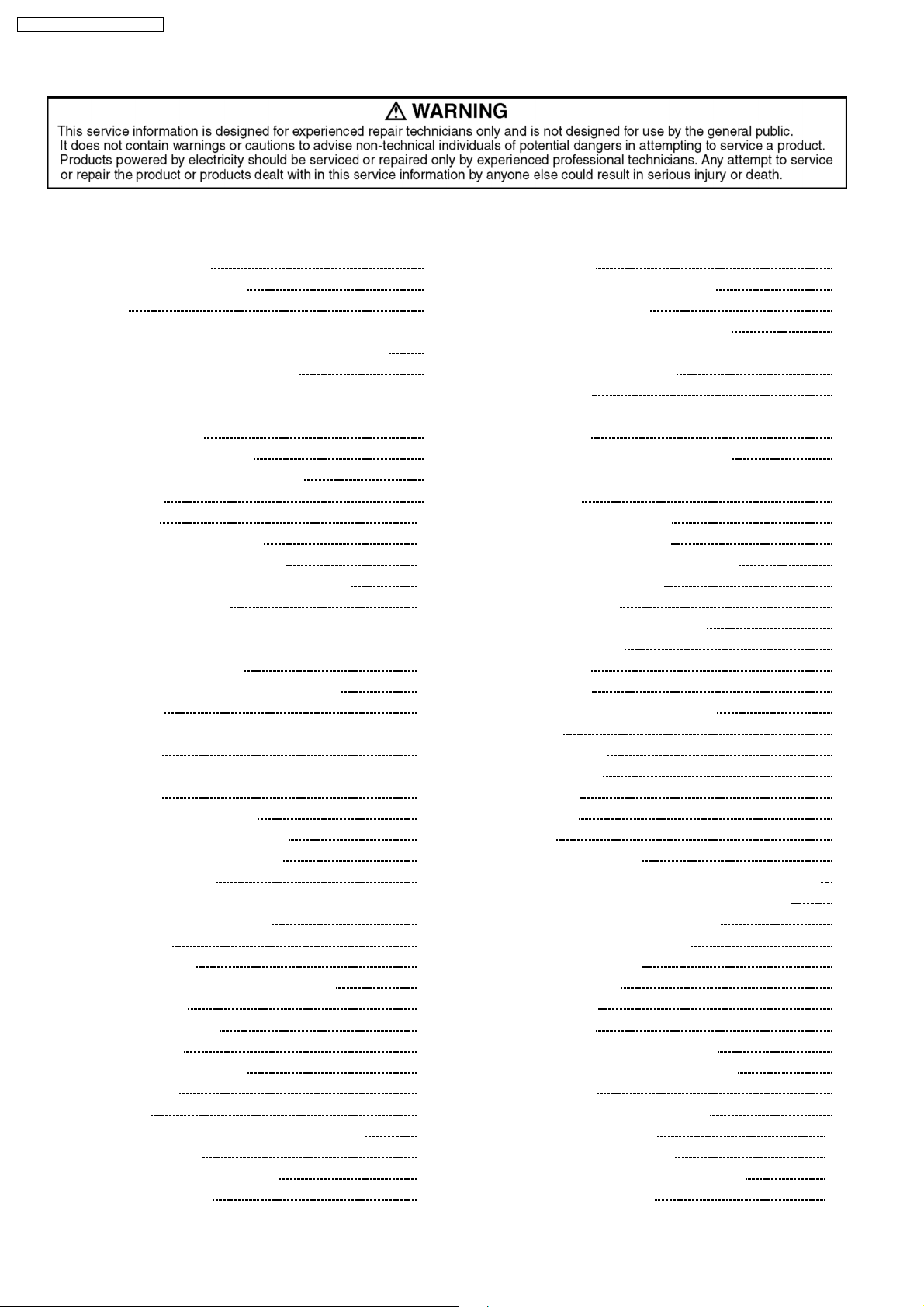

Figure 1

1.1.2. LEAKAGE CURRENT HOT CHECK

1. Plug the AC cord directly into the AC outlet. Do not use an

isolation transformer for this check.

2. Connect a 1.5kΩ, 10 watts resistor, in parallel with a 0.15µF

capacitors, between each exposed metallic part on the set

and a good earth ground such as a water pipe, as shown in

Figure 1.

3. Use an AC voltmeter, with 1000 ohms/volt or more

sensitivity, to measure the potential across the resistor.

4. Check each exposed metallic part, and measure the

voltage at each point.

5. Reverse the AC plug in theAC outlet and repeat each ofthe

above measurements.

6. The potential at any point should not exceed 0.75 volts

RMS. A leakage current tester (Simpson Model 229 or

equivalent) may be used to make the hot checks, leakage

current must not exceed 1/2 milliampere. In case a

measurement is outside of the limits specified, there is a

possibility of a shock hazard, and the equipment should be

repaired and rechecked before it is returned to the

customer.

4

Page 5

2 WARNING

2.1. PREVENTION OF ELECTROSTATIC DISCHARGE (ESD) TO

ELECTROSTATIC SENSITIVE (ES) DEVICES

DMR-EX95VEG / DMR-EX95VEB

Some semiconductor (solid state) devices can be damaged

easily by static electricity. Such components commonly are

called Electrostatic Sensitive (ES) Devices. Examples of typical

ES devices are integrated circuits and some field-effect

transistor-sand semiconductor "chip" components. The

following techniques should be used to help reduce the

incidence of component damage caused by electrostatic

discharge (ESD).

1. Immediately before handling any semiconductor

component or semiconductor-equipped assembly, drain off

any ESD on your body by touching a known earth ground.

Alternatively, obtain and wear a commercially available

discharging ESD wrist strap, which should be removed for

potential shock reasons prior to applying power to the unit

under test.

2. After removing an electrical assembly equipped with ES

devices, place the assembly on a conductive surface such

as aluminum foil, to prevent electrostatic charge buildup or

exposure of the assembly.

3. Use only a grounded-tip soldering iron to solder

or unsolder ES devices.

4. Use only an anti-static solder removal device.

Some solder removal devices not classified

as "anti-static (ESD protected)" can generate electrical

charge sufficient to damage ES devices.

5. Do not use freon-propelled chemicals. These can generate

electrical charges sufficient to damage ES devices.

6. Do not remove a replacement ES device from its protective

package until immediately before you are ready to install it.

(Most replacement ES devices are packaged with leads

electrically shorted together by conductive foam, aluminum

foil or comparable conductive material).

7. Immediately before removing the protective material from

the leads of a replacement ES device, touch the protective

material to the chassis or circuit assembly into which the

device will be installed.

Caution

Be sure no power is applied to the chassis or circuit, and

observe all other safety precautions.

8. Minimize bodily motions when handling unpacked

replacement ES devices. (Otherwise harmless motion such

as the brushing together of your clothes fabric or the lifting

of your foot from a carpeted floor can generate static

electricity sufficient to damage an ES device).

5

Page 6

DMR-EX95VEG / DMR-EX95VEB

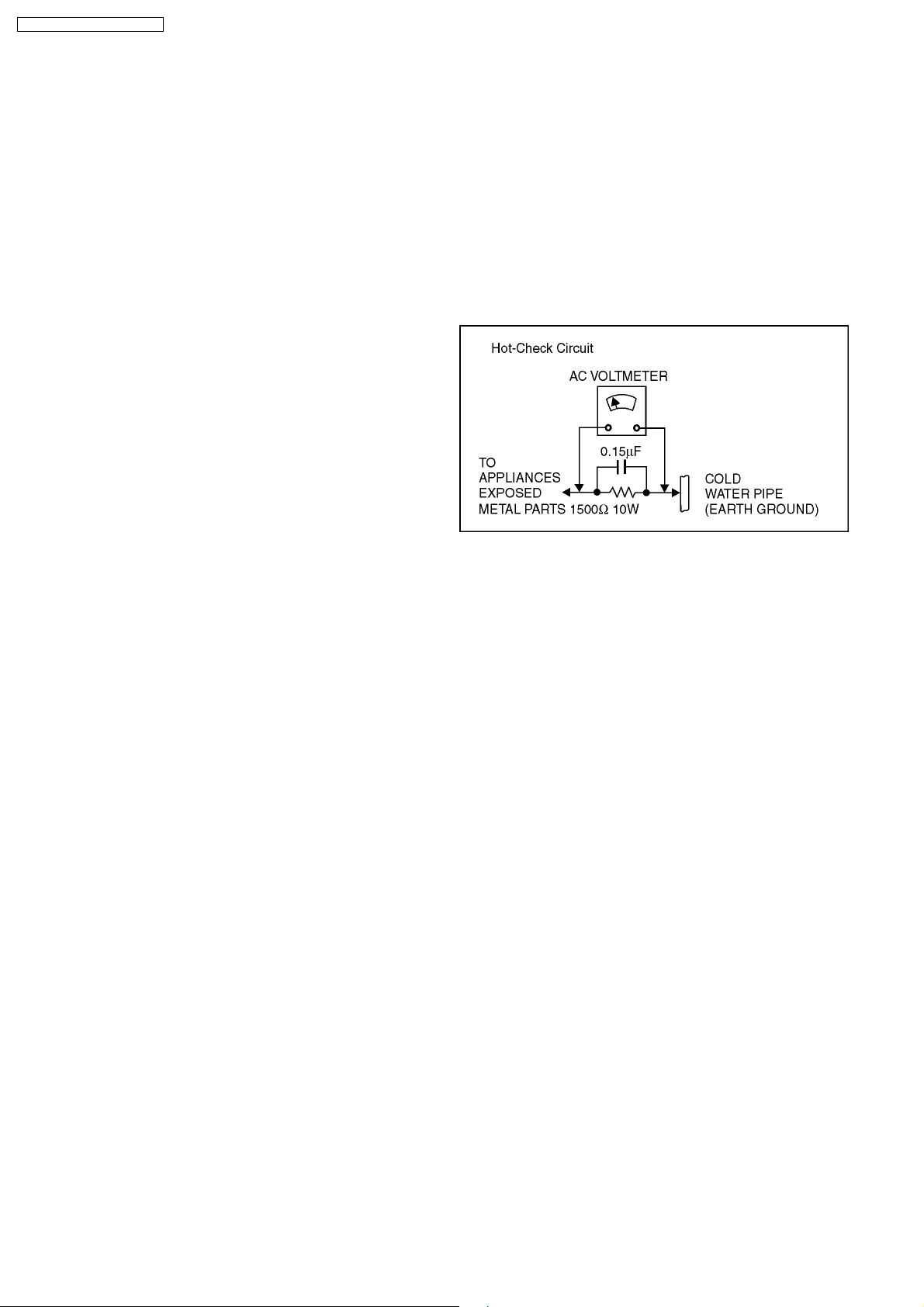

2.2. PRECAUTION OF LASER DIODE

CAUTION: ACHTUNG:

This product utilizes a laser diode with the unit turned “on”,

invisible laser radiation is emitted from the pickup lens.

Wave length: 662 nm/780 nm

Maximum output radiation power from pickup: 100µ W/VDE.

Laser radiation from the pickup lens is safety level, but be sure

the followings:

1. Do not disassemble the optical pickup unit, since radiation

from exposed laser diode is dangerous.

2. Do not adjust the variable resistor on the pickup unit.

It was already adjusted.

3. Do not look at the focus lens using optical instruments. 3. Nicht in die Fokussierlinse blicken.

4. Recommend not to look at pickup lens for a long time. 4. Auch nicht mit optischen Instrumenten in die Fokussierlinse blicken.

Dieses Produkt enthält eine Laserdiode.

Im eingeschalteten Zustand wird unsichtbare Laserstrahlung von der

Lasereinheit ausgestrahlt.

Wellenlänge: 662 nm/780 nm

Maximale Strahlungsleistung der Lasereinheit: 100µ W/VDE.

Die Strahlung der eingeschalteten Lasereinheit ist ungefährlich, wenn

folgende Punkte beachtet werden:

1. Die Lasereinheit nicht zerlegen, da die Strahlung an der freigelegten

Laserdiode gefährlich ist.

2. Den werksseitig justierten Einstellregler der Lasereinheit nicht

verstellen.

6

Page 7

DMR-EX95VEG / DMR-EX95VEB

2.3. SERVICE CAUTION BASED ON LEGAL RESTRICTIONS

General description about lead free Solder (PbF)

•

• The lead free solder has been used in the mounting process of all electrical components on the printed circuit boards used

• •

for this equipment in considering the globally environmental conservation.

•

• The normal solder is the alloy of tin (Sn) and lead (Pb). On the other hand, the lead free solder is the alloy mainly consists

• •

of tin (Sn), silver (Ag) and Copper (Cu), and the melting point of the lead free solder is higher approx. 30 degrees C (86°F)

more than that of the normal solder.

Service caution for repair work using Lead Free Solder (PbF)

•

• The lead free solder has to be used when repairing the equipment for which the lead free solder is used.

• •

•

• To put lead free solder, it should be well molten and mixed with the original lead free solder.

• •

•

• Remove the remaining lead free solder on the PCB cleanly for soldering of the new IC.

• •

•

• Since the melting point of the lead free solder is higher than that of the normal lead solder, it takes the longer time to melt

• •

the lead free solder.

•

• Use the soldering iron (more than 70W) equipped with the temperature control after setting the temperature

• •

at 350±30 degrees C (662±86°F). When soldering or unsoldering, please completely remove all of the solder

on the pins or solder area and be sure to heat the soldering points with the Pb free solder until it melts enough.

Definition of PCB Lead Free Solder being used

•

• The letter of “Pbf is printed either foil side or component side using the lead free solder.

• •

Recommended Lead Free Solder (Service Parts Route.)

•

• The following 3 types of lead free solder are available through the service parts route.

• •

RFKZ03D01K-----------(0.3mm 100g Reel)

RFKZ06D01K-----------(0.6mm 100g Reel)

RFKZ10D01K-----------(1.0mm 100g Reel)

Note

•

• Ingredient: tin (Sn), 96.5%, silver (Ag) 3.0%, Copper (Cu) 0.5%, Cobalt (Co) / Germanium (Ge) 0.1 to 0.3%

• •

7

Page 8

DMR-EX95VEG / DMR-EX95VEB

3 SERVICE NAVIGATION

3.1. SERVICE INFORMATION

This service manual contains technical information which will allow service personnel to understand and service these models.

Please place orders using the parts list and not the drawing reference numbers.

1. This service manual does not contain the following information, because of the impossibility of servicing at component level.

•

• Schematic Diagram, Block Diagram,

• •

Exploded View, Parts List and P.C.B. layout of

RAM / Digital P.C.B. Module and Back End P.C.B. Unit.

2. The following categories are recycling module part.

Please send them to Central Repair Center.

•

• RAM / Digital P.C.B. Module: RFKNEX95VEG

• •

•

• RAM / Digital P.C.B. Module: RFKNEX95VEB

• •

•

• Back End P.C.B. Unit: REPD0031F (EX95EG)

• •

•

• Back End P.C.B. Unit: REPD0031G (EX95EB)

• •

3. If the circuit is changed or modified, this information will be followed by supplement service manual to be filed with original

service manual.

4. Adjustment procedures, Disassembly Procedures and Assembly Procedures for VCR Mechanism Chassis are separate volume

from this service manual. Please refer to the service manual for R4 Mechanism Chassis for EURO model (MAD0403002C2).

3.2. CAUTION FOR DivX (For EG only)

Please give the information “Warning for Customers who use the DivX Video-on-Demand content.” always to the customer

together with the product, if you have to exchange EEPROM, P.C.B. including EEPROM or the product itself.

Also attach these information to every service part (EEPROM or P.C.B. including EEPROM).

This complete Information is needed for every customer who is using the DivX Video-on-Demand Serivce.

Appendix:

* Parts that memorize user’s information are only on the EEPROM.

* The registration of Registration Code is possible for half a year up to 6 recorders up to 10 recorders a year.

Every replacement of EEPROM or P.C.B. including EEPROM spends one of this.

•

• Registration Code is memorized in the EEPROM (RFKFxxxxxxx)

• •

•

• If the Power & Digital I/F P.C.B. or the EEPROM will be changed a new Registration Code

• •

different from the previous one will be generated.

•

• In this case the customer, who is useing DivX Video-on-Demand sercive, can not longer play any content that

• •

was or is purchased under that old registration code.

•

• Therefore the customer will need to register a new registration code.

