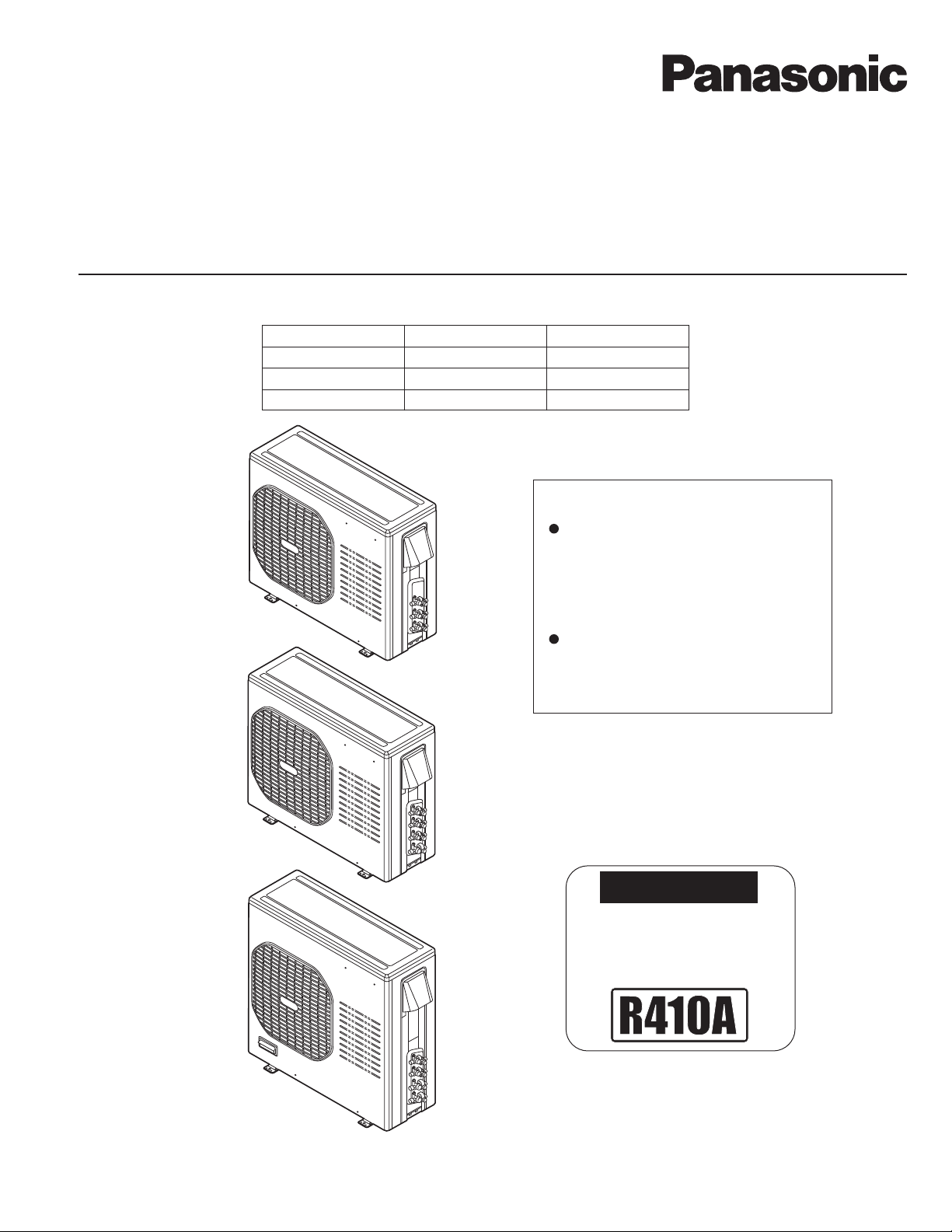

Panasonic CU-4KE24-31NBU Service Manual

TECHNICAL & SERVICE MANUAL

OUTDOOR UNIT : CU-3KE19NBU

CU-4KE24NBU

CU-4KE31NBU

DC INVERTER MULTI-SYSTEM AIR CONDITIONER

CU-3KE19NBU

CU-4KE24NBU

Capacity at 230V

19,100 BTU/h

23,200 BTU/h

30,600 BTU/h

Outdoor Model No.

CU-3KE19NBU

CU-4KE24NBU

CU-4KE31NBU

Product Code No.

1 852 361 27

1 852 361 28

1 852 361 29

< Applicable Indoor Units >

Wall mounted type

CS-MKE7NKU

CS-MKE9NKU

CS-MKE12NKU

CS-MKE18NKU

CS-MKE24NKU

Semi-concealed type

CS-MKE9NB4U & CZ-18BT1U

CS-MKE12NB4U & CZ-18BT1U

CS-KE12NB4UW & CZ-18BT1U

CU-4KE31NBU

IMPORTANT

These air conditioners employ new

refrigerant R410A.

Pay special attention when

servicing the unit.

REFERENCE NO.

SM700878

SAFETY PRECAUTIONS

• Before doing repair work, please read the " SAFETY PRECAUTIONS" carefully and fully understand them.

• The precautionary items here are divided into " Warning" and " Caution" items.

Items in particular which may cause death or serious injury to the service personnel if the work is not performed correctly,

are included in the " Warning" table.

However, even precautionary items identified as " Caution" also have the potential for serious consequences

if not performed correctly.

Important safety precautions are described for all items in both categories. Be sure to carefully follow all of them.

• Symbol Indication

: This symbol indicates items to which we need to pay attention.

In this triangle, a definite precautionary item is described.

: This symbol indicates the item to be prohibited.

In or close to this circle, a prohibited item is described.

: This symbol indicates the items requiring special attention or instruction.

In or close to this circle, a prohibited item is described.

• After doing repair work, perform a test run to confirm that there are no abnormalities.

At the same time, explain the precautions in use to the user.

Warning

Before performing an overhaul, disconnect the power plug or power cable from the unit.

Performing the work with the power supplied to the unit, may cause an electric shock.

When repair work or circuit inspection that requires power supply for the air conditioner, is to be performed,

do not touch the charging section.

Doing so may cause an electric shock.

Prohibit

For the step-up capacitor attached to the electric section, perform the repair work after sufficiently discharging it.

Insufficient capacitor discharge may cause an electric shock.

Do not perform repair work on the electric sections with wet hands.

Doing so may cause an electric shock.

Do not start or stop the air conditioner by means of connecting or disconnecting the power plug.

Doing so may cause an electric shock or fire.

When conducting repair work only use components included in the parts list for the corresponding unit and perform

the work with the appropriate tools.

Incorrect or poor repair work may cause an electric shock or fire.

Never modify the unit.

Doing so may cause an electric shock or fire.

Perform all electric work according to local applicable regulations related to electrical equipment or interior wiring

regulation and make sure to use the exclusive circuit.

Insufficient capacity to the electric circuit or defective arrangement results may cause an electric shock or fire.

Make sure to replace any power cable or lead wire showing any signs of scratch or deterioration.

Failure to do so may cause an electric shock, overheating or fire.

Make sure that there is no dust on or slack in the power plug and insert fully into the socket.

Dust or incomplete connections may cause an electric shock or fire.

Do not damage or process the power cord, as it may cause an electric shock or fire.

Prohibit

Prohibit

Prohibit

Prohibit

For the wiring between the indoor unit and outdoor unit, securely fix the specified cable onto the terminal plate.

Poorly fixed wiring may cause a heat or fire.

After connecting the wiring between the indoor unit and outdoor unit, attach the terminal cover securely.

Incomplete attachment of the terminal cover may cause overheating or fire.

2

Warning

If refrigerant gas blows off during the work, do not touch the refrigerant gas as it may cause frostbite.

If refrigerant gas leaks during the work, ventilate the room.

If refrigerant gas catches fire, harmful gas may be generated.

Do not mix any gas other than the specified refrigerant gas in the refrigerating cycle.

If air or other contaminants mix with the gas, pressure will become extremely high in the refrigerating cycle,

which may cause a unit breakdown."

When the welded section of the compressor intake or discharge pipe is to be disconnected, perform it in

a well-ventilated place after sufficiently recovering the refrigerant gas.

Any residue gas may jet out refrigerant or refrigerating machine oil, which may cause an injury.

When the work is to be performed in a high place (About 2 meters or more), make sure to wear a safety helmet,

gloves and safety belt. Insufficient safety gear may cause a serious injury in case of a fall.

When the unit is to be relocated, confirm that the new installation location has sufficient strength for the weight of the unit.

Insufficient strength of the installation location and incomplete installation work may cause an injury due to

the unit falling.

When the remote controller batteries are replaced, dispose of the old batteries out of the reach of children.

If a child swallows a battery, make sure that the child gets immediate medical attention.

Caution

Prohibit

Prohibit

Do not wash the air conditioner with water, as this may cause an electric shock or fire.

For the repair work in places with high humidity or moisture, make sure to ground the unit.

Failure to do so may cause an electric shock.

Confirm that the component attachment position, wiring condition, soldering condition and connector connection

are normal.

If not, it may cause overheating or fire.

Confirm that the temperature around the compressor is not too high, and then perform the repair work.

Failure to do so may cause a burn.

Perform welding work in a place with good ventilation.

If the work is performed in a poorly ventilated area, it might cause a lack of oxygen.

If the installation plate or attachment frame has deteriorated due to corrosion, etc., replace it.

Failure to do so may cause an injury due to the unit falling.

When the cleaning is to be performed, make sure to turn off the power and pull out the plug.

Touching the fan that is rotating at high speed may result in an injury.

When the indoor unit is to be removed, do not place it on an incline.

Doing so may cause wet furniture because water left inside may trickle down.

Do not hold the sharp end of the unit or the aluminum fins, as it may cause an injury to your hand or finger.

Prohibit

Prohibit

Prohibit

After repairs, make sure to measure the insulation resistance and confirm that the value is 1 Mohm or more.

Any insulation error may cause an electric shock.

After repairs, make sure to check the drainage of the indoor unit.

Inappropriate drainage may cause wet furniture and floors due to water leakage.

3

SAFETY PRECAUTIONS

Table of Contents

Page

..............................................................................................................

2

TABLE OF CONTENTS

APPLICABLE INDOOR UNITS

1. OPERATING RANGE

2. SPECIFICATIONS

2-1. Unit Specifications

2-2. Major Component Specifications

2-3. Other Component Specifications

3. DIMENSIONAL DATA

4. REFRIGERANT FLOW DIAGRAM

4-1. Refrigerant Flow Diagram

5. PERFORMANCE DATA

5-1. Temperature Charts

5-2. Cooling Capacity

5-3. Cooling Capacity (Low Ambient)

5-4. Heating Capacity

......................................................................................................................

.....................................................................................................

...................................................................................................................

.............................................................................................................

...................................................................................................................

............................................................................................................

................................................................................................................

................................................................................................................

.......................................................................................

.......................................................................................

...................................................................................................

........................................................................................

4

6

7

8

17

20

21

24

27

50

56

62

6. ELECTRICAL DATA

6-1. Electric Wiring Diagrams

7. FUNCTIONS

7-1. Explanation of Functions

7-2. Protective Functions

8. TROUBLESHOOTING (BEFORE CALLING FOR SERVICE)

8-1. Precautions before Performing Inspection or Repair

8-2. Trouble Diagnosis by Error Monitop Lamps

8-3. Checking the Outdoor System

8-4. Trouble Diagnosis of Each Part

8-5. Trouble Diagnosis of Fan Motor

....................................................................................................

.....................................................................................................

...........................................................................................................

.......................................................................

...........................................................................................

.........................................................................................

.........................................................................................

..........................................................

68

71

77

80

81

82

83

87

4

9. REFRIGERANT R410A:

SPECIAL PRECAUTIONS WHEN SERVICING UNIT

9-1. Characteristics of New Refrigerant R410A

9-2. Checklist before Servicing

9-3. Tools Specifically for R410A

9-4. Tubing Installation Procedures

9-5. In Case of Compressor Malfunction

9-6. In Case Refrigerant is Leaking

9-7. Charging Additional Refrigerant

9-8. Retro-Fitting Existing Systems

...................................................................................................

................................................................................................

............................................................................................

....................................................................................

............................................................................................

..........................................................................................

............................................................................................

Page

.........................................................................

88

89

90

90

91

93

94

94

APPENDIX A INSTALLATION INSTRUCTIONS

.............................................................................

A-1

5

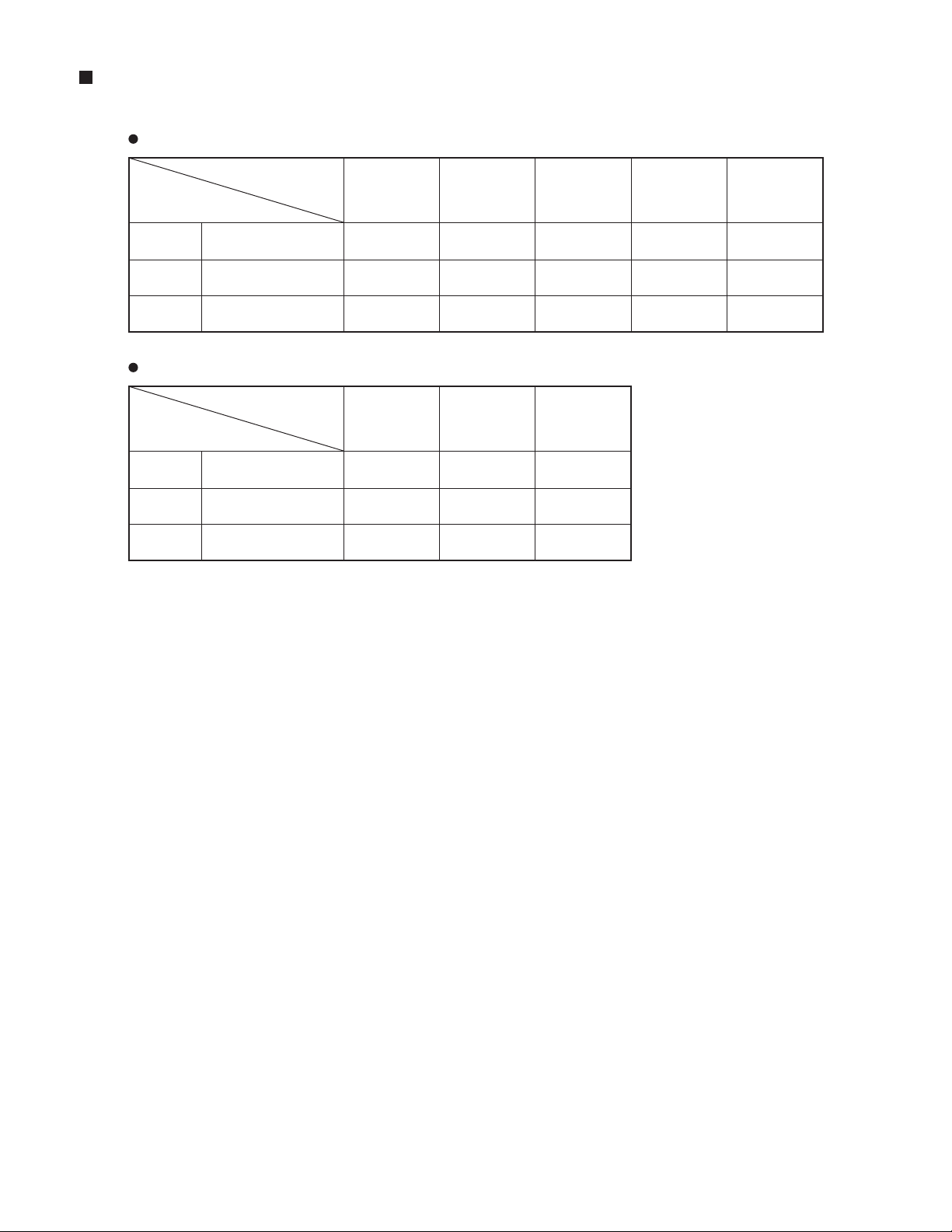

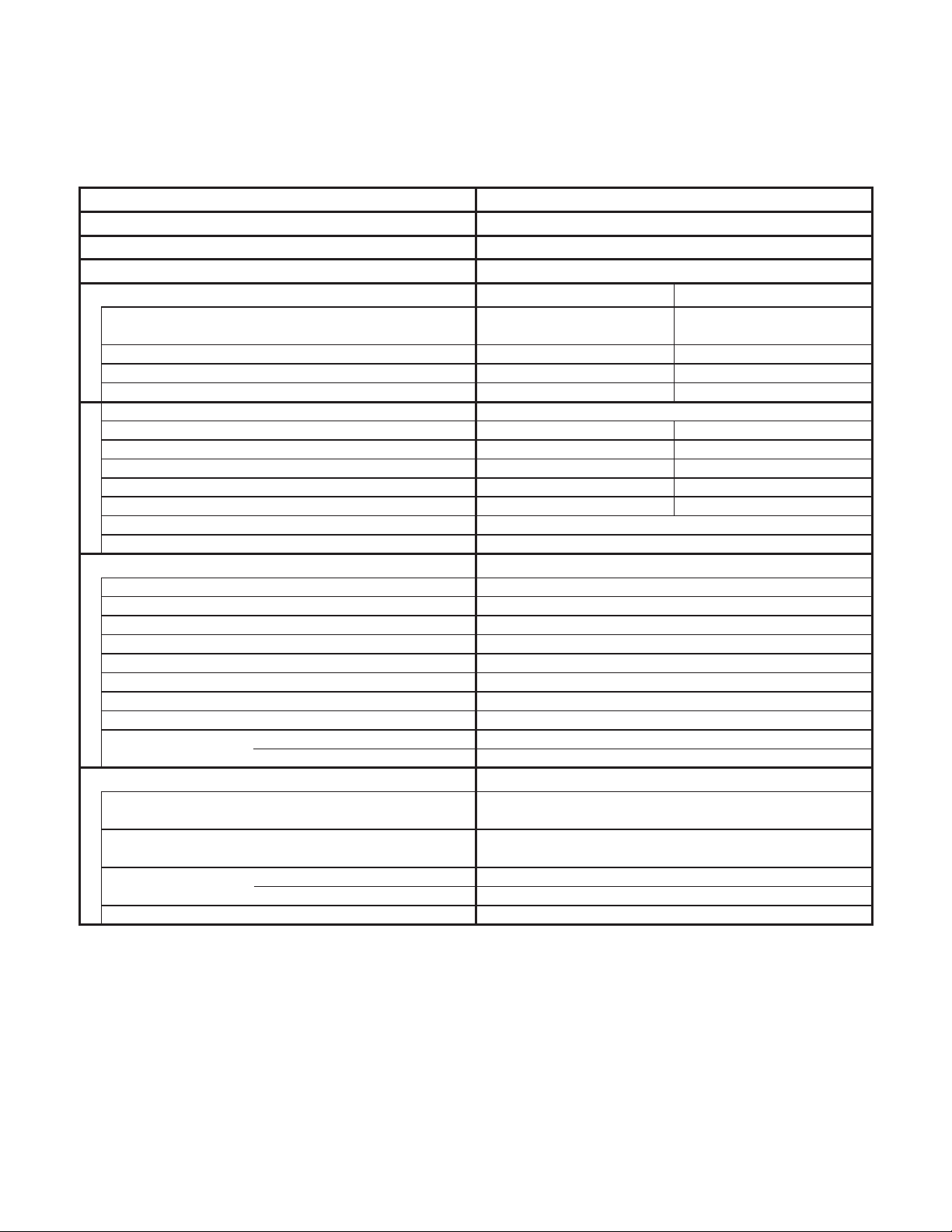

APPLICABLE INDOOR UNITS

Wall Mounted Type

Indoor Unit

CS-MKE7NKU

Multi-Outdoor Unit

CS-MKE9NKU CS-MKE12NKU CS-MKE18NKU CS-MKE24NKU

3-Room

4-Room

4-Room

CU-3KE19NBU

CU-4KE24NBU

CU-4KE31NBU

Semi-Concealed Type

Indoor Unit

Multi-Outdoor Unit

3-Room

4-Room

4-Room

CU-3KE19NBU

CU-4KE24NBU

CU-4KE31NBU

YES

YES

YES

CS-MKE9NB4U

&

CZ-18BT1U

YES

YES

YES

YES

YES

YES

CS-MKE12NB4U

&

CZ-18BT1U

YES

YES

YES

YES

YES

YES

CS-KE12NB4UW

&

CZ-18BT1U

YES

YES

YES

YES

YES

YES

NO

YES

YES

6

1. OPERATING RANGE

Temperature Indoor Air Intake Temp. Outdoor Air Intake Temp.

