Pace DUAL PATH SX-20, DUAL PATH SX-20V, DUAL PATH SX-25, DUAL PATH SX-25V, DUAL PATH SX-30 User manual

...Page 1

[PACE

|

INCORPORATED

|

OPERATION

INSTRUCTIONS

NO

DUAL

SOLDER

SX-20

SX-25

AND

MAINTENANCE

FOR

THE

CLOG

PATH"

EXTRACTOR

MODELS

SX-20V

SX-25V

SX-30

MANUAL

Featuring

Thermo-Drive™

HEAT

CONTROL

NO.

SX-30V

5050-0131

REV.

C

Page 2

(GENERAL

INFORMATION

START-UP

To

operate

a.

b.

c.

d.

e.

the

place

Solder

set

Temperature

allow

three

reduce

712

to

use

the

Solder

temperature. A temperature

8%

Extractor

DESOLDERING

Pace

Power

SX-30

Switching’

Desoldering

tacts

actuation

Desoldering

the

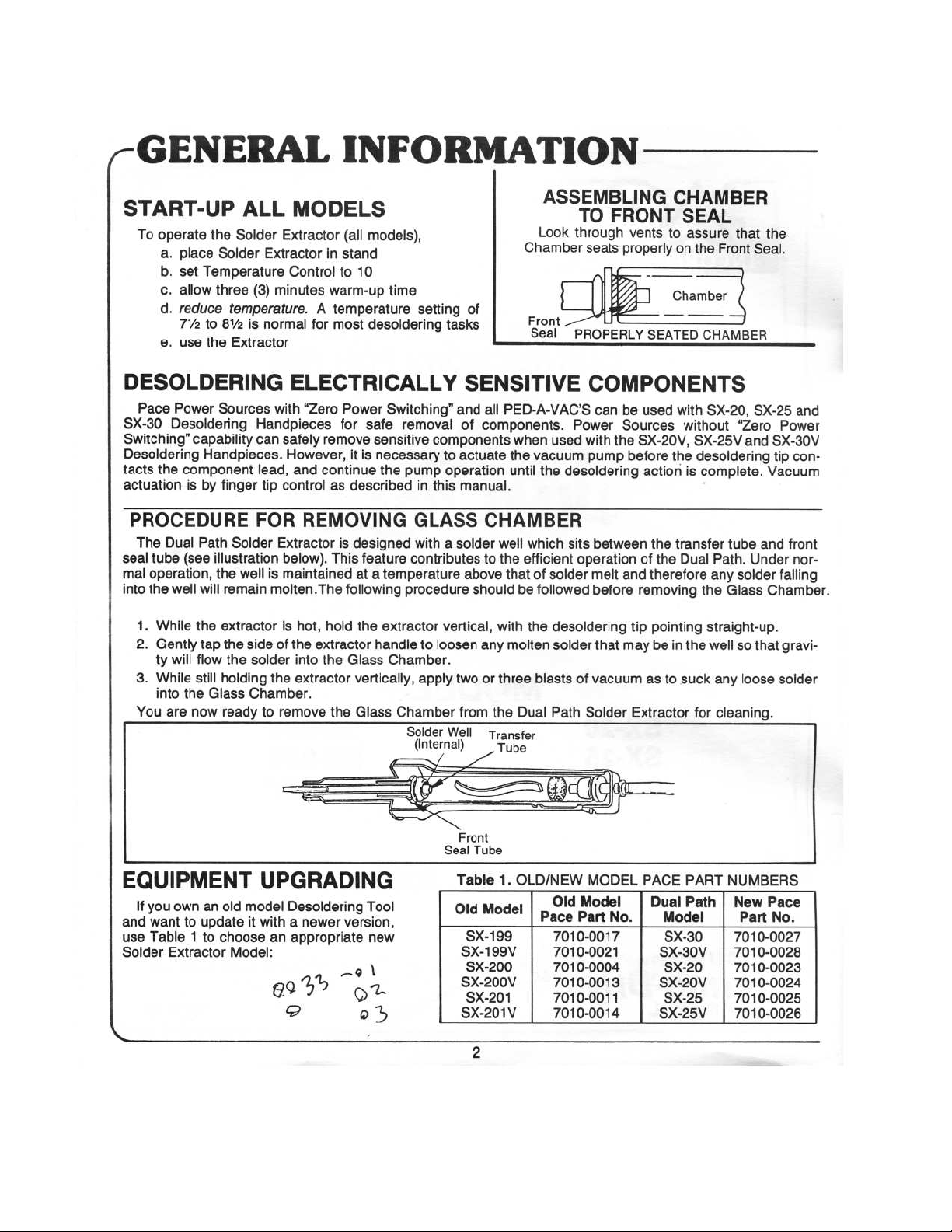

PROCEDURE

The

Dual

seal

tube

mal

operation,

into

the

well

1.

While

2.

Gently

ty

will

3.

While

into

You

are

Sources

capability

Handpieces.

component

is

by

finger

Path

(see

the

Solder

illustration

the

well

will

remain

the

extractor

tap

the

flow

the

still

holding

Glass

now

ready

ALL

Extractor

Extractor

(3)

minutes

is

normal

MODELS

(all

in

stand

Control

to

warm-up

for

most

models),

10

desoldering

ELECTRICALLY

with

“Zero

Handpieces

can

safely

However,

lead,

and

tip

control

FOR

Extractor

below).

is

maintained

molten.

is

side

of

the

solder

into

the

extractor

Chamber.

to

remove

Power

for

remove

it

continue

as

described

REMOVING

is

designed

This

at a

The

following

hot,

hold

the

extractor

the

Glass

vertically,

the

Glass

safe

sensitive

is

necessary

the

feature

temperature

extractor

handle

time

setting

tasks

Switching”

removal

components

to

pump

operation

in

this

GLASS

with a solder

contributes

procedure

vertical,

to

Chamber.

loosen

apply

Chamber

Solder

(Internal)

Well

ASSEMBLING

Look

Chamber

of

Front

Seal

SENSITIVE

and

all

PED-A-VAC’S

of

components.

actuate

manual.

above

two

from

when

the

until

CHAMBER

well

to

the

that

should

be

with

any

molten

or

three

the

Dual

Transfer

Tube

vacuum

the

which

efficient

of

followed

the

blasts

TO

FRONT

through

seats

_PROPERLY

COMPONENTS

can

Power

used

with

the

pump

desoldering

sits

between

operation

solder

melt

before

desoldering

solder

that

of

vacuum

Path

Solder

vents

properly

7

SEATED

be

used

Sources

SX-20V,

before

action

the

of

the

and

therefore

removing

tip

pointing

may

be

as

Extractor

CHAMBER

SEAL

to

assure

on

the

Chamber

ーー

CHAMBER

with

SX-20,

without

SX-25V

the

desoldering

is

complete.

transfer

Dual

Path.

any

the

straight-up.

in

the

well

to

suck

any

for

that

Seal.

