Panasonic CS/CU-YW9DKE, CS/CU-YW12DKE Service Manual

CS/CU-YW9DKE

CS/CU-YW12DKE

Air Conditioner

WARNING

This service information is designed for experienced repair technicians only and is not designed for use by the general public.

It does not contain warnings or cautions to advise non-techical individuals of potential dangers in attempting to service a product.

Products powered by electricity should be serviced or repaired only by experienced professional technicians. Any attempt to service

or repair the product or products dealt with in this service information by anyone else could result in serious injury or death.

1 Features 2

2 Functions 3

3 Product Specifications 6

4 Dimensions 11

5 Refrigeration Cycle Diagram 12

6 Block Diagram 13

7 Wiring Diagram 14

8 Operation Details 15

9

Installation instructions

29

10 Installation and Serving Air Conditioner Using R410A -----

11

Disassembly of The Parts

12 Troubleshooting Guide

13 Technical Data

14 Exploded View

15 Replacement Parts List

16 Exploded View

17 Replacement Parts List

18 Electronic Circuit Diagram

CONTENTS

Page Page

Order No.

Guangzhou Matsushita Air Conditioner Co., Ltd.

(GMAC) All rights reserved. Unauthorized copying

and distribution is violation of law.

C

R

49

50

53

55

58

59

60

61

62

------------------------------------------------------

--------------------------------------------------------

------------------------------------------

-----------------------------------------------------

-----------------------------------

--------------------------------------------------

-------------------------------------------------

-----------------------------------------------

---------------------------------------------------

--------------------------------------

----------------------------------------

--------------------------------------------------

--------------------------------------------------

-----------------------------------------

--------------------------------------------------

-----------------------------------------

--------------------------------------

R

OFF

MODE TEMP

OFF/ON

ON

CANCEL SET

STD

TIMER

FANSPEED

AIRSWING

GMAC0504037C3

2

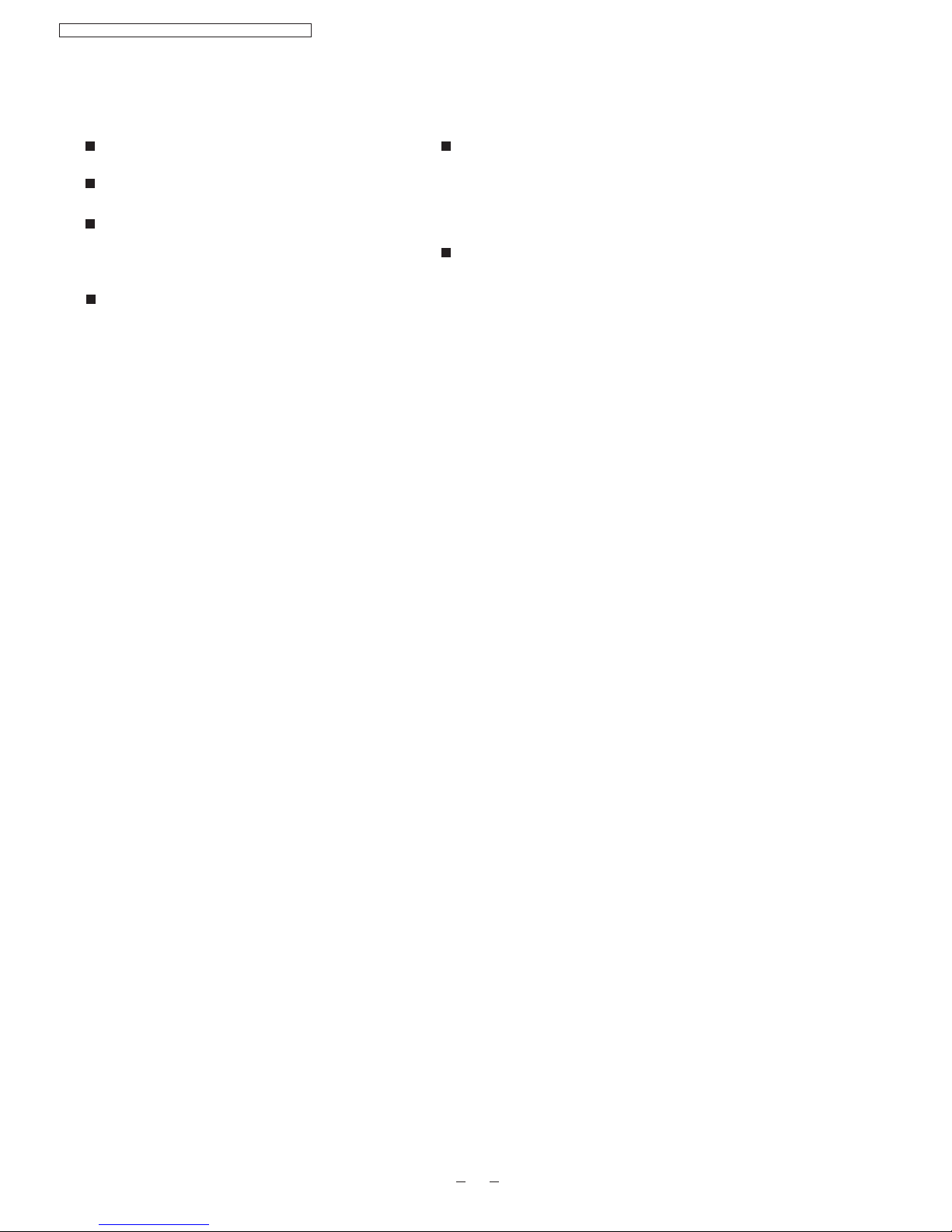

1 Features

High Efficiency

Air Quality Indicator

Comfort Environment

Air filter with function to reduce dust and smoke

Auto Restart Control

Automatically restart after power failure

CS-YW9DKE / CU-YW9DKE / CS-YW12DKE / CU-YW12DKE

Enviromental Friendly (For Refrigerant : R410A Model)

12-hour Timer Setting

Zero ozone depleting potential and low global

warming potential by using R410A refrigerant.

Operation START/STOP

Operation Mode Selection

Automatic Operation

Heating Mode Operation

Cooling Mode Operation

Soft Dry Mode Operation

Mode

Indoor Fan Speed Selection

Low Speed

Medium Speed

High Speed

Automatic Speed

Airflow Direction Control

Horizontal Airflow Direction Control

-Auto Control

-Manual Control

Vertical Airflow Direction Manual Control

Room Temperature Setting

Temperature Setting(16 to 30 )

Auto Operation

Timer Operation Selection

Stop/Start Operation Control

(set the ON/OFF Timer hourly later)

Set /Cancel Timer Operation

Set timer/Cancel the set timer

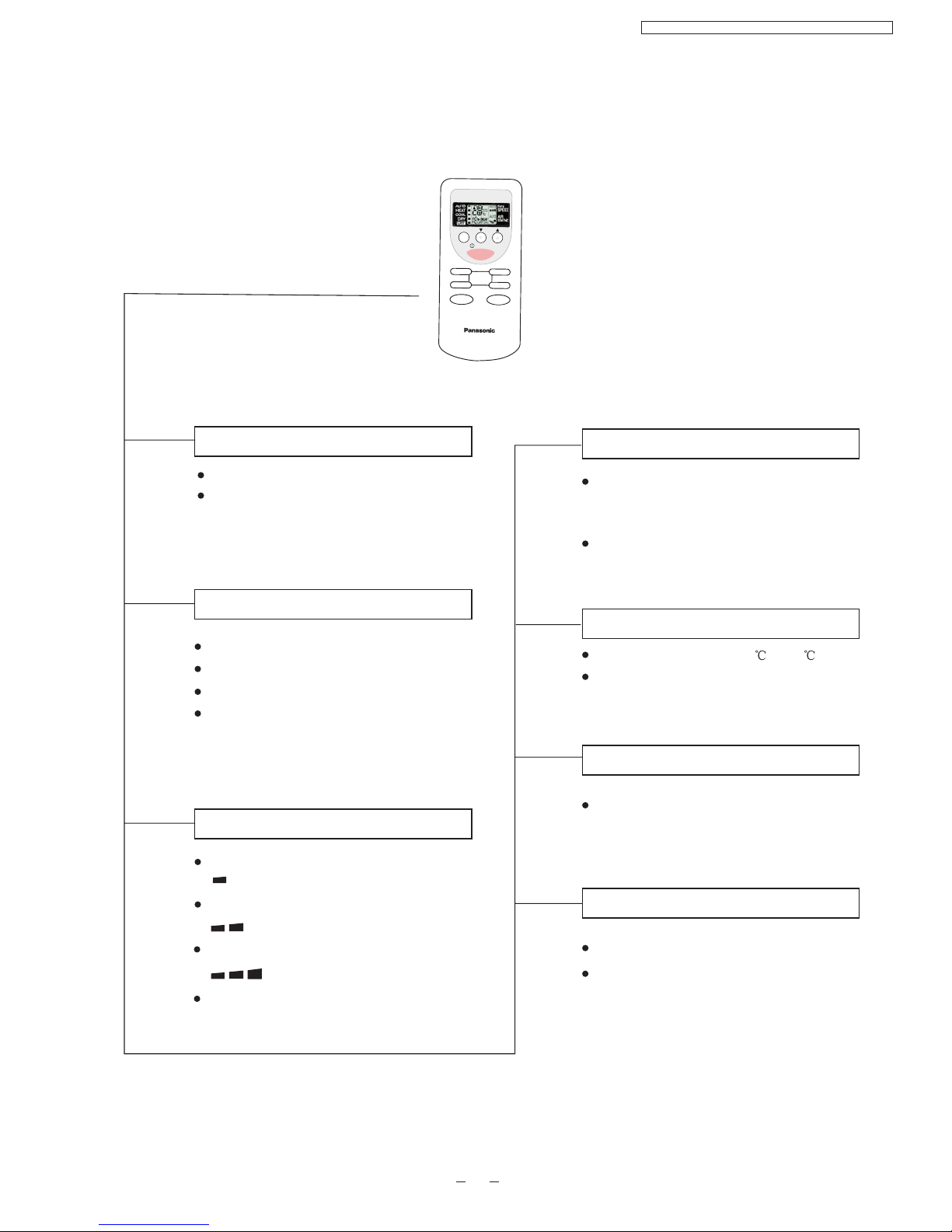

2 Functions

Remote Control

3

OFF/ON

MODE

FAN

SPEED

AIR

SWING

TEMP

TIMER

OFF/ON

TIMER

SET/

CANCEL

OFF

MODE TEMP

OFF/ON

ON

CANCEL SET

STD

TIMER

FANSPEED

AIRSWING

Turn on/off the air conditionor

When stop the operation by pressing

OFF/ON button,the cursor key points

to OFF.

By pressing SET button for 5seconds

continuously to switch to set the sensor

sensitivity.

CS-YW9DKE / CU-YW9DKE / CS-YW12DKE / CU-YW12DKE

Indoor Unit

Demonstration Mode

When the remote control cannot be used or

for repairing and testing ,please use this

button.

Power Switch ON/OFF

Signal Receiving Sound Control

Keep pressing this button for 10seconds to turn

on or turn off the signal receiving sound.

Operation Indication Lamps

Power (green)

Timer(orange)

Lights up in operation;

Blinks during Test

Run operation and

determining Auto

Operation mode

Timer in operation

Operation Mode

Cooling/Heating/Soft Dry /Auto Operation

Time Delay Safety Control

The unit will restart operation in 3-4

minutes after each pause.

7-Minutes Time Save Control

7-minutes automatic restarting at Cooling

Operation

National

4

Keep pressing this button for 15seconds to start

or end the Demonstration Mode.

