Panasonic CS-MZ20UD3EA, CU-Z25UBEA, CS-MZ20UB4EA, CS-Z25UB4EAW, CU-Z35UBEA Service Manual

...

© Panasonic Corporation 2018.

Order No: PAPAMY1805090CE

Indoor Unit

CS-MZ20UFEA

Destination

Europe

Turkey

Please file and use this manual together with the service manual for Model No. CU-2E12SBE, CU-2E15SBE, CU-2E18SBE,

CU-2Z35TBE, CU-2Z41TBE, CU-2Z50TBE, Order No. PAPAMY1601015CE, PAPAMY1702035CE.

WARNING

This service information is designed for experienced repair technicians only and is not designed for use by the general public.

It does not contain warnings or cautions to advise non-technical individuals of potential dangers in attempting to service a product.

Products powered by electricity should be serviced or repaired only by experienced professional technicians. Any attempt to service

or repair the products dealt with in this service information by anyone else could result in serious injury or death.

PRECAUTION OF LOW TEMPERATURE

In order to avoid frostbite, be assured of no refrigerant leakage during the installation or repairing of refrigerant circuit.

CAUTION

R32 REFRIGERANT

– This Air Conditioner contains and operates with refrigerant R32.

THIS PRODUCT MUST ONLY BE INSTALLED OR SERVICED BY QUALIFIED PERSONNEL.

Refer to Commonwealth, State, Territory and local legislation, regulations, codes, installation & operation manuals, before the

installation, maintenance and/or service of this product.

IMPORTANT SAFETY NOTICE

There are special components used in this equipment which are important for safety. These parts are marked by in the Schematic

Diagrams, Circuit Board Diagrams, Exploded Views and Replacement Parts List. It is essential that these critical parts should be replaced

with manufacturer’s specified parts to prevent shock, fire or other hazards. Do not modify the original design without permission of

manufacturer.

2

Specifications, designs and contents in this Service Manual are subject to change without notice.