SX-25

“Zero

and

tube

Under

solder

Glass

so

that

loose

the

SX-30V

tip

Vacuum

and

Chamber.

Front

cleaning.

and

Power

con-

front

nor-

falling

gravi-

solder

EQUIPMENT

If

you

own

an

and

want

to

use

Table 1 to

Solder

=

update

Extractor

old

model

it

choose

Model:

UPGRADING

Desoldering

with a newer

an

appropriate

8º

25

o

i

Tool

version,

new

ei

a

©

od

Front

Seal

Table

Old

SX-199V

SX-200V

SX-201V

Tube

1.

Model

SX-199

SX-200

SX-201

2

OLD/NEW MODEL

Old

Model

Pace

Part

7010-0017

7010-0021

7010-0004

7010-0013

7010-0011

7010-0014

No. | Model

PACE

PART

NUMBERS

Dual Path | New

Part

SX-30

SX-30V | 7010-0028

SX-20

SX-20V | 7010-0024

SX-25

SX-25V | 7010-0026

7010-0027

7010-0023

7010-0025

Pace

No.

Page 3

Before

it’s

operation,

Extractor

using

your Dual

capabilities,

will

serve

GENERAL

you

Path™

well

Solder

and

maintenance.

for

many

Extractor,

years.

INFORMATION

read

this

Used

and

maintained

manual

to

properly,

become

familiar

your

Dual Path

>

with

TABLE

Title

Generalinformation.................................

Theory

ОрегаНоп.........

Maintenance

Replacement

of

Operation

...

Parts

上

ユー

ユー・ に に に に に に に に に に

еее

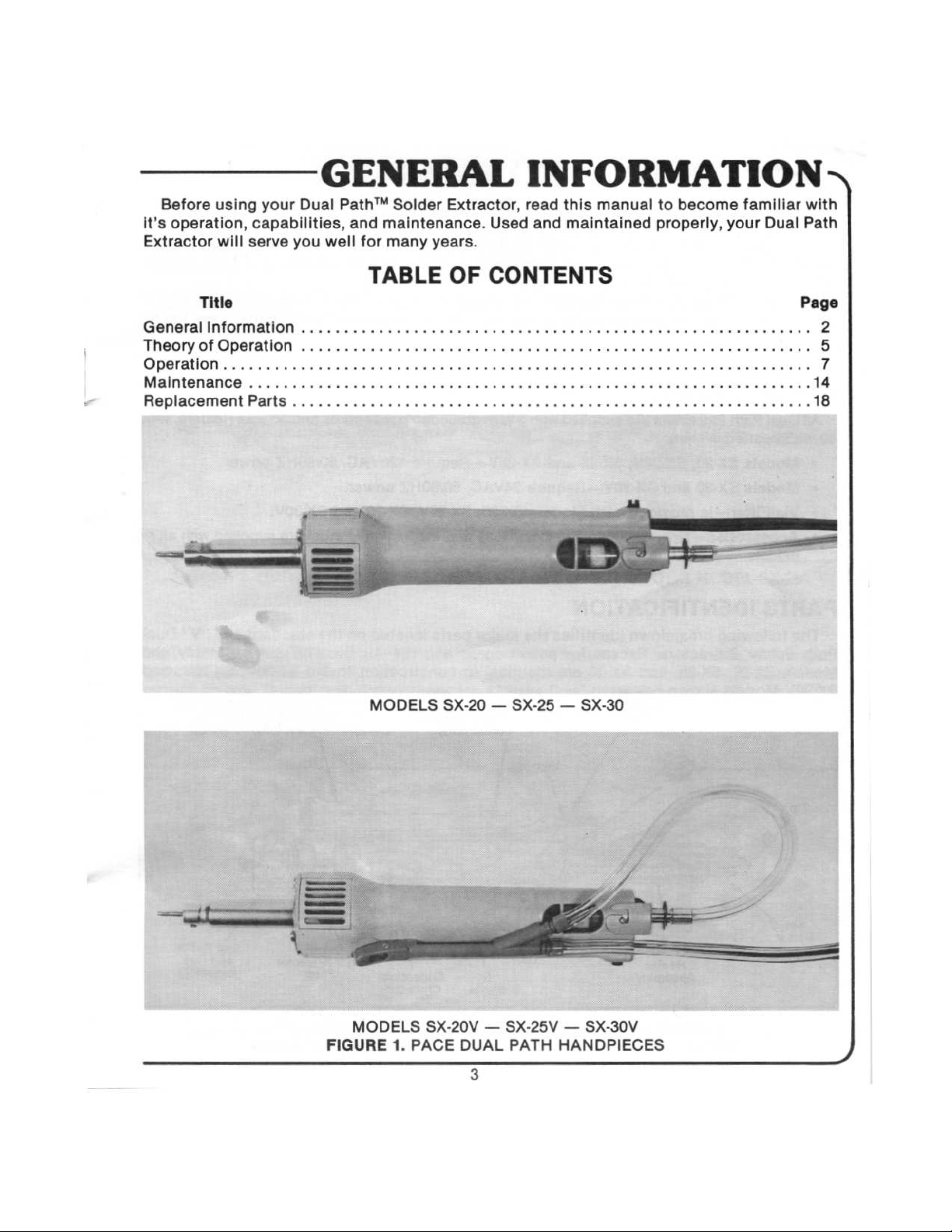

MODELS

OF

CONTENTS

トト

トト

еее

SX-20 — SX-25 — SX-30

トト

トト に トト

トレ

eee

トト レレ

еее

トト

トト

トレ

トト

トレ

トト

ーーー

наенннннь

Page

2

て

5

7

14

MODELS

FIGURE

SX-20V — SX-25V — SX-30V

1.

PACE

DUAL

3

PATH

HANDPIECES

Page 4

(C

GENERAL

INTRODUCTION

INFORMATION

Pace,

non-destructive

describes

Dual Path

Sources.

quired

Inc.

is

six

available

Solder

They

can

outputs.

continuously

rework,

Extractor

be

SPECIFICATIONS

All

Dual Path

60

watt

heat

+

Models

®

Models

»

VisiFilter—is

«

Accessories—

models.

