Page 1

Cat. No. W238-E1-10

SYSMAC

CQM1H/CQM1 Series

Dedicated I/O Units

OPERATION MANUAL

Page 2

CQM1H/CQM1Series Dedicated I/O Units

Operation Manual

Revised November 2003

Page 3

iv

Page 4

Notice:

r

f

OMRON products are manufactured for use accordin g to proper procedures by a qualified operator

and only for the purposes described in this manual.

The following conventions are used to ind icate and classify pr ecautions in this manual . Always heed

the information provided with them . Failure to heed precautions can result in in jur y to people or damage to property.

!DANGER Indicates an immine ntly hazardous situation whi ch, if not avoided, will result in death or

serious inj ury.

!WARNING Indicates a potentially hazardous situatio n which, if not avoided, could resu lt in death or

serious inj ury.

!Caution Indicates a potentially hazardous si tuation which, if not avoided, may result in minor or

moderate injury, or property damage.

OMRON Product References

All OMRON products are capitalized in this manual. The word “Unit” is also capitalized when it refers to

an OMRON product, regardless of whether or not it appears in the proper name of the product.

The abbreviation “Ch,” which appears in some displ ays and on some OMRON products, often means

“word” and is abbreviated “Wd” in documentation in this sense.

The abbreviation “PC" means Programmable Controller and is not used as an abbreviation for anything

else.

Visual Aids

The following headings appear in the left co lumn of the manual to help you locate different types of

information.

OMRON, 1993

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in an y fo rm, o

by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior written permission o

OMRON.

No patent liability is assumed with respect to th e use of the in fo rmation c ontain ed he rein. M oreover, because OMRON is constantly striving to improve its high-quality products, the information contained in this manual is subject to change without

notice. Every precaution has been taken in the preparation of this manual. Nevertheless, OMRON assumes no responsibility

for errors or omissions. Neither is any liability assumed for damages resulting from the use of the information contained in

this publication.

Note Indicates information of pa rticular interest for efficient and convenient opera-

tion of the product.

1,2,3... 1. Indicates lists of one sort or another, such as procedures, checklists, etc.

v

Page 5

vi

Page 6

TABLE OF CONTENTS

PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xv

1 Intended Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvi

2 General Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvi

3 Safety Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvi

4 Operating Environment Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvii

5 Application Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xviii

PART I

B7A Interface Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

SECTION 1

Features and System Configuration . . . . . . . . . . . . . . . . 3

1-1 Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1-2 System Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1-3 Connecting Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1-4 Word Allocation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1-5 Bit Allocation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

SECTION 2

Nomenclature and Settings . . . . . . . . . . . . . . . . . . . . . . . 11

2-1 Nomenclature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2-2 Switch Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

SECTION 3

Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3-1 Connections to B7A Link Terminals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3-2 Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Appendices

A Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

PART II

G730 Interface Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

SECTION 1

Features and System Configuration . . . . . . . . . . . . . . . . 29

1-1 Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

1-2 System Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

1-3 Connecting Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

SECTION 2

Nomenclature and Settings . . . . . . . . . . . . . . . . . . . . . . . 35

2-1 Nomenclature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

2-2 Switch Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

SECTION 3

Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

3-1 Transmission Cables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

3-2 External Output Connection Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

SECTION 4

Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

4-1 Word Allocation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

4-2 Handling Power On. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

4-3 Transmission Delay Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

vii

Page 7

TABLE OF CONTENTS

Appendices

A Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

B Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

PART III

I/O Link Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

SECTION 1

Features and System Configuration . . . . . . . . . . . . . . . . 65

1-1 Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

1-2 System Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

1-3 Connecting Devices. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

1-4 Word Allocation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

SECTION 2

Nomenclature and Settings. . . . . . . . . . . . . . . . . . . . . . . . 69

2-1 Nomenclature. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

2-2 Switch Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

SECTION 3

Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

3-1 SYSMAC BUS Cable Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Appendices

A Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

PART IV

Analog Input Unit and Analog Power Supply Units . . . 79

SECTION 1

Features and System Configuration . . . . . . . . . . . . . . . . 81

1-1 Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

1-2 System Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

1-3 Connecting Devices. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

1-4 System Construction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

SECTION 2

Nomenclature and Functions . . . . . . . . . . . . . . . . . . . . . . 85

2-1 Nomenclature. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

2-2 Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

SECTION 3

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

3-1 Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

3-2 Bit Number Allocation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

3-3 Programming and Adjustment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Appendices

A Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

B Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

viii

Page 8

TABLE OF CONTENTS

PART V

Analog Output Unit and Analog Power Supply Units. . 109

SECTION 1

Features and System Configuration . . . . . . . . . . . . . . . . 111

1-1 Features of Analog Output Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

1-2 System Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

SECTION 2

Nomenclature and Functions. . . . . . . . . . . . . . . . . . . . . . 115

2-1 Nomenclature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

2-2 Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

SECTION 3

Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

3-1 Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

3-2 Bit Number Allocation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

3-3 Programming and Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Appendices

A Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

B Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

PART VI

Sensor Unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

SECTION 1

Features and System Configuration . . . . . . . . . . . . . . . . 133

1-1 Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

1-2 System Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

1-3 Connecting Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

1-4 System Construction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

SECTION 2

Nomenclature and Functions. . . . . . . . . . . . . . . . . . . . . . 137

2-1 Nomenclature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

2-2 Switch Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

SECTION 3

Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

3-1 Wiring Precaution. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

3-2 Mounting and Dismoun ting the Sensor Module. . . . . . . . . . . . . . . . . . . . . . . . . . . 148

3-3 Connection of CQM1-TU001 Remote Console . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

3-4 Connection of a Variety of Sensors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

SECTION 4

Sensor Module Operation . . . . . . . . . . . . . . . . . . . . . . . . 153

4-1 Operation without CQM1-TU001 Remote Console. . . . . . . . . . . . . . . . . . . . . . . . 154

SECTION 5

Remote Console Operation . . . . . . . . . . . . . . . . . . . . . . . 161

5-1 Mode Setting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

5-2 Sensitivity Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

Appendices

A Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

ix

Page 9

TABLE OF CONTENTS

PART VII

Linear Sensor Interface Units . . . . . . . . . . . . . . . . . . . . . 175

SECTION 1

Features and System Configuration . . . . . . . . . . . . . . . . 177

1-1 Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 178

1-2 System Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

SECTION 2

Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 181

2-1 Scaling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 182

2-2 Timing Hold. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 183

2-3 Scaled Conversion Data/Comparison Result. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 186

2-4 Teaching. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 187

2-5 Forced Zero (Zero-shift) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 188

2-6 Voltage Monitor Output. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 188

SECTION 3

Nomenclature and Functions . . . . . . . . . . . . . . . . . . . . . . 191

3-1 Nomenclature. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 192

3-2 Terminals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 193

SECTION 4

Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 195

4-1 Mounting and Wiring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 196

SECTION 5

Basic Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 197

5-1 Operating Method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 198

5-2 Programming Console Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 199

5-3 Operation Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 200

5-4 Scaling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 202

5-5 Comparison . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 205

5-6 Monitoring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 207

SECTION 6

Applied Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 209

6-1 Scaling Value Teaching . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 210

6-2 Set Value Teaching . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 211

6-3 Forced-zero Shift. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 212

6-4 BCD Value Read . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 213

6-5 Monitor Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 214

SECTION 7

Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 215

7-1 Command Usage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 216

7-2 List of Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 218

7-3 Commands and Responses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 218

Appendices

A Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 229

B Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 231

C Data Processing Timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 233

D Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 237

x

Page 10

TABLE OF CONTENTS

PART VIII

Temperature Control Units . . . . . . . . . . . . . . . . . . . . . . . 239

SECTION 1

Temperature Control Unit Model Numbers . . . . . . . . . 241

SECTION 2

CQM1-TC20@/TC30@ Temperature Control Units. . . 243

2-1 Features and Word Allocations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 244

2-2 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 245

2-3 Nomenclature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 248

2-4 Terminology and Function Descriptions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 251

2-5 Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 253

2-6 Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 254

2-7 IOTC(––). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 262

2-8 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 269

2-9 Command Tables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 270

SECTION 3

CQM1-TC00@/TC10@ Temperature Control Units. . . 271

3-1 Features and Word Allocations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 272

3-2 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 273

3-3 Nomenclature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 274

3-4 Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 276

3-5 Application Examples. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 277

3-6 AT (Expansion Mode). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 282

3-7 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 287

Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 289

xi

Page 11

Page 12

About this Manual:

This manual descr ib es the i nst all ati on and op eration of the CQM1H/CQM1-series Dedicated I/O Un its

and includes the p ar ts and section s descri bed below. The CQM1H/CQM1-series Dedicated I/O Un its

consist of the Units listed below.

Please read this manual carefully and be sure you understand the information provided before

attempting to install and operate the CQM1H/CQM1-series Dedicated I/O Units.

Part I: B7A Interface Units

Section 1 describes th e general features, system configuration, and word allocati on of the B7A Interface Units.

Section 2 provides the nomenclature and switch settings for the B7A Interface Units.

Section 3 describes the connections between the B7A Interface Units and B7A Link Terminals.

The Appendix provides the specifications for the Units.

Part II: G730 Interface Units

Section 1 describes the general features, system configuration, and word allocation of the G730 Interface Units.

Section 2 provides the nomenclature and switch settings for the G730 Interface Units.

Section 3 describes the connections between the G730 Interface Units and G730 Remote Terminals.

Section 4 provides the operational procedures for the G730 Interface Unit.

The Appendices provide the specifications, dimensions, and troubleshooting procedure for the Units.

Part III: I/O Link Unit

Section 1 descr ibes the general features, system configuration, and word allocation of the CQM1LK501 I/O Link Unit.

