Page 1

DTP-80

DTP-80 Dual ThermoPik Handpiece

OPERATION & MAINTENANCE MANUAL

Page 2

2

PACE Incorporated retains the right to make changes to specifications contained

herein at any time, without notice.

Contact your local authorized PACE Distributor or PACE Incorporated to obtain the

latest specifications.

The following are registered trademarks and/or servicemarks of PACE Incorporated,

Laurel Maryland U.S.A. and may only be used to identify genuine PACE products or

services:

AdapTip, Arm-Evac, Cir-Kit, ComForm I, ConducTweez, CRAFT,

Dual Path, Flo-D-Sodr, FuseSet, HandiPik, HotSpot, LapFlo, MBT,

Micro Portable, MicroChine, MiniChine, Mini-Wave, PACE, Pacenter,

Ped-A-Vac, PETS, Pik-Vac, PRC, PRINT, Pro-Evac, Redi-Rak,

ResisTweez, SensaTemp, SMR, Snap-Vac, Sodr-Pen, Sodr-X-Tractor,

SR-3, SR-4, ST, StripTweez, SwaPlater, ThermoBand, Thermo-Drive,

ThermoJet, ThermoPart, ThermoPik, ThermoTweez, Tip-Evac, VisiFilter.

The following are trademarks and/or servicemarks of PACE Incorporated, Laurel

Maryland U.S.A. and may only be used to identify genuine PACE products or

services:

Auto Off, Cubby-Vac, Datastore, Dust Evac, EKO, Lab Evac, MicroSpin,

PaceLink, PaceNet, Pik & Paste, Prep-Set, Pulse Plate, Spa-Kleen,

ThermoBond, TinSpin, TweezPik, Uni-Frame, V-A-N, Ventur-Evac.

Since 1958, PACE Incorporated has provided advanced technology

training in all aspects of hand soldering, rework and repair.

Additional copies of this manual or other PACE literature may be obtained from:

PACE Incorporated (301) 490 - 9860

Sales Administration (301) 498 - 3252 Fax

9893 Brewers Court

Laurel MD 20723-1990

© 1995 PACE Incorporated, Laurel MD. All rights reserved. Printed in the U.S.A.

Page 3

3

DTP-80

DUAL THERMOPIK HANDPIECE

PACE P/N 7029-0001

OPERATION & MAINTENANCE

MANUAL

MANUAL NUMBER 5050-0403

REV. A

For any questions regarding the following instructions, contact your local authorized

PACE dealer or contact PACE directly at:

Telephone (301) 490-9860, Fax (301) 604-8782

PACE Incorporated

9893 Brewers Court

Laurel MD 20723-1990

Page 4

4

These instructions detail the basic operational guidelines for using the DTP-80 Dual

ThermoPik handpiece.

INTRODUCTION

The DTP-80 Dual ThermoPik handpiece provides safe, one-handed removal of a

wide variety of Quad FlatPacks (PQFPs) in a matter of seconds and can even remove

BGAs (Ball Grid Arrays). The Dual ThermoPik is a member of the PACE

SensaTemp family of advanced handpieces.

CAUTION

Always return heated handpieces to the appropriate Tip & Tool Stand

when not in use. Failure to do so may cause burns to the operator,

equipment or work surfaces and may be a potential ignition source if

combustible materials are nearby. Always use this handpiece in a well

ventilated area to avoid the inhalation of fumes created by solder flux

gases.

