Panasonic CU-3S28SBH, CU-3S27SBH, CS-MPS24SKH, CU-4S27SBH, CU-2S18SKH Service Manual

...

Order No: PAPAMY1611008CE

T MP

TIMER

S

C

O

O

1

3

CHEC

K

AUTO

FAN

SPEED

COOL

AIR

DRY

SWING

OFF

TIMERONTIMER

OFF/ON

OFF/ON

MODE

TEMP

TIMER

N

123

FF

SETCHECK CLOCK RESET

FANSPEED

AIRSWING

SET

ET

CANCELONOFF

ANCEL

AC RC

CS-MPS9SKH

CS-MPS12SKH

CS-MPS15SKH

CS-MPS18SKH

CS-MPS24SKH

CS-MPS28SKH

Destination

Indoor Unit

Brunei

Cambodia

Indonesia

Myanmar

Thailand

Vietnam

Please file and use this manual together with the service manual for Model No. CU-2S18SKH CU-3S27SBH CU-3S28SBH

CU-4S27SBH CU-4S34SBH, Order No. PAPAMY1611007CE.

WARNING

This service information is designed for experienced repair technicians only and is not designed for use by the general public.

It does not contain warnings or cautions to advise non-technical individuals of potential dangers in attempting to service a product.

Products powered by electricity should be serviced or repaired only by experienced professional technicians. Any attempt to service or

repair the products dealt with in this service information by anyone else could result in serious injury or death.

IMPORTANT SAFETY NOTICE

There are special components used in this equipment which are important for safety. These parts are marked by in the Schematic

Diagrams, Circuit Board Diagrams, Exploded Views and Replacement Parts List. It is essential that these critical parts should be replaced

with manufacturer’s specified parts to prevent shock, fire or other hazards. Do not modify the original design without permission of

manufacturer.

PRECAUTION OF LOW TEMPERATURE

In order to avoid frostbite, be assured of no refrigerant leakage during the installation or repairing of refrigerant circuit.

© Panasonic Corporation 2016

!

TABLE OF CONTENTS

PAGE

1. Safety Precautions ............................................. 3

2. Specification ....................................................... 5

3. Location of Controls and Components .......... 22

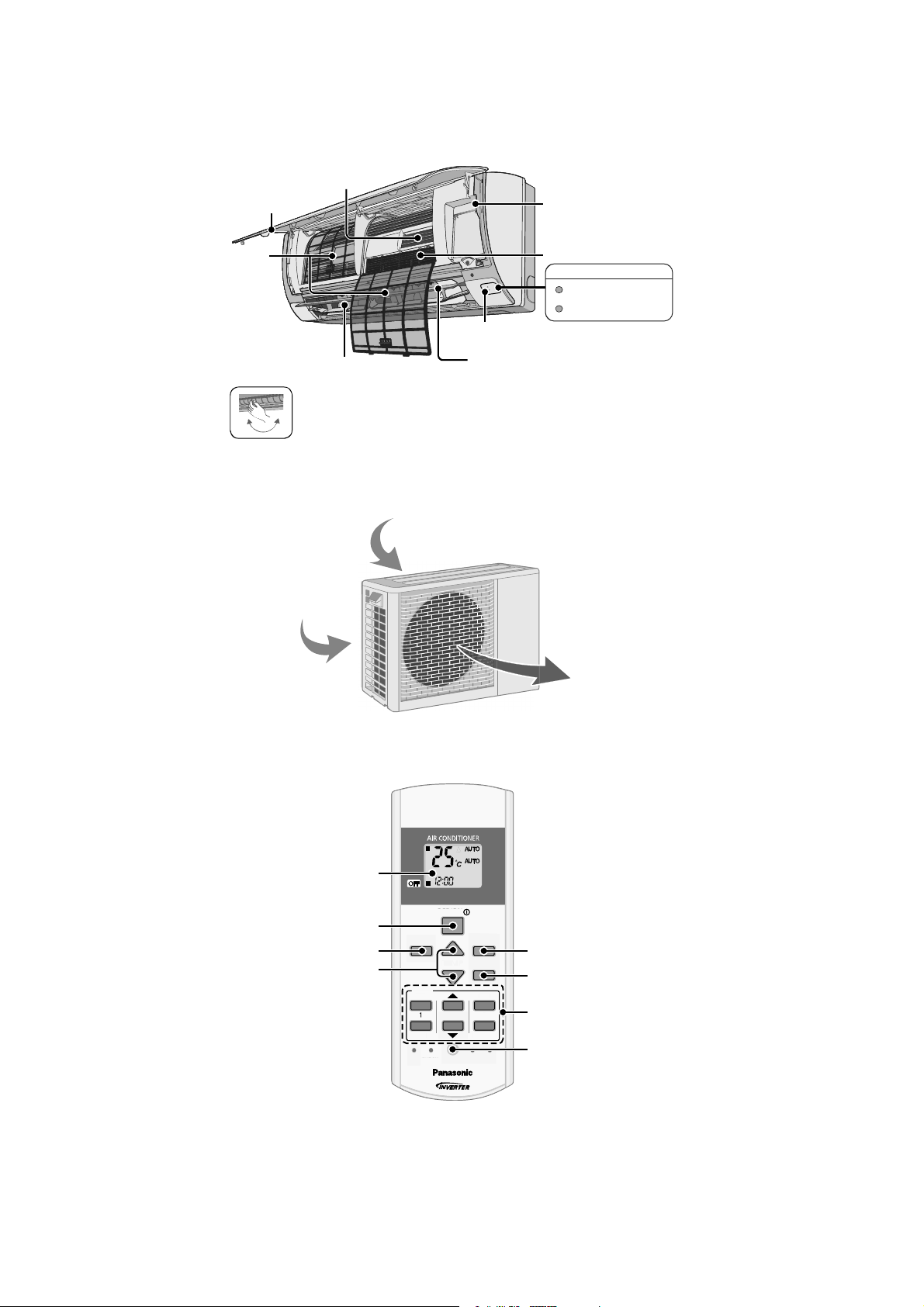

3.1 Indoor Unit .................................................. 22

3.2 Outdoor Unit ............................................... 22

3.3 Remote Control .......................................... 22

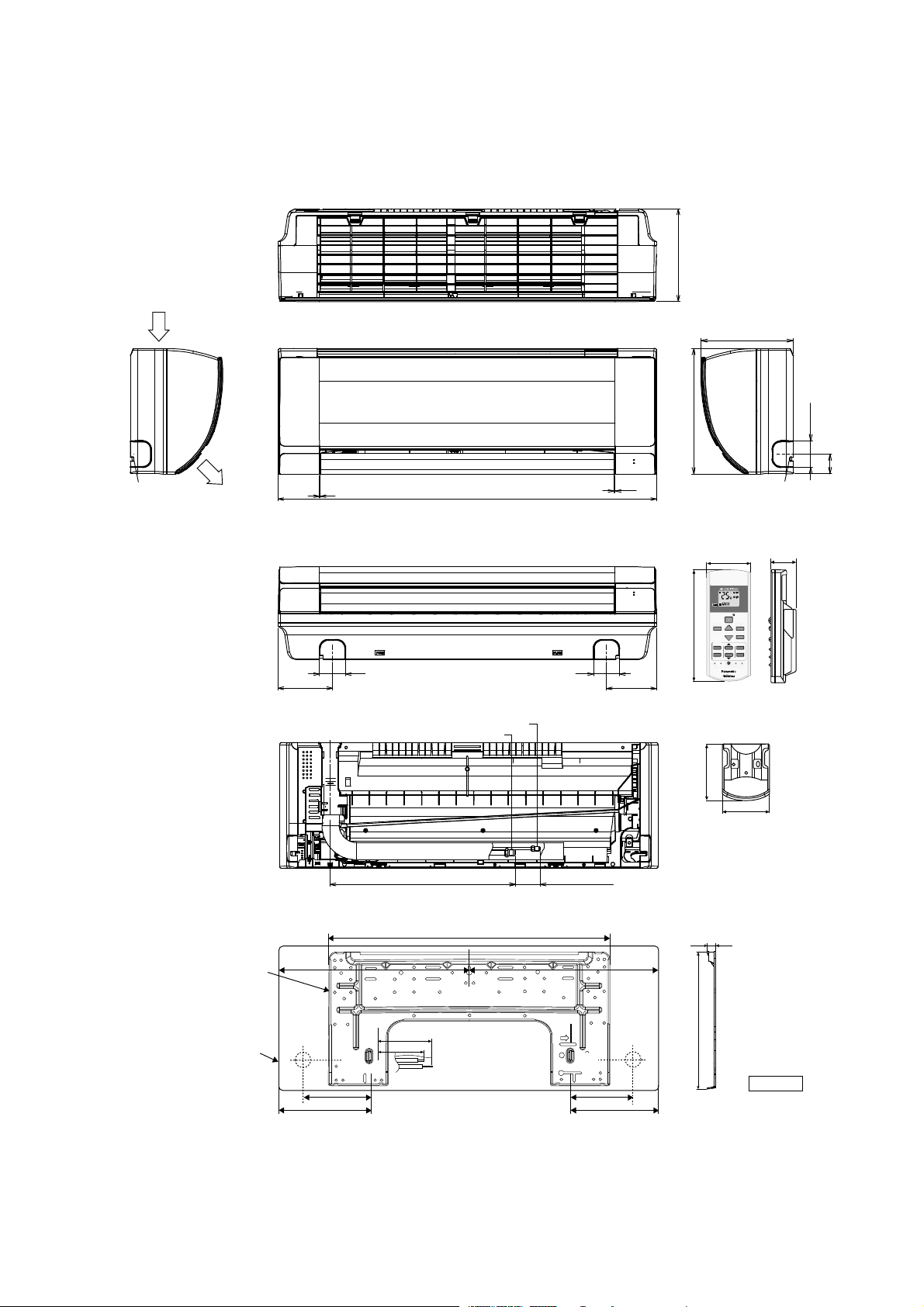

4. Dimensions ....................................................... 23

4.1 Indoor Unit .................................................. 23

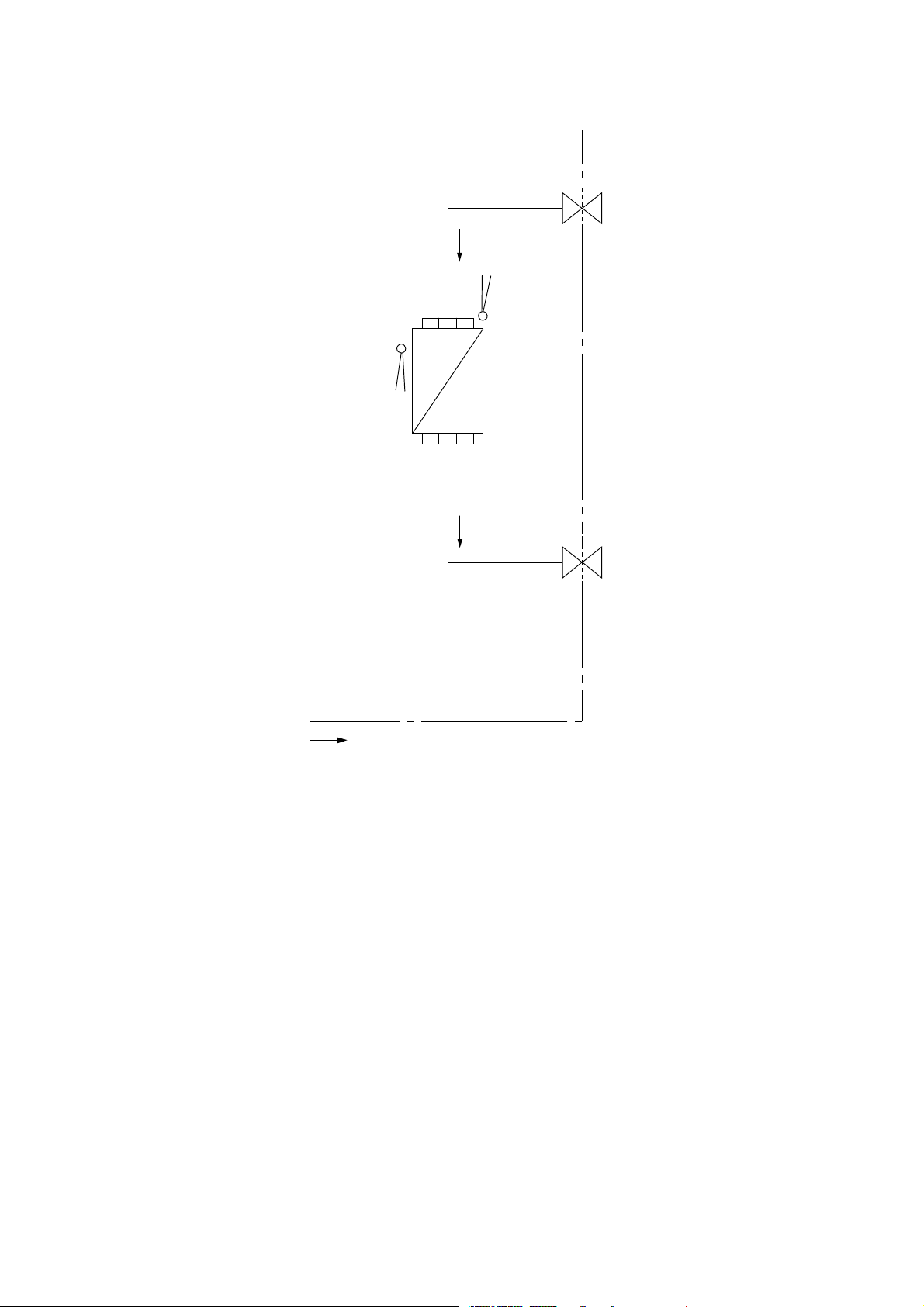

5. Refrigeration Cycle Diagram ........................... 25

6. Block Diagram .................................................. 26

6.1 CS-MPS9SKH CS-MPS12SKH

CS-MPS15SKH .......................................... 26

6.2 CS-MPS18SKH CS-MPS24SKH

CS-MPS28SKH .......................................... 26

7. Wiring Connection Diagram ............................ 27

7.1 Indoor Unit .................................................. 27

8. Electronic Circuit Diagram .............................. 29

8.1 Indoor Unit .................................................. 29

9. Printed Circuit Board ....................................... 31

9.1 Indoor Unit .................................................. 31

10. Installation Instruction ..................................... 33

10.1 Select the Best Location ............................. 33

10.2 Indoor Unit .................................................. 34

11. Operation Control ............................................. 38

11.1 Basic Function ............................................ 38

11.2 Indoor Fan Motor Operation ....................... 39

11.3 Airflow Direction .......................................... 39

11.4 Timer Control .............................................. 40

11.5 Random Auto Restart Control .................... 40

11.6 Indication Panel .......................................... 40

12. Servicing Mode ................................................. 41

12.1 Auto Off/On Button ..................................... 41

12.2 Remote Control Button ............................... 42

13. Troubleshooting Guide .................................... 43

13.1 Refrigeration Cycle System ........................ 43

13.2 Breakdown Self Diagnosis Function ........... 45

13.3 Error Code Table ........................................ 46

13.4 Troubleshooting Flowchart ......................... 48

14. Disassembly and Assembly Instructions ...... 74

14.1 CS-MPS9SKH CS-MPS12SKH

CS-MPS15SKH .......................................... 74

14.2 CS-MPS18SKH CS-MPS24SKH

CS-MPS28SKH .......................................... 78

15. Exploded View and Replacement Parts

List ..................................................................... 81

15.1 Indoor Unit .................................................. 81

2

1. Safety Precautions

Read the following “SAFETY PRECAUTIONS” carefully before perform any servicing.

Electrical work must be installed or serviced by a licensed electrician. Be sure to use the correct rating of the

power plug and main circuit for the model installed.

The caution items stated here must be followed because these important contents are related to safety. The

meaning of each indication used is as below. Incorrect installation or servicing due to ignoring of the instruction

will cause harm or damage, and the seriousness is classified by the following indications.

WARNING

CAUTION

The items to be followed are classified by the symbols:

Carry out test run to confirm that no abnormality occurs after the servicing. Then, explain to user the operation,

care and maintenance as stated in instructions. Please remind the customer to keep the operating instructions for

future reference.

1. Do not modify the machine, part, material during repairing service.

2. If wiring unit is supplied as repairing part, do not repair or connect the wire even only partial wire break. Exchange the whole wiring unit.

This indication shows the possibility of causing death or serious injury.

This indication shows the possibility of causing injury or damage to properties.

This symbol denotes item that is PROHIBITED from doing.

WARNING

3. Do not wrench the fasten terminal. Pull it out or insert it straightly.

4. Engage dealer or specialist for installation and servicing. If installation of servicing done by the user is defective, it will cause water leakage,

electrical shock or fire.

5. Install according to this installation instructions strictly. If installation is defective, it will cause water leakage, electric shock or fire.

6. Use the attached accessories parts and specified parts for installation and servicing. Otherwise, it will cause the set to fall, water leakage, fire

or electrical shock.

7. Install at a strong and firm location which is able to withstand the set’s weight. If the strength is not enough or installation is not properly done,

the set will drop and cause injury.

8. For electrical work, follow the local national wiring standard, regulation and the installation instruction. An independent circuit and single outlet

must be used. If electrical circuit capacity is not enough or defect found in electrical work, it will cause electrical shock or fire.

9. This equipment is strongly recommended to install with Earth Leakage Circuit Breaker (ELCB) or Residual Current Device (RCD). Otherwise, it

may cause electrical shock and fire in case equipment breakdown or insulation breakdown.

10. Do not use joint cable for indoor / outdoor connection cable. Use the specified indoor / outdoor connection cable, refer to installation instruction

CONNECT THE CABLE TO THE INDOOR UNIT and connect tightly for indoor / outdoor connection. Clamp the cable so that no external force

will be acted on the terminal. If connecting or fixing is not perfect, it will cause heat up or fire at the connection.

11. Wire routing must be properly arranged so that control board cover is fixed properly. If control board cover is not fixed perfectly, it will cause

heat-up or fire at the connection point of terminal, fire or electrical shock.

12. When install or relocate air conditioner, do not let any substance other than the specified refrigerant, eg.air etc. mix into refrigeration cycle

(piping). (Mixing of air etc. will cause abnormal high pressure in refrigeration cycle and result in explosion, injury etc.).

13. Do not install outdoor unit near handrail of veranda. When installing air-conditioner unit at veranda of high rise building, child may

climb up to outdoor unit and cross over the handrail and causing accident.

14. This equipment must be properly earthed. Earth line must not be connected to gas pipe, water pipe, earth of lightning rod and

telephone. Otherwise, it may cause electric shock in case equipment breakdown or insulation breakdown.

15. Keep away from small children, the thin film may cling to nose and mouth and prevent breathing.

16. Do not use unspecified cord, modified cord, joint cord or extension cord for power supply cord. Do not share the single outlet with

other electrical appliances. Poor contact, poor insulation or over current will cause electrical shock or fire.

17. Tighten the flare nut with torque wrench according to specified method. If the flare nut is over-tightened, after a long period, the flare may

break and cause refrigerant gas leakage.

18. For R410A model, use piping, flare nut and tools which is specified for R410A refrigerant. Using of existing (R22) piping, flare nut

and tools may cause abnormally high pressure in the refrigerant cycle (piping), and possibly result in explosion and injury.

Thickness or copper pipes used with R410A must be more than 0.6 mm. Never use copper pipes thinner than 0.6 mm.

It is desirable that the amount of residual oil less than 40 mg/10 m.

19. During installation, before run the compressor, confirm the refrigerant pipes are fixed. Operation of compressor without fixing the piping,

setting the valves at open condition, a burst may occur and cause injury.

3

WARNING

20. During pump down operation, stop the compressor before remove the refrigerant piping. (Removal of refrigeration piping while compressor is

operating and valves are opened condition will cause suck-in of air, abnormal high pressure in refrigeration cycle and result in explosion,

injury etc.)

21. After completion of installation or service, confirm there is no leakage or refrigerant gas. It may generate toxic gas when the refrigerant

contacts with fire.

22. Ventilate if there is refrigerant gas leakage during operation. It may cause toxic gas when refrigerant contacts with fire.

23. Do not insert your fingers or other objects into the unit, high speed rotating fan may cause injury.

24. Must not use other parts except original parts describe in catalog and manual.

25. Using of refrigerant other than the specified type may cause product damage, burst and injury etc.

CAUTION

1. Do not install the unit at place where leakage of flammable gas may occur. In case gas leaks and accumulates at surrounding of the

unit, it may cause fire.

2. Carry out drainage piping as mentioned in installation instructions. If drainage is not perfect, water may enter the room and damage

the furniture.

3. Tighten the flare nut with torque wrench according to specified method. If the flare nut is over-tightened, after a long period, the flare

may break and cause refrigerant gas leakage.

