Page 1

INSTRUCTIONS

MOBILE WORKSTATION

WM-DP1

Page 2

Contents

Important Information — Please Read Before Use. . . . . . . . . . . . . . . 2

Intended use. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Instruction manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Signal words . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Chapter 1 Standard Set and Accessories . . . . . . . . . . . . . . . . . . . 3

1.1 Optional accessories. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Chapter 2 Warnings and Cautions . . . . . . . . . . . . . . . . . . . . . . . . 5

Chapter 3 Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Chapter 4 Preparation for Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4.1 General information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4.2 Shelf positions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.3 Remote switch. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.4 Equipment installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4.5 Cable hanger and blanking caps. . . . . . . . . . . . . . . . . . . . . . 16

4.6 Water container holder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.7 Rear panels. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.8 Fitting the MAJ-181 restrictor . . . . . . . . . . . . . . . . . . . . . . . . 18

Chapter 5 Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Chapter 6 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

6.1 Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

6.2 Manoeuvring and Transportation . . . . . . . . . . . . . . . . . . . . . 24

Chapter 7 Care, Storage and Maintenance . . . . . . . . . . . . . . . . . . 26

7.1 Care. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

7.2 Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

7.3 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Chapter 8 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

8.1 WM-DP1 mobile workstation. . . . . . . . . . . . . . . . . . . . . . . . . 28

8.2 Separation transformer (WM-T1) . . . . . . . . . . . . . . . . . . . . . 28

Chapter 9 Spares . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Chapter 10 Technical Description . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Chapter 11 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Chapter 12 End of Life . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

1

WM-DP1 MOBILE WORKSTATION

Page 3

Important Information — Please Read Before Use

Important Information — Please Read Before Use

Intended use

The Olympus WM-DP1 mobile workstation is intended for use in medical facilities

under the direction of a trained physician, and has been designed to be used with

a range of Olympus equipment to facilitate GI endoscopy, endoscopic

ultrasound, respiratory and surgical endoscopic procedures. Do not use the

equipment for any purpose other than its intended application.

The safety and performance of an endoscopic system depends not only on the

endoscope but also on the ancillary equipment used with it. Ensure any ancillary

equipment is compatible with the endoscope and other equipment used.

Instruction manual

Please read this manual carefully before attempting to use the Olympus

WM-DP1 mobile workstation as it contains important information on the proper

care, handling and use of the equipment. In addition, read the manuals of any

other units (light source, endoscope, etc.) that form part of the system.

If you have any questions or comments regarding the information in this manual,

please contact Olympus. These instructions should be retained for reference

during the life of the product.

Signal words

The following signal words are used throughout this manual:

WARNING

Indicates a potentially hazardous situation which, if not avoided, could

result in death or serious injury.

CAUTION

Indicates a potentially hazardous situation which, if not avoided, may

result in minor or moderate injury. It may also be used to alert against

unsafe practices or potential equipment damage.

NOTE

Indicates additional helpful information.

MOBILE WORKSTATION WM-DP1

2

Page 4

Standard Set and Accessories

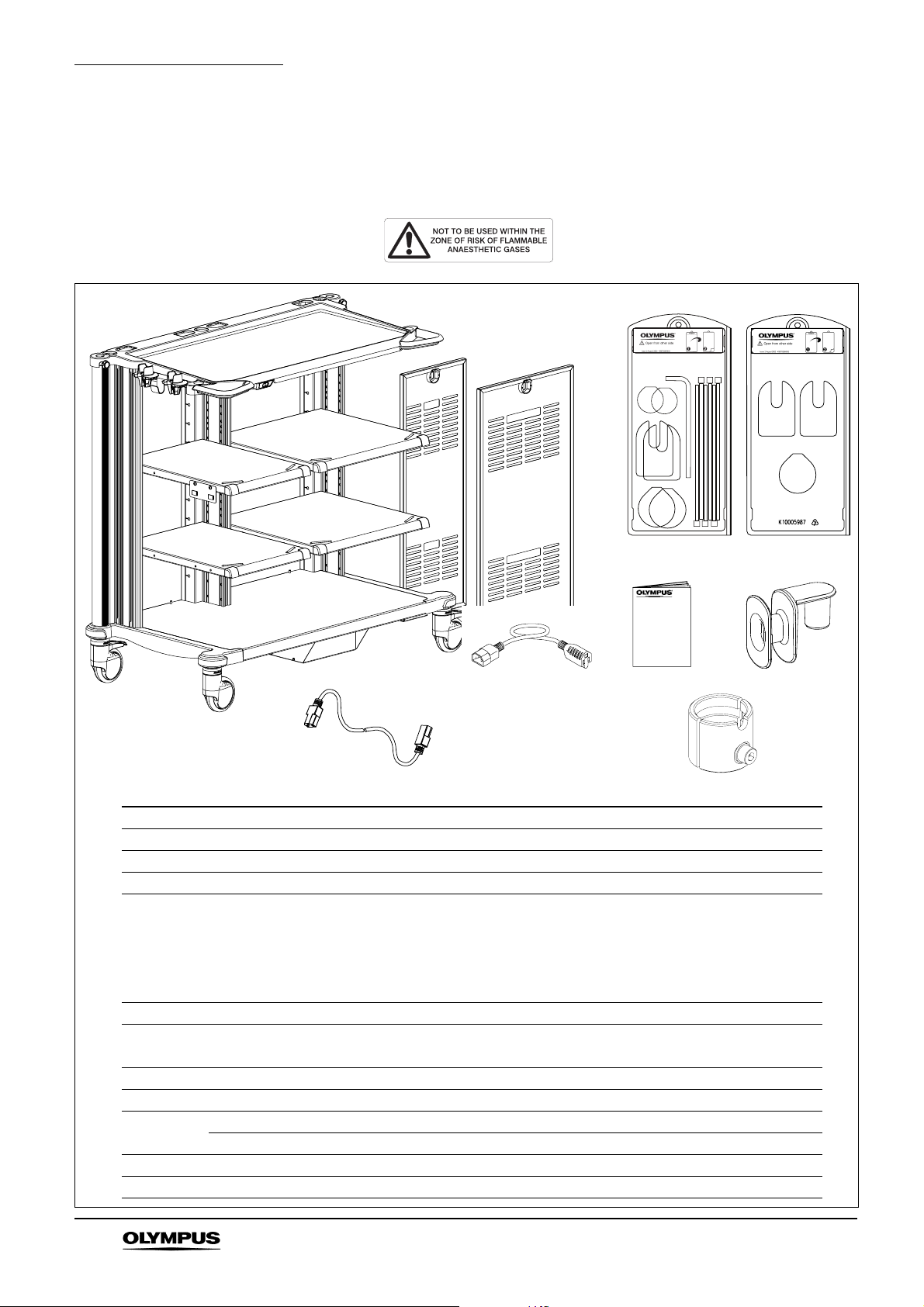

Chapter 1 Standard Set and Accessories

Please refer to the standard set below and check that all items are present. Contact Olympus

if any parts are damaged or missing. Workstations that are fitted with antistatic castors can

be identified by the following label affixed to the rear of each shelf.

