Page 1

LS 3000

Optical Inspection System

Operation Manual

P/N 5050-0517

Rev A-CB

Page 2

System Operations Manual, Rev A

CAUTION: RIGID PROBE IS EXTREMELY FRAGILE. PLEASE USE

EXTREME CARE WHILE HANDLING AND USING

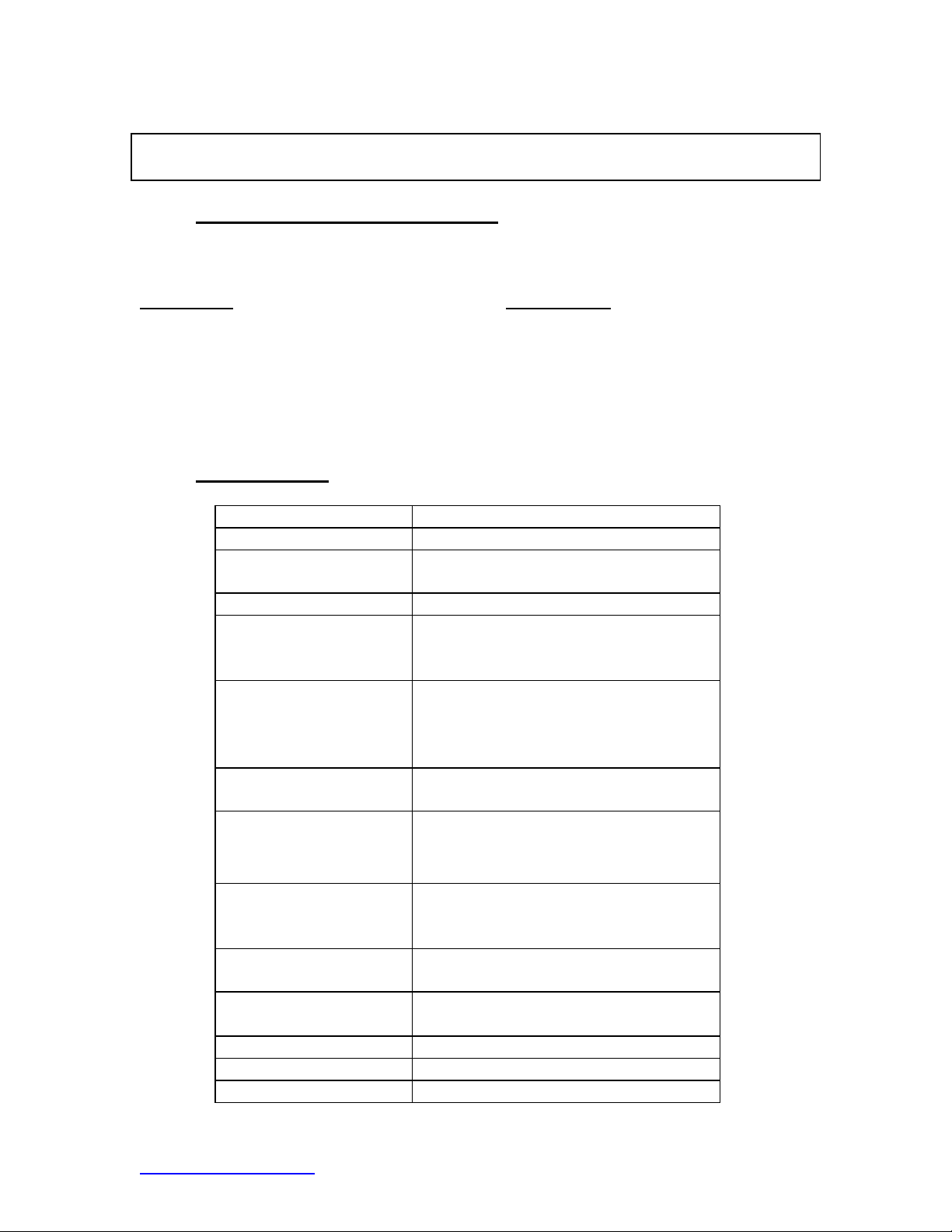

1. Packing Contents, Standard Items

a. Packing contents (Standard Items)

