Page 1

10 Series CNC

WinPLUS LIBRARY

User Manual

Code: 45006867F

Rev. 04

PUBLICATION ISSUED BY:

OSAI S.p.A.

Via Torino, 14 - 10010 Barone Canavese (TO) – Italy

Phone: +39-0119899711

Web: www.osai.it

e-mail: sales@osai.it

service@osai.it

Copyright 2001-2005 by OSAI

All rights reserved

Edition: October 2005

IMPORTANT USER INFORMATION

This document has been prepared in order to be used by OSAI. It describes the latest release of

the product.

OSAI reserves the right to modify and improve the product described by this document at any time

and without prior notice.

Actual application of this product is up to the user. In no event will OSAI be responsible or liable for

indirect or consequential damages that may result from installation or use of the equipment

described in this text.

Page 2

ABC

ABC

Page 3

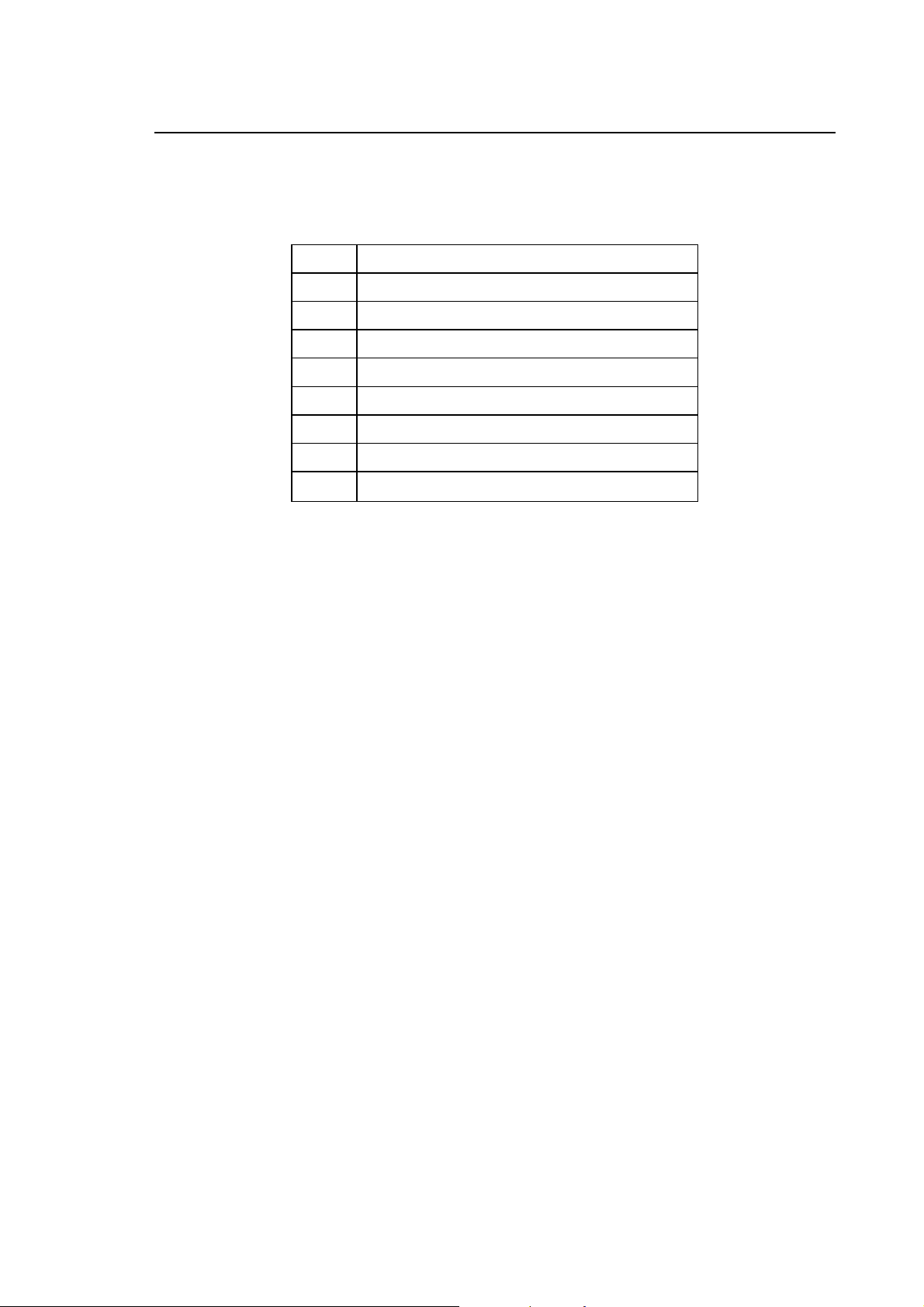

UPDATES TO THE PRESENT EDITION

General

This issue completely replaces the previous ones.

PAGES UPDATES

Update

10 Series CNC WINPLUS Library- User Manual

Preface

Page 2

INDEX

CHAP. 2

Page 20

Page 21

Page 22

CHAP. 3

Page 15

Page 47

CHAP. 4

Page 30

Page 31

CHAP. 6

Page 15

Page 16

Page 17

Page 18

CHAP. 8

Page 14

Page 39

Page 45

Page 46

Page 60

Page 62

Page 63

Page 76

Page 88

Page 90

Page 91

Page 92

Updated

Changed description

Updated

Changed LIMITSW function

Changed description of A_TO_ID function

Changed description of ID_TO_A function

Changed description of ANAIN function

Changed description of ENCODER function

Changed description of PARK_SP function

Changed description of GET_SP function

Changed GETUSED function

Added new function PUTUSED

Added new function GETUSEC

Added new function PUTUSEC

Changed description of AX_SETZ function

Changed description and NOTE of AX_GET8 function

Added NOTE

Added NOTE

Changed description and NOTES of TC_CONF function

Changed description of TC_READ1 function

Changed description and NOTES of TC_WRIT function

Changed AXD_CMD function

Added new function AX_MECS

Added new function AX_MECR

Added new function AX_MECW

Added new function AX_RTFBCK

CHAP. 10

APPENDIX H

10 Series CNC WINPLUS Library- User Manual (04)

Added new charter “CANOPEN-HILSCHER MANAGEMENT FUNCTIONS”

Added new appendix “TABLE OF MAIN RESOURCES OF AXIS BOARDS”

Page 4

Page 5

Preface

10 Series CNC WinPLUS Library - User Manual

PREFACE

This manual contains the description of all block functions (FB) needed for the logic application

projects of the 10 Series CNC.

It contains the corresponding Structured Text (ST) code for each FB and a description of the input

and output variables.

This manual deals specifically with functions and function blocks. For further information on

WinPLUS, its language and its applications in the 10 Series CNC environment consult the following

manuals:

10 Series CNC WinPLUS APPLICATION MANUAL Code 45006926D

10 Series CNC WinPLUS development tool Code 45006877B

You can find an FB or a function more easily if you look up the Function Reference List below in

this preface.

In this list the functions are ordered alphabetically and for each of them there is a short description

plus the page number.

In this manual the various function blocks have been subdivided into groups depending on the type

of operation they fulfil or the environment to which they belong. So if you do not know the exact

name of an FB, but know the environment to which it refers, you can easily find the FB in the

manual by consulting the index.

COMMON FEATURES OF FUNCTION BLOCKS:

All function blocks can be used in the Ladder Diagram / Function Block Diagram (LD/FBD) editors

and the Structured Text (ST). All the other function blocks are extensions which internally use a

function call. These functions can also be used in the ST editor. For each FB there is an example

for the calls and the necessary parameters in ST.

stat_wrd output (function status output word)

The function status output is available on all system function blocks. After the relevant function has

been completed, this word contain a value indicating that all went well or that there was some kind

of problem. When everything was ok, the status word will be zero. In case of problems the value of

the status word is different from zero. Please refer to the specific function block for the meaning of

the values returned in the status word.

10 Series CNC WinPLUS Library - User Manual (04) 1

Page 6

Preface

10 Series CNC WinPLUS Library - User Manual

Often you're not interested in knowing the status of the functions because your program has been

tested and always works well. You can then hook up only one single short variable, e.g. MW 999,

to the status output of many functions.

ax_id input (physical axis identifier)

The axis identifier is used for many system functions. It is a number identifying the internal

resources for one axis on an axes module. For non OS-Wire systems , each axes module supports

8 axes, 6 resources are reserved for physical axes (which read encoders and/or write to D/A

converters) and 2 for virtual axes. A machine axis (e.g. "X") may be related to any of the available

physical axis resources on any of the axes modules.

There can be up to 4 axes modules in the 10 Series CNC chassis, allowing for up to 32 axes

(theoretically). The axis identifier now, is a number in the range of 1 through 32. It must be

assigned during the axes configuration in AMP and will also serve to define the page number of the

axes table on which this axis will be managed.

OS-Wire systems are not subjected to any hardware limitation and therefore the number of

physical axes may range from 1 to 32, and the same applies to the total number of transducers and

converters.

Even when you move the physical connections (encoder, D/A) of an axis to another axes module,

its ax_id will remain unchanged and the axis data will remain available on the same page of the

axes table.

The function A_TO_ID converts an ASCII axis address to its physical axis identifier number.

tc_id input (transducer/converter physical identifier)

For non OS-Wire systems , the identifiers of the tansducer inputs are numbers in the range of

100Hex up to 1nnHex. On the first servo module you will find (top to bottom) the transducers

100Hex through 105Hex, on the second 106Hex through 10BHex, on the third module 10CHex

through 111, and so on. The D/A converters have a similar numbering system. On the first module

you will find the converters 200Hex through 205Hex, on the second module 206Hex through

20BHex, and so on.

In OS-Wire systems, the identifiers mapped on the bus use code 1nntHex, where ‘nn’ is the

address (from 0 to 3DHex) of the device and ‘t’ is the transducer number from 1 to 3. On the OS3

drive you can fit (as an option) only one incremental transducer, on the Bridge you can have up to

3 transducers. D/A converters use a similar system of codes (this applies only to Bridge devices):

2nncHex, where ‘nn’ is the address of the device (from 0 to 3DHex) and ‘c’ is the converter number

from 1 to 3.

In OS-Wire systems fitted with local transducers and converters (i.e., not mapped on a digital bus

but present on the board connector), the identifier codes are the same as are used in non OS-Wire

systems.

2 10 Series CNC WinPLUS Library - User Manual (04)

Page 7

Preface

10 Series CNCWinPLUS Library - User Manual

TYPES OF SYSTEM FUNCTION CALLS

There can be 3 different types of system function calls (system function blocks):

WAIT

A WAIT function call suspends the execution of the task that called it. This task will resume its

activity after the function has been completely executed.

The suspension of a task implies the suspension of all routines that make up this task. The WAIT

function is normally executed by an environment other than the I/O processor module (the system).

For this reason a WAIT function is a synchronous call: when the logic scan exits from a WAIT

function block, this block has been completely executed.

NOWAIT

A NOWAIT function call does not suspend the execution of the logic task that called it. Immediately

after the call has been issued, the logic task resumes execution. The function call will be executed

by an environment other than the I/O processor module (system).

For this reason a NOWAIT function is an asynchronous call: when the logic scan exits from a

NOWAIT function block, the function is still being executed by another environment.

The execution of many NOWAIT function calls from a logic task may cause a system overloading

since the simultaneous execution of many functions is required.

