10 Series CNC

PLUS

Application Manual

Code: 45006677Z

Rev. 11

PUBLICATION ISSUED BY:

OSAI S.p.A.

Via Torino, 14 - 10010 Barone Canavese (TO) – Italy

e-mail: sales@osai.it

Web: www.osai.it

Copyright 2002-2003 by OSAI

All rights reserved

Edition: July 2003

IMPORTANT USER INFORMATION

This document has been prepared in order to be used by OSAI. It describes the latest release of the

product.

OSAI reserves the right to modify and improve the product described by this document at any time

and without prior notice.

Actual application of this product is up to the user. In no event will OSAI be responsible or liable for

indirect or consequential damages that may result from installation or use of the equipment described

in this text.

abc

SUMMARY OF CHANGES

General

This publication has been issued with the software release 7.2.

This issue completely replaces the previous ones.

PAGE UPDATE TYPE

Chapter 3

Page 3 Updates values in SW02 system status flag tables.

Chapter 6

Page 2,3

Page 10,11

Page 13

Modified error codes in FB $EMERGNR

Modified error codes in $EMERGR

Added paragraph on FastWire emergency conditions

UPDATE

10 Series CNC PLUS Application Manual

Chapter 11

Chapter 12

Added new chapter on CANOPEN

Added new chapter on FASTWIRE

10 Series CNC PLUS Application Manual (11)

abc

Preface

10 Series CNC PLUS Application Manual

PREFACE

The 10 Series numerical control introduces many new Technical concepts. One of the most important

of these concepts is the concept of information exchange between the CNC and the integrated PLC

(Programmable Logic Controller).

Conventional controls use a window with a large amount of fixed flags, which are continuously

scanned and updated by both CNC and programmable logic control.

The concept of 10 Series by-passes this general conception with a simple but unique solution: both

CNC and PLC use function calls to alert each other, to pass information or to request a certain

action. These function calls need only be executed on event, thus freeing up CPU capacity and

increasing the general system performance.

This manual explains the new concept and shows how applications can use its power.

ABOUT THIS MANUAL

This manual is intended to be used by the OEM personnel in charge with the programming of the

machine tool interface. It gives an overview of the software architecture to be used to develop the

programmable logic.

• it does NOT explain the PLUS programming language and the use of any of its language

elements.

• it does NOT explain the use of the PLUSEDIT development software.

10 Series CNC PLUS Application Manual (10) 1

Preface

10 Series CNC PLUS Application Manual

This manual is structured as follows:

Chapter 1 explains the concepts of communication between the logic and the system.

Chapter 2 gives a detailed view of the structure of the routines running on the PLC module: it

shows the timing and the execution priorities of the different routines on the I/O

processor and it makes you familiar with the special execution mode of the

background logic programs. Finally, it gives a list of declarations needed to define

the different routines.

Chapter 3 deals with the data areas in the PLC module's memory and in its dual port.

Chapter 4 explains the routines which make up the interface between the part program and

the logic.

Chapter 5 shows how the executive command filters can be used.

Chapter 6 covers the emergency routines.

Chapter 7 explains the OEM softkey routine.

Chapter 8 is the practical part of the manual which explains how the controls communication

concept can be used to create powerful applications.

Chapter 9 this chapter describes how to use the INTERBUS feature on 10 Series systems.

Chapter 10 this chapter describes the configuration modality of PROFIBUS on 10 Series

systems.

Appendix A contains a glossary of verbs and expressions used in this manual.

OTHER MANUALS ABOUT PLUS

Beside this manual there are 2 other specific manuals about PLUS:

• 10 Series CNC PLUS LIBRARY code 4500 6682 C

This manual covers the library function calls and the function blocks available in the PLUS

programming language:

− Basic language function blocks

− Language extensions

− Counters and timers

− System function calls

− function calls

• 10 Series CNC PLUS LANGUAGE & PLUSEDIT code 4500 6672 P

This manual describes the PLUS language, the editors and the utilities to generate an executable

logic program:

− instruction list editor (IL) + basic language elements

− ladder diagram / function block diagram editor (FBD/LD)

− macro instruction list editor (MACRO-IL)

− sequential function chart editor (SFC)

− PLUSGEN generator (compiler)

− I/O configurator

− ASCII editor

2 10 Series CNC PLUS Application Manual (10)

Preface

CAUTION

IMPORTANT

10 Series CNC PLUS Application Manual

Other manuals may be of interest when programming a machine tool interface:

1. 10 Series CNC AMP - Software Characterisation Code : 4500 6667 V

describes the system/process software configuration utility and its parameters

2. 10 Series CNC Programming Manual Code: 4500 4457 K

describes the 10 Series CNC part program language

3. 10 Series CNC User Manual Code: 4500 4452 H

describes the use of the human interface, the CNC manual functions and the utilities available to

the operator

4. 10 Series Family Installation Guide Code 4500 6657 R

contains the complete information needed to realise a correct installation of the 10 Series CNC

system.

5. 10 Series CNC Software Installation Manual Code 4500 6687 N

contains the complete information needed to install the software release.

WARNINGS

For correct control operation, it is important to follow the information given in this manual. Take

particular care with topics bearing one of the mentions: WARNING, CAUTION or IMPORTANT, which

indicate the following types of information:

Draws attention to facts or circumstances that may cause damage to the control,

WARNING

to the machine or to operators.

Indicates information to be followed in order to avoid damage to equipment in

general.

Indicates information that must be followed carefully in order to ensure full

success of the application.

10 Series CNC PLUS Application Manual (10) 3

Preface

10 Series CNC PLUS Application Manual

END OF PREFACE

4 10 Series CNC PLUS Application Manual (10)

10 Series CNC PLUS Application Manual

INDEX

SYSTEM - APPLICATION LOGIC HANDSHAKE

LOGIC INTERFACE TASKS......................................................................................1-2

SYSTEM FUNCTION CALLS.....................................................................................1-2

COMMON DATA AREAS ..........................................................................................1-2

Index

ORGANIZATION OF THE APPLICATION LOGIC

AVAILABLE ROUTINES ...........................................................................................2-1

Routines activated on event (fast input routines).................................................2-1

Routines activated on clock (foreground) ............................................................2-1

Routines activated on emergency (emergency routine) ........................................2-2

Routines activated on softkey - (OEM softkey routine) ........................................2-2

Routines activated background routines.............................................................2-2

Routines activated on part program events (part program interface).......................2-2

Routines activated on system commands (consent request)................................2-2

TASK SYNCHRONIZATION.......................................................................................2-5

BACKGROUND EXECUTION.....................................................................................2-9

PLUS ROUTINES DECLARATION .............................................................................2-12

I/O PROCESSOR /SYSTEM DATA AREAS

SYSTEM STATUS FLAGS ........................................................................................3-2

PROCESS STATUS FLAGS .....................................................................................3-6

USER DEFINED / GLOBAL VARIABLES (G VARIABLES)...........................................3-15

M VARIABLES.........................................................................................................3-16

TABLES ..................................................................................................................3-17

Axes Table .....................................................................................................3-17

Tool table........................................................................................................3-21

Tool offset table ...............................................................................................3-23

User table .......................................................................................................3-27

PART PROGRAM INTERFACE

STRUCTURE............................................................................................................4-1

PART PROGRAM INTERFACE TASK........................................................................4-2

10 Series CNC PLUS Application Manual (11) i

Index

10 Series CNC PLUS Application Manual

PART PROGRAM INTERFACE ROUTINES ................................................................4-6

COORDINATED AXES..............................................................................................4-8

Consent to move routine...................................................................................4-8

Motion blocks .................................................................................................4-10

Consent to move management ..........................................................................4-11

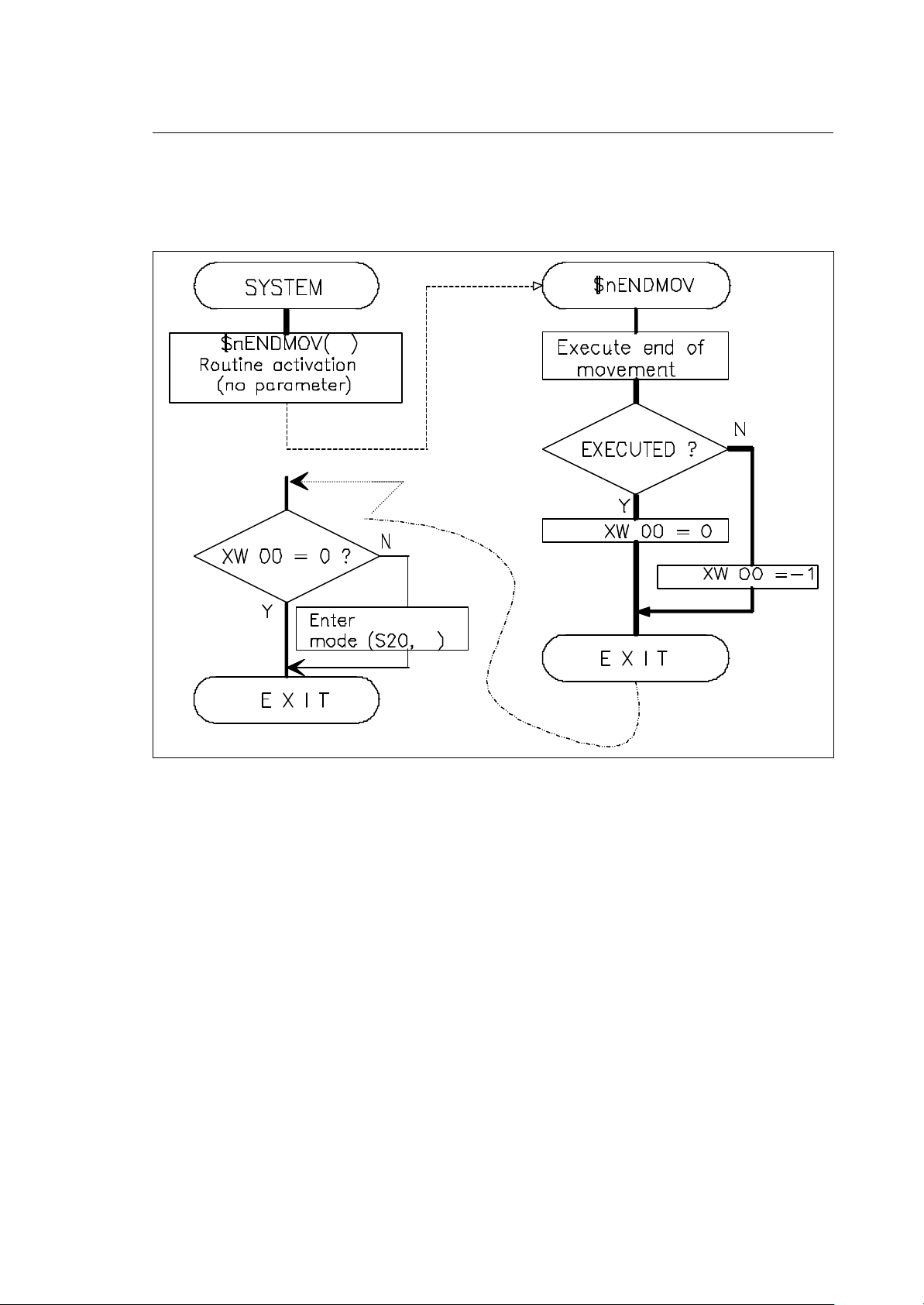

End of motion routine .......................................................................................4-12

End of move management ................................................................................4-13

M FUNCTIONS .........................................................................................................4-14

M decode routine.............................................................................................4-15

M code management (EXPEDITE).....................................................................4-18

AMP set up for M functions ..............................................................................4-19

PSEUDO AXES........................................................................................................4-25

Pseudo axes routine ........................................................................................4-25

S WORD..................................................................................................................4-29

S decode routine.............................................................................................4-29

T WORD ..................................................................................................................4-34

T decode routine..............................................................................................4-37

END OF BLOCK ROUTINE........................................................................................4-43

TOOL OFFSET PRESETTING ...................................................................................4-45

TOOL OFFSET REQUALIFICATION ..........................................................................4-48

DECLARE TOOL LIFE EXPIRED...............................................................................4-51

PROBING CYCLE COMPLETED................................................................................4-53

EXECUTIVE COMMAND FILTER ROUTINES

CYCLE START PUSH BUTTON (PRESSED) ..............................................................5-5

CYCLE START PUSH BUTTON (RELEASED).............................................................5-6

CONTROL RESET....................................................................................................5-7

MODE SELECT........................................................................................................5-8

AXIS SELECT ..........................................................................................................5-9

MANUAL FEEDRATE OVERRIDE SELECTOR ............................................................5-10

FEEDRATE OVERRIDE SELECTOR...........................................................................5-11

SPINDLE SPEED OVERRIDE SELECTOR..................................................................5-12

RAPID FEEDRATE OVERRIDE SELECTOR................................................................5-13

INTERPOLATOR STOP (HOLD) REQUESTED ...........................................................5-14

RE-START INTERPOLATOR (EXIT FROM HOLD)......................................................5-15

EMERGENCY MANAGEMENT

UNRECOVERABLE EMERGENCIES ..........................................................................6-2

DSI Emergencies ............................................................................................6-5

RECOVERABLE EMERGENCIES...............................................................................6-10

DSI Emergencies ............................................................................................6-12

FASTWIRE EMERGENCY CONDITIONS ..........................................................6-13

OEM SOFTKEYS

INTERFACE ROUTINE ..............................................................................................7-1

ON/OFF Softkeys............................................................................................7-3

MAINTAINED Softkey ......................................................................................7-3

DATA ENTRY Softkeys....................................................................................7-4

10 Series CNC PLUS Application Manual (11)ii

10 Series CNC PLUS Application Manual

NORMAL Softkeys..........................................................................................7-5

OPLink Function Keys .....................................................................................7-5

STANDARD APPLICATION NOTES

PLUS INITIALIZATION.............................................................................................8-1

MACHINE TOOL POWER UP AND RE-POWER UP AFTER E-STOP ...........................8-2

HOLD MANAGEMENT..............................................................................................8-3

RESET MANAGEMENT.............................................................................................8-6

SPINDLE MANAGEMENT.........................................................................................8-9

CO-ORDINATED AXES MOVES (MAS) FROM PLUS ..................................................8-11

HARDWARE OVER TRAVEL LIMIT SWITCHES .........................................................8-16

AXES HOMING........................................................................................................8-19

PLUS MESSAGES DISPLAY....................................................................................8-22

FEED HOLD .............................................................................................................8-25

ACTIVE RESET........................................................................................................8-27

MANUAL JOG BY THE LOGIC..................................................................................8-33

FEED RATE OVERRIDE CONTROL...........................................................................8-34

FEED RATE BYPASS...............................................................................................8-37

SERIAL LINE MANAGEMENT (RS-232) .....................................................................8-39

AXIS POSTIONING VIA RS-232 SERIAL LINE...........................................................8-41

Configuration...................................................................................................8-41

Programming ..................................................................................................8-42

Installation Specifications.................................................................................8-45

Index

INTERBUS® FEATURES ON 10 SERIES SYSTEMS

CONFIGURATION APPLICATION IBS CMD..............................................................9-3

On-line Operations ...........................................................................................9-5

Off-line Operations...........................................................................................9-13

TRANSFERRING THE CONFIGURATION FILE TO THE 10 SERIES CNC .....................9-15

INTERBUS ERRORS ................................................................................................9-16

SLAVE PROFIBUS® FUNCTIONALITIES ON 10 SERIES

SYSTEMS

SLAVE PROFIBUS CONFIGURATION.......................................................................10-2

DESCRIPTION OF ERROR CODES RETURNED DURING THE FUNCTIONING OF

THE SLAVE PROFIBUS. ..........................................................................................10-4

CANOPEN® FUNCTIONS ON SERIES 10 SYSTEMS

CANOPEN BUS CONFIGURATION............................................................................11-2

CONFIGURATION EXAMPLE....................................................................................11-4

DESCRIPTION OF ERROR CODES RETURNED DURING OPERATION OF

CANOPEN BUS ........................................................................................................11-5

Errors from RIO EC modules ............................................................................11-5

Errors from CWIO modules ...............................................................................11-7

