Omron NT21 DATASHEET

Cat. No. V068-E1-01

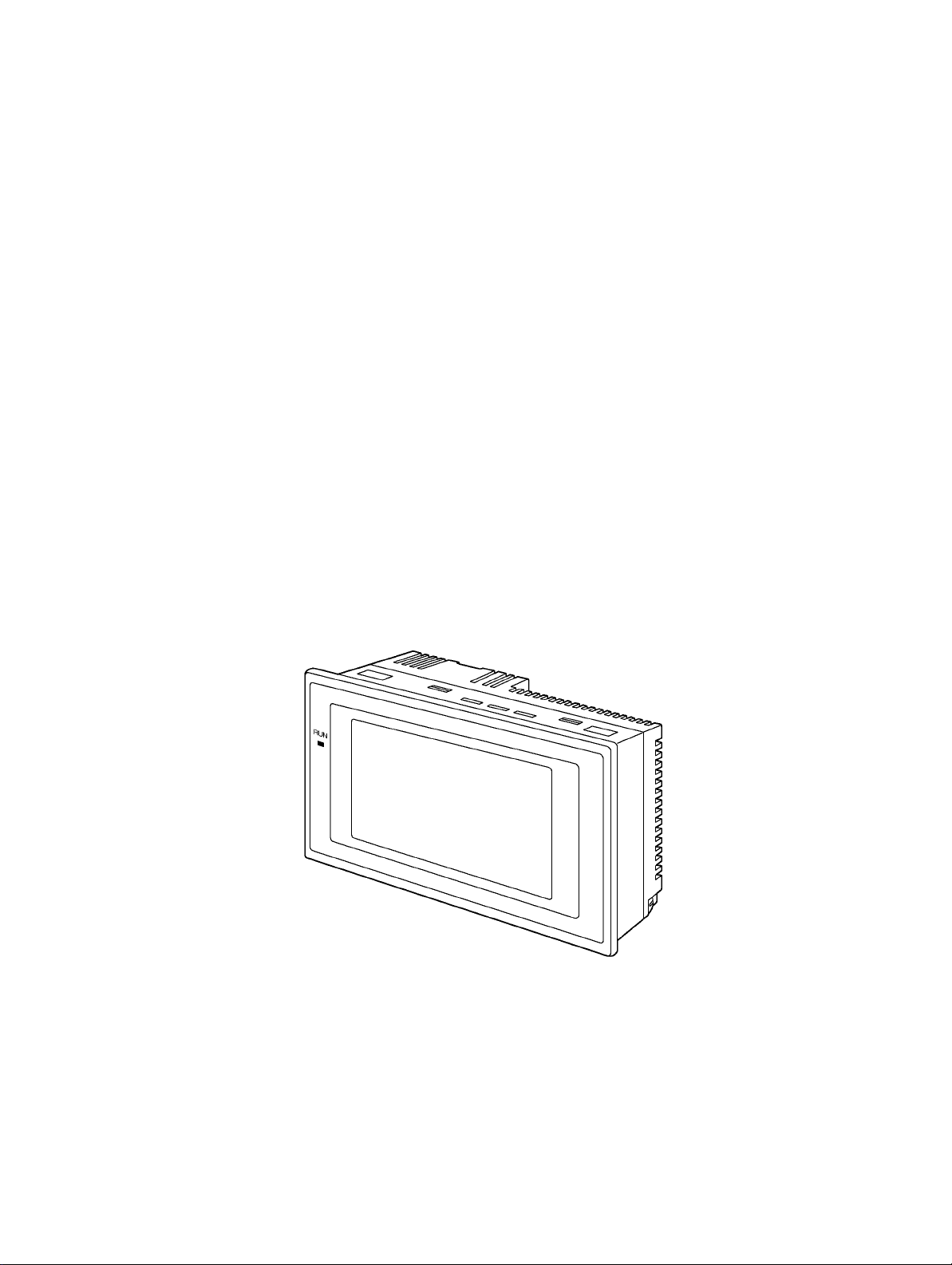

NT21

Programmable Terminal

Setup Manual

NT21

Programmable Terminal

Setup Manual

Produced October 2001

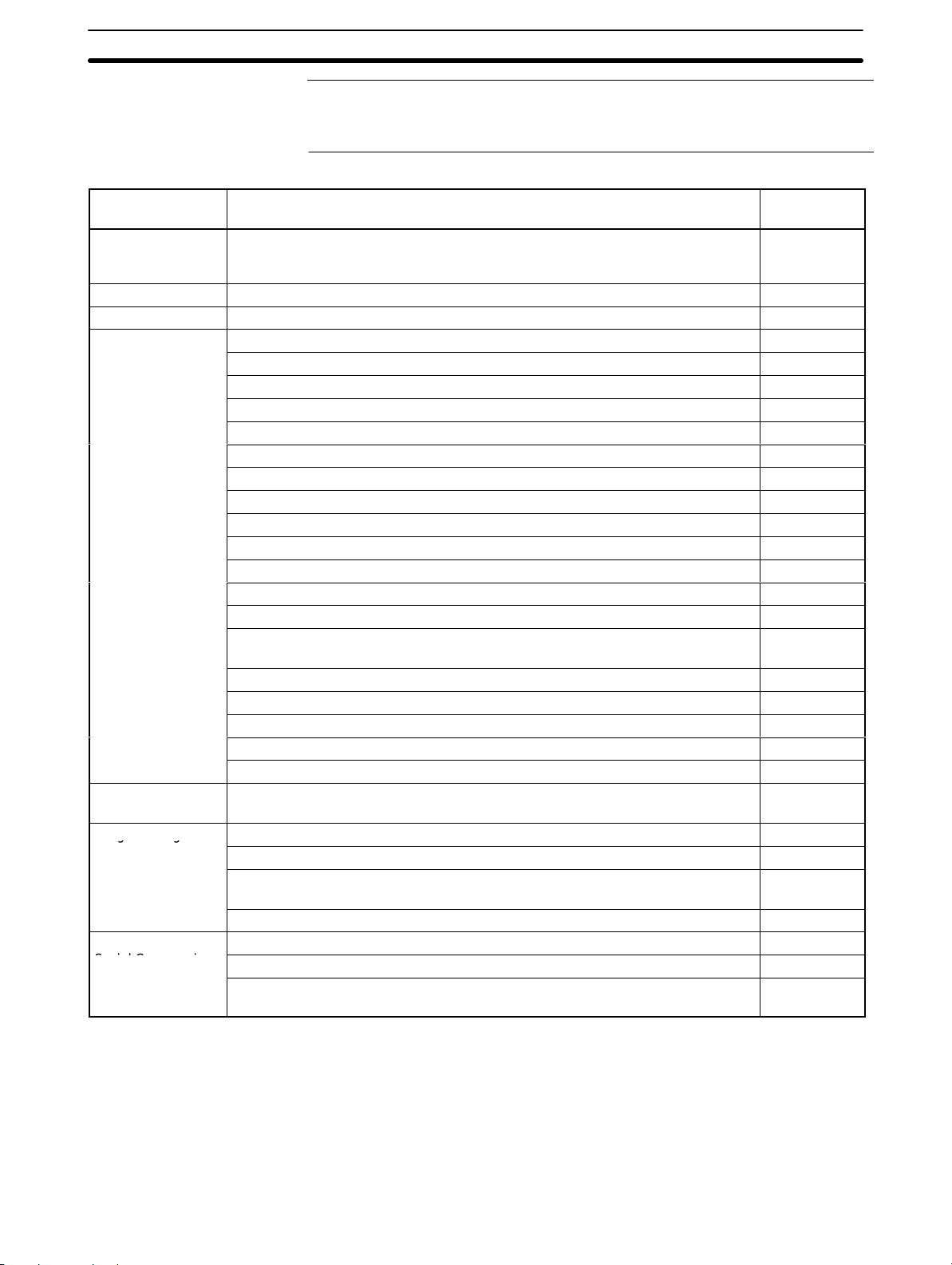

TABLE OF CONTENTS

PRECAUTIONS xi. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1 Intended Audience xii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 General Precautions xii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 Safety Precautions xii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 1

General 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-1 Role and Operation of the NT21 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-2 Comparison between NT20S and NT21 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-3 System Configuration 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-4 Before Operating 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 2

Preparing for Connection 9. . . . . . . . . . . . . . . . . . . . . . . . .

2-1 Method for Connection to the Host 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-2 Names and Functions of Parts 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 3

Hardware Installation and Connections 15. . . . . . . . . . . . .

3-1 Installation 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-2 Connecting Link Adapters 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-3 Connecting the NT Support Tool 28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-4 Connecting a Bar Code Reader 29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-5 Using a Memory Unit 31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 4

Connecting to the Host from the RS-232C Port 39. . . . . . .

4-1 Connecting to the RS-232C Port at the Host 40. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 5

Connecting to the Host from the RS-422A/485 Port 67. . . .

5-1 Connecting to the Host’s RS-422A/485 Port 68. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-2 Connecting to the Host’s RS-232C Port 94. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 6

System Menu Operation 101. . . . . . . . . . . . . . . . . . . . . . . . . .

6-1 System Menu Operation Flow 103. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-2 Starting the NT21 104. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-3 Operation Modes and the System Menu 105. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-4 Memory Initialization 110. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-5 Operations in the System Installer Mode 118. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-6 Transmitting the Screen Data 123. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-7 Setting Conditions for Communications with Host by Using Memory Switches 125. . . . . . .

6-8 Starting Operation 133. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-9 System Settings 134. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-10 Setting the Bar Code Reader Input Function 144. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-11 System Maintenance 147. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-12 Programming Console Function 165. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-13 Version Display 171. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

vii

TABLE OF CONTENTS

SECTION 7

Troubleshooting and Maintenance 173. . . . . . . . . . . . . . . . . .

7-1 Troubleshooting 174. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-2 Responding to Displayed Error Messages 176. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-3 Maintenance of the NT21 183. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-4 Inspection and Cleaning 185. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendices

A Specifications 187. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B External Dimensions and Mounting Dimensions 193. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C Transporting and Storing the NT21 195. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

D Making the Cable 197. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

E Making the Cable for Connecting a Personal Computer 199. . . . . . . . . . . . . . . . . . . . . . . . . . . .

F Model List 201. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

G Option List 207. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Index 209. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Revision History 213. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

viii

iv

Notice:

OMRON products are manufactured for use according to proper procedures by a qualified operator

and only for the purposes described in this manual.

The following conventions are used to indicate and classify precautions in this manual. Always heed

the information provided with them. Failure to heed precautions can result in injury to people or damage to property.