When 15 NOWAIT functions are in parallel execution, the function that has generated the last call

is in any case executed and it returns to the word status a warning code (1000 hexadecimal).

If you continue to call NOWAIT functions after the warning message, that is when 25 functions are

in parallel execution, an unrecoverable emergency is generated ("too many requests").

INTERNAL

An INTERNAL function is similar to a WAIT function call but its execution is much faster because

it's done by the same environment that calls the function (WinPLUS). An INTERNAL function call is

in all aspects like a subroutine available to the WinPLUS environment. For this reason an

INTERNAL function is a synchronous call: when the logic scan exits from an INTERNAL function

block, this block has been completely executed.

10 Series CNC WinPLUS Library - User Manual (04) 3

Page 8

Preface

10 Series CNC WinPLUS Library - User Manual

LIST OF THE BASE ELEMENTS OF THE LANGUAGE

AABORT: Abort a point-to-point-interpolator................................................................ 4-5

ACK_STRB: Send acknowlegde signal............................................................................ 3-37

ACLOSE: Close channel for point-to-point-interpolator ............................................... 4-6

ACTOFFS: Request activation of a tool offset................................................................ 5-5

ACTRES: Active reset request ..................................................................................... 9-2

ANAIN: Read analog input........................................................................................ 3-15

AOPEN: Open channel for point-to-point-interpolator................................................ 4-7

ARESET: Request to reset a point-to-point-interpolator.............................................. 4-8

AUX_STAT: Read point-to-point axis or spindle status ...................................................4-20

AX_CHAS: Change the servo mode of an axis.............................................................. 8-4

AX_DISA: Disable servo loop of an axis or disable its D/A converter. ......................... 2-3

AX_ENAB: Enable servo loop of an axis or enable its D/A converter............................ 2-2

AX_FWR: Read OS3 axes drive parameter ……………………………………………….8-86

AX_FWW: Write OS3 axes drive parameter………………………………………………..8_85

AX_GET1: Get axis (spindle) servo parameters............................................................ 8-15

AX_GET2: Get axis (spindle) servo parameters............................................................ 8-17

AX_GET2B: Get axis (spindle) servo parameters……………………………………………8-20

AX_GET3: Get axis (spindle) servo parameters............................................................ 8-23

AX_GET4: Get axis (spindle) servo parameters............................................................ 8-25

AX_GET5: Get axis (spindle) servo parameters............................................................ 8-27

AX_GET6: Get axis (spindle) servo parameters............................................................ 8-29

AX_GET7: Get axis (spindle) servo parameters............................................................ 8-34

AX_GET8: Get axis (spindle) servo parameters............................................................ 8-39

AX_GETS: Get axis status ............................................................................................. 8-58

AX_MECR: Read the parameters of a Mechatrolink drive ............................................. 8-90

AX_MECS: Read the status of a Mechatrolink drive ...................................................... 8-88

AX_MECW: Write the parameters of a Mechatrolink drive.............................................. 8-91

AX_PROB: Enable probing signal for one or more axis................................................. 8-5

AX_PUT1: Set axis servo parameter............................................................................. 8-41

AX_PUT2: Set axis servo parameter............................................................................. 8-48

AX_PUT2B: Set axis servo parameter………………………………………………………..8-50

AX_PUT3: Set axis servo parameter............................................................................. 8-52

AX_PUT4: Set axis servo parameter............................................................................. 8-54

AX_RESE: Abort the actual operation of the addressed axis ........................................8-8

AX_RPAR: Read AMP parameter from axis…………………………………………………8-84

AX_RTFBCK: Read OS-WIRE variables in real time .........................................................8-92

AX_RPOS: Resets the axis' position .............................................................................. 8-13

AX_SELE: Activate axis monitor functions / gear range................................................ 8-11

AX_SETZ: Allows the activation of different functions for the specified axis................. 8-14

AX_ZSH1: Write zero shift offset #1 .............................................................................. 8-9

AX_ZSH2: Write zero shift offset #2 .............................................................................. 8-10

AXD_CMD: Send a command to a digital drive .............................................................. 8-76

AX_WPAR: Write AMP axis parameter ……………………………………………………. 8-78

AXD_PUT: Set the enable/disable bits for a digital drive ............................................... 8-75

AXD_RDD: Read a numerical parameter from a digital drive ........................................ 8-70

AXD_RDS: Read a string parameter from a digital drive ............................................... 8-73

AXD_WRD: Write a numerical parameter to a digital drive ............................................. 8-72

AXD_WRS: Write a string parameter to a digital drive.................................................... 8-74

AXMANFED: Set feedrate override of axes in manual movement.................................... 1-44

AXSELEC: Select one or more axes for manual movement.......................................... 1-18

AXSELFED: Selects axes allowing to change feedrate override..................................... 1-42

AXTAN_D: Disables tangent axis algorithm................................................................... 2-14

AXTAN_E: Enable tangent axis algorithm .....................................................................2-12

4 10 Series CNC WinPLUS Library - User Manual (04)

Page 9

Preface

10 Series CNCWinPLUS Library - User Manual

CAN_BOARD_CMD: Send commands to Hilscher master board ................................................. 10-15

CAN_INIT: CANopen parameters initialisation.............................................................. 10-2

COMPOFF: Compute new axes offset............................................................................ 5-7

CON_LED: Manage leds on the OPLink operator panel ............................................... 7-10

CONN_AX: Connect an axis to the interpolator of the logic........................................... 4-26

CONN_SP: Connect a spindle to an interpolator ........................................................... 4-32

CYCLE: Request cycle for a selected process ......................................................... 1-4

CYSTART: Request cycle start for a selected process ................................................. 1-3

CYSTOP: Request cycle stop for the selected process .............................................. 1-5

DE_ETH: Enable/disable communication via Ethernet ............................................... 9-10

DECODE: Decodify a word with some data ................................................................. 3-46

DELAY: Delay function.............................................................................................. 3-39

ENCODER: Decodify a bit on a word.............................................................................. 3-47

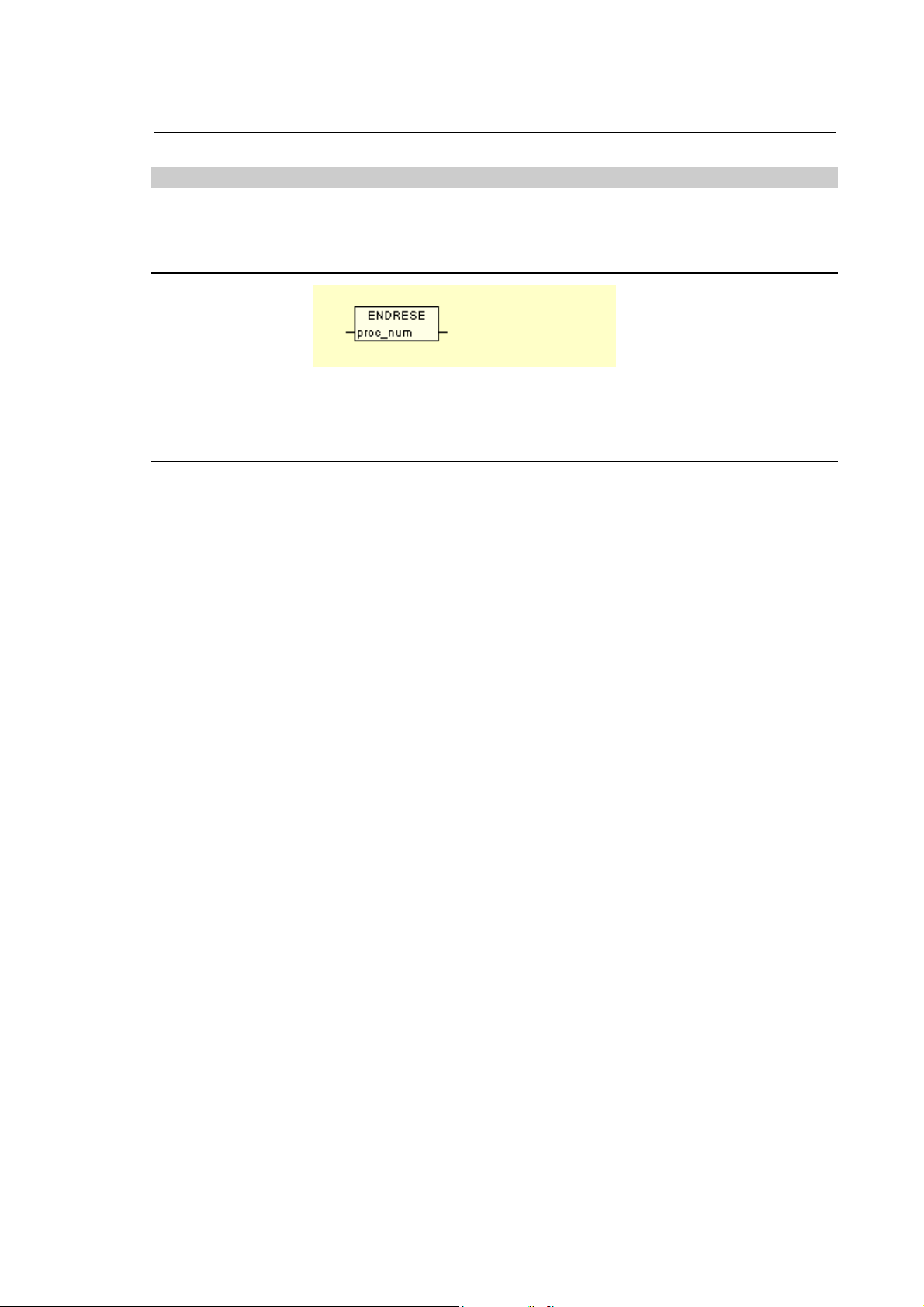

ENDRESE: Notify end of reset from WinPLUS .............................................................. 1-21

FAST_RD: Fast data reading from DP .......................................................................... 9-8

FAST_WR: Fast data writing on DP ............................................................................... 9-6

FAX_GET: Read in real time a number of axis parameters .......................................... 8-68

FAX_PUT: Real time updating of an axis' zero shift value............................................ 8-67

FAX_RCON: Configures the driver for real time data communication ............................. 8-66

FAX_WCON: Configures driver for real time data communication ................................... 8-65

FEED_GO: Request the interpolator to exit the feedhold status.................................... 1-7

FEEDBYOF: Restore programmed feedrate after feedrate bypass ................................. 1-35

FEEDBYON: Activate feedrate bypass ............................................................................. 1-33

FEEDHLD: Request the interpolator to enter the feedhold status ................................. 1-6

FEEDHEM: Tells the interpolator to change to feedhold mode at end of movement……1-8

FOUT: Force a fast output ...................................................................................... 3-17

FRORIDE: Set feedrate override................................................................................... 1-13

GBPROVAR: Get Boolean process variable ..................................................................... 6-3

GET_AX: Plus gets a parked axis ............................................................................... 4-24

GET_EMCY_INFORead node information and diagnostic data ............................................... 10-8

GET_INTP: Reads in real time a number of interpolator data........................................ 1-38

GET_POSD: Read position and feed rate of an axis controlled via serial line RS-232.... 4-23

GET_SP: Process gets a spindle already parked ....................................................... 4-31

GETAXINT: Get real axis position................................................................................... 8-3

GETEPAR: Get part program E-parameter .................................................................... 6-5

GETHFL: Get part program H parameter flag (HF) ..................................................... 6-9