• •

8

Page 9

4 SPECIFICATION

DMR-EX95VEG / DMR-EX95VEB

Power supply: AC220-240 V, 50/60 Hz

Power consumption: 38 W ±1,3 W

Dimensions and Mass: 430 (W) x 352 (D) x 84 (H) mm

Operating temperature range: +5 to +40 °C

Operating humility range: 35 to 80 % RH (no condensation)

Pickup Laser power: CLASS1

Pickup Wave length: DVD 662 nm / CD 780 nm

Recording format Heads VHS Video Cassette System

Recording system: MPEG2 (Hybrid VBR)

Signal system: PAL 625/50, NTSC 525/60

DVD Region number: Region No. 2

Internal HDD Capacity: 250 GB

DVD Recording /

Playable discs:

Power save mode 3 W ±0,4 W

excluding (protrusions) / 6.4 kg

No hazardous radiation is emitted

with the safety protection

Standard with FM audio

NTSC (only from extern and DVD)

4 Helical Scan Heads for Video

2 Helical Scan Heads for FM audio

1 Fixed Head for Normal audio

Audio: Dolby Digital 2CH

DVD-RAM (12 cm 4.7 GB)

DVD-RAM (12 cm 9.4 GB)

DVD-RAM (8 cm 2.8 GB)

DVD-R (12 cm 4.7 GB)

DVD-R (8 cm 1.4 GB)

DVD-RW (12 cm 4.7GB)

DVD+R (12 cm 4.7 GB)

DVD+RW (12 cm 4.7 GB)

DVD-R DL (12 cm 8.5 GB)

DVD+R DL (12 cm 8.5 GB)

SD Card Slot: JPEG (Still Picture DCF Standard)

TIFF (uncompressed)

MPEG2 (rec. by Panasonic cam)

Campatible Cards: SD Card, Multimedia Card

miniSD™ Card (with adapter)

Card format: FAT12, FAT16

Card picture pixels: 34x34 to 6144x4096

Video input AV1 / AV2: 21 pin connector (1.0 Vp-p 75 Ω )

Video input AV3 / AV4: pin jack connector (1.0 Vp-p 75 Ω)

S-Video input AV1 / AV2: 21 pin connector

(Y: 1.0 Vp-p, C: 0.3 Vp-p 75 Ω)

S-Video input AV3 / AV4: pin jack connector

(Y: 1.0 Vp-p, C: 0.3 Vp-p 75 Ω)

RGB Video input AV3 (PAL): 21 pin connector (0.7 Vp-p 75 Ω)

DV input: IEEE 1394 Standard 4 pin

Video output AV1 / AV2: 21 pin connector (1.0 Vp-p 75 Ω)

FBAS Video output (composit): pin jack connector (1.0 Vp-p 75 Ω)

S-Video output AV1: 21 pin connector (1.0 Vp-p 75 Ω)

S-Video output (cinch): pin jack connector (1.0 Vp-p 75 Ω)

S-Video output: S connector (1.0 Vp-p 75 Ω)

RGB Video output AV1: 21 pin connector (0.7 Vp-p 75 Ω)

Component Video output: Y pin jack (1.0 Vp-p 75 Ω)

PB pin jack (0.7 Vp-p 75 Ω)

PR pin jack (0.7 Vp-p 75 Ω)

HDMI output (19 pin type A): Version 1.2a (EDID Vers. 1.3)

Audio input AV1 / AV2: 21 pin connector (-6 dBV 500 mV)

Audio input AV3 / AV4: pin jack (-6 dBV 500 mV)

Audio output (cinch): pin jack (-6 dBV 500 mV)

Optical output: PCM, Dolby Digital, DTS, MPEG

Videotape speed and Recording time (PAL/SECAM 240 min. tape):

SP: 23.39 mm/s, 240 min.

LP: 11.695 mm/s, 480 min.

EP: 7.796 mm/s, 720 min.

FF/REW time: 60 sec. (180 min. tape)

Videotape speed and Recording time (NTSC 240 min. tape):

SP: 33.35 mm/s, 168 min.

EP: 11.12 mm/s, 505 min.

DVD approximate Recording

time:

Additional playable discs: DVD-RAM (VR format)

TV tuner system EB (PAL): UHF: CH21-CH68 (analog/DVB-T)

TV tuner system EG (PAL): UHF: CH21-CH69 (analog/DVB-T)

RF Converter Output: not provided

XP: 10 MBps (60 min)

SP: 5 MBps (120 min)

LP: 3 MBps (240 min)

EP: 1.7 / 1.2 MBps (360 - 480 min)

DVD-RW (VR format)

DVD-R (MP3, JPG)

DVD-R DL, DVD+R DL

DVD-Video, DVD-Audio

CD-Audio (CD-DA), Video CD

SVCD (IEC62107)

CD-R, CD-RW

CD-DA, MP3, JPG, VCD,

DivX formatted discs (for EG only)

VHF: CH E2-CH E12 (analog)

VHF: CH 05-CH 12 (DVB-T)

CATV: CH S01-S05(S1-S3)

CATV: S1-S20(M1-U10), S21-S41

Winding Speed

(180 min. tape):

FF time approximate 60 sec.

REW time approximate 43 sec.

Note:

Specifications are subject to change without notice.

Mass and dimensions are approximate.

■ Build-in decoders: You can play discs with following symbols

9

Page 10

DMR-EX95VEG / DMR-EX95VEB

5 NEW FEATURE

5.1. ABOUT DivX (EXCEPT EB)

5.1.1. GENERAL

DivX is a new video compressing format that is applied

MPEG-4 technology to improve quality and the compressibility

and it is developed by the DivXNetworks, Inc., Video file of high

resolution and the high picture quality can be made thought it

is a high compressibility.

DivX codec is necessary for converting video to DivX file and

playback files made.

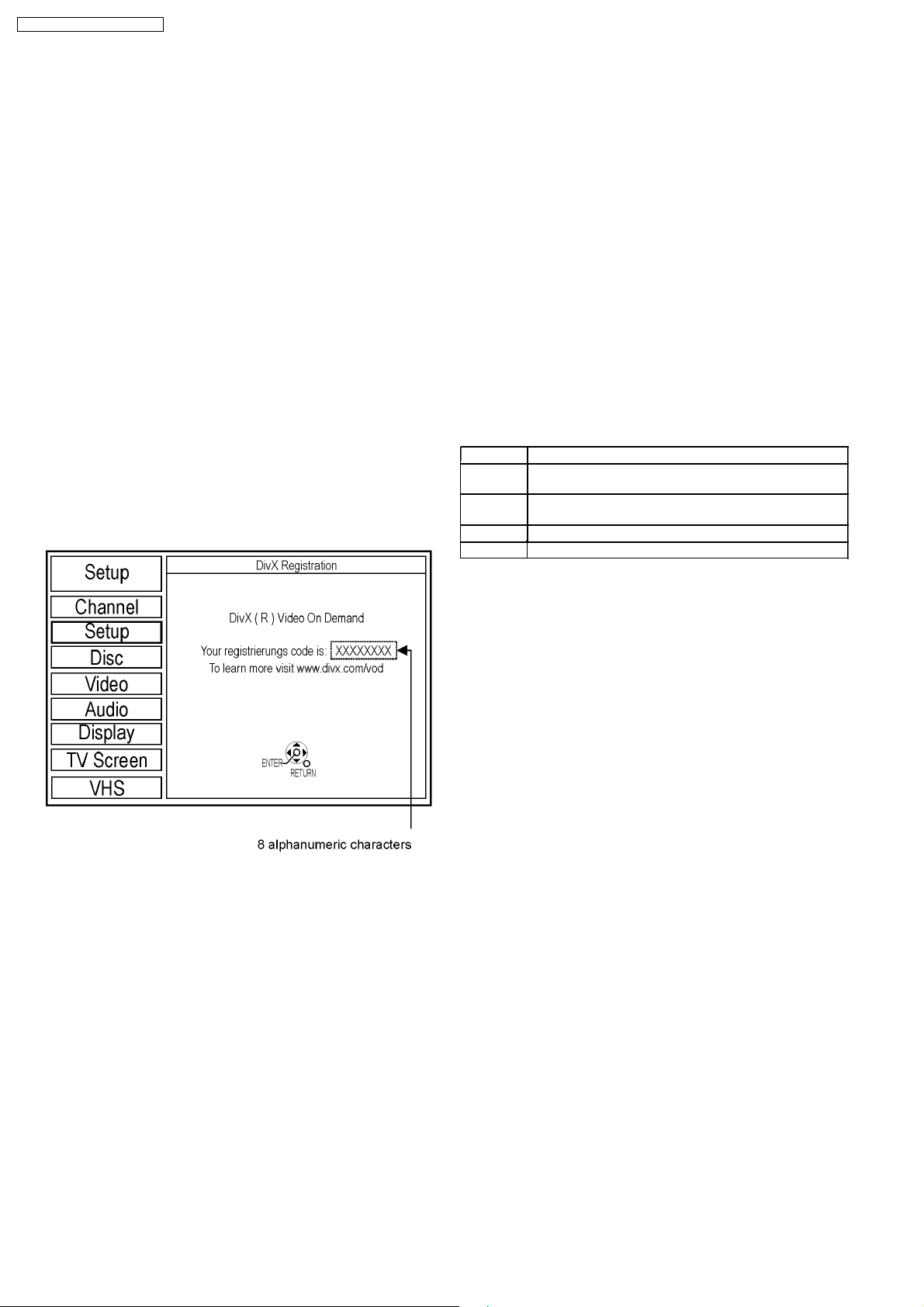

5.1.2. OPERATING INSTRUCTIONS

ABOUT DivX VIDEO-ON-DEMAND

CONTENT

DivX Video-on-Demand (VOD) content is encrypted for

copyright protection. In order to play DivX VOD content on this

unit, you first need to register the unit.

Follow the online instructions for purchasing DivX VOD content

to enter unit’s registration code and register unit. Visit

www.divx.com/vod for mor information.

Display unit’s registration code:

When playing this content

•

• Number of remaining plays is reduced by one if

• •

−

− you press [POWER]

− −

−

− you press [STOP]

− −

−

− you press [backwards SKIP],

− −

[backwards SLOW / SEARCH] or

[forwards SLOW / SEARCH]

etc. and arrive at another content or start of content

being played.

−

− scheduled [DRIVE SELECT] to change drive

− −

* Resume functions do not work.

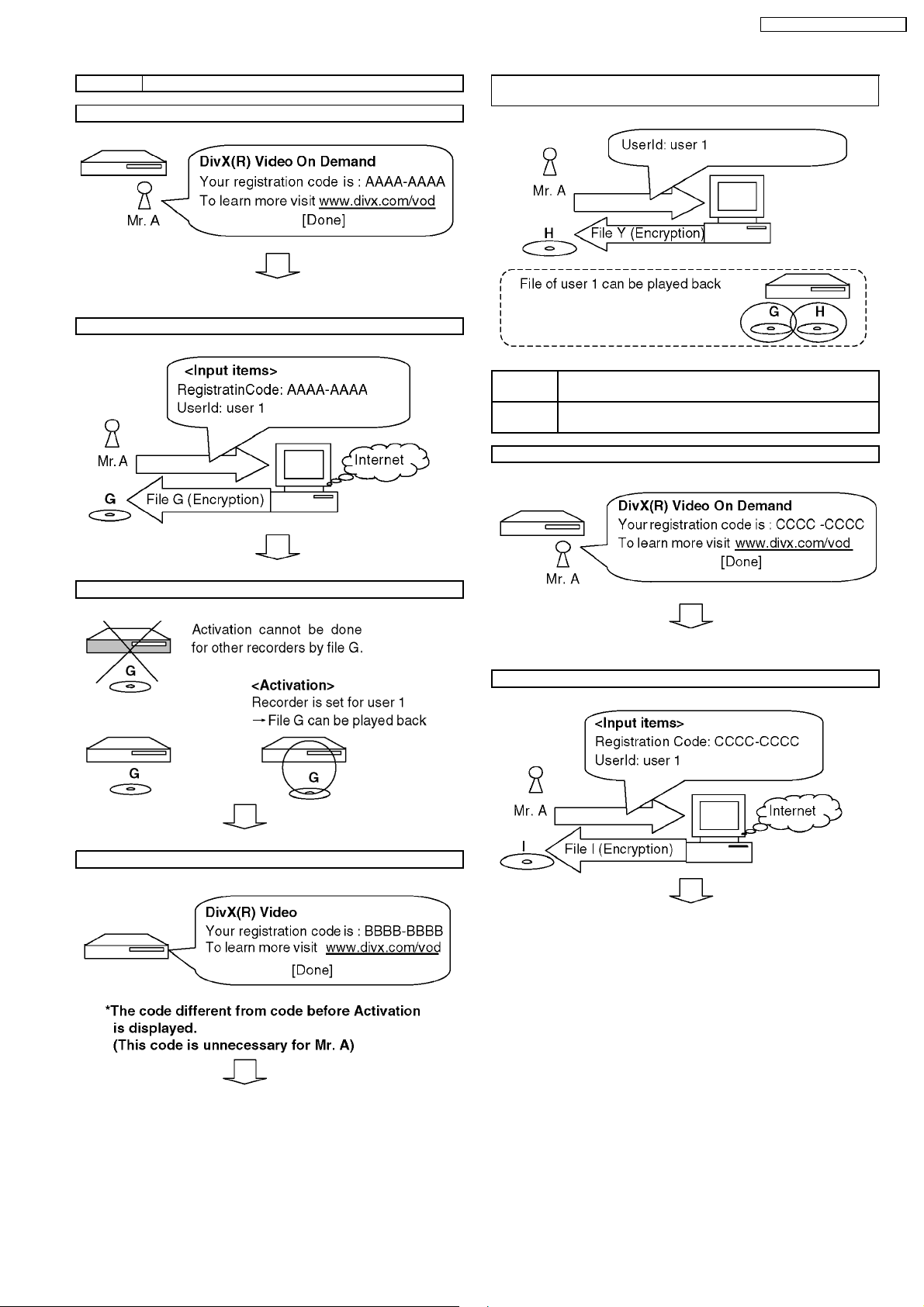

Typical Playback procedure of DivX VOD

(Video On Demand):

Case 1 When DivX VOD is used newly.

Case 2 When EEPROM or P.C.B. includin EEPROM was

Case 3 When recorder was exchanged to another recorder for

Case 4 When customer own second recorder.

Case 5 When owner of recorder was changed to another.

replaced for repairing.

repairing.

•

• We recommend that you make a note of this code for future

• •

reference.

•

• After playing DivX VOD content for first time, another

• •

registration code is then displayed in “DivX Registration”. do

not use this registration code to purchase DivX VOD

content. If you use this code to purchase DivX VOD content

and the play content on this unit, you will no longer be able

to play any content that you purchased using previous

code.

•

• If you purchase DivX VOD content using a registration code

• •

different from this unit’s code, you will not be able to play

this content. (“Authorization Error” is displayed.)

Some DivX VOD content can only be played a set number of

times.

When you play this content, remaining number of plays is

displayed. You cannot play this content when number of

remaining plays is zero. (“Rental Expired” is displayed.)

10

Page 11

DMR-EX95VEG / DMR-EX95VEB

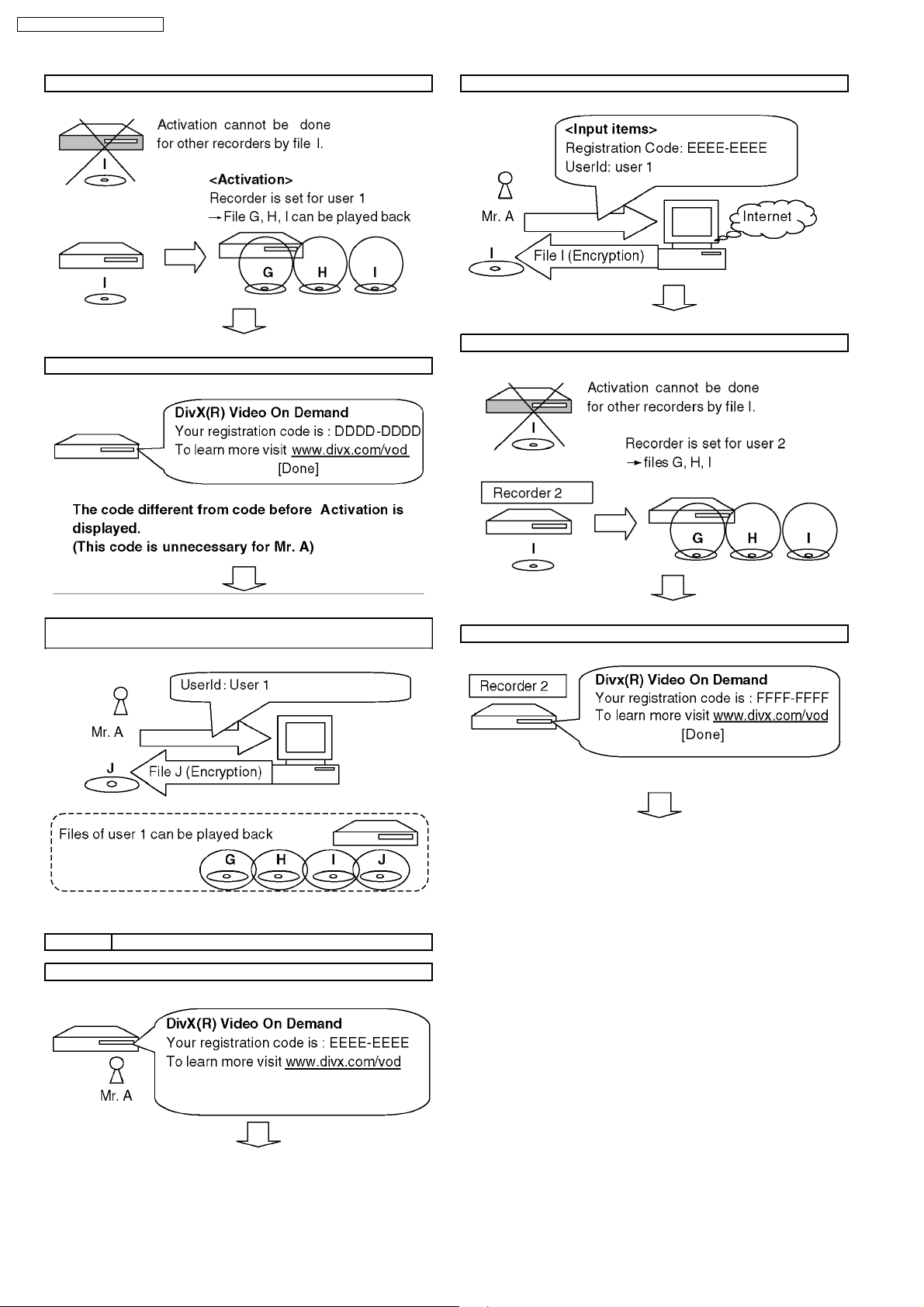

CASE 1 WHEN DivX IS USED NEWLY

Registration Code display (code is an example)