Cooling

Heating

Maximum

Minimum

Maximum

Minimum

95 °F DB / 71 °F WB

67 °F DB / 57 °F WB

80 °F DB / 67 °F WB

– DB / – WB

115 °F DB

14 °F DB

75 °F DB / 65 °F WB

– DB / 0 °F WB

7

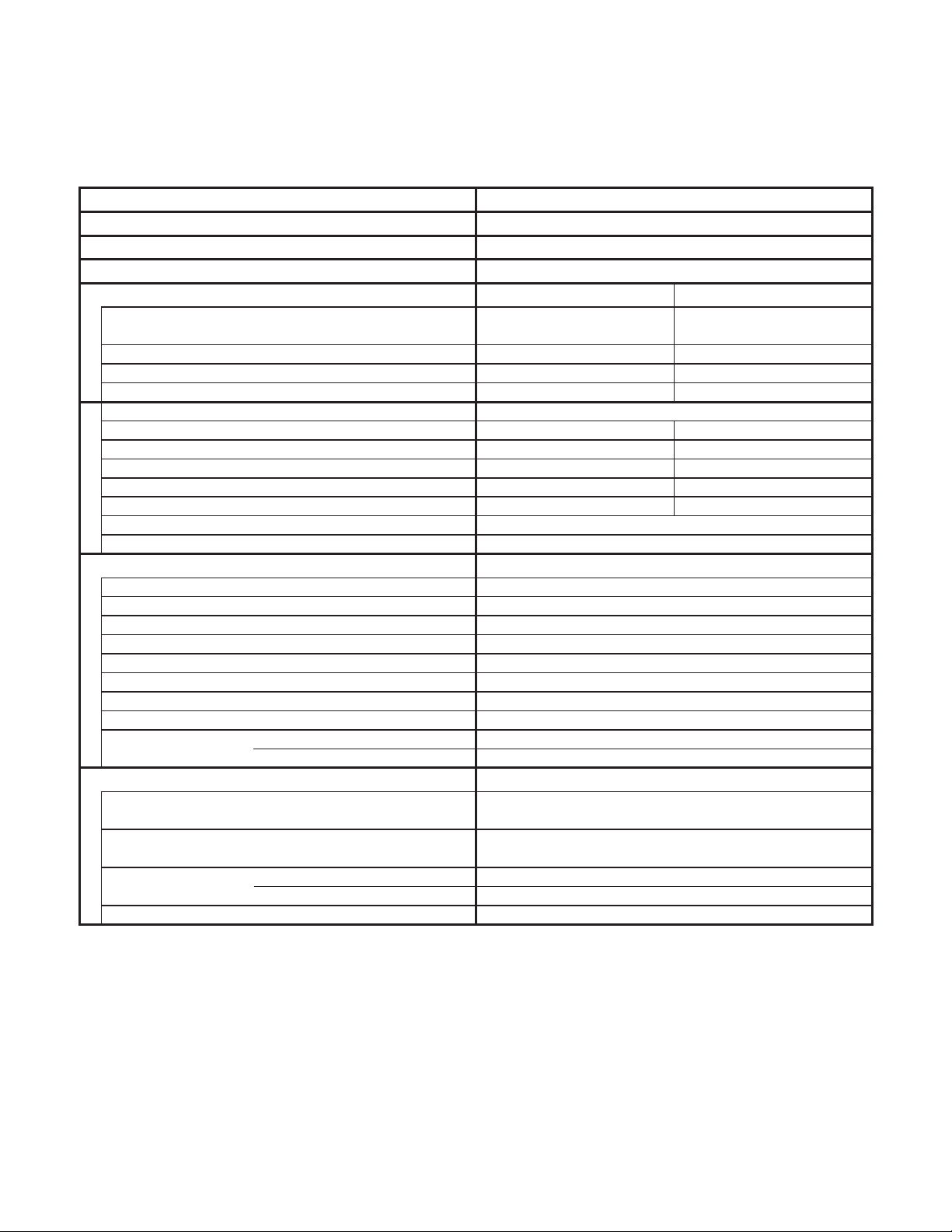

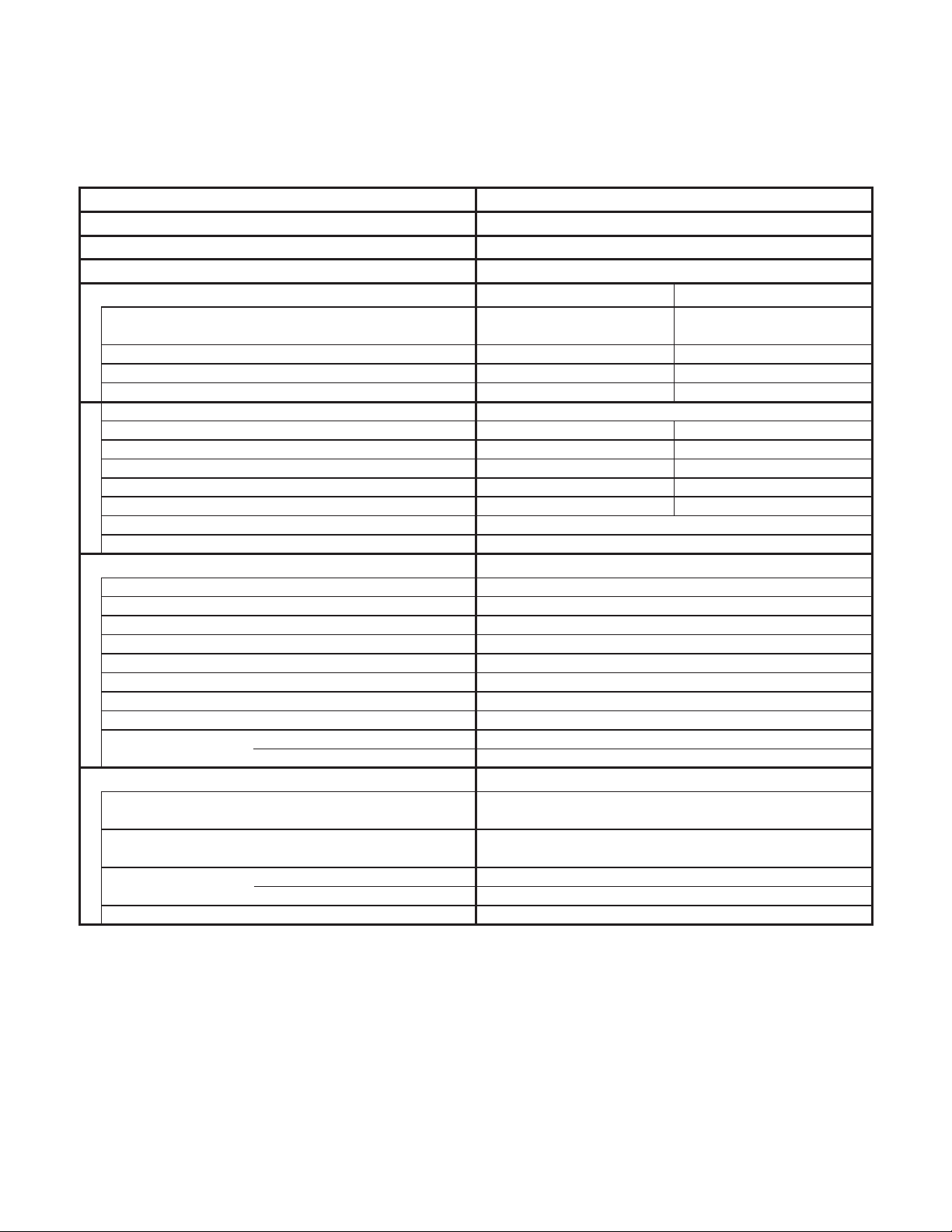

2. SPECIFICATIONS

2-1. Unit Specifications

Outdoor Unit CU-3KE19NBU

Indoor Unit CS-MKE9NKU × 2

Duct Less Type Rated

Type

Total Capacity

Sensible Capacity

Latent Capacity

Performance

Available Voltage Range

Running Amperes

EER BTU/h/W 12.0 COP W/W - 11.3

SEER BTU/Wh 18.0 HSPF

Electrical Rating

Compressor Locked Rotor Amperes

Fuse or Circuit Breaker Capacity A 15

Control Microprocessor

Fan Speeds Auto (Hi, Me, Lo)

Compressor

Refrigerant / Amount charged at shipment Ibs (g)

Refrigerant Control

Operation Sound (High) Cool / Heat

Features

Refrigerant Tubing Connections

Max. allowable tubing length per unit

Refrigerant inch (mm)

Tube Diameter inch (mm)

Unit Dimensions

Height × Width × Depth

Package Dimensions

Height × Width × Depth

Weight

Dimensions & Weight

Shipping Volume

Narrow tube

Wide tube

Net

Shipping

BTU/h

BTU/h

BTU/h

BTU/Wh

dB-A

ft (m)

(mm)

(mm)

Ibs (kg)

Ibs (kg)

cu.ft (m

17,000

kW

V

A

WPower Input

%Power Factor 98 98

A 14.5

inch

inch

3

)

( 6,800 to 18,600 )

5.00

( 1.90 to 5.45)

1,707 (2,900) 1,707 (2,900)Air Circulation (High) ft3/min (m3/h)

3-Room Multi Outdoor Unit

3Number of Connectable Indoor Units

3Number of Operatable Indoor Units

230V Single-Phase 60HzVoltage Rating

Cooling Heating

23,200

6.80

14,300

2,700

187 to 253

6.3

1,420

- 8.8

Outdoor Unit

DC Twin Rotary (Inverter)

R410A / 6.17 (2,800)

Electric Expansion Valve

50 / 52

Flare Type

82 (25)

1/4 (6.35) × 3

3/8 (9.52) × 3

Outdoor Unit

29-1/8 × 35-7/16 × 12-19/32

(740 × 900 × 320)

34-3/16 × 41-11/32 × 16-21/32

(868 × 1,050 × 423)

143.3 (65.0)

152.1 (69.0)

13.41 (0.38)

DATA SUBJECT TO CHANGE WITHOUT NOTICE.

< 230V >

( 7,800 to 24,800 )

( 2.30 to 7.30)

-

-

9.1

2,050

Remarks:

1. The values shown in performance section and electrical rating section above are based on the following unit combination.

For other combination unit, please refer to the "Unit Combination Tables" in this manual.

Indoor Unit : CS-MKE9NKU 2units Outdoor Unit : CU-3KE19NBU 1unit

The combination indoor unit is AHRI 210/240.

2. Rating conditions are: Cooling : Indoor air temp. 80 °F DB / 67 °F WB Heating : Indoor air temp. 70 °F DB

Outdoor air temp. 95 °F DB / 75 °F WB Outdoor air temp. 47 °F DB / 43 °F WB

8

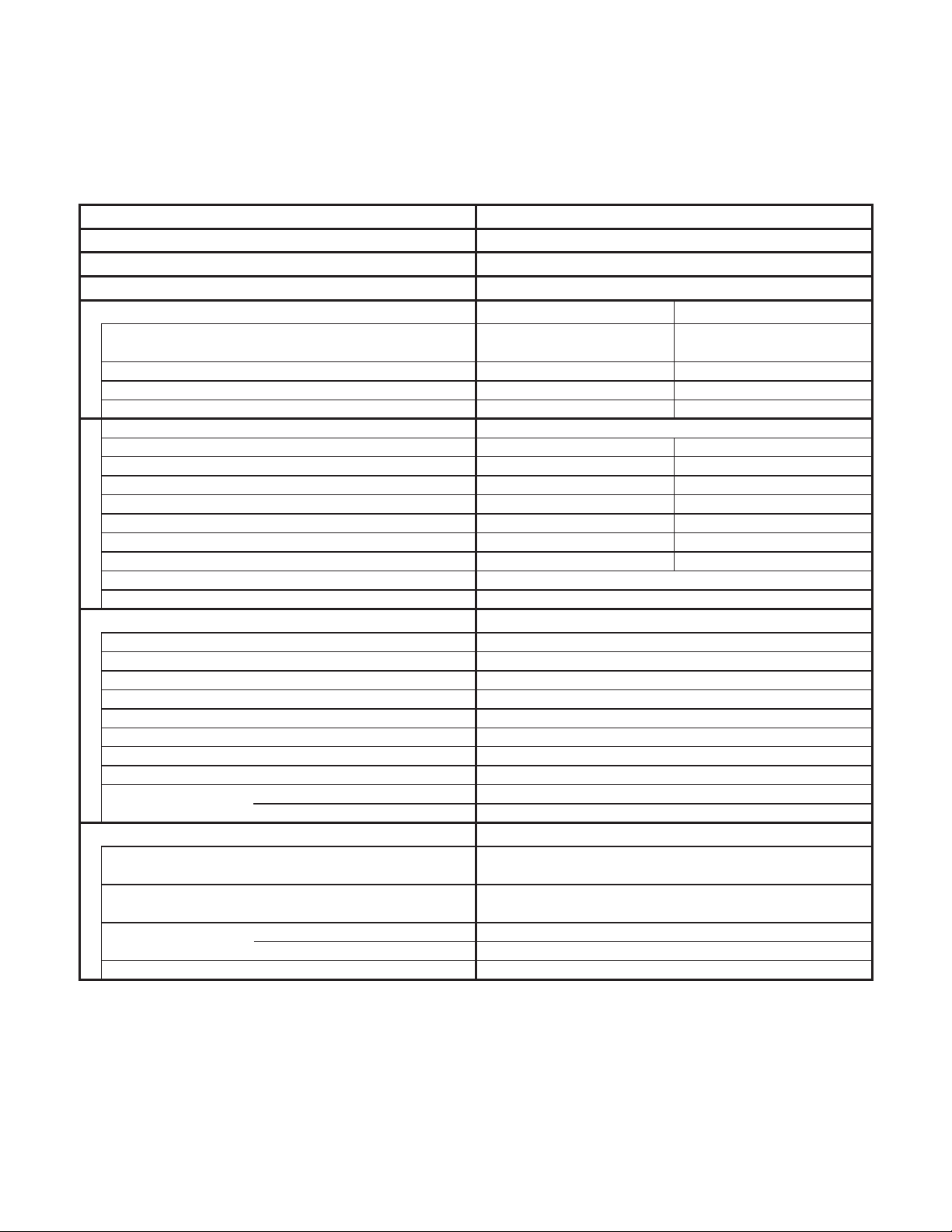

Outdoor Unit CU-3KE19NBU

Indoor Unit CS-MKE9NKU × 3

Type

Total Capacity

Sensible Capacity

Latent Capacity

Performance

Available Voltage Range

Running Amperes

EER BTU/h/W 12.7 COP W/W - 4.2

Electrical Rating

Compressor Locked Rotor Amperes

Fuse or Circuit Breaker Capacity A 15

Control Microprocessor

Fan Speeds Auto (Hi, Me, Lo)

Compressor

Refrigerant / Amount charged at shipment Ibs (g)

Refrigerant Control

Operation Sound (High) Cool / Heat

Features

Refrigerant Tubing Connections

Max. allowable tubing length per unit

Refrigerant inch (mm)

Tube Diameter inch (mm)

Unit Dimensions

Height × Width × Depth

Package Dimensions

Height × Width × Depth

Weight

Dimensions & Weight

Shipping Volume

Narrow tube

Wide tube

Net

Shipping

BTU/h

BTU/h

BTU/h

dB-A

ft (m)

(mm)

(mm)

Ibs (kg)

Ibs (kg)

cu.ft (m

18,600

kW

V

A

WPower Input

%Power Factor 98 98

A 14.5

inch

inch

3

)

( 9,800 to 18,600 )

5.45

( 2.90 to 5.45 )

1,707 (2,900) 1,707 (2,900)Air Circulation (High) ft3/min (m3/h)

3-Room Multi Outdoor Unit

3Number of Connectable Indoor Units

3Number of Operatable Indoor Units

230V Single-Phase 60HzVoltage Rating

Cooling Heating

24,800

7.30

15,800

2,800

187 to 253

6.5

1,470

Outdoor Unit

DC Twin Rotary (Inverter)

R410A / 6.17 (2,800)

Electric Expansion Valve

50 / 52

Flare Type

82 (25)

1/4 (6.35) × 3

3/8 (9.52) × 3

Outdoor Unit

29-1/8 × 35-7/16 × 12-19/32

(740 × 900 × 320)

34-3/16 × 41-11/32 × 16-21/32

(868 × 1,050 × 423)

143.3 (65.0)

152.1 (69.0)

13.41 (0.38)

DATA SUBJECT TO CHANGE WITHOUT NOTICE.

< 230V >

( 11,600 to 24,800 )

( 3.40 to 7.30 )

-

-

7.7

1,735

Remarks:

1. The values shown in performance section and electrical rating section above are based on the following unit combination.

For other combination unit, please refer to the "Unit Combination Tables" in this manual.

Indoor Unit : CS-MKE9NKU 3units Outdoor Unit : CU-3KE19NBU 1unit

2. Rating conditions are: Cooling : Indoor air temp. 80 °F DB / 67 °F WB Heating : Indoor air temp. 70 °F DB

Outdoor air temp. 95 °F DB / 75 °F WB Outdoor air temp. 47 °F DB / 43 °F WB

9

Outdoor Unit CU-3KE19NBU

Indoor Unit CS-MKE9NKU ×

Type

Total Capacity

Sensible Capacity

Latent Capacity

Performance

Available Voltage Range

Running Amperes

EER BTU/h/W 12.7 COP W/W - 4.2

Compressor Locked Rotor Amperes

Electrical Rating

Fuse or Circuit Breaker Capacity A 15

Control Microprocessor

Fan Speeds Auto (Hi, Me, Lo)

Compressor

Refrigerant / Amount charged at shipment Ibs (g)

Refrigerant Control

Operation Sound (High) Cool / Heat

Features

Refrigerant Tubing Connections

Max. allowable tubing length per unit

Refrigerant inch (mm)

Tube Diameter inch (mm)

Unit Dimensions

Height × Width × Depth

Package Dimensions

Height × Width × Depth

Weight

Dimensions & Weight

Shipping Volume

3

Narrow tube

Wide tube

Net

Shipping

3-Room Multi Outdoor Unit

3Number of Connectable Indoor Units

3Number of Operatable Indoor Units

208V Single-Phase 60HzVoltage Rating

Cooling Heating

BTU/h

BTU/h

BTU/h

dB-A

ft (m)

(mm)

(mm)

Ibs (kg)

Ibs (kg)

cu.ft (m

18,600

kW

V

A

WPower Input

%Power Factor 98 98

A 14.5

inch

inch

3

)

( 9,800 to 18,600 )

5.45

( 2.90 to 5.45 )

1,707 (2,900) 1,707 (2,900)Air Circulation (High) ft3/min (m3/h)

15,800

2,800

187 to 253

7.2

1,470

Outdoor Unit

DC Twin Rotary (Inverter)

R410A / 6.17 (2,800)

Electric Expansion Valve

50 / 52

Flare Type

82 (25)

1/4 (6.35) × 3

3/8 (9.52) × 3

Outdoor Unit

29-1/8 × 35-7/16 × 12-19/32

(740 × 900 × 320)

34-3/16 × 41-11/32 × 16-21/32

(868 × 1,050 × 423)

143.3

(65.0)

152.1

(69.0)

13.41 (0.38)

DATA SUBJECT TO CHANGE WITHOUT NOTICE.

