Page 1

MAINTENANCE & REPAIR MANUAL

WM--P1 SERIES MOBILE WORKSTATIONS

WM--NP1

WM--WP1

WM--DP1

OLYMPUS MEDICAL SYSTEMS CORP.

2951 Ishikawa-cho, Hachioji-shi, Tokyo 192-8507, Japan

Fax: (042) 646-2429 Telephone: (042) 642-2111

OLYMPUS EUROPA HOLDING GMBH

(Premises/Goods delivery) Wendenstrasse 14-18, 20097 Hamburg, Germany

(Letters) Postfach 10 49 08, 20034 Hamburg, Germany

Fax: (040)23773-4656 Telephone: (040)23773-0

OLYMPUS AMERICA INC.

3500 Corporate Parkway, P.O. Box 610, Center Valley, PA

Fax: (484) 896-7128 Telephone: (484) 896-5000

18034-0610, U.S.A.

KEYMED LTD.

KeyMed House, Stock Road, Southend-on-Sea, Essex SS2 5QH, United Kingdom

Fax: (01702) 465677 Telephone: (01702) 616333

OLYMPUS SINGAPORE PTE LTD.

491B, River Valley Road #12-01/04, Valley Point Office Tower, Singapore 248373

Fax: 6834-2438 Telephone: 6834-0010

OLYMPUS (BEIJING) SALES & SERVICE CO,. LTD.

A8F, Ping An International Financial Center, No. 1-3, Xinyuan South Road,

Chaoyang District, Beijing, 100027 P.R.C.

Fax: (86)10-5976-1299 Telephone: (86)10-5819-9000

OLYMPUS MOSCOW LIMITED LIABILITY COMPANY

117071, Moscow, Malaya Kaluzhskaya 19, bld. 1, fl.2, Russia

Fax: (095) 958-2277 Telephone: (095) 958-2245

OLYMPUS AUSTRALIA PTY. LTD.

31 Gilby Road, Mount Waverley, VIC., 3149, Australia

Fax: (03)9543-1350 Telephone: (03)9265-5400

OLYMPUS LATIN AMERICA INC.

5301 Blue Lagoon Drive, Suite 290 Miami, FL 33126-2097, U.S.A.

Fax: (305)261-4421 Telephone: (305)266-2332

OLYMPUS KOREA CO,. LTD.

Olympus-Tower, 114-9 Samseong-Dong, Gangnam-Gu, Seoul 135-090 Korea

Fax: (02)6255-3494 Telephone: (02)6255-3210

Issue 20

July 2012

EKeyMed 2012

K 5070557

Page 2

MAINTENANCE & REPAIR MANUAL

M- NP1 / WM- WP1 / WM- DP1 WORKSTATIONS

CHANGE OF ISSUE LOG

When an up--issued copy of this manual is received, record its receipt on this page.

A brief description of the change can be found on the last page of the manual : Summary of Change History.

Changes made to the current issue are highlighted in the manual by a vertical line in the right hand margin.

Each up--issued copy of the manual will include an up--issued copy of this page but it does not have to be retained unless needed as a

continuation sheet.

Date Issue

number of

manual

Signature Date Issue

number of

manual

Signature

WM--P1 SERIES WORKSTATIONS

Page2of 76

Issue 20 : July 2012

Page 3

MAINTENANCE & REPAIR MANUAL

WM- NP1 / WM- WP1 WM - DP1

Manual Contents

Page

Preliminary Material

Title Page 1..................................................................

Change of issue log 2...........................................................

Manual Contents (this page) 3.....................................................

Chapters

1 Introduction 4.........................................................

2 General Information 6...................................................

3 Specifications 8.......................................................

4 Tools & Test Equipment 12...............................................

5 Test and Inspection 14..................................................

6 Part Replacement 16...................................................

7 Illustrated Parts List 27..................................................

8 Accessories Illustrated Parts List 39.........................................

Summary of Change History 76............................................

WM--P1 SERIES WORKSTATIONS

Page3of 76

Issue 20 : July 2012

Page 4

Chapter 1 Introduction

Table of Contents

Page

Introduction 5.........................................................

WM--P1 SERIES WORKSTATIONS

Page4of 76

Issue 20 : July 2012

Page 5

1 INTRODUCTION

This Maintenance and Repair Manual has been produced by KeyMed to enable the repair and servicing of the Olympus WM--P1

series mobile workstation.

Although every effort has been made to ensure that this document is correct and complete, KeyMed cannot be held responsible

for the safety or reliability of any equipment which has been repaired other than by suitably qualified personnel. It is essential

that this manual is read and understood before commencing any work.

Should any additional information or advice be required, please contact:

Olympus KeyMed

Technical Services

Technical Support

KeyMed House

Stock Road

SOUTHEND--ON--SEA

Essex SS2 5QH

United Kingdom

Tel: (01702) 616333

Fax: (01702) 465677

Telex: 995283

WM--P1 SERIES WORKSTATIONS

Page5of 76

Issue 20 : July 2012

Page 6

Chapter 2 General Information

Table of Contents

Page

General information 7...................................................

WM--P1 SERIES WORKSTATIONS

Page6of 76

Issue 20 : July 2012

Page 7

2 GENERAL INFORMATION

The Olympus WM--P1 series mobile workstation is intended for use in medical facilities under the direction of a trained

physician, and has been designed to accommodate the Olympus video system center and associated ancillary devices as a

practical mobile workstation to facilitate GI endoscopy, endoscopic ultrasound, respiratory and surgical endoscopic procedures.

Olympus will not be responsible for damage or injury to equipment or personnel, caused by unauthorised modification or repair

to this unit.

Maintenance

In the interest of safety and good maintenance, ensure that all fixings are secure. It is recommended that the security fixing

torques of the monitor platform, shelf’s, castors and side column fixings specified in the illustrated parts list, are checked every

six months.

WM--P1 SERIES WORKSTATIONS

Page7of 76

Issue 20 : July 2012

Page 8

Chapter 3 Specifications

Table of Contents

Page

3.1 WM--NP1 / WM--WP1 series mobile workstations 9..............................

3.2 WM--DP1 series mobile workstations 10......................................

3.3 WM--T1 series separation transformers 10....................................

WM--P1 SERIES WORKSTATIONS

Page8of 76

Issue 20 : July 2012

Page 9

3 SPECIFICATIONS

3.1 WM- NP1 / WM- WP1 series mobile workstations

Product name WM--NP1 / WM--WP1 mobile workstation

Dimensions (mm) Height: 1370 (scope in lowest position)

2140 (scope in highest position)

1160 (to top tray)

1826 max (with 19” LCD monitor in highest position)

Depth: 650

Width: 645 (WM--NP1) 795 (WM--WP1)

Weight 85kg (WM-- NP1) 90kg (WM-- WP1) unladen, including fitted transformer.

Load capacity

(evenly distributed)

Castors 4 x 125mm non--antistatic, two with brakes.*

Ambient temperature Storage: --40Cto+70C

(--40F to +158F)

Relative humidity 95% maximum @ 40C (104F) non--condensing

Atmospheric pressure

* UK workstations fitted with Antistatic castors from Oct 2007.

Top tray 20kg

Intermediate shelves 31kg each

Base panel 31kg

NOTE: Equipment stored on the mobile workstation should not exceed

the size of the shelf.

Operation: 10 -- 40C (50 -- 104F)

Storage: 23.5-- 106 kPa (3.4 --15.37lbf/in

Operation: 70-- 106 kPa (10.15 --15.37lbf/in

2

)

2

)

WM--P1 SERIES WORKSTATIONS

Page9of 76

Issue 20 : July 2012

Page 10

3.2 WM- DP1 series mobile workstations

Product name WM--DP1 mobile workstation

Dimensions (mm) Height: 1370 (scope in lowest position)

2140 (scope in highest position)

1160 (to top tray)

1826 max (with 19” LCD monitor in highest position)

Depth: 655

Width: 1100

Weight 120kg unladen, including fitted transformer.

Load capacity

(evenly distributed)

Top tray 10kg

Intermediate shelves 26kg each

Base panel 45kg

NOTE: Equipment stored on the mobile workstation should not exceed

the size of the shelf.

Castors 4 x 125mm non--antistatic, two with brakes.*

Ambient temperature Storage: --40Cto+70C

(--40F to +158F)

Operation: 10 -- 40C (50 -- 104F)

Relative humidity 95% maximum @ 40C (104F) non--condensing

Atmospheric pressure

Storage: 23.5-- 106 kPa (3.4 --15.37lbf/in

Operation: 70-- 106 kPa (10.15 --15.37lbf/in

* UK workstations fitted with Antistatic castors from Oct 2007.

2

)

2

)

3.3 WM- T1 series separation transformers

Product name Olympus Separation Transformer

Identification Market Japan USA UK, Europe,

Rest of the world

Model No. MAJ--173 MAJ--174 MAJ--175

Part No. K10000289 K10000290 K10000291

Power input

requirements

Input voltage 100V 110-- 120V 220 --240V

Frequency 50/60Hz 60Hz 50/60Hz

Power input (max) 1350VA 1300VA 1900VA

Power cable part No. K10001001 K10001002 K10001003 (UK)

K10001004 (Europe)

K10001005 (RoW)

Power output Maximum load 1250VA * 1250VA 1800VA

* Maximum 10A load per IEC socket outlet (MAJ--173 only)

Overload

protection

WM--P1 SERIES WORKSTATIONS

Input circuit breakers 2 x 15A 2 x 13A 2 x 9A

Output fuse T15AH T15AH T10AH

Issue 20 : July 2012

Page 10 of 76

Page 11

Potential

Classificatio

Classificatio

n

Amb

ient

t

EnvironmentalconditionsAt

S

t

/

O

t

i

7

0--106kPa(10.3--1

5.4lbf/

in2

)

equalisation

Terminals fitted 2 at input, 2 x 6 at output

The Separation Transformer conforms to the relevant

Standards compliance

requirements of

EN IEC 60601--1/EN IEC 60601--1--1:2001, Annex EEE/UL

60601--1 and CAN/CSA Std. No. C22.2 No. 601.1--M90

n

Environmental

Regulatory status

End of Life

Type of protection against electric

Class I equipment.

shock.

Degree of protection against

explosion

Degree of protection against ingress

of water.

NONE -- The Separation transformer should not be used

within the zone of risk of flammable gases

IPXO as defined in EN IEC 60529:1992, ordinary equipment.

Mode of operation Continuous

Storage: --40Cto70C(--40F to 158F)

emperature

mospheric pressure

Operation: 10Cto40C(50F to 104F)

orage

pera

on:

Relative humidity 95% maximum @ 40C (104F) non--condensing

220--240V units are CE marked in

accordance with Directive 93/42/EEC of

14 June 1993 concerning medical

devices, as an accessory to a medical

device, Class I. Year of manufacture is

given in first two digits of serial number.

In accordance with European Directive

European Economic Area (EEA)

2002/96/EC on Waste Electrical and

Electronic Equipment, this symbol

indicates that the product must not be

disposed of as unsorted municipal waste,

but should be collected separately. Refer

to your local Olympus distributor for r eturn

and/or collection systems available in your

country.

The Olympus WM--P1 series Mobile Workstation and Separation Transformer is manufactured in the

UK by KeyMed (Medical & Industrial Equipment) Ltd.

Page 11 of 76

WM--P1 SERIES WORKSTATIONS

Issue 20 : July 2012

Page 12

Chapter 4 Tools & Test Equipment

Table of Contents

4.1 Standard Tools and Test equipment required 13................................

4.2 Specialised tools required 13..............................................

4.3 Consumables 13......................................................

WM--P1 SERIES WORKSTATIONS

Page 12 of 76

Issue 20 : July 2012

Page 13

4 TOOLS & TEST EQUIPMENT

4.1 Standard Tools required

Flat blade screwdriver Torque driver

No 2 Pozidrive tool bit No 3 Pozidrive tool bit

4mm Hex tool bit 8mm Hex tool bit

10mm Hex tool bit 10mm A/F socket

13mm A/F Slim socket Ball driver 6mm A/F

Short No 2 Pozidrive screwdriver Torx bit T30

Torque wrench (1/2” drive).. M12 tap

Britool part no AVT300A Torque range 5 to 33 Nm.

Insulation tester which works at 500Vdc. --

4.2 Specialised Tools

Castor spanner WM--P1 -- K10005023 --used with 1/2” drive torque wrench.

4.3 Consumables

Loctite 243 10ml bottle -- part number K10006486

FIGURE 4-1

CASTOR SPANNER WM--P1 --

K10005023

Loctite 243 -- part number 3001857

WM--P1 SERIES WORKSTATIONS

Page 13 of 76

Issue 20 : July 2012

Page 14

Chapter 5 Test and Inspection

Table of Contents

5.1 Power supply 15.......................................................

5.2 Castor security 15.....................................................

5.3 Castor -- electrical resistance test 15........................................

Page

WM--P1 SERIES WORKSTATIONS

Page 14 of 76

Issue 20 : July 2012

Page 15

5 TEST AND INSPECTION

5.1 Power supply

(1) Check the power supply cable and plug for excessive protrusion, twists, deformation or other irregularities.

5.2 Castor security

(1) Check the security of castors at six--monthly intervals. If loose use castor spanner ( K10005023) fitted to a standard 1/2”

drive torque driver to tighten to a torque of 30Nm.

