Page 1

10 Series CNC

Software Release 7.5.4

Installation Manual

Code: 45006687N

Rev. 18

PUBLICATION ISSUED BY:

OSAI S.p.A.

Via Torino, 14 - 10010 Barone Canavese (TO) – Italy

Phone: +39-0119899711

Web: www.osai.it

e-mail: sales@osai.it

service@osai.it

Copyright 2001-2006 by OSAI

All rights reserved

Edition: April 2006

IMPORTANT USER INFORMATION

This document has been prepared in order to be used by OSAI. It describes the latest release of

the product.

OSAI reserves the right to modify and improve the product described by this document at any time

and without prior notice.

Actual application of this product is up to the user. In no event will OSAI be responsible or liable for

indirect or consequential damages that may result from installation or use of the equipment

described in this text.

Page 2

abc

Page 3

UPDATE

10 Series CNC Software Installation Manual

SUMMARY OF CHANGES

General

This document was published following the issue of Software Release 7.5.4 (E69); it contains

information about the new functions of the 10 Series CNC.

NOTE:

This document contains the updates related to the issue of Software Release 7.5 (FIXUP 4) and to

the management of the 10 Series Systems, based on CPU PROX-1635.

PAGE TYPE OF MODIFICATION

INDEX

PREFACE

CHP. 0

CHP. 1

Page 1

Updated

Summary and all references to the software release updated

Added a new chapter “Important warnings”

All references to software release updated

Updated note

CHP. 3 New chapter describing changes and improvements introduced with

the new release

APP. A

Page 3

APP. D

Updated compatibility tables

Modified description in the paragraph “Mass storage size compatibility”

Updated appendix containing a list of changes compared to earlier

releases.

At the end of the description of each Release (from release 6.0 on), added

the relative table as given in Appendix A.

10 Series CNC Software Installation Manual (18)

Page 4

abc

abc

Page 5

Preface

10 Series CNC Software Installation Manual

PREFACE

This manual describes the methods for correct installation of release 7.5 on 10 Series CNC

systems, the new features and the differences from the previous release, so that operators can

tune their systems to obtain optimum performance.

We have written this manual for OEM and end user personnel charged with installing,

characterising and developing system applications.

REFERENCES

For more information about 10 Series read the following:

• 10 Series CNC User Manual

• 10 Series CNC AMP - Software Characterisation Manual

• 10 Series CNC Programming Manual

• 10 Series CNC PLUS Language and PLUSEDIT

• 10 Series CNC PLUS Application Manual

10 Series CNC Software Installation Manual (17) 1

Page 6

Preface

10 Series CNC Software Installation Manual

SUMMARY

This manual provides the operator with procedures for correct SW installation, a brief description of

the feature enhancements of the new release, and the major differences with respect to previous

release.

1. Installation

Describes SW installation procedures

2. OSAI security

Contains a description of the E69 software option, OSAI Security.

3. Modifications and enhancements introduced with release 7.5

Contains a description of the new features and the improvements on the previous release

A. Options compatibility tables

B. Error messages

Lists the error messages displayed by the system during installation

C. Instructions for CNC Set-up

Contains a description of the setup utility for selecting the type of Operator Panel connected to

the basic unit.

D. Summary of modifications made with earlier releases

Contains a description of the new functions or enhancements introduced on 10 Series

systems with releases earlier than 7.5.

2 10 Series CNC Software Installation Manual (17)

Page 7

Preface

10 Series CNC Software Installation Manual

GENERAL CONVENTIONS

Following are a number of terms used in this document:

Control is the 10 Series numerical control system with front panel and basic unit.

Front Panel is the machine/operator interface module. It has a monitor where all

messages are displayed and a keyboard for data inputs. It is connected

to the basic unit.

Basic Unit is the hardware-software unit that handles the machine functions. It is

connected to the front panel and the machine tool.

WARNINGS

For correct control operation, it is important to follow the information given in this manual. Take

particular care with topics bearing one of the mentions: WARNING, CAUTION or IMPORTANT,

which indicate the following types of information:

WARNING

CAUTION

IMPORTANT

Draws attention to facts or circumstances that may cause damage to the

control, to the machine or to operators.

Indicates information to be followed in order to avoid damage to equipment

in general.

Indicates information that must be followed carefully in order to ensure full

success of the application.

10 Series CNC Software Installation Manual (17) 3

Page 8

Preface

10 Series CNC Software Installation Manual

END OF PREFACE

4 10 Series CNC Software Installation Manual (17)

Page 9

INDEX

IMPORTANT WARNINGS

INSTALLATION PROCEDURE

Index

10 Series CNC Software Installation Manual

Installation Procedure............................................................................................ 1-2

Installing the Release ............................................................................................ 1-4

Installing Fixup and Options .................................................................................. 1-5

Backing-up the Release ........................................................................................ 1-6

Installing the Macros.............................................................................................. 1-8

OSAI SECURITY

GENERALITIES .............................................................................................................. 2-1

Hardware Requirements........................................................................................ 2-2

Software Requirements ......................................................................................... 2-2

Functionalities........................................................................................................ 2-4

Preliminary operations........................................................................................... 2-4

New hard disk installed.......................................................................................... 2-4

Impossibility of connecting the CNC through the net ............................................ 2-5

INSTALLATION AND ACTIVATION............................................................................... 2-6

“OSAI SECURITY” user interface.......................................................................... 2-7

Information on Fixup .............................................................................................. 2-9

Information on Options .......................................................................................... 2-10

Security protection levels....................................................................................... 2-11

Name of the CN in the net ..................................................................................... 2-12

Password ............................................................................................................... 2-13

Product Authorization Key ..................................................................................... 2-14

SETUP FUNCTIONALITY............................................................................................... 2-15

Installation on a new control .................................................................................. 2-15

Release update...................................................................................................... 2-17

Backup ................................................................................................................... 2-18

Restore .................................................................................................................. 2-19

Import files ............................................................................................................. 2-20

10 Series CNC Software Installation Manual (18) i

Page 10

Index

10 Series CNC Software Installation Manual

MODIFICATIONS AND IMPROVEMENTS INTRODUCED WITH

RELEASE E69 V7.4

FOREWORD ....................................................................................................................3-1

Changes made to the SYSTEM environment........................................................ 3-2

Changes made to the AMP environment............................................................... 3-3

Changes made to the PLUS, WINPLUS, I/O environment.................................... 3-4

Changes made to the PROCESS, AXES environment .........................................3-5

OPTIONS COMPATIBILITY TABLES

OPTIONS .........................................................................................................................A-1

Mass storage size compatibility ............................................................................. A-3

ERROR MESSAGES

ERROR MESSAGES LIST .............................................................................................. B-1

INSTRUCTIONS FOR CNC SETUP

SETUP UTILITY............................................................................................................... C-2

BIOS UTILITIES (E104, E109, E113, E114) ...................................................................C-4

E104 .................................................................................................................................C-6

Bios loading procedure for 10/565,10/585 CNC systems with 10.4" tft

operator panel or 10.4” tft operator panel WinLink ................................................ C-6

Bios loading procedure for 10/110 CNC systems.................................................. C-6

Bios loading procedure for 10/510, 10/100 10.4" CNC systems ........................... C-6

Bios loading procedure for 10/510 WinLink 12.1" systems, CNC side.................. C-7

Bios loading procedure for 10/510 WinLink 12.1" systems, PC side..................... C-7

Bios loading procedure for 10/565, 10/585 CNC systems with WinLink

12.1" tft operator panel........................................................................................... C-7

Bios loading procedure for 12.1" tft operator panel WinLink systems ...................C-8

Bios loading procedure for 10.4" tft operator panel WinLink systems ...................C-9

E109 .................................................................................................................................C-10

Bios loading procedure for 10/510i WinLink 12.1" systems, CNC side ................. C-10

Bios loading procedure for 10/510i WinLink 12.1" systems, PC side.................... C-10

Bios loading procedure for 10/150i 10.4” CNC systems........................................ C-11