TABLE OF CONTENTS

PAGE PAGE

1. Safety Precautions ............................................. 3

2. Precaution for Using R32 Refrigerant .............. 6

3. Specifications ................................................... 10

4. Features ............................................................. 14

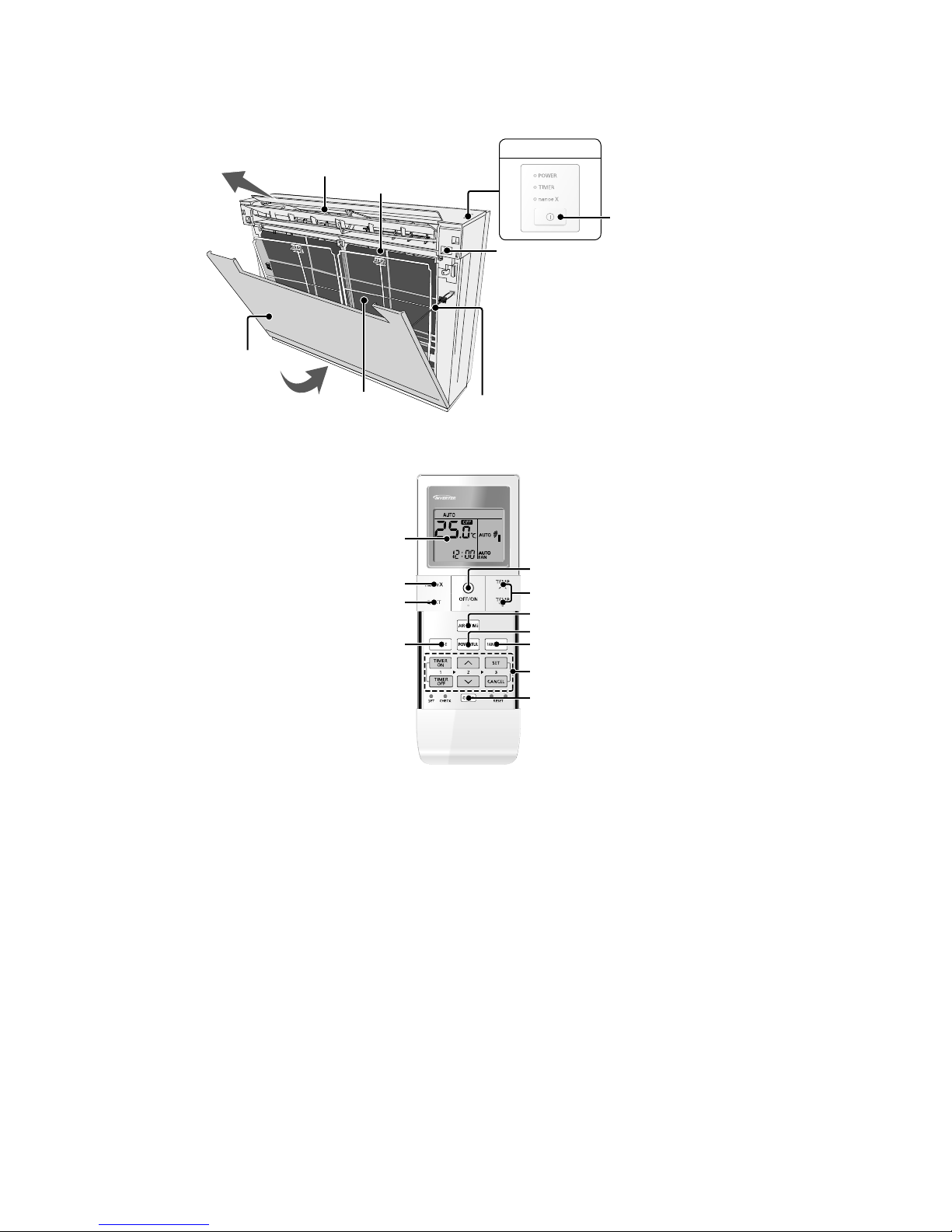

5. Location of Controls and Components .......... 15

5.1 Indoor Unit .................................................. 15

5.2 Remote Control .......................................... 15

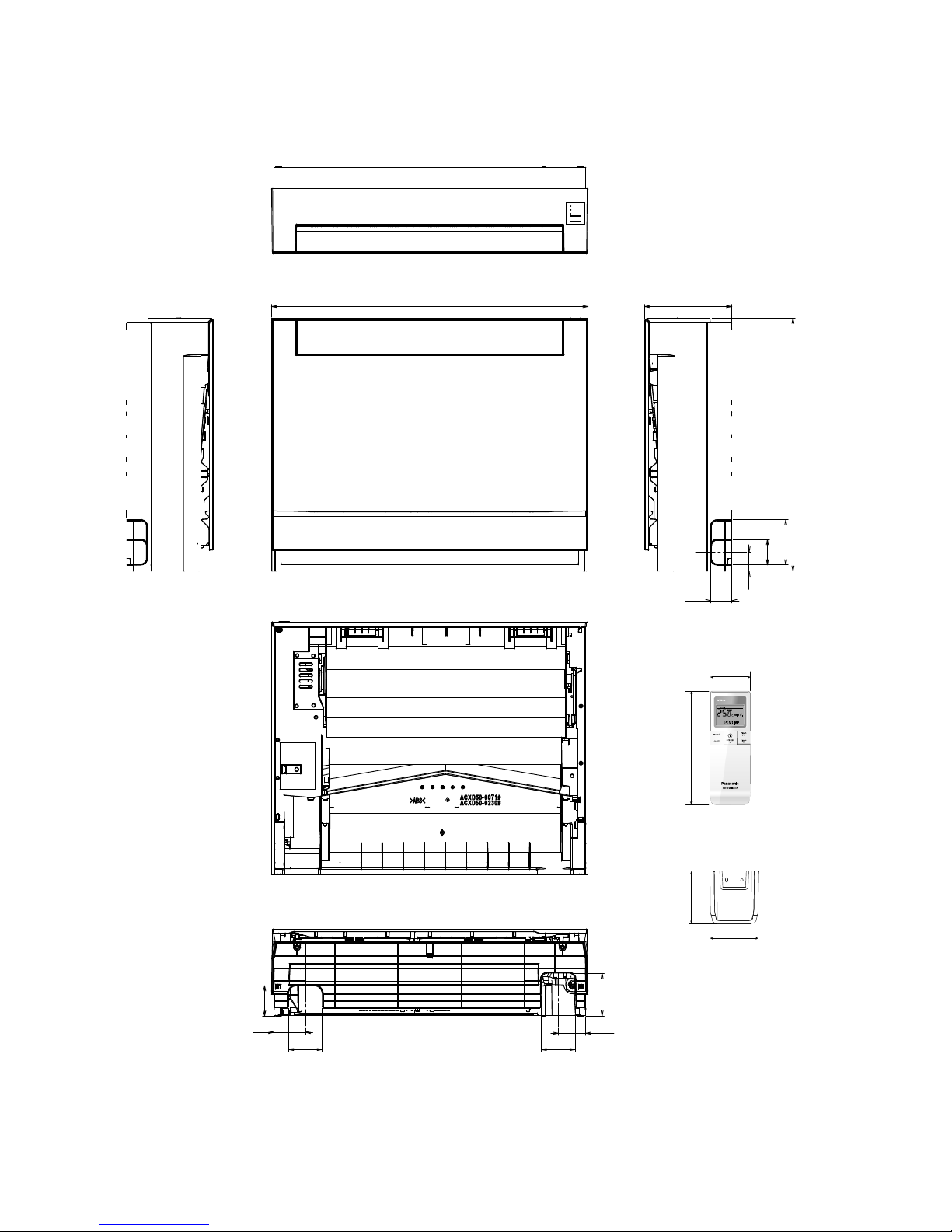

6. Dimensions ....................................................... 16

6.1 Indoor Unit .................................................. 16

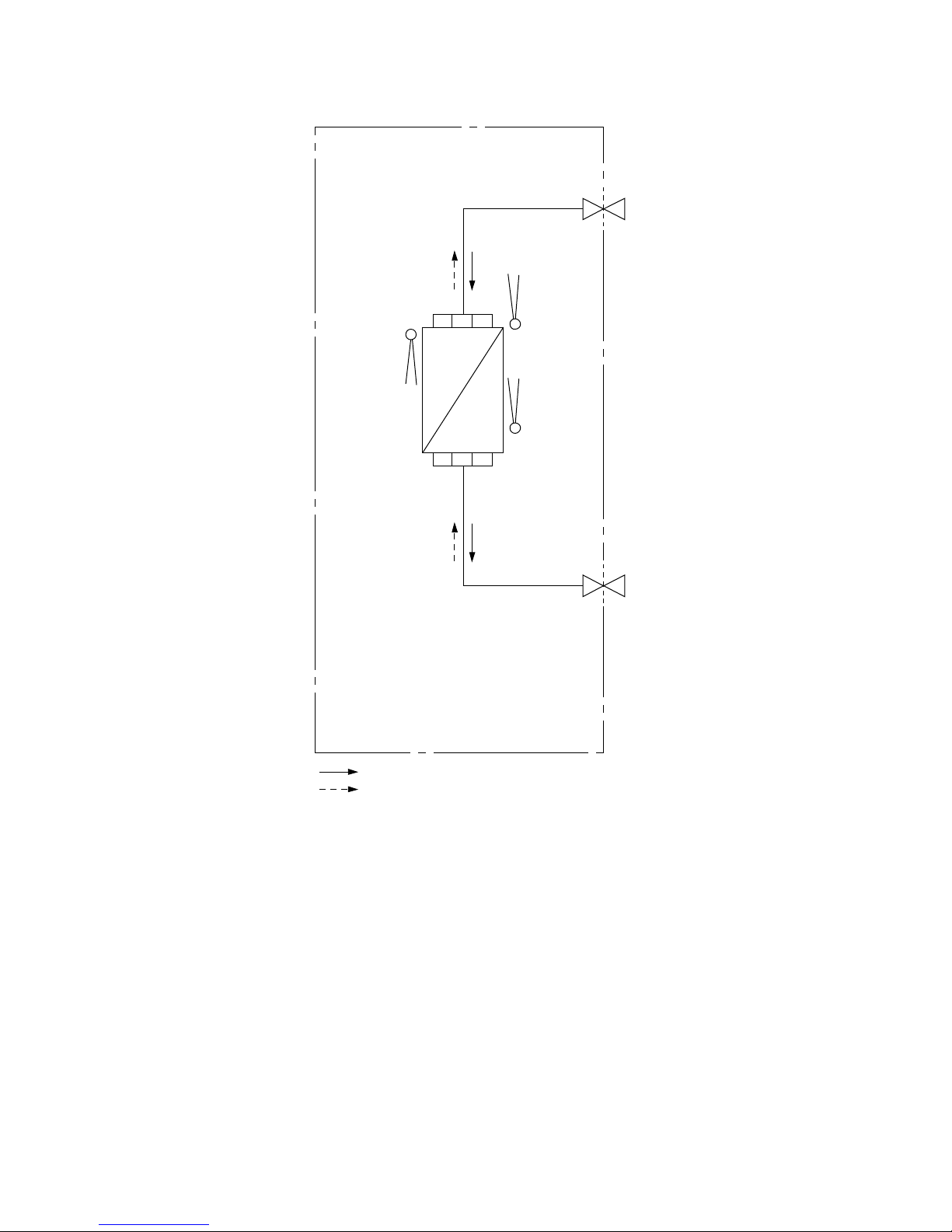

7. Refrigeration Cycle Diagram ........................... 17

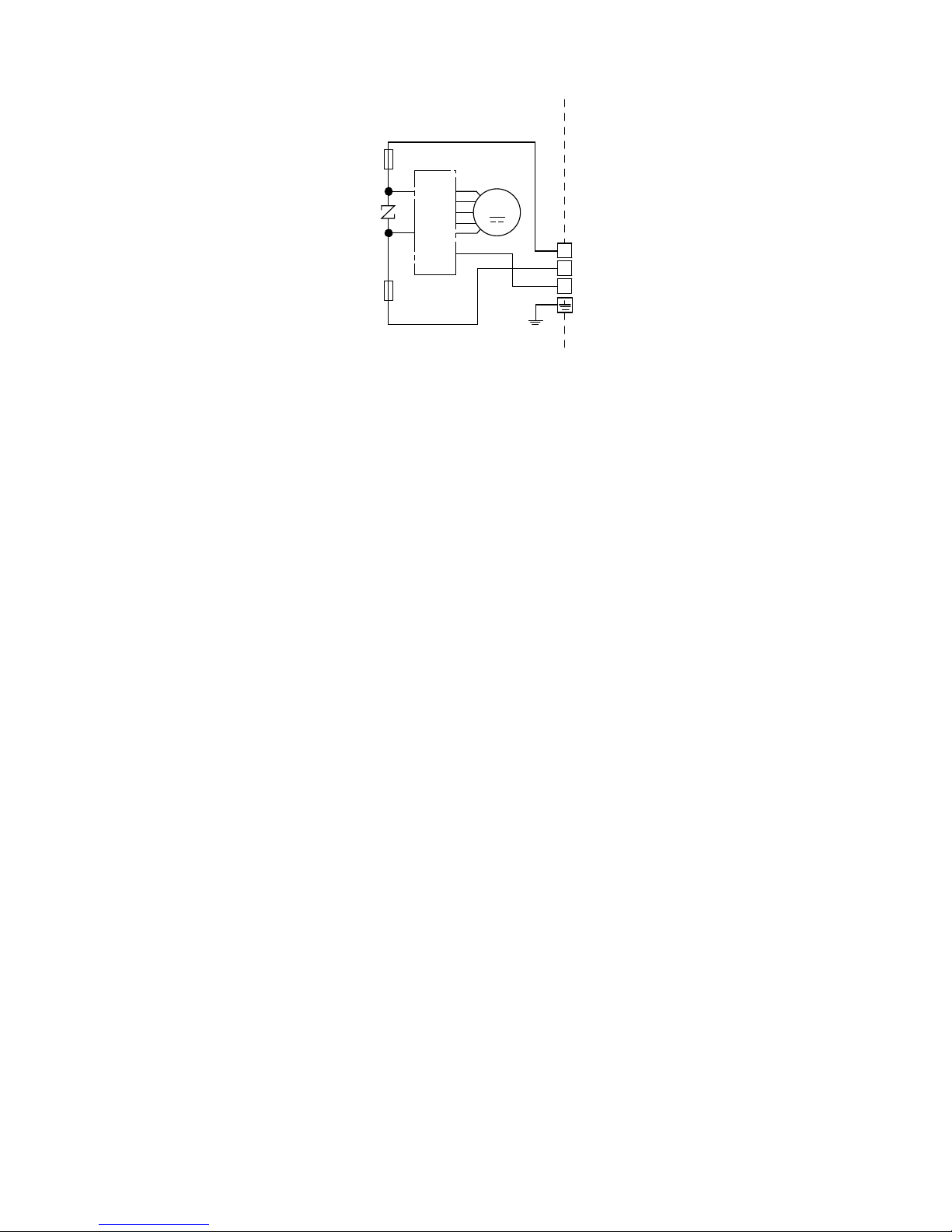

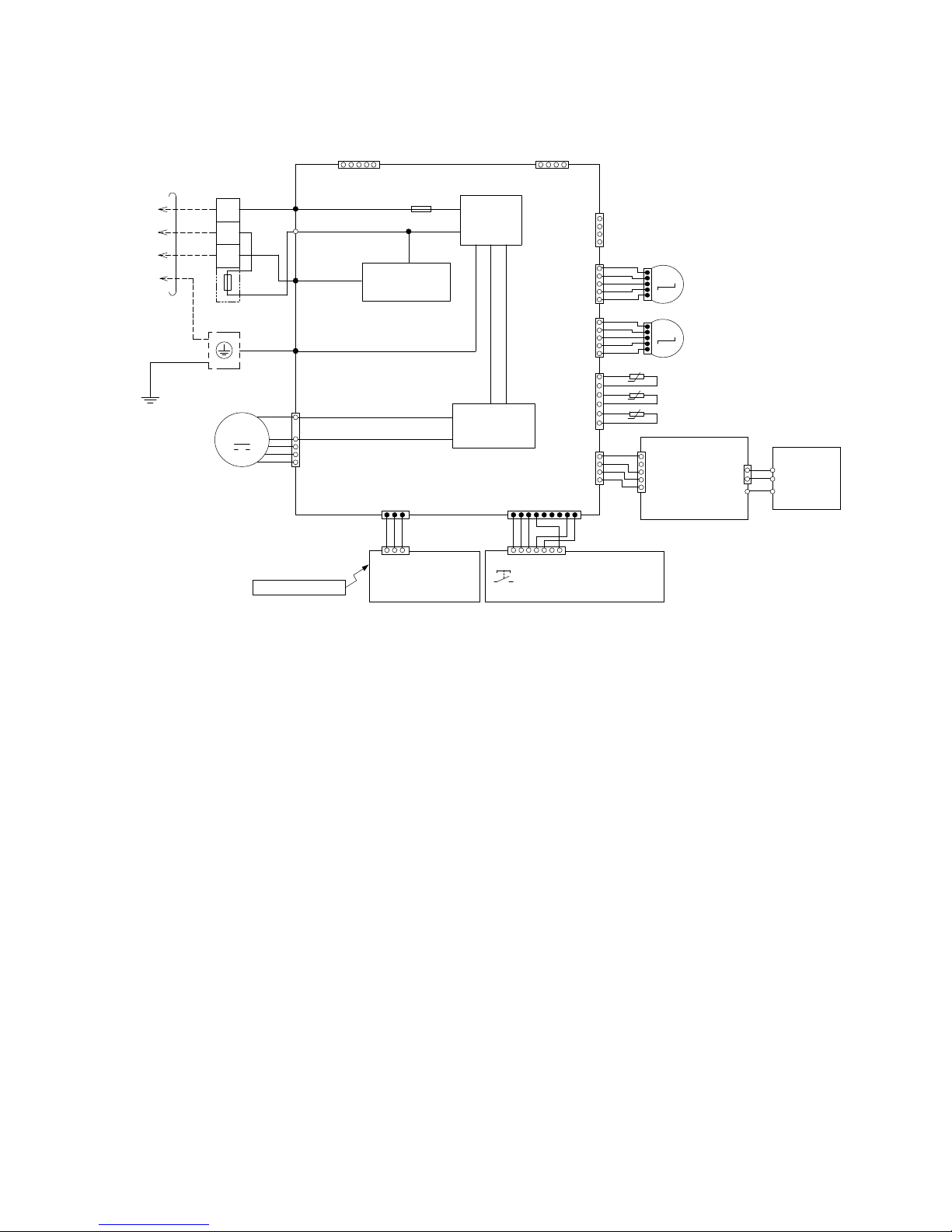

8. Block Diagram .................................................. 18

9. Wiring Connection Diagram ............................ 19

9.1 Indoor Unit .................................................. 19

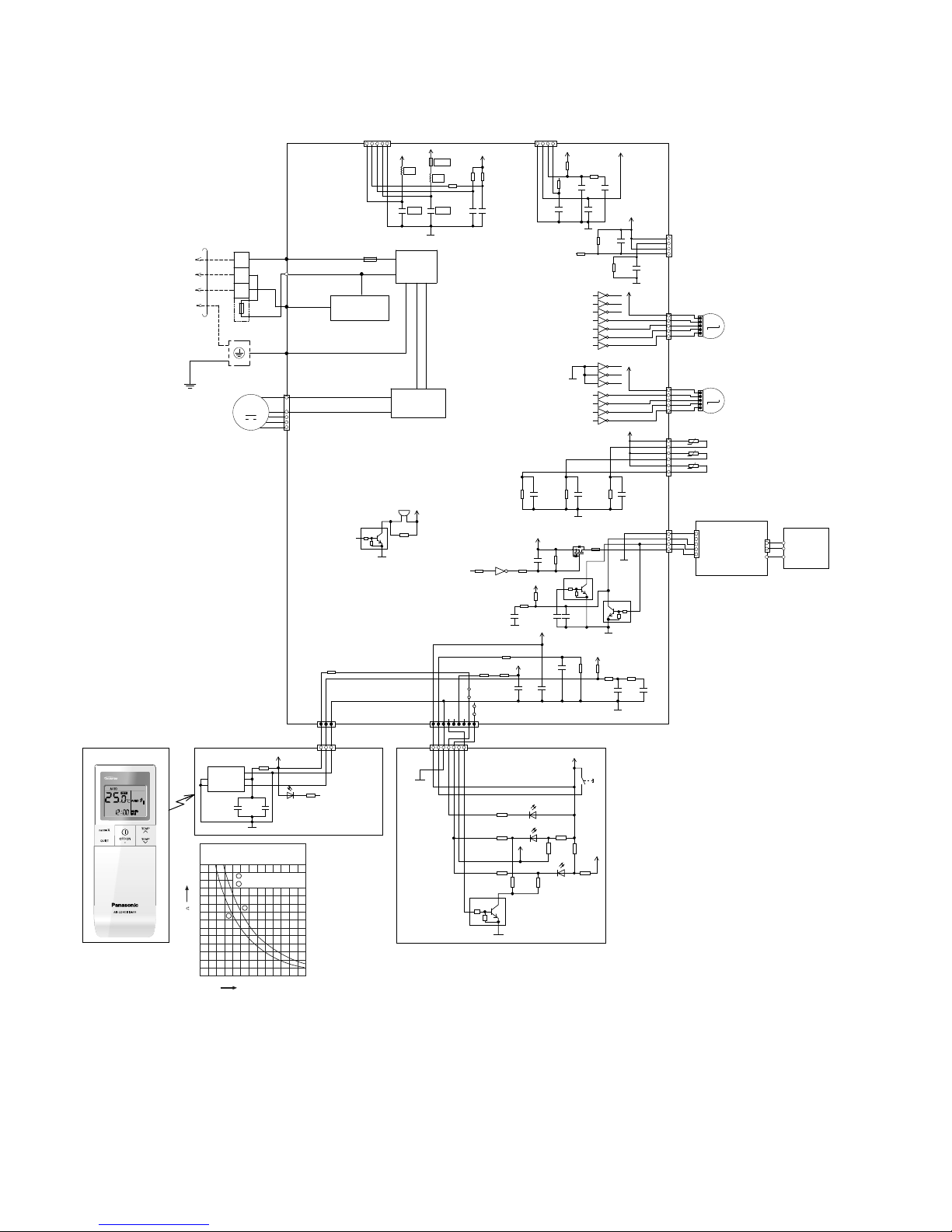

10. Electronic Circuit Diagram .............................. 20

10.1 Indoor Unit .................................................. 20

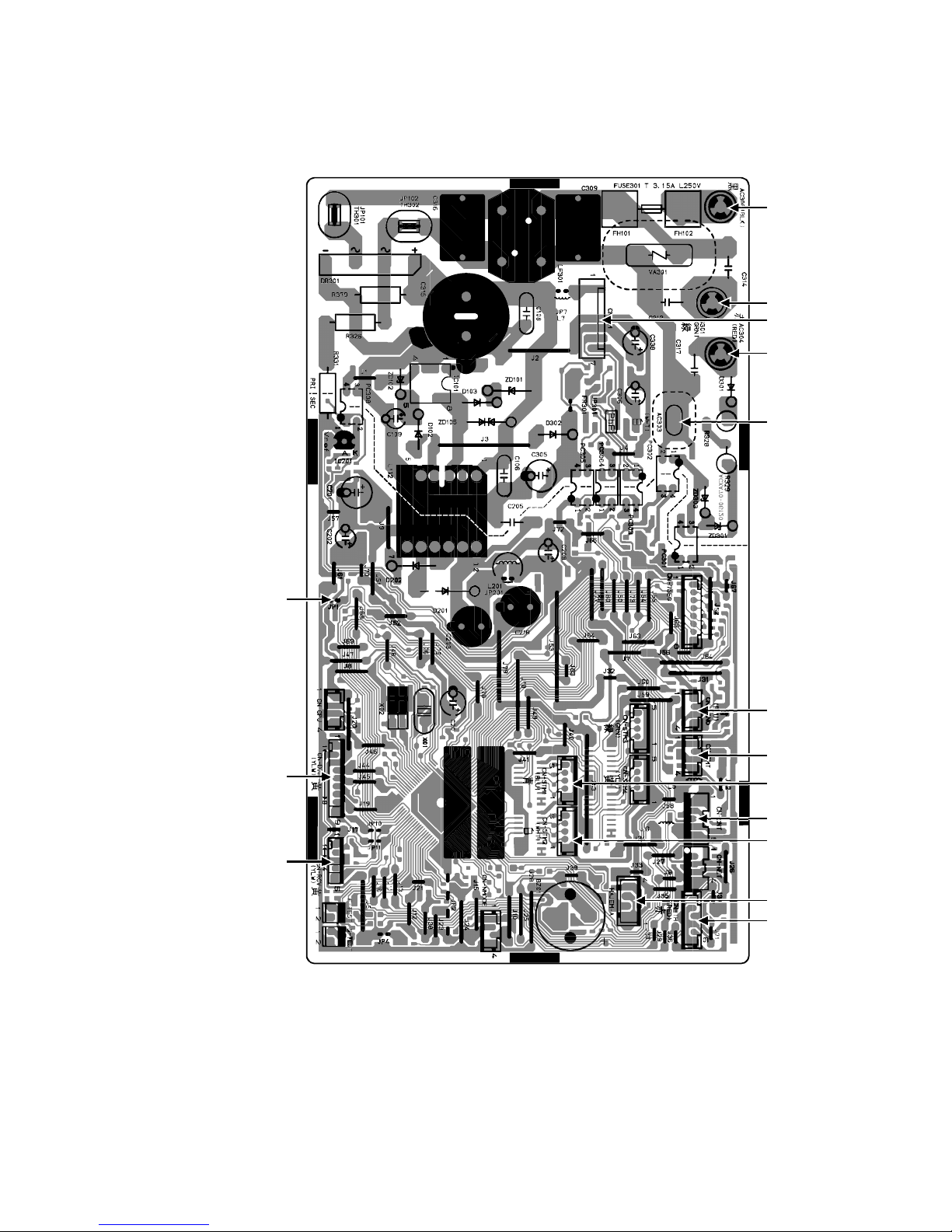

11. Printed Circuit Board ....................................... 21

11.1 Indoor Unit .................................................. 21

12. Installation Instruction ..................................... 23

12.1 Indoor Unit .................................................. 23

13. Installation and Servicing Air Conditioner

using R32 .......................................................... 31

13.1 About R32 Refrigerant ................................ 31

13.2 Characteristics of R32 Refrigerant ............. 31

13.3 Refrigerant piping installation • Tools used

in services ................................................... 33

13.4 New installation, Relocation,

Repairing of Refrigerant Cycle System

The Procedures .......................................... 37

13.5 Piping installation of R32 ............................ 38

13.6 Installation, Relocation, and Service .......... 39

13.7 Repairing of refrigerant cycle /

Brazing point ............................................... 43

13.8 <Reference> Analysis method for no error

code, no cooling / no warming .................... 49

14. Operation Control ............................................. 51

14.1 Basic Function ............................................ 51

14.2 Indoor Fan Motor Operation ....................... 52

14.3 Airflow Direction .......................................... 53

14.4 Quiet Operation (Cooling Mode/Cooling

Area of Dry Mode) ...................................... 54

14.5 Quiet Operation (Heating) .......................... 54

14.6 Powerful Mode Operation ........................... 54

14.7 Timer Control .............................................. 55

14.8 Auto Restart Control ................................... 55

14.9 Indication Panel .......................................... 55

14.10 HA Terminal (HAJEM-A) ............................ 56

14.11 nanoeX Operation ...................................... 57

15. Operation Control

(For Multi Split Connection) ............................ 59

15.1 Cooling operation ....................................... 59

15.2 Soft Dry Operation ...................................... 59

15.3 Heating Operation ...................................... 59

15.4 Automatic Operation ...................................60

15.5 Indoor Fan Motor Operation .......................60

15.6 Powerful Mode Operation ...........................60

15.7 Auto Restart Control ...................................60

15.8 Indication Panel ..........................................60

16. Servicing Mode .................................................61

16.1 Auto OFF/ON Button ..................................61

16.2 Remote Control Button ...............................62

17. Troubleshooting Guide ....................................65

17.1 Refrigeration Cycle System ........................65

17.2 Breakdown Self Diagnosis Function ...........67

17.3 Error Codes Table ......................................68

17.4 Self-diagnosis Method ................................70

18. Disassembly and Assembly Instructions ......99

18.1 Remove the Front Panel ............................99

18.2 Remove the Front Grille .......................... 100

18.3 Remove the Discharge Grille. ................. 101

18.4 Remove the Control Board ...................... 101

18.5 Remove the Drain Pan ............................ 103

18.6 Remove the Cross Flow Fan and

Fan Motor ................................................ 103

19. Exploded View and Replacement Parts

List .................................................................. 105

19.1 Indoor Unit ............................................... 105

3

1. Safety Precautions

Read the following “SAFETY PRECAUTIONS” carefully before perform any servicing.

Electrical work must be installed or serviced by a licensed electrician. Be sure to use the correct rating of the

power plug and main circuit for the model installed.

The caution items stated here must be followed because these important contents are related to safety. The

meaning of each indication used is as below. Incorrect installation or servicing due to ignoring of the instruction

will cause harm or damage, and the seriousness is classified by the following indications.

WARNING

This indication shows the possibility of causing death or serious injury.

CAUTION

This indication shows the possibility of causing injury or damage to properties.

The items to be followed are classified by the symbols:

Explanation of symbols displayed on the indoor unit or outdoor unit.

WARNING

This symbol shows that this equipment uses a flammable refrigerant.

If the refrigerant is leaked, together with an external ignition source, there is a possibility of ignition.

CAUTION

This symbol shows that the Operation Manual should be read carefully.

CAUTION

This symbol shows that a service personnel should be handling this equipment with reference to the

Installation Manual.

CAUTION

This symbol shows that there is information included in the Operation Manual and/or Installation Manual.

Carry out test run to confirm that no abnormality occurs after the servicing. Then, explain to user the operation,

care and maintenance as stated in instructions. Please remind the customer to keep the operating instructions for

future reference.

WARNING

1.

Do not use means to accelerate the defrosting process or to clean, other than those recommended by the manufacturer. Any

unfit method or using incompatible material may cause product damage, burst and serious injury.

2.

Do not install outdoor unit near handrail of veranda. When installing air-conditioner unit on veranda of a high rise building, child

may climb up to outdoor unit and cross over the handrail causing an accident.

3.

Do not use unspecified cord, modified cord, joint cord or extension cord for power supply cord. Do not share the single outlet

with other electrical appliances.

Poor contact, poor insulation or over current will cause electrical shock or fire.

4.

The appliance shall be stored in a well ventilated room with floor area larger than A min (m

2

) [refer Table A] and without any

continuously operating ignition sources.

Keep away from open flames, any operating gas appliances or any operating electric heater. Else, it may explode and cause

injury or death.

5. Do not tie up the power supply cord into a bundle by band. Abnormal temperature rise on power supply cord may happen.

6. Do not insert your fingers or other objects into the unit, high speed rotating fan may cause injury.

7. Do not sit or step on the unit, you may fall down accidentally.

8.

The appliance shall be installed, and/or operated in a room with floor area larger than A min (m

2

) [refer Table A] and keep away

from ignition sources, such as heat/sparks/open flame, or, hazardous areas, such as gas appliances, gas cooking, reticulated

gas supply systems, or electric cooking appliances, etc.

9. Keep plastic bag (packaging material) away from small children, it may cling to nose and mouth and prevent breathing.

10.