Auto Switch

Button

Air quality

Green

Orange

Red

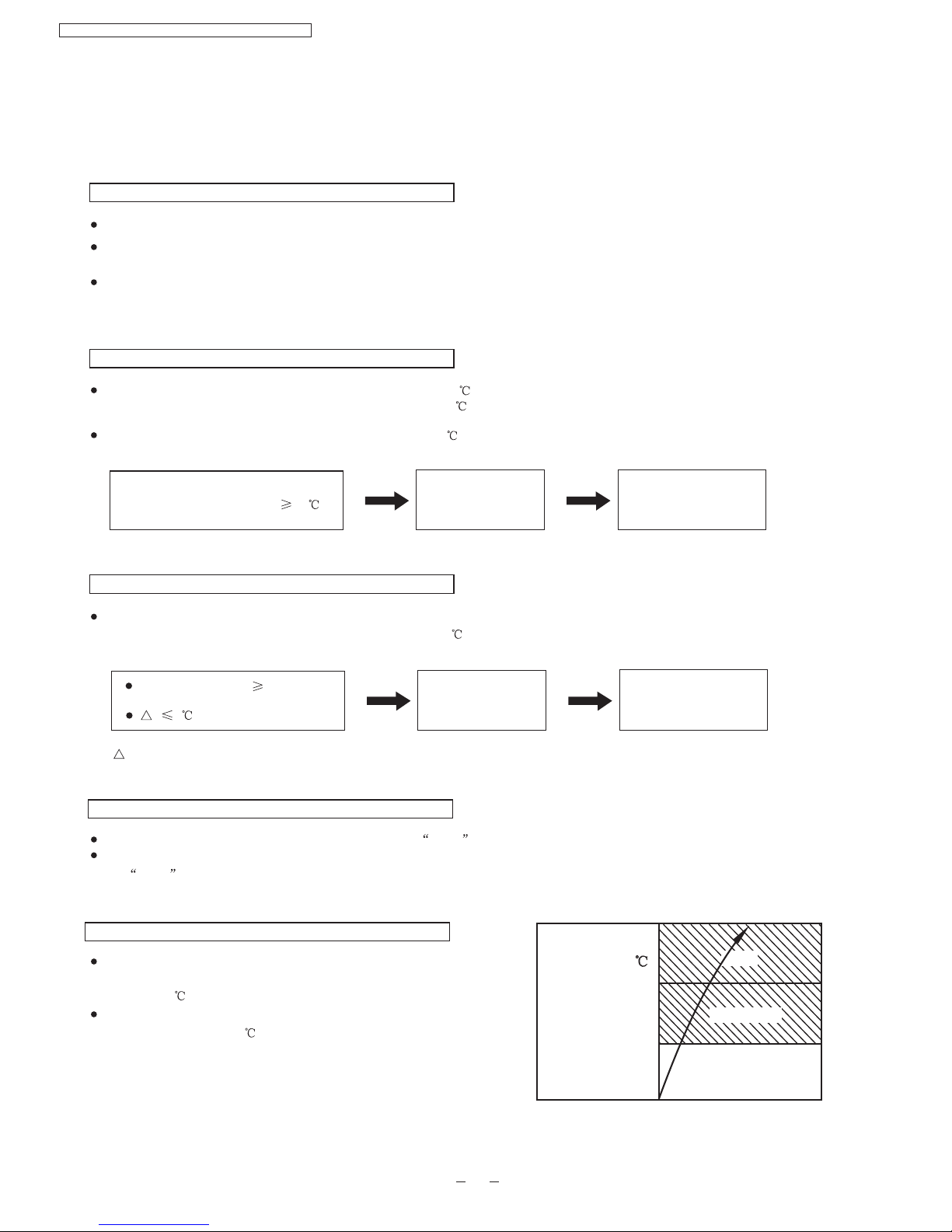

Anti-freezing Control for the Evaporator

Cooling or Soft Dry Operation

Warm Booting Control

Indoor fan starts running when temperature

of evaporator reaches 30 or above.

When temperature of evaporator is between

30 and 34 ,indoor fan will run at Super Low

or Low speed.

When temperature of evaporator reaches 34 ,

Warm Booting Operation ends.

High,Med,Low

Auto Fan Speed

Indoor Fan Speed Control

Automatic Airflow Direction Control

The louver automatically swings up and down

Airflow Direction Manual Control

Airflow Direction Control

Delayed On-timer Control

For cooling or soft dry mode, the unit

starts 15 minutes before the set time with

the remote control, but for heating mode

30 minutes before the set time.

CS-YW9DKE / CU-YW9DKE / CS-YW12DKE / CU-YW12DKE

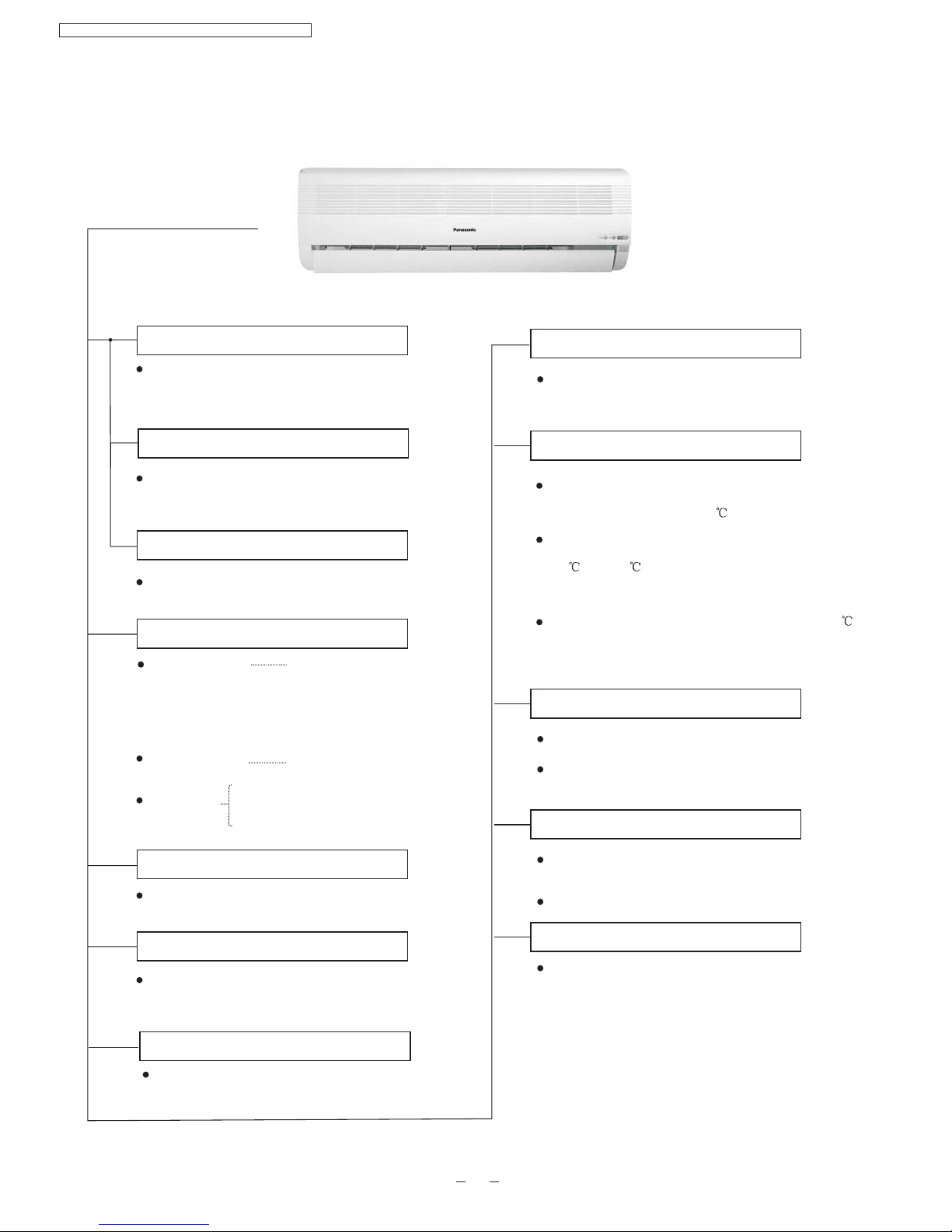

Outdoor Unit

5

Panasonic

Anti-reverse Protection

To protect the compressor from reverse

rotation when power off suddenly.

Overload Protector

The 2-step Overload Protector is to protect

the compressor when

1)Temperature of compressor reaches 153

(YW9DKE) or

2)High temperature or current enters into the

compressor

146 (YW12DKE)

60-seconds Test Operation Control

Once the compressor is activated, it does not

stop for 60 seconds. It stops immediately with

remote control ON/OFF button.

Anti-freezing operation for outdoor unit

(during Heating Mode Operation only)

Temperature of the condenser is tested

by TRS.

Deicing Control

4-way Valve Control

If the unit is stopped during Heating

Operation,the 4-way valve will remain in

heating mode operation for 5 minutes.

CS-YW9DKE / CU-YW9DKE / CS-YW12DKE / CU-YW12DKE

Overload Protection Control

When the temperature of evaporator

reaches 51 ,outdoor fan stops,and will

restart when the temperature of evaporator

declines to 49 .

When the temperature of evaporator

reaches 65 ,compressor will stop.

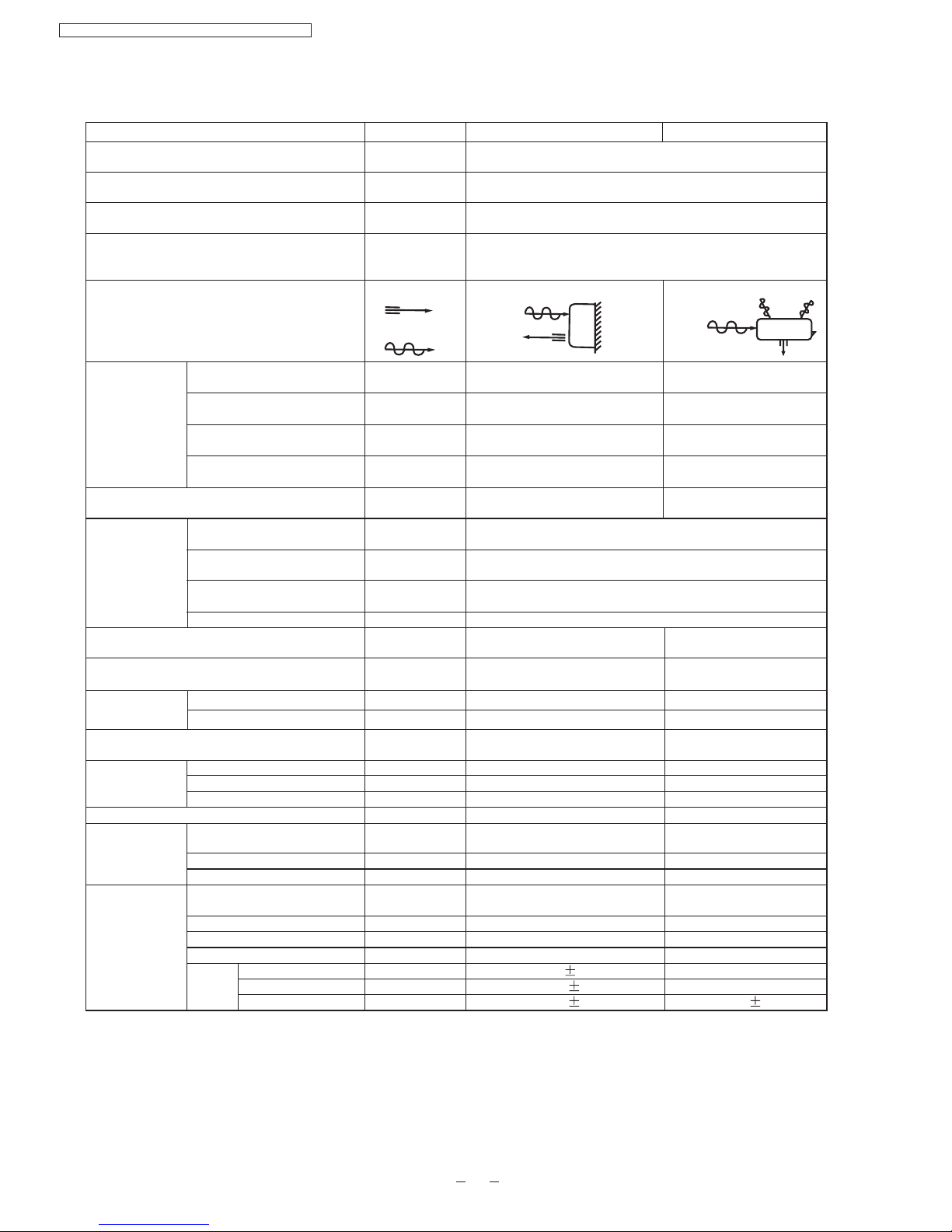

Cooling Capacity

Heating Capacity

Moisture Removal

Power Source

Airflow Method

Air Circulation

Indoor Air (low)