Section 2 provides the nomenclature and switch settings for the CQM1-LK501 I/O Link Unit.

Section 3 describes the SYSMAC BUS cable connections for the CQM1-LK501 I/O Link Unit.

The Appendix provides the specifications for the Unit.

Part IV: Analog Input Unit and Analog Power Supply Units

Section 1 provides the features and system configuration relating to the Analog Input Unit and Analog

Power Supply Units.

Section 2 provides the nomenclature and functions of the Analog Input Unit and Analog Power Supply

Units.

Section 3 provides the operational pr ocedures for the Analog Input Unit and Analog Power Supply

Units.

The Appendices provide the sp ecifications, internal configuration , dimension s, and troubleshooting

procedure for the Units.

Part V: Analog Output Unit and Analog Power Supply Units

Section 1 provides the features and s ystem configuration relating to the A nal og O utpu t Un it and A nalog Power Supply Units.

Section 2 provides the nomenclature and functions of the Analog Output Unit.

Section 3 provides the operational procedures for the Analog Output Unit.

The Appendices provide the specifications and troubleshooting procedures for the Units.

!WARNING Failure to read and under stand the informati on provided i n this ma nual may result in p er-

sonal injury or death, damage to th e product, or product failure. Please rea d ea ch section

in its entirety and be sure you understand the information provided in the section and

related sections before attempting any of the procedures or operations given.

xiii

Page 13

Part VI: Sensor Unit

Section 1 provides the features and system con figuration relating to t he Sensor Unit and dedicated

sensor modules.

Section 2 provides the nomencla ture and switch setting s for the CQM1-SEN01, CQM1- TU001, E3XMA11, E3C-MA11, and E2C-MA11.

Section 3 describes the connections between the CQM1-SEN01 and E3X-MA11, E3C-MA11, E2CMA11, and CQM1-TU001.

Section 4 provides information on the operation of the CQM1-SEN01.

Section 5 provides information on the operation of the CQM1-TU001 Remote Console.

The Appendix provides the specifications for the Units.

Part VII: Linear Sensor Interface Units

Section 1 provides the features and system configuration relating to the Linear Sensor Interface Unit.

Section 2 provides an explanation o f the scal ing, timin g hold, mea sured value, teaching , forced-zero

shift, and monitor output functions.

Section 3 provides the nomencla ture, and ter mi nal an d indicato r func tions of the Linear Sens or Inter-

face Unit.

Section 4 describes the connections of the Linear Sensor Interface Unit.

Section 5 descr ibes the basic operation of the Linear Senso r Interface Unit using the Programming

Console.

Section 6 descr ibes the app lied opera tion of t he L inear Se nsor Inte rface Unit us ing the Programmin g

Console.

Section 7 provides details on the commands and responses of the Linear Sensor Interface Unit.

The Appendices provide the s peci fications, block dia gram, data proces sing timin g, and troubleshoot-

ing for the Units.

Part VIII: Temperature Control Units

Section 1 lists the Temperature Control Unit model numbers and the basic specifications for each Unit.

Section 2 describes the features and operation of the CQM1-TC20@/TC30@ Temperature Control

Units.

Section 3 describes the features and operation of the CQM1-TC00@/TC10@ Temperature Control

Units.

The Appendix provides the specifications for the Unit.

xiv

Page 14

PRECAUTIONS

This section provides general precautions for using the Programmable Controller (PC) and related devices.

The information contained in this section is important for the safe and reliable application of the Programmable

Controller. You must read this section and understand the information contained before attempting to set up or

operate a PC system.

1 Intended Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvi

2 General Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvi

3 Safety Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvi

4 Operating Environment Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvii

5 Application Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xviii

xv

Page 15

Intended Audience 1

1 Intended Audience

This manual is intended for the following personnel, who must also have

knowledge of electrical systems (an electrical engineer or the equivalent).

• Personnel in charge of installing FA systems.

• Personnel in charge of designing FA systems.

• Personnel in charge of managing FA systems and facilities.

2 General Precautions

The user must operate t he product according to t he performance specifications described in the operation manuals.

Before using the product under conditions which are not described in the

manual or applying the produ ct to nuclear control s ystems, railroad systems,

aviation systems, vehicles, combustion systems, medic al equipmen t, amusement machines, safety equipment, and oth er systems, machines, and equi pment that may have a serious influence on lives and property if used

improperly, consult your OMRON representative.

Make sure that the ratings and performan ce charact er is ti cs of the pr od uc t are

sufficient for the systems, machi nes, and equipment, and be sure to provide

the systems, machines, and equipment with double safety mechanisms.

This manual provides informat ion for programming and operat ing the Un it. B e

sure to read this manual before attempting to use the Unit and keep this manual close at hand for reference during operation.

!WARNING It is extremely impor tant th at a PC and all PC Units be u sed for the spe cified

purpose and under the specified conditions, especially in applications that can

directly or indirectly affect human life. You must consult with your OMRON

representative before applying a PC Sy stem to the above-mentioned a pplic ations.

3 Safety Precautions

!WARNING Do not attempt to take any Unit apart while the power is being supplied. Doing

so may result in electric shock.

!WARNING Do not touch any of the te r minals o r ter minal blocks while the power is bein g

supplied. Doing so may result in electric shock.

!WARNING Provide safety measures in external circuits, i.e., not in the Programmable

Controller (CPU U nit and associated Units; referred to as “PC”), in order to

ensure safety in the system if an abnormality occurs due to malfunction of the

PC or another extern al factor affecting the PC operation. Not doing so may

result in serious a cci dent s.

• Emergency stop ci rcuits, inte r lock circuits, limit c ircuits, and s imilar safety

measures must be provided in external control circuits.

• The PC will tur n OFF all outputs when its self-diagnos is function detects

any error or when a severe failure alarm (FALS) instruction is executed.

As a counterme asure for such errors, external safety measures must be

provided to ensure safety in the system.

xvi

Page 16

Operating Environment Precautions 4

• The PC outputs may remain O N or OFF due to deposition or burnin g of

the output relays or destr uction of the output transistors. As a cou ntermeasure for such problems, extern al safety measures must be provide d

to ensure safety in the system.

• When the 24-VDC ou tput (ser vice power supply to the PC) is overloaded

or short- circuited, the voltage may drop and result in the outputs b eing

turned OFF. As a countermeasure for such problems, external safety

measures must be provided to ensure safety in the system.

!Caution Execute online edit only after confirming that no adverse effects will be

caused by extending the cycle time. Other wise, the input signals may not be

readable.

!Caution Confirm safety at the destination node before transferring a program to

another node or editing the I/O area. Doing either of thes e withou t confir m ing

safety may result in inju ry.

!WARNING Do not attempt to disassemble, repair, or modify any Units. Any attempt to do

so may result in malfunction, fire, or electric shock.

!Caution Provide appropriate safety measures, such as overheat prevention and alarm

systems, in separate circuit s to ens ure safety of the en tire s ystem even when

the Temperature Controller malfunctions.

4 Operating Environment Precautions

!Caution Do not operate the control system in the following places:

• Locations subject to direct sunlight.

• Locations subject to temperatures or humidity outside the range specified

in the specifications.

• Locations subject to condensation as the result of severe changes in temperature.

• Locations subject to corrosive or flammable gases.

• Locations subject to dust (especially iron dust) or salts.

• Locations subject to exposure to water, oil, or chemicals.

• Locations subject to shock or vibration.

!Caution Take appropriate and sufficient c ountermeasures whe n installing systems in

the following locations:

• Locations subject to static electricity or other forms of noise.

• Locations subject to strong electromagnetic fields.

• Locations subject to possible exposure to radioactivity.

• Locations close to power supplies.

xvii

Page 17

Application Precautions 5

!Caution The operating environment of the PC System ca n have a large effect on the

longevity and reliability of the sy stem. Improper operating environme nts can

lead to malfunction, failure, and other unforeseeable problems with the PC

System. Be sure that the op erating environmen t is within the sp ecified c onditions at installation and remai ns within the specifi ed conditions dur ing the life

of the system.

5 Application Precautions

Observe the following precautions when using the PC System.

!WARNING Always heed these precautions. Failure to abide by the following precautions

could lead to serious or possibly fatal injury.

• Always ground to 100

grounding may result in electric shock.

• Always turn OFF the power supply to the PC before attempting any of the

following. Not turnin g OFF the power s upply may result in malfunct ion or

electric shock.

• Assembling t he Units.

• Setting DIP switches or rotary switches.

• Connecting or wiring the cables.

• Connecting or disconnecting the connectors.

!Caution Failure to abide by the following precautions could lead to faulty operation of

the PC or the system, or could damage the PC or PC Units. Always heed

these precautions.

• Fail-safe measures must be taken by the customer to ensure safety in the

event of incorrect, missing, or abnorm al signals caused by broken signal

lines, momentary power interruptions, or other causes.

• Install external breakers and take other safety measures against short-circuiting in external wiring. Insufficient safety measures agai nst short-circuiting may result in burning.

• Mount the Unit only after checking the terminal block completely.

• Be sure th at al l the mou nti ng s c rews, ter m ina l s c rews, and cable co nne ctor screws are tightene d to the torque s pecified in the r elevant manuals.

Incorrect tightening torque may result in malfunction.

• Always use the power supply voltage specified in this operation manual.

An incorrect voltage may result in malfunction or burning.

• Take appropriate m easures to ensure that the specified power with the

rated voltage and frequency is supplied. Be partic ularly car eful in places

where the power supply is unstable. An incorrect power supply may result

in malfunction.

