Page 1

Order No: PAPAMY1601004CE

O

O

N

CHEC

K

O

N

O

S

123

TIMER

TEM

P

Installation Manual

Air Conditioner

Indoor Unit Outdoor Unit

AIRCONDITIONER

MODE

ECONAVI

OFF/ON

FF/

MODE

TEMP

POWERFUL/

QUIET

FANSPEED

TIMER

ON

123

OFF

FF

CLOCK

SET CHECK RESET

COMFORT

AIRSWING

AC

CS-XE9SKUA

CS-XE12SKUA

AUTO

RFP

SET

ET

CANCEL

RC

CU-XE9SKUA

CU-XE12SKUA

Destination

U.S.A.

Canada

WARNING

This service information is designed for experienced repair technicians only and is not designed for use by the general public.

It does not contain warnings or cautions to advise non-technical individuals of potential dangers in attempting to service a product.

Products powered by electricity should be serviced or repaired only by experienced professional technicians. Any attempt to service

or repair the products dealt with in this service information by anyone else could result in serious injury or death.

IMPORTANT SAFETY NOTICE

There are special components used in this equipment which are important for safety. These parts are marked by in the Schematic

Diagrams, Circuit Board Diagrams, Exploded Views and Replacement Parts List. It is essential that these critical parts should be replaced

with manufacturer’s specified parts to prevent shock, fire or other hazards. Do not modify the original design without permission of

manufacturer.

PRECAUTION OF LOW TEMPERATURE

In order to avoid frostbite, be assured of no refrigerant leakage during the installation or repairing of refrigerant circuit.

© Panasonic Corporation 2016.

!

Page 2

11. Installation Instruction

s

11.1 Select the Best Location

11.1.1 Indoor Unit

Do not install the unit in excessive oil fume area

such as kitchen, workshop and etc.

There should not be any heat source or steam

near the unit.

There should not be any obstacles blocking the air

circulation.

A place where air circulation in the room is good.

A place where drainage can be easily done.

A place where noise prevention is taken into

consideration.

Do not install the unit near the door way.

Ensure the spaces indicated by arrows from the

wall, ceiling, fence or other obstacles.

Mount with the lowest moving parts at least 8ft

(2.4 m) above floor or grade level.

11.1.2 Outdoor Unit

If an awning is built over the unit to prevent direct

sunlight or rain, be careful that heat radiation from

the condenser is not obstructed.

There should not be any animal or plant which

could be affected by hot air discharged.

Keep the spaces indicated by arrows from wall,

ceiling, fence or other obstacles.

Do not place any obstacles which may cause a

short circuit of the discharged air.

If piping length is over the [piping length for

additional gas], additional refrigerant should be

added as shown in the table.

Recommended installation height for outdoor unit

should be above the seasonal snow level.

Be careful not to locate outdoor unit directly under

a roof line where falling snow or ice can cause

damage or dripping water can increase ice

accumulation and defrost cycles.

Model

XE9SKUA

XE12SKUA

Capacity

(Btu/h)

8700

11500

Piping size

Gas Liquid

3/8"

(9.52 mm )

1/2"

(12.7 mm )

1/4"

(6.35 mm )

Std.

Length

24.6 ft

(7.5 m)

Example: For XE9SKUA

If the unit is installed at 32.8 ft (10 m) distance, the

quantity of additional refrigerant should be 1.64 oz

(50 g) .... (32.8 - 24.6) ft x 0.2 oz/ft = 1.64 oz.

((10-7.5) m x 20 g/m = 50 g)

Max.

Elevation

49.2 ft

(15 m)

Min.

Piping

Length

9.8 ft

(3 m)

Max.

Piping

Length

65.6 ft

(20 m)

Additional

Refrigerant

0.2 oz/ft

(20 g/m)

Piping

Length for

add. gas

24.6 ft

(7.5 m)

11.1.3 Indoor/Outdoor Unit Installation

Diagram

Piping direction Do not bend up

Right

Rear

Right

bottom

131/32"

(50 mm)

or more

Insulation of piping connections

• Carr y out insulation after

checking for gas leaks and

secure with vinyl tape.

Attaching t he remote control holder

to the wall

Remote control holder fixing screws

Remote

control

(Front side)

Left

Left

Left bottom

Rear

(Left and right are identical)

Floor / Grade level

3

Remote controlholder

It is advisable to avoid more

than 2 blockage directions.

For better ventilation &

multiple-outdoor installation,

please consult authorized

dealer/specialist.