GETHPAR: Get part program H-parameter.................................................................... 6-7

GETPNTR: Request information about part program execution.................................... 1-24

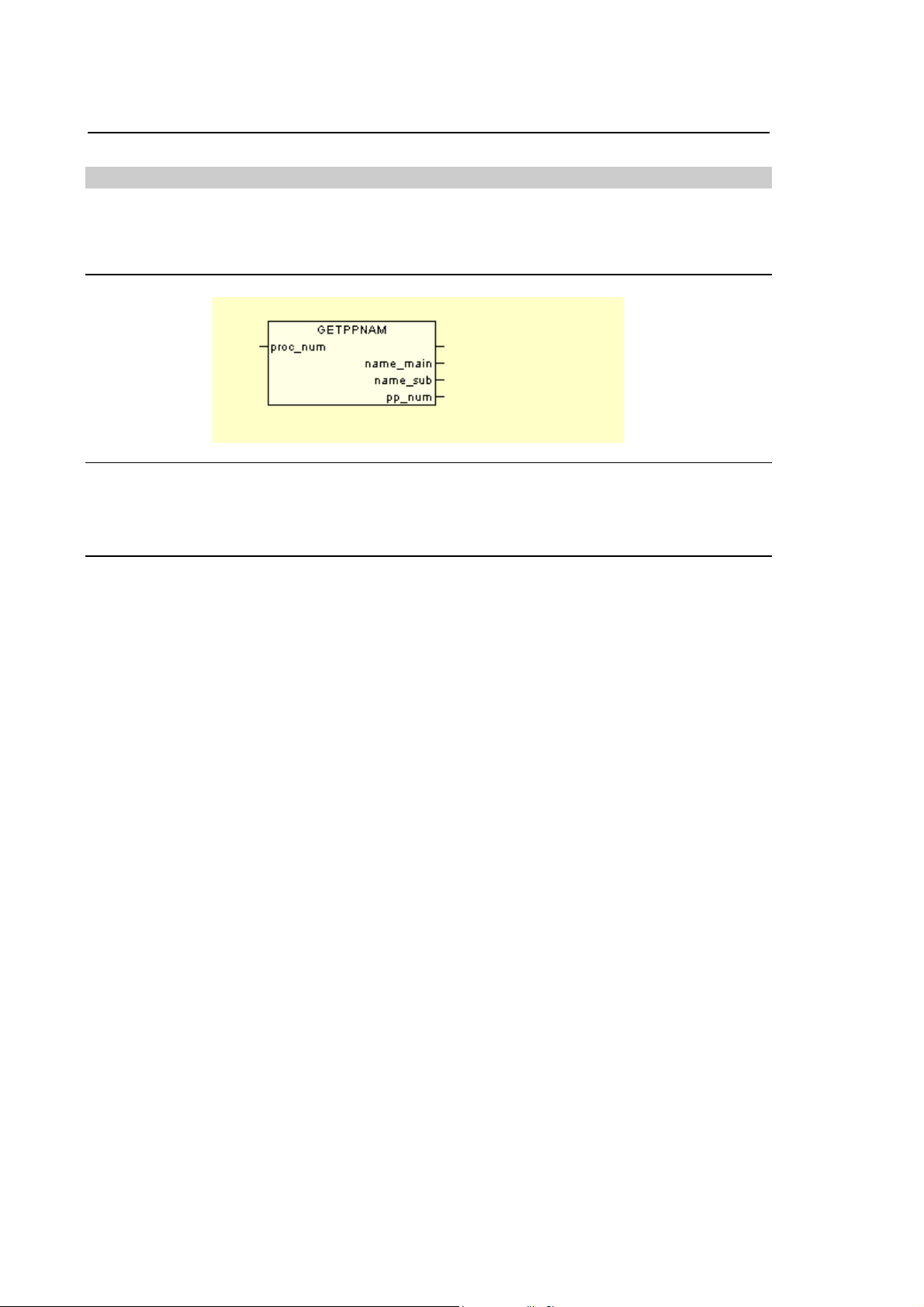

GETPPNAM: Get information from selected part program ............................................... 1-22

GETSC: Get ASCII global part program variable ...................................................... 6-11

GETSN: Get lreal global part program variable......................................................... 6-13

GETDATE: Read system data…………………………………………………………………3-65

GETTIME: Read system time…………………………………………………………………3-67

GETUSEC: Read the user variables of a char type process.......................................... 6-17

GETUSED: Read the user variables of a double type process ...................................... 6-15

GJOG: Get Jog increment.............................................................................................. 1-16

HISPROC: Select a process to control.......................................................................... 7-2

HOLDOFF: Exit from hold............................................................................................... 1-10

HOLDON: Enter in hold ................................................................................................ 1-9

HPG_OFF: Disables hand pulse generator (HPG) ........................................................ 2-11

HPG_ON: Enable hand pulse generator (HPG)........................................................... 2-9

HUM_ABI: Enable specified softkeys............................................................................ 7-11

HUM_DIS: It disables specified softkeys....................................................................... 7-13

IBS_INP: Transfer of INTERBUS inputs to the MW variables.................................... 3-35

IBS_OUT: Transfer MW variables to INTERBUS outputs ............................................ 3-36

10 Series CNC WinPLUS Library - User Manual (04) 5

Page 10

Preface

10 Series CNC WinPLUS Library - User Manual

ID_TO_A: Request for conversion from axis identifier into axis name (ASCII) ............ 2-22

IFWAIT: Semaphore status........................................................................................ 3-40

INDEX: Copy a range of M variables........................................................................6-19

INDEXA: Copy a range of ASCII variabiles................................................................. 6-20

INTP_ABI: Enable driver for real time reading of interpolator parameters.................... 1-36

INTP_CMD: Send a command to the interpolator ........................................................... 1-46

INTP_DIS: Disable driver for real time reading of the interp. parameters. .................... 1-37

INWORD: Read input word........................................................................................... 3-18

IO_FILE: Read/write formatted file…………………………………………………………3-69

XDA-COMD: Master/slave axis management…………………………………………………1-53

LIMITSW: Manage hardware overtravel limits.............................................................. 2-20

LOCKTAB: Set table interlock status.............................................................................. 9-3

MANFEED: Set manual feedrate override ......................................................................1-11

MDI_CMD: Execute a block in MDI ................................................................................ 1-27

MESSROT: Display rotating messages...........................................................................3-48

MTB_OFF: Disconnect a Pilot panel from a process ..................................................... 7-9

MTB_ON: Assign a Pilot panel to a process ................................................................ 7-7

NAXOFF: Activate new axes offset .............................................................................. 5-8

NMT_CMD: Send CANopen network or remote node management commands............. 10-5

OUTWORD: Write output word......................................................................................... 3-19

PALMOVE: Move a point-to-point-axis ........................................................................... 4-9

PARK_AX: Park an axis belonging to the logic .............................................................. 4-29

PARK_SP: Park a spindle .............................................................................................. 4-30

PP_BSRC: Position the active Part Program on the selected block .............................. 1-40

PP_EXEC: Select a block from part program for execution........................................... 1-26

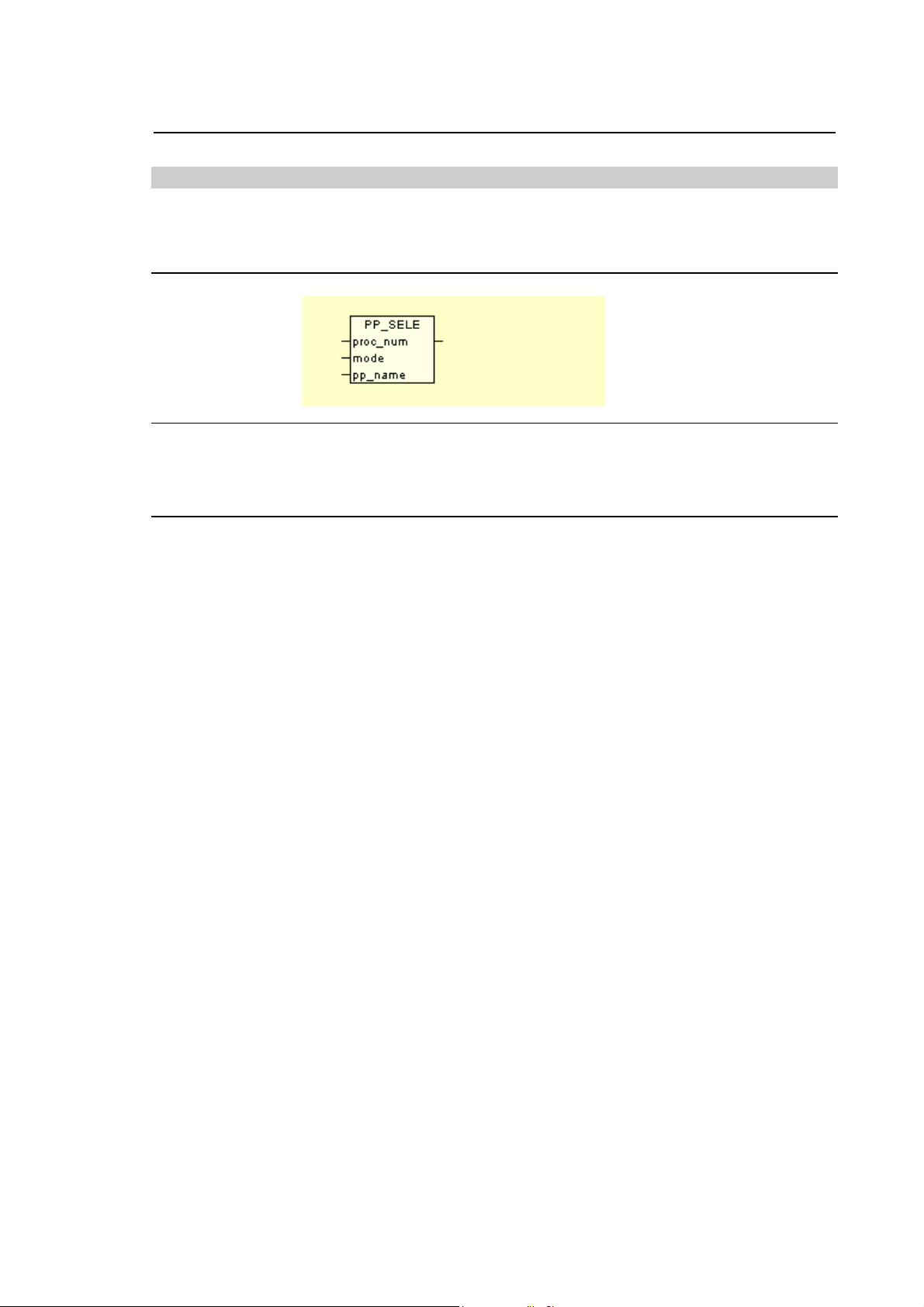

PP_SELE: Select a part program for execution ............................................................1-25

PP_TSRC: Finds a string inside the active part program............................................... 1-39

PPRESUME: Resume part program execution after M06 ................................................. 1-30

PPRUNINFO: Part Program execution monitoring management…………………………….1-47

PREC_OFF: Disable part program block precalculation ..................................................1-31

PREC_ON: Enable part program block precalculation ...................................................1-32

PUTUSEC: Write the user variables of a type char process ..........................................6-18

PUTUSED: Write the user variables of a double type process ......................................6-16

