osai 10 CNC Reference Manual

10 Series CNC

High Speed Machining

Reference Manual

Code: 45006842M

Rev. 02

PUBLICATION ISSUED BY:

OSAI S.p.A.

Via Torino, 14 - 10010 Barone Canavese (TO) – Italy

e-mail: sales@osai.it Web: www.osai.it

Copyright © 2001-2002 by OSAI

All rights reserved

Edition: July 2001

IMPORTANT USER INFORMATION

This document has been prepared in order to be used by OSAI. It describes the latest release of the product.

OSAI reserves the right to modify and improve the product described by this document at any time and without prior notice.

Actual application of this product is up to the user. In no event will OSAI be responsible or liable for indirect or consequential damages that may result from installation or use of the equipment described in this text.

UPDATE

10 Series CNC High Speed Machining

UPDATES IN THIS ISSUE

PAGE |

TYPE OF UPDATE |

|

|

|

|

INDEX |

updated |

|

CHAPTER 4 |

new chapter containing additional programming modes |

|

CHAPTER 5 |

|

|

page 2 |

added: the parameter “Format” to the triletteral PNT for specifying the input |

|

|

type for the profile programming |

|

page 12 |

added: the parameter “Diam” to the triletteral AXI and the value TAO in the |

|

|

parameter “Type” |

|

page 16 |

inserted: an extension of the machine kinematics for positioning 2 rotation |

|

|

axes to the linear axes. Extension of the triletteral MAC with new values. |

|

page 25 |

inserted: a paragraph dealing with the Smoothing tolerances and |

|

|

parameters |

|

CHAPTER 6 |

Inserted: a new chapter concerning the Path Optimizer |

|

|

|

10 Series CNC High Speed Machining (02)

Preface

10 Series CNC High Speed Machining

PREFACE

Mechanical technology has evolved to such a degree that what were once considered insuperable limits as regards machining speeds and accelerations have now become the norm in the world of machine tools. It is now common to hear of machines capable of transverse speeds of the order of 80 - 100 m/minute and accelerations in the order of one or more g, traverse. The field of application typical of these machines is the high-speed milling of surfaces.

The solution normally adopted with numeric controls, that is, the machining of profiles as a sequence of linear micro steps is no longer applicable, because the mechanics follow the continual changes in direction, with undesirable effects on the surface finish. The programmed points are taken as obligatory points, through which machining must pass. In addition, “G01” programming is understood strictly as a linear interpolation between points. This means that, to obtain a sufficiently accurate curve, the points must be programmed so close to one another that the programmed broken line is indistinguishable from the desired curve. This type of approach is still normally used with machine tools having a high level of inertia which has the effect mechanically smoothing the broken line.

With the introduction of particularly rigid machines together with motor drives of an acceptable size capable of providing high torque levels (brushless motors), this solution was no longer applicable, as all the sudden changes in direction could be recognized by the machine tool resulting, at best, in a poor quality surface finish.

At this point, there were two possible ways of solving the problem, by modifying the motion dynamics and the geometry of the paths. In fact, the execution of the commands has to be filtered, in order to obtain a “smooth” output to the servo motors, and the path program design has to be modified through the interpretation of the programmed values as a set of points to be approximated in the best possible way.

The solution chosen by Osai led to the implementation of the new Polynomial Interpolation Algorithms.

This manual provides all the information necessary for the use of the new feature known as High Speed Machining. In particular, this manual refers to the HIGH SPEED INTERPOLATION option, specific for applications in which machining involves more than 3 axes.

The HSM feature for machining processes that involve 3 axes or less, is IMPORTANT included as standard in the E69 System Software for all models of 10 Series

numeric controls.

To extend this feature to more than three axes (max.6), the E96 option (High Speed Interpolation) has to be installed.

10 Series CNC High Speed Machining (00) |

1 |

Preface

10 Series CNC High Speed Machining

WARNINGS

To ensure that the system is used correctly, the indications given in the manual should be followed, paying particular attention to the paragraphs preceded by the signs: WARNING, CAUTION or IMPORTANT.

WARNING

Indicates situations that may cause damage to the system, the equipment or the operator.

CAUTION

IMPORTANT

Precedes information to be borne in mind to avoid damage to the equipment in general.