DANGER Indicates an imminently hazardous situation which, if not avoided, will result in death or

!

serious injury.

WARNING Indicates a potentially hazardous situation which, if not avoided, could result in death or

!

serious injury.

Caution Indicates a potentially hazardous situation which, if not avoided, may result in minor or

!

moderate injury, or property damage.

OMRON Product References

All OMRON products are capitalized in this manual. The word “Unit” is also capitalized when it refers

to an OMRON product, regardless of whether or not it appears in the proper name of the product.

The abbreviation “Ch,” which appears in some displays and on some OMRON products, often means

“word” and is abbreviated “Wd” in documentation in this sense.

The abbreviation “PC” means Programmable Controller and is not used as an abbreviation for anything else.

Visual Aids

The following headings appear in the left column of the manual to help you locate different types of

information.

OMRON, 2001

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any

form, or by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior written permission of OMRON.

No patent liability is assumed with respect to the use of the information contained herein. Moreover, because OMRON is

constantly striving to improve its high-quality products, the information contained in this manual is subject to change

without notice. Every precaution has been taken in the preparation of this manual. Nevertheless, OMRON assumes no

responsibility for errors or omissions. Neither is any liability assumed for damages resulting from the use of the information contained in this publication.

Note Indicates

of the product.

1, 2, 3... 1. Indicates lists of one sort or another, such as procedures, checklists, etc.

information of particular interest for ef

ficient and convenient operation

v

vi

About this Manual:

This

manual describes connecting the NT

Controller) or other host and peripheral devices and the settings required for communications and applications. It includes the sections described below.

-series NT21 Programmable T

erminal to a PC

(Programmable

Please

to install and operate the Programmable Terminal.

Section

tion,

PTs.

Section

of PTs, as the required knowledge before connecting to the host and to the peripheral devices.

Section 3 describes the settings of the PTs and methods for connection to peripheral devices.

Section 4 describes the method for connecting to the host using the RS-232C port of the PT.

Section 5 describes the method for connecting to the host using the RS-422A/485 port of the PT.

Section

tions

explained here.

Section

inspection to prevent the occurrence of errors.

The

formation

ware, and product lists.

read this manual carefully and be sure you understand the information provided before attempting

1

provides fundamental information about the functions and

communication methods, etc. This information

2

describes the connection methods that

6

describes the operation of the System Menu, focusing on the procedure to start the PT

that are convenient when using the PT and those that are useful for system maintenance are also

7

describes the action to take when errors occur in

Appendices

on cable preparation, information on the relationship between the system program and hard

provide specifications,

dimensions, procedures for transporting and storing the PT

will enable you to understand the applications of the

are possible with the PT

the PT

features of the PT

s, and the functions of the parts

, and how to carry out maintenance and

s, types of connec

. Func

, in

-

-

-

-

!

WARNING Failure to read and understand the information provided in this manual may result in

personal injury or death, damage to the product, or product failure. Please read each

section

and related sections before attempting any of the procedures or operations given.

in its entirety and be sure you understand the information provided

in the section

ix

Related Manuals:

Related manuals are listed below.

The j symbol at the end of the catalog number is the revision number.

Connecting and Setting Up the Programmable Terminal

S NT21 PT Setup Manual (V068-E1-j, this manual)

This manual describes connecting the Programmable Terminals to a host and

peripheral devices and settings required for communications and applications.

The functions and actual operating methods for the NT21 are provided in the

Reference Manual (V069-E1-j).

Programmable Terminal Functions and Operation

S NT21 PT Reference Manual (V069-E1-j)

This

manual is used for NT21 PT

tions, host control methods, and other application information.

. It describes screen configurations, part func

-

connection and setup procedures are described in the

PT

al (V068-E1-j).

Creating and Transferring Screen Data, and Installing the System Program

Faulty Display Pixels

S NT-series

The screens displayed on the NT21 are created with the NT Support Tool and

transferred

data.

tem Installer.

NT

The

Support Tool.

Although the LCD panel has been manufactured with extremely high-level

technology, there can sometimes be pixels that will not light or that will be lit

constantly.

faulty display. Please understand that, although we are constantly striving to

keep

inate them completely.

Support T

to the PT

It also describes how to download a system program to a PT using the Sys

-series Support T

These are characteristic of LCD panels and are

these pixels to

ool for Windows Ver. 4.6 Operation Manual

. This manual describes how to create and transfer screen

ool for Windows is normally referred to as merely the NT

a minimum, it is not possible with present technology to elim

NT21 PT Setup Manu

(V061-E1-

not an indication of a

j)

-

-

-

x

This section provides general precautions for using the Programmable Terminal.

The

information contained in this section is important for

Y

minal.

Programmable Terminal.

ou must r

1 Intended Audience xii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 General Precautions xii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 Safety Precautions xii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ead this section

and understand the information contained befor

the safe and r

eliable application of the Pr

e attempting to set up or operate a

PRECAUTIONS

ogrammable T

er-

xi

1 Intended Audience

This

manual is intended for the following personnel, who must also have knowl

edge of electrical systems (an electrical engineer or the equivalent).

• Personnel in charge of introducing FA systems into production facilities.

• Personnel in charge of designing FA systems.

• Personnel in charge of installing and connecting FA systems.

• Personnel in charge of managing FA systems and facilities.

2 General Precautions

The

user must operate the product according to the performance specifications

described in the operation manuals.

using the product under conditions that are

Before

or applying the product to nuclear control systems, railroad systems, aviation

systems, vehicles, combustion systems, medical equipment, amusement machines, safety equipment, and other systems, machines and equipment that

have a serious influence on lives and property if

may

your OMRON representative.

Make sure that the ratings and performance characteristics of the product are

sufficient

systems, machines, and equipment with double safety mechanisms.

This

to

read this manual before attempting to use the

close at hand for reference during operation.

for

manual provides information

3Safety Precautions

-

not described in the manual

used improperly

the systems, machines, and equipment, and be sure to provide the

for using the Programmable T

software and keep this manual

erminal. Be sure

, consult

WARNING It is extremely important that Programmable Terminals and related devices be

!

for the specified purpose and under the specified conditions, especially in

used

applications that can directly or indirectly affect human life. You must consult

your OMRON representative before applying Programmable T

with

the above-mentioned applications.

WARNING Do not use input functions such as PT touch switches for applications where

!

danger to human life or serious damage is possible, or for emergency switch

applications.

3 Safety Precautions

Read these safety precautions carefully and make sure you understand them

using the Programmable T

before

rectly.

This

Safety Conventions and

their Meanings

operation manual uses the following conventions and symbols to indicate

cautions, warnings, and dangers in order to ensure safe use of the NT21.

cautions, warnings, and dangers shown here contain important

The

related

be observed.

The conventions used and their meanings are presented below.

to safety

erminals

erminal so that you can use it

. The instructions in these cautions, warnings, and dangers must

safely and cor

information

to

-

xii

WARNING Indicates information that, if not heeded, could possibly result in loss of life or

!

serious injury.

Caution Indicates

injury, damage to the product, or faulty operation.

information that, if not heeded, could result in relatively serious or minor

WARNING

Do not attempt to take the Unit apart and do not touch any

internal parts while the power is being supplied. Doing either of

these may result in electrical shock.

3Safety Precautions

xiii

This

section provides fundamental information about the functions and features of the PT

tion methods, etc. This information will enable you to understand the applications of the PTs.

1-1 Role and Operation of the NT21 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-1-1 Operation of an NT21 at an FA Production Site 2. . . . . . . . . . . . . . . . . . . . . . . . . .

1-1-2 Operations of the NT21 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-2 Comparison between NT20S and NT21 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-3 System Configuration 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-3-1

1-3-2

1-4 Before Operating 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Peripheral Devices That Can Be Connected

Connecting to the Host

s, types

SECTION 1

General

of connection, communica

6. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

-

1

1-1 Role and Operation of the NT21

The NT21 is a sophisticated operator interface (Programmable Terminal) that

automatically displays information and can also be used for operations when

necessary.

the NT21 for those using a Programmable Terminal (PT) for the first time.

1-1-1 Operation of an NT21 at an FA Production Site

The

Production Line Status

Monitoring

NT21 displays real-time information about the system and equipment oper

ating

als, making the displays easy to understand.

The following gives a general description of the role and operation of

status, etc. Its power of expression is enhanced by graphs

1-1SectionRole and Operation of the NT21

and other visu

-

-

Directions to Workers on

the Shop Floor

Panel Switch Functions

Production

Today’s

Current production 305

Number defective 2

Number repaired 7

% achieved

NT21 5%

The

NT21 warns of system or equipment failures and prompts the appropriate

Product

target

Control (3)

NT21

560

remedial action.

Alarm

Assembly

Positioning pin

is defective. Line stopped.

Check the following.

1. Defective pin L3

2. Position of dog M2

3. Mounting of photosensor P5

Setting

touch switches on the NT21 allows workers to use the NT21 as an

ating panel; the results of the operations are transmitted to the host.

line B

oper

-

Electroplating

Transport

Int. stop

Clamp

Unclamp

Adv.