Description Part Number

Rigid Probe 1106-0046-P1

Fiber Probe End piece 1106-0049-P1

Large PCB Holder (2) 1400-0001-01-P1

Med PCB Holder (2) 1400-0001-02-P1

Small PCB Holder (4) 1400-0001-03-P1

Small PCB Tray 1400-0050-P1

Single Gooseneck 6007-0020-P1

2. Specifications:

120 VAC Unit 8007-0401

230 VAC Unit 8007-0402

Dimensions H: 510mm (20”) W: 635mm (25”)

D: 660mm (26”)

Weight 32kg (70lbs)

Magnification 100x – 375x with object 3.3mm

(13”) away from probe using a

381mm (15”) diagonal monitor

Field of View 1.5mm (.06”) – 6.35mm (.25”) with

object at 6.35mm (.25mm) away

from probe using 381mm (15”)

diagonal monitor

Focus Distance 0 – 228mm (9”) with 381mm (15”)

diagonal monitor

Minimum Standoff

.05mm (.002”)

Height (distance between

top of PCB and underside of

component)

Minimum Distance

2.54mm (.1”)

Between

Components

Optics Probe Fiber Optic rigid probe with

stainless steel protective cap

Lighting Type Adjustable Metal Halide Light

Source

Maximum PCB Size 510mm (20”) x 610mm (24”)