• Leave the label attached to the Unit when wiring. Removing the label may

result in malfunction.

• Remove the label after the completion of wiring to ensure proper heat dissipation. Leaving the label attached may result in malfunction.

• Use crimp terminals for wiring. Do not connect bare stranded wires

directly to terminals. Connection of bare stranded wires may result in

burning.

Ω or less when installing the Units. Improper

xviii

Page 18

Application Precautions 5

• Do not appl y voltages to the Inp ut Units in excess of the rate d input voltage. Excess voltages may result in burning.

• Do not apply voltages or connect loads to t he Output Units in excess of

the maximum switching capacity. Excess voltage or loads may result in

burning.

• Be sure that the te rminal blocks, Memory Units, expansion cables, and

other items with locking devices are prop erly locked into place. Impro per

locking may result in malfunction.

• Disconnect the functional ground terminal when performing withstand

voltage tests. Not disconnecting the functional ground terminal may result

in burning.

• Double-check all the wiring and switch settings before turning ON the

power supply. Incorrect wiring or switch settings may result in burning.

• Check that the DIP switches and data memory (DM) are properly set

before starting operation .

• Check the user program for proper execution before actually r unn ing it o n

the Unit. Not checking the program may result in an unexpected operation.

• Resume operat ion only after transferring to the new CPU Unit the contents of the DM and HR Areas required for resuming operation. Not doing

so may result in an unexpected operation.

• Confir m that no adverse effect will occur in the syste m before attempting

any of the following. Not doing so may result in an unexpected operation.

• Changing the operating mode of the PC.

• Force-setting/force-resetting any bit in memory.

• Changing the present value of any word or any set value in memory.

• Do not pull on the cables or bend the cables beyond their natural limit.

Doing either of these may break the cables.

• Do not place objects on top of the cables. Doing so may break the cables.

• When repl acing par ts, be sure to confir m that the rating of a new par t is

correct. Not doing so may result in malfunction or burning.

• Before touching the Unit, be sure to firs t to uch a grou nde d m etal lic obj ec t

in order to discharge any static built-up. Not doing so may result in malfunction or damage.

• Do not tur n OFF the power supply to the Unit while data is being transferred.

• When transporting or storing the product, cover the PCBs with electrically

conductive materials to prevent LSIs and ICs from being damaged by

static electricity, and also keep the product within the specified storage

temperature range.

• Install the Unit properly as specified in the operation manual. Improper

installation of the Unit may result in malfunction.

• Provide a co ntrol circuit s o that the power to the I/ O circuits will turn ON

after the power to the PC turns ON. If the power to the I/O circuits tur ns

ON before the power to the PC turns ON, the system may malfunction

temporarily.

• If the I/O Hold Bit (SR 25212) is turn ed ON, the outp uts from the PC wi ll

not be turn ed OFF and wi ll ma intai n their previous status when t he PC is

switched from RUN or MONITOR mode to PROGRAM mode. Make sure

that the external loads will not produce dangerous conditi ons when this

occurs. (When operation stops for a fatal error, including those produced

xix

Page 19

Application Precautions 5

with the FALS(07) instruction, all outputs from Outpu t Unit will be turned

OFF and only the internal output status will be maintained.)

• When assem bling the Units or mounting the end cover, be sure to lock

them securely as shown in the following illustrations. If they are not properly locked, desired functionality may not be achieved.

• Be sure to mount the end cover to the rightmost Unit.

• Be sure that the connectors, terminal blocks, connection cables, and

other items with locking devices are prop erly locked into place. Impro per

locking may result in malfunction.

• Be sure to confirm the orientation and polarities when connecting terminal

blocks and connectors.

• Do not touch the ba ck side of circuit boards or the components mo unted

to them with your bare hands. There ar e sharp l eads and other par ts on

the boards that may cause injur y if hand led impr ope rly.

• Provide sufficient clearances around the Unit and other devices to ensure

proper heat dissipation. Do not cover the ventilation openings of the Unit.

• Do not allow metallic objects or conductive wires to enter the Unit.

• Set the operatin g settings of t he Temperature Control ler proper ly according to the system to be controlled.

• Allow at least 30 mi nutes after tur ning ON the Temperature Control ler as

warmup time.

• Do not use thinner to clean the product. Use commercially available

cleaning alcohol.

xx

Page 20

PART I B7A Interface Unit

CQM1-B7A02

CQM1-B7A03

CQM1-B7A12

CQM1-B7A13

CQM1-B7A21

1

Page 21

Page 22

SECTION 1

Features and System Configuration

This section describes the general features, system configuration, and word allocation of the CQM1-B7A@@ Interface

Units.

1-1 Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1-2 System Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1-3 Connecting Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1-3-1 CPU. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1-3-2 B7A Link Terminal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1-4 Word Allocation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1-5 Bit Allocation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3

Page 23

Features Section 1-1

1-1 Features

• The CQM1-B7A@@ Interface Unit incorporates the B7A transmission

operations for the CQM1H/CQM1 I/O Unit.

• The following five models of CQM1H/CQM1 B7A Inter face Unit are available.

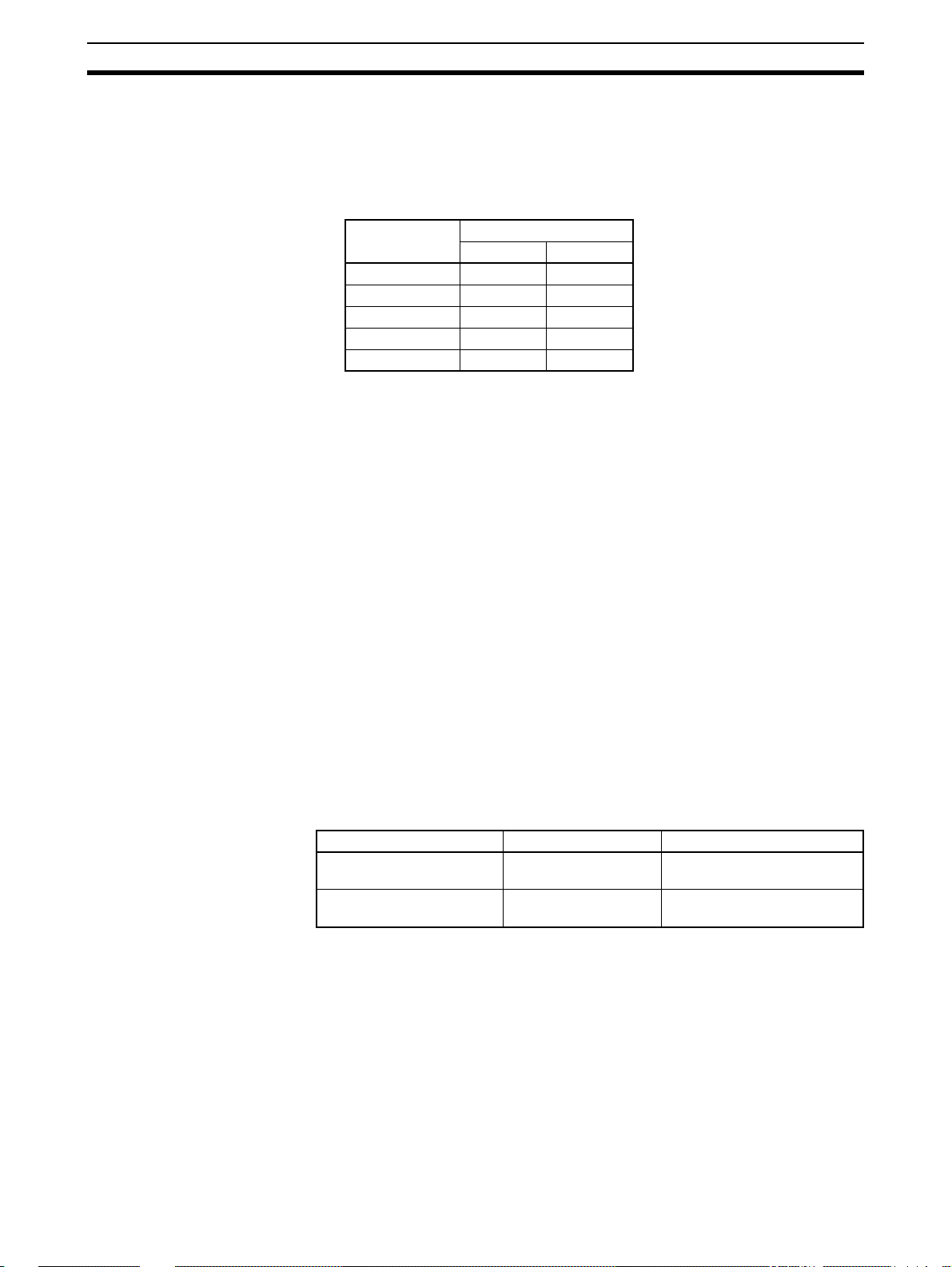

Model No. of points

Input Output

CQM1-B7A21 16 16

CQM1-B7A13 32 0

CQM1-B7A03 0 32

CQM1-B7A12 16 0

CQM1-B7A02 0 16

• Each Unit ca n be connected to the same number of poin ts on 16-point

B7A Link Terminals as provided by the Unit. For example, two B7A Link

Terminal Units with 1 6 input points each can be connected to a CQM1B7A13.

• The transm ission de lay time can be switched betwe en STANDARD (19.2

ms rated) or RAPID (3 ms rated).

• The data pr ocessing when a transmission error oc curs can be switched

between HOLD (see note 1) and LOAD OFF (see note 2).