ERRORS RETURNED DURING CNC POWER UP .......................................................11-7

10 Series CNC PLUS Application Manual (11) iii

Index

10 Series CNC PLUS Application Manual

FASTWIRE® FUNCTIONS ON SERIES 10 SYSTEMS

FASTWIRE BUS CONFIGURATION ..........................................................................12-2

CONFIGURATION EXAMPLE....................................................................................12-4

DESCRIPTION OF ERROR CODES RETURNED DURING OPERATION OF

FASTWIRE BUS ......................................................................................................12-5

ERRORS RETURNED DURING CNC POWER UP .......................................................12-6

GLOSSARY

GLOSSARY.............................................................................................................A-1

END INDEX

10 Series CNC PLUS Application Manual (11)iv

1

SYSTEM - APPLICATION LOGIC HANDSHAKE

Chapter

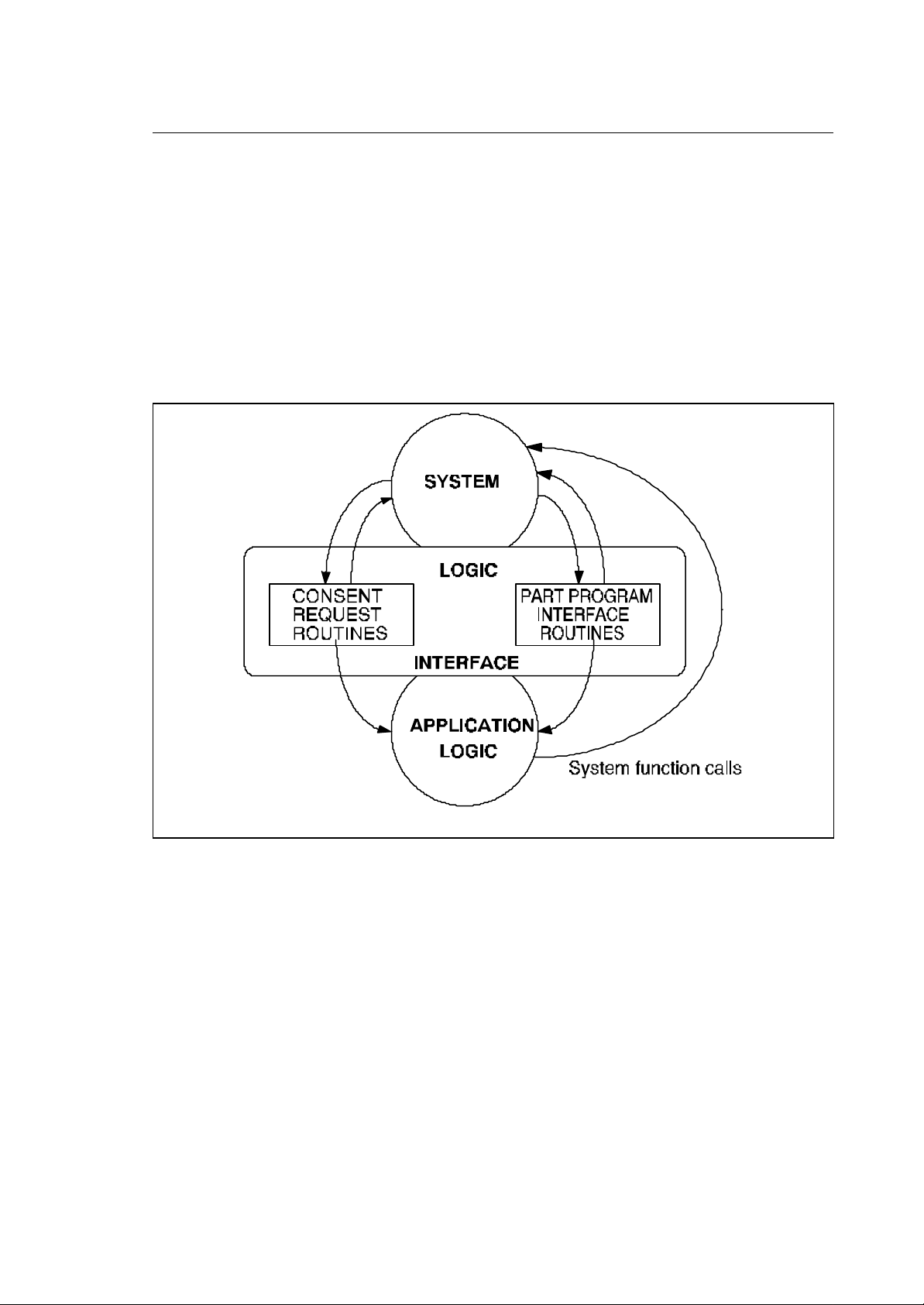

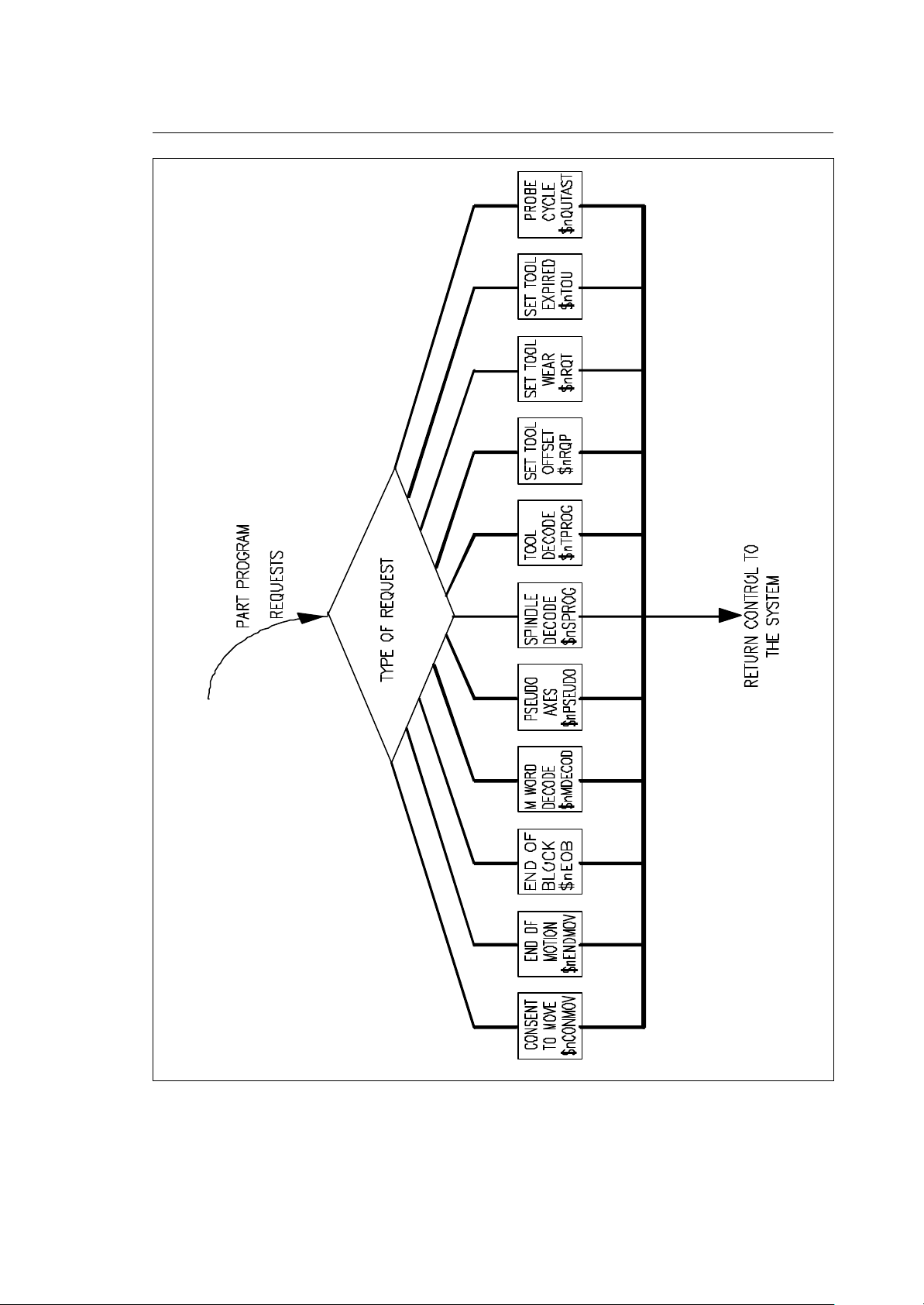

Fig. 1-1 System - Application Logic Handshake

10 Series CNC PLUS Application Manual (02) 1-1

Chapter 1

System - Application Logic Handshake

LOGIC INTERFACE TASKS

The system communicates to the logic through the logic interface. This Interface consists of two

tasks, the "consent request task " and the "part program interface " task. These tasks receive the

commands and the parameters from the system, process them and sends some of them to the

application logic program.

Each one of these tasks can be made up of several routines which have to be written by the PLUS

programmer. Some of the routines are optional, i.e. if they have not been written, they will not be

activated by the system.

SYSTEM FUNCTION CALLS

The logic from its part communicates with the system through a set of function calls which can

include a parameter exchange between the two parties. There are two types of function calls:

• NO WAIT functions pass a command (with parameters) to the system without waiting for an

answer (the application program execution is not suspended).

• WAIT functions pass a command to the system and wait for a res ponse ( the logic execution is

suspended until the response arrives)

COMMON DATA AREAS

The third communication channel between the logic and the system are the common data areas in

the battery buffered dual ported memory of the I/O processor board. These areas can be divided in:

• System area. This is a group of 100 variables of the type short (16 bit integer word) containing the

status of the system and/or the processes.

• Global variables. These variables are referred to as "G" variables. They have two formats; short

and double (precision floating point). They can be read and written by both part program and logic

program. The G variables are retentive, i.e. they are not cleared after powering up the system.

• Tables. Tables are retentive memory areas in the dual port of the I/O processor module. They can

be commonly accessed by the system and by the logic programs. The data contained in tables

includes:

− tool data

− tool offset data

− axes origin data

− axes offsets

END OF CHAPTER

1-2 10 Series CNC PLUS Application Manual (02)

Chapter

2

ORGANIZATION OF THE APPLICATION LOGIC

The logic program is organised in independent routines. All these routines run on the I/O processor

module and have different priorities depending on their use. The program's various routines are

activated by the PLC's Operating System either following specific events or on clock or they are

continuously executed (in loop).

AVAILABLE ROUTINES

Routines activated on event (fast input routines)

You can define up to 4 interrupt routines (one for each input) which are executed when the relevant

"fast input" on the I/O processor module is set true. Each routine is dedicated to a specific fast input.

The association of fast input and corresponding routine is given by the predefined names for the

routines. The execution starts on the true-going edge of the corresponding fast input signal. All other

activities of the I/O processor task will be suspended for the duration of the execution of the routines.

In other words, the fast input routines have the highest execution priority of all routines. For this

reason these routines must be as short as possible (<< 5ms).

Routines activated on clock (foreground)

This routine (only one can be present) will be executed on each clock tick of the I/O processor

module. This clock tick is presently set to 10 ms. If the foreground routine execution time exceeds

the available time (max. 10 ms), the system will generate an "overrun error" and go in emergency

status.

The primary use of the foreground routine is to "latch" events to be executed with precise and fast

timing such as read/write physical I/O device status or handling of security/emergency devices.

10 Series CNC PLUS Application Manual (08) 2-1

Chapter 2

Organization of the Application Logic

Routines activated on emergency (emergency routine)

Two emergency routines are available: their task is to handle the anomalies (emergencies) detected

by the system. The anomaly detected can be recoverable or not recoverable. On emergency, the

logic may have to execute sequences of logic in parallel to the steps taken by the system.

Routines activated on softkey - (OEM softkey routine)

There is one routine related to the OEM configured softkeys. Every time an OEM softkey is pressed

(or released), this routine will be executed and the softkey's parameters will be passed to it.

The OEM softkeys are defined in AMP, allowing OEM to provide its application with the identical look

and feel as the standard system operations (refer to AMP configuration manual). The OEM softkey

routine runs at a very low priority.

Routines activated background routines

A background routine is continuously executed in a loop like a program in a standard PLC. The I/O

processor can run up to 12 background routines in parallel.

Each background routine can execute functions of the WAIT type which will suspend the execution of

that background routine until arrival of the response. In the mean time the other background routines

will continue executing. In reality, when one routine is suspended, control will be passed to the next

one.

The logic programmer has to optimise the performance of the I/O processor using an optimised

distribution of the logic in the available background routines.

Routines activated on part program events (part program interface)

These routines (one for each configured process) will run every time, a part program block contains

information related to the logic (like M code, S word and Tool information and all other functions that

can be grouped under the definition of logic auxiliary functions).

Routines activated on system commands (consent request)

These routines (one for each configured process) run every time, a command is given to the system

(like cycle start, reset, etc.), allowing the logic to read and/or to inhibit the commands given to the

system by the operator.

This routine covers most commands given to the system from softkey and/or MTB panel.

2-2 10 Series CNC PLUS Application Manual (08)