4. Do not touch outdoor unit air inlet and aluminium fin. It may cause injury.

5. Select an installation location which is easy for maintenance.

6. Pb free solder has a higher melting point than standard solder; typically the melting point is 50°F – 70°F (30°C – 40°C) higher. Please use

a high temperature solder iron. In case of the soldering iron with temperature control, please set it to 700 ± 20°F (370 ± 10°C).

Pb free solder will tend to splash when heated too high (about 1100°F / 600°C).

7. Do not release refrigerant during piping work for installation, servicing, reinstallation and during repairing a refrigerant parts. Take

care of the liquid refrigerant, it may cause frostbite.

8. Installation or servicing work: It may need two people to carry out the installation or servicing work.

9. Do not install this appliance in a laundry room or other location where water may drip from the ceiling, etc.

10. Do not sit or step on the unit, you may fall down accidentally.

11. Do not touch the sharp aluminum fins or edges of metal parts.

If you are required to handle sharp parts during installation or servicing, please wear hand glove.

Sharp parts may cause injury

4

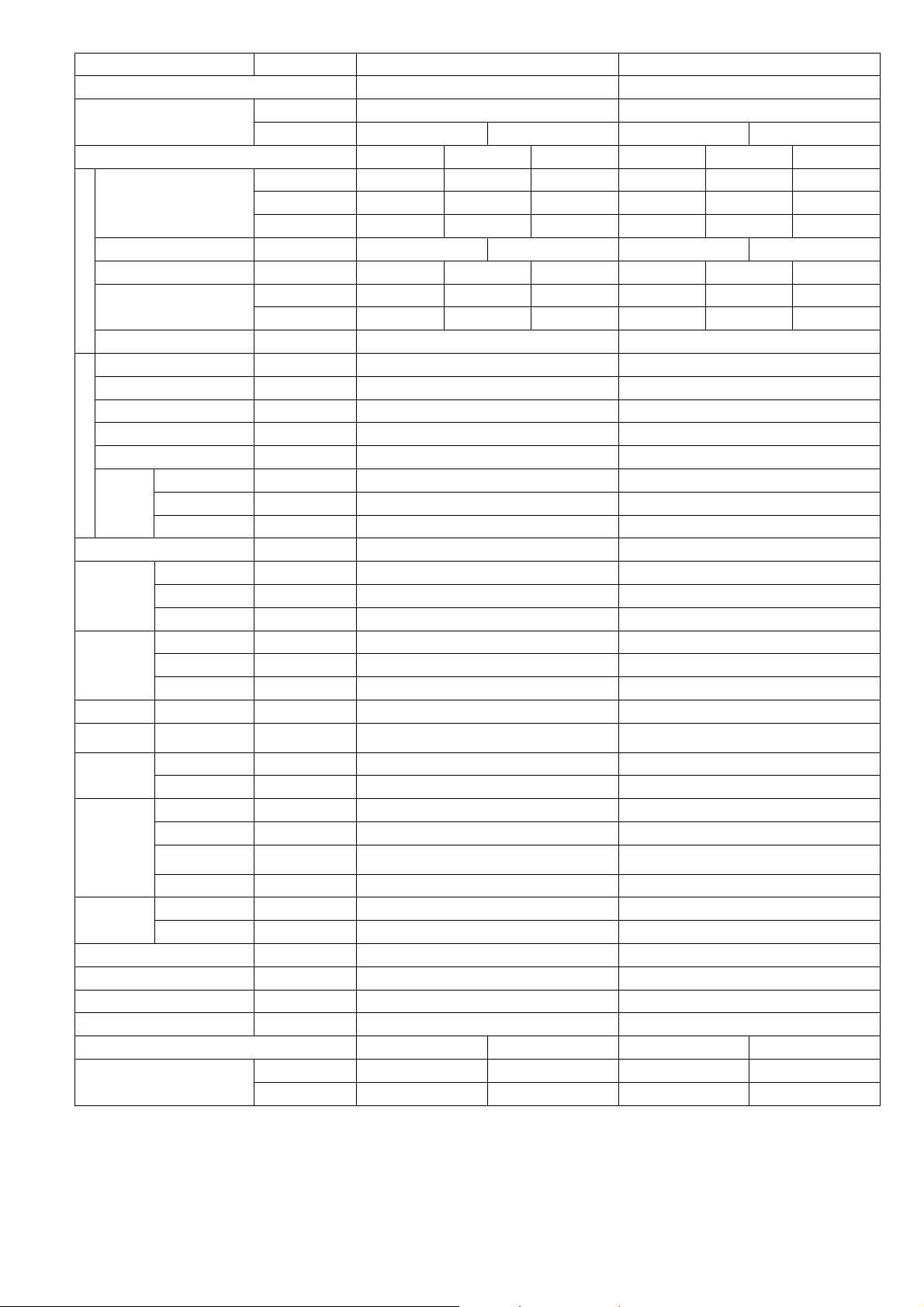

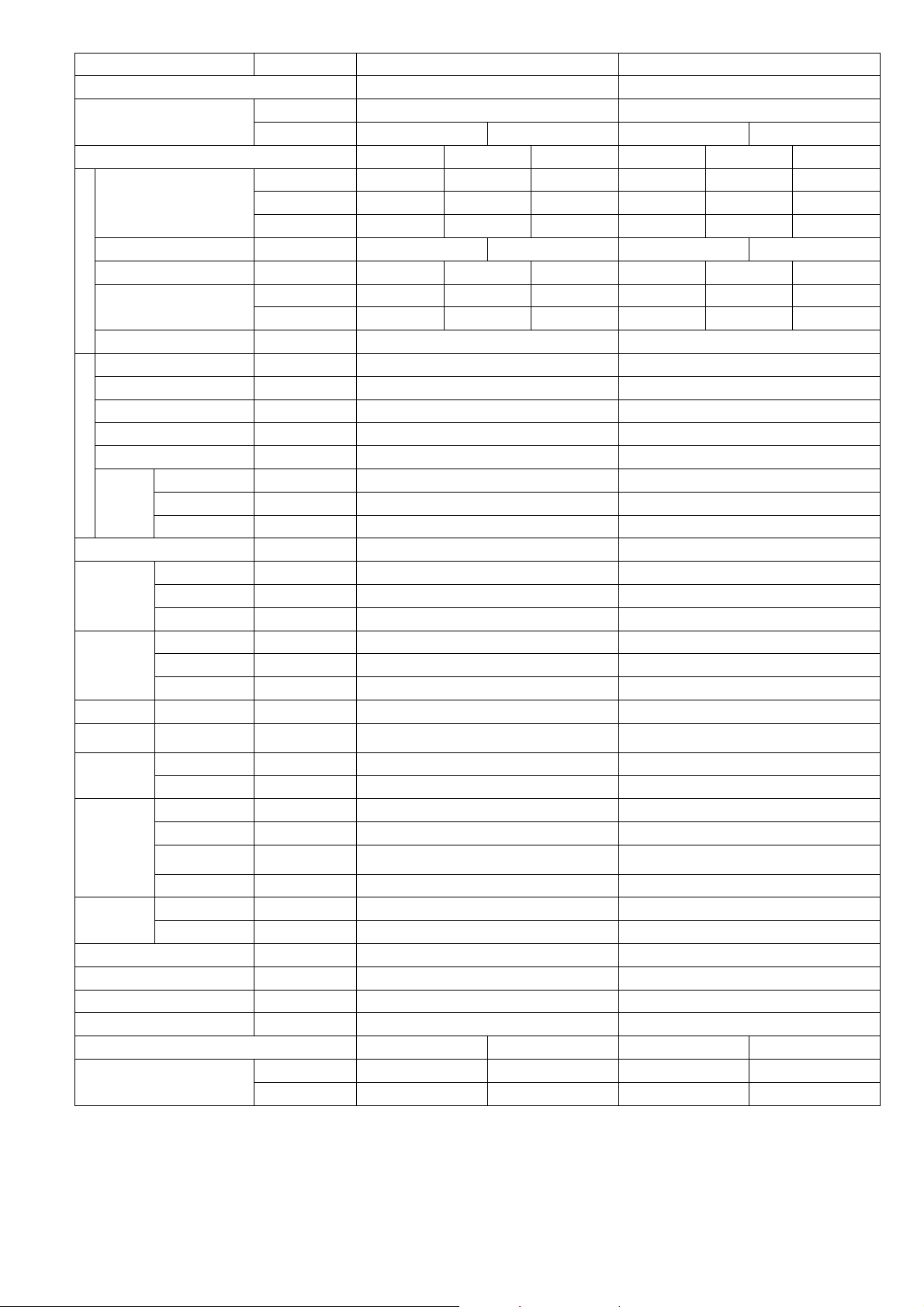

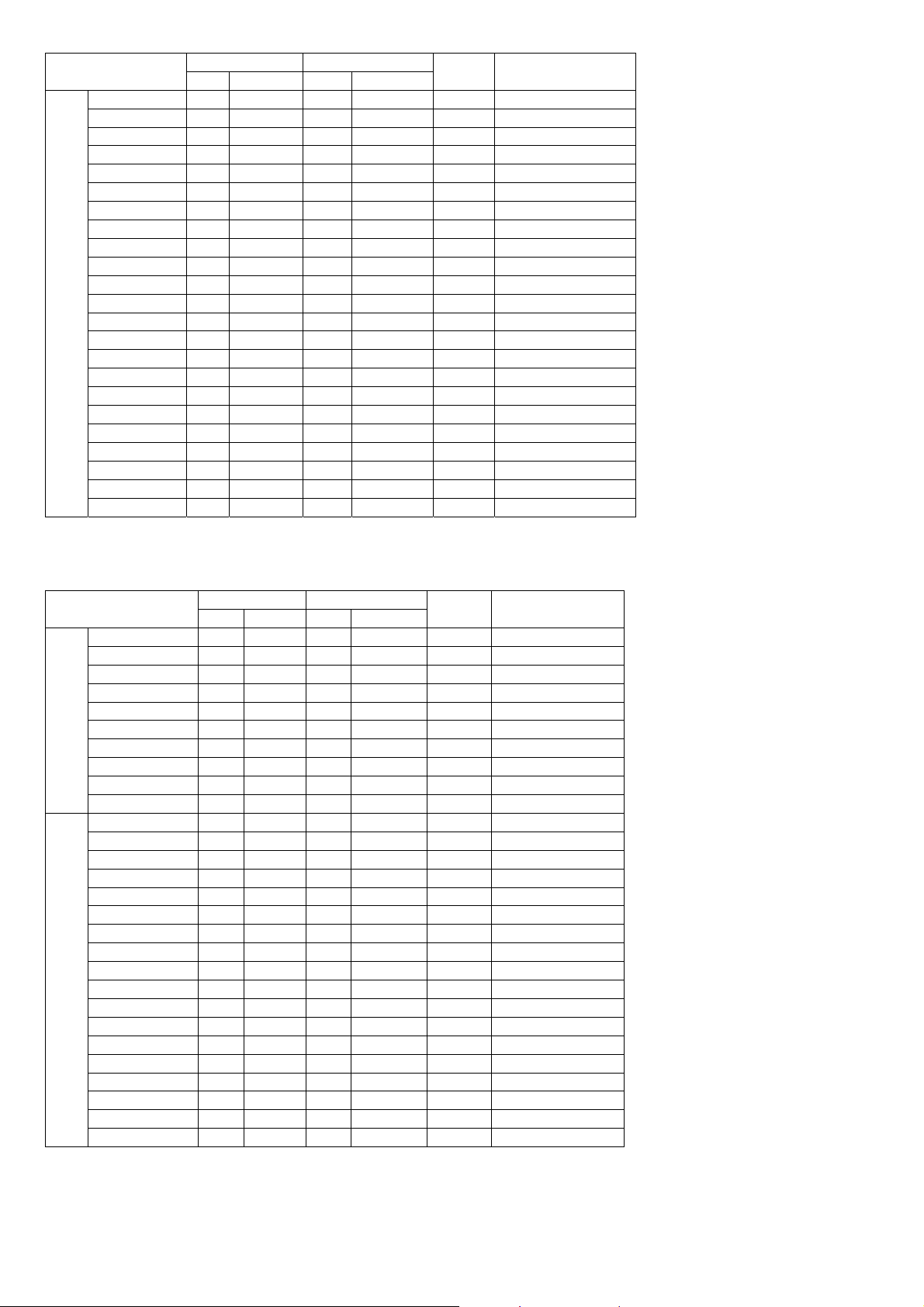

2. Specification

Model Indoor/Outdoor CS-MPS9SKH / CU-2S18SKH CS-MPS12SKH / CU-2S18SKH

Performance Test Condition JIS JIS

Power Supply

Min. Mid. Max. Min. Mid. Max.

Capacity

Running Current A 3.65 3.40 4.50 4.20

Cooling

Indoor Fan

Indoor Airflow

Dimension

Drain Hose

Indoor Heat

Exchanger

Air Filter

Input Power W 220 750 1.00k 220 920 1.22k

EER

Indoor Noise (H / L / QLo) dB-A 40 / 29 / - 44 / 32 / -

Type Cross-flow fan Cross-flow fan

Material ASG20K1 ASG20K1

Motor Type AC / Induction (4 poles) AC / Induction (4 poles)

Input Power W 51 - 58 51 - 58

Output Power W 24 24

Lo rpm 680 720

Speed

Moisture Removal L/h 1.6 1.8

Weight Net (I/D) kg (lb) 9 (20) 9 (20)

Piping

Power Supply Outdoor Outdoor

Power Supply Cord A - -

Thermostat - -

Protection Device - -

Indoor Operation Range

Me rpm 840 890

Hi rpm 1000 1060

Lo m

Me m3/min (ft3/m) 8.26 (292) 8.92 (315)

Hi m3/min (ft3/m) 10.10 (355) 10.90 (385)

Height (I/D) mm (inch) 290 (11-7/16) 290 (11-7/16)

Width (I/D) mm (inch) 870 (34-9/32) 870 (34-9/32)

Depth (I/D) mm (inch) 214 (8-7/16) 214 (8-7/16)

Pipe Diameter

(Liquid / Gas)

Inner Diameter mm 16.2 16.2

Length mm 550 550

Fin Material Aluminium (Pre coated) Aluminium (Pre coated)

Fin Type Slit Fin Slit Fin

Row x Stage x

FPI

Size (W x H x L) mm 610 x 315 x 25.4 610 x 315 x 25.4

Material Polypropelene Polypropelene

Type One-touch One-touch

DRY BULB WET BULB DRY BULB WET BULB

1. Cooling capacities are based on indoor temperature of 27°C DRY BULB (80.6°F DRY BULB), 19.0°C WET BULB (66°F WET BULB) and

outdoor air temperature of 35°C DRY BULB (95°F DRY BULB), 24°C WET BULB (75.2°F WET BULB)

2. Specifications are subject to change without notice for further improvement.

Phase, Hz Single, 50 Single, 50

V 220 240 220 240

kW 1.10 2.80 3.50 1.10 3.20 4.00

BTU/h 3750 9550 11900 3750 10900 13600

kJ/h 3960 10080 12600 3960 11520 14400

W/W 5.00 3.73 3.50 5.00 3.48 3.28

kJ/hW 18.00 13.44 12.60 18.00 12.52 11.80

3

/min (ft3/m) 6.90 (244) 6.95 (245)

mm (inch) 6.35 (1/4) / 9.52 (3/8) 6.35 (1/4) / 9.52 (3/8)

2 x 15 x 17 2 x 15 x 17

Maximum °C 32 23 32 23

Minimum °C 16 11 16 11

5

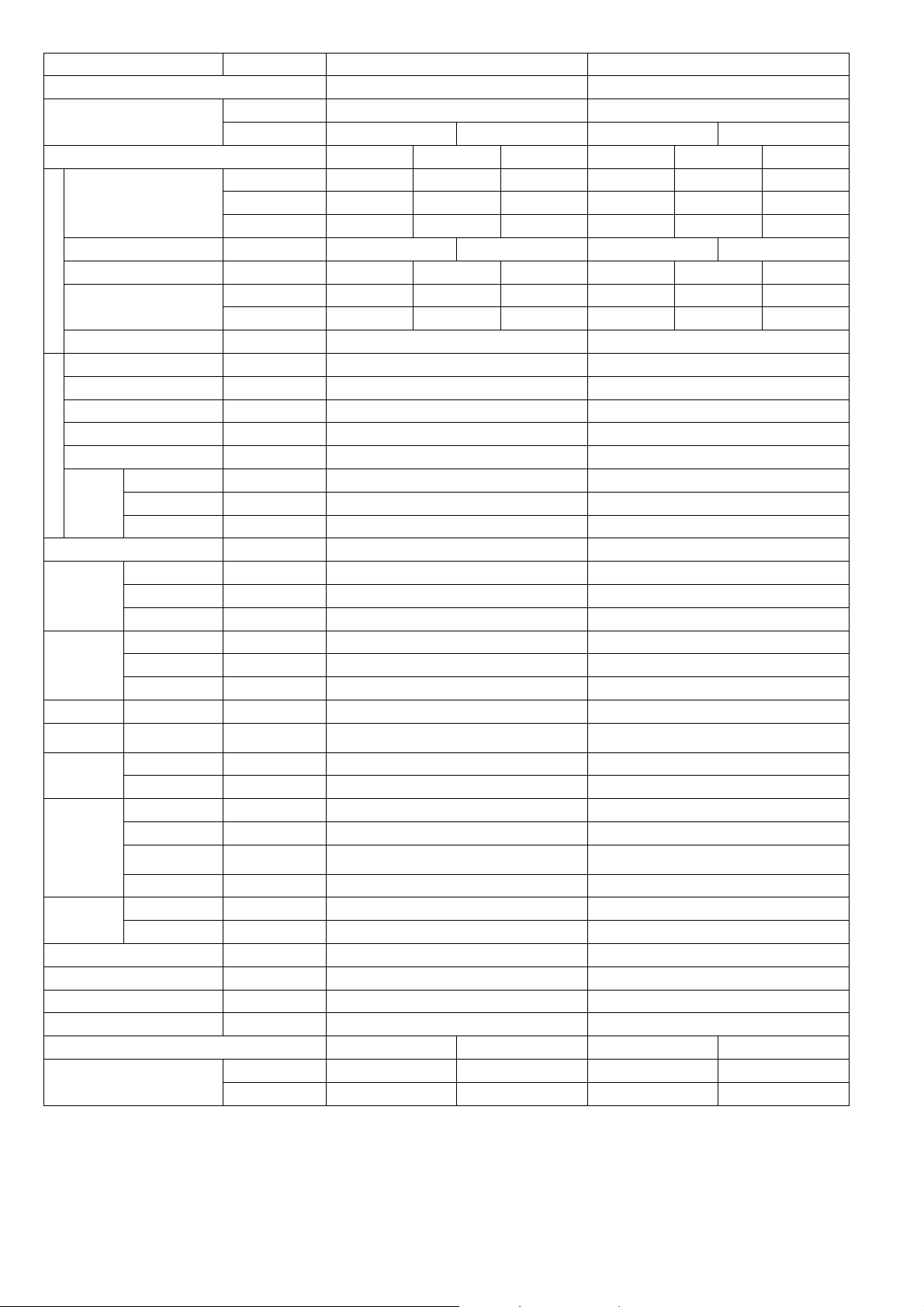

Model Indoor/Outdoor CS-MPS9SKH / CU-3S27SBH CS-MPS12SKH / CU-3S27SBH

Performance Test Condition JIS JIS

Power Supply

Min. Mid. Max. Min. Mid. Max.