Indoor Air (medium)

Indoor Air (high)

Outdoor Air

Noise Level

Electrical

Data

Piping Connection Port(Flare piping)

Piping Size(Flare piping)

Drain Hose

Power Supply Cord Length

(Number of core-wire)

Dimensions

Net Weight

Compressor

Air Circulation

Unit

kW

kW

L/h

Phase

V

Cycle

OUTLET

INTAKE

m /min

3

m /min

3

m /min

3

m /min

3

dB(A)

W

A

W/W

A

Input

Running Current

EER/COP

Starting Current

Inner Diameter

Length

Height

Width

Depth

Type

Motor Type

Rated output

type

Motor type

Fan

Speed

Low

Med

High

Rated Output

Input

Inch

Inch

Inch

Inch

mm

m

mm

mm

mm

kg

W

W

W

rpm

rpm

rpm

CS-YW9DKE

CU-YW9DKE

2.65

2.95

1.6

Single

230

50

SIDE VIEW

TOP VIEW

7.34

8.5

9.6

-

-

-

-

Cooling:high48

Heating:high49

Cooling:high39,Low31

Heating:high39,Low31

Cooling:880

Heating:830

Cooling:3.90

Heating:3.70

Cooling:3.01

Heating:3.55

18.4

G:half union3/8

L:half union1/4""

G:gas side3/8"

L:liquid side1/4"

G:3-way valve3/8"

L:2-way valve1/4"

G:gas side3/8"

L:liquid side1/4"

-

-

-

-

-

-

-

m

14

0.5

1.3

3 core-wire/1.0mm

2

250

770

205

7.5

530

650

230

27

-

-

-

Cross-flow fan

Induction(4 pole)

-

13

Rotary(1 cylinder)

Rolling piston type

Induction(2 pole)

750

Propeller fan

Induction(6 pole)

-

28

-

940 60

1090 60

1230 60

-

800 60

-

6

3 Product Specifications

CS-YW9DKE / CU-YW9DKE / CS-YW12DKE / CU-YW12DKE

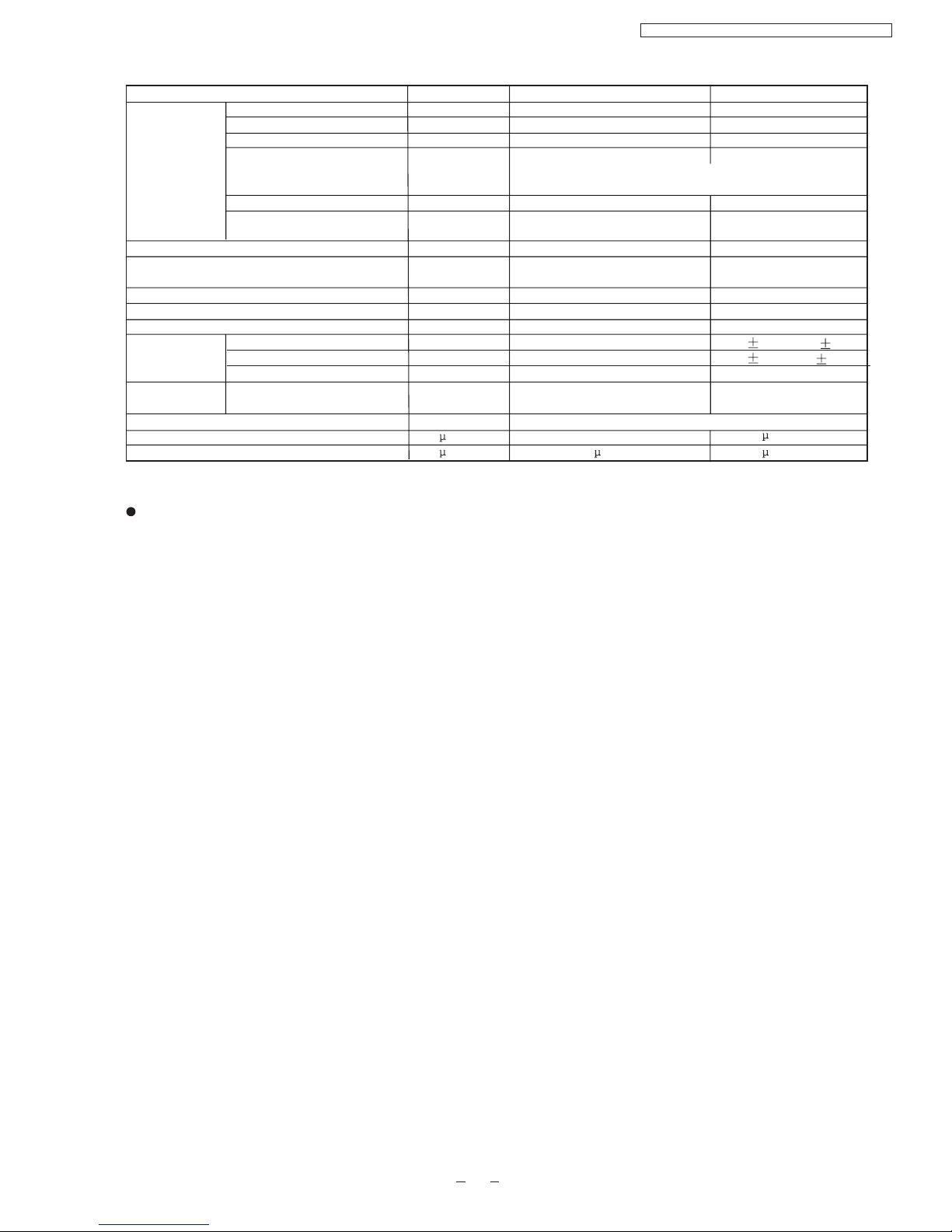

Heat

Exchanger

Description

Tube Material

Fin Type

FPI

Refrigerant Control Device

Refrigeration Oil

Refrigerant (R-22)

Thermostat

Protection Device

Capillary

Air Filter

Refrigerant Circulation Control Device

Compressor Capacitor

Fan Motor Capacitor

Unit CS-YW9DKE CU-YW9DKE

Length

Circulation

Inner Diameter

mm

(c.c)

g

mm

L/min

mm

F,V

F,V

Evaporator

Copper

Slot type

(Plate fin configuration,forced draft)

2x12

2X24

Condenser

Copper

Corrugation type

21

610x252x25.4

-

-

-

-

-

-

-

Electronic Control

P.P. Honeycomb

-

17

Capillary Tube

870(*)

-

O.L.P.(230V,16A)

609 10

10.0 0.2

1.4

F,2.0 400V

Specifications are subject to change without notice for further improvement.

F , 400V

Dimensions

Rows/Stage

Capillary

F,30 370V

1.5

X504x36.38

SUNISO 4GDID or ATMOS

M60 or ATMOS 56M

569.1

540.5

* 60g for air purging is not included.

530 10

7.0 0.2

1.2

7

CS-YW9DKE / CU-YW9DKE / CS-YW12DKE / CU-YW12DKE

8

CS-YW9DKE / CU-YW9DKE / CS-YW12DKE / CU-YW12DKE

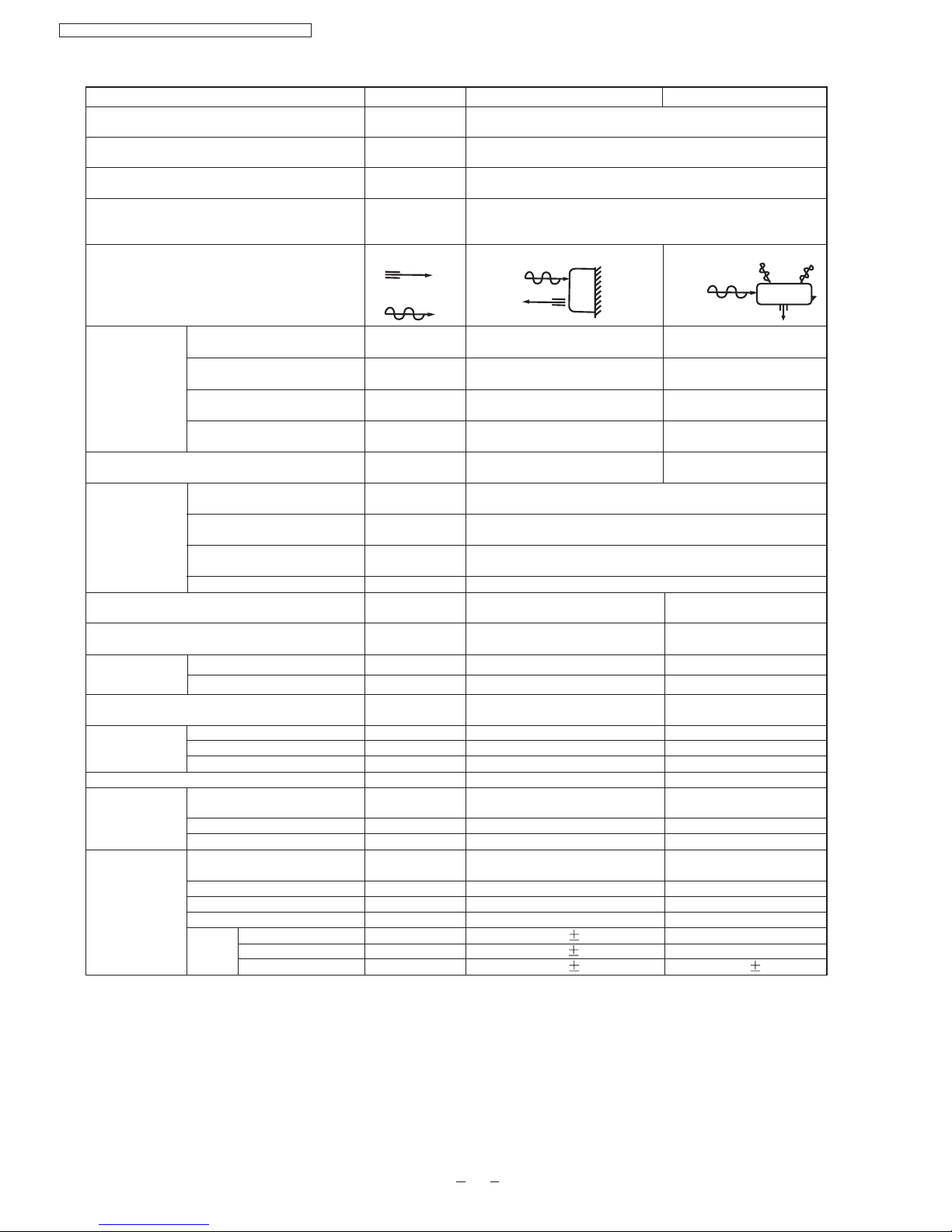

Cooling Capacity

Heating Capacity

Moisture Removal

Power Source

Airflow Method

Air Circulation

Indoor Air (low)

