Page 1

Operation and Maintenance Manual for the

SODRTEK

ST 300 Analog Convective

®

Soldering/Desoldering System

P/N 5050-0536

Page 2

TITLE PAGE

General Information

Introduction...........................................................................................................3

ST 300 Handpiece................................................................................................3

Specifications .......................................................................................................3

Parts Identification................................................................................................4

Safety.............................................................................................................................5

Safety Guidelines.................................................................................................5

Usage Warnings/Cautions....................................................................................5

Servicing Precautions...........................................................................................6

System Set-Up...............................................................................................................6

Power Source...........................................................................................................6

Tip & Tool Stand......................................................................................................7

Vacuum Pick............................................................................................................7

Nozzle Changeout..........................................................................................................7

Removal..................................................................................................................7

Installation...............................................................................................................8

System Power Up ..........................................................................................................8

Operation........................................................................................................................8

Variable Temperature Control..............................................................................8

LED Operation......................................................................................................8

Variable Airflow Control........................................................................................8

Handpiece Vacuum/Pressure...............................................................................9

Component Removal............................................................................................9

Component Installation........................................................................................10

PikVac Operation ................................................................................................11

Corrective Maintenance................................................................................................12

Packing List...................................................................................................................13

Spare Parts...................................................................................................................13

Service ..........................................................................................................................13

SODRTEK by PACE” LIMITED WARRANTY STATEMENT........................................14

Contact Information.......................................................................................................15

©2004 PACE Inc., Annapolis Junction, Maryland Page 2 of 15

All Rights Reserved

Page 3

General Information

Introduction

Thank you for purchasing the PACE SODRTEK

®

model ST 300 Analog Convective

Soldering/Desoldering System. This manual will provide you with the information necessary to

properly set up, operate and maintain the ST 300.

Please read this manual thoroughly before using the unit. The ST 300 system is a complete system

designed for hot air removal and installation of SMD components, including Ball Grid Arrays (BGAs).

The following key features allow process controlled placement and reflow of BGAs and SMD

components.

ST 300 Handpiece

The user-friendly ST 300 static-safe handpiece incorporates a powerful heater and has easy-access

heat cycle and vacuum pick switches on the handle. A built-in, self-adjusting vacuum pick has a pushpull action, allowing components to be lifted automatically after solder reflow. When utilized with the

ThermoFlo System work platform, the handpiece is easily converted to a precision reflow head.

The ST 300 unit is available in either the 115 VAC or 230 VAC version. The 230 VAC version system

bears the CE Conformity Marking which assures the user that it conforms to all the requirements of

(EU) directive EMC 89/336/EEC & 73/23/EEC.

Specifications

ST 300 - Operates on 97-127 VAC, 60 Hz (115 VAC version)

575 Watts maximum at 120 VAC, 60 Hz

ST 300E - Operates on 197-264 VAC, 50 Hz (230 VAC version)

575 Watts maximum at 230 VAC, 50 Hz

Air Temperature Range - 149°C - 482°C (300°F - 900°F)

Blower Air Flow Rate (measured at heater) - 20 SLPM (0.7 SCFM) minimum at highest speed (9).

- 5 SLPM (0.18 SCFM) minimum at lowest speed (1).

Vacuum (at Pik-Vac Port) - 7.6 cm Hg. (3 in. Hg.) minimum.

NOTE: The ST 300 is designed for cyclical usage. Attempts to use in continuous operations by

taping the handpiece Cycle Switch or other methods will void Blower Assembly warranty.

Component Capacity - (maximum size) - 5.1 cm x 5.1 cm (2” x 2”)

Physical Parameters

Size - 133 mm H x 260 mm W x 248 mm D (5.25” H x 10.25” W x 9.75” D)

Unit Weight - 4.3 Kg. (9.5 lbs.)

