Page 1

10 Series CNC

User Manual

Code: 45004452H

Rev. 15

PUBLICATION ISSUED BY:

OSAI S.p.A.

Via Torino, 14 - 10010 Barone Canavese (TO) – Italy

Tel. +39-0119899711

Web: www.osai.it

e-mail: sales@osai.it

service@osai.it

Copyright 2001-2004 by OSAI

All rights reserved

Edition:November 2004

IMPORTANT USER INFORMATION

This document has been prepared in order to be used by OSAI. It describes the latest release of

the product.

OSAI reserves the right to modify and improve the product described by this document at any time

and without prior notice.

Actual application of this product is up to the user. In no event will OSAI be responsible or liable for

indirect or consequential damages that may result from installation or use of the equipment

described in this text.

Page 2

abc

Page 3

UPDATE

10 Series CNC User Manual

SUMMARY OF CHANGES

General

This publication is issued with reference to Software Release 7.4 for the 10 Series systems (E69).

The following modifications have been made to this revision.

PAGES UPDATE TYPE

INDEX

Chapter 2

page 10 Added new description: PLUS SD000

Chapter 3

page 47 Added description of softkey: SYSTEM SHUT DOWN

Chapter 11

page 8

Appendix A

page 25 Added new codes: SD214-SD215-SD216-SD217

Updated

Added new description: Execution of paramacros in MDI mode

10 Series CNC User Manual (15)

Page 4

abc

abc

Page 5

Preface

10 Series CNC User Manual

PREFACE

This manual describes how to operate a 10 Series CNC. It provides the end user with all the

necessary information for using and programming the system.

REFERENCE

Consult:

• 10 Series CNC Product Specifications

• 10 Series CNC AMP - Software Characterisation Manual

For further information refer to:

• 10 Series CNC Programming Manual

SUMMARY

This manual describes how your 10 Series CNC works and explains how to operate the system.

Each chapter deals with a separate topic.

1. Features and specifications

This chapter lists the general hardware and software characteristics of 10 Series CNC’s. It also

describes the major features of the front panel.

2. System start up

This chapter explains how to switch an and start up the system. It discusses the screens and

messages displayed when the system runs the self diagnostic.

3. User interface

This chapter describes the function of the softkeys, pushbuttons and controls available on the

panel. An overview of all the softkeys levels available gives the user a reference guide of all the

softkeys available. It provides a detailed description of the various video pages and discusses

the optional operator console.

10 Series CNC User Manual (09) 1

Page 6

Preface

10 Series CNC User Manual

4. Setting system variables and parameters

This chapter explains how to set the local and system variables used for program writing. It also

describes how to set the machine operation parameters accessible with the MACHINE SET UP

softkey.

5. Establishing origins and homing the axes

This chapter describes how to home the axes and establish the machine origins. In addition, it

provides a definition of the various reference and origin points managed by the control.

6. Axes jogging and stop function

This chapter describes how to move the axes manually.

7. Using tables

This chapter deals with the tables controlled by the system. It describes the Table Editor, a

utility with which to compile and edit system tables.

8. Table editor configurator

This chapter deals with the Table Editor, a utility for customising the tables visualised or printed

by the system, the video pages and the softkey labels. It also discusses how to configure and

handle customised tables.

9. Tool management

This chapter explains how to define tool offsets and part origins an the spindle axis. In addition

it describes how to manage the information stored in the Tool Data Base (tool mounting,

transfer, etc.).

10. Part program file manager

The chapter describes the part program management environment, the directories display, the

copy, rename and edit of the part programs.

11. Part program execution

This chapter explains how to set the machine for part program execution as well as the various

execution modes.

12. Machine Plot

This chapter introduces the MACHINE PLOT, a utility with which to visualise the tool path

graphics in real time while the machine is executing the program.

13. DOS Shell

This chapter describes the procedures for hard disk file management using the DOS operating

system functions.

2 10 Series CNC User Manual (09)

Page 7

Preface

10 Series CNC User Manual

14. Security

This chapter describes a series of security functions that regulate the access to the system

resources.

15. Peripherals

This chapter describes the programs used to configure and use the systems with

communication ports connected to external devices (via a serial, parallel or Ethernet line).

16. Ethernet Communication

This chapter provides the most important information about Ethernet communication and

describes how to configure the network and the network services.

17. Function tables

Lists the enabling tables.

A. Error messages

Lists the error codes and messages and the related recovery operations.

10 Series CNC User Manual (09) 3

Page 8

Preface

10 Series CNC User Manual

Warnings

For correct control operation, it is important to follow the information given in this manual. Take

particular care with topics bearing one of the mentions: WARNING, CAUTION or IMPORTANT,

which indicate the following types of information:

Draws attention to facts or circumstances that may cause damage to the

WARNING

control, to the machine or to operators.

CAUTION

IMPORTANT

Indicates information to be followed in order to avoid damage to equipment

in general.

Indicates information that must be followed carefully in order to ensure full

success of the application.

Terminology

Some terms appearing throughout the manual are explained below.

Control Refers to the 10 Series numerical control unit comprising front panel unit and

basic unit.

Front Panel Is the interface module between machine and operator; it has a monitor on

which messages are output and a keyboard to input the data. It is connected to

the basic unit.

Basic Unit Is the hardware-software unit handling all the machine functions. It is connected

to the front panel and to the machine tool.

END OF PREFACE

4 10 Series CNC User Manual (09)

Page 9

10 Series CNC User Manual

INDEX

FEATURES AND SPECIFICATIONS

INTRODUCTION ............................................................................................................. 1-1

Processes .............................................................................................................. 1-1

HARDWARE STRUCTURE ............................................................................................ 1-2

Central Unit............................................................................................................ 1-2

Operator Panel ...................................................................................................... 1-4

WINMEDIA....................................................................................................................... 1-7

General .................................................................................................................. 1-7

Mass storage ......................................................................................................... 1-14

FDU peripheral ...................................................................................................... 1-14

CD-ROM peripheral............................................................................................... 1-14

Keyboard connection............................................................................................. 1-14

Mouse connection.................................................................................................. 1-14

Ethernet connection............................................................................................... 1-14

Riser Card.............................................................................................................. 1-14

External connections ............................................................................................. 1-14

Keyboard ............................................................................................................... 1-15

Operator Console .................................................................................................. 1-16

SOFTWARE STRUCTURE ............................................................................................. 1-18

Utilities ................................................................................................................... 1-20

Index

SYSTEM START UP

SYSTEM POWER UP...................................................................................................... 2-1

DIAGNOSTIC SCREENS................................................................................................ 2-1

Modules ................................................................................................................. 2-4

EMERGENCY SYSTEM SWITCH-ON ............................................................................ 2-5

DIAGNOSTIC MESSAGES............................................................................................. 2-7

PASSED Tests ...................................................................................................... 2-8

REPORTS about devices and actions in progress ............................................... 2-9

Error messages ..................................................................................................... 2-10

USER INTERFACE

KEYBOARD .................................................................................................................... 3-1

Function keys......................................................................................................... 3-2

Alphanumeric Section............................................................................................ 3-2

10 Series CNC User Manual (15) i

Page 10

Index

10 Series CNC User Manual

OPERATOR PANEL FUNCTION KEYS ......................................................................... 3-4

Fixed Keys ............................................................................................................. 3-4

Special keys ........................................................................................................... 3-5

CONTROL BUTTONS ..................................................................................................... 3-6

VIDEO ..............................................................................................................................3-7

Main screen............................................................................................................ 3-9

Status information area.......................................................................................... 3-10

Axes data area .......................................................................................................3-12

General data area .................................................................................................. 3-13

Part program data area.......................................................................................... 3-15

Large font display................................................................................................... 3-16

Configurable screen pages .................................................................................... 3-19

System status (SYS_STA) ..................................................................................... 3-20

Axes position (AXES_POS) ................................................................................... 3-22

Program display (PRG_DISP) ............................................................................... 3-23

Process status (PROC_STA)................................................................................. 3-24

Programmed code state (CODE_STA).................................................................. 3-26

Axes offsets (AXIS_OFF)....................................................................................... 3-27

Selecting a screen.................................................................................................. 3-27

Enlarging an elementary quadrant......................................................................... 3-28

Directory of Programs screen ................................................................................ 3-29

Additional data windows ........................................................................................ 3-30

General rules about data entry windows ...............................................................3-32

SOFTKEYS ...................................................................................................................... 3-35

Main menu .............................................................................................................3-38

Auto ........................................................................................................................ 3-39

Manual.................................................................................................................... 3-41

Part Program.......................................................................................................... 3-42

Variables ................................................................................................................3-43

OEM ....................................................................................................................... 3-43

Machine Set-Up .....................................................................................................3-44

Tables..................................................................................................................... 3-46

Diagnostics............................................................................................................. 3-47

Utility....................................................................................................................... 3-48

OPERATOR CONSOLE .................................................................................................. 3-49

Operator Console Keys and Functions.................................................................. 3-49

Pilot Panel Selectors and Functions ...................................................................... 3-52

Controls and functions of the WinMedia operator console .................................... 3-55

SETTING SYSTEM VARIABLES AND PARAMETERS

LOCAL AND SYSTEM VARIABLES ..............................................................................4-1

E variables ............................................................................................................. 4-2

User variables ........................................................................................................ 4-3

H variables ............................................................................................................. 4-4

SN variables........................................................................................................... 4-5

SC variables........................................................................................................... 4-6

PLUS variables ......................................................................................................4-9

Searching for pages and variable indexes............................................................. 4-10

Using variables for calculations .............................................................................4-11

SETTING MACHINE PARAMETERS.............................................................................. 4-12

Dynamic Params.................................................................................................... 4-13

Dynamic limits ........................................................................................................ 4-15

Program SET-UP ................................................................................................... 4-16

Block Retrace......................................................................................................... 4-16

ii 10 Series CNC User Manual (15)

Page 11

10 Series CNC User Manual

Probe parameters.................................................................................................. 4-17

Axes Reference ..................................................................................................... 4-18

Accuracy ................................................................................................................ 4-19

Time/date............................................................................................................... 4-20

ESTABLISHING ORIGINS AND HOMING THE AXES

GENERAL........................................................................................................................ 5-1

HOMING THE AXES ....................................................................................................... 5-3

Manual Homing ................................................................................................ 5-3

Automatic Homing ............................................................................................ 5-3

DEFINING ORIGINS........................................................................................................ 5-5

DEFINING THE PART ZERO ON THE SPINDLE AXIS................................................. 5-8

Part zero on tool tip................................................................................................ 5-8

Part zero on spindle nose...................................................................................... 5-10

HOMING AND ORIGIN PRESETTING FOR DIAMETER AXES.................................... 5-11

AXES JOGGING AND STOP FUNCTIONS

Index

JOG.................................................................................................................................. 6-1

Continuous Jog...................................................................................................... 6-2

Incremental Jog ..................................................................................................... 6-2

DEFINING THE JOG INCREMENT ................................................................................ 6-3

FEEDRATE OVERRIDE.................................................................................................. 6-4

ALTERING THE JOG INCREMENT ............................................................................... 6-5

JOG RETURN TO THE PROFILE .................................................................................. 6-6

SPINDLE SPEED OVERRIDE ........................................................................................ 6-7

STOP FUNCTIONS ......................................................................................................... 6-8

Reset...................................................................................................................... 6-8

Hold........................................................................................................................ 6-8

EMERGENCY STOP ....................................................................................................... 6-9

ACTIVE RESET............................................................................................................... 6-9

REMOVING THE TOOL AFTER AN EMERGENCY ...................................................... 6-12

USING TABLES

WHAT IS A TABLE? ....................................................................................................... 7-2

USING THE TABLE EDITOR.......................................................................................... 7-3

Directory Window................................................................................................... 7-5

Softkeys common to all Tables.............................................................................. 7-6

Table Editor Keys .................................................................................................. 7-7

TABLE EDITOR FUNCTIONS ........................................................................................ 7-8

Opening a Table .................................................................................................... 7-8

Loading a Table ..................................................................................................... 7-9

Altering a Table...................................................................................................... 7-10

Incremental Parameter Modification...................................................................... 7-11

Inserting a Record in a Table ................................................................................ 7-12

Canceling a Record from a Table.......................................................................... 7-13

Saving a Table....................................................................................................... 7-14

Printing a Table...................................................................................................... 7-14

Sorting Lines and Columns ................................................................................... 7-15

Search for an Element........................................................................................... 7-16

Changing the Measuring Unit ................................................................................ 7-16

10 Series CNC User Manual (15) iii

Page 12

Index

10 Series CNC User Manual

Table Backup ......................................................................................................... 7-17

Restoring Tables .................................................................................................... 7-18

ORIGINS TABLE ............................................................................................................. 7-19

TOOLS TABLE ................................................................................................................ 7-21

TOOL OFFSETS TABLE................................................................................................. 7-26

TOOL DATA BASE .........................................................................................................7-29

MAGAZINE TABLE ......................................................................................................... 7-32

