Page 1

10 Series CNC

High Speed Machining

Reference Manual

Code: 45006842M

Rev. 02

PUBLICATION ISSUED BY:

OSAI S.p.A.

Via Torino, 14 - 10010 Barone Canavese (TO) – Italy

e-mail: sales@osai.it

Web: www.osai.it

Copyright 2001-2002 by OSAI

All rights reserved

Edition: July 2001

IMPORTANT USER INFORMATION

This document has been prepared in order to be used by OSAI. It describes the latest release of the

product.

OSAI reserves the right to modify and improve the product described by this document at any time

and without prior notice.

Actual application of this product is up to the user. In no event will OSAI be responsible or liable for

indirect or consequential damages that may result from installation or use of the equipment described

in this text.

Page 2

abc

Page 3

10 Series CNC High Speed Machining

UPDATES IN THIS ISSUE

PAGE TYPE OF UPDATE

INDEX updated

CHAPTER 4 new chapter containing additional programming modes

CHAPTER 5

page 2 added: the parameter “Format” to the triletteral PNT for specifying the input

type for the profile programming

UPDATE

page 12 added: the parameter “Diam” to the triletteral AXI and the value TAO in the

parameter “Type”

page 16 inserted: an extension of the machine kinematics for positioning 2 rotation

axes to the linear axes. Extension of the triletteral MAC with new values.

page 25 inserted: a paragraph dealing with the Smoothing tolerances and

parameters

CHAPTER 6 Inserted: a new chapter concerning the Path Optimizer

10 Series CNC High Speed Machining (02)

Page 4

abc

Page 5

Preface

10 Series CNC High Speed Machining

PREFACE

Mechanical technology has evolved to such a degree that what were once considered insuperable

limits as regards machining speeds and accelerations have now become the norm in the world of

machine tools. It is now common to hear of machines capable of transverse speeds of the order of 80

- 100 m/minute and accelerations in the order of one or more g, traverse. The field of application

typical of these machines is the high-speed milling of surfaces.

The solution normally adopted with numeric controls, that is, the machining of profiles as a sequence

of linear micro steps is no longer applicable, because the mechanics follow the continual changes in

direction, with undesirable effects on the surface finish. The programmed points are taken as

obligatory points, through which machining must pass. In addition, “G01” programming is understood

strictly as a linear interpolation between points. This means that, to obtain a sufficiently accurate

curve, the points must be programmed so close to one another that the programmed broken line is

indistinguishable from the desired curve. This type of approach is still normally used with machine

tools having a high level of inertia which has the effect mechanically smoothing the broken line.

With the introduction of particularly rigid machines together with motor drives of an acceptable size

capable of providing high torque levels (brushless motors), this solution was no longer applicable, as

all the sudden changes in direction could be recognized by the machine tool resulting, at best, in a

poor quality surface finish.

At this point, there were two possible ways of solving the problem, by modifying the motion dynamics

and the geometry of the paths. In fact, the execution of the commands has to be filtered, in order to

obtain a “smooth” output to the servo motors, and the path program design has to be modified through

the interpretation of the programmed values as a set of points to be approximated in the best possible

way.

The solution chosen by Osai led to the implementation of the new Polynomial Interpolation

Algorithms.

This manual provides all the information necessary for the use of the new feature known as High

Speed Machining. In particular, this manual refers to the HIGH SPEED INTERPOLATION option,

specific for applications in which machining involves more than 3 axes.

The HSM feature for machining processes that involve 3 axes or less, is

IMPORTANT

10 Series CNC High Speed Machining (00) 1

included as standard in the E69 System Software for all models of 10 Series

numeric controls.

To extend this feature to more than three axes (max.6), the E96 option (High

Speed Interpolation) has to be installed.

Page 6

Preface

CAUTION

10 Series CNC High Speed Machining

WARNINGS

To ensure that the system is used correctly, the indications given in the manual should be followed,

paying particular attention to the paragraphs preceded by the signs: WARNING, CAUTION or

IMPORTANT.

WARNING

IMPORTANT

Indicates situations that may cause damage to the system, the equipment or

the operator.

Precedes information to be borne in mind to avoid damage to the equipment in

general.

Precedes operations that must be performed with care to ensure the complete

success of the application.

2 10 Series CNC High Speed Machining (00)

Page 7

END OF PREFACE

Chapter 1

Title of Chapter

CNC Serie 10 Titolo Manuale (00) 3

Page 8

INDEX

HIGH SPEED MACHINING

Indice

10 Series CNC High Speed Machining

GENERAL CONSIDERATIONS..................................................................................1-1

PROGRAMMING POINTS AND CHARACTERISTICS OF THE PROFILE......................1-3

Considerations on the use of the G62,G63,G66 and G67 functions

(transition codes).............................................................................................1-6

GENERAL HIGH SPEED MACHINING PROGRAMMING STRUCTURE .........................1-7

Interaction with Machine Logic ..........................................................................1-7

POINT DEFINING CONVENTIONS

POINTS AND MACHINING COORDINATES ...............................................................2-1

Tool Direction ..................................................................................................2-2

Normal to the Surface Direction ........................................................................2-2

Tool Radius Application Direction ......................................................................2-3

Tangential Axis ...............................................................................................2-3

FEATURES PROVIDED BY HIGH SPEED MACHINING

MACHINES WITH 5 AXES ........................................................................................3-1

Tool Radius and Length Compensation ..............................................................3-2

Tool Length Compensation...............................................................................3-2

No Tool Compensation .....................................................................................3-3

Tangential Axis Management ............................................................................3-3

MACHINES WITH 3 AXES ........................................................................................3-4

Tool Radius and Length Compensation ..............................................................3-4

Tool Length Compensation...............................................................................3-5

No Tool Compensation .....................................................................................3-5

Tangential Axis Management ............................................................................3-6

ADDITIONAL PROGRAMMING MODES

POLYNOMIAL PROGRAMMING ...............................................................................4-1

POLYNOMIAL PROGRAMMING TYPES AND LIMITS................................................4-3

10 Series CNC High Speed Machining (02) i

Page 9

Contents

10 Series CNC High Speed Machining

Polynomial for the Cutter Contact......................................................................4-3

Polynomials for the Cutter Location ...................................................................4-4

Polynomials for the Axis Location.....................................................................4-5

B-SPLINES PROGRAMMING....................................................................................4-6

B-SPLINE PROGRAMMING TYPES AND LIMITS.......................................................4-7

B-Splines for Cutter Contact.............................................................................4-7

B-Splines for Cutter Location............................................................................4-7

B-Splines for Axis Location ..............................................................................4-7

SETUP

TYPE OF POINTS DESCRIBED IN THE PART PROGRAM ..........................................5-2

VERSOR MANAGEMENT METHODS .........................................................................5-3

LOOK AHEAD MANAGEMENT ..................................................................................5-4

THRESHOLDS .........................................................................................................5-6

TOOL DEFINITION ...................................................................................................5-7

TOOL DIRECTION (3D).............................................................................................5-8

CHANGE IN CURVATURE MANAGEMENT.................................................................5-9

EDGE MANAGEMENT ..............................................................................................5-10

AXIS DEFINITION....................................................................................................5-11

AXIS PARAMETERS ................................................................................................5-13

AXIS DYNAMICS .....................................................................................................5-14

MACHINE KINEMATICS ...........................................................................................5-15

Definition of the Kinematic Chain.......................................................................5-15

Description of the Kinematic Chain....................................................................5-20

SMOOTHING TOLERANCES AND PARAMETERS .....................................................5-25

SPECIAL SMOOTHING PARAMETERS.....................................................................5-27

PATH OPTIMIZER

GENERAL................................................................................................................6-1

PROGRAM INSTALLATION ON A PC .......................................................................6-2

EXECUTION MODES................................................................................................6-3

USAGE MODES .......................................................................................................6-4

Tolerances: Toll, TollX and TollV........................................................................6-4

Buffer management: Pnt ...................................................................................6-4

Edge management: Racc, C0, RaccX, C0X, RaccV, C0V....................................6-5

POINT TYPES ..........................................................................................................6-6

ISO Part program for a 3-axes machine.............................................................6-6

ISO Part program for a 5-axes machine.............................................................6-6

END OF INDEX

ii 10 Series CNC High Speed Machining (02

Page 10

Chapter

1

HIGH SPEED MACHINING

GENERAL CONSIDERATIONS

The High Speed Machining feature is used for machining surfaces (profiles) defined by points, created

by CAD/CAM systems, on machine tools having 3 to 5 axes (3 linear + 2 rotary).

The High Speed Machining feature must be enabled in the AMP environment, by selecting the

appropriate field in the PROCESS CONFIG section (PROC CHAR softkey).

WARNING

To program this feature, proceed as follows:

1. Create a setup file (part program) that contains all the parameters for handling the profile: tools,

axes and kinematics of the machine.

The setup file (whose structure is described in chapter 5) will be recalled in the main program by

means of a three-letter command with the following format:

(HSM, setup file name)

2. Create the profile by inserting it directly in the main program:

Example:

; HSM PROGRAMMING EXAMPLE

G1 X..Y..Z.. A.. B.. F…

------

(HSM, CONFIG1)

G61

G1 X..Y..Z..A..B..

-----G60

; END OF PROGRAM

This feature may only be enabled for the first 4 processes.

10 Series CNC High Speed Machining (00) 1-1

Page 11

Chapter 1

High Speed Machining

The profile may also be inserted in a specific file which will be recalled as a subprogram by the

CLS instruction.

Example 2:

; HSM PROGRAMMING EXAMPLE

G0 X..Y..Z.. A.. B.. F…

------

(HSM, CONFIG1)

------

(CLS,PROFILO1--------------------------------------------------à G61

------ G1 X…Y..Z..A..B..

------ ------------------------------

; END OF PROGRAM ------------------------------

------ G60

1-2 10 Series CNC High Speed Machining (00)

Page 12

Chapter 1

High Speed Machining

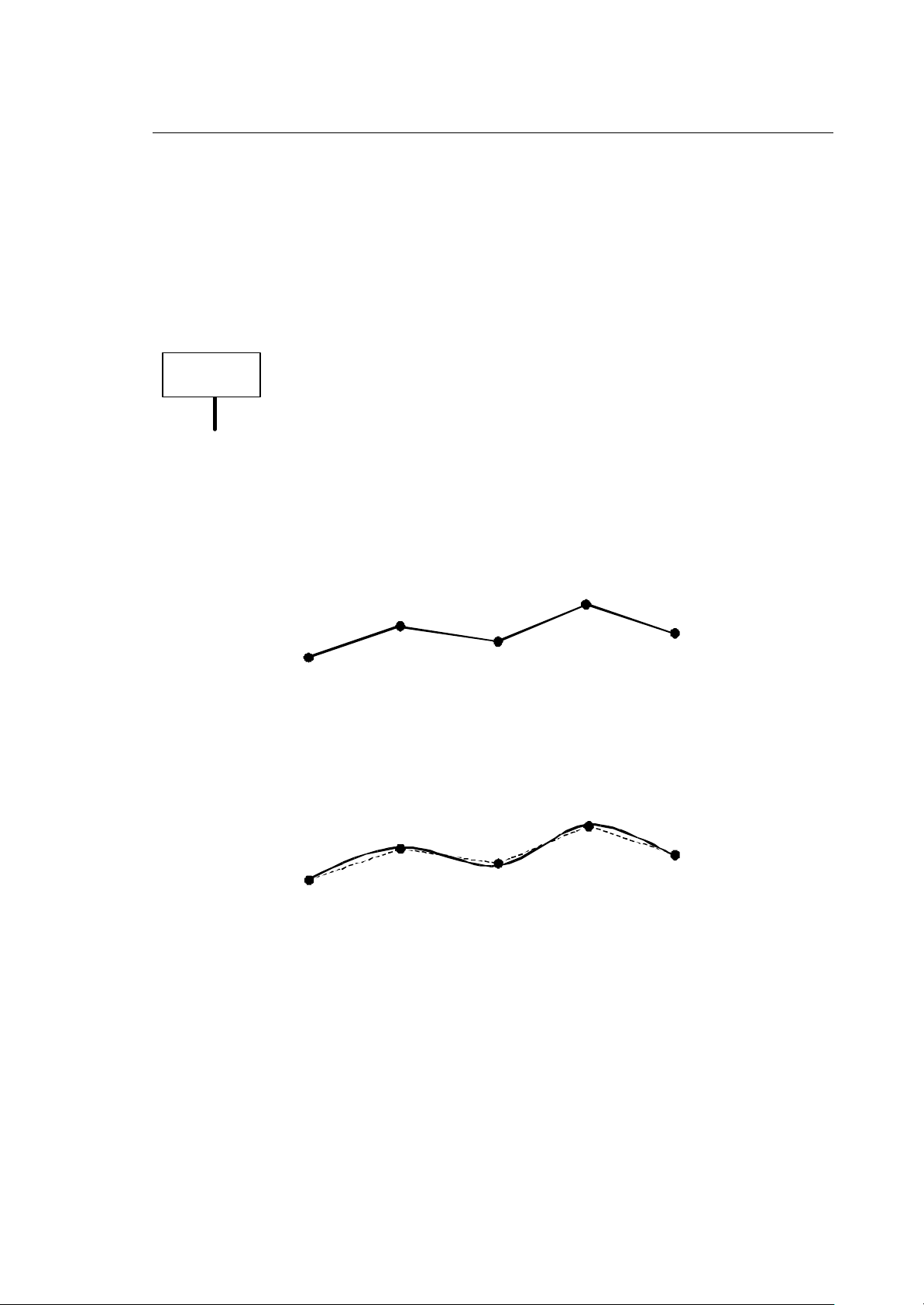

PROGRAMMING POINTS AND CHARACTERISTICS OF THE PROFILE

A profile is a set of points that make up the ISO part-program of the surface to be machined, created

by the CAD/CAM system in which the characteristics described in this chapter are to be respected.