©2004 PACE Inc., Annapolis Junction, Maryland Page 3 of 15

All Rights Reserved

Page 4

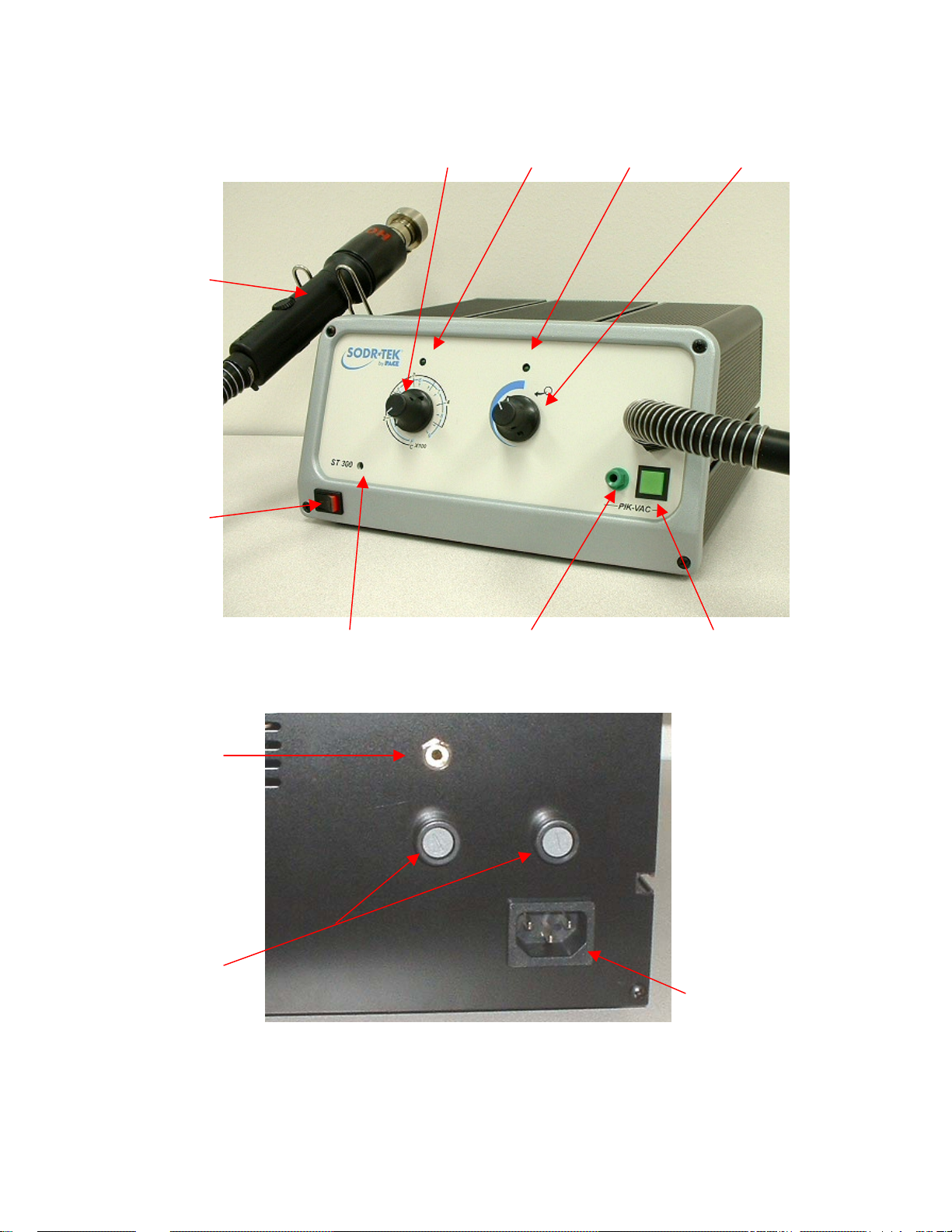

Parts Identification

p

Handpiece

Power Switch

Earth Ground Rece

Fuses

tacle

Variable Temperature

Selection Knob

Temp LED Blower LED

Variable Blower

Speed Knob

Power On LED LoFlo Vacuum Port Illuminated LoFlo

Pump Switch

AC Power Receptacle

©2004 PACE Inc., Annapolis Junction, Maryland Page 4 of 15

All Rights Reserved

Page 5

Safety

Safety Guidelines

The following are safety precautions that personnel must understand and follow when using or

servicing this product.

“NOTE”

Used to indicate a statement of company recommendation or policy. The message may relate

directly or indirectly to the safety of personnel or protection of property. NOTE is not associated

directly with a hazard or hazardous situation and is not used in place of "CAUTION", "WARNING"

or "DANGER".