Camera Hi-Resolution CCD Camera

Agency Approvals CE

www.paceworldwide.com Page 2 of 20

Page 3

System Operations Manual, Rev A

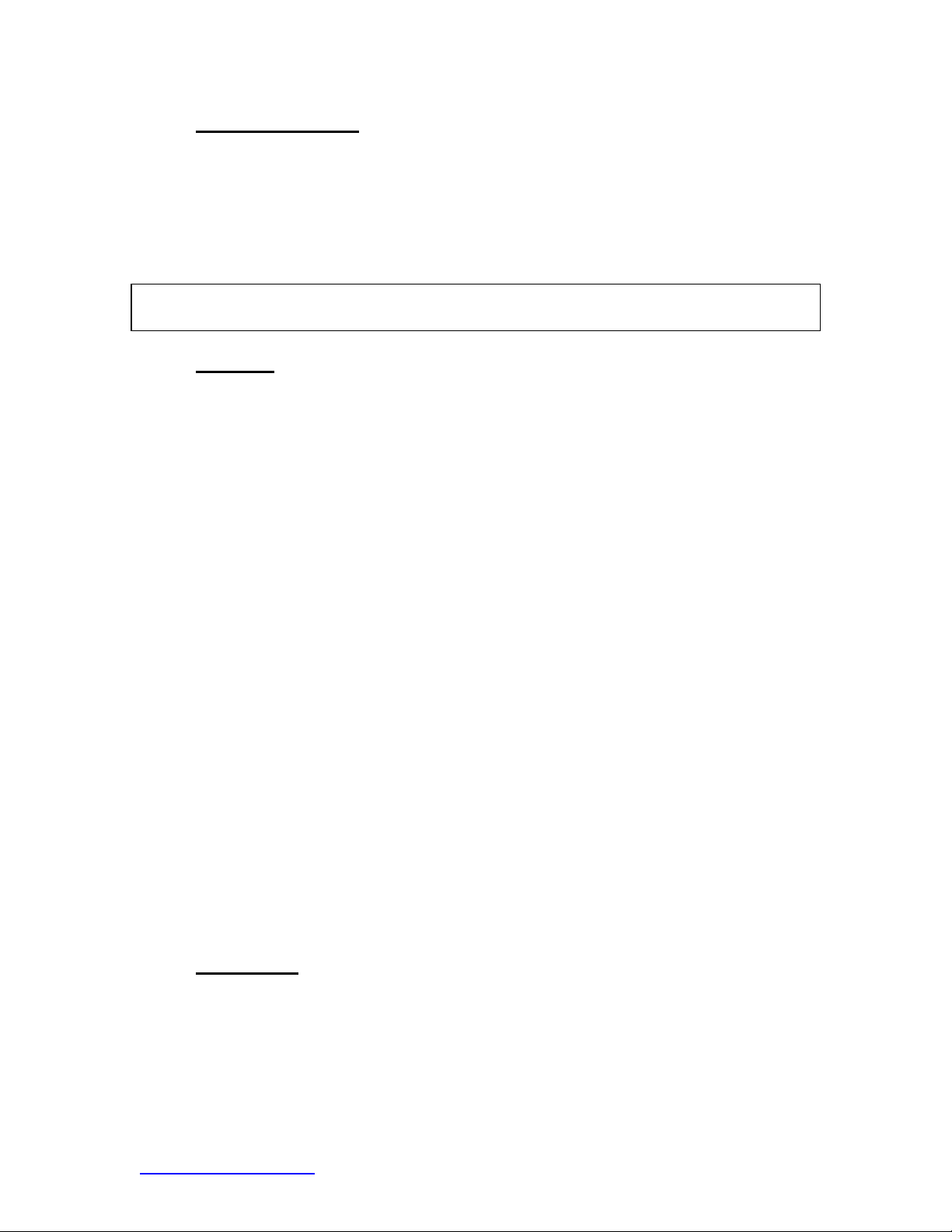

Optional Accessories

- Flexible Optics Probe 0.38mm (.015”)

diameter. P/N 1106-0047-P1

- Dual Fiber Light Gooseneck. P/N 6007-

0021-P1

- 15” LCD Flat Panel Monitor P/N 7015-

0010

Right Angle Light Bar:

- 12.7mm (.5”) Wide: P/N 1106 -

0048-03-P1

- 25.4mm (1”) Wide: P/N 1106-

0048-02-P1

- 38.1mm (1.5”) Wide: P/N 1106-

0048-01-P1

Figure 1: LS 3000

www.paceworldwide.com Page 3 of 20

Page 4

System Operations Manual, Rev A

3. Safety Information

a. Follow all manufacturer safety precautions listed in this manual.

b. Ensure system is used only in accordance with the following

procedures.

c. Immediately replace any worn or damaged items

d. Do not open the back panel while system is in use.

CAUTION: RIGID PROBE IS EXTREMELY FRAGILE. PLEASE USE

EXTREME CARE WHILE HANDLING AND USING

4. Features

a. The LS 3000 is the newest, cost effective, optical inspection system

specifically designed for today’s electronics. It’s primary use is for

inspection of area array devices including PBGA’s, CSP’s, Flip

Chips, LBGA’s, CBGA’s etc. However, the LS 3000 has a wide

range of other inspection used on any SMT or through-hole base

PCB. The LS 3000 is ideal for periodically monitoring the

performance of production or rework reflow equipment. It is also a

critical inspection/monitoring instrument for R&D labs and process

development departments when developing new processes of

troubleshooting problems.

b. The LS 3000 features a high resolution CCD chip camera and

incorporates industrial quality endoscopic components to acquire

images. The video signal can be sent to a stand-alone monitor or

can be routed to a PC via a video acquisition card. The system

comes standard with front lighting through the endoscope and with

back lighting from one fiber light gooseneck and one end piece.

Both back and front lighting can be adjusted independently. An

optional dual gooseneck for back lighting is also available. The

camera head on the LS 3000 can be moved in the Y direction using

a fine adjustment knob on the side of the system, which allows the

user to scan an entire side of a device with ease.

c. The LS 3000 verifies your process integrity so you can have

absolute confidence in your production or rework process.