On the basis of the programmed points a polynomial curve will be constructed, defining the path to be

followed. This path will pass through the programmed points with a configurable tolerance. The

methods by which the points are to be linked will be defined by the G01 and G00 codes that may be

programmed together with the points.

IMPORTANT

The sections executed in G00 will be considered as individual positioning operations; each point will

be linked to the next by means of a “linear” movement to be performed with the dynamic traverse

positioning (each section in G00 will start at zero speed and end at zero speed). For this reason, G00

mode will not calculate the polynomial curve. At the end of a section in G00 there will be no pause

(end of movement synchronism, entry into tolerance status, etc..) and the next movement will be

carried out immediately. This behaviour is similar to the programming of G01 and G09 codes in the

same block.

To ensure that the polynomial curves are calculated correctly, we recommend

the points be programmed with at least 5 figures after the decimal point (e.g.

10.37854); programming with fewer figures may cause irregularities on the

profile.

p3

p1

p2

p4

p0

With G01, each point will be linked geometrically to the following ones by means of a polynomial

curve, so the generated path may be considered “continuous”. This link will be interrupted by the

programming of a G00 or the programming of special G codes described below. The dynamics of the

sections in G01 are the same as the “cutting” movements (such as normal G01 movements in ISO

programming).

p3

p1

p2

p4

p0

10 Series CNC High Speed Machining (00) 1-3

Page 13

Chapter 1

G62

High Speed Machining

In addition to the G01 and G00 functions, the following G functions, specific for the HSM feature, may

be programmed in the profile.

G61

Determines the start of the profile and must be programmed in a block on its own. When the G61

function is activated, there must be no form of virtualization active (UPR,UVP,UVC,TCP).

Before activating the G61 function, the setup file must be defined by means of the instruction:

(HSM, setup file name)

The G61 command may ONLY be executed within a part program in AUTO or BLK BY BLK status.

G60

Determines the end of the profile and must be programmed in a block on its own.

If the machine is in single STEP execution, the profile between G61 and G60 is considered as a

single instruction. To stop its execution, it is necessary to switch to HOLD status.

G62

Splits a profile in two parts and determines the point where one profile ends and another begins,

maintaining continuity between the two curves.

The points preceding the G62 function will be used to generate a first curve, while the subsequent

points will be used to generate another one. These curves will be linked and will therefore be

continuous; the initial inclination of the second curve will correspond to the final inclination of the

previous curve.

G62

p1

p2

p3

p4

p0

As regards dynamics, with G62 no deceleration and acceleration ramp will be generated to link the

two curves. This G function must be programmed in a part program block on its own.

1-4 10 Series CNC High Speed Machining (00)

Page 14

Chapter 1

t

High Speed Machining

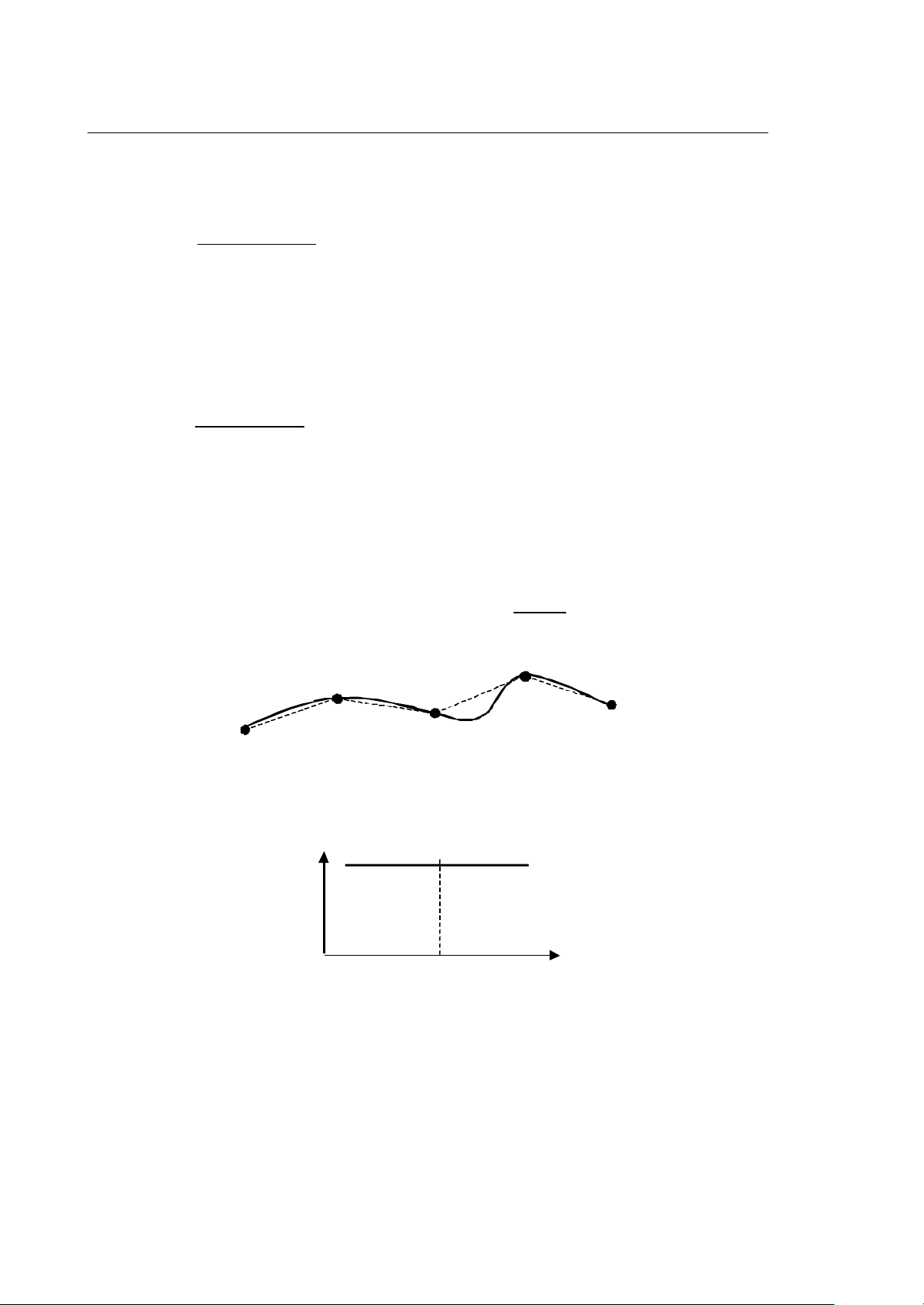

G63

Splits a profile into two parts and determines the point where one profile ends and the other one

begins, maintaining continuity between the two curves. The points preceding the G63 function will

be used to generate a first curve, while the subsequent points will be used to generate another one.

While with G62, the initial inclination of the second curve depends strictly on the final inclination of

the first, with G63, the initial inclination of the second curve IS NOT influenced by that of the first. To

maintain continuity, a “radius” that depends on the chordal error with which the splines are to be

calculated is inserted.

With G63 a reduction in speed may occur at the point where the two curves are linked. This G

function must be programmed in a part program block on its own.

G66

Splits a profile into two parts and determines the point where one profile ends and the other one

begins, creating a discontinuity between the two curves, that is, the point preceding the G66

represents an edge. At this point, two curves are generated, the first using the points preceding the

G66 function and the second using the subsequent points. These curves will NOT be linked, and so

there will be a discontinuity.

G66

p3

p1

p4

p2

p0

This discontinuity will be reached at zero speed; the first curve will therefore end with a deceleration

ramp to 0 (zero) speed after which the second curve will be tackled with an acceleration ramp to

reach the required machining speed. This G function must be programmed in a part program block on

its own.

v

G66

10 Series CNC High Speed Machining (00) 1-5

Page 15

Chapter 1

High Speed Machining

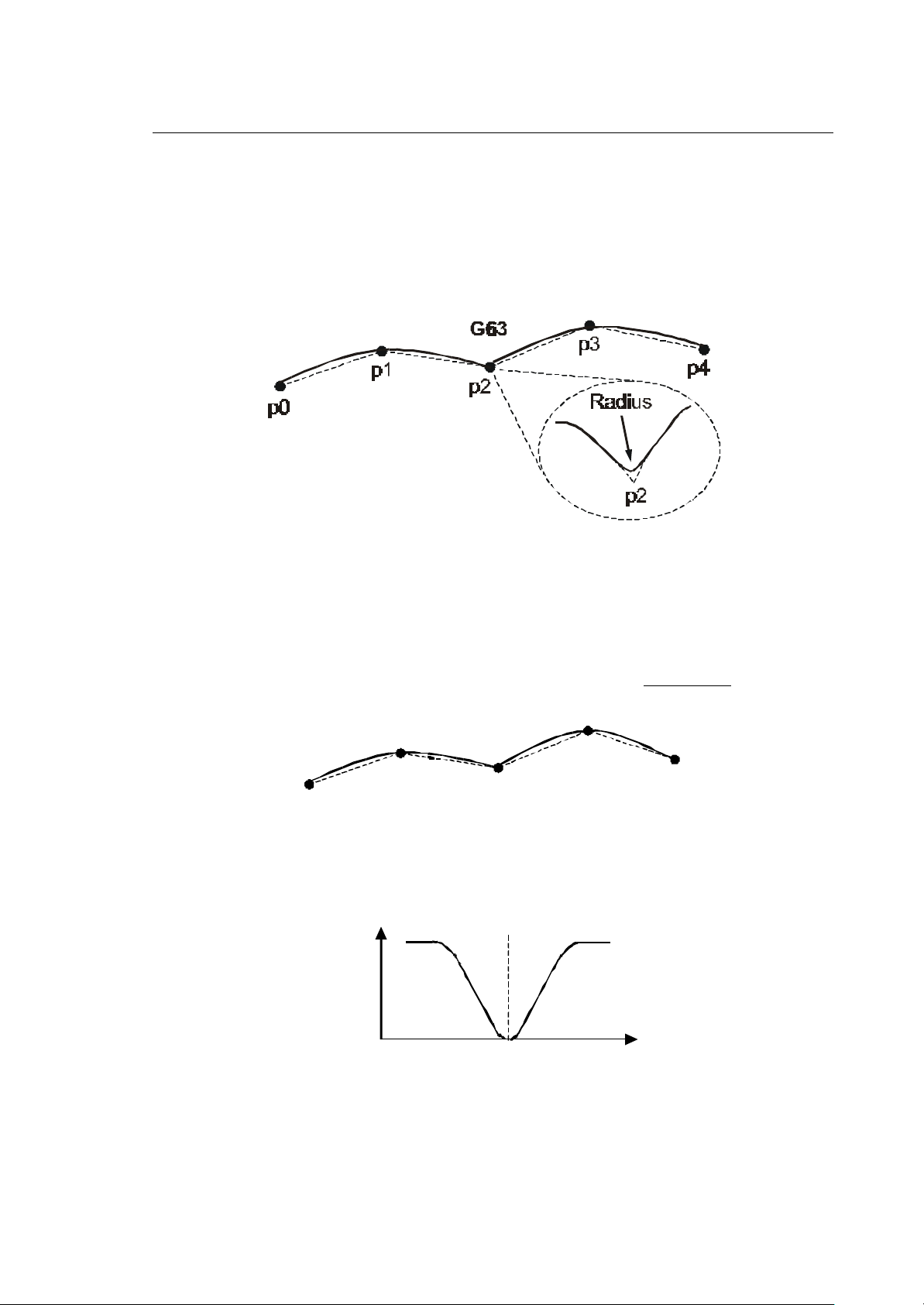

G67

With G67, a “discontinuity” may be defined on the profile defined with G66. What changes is the

dynamic approach to the edge, that is, the end of the curve is not reached at zero speed but at a

speed value (vs) that enables the axes to reach the edge without any dynamic problems. This speed

value is calculated on the basis of the acceleration that may be withstood by each axis. This G

function must be programmed in a part program block on its own.

v

G67

vs

Considerations on the use of the G62,G63,G66 and G67 functions (transition

codes)

The transition G codes are particularly useful when “similar”, repetitive curves are to be defined

(providing the programmed points are also similar and repetitive).