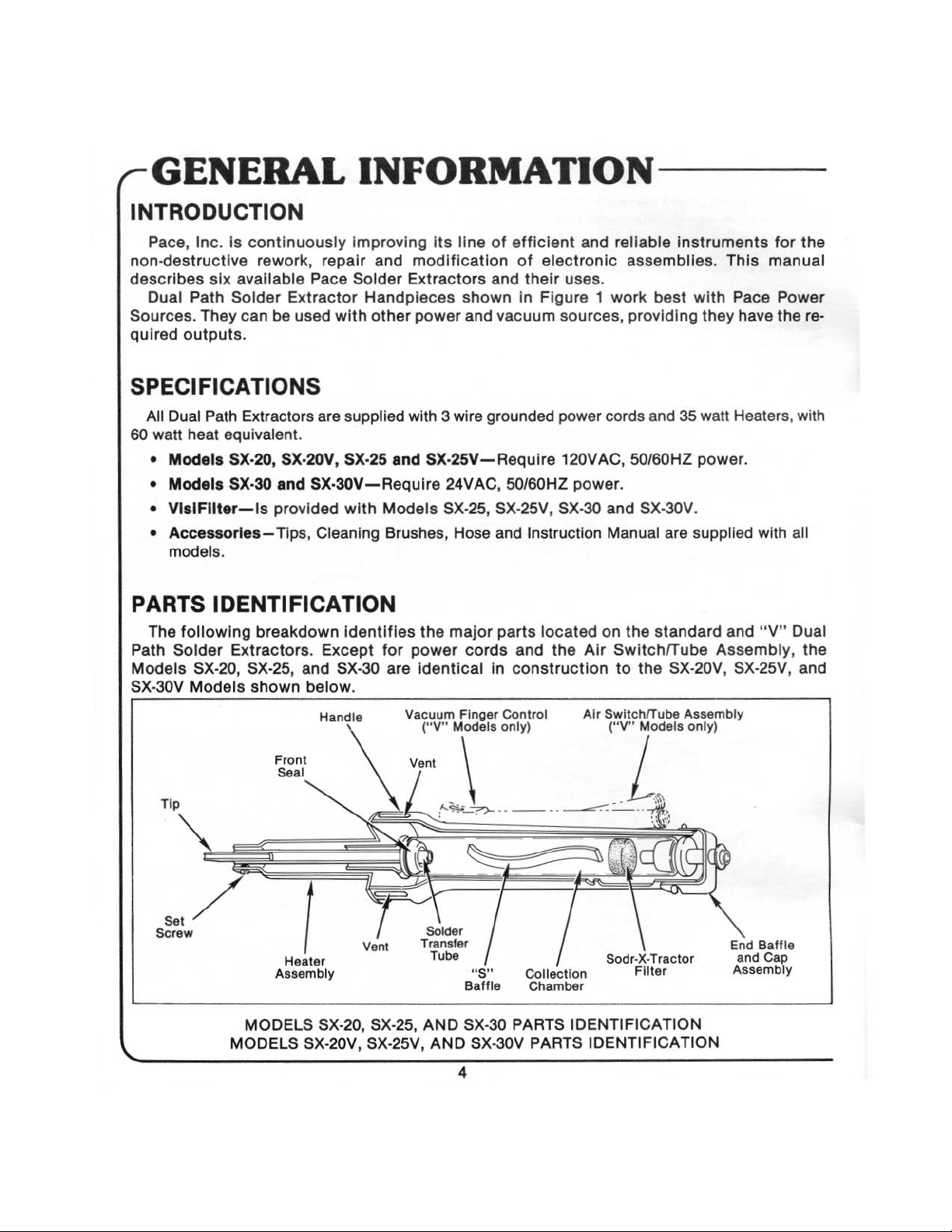

PARTS

The

following

Path

Solder

Models

SX-30V

Models

SX-20,

Extractors

equivalent.

SX-20,

SX-30

SX-20V,

and

provided

Tips,

IDENTIFICATION

breakdown

Extractors.

SX-25,

shown

improving

repair

Pace

used

are

SX-30V—Require

Cleaning

Except

and

below.

Handle

and

Solder

Handpieces

with

other

supplied

SX-25

with

identifies

SX-30

its

modification

Extractors

power

with 3 wire

and

SX-25V—Require

Models

Brushes,

for

are

SX-25,

the

power

identical

Vacuum

(“V"

line

shown

and

grounded

24VAC,

Hose

major

cords

Finger

Models

of

efficient

of

electronic

and

their

in

Figure 1 work

vacuum

50/60HZ

SX-25V,

and

Instruction

parts

located

and

the

in

construction

Control

only)

and

uses.

sources,

power

SX-30

cords and

120VAC,

power.

and

Manual

on

Air

Air

Switch/Tube

(“V"

Switch/Tube

reliable

assemblies.

best

providing

50/60HZ

SX-30V.

are

the

standard

to

the

SX-20V,

Models

instruments

This

with

Pace

they

have

35

watt

Heaters,

power.

supplied

Assembly

only)

with

and

Assembly,

SX-25V,

for

manual

Power

the

“V”

the

re-

with

all

Dual

the

and

Front

Seal

Tip

VA

Set

Screw

Heater

Assembly

MODELS

C

MODELS

SX-20, SX-25,

SX-20V, SX-25V,

Vent

Vent

o

A

E

Solder

Transfer

Tube

"s"