USER TABLE .................................................................................................................. 7-32

TABLE EDITOR CONFIGURATOR

GENERAL........................................................................................................................ 8-1

CONFIGURATOR SCREENS ......................................................................................... 8-2

Main configurator screen ....................................................................................... 8-2

Configurator screen ............................................................................................... 8-3

SOFTKEYS ...................................................................................................................... 8-7

Softkeys in the main configurator screen............................................................... 8-7

Configuration screen softkeys single tables ..........................................................8-8

LOADING A CONFIGURATION FILE............................................................................. 8-10

SAVING A CONFIGURATION ........................................................................................8-11

RESTORING THE DEFAULT CONFIGURATION .......................................................... 8-12

AXES CONFIGURATION ................................................................................................ 8-13

CONFIGURING A TABLE ............................................................................................... 8-14

Configuring fields ...................................................................................................8-17

LINKING TABLE FIELDS................................................................................................ 8-20

UNLINKING TABLE FIELDS .......................................................................................... 8-22

ARRANGING THE TABLE FIELDS ................................................................................ 8-23

CONFIGURING THE PRINTING OUTPUT .....................................................................8-26

CONFIGURING HELP ..................................................................................................... 8-28

CONFIGURING SOFTKEYS ...........................................................................................8-29

QUITTING THE CONFIGURATOR ENVIRONMENT...................................................... 8-30

PERSONALISING USER TABLES ................................................................................. 8-31

User Table Manager screens and softkeys ........................................................... 8-32

Configuring a table ................................................................................................. 8-37

Configuring the table fields .................................................................................... 8-39

Copying a table or the fields of a table................................................................... 8-40

Copying a table ...................................................................................................... 8-40

Copying table fields................................................................................................ 8-41

Configuring HELP MESSAGES ............................................................................. 8-42

Loading and saving a table on a file ......................................................................8-43

Printing a user table ............................................................................................... 8-43

TOOL MANAGEMENT

GENERAL........................................................................................................................ 9-1

TOOL PRESETTING .......................................................................................................9-2

Tool presetting on an external system ................................................................... 9-3

Tool presetting on the machining part ................................................................... 9-4

DEFINING A MULTIPLE CUTTER TOOL....................................................................... 9-6

MANAGING THE TOOL DATA BASE ............................................................................ 9-7

Transfering tool data between the Tool Data Base and the Tool Table ................ 9-7

Entry of data fora new tool in the Tool Table (retrieved from Data Base) .............9-7

Overwriting the data of a tool already in the Tool Table with the Data Base data. 9-9

iv 10 Series CNC User Manual (15)

Page 13

10 Series CNC User Manual

PART PROGRAM FILE MANAGER

Main screen ........................................................................................................... 10-1

SOFTKEYS...................................................................................................................... 10-3

LINE EDITOR .................................................................................................................. 10-4

Line Editor screen.................................................................................................. 10-4

Creating a new part program................................................................................. 10-7

Loading an existing Part Program ......................................................................... 10-7

Loading a running Part Program ........................................................................... 10-7

Characteristics of the Line Editor........................................................................... 10-8

Line Editor function keys ....................................................................................... 10-9

Writing new characters in a block.......................................................................... 10-11

Opening a new line ................................................................................................ 10-11

Deleting lines ......................................................................................................... 10-12

Retrieving lines ...................................................................................................... 10-13

Configuration Editor............................................................................................... 10-14

Numbering program blocks ................................................................................... 10-16

Search for strings and block numbers................................................................... 10-17

Cut & Paste............................................................................................................ 10-18

Inserting a part program ........................................................................................ 10-20

Saving a part program ........................................................................................... 10-20

Index

PART PROGRAM EXECUTION

SETTING PART PROGRAM PARAMETERS ................................................................ 11-1

EXECUTION OF A PART PROGRAM............................................................................ 11-4

Selecting and activating a part program................................................................ 11-4

Automatic execution .............................................................................................. 11-4

Semiauto (block-by-block) execution .................................................................... 11-5

Multiblock retrace................................................................................................... 11-6

Executing blocks from keyboard............................................................................ 11-7

MDI execution without an active part program ...................................................... 11-7

MDI execution with an active part program ........................................................... 11-8

Executing part of a program .................................................................................. 11-9

Modifying blocks in BLK/BLK mode....................................................................... 11-10

Restoring a part program....................................................................................... 11-10

Search for a string ................................................................................................. 11-11

Overriding the programmed feedrate .................................................................... 11-12

Overriding the spindle speed................................................................................. 11-13

Overriding the rapid ............................................................................................... 11-14

Execution in Dry Run mode................................................................................... 11-14

MEMORY SEARCHING .................................................................................................. 11-15

Automatic searching .............................................................................................. 11-15

Searching for a pre-set block................................................................................. 11-16

Restarting a working cycle..................................................................................... 11-16

Searching mode..................................................................................................... 11-17

MACHINE PLOT

MACHINE PLOT USED WITH AXES CONNECTED ..................................................... 12-1

User interface with axes connected ...................................................................... 12-2

Machine Plot video page with axes connected ..................................................... 12-3

Softkeys active in axes connected mode .............................................................. 12-4

SETTING MACHINE PLOT PARAMETERS WITH AXES CONNECTED ..................... 12-5

10 Series CNC User Manual (15) v

Page 14

Index

10 Series CNC User Manual

DRAWING A PROFILE WITH CONNECTED AXES ......................................................12-9

CHECKING THE GRAPHICS.......................................................................................... 12-10

ZOOM............................................................................................................................... 12-11

CAPTURING POINT COORDINATES ............................................................................ 12-13

MACHINE PLOT WITH AXES DISCONNECTED (DRY RUN MODE) ........................... 12-15

Configuration and functionality in use with axes disconnected .............................12-15

Video page with axes disconnected (Dry Run Active)........................................... 12-16

Softkeys active in axes disconnected mode (dry run) ...........................................12-17

SETTING THE MACHINE PLOT PARAMETERS WITH AXES DISCONNECTED 12-18

VERIFY............................................................................................................................. 12-21

CLEAR SCREEN ............................................................................................................. 12-21

EXAME GRAPHIC ........................................................................................................... 12-21

DOS SHELL

LAUNCHING DOS SHELL .............................................................................................. 13-1

DEFAULT PARAMETER VALUES ................................................................................. 13-2

DISPLAYING A DIRECTORY ......................................................................................... 13-4

DOS SHELL COMMANDS .............................................................................................. 13-6

ABORT................................................................................................................... 13-7

BACKUP................................................................................................................. 13-7

COPY ..................................................................................................................... 13-8

DELETE .................................................................................................................13-9

DIRECTORY ..........................................................................................................13-10

EDIT ....................................................................................................................... 13-11

EXIT .......................................................................................................................13-11

FORMAT ................................................................................................................ 13-12

HELP ...................................................................................................................... 13-13

MKDIR.................................................................................................................... 13-14

PRINT..................................................................................................................... 13-15

RENAME................................................................................................................ 13-16

RESTORE.............................................................................................................. 13-17

SHOW DRIVES...................................................................................................... 13-18

XCOPY................................................................................................................... 13-19

SECURITY

USER LEVELS................................................................................................................. 14-2

ABILITY TO USE SYSTEM FUNCTIONS .......................................................................14-3

ABILITY TO INSTALL OPTIONS.................................................................................... 14-4

ENABLING THE SECURITY ENVIRONMENT ...............................................................14-5

SET LEVEL ............................................................................................................ 14-6

SET PASSWORD .................................................................................................. 14-7

SET SECURITY ..................................................................................................... 14-8

SHOW SECURITY................................................................................................. 14-10

PRODUCT INFO.................................................................................................... 14-11

PRODUCT KEYS................................................................................................... 14-11

INSTALL................................................................................................................. 14-12

SHOW OPTION and SHOW FIXUPS.................................................................... 14-13

PERIPHERALS

ACTIVATING PERIPHERALS........................................................................................ 15-2

vi 10 Series CNC User Manual (15)

Page 15

10 Series CNC User Manual

INTERLNK....................................................................................................................... 15-3

Configuration ......................................................................................................... 15-3

Interlnk Configuration for 10 Series System.......................................................... 15-3

Interlnk Configuration Personal Computer ............................................................ 15-7

PRINT DEVICE................................................................................................................ 15-8

REMOTE BOOT .............................................................................................................. 15-9

ETHERNET COMUNICATION

INTRODUCTION ............................................................................................................. 16-1

COMMENTS ON THE NETWORKS ............................................................................... 16-3

Definitions .............................................................................................................. 16-3

Network topology................................................................................................... 16-5

CONFIGURATION OF THE NETWORK ........................................................................ 16-7

General view.......................................................................................................... 16-7

Network configurator ............................................................................................. 16-7

FUNCTIONS OFFERED BY THE NETWORK................................................................ 16-8

File Transfer........................................................................................................... 16-8

Server services ...................................................................................................... 16-8

Access from a client............................................................................................... 16-9

Exchanges of messages between tasks ............................................................... 16-9

USER INTERFACE ......................................................................................................... 16-12

Access to the configuration environment .............................................................. 16-12

Network configurator screen displays ................................................................... 16-13

Main screen ...................................................................................................... 16-13

First screen display: Advanced Level............................................................... 16-13

Second screen display ..................................................................................... 16-14

Third screen display (optional) ......................................................................... 16-16

NETWORK CONFIGURATOR SOFTKEYS ................................................................... 16-18

Level selection (LEVEL Softkey) ........................................................................... 16-20

Channel configuration (CHAN GENERAL Softkey) .............................................. 16-20

Configuration of server type services (SERVER Softkey)..................................... 16-22

Configuration of client type services (CLIENT Softkey) ........................................ 16-24

CONFIGURATION OF TASK-TO-TASK TYPE SERVICES .......................................... 16-26

Enabling Task-To-Task communication ................................................................ 16-26

Defining a local environment as sharable in the network (SHARED ENV

softkey) .................................................................................................................. 16-26

Connection to a remote environment (REMOTE ENV. Softkey)........................... 16-28

Immediate connection of remote environments (Softkey ENVIR. CONNECT)..... 16-30

Automatic connection of remote devices (Softkey SERVICES CONN.) ............... 16-31

USE OF THE SERVICES IN THE NETWORK................................................................ 16-32

Network activation on the 10 Series system ......................................................... 16-32

Enabling the net on a Windows PC ....................................................................... 16-32

ACCESS TO A SERVICE FROM DOS SHELL .............................................................. 16-33

Display of the drives .............................................................................................. 16-33

ACCESS TO A PART PROGRAM.................................................................................. 16-34

DOS REAL TIME ENVIRONMENT ................................................................................. 16-34

Index

FUNCTION TABLES

FUNCTION TABLES: BYTE 0 - Reserved ............................................................ 17-1

FUNCTION TABLES: BYTE 1 - Reserved ............................................................ 17-2

FUNCTION TABLES: BYTE 2 - Maintenance....................................................... 17-2

FUNCTION TABLES: BYTE 3 - Directory Protection............................................ 17-3

10 Series CNC User Manual (15) vii

Page 16

Index

10 Series CNC User Manual

FUNCTION TABLES: BYTE 4 - System Tables Protection................................... 17-3

FUNCTION TABLES: BYTE 5 - Configuration ......................................................17-4

FUNCTION TABLES: BYTE 6 - PLUS Execution.................................................. 17-4

FUNCTION TABLES: BYTE 7 - Part Program Development ................................ 17-5

FUNCTION TABLES: BYTE 8 - Execution of CNC Functions .............................. 17-5

FUNCTION TABLES: BYTE 9 - Reserved OEM ................................................... 17-6

ERROR MESSAGES

USER INTERFACE ERRORS ......................................................................................... A-2

PART PROGRAM ERROR MESSAGES ........................................................................ A-5

TABLE EDITOR ERRORS ..............................................................................................A-6

DOS SHELL ERROR MESSAGES ................................................................................. A-11

SECURITY ERRORS....................................................................................................... A-13

EMERGENCY MESSAGES............................................................................................. A-15

MESSAGES FOR D.S.I. ANOMALIES............................................................................ A-17

MESSAGES ON FASTWIRE ANOMALIES .................................................................... A-17

RESERVED MESSAGES ................................................................................................ A-17

HARDWARE DIAGNOSTICS ERRORS .........................................................................A-18

Base unit (main CPU) ............................................................................................A-18

Other boards .......................................................................................................... A-19

SOFTWARE DIAGNOSTICS ERRORS .......................................................................... A-21

Operating system ................................................................................................... A-21

Software Configuration Errors................................................................................ A-23

APPLICATION ERRORS................................................................................................. A-27

EDITOR ERRORS ...........................................................................................................A-28

ERROR FROM PERIPHERALS ...................................................................................... A-31

ERRORS COMMON TO ALL OPERATOR PANELS..................................................... A-32

CONFIGURATOR ERROR MESSAGES OF NETWORKS ............................................ A-34

ERROR MESSAGES DURING NETWORK BOOTSTRAP ............................................ A-36

END INDEX

viii 10 Series CNC User Manual (15)

Page 17

Chapter 1

FEATURES AND SPECIFICATIONS

INTRODUCTION

10 Series is a family of state-of-the-art controls capable of meeting a vast range of standard and

non standard application requirements: milling machines, grinding machines, wood-, glass- and

marble-working machines, oxygen cutters, etc. The upper segment in 10 Series can control up to

32 digital axes.

