Page 1

INSTRUCTIONS

BX61

MOTORIZED SYSTEM

MICROSCOPES

This instruction manual is for the Olympus Motorized System Microscopes Models BX61 and BX62.

To ensure the safety, obtain optimum performance and to familiarize yourself fully with the use of

this microscope, we recommend that you study this manual thoroughly before operating the microscope. Retain this instruction manual in an easily accessible place near the work desk for future

reference.

A X 7 6 1 1

Page 2

Page 3

CONTENTS

Correct assembly and adjustments are indispensable to allow the microscope manifest its full performance. If you

are going to assemble the microscope by yourself, please read chapter 7, “ASSEMBLY” (pages. 29 to 32).

BX61

IMPORTANT — Be sure to read this section for safe use of the equipment. —

1 NOMENCLATURE

2

TRANSMITTED LIGHT BRIGHTFIELD OBSERVATION PROCEDURE

3 USING THE CONTROLS

3-1 Base ................................................................................................................................................................................................................. 8-10

1 Voltage Indication 2 Transmitted/Reflected Light Switch

3 Light Preset Switch 4 Using the Filters

3-2 Focusing Block............................................................................................................................................................................... 11- 12

1 Replacing the Focus Adjustment Knob 2 F/C button

3 Stage UP/DOWN Buttons 4 Stage Escape Button

3-3 Stage ............................................................................................................................................................................................................ 13-15

1 Placing the Specimen 2 Adjusting the X/Y-Axis Knob Tension

3 Rotating the Stage 4 Adjusting the Stage Height

3-4 Observation Tube ....................................................................................................................................................................... 16-18

1 Adjusting the Interpupillar Distance 2 Adjusting the Diopter

3 Using the Eye Shades 4 Using the Eyepiece Micrometer Disk

5 Selecting the Light Path of the Trinocular Tube

6 Adjusting the Tilt

3-5 Condenser .......................................................................................................................................................................................... 19-20

1 Centering the Condenser 2 Compatibility of Objectives and Condensers

3-6 Immersion Objectives................................................................................................................................................................... 21

3-7 Objectives with Correction Collar ............................................................................................................................... 21

1-3

4-5

6-7

8-21

4 TROUBLESHOOTING GUIDE

5 SPECIFICATIONS

6 OPTICAL CHARACTERISTICS <<UIS2 (UIS) Series>>

ASSEMBLY

7

PROPER SELECTION OF THE POWER SUPPLY CORD...................................................................

—

See this section for the replacement of the light bulb. —

22-24

25-26

27-28

29-32

33-34

Page 4

This device complies with the requirements of directive 98/79/EC concerning in vitro diagnostic medical devices. CE marking means the conformity to the directive.

NOTE: This equipment has been tested and found to comply with the limits for a Class A digital device,

pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection

against harmful interference when the equipment is operated in a commercial environment. This

equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in

accordance with the instruction manual, may cause harmful interference to radio communications.

Operation of this equipment in a residential area is likely to cause harmful interference in which case

the user will be required to correct the interference at his own expense.

FCC WARNING: Changes or modifications not expressly approved by the party responsible for compliance

could void the user’s authority to operate the equipment.

Page 5

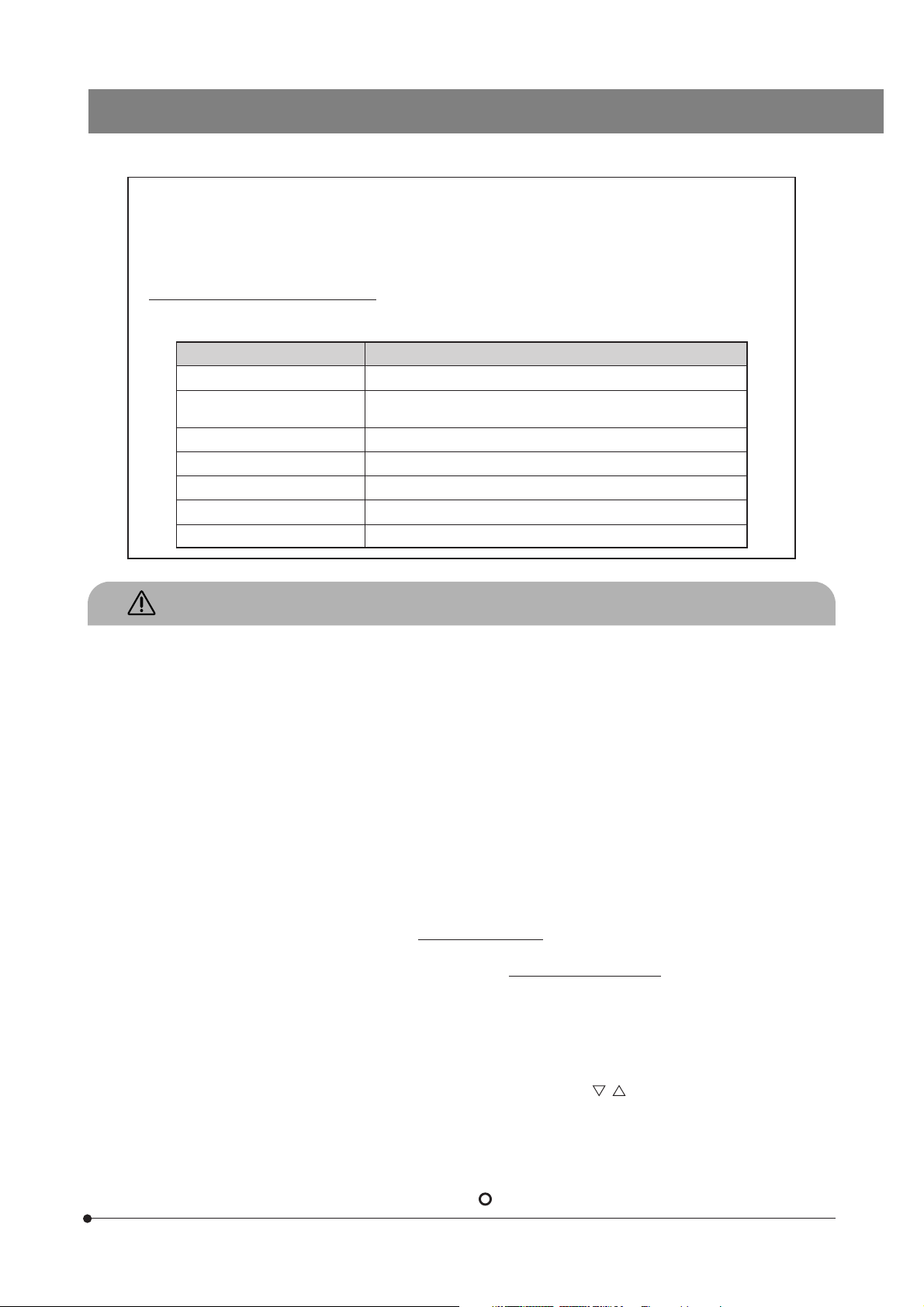

IMPORTANT

Each of these microscopes employs a UIS2/UIS (Universal Infinity System) optical design, and should

be used only with modules designed for the BX2 series (which belong to the Olympus BX series

microscopes) and objectives/eyepieces for the UIS series.

For the applicable module, please consult Olympus or the catalogues. Less than optimum performance

may result if inappropriate accessories are used.

Configuration of Instruction Manuals

Since these microscopes are expandable to a variety of systems, separate instruction manuals are provided

so that the user has to read only the manuals according to the user’s own system.

Manual Name Main Contents

BX61 Transmitted light brightfield observation procedure

BX-UCB/U-HSTR2

BX2 Software for PC (CD-ROM) Methods of PC Control of Functions

BX-RFAA

BX-RLAA Reflected light brightfield/darkfield observation

U-UCD8A Motorized universal condenser

U-FWT/FWR/FWO Motorized filter wheels

Functions of the Control Box (incorporating the power supply)

and Hand Switch

Reflected light fluorescence observation procedure

BX61

SAFETY PRECAUTIONS

1. After the equipment has been used in an observation of a specimen that

is accompanied with a potential of infection, clean the parts coming in

contact with the specimen to prevent infection.

· Moving this product is accompanied with the risk of dropping the

specimen. Be sure to remove the specimen before moving this

product.

· In case the specimen is damaged by erroneous operation, promptly

take the infection prevention measures.

· The product becomes unstable if its height is increased by an accessory

mounted on it. In this case, take anti-toppling measures to prevent the

specimen from being dropped when the product topples down.

2. Install the microscope on a sturdy, level table or bench so as not to block

the air vents on the underside of the base.

Do not place the microscope on a flexible surface, as this could result in

blocking the air vents and cause overheating or a fire.

3. If a foreign object is caught during motorized focusing operation, there

will be an error in the focusing block and the motorized focusing operation will be suspended.

Recovery procedure

· If there is no error in motorized operation, the caught object can be

removed by turning the focusing knob.

· If there is an error in motorized operation, the focusing knob becomes

inoperable. Disassemble the relevant modules to remove the caught

object. Replace the relevant modules afterward.

· Turn off the power and then on again. The system will restart unless

there is a malfunction in the motor.

4. To activate temporary stop during focusing operation, turn the focusing

knob (or dial) on the microscope frame (in either direction) or press any of

the FOCUS control buttons ( , , F/C and ESC) (except during PC

communication).

When the main switch of the BX-UCB control box is set to “ I ” (ON), the

focusing operation starts automatically as part of initialization (this operation consists of temporary lowering and then returning to the original

position of the stage). If any of the operations mentioned above is performed, an emergency stop will also occur. In this case, set the main

switch to “ ” (OFF) and then “ I ” (ON) again.