Baffle

AND

SX-30

AND

SX-30V

4

Collection

Chamber

PARTS

PARTS

Sodr-X-Tractor

Filter

IDENTIFICATION

IDENTIFICATION

End

Baffle

Cap

and

Assembly

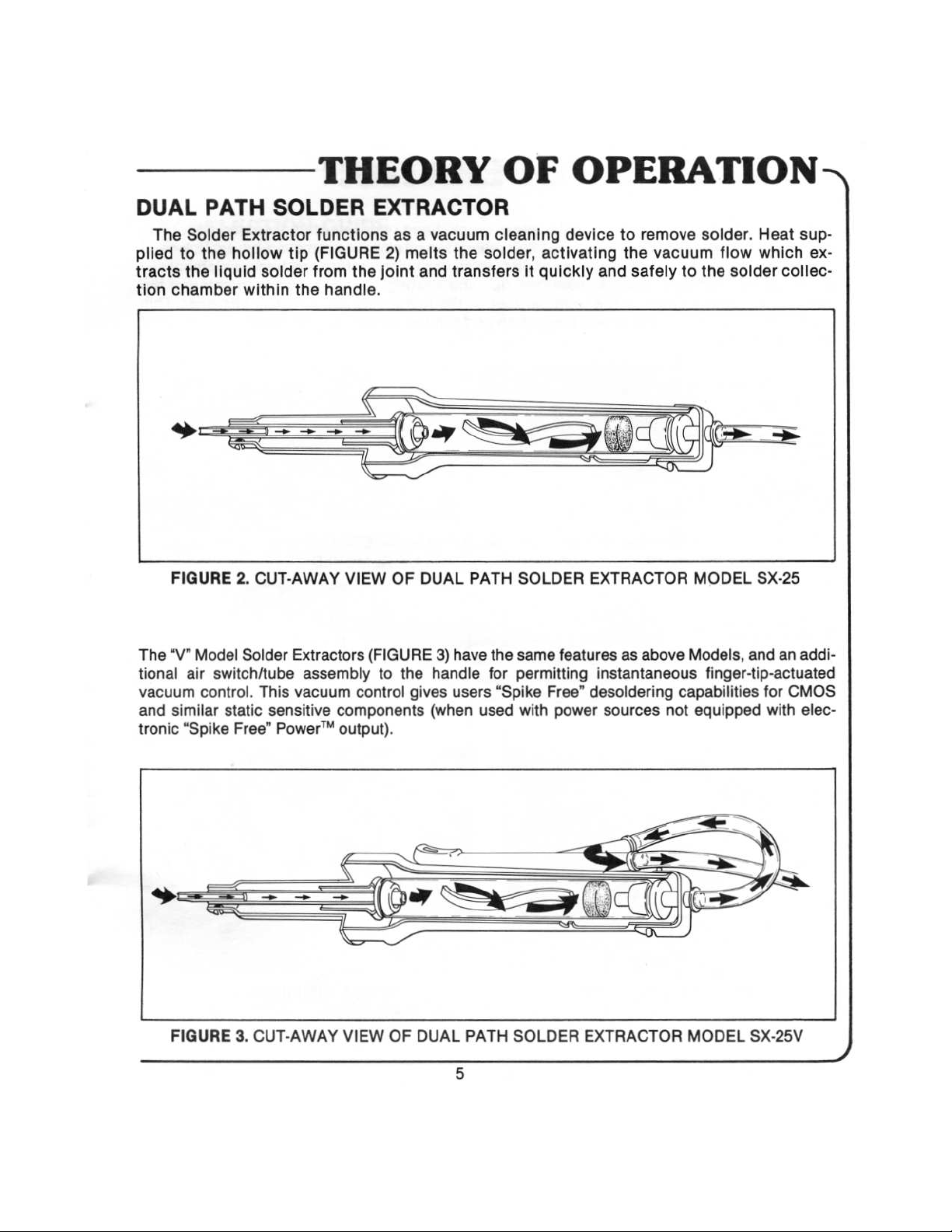

Page 5

THEORY

OF

OPERATIONS,

DUAL

The

Solder

plied

to

tracts

tion

the

chamber

==

FIGURE

The

“V”

tional

vacuum

and

tronic

air

similar

“Spike

PATH

Extractor

the

hollow

liquid

within

2.

CUT-AWAY

Model

Solder

switch/tube

control.

This

static

Free”

SOLDER

functions

tip

(FIGURE

solder

from

the

Extractors

assembly

vacuum

sensitive

Power™

EXTRACTOR

the

joint

handle.

VIEW

(FIGURE

to

control

components

output).

as a vacuum

2)

melts

OF

the

and

DUAL

3)

handle

gives

(when

the

transfers

have

users

cleaning

solder,

PATH

the

for

“Spike

used

device

activating

it

quickly and

SOLDER

same

features

permitting

Free”

with

power

to

remove

the

vacuum

safely

=

EXTRACTOR

as

above

instantaneous

desoldering

sources

capabilities

not

solder.

to

the

MODEL

Models,

finger-tip-actuated

equipped

flow

solder

and

Heat

which

collec-

SX-25

an

for

CMOS

with

sup-

addi-

elec-

ex-

FIGURE

3.

CUT-AWAY

VIEW

OF

DUAL

PATH

5

SOLDER

EXTRACTOR

MODEL

SX-25V

_)

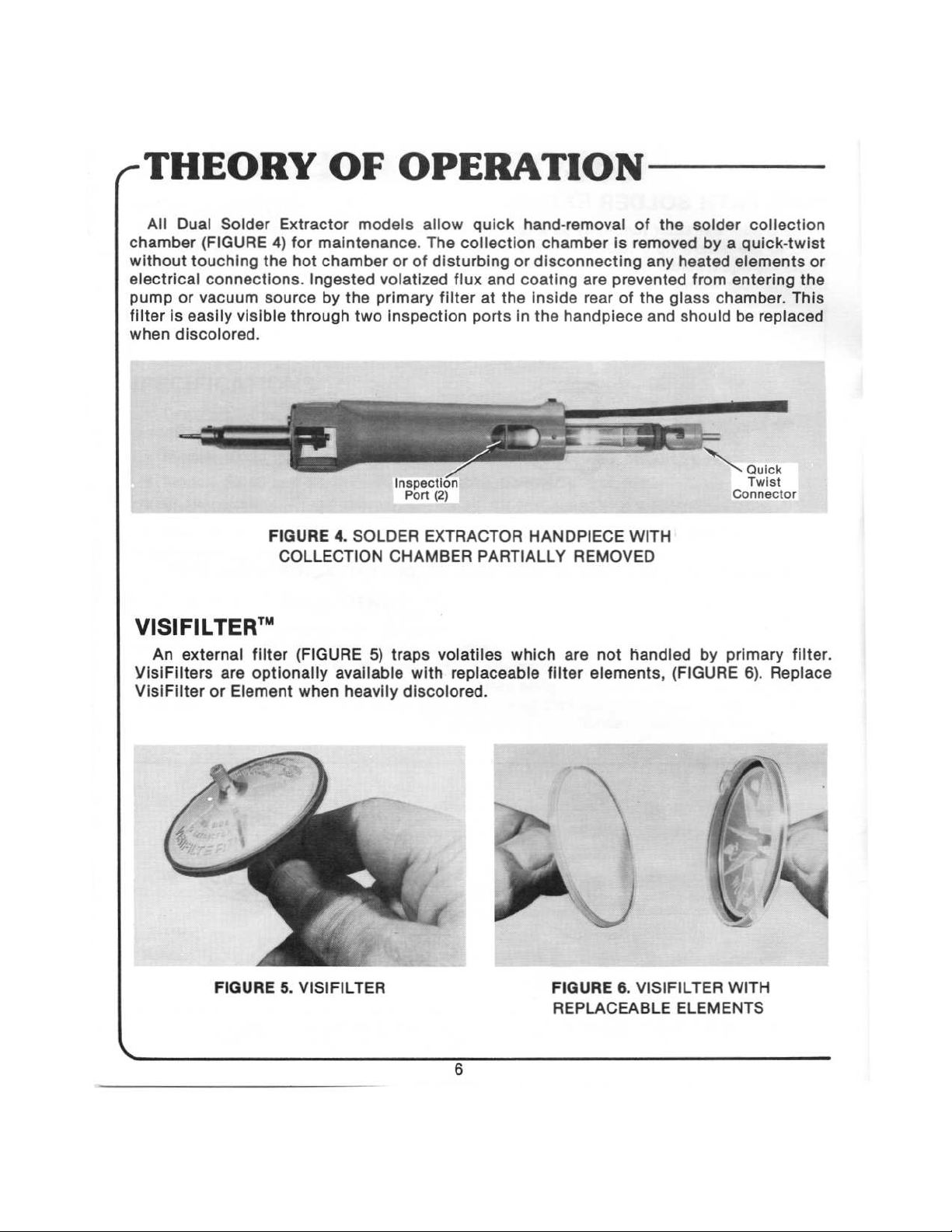

Page 6

THEORY

All

Dual

Solder

chamber

without

electrical

pump

filter

when

(FIGURE

touching

connections.

or

vacuum

is

easily

discolored.

visible

Extractor

4)

for

the hot

source

through

OF

models

maintenance.

chamber

Ingested

by

the

two

primary

volatized

OPERATION

allow

The

or of

inspection

guick

collection

disturbing

flux

and

filter

at

the

ports

hand-removal

chamber

or

disconnecting

coating

inside

in

the

is

are

prevented

rear

of

handpiece

of

the

removed

any

the

glass

and

solder

by a guick-twist

heated

from

should

collection

elements

entering

chamber.

be

replaced

or

the

This

FIGURE

VISIFILTER'"

An

external

VisiFilters

VisiFilter

are

or

Element

filter

optionally

4.