Case 1

Activation: File obtaining (code/ID are examples)

Ovtainment/Playback of additional file after Activation

(code/ID is an example)

CASE 2 WHEN EEPROM OR P.C.B. INCLUDING EEPROM

WAS REPLACED FOR REPAIRING

CASE 3 WHEN RECORDER WAS EXCHANGED TO ANOTHER

RECORDER FOR REPAIRING

New Registration Code is displayed (code is an example)

Activation: File Playback

Registration Code display (code is an example)

Case 2

Activation: File obtaining (code/ID are example)

11

Page 12

DMR-EX95VEG / DMR-EX95VEB

Activation: File Playback

Registration Code display after Activation (example)

Activation: File obtaining (code/ID are example)

Activation: File Playback

Obtainment/Playback od additional file after Activation

(code/ID is an example)

Case 3

CASE 4 WHEN CUSTOMER OWN SECOND RECORDER

Registration Code display of second recorder (code is an example)

Registration Code display after Activation (example)

Case 4

12

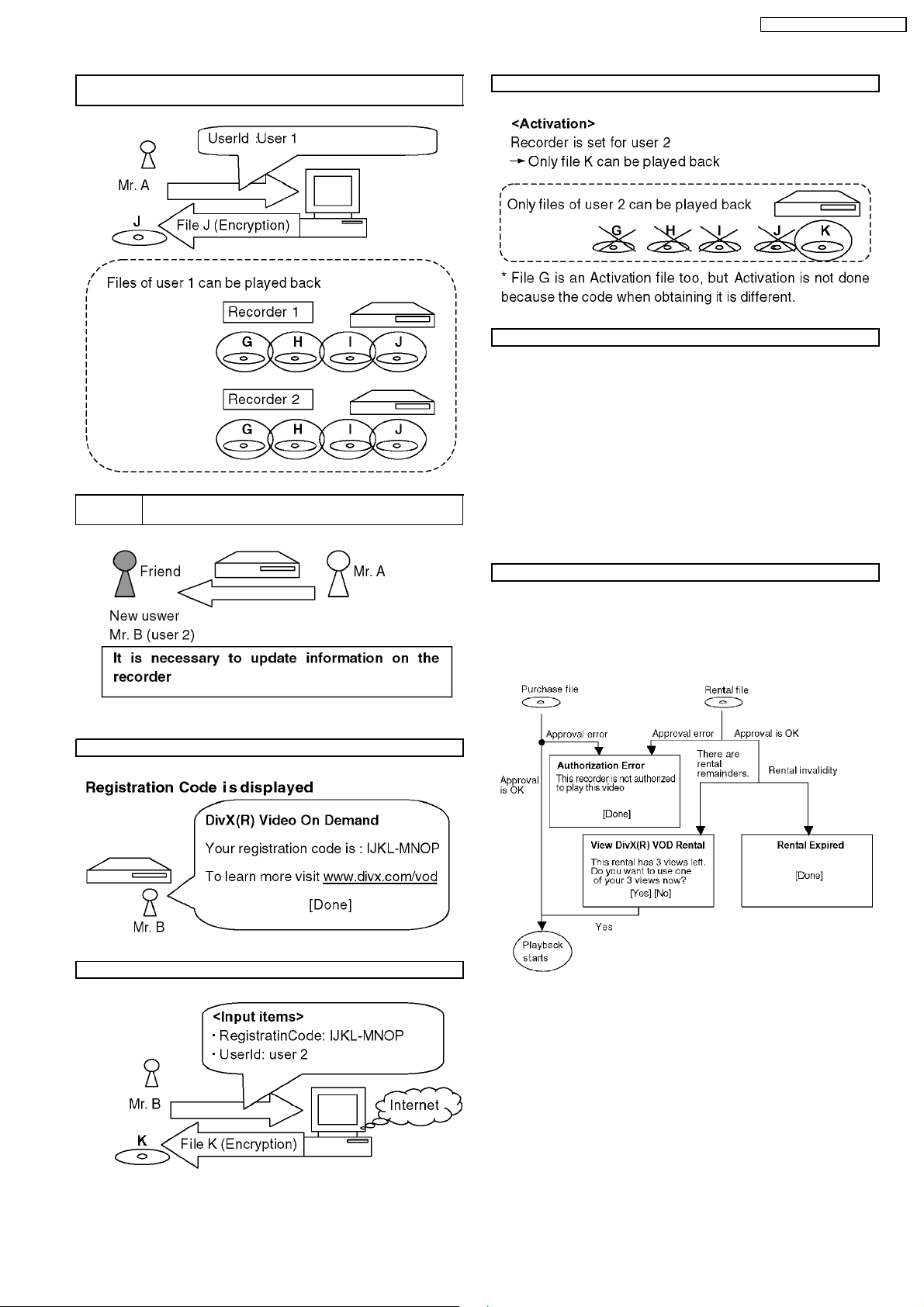

Page 13

DMR-EX95VEG / DMR-EX95VEB

Obtainment/Playback od additional file after Activation

(code/ID is an example)

CASE 5 WHEN OWNER OF RECORDER WAS CHANGED TO

ANOTHER

Activation: File Playback

FILE KIND

(There are two kinf of Activation files as follows too.)

•

• Rental: There is a playback limitation

• •

•

• Purchase: Unrestricted

• •

Also there is next file as DRM files besides the abovementioned.

•

• Base:

• •

It is not necessary to approve though the contents is being

endode.

If it is recorder/player for DRM, any can play back. (It is the

same as usual DivX file when seeing from user.)

SCREEN SHIFT (Error display)

Case 5

Activation

Activation: File obtaining (code/ID are example)

Wheter approval is OK or not.

Wheter the recorder is corresponding to User information on

the file or not.

13

Page 14

DMR-EX95VEG / DMR-EX95VEB

5.1.3. ABOUT DivX DRM

Divx file includes file to which DRM(Digital Right Management) is applied and file not applied. This item is a content that relates only

in treating file to which DRM is applied.

1. Registration Code display function

2. User’s registration and approval function

3. Rental management function

5.1.3.1. REGISTRATION CODE DISPLAY FUNCTION

Registration Code is alphanumeric character sequence 8 bytes inputted as recorder information, in case a use purchases or rent

a DivX DRM file in a network. Registration code is a character sequence generated at random, and differs in each recorder.

Moreover, Registration code is updated by new user authentication ever if same recorder.

5.1.3.2. USER’S REGISTRATION AND APPROVAL FUNCTION

•

• Only one user can register for one recorder. If user’s

• •

registration is not done with the recorder, DivX file cannot

be played back.

•

• User’s registration is performed only when a DivX DRM

• •

file is first chosen by recorder

•

• DivX DRM file that can perform user’s registration is only a file that is registered Registration Code and purchased or rented.

• •

•

• User authentication is performed whenever DivX DRM file is played back. Error message is displayed when failing in user’s

• •

registration and approval.

5.1.3.3. RENTAL MANAGEMENT FUNCTION

There are purchase file without registration of number of playback and rental files with registration of number of playback as Divx

file. Number of playback of rental file is counted by the recorder. When rental file is played, remaining number of times that can be

played back will be shown to users, recorder requests users to input yes or no. Following specifications have been installed for the

rental files in the purpose to clarify the count condition of number of times of playback.

•

• Conditions on counting number of times of play.

• •

1. When a file was opened successfully. (At the time of playback start)

2. When you have done review operation from the start. (Skip to file head)

−

− At this time, remaining number of times that can be played back and confirmation message

− −

[Do you play really?] are displayed.

−

− When the playback point has been skipped to the top of title, number of playback is not counted if the top of title was

− −

not recognized.

−

− Even if the power failure occurs after start of playback of rental file, number of times of playback counted at start of the

− −

playback is held as it is.

(Though playback stops by power failure,

the number of times of playback is not counted.)

When it has reached head of title, the playback is ended, and screen becomes DivX menu (There is no resume) and then cursor

is located on title that has been played back.Then if the same file was continuously played back, it begins to playback from the

file head.

Note:

Above mentioned stored user information and number of times of playback are not erased by update of firmware or by

initialization by test mode.

14

Page 15

DMR-EX95VEG / DMR-EX95VEB

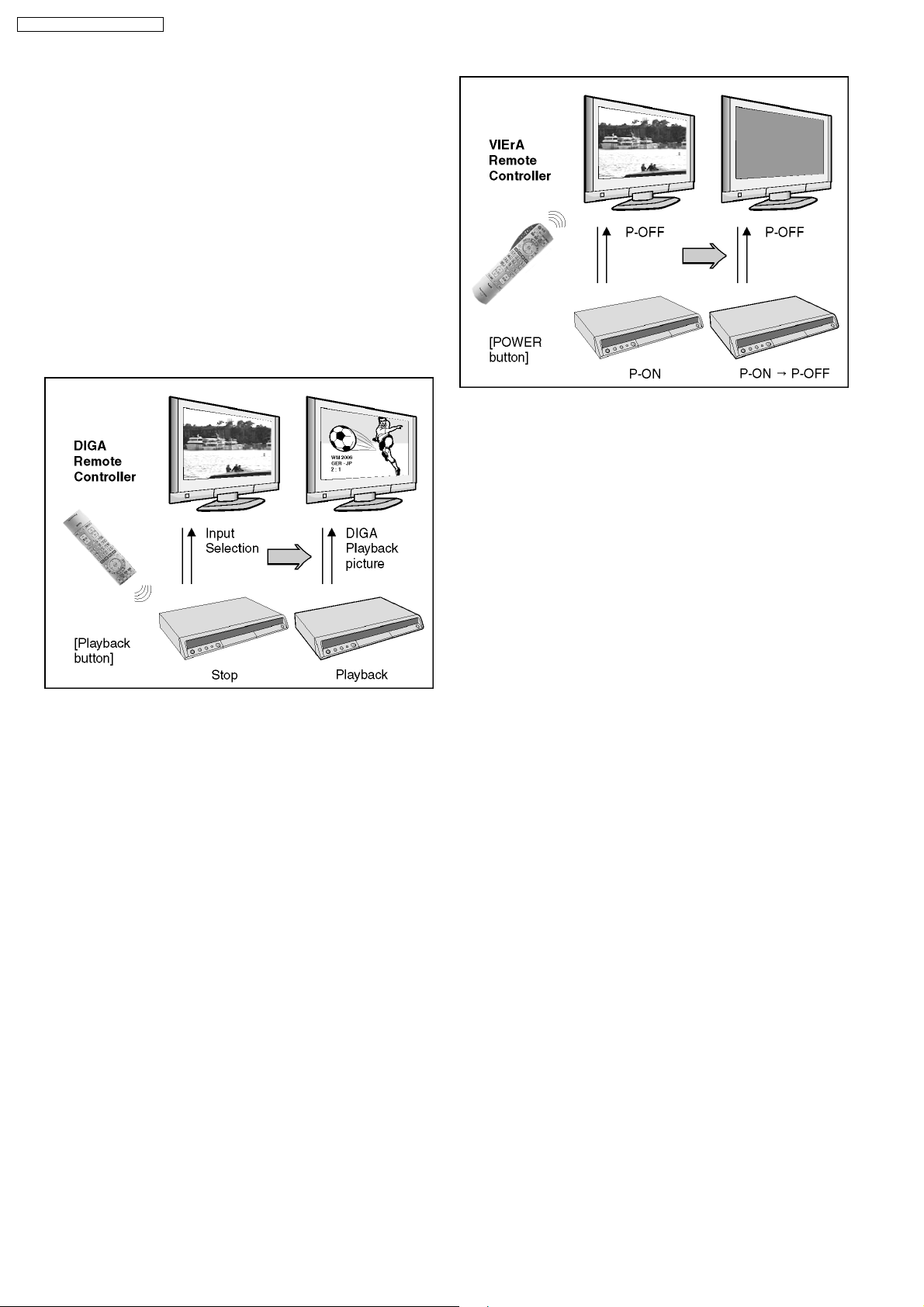

5.2. HDAVI CONTROL (HDMI LINK)

Linked operations by HDAVI Control (HDMI Link)

5.2.1. WHAT IS HDMI

HDMI is abbreviation of [High-Definition Multimedia Interface], and is digital interface standard for next generation TV

corresponding to follows.

1. Non-compressing high quality digital image

2. Digital transmission of multi channel digital audio.

3. Two way communication of control signal of control straightening between equipments.

Cable Transmission

HDMI

Cable

method

Digital

(~4.455Gbps)

Directionality Transmission

signal

One-way Digital image

(none-compression highdefinition television image)

One-way Digital Audio

(6ch/24 bit high sound quality

PCM of DVD audio/Bit stream

of surround to 8ch of DVD

video)

Interactive Digital control signal

(Advanced control between

equipments)

Feature

Clock line in one system and data line in three systems

can high-speed communicate high reliability because of

balance communication that uses three respectively

every one system.

Moreover, because high-speed data line in three system

can be used at same time, it has ten of other digital

cables times or more transmission ability.

And can transmit high-definition television image of noncompression, 24 bit high sound quality PCM voice of

multi-CH of DVD audio (to 6ch) and Bit stream signal of

surround to 8ch of DVD video (5.1ch, 6.1ch, and 7.1ch,

etc.) as a digital signal of no deterioration.

It has power supply line and a interactive control signal

line communication independent of AV signal, a Cd can

an advanced control between equipments. Therefore it

can correspond to making of AV equipment in the future

highly a network.

5.2.2. LINK FUNCTIONS

Functions

(1) Automatic Input switch

(2) Link of Power

15

Page 16

DMR-EX95VEG / DMR-EX95VEB

5.2.3. OUTLINE OF EQUIPMENTS

LINKED FUNCTIONS

1. Automatic Input switch

At starting of playback / GUI (Graphical User Interface)

display by DIGA, it turn on power of VIErA, and it displays

picture of DIGA onto screen of VIErA.

a. Starting of playback:

It includes automatic playback of DVD-Video and so on.

And it includes picture of screen saver too.

b. GUI display:

FUNCTIONS, DIRECT NAVIGATOR, TV PROGRAM,

PROG/CHECK, Timer Recording, G-code, Initial setting,

Playback setting, Play list, SD/DVD guide, Warning

messages that user can select and so on.

2. Power Link

Power of DIGA is turned off linking to POWER OFF of

VIErA.

•

• Power not turned on linking to POWER ON of VIErA.

• •

•

• It is limited in following cases that DIGA links to POWER

• •

OFF of VIErA.

•

• During EE display (While Timer recording is being

• •

executed/Functions is being displayed are included.)

However except cases below.

•

• During EE display, but manual recording is being

• •

executing/during EXT_Link recording.

•

• During Tray is being opened.

• •

•

• Case that DIGA is in status that power cannot turn off

• •

(during dubbing, during finalize).