Chapter 2

Organization of the Application Logic

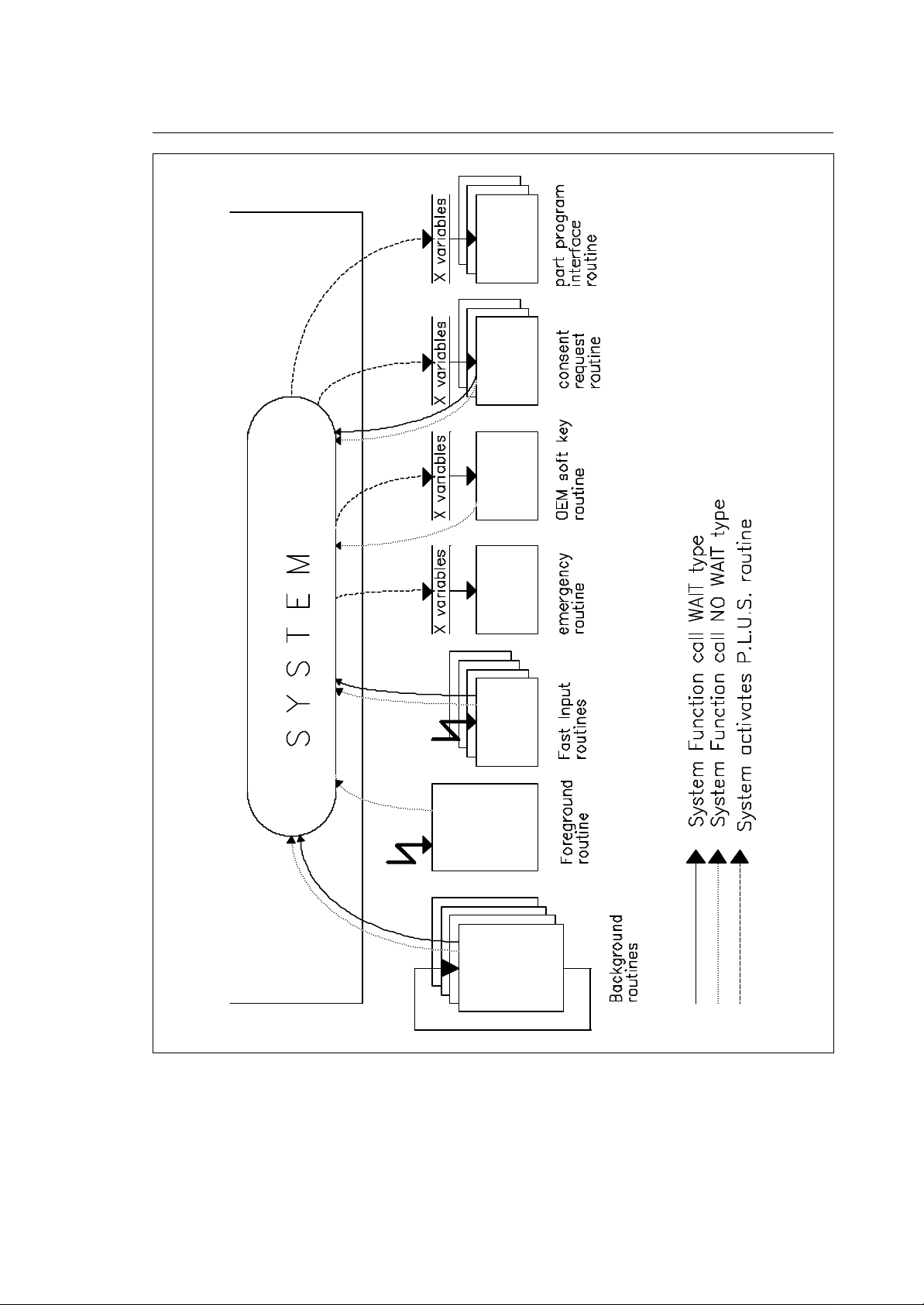

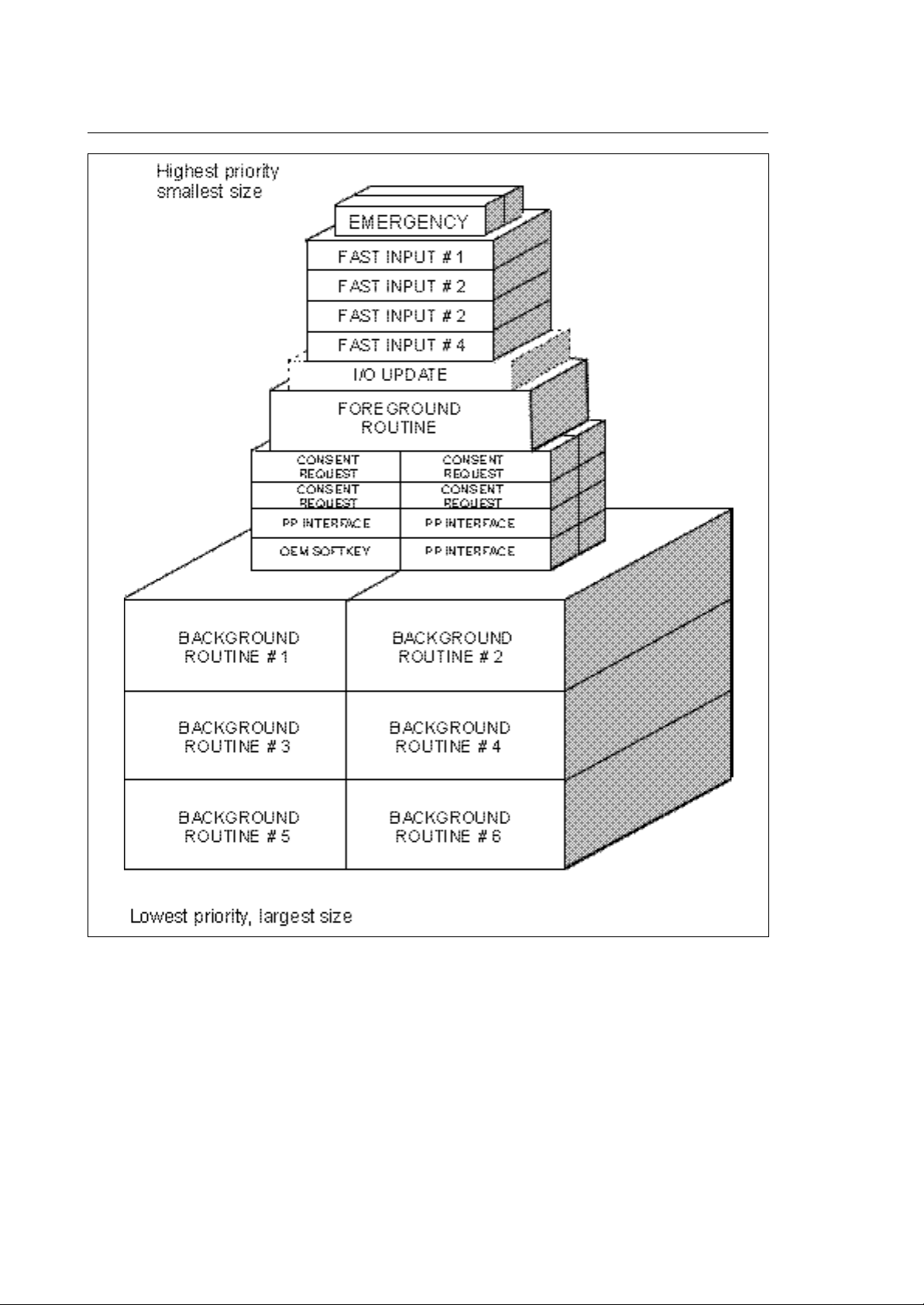

Fig. 2-1 Logic organisation and communication channels

10 Series CNC PLUS Application Manual (08) 2-3

Chapter 2

Organization of the Application Logic

SYSTEM CPU

PART

PROGRAM

INTERFACE

BACKGROUND

ROUTINE

# 1

SYSTEM

EMERGENCY

ROUTINE

LOGIC INTERFACE

OEM SOFTKEY

ROUTINE

FOREGROUND

ROUTINE

REQUEST TO

EXECUTE LOGIC

ROUTINES

CONSENT

REQUEST

ROUTINE

10 MS

TIMED

INTERRUPT

BACKGROUND

ROUTINE

# 2

BACKGROUND

ROUTINE

# 3

FAST INPUT

ROUTINES

I/O PROCESSOR MODULE

Fig. 2-2 Routine scheduling

FAST INPUT

HARDWARE

INTERRUPT

2-4 10 Series CNC PLUS Application Manual (08)

Chapter 2

Organization of the Application Logic

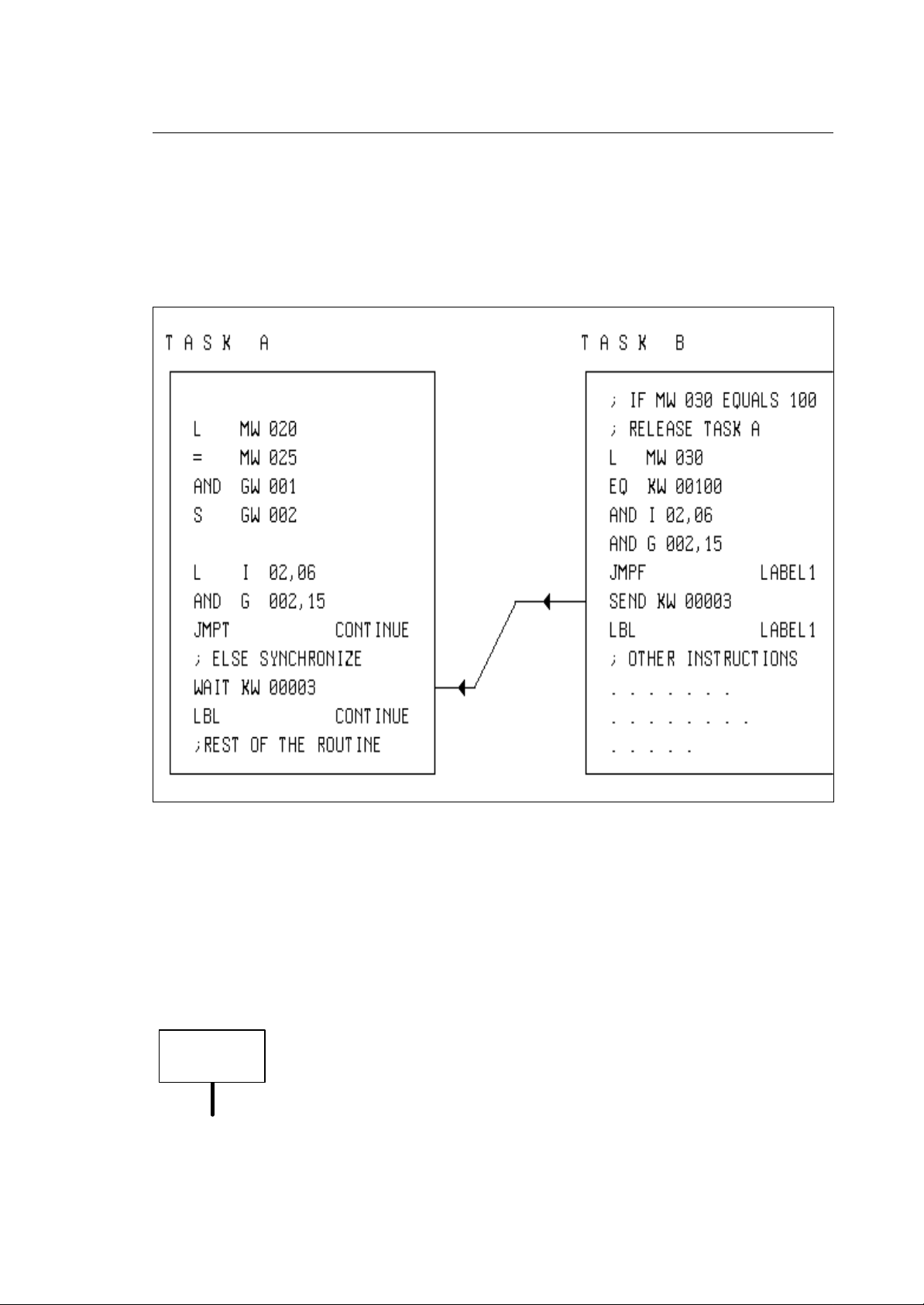

TASK SYNCHRONIZATION

You can synchronize some of the different previously discussed routines with a set of semaphores

(32) together with the instructions WAIT and SEND. With the WAIT instruction and one of the

semaphore numbers (0-31) you can suspend the execution of a routine (task) until one of the other

routines uses the SEND instruction with the same semaphore number. In this way you can

synchronize the execution of one task with an event in another task.

Fig. 2-3 Task Synchronization

The WAIT (3) instruction suspends the execution of task A until the SEND (3) command in task B is

executed on the same semaphore. Of course the exact point in time of the task's resumption also

depends on its priority.

NOTE:

A SEND on a semaphore can be issued without a task waiting for this semaphore. The SEND

instruction will simply be ignored. Any routine in WAIT status can only be released by the relative

SEND instruction. The routine that holds the SEND instruction must be synchronized with the routine

holding the WAIT status request.

You are not allowed to use the WAIT/DLY instructions in foreground, fast input

IMPORTANT

10 Series CNC PLUS Application Manual (08) 2-5

and emergency routines

Chapter 2

Organization of the Application Logic

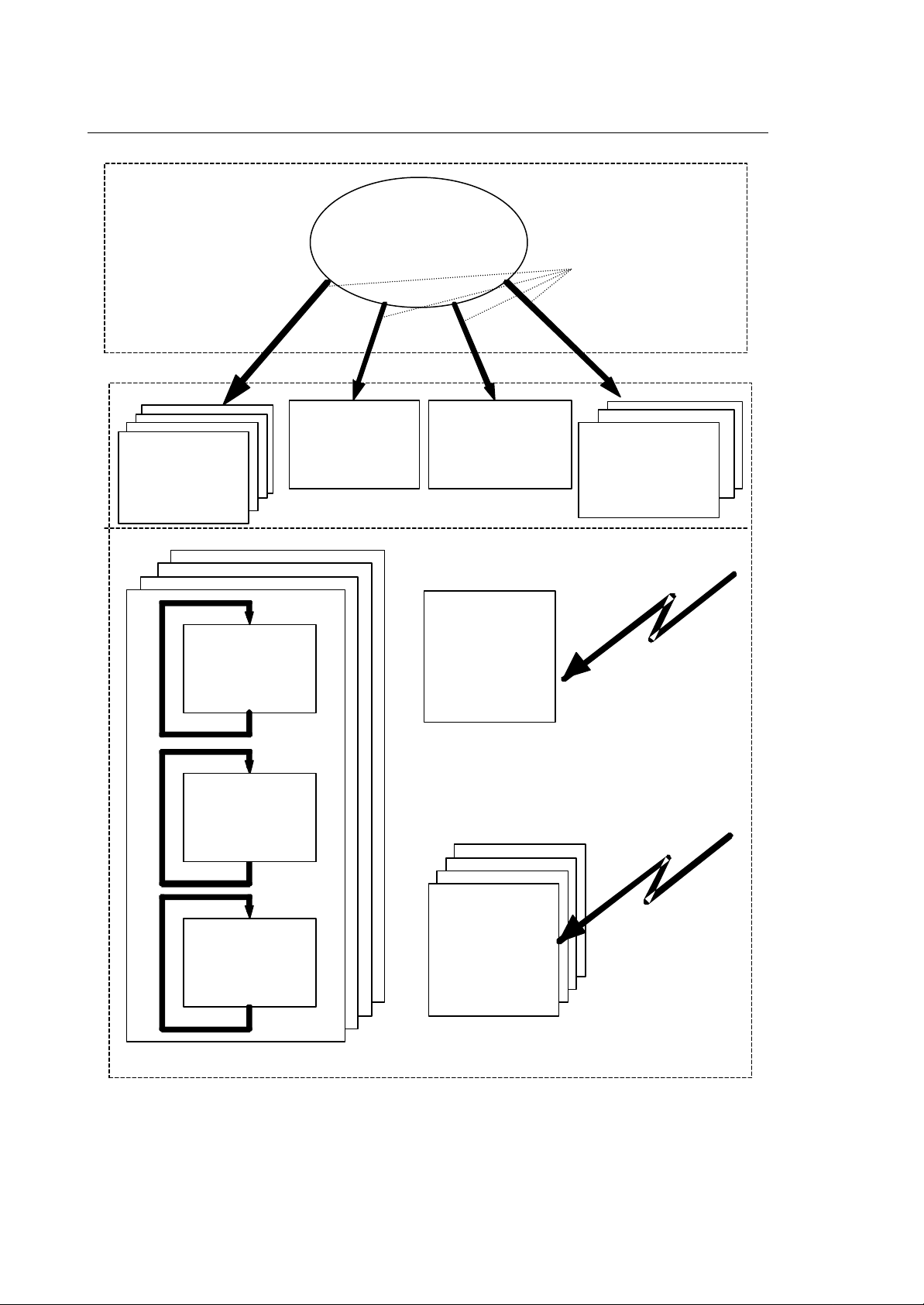

Fig. 2-4 Routine priority and size

2-6 10 Series CNC PLUS Application Manual (08)