Supposing we have a profile defined by 100 points of which the first 50 represent the first machining

pass (from p1 to p50) and the other 50 (from p50 to p99) the same profile shifted slightly (second

pass).

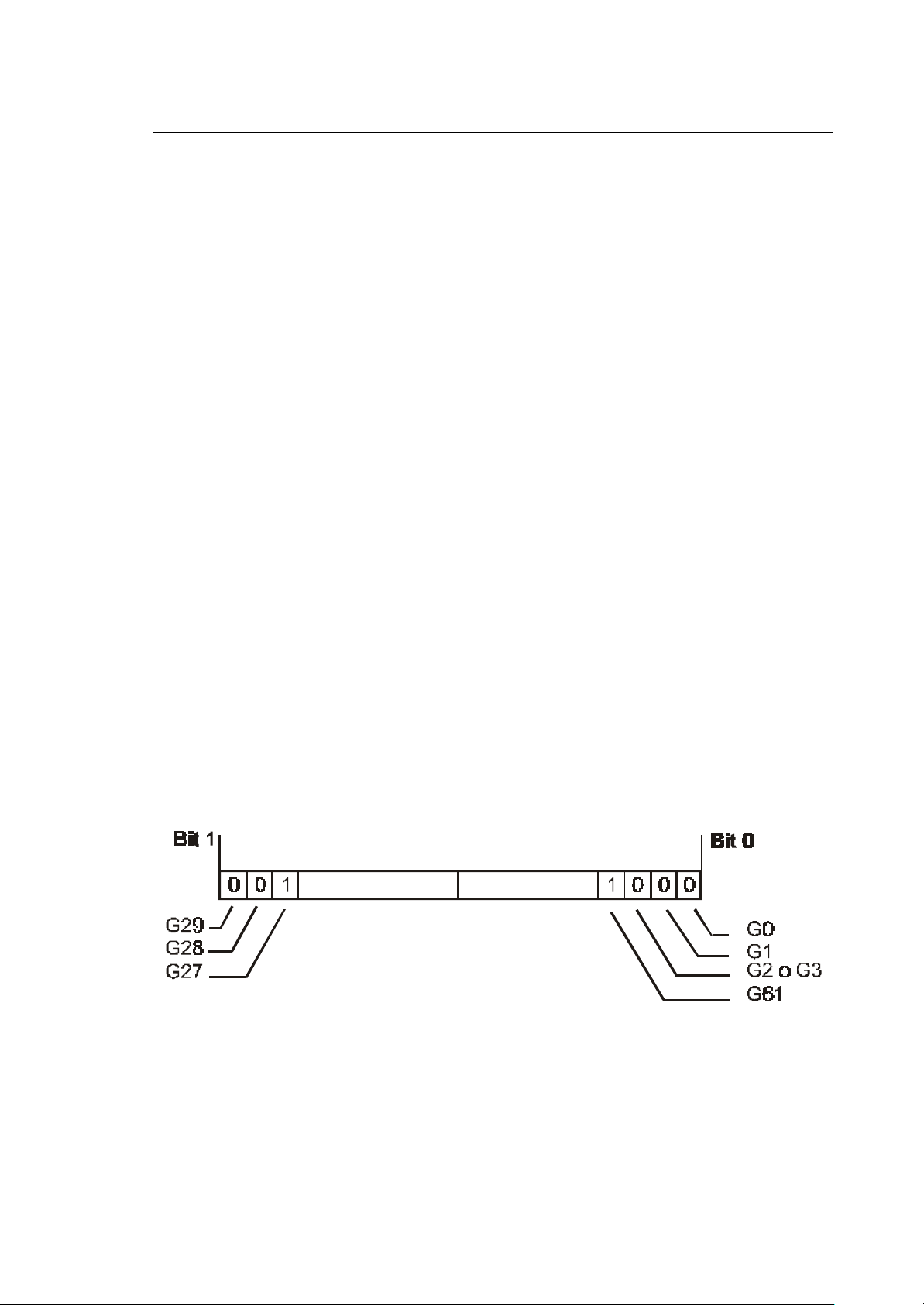

p1

p50

As the points between p1 and p50 are “similar” to the points between p50 and p99, the conditions for

calculating the two polynomial curves will also be similar. Two “parallel”, almost identical curves will

therefore be generated.

If the G62 function has not been programmed on point p50 the NC may generate curves that are not

perfectly parallel. This normally undesired effect is due to the fact that the calculation of the

polynomial takes into account the “history” along the calculated paths.

The “history” of point p1 is clearly different from that of point p50. In fact, point p1 has no history while

in point p50, the NC has followed a path determined by the first 49 points.

p99

When the G62 function is inserted, it cancels the “history” and produces a geometrical pattern almost

identical to the one calculated starting from point p1.

In machining processes that entail several passes, failure to program G62 would have the undesirable

effect of producing different levels of machining between one pass and another.

1-6 10 Series CNC High Speed Machining (00)

Page 16

Chapter 1

High Speed Machining

GENERAL HIGH SPEED MACHINING PROGRAMMING STRUCTURE

Between the G61 and G60 blocks it will only be possible to program the points that make up the

profile to be machined or the G codes for defining their management method: no other type of

programming will be allowed.

Points may be programmed using, absolute programming may be used by means of (G90) or

incremental programming by means of (G91). All numerical parameters required may be defined

directly or by means of E or L variables: programming with expressions is not valid so XE(E2) or

X(E1+E2) type programming is not allowed, while XE1 is allowed.

The syntax of the allowed program lines will be:

N… [G00 | G01] [G90 | G91] [points] F….

N… [G62 | G63 | G66 |G67 ]

Activation of the HSM (High Speed Machining) feature G61 forces of G01 and G90, modes while at

the exit (G60) the G functions active when G61 was programmed will be restored.

The first point programmed MUST be expressed in absolute positions (G90) and must contain the

programming of all axes associated with the HSM programming (axes configured in the HSM setup

file).

Interaction with Machine Logic

The G61/G60 program section will be considered, from the system point of view, as a single program

block. As regards interfacing with the machine logic, a request for consent for movement will be made

when the G61 function is reached, and an end of movement request will be made when the G60

function is reached (in the same way as for the G27 and G28 continuous movements).

A regards consent for movement, the XW03 variable, which contains the type of movement, will be

set as shown below:

10 Series CNC High Speed Machining (00) 1-7

Page 17

Chapter 1

High Speed Machining

END OF CHAPTER

1-8 10 Series CNC High Speed Machining (00)

Page 18

Chapter

2

Axis location points

POINT DEFINING CONVENTIONS

POINTS AND MACHINING COORDINATES

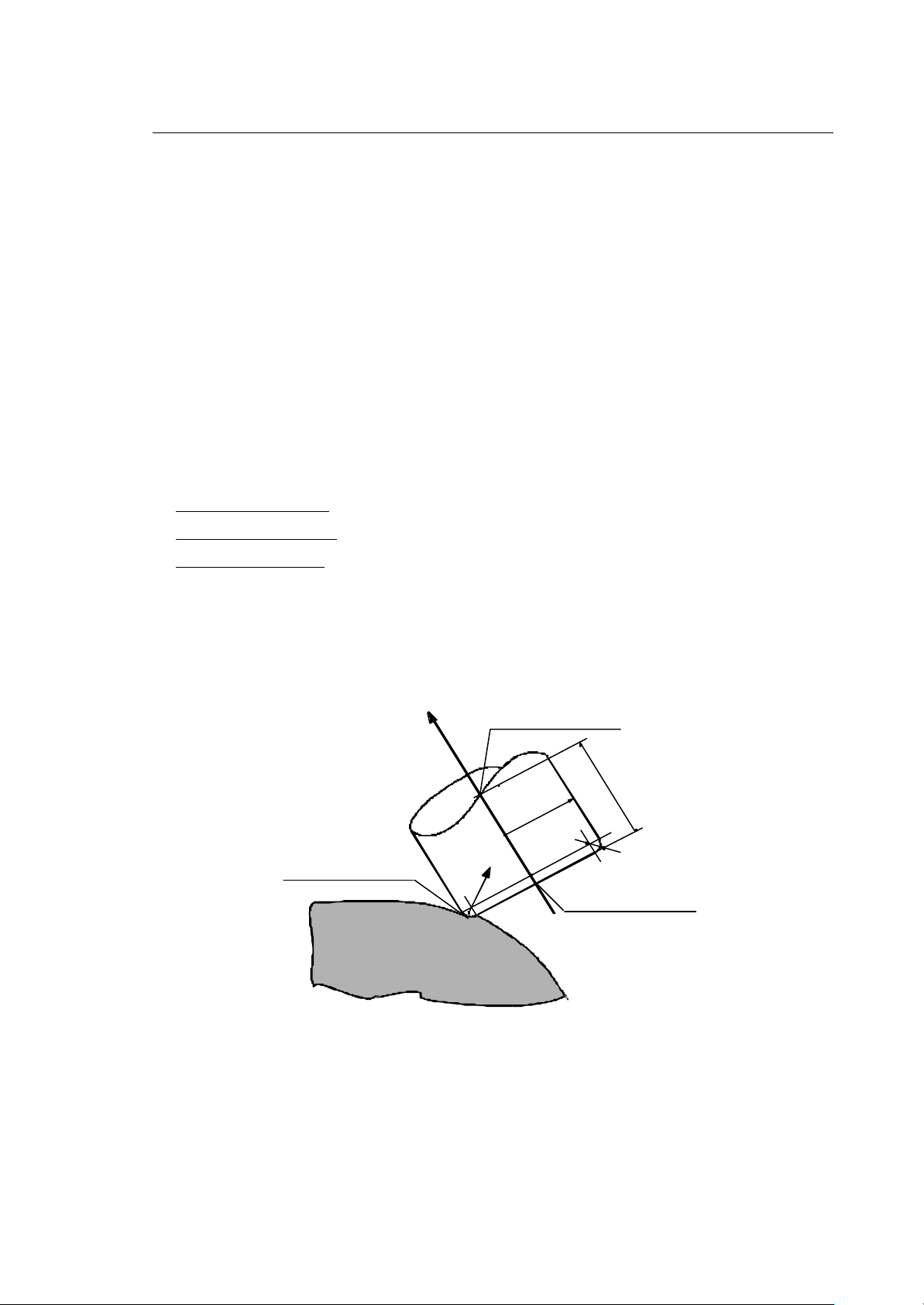

Before defining how the points are handled, it is necessary to specify what they represent as

programming may be executed in relation to three types of coordinates, that is:

• Cutter Contact Points, which refer to the actual cutting point

• Cutter Location Points, which refer to the point normally indicated as the centre of the tool

• Axis Location Points, which refer to an arbitrary point fixed to the machining axes

The cutter contact points are linked to the cutter location points through the geometry and orientation

of the tool. The axis location points are linked to the cutter location points through the geometry of

the machine tool. In machining processes with three axes, the coordinates will simply be translated

while, in those with five coordinated axes, rototranslation matrices that take into account the

geometrical transformations due to the movement of the rotary axes will be applied. The figure below

shows what is meant by cutter contact points, cutter location points and axis location points.