If castor spanner ( K10005023) is not used, then torque value on the driver should be set to 38Nm. Refer to Chap 6.6.

5.3 Castors - electrical resistance test

NOTE

This test is only applicable to workstations fitted with ’anti--static’ castors, indicated by a yellow wheel centre or

swivel bearing collar, or a yellow dot on the tyre.

(1) Ensure that the workstation power cable is disconnected from the wall socket.

(2) Thoroughly clean each of the tyres.

(3) Roll a castor onto a metal plate which is insulated from the floor.

(4) Using a proprietary insulation tester working at 500Vdc, measure the resistance between the castor mounting point and

the plate. In cases where it is difficult to attach the test lead directly to the the castor mountings it is permissible to

connect to exposed metalwork (such as a screw head) on the base of the workstation, provided that it is electrically

connected to the castor mounting point.

The average resistance should not exceed 100k for castors rated as ’Conductive’ according to ISO22881:2004,

measured at three different points on the tyre’s circumference.

(5) Repeat the procedure on the other castors.

WM--P1 SERIES WORKSTATIONS

Page 15 of 76

Issue 20 : July 2012

Page 16

Chapter 6 Part Replacement

Table of Contents

6.1 General 17...........................................................

6.2 Blanking caps & Cable tidy replacement 17...................................

6.3 Bracket twin LG holder replacement 17......................................

6.4 Rear panel replacement 18...............................................

6.5 Shelf corner moulding replacement 18.......................................

6.6 Castor replacement 19..................................................

6.7 Remote switch replacement 20............................................

6.8 Top tray replacement WM--NP1 21..........................................

6.9 Top tray replacement WM--WP1 22.........................................

6.10 Top tray replacement WM --DP1 23..........................................

6.11 Shelf replacement 24...................................................

6.12 Scope pole clamp P1 series replacement 25...................................

6.13 Runner--scope pole P1 series replacement 25.................................

6.14 Nutstrip P1 series replacement 25..........................................

6.15 Power cable replacement 26..............................................

6.16 Separation transformer replacement 26......................................

Page

WM--P1 SERIES WORKSTATIONS

Page 16 of 76

Issue 20 : July 2012

Page 17

6 PART REPLACEMENT

6.1 General

The item numbers referred to throughout this Chapter are the same as those used in the Illustrated Parts List, Chapter 6.

To aid part replacement the following are available :

MAJ--198 WN--NP1 Sheft kit (Narrow) -- K10001429 MAJ--199 WN--WP1 Shelf kit (Wide) -- K10001430

Rear panel kit WM--NP1 K10005044 Rear panelkit WM--WP K10005041

Free castor kit K10004627 Braked castor kit K10004626

Castor free kit WM--P1 series A/S K10005041 Castor braked kit WM--P1 series A/S K10005040

Castor spanner WM--P1 series K10005023 Remote switch kit WM--P1 series K10005049

Umbilical/camera head holder kit K10006648

Before replacing any part on the workstation ensure that all mains power is disconnected.

Olympus will not be responsible for damage or injury to equipment or personnel, caused by unauthorised modification or

repair to this unit.

In the interests of safety and good maintenance ensure that fixings are tightened to the torque settings shown in the

parts list, illustrated parts list and part replacement chapter.

6.2 Blanking caps & Cable tidy replacement

(1) Refer to Figure 6-1. Blanking caps: Cable port (item 17), Monitor (item 18) and Scope pole (item 19) are a push fit and

so require to be carefully prised out of position.

(2) Unscrew Handknob (item 31) to release Cable tidy (item 29).

FIGURE 6-1

BLANKING CAPS & CABLE TIDY

37

21

2

50

2

47

17

2

20

2

67

2

31

18

19

2

2

29

6.3 Bracket twin LG holder replacement

(1) Refer to Figure 6-1 . and using 4mm hex drive tool bit remove Bracket twin LG holder (item 20) release two screws

(item 37) and washer crinkle (item 50) with washer (item 47) from jetnut (item 67).

(2) Replace/refit in reverse order. Using 4mm hex drive tool bit in torque driver ensure that screw (item 37) is tightened to a

torque of 6Nm.

WM--P1 SERIES WORKSTATIONS

Page 17 of 76

Issue 20 : July 2012

Page 18

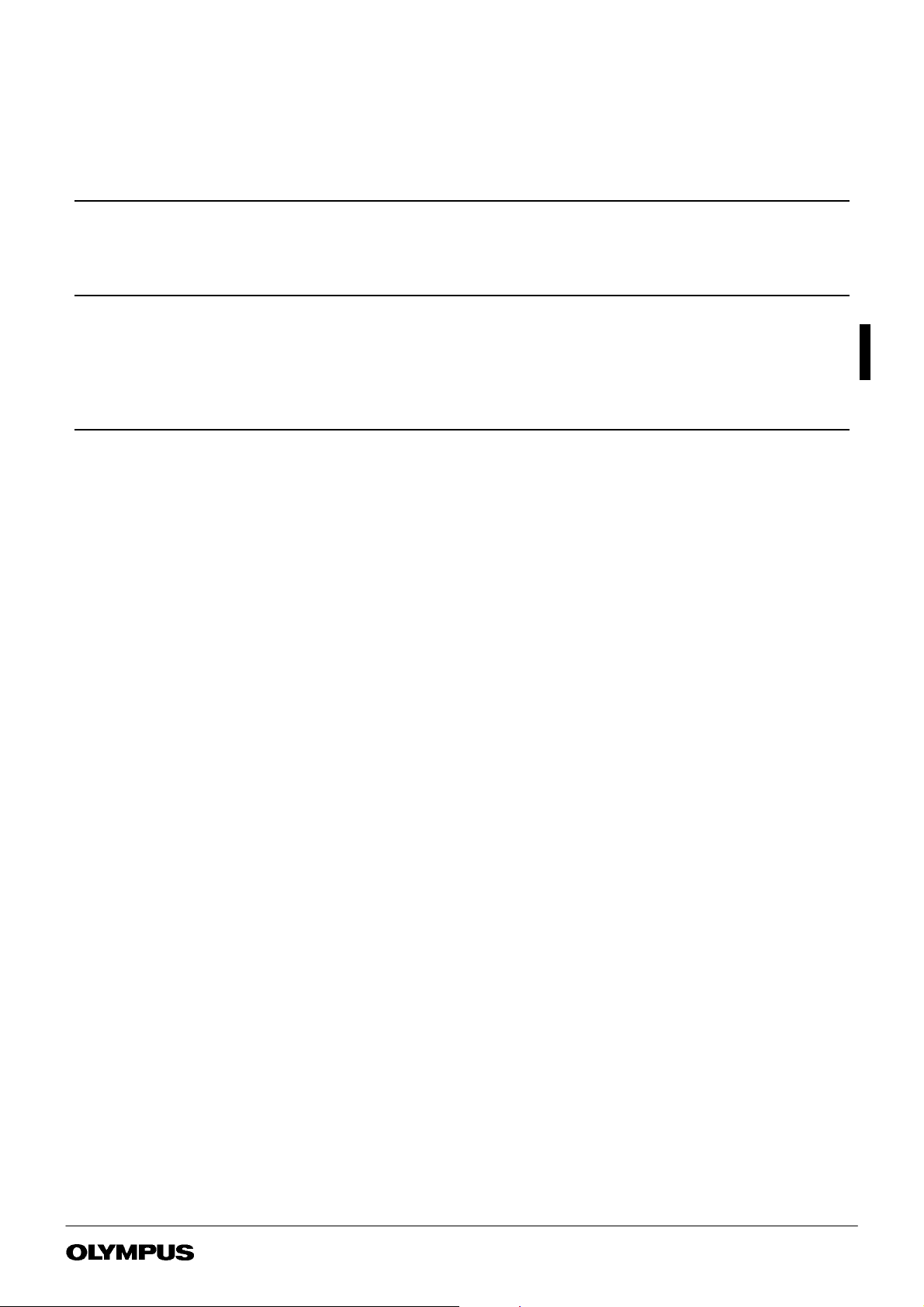

6.4 Rear panel replacement

Each Rear panel is available as a kit which inclues two feet and a finger latch pack. Fit the finger latch as shown in

Figure 6-2 and discard the keeper plate, if supplied.

WM--NP1 Rear panel -- part no K10005044. WM--WP1 Rear panel -- part no K10005045

(1) Refer to Figure 6-2, pull the finger latch to release the top of the rear panel.

(2) Lift the rear panel from the two studs on the base of the workstation.

(3) Refit /replace the rear panel.

FIGURE 6-2

REAR PANEL REPLACEMENT

Contents of

Finger latch pack

Discard

keeper plate

Finger

latch

WM--WP1

Rear panel

WM--NP1

Rear panel

6.5 Shelf corner moulding replacement

(1) Refer to Figure 6-3 each corner buffer (item 23 & 24) may be levered off.

(2) Reassemble by pushing each buffer into place.

24

23

FIGURE 6-3

SHELF CORNER MOULDINGS

WM--P1 SERIES WORKSTATIONS

Page 18 of 76

Issue 20 : July 2012

Page 19

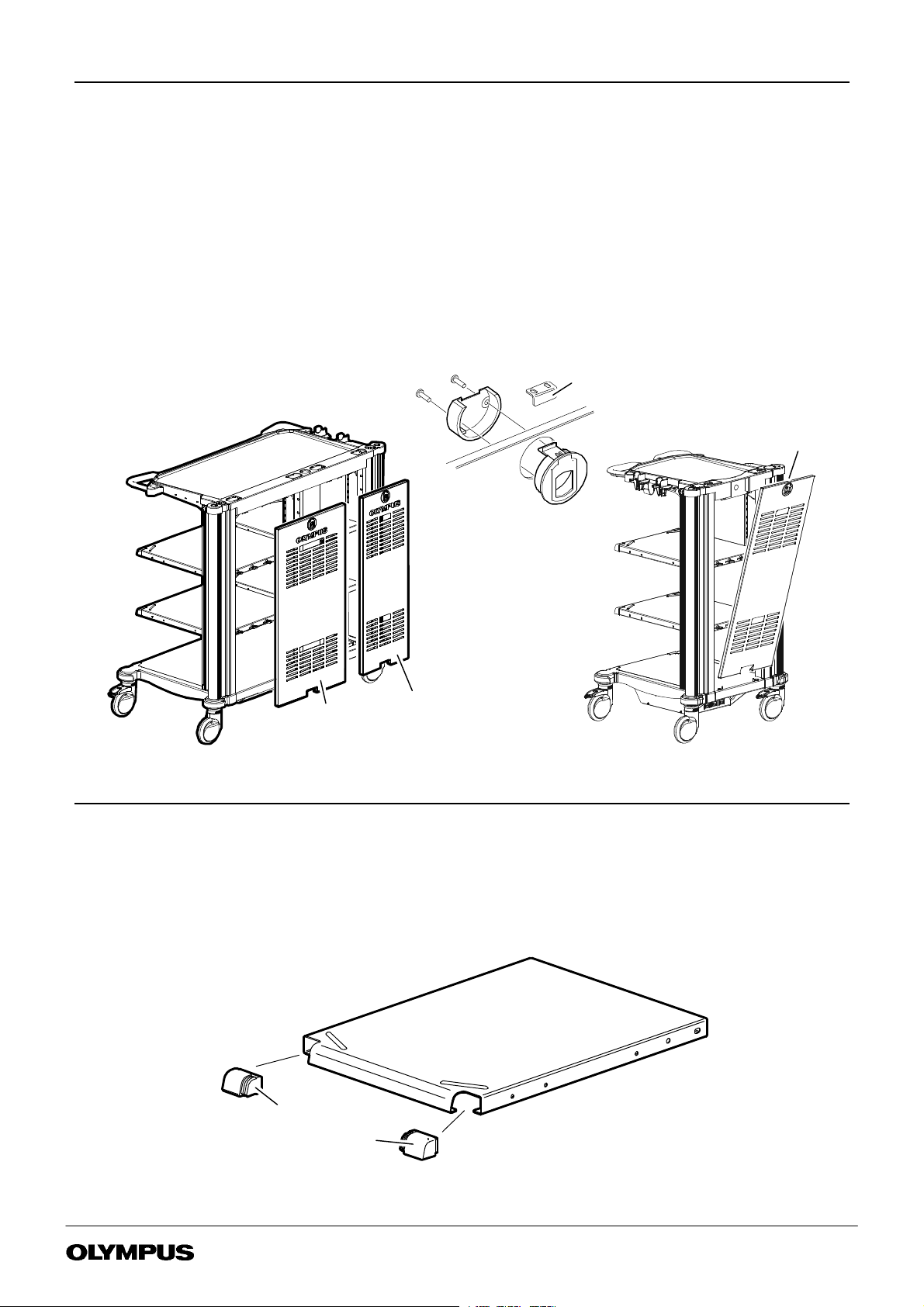

6.6 Castor replacement

Each workstation has two lockable castors (item 4) and two free castors (item 3).

Maintenance/Repair kits available:--

Free castor kit K10004627 Braked castor kit K10004626

Castor free kit WM--P1 series A/S K10005041 Castor braked kit WM--P1 series A/S K10005040

Special tool :

Castor spanner WM--P1 series K10005023

(1) Disconnect all power to the workstation.