Page 5

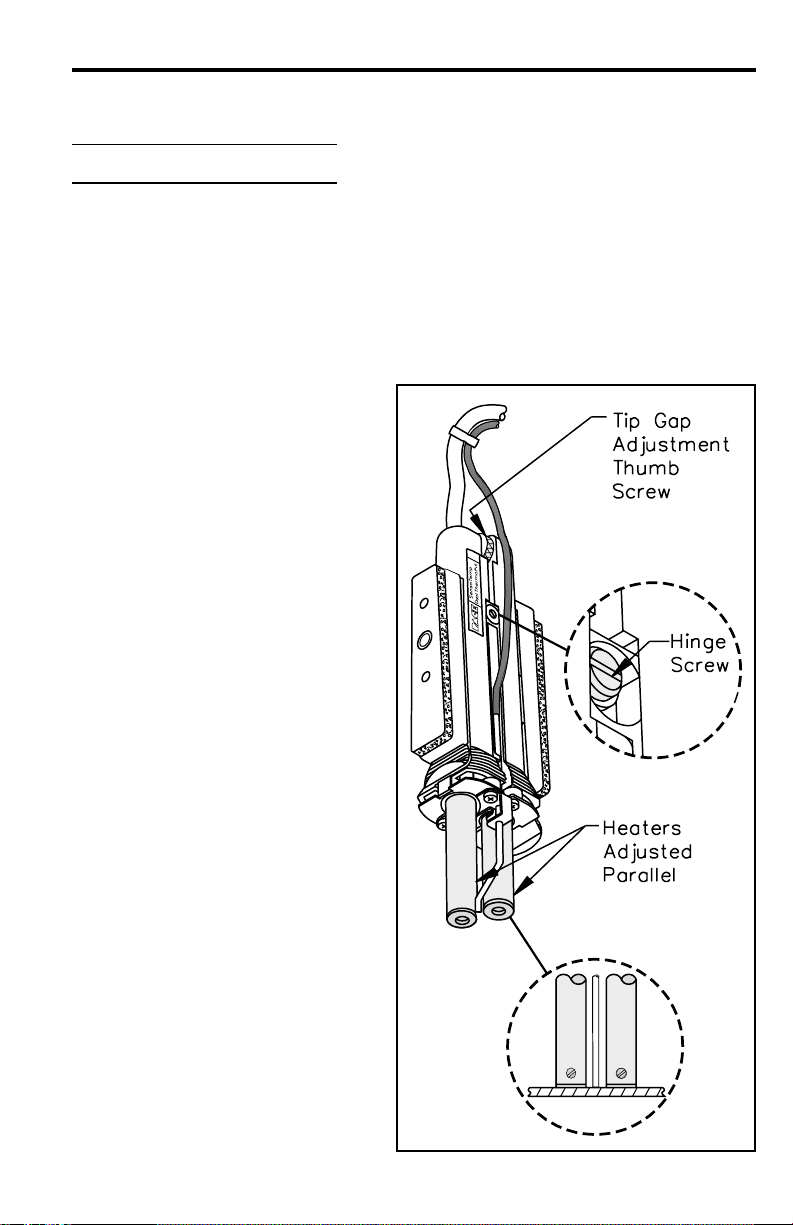

HANDPIECE SETUP

HANDPIECE ALIGNMENT

Check the handpiece heaters for proper alignment with each other. Proper handpiece

(and tip) alignment is essential for effective operation.

1. Remove any installed tip.

2. With the handpiece at room

temperature, adjust the

heaters parallel to each other

(refer to illustration) using the

Tip Gap Adjustment Thumb

Screw. If the heater ends are

even with each other, go to

"Power Source Connection".

If the ends are not even, go to

step 3.

3. Loosen the handpiece Hinge

Screw 1/2 turn.

4. Holding the handpiece in a

vertical position (heaters

facing down), place the ends

of the two heaters against a

hard flat surface to insure

proper alignment. The heater

ends should be even with each

other and flush against the flat

surface. Gently push the rear

of the handpiece handles to

force both heaters against the

flat surface.

5. Tighten Hinge Screw to secure

in position.

5

Page 6

6

POWER SOURCE CONNECTION

NOTE

If using your DTP-80 ThermoPik for the first time or if you have just

replaced the heater, you must follow the “DTP-80 Heater Burn-in”

procedure (red tag on handpiece) to increase the life expectancy of the

heater and to minimize any smoke and fumes generated by the heater on

its initial power-up.