COLLECTION

(FIGURE

available

when

heavily

Inspection

Port

SOLDER

5)

EXTRACTOR

CHAMBER

traps volatiles

with

discolored.

(2)

PARTIALLY

replaceable

HANDPIECE

which

filter

REMOVED

are not

elements,

WITH

handled

(FIGURE

RS

by

Quick

Twist

Connector

primary

6).

Replace

filter.

FIGURE

5.

VISIFILTER

FIGURE

REPLACEABLE

6.

VISIFILTER

WITH

ELEMENTS

Page 7

TIP

size

SELECTION

One

of

the

of

Tip

for

most

the

GUIDE

important

job.

Keep

|

Clearance

aspects

several

for

successful

points

in

mind

solder

while

OPERATION

extraction

selecting

is

the

the

selection

Tips:

of

the

~

proper

STEP

1.

enough

and

STEP

leads,

The

to

molten

3.

Match

larger

Extractor

Tip

Inside

fit

loosely

solder

the Tip

Tips

for

%

(952cm)

Diameter

over

flow.

inch

(1.D.)

lead

to

to

the

work.

heavier

leads.

of

the Tip

provide

Small

must

clearance

I.D.

Tips

Assembly

be large

for

air

for

small

Heater

STEP

2.

The

than

pad

while

4.

For

use

Tool

에:

Tip

Outside

the

desoldering

largest

smaller

copper

STEP

removal,

Tip

Screwdriver

Extractor

NM

Diameter

pad

diameter

preventing

I.D.

(0.D.)

to

contact

terminals

Tip

available.

of

the

permit

contact

with

the

and

us,

Tip

must

with

base

material.

solder

splash

Heater

be

the

STEP

5.

Adjust

the

Ye

inch

desoldering

(952cm)

tasks.

selected

beyond

Tip

the

heater

to

extend

body

approximately

for

all

normal

STEP

6.

Tighten

screw

contacts

retaining

Tip.

DO

screw

approximately

NOT

overtighten.

Ya

turn

after

Page 8

OPERATION

SET-UP

STEP

1.Attach

handpiece.

vacuum

hose

to

SX-20/SX-25/SX-30

STEP

2.

shown.

cluded.

Attach

Assemble

hoses

the

to

the

“V"

separate

Model

12”

handpiece

piece

of

hose

as

in-

STEP

3.

Attach

hose

to

STEP

5.

Select

and

Refer

to

Tip

outlet.

Model

X

Model

SX-30

attach

Selection

SX-25

uses

24VAC

Guide

uses

uret

cord

with

the

tip

(page

120VAC

50-60

retainer

with a screw

14).

50-60HZ

HZ

supply.

clamps.

driver.

supply;

STEP

4.

handpiece.

and

SX-20(V)

Attach

Connect

VisiFilter.

models.

STEP

6.

maximum

are

STEP

without

Attach

vacuum

available

8.

Solder

removing

to

VisiFilter

NOTE:

αι

air/vacuum

fit

with

short

VisiFilter

ad

available.

all

Pace

Extractor

heater

assembly

hose

hose

Optional

Power

vents

raised

between

is

to

Sources.

lettering

Power

not

used

Power

air

hose

may

be

towards

Source

with

LA

Source.

fittings

replaced

the

Use

Page 9

INITIAL

To

operate

START-UP

the

Solder

a.

place

Solder

b.

set

Temperature

c.

allow

three

d.

reduce

desoldering

e.

use

temperature. A temperature

the

Extractor

ALL

Extractor

Extractor

Control

(3)

minutes

tasks

MODELS

(all

models),

in

stand

to

warm-up

10

time

setting

OPERATION

of

7%

to

8%

is

normal

for

>

most

V-MODEL

To

operate

Extractors:

OPERATION

the

“V”

Model

a.

Hold

the

finger

Vacuum

b.

On

tion

c.

To

orifice.

Tractor

full

d.

After

your

completed,

your

bent,

Control

the

Power

and

actuate

As

tip.

vacuum

extracting

finger

Power

SX-20V,

handpiece

with

the

Bar,

Source,

Maintenance

the

vacuum,

long

as

the

Keep

moving

operation.

the

tip

back

turn

off

Source).

SX-25V

as

you

would

tip

of

the

and

just

turn

Pump

Instructions

slide

your

orifice

solder,

off

pump.

is

the

component

Continue

remove

the

orifice

See

and

hold a pencil

finger

behind

switch

for

finger

closed,

stirring

the

to

Operation

SX-30V

resting

the

orifice.

to

the

your

tip

firmly

the

vacuum

lead

lead

to

extractor

terminate

Handpiece

(FIGURE

firmly

“ON”

Power

forward

is

actuated

with

the

cool

down

tip

the

and

Maintenance

controlled

7).

on

the

position

Source).

to

Solder

the

from

the

vacuum.

Hold

your

flat

portion

(Refer

completely

through

Extractor

joint.

joint,

to

the

tip

then

(If

operation

instruction

vacuum

index

of

the

Opera-

seal

the

Sodr-X-

during

slide

for

is

FIGURE

7.

CORRECT

POSITION

9

Vacuum

Control

FOR

Bar

HOLDING

THE

HANDPIECE

2)

Page 10

(OPERATION

VACUUM

When

STEP

1.

solder. As

a

film

of

EXTRACTION

performing a desoldering

Position

the Tip

over

the

the

solder

solder

between

melts,

lead

allow

the

solder

and

operation,

making

contact

Tip

to

gently

Tip.

the

with

rest

on

following

STEP

2.

moves

lead

indicates

steps

should

Move

Tip

freely

within

complete

be

followed

with a stirring

the

board

hole.

solder

motion,

Free

melt.

for

best

results.

dwelling

until

movement

lead

of

the

STEP

3.

Apply

ing

vacuum

contact.

STEP

5.

seconds

plete

transfer

vacuum

application.

(NOTE:

Continue

after

removing

of

and

To

Pressure

the

vacuum

Tip

solder

can

from

continue

remove

flow

to

stirring

solder,

damage

one

the

board

Chamber.

action

maintain

or

lift

the pad).

or

two

additional

to

assure

STEP

4.

dur-

light

com-

joint

STEP

thru

Allow

10

Continue

area.

6.

Check

hole

(PTH)

cool

down

stirring

action

your

work.

If

after

between

any

extraction,

resoldering

and

vacuum

solder

remains

resolder

and

extract

and

extraction

flow

to

cool

in a plated-

again

Page 11

OPERATION

>

VACUUM

STEP

7.

of

Hot-air

thru-hole

EXTRACTION

HOT-AIR

pressure

joints.