“CAUTION”

Used to indicate a hazardous situation, which may result in minor or moderate injury. May also be

used to alert personnel to conditions, procedures and practices which, if not observed, could

result in damage to or destruction of the product or other equipment.

“WARNING”

Used to define additional information that if not closely followed might result in serious damage to

equipment and represent a potential for serious personnel injury.

“DANGER”

Defines additional information that if not closely followed might result in severe personnel injury or

death. Danger is not used for property damage unless personal injury risk is present.

Usage Warnings/Cautions

WARNINGS

1. A fire hazard may arise if the ST 300 is used improperly.

2. Do not use the ST 300 in the presence of an explosive atmosphere.

3. Be careful when using the ST 300 in places where there are combustible materials. Heat

may be conducted to combustible materials which are out of sight.

4. Do not apply heat from the ST 300 to one place for a long time.

5. Do not leave the ST 300 unattended while powered on.

CAUTIONS

1. The ST 300 handpiece heater assembly housing and any installed nozzle are hot when

the system is being cycled and for a period of time thereafter. DO NOT touch either the

heater assembly housing, nozzle or direct heated air stream. Severe burns may result!

2. Always use the handpiece with the Heat Shield installed except when the handpiece is

mounted to its work platform. The Heat Shield helps to prevent unintentional contact with

the heater.

©2004 PACE Inc., Annapolis Junction, Maryland Page 5 of 15

All Rights Reserved

Page 6

3. Utilize all standard electrical safety precautions when using this or any other electrical

equipment.

4. Always use this system in a well-ventilated area. A fume extraction system such as those

available from PACE are highly recommended to protect personnel from solder flux

fumes.

5. Exercise proper precautions when using chemicals (e.g., solder paste). Refer to the

Material Safety Data Sheet (MSDS) supplied with each chemical and adhere to all safety

precautions recommended by the manufacturer.

Servicing Precautions

DANGERS

POTENTIAL SHOCK HAZARD - Repair procedures performed on this product should be

performed by qualified service personnel only. Line voltage parts will be exposed when

equipment is disassembled. Service personnel must avoid contact with these parts when

troubleshooting.

Precautions

The following are general safety precautions that personnel must understand and follow when

using or servicing this product. These precautions may or may not be included elsewhere in this

manual.

Safety

Electrical Requirements

The ST 300 unit draws approximately 575 Watts, which is listed on the nameplate on the

power source rear panel. A separate, dedicated AC supply line circuit may be required to

adequately power the unit/system. If your power outlet cannot provide suitable power,

arrange for a qualified, licensed electrician to install one for you.

System Set-Up

Power Source

Set up the ST 300 system using the following steps and associated drawings.

1. Remove the ST 300 from its shipping container(s). Store the shipping container(s) in a

convenient location. Reuse of these containers will prevent damage if you ship or store

the system.

2. Set the ST 300 unit on a convenient workbench.

3. Place the POWER Switch (on power source front panel) in the

"OFF" or "0" position.

4. Inspect all system components, check for shipping damage, and ensure that all

purchased components (standard and options) are present. Use the drawings provided

in the following pages as a guide for checking the parts that come with the unit.

©2004 PACE Inc., Annapolis Junction, Maryland Page 6 of 15

All Rights Reserved

Page 7

Tip & Tool Stand

Using the supplied hardware, attach the Handpiece

Retainer and the Mounting Bracket as shown.

Handpiece

Retainer

Mounting

Bracket

Need hose retention kit

Get with Vince on

Tuesday

Vacuum Pick

Set-Up

1. Locate the Pik-Vac (P/N 7027-0001-P1) and the Vacuum

Cup Kit (P/N 6993-0154) supplied with the system.

2. Attach the ridged end of a male quick connect hose mount

Fitting to each end of the Air Hose.

3. Attach one male quick connect hose Fitting (with attached

Air Hose) to the rear of the Pik-Vac Handpiece.

4. Insert the other male quick connect hose

Fitting (with attached Air Hose) into the LoFlo Vacuum Port.

5. Attach the Metal Vacuum Tip, with the appropriate vacuum cup, to

the end of the Pik-Vac Handpiece.

Nozzle Changeout

Removal

WARNING: Never remove a heated nozzle using bare hands. Use the Rubber

Pad. Never use a wrench or pliers when removing a nozzle.