1

Page 6

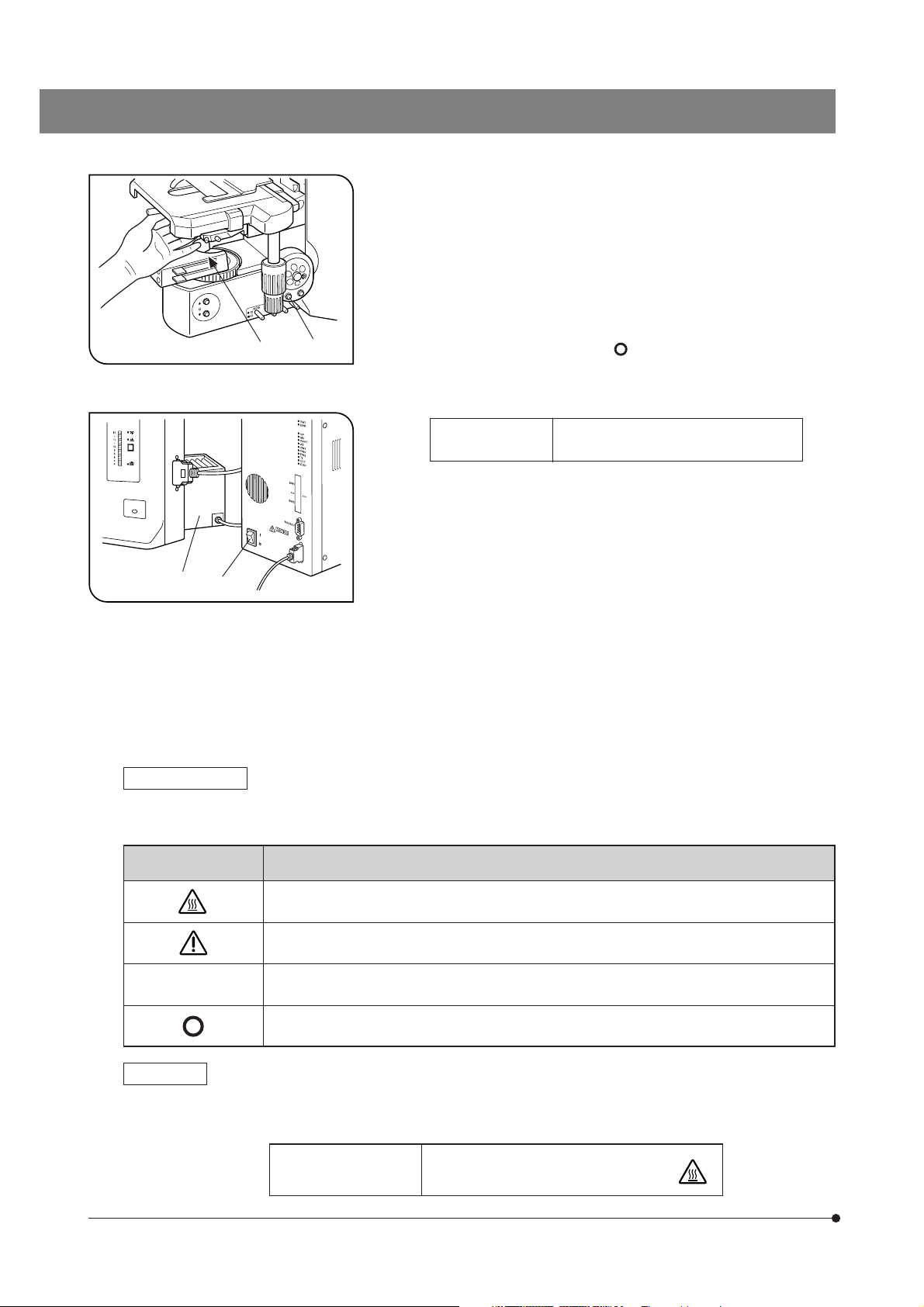

Fig. 1

²

@

5. When lowering the stage by pressing the stage DOWN button @, be

careful not to have your hand caught between the bottom ² of the condenser and the base.

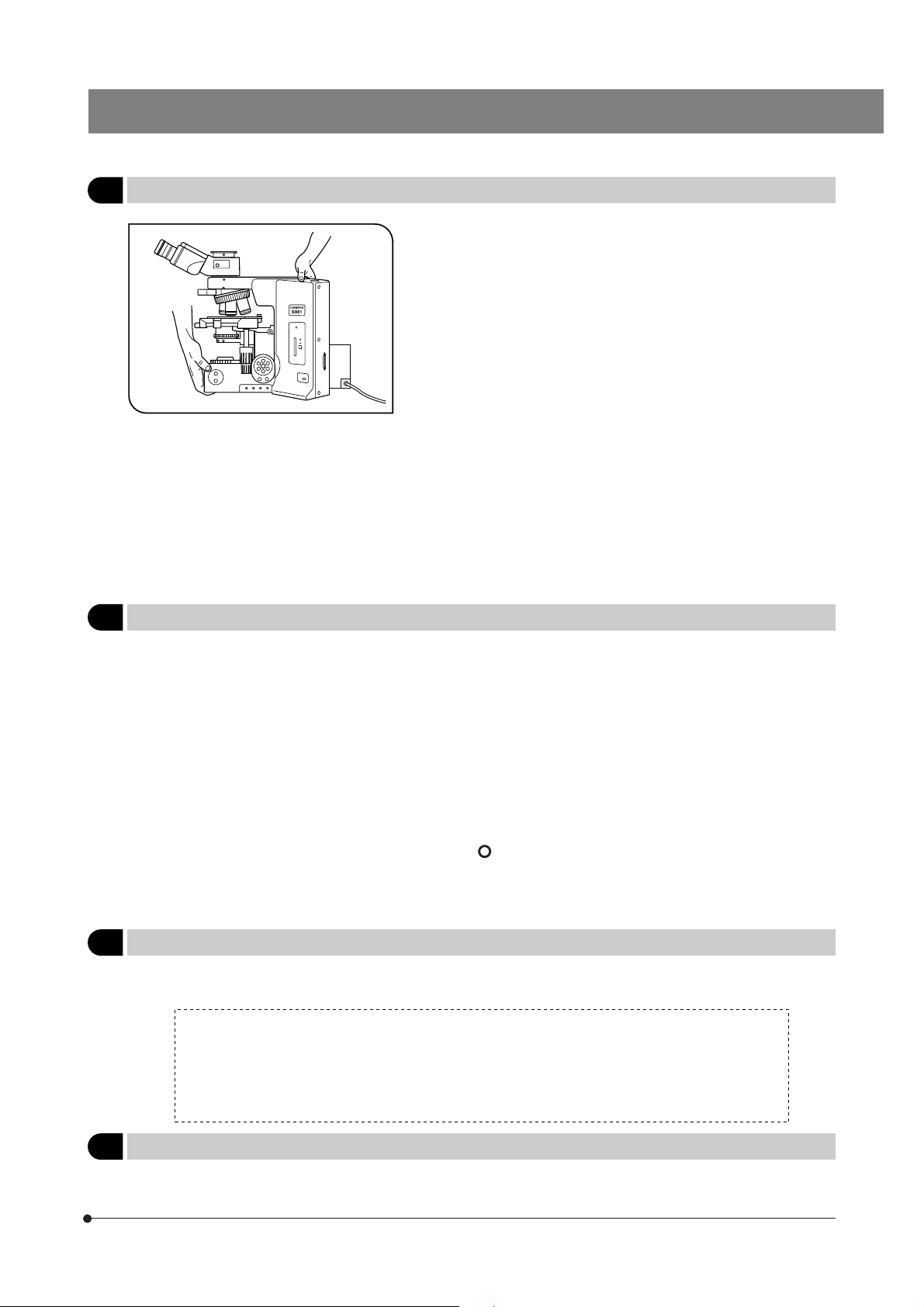

6. The surfaces of the lamp housing on the rear of the microscope will

become extremely hot during operation. When installing the microscope,

make sure to allow ample free space (10 cm or more) around and in

particular above the lamp housing.

7. When installing the microscope, route the power cord away from the

lamp housing. Should the power cord come in contact with the hot lamp

housing, the power cord could melt and cause electric shock.

8. To avoid potential shock hazards and burns when replacing the light

bulb, set the main switch ³ to “ ” (OFF) then disconnect the power cord

from the wall outlet in advance. Whenever you replace the bulb during

use or right after use, allow the lamp housing | and bulb to cool before

touching. (Fig. 2)

|

³

Fig. 2

Designated

haiogen bulbs:

# The microscope also incorporate a fuse (this should be

replaced by the manufacturer or an authorized agent).

9. Always use the power cord provided by Olympus. If no power cord is

provided, please select the proper power cord by referring to the section

“PROPER SELECTION OF THE POWER SUPPLY CORD” at the end of

this instruction manual. If the proper power cord is not used, product

safety performance cannot be warranted.

10.

Always ensure that the grounding terminal of the microscope and that

of the wall outlet are properly connected. If the equipment is not grounded,

Olympus can no longer warrant the electrical safety performance of the

equipment.

11.

Never insert metallic objects into the air vents of the microscope frame

as this could result in electrical shock, personal injury and equipment

damage.

When using the U-FWR motorized filter wheel for reflected light observa-

12.

tion, remove the push ring driver from the position where it is attached by

magnetism in advance to prevent it from dropping.

If the driver drops in a certain place, an electric shock and/or burns may result.

12V100WHAL (PHILIPS 7724)

12V50WHAL-L (LIFE JC)

Safety Symbols

The following symbols are found on the microscope. Study the meaning of the symbols and always use the equipment in the safest possible manner.

Symbol Explanation

2

Indicates that the surface becomes hot, and should not be touched with bare hands.

Before use, carefully read the instruction manual. Improper use could result in personal injury to

the user and/or damage to the equipment.

l

Indicates that the main switch is ON.

Indicates that the main switch is OFF.

Warnings

Warning engraving/stickers are placed at parts where special precaution is required when handling and using the

microscope. Always heed the warnings.

Warning engraving

position

Lamp housing

(Warning against high temperature)

Page 7

1 Getting Ready

Fig. 3

BX61

1. A microscope is a precision instrument. Handle it with care and avoid

subjecting it to sudden or severe impact.

2. Do not use the microscope where it is subjected to direct sunlight, high

temperature and humidity, dust or vibrations. (For the operating conditions, refer to chapter 5, “SPECIFICATIONS”.)

3. When moving the microscope, remove the modules that may drop

including the specimen from the microscope in advance, hold it by the

hand hook on the rear and the base as shown on the left (Fig. 3) and

carry carefully (Weight: approx. 16 kg).

#Before transporting the microscope, be sure to remove the speci-

men, eyepieces and color glass filter so that they will not drop. Also

remove other modules attached to the microscope because they

increase the system weight.

# Damage to the microscope will occur if you grasp it by the stage,

focus adjustment knob or binocular section of the observation tube.

4. The BX61 series can be used with up to two intermediate attachments

including a U-CA magnification changer, U-EPA2 eyepoint adjuster, etc.

For restrictions when using two intermediate attachments, make sure to

read the instruction manuals provided with the respective intermediate

attachments.

2 Maintenance and Storage

1. To clean the lenses and other glass components, simply blow dirty away using a commercially available blower and

wipe gently using a piece of cleaning paper (or clean gauze).

If a lens is stained with fingerprints or oil smudges, wipe it gauze slightly moistened with commercially available absolute

alcohol.

!Since the absolute alcohol is highly flammable, it must be handled carefully.

Be sure to keep it away from open flames or potential sources of electrical sparks –– for example, electrical

equipment that is being switched on or off, which could cause ignition of a fire.

Also remember to always use it only in a well-ventilated room.

2. Do not attempt to use organic solvents to clean the microscope components other than the glass components. To clean

them, use a lint-free, soft cloth slightly moistened with a diluted neutral detergent.