Indoor Air (medium)

Indoor Air (high)

Outdoor Air

Noise Level

Electrical

Data

Piping Connection Port(Flare piping)

Piping Size(Flare piping)

Drain Hose

Power Supply Cord Length

(Number of core-wire)

Dimensions

Net Weight

Compressor

Air Circulation

Unit

kW

kW

L/h

Phase

V

Cycle

OUTLET

INTAKE

m /min

3

m /min

3

m /min

3

m /min

3

dB(A)

W

A

W/W

A

Input

Running Current

EER/COP

Starting Current

Inner Diameter

Length

Height

Width

Depth

Type

Motor Type

Rated output

type

Motor type

Fan

Speed

Low

Med

High

Rated Output

Input

Inch

Inch

Inch

Inch

mm

m

mm

mm

mm

kg

W

W

W

rpm

rpm

rpm

CS-YW12DKE

CU-YW12DKE

3.10

3.60

1.9

Single

230

50

SIDE VIEW

TOP VIEW

7.40

8.34

9.2

-

-

-

-

Cooling:high49

Heating:high50

Cooling:high40,Low33

Heating:high39,Low32

Cooling:1170

Heating:1140

Cooling:5.30

Heating:5.10

Cooling:2.65

Heating:3.16

22.4

G:half union3/8

L:half union1/4""

G:gas side3/8"

L:liquid side1/4"

G:3-way valve3/8"

L:2-way valve1/4"

G:gas side3/8"

L:liquid side1/4"

-

-

-

-

-

-

-

m

14

0.5

1.3

3 core-wire/1.0mm

2

250

770

205

7.5

530

650

230

27

-

-

-

Cross-flow fan

Induction(4 pole)

-

13

Rotary(1 cylinder)

Rolling piston type

Induction(2 pole)

900

Propeller fan

Induction(6 pole)

-

28

-

1030 60

1160 60

1280 60

-

800 60

-

9

CS-YW9DKE / CU-YW9DKE / CS-YW12DKE / CU-YW12DKE

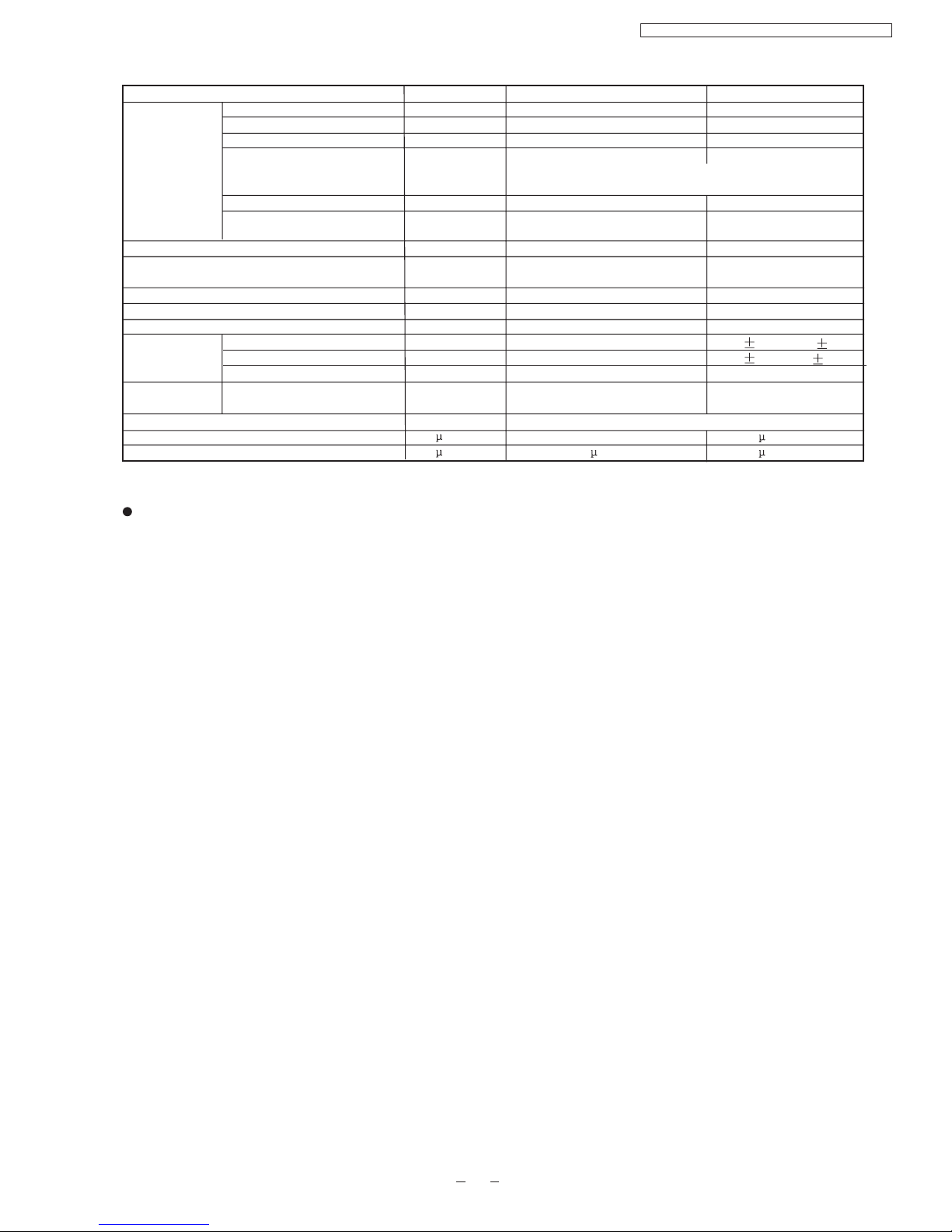

Heat

Exchanger

Description

Tube Material

Fin Type

FPI

Refrigerant Control Device

Refrigeration Oil

Refrigerant (R-22)

Thermostat

Protection Device

Capillary

Air Filter

Refrigerant Circulation Control Device

Compressor Capacitor

Fan Motor Capacitor

Unit CS-YW12DKE CU-YW12DKE

Length

Circulation

Inner Diameter

mm

(c.c)

g

mm

L/min

mm

F,V

F,V

Evaporator

Copper

Slot type

(Plate fin configuration,forced draft)

2x12

2X24

Condenser

Copper

Corrugation type

21

610x252x25.4

-

-

-

-

-

-

-

Electronic Control

P.P. Honeycomb

-

17

Capillary Tube

920(*)

-

O.L.P.(230V,20A)

609 10

10.0 0.2

1.4

F,2.0 400V

Specifications are subject to change without notice for further improvement.

F , 400V

Dimensions

Rows/Stage

Capillary

F,25370V

1.5

X504x36.38

SUNISO 4GDID or ATMOS

M60 or ATMOS 56M

569.1

540.5

* 60g for air purging is not included.

590 10

8.2 0.2

1.3

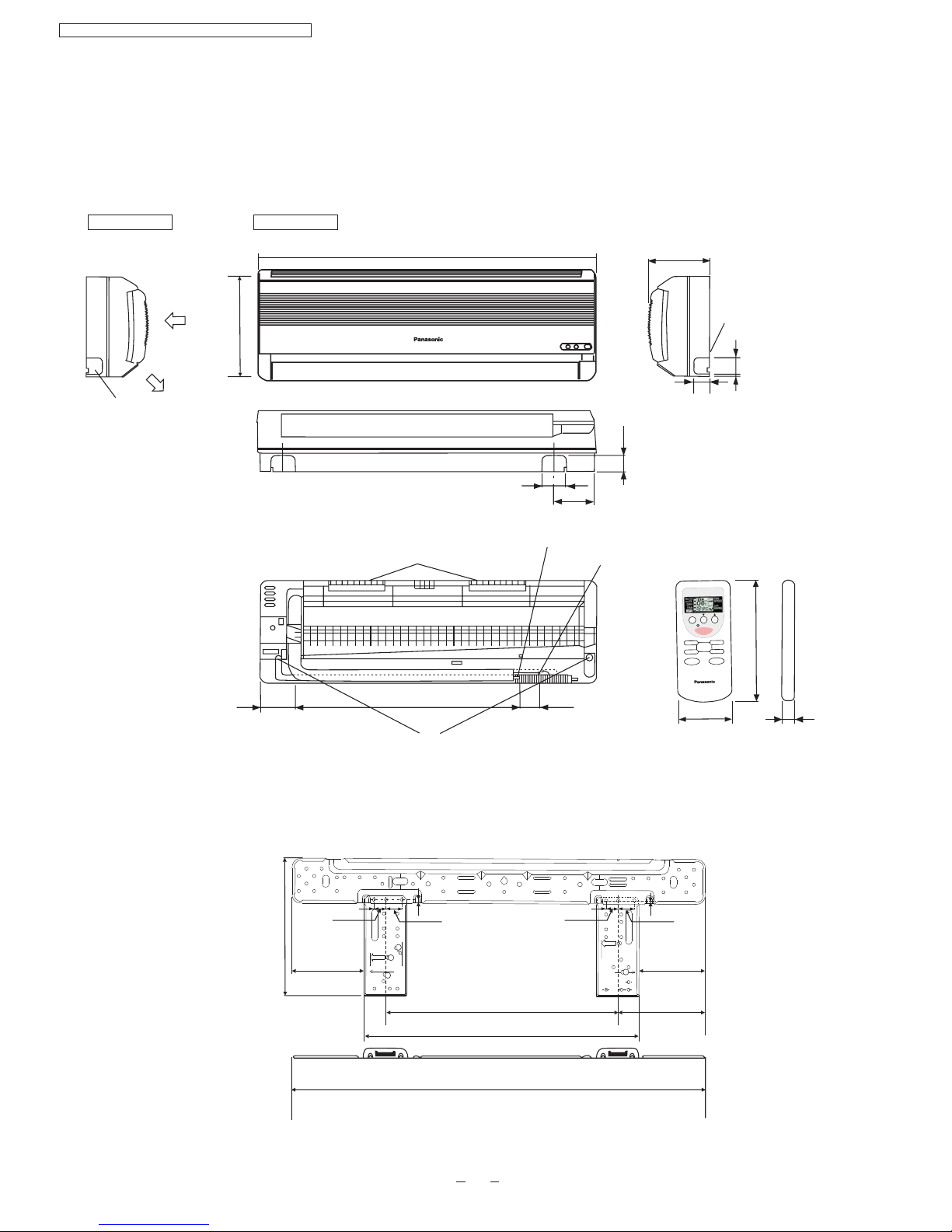

4 Dimensions

Indoor Unit

61

165

49

(410)

(43)

Front View

<Back View>

Installation Plate Hook

Gas Side

Liquid

Side

Relative position between the unit and the installation plate (Front View)