10 Series systems are the result of the most advanced technologies (32 bit microprocessor,

surface mounting, etc.). The powerful multi-task, real time, event driven, operating system is

enhanced by an open hardware and software architecture that permits MTB's to personalise the

application by incorporating custom-specific packages. Access to the sophisticated NC functions is

provided by an easy-to-use user interface that can be tailored to the MTB requirements.

Processes

The word "process" usually refers to the management of a machine tool: control of the machine

axes, execution of machining programs, activation and control of the machine logic, etc. More in

general, the notion of process may include any auxiliary task supporting the operation of the main

machine: tool change, part loading/unloading, statistic calculations, report production, etc.

Multiprocess capabilities are among the major assets of 10 Series CNC, which can manage up to

twenty processes. When synchronised, processes can be managed faster and more flexibly than

with separate control systems.

10 Series CNC User Manual (14) 1-1

Page 18

Chapter 1

Features and Specifications

HARDWARE STRUCTURE

The hardware structure of 10 Series systems is made up of different modules that can be

combined to satisfy the application requeriments.

Two of these modules are present in every configuration:

• the operator panel

• the central unit

Central Unit

The central unit may be of the monoboard type, i.e all in one board, or consist of a rack that

accomodates all of the electronic boards:

− the system CPU

− the axes control board(s)

− the I/O board(s)

− the PLC card

In addition, the system may include a series of optional modules picked up from the following list:

• one or more Pilot Panel operator consoles connected to the Central Unit

• a teach pendant connected to the central unit via the serial line

• up to two electronic handwheels connected to the encoder inputs available on the axes board

• local and remote I/O modules:

− high density I/O (HD I/O)

− medium density I/O (OSARING)

− digital I/O

− analog I/O

− digital and analog I/O's for INTERBUS

All the I/O modules and the operator consoles are connected to the central unit over an optical fiber

ring that protects the system against the electrical noise produced by the machine tool.

The I/O ring may include up to 1000 I/O points.

For more information about the system modules and how to connect them, please refer to the 10

Series Product Specifications and to the 10 Series Family Installation Guide.

From release sw 5.1.2, the INTERBUS connecting system may be used. Up to 2048 inputs and

2048 outputs may be managed on this system.

1-2 10 Series CNC User Manual (14)

Page 19

Chapter 1

Features and Specifications

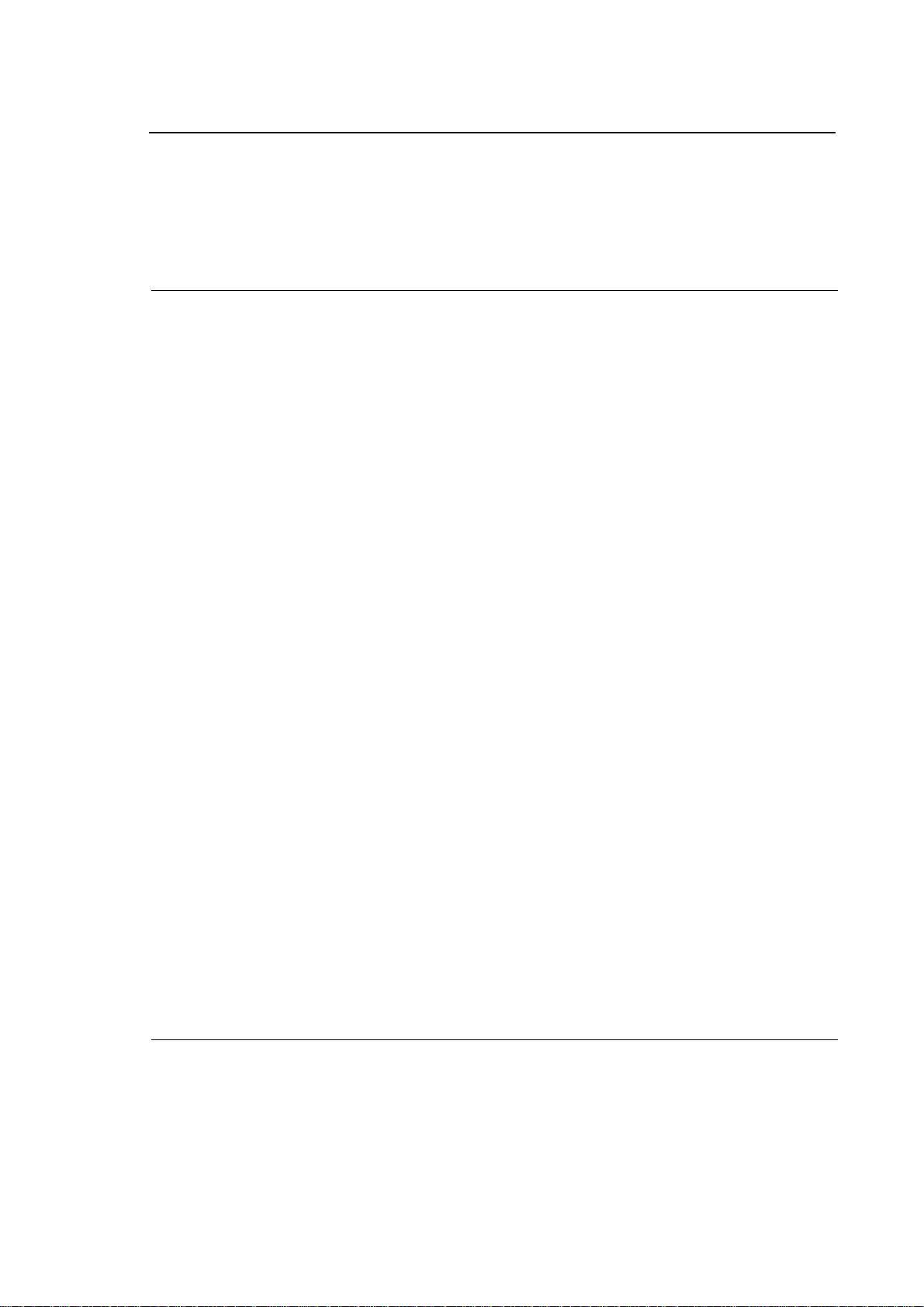

The figure that follows shows an example of how to connect the various 10 Series system

modules.

Configuration of the Series 10 System

10 Series CNC User Manual (14) 1-3

Page 20

Chapter 1

Features and Specifications

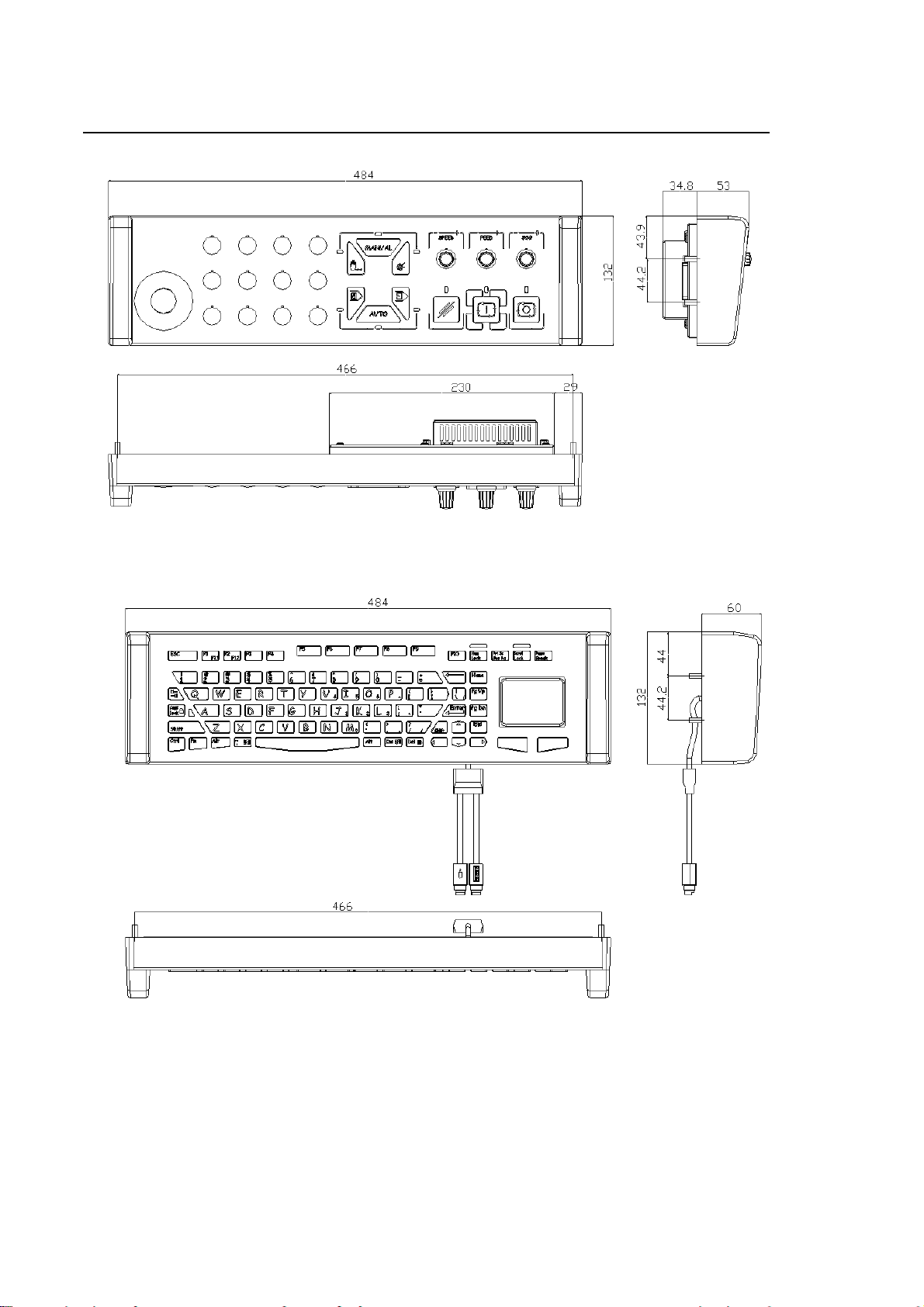

Operator Panel

The Operator Panel or front panel is the interface between the system and the operator.

There are 3 models of operator panel:

− BLink

− OPLink

− WinLink

In all versions, the Operator Panel comprises a screen with a liquid crystal display, a USA-ASCII

standard keyboard separate from the monitor to increase the ergonomics of the system and 7

softkeys. It uses the latest Man-Machine interface techniques in a simple, friendly manner and its

main functions are:

• key in operating commands by means of the softkeys;

• enter the start, stop and reset commands;

• enter data, in terms of commands, through the keyboard;

• enter data and software (part programs, software options, etc.), using diskettes;

• display system data and operating conditions;

• control the NC environment or integrated PC environment (on the WinLink model using the

yellow key).

