Panasonic DMR-ES35VEE, DMR-ES35VGC, DMR-ES35VGCS, DMR-ES35VGN Service Manual

ORDER NO. MD0605164CE

DVD Recorder

DMR-ES35VEE

DMR-ES35VGC

DMR-ES35VGCS

DMR-ES35VGN

Vol. 1

Colour

(S).......................Silver Type

© 2006 Matsushita Electric Industrial Co., Ltd. All

rights reserved. Unauthorized copying and

distribution is a violation of law.

DMR-ES35VGN / DMR-ES35VGC / DMR-ES35 VGCS / DMR-ES35 VEE

CONTENTS

Page Page

1 Safety Precautions 3

1.1. GENERAL GUIDELINES

1.2. Caution for AC Mains Lead (For GC only)

1.3. Before Repair and Adjustment

1.4. Protection Circuitry

2 Prevention of Electro Static Discharge (ESD) to

Electrostatically Sensitive (ES) Devices

3 Precaution of Laser Diode

4 Handling the Lead free Solder

4.1. General description about Lead Free Solder (PbF)

5 Service Navigation

5.1. Service Information

5.2. CAUTION FOR DivX

6 Specifications

7 Accessories

8 Operation Instructions Procedures

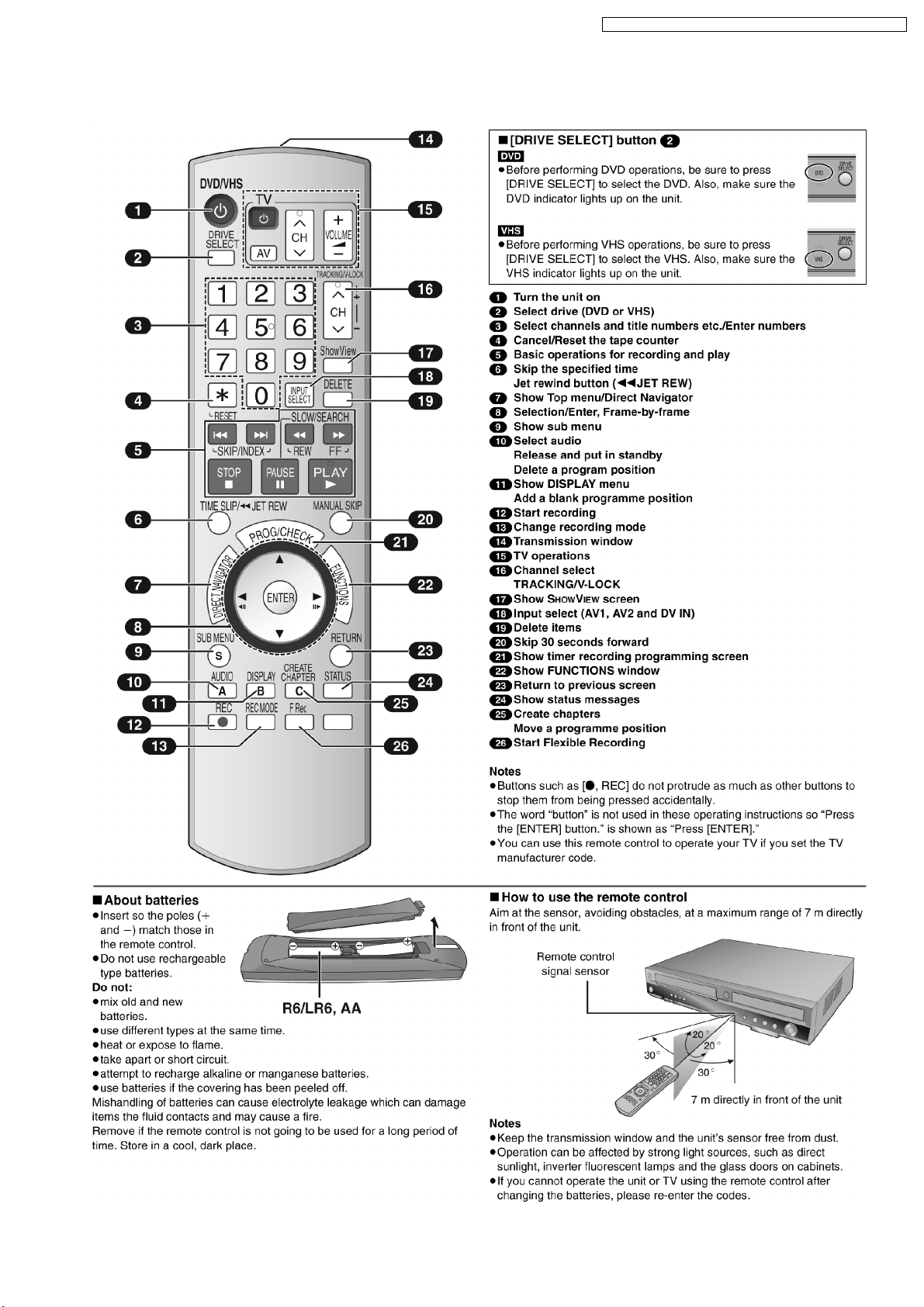

8.1. Remote Control Operation (For GN/GC/GCS)

8.2. Remote Control Operation (For EE)

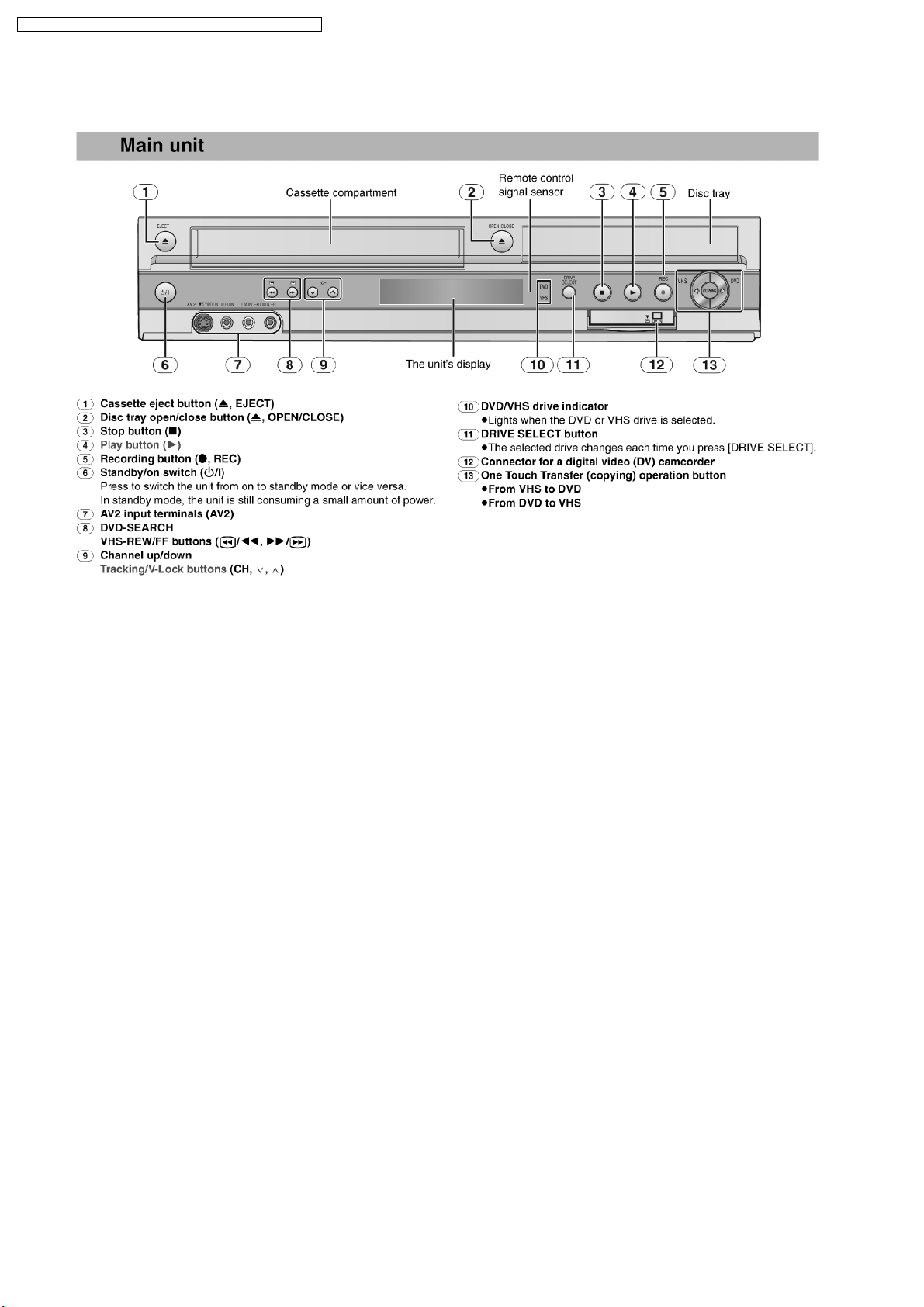

8.3. Main Unit Operation

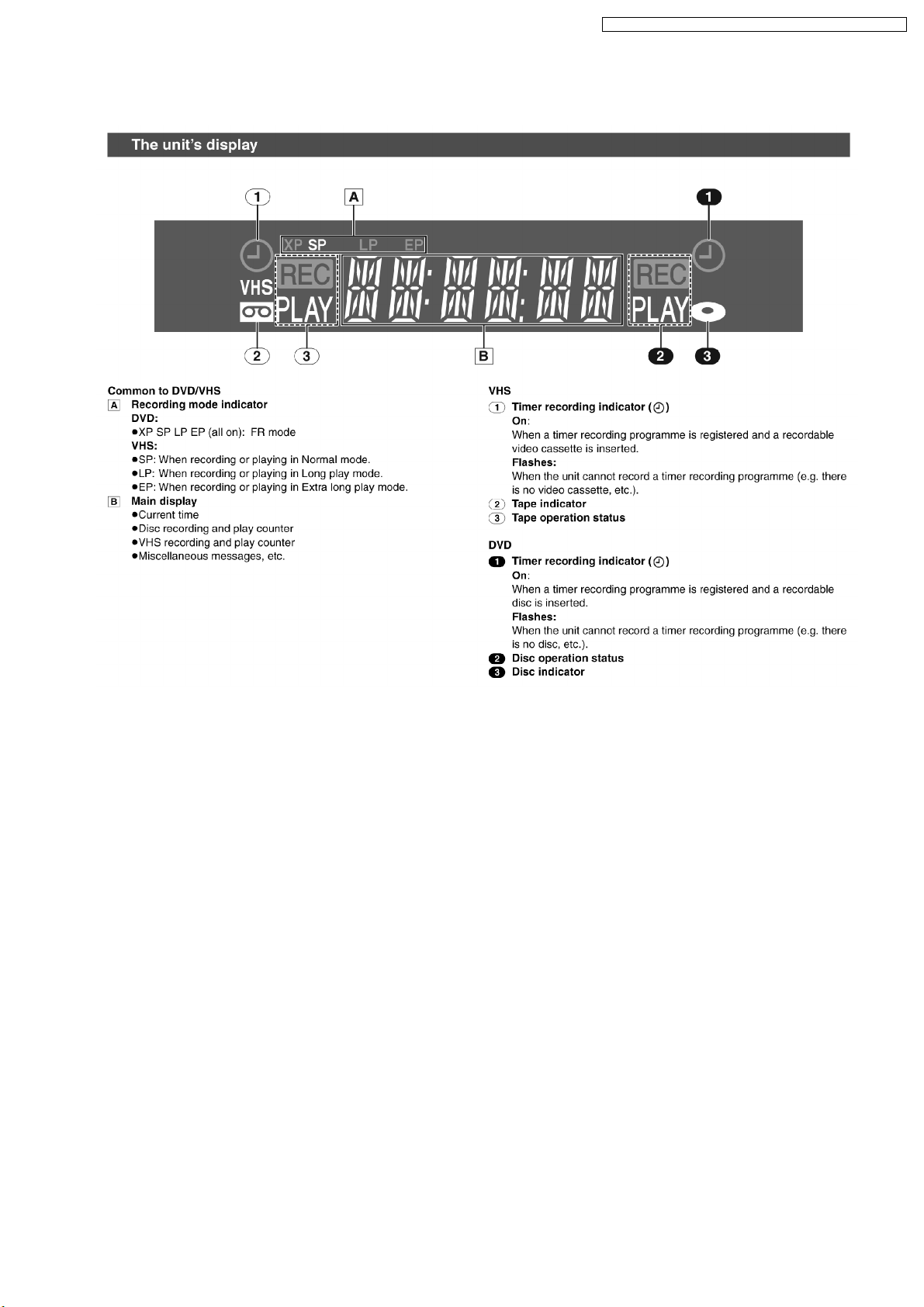

8.4. Main Unit Panel Display

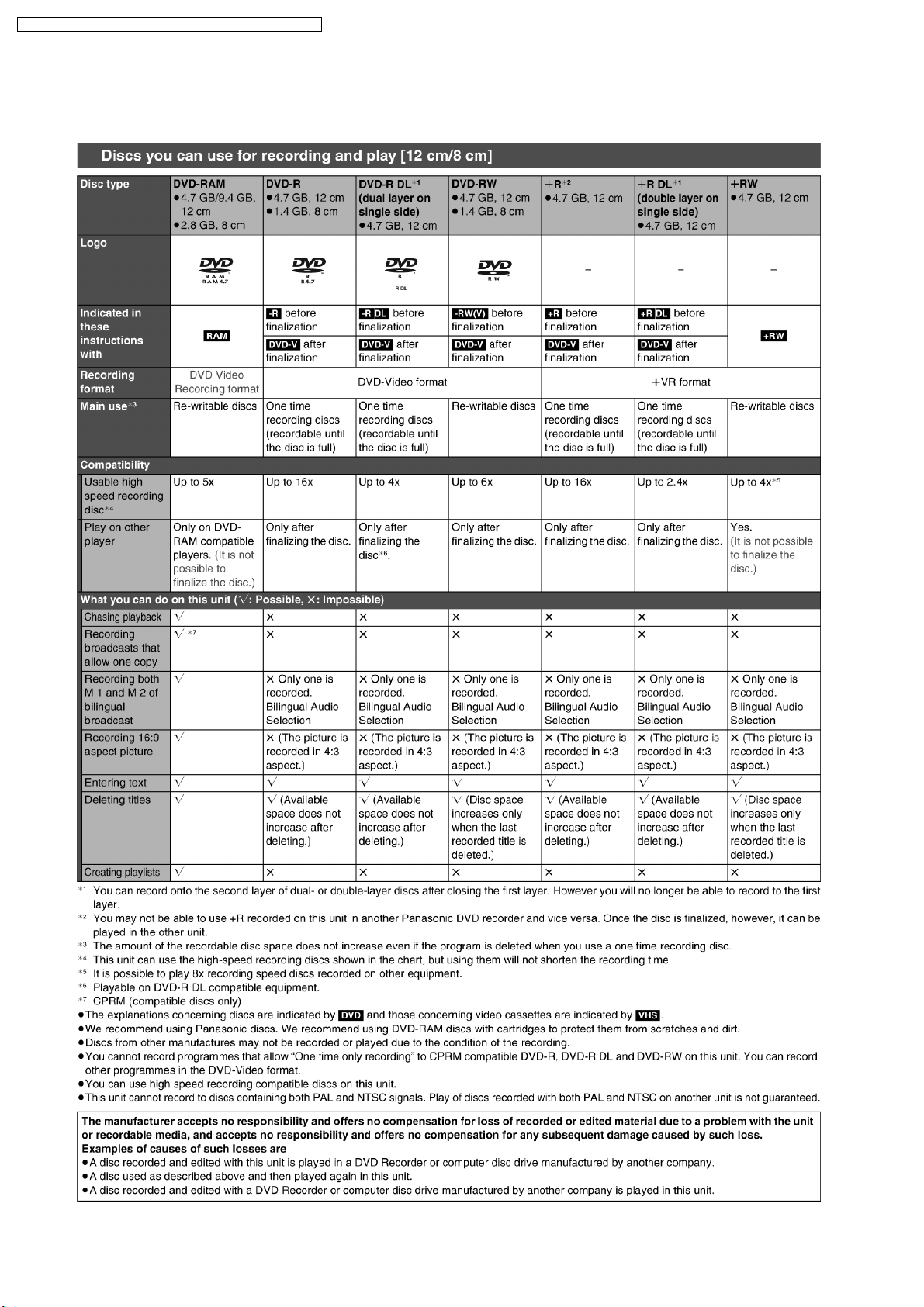

8.5. Disc Information

8.6. ABOUT DivX

8.7. Connection to other Devices

8.8. Connection to other Devices

9 Operation Instructions

9.1. (DVD) Taking out the Disc from RAM-Drive Unit when the

Disc cannot be ejected by OPEN/CLOSE button

9.2. (VHS) Removing Cassette Tape manually

10 Service Mode

10.1. (DVD) Self-Diagnosis and Special Mode Setting

10.2. (VHS) Self-Diagnosis and Special Mode Setting

11 Service Fixture & Tools

12 Assembling and Disassembling

12.1. Caution

12.2. Disassembly Flow Chart

12.3. Main Parts Location Diagram

12.4. Caution with inserting cassette tape when disassembling

the unit

12.5. Disassembly of Top Panel

12.6. Disassembly of Nicam Decoder P.C.B.

12.7. Disassembly of Front Panel

12.8. Disassembly of Front Jack P.C.B. & Panel P.C.B.

10

14

16

16

17

18

19

20

25

31

33

35

35

36

38

38

46

49

50

50

51

52

53

54

54

55

55

3

4

5

5

6

7

8

8

9

9

9

12.9. Disassembly of RAM / Digital P.C.B. Module

12.10. Disassembly of DV Jack P.C.B.

12.11. Disassembly of VTR Mechanism Unit

12.12. Disassembly of Rear Panel

12.13. Disassembly of Fan Motor

12.14. Disassembly of Digital I/F P.C.B.

12.15. Main P.C.B.

13 Measurements and Adjustments

13.1. Service Positions

13.2. Caution for Replacing Parts

13.3. Standard Inspection Specifications after Making Repairs

14 Miscellane ous

14.1. Abbreviations

15 Voltage Measurement and Waveform Chart

15.1. Voltage Measurement

15.2. Waveform Chart

16 Wiring Diagram

17 Block Diagram

17.1. Analog Audio Block Diagram

17.2. Analog Timer Block Diagram

17.3. Analog Video Block Diagram

17.4. Power Supply Block Diagram

17.5. System Control & ServoBlock Diagram

18 Notes of Schematic Diagram

19 Schematic Diagram

19.1. DIGITAL IF CIRCUIT

19.2. MAIN CIRCUIT

19.3. PANEL CIRCUIT

19.4. FRONT JACK CIRCUIT

19.5. NICAM DECODER CIRCUIT

19.6. DV JACK CIRCUIT

20 Printed Circuit Board

20.1. DIGITAL I/F P.C.B

20.2. MAIN P.C.B

20.3. PANEL P.C.B, FRONT JACK P.C.B, NICAM DECODER

P.C.B and DV JACK P.C.B

21 Exploded Views

21.1. Casing Parts & Mechanism Section1

21.2. Casing Parts & Mechanism Section 2

21.3. VHS Mechanism Section

21.4. Packing

22 Replacement Parts List

56

57

58

59

59

59

60

61

61

64