Tool direction

Cutter contact points

Points are defined by means of normal axis coordinates in the format [Axis name][Position];

example: X100 Y200 Z40.

Normal

to surface

Tool

length

Radius

Edge

radius

Cutter location points

10 Series CNC High Speed Machining (00) 2-1

Page 19

Chapter 2

Point Defining Conventions

Tool Direction

The tool direction represents the orientation of the tool (from the tip to the attachment) within the part

reference system.

WARNING

Two methods may be used to define the tool direction. The first is by directly programming the versor

that identifies the tool direction. This versor is expressed using the ijk coordinates in the format:

[i] [X-coordinate component] [j][Y-coordinate component] [k][Z-coordinate component]

The system will automatically normalize the length of the versor to the unitary length (1.0).

The second way of defining the tool direction is by programming the rotary axes. The system will

automatically determine the three components of the ijk versor depending on the kinematics of the

machine.

In the following sections reference to versor means versor of unitary lenght.

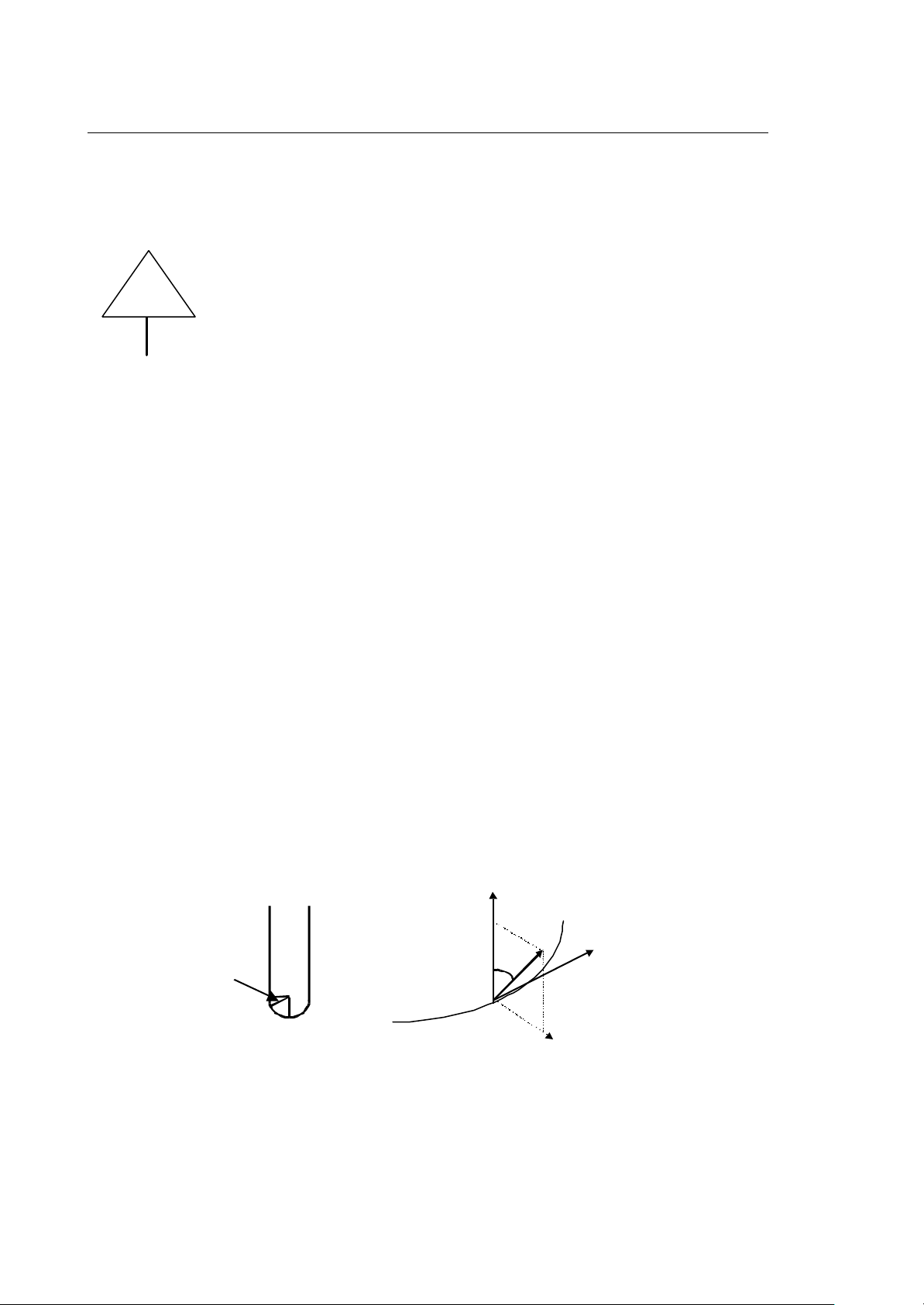

Normal to the Surface Direction

The normal to the surface direction represents the direction of the “line” perpendicular to the surface

to be machined (starting from the surface) within the part reference system.

There are two ways of defining the direction normal to the part. The first is by directly programming

the versor that identifies the normal direction. This versor (of a unitary length) is expressed using the

mno coordinates in the format:

[m] [X-coordinate component] [n][Y-coordinate component] [o][ Z-coordinate component]

The system will automatically normalize the length of the versor to the unitary length (1.0).

The second way is to have this direction calculated automatically by the system. The direction is

calculated on the basis of the tangent to the profile (direction of the movement), on the basis of the

tool direction (ijk versor) and an angle of contact between the part and the tool. This calculation

makes sure that the mno versor is normal to the tangent to the profile and that it defines an angle αα

(angle of contact) with the tool versor ijk.

ijk

mno

α

This type of approach is only significant when the contour is to be machined. When a surface is to be

machined, this approach could fail as there is no information about the “surface” to be machined, only

information about the “direction” of displacement.

α

tg profile

2-2 10 Series CNC High Speed Machining (00)

Page 20

Chapter 2

ijk

x

Point Defining Conventions

Tool Radius Application Direction

The direction of application of the tool radius represents the direction in which radius compensation is

to be applied (starting from the centre of the tool) within the part reference system.

There are two ways of defining the tool radius application direction. The first is by directly

programming the versor that identifies the direction. This versor (of a unitary length) is expressed

using the pqd coordinates in the format

[p] [X-coordinate component] [q][Y-coordinate component] [d][Z-coordinate component]

The system will automatically normalize the length of the versor to the unitary length (1.0).

The second way is to have this direction calculated automatically by the system. The direction is

calculated automatically on the basis of the tool direction (ijk versor) and the normal to the part (mno

versor). This calculation ensures that the pqd versor is normal to the tool direction and is on the plane

formed by the ijk and mno versors.

ijk

pqd

pqd

mno

mno

Programming of the versor pqd is only significant when specific cutting strategies are applied.

Tangential Axis

The tangential axis is an axis whose position is calculated so as to remain tangential to the profile

described. It is calculated on the basis of the tangent to the polynomial curve on the work plane.

y

Tangential axis

An initial value of the tangential axis (first programmed point) may be defined and the subsequent

positions may be calculated on the basis of this value.

10 Series CNC High Speed Machining (00) 2-3

Page 21

Chapter 2

Point Defining Conventions

END OF CHAPTER

2-4 10 Series CNC High Speed Machining (00)

Page 22

Chapter

3

FEATURES PROVIDED BY HIGH SPEED MACHINING

Depending on the type of machine tool used, the points programmed and a series of additional

parameters, the features may be obtained using “High Speed Machining”.

MACHINES WITH 5 AXES

Machines with 5 axes are characterised by the fact that they have two rotary axes that are used to

orient the tool during the machining phase. The direction of the tool and the position of the rotary axes

are two closely related parameters.

One feature of High Speed Machining is that it “automatically” calculates the position of the rotary

axes on the basis of the tool direction (ijk vector). In this way, the same part program may be used on

machines having different kinematics providing both machines can reach the same positions.

10 Series CNC High Speed Machining (00) 3-1

Page 23

Chapter 3

Features Provided by High Speed Machining

Tool Radius and Length Compensation

In order to use tool radius and length compensation, the type of axis positions and vectors as defined

in the table below must be included in the part program. The feed rate may refer to the point of

contact between the tool and the part (chip removal speed, therefore at the Cutter Contact Point) or

the centre of the tool (at the Cutter Location Point). The difference between these two types of

settings is significant when tools with a large diameter are used, that is, where the path of the centre

of the tool is significantly different from that of the profile of the part.

Setting Description

Axis positions The points must be expressed in Cutter Contact Points

Tool Direction The ijk vector or the positions of the rotary axes must be programmed

Normal to Surface The mno vector must be programmed or automatically calculated by the

system

Radius Application The pqd vector must be programmed or automatically calculated by the

system

Example:

N001 G61

N002 G1 X10Y10Z10 i0j0k1 m0n0o1 p0q0d1 F10000

N002 X20Y10Z10

…..

N100 G60

Tool Length Compensation

In order to use tool length compensation, the type of axis position and vectors as defined in the table

below must be included in the part program. The feed rate will refer to the centre of the tool (at the

Cutter Location Point).

Setting Description

Axis Position The points must be expressed in Cutter Location Points

Tool Direction The ijk vector or the positions of the rotary axes must be programmed

Normal to Surface Ignored

Radius Application Ignored

Example:

N001 G61

N002 G1 X10Y10Z10 i0j0k1 F10000

N002 X20Y10Z10 ….

…..

N100 G60

3-2 10 Series CNC Hi gh Speed Machining (00)

Page 24

Chapter 3

Features Provided by High Speed Machining

No Tool Compensation

In this case, only the positions of the axes as defined in the table below have to be included in the

part program. The feed rate will refer to the actual movement of the axes (Axis Location Point). The

feed rate may however be set is relation to the centre of the tool (Cutter Location Points).

Setting Description

Axis Positions The points must be expressed in Axis Location Points

Tool Direction The positions of the rotary axes must only be programmed if the setting of

the feed rate in relation to the tool centre has been requested. If it has not,

the setting is ignored. The ijk vector cannot be programmed.

Normal to Surface Ignored

Radius Application Ignored

Example:

N001 G61

N002 G1 X10Y10Z10 A10 B10 F10000

N002 X20Y10Z10 ….

…..

N100 G60

Tangential Axis Management

If the tangential axis is associated with a rotary axis, its position (calculated by the system) is used

to rotate the Tool Direction vector (ijk) so as to keep it tangential to the profile. In this case, the Tool

Direction vector must NOT be programmed in the part reference system but in relation to the direction

of the movement.

10 Series CNC High Speed Machining (00) 3-3

Page 25

Chapter 3

Features Provided by High Speed Machining

MACHINES WITH 3 AXES

Generic machines or machines with 3 axes are characterised by the fact that they do not have axes

for orienting the tool during the machining phase. The tool direction is generally fixed.

Tool Radius and Length Compensation

In order to use tool radius and length compensation, the type of axis positions and vectors as defined

in the table below must be included in the part program. The feed rate may refer to the point of

contact between the tool and the part (chip removal speed, therefore at the Cutter Contact Point) or

the centre of the tool (at the Cutter Location Point). The difference between these two types of

settings is significant when tools with a large diameter are used, that is, where the path of the centre

of the tool is significantly different from that of the profile of the part.

Setting Description

Axis positions The points must be expressed in Cutter Contact Points

Tool Direction The tool direction vector is defined during the setup phase (on a 3-axis

machine, it is fixed) and remains unchanged throughout the machining

process. Programming of the ijk vector is ignored.

Normal to Surface The mno vector must be programmed or automatically calculated by the

system

Radius Application The pqd vector must be programmed or automatically calculated by the

system

Example:

N001 G61

N002 G1 X10Y10Z10 m0n0o1 p0q0d1 F10000

N002 X20Y10Z10 ….