Precedes operations that must be performed with care to ensure the complete success of the application.

2 |

10 Series CNC High Speed Machining (00) |

Chapter 1

Title of Chapter

END OF PREFACE

CNC Serie 10 Titolo Manuale (00) |

3 |

Indice

10 Series CNC High Speed Machining

INDEX

HIGH SPEED MACHINING

GENERAL CONSIDERATIONS .................................................................................. |

1-1 |

PROGRAMMING POINTS AND CHARACTERISTICS OF THE PROFILE...................... |

1-3 |

Considerations on the use of the G62,G63,G66 and G67 functions |

|

(transition codes)............................................................................................. |

1-6 |

GENERAL HIGH SPEED MACHINING PROGRAMMING STRUCTURE......................... |

1-7 |

Interaction with Machine Logic.......................................................................... |

1-7 |

POINT DEFINING CONVENTIONS

POINTS AND MACHINING COORDINATES ............................................................... |

2-1 |

Tool Direction.................................................................................................. |

2-2 |

Normal to the Surface Direction ........................................................................ |

2-2 |

Tool Radius Application Direction...................................................................... |

2-3 |

Tangential Axis ............................................................................................... |

2-3 |

FEATURES PROVIDED BY HIGH SPEED MACHINING

MACHINES WITH 5 AXES ........................................................................................ |

3-1 |

Tool Radius and Length Compensation.............................................................. |

3-2 |

Tool Length Compensation ............................................................................... |

3-2 |

No Tool Compensation..................................................................................... |

3-3 |

Tangential Axis Management............................................................................ |

3-3 |

MACHINES WITH 3 AXES ........................................................................................ |

3-4 |

Tool Radius and Length Compensation.............................................................. |

3-4 |

Tool Length Compensation ............................................................................... |

3-5 |

No Tool Compensation..................................................................................... |

3-5 |

Tangential Axis Management............................................................................ |

3-6 |

ADDITIONAL PROGRAMMING MODES

POLYNOMIAL PROGRAMMING ............................................................................... |

4-1 |

POLYNOMIAL PROGRAMMING TYPES AND LIMITS ................................................ |

4-3 |

10 Series CNC High Speed Machining (02) |

i |

Contents

10 Series CNC High Speed Machining

Polynomial for the Cutter Contact...................................................................... |

4-3 |

Polynomials for the Cutter Location................................................................... |

4-4 |

Polynomials for the Axis Location ..................................................................... |

4-5 |

B-SPLINES PROGRAMMING.................................................................................... |

4-6 |

B-SPLINE PROGRAMMING TYPES AND LIMITS....................................................... |

4-7 |

B-Splines for Cutter Contact ............................................................................. |

4-7 |

B-Splines for Cutter Location ............................................................................ |

4-7 |

B-Splines for Axis Location .............................................................................. |

4-7 |

SETUP

TYPE OF POINTS DESCRIBED IN THE PART PROGRAM.......................................... |

5-2 |

VERSOR MANAGEMENT METHODS......................................................................... |

5-3 |

LOOK AHEAD MANAGEMENT.................................................................................. |

5-4 |

THRESHOLDS ......................................................................................................... |

5-6 |

TOOL DEFINITION................................................................................................... |

5-7 |

TOOL DIRECTION (3D)............................................................................................. |

5-8 |

CHANGE IN CURVATURE MANAGEMENT................................................................. |

5-9 |

EDGE MANAGEMENT .............................................................................................. |

5-10 |

AXIS DEFINITION .................................................................................................... |

5-11 |

AXIS PARAMETERS ................................................................................................ |

5-13 |

AXIS DYNAMICS ..................................................................................................... |

5-14 |

MACHINE KINEMATICS ........................................................................................... |

5-15 |

Definition of the Kinematic Chain....................................................................... |

5-15 |

Description of the Kinematic Chain.................................................................... |

5-20 |

SMOOTHING TOLERANCES AND PARAMETERS ..................................................... |

5-25 |

SPECIAL SMOOTHING PARAMETERS ..................................................................... |

5-27 |

PATH OPTIMIZER

GENERAL................................................................................................................ |