3. Do not disassemble any part of the microscope as this could result in malfunction or reduced performance.

4. When not using the microscope, set the main switch to “ ” (OFF), wait until the lamp housing has cooled down, and

cover the microscope with a dust cover before storage.

5. When disposing of the microscope, check the regulations and rules of your local government and be sure to observe

them.

3 Caution

If the microscope is used in a manner not specified by this manual, the safety of the user may be imperiled. In addition,

the equipment may also be damaged. Always use the equipment as outlined in this instruction manual.

The warning, caution and other notes in this manual use the following symbols.

!: Indicates that failure to follow the instructions in the warning could result in bodily harm to the

user and/or damage to equipment (including objects in the vicinity of the equipment).

# : Indicates that failure to follow the instructions could result in damage to equipment.

} : Indicates commentary (for ease of operation and maintenance).

Intended use

4

This instrument has been designed to be used to observe magnified images of specimens in routine and research

applications. Do not use this instrument for any purpose other than its intended use.

3

Page 8

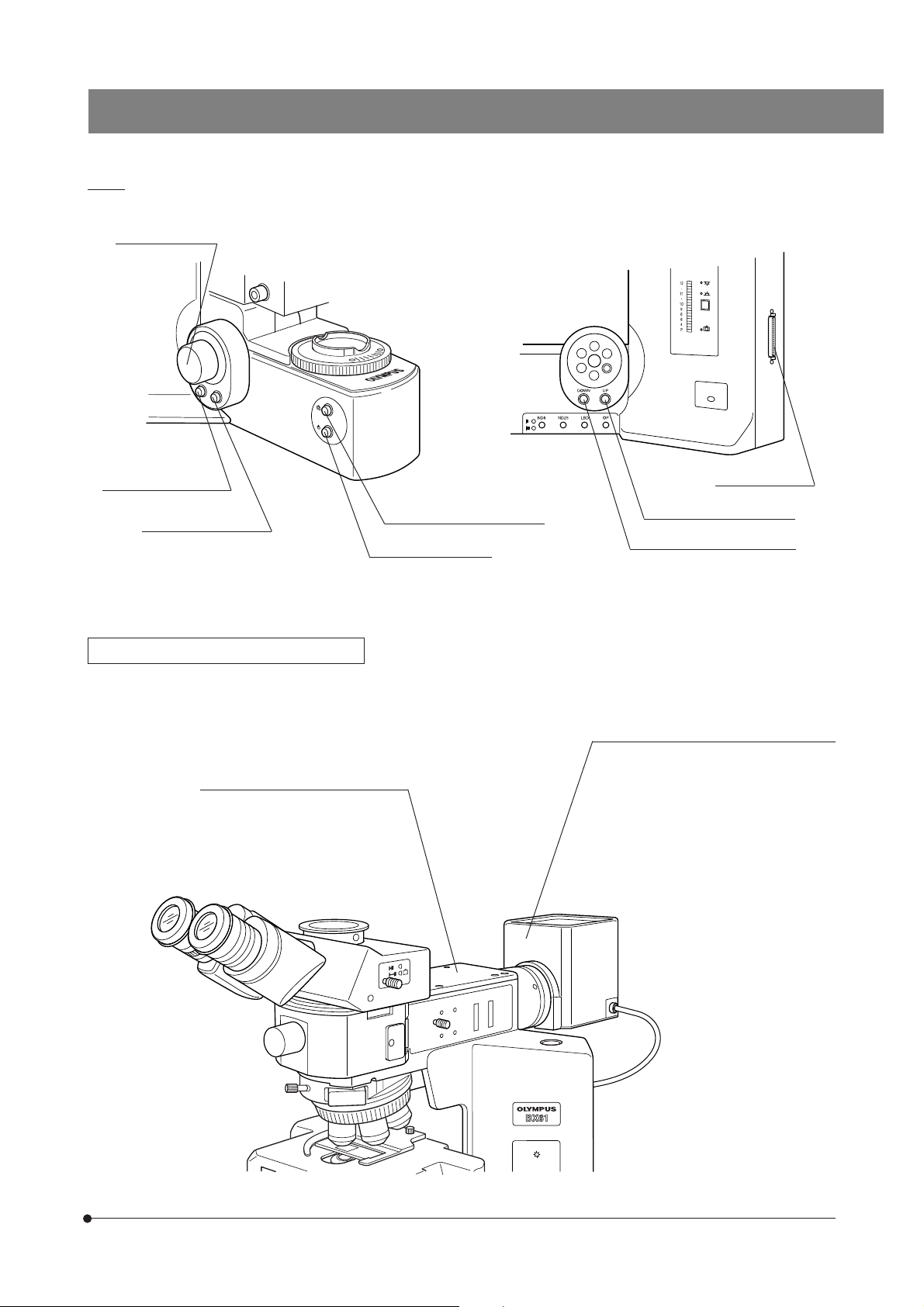

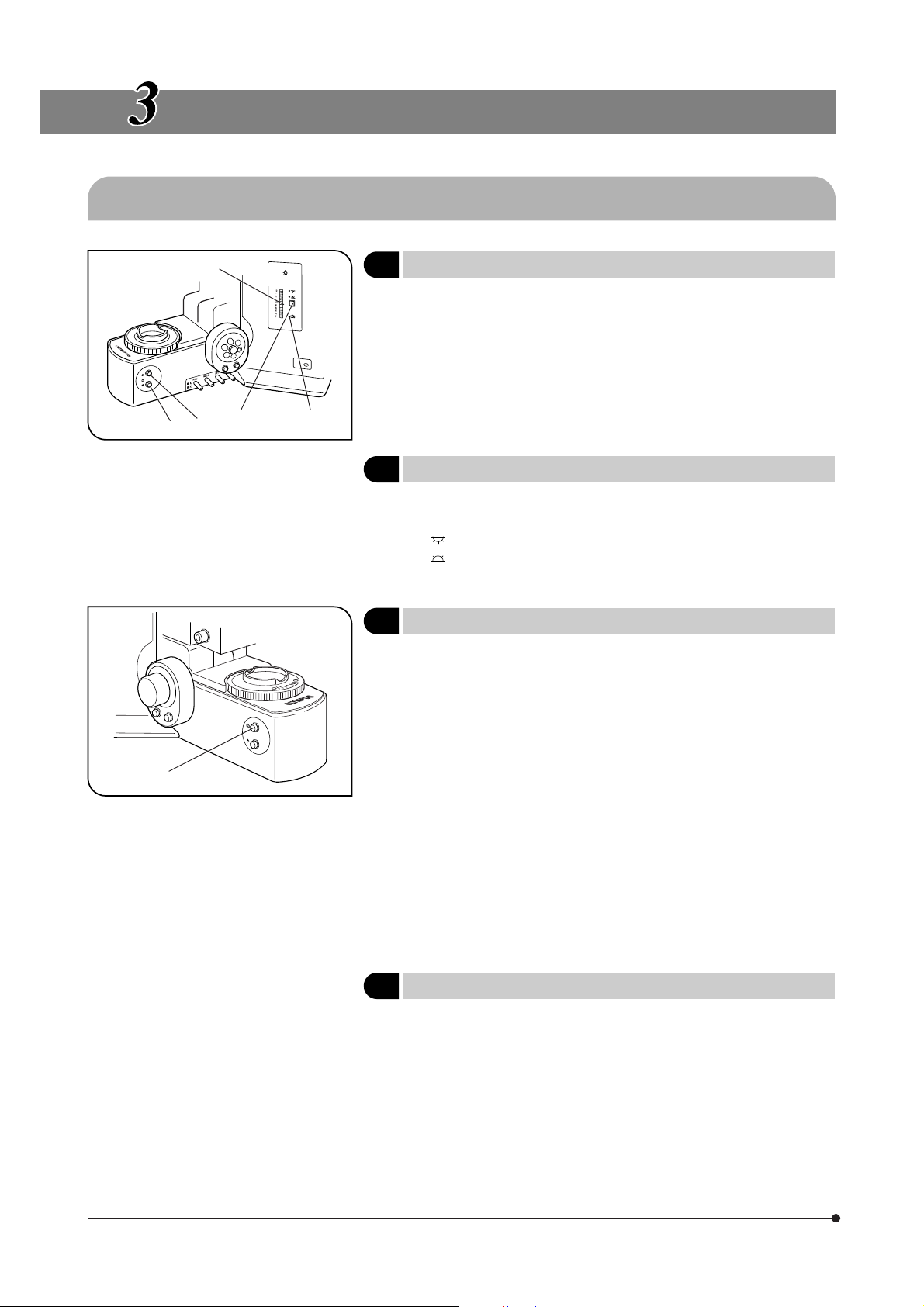

1

}If you have not yet assembled the microscope, read chapter 7, “ASSEMBLY” (pages 29 to 32).

Transmitted light specification models

Interpupillary distance

adjustment scale (Page 16)

NOMENCLATURE

Light path selector knob (Page 17)

Condenser height adjustment

screw (Page 19)

Allen screwdriver

(accommodation position)

Diopter adjustment

ring (Page 16)

Specimen holder (Page 13)

Aperture iris diaphragm ring

(Page 20)

Filter mount (Page 9)

Field iris diaphragm ring

(Page 19)

Brightness adjustment buttons

(Page 8)

Lamp voltage indicator

Transmitted/reflected

light switch (Page 8)

PHOTO indicator

(Page 8)

Y-axis knob (Page 14)

X-axis knob (Page 14)

Optional filter knob

4

Filter knobs (Page 9)

ND6, ND25 and LBD from the front to the rear

Page 9

Base

Focus adjustment

knob (Page 11)

BX61

Stage escape button

(Page 12)

F/C button (Page 11)

Reflected light specification models

Motorized reflected light illuminator*

· Motorized fluorescence illuminator

(BX-RFAA)

· Motorized reflected light illuminator

(BX-RLAA)

UCB connector

Light Preset switch (Page 8)

Lamp ON-OFF switch

* For the reflected illuminators and reflected lamp housings, please also

refer to their instruction manuals.