…..

N100 G60

3-4 10 Series CNC Hi gh Speed Machining (00)

Page 26

Chapter 3

Features Provided by High Speed Machining

Tool Length Compensation

In order to use tool length compensation, the type of axis position and vectors as defined in the table

below must be included in the part program. The feed rate will refer to the centre of the tool (at the

Cutter Location Point).

Setting Description

Axis Position The points must be expressed in Cutter Location Points

Tool Direction The tool direction vector is defined in the setup phase (on a 3-axis machine,

it is fixed) and remains unchanged throughout the machining process.

Programming of the ijk vector is ignored.

Normal to Surface Ignored

Radius Application Ignored

Example:

N001 G61

N002 G1 X10Y10Z10 F10000

N002 X20Y10Z10 ….

…..

N100 G60

No Tool Compensation

In this case, only the positions of the axes as defined in the table below have to be included in the

part program. The feed rate will refer to the actual movement of the axes (Axis Location Point). The

feed rate may however be set in relation to the centre of the tool (Cutter Location Points).

Setting Description

Axis Positions The points must be expressed in Axis Location Points

Tool Direction The tool direction vector is defined during the setup phase (on a 3-axis

machine it is fixed) and remains unchanged throughout the machining

process. It is only used if the setting of the feed rate in relation to the centre

of the tool has been requested, otherwise it is ignored. Programming of the

ijk vector is ignored.

Normal Surface Ignored

Radius Application Ignored

Example

N001 G61

N002 G1 X10Y10Z10 F10000

N002 X20Y10Z10 ….

…..

N100 G60

10 Series CNC High Speed Machining (00) 3-5

Page 27

Chapter 3

Features Provided by High Speed Machining

Tangential Axis Management

When management of the tangential axis is requested, its position is calculated automatically by the

system. Any programming of the tangential axis within the part program defines further rotations of

the axis with respect to the tangent calculated by the system. The programming of the value 0 (zero)

on the axis activates the calculation of the position by the High Speed algorithms.

END OF CHAPTER

3-6 10 Series CNC Hi gh Speed Machining (00)

Page 28

Chapter

4

ADDITIONAL PROGRAMMING MODES

Up to now we have always talked about programming by means of points i.e. the points defined in the

part program represent the entities out of which polynomial curves are calculated. But appropriate

programming allows direct definition of polynomial curves or to define curves using B-Splines.

POLYNOMIAL PROGRAMMING

A polynomial curve is defined by a function of the type:

f(s) = a0 + a1s1 + a2s2 + a3s3 + a4s4 + a5s

in which

a0 an are the polynomial coefficients

s1 sn are the polynomial parameters which run from 0 to a certain value S (Length of the

polynomial)

The example above defines a polynomial of the 5th degree. On programming level you can also define

polynomials of the 3rd and the 4th degree. The degree of a polynomial is defined by associating the

parameter P to G61 at High Speed start.

For example, in order to program with 3rd degree polynomials you have to write:

G61 P3

In case the P parameter is omitted, the 5th degree is programmed as default.

In order to program a polynomial curve you firstly have to define some global parameters of the

polynomial and then the polynomial coefficients for all axes configured in the HIGH SPEED set-up.

For example, polynomials directly referring to the positions of the X, Y and Z axis are programmed as

follows:

<*, Polynomial Length, Block Number, Feed, Transition Code

<X, x0 , x1 , x2 , x3 , x4 , x

<Y, y0 , y1 , y2 , y3 , y4 , y

<Z, z0 , z1 , z2 , z3 , z4 , z

5

5

5

5

10 Series CNC High Speed Machining (02) 4-1

Page 29

Chapter 4

Additional Programming Modes

where the line <* defines the global parameter of the polynomial with the following meaning:

PROGRAMMING DESCRIPTION

Polynomial Length defines the upper limit for the parameter s

Block Number represents the N of normal ISO programming

Feed speed of executing the polynomial

Transition code defines how to finish the polynomial and corresponds to the codes

G66 (1) and G67 (2). All other values are ignored. Therefore you

cannot program some G codes between one polynomial curve and the

next. The only G code admitted is G60 for closing programming.

The line <axis defines the polynomial coefficients.

IMPORTANT

It has to be stressed that the final point of a polynomial (the point defined by fn(S))

MUST be identical to the starting point of the next polynomial (defined by f

n+1

(0)).

4-2 10 Series CNC High Speed Machining (02)

Page 30

Chapter 4

Additional Programming Modes

POLYNOMIAL PROGRAMMING TYPES AND LIMITS

Based on the type of points defined you also have to program the polynomials for the versors along

which to calculate the tool length and the tool radius compensation in addition to the axes

polynomials:

Polynomial for the Cutter Contact

<*, Polynomial Length, Block Number, Feed, Transition Code

<X, x0 , x1 , x2 , x3 , x4 , x

<Y, y0 , y1 , y2 , y3 , y4 , y

<Z, z0 , z1 , z2 , z3 , z4 , z

<i, i0 , i1 , i2 , i3 , i4 , i

<j, j0 , j1 , j2 , j3 , j4 , j

<k, k0 , k1 , k2 , k3 , k4 , k

<m, m0 , m1 , m2 , m3 , m4 , m

<n, n0 , n1 , n2 , n3 , n4 , n

<o, o0 , o1 , o2 , o3 , o4 , o

<p, p0 , p1 , p2 , p3 , p4 , p

<q, q0 , q1 , q2 , q3 , q4 , q

<d, d0 , d1 , d2 , d3 , d4 , d

5

5

5

5

5

5

5

5

5

5

5

5

The following considerations apply:

• The parameters "Polynomial Length" and the relative “Feed” have to refer to the

IMPORTANT

curve on the Cutter Contact.

• The polynomials for the three versors (ijk, mno and pqd) MUST always be

programmed. Therefore you CANNOT request their automatic calculation or

determine their values based on the positions (polynomials) of the rotational

axes.

• The automatic calculation of the tangent axis is not managed.

10 Series CNC High Speed Machining (02) 4-3

Page 31

Chapter 4

Additional Programming Modes

Polynomials for the Cutter Location

<*, Polynomial Length, Block Number, Feed, Transition Code

<X, x0 , x1 , x2 , x3 , x4 , x

<Y, y0 , y1 , y2 , y3 , y4 , y

<Z, z0 , z1 , z2 , z3 , z4 , z

<i, i0 , i1 , i2 , i3 , i4 , i

<j, j0 , j1 , j2 , j3 , j4 , j

<k, k0 , k1 , k2 , k3 , k4 , k

5

5

5

5

5

5

The following considerations apply:

• The parameters "Polynomial Length" and the relative “Feed” may refer to any

IMPORTANT

curve (Cutter Contact, Cutter Location, arbitrary), therefore the

parameterisation of the polynomial is free.

• The polynomial for the tool direction versor (ijk) MUST always be programmed.

Therefore you CANNOT determine their values based on the positions

(polynomials) of the rotational axes.

• The automatic calculation of the tangent axis is not managed.

4-4 10 Series CNC High Speed Machining (02)

Page 32

Polynomials for the Axis Location

<*, Polynomial Length, Block Number, Feed, Transition Code

Chapter 4

Additional Programming Modes

<X, x0 , x1 , x2 , x3 , x4 , x

<Y, y0 , y1 , y2 , y3 , y4 , y

<Z, z0 , z1 , z2 , z3 , z4 , z

5

5

5

The following considerations apply:

• The parameters "Polynomial Length" and the relative “Feed” may refer to any

IMPORTANT

curve (Cutter Contact, Cutter Location, arbitrary), therefore the

parameterisation of the polynomial is free.

• The automatic calculation of the tangent axis is not managed.

For all programming types described above you can also calculate polynomials for

additional axes but you have to apply the HSM configuration rules described

WARNING

below.

Example:

G61 P5

<*,4.000000000e+001,3,3000,1

<X,-3.835260000e+002,0.000000000e+000,-4.440892099e-016,1.850371708e-017,-5.782411587e-019,1.355252716e021

<Y,-1.121540000e+002,-1.776356839e-015,1.110223025e-016,4.625929269e-018,7.228014483e020,0.000000000e+000

<Z,2.000000000e+002,-1.000000000e+000,-2.220446049e-016,0.000000000e+000,7.228014483e-020,-6.776263578e022

<i,0.000000000e+000,0.000000000e+000,0.000000000e+000,0.000000000e+000,0.000000000e+000,0.000000000e+000

<j,-5.375997577e-003,-1.084202172e-019,0.000000000e+000,0.000000000e+000,-8.823259867e-024,6.893171771e027

<k,9.999855492e-001,1.387778781e-017,-8.673617380e-019,0.000000000e+000,-1.411721579e-021,-1.764651973e024

<*,2.488900000e+001,5,3000,5

<X,-3.835260000e+002,0.000000000e+000,-8.881784197e-016,7.401486831e-017,0.000000000e+000,-1.445602897e020

<Y,-1.121540000e+002,-3.552713679e-015,0.000000000e+000,9.251858539e-018,0.000000000e+000,1.807003621e021

<Z,1.600000000e+002,-1.000000000e+000,0.000000000e+000,-3.700743415e-017,-2.023844055e-018,1.626303259e020

<i,0.000000000e+000,0.000000000e+000,0.000000000e+000,0.000000000e+000,0.000000000e+000,0.000000000e+000

<j,-5.375997577e-003,-2.168404345e-019,1.355252716e-020,0.000000000e+000,6.176281907e-023,2.205814967e-025

<k,9.999855492e-001,0.000000000e+000,0.000000000e+000,0.000000000e+000,-6.776263578e-021,2.823443158e-023

<*,6.557923113e+001,64,3000,5

<X,-3.836260000e+002,-8.775202787e-013,8.304468224e-014,-2.544261098e-015,3.13695828e-017,-1.359876104e019

10 Series CNC High Speed Machining (02) 4-5

Page 33

Chapter 4

Additional Programming Modes

<Y,-1.736380000e+002,4.116045842e-001,3.370526100e-003,1.039559753e-005,1.237013981e-007,-1.997131743e009

<Z,8.603200000e+001,9.164030615e-001,-2.215163382e-003,1.562230248e-005,-6.930401526e-007,3.106008361e009

<i,0.000000000e+000,0.000000000e+000,0.000000000e+000,0.000000000e+000,0.000000000e+000,0.000000000e+000

<j,-9.155922041e-001,5.944508142e-003,-1.757065214e-004,6.214612678e-006,-5.203550510e-008,1.330231937e-010

<k,4.021080896e-001,6.332656007e-003,9.717969494e-005,-8.784047262e-007,-5.093874428e-009,3.500516597e-011

G60

4-6 10 Series CNC High Speed Machining (02)

Page 34

Chapter 4

Additional Programming Modes

B-SPLINES PROGRAMMING

Programming with B-Splines is similar to programming by means of points. The only difference is that

the programmed points are NOT points through which the curve runs: they are the "curve control

points". In this sense the curve tries to pass as smoothly as possible between the programmed

points. If you are not familiar with B-Splines, you should study their theory in order to understand their

programming and the terminology used.

A B-Spline curve is defined as:

n

P(s) = Σ P

i=1

i Ni,d

(s)

where

s B-Spline parameter

n number of control points

P(s) the point calculated for the parameter s

P

i

N

i,d

ith control point

dth B-Spline base function value

The formula defined above defines a B-Spline curve of the nth degree. You can program B-Spline

curves of the 3rd, 4th and 5th degree. The degree of the programmed B-Splines is defined by

associating the parameter P to G61 at High Speed start.

For example, in order to program with 3rd degree B-Splines you have to write:

G61 P3

In case the P parameter is omitted, the 5th degree is programmed as default.

In order to program a B-Spline curve you have to define the control points for all axes configured in the

HIGH SPEED set-up as well as the elements of the knot vector. For example, B-Splines directly

referring to the positions of the X, Y and Z axis are programmed as follows:

N100 X… Y… Z.. K.. F..

where

X Y and Z define the control points

N defines the Block Number

F defines the Feed

K defines the knot. The number of knots has to be equal to the number of control

points plus the B-Spline degree plus 1. So for a 5th B-Spline operating on 10 point

you have to define 16 knots. In addition the first n+1 and the last n+1 values (n

being the B-Spline degree) HAVE to have the same value and all values must be

expressed in incremental order. You can re-initialise the knot vector after each G.

