Panasonic CS-W34BB4P, CU-V34BBP5, CU-W34BBP5 Service Manual

1 SERVICE INFORMATION 3

2 FEATURES

4

3 SPECIFICATION (HEAT PUMP TYPE )

10

4 SPECIFICATION (COOLING ONLY TYPE )

11

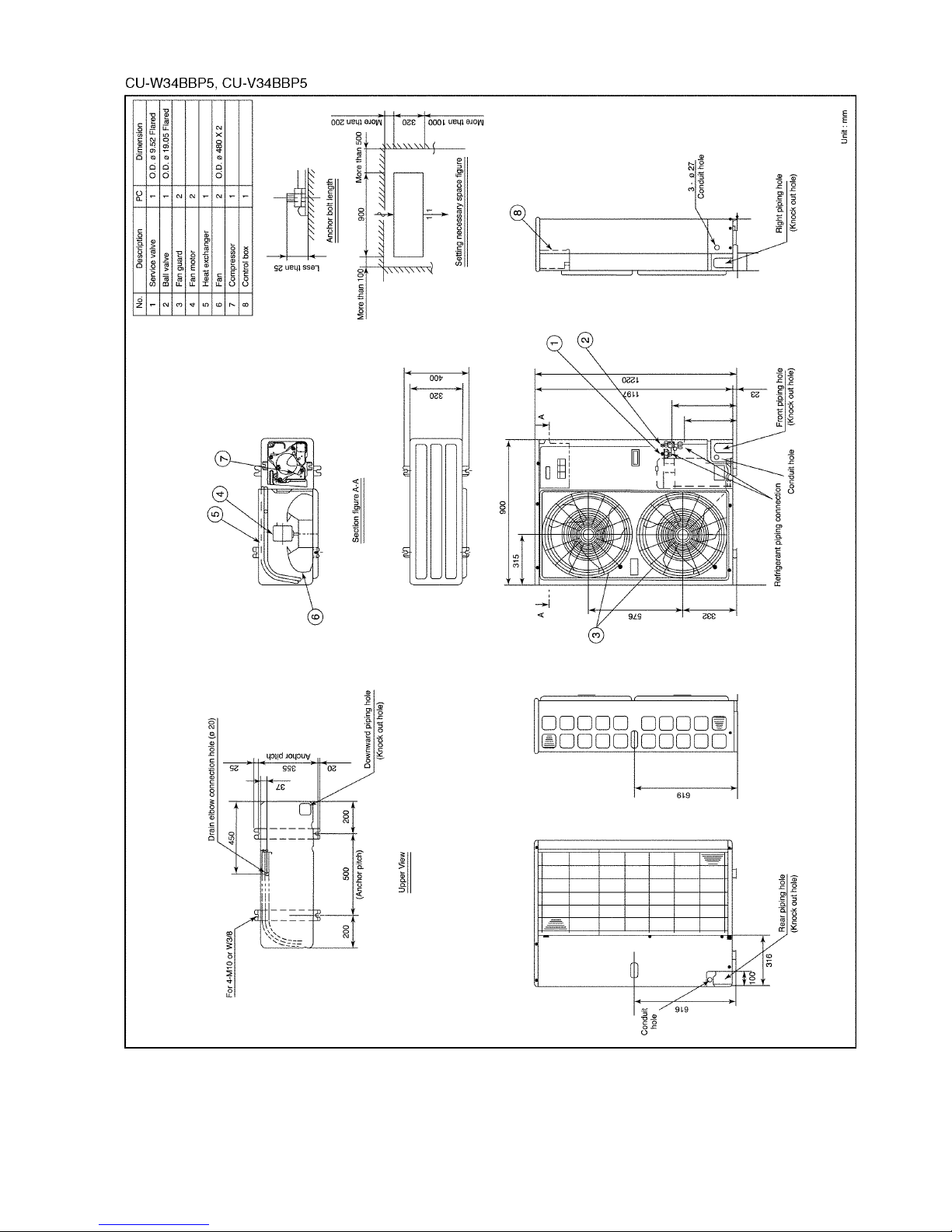

5 TECHNICAL DRAWING

12

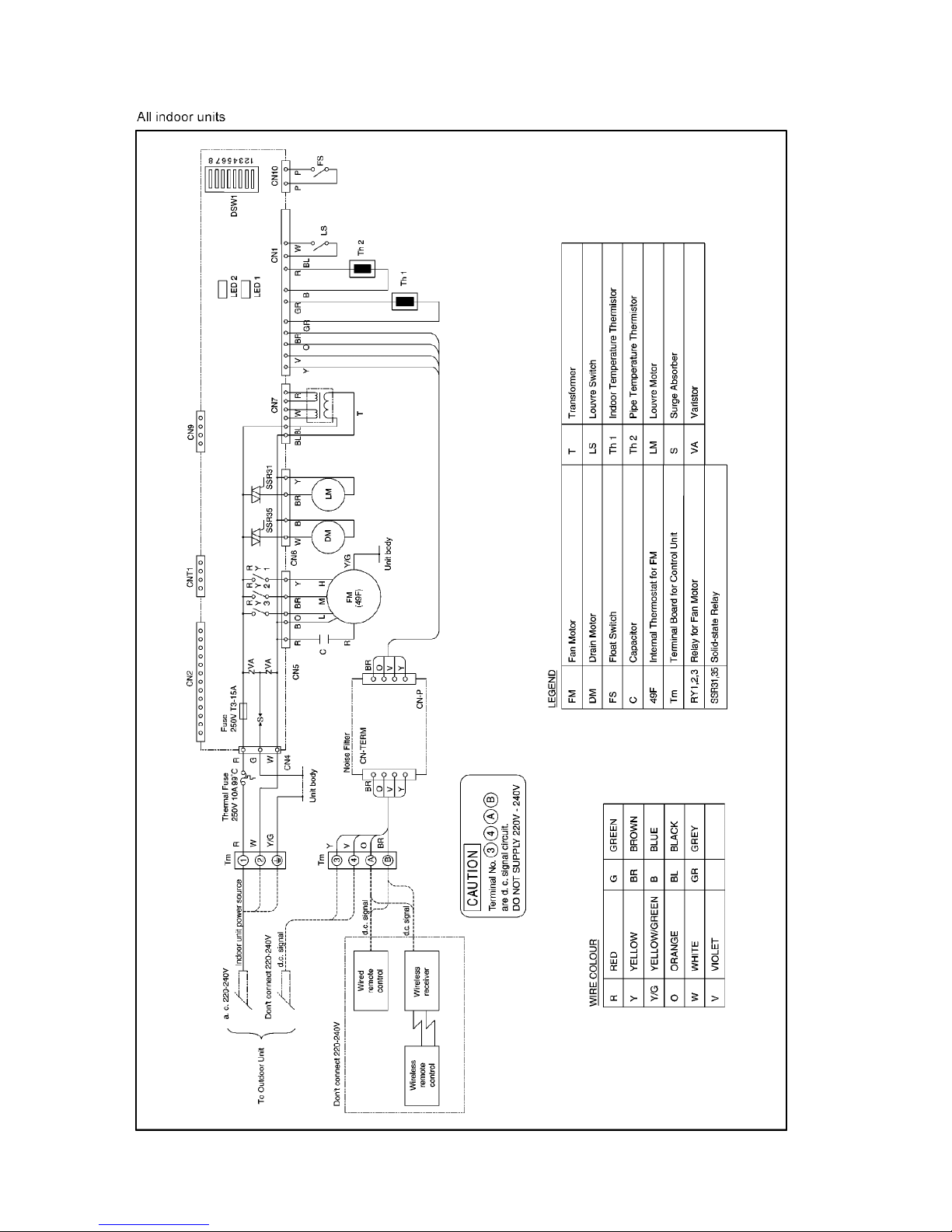

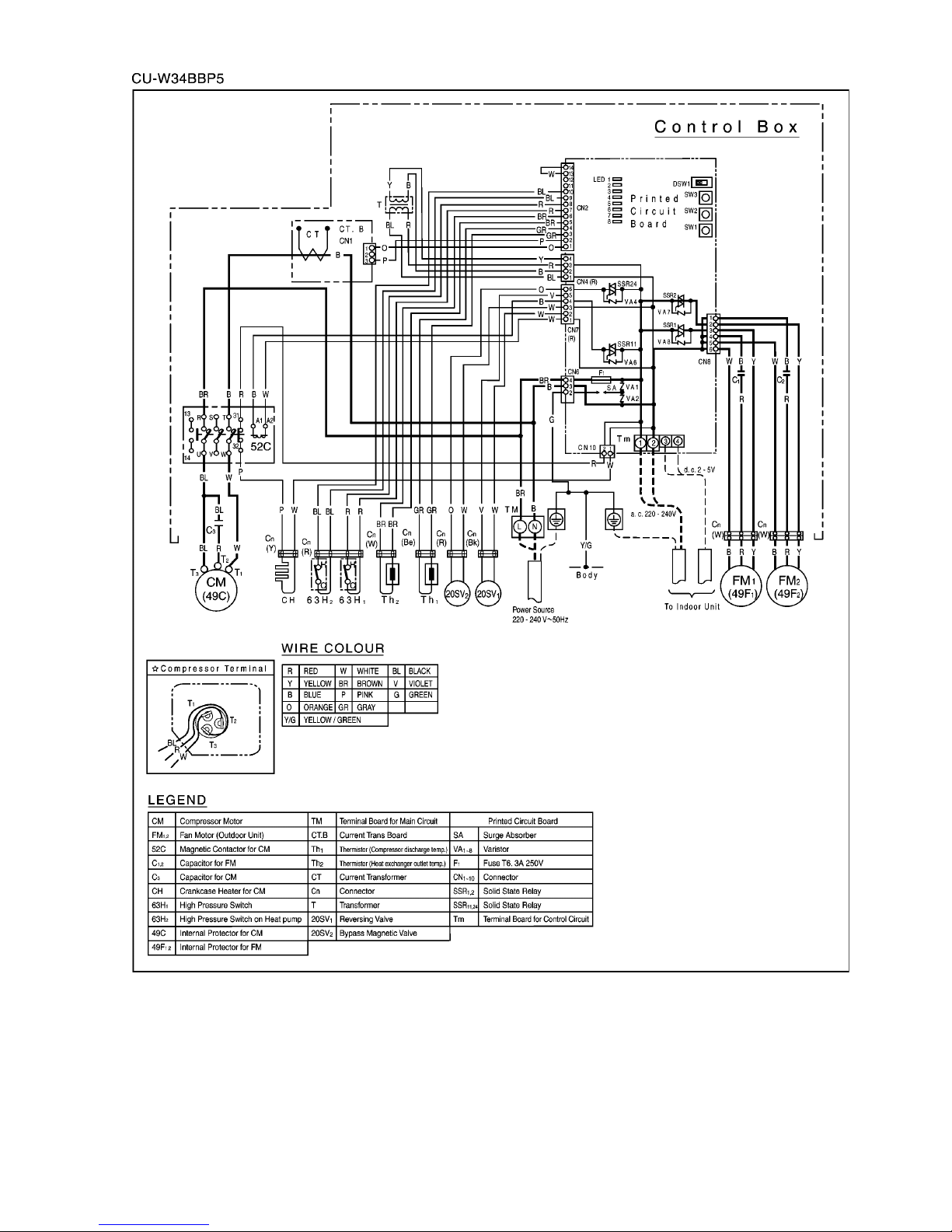

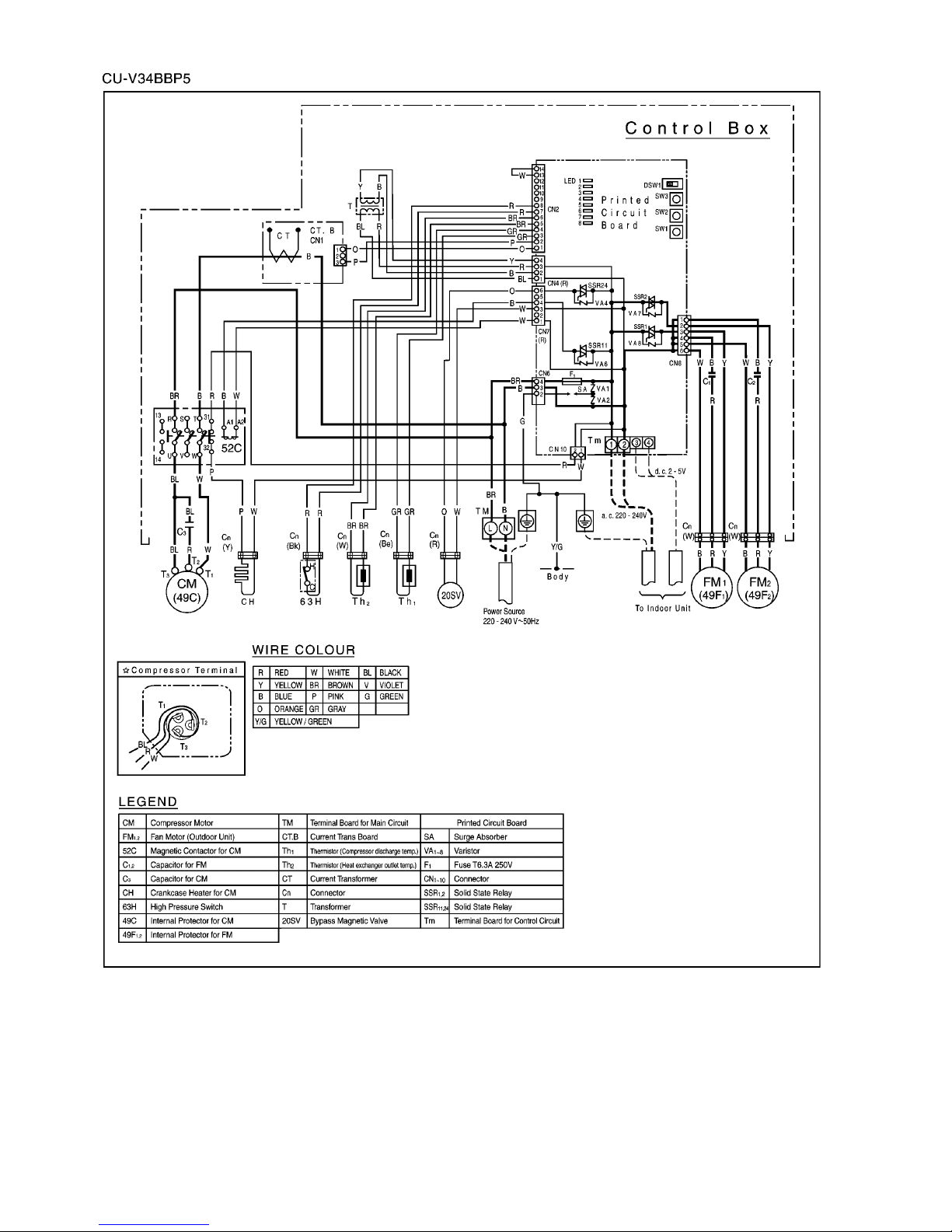

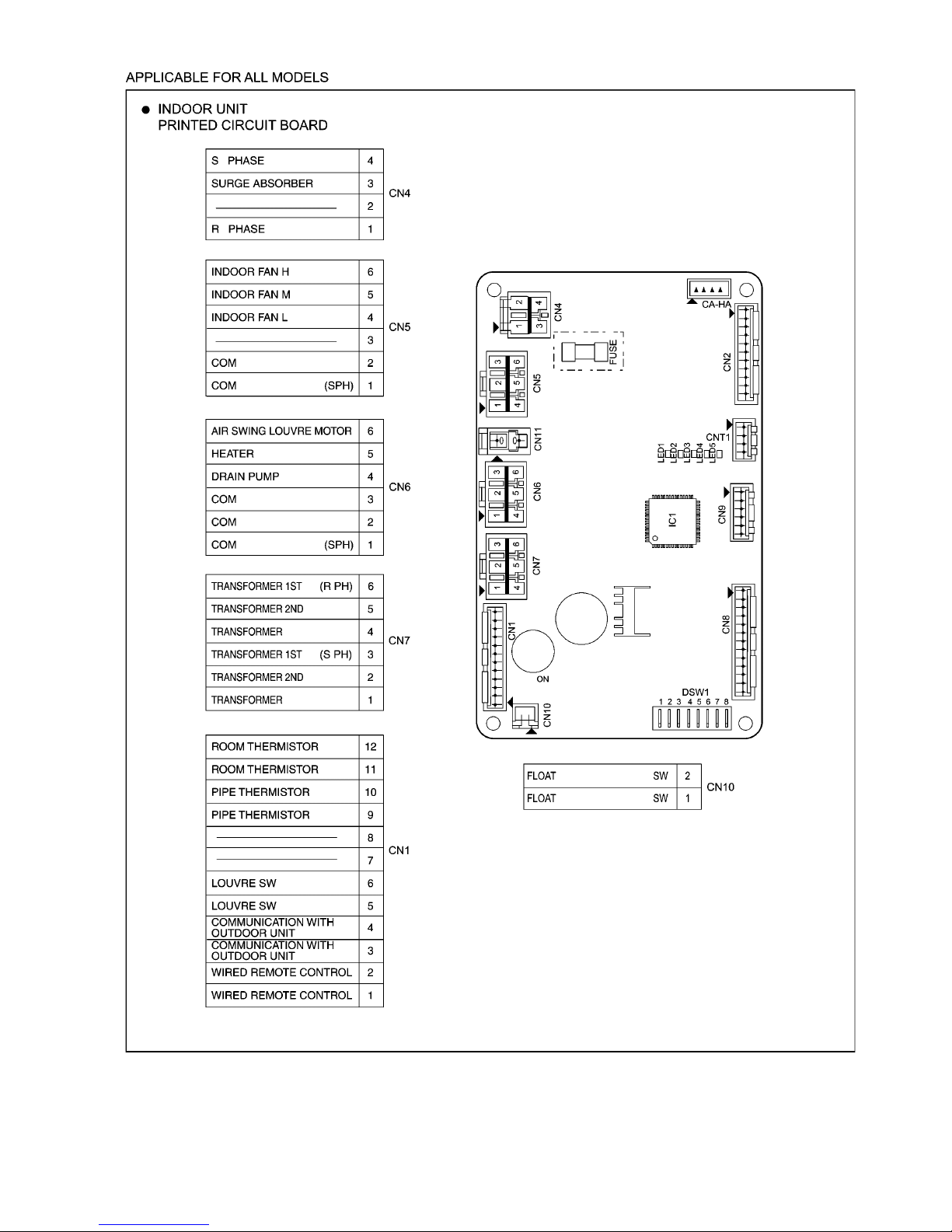

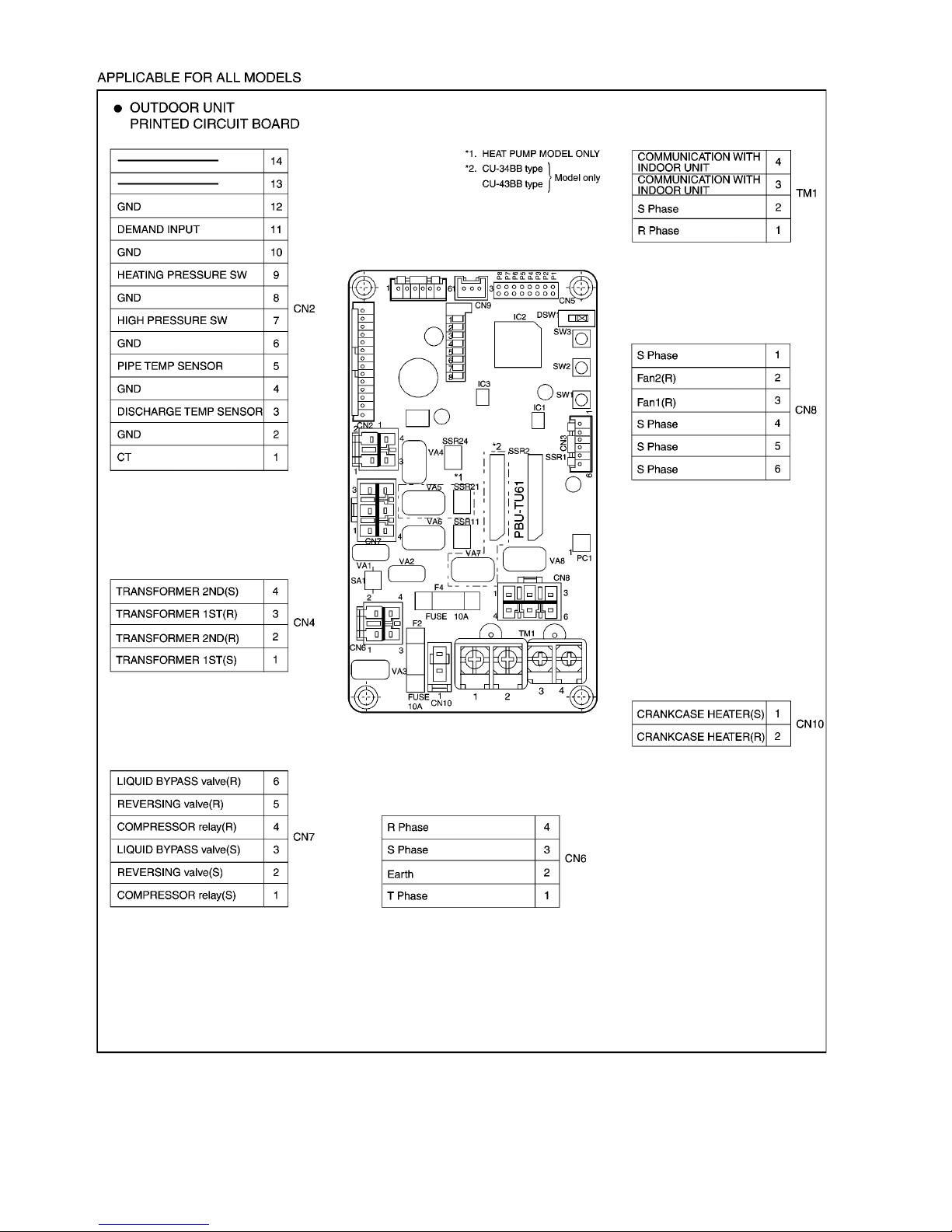

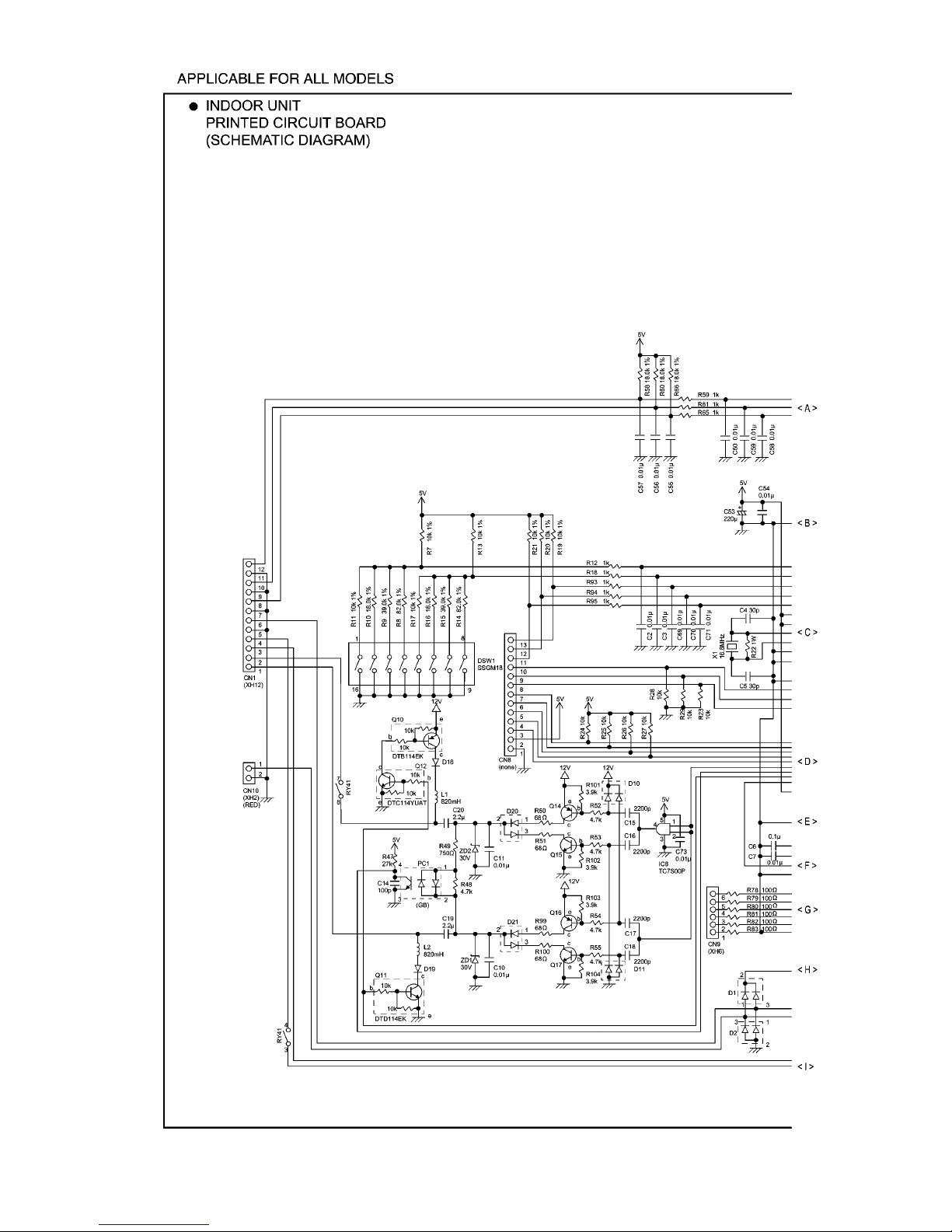

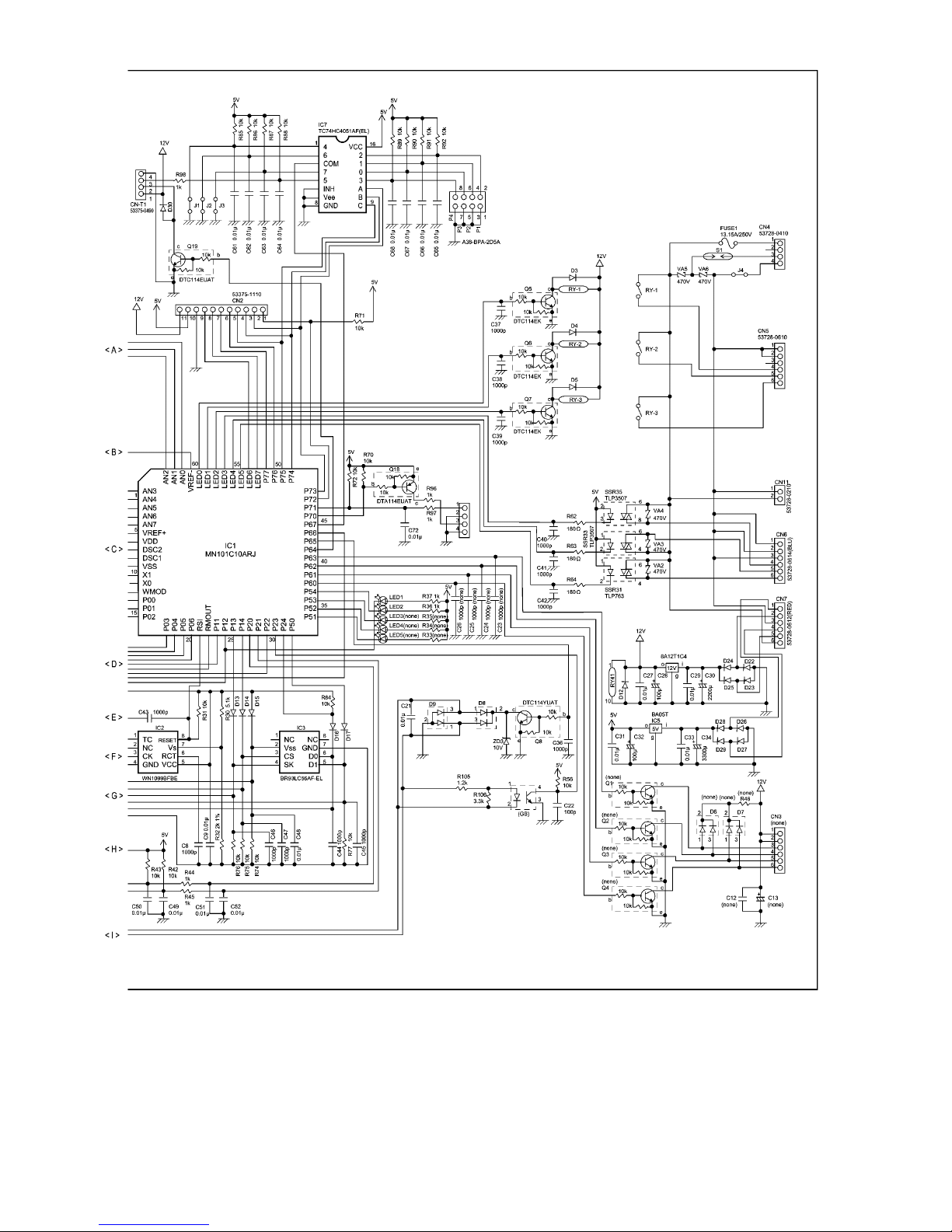

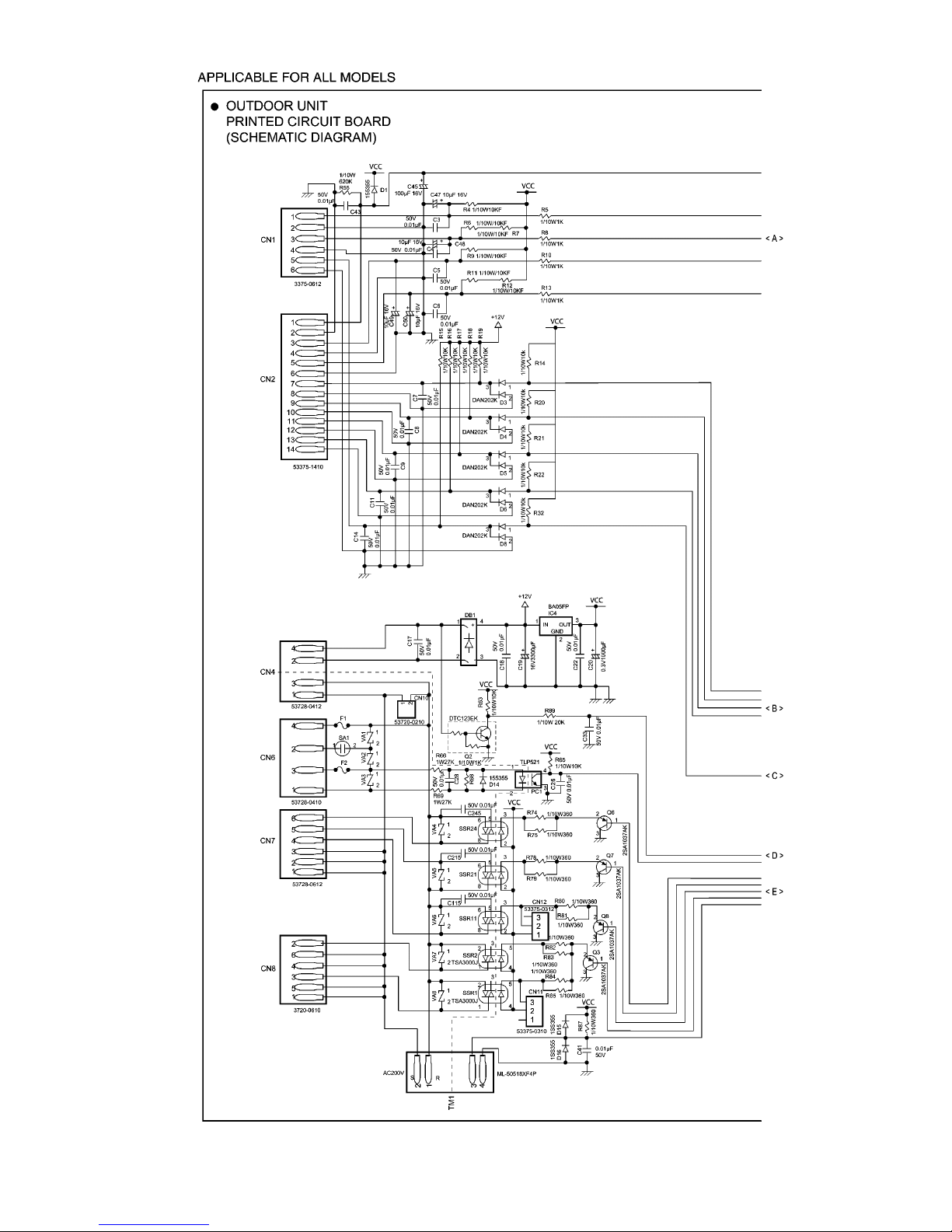

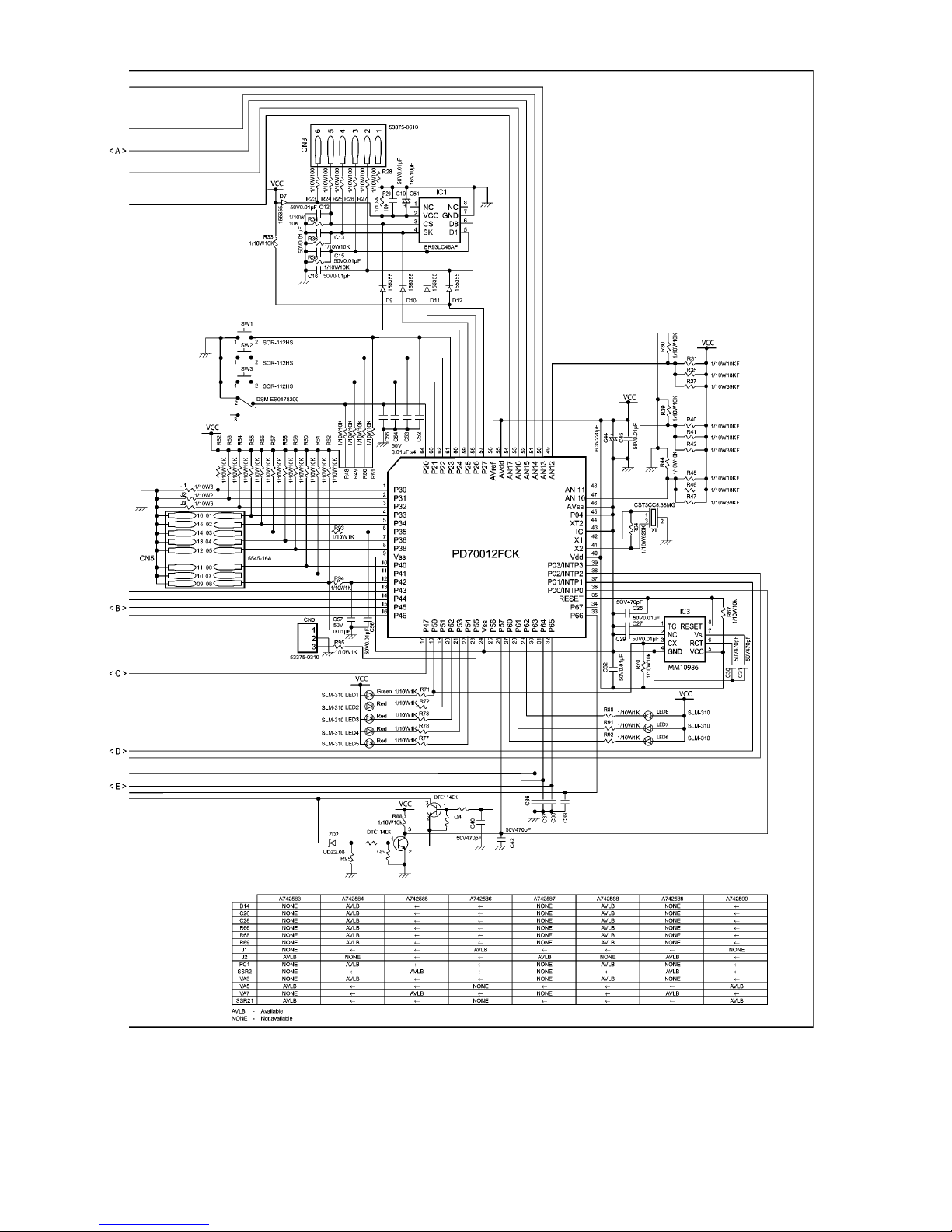

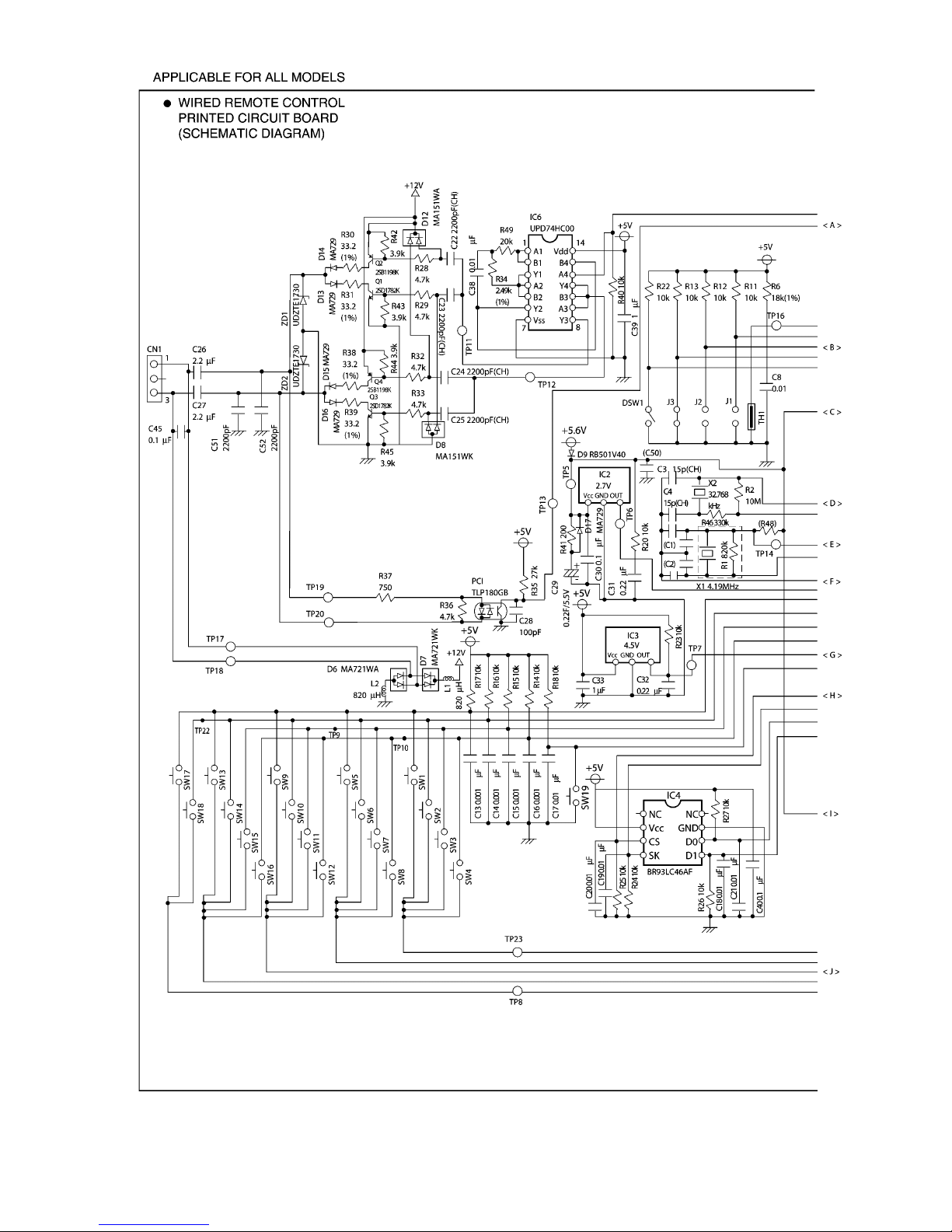

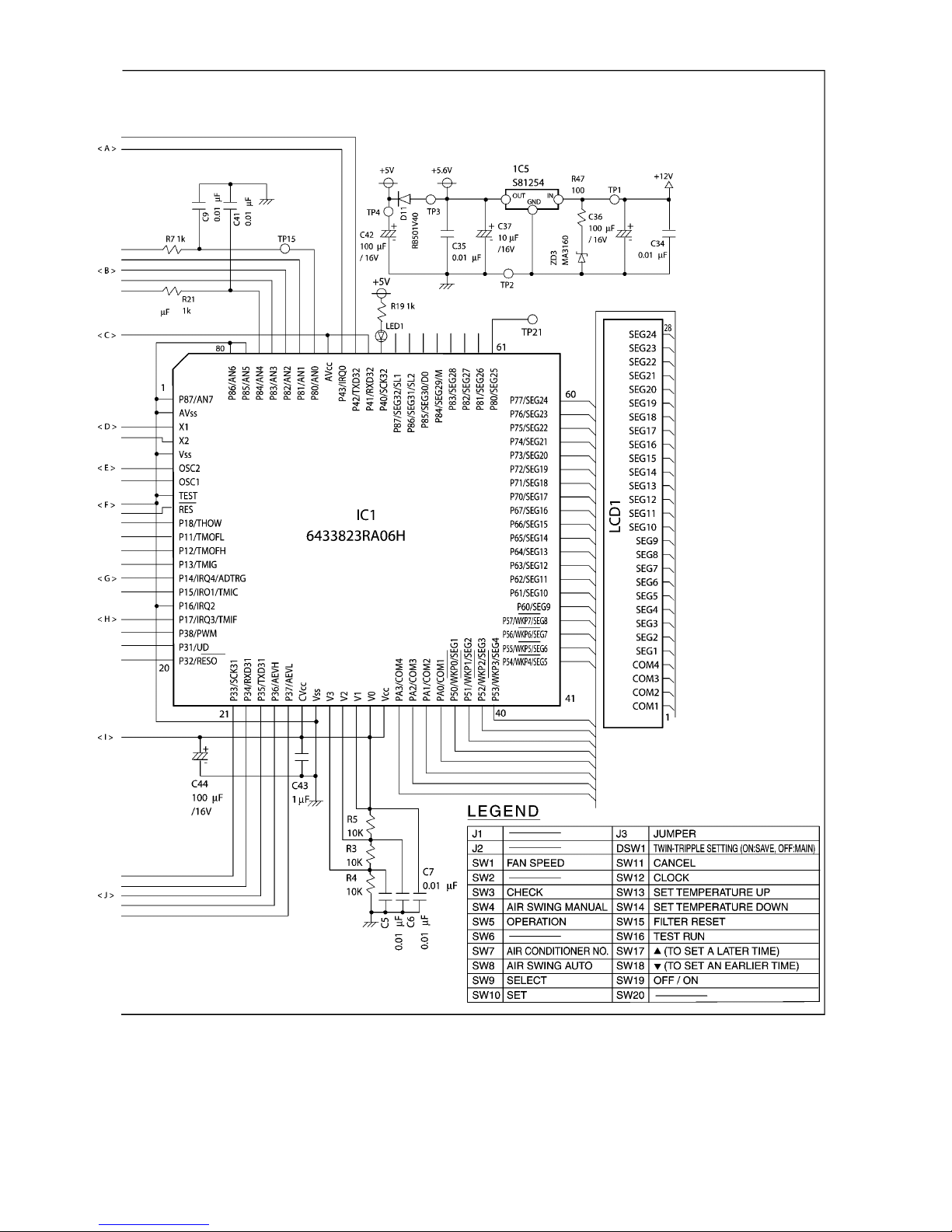

6 CIRCUIT DIAGRAM

14

7 OPERATING INSTRUCTION

26

© 2002 Matsushita Industrial Corporation Sdn. Bhd.

(11969-T). All rights reserved. Unauthorized copying

and distribution is a violation of law.

CS-W34BB4P CU-V34BBP5

CS-W34BB4P CU-W34BBP5

8 REFRIGERATION CYCLE 28

9 OPERATION RANGE

29

10 PIPE LENGTH

30

11 OPERATING CHARACTERISTIC

32

12 FAN PERFORMANCE

33

13 SAFETY DEVICE

34

AIR CONDITIONER

CONTENTS

Page Page

ORDER NO. MAC0208027C2

14 COMPONE NT SPECIFICATION 35

15 CAPACITY AND POWER CONSUMPTION

36

16 DISCHARG E AND SUCTION PRESSURE

38

17 SOUND DATA

39