6-1 |

PROGRAM INSTALLATION ON A PC....................................................................... |

6-2 |

EXECUTION MODES ................................................................................................ |

6-3 |

USAGE MODES ....................................................................................................... |

6-4 |

Tolerances: Toll, TollX and TollV........................................................................ |

6-4 |

Buffer management: Pnt................................................................................... |

6-4 |

Edge management: Racc, C0, RaccX, C0X, RaccV, C0V .................................... |

6-5 |

POINT TYPES.......................................................................................................... |

6-6 |

ISO Part program for a 3-axes machine ............................................................. |

6-6 |

ISO Part program for a 5-axes machine ............................................................. |

6-6 |

END OF INDEX

ii |

10 Series CNC High Speed Machining (02 |

Chapter 1

HIGH SPEED MACHINING

GENERAL CONSIDERATIONS

The High Speed Machining feature is used for machining surfaces (profiles) defined by points, created by CAD/CAM systems, on machine tools having 3 to 5 axes (3 linear + 2 rotary).

The High Speed Machining feature must be enabled in the AMP environment, by selecting the appropriate field in the PROCESS CONFIG section (PROC CHAR softkey).

This feature may only be enabled for the first 4 processes.

WARNING

To program this feature, proceed as follows:

1.Create a setup file (part program) that contains all the parameters for handling the profile: tools, axes and kinematics of the machine.

The setup file (whose structure is described in chapter 5) will be recalled in the main program by means of a three-letter command with the following format:

(HSM, setup file name)

2.Create the profile by inserting it directly in the main program:

Example:

;HSM PROGRAMMING EXAMPLE G1 X..Y..Z.. A.. B.. F…

------

(HSM, CONFIG1)

G61

G1 X..Y..Z..A..B..

------

G60

;END OF PROGRAM

10 Series CNC High Speed Machining (00) |

1-1 |

Chapter 1

High Speed Machining

The profile may also be inserted in a specific file which will be recalled as a subprogram by the CLS instruction.

Example 2: |

|

; HSM PROGRAMMING EXAMPLE |

|

G0 X..Y..Z.. A.. B.. F… |

|

------ |

|

(HSM, CONFIG1) |

|

------ |

|

(CLS,PROFILO1-------------------------------------------------- |

à G61 |

------ |

G1 X…Y..Z..A..B.. |

------ |

------------------------------ |

; END OF PROGRAM |

------------------------------ |

------ |

G60 |

1-2 |

10 Series CNC High Speed Machining (00) |

Chapter 1

High Speed Machining

PROGRAMMING POINTS AND CHARACTERISTICS OF THE PROFILE

A profile is a set of points that make up the ISO part-program of the surface to be machined, created by the CAD/CAM system in which the characteristics described in this chapter are to be respected.

On the basis of the programmed points a polynomial curve will be constructed, defining the path to be followed. This path will pass through the programmed points with a configurable tolerance. The methods by which the points are to be linked will be defined by the G01 and G00 codes that may be programmed together with the points.

To ensure that the polynomial curves are calculated correctly, we recommend IMPORTANT the points be programmed with at least 5 figures after the decimal point (e.g.

10.37854); programming with fewer figures may cause irregularities on the profile.

The sections executed in G00 will be considered as individual positioning operations; each point will be linked to the next by means of a “linear” movement to be performed with the dynamic traverse positioning (each section in G00 will start at zero speed and end at zero speed). For this reason, G00 mode will not calculate the polynomial curve. At the end of a section in G00 there will be no pause (end of movement synchronism, entry into tolerance status, etc..) and the next movement will be carried out immediately. This behaviour is similar to the programming of G01 and G09 codes in the same block.

p1 |

|

p3 |

|

p2 |

p4 |

||

|

|||

|

|

p0

With G01, each point will be linked geometrically to the following ones by means of a polynomial curve, so the generated path may be considered “continuous”. This link will be interrupted by the programming of a G00 or the programming of special G codes described below. The dynamics of the sections in G01 are the same as the “cutting” movements (such as normal G01 movements in ISO programming).

p1 |

|

p3 |

|

p2 |

p4 |

||

|

|||

|

|

p0

10 Series CNC High Speed Machining (00) |

1-3 |

Chapter 1

High Speed Machining

In addition to the G01 and G00 functions, the following G functions, specific for the HSM feature, may be programmed in the profile.