Connect the handpiece power cable connector to one of the front panel power

receptacles on your PACE power source. PACE recommends that air handpieces

utilize the power receptacles closest to the AUTO SNAP-VAC (or SNAP-VAC) Port

to minimize cord tangles.

NOTE

To insure optimum performance, use only one Dual ThermoPik

handpiece and any other SensaTemp handpiece (except TT-65

ThermoTweez) on 2 channel power sources. On MBT 250A/220A or

PRC 2000 systems, use of 2 Dual ThermoPiks or a Dual ThermoPik

and a ThermoTweez handpiece may be powered by the same power

source with the third channel left vacant (no handpiece connected).

Page 7

7

TIP TEMPERATURE

The DTP-80 rapidly transfers heat by contact and typically allows component

removal at relatively low temperatures in the 288 - 343°C (550 - 650°F) range. Tip

temperature and removal times will vary with each application. PACE recommends

the use of a 316°C (600°F) tip temperature setting for initial use in any particular

application. With practice, many components can be removed at lower

temperatures. Use the lowest possible tip temperature that will provide rapid, yet

controlled solder reflow. Lower temperatures extend tip and heater life, allow solder

to remain on the lower surfaces of the tip (to improve thermal linkage between the

tip and the component during component removal) and help prevent possible board

damage.

Refer to the Tip & Temperature Selection System booklet for your particular

handpiece/tip combination. For all Dial Display SensaTemp systems, the booklet

will indicate the correct Dial Settings for the True Tip Temperature. On systems

incorporating a Digital Readout, set the desired operating temperature and Tip Offset

Constant for the DTP-80 handpiece/tip combination into the channel powering the

DTP-80.

Page 8

AIR HOSE CONNECTION

Use the following procedure to attach the handpiece air hose to your PACE power

source.

NOTE

Ensure that only one air hose is connected to the AUTO SNAP-V AC (or

SNAP-VAC) or Controllable PRESSURE Port at one time. Attachment

to both ports simultaneously will cause a deterioration of performance.

To set up your DTP-80 for operation, perform the following steps:

1. Connect the 152 cm (60 inch)

length of black silicone air hose

to the Vacuum Pick tube (metal

tube) in the middle of the

handpiece.

2. Attach the male quick connect

hose mount fitting (P/N 1259-

0102) supplied with the

handpiece to the other end of

the black silicone air hose. This

fitting has a special Vacuum

Release Opening to provide a

quick component release during

component removal operations;

DO NOT use any other male

fitting.

3. Secure the air hose to the

handpiece power cable with

hose clamps (P/N 1321-0274).

8

Page 9

9

4. Prepare a VisiFilter by

connecting a 2.5cm (1 inch)

length of clear pvc air hose to

each side of the VisiFilter.

Connect a female quick

connect hose mount fitting

(P/N 1259-0086) to one of

the air hose ends . Connect

the 152cm (60 inch) length of

black silicone air hose to this

end of the VisiFilter and the

DTP-80 handpiece.

5. To the other air hose end (on VisiFilter), attach a male quick connect hose

mount fitting (P/N 1259-0087).

6. Attach the male quick connect hose mount fitting (on VisiFilter air hose)

to the power source AUTO SNAP-VAC (or SNAP-VAC) Port.

NOTE

Always use your Dual ThermoPik handpiece with a clean VisiFilter

element. Otherwise a deterioration in performance or damage to the unit

may occur.

Page 10

10

TIP SELECTION

Selection of the proper tip is essential for effective operation. Attempts to use an

improperly sized tip will result in unsatisfactory handpiece operation and may result

in lifted lands or board damage.

Table I details a partial listing of available tips. Contact your local authorized PACE

dealer for the latest Tips & Accessories Catalogue which details all available tips

and accessories.

TIP INSTALLATION

The following instructions are for tip installation only. If a tip is currently installed

in the handpiece, remove the installed tip (heater hot) and clean both heater bores

using the supplied 3/16" diameter wire brush prior to the installation of a new tip.