24,800

7.30

< 208V >

( 11,600 to 24,800 )

( 3.40 to 7.30 )

-

-

8.5

1,735

Remarks:

1. The values shown in performance section and electrical rating section above are based on the following unit combination.

For other combination unit, please refer to the "Unit Combination Tables" in this manual.

Indoor Unit : CS-MKE9NKU 3units Outdoor Unit : CU-3KE19NBU 1unit

2. Rating conditions are: Cooling : Indoor air temp. 80 °F DB / 67 °F WB Heating : Indoor air temp. 70 °F DB

Outdoor air temp. 95 °F DB / 75 °F WB Outdoor air temp. 47 °F DB / 43 °F WB

10

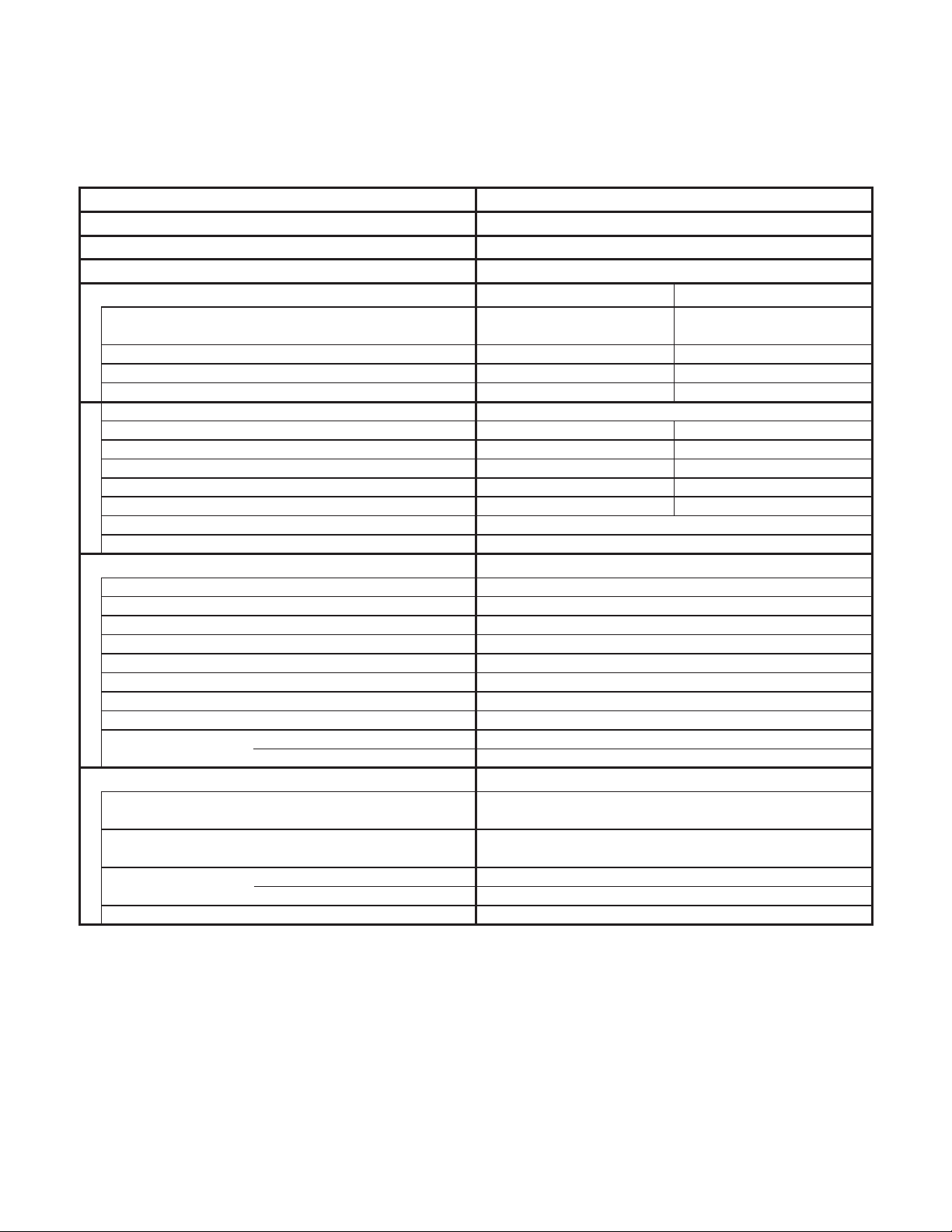

Outdoor Unit CU-4KE24NBU

Indoor Unit

CS-MKE7NKU × 2 + CS-MKE9NKU

Duct Less Type Rated

Type

Total Capacity

Sensible Capacity

Latent Capacity

Performance

Available Voltage Range

Running Amperes

EER BTU/h/W 11.5 COP W/W - 12.1

SEER BTU/Wh 18.0 HSPF

Electrical Rating

Compressor Locked Rotor Amperes

Fuse or Circuit Breaker Capacity A 20

Control Microprocessor

Fan Speeds Auto (Hi, Me, Lo)

Compressor

Refrigerant / Amount charged at shipment Ibs (g)

Refrigerant Control

Operation Sound (High) Cool / Heat

Features

Refrigerant Tubing Connections

Max. allowable tubing length per unit

Refrigerant inch (mm)

Tube Diameter inch (mm)

Unit Dimensions

Height × Width × Depth

Package Dimensions

Height × Width × Depth

Weight

Dimensions & Weight

Shipping Volume

Narrow tube

Wide tube

Net

Shipping

BTU/h

BTU/h

BTU/h

BTU/Wh

dB-A

ft (m)

(mm)

(mm)

Ibs (kg)

Ibs (kg)

cu.ft (m

22,400

kW

V

A

WPower Input

%Power Factor 98 98

A 14.5

inch

inch

3

)

( 8,500 to 23,200 )

6.60

( 2.50 to 6.80 )

1,707 (2,900) 1,707 (2,900)Air Circulation (High) ft3/min (m3/h)

4-Room Multi Outdoor Unit

4Number of Connectable Indoor Units

4Number of Operatable Indoor Units

230V Single-Phase 60HzVoltage Rating

Cooling Heating

27,200

8.00

18,800

3,600

187 to 253

8.7

1,950

- 8.5

Outdoor Unit

DC Twin Rotary (Inverter)

R410A / 6.17 (2,800)

Electric Expansion Valve

50 / 52

Flare Type

82 (25)

1/4 (6.35) × 4

3/8 (9.52) × 3 + 1/2 (12.7) × 1

Outdoor Unit

29-1/8 × 35-7/16 × 12-19/32

(740 × 900 × 320)

34-3/16 × 41-11/32 × 16-21/32

(868 × 1,050 × 423)

143.3

(65.0)

152.1

(69.0)

13.41 (0.38)

DATA SUBJECT TO CHANGE WITHOUT NOTICE.

< 230V >

( 10,200 to 29,200 )

( 3.00 to 8.60 )

-

-

10.0

2,250

Remarks:

1. The values shown in performance section and electrical rating section above are based on the following unit combination.

For other combination unit, please refer to the "Unit Combination Tables" in this manual.

Indoor Unit : CS-MKE7NKU 2units / CS-MKE9NKU 1units Outdoor Unit : CU-4KE24NBU 1unit

The combination indoor unit is AHRI 210/240.

2. Rating conditions are: Cooling : Indoor air temp. 80 °F DB / 67 °F WB Heating : Indoor air temp. 70 °F DB

Outdoor air temp. 95 °F DB / 75 °F WB Outdoor air temp. 47 °F DB / 43 °F WB

11

Outdoor Unit CU-4KE24NBU

Indoor Unit CS-MKE9NKU × 3

Type

Total Capacity

Sensible Capacity

Latent Capacity

Performance

Available Voltage Range

Running Amperes

EER BTU/h/W 11.4 COP W/W - 3.8

Compressor Locked Rotor Amperes

Electrical Rating

Fuse or Circuit Breaker Capacity A 20

Control Microprocessor

Fan Speeds Auto (Hi, Me, Lo)

Compressor

Refrigerant / Amount charged at shipment Ibs (g)

Refrigerant Control

Operation Sound (High) Cool / Heat

Features

Refrigerant Tubing Connections

Max. allowable tubing length per unit

Refrigerant inch (mm)

Tube Diameter inch (mm)

Unit Dimensions

Height × Width × Depth

Package Dimensions

Height × Width × Depth

Weight

Dimensions & Weight

Shipping Volume

Narrow tube

Wide tube

Net

Shipping

BTU/h

BTU/h

BTU/h

dB-A

ft (m)

(mm)

(mm)

Ibs (kg)

Ibs (kg)

cu.ft (m

23,200

kW

V

A

WPower Input

%Power Factor 98 98

A 14.5

inch

inch

3

)

( 9,800 to 23,200 )

6.80

( 2.90 to 6.80 )

1,707 (2,900) 1,707 (2,900)Air Circulation (High) ft3/min (m3/h)

4-Room Multi Outdoor Unit

4Number of Connectable Indoor Units

4Number of Operatable Indoor Units

230V Single-Phase 60HzVoltage Rating

Cooling Heating

29,200

8.60

19,600

3,600

187 to 253

9.0

2,040

Outdoor Unit

DC Twin Rotary (Inverter)

R410A / 6.17 (2,800)

Electric Expansion Valve

50 / 52

Flare Type

82 (25)

1/4 (6.35) × 4

3/8 (9.52) × 3 + 1/2 (12.7) × 1

Outdoor Unit

29-1/8 × 35-7/16 × 12-19/32

(740 × 900 × 320)

34-3/16 × 41-11/32 × 16-21/32

(868 × 1,050 × 423)

143.3

(65.0)

152.1

(69.0)

13.41 (0.38)

DATA SUBJECT TO CHANGE WITHOUT NOTICE.

< 230V >

( 11,600 to 29,200 )

( 3.40 to 8.60 )

-

-

10.1

2,270

Remarks:

1. The values shown in performance section and electrical rating section above are based on the following unit combination.

For other combination unit, please refer to the "Unit Combination Tables" in this manual.

Indoor Unit : CS-MKE9NKU 3units Outdoor Unit : CU-4KE24NBU 1unit

2. Rating conditions are: Cooling : Indoor air temp. 80 °F DB / 67 °F WB Heating : Indoor air temp. 70 °F DB

Outdoor air temp. 95 °F DB / 75 °F WB Outdoor air temp. 47 °F DB / 43 °F WB

12

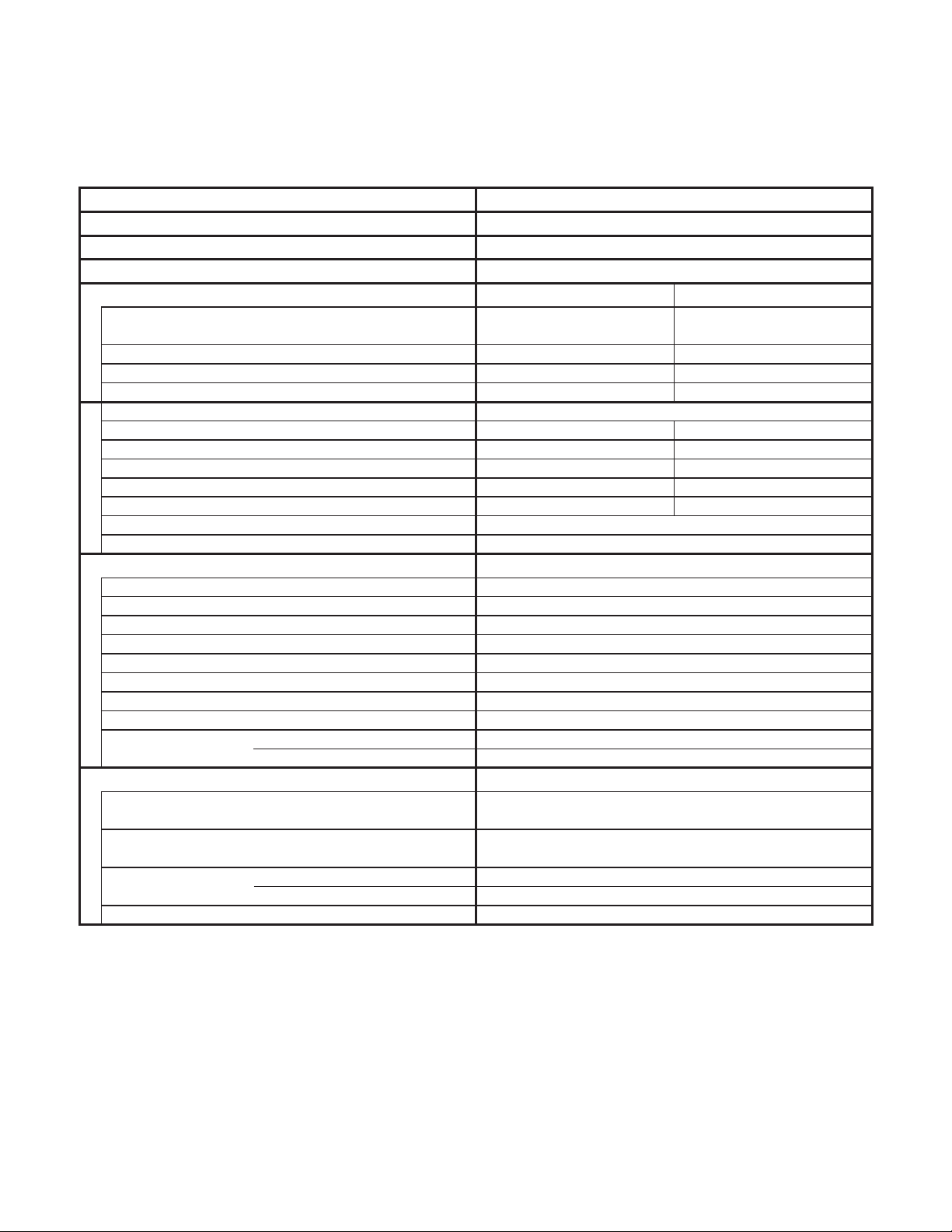

Outdoor Unit CU-4KE24NBU

Indoor Unit CS-MKE9NKU × 3

Type

Total Capacity

Sensible Capacity

Latent Capacity

Performance

Available Voltage Range

Running Amperes

EER BTU/h/W 11.4 COP W/W - 3.8

Compressor Locked Rotor Amperes

Electrical Rating

Fuse or Circuit Breaker Capacity A 20

Control Microprocessor

Fan Speeds Auto (Hi, Me, Lo)

Compressor

Refrigerant / Amount charged at shipment Ibs (g)

Refrigerant Control

Operation Sound (High) Cool / Heat

Features

Refrigerant Tubing Connections

Max. allowable tubing length per unit

Refrigerant inch (mm)

Tube Diameter inch (mm)

Unit Dimensions

Height × Width × Depth

Package Dimensions

Height × Width × Depth

Weight

Dimensions & Weight

Shipping Volume

Narrow tube

Wide tube

Net

Shipping

BTU/h

BTU/h

BTU/h

dB-A

ft (m)

(mm)

(mm)

Ibs (kg)

Ibs (kg)

cu.ft (m

23,200

kW

V

A

WPower Input

%Power Factor 98 98

A 14.5

inch

inch

3

)

( 9,800 to 23,200 )

6.80

( 2.90 to 6.80 )

1,707 (2,900) 1,707 (2,900)Air Circulation (High) ft3/min (m3/h)

4-Room Multi Outdoor Unit

4Number of Connectable Indoor Units

4Number of Operatable Indoor Units

208V Single-Phase 60HzVoltage Rating

Cooling Heating

29,200

8.60

19,600

3,600

187 to 253

10.0

2,040

Outdoor Unit

DC Twin Rotary (Inverter)

R410A / 6.17 (2,800)

Electric Expansion Valve

50 / 52

Flare Type

82 (25)

1/4 (6.35) × 4

3/8 (9.52) × 3 + 1/2 (12.7) × 1

Outdoor Unit

29-1/8 × 35-7/16 × 12-19/32

(740 × 900 × 320)

34-3/16 × 41-11/32 × 16-21/32

(868 × 1,050 × 423)

143.3

(65.0)

152.1

(69.0)

13.41 (0.38)

DATA SUBJECT TO CHANGE WITHOUT NOTICE.

< 208V >

( 11,600 to 29,200 )

( 2.90 to 8.60 )

-

-

11.1

2,270

Remarks:

1. The values shown in performance section and electrical rating section above are based on the following unit combination.

For other combination unit, please refer to the "Unit Combination Tables" in this manual.