18 TWIN AND TRIPLE

41

19 WIRING MISTAKE PREVENTI ON

46

20 TEST OPERATIO N AND SELF DIAGNOSI S

47

21 SETTING OF SAVE ENERGY AND THERMISTOR SWITCH

51

22 GROUP CONTROL

52

23 TROUBLESHOOTING

53

24 EMERGEN CY OPERATIO N

58

25 CONTROL

59

26 WIRED REMOTE CONTROL INSTALLATION MANUAL

71

27 WIRELESS REMOTE CONTROL INSTALLATION MANUAL

76

28 INSTALLATION (INDOOR UNIT)

83

29 INSTALLATION (OUTDOOR UNIT)

92

30 REPLACEM E NT PARTS

103

2

1 SERVICE INFORMATION

Caution:

●

Pb free solder has a higher melting point than standard solder; Typically the melting point is 50 - 70°F (30 - 40°C) higher. Please

use a high temperature soldering iron. In case of the soldering iron with temperature control, please set it to 700 ± 20°F (370 ±

10°C).

●

Pb free solder will tend to splash when heated too high (about 1100° F/600°C).

Notice of Address setting for NEW Cassette / NEW Outdoor Unit.

The new Cassette / new Outdoor models are possible to have address setting for twin / triple control or group control

automatically when main power supply is switched on.

(Manual address setting is also possible by using DSW1 switch on the indoor unit P.C. board.) However,

this address setting is

only possible when proper wiring connection is made and indoor unit must be of original unit

.

1.1. Example of trouble during test operation

If the below phenomenon is found during test operation, wrong address setting is possible.

Therefore, please inspect the address setting.

1. LCD display of the wired remote control is not illuminated although the main power supply switch is ‘on’.

2. LCD display had indicated as normal illumination when power supply switch is ‘on’, however outdoor unit cannot be operated.

(But, it is necessary to take 3 to 5 minutes for outdoor unit to start from the timing of remote control OFF/ON button is ‘on’.)

(For normal operation, the outdoor unit will only start its operation after 3 to 5 minutes upon pressing the OFF/ON button.)

3. P.C. board had memorized wrong setting information.

a. If main power supply is switched on with the wrong connection.

b. When changing the connection or combination of units due to re-installation etc.

•

• •

•

When changing the system from twin to triple (triple to twin).

•

• •

•

When changing the system from group control to normal one to one system.

•

• •

•

When making the replacement of units of master and slave etc.

1.2. Caution during test operation

Do not touch the remote control button and do not change any wirings for one minute when the main power supply switch is ‘on’.