5. Un-packing

Your LS 3000 system comes completely contained in one cardboard box,

which has been secured to a shipping palette. If you have purchased the

optional monitor, it will come packaged in it’s own box and will be attached

to the top of the system box.

www.paceworldwide.com Page 4 of 20

Page 5

System Operations Manual, Rev A

Starting with the LS 3000 container, please use the following steps to

safely unpack;

a. If your system came with the monitor, cut or loosen any straps,

which hold the monitor box to the main assembly box. Set monitor

box aside.

b. The cardboard box holding your LS 3000 will come strapped to a

palette. This can be left intact or the straps holding it to the palette

can be removed and the box removed from the palette.

c. Carefully cut any tape holding the main assembly box top together

and open the box top.

d. The interior of the box contains several, custom cut, foam packing

trays. The top packing tray will have a set of Velcro straps running

though it.

e. Un-do the Velcro straps as shown in figure 2 and carefully remove

the top foam-packing tray. This will reveal the camera head

assembly, which has been removed from the main system for

shipping.

Figure 2 Und oing the Velcro Straps

f. The camera head assembly is still connected to the main unit via

it’s wiring which will be clearly seen. Carefully lift the camera head

assembly without placing any strain on the wiring and remove the

second foam-packing tray as shown in figure 3. This is the packing

tray that previously cradled the camera head assembly.

www.paceworldwide.com Page 5 of 20

Page 6

System Operations Manual, Rev A

Figure 3. Removing the Camera Head Assembly from Packaging

g. Prior to proceeding with the unpacking process it is advisable to

first attach the camera head assembly to the main unit. This can

be done as follows;

i. Loosen the coarse height adjustment knob as show in figure

4. Do not remove the knob.

Figure 4. Loosening the Coarse Adjustment Knob

ii. Carefully slide the camera head assembly onto the camera

head assembly post on the main frame of the system as

show in figure 5. It does not need to be at any specific

height at this point.

www.paceworldwide.com Page 6 of 20

Page 7

6. Set-up

System Operations Manual, Rev A

Figure 5. Placing the Camera Head Assembly onto the Camera Post

iii. Tighten the coarse height adjustment knob so th e camera

head assembly is now fixed on the camera head assembly

post.

iv. Proceed with the un-packing procedure.

h. Carefully lift the main system out of the box and place on a firm,

sturdy surface.

i. In the bottom of the packing box, the accessories bag will be f ound.

Remove this bag from the main box and set aside.

j. Check the main shipping box for any other items and remove as

necessary.

k. Proceed to set-up

Prior to use, it is necessary to use the following procedure to safely set -up

your LS 3000 system.

a. Place your LS 3000 system on a sturdy, firm surface. Ensure the

surface has enough space to support the four legs under the

system.

b. Ensure the system sits level on its bench. If it does not, the four

individual legs can be adjusted as show using a medium sized

adjustable wrench.

c. Locate the main power cord in the accessories kit.

d. Attach the main power cord to the rear of the unit as shown in

figure 6. Do not turn on main power at this time.

www.paceworldwide.com Page 7 of 20

Page 8

System Operations Manual, Rev A

Figure 6. Attaching the Main Power Cord

e. Connect the system to a monitor. This can be done using your own

existing monitor or with the optional monitor. Ensure all power and

video cables are connected correctly if using an existing monitor.

Do not turn on the main power at this time.

f. If using the optional monitor, use the following procedure to

properly connect;

i. Carefully remove the monitor from its box.

ii. Locate the accessories bag and remove

iii. Set-up the monitor base using the enclosed instructions.

iv. Attach the main power cord and the video cables to the back

of the monitor as shown in figure 7. Do not turn on the main

power at this time.

Figure 7. Power and Video Cables Attached to Back of Monitor

www.paceworldwide.com Page 8 of 20

Page 9

v. Attach the video cable to the back of the LS 3000 as shown

Figure 8. Attaching the Video cable to the LS 3000

g. Proceed with accessories set-up

7. Accessories Set-Up

a. Locate the accessories drawer keys in the accessories package.

b. The accessories drawer can be found on the front of your LS 3000

system shown in figure 9 and can be used to safely store your

system accessories when they are not in use.

System Operations Manual, Rev A

in figure 8.