You can program G62, G66 and G67 between one B-Spline and the next. The

IMPORTANT

final control point of a B-Spline must coincide with the first one of the following BSpline.

10 Series CNC High Speed Machining (02) 4-7

Page 35

Chapter 4

Additional Programming Modes

B-SPLINE PROGRAMMING TYPES AND LIMITS

Based on the type of points defined you also have to program the B-Splines for the versors along

which to calculate the tool length and the tool radius compensation in addition to the axes B-Splines:

B-Splines for Cutter Contact

N100 X… Y… Z.. i… j… k… m… n… o.. p.. q... d.. K.. F…

The following considerations apply:

• The parameters K and the relative “Feed” have to refer to the curve on the Cutter Contact.

• The control points for the three versors (ijk, mno and pqd) MUST always be programmed.

Therefore you CANNOT request their automatic calculation or determine their values based on the

positions (B-Splines) of the rotational axes.

• The automatic calculation of the tangent axis is not managed.

B-Splines for Cutter Location

N100 X… Y… Z… i.. j.. k.. K.. F…

The following considerations apply:

• The parameters K and the relative “Feed” may refer to any curve (Cutter Contact, Cutter Location,

arbitrary), therefore the parameterisation of the B-Spline is free.

• The control points for the tool direction versor (ijk) MUST always be programmed. Therefore you

CANNOT determine their values based on the positions (B-Splines) of the rotational axes.

• The automatic calculation of the tangent axis is not managed.

B-Splines for Axis Location

N100 X… Y… Z… K.. F…

The following considerations apply:

• The parameters K and the relative “Feed” may refer to any curve (Cutter Contact, Cutter Location,

arbitrary), therefore the parameterisation of the B-Spline is free.

• The automatic calculation of the tangent axis is not managed.

4-8 10 Series CNC High Speed Machining (02)

Page 36

WARNING

Example:

G61 P3

X0 Y0 Z0 K0 F3000

X0.7 Y2.3 Z0 K0

X3.8 Y2.6 Z0 K0

X2.3 Y-1.5 Z0 K0

X6.9 Y-1.5 Z0 K2.5

X6.1 Y1.2 Z0 K5

X8.4 Y1.5 Z0 K7.5

K10.

K10

K10

K10

G60

Chapter 4

Additional Programming Modes

For all programming types described above you can also calculate B-Splines for

additional axes but you have to apply the HSM configuration rules described

below.

10 Series CNC High Speed Machining (02) 4-9

Page 37

Chapter 4

Additional Programming Modes

END OF CHAPTER

4-10 10 Series CNC High Speed Machining (02)

Page 38

5

SETUP

A special file (part program) contains the setup of the HSM environment.

This setup is activated whenever the G61 code is programmed.

All numerical values may be defined directly or by means of E or L parameters.

The setup file may be divided into three sections:

− a section of General three-letter codes

− a section of Axis Setup three-letter codes

Chapter

− a section of Machine Setup three-letter codes, which define the kinematics of the machine.

General Three-Letter Codes

(PNT,Type,Param,Poly,Format) Definition of types of points

(VER,Ijk,Mno,Pqd) Versor management

(JRK,Mode,Jrs,Entities,Tstab,Tintgr,Ttop) Look Ahead management

(THR,Tol,TolV,Scale,NullMov,Chord) Threshold programming

(TOL,Len,Radius,EdgeRad,Angle,OriginLen) Tool definition

(TOD,Xcomp,Ycomp,Zcomp) Tool direction (3D)

(CRV,Len,Ratio,Mode) Change in curvature management

(EDG,Angle,VAngle,Mode,Acc) Edge management

Axis Setup Three-Letter Codes

(AXI,Name,Id,Type,CinType,Diam) Definition of types of axis

(AXP,Name,NullMov,Pitch,Lim-,Lim+) Definition of axis parameters

(DIN,Name,Vmax,Amax,Jmax,Vrap,Arap,Jrap) Definition of axis dynamics

Machine Setup Three-Letter Codes

(MAC,Type,Bed) Definition of type of machine

(CIN,Name,Xoff,Yoff,Zoff,Xrot,Yrot,Zrot) Definition of machine kinemat ics

Path Optimizer configuration Three-Letter Codes

(SMT,Toll,TollV,Racc,RaccV,C0,C0V) Tolerances and smoothing parameters

(SMS,Split,SplitV,CondI,CondU,Len,Pnt,C1,Dbg) Special smoothing parameters

10 Series CNC High Speed Machining (02) 5-1

Page 39

Chapter 5

Setup

TYPE OF POINTS DESCRIBED IN THE PART PROGRAM

The syntax of the three-letter code that defines the type of points described in the part program is as

follows:

(PNT, Type, Param, Poly, Format) example: (PNT, CLP,CLP,QUI,PNT)

Parameter Type Values Description

Type Character CCP

CLP

AXI

Obligatory

Param Character CCP

CLP

AXI

Obligatory

Defines the type of points described in the Part Program

CCP Cutter Contact Points: the points entered are

defined in “Cutter contact points”, so tool

compensation (radius and length) may be

executed on these points.

CLP Cutter Location Points: the points entered are

defined in “Cutter location points“, so tool

compensation (length only) may be executed on

these points.

AXI Axis Location Points: the points entered are

defined in “Axis location points”, so no type of

compensation may be executed on these points.

Defines the type of profile for which the feed rate is

programmed in the Part Program and depends on the

type of points entered. The feed rate always refers to the

“3D” profile. Any rotary or additional axes present are not

involved in the calculation of the feed rate but “follow” the

execution of the 3D profile. The feed rate is however

limited when the latter axes, in following the 3D axes,

tend to exceed their dynamic limits.

CCP The programmed Feed rate refers to the profile

generated on the “Cutter contact points”; this

setting is clearly only valid if the points entered are

of the CCP type.

CLP The programmed Feed rate refers to the profile

generated on the “Cutter location points”; it may be

used for the CCP and CLP type points, while for

AXI type points it is only valid when the tool

direction can be determined (either from the

programming of the rotary axes or from the

programming of the ijk versors).

AXI The programmed Feed rate refers to the profile

generated on the “Axis location points”; it may only

be used for AXI type points.

Poly Car. CUB or QUI

Obligatory

Format Characters PNT, POL or

BSP

optional

5-2 10 Series CNC High Speed Machining (02)

Defines the degree of the polynomial curve generated for

the execution of the programmed profile.

CUB A cubic polynomial is generated.

QUI A quintic polynomial is generated.

defines the profile programming method i.e. the input

format used.

PNT input in point format

POL input in polynomial format

BSP input in B-Spline format

Page 40

Chapter 5

Setup

VERSOR MANAGEMENT METHODS

The syntax of the three-letter code that defines how to manage the versors is as follows:

(VER, Ijk, Mno, Pqd) example: (VER , REL , PRG , PRG )

Parameter Type Values Description

Ijk Character PRG or REL

Obligatory

Mno Character PRG or REL

Obligatory

Pqd Character PRG or REL

Obligatory

Defines whether the “Tool Direction” vector is programmed

directly by means of the ijk components or whether it is

to be calculated on the basis of the position of the rotary

axes. When the versor is not necessary, this setting is

ignored.

PRG The versor is programmed using the ijk

components.

REL The versor is to be determined from the position of

the rotary axes.

Defines whether the “Normal to Surface” vector is

programmed directly using the mno components or

whether it is to be calculated automatically by the

system. If the versor is not necessary, this setting is

ignored.

PRG The versor is programmed using the mno

components.

REL The versor is to be determined automatically by

the system.

Defines whether the “Tool Radius Application Direction”

vector is programmed directly using the pqd components

or whether it is to be calculated automatically by the

system. When the versor is not necessary, this setting is

ignored.

PRG The versor is programmed using the pqd

components.

REL The versor is to be determined automatically by the

system.

10 Series CNC High Speed Machining (02) 5-3

Page 41

Chapter 5

Setup

LOOK AHEAD MANAGEMENT

The syntax of the three-letter code that defines the method of look ahead and dynamics management

is as follows:

(JRK, Mode, Jrs, Entities, Tstab, Tintgr, Ttop) example: (JRK, ENA,, )

Parameter Type Values Description

Mode Character ENA,DIS or

AXI

Obligatory

Jrs Number Taken from

JRS variable

Optional

Entities Number Optional The High Speed algorithm works with a dynamic code

Tstab Number Optional Defines the time window (in ms) within which the speed

Defines the type of dynamics to be used.

ENA Enables the use of Jerk Limitation (Mov=8). The

specified jerk refers to the dynamics described on

the profile.

DIS Disables Jerk Limitation, only uses “S ramps”

(Mov=2).

AXI Enables the use of Jerk Limitation (Mov=8). The

specified jerk refers to the dynamics described by

the axes and how this affects the dynamics of the

profile. The use of this method is closely

associated with the quality of the points entered

(number of decimals and distribution).

Modifies the value of the JRS variable of the system only

for the G61 section being processed; if the value is

omitted, the JRS variable active in the system is used.

(polynomial curves) and only after having calculated and

having filled in the whole queue from the start to the

movement.The start may be adjusted by programming the

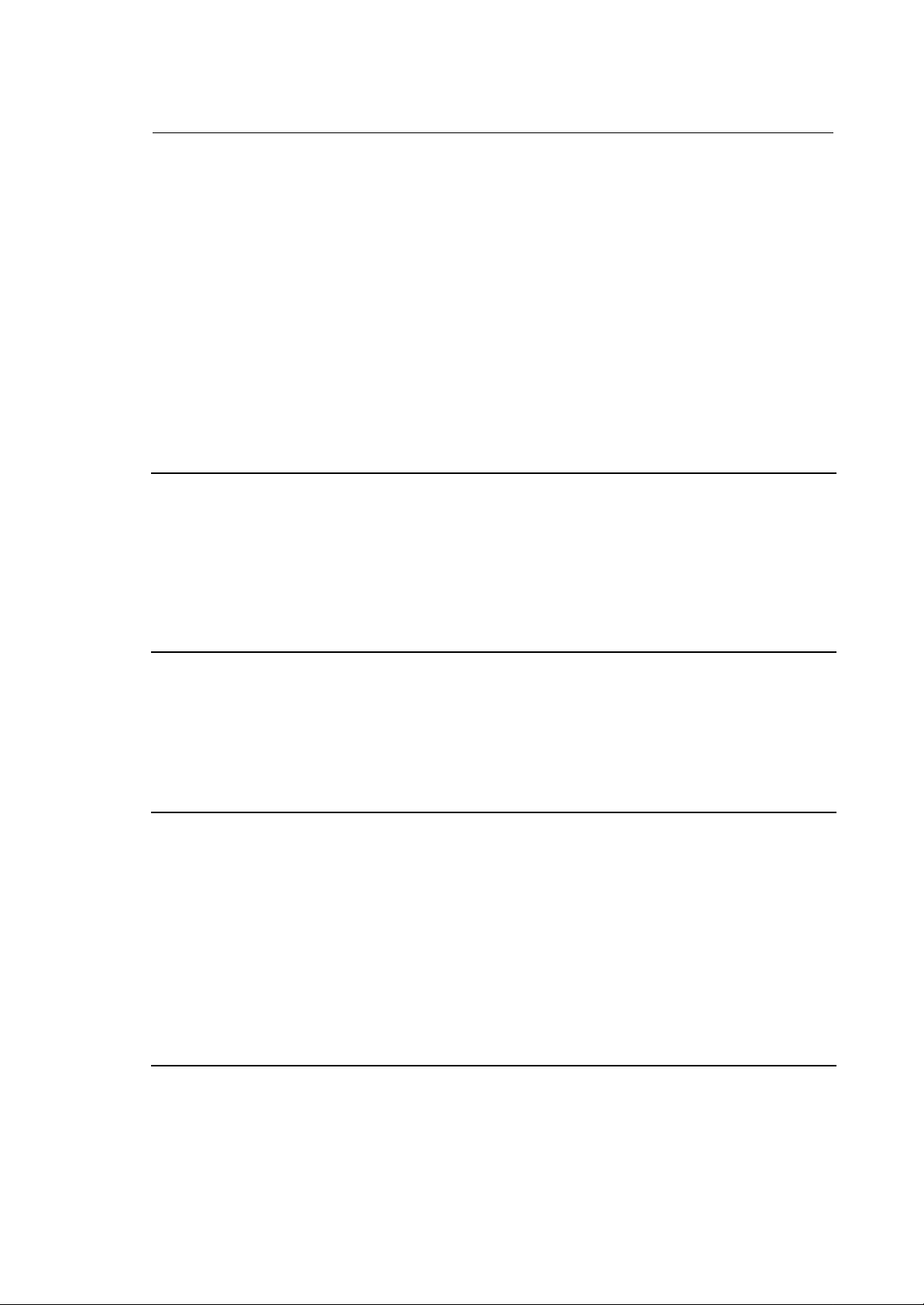

number of elements to be calculated before starting

movement. 0 means maximum number of elements.