Rev.

control

Electr.

head

Electro-

lyte

Wash.

head

Wash

Corr. prv.

head

Corr.

prv.fluid

2

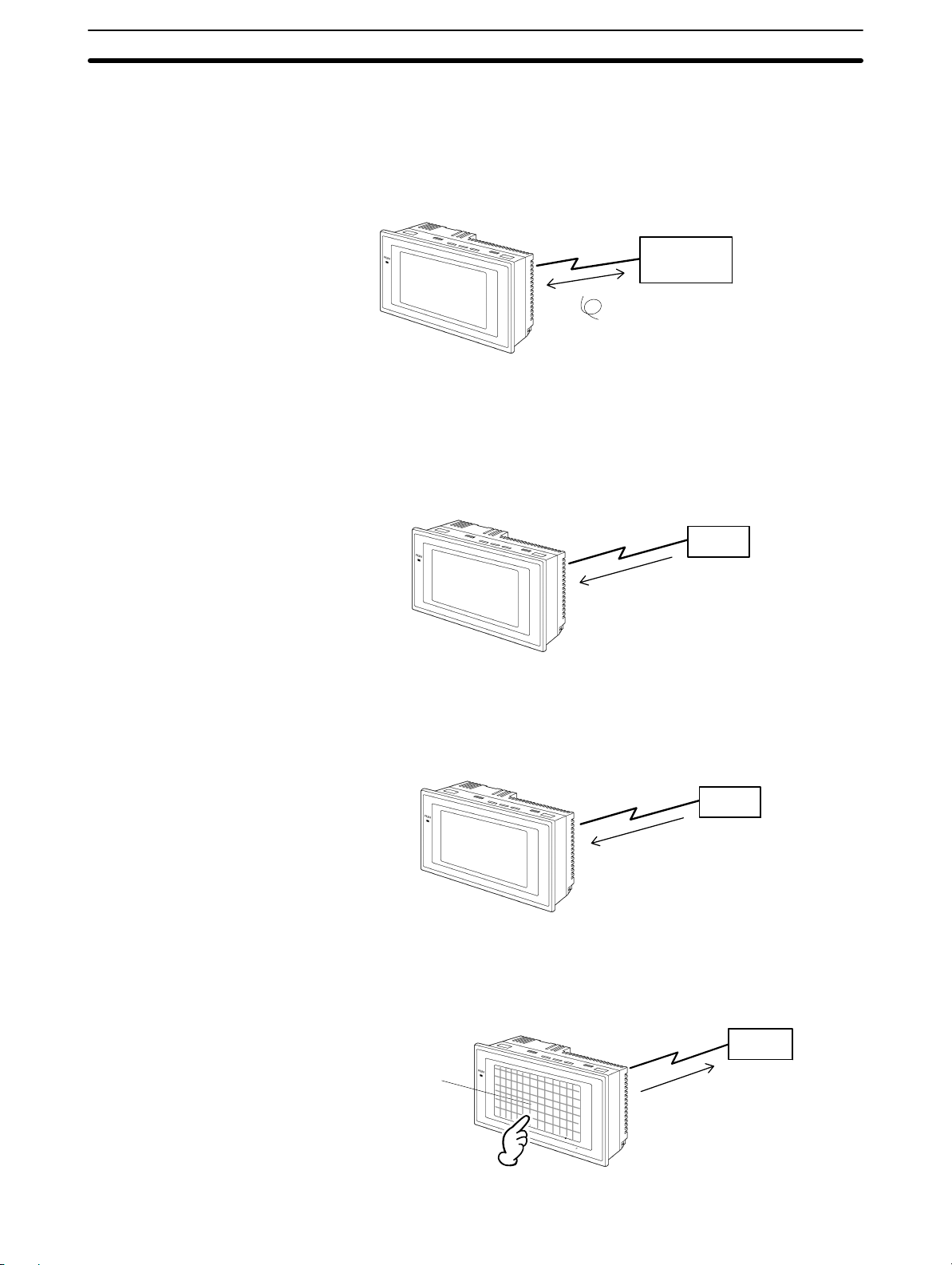

1-1-2 Operations of the NT21

The

Transfers Screen Data

Displays Screens

screen data to be displayed on the NT21 can be created on a personal com

puter using the NT Support Tool. Connect the NT21 to the personal computer

with an RS-232C cable and transfer the screen data to the NT21.

The

information to be displayed (screen data) can be created on a computer

ing the NT Support Tool and stored in the NT21. The screen data can be dis-

on

played

eration.

1-1SectionRole and Operation of the NT21

-

Create screen data.

RS-232C

Screen data

When the host is connected at serial port A,

the personal computer is only connected

when communicating screen data between

the NT21 and NT Support Tool.

the NT21 in response to commands from the host or touch switch op

Personal

computer

(NT Support Tool)

us

-

-

Receives Data from a

Host

Sends Data to a Host

Host

The screen data designated by

commands from the host or touch

switch operation is displayed.

The NT21 can be connected to the host by a Host Link or NT link and receive

necessary data from the host.

Host Link, NT link

Host

Data inputs (switch ON/OFF statuses, numeric values, character strings) that

input with devices such as touch switches can be transmitted to the host.

were

Touch panel

Host

ON/OFF information, numeric

data, etc.

3

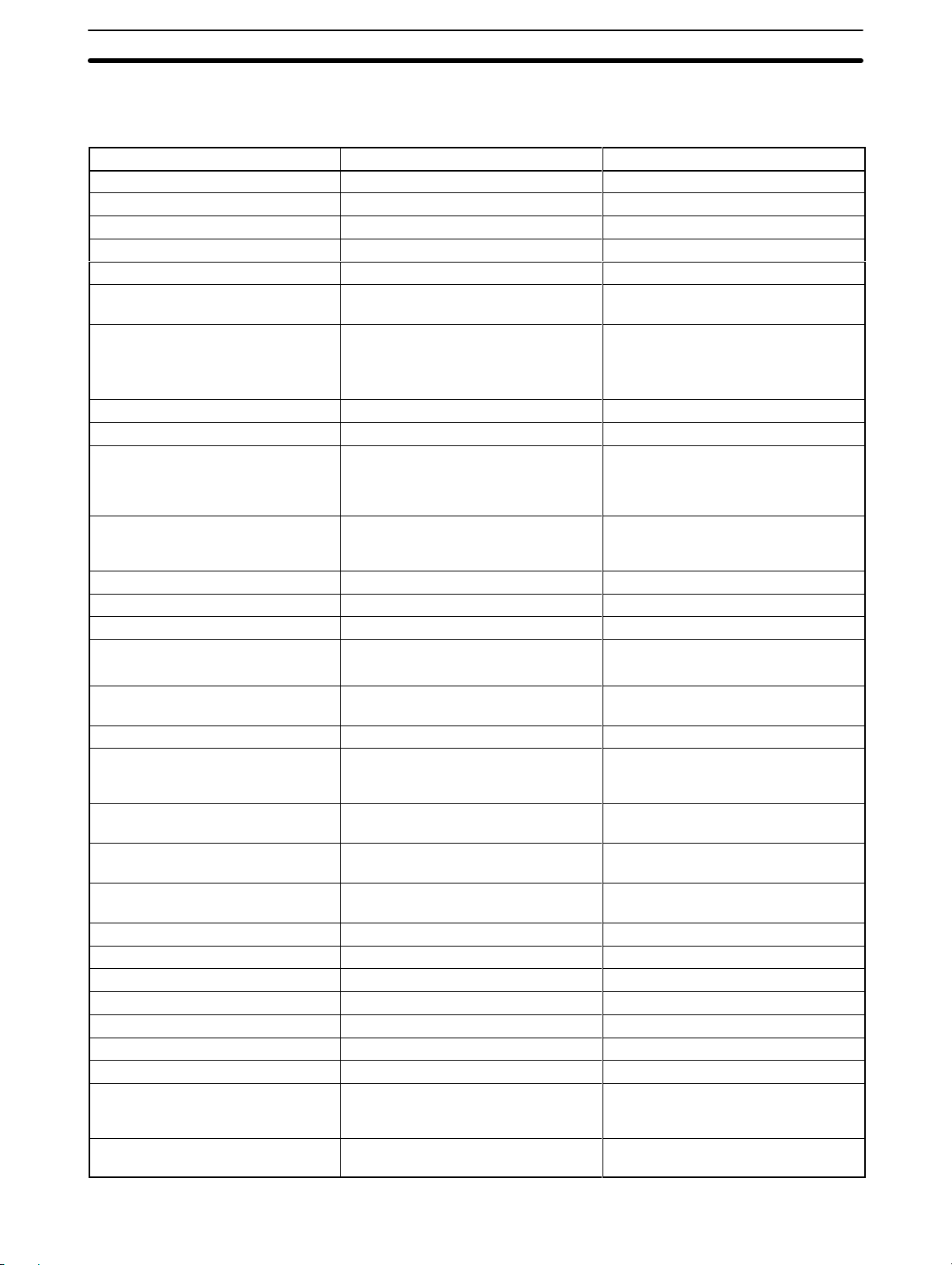

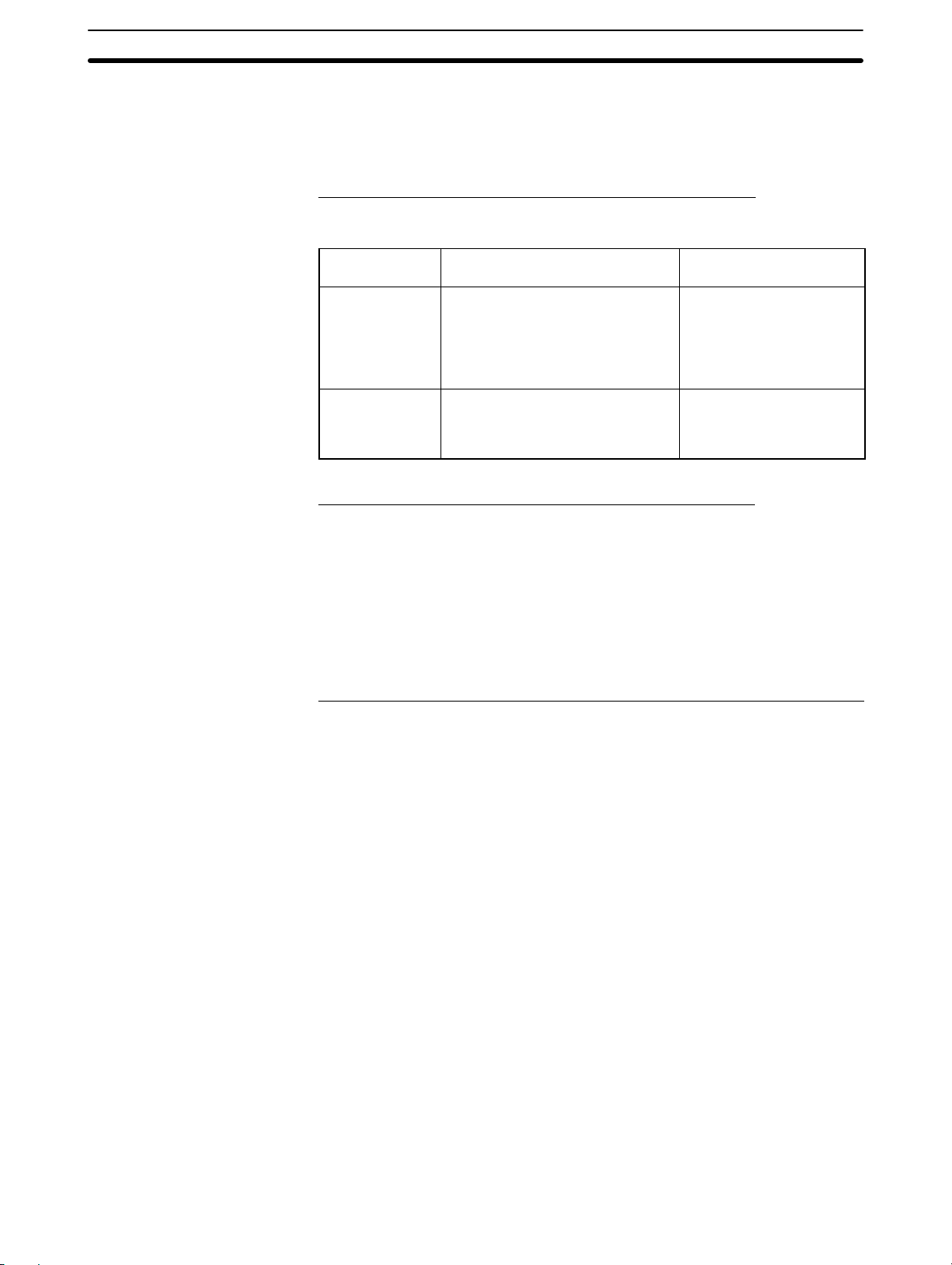

1-2 Comparison between NT20S and NT21

Item NT20S NT21

NT Support Tool used NT-ZJCAT1-EV4 or NT-ZA3AT-EV2 NT-ZJCAT1-EV4.6

Effective display area 112 x 56 mm (horizontal x vertical) 117 x 63 mm (horizontal x vertical)

Number of screen dots (resolution) 256 x 128 dots (horizontal x vertical) 260 x 140 dots (horizontal x vertical)

Number of touch switches 12 x 6 dots (horizontal x vertical) 13 x 7 dots (horizontal x vertical)

DIP switch settings On rear of Unit None (software settings)

Use of Memory Unit Not possible Possible (to transfer system program

data and screen data)

RS-232C interface Connector (9-pin) also used as port for

screen data transfer

Backlight life

Replacement backlight NT20S-CFL01 Not replaceable.