1

4

5

2

3

6

9

8

INSTRUCTIONS

10

7

Contents Qty

1 WM-DP1 mobile workstation (includes separation transformer) 1

2 Rear panel - narrow 1

3 Rear panel - wide 1

4 Blister pack 1

Blanking cap (cable port, 2pcs)

Blanking cap (monitor port, 2pcs)

Blanking cap (scope pole, 2pcs)

L-wrench ball driver 6mm A/F, 1 piece

Cable tie, 6 pcs

5 Blister pack 1

Blanking cap (cable port, 2pcs)

Blanking cap (monitor port, 1 piece)

6 Instruction manual 1

7 Cable hanger 2

8 Universal IEC cable 2.5m 4

Universal IEC cable 1.5m 4

9 IEC adaptor cable (USA only) 2

10 MAJ-181 restrictor assembly 2

3

MOBILE WORKSTATION WM-DP1

Page 5

1.1 Optional accessories

The following items are available as optional accessories. Each accessory is supplied

complete with the necessary fixings, tools and instructions to enable assembly to the mobile

workstation.

Description Ref No. GI SP EUS

14” CRT Platform WM-NP1 MAJ-1620

20” CRT Platform WM-NP1 MAJ-1621

Cable retaining hook MAJ-195

cylinder bracket kit large MAJ-188 – –

CO

2

cylinder bracket kit small MAJ-1614 – –

CO

2

Drawer pack narrow deep MAJ-194

Drawer pack narrow standard MAJ-193

Drawer pack wide deep MAJ-1612

Drawer pack wide standard MAJ-1611

Standard Set and Accessories

Recommended use

ECS cable kit 10m MAJ-186 –

ECS cable kit 15m MAJ-1616 –

Equipment support rail MAJ-190

EU-C60/2000 shelf kit MAJ-1627 – –

EUS Arm Mount Kit WM-P1 MAJ-1626 – –

IV pole kit MAJ-187 – –

Keyboard arm side mounted MAJ-180 –

Keyboard tray sliding MAJ-179

EU-M30 Keyboard Tray MAJ-1625 – –

LCD handle MAJ-1610

LCD monitor arm MAJ-181

Nurse’s control panel arm (long) MAJ-1628

Nurse’s control panel arm (short) MAJ-1624 – –

Scope pole kit MAJ-183

Shelf kit narrow MAJ-198

Shelf kit wide MAJ-199

Universal display arm CRT MAJ-1613 – –

Universal stowage container MAJ-185

Videoscope cable holder MAJ-1630

compatible – incompatible

CAUTION

Do not attempt to install any other accessories on the WM-DP1.

MOBILE WORKSTATION WM-DP1

4

Page 6

Warnings and Cautions

Chapter 2 Warnings and Cautions

WARNING

• The WM-DP1 mobile workstation should only be used in a medical

facility under the direction of a trained physician.

• Explosion hazard - never install or use the WM-DP1 mobile workstation

within the zone of risk of flammable gases. If the workstation is fitted

with antistatic castors (see Chapter 8), none of the medical electrical

equipment with which the workstation is intended to be used is ‘AP’ or

‘APG’ rated, therefore never install or use the WM-P1 series mobile

workstation within the zone of risk of flammable gases.

• To prevent patient shock, the combination of equipment used on the

WM-DP1 mobile workstation should never be applied directly to the

heart.

• If the fuse holder cap on the transformer is not fitted correctly, there is a

possibility that the fuse holder will overheat. When replacing the fuse,

ensure the fuse holder cap (Figure 4.3) is tightened using a 6mm to

8mm flat bladed screwdriver. The recommended tightening torque is

0.5Nm.

• Should the equipment become soiled with blood or other potentially

infectious materials, first wipe off all gross debris and then

decontaminate the equipment using a surface disinfectant, otherwise,

blood, mucus and other potentially infectious material from the patient

could pose an infection risk. Confirm that the equipment is completely

dry before use.

• Use personal protective equipment to guard against dangerous

chemicals and potentially infectious material, otherwise, blood, mucus

and other potentially infectious material from the patient could pose an

infection risk. During cleaning, wear appropriate protective equipment,

such as eye wear, face mask, moisture-resistant clothing and chemicalresistant gloves that fit properly and are long enough so that your skin is

not exposed.

• To prevent user or patient cross-contamination, do not hang

contaminated endoscopes on the scope hanger.

• The WM-DP1 should be used in accordance with the following.

Otherwise, the workstation will be ‘top heavy’ and may lose stability and

topple, causing equipment damage and/or personal injury.

- Two MAJ-181 restrictors are supplied which must be fitted to

MAJ-181 LCD monitor arm(s) if used (refer to section 4.8).

- LCD monitor arms and monitors should be installed after all

other equipment is installed on an appropriate place on the

workstation.

- LCD monitor arms should not be installed or used to the rear

of the workstation, see Figure 2.1.

- Confirm that the workstation does not lose stability when the

monitor arm is extended. If the workstation looks unstable,

relocate heavy equipment from the upper shelf to the bottom

shelf.

5

MOBILE WORKSTATION WM-DP1

Page 7

Warnings and Cautions

MAJ-181

(restrictor fitted)

MAJ-1624

or

MAJ-1628

Do not install or operate

LCD monitor arms in this zone

• Thoroughly review the manuals of all other equipment which will be

used. The manuals contain essential information on using this

equipment safely and effectively.

CAUTION

• Do not exceed the load capacity detailed in Chapter 8.

• Do not lean or stand on any part of the mobile workstation or accessory

as failure of the product may result.

• When assembling equipment onto the mobile workstation, the

installation should meet the requirements of EN IEC 60601-1-1:2001,

the safety standard for medical electrical systems.