(2) Remove rear panel and all equipment.

(3) Where fitted remove the scope pole or IV pole.

(4) Where fitted stow Keyboard Tray or Keyboard Arm -- Side Mounted.

(5) Remove the cable winder (item 19)

(6) Place the workstation carefully on to it’s back. The WM--DP1 exceeds 30Kg and must be handled by two people.

(7) Refer to Figure 6-4. For ease of access to the lower castors elevate and securely support the base end of the workstation.

(8) Using Castor spanner tool K10005023 fitted to a 1/2” drive wrench release the castor (item 3 or 4) and washer (item 5).

(9) Ensure that lockable castors(item 4) are refitted in the original location, refer to Figure 6-4

Run a M12 tap through the castor fixing hole to clear any residual Loctite adhesive.

When attaching a castor ensure that the thread of the bolt is smeared with loctite 243 ( item 60 ), use Castor spanner tool

K10005023 fitted to a torque driver to tighten to a torque of 30Nm.

NOTE If Castor spanner tool K10005023 is not used, then the torque value on the driver should be set to 38Nm.

Stand the workstation on it’s castors, re--install the equipment.

To allow the loctite to cure, the workstation should be kept in a location for 24 hours where the temperature is not below

22C and manouvering on bumpy surfaces is avoided.

4

LOCKABLE

3

5

5

Support

4

LOCKABLE

FIGURE 6-4

5

CASTOR SPANNER WM--P1SERIES -- K10005023

CASTOR REPLACEMENT

WM--P1 SERIES WORKSTATIONS

5

3

Page 19 of 76

Issue 20 : July 2012

Page 20

6.7 Remote switch replacement

(1) Unplug the Remote switch plug from the separation transformer.

(2) Refer to Figure 6-5 for WM--NP1, Figure 6-6 for WM--WP1 and Figure 6-7 for WM--DP1, use a No 2 Pozi drive tool to

release four screws (item 77) securing four p clips (item 78).

(3) Release the remote switch cable from releasable cable tie (item 34).

(4) Free the cable from the column side cable retainer.

(5) Using 4mm hex drive tool release two screws (item 40) with washer (item 50) to release remote switch (item 2).

(6) Reassemble in reverse order, use 4mm hex drive tool in torque wrench to tighten remote switch fixings to 2Nm.

(7) Fit four p clips to remote switch cable. Use a No 2 pozi driver in a torque wrench to fasten four screws (item 77) securing

four p clips (item 78) tighten to torque of 2.2Nm.

(8) Route the remote switch cable to releasable cable tie (item 34). Take up any slack in the cable toward the switch and

tighten the cable tie.

(9) Plug the Remote switch cable into the separation transformer.

(10) Route remaining cable into column side cable retainer.

WM--P1 SERIES WORKSTATIONS

Page 20 of 76

Issue 20 : July 2012

Page 21

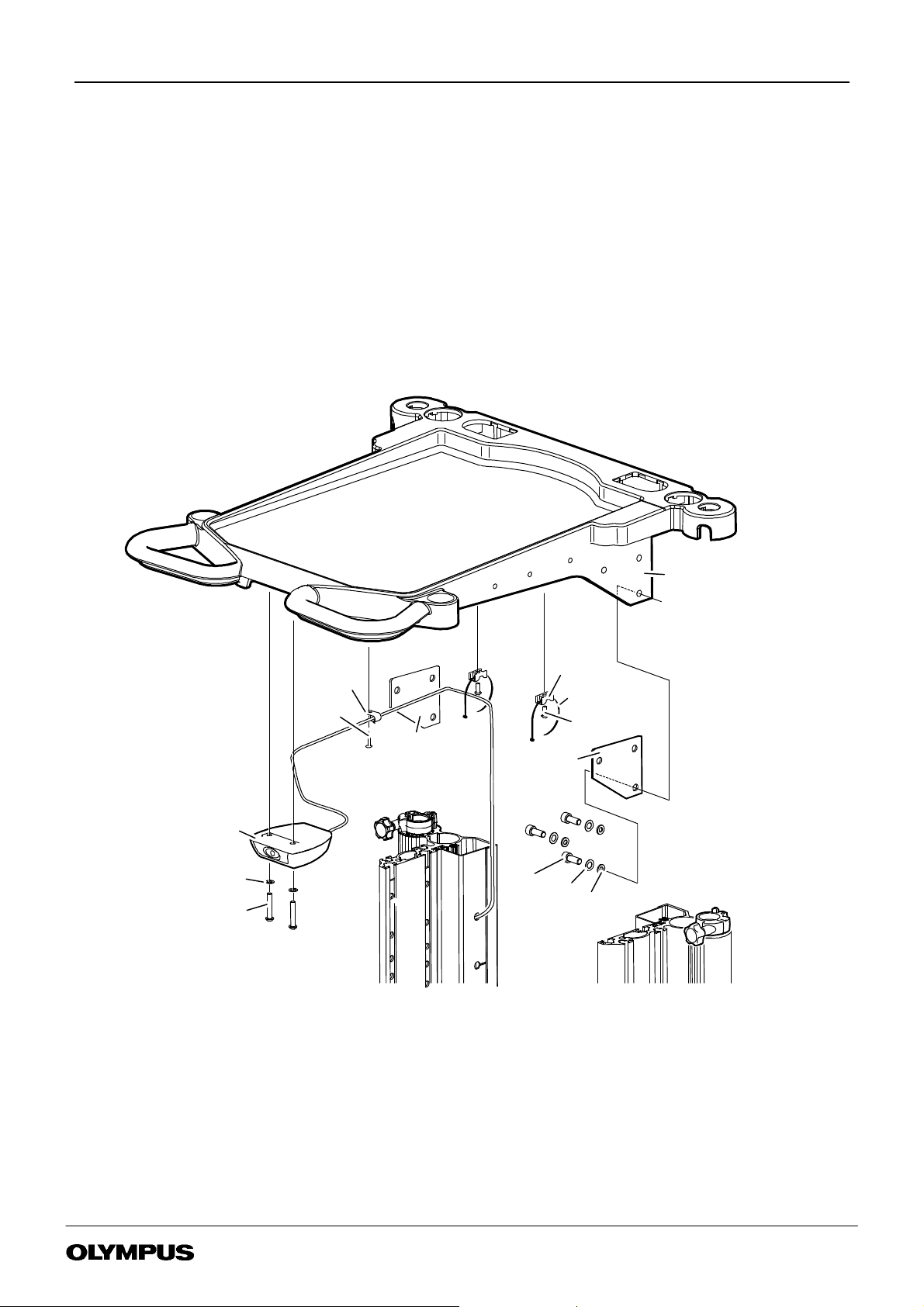

6.8 Top Tray replacement WM- N P1

(1) Remove all equipment from the top tray (item 14)

(2) Refer to Section 6.7 and remove the Remote switch assembly and cable (item 2) from the top tray.

(3) Refer to Figure 6-5 to release Support plates WM--DP1 (item 10) and Top tray (item 14). Using a 6mm allen key unscrew

six screws (item 75) with washer crinkle (item 49) and washer (item 45).

(4) Reassemble in reverse order . Place top tray assembly into place between the side columns. Position each Support plate

WM--DP1 (item 10) insert but do not fully tighten, three screws (item 75) with washer crinkle (item 49) and

washer (item 45) using 6mm hex drive tool. Using 6mm hex drive tool in torque wrench fully tighten to 20Nm.

(5) Refer to section 6.7 to refit remote switch.

FIGURE 6-5

WM--NP1 REMOTE SWITCH &

TOP TRAY REPLACEMENT

50

40

14

32

77

78

42.2Nm

4

34

42

2

2

22Nm

10

10

2

75

2

22Nm

6 20Nm

49

6

45

6

WM--P1 SERIES WORKSTATIONS

Page 21 of 76

Issue 20 : July 2012

Page 22

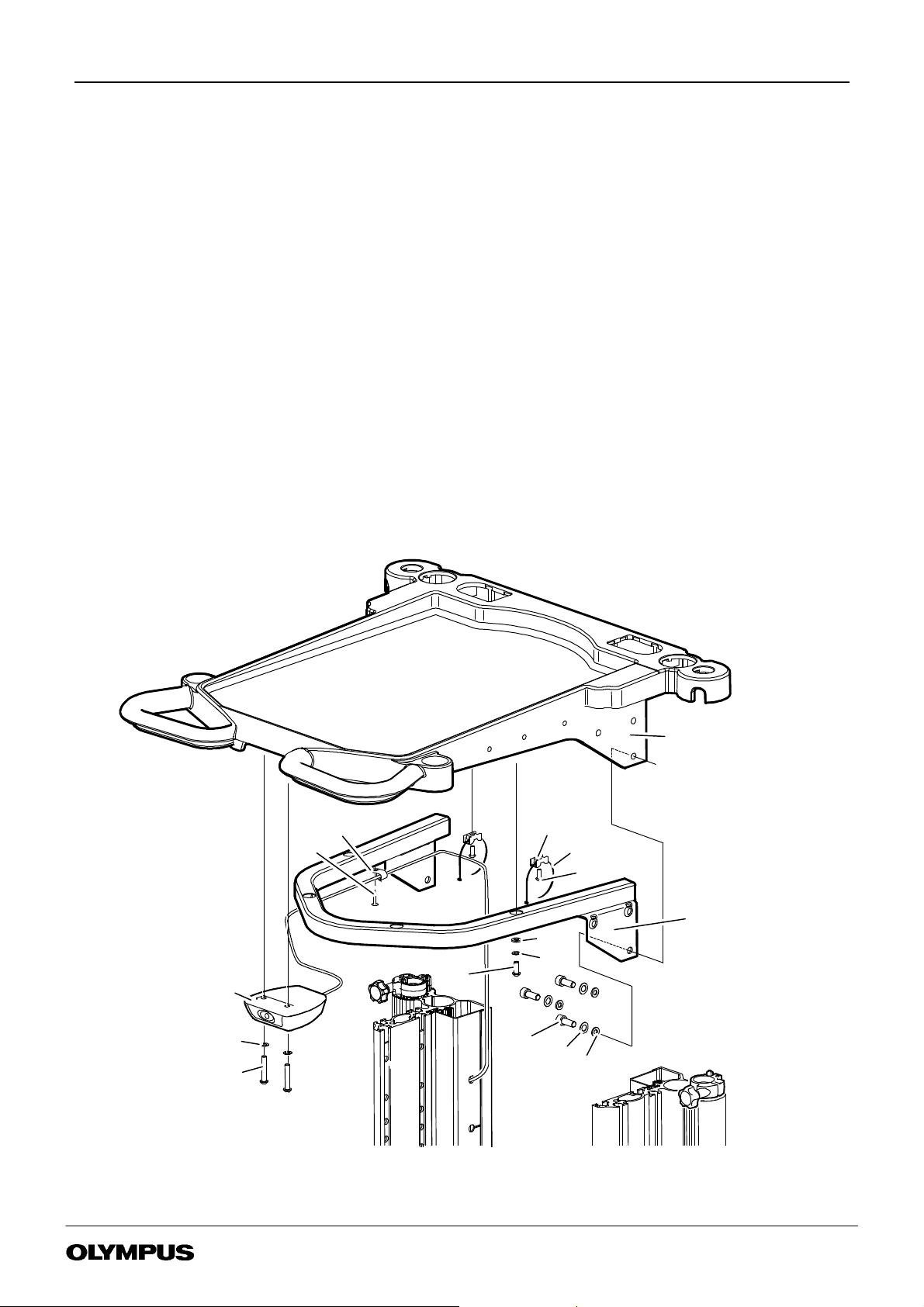

6.9 Top Tray replacement WM- WP1

(1) Remove all equipment from the top tray (item 14)

(2) Refer to Section 6.7 and remove the Remote switch assembly and cable (item 2) from the top tray.

(3) Refer to Figure 6-6. Using a 6mm allen key unscrew six screws (item 75) with washer crinkle (item 49) and

washer (item 45).

(4) Remove and invert the top tray. Using a 6mm allen key relaese four screws (item28) with washer (item 50) and crinkle

washer (item 45). Separate the Top tray (item 14) from Support top tray wide (item 15).

(5) Reassemble in reverse order. Secure top tray (item 14) to Top tray support wide (item 15) using a 6mm allen key to

fasten four screws (item 28) with washer (item 50) and crinkle washer (item 47) Do not fully tighten.

(6) Place top tray assembly into place between the side columns. Using 6mm hex drive tool in torque wrench tighten six

screws (item 75) with washer crinkle (item 49) and washer (item 45) to 20Nm.

(7) Fully tighten four screws (item 28) securing support toptray narrow to top tray using 6mm hex drive tool in torque wrench

to 4Nm

(8) Refer to section 6.7 to refit remote switch.