• This illustration is for

explanation purposes only.

The indoor unit will actually face

a different way.

drain hose

Vinyl tape

6

5

Installation parts you

or more

1

/

5

1

3

0

1

(

"

)

6

m

e

m

r

o

0

m

r

o

(

3

o

r

should purchase (

Installation plate 1

Bushing-Sleeve (

Sleeve (

Putty (

(Gum Type Sealer)

Bend the pipe as

closely on the wall

as possi ble, but be

careful that it doesn’t

break.

Vinyl tape (wide) ( )

• Apply after carrying

• To carr y out the

Saddle (

Connection cable (

Liquid side piping (

Gas side piping (

Additional drain

1

1

hose (

1

3

0

/

0

1

6

m

"

m

m

o

)

r

e

out a drainage test.

drainage test,

remove the air filter

and pour water into

the heat exchanger.

)

e

"

6

or

1

mm

/

m

9

5

r

2

6

o

(

8ft(2.4m)

3

1

5

(

1

/

1

0

6

0

"

o

m

r

m

m

)

o

r

e

"

)

8

/

3

m

m

9

e

3

r

0

o

0

0

m

1

r

(

o

)

)

)

)

)

)

)

)

)

24

Page 3

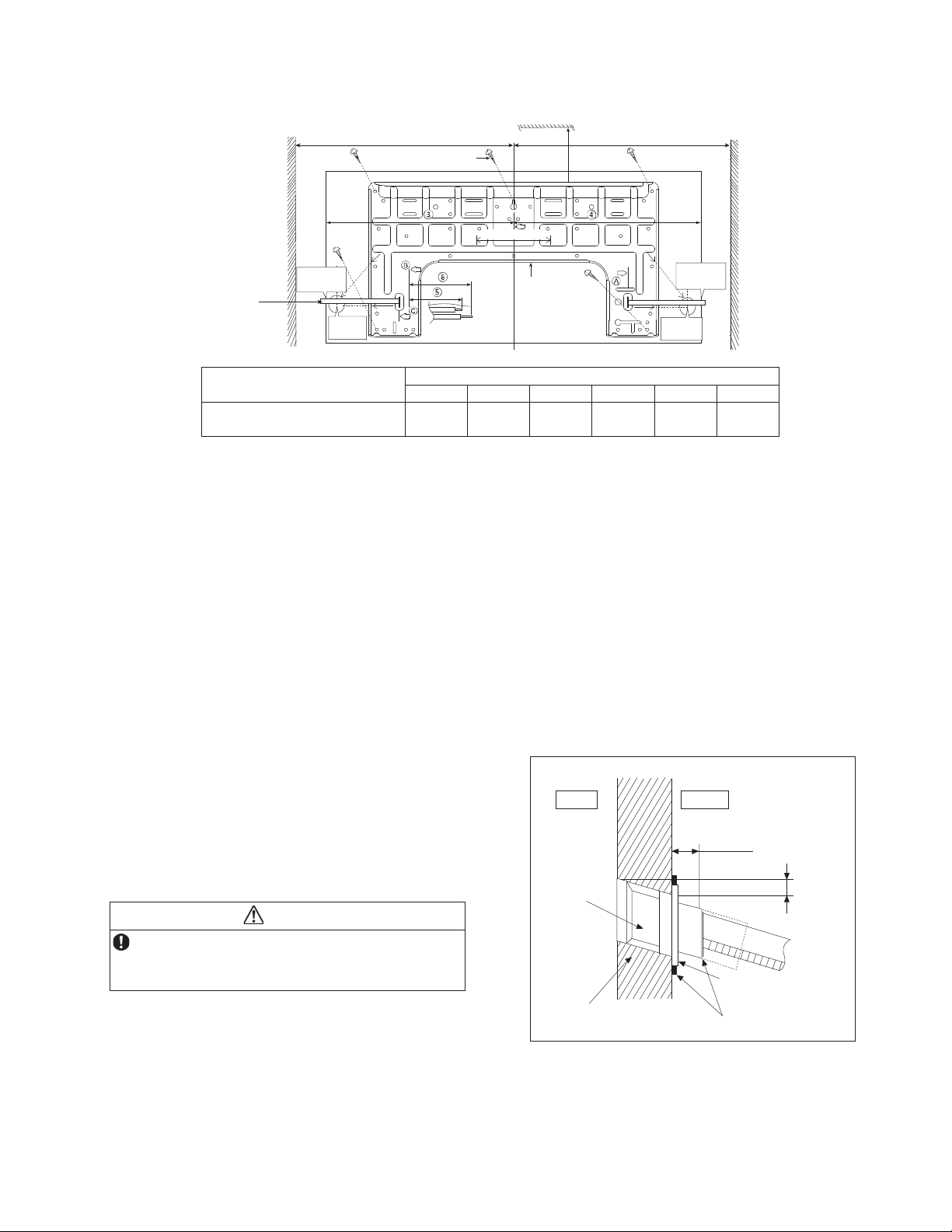

11.2 Indoor Unit

The mounting wall shall be strong and solid enough to prevent it from vibration.