Indoor Unit : CS-MKE9NKU 3units Outdoor Unit : CU-4KE24NBU 1unit

2. Rating conditions are: Cooling : Indoor air temp. 80 °F DB / 67 °F WB Heating : Indoor air temp. 70 °F DB

Outdoor air temp. 95 °F DB / 75 °F WB Outdoor air temp. 47 °F DB / 43 °F WB

13

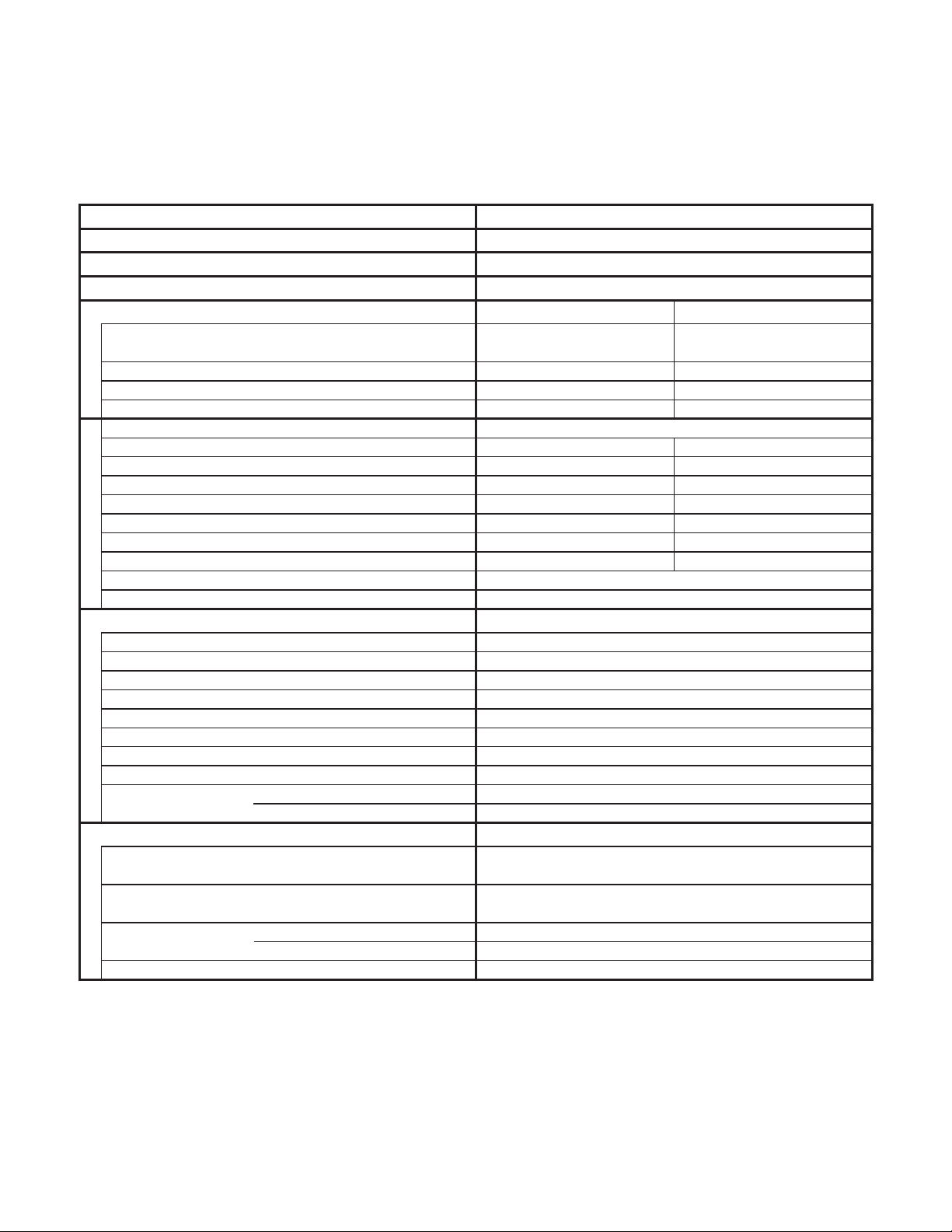

Outdoor Unit CU-4KE31NBU

Indoor Unit CS-MKE7NKU × 3 + CS-MKE9NKU

Duct Less Type Rated

Type

Total Capacity

Sensible Capacity

Latent Capacity

Performance

Available Voltage Range

Running Amperes

EER BTU/h/W 11.2 COP W/W - 13.3

SEER BTU/Wh 17.2 HSPF

Electrical Rating

Compressor Locked Rotor Amperes

Fuse or Circuit Breaker Capacity A 20

Control Microprocessor

Fan Speeds Auto (Hi, Me, Lo)

Compressor

Refrigerant / Amount charged at shipment Ibs (g)

Refrigerant Control

Operation Sound (High) Cool / Heat

Features

Refrigerant Tubing Connections

Max. allowable tubing length per unit

Refrigerant inch (mm)

Tube Diameter inch (mm)

Unit Dimensions

Height × Width × Depth

Package Dimensions

Height × Width × Depth

Weight

Dimensions & Weight

Shipping Volume

Narrow tube

Wide tube

Net

Shipping

BTU/h

BTU/h

BTU/h

BTU/Wh

dB-A

ft (m)

(mm)

(mm)

Ibs (kg)

Ibs (kg)

cu.ft (m

29,000

kW

V

A

WPower Input

%Power Factor 99 99

A 17.0

inch

inch

3

)

( 9,800 to 29,000 )

8.50

( 2.90 to 8.50 )

1,942 (3,300) 1,942 (3,300)Air Circulation (High) ft3/min (m3/h)

4-Room Multi Outdoor Unit

4Number of Connectable Indoor Units

4Number of Operatable Indoor Units

230V Single-Phase 60HzVoltage Rating

Cooling Heating

30,600

9.00

24,400

4,600

187 to 253

11.4

2,600

- 9.3

Outdoor Unit

DC Twin Rotary (Inverter)

R410A / 8.38 (3,800)

Electric Expansion Valve

53 / 55

Flare Type

100 (30.5)

1/4 (6.35) × 4

3/8 (9.52) × 2 + 1/2 (12.7) × 2

Outdoor Unit

35-1/32 × 35-7/16 × 12-19/32

(890 × 900 × 320)

40-1/8 × 41-11/32 × 16-21/32

(1,019 × 1,050 × 423)

180.8

(82.0)

189.6

(86.0)

15.88 (0.45)

DATA SUBJECT TO CHANGE WITHOUT NOTICE.

< 230V >

( 11,600 to 32,000 )

( 3.40 to 9.40 )

-

-

10.1

2,300

Remarks:

1. The values shown in performance section and electrical rating section above are based on the following unit combination.

For other combination unit, please refer to the "Unit Combination Tables" in this manual.

Indoor Unit : CS-MKE7NKU 3units / CS-MKE9NKU 1units Outdoor Unit : CU-4KE31NBU 1unit

The combination indoor unit is AHRI 210/240.

2. Rating conditions are: Cooling : Indoor air temp. 80 °F DB / 67 °F WB Heating : Indoor air temp. 70 °F DB

Outdoor air temp. 95 °F DB / 75 °F WB Outdoor air temp. 47 °F DB / 43 °F WB

14

Outdoor Unit CU-4KE31NBU

Indoor Unit CS-MKE9NKU × 4

Type

Total Capacity

Sensible Capacity

Latent Capacity

Performance

Available Voltage Range

Running Amperes

EER BTU/h/W 10.9 COP W/W - 4.0

Compressor Locked Rotor Amperes

Electrical Rating

Fuse or Circuit Breaker Capacity A 20

Control Microprocessor

Fan Speeds Auto (Hi, Me, Lo)

Compressor

Refrigerant / Amount charged at shipment Ibs (g)

Refrigerant Control

Operation Sound (High) Cool / Heat

Features

Refrigerant Tubing Connections

Max. allowable tubing length per unit

Refrigerant inch (mm)

Tube Diameter inch (mm)

Unit Dimensions

Height × Width × Depth

Package Dimensions

Height × Width × Depth

Weight

Dimensions & Weight

Shipping Volume

Narrow tube

Wide tube

Net

Shipping

BTU/h

BTU/h

BTU/h

dB-A

ft (m)

(mm)

(mm)

Ibs (kg)

Ibs (kg)

cu.ft (m

30,600

kW

V

A

WPower Input

%Power Factor 99 99

A 17.0

inch

inch

3

)

( 9,800 to 30,600 )

9.00

( 2.90 to 9.00 )

1,942 (3,300) 1,942 (3,300)Air Circulation (High) ft3/min (m3/h)

4-Room Multi Outdoor Unit

4Number of Connectable Indoor Units

4Number of Operatable Indoor Units

230V Single-Phase 60HzVoltage Rating

Cooling Heating

32,000

9.40

25,800

4,800

187 to 253

12.3

2,800

Outdoor Unit

DC Twin Rotary (Inverter)

R410A / 8.38 (3,800)

Electric Expansion Valve

53 / 55

Flare Type

100 (30.5)

1/4 (6.35) × 4

3/8 (9.52) × 2 + 1/2 (12.7) × 2

Outdoor Unit

35-1/32 × 35-7/16 × 12-19/32

(890 × 900 × 320)

40-1/8 × 41-11/32 × 16-21/32

(1,019 × 1,050 × 423)

180.8

(82.0)

189.6

(86.0)

15.88 (0.45)

DATA SUBJECT TO CHANGE WITHOUT NOTICE.

< 230V >

( 11,600 to 32,000 )

( 3.40 to 9.40 )

-

-

10.3

2,350

Remarks:

1. The values shown in performance section and electrical rating section above are based on the following unit combination.

For other combination unit, please refer to the "Unit Combination Tables" in this manual.

Indoor Unit : CS-MKE9NKU 4units Outdoor Unit : CU-4KE31NBU 1unit

2. Rating conditions are: Cooling : Indoor air temp. 80 °F DB / 67 °F WB Heating : Indoor air temp. 70 °F DB

Outdoor air temp. 95 °F DB / 75 °F WB Outdoor air temp. 47 °F DB / 43 °F WB

15

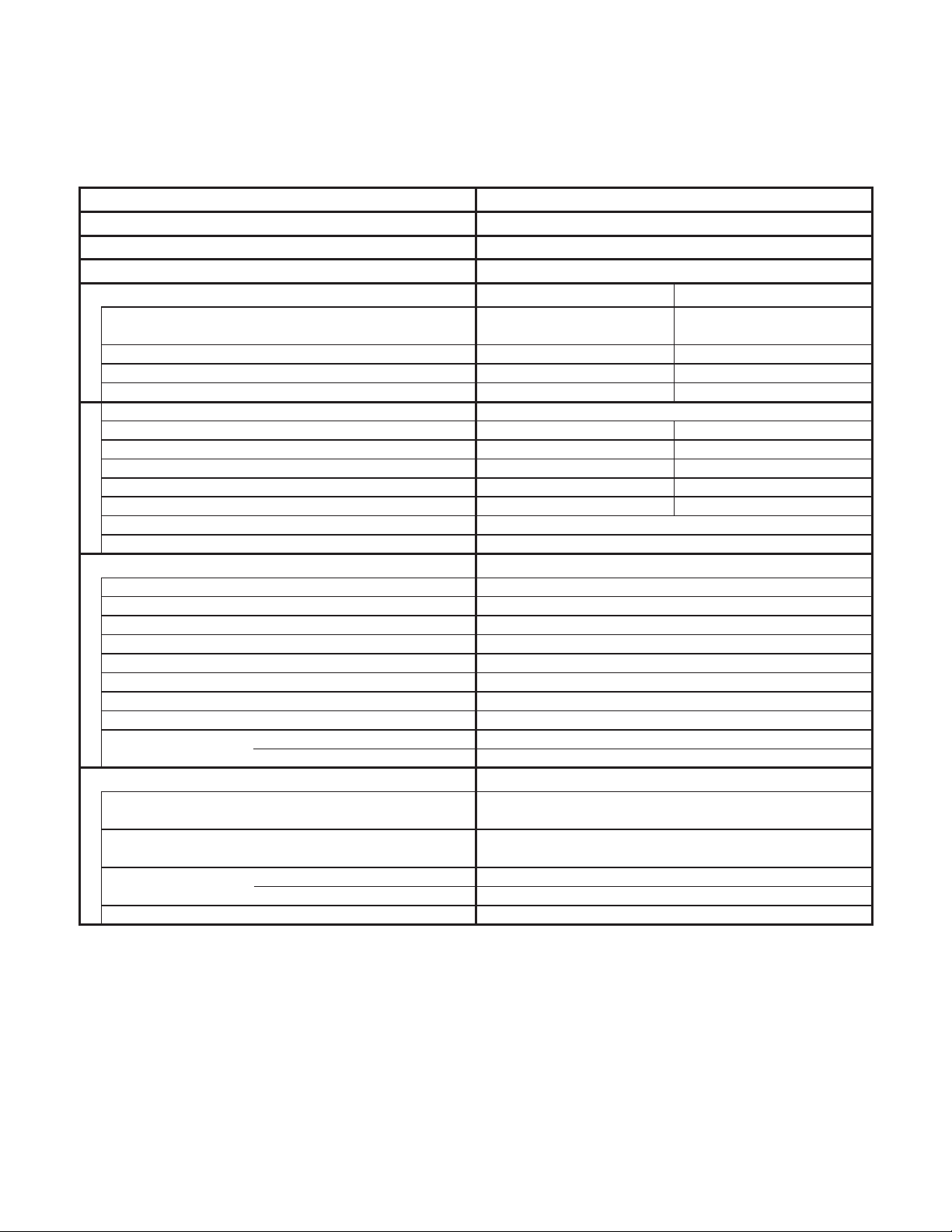

Outdoor Unit CU-4KE31NBU

Indoor Unit CS-MKE9NKU × 4

Type

Total Capacity

Sensible Capacity

Latent Capacity

Performance

Available Voltage Range

Running Amperes

EER BTU/h/W 11.2 COP W/W - 4.0

Compressor Locked Rotor Amperes

Electrical Rating

Fuse or Circuit Breaker Capacity A 20

Control Microprocessor

Fan Speeds Auto (Hi, Me, Lo)

Compressor

Refrigerant / Amount charged at shipment Ibs (g)

Refrigerant Control

Operation Sound (High) Cool / Heat

Features

Refrigerant Tubing Connections

Max. allowable tubing length per unit

Refrigerant inch (mm)

Tube Diameter inch (mm)

Unit Dimensions

Height × Width × Depth

Package Dimensions

Height × Width × Depth

Weight

Dimensions & Weight

Shipping Volume

Narrow tube

Wide tube

Net

Shipping

BTU/h

BTU/h

BTU/h

dB-A

ft (m)

(mm)

(mm)

Ibs (kg)

Ibs (kg)

cu.ft (m

28,600

kW

V

A

WPower Input

%Power Factor 99 99

A 17.0

inch

inch

3

)

( 9,800 to 28,600 )

8.40

( 2.90 to 8.40 )

1,942 (3,300) 1,942 (3,300)Air Circulation (High) ft3/min (m3/h)

4-Room Multi Outdoor Unit

4Number of Connectable Indoor Units

4Number of Operatable Indoor Units

208V Single-Phase 60HzVoltage Rating

Cooling Heating

32,000

9.40

24,200

4,400

187 to 253

12.7

2,560

Outdoor Unit

DC Twin Rotary (Inverter)

R410A / 8.38 (3,800)

Electric Expansion Valve

53 / 55

Flare Type

100 (30.5)

1/4 (6.35) × 4

3/8 (9.52) × 2 + 1/2 (12.7) × 2

Outdoor Unit

35-1/32 × 35-7/16 × 12-19/32

(890 × 900 × 320)

40-1/8 × 41-11/32 × 16-21/32

(1,019 × 1,050 × 423)

180.8

(82.0)

189.6

(86.0)

15.88 (0.45)

DATA SUBJECT TO CHANGE WITHOUT NOTICE.

< 208V >

( 11,600 to 32,000 )

( 3.40 to 9.40 )

-

-

11.4

2,350

Remarks:

1. The values shown in performance section and electrical rating section above are based on the following unit combination.

For other combination unit, please refer to the "Unit Combination Tables" in this manual.

Indoor Unit : CS-MKE9NKU 4units Outdoor Unit : CU-4KE31NBU 1unit

2. Rating conditions are: Cooling : Indoor air temp. 80 °F DB / 67 °F WB Heating : Indoor air temp. 70 °F DB

Outdoor air temp. 95 °F DB / 75 °F WB Outdoor air temp. 47 °F DB / 43 °F WB

16

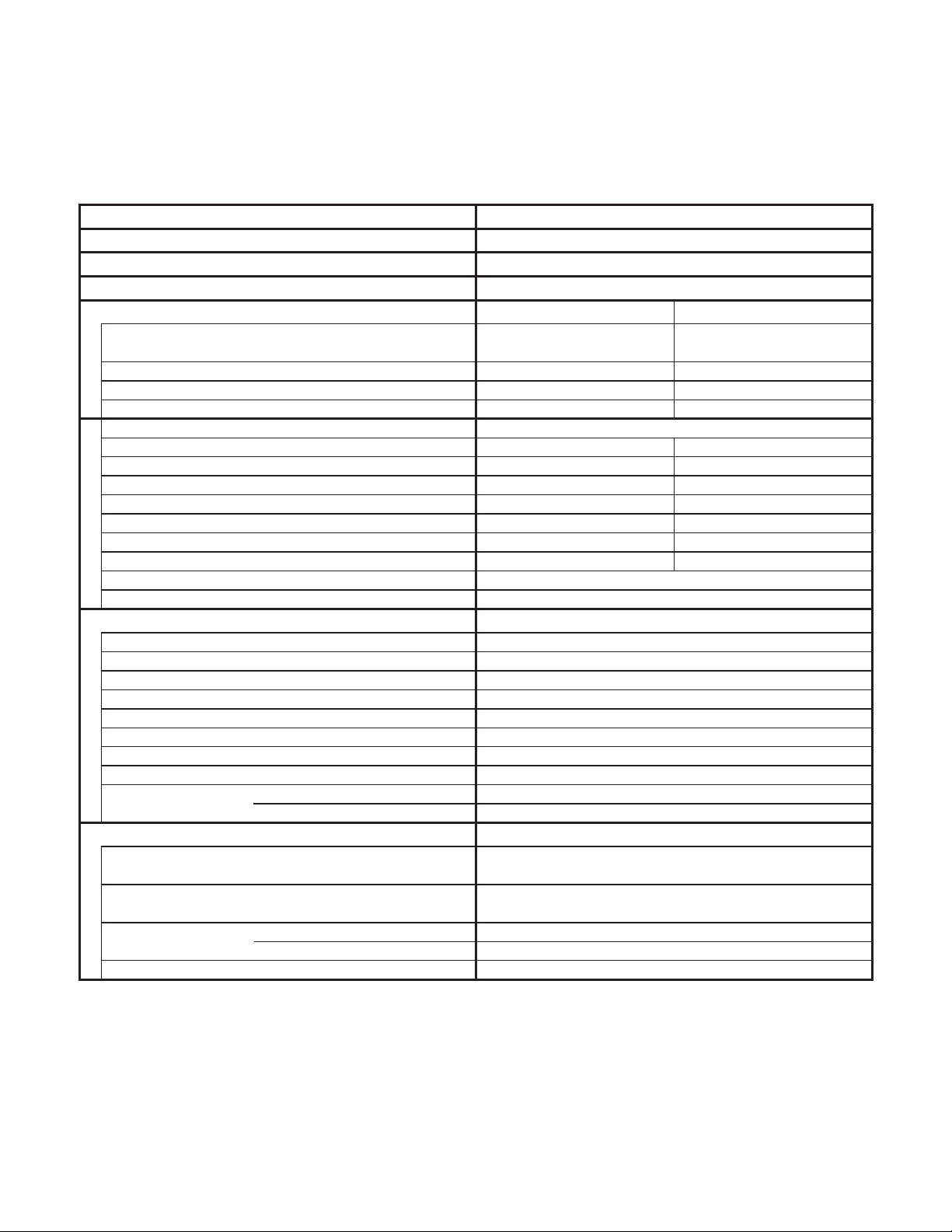

2-2. Major Component Specifications

2-2-1. Outdoor Unit

Outdoor Unit CU-3KE19NBU

Control PCB

Part No.

Controls

Control Circuit Fuse

Compressor

Type

Compressor Model / Nominal Output

Compressor Oil ... Amount

Coil Resistance (Ambient Temp. 68 °F (20 °C))

Safety Device

CT (Peak current cut-off control)

Compressor Discharge Temp. Control

Operation cut-off control in abnormal ambient Temp.

Overload Relay

Operation Temp.

Run Capacitor

Crankcase Heater

Pints (cc)

Ohm

Model

Micro F

VAC

CB-CU-3KE19NBU

Microprocessor

250V 25A

DC Twin Rotary (Hermetic)

5KD240XAB21 / 1,700W

FV50S ... 1.91 (900)

U - V :

0.720

V - W :

W - U :

CS-7L-2515

Open : 239 °F (115 °C), Close : 212 °F (100 °C)

230V 30W

0.708

0.726

Yes

Yes

Yes

-

-

Fan

Type

Q'ty ... Dia. inch (mm)

Fan Motor

Type

Model ... Q'ty

No. of Poles

Rough Measure RPM (Cool / Heat)

Nominal Output

Coil Resistance

(Ambient Temp. 68 °F (20 °C))

Safety Device

Type

Over-Current Protection

Run Capacitor

Heat Exchanger Coil

Coil

Rows

Fins per inch

Face Area

Over-Heat Protection

W

Ohm

Micro F

VAC

2

ft

(m2)

Propeller

1 ... D18-1/8 (D460)

DC Motor

SIC-71FW-D490-1 ... 1

8

750 / 750

90

-

Internal Controller

Yes

Yes

-

-

Aluminum Plate Fin / Copper Tube

2

18.1

6.40 (0.595)

External Finish Acrylic baked-on enamel finish

DATA SUBJECT TO CHANGE WITHOUT NOTICE.