1-4 10 Series CNC User Manual (14)

Page 21

Chapter 1

Features and Specifications

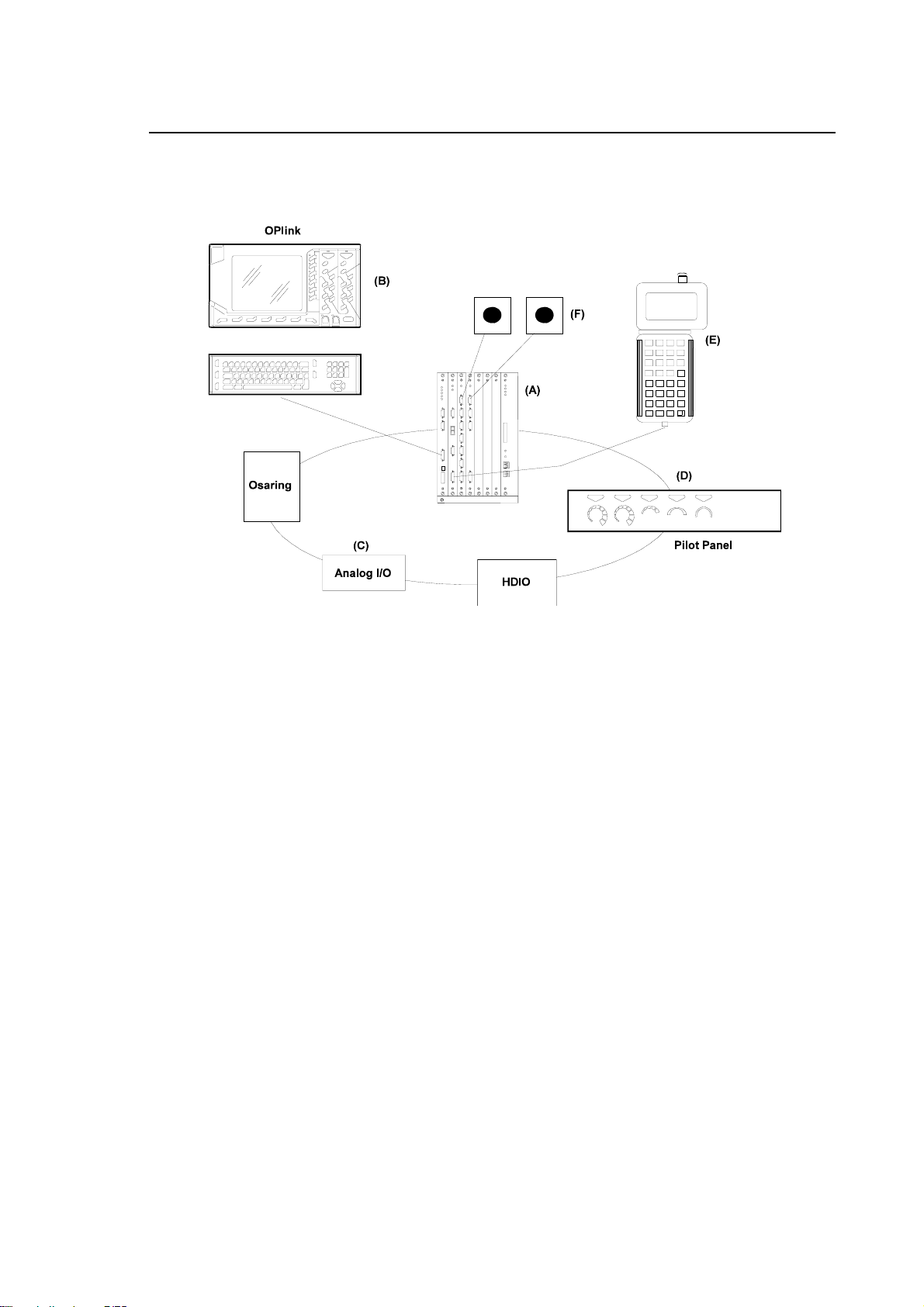

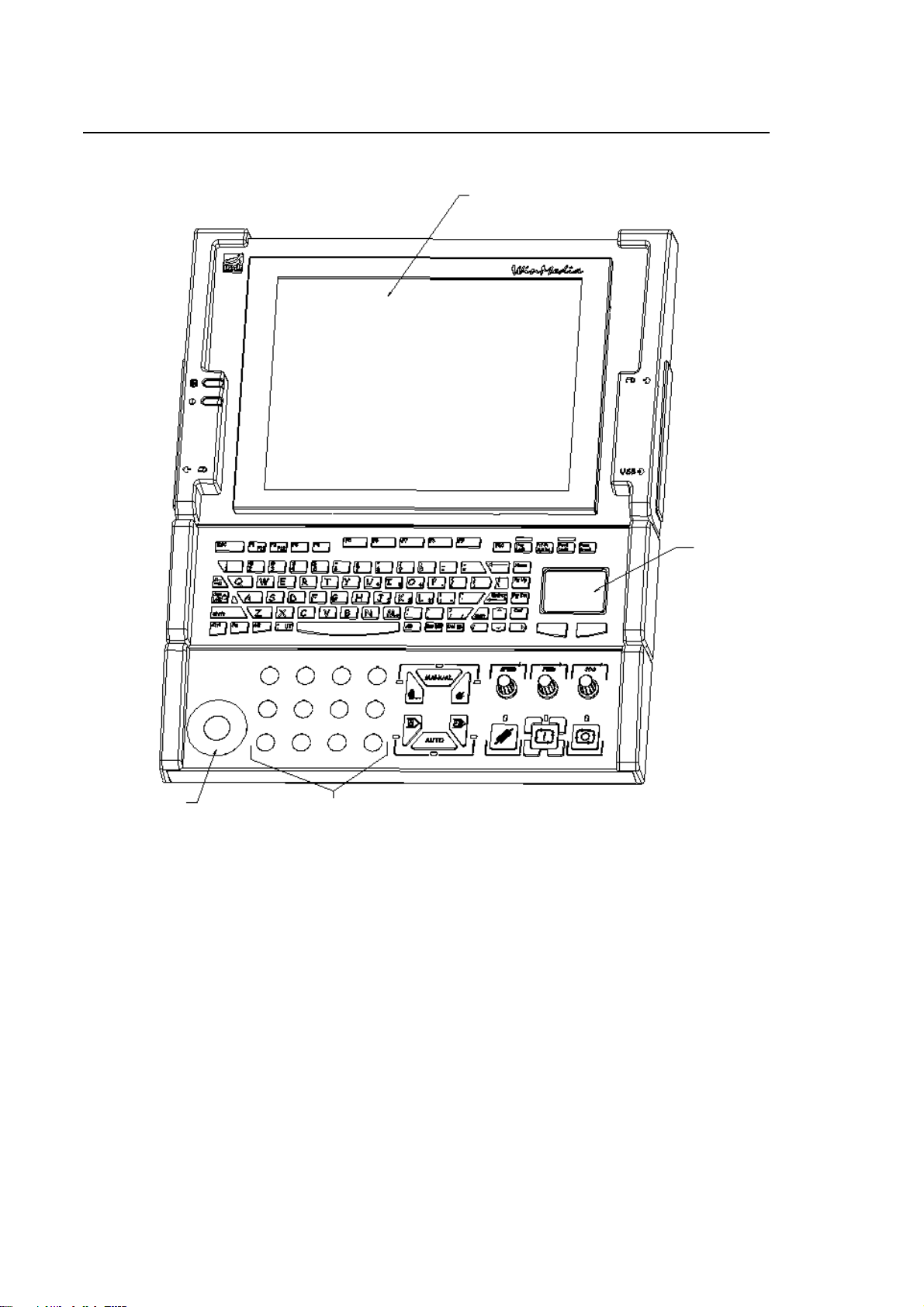

• BLink Operator Panel

Is the basic version to be used with an external Operator Console, available with a 10.4” TFT

colour screen.

BLink Operator Panel

• OPLink Operator Panel

Is the version with a built-in Operator Console that provides CYCLE START; HOLD and RESET

buttons; keys for selecting the AUTO and MANUAL modes, for changing the spindle working and

rotating speed and 6 function keys with LED's which may be used by the manufacturer for machine

logic customization. It is available with a 10.4” TFT colour screen.

OPLink Operator Panel

10 Series CNC User Manual (14) 1-5

Page 22

Chapter 1

Features and Specifications

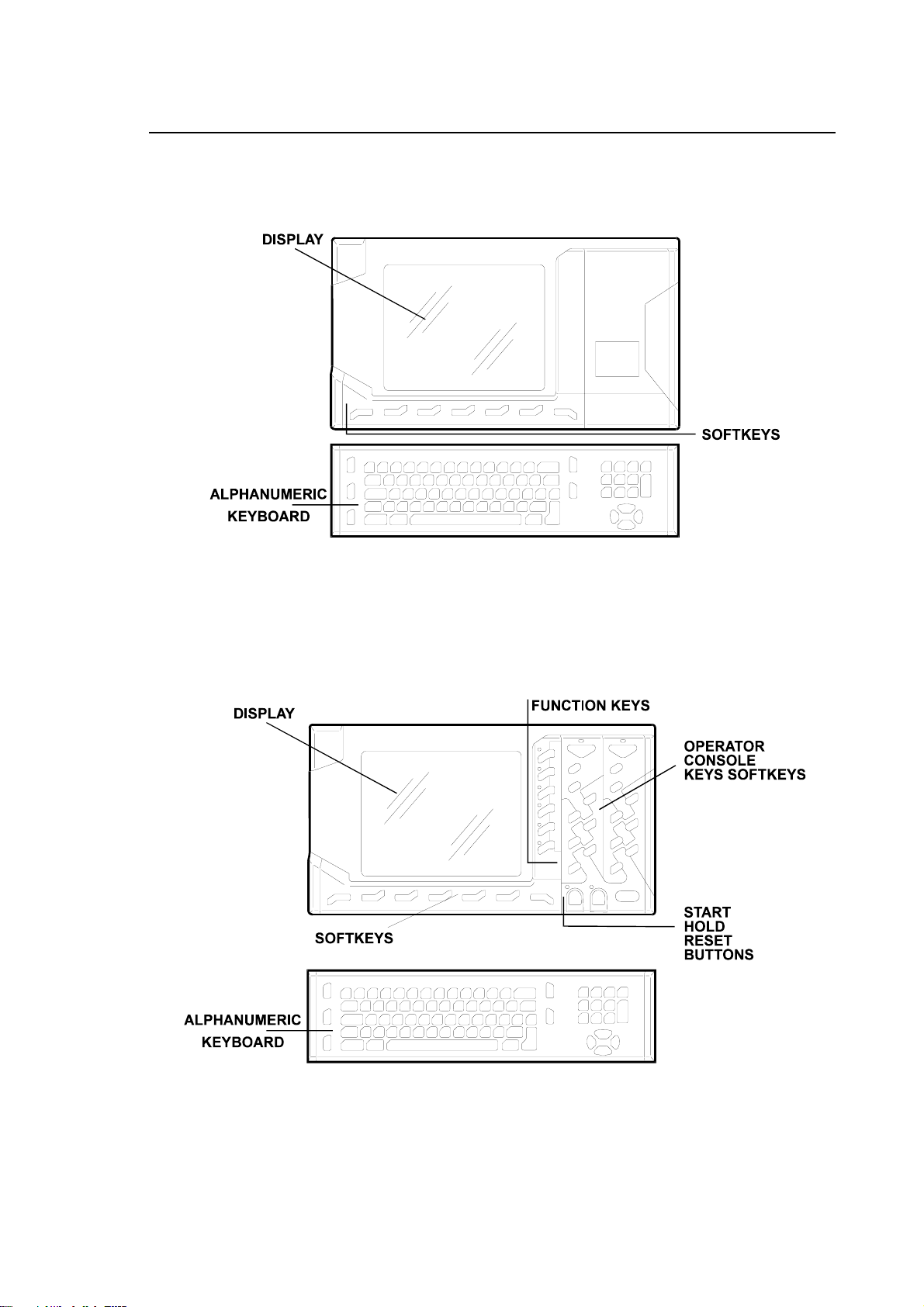

• WinLink Operator Panel

The WinLink front panel, shown in the diagram below, consists of a 10.4" o 12.1” TFT monitor,

alphanumeric keyboard, built-in mouse and built-in PC board (with its own HDU and 3.5" floppy

disk drive).

It has no RESET, START or STOP key.

It has a button ("yellow key") which is used for switching the monitor and keyboard from the NC

environment to the PC environment, and vice versa.

This front panel enables the monitor and keyboard to be shared by the NC and PC environments,

which remain completely separate.

On the built-in PC, you can use Windows applications that communicate with the NC using the Mini

DNC Ethernet option supplied with the dynamic library (DLL) developed for Windows.