• When configuring a system, the user should ensure that there is

sufficient spare equipment available that in the event of a fault in any

part of the system, the endoscopy procedure may be completed or

terminated without endangering the patient.

• Before commissioning an installation including a separation transformer,

ensure its rating will not be exceeded by the equipment connected to it.

• When installing the mobile workstation in the procedure or operating

room, ensure that the mains cable has sufficient slack that it cannot be

pulled taught as the mobile workstation is moved around the working

area. If necessary, relocate the mains connector to a nearer supply

socket.

Figure 2.1

• Section 6.2 Manoeuvring and Transportation gives detailed instructions

and precautions which must be read and understood before attempting

to move the mobile workstation.

MOBILE WORKSTATION WM-DP1

• Spray type medical agents, such as lubricants, anaesthetic or alcohol,

should be used away from the mobile workstation.

6

Page 8

Warnings and Cautions

• Keep open containers of liquid away from electrical equipment used on

the mobile workstation to prevent operator electrical shock and

equipment damage. Do not use the system if liquid has entered the

equipment.

• To minimise risk of injury, it is recommended that heavy items are placed

on the mobile workstation by two people working together. This is

particularly important when placing a monitor on the optional monitor

platform (if fitted). Ensure electrical items used on the mobile

workstation are positioned centrally on the shelves.

• Never place any items on top of a monitor (if fitted) as these may topple

when the mobile workstation is moved.

• Where fitted, the electrical resistance of the conductive antistatic castors

should be tested at regular intervals in accordance with ISO 2878 to

assess antistatic effectiveness.

• Where antistatic castors are fitted, avoid contact of the castor wheels

with oil and avoid a build up of floor cleaning wax and polish as these

will impair the antistatic effectiveness of the castors.

• Store and use the WM-DP1 mobile workstation within the environmental

conditions described in Chapter 8; failure to do so may lead to

equipment malfunction or failure.

• There are no operator-serviceable components on the WM-DP1 mobile

workstation. Refer servicing to qualified service personnel.

• To minimise the risk of injury and/or damage, do not fit accessories other

than those described in Section 1.1 to the WM-DP1 mobile workstation.

7

MOBILE WORKSTATION WM-DP1

Page 9

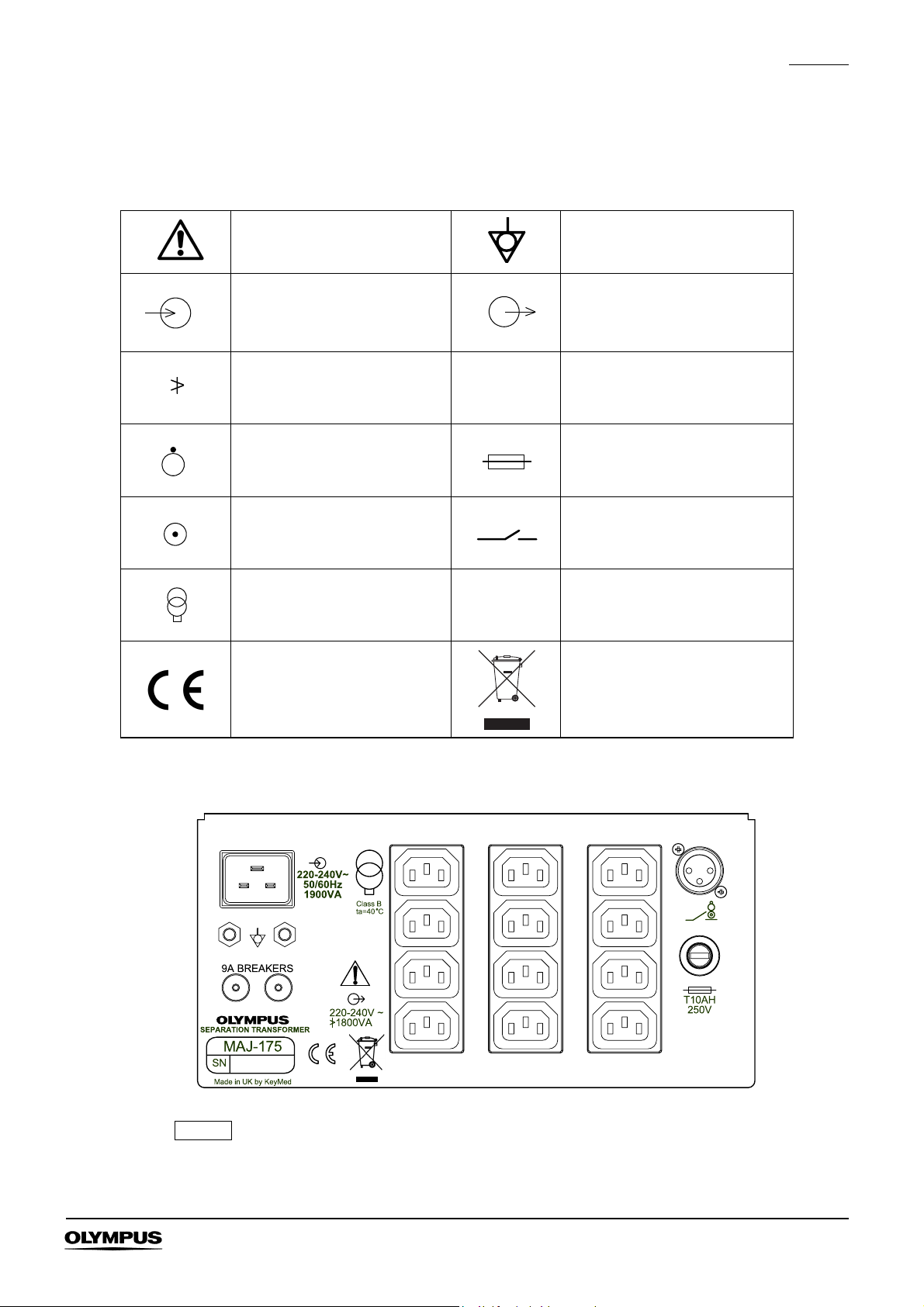

Chapter 3 Symbols

The following symbols are used on the separation transformer

Refer to instructions Potential equalisation terminal

Input Output

Symbols

Not exceeding

Standby position Fuse (output)

Output ON position Remote switch

Non-inherently short circuit

proof separation transformer

Unit complies with relevant

European directives

(MAJ-175 only)

View of the separation transformer rear panel

Ta=40°C

Class B

Maximum ambient

temperature

Insulation temperature rating

of transformer according to

IEC 60085:2004

Disposal conditions - see End

of Life (Chapter 12) (MAJ-175

only)

NOTE

MAJ-175 (220-240V) is shown. Other versions are similar.