When installing or relocating air conditioner, do not let any substance other than the specified refrigerant, eg. air etc mix into

refrigeration cycle (piping).

Mixing of air etc. will cause abnormal high pressure in refrigeration cycle and result in explosion, injury etc.

11.

Do not pierce or burn as the appliance is pressurized. Do not expose the appliance to heat, flame, sparks, or other sources of

ignition.

Else, it may explode and cause injury or death.

12. Do not add or replace refrigerant other than specified type. It may cause product damage, burst and injury etc.

This symbol denotes item that is PROHIBITTED from doing.

4

WARNING

13.

Do not perform flare connection inside a building or dwelling or room, when joining the heat exchanger of indoor unit with

interconnecting piping. Refrigerant connection inside a building or dwelling or room must be made by brazing or welding. Joint

connection of indoor unit by flaring method can only be made at outdoor or at outside of a building or dwelling or room. Flare

connection may cause gas leak and flammable atmosphere.

14.

For R32 model, use piping, flare nut and tools which is specified for R32 refrigerant. Using of existing (R22) piping, flare nut and

tools may cause abnormally high pressure in the refrigerant cycle (piping), and possibly result in explosion and injury.

Thickness or copper pipes used with R32 must be more than 0.8 mm. Never use copper pipes thinner than 0.8 mm.

It is desirable that the amount of residual oil less than 40 mg/10 m.

15.

Engage authorized dealer or specialist for installation and servicing. If installation or servicing done by the user is defective, it will cause

water leakage, electrical shock or fire.

16.

For refrigeration system work, Install according to this installation instructions strictly. If installation is defective, it will cause water

leakage, electrical shock or fire.

17.

Use the attached accessories parts and specified parts for installation and servicing. Otherwise, it will cause the set to fall, water

leakage, fire or electrical shock.

18.

Install at a strong and firm location which is able to withstand weight of the set. If the strength is not enough or installation is not properly

done, the set will drop and cause injury.

19.

For electrical work, follow the national regulation, legistration and this installation instructions. An independent circuit and single outlet

must be used. If electrical circuit capacity is not enough or defect found in the electrical work, it will cause electrical shock or fire.

20.

Do not use joint cable for indoor/outdoor connection cable. Use the specified indoor/outdoor connection cable, refer to instruction

CONNECT THE CABLE TO THE INDOOR UNIT and connect tightly for indoor/outdoor connection. Clamp the cable so that no external

force will have impact on the terminal.

If connection or fixing is not perfect, it will cause heat up or fire at the connection.

21.

Wire routing must be properly arranged so that control board cover is fixed properly. If control board cover is not fixed perfectly, it will

cause heat-up or fire at connection point of terminal, fire or electrical shock.

22.

This equipment is strongly recommended to be installed with Earth Leakage Circuit Breaker (ELCB) or Residual Current Device (RCD),

with sensitivity of 30mA at 0.1 sec or less. Otherwise, it may cause electrical shock and fire in case of equipment breakdown or

insulation breakdown.

23.

During installation, install the refrigerant piping properly before running the compressor. Operation of compressor without fixing

refrigeration piping and valves at opened position will cause suck-in of air, abnormal high pressure in refrigeration cycle and result in

explosion, injury etc.

24.

During pump down operation, stop the compressor before removing the refrigeration piping. Removal of refrigeration piping while

compressor is operating and valves are opened will cause suck-in of air, abnormal high pressure in refrigeration cycle and result in

explosion, injury etc.

25.

Tighten the flare nut with torque wrench according to specified method. If the flare nut is over-tightened, after a long period, the flare

may break and cause refrigerant gas leakage.

26.

After completion of installation or service, confirm there is no leakage of refrigerant gas. It may generate toxic gas when the refrigerant

contacts with fire.

27. Ventilate if there is refrigerant gas leakage during operation. It may cause toxic gas when the refrigerant contacts with fire.

28. Be aware that refrigerants may not contain an odour.

29.

This equipment must be properly earthed. Earth line must not be connected to gas pipe, water pipe, earth of lightning rod and

telephone. Otherwise, it may cause electrical shock in case of equipment breakdown or insulation breakdown.

30. Do not modify the machine, part, material during repairing service.

31. If wiring unit is supplied as repairing part, do not repair or connect the wire even only partial wire break. Exchange the whole wiring unit.

32. Do not wrench the fasten terminal. Pull it out or insert it straightly.

33. Must not use other parts except original parts describe in catalog and manual.

CAUTION

1.

Do not install the unit in a place where leakage of flammable gas may occur. In case gas leaks and accumulates at surrounding

of the unit, it may cause fire.

2. Prevent liquid or vapor from entering sumps or sewers since vapor is heavier than air and may form suffocating atmospheres.

3.

Do not release refrigerant during piping work for installation, servicing, reinstallation and during repairing a refrigerant parts.

Take care of the liquid refrigerant, it may cause frostbite.

4. Do not install this appliance in a laundry room or other location where water may drip from the ceiling, etc.

5

CAUTION

5. Do not touch the sharp aluminium fin, sharp parts may cause injury.

6.

Carry out drainage piping as mentioned in installation instructions. If drainage is not perfect, water may enter the room and damage the

furniture.

7.

Select an installation location which is easy for maintenance.

Incorrect installation, service or repair of this air conditioner may increase the risk of rupture and this may result in loss damage or injury

and/or property.

8. Installation or servicing work: It may need two people to carry out the installation or servicing work.

9

Pb free solder has a higher melting point than standard solder; typically the melting point is 50°F – 70°F (30°C – 40°C) higher.

Please use a high temperature solder iron. In case of the soldering iron with temperature control, please set it to 700 ± 20°F

(370 ± 10°C).

Pb free solder will tend to splash when heated too high (about 1100°F / 600°C).

10.

Do not touch the sharp aluminum fins or edges of metal parts.

If you are required to handle sharp parts during installation or servicing, please wear hand glove.

Sharp parts may cause injury.

11.

Tighten the flare nut with torque wrench according to specified method. If the flare nut is over-tightened, after a long period, the flare may

break and cause refrigerant gas leakage.

12. Do not touch outdoor unit air inlet and aluminium fin. It may cause injury.

6

2. Precaution for Using R32 Refrigerant

The basic installation work procedures are the same as conventional refrigerant (R410A, R22) models.

However, pay careful attention to the following points:

WARNING

1.

Since the working pressure is higher than that of refrigerant R22 models, some of the piping and installation and service tools are

special.

(See “2.1. Special tools for R32 (R410A)”.)

Especially, when replacing a refrigerant R22 model with a new refrigerant R32 model, always replace the conventional piping and flare

nuts with the R32 and R410A piping and flare nuts on the outdoor unit side.

For R32 and R410A, the same flare nut on the outdoor unit side and pipe can be used.

2.

Models that use refrigerant R32 and R410A have a different charging port thread diameter to prevent erroneous charging with refrigerant

R22 and for safety.

Therefore, check beforehand. [The charging port thread diameter for R32 and R410A is 12.7 mm (1/2 inch).]

3.

Be more careful than R22 so that foreign matter (oil, water, etc.) does not enter the piping.

Also, when storing the piping, securely seal the opening by pinching, taping, etc. (Handling of R32 is similar to R410A.)

CAUTION

1.

Installation (Space)

Must ensure the installation of pipe-work shall be kept to a minimum. Avoid use dented pipe and do not allow acute bending.

Must ensure that pipe-work shall be protected from physical damage.

Must comply with national gas regulations, state municipal rules and legislation. Notify relevant authorities in accordance with all

applicable regulations.

Must ensure mechanical connections be accessible for maintenance purposes.

In cases that require mechanical ventilation, ventilation openings shall be kept clear of obstruction.

When disposal of the product, do follow to the precautions in #12 and comply with national regulations.

Always contact to local municipal offices for proper handling.

Interconnecting refrigerant pipework, i.e. pipework external to the unitary components, should be marked with a Class label (see

Figure 9.1 of Code of Practice) every two metres where the pipework is visible. This includes pipework located in a ceiling space or

any void which a person may access for maintenance or repair work within that space.

2.

Servicing

2-1. Service personnel

Any qualified person who is involved with working on or breaking into a refrigerant circuit should hold a current valid certificate from

an industry-accredited assessment authority, which authorizes their competence to handle refrigerants safely in accordance with an

industry recognised assessment specification.

Servicing shall only be performed as recommended by the equipment manufacturer. Maintenance and repair requiring the

assistance of other skilled personnel shall be carried out under the supervision of the person competent in the use of flammable

refrigerants.

Servicing shall be performed only as recommended by the manufacturer.

2-2. Work

Prior to beginning work on systems containing flammable refrigerants, safety checks are necessary to ensure that the risk of

ignition is minimised.

For repair to the refrigerating system, the precautions in #2-2 to #2-8 must be followed before conducting work on the system.

Work shall be undertaken under a controlled procedure so as to minimize the risk of a flammable gas or vapor being present while

the work is being performed.

All maintenance staff and others working in the local area shall be instructed and supervised on the nature of work being carried

out.

Avoid working in confined spaces.

Wear appropriate protective equipment, including respiratory protection, as conditions warrant.

Ensure that the conditions within the area have been made safe by limit of use of any flammable material. Keep all sources of

ignition and hot metal surfaces away.

2-3. Checking for presence of refrigerant

The area shall be checked with an appropriate refrigerant detector prior to and during work, to ensure the technician is aware of

potentially flammable atmospheres.

Ensure that the leak detection equipment being used is suitable for use with flammable refrigerants, i.e. non sparking, adequately

sealed or intrinsically safe.

In case of leakage/spillage happened, immediately ventilate area and stay upwind and away from spill/release.

In case of leakage/spillage happened, do notify persons downwind of the leaking/spill, isolate immediate hazard area and keep

unauthorized personnel out.

2-4. Presence of fire extinguisher

If any hot work is to be conducted on the refrigeration equipment or any associated parts, appropriate fire extinguishing equipment

shall be available at hand.

Have a dry powder or CO

2

fire extinguisher adjacent to the charging area.

7

CAUTION

2-5. No ignition sources

No person carrying out work in relation to a refrigeration system which involves exposing any pipe work that contains or has

contained flammable refrigerant shall use any sources of ignition in such a manner that it may lead to the risk of fire or explosion.

He/She must not be smoking when carrying out such work.

All possible ignition sources, including cigarette smoking, should be kept sufficiently far away from the site of installation, repairing,

removing and disposal, during which flammable refrigerant can possibly be released to the surrounding space.

Prior to work taking place, the area around the equipment is to be surveyed to make sure that there are no flammable hazards or

ignition risks.

“No Smoking” signs shall be displayed.

2-6. Ventilated area

Ensure that the area is in the open or that it is adequately ventilated before breaking into the system or conducting any hot work.

A degree of ventilation shall continue during the period that the work is carried out.

The ventilation should safely disperse any released refrigerant and preferably expel it externally into the atmosphere.

2-7. Checks to the refrigeration equipment

Where electrical components are being changed, they shall be fit for the purpose and to the correct specification.

At all times the manufacturer’s maintenance and service guidelines shall be followed.

If in doubt consult the manufacturer’s technical department for assistance.

The following checks shall be applied to installations using flammable refrigerants.

- The charge size is in accordance with the room size within which the refrigerant containing parts are installed.

- The ventilation machinery and outlets are operating adequately and are not obstructed.

- If an indirect refrigerating circuit is being used, the secondary circuit shall be checked for the presence of refrigerant.

- Marking to the equipment continues to be visible and legible. Markings and signs that are illegible shall be corrected.

- Refrigeration pipe or components are installed in a position where they are unlikely to be exposed to any substance

which may corrode refrigerant containing components, unless the components are constructed of materials which are

inherently resistant to being corroded or are properly protected against being so corroded.

2-8. Checks to electrical devices

Repair and maintenance to electrical components shall include initial safety checks and component inspection procedures.

Initial safety checks shall include but not limit to:-

- That capacitors are discharged: this shall be done in a safe manner to avoid possibility of sparking.

- That there is no live electrical components and wiring are exposed while charging, recovering or purging the system.

- That there is continuity of earth bonding.

At all times the manufacturer’s maintenance and service guidelines shall be followed.

If in doubt consult the manufacturer’s technical department for assistance.

If a fault exists that could compromise safety, then no electrical supply shall be connected to the circuit until it is satisfactorily dealt

with.

If the fault cannot be corrected immediately but it is necessary to continue operation, an adequate temporary solution shall be used.

The owner of the equipment must be informed or reported so all parties are advised thereinafter.

3.

Repairs to sealed components

During repairs to sealed components, all electrical supplies shall be disconnected from the equipment being worked upon prior to

any removal of sealed covers, etc.

If it is absolutely necessary to have an electrical supply to equipment during servicing, then a permanently operating form of leak

detection shall be located at the most critical point to warn of a potentially hazardous situation.

Particular attention shall be paid to the following to ensure that by working on electrical components, the casing is not altered in

such a way that the level of protection is affected. This shall include damage to cables, excessive number of connections, terminals

not made to original specification, damage to seals, incorrect fitting of glands, etc.

Ensure that apparatus is mounted securely.

Ensure that seals or sealing materials have not degraded such that they no longer serve the purpose of preventing the ingress of

flammable atmospheres.

Replacement parts shall be in accordance with the manufacturer’s specifications.

NOTE:

The use of silicon sealant may inhibit the effectiveness of some types of leak detection equipment.

Intrinsically safe components do not have to be isolated prior to working on them.

4.

Repair to intrinsically safe components

Do not apply any permanent inductive or capacitance loads to the circuit without ensuring that this will not exceed the permissible

voltage and current permitted for the equipment in use.

Intrinsically safe components are the only types that can be worked on while live in the presence of a flammable atmosphere.

The test apparatus shall be at the correct rating.

Replace components only with parts specified by the manufacturer. Unspecified parts by manufacturer may result ignition of

refrigerant in the atmosphere from a leak.

5.

Cabling

Check that cabling will not be subject to wear, corrosion, excessive pressure, vibration, sharp edges or any other adverse

environmental effects.

The check shall also take into account the effects of aging or continual vibration from sources such as compressors or fans.

6.

Detection of flammable refrigerants

Under no circumstances shall potential sources of ignition be used in the searching or detection of refrigerant leaks.

A halide torch (or any other detector using a naked flame) shall not be used.

8

CAUTION

7.

Leak detection methods

Electronic leak detectors shall be used to detect flammable refrigerants, but the sensitivity may not be adequate, or may need re-

calibration.

(Detection equipment shall be calibrated in a refrigerant-free area.)

Ensure that the detector is not a potential source of ignition and is suitable for the refrigerant used.

Leak detection equipment shall be set at a percentage of the LFL of the refrigerant and shall be calibrated to the refrigerant

employed and the appropriate percentage of gas (25 % maximum) is confirmed.

Leak detection fluids are suitable for use with most refrigerants but the use of detergents containing chlorine shall be avoided as the

chlorine may react with the refrigerant and corrode the copper pipe-work.

If a leak is suspected, all naked flames shall be removed/extinguished.

If a leakage of refrigerant is found which requires brazing, all of the refrigerant shall be recovered from the system, or isolated (by

means of shut off valves) in a part of the system remote from the leak. Oxygen free nitrogen (OFN) shall then be purged through

the system both before and during the brazing process.

8.

Removal and evacuation

When breaking into the refrigerant circuit to make repairs – or for any other purpose – conventional procedures shall be used.

However, it is important that best practice is followed since flammability is a consideration.

The following procedure shall be adhered to:

• remove refrigerant -> • purge the circuit with inert gas -> • evacuate -> • purge again with inert gas ->

• open the circuit by cutting or brazing

The refrigerant charge shall be recovered into the correct recovery cylinders.

The system shall be “flushed” with OFN to render the unit safe.

This process may need to be repeated several times.

Compressed air or oxygen shall not be used for this task.

Flushing shall be achieved by breaking the vacuum in the system with OFN and continuing to fill until the working pressure is

achieved, then venting to atmosphere, and finally pulling down to a vacuum.

This process shall be repeated until no refrigerant is within the system.

When the final OFN charge is used, the system shall be vented down to atmospheric pressure to enable work to take place.

This operation is absolutely vital if brazing operations on the pipe work are to take place.

Ensure that the outlet for the vacuum pump is not close to any ignition sources and there is ventilation available.

9.

Charging procedures

In addition to conventional charging procedures, the following requirements shall be followed.

- Ensure that contamination of different refrigerants does not occur when using charging equipment.

- Hoses or lines shall be as short as possible to minimize the amount of refrigerant contained in them.

- Cylinders shall be kept upright.

- Ensure that the refrigeration system is earthed prior to charging the system with refrigerant.

- Label the system when charging is complete (if not already).

- Extreme care shall be taken not to over fill the refrigeration system.

Prior to recharging the system it shall be pressure tested with OFN (refer to #7).

The system shall be leak tested on completion of charging but prior to commissioning.

A follow up leak test shall be carried out prior to leaving the site.