• The CPU treats the B7A Interface Units as the equivalent number of

points. It can handle remo te I/O e quipme nt, su ch as switches and la mps,

without recognizing communications.

Differences Between

CQM1-B7A01 and

CQM1-B7A21

Note 1. HOLD: When an error occurs, the input bit s tatu s imm edi ate ly prior to the

error is held.

2. LOAD OFF: When an error occurs, all input bits turn off.

The B7A Link Terminal is a terminal board that incorporates a communicatio n

function, connects to exter nal I/O devices, and com municate s wit h a P C over

a single cable, thus reducing wiring effort.

CQM1-B7A21 is an upgraded version of the CQM1-B7A01 and can repl ace

the CQM1-B7A01.

The features listed in the table below have been added to the CQM1-B7A21.

Item CQM1-B7A01 CQM1-B7A21

Transmission delay time STANDARD only STANDARD/RAPID

switchable

Transmission error

processing

HOLD HOLD/LOAD OFF switchable

Note CQM1-B7A01 is no longer in production. Use the upgraded CQM1-B7A21.

4

Page 24

System Configuration Section 1-2

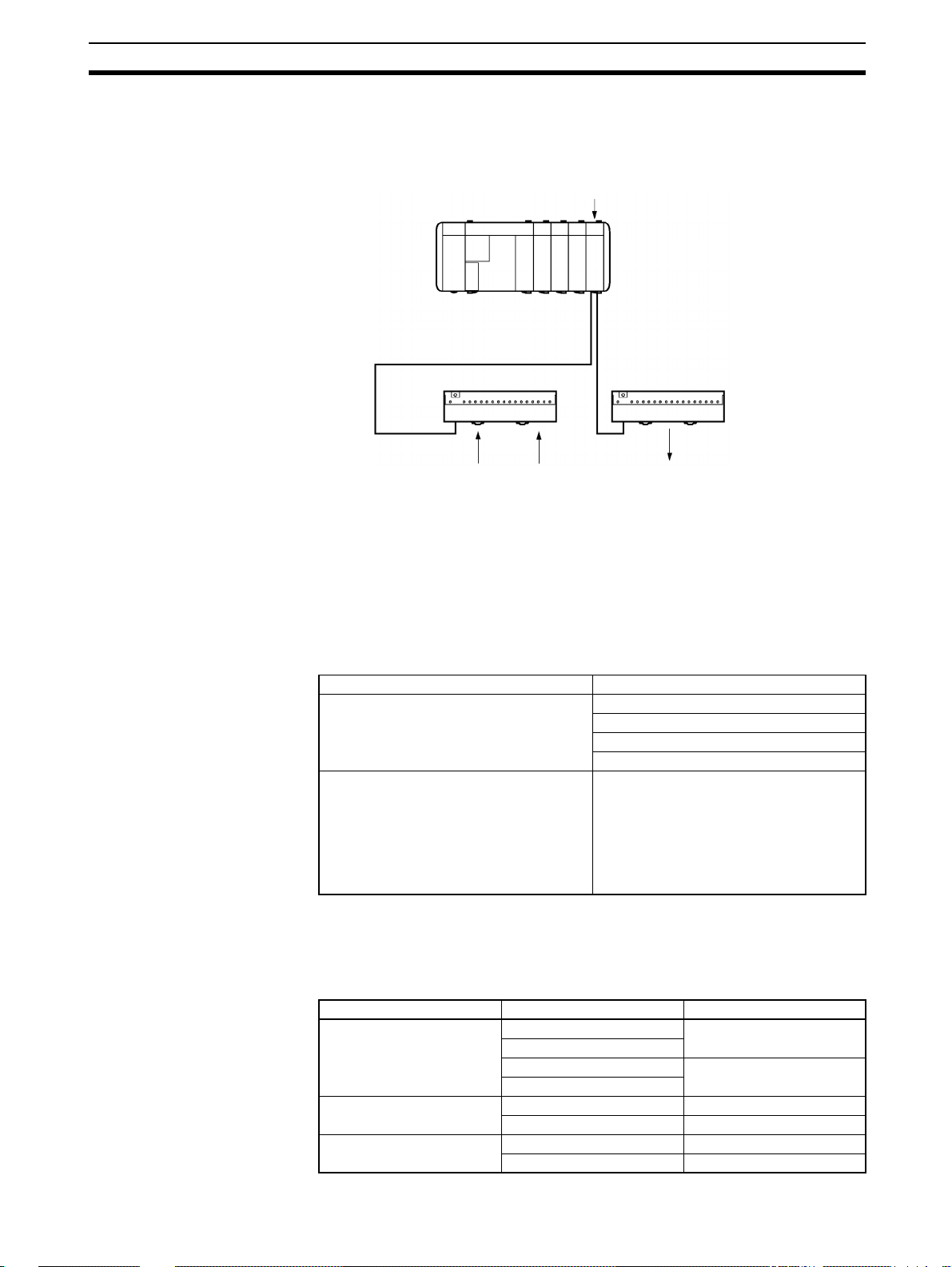

1-2 System Configuration

The following is a CQM1H/CQM1 sy stem configuration with a B7A Interface

Unit.

Note The maximum transmission di stance depe nds on the transmiss ion del ay time

and the power supply wiring.

Refer to 3-1 Connections to B7A Link Terminals.

1-3 Connecting Devices

1-3-1 CPU

The B7A Interface Unit connects to the following CPUs.

CQM1H-series CPU CQM1H-CPU11

CQM1-series CPU CQM1-CPU11-E

CQM1H/CQM1

B7A Interface Unit

Transmission distance: 500 m max.

B7A Link Terminal (for input) B7A Link Terminal (for output)

Switch Sensor Lamps

Name Model

CQM1H-CPU21

CQM1H-CPU51

CQM1H-CPU61

CQM1-CPU21-E

CQM1-CPU41-EV1

CQM1-CPU42-EV1

CQM1-CPU43-EV1

CQM1-CPU44-EV1

1-3-2 B7A Link Terminal

The B7A Interface Unit connects to the following 16-poin t B7 A Link Terminals

with a standard I/O delay of 19.2 ms (typical).

Input

Screw terminal models B7A-T6@1 STANDARD (19.2 ms)

Module models B7A-T6D2 STANDARD (19.2 ms)

PC connector models B7A-T@E3 STANDARD (19.2 ms)

Name Model Transmission delay time

B7AS-T6@1

B7A-T6@6 RAPID (3 ms)

B7AS-T6@6

B7A-T6D7 RAPID (3 ms)

B7A-T@E8 RAPID (3 ms)

5

Page 25

Word Allocation Section 1-4

Output

Name Model Transmission delay time

Screw terminal model B7A-R6@@1 STANDARD (19.2 ms)

B7AS-R6@@1

B7A-R6@@6 RAPID (3 ms)

B7AS-R6@@6

Module model B7A-R6A52 STANDARD (19.2 ms)

B7A-R6A57 RAPID (3 ms)

PC connector models B7A-R@A@3 STANDARD (19.2 ms)

B7A-R@A@8 RAPID (3 ms)

Note Combine B7A Interface Units and B7A Link Terminals with equal transmission

delay times.

Transmission errors will occur if the transmission delay times used in the combination are not equal.

Do not connect B7A Link Terminals with 10 points and I/O mi xed points. Connect only 16-point transmission models.