Chapter 2

Organization of the Application Logic

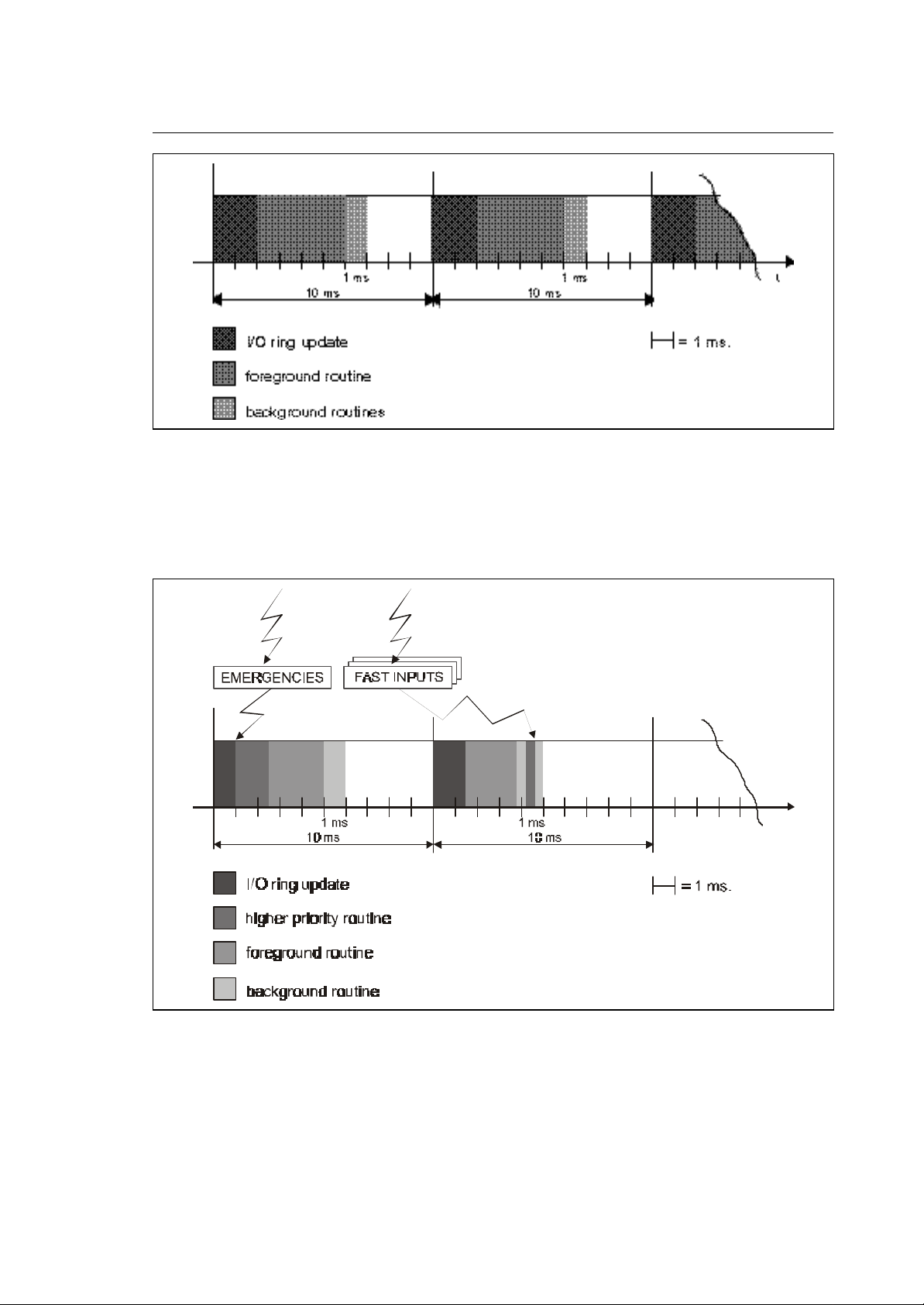

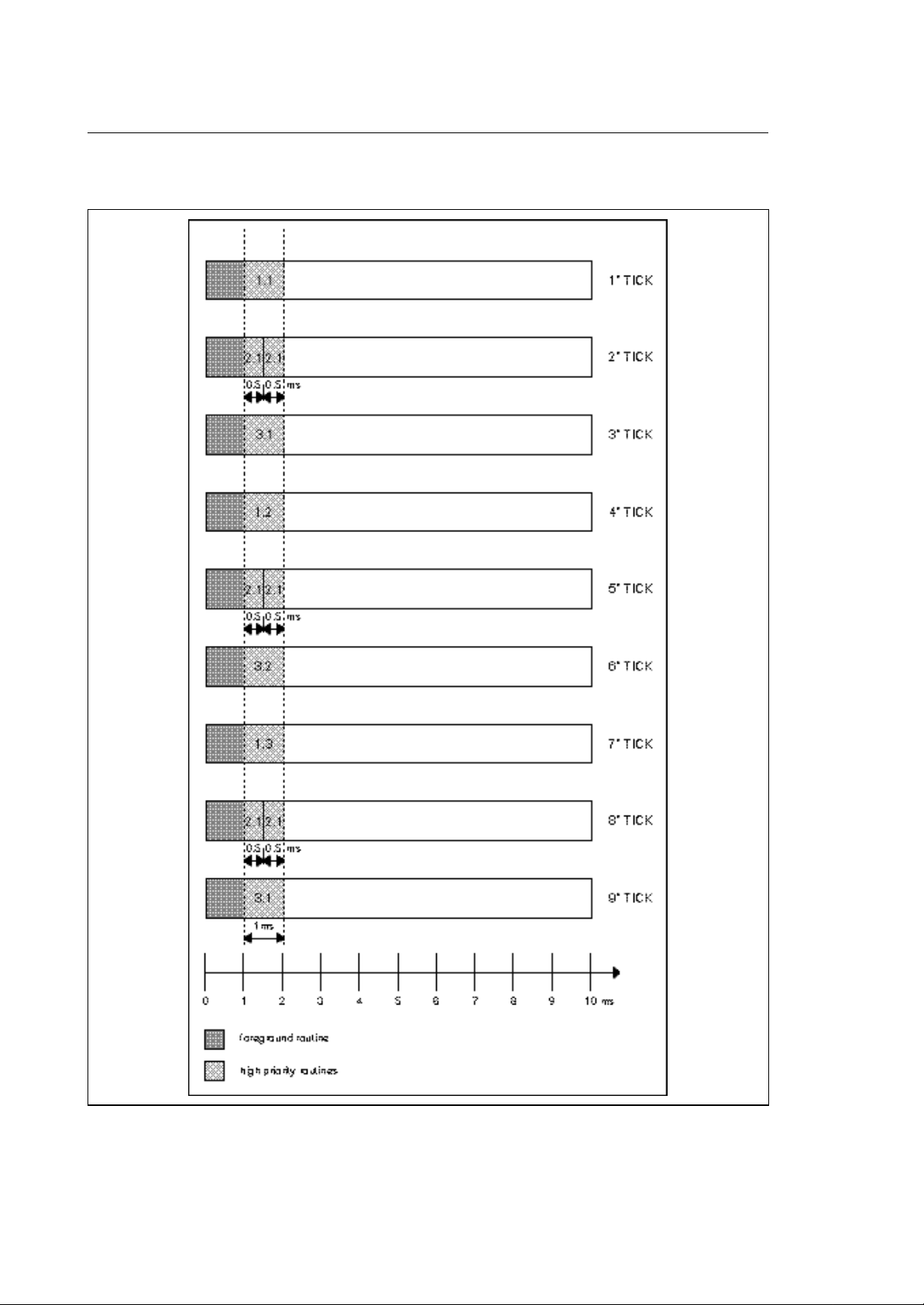

Fig. 2-5 Steady Operation

Every 10 ms the system updates the I/O's, executes the all foreground routines and executes one of

the background ones for 1 ms. Every 10 ms one of the background routines present will be executed

in sequence. If a background routine takes less than 1 ms, it will be rerun from the start, until this

time runs out. No routine will be interrupted.

Fig. 2-6 High Priority Interrupt Operation

10 Series CNC PLUS Application Manual (08) 2-7

Chapter 2

Organization of the Application Logic

When emergencies occur or fast input routines have to be processed, the steady operation of the I/O

processor will be interrupted and the high priority routines required will be executed immediately. Note

that the steady execution may be interrupted anywhere during the execution of the I/O ring update, of

the foreground logic or of the background logic.

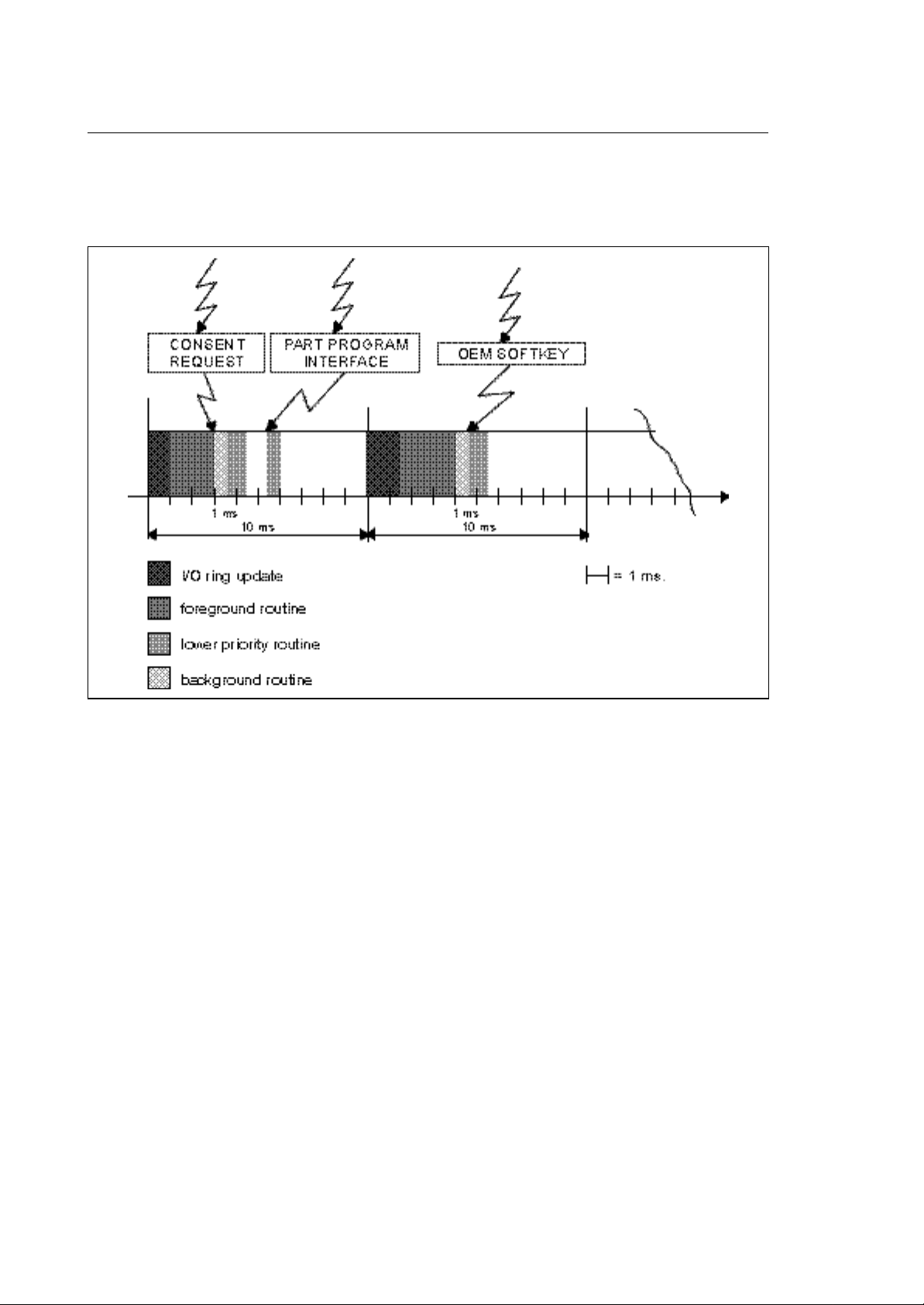

Fig. 2-7 Low Priority Interrupt Operation

When low priority events occur, like consent request calls, part program Interface calls or even OEM

softkey calls, the foreground routine and all other higher priority tasks will not be interrupted. These

low priority routines will only run during the time available for background logic execution.

2-8 10 Series CNC PLUS Application Manual (08)

Chapter 2

Organization of the Application Logic

BACKGROUND EXECUTION

There can be up to 12 background routines. The background routines are those with the lowest

priorities among the routines making up the logic application and are executed in turn every 10 ms

(Tick Plus) for 1 ms.

At each Tick Plus the integrated PLC updates the I/O's and the foreground routines.

Consensus routines, part program interfaces and OEM softkeys are enabled at system request and

interrupt background execution.

After enabling all high priority routines at each Tick Plus, the system enables one of the background

routines and lets it run for 1 ms.

At each Tick Plus the system enables a different background routine. The sequence of activation is

determined by the number associated with the routine name. At the first Tick Plus the background

routine 1 ($BACK1) is enabled, at the second the background routine 2 ($BACK2) and so on.

Once the last background routine has been enabled, the system again starts with the first.

Therefore an individual background routine is executed over several Tick Plus, alternating part of its

code with that of other background routines in time slicing. If a background routine suspends its

execution voluntarily by calling a function such as WAIT or DELAY or indirectly by calling system

functions of the WAIT type, the remaining time up to the end of the millisecond is free for other

system operations (processing a part program, displaying, etc).

If a background routines is shorter than 1 ms, this is executed several times during the Tick Plus. If

the background task to be enabled is suspended at a new Tick Plus, no other background routine is

executed and the millisecond reserved for it is used by the system.

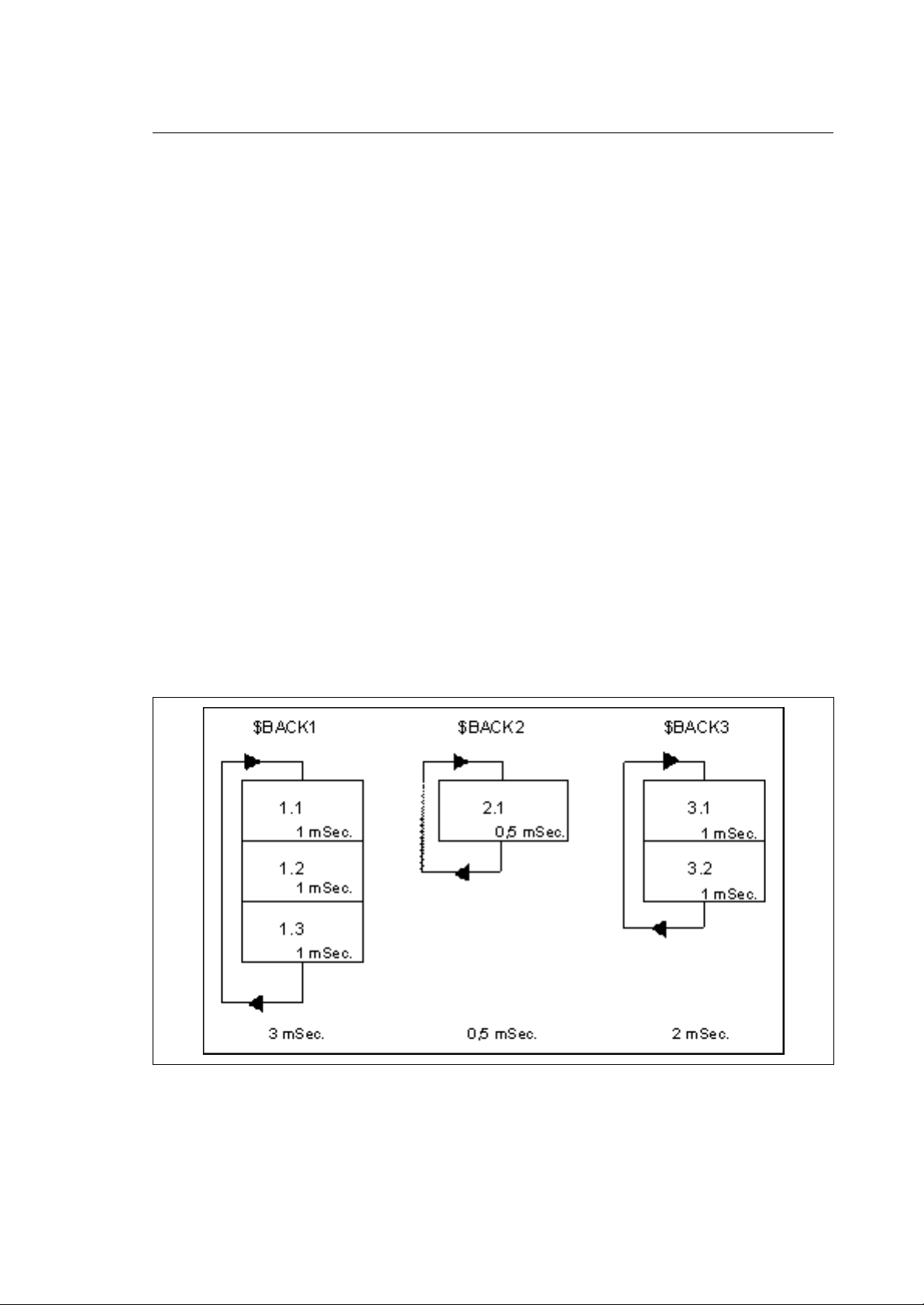

Fig. 2-8 Background logic execution

Fig. 2.8 shows 3 background loops with total execution times of 3, of 0.5 and 2 ms respectively.

10 Series CNC PLUS Application Manual (08) 2-9

Chapter 2

Organization of the Application Logic

Supposing after foreground execution + I/O ring management the remaining time for each sampling is

constant at 5 mSec, the above routine are executed in the following sequence:

Fig. 2-9 Background execution sequence

2-10 10 Series CNC PLUS Application Manual (08)

Chapter 2

Organization of the Application Logic

As can be seen, at each cycle a different background routine is started, which means that a short

background routine is executed more often than a long one.

Referring to the example, the repeat frequency of the 3 loops will be:

$BACK 1 90 ms

$BACK 2 30 ms

$BACK 3 60 ms

The formula for calculating the frequency of a background routine is:

duration of the background routine x number of background routines x 10

IMPORTANT

In this example it is assumed, that there are no interrupts (fast inputs, OEM

softkey, requests form a part program or from the operator)

10 Series CNC PLUS Application Manual (08) 2-11

Chapter 2

Organization of the Application Logic

PLUS ROUTINES DECLARATION

To make all the routines described before available to be used, they must be declared in the source

program for the logic.