16

Page 17

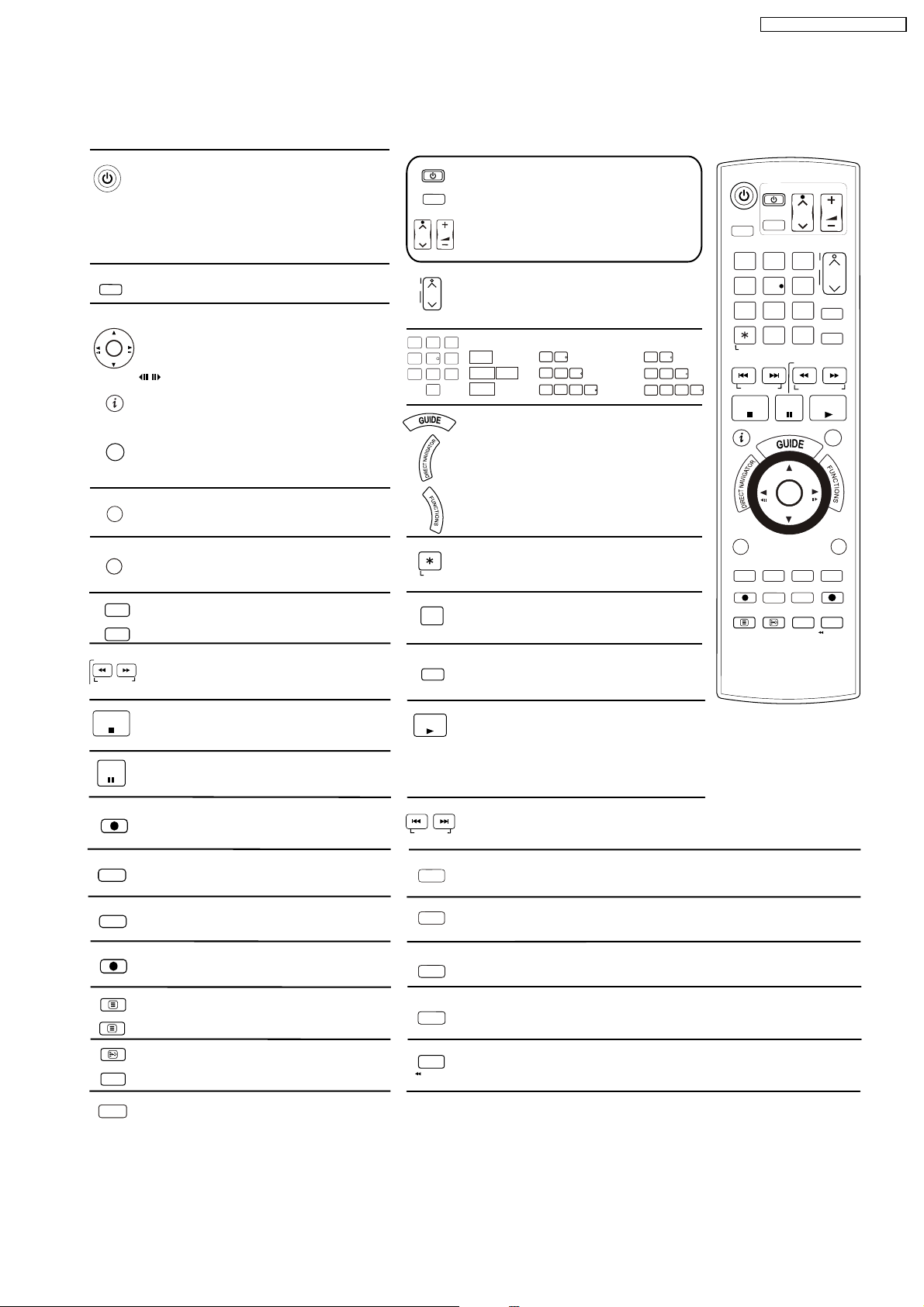

6 LOCATION OF CONTROLS AND COMPONENTS

Remote Control

DVD/VHS

Stand-by/on switch

Press to switch the unit from on to stand-by mode

or vice versa. In stand-by mode, the unit is still consuming

a small amount of power.

Switching this unit into standby mode does not

disconnect it from the mains.

DRIVE

SELECT

Select the HDD, DVD or SD drive.

Direction buttons in the menu guide.

Select groups or titles.

ENTER

OK

ENTER: Select or save a setting.

Still picture or slow motion playback.

Display the programme information from

the TV GUIDE or the Banner.

PROG/CHECK

Check / Change a Timer recording.

SUB MENU

Launch DVD sub menus.

S

RETURN

Return to the previous menu.

VIDEO Plus+

VIDEO Plus+ menu (EB-model)

ShowView

ShowView menu (EG-model)

SLOW/SEARCH

Search or slow motion playback.

REW: VHS Jet Rewind and Rewind Search

REW

FF

FF: VHS Forward Search

TV

AV

CH

TRACKING/V-LOCK/PAGE

+

CH

-

2

5

4

0

RESET

INPUT

SELECT

DELETE

Turn the television set on and off.

Select the AV input on the television set.

CH: Select the channel on the television set.

VOLUME

VOLUME: Volume control of the television set.

CH: Select the channel on the Recorder.

PAGE: Scroll in the electronic TV Guide.

TRACKING / V-LOCK: Optimise the VHS

playback picture.

Number buttons - direct input

3

6

VCD

9

JPEG

JPEG

MP3

0

5

5:

0

0

5:

5:

5

0

0

0

15:

15:

5

15:

GUIDE: Launch the TV Guide menu.

DIRECT NAVIGATOR: title view

TOP MENU: Main menu of DVD-video.

FUNCTION selection menu.

Cancel a function.

Reset the VHS tape counter.

Switch button of the AV input between AV1, AV2

AV3 (front), AV4 and DV in.

Delete a title.

DVD/VHS

DRIVE

SELECT

5

1

0

5

1

5

0

1

0

SUB MENU

S

DMR-EX95VEG / DMR-EX95VEB

TV

VOLUME

CH

AV

TRACKING/V-LOCK/PAGE

5

0

PAUSE

ENTER

OK

CHAPTER

REC MODE

EXT LINK

STTL

3

+

6

-

VIDEO Plus+

DELETE

INPUT

SELECT

SLOW/SEARCH

REW

PLAY

PROG/CHECK

RETURN

CREATE

MANUAL SKIP

DIRECT TV REC

DISPLAY

TIME SLIP

JET REW

CH

FF

112

4

77889

RESET

SKIP/INDEX

STOP

REC

TEXT

Stops recording, replay or forward / reverse action

STOP

Hold more than 3 seconds to eject the VHS tape.

Pause a recording or playback.

PAU SE

Hold more than 2 seconds for VHS slow-motion playback.

REC

Start the recording.

REC MODE

Record mode button XP, SP, LP, EP

EXT LINK

Record with external recording control.

DIRECT TV REC

Direct TV recording.

TEXT

Launch the MHEG Service (EB-model).

AUDIO

Select the audio channel/soundtrack (EG-model).

STTL

Displays subtitles (EB-model)

F Rec

Flexible Recording (EG-model)

DISPLAY

Launch the disc menus.

PLAY

Starts playback.

RAM - You can increase the playback speed

.

Hold PLAY during playback.

VHS - Playback or continuous playback

SKIP: Skip chapters, titles, or pictures.

SKIP/INDEX

INDEX: Find the beginning of a VHS recording.

Menu guide (red button): Profile, GUIDE, MHEG, Manual Tuning

Menu guide (green button): Profile, GUIDE, MHEG

CREATE

Menu guide (yellow button): Profile, GUIDE, MHEG

CHAPTER

CREATE CHAPTER: Deviding a recording into chapters.

MANUAL SKIP

Menu guide (blue button): Profile, GUIDE

MANUAL SKIP: Jump forwards 30 seconds.

TIME SLIP

Select the time frame.

Jet rewind to the beginning of the VHS tape.

JET REW

17

Page 18

DMR-EX95VEG / DMR-EX95VEB

7 OPERATING INTRUCTIONS

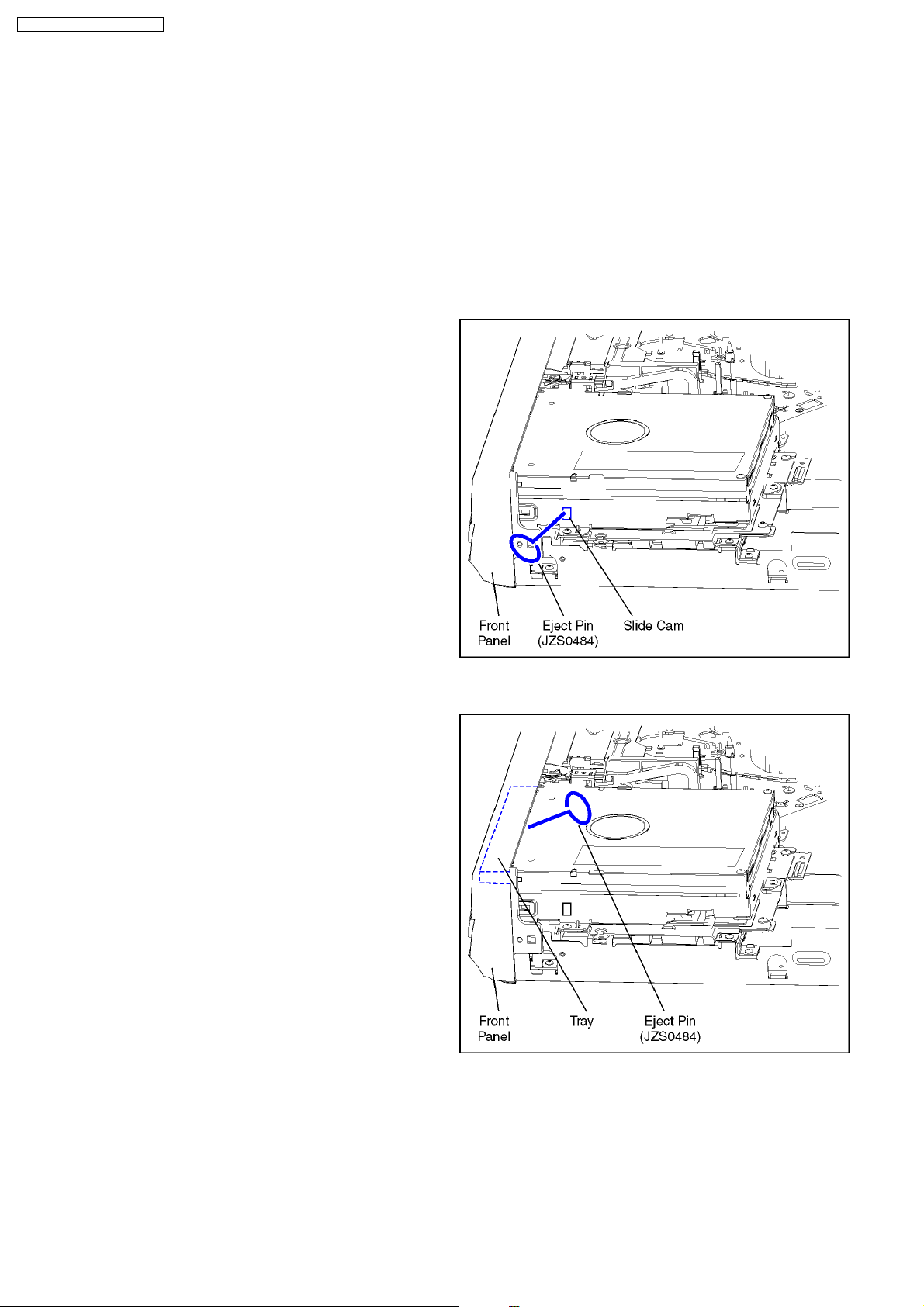

7.1. (DVD) TAKING OUT THE DISC FROM RAM-DRIVE UNIT WHEN THE

DISC CANNOT BE EJECTED BY OPEN/CLOSE BUTTON

7.1.1. (DVD) FORCIBLE DISC EJECT

7.1.1.1. (DVD) WHEN THE POWER CAN

BE TURNED OFF.

1. Turn off the power and press [STOP], [CH UP] keys on the

front panel simultaneously for 5 seconds.

7.1.1.2. (DVD) THE POWER CAN NOT BE

TURNED OFF.

1. Press [POWER] key on the front panel for over 10 seconds

to turn off the power forcibly and press [STOP] [CH UP]

keys on the front panel simultaneously for 5 seconds.

7.1.2. (DVD) WHEN THE FORCIBLE DISC

EJECT CAN NOT BE DONE.

1. Turn off the power and pull out AC cord.

2. Remove the Top Case.

3. Push in SLIDE CAM by Eject Pin (JZS0484) or minus screw

driver (small) to eject tray slightly.

4. Push out Tray by Eject Pin (JZS0484) or minus screw driver

(small).

18

Page 19

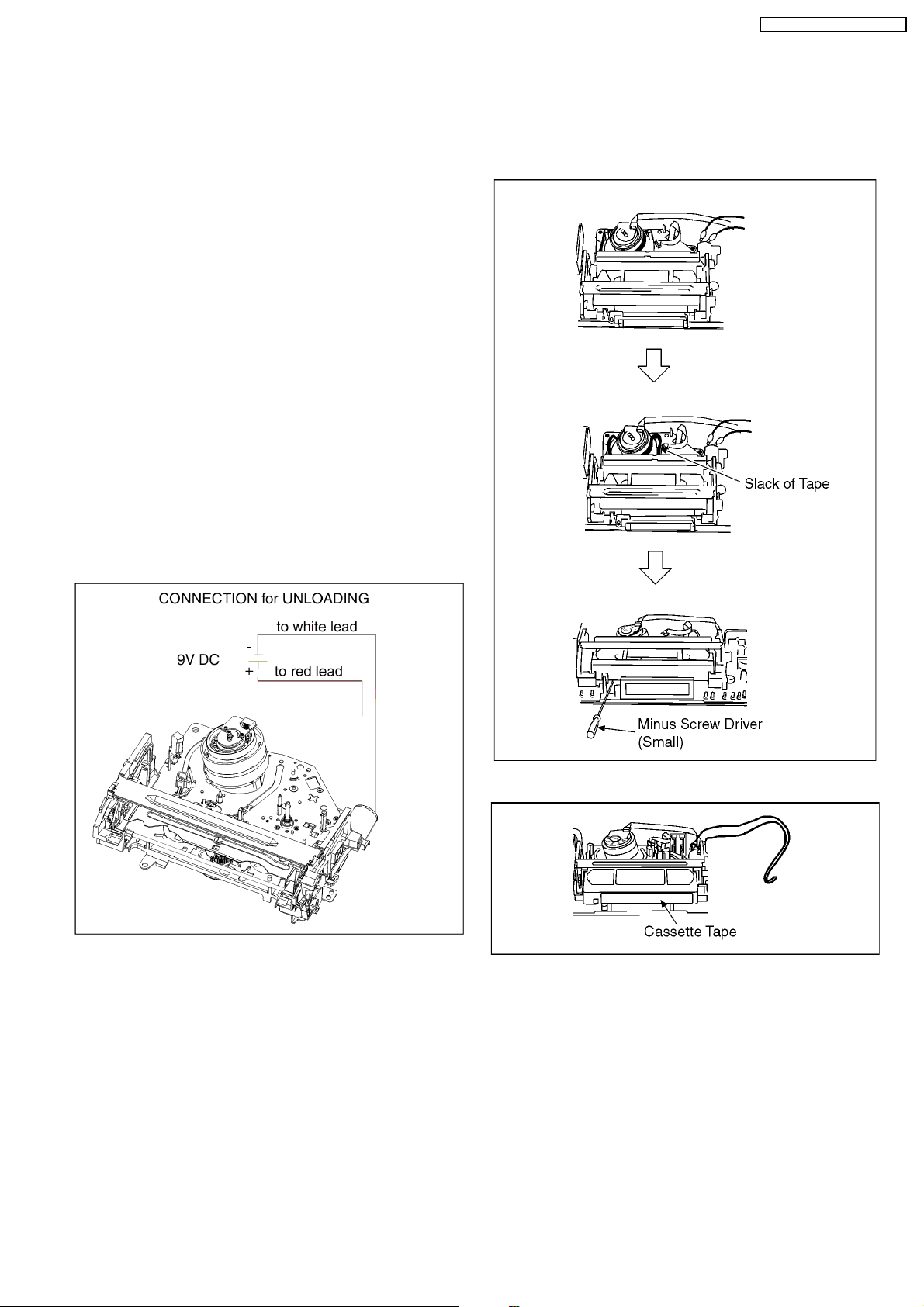

7.2. (VHS) REMOVING OF

CASSETTE TAPE

When the cassette tape could not be removed after an

electrical malfunction, there are 2 ways to remove a cassette

tape.

7.2.1. (VHS) REMOVAL BY

COMPULSORY UNLOADING.

If Service Mode can be activated when the power can not be

turned on, this operation is able.

1. Press [STOP] and [EJECT] button simultaneously for more

than 3 seconds and set Drive to [VHS] and set the Service

Mode to 7.

2. Press [STOP] button in order to unload the mechanism.

(Pay attention to tape slack)

Service Mode Display:

7 ** ** (STOP) → 7 0L ** (EJECT)

7.2.2. (VHS) REMOVAL BY MANUAL

OPERATION.

DMR-EX95VEG / DMR-EX95VEB

3. Stop unloading just before unloading willbe completed. The

tape becomes slack.

4. Rotate the S-Reel by a small minus screwdriver to remove

the slack tape.

1. Disconnect the AC plug, and remove the Top Panel and the

Front Panel by referring to the Disassembly Procedures.

2. Connect a batterie (9V spec.) to the Loading Motor in series

for supplying 9V to rotate the Loading Motor.