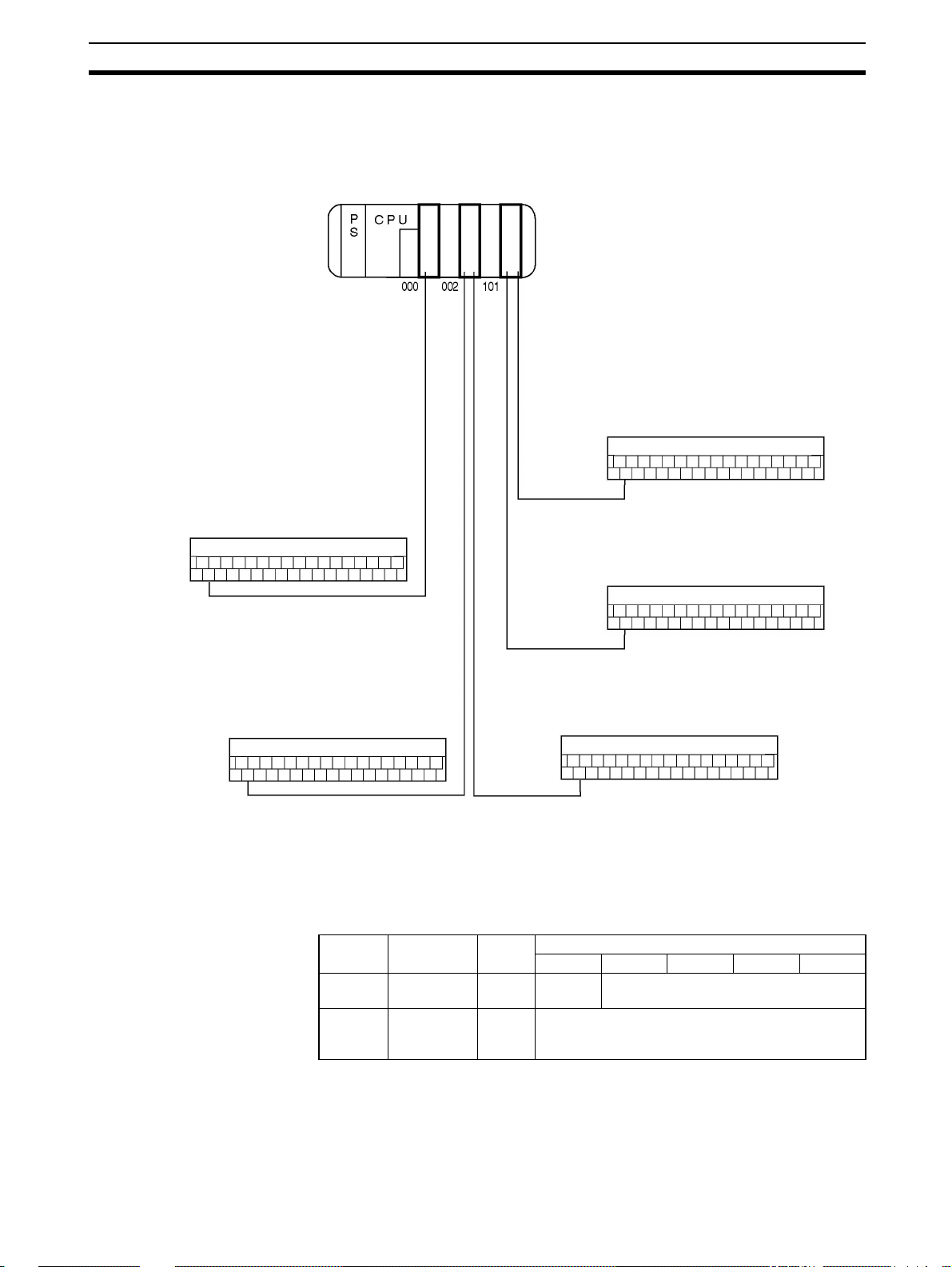

1-4 Word Allocation

The CPU treats the B7A Int erface Unit as an equi valent numbe r of co nne cted

I/O Units. The words allocation is identical to that for I/O Units, with inputs and

outputs allocated from left to right.

6

Page 26

Bit Allocation Section 1-5

Words from 000 including the input bits incorporated by the CPU are allocated

for input and words from 100 are allocated for output as shown in the following

illustration. Refer to the CQM1H or CQM1 Operation Manual for details on I/O

word allocation.

CQM1H/CQM1

PS : Power Supply Unit

CPU : CPU

IN : Input Unit and terminals

OUT : Output Unit

B7A21 : B7A Interface Unit

(16 input and 16 output points)

B7A12 : B7A Interface Unit

(16 input points)

B7A03 : B7A Interface Unit

(16 output points)

B7A Link Terminal (for output)

Word 103

Points: 0 to 15

Bit no.: 10300 to 10315

Word

B7A Link Terminal (for input)

16

pts

IN

IN

B7A12

16

pts

OUT

B7A21

16

pts

Connection terminals 1

B7A03

Connection terminals 2

Word 001

Points: 0 to 15

Bit no.: 00100 to 00115

B7A Link Terminal (for input)

Word 003

Points: 0 to 15

Bit no.: 00300 to 00315

1-5 Bit Allocation

CQM1-B7A21

B7A Link Terminal (for output)

Word 102

Points: 0 to 15

Bit no.: 10200 to 10215

B7A Link Terminal (for output)

Word 100

Points: 0 to 15

Bit no.: 10000 to 10015

The bit allocation for each model is described below.