FIGURE 6-6

WM--WP1 REMOTE SWITCH & TOP

TRAY REPLACEMENT

14

77

78

42.2Nm

4

32

2

34

2

42

22Nm

15

47

4

50

4

38

2

44Nm

50

2

40

22Nm

WM--P1 SERIES WORKSTATIONS

75

6 20Nm

49

6

45

6

Page 22 of 76

Issue 20 : July 2012

Page 23

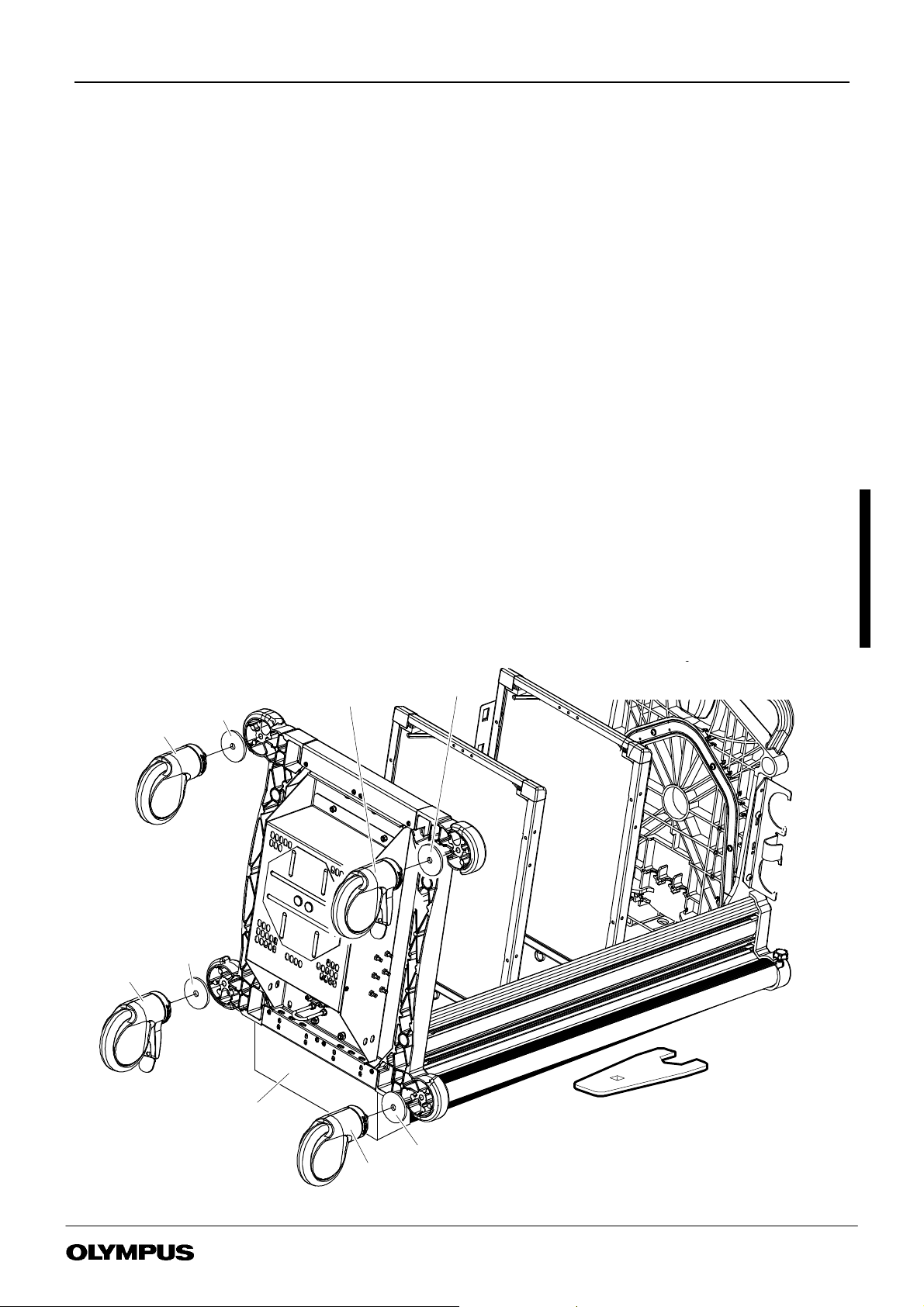

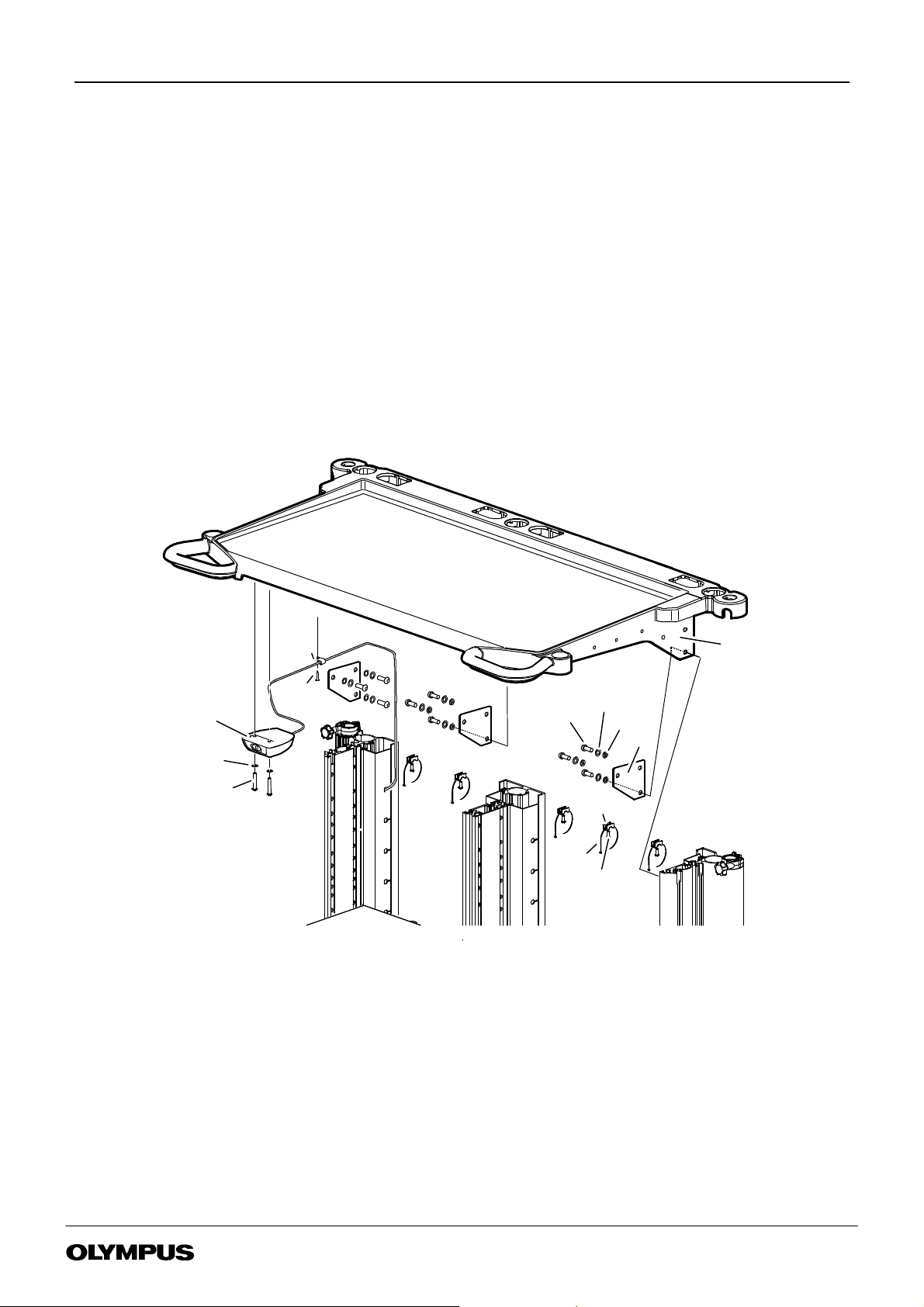

6.10 Top Tray Replacement WM- DP1

(1) Remove all equipment from the top tray (item 14)

(2) Refer to Section 6.7 and remove the Remote switch assembly and cable (item 2) from the top tray.

(3) Refer to Figure 6-7 to release Support plates WM--DP1 (item 10) and Top tray (item 14). Using a 6mm allen key unscrew

nine screws (item 75) with washer crinkle (item 49) and washer (item 45).

(4) Reassemble in reverse order. Place top tray assembly into place between the side columns. Position each Support plate

WM--DP1 (item 10) insert but do not fully tighten, three screws (item 75) with washer crinkle (item 49) and

washer (item 45) using 6mm hex drive tool. Using 6mm hex drive tool in torque wrench fully tighten to 20Nm.

(5) Refer to section 6.7 to refit remote switch.

FIGURE 6-7

WM--DP1 REMOTE SWITCH AND TOP

TRAY REPLACEMENT

50

40

78

4

77

42.2Nm

2

75

92Nm

49

9

45

9

14

10

2

22Nm

34

32

5

42

5

5

WM--P1 SERIES WORKSTATIONS

Page 23 of 76

Issue 20 : July 2012

Page 24

6.11 Shelf replacement

Shelf kits : -- MAJ--198 WM--NP1 SHELF KIT (NARROW) -- K10001429

MAJ--199 WM--WP1 SHELF KIT (WIDE) -- K10001430

(1) To remove shelf (item 22) refer to Figure 6-8.

(2) If the shelf is to be refitted at the same height make carefull note of the fixing holes used.

(3) Using 6mm hex drive tool bit in power torque tool release four screws (item 36) with washer crinkle (item 49) and washer

(item 43).

(4) Reassemble ensuring that the fixings are tightened to a torque of 15Nm.

FIGURE 6-8

SHELF REPLACEMENT

33

3

38

26Nm

50

36

4 15Nm49

43

2

47

2

25

22

2

4

4

67

WM--P1 SERIES WORKSTATIONS

Page 24 of 76

Issue 20 : July 2012

Page 25

6.12 Scope pole clamp P1 series

(1) Refer to Figure 6-1. Blanking caps : Cable port (item 17), Monitor (item 18) and Scope pole (item 19) are a push fit and

so require to be carefully prised out of position.

(2) Refer to Figure 6-9 Unscrew Handknob (item 6) to release Cable tidy (item 29).

(3) Remove the top tray, refer to section 6.8 for WM--NP1,section 6.9 for WM--WP1 and section 6.10 for WM--DP1.

(4) Refer to Figure 6-9 Use a pozi screwdriver to release screw (item 41) with washer (item 48) and remove Scope Pole

Clamp Assy (item 46).

(5) Refit in reverse order ensuring that Screw (item 41) is tightend to 2.5Nm using a No2 pozi drive tool bit in powered torque

tool.

(6) Refit remaining parts in reverse order.

12

28

4

46

2

8

41

48

29

SCOPE POLE CLAMP, SCOPE POLE

FIGURE 6-9

RUNNERS & NUT STRIPS

7

6

2

13

8

6.13 Runner- scope pole P1 series

(1) Refer to section 5.11 to remove scope pole clamp P1 series.

(2) Lift each runner from it’s slot in the side column.

(3) Re fit in reverse order.

6.14 Nutstrip P1 series

(1) Remove the top tray refer to section 5.8 for WM--NP1, section 5.9 for WM--WP1 and section 5.10 for WM--DP1

(2) Refer to Figure 6-9 and remove Nutstips (item 12) noting which side of the nutstrip is facing outward.

(3) Replace/refit in reverse order.

WM--P1 SERIES WORKSTATIONS

Page 25 of 76

Issue 20 : July 2012

Page 26

6.15 Power cable replacement

The power cable (item 58) may be replaced while the transformer is within the workstation.

(1) Disconnect from mains power supply.

(2) Disconnect the power cable from the transformer.

(3) Disconnect output cables.

(4) Refer to Figure 6-10. Using a short No 2 Pozidrive screwdriver release the four screws from cable clamps.

FIGURE 6-10

POWER CABLE CLAMP

(5) Position a new power cable to ensure that the input connector cable end is 30cm from the clamp.

(6) T ighten one clamp sufficient to ensure that a firm pull on the power cable is not trasmitted to the loop between the clamp

and the input connector. Tighten the second clamp a similar amount to the first.

6.16 Separation Transformer replacement

Refer to Transformers for Mobile Workstations Maintenance & Repair Manual part no: K5070505

CAUTION

The Separation Transformer weighs up to 30 kg, take care when lifting.

It is recommended that two people are involved in the disassembly and reassembly of the Separation Transformer.

