Option Copier

SERVICE MANUAL

Code Y104371-8

DF-650

MT-1(A)

BF1(A)

PH-4A/PH-4C

PUBLICATION ISSUED BY:

Olivetti S.p.A.

77, Via Jervis - 10015 Ivrea (TO)

Italy

Copyright © 2008, Olivetti

All rights reserved

This page is intentionally left blank.

Safety precautions

This booklet provides safety warnings and precautions for our service personnel to ensure the safety of

their customers, their machines as well as themselves during maintenance activities. Service personnel

are advised to read this booklet carefully to familiarize themselves with the warnings and precautions

described here before engaging in maintenance activities.

Safety warnings and precautions

Various symbols are used to protect our service personnel and customers from physical danger and

to prevent damage to their property. These symbols are described below:

DANGER: High risk of serious bodily injury or death may result from insufficient attention to or incorrect

compliance with warning messages using this symbol.

WARNING: Serious bodily injury or death may result from insufficient attention to or incorrect compliance

with warning messages using this symbol.

CAUTION: Bodily injury or damage to property may result from insufficient attention to or incorrect

compliance with warning messages using this symbol.

Symbols

The triangle ( ) symbol indicates a warning including danger and caution. The specific point

of attention is shown inside the symbol.

General warning.

Warning of risk of electric shock.

Warning of high temperature.

indicates a prohibited action. The specific prohibition is shown inside the symbol.

General prohibited action.

Disassembly prohibited.

indicates that action is required. The specific action required is shown inside the symbol.

General action required.

Remove the power plug from the wall outlet.

Always ground the copier.

1.Installation Precautions

WARNING

• Do not use a power supply with a voltage other than that specified. Avoid multiple connections to

one outlet: they may cause fire or electric shock. When using an extension cable, always check

that it is adequate for the rated current. .............................................................................................

• Connect the ground wire to a suitable grounding point. Not grounding the copier may cause fire or

electric shock. Connecting the earth wire to an object not approved for the purpose may cause

explosion or electric shock. Never connect the ground cable to any of the following: gas pipes,

lightning rods, ground cables for telephone lines and water pipes or faucets not approved by the

proper authorities. ............................................................................................................................

CAUTION:

• Do not place the copier on an infirm or angled surface: the copier may tip over, causing injury. .......

• Do not install the copier in a humid or dusty place. This may cause fire or electric shock. ................

• Do not install the copier near a radiator, heater, other heat source or near flammable material.

This may cause fire. .........................................................................................................................

• Allow sufficient space around the copier to allow the ventilation grills to keep the machine as cool

as possible. Insufficient ventilation may cause heat buildup and poor copying performance. ...........

• Always handle the machine by the correct locations when moving it. ...............................................

• Always use anti-toppling and locking devices on copiers so equipped. Failure to do this may cause

the copier to move unexpectedly or topple, leading to injury. ...........................................................

• Avoid inhaling toner or developer excessively. Protect the eyes. If toner or developer is accidentally ingested, drink a lot of water to dilute it in the stomach and obtain medical attention immediately. If it gets into the eyes, rinse immediately with copious amounts of water and obtain medical

attention. ......................................................................................................................................

• Advice customers that they must always follow the safety warnings and precautions in the copier’s

instruction handbook. .....................................................................................................................

2.Precautions for Maintenance

WARNING

• Always remove the power plug from the wall outlet before starting machine disassembly. ...............

• Always follow the procedures for maintenance described in the service manual and other related

brochures. .......................................................................................................................................

• Under no circumstances attempt to bypass or disable safety features including safety mechanisms

and protective circuits. .....................................................................................................................

• Always use parts having the correct specifications. ..........................................................................

• Always use the thermostat or thermal fuse specified in the service manual or other related brochure when replacing them. Using a piece of wire, for example, could lead to fire or other serious

accident. ..........................................................................................................................................

• When the service manual or other serious brochure specifies a distance or gap for installation of a

part, always use the correct scale and measure carefully. ................................................................

• Always check that the copier is correctly connected to an outlet with a ground connection. .............

• Check that the power cable covering is free of damage. Check that the power plug is dust-free. If it

is dirty, clean it to remove the risk of fire or electric shock. ..............................................................

• Never attempt to disassemble the optical unit in machines using lasers. Leaking laser light may

damage eyesight. ...........................................................................................................................

• Handle the charger sections with care. They are charged to high potentials and may cause electric

shock if handled improperly. ............................................................................................................

CAUTION

• Wear safe clothing. If wearing loose clothing or accessories such as ties, make sure they are

safely secured so they will not be caught in rotating sections. ..........................................................