R232_INI: Set termination character for the serial line ................................................. 3-4

R232_RES: Reset RS 232 interface................................................................................ 3-12

R232_RXD: Receive lreal data buffer via the RS-232 interface...................................... 3-9

R232_RXS: Receive an ASCII string via the RS 232 interface....................................... 3-11

R232_RXW: Receive int data buffer via the RS 232 interface .........................................3-10

R232_STS: Read RS-232 status .................................................................................... 3-13

R232_TRM: Set termination characters used in message handling................................ 3-5

R232_TXD: Transmit lreal data buffer via the RS 232 interface .....................................3-6

R232_TXS: Transmit an ASCII string via the RS 232 interface...................................... 3-8

R232_TXW: Trasmit int data buffer via RS 232 interface ................................................ 3-7

RCM_MOD: Define the mode for the search in memory. ................................................1-41

RD_ADA: Read an ADARING device A/D channel...................................................... 3-24

READ_SDO_CMD Send read objects through SDO commands............................................... 10-11

RESRIF: Reset axis homed flag .................................................................................2-6

RIO_INP: Read remote I/O inputs................................................................................ 3-33

RIO_OUT: Write the remote I/O outputs........................................................................3-34

RQESTOP: Request process E-STOP ...........................................................................3-20

RQRESET: Request reset of NC ....................................................................................1-19

RTIRES: Read RTI axes monitor table ....................................................................... 4-19

SBPROVAR: Set Boolean process variable ...................................................................... 6-4

SCLOSE: Close RTI channel for spindle ..................................................................... 4-11

SCONN_AX: Disconnect an axis from the interpolator of the logic................................... 4-28

6 10 Series CNC WinPLUS Library - User Manual (04)

Page 11

Preface

10 Series CNCWinPLUS Library - User Manual

SCONN_SP: Disconnect a spindle from the associated interpolator ............................... 4-33

SEL_SCR: Display a screen.......................................................................................... 3-27

SEND: Send to semaphore ..................................................................................... 3-43

SEND_MSG: Trasmit message to a queue....................................................................... 3-44

SETCUSK: Set OEM softkey status; ON/OFF type ....................................................... 7-3

SETCUSL: Set OEM softkey status; Maintained, Data Entry and Normal .................... 7-4

SETDATE: Set system data……………………………………………………………………3-66

SETEPAR: Set part program E parameter..................................................................... 6-6

SETHFL: Set part program H parameter flag ............................................................. 6-10

SETHINT: Set human interface protection bits............................................................. 7-5

SETHPAR: Set part program H-parameter .................................................................... 6-8

SETMODE: Request mode of operation for a selected process .................................... 1-15

SETRANG: Select spindle gear range............................................................................ 4-12

SETRIF: Set axis homed flag..................................................................................... 2-5

SETSC: Set ASCII global part program variable....................................................... 6-12

SETSN: Set lreal global part program parameter ..................................................... 6-14

SETTEST: Set axes to test mode.................................................................................. 2-8

SETTIME: Write system time…………………………………………………………………3-68

SG96RPM: Request G96 constant surface speed spindle control ................................ 4-13

SG97RPM: Set spindle speed in RPM ........................................................................... 4-15

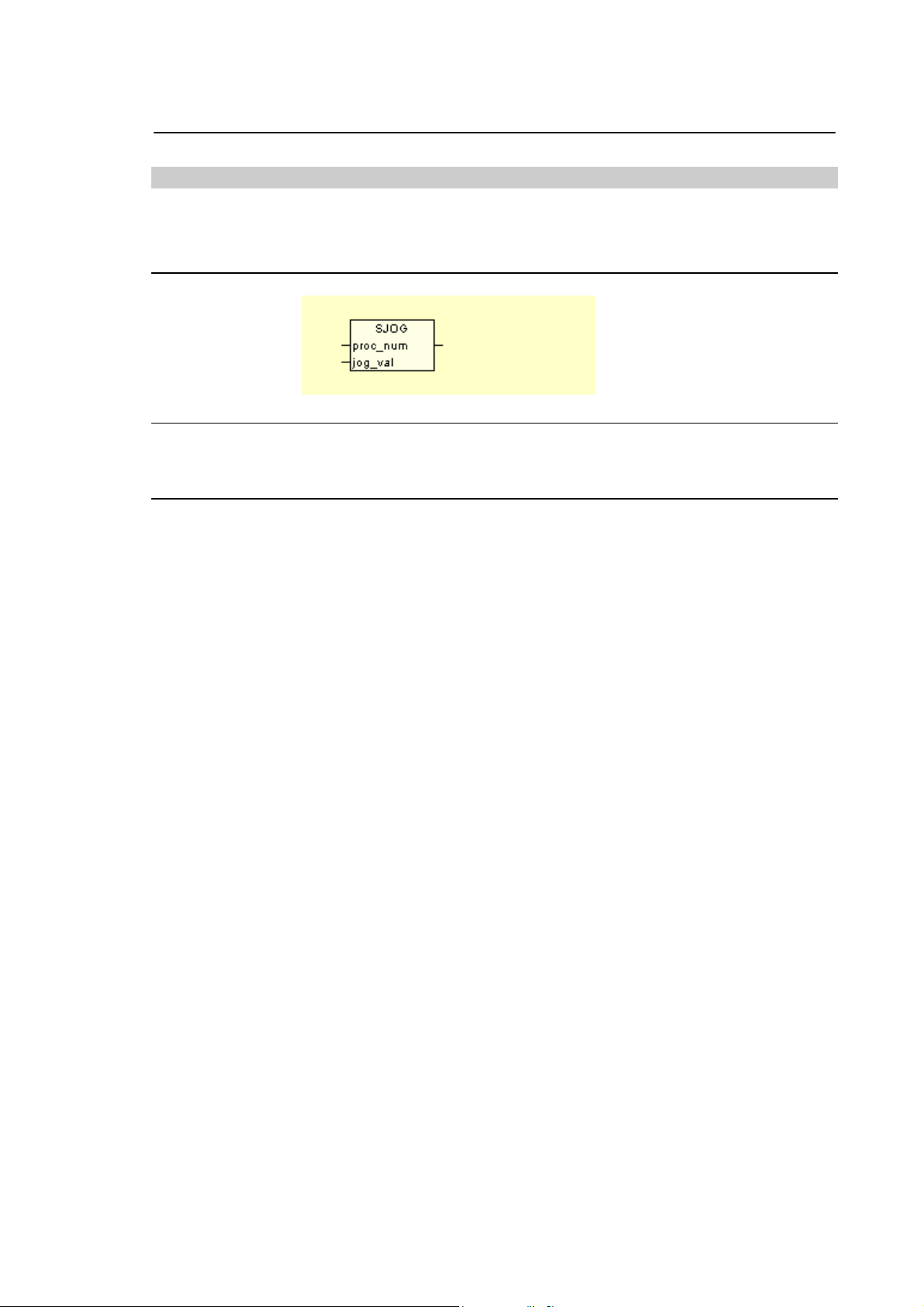

SJOG: Set jog incremen ......................................................................................... 1-17

SL_CLOSE: Release posses of the serial line COM1 or COM2 ..................................... 3-52

SL_OPEN: Obtain exclusive possession of serial line COM1 or COM2 ....................... 3-51

SL_RESET: Reset the transmission status on COM1 or COM2..................................... 3-54

SL_RXD: Receive lreal buffer data from COM1 or COM2.......................................... 3-61

SL_RXS: Receive string buffer data from COM1 or COM2 ........................................ 3-62

SL_RXW: Receive short data buffer from COM1 or COM2......................................... 3-59

SL_SETUP: Set parameters for serial lines COM1 or COM2 ......................................... 3-49

SL_STAT: Status of the serial line COM1 or COM2..................................................... 3-53

SL_TXD: Transmit lreal data buffer on COM1 or COM2 ............................................ 3-57

SL_TXS: Transmit string data buffer on COM1 or COM2 .......................................... 3-58

SL_TXW: Transmit short data buffer on COM1 or COM2........................................... 3-56

SOFTOTL: Enable /disable software overtravel limits ................................................... 2-4

SOPEN: Open a channel for spindle management ................................................... 4-16

SORIENT: Request spindle orientation......................................................................... 4-17

SPEPN: Request to energize the E-STOP relay(s)................................................... 3-21

SPORIDE: Set speed override ...................................................................................... 1-14

SRESET: Request to reset a spindle........................................................................... 4-18

STTRAVEL: Set H/W overtravel status............................................................................ 2-7

SYNC_CMD: Send SYNC command to all the nodes....................................................... 10-7

TBLGETD: Read lreal value from a table ...................................................................... 5-10

TBLGETW: Read int value from a table ......................................................................... 5-9

TBLPUTD: Write lreal value to a table.......................................................................... 5-12

TBLPUTW: Write int value to a table.............................................................................. 5-11

TBLSRCD: Table lreal search........................................................................................ 5-13

TBLSRCW: Table int search ........................................................................................... 5-15

TC_CONF: Set the transducer ERDC ............................................................................ 8-60

TC_READ1: Read the physical position of the transducer.............................................. 8-62

TC_WRIT: Set D/A Converter output ............................................................................ 8-63

TCPACT: Enable/disable the Tool Center Point feature ............................................. 2-15

TCPREAD: Read associated variables to Tool Center Point......................................... 2-18

TCPWRT: Write associated variables to Tool Center Point ......................................... 2-16

TOOL_RD: Get tool slave identifier ................................................................................ 5-17

TOOLACT: Update axis table with new tool offset ......................................................... 5-2

UNLKTAB: Cancel table interlock status ....................................................................... 9-5

10 Series CNC WinPLUS Library - User Manual (04) 7

Page 12

Preface

10 Series CNC WinPLUS Library - User Manual

URLFEED: Set rapid feedrate override .......................................................................... 1-12

WAIT: Wait on semaphore...................................................................................... 3-41

WAIT_MSG: Wait a message in a queue ......................................................................... 3-42

WARN_HIS: Display a message and store it in system history. ......................................3-26

WARNING: Display error message ................................................................................. 3-3

WR_ADA: Write an ADARING device D/A channel...................................................... 3-22

WRI_SCR: Display a user message .............................................................................. 3-30

WRITE_SDO_CMD: Scrive parametri tramite SDO...................................................................... 10-13

END OF PREFACE

8 10 Series CNC WinPLUS Library - User Manual (04)

Page 13

INDEX

NC RELATED FUNCTIONS

CYSTART: Request cycle start for a selected process......................................... 1-3

CYCLE: Request cycle for a selected process...................................................... 1-4

CYSTOP: Request cycle stop for the selected process........................................ 1-5

FEEDHLD: Request the interpolator to enter the feedhold status ........................ 1-6

FEED_GO: Request the interpolator to exit the feedhold status........................... 1-7

FEEDHEM: request to interpolator to enter in feedhold at end of movement....... 1-8

HOLDON: Enter in hold ......................................................................................... 1-9

HOLDOFF: Exit from hold ..................................................................................... 1-10

MANFEED: Set manual feedrate override ............................................................ 1-11

URLFEED: Set rapid feedrate override ................................................................. 1-12

FRORIDE: Set feedrate override........................................................................... 1-13

SPORIDE: Set speed override .............................................................................. 1-14

SETMODE: Request mode of operation for a selected process........................... 1-15

GJOG: Get jog increment ...................................................................................... 1-16

SJOG: Set jog incremen........................................................................................ 1-17