ALPHANUMERIC

KEYBOARD

MOUSE

YELLOW BUTTON

WinLink type Operator Panel

1-6 10 Series CNC User Manual (14)

Page 23

Chapter 1

Features and Specifications

WINMEDIA

General

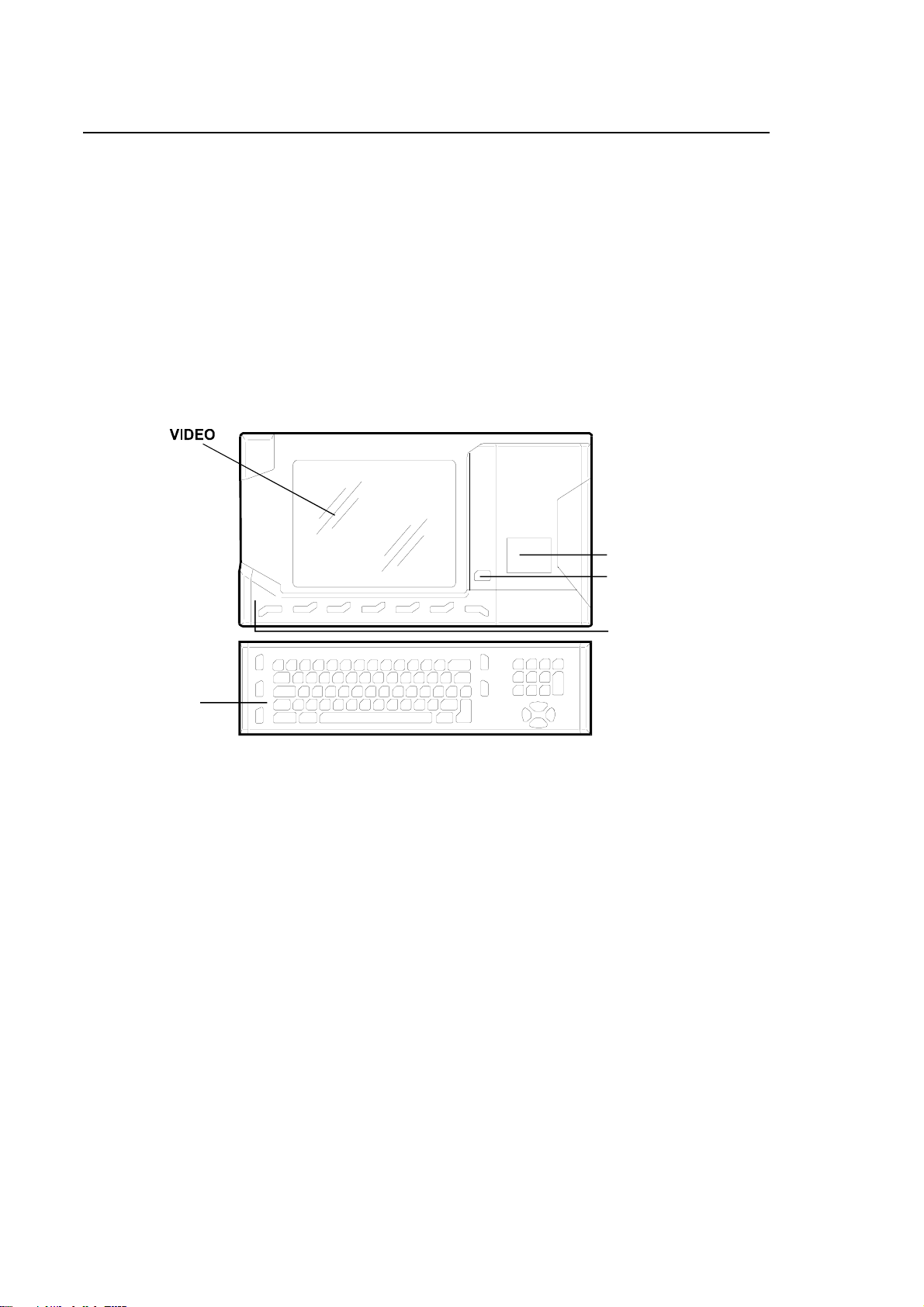

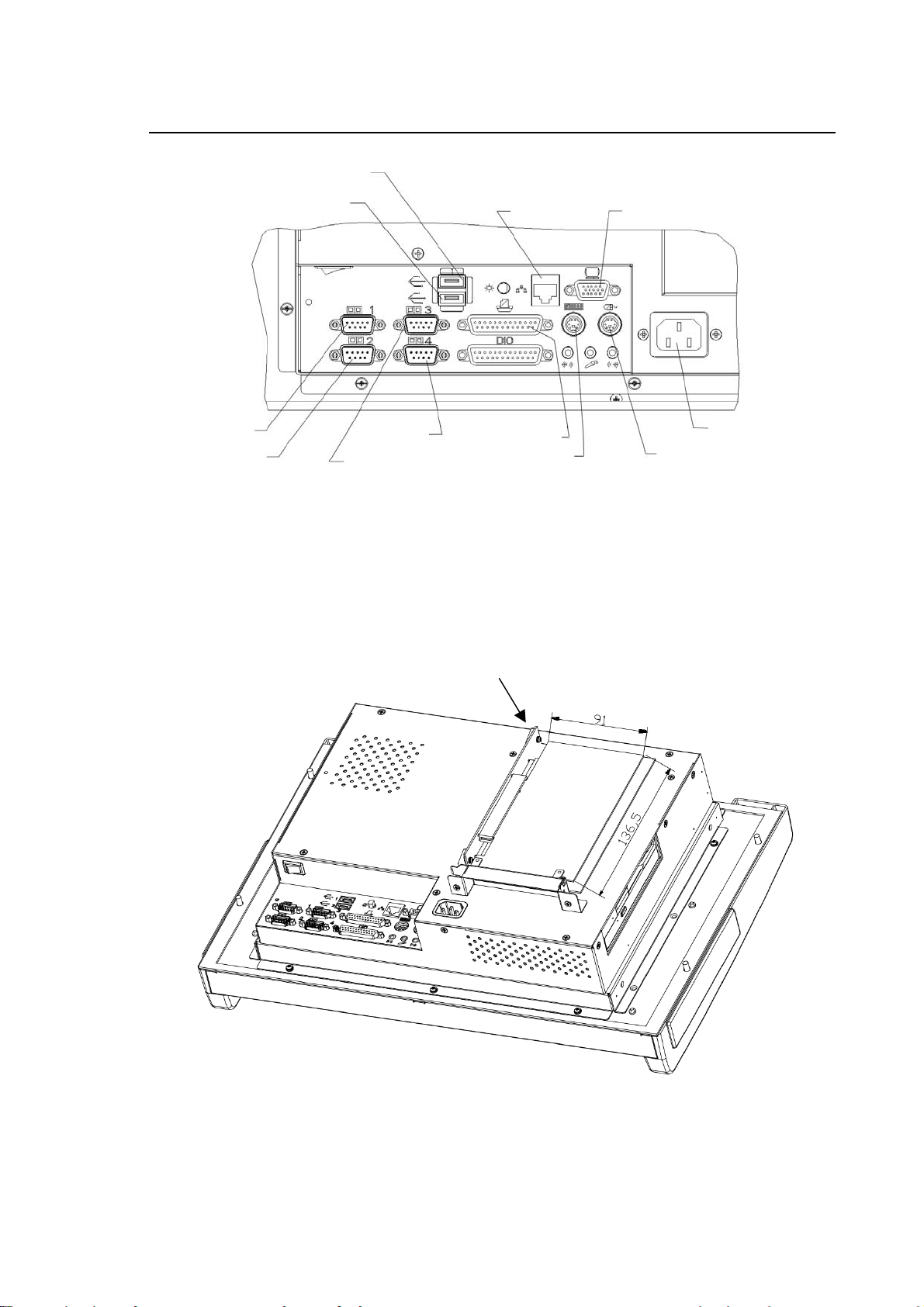

The WinMedia Operator Panel is a front-end module for use by the operators of the CNC to which

it is connected via the Ethernet line.

The panel can be supplemented with a keyboard connected directly to it and with an operator

console connected to a bus line extraneous to the module (communication bus lines such as

FastWire/CanOpen). The figure below shows a front view of the panel with the keyboard and the

console.

Main characteristics of the panel

Anchoring compatible with 19” pitch rack

15” TFT display screen

Fdu and Cd-Rom accessed from the front

Power supply: 90~265Vac 50~60Hz (100W max) *

connector conforming to IEC/EN60320-1/C14 (INLET type, i.e., with male contacts)

* Connection to safety GND by means of the power supply cord

Characteristics of Cpu board (ProX-3650)

850 MHz Celeron processor

CRT controller/ 640x480, 800x600, 1024x768 FLAT PANEL

256/512 Mbyte DDR SDRAM

128/256 Kbyte cache

4 Mbyte Flash BIOS (I/O Setup and VGA)

Mini DIN connectors for keyboard and Mouse

IDE (Hdu) controller

Fdu controller

3 RS232 serial ports

1 RS232/422/485 serial port

1 SPP, ECP, EPP parallel port

RJ-45 connector for 10/100 Base-Tx Ethernet

2 USB 2.0 ports on back

1 2.0 USB port on front panel

1 dedicated 2.0 USB port for Touch Screen

1 PISA slot for Riser Card

10 Series CNC User Manual (14) 1-7

Page 24

Chapter 1

Features and Specifications

LCD 15”

CDU FDU

USB

T. PAD

22 mm diameter

custom operator

16 mm diameter

12 custom operators

PC panel with keyboard and console – front view

1-8 10 Series CNC User Manual (14)