Electrostatic charge may accumulate and create a hazardous condition when charging and discharging the refrigerant.

To avoid fire or explosion, dissipate static electricity during transfer by grounding and bonding containers and equipment before

charging/discharging.

10.

Decommissioning

Before carrying out this procedure, it is essential that the technician is completely familiar with the equipment and all its details.

It is recommended good practice that all refrigerants are recovered safely.

Prior to the task being carried out, an oil and refrigerant sample shall be taken in case analysis is required prior to re-use of

reclaimed refrigerant.

It is essential that electrical power is available before the task is commenced.

a)

Become familiar with the equipment and its operation.

b)

Isolate system electrically.

c)

Before attempting the procedure ensure that:

• mechanical handling equipment is available, if required, for handling refrigerant cylinders;

• all personal protective equipment is available and being used correctly;

• the recovery process is supervised at all times by a competent person;

• recovery equipment and cylinders conform to the appropriate standards.

d)

Pump down refrigerant system, if possible.

e)

If a vacuum is not possible, make a manifold so that refrigerant can be removed from various parts of the system.

f)

Make sure that cylinder is situated on the scales before recovery takes place.

g)

Start the recovery machine and operate in accordance with manufacturer’s instructions.

h)

Do not over fill cylinders. (No more than 80 % volume liquid charge).

i)

Do not exceed the maximum working pressure of the cylinder, even temporarily.

j)

When the cylinders have been filled correctly and the process completed, make sure that the cylinders and the

equipment are removed from site promptly and all isolation valves on the equipment are closed off.

k)

Recovered refrigerant shall not be charged into another refrigeration system unless it has been cleaned and checked.

Electrostatic charge may accumulate and create a hazardous condition when charging or discharging the refrigerant.

To avoid fire or explosion, dissipate static electricity during transfer by grounding and bonding containers and equipment before

charging/discharging.

9

CAUTION

11.

Labelling

Equipment shall be labelled stating that it has been de-commissioned and emptied of refrigerant.

The label shall be dated and signed.

Ensure that there are labels on the equipment stating the equipment contains flammable refrigerant.

12.

Recovery

When removing refrigerant from a system, either for servicing or decommissioning, it is recommended good practice that all

refrigerants are removed safely.

When transferring refrigerant into cylinders, ensure that only appropriate refrigerant recovery cylinders are employed.

Ensure that the correct number of cylinders for holding the total system charge are available.

All cylinders to be used are designated for the recovered refrigerant and labelled for that refrigerant (i.e. special cylinders for the

recovery of refrigerant).

Cylinders shall be complete with pressure relief valve and associated shut-off valves in good working order.

Recovery cylinders are evacuated and, if possible, cooled before recovery occurs.

The recovery equipment shall be in good working order with a set of instructions concerning the equipment that is at hand and shall

be suitable for the recovery of flammable refrigerants.

In addition, a set of calibrated weighing scales shall be available and in good working order.

Hoses shall be complete with leak-free disconnect couplings and in good condition.

Before using the recovery machine, check that it is in satisfactory working order, has been properly maintained and that any

associated electrical components are sealed to prevent ignition in the event of a refrigerant release.

Consult manufacturer if in doubt.

The recovered refrigerant shall be returned to the refrigerant supplier in the correct recovery cylinder, and the relevant Waste

Transfer Note arranged.

Do not mix refrigerants in recovery units and especially not in cylinders.

If compressors or compressor oils are to be removed, ensure that they have been evacuated to an acceptable level to make certain

that flammable refrigerant does not remain within the lubricant.

The evacuation process shall be carried out prior to returning the compressor to the suppliers.

Only electric heating to the compressor body shall be employed to accelerate this process.

When oil is drained from a system, it shall be carried out safely.

10

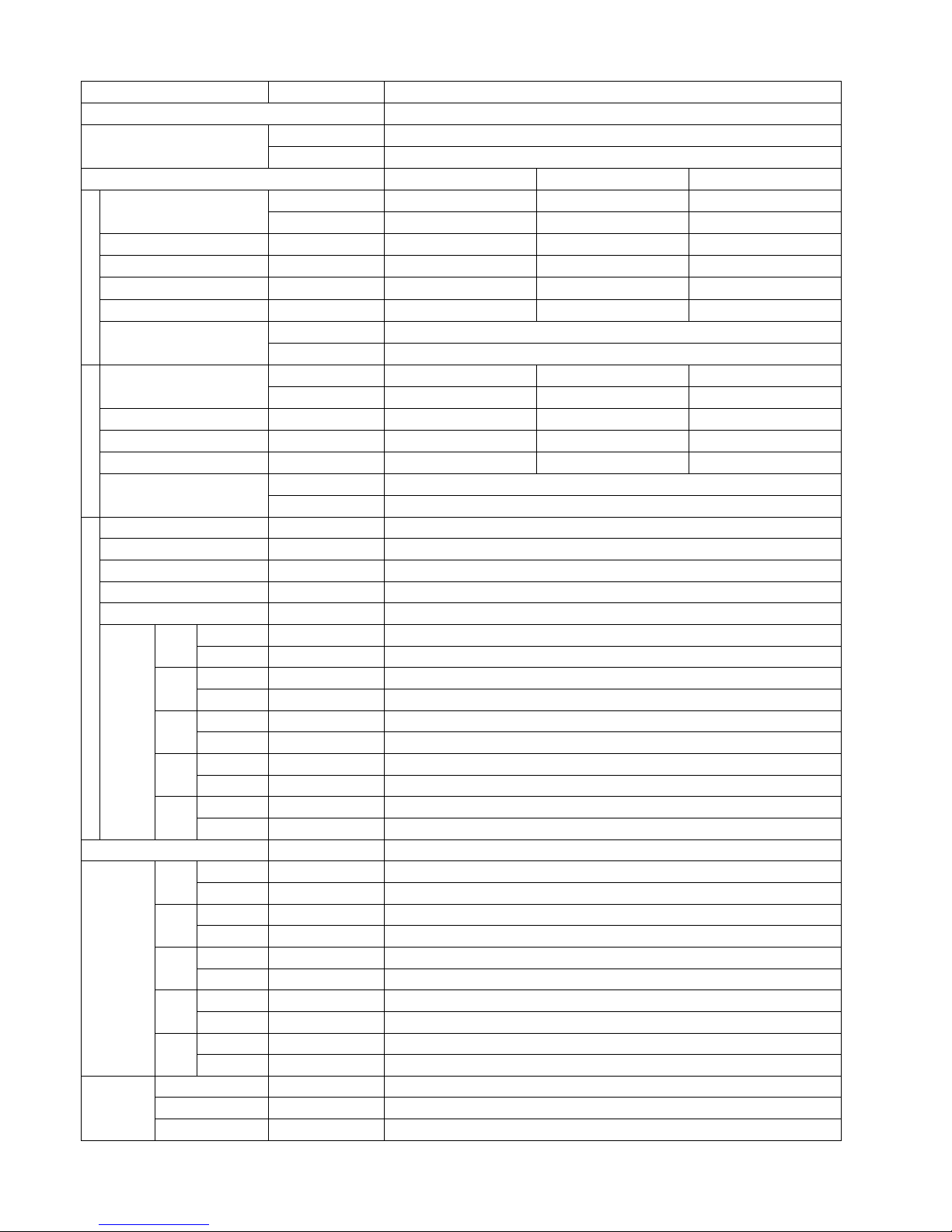

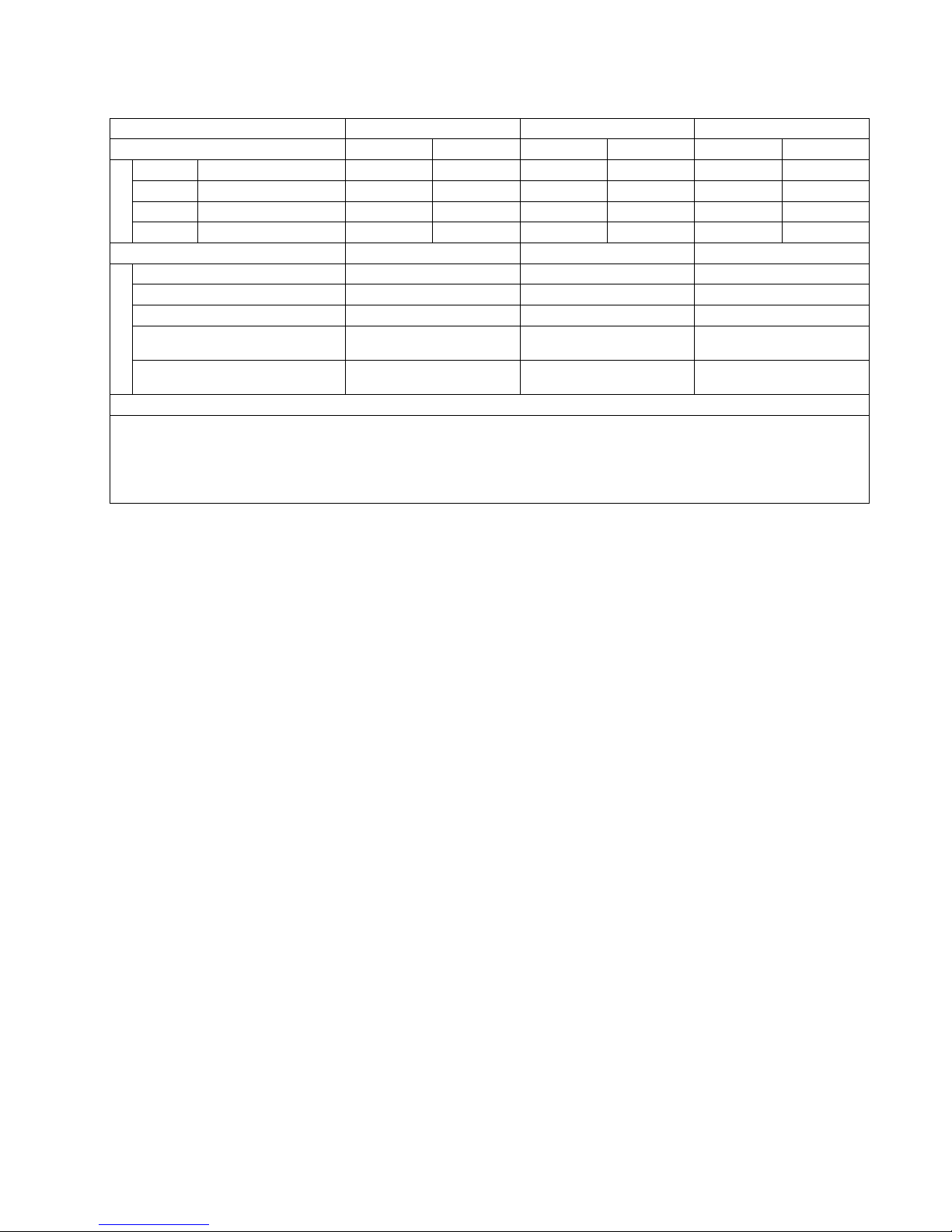

3. Specifications

Model Indoor CS-MZ20UFEA

Performance Test Condition EUROVENT

Power Supply

Phase, Hz Single, 50

V 230

Min. Mid. Max.

Cooling

Capacity

kW 1.80 2.00 2.90

BTU/h 6140 6820 9890

Running Current A – 2.70 –

Input Power W 340 550 860

Annual Consumption kWh – 275 –

EER W/W 5.29 3.64 3.37

Indoor Noise (H / L / QLo)

dB-A 39 / 27 / 22

Power Level dB 55 / – / –

Heating

Capacity

kW 1.20 3.20 4.10

BTU/h 4090 10900 14000

Running Current A – 4.10 –

Input Power W 300 840 1.33k

COP W/W 4.00 3.81 3.08

Indoor Noise (H / L / QLo)

dB-A 39 / 27 / 21

Power Level dB 55 / – / –

Indoor Fan

Type Cross Flow Fan

Material ASG33

Motor Type DC / Transistor (8-poles)

Input Power W 44

Output Power W 30

Speed

QLo

Cool rpm 520

Heat rpm 520

Lo

Cool rpm 640

Heat rpm 670

Me

Cool rpm 820

Heat rpm 850

Hi

Cool rpm 990

Heat rpm 1050

SHi

Cool rpm 1040

Heat rpm 1100

Moisture Removal L/h (Pt/h) 1.3 (2.7)

Indoor

Airflow

QLo

Cool m

3

/min (ft3/min.) 5.0 (177)

Heat m3/min (ft3/min.) 5.0 (177)

Lo

Cool m

3

/min (ft3/min.) 6.1 (215)

Heat m3/min (ft3/min.) 6.4 (226)

Me

Cool m

3

/min (ft3/min.) 7.8 (275)

Heat m3/min (ft3/min.) 8.1 (286)

Hi

Cool m

3

/min (ft3/min.) 9.60 (340)

Heat m3/min (ft3/min.) 10.20 (360)

SHi

Cool m

3

/min (ft3/min.) 9.8 (346)

Heat m3/min (ft3/min.) 10.5 (370)

Dimension

Height (I/D) mm (inch) 600 (23-5/8)

Width (I/D) mm (inch) 750 (29-17/32)

Depth (I/D) mm (inch) 207 (8-5/32)

11

Model Indoor CS-MZ20UFEA

Weight Net (I/D) kg (lb) 13 (29)

Piping

Pipe Diameter

(Liquid / Gas)

mm (inch) 6.35 (1/4) / 9.52 (3/8)

Drain Hose

Inner Diameter mm 28.5

Length mm 270

Indoor Heat

Exchanger

Fin Material Aluminium (Pre Coat)

Fin Type Slit Fin

Row × Stage × FPI 2 × 17 × 21

Size (W × H × L) mm 554 × 357 × 25.4

Air Filter

Material Polypropelene

Type One-touch

Power Supply Outdoor

Power Supply Cord A Nil

Thermostat Electronic Control

Protection Device Electronic Control

Dry Bulb Wet Bulb

Indoor

Operation

Range

Cooling

Maximum °C 32 23

Minimum °C 16 11

Heating

Maximum °C 30 –

Minimum °C 16 –

1. Cooling capacities are based on indoor temperature of 27°C Dry Bulb (80.6°F Dry Bulb), 19.0°C Wet Bulb (66.2°F Wet Bulb) and outdoor air

temperature of 35°C DRY BULB (95°F Dry Bulb), 24°C Wet Bulb (75.2°F Wet Bulb).

2. Heating capacities are based on indoor temperature of 20°C Dry Bulb (68°F Dry Bulb) and outdoor air temperature of 7°C Dry Bulb (44.6°F

Dry Bulb), 6°C Wet Bulb (42.8°F Wet Bulb).

3. Heating low temperature capacity, Input Power and COP measured at 230 V, indoor temperature 20°C, outdoor 2/1°C.

4. Heating extreme low temperature capacity, Input Power and COP measured at 230 V, indoor temperature 20°C, outdoor -7/-8°C.