(Because the unit is having automatic address setting during the first one minute.)

1.3. Caution during automatic address setting

When the main power supply switch is ‘on’, the P.C. board will automatically memorize the connecting system.

Consequently, when initial power supply is ‘on’, there mustn’t be any interchanging of units even of the same type and same

capacity unit.

Therefore, connection of the unit to another system is prohibited.

3

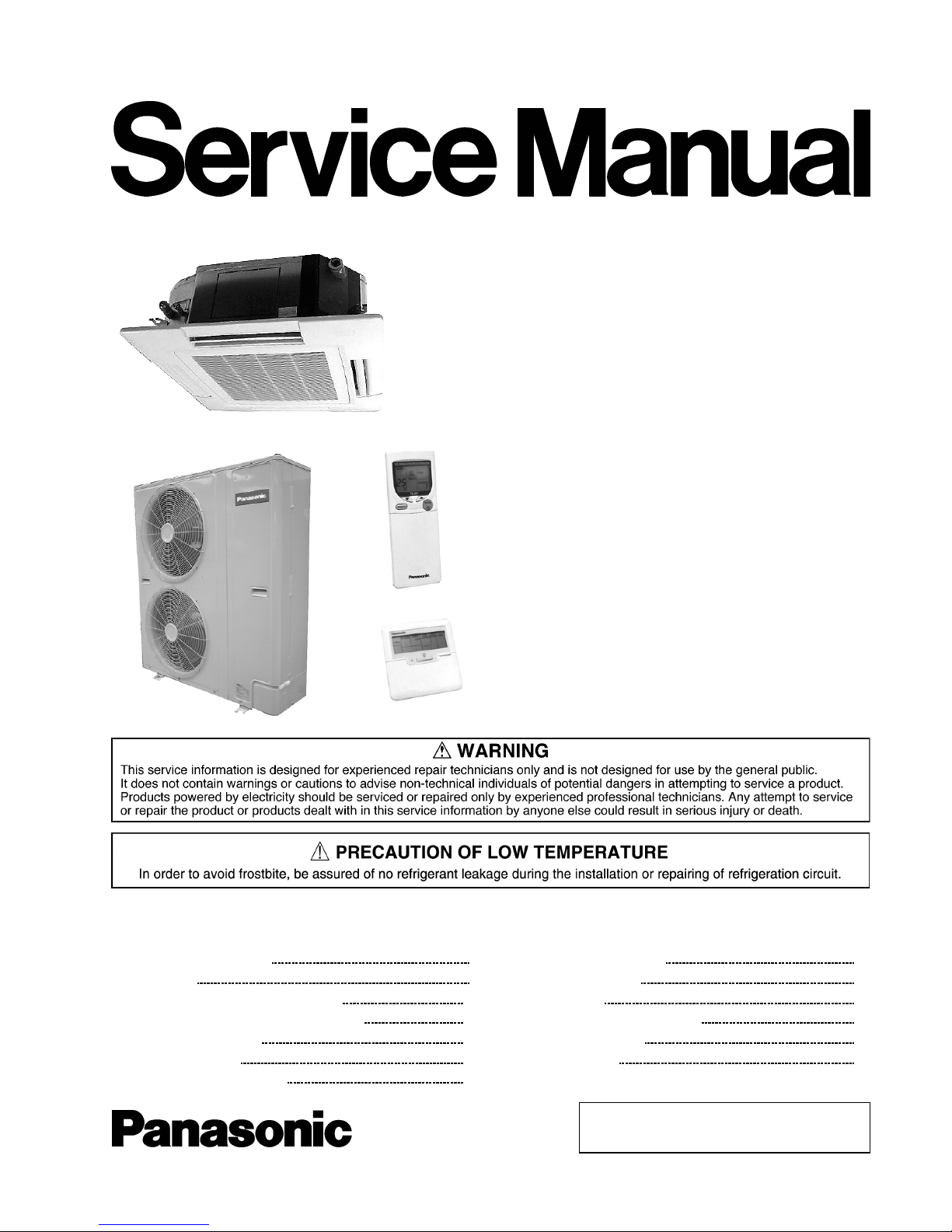

2.1. Variety of excellent features

•

• •

•

Compact design

Compact design 290 mm height, 840 mm width and 840

mm depth.

•

• •

•

Automatic restart function

When the electric power resumes after a power failure, the

unit will automatically restarts the operation in the prefailure mode.

•

• •

•

Auto fan mode (indoor unit)

Auto fan mode is added besides HI, ME and LO.

It automatically adjusts the fan speed according to the

indoor temperature.

•

• •

•

Dry mode function

Dry mode can make a comfor table indoor environment

during wet season.

•

• •

•

Quiet operation

The sound level is 45dB (A) for 34BB model during High

Fan speed and suitable for offices, shops, homes etc, when

quiet operation is essential.

•

• •

•

Auto Swing Louvre

The air flow angle can be changed automatically (or

manually) to an angle between 10° to 70° using the remote

control.

•

• •

•

Low ambient cooling operation

Cooling operation is possible at outdoor temperature of

-5°C.

•

• •

•

Automatic changeover function (heat pump models)

The unit automatically switches between cooling and

heating in accordance with operating load in order to

maintain a comfortable indoor temperature.

•

• •

•

Hot start system (heat pump models)

•

• •

•

Pipes and drainage

Built-in upward draining mechanism.

2 FEATURES

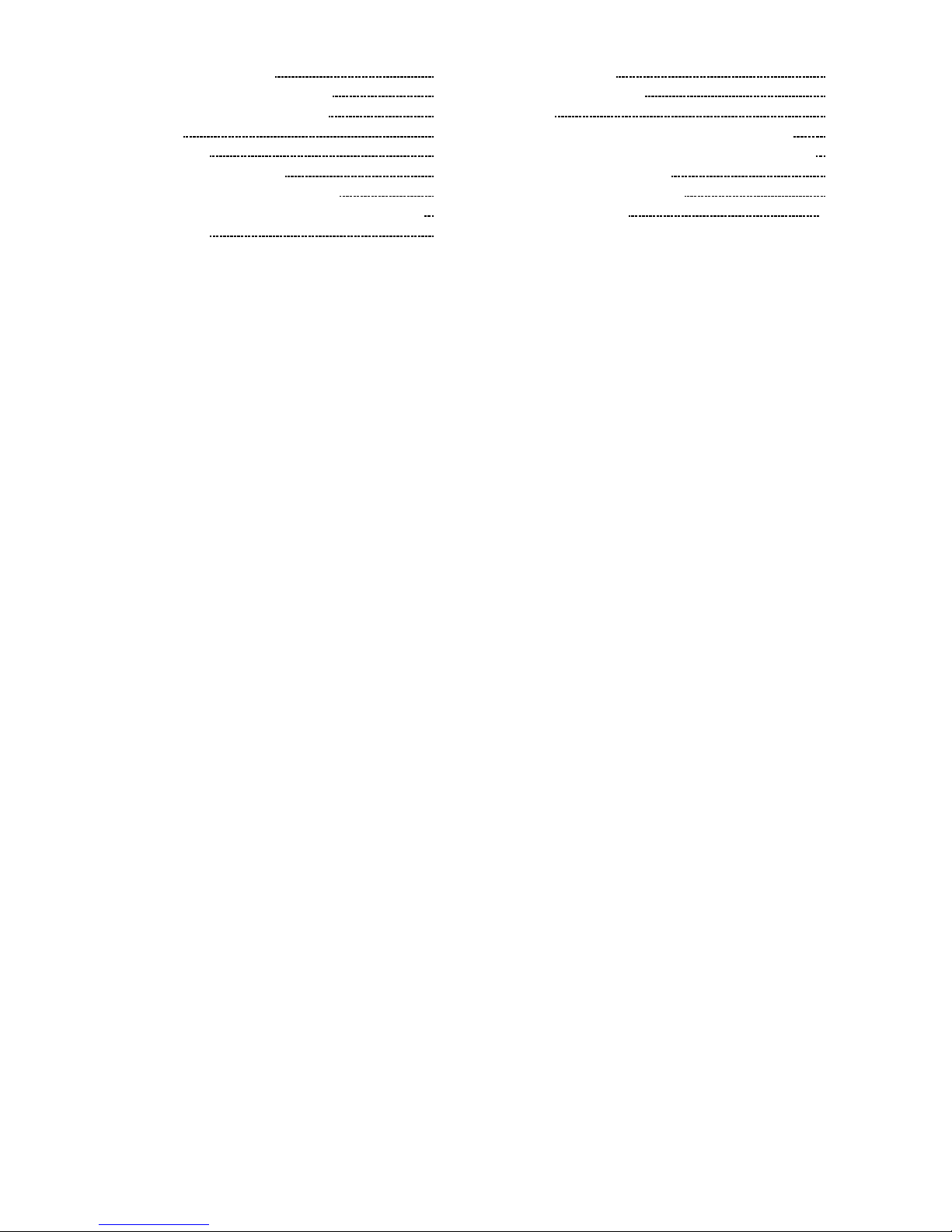

2.2. Low-noise outdoor units

4

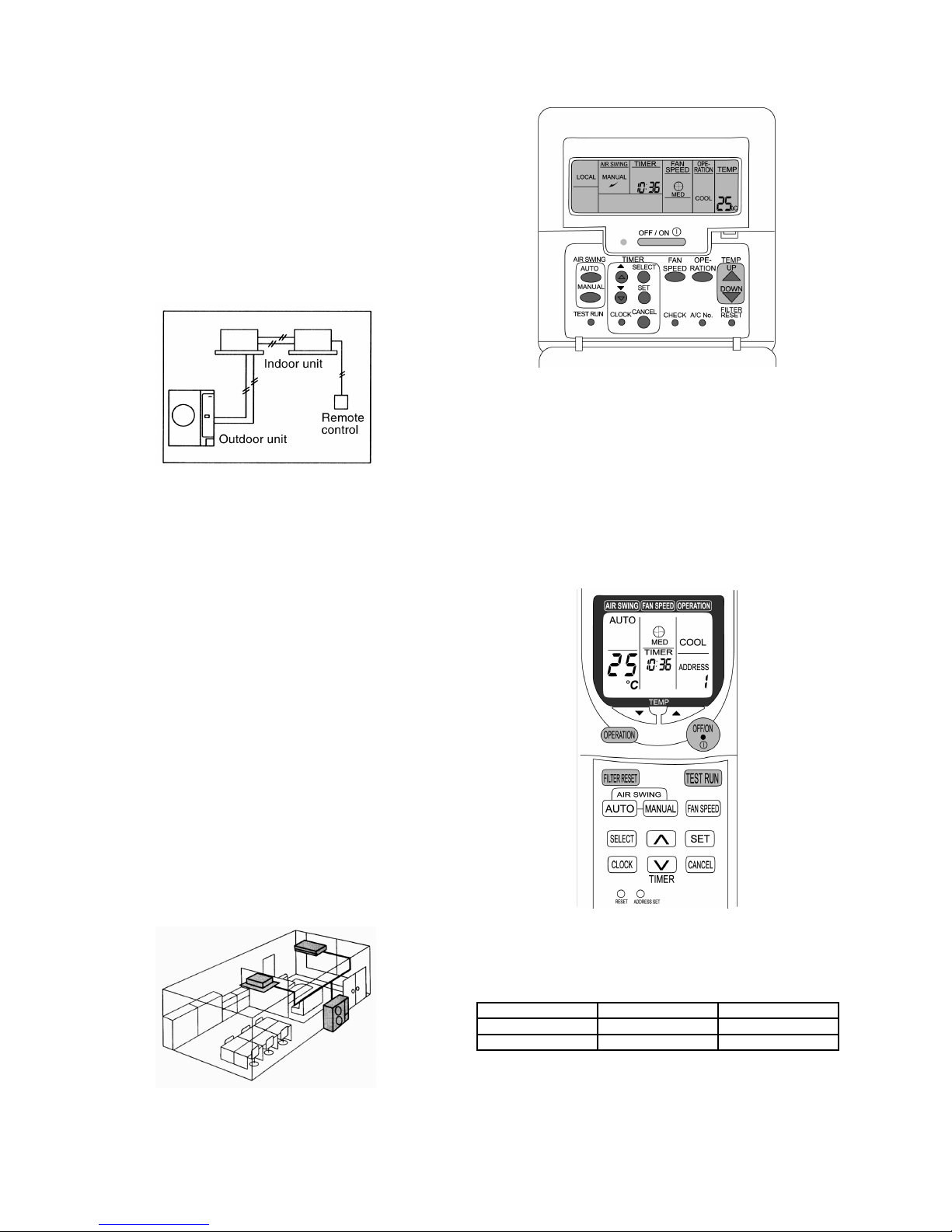

2.2.1. Product features

•

• •

•

Low-noise design improves comfort in surrounding

areas

1. The noise-suppressing winglet fan is a result of new

research into vane design theory. The unique curved

shape suppresses the generation of vortexes, thus

reducing air flow noise.

2. The adoption of double-orifice rings reduces air

passage resistance.

3. Strengthening of the noise insulation materials in the

compressor and the sealing-in of mechanical noise

allows vibration noise to be greatly enclosed and

suppressed.

4. The heat exchanger has an L-shaped design to allow air

to flow more smoothly.

5. Noise is automatically reduced further during night-time

operation with lower outdoor air temperatures.

2.3. Greatly improved workability

increases system renewal

capability

•

• •

•

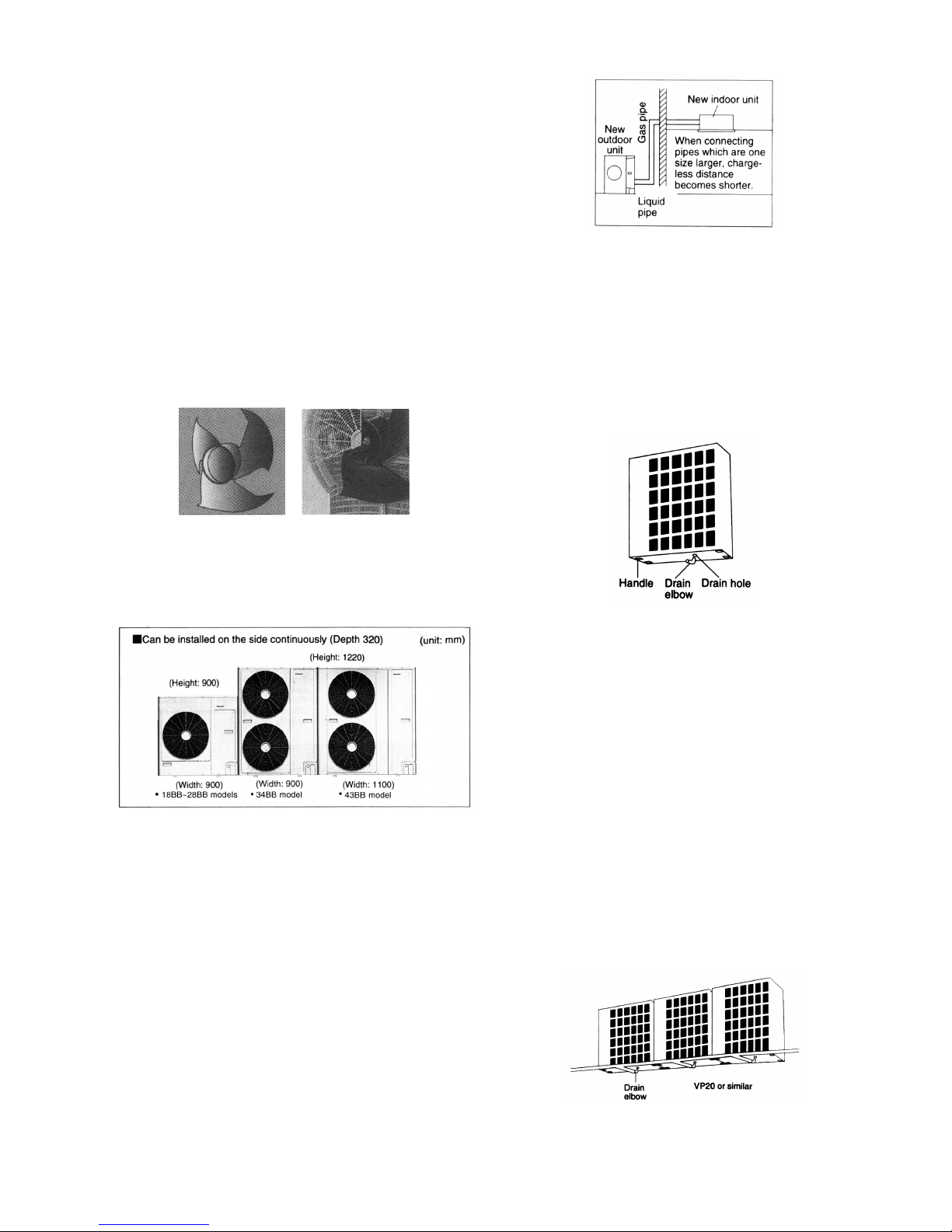

Pipes that are one size larger can also be connected for

renewal.