MOBILE WORKSTATION WM-DP1

8

Page 10

Preparation for Use

Chapter 4 Preparation for Use

NOTE

• Multiple fixing positions are provided enabling the shelves to be raised

or lowered to accommodate varying equipment configurations (see 4.2).

• The mobile workstation is designed for use with Olympus OEV LCD

monitors and other monitors that meet the VESA standard. Contact

Olympus regarding compatibility of other monitors.

4.1 General information

Installation of endoscopic video systems requires an understanding of EN IEC 60601-1-1:2001,

the international collateral standard for the safety of medical electrical systems.

This standard requires systems to meet the leakage current requirements of the general medical

electrical safety standard, EN IEC 60601-1, which allows a maximum earth leakage current of

0.5mA in normal condition.

A separation transformer is required under certain circumstances, as combined earth leakage

currents may result in excessive enclosure leakage current under single fault conditions, such as

the interruption of a common protective earth path.

In order to meet EN IEC 60601-1-1:2001, a separation transformer will be required in a system

under one of the following conditions:

(i) Ancillary equipment that does not meet the leakage current requirements of

EN IEC 60601-1 is used (or could be used) within the ‘patient environment’ (as defined

in EN IEC 60601-1-1:2001, that is within a 1.5m radius of, or 2.5m above, the patient

bed). The separation transformer must be used to supply the ancillary equipment, but

may also be used to supply medical electrical equipment, as long as the maximum

transformer rating is not exceeded.

(ii) The total earth leakage current from a combination of medical equipment is above

0.5mA. The separation transformer must be used to supply sufficient of the medical

electrical equipment to reduce the total system earth leakage current to below the above

limit, as long as the maximum transformer rating is not exceeded. High intensity light

sources use arc lamps, which require a high start-up current. It is not recommended for

these to be supplied from the isolation transformer, otherwise its maximum rating may be

exceeded. The transformer may also be used to supply ancillary equipment forming part

of the system as long as the maximum transformer rating is not exceeded.

9

MOBILE WORKSTATION WM-DP1

Page 11

Preparation for Use

Some system installations, for instance those using two mobile workstations, may require two

separation transformers to be fitted.

NOTE

• The total impedance of the protective earth path for a system may be up

Ω

to 0.4

or higher if the conditions of clause 18 g) of EN IEC 60601-1 are

satisfied.

• The power outlets should only be used for powering equipment which

forms part of the endoscopy imaging system.

• All equipment forming part of the system should be powered from the

transformer, unless appropriate isolation is employed as described in

Annex BBB of EN IEC 60601-1-1:2001. This particularly applies where

ancillary equipment as described in (i) forming part of the system is

remotely situated.

CAUTION

• Failure to observe either of the above mentioned points could result in

the isolation of the entire system being compromised, defeating the

protection provided by the transformer in a single fault condition.

Additional fixings are provided (Figure 4.1) to facilitate shelf adjustment or the fitting of the optional

drawer pack(s).

MOBILE WORKSTATION WM-DP1

10

Page 12

Preparation for Use

318.00

11

Figure 4.1

MOBILE WORKSTATION WM-DP1

Page 13

Preparation for Use

4.2 Shelf positions

NOTE

The WM-DP1 mobile workstation is supplied with the shelves fitted as

shown in Figure 4.1. It is recommended that shelves are repositioned, if

required, before commencing equipment installation as described

below.

1. Position the mobile workstation on a flat surface and apply both castor brakes (diagonally

opposed).

2. Referring to Figure 4.2, use the 6mm A/F L-wrench to remove the four M8 screws with

crinkle and plain washers from the underside of the shelf.

Figure 4.2

3. Locate the shelf at the new position and fit the four side fixing screws with crinkle and plain

washers. Tighten all screws using a 6mm A/F L-wrench. It is recommended that after fitting,

the screws are tightened to a torque of 10.5Nm (tool not provided).

MOBILE WORKSTATION WM-DP1

12

Page 14

Preparation for Use

4.3 Remote switch

The remote switch enables the power to the system components to be controlled from a

single point. The switch is located beneath the top tray and connects to the remote switch

connector on the separation transformer via a 2m cable.

The remote switch has an integral two-colour LED which illuminates whenever the

transformer is connected to the mains supply. Yellow indicates ‘standby’, green indicates

‘output on’.

NOTE

• The remote switch only controls the output socket on the transformer. To

switch OFF the input power supply, set the remote switch to its

‘stand-by’ position, then disconnect the mains connector from the wall

outlet socket.

• In ‘stand-by’ condition, the transformer consumes a small amount of

power, typically 4% of its full load rating. If it is anticipated that the

system will not be used for a significant period of time, it is

recommended that the mains connector is removed from the wall outlet

socket to conserve energy.

1. The mobile workstation is supplied with the remote switch connected to the separation

transformer and no assembly is required. However, check the connection (see Figure 4.3) is

secure before completing full installation.

Potential

equalisation

terminals

Fuse

Remote switch

connector

13

Figure 4.3

MOBILE WORKSTATION WM-DP1

Page 15

4.4 Equipment installation

refer to section 4.1for additional information regarding system installations.

CAUTION

• To minimise risk of injury, it is recommended that two people, working

together, place heavy items of equipment on the mobile workstation.

• High intensity light sources may need to be connected to a properly

grounded AC power outlet and not one of the IEC power sockets on the

mobile workstation, depending on the total system power rating.

• Ensure the fully installed system meets the requirements of

EN IEC 60601-1-1:2001, Medical Electrical Equipment, Collateral

Standard: Safety Requirements for Medical Electrical Systems. For

advice, contact your Olympus representative or qualified service

personnel.

NOTE

Releasable cable straps are provided on the rear of each shelf and

cable ties are provided to secure equipment power cables to the case of

the transformer. Cable access holes are provided in the base of the

mobile workstation. Excess lengths of cables should be coiled neatly

and secured to the rear of a shelf using the cable straps provided.