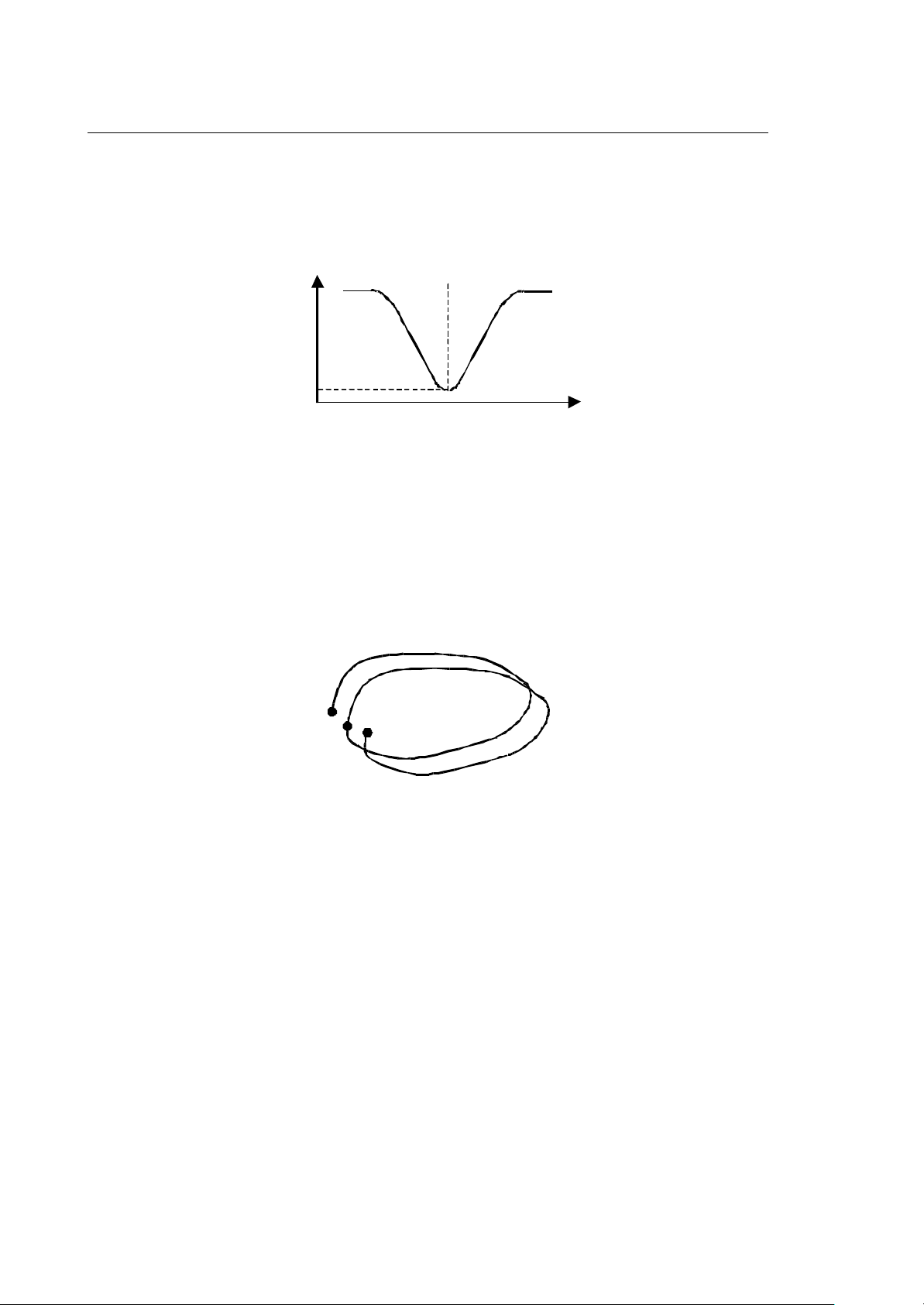

smoothing algorithm is to be applied. This algorithm

removes unnecessary accelerations so as to avoid

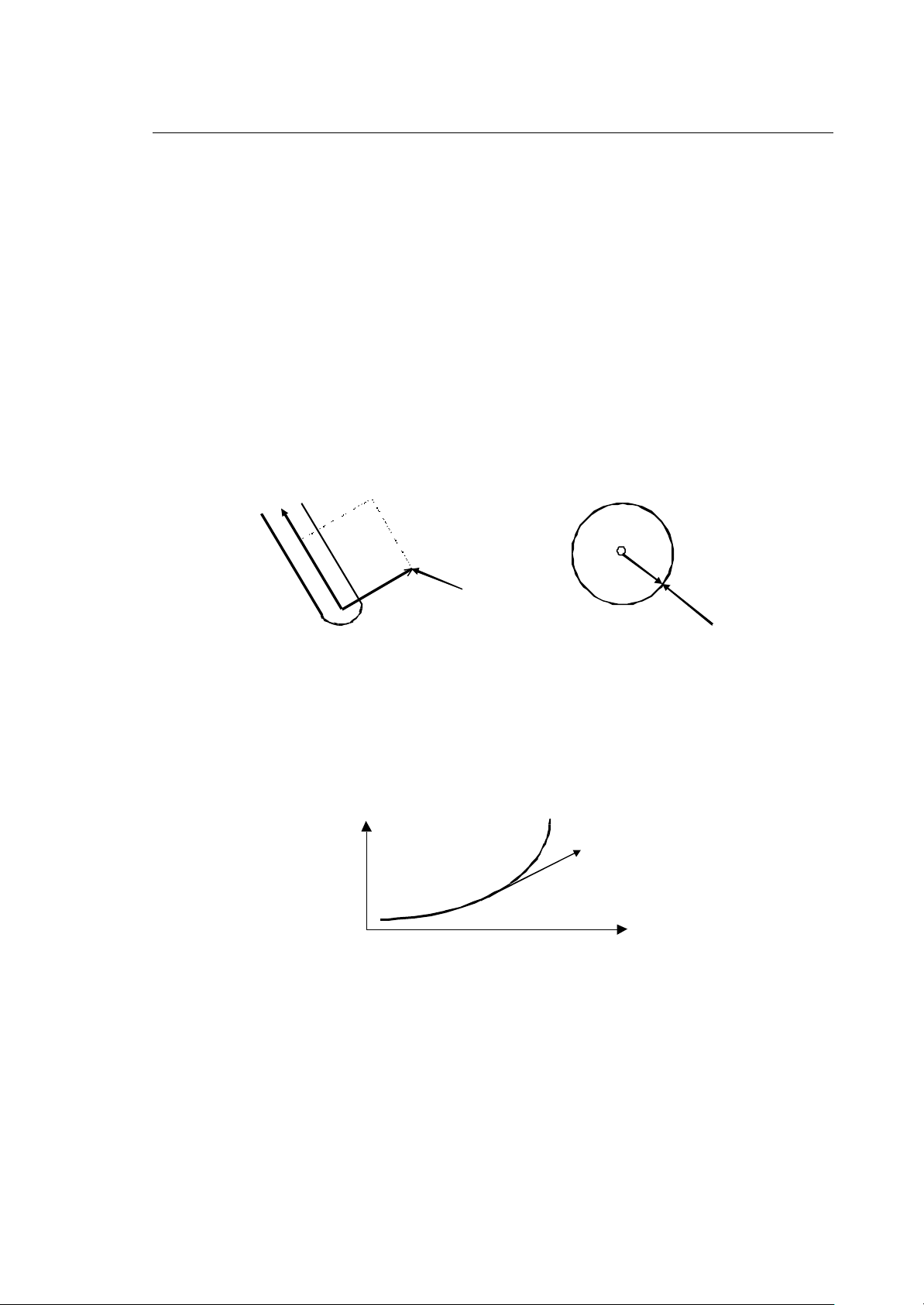

machine oscillations (see Figure 1).

Tintgr Number Optional Defines the maximum time (in ms) for integrating the

acceleration (or deceleration) phases with the sections at

a constant feed rate (see Figure 1).

Ttop Number Optional Defines the minimum time (in ms) for executing a section

with a constant feed rate V (see Figure 1).

5-4 10 Series CNC High Speed Machining (02)

Page 42

Chapter 5

Setup

Figure 1

10 Series CNC High Speed Machining (02) 5-5

Page 43

Chapter 5

refers to entities like versors which always have a

Setup

THRESHOLDS

The syntax of the three-letter code that defines the value of thresholds used in generating the

polynomial curves is as follows:

(THR, Tol, TolV, Scale, NullMov, Chord) example: (THR , 0.01 , 0.0001 , 0 , 0 , 0.1 )

Parameter Type Values Description

Tol Number Obligatory Defines the tolerance range to be used in generating the

polynomial curves. As defined previously, the polynomial

curves generated pass through the programmed points,

within a given tolerance threshold. This parameter defines

the tolerance value. It is defined in mm (or inches if the

machine is configured in inches).

TolV Number Obligatory Defines the tolerance range to be used in generating the

polynomial curves calculated on the versors. This value is

important because the precision with which the rotary

axes are positioned depends on the precision with which

the curves are generated on the versors (in particular, on

the ijk versor). The number has no dimension in that it

dimension of 1. We suggest a value equal to 0.1 times

the Toll value defined previously be set. 0 disables the

management of a tolerance on the versors.

Scale Number Obligatory Scale factor to be applied to the programmed axes. If 0 is

set, the scale factor is not to be applied. It is not applied

to the versors and rotary axes, when programmed.

NullMov Number Obligatory Null movement threshold. If the distance between one

point and the next is less than this threshold in mm (or

inches if the machine is configured in inches) the next

point is eliminated.

Chord Number Obligatory Maximum allowed chordal error at input and output during

the generation of a polynomial. Value expressed in mm

(or inches if the machine is configured in inches).

5-6 10 Series CNC High Speed Machining (02)

Page 44

Chapter 5

Setup

TOOL DEFINITION

In the High Speed Machining system, “Cylindrical”, “Ball-ended” and “Toroidal” type tools may be

managed. The syntax of the three-letter code that defines the characteristics of the tool to be used for

machining is as follows:

(TOL, Len, Radius, EdgeRad, Angle, OriginLen) example: (TOL , , , 1 , -90 , 0 )

Parameter Type Values Description

Len Number Taken from the

offset active on

G61

Optional

Radius Number Taken from the

offset active on

G61

Optional

EdgeRad Number Obligatory Defines the radius on the edge of the tool. As this value is

Angle Number Obligatory Defines the angle of contact between the tool and the

OriginLen Number Obligatory Defines the length of the tool for which the part program

Defines the length of the tool to be used for tool length

compensation. If no value is set, the tool length is taken

from the offsets active in the system on the activation of

the G61. The value set here is only active during the

machining of the current section of G61/G60.

Defines the radius of the tool to be used for tool radius

compensation. If no value is set, the tool radius is taken

from the offsets active in the system on the activation of

G61. The value set here is only active during the

machining of the current section of G61/G60.

not handled by the system offsets, it has to be set.

part. It is used in the automatic calculation of the vector

normal to the surface.

was generated. This field is used when the points entered

refer to “Axis location points” and the feed rate is to be

set in relation to the “Cutter location points”.