CLINCHED

PRESSURES.

mode

removes

LEADS

(continued)

solder

from

blind

HOT—AIR

PRESSURES

こき

STEP

8.

Hot-air

jet

mode

melts

planar

solder

connections

and

shrinks

CLINCHED

component

tubing.

LEADS

leads,

STEP

9.

To

melts.

STEP

setting.

for

tract

unclinched

11.

For

solder

Place

complete

solder.

Tip

melt.

Keep

leads,

TERMINALS

extraction

in

contact

Wiggle

wire

wire

moving

place

Tip

on

on

terminals,

with

wire

and

and

apply

during

cool

lead

until

solder

increase

solder.

Watch

vacuum

to

down.

STEP

10.

(WARNING:

in

Move

Steps 3 through

Lift,

heat

ex-

11

STEP

12.

quire

the

System

Solder

application

convenient

or

hot

soldering

Tip

to

end

of

dont

6.

AUXILIARY

extraction

of a second

side.

Use a PACE

lead

pry!).

Extract

HEATING

on

heat

iron

tip

and

lift

to

solder

multilayer

source

Conductive

for

auxiliary

straighten.

as

described

boards

at

the

heat.

may

re-

joint

on

Heating

Page 12

OPERATION

PRESSURE

(USE

controlled

OF

The

following

air

Circumstances

solder

Sided

the

flow.

the

The

uses

joint.

Solder

board.

In

this

hole

thus

“Pressure

the

following

MODE

AIR

PRESSURE)

procedures

pressure

This

Joint”

This

case

causing a sweat

Mode”

a.

Connect

to

b.

Place

Cubbies”,

the

outlet.

may

is

most

is

so

is

common

the

vacuum

is

steps:

the

“maximum”.

the

heater

apply

when

occur

when

the

often

the

case

named

now

tip

and

tube.

because

when a terminals

method

joint.

required

air

line

to

of

the

use a burst

the

extractor

Vacuum

when a “Blind-Sided

of

its

is

not

applicable

So

in

this

to

break

up

the

Pressure

Extractor

of

pressure

is

Mode

inaccessibility,

flanged

case

this

Blind-Sided

Flow

into

the

used

of

end

since

(see

control

to

clear

“Solder

with

Power

operation

Solder

usually

(on

opposite

no

cooling

Step 7 on

Solder

valve

Dump”

any

molten

Sources

will

Joint”

on

air

page

Joint.

and

not

completely

is

found.

the

component

side

of

can

11;

and

The

adjust

between

solder

equipped

The

board)

be

pulled

steps

“Pressure

Pressure

the

which

might

with

remove

“Blind-

side

blocks

through

below).

Mode”

control

two

“Hot

be

a

a

of

air

in

c.

Heat

must

Place

the

heated

WARNING—ALLOW

AREA.

d.

When

the

Blind-Sided

vide

continuous

joints

caused

If

conformal

desoldering

(See

hot

ς

coating

operation.

air

jet

page

is

Try

13.)

be

transmitted

tip

burst

by

the

blocking

hot

air jet

through

over

and

THE

TIP

Solder

continuing

air

to

Joint

of

pressure.

flow,

the

decure

12

the

in

contact

TO

COME

is

heated

Stir

flow

of

coating

coatings;

lead

to

melt

with

the

INTO

LIGHT

sufficiently,

the

lead

to

air.

must

be

or

thermo-plating

the

lead.

CONTACT

prevent

removed

Blind-Sided

WITH

actuate

the

reformation

before

tool

to

remove

Solder

THE PAD

airflow

of

the

vacuum

coatings

to

Joint.

pro-

sweat

Page 13

OPERATIONS

HOT

The

+

SURFACE

Surface

ing

AIR

hot

JET

air

solder

steps

a.

b.

c. A carefully-directed

d.

MODE

mode

of

operation

SOLDERED

joints

should

With

Source,

solder.

Reduce

approximately

lead

you

Repeat

the

If

desirable

prior

be

taken

the

air

set

the

with a soldering

might

component

surface

to

lift

this

joints

to

using

are

line

Pressure

Pressure

process

is

JOINTS

removed

for

connected

Ys”

the

pads

is

free.

are

use

the

Hot

Air

used

the

valve

valve

Hot

from

aid

from

for

GENERAL

heavily

Vacuum

Jet

for

several

with

the

“Hot

succesful

to

the

and

power

setting

Air

Jet

will

the

surface.

or

tweezer.

the

each

individual

mounded

Mode

Method.

different

Air

Jet

removal

Pressure

to

“MAX”

to

“MIN”

melt

the

When

Do

not

substrate.

lead

NOTE

with

to

remove

applications:

Mode”

of

surface

Flow

Control

and

and

use

solder

you see

lift

until

solder,

joint

before

all

it

excess

of

operation.

mounted

Valve

blow

out

.036

1.D.

when

the

solder

melting

leads

may

be

solder

The

components.

on the

excess

Tip.

the

tip

melt,

is

observed,

are

removed

follow-

Power

molten

is

held

lift

the

or

and

¢

HEAT

To

use Hot

jet

slowly

evenly

allowing

¢

CONFORMAL

Apply

with

*

REMOVAL

Apply

material.

be

required

thickness

SHRINKABLE

Air

along

distribute

it

to

cool.

Hot

Air

Jet

an

orange

OF

Hot

Air

Jet

Then

for 2 or 3 minutes,

of

the

TUBING

Jet

Mode

the

entire

heat

COATING

to

the

stick

so

BONDED

to

the

twist

the

coating.

of

Operation

length

to

shrink

REMOVAL

conformal

you

won't

COMPONENTS

component

component

of

the

tubing.

(Epoxy

coating

damage

body

to

depending

for

shrinking

tubing.

Be

sure

to

and

be

removed

13

tubing,

Do

not

all

tubing

and

Polyurethane)

be

removed.

the

board.

surrounding

with

upon

the

apply

play

the

has

Remove

pliers

size

hot

shrunk

area

or

of

the

the

properly

air

at

completely

the

softened

to

soften

tweezers.

component

one

point,

the

Heating

adjusted

but

before

coating

bonding

may

and

the

Page 14

„MAINTENANCE

TIP

CARE

The

Extractor

following

*

Remove

a

non-contaminating

+

The

during

in

the

*

Charred

the

suggestions

Solder

tip

Tips

should

will

excess

normal

heater

coating

with a length

solder,

Extractor

use.

assembly.

of

prevent

material.