69

71

71

77

77

82

85

87

87

88

89

91

93

95

97

97

102

115

116

117

118

123

123

124

125

127

127

128

129

130

131

2

DMR-ES35VGN / DMR-ES35VGC / DMR-ES35 VGCS / DMR-ES35 VEE

1 Safety Precautions

1.1. GENERAL GUIDELINES

1. When servicing, observe the original lead dress. If a short circuit is found, replace all parts which have been overheated or

damaged by the short circuit.

2. After servicing, ensure that all the protective devices such as insulation barriers, insulation papers shields are properly installed.

3. After servicing, check for leakage current checks to prevent from being expose d to shock hazards.

1.1.1. LEAKAGE CURRENT COLD CHECK

1. Unplug the AC cord and connect a jumper between the two prongs on the plug.

2. Using an ohmmeter measure the resistance value, between the jumpered AC plug and each exposed metallic cabinet part on

the equipment such as screwheads, connectors, control shafts, etc. When the exposed metallic part has a return path to the

chassis, the reading should be between 1MΩ and 5.2Ω.

When the exposed metal does not have a return path to the chassis, the reading must be

.

Figure. 1

1.1.2. LEAKAGE CURRENT HOT CHECK (See Figure 1.)

1. Plug the AC cord directly into the AC outlet. Do not use an isolation transfo rmer for this check.

2. Connect a 1.5kΩ, 10 watts resistor, in parallel with a 0.15µF capacitors, between each exposed metallic part on the set and a

good earth ground such as a water pipe, as shown in Figure 1.

3. Use an AC voltmeter, with 1000 ohms/volt or more sensitivity, to measure the potential across the resistor.

4. Check each exposed metallic part, and measure the voltage at each point.

5. Reverse the AC plug in the AC outlet and repeat each of the above measurements.

6. The potential at any point should not exceed 0.75 volts RMS. A leakage current tester (Simpson Model 229 or equivalent) may

be used to make the hot checks, leakage current must not exceed 1/2 milliamp. should the measurement is outside of the limits

specified, there is a possibility of a shock hazard, and the equipment should be repaired and re-checked before it is returned

to the customer.

3

DMR-ES35VGN / DMR-ES35VGC / DMR-ES35 VGCS / DMR-ES35 VEE

1.2. Caution for AC Mains Lead (For GC only)

4

DMR-ES35VGN / DMR-ES35VGC / DMR-ES35 VGCS / DMR-ES35 VEE

1.3. Before Repair and Adjustment

Disconnect AC power, discharge Power Supply Capacitors C11101, C11104, C11105 and C11106 through a 10Ω, 1W resistor to

ground.

DO NOT SHORT-CIRCUIT DIRECTLY (with a screwdriver blade, for instance), as this may destroy solid state devices.

After repairs are completed, restore power gradually using a variac, to avoid overcurrent.

1.4. Protection Circuitry

The protection circuitry may have operated if either of the following conditions are noticed:

· No sound is heard when the power is turned on.

· Sound stops during a performance.

The function of this circuitry is to prevent circuitry damage if, for example, the positive and negative speaker connection wires are

"shorted", or if speaker systems with an impedance less than the indicated rated impedance of the amplifier are used.

If this occurs, follow the procedure outlines below:

1. Turn off the power.

2. Determine the cause of the problem and correct it.

3. Turn on the power once again after one minute.

Note:

When the protection circuitry functions, the unit will not operate unless the power is first turned off and then on again.