FOREGROUND routine ( 10 ms execution)

DTSK $FORE

foreground routine body

ETSK

BACKGROUND routines (loop execution)

DTSK $BACK1

background routine body

ETSK

and so on, up to

DTSK $BACK12

background routine body

ETSK

FAST INPUT routines (on event execution)

DTSK $FIN1

fast input #1 routine body

ETSK

DTSK $FIN2

fast input #2 routine body

ETSK

DTSK $FIN3

fast input #3 routine body

ETSK

DTSK $FIN4

fast input #4 routine body

ETSK

EMERGENCY routines (on event execution)

DTSK $EMERGR recoverable emergency

emergency routine body

ETSK

DTSK $EMERGNR unrecoverable emergency

emergency routine body

ETSK

2-12 10 Series CNC PLUS Application Manual (08)

OEM SOFTKEY INTERFACE routine

DTSK $OEMSFTK

OEM Softkey interface routine body

ETSK

PART PROGRAM INTERFACE routines (on part program events)

DTSK $nCONMOV

body of consent to move routine

ETSK

DTSK $nENDMOV

body of end of motion routine

ETSK

DTSK $nMDECOD

body of M function decode routine

ETSK

Chapter 2

Organization of the Application Logic

DTSK $nPSEUDO

body of pseudo axes decode routine

ETSK

DTSK $nSPROG

body of S word decode routine

ETSK

DTSK $nTPROG

body of T word decode routine

ETSK

DTSK $nEOB

body of End Of Block routine

ETSK

DTSK $nRQP

body of tool dimension offset interface

ETSK

DTSK $nRQT

body of tool wear offset interface routine

ETSK

DTSK $nTOU

body of tool life interface routine

ETSK

DTSK $nQUTAST

body of interface routine for measuring cycles

ETSK

10 Series CNC PLUS Application Manual (08) 2-13

Chapter 2

Organization of the Application Logic

CONSENT REQUEST routines (on softkey or MTB panel)

DTSK $n_CYCLE

cycle start pushed

ETSK

DTSK $n_CYOFF

cycle start released

ETSK

DTSK $n_HOLDON

Request to enter HOLD status

ETSK

DTSK $n_HOLDOF

Request to exit from HOLD status

ETSK

DTSK $n_RESET

reset button pushed

ETSK

DTSK $n_SETMOD

mode selected

ETSK

DTSK $n_PUTFMA

manual feedrate selected

ETSK

DTSK $n_PUTFED

feedrate override value selected

ETSK

DTSK $n_PUTRAP

rapid feedrate override value

ETSK

DTSK $n_PUTSPE

spindle speed override value selected

ETSK

DTSK $n_SELAXI

axis selected for manual motion

ETSK

NOTE:

"n" indicates the process number (a number in the range 1...20)

END OF CHAPTER

2-14 10 Series CNC PLUS Application Manual (08)

Chapter

3

I/O PROCESSOR /SYSTEM DATA AREAS

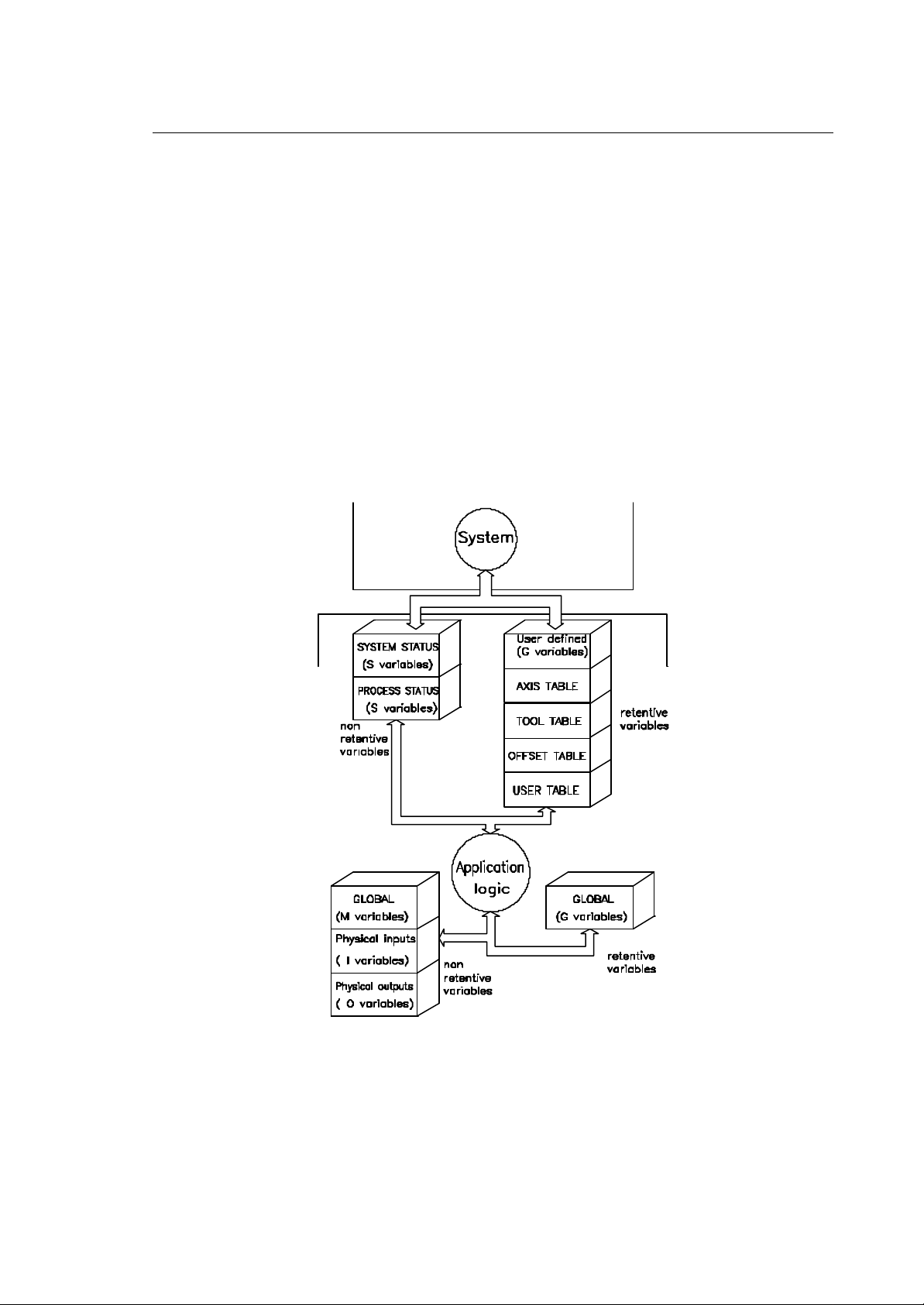

The I/O processor and the system share a data area in the dual ported memory of the I/O processor

module. This data area contains an I/O image, global retentive variables (G), system status variables

and 4 retentive tables with machine tool related data. Fig. 3-1 gives a detailed overview of all data

areas on the I/O processor, which are available to the application logic.

Fig. 3-1 Memory areas available to PLUS

10 Series CNC PLUS Application Manual (11) 3-1

Chapter 3

I/O Processor /System Data Areas

SYSTEM STATUS FLAGS

There are 500 system variables. They all have the short format. The first 20 variables (SW 00-SW 19)

are used to exchange some general system information between the logic program and the system.

Since the purpose of these variables is predefined, they have predefined symbolic names. Most of the

variables are read only to the logic (R/O). Only SW 03, SW 04 and SW 12 can be written and read by

the logic (R/W). SW Variables can be managed as words (I) or as single bits (B) or both (B/I).:

WORD MNEMONIC TITLE ACCESS PROT

SW 00 RESERVED FOR FUTURE USE

SW 01 S_SECURLEV ACTIVE SECURITY LEVEL I R/O

SW 02 S_CNINFO NC STATE INFORMATION B R/O

SW 03 S_HLS1 HOME LIMIT SWITCHES 1 B/I R/W

SW 04 S_HLS2 HOME LIMIT SWITCHES 2 B/I R/W

SW 05 RESERVED FOR FUTURE USE

SW 06 RESERVED FOR FUTURE USE

SW 07 RESERVED FOR FUTURE USE

SW 08 RESERVED FOR FUTURE USE

SW 09 S_PROCSEL SELECTED PROCESS I R/O

SW 10 S_SCRNSEL SELECTED SCREEN I R/O

SW 11 S_UNITS CONFIGURED UNITS B R/O

SW 12 RESERVED FOR FUTURE USE

SW 13 RESERVED FOR FUTURE USE

SW 14 RESERVED FOR FUTURE USE

SW 15 RESERVED FOR FUTURE USE

SW 16 S_NOWAIT NO WAIT CALL COUNTER I R/O

SW 17 S_CNCTYPE CONTROL TYPE B/I R/O

SW 18 RESERVED FOR FUTURE USE

SW 19 RESERVED FOR FUTURE USE

Hereafter, all variables and their functions will be discussed in more detail.

R/W SYSTEM VARIABLE SW 01 S_SECURLEV

WORD Title: Home Limit switches

SW 01 S_SECURLEV actually active security level value in the range of 0-6

(see SECURITY chapter in User Manual)

3-2 10 Series CNC PLUS Application Manual (11)

I/O Processor /System Data Areas

R/O SYSTEM VARIABLE SW 02 S_CNINFO

BIT Title: NC state information

Chapter 3

S 02,00

S 02,01

S 02,02

S 02,03

up to

S 02,15

R/W SYSTEM VARIABLE SW 03 S_HLS1

BIT Title: Home limit switches

S 03,00

S 03,01

through

S 03,15

S_OVRT.00

S_AXES

S_TUNING

reserved

S_HLS1.00 Home limit switch axis with ID 1

S_HLS1.01 Home limit switch axis with ID 2

S_HLS1.15 Home limit switch axis with ID 16

The system temperature has reached 45° C.

If the temperature goes higher, the controller switches off (50° C)

This signal is only valid for systems equipped with temperature

sensors

This indicates that the axes boards are ready to receive commands

from the logic

Flag correlated to FastWire. Shows that the CNC has shifted to

TUNING modality for setup of OS3 drives.

R/W SYSTEM VARIABLE SW 04 S_HLS2

BIT Title: Home limit switches

S 04,00

S 04,01

through

S 04,15

S_HLS2.00 Home limit switch axis with ID 17

S_HLS2.01 Home limit switch axis with ID 18

S_HLS2.15 Home limit switch axis with ID 32

Home limit switches are wired as NC contacts: The input goes to a low level when the machine hits

the switch.

R/O SYSTEM VARIABLE SW 09 S_PROCSEL

WORD Title: Actually selected process for operation

SW 09 S_PROCSEL This flag contains the number of the actually selected

process. It is an integer in the range from 1 to 20.

10 Series CNC PLUS Application Manual (11) 3-3

Chapter 3

I/O Processor /System Data Areas

R/O SYSTEM VARIABLE SW 10 S_SCRNSEL

WORD Title: Actually selected screen number

SW 10 S_SCRNSEL This flag contains the number of the screen actually

selected. It is a positive integer number (AMP - SW

Characterisation Manual)

The S_SCRNSEL variable contains the number corresponding to the selected screen as configured in

AMP. The variable can have the following values:

SCREEN NAME SCREEN NUMBER

Process main screen

Logic main screen

Large axes position

Logic screen 1 (full)

Logic screen 2 (full)

Logic screen 3 (full)

Logic screen 4 (full)

Additional screen 1

Additional screen 2

Additional screen 3

Additional screen 4

Additional screen 5

R/O SYSTEM VARIABLE SW 11 S_UNITS

BIT Title: Configured units (metric/inch)

S 11,00

S 11,01

through

S 11,15

S_UNITS.00 METRIC = 1 , INCH = 0

reserved spares

1

2

3

4

5

6

7

8

9

10

11

12

3-4 10 Series CNC PLUS Application Manual (11)

R/O PROCESS VARIABLE SW 16 S_NOWAIT

WORD Title: NO WAIT call counter

SW 16 S_NOWAIT This word contains the number of NOWAIT calls placed. It is valid

only for 10/365 and 10/385 systems.

R/O PROCESS VARIABLE SW 17 S_CNCTYPE

WORD Title: Controller type

SW 17 S_CNCTYPE This word is used for indicating the control type.

The lower byte of SW17 is used for indicating the CNC model:

Value = 0 10/110 NC

Chapter 3

I/O Processor /System Data Areas

IMPORTANT

Value = 1 10/510 NC

Value = 4 10/565 NC

Value = 5 10/100 NC

Value = 8 10/585 NC

Value = 255 10/3xx NC

The higher byte of SW17 is reserved for future developments.

10 Series CNC PLUS Application Manual (11) 3-5

Chapter 3

CAUTION

I/O Processor /System Data Areas

PROCESS STATUS FLAGS

All words in the process flag window have mnemonic names which start with the process number

(S_1 through S_20 prefixes for the processes 1 through 20). For each process there is one group of

20 words. Each group is identically struc tured.

The access to process variables is as discussed for the system variables.

For every process there will be a group of flags as for process number 1. The functionality is identical,

the mnemonics only differ by the number of the process. The symbolic addresses SW nn must be

incremented by 20 for each further process.

These flags are dynamically updated. They are not synchronized with the

execution of the logic (except S_nRESE and S_nHOLDA). Do therefore not use

these flags to synchronize the logic: the signals may change state during the

execution of a routine.

WORD MNEMONIC NAME TITLE ACCESS

SW20 S_nSYSSTA Process Status Control Word B

SW 21 S_nGMACRO Active G Code Of Paramacro I

SW 22 S_nGCODE1 Active G Codes G00-G15 B

SW 23 S_nGCODE2 Active G Codes G16-G31 B

SW 24 S_nGCODE3 Active G Codes G32-G47 B

SW 25 S_nGCODE4 Active G Codes G48-G63 B

SW 26 S_nGCODE5 Active G Codes G64-G79 B

SW 27 S_nGCODE6 Active G Codes G80-G95 B

SW 28 S_nGCODE7 Active G Codes G96-G99 B

SW 29 S_nAXSEL Axis Selected I

SW 30 S_nPROINF Process Informations B

SW 31 S_nPROMOD Active Process Mode B

SW 32 S_nFIXSTA Fixed Cycle Active State B

SW 33 S_nOFFS Number of the tool offset activated by 'h'

SW 34 S_wRAP Rapid traverse feed override percentage

SW 35 SnMFO Manual Feedrate Override Value I

SW 36 S_nFRO Feedrate Override Value I

SW 37 S_nSSO Spindle Speed Override Value I

SW 38 S_nPROMSG Process Message Number I

SW 39 S_nTYPE Type Of Application I

3-6 10 Series CNC PLUS Application Manual (11)

I/O Processor /System Data Areas

R/O PROCESS VARIABLE SW 20 (40, 60, 80,100,120, ,480) S_nSYSSTA

BIT Title: Process Status Control Word

S 20,00 S_nIDLE process is in idle state

S 20,01 S_nCYCLE process executes a program block (run status)

S 20,02 S_nHOLDA process in hold status

S 20,03 S_nRUNH process in hold,motion aux. func. allowed

S 20,04 S_nHRUN process waiting to exit from hold state

S 20,05 S_nERRO process is in error state

S 20,06 RESERVED

S 20,07 S_nRESE process is being reset

S 20,08 RESERVED

S 20,09 S_nWAIT process is in WAIT substatus

S 20,10 S_nINPUT process is in INPUT substatus

S 20,11 RESERVED

S20,12 RESERVED

S 20,13 s_nMAS process in calculation stop (transfer. inh.)

S 20,14 RESERVED

S 20,15 S_nFEEDH process in feedhold

Chapter 3

Bits from S20,09 a S20,14 represent "under status" of previous bits (from S20,00 to S20,08)

therefore, when a status is active, an "understatus" bit may be activated.

The association "status/understatus" is given by the following table:

STATUS POSSIBLE UNDERSTATUS

IDLE MAS

RUN MAS

WAIT

INPUT

HOLD MAS

RUNH MAS

HRUN MAS

ERRO none

RESE nome

10 Series CNC PLUS Application Manual (11) 3-7

Chapter 3

IMPORTANT

I/O Processor /System Data Areas

R/O PROCESS VARIABLE SW 21 (41,61,81,101,121, ,481) S_nGMACRO

BIT Title: Active paramacro G code

SW 21 S_nGMACRO Number of active paramacro (300...998)

The variable provides the number of G-code of the active paramacro. In case of paramacro nesting the

paramacro G that is passed is the last programmed one.

For the G-codes G00 up to G99, there are 100 reserved bits in the dual port

memory. The G-codes are divided into groups. In one group only one G-code can

be active. The different groups are indicated by the letters a-m. The G-codes with

the "*" are non-modal, i.e. they are only active for the duration of the part program

block they were used in.

R/O PROCESS VARIABLES SW 22 (42, 62, 82,102,122, ,482) S_nGCODE1

BIT Title: Active G-codes

S 22,00 S_nG00 a rapid positioning

S 22,01 S_nG01 a linear interpolation

S 22,02 S_nG02 a circular interpolation CW

S 22,03 S_nG03 a circular interpolation CCW

S 22,04 S_nG04 j * dwell time at end of block

S 22,05 S_nG05 not used

S 22,06 S_nG06 not used

S 22,07 S_nG07 not used

S 22,08 S_nG08 not used

S 22,09 S_nG09 j * deceleration at end of block

S 22,10 S_nG10 not used

S 22,11 S_nG11 not used

S 22,12 S_nG12 not used

S 22,13 S_nG13 not used

S 22,14 S_nG14 not used

S 22,15 S_nG15 not used

3-8 10 Series CNC PLUS Application Manual (11)

I/O Processor /System Data Areas

R/O PROCESS VARIABLES SW 23 (43,63,83,103,123, , 483) S_nGCODE2

BIT Title: Active G-codes

S 23,00 S_nG16 not used

S 23,01 S_nG17

S 23,02 S_nG18

S 23,03 S_nG19

S 23,04 S_nG20 not used

S 23,05 S_nG21 not used

S 23,06 S_nG22 not used

S 23,07 S_nG23 not used

S 23,08 S_nG24 not used

S 23,09 S_nG25 not used

S 23,10 S_nG26 not used

S 23,11 S_nG27 c acc/dec on corners

S 23,12 S_nG28 c no acc/dec on corners

S 23,13 S_nG29 c point to point positioning mode

S 23,14 S_nG30 not used

S 23,15 S_nG31 not used

b interpolation on the plane formed by the 1st and 2nd axis (AMP) À

b interpolation on the plane formed by the 3rd and 1st axis (AMP) À

b interpolation on the plane formed by the 2nd and 3rd axis (AMP) À

Chapter 3

NOTE:

À In many applications the 1st, 2nd, 3rd axes are called X, Y, Z, respectively.