Page 25

Chapter 1

Features and Specifications

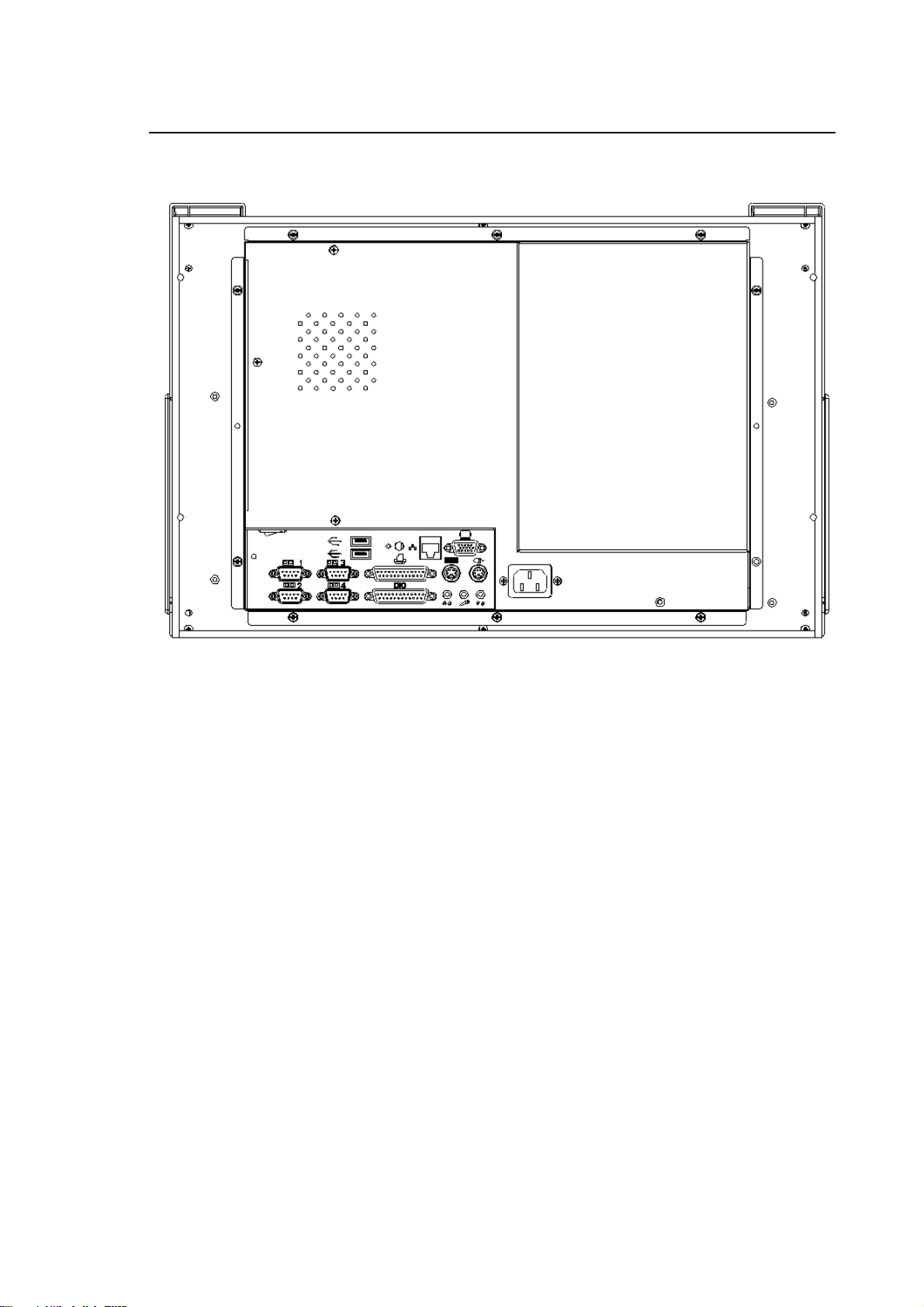

PC panel - rear view

10 Series CNC User Manual (14) 1-9

Page 26

Chapter 1

Features and Specifications

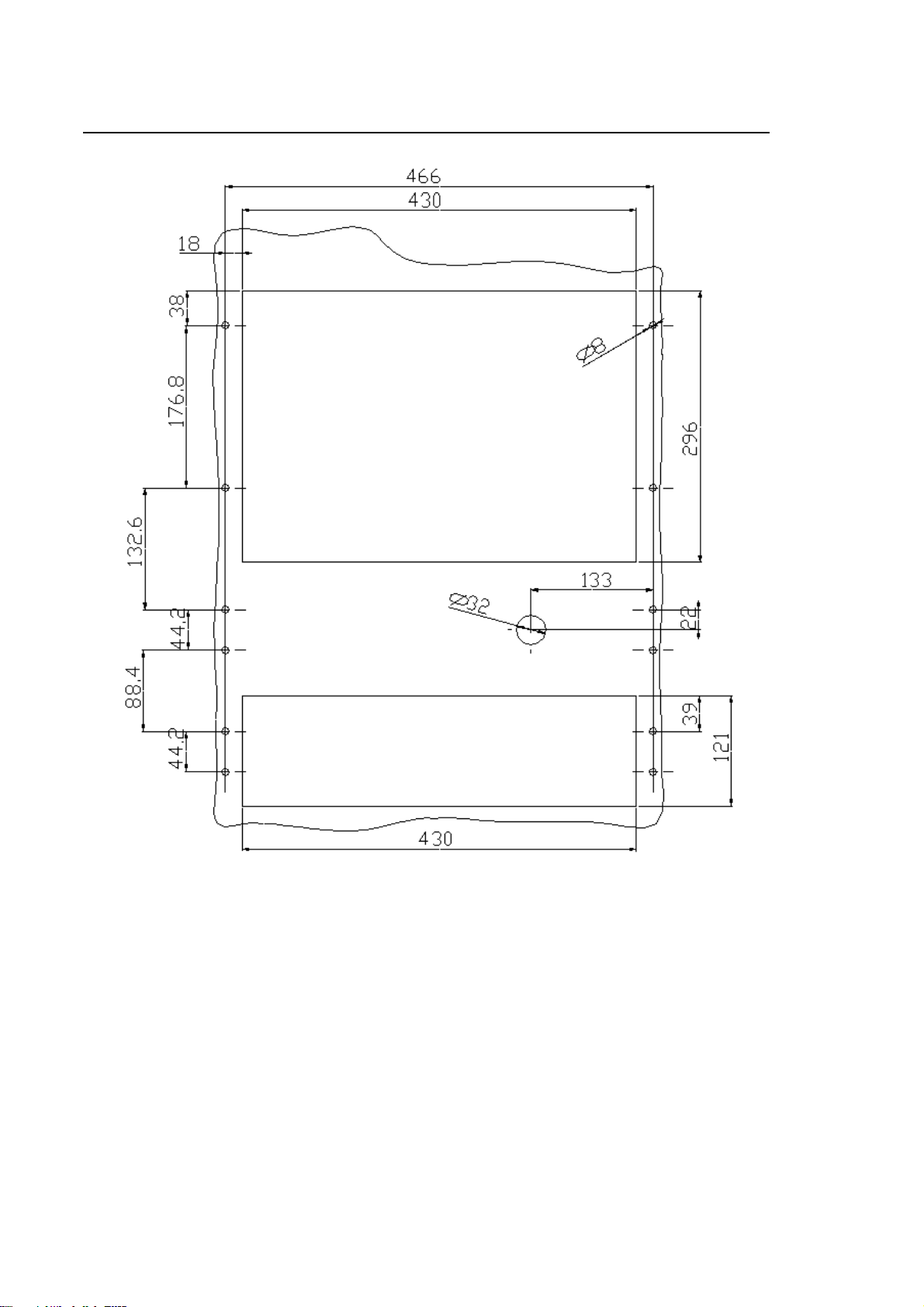

Panel - Keyboard - Console drilling template

1-10 10 Series CNC User Manual (14)

Page 27

Chapter 1

f

Features and Specifications

4 M5 threaded pins

ATTENTION: when the FDU and CDROM options are present, it is

necessary to ensure an obstructionfree area, on the respective side, o

140 mm, to provide sufficient room to

introduce the floppy/compact disks

(zone marked with *).

On the right hand side, this area must

also be left unobstructed if one wants

to use the USB port for external units

(this port is always present).

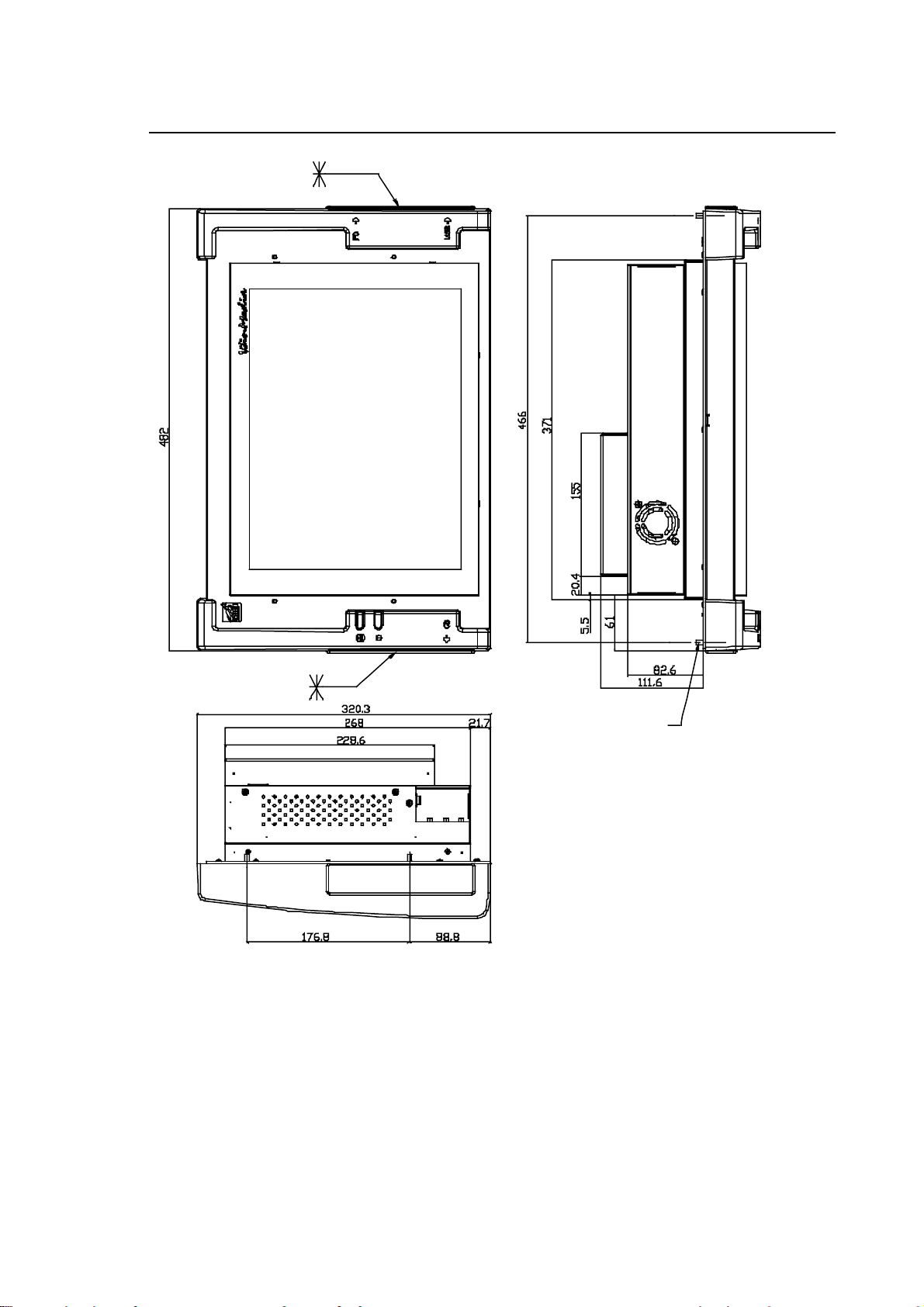

Display panel drilling template

10 Series CNC User Manual (14) 1-11

Page 28

Chapter 1

Features and Specifications

Operator console drilling template

Keyboard drilling template

1-12 10 Series CNC User Manual (14)

Page 29

y

USB

A

Chapter 1

Features and Specifications

Com1

Com2

USB

Ethernet VG

Com4 Parallel port

Com3

Keyboard

PC Panel – Details of connectors

Power suppl

Mouse

Riser Card

PC Panel – Position of Riser Card

10 Series CNC User Manual (14) 1-13

Page 30

Chapter 1

Features and Specifications

Mass storage

Mass storage by means of an HDU with a capacity of 20 and more Gbytes, mounted inside the

module.

FDU peripheral

The module uses an integrated FDU peripheral, fitted to the left part of the panel (option).

CD-ROM peripheral

The module has an integrated CD-ROM peripheral, fitted to the right part of the panel (option).

Keyboard connection

The keyboard is connected by means of a special Mini Din connector on the back of the module.

Mouse connection

The mouse is connected by means of a special Mini Din connector on the back of the module.

Ethernet connection

The Ethernet connection of the module to an external unit or a network is by means of a special

connector on the back. To connect the module to a PC or other similar units you need a crossover

cable, to connect it to a HUB you need a straight cable (see the Connectors/Cables section).

Riser Card

A Riser Card fitted to the special PISA connector makes available a PCI/ISA expansion connector

on the back.

External connections

Back

Com1, Com3, Com4 RS232

Com2 RS232/RS422/RS485 (configurable)

Parallel port

LAN (Ethernet)

Keyboard (6-pin Mini DIN)

Mouse (6-pin Mini DIN)

Display screen (15-pin) Not used

USB, USB (two ports)

AC Pwr in Module power supply

Front

USB (one port)

1-14 10 Series CNC User Manual (14)

Page 31

Chapter 1

Features and Specifications

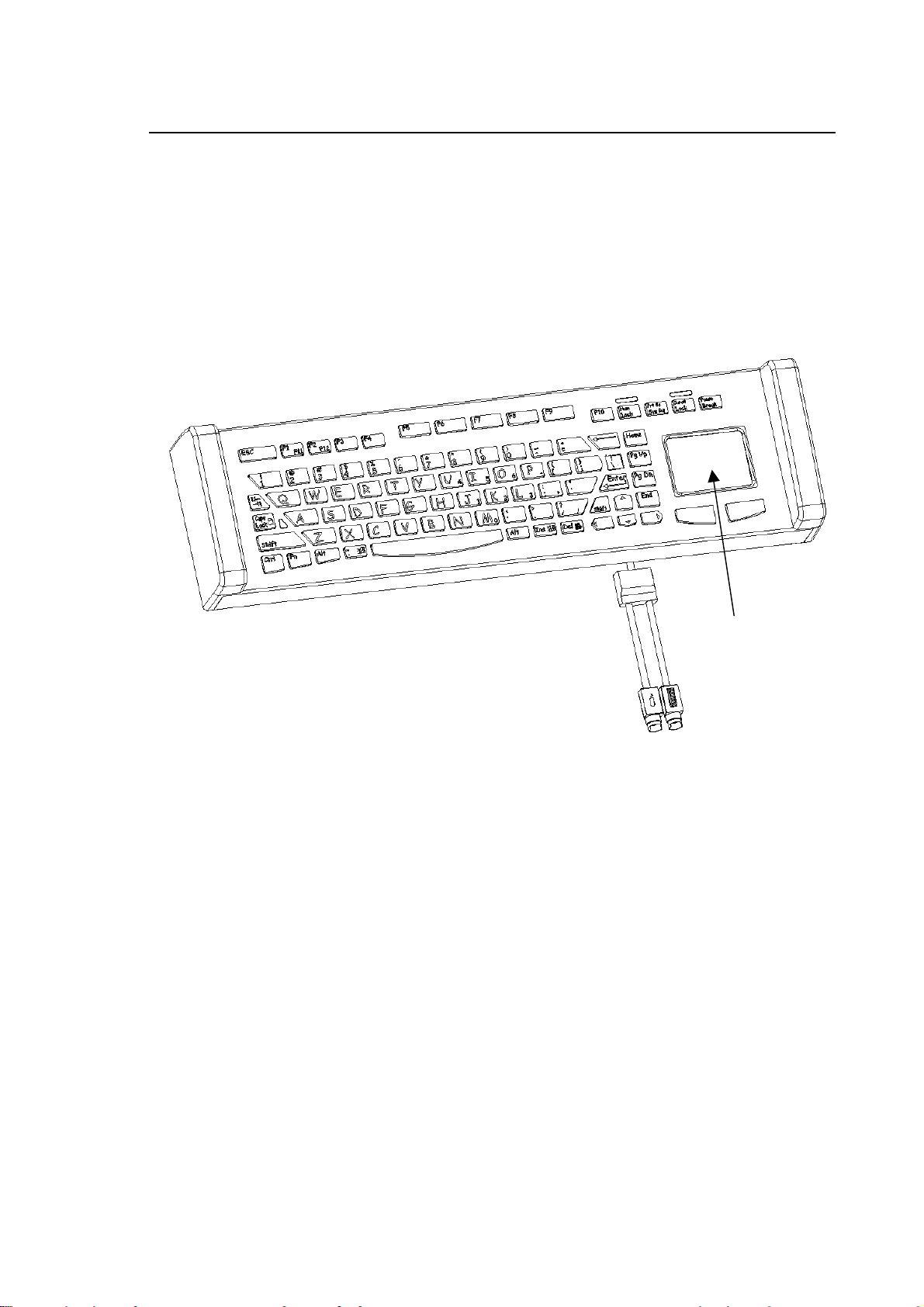

Keyboard

The keyboard has a standard Windows PC configuration with 83 short-stroke keys of silicone

rubber and a built-in mouse pad with right and left mouse keys. The two (independent) sections are

connected to the WinMedia module by means of two cables ending with Mini DIN connectors. PS2

standard communication protocol.