E113 .................................................................................................................................C-12

Bios loading procedure for 10/510s and 10/110 light 10.4” CNC

systems ..................................................................................................................C-12

E114 .................................................................................................................................C-13

Loading the Bios for WinMedia systems with 15” TFT - ProX 3655

CPU........................................................................................................................ C-13

SUMMARY OF MODIFICATIONS MADE WITH EARLIER

RELEASES

RELEASE 5.0................................................................................................................... D-1

Changes to SYSTEM environment ........................................................................ D-2

Changes to AMP environment ............................................................................... D-2

ii 10 Series CNC Software Installation Manual (18)

Page 11

Index

10 Series CNC Software Installation Manual

Changes to PROGRAMMING environment .......................................................... D-3

Changes to PLUS environment ............................................................................. D-4

Changes to OPERATOR INTERFACE ................................................................. D-5

Changes to EMERGENCY START-UP environment ............................................ D-5

Changes to PERIPHERAL environment ............................................................... D-6

Changes to "SERVO MONITOR" environment ..................................................... D-6

RELEASE 5.1 .................................................................................................................. D-7

Changes made to the AMP environment .............................................................. D-8

Changes made to the PROGRAMMING environment .......................................... D-10

Changes made to the PLUS environment............................................................. D-12

Changes made to the OPERATOR INTERFACE ................................................. D-13

Changes made to the TABLE EDITOR ................................................................. D-13

Changes made to the EMERGENCY START-UP environment............................ D-13

Changes made to the SECURITY environment .................................................... D-14

Changes made to the ASSET environment .......................................................... D-14

Changes made to the PHERIPERAL environment ............................................... D-14

RELEASE 5.2 .................................................................................................................. D-15

Changes made to the AMP environment .............................................................. D-15

Changes made to the PROGRAMMING environment .......................................... D-16

Changes made to the PLUS environment............................................................. D-16

Changes made to the PROCESS environment..................................................... D-18

Changes made to the EMERGENCY START-UP environment............................ D-18

Changes made to the OPERATOR INTERFACE environment ............................ D-18

RELEASE 5.3 .................................................................................................................. D-19

Changes Made to the AMP Environment .............................................................. D-19

Changes Made to the PROGRAMMING Environment.......................................... D-20

Changes Made to the PLUS Environment ............................................................ D-20

Changes Made to the PROCESS Environment .................................................... D-21

RELEASE 6.0 .................................................................................................................. D-22

Changes made to the SYSTEM environment ....................................................... D-22

Changes made to the AMP environment .............................................................. D-22

Changes made to the PLUS environment............................................................. D-24

Changes made to the PROCESS environment..................................................... D-25

Changes made to the PERIPHERALS environment ............................................. D-25

Options .................................................................................................................. D-26

RELEASE 6.1 .................................................................................................................. D-27

Changes made to the AMP environment .............................................................. D-27

Changes made to the PLUS environment............................................................. D-28

Changes made to the PROCESS environment..................................................... D-29

Changes made to the PERIPHERALS environment ............................................. D-29

Options .................................................................................................................. D-30

RELEASE 7.0 .................................................................................................................. D-31

Changes made to the SYSTEM environment ....................................................... D-31

Changes made to the AMP environment .............................................................. D-32

Changes made to the PLUS environment............................................................. D-33

Changes made to the PROCESS environment..................................................... D-35

Changes made to the SECURITY environment .................................................... D-37

Options .................................................................................................................. D-38

RELEASE 7.1 .................................................................................................................. D-39

Changes made to the SYSTEM environment ....................................................... D-39

Changes made to the AMP environment .............................................................. D-40

Changes made to the PLUS environment............................................................. D-41

Changes made to the PROCESS environment..................................................... D-41

Options .................................................................................................................. D-42

RELEASE 7.2 .................................................................................................................. D-43

10 Series CNC Software Installation Manual (18) iii

Page 12

Index

10 Series CNC Software Installation Manual

Changes made to the SYSTEM environment........................................................ D-43

Changes made to the AMP environment............................................................... D-44

Changes made to the PLUS environment .............................................................D-45

Changes made to the PROCESS environment ..................................................... D-45

Changes made to the SECURITY environment ....................................................D-46

Options................................................................................................................... D-47

RELEASE 7.3................................................................................................................... D-49

Changes made to the SYSTEM environment........................................................ D-49

Changes made to the AMP environment............................................................... D-50

Changes to PLUS/WINPLUS environment............................................................ D-51

Changes made to the PROCESS environment ..................................................... D-53

Changes made to the SECURITY environment ....................................................D-53

Options................................................................................................................... D-54

RELEASE 7.4................................................................................................................... D-56

Changes made to the SYSTEM environment........................................................ D-56

Changes made to the AMP environment............................................................... D-58

Changes made to the PLUS, WINPLUS, I/O environment.................................... D-59

Changes made to the PROCESS, AXES environment .........................................D-63

Changes made to the ASSET environment........................................................... D-64

Changes made to the SECURITY environment ....................................................D-64

Options................................................................................................................... D-65

END OF INDEX

iv 10 Series CNC Software Installation Manual (18)

Page 13

IMPORTANT WARNINGS

WARNING

Chapter 0

IMPORTANT

When installing 10 Series systems based on PROX-1635 CPU, some important rules must be

followed when installing the complete software or a complete system backup:

1) The minimum level of software release compatible with PROX-1635 CPU are:

E69 v7.3 Fix up 9 – E69 v7.4 Fix up 7 – E69 v.7.5 Fix up 4

2) The Fix up must be installed immediately after the main software release without

powering down or rebooting the CN

If such procedure is not accurately followed, the network drivers risk to be overwritten and it won’t

be possible to connect again with the WinNBI Setup.

In case the above mis-operation would have happened, in order to restore the network

communication it will be necessary to restore the network drivers using the E108 “CNC Recovery

Disk” floppy disk through the external floppy drive directly connected to the CNC.

After having installed the E108 disk, the network drivers will be restored and then, through the

WinNBI Setup, it will be possible to re-start the procedure.

10 Series CNC Software Installation Manual (18) 0-1

Page 14

Chapter 0

Important warnings

The following table shows the software levels compatible with PROX-1635 CPU:

E 69 V7.3 E 69 V7.4 E 69 V7.5

OPTION Level Level Level

Problem Fix fixup lev. 4 fixup lev. 7 fixup lev. 4

BIOS utilities E116 v1.0 E116 v1.0 E116 v1.0

CNC Init Disk E107 v7.3.3 E107 v7.4.1 E107 v7.5.1

CNC Recovery Disk E108 v7.3.3 E108 v7.4.1 E108 v7.5.1

NOTE:

In case of operation in Windows 98 environment, in order to correctly execute the “in sequence”

installation of problem-fix immediately after software or backup installation, it is necessary to use

WinNBI C07 v2.5.1

The 10 Series Systems equipped whit PROX-1635 CPU, can be identified from the following Part

Numbers, shown on a label on the CNC chassis:

10/510i Light 93000659U

10/510i 93000660N

10/510i Blink 93000661F

10/510i OPLink 93000662H

10/510i WinLink 93000663B

END OF CHAPTER

0-2 10 Series CNC Software Installation Manual (18)

Page 15

Chapter 1

INSTALLATION PROCEDURE

For security reasons, the software release is not installed on the hard disk when the system is

shipped to you. Therefore, the first operation you must perform on receipt of your system is to

install the software supplied with the machine.

Read carefully the instructions on the Operator Panel setup given in Appendix

C of this manual before proceeding to install the software release.