Tip

The

flux

of

be

cared

burned

is

expendable;

Tip

must

can

cause

small-diameter

for

damage

flux,

and

be

replaced

blockage

in

the

to

the

conformal

washout

stiff

same

handpiece

before

in

the

tip

wire.

manner

coatings

(thinning)

it

becomes

bore.

as

assembly:

by

Clear

soldering

lightly

of

the

so

thin

the

iron

wiping

inside

that

residue

tips.

the

bore

it

breaks

from

The

tip

on

occurs

off

inside

BROKEN

If

the

tip

steel

rod,

while

the

front

face

TIP

breaks

slightly

Extractor

of

the

less

heater

REMOVAL

off

in

the

Heater

than

1/8

is

still

hot.

is

supported

inch

With

assembly,

in

diameter,

set

screw

and

drive

remove

to

ram

removed,

the

broken

power

the

insert

tip

cord

broken

ram

out.

from

power

tip

out

from

handle

(FIGURE

of

source.

the

Heater

end

8)

Use

tube

while

a

the

FIGURE

8.

BROKEN

14

TIP

REMOVAL

Page 15

TIP

REPLACEMENT

a.

While

the

.

Remove

.

Clean

.

Place

.

Tighten

200

Although

that

the

once

every

SOLDER

buildup

with a large

and

CLEANING

Solder

often

inside

and

as

necessary

of

Chamber

flux

unit

the Tip

Heater

new

Tip

set

screw

set

screw

“S”

PROCEDURE

is

idling

hot,

loosen

from

the

Heater.

with

small

wire

brush

in

Heater

screws

be

eight

operating

COLLECTION

in

Chamber

bristle

Baffle.

1/8

turn

are

loosened

with

hangout

past

the

NOTE

permanently

and

hours.

depends

brush.

Apply mineral

MAINTENANCE.

set

screw

to

free

the

tip.

to

remove

of

point

lubricated,

the

CHAMBER

upon

1%

of

tip

use.

oxide

to

%.

contact

be

removed

Clean

oil

buildup.

to

secure

it

is

essential

at

Chamber

to

the

brush

Tip

least

and

in

“S”

and

place.

Baffle

lightly

as

coat

REPLACING

The

white,

(FIGURE

very

restriction,

9)

should

important

and

PRIMARY

primary

be

that

this

keeps

Sodr-X-Tractor

changed

filter

contaminants

VISIBLE

whenever

be

kept

FIGURE

9.

SODR-X-TRACTOR

FILTER

Filter

clean;

from

Sodr-X-Tractor

located

heavy

this

reaching

Filter

deposits

assures

within

of

optimum

the

vacuum

FILTER

the

rear

of

contaminants

air

flow

source.

Rear

Seal

LOCATION.

the

Glass

are

noticeable.

and

minimum

Baffle

End

Cap

Assembly

and

Chamber

It

flow

is

15

Page 16

(MAINTENANCE

CORRECTIVE

Table

tion

The

joints

removed

(2)

outlines

to

each:

TABLE

SYMPTOMS

operator

are not

on a consistent

notices

MAINTENANCE

the

most

2.

CORRECTIVE

that

solder

being

completely

basis.

common

ACTION

Loss

deficiencies

FOR

CAUSE

of

Vacuum

MOST

which

might

COMMON

A.

wire

C.

a

Transfer

THE

occur

MALFUNCTIONS

Clean

Tip

B.

Clean

bristle

Check

has shifted

position

Tube,

reduced.

Baffle

maintains a constant

Chamber.

bending

fingers.

GLASS

be

Baffle

room

9).

D.

is

Е.

contaminant

air

F.

air

of

replace

G.

or filter

Dark

replacement.

H.

Vacuum

“Operation

Source

manual.

It

have

the

DO

“S”

BAFFLE

CHAMBER.

seated

Assembly,

for

Front

Seal—Assure

properly

Sodr-X-Tractor

flow.

Replace.

Damaged

hose

can

vacuum.

if

Clogged

element

discoloration

Clogged,

Transducer—Refer

or

SOLUTION

Heater

brush.

“S”

within

is

enough

This

“S"

NOT

just

the

seated

necessary.

VisiFilter—Replace

and

the

bore.

solder

Baffle.

where

Filter

loaded

Air

cause

Vacuum

If

the

it

the

vacuum

important

tension

may

be

Baffle

ATTEMPT

WHILE

The

in

front

leaving

(refer

on the front

Visible

filter

Hose—A

partial

Examine

when

indicates

Damaged

Maintenance

easiest

transfer

the

Glass

that the

position

between

Baffle

of

that

filter

Transducer”

solu-

“S”

Baffle

Tube

blocks

could

so that

in

adjusted

TO

BEND

IT IS

IN

should

the

End

sufficient

to

FIGURE

Chamber

seal.

Filter—A

will

reduce

damaged

or

full

hose

is

loaded.

time

Pump

to

Power

with

to

the

be

“S"