5

DMR-ES35VGN / DMR-ES35VGC / DMR-ES35 VGCS / DMR-ES35 VEE

2 Prevention of Electro Static Discharge (ESD) to

Electrostatically Sensitive (ES) Devices

Some semiconductor (solid state) devices can be damaged easily by electricity. Such components commonly are called

Electrostatically Sensitive (ES) Devices. Examples of typical ES devices are integrated circuits and some field-effect transistors and

semiconductor “chip” components. The following techniques should be used to help reduce the incidence of component damage

caused by electro static discharge (ESD).

1. Immediately before handling any semiconductor component or semiconductor-equiped assembly, drain off any ESD on your

body by touching a known earth ground. Alternatively, obtain and wear a commercially available discharging ESD wrist strap,

which should be removed for potential shock reasons prior to applyin g power to the unit under test.

2. After removing an electrical assembly equiped with ES devices, place the assembly on a conductive surface such as aluminium

foil, to prevent electrostatic charge build up or exposure of the assembly.

3. Use only a grounded-tip soldering iron to solder or unsolder ES devices.

4. Use only an anti-static solder removal device. Some solder removal devices not classified as “anti-static (ESD protected)” can

generate electrical charge to damage ES devices.

5. Do not use freon-propelled chemicals. These can generate electrical charges sufficient to damage ES devices.

6. Do not remove a replacement ES device from its protective package until immediately before you are ready to install it. (Most

replacement ES devices are packaged with leads electrically shorted together by conductive foam, aluminium foil or

comparable conductive material).

7. Immediately before removing the protective material from the leads of a replacement ES device, touch the protective material

to the chassis or circuit assembly into which the device will be installed.

Caution

Be sure no power is applied to the chassis or circuit, and observe all other safety precautions.

8. Minimize bodily motions when handling unpackaged replacement ES devices. (Otherwise harmless motion such as the

brushing together of your clothes fabric or the lifting of your foot from a carpeted floor can generate static electricity (ESD)

sufficient to damage an ES device).

6

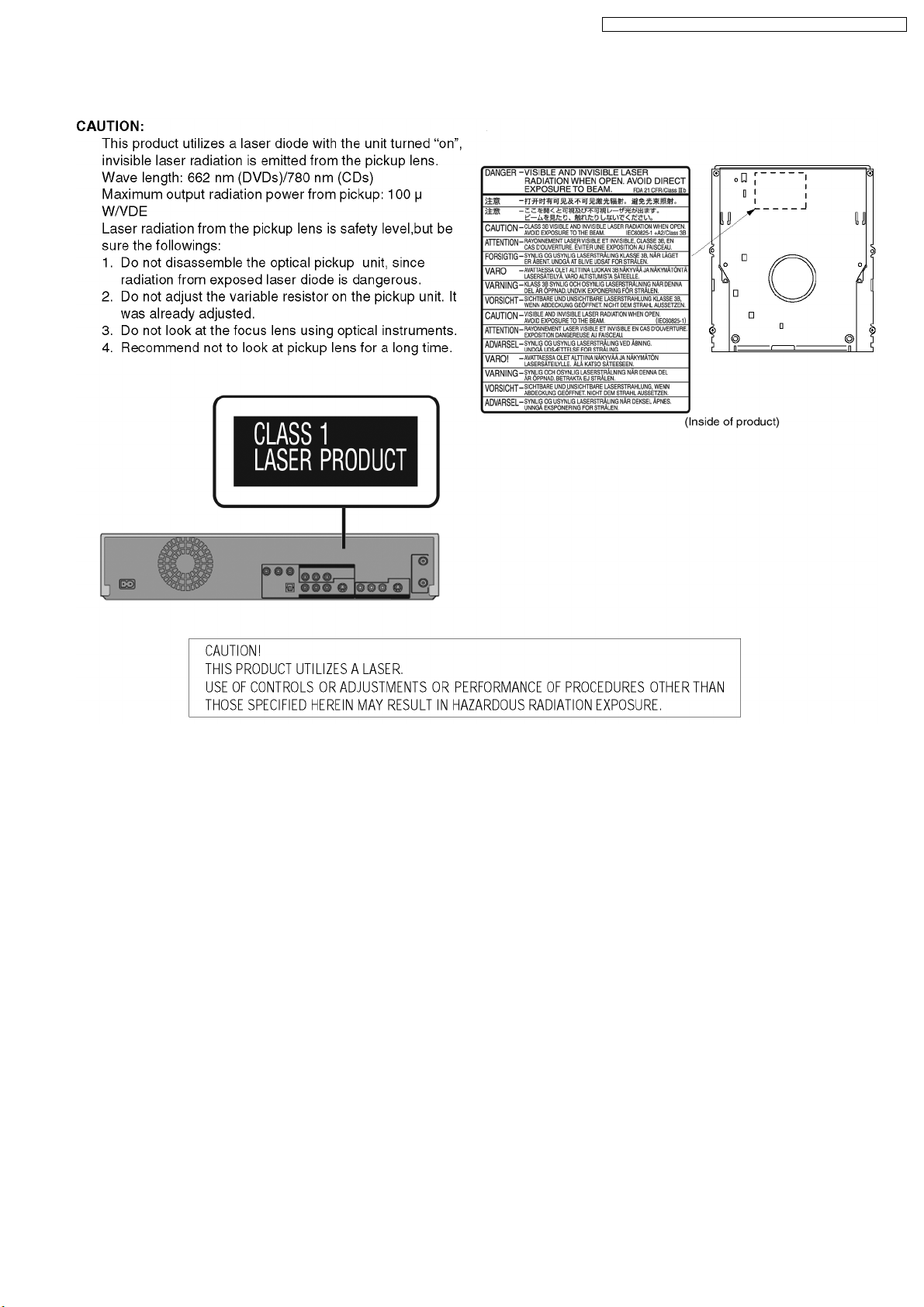

3 Precaution of Laser Diode

DMR-ES35VGN / DMR-ES35VGC / DMR-ES35 VGCS / DMR-ES35 VEE

7

DMR-ES35VGN / DMR-ES35VGC / DMR-ES35 VGCS / DMR-ES35 VEE

4 Handling the Lead free Solder

4.1. General description about Lead Free Solder (PbF)

The lead free solder has been used in the mounting process of all electrical components on the printed circuit boards used for this

equipment in considering the globally environmental conservation.

The normal solder is the alloy of tin (Sn) and lead (Pb). On the other hand, the lead free solder is the alloy mainly consists of tin

(Sn), silver (Ag) and Copper (Cu), and the melting point of the lead free solder is higher approx.30 degrees C (86°F) more than that

of the normal solder.

Definition of PCB Lead Free Solder being used

The letter of “PbF” is printed either foil side or components side on the PCB using the lead free solder.

(See right figure)

Service caution for repair work using Lead Free Solder (PbF)

· The lead free solder has to be used when repairing the equipment for which the lead free solder is used.

(Definition: The letter of “PbF” is printed on the PCB using the lead free solder.)

· To put lead free solder, it should be well molten and mixed with the original lead free solder.

· Remove the remaining lead free solder on the PCB cleanly for soldering of the new IC.

· Since the melting point of the lead free solder is higher than that of the normal lead solder, it takes the longer time to melt

the lead free solder.

· Use the soldering iron (more than 70W) equipped with the temperature control after setting the temperature at 350±30

degrees C (662±86°F).

Recommended Lead Free Solder (Service Parts Route.)

· The following 3 types of lead free solder are available through the service parts route.

RFKZ03D01K-----------(0.3mm 100g Reel)

RFKZ06D01K-----------(0.6mm 100g Reel)

RFKZ10D01K-----------(1.0mm 100g Reel)

Note

* Ingredient: Tin (Sn), 96.5%, Silver (Ag) 3.0%, Copper (Cu) 0.5%, Cobalt (Co) / Germanium (Ge) 0.1 to 0.3%