Battery backup Not possible Possible

System program data Pre-installed (cannot be changed) The system installer and system pro-

1:N NT Links Standard Standard or high-speed

Memory Links Not possible*2 Possible

Number of user-registered screens Maximum of 500 Maximum of 3999

Screen data capacity*3

(User program memory)

Numeral and character string

memory tables

Bit memory table None Maximum of 1000 bits

Mathematical table None 256 entries max.

Image data

Library data None Maximum of 12,288 (896 in

Fixed graphics (rectangles, polygons, arcs, sectors, tiling)

Image library display None 256 per screen max.

Analog meters None 50 per screen max.

Trend graphs None 1 per screen max.

Broken-line graphs None 1 per screen max.

Alarm list/history None 4 per screen max.

Recipes None 1 per screen max.

Windows None Maximum of 3

Method for storing numeric values

(numeral memory data and PT Status Control Area)

PT Status Control Area size 4 words 5 words (partial change of contents) (4

10,000 h min. 50,000 h min.

96 KB 512 KB

Maximum of 128 entries Maximum of 2,000 entries

None Maximum of 4,095 (224 in

None 65,535 per screen including all fixed

Fixed as BCD (binary coded decimal) Selectable from BCD (binary coded

- Port A connector (also used for

screen data transfer, 9-pin)

- Port B connector (for host

communications only, 9-pin)

*1

(numeral/character string memory

tables, history data, recipe data, and

clock data)

gram data are transferred from the NT

Support Tool.

Calculations can be executed

automatically in the PT.

NT20S-compatible mode)

NT20S-compatible mode)

display elements

decimal) or binary

words in NT20S-compatible mode)

1-2SectionComparison between NT20S and NT21

4

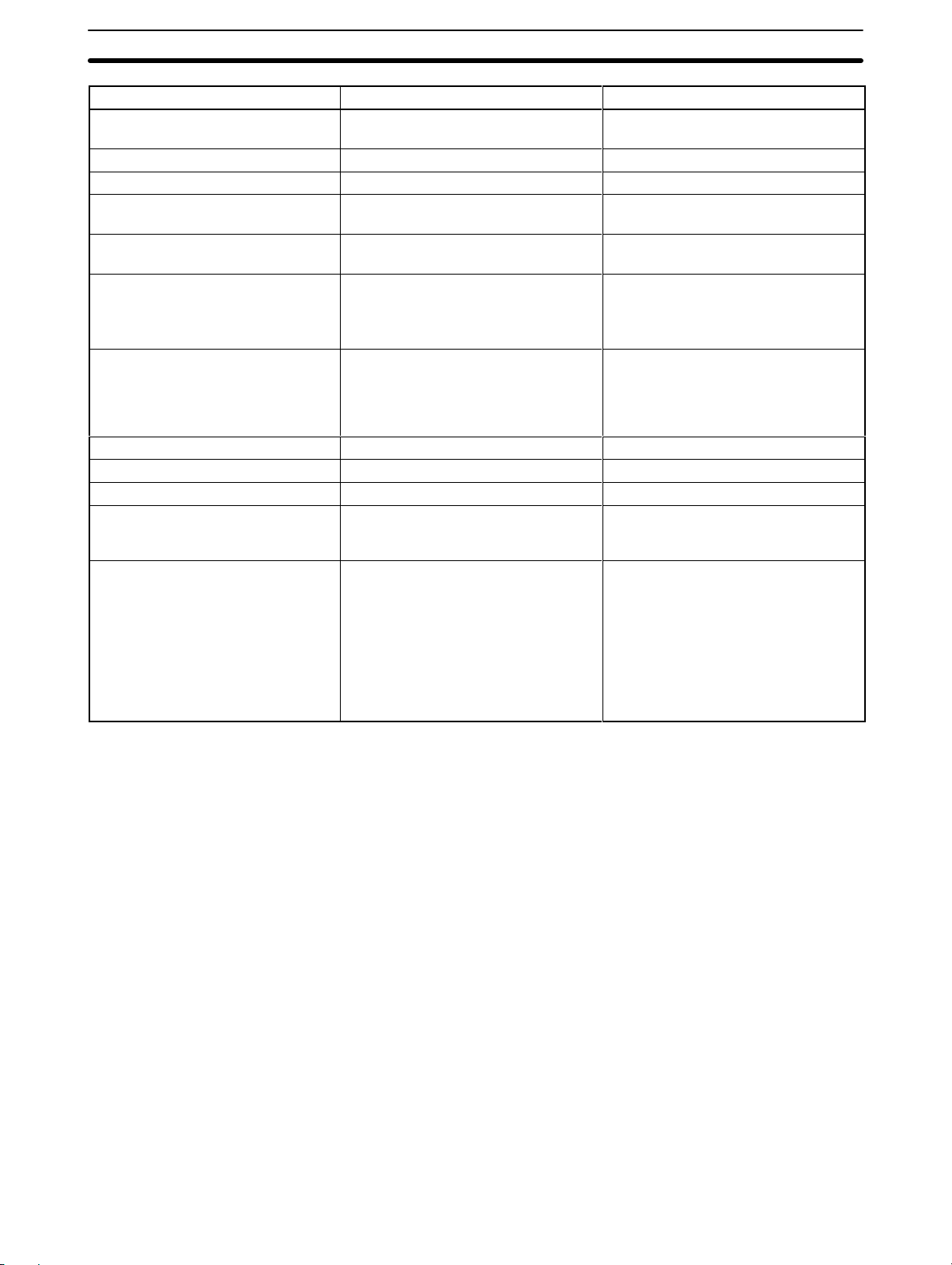

1-2SectionComparison between NT20S and NT21

Item NT21NT20S

PT Status Notify Area size 3 words 2 words (partial change of contents) (3

words in NT20S-compatible mode)

Window Control Area size None 9 words

Clock Data Area size None 4 words

Registering continuous screen Possible Not possible (Use a screen switchover

as a substitute.)

System tenkey Possible Not possible (Use the normal tenkey

as a substitute.)

Lamp/Touch switch labels Fixed display (1 line only) - Multiple lines can be displayed

- ON/OFF switching is possible

- Numeral display is possible

- Character string display is possible

Interlock function None Operations can be disabled from the

PC by allocating interlock bits to the

corresponding touch switch, numeral

input, character string input,

thumbwheel switch, or recipe.

Programming Console function Not possible Possible

Bar code reader connection Not possible Possible

High-resolution fonts Not possible Possible

Applicable character codes CP437 (equivalent to English DOS) CP437 (equivalent to English DOS) or

ISO8859/1 (equivalent to English Win-

dows)

Accessible CS/CJ PC data Areas --- The data Areas listed below can be

accessed in addition to the data Areas

accessible with the NT30/NT30C.

- EM banks (EM_0 to EM_C)

- Timer completion flags (TU)

- Counter completion flags (CU)

- Work Areas (WR)

- Task flags (TK)

- HR Area

*4

*1: The Battery is optional.

*2: An RS-232C command system is supported instead (NT20S-ST128 only)

*3: The capacity of the flash memory that stores image data.

*4: Only when communicating with a CS/CJ-series PC on a 1:N NT Link. (Access is not possible via a Host Link.)