1. Select the proper tip for your application. Refer to Table 1.

2. Insert the tip shafts fully into the heater bores.

3. Using the supplied Tip & Vacuum Cup Tool

(P/N 1100-0239) or small screwdriver,

tighten the heater assembly set screws for a

snug fit. Do not over tighten.

NOTE

The DTP-80 tips must be kept properly tinned and free of oxidation to

maximize tip life. Use the tip cleaning tools to remove all traces of solder

from the heated tip. Carefully inspect for any oxidation buildup. If

oxidation is present, re-tin and clean the tip until no oxidation spots

remain. Immediately tin the tip surfaces and keep them tinned at all times.

Page 11

11

PQFP Removal Tip Descriptio

PQFP 100

PQFP 132

PQFP 144

A

Application

B

PQFP 208

PQFP

160/208

PQFP 240

PQFP 196

PQFP 304

Tip Size

A X B

0.83" x 0.83"

(21.1mm x

21.1mm)

1.03" x 1.03"

(26.2mm x

26.2mm)

1.15" x 1.15"

(29.2mm x

29.2mm)

1.17" x 1.17"

(29.7mm x

29.7mm)

1.21" x 1.21"

(30.7mm x

30.7mm)

1.33" x 1.33"

(33.8mm x

33.8mm)

1.42" x 1.42"

(36.1mm x

36.1mm)

1.67" x 1.67"

(42.4mm x

42.4mm)

Part

Number

1121-0549

1121-0551

1121-0553

1121-0557

1121-0552

1121-0558

1121-0554

1121-0593

BGA Removal Tips

BGA-169

A

B

Application

BGA-225

All dimensions are no minal.

Consult your authorized PACE Distributor for

Table I. Dual ThermoPik Tip Selection Guide

.88" x .88"

(22.4mm x

22.4mm)

1.10" x 1.10"

(27mm x 27mm)

NOTE:

sizes not listed.

1121-0594

1121-0596

Page 12

VACUUM CUP INSTALLATION/REMOVAL

Three vacuum cup sizes are available for use with the DTP-80 handpiece. For

optimum performance, select the largest vacuum cup which is smaller than the body

of the component being removed. Use the supplied Tip & Vacuum Cup Tool and the

following instructions to remove or install the vacuum cup.

WARNING

Do NOT install or remov e a Vacuum Cup with bare hands! Alwa ys use

the Tip & Vacuum Cup Tool! Installation by any other means may cause

burns to the operator.

INSTALLATION

1. Ensure that the proper tip is installed in the

handpiece.

2. Place the selected Vacuum Cup on the Pin of

the Tip & Vacuum Cup Tool as shown.

3. Press the vacuum hose against the

handpiece handle as shown. This will

hold the Vacuum Pick in position.

12

Page 13

4. Insert the Tip & Vacuum Cup

Tool Pin into the end of the

handpiece Vacuum Pick.

5. Gently push the Vacuum Cup

onto the Vacuum Pick.

6. Remove the Tip & Vacuum Cup

Tool.

REMOVAL

1. Place the open-slotted end

of the Tip & Vacuum Cup

Tool around the Vacuum

Pick and behind the Vacuum

Cup as shown.

2. Press the vacuum hose

against the handpiece

handle to hold the Vacuum

Pick in position.

3. Pull the Vacuum Cup off the

end of the Vacuum Pick.

13

Page 14

VACUUM PICK ADJUSTMENT

Proper vacuum must be maintained to lift and hold the component during a removal

operation. The Vacuum Pick Assembly within the DTP-80 handpiece adjusts

quickly and easily to provide an optimum setting where the vacuum cup makes

contact with the component body as the tip makes contact with the component leads.

To adjust the Vacuum Pick Assembly, perform the following procedure:

1. Ensure that the proper tip and vacuum cup are installed on the DTP-80.

2. Using the Tip & Vacuum Cup Tool,

grasp the Vacuum Pick as shown in

the illustration.

3. Adjust the Vacuum Pick position to a

point where the end of the Vacuum

Cup is flush (even) with the bottom

edges of the tip.