5. Then unload again to remove the cassette tape.

19

Page 20

DMR-EX95VEG / DMR-EX95VEB

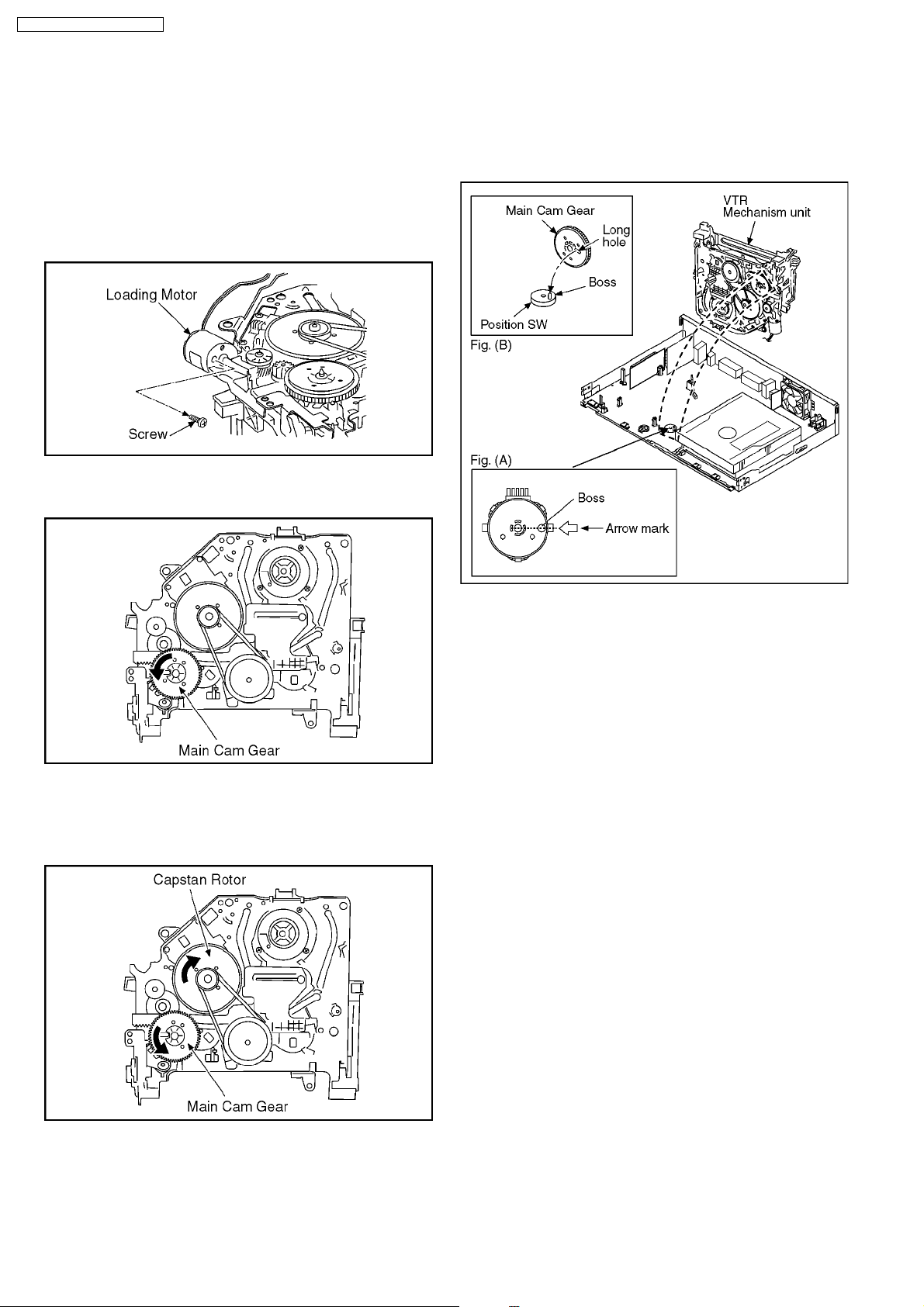

7.2.3. (VHS) TAKE OUT CASSETTE TAPE

MANUALLY AFTER REMOVING

THE MECHANNISM

1. Disconnect the AC plug, and remove the Top Panel, Front

Panel and the Mechanism by referring assembling and

disassembling description.

2. Remove the Screw and remove the Loading Motor.

6. Attach Loading Motor and tighten the screw.

7. Set the Position Switch to EJECT POSITION certainly and

attach the mechanism to chassis.

3. Rotate the Main Cam Gear counter-clockwise until just

before the unloading will be completed.

4. Rotate the Capstan Motor clockwise to remove the slack

tape.

5. Rotate the Main Cam Gear counter-clockwise again to

remove the cassette-tape.

20

Page 21

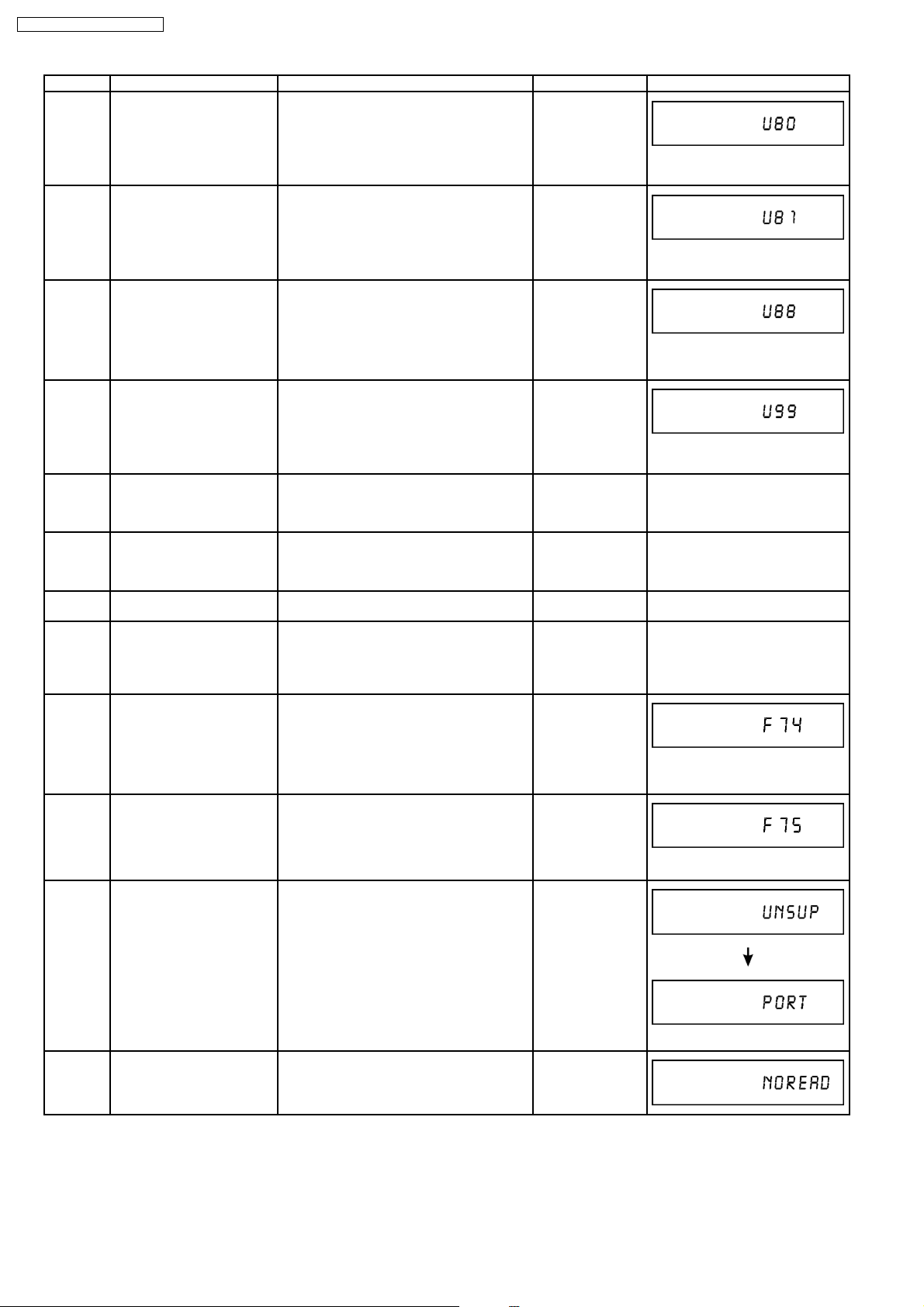

DMR-EX95VEG / DMR-EX95VEB

8 SERVICE MODE

8.1. (DVD) SELF-DIAGNOSIS AND SPECIAL MODE SETTING

8.1.1. (DVD) SELF-DIAGNOSIS FUNCTIONS

Self-Diagnosis Function provides information for errors to service personnel by “Self-Diagnosis Display” when any error has

occurred.

U**, H** and F** are stored in memory and held.

You can check latest error code by transmitting [0] [1] of Remote Controller in Service Mode.

Automatic Display on FL will be cancelled when the power is turned off or AC input is turned off during self-diagnosis display is ON.

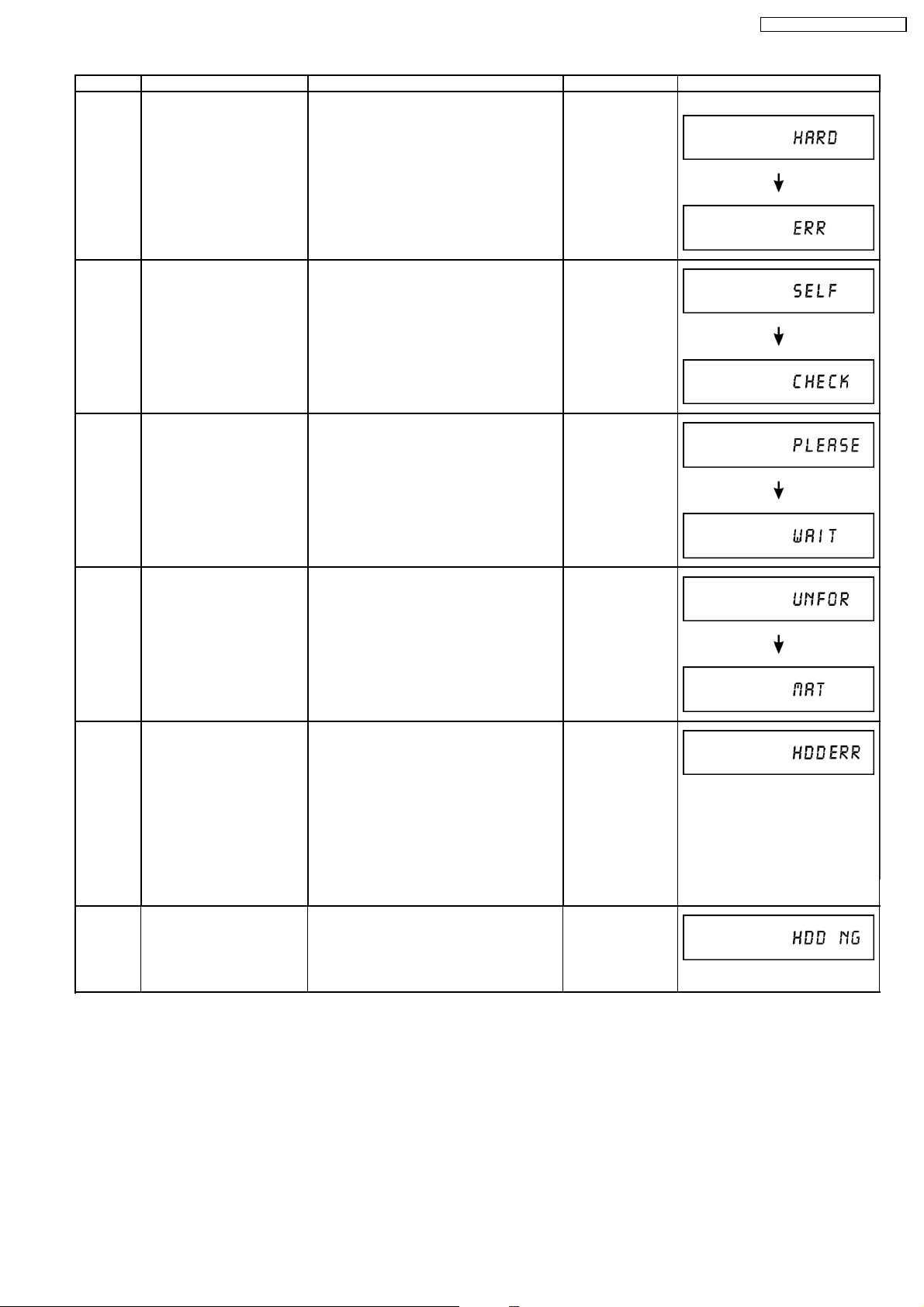

Error Code Diagnosis contents Description Monitor Display Automatic FL display

IR ERR IR communication error [IR ERR] is display when communication

between Timer microprocessor and IR

microprocessor fails.

No display

No REC Recording is impossible [No REC] is displayed when recording is

U30 Remote control code error Display appears when main unit and remote

U50 Antenna Short Short circuit was detected at antenna input.

U59 Abnormal inner temperature

detected

U61 The unit is carrying out its

recovery process (with no

disc in the disc tray).

U71 HDMI incompatible

error(HDCP incompatible)

U72 HDMI connection error

(communication error)

U73 HDMI connection error

(authentication error)

impossible due to the defect, dirt or wound

of media.

controller codes are not matched.

Please check antenna.

Display appears when the drive temperature

exceeds 70°C.

The power is turned off forcibly.

For 30 minutes after this, all key entries are

disabled. (Fan motor operates at the highest

speed for the first 5 minutes. For the

remaining 25 minutes, fan motor is also

stopped.) The event is saved in memory as

well.

* The unit detected an error while recording

or playing with with no disc in the disc

tray.

The unit is carrying out its recovery process.

This process restores the unit to normal

operation. The unit is not broken. Wait until

the message disappears.

Display this error when the equipment

(compatible with DVI such as TV, amplifier

etc.) connected to the unit by HDMI is

incompatible with HDCP. *HDCP=Highbandwidth Digital Content

Protection.

This error is displayed when there are any

communication problems with the unit and

the equipments (TV, amplifier etc.)

connected to the unit by HDMI. (or when

there is a problem with the HDMI cable).

When authentication error occurs while the

equipments (TV, amplifier etc.) are

connected by HDMI. (or when there is a

problem with the HDMI cable).

No display

No display

’Short Circuit was

detected at the

antenna input.

Please check your

antenna...’

No display

No display

No display

No display

No display

“*” is remote controller code of the

main unit.

Display for 5 seconds.

Display for 5 seconds.

“U59 is displayed for 30 minutes.

“U72” display disappears when

error has been solved by

Power OFF/ON of connecting

equipment or by inserting/removing

of HDMI cable.

“U73” display disappears when

error has been solved by Power

OFF/ON of connecting equipment

or by inserting/removing of HDMI

cable.

21

Page 22

DMR-EX95VEG / DMR-EX95VEB

Error Code Diagnosis contents Description Monitor Display Automatic FL display

U80 ST Microprocessor

Communication Error on

Displayed appears when ST Microprocessor

Communication Error on Timer Bus occurs.

No display

Timer Bus

“U80” is displayed till Power Key is

pressed.

U81 ST Microprocessor

Communication Error on

Displayed appears when ST Microprocessor

Communication Error on UART occurs.

No display

UART

“U81” is displayed till Power Key is

pressed.

U88 The unit is carrying out its

recovery process (with no

disc in the disc tray).

* The unit detected an error while recording

or playing with with no disc in the disc

tray.

No display

The unit is carrying out its recovery process.

This process restores the unit to normal

operation. The unit is not broken. Wait until

the message disappears.

U99 Hang-up Displayed when communication error has

No display

occurred between Main microprocessor and

Timer microprocessor.

Displayed is left until the [POWER]

key is pressed.

H19 Inoperative fan motor When inoperative fan motor is detected after

No display No display

powered on, the power is turned off

automatically.

The event is saved in memory.

F00 No error information Initial setting for error code in memory

No display No display

(Error code Initialization is possible with error

code initialization and main unit

initialization.)

F58 Drive hardware error When drive unit error is detected, the event

No display No display

is saved in memory.

F34 Initialization error when main

microprocessor is started up

for program recording

When initialization error is detected after

starting up main microprocessor for program

recording, the power is turned off

No display No display

automatically.

The event is saved in memory.

F74 HDIM Device Key

Communication error.

HDMI connection could not be authenticated

due to a transfer malfunction.Factor of HDMI

No display

Device key-road failure- When HDMI LSI is

damaged.- When the bus line of I2C doesn´t

operate normally.- When device key

information

recorded is damaged.

F75 HDIM Device Key Information

error.

HDMI connection could not be authenticated

due to an internal data malfunction.Factor of

No display

HDMI Device key-road failure- When HDMI

LSI is damaged.- When the bus line of I2C

doesn´t operate normally.- When device key

information recorded is damaged.

UNSUPPORT

Unsupported disc error *An unsupported format disc was played,

although the drive starts normally.

“This disc is

incompatible.”

*The data format is not supported, although

the media type is supported.

*Exceptionally in case of the disc is dirty.

NO READ Disc read error *A disc is flawed or dirty.

*A poor quality failed to start.

*The track information could not be read.

Display for 5 seconds.

“Cannot read.

Please check the

disc.”

22

Page 23

DMR-EX95VEG / DMR-EX95VEB

Error Code Diagnosis contents Description Monitor Display Automatic FL display

HARD

Drive error The drive detected a hard error. “DVD drive error.” Display for 5 seconds.

ERR

SELF

CHECK

PLEASE

WAIT

UNFORMAT

Restoration operation Since the power cord fell out during a power

failure or operation, it is under restoration

operation.

*It will OK, if a display disappears

automatically. If a display does not

disappear, there is the possibility that

defective Digital P.C.B. / RAM drive.

Unit is in termination process Unit is in termination process now.

“BYE” is displayed and power will be turned

off.

In case “Quick Start” of setup menu is ON, it

is displayed in restoration operation for AC

off.

Unformatted disc error You have inserted an unformatted DVD-

RAM or DVD-RW that is unformatted or

recorded on other equipment.

No display

No display

Format:

This disc is not

formatted properly.

Format the disc in

DISK

MANAGEMENT?