WM--P1 SERIES WORKSTATIONS

Page 26 of 76

Issue 20 : July 2012

Page 27

Chapter 7 Illustrated Parts List

Table of Contents

7.1 WM--NP1, WM--WP1 & WM--DP1 Mobile Workstation 28.........................

Page

WM--P1 SERIES WORKSTATIONS

Page 27 of 76

Issue 20 : July 2012

Page 28

7 ILLUSTRATED PARTS LIST

7.1 WM- N P1, WM- WP1 &WM-DP1 MOBILE WORKSTATION

93

ITEM

FIGURE 7-1

WM--NP1 & WM--WP1 PART LOCATION

93/1

93/2

21

20

93/4

37

93/5

26Nm

93/3

50

2

47

17

2

19

18

2

2

29

16

2

67

2

54

27

26

88

2

WM--DP1 -- 4

WM--P1 SERIES WORKSTATIONS

88

55

Page 28 of 76

Issue 20 : July 2012

Page 29

49

92

FIGURE 7-2

WM--DP1 PART LOCATION

26

WM--NP1

26

4

91

4

4

83

WM--WP1

FIGURE 7-3

WM--NP1 PART LOCATION

14

10

32

77

78

42.2Nm

4

34

42

2

2

22Nm

10

2

50

2

40

22Nm

WM--P1 SERIES WORKSTATIONS

75

6 20Nm

49

6

45

6

Page 29 of 76

Issue 20 : July 2012

Page 30

FIGURE 7-4

WM--WP1 PART LOCATION

14

50

40

77

78

42.2Nm

4

32

2

34

2

42

22Nm

15

47

4

50

4

38

2

2

22Nm

44Nm

75

6 20Nm

49

6

45

6

FIGURE 7-5

WM--DP1 PART LOCATION

78

77

2

50

2

40

22Nm

WM--P1 SERIES WORKSTATIONS

4

42.2Nm

75

92Nm

34

32

5

49

42

5

45

5

14

9

9

10

Page 30 of 76

Issue 20 : July 2012

Page 31

38

26Nm

50

FIGURE 7-6

WM--NP1 & WM--WP1 PART LOCATION

33

36

4 15Nm49

43

2

47

2

25

22

2

4

4

3

24

67

2

88

23

2

WM--P1 SERIES WORKSTATIONS

Page 31 of 76

Issue 20 : July 2012

Page 32

12

28

4

46

48

2.5Nm

WM--NP1 & WM--WP1 PART LOCATION

2

8

7

FIGURE 7-7

41

6

2

13

8

11

1

45

52

4

4 15Mm

32

4

2 30Nm/38Nm

60

86

34

5

A/R

4

4

4

11

11

5

2

3

2 30Nm/38Nm

60

A/R

2

WM--P1 SERIES WORKSTATIONS

Page 32 of 76

Issue 20 : July 2012

Page 33

WM- NP1 100V JP p/no K10000284 WM- DP1 100V JP p/no K10003725

WM- NP1 110- 120V US p/no K10000285 WM- DP1 110- 120V US p/no K10003726

WM- NP1 220- 240V UK A/S p/no K10000286 WM- DP1 220- 240V UK A/S p/no K10003727

WM- NP1 220- 240V EU p/no K10000287 WM- DP1 220- 240V EU p/no K10003728

WM- NP1 220- 240V ROW p/no K10000288 WM- DP1 220- 240V ROW p/no K10003729

WM- NP1 220- 240V EU- A/S p/no K10004412

WM- NP1 A/S p/no K10004537

WM- WP1 100V JP p/no K10001332

WM- WP1 110-120V US p/no K10001333

WM- WP1 220- 240V UK A/S p/no K10001334

WM- WP1 220- 240V EU p/no K10001335

WM- WP1 220- 240V ROW p/no K10001336

WM- WP1 220- 240V EU- A/S p/no K10004413

WM- WP1 A/S p/no K10004538

Item Description Part No Qty

1 MAJ--173 TRANSFORMER WM--T1 100V .............. K10006316 1 -- Packaged

K10000289 1 -- JP

MAJ--174TRANSFORMER ........................ K10006317 1 -- Packaged

K10000290 1 -- US

MAJ--175 TRANSFORMER WM--T1 220--240V .......... K10006318 1 -- Packaged

K10000291 1 -- UK, EU,ROW

BALLAST WEIGHT ASSEMBLY ...................... K10004504 1 -- N, NS

2 REMOTE SWITCH WM--260 ASSY ................... K7504585 1 -- V

3 CASTOR--FREE ................................. -- 2 -- L,BB

CASTOR--FREE(ANTISTATIC) ...................... K10004419 2 -- N,P, U, BB

4 CASTOR--BRAKED ............................... -- 2 -- M,BB

CASTOR--BRAKED (ANTISTATIC) .................... K10004420 2 -- N,P, T, BB

5 WASHERCASTOR5mmTHICK ..................... K7505795 4 -- L, M

6 HANDKNOB BLACK M6 K3921470 1 --

7 WASHER M6 K3921292 1 --

8 SCOPE POLE CLAMP P1 SERIES K7506327 1

9SPARE

10 PLATESSUPPORTWM--DP1 ...................... K10006102 NP1--2. DP1--3 -- --

11 BUMPERCORNERWRAP ......................... K10001042 4 -- --

12 NUTSTRIPP1SERIES............................ K10000089 4 -- --

13 RUNNER--SCOPE POLE P1 SERIES ................. K10008227 8 -- --

14 TOPTRAYWM--NP1SERIES ....................... K10000088 1 -- NP1, Z

TOPTRAYWM--WP1SERIES....................... K10003423 1 -- WP1

TOPTRAYWM--DP1SERIES ....................... K10005448 1 -- DP1

15 SUPPORTTOPTRAYWIDE........................ K10001312 1 -- WP1

16 INSERT ROUND RIBBED ......................... K10003374 1 -- --

Torque

Remarks

spare JP

spare US

spare UK, EU,

ROW

WM--P1 SERIES WORKSTATIONS

Page 33 of 76

Issue 20 : July 2012

Page 34

Item Description Part No Qty

17 BLANKINGCAPCABLEPORTWM--260 ............... K7503929 -- -- C

18 BLANKINGCAPMONITORWM--260.................. K7504466 -- -- C

19 BLANKINGCAPSCOPEPOLEWM--260............... K7504468 -- -- C

20 CONNECTORHOLDERBRACKET ................... K10001392 1 -- W

21 CONNECTORHOLDERWM--P1SERIES .............. K10000054 2 -- W

22 SHELFWM--NP1SERIES.......................... K10000203 2 -- R, NP1, DP1

SHELFWM--WP1SERIES ......................... K10001307 2 -- S, WP1,DP1

23 CORNERBUFFER--SHELFR/H .................... K10001123 2 -- R, S

24 CORNERBUFFER--SHELFL/H..................... K10001124 2 -- R, S

25 WATERBOTTLEBRACKET ........................ K7503823 1 -- --

26 REARDOORWM--NP1SERIES ..................... -- 1 -- H

REARDOORWM--WP1SERIES..................... -- 1 -- J

27 LATCHSPAREFORWM--*P1RANGE ............... K10016172 1 -- H, J

28 RETAINERCABLECO--EXTRUSION ................. K7506066 2 -- --

29 CABLEHANGER--WITHPIN ....................... K10001377 -- -- C

30 SPARE

31 SPARE

32 CABLETIEMOUNTINGCRADLE .................... K10003392 6 -- --

33 CABLE CLIP RELEASABLE NYLON .................. 3920309 NP1, WP1--6.

DP1--14

34 CABLE TIE REL 4.8W x 200L BLACK ................. K3921530 -- -- C

35 SPARE

36 SCREWM8x16HEXSKTCAPHD .................. K3921515 NP1, WP1--8.

DP1--16

37 SCREWM6x25HEXSKTBUTTHD ................. 3920369 2 6Nm W

38 SCREWM6x12HEXSKTBUTTHD ................. 3920326 NP1--2

WP1--6

39 SCREWM6x20THREADFORMING PANHD ......... K10006549 8 -- DP1

40 SCREWM6x35HEXSKTBUTTHD ................. 3050858 2 2Nm --

41 SCREW 4.2 x 32 POZI PAN HD SELF TAPPING ......... K3921389 2 -- --

42 SCREW M6 x 12 SELF TAPPING .................... K10003437 2 -- --

43 WASHER24OD................................. K3921536 8 -- R, S

44 SPARE

45 WASHERM8 ................................... 3920372 10, DP1--15 -- Y

46 SCOPE POLE CLAMP ASSEMBLY .................. K10006167 2 -- --

47 WASHERM6 ................................... 3920333 4, DP1--14 -- W

48 WASHERM4 ................................... 3072461 2 -- --

49 WASHERCRINKLEM8 ........................... K3920997 NP1, WP1--14,

DP1--31

50 WASHERCRINKLEM6 ........................... 3072622 NP1, WP1--6

DP1--16

51 NUTM6 ....................................... 3920335 10 -- DP1

52 NUTM8NYLOCST.ST............................ K10006624 4 15Nm --

53 SPARE

54 FOOTSELFADHESIVE ........................... 3116247 2 -- --

Torque

-- R , S

15Nm R, S

-- A , B

-- R , S , Y

-- W

Remarks

WM--P1 SERIES WORKSTATIONS

Page 34 of 76

Issue 20 : July 2012

Page 35

Item Description Part No Qty

55 FOOTPUSH--IN ................................. K10003425 NP1, WP1--2

DP1--4

56 POWERCABLEUNIVERSALIEC3200.8M............. K3921014 -- -- C

57 POWERCABLEUNIVERSALIEC320................. K3921015 -- -- JP, UK, EU,C

58 POWER CABLE JAPAN HOSP GRADE -- IEC320.C19 ..... K10001001 1 -- JP

POWERCABLEU.S. ............................ K10001002 1 -- US

CABLE U.K. 13A -- IEC320.C19 K10001003 1 -- UK

POWER CABLE SCHUKO -- IEC320.C19 ............... K10001004 1 -- EU

POWER CABLE FLYING LEADS -- IEC320.C19 .......... K10001005 1 -- ROW

59 SPARE

60 LOCTITE243 ................................... 3001857 A//R -- L, M

61 SPARE

62 SPARE

63 L--WRENCHBALLDRIVE6MMA/F................... K3921444 1 -- C, R, S

64 INSTRUCTIONS WM--P1 SERIES JP ................ K10000545 1 -- JP

INSTRUCTIONS WM--P1 SERIES ................... K10003436 1 -- US, UK, EU,

INSTRUCTIONS WM--P1 SERIES A/S ................. K10004838 1 -- N, P

INSTRUCTIONS WM--DP1 ......................... K10005955 1 -- US, UK, EU,

65 WARRANTY CARD (JAPANESE) .................... 5041015 1 -- JP

66 NYLONCABLETIE .............................. 3006026 1 -- --

67 JETNUTM6SINGLENUTPLATE .................... 3920573 4 -- W

68 CABLEUNIVERSALIEC2.5M ...................... K10000449 1 -- WP1 E, G

69 SPARE

70 SPARE

71 SPARE

72 SPARE

73 SPARE

74 SPARE

75 SCREWM8x25HEXSKTBUTTHD ................. K10003945 NP1, WP1--6.

DP1--9

77 SCREW4.2x12.7POSIPANST .................... K10004107 4 2.2Nm --

78 P--CLIPID4.8NYLONBLACK ...................... K10001199 4 -- --

79 VELCRO20mmONEWRAPBLACK .................. K10003972 0.46 -- --

80 SUCTIONTUBECLIPS ........................... K3921393 10 -- JP, C

81 ADAPTORCABLEIEC--JAPAN/U.S. .................. K3921594 2 -- JP, C

82 INSTRUCTIONS FOR USE MAJ--150 ................ K5070401 1 -- C

83 GROMMET22.2MMCABLEHOLE .................. K10005673 1 -- DP1

84 SPARE

85 SPARE

86 SCREWM6x10HEXSKTBUTTHD ................. K3921284 NP1, WP1--4

DP1--6

88 LABEL -- CAUTION ANTI S TATIC .................... K10004445 NP1, WP1--5

DP1--10

Continued

Torque

-- H , J

-- --

-- --

-- N , P

Remarks

ROW

ROW

WM--P1 SERIES WORKSTATIONS

Page 35 of 76

Issue 20 : July 2012

Page 36

Item Description Part No Qty

89 ACCESSORY KIT FOR WM--NP1 UK EU ROW .......... K10004462 1 -- --

CABLE HANGER -- WITH PIN K10001377 3 -- --

CABLE UNIVERSAL IEC 320 0.8M K3921014 5 -- --

CABLE UNIVERSAL IEC 320 K3921015 1 -- --

INSTRUCTIONS WM--P1 SERIES ENG K10003436 1 -- --

ACCESSORY KIT FOR WM--WP1 UK,EU,ROW ......... K10004466 1 -- --