AXSELEC: Select one or more axes for manual movement................................. 1-18

RQRESET: Request reset of NC........................................................................... 1-19

ENDRESE: Notify end of reset from WinPLUS ..................................................... 1-21

GETPPNAM: Get information from selected part program ................................... 1-22

GETPNTR: Request information about part program execution........................... 1-24

PP_SELE: Select a part program for execution .................................................... 1-25

PP_EXEC: Select a block from part program for execution.................................. 1-26

MDI_CMD: Execute a block in MDI ....................................................................... 1-27

MDI_EXEC: Executes program blocks from WinPLUS in MDI mode ................... 1-29

PPRESUME: Resume part program execution after M06 .................................... 1-30

PREC_OFF: Disable part program block precalculation....................................... 1-31

PREC_ON: Enable part program block precalculation ......................................... 1-32

FEEDBYON: Activate feedrate bypass ................................................................. 1-33

FEEDBYOF: Restore programmed feedrate after feedrate bypass...................... 1-35

INTP_ABI: Enable driver for real time reading of interpolator parameters............ 1-36

INTP_DIS: Disable driver for real time reading of the interpolator

parameters............................................................................................................. 1-37

GET_INTP: Reads in real time a number of interpolator data .............................. 1-38

PP_TSRC: Finds a string inside the active part program...................................... 1-39

PP_BSRC: Position the active Part Program on the selected block ..................... 1-40

RCM_MOD: Define the mode for the search in memory. ..................................... 1-41

AXSELFED: Selects axes allowing to change feedrate override .......................... 1-42

AXMANFED: Set feedrate override of axes in manual movement........................ 1-44

Index

10 Series CNC WinPLUS Library - User Manual

10 Series CNC WinPLUS Library - User Manual (04) i

Page 14

Index

10 Series CNC WinPLUS Library - User Manual

INTP_CMD: Send a command to the interpolator ................................................. 1-46

PPRUNINFO: Part Program execution monitoring management.......................... 1-47

XDA_COMD: Master/Slave axes management..................................................... 1-53

Master/Slave association ....................................................................................... 1-54

Mode 0 ...................................................................................................................1-55

Mode 1 ...................................................................................................................1-55

Mode 2 ...................................................................................................................1-57

Mode 3 ...................................................................................................................1-58

Deactivating the Master/Slave Association............................................................ 1-59

Definition/Variation of Following Ratio ................................................................... 1-59

Activating the Following function............................................................................ 1-59

Deactivating the following function......................................................................... 1-60

Monitoring the following function............................................................................ 1-60

AXIS MOTION FUNCTIONS

AX_ENAB: Enable servo loop of an axis or enable its D/A converter. .................. 2-2

AX_DISA: Disable servo loop of an axis or disable its D/A converter. .................. 2-3

SOFTOTL: Enable /disable software overtravel limits ........................................... 2-4

SETRIF: Set axis homed flag................................................................................. 2-5

RESRIF: Reset axis homed flag ............................................................................2-6

STTRAVEL: Set H/W overtravel status.................................................................. 2-7

SETTEST: Set axes to test mode .......................................................................... 2-8

HPG_ON: Enable hand pulse generator (HPG) .................................................... 2-9

HPG_OFF: Disables hand pulse generator (HPG)................................................ 2-11

AXTAN_E: Enable tangent axis algorithm ............................................................. 2-12

AXTAN_D: Disables tangent axis algorithm .......................................................... 2-14

TCPACT: Enable/disable the Tool Center Point feature ....................................... 2-15

TCPWRT: Write associated variables to Tool Center Point ..................................2-16

TCPREAD: Read associated variables to Tool Center Point ................................ 2-18

LIMITSW: Manage hardware overtravel limits....................................................... 2-20

A_TO_ID: Request for conversion from axis name into axis identifier .................. 2-21

ID_TO_A: Request for conversion from axis identifier into axis name (ASCII) ..... 2-22

GENERAL PURPOSE FUNCTIONS

WARNING: Display error message ....................................................................... 3-3

R232_INI: Set termination character for the serial line.......................................... 3-4

R232_TRM: Set termination characters used in message handling .....................3-5

R232_TXD: Transmit lreal data buffer via the RS 232 interface ...........................3-6

R232_TXW: Trasmit int data buffer via RS 232 interface...................................... 3-7

R232_TXS: Transmit an ASCII string via the RS 232 interface ............................3-8

R232_RXD: Receive lreal data buffer via the RS-232 interface............................ 3-9

R232_RXW: Receive int data buffer via the RS 232 interface .............................. 3-10

R232_RXS: Receive an ASCII string via the RS 232 interface ............................. 3-11

R232_RES: Reset RS 232 interface......................................................................3-12

R232_STS: Read RS-232 status ........................................................................... 3-13

ANAIN: Read analog input..................................................................................... 3-15

FOUT: Force a fast output .....................................................................................3-17

INWORD: Read input word.................................................................................... 3-18

OUTWORD: Write output word..............................................................................3-19

RQESTOP: Request process E-STOP.................................................................. 3-20

SPEPN: Request to energize the E-STOP relay(s) ............................................... 3-21

WR_ADA: Write an ADARING device D/A channel............................................... 3-22

ii 10 Series CNC WinPLUS Library - User Manual (04)

Page 15

Index

10 Series CNC WinPLUS Library - User Manual

RD_ADA: Read an ADARING device A/D channel............................................... 3-24

WARN_HIS: Display a message and store it in system history. ........................... 3-26

SEL_SCR: Display a screen.................................................................................. 3-27

WRI_SCR: Display a user message ..................................................................... 3-30

RIO_INP: Read remote I/O inputs ......................................................................... 3-33

RIO_OUT: Write the remote I/O outputs ............................................................... 3-34

$IBS_INP: Transfer of physical inputs from the INTERBUS or

CANOPEN, OSWIRE, PROFIBUS modules to the MW variables ........................ 3-35

$IBS_OUT: Transfer of the MW variables to the physical outputs of

the INTERBUS, CANOPEN, OSWIRE or PROFIBUS modules ........................... 3-36

ACK_STRB: Send acknowlegde signal................................................................. 3-37

DELAY: Delay function .......................................................................................... 3-39

IFWAIT: Semaphore status ................................................................................... 3-40

WAIT: Wait on semaphore .................................................................................... 3-41

WAIT_MSG: Wait a message in a queue.............................................................. 3-42

SEND: Send to semaphore ................................................................................... 3-43

SEND_MSG: Trasmit message to a queue........................................................... 3-44

DECODE: Decodify a word with some data .......................................................... 3-46

ENCODER: Decodify a bit on a word.................................................................... 3-47

MESSROT: Display rotating messages ................................................................ 3-48

SL_SETUP: Set parameters for serial lines COM1 or COM2 ............................... 3-49

SL_OPEN: Obtain exclusive possession of serial line COM1 or COM2............... 3-51

SL_CLOSE: Release posses of the serial line COM1 or COM2........................... 3-52

SL_STAT: Status of the serial line COM1 or COM2 ............................................. 3-53

SL_RESET: Reset the transmission status on COM1 or COM2........................... 3-54

SL_TXB: Transmits byte data buffer on COM1 or COM2 ..................................... 3-55

SL_TXW: Transmit short data buffer on COM1 or COM2..................................... 3-56

SL_TXD: Transmit lreal data buffer on COM1 or COM2....................................... 3-57

SL_TXS: Transmit string data buffer on COM1 or COM2..................................... 3-58

SL_RXW: Receive short data buffer from COM1 or COM2 .................................. 3-59

SL_RXB: Receives byte data buffer from COM1 or COM2 .................................. 3-60

SL_RXD: Receive lreal buffer data from COM1 or COM2 .................................... 3-61

SL_RXS: Receive string buffer data from COM1 or COM2 .................................. 3-62

MOVEDATA: Copies/transfers variables in indexed mode ................................... 3-63

TCPSYS_I: Enables Teach Pendant on serial line (CPU board) .......................... 3-64

GETDATE: read system date ................................................................................ 3-65

SETDATE: Write system date ............................................................................... 3-66

GETTIME: Read system time................................................................................ 3-67

SETTIME: writes system time ............................................................................... 3-68

IO_FILE : Reading / writing formatted files............................................................ 3-69

POINT-TO-POINT-AXES / SPINDLE LIBRARY

AX_SHARE: Shares/releases axes between a process and the logic.................. 4-3

AABORT: Abort a point-to-point-interpolator......................................................... 4-5

ACLOSE: Close channel for point-to-point-interpolator ........................................ 4-6

AOPEN: Open channel for point-to-point-interpolator........................................... 4-7

ARESET: Request to reset a point-to-point-interpolator ....................................... 4-8

PALMOVE: Move a point-to-point-axis.................................................................. 4-9

SCLOSE: Close RTI channel for spindle............................................................... 4-11

SETRANG: Select spindle gear range .................................................................. 4-12

SG96RPM: Request G96 constant surface speed spindle control ....................... 4-13

SG97RPM: Set spindle speed in RPM.................................................................. 4-15

SOPEN: Open a channel for spindle management............................................... 4-16

SORIENT: Request spindle orientation................................................................. 4-17

10 Series CNC WinPLUS Library - User Manual (04) iii

Page 16

Index

10 Series CNC WinPLUS Library - User Manual

SRESET: Request to reset a spindle.....................................................................4-18

RTIRES: Read RTI axes monitor table.................................................................. 4-19

AUX_STAT: Read point-to-point axis or spindle status......................................... 4-20

GET_POSD: Read position and feed rate of an axis controlled via

serial line RS-232................................................................................................... 4-23

GET_AX: Plus gets a parked axis.......................................................................... 4-24

CONN_AX: Connect an axis to the interpolator of the logic .................................. 4-26

SCONN_AX: Disconnect an axis from the interpolator of the logic ....................... 4-28

PARK_AX: Park an axis belonging to the logic .....................................................4-29

PARK_SP: Park a spindle...................................................................................... 4-30

GET_SP: Process gets a spindle already parked.................................................. 4-31

CONN_SP: Connect a spindle to an interpolator................................................... 4-32

SCONN_SP: Disconnect a spindle from the associated interpolator .................... 4-33

OFFSET AND TOOLS HANDLING

TOOLACT: Update axis table with new tool offset ................................................5-2

ACTOFFS: Request activation of a tool offset....................................................... 5-5

COMPOFF: Compute new axes offset ..................................................................5-7

NAXOFF: Activate new axes offset........................................................................ 5-8

TBLGETW: Read int value from a table................................................................. 5-9

TBLGETD: Read lreal value from a table ..............................................................5-10

TBLPUTW: Write int value to a table ..................................................................... 5-11

TBLPUTD: Write lreal value to a table .................................................................. 5-12

TBLSRCD: Table lreal search................................................................................ 5-13

TBLSRCW: Table int search.................................................................................. 5-15

TOOL_RD: Get tool slave identifier .......................................................................5-17

PROCESS/SYSTEM VARIABLES HANDLING

GBPROVAR: Get Boolean process variable ......................................................... 6-3

SBPROVAR: Set Boolean process variable .......................................................... 6-4

GETEPAR: Get part program E-parameter ...........................................................6-5

SETEPAR: Set part program E parameter ............................................................6-6

GETHPAR: Get part program H-parameter........................................................... 6-7

SETHPAR: Set part program H-parameter............................................................ 6-8

GETHFL: Get part program H parameter flag (HF) ............................................... 6-9