Preparation for Use

1. Place items of equipment centrally on the shelving and connect according to individual

instructions. The WM-DP1 mobile workstation is supplied with a universal IEC lead set to

connect equipment on the mobile workstation to the transformer. Potential equalisation

terminals are fitted to both sides of the transformer enclosure for connection to equipment

potential equalisation terminals where fitted. Route all cabling neatly in the side column cable

ducts on the extrusion and along the rear of the shelves, secure using the releasable cable

ties (see Figure 4.4).

Centre column cable ducts are used for interconnection of equipment located on the base,

intermediate and upper shelves.

MOBILE WORKSTATION WM-DP1

14

Page 16

Preparation for Use

*****

*

*

*

*

*

*

* Denotes hidden cable ties

When all equipment is positioned on the workstation, install LCD monitor arms or control

2.

panels as required according to their instructions and noting the configuration diagrams

given in Chapter 2 Warnings and Cautions.

MAJ-181 only: One MAJ-181 restrictor (supplied) must be fitted to each MAJ-181 being

fitted, up to a maximum of two. The restrictor provides additional stability by preventing the

monitor arm from swinging outside the footprint of the workstation. Refer to Section 4.8 for

assembly.

WARNING

Do not use the MAJ-181 LCD monitor arm on the workstation without a

restrictor fitted. Otherwise the workstation may lose stability and topple,

causing equipment damage and/or personal injury.

Figure 4.4

3. Check that all equipment power ON/OFF switches are in the OFF position and connect the

separation transformer (and light source, where separate) power supply cables to properly

grounded AC power outlets. The power outlets should be located such that they are not

obstructed when the mobile workstation is in its normal operating position. The remote switch

LED will illuminate yellow indicating ‘standby’.

4. Set the mobile workstation remote switch to the ON position, the LED will now illuminate

green indicating ‘output on’.

5. Set the power switches for the installed equipment to the ON position.

15

MOBILE WORKSTATION WM-DP1

Page 17

CAUTION

• Check that all installed equipment operates correctly before using the

system ‘on patient’.

• The WM-T1 separation transformer incorporates a circuit to limit the

input current surge when power is applied. Operating an input power

ON/OFF switch several times in rapid succession may interfere with the

correct functioning of this circuit and may cause the mains power supply

protection to operate.

• Ensure that the video system centre is switched OFF when attaching or

removing the videoscope cable. Serious damage may result if the

videoscope is connected with the video system centre switched ON.

6. When equipment installation is complete, fit the rear door(s) taking care not to trap any

cables.

4.5 Cable hanger and blanking caps

NOTE

• If the cable hanger is not required, fit one blanking cap to the left hand

port in the top tray.

Preparation for Use

• Blanking caps are provided for each of the accessory fittings and cable

exits in the top tray. If accessories are fitted, the appropriate blanking

cap will not be required and should be stored in case of future use.

1. The blanking caps locate in the positions shown in Figure 4.5 and can be removed/fitted if

required.

Cable winder (or blanking cap, scope port if cable winder is not used)

Blanking cap, monitor port

Blanking cap, cable port

Handwheel

Figure 4.5

2. The cable hanger locates into either left or right hand port in the top tray and is secured in the

required position using handwheel as shown in Figure 4.5.

MOBILE WORKSTATION WM-DP1

16

Page 18

Preparation for Use

4.6 Water container holder

1. The WM-DP1 mobile workstation is fitted with a water container bracket to hold two water

containers (not supplied). The water container simply clips onto the bracket as shown in

Figure 4.6.

4.7 Rear panels

1. When installation of equipment is complete, lift each rear panel in turn onto the locating studs

on the base of the workstation (Figure 4.7) then push the top of the panel until the latch

engages with an audible click.

Figure 4.6

17

Rear panel - narrow

Rear panel - wide

Figure 4.7

MOBILE WORKSTATION WM-DP1

Page 19

Preparation for Use

4.8 Fitting the MAJ-181 restrictor

This procedure is only applicable if fitting a MAJ-181 LCD monitor arm to the WM-DP1 workstation.

WARNING

• If using a MAJ-181 on the workstation, the restrictor supplied in this kit

must be fitted to the MAJ-181 and is best assembled with the MAJ-181

in position on the workstation.

• To maintain stability, before installing a second MAJ-181, ensure the first

is assembled with the restrictor fitted.

• Read the instruction manual supplied with the MAJ-181, it contains

important information regarding proper care and use of the equipment.

• The WM-DP1 should be used in accordance with the following.

Otherwise, the workstation will be ‘top heavy’ and may lose stability and

topple, causing equipment damage and/or personal injury.

- Two MAJ-181 restrictors are supplied which must be fitted to

MAJ-181 LCD monitor arm(s) if used.

- LCD monitor arms and monitors should be installed after all

other equipment is installed on an appropriate place on the

workstation.

- LCD monitor arms should not be installed or used to the rear

of the workstation, see Figure 2.1.

- Confirm that the workstation does not lose stability when the

monitor arm is extended. If the workstation looks unstable,

relocate heavy equipment from the upper shelf to the bottom

shelf.

1. Referring to the MAJ-181 instruction manual, relocate the clamp support to another fixing

hole in the support tube (see Figure 4.8) as the restrictor will be fitted through the top hole,

then insert the MAJ-181 into the monitor port in the top tray of the workstation.

MOBILE WORKSTATION WM-DP1

18

Page 20

Preparation for Use

Referring to Figure 4.9, pull out the finger grip on the lower index plunger and rotate it 90°,

2.

the arm is now free to rotate. Rotate the arm until parallel with the top tray as shown.

Top view

Rotate arm

MAJ-181

Index plunger

to disengage

3. Remove the M8 screw to separate the MAJ-181 restrictor assembly.

Figure 4.8

Figure 4.9

4. Referring to Figure 4.10, secure the MAJ-181 restrictor - front to the MAJ-181 restrictor - rear

through the uppermost hole in the monitor arm using the M8 coil washer, M8 plain washer

and M8 x 50mm screw. Fully tighten the screw using the M6 A/F Allen key supplied.

NOTE

The monitor arm must be parallel to the top tray to ensure the tag on the

monitor arm aligns with the cutout in the restrictor (Figure 4.10 inset).

19

MOBILE WORKSTATION WM-DP1

Page 21

MAJ-181 restrictor - rear

Preparation for Use

MAJ-181 restrictor - front

Repeat for second MAJ-181 if used.

5.