5

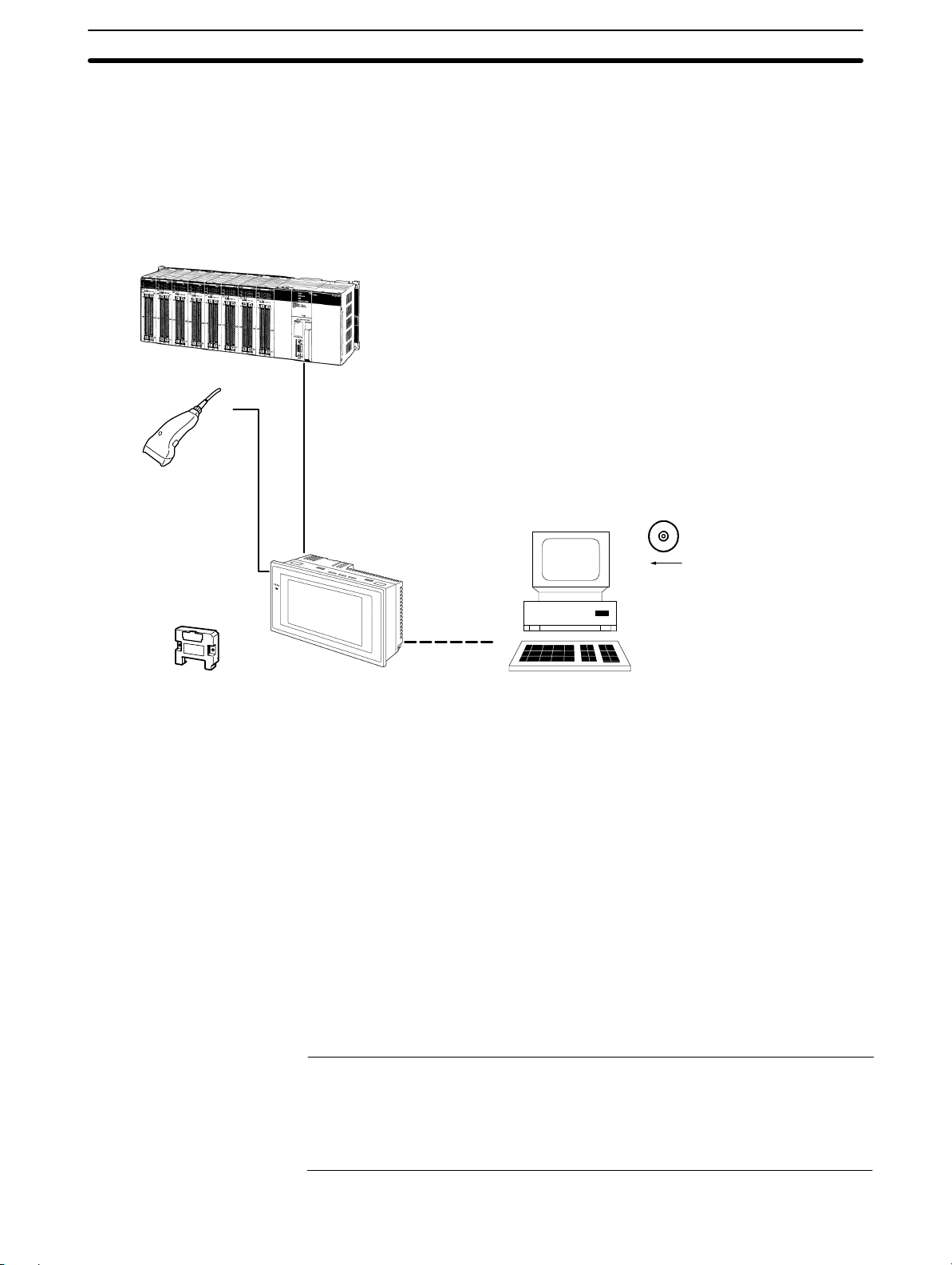

1-3 System Configuration

This

section shows the configuration of a system that uses an NT21. For details

on product models, refer to Appendix F Model List (page 201).

1-3-1 Peripheral Devices That Can Be Connected

The following peripheral devices can be connected to an NT21.

Host

Controls

the NT21 as required while controlling machines and monitoring the

production line.

Bar code reader

Bar

codes can be read

as character strings.

RS-232C cable

(15 m max.)

An RS-422A/485 cable

(500 m max.) can be

connected through an

RS-232C/RS-422A

Adapter.

Host Link:

Can be connected to CPU Units, Host Link Units, and SRM1. However

connection is not possible to some models of CPU Unit and SRM1 (pages

and

NT Link:

Can be connected to CPU Units and SRM1. However

possible to some models (pages

Memory Link:

Other companies’ PCs can also be connected.

CS-series/CJ-series/C-series PCs, CVM1/CV

69).

CS-series/CJ-series/C-series PCs, CVM1/CV

Can be connected to a personal computer

Personal computer

Running

Windows 95/98/NT

51, 55, 77 and

-series PCs, SRM1

,

40

-series PCs, SRM1

, connection is not

80).

, F

A computer

, etc.

NT Support Tool

Used

to create screens for the

NT21 at the personal computer

and transfer them to the NT21,

and to make NT21 settings.

1-3SectionSystem Configuration

Memory Unit

Can

store screen data

and system program to

be read out

automatically at startup.

Reference: The following optional devices are available.

NT21

Displays production line monitoring and

commands to the operation site, and

notifies the switch ON/OFF status and

numeric value inputs to the host.

When a 1:N NT Link is being used, up to

8 PT

s can be connected to a single PC.

• Bar code reader (page 29)

• Memory Unit (page 31)

NT-MF261 (made by OMRON)

• NT Support Tool (page 28)

NT-series Support Tool Version 4.6 for Windows (Made by OMRON)

• NT-ZJCAT1-EV4.6 (CD-ROM version for IBM PC/AT and compatible

computers)

• System installer (page 28)

System Installer (made by OMRON)

The

System Installer is

port Tool (NTZJCAT1-EV4.6).

System installer

Used

to change the system

program of the NT21.

supplied as a standard accessory with the NT Sup

-

Reflection-suppressing Protective Sheets (5) NT20S-KBA04

Chemical-resistant cover NT20S-KBA01

Battery 3G2A9-BAT08

6

1-3-2 Connecting to the Host

The NT21 has the following two communication ports.

• Serial port A:

D-SUB 9-pin connector (female)

For RS-232C only (The NT Support Tool and bar code readers can be con-

nected here, but an NS-AL002 Link Adapter cannot be connected.)

• Serial port B:

D-SUB 9-pin connector (female)

For

RS-232C only (The NT Support T

nected here, but an NS-AL002 Link Adapter can be connected.)

The host can be connected at either of these two ports.

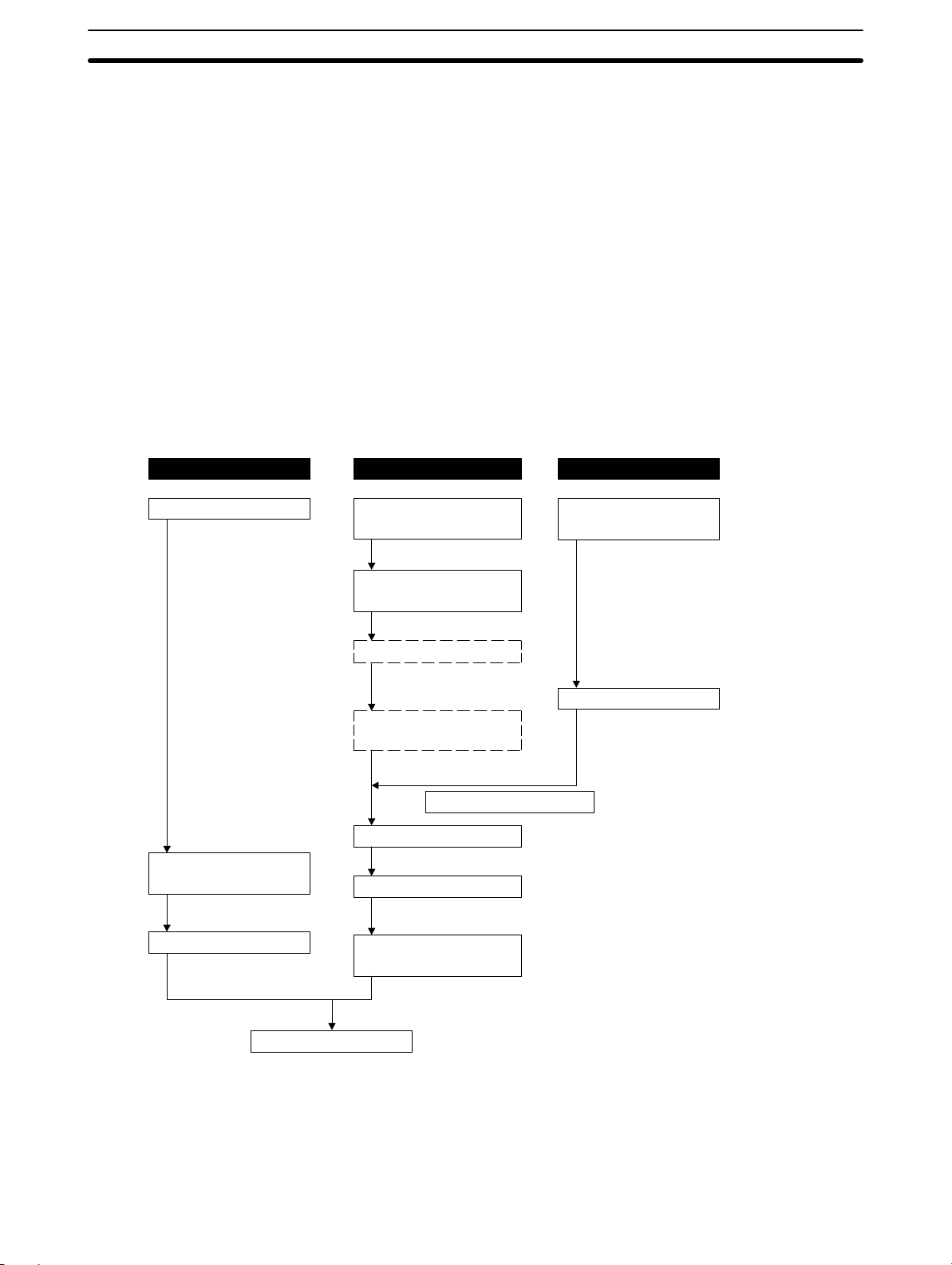

1-4 Before Operating

Follow the procedure given below to start the system of the NT21.

ool and bar

1-4SectionBefore Operating

code readers cannot be con

-

Host

Set the host settings.

• For

the Host Link, refer to

pages

40 and

manuals

Unit and Programming

Device.

• For

a

1:1 NT Link, refer to

pages

• For

1:N NT Links, refer

pages

• For high-speed 1:N NT

Links, refer to pages 60

and

83.

• For Memory Links, refer

pages

to

Connect to the NT21.

Create the host program.

69, and the

for the Host Link

51 and

77.

55 and

80.

55 and

85

to

NT21

Install the PT in the

operation panel.

(page 16)

Connect

the power supply

and peripheral device.

(page 15)

Install

the system program.

(Refer

to page 119 and

the NT Support T

operation manual.)

Make

the settings in the

system installer mode.

(page 118)

Transmit

Set

the memory switches.

(page 125)

Connect

to the host.

Using

only RS-232C: Refer to Section 4 for details.

Using RS-422A/485: Refer to Section 5 for details.

Confirm

the settings and

check communication.

*1

ool

*2

the screen data.

NT Support Tool

Install

the NT Support

T

ool in the computer

(refer

to the manual for

the NT Support T

Create the screens.

(Refer

to the

Programmable T

and the

Manual.)

(page

NT31/NT31C/NT631/NT631C

erminal Reference Manual

NT Support T

123)

.

ool)

ool Operation

Start operation.

*1: System program installation is only done in special circumstances, for example

when changing the system program, or when recovering the original status of the

installed program. This operation is not normally necessary.

*2: Display of the system menu, and all change operations, can be inhibited. This

enables you to prevent the accidental deletion or alteration of screens and

settings.

7

1-4SectionBefore Operating

gg

ti

d

Reference: S For

the system program, use the NT21 system

program supplied as an acces

sory with the NT-series Support Tool (NT-ZJCAT1-EV4.6).

the NT Support T

S For

ool, use NT

-series Support Tool for Windows (Ver. 4.6).