Drain Port

770

Air intake

250

49

61

5

Side view

205

Air outlet

Left Piping

Hole

Right Piping

Hole

(79)

OFF

MODE

TEMP

OFF/ON

ON

CANCEL

SET

STD

TIMER

FANSPEED

AIRSWING

125

16.5

56

B

D

D

229

118.8

6

15.5

20

26.5

(382)

(452)

109.2

144.2

(680)

6

15.5

20

26.5

Unit : mm

E

B

C

B

10

CS-YW9DKE / CU-YW9DKE / CS-YW12DKE / CU-YW12DKE

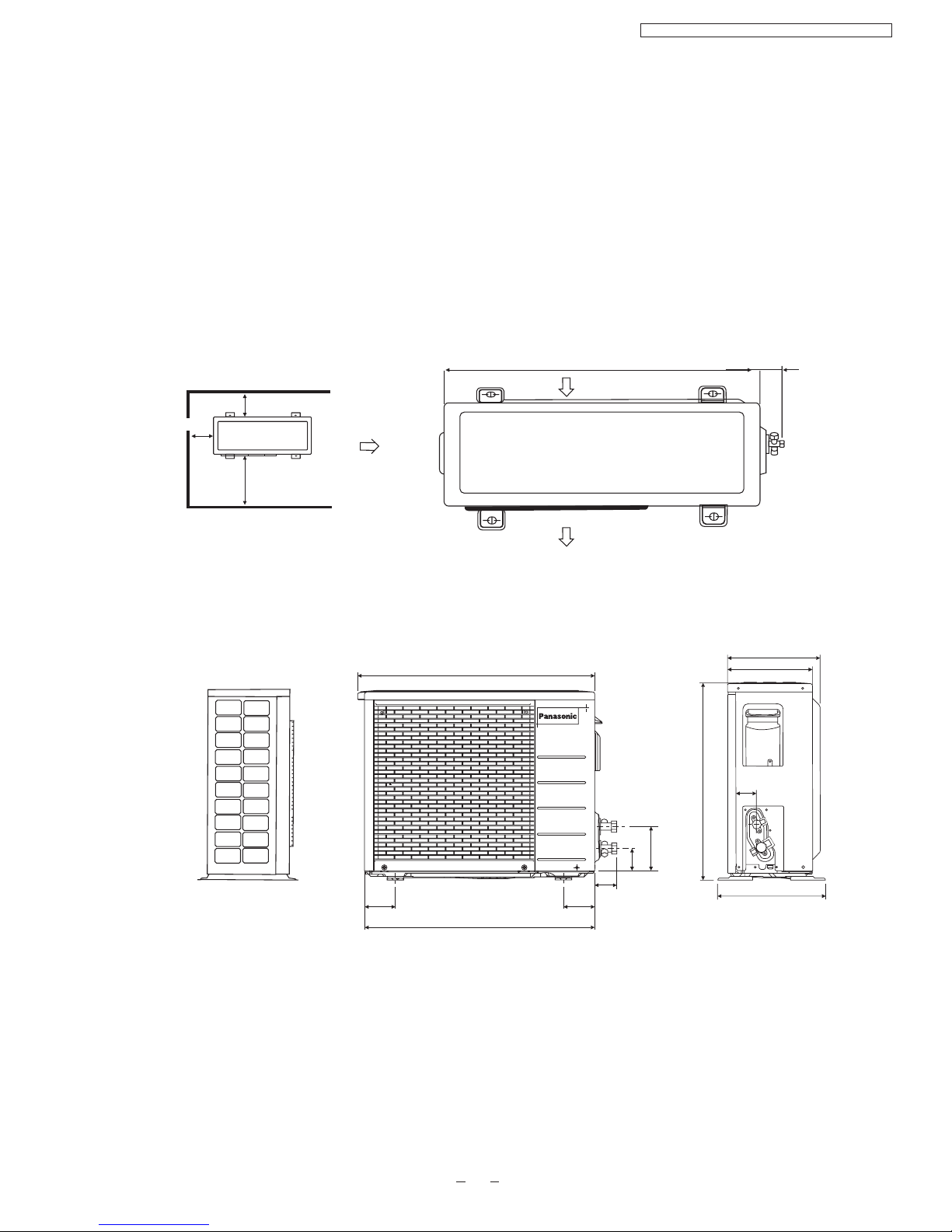

Outdoor Unit

CU-YW9DKE

650

61.6

10cm

100cm

Required space for installation

<Front View>

<Side View>

<Top View>

Unit : mm

123.8

62.2

61.6

88 88

650

668

250

230

530

55.8

293

Air intake

Air outlet

CU-YW12DKE

10cm

11

CS-YW9DKE / CU-YW9DKE / CS-YW12DKE / CU-YW12DKE

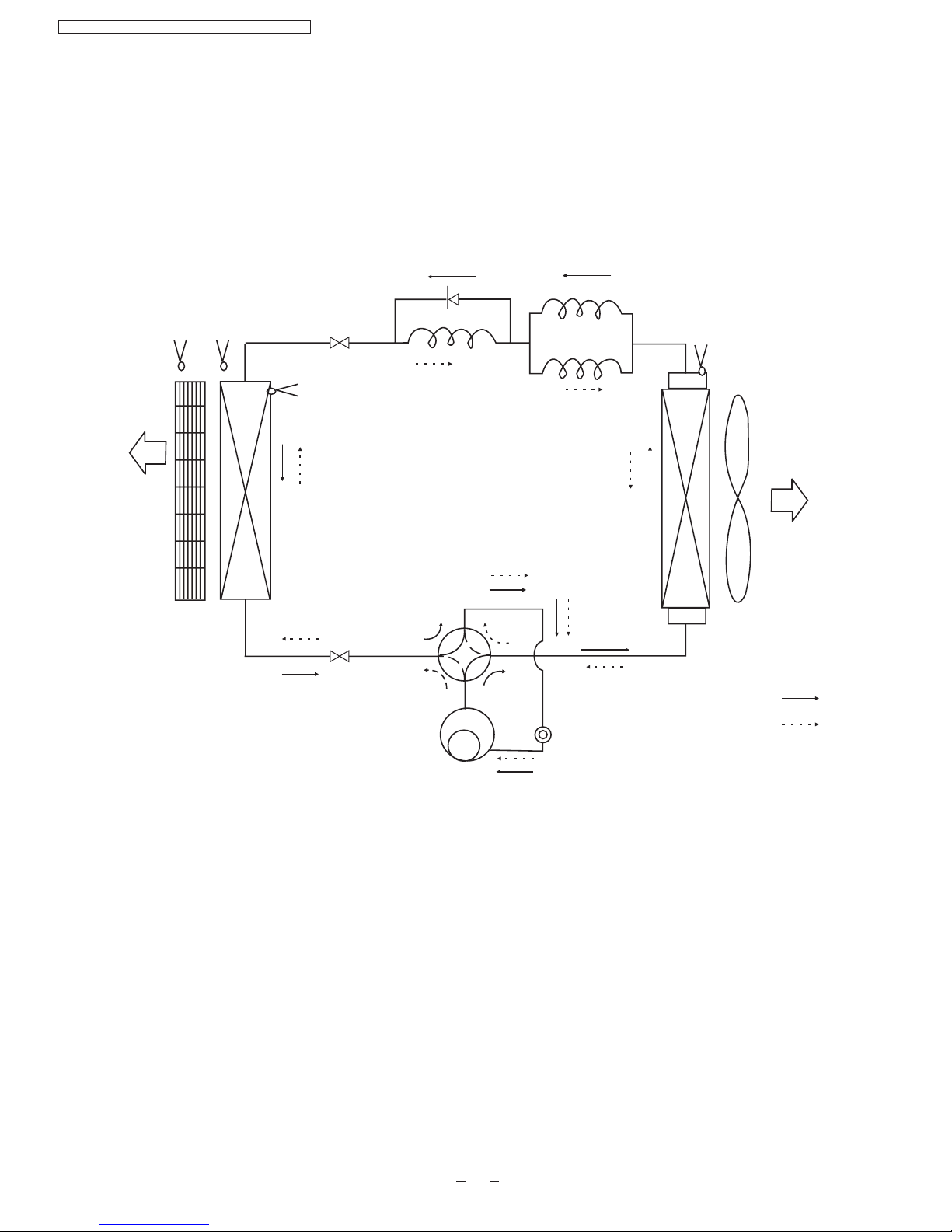

CS/CU-YW9DKE

CS/CU-YW12DKE

5 Refrigeration Cycle Diagram

INTAKE AIR

SENSOR

PIPING

SENSOR

4-way valve

PIPING

SENSOR

AIR QUALITY

SENSOR

Cooling

Heating

12

CS-YW9DKE / CU-YW9DKE / CS-YW12DKE / CU-YW12DKE

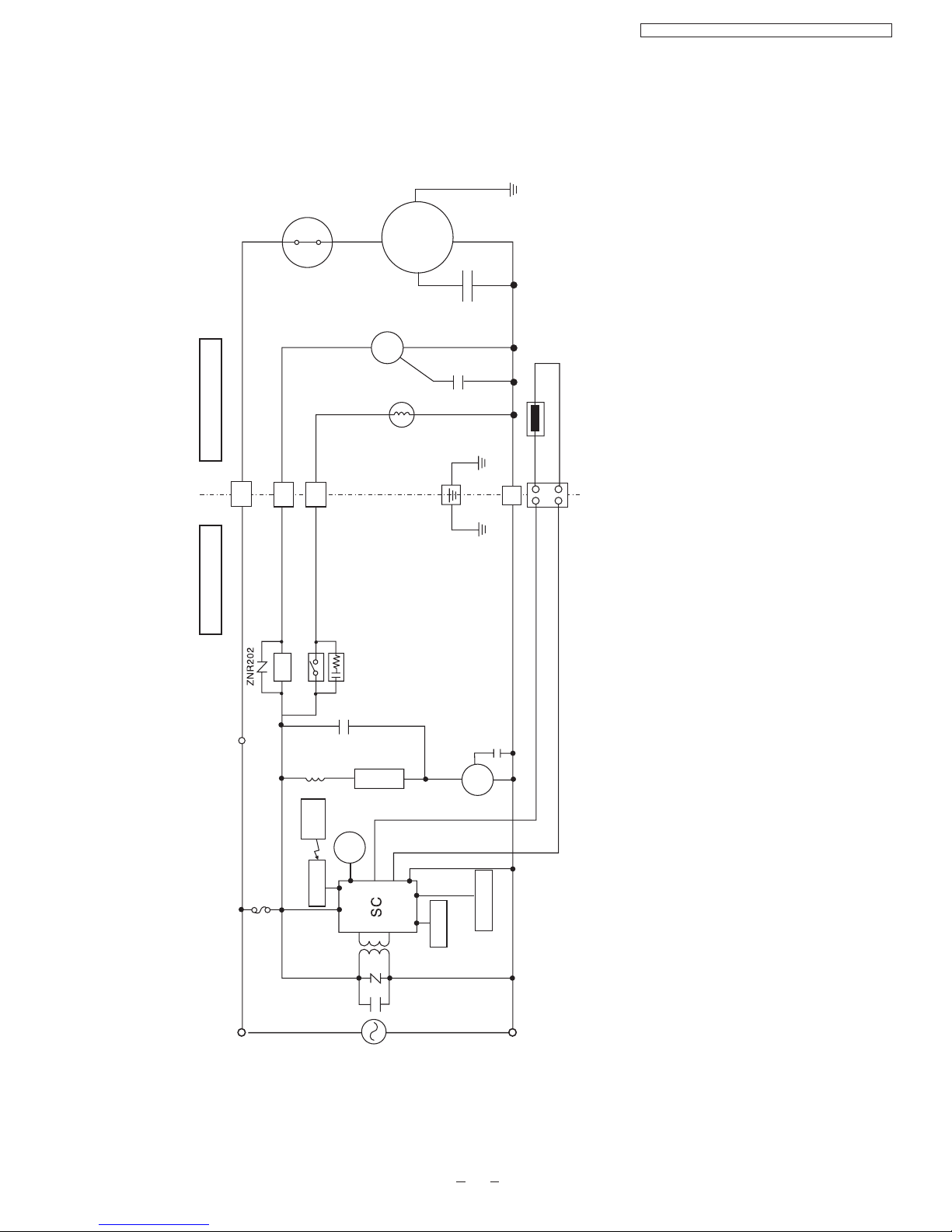

CS-YW9DKE/CU-YW9DKE

6 Block Diagram

FM

FM

2

CR201

3

4

1

RY-HOT

SSR202

SSR201

FUSE

RY-PWR

OUTDOOR UNIT

Receiver

Remote

Control

FM

4-Valve

Compressor

Sensor

Indicator

Piping Sensor

O.L.P.