SETHFL: Set part program H parameter flag ........................................................6-10

GETSC: Get ASCII global part program variable ..................................................6-11

SETSC: Set ASCII global part program variable ................................................... 6-12

GETSN: Get lreal global part program variable ..................................................... 6-13

SETSN: Set lreal global part program parameter .................................................. 6-14

GETUSED: Read the user variables of a double type process ............................. 6-15

PUTUSED: Write the user variables of a double type process .............................6-16

GETUSEC: Read the user variables of a char type process................................. 6-17

PUTUSEC: Write the user variables of a type char process .................................6-18

INDEX: Copy a range of M variables ..................................................................... 6-19

INDEXA: Copy a range of ASCII variabiles ...........................................................6-20

HUMAN INTERFACE

HISPROC: Select a process to control .................................................................. 7-2

SETCUSK: Set OEM softkey status; ON/OFF type............................................... 7-3

iv 10 Series CNC WinPLUS Library - User Manual (04)

Page 17

SETCUSL: Set OEM softkey status; Maintained, Data Entry and Normal............ 7-4

SETHINT: Set human interface protection bits ..................................................... 7-5

MTB_ON: Assign a Pilot panel to a process ......................................................... 7-7

MTB_OFF: Disconnect a Pilot panel from a process ............................................ 7-9

CONS_LED: Manage leds on the OPLink operator panel .................................... 7-10

HUM_ABI: Enable specified softkeys.................................................................... 7-11

HUM_DIS: It disables specified softkeys............................................................... 7-13

CONS_ON: Connects a WinMedia Operator Console to a process ..................... 7-15

CONS_OFF: Disconnects a WinMedia Operator Console from a process .......... 7-17

CONS_PUT: Sets the parameters of a WinMedia Operator Console................... 7-18

AXES RELATED FUNCTIONS

GETAXINT: Get real axis position ......................................................................... 8-3

AX_CHAS: Change the servo mode of an axis..................................................... 8-4

AX_PROB: Enable probing signal for one or more axis........................................ 8-5

AX_RDPB: Read the probed positions of one or more axes ................................ 8-6

AX_RESE: Abort the actual operation of the addressed axis ............................... 8-8

AX_ZSH1: Write zero shift offset #1...................................................................... 8-9

AX_ZSH2: Write zero shift offset #2...................................................................... 8-10

AX_SELE: Activate axis monitor functions / gear range ....................................... 8-11

AX_RPOS: Resets the axis' position..................................................................... 8-13

AX_SETZ: Allows the activation of different functions for the specified axis ........ 8-14

AX_GET1: Get axis (spindle) servo parameters ................................................... 8-15

AX_GET2: Get axis (spindle) servo parameters ................................................... 8-17

AX_GET2B: Get axis (spindle) servo parameters................................................. 8-20

AX_GET3: Get axis (spindle) servo parameters ................................................... 8-23

AX_GET4: Get axis (spindle) servo parameters ................................................... 8-25

AX_GET5: Get axis (spindle) servo parameters ................................................... 8-27

AX_GET6: Get axis (spindle) servo parameters ................................................... 8-29

AX_GET7: Get axis (spindle) servo parameters ................................................... 8-34

AX_GET8: Get axis (spindle) servo parameters ................................................... 8-39

AX_PUT1: Set axis servo parameter..................................................................... 8-41

Notes to the parameter “CHANGECONV” ............................................................ 8-44

Notes to the parameter “CHANGETRAS” ............................................................. 8-45

Notes concerning the “STANDSTILL-GAIN” parameter........................................ 8-46

Notes on the parameter “BACKLASH_TIME” ....................................................... 8-47

AX_PUT2: Set axis servo parameter..................................................................... 8-48

AX_PUT2B: Sets axis interlocking parameter....................................................... 8-50

AX_PUT3: Set axis servo parameter..................................................................... 8-52

AX_PUT4: Set axis servo parameter..................................................................... 8-54

AX_PUTS: Writes axis status ................................................................................ 8-57

AX_GETS: Get axis status .................................................................................... 8-59

TC_CONF: Set the transducer ERDC................................................................... 8-61

TC_READ1: Read the physical position of the transducer ................................... 8-63

TC_WRIT: Set D/A Converter output .................................................................... 8-64

FAX_WCON: Configures driver for real time data communication ....................... 8-66

FAX_RCON: Configures the driver for real time data communication .................. 8-67

FAX_PUT: Real time updating of an axis' zero shift value.................................... 8-68

FAX_GET: Read in real time a number of axis parameters.................................. 8-69

AXD_RDD: Read a numerical parameter from a digital drive ............................... 8-71

AXD_WRD: Write a numerical parameter to a digital drive................................... 8-73

AXD_RDS: Read a string parameter from a digital drive ...................................... 8-74

AXD_WRS: Write a string parameter to a digital drive.......................................... 8-75

AXD_PUT: Set the enable/disable bits for a digital drive ...................................... 8-76

Index

10 Series CNC WinPLUS Library - User Manual

10 Series CNC WinPLUS Library - User Manual (04) v

Page 18

Index

10 Series CNC WinPLUS Library - User Manual

AXD_CMD: Send a command to a digital drive..................................................... 8-77

AX_WPAR: Writes the AMP parameters of an axis............................................... 8-79

AX_RPAR: Reads the AMP parameters of an axis ............................................... 8-85

AX_FWW: Writes the parameters of an OS3 drive associated with an axis .........8-86

AX_FWR: Reads the parameters of an OS3 drive associated with an axis.......... 8-87

AX_MECS: Read the status of a Mechatrolink drive ............................................. 8-90

AX_MECR: Read the parameters of a Mechatrolink drive .................................... 8-91

AX_MECW: Write the parameters of a Mechatrolink drive.................................... 8-92

AX_RTFBCK: Read OS-WIRE variables in real time ............................................ 8-93

SPECIAL FUNCTIONS

ACTRES: Active reset request............................................................................... 9-2

LOCKTAB: Set table interlock status ..................................................................... 9-3

UNLKTAB: Cancel table interlock status ...............................................................9-5

FAST_WR: Fast data writing on DP ......................................................................9-6

FAST_RD: Fast data reading from DP ..................................................................9-8

DE_ETH: Enable/disable communication via Ethernet ......................................... 9-10

CANOPEN® HILSCHER MANAGEMENT FUNCTIONS

CAN_INIT: CANopen parameters initialisation ...................................................... 10-2

NMT_CMD: Send CANopen network or remote node management commands ... 10-5

SYNC_CMD: Send SYNC command to all the nodes........................................... 10-7

GET_EMCY_INFO: Read node information and diagnostic data.......................... 10-8

READ_SDO_CMD: Send read objects through SDO commands......................... 10-11

WRITE_SDO_CMD: Send write objects through SDO commands....................... 10-13

CAN_BOARD_CMD: Send commands to Hilscher mster board........................... 10-15

ERROR MESSAGES FOR SERIAL LINES COM1 OR COM2

General errors ........................................................................................................ A-1

Transmit errors....................................................................................................... A-1

Receive errors........................................................................................................ A-1

Line errors .............................................................................................................. A-2

System errors......................................................................................................... A-2

NC MESSAGES

ERROR CODES DISPLAYED IN THE NC ENVIRONMENT.......................................... B-1

POINT-TO-POINT AXES / SPINDLE MESSAGES

POINT-TO-POINT AXES / SPINDLE MESSAGES ......................................................... C-1

AVAILABLE TABLES

AVAILABLE TABLES .....................................................................................................D-1

Axes table .............................................................................................................. D-1

Tool table ............................................................................................................... D-2

Tool offset table...................................................................................................... D-2

vi 10 Series CNC WinPLUS Library - User Manual (04)

Page 19

10 Series CNC WinPLUS Library - User Manual

User table .............................................................................................................. D-2

HUMAN INTERFACE AND PLUS RELATED MESSAGES

Human Interface Related Messages .................................................................... E-1

PLUS Related Messages ...................................................................................... E-1

ERROR MESSAGES FOR THE D.S.I. INTERFACE

ERROR LIST ................................................................................................................... F-1

MESSAGES FOR POINT TO POINT AXIS CONTROLLED VIA RS232 SERIAL LINE

Serial Driver ........................................................................................................... G-1

DAC/DSC Osai Drive............................................................................................. G-2

Index

APPENDIX H

TABLE OF MAIN RESOURCES OF AXIS BOARDS:........................................... H-1

10 Series CNC WinPLUS Library - User Manual (04) vii

Page 20

Index

10 Series CNC WinPLUS Library - User Manual

END OF INDEX

viii 10 Series CNC WinPLUS Library - User Manual (04)

Page 21

Chapter 1

NC RELATED FUNCTIONS

The NC system function calls allow the WinPLUS logic program to communicate with the system

and to request the execution of typical CNC related functions (operator functions, part program

related functions). All functions can be used as a function block or can be called as a function in

the Structured Text. This chapter gives the type and sequence of parameters for the Structured

Text call. Where necessary, the function and its conditions are explained.

Each function has a return value (parameter 'stat_wrd') which can be found in Appendix B

("Messages relative to NC) or a zero value if the execution was completed without errors.

REQUEST CYCLE START FOR A SELECTED PROCESS.......................................

REQUEST CYCLE FOR A SELECTED PROCESS....................................................

REQUEST CYCLE STOP FOR THE SELECTED PROCESS ....................................

REQUEST THE INTERPOLATOR TO ENTER IN FEEDHOLD STATUS ..................

REQUEST THE INTERPOLATOR TO EXIT FROM FEEDHOLD...............................

ENTER IN HOLD .........................................................................................................

EXIT FROM HOLD.......................................................................................................

SET MANUAL FEEDRATE OVERRIDE......................................................................

SET RAPID FEEDRATE OVERRIDE ..........................................................................

SET FEEDRATE OVERRIDE ......................................................................................

SET SPEED OVERRIDE .............................................................................................

REQUEST MODE OF OPERATION FOR A SELECTED PROCESS.........................

GET JOG INCREMENT...............................................................................................

SET JOG INCREMENT ...............................................................................................

SELECT ONE OR MORE AXES FOR MANUAL MOVEMENT...................................

REQUEST RESET OF NC ..........................................................................................

NOTIFY END OF RESET FROM WINPLUS ...............................................................

GET INFORMATION FROM SELECTED PART PROGRAM .....................................

REQUEST INFORMATION ABOUT PP EXECUTION ................................................

SELECT A PART PROGRAM FOR EXECUTION.......................................................

SELECT A BLOCK FROM PART PROGRAM FOR EXECUTION..............................

EXECUTE A BLOCK IN MDI .......................................................................................

EXECUTES PROGRAM BLOCKS FROM WINPLUS IN MDI MODE .........................

RESUME PART PROGRAM EXECUTION AFTER M06 ............................................

DISABLE PART PROGRAM BLOCK PRECALCULATION ........................................

ENABLE PART PROGRAM BLOCK PRECALCULATION .........................................

ACTIVATE FEEDRATE BYPASS................................................................................

RESTORE PROGRAMMED FEEDRATE AFTER FEEDRATE BYPASS ...................

ENABLE DRIVER FOR R.T. READING OF INTERP. PARAMETERS .......................

DISABLE DRIVER FOR R.T. READING OF THE INTERP. PARAM..........................

READS IN R.T. A NUMBER OF INTERP. DATA ........................................................

FIND A STRING INSIDE THE ACTIVE PART PROGRAM .........................................