• Use utmost caution when working on a powered machine. Keep away from chains and belts. ........

• Handle the fixing section with care to avoid burns as it can be extremely hot. ..................................

• Check that the fixing unit thermistor, heat and press rollers are clean. Dirt on them can cause

abnormally high temperatures. ........................................................................................................

• Do not remove the ozone filter, if any, from the copier except for routine replacement. ....................

• Do not pull on the AC power cord or connector wires on high-voltage components when removing

them; always hold the plug itself. .....................................................................................................

• Do not route the power cable where it may be stood on or trapped. If necessary, protect it with a

cable cover or other appropriate item. .............................................................................................

• Treat the ends of the wire carefully when installing a new charger wire to avoid electric leaks. ........

• Remove toner completely from electronic components. ...................................................................

• Run wire harnesses carefully so that wires will not be trapped or damaged. ....................................

• After maintenance, always check that all the parts, screws, connectors and wires that were

removed, have been refitted correctly. Special attention should be paid to any forgotten connector,

trapped wire and missing screws. ...................................................................................................

• Check that all the caution labels that should be present on the machine according to the instruction

handbook are clean and not peeling. Replace with new ones if necessary. ......................................

• Handle greases and solvents with care by following the instructions below: .....................................

· Use only a small amount of solvent at a time, being careful not to spill. Wipe spills off completely.

· Ventilate the room well while using grease or solvents.

· Allow applied solvents to evaporate completely before refitting the covers or turning the power

switch on.

· Always wash hands afterwards.

• Never dispose of toner or toner bottles in fire. Toner may cause sparks when exposed directly to

fire in a furnace, etc. .......................................................................................................................

• Should smoke be seen coming from the copier, remove the power plug from the wall outlet imme-

diately. ............................................................................................................................................

3.Miscellaneous

WARNING

• Never attempt to heat the drum or expose it to any organic solvents such as alcohol, other than the

specified refiner; it may generate toxic gas. .....................................................................................

This page is intentionally left blank.

3H3-2.0

CONTENTS

1-1 Specifications

1-1-1 Specifications..........................................................................................................................................1-1-1

1-1-2 Parts names............................................................................................................................................1-1-2

1-1-3 Machine cross sectional view .................................................................................................................1-1-3

1-1-4 Machine drive system .............................................................................................................................1-1-4

(1) Finisher (paper feed and conveying section) ....................................................................................1-1-4

(2) Finisher (main tray driving section) ...................................................................................................1-1-5

(3) Multi job tray ......................................................................................................................................1-1-6

(4) Centerfold unit...................................................................................................................................1-1-7

(5) Punch unit .........................................................................................................................................1-1-7

1-2 Installation

1-2-1 Unpacking and installation......................................................................................................................1-2-1

1-2-2 Installing the centerfold unit (option) .......................................................................................................1-2-3

1-2-3 Installing the multi job tray (option) .......................................................................................................1-2-11

1-2-4 Installing the punch unit (option) ...........................................................................................................1-2-17

1-2-5 Installing the stopper guide (option)......................................................................................................1-2-21

(1) Installing the stopper guide (To the finisher without the multi job tray) ...........................................1-2-21

(2) Installing the stopper guide (To the finisher with the multi job tray) ................................................1-2-22

1-3 Maintenance Mode

1-3-1 Maintenance mode .................................................................................................................................1-3-1

(1) Executing a maintenance item ..........................................................................................................1-3-1

(2) Contents of the maintenance mode items.........................................................................................1-3-2

1-4 Troubleshooting

1-4-1 Paper misfeed detection .........................................................................................................................1-4-1

(1) Paper misfeed indication ...................................................................................................................1-4-1

(2) Paper misfeed detection conditions ..................................................................................................1-4-2

(3) Paper misfeeds .................................................................................................................................1-4-3

1-4-2 Self-diagnosis .........................................................................................................................................1-4-6

(1) Self-diagnostic function .....................................................................................................................1-4-6

(2) Self diagnostic codes ........................................................................................................................1-4-7

1-4-3 Electric problems ..................................................................................................................................1-4-14

1-4-4 Mechanical problems............................................................................................................................1-4-22

1-5 Assembly and Disassembly

1-5-1 Finisher ...................................................................................................................................................1-5-1

(1) Correcting paper curling ....................................................................................................................1-5-1

(2) Correcting centerfold-stapling ...........................................................................................................1-5-3

(3) Adjusting the stapler unit mounting position......................................................................................1-5-4