8

5 Service Navigation

5.1. Service Information

DMR-ES35VGN / DMR-ES35VGC / DMR-ES35 VGCS / DMR-ES35 VEE

5.2. CAUTION FOR DivX

9

DMR-ES35VGN / DMR-ES35VGC / DMR-ES35 VGCS / DMR-ES35 VEE

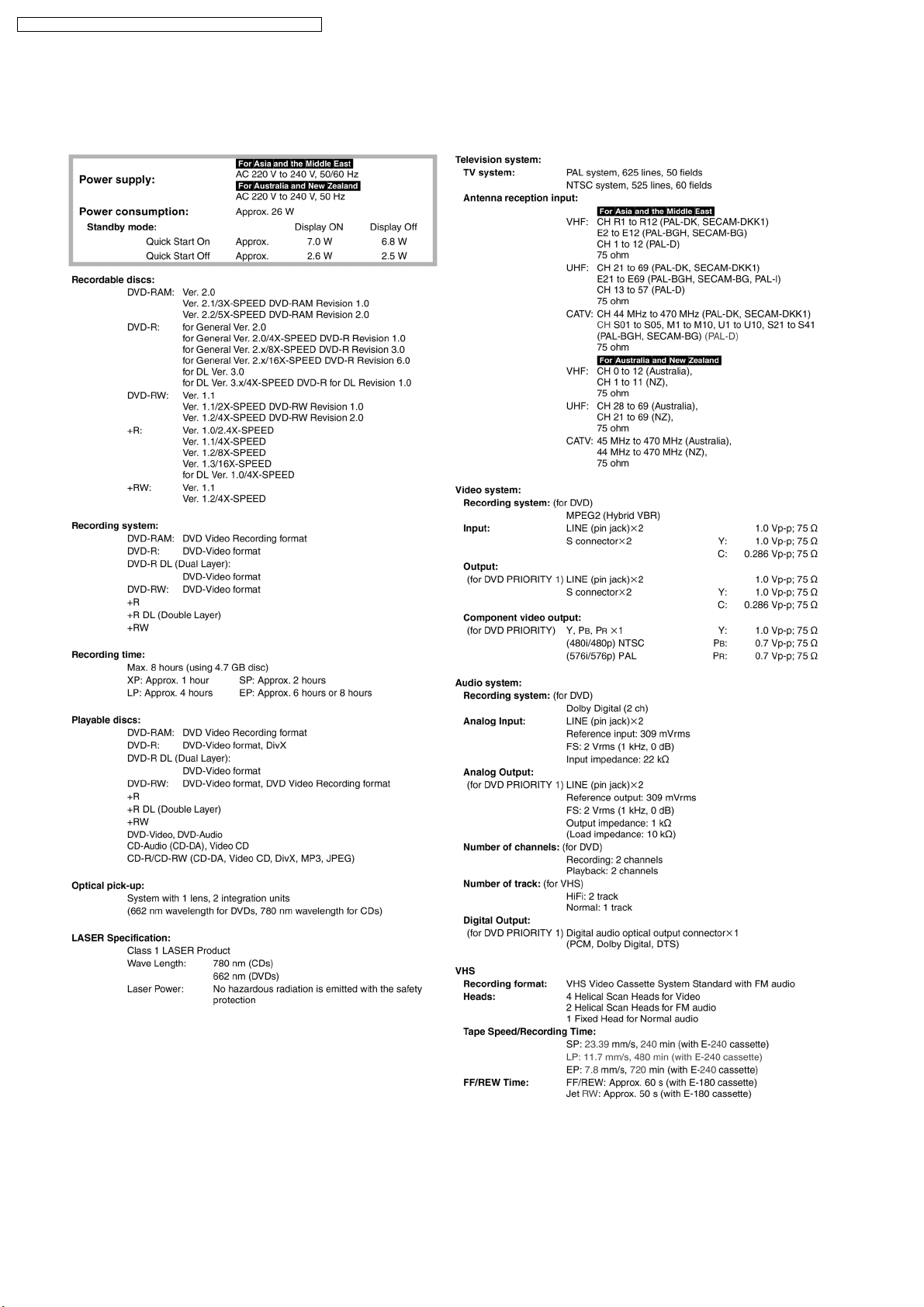

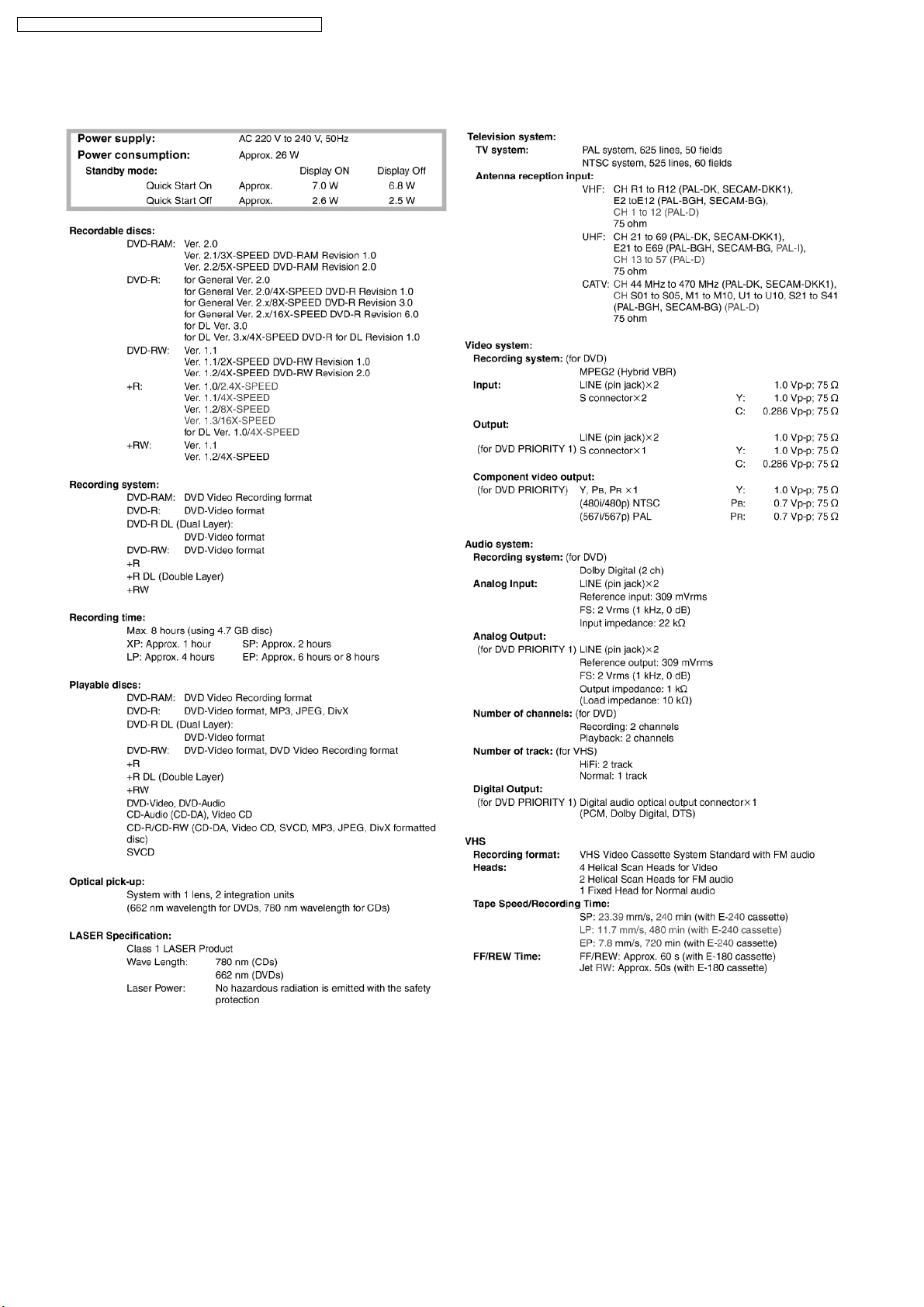

6 Specifications

(For GN/GC/GCS)

10

DMR-ES35VGN / DMR-ES35VGC / DMR-ES35 VGCS / DMR-ES35 VEE

11

DMR-ES35VGN / DMR-ES35VGC / DMR-ES35 VGCS / DMR-ES35 VEE

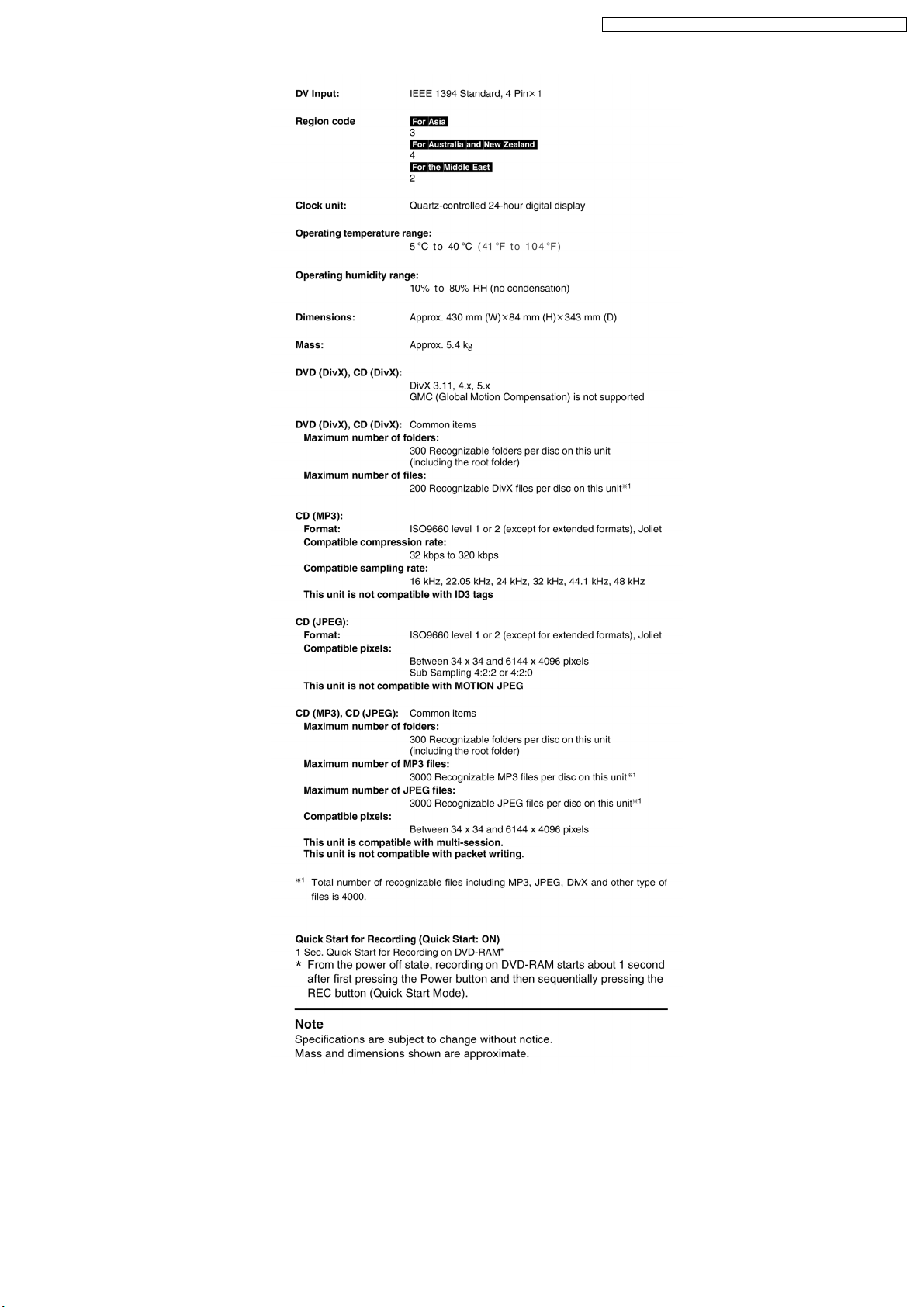

(For EE)

12

DMR-ES35VGN / DMR-ES35VGC / DMR-ES35 VGCS / DMR-ES35 VEE

13

DMR-ES35VGN / DMR-ES35VGC / DMR-ES35 VGCS / DMR-ES35 VEE

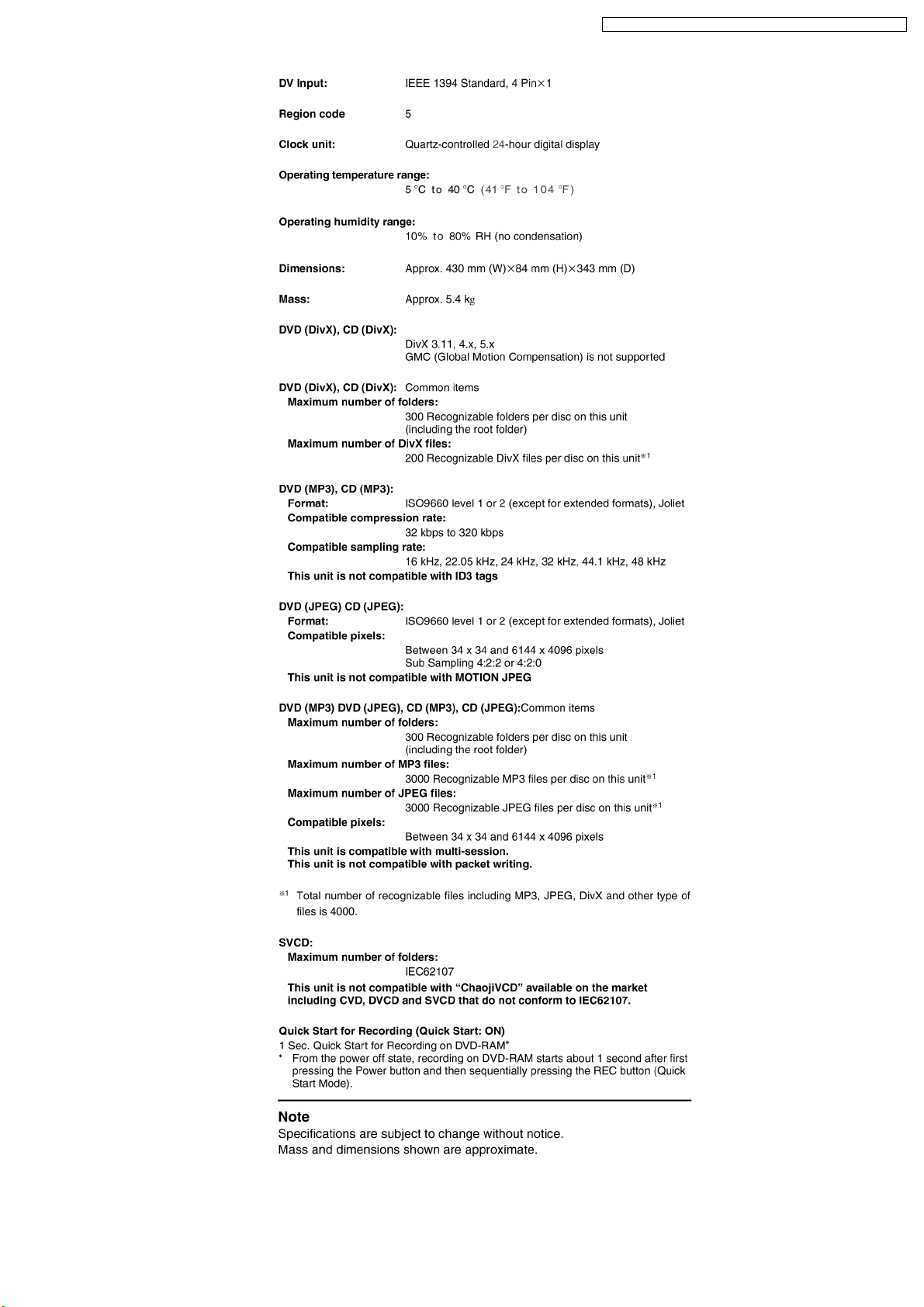

7 Accessories

Note : Refer to Replacement Parts List (Section 22) for the part number.