POSITION THE ACTIVE PART PROGRAM ON THE SELECTED BLOCK ...............

DEFINE THE MODE FOR THE SEARCH IN MEMORY .............................................

SELECT AXES ALLOWING TO CHANGE FEEDRATE OVERRIDE..........................

SET FEED RATE OVERRIDE OF AXES FOR MANUAL MOVEMENT......................

SEND A COMMAND TO THE INTERPOLATOR ........................................................

CYSTART

CYCLE

CYSTOP

FEEDHLD

FEED_GO

HOLDON

HOLDOFF

MANFEED

URLFEED

FRORIDE

SPORIDE

SETMODE

GJOG

SJOG

AXSELEC

RQRESET

ENDRESE

GETPPNAM

GETPNTR

PP_SELE

PP_EXEC

MDI_CMD

MDI_EXEC

PPRESUME

PREC_OFF

PREC_ON

FEEDBYON

FEEDBYOF

INTP_ABI

INTP_DIS

GET_INTP

PP_TRSC

PP_BRSC

RCM_MOD

AXSELFED

AXMANFED

INTP_CMD

10 Series CNC WinPLUS Library - User Manual (03) 1-1

Page 22

Chapter 1

NC Related Functions

REQUEST THE INTERPOLATOR TO ENTER IN FEEDHOLD STATUS AT END

OF MOVEMENT..........................................................................................................

PART PROGRAM EXECUTION MONITORING MANAGEMENT…………………….

MASTER/SLAVE AXES MANAGEMENT………………………………………………..

FEEDHEM

PPRUNINFO

XDA_COMD

1-2 10 Series CNC WinPLUS Library - User Manual (03)

Page 23

Chapter 1

NC Related Functions

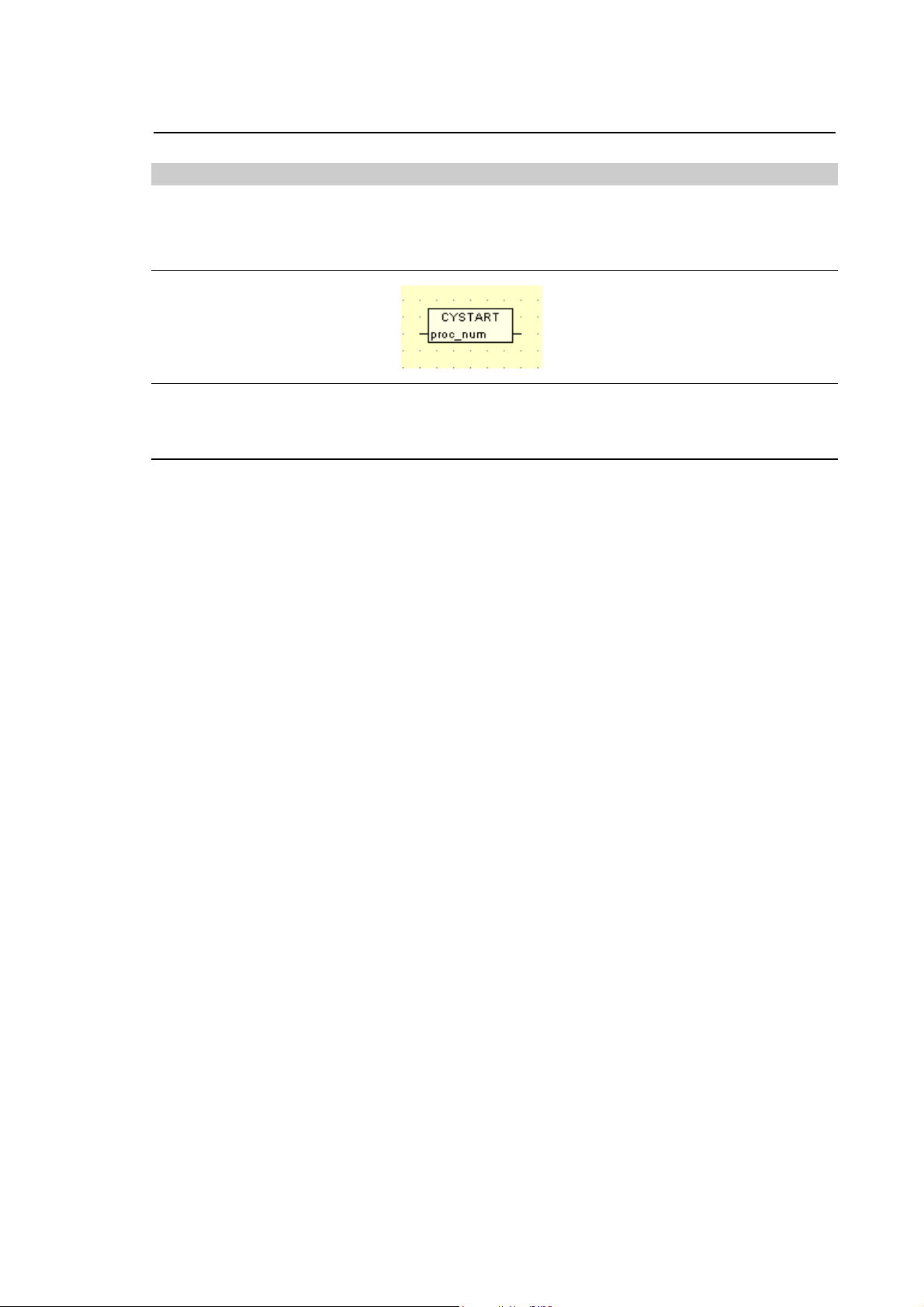

CYSTART: Request cycle start for a selected process

Type: No Wait

LD/FBD:

stat_wrd

ST:

stat_wrd := CYSTART(proc_num) ;

INPUT VARIABLE: process number (1..20) (int)

OUTPUT VARIABLE: status word (int)

Description:

This function is used to simulate the front panel's cycle start button in WinPLUS

NOTE:

The CYCLE has the same functionalities as CYSTART but it is a WAIT function.

10 Series CNC WinPLUS Library - User Manual (03) 1-3

Page 24

Chapter 1

NC Related Functions

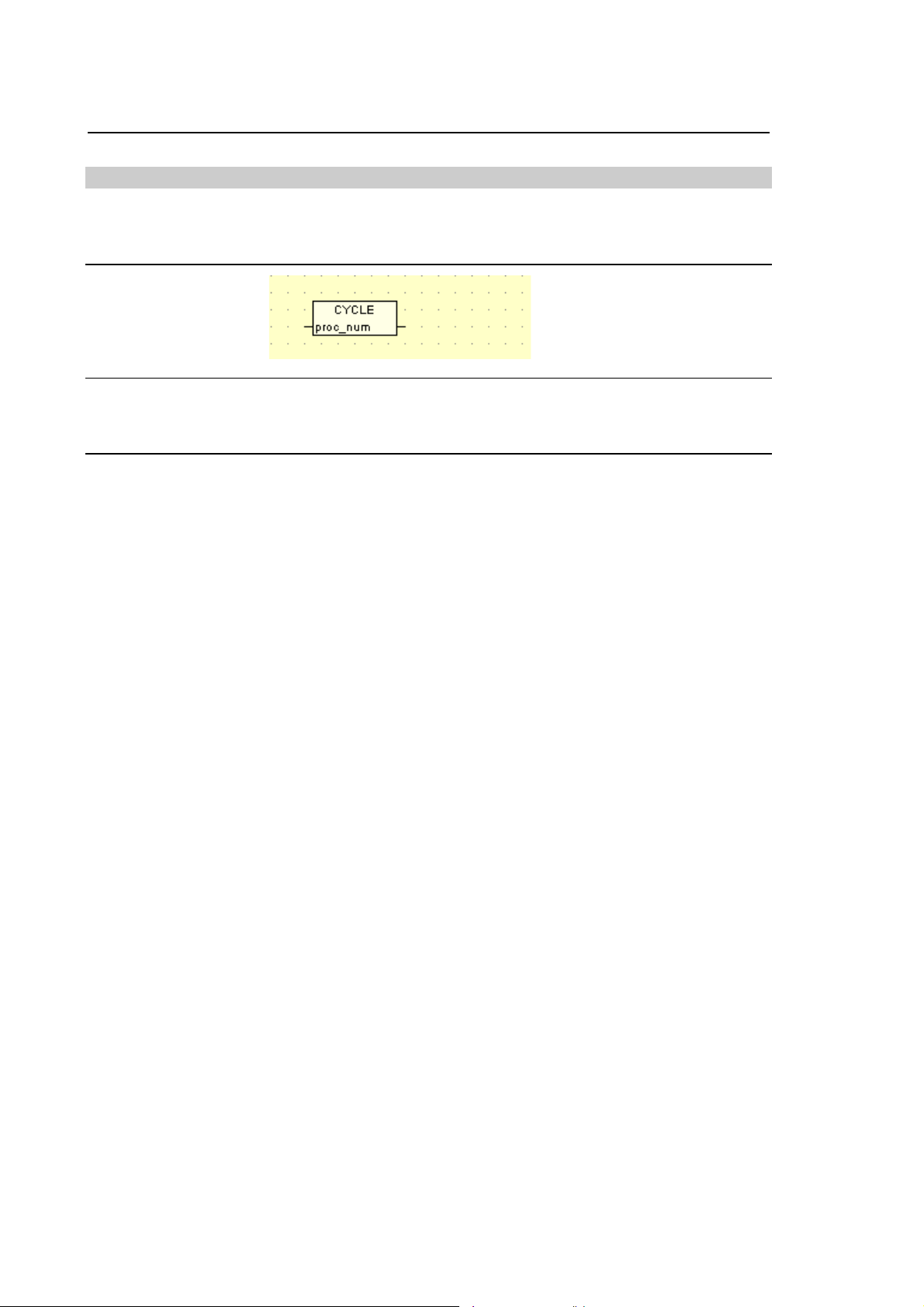

CYCLE: Request cycle for a selected process

Type: Wait

LD/FBD:

stat_wrd

ST:

stat_wrd := CYCLE(proc_num);

INPUT VARIABLE: process number (1..20) (int)

OUTPUT VARIABLE: status word (int)

Description:

This function is utilized to simulate pressing of the command module's cycle start button from

WinPLUS

The WAIT CYCLE function allows synchronization with the NC module and always receives an

acknowledge from the process.

On exit from the CYCLE call two situations can take place, according to the process' status:

• Process in "IDLE" status:

• Process in "RUN" status:

NOTE:

This function can be used, when the logic sends the blocks MDI (MDI_CMD) to execution.

In presence of a CYCLE command, the logic can synchronise with the NC environment as follows:

• execution of a block in MDI with actual axes movements using the routines CONMOV and

ENDMOV

• execution of a block in MDI without moving the axes by testing the process signal status IDLE

and RUN.

The command that has been sent in execution following the

CYCLE call is being executed; you must wait for the process

to enter "IDLE" status so that the command can be executed

The command sent in execution following the CYCLE call

has already been executed.

The function CYSTART has the same features as the function CYCLE, but as it is a NOWAIT, it

does not allow a proper synchronisation between the logic and the NC environment, if the block

sent to execution does not contain an actual axis move.

