Olivetti MT-502, d-Color MF201Plus, d-Color MF450, d-Color MF350, d-Color MF250 Service Manual

MT-502

Option Printer

SERVICE MANUAL

Code Y108462-9

d-Color MF201Plus - MF250 - MF350

d-Color MF450

PUBLICATION ISSUED BY:

Olivetti S.p.A.

77, Via Jervis - 10015 Ivrea (TO)

Italy

Copyright © 2008, Olivetti

All rights reserved

MT-502GeneralMaintenanceAdjustment / Setting

Troubleshooting

Field Service Ver. 2.0 Jan. 2008

i

CONTENTS

MT-502

Outline

1. Product specification ............................................................................................... 1

Maintenance

2. Other ....................................................................................................................... 3

2.1 Disassembly/adjustment prohibited items ............................................................ 3

2.2 Disassembly/Assembly/Cleaning list (Other parts)............................................... 4

2.2.1 Disassembly/Assembly parts list................................................................... 4

2.2.2 Cleaning parts list ......................................................................................... 4

2.3 Disassembly/Assembly procedure........................................................................ 4

2.3.1 Rear cover/Right door ................................................................................... 4

2.3.2 Front cover/Upper cover/Paper output tray ................................................... 5

2.4 Cleaning procedure .............................................................................................. 5

2.4.1 Cleaning of the roller and roll ........................................................................ 5

Adjustment/Setting

3. How to use the adjustment section ......................................................................... 7

4. Sensor check........................................................................................................... 8

4.1 Check procedure .................................................................................................. 8

4.1.1 Sensor check screen..................................................................................... 8

4.1.2 Sensor check list ........................................................................................... 9

5. Finisher operations................................................................................................ 10

5.1 Entering Finisher Check ..................................................................................... 10

5.2 Finisher Check modes ........................................................................................ 10

Troubleshooting for d-Color 350 / MF250 / MF201Plus

6. Jam display ........................................................................................................... 11

6.1 Misfeed display................................................................................................... 11

6.1.1 Misfeed display resetting procedure ........................................................... 11

6.2 Sensor layout...................................................................................................... 12

6.3 Solution............................................................................................................... 13

6.3.1 Initial check items........................................................................................ 13

6.3.2 Solution when paper curl occurs................................................................. 13

6.3.3 Transport section misfeed ........................................................................... 14

MT-502

GeneralMaintenanceAdjustment / Setting

Troubleshooting

Field Service Ver. 2.0 Jan. 2008

ii

Troubleshooting for d-Color MF450

7.Jam display...........................................................................................................15

7

.1Misfeed display...................................................................................................15

7

.1.1Misfeed display resetting procedure...........................................................15

7

.2Sensor layout......................................................................................................16

7

.3Solution...............................................................................................................17

7

.3.1Initial check items........................................................................................17

7

.3.2Transport section misfeed...........................................................................18