IMPORTANT - The Vacuum Pick is now in a proper position for initial operation.

During the first component removal operation, the vacuum cup will contact the

component body as the tip is lowered over the component. As the tip moves down

to contact the component leads, the vacuum pick slides into position. Readjustment

will not be required until the component removal application changes (e.g., different

component, tip, vacuum cup).

14

Page 15

TIP PREPARATION

DTP-80 tips must be kept free of oxidation to ensure that maximum heat transfer

will take place at all times.

BGA Removal Tips - are not tinnable; use the tip cleaning tools (provided with the

optional Tip Maintenance Station P/N 6993-0138) to remove all traces of oxidation

from the heated tip.

PQFP Removal Tips - must be kept properly cleaned and tinned. Carefully inspect

for any oxidation buildup. Use the tip cleaning tools (provided with the optional Tip

Maintenance Station P/N 6993-0138) to remove all traces of oxidation and solder

from the heated tip. If oxidation is present, clean the tip until no oxidation spots

remain. Immediately tin the tip surfaces and keep them tinned at all times.

Prepare the installed tip using the following procedure:

1. Clean all bottom edges of the installed tip using a PACE fiber cleaning

tool.

2. Shock the bottom edges of the installed tip using a PACE sponge tool or

sponge.

3. When using a PQFP Removal Tip, apply

a continuous bead of solder along the

bottom edges of the installed tip.

NOTE

The molten solder of a properly tinned PQFP Removal Tip is the medium

through which an efficient heat transfer takes place making sim ultaneous

reflow of all solder joints and component removal possible.

15

Page 16

BOARD/COMPONENT PREPARATION

Proper preparation is the key to successful component removal. To obtain optimum

results, this procedure should be followed.

Once you become familiar with the use of the handpiece, you may find it beneficial

to develop procedure variations which comply with your company guidelines.

1. Remove any protective coatings and clean the component leads and land

areas using an approved solvent or cleaner.

2. Ensure that the PCB is free of moisture. You may wish to gently dry the

area using a heated air tool ( i.e., TJ-70 ThermoJet).

3. Preheat the PCB as necessary. PCBs consisting of heat sinking materials

(e.g., ceramic, polyamide, etc.) or those with an exceptionally heavy

ground or power planes may require the use of a preheating system such

as the PACE HotSpot.

16

Page 17

4. In order to maximize heat transfer from the handpiece tip to PQFP

component lead/land connections, PACE recommends adding

bridgefill ..............

solder wrap ..........

or

flux ......................

to maximize heat transfer across all connections.

When removing BGA components, the use of flux is an option which can

be used to enhance heat transfer.

17

Page 18

COMPONENT REMOVAL

Use the following procedure to remove the component. Ensure that the component

and board have been properly prepared (see “Board/Component Preparation”) before

removing component.

1. Set the PCB Assembly so that the component side to be worked on is flat

and steady.

2. Clean the tip and apply a fresh bead of solder to its bottom edges.

3. Position the handpiece

directly over the component

to be removed.

4. Bring the handpiece down

over the component. The

vacuum cup should make

contact with the component

body before the tip makes

contact with the leads. If the

vacuum cup does not make

contact, then the vacuum

pick assembly is not

properly adjusted. Remove

the handpiece and readjust

the pick before proceeding.

18

PQFP Component

Page 19

19

NOTE

If the Vacuum Pick adjustment is incorrect (the vacuum cup not resting

on the component body correctly), refer to the "Vacuum Pick

Adjustment" portion of this manual.

6. The installed tip, when used to remove . . .

a) PQFP components - should make contact

with all the leads/solder joints

simultaneously. After 1-5 seconds, all the

leads should have reflowed.

Activate and hold the Vacuum Switch to

apply vacuum. If any adhesive is located

beneath the component, gently slide the

component to break adhesive loose.

NOTE - Total time for the operation from

tip placement to component lifting should

take no longer than 6-8 seconds. If

complete solder melt has not been

achieved, remove the tool and allow the

board and component to cool before a

second attempt.

b) BGA components - should make contact

with the package. Dwell times may be

longer than one minute & will vary

depending on your particular component

and PCB.