−

− −

− If renewing the system, existing refrigerant pipes can be

utilized so that only the indoor and outdoor units need to

be replaced.

−

− −

− For example, liquid and gas pipes from 10 years ago

can be connected to current pipes with the same size or

one size larger. Effective utilization of materials reduces

working time and trouble. (Adaptor sockets are not

supplied.)

•

• •

•

Additional refrigerant charging unnecessary for 30 m

−

− −

− All models do not require any additional charging of

refrigerant for 30 m of pipe length. This makes

installation much easier.

•

• •

•

Drain water dripping-prevention structure

−

− −

− The base of the outdoor unit is provided with a single

drain hole in order to prevent drain water from leaking

out of the unit. By connecting a drain elbow and a

discharge pipe, water leakages can be prevented even

when the unit is installed to a wall.

•

• •

•

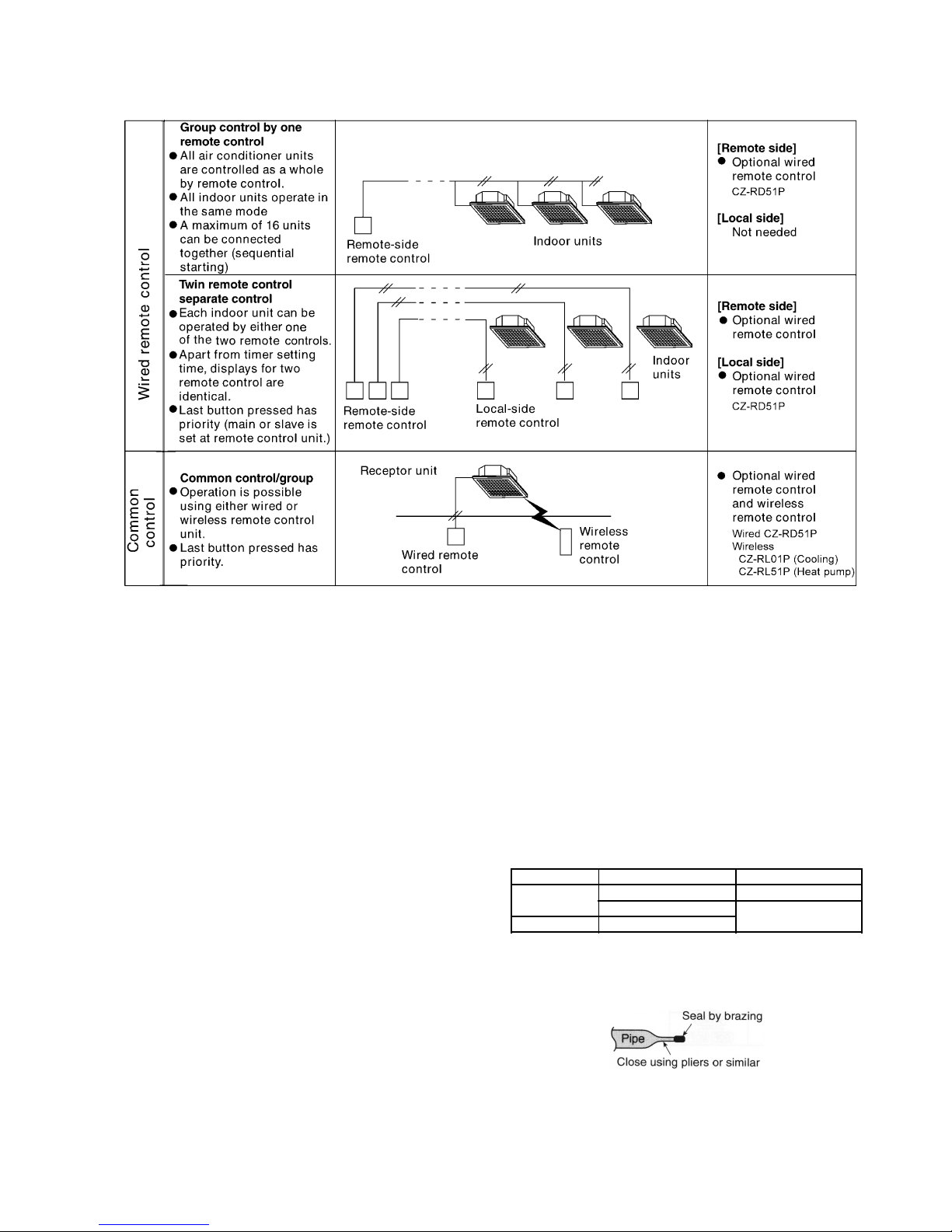

Save space design allows units to be installed side-byside continuously

−

− −

− Servicing after installation can be carried out by

removing the front covers.

•

• •

•

Long pipe design for refrigerant pipes

−

− −

− Maximum piping length of 50m for all models.

•

• •

•

Internal pipe connection

−

− −

− Pipes are connected inside the units (inside the side

covers), making the final appearance more attractive.

−

− −

− Pipes can be diverted outward in any of four directions

(forward, right, down, rear).

−

− −

− Small liquid pipe diameters of 9.52mm for 34BB model,

making installation work much easier.

•

• •

•

Centralized draining method

−

− −

− Even when multiple outdoor units are installed to a wall,

the drain outlets can be concentrated into a single drain

pipe. This makes installation easier and also improves

appearance.

5

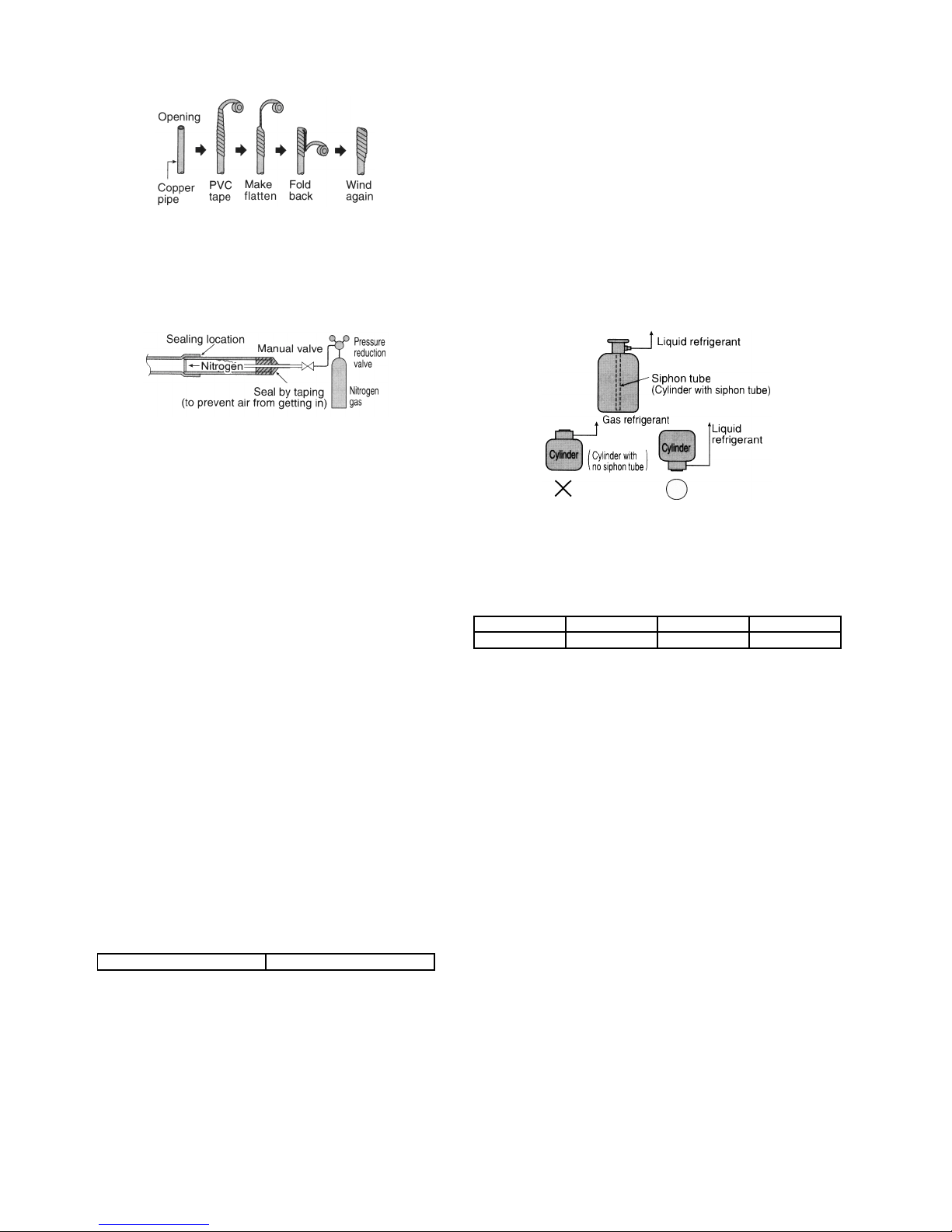

2.4. A brand-new control method

using the latest in technology

•

• •

• Easier power supply wiring connection

Power supply wiring and other wiring tasks can be carried

out more easily.

−

− −

− Twin non-polar wires used to connect indoor and

outdoor units.

−

− −

− Adoption of connection error prevention circuits for drive

wires and signal wires. If a connection error is made, the

relay does not operate and current does not flow to the

circuit boards.

•

• •

•

Twin and Triple operation

−

− −

− Simultaneous air conditioning of wide spaces and

corners is possible. Indoor units of different

horsepowers can even be used in combination.

−

− −

− Master unit and slave-units can be set automatically in

twin and triple systems. No address setting is

necessary.

−

− −

− Multiple indoor units can be operated simultaneously

with a single remote control. Note that individual

operation is not possible.

•

• •

•

Separate indoor/outdoor unit power supplies

The power supply can be connected to (1) just the outdoor

units, or (2) to both the indoor and outdoor units.

•

• •

•

Easy test operation

Test operation can be carried out for both indoor and

outdoor units.

•

• •

•

Automatic setting initialization function

(Remote control

and Indoor unit)

In accordance with the indoor and outdoor units connected

and the connection methods, conditions such as the

connection configuration (twin or triple format) and remote

control functions such as automatic louvre operation and

cooling or heating mode are automatically detected and set

instantly.

2.5. Wired Remote Control

•

• •

• The new design includes an easily-visible red pilot lamp.

The power can be turned on and off at a single touch,

without opening the cover.

•

• •

• Has a built-in thermistor, allowing indoor temperature

detection in accordance with indoor conditions by switching

with main unit thermistor.

•

• •

• Twin non-polar wires make installation work easy. (10 m

cable supplied as accessory.)

2.6. Wireless Remote Control

•

• •

• New design with compact size. (Operation range within

approximately 8 m.)

•

• •

• Built-in timer with ON/OFF timer setting (within 24 hours)

Wired Wireless

Heat Pump CZ-RD51P CZ-RL51P

Cooling CZ-RD51P CZ-RL01P

NOTE: Both of the above remote control is packed separately

from the indoor unit.

6

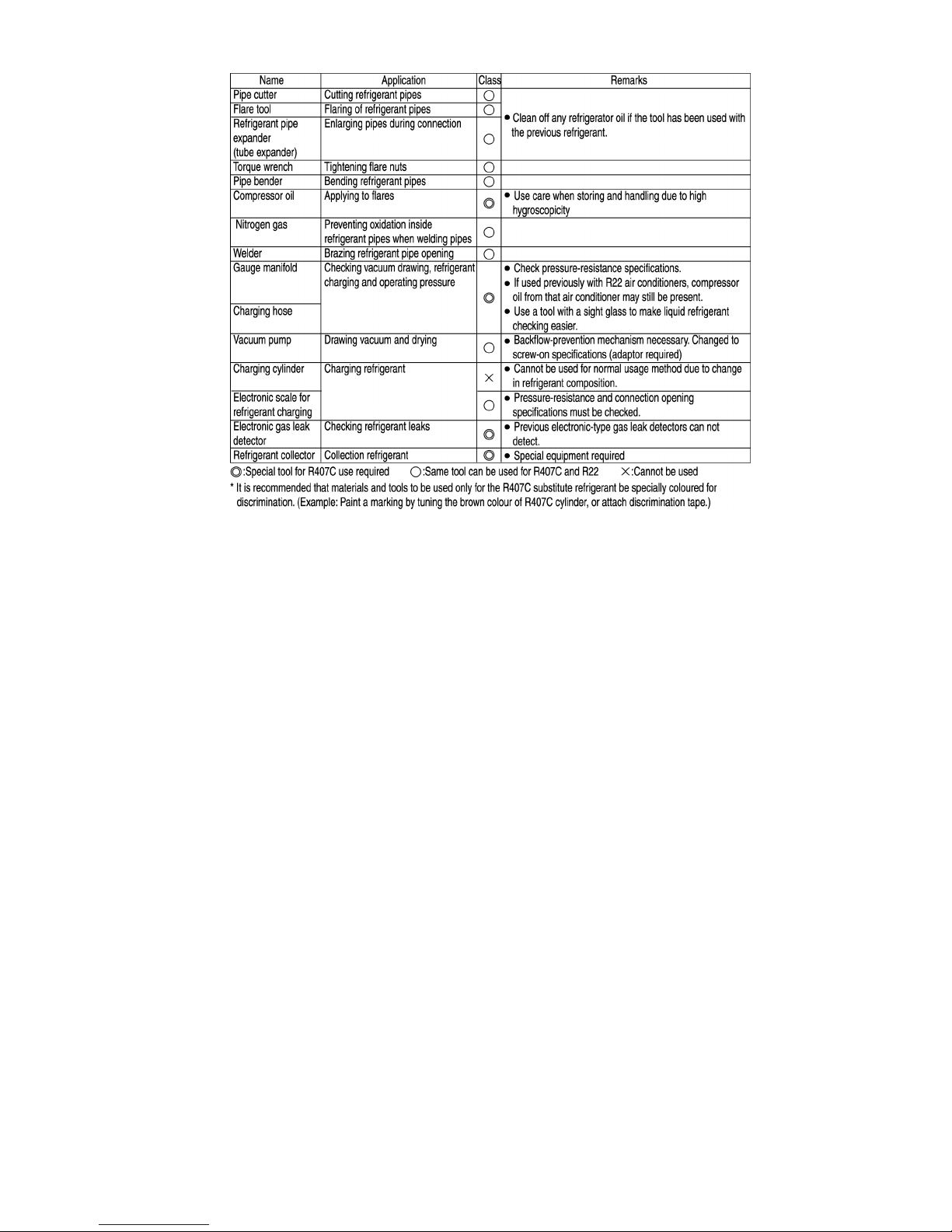

2.8. New refrigerant Series [R407C]

pipe installation

2.8.1. Procedure

•

• •

• The new refrigerant (R407C) has a different composition to

the previously-used refrigerant (R22), so some contents

and method of pipe installation and charging work are

different from before. Care should be taken when carrying

out this work.