· 100 W mercury burner housing

· 100 W mercury apo-burner housing

· 75 W xenon lamp housing

· 100 W halogen lamp housing

· 50 W metal hydride lamp housing

Stage UP button (Page 12)

Stage DOWN button (Page 12)

Reflected lamp housing*

(U-LH100HG)

(U-LH100HGAPO)

(U-LH75XEAPO)

(U-LH100-3)

(U-LH50MH)

5

Page 10

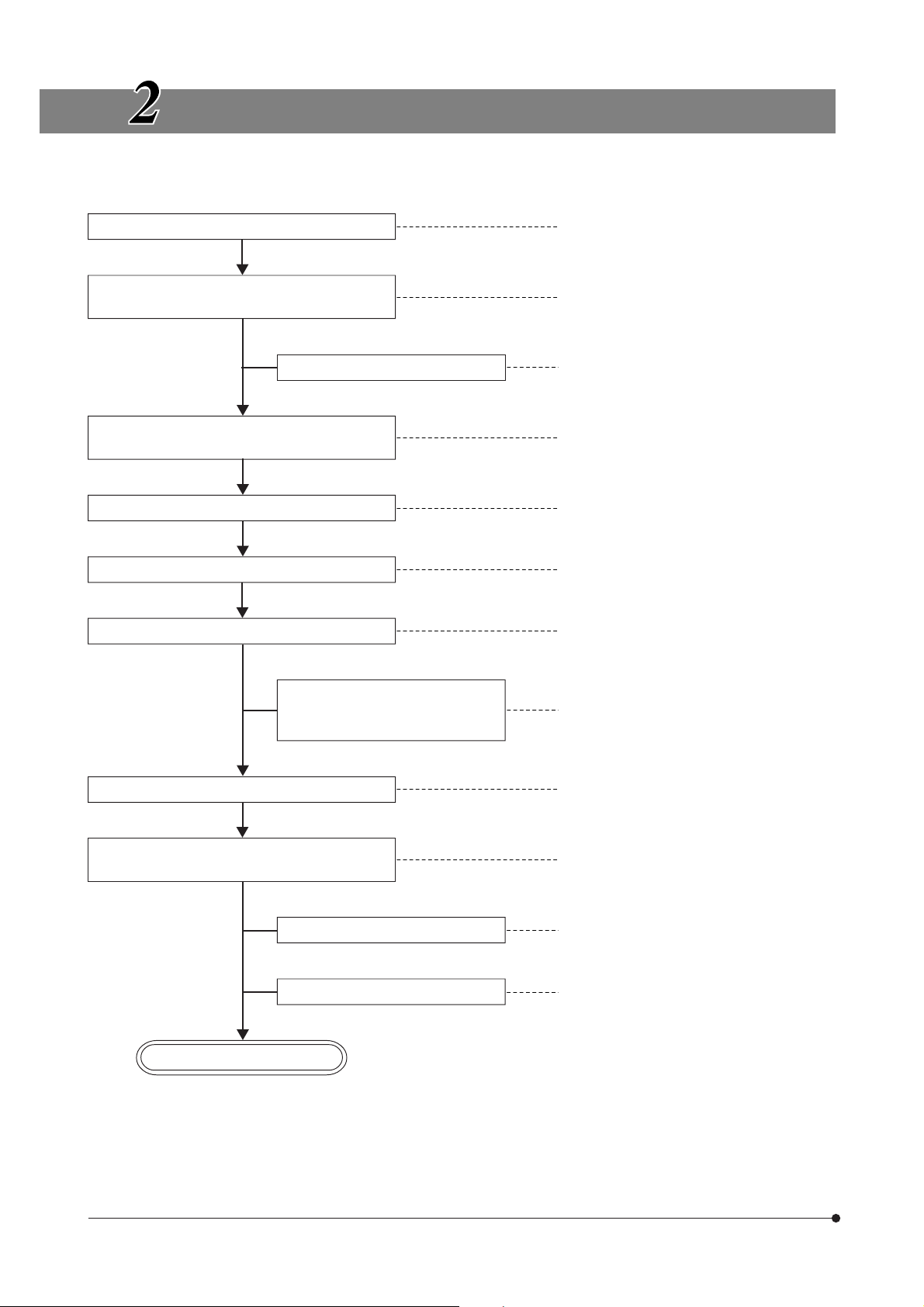

TRANSMITTED LIGHT BRIGHTFIELD

OBSERVATION PROCEDURE

Set the main switch to “ I ” (ON).

Select the transmitted light and adjust the

brightness.

Engage the LBD filter in light path. ƒLBD filter knob

Select the light path (when a trinocular tube is

used).

Place the specimen on the stage.

Engage the 10X objective in the light path.

Bring the specimen in focus.

(Controls Used)

@Main switch “ I ” (ON)

²Lamp ON-OFF switch ON

³Transmitted/reflected light switch (P. 8)

|Brightness adjustment buttons (P. 8)

…Light path selector knob (P. 17)

†Specimen holder (P. 13)

‡X/Y-axis knobs (P. 14)

ŠRevolving nosepiece button

‰Stage UP/DOWN button, focus

adjustment knob

(Page)

(P. 12)

Adjust the interpupillary distance.

Adjust the diopter.

Adjust the light axis.

Adjust the aperture iris and field iris diaphragms.

Engage the objective to be used in the light

path and bring the specimen in focus.

Engage the required filters.

Adjust the brightness.

Start observation.

‹Binocular tube (P. 16)

ŒDiopter adjustment ring (P. 16)

™Condenser height adjustment screw (P. 19)

šCondenser centering screws (P. 19)

›Aperture iris diaphragm ring (P. 20)

œField iris diaphragm ring (P. 19)

ŠRevolving nosepiece button

‰Stage UP/DOWN button, focus

adjustment knob

ŸFilters (P. 9)

|Brightness adjustment buttons (P. 8)

(P. 12)

6

Page 11

Œ

…

Use the Allen screwdriver.

™

BX61

‹

†

›

š

Use the Allen screwdriver.

œ

|

Ÿ

ƒ

³

‡

‰

‰

@

Control Box*

BX-UCB

* Set the Z-board or AF-board. For the setup

²

Hand Switch

U-HSTR2

} Make a photocopy of the observation procedure pages and post it near your microscope.

Š

and installation of the Z-board, refer to

page 30. For the information regarding

the AF-board, refer to the instruction

manual of the AF unit.

7

Page 12

USING THE CONTROLS

3-1 Base

ƒ

²

@

³

Fig. 4

Fig. 5

|

…

1 Voltage Indication

1. Press the Brightness adjustment button @ to increase the voltage and

make illumination brighter.

Pressing the button ² makes the illumination darker.

2. The numerals on the left of the lamp voltage LEDs ³ indicate the

approximate voltage.

#The LED may sometimes go out (temporarily) when the motor is

driving. Even in this case, there is no fluctuation in illumination

voltage.

2 Transmitted/Reflected Light Switch

The illumination can be switched between the transmitted light and reflected light by pressing the transmitted/reflected light switch |.

: Reflected light illumination

: Transmitted light illumination

The indicator of the selected illumination lights.

3 Light Preset Switch

}The Light Preset switch sets the light intensity voltage to a voltage suit-

able for color photography* (the factory default is 9 V) regardless of the

current setting of the light intensity adjustment buttons.

* Achieved by engaging the built-in LBD filter.

Setting the Desired Brightness (Figs. 4 & 5)

1. Press the Light Preset switch ƒ The PHOTO indicator … lights up.

2. Press one of the light intensity adjustment buttons @ ² to set the desired brightness.

3. Press the Light Preset switch again. The indictor turns off, the brightness

returns to the original brightness but the setting made above is stored in

memory.

4. Hereafter, pressing the Light Preset switch sets the brightness to the intensity value set in step 2 above.

#Be sure to set the light intensity voltage back to 9 V when color

photography is to be performed.

}When the Light Preset switch ƒ is pressed, a note sound (short beep) is

generated at the 9 V position.

(Fig. 4)

(Fig. 4)

(Fig. 5)

8

4 Using the Filters

}You can place a filter in the light path with one of the following four

methods.

· Push in the knob of a built-in filter to engage it in the light path. (Page 9)

· Place a filter on the filter mount on the base and engage in the light path.

(Page 9)

· Insert a filter in the U-FC filter cassette, attach it on the filter mount and

engage it in the light path by sliding the filter lever. (Page 9)

· Insert a filter in the U-FWT filter wheel, attach it on the filter mount and

engage it in the light path by motorized operation (using the PC). (Refer

to the separate instruction manual.)

(Figs. 6 - 11)

Page 13

@

Fig. 6

²

³

|

Using Built-In Filters (Fig. 6)

Each filter can be engaged into the light path by pressing one of the filter

knobs @ to | in. Pressing the button again disengages the filter from the

light path.

Filter Type/Purpose

@

ND6 (Neutral Density filter for light adjustment, transmittance 6%)

²

ND25 (Neutral Density filter for light adjustment, transmittance 25%)

³ LBD (for color balancing, daylight filter)

| OP (optional) filter set*

* Ask your Olympus representative to mount the filters.

BX61

ƒ

Fig. 7

Fig. 8

…

Mounting a Single Filter (Fig. 7)

A filter with a diameter of 45 mm ƒ can be placed on the filter mount on

the base. If you need to place multiple filters, please purchase the U-FC

filter cassette.

# Even when a filter cassette is used, a filter with thickness of no more

than 3 mm can still be placed on the filter mount.

Using the Filter Cassette (Figs. 8 - 11)

Loading Filters into Filter Cassette

}The filter cassette accommodates filters with a diameter of 45 mm and

thickness of 2.7 mm or less.

}The filter cassette has two filter levers on the right side and one on the left

side.

1. Move all filter levers to the OUT position except for the one belonging to

the slot into which the filter is to be inserted.

2. Slide the lever … to the IN position. Make sure that it clicks securely into

place. (Fig. 8)

3. Holding the lever in the position shown in Fig. 8, put the filter into the

cassette by inserting it in the direction indicated by the arrow.

4. Insert the other two filters in the same manner.

9

Page 14

‰

‡

Fig. 9

Fig. 10

†

Š

Mounting the Filter Cassette

1. Fully loosen the filter cassette clamping screw †. (Fig. 9)

2. Align the key ‡ on the bottom surface of the filter cassette with the

positioning slot Š on the filter mount, then snap the filter cassette into

place from above.

3. Rotate the filter cassette to align its sides with the base. (Fig. 10)

4. Align the clamping screw † with the positioning hole ‰ on the filter

mount, then tighten the screw to fasten the filter cassette.

#When the filter cassette is installed, the condenser may hit the filter

cassette when the stage is lowered. Therefore, exercise caution

when lowering the stage with the filter cassette installed.

Fig. 11

‹

Using the Filter Cassette (Fig. 11)

Usable Filters Applications

45ND-6, 45ND-25 Neutral density filter

45G-530, 45G-533, 45IF550 Green

45Y-48 Yellow B&W contrast filter

45O-560 Orange

Up to three of the above filters can be loaded in the filter cassette. Moving the levers ‹ on the left and right sides of the cassette to the IN

position brings the corresponding filter into the light path.

10

Page 15

3-2 Focusing Block

²

@

³

Fig. 12

BX61

#If the substage is not installed in the correct position, it

may deviate from the coverage range of the damper spring

of the objective and damage the specimen.

Ensure that the top surface @ of the substage is flush with the bottom

surface of the notch ² on the mount dovetail. If they are not flush, loosen

the clamping screw ³ and lower the substage until it is stopped.

@

³

²

Fig. 13

@

|

1 Replacing the Focus Adjustment Knob

# The focus adjustment knob is installed on the right side of the micro-

scope when it left the factory.