Capacity

Running Current A 3.80 3.50 4.30 3.90

Cooling

Indoor Fan

Indoor Airflow

Dimension

Drain Hose

Indoor Heat

Exchanger

Air Filter

Input Power W 380 700 890 380 800 1.20k

EER

Indoor Noise (H / L / QLo) dB-A 40 / 29 / - 44 / 32 / -

Type Cross-flow fan Cross-flow fan

Material ASG20K1 ASG20K1

Motor Type AC / Induction (4 poles) AC / Induction (4 poles)

Input Power W 51 - 58 51 - 58

Output Power W 24 24

Lo rpm 680 720

Speed

Moisture Removal L/h 1.6 1.8

Weight Net (I/D) kg (lb) 9 (20) 9 (20)

Piping

Power Supply Outdoor Outdoor

Power Supply Cord A - -

Thermostat - -

Protection Device - -

Indoor Operation Range

Me rpm 840 890

Hi rpm 1000 1060

Lo m

Me m3/min (ft3/m) 8.26 (292) 8.92 (315)

Hi m3/min (ft3/m) 10.10 (355) 10.90 (385)

Height (I/D) mm (inch) 290 (11-7/16) 290 (11-7/16)

Width (I/D) mm (inch) 870 (34-9/32) 870 (34-9/32)

Depth (I/D) mm (inch) 214 (8-7/16) 214 (8-7/16)

Pipe Diameter

(Liquid / Gas)

Inner Diameter mm 16.2 16.2

Length mm 550 550

Fin Material Aluminium (Pre coated) Aluminium (Pre coated)

Fin Type Slit Fin Slit Fin

Row x Stage x

FPI

Size (W x H x L) mm 610 x 315 x 25.4 610 x 315 x 25.4

Material Polypropelene Polypropelene

Type One-touch One-touch

DRY BULB WET BULB DRY BULB WET BULB

Phase, Hz Single, 50 Single, 50

V 220 240 220 240

kW 1.70 2.80 3.40 1.70 3.20 4.00

BTU/h 5800 9550 11600 5800 10900 13600

kJ/h 6120 10080 12240 6120 11520 14400

W/W 4.47 4.00 3.82 4.47 4.00 3.33

kJ/hW 16.11 14.40 13.75 16.11 14.40 12.00

3

/min (ft3/m) 6.90 (244) 6.95 (245)

mm (inch) 6.35 (1/4) / 9.52 (3/8) 6.35 (1/4) / 9.52 (3/8)

2 x 15 x 17 2 x 15 x 17

Maximum °C 32 23 32 23

Minimum °C 16 11 16 11

1. Cooling capacities are based on indoor temperature of 27°C DRY BULB (80.6°F DRY BULB), 19.0°C WET BULB (66°F WET BULB) and

outdoor air temperature of 35°C DRY BULB (95°F DRY BULB), 24°C WET BULB (75.2°F WET BULB)

2. Specifications are subject to change without notice for further improvement.

6

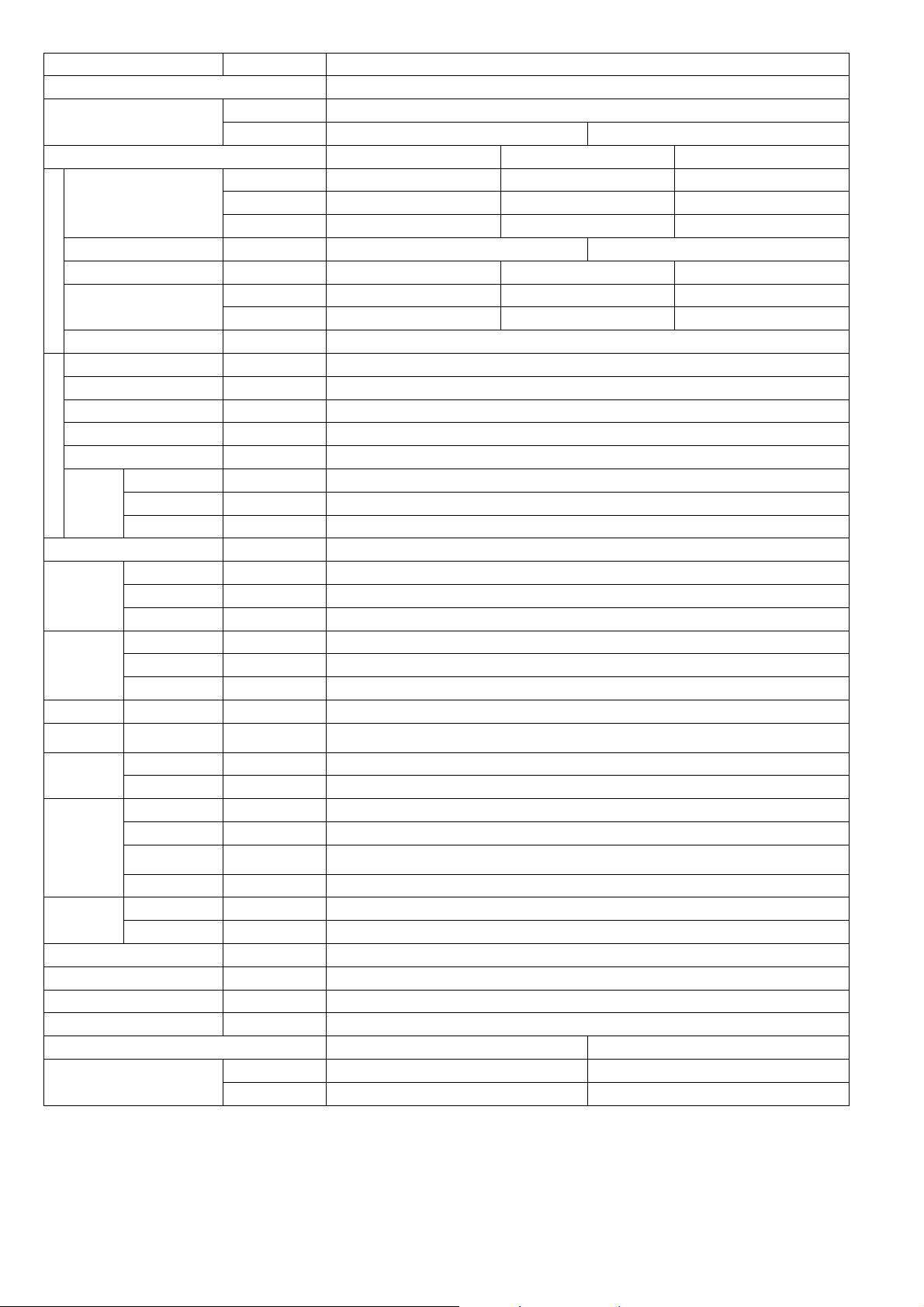

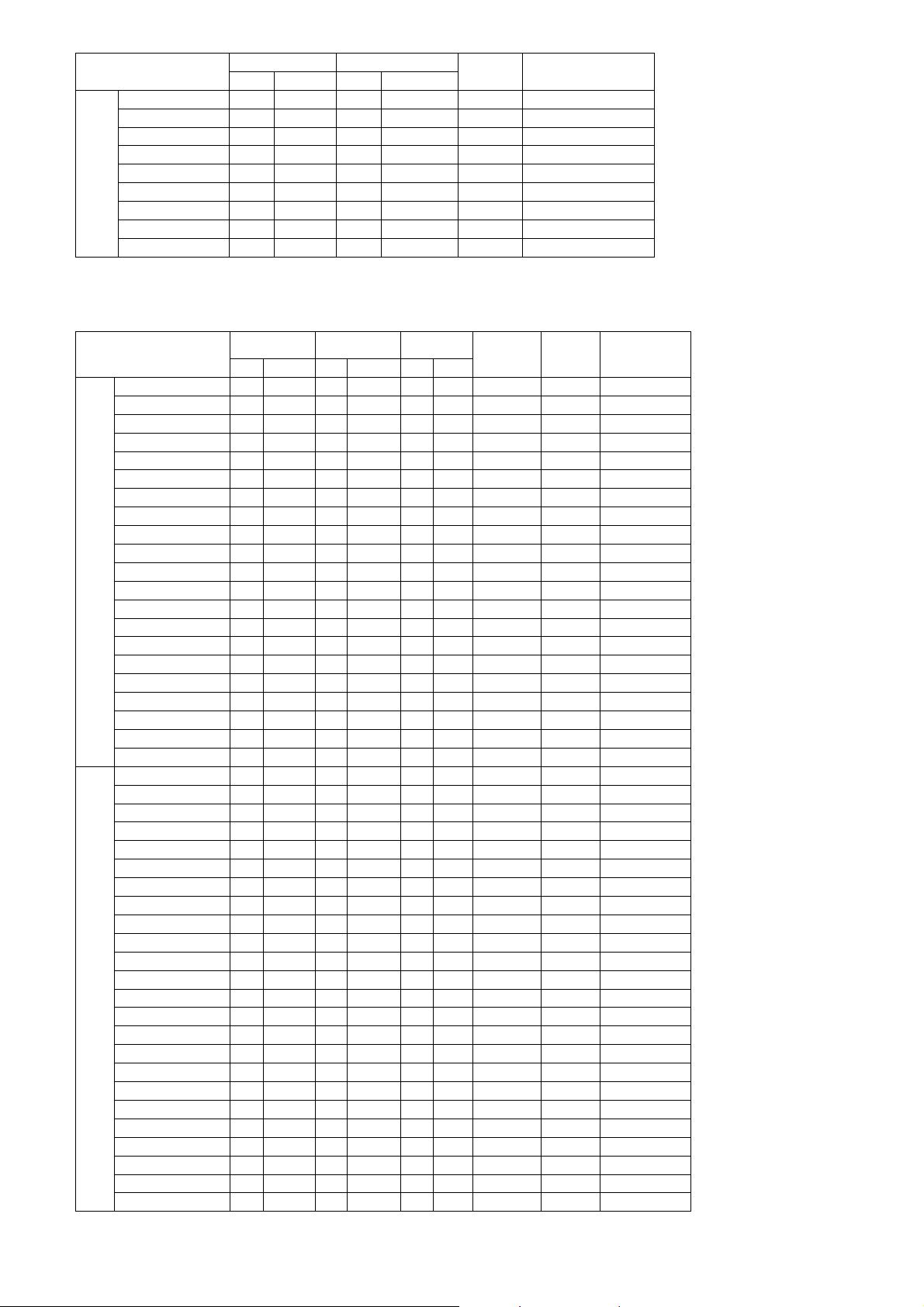

Model Indoor/Outdoor CS-MPS15SKH / CU-3S27SBH CS-MPS18SKH / CU-3S27SBH

Performance Test Condition JIS JIS

Power Supply

Min. Mid. Max. Min. Mid. Max.

Capacity

Running Current A 6.10 5.60 7.40 6.80

Cooling

Indoor Fan

Indoor Airflow

Dimension

Drain Hose

Indoor Heat

Exchanger

Air Filter

Input Power W 380 1.18k 1.48k 400 1.46k 1.89k

EER

Indoor Noise (H / L / QLo) dB-A 45 / 32 / - 47 / 38 / -

Type Cross-flow fan Cross-flow fan

Material ASG20K1 ASG30K1

Motor Type AC / Induction (4 poles) DC / Transistor (8 poles)

Input Power W 51 - 58 94.8

Output Power W 24 40

Lo rpm 720 930

Speed

Moisture Removal L/h 2.3 2.7

Weight Net (I/D) kg (lb) 9 (20) 12 (26)

Piping

Power Supply Outdoor Outdoor

Power Supply Cord A - -

Thermostat - -

Protection Device - -

Indoor Operation Range

Me rpm 900 1120

Hi rpm 1090 1300

Lo m

Me m3/min (ft3/m) 9.00 (318) 14.23 (503)

Hi m3/min (ft3/m) 11.20 (395) 17.08 (603)

Height (I/D) mm (inch) 290 (11-7/16) 290 (11-7/16)

Width (I/D) mm (inch) 870 (34-9/32) 1070 (42-5/32)

Depth (I/D) mm (inch) 214 (8-7/16) 240 (9-15/32)

Pipe Diameter

(Liquid / Gas)

Inner Diameter mm 16.2 16.2

Length mm 550 550

Fin Material Aluminium (Pre coated) Aluminium (Pre coated)

Fin Type Slit Fin Slit Fin

Row x Stage x

FPI

Size (W x H x L) mm 610 x 315 x 25.4 810 x 315 x 25.4

Material Polypropelene Polypropelene

Type One-touch One-touch

DRY BULB WET BULB DRY BULB WET BULB

Phase, Hz Single, 50 Single, 50

V 220 240 220 240

kW 1.70 4.00 4.80 1.90 5.00 5.80

BTU/h 5800 13600 16400 6480 17100 19800

kJ/h 6120 14400 17280 6840 18000 20880

W/W 4.47 3.39 3.24 4.75 3.42 3.07

kJ/hW 16.11 12.20 11.68 17.10 12.33 11.05

3

/min (ft3/m) 6.92 (244) 11.23 (397)

mm (inch) 6.35 (1/4) / 9.52 (3/8) 6.35 (1/4) / 9.52 (3/8)

2 x 15 x 17 2 x 15 x 17

Maximum °C 32 23 32 23

Minimum °C 16 11 16 11

1. Cooling capacities are based on indoor temperature of 27°C DRY BULB (80.6°F DRY BULB), 19.0°C WET BULB (66°F WET BULB) and

outdoor air temperature of 35°C DRY BULB (95°F DRY BULB), 24°C WET BULB (75.2°F WET BULB)

2. Specifications are subject to change without notice for further improvement.

7

Model Indoor/Outdoor CS-MPS9SKH / CU-3S28SBH CS-MPS12SKH / CU-3S28SBH

Performance Test Condition JIS JIS

Power Supply

Min. Mid. Max. Min. Mid. Max.

Capacity

Running Current A 3.70 3.40 4.20 3.90

Cooling

Indoor Fan

Indoor Airflow

Dimension

Drain Hose

Indoor Heat

Exchanger

Air Filter

Input Power W 380 700 890 380 800 1.20k

EER

Indoor Noise (H / L / QLo) dB-A 40 / 29 / - 44 / 32 / -

Type Cross-flow fan Cross-flow fan

Material ASG20K1 ASG20K1

Motor Type AC / Induction (4 poles) AC / Induction (4 poles)

Input Power W 51 - 58 51 - 58

Output Power W 24 24

Lo rpm 680 720

Speed

Moisture Removal L/h 1.6 1.8

Weight Net (I/D) kg (lb) 9 (20) 9 (20)

Piping

Power Supply Outdoor Outdoor

Power Supply Cord A - -

Thermostat - -

Protection Device - -

Indoor Operation Range

Me rpm 840 890

Hi rpm 1000 1060

Lo m

Me m3/min (ft3/m) 8.26 (292) 8.92 (315)

Hi m3/min (ft3/m) 10.10 (355) 10.90 (385)

Height (I/D) mm (inch) 290 (11-7/16) 290 (11-7/16)

Width (I/D) mm (inch) 870 (34-9/32) 870 (34-9/32)

Depth (I/D) mm (inch) 214 (8-7/16) 214 (8-7/16)

Pipe Diameter

(Liquid / Gas)

Inner Diameter mm 16.2 16.2

Length mm 550 550

Fin Material Aluminium (Pre coated) Aluminium (Pre coated)

Fin Type Slit Fin Slit Fin

Row x Stage x

FPI

Size (W x H x L) mm 610 x 315 x 25.4 610 x 315 x 25.4

Material Polypropelene Polypropelene

Type One-touch One-touch

DRY BULB WET BULB DRY BULB WET BULB

Phase, Hz Single, 50 Single, 50

V 220 240 220 240

kW 1.70 2.80 3.40 1.70 3.20 4.00

BTU/h 5800 9550 11600 5800 10900 13600

kJ/h 6120 10080 12240 6120 11520 14400

W/W 4.47 4.00 3.82 4.47 4.00 3.33

kJ/hW 16.11 14.40 13.75 16.11 14.40 12.00

3

/min (ft3/m) 6.90 (244) 6.95 (245)

mm (inch) 6.35 (1/4) / 9.52 (3/8) 6.35 (1/4) / 9.52 (3/8)

2 x 15 x 17 2 x 15 x 17

Maximum °C 32 23 32 23

Minimum °C 16 11 16 11

1. Cooling capacities are based on indoor temperature of 27°C DRY BULB (80.6°F DRY BULB), 19.0°C WET BULB (66°F WET BULB) and

outdoor air temperature of 35°C DRY BULB (95°F DRY BULB), 24°C WET BULB (75.2°F WET BULB)

2. Specifications are subject to change without notice for further improvement.

8

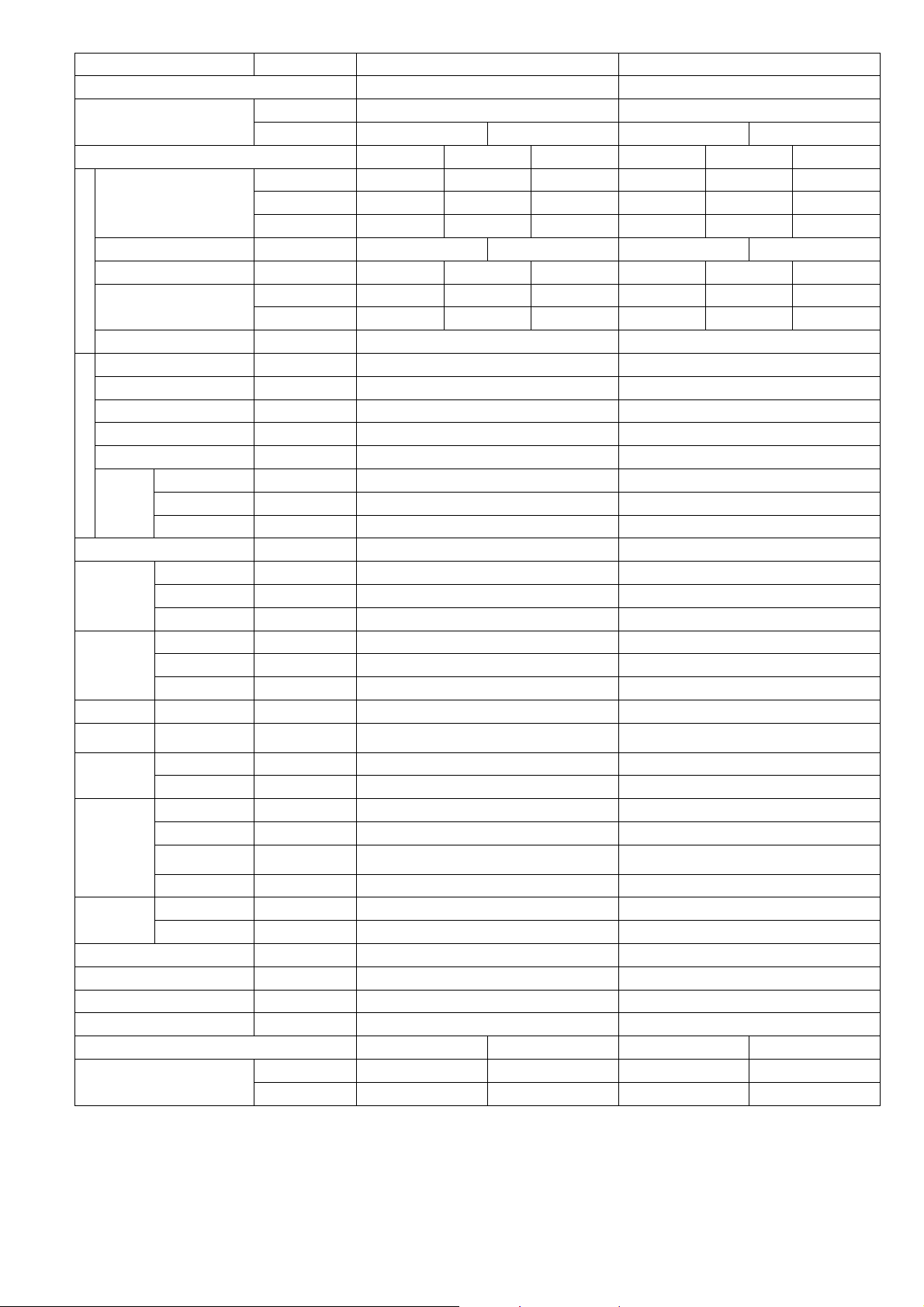

Model Indoor/Outdoor CS-MPS15SKH / CU-3S28SBH CS-MPS18SKH / CU-3S28SBH

Performance Test Condition JIS JIS

Power Supply

Min. Mid. Max. Min. Mid. Max.