G61

Determines the start of the profile and must be programmed in a block on its own. When the G61 function is activated, there must be no form of virtualization active (UPR,UVP,UVC,TCP).

Before activating the G61 function, the setup file must be defined by means of the instruction:

(HSM, setup file name)

The G61 command may ONLY be executed within a part program in AUTO or BLK BY BLK status.

G60

Determines the end of the profile and must be programmed in a block on its own.

If the machine is in single STEP execution, the profile between G61 and G60 is considered as a single instruction. To stop its execution, it is necessary to switch to HOLD status.

G62

Splits a profile in two parts and determines the point where one profile ends and another begins, maintaining continuity between the two curves.

The points preceding the G62 function will be used to generate a first curve, while the subsequent points will be used to generate another one. These curves will be linked and will therefore be continuous; the initial inclination of the second curve will correspond to the final inclination of the previous curve.

G62

p3

p3

p1 |

p2 |

|

p4 |

|

|

||

|

|

|

p0

As regards dynamics, with G62 no deceleration and acceleration ramp will be generated to link the two curves. This G function must be programmed in a part program block on its own.

G62

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1-4 |

|

|

10 Series CNC High Speed Machining (00) |

|

Chapter 1

High Speed Machining

G63

Splits a profile into two parts and determines the point where one profile ends and the other one begins, maintaining continuity between the two curves. The points preceding the G63 function will be used to generate a first curve, while the subsequent points will be used to generate another one. While with G62, the initial inclination of the second curve depends strictly on the final inclination of the first, with G63, the initial inclination of the second curve IS NOT influenced by that of the first. To maintain continuity, a “radius” that depends on the chordal error with which the splines are to be calculated is inserted.

With G63 a reduction in speed may occur at the point where the two curves are linked. This G function must be programmed in a part program block on its own.

G66

Splits a profile into two parts and determines the point where one profile ends and the other one begins, creating a discontinuity between the two curves, that is, the point preceding the G66 represents an edge. At this point, two curves are generated, the first using the points preceding the G66 function and the second using the subsequent points. These curves will NOT be linked, and so there will be a discontinuity.

|

|

|

|

|

|

|

G66 |

|

|

|

||

|

|

|

|

|

|

|

p3 |

|||||

p1 |

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

p4 |

||||

|

|

|

p2 |

|||||||||

p0 |

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

||||

This discontinuity will be reached at zero speed; the first curve will therefore end with a deceleration ramp to 0 (zero) speed after which the second curve will be tackled with an acceleration ramp to reach the required machining speed. This G function must be programmed in a part program block on its own.

v

G66

t

10 Series CNC High Speed Machining (00) |

1-5 |

Chapter 1

High Speed Machining

G67

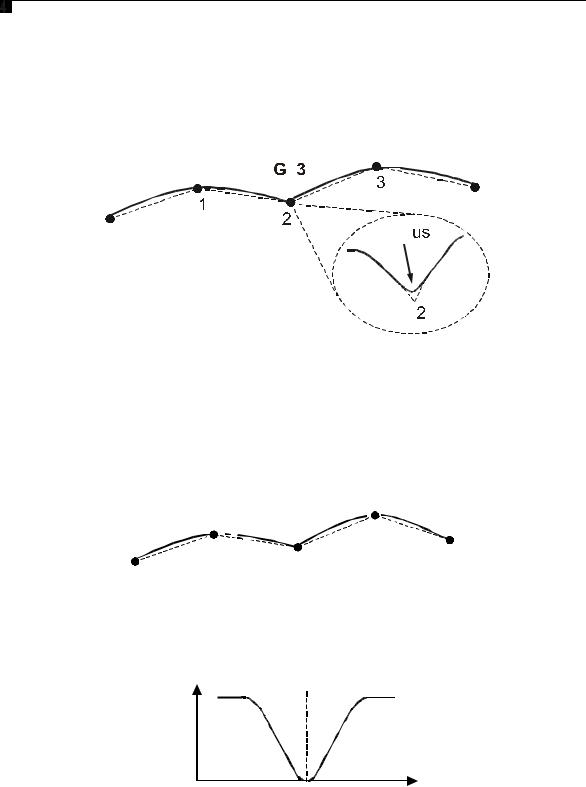

With G67, a “discontinuity” may be defined on the profile defined with G66. What changes is the dynamic approach to the edge, that is, the end of the curve is not reached at zero speed but at a speed value (vs) that enables the axes to reach the edge without any dynamic problems. This speed value is calculated on the basis of the acceleration that may be withstood by each axis. This G function must be programmed in a part program block on its own.