WARNING

NOTE:

There is no Operator Panel setup for the 10/110 and 10/510 systems

The first diskette in the kit contains a program for installing and backing up the system software

and the user data. You must run this program in order to install the software release but may also

use it for:

Saving the OEM release: to complete the application, the original equipment manufacturer (OEM)

may create diskettes containing the customised software release complete with configuration,

interface logic, options and fixups. Then the OEM can supply these diskettes to the end user,

which will use them to install the software or when a service intervention on the hard disk is

required. It is in fact advisable to clear the hard disk before relocating the machine. This way the

end user is forced to install the OEM release on receipt of the machine, thus ensuring the integrity

of the hard disk data;

Saving user data: the end user may save the part programs and user data contained in the user

disk. For a good system performance after technological programs have been set up, it is

advisable to back these programs up, reinstall the user disk and bootstrap the user disk and

confirm the bootstrap prompt. This procedure permits to recover fragmented files and optimise

their reallocation on the disk.

NOTE:

The control hard disk is divided into 4 logical partitions; C: and D: are system disks containing the

supplied software release.

E: disk is for User and contains all data generated by the User of the control except for part

program. F: disk is the User disk containing part program.

For disk partitions size and compatibility, see appendix A.

10 Series CNC Software Installation Manual (17) 1-1

Page 16

Chapter 1

Installation Procedure

Installation Procedure

IMPORTANT

Release 7.5 CANNOT be installed on HDU smaller than 80 Mbytes.

IMPORTANT

To install release 7.5 not on a new control but on a machine with release 5.3

or lower, you must:

1) Back up user data (read this manual carefully to make sure there are

user data to be backed up before installing the new release).

2) Install the release as if the control were new.

3) Restore user data.

The installing procedure must be executed using the disks of the release 7.5.

The installation and back up procedure is very simple and is thoroughly guided: at each step the

system displays a prompt with the steps to follow.

1. If the CNC is equipped with a new hard disk, use the E107 initialisation floppy disk to partition it

(create partitions C,D,E and F).

2. Before switching the system on, insert the first diskette in the disk drive (floppy A).

3. Switch the system on. The following screen will appear, asking for the language in which

prompts will be displayed during installation/back up.

1) English Language

2) Italian Language

3) German Language

4) French Language

5) Spanish Language

Type your choice and press ENTER [ ]

or press ESC to exit

1-2 10 Series CNC Software Installation Manual (17)

Page 17

Chapter 1

Installation Procedure

3. After the language choice has been made, the system displays the following menu of

operations.

1) Install

2) Backup

3) Reset fixed disk to ship

Type your choice and press ENTER [ ]

or press ESC to exit

The meaning of each operation is as follows:

1. Installs the release or backs up the one created with selection 2.

2. Creates a system back up.

3. If the machine is transported elsewhere, the contents of the hard disk may be corrupted.

Therefore, to guarantee a correct machine start-up, you must delete all system and user data

stored in the hard disk and completely re-install the release after the machine has been

positioned in its new location. This option clears the hard disk.

IMPORTANT

With selection 3, all the data and the programs stored in the hard disk will

be deleted. For security reasons only use it before relocating the machine.

10 Series CNC Software Installation Manual (17) 1-3

Page 18

Chapter 1

Installation Procedure

Installing the Release

If you select the first option (Install), the system prompts you to select the type of installation

required, with the following screen.

During installation, the program checks for compatibility between the selected type and the

contents of the back up diskettes. If there is no compatibility, an error message will be displayed.

1) Complete installation

2) Install Release

Type your choice and press ENTER [ ]

or press ESC to exit

The meaning of each selection is as follows:

1 With this selection, the program formats the C,D,E and F partitions of the hard disk, and installs

the release or the backup. The hard disk must have been partitioned beforehand with option

E107.This selection is convenient both when the OEM receives a new control and must install

its system software release, and when the end user receives the machine tool and must install

the release supplied by the manufacturer.

2 With this selection, the program installs all the system files and initialises only the system disks

(C: and D:). The data stored in user disks E: and F: will not be altered. This selection is

mandatory when the release installed on a control or a machine tool must be updated.

1-4 10 Series CNC Software Installation Manual (17)

Page 19

Chapter 1

Installation Procedure

Installing Fixup and Options

When release is installed, the program offers the possibility to install options or fixups that are not

standard with the system by displaying the following message:

Do you want to install any option or fixup?

Press ENTER to confirm, ESC to exit

If the [Enter] key is pressed the system will display the following message:

Insert option or fixup floppy number 1

Press ENTER to confirm, ESC to exit

If the [Enter] key is pressed, the program starts to install the contents of the diskette in the drive. If

the [Esc] key is pressed, the installation procedure will be aborted.

10 Series CNC Software Installation Manual (17) 1-5

Page 20

Chapter 1

Installation Procedure

Backing-up the Release

If you have selected 2 (backup) the procedure requests you to choose a type of back from the

following menu.

1) Backup all the control

2) Backup system disk

3) Backup user disk

Type your selection and press ENTER [ ]

or press ESC to exit

The meaning of each selection is as follows:

1 With this selection, the program backs up the system files (disks C: and D:) and, if they exist,

the user disk files (E: and F:). It is this selection that permits the OEM to create their own

release with the control configured and custom prepared for a specific machine tool. The OEM

can then deliver the set of diskettes obtained from this operation to the end user.

2 With this selection, the program backs up system files only. It can be used by the manufacturer

that is building similar machines, i.e. with the same release, fixups and options but with different

characterisations (AMP and PLUS). In this case, the manufacturer may back up the control

system disks that contain only the basic release and the options. Later the OEM can use

selection 3 to back up the specific characterisation of each machine.

3 With this selection, the program opens a data entry for the user to back up user disks.

If you want to back up the user area of a system with a previous release in

IMPORTANT

order to download this back up on a machine with release 7.5, you need to

start the back up from the first diskette of release 7.5. Thus a back up version

appropriate is generated and can be installed on any system with such a

release 7.5.

The user can back up the user disk or the part program disk or both (if the system features an 80

Mb HDU).

1-6 10 Series CNC Software Installation Manual (17)

Page 21

If you select 3, the following data entry will be displayed:

BACKUPPING USER DISK

Press ENTER to confirm, ESC to skip

Then the following prompt will be displayed:

BACKUPPING PART PROGRAM DISK

Press ENTER to confirm, ESC to skip

After you press [Enter], only the selected disks will be backed up.

Chapter 1

Installation Procedure

To make a back up copy you need a set of diskettes. They can be new (and unformatted) or used

(and contain data you no longer need). In any case, they are always reformatted by the system

before back up starts. NEVER use the original diskettes supplied with the release for back up

purposes.

The number of diskettes needed for this operation varies with the configuration.

The program prompts you to insert the diskettes on which the back up will be copied starting from

the second diskette. The first diskette will be requested at the end of the back up, because it

contains all the information needed for subsequent restore, such as diskette numbers and file

allocations. Therefore, pay particular attention to the displayed prompts as well as to labels

attached to each diskette.

If the disks are new (unformatted) or they contain data, they must be reformatted before the

execution of the backup.

IMPORTANT

If during the back up operation the program finds that a file in the user

disk cannot be compressed to a single diskette, it will display a warning.

When this happens, use the DOS SHELL backup utility to save these

files.

IMPORTANT

When files are backed up with the DOS SHELL utility, files are not

compressed. Therefore, the number of diskettes you need to backup your

disk may be considerably higher.

10 Series CNC Software Installation Manual (17) 1-7

Page 22

Chapter 1

Installation Procedure

Installing the Macros

In order to use the macros, the files present in the PMM directory of partition E must be transferred

to the work directory of partition F which contains the machining part programs.

This operation is to be performed using the DOS SHELL utility.

END OF CHAPTER

1-8 10 Series CNC Software Installation Manual (17)

Page 23

Chapter 2

OSAI SECURITY

GENERALITIES

“OSAI Security” is an application that supplies a number of functionalities for the

installation/fixup/options of the release and the saving/restore of the present data of the 10 Series

Numeric Control through a remote PC, connected via Ethernet.

The application “OSAI Security” is part of the software package WinNBI (kit 93000494G), that

includes all the interface sections that can be used for the CNC configuration, the control of the

bootstrap phases and of the working phases of the piece.