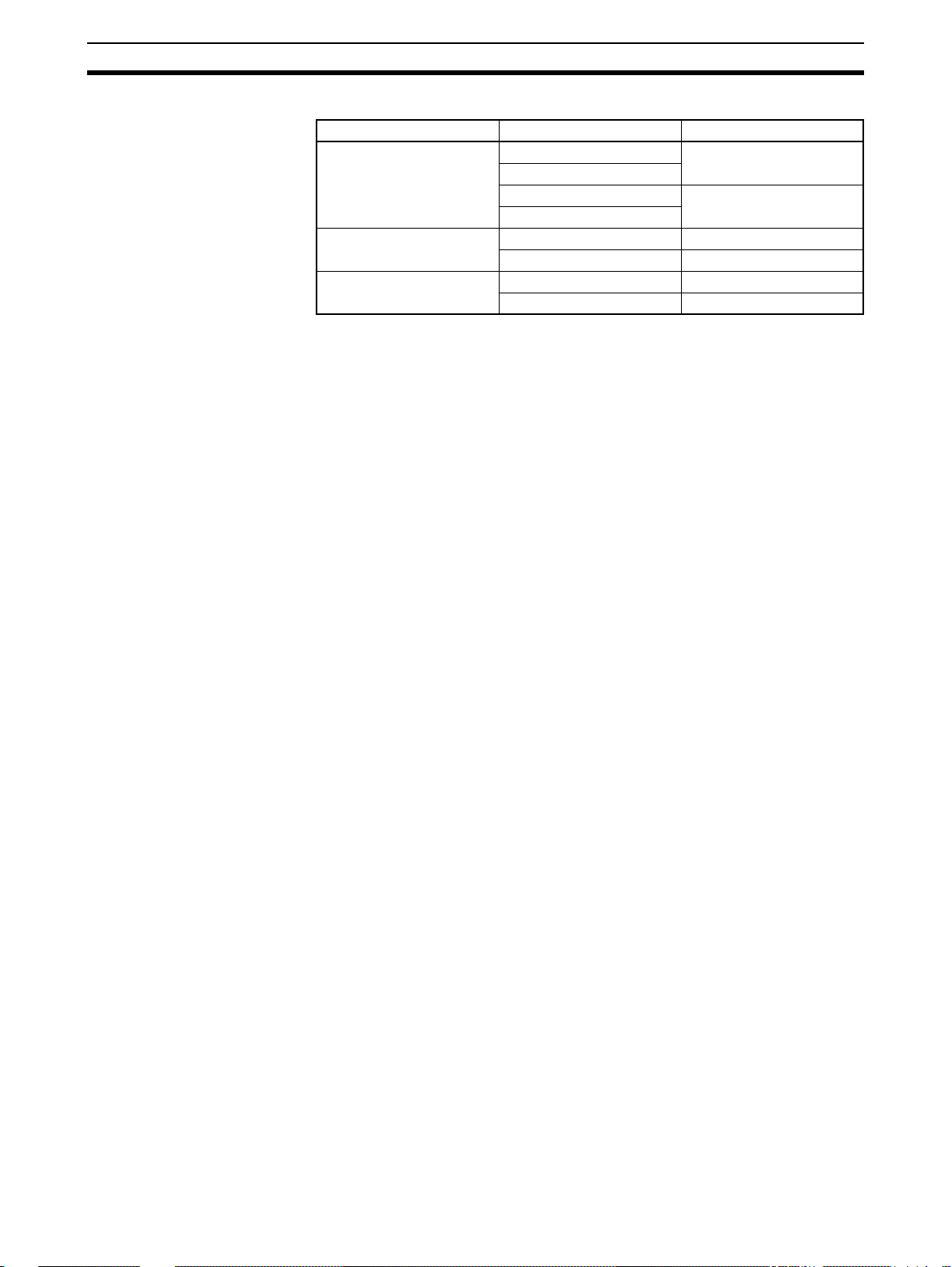

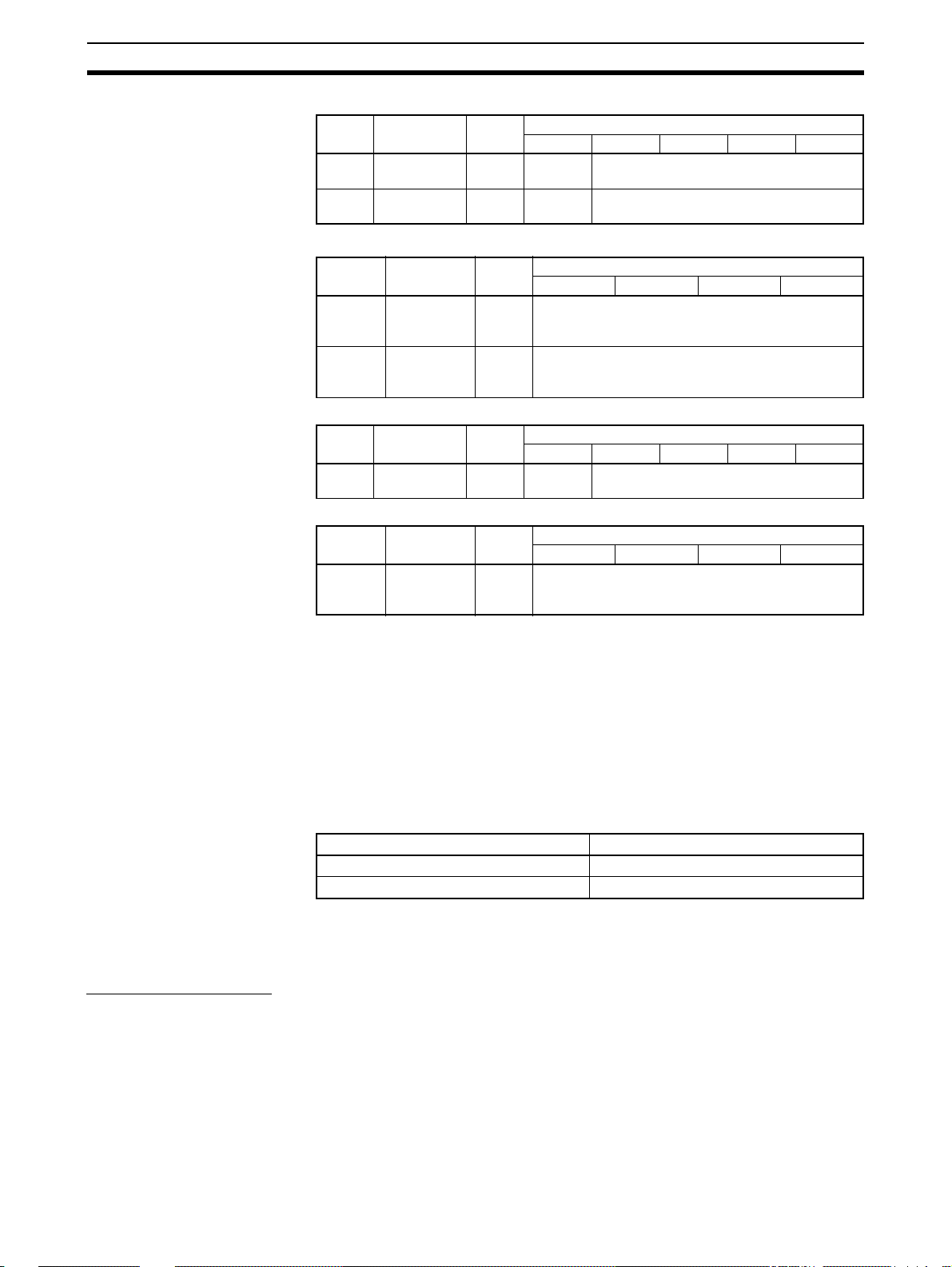

I/O Word no. Termi-

Input n

Output

(see

note 3)

(see note 2)

m

(see note 2)

nal

1See

2 Output bits

15 14 to 12 11 to 8 7 to 4 3 to 0

Input bits

note 1

Bit

7

Page 27

Bit Allocation Section 1-5

CQM-B7A13

CQM1-B7A03

CQM1-B7A12

CQM1-B7A02

I/O Word no. Termi-

nal

Input n 1 See

Input n + 1 2 See

I/O Word no. Termi-

nal

Output

(see

note 3)

Output

(see

note 3)

I/O Word no. Termi-

Input n 1 See note

I/O Word no. Termi-

Output

(see

note 3)

m 1 Output bits

m + 1 2 Output bit s

nal

nal

m 1 Output bits

15 14 to 12 11 to 8 7 to 4 3 to 0

Input bits

note 1

Input bits

note 1

15 to 12 11 to 8 7 to 4 3 to 0

15 14 to 12 11 to 8 7 to 4 3 to 0

Input bits

1

15 to 12 11 to 8 7 to 4 3 to 0

Note 1. Bit 15 of the input addre ss is allocated as follows, accordi ng to the DIP

switch input mode setting.

15-point input + 1 error mode setting = transmission error bit

16-point input = input bit 15

Refer to 2-2 Switch Settings.

2. Start word address (n: input, m: output)

3. See the following caution.

Bit

Bit

Bit

Bit

!Caution The minimum input time (minimum required time to read input signal from

CPU) at output bit of the B7A Interface Unit is as follows:

Transmission delay time Minimum input time

STANDARD (19.2 ms) 16 ms

RAPID (3 ms) 2.4 ms

When a user program is created, make sure the ON/O FF signal range from

the CPU to the B7A Interface Unit’s output bit is larger th an th e above values.

If smaller than the above values, data might not be correct transmitted.

Transmission Errors

Power On If the input mode is set to 15IN+ERR, the transmission error bit becomes OFF

when the CQM1H/CQM1 power is turned on.

The transmission error bi t tur ns O N if nor m al transmi ssion wit h the inpu t B7A

Link Terminal is not established within 10 ms.

All input bits remain OFF from the tim e CQM1H/CQM 1 is turn ed on until nor-

mal transmission is established.

8

Page 28

Bit Allocation Section 1-5

Inputs When a transmission error occurs, the input bits are proces sed according to

the transmission error processing setting: HOLD or LOAD OFF.

If the input mode is set to 15IN+ERR, the transmission error bit turns ON.

The transmission error bit turns OFF when nor mal transmission is re-est ab-

lished.

The normally received signals are then input to the input bits.

Outputs A transmission error with an output B7A Link Terminal can only be detected at

the Link Terminal . Co nfirm the error wi th the L ink Terminal ERR indicator and

error output.

9

Page 29

Page 30

Nomenclature and Settings

This section provides the nomenclature and switch settings for the CQM1-B7A@@ Interface Units.

2-1 Nomenclature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2-2 Switch Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

SECTION 2

11

Page 31

Nomenclature Section 2-1

2-1 Nomenclature

CQM1-B7A21

Front View

Indicators (see following table)

B7A Link Terminal connection terminals 1

For connection of a 16-point output B7A Link Terminal.

B7A Link Terminal connection terminals 2

For connection of a 16-point Input B7A Link Terminal.

Indicators

External power terminals

Required for transmission with the B7A Link Terminal. Connect a 12- to-24 VDC power supply.

Terminal screws: M3

(Optimum tightening torque: 0.5 N • m)

Name Color Function

RD Y Unit ready Green Lit while the CQM1H/CQM1 is supplied w ith

ERR Input

3ms Transmission

LOAD

OFF

15IN+ERR Input mode Orange Lit while input mode is set to 15IN+ERR.

transmission

error

delay time

Transmission

error

processing

Red Lit if the B7A Link Terminal for input is mal-

Orange Lit while transmission delay time is set to

Orange Lit while transmission error processing is

power.

functioning or the B7A Link Terminal for

input is disconnected.

RAPID (3 ms). Not lit when set to STANDARD (19.2 ms).

set to LOAD OFF. Not lit when set to HOLD .

Not lit when set to 16IN.

12

Page 32

Nomenclature Section 2-1

CQM1-B7A13

Front View

Indicators (see following table)

B7A Link Terminal connection terminals 1

For connection of a 16-point Input B7A Link Terminal.

Inputs least-significant word (n) data.

B7A Link Terminal connection terminals 2

For connection of a 16-point Input B7A Link Terminal.

Inputs most-significant word (n+1) data.

External power terminals

Required for transmission with the B7A Link Terminal. Connect a 12- to 24-VDC power supply.

Indicators

Terminal screws: M3

(Optimum tightening torque: 0.5 N • m)

Name Color Function

RD Y Unit ready Green Lit while the CQM1H/CQM1 is supplied w ith

power.

3ms Transmission

LOAD

OFF

15IN+ERR Input mode Orange Lit while input mode is set to 15IN+ERR.

ERR1 Input 1

ERR2 Input 2

delay time

Transmission

error

processing

transmission

error

transmission

error

Orange Lit while transmission delay time is set to

RAPID (3 ms). Not lit when set to STANDARD (19.2 ms).

Orange Lit while transmission error processing is

set to LOAD OFF. Not lit when set to HOLD .

Not lit when set to 16IN.

Red Lit when normal tra nsm is s ion with th e Input

B7A Link Terminal connecte d to conne ction

terminals 1 is not possible or when no Input

B7A Link Terminal is connected.

Red Lit when normal tra nsm is s ion with th e Input

B7A Link Terminal connecte d to conne ction

terminals 2 is not possible or when no Input

B7A Link Terminal is connected.

13

Page 33

Nomenclature Section 2-1

CQM1-B7A03

Front View

Indicators (see following table)

B7A Link Terminal connection terminals 1

For connection of a 16-point output B7A Link Terminal.

outputs least-significant word (m) data.

B7A Link Terminal connection terminals 2

For connection of a 16-point output B7A Link Terminal.

outputs most-significant word (m+1) data.

External power terminals

Required for transmission with the B7A Link Terminal. Connect a 12- to 24-VDC power supply.

Indicators

Terminal screws: M3

(Optimum tightening torque: 0.5 N • m)

Name Color Function

RD Y Unit ready Green Lit while the CQM1H/CQM1 is supplied with

power.

19ms/3ms Transmission

delay time

Orange Lit while transmission delay time is set to

RAPID (3 ms). Not lit when set to STANDARD (19.2 ms).

14

Page 34

Nomenclature Section 2-1

CQM1-B7A12

Front View

Indicators (see following table)

B7A Link Terminal connection terminals 1

For connection of a 16-point Input B7A Link Terminal.

External power terminals

Required for transmission with the B7A Link Terminal. Connect a 12- to-24 VDC power supply.

Indicators

Terminal screws: M3

(Optimum tightening torque: 0.5 N • m)

Name Color Function

RD Y Unit ready Green Lit while the CQM1H/CQM1 is supplied w ith

ERR Input

3ms Transmission

LOAD

OFF

15IN+ERR Input mode Orange Lit while input mode is set to 15IN+ERR.

transmission

error

delay time

Transmission

error

processing

Red Lit if the B7A Link Terminal for input is mal-

Orange Lit while transmission delay time is set to

Orange Lit while transmission error processing is

power.

functioning or the B7A Link Terminal for

input is disconnected.

RAPID (3 ms). Not lit when set to STANDARD (19.2 ms).

set to LOAD OFF. Not lit when set to HOLD .

Not lit when set to 16IN.

15

Page 35

Nomenclature Section 2-1

CQM1-B7A02

Front View

Indicators (see following table)

B7A Link Terminal connection terminals 1

For connection of a 16-point output B7A Link Terminal.

External power terminals

Required for transmission with the B7A Link Terminal. Connect a 12- to 24-VDC power supply.

Terminal screws: M3

(Optimum tightening torque: 0.5 N • m)

Indicators

Name Color Function

RD Y Unit ready Green Lit while the CQM1H/CQM1 is supplied w ith

19ms/3ms Transmission

delay time

Left-side View Common to all models.

power.