CABLE HANGER -- WITH PIN K10001377 2 -- --

CABLE UNIVERSAL IEC 320 0.8M K3921014 3 -- --

CABLE UNIVERSAL IEC 320 K3921015 5 -- --

CABLE UNIVERSAL IEC 320 M--FEM 2.5m K10000449 2 -- --

INSTRUCTIONS WM--P1 SERIES ENG K10003436 1 -- --

ACCESSORY KIT WM--NP1 100V JP ................ K10004488 1 -- --

CABLE HANGER -- WITH PIN K10001377 2 -- --

CABLE UNIVERSAL IEC 320 0.8M K3921014 3 -- --

CABLE UNIVERSAL IEC 320 K3921015 4 -- --

INSTRUCTIONS WM--P1 SERIES JP K10000545 1 -- --

SUCTION TUBE CLIPS K3921393 10 -- --

ADAPTOR CABLE IEC--JAPAN/U.S. K3921594 1 -- --

INSTRUCTIONS FOR USE MAJ--150 K5070401 2 -- --

ACCESSORY KIT WM--NP1 100V--120V US ........... K10004489 1 -- --

CABLE HANGER -- WITH PIN K10001377 2 -- --

CABLE UNIVERSAL IEC 320 0.8M K3921014 3 -- --

CABLE UNIVERSAL IEC 320 K3921015 5 -- --

ADAPTOR CABLE IEC--JAPAN/U.S. K3921594 2 -- --

INSTRUCTIONS WM--P1 SERIES ENG K10003436 1 -- --

INSTRUCTIONS FOR USE MAJ--150 K5070401 2 -- --

ACCESSORY KIT 1332 WM--WP1 100V JP ............ K10004498 1 -- --

CABLE HANGER -- WITH PIN K10001377 2 -- --

CABLE UNIVERSAL IEC 320 0.8M K3921014 3 -- --

CABLE UNIVERSAL IEC 320 K3921015 5 -- --

INSTRUCTIONS WM--P1 SERIES JP K10000545 1 -- --

SUCTION TUBE CLIPS K3921393 10 -- --

ADAPTOR CABLE IEC--JAPAN/U.S. K3921594 2 -- --

INSTRUCTIONS FOR USE MAJ--150 K5070401 1 -- --

CABLE UNIVERSAL IEC 320 M--FEM 2.5m K10000449 1 -- --

ACCESSORY KIT 1333 WM--WP1 110--120V US ........ K10004499 1 -- --

CABLE HANGER -- WITH PIN K10001377 2 -- --

CABLE UNIVERSAL IEC 320 0.8M K3921014 3 -- --

CABLE UNIVERSAL IEC 320 K3921015 5 -- --

INSTRUCTIONS WM--P1 SERIES ENG K10003436 1 -- --

ADAPTOR CABLE IEC--JAPAN/U.S. K3921594 2 -- --

INSTRUCTIONS FOR USE MAJ--150 K5070401 2 -- --

CABLE UNIVERSAL IEC 320 M--FEM 2.5m K10000449 2 -- --

Continued

Torque

Remarks

WM--P1 SERIES WORKSTATIONS

Page 36 of 76

Issue 20 : July 2012

Page 37

Item Description Part No Qty

ACCESSORY KIT FOR WM--N/WP1 (NON--TX) .......... K10004791 1 -- --

CABLE HANGER -- WITH PIN K10001377 2 -- --

INSTRUCTIONS WM--P1 A/S K10004834 1 -- --

ACCESSORY KIT FOR WM--NP1 EU--A/S ............. K10004832 1 -- --

CABLE HANGER -- WITH PIN K10001377 2 -- --

CABLE UNIVERSAL IEC 320 0.8M K3921014 3 -- --

CABLE UNIVERSAL IEC 320 K3921015 5 -- --

INSTRUCTIONS WM--P1 A/S K10004834 1 -- --

ACCESSORY KIT FOR WM--WP1 EU--A/S ............. K10004833 1 -- --

CABLE HANGER -- WITH PIN K10001377 2 -- --

CABLE UNIVERSAL IEC 320 0.8M K3921014 3 -- --

CABLE UNIVERSAL IEC 320 K3921015 5 -- --

CABLE UNIVERSAL IEC 320 M--FEM 2.5m K10000449 2 -- --

INSTRUCTIONS WM--P1 A/S K10004834 1 -- --

ACCESSORY KIT FOR WM--DP1 UK EU ROW .......... K10005985 1 -- --

BLANKING CAP CABLE PORT WM--260 K7503929 2 -- --

BLANKING CAP MONITOR WM--260 K7504466 1 -- --

CABLE HANGER -- WITH PIN K10001377 2 -- --

CABLE UNIVERSAL IEC 320 K3921015 4 -- --

CABLE UNIVERSAL IEC 320 M--FEM 2.5m K10000449 4 -- --

INSTRUCTIONS WM --DP1 ENG K10005955 1 -- --

BLISTER PACK ASSY WM--P1 K10006169 1 -- --

BLANKING CAP CABLE PORT WM--260 K7503929 2 -- --

BLANKING CAP MONITOR WM--260 K7504466 2 -- --

BLANKING CAP SCOPE POLE WM--260 K7504468 2 -- --

CABLE TIE REL 4.8Wx200L BLACK K3921530 6 -- --

L--WRENCH BALL DRIVE 6MM A/F K3921444 1 -- --

ACCESSORY KIT WM--DP1 110-- 120V US ............. K10005986 1 -- --

BLANKING CAP CABLE PORT WM--260 K7503929 2 -- --

BLANKING CAP MONITOR WM--260 K7504466 1 -- --

CABLE HANGER -- WITH PIN K10001377 2 -- --

CABLE UNIVERSAL IEC 320 K3921015 4 -- --

INSTRUCTIONS WM --DP1 ENG K10005955 1 -- --

ADAPTOR CABLE IEC--JAPAN/U.S. K3921594 2 -- --

INSTRUCTIONS FOR USE MAJ--150 K5070401 1 -- --

CABLE UNIVERSAL IEC 320 M--FEM 2.5m K10000449 4 -- --

BLISTER PACK ASSY WM--P1 K10006169 1 -- --

BLANKING CAP CABLE PORT WM--260 K7503929 2 -- --

BLANKING CAP MONITOR WM--260 K7504466 2 -- --

BLANKING CAP SCOPE POLE WM--260 K7504468 2 -- --

CABLE TIE REL 4.8Wx200L BLACK K3921530 6 -- --

L--WRENCH BALL DRIVE 6MM A/F K3921444 1 -- --

Torque

Remarks

Continued

WM--P1 SERIES WORKSTATIONS

Page 37 of 76

Issue 20 : July 2012

Page 38

Item Description Part No Qty

90 SPARE

91 NUTM8DOMEDNATURALNYLON .................. K10006640 1 -- DP1

92 SPACER18MMODx8.2MMIDx5MMLG ............. K10006641 1 -- DP1

93 LIMITER--FRONT(MAJ--181)...................... K10007121 1 -- DP1, Y

94 LIMITER REAR (MAJ--181) ......................... K10007122 2 -- Y

95 SCREWM8x50SKTCAPHD ...................... 3050998 2 -- Y

96 PAINT -- WHITE KEYMED SPEC 74 .................. K10006564 400ML -- --

97 PAINT -- LILAC KEYMED SPEC 76 ................... K10006565 400ML -- --

REMARKS

A Tighten to 4Nm when used to secure item 15, Support Top Tray. Ref figure 6--1

B Tighten to 6Nm when used to secure item 25, Water Bottle Bracket. Ref figure 6--3

C Supplied in ACCESSORY KIT WM--NP1 100V JP K10004488

D Supplied in ACCESSORY KIT WM--NP1 100V--120V US K10004489

E Supplied in ACCESSORY KIT 1332 WM--WP1 100V JP K10004498

F Supplied in ACCESSORY KIT 1333 WM--WP1 110--120V US K10004499

G Supplied in ACCESSORY KIT FOR WM--WP1 UK,EU,ROW K10004466

H Supplied in REAR PANEL KIT WM--NP1 K10005044

J Supplied in REAR PANEL KIT WM--WP1 K10005045

L Supplied in FREE CASTOR KIT -- WM--P1 SERIES ( NON A/S ) K10004627

M Supplied in BRAKED CASTOR KIT ( NON A/S ) K10004626

N Used on WM--NP1 A/S & WM--WP1 A/S ( and all UK after Oct 07)

P Used on WM--NP1 220--240V EU--A/S & WM--WP1 220--240V EU--A/S (and all UK after Oct 07)

R Supplied in MAJ--198 WM--NP1 SHELF KIT (NARROW) K10001429

S Supplied in MAJ--199 WM--WP1 SHELF KIT (WIDE) K10001430

T Supplied in CASTOR BRAKED KIT WM--P1 SERIES A/S K10005040

U Supplied in CASTOR FREE KIT WM--P1 SERIES A/S K10005041

V Supplied in REMOTE SWITCH KIT WM--P1 SERIES K10005049

W Supplied in UMIBILICAL/CAMERA HEAD HOLDER KIT K10006648

Y Supplied in LIMITER -- MOVEMENT ( MAJ--181 ) K10007108 Contents :--

93/1LIMITERFRONT(MAJ--181) .................... K10007121

93/2LIMITERREAR(MAJ--181)...................... K10007122

93/3SCREWM8x50 .............................. 3050998

93/4WASHERCRINKLEM8 ......................... K3920997

93/5WASHERM8................................. 3920372

93/6 INSTRUCTIONS LIMITERS FOR MAJ-- 181 ........... K10008095

Z Early models of WM--NP1 were fitted with a ’Support T op Tray’ ( item 15). On later models a redesigned top tray reduced

the support required to; 2, PLATES SUPPORT WM--DP1, item 10, p/no K10006102.

The early model top tray is no longer available and a current top tray and plates support must be used. The ’Support Top

Tray’ ( item 15) cannot be used and should be discarded.

AA Oct 2007 -- all UK workstations now supplied fitted with antistatic castors.

BB Refer to Chapter 6.6 for torque tightening figures.

NS Not Shown

Torque

Remarks

WM--P1 SERIES WORKSTATIONS

Page 38 of 76

Issue 20 : July 2012

Page 39

Chapter 8 Accessories Illustrated Parts List

Table of Contents

8.1 MAJ--155 Universal display arm --LCD 40.....................................

8.2 MAJ--179 Keyboard tray sliding 41..........................................

8.3 MAJ--180 Keyboard arm -- side mounted 43...................................

8.4 MAJ--181 LCD monitor arm 45............................................

8.5 MAJ--183 Scope pole kit 48...............................................

8.6 MAJ--185 Universal stowage container 49....................................

8.7 MAJ--187 IV pole kit 50..................................................

8.8 MAJ--188 / MAJ--1614 CO

8.9 MAJ--190 Equipment support rail 52.........................................

8.10 MAJ--192 Side shelf 53..................................................

8.11 MAJ--195 Cable retaining hook 53..........................................

8.12 MAJ--193, 194, 1611 & 1612 Lockable drawer 54...............................

8.13 MAJ--196 Rear/front panel kit 56...........................................

8.14 MAJ--198 WM--NP1 Shelf kit (Narrow)

MAJ--199 WM--WP1 Shelf kit (Wide) 57......................................

8.15 MAJ--1600 14” CRT bracket kit

MAJ--1601 14” CRT bracket kit wide

MAJ--1602 20” CRT bracket kit wide 58......................................

8.16 MAJ--1609 LCD Arm --adjustable 59........................................

8.17 MAJ--1610 LCD Manoeuvring handle 61.....................................

8.18 MAJ--1613 Universal display arm (CRT) 62....................................

8.19 MAJ--1620 14” CRT mount (Narrow)

MAJ--1621 20” CRT mount (Narrow)

MAJ--1622 14” CRT mount (Wide)

MAJ--1623 20” CRT mount 64.............................................

8.20 MAJ--1624 Nurses control panel arm 66......................................

8.21 MAJ--1625 EUM30 keyboard 67...........................................

8.22 MAJ--1626 EUS arm mount 68............................................

8.23 MAJ--1627 EU--C60\200 shelf kit 69.........................................

8.24 MAJ--1628 Nurses control panel arm 71......................................

8.25 MAJ--1630 Video/Scope cable bracket 73.....................................

8.26 MAJ--1631 Plug block kit -- EU 74..........................................

8.27 MAJ--1635 MAJ--1635 EUS Connector holder 75...............................

cylinder bracket kit 51..............................