}The focus adjustment knob is designed detachable to prevent interfer-

ence with hand during manipulation of the focus adjustment knob or X/

Y-axis knobs.

Usually attach the knob on the opposite side to the stage feed knobs.

1. Loosen the clamping screw @ and remove the focus adjustment knob

².

2. Remove the seal from the focus adjustment knob screw hole on the

other side and attach the knob by reversing the removal procedure.

3. Attach a provided seal on the screw hole | of the focus adjustment dial

³, from which the focus adjustment knob has been removed.

}The focus adjustment dial ³ can be operated with your fingertip or finger

surface at the same time as manipulating the X/Y-axis knobs.

2 F/C button

}This button switches the movement of the stage using the focusing

knob @ or dial between F (Fine) and C (Coarse). (For the purpose of

safety, this button is set automatically to F at the moment the main

switch of the BX-UCB control box is set to “ I ” (ON).)

· Each press of the F/C button ² switches F and C alternately.

(Fig. 13)

(Fig. 14)

²

Fig. 14

Stage Fine movement: 0.1 mm per turn

Stage Coarse movement: 1 mm per turn

11

Page 16

²

@

Fig. 15

3 Stage UP/DOWN Buttons

!When lowering the stage, be careful not to have your hand caught

between the bottom of the condenser and the base.

· Press the stage UP button @ to raise the stage and press the stage

DOWN button ² to lower the stage.

· The stroke is 25 mm. It becomes 14 mm when the U-FWT filter wheel is

used.

· The upper limit of stage movement has been set so that the stage stops

within the coverage range of the damper spring of objective when a slide

specimen (thickness 1.2 mm) is used.

#When observing a metallurgic specimen with thickness above 1.2

mm, take care so that the stage does not hit the objective.

(Fig. 15)

@

Fig. 16

4 Stage Escape Button

When replacing the specimen, press the stage escape button @. The

stage will lower by 5 mm (in 1 sec.). Pressing the button again returns the

stage to the original height.

(Fig. 16)

12

Page 17

BX61

3-3 Stage

}The following description deals with biological specimens. When observing a metallurgic specimen, it is more convenient

to replace the special stage or slide holder with the stage plate. (For details, refer to the instruction manual for the BX-RLAA.)

²

Fig. 17

Fig. 18

@

1 Placing the Specimen

# The dimensions of the slide glass should be 26 x 76 mm with thick-

ness of 0.9 to 1.2 mm, and the cover glass should have thickness of

0.17 mm.

# When observing very large specimens, remove the slide holder and

place the specimen directly on the stage.

Microscopy with Double-Slide Holder (Fig. 17)

1. Press the stage DOWN button @ or stage escape button to lower the

stage.

2. Open the specimen holder clamping lever ² and place the specimen

slides on the stage by sliding each slide from the front.

3. After placing the slides as far as they will go, gently release the clamping

lever.

Microscopy with Single-Slide Holder (Fig. 18)

The specimen slide can easily be placed by sliding it into the slide holder

from the front.

Examining a whole specimen

Use one of the thin slide holders listed below that cause less interference

with the objectives*.

· U-HRD-4 · U-HLD-4 · U-HLS-4

* The applicable objectives are ones are ones with 40X or less

magnification (except Apo series).

³

Using an Oil Immersion Objective

Adsorption of immersion oil can cause the specimen to drift. In such

cases, it is recommended to use the optional BH2-SCB-3 specimen clip

³ for oil immersion objectives. (Fig. 19)

Using an Oil Immersion Condenser

It may be effective to use the optional U-SVRO (right-hand knob) or USVLO (left-hand knob) slotted stage which prevents close contact between the specimen and stage.

Fig. 19

13

Page 18

2 Adjusting the X/Y-Axis Knob Tension

(Fig. 20)

²

|

³

@

Fig. 20

1. Hold the X-axis knob @ and slide up the Y-axis knob ² up to expose the

adjustment knobs.

2. Turning the X-axis adjustment knob ³ or Y-axis adjustment knob | clockwise (in the direction of the arrow) increases the rotation tension and

counterclockwise decreases it.

#If the tension is adjusted too tight, a creaking sound may be heard

during stage travel, and the stage stopping accuracy may be imperiled.

CAUTION

[Treatment] X-axis direction: Hold the specimen holder and move the

Rubber Stage Knob Caps (Optional)

}When the X/Y-axis knobs are fitted with the rubber caps, the knobs can

be adjusted without slipping and fine adjustment is possible by holding

the knobs with a very light force. The knob rubber caps also reduce

fatigue after long hours of operation.

The U-SHGT thick type (thickness 5 mm) and U-SHG thin type (thickness

2 mm) knob rubber caps are available.

To attach the knob rubber caps:

First fit the larger rubber knob cap to the Y-axis (upper) knob from below

it, then fit the smaller rubber knob cap to the X-axis (lower) knob from

below it.

After long hours of use, the stage guide may be deviated and the stage travel range may be decreased.

However, this is not malfunction and can be corrected

easily as described below.

stage guide to the left and right so that it hits

the stoppers.

Y-axis direction: Hold the upper stage and move it to the front

and rear so that it hits the stoppers.

14

@

Fig. 21

3 Rotating the Stage

1. Slightly loosen the stage clamping knob @.

2. The stage can be rotated both clockwise and counterclockwise while

holding the stage clamping knob.

#A click may be heard and felt during rotation. However, this is due to

the construction of the substage and does not indicate a malfunction.

}The angle of rotation varies depending on the positions of the feed knobs.

Angle of Rotation

Clockwise Counterclockwise

Right-hand knobs 230° 20°

Left-hand knobs 20° 230°

(Fig. 21)

Page 19

BX61

²

Fig. 22

|

Fig. 23

@

ƒ

³

4 Adjusting the Stage Height

}By lowering the position of the substage, the microscope will accommo-

date specimens with maximum height of 35 mm. This is useful when

observing metallurgical specimens and other thick objects.

1. Press the stage DOWN button @ to lower the stage to the lower limit,

then remove the stage from the microscope.

2. Using an Allen screwdriver, loosen the substage bracket clamping screw

² and remove the substage.

3. Press the stage UP button ³ and raise the focusing block ƒ to where

the stopper screw | on the arm becomes visible.

4. Using the Allen screwdriver, loosen and remove the upper stopper screw

|.

5. Reattach substage bracket and stage.

}Retain the removed stopper screw | and take care not to lose it.

(Figs. 22 & 23)

15

Page 20

3-4 Observation Tube

²

Fig. 24

Fig. 25

@

1 Adjusting the Interpupillar Distance

While looking through the eyepieces, adjust for binocular vision until the

left and right fields of view coincide completely. The index dot · indicates

the interpupillary distance.

}Note your interpupillary distance so that it can be quickly duplicated.

2 Adjusting the Diopter

1. Looking through the eyepiece without the diopter adjustment ring, rotate

the coarse and fine focus adjustment knob to bring the specimen into

focus.

2. Looking through the eyepiece with the diopter adjustment ring @, turn it

to focus on the specimen. (Fig. 25)

(Figs 25 & 26)

(Fig. 24)

Fig. 26

Using a Finder Eyepiece

1. Looking through the right eyepiece with your right eye, turn the top of the

eyepiece ² until a clearly defined double crossline can be seen in the

field of view. (Figs. 25 & 26)

2. Looking through the right eyepiece, rotate the coarse and fine focus adjustment knob to bring the specimen and double crossline into simultaneous focus.

3. Looking through the left eyepiece with your left eye, turn the diopter adjustment ring @ to focus on the specimen.

Using an Super Widefield Observation Tube

The operation is similar to the above. However, as the super widefield

tube does not have the diopter adjustment ring on the left sleeve, focus

on the specimen by turning the top of the left sleeve.

3 Using the Eye Shades

When Wearing Eyeglasses

Use with the eye shades in the normal, folded-down position. This will

prevent the eyeglasses from being scratched.

When Not Wearing Eyeglasses

Extend the folded eye shades in the direction of the arrow to prevent

extraneous light from entering between the eyepieces and eyes.

(Fig. 27)

16

Fig. 27

Page 21

BX61

Fig. 28

Fig. 29

@

@

²

4 Using the Eyepiece Micrometer Disk

When the WHN10X-H (or WHN10X) eyepieces are used, an eyepiece

micrometer disk can be inserted in one of them. When the eyepiece

does not have a diopter adjustment mechanism, however, it is hard to

focus on the micrometer disk if the operator has poor eyesight. Should

that be the case, adjust the focus with eyeglasses on.

Use 24 mm dia. x 1.5 mm thick micrometer disks.

Following Fig. 28, turn the built-in micrometer-mounting frame ²

counterclockwise to remove it from the eyepiece and place a micrometer

disk.

Screw the micrometer mounting frame back into the eyepiece sleeve.

Selecting the Light Path of the

5

Trinocular Tube

Slide the light path selector knob @ to select the desired light path.

Trinocular tube

U-TR30-2

U-SWTR-3

U-TR30NIR

*

100% for binocular eyepieces

Light path selector knob position

Pushed in

Middle position

20% for binocular

eyepieces, 80% for

TV/photography

50% for binocular

eyepieces, 50% for

TV/photography

100% for TV/

photography

(Fig. 28)

(Fig. 29)

Pulled out

* With the infrared trinocular tube, infrared observation up to 1000 nm is

possible. For details, consult your Olympus representative.

17

Page 22

Fig. 30

6 Adjusting the Tilt (with the U-TBI3)

}Adjust the height and tilt of the observation tube to obtain the most

comfortable viewing position.

Holding the binocular section with both hands, raise or lower it to the

desired position.

# Never attempt to force the binocular section past the upper or lower

stop position. Applying excessive force could destroy the limiting

mechanism.

}The U-TBI3 can be used in combination with only one intermediate at-

tachment. However, no intermediate attachment can be combined when

the BX-RFAA or BX-RLAA reflected light illuminator is used.

}If you need photography using the U-TBI3, also use the U-TRU trinocular

intermediate tube.

With the U-ETBI/U-TTBI (Fig. 31)

The U-ETBI and U-TTBI are ergonomic observation tubes with normal

field, capable of the tilting adjustment as well as the adjustment of the

eyepiece position toward the front and rear (by 45 mm). The U-ETBI is the

erect image model and the U-TTBI is the inverted image model, and

both models are of the same size.

#The intermediate attachments that can be combined with the U-

TTBI are limited. For details, please contact Olympus.

(Fig. 30)

Fig. 31

18

Page 23

3-5 Condenser

BX61

@

²

Fig. 32

³

1 Centering the Condenser

1. Fit the Allen screwdriver @ into the condenser height adjustment screw

and turn the tool counterclockwise to raise the condenser to its upper

limit.