Capacity

Running Current A 6.00 5.50 7.30 6.70

Cooling

Indoor Fan

Indoor Airflow

Dimension

Drain Hose

Indoor Heat

Exchanger

Air Filter

Input Power W 380 1.18k 1.48k 400 1.46k 1.89k

EER

Indoor Noise (H / L / QLo) dB-A 45 / 32 / - 47 / 38 / -

Type Cross-flow fan Cross-flow fan

Material ASG20K1 ASG30K1

Motor Type AC / Induction (4 poles) DC / Transistor (8 poles)

Input Power W 51 – 58 94.8

Output Power W 24 40

Lo rpm 720 930

Speed

Moisture Removal L/h 2.3 2.7

Weight Net (I/D) kg (lb) 9 (20) 12 (26)

Piping

Power Supply Outdoor Outdoor

Power Supply Cord A - -

Thermostat - -

Protection Device - -

Indoor Operation Range

Me rpm 900 1120

Hi rpm 1090 1300

Lo m

Me m3/min (ft3/m) 9.00 (318) 14.23 (503)

Hi m3/min (ft3/m) 11.20 (395) 17.08 (603)

Height (I/D) mm (inch) 290 (11-7/16) 290 (11-7/16)

Width (I/D) mm (inch) 870 (34-9/32) 1070 (42-5/32)

Depth (I/D) mm (inch) 214 (8-7/16) 240 (9-15/32)

Pipe Diameter

(Liquid / Gas)

Inner Diameter mm 16.2 16.2

Length mm 550 550

Fin Material Aluminium (Pre coated) Aluminium (Pre coated)

Fin Type Slit Fin Slit Fin

Row x Stage x

FPI

Size (W x H x L) mm 610 x 315 x 25.4 810 x 315 x 25.4

Material Polypropelene Polypropelene

Type One-touch One-touch

DRY BULB WET BULB DRY BULB WET BULB

Phase, Hz Single, 50 Single, 50

V 220 240 220 240

kW 1.70 4.00 4.80 1.90 5.00 5.80

BTU/h 5800 13600 16400 6480 17100 19800

kJ/h 6120 14400 17280 6840 18000 20880

W/W 4.47 3.39 3.24 4.75 3.42 3.07

kJ/hW 16.11 12.20 11.68 17.10 12.33 11.05

3

/min (ft3/m) 6.92 (244) 11.23 (397)

mm (inch) 6.35 (1/4) / 9.52 (3/8) 6.35 (1/4) / 9.52 (3/8)

2 x 15 x 17 2 x 15 x 17

Maximum °C 32 23 32 23

Minimum °C 16 11 16 11

1. Cooling capacities are based on indoor temperature of 27°C DRY BULB (80.6°F DRY BULB), 19.0°C WET BULB (66°F WET BULB) and

outdoor air temperature of 35°C DRY BULB (95°F DRY BULB), 24°C WET BULB (75.2°F WET BULB)

2. Specifications are subject to change without notice for further improvement.

9

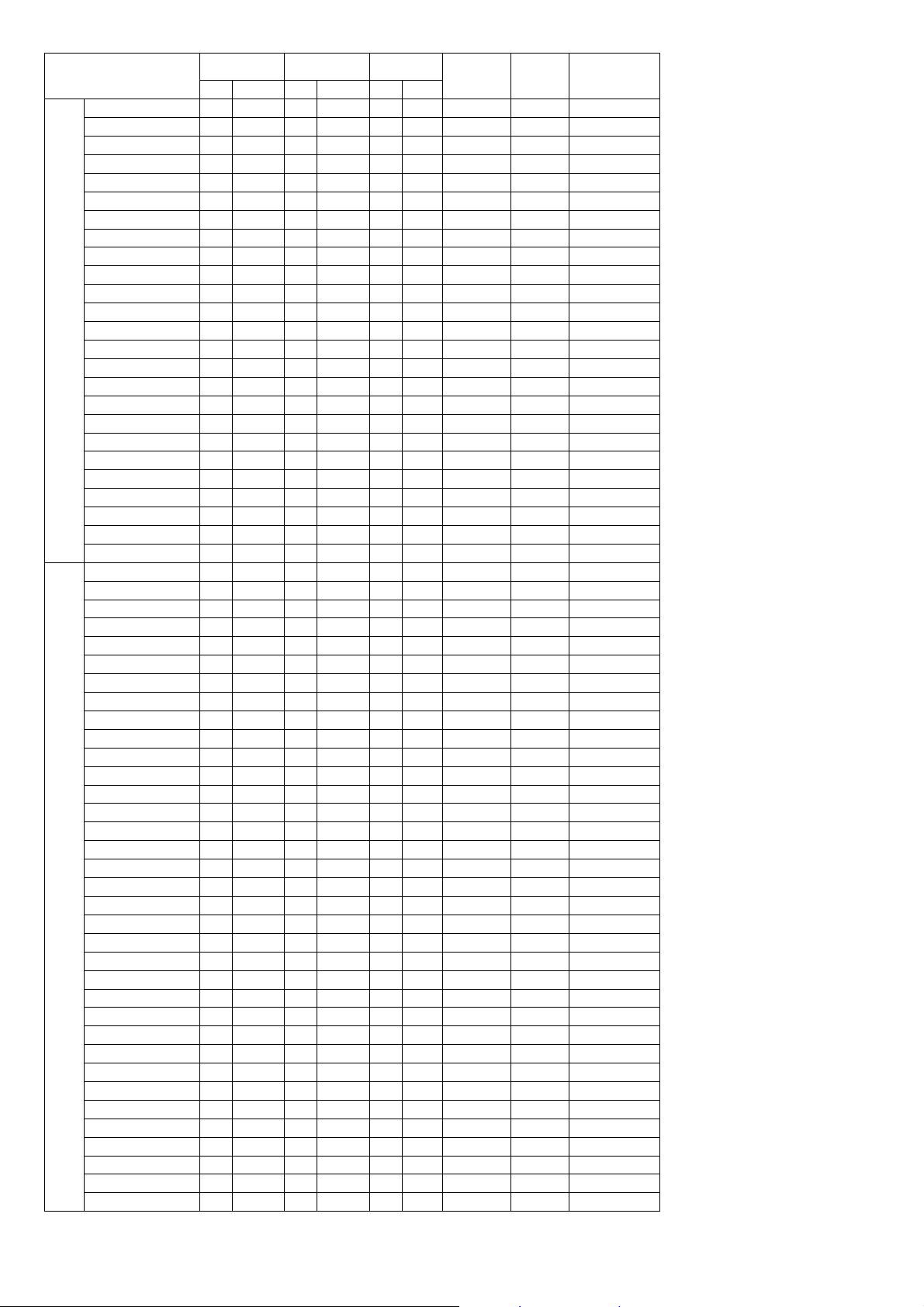

Model Indoor/Outdoor CS-MPS24SKH / CU-3S28SBH

Performance Test Condition JIS

Power Supply

Min. Mid. Max.

Capacity

Running Current A 9.30 8.60

Cooling

Indoor Fan

Indoor Airflow

Dimension

Drain Hose

Indoor Heat

Exchanger

Air Filter

Input Power W 400 1.92k 2.07k

EER

Indoor Noise (H / L / QLo) dB-A 48 / 39 / -

Type Cross-flow fan

Material ASG30K1

Motor Type DC / Transistor (8 poles)

Input Power W 94.8

Output Power W 40

Lo rpm 1000

Speed

Moisture Removal L/h 3.3

Weight Net (I/D) kg (lb) 12 (26)

Piping

Power Supply Outdoor

Power Supply Cord A -

Thermostat -

Protection Device -

Indoor Operation Range

Me rpm 1200

Hi rpm 1400

Lo m

Me m3/min (ft3/m) 15.37 (543)

Hi m3/min (ft3/m) 18.50 (655)

Height (I/D) mm (inch) 290 (11-7/16)

Width (I/D) mm (inch) 1070 (42-5/32)

Depth (I/D) mm (inch) 240 (9-15/32)

Pipe Diameter

(Liquid / Gas)

Inner Diameter mm 16.2

Length mm 550

Fin Material Aluminium (Pre coated)

Fin Type Slit Fin

Row x Stage x

FPI

Size (W x H x L) mm 810 x 315 x 25.4

Material Polypropelene

Type One-touch

DRY BULB WET BULB

Phase, Hz Single, 50

V 220 240

kW 1.90 6.00 6.20

BTU/h 6480 20500 21100

kJ/h 6840 21600 22320

W/W 4.75 3.13 3.00

kJ/hW 17.10 11.25 10.78

3

/min (ft3/m) 12.23 (432)

mm (inch) 6.35 (1/4) / 12.70 (1/2)

2 x 15 x 21

Maximum °C 32 23

Minimum °C 16 11

1. Cooling capacities are based on indoor temperature of 27°C DRY BULB (80.6°F DRY BULB), 19.0°C WET BULB (66°F WET BULB) and

outdoor air temperature of 35°C DRY BULB (95°F DRY BULB), 24°C WET BULB (75.2°F WET BULB)

2. Specifications are subject to change without notice for further improvement.

10

Model Indoor/Outdoor CS-MPS9SKH / CU-4S27SBH CS-MPS12SKH / CU-4S27SBH

Performance Test Condition JIS JIS

Power Supply

Min. Mid. Max. Min. Mid. Max.

Capacity

Running Current A 3.80 3.50 4.30 3.90

Cooling

Indoor Fan

Indoor Airflow

Dimension

Drain Hose

Indoor Heat

Exchanger

Air Filter

Input Power W 380 700 890 380 800 1.20k

EER

Indoor Noise (H / L / QLo) dB-A 40 / 29 / - 44 / 32 / -

Type Cross-flow fan Cross-flow fan

Material ASG20K1 ASG20K1

Motor Type AC / Induction (4 poles) AC / Induction (4 poles)

Input Power W 51 - 58 51 - 58

Output Power W 24 24

Lo rpm 680 720

Speed

Moisture Removal L/h 1.6 1.8

Weight Net (I/D) kg (lb) 9 (20) 9 (20)

Piping

Power Supply Outdoor Outdoor

Power Supply Cord A - -

Thermostat - -

Protection Device - -

Indoor Operation Range

Me rpm 840 890

Hi rpm 1000 1060

Lo m

Me m3/min (ft3/m) 8.26 (292) 8.92 (315)

Hi m3/min (ft3/m) 10.10 (355) 10.90 (385)

Height (I/D) mm (inch) 290 (11-7/16) 290 (11-7/16)

Width (I/D) mm (inch) 870 (34-9/32) 870 (34-9/32)

Depth (I/D) mm (inch) 214 (8-7/16) 214 (8-7/16)

Pipe Diameter

(Liquid / Gas)

Inner Diameter mm 16.2 16.2

Length mm 550 550

Fin Material Aluminium (Pre coated) Aluminium (Pre coated)

Fin Type Slit Fin Slit Fin

Row x Stage x

FPI

Size (W x H x L) mm 610 x 315 x 25.4 610 x 315 x 25.4

Material Polypropelene Polypropelene

Type One-touch One-touch

DRY BULB WET BULB DRY BULB WET BULB

Phase, Hz Single, 50 Single, 50

V 220 240 220 240

kW 1.70 2.80 3.40 1.70 3.20 4.00

BTU/h 5800 9550 11600 5800 10900 13600

kJ/h 6120 10080 12240 6120 11520 14400

W/W 4.47 4.00 3.82 4.47 4.00 3.33

kJ/hW 16.11 14.40 13.75 16.11 14.40 12.00

3

/min (ft3/m) 6.90 (244) 6.95 (245)

mm (inch) 6.35 (1/4) / 9.52 (3/8) 6.35 (1/4) / 9.52 (3/8)

2 x 15 x 17 2 x 15 x 17

Maximum °C 32 23 32 23

Minimum °C 16 11 16 11

1. Cooling capacities are based on indoor temperature of 27°C DRY BULB (80.6°F DRY BULB), 19.0°C WET BULB (66°F WET BULB) and

outdoor air temperature of 35°C DRY BULB (95°F DRY BULB), 24°C WET BULB (75.2°F WET BULB)

2. Specifications are subject to change without notice for further improvement.

11

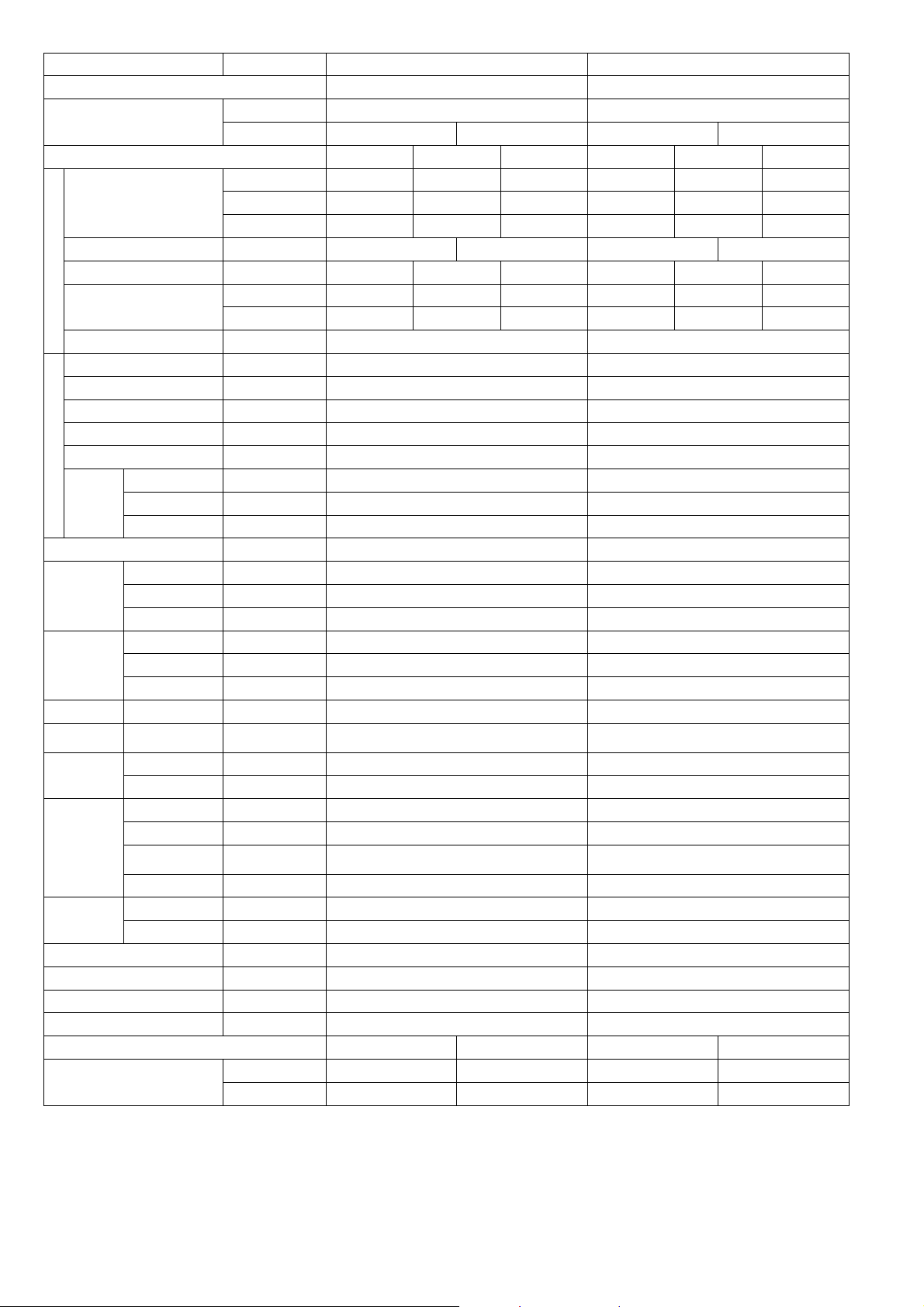

Model Indoor/Outdoor CS-MPS15SKH / CU-4S27SBH CS-MPS18SKH / CU-4S27SBH

Performance Test Condition JIS JIS

Power Supply

Min. Mid. Max. Min. Mid. Max.

Capacity

Running Current A 6.10 5.60 7.40 6.80

Cooling

Indoor Fan

Indoor Airflow

Dimension

Drain Hose

Indoor Heat

Exchanger

Air Filter

Input Power W 380 1.18k 1.48k 400 1.46k 1.89k

EER

Indoor Noise (H / L / QLo) dB-A 45 / 32 / - 47 / 38 / -

Type Cross-flow fan Cross-flow fan

Material ASG20K1 ASG30K1

Motor Type AC / Induction (4 poles) DC / Transistor (8 poles)

Input Power W 51 – 58 94.8

Output Power W 24 40

Lo rpm 720 930

Speed

Moisture Removal L/h 2.3 2.7

Weight Net (I/D) kg (lb) 9 (20) 12 (26)

Piping

Power Supply Outdoor Outdoor

Power Supply Cord A - -

Thermostat - -

Protection Device - -

Indoor Operation Range

Me rpm 900 1120

Hi rpm 1090 1300

Lo m

Me m3/min (ft3/m) 9.00 (318) 14.23 (503)

Hi m3/min (ft3/m) 11.20 (395) 17.08 (603)

Height (I/D) mm (inch) 290 (11-7/16) 290 (11-7/16)

Width (I/D) mm (inch) 870 (34-9/32) 1070 (42-5/32)

Depth (I/D) mm (inch) 214 (8-7/16) 240 (9-15/32)

Pipe Diameter

(Liquid / Gas)

Inner Diameter mm 16.2 16.2

Length mm 550 550

Fin Material Aluminium (Pre coated) Aluminium (Pre coated)

Fin Type Slit Fin Slit Fin

Row x Stage x

FPI

Size (W x H x L) mm 610 x 315 x 25.4 810 x 315 x 25.4

Material Polypropelene Polypropelene

Type One-touch One-touch

DRY BULB WET BULB DRY BULB WET BULB

Phase, Hz Single, 50 Single, 50

V 220 240 220 240

kW 1.70 4.00 4.80 1.90 5.00 5.80

BTU/h 5800 13600 16400 6480 17100 19800

kJ/h 6120 14400 17280 6840 18000 20880

W/W 4.47 3.39 3.24 4.75 3.42 3.07

kJ/hW 16.11 12.20 11.68 17.10 12.33 11.05

3

/min (ft3/m) 6.92 (244) 11.23 (397)

mm (inch) 6.35 (1/4) / 9.52 (3/8) 6.35 (1/4) / 9.52 (3/8)

2 x 15 x 17 2 x 15 x 17

Maximum °C 32 23 32 23

Minimum °C 16 11 16 11

1. Cooling capacities are based on indoor temperature of 27°C DRY BULB (80.6°F DRY BULB), 19.0°C WET BULB (66°F WET BULB) and

outdoor air temperature of 35°C DRY BULB (95°F DRY BULB), 24°C WET BULB (75.2°F WET BULB)

2. Specifications are subject to change without notice for further improvement.

12

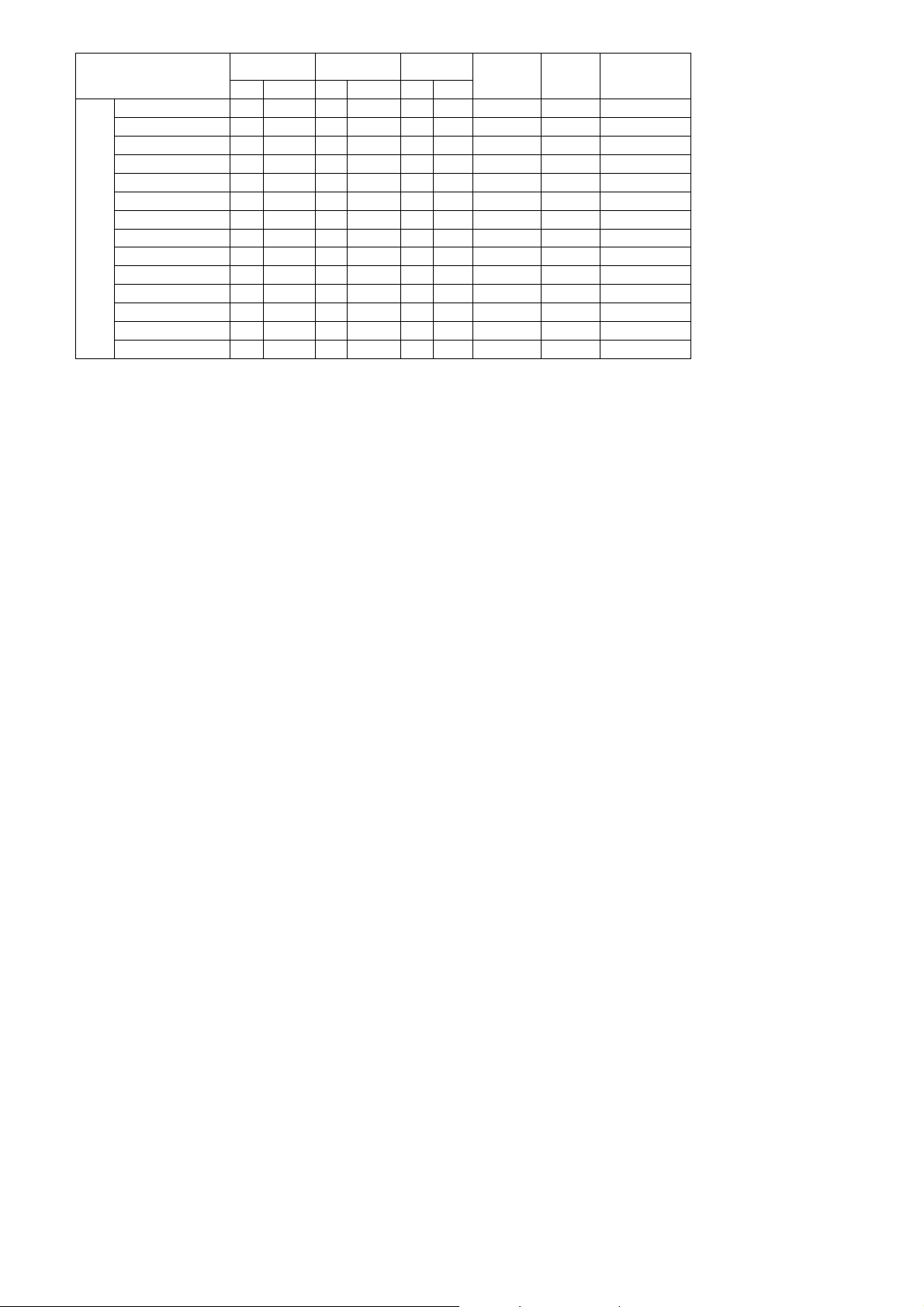

Model Indoor/Outdoor CS-MPS9SKH / CU-34S34SBH CS-MPS12SKH / CU-4S34SBH

Performance Test Condition JIS JIS

Power Supply

Min. Mid. Max. Min. Mid. Max.