INDOOR UNIT

13

POWER SUPPLY

AC230V 50Hz

CS-YW12DKE/CU-YW12DKE

CS-YW9DKE / CU-YW9DKE / CS-YW12DKE / CU-YW12DKE

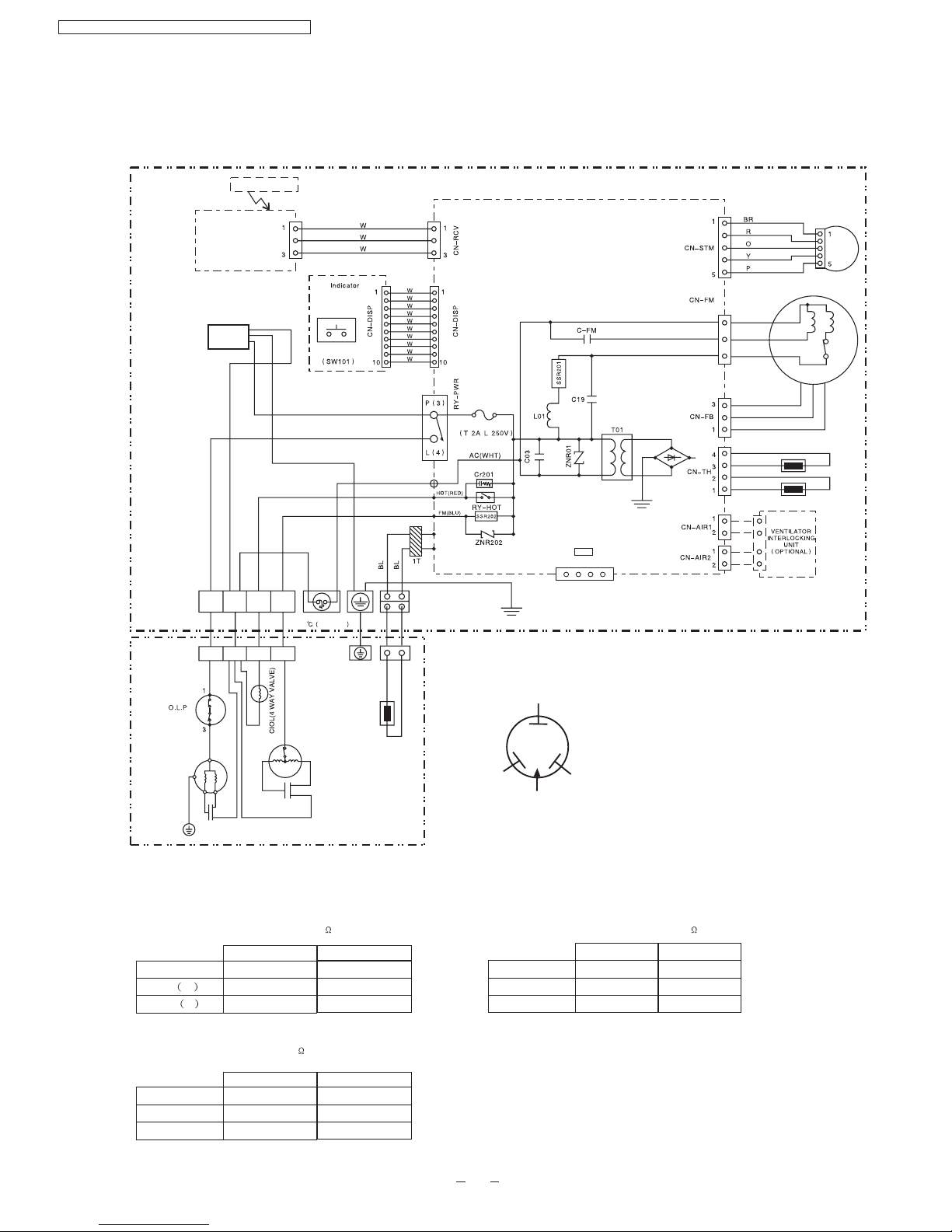

C-R

C-S

INDOOR FAN MOTOR RESISTANCE( )

CONNECTING

Y-B M

Y-R A

CS-YW9DKE CS-YW12DKE

CWA921329 CWA921329

395

325

275

260

Y-B

Y-R

CWA951419 CWA951419

COMPRESSOR TERMINAL

Signal Receiver

Remote Control

CN-RCV

BR

BL

W

R

B

B

Y/G

INDOOR UNIT

TERMINAL BOARD

FUSE

102 250V3A

YW

B

B

B

Y

Y

R

Y/G

CAPACITOR

CAPACITOR

R

COMPRESSOR

FAN MOTOR

SENSOR(PIPING TEMP.)

Y/G

FUSE

ELECTRONIC CONTROLLER

1

3

5

B

R

Y

FAN MOTOR

W

BR

BL

SENSOR(PIPING TEMP.)

SENSOR(INTAKETEMP.)

INDOOR UNIT

POWER SUPPLY

CORD

POWER SUPPLY

CORD

AC 230 50Hz

AC 230 50Hz

STEPPING

MOTOR

OUTDOOR UNIT

TERMINAL BOARD

1(L) 2(N) 3 4

1(L) 2(N) 3 4

OUTDOOR UNIT

OUTDOOR FAN MOTOR RESISTANCE( )

CONNECTING

COMPRESSOR RESISTANCE( )

CONNECTING

CWB092240

3.863

3.309

CU-YW9DKE CU-YW12DKE

CS-YW9DKE/CU-YW9DKE

7 Wiring Diagram

R : RED

BL : BLACK

B : BLUE

BR : BROWN

O : ORANGE

GRY : GREY

G : GREEN

Y : YELLOW

W : WHITE

Y/G : YELLOW/GREEN

P : PINK

CWB092313

YELLOW

RED

S

BLUE

R

C

TRADE MARK

AUTO SWITCH

390

390

2.798

5.432

275

260

14

1234

HA

CS-YW12DKE/CU-YW12DKE

CS-YW9DKE / CU-YW9DKE / CS-YW12DKE / CU-YW12DKE

CS-YW9DKE CS-YW12DKE

15

8 Operation Details

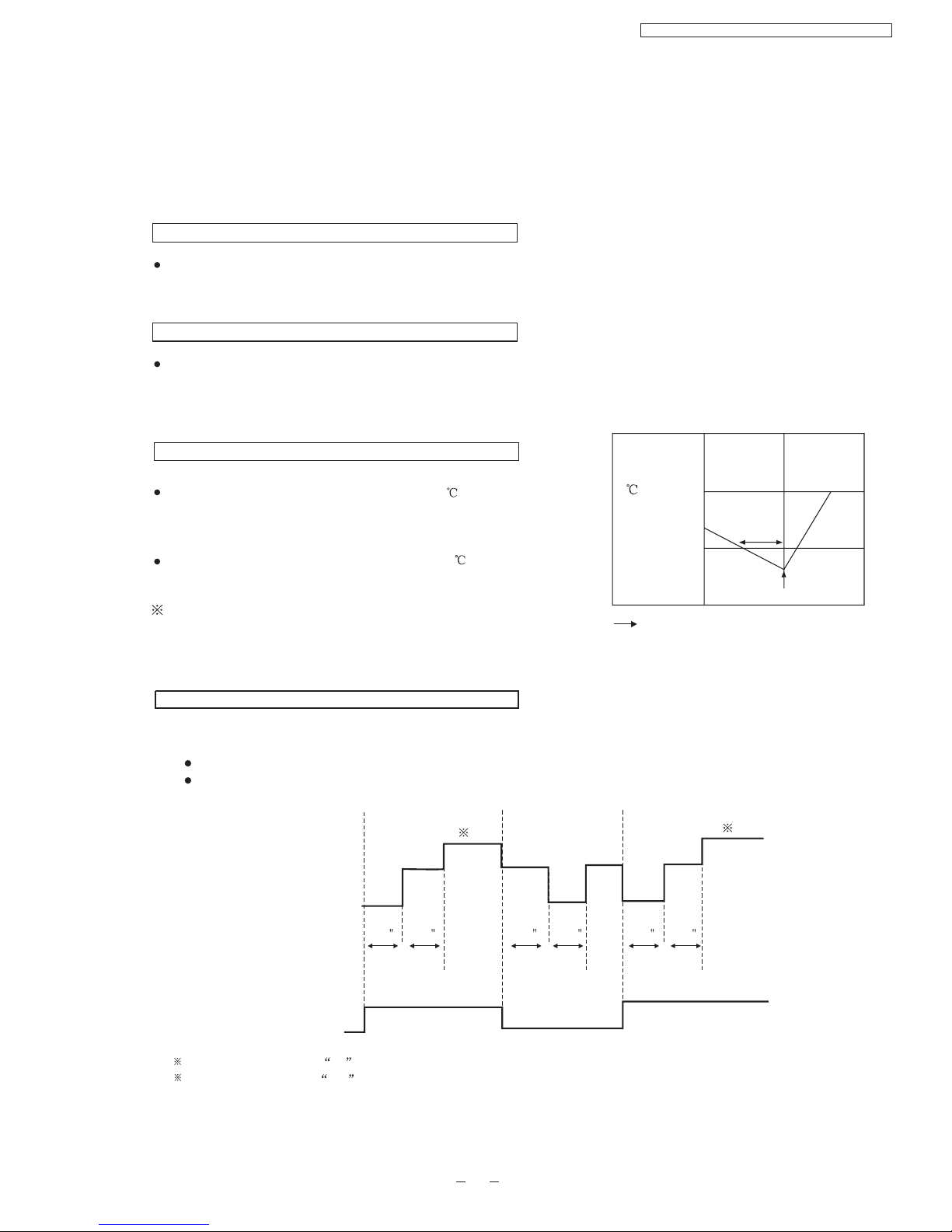

8.1 .Cooling Mode Operation

When selecting the Cooling Mode Operation, the unit will operate according to the setting by the Remote Controller or

the control panel on the indoor unit and the operation is as the following.