2. Focus on the specimen using the 10X objective.

# When using a swing-out condenser, move the top lens into the light

path.

3. Rotate the field iris diaphragm ring ² in the direction of the arrow so that

the diaphragm image comes inside the field of view.

4. Turn the Allen screwdriver @ to focus on the diaphragm image.

5. Fit the Allen screwdrivers into the two condenser centering screws ³

and turn them to move the iris diaphragm image to the center of the field

of view.

6. Gradually open the field iris diaphragm. The condenser is properly centered if the iris image is centered and inscribed in the field of view.

7. During actual use, open the field diaphragm slightly until its image circumscribes the field of view.

(Figs. 32 & 33)

Fig. 33

Effects of Field Iris Diaphragm (Fig. 33)

The field iris diaphragm restricts the diameter of the beam of light entering the objective and thus excludes extraneous light, improving image

contrast. The diameter of the field iris should e adjusted for objective

power to the extent that it just circumscribes the field of view. (See “Compatibility of Objectives and Condensers” on the next page.)

19

Page 24

Aperture iris

diaphragm image

Objective pupil

Fig. 34

70-80%

30-20%

²

Aperture Iris Diaphragm (Figs. 34 & 35)

· The aperture iris diaphragm determines the numerical aperture of the

illumination system. It has an effect of adjusting image resolution and

contrast. Stopping down the aperture iris diaphragm increases the depth

of focus.

· Since the contrast of microscope specimens is ordinarily low, setting the

condenser aperture iris diaphragm to between 70 and 80% of the N.A. ²

of the objective in use is usually recommended.

Adjust the ratio by removing the eyepiece and looking into the eyepiece

sleeve while adjusting the aperture iris diaphragm ring @ until the image

shown in Fig. 34 is seen.

}Using the numerical aperture scale:

You can use the condenser numerical aperture scale by adjusting the

aperture iris diaphragm ring @. (Fig. 35)

@

Fig. 35

N.A. scale

2 Compatibility of Objectives and Condensers

Objective

Magnification

1.25X Applicable to FN 22

2X

4X

10-60X

100X

* When using the U-SC3 swing-out condenser together with a 1.25X to 4X objective, fully open the condenser aperture iris

diaphragm and use the field iris diaphragm in the base as aperture diaphragm. With the 1.25X to 2X objectives, the

surroundings of the field of view may become dark.

}To obtain better illumination in photomicrography using a 1.25X to 4X objective, use of the U-ULC-2 for ultralow magnifi-

cation is recommended.

Achromat/aplanat

U-AAC

Applicable

(FN 26.5)

Applicable (FN 26.5) by moving

top lens out of the light path.*

Engage top lens in light path.

Condenser

Swing-out

U-SC3

(FN 26.5)

Motorized universal

U-UCD8A

Applicable when U-FWCO1.25X

is combined.

Applicable (FN 26.5) by moving

top lens out of the light path.

Engage top lens in light path.

(FN 26.5)

20

Page 25

3-6 Immersion Objectives

# Be sure to use the provided Olympus Immersion oil.

BX61

Fig. 36

1 Using Immersion Objectives

1. Focus on the specimen using all objectives, starting from the lowestpower objective to higher-power objectives.

2. Press the stage escape button to lower the stage, then place a drop of

provided immersion oil onto the specimen at the area to be observed.

3. Turn the revolving nosepiece to engage the immersion objective.

4. Press the stage escape button to raise the stage, then turn the focus

adjustment knob to focus on the specimen.

# Since air bubbles in the oil will affect the image quality, make sure

that the oil is free of bubbles.

a. To check for bubbles, remove the eyepiece and fully open the field and

aperture iris diaphragms, then look at the exit pupil of the objective inside

the observation tube. (The pupil should appear round and bright.)

b. To remove bubbles, turn the revolving nosepiece toward the shorter ob-

jectives and repeatedly defocus and refocus the oil immersion objective.

}If the condenser engraving shows a numerical aperture (NA) of 1.0 or

higher, the number applies only when oil is applied between the slide

glass and the top surface of the condenser. When oil is not present, the

NA is about 0.9.

5. After use, remove oil from the objective front lens by wiping with gauze

slightly moistened with absolute alcohol.

!Caution in use of immersion oil

If immersion oil enters your eyes or contacts with your skin, immediately

take the following treatment.

Eyes: Rinse with fresh water (for 15 minutes or more).

Skin: Rise with water and soap.

If the appearance of the eyes or skin is altered or pain persists, immediately see your doctor.

(Fig. 36)

3-7 Objectives with Correction Collar

}If the cover glass thickness is not 0.17 mm, the objectives cannot mani-

fest their performances. If a correction collar equipped objective is used

in this case, the difference in thickness can be compensated for by adjusting the collar.

Adjustment Procedure

· If the cover glass thickness is known, set the correction collar @ to that

@

Fig. 37

value. (Fig. 37)

· If the cover glass thickness is unknown, adjust the correction collar @

and focus adjustment knob alternately until the positioning with the highest

resolution is obtained.

# Be careful not to touch the correction collar @ when turning the

revolving nosepiece.

21

Page 26

TROUBLESHOOTING GUIDE

Under certain conditions, performance of the unit may be adversely affected by factors other than defects. If problems occur,

please review the following list and take remedial action as needed. If you cannot solve the problem after checking the

entire list, please contact your local Olympus representative for assistance.

Problem

1. Optical System

a) Bulb does not light. Power cord of BX-UCB is unplugged.

Main switch of BX-UCB is not on. Set main switch to “ I ” (ON). –

Lamp ON-OFF switch on the base of

BX61 is not on.

Bulb is burned out. Replace bulb with a new specified

Transmitted/reflected light switch is set

to reflected light ( ).

b) Bulb operates, but field of view re-

mains dark.

c) Field of view is obscured or not

evenly illuminated

Aperture and field iris diaphragms are not

opened wide enough.

Condenser is lowered too much. Adjust the condenser height position. 19

Light path selector knob is set to the

position.

Light path selector knob is in an positioned halfway.

Revolving nosepiece is not correctly engaged.

Condenser is not attached properly. Re-attach it. 32

Revolving nosepiece is not attached

properly.

An objective that falls outside of the

condenser’s illumination range is used.

Condenser is not properly centered. Center the condenser. 19

Cause Remedy Page

Insert power plug firmly into power

outlet.

Set the lamp ON-OFF switch to ON.

bulb.

Set the switch to (transmitted light

illumination).

Adjust them to proper sizes.

Move the knob to the or position.

Set the knob according to the observation method.

Make sure that the revolving nosepiece clicks properly into place.

Push the side dovetail all the way until it is stopped.

Use a condenser to match the purpose.

–

–

31

8

19/20

17

17

–

–

20

22

d) Dirt or dust is visible in the field of

view.

e) Visibility is poor.

· Image is not sharp.

· Contrast is poor.

· Details are indistinct.

· Image glares.

Field iris diaphragm is stopped down too

far.

Bulb is not mounted correctly. Push the pins of halogen bulb all the

Dirt/dust on the eyepiece Clean thoroughly.

Dirt or the to surface of the condenser

Dirt/dust on the specimen

A non-UIS2/UIS objective is used. Use only UIS2/UIS series objectives

Condenser is lowered too far. Adjust the condenser height position. 19

Aperture iris diaphragm is stopped down

too far.

Revolving nosepiece is not mounted

properly.

Open the field iris diaphragm until it

circumscribes the field.

way until the stop position.

with this microscope.

Open aperture iris diaphragm.

Push the slide dovetail all the way until

it is stopped.

19

31

27/28

20

3

–

Page 27

BX61

Problem

e) Visibility is poor.

· Image is not sharp.

· Contrast is poor.

· Details are indistinct.

· Image glares.

f ) One side of image is blurred. Revolving nosepiece is not correctly

g) Image appears to waver. Revolving nosepiece is not corrected

Correction collar on correction collar

equipped objective is not properly adjusted.

Front lens of objective is dirty. Clean objective. 3

Immersion oil is not being used with an

oil immersion objective.

Immersion oil contains bubbles. Remove the bubbles. 21

Recommended immersion oil is not

used.

Dirt/dust on specimen. Clean it.

Dirt/dust on condenser

Inappropriate object side or cover glass

thickness.

mounted.

Stage is not correctly mounted. Re-attach it. 15

Objective is not correctly engaged in light

path.

Specimen is not correctly mounted on

stage.

mounted.

Objective is not correctly engaged in

light path.

Condenser is not properly centered. Center the condenser. 19

Cause Remedy Page

While focusing, turn the correction collar to find the best position.

Use immersion oil.

Use the provided immersion oil.

Replace with glass of recommended

thickness.

Push slide dovetail all the way until it

is stopped.

Make sure that revolving nosepiece

clicks into place correctly.

Place specimen correctly on to of

stage and secure it with slide holder.

Push slide dovetail all the way until it

is stopped.

Make sure that revolving nosepiece

clicks into place correctly.

21

21

21

3

13

–

–

13

–

–

h) Field of view becomes only slightly

brighter when the voltage is raised.

2. Electrical System

a) Bulb intermittently lights and goes

out.

b) Bulb burns out almost immediately. Wrong type of bulb is being used. Use correct bulb type. 31

c) All voltage indicator LEDs light and

voltage cannot be varied by pressing light intensity adjustment button.

d) Brightness does not change when

you press light intensity adjustment

button.

3. Focusing Block

a) Image cannot be focused. When adjusting stage height, you forgot

b) Stage rises too high and destroys

specimen.

Condenser is not properly centered. Center the condenser. 19

Condenser is lowered too far. Adjust the condenser height position. 19

Bulb is nearly burned out. Replace bulb. 31

A connector is not properly connected.

Bulb is not installed. Install bulb. 31

Bulb is burned out. Replace bulb. 31

Lamp housing is not connected. Connect lamp housing correctly. –

Bulb is burned out. Replace bulb.

to reattach upper stopper screw.

Substage is not installed properly. Re-attach substage.

Check all connectors.

Re-attach upper stopper screw.

31

15

11

–

23

Page 28

Problem

c) Coarse adjustment will not go all

the way down.

d) Objective makes contact with speci-

men before focus is obtained.

4. Observation Tube

Cause Remedy Page

Condenser holder is too low. Raise condenser holder.

Specimen is mounted upside down.

Mount specimen correctly.

32

–

a) Field of view of one eye does not

match that of the other.

5. Stage

a) Image shifts when you touch stage. Stage is not properly mounted. Clamp stage. –

b) Specimen stops midway on the X-

axis traverse.

c) X-axis and/or Y-axis knobs are too

tight or too loose.

d) Stroke is decreased. Stage guide is deviated. Correct deviation as instructed on

Interpupillary distance is incorrect. Adjust interpupillary distance. 16

Incorrect diopter adjustment. Adjust diopter. 16

Different eyepieces are used on left and

right.