The basic functionalities offered by the new program “OSAI Security” are similar to the ones that

can be found in the installation program on 10 Series system and in “Remote Setup” E103 option.

The option E103 “Remote Setup cannot be used from E69 v7.1 Software Release onwards. The

application “OSAI Security” can be used with Software Release E69 v.7.1 including Fixup 1 (or

following ones). OSAI Security substitutes the Remote Setup for all the CNC that are provided

with E69 v.7.1.1 or following versions.

In any case the compatibility of the files of the previous releases saved with the “Remote setup” is

guaranteed by a function that converts them in a format that is compatible with “Osai Security”.

10 Series CNC Software Installation Manual (16) 2-1

Page 24

Capitolo 2

Osai Security

Hardware Requirements

• The personal computer must be equipped with an Ethernet communication interface.

• Also the numeric control must be equipped with an Ethernet communication net integrated

with OSAI .

Software Requirements

• The Personal computer must use Windows 98, Windows 2000 or Windows XP Professional as

operative systems. The installation of the net board PC side is the default Netbeui protocol.

• The 10 Series control must have the initialised hard disk and the part C already charged with

the net drivers (for further details see paragraph “preliminary operations” in the next pages).

WARNING: OSAI’S CNC are delivered already configured with the net name “NCLOAD”

• The software of the release to be installed on the CNC is distributed with a CD-ROM entitled

C09 MC Software Kit which contains the following elements:

1. MC (E69) system release and a number of software options aligned with the version of the

system release. The files are in a format which can be read by the Security (file.CAB). In

particular the software releases that are available are:

E 041 TOOL MAGAZINE

E 042 MANUAL DIGITIZING

E 043 DOS GRAPHIC INTERFACE

E 058 DOS REAL TIME INTERFACE

E 059 ELECTRONIC CAM

E 069 MACHINING CENTER

E 070 ENGLISH HELP

E 071 HELP ITALIANO

E 073 ASSET from PART PROGRAM

E 074 END USER DOS

E 075 MULTIPROCESS

E 077 GERMAN HELP

E 078 FRENCH HELP

E 087 SUPER MULTIPROCESS

E 090 CONTINUOUS LASER DIGITIZING

E 096 HIGH SPEED INTERPOLATION

E 099 SPANISH HELP

2. Files in Winlmage format (.EXE), each of which has got the image of one of the installation

floppy disk of the MC Software release (six disks). From these it is possible to generate the

floppy disks for an installation through FDU on CNC.

2-2 10 Series CNC Software Installation Manual (16)

Page 25

Capitolo 2

Osai Security

3. Files in Winlmage format (.EXE) each of which contains the image of a software option.

The options are aligned with the version of the software release MC in the CD-ROM. From

these it is possible to generate the floppy disks for an installation of the software options

through FDU on the CNC. The available software options are the following:

E 041 TOOL MAGAZINE

E 042 MANUAL DIGITIZING

E 043 DOS GRAPHIC INTERFACE

E 058 DOS REAL TIME INTERFACE

E 059 ELECTRONIC CAM

E 069 MACHINING CENTER

E 070 ENGLISH HELP

E 071 HELP ITALIANO

E 073 ASSET from PART PROGRAM

E 074 END USER DOS

E 075 MULTIPROCESS

E 077 GERMAN HELP

E 078 FRENCH HELP

E 087 SUPER MULTIPROCESS

E 090 CONTINUOUS LASER DIGITIZING

E 096 HIGH SPEED INTERPOLATION

E 099 SPANISH HELP

E 106 PATH OPTIMIZER

4. A file in Winlmage format (.EXE) which contains the image of a restore floppy disk, code

E108 “CNC Recovery disk”, to use when the C partition of the Hard Disk of the CNC

cannot be used.

5. A file in Winlmage format (.EXE) which contains the image of the initialisation floppy disk

of CNC, code E107 “CNC Init Disk”. It divides the disk in the four parts C, D,E,F,

cancelling them and it charges the software just of part C.

6. A file in WinImage (.EXE) format, containing the image of the floppy disk with the firmware

for OS 3 drivers: “ OS 3 Firmware”, code E110.

7. A directory (code E111 OS 3 Motors Library) containing all the OSAI motors library files.

The files must be installed directly from Windows (Setup.exe).

10 Series CNC Software Installation Manual (16) 2-3

Page 26

Capitolo 2

Osai Security

Functionalities

The application “OSAI Security” allows the following operations:

• Release installation, fixup and options

• Partitions saving

• Partitions restore

Preliminary operations

No particular operation must be done on the CNC, you just have to bootstrap it. Infact the CNC’s

hard disk is already divided into partitions and the partition C is already loaded for the connection

via Ethernet in order to communicate with the Security.

New hard disk installed

If the control should have a newly installed hard disk (usually this happens when substituted

because broken) you will have to use the initialising floppy (E107 ”CNC Init Disk”) that executes the

following operations:

1) Creates 4 partions C, D, E, F.

2) Formats the partitions C, D and E (the partition F is formatted while installing the base

software)

3) Loads the partition C with the necessary software in order to execute the first bootstrap and the

connection via Ethernet to communicate with the Security

The operations for the initialisation of the whole hard disk are:

1) Insert Floppy E107 “CNC Init Disk” in the floppy drive of the CNC

2) Bootstrap the CNC

3) Wait for the visual and acoustic message that signals the end of the operations

After these operations all the disks of the CNC will be initialised and after

WARNING

having turned the CNC on and OFF, the net name of the CNC will be

“NCLOAD”.

2-4 10 Series CNC Software Installation Manual (16)

Page 27

Capitolo 2

Osai Security

Impossibility of connecting the CNC through the net

This situation should never occur. If the original configuration of net protocol and the name of CNC

is unique the CNC should always be visible in Ethernet with the NetBEui protocol.

After having verified that the cables are connected properly, the configuration of the communication

protocols, the unique name of the CNC, you may hypothesise that the files that allow the CNC to

connect to the net (installed on disk C) are damaged and so it is necessary to restore them.

The necessary operations to restore CNC software are:

1) insert Floppy E108 “CNC Recovery Disk” in the floppy drive of the CNC

2) turn on the CNC

3) wait for the visual and acoustic message that signals the end of the operations

WARNING

After having turned the CNC ON and OFF, the net name of the CNC will be

“NCLOAD”.

After these operations only the disk C will be initialised. The user’s data will

not be cancelled.

10 Series CNC Software Installation Manual (16) 2-5

Page 28

Capitolo 2

Osai Security

INSTALLATION AND ACTIVATION

“OSAI Security” is a WinNBI tool, so in order to use it, it is necessary to install C07 software

supplied on CD-ROM (commercial code 93000494G)

The installation is a step by step program according to the Windows standard. Once the WinNBI is

installed an icon called “ProVideo” will appear on the desktop. Double click on it to activate it, wait

for the message that indicates that the communication with the CNC is active. To activate “OSAI

Security” choose the function tool [Utility], and then choose [Security].

According to the state in which the connected CN is, the program will have all the function keys

enabled (CN in Setup mode), otherwise it will have only the Options and Fixup keys available.

− To enable all the functions in “OSAI Security” environment, it is necessary to boot the CN in

the Setup mode through the program “Boot Controller” of WinNBI

− You must activate the BootController (ProVideo, menu [Utility], choose [Boot Controller]).

− Select menu [Mode] and choose [Setup mode]

− Rebootstrap the CN through the menu command [Boot], and then [Re-Boot]

At the end of the bootstrapping the CNC will be in Setup mode and the program “OSAI Security”

will have all its commands enabled.