(4) Centering stapling position ................................................................................................................1-5-7

1-5-2 Centerfold unit.........................................................................................................................................1-5-9

(1) Detaching and refitting the centerfold blade......................................................................................1-5-9

(2) Adjusting the paper folding position ................................................................................................1-5-11

1-5-3 Punch unit.............................................................................................................................................1-5-12

(1) Centering punch-holes ....................................................................................................................1-5-12

(2) Setting margin from the leading edge to punch holes .....................................................................1-5-13

1-6 Requirements on PWB Replacement

1-6-1 Upgrading the version of the firmware of the finisher main PWB ...........................................................1-6-1

1-6-2 Requirements on finisher main PWB replacement .................................................................................1-6-2

3H3-2.0

2-1 Mechanical construction

2-1-1 Finisher ...................................................................................................................................................2-1-1

(1) Paper insertion section......................................................................................................................2-1-1

(2) Feedshift section ...............................................................................................................................2-1-2

(3) Intermediate tray section ...................................................................................................................2-1-5

(4) Paper eject section..........................................................................................................................2-1-13

2-1-2 Multi job tray..........................................................................................................................................2-1-15

2-1-3 Centerfold unit.......................................................................................................................................2-1-17

2-1-4 Punch unit.............................................................................................................................................2-1-20

2-2 Electrical Parts Layout

2-2-1 Electrical parts layout..............................................................................................................................2-2-1