HDD ERR [HDD ERR] is displayed

when start up of HDD was

failed.

(Except error of setting of

Power on Stand-by)

HDD NG Power on Stand-by setting

error

1. When normal start up was failed

2. When start up at HDD boot was failed

3. When start up from state of P-OFF was

failed

4. When start up from state of HDD

SLEEP was failed.

[HDDERR] is displayed when above each

start up of HDD was failed.

* In case 1.), tray opens automatically and

[HDDERR] is displayed until version up disc

is inserted.

[HDD NG] is displayed when power on

Stand-by setting of HDD is NG or when

HDD which power on Stand-by is not set to

is used.

Please try to replace HDD with junine HDD

as service parts.

No display

No display

23

Page 24

DMR-EX95VEG / DMR-EX95VEB

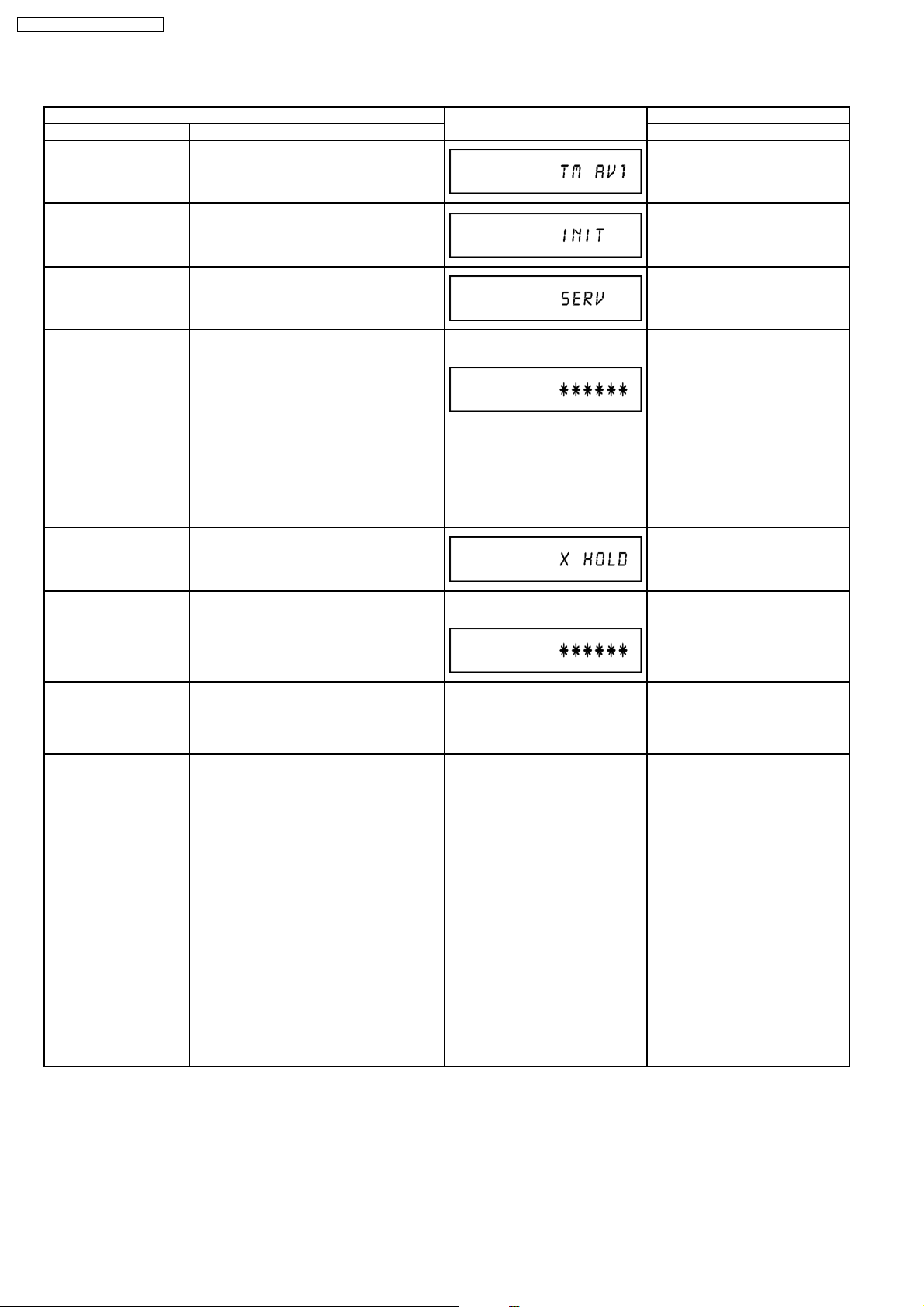

8.1.2. SPECIAL MODES SETTING

Item FL display Key operation

Mode name Description Front Key

TEST Mode *All the main unit´s parameters (include

tuner) are initialized.

Rating password The audiovisual level setting password is

initialized to “Level 8”.

Press [VHS to DVD COPYING],

[REC] and [OPEN/CLOSE] keys

simultaneously for five seconds

when power is off.

Open the tray, and press [REC]

and [PLAY] simultaneously for 5

seconds.

Service Mode Setting every kind of modes for servicing.

Forced disc eject Removing a disc that cannot be ejected.

Child lock/unlock Set or release “Child Lock”. Press [ENTER] and [RETURN] by

NTSC/PAL system select To switch PAL/NTSC altemately. The display before execution

Forced power-off When the power button is not effective while

Aging Perform sequence of modes as * Aging

*Details are described in “Service Mode”.

The tray will open and unit will shift to P-off

mode.

*When Timer REC is ON or EXT-LINK is

ON, execute " Forced disc eject " after

releasing Timer REC or EXT-LINK.

*This command is not effective during "Child

lock" is ON.

While Demonstration Lock is being set, this

Forced disc eject function is not accepted.

If this command was executed while

TIMER REC is being set, TIMER REC

setting will turn to OFF.

power is ON, turn off the power forcibly.

*When Timer REC is ON or EXT-LINK is

ON, execute “Forced Power-off” after

releasing Timer REC or EXT-LINK.

Description shown below continually.

Caution:

All programs in DVD-RAM disc will be

deleted because Formatting is done once

in Aging process.

The display before execution

leaves.

leaves.

Display in P-off mode. Press [Power] key over than 10

Display following the then mode. When the power is ON, press [CH

When the power is off, press

[STOP], [OPEN/CLOSE] and [VHS

to DVD COPYING] keys

simultaneously for 5 seconds.

When the power is off, press

[STOP] and [CH UP] keys

simultaneously for 5 seconds.

remote controller simultaneously

until [X-HOLD] is displayed.

While the power is on (E-E mode),

press [STOP] and [OPEN/CLOSE]

simultaneously for 5 seconds.

seconds.

DOWN], [VHS to DVD COPYING]

and [OPEN/CLOSE]

simultaneously for over 5 seconds

and less than 10 seconds.

NOTE1:

If Unit has not turned into Aging

mode by operations shown above,

execute TEST MODE once and reexecute operation shown above.

(*All the main unit’s parameters

include tuner are initialized by

TEST mode.)

24

NOTE2:

If the unit has hung-up because of

pressing keys for over 10 seconds,

once turn off the power, and reexecute this command.

*When releasing Aging mode,

press [POWER] key.

Page 25

DMR-EX95VEG / DMR-EX95VEB

Item FL display Key operation

Mode name Description Front Key

Aging Contents (Example):

Demonstration

lock/unlock

Ejection of the disc is prohibited.

The lock setting is effective until unlocking

the tray and not released by “Main unit

*When lock the tray.

When the power is on, press

[STOP] and [POWER] keys

simultaneously for 5 seconds.

initialization” of service mode.

“LOCK” is displayed for 3 seconds.

*When unlock the tray.

When the power is on, press

[STOP] and [POWER] keys

simultaneously for 5 seconds.

“UNLOCK” is displayed for 3

seconds.

*When press OPEN/CLOSE key

while the tray being locked.

Press [OPEN/CLOSE] key while

the tray being locked.

Display “LOCK” for 3 seconds.

ATP re-execution Re-execute ATP. Display at ATP executing. When the power is on (E-E mode),

press [CH UP] and [CH DOWN]

simultaneously for 5 seconds.

Progressive initialization The progressive setting is initialized to

Interlace.

The display before execution

leaves.

When the power is on (E-E mode),

press [STOP] and [VHS to DVD

COPYING] simultaneously for 5

seconds.

25

Page 26

DMR-EX95VEG / DMR-EX95VEB

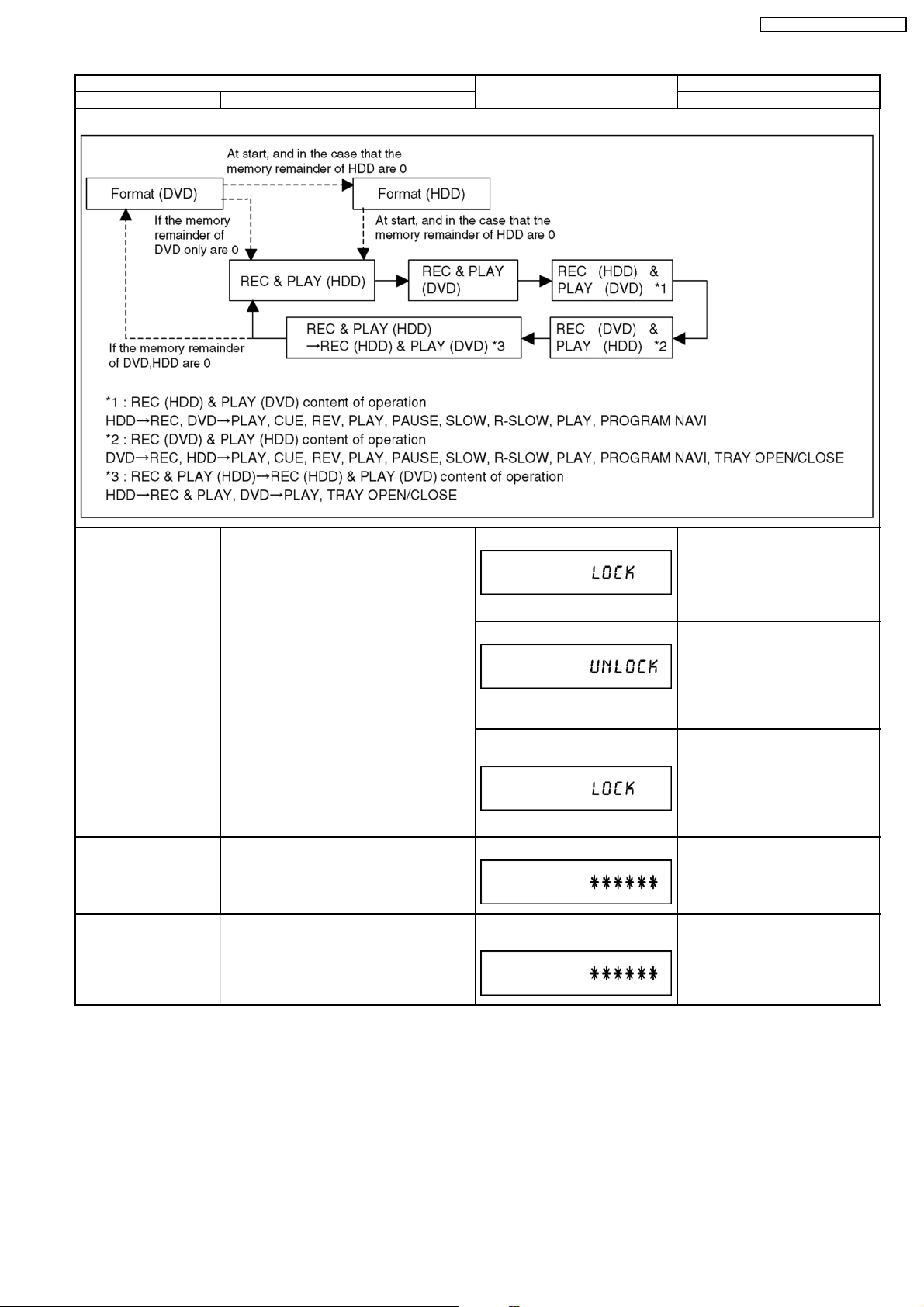

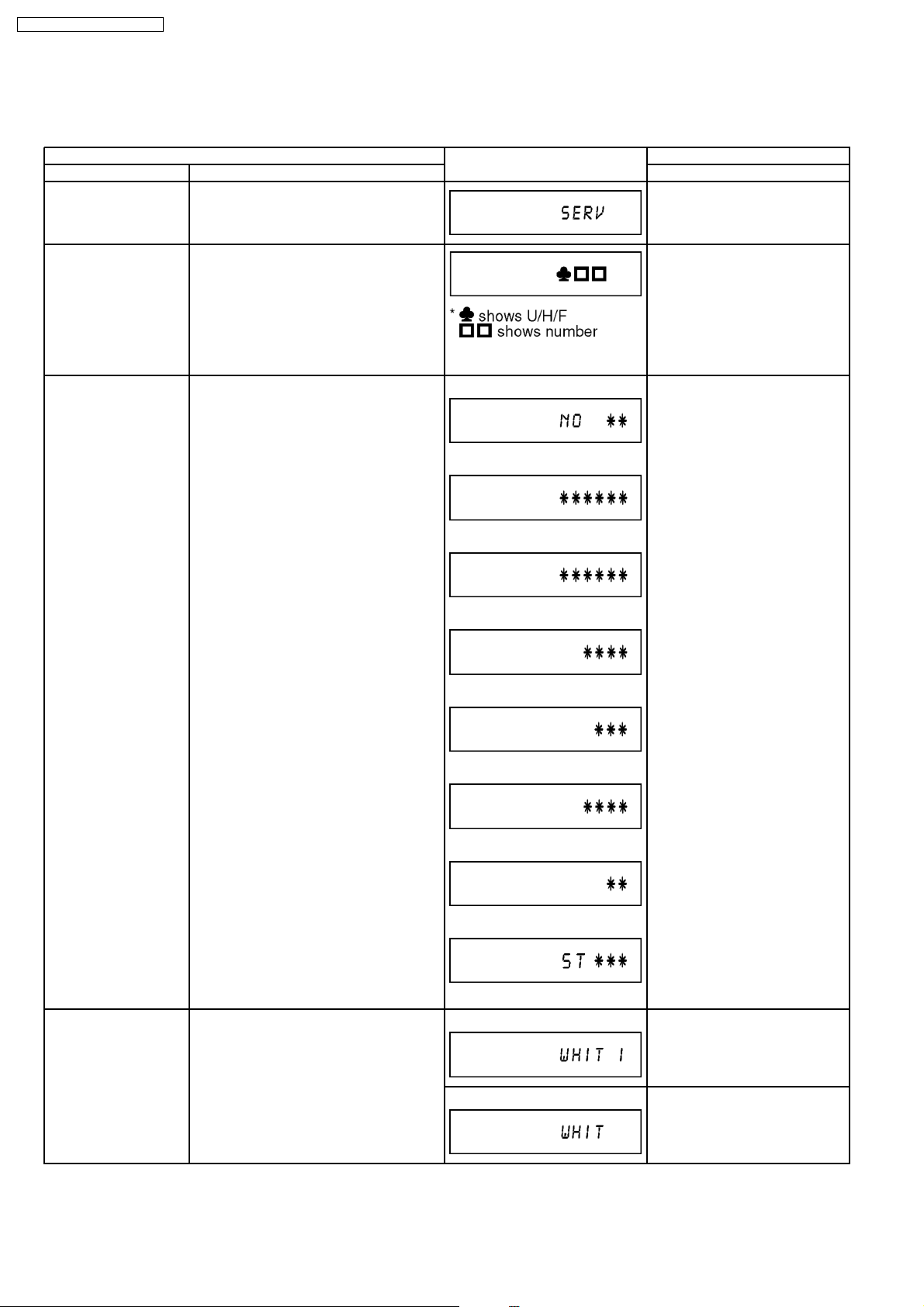

8.1.3. (DVD) SERVICE MODES

Service mode setting: While the power is off, press [STOP], [VHS to DVD COPYING] and [OPEN/CLOSE] simultaneously for five

seconds.

Item FL display Key operation

Mode name Description (Remote controller key)

Release Items Item of Service Mode executing is cancelled. Press [0] [0] or [Return] in service

mode.

Error Code Display Last Error Code of U/H/F held by Timer is

displayed on FL.

*Details are described in “Self-Diagnosis

Functions”.

ROM Version Display 1. Region code

(displayed for 5 sec.)

2. Main firm version

(displayed for 5 sec.)

3. Timer firm version

(displayed for 5 sec.)

4. Drive firm version

(displayed for 5 sec.)

If any error history dose not exist,

[F00] is displayed.

1.

2.

3.

4.

5.

Press [0] [1] in service mode

Press [0] [2] in service mode

5. ROM correction version

(displayed for 5 sec.)

6. VHS Microprocessor version

(displayed for 5 sec.)

7. VHS ROM Correction version

(displayed for 5 sec.)

8. ST Microprocessor version

(left displayed)

White Picture Output White picture is output as component Output

from AV Decoder.

*White picture

(Saturation rate : 100%)

*It is enable to switch Interlace/Progressive

by “I/P switch: [1] [4]”

6.