2-6 10 Series CNC Software Installation Manual (16)

Page 29

Capitolo 2

Osai Security

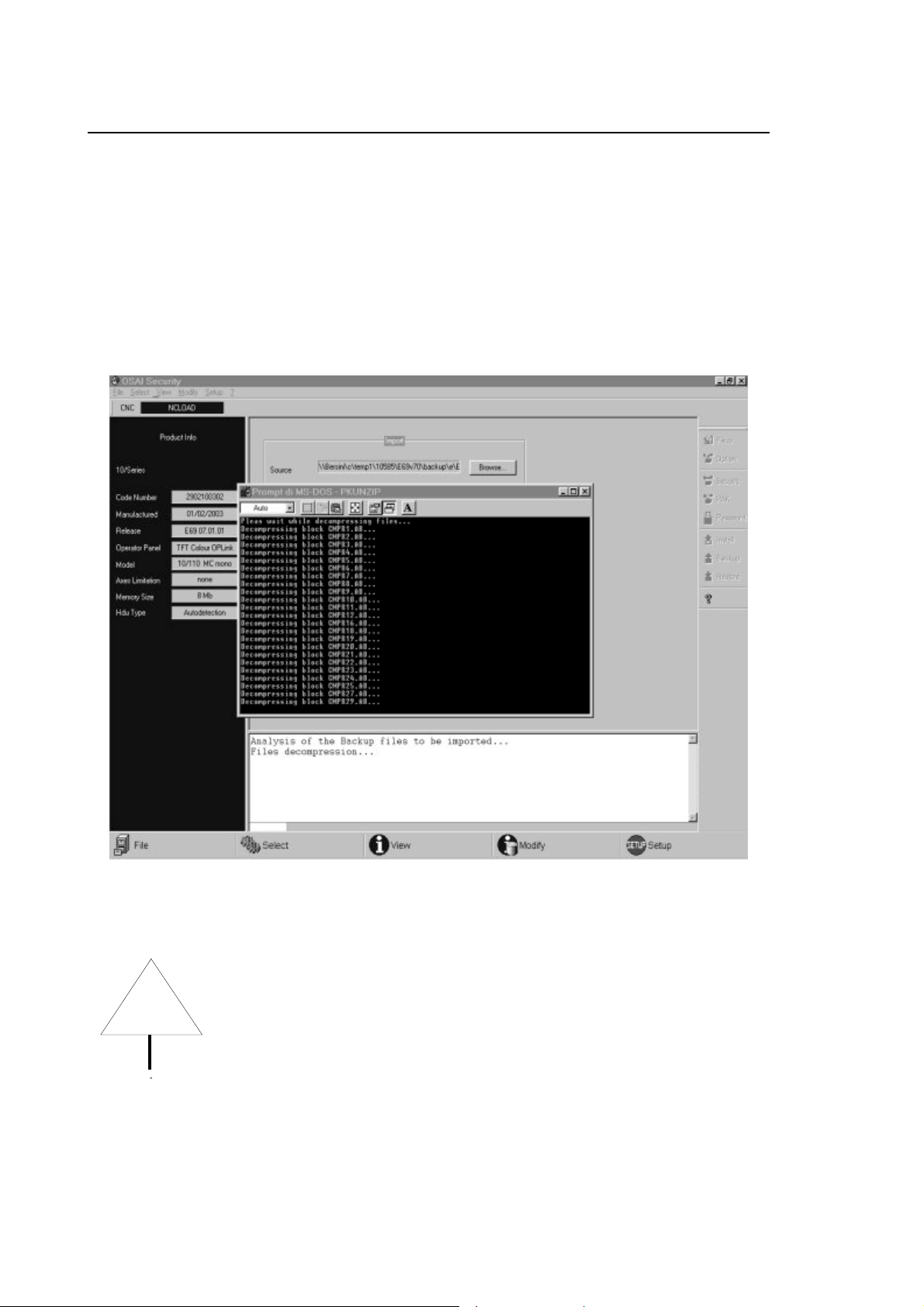

“OSAI SECURITY” user interface

Once the program is activated the video page is visualised from which it is possible to choose the

type of function to execute. If the CN is in the Setup mode all the functions are enabled, if the CN is

in Emergency mode only the Option functions and the Fixup will be enabled.

To enable all the functions you must follow the procedure that is explained previously.

The main screen is as follows :

The screen is divided in three principal panels:

• The panel on the left visualises the data of the connected control.

• The panel on the right visualises the data and the keys that concern the operation selected by

the user

• The lower panel visualises the control messages when an operation is activated and a

progression bar is visualised during the elaboration time

The commands are activated by a drop down menu, through the softkey bar at the bottom and the

activation bar on the right. When the user selects an operation all these commands are not

enabled.

10 Series CNC Software Installation Manual (16) 2-7

Page 30

Capitolo 2

Osai Security

“OSAI Security” can visualise and manage:

• Information on installed software Fixup

• Information on enabled options on CNC

• The access authorisations

• passwords for all levels

• the product Authorization Key

it is also possible:

• to install the software, the options and the fixup of the CNC

• to backup the existing files on the CNC

• to restore files on the CNC

• to modify the CNC’s name in the net

2-8 10 Series CNC Software Installation Manual (16)

Page 31

Capitolo 2

Osai Security

Information on Fixup

For Fixup we intend all the corrections and/or the new performances that have been done on the

basic release of the CNC. Each Fixup is identified by a code related to the product and the version.

The Fixups of the basic release E69 are cumulative, that is to say that a new version includes all

the corrections and/or new performances and the previous ones

When you install a release the associated Fixup level is 0.

The application visualises this information in the right panel.

A list contains the fixup versions installed on CNC. If you select an element of this list the details

are visualised in the window on the side.

10 Series CNC Software Installation Manual (16) 2-9

Page 32

Capitolo 2

Osai Security

Information on Options

The options are system functionalities which are enabled by the introduction of the Product

Authorisation Keys (PAK).

The options that are identified by a code which starts with letter “E” (Exx) are not part of the basic

release E69 and must be installed on the CNC after having installed the basis software identified

by the code E69

The options which are identified with a code that starts with the letter “A” (Axx) indicate the

functionalities that must not be installed but simply enabled through PAK.

The application visualises the information on the enabled/disabled options on the right panel.

There is also a list with all the options enabled by the PAK. There is a second list with all the codes

of the options installed on the CNC; selecting an element from this list the details of the option are

visualised in window on the side.

2-10 10 Series CNC Software Installation Manual (16)

Page 33

Capitolo 2

Osai Security

Security protection levels

Security protection levels can be changed only when the CNC connected is in SETUP modality,

but they can be viewed in other modalities too.

These protection levels allow or don’t allow the use of some system instruments for the machine

tuning.

There are 7 protection levels (from level 0 higher priority to level 6 lower priority):

LEVEL USER FUNCTIONS

0 Osai R&D reserved

1 Osai R&D reserved

2 Osai SERVICE technical assistence

3 APPLICATION/OEM application development and integration

4 END USER option installation

5 END USER TEC technological program development, tool

management

6 OPERATOR machine tool use

To change the protection level in use, with higher priority one it is necessary to digit, if decided, the

protection password and press the key [Apply]; it is not necessary to digit any password when

lower priority levels are activated. The maximum length of the password string is 20 characters.

After the installation of the basic release E69 the default protection level is 6, and the passwords

for the levels 3, 4 and 5 are not set.

To modify the protection levels you must double click on the left button of the mouse on the

element of the list or press the space bar after having selected it.

10 Series CNC Software Installation Manual (16) 2-11

Page 34

Capitolo 2

Osai Security

The protection levels modification follows these rules (a part from level 0 which cannot be

modified):

1. it is possible to modify just the successive levels,

2. it is possible to modify a protection level only if the previous one (higher priority) allows it.

3. If it is not possible to modify a certain level this will automatically be extended to less priority

levels.

The modifications will be activated on the control only after having clicked

WARNING

[Apply]; it is possible to restore the previous situation clicking [Restore] that

reads the last data that has been saved on the control.

Name of the CN in the net

The field “Assign net name” allows to modify the name of CNC on the net.

The new name will be used by the CNC only when you have bootstrapped

WARNING

the CNC.

2-12 10 Series CNC Software Installation Manual (16)

Page 35

Osai Security

Password

It is possible to modify the password only when the connected CNC is in SETUP modality.