2.8.2. Installation and precautions

2.8.2.1. Before installation

1. Determine the installation division.

2. Check the refrigerant to be used.

•

• •

• Check that the refrigerant is R407C.

•

• •

• Check that the gauge pressure is at a maximum of 3.3

MPa.

3. Make a drawing of the Installation.

2.8.2.2. Installation

1. Install the sleeve and the insert.

2. Install the indoor unit.

3. Install the refrigerant piping.

•

• •

• Pipe materials (Phosphours Deoxidization Seamless

Pipe)

•

• •

• Refrigerant pipes which were previously used to carry

R22 must not be re-used. If replacing the indoor and

outdoor units, be sure to replace all refrigerant pipes

also.

•

• •

• Check the pipe thickness.

(1/4, 3/8, 1/2 : t = 0.8mm 5/8, 3/4 : t = 1.0mm)

•

• •

• Clean the inside of the pipes.

•

• •

• When storing pipes, seal both ends of the pipes and

store them indoors to prevent water, dust and other

foreign particles from getting inside.

•

• •

• Take care not to let any foreign particles (oxide scales,

water or dirt) get inside the refrigerant lines (same as for

R22).

■

Refrigerant pipe storing

Location Installation period Storing method

Outdoors 1 month or more Pinching

Less than 1 month Pinching or taping

Indoors Any

•

• •

• Pinching method

Close off the ends of the pipes with pliers or similar tool

and seal the opening by brazing.

•

• •

• Taping method

Wind PVC tape around the ends of the pipes to seal the

2.7. Group Control Equipment

7

openings.

•

• •

• Do not work for refrigerant piping on outdoor on rainy

days.

•

• •

• Seal by brazing.

•

• •

• Be sure to use only a non-oxidizing brazing material.

(Use nitrogen. Anti-oxidants cannot be used.)

•

• •

• When brazing pipes together, or when brazing copper

pipes and copper joints, use a brazing material (Bcup-3)

which does not require flux.

•

• •

• Flare processing and ester oil.

•

• •

• Sealing can be improved by applying ester oil or mineral

oil (the minimum amount necessary) to flares and flange

connections.

•

• •

• Due to the high hygroscopic tendency for ester oil, do

not mix or use any other impurities. (This can cause

deterioration of the compressor oil and problems with

the compressor.)

•

• •

• After preparing the refrigerant pipes, close both ends of

the pipes by brazing if not immediately connecting them.

•

• •

• A torque wrench must be used.

4. Install the drain pipe.

5. Install the ducts.

6. Insulate against heat.

7. Carry out the electrical work.

•

• •

• Connecting cables and power cables.

8. Make all necessary settings.

9. Prepare the outdoor unit foundation.

10. Install the outdoor unit.

11. Air-tightness test.

For the final check, there should be no pressure drop when

3.3 MPa is applied for 24 hours.

12. Vacuum drying.

Vacuum draw time 60 min. or more

* Vacuum pump capacity 60 l/min. or higher

•

• •

• D rawing the vacuum will remove any moisture.

•

• •

• The pressure after vacuum drawing should be 755

mmHg or less.

•

• •

• Use a special vacuum pump (with backflow-prevention

mechanism).

•

• •

• Gas must never be used for air purging.

13. Additional refrigerant charging.

•

• •

• Check that refrigerant volume is correct.

•

• •

• Be sure to charge refrigerant in liquid state.

•

• •

• Always charge in liquid state.

When the refrigerant is charged from the cylinder, the

composition may change greatly (compounds which do

not easily evaporate may remain inside the cylinder), so

the refrigerant must always be charged in a liquid state.

(It is recommended that a manifold with sight glass be

used.)

■ Boiling point at normal atmospheric pressure

(reference)

Refrigerant HFC32 HFC125 HFC134a

Boiling point -52°C -49°C -26°C

•

• •

• Use a special gauge manifold and charging hose.

•

• •

• If refrigerant leaks occur, replace all of the refrigerant

(same as for R22).

•

• •

• Note that a R22 leak detector cannot be use to detect

leaks.

•

• •

• Refer to the Installation Instructions included for the

correct charging amount.

•

• •

• Make a note of additional refrigerant charging amounts

in the record table.

14. Test operation and adjustment.

15. Organize documentation before handover.

16. Handover and explanation of operation.

•

• •

• Ventilation of closed rooms

R407C is a non-flammable refrigerant with low toxicity,

but in the gas state its specific gravity is heavier than

that of air, and so if leaks occur in a closed room,

suffocation may occur. Toxic gases may also be

generated if it comes into direct contact with flames, so

adequate ventilation must be provided.

8

9

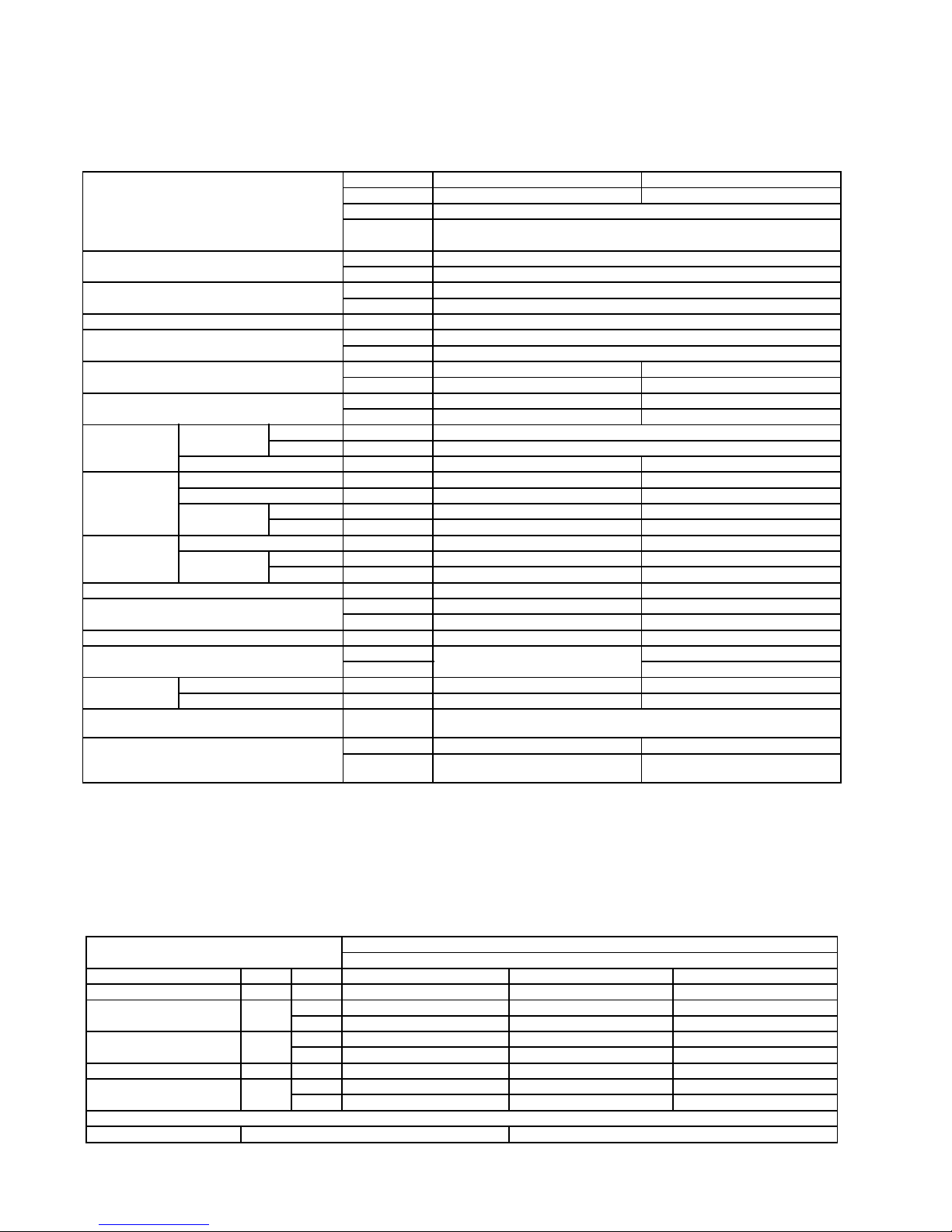

3 SPECIFICATION (HEAT PUMP TYPE )

3.1. CS-W34BB4P / CU-W34BBP5

ITEM / MODEL Indoor Unit Outdoor unit

Main Body CS-W34BB4P CU-W34BBP5

Panel CZ-BT01P

Remote CZ-RD51P (Wired)

Control CZ-RL51P (Wireless)

Cooling Capacity kW 10.0

BTU/h 34,100

Heating Capacity kW 11.2

BTU/h 38,200

Refrigerant Charge-less m 30

Standard Air Volume for High Speed m3/min 23

cfm 812

Outside Dimension (H x W x D) mm 290 x 840 x 840 1220 x 900 x 320

inch 11-7/16 x 33-1/24 x 33-1/24 48-1/24 x 35-7/16 x 12-19/32

Net Weight kg 30 97

lbs 66 214

Piping

Connection

Refrigerant Gas mm (inch) O.D Ø 19.05 (3/4) Flared Type

Liquid mm (inch) O.D Ø 9.52 (3/8) Flared Type

Drain mm O.D Ø 32 I.D Ø 20 x 1

Compressor Type, Number of Set - Hermetic-1 (Rotary), 1

Starting Method - Direct on-line starting

Motor Type - 2-pole 1-phase induction motor

Rated Output kW - 3.0

Fan Type, Number of Set Turbo fan Propeller fan

Motor Type 6-pole single phase induction motor 6-pole single phase induction motor

Rated Output kW 0.05 0.05 x 2

Air-heat Exchanger Slit-fin type X-Louvre-fin type

Refrigerant Control Cool Capillary tube -

Heat - Capillary tube

Refrigerant Oil (Charged) litre - MMMAPOE (1.2)

Refrigerant (Charged) kg - R407C (3.2)

(oz) (113)

Running

Adjustment

Control Switch Wireless or Wired Remote Control Room Temperature Thermostat (Main Body) -

Safety Devices Internal protector for compressor, Internal thermostat for fan motor,

Crankcase heater, High and heating pressure switch, Current transformer

Noise Level dB (A) Hi 45 Lo 41 Cooling 56, Heating 58

Power level dB Cooling : Hi 60 Lo 56

Heating : Hi 60 Lo 56

Cooling 69, Heating 71

1. Cooling capacities are based on indoor temperature of 27°C D.B. (80.6°F D.B.), 19.0°C W.B. (66.2°F W.B.) and outdoor air

temperature of 35°C D.B. (95°F D.B.), 24°C W.B. (75.2°F W.B.)

2. Heating capacities are based on indoor temperature of 20°C D.B. (68°F D.B.) and outdoor air temperature of 7°C D.B. (44.6°F

D.B.), 6°C W.B. (42.8°F W.B.)

ELECTRICAL DATA (50Hz)

ITEM / MODEL CS-W34BB4P, CU-W34BBP5

Condition by JIS B 8615

Volts V 220 230 240

Phase Single Single Single

Power Consumption kW Cool 3.88 3.88 3.88

Heat 4.07 4.07 4.07

Running Current A Cool 18.6 18.7 18.8

Heat 18.7 18.8 18.9

Starting Current A 94 99 103

Power Factor % Cool 95 90 86

Heat 99 94 90

*Power Factor means total figure of compressor, indoor fan motor and outdoor fan motor.

Panasonic Power source AC, 1~220V, 230V, 240V 50Hz

10

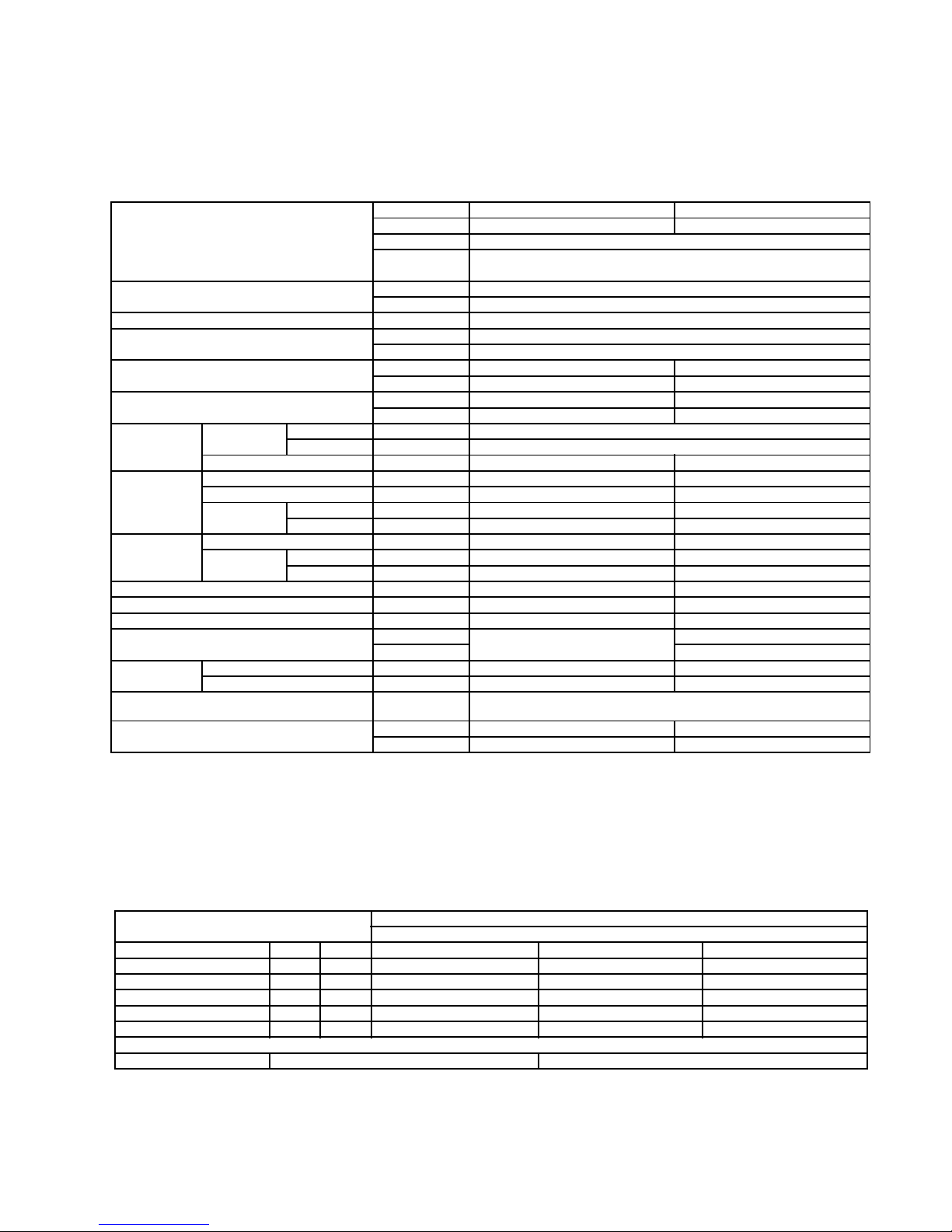

4 SPECIFICATION (COOLING ONLY TYPE )

4.1. CS-W34BB4P / CU-V34BBP5

ITEM / MODEL Indoor Unit Outdoor unit

Main Body CS-W34BB4P CU-V34BBP5

Panel CZ-BT01P

Remote CZ-RD51P (Wired)

Control CZ-RL01P (Wireless)

Cooling Capacity kW 10.0

BTU/h 34,100

Refrigerant Charge-less m 30

Standard Air Volume for High Speed m3/min 23

cfm 812

Outside Dimension (H x W x D) mm 290 x 840 x 840 1220 x 900 x 320

inch 11-7/16 x 33-1/24 x 33-1/24 48-1/24 x 35-7/16 x 12-19/32

Net Weight kg 30 95

lbs 66 209

Piping

Connection

Refrigerant Gas mm (inch) O.D Ø 19.05 (3/4) Flared Type

Liquid mm (inch) O.D Ø 9.52 (3/8) Flared Type

Drain mm O.D Ø 20 I.D Ø 20 x 1

Compressor Type, Number of Set - Hermetic-1 (Rotary), 1

Starting Method - Direct on-line starting

Motor Type - 2-pole 1-phase induction motor

Rated Output kW - 3.0

Fan Type, Number of Set Turbo fan Propeller fan

Motor Type 6-pole single phase induction motor 6-pole single phase induction motor

Rated Output kW 0.05 0.05 x 2

Air-heat Exchanger Slit-fin type X-Louvre-fin type

Refrigerant Control Capillary tube Capillary tube

Refrigerant Oil (Charged) litre - MMMAPOE (1.3)

Refrigerant (Charged) kg - R407C (3.2)

(oz) (113)

Running

Adjustment

Control Switch Wireless or Wired Remote Control Room Temperature Thermostat (Main Body) -

Safety Devices Internal protector for compressor, Internal thermostat for fan motor,

Crankcase heater, High pressure switch, Current transformer

Noise Level dB (A) Hi 45 Lo 41 56

Power level dB Hi 60 Lo 56 69

1. Cooling capacities are based on indoor temperature of 27°C D.B. (80.6°F D.B.), 19.0°C W.B. (66.2°F W.B.) and outdoor air

temperature of 35°C D.B. (95°F D.B.), 24°C W.B. (75.2°F W.B.)