Figure 9. Accessories Drawer Location w/keys)

c. Using the keys, open the accessories drawer.

d. Place all system accessories in the accessories drawer.

e. Locate the Rigid Probe and attach using the following steps;

www.paceworldwide.com Page 9 of 20

Page 10

System Operations Manual, Rev A

i. Attach the rigid probe to the camera head assembly by

carefully inserting it into the underside of the camera head

as shown in figure 10.

Figure 10. Installing the Rigid Probe

ii. Rotate the Rigid probe until it clicks into place on the factory

set detent. Probe should be facing to the right as shown.

iii. Using the coarse height adjustment knob, raise the camera

head assembly on the camera head assembly post to the

highest position to avoid damaging the Rigid Probe

CAUTION: RIGID PROBE IS EXTREMELY FRAGILE. PLEASE USE

EXTREME CARE WHILE HANDLING AND USING

f. Locate the Gooseneck light and attach using the following steps;

i. Attach the Gooseneck light by carefully inserting it into the

Back Light Adapter as show in figure 11. Tighten the

setscrew knob.

www.paceworldwide.com Page 10 of 20

Page 11

System Operations Manual, Rev A

Figure 11. Attaching the Gooseneck Light

g. Locate the PCB manipulator and the PCB holders and set up using

the following steps;

i. Place the PCB manipulator of the LS 3000 table as shown in

figure 12.

Figure 12. Placing the PCB Manipulator

ii. Place the PCB holders on the PCB manipulator as shown in

figure 13 being careful not to contact the Rigid Probe. The

PCB holding blocks are equipped with both V-shaped and Lshaped notches.

Figure 13. Placing the PCB Holders

You are now ready to use your LS 3000 Optical Inspection System.

www.paceworldwide.com Page 11 of 20

Page 12

8. Operation

Use the following steps to safely use your LS 3000 Optical Inspection

System;

System Operations Manual, Rev A

a. Turn on the main power switch on the LS 3000 as shown in figure

14. You should now have light showing through the camera head

assembly. At this time you should also turn on the power to the

gooseneck light.

Figure 14. Main Power Switch in the On Position

b. Turn on the main power to the monitor.

c. Adjust your PCB holders on the PCB Manipulator so your PCB is

held securely in place.

d. Place the entire assembly under the camera head assembly.

e. Using the coarse height adjustment knob, carefully lower the

camera head assembly and Rigid Probe so the bottom of the rigid

probe is slightly higher than the PCB.

f. Carefully position the PCB Manipulator so the component to be

inspected is directly under the Rigid Probe.

CAUTION: RIGID PROBE IS EXTREMELY FRAGILE. PLEASE USE

EXTREME CARE WHILE HANDLING AND USING

g. Using the Fine Height adjustment as shown in figure 15 and while

adjusting the position of the PCB Manipulator, position the Rigid

Probe so that it is along the side of the component to be inspected.

Do not contact the PCB with the Rigid Probe. The ideal position of

the Rigid Probe will be just slightly above the board surface to allow

freedom of movement.

www.paceworldwide.com Page 12 of 20

Page 13

System Operations Manual, Rev A

Tension Adjustment

Figure 15. Fine Height Adjustment

h. Using both the focus adjustment and the zoom adjustment as

shown in figure 16, adjust the image on the monitor screen for a

clear picture. If a clear picture is not seen on the monitor screen,

refer to the troubleshooting section of this manual.

Zoom

Focus

Figure 16. Focus and Zoom Adjustments

i. Position the Gooseneck light on the side of the component opposite

the Rigid Probe as shown in figure 17. This will provide

backlighting to further enhance the image on the monitor.

www.paceworldwide.com Page 13 of 20

Page 14

System Operations Manual, Rev A

Figure 17. Positioning the Gooseneck w/ the Plastic Fiber Probe

j. Once a clear picture is displayed on the monitor screen, use the

camera head position adjustment as shown in figure 18 to move the

Rigid Probe along the length of the component to be inspected.

Figure 18. Camera Head Assembly Position Adjustment

k. Use the focus adjustment to extend the picture further under the

component as necessary.