Refer to the following manuals for the devices and software.

Device or Soft-

ware

NT21

NT31/NT31C,

NT631/NT631C

System Installer NT-series Support Tool for Windows (Ver. 4.6) Operation Manual V061-E1-j

NT Support Tool NT-series Support Tool for Windows (Ver. 4.6) Operation Manual V061-E1-j

PC SYSMAC CPM1 Operation Manual W262-E1-j

CompoBus Master

Control Unit

Programming Tools SYSMAC Support Software Operation Manual: C-series PCs W248-E1-j

Host Link Unit/

Serial Communica-

ons Boar

Reference Manual V069-E1-j

SYSMAC CPM1A Operation Manual W317-E1-j

SYSMAC CPM2A Operation Manual W352-E1-j

SYSMAC CPM2C Operation Manual W356-E1-j

SYSMAC C200H Operation Manual (for CPU01/03/11) (Programming) W130-E1-j

SYSMAC C200H Operation Manual (for CPU21/23/31) (Programming) W217-E1-j

SYSMAC C200HS Installation Guide W236-E1-j

SYSMAC C200HS Operation Manual (Programming) W235-E1-j

SYSMAC C200HX/HG/HE (-Z) Installation Guide W302-E1-j

SYSMAC C200HX/HG/HE Operation Manual W303-E1-j

SYSMAC C200HX/HG/HE-Z Operation Manual W322-E1-j

SYSMAC CQM1/CPM1/CPM1A/SRM1 Programming Manual W228-E1-j

SYSMAC CQM1H Operation Manual W363-E1-j

SYSMAC CVM1/CV500/CV1000/CV2000/CVM1 Operation Manual: Ladder Dia-

grams

CS Series Programmable Controllers Operation Manual W339-E1-j

CJ Series CJ1G-CPUjj-E Programmable Controllers Operation Manual W393-E1-j

CS/CJ Series Programming Manual W394-E1-j

CS/CJ Series Serial Communications Boards/Units Operation Manual W336-E1-j

SYSMAC CQM1H Series Serial Communications Board Operation Manual W365-E1-j

SRM1 (-V2) Operation Manual W318-E1-j

SYSMAC Support Software Operation Manual: CVM1 PCs W249-E1-j

SYSMAC CPT User Manual and Quick Start Guide W332-E1-j

CX-Programmer User Manual SYSMAC C Series Host Link Unit System Manual W143-E1-j

SYSMAC CVM1/CV Series Host Link Operation Manual W205-E1-j

SYSMAC C200HW-COM01 C200HW-COM02-V1 to C200HW-COM06-EV1 Com-

munications Board Operation Manual

Manual Title Cat. No.

W202-E1-j

W333-E1-j

W304-E1-j

-

8

SECTION 2

Preparing for Connection

This section describes the connection methods that are possible with the PTs, and the functions of the parts of PTs, as the

required knowledge before connecting to the host and to other devices.

2-1 Method for Connection to the Host 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Names and Functions of Parts

2-2

13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9

2-1 Method for Connection to the Host

This section describes the methods for connection to the host used with the

NT21, and the relationship between the connection method and the communication method.

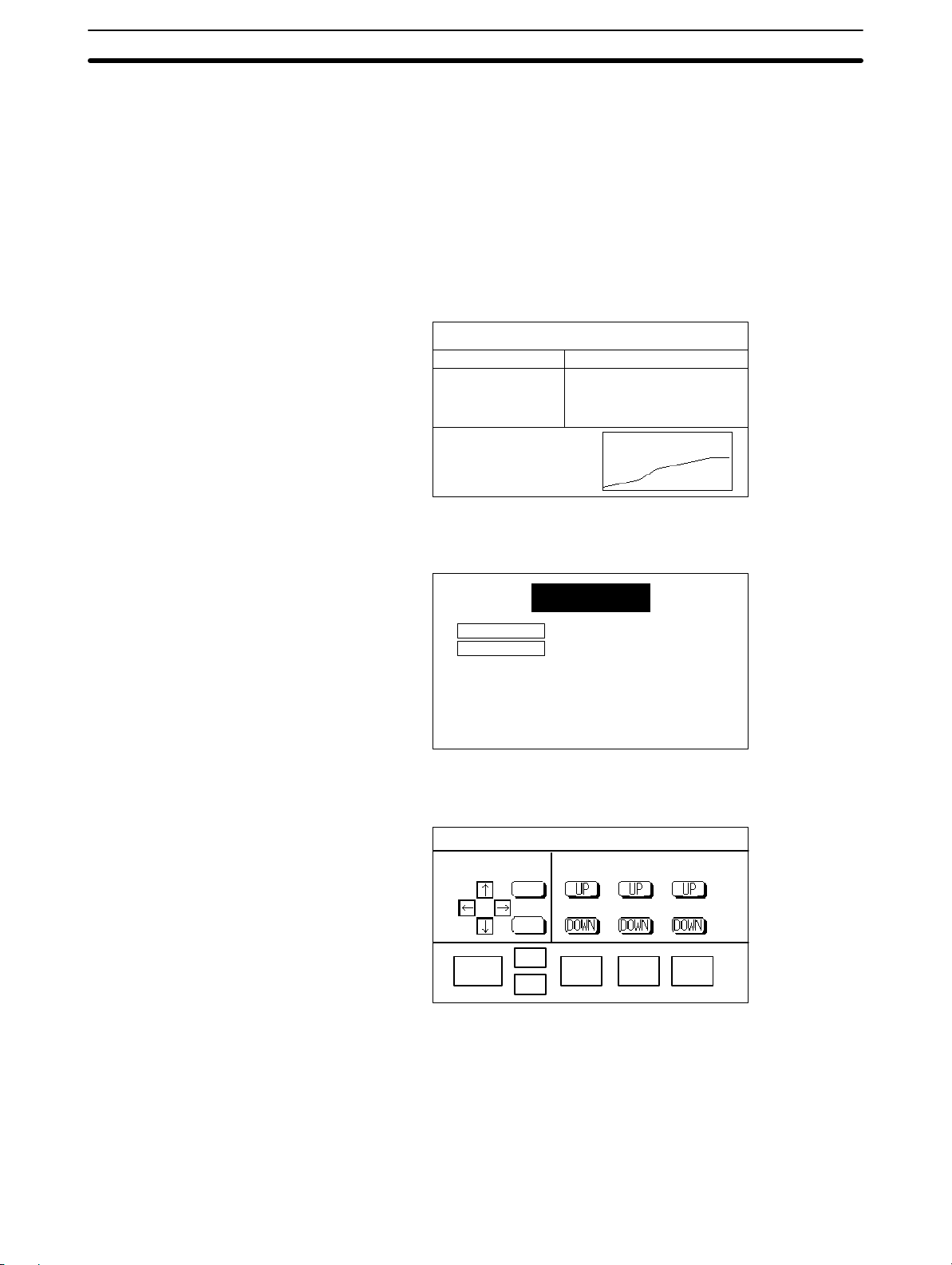

NT21 Communication Ports and Communication Methods

The NT21 has two communication ports. Their uses are indicated in the table

below.

2-1SectionMethod for Connection to the Host

Communication

Port

Serial port A

Serial port B

* There are two 1:N NT Link communications rates: standard and high-speed.

Usable Communication Methods Communications

Host Link

1:1 NT Link

1:N NT Link

Memory Link

(NT Support Tool connection)

(Bar code reader input function)

Host Link

1:1 NT Link

1:N NT Link

Memory Link

*

*

RS-232C

RS-232C

Communication Methods That Can Be Used with the Host

The following communication methods

can be used with the hosts that can be

connected to the NT21.

• RS-232C

• RS-422A

• RS-485

The communications types that are actually supported vary with the host. For

details, refer to Section 4 Connecting to the Host from the RS-232C Port and

Section 5 Connecting to the Host from the RS-422A/485 Port.

Converting

Communication T

ype with the RS-232C/RS-422A Link

Adapter

An OMRON NT-AL001-E or NS-AL002-E Link Adapter can be used convert

from RS-232C communications to either RS-422A or RS-485.

• RS-232C ⇔ RS-422A

• RS-232C ⇔ RS-485

There are two models of Link Adapters available with different features:

• NT-AL001 Link Adapter

RS-232C port is

The

insulated from the RS-422A/485 terminals. An RS-232C

cable (2 m max.) can be connected to either serial port A or B on the NT21.

• NS-AL002 Link Adapter

RS-232C port is

The

not

insulated from the RS-422A/485 terminals. The NSAL002 Link Adapter can be connected directly to serial port B on the NT21.

(The NS-AL002 cannot be connected directly to serial port A on the NT21.)