Measuring

Tape

Wall

17

9

/32"

(241.5 m m )

(128 mm)

More than 1

2 screw

51/16" (128 mm)

PIPE HOLE CENTER

DISTANCE

TO PIPE

HOLE

CENTER

1

5

/16"

128 mm

Model

XE9SKUA, XE12SKUA

1 2 3 4 5 6

19-9/32"

(490 mm)

3-7/32"

(82 mm)

The center of installation plate should be at more than 1 at right and left of the wall.

The distance from installation plate edge to ceiling should more than 2.

From installation plate left edge to unit’s left side is 3.

From installation plate right edge to unit’s right is 4.

B : For left side piping, piping connection for liquid should be about 5 from this line.

ƻ

: For left side piping, piping connection for gas should be about 6 from this line.

1 Mount the installation plate on the wall with 5 screws or more (at least 5 screws).

(If mounting the unit on the concrete wall, consider using anchor bolts.)

o Always mount the installation plate horizontally by aligning the marking-off line with the thread and using

a level gauge.

2 Drill the piping plate hole with ø2-3/4" (ø70 mm) hole-core drill.

o Line according to the left and right side of the installation plate. The meeting point of the extended line is

the center of the hole. Another method is by putting measuring tape at position as shown in the diagram

above. The hole center is obtained by measuring the distance namely 5-1/16" (128 mm) for left and right

hole respectively.

o Drill the piping hole at either the right or the left and the hole should be slightly slanting to the outdoor

side.

11.2.1 To Drill a Hole in the Wall and

Install a Sleeve of Piping

1 Insert the piping sleeve to the hole.

2 Fix the bushing to the sleeve.

3 Cut the sleeve until it extrudes about 19/32"

(15 mm) from the wall.

CAUTION

When the wall is hollow, please be sure to use the

sleeve for tube assembly to prevent dangers

caused by mice biting the connection cable.

4 Finish by sealing the sleeve with putty or

caulking compound at the final stage.

Wall

More

than 2

Installation

plate 1

17-9/32"

(439 mm)

ø2

through hole

Dimension

Indoor

Sleeve

for tube

assembly

3

/4" (ø70 mm)

More than 1

DISTANCE TO

PIPE HOLE

CENTER 128 mm

PIPE HOLE

CENTER

17"

(432 mm)

Wall

51/16"

(128 mm)

1-11/16"

(43 mm)

Wall

17

/32"

9

(241.5 mm)

3-3/4"

(95 mm)

Outdoor

19

/32"(15mm)

Approx.7/32"-9/32"

(5-7 mm)

Bushing for tube

assembly

Putty or caulking compound

25

Page 4

11.2.2 Indoor Unit Installation

•

Do not turn over the unit

without it’s shock absorber

l

l

o

u

t

t

h

e

p

i

p

i

n

g

during pulling out the piping.

It may cause intake grille

damage.

Piping

p

u

Piping

Use shock absorber

during pulling out

l

l

o

u

t

t

h

the piping to protect

the intake grille from

e

p

i

p

i

damage.

n

g

p

u

PUSH PUSH

Intake grille

11.2.2.1 For the right rear piping

Step-1

Step-2

Step-3

Step-4

Pull out the Indoor piping

Install the Indoor Unit

Secure the Indoor Unit

Insert the connection cable

11.2.2.2 For the right bottom piping

Step-1

Step-2

Step-3

Step-4

Pull out the Indoor piping

Install the Indoor Unit

Insert the connection c able

Secure the Indoor Unit

11.2.2.3 For the embedded piping

Step-1

Step-2

Step-3

Step-4

Step-5

Step-6

Step-7

Step-8

Replace the drain hose

Bend the embedded piping

• Use a spring bender or equivalent to bend the piping so that the

piping is not crushed.

Pull the connection cable into Indoor Unit

• The inside and outside connection cable can be connected without

removing the front grille.