After reflow of all connections, activate

and hold the Vacuum Switch to apply

vacuum.

7. Lift the handpiece straight up with the vacuum still running. Release the

Vacuum Switch to deposit the component on an insulated surface.

8. Clean the tip; re-tin if using a PQFP Removal Tip (BGA Removal Tips

are not tinnable). Return the handpiece to its Tip & Tool Stand.

You may wish to alter your procedure for best results in your application.

Use the SX-70 Sodr-X-Tractor handpiece to remove the old solder from the PCB

and to prepare the lands for installation of a new part. Refer to one of the SX-70

Sodr-X-Tractor manuals for suggested solder removal techniques.

Page 20

20

SPECIAL APPLICATIONS

If you require assistance in the use of this handpiece or require assistance with a

special application, contact PACE Applications Engineering at:

Telephone: (301) 490 - 9860

Fax: (301) 604 - 8782

CORRECTIVE MAINTENANCE

Your DTP-80 requires no special maintenance other than being kept clean. The

heater bore must be kept free of oxidation and debris in order to maintain the

proper tip-to-ground resistance. Periodically inspect the power cable, connector

and handpiece itself for evidence of physical damage. Do not use a handpiece with

a damaged power cable. Refer to Table II and the illustration following for

information on troubleshooting most handpiece problems. Table III lists the

common handpiece parts.

Use Table II and the Connector Plug illustration to troubleshoot your DTP-80 Dual

ThermoPik handpiece. Disconnect the handpiece from the PACE power source.

Use a voltmeter to check the resistance across the handpiece Connector Plug pins as

outlined in the “Checkout Procedure” column.

NOTE

The handpiece Heater Assembly must be at room temperature (22° C or

72°F) before performing "Heater Assembly Checkout Procedures".

Page 21

21

SYMPT

No heat on

either

heater.

Handpiece

overheating.

Heat on

only 1

heater.

Fuse blows

when unit is

turned on.

CHECKOUT

PROCEDURE

Check resistance - Pin 3 to Pin 6.

Resistance should be 110 ohms.

If circuit reads open - -

Check resistance - Pin 2 to Pin 5.

Resistance should be 6 ohms.

If circuit reads open - -

Check resistance - Pin 3 to Pin 6.

Resistance should be 110 ohms.

If circuit reads less than 105 ohms

- Check resistance - Pin 2 to Pin 5.

If resistance equals 12 ohms - -

Check resistance - Pin 4 to Pin 5

and Pin 4 to Pin 2.

Circuit should read open. If not - -

CAU SOLUTION

Open

Sensor

Open

Heater

Shorte

Sensor

Open

Heater

Shorte

Heater

Table II. Heater Assembly Checkout Procedures

Replace Heater

Assembly "A".

Replace both Heater

Assemblies.

Replace Heater Assembly

"A".

Replace cold Heater

Assembly.

Remove handpiece side

cover "B". Disconnect

wire connections to Heater

"B". Check resistance

again. If circuit reads

Page 22

22

REPLACEMENT P ARTS

Description Part Number

Heater Assembly "A" (with sensor) 6010-0082-P1

Heater Assembly "B" (without sensor) 6010-0083-P1

Heater Set Screw 1348-0547-P10

Tip (and Vacuum Cup) Tool 1100-0239

Vacuum Tubing 1342-0027

Holder, Tube to Wire (hose clamps) 1321-0274-P6

Vacuum Cup Kit 6993-0153-P1

DTP Tip & Tool Stand 6019-0047

Replacement Pads For Cushion Grips 1317-0029-P2

Tip Redi-Rak 6021-0007-P1

Tip & Tool Stand Tip Redi-Rak 6021-0008-P1

3/16 inch O.D. Wire Brush For Cleaning 1127-0014-P5

Tip Maintenance Station 6993-0138

Table III. DTP-80 Replacement Parts

Loading...

Loading...