7.

8.

‘’ ’’ are version displays.

*Initial mode is “Interlace”. Press [1] [1] in service mode.

Switch Interlace/Progressive Press [1] [4] in White Picture

Output mode.

*I/P are switched alternately.

26

Page 27

Item FL display Key operation

Mode name Description (Remote controller key)

Magenta Picture Output Magenta picture is output with Component

*Initial mode is “Interlace”. Press [1] [2] in service mode.

Output from AV Decoder.

*Magenta picture

(Saturation rate: 100%)

*It is enable to switch Interlace/Progressive

by “I/P switch: [1] [4]”

Switch Interlace/Progressive Press [1] [4] in Magenta Picture

Output mode.

*I/P are switched alternately.

DMR-EX95VEG / DMR-EX95VEB

RTSC Return in XP

(A & V)

AV1 input signal is encoded (XP), decoded

(XP) and output decoded signal to external

without DISC recording and DISC playback.

I/P Switch Switch Interlace and Progressive in EE

mode.

*Initial setting is “Interlace”.

*This command is effective during executing

“White Picture Output”, “Magenta Picture

Output” and “RTSC Return in XP (A & V)”

modes.

Audio Mute (XTMUTE) Check whether mute is applied normally by

the timer microprocessor.

Initial mode: EE2/ Interlace/ XP/

Press [1] [3] in service mode.

Audio 48kHz

Switch Interlace/Progressive Press [1] [4] in RTSC Return XP

mode.

*I/P are switched alternately.

Audio 44.1 kHz/ 48 kHz Switch Press [2] [4] in RTSC Return XP

mode.

*48 kHz / 44.1 kHz are switched

alternately.

Initial mode is Interlace

Press [1] [4] in I/P Switch mode.

*I/P are switched alternately.

Switch Interlace/Progressive

Press [2] [1] in service mode.

Audio Mute (XDMUTE) Check whether mute is applied normally by

the Digital P.C.B..

Audio Pattern Output The audio pattern stored in the internal

memory is output

(Lch: 1kHz/-18dB)

(Rch: 400Hz/-18dB)

*Audio sound clock switching operation of

DAC can be confirmed by sub command [2]

[4].

Press [2] [2] in service mode.

Initial mode (Audio 48kHz) Press [2] [3] in service mode.

Audio 44.1kHz/48kHz switching Press [2] [4] in Audio Pattern

Output mode.

*48 kHz / 44.1 kHz are switched

alternately.

27

Page 28

DMR-EX95VEG / DMR-EX95VEB

Item FL display Key operation

Mode name Description (Remote controller key)

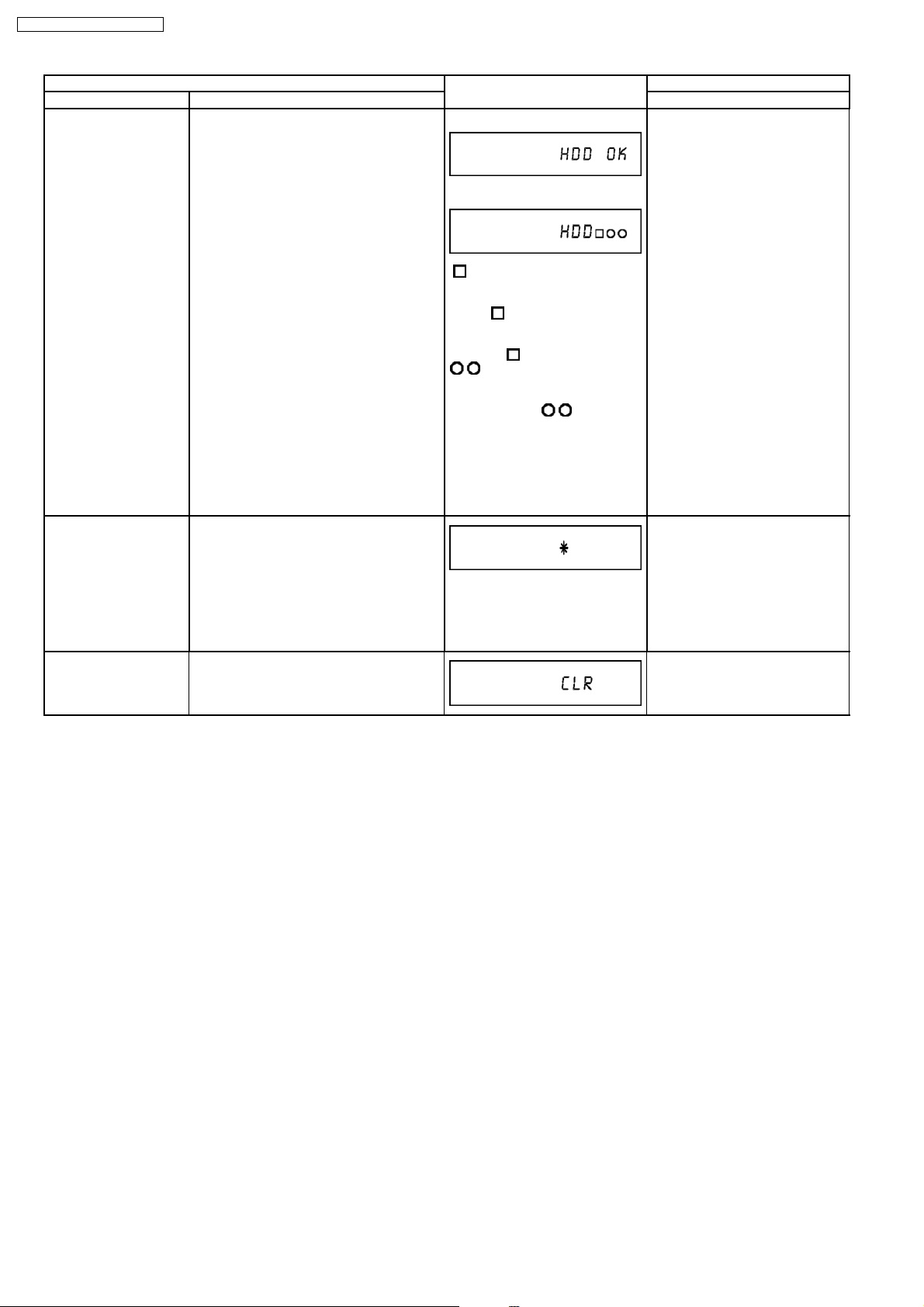

HDD READ inspection Perform a complete read inspection of the

HDD.

Laser Used Time

Check laser used time (hours) of drive.

Indiction

When the HDD is OK

If the HDD is defective

: Judge of Forward rate.

* When normal (Forward rate is 35

Mbps or more and there is no HDD

error):

is Space.

* When Abnormal (Forward rate is

less than 35 Mbps or HDD error

existing):

is X.

: Number of what have

spent time for seeking is over

100ms.

* When normal:

are spaces.

* When Abnormal: Display Number

of what have spent time fore

seeking over 100 ms.

However, if the number is more

than 100, display [XX].

We judge it is normal that the

number is less than 4.

Press [3] [1] in the service mode.

* When canceling the checking

mode while executing, do “forced

power-off”.

Method: Press the “POWER”

button more than 10 seconds.

Press [4] [1] in service mode.

Delete the Laser Used

Time

Laser used time stored in the memory of the

unit is deleted.

●(*****) is the used time display in

hour.

●Laser used time of DVD/ CD in

Playback/Recording mode is

counted.

Press [9] [5] in service mode.

28

Page 29

Item FL display Key operation

Mode name Description (Remote controller key)

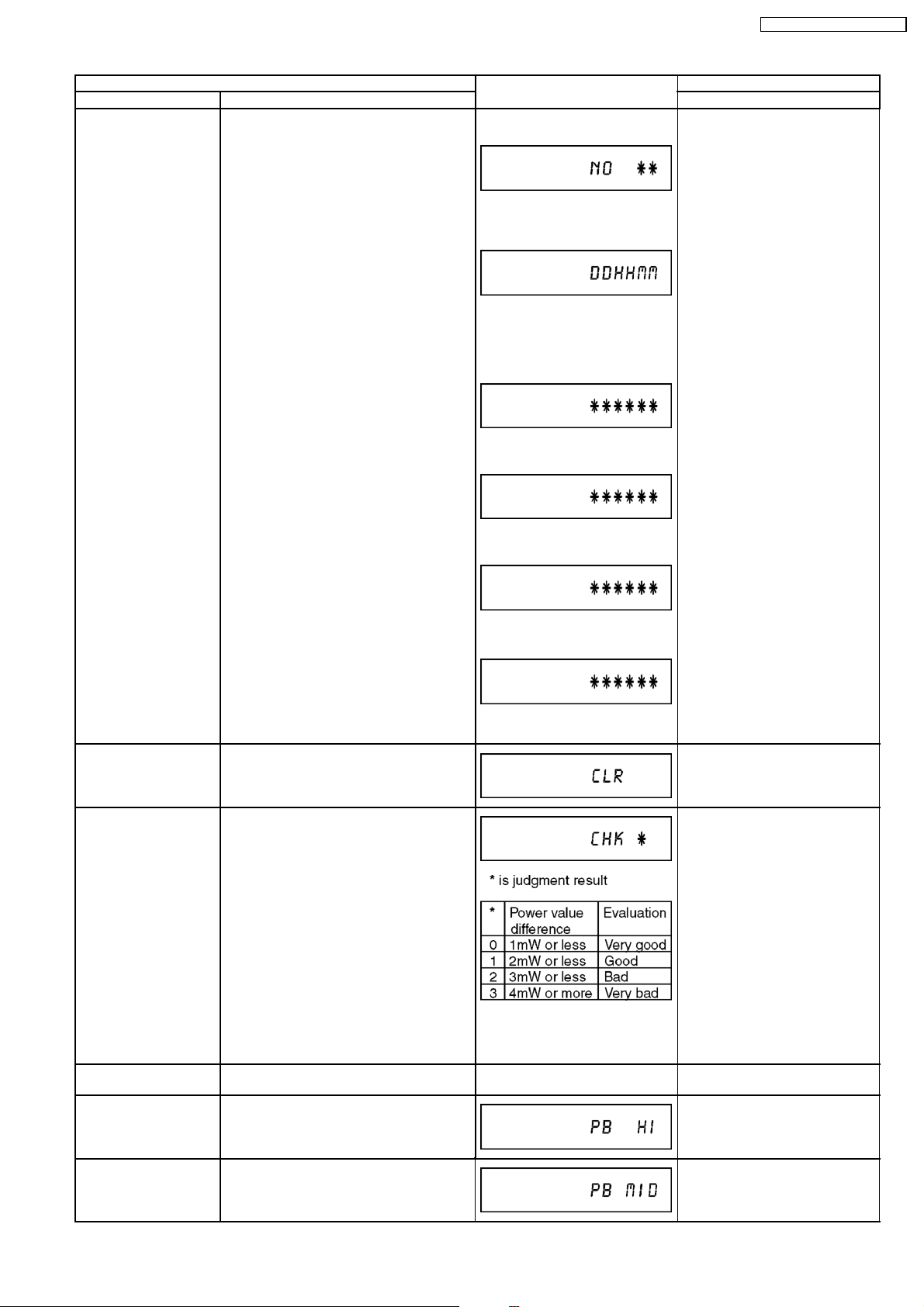

RAM Drive Last Error RAM Drive error code display.

*For details about the drive error code, refer

to the Service Manual for the specific RAM

Drive.

1. Error Number is displayed for 5

seconds.

Press [4] [2] in service mode.

When “INFO******” is being

displayed, past 19 error histories

can be displayed by pressing [0]

[1] - [1] [9]

2. Time when the error has

occurred is displayed for 5

seconds.

DD: Day

hh: Hour

mm: Minute

3. Last Drive Error (1/2) is

displayed for 5 seconds.

4. Last Drive Error (2/2) is

displayed for 5 seconds.

DMR-EX95VEG / DMR-EX95VEB

Delete the Last Drive

Error

Delete the Last Drive Error information

stored on the DVD RAM-Drive.

Laser power confirmation Drive state is judged based on difference

between laser power value at shipping and

present laser power value.

5. Error occurring Disc type is

displayed for 5 seconds.

6. Disc Maker ID is displayed for 5

seconds.

In case that the maker cannot be

identified, display is black out.

7. Factor of Drive Error occurring is

left displayed

Press [9] [6] in service mode.

1. Insert DVD-RAM disc

into RAM Drive in service

mode. (Other media are

assumed to be noncorrespondence.)

2. Press [4] [4].

Turn on all FL/LEDs All segments of FL and all LEDs are turned

on.

PB HIGH Signal Output 8 pin of AV 1 Jack (PB HIGH terminal) is

High (approx. 11V DC).

PB MIDDLE Signal

Output

8 pin of AV 1 Jack (PB HIGH terminal) is

Middle (approx. 5.5V DC)

If DVD-RAM disc in not inserted,

[NO DISC] is displayed.

If power value study was filed,

[ERROR] is displayed.

All segments are turned on. Press [5] [1] in service mode.

Press [5] [2] in service mode.

Press [5] [3] in service mode.

29

Page 30

DMR-EX95VEG / DMR-EX95VEB

Item FL display Key operation

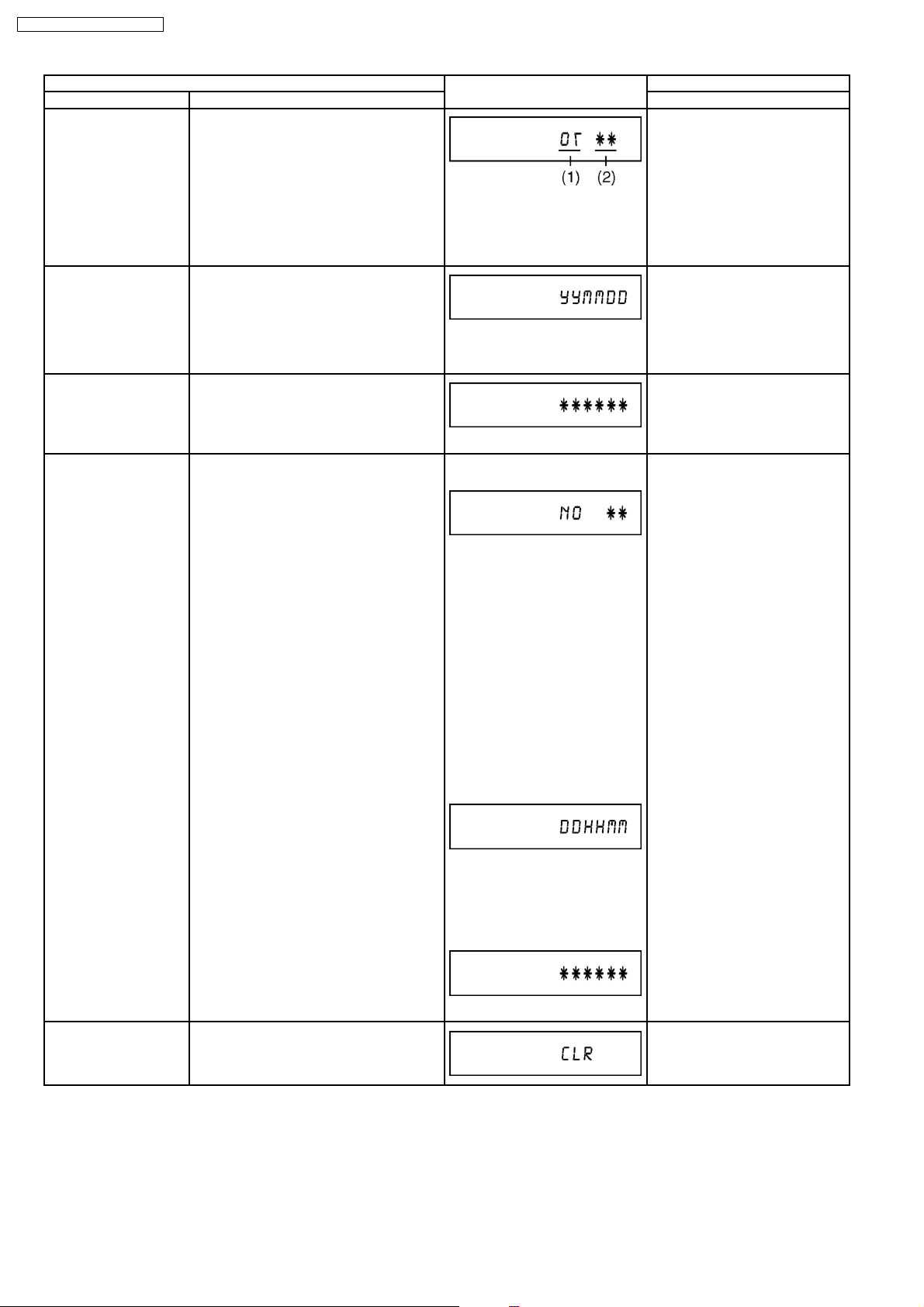

Mode name Description (Remote controller key)

Front connection

inspection

Press all front keys and check the

connection between Main P.C.B. and Front

key Switches.

(1) Each time a key is pressed,

segment turned on increases one

by one.

(2) Total umber of keys that have

been pressed.