ELECTRICAL DATA (50Hz)

ITEM / MODEL CS-W34BB4P, CU- V34BBP5

Condition by JIS B 8615

Volts V 220 230 240

Phase Single Single Single

Power Consumption kW Cool 3.88 3.88 3.88

Running Current A Cool 18.6 18.7 18.8

Starting Current A 94 99 103

Power Factor % Cool 95 90 86

*Power Factor means total figure of compressor, indoor fan motor and outdoor fan motor.

Panasonic Power source AC, 1~220V, 230V, 240V 50Hz

11

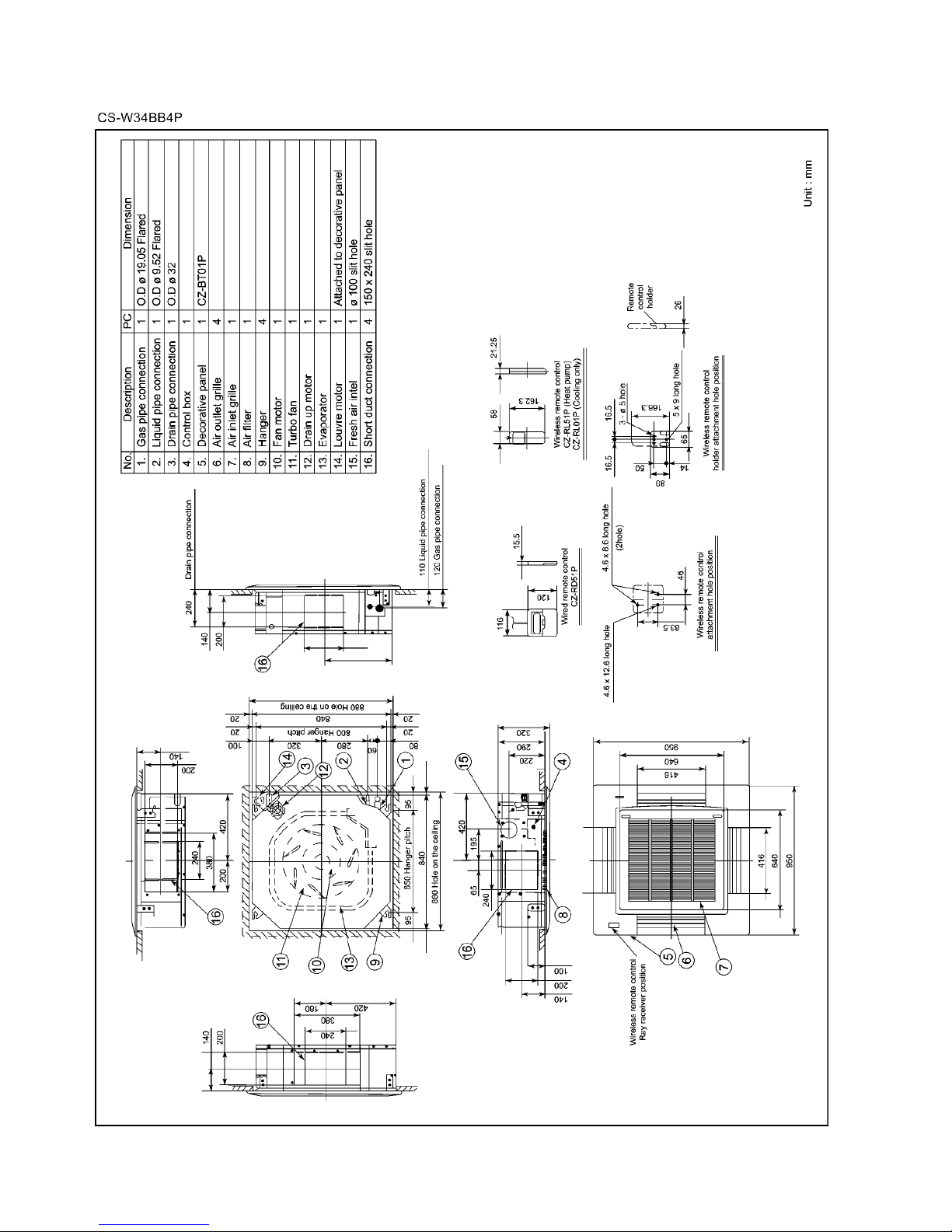

5 TECHNICAL DRAWING

12

13

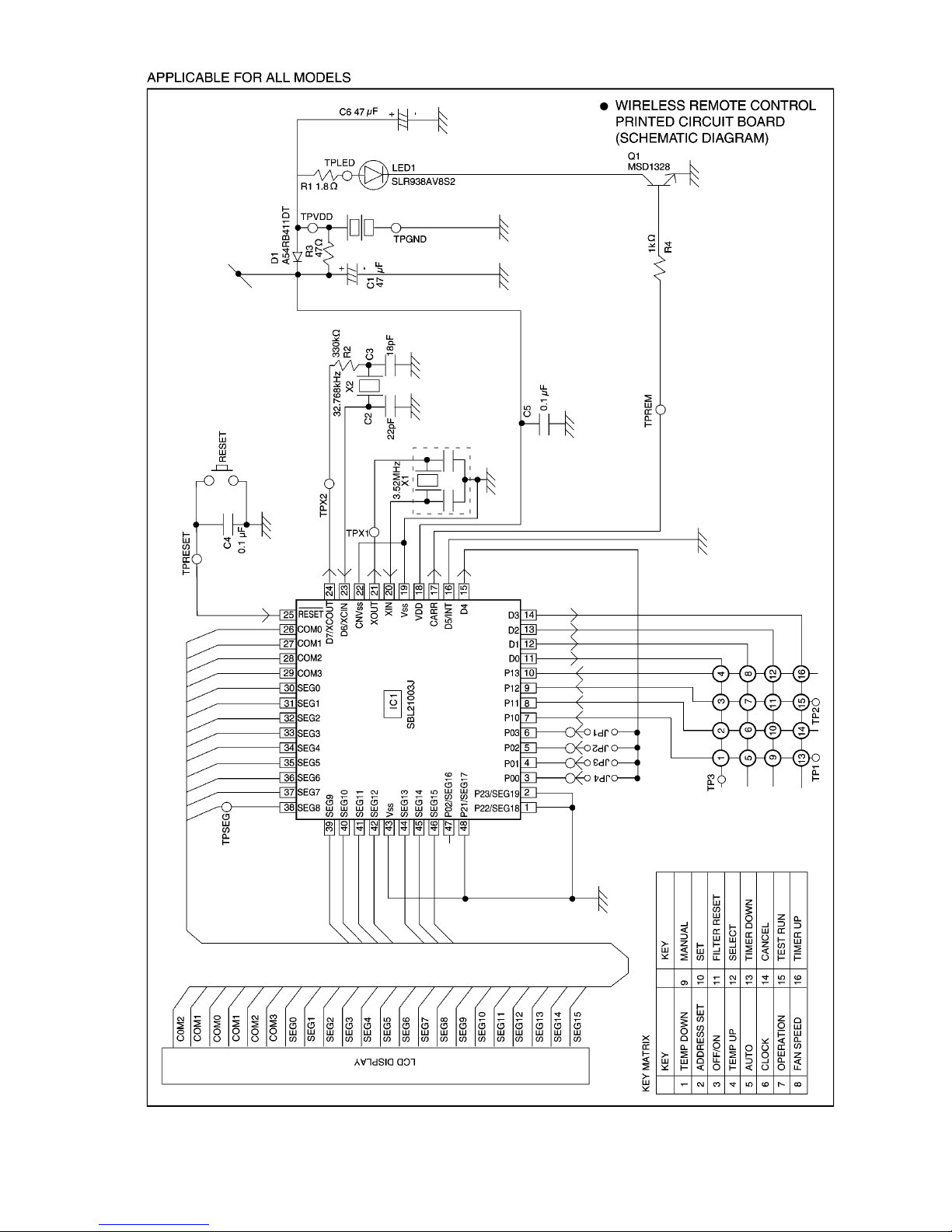

6 CIRCUIT DIAGRAM

14

15

16

17

18

19

20

21

22

23

24

25

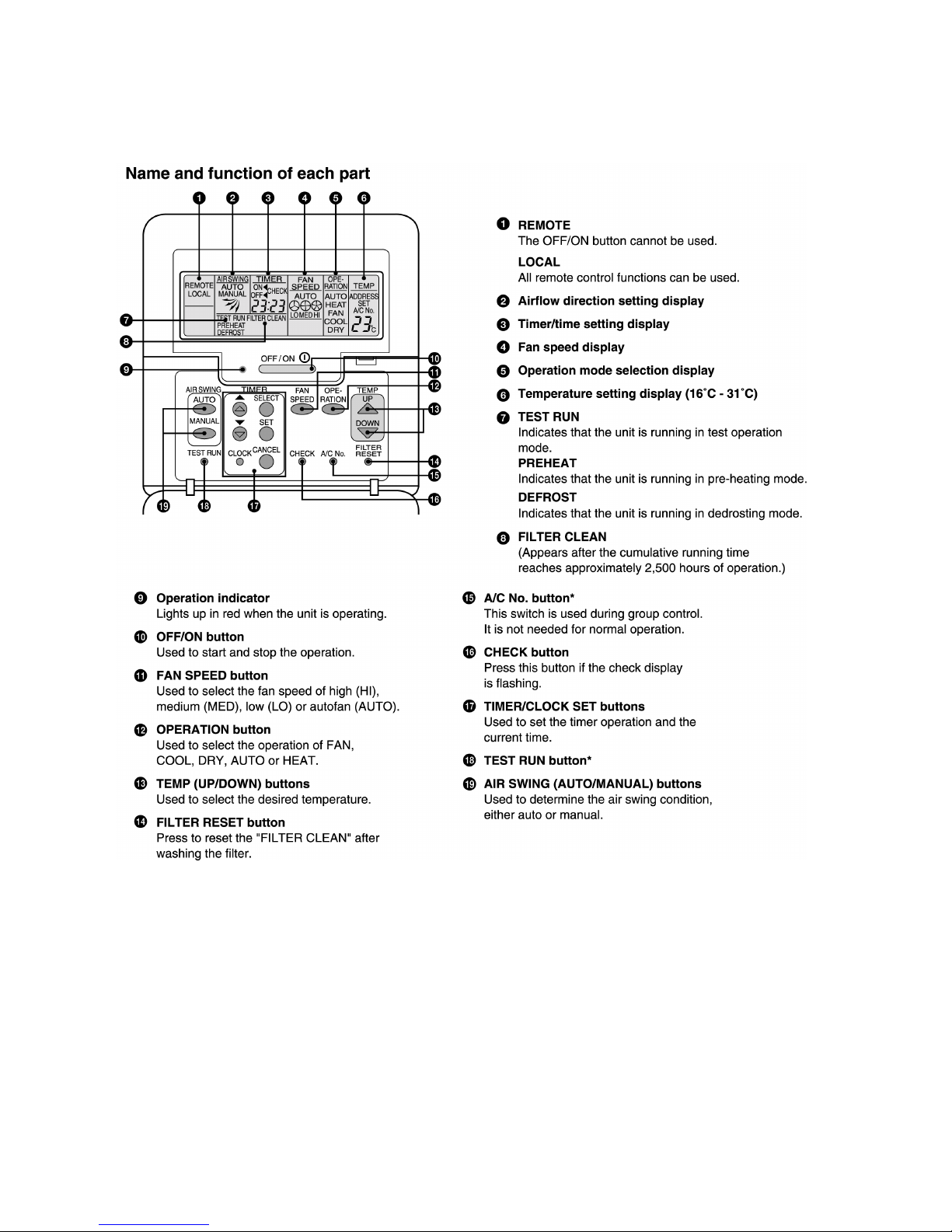

7 OPERATING INSTRUCTION

7.1. Wired Remote Control (OPTIONAL PARTS)

NOTES:

•

• •

• Ensure that the correct button is pressed as simultaneous pressing of the multiple buttons will not make the setting correct.

•

• •

• The illustration above is for explanatory purposes only. The appearance will be different during actual operation.

•

• •

• Do not operate the remote control with wet hands. Otherwise, electric shock or malfunction may occur.

•

• •

• Do not press the remote control buttons with sharp object as this may damage the remote control.

•

• •

• Buttons marked with * are not needed for normal operation. If one of these buttons is pressed by mistake, press the same

button once more to cancel the operation.