Capitolo 2

It is possible to control the activation of the protection levels through a password; the definition of

the passwords at different levels generates a level protection mechanism that a user of a superior

level can exploit to block access to the users of a lower level.

To insert a password on a level that didn’t have one, leave the field empty of the old password and

digit the same characters on the fields new password and password confirmation and press

[Apply].

To take away the password on a level that had it, digit the characters in the field of the old

password and leave the fields new password and confirm password empty and press [Apply].

To modify a password on a level that already had it, digit the right characters in the three fields old

password, new password and confirm password and press [Apply].

The maximum length of the password is 20 characters.

10 Series CNC Software Installation Manual (16) 2-13

Page 36

Capitolo 2

Osai Security

Product Authorization Key

The modification of the Product Authorization Key (PAK) is possibile only when the connected

CNC is in SETUP mode.

If the introduction of the PAK takes place correctly the system enables the functionalities or

installation of the optional component.

The Product Authorization Key is composed of three alfanumerical strings each of which has 20

characters.

2-14 10 Series CNC Software Installation Manual (16)

Page 37

Capitolo 2

Osai Security

SETUP FUNCTIONALITY

The Setup allows to install, save and restore the system software of the CNC and user’s data.

The Security has also got an import function of backups generated with the “Remote Setup”

(option E103 obsolete and substituted by this application). This function transforms the backup in

the new format using “OSAI Security “ to guarantee the compatibility.

Installation on a new control

One of the Setup functionalities allows to install the software release of the CNC on a control (that

has Ethernet connection) just delivered by OSAI. Once the control is on it is available in local net

with NCLOAD name.

The following operations are the one that have to be executed:

1) Connect in Ethernet the numerical control and the system with the WinNBI

2) Start the BootController and select with the softkey [Select] [CNC] the name NCLOAD and

request the boot SETUP modality.

3) Switch on the numeric control and wait for BootController to connect with it.

10 Series CNC Software Installation Manual (16) 2-15

Page 38

Capitolo 2

Osai Security

4) Launch the application “OSAI Security”

5) Select the modality [INSTALL]

6) Select, using [Browse…] a file that has extension “.inf” associated to a release

7) Select a the option New Control

8) Press the key [Start].

The installation procedure will label and update the parts of System, OEM and End User.

The operations which are been carried out are shown in a notification window where a progress

bar shows the state of the single operations when these need a certain amount of time to end.

2-16 10 Series CNC Software Installation Manual (16)

Page 39

Capitolo 2

Osai Security

Release update

The setup can be used to update the release on a control (with hardware Ethernet connection) that

works correctly and is operative.

The sequence of operations are the following:

1) Launch BootController and select with the softkey [Select] [CNC] the given name to the

numerical control (visible in boot phase on the display of the CNC) and force the boot

[SETUP] modality.

2) Switch on the numerical control and wait for BootController to connect with it

3) Launch “OSAI Security”

4) Select [INSTALL] modality

Select through the key Browse a file with “.inf” extension associated to a release

Select the option release update

Press the key [Start].

Once the installation procedure is activated it will label and update the system and OEM partitions.

If it is not possible to connect to the control with the BootController (damage to HDU unit or loss of

data in the partitions) you can try to restore the functionalities (see paragraphs “Hard Disk” just

installed and “Impossibility to connect the CNC though net”.

The operations that have been carried out are visualised in the notify window where a progress bar

allows to control the state of the single operations when these need a long time to finish.

10 Series CNC Software Installation Manual (16) 2-17

Page 40

Capitolo 2

Osai Security

Backup

This operation concerns partition D, E, F of the numerical control. The files contained in these

partitions are memorised in a file which is specified by the user with extension “.inf”. Identifing

infomation is also saved here, like the date of the backup and the partition labels.

The saving operation (Backup) allows to choose between 4 types of options, which can or not be

summed by the user:

1. Saving of all the control (disables the other options)

2. Saving of the system areas

3. Saving of the user’s area

4. Saving of OEM area

2-18 10 Series CNC Software Installation Manual (16)

Page 41

Capitolo 2

Osai Security

Restore

The restore operation allows to restore the content of the system area, OEM and End User of the

CNC saved previously with the Backup operation. The files saved with the old option ”Remote

Setup” can be charged after they have been converted in the new format using the option “Import”

(see next paragraph).

The operation allows to choose the three enabled areas, specifying through the key [Browse] the

name of the file with “.inf” extension where you can find the data. To start the operation press

[Start]. At the bottom there will be a window with the execution messages of the program and a

status bar that indicates the execution time.

10 Series CNC Software Installation Manual (16) 2-19

Page 42

Capitolo 2

Osai Security

Import files

The operation “import” allows to tranform the backup files generated with the tool “Remote Setup”

in a format which is compatible with “OSAI Security”.

The operation can only be activated with the toolbar at the bottom, choosing the key [Setup] and

from the menù [Import]; at this point a window will open where you will have to specify the name of

the file that must be converted with extension “.dat” and the output file name that has to be

generated with extension “.inf”.

In the lower window you will find the execution messages of the operation.

Only files concerning partition E and F (name used by “Remote Setup”) that

WARNING

correspond to partitions OEM and End User will be copied in the output

files.

END OF CHAPTER

2-20 10 Series CNC Software Installation Manual (16)

Page 43

Chapter 3

MODIFICATIONS AND IMPROVEMENTS INTRODUCED WITH

RELEASE E69 V7.5

FOREWORD

This chapter contains information about the new software features and improvements introduced

on 10 Series systems with release 7.5.

We recommend that you read this chapter carefully to make sure that no problems arise when the

system is upgraded to the new release.

NOTE:

Appendix D of this manual provides a description of the software features and improvements

introduced with the previous releases of the product, starting from Rel. 5.0.

10/365 and 10/385 systems are NOT compatible with Release 6.0 and

WARNING

WARNING

In release 7.5, changes have been made to the following environments:

• SYSTEM

• AMP

• PLUS, WINPLUS, I/O

higher.

Systems 10/310 are NOT compatible with release 7.0 and higher.

• PROCESS, AXES

These changes are described in detail on the pages that follow.

10 Series CNC Software Installation Manual (17) 3-1

Page 44

Chapter 3

Modifications and Improvements Introduced with Release 7.5

Changes made to the SYSTEM environment

• New OS8516 board

The management software for a new board, OS 8516, has been added. It is available in various

versions and it is able to manage two Mechatrolink channels, an encoder channel, field bus I/Os

and analog I/Os.

• Extension of Continuous Laser Digitizing option

Now it is possible to use either the OS8531 board or the OS8532 board with OS8521/3 for

“laser digitisation”.

• Extension of D.S.I. digital drives management

The management software for Indramat D.S.I. digital drives has been added.

• New Canopen RIO modules

The management software for new Canopen RIO modules has been added: 8 digital 2A

Outputs and 4 digital Relay Outputs.

• New Os-Wire parameters

The management software for two new OS-Wire axis parameters has been added: parameter

98 to define the “blind zone” and a “volatile” parameter, 500, defining “Current limitation”.

“Volatile” parameters are not saved in a parameter file and are initialised with a default value at

each power-up. Now these parameters can be read/written only from the Plus/WinPlus

environment (Functions AX_FWR, AX_FWW) and require the new versions of the firmware for

drives E110 V2.0 and WinNBI V2.4.

• Spanish Help menu completed

The Help menu in Spanish (E99) has now been completed with the Spanish translation of the

softkeys and data entry modalities, and is in line with other Help menus in French and German.

3-2 10 Series CNC Software Installation Manual (17)

Page 45

Chapter 3

Modifications and Improvements Introduced with Release 7.5

Changes made to the AMP environment

• Characterisation of new D.S.I. board

The HARDWARE CONFIGURATION section now includes the characterisation of a new board,

OS 8512, whose management software will be made available with an E69 V7.5 Problem Fix.

• Os-Wire axes servo loop clock

For OS-Wire systems, it is now possible to configure the servo loop clock as a multiple of that of

the system. In the earlier release, these values had to be the same.