Remote control (For

GC/GCS)

Remote control (For

GN)

Remote control (For

EE)

AC Cord (For GN)

AC Cord (For

GC/GCS/EE)

AC Cord (For GC)

RF coaxial cable

14

Audio/Video cable

DMR-ES35VGN / DMR-ES35VGC / DMR-ES35 VGCS / DMR-ES35 VEE

15

DMR-ES35VGN / DMR-ES35VGC / DMR-ES35 VGCS / DMR-ES35 VEE

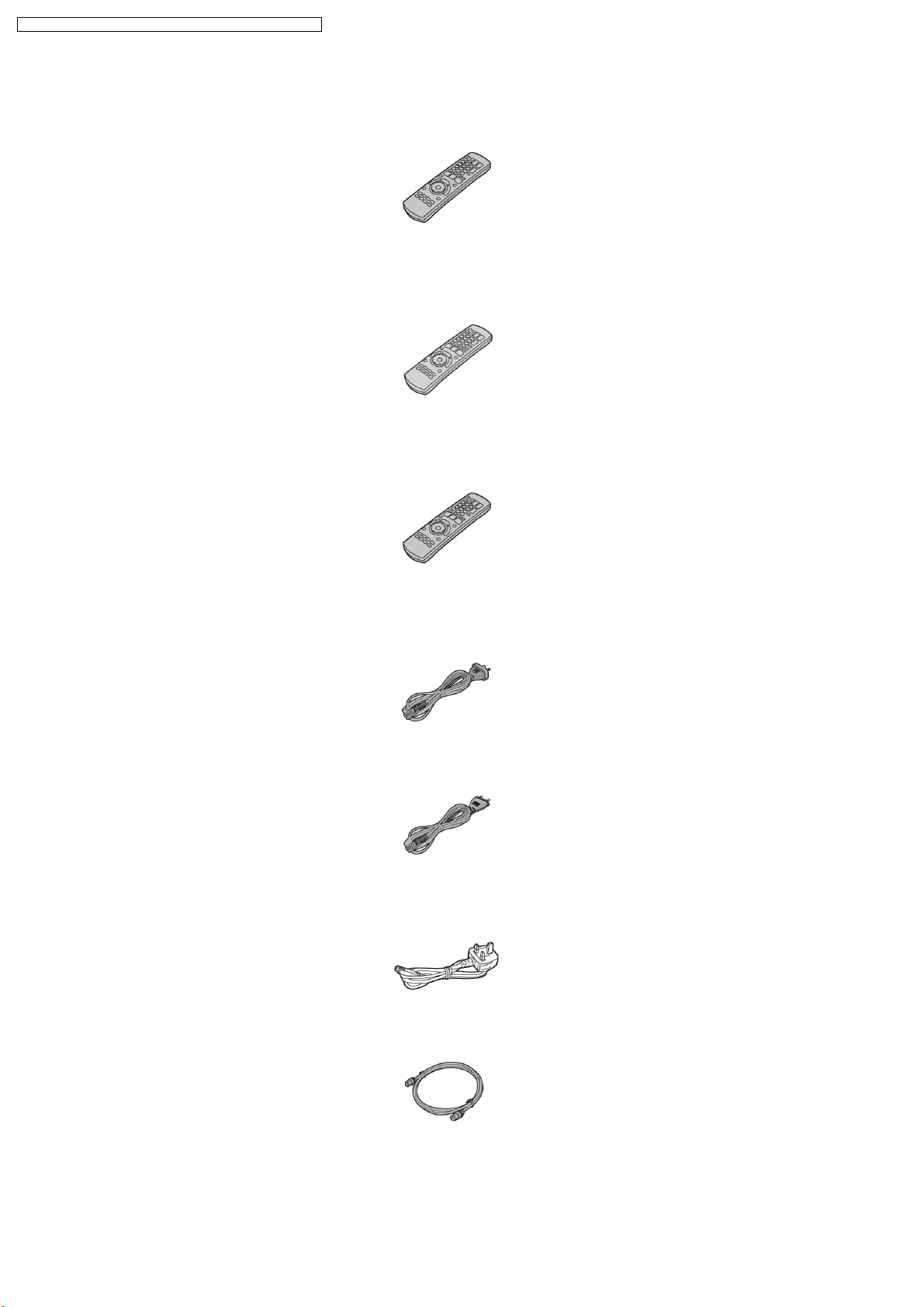

8 Operation Instructions Procedures

8.1. Remote Control Operation (For GN/GC/GCS)

16

8.2. Remote Control Operation (For EE)