Orange Lit while transmission delay time is set to

RAPID (3 ms). Not lit when set to STANDARD (19.2 ms).

Operation setting DIP Switch

Sets to the operation of the

B7A Interface Unit (see page

15). Set the switches before

mounting the B7A Interface

Unit in CQM1H/CQM1. To set

after mounting, remove the terminal block and make the setting from the front face.

16

Page 36

Switch Settings Section 2-2

→

→

2-2 Switch Settings

Remove the terminal block to expose the DIP switch under n eat h. Refer to the

CQM1H Operation Manual (W 363) or the CQM1 Operation Manual (W226)

for the method of removing the terminal block.

Use a thin-tipped object, such as a small screwdriver, to set the pins.

DIP switch

CQM1-B7A21/CQM1-B7A12

Pin no. Setting OFF ON

4 Transmission delay

time

3 Transmission error

processing

2 Input mode 16IN 15IN+ERR

1 ERR indicator Not lit Lit

STANDARD (19.2 ms) RAPID (3 ms)

HOLD LOAD OFF

→

Note On delivery from the factory, pin 1 is set ON and all others OFF.

CQM1-B7A03/CQM1-B7A02

Pin no. Setting OFF ON

4 Transmission delay

time

3 Not used (set OFF) ––– –––

2 Not used (set OFF) ––– –––

1 Not used (set OFF) ––– –––

STANDARD (19.2 ms) RAPID (3 ms)

Note On delivery from the factory, all pins set OFF.

CQM1-B7A13

Pin no. Setting OFF ON

6 Transmission delay

time

5 Transmission error

processing

4 Input mode 16IN 15IN+ERR

3 ERR1 indicator Not lit Lit

2 ERR2 indicator Not lit Lit

1 Not used (set OFF) ––– –––

STANDARD (19.2 ms) RAPID (3 ms)

HOLD LOAD OFF

Note On delivery from the factory, pins 2 and 3 are set ON and all others OFF.

!Caution Turn off the CQM1H/CQM1 power before setting the pins.

17

Page 37

Switch Settings Section 2-2

Transmission Delay Time

Setting

Sets the transmission delay time for the B7A Interface Unit.

Setting Transmission Delay Time

ON RAPID (3 ms)

OFF STANDARD (19.2 ms) (factory setting)

Set the transmission delay time to RAPID to enable transmis sion with highspeed B7A Link Terminals with a transmission delay time of 3 ms. Set the

transmission delay time to STANDARD to enable transmission with standar d

B7A Link Terminals with a transmission delay time of 19.2 ms.

Set the pin to match the transmis sion delay time of the type of B7 A Link Terminal connected. A transm ission erro r will oc cur if t he sett ing doe s n ot matc h

the transmission delay time of the B7A Link Terminal.

The transmission delay time setting is made for the entire Uni t. It is no t pos sible to make separate settings for each word if multiple words are used.

Transmission Error

Processing Setting

This setting deter mines whether the input bit status immed iately prior to th e

error is held when a transmission error occurs (HOLD) or whether all input bits

turn off (LOAD OFF).

Setting Transmission error processing

ON LOAD OFF

OFF HOLD (factory setting)

Input Mode Setting Set the input mode (the use of bit 15) from the Input B7A Link Terminal to one

of the modes shown in the table below. Match the pin setting to the Input B7A

Link Terminal.

Setting Input mode Description

ON 15-point input + 1 error

(15IN+ERR)

OFF 16-point input (16IN) Bit 15 also used as a normal input bit. The

Bit 15 used as transmission error bit. The

bits available for input are the 15 bits from

00 to 14.

bits available for input are the 16 bits from

00 to 15. (factory setting)

ERR Indicator Lighting

Setting

Sets whether the ERR indicator lights when an input transmission error

occurs.

Setting Description

ON ERR indicator lights (factory setting)

OFF ERR indicator does not light

To avoid indicator lighting unnecessari ly, set pin OFF if the input side of the

B7A Interface Unit is not used.

18

Page 38

SECTION 3 Connections

This section describes the connections between the CQM1-B7A@@ Interface Units and B7A Link Terminals.

3-1 Connections to B7A Link Terminals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3-1-1 Recommended Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3-1-2 Connecting Terminals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3-2 Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

19

Page 39

Connections to B7A Link Terminals Section 3-1

3-1 Connections to B7A Link Terminals

3-1-1 Recommended Cables

The B7A Interface Unit can be connected to the input an d output B7A Link

Terminals using the following cables.

Standard Transmission Delay-time Type

Cabtire Cable Use a VCTF 0.75 x 3 C cabtire cable (100 m max.) if a power supply is shared

and a VCTF 0.75 x 2 C cabtire cable (500 m max.) if power is s upplied independently.

Rapid Transmission Delay-time Type

Shielded Cable Use a 0.75 x 3 C shielded cable (50 m max.) if a power supply is shared and a

0.75 x 2 C shielded cable (100 m max.) if power is supplied independently.

!Caution If shielded cable is not used for the high-sp eed transmission delay-time Link

Terminal, the transmission distance is not to exceed 10 m regardless of

whether power supply is shared or wired separately.

3-1-2 Connecting Terminals

CQM1-B7A21

CQM1-B7A13

Connect the input and output B7A Link Terminals to the B7A Interface Unit via

the following terminal s using cr imp-style term inals used for CQM1H /CQM1 I/

O Units.

Connect to the SIG terminal of

the output B7A Link terminal.

B

Unused

Unused

0

A

0

B

1

A

1

B

2

A

2

B

3

A

3

B

0

A

0

B

1

A

1

B

2

A

2

B

3

A

3

Connect to the negative power supply terminal of the output B7A Link Terminal.

Connect to the SIG terminal of

the input B7A Link Terminal.

Connect to the negative power supply terminal of the input B7A Link Terminal.

Connect to the SIG terminal of

the input B7A Link terminal.

Connect to the negative power supply terminal of the input B7A Link Terminal.

Connect to the SIG terminal of

the input B7A Link Terminal.

Connect to the negative power supply terminal of the input B7A Link Terminal.

Word m

Word n

Word n

Word n + 1

20

Page 40

Connections to B7A Link Terminals Section 3-1

CQM1-B7A03

Connect to the SIG terminal of

the output B7A Link terminal.

Connect to the negative power supply terminal of the output B7A Link Terminal.

Connect to the SIG terminal of

the output B7A Link Terminal.

Connect to the negative power supply terminal of the output B7A Link Terminal.

Connect to the SIG terminal of

the input B7A Link terminal.

0

1

2

3

Connect to the negative power supply terminal of the input B7A Link Terminal.

Unused

Word m

Word m + 1

Word n

CQM1-B7A12

Unused

Unused

B

0

A

0

B

1

A

1

B

2

A

2

B

3

A

3

B

A

0

B

A

1

B

A

2

B

A

3

CQM1-B7A02

Connect to the SIG terminal of

the output B7A Link terminal.

Word m

Connect to the negative power supply terminal of the output B7A Link Terminal.

Unused

Unused

B

0

A

0

B

1

A

1

B

2

A

2

B

3

A

3

Connectors Crimp connectors for I/O Unit wiring should be l ess than 6.2 mm wide (M 3),

and the wire should be AWG22 to 18 (0.3 to 0.75 mm

2)

.

Terminal screws should be tightened with a torque of 0.5 N • m.

6.2 mm max.

6.2 mm max.

!Caution Forked crimp connectors are required by UL and CSA standards.

21

Page 41

Wiring Section 3-2

3-2 Wiring

Wiring between the B 7A Interface Unit, input B7A Link Terminal, and output

B7A Link Terminal s haring a si ngle power supply differs from wi ring between

Units using independent power supplies as shown in the following diagrams.

Standard Transmission Delay-time Link Terminal

Single Power Supply

B7A Interface Unit

Terminal screws: M3

–

+

12 to 24 VDC

Independent Po wer Supplies

B7A Interface Unit

Terminal screws: M3

Terminal screws: M3.5

Transmission distance: 100 m max.

–

2

Transmission cable: VCTF 0.75 mm

Transmission distance: 500 m max.

min.

Terminal screws: M3.5

12 to 24 VDC

+

B7A Link Terminal

B7A Link Terminal

B7A Link Terminal

22

12 to 24 VDC

–

–

12 to 24 VDC

+

Transmission cable: VCTF 0.75 mm

2

min.

+

B7A Link Terminal

Note 1. The transmission distance depends on the type of wiring used.

2. The size of termi nal s crew differs for the B7A In terface Unit a nd B7A Link

T erminal. Consider the size of the terminal screws when using crimped terminals.

Page 42

Wiring Section 3-2

3. Locate transmission c ables away from power cables and high -voltage c ables to eliminate the effects of noise.

Rapid Transmission Delay-time Link Terminal

Single Power Supply

Terminal screws: M3.5

B7A Interface Unit

Terminal screws: M3

–

–

+

12 to 24 VDC

Independent Po wer Supplies

B7A Interface Unit

Terminal screws: M3

Ground

Ground

Transmission distance:

50 m max.

Shielded cable:

0.75 mm

Transmission cable:

shielded, 0.75 mm

Transmission distance:

50 m max.

2

min.

2

min.

Terminal screws: M3.5

12 to 24 VDC

B7A Link Terminal

B7A Link Terminal

+

B7A Link Terminal

12 to 24 VDC

–

–

+

Ground

Shielded cable:

0.75 mm

2

min.

Transmission cable:

shielded, 0.75 mm

12 to 24 VDC

2

min.

+

B7A Link Terminal

Ground

Note 1. The transmission distance depends on the type of wiring used.