1-4 10 Series CNC WinPLUS Library - User Manual (03)

Page 25

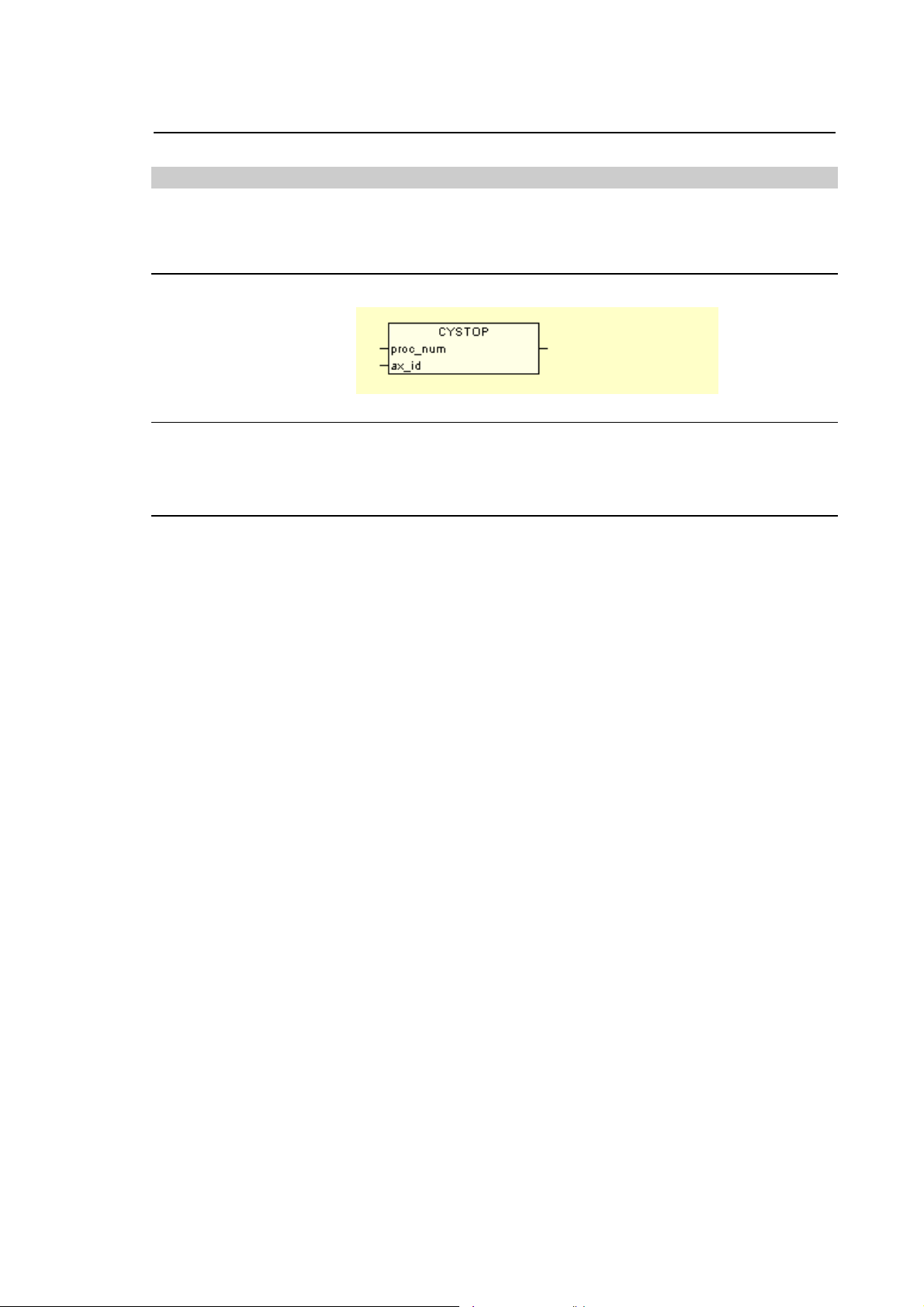

CYSTOP: Request cycle stop for the selected process

LD/FBD:

stat_wrd

ST:

stat_wrd := CYSTOP(proc_num,ax_id);

Chapter 1

NC Related Functions

Type: No Wait

INPUT VARIABLES: process number (1..20) (int)

axes identifier of axis to be stopped (int)

OUTPUT VARIABLE: status word (int)

Description:

This function stops the axis' motion (ax_id) relative to the process specified by the user

("proc_num").

The "ax_id" parameter is insignificant, in fact the axis in motion can be stopped without the "ax_id"

axis identify;

Despite this we advise to give the identifier of the axis to be stopped to the "ax_id" parameter for

reasons of future developments compatibility.

10 Series CNC WinPLUS Library - User Manual (03) 1-5

Page 26

Chapter 1

NC Related Functions

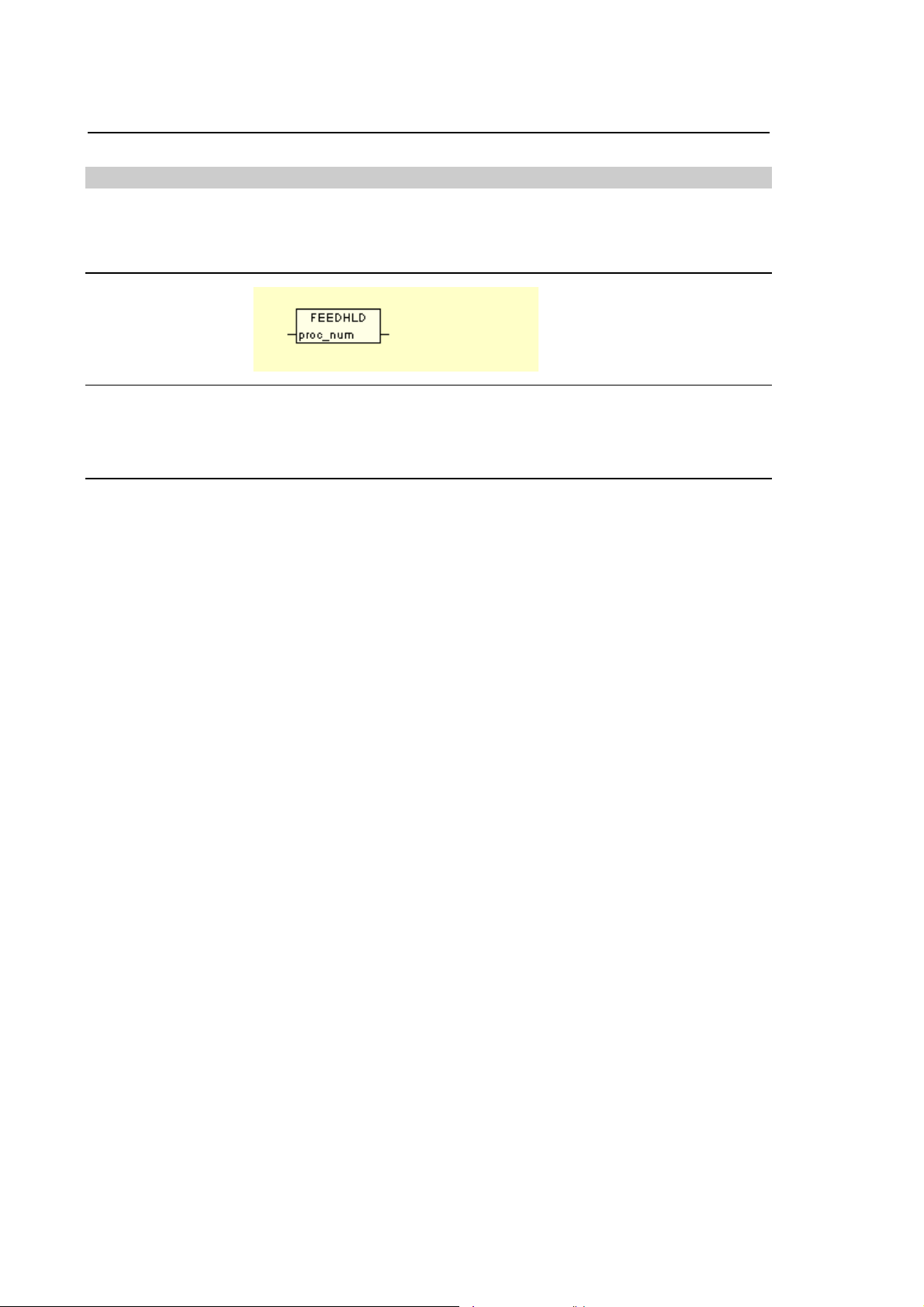

FEEDHLD: Request the interpolator to enter the feedhold status

Type: No Wait

LD/FBD:

stat_wrd

ST:

stat_wrd := FEEDHLD(proc_num);

INPUT VARIABLE: process number (1..20) (int)

OUTPUT VARIABLE: status word (int)

Description:

This function simply sets the feedrate to a zero value. Any on-going interpolating axes motion in

the selected process is suspended. The motion can be resumed with FEED_GO.

NOTES:

• This function is not executed when the control is working in G33 (thread cutting) or G84

(tapping). The stat_wrd variable contains a corresponding error code.

• The feedhold state is not cancelled by a RESET.

• Flag S_nFEEDH (S 20_15) informs the logic about the actual state of the control.

1-6 10 Series CNC WinPLUS Library - User Manual (03)

Page 27

Chapter 1

NC Related Functions

FEED_GO: Request the interpolator to exit the feedhold status

Type: No Wait

LD/FBD:

stat_wrd

ST:

stat_wrd := FEED_GO(proc_num);

INPUT VARIABLE: process number 1-20 (int)

OUTPUT VARIABLE: status word (int)

Description:

This function makes the interpolator exit the feedhold state requested by the function FEEDHLD.

The feedrate with the value previous to the entry in feedhold state is restored. The motion of the

axes resumes.

If you call this function when the interpolator is not in feedhold state, nothing happens.

See also:

FEEDHLD request feedhold system function call

System flags:

S_nFEEDH (S 20_15) process in feedhold status.

10 Series CNC WinPLUS Library - User Manual (03) 1-7

Page 28

Chapter 1

NC Related Functions

FEEDHEM: request to interpolator to enter in feedhold at end of movement

Type: No Wait

LD/FBD:

stat_wrd

ST:

stat_wrd := FEEDHEM(proc_num);

INPUT VARIABLE : number of process 1-20 (int)

OUTPUT VARIABILE : status word (int)

Description:

With this function the final point of the movement (program block) currently executed is reached at

zero speed. At this point feedrate is set on zero as is done with the FEEDHLD function. The

movement can be resumed with FEED_GO.

NOTES:

• This function applies continuous motions, as reaching the final point at zero speed is an intrinsic

characteristic in all other types of movement and hence the function in question is an integral part

of the movement. However, at the end of all types of movement, feedrate is set on zero.

• Stopping at the final point of a movement is not ensured if the stop request is executed at a

distance from the final point of the movement which is not sufficient to stop the movement

(compatibly with the acceleration values configured on the axes); in this case, the stop will occur

on the subsequent movement(s), as in a regular feedHold.

• If the stop at final point has been correctly requested, stop coordinates may differ from the final

point of the movement by a distance of the order of 0.01 mm.

• This function is not performed when the control is working in G33 mode (threading) or G84

(tapping). The stat_wrd variable contains the corresponding error code.

• Feedhold status is not deleted by a RESET.

• The S_nFEEDH (S 20_15) flag informs the logic as to the current control status.

1-8 10 Series CNC WinPLUS Library - User Manual (03)

Page 29

Chapter 1

NC Related Functions

HOLDON: Enter in hold

Type: No Wait