10

2-1SectionMethod for Connection to the Host

C

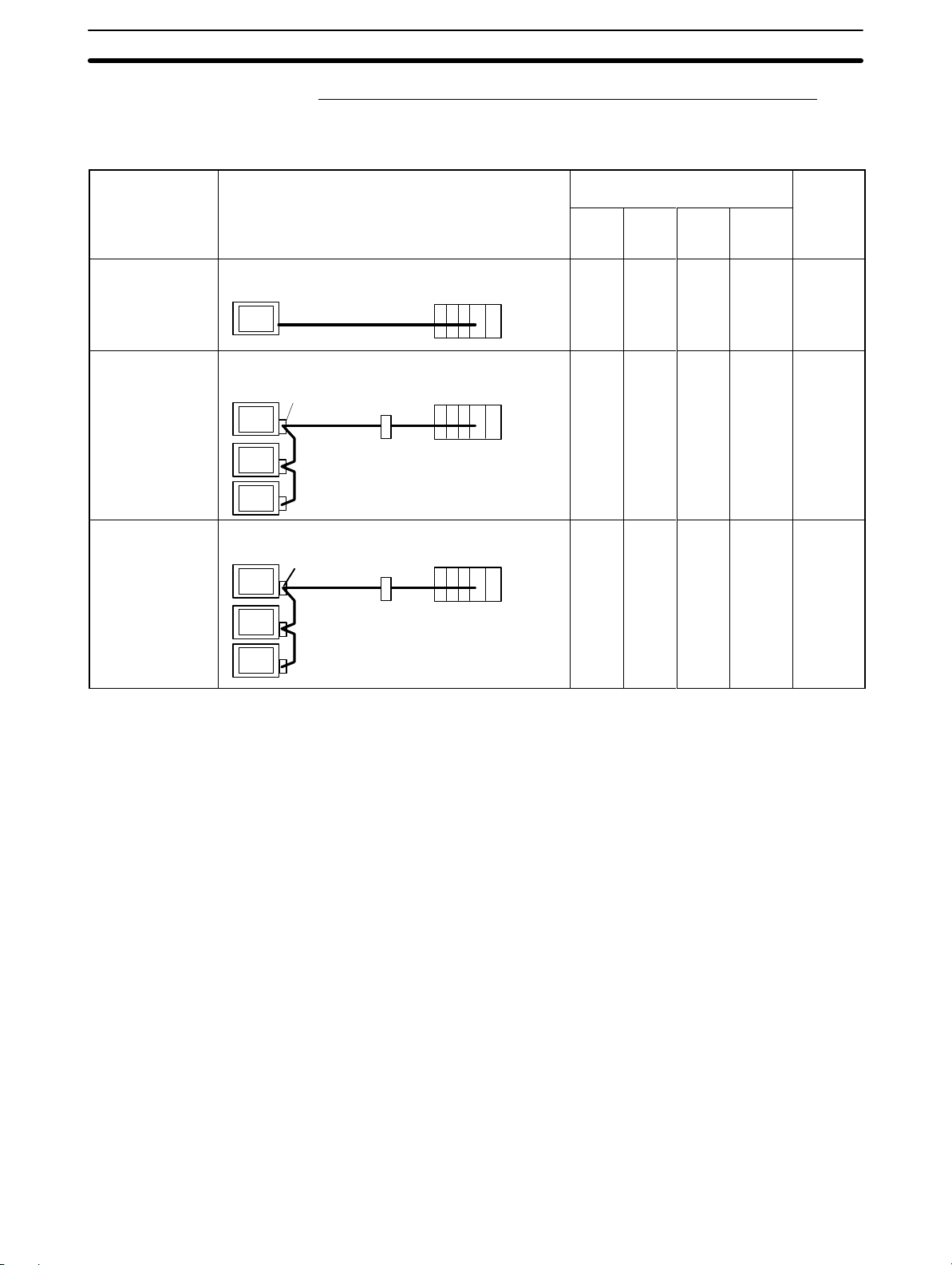

Combinations of Communication Method and Connection Method

The connection methods that can be used depending on the communication

method used and the communications type for communication between the

NT21 and the host are indicated in the table below.

ommunication

type at Host

RS-232C

RS-232C

RS-232C

Usable Connection Method

Direct 1:1 connection

PT

(max. 15 m)

RS-232C

1:N connection with RS-422A through Link Adapters

1:N connection with RS-485 through Link Adapters

PT

PT

NT-AL001* or

NS-AL002

Link Adapter

RS-422A

(total length 500 m)

NT-AL001* or

NS-AL002

Link Adapter

RS-485

(total

length 500 m)

NT-AL001

Link Adapter

RS-232C

(max. 2 m)

NT-AL001

Link Adapter

(max. 2 m)

Host

Host

Host

RS232C

Usable Communication

Method

Host

Link

1:1 NT

Link

1:N

NT

Link

Memory

link

Details

f f f f 63

f 95

f 95

Note *An

RS-232C Cable (not shown in the diagram) is required when connecting an

NT-AL001 Link Adapter to a PT.

f: Connection possible : Connection not possible

11

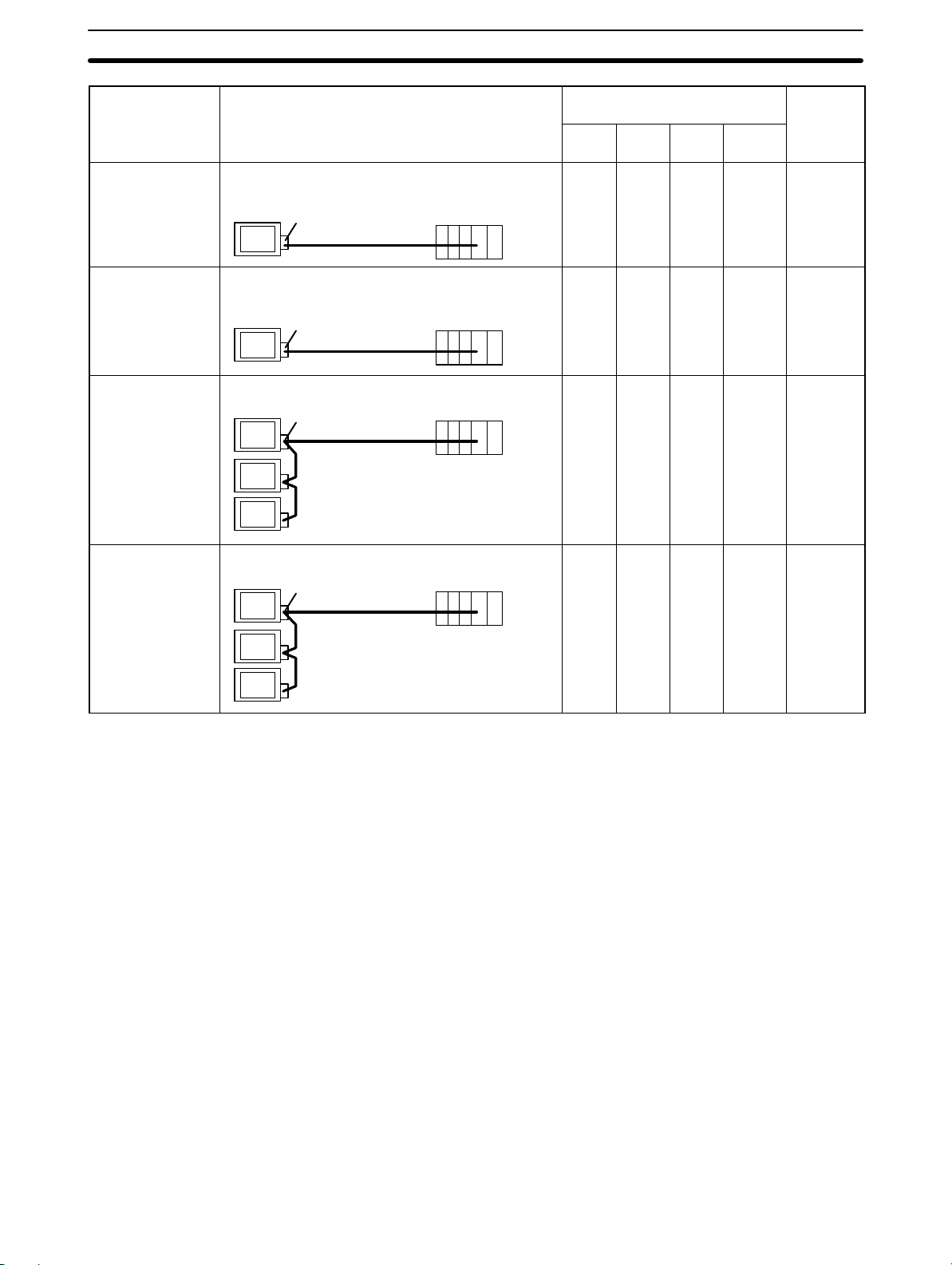

2-1SectionMethod for Connection to the Host

Communication

Communication

type at Host

RS-422A

RS-485

RS-422A

Usable Connection Method

Direct 1:1 connection with RS-422A through a Link

Adapter

PT

NT-AL001* or

NS-AL002

Link Adapter

RS-422A

Host

(max. 500 m)

Direct 1:1 connection with RS-485 through a Link

Adapter

NT-AL001*

PT

NS-AL002

Link Adapter

RS-485

or

(max. 500 m)

Host

1:N connection with RS-422A through Link Adapters

PT

NT-AL001* or

NS-AL002

Link Adapter

RS-422A (total length 500 m)

Host

1:N connection with RS-485 through Link Adapters

NT-AL001*

PT

NS-AL002

Link Adapter

or

Host

Usable Communication Meth-

Host

Link

1:1 NT

Link

od

1:N NT

Link

Memory

link

Details

f f f f 85

f 88

f 89

RS-485

(total length 500 m)

RS-485

f 92

f: Connection possible : Connection not possible

Note *An

RS-232C Cable (not shown in the diagram) is required when connecting an

NT-AL001 Link Adapter to a PT.

NT

• The

the

a

-AL001 Link Adapter requires a +5-V

RS-232C connector

. When the NT

5-V power supply is output from pin 6 of serial port A or B in the NT21.

, 150 mA power supply at pin 6 of

-AL001 is being connected to the NT21,

nect pin 6 of the Link Adapter’s RS-232C connector with pin 6 of the NT21’s

RS-232C connector.

When the NT-AL001 is being connected to a host and power is not supplied

the host’

from

Link

Adapter’s RS-232C

s port, connect an external power supply to pins 6 and 9 of

connector

. Connect the +5-V line to pin 6 and the SG

line to pin 9.

• Never connect or disconnect cables or Units to an NT-AL001 or NS-AL002

the power is ON. Be sure to turn OFF the power supply of

while

host before connecting or disconnecting the cables.

+5-V power supply is output from pin 6 of serial ports A

• A

and B in the NT21. It is

possible to use the power from both ports simultaneously, but the maximum

capacity is 150 mA max. total. Do not exceed 150 mA total output.

• When using RS-422A or RS-485 communications, it is convenient to use an

NS-AL002 Link Adapter and make a direct connection to serial port B of the

NT21.

However

, there is no insulation between the NS-AL002’

s RS-232C port

and RS-422A/RS-485 port.

Con

the

the NT21 or

-

12

2-2 Names and Functions of Parts

Before

starting operation, the names and functions of the parts of the NT21 are

described here as a confirmation. A method of hardware settings is also described.

V

Front

iew

2-2SectionNames and Functions of Parts

RUN Indicator

•

Lit in green while the

NT21 is in the RUN

mode.

in orange

• Lit

the

battery is low (orange

in the RUN mode, red in

other modes).

or red when

Display

Monochrome LCD screen with backlight

The whole area of the screen is a touch

panel that works as an input device.

Reference: The NT21 comes in two body colors.

NT21 Body Color

NT21-ST121-E Beige

NT21-ST121B-E Black

13

Rear View

Expansion interface connector

When using an Expansion Interface Unit

such as a Memory Unit, connect it here.

Battery cover

There is a battery holder beneath this cover

battery is optional (sold separately) and is not

installed when the NT21 is shipped.

Serial port B connector

Connect the cable for connection to the

host here. An NS-AL002 Link Adapter can

be connected directly to this port. This is a

9-pin connector for RS-232C only

2-2SectionNames and Functions of Parts

. The

.

Power input terminals

Connect the power to the

NT21 at these terminals.

GR terminal

Grounding terminal to

prevent malfunction

due to noise.