5. Standby power consumption ≤10.0w (when switched OFF by remote control, except under self protection control).

6. Specifications are subjected to change without prior notice for further improvement.

12

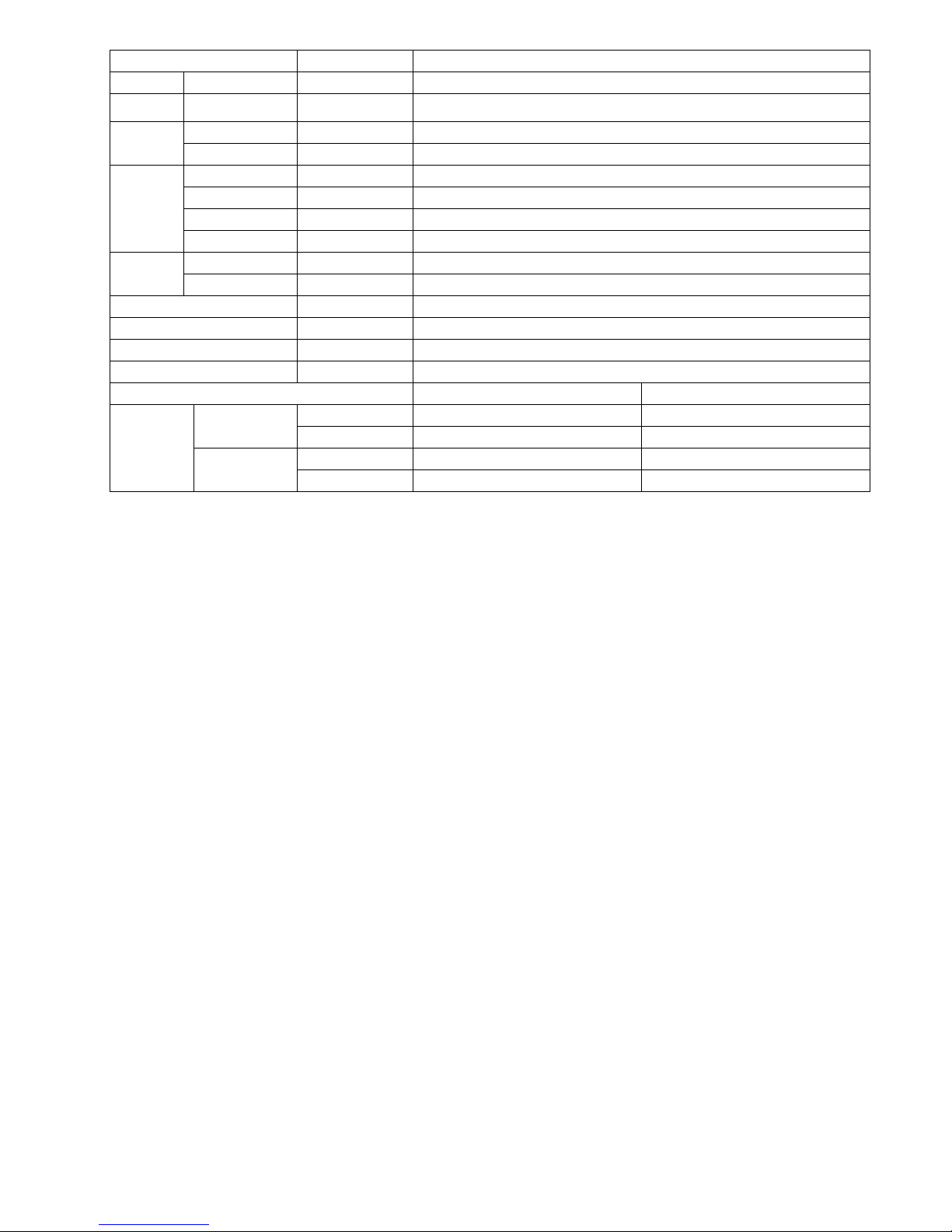

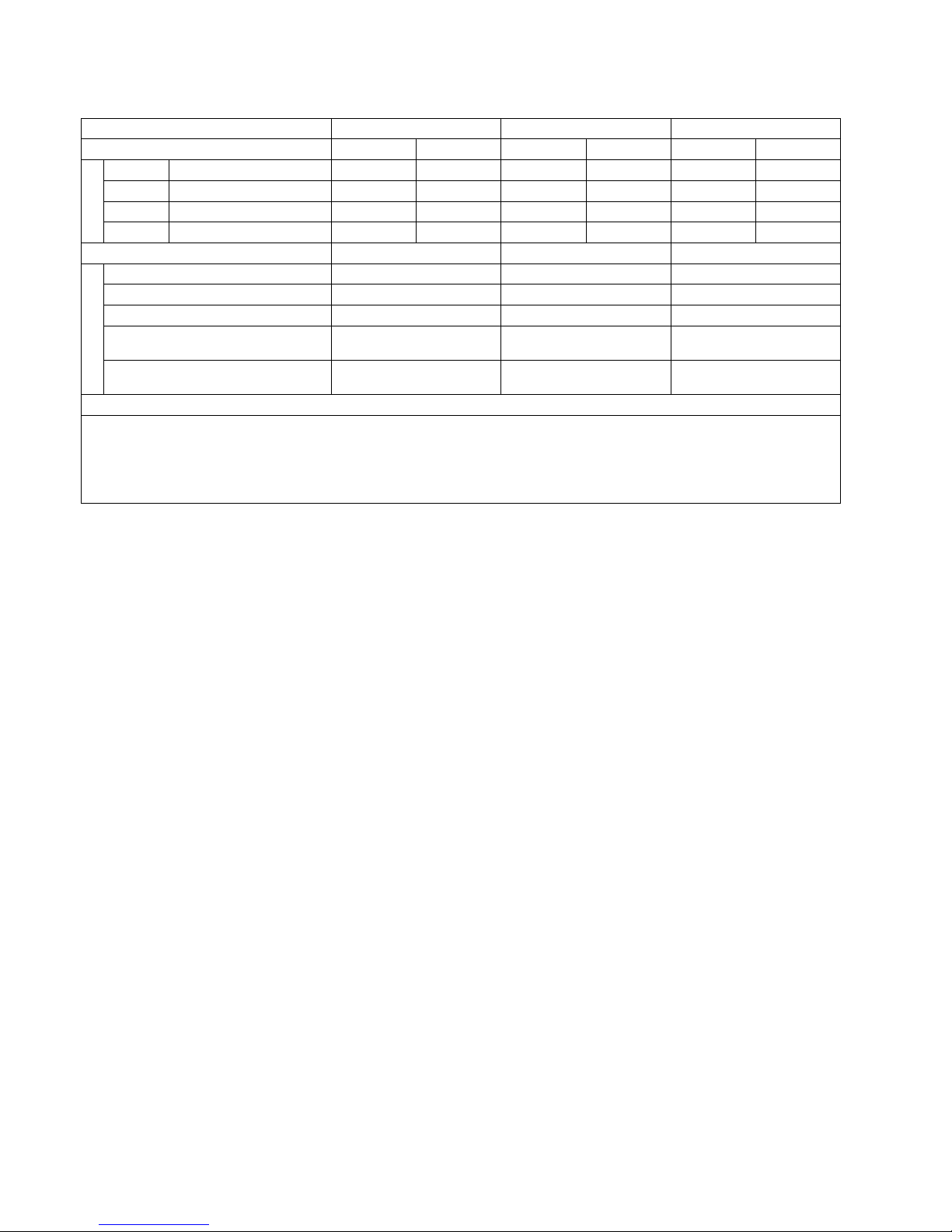

Multi Split Combination Possibility:

o A single outdoor unit enables air conditioning of up to two separate rooms for CU-2Z35TBE, CU-2Z41TBE,

CU-2Z50TBE.

CONNECTABLE INDOOR UNIT CU-2Z35TBE CU-2Z41TBE CU-2Z50TBE

ROOM A B A B A B

Wall

2.0kW CS-MZ20UFEA ● ● ● ● ● ●

2.5kW CS-Z25UFEAW ● ● ● ● ● ●

3.5kW CS-Z35UFEAW ● – ● – ● ●

5.0kW CS-Z50UFEAW – – – – ● –

Capacity range of connectable units From 3.2kW to 6.0kW From 3.2kW to 6.0kW From 3.2kW to 7.7kW

Pipe length

1 room maximum pipe length (m) 20 20 20

Allowable elevation (m) 10 10 10

Total allowable pipe length (m) 30 30 30

Total pipe length for maximum

chargeless length (m)

20 20 20

Additional gas amount over

chargeless length (g/m)

15 15 15

Note: “●” : Available

Remarks for CU-2Z35TBE / CU-2Z41TBE / CU-2Z50TBE

1. The total nominal cooling capacity of indoor unit that will be connected to outdoor unit must be within connectable capacity range of indoor

unit. (as shown in the table above)

Example: The indoor units’ combination below is possible to connect to CU-2Z41TBE. (Total nominal capacity of indoor units is between

3.2kW to 6.0kW)

1) Two CS-MZ20UFEA only. (Total nominal cooling capacity is 4.0kW)

13

Multi Split Combination Possibility:

o A single outdoor unit enables air conditioning of up to two separate rooms for CU-2E12SBE, CU-2E15SBE,

CU-2E18SBE.

CONNECTABLE INDOOR UNIT CU-2E12SBE* CU-2E15SBE* CU-2E18SBE*

ROOM A B A B A B

Wall

2.0kW CS-MZ20UFEA ● ● ● ● ● ●

2.5kW CS-Z25UFEAW ● ● ● ● ● ●

3.2kW CS-Z35UFEAW ● – ● – ● ●

5.0kW CS-Z50UFEAW – – – – ● –

Capacity range of connectable units From 3.2kW to 5.7kW From 3.2kW to 5.7kW From 3.2kW to 7.5kW

Pipe length

1 room maximum pipe length (m) 20 20 20

Allowable elevation (m) 10 10 10

Total allowable pipe length (m) 30 30 30

Total pipe length for maximum

chargeless length (m)

20 20 20

Additional gas amount over

chargeless length (g/m)

15 15 15

Note: “●” : Available

Remarks for CU-2E12SBE / CU-2E15SBE / CU-2E18SBE

1. The total nominal cooling capacity of indoor unit that will be connected to outdoor unit must be within connectable capacity range of indoor

unit. (as shown in the table above)

Example: The indoor units’ combination below is possible to connect to CU-2E15SBE. (Total nominal capacity of indoor units is between

3.2kW to 5.7kW)

1) Two CS-MZ20UFEA only. (Total nominal cooling capacity is 4.0kW)

Note*: Above outdoor unit is contains and operates with refrigerant R410A gas.

14

4. Features

Inverter Technology

o Wider output power range

o Energy saving

o Quick Cooling

o Quick Heating

o More precise temperature control

Environment Protection

o Non-ozone depletion substances refrigerant (R32)

Easy to use remote control

Quality Improvement

o Random auto restart after power failure for safety restart operation

o Gas leakage protection

o Prevent compressor reverse cycle

o Inner protector to protect compressor

o Noise prevention during soft dry operation

Operation Improvement

o Quiet mode to reduce the indoor unit operating sound

o Powerful mode to reach the desired room temperature quickly

o 24-hour timer setting

Serviceability Feature

o Breakdown Self Diagnosis function

15

5. Location of Controls and Components

5.1 Indoor Unit

5.2 Remote Control

Receiver Remote Control

Airflow Direction Louver

Air Outlet

Aluminium Fin

Air filters

Air Inlet

String

Front Panel

INDICATOR

Auto OFF/ON button

• Use when remote control is

misplaced or a malfunction occurs

.

nanoe X operation

LCD display

Quiet operation

Operation mode

Fan speed selection

Powerful operation

OFF/ON

Temperature setting

Airflow direction adjustmen

t

Clock setting

Time r s ettin g

16

6. Dimensions

6.1 Indoor Unit

Unit : mm

<Remote Control Holder>

<Remote Control>

59

165

69

64

750 207

<Side View><Side View> <Front View>

<Top View>

<Back View>

<Bottom View>

49.7

101.3

71.6

60

45

106.5

600

65.4

80.4

75

80.5

17

7. Refrigeration Cycle Diagram

INDOO

R

INTAKE

AIR

TEMP.

SENSOR

PIPE

TEMP.

SENSOR 1

PIPE

TEMP.

SENSOR 2

LIQUID

SIDE

2-WAY

VALV E

3-WAY

VALV E

GAS

SIDE

COOLING

HEAT EXCHANGER

(EVAPORATOR)

HEATING

18

8. Block Diagram

FUSE 301

V

A301

SC

TEMP.

FUSE

M

1

2

3

(INDOOR UNIT)

19

9. Wiring Connection Diagram

9.1 Indoor Unit

COMMUNICATION

CIRCUIT

RECTIFICATION

CIRCUIT

AC303 (WHT)

AC306 (BLK)

AC304 (RED)

G301 (GRN)

FUSE301

T3.15A L250V

NOISE

FILTER

CIRCUIT

FAN MOTOR

1

7

4

CN–FM

(WHT)

B

BL

Y

W

R

M

GROUNDING

TERMINAL

Y/G

EVAPORATOR

1

W

R

G

2

3

BL

TEMP. FUSE

102°C (250V 3A)

TERMINAL

BOARD

TO OUTDOOR UNIT

ELECTRONIC CONTROLLER

(MAIN)

WW WWWW

CN-CNT

(WHT)

1

5

9

1

7

1

CN-DISP

(WHT)

CN–DISP

(YLW)

WWW

113

3

CN–RCV

(YLW)

CN-RCV

(WHT)

ELECTRONIC CONTROLLER

(DISPLAY)

ELECTRONIC

CONTROLLER

(RECEIVER)

REMOTE CONTROLLER

1

4

GR + R

GR

W

W

BL

GR

GR

1

1

2

5

CN1

(WHT)

CN2

(WHT)

NANOE ION

GENERATOR

CN–RMT

(WHT)

4

1

CN–STM1

(BLU)

1

5

CN–NANO

(BLU)

1

4

HAJEM-A

(WHT)

CN–STM2

(WHT)

1

5

6

1

CN–TH

(RED)

1

M

5

PIPING TEMPERATURE SENSOR 1 (THERMISTOR)

PIPING TEMPERATURE SENSOR 2 (THERMISTOR)

UP DOWN

LOUVER MOTOR

(TOP)

UP DOWN

LOUVER MOTOR

(FRONT)

t°

SUCTION TEMPERATURE SENSOR (THERMISTOR)

t°

t°

1

M

5

HIGH VOLTAGE

POWER SUPPLY

BR

R

O

Y

P

BR

R

O

Y

P

(SW01)

REMARKS

B : BLUE

P : PINK

BR : BROWN

O : ORANGE

BL : BLACK

G/GRN : GREEN

Y/YLW : YELLOW

W/WHT : WHITE

R : RED

Y/G : YELLOW/GREEN

GR : GRAY

20

10. Electronic Circuit Diagram

10.1 Indoor Unit

REMOTE CONTRO LLER

Sensor (Thermistor)

Charac teristics

70

60

50

40

30

20

10

0

-10 0 10

Temperature (

o

C)

Resistance (k )

20 30 40 50

1

2

2

1

Pipe temp. Sensor

Intake Air Temp. Sensor

COMMUNICATION

CIRCUIT

RECTIFICATION

CIRCUIT

AC303 (WHT)

AC306 (BLK)

AC304 (RED)

G301 (GRN)

FUSE301

T3.15A L250V

NOISE

FILTER

CIRCUIT

FAN MOTOR

1

7

4

CN–FM

(WHT)

B

BL

Y

W

R

M

GROUNDING

TERMINAL

Y/G

EVAPORATOR

1

W

R

G

2

3

BL

TEMP. FUSE

102°C (250V 3A)

TERMINAL

BOARD

TO OUTDOOR UNIT

ELECTRONIC CONTROLLER

(MAIN)

WW WWWW

CN-CNT

(WHT)

1

5

9

1

71CN-DISP

(WHT)

CN–DISP

(YLW)

WWW

113

3

CN–RCV

(YLW)

CN-RCV

(WHT)

ELECTRONIC CONTROLLER

(DISPLAY)

ELECTRONIC

CONTROLLER

(RECEIVE R)

1

4

GR + R

GR

W

W

BL

GR

GR

1

1

2

5

CN1

(WHT)

CN2

(WHT)

NANOE ION

GENERATOR

CN–RMT

(WHT)

4

1

CN–STM1

(BLU)

1

5

CN–NANO

(BLU)

1

4

HAJEM-A

(WHT)

CN–STM2

(WHT)

1

5

6

1

CN–TH

(RED)

1

M

5

PIPING TEMPERATURE SENSOR 1 (THERMISTOR)

PIPING TEMPERATURE SENSOR 2 (THERMISTOR)

UP DOWN

LOUVER MOTOR

(TOP)

UP DOWN

LOUVER MOTOR

(FRONT)

t°

SUCTION TEMPERATURE SENSOR (THERMISTOR)

t°

t°

1

M

5

HIGH VOLTAGE

POWER SUPPLY

BR

R

O

Y

P

BR

R

O

Y

P

5V

C25

1µ

16V

R62

15.0k

1%

C27

1µ

16V

R61

20.0k

1%

C28

1µ

16V

R63

20.0k

1%

13V

1

2

3

4

5

6

7

16

9

15

14

13

12

11

10

IC02

13V

1

2

3

4

5

6

7

16

9

15

14

13

12

11

10

IC03

C52

1000p

50V

*C57

*F302

*C56

*L5

5V

*L6

13V

C51

1000p

50V

R90

10k

R82

10k

JR4

5V

C10

0.01µ

R33

10k

R34

1k

5V

C11

0.01µ

R35

10k

C45

0.1µ

C49

R54

270

R37

10k

5V

5V

C47

C48

R85

5.1k

13V

R109

33k

JR5

0

IC05

710

G

SD

E

C

B

C651µR108

33k

R113

1k

R107

10k

F303

Q18

Q20

C67

1000p

G7

G7

C69

1000p

4.7K

10K

C68

1000p

5V

E

C

B

Q21

4.7K

10K

G7

*C15

1000p

R39

5.1k

R121

10k

*R40

R89

*C14

2200p

*JP11

*JP10

R43

10K

5V

5V

13V

C4

0.01µ

C3

0.1µ

*C70

*R96*R95

R42

1k

5V

SW01

13V

13V

*R201

*LED201

*R202 *R209

*R208

*R206

*R207*R205

*R203

C

A

B

E

B

*R204

10K

4.7K

Q202

G1

G1

*LED202

*LED203

5V

IC201

+

C202

0.01µ

G1

*LED201

*R201

R203

47

3

GND

VCC

VOUT

@cirPi

@cirPi

2

1

4

5

C201

47µ

Q13

B

C

E

5V

BZ301

R30

1k

21

11. Printed Circuit Board

11.1 Indoor Unit

11.1.1 Main Printed Circuit Board

CN-RCV

AC306

G301

CN-FM

AC304

AC303

CN-NANO

CN-RMT

CN-CNT

CN-STM1

CN-STM2

HAJEM-A

CN-TH

CN-DISP

JP1

(Random Auto Restart

enable/disable)