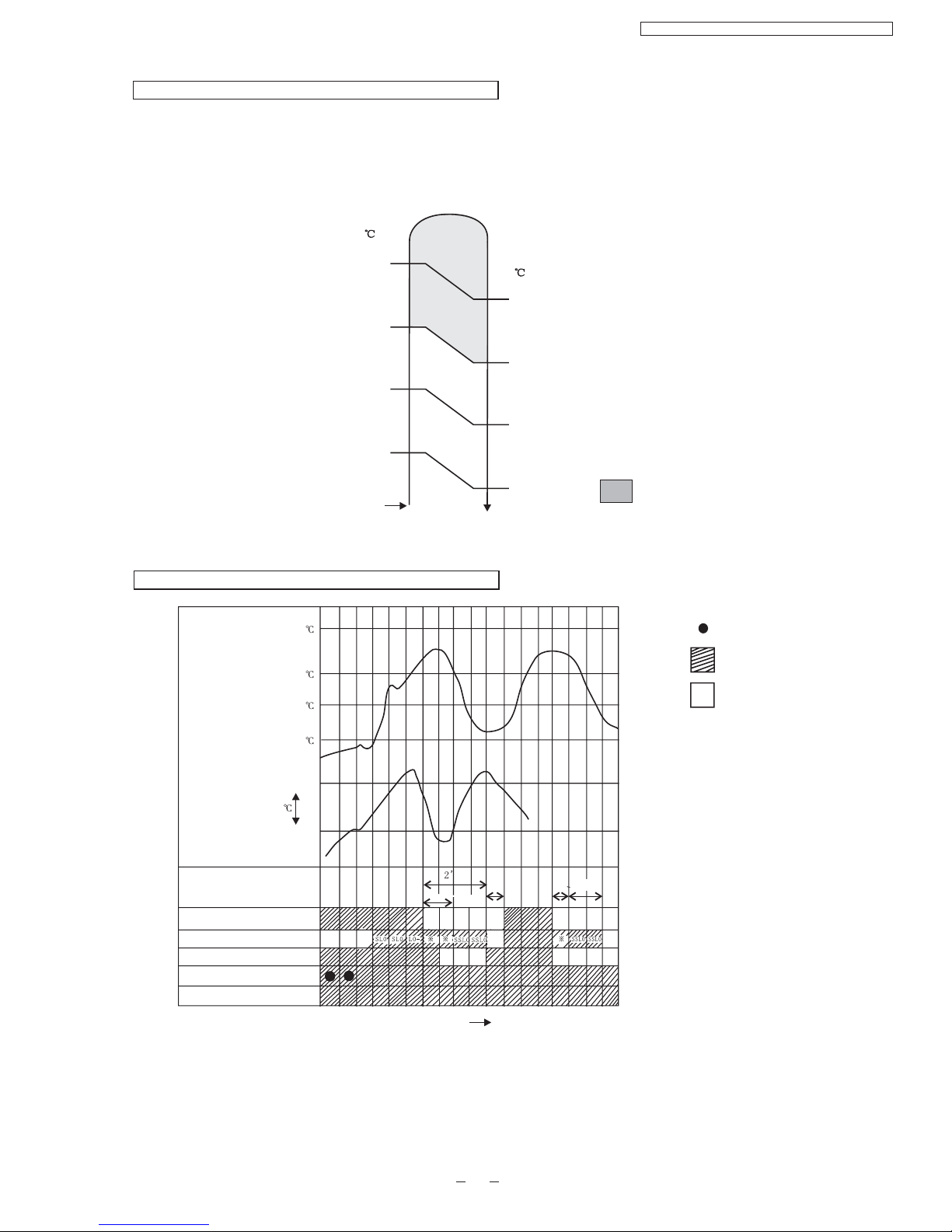

Time Delay Safety Control

3 min.----If the compressor stops, it will not restart within 3 minutes.(Protection of compressor).

7 Minutes Time Save Control

7 min.----The unit will automatically operate in 7 minutes even if the room temperature is not reached.

(Prevention of raising the humidity)

Evaporator

Temperature

()

10

2

Restart

4 minutes

Compressor ceases

Time

Anti-Freezing Control

If temperature of evaporator is lower than 2 continuously

for 4 minutes, the compressor will cease to prevent the

evaporator from freezing. Fan speed setting will not be

changed.

When temperature of evaporator reaches 10 ,compressor

will restart.

During Cooling Mode Operation, the Time Delay Safety

Control is available.

Indoor Fan

STOP

Slow

Slow

STOP STOP

Slow Slow

STOP

ON

Compressor

ON

1 Fan speed will be at Hi till the compressor ceases (set temperature reached).

2 Fan speed will be at Me when the compressor restarts.

40 30 40 3020 160

1

2

Automatic Fan Speed Mode

During Cooling Mode Operation, use remote controller to select Automatic Fan Speed.

Deodorization control.

Fan speed will be at the point between "High speed" and "Medium speed".

CS-YW9DKE / CU-YW9DKE / CS-YW12DKE / CU-YW12DKE

16

Intake air temperature

Evaporater

temperature

10

2

Start

Stop

1.5

Basic Time

Comp.

Indoor Fan

Outdoor Fan

Operation Indicator

1 1

3

7

Operation status

Time delay safety control

Compressor Test control

Auto restart control

Anti-freezing Control

Time

d-g

g-h

h-o

q-t

:

:

:

:

Operate

Stop

abcdefghi j k lmnopqrstuvwxyz

3

4’

1’

Time Graph for Cooling Operation

Set temperature

31

29

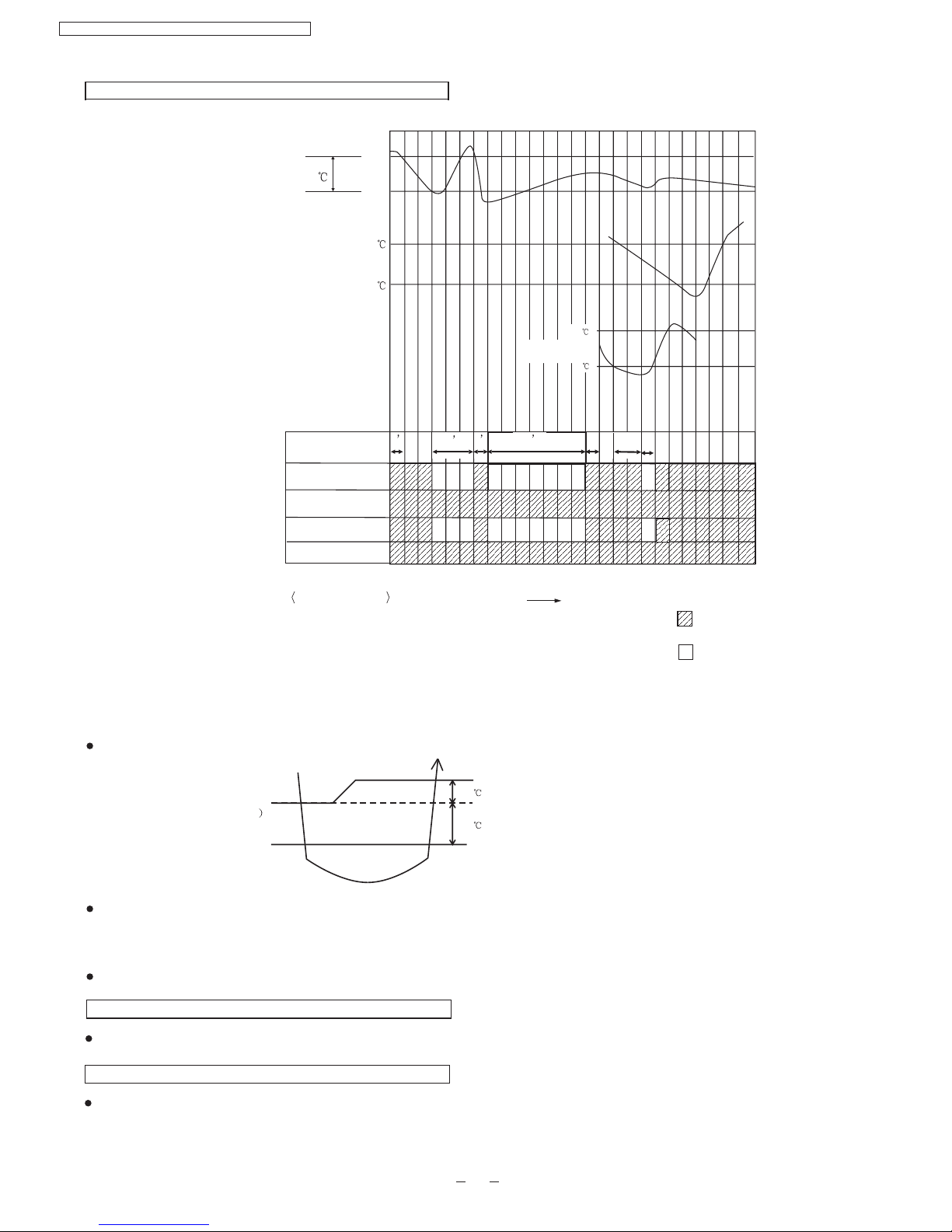

8.2. Soft Dry Mode Operation

When selecting Soft Dry mode operation, the operation will be cooling until the room temperature reaches the set temp on

remote control, and then Soft Dry will be activated. (During Soft Dry Mode the fan of indoor unit will operate at super low

speed. The soft dry mode will run for less than 10 minutes.)

Once Soft Dry mode operation is turned off, indoor fan, compressor and outdoor fan will stop for 6 minutes.

COOLING(OFF)

DRY(ON

DRY(OFF)

DRY

COOLING

COOLING(ON)

DRY(ON)

1.5

1.0

DRY(OFF)

Operation area

Time Delay Safety Protection

During cooling mode operation, if the compressor ceased, it will not restart within 3 minutes.

Anti Freezing Control

Same as the denotation in Cooling Operation.( )

(During Soft Dry Mode Operation, compressor will stop for at least 6 min.)

P21

CS-YW9DKE / CU-YW9DKE / CS-YW12DKE / CU-YW12DKE

17

Automatic Fan Speed

During Soft Dry Operation, use remote controller to select Auto Fan Speed mode.

Indoor Fan Speed is at “Lo-”

70

T2

40

T1

Slo

Lo-

OFF

ON

OFF

10

6

70

T2

40

T1

10

Slo Slo

Lo-

ON

OFF OFF OFF

Indoor

fan

Compressor

Time Graph for soft dry operation

abcdef g hi jklmnopq rst u

Evaporator

temperature

10 C

o

2C

o

Basic Time

Comp.