v

G67

vs

Considerations on the use of the G62,G63,G66 and G67 functions (transition codes)

The transition G codes are particularly useful when “similar”, repetitive curves are to be defined (providing the programmed points are also similar and repetitive).

Supposing we have a profile defined by 100 points of which the first 50 represent the first machining pass (from p1 to p50) and the other 50 (from p50 to p99) the same profile shifted slightly (second pass).

p1

p50

p99

p99

As the points between p1 and p50 are “similar” to the points between p50 and p99, the conditions for calculating the two polynomial curves will also be similar. Two “parallel”, almost identical curves will therefore be generated.

If the G62 function has not been programmed on point p50 the NC may generate curves that are not perfectly parallel. This normally undesired effect is due to the fact that the calculation of the polynomial takes into account the “history” along the calculated paths.

The “history” of point p1 is clearly different from that of point p50. In fact, point p1 has no history while in point p50, the NC has followed a path determined by the first 49 points.

When the G62 function is inserted, it cancels the “history” and produces a geometrical pattern almost identical to the one calculated starting from point p1.

In machining processes that entail several passes, failure to program G62 would have the undesirable effect of producing different levels of machining between one pass and another.

1-6 |

10 Series CNC High Speed Machining (00) |

Chapter 1

High Speed Machining

GENERAL HIGH SPEED MACHINING PROGRAMMING STRUCTURE

Between the G61 and G60 blocks it will only be possible to program the points that make up the profile to be machined or the G codes for defining their management method: no other type of programming will be allowed.

Points may be programmed using, absolute programming may be used by means of (G90) or incremental programming by means of (G91). All numerical parameters required may be defined directly or by means of E or L variables: programming with expressions is not valid so XE(E2) or X(E1+E2) type programming is not allowed, while XE1 is allowed.

The syntax of the allowed program lines will be:

N… [G00 | G01] [G90 | G91] [points] F….

N… [G62 | G63 | G66 |G67 ]

Activation of the HSM (High Speed Machining) feature G61 forces of G01 and G90, modes while at the exit (G60) the G functions active when G61 was programmed will be restored.

The first point programmed MUST be expressed in absolute positions (G90) and must contain the programming of all axes associated with the HSM programming (axes configured in the HSM setup file).

Interaction with Machine Logic

The G61/G60 program section will be considered, from the system point of view, as a single program block. As regards interfacing with the machine logic, a request for consent for movement will be made when the G61 function is reached, and an end of movement request will be made when the G60 function is reached (in the same way as for the G27 and G28 continuous movements).

A regards consent for movement, the XW03 variable, which contains the type of movement, will be set as shown below:

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

10 Series CNC High Speed Machining (00) |

1-7 |

||||||||

Chapter 1

High Speed Machining

END OF CHAPTER

1-8 |

10 Series CNC High Speed Machining (00) |

Chapter 2

POINT DEFINING CONVENTIONS

POINTS AND MACHINING COORDINATES

Before defining how the points are handled, it is necessary to specify what they represent as programming may be executed in relation to three types of coordinates, that is:

∙Cutter Contact Points, which refer to the actual cutting point

∙Cutter Location Points, which refer to the point normally indicated as the centre of the tool

∙Axis Location Points, which refer to an arbitrary point fixed to the machining axes

The cutter contact points are linked to the cutter location points through the geometry and orientation of the tool. The axis location points are linked to the cutter location points through the geometry of the machine tool. In machining processes with three axes, the coordinates will simply be translated while, in those with five coordinated axes, rototranslation matrices that take into account the geometrical transformations due to the movement of the rotary axes will be applied. The figure below shows what is meant by cutter contact points, cutter location points and axis location points.