Capacity

Running Current A 3.60 3.30 4.10 3.80

Cooling

Indoor Fan

Indoor Airflow

Dimension

Drain Hose

Indoor Heat

Exchanger

Air Filter

Input Power W 380 700 890 380 800 1.20k

EER

Indoor Noise (H / L / QLo) dB-A 40 / 29 / - 44 / 32 / -

Type Cross-flow fan Cross-flow fan

Material ASG20K1 ASG20K1

Motor Type AC / Induction (4 poles) AC / Induction (4 poles)

Input Power W 51 - 58 51 - 58

Output Power W 24 24

Lo rpm 680 720

Speed

Moisture Removal L/h 1.6 1.8

Weight Net (I/D) kg (lb) 9 (20) 9 (20)

Piping

Power Supply Outdoor Outdoor

Power Supply Cord A - -

Thermostat - -

Protection Device - -

Indoor Operation Range

Me rpm 840 890

Hi rpm 1000 1060

Lo m

Me m3/min (ft3/m) 8.26 (292) 8.92 (315)

Hi m3/min (ft3/m) 10.10 (355) 10.90 (385)

Height (I/D) mm (inch) 290 (11-7/16) 290 (11-7/16)

Width (I/D) mm (inch) 870 (34-9/32) 870 (34-9/32)

Depth (I/D) mm (inch) 214 (8-7/16) 214 (8-7/16)

Pipe Diameter

(Liquid / Gas)

Inner Diameter mm 16.2 16.2

Length mm 550 550

Fin Material Aluminium (Pre coated) Aluminium (Pre coated)

Fin Type Slit Fin Slit Fin

Row x Stage x

FPI

Size (W x H x L) mm 610 x 315 x 25.4 610 x 315 x 25.4

Material Polypropelene Polypropelene

Type One-touch One-touch

DRY BULB WET BULB DRY BULB WET BULB

Phase, Hz Single, 50 Single, 50

V 220 240 220 240

kW 1.70 2.80 3.40 1.70 3.20 4.00

BTU/h 5800 9550 11600 5800 10900 13600

kJ/h 6120 10080 12240 6120 11520 14400

W/W 4.47 4.00 3.82 4.47 4.00 3.33

kJ/hW 16.11 14.40 13.75 16.11 14.40 12.00

3

/min (ft3/m) 6.90 (244) 6.95 (245)

mm (inch) 6.35 (1/4) / 9.52 (3/8) 6.35 (1/4) / 9.52 (3/8)

2 x 15 x 17 2 x 15 x 17

Maximum °C 32 23 32 23

Minimum °C 16 11 16 11

1. Cooling capacities are based on indoor temperature of 27°C DRY BULB (80.6°F DRY BULB), 19.0°C WET BULB (66°F WET BULB) and

outdoor air temperature of 35°C DRY BULB (95°F DRY BULB), 24°C WET BULB (75.2°F WET BULB)

2. Specifications are subject to change without notice for further improvement.

13

Model Indoor/Outdoor CS-MPS15SKH / CU-4S34SBH CS-MPS18SKH / CU-4S34SBH

Performance Test Condition JIS JIS

Power Supply

Min. Mid. Max. Min. Mid. Max.

Capacity

Running Current A 6.00 5.50 7.50 6.90

Cooling

Indoor Fan

Indoor Airflow

Dimension

Drain Hose

Indoor Heat

Exchanger

Air Filter

Input Power W 380 1.24k 1.48k 400 1.55k 1.89k

EER

Indoor Noise (H / L / QLo) dB-A 45 / 32 / - 47 / 38 / -

Type Cross-flow fan Cross-flow fan

Material ASG20K1 ASG30K1

Motor Type AC / Induction (4 poles) DC / Transistor (8 poles)

Input Power W 51 - 58 94.8

Output Power W 24 40

Lo rpm 720 930

Speed

Moisture Removal L/h 2.3 2.7

Weight Net (I/D) kg (lb) 9 (20) 12 (26)

Piping

Power Supply Outdoor Outdoor

Power Supply Cord A - -

Thermostat - -

Protection Device - -

Indoor Operation Range

Me rpm 900 1120

Hi rpm 1090 1300

Lo m

Me m3/min (ft3/m) 9.00 (318) 14.23 (503)

Hi m3/min (ft3/m) 11.20 (395) 17.08 (603)

Height (I/D) mm (inch) 290 (11-7/16) 290 (11-7/16)

Width (I/D) mm (inch) 870 (34-9/32) 1070 (42-5/32)

Depth (I/D) mm (inch) 214 (8-7/16) 240 (9-15/32)

Pipe Diameter

(Liquid / Gas)

Inner Diameter mm 16.2 16.2

Length mm 550 550

Fin Material Aluminium (Pre coated) Aluminium (Pre coated)

Fin Type Slit Fin Slit Fin

Row x Stage x

FPI

Size (W x H x L) mm 610 x 315 x 25.4 810 x 315 x 25.4

Material Polypropelene Polypropelene

Type One-touch One-touch

DRY BULB WET BULB DRY BULB WET BULB

Phase, Hz Single, 50 Single, 50

V 220 240 220 240

kW 1.70 4.00 4.80 1.90 5.00 5.80

BTU/h 5800 13600 16400 6480 17100 19800

kJ/h 6120 14400 17280 6840 18000 20880

W/W 4.47 3.23 3.24 4.75 3.23 3.07

kJ/hW 16.11 11.61 11.68 17.10 11.61 11.05

3

/min (ft3/m) 6.92 (244) 11.23 (397)

mm (inch) 6.35 (1/4) / 9.52 (3/8) 6.35 (1/4) / 9.52 (3/8)

2 x 15 x 17 2 x 15 x 17

Maximum °C 32 23 32 23

Minimum °C 16 11 16 11

1. Cooling capacities are based on indoor temperature of 27°C DRY BULB (80.6°F DRY BULB), 19.0°C WET BULB (66°F WET BULB) and

outdoor air temperature of 35°C DRY BULB (95°F DRY BULB), 24°C WET BULB (75.2°F WET BULB)

2. Specifications are subject to change without notice for further improvement.

14

Model Indoor/Outdoor CS-MPS24SKH / CU-4S34SBH CS-MPS28SKH / CU-4S34SBH

Performance Test Condition JIS JIS

Power Supply

Min. Mid. Max. Min. Mid. Max.

Capacity

Running Current A 9.60 8.80 11.80 10.80

Cooling

Indoor Fan

Indoor Airflow

Dimension

Drain Hose

Indoor Heat

Exchanger

Air Filter

Input Power W 400 2.03k 2.07k 400 2.49k 2.77k

EER

Indoor Noise (H / L / QLo) dB-A 48 / 39 / - 48 / 39 / -

Type Cross-flow fan Cross-flow fan

Material ASG30K1 ASG30K1

Motor Type DC / Transistor (8 poles) DC / Transistor (8 poles)

Input Power W 94.8 94.8

Output Power W 40 40

Lo rpm 1000 1000

Speed

Moisture Removal L/h 3.3 3.9

Weight Net (I/D) kg (lb) 12 (26) 12 (26)

Piping

Power Supply Outdoor Outdoor

Power Supply Cord A - -

Thermostat - -

Protection Device - -

Indoor Operation Range

Me rpm 1200 1250

Hi rpm 1400 1500

Lo m

Me m3/min (ft3/m) 15.37 (543) 16.15 (570)

Hi m3/min (ft3/m) 18.50 (655) 20.07 (709)

Height (I/D) mm (inch) 290 (11-7/16) 290 (11-7/16)

Width (I/D) mm (inch) 1070 (42-5/32) 1070 (42-5/32)

Depth (I/D) mm (inch) 240 (9-15/32) 240 (9-15/32)

Pipe Diameter

(Liquid / Gas)

Inner Diameter mm 16.2 16.2

Length mm 550 550

Fin Material Aluminium (Pre coated) Aluminium (Pre coated)

Fin Type Slit Fin Slit Fin

Row x Stage x

FPI

Size (W x H x L) mm 810 x 315 x 25.4 810 x 315 x 25.4

Material Polypropelene Polypropelene

Type One-touch One-touch

DRY BULB WET BULB DRY BULB WET BULB

Phase, Hz Single, 50 Single, 50

V 220 240 220 240

kW 1.90 6.00 6.20 2.00 7.00 7.20

BTU/h 6480 20500 21100 6820 23900 24600

kJ/h 6840 21600 22320 7200 25200 25920

W/W 4.75 2.96 3.00 5.00 2.81 2.60

kJ/hW 17.10 10.64 10.78 18.00 10.12 9.36

3

/min (ft3/m) 12.23 (432) 12.23 (432)

mm (inch) 6.35 (1/4) / 12.70 (1/2) 6.35 (1/4) / 12.70 (1/2)

2 x 15 x 21 2 x 15 x 21

Maximum °C 32 23 32 23

Minimum °C 16 11 16 11

1. Cooling capacities are based on indoor temperature of 27°C DRY BULB (80.6°F DRY BULB), 19.0°C WET BULB (66°F WET BULB) and

outdoor air temperature of 35°C DRY BULB (95°F DRY BULB), 24°C WET BULB (75.2°F WET BULB)

2. Specifications are subject to change without notice for further improvement.

15

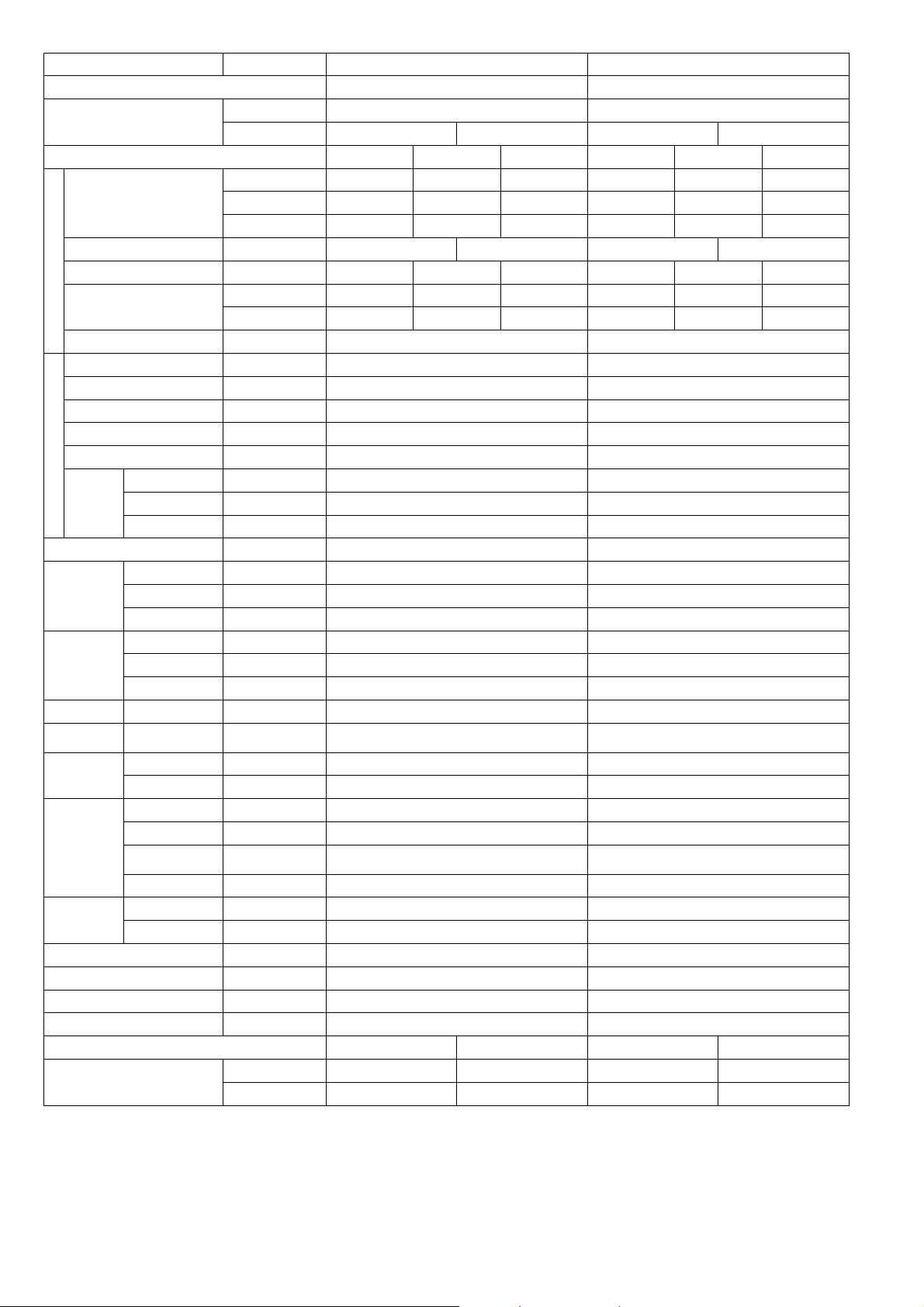

Multi split combination possibility:

- A single outdoor unit enables air conditioning of up to two separate rooms for CU-2S18SKH.

- A single outdoor unit enables air conditioning of up to three separate rooms for CU-3S27SBH, CU-3S28SBH.

- A single outdoor unit enables air conditioning of up to four separate rooms for CU-4S27SBH, CU-4S34SBH.

Outdoor Unit

CU-2S18SKH CU-3S27SBH CU-3S28SBH CU-4S27SBH CU-4S34SBH

A B A B C A B C A B C D A B C D

2.8 kW MPS9SKH ● ● ● ● ● ● ● ● ● ● ● ● ● ● ● ●

3.2 kW MPS12SKH ● ● ● ● ● ● ● ● ● ● ● ● ● ● ● ●

4.0 kW MPS15SKH - - ● ● ● ● ● ● ● ● ● ● ● ● ● ●

Wall

5.0 kW MPS18SKH - - ● ● ● ● ● ● ● ● ● ● ● ● ● ●

6.0 kW MPS24SKH - - - - - ● ● ● - - - - ● ● ● ●

7.0 kW MPS28SKH - - - - - - - - - - - - ● ● ● ●

Capacity range of

connectable indoor units

1 room maximum pipe

length (m)

From 5.6 kW to

6.4 kW

From 5.6 kW to

13.2 kW

From 5.6 kW to

13.2 kW

From 5.6 kW to 13.4 kW From 5.6 kW to 17.4 kW

20 25 25 25 25

Allowable elevation (m) 10 15 15 15 15

Total allowable pipe

length (m)

30 60 60 60 70

Total pipe length for

maximum chargeless

Piping Length

length (m)

20 30 30 35 45

Additional gas amount

over chargeless length

15 20 20 20 20

(g/m)

Note: “●” : Available

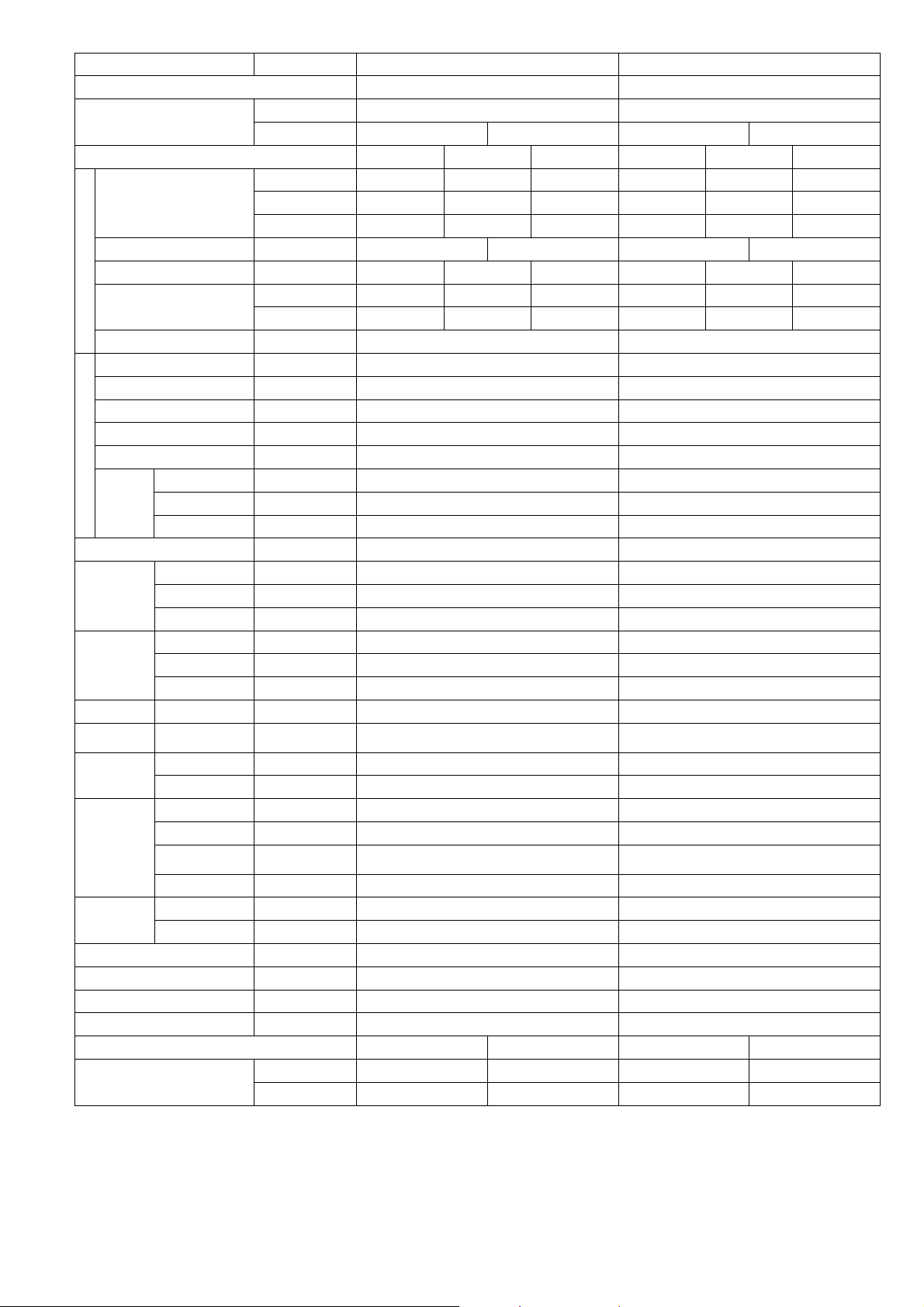

Indoor Unit: CS-MPS9/12SKH

Outdoor Unit: CU-2S18SKH

Indoor unit capacity

Cooling

2.8 + 2.8 4.80 1.50 ~ 5.80 1.34 0.25 ~ 1.72 6.50 / 6.05 1.5 + 1.5

2 Room

2.8 + 3.2 5.00 1.50 ~ 5.90 1.52 0.25 ~ 1.74 7.40 / 6.90 1.5 + 1.6

3.2 + 3.2 5.00 1.50 ~ 6.00 1.43 0.25 ~ 1.78 6.75 / 6.25 1.5 + 1.5

Cooling Capacity (kW) Input Power (kW)

Total min ~ max Rating min ~ m ax

Current, 50Hz, 220V /

240V (A)

MOISTURE REMOVAL

VOLUME

l/h

Indoor Unit: CS-MPS9/12/15/18SKH

Outdoor Unit: CU-3S27SBH

2 Room

Indoor unit capacity

Cooling

2.8 + 2.8 5.60 1.7 ~ 6.4 1750 420~ 2600 8.7 / 8.0 1.6 + 1.6

2.8 + 3.2 6.00 1.7 ~ 6.5 2010 420 ~ 2600 10.0 / 9.2 1.6 + 1.8

2.8 + 4.0 6.80 2.5 ~ 7.3 2420 550 ~ 3330 12.0 / 11.0 1.6 + 2.3

2.8 + 5.0 7.50 2.7 ~ 7.7 2810 530 ~ 3310 13.9 / 12.7 1.6 + 2.6

3.2 + 3.2 6.40 2.3 ~ 7.1 2290 570 ~ 3350 11.3 / 10.4 1.8 + 1.8

3.2 + 4.0 7.20 2.5 ~ 7.4 2770 550 ~ 3330 13.7 / 12.5 1.8 + 2.3

3.2 + 5.0 7.50 2.8 ~ 7.7 2760 530 ~ 3310 13.6 / 12.5 1.7 + 2.5

4.0 + 4.0 7.50 2.7 ~ 7.6 2870 540 ~ 3310 14.2 / 13.0 2.2 + 2.2

4.0 + 5.0 7.50 2.8 ~ 7.8 2600 530 ~ 3300 12.8 / 11.8 1.9 + 2.4

5.0 + 5.0 7.50 2.9 ~ 8.0 2440 520 ~ 3300 12.1 / 11.1 2.2 + 2.2

Cooling Capacity (kW) Input Power (W)