1. While holding the Rubber Pad, gently twist the nozzle as shown. The nozzle

will easily release from the Nozzle Adapter.

2. Place the nozzle (still hot) on a heat resistant surface.

©2004 PACE Inc., Annapolis Junction, Maryland Page 7 of 15

All Rights Reserved

Page 8

Installation

1. Select the proper Nozzle for your application; see the “Replacement

Parts” section of this manual.

2. Orient the Nozzle for best use on the component.

3. Insert the Nozzle up into the Nozzle Adapter (use Rubber Pad if nozzle

is hot). Gently twist the nozzle as shown to lock nozzle in place.

System Power Up

1. Insert the female end of the power cord into the AC Power Receptacle on the rear panel of

the power source.

2. Plug the prong end (male end) of the power cord into an appropriate 3 wire grounded AC

supply receptacle.

CAUTION: To insure operator and ESD/EOS safety, the AC power supply receptacle must be

checked for proper grounding before initial operation.

Operation

LED Power Indicator

Variable Temperature Control

Adjust the Variable Temperature Control Knob to the desired temperature setting.

Notice that the control panel has an outer graphic scale denoting temperature in °C

(Celsius) and an inner graphic scale denoting temperature in °F (Fahrenheit).

These numerical scales denote the set tip temperature times 100 (e.g., “3” on the

outer scale is 3 x 100 or 300°C).

LED Operation

The Green colored Temperature LED on the power source front panel indicates System Status.

LED Full On - Continuous power is being delivered to the handpiece. This condition is evident

when the system is first powered up (handpiece heater cold) or the Variable Temperature Control

setting is increased.

LED Flashing - Indicates that the set tip temperature (as set on the Variable Temperature

Control) has been reached. Power to the handpiece is cycling Off and On to maintain set

temperature.

LED Off - No power is being delivered to the handpiece heater. This condition is evident for a

short period of time when set temperature is reached and stabilizing or if the Variable

Temperature Control setting is decreased. If the LED

never illuminates, check for a faulty

handpiece heater (see Corrective Maintenance section).

Variable Airflow Control

Adjust the Variable Airflow Control Knob to the desired airflow setting.

NOTE: The Variable Airflow Control LED will be illuminated whenever the ST 300

blower is running.

©2004 PACE Inc., Annapolis Junction, Maryland Page 8 of 15

All Rights Reserved

Page 9

Handpiece Vacuum/Pressure

The Air Hose and Slide Rod must be positioned to prevent any kinking of the Hose. Kinks in the Hose

will prevent proper airflow when the system is operated and will cause a deterioration in performance.

Component Removal

1. Install the proper Nozzle Assembly and Vacuum Cup onto the handpiece. Ensure that the PCB

assembly to be reworked and any replacement component have been properly prepared.

NOTE: Any required preheating operating should be completed before advancing beyond this

point.

2. Set unit POWER Switch (on power source front panel) to the ON p osition.

3. Adjust the Temperature as desired using the Variable Temperature Control Knob.

4. Adjust the Airflow as desired using the Variable Airflow Control Knob.

5. If using a Single Jet Nozzle, no vacuum cup is used; proceed to step 10.

6. Using the Vacuum Pick Adjust Control, adjust the vacuum cup to a point

where the bottom of the vacuum cup is flush with the bottom edge of the

nozzle.

7. Ensure that the Nozzle is square to the PCB.

8. Lower the nozzle:

a) Approximately 1mm (.040”) above the PCB when using a Box nozzle.

b) Approximately (depending on component) 1mm (.040”) above the PCB

when using a Pattern nozzle.

c) Contacting BGA component when using a Vented Air Nozzle (V-A-N).

9. Press and release handpiece Vacuum Pick Swit ch to activate vacuum.

10. For Single Jet nozzles, hold the end of the nozzle tube above the

rework area at a height and angle which gives the best results in your

particular application.

11. Press and hold the handpiece Cycle Switch to activate heat cycle.

12. When complete solder melt is observed, gently lift the handpiece to remove the component from

the PCB. When using a Curved, Single Jet nozzle, use a vacuum pickup device or tweezers to lift

the component from the PCB; steps 13 & 14 are not used.

13. Position the nozzle (with component) over a heat resistant surface.

14. Press and hold the Vacuum Pick Switch for 0.5 second (minimum) to

deactivate vacuum and release component.