2. The size of termi nal s crew differs for the B7A In terface Unit a nd B7A Link

T erminal. Consider the size of the terminal screws when using crimped terminals.

3. It is recommend that the shield wire be grounded.

23

Page 43

Wiring Section 3-2

4. If shielded cable is not us ed, the transmission distan ce is not to exceed

10 m regard less of whe ther power supply i s common or wired sep arately

(using VCTF 0.75 mm

5. Locate transmission c ables away from power cables and high -voltage cables to eliminate the effects of noise.

2

min.).

24

Page 44

Appendix A

Specifications

Standard Specifications

The standard specifications of the B7A Interface Unit conform to those of the CQM1H/CQM1 PC.

Performance Specifications

Item Specification

I/O points B7A21: 16 input points (see note 1), 16 output points

B7A13: 32 input points (see note 2)

B7A03: 32 output points

B7A12: 16 input points (see note 1)

B7A02: 16 output points

I/O word allocation B7A21: 1 word each for input and output (2 words in total)

B7A13: 2 words for input

B7A03: 2 words for output

B7A12: 1 word for input

B7A02: 1 word for output

Communication method Unidirectional, time-division multiplex

Transmission distance

(see note 3)

Transmission delay time STANDARD: 19.2 ms (rated delay), 31 ms max.

Minimum input time

(see note 4)

Power consumption 100 mA at 5 VDC

External power supply 12 to 24 VDC ±10% (excluding the power required by the B7A Link Terminals)

Weight 200 g max.

Dimensions 32 x 110 x 107 (W x H x D) mm

STANDARD: 500 m max.

RAPID: 100 m max.

RAPID: 3 ms (rated delay), 5 ms max.

STANDARD: 16 ms

RAPID: 2.4 ms

B7A21: 0.11 A min.

B7A13: 0.07 A min.

B7A03: 0.10 A min.

B7A12: 0.05 A min.

B7A02: 0.04 A min.

1. Input mode setting allows selection between 16-point input and 15-point+1 error input.

2. Input mode setting allows selec tion between 32- point input and 30-point+2 err or input. Re fer to 2-2

Switch Settings.

3. The maximum transmission distance of the B7A Interface Unit varies with the transmission delay time

and the method of wiring. Refer to 3-1 Connections to B7A Link Terminals for details.

4. Minimum input time is the minimum required time to read an input signal from the CPU. The ON/OFF

signal range from the CPU to the B7A Inter face Unit’s output bit should be larger than the mi nimum

input time.

25

Page 45

Specifications Appendix A

Dimensions

These dimensions are the same for all B7A Interface Unit models.

(Unit: mm)

26

Page 46

PART II G730 Interface Unit

CQM1-G7M21

CQM1-G7N01

CQM1-G7N11

27

Page 47

Page 48

SECTION 1

Features and System Configuration

This section describes the general features, system configuration, and word allocation of the G730 Interface Units.

1-1 Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

1-2 System Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

1-3 Connecting Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

1-3-1 CPU. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

1-3-2 G730 Remote Terminal (Slave) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

29

Page 49

Features Section 1-1

1-1 Features

The CPU handles the Interface Units as I/O Units, thereby eliminating tedious

procedures. Using a G730 Interface Unit allows signa ls for remote I/O equipment, such as switches and lam ps, to b e ha ndl ed and co ntr olled by the G730

Remote Terminal.

The G730 Remote Termin al is a terminal block with added communications

functions. It is connected to remote I/O equipment and PC s. Connecti on to

the PC by a single pair of cables reduces wiring effort.

For more information about the G730 Remote Terminal, refer to the I/O T ermi-

nal Series Catalog (X044).

CQM1-G7M21 Master Switch settings on the Master allow simultaneous connection of G730

Remote Terminals (Slaves) with up to 32 input points and 32 output points.

Up to two Expansion Maste rs c an be con nec te d to ea ch Mas ter ( one syst em)

to permit control of up to 128 points.

Multiple Masters can be used.

Connection of multiple Masters in separate systems permits control within the

range permitted for the CPU.

The number of inpu t points a nd ou tput poin ts can in depend ently be switche d

between 32 and 16.

The HOLD/HOLD OFF setting d etermines whether the si gnals into the CPU

are held (HOLD) or cleared (HOLD OFF) when a transmission error occurs.

CQM1-G7N@1 Expansion

Master

An Expansion Master is used if the Master alone does not allow connection of

sufficient points. The Exp ansion Ma sters are always connected in series with

the Master and up to two Expansion Mas ters can be c onnected to eac h Master.

Expansion Masters are available as Input Units (G7N11) and Output Units

(G7N01). Switch settings allow connection of G730 Remote Terminals

(Slaves) with up to 32 points.

The number of inpu t points a nd ou tput poin ts can in depend ently be switche d

between 32 and 16 for both Input Units and Output Units.

30

Page 50

System Configuration Section 1-2

1-2 System Configuration

The following are CQM1H/CQM1 system configu ration examples with G730

Interface Units.

Configuration with One Master

Master (32 input points/32 output points max.)

CQM1H/CQM1

RS-485, 200 m max.

G730-VI (input model) G730-VO (output model) G730-RI (input model) G730-RO (output model)

Switch Sensor Lamp ValveSwitch

Note 1. Sw itches o n the M aster allow in put and output to be i ndepen dently set t o

2 words (32 points) or 1 word (16 points). Connect Slaves according to the

set number of points.

2. If both input and output are set to 2 words (32 points), up to eight Input

Units and eight Output Units can be connected, if 4-point Slaves are used.

31

Page 51

System Configuration Section 1-2

Configuration as a Single System with Expansion Masters

Master (32 input points/32 output points max.)

Expansion Master Unit 1 (max. 32 input points or 32 output points)

CQM1H/CQM1

RS-485, 200 m max.

G730-VI (input model) G730-VO (output model) G730-RI (input model) G730-RO (output model)

Switch Sensor Lamp ValveSwitch

Expansion Master Unit 2 (max. 32 input points or 32 output points)

Note 1. Use one Master in any system. The systems must be separated if multiple

Masters are used. (See page 33)

2. Up to two Expansion Masters can be connected to each Master.

3. When two Expansion Masters are used, set one as Unit 1 and the other as

Unit 2. The Slave address for Unit 2 can only be used for an 8-point or 16point Slave. It cannot be used for a 4-point Slave.

4. The combination of one Master with two Expansion Masters allows control

of up to 128 points.

5. The maximum number o f connectable Slaves is 24 4-poi nt Slaves and 4

8-point Slaves, making a total or 28 Units.

32

Page 52

System Configuration Section 1-2

Configuration as Multiple Systems

Master, System 1 (32 input points/32 output points max.)

Expansion Master Unit 1 (max. 32 input points or 32 output points)

Expansion Master Unit 2 (max. 32 input points or 32 output points)

Master, System 2 (32 input points/32 output points max.)

Expansion Master Unit 1 (max. 32 input points or 32 output points)

RS-485, 200 m max.

G730-VI (input model) G730-VO (output model) G730-RI (input model)

Switch Sensor Lamp ValveSwitch

G730-VI (input model) G730-VO (output model) G730-RI (input model) G730-RO (output model)

Switch Sensor Lamp ValveSwitch

G730-RO (output model)

Note 1. Wh en multi ple Ma st er s ar e us ed , al lo ca te s ystem numbers to them i n s e-

quence from 1, starting from the Master nearest the CPU. The system

numbers have no special significance. Refer to 4-1 Word Allocation.

2. Up to two Expansion Masters can be connected to each Master.

3. When two Expansion Masters are used, set one as Unit 1 and the other as

Unit 2. The Slave address for Unit 2 can only be used for an 8-point or 16point Slave. It cannot be used for a 4-point Slave.

4. Masters and Expansion Masters can be used in any combination, provided

that the maximum numb er of input and output points remains with in the

range permitted for the CPU.

33

Page 53

Connecting Devices Section 1-3

1-3 Connecting Devices

1-3-1 CPU

The G730 Interface Unit connects to the following CPUs.

Name Model Max. I/O Points (see note)

CQM1H-series CQM1H-CPU11 256 (16 words)

CQM1H-CPU21

CQM1H-CPU51 512 (32 words)

CQM1H-CPU61

CQM1-series CQM1-CPU11-E 128 (8 words)

CQM1-CPU21-E

CQM1-CPU41-EV1 256 (16 words)

CQM1-CPU42-EV1

CQM1-CPU43-EV1

CQM1-CPU44-EV1

Note The number of points includes the CP U internal 16 input poin ts (one word).

Therefore, the actual maximum number s of points usable by the G73 0 Interface Unit are 112 points (7 words), 240 points (1 5 words), and 49 6 points (3 1

words) respectively.

1-3-2 G730 Remote Terminal (Slave)

The following G730 Remote Terminals can be connected to a G730 Inter face

Unit.

Model I/O type I/O points

G730-RID04 Relay input (DC) 4

G730-RIA04 Re lay input (AC)

G730-ROC04 Re lay output

G730-ROC04-A Relay output (with error detection function)

G730-VID04 DC inp ut, NPN (comm on +)

G730-VOD04 Transistor output , NPN (common –)

G730-ROC08 Re lay output 8

G730-AOM08 Relay output (power MOS FET)

G730-VID08 DC inp ut, NPN (comm on +)

G730-VID08-1 DC input, PNP (common –)

G730-VOD08 Transistor output , NPN (common –)

G730-VOD08-1 Transistor output, PNP (common +)

G730-ROC16 Relay output 16

G730-AOM16 Relay output (power MOS FET)