Production Date Display Display the date when the unit was produced.

YY: Year

MM: Month

DD: Day

Display the accumlated

Display the accumulated unit´s working time.

working time

(Indicating unit: Second)

Display the Error History Display the Error History stored on the unit. Display reason of error for

5 seconds.

Press [5] [4] in service mode.

Press [6] [1] in service mode.

Press [6] [4] in service mode.

Press [6] [5] in service mode.

Then press [0] [1] ~ [1] [9], the

past 19 error histories are

displayed.

01:

Defect of Digital P.C.B.

(AV DEC / MAIN CPU)

02:

Defect of RAM Drive.

03:

Defect of Disc.

04:

Defect of Digital P.C.B. or

Communication Error.

05:

Defect of Digital P.C.B.

(AV DEC / MAIN CPU)

06:

Defect of HDD.

Display the time when the error

has occurred for 5 seconds.

DD: Day

hh: Hour

mm: Minute

Accumulated working time till

occuring of the error is left

displayed.

Delete the Error History Delete Error History information stored on

the unit.

(Indicating unit: Second)

Press [9] [7] in service mode.

30

Page 31

Item FL display Key operation

Mode name Description (Remote controller key)

SD card WRITE check Check SD card WRITE function with SD

slot.

When the WRITE check is OK.

Insert a SC card to SD card slot,

and press [7] [4] in service mode.

* Insert SD card while the power is

off.

* Check for [CARD SD] display on

When the WRITE check is NG.

the FL display and go on the

procedure.

*Note:

The image stored in the SD

card will be erased.

AV4(V)/AV1(RGB) I/O

Setting

Set input to AV4 (V) and set output to AV1

(RGB) for I/O checking

Press [8] [0] in service mode.

DMR-EX95VEG / DMR-EX95VEB

AV2(Y/C)/AV1(V) I/O

Setting

AV2(V)/AV1(Y/C) I/O

Setting

AV2(RGB)/AV1(V) I/O

Setting

Set input to AV2 (Y/C) and set output to

AV1 (V) for I/O checking

Set input to AV2 (V) and set output to AV1

(Y/C) for I/O checking

Set input to AV2 (RGB) and set output to

AV1 (V) for I/O checking

P50(H) Output Timer Microprocessor IC9704-76 output

High signal for AV1-pin 10 passing through

inverter (approx. 0V DC at AV1-pin 10).

P50(L) Output Timer Microprocessor IC9704-76 output Low

signal for AV1-pin 10 passing through

inverter (approx. 4.4V DC at AV1-pin 10).

When OK.

When NG.

When OK.

When NG.

Press [8] [1] in service mode.

Press [8] [2] in service mode.

Press [8] [3] in service mode.

Press [8] [4] in service mode.

Press [8] [5] in service mode.

Tray OPEN/CLOSE Test The RAM drive tray is opened and closed

repeatedly.

Press [9] [1] in service mode

*When releasing this mode, press

the [POWER] button of Remote

Controller more than 10 seconds.

“*” is number of open/close cycle

times.

Error code initialization Initialization of the last error code held by

Press [9] [8] in service mode.

timer (Write in F00)

Initialize Service Last Drive Error, Error history and Error

Press [9] [9] in service mode.

Codes stored on the unit are initialized to

factory setting.

Finishing service mode Release Service Mode. Display in STOP (E-E) mode. Press power button on the front

panel or Remote controller in

service mode.

31

Page 32

DMR-EX95VEG / DMR-EX95VEB

8.2. (VHS) SELF-DIAGNOSIS AND SPECIAL MODE SETTING

8.2.1. (VHS) SPECIAL MODES SETTING

Item FL display Key operation

Mode name Description Front Key

Tracking Center Tape Tracking is adj usted to center

FIX position.

VHS Service Mode In order to make service easy, a part of

inside information of a microprocessor

is displayed on FIP.

*Details are described in

"VHS Service Mode".

No display. During PLAYBACK, press [VHS CH

UP] and [VHS CH DOWN] keys

simultaneously.

Press [STOP], and [EJECT] keys

simultaneously for three seconds

when power is off.

Set Drive to VHS.

Releasing EXT LINK &

Timer Program

Eject Ejecting Cassette Tape No display. While in other than Timer REC

Releasing Continuation EXT LINK &

Continuation Timer Program

No display. While in EXT LINK or Timer REC

mode, press [VHS STOP] key for 3

seconds.

mode, press [STOP] key for 3

seconds or press [STOP] key of the

Remote Controller for 3 seconds in

VHS mode.

8.2.2. (VHS) SERVICE MODES

(Service Mode Setting)

1. When power is OFF, press [STOP] and [EJECT] keys simultaneously for 3 seconds to into Service Mode and

set Drive to VHS.

2. In Service Mode, press [STOP] and [EJECT] keys simultaneously to add Service Number.

Service Mode

Number

0 Indication for the

1 Indication for the

2 Indication for the

3 Self-diagnosis

4 Self-diagnosis

5 Self-diagnosis

6 Indication for the

Contents Contents of Indication on minute Contents of Indication on second Remarks

inner data of

IC6001

inner data of

IC6001

inner data of

IC6001

history (1st)

history (2nd)

history (3rd)

inner data of

IC6001

VHS mode

(Real time)

Tape beginning and ending

detection data (Real time)

00: Both tape beginning and

ending have not been detected

01: Tape ending is detecting now

02: Tape beginning is detecting

now

03: Both tape beginning and

ending are detecting now

Mechanism position (Real time) Ordering for the Motors (Real time) The following functions are

0L: EJECT position

02: DOWN position

03: RREW position

04: LOAD position

05: REV position

06: PLAY position

07: POFF position

08: STOP_R position

09: STOP_F position

0- : FF/REW position

0_ : Intermediate between each

positions

1st history of error number "- -" is displayed.

2nd history of error number "- -" is displayed

3rd history of error number "- -" is displayed

Servo data (4 digits)

(Real time)

Process number of the mechanism

movement

(Real time)

Key code

(Real time)

Indicate the receiving code when

the key of VCR or remote

controller being operated.

0*, 2*: CYL off,

CAP off

1*: CYL off,

CAP on (fwd)

3*: CYL off,

CAPon (rev)

8*, A*: CYL on,

CAP off

9*: CYL on,

CAPon (fwd)

B*: CYL on,

CAP on (rev)

*0: Motor off

*1:Loading

*2: Unloading

*3: Break (Load + Unload)

prohibited to operate the

mechanism without cassette tape.

●Tape beginning and ending

detection.

●Reel lock detection

●Tape detection and tape position

detection

Press the EJET key for over 3

seconds in this mode, and then the

VCR is shifted into the special

modes, such as PG Adjustment,

Model Code Setting, and so on.

The orders for the motors are

asfollows.

32

Page 33

DMR-EX95VEG / DMR-EX95VEB

Service Mode

Number

7 Manual mechanism

Contents Contents of Indication on minute Contents of Indication on second Remarks

operation

Mechanism position (Real time) Ordering for the Motors Press the following key;

0L: EJECT position

02: DOWN position

03: RREW position

04: LOAD position

05: REV position

06: PLAY position

07: POFF position

08: STOP_R position

09: STOP_F position

0- : FF/REW position

0 _: Intermediate between each

positions

0*, 2*: CYL off,

CAP off

1*:CYL off,

CAP on (fwd)

3*: CYL off,

CAPon (rev)

8*, A*: CYL on,

CAP off

9*: CYL on,

CAPon (fwd)

B*: CYL on,

CAP on (rev)

*0: Motor off

*1:Loading

*2: Unloading

*3: Break (Load + Unload)

PLAY key: Loading

STOP key: Unloading

8.2.3. (VHS) SELF-DIAGNOSIS FUNCTIONS

This model has a self-diagnosis. If the VHS section detects trouble during installation or during use, the power is automatically

turned off or become power-save mode and it is memorized into the EEPROM (IC9705) as error code of two-digit number. It’s

memorized error code can be displayed in "second" display portion (the last 2 digits of the FIP) by placing the unit is Service Mode

Number 2 when turning on the Service Information Display as for example "01" or "02" etc. as below. If a second error occurs, the

most recent error will be memorized and can be displayed in Service Mode Number 2. It can be memorized until 3 self-diagnosis

histories in maximum.

In order to erase the memorized error code, press STOP and EJECT buttons on the Front Panel simultaneously over 5 seconds

during turning on Service Information Display mode.

8.2.3.1. MEMORY OF THE SELF-DIAGNOSIS HISTORY

*This is effective only in Service Mode 3, 4, 5.

8.2.3.1.1. ERROR NUMBERS AT A GLANCE

Memory No. (Error Code) Reason

01 The cylinder could not be started. (Error of the cylinder or the cylinder driver.)

02 The CAP FG could not be detected.

03 Mechanism lock during without the unloading and the cassette-up.

04 Mechanism lock during unloading

05 S-reel pulse cannot be detected during unloading. (Error of the S-reel circuit or the Capstan circuit)

06 Mechanism lock during the Cassette-up.

09 Communication error between VHS Microprocessor (IC6001) and Timer Microprocessor (IC9704).

15 S-reel pulse cannot be detected when a cassette tape is inserted.

16 Detection of the Cylinder lock during the constant rotation

17 Detection of S-reel lock during the constant tape running

18 Detection of T-reel lock during the constant tape running

2*

Refer to following table

80 An exceptional ejection depends on a accidental error

Note:

2* is as follows.

20 NG1 in the PG Shifter Automatic Adjustment (The cylinder rotation is unstable during the automatic adjustment.)

21 NG2 in the PG Shifter Automatic Adjustment (The vertical sync signal is lacked while over 5 seconds on the alignment tape.)

22 NG3 in the PG Shifter Automatic Adjustment (The installing position of Heads to the cylinder is our of specification.

23 NG4 in the PG Shifter Automatic Adjustment (The servo is not locked to the cylinder for more than 10 sec.)

(Error of the S-reel circuit or the Capstan circuit)

An error while the PG Automatic Adjustment

8.2.3.1.2. MEMORY FOR THE SELF-DIAGNOSIS HISTORY

3. The self-diagnosis result is memorized the state of the moment of detecting.

4. There are the histories from number 1 to number 3.

5. The latest error is memorized on history number 1, and then the old histories are shifted to the history number 2 and 3.

The error code memorized in the history number 2 and 3 is over-written by shift.

4. If the latest error is the same with the history number 1 (2nd-latest), it is not memorized.

(The same error code is not memorized in succession)

33

Page 34

DMR-EX95VEG / DMR-EX95VEB

8.2.3.1.3. CLEAR FOR THE SELF-DIAGNOSIS HISTORY

1. Press STOP and EJECT buttons simultaneously over 5 seconds during turning on Service Information Display mode.

8.2.3.1.4. INDICATION OF THE SELF-DIAGNOSIS HISTORY

The self-diagnosis histories can be indicated on the FIP with Service Mode number 3 to 5.

The procedure of service mode setting and indication format are the same as usual.

9 SERVICE FIXTURE AND TOOLS

Part Number Description Pcs Compatibility

RFKZ03D01K Lead Free Solder (0.3 mm / 100 g Reel) 1 Same as ES15

RFKZ06D01K Lead Free Solder (O.6 mm / 100 g Reel) 1 Same as ES15

RFKZ010D01 Lead Free Solder (1.0 mm / 100 g Reel) 1 Same as ES15

RFKZ0316 Solder Remover (Lead free 10 W temperature Solder / 180 g) 1 Same as ES15

RFKZ0328 Flux 1 Same as ES15

RFKZ0329 Bottle of Flux 1 Same as ES15

JZS0484 Eject Pin 1 Same as ES15

Part Number Description Pcs Compatibility

RFKZ0240 Extension Cable (Main P.C.B. - Power & Digital I/F P.C.B. / 19 pin) 2 Same as ES75V

RFKZ0327 Extension Cable (Main P.C.B. - Power & Digital I/F P.C.B. / 15 pin) 1 Same as ES40V

RFKZ0323 Extension Cable (Main P.C.B. - Power & Digital I/F P.C.B. / 9 pin) 1 New

RFKZ0365 Extension Cable (Power Digital I/F P.C.B. - Digital P.C.B. / 64 pin) 1 Same as ES35

RFKZ0239 Extension Cable (to Front Jack P.C.B. and FL P.C.B. / 10 pin) 4 Same as E75V

RFKZ0260 Extension Cable (Power Digital I/F P.C.B. - Digital P.C.B. / 88 pin) 1 Same as EH50 series

RFKZ0366 Extension Cable (HDMI P.C.B. - Digital P.C.B. / 40 pin / 500 mm) 1 Same as EH55 / EH56 series

(for VHS)

Part Number Description Pcs Compatibility

VFJ8125H3F PAL VHS Alignment Tape 1 Same as E75V

VFK0329 Post Adjustment Screwdriver 1 Same as E75V

VFK0330 Fine Adjustment Gear Driver 1 Same as E75V

34

Page 35

10 ASSEMBLING AND DISASSEMBLING

10.1. DISASSEMBLY FLOW CHART

The following chart is the procedure for disassembling the casing

and inside parts for internal inspection when carrying out the servicing.

To assemble the unit, reverse the steps shown in the chart below.

DMR-EX95VEG / DMR-EX95VEB

10.2. P.C.B. POSITIONS 10.3. CAUTION WHILE INSERTING

CASSETTE TAPE WHEN

DISASSEMBLING THE UNIT

NOTE:

Video Cassette might not enter when a strong lighting is

applied to VHS Mechanism when Video Cassette is

inserted. Please weaken the lighting or cover with the top

panel etc.

35

Page 36

DMR-EX95VEG / DMR-EX95VEB

10.4. TOP CASE

1. Remove the 4 screws (A) and 3 screws (B).

2. Slide the Top Case for rear direction slightly, and open the

both ends at rear side of the Top Case a little and lift up the

Top Case for the direction of the arrows.

10.5. FRONT PANEL

1. Remove one screw (A).

2. Unlock tab (A) and tab (B) simultaneously.

3. Unlock tab (C) and tab (D) simultaneously.

4. Unlock 2 tabs (E) respectively and pull out Front Panel with

connector slightly.

36

Page 37

DMR-EX95VEG / DMR-EX95VEB

Note:

When attaching Front Panel, in order to hook Cassette

Door Opener Lever to Cassette Door, push up cassette

door in the direction of arrow and insert a front panel.

10.7. REAR PANEL

1. Remove Screws (A), Screw (B) and (C)

and Fan Connector.

2. Unlock 2 Locking Tabs (A) and lift up HDD out of the

Locking Tab (B) inside Rearpanel, to remove Rear Panel

without Fan Motor.

3. Attention when inserting Rear Panel:

Don’t shut the Fan Cable between Rear Panel

and Chassis.

Check that the Locking Tabs on both sides on

the Rear Panel snap into the holes of the Chassis.

Note:

When attiching Front Panel push up the Earthspring on

Top of the DV IN Connector.

10.6. FRONT JACK P.C.B. &

FL DRIVE P.C.B.

1. Remove one 6 screws (A) to remove FL Drive P.C.B.

2. Remove 3 screws (B) and unlock the Locking Tab (B) to

remove Front Jack P.C.B.

37

Page 38

DMR-EX95VEG / DMR-EX95VEB

10.8. HARD DISC DRIVE

NOTE:

After replacing HDD, "UNFORMAT" indication is displayed,

then HDD must be formatted.

After that, programme in HDD will be lost.

1. Remove 2 screws on Rear Panel

2. Remove 1 screw on HDD Angle

3. Remove FFC HDD Data Cable from Atapi Connector

4. Lift up HDD

Note:

When you lift up VCR Mechanism Unit, because

connections of P2501 and P3001 are tight,

pay attention to that.

10.9. FAN MOTOR

1. Remove the Fan Connector.

2. Remove 2 Screws to remove Fan Motor.

10.10. VCR MECHANISM UNIT

10.10.1. CAUTION FOR ATTACHING VCR

MECHANISM UNIT

1. Because Position SW should be set to "Eject Position",

refer to fig.(A) and set the position switch so that the boss

and arrow mark come on a straight line.

2. Attach VCR Mechanism Unit so that Boss of Position SW is

put into long hole of Main Cam Gear, refer to Fig. (B).

1. Disconnect 3 Connectors (P1531, P2501 and P4002).

2. Remove 3 black Screws (A), Screw (B), Screw (C)

and Screw D).

3. Lift up VCR Mechanism Unit perpendicularly so to

disconnect Connectors (P2571 and P3001).

38

Page 39

DMR-EX95VEG / DMR-EX95VEB

10.11. MAIN P.C.B.

1. Disconnect 3 Connectors.

2. Remove 3 Screws and remove Main P.C.B.

10.13. DVD-RAM DRIVE / DIGITAL

P.C.B. MODULE

NOTE:

After replacing RAM/Digital P.C.B. Module,

FORMAT of HDD is unnecessary.

CAUTION:

The DVD-RAM Drive and the Digital P.C.B. have

to be replaced together as one Module.

If the Module is changed the DVD-RAM Drive has to

be re-aligned because the aligment data for the

DVD-RAM Drive is stored in the Digital P.C.B.

1. Remove 3 Screws.

2. Lift up DVD-RAM Drive slightly.

10.12. TUNER

1. Remove the solders.

2. Pull out the Tuner from Main P.C.B.