Total min ~ max Rating min ~ max

Current, 50Hz,

220V / 240V

(A)

MOISTURE REMOVAL VOLUME

l/h

16

Indoor unit capacity

3 Room

Cooling

2.8 + 2.8 + 2.8 7.50 2.4 ~ 7.6 2740 580 ~ 3170 13.5 / 12.4 1.5 + 1.5 + 1.5

2.8 + 2.8 + 3.2 7.50 2.4 ~ 7.7 2690 580 ~ 3170 13.3 / 12.2 1.5 + 1.5 + 1.6

2.8 + 2.8 + 4.0 7.50 2.6 ~ 8.0 2490 600 ~ 3260 12.3 / 11.3 1.4 + 1.4 + 1.8

2.8 + 2.8 + 5.0 7.50 2.8 ~ 8.0 2250 600 ~ 2910 11.1 / 10.2 1.3 + 1.3 + 2.0

2.8 + 3.2 + 3.2 7.50 2.4 ~ 7.7 2690 580 ~ 3180 13.3 / 12.2 1.5 + 1.6 + 1.6

2.8 + 3.2 + 4.0 7.50 2.6 ~ 8.0 2450 600 ~ 3200 12.1 / 11.1 1.4 + 1.5 + 1.7

2.8 + 3.2 + 5.0 7.50 2.8 ~ 8.0 2250 600 ~ 2910 11.1 / 10.2 1.2 + 1.4 + 2.0

2.8 + 4.0 + 4.0 7.50 2.7 ~ 8.0 2290 600 ~ 3020 11.3 / 10.4 1.3 + 1.6 + 1.6

2.8 + 4.0 + 5.0 7.50 2.8 ~ 8.0 2170 580 ~ 2760 10.7 / 9.8 1.1 + 1.6 + 1.8

2.8 + 5.0 + 5.0 7.50 2.8 ~ 8.0 2070 520 ~ 2650 10.2 / 9.4 1.0 + 1.7 + 1.7

3.2 + 3.2 + 3.2 7.50 2.4 ~ 7.7 2650 590 ~ 3190 13.1 / 12.0 1.5 + 1.5 + 1.5

3.2 + 3.2 + 4.0 7.50 2.6 ~ 8.0 2450 600 ~ 3210 12.1 / 11.1 1.5 + 1.5 + 1.7

3.2 + 3.2 + 5.0 7.50 2.8 ~ 8.0 2250 600 ~ 2920 11.1 / 10.2 1.4 + 1.4 + 1.9

3.2 + 4.0 + 4.0 7.50 2.8 ~ 8.0 2290 600 ~ 2960 11.3 / 10.4 1.4 + 1.6 + 1.6

3.2 + 4.0 + 5.0 7.50 2.8 ~ 8.0 2170 580 ~ 2760 10.7 / 9.8 1.3 + 1.5 + 1.7

3.2 + 5.0 + 5.0 7.50 2.8 ~ 8.0 2060 520 ~ 2650 10.2 / 9.4 1.2 + 1.7 + 1.7

4.0 + 4.0 + 4.0 7.50 2.8 ~ 8.0 2170 590 ~ 2820 10.7 / 9.8 1.5 + 1.5 + 1.5

4.0 + 4.0 + 5.0 7.50 2.8 ~ 8.0 2070 540 ~ 2650 10.2 / 9.4 1.5 + 1.5 + 1.7

Cooling Capacity (kW) Input Power (W)

Total min ~ max Rating min ~ max

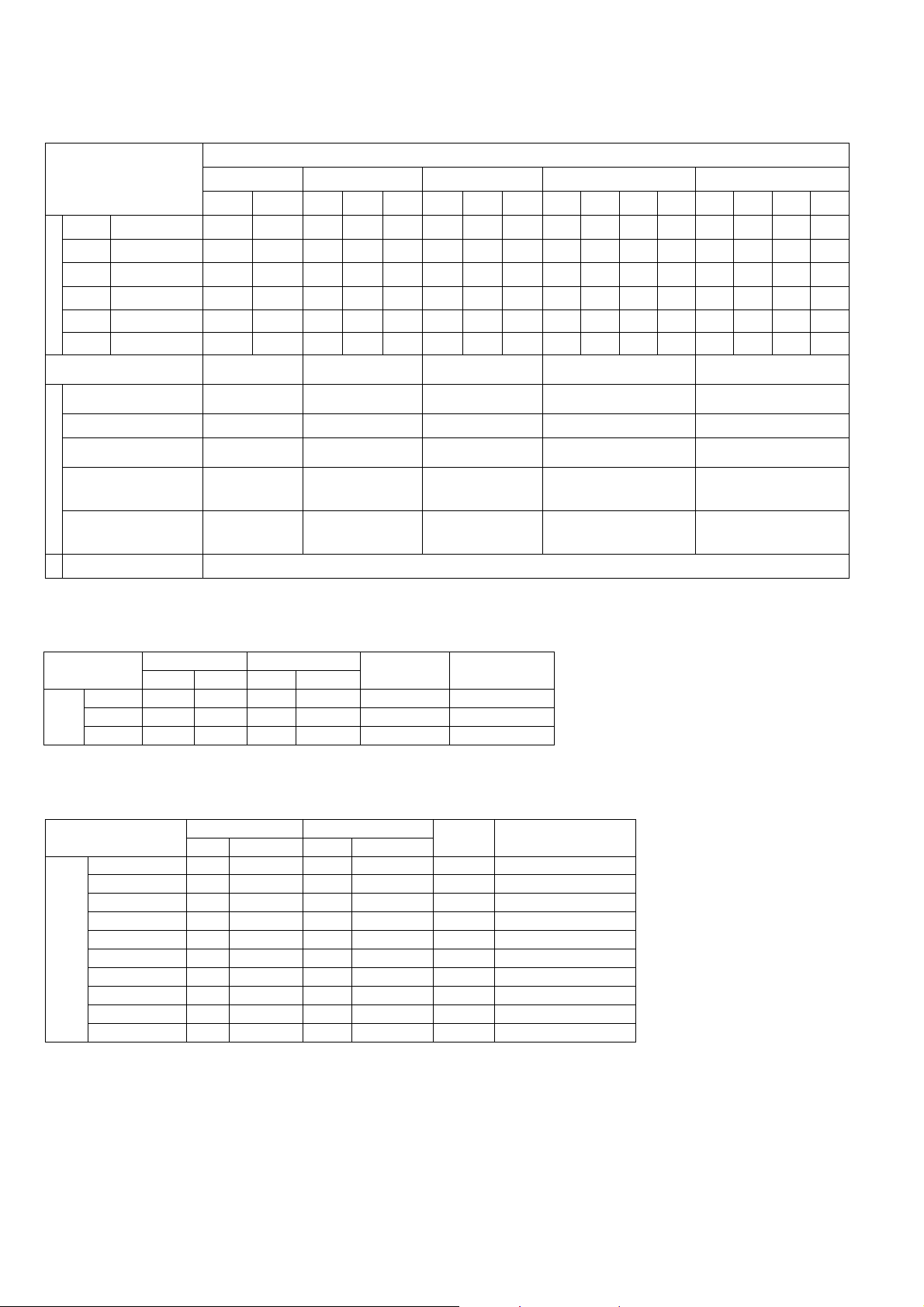

Indoor Unit: CS-MPS9/12/15/18/24SKH

Outdoor Unit: CU-3S28SBH

Indoor unit capacity

1 Room

2 Room

Cooling

2.8 2.80 1.7 ~ 3.4 700 380 ~ 890 3.7 / 3.4 1.6

3.2 3.20 1.7 ~ 4.0 800 380 ~ 1200 4.2 / 3.9 1.8

4.0 4.00 1.7 ~ 4.8 1180 380 ~ 1480 6.0 / 5.5 2.3

5.0 5.00 1.9 ~ 5.8 1460 400 ~ 1890 7.3 / 6.7 2.7

6.0 6.00 1.9 ~ 6.2 1920 400 ~ 2070 9.3 / 8.6 3.3

2.8 + 2.8 5.60 1.7 ~ 6.7 1750 420~ 2340 8.6 / 7.9 1.6 + 1.6

2.8 + 3.2 6.00 1.7 ~ 6.7 2010 420~ 2340 9.8 / 9.0 1.6 + 1.8

2.8 + 4.0 6.80 2.5 ~ 7.6 2420 550 ~ 2990 11.8 / 10.8 1.6 + 2.3

2.8 + 5.0 7.50 2.7 ~ 8.0 2810 530 ~ 2980 13.7 / 12.6 1.6 + 2.6

2.8 + 6.0 7.50 2.7 ~ 8.0 2810 530 ~ 2980 13.7 / 12.6 1.5 + 2.8

3.2 + 3.2 6.40 2.3 ~ 7.4 2290 570 ~ 3010 11.2 / 10.3 1.8 + 1.8

3.2 + 4.0 7.20 2.5 ~ 7.7 2770 550 ~ 2990 13.5 / 12.4 1.8 + 2.3

3.2 + 5.0 7.50 2.8 ~ 8.0 2760 530 ~ 2970 13.5 / 12.4 1.7 + 2.5

3.2 + 6.0 7.50 2.8 ~ 8.0 2760 530 ~ 2970 13.5 / 12.4 1.6 + 2.7

4.0 + 4.0 7.50 2.7 ~ 7.9 2870 540 ~ 2980 14.0 / 12.9 2.2 + 2.2

4.0 + 5.0 7.50 2.8 ~ 8.1 2600 530 ~ 2970 12.7 / 11.6 1.9 + 2.4

4.0 + 6.0 7.50 2.8 ~ 8.1 2600 530 ~ 2970 12.7 / 11.6 1.7 + 2.5

5.0 + 5.0 7.50 2.9 ~ 8.3 2440 520 ~ 2970 11.9 / 10.9 2.2 + 2.2

5.0 + 6.0 7.50 2.9 ~ 8.3 2440 520 ~ 2970 11.9 / 10.9 2.0 + 2.3

6.0 + 6.0 7.50 2.9 ~ 8.3 2440 520 ~ 2970 11.9 / 10.9 2.2 + 2.2

Cooling Capacity (kW) Input Power (W)

Total min ~ max Rating min ~ max

Current, 50Hz,

220V / 240V

(A)

Current, 50Hz,

220V / 240V

(A)

MOISTURE REMOVAL VOLUME

MOISTURE REMOVAL VOLUME

l/h

l/h

17

Cooling Capacity (kW) Input Power (W)

Total min ~ max Rating min ~ max

3 Room

Indoor unit capacity

Cooling

2.8 + 2.8 + 2.8 7.50 2.4 ~ 7.9 2740 580 ~ 2840 13.4 / 12.3 1.5 + 1.5 + 1.5

2.8 + 2.8 + 3.2 7.50 2.4 ~ 8.0 2690 580 ~ 2850 13.1 / 12.1 1.5 + 1.5 + 1.6

2.8 + 2.8 + 4.0 7.50 2.6 ~ 8.4 2490 600 ~ 2930 12.2 / 11.2 1.4 + 1.4 + 1.8

2.8 + 2.8 + 5.0 7.50 2.8 ~ 8.8 2250 600 ~ 3010 11.0 / 10.1 1.3 + 1.3 + 2.0

2.8 + 2.8 + 6.0 7.50 2.8 ~ 8.8 2250 600 ~ 3010 11.0 / 10.1 1.2 + 1.2 + 2.3

2.8 + 3.2 + 3.2 7.50 2.4 ~ 8.0 2690 580 ~ 2860 13.1 / 12.1 1.5 + 1.6 + 1.6

2.8 + 3.2 + 4.0 7.50 2.6 ~ 8.4 2450 600 ~ 2930 12.0 / 11.0 1.4 + 1.5 + 1.7

2.8 + 3.2 + 5.0 7.50 2.8 ~ 8.8 2250 600 ~ 3020 11.0 / 10.1 1.2 + 1.4 + 2.0

2.8 + 3.2 + 6.0 7.50 2.8 ~ 8.8 2250 600 ~ 3020 11.0 / 10.1 1.1 + 1.3 + 2.2

2.8 + 4.0 + 4.0 7.50 2.7 ~ 8.7 2290 600 ~ 3000 11.2 / 10.3 1.3 + 1.6 + 1.6

2.8 + 4.0 + 5.0 7.50 2.8 ~ 9.0 2170 580 ~ 3050 10.6 / 9.7 1.1 + 1.6 + 1.8

2.8 + 4.0 + 6.0 7.50 2.8 ~ 9.0 2170 580 ~ 3050 10.6 / 9.7 1.0 + 1.5 + 2.0

2.8 + 5.0 + 5.0 7.50 2.8 ~ 9.0 2070 520 ~ 2830 10.1 / 9.3 1.0 + 1.7 + 1.7

3.2 + 3.2 + 3.2 7.50 2.4 ~ 8.0 2650 590 ~ 2860 13.0 / 11.9 1.5 + 1.5 + 1.5

3.2 + 3.2 + 4.0 7.50 2.6 ~ 8.4 2450 600 ~ 2940 12.0 / 11.0 1.5 + 1.5 + 1.7

3.2 + 3.2 + 5.0 7.50 2.8 ~ 8.8 2250 600 ~ 3020 11.0 / 10.1 1.4 + 1.4 + 1.9

3.2 + 3.2 + 6.0 7.50 2.8 ~ 8.8 2250 600 ~ 3020 11.0 / 10.1 1.3 + 1.3 + 2.1

3.2 + 4.0 + 4.0 7.50 2.8 ~ 8.7 2290 600 ~ 3000 11.2 / 10.3 1.4 + 1.6 + 1.6

3.2 + 4.0 + 5.0 7.50 2.8 ~ 9.0 2170 580 ~ 3060 10.6 / 9.7 1.3 + 1.5 + 1.7

3.2 + 4.0 + 6.0 7.50 2.8 ~ 9.0 2170 580 ~ 3060 10.6 / 9.7 1.2 + 1.5 + 2.0

3.2 + 5.0 + 5.0 7.50 2.8 ~ 9.0 2060 520 ~ 2830 10.1 / 9.2 1.2 + 1.7 + 1.7

4.0 + 4.0 + 4.0 7.50 2.8 ~ 9.0 2170 590 ~ 3040 10.6 / 9.7 1.5 + 1.5 + 1.5

4.0 + 4.0 + 5.0 7.50 2.8 ~ 9.0 2070 540 ~ 2830 10.1 / 9.3 1.5 + 1.5 + 1.7

Indoor Unit: CS-MPS9/12/15/18SKH

Outdoor Unit: CU-4S27SBH

Cooling Capacity (kW) Input Power (W)

Total min ~ max Rating min ~ max

2 Room

3 Room

Indoor unit capacity

Cooling

2.8 + 2.8 5.60 1.7 ~ 6.4 1750 420 ~ 2600 8.7 / 8.0 1.6 + 1.6

2.8 + 3.2 6.00 1.7 ~ 6.5 2010 420 ~ 2600 10.0 / 9.2 1.6 + 1.8

2.8 + 4.0 6.80 2.5 ~ 7.3 2420 550 ~ 3330 12.0 / 11.0 1.6 + 2.3

2.8 + 5.0 7.50 2.7 ~ 7.7 2810 530 ~ 3310 13.9 / 12.7 1.6 + 2.6

3.2 + 3.2 6.40 2.3 ~ 7.1 2290 570 ~ 3350 11.3 / 10.4 1.8 + 1.8

3.2 + 4.0 7.20 2.5 ~ 7.4 2770 550 ~ 3330 13.7 / 12.5 1.8 + 2.3

3.2 + 5.0 7.50 2.8 ~ 7.7 2760 530 ~ 3310 13.6 / 12.5 1.7 + 2.5

4.0 + 4.0 7.50 2.7 ~ 7.6 2870 540 ~ 3310 14.2 / 13.0 2.2 + 2.2

4.0 + 5.0 7.50 2.8 ~ 7.8 2600 530 ~ 3300 12.8 / 11.8 1.9 + 2.4

5.0 + 5.0 7.50 2.9 ~ 8.0 2440 520 ~ 3300 12.1 / 11.1 2.2 + 2.2

2.8 + 2.8 + 2.8 7.50 2.4 ~ 7.6 2740 580 ~ 3170 13.5 / 12.4 1.5 + 1.5 + 1.5

2.8 + 2.8 + 3.2 7.50 2.4 ~ 7.7 2690 580 ~ 3170 13.3 / 12.2 1.5 + 1.5 + 1.6

2.8 + 2.8 + 4.0 7.50 2.6 ~ 8.0 2490 600 ~ 3260 12.3 / 11.3 1.4 + 1.4 + 1.8

2.8 + 2.8 + 5.0 7.50 2.8 ~ 8.0 2250 600 ~ 2910 11.1 / 10.2 1.3 + 1.3 + 2.0

2.8 + 3.2 + 3.2 7.50 2.4 ~ 7.7 2690 580 ~ 3180 13.2 / 12.2 1.5 + 1.6 + 1.6

2.8 + 3.2 + 4.0 7.50 2.6 ~ 8.0 2450 600 ~ 3200 12.1 / 11.1 1.4 + 1.5 + 1.7

2.8 + 3.2 + 5.0 7.50 2.8 ~ 8.0 2250 600 ~ 2910 11.1 / 10.2 1.2 + 1.4 + 2.0

2.8 + 4.0 + 4.0 7.50 2.7 ~ 8.0 2290 600 ~ 3020 11.3 / 10.4 1.3 + 1.6 + 1.6

2.8 + 4.0 + 5.0 7.50 2.8 ~ 8.0 2170 580 ~ 2760 10.7 / 9.8 1.1 + 1.6 + 1.8

2.8 + 5.0 + 5.0 7.50 2.8 ~ 8.0 2070 520 ~ 2650 10.2 / 9.4 1.0 + 1.7 + 1.7

3.2 + 3.2 + 3.2 7.50 2.4 ~ 7.7 2650 590 ~ 3190 13.1 / 12.0 1.5 + 1.5 + 1.5

3.2 + 3.2 + 4.0 7.50 2.6 ~ 8.0 2450 600 ~ 3210 12.1 / 11.1 1.5 + 1.5 + 1.7

3.2 + 3.2 + 5.0 7.50 2.8 ~ 8.0 2250 600 ~ 2920 11.1 / 10.2 1.4 + 1.4 + 1.9

3.2 + 4.0 + 4.0 7.50 2.8 ~ 8.0 2290 600 ~ 2960 11.3 / 10.4 1.4 + 1.6 + 1.6

3.2 + 4.0 + 5.0 7.50 2.8 ~ 8.0 2170 580 ~ 2760 10.7 / 9.8 1.3 + 1.5 + 1.7

3.2 + 5.0 + 5.0 7.50 2.8 ~ 8.0 2060 520 ~ 2650 10.2 / 9.4 1.2 + 1.7 + 1.7

4.0 + 4.0 + 4.0 7.50 2.8 ~ 8.0 2170 590 ~ 2820 10.7 / 9.8 1.5 + 1.5 + 1.5

4.0 + 4.0 + 5.0 7.50 2.8 ~ 8.0 2070 540 ~ 2650 10.2 / 9.4 1.5 + 1.5 + 1.7

Current, 50Hz,

220V / 240V

(A)

Current, 50Hz,

220V / 240V

(A)