©2004 PACE Inc., Annapolis Junction, Maryland Page 9 of 15

All Rights Reserved

Page 10

WARNING: The component is HOT! DO NOT remove or catch the component with bare hands.

Component Installation

1. Install the proper Nozzle and Vacuum Cup (if not using Single Jet nozzle) onto the

handpiece.

2. Set the unit POWER Switch (on front panel of power source) to the ON po sition.

3. Adjust the Temperature as desired using the Variable Temperature Control Knob.

4. Adjust the Airflow as desired using the Variable Blower Control Knob.

5. Press and release Handpiece Vacuum Pick Switch to activate vacuum.

NOTE: As an alternative to the component placement methods shown below in

6. Position the component directly beneath and square to nozzle.

a) When using Box or V-A-N nozzles, insert component body into the bottom

of the nozzle. BGA components will rest against the walls of the nozzle.

b) When using Pattern nozzles, position component leads beneath and in

line with the air jets on the nozzle.

c) When using a Curved, Single Jet nozzle, position the component on its

land pattern (prefilled or with solder paste deposition). Solder tack

lead(s) if necessary.

7. If using a Single Jet nozzle proceed to step 12.

8. Using the Vacuum Pick Adjust Control on the handpiece, adjust the vacuum cup to a point

where the bottom of the vacuum cup touches the component body. The component is now

held in position with the vacuum cup.

9. Using the Vacuum Pick Adjust Control, adjust the position of the component:

a) To a spacing (depending on component) of 1-1.5mm (.040-.060”) between

the bottom of the component and the bottom of the nozzle when using a

Box or Pattern nozzle.

b) To contact a BGA component when using a V-A-N nozzle.

10. Lower nozzle (with component) to a point where the component

leads/contacts rest gently on or just above the component land pattern.

Allow the component to drop onto the heat resistant surface. Allow sufficient time

for the component and PCB to cool to room temperature before handling.

steps 7 through 10, the component (except BGAs) may be positioned and

solder tacked in place on land pattern. See “Component Positioning”.

©2004 PACE Inc., Annapolis Junction, Maryland

All Rights Reserved

Page 10 of 15

Page 11

NOTE: If component has been prepositioned on land pattern, lower nozzle to desired height

above PCB. A height of 1-1.5mm (.040-.060") above the PCB when using Box or

Pattern nozzles is recommended.

11. Ensure that the handpiece is held vertical to the PCB (except with Single Jet nozzles).

12. For Single Jet nozzles, hold the end of the nozzle tube above the rework area at a height and

angle which gives the best results in your particular application.

NOTE: Any required preheating should be completed before advancing beyond this point.

13. Press and hold the handpiece Cycle Switch to activate heat cycle.

Heated air is now being applied to the rework area.

14. If using a Single Jet nozzle in a hand held operation, move the

handpiece as necessary to direct air flow to the solder areas

requiring reflow.

15. If vacuum is being used to hold component, depress and hold the Vacuum

Pick Switch for 0.5 second (minimum) to stop vacuum and release the

component. Release the Vacuum Pick Switch.

16. When complete solder melt is observed, release the handpiece Cycle Switch

(to cease air flow) and gently lift the handpiece from the PCB.

Pik-Vac Operation

1. Use of the Metal Vacuum Tip without a Vacuum Cup attached for removal/replacement of very

small component works well but for larger components, install one of the supplied Vacuum

Cups onto the tip. For best results, use a size slightly smaller than the body of the component

to be removed or placed. For very large components, use the largest Vacuum Cup.

2. Press the Illuminated LoFlo Pump Switch to activate vacuum at the handpiece. The LoFlo

Pump Switch will illuminate whenever the switch is depressed.

3. Grasp the handpiece as you would a pen, with the

Vacuum Cup (or tip) pointing down and the Vacuum

Control Port pointing up.

©2004 PACE Inc., Annapolis Junction, Maryland

All Rights Reserved

Page 11 of 15

Page 12

4. Place the Vacuum Cup and/or the Metal Vacuum Tip gently onto the top surface of the

Component body. Exercise caution to avoid bending of leads on fine pitch devices.

5. Place one finger over the Vacuum Control Port. Vacuum is now being applied to the

Component body.