• Handwheel programmability

For all systems, in the management of the electronic handwheel, the control over the maximum

number of programmable transducers has been eliminated (value set from PAK). In actual

practice, when the handwheel is activated, the handwheel associated with it is no longer

counted for purposes of the aforementioned control. The logic functions affected by this change

are: HPG_ON, HPG_OFF.

• New ”homing” modalities for D.S.I. axes

A new homing modality has been introduced for D.S.I. axes (HOMING TYPE field in axis

characterisation). It is equivalent to modality 3 (automatic homing executed by the drive) save

for axis repositioning on NULL OFFSET, a step which is not performed with this new modality. It

can also be used for point-by-point axes.

IMPORTANT

Keep in mind that AMP files cannot be transferred to a system where the

version of the release installed is earlier than that of the system the AMP

files originate from.

10 Series CNC Software Installation Manual (17) 3-3

Page 46

Chapter 3

Modifications and Improvements Introduced with Release 7.5

Changes made to the PLUS, WINPLUS, I/O environment

• New GetTaskSlotn function

New WinPlus GetTaskSlotn function has been introduced to be able to determine the current

task and the slot in which it is running.

• New AX_RTFBCK function

Now it is possible to monitor the “internal” variables of the OS3 drive. This can be done thanks

to the new function WinPlus AX_RTFBCK. It requires the new versions of the firmware for

drives E110 V2.0 and WinPlus V2.10.2.

• New filters for GTS,GTA,SPG

New filter routines have been introduced in both the PLUS and the WinPlus environment; they

are activated on the ACTIVATE/DEACTIVATE Part Program ($N_SPGFUN), axis migration

($n_GTAFUN) and spindle sharing ($n_GTSFUN).

• New functions for CANopen devices managed by intelligent module

New functions CAN_INIT, GET_EMCY_INFO, NMT_CMD, SYNC_CMD, READ_SDO_CMD,

WRITE_SDO_CMD and CAN_BOARD_CMD have been added for the management from

WinPLUS of CANopen devices connected to the “intelligent” CANopen module.

• New function MOVBYTE

Limited to the WinPLUS environment, a new function MOVBYTE has been added for buffer

copy generation.

• New functions PUTUSED, GETUSEC and PUTUSEC

New functions have been added to the WinPLUS library: PUTUSED for writing double type

process variables, GETUSEC and PUTUSEC for reading/writing char type process variables.

• New event task EventTaskFIN

A new event task has been introduced for the management of “Fast Inputs”.

• Extension of ANAIN function block

The ANAIN function block has been extended to read the analog channels in the new board

(OS8516).

• Extension of $AX_SETZ function block

Function block $AX_SETZ has been extended so that it can work on Mechatrolink digital axes.

• Change to Tool Magazine error codes

Now, the error codes returned by the WinPlus functions for the management of tool magazines

(Tool Magazine option) are the same as those of the corresponding F.B.s in the PLUS

environment.

PLUS environment: after installing the release it is indispensable to

IMPORTANT

regenerate the “C“ code and to recompile the machine logic for the Plus

environment (PLUSGEN softkey)

WinPlus environment: after the installation of this release, you must

IMPORTANT

recompile the machine logic with the new version of WinPlus C08 V2.10.2

by making the appropriate changes to the <firmware version> parameter.

Logics compiled with earlier versions will not work !

3-4 10 Series CNC Software Installation Manual (17)

Page 47

Chapter 3

Modifications and Improvements Introduced with Release 7.5

Changes made to the PROCESS, AXES environment

• Spindle sharing by several processes

Now, with the new triliteral GTS, several processes can share the same spindle. The triliteral

enables each process to release its spindle and change its status or acquire a new spindle.

• Extension of the UPR function

A new type of UPR 5 has been implemented: it returns in the E variables the physical or virtual

coordinates of rotary axes relative to an active UPR.

The software for the management of the origins on the rotary axes has also been introduced.

These origins must be entered in the triliteral itself.

• HSM: new management for ijk versors

A new management software for ijk versors in the HSM environment has been implemented.

This is based on the punctual conversion of such versors into the corresponding coordinates of

the rotary axes and the ensuing determination of the relative splines. This software remedies

the problems arising from the oscillation of rotary axes when moving to critical (indeterminate)

positions.

IMPORTANT

Keep in mind that in this release, and after the introduction of Problem Fix 2

of E69 V7.4, the algorithms associated with function UPR have been modified

to solve a number of problems encountered with said function.

As a result, axis movements arising from the virtualisation may differ from

those generated by the earlier algorithms (releases lower than 7.4.2).

To keep the earlier algorithms working, the new user variable must be set as

!R73MODE=1. Otherwise, if !R73MODE=0, or not defined, the new

algorithms will be applied. This user variable is read only in conjunction with

the programming of lower case UPR.

10 Series CNC Software Installation Manual (17) 3-5

Page 48

Chapter 3

Modifications and Improvements Introduced with Release 7.5

END OF CHAPTER

3-6 10 Series CNC Software Installation Manual (17)

Page 49

A

OPTIONS COMPATIBILITY TABLES

OPTIONS

ONLINE OPTIONS Sw rel.

Tool magazine management E41 7.5 YES YES

Appendix

10 MC Series

7.4 7.5

Manual digitizing E42 7.5 YES YES

DOS graphic interface E43 7.5 YES YES

DOS real time interface E58 7.5 YES YES

Electronic cam E59 7.5 YES YES

English help E70 7.5 NO YES

Italian help E71 7.5 NO YES

French help E78 7.5 NO YES

German help E77 7.5 NO YES

Spanish help E99 7.5 NO YES

Asset E73 7.5 YES YES

End user DOS E74 7.5 YES YES

Wood option E72 5.0.1c YES YES

Remote diagnostic E84 6.0.1 YES YES

Super Multi-process option E87 7.5 YES YES

Continuous Laser Digitizing E90 7.5 YES YES

Serial Mini DNC for Windows E94 6.0.1 YES YES

High speed interpolation E96 7.5 YES YES

Multi process E75 7.5 YES YES

CNC setup utility E97 6.0

7.4

BIOS utilities E104 7.1 YES YES

10 Series CNC Software Installation Manual (18) A-1

YES

YES

NO

YES

Page 50

Appendix A

Options Compatibility Tables

BIOS utilities E109 1.0 YES YES

BIOS utilities E113 1.3 YES YES

CNC Init Disk E107 7.4

7.5

CNC Recovery Disk E108 7.4

7.5

OS3 Firmware E110 1.3

1.4

Motors Library E111 1.3

1.4

YES

NO

YES

NO

YES

YES

YES

YES

NO

YES

NO

YES

YES

YES

YES

YES

For additional information on the compatibility of E110, E69, C07, see the “OS3 Drive

Installation” Manual and the individual release issuing documents.

c When the option has been installed, it is indispensable to regenerate code “C“ and

recompile the DEF_WOOD default logic to achieve compatibility with the system release.

10 MC Series

7.4 7.5

OFFLINE OPTIONS Sw Rel.

Dicadig E35 5.3 YES YES

Lathe graphic editor E36 4.0 YES YES

Mill graphic editor E37 4.0 YES YES

Wood Editor E85 5.1 YES YES

Ethernet Mini Dnc Communication E66 6.0 YES YES

Remote Development Kit E88 7.5 NO YES

Remote Setup E103 6.1 NO NO

Path optimizer E106 2.2

2.3

WinNBI C07 2.4

2.4.3

WinPLUS C08 2.08

2.10

2.10.2

YES

YES

YES

YES

NO

YES

YES

YES

YES

YES

YES

NO

NO

YES

A-2 10 Series CNC Software Installation Manual (18)

Page 51

Appendix A

Options Compatibility Tables

Mass storage size compatibility

Depending on the option selected, controls 10/110 and 10/510 Light can be equipped with different

mass storage devices: either Hard Disk modules or solid state “DOMs” (= Disk on Module).