MOISTURE REMOVAL VOLUME

MOISTURE REMOVAL VOLUME

l/h

l/h

18

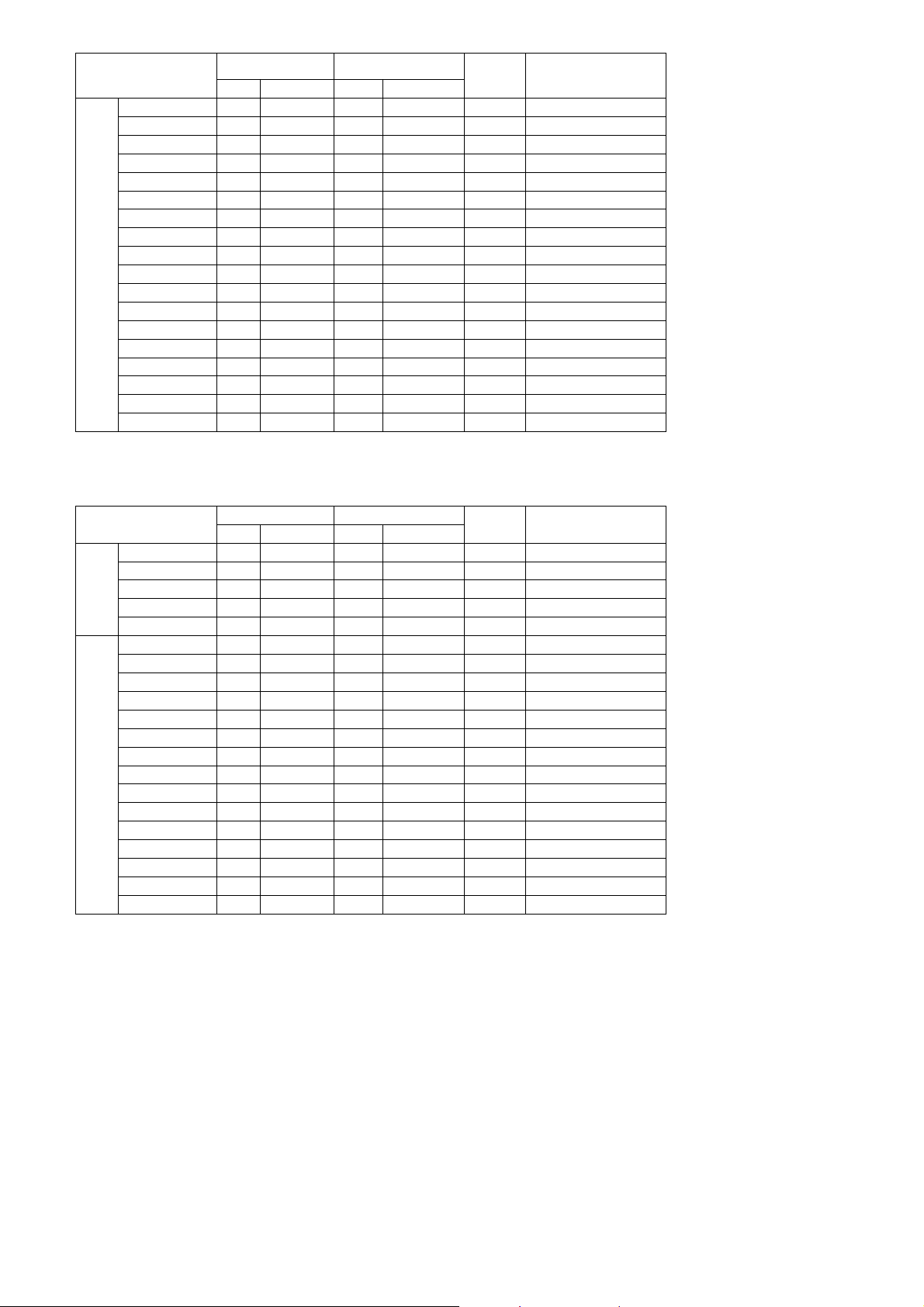

Cooling Capacity (kW) Input Power (W)

Total min ~ max Rating min ~ max

4 Room

Indoor unit capacity

Cooling

2.8 + 2.8 + 2.8 + 2.8 7.50 2.8 ~ 8.0 2060 520 ~ 2 650 10.2 / 9.4 1.2 + 1.2 + 1.2 + 1.2

2.8 + 2.8 + 2.8 + 3.2 7.50 2.8 ~ 8.0 2060 520 ~ 2 650 10.2 / 9.4 1.2 + 1.2 + 1.2 + 1.3

2.8 + 2.8 + 2.8 + 4.0 7.50 2.8 ~ 8.0 2060 520 ~ 2 590 10.2 / 9.4 1.1 + 1.1 + 1.1 + 1.5

2.8 + 2.8 + 2.8 + 5.0 7.50 2.8 ~ 8.0 2060 520 ~ 2 530 10.2 / 9.4 1.0 + 1.0 + 1.0 + 1.6

2.8 + 2.8 + 3.2 + 3.2 7.50 2.8 ~ 8.0 2060 520 ~ 2 650 10.2 / 9.4 1.1 + 1.1 + 1.3 + 1.3

2.8 + 2.8 + 3.2 + 4.0 7.50 2.8 ~ 8.0 2060 520 ~ 2 590 10.2 / 9.4 1.0 + 1.0 + 1.2 + 1.5

2.8 + 3.2 + 3.2 + 3.2 7.50 2.8 ~ 8.0 2060 520 ~ 2 650 10.2 / 9.4 1.0 + 1.3 + 1.3 + 1.3

2.8 + 3.2 + 3.2 + 4.0 7.50 2.8 ~ 8.0 2060 520 ~ 2 590 10.2 / 9.4 1.0 + 1.2 + 1.2 + 1.5

3.2 + 3.2 + 3.2 + 3.2 7.50 2.8 ~ 8.0 2060 520 ~ 2 590 10.2 / 9.4 1.2 + 1.2 + 1.2 + 1.2

Indoor Unit: CS-MPS9/12/15/18/24/28SKH

Outdoor Unit: CU-4S34SBH

2 Room

3 Room

Cooling Capacity

Indoor unit capacity

Cooling

2.8 + 2.8 5.60 2.4 ~ 5.8 1740 300 ~ 1860 3.22 A 870 8.5 / 7.8 1.6 + 1.6

2.8 + 3.2 6.00 2.4 ~ 6.7 1920 300 ~ 2360 3.13 B 960 9.3 / 8.5 1.6 + 1.8

2.8 + 4.0 6.80 2.4 ~ 7.2 2420 300 ~ 2760 2.81 C 1210 11.7 / 10.7 1.6 + 2.3

2.8 + 5.0 7.80 2.4 ~ 8.6 2680 280 ~ 3330 2.91 C 1340 12.9 / 11.8 1.6 + 2.7

2.8 + 6.0 8.80 2.5 ~ 9.1 3450 310 ~ 3640 2.55 E 1725 16.6 / 15.2 1.6 + 3.3

2.8 + 7.0 9.80 2.5 ~ 10.1 4140 310 ~ 4 620 2.37 F 2070 20.0 / 18.3 1.6 + 4.0

3.2 + 3.2 6.40 2.4 ~ 7.2 2100 290 ~ 2620 3.05 B 1050 10.1 / 9.3 1.8 + 1.8

3.2 + 4.0 7.20 2.4 ~ 8.1 2620 290 ~ 3390 2.75 D 1310 12.6 / 11.6 1.8 + 2.3

3.2 + 5.0 8.20 2.5 ~ 9.1 2890 310 ~ 3490 2.84 C 1445 13.9 / 12.8 1.8 + 2.7

3.2 + 6.0 9.20 2.5 ~ 10.0 3570 310 ~ 4 460 2.58 E 1785 17.2 / 15.8 1.8 + 3.3

3.2 + 7.0 10.00 2.5 ~ 10.4 4220 310 ~ 4800 2.37 F 2110 20.3 / 18.6 1.8 + 3.9

4.0 + 4.0 8.00 2.5 ~ 8.6 3240 320 ~ 3930 2.47 E 1620 15.6 / 14.3 2.3 + 2.3

4.0 + 5.0 9.00 2.5 ~ 10.0 3460 310 ~ 4 460 2.60 D 1730 16.7 / 15.3 2.3 + 2.7

4.0 + 6.0 10.00 2.5 ~ 10.4 4460 310 ~ 4790 2.24 F 2230 21.5 / 19.7 2.3 + 3.3

4.0 + 7.0 10.00 2.5 ~ 10.4 4150 310 ~ 4800 2.41 E 2075 20.0 / 18.3 2.1 + 3.6

5.0 + 5.0 10.00 2.5 ~ 10.4 3610 300 ~ 4000 2.77 D 1805 17.4 / 16.0 2.7 + 2.7

5.0 + 6.0 10.00 2.5 ~ 10.4 3610 300 ~ 4000 2.77 D 1805 17.4 / 16.0 2.5 + 2.9

5.0 + 7.0 10.00 2.5 ~ 10.4 3470 300 ~ 3850 2.88 C 1735 16.7 / 15.3 2.4 + 3.2

6.0 + 6.0 10.00 2.5 ~ 10.4 3610 300 ~ 4000 2.77 D 1805 17.4 / 16.0 2.7 + 2.7

6.0 + 7.0 10.00 2.5 ~ 10.4 3470 300 ~ 3850 2.88 C 1735 16.7 / 15.3 2.5 + 2.9

7.0 + 7.0 10.00 2.5 ~ 10.4 3320 330 ~ 3690 3.01 B 1660 16.0 / 14.7 2.7 + 2.7

2.8 + 2.8 + 2.8 8.40 2.9 ~ 8.7 2750 360 ~ 2880 3.05 B 1375 13.3 / 12.2 1.6 + 1.6 + 1.6

2.8 + 2.8 + 3.2 8.80 2.9 ~ 9.6 2880 390 ~ 3320 3.06 B 1440 13.9 / 12.7 1.6 + 1.6 + 1.8

2.8 + 2.8 + 4.0 9.60 2.9 ~ 10 .1 3320 390 ~ 3 770 2.89 C 1660 16.0 / 14.7 1.6 + 1.6 + 2.3

2.8 + 2.8 + 5.0 10.0 0 2.9 ~ 10.7 3180 390 ~ 3770 3.14 B 1590 15.3 / 14.1 1.6 + 1.6 + 2.5

2.8 + 2.8 + 6.0 10.0 0 2.9 ~ 10.7 3180 390 ~ 3770 3.14 B 1590 15.3 / 14.1 1.5 + 1.5 + 2.9

2.8 + 2.8 + 7.0 10.0 0 2.9 ~ 10.7 3110 390 ~ 3620 3.22 A 1555 15.0 / 13.7 1.4 + 1.4 + 3.0

2.8 + 3.2 + 3.2 9.20 2.9 ~ 10 .1 2990 390 ~ 3 690 3.08 B 1495 14.4 / 13.2 1.6 + 1.8 + 1.8

2.8 + 3.2 + 4.0 10.0 0 2.9 ~ 10.7 3540 390 ~ 4320 2.82 C 1770 17.1 / 15. 6 1.6 + 1.8 + 2.3

2.8 + 3.2 + 5.0 10.0 0 2.9 ~ 10.7 3110 390 ~ 3700 3.22 A 1555 15.0 / 13.7 1.6 + 1.7 + 2.5

2.8 + 3.2 + 6.0 10.0 0 2.9 ~ 10.7 3110 390 ~ 3700 3.22 A 1555 15.0 / 13.7 1.5 + 1.6 + 2.7

2.8 + 3.2 + 7.0 10.0 0 2.9 ~ 10.7 3040 420 ~ 3540 3.29 A 1520 14.7 / 13.4 1.4 + 1.5 + 2.9

2.8 + 4.0 + 4.0 10.0 0 2.9 ~ 10.7 3540 390 ~ 4320 2.82 C 1770 17.1 / 15.6 1.6 + 2. 2 + 2.2

2.8 + 4.0 + 5.0 10.0 0 2.9 ~ 10.7 3110 390 ~ 3620 3.22 A 1555 15.0 / 13.7 1.5 + 1.9 + 2.4

2.8 + 4.0 + 6.0 10.0 0 2.9 ~ 10.7 3110 390 ~ 3620 3.22 A 1555 15.0 / 13.7 1.4 + 1.8 + 2.5

2.8 + 4.0 + 7.0 10.0 0 2.9 ~ 10.7 2970 420 ~ 3540 3.37 A 1485 14.3 / 13.1 1.3 + 1.7 + 2.8

2.8 + 5.0 + 5.0 10.0 0 2.9 ~ 10.7 2830 430 ~ 3250 3.53 A 1415 13.6 / 12.5 1.4 + 2.3 + 2.3

2.8 + 5.0 + 6.0 10.0 0 2.9 ~ 10.7 2830 430 ~ 3250 3.53 A 1415 13.6 / 12.5 1.3 + 2.1 + 2.4

2.8 + 5.0 + 7.0 10.0 0 2.9 ~ 10.7 2760 460 ~ 3180 3.62 A 1380 13.3 / 12.2 1.2 + 1.9 + 2.6

2.8 + 6.0 + 6.0 10.0 0 2.9 ~ 10.7 2830 430 ~ 3250 3.53 A 1415 13.6 / 12.5 1.2 + 2.3 + 2.3

2.8 + 6.0 + 7.0 10.0 0 2.9 ~ 10.7 2760 460 ~ 3180 3.62 A 1380 13.3 / 12.2 1.1 + 2.2 + 2.5

2.8 + 7.0 + 7.0 10.0 0 2.9 ~ 10.7 2690 460 ~ 3110 3.72 A 1345 13.0 / 11.9 1.1 + 2.4 + 2.4

3.2 + 3.2 + 3.2 9.60 2.9 ~ 10 .1 3110 390 ~ 3 540 3.09 B 1555 15.0 / 13.7 1.8 + 1.8 + 1.8

3.2 + 3.2 + 4.0 10.0 0 2.9 ~ 10.7 3470 390 ~ 4160 2.88 C 1735 16.7 / 15. 3 1.7 + 1.7 + 2.2

3.2 + 3.2 + 5.0 10.0 0 2.9 ~ 10.7 3040 390 ~ 3540 3.29 A 1520 14.7 / 13.4 1.6 + 1.6 + 2.4

(kW)

Total min ~ max Rating min ~ max W/W CLASS

Input Power (W) EER

Current, 50Hz,

220V / 240V

(A)

ANNUAL

ENERGY

CONSUMPTION

(kWh)

MOISTURE REMOVAL VOLUME

Current,

50Hz, 220V /

240V (A)