Your view is not accustomed to microscope observation.

Specimen is not correctly positioned. Place specimen correctly.

X-axis and/or Y-axis adjustment knobs

are set at a position where tension is too

high or too low.

Change on eyepiece to match the

other so that both sides are the same

type.

Upon looking into eyepieces, try looking at overall field before concentrating on specimen range. You may also

find it helpful to look up and into distance for a moment before looking

back into microscope.

Adjust tension.

page 14.

–

–

13

14

14

24

Page 29

SPECIFICATIONS

Item Specification

1. Optical system UIS2/UIS (Universal Infinity System) optical system (featuring infinity correction)

2. Illumination

3. Focusing mechanism Drive system: Motorized focusing using a stepping motor and ball screw.

Built-in transmitted Koehler illumination

12 V , 100 W long-life halogen bulb (pre-centered) 12 V 100 W HAL-L (PHILIPS 7724) or 12 V ,

50 W long-life halogen bulb (pre-centered) 12 V 50 W HAL-L (LIFE JC)

(Average life time: Approx. 2,000 hr. when used as directed)

Light intensity voltage range: 2 V or less to 12.0 V (continuous)

With a light intensity preset switch (voltage variation range: 2 V or less to 12.0 V )

Rated voltage of external power supply (BX-UCB): 100-120/220-240 V , 50/60 Hz, 3.5 A /1.5 A

Power consumption (BX-UCB):50–300 W (variable with number of connected modules)

(Ex.) Approx. 200 W with 100 W halogen bulb and motorized

focusing unit

Stage height movement by cross roller guides.

Finest adjustment scale: 1 μm (fine movement sensitivity 1 μm)

Resolution: 0.01 μm

Highest stage speed: 3 mm/sec.

Stroke per rotation: 0.1 mm (fine), 1 mm (coarse)

Full stroke range: 25 mm to 14 mm (when the U-FWT filter wheel is used)

BX61

4. Revolving nosepiece

5. Observation tube Type U-BI30-2 U-TBI3

6. Stage Type U-SVRB-4 U-SVLB-4

Manual revolving nosepieces:

U-5RE-2, U-D6RE, U-D7RE, U-P6RE

Motorized revolving nosepieces:

U-D6REM, U-D5BDREM, U-D6REMC, U-D6BDREMC, U-D5BDREMC, U-P5REMC, U-P5BDREMC

U-TR30-2

Widefield binocular tube

Field No. 22 26.5

Tube inclination

Interpupillary

distance adjustment

Light path selector

30°

Common-axis knobs on bottom right. Common-axis knobs on bottom left.

Widefield tilting

binocular

5°-35°

continuous

50 mm to 76 mm

None

Rectangular ceramic coated. wire driven stage

Widefield trinocular tube

U-TR30NIR

Super widefield

trinocular

30°

3 steps: @ Bi 100%

² Bi 20%, Photo 80%

Bi 50%, Photo 50%

for U-TR30NIR only

³ TV, Photo 100%

U-SWTR-3

Size 156 mm (H) x 191 mm (W)

Movement

mechanism

Specimen

holders (single

slide holder)

Specimen

holders (double

slide holder)

X/Y-axis knobs with adjustable tension.

Movement range: 52 mm in Y-axis direction, 76 mm in X-axis direction.

U-HLST-4 (thick slide holder)

U-HLS-4 (thin slide holder)

U-HLDT-4 (left opening, thick slide holder)

U-HLD-4 (left opening, thin slide holder)

U-HRDT-4 (right opening, thick slide holder)

U-HRD-4 (right opening, thin slide holder)

25

Page 30

Item Specification

7. Condenser Type

N.A. 1.40 0.9 - 0.1 1.4 - 0.2

Aperture iris

diaphragm

Objective

range

U-AAC

Achromat/aplanat

10X - 100X

(for FN 26.5 super

widefield)

U-SC3

Swing-out

With numerical aperture scale

1.25X (for FN 22

widefield),

2X - 100X (for FN 26.5

super widefield)

U-UCD8A

Motorized, achromat/

aplanat, swing-out

2X - 100X (for FN 26.5

super widefield)

8. Operating environment

· Indoor use.

· Altitude: Max. 2000 meters

· Ambient temperature: 5° to 40°C (41° to 104° F)

· Maximum relative humidity: 80% for temperatures up to 31°C (88°F), decreasing linearly

through 70% at 34°C (93°F), 60% at 37°C (99°F), to 50% relative humidity at 40°C (104°F).

· Supply voltage fluctuations; Not to exceed ±10% of the normal voltage.

· Pollution degree: 2 (in accordance with IEC60664)

· Installation/Overvoltage category: II (in accordance with IEC60664)

26

Page 31

BX61

OPTICAL CHARACTERISTICS «UIS2 (UIS) Series»

UIS series objectives not listed here can also be combined with this microscope.

The following table shows the optical characteristics of combinations of eyepieces and objectives. The figure on the right

shows the performance data engraved on the objectives.

NOTE

Refer to the latest catalogue or consult your local Olympus

representative for the updated information on the eyepieces

and objectives that can be combined with this microscope.

Optical

Objective

UIS2

Series

character

PlanN-P Plan

Achromat for

polarized light

(FN22)

AchN-P Achromat

for polarized light

(FN22)

PlanN Plan

Achromat (FN22)

UPlanFLN Plan

Semi Apochromat

(FN26.5)

UPlanSApo Plan

Apochromat

(FN26.5)

PlanApoN Plan

Apochromat

(FN26.5)

MPlanFLN

Plan

Semi

Apochromat

(FN26.5)

MPlanApoN

No Cover Plan

Apochromat

(FN26.5)

Magnifi-

cation

4X 0.1 18.5

10X 0.25 6.0

20X 0.4 3.0 0.17 0.84 200X 9.3 1.1

40X 0.65 0.45 0.17 0.52 400X 2.0 0.55

100XO 1.25 0.13

2X 0.06 5.8

4X 0.1 18.5

10X 0.25 10.6

20X 0.4 1.2 0.17 0.84 200X 9.27 1.1

40X 0.65 0.6 0.17 0.52 400X 3.04 0.55

50XOI 0.5-0.9 0.2 0.17 0.37 500X 1.7 0.44

100XO 1.25 0.15

4X 0.13 17.0

10X2 0.3 10.0

20X 0.5 2.1 0.17 0.67 200X 7.0 1.1

40X 0.75 0.51 0.17 0.45 400X 2.52 0.55

40XO 1.3 0.2 0.17 0.26 400X 1.27 0.55

60X 0.9 0.2 0.17 0.37 600X 1.5 0.37

60XOI 0.65-1.25 0.12 0.17 0.27 600X 0.98 0.37

100XO2 1.30 0.2 0.17 0.26 1000X 0.66 0.22

100XOI2 0.6-1.30 0.2 0.17 0.26 1000X 0.66 0.22

4X 0.16 13.0

10X2 0.4 3.1 0.17 0.84 100X 15.9 2.2

20X 0.75 0.6 0.17 0.45 200X 4.29 1.1

20XO 0.85 0.17

40X2 0.95 0.18 0.17 0.35 400X 1.9 0.55

60XW 1.2 0.28 0.17 0.28 600X 1.03 0.37

60XO 1.35 0.15 0.17 0.25 600X 0.89 0.37

100XO 1.4 0.13 0.17 0.24 1000X 0.59 0.22

1.25X 0.04 5.0

2X 0.08 6.2

60XO 1.42 0.15 0.17 0.24 600X 0.83 0.37

40X 0.75 0.63 0 0.45 400X 1.7 0.55

100XO 1.40 0.10 0 0.24 1000X 0.59 0.22

N.A.

W.D.

(mm)

Cover

glass

thick-

ness

(mm)

—

—

—

—

—

—

—

—

—

—

—

—

—

Magnification

Mechanical tube

length

Color band

Resolution

(μm)

3.40 40X 180.0 5.5

1.30 100X 28.0 2.2

0.27 1000X 0.69 0.22

5.59 20X 560.1 11.0

3.36 40X 175.0 5.5

1.34 100X 28.0 2.2

0.27 1000X 0.69 0.22

2.58 40X 127.2 5.5

1.12 100X 22.4 2.2

2.50 40X 99.6 5.5

0.39 200X 3.5 1.1

8.39 12.5X 1326.8 17.6

4.19 20X 398.3 11.0

Total mag.

Eyepiece

WHN10X (FN22)

Depth of

focus

(μm)

Objective type

Number of aperture

Oil: Oil immersion

Iris: Iris diaphragm

Field number (FN)

Cover glass thickness

Field of

view

Remark

Oil immersion/Iris

Oil immersion

Oil immersion

Correction collar

Oil immersion/Iris

Oil immersion

Oil immersion/Iris

Oil immersion

Correction collar

Water immersion

Oil immersion

Oil immersion

Oil immersion

Oil immersion

27

Page 32

Objective

UIS

Series

Optical

character

PlanFl

Plan Semi

Apochromat

(FN26.5)

UApo

Apochromat

(FN22)

Cover

Magnifi-

cation

100X 0.95 0.20 0.14-0.20 0.35 1000X 1.0 0.22

20X3/340 0.75 0.55 0.17 0.45 200X 4.3 1.1

20XW3/340

40X3/340 0.90 0.20 0.11-0.23 0.37 400X 2.0 0.55

40XW3/340

40XOI3/340

N.A.

0.70 0.40 0.17 0.48 200X 4.08 1.1

1.15 0.26 0.13-0.25 0.29 400X 1.29 0.55

0.65-1.35 0.10 0.17 0.25 400X 1.2 0.55

W.D.

(mm)

glass

thick-

ness

(mm)

Resolution

(μm)

Total mag.

Eyepiece

WHN10X (FN22)

Depth of

focus

(μm)

Field of

Remark

view

Correction collar

Correction collar

Correction collar

Oil immersion/Iris

28

Page 33

BX61

ASSEMBLY

7-1 Assembly Diagram

The diagram below shows the sequence of assembly of the various modules. The numbers indicate the order of assembly.

The BX61TRF microscope frame is assembled in the same procedures.

The module model numbers shown in the following diagram are merely the typical examples. For the modules with which

the model numbers are not given, please consult your Olympus representative or the catalogues.

# When assembling the microscope, make sure that all parts are free of dust and dirt, and avoid scratching any parts

or touching glass surfaces.

Assembly steps enclosed in will be detailed on the subsequent pages.

}Most assembly operations are possible by using the Allen screwdriver ( ) provided with the microscope. How-

ever, the assembly of the reflected light illuminator requires the use of the provided Allen wrench ( ) for clamping the

internal screws (to ensure the performance, we recommend that you have your Olympus representative assemble or

remove this module).