WinMedia keyboard

Touch Pad

KeyboardMouse

10 Series CNC User Manual (14) 1-15

Page 32

Chapter 1

Features and Specifications

Operator Console

Specification

The Operator Console is recognised by the NC as an I/O module managed through the FastWire

or CanOpen line and it includes:

* Operators (trimmers): SPEED – FEED – JOG

* Selector buttons: CYCLE START – HOLD – RESET

JOG INC – MANUAL – HOME

MDI – AUTO – BLK/BLK

* Active functions LEDs

* 12 locations for 16 mm diameter custom operators

* 1 location for a 22 mm diameter custom operator

22 diameter

custom operator

(yellow badge for

emergency button)

12 16mm diameter

custom operators

Front view of console

1-16 10 Series CNC User Manual (14)

Page 33

Chapter 1

CONN. ALIM

Features and Specifications

24 V OUT

CONN. ALIM.

SW1

POWER CONN.

SW2

OUT 24V

FASTWIRE LINE CONN.

CONN. LINEA FAST WIRE

CanOpen LINE

CONNECTOR

& NETWORK

SIDE POWER

SUPPLY

SW1

SW2

MODULE POWER

SUPPLY CONN.

“BUS” LED “RUN” LED

LED "BUS"

CONN. LINEA CanOpen

E ALIM. LATO RETE

“BUS” LED “RUN” LED

LED "BUS"

LED "RUN"

“FAULT” LED

LED "FAULT"

MODULE POWER

SUPPLY CONN.

LED "RUN"

“FAULT” LED

LED "FAULT"

.

MODULO

12 16mm DIAMETER CUSTOM OPERATORS

12 OPERATORI CUSTOM DIAMETRO 16 mm

CUSTOM

CONN.I/O 24V

24V I/O CONN.

CUSTOM

Console - Rear view of FastWire version

CONN. ALIM.

MODULO

12 16mm DIAMETER CUSTOM OPERATORS

12 OPERATORI CUSTOM DIAMETRO 16 mm

CUSTOM

CONN. I/O 24V

24V I/O CONN.

CUSTOM

22mm DIAMETER

OPERATORE CUSTOM

CUSTOM OPERATOR

DIAMETRO 22 mm

22mm DIAMETER

OPERATORE CUSTOM

DIAMETRO 22 mm

CUSTOM OPERATOR

Console - Rear view of CanOpen version

10 Series CNC User Manual (14) 1-17

Page 34

Chapter 1

t

Features and Specifications

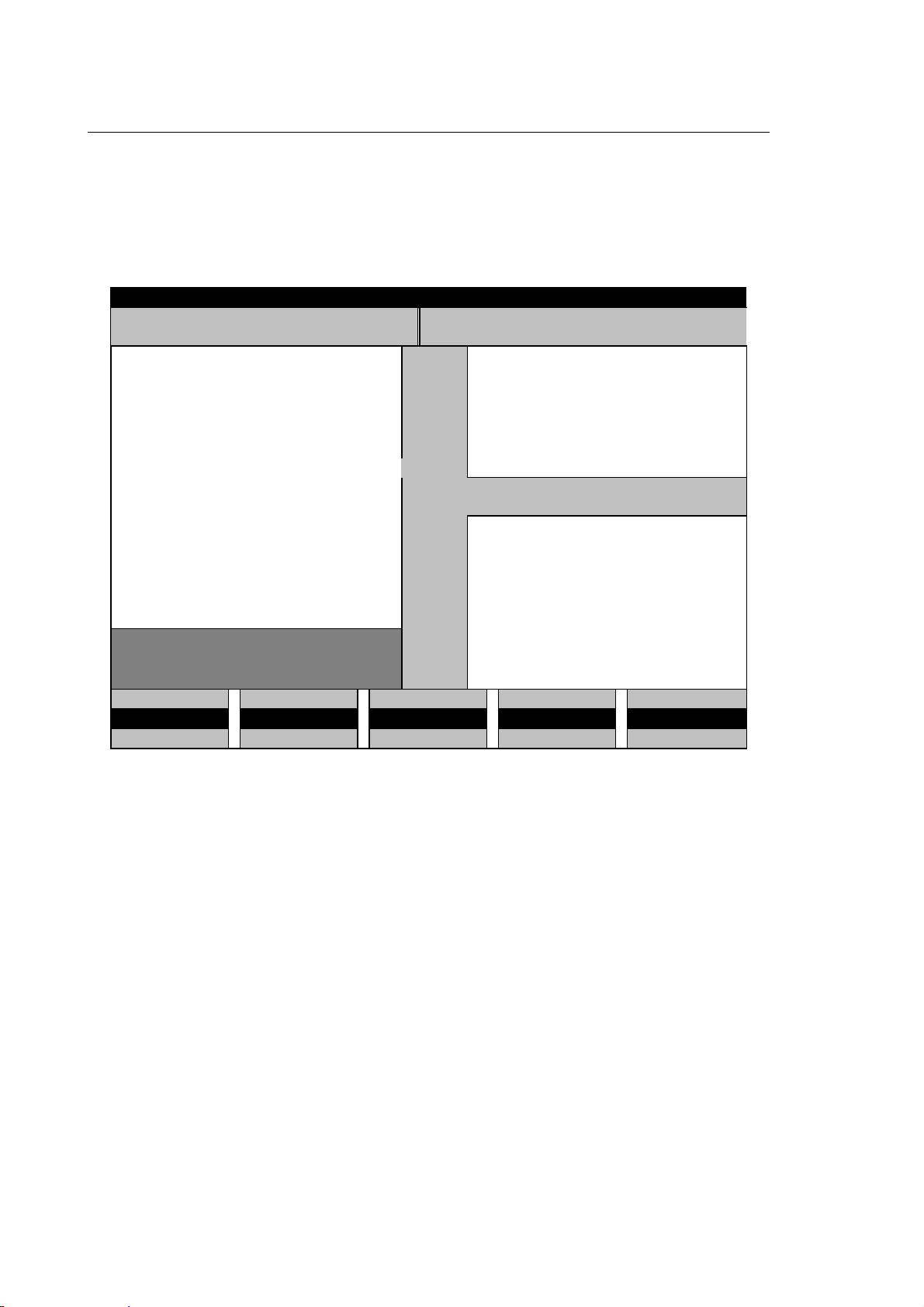

SOFTWARE STRUCTURE

The figure that follows illustrates the software structure. Note that the Event-Driven Real-Time

Multi-Task IntePprocess Communications software (IPC) overlaps the basic operating system that

manages communications with the operator panel. IPC also supervises and synchronises

communications between the five software partitions.

Communications with

Operator Panel

Operating System

IPC (Interprocess Communication)

Real Time

DOS

Interface

Table

Editor

PLUS

Editor

Human

Interface

Graphic

Editor

Utility

Digitizing

Option

AMP

Machine

Logic

Interface

DOS

Graphic

Interface

Numerically

Controlled

Proces

Serial

Mini

DNC

Etherne

SOFTPIT.DRW

1-18 10 Series CNC User Manual (14)

Page 35

Chapter 1

Features and Specifications

The functions of the five system partitions are as follows:

NC Process: Includes the Part Program interpreter. It interpolates the controlled

axes and manages processes in machining centers.

Machine Logic Interface: Executes the OEM-developed interfaces between the NC and the MT.

Utilities: Includes a series of packages aimed at the end user, the MTB or the

technical assistance engineer. Some are described later in the

manual, others are optional (purchased separately).

Human Interface: The NC-operator interface manages visualisation, program editing

procedures, softkey operation, help pages, etc.

Real-time DOS Interface: Is the 10 Series "aperture" to OEM for the building of personalised

applications.

These applications can use all the 10 Series resources (axes, logic,

human interface, etc.), as well as those of the Operating System

(realtime, multitask, etc.).

10 Series CNC User Manual (14) 1-19

Page 36

Chapter 1

Features and Specifications

Utilities

A utility is a standard or optional program addressed to various users levels (end user, MTB,

technical assistance engineer, etc.). The 10 Series Utilities partition includes:

Table Editor Permits to key in, display and edit the parameters that define the

following features:

− origins

− tools

− tool offsets

− tool tables

− tool magazines

− tool data base

The Table Editor includes the Editor Configurator Table, which permits to

personalise the contents and the layout of the tables displayed by the

system. For details, refer to Chapters 7 and 8.

PLUS Editor PLUS (Parallel Logic Universal System) is a complete universal

programming language used for writing the machine logic that manages

the interface between the 10 Series and the machine tool. PLUS collects

information about the current process, the axes functions and the system

variables and uses this data to make decisions about the machining

process and other actions. For more information see the relative

documentation, particularly the 10 Series CNC PLUS Library Manual.

Graphic Editor This option permits to write programs using graphic menus. The Graphic

Editor can be broken down into two utilities:

The Geometric Editor generates a profile from the definition of its

elementary geometric constituents. The desired profile is obtained by

linking these constituents.

The Cycle Editor permits to program canned machining or measuring

cycles. The programmer is presented with a choice of graphic options

and of parameters that define them.

For more information about this option, refer to the 10 Series CNC

Graphic Editor Manual.

1-20 10 Series CNC User Manual (14)

Page 37

Chapter 1

Features and Specifications

Digitizing This option permits to program complex profiles (such as those including

spline curves) using points captured with different methods. Digitizing

methods include manual moves, probing cycles and keyboard entries.

Points can also be uploaded from an external computer.

For more information about this option, refer to the 10 Series CNC

DIGICAD User Manual.

AMP The Adjustable Machine Parameters (AMP) permits the user to tailor the

10 Series control to the system applications.

The following is a list of configurable system parameters:

− number of axes and axes parameters (gain, velocity, electrical and

mechanical pitch, etc.)

− operator interface or visualisation technique

− system variables

− hardware system configuration

− number of processes

− user-specific DOS packages

− auxiliary functions

− travel limits

− etc.

For more information about this option, refer to the 10 Series AMP

Software Characterization Manual.

DOS Graphic Interface This option permits the user to customise the machine by writing

application programs in C language and using the DOS Graphic Interface

libraries. For more information about this option, refer to the 10 Series

CNC DOS Graphic Interface Manual.

MINI DNC This option permits network connection of 10 Series systems and a PC

for exchanging files (part programs, etc.) and for communication between

processes ("task to task").

There are two types of connections:

− over a RS-232 serial line

− PC connected over an Ethernet link to various systems.

For more information about this option, refer to the MINI DNC

Serial/Ethernet Manual.

10 Series CNC User Manual (14) 1-21

Page 38

Chapter 1

Features and Specifications

In addition to the options listed and displayed in the figure, 10 Series systems offer other options

now listed below:

Tool Management Manages the flow of tool information between the Tool Magazine and the

shop floor, and the operations for moving the tools in the machine.

For more information about this option, refer to the 10 Series CNC Tool

Magazine Option.

Electronic Cam This option permits to define a master axis and a slave using the

positioning values stored in predifined tables. The master/slave pair

sampling tick can be much smaller than that available with ordinary

programming and calculation methods.

Oscilloscope This standard feature permits to visualise in a continuous graphic the

feedrate or the following error of the axes, and to store the relevant data

in a file.

System History This standard feature permits to store in a file all the diagnostic

messages sent by the system when erroneous operations are performed

or a mulfunctioning occurs. Messages are complete with date and time.

This file is of considerable importance for troubleshooting and diagnostic

purposes.

END OF CHAPTER

1-22 10 Series CNC User Manual (14)

Page 39

Chapter 2

SYSTEM START UP

SYSTEM POWER UP

The system is powered up when power is supplied to the central unit and the front panel. To do this

you must typically operate the machine main power switch.

Since most of the system software is stored in the hard disk, at power up the system automatically

loads the NC management software in the system memory.

DIAGNOSTIC SCREENS

At power up the system also launches a diagnostics of the system hardware and software

modules. The diagnostic sequence is as follows:

• hardware (CPU, ROM, RAM, keyboard and hard disk)

• additional boards and devices

• NC software

To each diagnostic module corresponds a screen similar to the one shown in the figure below.

On the intelligent front panel (in systems equipped with this model of front

CAUTION

panel), the messages displayed on the screens may vary.

For a list of all error messages for this type of operator panel, see the

relevant section of Appendix A.