Field Service Ver. 2.0 Jan. 2008 1. Product specification

1

MT-502General

Outline

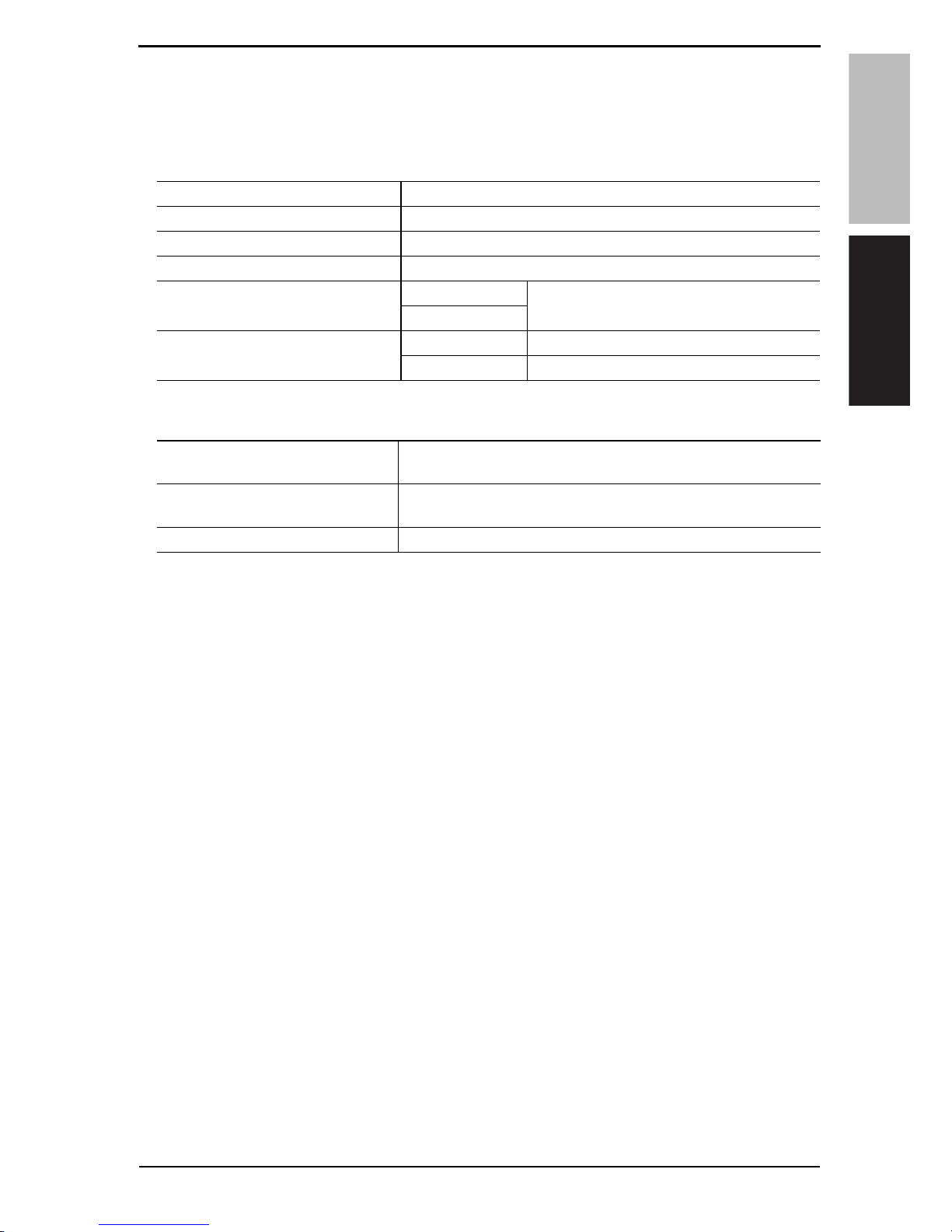

1. Product specification

A. Type

B. Machine specifications

C. Operating environment

• Conforms to the operating environment of the main body.

NOTE

• These specifications are subject to change without notice.

Name Mailbin kit

Installation Install at the top section of the finisher elevator tray.

Number of bins 4 bins

Number of sheets stored per bin 125 sheets (Total 500 sheets) (90 g/m

2

, 24 lb)

Storable paper

Plain paper

60 to 90 g/m

2

(16 to 24 lb)

Recycled paper

Storable paper size

Metric area A5S, B5, A4

Inch area

5-

1

/2 x 8-1/2S, 8-1/2 x 11

Power requirements

DC 24 V (Supplied from the finisher)

DC 5 V (Generated inside the mail bin)

Dimensions

340 mm (W) x 509 mm (D) x 387 mm (H)

13.5 inch (W) x 20 inch (D) x 15.25 inch (H)

Weight 8.0 kg (17.75 lb)

Y108462-99 Service Manual

1. Product specification Field Service Ver. 2.0 Jan. 2008

2

MT-502

General

Blank Page

Service Manual Y108462-9

Field Service Ver. 2.0 Jan. 2008 2. Other

3

MT-502Maintenance

Maintenance

2. Other

2.1 Disassembly/adjustment prohibited items

A. Paint-locked screws

NOTE

• To prevent loose screws, a screw lock in blue or green series color is applied to

the screws.

• The screw lock is applied to the screws that may get loose due to the vibrations

and loads created by the use of machine or due to the vibrations created during

transportation.

• If the screw lock coated screws are loosened or removed, be sure to apply a screw

lock after the screws are tightened.

B. Red-painted screws

NOTE

• The screws which are difficult to be adjusted in the field are painted in red in order

to prevent them from being removed by mistake.

• Do not remove or loosen any of the red-painted screws in the field. It should also

be noted that, when two or more screws are used for a single part, only one representative screw may be marked with the red paint.

C. Variable resistors on board

NOTE

• Do not turn the variable resistors on boards for which no adjusting instructions

are given in Adjustment/Setting.

D. Removal of PWBs

CAUTION

• When removing a circuit board or other electrical component, refer to “Handling of

PWBs” and follow the corresponding removal procedures.

• The removal procedures given in the following omit the removal of connectors and

screws securing the circuit board support or circuit board.

• Where it is absolutely necessary to touch the ICs and other electrical components

on the board, be sure to ground your body.

Y108462-9 Service Manual

Loading...

Loading...