Cut and flare the embedded piping

• When determining the dimensions of the piping, sli de the unit all the

way to the left on the installation plate.

• Refer to the section “Cutting and flaring the piping”.

Install the Indoor Unit

Connect the piping

• Please refer to “Connecti ng the piping” column in outdoor unit

section. (Below steps are done after connecting the outdoor piping

and gas-leakage confirmation.)

Insulate and finish the piping

• Pl ea se r ef e r t o “Insulation of piping connection” column as

mentioned in indoor/outdoor unit installation.

Secure the Indoor Unit

PUSH PUSH

Shock absorber

Right Rear piping

Tape it with

piping in a position as

mentioned in

Fig. below.

Piping

Drain

hose

Cover for the

bottom piping

Cover for the

bottom piping

Cover

for the

left

piping

Cover for piping

How to keep the cover

In case the cover is cut, keep the cover at the rear

of chassis as shown in the illustration for future

reinstallation.

(Left and 2 bottom covers for piping.)

Right and Right Bottom piping

Tape it with piping in a

position as mentioned in

Fig. below.

Piping

Drain hose

Cover for

the right

piping

Cover for the

bottom pip in g

Install the indoor unit

Hook the indoor unit onto the upper portion

of installation plate. (Engage the indoor unit

with the upper edge of the installation plate).

Ensure the hooks are properly seated on

the installation plate by m oving it in left and

right.

Indoor unit

Cover for

the left

piping

Hooks at

installation

plate

Sleeve for

piping hole

Piping

Drain hose

Secure the Indoor Unit

1. Press the lower left and right side of the

unit against the installation plate until hooks

engages with their slot (sound click).

Unit’s

hook

To take out the unit, push the marking

at the bottom unit, and pull it slightly towards

you to disengage the hooks from the unit.

m

r

a

g

i

n

k

Installation

plate

Insert the connection cable

2

A

3

b

/

4

o

(

"

7

u

0

-

t

-

3

8

5

0

/

3

m

2

"

m

)

Guide

surface

Connection

cable

Connection cable

Gas side

piping

Liquid side

piping

Drain hose

(This can be used for left rear piping and bottom

piping also.)

26

Page 5

Replace the drain hose

Rear view for left piping installation

Drain cap

Drain hose

Drain hose

Connection cable

Adjust the piping

slightly downwards.

Piping

Drain hose

Connection cable

9

More than 45

(1150 mm)

Sleeve for piping hole

/32"

How to pull the piping and drain hose out, in case

•

of embedded piping

Apply putty or

caulking material

to seal the wall

opening.

PVC tube for drain

hose (VP-20)

PVC tube

for drain

hose

Drain hose adapter

Join indoor drain hose to 3/4"

•

.

"

16

/

9

27

(700 mm)

More than

PVC tube for drain hose (VP-30)

Indoor unit

27

/32"(72mm)

2

7

usage

n

ha

t

re

o

"

2

9

M

1

15

3

/

o

2

/

m

0

h

t

e

r

4

(

"

Cable

Piping

)

m

n

a

m

0

7

Connection

cable

Piping

)

Drain hose

m

from main unit

M

5

4

(1

8

1

PVC tube (VP-65) for piping

and connection cable

(20 mm) nominal PVC pipe size

by using drain hose adapter

7

when necessary.

How to insert the connection cable

•

and drain hose in the case of left

piping.

°

5

4

Drain

hose

Cable

Piping

(For right piping, follow the same

procedure)

Indoor unit

drain hose

Close join by Vinyl Tape ( )

Remarks :

Make sure indoor unit drain hose

& 3/4" (20 mm) nominal PVC pipe

are fully inserted to drain hose

adapter

7

.

Drain hose adapter

3/4" (20 mm) nominal PVC pipe

- Install incline downward more than 1°

- Apply PVC glue at the join.

7

27

Page 6

11.2.3 Connect the Cable to the Indoor Unit

restrip

pin

g

1 The inside and outside connection cable can

be connected without removing the front grille.

2 Unscrew the conduit cover and fix the conduit

connector to conduit cover with lock nut, then

secure it against chassis.

3 Connection cable between indoor unit and

outdoor unit should be UL listed or CSA

approved 4 conductor wires minimum AWG16

in accordance with local electric codes.

o Ensure the colour of wires of outdoor unit

and terminal number are the same as the

indoor's respectively.