10 Series CNC User Manual (15) 2-1

Page 40

Chapter 2

System Start up

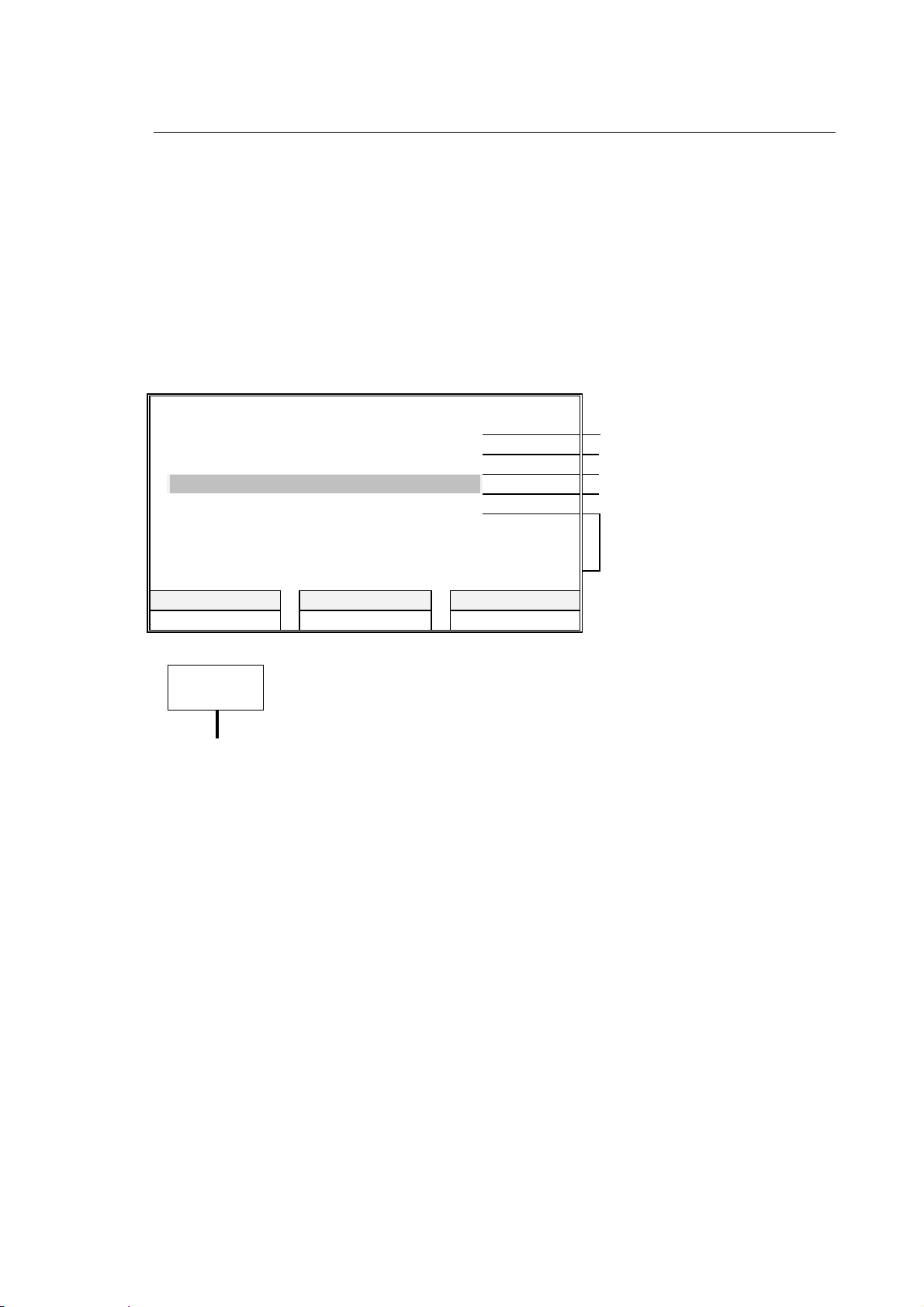

A

MAIN CPU HARDWARE DIAGNOSTIC

CPU ROM

B5.1.2

RAM KEYB DISK

B

10% 20% 30% 40% 50% 60% 70% 80% 90% 100%

RAM : BD002 CMOS Memory Battery backup PASSED

C CPU : BD000 Math Processor PASSED

DISK : BD004 Fixed Disk: 1 present PASSED

DISK : BD004 Floppy Disk : 1 present PASSED

Data Logger Display

A "LED" Area

B Percentage of Loaded Software

C Message Area

The diagnostic screen can be partitioned into three main areas:

A "LED" Area: this area displays 5 or 6 boxes, each one of which represents a diagnostic LED.

The name of the label indicates the device tested by the diagnostic routine. The boxes are

displayed in green when the modules pass the test. They are displayed in red when a failure

occurs. In this case, a fixed label indicates a locking error, whereas a blinking label indicates a

non-locking error. The error will be further described in the data logger display area.

B Percentage of Loaded Software: as the software is loaded in the system memory during

initialisation, the color bar displayed in this area shows the loaded percentage.

C Data Logger Display: this area displays the test results. The layout of a typical message line is

as follows:

2-2 10 Series CNC User Manual (15)

Page 41

Chapter 2

System Start up

KEYBO: BD003 KEYBOARD PASSED

test results

test description

message code

tested device

The meaning of these columns is as follows:

Tested Device is the acronym of the device, typically the label displayed on the diagnostic

"LED" area.

Message Code is the acronym of the diagnostic message. It is made up of two letters and

three digits. In the standard front panel this acronym corresponds to the

message code listed in Appendix A. Note that this appendix also provides

the description of the failure and the remedial action.

Test Description provides a short description of the test (if passed) or an error message when

an error has been detected.

Test Results this column may display one of these messages:

PASSED the device has passed the test.

WARNING the device has not passed the test but the error is not a

locking one. When this occurs, the LED is displayed in red

with a blinking label. The WARNING message is written in

white letters on a red background.

FAILED the device has not passed the test and the relevant LED is

red.

REPORT an optional device (mathematical coprocessor, software

package, etc.) is present. This message also appears to

indicate that the system is going through initialisation or is

configuring the software.

In general only one FAILED message is displayed when a locking error occurs. On the contrary,

when more than one WARNING must be displayed, the following string appears:

Press enter to continue

When this message appears, the test stops. To display all the messages that cannot be

accomodated in the message area it is necessary to press the [Arrow Up/Down] arrow keys. To

resume the test press [Enter].

10 Series CNC User Manual (15) 2-3

Page 42

Chapter 2

System Start up

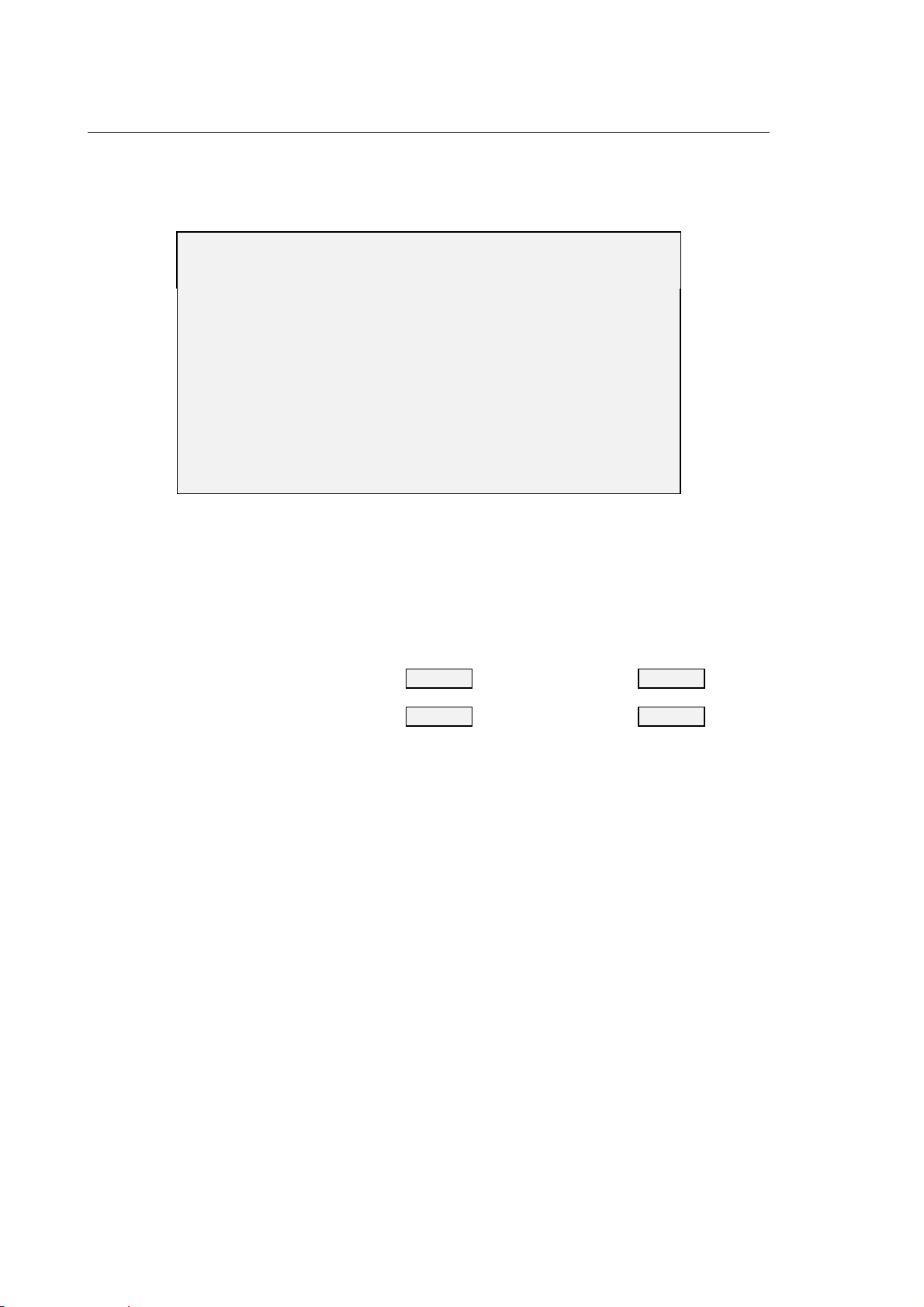

Modules

The LED labels and the messages displayed in the Data Logger Display vary with the type of

tested module.

As a result various possible conditions may be displayed sequentially while the relevant module is

tested:

MAIN CPU HARDWARE DIAGNOSTIC

Basic hardware

(system CPU)

Additional hardware

(any boards installed)

NC software

CPU ROM

B02.03A

CNC SOFTWARE DIAGNOSTICS

PLUS AXIS

CNC SOFTWARE DIAGNOSTICS

OS

V03.00

PLUS

V03.00

RAM KEYB DISK

SERVO

V03.00

PROCESS

V03.00

HUMAN

V03.00

On the new 10/110 controls of the 10 Series, the initial diagnostic phase in which the basic

hardware components are tested is displayed in a different format typical of the diagnostic

messages displayed on standard personal computers.

On the other two models, the diagnostic screens are as described.

2-4 10 Series CNC User Manual (15)

Page 43

Chapter 2

System Start up

EMERGENCY SYSTEM SWITCH-ON

It is possible to perform a "minimum" bootstrap on 10 Series systems in which some operations

only executed in this environment can be perfromed, while not activating all the system features.

IMPORTANT

The minimum bootstrap is activated by holding down the [F1] button when

switching the system on.

The system will be brought up with the EMERGENCY DIAGNOSTIC

screen:

IMPORTANT

If the front panel is WinLink type, first press the "yellow button" when

switching on and then, after switching video and keyboard to NC

environment, press [F1].

The system will be brought up with the EMERGENCY DIAGNOSTIC

screen:

In emergency, the following softkeys are available:

• AMP

This softkey grants access to the AMP utility for system characterisation. The functions of this

utility are described in the Characterisation Manual.

• PLUS

Grants access to the PLUS environment for development of the machine logic programs. For

further details, read the PLUS manuals.

• VARIABLE RESET

With this utility, the dual port memory areas present in the system can be initialised, saved in a

file and restored from a file. This topic is discussed in the Characterisation Manual.

• SYSTEM HISTORY

This softkey grants access to the utility for display/printing/deleting of the history log of errors

and system messages displayed during operation of the machine. This file has a fixed size,

which means that beyond a certain number of messages, new incoming reports will involve the

oldest reports being pushed out.

• HELP

Displays the on-line help window.

• DOS SHELL

This softkey grants access to the DOS SHELL utility.

This utility permits execution of commands for control of the files in the drives acknowledged by

the system (local or remote). Further information on this utility may be found in this manual.

• SECURITY

Manages the system security levels at the different user levels. Further information on this utility

may be found in this manual.

10 Series CNC User Manual (15) 2-5

Page 44

Chapter 2

System Start up

• TABLE EDITOR

This utility grants management of the system tables; further information on this utility may be

found in the 10 Series CNC user manual.

• PERIPHERALS

Permits selection of the output port for the system printer or for use in the DOS environment.

• LANGUAGES

This is a utility permitting personalization of the national language of the mesages displayed in

the HELP, SOFTKEY, etc. Further information on this utility may be found in the

Characterisation Manual.

• SYSTEM SHUT DOWN

This is used to perform a bootstrap, as recommended after making changes to the software

characterisation or the machine logic, and it is also used to shut down the system.

• COMPILER

Allows compiling and linking of source files written in C or ASSEMBLER.

• UTILITY

Permits execution of what is specified in file E:UTY\AUTOEMG.BAT or in file

A:\AUTOEMG.BAT, present on a diskette.

This is a utility permitting execution of programs for Hard Disk compacting, system scanning in

search for "viruses", or other programs selected by the OEM.