17

Outdoor Unit CU-4KE24NBU

Control PCB

Part No.

Controls

Control Circuit Fuse

Compressor

Type

Compressor Model / Nominal Output

Compressor Oil ... Amount

Coil Resistance (Ambient Temp. 68 °F (20 °C))

Safety Device

CT (Peak current cut-off control)

Compressor Discharge Temp. Control

Operation cut-off control in abnormal ambient Temp.

Overload Relay

Run Capacitor

Crankcase Heater

Pints (cc)

Ohm

Model

Operation Temp.

Micro F

VAC

CB-CU-4KE24NBU

Microprocessor

250V 25A

DC Twin Rotary (Hermetic)

5KD240XAB21 / 1,700W

FV50S ... 1.91 (900)

U - V :

0.720

V - W :

W - U :

0.708

0.726

Yes

Yes

Yes

CS-7L-2515

Open : 239 °F (115 °C), Close : 212 °F (100 °C)

-

-

230V 30W

Fan

Type

Q'ty ... Dia. inch (mm)

Fan Motor

Type

Model ... Q'ty

No. of Poles

Rough Measure RPM (Cool / Heat)

Nominal Output

Coil Resistance

(Ambient Temp. 68 °F (20 °C))

Safety Device

Type

Over-Current Protection

Over-Heat Protection

Run Capacitor

Heat Exchanger Coil

Coil

Rows

Fins per inch

Face Area

W

Ohm

Micro F

VAC

2

ft

(m2)

Propeller

1 ... D18-1/8 (D460)

DC Motor

SIC-71FW-D490-1 ... 1

8

750 / 750

90

-

Internal Controller

Yes

Yes

-

-

Aluminum Plate Fin / Copper Tube

2

18.1

6.40 (0.595)

External Finish Acrylic baked-on enamel finish

DATA SUBJECT TO CHANGE WITHOUT NOTICE.

18

Outdoor Unit CU-4KE31NBU

Control PCB

Part No.

Controls

Control Circuit Fuse

Compressor

Type

Compressor Model / Nominal Output

Compressor Oil ... Amount

Coil Resistance (Ambient Temp. 68 °F (20 °C))

Safety Device

CT (Peak current cut-off control)

Compressor Discharge Temp. Control

Operation cut-off control in abnormal ambient Temp.

Overload Relay

Run Capacitor

Crankcase Heater

Pints (cc)

Ohm

Model

Operation Temp.

Micro F

VAC

CB-CU-4KE31NBU

Microprocessor

250V 25A

DC Twin Rotary (Hermetic)

5JD420XAB22 / 3,000W

FV50S ... 2.55 (1,200)

U - V :

0.435

V - W :

W - U :

0.441

0.452

Yes

Yes

Yes

CS-7L-2515

Open : 239 °F (115 °C), Close : 212 °F (100 °C)

-

-

230V 30W

Fan

Type

Q'ty ... Dia. inch (mm)

Fan Motor

Type

Model ... Q'ty

No. of Poles

Rough Measure RPM (Cool / Heat)

Nominal Output

Coil Resistance

(Ambient Temp. 68 °F (20 °C))

Safety Device

Type

Over-Current Protection

Over-Heat Protection

Run Capacitor

Heat Exchanger Coil

Coil

Rows

Fins per inch

Face Area

W

Ohm

Micro F

VAC

2

ft

(m2)

Propeller

1 ... D18-1/8 (D460)

DC Motor

SIC-71FW-D490-1 ... 1

8

800 / 800

90

-

Internal Controller

Yes

Yes

-

-

Aluminum Plate Fin / Copper Tube

2

18.1

7.75 (0.72)

External Finish Acrylic baked-on enamel finish

DATA SUBJECT TO CHANGE WITHOUT NOTICE.

19

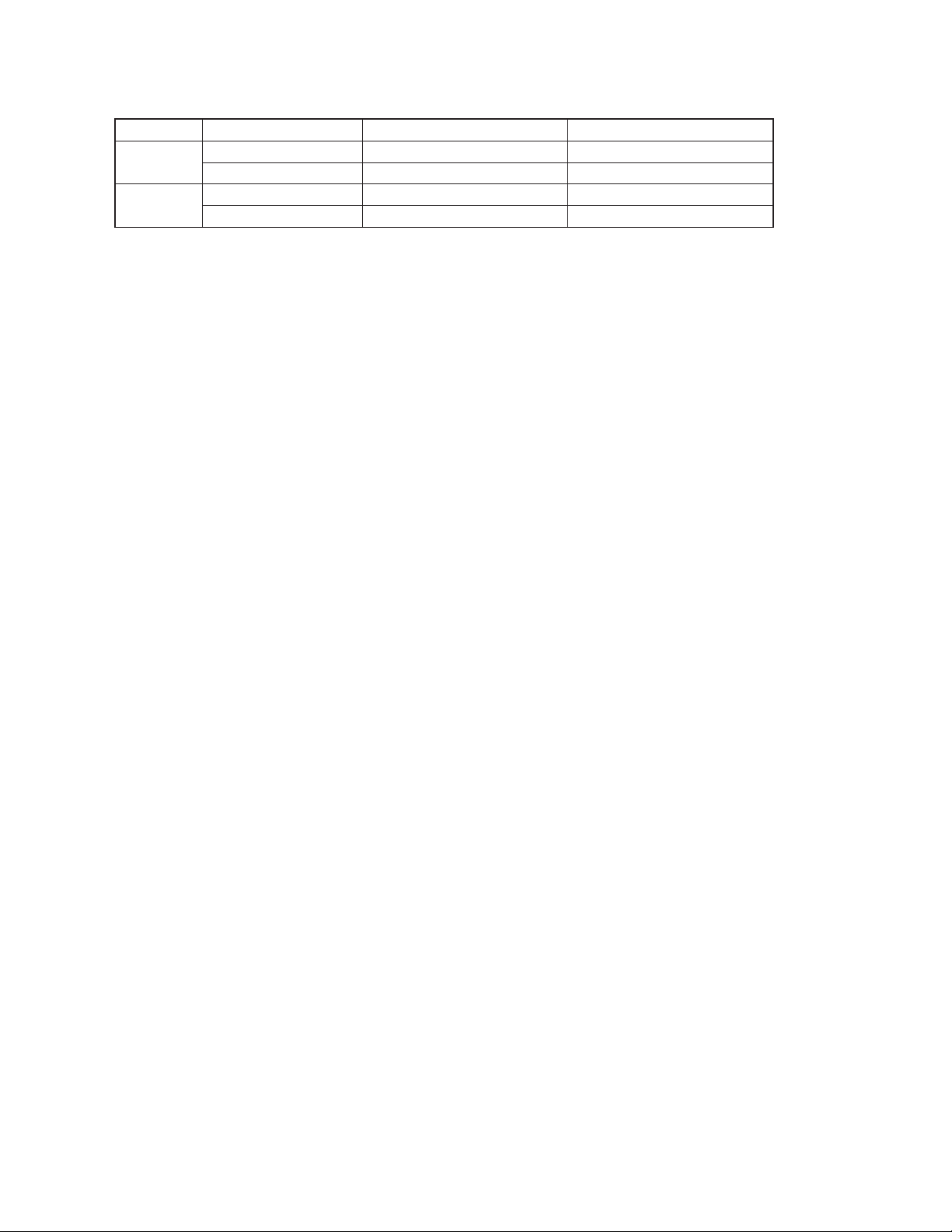

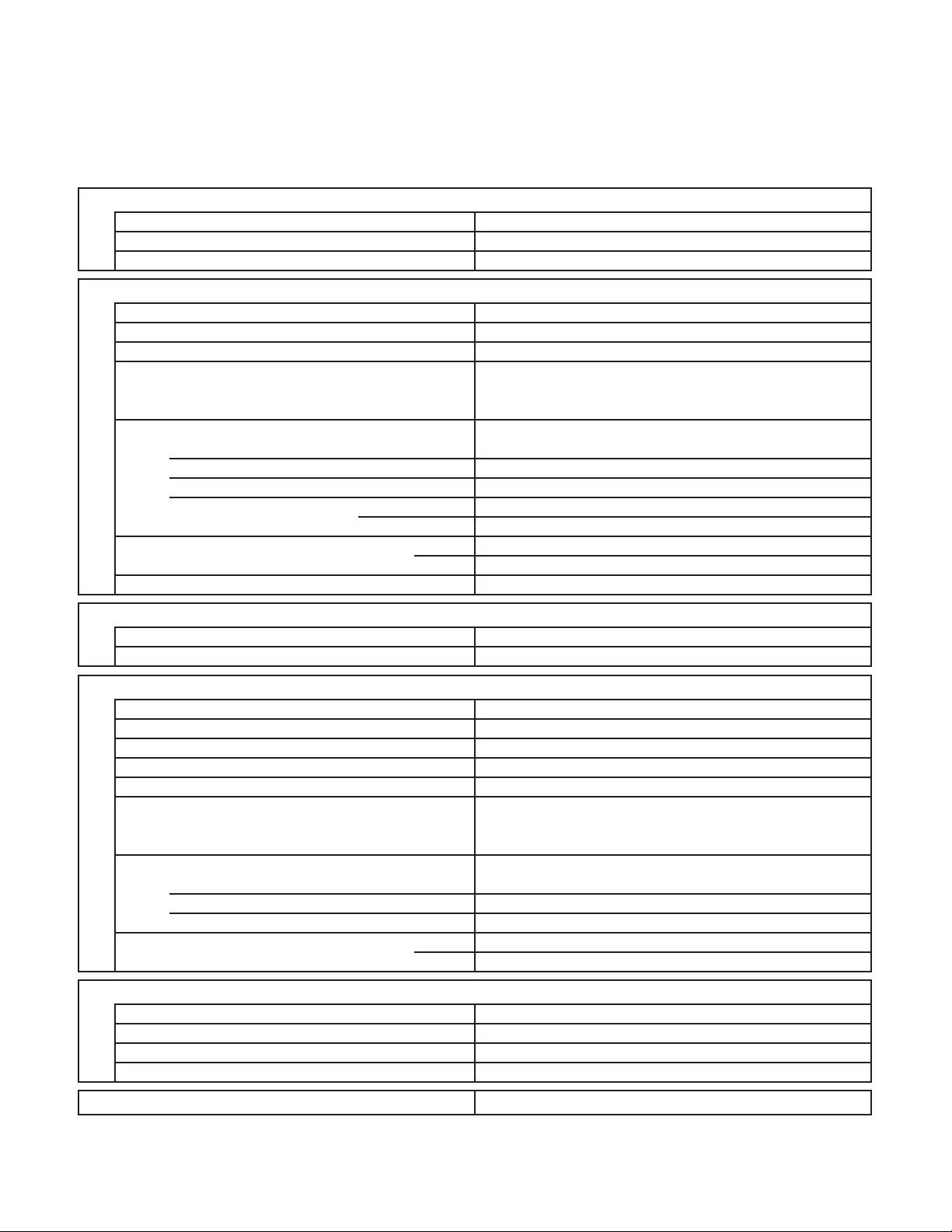

2-3. Other Component Specifications

Sensor Name

Outdoor air temp sensor

Outdoor heat exchanger sensor

AW / AN sensor

BW / BN sensor

CW / CN sensor

DW / DN sensor

Model No.

of sensor

TKS295B

TKS292B

TKS292B

TKS292B

TKS292B

TKS292B

40

35

30

25

20

Resistance (k ohm)

15

10

5

Quantity of Sensor

CU-3KE19NBU CU-4KE24NBU CU-4KE31NBU

1

1

1 / 1

1 / 1

1 / 1

0

1

1

1 / 1

1 / 1

1 / 1

1 / 1

1

1

1 / 1

1 / 1

1 / 1

1 / 1

0

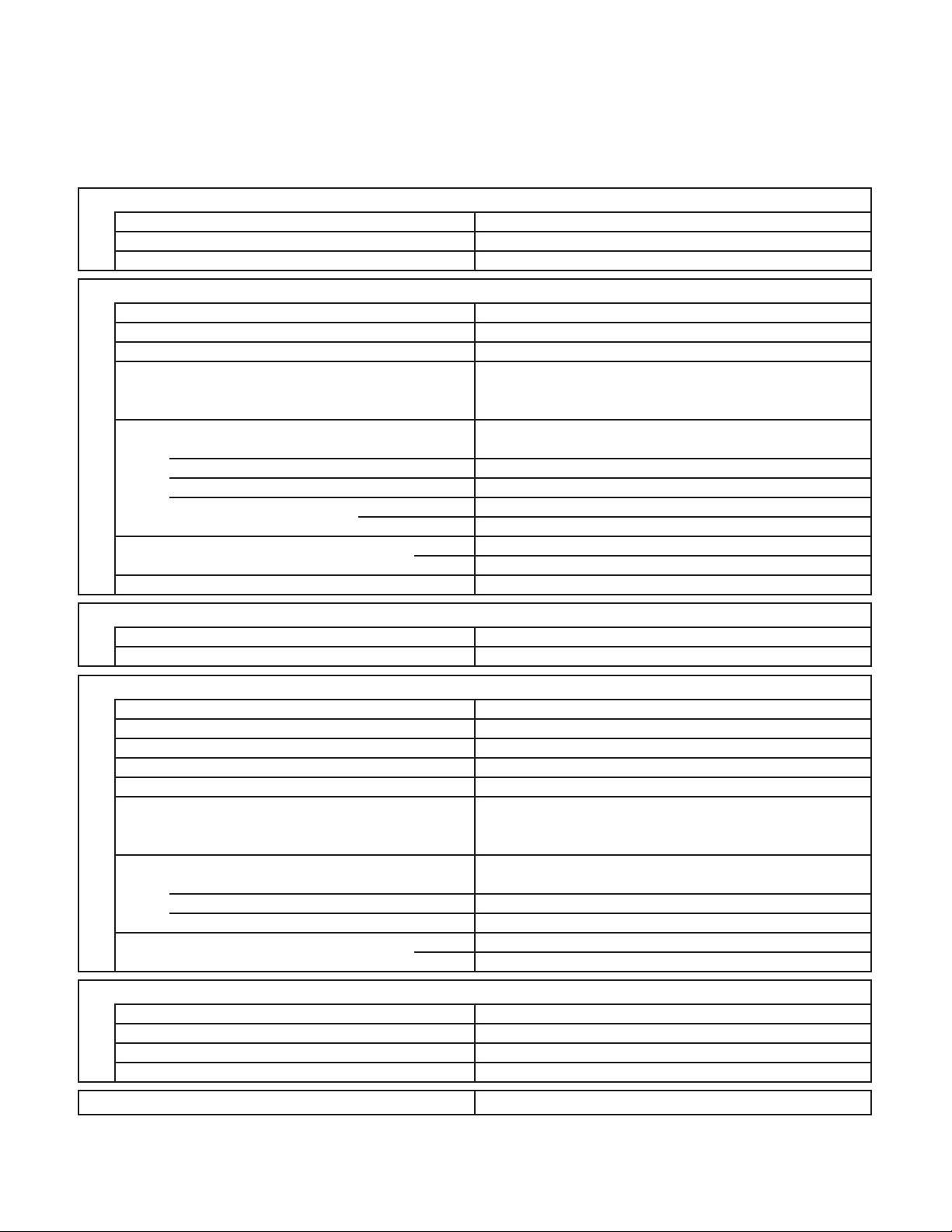

Sensor Name

Compressor temp sensor TKS293B

Model No.

of sensor

200

180

160

140

120

100

Resistance (k ohm)

80

60

40

-

4 5 14 23 32 41 50 59 68

(

-

20)(-15)(-10) (-5) (0) (5) (10) (15) (20)

Temperature F ( C)

Quantity of Sensor

CU-3KE19NBU CU-4KE24NBU CU-4KE31NBU

11

1

20

0

32 50 68 86 104 122 140 158 176 194

(0) (10) (20) (30) (40) (50) (60)(70) (80) (90)

Temperature F ( C)

20

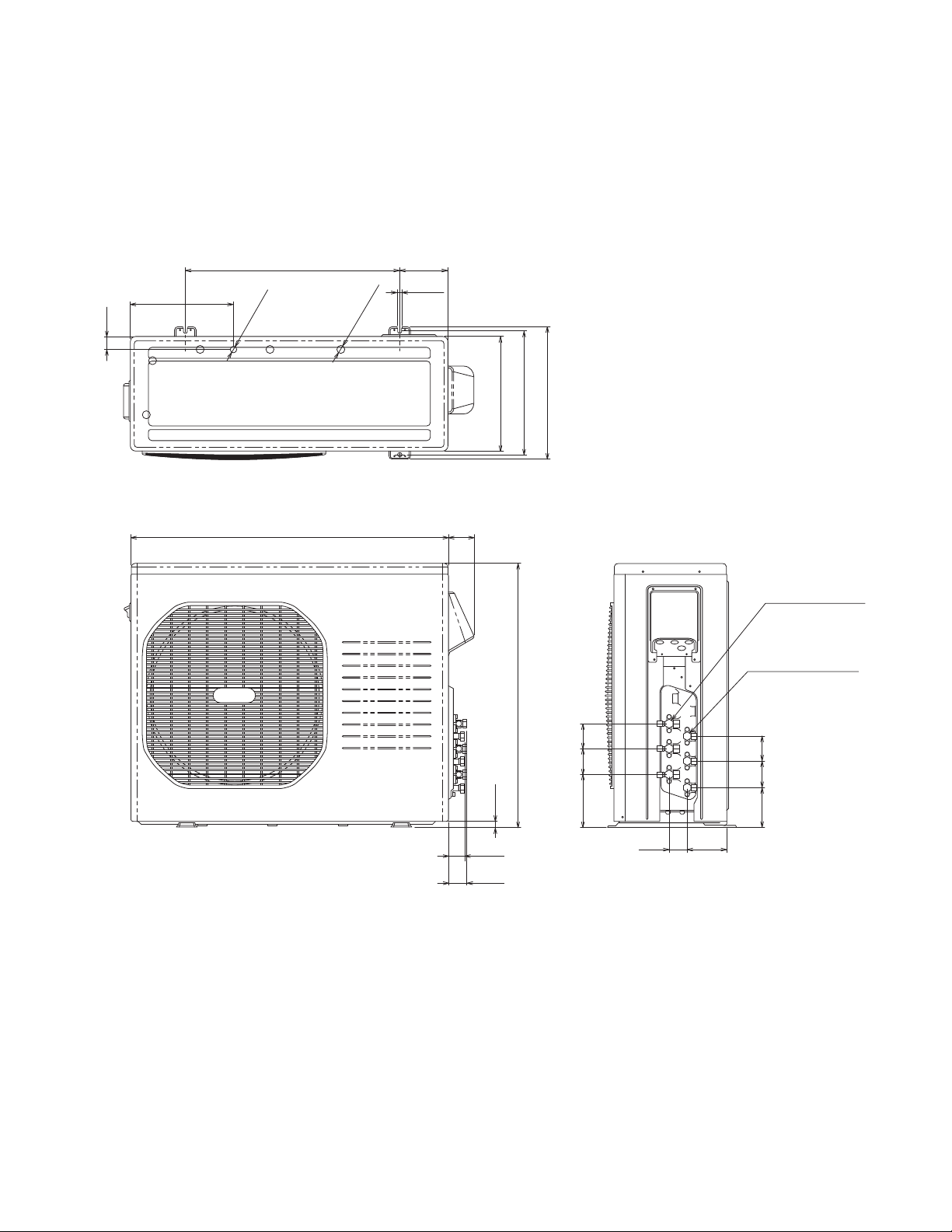

3. DIMENSIONAL DATA

Outdoor Unit CU-3KE19NBU

23-15/16 5-11/32

11-17/32

1-3/8

ID:23/32

5-ID:15/16

15/32

13-19/32

12-19/32(320)