M8 x 50mm screw

M8 coil washer

M8 plain washer

Figure 4.10

MOBILE WORKSTATION WM-DP1

20

Page 22

Inspection

Chapter 5 Inspection

WARNING

Should the slightest irregularity be suspected, do not use the mobile

workstation and refer to Chapter 11 Troubleshooting. If the problem

cannot be resolved, contact Olympus for service.

1. Check the power supply cable and plug for damage, twists, deformation or other

irregularities.

2. Where antistatic castors are fitted, periodically check the electrical resistance of the

conductive antistatic castors to assess antistatic effectiveness.

3. Check the security of castors at six-monthly intervals. If loose, contact Olympus for service.

4. Regularly check the shelf fixing screws and the fixing screws of any accessories that are

fitted, particularly monitor mounts. If necessary, retighten the screws using the tools

provided.

21

MOBILE WORKSTATION WM-DP1

Page 23

Chapter 6 Operation

6.1 Operation

WARNING

• The WM-DP1 should be used in accordance with the following.

Otherwise, the workstation will be ‘top heavy’ and may lose stability and

topple, causing equipment damage and/or personal injury.

Operation

- Two MAJ-181 restrictors are supplied which must be fitted to

MAJ-181 LCD monitor arm(s) if used (refer to section 4.8).

- LCD monitor arms and monitors should be installed after all

other equipment is installed on an appropriate place on the

workstation.

- LCD monitor arms should not be installed or used to the rear

of the workstation, see Figure 2.1.

- Confirm that the workstation does not lose stability when the

monitor arm is extended. If the workstation looks unstable,

relocate heavy equipment from the upper shelf to the bottom

shelf.

CAUTION

• Place the mobile workstation on a flat level surface and lock the castor

brakes.

• Confirm that any mounted instruments function normally before using

the system on a patient.

1. Plug the power cord of the mobile workstation into a hospital-grade power outlet.

2. Confirm that the power indicator on the remote switch lights yellow.

3. When the remote switch is ON, confirm that the power indicator lights green.

4. For use of Optional accessories, please refer to each accessory instruction manual.

5. During use, do not position LCD monitor arms to the rear as shown below. Otherwise, the

workstation may lose stability and topple, causing equipment damage and/or personal injury.

MOBILE WORKSTATION WM-DP1

22

Page 24

Operation

After use, turn off the remote switch.

6.

Figure 6.1

23

MOBILE WORKSTATION WM-DP1

Page 25

6.2 Manoeuvring and Transportation

WARNING

• The WM-DP1 should be manoeuvred or transported in accordance with

the following. Otherwise, the workstation may lose stability and topple,

causing equipment damage and/or personal injury.

- Two people are required to safely manoeuvre or transport a

loaded mobile workstation.

- Do not manoeuvre or transport the workstation quickly or

aggressively, especially when negotiating bumps.

- Check that all cables are secure and clear of the castors.

- All optional accessories fitted to the workstation should be

placed in the stowage position in accordance with their

instructions for use.

1. The mobile workstation has two diagonally located braked castors. Ensure both brakes are

applied prior to use.

2. Ensure both brakes are released before attempting to move the mobile workstation.

Operation

3. Always manoeuvre the mobile workstation using the handles provided on the front of the top

tray. Care must be exercised when moving it, particularly over uneven surfaces or trailing

cables, to avoid tipping.

4. Before attempting to move the mobile workstation outside the operating room, ensure that its

mains cable is disconnected from the supply socket and is safely coiled away from the

castors, and that the equipment housed on the mobile workstation is secure. Ensure that the

endoscope is removed and transported separately and fluid containers are removed and

emptied. Optional accessories such as LCD monitors or control panels, if fitted, should be

rotated within the footprint of the mobile workstation and locked in position. Take particular

care of any accessories (if fitted) which protrude from the frame.

5. Two people are required to safely transport a loaded mobile workstation outside the

procedure room. Particular care must be taken when moving up or down slopes to prevent

loss of control of the mobile workstation.

6. When the mobile workstation is fully loaded with equipment, do not attempt to `park' it on

slopes or inclines as the castor brakes may not be fully effective.

7. It is recommended that the mobile workstation is manoeuvred over lips or door thresholds

diagonally (see Figure 6.2) , that is one castor at a time, to minimise the potential for tipping.

MOBILE WORKSTATION WM-DP1

24

Page 26

Operation

Higher level

Lower level

Higher level

Lower level

NOTE

1

2

Figure 6.2

Repeated transportation over uneven surfaces may result in damage to

the equipment carried on the mobile workstation.

25

MOBILE WORKSTATION WM-DP1

Page 27

Care, Storage and Maintenance

Chapter 7 Care, Storage and Maintenance

7.1 Care

1. Clean the mobile workstation with a soft cloth or gauze moistened with a neutral detergent,

then wipe over with a cloth dampened with 70% alcohol.

2. The umbilical holders should be removed and cleaned/sterilised before use by autoclaving

(to a maximum of 138°C (280°F)) or disinfected by cold fluid immersion following solution

manufacturer’s instructions.

To remove the umbilical holder, squeeze and rotate to the left or right to disengage from the

tabs on the bracket. To replace, locate the left or right side onto the tab and rotate into the

holder until the second tab engages.

WARNING

Figure 7.1

• Should the equipment become soiled with blood or other potentially

infectious materials, first wipe off all gross debris and then

decontaminate the equipment using a surface disinfectant, otherwise,

blood, mucus and other potentially infectious material from the patient

could pose an infection risk. Confirm that the equipment is completely

dry before use.

• Use personal protective equipment to guard against dangerous

chemicals and potentially infectious material, otherwise, blood, mucus

and other potentially infectious material from the patient could pose an

infection risk. During cleaning, wear appropriate protective equipment,

such as eye wear, face mask, moisture-resistant clothing and chemicalresistant gloves that fit properly and are long enough so that your skin is

not exposed.

MOBILE WORKSTATION WM-DP1

26

Page 28

Care, Storage and Maintenance

CAUTION

• Do not allow any fluids into contact with electrical equipment installed on

the mobile workstation.

• Do not use harsh or abrasive cleaning materials on the mobile

workstation.

• Ensure all surfaces are thoroughly dried before reusing the mobile

workstation.

7.2 Storage

1. The WM-DP1 mobile workstation should be stored within the environmental conditions given

in Chapter 8.