R/O PROCESS VARIABLES SW 24 (44,64,84,104,124, ,484) S_nGCODE3

BIT Title: Active G-codes

S 24,00 S_nG32 not used

S 24,01 S_nG33 a threading

S 24,02 S_nG34 not used

S 24,03 S_nG35 not used

S 24,04 S_nG36 not used

S 24,05 S_nG37 not used

S 24,06 S_nG38 not used

S 24,07 S_nG39 not used

S 24,08 S_nG40 e no cutter compensation

S 24,09 S_nG41 e cutter compensation left of part

S 24,10 S_nG42 e cutter compensation right of part

S 24,11 S_nG43 not used

S 24,12 S_nG44 not used

S 24,13 S_nG45 not used

S 24,14 S_nG46 not used

S 24,15 S_nG47 not used

10 Series CNC PLUS Application Manual (11) 3-9

Chapter 3

I/O Processor /System Data Areas

The G code flags S_nG40 through S_nG42 will reflect the true status of the system after axes motion

has been programmed in one of these modes. The flags are not updated when just one of the G

codes G40, G41 or G42 are programmed in a block by its own (no motion).

3-10 10 Series CNC PLUS Application Manual (11)

I/O Processor /System Data Areas

R/O PROCESS VARIABLES SW 25 (45,65,85,105,125, ,485) S_nGCODE4

BIT Title: Active G-codes

S 25,00 S_nG48 not used

S 25,01 S_nG49 not used

S 25,02 S_nG50 not used

S 25,03 S_nG51 not used

S 25,04 S_nG52 not used

S 25,05 S_nG53 not used

S 25,06 S_nG54 not used

S 25,07 S_nG55 not used

S 25,08 S_nG56 not used

S 25,09 S_nG57 not used

S 25,10 S_nG58 not used

S 25,11 S_nG59 not used

S 25,12 S_nG60 not used

S 25,13 S_nG61 not used

S 25,14 S_nG62 not used

S 25,15 S_nG63 not used

Chapter 3

R/O PROCESS VARIABLES SW 26 (46,66,86,106,126, ,486) S_nGCODE5

BIT Title: Active G-codes

S 26,00 S_nG64 not used

S 26,01 S_nG65 not used

S 26,02 S_nG66 not used

S 26,03 S_nG67 not used

S 26,04 S_nG68 not used

S 26,05 S_nG69 not used

S 26,06 S_nG70 f inch programming mode

S 26,07 S_nG71 f metric programming mode

S 26,08 S_nG72 k * measuring cycle G72

S 26,09 S_nG73 k * measuring cycle G73

S 26,10 S_nG74 k * measuring cycle G74

S 26,11 S_nG75 not used

S 26,12 S_nG76 not used

S 26,13 S_nG77 not used

S 26,14 S_nG78 not used

S 26,15 S_nG79 i * absolute movement (home reference)

10 Series CNC PLUS Application Manual (11) 3-11

Chapter 3

I/O Processor /System Data Areas

R/O PROCESS VARIABLES SW 27 (47,67,87,107,127, ,487) S_nGCODE6

BIT Title: Active G-codes

S 27,00 S_nG80 g no fixed cycle active

S 27,01 S_nG81 g fixed cycle G81 active

S 27,02 S_nG82 g fixed cycle G82 active

S 27,03 S_nG83 g fixed cycle G83 active

S 27,04 S_nG84 g fixed cycle G84 active

S 27,05 S_nG85 g fixed cycle G85 active

S 27,06 S_nG86 g fixed cycle G86 active

S 27,07 S_nG87 not used

S 27,08 S_nG88 not used

S 27,09 S_nG89 g fixed cycle G89 active

S 27,10 S_nG90 h absolute programming

S 27,11 S_nG91 h incremental programming

S 27,12 S_nG92 d * axis datum offset

S 27,13 S_nG93 l inverse time feed coding

S 27,14 S_nG94 l feed coding in mm/min inch/min

S 27,15 S_nG95 l feed coding per spindle revolution

R/O PROCESS VARIABLES SW 28 (48,68,88,108,128, ,488) S_nGCODE7

BIT Title: Active G-codes

S 28,00 S_nG96 m constant surface speed active

S 28,01 S_nG97 m constant surface speed not active

S 28,02 S_nG98 not used

S 28,03 S_nG99 d * cancel G92 offset

S 28,04

through reserved spares

S 28,15

R/O PROCESS VARIABLES SW 29 (49,69,89,109,129, ,489) S_nAXSEL

BIT Title: Axis selected for manual operations

SW 29 S_nAXSEL physical axis identifier of selected axis

R/O PROCESS VARIABLES SW 30 (50,70,90,110,130, ,490) S_nPROINF

BIT Title: Process Informations

S 30,11 S_wAUX Auxiliary function emission running at the end of RCM

S 30,12 S_nRCM Search in memory

3-12 10 Series CNC PLUS Application Manual (11)

S 30,13 S_nDRY Dry Run activated

S 30,14 S_nEOB End of Block activated

S 30,15 S_nFRB Feed Rate Bypass activated

Chapter 3

I/O Processor /System Data Areas

10 Series CNC PLUS Application Manual (11) 3-13

Chapter 3

I/O Processor /System Data Areas

R/O PROCESS VARIABLES SW 31 (51, 71, 91,111,131, ,491) S_nPROMOD

BIT TITLE: Active process mode of operation

S 31,00 S_nMDI manual data input mode

S 31,01 S_nAUTO auto mode active

S 31,02 S_nSTEP single block mode active

S 31,03 S_nMANU continuous manual jog mode active

S 31,04 S_nMANJ incremental manual jog mode active

S 31,05 S_nPROF jog return mode active

S 31,06 S_nHOME axes homing selected

S 31,07 S_nHPG hand pulse generator active

S 31,08 not used

S 31,09 not used

S 31,10 not used

S 31,11 not used

S 31,12 not used

S 31,13 not used

S 31,14 not used

S 31,15 not used

R/O PROCESS VARIABLES SW 32 (52, 72, 92,112,132, 492) S_nFIXSTA

BIT TITLE: Fixed cycle status

S 32,00 S_nINVER spindle reverse in fixed cycle

S 32,01 S_nSTOPR spindle stop in fixed cycle

S 32,02 not used

S 32,03 not used

S 32,04 not used

S 32,05 not used

S 32,06 not used

S 32,07 not used

S 32,08 S_nTRAP touch probe cycle, rapid approach

S 32,09 not used

S 32,10 not used

S 32,11 not used

S 32,12 not used

S 32,13 not used

S 32,14 not used

S 32,15 not used

S_nINVER is set TRUE in the fixed cycle G84 in the moment in which the spindle needs to

be reversed at the bottom of the tapping hole.

3-14 10 Series CNC PLUS Application Manual (11)

Chapter 3

I/O Processor /System Data Areas

S_nSTOPR is set TRUE in the fixed cycle G86 before the axis' return movement and it is set

false at the end of the boring cycle.

NOTE:

30 ms of time are required at least, from the moment we set at 1 the value and the moment of the

axes’s return movement. This time is used by the logic machine to analize the connect strategy to

apply (ex.: stopping the axis for a long time before returning to allow the spindle stop).

S_nTRAP is set TRUE during the rapid approach phase of the touch probe cycles G72, G73

and G74. It can be used to clean the workpiece surfaces with compressed air.

10 Series CNC PLUS Application Manual (11) 3-15

Chapter 3

S_nPROMSG

I/O Processor /System Data Areas

R/O PROCESS VARIABLE SW 33 (53, 73, 93,113,133, ,493) S_nOFFS

WORD TITLE: Number of the tool offset activated by 'h'

SW 33 S_nOFFS number of the tool offset activated using the 'h'

R/O PROCESS VARIABLE SW 34 (54, 74, 94, 114, 134,...494) S_wRAP

WORD Title: Rapid Traverse feed override percentage

SW 34 S_wRAP Rapid Traverse feed override percentage:

R/O PROCESS VARIABLE SW 35 (55, 75, 95,115,135, ,495) S_nMFO

WORD TITLE: Manual feedrate override percentage

parameter

0 = 0% 10000 = 100% of the Rapid Traverse feed

SW 035 S_nMFO manual feedrate percentage value :

0 = 0% 10000 = 100% of max feedrate

Use bit 00 - 14 only (absolute value)

BIT TITLE: Manual feedrate direction

S 35,15 S_nMFO.15 Sign of anomaly adjusted feedrate: 0 = positive 1 =

negative

R/O PROCESS VARIABLE SW 36 (56, 76, 96,116,136, ,496) S_nFRO

WORD TITLE: Feedrate override percentage

SW 36 S_nFRO Feedrate override percentage value

0 = 0% 10000 = 100% of prog. feedrate

R/O PROCESS VARIABLE SW 37 (57, 77, 97117,137, ,497) S_nSSO

WORD TITLE: Spindle speed override percentage

SW 37 S_nSSO spindle override percentage value

0 = 0% 10000 = 100% of prog. value

R/O PROCESS VARIABLE SW 38 (58, 78, 98,118,138, ,498)

WORD TITLE: Process message number

SW 38 S_nPROMSG process related screen message number actually

displayed.

See appendix B of PLUS Library user manual for a list of

messages

R/O PROCESS VARIABLE SW 39 (59, 79, 99,119,139, ,499) S_nTYPE

WORD TITLE: Type of application

3-16 10 Series CNC PLUS Application Manual (11)

Chapter 3

I/O Processor /System Data Areas

SW 39 S_nTYPE

type of application

1 = Mill

2 = Lathe

3 = Grinder

USER DEFINED / GLOBAL VARIABLES (G VARIABLES)

In addition to the system flag area and the process areas there is one memory area reserved for user

defined variables. These variables are retentive, i.e. once stored, they will not be cleared at power turn

on. The variables in this memory area are called G-variables. There a 2 formats of G-variables:

• 16 bit words (value -32768..0..32767)

(you can also address the individual bits of these variables)

• 64 bit floating point (double) variables

GW 000

GW 255

GD 00

GD 63

Fig. 3-2 "G variables" memory area

Since the G variables are accessible by the system and by the I/O processor, you cannot only use

them in the logic program but also in a part program. In this way they can serve as a direct

communication channel between the part program and the logic or between the logic and the part

program. To render one or more of the variables available for part programs, you have to define them in

the AMP configuration program. In order to simplify access, you must assign a logical name to the

"physical" address. All logical names for variables in this area have to begin with the "@" character.

AMP allows 3 types of variables to be configured:

• Boolean (max. 128) You can assign any bit (00-15) of the G variables (000..255)

• Short (max. 64) You can assign any of the 256 GW variables (000..255)

• Double (max. 32) You can assign any of the 64 GD variables (00..63)

In AMP it is possible to assign a value to these variables that is loaded every time you switch on the

system.

The following examples show an assignment for each of the possible variable types:

Examples:

10 Series CNC PLUS Application Manual (11) 3-17

Chapter 3

User MD variables

User M and MW variables

Bit and/or short

I/O processor dual RAM memory

Area for automatic variable

distribution by PLUSEDIT

(double scratch variables)

MW 0000

MW xxxx

MW xxxx+2

MW 4999

MD 000

MD yyy

MD yyy+1

MD 999

I/O Processor /System Data Areas

@POS = G 006,04 (Bit 4 of word GW 006)

@SPEED = GW 200

@ACC = GD 18

M VARIABLES

The M variables make up the "memory work area" for the logic. There are 5000 variables of the type

short (MW 0000 -MW 4999) and 1000 variables of the type double (MD 000 - MD 999). Some ranges

of variables are reserved for future enhancements, other areas must be configured as area for the

automatic distribution of flags by the PLUSEDIT logic editor. The largest part of these variables is

available as read/write area to all logic routines. The system cannot directly access the M variables.

NOTES:

• These variables are NOT retentive! They will be cleared at power turn on.

• The variables MW 0000 - MW 4999 can be addressed as words (MW xxxx) or also as single bits

(Mxxxx,yy).

• For other variable types and memory areas refer to the PLUS language manual.

Area for automatic flag

distribution by

(BIT/SHORT SCRATCH

➁

Fig. 3-3 M variables memory area

Where:

À xxxx can be configured in the PLUSEDIT program. From this variable address up you can

define ranges for each of the variable types Boolean and short. The variables in these ranges

will be used for the automatic distribution by the PLUSEDIT software when you use the

MACRO-IL, the FBD/LD or the SFC editors.

➀

Á yyy can be configured in the PLUSEDIT program. From this variable address up you can define

a range of "double" format variables for the automatic distribution by the PLUSEDIT software.

These variables will be used in the MACRO-IL and the FBD/LD editors.

3-18 10 Series CNC PLUS Application Manual (11)

Chapter 3

I/O Processor /System Data Areas

TABLES

In the DUAL PORT memory, 4 table are made available:

• AXES TABLE

• TOOL TABLE

• TOOL OFFSET TABLE

• USER'S TABLE

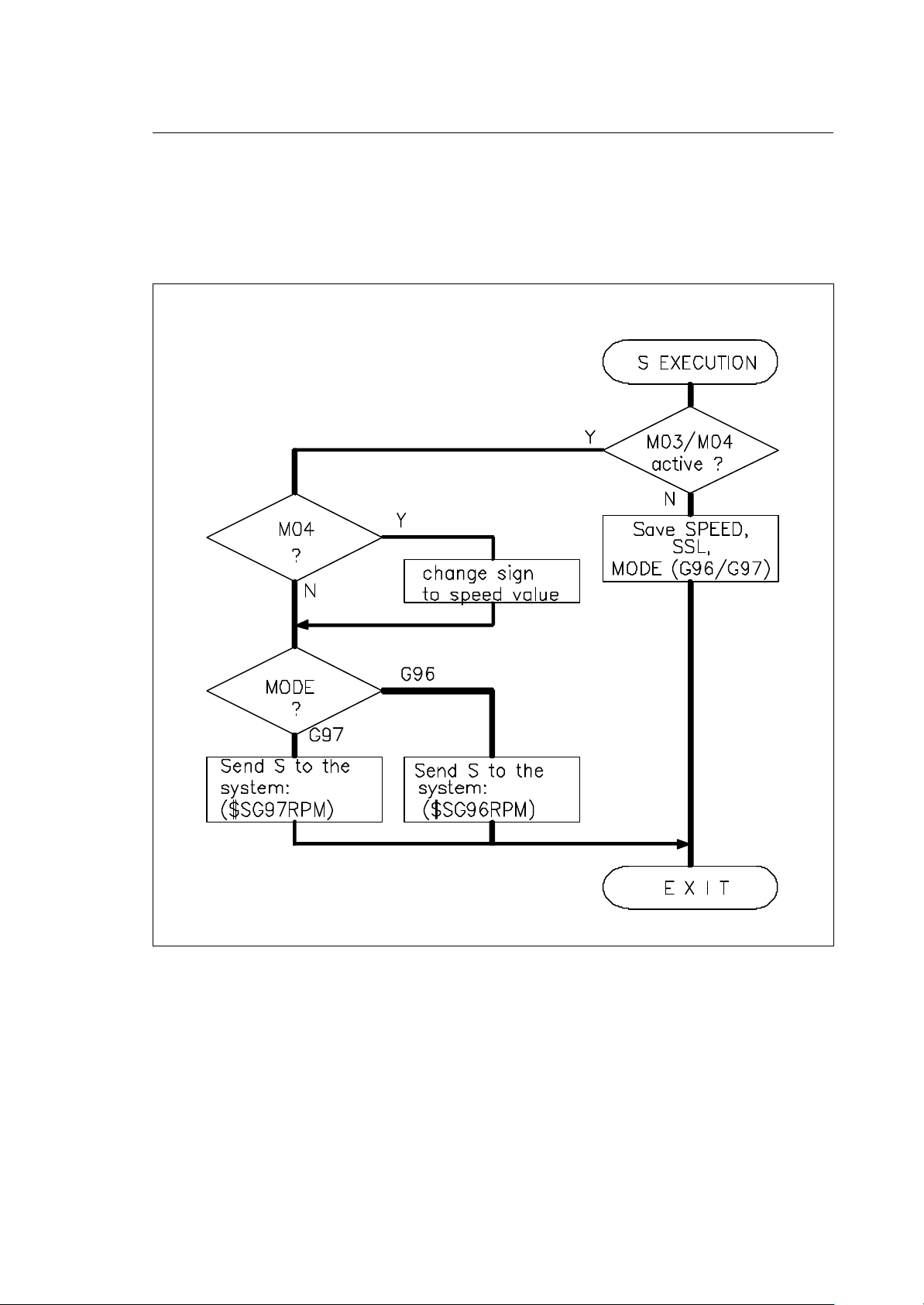

These tables are persistent: once they are memorized they are not deleted when the system is

switched on.