14-17/32

35-7/16(900)

2-15/16

1-13/16

2-1/16

23/32

29-1/8(740)

5-29/32 2-27/32 2-3/4

2-1/32 4-1/2

Wide tube service valve

dia.3/8" (9.52) ×3

Narrow tube service valve

dia.1/4" (6.35) ×3

2-3/4

2-15/16

4-7/16

Unit: inch(mm)

(852-0-0010-11200-0)

21

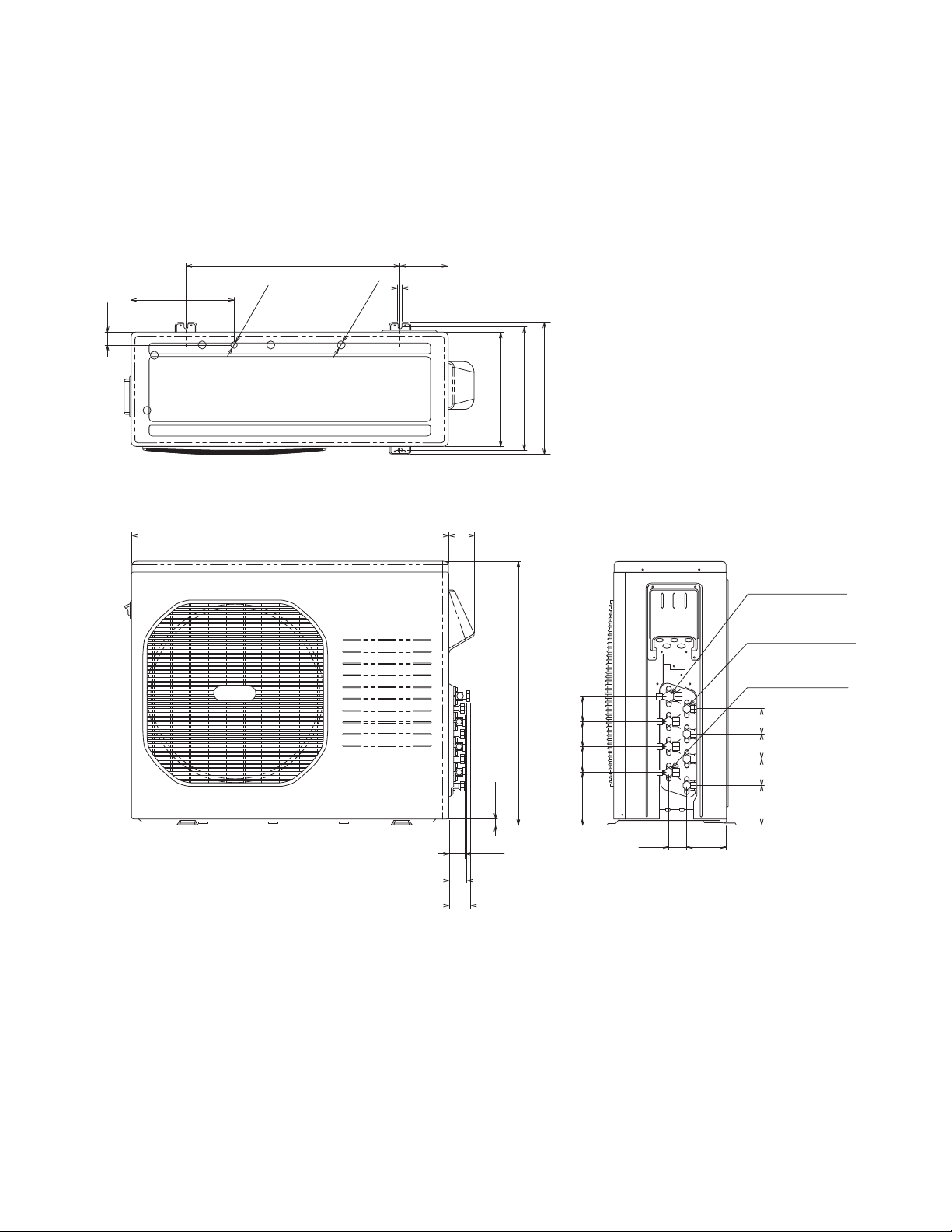

Outdoor Unit CU-4KE24NBU

23-15/16 5-11/32

11-17/32

1-3/8

ID:23/32

5-ID:15/16

15/32

13-19/32

14-17/32

12-19/32(320)

35-7/16(900)

2-15/16

23/32

1-13/16

2-1/16

2-13/32

29-1/8(740)

2-3/4

5-29/32 2-27/32 2-3/4

2-1/32 4-1/2

Wide tube service valve

dia.1/2" (12.70)

Narrow tube service valve

dia.1/4" (6.35)

Wide tube service valve

dia.3/8" (9.52)

2-3/4 2-3/4

2-15/16

4-7/16

×1

×4

×3

Unit: inch(mm)

(852-0-0010-20400-0)

22

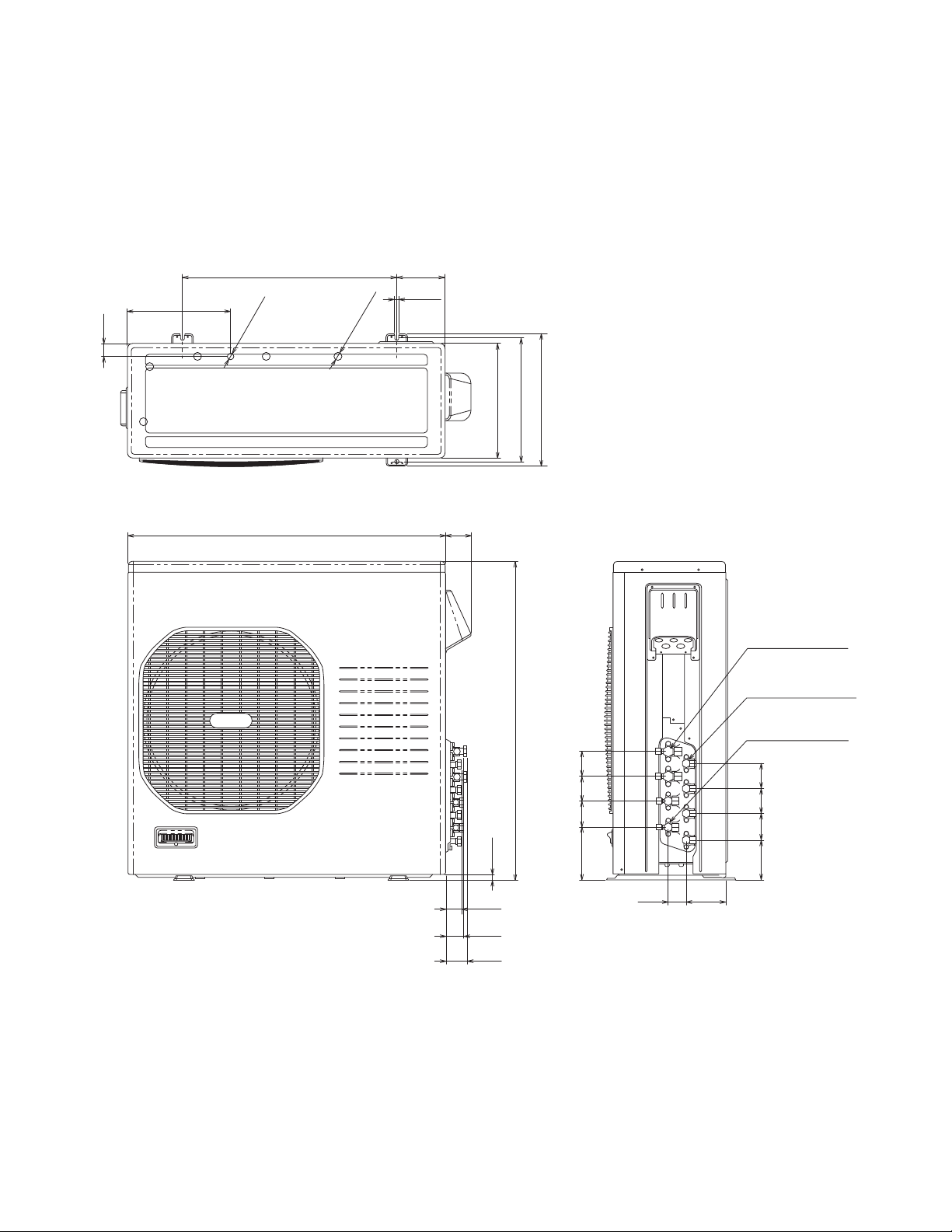

Outdoor Unit CU-4KE31NBU

23-15/16 5-11/32

11-17/32

1-3/8

ID:23/32

5-ID:15/16

15/32

13-19/32

14-17/32

12-19/32(320)

35-7/16(900)

2-15/16

1-13/16

2-1/16

2-13/32

23/32

35-1/32(890)

2-7/8 2-3/4 2-3/4

5-29/32

2-1/32 4-1/2

Wide tube service valve

dia.1/2" (12.70) ×2

Narrow tube service valve

dia.1/4" (6.35) ×4

Wide tube service valve

dia.3/8" (9.52) ×2

2-3/4 2-3/4

2-15/16

4-7/16

Unit: inch(mm)

(852-0-0010-20300-0)

23

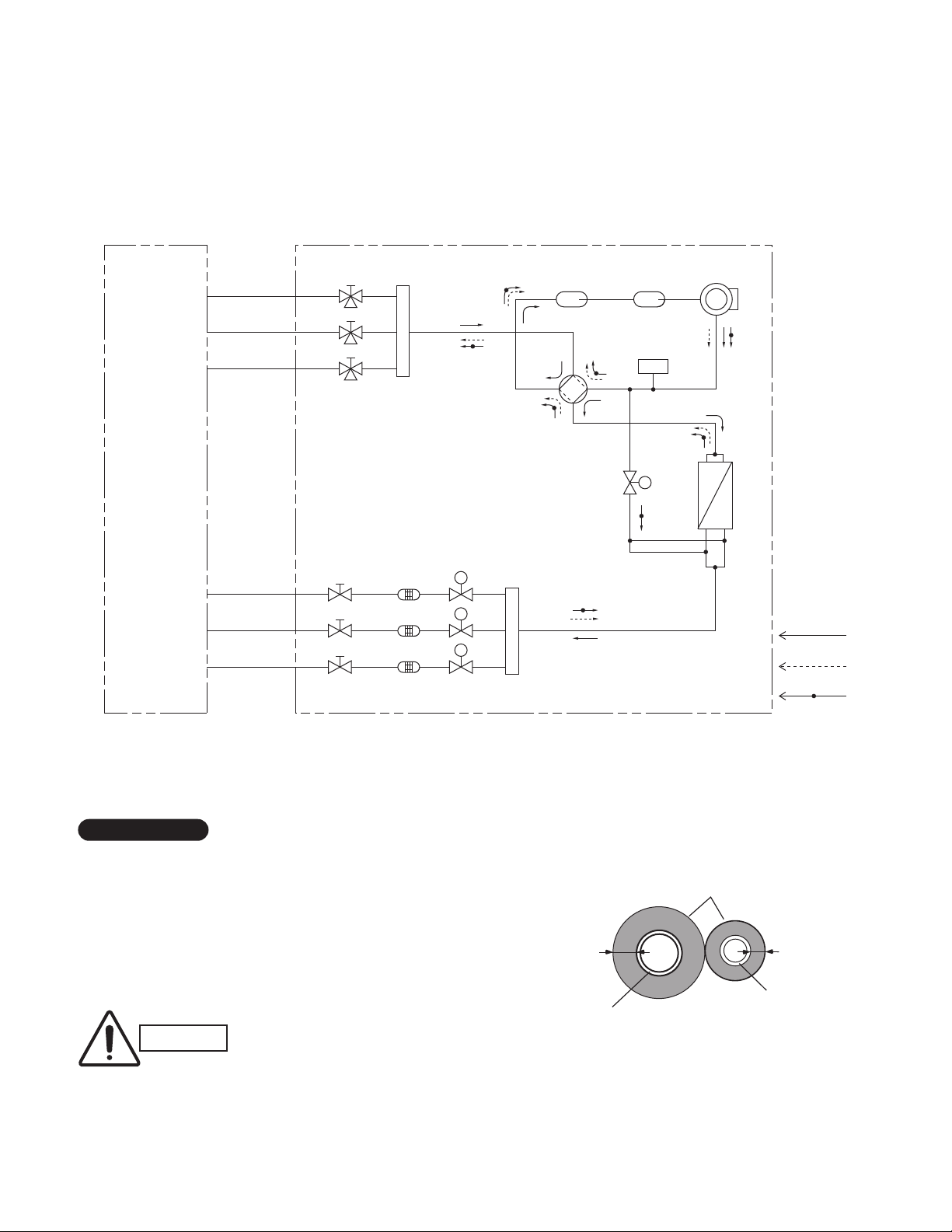

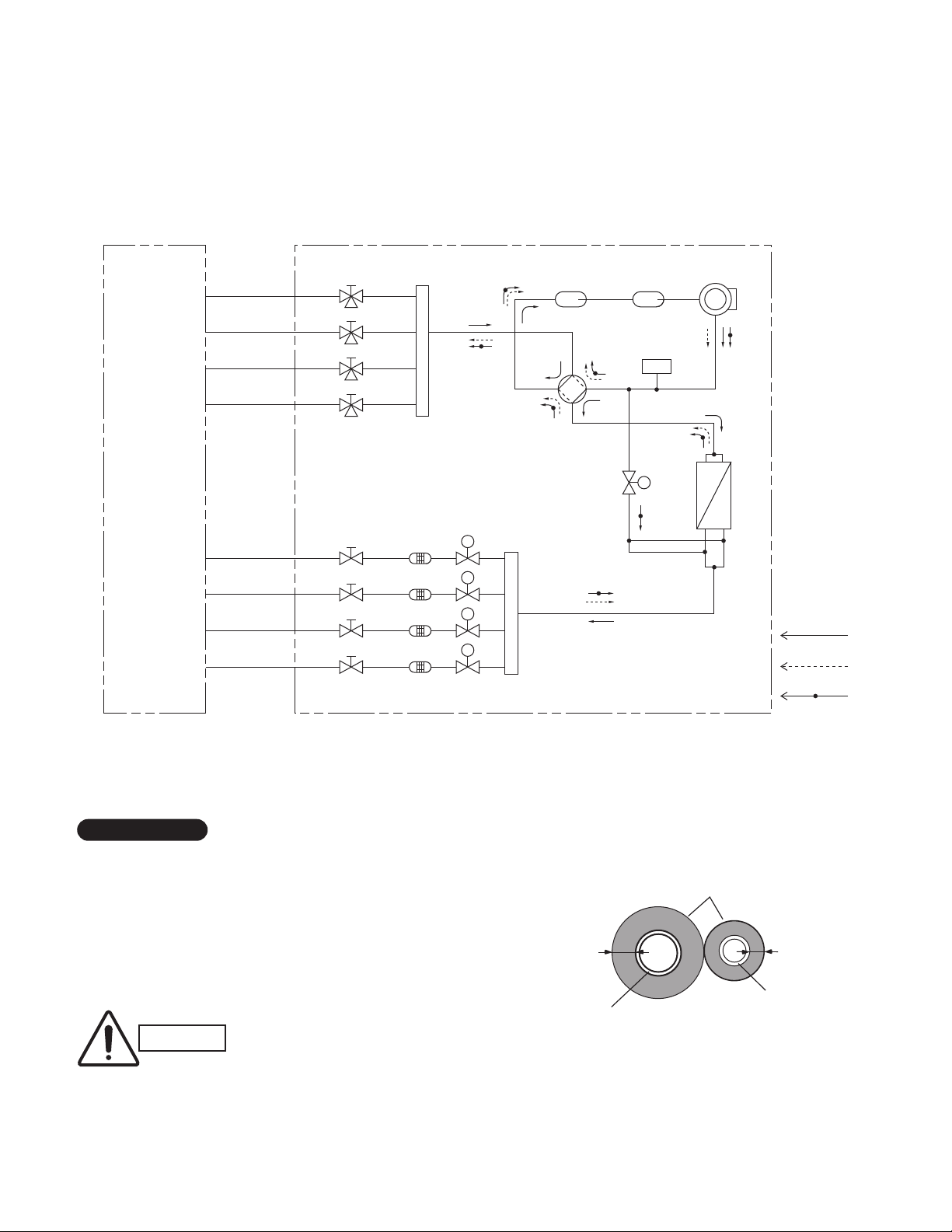

4. REFRIGERANT FLOW DIAGRAM

4-1. Refrigerant Flow Diagram

Outdoor Unit CU-3KE19NBU

Indoor unit Outdoor unit

Wide tube

O.D.3/8"

O.D.3/8"

O.D.3/8"

Narrow tube

O.D.1/4"

O.D.1/4"

O.D.1/4"

Service valve on

wide tube

CW

BW

AW

Header

Service valve on

narrow tube

CN

BN

AN

Strainer Header

Electric

expansion

valve

M

M

M

Sub

accumulator

4-way

valve

Defrost valve for

hot gas bypass

Main

accumulator

High pressure

switch

H.P.

S

Compressor

Heat exchanger

Cooling cycle

Heating cycle

Defrosting cycle

Insulation of Refrigerant Tubing

IMPORTANT

Because capillary tubing is used in the outdoor unit, both the

wide and narrow tubes of this air conditioner become cold. To

prevent heat loss and wet floors due to dripping of

condensation, both tubes must be well insulated with a

proper insulation material. The thickness of the insulation

should be a min.5/16"(8 mm).

After a tube has been insulated,

CAUTION

never try to bend it into a narrow

curve because it can cause the tube

to break or crack.