Axis location points

Tool direction

Normal

to surface Cutter contact points

Tool length

Radius

Edge

radius  Cutter location points

Cutter location points

Points are defined by means of normal axis coordinates in the format [Axis name][Position]; example: X100 Y200 Z40.

10 Series CNC High Speed Machining (00) |

2-1 |

Chapter 2

Point Defining Conventions

Tool Direction

The tool direction represents the orientation of the tool (from the tip to the attachment) within the part reference system.

In the following sections reference to versor means versor of unitary lenght.

WARNING

Two methods may be used to define the tool direction. The first is by directly programming the versor that identifies the tool direction. This versor is expressed using the ijk coordinates in the format:

[i] [X-coordinate component] [j][Y-coordinate component] [k][Z-coordinate component]

The system will automatically normalize the length of the versor to the unitary length (1.0).

The second way of defining the tool direction is by programming the rotary axes. The system will automatically determine the three components of the ijk versor depending on the kinematics of the machine.

Normal to the Surface Direction

The normal to the surface direction represents the direction of the “line” perpendicular to the surface to be machined (starting from the surface) within the part reference system.

There are two ways of defining the direction normal to the part. The first is by directly programming the versor that identifies the normal direction. This versor (of a unitary length) is expressed using the mno coordinates in the format:

[m] [X-coordinate component] [n][Y-coordinate component] [o][ Z-coordinate component]

The system will automatically normalize the length of the versor to the unitary length (1.0).

The second way is to have this direction calculated automatically by the system. The direction is calculated on the basis of the tangent to the profile (direction of the movement), on the basis of the tool direction (ijk versor) and an angle of contact between the part and the tool. This calculation makes sure that the mno versor is normal to the tangent to the profile and that it defines an angle α (angle of contact) with the tool versor ijk.

|

ijk |

mno |

|

|

|

α |

α |

|

|

tg profile |

|

|

|

This type of approach is only significant when the contour is to be machined. When a surface is to be machined, this approach could fail as there is no information about the “surface” to be machined, only information about the “direction” of displacement.

2-2 |

10 Series CNC High Speed Machining (00) |

Chapter 2

Point Defining Conventions

Tool Radius Application Direction

The direction of application of the tool radius represents the direction in which radius compensation is to be applied (starting from the centre of the tool) within the part reference system.

There are two ways of defining the tool radius application direction. The first is by directly programming the versor that identifies the direction. This versor (of a unitary length) is expressed using the pqd coordinates in the format

[p] [X-coordinate component] [q][Y-coordinate component] [d][Z-coordinate component]

The system will automatically normalize the length of the versor to the unitary length (1.0).

The second way is to have this direction calculated automatically by the system. The direction is calculated automatically on the basis of the tool direction (ijk versor) and the normal to the part (mno versor). This calculation ensures that the pqd versor is normal to the tool direction and is on the plane formed by the ijk and mno versors.

ijk

ijk

pqd pqd

pqd pqd  mno

mno

mno

Programming of the versor pqd is only significant when specific cutting strategies are applied.

Tangential Axis

The tangential axis is an axis whose position is calculated so as to remain tangential to the profile described. It is calculated on the basis of the tangent to the polynomial curve on the work plane.

y |

Tangential axis |

x |

An initial value of the tangential axis (first programmed point) may be defined and the subsequent positions may be calculated on the basis of this value.

10 Series CNC High Speed Machining (00) |

2-3 |

Chapter 2

Point Defining Conventions

END OF CHAPTER

2-4 |

10 Series CNC High Speed Machining (00) |

Chapter 3

FEATURES PROVIDED BY HIGH SPEED MACHINING

Depending on the type of machine tool used, the points programmed and a series of additional parameters, the features may be obtained using “High Speed Machining”.

MACHINES WITH 5 AXES

Machines with 5 axes are characterised by the fact that they have two rotary axes that are used to orient the tool during the machining phase. The direction of the tool and the position of the rotary axes are two closely related parameters.

One feature of High Speed Machining is that it “automatically” calculates the position of the rotary axes on the basis of the tool direction (ijk vector). In this way, the same part program may be used on machines having different kinematics providing both machines can reach the same positions.

10 Series CNC High Speed Machining (00) |

3-1 |

Loading...

Loading...