Axes Table

The axis table consists of up to 32 pages. Each page contains information regarding one specific

axis. This information is divided into fields:

etc..

32

3

2

1

Fig. 3-4 Axes Table (one page per axis)

10 Series CNC PLUS Application Manual (11) 3-19

Chapter 3

I/O Processor /System Data Areas

There is one page in the table for each configured axis (co-ordinate, point to point, transducer-only

axis, spindle and virtual axis). The page number of an axis corresponds to its physical identifier as

defined in the AMP configuration. The system supports up to 32 axes, so there are 32 pages in this

table and 32 physical axes identifiers (1-32).

You can select one of the pages of the axis table with the physical axis identifier of the axis. If you

only know the axis name ("X", "Y", etc. in field AXNAME) and process (field AXOWNER), you can

use the function $A_TO_ID to find the corresponding physical identifier. The field AXOWNER defines

which ambient (actually) controls that axis:

AXOWNER Meaning

5000H (20480T) point-to-point-axis or spindle (PLUS)

6100H (24832T) coordinated axis process 1

6200H (25088T) coordinated axis process 2

6300H (25344T) coordinated axis process 3

6400H (25600T) coordinated axis process 4

6500H (25856T) coordinated axis process 5

6600H (26112T) coordinated axis process 6

6700H (26368T) coordinated axis process 7

6800H (26624T) coordinated axis process 8

6900H (26880T) coordinated axis process 9

6A00H (27136T) coordinated axis process 10

6B00H (27392T) coordinated axis process 11

6C00H (27648T) coordinated axis process 12

6D00H (27904T) coordinated axis process 13

6E00H (28160T) coordinated axis process 14

6F00H (28416T) coordinated axis process 15

7000H (28672T) coordinated axis process 16

7100H (28928T) coordinated axis process 17

7200H (29184T) coordinated axis process 18

7300H (29440T) coordinated axis process 19

7400H (29696T) coordinated axis process 20

3-20 10 Series CNC PLUS Application Manual (11)

I/O Processor /System Data Areas

These are the fields and the formats for the axis table:

MNEMONIC CONTENTS FORMAT

Chapter 3

AXOWNER

AXNAME

AXORIG

---------AXOFG92

AXTOFF

PRO_OFFS

TOT_OFFS

ORIG1

ORIG2

ORIG3

ORIG4

ORIG5

ORIG6

ORIG7

ambient 'owning' this axis

ASCII axis name

current origin offset value

reserved

current G92 offset value

current tool offset value (introduced from logic)

current total offset value applied from the process by use of

“h” (with tool offset introduced by “h”)

current total axis offset value (with tool offset introduced by

logic)

origin #1 value

origin #2 value

origin #3 value

origin #4 value

origin #5 value

origin #6 value

origin #7 value

short

short

double

double

double

double

double

double

double

double

double

double

double

double

double

ORIG8

ORIG9

ORIG10

ACT_ORIG

----------

Generally speaking, the logic program should never directly address this table. Only in special

applications in which you have to handle either G92 offset or tool offset in a different way, you can

read or write table fields. To address a table field you must use the mnemonic for that field as given in

above table.

origin #8 value

origin #9 value

origin #10 value

number of the enabled origin

reserved

double

double

double

short

short

10 Series CNC PLUS Application Manual (11) 3-21

Chapter 3

I/O Processor /System Data Areas

The TOT_OFFS field contains the total offset value applied to the related axis. Its value is calculated

as follows:

TOT_OFFS = AXORIG + AXOFG92 + AXTOFF

Any time the logic has to change an axis offset (i.e. G92), the following sequence of operations

should be performed (Fig. 3.5):

Fig. 3-5 Axis Offset Activation Flowchart

3-22 10 Series CNC PLUS Application Manual (11)

Chapter 3

I/O Processor /System Data Areas

Tool table

The tool table consists of 250 pages. Each page contains information regarding one specific tool. This

information is divided into fields:

3

2

1

Fig. 3-6 Tool table (one page per tool)

There are 250 pages in the table for up to 250 tools with tool magazine option; It is possible to allot

250 tools to one or more tool magazines.

You can access a page of the tool table with the page number (1-250) or if you use the $TBLSRCD

function also with the tool identification code. Since the data for a specific tool may be in any of the

250 pages, the method using the $TBLSRCD function is to be preferred.

10 Series CNC PLUS Application Manual (11) 3-23

Chapter 3

I/O Processor /System Data Areas

MNEMONIC CONTENTS FORMAT UNITS

TCODE

TOOLPOS

TFAMCOL

TOOLTYPE

TSTATUS

TCNTRL

MAXLIFE

REMLIFE

TUSER1

TUSER2

TUSER3

TUSER4

TOLOFNR

tool identification code

tool position info

reserved

tool type info

tool status

tool control word

initial life

actual life

user parameter 1

user parameter 2

user parameter 3

user parameter 4

pointer on the offset table page

double

short

short

short

short

short

double

double

double

double

double

double

short

--

nnnn

--

--

--

-sec

sec

--

--

--

--

--

The $TBLSRCD function/ function block/ macro can be used to find the page number of the tool table

for a given tool identifier:

table # (TOLTAB=2)

field # (TCODE=1)

tool id to search

first page

last page

enable

# tool table page

function status word

Fig. 3-7 The table search function block (double search)

In above function block the inputs Tab and Fld define the Number of the table and the field containing

the tool identifier. The input Val is connected with the searched tool id, the tool identifier as

programmed in the part program. The inputs Sta and Sto indicate the first and the last table page

which define the table range to be scanned. (generally you will use 1 as the start index and the

maximum number of tools as the stop index).

For example, you will use different ranges in case a tool table is subdivided in areas, each belonging

to a single process.

3-24 10 Series CNC PLUS Application Manual (11)

Chapter 3

I/O Processor /System Data Areas

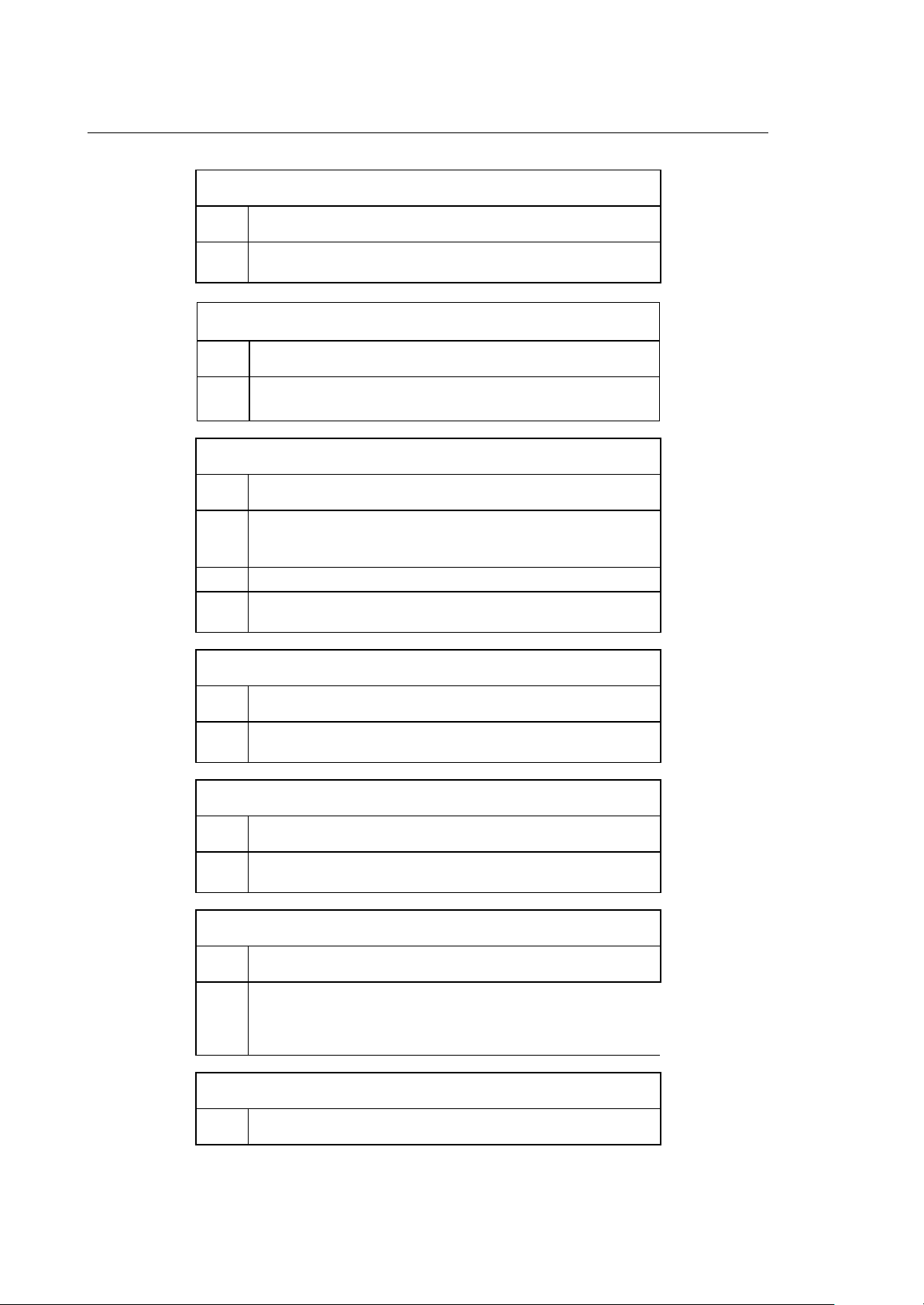

Tool offset table

The tool offset table consists of 300 pages. Each page contains all information describing the

dimensions of a tool. This information is divided into fields:

TACTL1

TCMAXL1

TCACTL1

TACTL2

TCMAXL2

TCACTL2

TDIAMETER

TCACDIAM

TORIENT

1

300

3

2

Fig. 3-8 Tool offset table (one page per offset)

The table contains 300 pages for 300 offset tools. This allows to define more offsets for a single tool.

You can access a page of the tool offset table via the tool offset number corresponding to the page

number (1-300). The tool offset number will be directly programmed into the part program using the

"T" function or can be found in the last field of the tool table (TOLOFNR). Depending on the

application type (milling, lathing or grinding), different fields of the tool offset table will be used. The

following shows all formats of the tables:

10 Series CNC PLUS Application Manual (11) 3-25

Chapter 3

I/O Processor /System Data Areas

Depending on the type of application (mill, lathe or grinder) you will use different tool offset table

fields. All table formats will be shown hereafter:

MNEMONIC CONTENTS MILL FORMAT

TACTL1

TCMAXL1

TCACTL1

TDIAMETER

TCACDIAM

actual tool length

allowable tool length wear

actual tool wear offset

actual tool diameter

actual tool diameter wear

Fig. 3-9 Mill Tool Offset Table

double

double

double

double

double

3-26 10 Series CNC PLUS Application Manual (11)

Chapter 3

I/O Processor /System Data Areas

MNEMONIC CONTENTS GRINDER FORMAT

TACTL1

TCMAXL1

TCACTL1

TACTL2

TCMAXL2

TCACTL2

TDIAMETER *

TCACDIAM

TORIENT

actual tool length 1 (wheel radius)

allowable tool length 1 wear

actual tool length 1 wear

actual tool length 2 (wheel width)

allowable tool length 2 wear

actual tool length 2 wear

actual wheel nose diameter

wheel nose diameter wear

orientation ( wheel orientation angle)