•

• •

• When the power resumed after power failure, the unit will restart automatically with all the previous settings preserved by the

memory function. (Auto restart function)

26

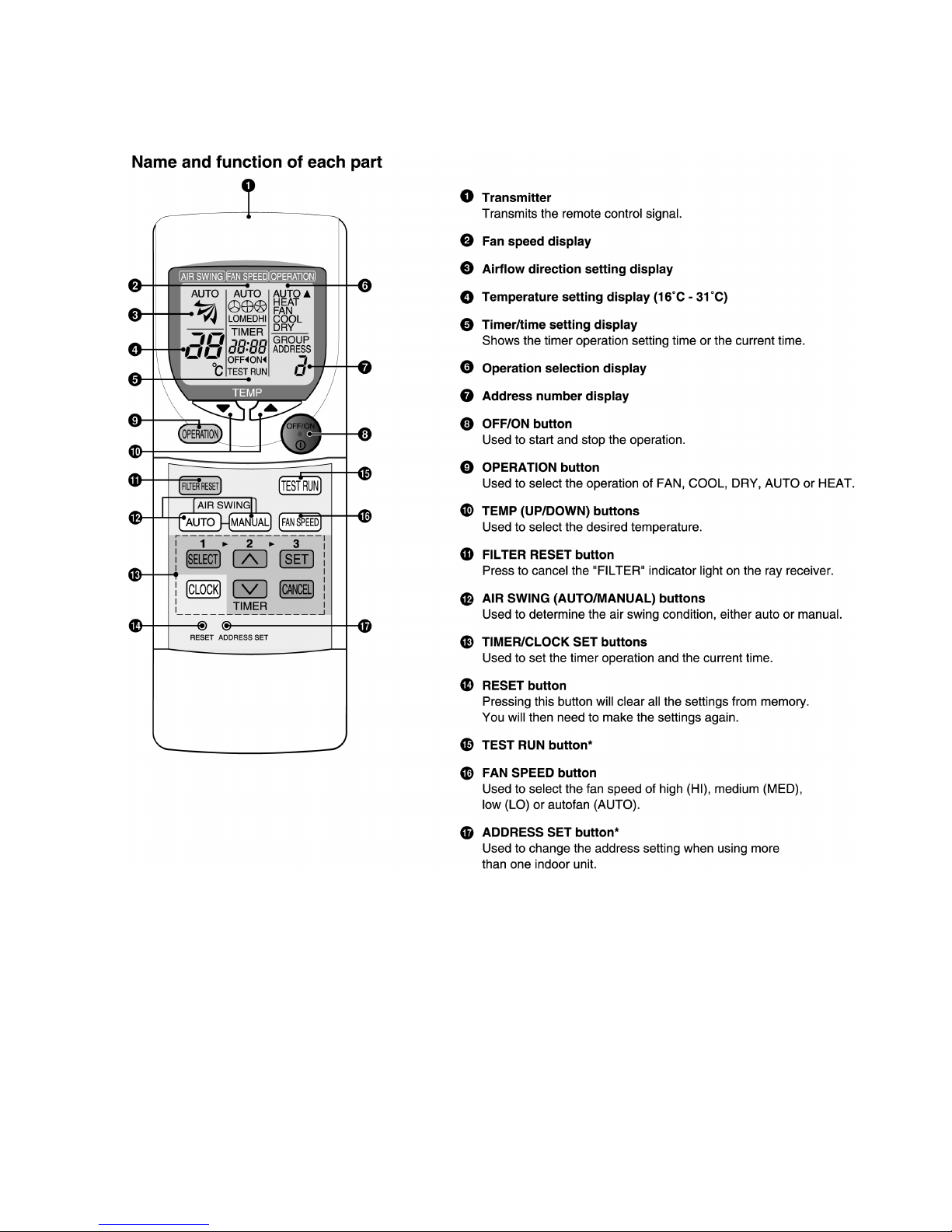

7.2. Wireless Remote Control (OPTIONAL PARTS)

NOTES:

•

• •

• Ensure that the correct button is pressed as simultaneous pressing of the multiple buttons will not make the setting correct.

•

• •

• The illustration above is for explanatory purpose only. The appearance will be different during actual operation.

•

• •

• If using the wireless remote control in conjunction with the wired remote control, the settings made from the wireless remote

control will appear on the wired remote control display (except when making timer settings).

•

• •

• Buttons marked with * are not needed for normal operation. If one of these buttons is pressed by mistake, press the same

button once more to cancel the operation.

•

• •

• When the power resumed after power failure, the unit will restart automatically with all previous settings preserved by the

memory function. (Auto restart function)

27

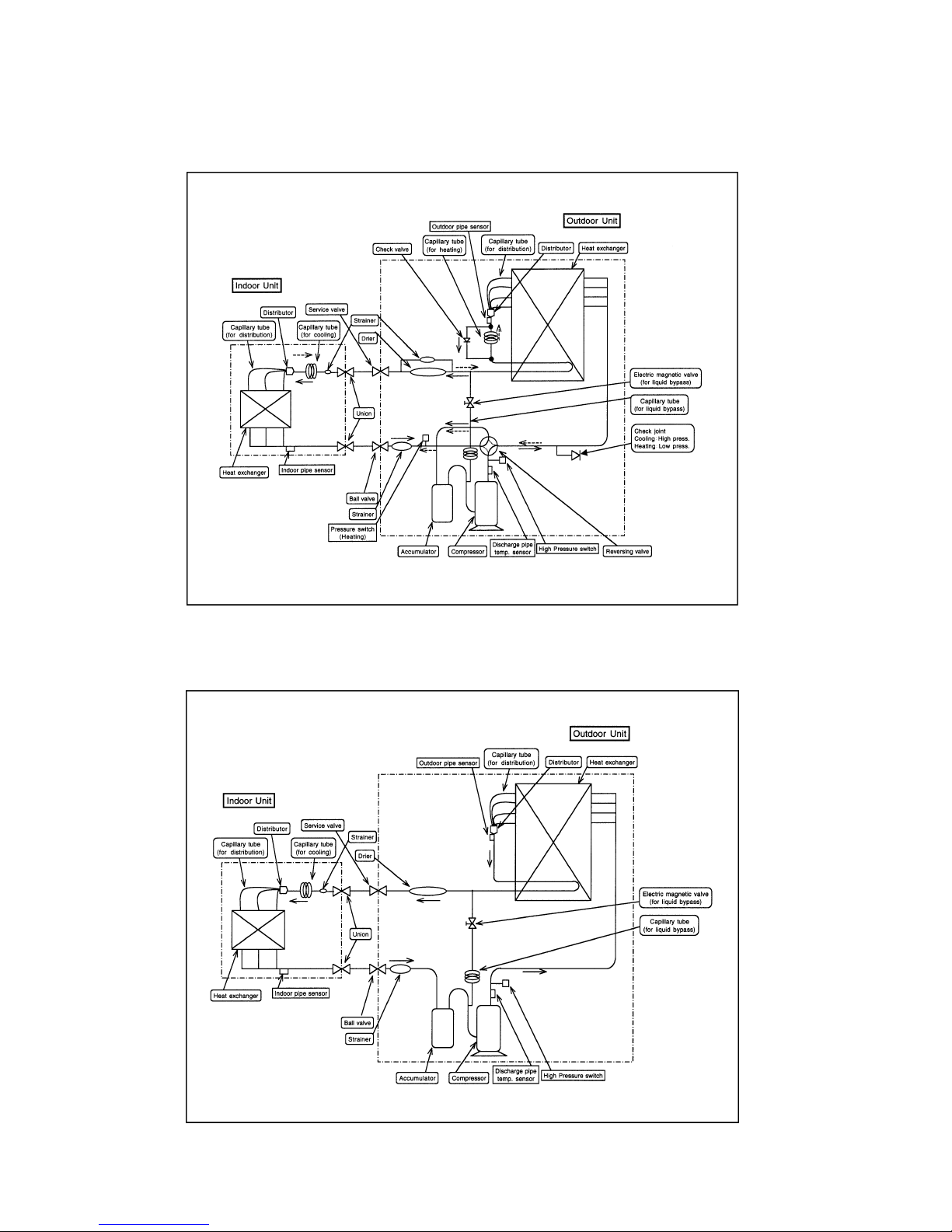

8 REFRIGERATION CYCLE

8.1. Heating Model

CS-W34BB4P / CU-W34BBP5

8.2. Cooling Only Model

CS-W34BB4P / CU-V34BBP5

28

9 OPERATION RANGE

Power Supply

The applicable voltage range for each unit is given in the following table. The working voltage among the three phases must be

balanced within a 3% deviation from each voltage at the compressor terminals. The starting voltage must be higher than 85% of

the rated voltage.

Power Supply

MODEL

Unit Main Power Applicable Voltage

Phase, Volts Hz Max Min

CU-W/V34BBP5 1~220 50 242 198

1~230 50 253 207

1~240 50 264 216

Indoor and Outdoor Temperature

•

• •

• Cooling only type

Model (50Hz) V34BBP5

Operating Hz Indoor Temp. (D.B./W.B.) (°C) Outdoor Temp. (D.B./W.B.) (°C)

Max Min Max Min

Cooling 50 32/23 21/15 43/- -5/-

•

• •

• Heat pump type

Model (50Hz) W34BBP5

Operating Hz Indoor Temp. (D.B./W.B.) (°C) Outdoor Temp. (D.B./W.B.) (°C)

Max Min Max Min

Cooling 50 32/23 21/15 43/- -5/Heating 50 27/- 16/- 24/18 -10/-

29

10 PIPE LENGTH

■■■■

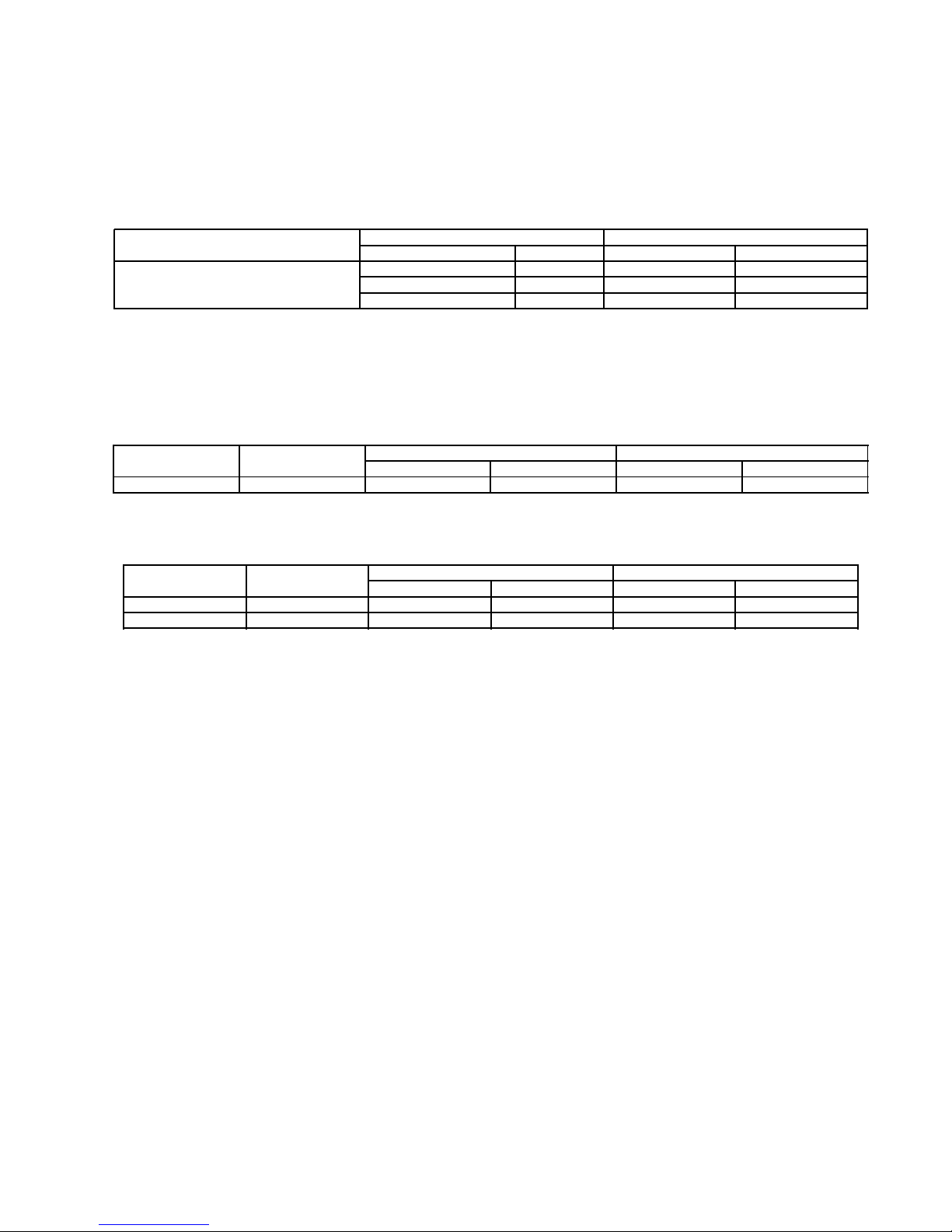

CORRECTION OF COOLING CAPACITY AND HEATING CAPACITIES

Correction of cooling and heating capacities according to the connecting pipe length.

The data of cooling capacities (marked on the name plate) are based on 5 meters connecting pipe and horizontal installation.

For other pipe length of other installation multiply by the following correction factor to determine the revised cooling capacity.

■■■■

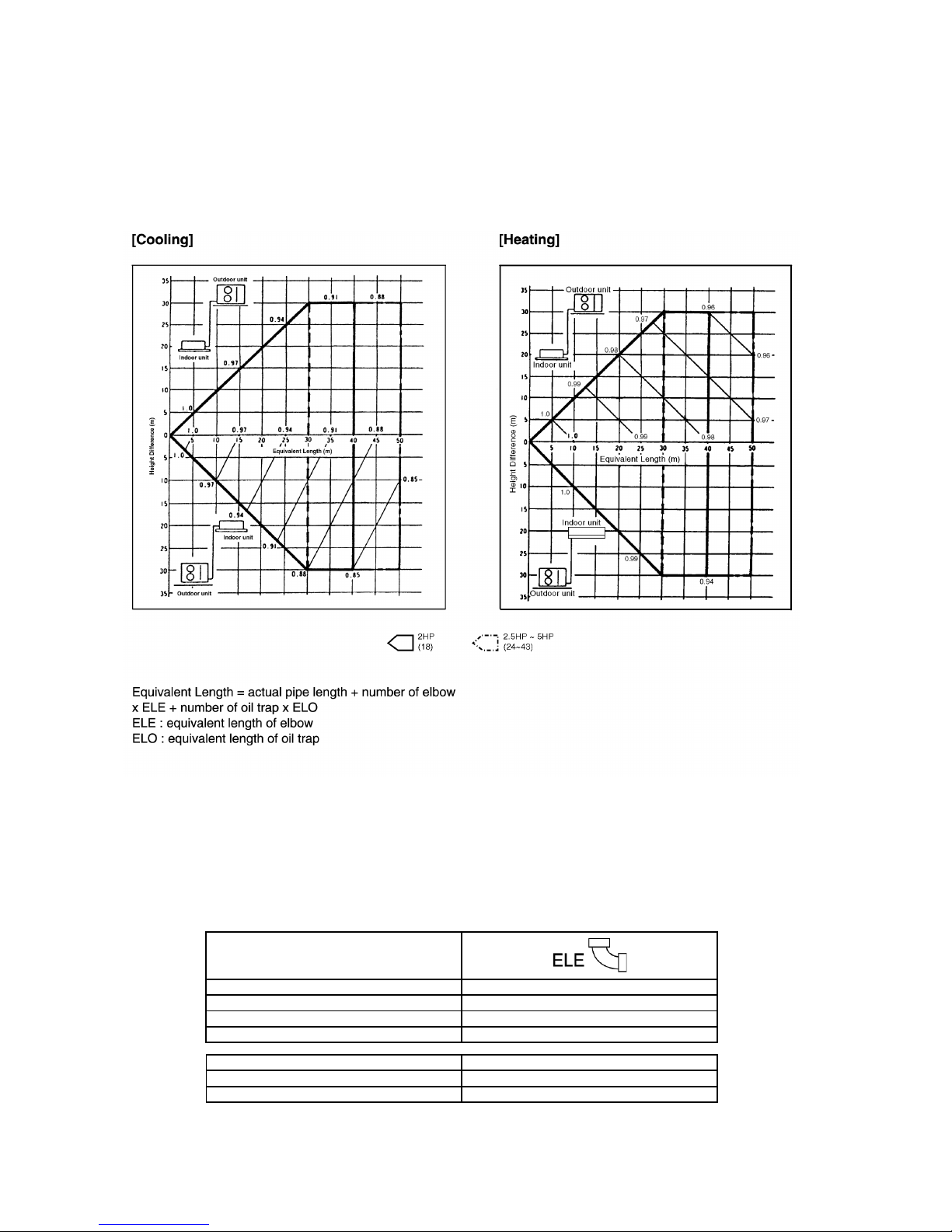

REFRIGERANT ADDITIONAL CHARGE

•

• •

•

The piping length exceeds 30 metres.

APPLICABLE FOR ALL MODELS

Before shipment, this air conditioner is filled with the rated amount of refrigerant subject to 30m piping length. (The rated

amount of refrigerant is indicated on the name plate.) But when the piping length exceeds 30m, additional charge is required

according to the following table.

Outer diameter of gas side pipe mm (inch)

9.52 (3/8) 0.18

12.7 (1/2) 0.20

15.88 (5/8) 0.25

19.05 (3/4) 0.35

Model Ref. Charge

2.0~2.5HP 20g per 1m

3~5HP 50g per 1m

30

Loading...

Loading...