Terminals on the indoor unit 1 2 3

Colour of wires (connection cable)

Terminals on the outdoor unit 1 2 3

WARNING

This equipment must be properly earthed.

o Earth lead wire shall be Yellow/Green

(Y/G) in colour and shall be longer than

other lead wires as shown in the figure

for electrical safety in case of slipping.

11.2.3.1 Wire Stripping and Connecting Requirement

Wi

(10 ± 1 mm)

13/32" ± 1/16"

No loose strand

when inser ted

Indoor/outdoor

connecting

terminal board

7

/32" (5 mm)

or more

(gap between wires)

Conductor

fully inser ted

ACCEPT

Conduit

Connector

Rear Side of Indoor Unit

Indoor and

outdoor

connection

cable

Conductor

over inserted

PROHIBITED

Conductor not

fully inser ted

PROHIBITED

Conduit Cover

Lock Nut

Chassis

Terminal

Board

Earth wire

longer than

others

AC wi res

for safety

reason

Holder

28

Page 7

11.3 Outdoor Unit

B

S

11.3.1 Install the Outdoor Unit

After selecting the best location, start installation according to Indoor/Outdoor Unit Installation Diagram.

1 Fix the unit on concrete or rigid frame firmly and horizontally with a bolt nut ø13/32" (ø10 mm).

2 When installing at roof, please consider strong wind and earthquake.

Please fasten the installation stand firmly with bolt or nails.

11.3.2 Connect the Piping

11.3.2.1 Connecting the Piping to

Indoor

Please make flare after inserting flare nut (locate at

joint portion, of tube assembly) onto the copper pipe.

(In case of using long piping)

Connect the piping

Align the center of piping and sufficiently tighten

the flare nut with fingers.

Further tighten the flare nut with torque wrench in

specified torque as stated in the table.

A

C

D

Model A B C D

XE9SKUA,

XE12SKUA

24-1/8"

(613 mm)

5-5/32"

(131 mm)

5/8"

(16 mm)

Do not over tighten, over tightening may cause gas leakage

Piping size Torque

1/4" (6.35 mm) 13.3 Ibf.ft [18N•m (1.8 kgf.m)]

3/8" (9.52 mm) 31.0 Ibf.ft [42 N•m (4.3 kgf.m)]

1/2" (12.7 mm) 40.6 Ibf.ft [55 N•m (5.6 kgf.m)]

5/8" (15.88 mm) 47.9 Ibf.ft [65 N•m (6.6 kgf.m)]

3/4" (19.05 mm) 73.8 Ibf.ft [100 N•m (10.2 kgf.m)]

14-3/16"

(360.5 mm)

11.3.2.2 Connecting the Piping to

Outdoor

Decide piping length and then cut by using pipe cutter.

Remove burrs from cut edge.

Make flare after inserting the flare nut (located at valve)

onto the copper pipe.

Align center of piping to valve and then tighten with

torque wrench to the specified torque as stated in the

table.

panner

or Wrench

11.3.2.3 Gas leak checking

Pressure test to system to 400 PSIG with dry nitrogen, in stages. Thoroughly leak check the system.

If the pressure holds, release the nitrogen and proceed to section 11.3.3.

Torque

wrench

29

Page 8

11.3.3 Evacuation of the Equipment

L

e

c

r

e

Ope

e

WHEN INSTALLING AN AIR CONDITIONER, BE SURE TO EVACUATE THE AIR INSIDE THE INDOOR UNIT AND

PIPES in the following procedure.

Indoor unit

Vac uu m

pump

1 Connect a charging hose with a push pin to the Low side of a charging set and the service port of the 3-way

valve.

2 Connect the micron gauge between vacuum pump and service port of outdoor units.

3 Turn on the power switch of the vacuum pump and make sure that connect digital micron gauge and to pull

down to a value of 500 microns.

4 To make sure micron gauge a value 500 microns and close the low side valve of the charging set and turn off

the vacuum pump.

5 Disconnect the vacuum pump house from the service port of the 3-way valve.

6 Tighten the service port caps of the 3-way valve at a torque of 13.3 Ibf.ft (18 N•m) with a torque wrench.

7 Remove the valve caps of both of the 2-way valve and 3-way valve. Position both of the valves to “Open”

using a hexagonal wrench (5/32" (4 mm)).

8 Mount valve caps onto the 2-way valve and the 3-way valve.

o Be sure to check for gas leakage.

If micron gauge value does not descend 500 microns, take the following measures:

- If the leak stops when the piping connections are tightened further, continue working from step e.

- If the leak does not stop when the connections are retightened, repair location of leak.