24

Thickness:

Min.5/16"(8 mm)

Wide tube

Insulation

Thickness:

Min.5/16"(8 mm)

Narrow tube

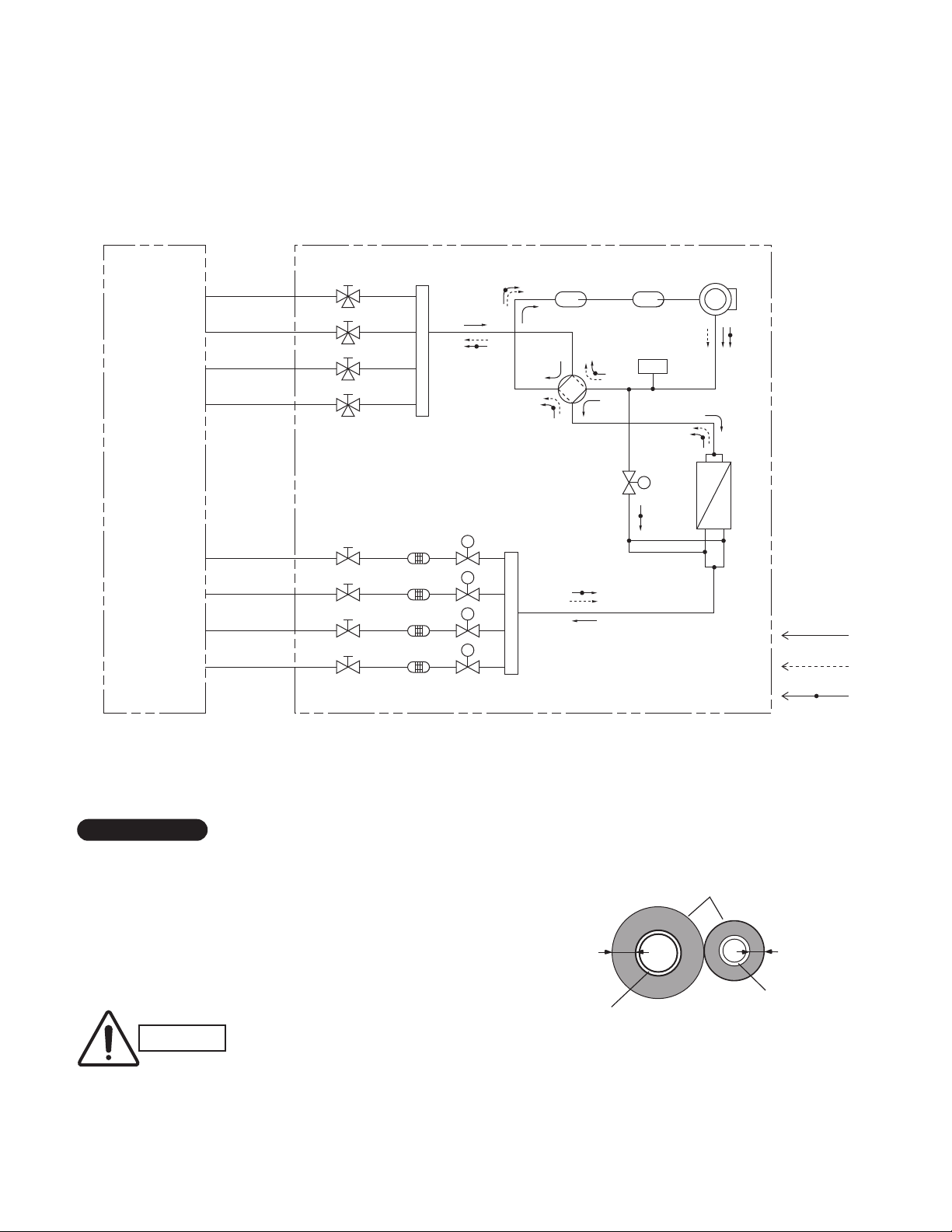

Outdoor Unit CU-4KE24NBU

Indoor unit Outdoor unit

Wide tube

O.D.1/2"

O.D.3/8"

O.D.3/8"

O.D.3/8"

Narrow tube

O.D.1/4"

O.D.1/4"

O.D.1/4"

O.D.1/4"

Service valve on

wide tube

DW

CW

BW

AW

Service valve on

narrow tube

DN

CN

BN

AN

Header

Electric

expansion

valve

M

M

M

M

Strainer Header

4-way

valve

Sub

accumulator

Defrost valve for

hot gas bypass

Main

accumulator

High pressure

switch

H.P.

S

Compressor

Heat exchanger

Cooling cycle

Heating cycle

Defrosting cycle

Insulation of Refrigerant Tubing

IMPORTANT

Because capillary tubing is used in the outdoor unit, both the

wide and narrow tubes of this air conditioner become cold. To

prevent heat loss and wet floors due to dripping of

condensation, both tubes must be well insulated with a

proper insulation material. The thickness of the insulation

should be a min.5/16"(8 mm).

After a tube has been insulated,

CAUTION

never try to bend it into a narrow

curve because it can cause the tube

to break or crack.

25

Thickness:

Min.5/16"(8 mm)

Wide tube

Insulation

Thickness:

Min.5/16"(8 mm)

Narrow tube

Outdoor Unit CU-4KE31NBU

Indoor unit Outdoor unit

Wide tube

O.D.1/2"

O.D.1/2"

O.D.3/8"

O.D.3/8"

Narrow tube

O.D.1/4"

O.D.1/4"

O.D.1/4"

O.D.1/4"

Service valve on

wide tube

DW

CW

BW

AW

Service valve on

narrow tube

DN

CN

BN

AN

Header

Electric

expansion

valve

M

M

M

M

Strainer Header

4-way

valve

Sub

accumulator

Defrost valve for

hot gas bypass

Main

accumulator

High pressure

switch

H.P.

S

Compressor

Heat exchanger

Cooling cycle

Heating cycle

Defrosting cycle

Insulation of Refrigerant Tubing

IMPORTANT

Because capillary tubing is used in the outdoor unit, both the

wide and narrow tubes of this air conditioner become cold. To

prevent heat loss and wet floors due to dripping of

condensation, both tubes must be well insulated with a

proper insulation material. The thickness of the insulation

should be a min.5/16"(8 mm).

After a tube has been insulated,

CAUTION

never try to bend it into a narrow

curve because it can cause the tube

to break or crack.

26

Thickness:

Min.5/16"(8 mm)

Wide tube

Insulation

Thickness:

Min.5/16"(8 mm)

Narrow tube

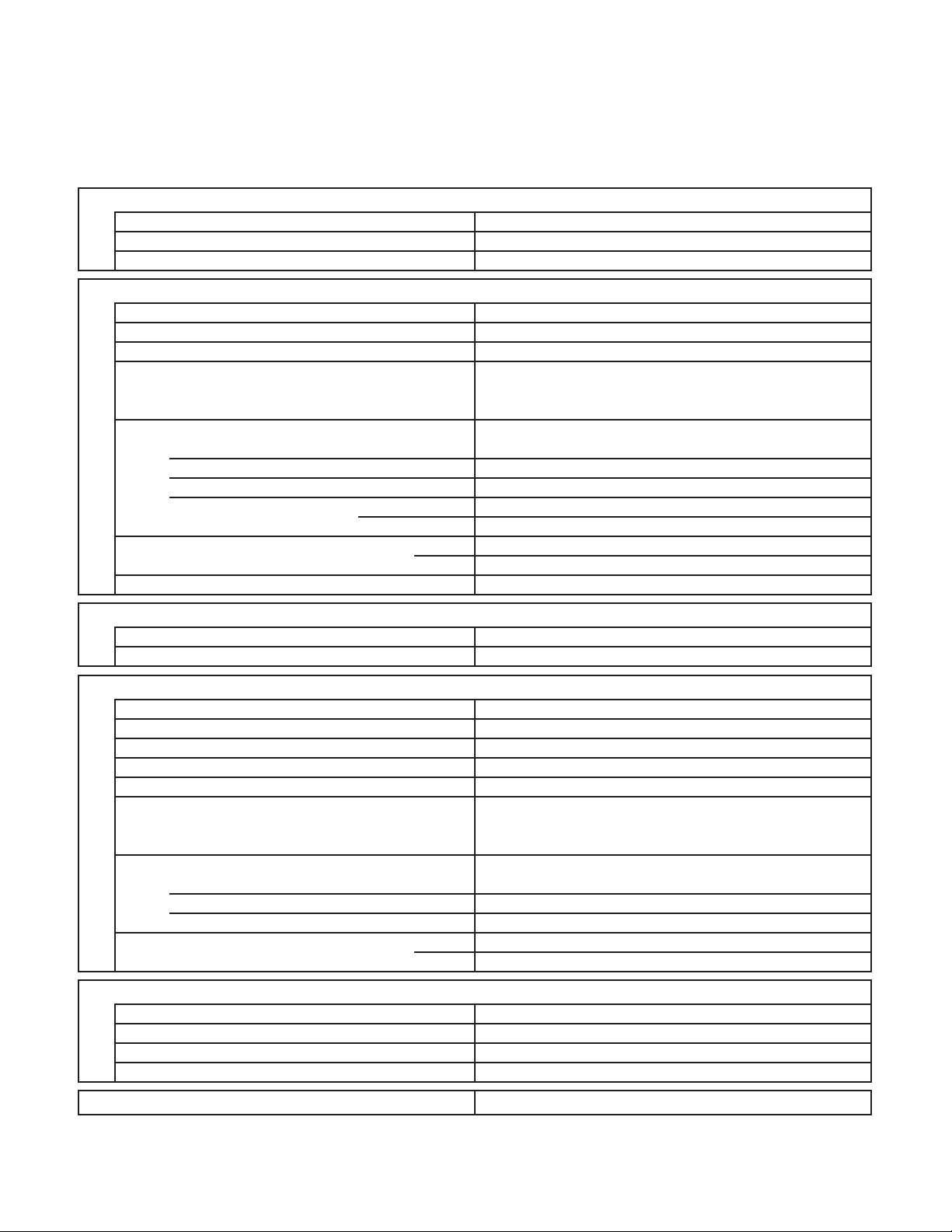

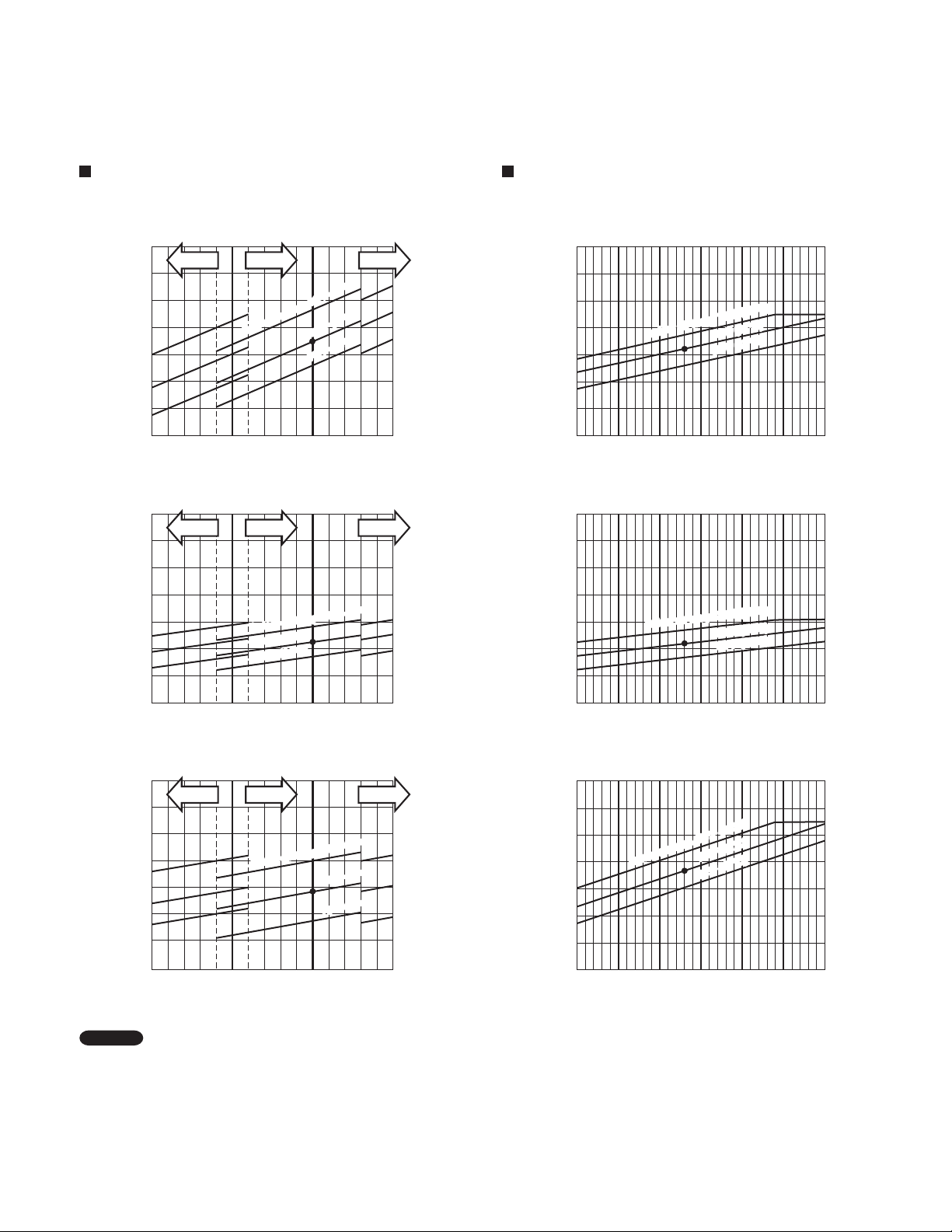

5. PERFORMANCE DATA

5-1. Temperature Charts

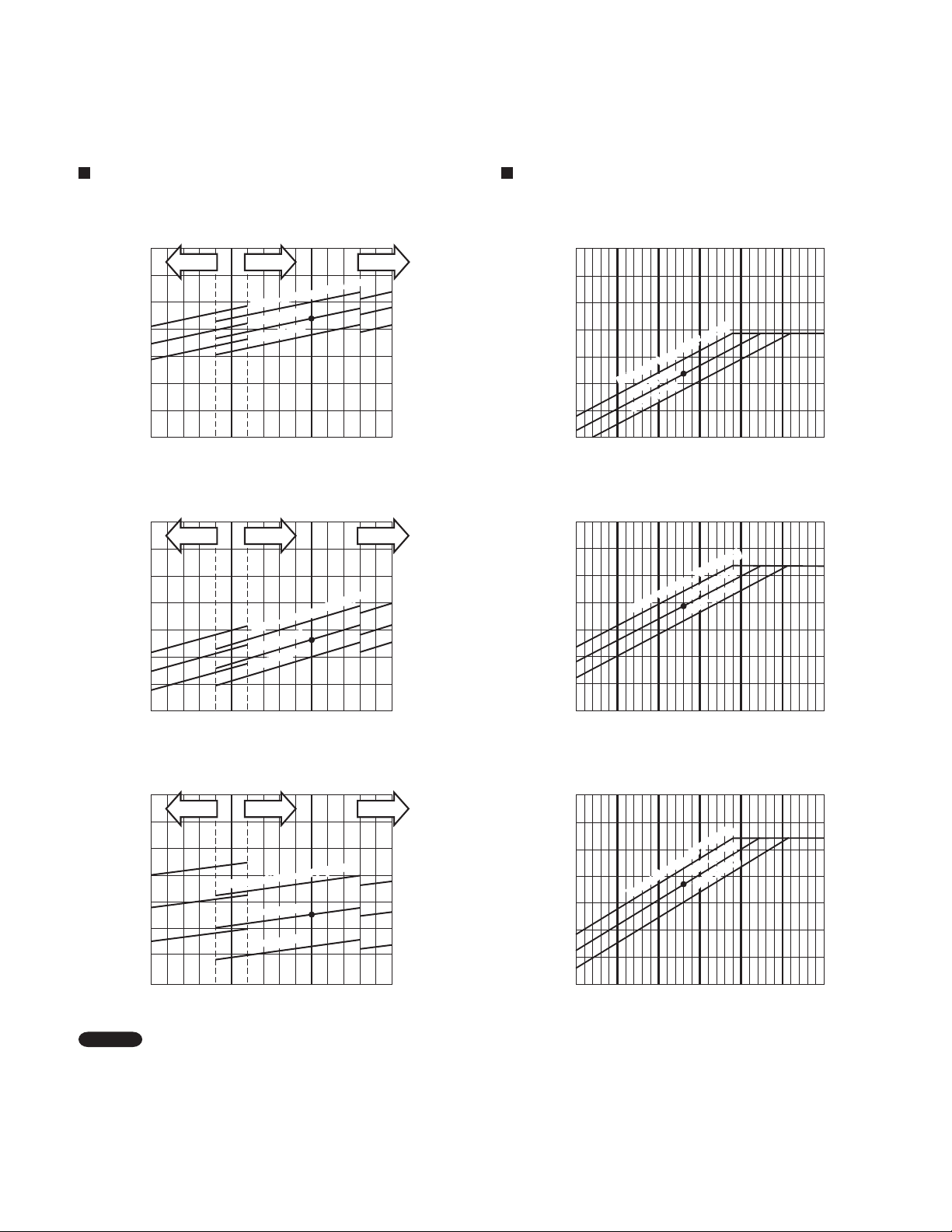

5-1-1. Temperature Charts (CU-3KE19NBU)

Outdoor Unit CU-3KE19NBU Indoor Unit CS-MKE7NKU×1

Cooling Characteristics

(RH : 46%, Indoor fan speed : High fan)

(230V, 60Hz)

(1) Low pressure performance chart (1) High pressure performance chart

Heating Characteristics

(RH : 85%, Indoor fan speed : High fan)

(230V, 60Hz)

188

(1.3)

psig (MPaG)

174

(1.2)

160

(1.1)

Low pressure at wide tube service valve

146

(1.0)

Lo fan Hi fan HH fan

77

(25)

Indoor air temp. 86°F (30°C)

86

(30)

Outdoor air temperature °F (°C) Outdoor air temperature °F (°C)

80°F (27°C)

75°F (24°C)

95

(35)

104

(40)

506

(3.5)

psig (MPaG)

434

(3.0)

362

(2.5)

High pressure at wide tube service valve

290

(2.0)

23

(-5)32(0)41(5)50(10)59(15)68(20)77(25)

Indoor air temp. 73°F (23°C)

70°F (21°C)

63°F (17°C)

(2) Operating current performance chart (2) Operating current performance chart

Lo fan Hi fan HH fan

5

4

3

Operating current (A)

2

77

(25)

Outdoor air temperature °F (°C) Outdoor air temperature °F (°C)

Indoor air temp. 86°F (30°C)

80°F (27°C)

75°F (24°C)

86

(30)

(35)

95

104

(40)

8

7

6

Operating current (A)

5

23

(-5)32(0)41(5)50(10)59(15)68(20)77(25)

Indoor air temp. 73°F (23°C)

70°F (21°C)

63°F (17°C)

(3) Indoor discharge air performance chart (3) Indoor discharge air performance chart

140(60)

131(55)

122(50)

113(45)

104(40)

95(35)

86(30)

Indoor air temp. 73°F (23°C)

70°F (21°C)

63°F (17°C)

68.0(20)

64.4(18)

60.8(16)

57.2(14)

53.6(12)

50.0(10)

Lo fan Hi fan HH fan

Indoor air temp. 86°F (30°C)

80°F (27°C)

75°F (24°C)

46.4( 8)

Indoor discharge air temperature °F (°C)

77

(25)

86

(30)

Outdoor air temperature °F (°C) Outdoor air temperature °F (°C)

95

(35)

104

(40)

77(25)

Indoor discharge air temperature °F (°C)

23

(-5)32(0)41(5)50(10)59(15)68(20)77(25)

NOTE

• This performance chart shows operation of a single wall-mounted indoor unit. The performance chart will vary depending on

the indoor unit type.

• Check each performance value in test-run mode. Electrical performance values represent a combined indoor/outdoor value.

(In this case, be sure to stop all the indoor units where performance is not being checked.)

• The performance is for a tubing length of 24.6t (7.5m). If the tubing length is different, the performance chart will vary.