7.3 Maintenance

1. Check the security of castors at six-monthly intervals. If loose, contact Olympus for service.

2. Where antistatic castors are fitted, periodically check the electrical resistance of the

conductive antistatic castors to assess antistatic effectiveness.

Periodically clean each castor wheel to remove non-conductive material such as cleaning

wax and floor polish as these will impair the antistatic effectiveness of the castors.

3. Regularly check the shelf and securing screws of any accessories that are fitted, particularly

monitor platforms. If necessary, retighten the screws using the tools provided.

4. The separation transformer should undergo routine checks for electrical safety and correct

function annually or as dictated by local policy. Typical checks would include inspection of the

power supply cable for damage, and tests for earth continuity and insulation resistance. Also

check (listen) for correct operation of the inrush limiting circuit (see Chapter 10) when power

is applied.

5. Annually, check that the fuse holder cap on the transformer (Figure 4.3) is correctly fitted. If

the fuse has been replaced and the cap is not sufficiently tightened, there is a possibility that

the fuse holder will overheat. When replacing the fuse, ensure the fuse holder cap is

tightened using a 6mm to 8mm flat bladed screwdriver. The recommended tightening torque

is 0.5Nm.

6. If it becomes necessary to remove the separation transformer from the mobile workstation

for testing, disconnect all cables from the transformer then place supports between the

transformer and the floor at the front and rear. Remove four M8 nuts using a 13mm A/F

socket, then carefully remove the supports and lower the transformer to the floor.

WARNING

Do not extend any monitor arm outside the footprint of the workstation

when the transformer is removed. Otherwise the workstation will be ‘top

heavy’ and may lose stability and topple, causing equipment damage

and/or personal injury.

CAUTION

• The transformer weighs up to 28kg, and care should therefore be

exercised during handling. When lifting the transformer, it is

recommended that the assistance of a second person is sought.

27

• Removal of the transformer should only be undertaken by suitably

qualified personnel.

• Electrical safety checks should only be performed by suitably qualified

personnel.

MOBILE WORKSTATION WM-DP1

Page 29

Chapter 8 Specifications

8.1 WM-DP1 mobile workstation

Product name WM-DP1 mobile workstation

Dimensions (mm) Height: 1192

1370 (scope in lowest position)

2140 (scope in highest position)

1826 max (with 19” LCD monitor in highest position)

Depth: 655

Width: 1238

Weight 120kg unladen, including fitted transformer.

Load capacity

(evenly distributed)

Top tray 10kg

Intermediate shelves 26kg each

Base panel 60kg

Total load 180kg maximum (inclusive of attached

accessories and equipment)

Specifications

NOTE: Equipment stored on the mobile workstation should not exceed

the size of the shelf.

Castors WM-DP1 p/no K10003727

4 x 125mm antistatic, two with brakes.

WM-DP1 p/no K10003726, K10003728, K10003729

4 x 125mm non-antistatic, two with brakes.

Ambient temperature Storage: -40°C to +70°C (-40°F to +158°F)

Operation: 10 - 40°C (50 - 104°F)

Relative humidity 95% maximum @ 40°C (104°F) non-condensing

Atmospheric pressure

Storage: 23.5-106 kPa (3.4-15.37lbf/in

Operation: 70-106 kPa (10.15-15.37lbf/in

2

)

2

)

8.2 Separation transformer (WM-T1)

Product name Olympus Separation Transformer

Identification Market USA UK, Europe,

Rest of the world

Model No. MAJ-174 MAJ-175

Part No. K10000290 K10000291

Power input

requirements

Power output Maximum load 1250VA 1800VA

Input voltage 110-120V 220-240V

Frequency 60Hz 50/60Hz

Power input (max) 1300VA 1900VA

Power cable part No. K10001002 K10001003 (UK)

K10001004 (Europe)

K10001005 (RoW)

MOBILE WORKSTATION WM-DP1

28

Page 30

Specifications

Overload

protection

Input circuit breakers 2 x 13A 2 x 9A

Output fuse T15AH T10AH

Tighten to 0.5Nm reference

IEC 60127-6:1994

Potential

Terminals fitted 2 at input, 2 x 6 at output

equalisation

Classification Standards compliance The Separation Transformer conforms to the relevant

requirements of: EN IEC 60601-1/

EN IEC 60601-1-1:2001, Annex EEE/UL 60601-1 and

CAN/CSA Std. No. C22.2 No. 601.1-M90

Type of protection against

Class I equipment.

electric shock.

Degree of protection against

explosion

Degree of protection against

ingress of water.

None, the Separation transformer should not be used

within the zone of risk of flammable gases

IPX0 as defined in EN IEC 60529:1992, ordinary

equipment.

Mode of operation Continuous

Environmental

conditions

Ambient temperature Storage: -40°C to +70°C (-40°F to +158°F)

Operation: 10 − 40°C (50 - 104°F)

Atmospheric pressure

Storage: 23.5-106 kPa (3.4-15.37lbf/in

Operation: 70-106 kPa (10.15-15.37lbf/in

2

)

2

)

Relative humidity 95% maximum @ 40°C (104°F) non-condensing

Regulatory

status

European Economic Area

(EEA)

220-240V units are CE marked in

accordance with Directive 93/42/EEC of

14 June 1993 concerning medical

devices, as an accessory to a medical

device, Class I. Year of manufacture is

given in first two digits of serial number.

End of Life

In accordance with European Directive

2002/96/EC on Waste Electrical and

Electronic Equipment, this symbol

indicates that the product must not be

disposed of as unsorted municipal waste,

but should be collected separately. Refer

to your local Olympus distributor for return

and/or collection systems available in

your country.

The Olympus WM-DP1 mobile workstation and separation transformer is manufactured in the UK

by KeyMed (Medical & Industrial Equipment) Ltd.

29

MOBILE WORKSTATION WM-DP1

Page 31

Chapter 9 Spares

NOTE

In order to maintain standards compliance, it is important that

replacement components should have the same specification as those

fitted originally. This can best be guaranteed by using only those spare

parts and components specified and supplied by Olympus.

1. If any item becomes damaged or lost, contact Olympus for replacement.

Spares

MOBILE WORKSTATION WM-DP1

30

Page 32

Technical Description

Chapter 10 Technical Description

The block diagram shown in Figure 10.1 shows the different sub-units within the Separation

Transformer.