Your system can also be equipped with an optional Flexible Probe, which

can be used with the following procedure;

Locate the Flexible Probe and attach using the following steps;

www.paceworldwide.com Page 14 of 20

Page 15

System Operations Manual, Rev A

i. Attach the Flexible Probe to the camera head assembly by

carefully inserting it into the underside of the camera head

as shown in figure 19.

Figure 19. Attaching the Flexible Probe

ii. Carefully remove the protective sleeve from the Flexible

Probe

iii. Place the Flexible Probe along the side of the component to

be inspected as shown in figure 20.

Figure 20. Positioning the Flexible Probe

iv. Using the focus and zoom adjustments, adjust so a clear

picture is seen on the monitor.

v. Move and position the Flexible Probe as necessary to

inspect the underside of the component.

www.paceworldwide.com Page 15 of 20

Page 16

9. Inspection Examples

a. The following images depict various good and bad soldered

connections for you to use as a general reference as you use your

LS 3000.

System Operations Manual, Rev A

A good solder joint. Note the smooth shiny surface of the ball and good fillets on the

top and bottom.

A solder bridge in which two solder balls have flown together

www.paceworldwide.com Page 16 of 20

Page 17

System Operations Manual, Rev A

An irregular shaped joint most likely caused by either poor initial alignment of the part moved

before the solder re-solidified. Note the rough surface of the solder indicating incomplete reflow.

Excessive Flux left at the bottom of the solder ball after reflow

www.paceworldwide.com Page 17 of 20

Page 18

System Operations Manual, Rev A

An open connection between the part and the PCB.

An example of a fillet on a LCCC type component

www.paceworldwide.com Page 18 of 20

Page 19

System Operations Manual, Rev A

10. Maintenance

a. The following procedures should be followed in order to periodically

check and inspect your LS 3000 system. Anything beyond normal

cleaning and checkup should be referred to a qualified PACE

service technician.

i. Periodically inspect the main power cord for signs of wear or

damage. If wear or damage is found, replace the cord

immediately.

ii. You may clean the rigid probe assembly with a soft cloth.

Do not use any type of cleaner for this process as damage to

the probe may occur. If the image seen with the rigid probe

is not clear and crisp, contact your local PACE

Representative

iii. The plastic fiber probe can be trimmed should the ends

become frayed or damaged. Trimming can be accomplished

by carefully using a razor knife and cutting all fibers to the

same length. Eventually the plastic fiber probe will need to

be replaced.

iv. The main tray and work surface can be periodically wiped

clean with a soft damp cloth. Avoid cleaning chemicals.

CAUTION: RIGID PROBE IS EXTREMELY FRAGILE. PLEASE USE

EXTREME CARE WHILE HANDLING AND USING

11. Major Replacement Parts

Part Name Part Number Comments

Replacement Bulb

1165-0031 Replacement Light Bulbs

12. Optional Items and Accessories

Flex Probe 1106-0047-P1

Light Bar 1.5" 1106-0048-01-P1

Light Bar 1.0" 1106-0048-02-P1

Light Bar .5" 1106-0048-03-P1

Analytical Software 1199-0009-P1

Large PCB Tray 1400-0002-P1

Dual Gooseneck 6007-0021-P1

13” Monitor Full Screen 1107-0029-P1

www.paceworldwide.com Page 19 of 20

Page 20

13. Regulation

a. This product is CE approved

b. PACE products meet of exceed all applicable military and civilian

EOS/ESD, temperature stability and other specifications, including

MIL-STD-2000, ANSI-J-STD-001, IPC 7711, IPC 7721 and IPC-A-

610.

14. Service

Please contact PACE or your local distributor for service and repair.

System Operations Manual, Rev A

www.paceworldwide.com

PACE USA PACE Europe

9030 Junction Drive Sherbourne House

Annapolis Junction, MD 20701 Sherbourne Drive

USA Tilbrook, Milton Keynes

MK7 8HX

United Kingdom

Tel: (301) 490-9860 (44) 1908-277666

Fax: (301) 498-3252 (44) 1908-277777

www.paceworldwide.com Page 20 of 20

Loading...

Loading...