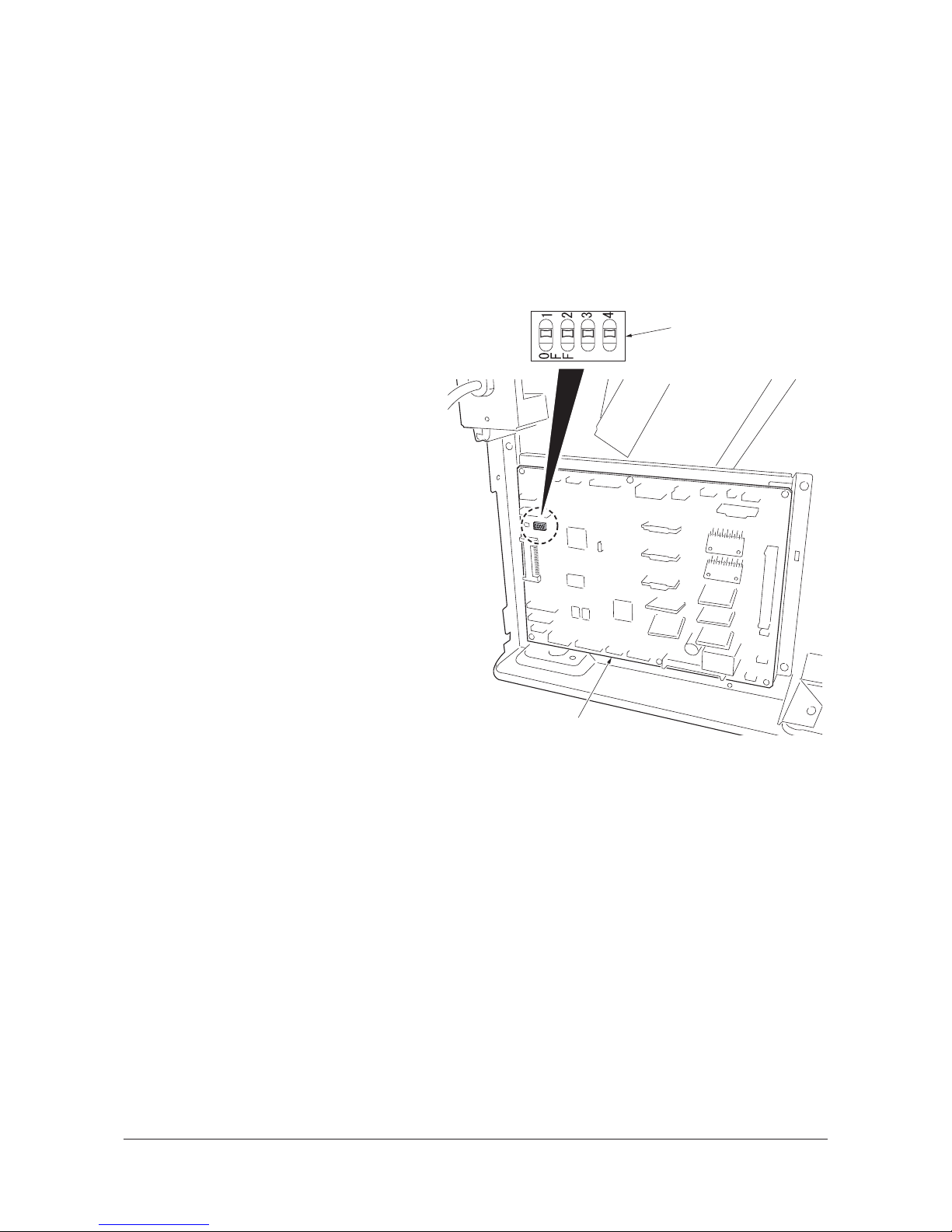

(1) PWBs (finisher) .................................................................................................................................2-2-1

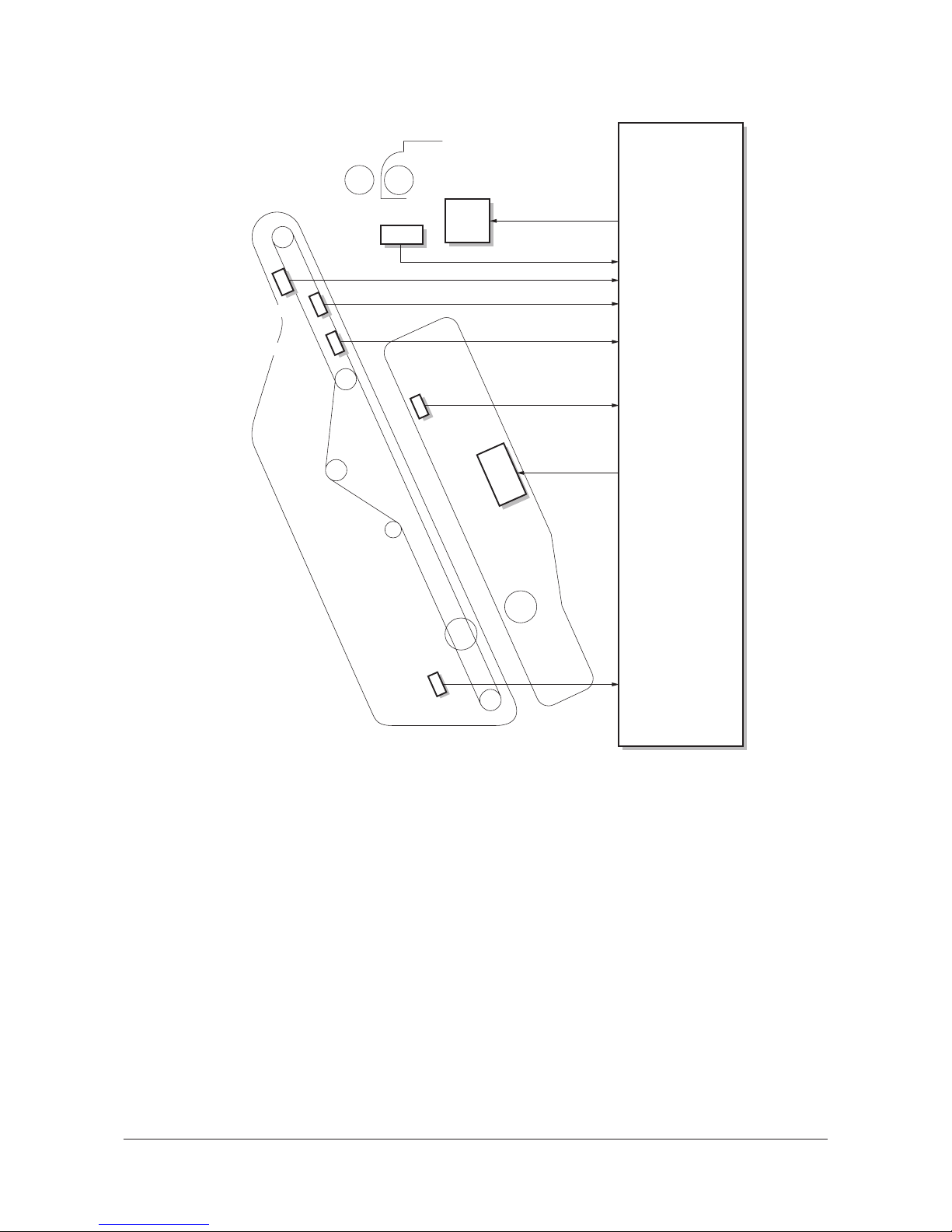

(2) Switches and sensors (finisher) ........................................................................................................2-2-2