Eyepiece

WHN10X (FN 22)

35WHN10X (FN 22)

SWH10X-H (FN 26.5)

35SWH10X (FN 26.5)

Observation tube

U-BI30-2 (FN 22)

U-TR30-2 (FN 22)

U-TR30NIR (FN 22)

U-TBI3 (FN 22)

U-SWTR-3 (FN 26.5)

U-ETBI (FN 22)

U-TTBI (FN 22)

Reflected light illuminator

BX-RFAA

BX-RLAA

Reflected

lamp

housing

Slide holder

U-HLDT-4

U-HRDT-4

U-HLST-4

Stage clamping

knob

Stage

U-SVRB-4

U-SVLB-4

U-SRG

Condenser

U-SC3

U-AAC

U-UCD8A

Revolving nosepiece

U-D6RE

U-D6REM

U-D6REMC, etc.

UIS2/UIS

series

objective

Specimen

holder

clamping

knobs

Condenser clamping

screw

Intermediate

attachment

U-EPA2

U-DO3

U-TRU, etc.

Tube clamping

screw

Revolving

nosepiece

clamping screw

Microscope frame

(Transmitted light

specification)

BX61TRF

Microscope frame

(Transmitted/reflected

light specification)

BX61TRF

100 W halogen

lamp housing

U-LH100-3

Lamp socket

clamping screw

}For the electrical connections, refer to the instruction manual of the BX-UCB control box.

For the setup and installation of the Z-board, see page 30.

100 W halogen bulb

12V100WHAL-L

12V50WHAL-L

29

Page 34

7-2 Detailed Assembly Procedures

# For use in focusing control, only either the Z-board or AF control board can be installed on the BX-UCB.

Installing different boards on it may result in malfunction. When using the AF control board instead of the Z-board,

set the on-board DIP switches on the AF control board to the same settings as the following settings that are

originally intended for the Z-board.

Setup and Installation of the Z-Board

}The on-board DIP switches on the Z-board have been set up for the

BX61 or BX62 (all of switches S1, S2 and S3 are set to OFF).

²

S1 S2 S3

Fig. 38

@

Fig. 39

³

Changing the Settings of On-Board DIP Switches (Fig. 38)

#Leave all other DIP switches than those mentioned below in the OFF

positions.

}Switch only the DIP switches mentioned below to the ON positions.

S2 No. 4

· This replaces the functions of the F/C switching and stage escape buttons on the left side of the BX61/BX62 with the stage DOWN and UP

buttons.

S3 No. 1

· This turns off the automatic initialization and sets the remote mode which

is the default.

S3 No. 4

· When the U-FWT filter wheel is not used, this changes the focus adjustment stroke from 15 mm to 25 mm.

}When the U-LWUCD long-WD universal condenser is used, set this to

the OFF position.

Mounting the Z-Board (Fig. 39)

}Be sure to set the main switch on the BX-UCB control box @ to “ ”

(OFF) before proceeding to mounting the Z-board.

1. Loosen the 6 clamping knobs on the 2 option slot covers on the rear of

the BX-UCB and remove the covers and knobs.

2. Insert the Z-board ² into the BX-UCB by aligning the orientation of the

connector inside the BX-UCB and that of the Z-board. Push in the board

along the board rails all the way so that the connector is plugged in

securely.

3. Clamp the Z-board ² using two of the clamping knobs removed above.

Also attach one of the removed covers ³ using the other four clamping

knobs removed above.

}Store the other, removed cover in a safe place.

30

Page 35

BX61

@

²

Fig. 40

Fig. 41

ƒ

³

…

1 Installing the Halogen Bulb

}Use only the designated bulb 12V100WHAL-L (PHILIPS 7724) or

12V50WHAL-L (LIFE JC).

1. Fully loosen the lamp housing clamping screw @ on top of the lamp

housing cover with the provided Allen screwdriver.

2. Lift the lamp housing cover ² upward to remove it.

3. Turn the lamp socket ³ by 90° in the direction indicated by the arrow.

4. Holding the bulb ƒ with gloves or a piece of gauze, depress the bulb

clamping lever | and insert the bulb pins … fully into the sections † as

far as they will go.

Gently release the bulb clamping lever to the original position to secure

the bulb.

To prevent reduced bulb life or cracking, do not touch the bulb with

bare hands. If fingerprints are accidentally left on the bulb, wipe the

bulb with a soft cloth.

5. Side the lamp housing cover onto the housing base from the above.

Tighten the clamping screw @ while pressing downward on the cover.

(Fig. 40)

Caution for Bulb Replacement During Use or Right After Use

The bulb, lamp socket and areas near these will be extremely hot

during and right after use.

Set the main switch to “ ” (OFF), disconnect the power cord from

the wall outlet, then allow the old bulb and lamp housing to cool

before replacing the bulb with a new of the designated type.

(Figs. 40 - 42)

|

Fig. 42

Fig. 43

†

@

²

6 Attaching the Eyepiece

Fit the eyepiece into each sleeve as far as it goes.

# When using the U-BI30-2 binocular tube, eyepiece with built-in mi-

crometer disk cannot be attached.

# When using a finder eyepiece or an eyepiece with focusing mirror,

attach it to the right-hand eyepiece sleeve.

When doing so, make sure that the eyepiece positioning pin @ fits

into the notch ² on the eyepiece sleeve.

# The super-widefield trinocular observation tube is equipped with a

positioning notch on both eyepiece sleeves. Make sure that the

positioning pins on both eyepieces fits into the respective notches.

(Fig. 43)

31

Page 36

Fig. 44

³

²

@

9 Attaching the Condenser

}This operation necessitates the operation of the motorized focusing. Con-

nect the cables and set the main switch to “ I ” (ON) before proceeding to

the following.

1. Press the stage UP button @ to raise the stage to its upper limit.

2. Fit the Allen screwdriver into the condenser height adjustment screw ²

and turn the tool counterclockwise to lower the condenser to its lower

limit.

3. Fully loosen the condenser clamping screw ³ using the Allen screwdriver.

}When attaching the U-SC3 swing-out condenser, align the positioning

pin at the back of the condenser with the groove in the condenser sleeve.

#When attaching a condenser with swing-out top lens, swing out the

top lens out of the way before inserting the condenser.

4. Position the condenser so that the aperture scale or optical device indication plate is located in front. Gently slide the condenser along the

dovetail all the way until it is stopped.

5. Tighten the condenser clamping screw ³ and gently raise the condenser

holder to its highest position.

(Fig. 44)

32

Page 37

BX61

PROPER SELECTION OF THE POWER SUPPLY CORD

If no power supply cord is provided, please select the proper power supply cord for the equipment by referring to “ Specifications ” and

“ Certified Cord ” below:

CAUTION:

In case you use a non-approved power supply cord for Olympus products, Olympus can no longer warrant the

electrical safety of the equipment.

Specifications

Voltage Rating

Current Rating

Temperature Rating

Length

Fittings Configuration

125V AC (for 100-120V AC area) or, 250V AC (for 220-240V AC area)

6A minimum

60°C minimum

3.05 m maximum

Grounding type attachment plug cap. Opposite terminates in molded-on IEC configuration appliance coupling.

Table 1 Certified Cord

A power supply cord should be certified by one of the agencies listed in Table 1 , or comprised of cordage marked with an

agency marking per Table 1 or marked per Table 2. The fittings are to be marked with at least one of agencies listed in

Table 1. In case you are unable to buy locally in your country the power supply cord which is approved by one of the

agencies mentioned in Table 1, please use replacements approved by any other equivalent and authorized agencies in

your country.

Country Agency

Argentina

Australia

IRAM

SAA

Certification

Mark

Country Agency

Italy

Japan

IMQ

JET, JQA, TÜV,

UL-APEX / MITI

Certification

Mark

Austria

Belgium

Canada

Denmark

Finland

France

Germany

Ireland

ÖVE

CEBEC

CSA

DEMKO

FEI

UTE

VDE

NSAI

Netherlands

Norway

Spain

Sweden

Switzerland

United

Kingdom

U.S.A.

KEMA

NEMKO

AEE

SEMKO

SEV

ASTA

BSI

UL

33

Page 38

Table 2 HAR Flexible Cord

APPROVAL ORGANIZATIONS AND CORDAGE HARMONIZATION MARKING METHODS

Approval Organization

Comite Electrotechnique Belge

(CEBEC)

Verband Deutscher Elektrotechniker

(VDE) e.V. Prüfstelle

Union Technique de l´Electricite´

(UTE)

Instituto Italiano del Marchio di

Qualita´ (IMQ)

British Approvals Service for Electric

Cables (BASEC)

N.V. KEMA

SEMKO AB Svenska Elektriska

Materielkontrollanstalter

Österreichischer Verband für

Elektrotechnik (ÖVE)

Danmarks Elektriske Materialkontroll

(DEMKO)

Printed or Embossed Harmonization Marking (May be located on

jacket or insulation of internal wiring)

CEBEC <HAR>

<VDE> <HAR>

USE <HAR>

IEMMEQU <HAR>

BASEC <HAR>

KEMA-KEUR <HAR>

SEMKO <HAR>

<ÖVE> <HAR>

<DEMKO> <HAR>

Alternative Marking Utilizing

Black-Red-Yellow Thread (Length

of color section in mm)

Black Red Yellow

10 30 10

30 10 10

30 10 30

10 30 50

10 10 3 0

10 30 30

10 10 5 0

30 10 50

30 10 30

National Standards Authority of Ireland

(NSAI)

Norges Elektriske Materiellkontroll

(NEMKO)

Asociacion Electrotecnica Y

Electronica Espanola (AEE)

Hellenic Organization for

Standardization (ELOT)

Instituto Portages da Qualidade

(IPQ)

Schweizerischer Elektro

Technischer Verein (SEV)

Elektriska Inspektoratet

Underwriters Laboratories Inc. (UL) SV, SVT, SJ or SJT, 3 X 18AWG

Canadian Standards Association (CSA) SV, SVT, SJ or SJT, 3 X 18AWG

<NSAI> <HAR>

NEMKO <HAR>

<UNED> <HAR>

ELOT <HAR>

np <HAR>

SEV <HAR>

SETI <HAR>

30 30 50

10 10 70

30 10 70

30 30 70

10 10 9 0

10 30 90

10 30 90

34

Page 39

Page 40

EC REP

Shinjuku Monolith, 3-1, Nishi Shinjuku 2-chome, Shinjuku-ku, Tokyo, Japan

Wendenstraße 14-18, 20097 Hamburg, Germany

3500 Corporate Parkway, P.O. Box 610, Center Valley, PA 18034-0610, U.S.A.

One Corporate Drive, Orangeburg, NY 10962, U.S.A.

491B River Valley Road, #12-01/04 Valley Point Office Tower, Singapore 248373

31 Gilby Road, Mount Waverley, VIC., 3149, Australia

Blue Lagoon Drive, Suite 290 Miami, FL 33126, U.S.A.

5301

01/10

Loading...

Loading...