The different versions provide different User Memory capacities, where by User memory is meant

the maximum capacity of user disk F:.

The size of these Modules changes as a function of the Software Release installed:

With Software Release 7.4 or higher, the options available for 10/510 LIGHT, and the respective

(approximate) E: and F: user disks capacities are as follows:

93000587B 510 LIGHT 15 MB USER PROGRAM MEM E: = 19 MByte, F: = 15 MByte

93000645F 510 LIGHT 40 MB USER PROGRAM MEM E: = 41 MByte, F: = 40 MByte

93000588W 510 LIGHT 2 GB USER PROGRAM MEM E: = 53 MByte, F: = 2 GByte

Control 10/110 LIGHT OS-WIRE, managed by Software Release 7.4 and higher, always has a 40

MBYTE user memory capacity and therefore, as above: E: = 41 MByte, F: = 40 MByte

In Software Release 7.3, (approximate) capacities were:

93000587B 510 LIGHT 19 MB USER PROGRAM MEM E: = 15 MByte, F: = 19 MByte

93000588W 510 LIGHT 2 GB USER PROGRAM MEM E: = 53 MByte, F: = 2 Gbyte

With Software Release 7.5 fix 4 or higher, the options available for 10/510 LIGHT, and the

respective (approximate) E: and F: user disks capacities are as follows:

93000587B 510 LIGHT 15 MB USER PROGRAM MEM E: = 19 MByte, F: = 15 MByte

93000645F 510 LIGHT 40 MB USER PROGRAM MEM E: = 43 MByte, F: = 40 Mbyte

93000664N 510 LIGHT 400 MB USER PROGRAM MEM E: = 64 MByte, F: = 400 MByte

93000665P 510 LIGHT 900 MB USER PROGRAM MEM E: = 64 MByte, F: = 900 MByte

93000666R 510 LIGHT 1.8GB USER PROGRAM MEM E: = 64 MByte, F: = 1,8 GByte

93000588W 510 LIGHT 2GB USER PROGRAM MEM HDU E: = 53 MByte, F: = 2 GByte

10 Series CNC Software Installation Manual (18) A-3

Page 52

Appendix A

Options Compatibility Tables

END OF APPENDIX

A-4 10 Series CNC Software Installation Manual (18)

Page 53

Appendix B

ERROR MESSAGES

ERROR MESSAGES LIST

This Appendix lists the error messages that may be displayed during system software installation.

For each message we suggest a recovery action.

MESSAGE FILE NOT FOUND

Internal software error. One of the utility support files is corrupt.

Contact the Technical Assistance Service.

BACKUP FILE NOT FOUND

Internal software error. back up binary files corrupt.

Contact the Technical Assistance Service.

INSUFFICIENT MEMORY

Not enough memory to copy the working areas used by the utility.

Contact the Technical Assistance Service.

BACKUP DATA CORRUPT

The backup to be installed is corrupt.

Contact the Technical Assistance Service.

INSTALLATION DISK UNDEFINED

If this error occurs when the initialisation process is launched, it means that the HD has not been

partitioned: use the E107 option. If the error persists, 0 occurs in a case other than the one

described. Contact the Technical Assistance Service.

WRONG DISKETTE

You are trying to install a release back up through the security utility.

Restart the system using the first back up floppy.

THE FLOPPY INSERTED IS NOT THE FIRST

The diskette from which installation has been launched is not the first back up diskette.

Restart the system inserting the first back up diskette (i.e. the one whose label ends by 01).

10 Series CNC Software Installation Manual (16) B-1

Page 54

Appendix B

Error Messages

ASCII FILE NOT FOUND

Internal software error. One of the utility support files is missing.

Contact the Technical Assistance Service.

OPTION NOT ALLOWED: CHECK SECURITY

Installation of this option has not been authorized by the security utility.

Start the system in emergency mode, write the Product Authorization Keys associated to the option

and resume installation with the INSTALL softkey.

STOP INSTALL: HDU TOO SMALL!

This message is displayed when trying to install release 5.0 on a hard disk smaller than 80 Mbytes.

END OF APPENDIX

B-2 10 Series CNC Software Installation Manual (16)

Page 55

Appendix C

INSTRUCTIONS FOR CNC SETUP

Three types of integrated Operator Panels can be connected to Series 10 controls:

• OPLink Operator Panel

• BLink Operator Panel

• WinLink Operator Panel

The 3 models of Operator Panel are available with a TFT color monitor, but each of them has

different characteristics, as shown in the following table:

the version with integrated Operator

Console (OPLink) includes:

the basic version (BLink) includes:

the version with integrated PC (WinLink)

includes:

For those differences each system has to be properly configured according to the Operator Panel

used.

Each 10 Series Control is prepared by OSAI to be connected to the type of Operator Panel

specified in the CNC SETUP module attached to each control.

The aim of this chapter is to describe the operations to be performed to modify this configuration

when required in order to avoid system damage and failures.

− Monitor 10.4"

− the Operator Console

− 7 softkey

− 3 keys for CYCLE START, HOLD and RESET;

− 6 function keys with LED which the manufacturer

can use for customisation through the machine

logic

− Monitor 10.4"

− 7 softkey

− 12.1” monitor

− “yellow” key

− 13 function keys available for the PC environment

For 10/585 and 10/565 systems the utility provided with the E97 option, called the “CNC Setup

Utility”, is to be used.

10 Series CNC Software Installation Manual (16) C-1

Page 56

Appendix C

Instructions for CNC Setup

SETUP UTILITY

The SETUP utility contained in the “E97 CNC Setup Utility” floppy disk makes it possible to

configure the type of Operator Panel connected to the control.

Insert the E97 bootstrap disk in the floppy disk drive before turning on the CNC: during the

bootstrap phase a window similar to the following will appear on the display.

The following screen appears after the bootstrap phase has been completed:

BIOS SETUP ver.x.y SYSTEM 10-5x5

LCD OPERATOR PANEL

MESSAGE

F5 Abort Setup F6 Save and exit Setup F10 Change item

Where:

LCD OPERATOR PANEL: area containing the Operator Panel version

MESSAGE: area reserved for the messages from the utility

[F5]: to exit from the SETUP without saving the data set on the display and

therefore, without changing the system configuration. After you exit

the system will be rebooted automatically.

[F6]: to exit from the SETUP saving the selected Operator Panel version in

the system configuration. When you exit from the utility, the system

will be rebooted automatically.

[F10]: to select Operator Panel model in the “LCD OPERATOR PANEL”

area.

C-2 10 Series CNC Software Installation Manual (16)

Page 57

Appendix C

Instructions for CNC Setup

When started, the SETUP utility reads the system’s Hardware Key (PAK) on which the

configuration data is stored.

The currently configured Operator Panel model is displayed in the “LCD OPERATOR PANEL”

area and the new model may be selected by pressing the [F10] key. The [F5] and [F6] keys may

be used to confirm or cancel the selection of the model and exit from the SETUP.

The error messages that can appear in the “MESSAGE” area, are the following:

1. “ERROR ON READ HW_KEY” (ERROR)

2. “ERROR ON WRITE HW_KEY” (ERROR)

3. “HW_KEY INCONGRUENT” (ERROR)

The messages 1 and 2 are referred to general errors during Hardware Key read/write operations:

In this case, please contact the OSAI engineering service.

Message 3 is displayed when it is not possible to read the Hardware Key (PAK) or when the data

contained are corrupted.

To restore the PAK it is necessary to install the release: insert the first disk of the E69 System

Software in the floppy disk drive and switch the system off and then on again and, when the

Control bootstraps, install the release following the instructions given in the Software Installation

Manual.

During the software release download, if the Hardware Key (PAK) is not correctly found or

recognised, the installation program will ask for the PAK.

The Hardware Key is ALWAYS provided in a specific module attached to the control.

If another error occurs after the release has been installed, contact the OSAI Technical Assistance

service.

10 Series CNC Software Installation Manual (16) C-3

Page 58