Indoor Fan

Outdoor Fan

Operation Indicator

666

1

61 1 4

Operation status

Time

Operate

Stop

Super

Low

Super

Low

Super

Low

Super

Low

Low

1.5

Cooling mode operation activated

Intake Air temp

1.0

Cooling mode operation stopped

Soft mode operation activated

Soft dry mode operation stop

Cooling Mode Operation

Soft Dry Mode Operation

Soft Dry Mode Operation Stopped

Compressor Test Operation Control

Anti Freezing Control

a-c,p-r

c-p,r-u

e-f

j-l

q-t

:

:

:

:

:

Slo Slo Slo Slo

Slo Slo

Slo Slo Slo

Slo

Slo

4-way Valve

CS-YW9DKE / CU-YW9DKE / CS-YW12DKE / CU-YW12DKE

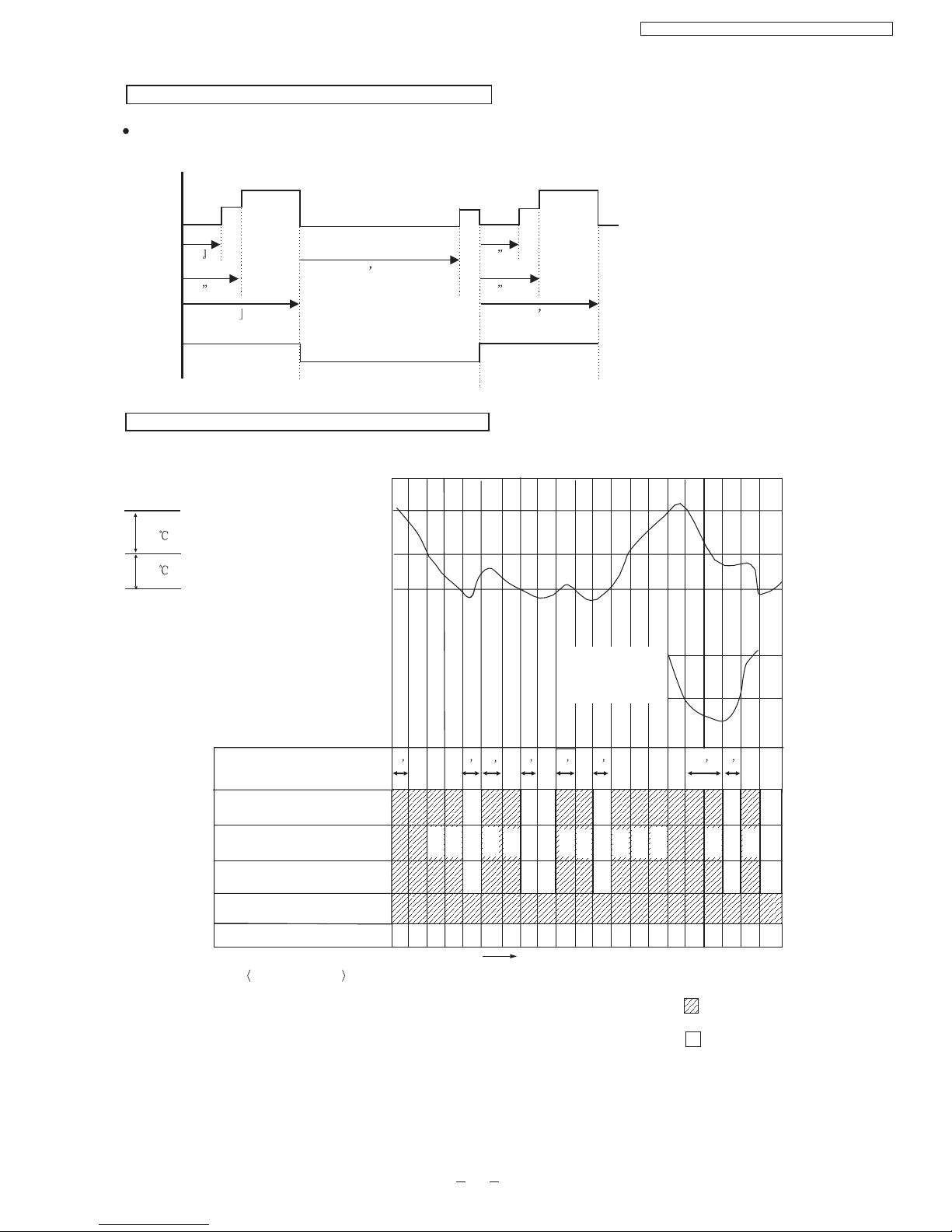

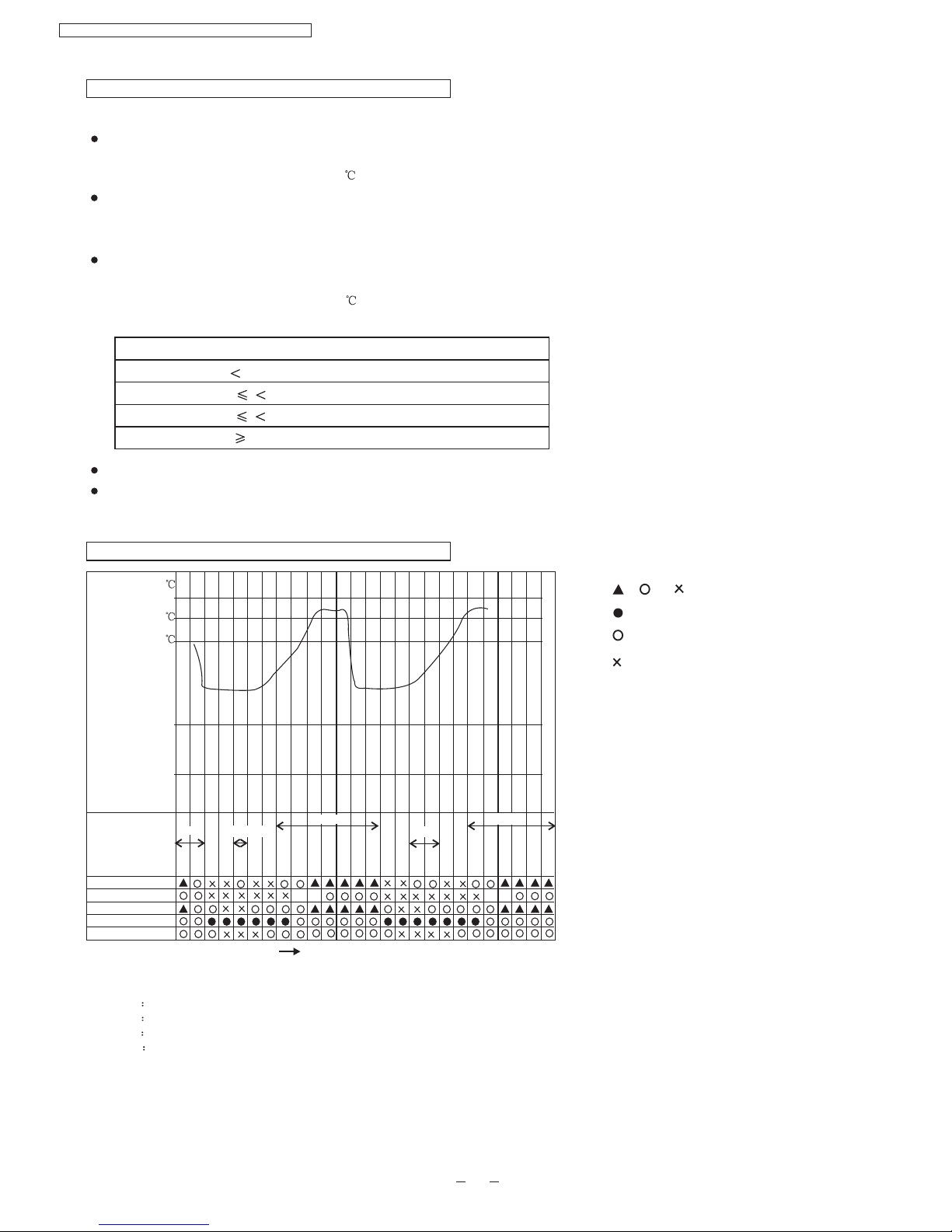

8.3. Heating Mode Operation(Only for PA7DKD,PA9DKD)

When selecting the Heating Mode Operation, the unit will operate according to the setting by the Remote Controller and

the operation is as the following.

Time Delay Safety Control

Over Load protection Control

When temperature of indoor heat exchanger rises to 51 , outdoor fan will stop

when temperature of indoor heat exchanger falls to 49 , outdoor fan will restart.

When temperature of indoor heat exchanger rises to 65 or above, compressor stops, and will restart 4 minutes later.

4-way valve control

Anti-reversing Control

If the compressor stopped by switching off, turning off by remote controller, or power off, it will not restart within 3 minutes.

When room temperature reaches the set temperature on the remote controller, compressor stops and will not restart within

4 minutes.

3 minutes after the compressor stopped, indoor fan will stop for 1 minute. Then indoor fan will resume operation with the

speed at ”super low”

.

Compressor

Stops

Compressor Restarts

4 minutes later

Indoor Heat Exchanger 65

Compressor

Stops

Compressor Restarts

3 minutes later

Compressor runs 5 min

T 5 last for 2 min

T= intake air temperature - evaporator temperature

If the compressor has been continuously running for 5 minutes or longer, and the difference of temperature between

intake air and evaporator is continuously lower than 5.0 or below for 2 minutes, the compressor will stop , and then

restart 3 minutes later.(Time Delay Protection Control is effective.)

During heating mode operation,4-way valve is at open mode.

During heating mode operation,if the unit turned off, the 4-way valve will remain

at open mode for 5 minutes.

Low

Super Low

Super Low

Indoor Fan

Stop

Indoor Fan

Stop

Indoor Heat

Exchanger

Indoor Heat

Exchanger

34

30

()

()

Warm Booting Control

When turning on the unit by heating mode operation,indoor fan

will be activated when temperature of indoor heat exchanger

reaches 30 . (See the figure on the right)

Warm boot operation ends when temperature of indoor heat

exchanger reaches 34 .

18

CS-YW9DKE / CU-YW9DKE / CS-YW12DKE / CU-YW12DKE

abcdefghi jk

l

m

nop qr

2

42

34

32

30

OFF

ON

1'

58''

30

30'

150'

Indoor heat

exchanget

Temp.

Intake Temp.

Basic Time

Compressor

Indoor Fan

Outdoor Fan

Operation Indicator

4-way valve

Automatic Fan Speed

During Heating Operation, use remote controller to select Auto Fan Speed mode.

Indoor Fan Speed is between “Me” and “Slo”.

Me

Lo

Lo-

SLo

S Lo

()

()

()

()

45

41

34

30

45

41

34

30

38

30

28

15

38

30

28

15

Temperature of heat exchanger

Temperature of heat exchanger

Stop

Tim e

Time Graph for Heating Operation

Warm booting control(indoor fan Off)

Prevent cool air blowing out

Warm booting control(indoor fan Super Slo)

a-b

c-d

h-k,o-r

:

:

:

<Operation status>

Blink

Operate

Stop

Manual fan speed

19

CS-YW9DKE / CU-YW9DKE / CS-YW12DKE / CU-YW12DKE

20

Deice Control

Deice operation is to protect the outdoor unit from freezing.

Normal Deice Operation

Deicing starts 30 minutes after heating mode operation or 60 minutes after the latest deicing operation. If temperature of

outdoor piping, tested by TRS, falls to -3 (TRS OFF) or below for continuously 50 seconds, deicing operation starts.

Overload Deicing Operation

During heating operation, if the accumulative stopping time of outdoor fan reaches 60 minutes,

deicing operation will start 1 minute after compressor starts.

Deicing operation ends under conditions below

(a) After 12 minutes.

(b) Temperature of outdoor unit rises to 4 .

(c) As the illustration showed bellow and due to Time Delay (Td), deicing won’t ends immediately.

Deicing Operation Time(T)

3min

3min T 7min

7 min T 9min

T 9min

Deicing Operation Time(T)

3

min

3min T 7min

7

min T 9min

T 9min

Td(s)

0

60

120

180

Td(s)

0

60

120

180

Once deicing operation starts, it won’t end until 60 seconds later.

When deicing operation ends, compressor will stop for 30 seconds, and 4-way valve remains at cooling mode operation

for 10 seconds.

Time Graph for Normal Deicing Operation

Tim e

<Operation status>

<Operation status>

a-c Deicing confirmation

c-g Deicing operation(time reset)

h-j,u-w Warm Booting

o-r Deicing(TRS )

42

34

30

Indoor Piping Temp.

abcd ef gh i j k

l

m

nopq r s t uvwxy z

Slo

Lo

10S20S 20S 20S 20S 20S 10S 20STd

Operatio n

Stop

Blink

or

Basic Time

Compressor

Indoor Fan

Outdoor Fan

Operation LED

4-way valve

max60'

max12'

max12'

max60'

60'

Slo

Lo

CS-YW9DKE / CU-YW9DKE / CS-YW12DKE / CU-YW12DKE

Loading...

Loading...