10 Series CNC High Speed Machining (02) 5-7

Page 45

Chapter 5

Setup

TOOL DIRECTION (3D)

Defines the tool direction (to be used for compensation purposes) for generic machines or machines

with 3 axes (it is not required on machines with 5 axes). In practice, the unitary vector (similar to ijk)

which identifies the tool direction in the part reference system has to be defined.

The syntax of the three-letter code that defines the direction of the tool to be used for machining is as

follows:

(TOD, Xcomp, Ycomp, Zcomp) example: (TOD , 0 , 0 , 1 )

Parameter Type Values Description

Xcomp Number Obligatory Component of the tool direction along the X axis.

Ycomp Number Obligatory Component of the tool direction along the Y axis.

Zcomp Number Obligatory Component of the tool direction along the Z axis.

5-8 10 Series CNC High Speed Machining (02)

Page 46

Chapter 5

Setup

CHANGE IN CURVATURE MANAGEMENT

The algorithm used by the CAM systems to generate the points of a profile takes into account the

“chordal error”, that is, it generates points closer together when the radius of curvature of the profile to

be described becomes more accentuated. A change in curvature may therefore be generically

identified by a variation in the distance between one set of points and the following ones. This

variation in curvature may be identified automatically by the High Speed Machining algorithms so as

to avoid oscillations around the point where this change takes place.

Supposing, for example, we have a curved section followed by a straight section. The spline on the

straight section would tend to oscillate or generate a “hump”, so it is important to identify it.

At the point of the “change in curvature” the system will automatically insert a G62 or a G63 as

requested by the user.

The syntax of the three-letter code that defines how to identify and then manage the change in

curvature is as follows:

(CRV, Len, Ratio, Mode) example: ( CRV , 1 , 6 , G63 )

Parameter Type Values Description

Len Number Obligatory Defines the minimum length of the “long section” for the

change in curvature to be managed. It is defined in mm

(or inches if the machine is configured in inches).

Ratio Number Obligatory Defines the ratio between the long section and short

section so that the change in curvature may be identified.

For example, the value 6 defines that the distance

between p2 and p3 must be greater than 6 times the

distance between p1 and p2 for the change in curvature to

be activated.

Mode Character G62 or G63

Obligatory

Defines the transition code to be set on the “change in

curvature” point

G62 The two segments are generated with two splines

tangential to one another, so the second spline will

have an initial inclination equal to the final

inclination of the first spline.

G63 The two segments are generated by two non-

tangential splines, but are linked on the basis of

the calculation tolerance set.

10 Series CNC High Speed Machining (02) 5-9

Page 47

Chapter 5

Setup

EDGE MANAGEMENT

The automatic identification of edges is important for the same reason as the identification of changes

in curvature. Failure to identify edges could generated incorrect oscillations on the splines. The

optimum dynamic approach for handling an edge is to stop at zero speed and then restart on the next

section. Stopping may be damaging however as the tool, as it turns, continues to remove material

and so some “notches” may be visible on the part. For this reason, it is possible to define whether

and how to stop at the edge.

The syntax of the three-letter code that defines how to identify and therefore how to manage the

presence of edges is as follows:

(EDG, Angle, VAngle, Mode, Acc) example: ( EDG , 30 , 0 , G66 , 1 )

Parameter Type Values Description

Angle Number Obligatory The system is capable of automatically determining the

edges defined by the programmed points (edges on the

linear axes) and automatically programming a G66. This

value, expressed in degrees, defines the threshold angle

beyond which a point is defined an “edge” point. See the

figure below.

VAngle Number Obligatory It is similar to the previous value and is to be used for the

versors. The presence of an edge on the versors

generates an “edge” in the movement of the rotary axes.

It is therefore advisable to add a G66 also in these cases.

See the figure below.

Mode Character G63, G66 or

G67

Obligatory

Acc Number Obligatory Acceleration that may be withstood by the axes in

Defines the transition code to be set on the edge

G63 The edge is executed by inserting a link which is

generated by taking the configured chordal error

into account.

G66 Movement ends at zero speed.

G67 Movement ends at the maximum speed at which

the edge may be faced in the best possible way.

tackling the edge: 1 means that an axis may withstand

an increase in speed equal to 1 acceleration. It only

applies to G67.

5-10 10 Series CNC High Speed Machining (02)

Page 48

Chapter 5

Setup

AXIS DEFINITION

The axes to be subjected to the High Speed Machining algorithms may be defined. A maximum of 6

axes may be defined, of which 3 axes make up the three Cartesian axes, 2 are rotary axes (for

machines with 5 axes) and other additional axes. The syntax of the three-letter code for defining the

axes is as follows:

(AXI, Name, Id, Type , CinType, Diam) example: (AXI , X , 1 , ABS , LI1, DIS)

Parameter Type Values Description

Name Character Obligatory Defines the name of the axis. This name may be different

from the one set in AMP for the axis, and may therefore

be compared to an implicit “DIN” in the HSM setup. This

association only applies to the G61/G60 section being

machined.

Id Number Obligatory Defines the ID of the axis. This axis must be under the

control of the Process in which the part program is being

executed.

Type Character ABS, ORD,

VRT, TAN,

OTH or TAO

Obligatory

Defines the axis type, and influences the method by

which the axis is managed by the HSM algorithms.

ABS The axis is of the x-coordinate type (in the

Cartesian coordinate system)

ORD The axis is of the y-coordinate type (in the

Cartesian coordinate system)

VRT The axis is of the z-coordinate type (in the

Cartesian coordinate system)

TAN Tangential axis, calculated automatically by the

system

TAO tangent axis, automatically calculated by the

system with the moving axis (positive direction) in

clockwise sense, i.e. in the sense opposite to the

trigonometric convention.

OTH Other type of axis, different from the previous ones.

10 Series CNC High Speed Machining (02) 5-11

Page 49

Chapter 5

Setup

Parameter Type Values Description

CinType Character LI1, LI2, LI3,

WRK, TOL or

OTH

Obligatory

Diam Character ENA or DIS

optional

Defines the position of the axis in the kinematic chain of

the machine (see following sections). For generic

machines or machines with 3 axes for which the

kinematic chain does not have to be defined, we

recommend the following setup:

LI1 To be associated with the axis defined as ABS (x-

coordinate) in the previous field.

LI2 To be associated with the axis defined as ORD (y-

coordinate) in the previous field.

LI3 To be associated with the axis defined as VRT (z-

coordinate) in the previous field.

OTH Additional axis.

For machines with 5 axes, the setup values are as

follows:

LI1 First axis in the kinematic chain.

LI2 Second axis in the kinematic chain.

LI3 Third axis in the kinematic chain.

WRK Rotary axis closest to the part.

TOL Rotary axis closest to the tool.

OTH Additional axis.

Allows to characterise the axis as Diametral. If not

defined, the analog active system parameter is used.

ENA the axis is defined as diametral.

DIS normal axis

5-12 10 Series CNC High Speed Machining (02)

Page 50

Chapter 5

Setup

AXIS PARAMETERS

Some characteristics of the axis set on the system may be varied. These variations are only active in

the G61/G60 section being machined. The syntax of the three-letter code is as follows:

(AXP, Name, NullMov, Pitch, Lim-, Lim+) example: (AXP , X , 0 , , , )

Parameter Type Values Description

Name Character Obligatory Axis name as defined in the three-letter code (AXI).

NullMov Number Obligatory Defines the null movement for the axis in question. If the

position programmed for an axis differs from the current

position (or last programmed position) for a value lower

than the null movement, the movement of the axis (the

new position) is not considered. We recommend it be left

set to 0 and activated only in cases in which the part

program under execution contains imprecisions in the

programming of the axes.

Pitch Number Optional Used for redefining the rollover pitch for the axis in

question. It may be used, for example, to program a nonrollover rotary axis with rollover values and vice versa. If

not defined, the analog active system parameter is used.

Lim- Number Optional Used for redefining the lower operating limit for the axis in

question. If not defined, the analog active system

parameter is used.

Lim+ Number Optional Used for redefining the upper operating limit for the axis in

question. If not defined, the analog active system

parameter is used.

10 Series CNC High Speed Machining (02) 5-13

Page 51

Chapter 5

Setup

AXIS DYNAMICS

Some dynamic characteristics of the axis set in the system may be varied. These variations are only

active in the G61/G60 section being machined. The syntax of the three-letter code is as follows:

(DIN,Name, Vmax, Amax, Jmax, Vrap, Arap, Jrap) example: (DIN , X , , , , , , )

Parameter Type Values Description

Name Character Obligatory Axis name as defined in the three-letter code (AXI).

Vmax Number Optional Used for redefining the maximum speed at which the axis

may be moved when a machining operation in G01 is in

progress. It must be defined in mm/min. If not defined, the

analog active system parameter is used.

Amax Number Optional Used for redefining the maximum acceleration at which

the axis may be moved when a machining operation in

G01 is in progress. It must be defined in mm/sec2. If not

defined, the analog active system parameter is used.

Jmax Number Optional Used for redefining the maximum Jerk to which the axis

may be moved when a machining operation in G01 is in

progress. It must be defined in mm/sec3. If not defined,

the analog active system parameter is used.

Vrap Number Optional Used for redefining the maximum speed at which the axis

may be moved when a machining operation in G00 is in

progress. It must be defined in mm/min. If not defined, the

analog active system parameter is used.

Arap Number Optional Used for redefining the maximum acceleration at which

the axis may be moved when a machining operation in

G00 is in progress. It must be defined in mm/sec2. If not

defined, the analog active system parameter is used.

Jrap Number Optional Used for redefining the maximum Jerk at which the axis

may be moved when a machining operation in G00 is in

progress. It must be defined in mm/sec3. If not defined,

the analog active system parameter is used.

5-14 10 Series CNC High Speed Machining (02)

Page 52

Chapter 5

Setup

MACHINE KINEMATICS

By configuring the machine kinematics, the various transformations that enable the machine to switch

from programming in “Cutter contact points” or “Cutter location points” to the actual movement of the

axes may be configured, programming the rotary axes automatically and carrying out the

compensation described previously for machines with 5 axes.

Definition of the Kinematic Chain

A fundamental operation in defining the machine kinematics is to identify the “Kinematic Chain” that

is, to define the sequence of movements of the axes and define how movement passes from one axis

to another. This chain must start from the tool and end at the part.

The kinematics managed by High Speed Machining include 2 rotary axes and 3 linear axes with the

possibility of handling the rotary axes in three different layouts:

a) Two rotary axes associated with two rotary tables on which the part to be machined is positioned.

In this case, the kinematic chain is defined as follows :

Tool →→ Linear axes →→ First table →→ Second table →→ Part

b) A rotary axis associated with a rotary table on which the part to be machined is positioned and

another rotary axis assembled on the head. In this case, the kinematic chain is defined as follows:

Tool →→ Head rotary axis →→ Linear axes →→ Rotary table →→ Part

c) Two rotary axes both assembled on the head (Double twist) that move around the part. In this

case, the kinematic chain is defined as follows :

Tool →→ First head rotary axis →→ Second head rotary axis →→ Linear axes →→ Part

This structure may be illustrated (using the symbols defined in the setup of the three-letter code AXI

for the TipoCin) field in the form of the table below:

Tool Rotary Rotary Linear 3 Linear 2 Linear 1 Rotary Rotary Part

T --- --- LI3 LI2 LI1 TOL WRK P

T --- TOL LI3 LI2 LI1 WRK --- P

T TOL WRK LI3 LI2 LI1 --- --- P

Another fundamental element in the kinematic chain is the “Machine Bed”.

It is a “theoretical” point fixed to the ground with respect to which the sequence of movement of the

axes (chain) may be split into two sections. The movements of the first section do not influence the

movements of the second section.

10 Series CNC High Speed Machining (02) 5-15

Page 53

Chapter 5

Setup

In the kinematic chain, the “Machine Bed” may have one of four positions, which may be illustrated by

means of the table below:

Tool Rotary Rotary Linear 3 Linear 2 Linear 1 Rotary Rotary Part

T --- --- LI3 LI2 LI1 TOL WRK P

T --- TOL LI3 LI2 LI1 WRK --- P

T TOL WRK LI3 LI2 LI1 --- --- P

Machine Bed

Toll

Machine Bed

B23

Machine Bed

B12

Machine Bed