6. Gently lift the Component off the PC Assembly (removal operation) or out of the component

holder (placement operation).

7. Lower the Component gently into position onto the PC Assembly (placement operation) or

component holder (removal operation).

8. Lift finger or gently slide finger back from the Vacuum Control Port to release the Component.

9. Press the Illuminated LoFlo Pump Switch again to turn off the LoFlo Pump when all Component

handling operations are completed.

Corrective Maintenance

Power Source

Refer to the table below. Most malfunctions are simple and easy to correct.

Symptom Probable Cause Solution

No power to system

Heater Assembly does

not heat

Little or no air flow,

heater heats and

blower is running

Little or no vacuum Worn vacuum

Vacuum Cup will not

hold component

Vacuum Pickup Rod

binding

Blown Fuse Inspect and replace the fuse(s) located on the

power source rear panel

Line cord

unplugged

Open Heater Contact PACE for assistance

Kinked air hose Change routing of air hose to remove

pump

Worn or broken

vacuum cup

Vacuum Pickup

rod is bent

Plug line cord into the appropriate AC outlet

kinks

Replace vacuum pump. Contact PACE for

assistance.

Replace vacuum cup

Contact PACE for assistance

©2004 PACE Inc., Annapolis Junction, Maryland Page 12 of 15

All Rights Reserved

Page 13

Packing List

Item # Description Part Number ST 300

Only

1 System Power Supply 7008-0276-01 1 0

2 System Power Supply (Export) 7008-0276-02 0 1

3 Power Cord, 115V 1332-0094 1 0

4 Power Cord, 230V 1332-0093 0 1

5 PV-65 Handpiece 7027-0001-P1 1 1

6 Nozzle Adapter 4028-0001-P1 1 1

7 Hose Retention Kit 6018-0096-P1 1 1

8 Cubby 6019-0048-P1 1 1

9 Hot Grip Removal Pad 1100-0307-P1 1 1

10 Operations Manual CD CD5050-0459 1 1

Spare Parts

Item # Description PACE Part Number

Fuse, 7 A, 125 V, Fast Acting (ST 300) 1159-0274-P5 1

Fuse, 5 A, 230 V, Fast Acting (ST 300E) 1159-0266-P5

2 Fuse, 1 A, 125 V, Time Lag (ST 300) 1159-0246-P5

Fuse, 500 mA, Time Lag, (ST 300E) 1159-0213-P5

Service

Please contact PACE or your local distributor for service and repair.

ST 300 E

Only

©2004 PACE Inc., Annapolis Junction, Maryland Page 13 of 15

All Rights Reserved

Page 14

PACE Incorporated retains the right to make changes to specifications contained herein at any time,

without notice. Contact your local authorized PACE Distributor or PACE Incorporated to obtain the latest

specifications.

The following are trademarks and/or service marks of PACE, Incorporated, MD, USA:

INSTACAL

POWERPORT

™

, FUMEFLO™, HEATWISE™, PACEWORLDWIDE™, PERMAGROUND™,

™

, POWERMODULE™, TEMPWISE™, TIP-BRITE™, AUTO-OFF™, and

TEKLINK™.

The following are registered trademarks and/or service marks of PACE Incorporated, Annapolis Junction

Maryland U.S.A.

ARM-EVAC

SODRTEK

VISIFILTER

®

, FLO-D-SODR®, MINIWAVE®, PACE®, SENSATEMP®, SNAP-VAC®,

®

, SODR-X-TRACTOR®, THERMOFLO®, THERMOJET®, THERMOTWEEZ®,

®

, THERMO-DRIVE®, and TOOLNET®.

PACE products meet or exceed all applicable military and civilian EOS/ESD, temperature stability and

other specifications including MIL STD 2000, ANSI/JSTD 001, IPC7711, and IPC A-610.

www.paceworldwide.comT

PACE USA PACE Europe

9030 Junction Drive Sherbourne House

Annapolis Junction, MD 20701 Sherbourne Drive

USA Tilbrook, Milton Keynes

MK7 8HX

United Kingdom

Tel: (301) 490-9860 (44) 01908-277666

Fax: (301) 498-3252 (44) 01908-277777

©2004 PACE Inc., Annapolis Junction, Maryland Page 15 of 15

All Rights Reserved

Loading...

Loading...