it

the

by

your

THE

Cap

loss

and

filter

for

or

your

16

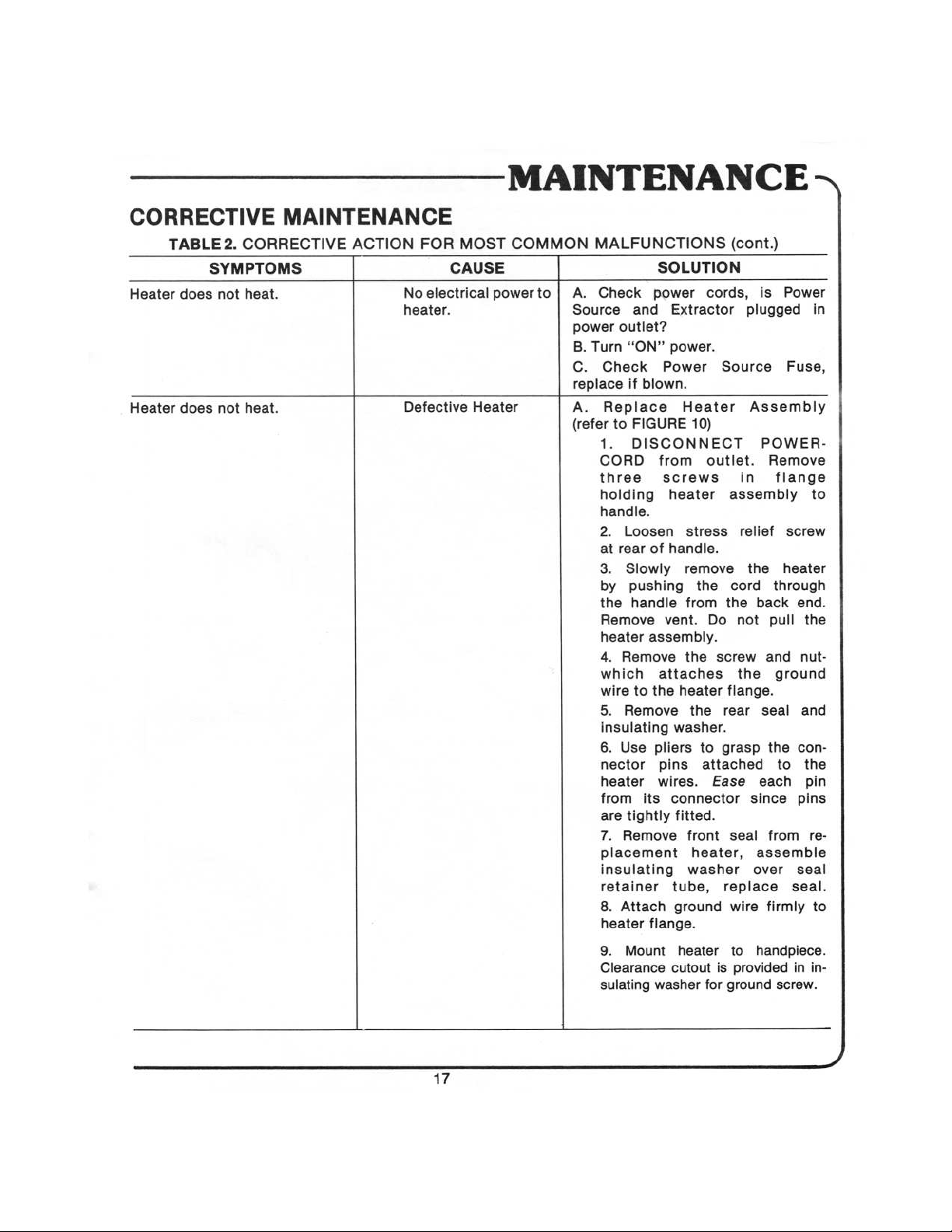

Page 17

MAINTENANCE

~

CORRECTIVE

Heater

Heater

TABLE

SYMPTOMS

does

does

not

2.

not

MAINTENANCE

CORRECTIVE

heat.

heat.

ACTION

No

heater.

FOR

CAUSE

electrical

Defective

MOST

COMMON

powerto | A.

Heater

MALFUNCTIONS

Check

Source

power

B.

C.

replace

A.

(refer

and

outlet?

Turn

“ON”

Check

if

blown.

Replace

to

FIGURE

1.

DISCONNECT

CORD

three

holding

handle.

2.

Loosen

at

rear

3.

Slowly

by

pushing

the

handle

Remove

heater

4.

Remove

which

wire

to

5.

Remove

insulating

6.

Use

nector

heater

from

its

are

tightly

7.

Remove

placement

insulating

retainer

8.

Attach

heater

of

assembly.

flange.

SOLUTION

power

attaches

the

pliers

wires.

cords,

Extractor

power.

Power

Heater

10)

from

pins

outlet.

screws

heater

stress

handle.

remove

the

from

vent.

Do

the

heater

the rear

washer.

to

attached

Ease

connector

fitted.

front seal

heater,

washer

tube,

ground

(cont.)

plugged

Source

Assembly

in

assembly

relief

the

cord

the

not

screw

the

flange.

grasp

since

over

replace

wire

is

Power

Fuse,

POWER-

Remove

flange

screw

heater

through

back

end.

pull

and

ground

seal

the

con-

to

each

pins

from

assemble

seal

seal.

firmly

in

to

the

nut-

and

the

pin

re-

to

9.

Mount

Clearance

sulating

heater

cutout

washer

is

for

to

handpiece.

provided

ground

in

screw.

in-

17

Page 18

REPLACEMENT

PARTS

q

FIGURE

10.

DIAGRAM

OF

18

REPLACEMENT

PARTS

Page 19

ITEM

20

22

23

30

TABLE

1

1A

2

2A

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

21

24

25

26

27

28

29

31

3.

NO.

REPLACEMENT

LIST

OF

REPLACEMENT

(Refer

Extractor

Extractor

Vents

Vent

Super

Glass

“S”

Sodr-X-Tractor

Heater

Heater

Heater

Screw,

Screw

Set

Nut

Line

Line

Line

VisiFilter

VisiFilter,

Filter

Twist

Tubing

Tubing

Tubing

Clamp,

Clamp,

Tubing,

Baffle

Bristle

Wire

Cushion

Front

Rear

Handle,

Handle, SX-20V,

(2)

(1)

Tip

Chamber

Baffle

and

Seal

and

Seal

Washer

Nylon 1405-0341

w/Lockwasher

Screw

(Pk/10)

#4-40,

Hex

Cord

Assembly

Cord

Assembly,

Cord

Assembly

Replaceable

Element,

Lock

Fitting

Assembly

Assembly

12”

Flat

Round

6°

Length

and

End

Brush

Brush

Grip

Seal

Seal

to

SX-20, SX-25,

Filter

Assembly,

Assembly,

Head

VisiFilter

w/VisiFilter

w/Twist

Cord

Type

Cord

Cap

(fits

standard

FIGURE

DESCRIPTION

SX-25V,

(Pk/10)

Dual Path

Dual Path

#4-40 x 5/16”

(1)

(VDE)

Standard

(24VAC)

Element

Lock

Type

Assembly,

handpiece

PARTS

10

SX-30

(120VAC)

Type

Fitting

Dual Path

for

SX-30V

120VAC,35W

24VAC,35W

SST

(4)

only)

FOR

Item

SOLDER

No.)

PARTS.

EXTRACTOR

PACE

PART

NO.

1119-0039

1119-0050

1119-0041

1119-0042

See

Tip

Chart

1265-0003

4010-0033

1309-0018

6010-0034

6010-0035

1213-0030

1348-0285

1332-0090

1332-0009

1332-0032

1309-0020

1309-0028

1309-0027

1263-0004

1325-0017

1325-0006

1342-0001

1211-0002

1321-0085-02

1325-0003

4010-0071

1127-0002

1127-0006

1346-0042

1213-0033

1213-0001

REPLACEMENT

Table 4 lists

the

Outside

Diameter

Inside

(1.D.)

replacement

Diameter

Nom.

TIPS

Tips

(O.D.)

and

TABLE

FIGURE

SUPER

TIPS

Outside

4.

REPLACEMENT

1.D.

(0.D.)

+

11.

FOR

in. | mm

018 | 0.45

.025 | 0.63

036 | 0.91

050 | 1.27

061

.095 | 2.43

Diameter

Ref.

MEASUREMENT

SOLDER

used

for

the

Inside

Diameter

NOMINAL | O.D.

1.55 .104

19

EXTRACTOR

Solder

in.

059

.060 1.52

072

„085

125

Extractor.

(I.D.),

PART

REFERENCE | PACE PART

OF

then

NUMBER

mm

1.34

1.83

2.16

2.64

3.17

REPLACEMENT

Use

select

FOR

NUMBER

1121-0213

1121-0214

1121-0215

1121-0216

1121-0217

1121-0091

FIGURE

the

Tip

TIPS

Super

have

1.D.

marks

(Trademark)

TIPS

11 to

part

tips

two

determine

from

Table

4.

ノ

Page 20

|

INCORPORATED

|

LAUREL,

©1982 PACE

ALL

SPECIFICATIONS

9893

MARYLAND

(301)

FAX

INCORPORATED

SUBJECT

490-9860

301

ALL

TO

498

RIGHTS

COURT

20723-1990

3252

RESERVED

CHANGE

WITHOUT

a

USA

PRINTED

NOTICE

IN

U.S.A.

Loading...

Loading...