27

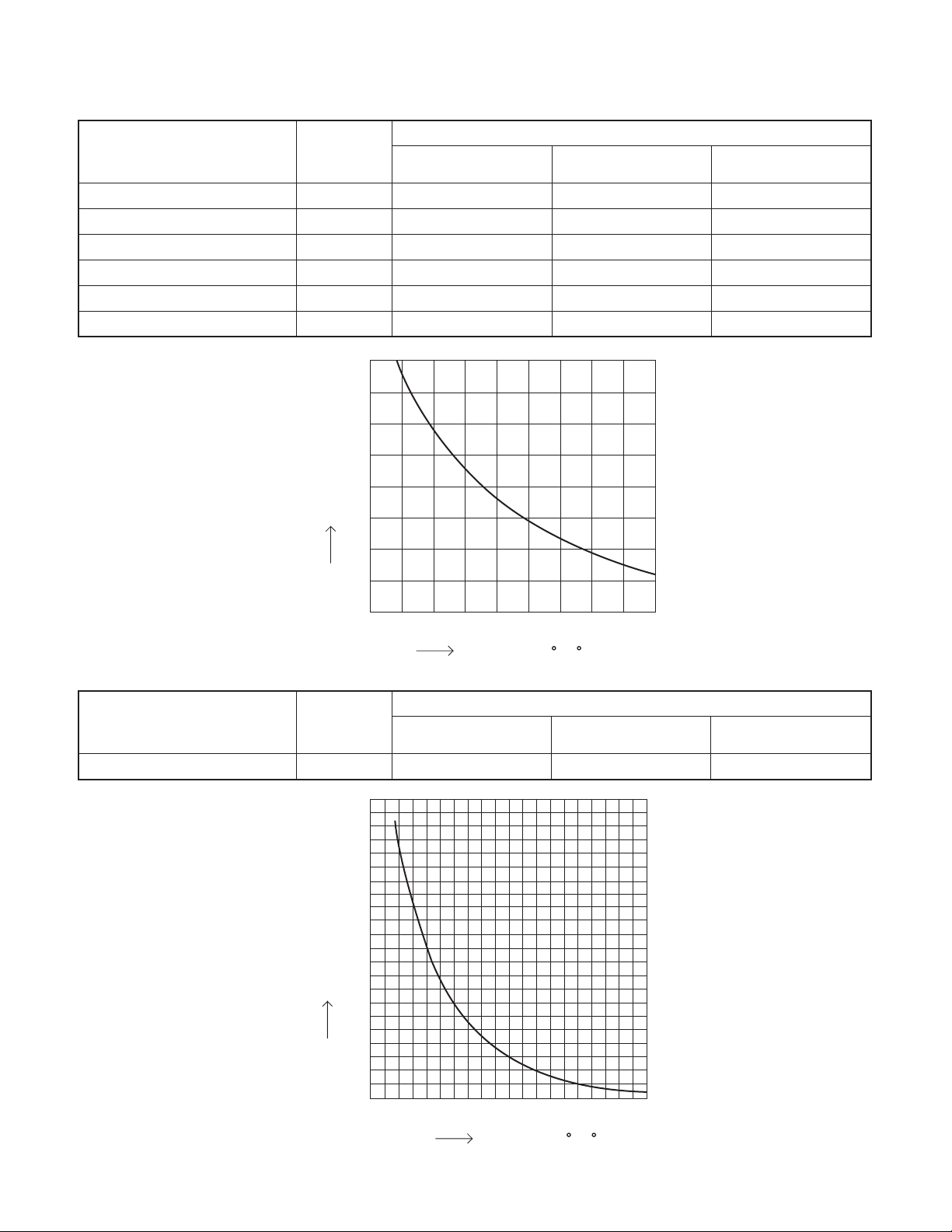

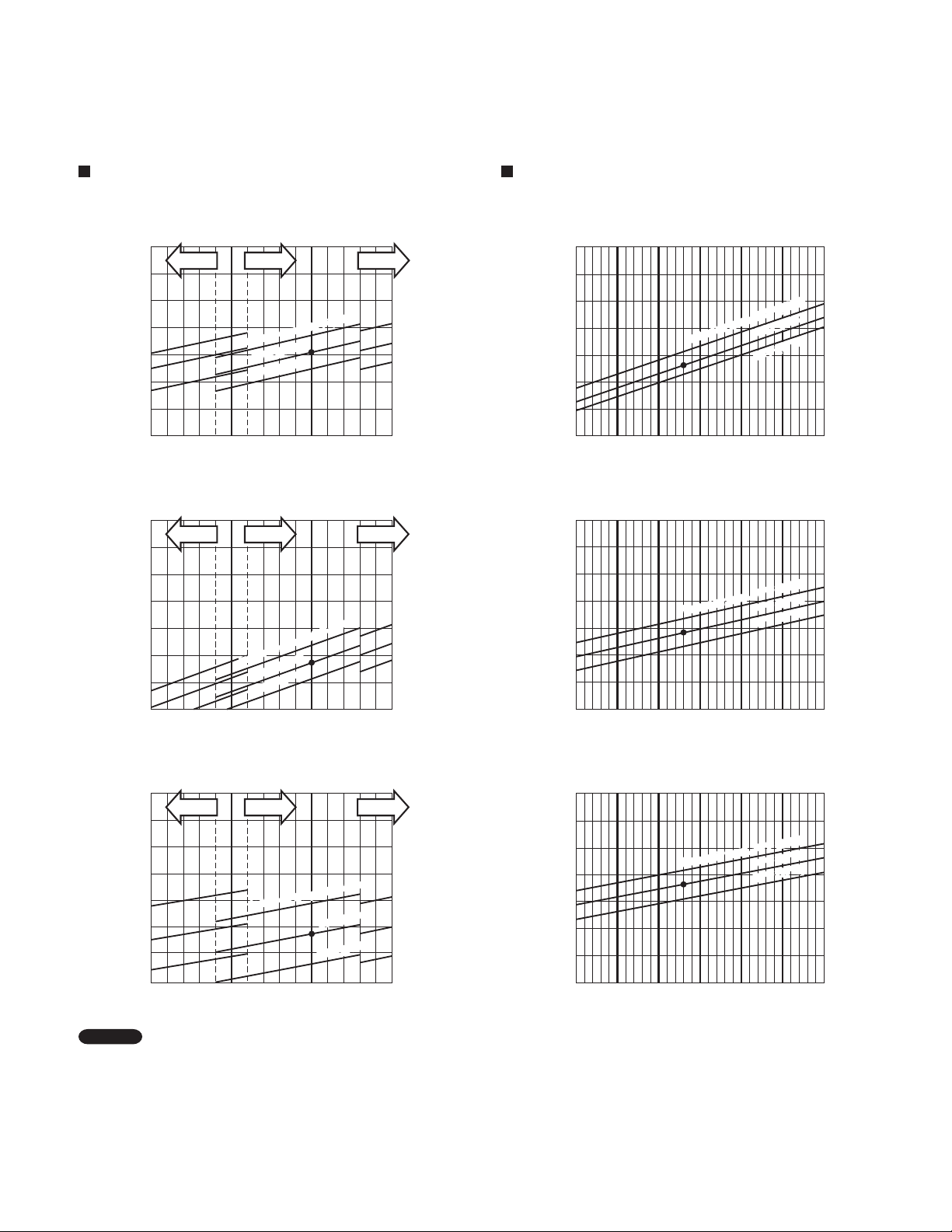

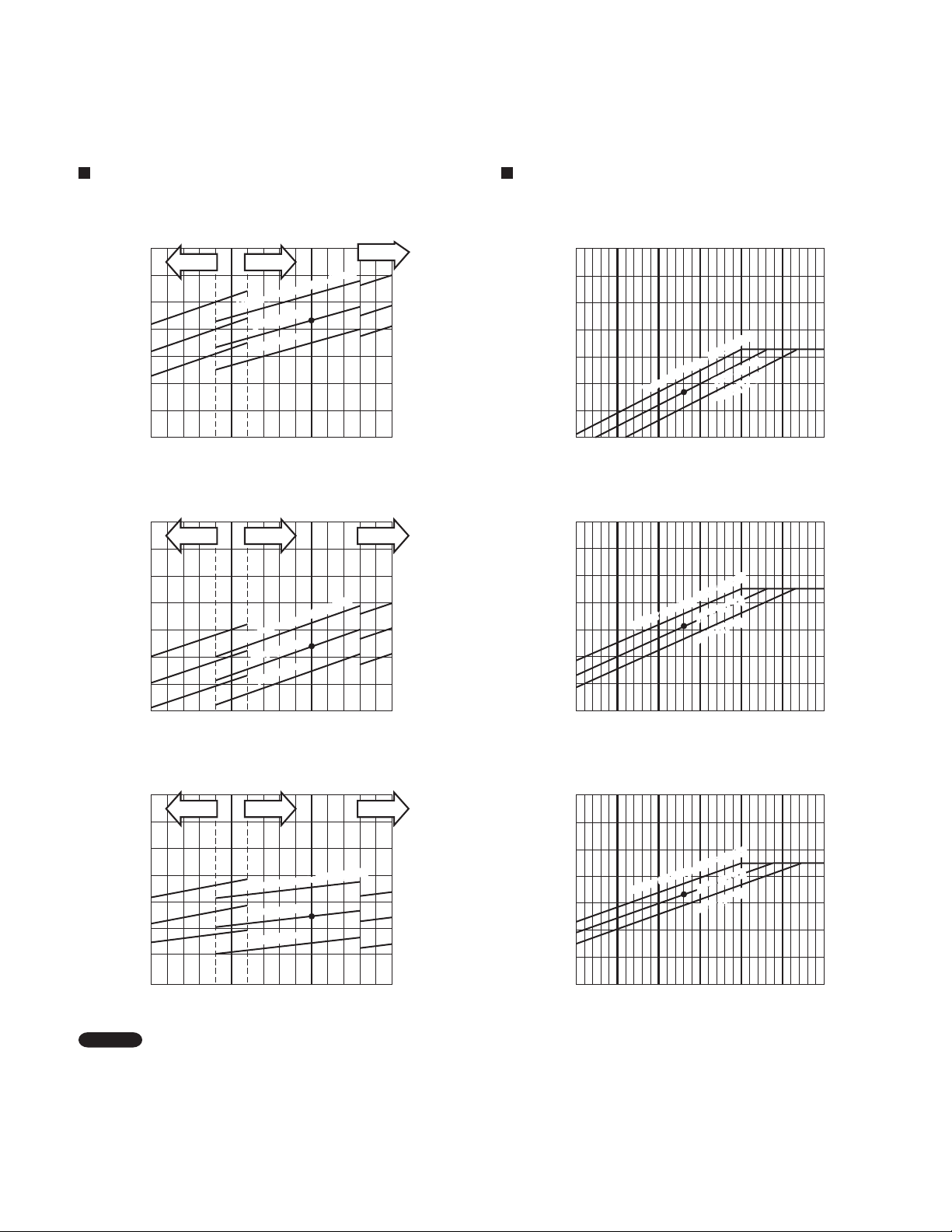

Outdoor Unit CU-3KE19NBU Indoor Unit CS-MKE9NKU ×1

Cooling Characteristics

(RH : 46%, Indoor fan speed : High fan)

(230V, 60Hz)

Heating Characteristics

(RH : 85%, Indoor fan speed : High fan)

(230V, 60Hz)

(1) Low pressure performance chart (1) High pressure performance chart

188

(1.3)

psig (MPaG)

174

(1.2)

160

(1.1)

Low pressure at wide tube service valve

146

(1.0)

Lo fan Hi fan

77

(25)

Indoor air temp. 86°F (30°C)

80°F (27°C)

75°F (24°C)

86

(30)

Outdoor air temperature °F (°C) Outdoor air temperature °F (°C)

95

(35)

HH fan

104

(40)

506

(3.5)

psig (MPaG)

434

(3.0)

362

(2.5)

High pressure at wide tube service valve

290

(2.0)

23

(-5)32(0)41(5)50(10)59(15)68(20)77(25)

Indoor air temp. 73°F (23°C)

Indoor air temp. 73°F (23°C)

70°F (21°C)

70°F (21°C)

63°F (17°C)

63°F (17°C)

(2) Operating current performance chart (2) Operating current performance chart

Lo fan Hi fan

6

5

4

Operating current (A)

3

77

(25)

HH fan

Indoor air temp. 86°F (30°C)

80°F (27°C)

75°F (24°C)

86

(30)

Outdoor air temperature °F (°C) Outdoor air temperature °F (°C)

95

(35)

104

(40)

8

7

Indoor air temp. 73°F (23°C)

6

Operating current (A)

5

23

(-5)32(0)41(5)50(10)59(15)68(20)77(25)

70°F (21°C)

63°F (17°C)

(3) Indoor discharge air performance chart (3) Indoor discharge air performance chart

68.0(20)

64.4(18)

60.8(16)

57.2(14)

53.6(12)

50.0(10)

46.4( 8)

Indoor discharge air temperature °F (°C)

Lo fan Hi fan

77

(25)

Indoor air temp. 86°F (30°C)

86

(30)

Outdoor air temperature °F (°C) Outdoor air temperature °F (°C)

95

(35)

80°F (27°C)

75°F (24°C)

HH fan

104

(40)

NOTE

• This performance chart shows operation of a single wall-mounted indoor unit. The performance chart will vary depending on

the indoor unit type.

• Check each performance value in test-run mode. Electrical performance values represent a combined indoor/outdoor value.

(In this case, be sure to stop all the indoor units where performance is not being checked.)

• The performance is for a tubing length of 24.6ft (7.5m). If the tubing length is different, the performance chart will vary.

140(60)

131(55)

122(50)

Indoor air temp. 73°F (23°C)

113(45)

104(40)

95(35)

86(30)

77(25)

Indoor discharge air temperature °F (°C)

23

(-5)32(0)41(5)50(10)59(15)68(20)77(25)

Indoor air temp. 73°F (23°C)

70°F (21°C)

70°F (21°C)

63°F (17°C)

63°F (17°C)

28

Outdoor Unit CU-3KE19NBU Indoor Unit CS-MKE12NKU ×1

Cooling Characteristics

(RH : 46%, Indoor fan speed : High fan)

(230V, 60Hz)

Heating Characteristics

(RH : 85%, Indoor fan speed : High fan)

(230V, 60Hz)

(1) Low pressure performance chart (1) High pressure performance chart

578

174

(1.2)

psig (MPaG)

160

(1.1)

146

(1.0)

Low pressure at wide tube service valve

132

(0.9)

Lo fan Hi fan

77

(25)

Indoor air temp. 86°F (30°C)

80°F (27°C)

75°F (24°C)

86

(30)

Outdoor air temperature °F (°C) Outdoor air temperature °F (°C)

95

(35)

HH fan

104

(40)

(4.0)

506

psig (MPaG)

(3.5)

434

(3.0)

Indoor air temp. 73°F (23°C)

Indoor air temp. 73°F (23°C)

362

(2.5)

High pressure at wide tube service valve

23

(-5)32(0)41(5)50(10)59(15)68(20)77(25)

20°F (21°C)70°F (21°C)

63°F (17°C)

63°F (17°C)

(2) Operating current performance chart (2) Operating current performance chart

10

Lo fan Hi fan

6

5

4

Operating current (A)

Indoor air temp. 86°F (30°C)

80°F (27°C)

75°F (24°C)

HH fan

9

8

7

6

5

Operating current (A)

4

Indoor air temp. 73°F (23°C)

Indoor air temp. 73°F (23°C)

70°F (21°C)70°F (21°C)

63°F (17°C)

63°F (17°C)

3

77

(25)

86

(30)

Outdoor air temperature °F (°C) Outdoor air temperature °F (°C)

95

(35)

104

(40)

3

23

(-5)32(0)41(5)50(10)59(15)68(20)77(25)

(3) Indoor discharge air performance chart (3) Indoor discharge air performance chart

68.0(20)

64.4(18)

60.8(16)

57.2(14)

53.6(12)

50.0(10)

46.4( 8)

Indoor discharge air temperature °F (°C)

Lo fan Hi fan

77

(25)

Indoor air temp. 86°F (30°C)

80°F (27°C)

75°F (24°C)

86

(30)

Outdoor air temperature °F (°C) Outdoor air temperature °F (°C)

95

(35)

HH fan

104

(40)

NOTE

• This performance chart shows operation of a single wall-mounted indoor unit. The performance chart will vary depending on

the indoor unit type.

• Check each performance value in test-run mode. Electrical performance values represent a combined indoor/outdoor value.

(In this case, be sure to stop all the indoor units where performance is not being checked.)

• The performance is for a tubing length of 24.6ft (7.5m). If the tubing length is different, the performance chart will vary.

140(60)

131(55)

122(50)

113(45)

Indoor air temp. 73°F (23°C)

104(40)

95(35)

86(30)

77(25)

Indoor discharge air temperature °F (°C)

23

(-5)32(0)41(5)50(10)59(15)68(20)77(25)

Indoor air temp. 73°F (23°C)

70°F (21°C)70°F (21°C)

63°F (17°C)

63°F (17°C)

29

Outdoor Unit CU-3KE19NBU Indoor Unit CS-MKE18NKU ×1

Cooling Characteristics

(RH : 46%, Indoor fan speed : High fan)

(230V, 60Hz)

Heating Characteristics

(RH : 85%, Indoor fan speed : High fan)

(230V, 60Hz)

(1) Low pressure performance chart (1) High pressure performance chart

HH fan

578

(4.0)

psig (MPaG)

506

(3.5)

174

(1.2)

psig (MPaG)

160

(1.1)

Lo fan Hi fan

Indoor air temp. 86°F (30°C)

80°F (27°C)

75°F (24°C)

146

(1.0)

Low pressure at wide tube service valve

132

(0.9)

77

(25)

86

(30)

Outdoor air temperature °F (°C) Outdoor air temperature °F (°C)

95

(35)

104

(40)

434

(3.0)

High pressure at wide tube service valve

362

(2.5)

23

(-5)32(0)41(5)50(10)59(15)68(20)77(25)

Indoor air temp. 73°F (23°C)

Indoor air temp. 73°F (23°C)

70°F (21°C)

70°F (21°C)

63°F (17°C)

63°F (17°C)

(2) Operating current performance chart (2) Operating current performance chart

8

Lo fan Hi fan

7

6

Operating current (A)

5

77

(25)

Indoor air temp. 86°F (30°C)

80°F (27°C)

75°F (24°C)

86

(30)

Outdoor air temperature °F (°C) Outdoor air temperature °F (°C)

95

(35)

HH fan

104

(40)

12

11

10

70°F (21°C)

Indoor air temp. 73°F (23°C)

9

8

Operating current (A)

7

6

23

(-5)32(0)41(5)50(10)59(15)68(20)77(25)

Indoor air temp. 73°F (23°C)

70°F (21°C)

63°F (17°C)

63°F (17°C)

(3) Indoor discharge air performance chart (3) Indoor discharge air performance chart

140(60)

131(55)

122(50)

68.0(20)

64.4(18)

Lo fan Hi fan

HH fan

60.8(16)

57.2(14)

53.6(12)

50.0(10)

Indoor discharge air temperature °F (°C)

46.4( 8)

77

(25)

Indoor air temp. 86°F (30°C)

80°F (27°C)

75°F (24°C)

86

(30)

Outdoor air temperature °F (°C) Outdoor air temperature °F (°C)

95

(35)

104

(40)

113(45)

104(40)

95(35)

86(30)

Indoor discharge air temperature °F (°C)

77(25)

23

(-5)32(0)41(5)50(10)59(15)68(20)77(25)

Indoor air temp. 73°F (23°C)

Indoor air temp. 73°F (23°C)

70°F (21°C)

70°F (21°C)

63°F (17°C)

63°F (17°C)

NOTE

• This performance chart shows operation of a single wall-mounted indoor unit. The performance chart will vary depending on

the indoor unit type.

• Check each performance value in test-run mode. Electrical performance values represent a combined indoor/outdoor value.

(In this case, be sure to stop all the indoor units where performance is not being checked.)

• The performance is for a tubing length of 24.6ft (7.5m). If the tubing length is different, the performance chart will vary.

30

Loading...

Loading...