2

Page

WM--P1 SERIES WORKSTATIONS

Page 39 of 76

Issue 20 : July 2012

Page 40

8 ILLUSTRATED PARTS LIST - ACCESSORIES

8.1 MAJ- 155 UNIVERSAL DISPLAY ARM - LCD

FIGURE 8-1

5

26

23

24

2

2

2

27

4

13

33

9

15

MAJ- 155 UNIVERSAL DISPLAY ARM - LCD p/no K7505210

Item Description Part No Qty

1 BRACKET--UNIVERSALDISPLAYLCD ................... K7505259 1 -- --

2--4 SPARE

5 MAJ--132LCDBRACKET ............................. K7504769 1 -- --

6SPARE

7 BOLTCOACHM10x75L ............................. K3921545 1 -- A, NS

8SPARE

9 FOOT ........................................... 3021521 1 -- --

10, 11 SPARE

12 NUTNORMALM10 ................................. 3038564 1 -- A, NS

13 M10PROTECTIONCAP.............................. K3921359 1 -- --

14 CABLE TIE RELEASABLE ............................ K3921530 4 -- NS

15 HANDLE ADJUSTABLE LEVER FEMALE .................. K3921195 1 -- A

16--19 SPARE

20 WASHERPLAINM10 ................................ K3921197 1 -- A, NS

21 WASHERBELVILLE ................................. K3921196 1 -- A, NS

22 WASHER--CORKLCD .............................. K7504371 2 -- A, NS

23 WASHERM6SINGLECOIL ........................... 3072771 6 -- --

24 WASHERM6 ...................................... 3117138 6 -- --

25 SPARE

26 SCREWM6x25HEXSKTBUTTHD .................... 3920369 6 -- --

27 SCREWM4x10PHILLIPSFLANGEPANHD .............. K3921655 4 -- --

28 SPARE

29 ALLENKEY4MMA/FSHORT.......................... 3066011 1 -- NS

30 INSTRUCTIONS FOR MAJ--155 (ENG) ................... K5070429 1 -- NS

31 SPARE

33 LABEL--CAUTION ARM .............................. K7505319 1 -- --

Remarks

NS Not shown

A Used on REPAIR KIT TILT FOR MAJ--132 p/no K7504865

MAJ--155 UNIVERSAL DISPLAY

ARM -- LCD

26

26Nm

23

2

24

2

1

Torque

AlsoprintedinWM--SC/TI--3

Remarks

WM--P1 SERIES WORKSTATIONS

Page 40 of 76

Issue 20 : July 2012

Page 41

8.2 MAJ- 179 KEYBOARD TRA Y SLIDING

30

REMARK

B

42

33

3

3

3

FIGURE 8-2

MAJ--179 KEYBOARD TRAY SLIDING

6

10

34

2

36

2

7

38

2

29

2

22

2

2

28

28Nm

25

5

WM--P1 SERIES WORKSTATIONS

Page 41 of 76

Issue 20 : July 2012

Page 42

MAJ- 179 KEYBOARD TRA Y SLIDING p/no K10001121

Item Description Part No Qty

1 RUNNER SUPPORT -- KEYBOARD ....................... K10001405 2 -- --

2 TRAY -- SLIDI NG KEYBOARD ........................... -- 1 -- A

3 IPF KEYBOARD DRAWER RUNNER ...................... K10003486 2 -- --

4&5 SPARE

6 KEYBOARD TRAY -- SLIDING ........................... -- 1 -- A

7 KEYBOARD CLAMP .................................. K10001122 1 -- --

8&9 SPARE

10 FINGERPULL ...................................... K7502154 1 -- --

11 SPARE

12 SPARE

13 to 20 SPARE

21 SPARE

22 THUMBSCREWM4x10L ............................ 3059375 2 -- --

23 & 24 SPARE

25 FOOTSELFADHESIVEDIA12.7 ........................ 3116247 5 -- --

26 SPARE

27 SPARE

28 SCREW SELF TAPPING 8 LG PAN HD POZI ................ K3921297 2 8Nm --

29 WASHERM4SINGLECOIL ............................ K10000038 2 -- --

30 SCREWM6x12HEXSKTBUTTHD ..................... 3920326 9 -- --

31 & 32 SPARE

33 WASHERM6 ....................................... 3920333 9 -- --

34 WASHERM3 ....................................... 3071227 2 -- --

35 SPARE

36 WASHERM3SINGLECOIL ............................ K10000037 2 -- --

37 SPARE

38 WASHERM4 ....................................... 3071219 2 -- --

39 SPARE

40 SPARE

41 WASHERM6SINGLECOIL ............................ 3072771 6 -- --

42 WASHERM6CRINKLE ............................... 3072622 3 -- --

43 INSTRUCTIONS FOR MAJ--179 ........................ K10003489 1 -- NS

44 SPARE

45 ALLENKEY4MMA/FSHORT........................... 3066011 1 -- NS

46 SPARE

47 SPARE

48 SPARE

49 NYLON CABLE TIE 140MM LG COLOUR WHITE ............ 3006042 1 -- --

Torque

Remarks

Remarks

NS Not shown

A Repair by replacing whole accessory .

B Supplied in Replacement Keyboard Tray Kit WM--P1 Series p/no K10004900. Reuse fixings 30, 42 & 33.

WM--P1 SERIES WORKSTATIONS

Page 42 of 76

Issue 20 : July 2012

Page 43

8.3 MAJ- 180 KEYBOARD ARM - SIDE MOUNTED

33

3

3

12

41

3

19

FIGURE 8-3

MAJ--180 KEYBOARD ARM --

SIDE MOUNTED

3

21

6

1

13

30

C

36Nm

41

3

7

33

3

29

6

9

20

33

4

41

46Nm

4

13

20

2

22

2

39

2

38

2

WM--P1 SERIES WORKSTATIONS

Page 43 of 76

Issue 20 : July 2012

Page 44

MAJ- 180 KEYBOARD ARM - SIDE MOUNTED p/no K10001112

Item Description Part No Qty

1 KEYBOARD ARM ASSY (MAJ--180) ..................... K10004899 1 -- --

2 DROP DOWN MECHANISM (MAJ--180) K10004898 1 -- --

3SPARE

4SPARE

5SPARE

6 KEYBOARD TRAY ................................... K10022407 1 -- C

7 KEYBOARD CLAMP ..................................

8SPARE

9

KEYBOARD LABEL ARM .............................. K10022378 1 -- B

10 SPARE

11 SPARE

1

2 SCREWM6x20HEXSKTBUTTHD ..................... K10001098 3 -- A

13 ARM STOP LABEL ................................... K10003740 2 -- A

19 SPRINGNUTM6 .................................... K7503840 3 -- A

20 M10PROTECTIONCAP............................... K3921359 2 -- A

21 NYLON CABLE TIE 140MM LG .......................... 3006042 6 -- A

22 THUMBSCREWM4x10L ............................ 3059375 2 -- C

23 & 24 SPARE

25 SPARE

26 & 27 SPARE

28

SPARE

29 SCREWM6x16HEXSKTBUTTHD ..................... 3109704

30 SCREWM6x10HEXSKTBUTTHD ..................... K10003509 3 6Nm B, C

31 & 32 SPARE

33 WASHERM6 ....................................... 3920333 10 -- A, B, C

34 SPARE

36 SPARE

37 SPARE

3

8 WASHERM4 ....................................... 3071219 2 -- C

39 WASHERM4SINGLECOIL ............................ K10000038 2 -- C

40 SPARE

41 WASHERCRINKLEM6 ............................... K3921473 10 -- A, B, C

43 INSTRUCTION MAJ--180 KEYBOARD ARM ................ K10003419 1 -- NS

44 ALLENKEY4MMA/FSHORT........................... 3066011 1 -- NS

K10022413 1 -- C

4 6Nm A, B

Torque

Remarks

Remarks

NS Not shown

A Used in item 1 -- Keyboard Arm Assy (MAJ--180) -- K10004899

B Used on Drop Down Mechanism (MAJ--180) item2. Washer Item 33 qty 7. Washer Item 41 qty 7.

C Used in Replacement Keyboard Tray Kit K10004900

WM--P1 SERIES WORKSTATIONS

Page 44 of 76

Issue 20 : July 2012

Page 45

8.4 MAJ- 181 LCD MONITOR ARM

30

FIGURE 8-4

MAJ--181 LCD MONITOR ARM

73

55

38

32

42.5Nm

50

4

4

44

12

23

58

43

72

23

24

34

55

73

60

6

4

23

51

61

6

27

28

6

6

23

22

75

2

70

A/R

6

23

90

20

LIMITER -- MOVEMENT (MAJ--181)

SUPPLIED WITH WM-- DP1

WORKSTATION

REFER TO ILLUSTRATED PARTS

LIST PAGE 7--1 & 7--11

1

WM--P1 SERIES WORKSTATIONS

Page 45 of 76

Issue 20 : July 2012

Page 46

MAJ- 181 LCD MONITOR ARM p/no K10001017

Item Description Part No Qty

1 CLAMPSUPPORTTUBE .............................. K10000091 1 -- --

2to5 SPARE

6 ADAPTOR PLATE VESA MOUNT ........................ K10001013 1 -- --

7to11 SPARE

12 WASHER--CORKLCD ............................... K7504371 2 -- A

13 to 19 SPARE

20 PIPEPIN .......................................... K10005669 1 -- --

21 SPARE

22 INDEXINGPLUNGER................................. K10001020 2 10 Nm --

23 HOLEPLUG........................................ K10001021 5 -- --

24 WASHERNYLON.................................... K10001022 2 -- --

25 & 26 SPARE

27 CABLETIEMOUNTM6 ............................... K10001109 6 -- --

28 CABLE TIE RELEASABLE ............................. K3921530 6 -- --

29 SPARE

30 HANDLE ADJUSTABLE LEVER .......................... K3921195 1 -- A

31 SPARE

32 NUTM4 .......................................... K3920728 4 2,5 Nm --

33 SPARE

34 NUTNORMALM10 .................................. 3038564 1 15 Nm A

35 SPARE

36 & 37 SPARE

38 WASHERM4 ....................................... 3072461 4 -- --

39 to 42 SPARE

43 WASHERM10 ...................................... K3920994 2 -- --

44 WASHERM10 ...................................... K3921197 1 -- A

45 to 49 SPARE

50 WASHERM4SINGLECOIL ............................ K10000038 4 -- --

51 WASHERCRINKLEM6 ............................... 3072622 6 -- --

52 to 54 SPARE

55 WASHERBELVILLE .................................. K3921196 3 -- A

56 & 57 SPARE

58 BOLTCOACHM10 .................................. K3921545 1 -- A

59 SPARE

60 SCREWM4PHILIPSFLANGEPANHD................... K3921581 4 -- --

61 SCREWM6x12TORX TAPTITESTLZNPL ............... K10015230 6 -- --

62 to 69 SPARE

70 LABEL--OLYMPUS ................................... K1000341 1 2 -- --

71 SPARE

72 LABEL--CAUTION .................................... K10003413 2 -- --

73 LABEL--WARNING TRIANGLE .......................... K10003463 2 -- --

74 SPARE

continued overleaf

Torque

Remarks

WM--P1 SERIES WORKSTATIONS

Page 46 of 76

Issue 20 : July 2012

Page 47

MAJ- 181 LCD MONITOR ARM p/no K10001017...continued

Item Description Part No Qty

75 ADHESIVELOCTITE243 ............................. 3001857 A/R -- --

76 SPARE

77 SPANNER7mmA/Fx80mm ........................... K10007298 1 -- N/S

78 to 80 SPARE

81 SPARE

82 INSTRUCTIONS MAJ-- 181 LCD ARM ..................... K10003454 1 -- N/S

83 to 85 SPARE

86 SPARE

87 SPARE

88 CABLEUNIVERSALIEC2.5m .......................... K10000449 1 -- N/S

90 THUMBSCREWBLACKKNOBM4 ...................... K10013478 1 -- --

Torque

Remarks

NS Not shown

A Used on REPAIR KIT TILT FOR MAJ--132 p/no K7504865

Remarks

WM--P1 SERIES WORKSTATIONS

Page 47 of 76

Issue 20 : July 2012

Page 48

8.5 MAJ- 183 SCOPE POLE KIT

13

9

8

2

18

2

17

MAJ--183 SCOPE POLE KIT

2

3

10

FIGURE 8-5

28

22

A/R

1

MAJ- 183 SCOPE POLE KIT p/no K10000124

Item Description Part No Qty

1 POLESCOPE ...................................... -- 1 -- A

2 ARMSCOPE ....................................... -- 1 -- A

3 HANGERSCOPE.................................... -- 1 -- A

4 SCOPE HOLDER WELDED ASSY WM--260 ................ K7504161 2 -- --

5 SPACERSCOPEPOLEWM--260 ........................ K7504164 2 -- --

6 LOGO LH SCOPE HOLDER (WM--260) .................... K7504165 2 -- --

7 LOGO RH SCOPE HOLDER (WM--260) .................... K7504166 2 -- --

8 CABLEHANGER--WITHHOLE ......................... K10001376 1 -- --

9 PLUG30mmSQ1.5--2mmWALLBLACK................... K10004147 2 -- --

10 BUSHFLANGED .................................... K10000126 2 -- --

11 HANDLE LEVER .................................... K10000439 1 -- --

12 SCREWM5x50HEXSKTBUTTHD ..................... K3921288 4 -- --

13 SCREWM5x8HEXSKTBUTTHD ...................... 3109640 2 -- --

14 WASHERPLAINM6x25DIA 1.5THK .................... 3072720 1 -- --

15 WASHERSINGLECOILM6 ............................ 3072771 1 -- --

16 WASHERM6STSTEEL ............................... K3921292 1 -- --

17 WASHERM5 ....................................... 3117162 2 -- --

18 WASHERCRINKLEM5STST .......................... 3920499 6 -- --

19 FOOTSELFADHESIVEDIA12.7 ........................ 3116247 2 -- --

20 ALLENKEY3MMA/F ................................. 3066142 1 -- NS

21 SPARE

22 ADHESIVELOCTITE638 .............................. 3001067 A/R -- --

23 MAJ--183 INSTRUCTIONS FOR USE ..................... K10003415 1 -- NS

24 PLUGSCOPEPOLE ................................. K10003390 1 -- --

25 WASHER6.4x24x2NATURALNYLON6.6 ................ K10004146 1 -- --

2

1 1 25 22

10

29

15

4

2

5

2

19

2

2

14

9

12

18

2

16

A/R

Torque

6

7

Remarks

Remarks

NS Not shown

A Repair by replacing whole accessory .