l/h

MOISTURE REMOVAL

VOLUME

l/h

19

3 Room

4 Room

Cooling Capacity

Indoor unit capacity

Cooling

3.2 + 3.2 + 6.0 10.0 0 2.9 ~ 10.7 3040 390 ~ 3540 3.29 A 1520 14.7 / 13.4 1.6 + 1.6 + 2.6

3.2 + 3.2 + 7.0 10.0 0 2.9 ~ 10.7 2970 420 ~ 3470 3.37 A 1485 14.3 / 13.1 1.5 + 1.5 + 2.9

3.2 + 4.0 + 4.0 10.0 0 2.9 ~ 10.7 3390 390 ~ 4160 2.95 C 1695 16.3 / 15.0 1.7 + 2. 1 + 2.1

3.2 + 4.0 + 5.0 10.0 0 2.9 ~ 10.7 3040 420 ~ 3540 3.29 A 1520 14.7 / 13.4 1.6 + 1.9 + 2.3

3.2 + 4.0 + 6.0 10.0 0 2.9 ~ 10.7 3040 420 ~ 3540 3.29 A 1520 14.7 / 13.4 1.5 + 1.7 + 2.5

3.2 + 4.0 + 7.0 10.0 0 2.9 ~ 10.7 2970 420 ~ 3470 3.37 A 1485 14.3 / 13.1 1.5 + 1.7 + 2.7

3.2 + 5.0 + 5.0 10.0 0 2.9 ~ 10.7 2760 460 ~3180 3.62 A 1380 13.3 / 12.2 1.5 + 2.2 + 2.2

3.2 + 5.0 + 6.0 10.0 0 2.9 ~ 10.7 2760 460 ~ 3180 3.62 A 1380 13.3 / 12.2 1.5 + 2.0 + 2.4

3.2 + 5.0 + 7.0 10.0 0 2.9 ~ 10.7 2690 460 ~ 3110 3.72 A 1345 13.0 / 11.9 1.4 + 1.9 + 2.5

3.2 + 6.0 + 6.0 10.0 0 2.9 ~ 10.7 2760 460 ~ 3180 3.62 A 1380 13.3 / 12.2 1.4 + 2.3 + 2.3

3.2 + 6.0 + 7.0 10.0 0 2.9 ~ 10.7 2690 460 ~ 3110 3.72 A 1345 13.0 / 11.9 1.3 + 2.2 + 2.4

3.2 + 7.0 + 7.0 10.0 0 2.9 ~ 10.7 2700 470 ~ 3110 3.70 A 1350 13.0 / 11.9 1.2 + 2.3 + 2.3

4.0 + 4.0 + 4.0 9.99 2.9 ~ 10 .7 3390 390 ~ 4 080 2.95 C 1695 16.3 / 15.0 1.9 + 1.9 + 1.9

4.0 + 4.0 + 5.0 10.0 0 2.9 ~ 10.7 2970 420 ~ 3540 3.37 A 1485 14.3 / 13.1 1.7 + 1.7 + 2.2

4.0 + 4.0 + 6.0 10.0 0 2.9 ~ 10.7 2970 420 ~ 3540 3.37 A 1485 14.3 / 13.1 1.7 + 1.7 + 2.4

4.0 + 4.0 + 7.0 10.0 0 2.9 ~ 10.7 2900 420 ~ 3400 3.45 A 1450 14.0 / 12.8 1.6 + 1.6 + 2.5

4.0 + 5.0 + 5.0 10.0 0 2.9 ~ 10.7 2760 460 ~ 3180 3.62 A 1380 13.3 / 12.2 1.7 + 2.1 + 2.1

4.0 + 5.0 + 6.0 10.0 0 2.9 ~ 10.7 2760 460 ~ 3180 3.62 A 1380 13.3 / 12.2 1.6 + 1.9 + 2.3

4.0 + 5.0 + 7.0 10.0 0 2.9 ~ 10.7 2690 460 ~ 3110 3.72 A 1345 13.0 / 11.9 1.5 + 1.8 + 2.4

4.0 + 6.0 + 6.0 10.0 0 2.9 ~ 10.7 2760 460 ~ 3180 3.62 A 1380 13.3 / 12.2 1.5 + 2.2 + 2.2

4.0 + 6.0 + 7.0 10.0 0 2.9 ~ 10.7 2690 460 ~ 3110 3.72 A 1345 13.0 / 11.9 1.5 + 2.0 + 2.3

5.0 + 5.0 + 5.0 9.99 2.9 ~ 10 .7 2570 510 ~ 2 970 3.89 A 1285 12.4 / 11.4 1.9 + 1.9 + 1.9

5.0 + 5.0 + 6.0 10.0 0 2.9 ~ 10.7 2630 510 ~ 2970 3.80 A 1315 12.7 / 11.6 1.8 + 1.8 + 2.2

5.0 + 5.0 + 7.0 10.0 0 2.9 ~ 10.7 2570 510 ~ 2970 3.89 A 1285 12.4 / 11.4 1.7 + 1.7 + 2.3

5.0 + 6.0 + 6.0 10.0 0 2.9 ~ 10.7 2630 510 ~ 2970 3.80 A 1315 12.7 / 11.6 1.7 + 2.0 + 2.0

2.8 + 2.8 + 2.8 + 2.8 10.00 2.9 ~ 10.6 3220 420 ~ 3770 3.11 B 1610 15.5 / 14.2 1.5 + 1.5 + 1.5 + 1.5

2.8 + 2.8 + 2.8 + 3.2 10.00 2.9 ~ 10.6 3150 420 ~ 3680 3.17 B 1575 15.2 / 13.9 1.5 + 1.5 + 1.5 + 1.6

2.8 + 2.8 + 2.8 + 4.0 10.00 2.9 ~ 10.8 3150 430 ~ 3850 3.17 B 1575 15.2 / 13.9 1.5 + 1.5 + 1.5 + 1.8

2.8 + 2.8 + 2.8 + 5.0 10.00 2.9 ~ 10.8 2930 470 ~ 3520 3.41 A 1465 14.1 / 12.9 1.4 + 1.4 + 1.4 + 2.2

2.8 + 2.8 + 2.8 + 6.0 10.00 2.9 ~ 11.0 2930 470 ~ 3690 3.41 A 1465 14.1 / 12.9 1.3 + 1.3 + 1.3 + 2.4

2.8 + 2.8 + 2.8 + 7.0 10.00 2.9 ~ 11.0 2930 500 ~ 3610 3.41 A 1465 14.1 / 12.9 1.2 + 1.2 + 1.2 + 2.5

2.8 + 2.8 + 3.2 + 3.2 10.00 2.9 ~ 10.6 3070 430 ~ 3600 3.26 A 1535 14.8 / 13.6 1.5 + 1.5 + 1.6 + 1.6

2.8 + 2.8 + 3.2 + 4.0 10.00 2.9 ~ 10.8 3070 430 ~ 3770 3.26 A 1535 14.8 / 13.6 1.4 + 1.4 + 1.5 + 1.8

2.8 + 2.8 + 3.2 + 5.0 10.00 2.9 ~ 10.8 2930 500 ~ 3440 3.41 A 1465 14.1 / 12.9 1.3 + 1.3 + 1.5 + 2.1

2.8 + 2.8 + 3.2 + 6.0 10.00 2.9 ~ 11.0 2930 500 ~ 3610 3.41 A 1465 14.1 / 12.9 1.2 + 1.2 + 1.4 + 2.3

2.8 + 2.8 + 3.2 + 7.0 10.00 2.9 ~ 11.2 2860 510 ~ 3690 3.50 A 1430 13.8 / 12.6 1.1 + 1.1 + 1.3 + 2.5

2.8 + 2.8 + 4.0 + 4.0 10.00 2.9 ~ 10.8 3070 430 ~ 3770 3.26 A 1535 14.8 / 13.6 1.3 + 1.3 + 1.7 + 1.7

2.8 + 2.8 + 4.0 + 5.0 10.00 2.9 ~ 11.0 2930 500 ~ 3610 3.41 A 1465 14.1 / 12.9 1.2 + 1.2 + 1.6 + 2.0

2.8 + 2.8 + 4.0 + 6.0 10.00 2.9 ~ 11.0 2930 500 ~ 3610 3.41 A 1465 14.1 / 12.9 1.2 + 1.2 + 1.6 + 2.3

2.8 + 2.8 + 4.0 + 7.0 10.00 2.9 ~ 11.2 2860 510 ~ 3690 3.50 A 1430 13.8 / 12.6 1.1 + 1.1 + 1.5 + 2.4

2.8 + 2.8 + 5.0 + 5.0 10.00 2.9 ~ 11.0 2800 560 ~ 3460 3.57 A 1400 13.5 / 12.4 1.2 + 1.2 + 1.8 + 1.8

2.8 + 2.8 + 5.0 + 6.0 10.00 2.9 ~ 11.2 2800 560 ~ 3540 3.57 A 1400 13.5 / 12.4 1.1 + 1.1 + 1.7 + 2.1

2.8 + 3.2 + 3.2 + 3.2 10.00 2.9 ~ 10.8 3070 460 ~ 3680 3.26 A 1535 14.8 / 13.6 1.5 + 1.6 + 1.6 + 1.6

2.8 + 3.2 + 3.2 + 4.0 10.00 2.9 ~ 10.8 3070 460 ~ 3680 3.26 A 1535 14.8 / 13.6 1.4 + 1.5 + 1.5 + 1.7

2.8 + 3.2 + 3.2 + 5.0 10.00 2.9 ~ 11.0 2860 510 ~ 3610 3..50 A 1430 13.8 / 12.6 1.3 + 1.5 + 1.5 + 2.0

2.8 + 3.2 + 3.2 + 6.0 10.00 2.9 ~ 11.0 2860 510 ~ 3610 3.50 A 1430 13.8 / 12.6 1.2 + 1.4 + 1.4 + 2.3

2.8 + 3.2 + 3.2 + 7.0 10.00 2.9 ~ 11.2 2860 510 ~ 3690 3.50 A 1430 13.8 / 12.6 1.1 + 1.3 + 1.3 + 2.4

2.8 + 3.2 + 4.0 + 4.0 10.00 2.9 ~ 10.8 3070 460 ~ 3680 3.26 A 1535 14..8 / 13.6 1.3 + 1.5 + 1.7 + 1.7

2.8 + 3.2 + 4.0 + 5.0 10.00 2.9 ~ 11.0 2860 510 ~ 2530 3.50 A 1430 13.8 / 12.6 1.2 + 1.4 + 1.6 + 1.9

2.8 + 3.2 + 4.0 + 6.0 10.00 2.9 ~ 11.2 2860 510 ~ 3690 3.50 A 1430 13.8 / 12.6 1.1 + 1.3 + 1.5 + 2.2

2.8 + 3.2 + 4.0 + 7.0 10.00 2.9 ~ 11.2 2860 510 ~ 3690 3.50 A 1430 13..8 / 12.6 1.1 + 1.2 + 1.5 + 2.3

2.8 + 3.2 + 5.0 + 5.0 10.00 2.9 ~ 11.2 2800 560 ~ 3540 3.57 A 1400 13.5 / 12.4 1.1 + 1.3 + 1.8 + 1.8

2.8 + 3.2 + 5.0 + 6.0 10.00 2.9 ~ 11.2 2800 560 ~ 3540 3.57 A 1400 13.5 / 12.4 1.1 + 1.2 + 1.7 + 2.0

2.8 + 4.0 + 4.0 + 4.0 10.00 2.9 ~ 11.0 3000 460 ~ 3770 3.33 A 1500 14.5 / 13.3 1.2 + 1.6 + 1.6 + 1.6

2.8 + 4.0 + 4.0 + 5.0 10.00 2.9 ~ 11.2 2860 510 ~ 3690 3.50 A 1430 13.8 / 12.6 1.1 + 1.6 + 1.6 + 1.8

2.8 + 4.0 + 4.0 + 6.0 10.00 2.9 ~ 11.2 2860 510 ~ 3690 3.50 A 1430 13.8 / 12.6 1.1 + 1.5 + 1.5 + 2.1

2.8 + 4.0 + 5.0 + 5.0 10.00 2.9 ~ 11.2 2800 560 ~ 3540 3.57 A 1400 13.5 / 12.4 1.1 + 1.5 + 1.7 + 1.7

3.2 + 3.2 + 3.2 + 3.2 10.00 2.9 ~ 10.8 3000 460 ~ 3600 3.33 A 1500 14.5 / 13.3 1.5 + 1.5 + 1.5 + 1.5

3.2 + 3.2 + 3.2 + 4.0 10.00 2.9 ~ 10.8 3000 460 ~ 3600 3.33 A 1500 14.5 / 13.3 1.5 + 1.5 + 1.5 + 1.7

3.2 + 3.2 + 3.2 + 5.0 10.00 2.9 ~ 11.0 2860 510 ~ 3530 3.50 A 1430 13.8 / 12.6 1.4 + 1.4 + 1.4 + 2.0

(kW)

Total min ~ max Rating min ~ max W/W CLASS

Input Power (W) EER

ANNUAL

ENERGY

CONSUMPTION

(kWh)

Current,

50Hz, 220V /

240V (A)

MOISTURE REMOVAL

VOLUME

l/h

20

4 Room

Cooling Capacity

Indoor unit capacity

Cooling

3.2 + 3.2 + 3.2 + 6.0 10.00 2.9 ~ 11.0 2860 510 ~ 3530 3.50 A 1430 13.8 / 12.6 1.3 + 1.3 + 1.3 + 2.3

3.2 + 3.2 + 3.2 + 7.0 10.00 2.9 ~ 11.2 2860 520 ~ 3610 3.50 A 1430 13.8 / 12.6 1.2 + 1.2 + 1.2 + 2.4

3.2 + 3.2 + 4.0 + 4.0 10.00 2.9 ~ 11.0 3000 460 ~ 3770 3.33 A 1500 14.5 / 13.3 1.4 + 1.4 + 1.6 + 1.6

3.2 + 3.2 + 4.0 + 5.0 10.00 2.9 ~ 11.0 2860 510 ~ 3530 3.50 A 1430 13.8 / 12.6 1.3 + 1.3 + 1.6 + 1.8

3.2 + 3.2 + 4.0 + 6.0 10.00 2.9 ~ 11.2 2860 510 ~ 3690 3.50 A 1430 13.8 / 12.6 1.3 + 1.3 + 1.5 + 2.1

3.2 + 3.2 + 4.0 + 7.0 10.00 2.9 ~ 11.2 2860 550 ~ 3610 3.50 A 1430 13.8 / 12.6 1.2 + 1.2 + 1.5 + 2.3

3.2 + 3.2 + 5.0 + 5.0 10.00 2.9 ~ 11.2 2800 600 ~ 3540 3.57 A 1400 13.5 / 12.4 1.3 + 1.3 + 1.7 + 1.7

3.2 + 3.2 + 5.0 + 6.0 10.00 2.9 ~ 11.2 2800 600 ~ 3540 3.57 A 1400 13.5 / 12.4 1.2 + 1.2 + 1.7 + 2.0

3.2 + 4.0 + 4.0 + 4.0 10.00 2.9 ~ 11.0 3000 460 ~ 3770 3.33 A 1500 14.5 / 13.3 1.4 + 1.6 + 1.6 + 1.6

3.2 + 4.0 + 4.0 + 5.0 10.00 2.9 ~ 11.2 2860 510 ~ 3690 3.50 A 1430 13.8 / 12.6 1.3 + 1.5 + 1.5 + 1.7

3.2 + 4.0 + 4.0 + 6.0 10.00 2.9 ~ 11.2 2860 510 ~ 3690 3.50 A 1430 13.8 / 12.6 1.2 + 1.5 + 1.5 + 2.0

3.2 + 4.0 + 5.0 + 5.0 10.00 2.9 ~ 11.2 2810 600 ~ 3540 3.56 A 1405 13.5 / 12.4 1.2 + 1.5 + 1.7 + 1.7

4.0 + 4.0 + 4.0 + 4.0 10.00 2.9 ~ 11.2 3000 470 ~ 3850 3.33 A 1500 14.5 / 13.3 1.5 + 1.5 + 1.5 + 1.5

4.0 + 4.0 + 4.0 + 5.0 10.00 2.9 ~ 11.2 2860 520 ~ 3610 3.50 A 1430 13.8 / 12.6 1.5 + 1.5 + 1.5 + 1.7

(kW)

Total min ~ max Rating min ~ max W/W CLASS

Input Power (W) EER

ANNUAL

ENERGY

CONSUMPTION

(kWh)

Current,

50Hz, 220V /

240V (A)

MOISTURE REMOVAL

VOLUME

l/h

21

3. Location of Controls and Components

A

TEMP

O

TIMER

S

CANCEL

O

N

O

1

3

R

3.1 Indoor Unit

Aluminium fin

Front Panel

Air filters

R

E

W

O

P

R

E

I

M

T

Remote control receiver

Maximum distances: 8m

Horizontal airflow direction louver

• Manually adjustable.

3.2 Outdoor Unit

Air inlet (rear)

Vertical airflow

direction louver

• Do not adjust by hand

Auto OFF/ON button

• Use when remote control is misplaced

or a malfunction occurs.

Anti-bacterial filter

Indicator

POWER

TIMER

(Green)

(Orange)

3.3 Remote Control

ir inlet (side)

emote control display

OFF/ON

Operation mode

Temperature setting

AUTO

COOL

DRY

OFF

TIMERONTIMER

OFF/ON

FF/ON

MODE

TEMP

TIMER

ON

12

FF

OFF

SET CHECK CLOCK RESET

CHECK

FAN

SPEED

AIR

SWING

FAN SPEED

AIR SWING

ET

SET

3

CANCEL

AC RC

Air outlet

Fan speed selection

Air flow direction

selection

Timer setting

Clock setting

22

4. Dimensions

TEMP

O

T

S

CANCEL

O

O

1

CHEC

K

4.1 Indoor Unit

4.1.1 CS-MPS9SKH CS-MPS12SKH CS-MPS15SKH

<Top View>

<Side View> <Side View>

(214)

Left piping

hole

Air intake

direction

Air outlet

direction

<Front View>

1~2

<Bottom View>

125

<Rear View>

870

Liquid side

Gas side

214

290

61.1

45

1~2

Right piping

hole

<Remote Control>

47

AUTO

COOL

DRY

OFF

TIMERONTIMER

OFF/ON

FF/ON

MODE

TEMP

120

TIMER

IMER

N

12

FF

6060

SETCH ECK CLOCK RESET

115

22

FAN

SPEED

AIR

SWING

FANSPEED

AIRSWING

SET

ET

3

3

CANCELONOFF

AC RC

<Remote Control Holder>

61

Installation

plate

Indoor unit

external

dimensions

line

360

(41~61)

Relative position between the indoor unit and the installation plate <Front View>

497.2

432439

128

Right

piping

hole

Left

piping

hole

128

145

93

241.5 241.5

23

51

13.5

264.2

Unit: mm

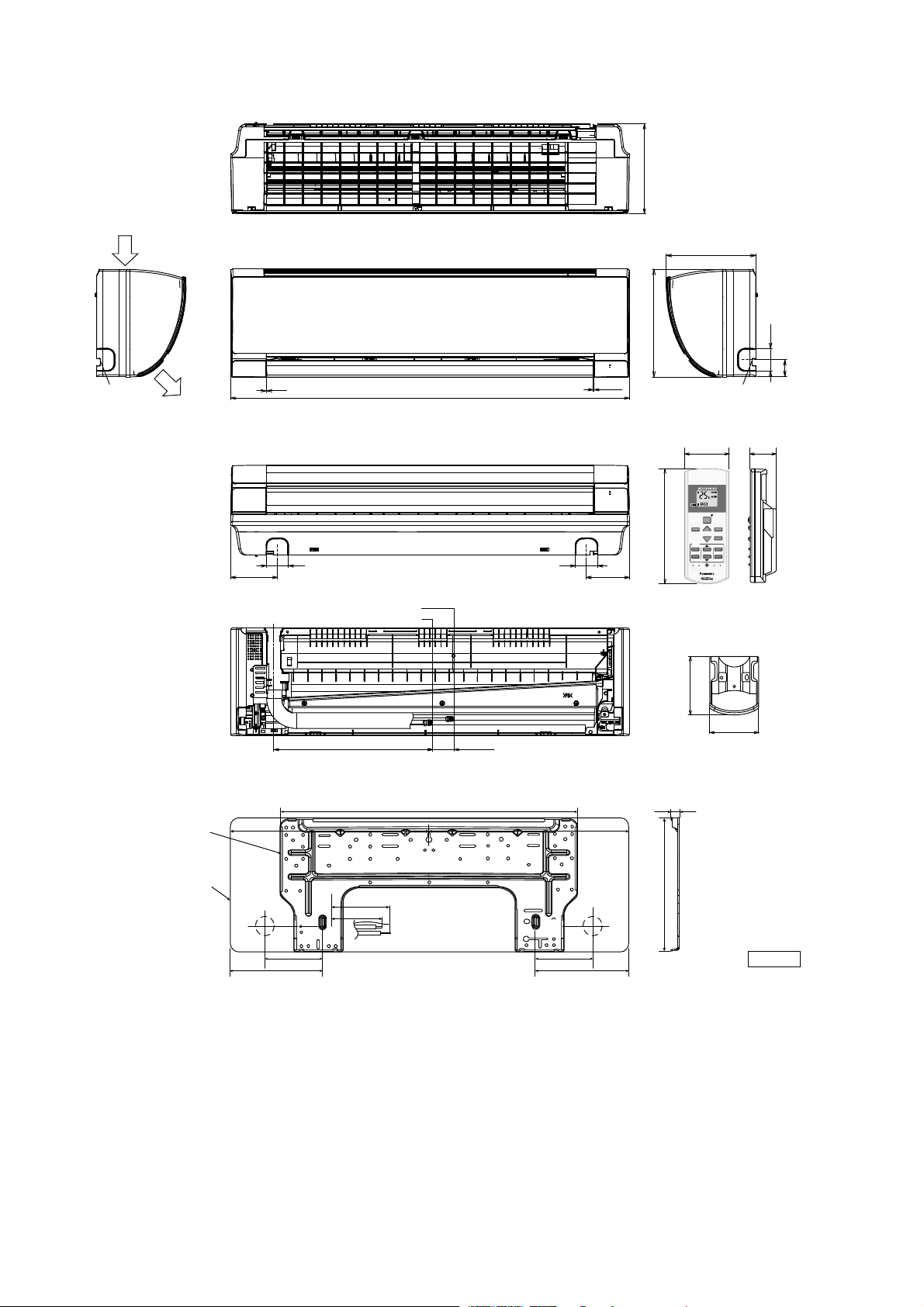

4.1.2 CS-MPS18SKH CS-MPS24SKH CS-MPS28SKH

TEMP

O

T

S

CANCEL

O

O

1

CHEC

K

<Top View>

<Side View> <Side View>

Air intake

direction

<Front View>

240

240

Left piping

hole

Air outlet

direction

1~2

<Bottom View>

125

60

<Rear View>

1070

Liquid side

Gas side

360 (41~61)

290

61.1

45

1~2

Right piping

hole

<Remote Control>

47

AUTO

COOL

DRY

OFF

TIMERONTIMER

OFF/ON

FF/ON

MODE

TEMP

120

TIMER

IMER

N

123

60

115

FF

SET CHECK CLOCK RESET

22

FAN

SPEED

AIR

SWING

FANSPEE D

AIRSWING

SET

ET

3

CANCELONOFF

AC RC

<Remote Control Holder>

61

51

Installation

plate

Indoor unit

external

dimensions

line

Relative position between the indoor unit and the installation plate <Front View>

748

128

241.5

532

Right

piping

hole

539

Left

piping

hole

241.5

128

269

219

13.5

264.3

Unit:mm

24

5. Refrigeration Cycle Diagram

INDOOR

INTAKE

TEMP.

SENSOR

HEAT EXCHANGER

(EVAPORATOR)

LIQUID

SIDE

2-WAY

VALVE

PIPE

TEMP.

SENSOR

GAS

SIDE

3-WAY

VALVE

COOLING

25

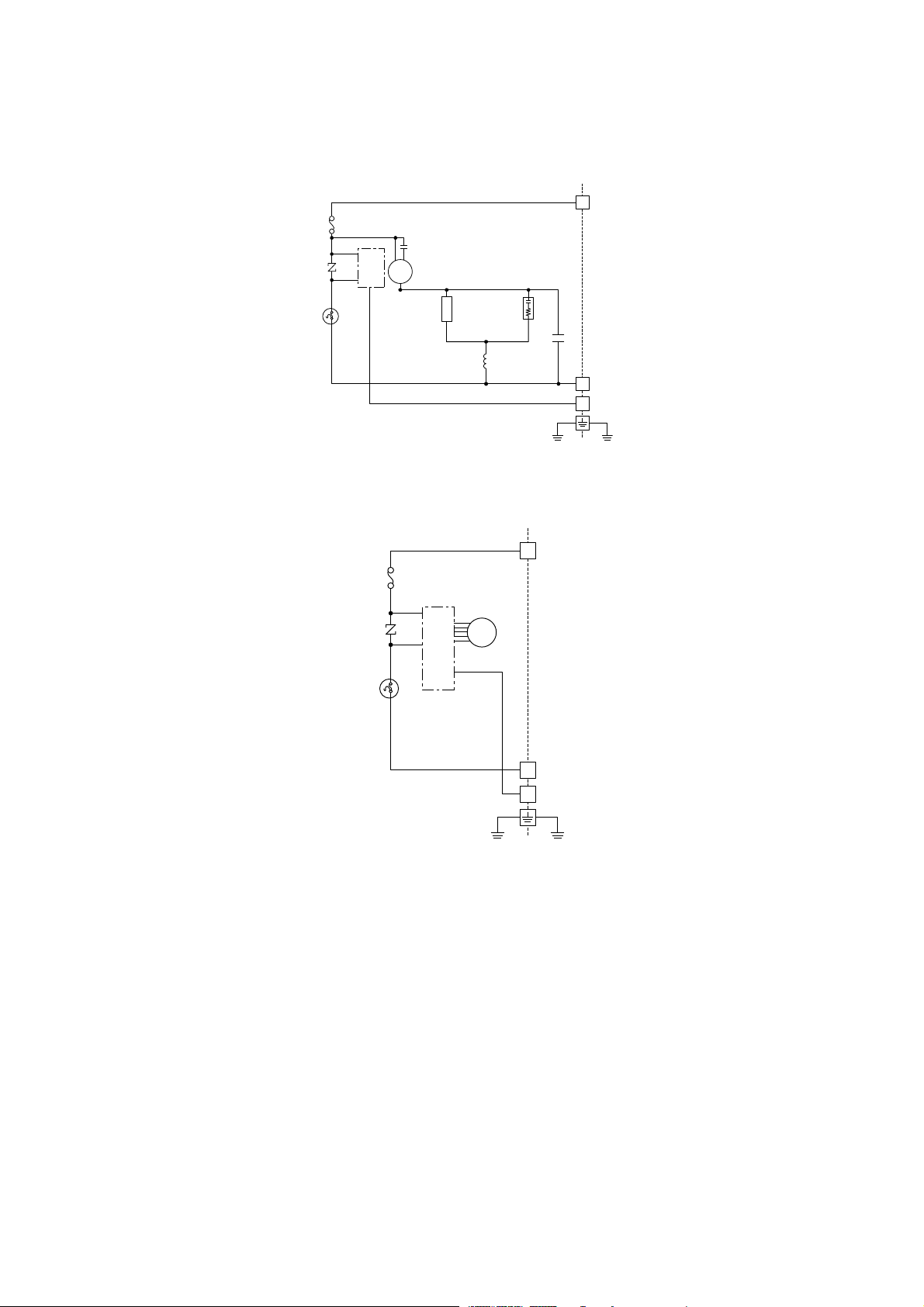

6. Block Diagram

6.1 CS-MPS9SKH CS-MPS12SKH CS-MPS15SKH

(INDOOR UNIT)

1

THERMAL

FUSE

FUSE

SC

FM

C-FM

FAN MOTOR

SSR301

L301

CR303

C330

2

3

6.2 CS-MPS18SKH CS-MPS24SKH CS-MPS28SKH

FUSE

THERMAL

FUSE

(INDOOR UNIT)

1

FM

SC

2

3

26

Loading...

Loading...