DMR-ES35VGN / DMR-ES35VGC / DMR-ES35 VGCS / DMR-ES35 VEE

17

DMR-ES35VGN / DMR-ES35VGC / DMR-ES35 VGCS / DMR-ES35 VEE

8.3. Main Unit Operation

18

8.4. Main Unit Panel Display

DMR-ES35VGN / DMR-ES35VGC / DMR-ES35 VGCS / DMR-ES35 VEE

19

DMR-ES35VGN / DMR-ES35VGC / DMR-ES35 VGCS / DMR-ES35 VEE

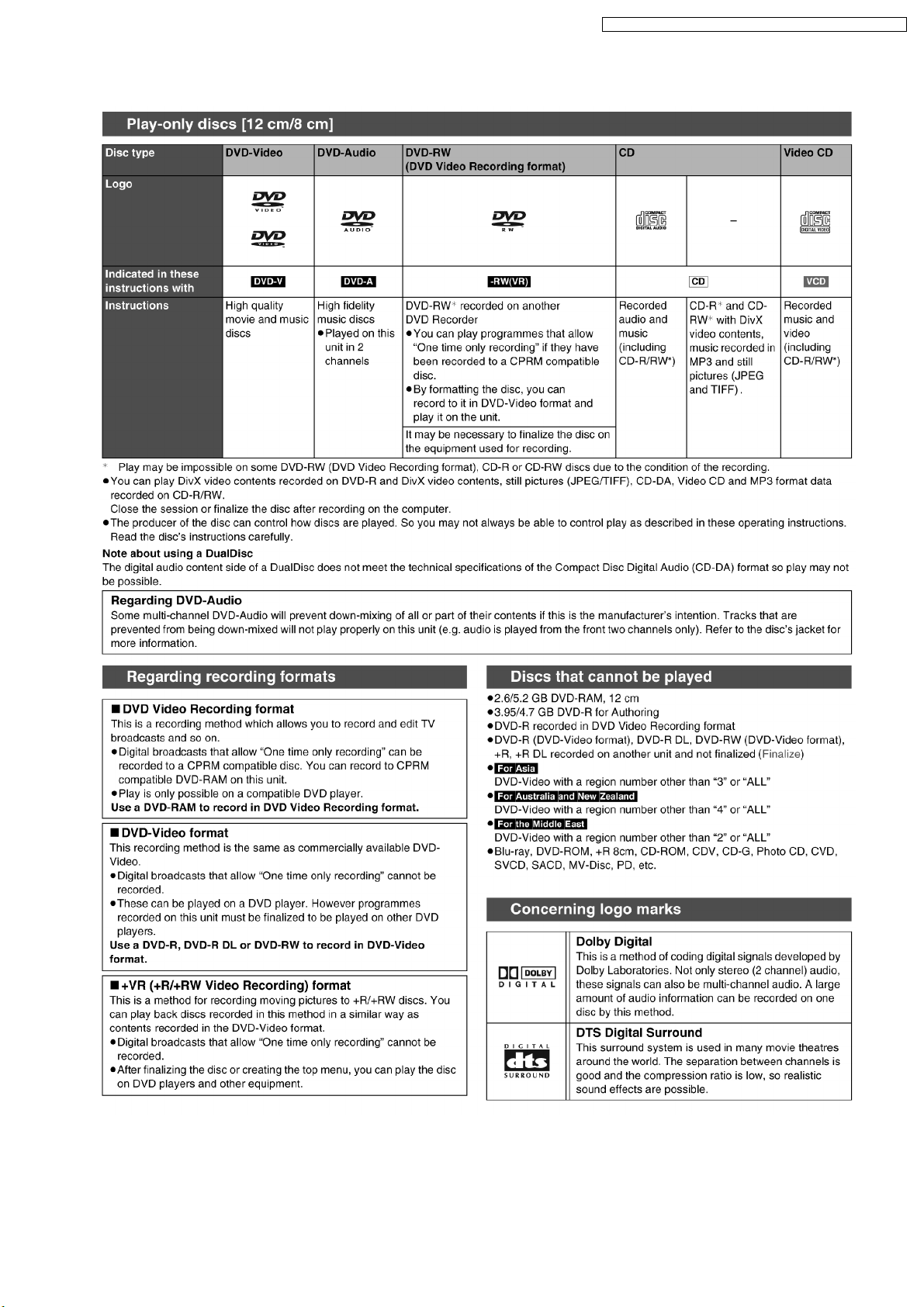

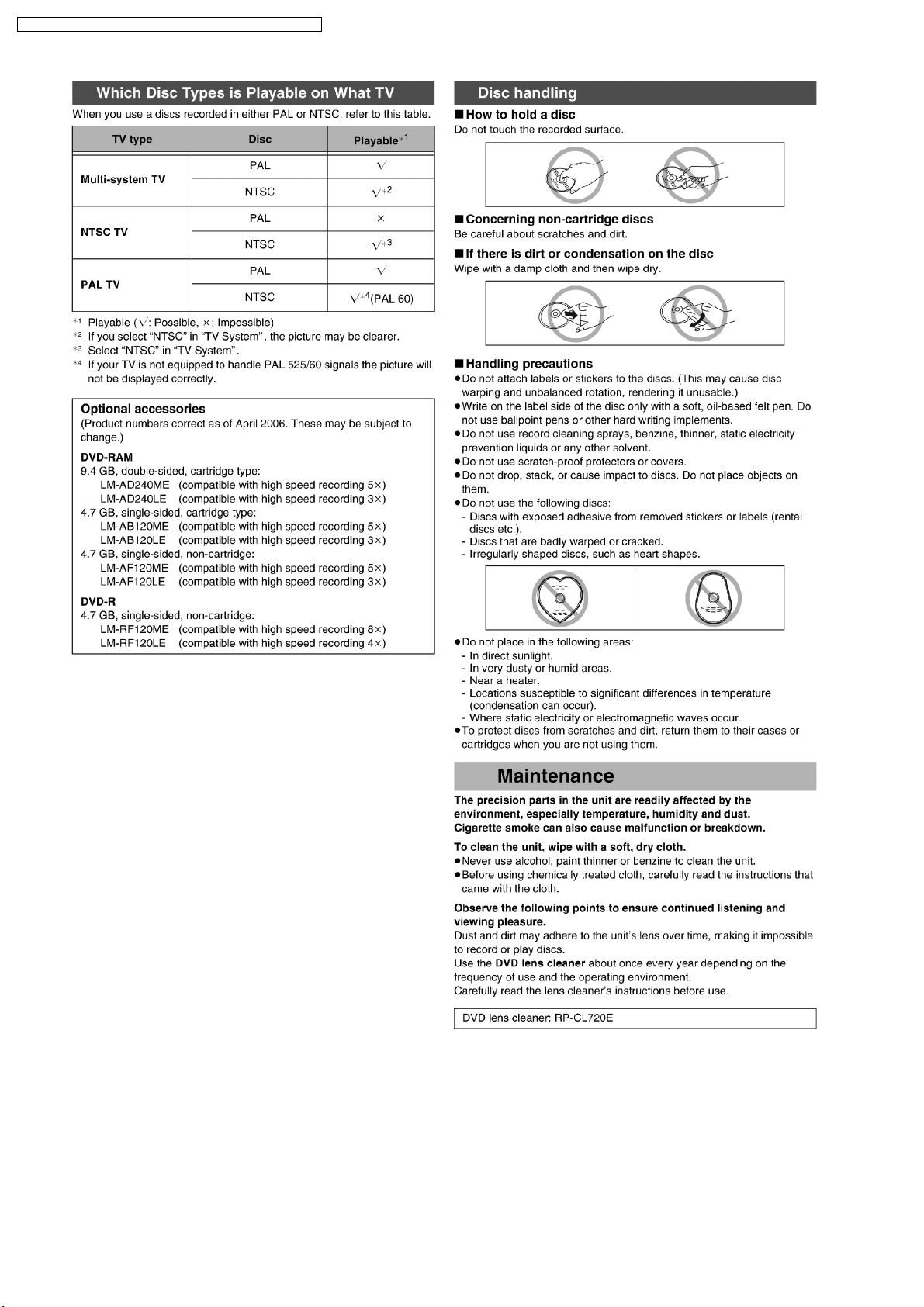

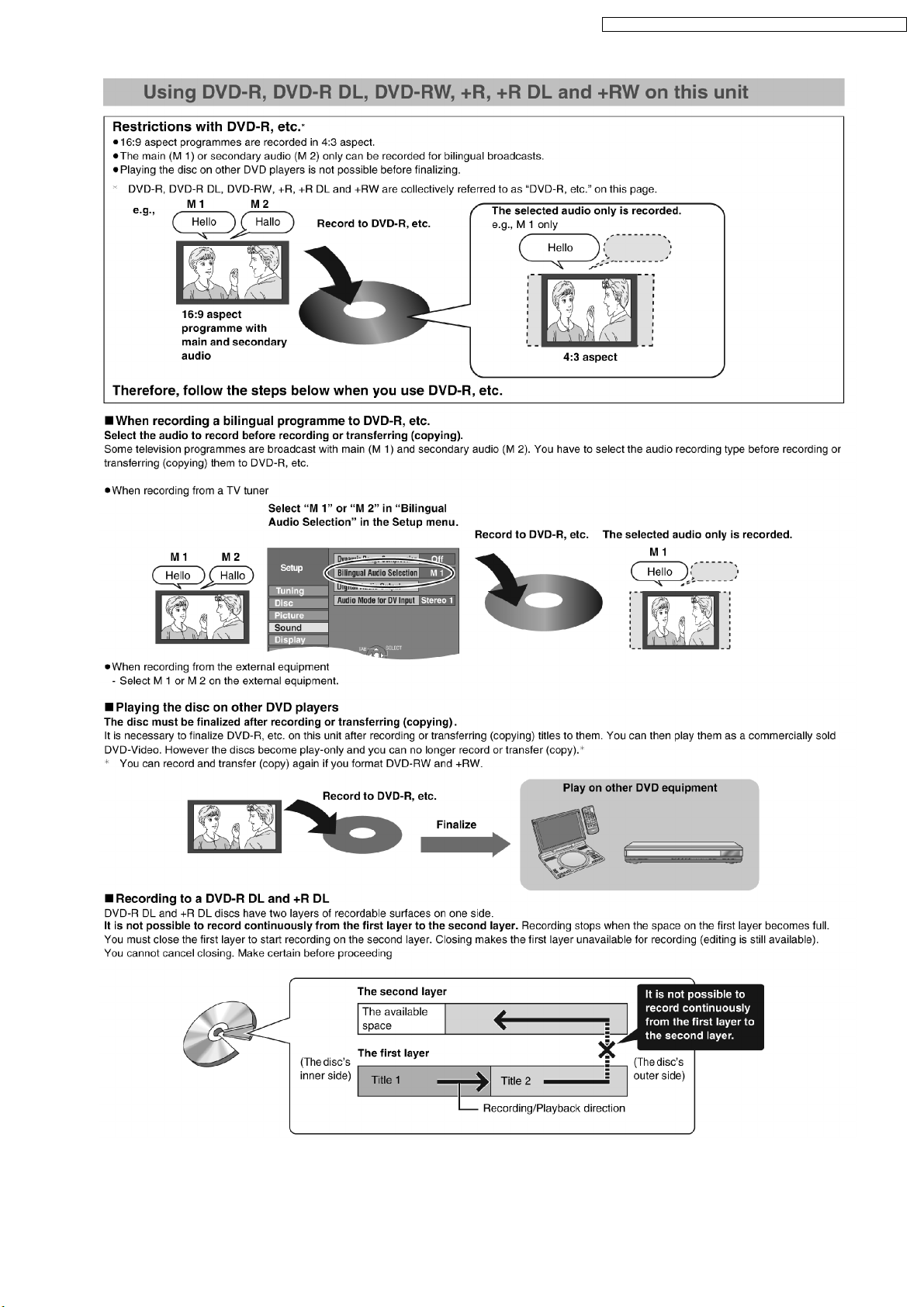

8.5. Disc Information

8.5.1. Discs for recording & play

20

8.5.2. Discs for playing