22

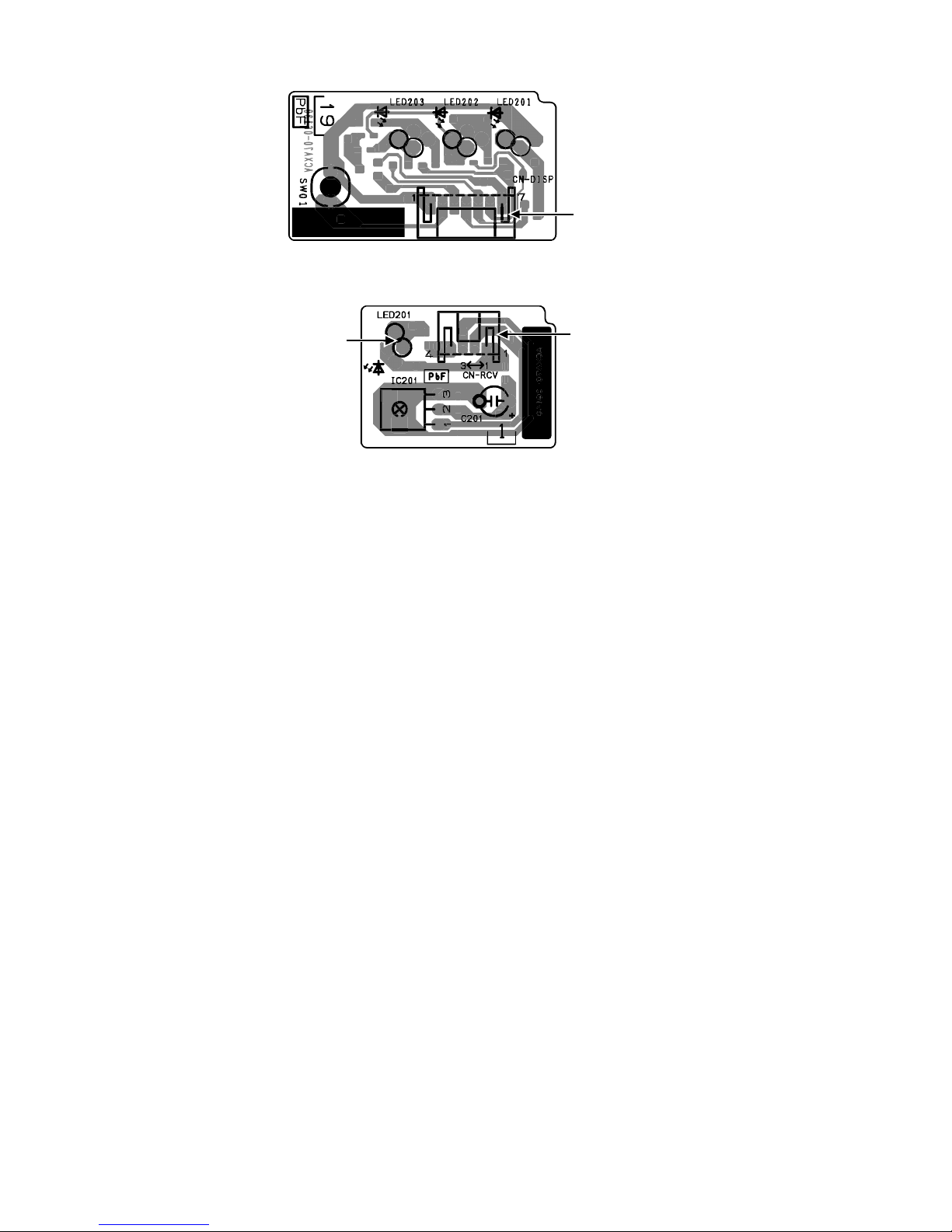

11.1.2 Display Printed Circuit Board

11.1.3 Receiver Printed Circuit Board

CN-DISP

CN-RCV

LED201

23

12. Installation Instruction

12.1 Indoor Unit

Required Materials

Read catalog and other technical materials and prepare the required materials.

Pipe Size Reducer (CZ-MA1P) for CS-Z50*** when connect to multi.

Other Items to be Prepared (Locally Purchased)

Product name Remarks

Rigid PVC pipe

VP20 (outer diameter ø26mm), VP30 (outer diameter ø38mm), Reducer (VP30-VP20) ; also socket, elbow

and other parts as necessary.

Adhesive PVC adhesive

Insulation For drain piping insulation (formed polyethylene with a thickness of 10mm or more)

Indoor/outdoor connecting cable 4 × 1.5mm2 flexible cord : type designation 245 IEC57 (H05RN-F)

Table A

Model Capacity Indoor A

min

(m2)

MZ20*** 0.75HP Refer outdoor

Z25*** 1.0HP 8.67

Z35*** 1.5HP 9.55

Z50*** 2.0HP 18.48

* Table “A” only applicable for single split connection.

* In case of connection to outdoor multi inverter, refer to installation manual at outdoor unit.

A

min

= (M / (2.5 x (LFL)

(5/4)

x h0))2

A

min

= Required minimum room area, in m2

M = Refrigerant charge amount in appliance, in kg

LFL = Lower flammable limit (0.306 kg/m

3

)

h

0

= Installation height of the appliance (0.6m for floor console)

12.1.1 Selecting the Installation Location

12.1.1.1 Indoor Unit

Before choosing the installation site, obtain user approval.

There should not be any heat source or steam near the unit.

There should not be any obstacles blocking the air circulation.

A place where air circulation in the room is good.

A place where drainage can be easily done.

A place where noise prevention is taken into consideration.

Do not install the unit near the door way.

Locate the indoor unit at least 1m or more from TV, radio, wireless equipment, antenna cables and fluorescent

light, and 2m or more away from a telephone.

Ensure the spaces indicated by arrows from the wall, ceiling, fence or other obstacles.

Installation Diagram

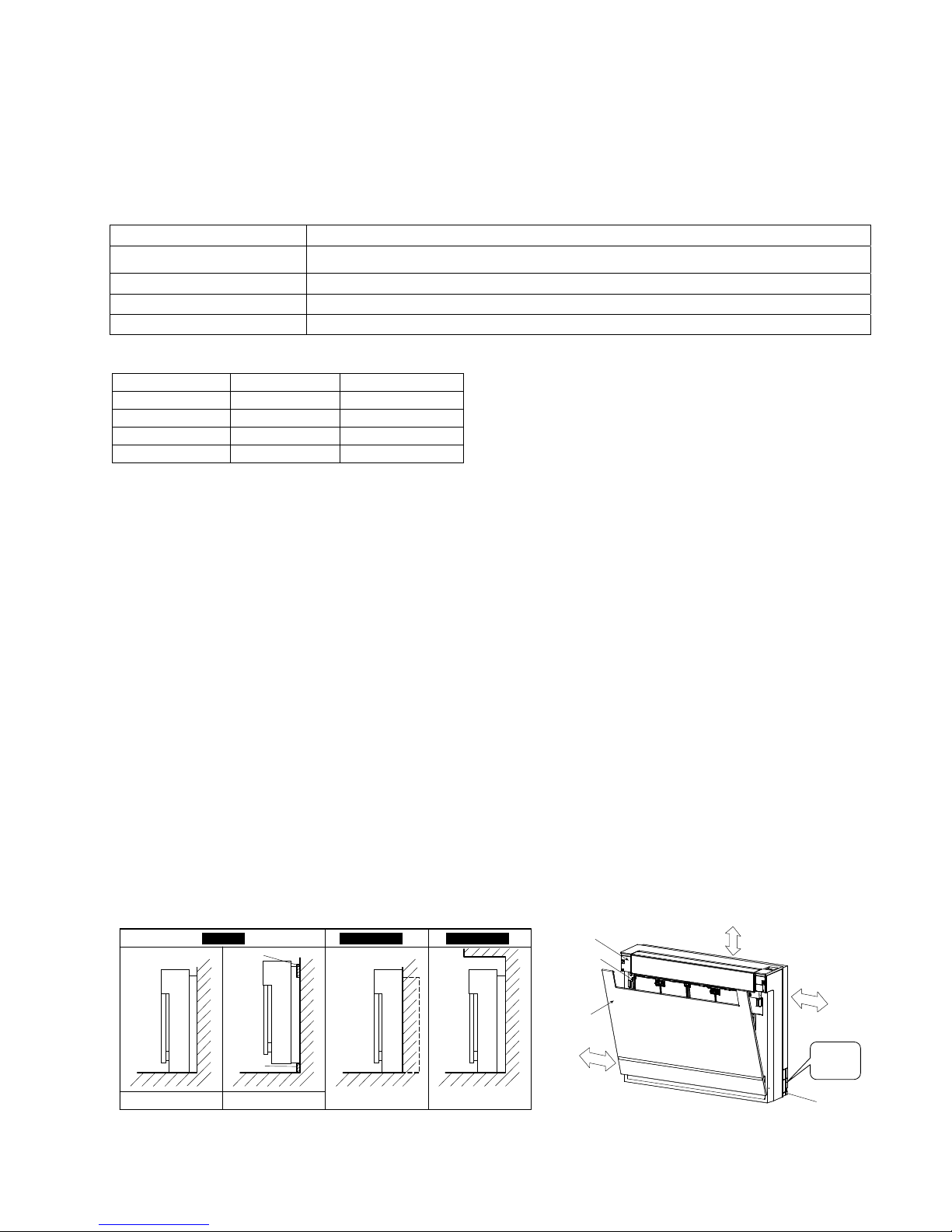

The indoor unit may be mounted in any of the three styles shown here.

Front grille

Front panel

Air filter

50mm or more

from walls

50mm or more

from walls

70mm or more

Caulk pipe

hole gap

with putty.

Expose d

Floor Installation Wall Insta llation

Mountin g

plate 1

Molding

Half concealed Concealed

24

12.1.1.2 Remote Controller

Signals may not be transmitted and received

correctly when the remote controller is operated

while in the holder. Take the remote controller in

your hand to operate the unit.

Mount the holder in a location that is not subject to

the effects of heat (direct sunlight and stoves,

etc.).

12.1.2 Selection of Pipe and Heat Insulation Materials

When using commercial copper pipes and fittings, observe the following:

1 Insulation material: Polyethylene foam

Heat transfer rate: 0.041 to 0.052 W/mk (0.035 to 0.045kal/mh°C)

Refrigerant gas pipe’s surface temperature reaches 110°C max.

Choose heat insulation materials that will withstand this temperature.

2 Be sure to insulate both the gas and liquid piping and to provide insulation dimension as below.

Pipe Dimension Heat Insulation Dimension

Gas side 3/8”(O.D. 9.5mm t0.8mm) I.D.12-15mm t10mm Min

Liquid side 1/4”(O.D. 6.4mm t0.8mm) I.D. 8-10mm t10mm Min

3 Use separate heat insulation pipes for gas and liquid refrigerant pipes.

Required material

o Pipe size reducer (CZ-MA1P) for CS-Z50*** when connect to multi.

12.1.3 Installing the Indoor Unit

12.1.3.1 Exposed Installation

12.1.3.1.1 Refrigerant piping

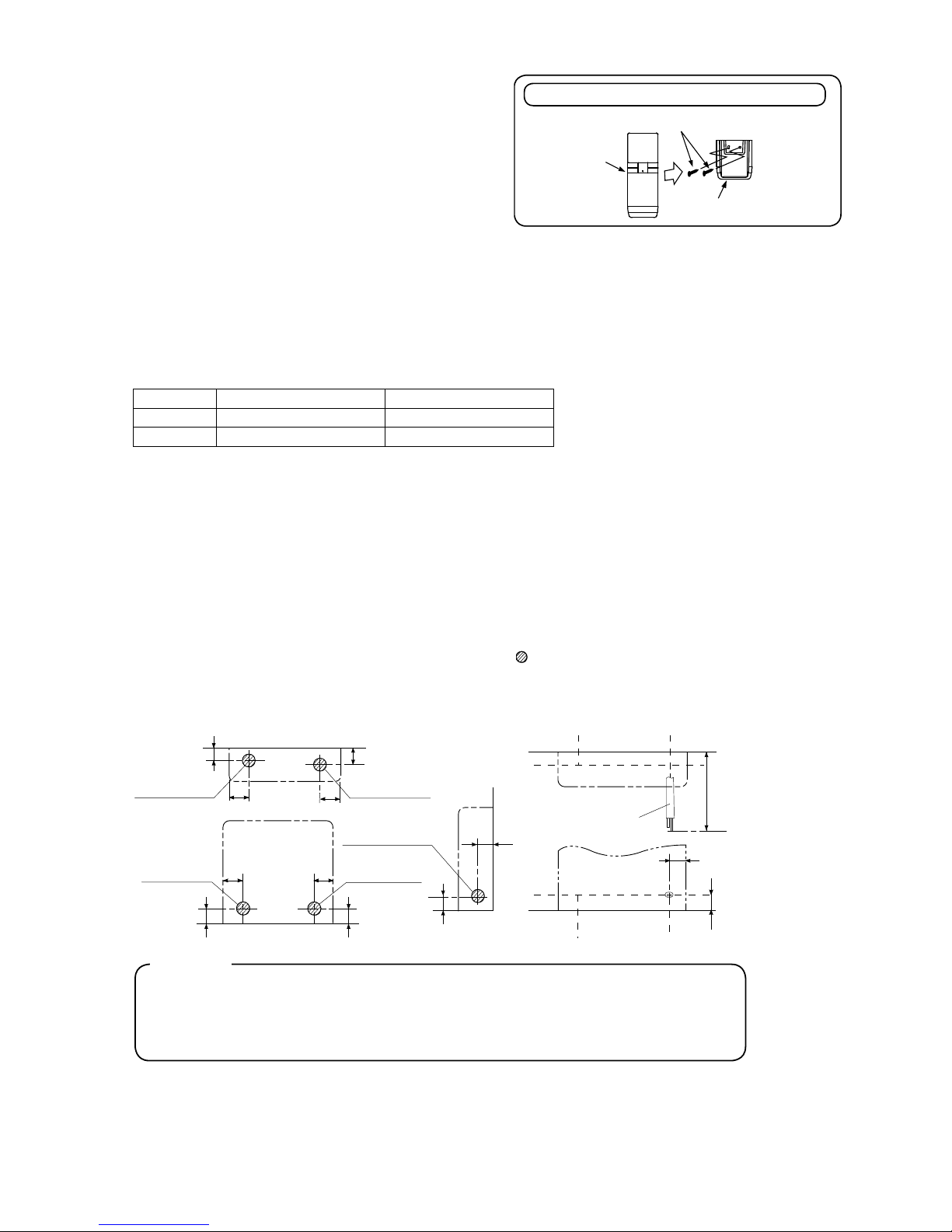

1 Drill a hole (70mm in diameter) in the spot indicated by the symbol in the illustration as below.

2 The location of the hole is different depending on which side of the pipe is taken out.

3 For piping, see 12.1.5. Connecting the refrigerant piping.

4 Allow space around the pipe for a easier indoor unit pipe connection.

Remote control holder fixing screws

7

Remote control holder

6

Remote

control

4

Attaching the remote control holder to the wall

45

35

Left/right side piping

350

Wall

Refrigerant pipe/

70

45

Floo

r

45

60

70

80

gnipipmottobthgiRgnipipmottobtfeL

W

all

(Unit : mm)

45

45

70

80

Left back piping

Right back piping

CAUTION

Min. allowable length

• The suggested shortest pipe length is 3.0m, in order to avoid noise from the outdoor unit and vibration.

(Mechanical noise and vibration may occur depending on how the unit is installed and the environment in which it is used.)

• See the installation manual for the outdoor unit for the maximum pipe length.

• For multi-connections, see the installation manual for the multi-outdoor unit.