GRINDING WHEEL GEOMETRY

double

double

double

double

double

double

double

double

short

Fig. 3-10 Grinder tool offset table

10 Series CNC PLUS Application Manual (11) 3-27

Chapter 3

I/O Processor /System Data Areas

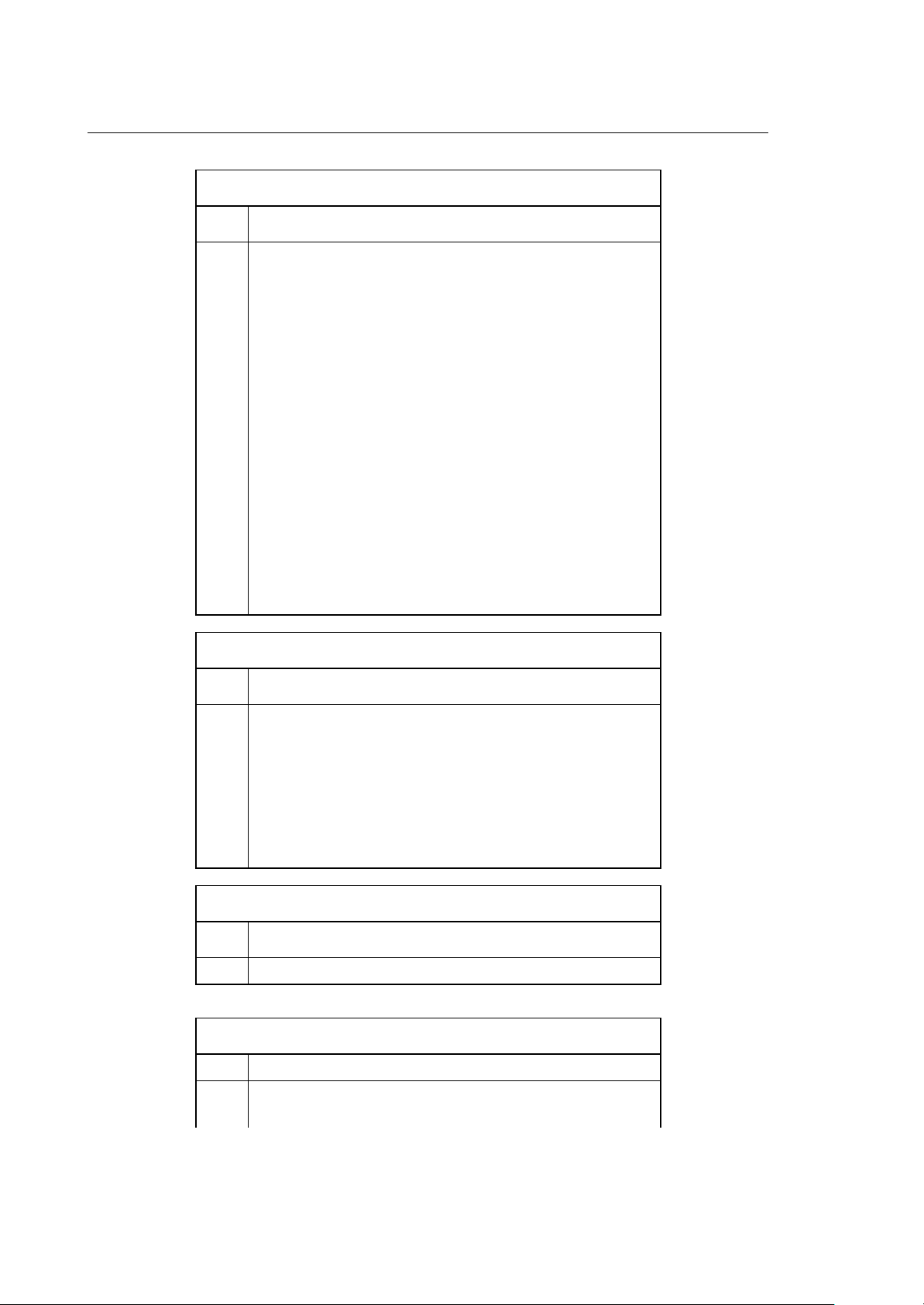

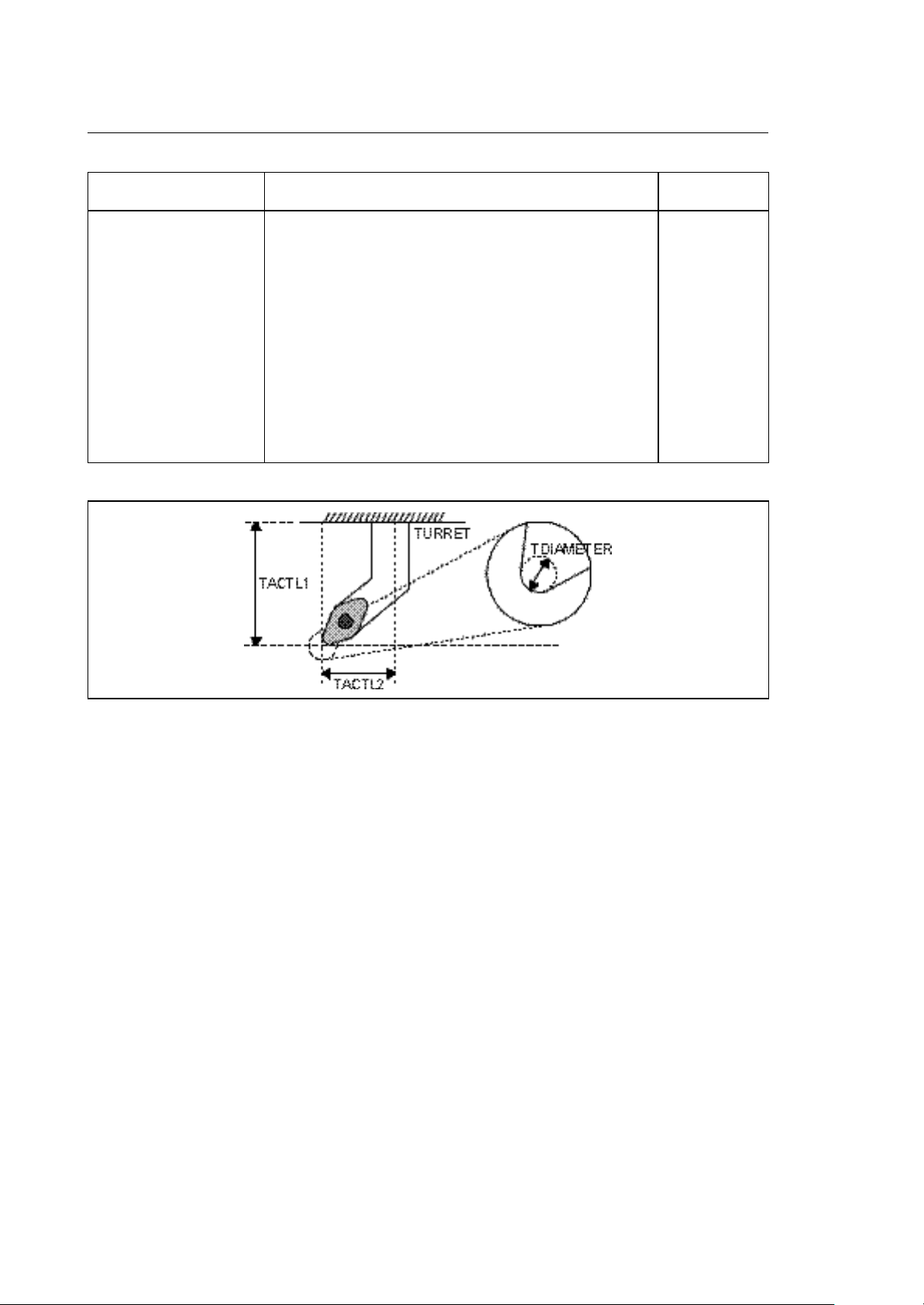

MNEMONIC CONTENTS LATHE FORMAT

TACTL1

TCMAXL1

TCACTL1

TACTL2

TCMAXL2

TCACTL2

TDIAMETER À

TCACDIAM

TORIENT

actual tool length 1 (length in X axis)

allowable tool length 1 wear

actual tool length 1 wear

actual tool length 2 (length in Z axis)

allowable tool length 2 wear

actual tool length 2 wear

actual tool tip diameter

tool tip diameter wear

orientation ( tool tip orientation angle)

double

double

double

double

double

double

double

double

short

Fig. 3-11 Lathe tool offset table

NOTE:

À The wheel nose radius resp. tool tip radius is internally (table) managed as a diameter.

The entry in the table editor is a radius.

3-28 10 Series CNC PLUS Application Manual (11)

User table

Chapter 3

I/O Processor /System Data Areas

USER1

USER2

USER3

USER4

3

2

1

100

Fig. 3-12 User table

The user table has 100 pages. Each page contains 4 "double" fields. You can read or write to this

table with the page number (index) to select the page and the field name (USERn) to address the

desired field. The use of the fields depends on the requirements of the application. The system never

accesses this table.

One page of the table in detail:

MNEMONIC CONTENTS FORMAT

USER1

USER2

USER3

USER4

user variable 1

user variable 2

user variable 3

user variable 4

double

double

double

double

10 Series CNC PLUS Application Manual (11) 3-29

Chapter 3

I/O Processor /System Data Areas

END OF CHAPTER

3-30 10 Series CNC PLUS Application Manual (11)

Chapter

4

PART PROGRAM INTERFACE

STRUCTURE

A part program block can contain:

• 1 S word to control the spindle speed

• 1T word to control the tool and offset to be used

• up to 4 M words for miscellaneous functions (prelude, postlude and expedite M codes are

supported)

• up to 6 pseudo axes used to transfer information to the logic

• up to 6 motion axes (for coordinated motion)

For each one of these part program information groups the system will activate a routine written by

PLUS programmer. To identify the different routines in correspondence with their specific purpose,

you have to use the DTSK and ETSK statements and pre-assigned routine names (refer to chapter 2).

You do not need to define ALL routines. If the system finds that a certain routine is not available, it

will assume that the logic is not interested in the part program information and continue the execution

of the block.

For each one of the processes, these interfacing routines have to be defined. All routines for one

specific process will be collected by the PLUSGEN utility and combined to one "task".

In this context the word TASK represents a collection of routines having the same priority.

Though optional, some routines like $nMDECOD, $nSPROG and $nTPROG must be defined to be

able to have the 10 Series CNC actually execute M codes, handle spindle, tools, etc.

10 Series CNC PLUS Application Manual (10) 4-1

Chapter 4

Part Program Interface

PART PROGRAM INTERFACE TASK

For each configured process there is one task dedicated to the management of requests coming from

the part program execution. This task is divided into several user-defined routines, each one

dedicated to a certain request. Due to the fact that this task has a higher priority than the background

tasks, it is strongly recommended not to use loops in the single routines but to use the WAIT and

DLY instructions (function blocks for routine interrupt) instead.

All the routines in this task will not be executed cyclically like the background. The execution of a

routine in the interface task is a single shot type execution (S,T, ..... function programming).

If these routines need to communicate with background tasks (e.g. to pass information and wait for a

result) you must synchronize the routine and the background using the WAIT and SEND instructions.

It is very important to remember that in case of HOLD or RESET, a pending part program interface

task has to be released from the wait status. Even if the activity it is waiting for is not completed yet,

the routine must be released.

In the background task we suggest to test the system status flags (S variables SW 20) for hold

and/or reset and if set release the pending interface task using the SEND instruction as shown in the

flow chart below.

4-2 10 Series CNC PLUS Application Manual (10)

Chapter 4

Part Program Interface

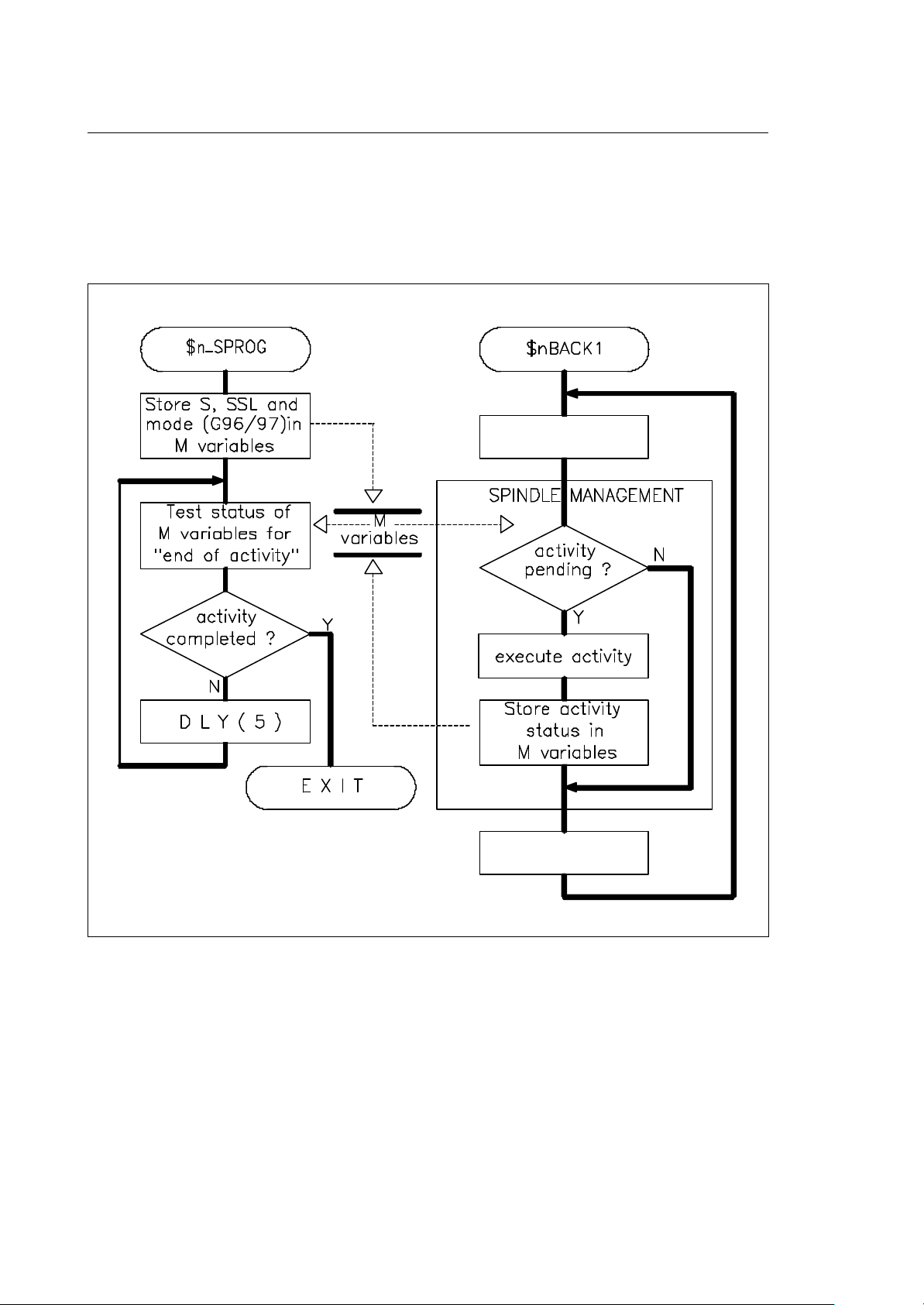

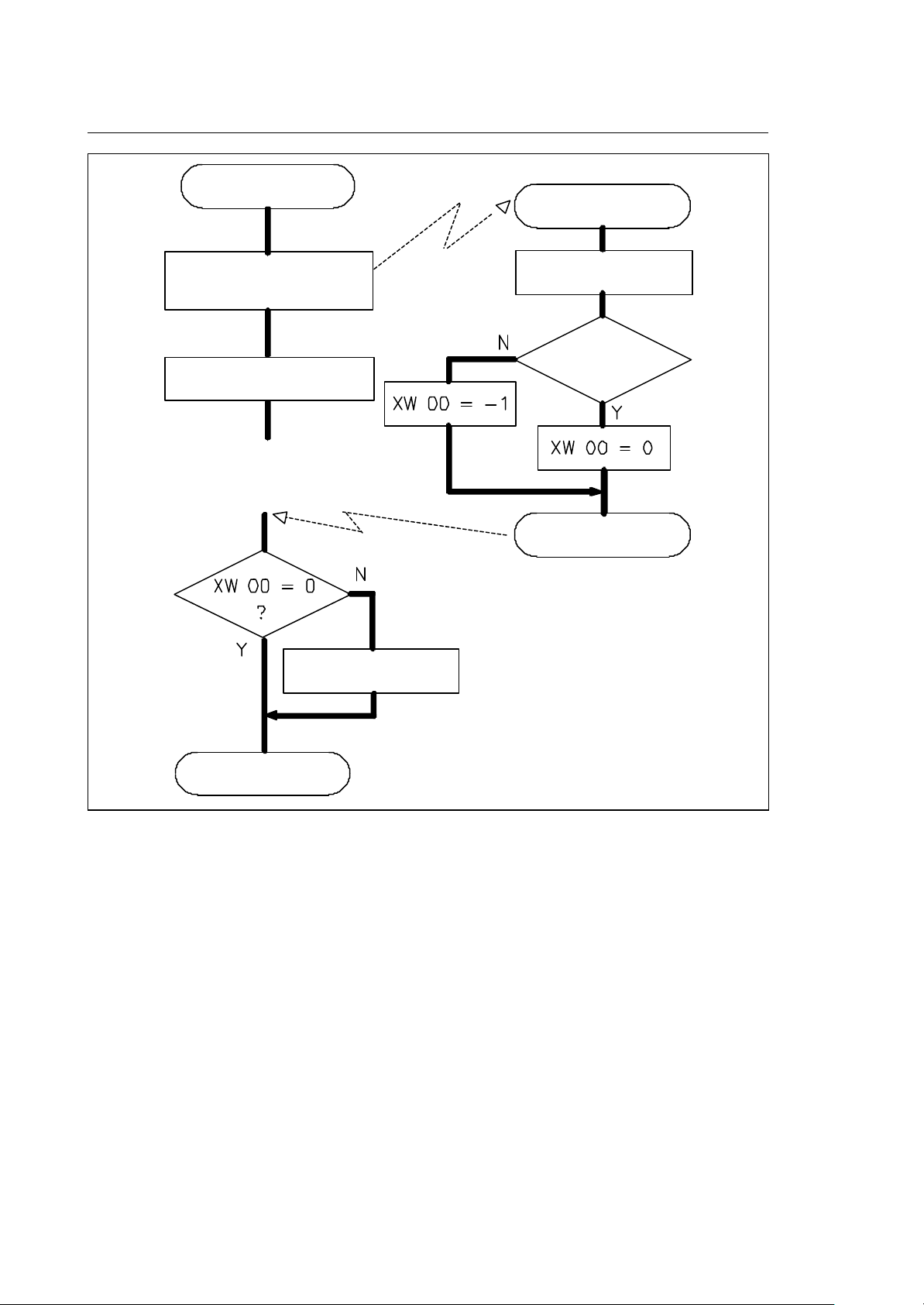

Fig. 4-1 HOLD and RESET request during pending interface routine

10 Series CNC PLUS Application Manual (10) 4-3

Chapter 4

Part Program Interface

Another technique which can be used to synchronize the interface routine with the background is to

use the DLY instruction. This instruction suspends the execution of the interface routine for the

programmed period of time, thus enabling the background to run and to process the information. After

the time is expired, the interface routine can check if the background finished its process (M variable)

and depending on the result decide to repeat the delay or to release the routine ($nSPROG in the

example of Fig. 4.2).

Fig. 4-2 Alternative synchronization technique

In the previous example the DLY(5) statement suspends the execution of the $nSPROG task for 50

ms before it resumes the execution and tests the completion of the background activity.

4-4 10 Series CNC PLUS Application Manual (10)

Chapter 4

Part Program Interface

Fig. 4-3 Part program interface routines

10 Series CNC PLUS Application Manual (10) 4-5

Chapter 4

IMPORTANT

Part Program Interface

PART PROGRAM INTERFACE ROUTINES

• Each one of the following routines is executed once every time one of the following conditions is

encountered in the part program:

− axis motion programmed (SnCONMOV, $nENDMOV)

− M word programmed ($nMDECOD)

− S word programmed ($nSPROG)

− T word programmed ($nTPROG)

− pseudo axis programmed ($nPSEUDO)

− End Of Block encountered($nEOB)

− adjust tool dimension offset ($nRQP)

− adjust tool wear offset ($nRQT)

− tool life expired ($nTOU)

− probing cycle completed ($nQUTAST)

• The purpose of these routines is to allow the logic to take the correct actions and to process the

part program information.

• The part program information to be processed is stored in X variables. If there are output variables,

they have to be returned using the X variables. The routine must return an answer (acknowledge/

no acknowledge) in XW 00.

• XW 00 has to be used to return an answer to the system:

0 = acknowledge to the system

-1 = error

• XW01 and XW02 are reserved and must not be modified

• All routines are optional. If they are not present, they will not be called. In some cases the system

executes some minimal action. If routines are not defined, the system will assume an

acknowledge and continue the execution of the part program.

The input parameters to the task are reserved locations which may not be

changed (except where specifically allowed).