DMR-ES35VGN / DMR-ES35VGC / DMR-ES35 VGCS / DMR-ES35 VEE

21

DMR-ES35VGN / DMR-ES35VGC / DMR-ES35 VGCS / DMR-ES35 VEE

22

DMR-ES35VGN / DMR-ES35VGC / DMR-ES35 VGCS / DMR-ES35 VEE

23

DMR-ES35VGN / DMR-ES35VGC / DMR-ES35 VGCS / DMR-ES35 VEE

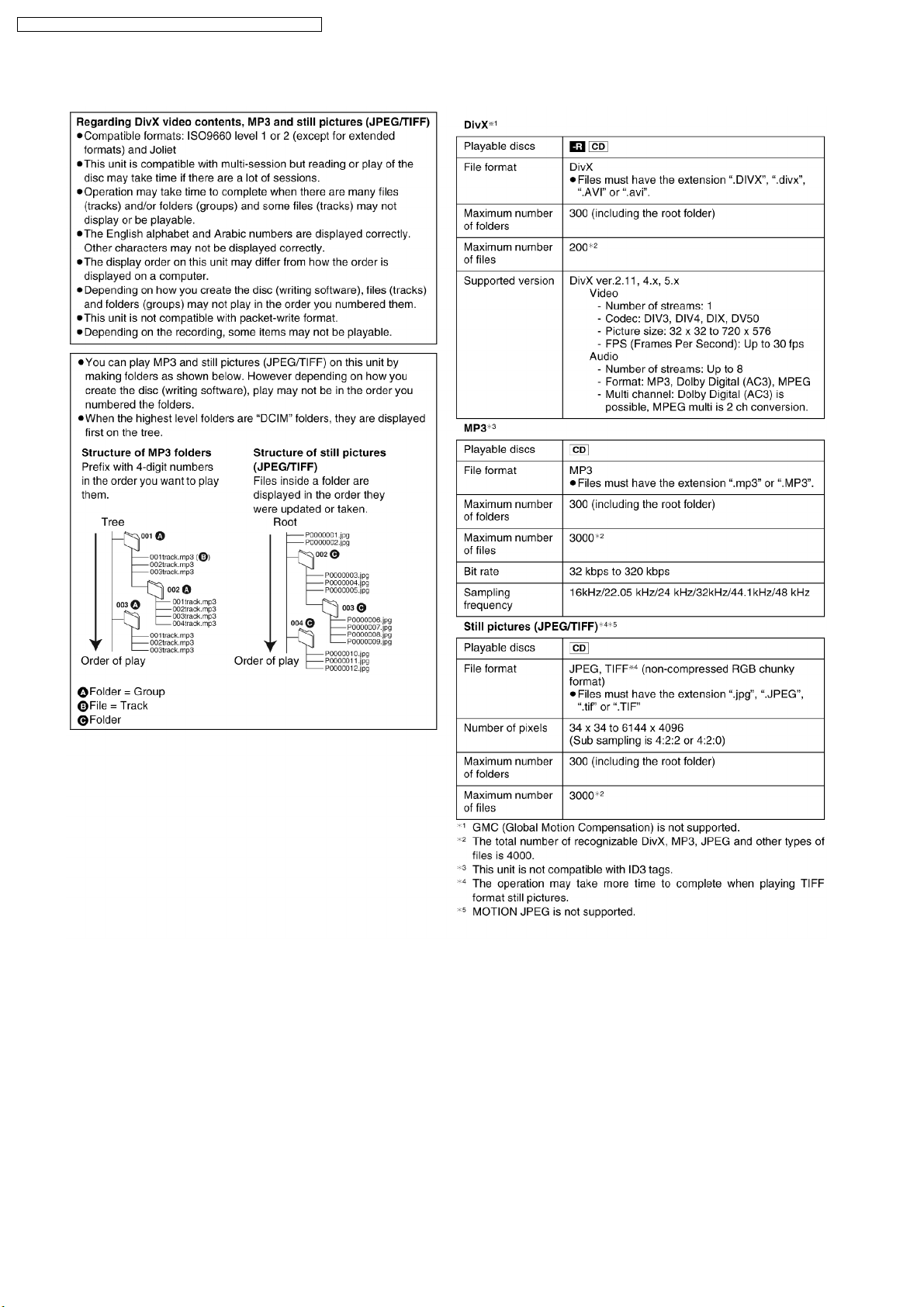

8.5.3. Data playable format (DivX, MP3, JPEG, TIFF)

24

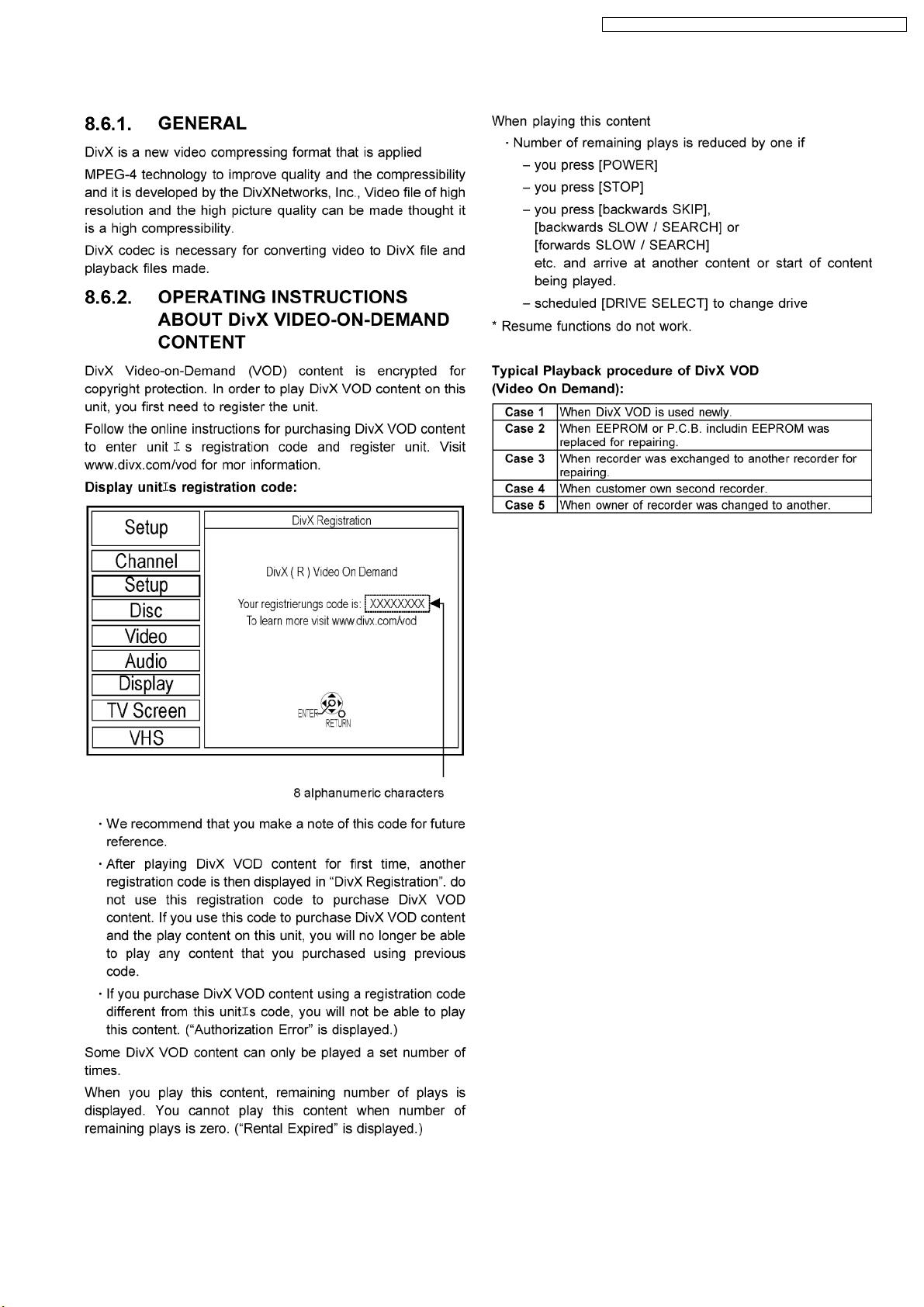

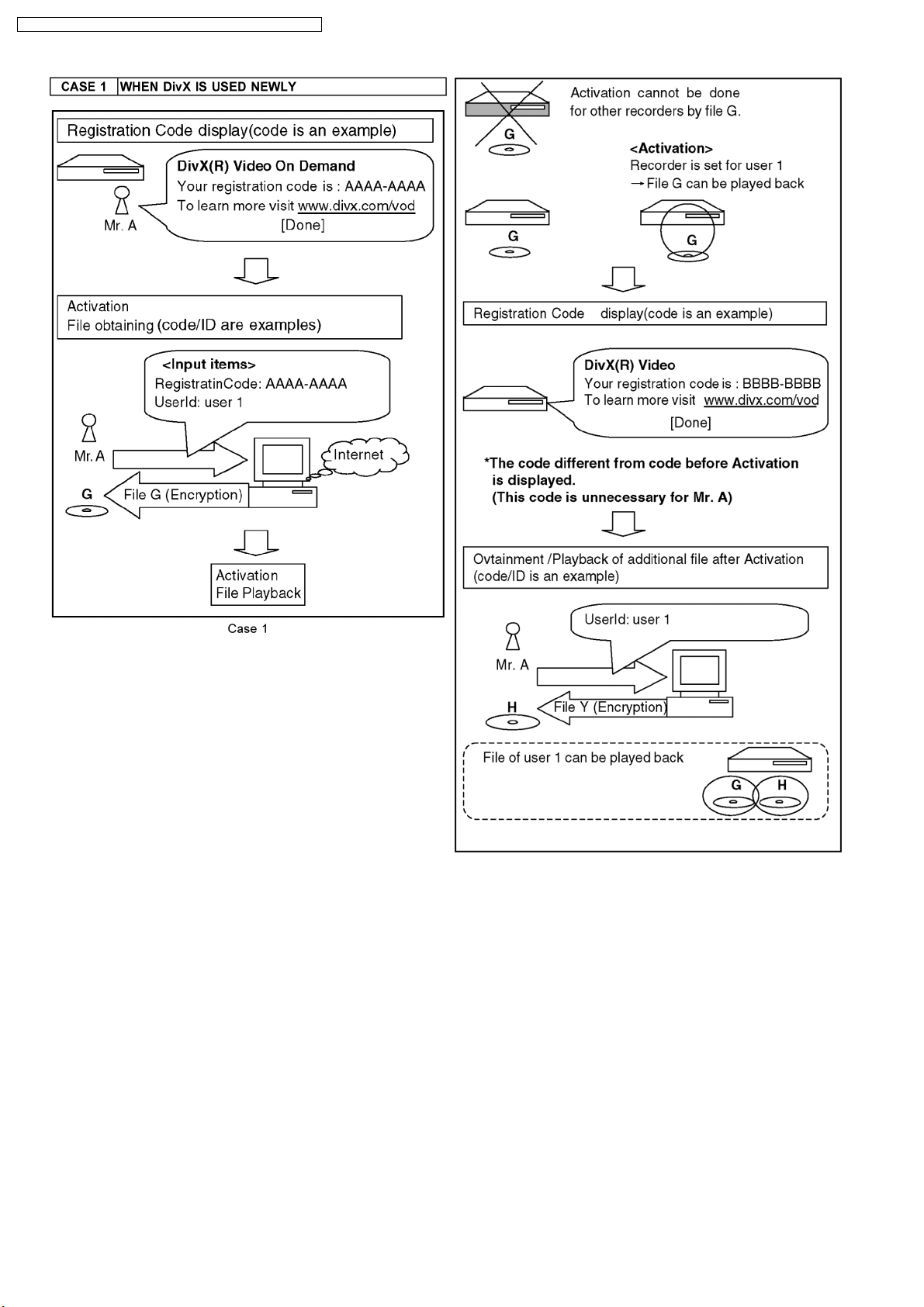

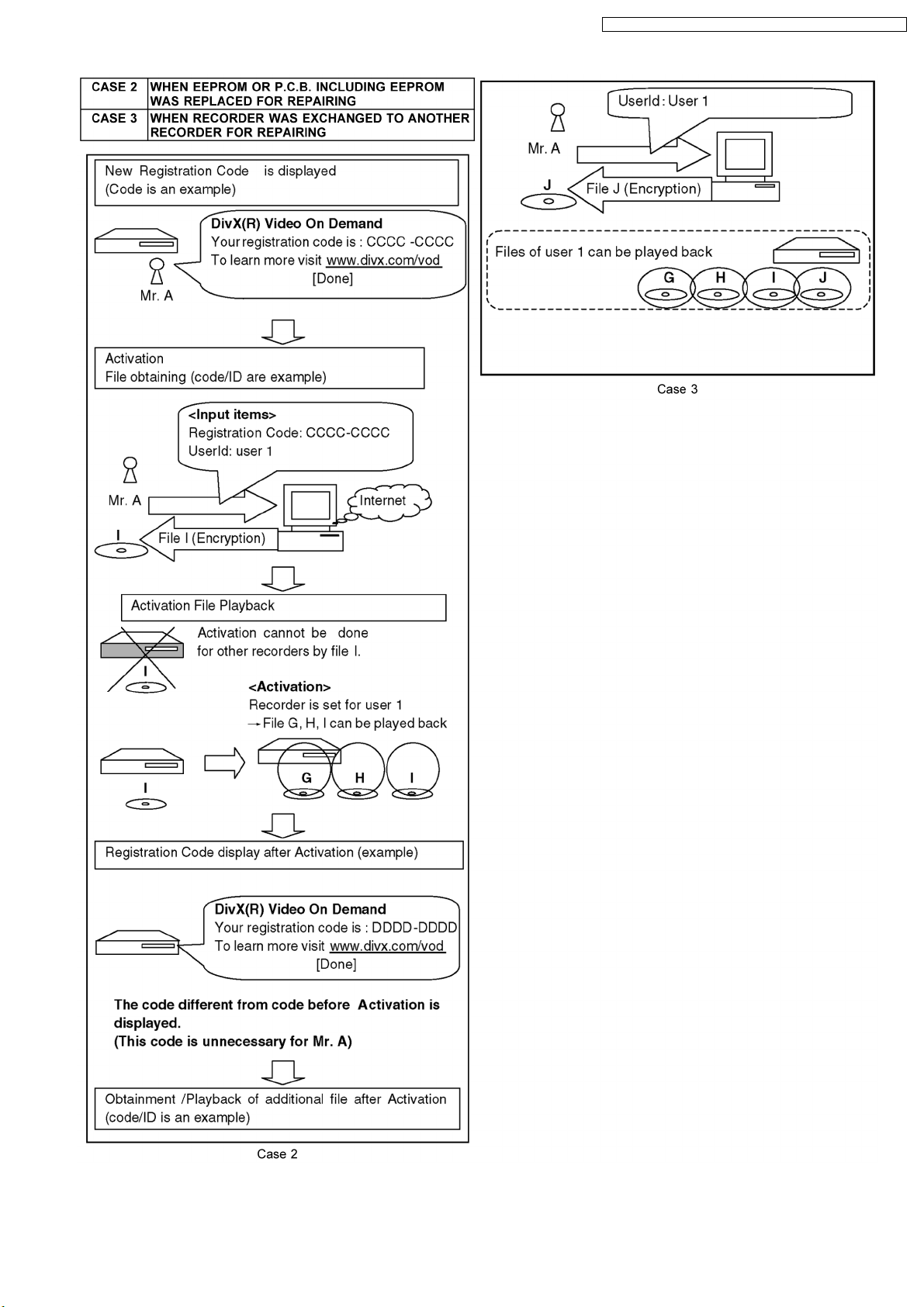

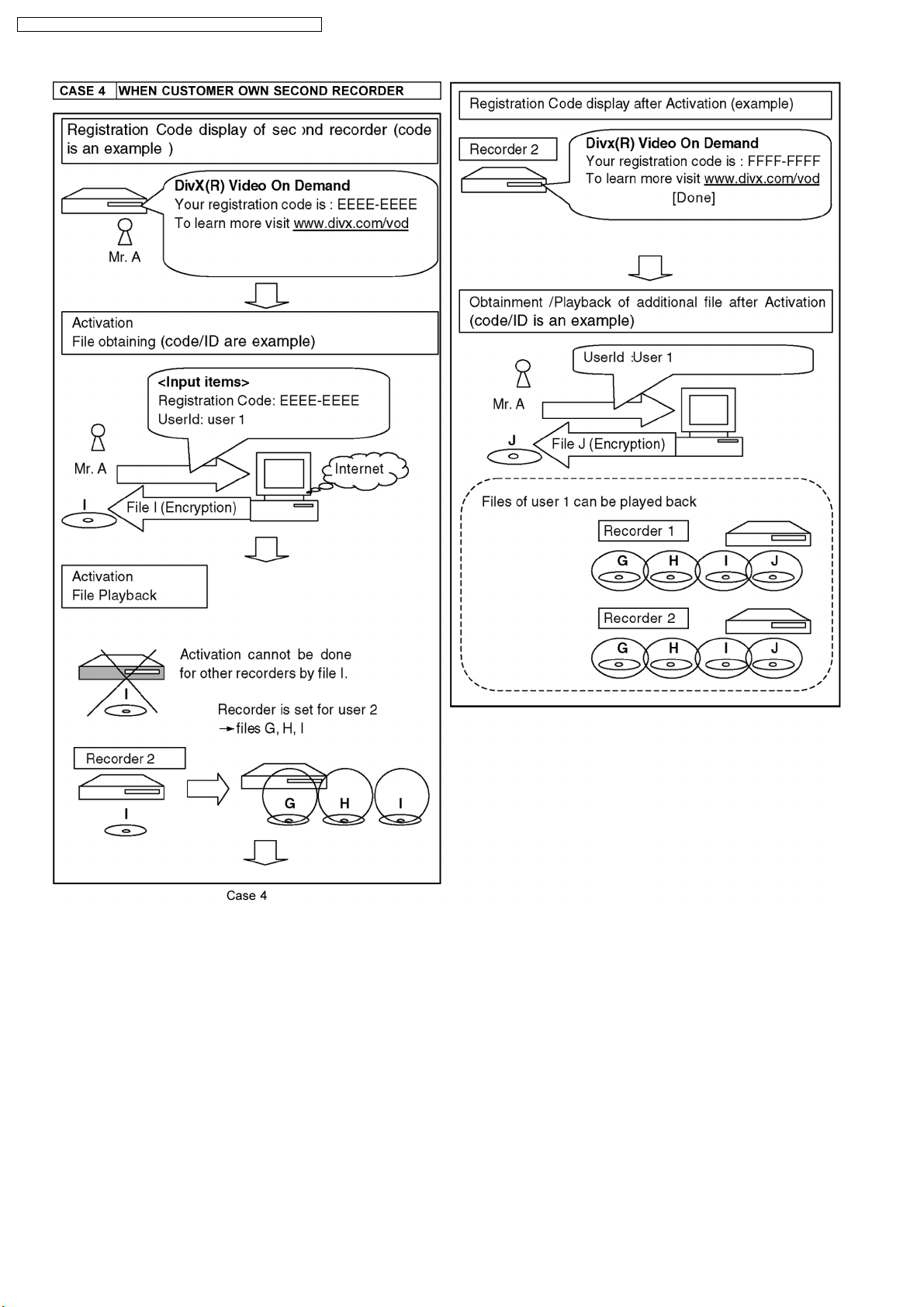