The mains cable connects to the transformer through a high current IEC-320 style connector,

allowing it to be easily replaced if it becomes damaged during use. It is secured to the transformer

by a pair of clamps, to prevent accidental disconnection during use. The protective earth terminal

connects to the metal enclosure of the unit and the output socket earthing system; the line and

neutral conductors connect to the primary side of the transformer via two thermal circuit breakers

and an inrush limiting circuit.

As with any transformer, the primary circuit will draw an inrush current surge when it is connected

to the mains supply, which can sometimes be very large, depending on the magnetic state of its

core at the instant it is powered. The inrush limiting circuit inserts a high power thermistor in series

with the primary winding to limit the initial surge, dissipating it as heat. After approximately 0.5

seconds a relay closes (producing an audible ‘click’) to by-pass the thermistor, both to avoid any

steady-state losses that would adversely affect the load regulation and to allow it to cool in

readiness for the next switch-on.

The transformer is wound with a nominal input-to-output ratio of 1:1, with concentric primary and

secondary windings. An additional low voltage secondary winding powers the circuit for the remote

switch. Electrical separation between windings is maintained by overlapping layers of “Nomex” and

“Melinex” tapes.

The secondary winding supplies power to the separated output sockets via a fuse to protect the

unit against short-circuit faults in the external equipment. An additional socket enables a remote

switch to be connected if required, operating a relay to control the power to the output sockets.

This provides a convenient way of turning the entire system (apart from the transformer itself) on or

off from a central point on the mobile workstation. When the remote switch is not connected, the

outputs default to the permanently energised state. To isolate the unit from the mains supply, set

the remote switch to its stand-by’ position, then disconnect the mains connector from the wall

outlet socket.

Potential equalisation terminals are provided adjacent to the input cable and either side of the top

cover, for use where local regulations require the enclosures of each part of the system be

connected to a common earth point, independently of the mains supply cables.

31

MOBILE WORKSTATION WM-DP1

Page 33

SOCKETS

OUTPUT

FUSE

OUTPUT

(COVER)

TERMINALS

EQUIPOTENTIAL

Technical Description

CIRCUIT

BREAKER

L

INRUSH

CIRCUIT

LIMITING

MAINS

CABLE

RELAY

SWITCH

CIRCUIT

BREAKER

N

CIRCUIT

INLET

CONNECTOR

REMOTE

ENCLOSURE

SWITCH

MOBILE WORKSTATION WM-DP1

Figure 10.1

32

Page 34

Troubleshooting

Chapter 11 Troubleshooting

Problem Possible cause Remedy

No power to separation

transformer

Output fuse blows Item of equipment connected

Circuit breaker(s) ‘trip’ Combined rating of equipment

Interference to equipment

connected to the transformer.

Separation transformer not

connected to AC wall outlet

No power at AC wall outlet Check power supply to AC wall

to transformer is faulty

connected to power sockets

exceeds the maximum VA

rating of the transformer.

Magnetic - proximity of

sensitive equipment to

transformer magnetic field.

Electrical - typically distortion /

interference on monitor display

when equipment is operated.

Connect transformer cable to

AC wall outlet

outlet

Disconnect transformer from

power supply. Locate and

repair faulty equipment.

Replace output fuse and

reconnect all equipment.

Check combined rating is

within the maximum limit,

disconnect equipment if

necessary. Reset circuit

breaker(s) by pressing in

circuit breaker button.

Relocate sensitive equipment

to a higher shelf.

Check system for damaged

cables or connections.

Electromagnetic - interference

from other systems.

If the problem cannot be resolved, contact Olympus for service. There are no user-serviceable

parts inside the separation transformer. This equipment must not be modified without written

authorisation from Olympus.

As above, plus investigate

source of interference.

33

MOBILE WORKSTATION WM-DP1

Page 35

Chapter 12 End of Life

Equipment which has reached the end of its useful life should be disposed of according to local

regulations, refer to section 8.2 for additional information.

End of Life

MOBILE WORKSTATION WM-DP1

34

Page 36

OLYMPUS MEDICAL SYSTEMS CORP.

2951 Ishikawa-cho, Hachioji-shi, Tokyo 192-8507, Japan

Fax: (042) 646-2429 Telephone: (042) 642-2111

OLYMPUS MEDICAL SYSTEMS EUROPA GMBH

(Premises/Goods delivery) Wendenstrasse 14-18, D-20097 Hamburg, Germany

(Letters) Postfach 10 49 08, D-20034 Hamburg, Germany Telephone: (040) 237730

EC REP

OLYMPUS AMERICA INC.

3500 Corporate Parkway, P.O. Box 610 Center Valley, PA 18034-0610, U.S.A.

Fax: (484) 896-7128 Telephone: (484) 896-5000

KEYMED LTD.

KeyMed House, Stock Road, Southend-on-Sea, Essex SS2 5QH, United Kingdom

Fax: (01702) 465677 Telephone: (01702) 616333

EC REP

OLYMPUS SINGAPORE PTE LTD.

491B, River Valley Road #12-01/04, Valley Point Office Tower, Singapore 248373

Fax: 6834-2438 Telephone: 6834-0010

OLYMPUS (BEIJING) SALES & SERVICE CO,. LTD.

Room 1202, NCI Tower, A12 Jianguomenwai Avenue, Chaoyang District, Beijing, 100022 P.R.C.

Fax: (10) 6569-3545 Telephone: (10) 6569-3535

OLYMPUS MOSCOW LIMITED LIABILITY COMPANY

117071, Moscow, Malaya Kaluzhskaya 19, bld. 1, fl.2, Russia

Fax: (095) 958-2277 Telephone: (095) 958-2245

OLYMPUS AUSTRALIA PTY. LTD.

31 Gilby Road, Mount Waverley, Victoria 3149, Australia

Fax: (03) 9543-1350 Telephone: (03) 9265-5400

Issue 4

May 2009

OLYMPUS LATIN AMERICA INC.

5301 Blue Lagoon Drive, Suite 290, Miami, FL 33126, U.S.A.

Fax: (305) 261-4421 Telephone: (305) 266-2332

OLYMPUS KOREA CO,. LTD.

4F, 5F, Gyeongam Bldg., 157-27 Samseong-Dong, Kangnam-Gu, Seoul 135-090 Korea

Fax: (02) 6255-3499 Telephone: (02) 1544-3200

©KeyMed 2009

Printed in UK

K10005955/509

Loading...

Loading...