25

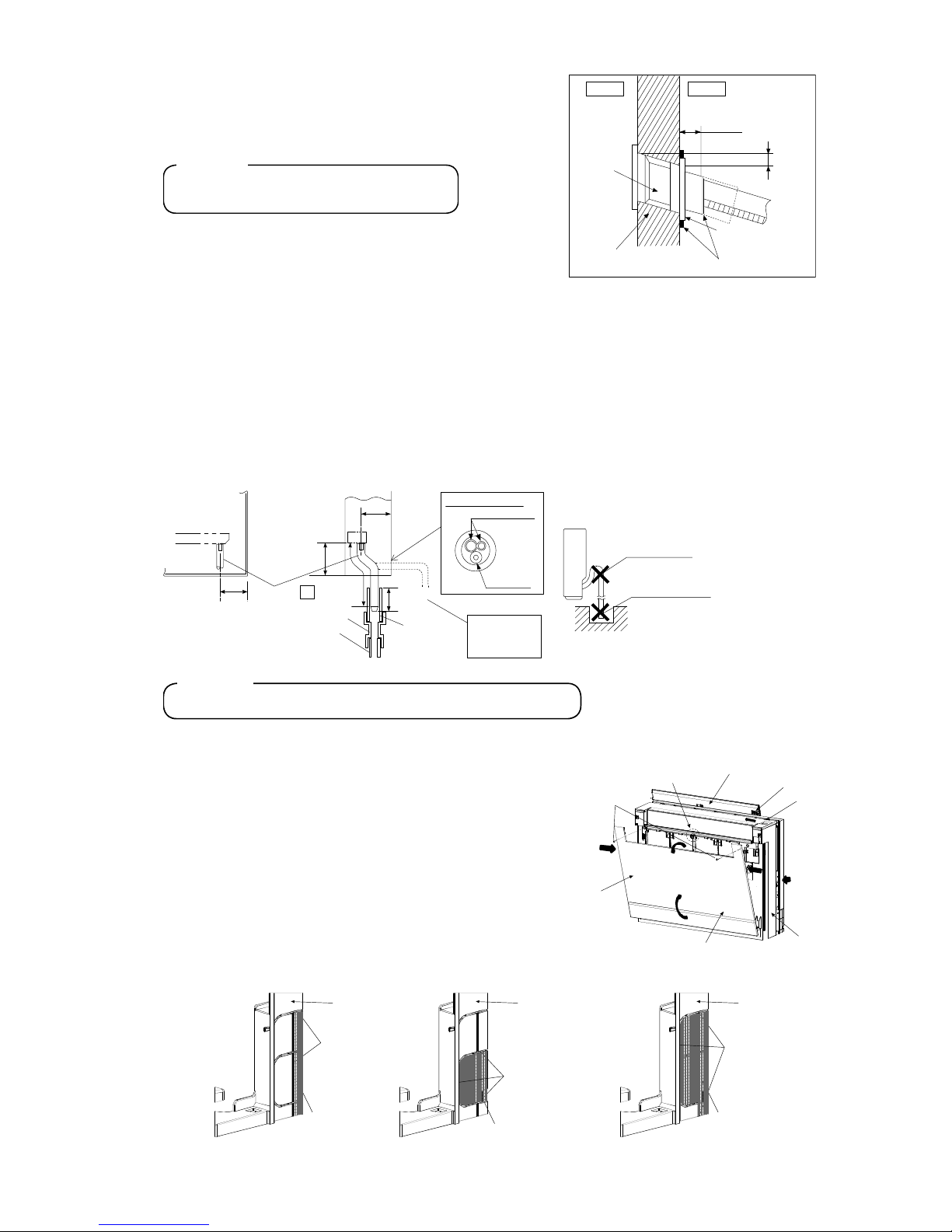

12.1.3.1.2 To drill a hole in the wall and install a sleeve of piping

1 Insert the piping sleeve to the hole.

2 Fix the bushing to the sleeve.

3 Cut the sleeve until it extrudes about 15 mm

from the wall.

4 Finish by sealing the sleeve with putty or

caulking compound at the final stage.

12.1.3.1.3 Drain piping

1 Use commercial rigid polyvinyl chloride pipe (general VP 20 pipe, outer diameter 26mm, inner diameter

20mm) for the drain pipe.

2 The drain hose (outer diameter 18mm at connecting end, 270mm long) is supplied with the indoor unit.

Prepare the drain pipe picture below position.

3 The drain pipe should be inclined downward so that water will flow smoothly without any accumulation.

(Should not be trap.)

4 Insert the drain hose to this depth so it won’t be pulled out of the drain pipe.

5 Insulate the indoor drain pipe with 10mm or more of insulation material to prevent condensation.

6 Remove the air filters and pour some water into the drain pan to check the water flows smoothly.

12.1.3.1.4 Indoor unit preparation

Push in the tab on both sides of front panel to

open front panel.

Unhook the string, lift up the front panel to remove

it.

Slide Shaft to disassemble top vane

Remove 2 screws and disengage center hook

then dismount front grille.

For Moldings and Side Piping

Remove the pillars. (Remove the slit portions on

the bottom frame using nippers.)

CAUTION

When the wall is hollow, please be sure to use the sleeve for tube

ass’y to prevent dangers caused by mice biting the connecting cable.

15 mm

ø70 through hole

Indoor Outdoor

Sleeve

(Locally

purchased)

Approx. 5 - 7 mm

Bushing

(Locally purchased)

Putty or caulking compound

Must be no trap.

Do not touch water.

3

50mm

or more

270

105

130

100

Reduce r

Vinyl chloride

drain pipe

(VP-30)

Vinyl chlo ride

drain pipe

(VP-20)

Drain hose

(Unit: mm)

Insert drain hose

to this depth so it

won’t be pulled

out of drain pipe.

In case back piping

Refrigerant pipe

Drain hose

at below

CAUTION

Use polyvinyl chloride adhesive agent for gluing. Failure to do so may cause water leakage.

T

op va

n

e

Front panel

Shaft

3 Slide left to

disassemble

top vane

2

Opena

nd remove front panel

1 Push in

tab to unhook

front panel

4 Remove 2 screws

5 Disengage center hook

Front grille

6 Remove

front grille

For Side Piping without MoldingsFor Moldings For Side Piping with Moldings

Bottom frame

Cut

Remove the

pillars (Cut off)

Bottom frame

Bottom frame

Cut

Cut

Remove the

pillars (Cut off)

Remove the

pillars (Cut off)

26

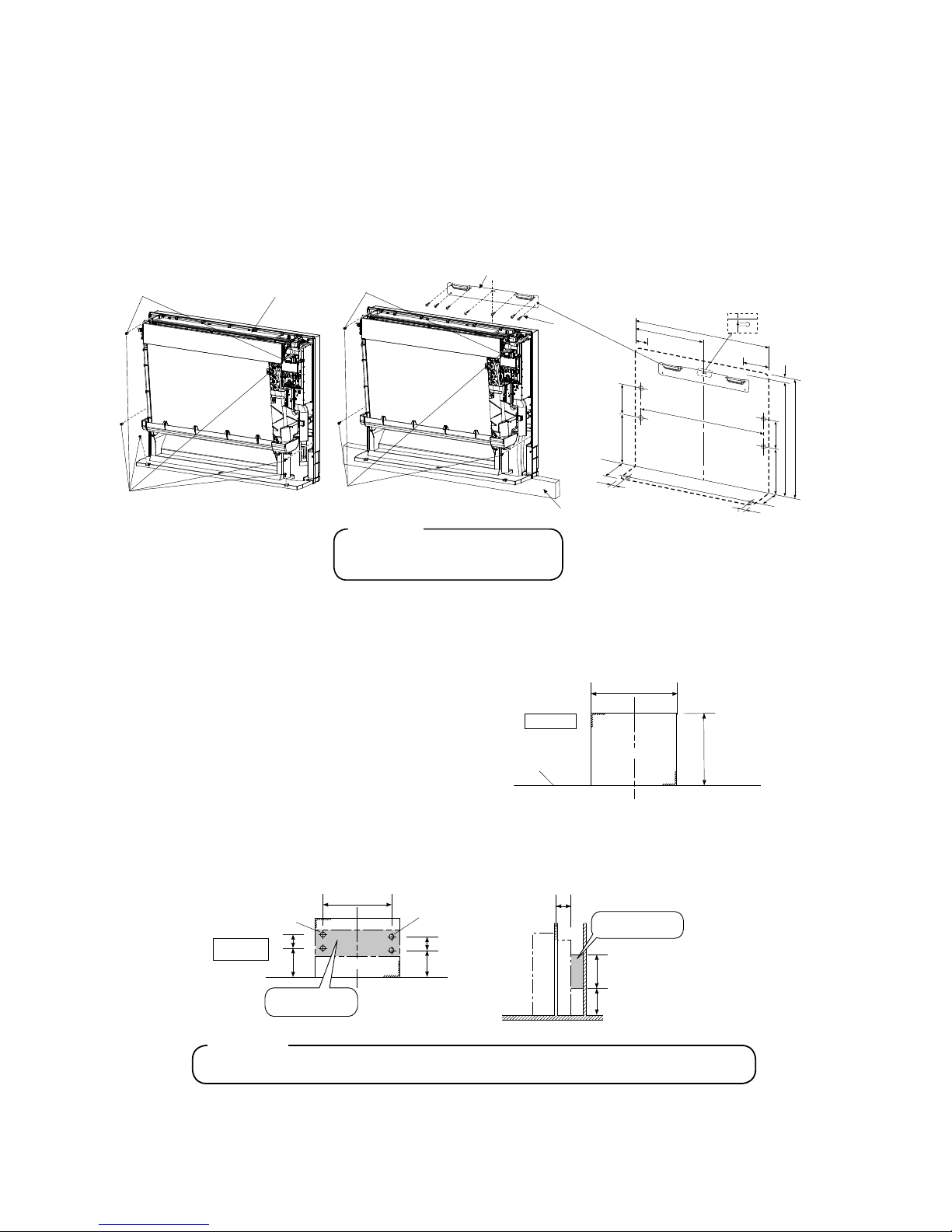

12.1.3.1.5 Indoor unit installation

For floor installations, secure the indoor unit using 6 screws.

For wall installations, secure the mounting plate using 7 screws and the indoor unit using 4 screws.

o Temporarily secure the mounting plate to the wall, make sure that the panel is completely level, and mark the

drilling points on the wall.

Once refrigerant piping and drain piping connections are complete, fill in the gap of the through hole with putty. A

gap can lead to condensation on the refrigerant pipe, and drain pipe, and the entry of insects into the pipes.

Attach the front panel and front grille by following the removal procedure in reverse once all connections are

complete.

12.1.3.2 Half concealed installation

Only item peculiar to this installation method are given here. See Exposed installation for additional instructions.

12.1.3.2.1 Wall hole

Drill a wall hole of the size shown in the illustration

on the right.

12.1.3.2.2 Installation of supplemental plate for attaching indoor unit

The rear of the unit can be fixed with screws at the points shown in the illustration as below. Be sure to install the

supplemental plate in accordance with the depth of the inner wall.

Floor Installation Wall Installation

Casing

6screws2

(M4 × 25L)

To access these 2 locations,

long screw driver is required.

To access these 2 locations,

long screw driver is required.

(

7

5

0

)

1

2

8

7

2

0

0

2

0

9

0

3

2

0

8

5

)

0

0

6

(

3

2

3

5

0

5

6

2

5

3

1

6

0

6

0

1

6

2

2

0

7

(Unit: mm)

Mounting

plate 1

Molding

7screws2

(M4 × 25L)

4screws2

(M4 × 25L)

CAUTION

The mounting plate should be installed on a wall

which can support the weight of the indoor unit.

• Location for securing the mounting plate.

742-746

592-598

(Unit: mm)

Open size

Opening hole

Floor

Fixing point

on the back

90

230

720

Screw hole

Screw hole

Opening hole

135

265

Supplemental plate

(Locally purchased)

(Unit: mm)

50

Supplemental plate

(Locally purchased)

250

200

CAUTION

• The supplemental plate for installing the main unit must be used, or there will be a gap between the unit and the wall.

27

12.1.3.2.3 Refrigerant piping

See Refrigerant piping under Exposed Installation.

12.1.3.3 Concealed installation

Only item peculiar to this installation method are given here. See Exposed installation for additional instructions.

12.1.3.3.1 Preparation

Install the unit according to the instructions below. Failure to do so may cause lead to both cooling and heating

failure and the condensation inside the house.

1 Allow enough space between the main unit and ceiling not to obstruct the flow of cool/warm air.

2 Use remote controller to change the upward air flow limit restriction. When the unit in standby mode, follow

the steps below:

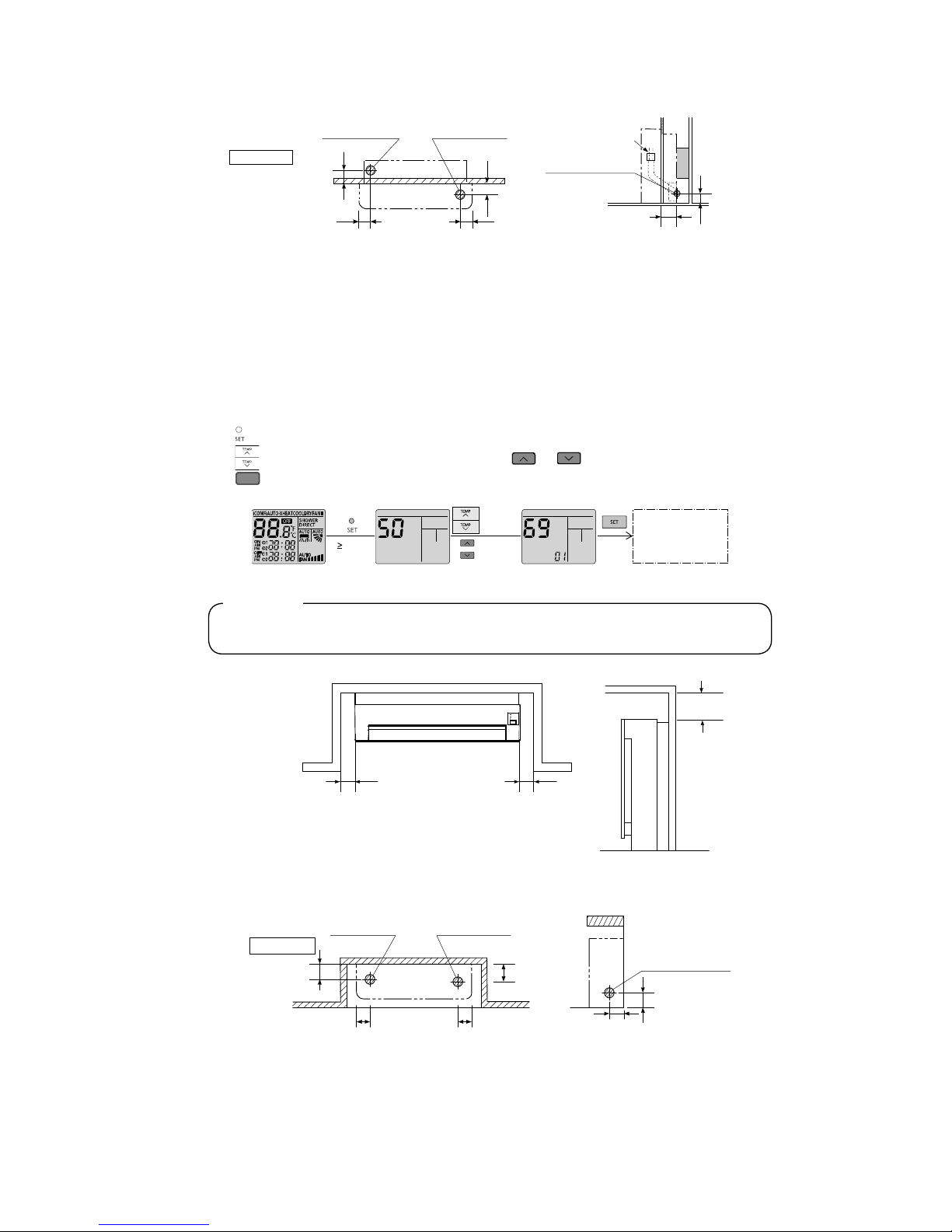

o Press continuously for more than 5 seconds to enter special setting mode.

o Press to choose function 69, and then press or to set “01”

o Press to activate “Up/down air swing upper limit restriction”

12.1.3.3.2 Refrigerant piping

Left bottom piping Right bottom piping

70

10

80

Hole location

5

Wall

45

50

Wall

Right/left side piping

Unit piping position

(Unit: mm)

SET

T 5secs

Special setting mo de

(Function

no.)

(Options)

Activate or dea ctivate

“Air swing upper limit

restriction”

CAUTION

If there is an obstruction to upward air ow, it is recommanded to turn on upward air ow limit restriction. Failure to

do so may cause incomplete cooling/heating and formation of condensation inside the house.