WM--P1 SERIES WORKSTATIONS

Page 48 of 76

Issue 20 : July 2012

Page 49

8.6 MAJ- 185 UNIVERSAL STOWAGE CONTAINER

FIGURE 8-6

MAJ--185 UNIVERSAL STOWAGE CONTAINER

1

6

2

5

2

4

2

3

2

2

MAJ- 185 UNIVERSAL STOWAGE CONTAINER p/no K10001111

Item Description Part No Qty

1 UNIVERSALSTOWAGECONTAINER..................... K10000116 1 -- --

2 BRACKET--STOWAGECONTAINER ...................... K100001 17 1 -- --

3 SCREWM6x16HEXSKTBUTTHD ..................... 3109704 2 -- --

4 WASHERCRINKLEM6 ............................... K3921473 2 -- --

5 WASHERM6STSTEEL ............................... K3921292 2 -- --

6 SPRINGNUTM6 .................................... K7503840 2 -- --

7 ALLENKEY4MMA/FSHORT........................... 3066011 1 -- NS

8SPARE

9SPARE

10 MAJ--185 INSTRUCTIONS FOR USE ..................... K10002789 1 -- NS

11 SPARE

Torque

Remarks

REMARKS

NS Not Shown

WM--P1 SERIES WORKSTATIONS

Page 49 of 76

Issue 20 : July 2012

Page 50

8.7 MAJ- 187 IF POLE KIT

FIGURE 8-7

1

4

MAJ--187 IV POLE KIT

3

MAJ- 187 IV POLE KIT p/no K10001110

Item Description Part No Qty

1 IVHANGER(PAINTED) ............................... -- 1 -- A

2 POLESCOPE ...................................... -- 1 -- A

3 CABLEHANGER--WITHHOLE ......................... -- 1 -- A

4 GRUBSCREW M6 x 6 KNURLED CUP PT .................. K10001060 1 -- --

5 ALLENKEY3MMA/F ................................. 3066142 1 -- NS

6SPARE

7SPARE

8 MAJ--187 INSTRUCTIONS FOR USE ..................... K10002785 1 -- NS

2

Torque

Remarks

REMARKS

NS Not Shown

A Repair by replacing whole accessory.

WM--P1 SERIES WORKSTATIONS

Page 50 of 76

Issue 20 : July 2012

Page 51

8.8 MAJ- 188 / MAJ- 1614 CO2CYLINDER BRACKET KIT

2

6

4

5

7

4

3

3

4

4

4

MAJ--188 / 1614 CO

FIGURE 8-8

CYLINDER BRACKET

2

2

6

4

5

4

4

7

4

4

4

4

3

1

6

4

5

4

4

4

7

4

7

4

1

6

4

5

4

4

4

3

MAJ- 188

MAJ- 188 CO2HOLDER 205mm DIA p/no K10001113

MAJ- 1614 CO

Item Description Part No Qty

1 CRADLE CO2BOTTLE 205mm DIA ....................... -- 1 -- C

2 STRAP PLATE CO

3 CAMBUCKLESTRAP0,75mLONGBLACK ................. K10003981 2 -- A,B

4 SCREWM6HEXSKTBUTTHD ......................... 3920327 8 -- A,B

5 WASHERCRINKLEM6 ............................... K3921473 8 -- A,B

6 WASHERSTSTEELM6 ............................... K3921292 8 -- A,B

7 SPRINGNUTM6 .................................... K7503840 8 -- A,B

8 ALLENKEY4MMA/FSHORT........................... 3066011 1 -- A,B, NS

9 MAJ--188/1614 INSTRUCTIONS FOR USE ................. K10003501 1 -- A,B NS

HOLDER 140mm DIA MAX p/no K10003499

2

CRADLE CO

STRAP PLATE CO

BOTTLE 89--140mm DIA .................... -- 1 -- C

2

BOTTLE 205mm DIA .................. -- 1 -- C

2

BOTTLE 89--140mm DIA ................ -- 1 -- C

2

3

MAJ- 1614

Torque

Remarks

REMARKS

A K10001113 --MAJ--188 CO

B K10003499 -- MAJ--1614 CO

C Repair by replacing whole accessory.

NS Not Shown

WM--P1 SERIES WORKSTATIONS

HOLDER 205mm DIA MAX

2

HOLDER 140mm DIA MAX

2

Page 51 of 76

Issue 20 : July 2012

Page 52

8.9 MAJ- 190 EQUIPMENT SUPPORT RAIL

FIGURE 8-9

MAJ--190 EQUIPMENT SUPPORT RAIL

7

5

2

6

2

4

2

1

2

MAJ- 190 EQUIPMENT SUPPORT RAIL p/no K10001115

Item Description Part No Qty

1 ACCESSORY BAR ................................... -- 1 -- A

2 EQUIPMENTRAILCLAMP ............................. K10002819 2 -- --

3SPARE

4 SCREWM6x20HEXSKTBUTTHD ..................... K10001098 2 -- --

5 WASHERM6 ....................................... 3920333 2 -- --

6 WASHERCRINKLEM6 ............................... 3072622 2 -- --

7 SPRINGNUTM6 .................................... K7503840 2 -- --

8 ALLENKEY4MMA/FSHORT........................... 3066011 1 -- NS

9SPARE

10 SPARE

11 MAJ--190 INSTRUCTIONS FOR USE ..................... K10002820 1 -- NS

12 SPARE

Torque

Remarks

REMARKS

NS Not Shown

A Repair by replacing whole accessory.

WM--P1 SERIES WORKSTATIONS

Page 52 of 76

Issue 20 : July 2012

Page 53

8.10 MAJ- 192 SIDE SHELF

FIGURE 8-10

MAJ--192 SIDE SHELF

MAJ- 192 SIDE SHELF p/no K10001117

Item Description Part No Qty

1 SIDESHELFSCREENPRINTED ........................ K10001117 1 -- --

2 INSTRUCTIONS FOR USE MAJ --192 ..................... K10003583 1 -- NS

REMARKS

NS Not Shown

Torque

8.11 MAJ- 195 CABLE RETAINING HOOK

Remarks

FIGURE 8-11

MAJ--195 CABLE RETAINING HOOK

1

7

3

2

4

2

2

2

MAJ- 195 CABLE RETAINING HOOK p/no K10001120

Item Description Part No Qty

1 CABLEHANGERBRACKET ............................ K10001120 1 -- A

2 SCREWM6x12HEXSKTBUTTHD ..................... 3920326 2 -- --

3 WASHERM6 ....................................... 3920333 2 -- --

4 WASHERCRINKLEM6 ............................... 3072622 2 -- --

5 SPRINGNUTM6 .................................... K7503840 2 -- --

6 ALLENKEY4MMA/FSHORT........................... 3066011 1 -- NS

7 JETNUTM6SINGLENUTPLATE ........................ 3920573 2 -- --

8 MAJ--195 INSTRUCTIONS FOR USE ..................... K10002790 1 -- NS

REMARKS

A Repair by replacing whole accessory.

NS Not Shown

2

5

2

Torque

Remarks

WM--P1 SERIES WORKSTATIONS

Page 53 of 76

Issue 20 : July 2012

Page 54

8.12 MAJ- 193, 194, 1611 & 1612 LOCKABLE DRAWER

6

10

4

8

4

1

2

24

3

23

3

22

3

4

20

FIGURE 8-12

MAJ--193 & MAJ--194 LOCKABLE DRAWER

9

4

11

4

7

4

5

62Nm

6

MAJ--193

22

3

21

23

3

4

20

62Nm

8

10

4

6

6

4

4

25

3

2

2

9

4

11

4

7

4

1

20

2

24

3

3

6

5

62Nm

21

4

WM--P1 SERIES WORKSTATIONS

25

62Nm

20

MAJ--194

6

Page 54 of 76

Issue 20 : July 2012

Page 55

MAJ- 193 LOCKABLE DRAWER (STANDARD) p/no K10001118

MAJ- 194 LOCKABLE DRAWER (DEEP) p/no K10001119

MAJ- 1611 LOCKABLE DRAWER (WIDE) p/no K10001383

MAJ- 1612 LOCKABLE DRAWER WIDE DEEP p/no K10001384

Item Description Part No Qty

1 DRAWEROUTER ................................ -- 1 -- E

2 DRAWERSHALLOW--WELDED ...................... -- 1 -- E

3 SLIDETELESCOPIC .............................. K3920693 2 -- A, B, C, D

4 CAMLOCK 1335032A 2 KEY TO PASS ................. K3921294 1 -- A, B, C, D

5 NUTM4 ........................................ 3038114 6 -- A, B, C, D

6 NUTM5 ........................................ 3038410 4 -- A, B, C, D

7 SCREWM8x16HEXSKTCAPHD .................... K3921515 4 -- A, B, C, D

8 SCREWM5x12BUTTHDSKTST.ST .................. 3108601 4 -- A, B, C, D

9 WASHER24ODx8.4IDx2MMTHK ................... K3921536 4 -- A, B, C, D

10 WASHERM5 .................................... 3071286 4 -- A, B, C, D

11 WASHERCRINKLEM8 ............................ K3920997 4 -- A, B, C, D

12 8--10MMOPENENDEDSPANNER .................... K3921063 1 -- A, B, C, D, NS

13 L--WRENCHBALLDRIVE6MMA/F.................... K3921444 1 -- A, B, C, D, NS

14 ALLENKEY3MMA/F .............................. 3066142 1 -- A, B, C, D, NS

15 I N STRUCTIONS MAJ193--194 & 1611--1612 ............. K10003550 1 -- A, B, C, D, NS

16 SPARE

17 SPARE

18 LABEL INSERT .................................. K5070306 1 -- A, B, C, D, NS

19 I NSTRUCTION MAJ193,194,1611,1612 JP ............... K10003589 1 -- A, B, C, D, NS

20 WASHERCRINKLEM4 ............................ 3920332 12 -- A, B, C, D

21 FINGERPULL ................................... K7502154 1 -- A, B, C, D

22 WASHERM3 .................................... 3071227 3 -- A, B, C, D

23 WASHERM3SINGLECOIL ......................... K10000037 3 -- A, B, C, D

24 SCREW SELF TAPPING DIA 3x8LG PAN HD POZI ........ K3921297 3 -- A, B, C, D

25 SCREWM4x612.9HEXSKTBUTHD.................. 3109135 6 -- A, B, C, D

Torque

Remarks

REMARKS

A Used on MAJ--193 LOCKABLE DRAWER (STANDARD) p/no K10001118

B Used on MAJ--194 LOCKABLE DRAWER (DEEP) p/no K10001119

C Used on MAJ--1611 LOCKABLE DRAWER (WIDE) p/no K10001383

D Used on MAJ--1612 LOCKABLE DRAWER WIDE DEEP p/no K10001384

E Repair by replacing whole accessory

NS Not Shown

WM--P1 SERIES WORKSTATIONS

Page 55 of 76

Issue 20 : July 2012

Page 56

8.13 MAJ- 196 REAR/FRONT PANEL KIT

2

7

10

4

4

FIGURE 8-13

MAJ--196

1

5

REAR/FRONT

PANEL K I T

9

7

8

10

4

4

4

4

8

4

4

3

6

2

MAJ- 196 REAR/FRONT PANEL KIT p/no K10001428

MAJ- 1629 RR/FT PANEL KIT- WIDE p/no K10004395

Item Description Part No Qty

1 FRONTCOVERLH .................................. K10003464 1 -- A, B

2 FRONTCOVERCENTRE.............................. K10003465 1 -- A

FRONTCOVERCENTREWIDE ......................... K10004398 1 -- B, NS

3 FRONTCOVERRH .................................. K10003466 1 -- A, B

4 REARDOOR ....................................... K10003548 1 -- A,C

REARDOOR WIDE.................................. K10004399 1 -- B, D,NS

5 LATCHSPAREFORWM--*P1RANGE .................... K10016172 1 -- A, B, C, D

6 FOOTPUSH--IN ..................................... K10003425 2 -- A, B, C, D

7 WASHERM6 ....................................... 3920333 8 -- A, B

8 WASHERCRINKLEM6 ............................... K3921473 8 -- A, B

9 JETNUTM6SINGLENUTPLATE ........................ 3920573 4 -- A, B

10 SCREWM6x16HEXSKTBUTTHD ..................... 3920327 8 -- A, B

11 ALLENKEY4MMA/FSHORT........................... 3066011 1 -- A, B, NS

12 SPARE

13 INSTRUCTIONS MAJ--196 / MAJ--1629 .................... K10003554 1 -- A, B, NS

REMARKS

A Used on MAJ--196 REAR/FRONT PANEL KIT p/no K10001428

B Used on MAJ--1629 RR/FT PANEL KIT--WIDE p/no K10004395

C Used on REAR PANEL KIT WM--NP1 p/no K10005044

D Used on REAR PANEL KIT WM--WP1 p/no K10005045

NS Not Shown

Torque

Remarks

WM--P1 SERIES WORKSTATIONS

Page 56 of 76

Issue 20 : July 2012

Page 57

8.14 MAJ- 198 WM- NP1 SHELF KIT (Narrow)

MAJ- 199 WM- WP1 SHELF KIT (Wide)

FIGURE 8-14

MAJ--198 WM--NP1 SHELF KIT (NARROW)

1

7

3

5

2

MAJ- 198 WM- NP1 SHELF KIT (Narrow) p/no K10001429

MAJ- 199 WM- WP1 SHELF KIT (Wide) p/no K10001430

Item Description Part No Qty

1 SHELFWM--NP1SERIES.............................. -- 1 -- A,C

SHELFWM--WP1SERIES ............................. -- 1 -- B,C,NS

2 CORNERBUFFER--SHELFR/H ........................ K10001123 1 -- A, B

3 CORNERBUFFER--SHELFL/H......................... K10001124 1 -- A, B

4 SCREWM8x16HEXSKTCAPHD ...................... K3921515 4 -- A, B

5 WASHER24ODx8.4IDx2MMTHK ..................... K3921536 4 -- A, B

6 WASHERCRINKLEM8 ............................... K3920997 4 -- A, B

7 CABLE CLIP RELEASABLE NYLON ...................... 3920309 4 -- A, B