Note Before

turning the power ON/OFF

may operate unpredictably.

Serial port A connector

Connect the cable for connection to the host or NT Support

T

ool here. A bar code reader can also be connected here.

This is a 9-pin connector for RS-232C only

.

, confirm system safety

, otherwise the

system

14

Hardware Installation and Connections

This section describes the installation of the PTs and methods for connection to other devices.

For

details on connecting to the host, refer

the

Host fr

om the RS-422A/485 Port.

3-1 Installation 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-1-1 Installation Environment 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-1-2 Installation in the Operation Panel 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-1-3 Power Supply Connection 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-1-4 Grounding 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-2 Connecting Link Adapters 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-2-1 Connecting an NS-AL002 Link Adapter 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-2-2 Connecting an NT-AL001 Link Adapter 22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-3 Connecting the NT Support Tool 28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-4

Connecting a Bar Code Reader

3-4-1

3-4-2

3-4-3 Data Format 30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-5

Using a Memory Unit

3-5-1

3-5-2

Connection Method

Setting a Bar Code Reader

Installation Method

Method of Use

Section 4 Connecting to the Host fr

om the

RS-232C Port

SECTION 3

or

Section

5 Connecting to

29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

15

3-1SectionInstallation

Note On

unpacking the NT21 check the external appearance and confirm that there is

no

damage. Also confirm that there is no abnormal noise on shaking

ly.

3-1 Installation

Install the NT21 in the operation panel and connect the power to the NT21 as

described below.

3-1-1 Installation Environment

Observe the following points when installing the PT in an operation panel.

Note 1. Do not install the NT21 at sites subject to the following conditions.

Otherwise the product may malfunction.

• Severe temperature variations

• Temperatures

• High humidity, condensation

• Splashing chemical agents

• Severe oil splashing

• Corrosive or flammable gases

• Strong vibrations or shocks

• Direct exposure to wind and rain (outdoor sites)

• Strong ultra-violet irradiation

2. Take

adequate measures to ensure shielding if the NT21

tion subject to any of the following conditions. Otherwise the product may

malfunction.

• Static electricity, or noise from other equipment

• Strong electromagnetic fields

• Nearby power cables

• Potential exposure to radioactivity

the PT light

-

or humidities outside the ranges stated in the specifications

is used at a loca

-

3-1-2 Installation in the Operation Panel

The NT21 is mounted in an operation panel by embedding it in the panel.

the

Use

age and follow the procedure below.

1, 2, 3... 1. Open a hole of the dimensions shown below in the panel and install the

16

panel fittings and tool (Philips screwdriver) included in the product pack

NT21 from the front side of the panel.

+0.5mm

178.5

0mm

2. Attach

the panel

fittings at the four positions at top and bottom, shown be

low, from the rear of the NT21.

100.5

+0.5mm

0mm

-

-

Fit

the

hook of the fitting in the square hole in the body and tighten the screw

with the Philips head screwdriver while lightly pulling the fitting.

Note 1. During work at the panel, do not allow any metal filings or wire strands to

enter the NT21. Otherwise, the product may malfunction.

thickness of applicable operation panel is 1.6 mm to 4.8 mm. All fittings

2. The

must

be tightened uniformly to a torque of 0.5 to 0.6 N⋅m in order to ensure

water-

and dust-resistance. Front sheet of NT21 may be warped if the tight

is too strong or not uniformity

ening

and must be able to support an installation that will remain secure and

strong. Otherwise, the product may malfunction.

3-1-3 Power Supply Connection

Connect a 24 VDC power supply to the power input terminals.

3-1SectionInstallation

-

. The panel must not be soiled or warped,

Caution Carefully check the wiring before switching ON the power.

!

Caution Do not connect AC power to the DC terminals. Incorrect wiring may result in

!

burning.

Note 1. Depending on how the power is switched ON/OFF, the entire system

stop. Follow the correct procedure when switching the power ON/OFF.

Otherwise the system may operate unpredictably.

2. Use

DC power

supplies with low voltage fluctuation. An incorrect power sup

ply may result in malfunctions.

not perform a dielectric strength test. Otherwise, the

3. Do

product may mal

function.

complying with EC directives (low voltage directives), use a power supply

4. If

with

reinforced insulation (compliance with EC directives is planned for June

1998).

24 VDC

Circuit

breaker

24 VDC

power supply

may

-

-

Power Supply

The applicable power supply specifications are as follows.

Item Value

Power supply 24 VDC

Allowable power supply voltage fluctuation range 20.4 VDC to 27.6 VDC

(24 VDC ±15%)

Power supply voltage capacity 7 W or more

17

Parts Used for Connection

(14 to 13 AWG)

3-2SectionConnecting Link Adapters

3-1-4 Grounding

1, 2, 3... 1. In cases where the distance between the NT21 is short and it is assumed

Note For the connection to the power supply terminal block, use stranded wire of

2

or greater cross sectional Area (14 A

2 mm

WG stranded wire) and M3.5 size

crimp terminals.

Tighten the screws on the terminal block to a torque of 0.8 N⋅m.

Otherwise the product may malfunction.

Fork

type

7 mm or less 7 mm or less

Round type

Recommended Terminals

Maker Fork type Round type

Japan Solderless Terminal MFG 2-YS3A 2-3.5

Fuji Terminal 2-YAS3.5 V2-S3.5

Nichifu Terminal 2Y-3.5 2-3.5

Stranded wire

size

2.0 to 2.63 mm

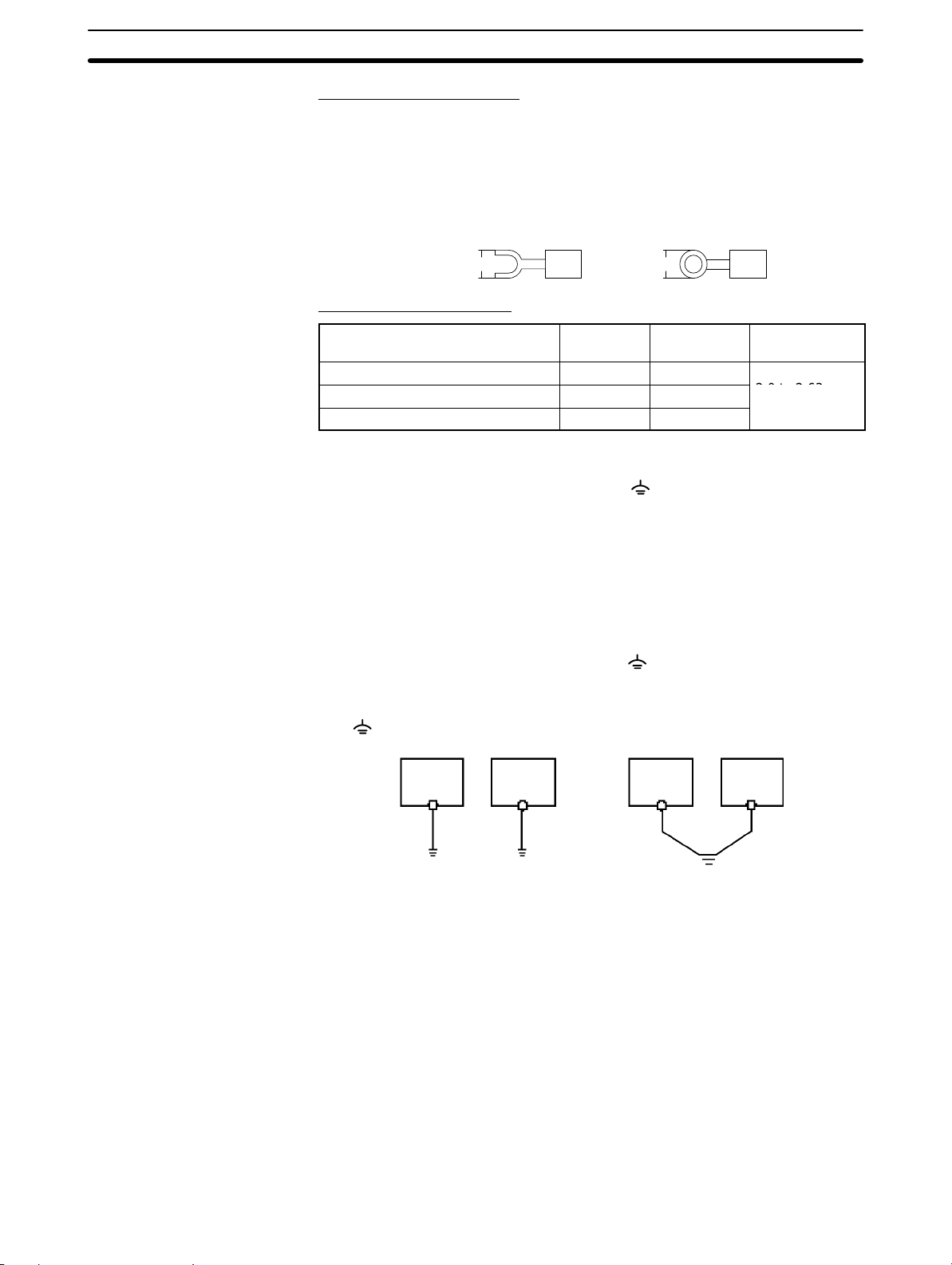

The NT21 has a functional ground terminal ( ).

Carry out wiring under the following conditions.

there is no potential dif

that

ference between grounds, ground as shown in

Fig. (a) below.

2. In cases where there is a potential difference between the grounds of the

NT21 and the host, ground as shown in Fig. (b). If there is some distance

between

the NT21 and host and grounding at a single point is dif

ficult, do not

connect the functional ground terminal ( ) of the NT21.

3. If

the NT21 is installed in the same panel as equipment that generates noise,

such as a motor or inverter, do not ground the functional ground terminal

) of the NT21.

(

2

3-2 Connecting Link Adapters

3-2-1 Connecting an NS-AL002 Link Adapter

18

Note Carry

NT21 Host NT21

Ground at a

single point

Ground to

100 Ω max.

Fig.

(a)

Fig. (b)

out grounding correctly in order to prevent operating errors due to noise.

Host

This section describes the installation of the NT-AL001 and NS-AL002 Link

Adapters, including the external dimensions, procedure for mounting and re-

and specifications. Refer to this information when designing the control

moval,

panel. For further details, refer to the Instruction Sheet supplied with the NT-

AL001 or NS-AL002.

The NS-AL002 Link Adapter connects directly to the NT21’s serial port B and

converts

RS-232C communications to RS-422A or RS-485. The NT21 supplies

Loading...

Loading...