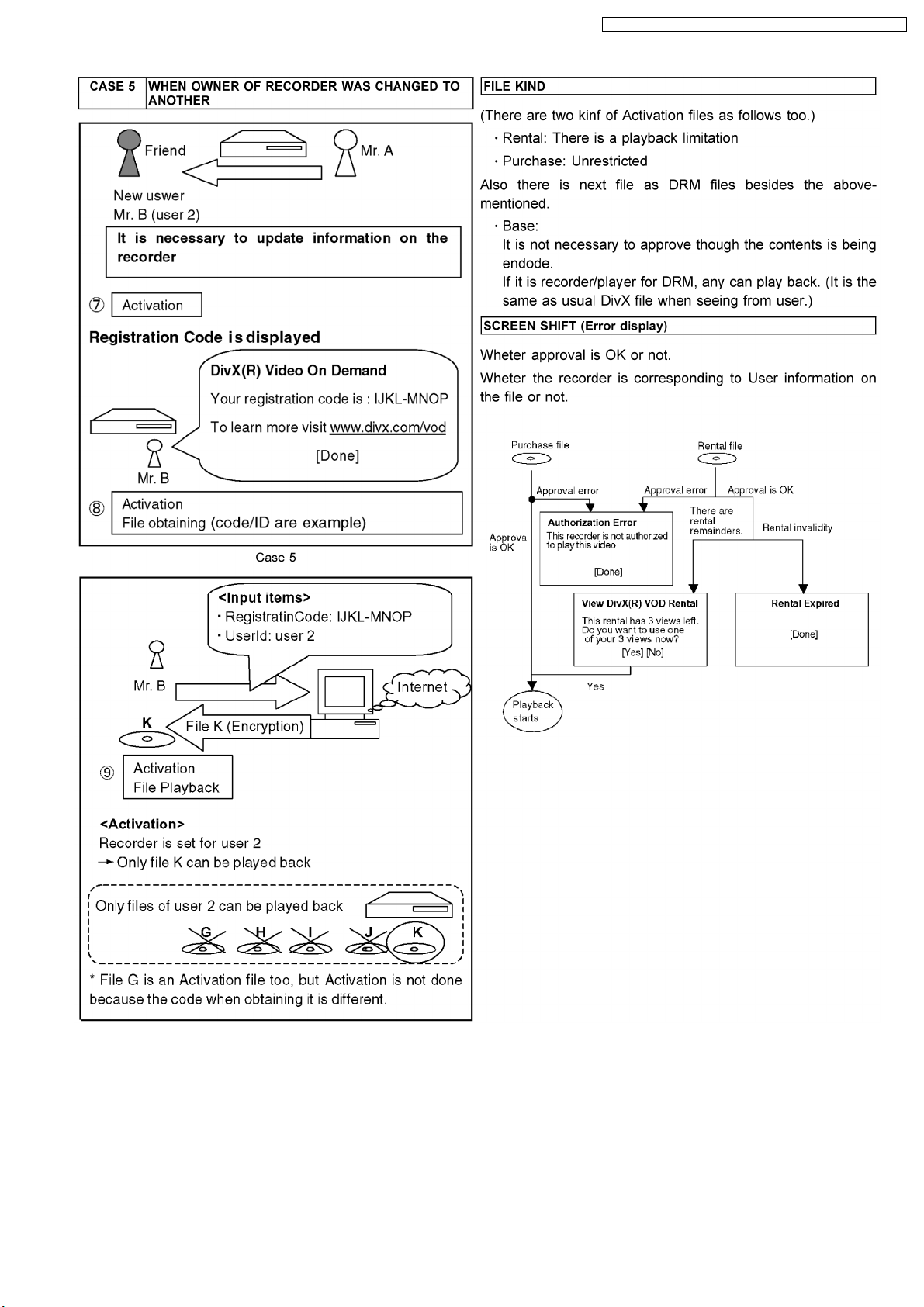

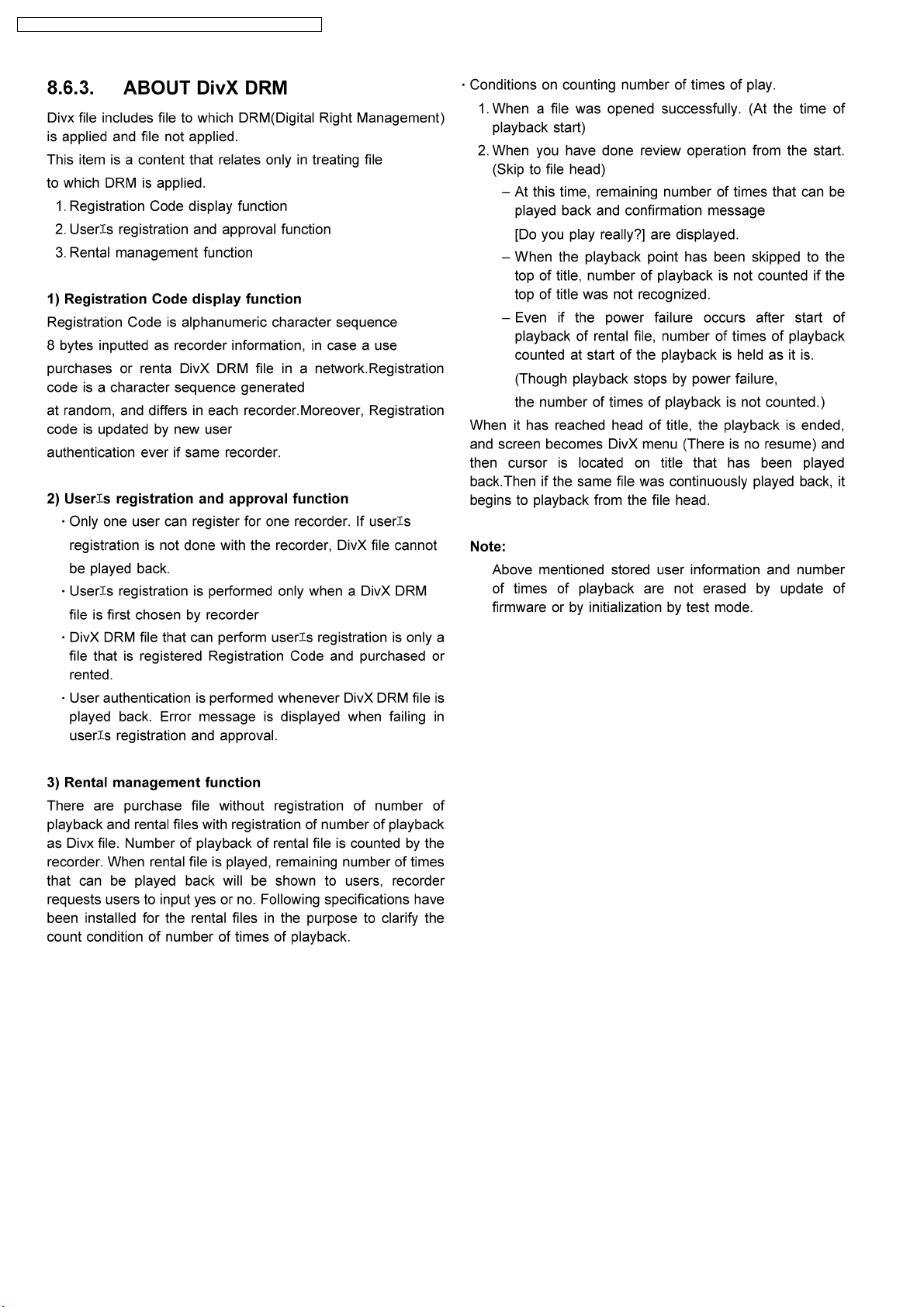

8.6. ABOUT DivX

DMR-ES35VGN / DMR-ES35VGC / DMR-ES35 VGCS / DMR-ES35 VEE

25

DMR-ES35VGN / DMR-ES35VGC / DMR-ES35 VGCS / DMR-ES35 VEE

26

DMR-ES35VGN / DMR-ES35VGC / DMR-ES35 VGCS / DMR-ES35 VEE

27

DMR-ES35VGN / DMR-ES35VGC / DMR-ES35 VGCS / DMR-ES35 VEE

28

DMR-ES35VGN / DMR-ES35VGC / DMR-ES35 VGCS / DMR-ES35 VEE

29

DMR-ES35VGN / DMR-ES35VGC / DMR-ES35 VGCS / DMR-ES35 VEE

30

Loading...

Loading...