50 or more 50 or more

70 or more

Left bottom piping Right bottom piping

45

60

70

Hole location

Right/left side piping

45

35

80

(Unit: mm)

28

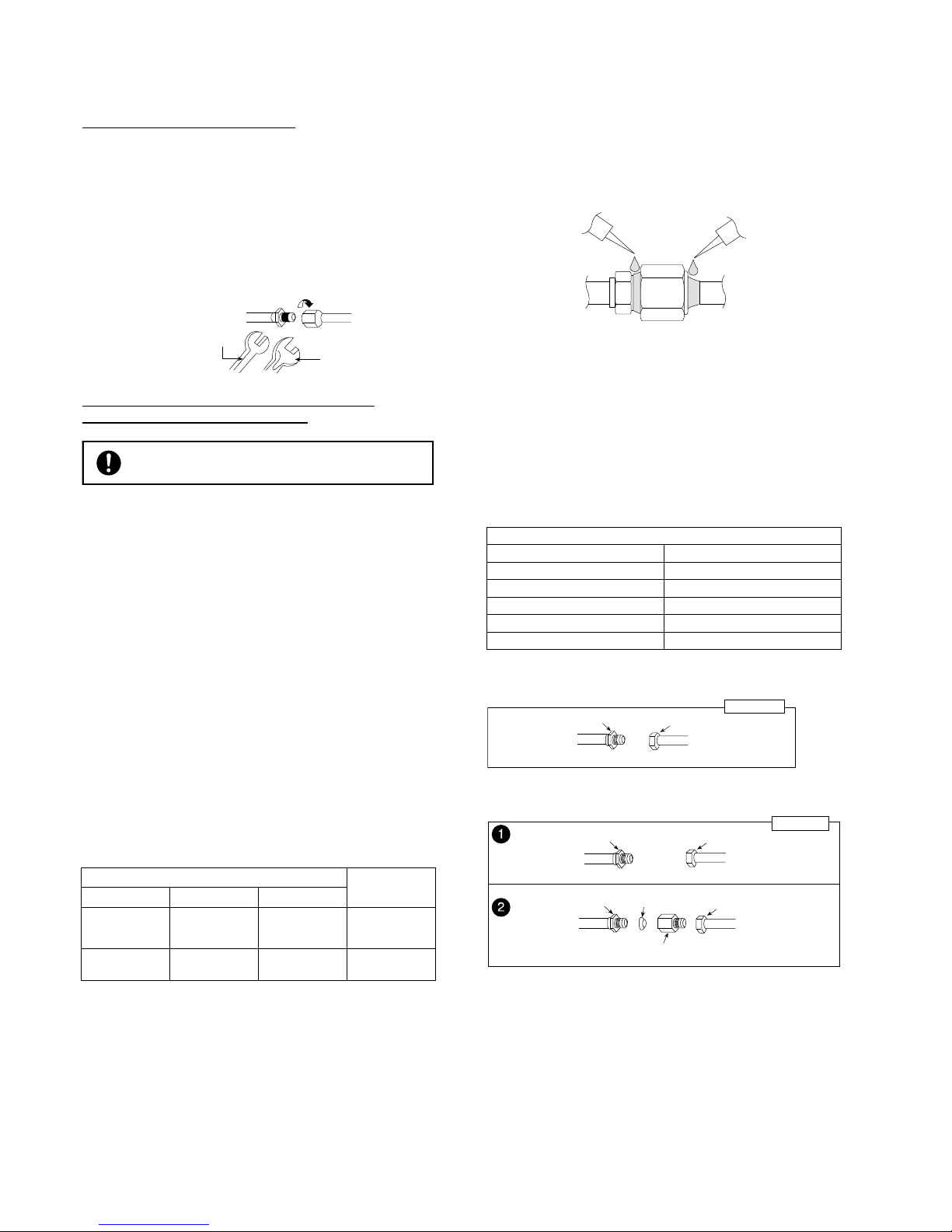

12.1.4 Connecting the Refrigerant Piping

12.1.4.1 Connecting The Piping to Indoor

For connection joint of all models

Please make flare after inserting flare nut (locate at

joint portion of tube assembly) onto the copper pipe.

(In case of using long piping)

Connect the piping

Align the center of piping and sufficiently tighten

the flare nut with fingers.

Further tighten the flare nut with torque wrench in

specified torque as stated in the table.

Additional Precautions For R32 Models when

connecting by flaring at indoor side

Seal sufficiently the flare nut (both gas and liquid sides)

with neutral cure (Alkoxy type) & ammonia-free

silicone sealant and insulation material to avoid the

gas leak caused by freezing.

Neutral cure (Alkoxy type) & ammonia-free silicone

sealant is only to be applied after pressure testing and

cleaning up by following instructions of sealant, only to

the outside of the connection. The aim is to prevent

moisture from entering the connection joint and

possible occurrence of freezing. Curing sealant will

take some time. Make sure sealant will not peel off

when wrapping the insulation.

12.1.4.2 Connecting The Piping to Outdoor

Decide piping length and then cut by using pipe cutter.

Remove burrs from cut edge.

Make flare after inserting the flare nut (locate at valve)

onto the copper pipe. Align center of piping to valve

and then tighten with torque wrench to the specified

torque as stated in the table.

Do not overtighten, overtightening may cause gas leakage.

Piping size Torque

6.35 mm (1/4") [18 N•m (1.8 kgf•cm)]

9.52 mm (3/8") [42 N•m (4.3 kgf•cm)]

12.7 mm (1/2") [55 N•m (5.6 kgf•cm)]

15.88 mm (5/8") [65 N•m (6.6 kgf•cm)]

19.05 mm (3/4") [100 N•m (10.2 kgf•cm)]

12.1.4.3 Connecting The Piping to Outdoor Multi

Decide piping length and then cut by using pipe cutter.

Remove burrs from cut edge. Make flare after

inserting the flare nut (locate at valve) onto the copper

pipe. Align center of piping to valve and then tighten

with torque wrench to the specified torque as stated in

the table.

* For Gas side piping please refer table and diagram

below

Outdoor Multi Combination Model

Pipe size (refer

to diagram)

R32 Model R410A Model

CS-MZ20***,

CS-Z25***,

CS-Z35***

CU-2Z35***,

CU-2Z41***,

CU-2Z50***

CU-2E12***,

CU-2E15***,

CU-2E18***

1

CS-Z50*** CU-2Z50*** CU-2E18***

2

(CZ-MA1P)

Torque wrenc

h

Spanner or Wrench

Ensure to do the re-flaring of pipes before

connecting to units to avoid leaking.

Apply neutral cure

(Alkoxy type) and

ammonia-free silicone

sealant along the

circumference

Connection pipe

(female side)

Auxiliary pipe

(male side)

Flare Nut

Hall Union

Liquid side

Hall Union

Connection pipe

(female side)

Auxiliary pipe

(male side)

Flare Nut

Hall Union

Packing

Connection pipe

(female side)

Auxiliary pipe

(male side)

Pipe size reducer (CZ-MA1P)

Flare Nut

Gas side

29

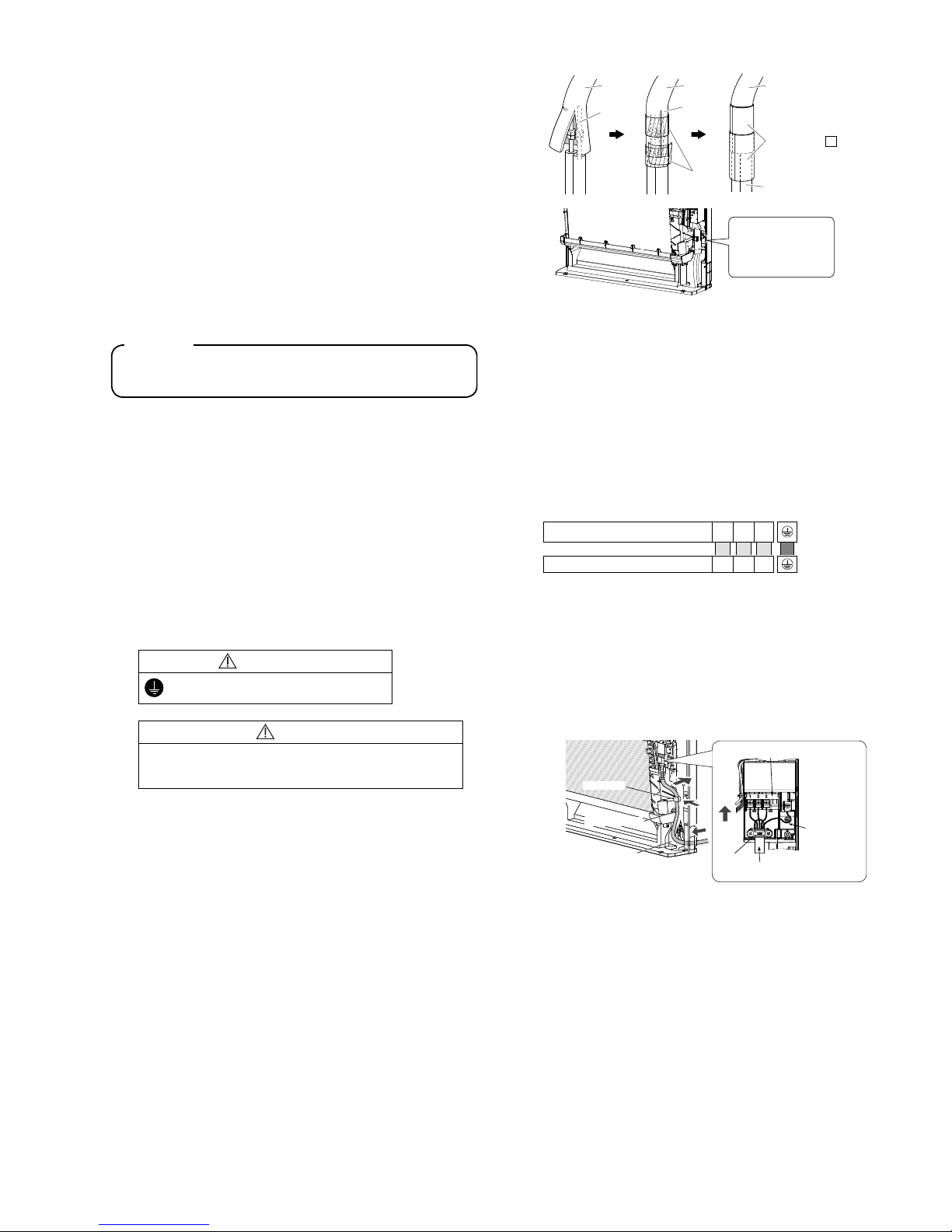

12.1.4.4 Insulating the refrigerant piping

Attach the pipe after checking for gas leakage,

described above.

1 Cut the insulated portion of the on-site piping,

matching it up with the connecting portion.

2 Secure the slit on the auxiliary pipe side with

the butt joint on the connection pipe using the

tape, making sure there are no gaps.

3 Wrap the slit and the butt joint with the

included insulation sheet, making sure there

are no gaps.

12.1.4.5 Checking for gas leakage

Check for leakage of gas after air purging.

See the in the installation manual for the outdoor.

12.1.5 Connecting the Indoor/Outdoor

Connection Cable

Guide connection cable pass through refrigerant

piping port and lead the connection cable into the

control box.

Check the color of the wires on the terminal board

and secure them with screws.

Secure the connection cable with cord holder.

Guide and push the connection cable inside so

that it does not apply undue force on the front

grille.

Fix the connection cable into cable holder.

WARNING

This equipment must be properly earthed.

CAUTION

When the wall is hollow, please be sure to use the sleeve for

tube ass’y to prevent dangers caused by mice biting the

connection cable.

Connection cable between indoor unit and

outdoor unit should be approved polychloroprene

sheathed 4 x 1.5 mm

2

flexible cord, designation

type 60245 IEC 57 (H05RN-F) or heavier cord.

Allowable connection cable length of each indoor

unit shall be 30 m or less.

o Ensure that the terminal numbers on the

indoor unit are connected to the same

terminal numbers on the outdoor unit by the

right coloured wires as shown in the diagram.

o Earth lead wire should be longer than the

other lead wires as shown in the diagram for

electrical safety purpose in case the cord slips

out from the anchorage.

Secure the cable onto the control board with the

holder (clamper).

Ensure the colour of wires of outdoor unit and the

terminal Nos. are the same to the indoor’s

respectively.

Earth wire shall be Yellow/Green (Y/G) in colour

and longer than other AC wires for safety reason.

Check for leakage here.

• Apply soapy water and

check carefully for leaking

gas.

• Wipe soapy water off after

the check is comp lete.

Auxiliary pipe Auxiliary pipe Auxiliary pipe

2

))

3)1

Connection

pipe

Slit

Slit

Tape

Insulation sheet

3

CAUTION

1) Insulate the joint of the pipes securely.

Incomplete insulation may lead to water leakage.

2) Push the pipe inside so it does not apply undue forc e on the front grille.

Terminals on the indoor unit 1 2 3

123

Colour of wires

Terminals on the outdoor unit

①

⑤

③

②

④

Cord

holder

Connection cable

Terminal Board

Earth Wire

longer than

others AC wires

for safety reason

Connection cable

Refrigerant piping port

Cable holder

30

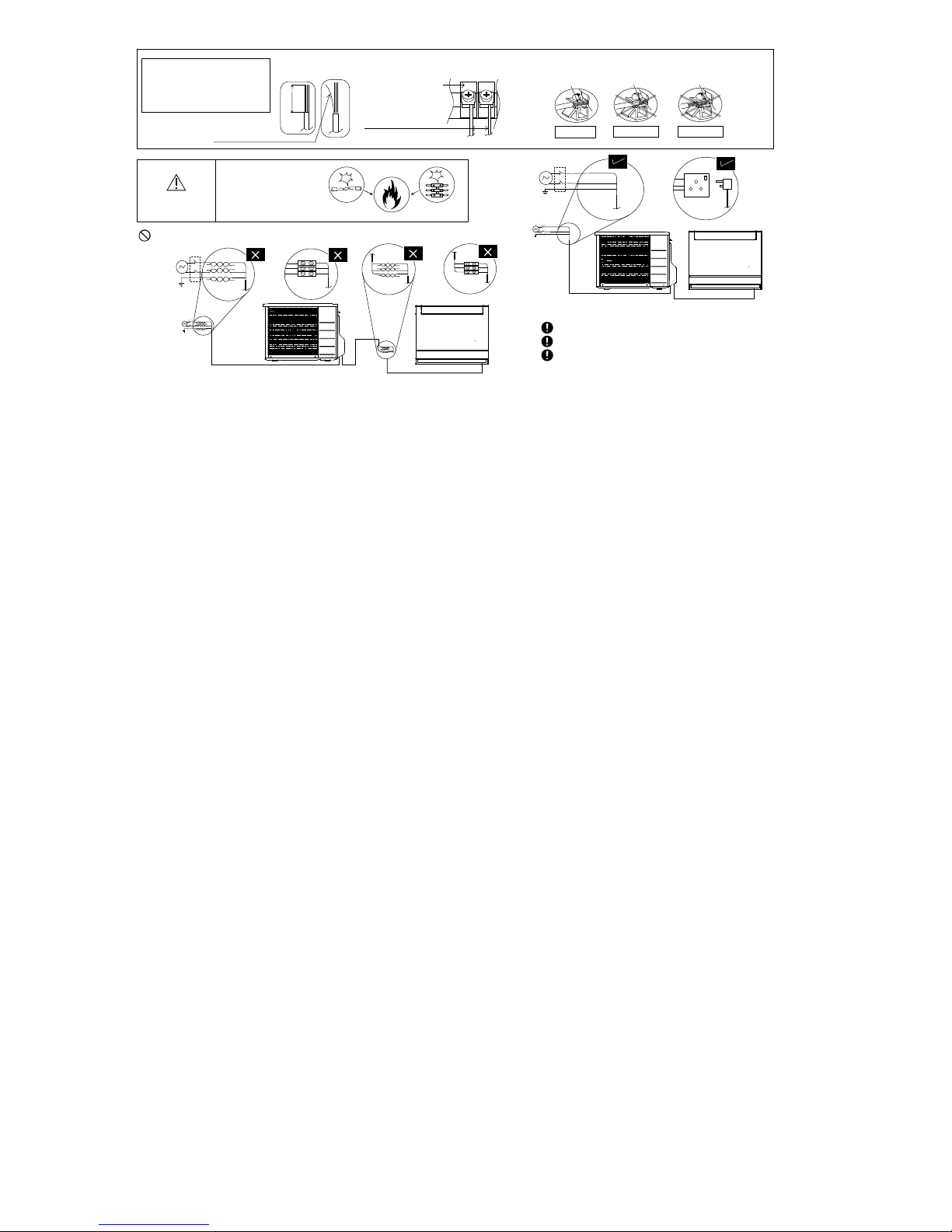

Conductor

over inser ted

WIRE STRIPPING,

CONNECTING

REQUIREMENT

Conductor

fully inserted

Conductor not

fully inserted

5 mm or more

Indoor/outdoor

connection

terminal board

(gap between wires)

WARNING

RISK OF FIRE

JOINING OF

WIRES MAY CAUSE

OVERHEATING AND

FIRE.

Do not joint wires

OR

OR

OR

Use complete wire without joining.

Use approved socket and plug with earth pin.

Wire connection in this area must follow to

national wiring rules.

ACCEPT

PROHIBITED PROHIBITED

Wire stripping

No loose strand

when inserted

10 ± 1 mm

Loading...

Loading...