- Do not release refrigerant during piping work for installation and reinstallation.

- Be careful with the liquid refrigerant, it may cause frostbite.

Liquid side

Gas side

Tw o -way va l v e

Close

Three-way valve

Close

Outdoor unit

11.3.4 Connect the Cable to the Outdoor Unit

1 Remove control board cover (Resin and

Metal).

2 Remove particular plate.

3 Remove plugs.

4 Fix the conduit connectors to the knockout

holes with lock-nuts, then secure them against

the side panel.

5 All wires pass through conduits & particular

plate’s opening hole.

6 Connecting wire between indoor unit and

outdoor unit should be UL listed or CSA

approved 4 conductor wires minimum AWG16

in accordance with local electric codes.

7 Wire connection to the power supply

(208/230V 60Hz) through circuit breaker.

o Connect the UL listed or CSA approved

wires minimum AWG14 to the terminal

board, and connect the other end of the

wires to ELCB/ GFCI.

8 Connect the power supply cord and

connecting wire between indoor unit and

outdoor unit according to the diagram below.

ock Nuts

Knockout

Holes

Fron t

Panel

Particular

Plate

Conn

ting wi

s

Plugs

Particular Plate

ninghol

Control Board

Cover (Metal)

Connectors

Control Board

Cover (Resin)

30

Page 9

Indoor Unit

Disconne

c

mproperflairin

g

1

2

3

t

Switch

Field supply

Grounding wire min AWG16

208/230V min AWG16

208/230V min AWG16

208/230V min AWG16

9 Secure the wire onto the control board with

the holder (clamper).

10 After completing wiring connections, reattach

the particular plate and control board cover

(metal and resin) to the original position with

the screws.

11 For wire stripping and connection

requirement, refer to instruction 11.2.3.1 of

indoor unit.

WARNING

This equipment must be properly earthed.

Earth lead wire shall be Yellow/Green (Y/G) in

colour and should be longer than other lead wires

as shown in the figure for electrical safety in case

of slipping.

Outdoor Unit

1

2

3

L1

L2

lanimreTlanimreT

Disconnect

Switch

Field supply

Grounding wire

Earth wire

longer

than other

AC wi res

for safety

reasons

Power Supply

Single P hase

208/230V 60Hz

min AWG14

Powe r

supply

cord

Indoor &

outdoor

connection

cable

Terminal

Board

Earth wire

longer

than other

AC wi res

for s afety

reasons

Holder

11.3.5 Piping Insulation

1 Please carry out insulation at pipe connection portion as mentioned in Indoor/Outdoor Unit Installation

Diagram. Please wrap the insulated piping end to prevent water from going inside the piping.

2 If drain hose or connecting piping is in the room (where dew may form), please increase the insulation by

using POLY-E FOAM with thickness 1/4" (6 mm) or above.

11.3.5.1 Cutting and flaring the piping

1 Please cut using pipe cutter and then remove the burrs.

2 Remove the burrs by using reamer. If burrs are not removed, gas leakage may be caused. Turn the piping

end down to avoid the metal powder entering the pipe.

3 Please make flare after inserting the flare nut onto the copper pipes.

1. To cut

Pipe

Poi nt down

2. To re move burrs

Reamer

Clamp handle

Bar

3. To flare

Handle

Yo k e

Core

Red arrow mark

0–1/32" (0-0.5 mm)

Bar

Copper

pipe

When properly flared, the internal surface of the

flare will evenly shine and be of even thickness.

Since the flare part comes into contact with the

connections, carefully check the flare finish.

I

Inclined Surface

damaged

Cracked Uneven

thickness

31

Page 10

11.3.6 Disposal of Outdoor Unit Drain Water

R

The unit should be mounted on a stand that suits to a local environmental requirement.

When the Drain elbow being used, please ensure to:-

o Provide a minimum clearance of 2" (50mm) to access the bottom of base pan.

o Seal the four 25/32" (20mm) diameter holes with Rubber caps (refer to illustration below).

o Use a rigid or flexible PVC pipe (local supply) to dispose drained water from the elbow or use a stainless

steel tray (local supplied) to collect and dispose water.

Drain

elbow

ubber cap

x4

If the unit is used in an area where temperature falls below 32°F (0°C) for 2 or 3 consecutive days, it is

recommended not to use the Drain elbow and Rubber caps, water from defrost process will trap, freeze up and

obstruct fan rotation. Water may drip from the basepan hole area during defrost function, do not stand or place

objects underneath.

32

Loading...

Loading...