(3) Clutches and solenoids (finisher) ......................................................................................................2-2-4

(4) Motors and others (finisher) ..............................................................................................................2-2-5

(5) Stapler ...............................................................................................................................................2-2-6

(6) PWBs (optional centerfold unit).........................................................................................................2-2-7

(7) Switches and sensors (optional centerfold unit)................................................................................2-2-8

(8) Motors and solenoids (optional centerfold unit).................................................................................2-2-9

(9) Switches and motors (optional multi job tray)..................................................................................2-2-10

(10) Switches and motors (optional punch unit) .....................................................................................2-2-11

2-3 Operation of the PWBs

2-3-1 Finisher main PWB .................................................................................................................................2-3-1

2-3-2 Finisher drive PWB ...............................................................................................................................2-3-10

2-3-3 Centerfold unit main PWB.....................................................................................................................2-3-14

2-4 Appendixes

Timing chart No.1....................................................................................................................................2-4-1

Timing chart No.2....................................................................................................................................2-4-2

Timing chart No.3....................................................................................................................................2-4-3

Timing chart No.4....................................................................................................................................2-4-4

Maintenance parts list.............................................................................................................................2-4-5

Periodic maintenance procedures ..........................................................................................................2-4-7

Optional devices supplied parts list.......................................................................................................2-4-11

Centerfold unit wiring diagram ..............................................................................................................2-4-13

General wiring diagram No.1 ................................................................................................................2-4-14

General wiring diagram No.2 ................................................................................................................2-4-15

General wiring diagram No.3 ................................................................................................................2-4-16

General wiring diagram No.4 ................................................................................................................2-4-17

General wiring diagram No.5 ................................................................................................................2-4-18

General wiring diagram No.6 ................................................................................................................2-4-19

General wiring diagram No.7 ................................................................................................................2-4-20

3H3

1-1-1

1-1 Specifications

1-1-1 Specifications

Finisher

Type................................................ Floor type

Number of trays ..............................2 trays

Tray capacity ................................... Main tray (80 g/m2 weight paper)

A3, B4 (257 x 364 mm), 11" x 17", 8

1/2

" x 14": 1500 sheets

A4 - A6R, Folio, 8

1/2

" x 11", 11" x 8

1/2

", 5

1/2

" x 8

1/2

": 3000 sheets

Sub tray (80 g/m2 weight paper)

A3 - A6R, Folio, 11" x 17", 8 1/2" x 14", 8 1/2" x 11", 11" x 8 1/2", 5 1/2" x 8 1/2": 200

sheets

Stapling capacity ............................. A3, B4 (257 x 364 mm), 11" x 17", 8

1/2" x 14": 30 sheets

A4, A4R, B5, 8 1/2" x 11", 11" x 8 1/2": 50 sheets

Storage capacity.............................A3, B4 (257 x 364 mm), 11" x 17", 8

1/2" x 14"

Stapling 2 - 4 sheets: 150 sets

Stapling 5 - 10 sheets: 100 sets

Stapling 11 - 30 sheets: 50 sets

A4, A4R, 8

1/2" x 11", 11" x 8 1/2", 5 1/2" x 8 1/2"

Stapling 2 - 4 sheets: 150 sets

Stapling 5 - 10 sheets: 100 sets

Stapling 11 - 30 sheets: 50 sets

Stapling 31 - 50 sheets: 3000 sheets

Power source..................................Supplied via machine

Dimensions (W x D x H) ................ 796 x 640 x 1070 mm

31

5/16" x 25 3/16" x 42 1/8"

Weight.............................................Approx. 73 kg/160.6 lbs.

Multi job tray (option)

Number of trays ..............................Job tray: 5

Paper size.......................................A3, B4 (257 x 364 mm), A4, A4R, A5R, B6R, Folio, 11" x 17", 8

1/2" x 14", 8 1/2" x 11",

11" x 8 1/2", 5 1/2" x 8 1/2"

Tray capacity................................... A3, B4 (257 x 364 mm), 11" x 17", 8

1/2" x 14": 100 sheets (80 g/m

2

weight paper)

A4 - B6R, Folio, 8

1/2" x 11", 11" x 8 1/2", 5 1/2" x 8 1/2": 150 sheets (80 g/m

2

weight

paper)

Dimensions (W x D x H) .................368 x 392 x 573 mm

14

1/2" x 15 7/16" x 22 9/16"

Weight ............................................Approx.15 kg/33 lbs.

Centerfold unit (option)

Foldable sizes.................................A3, B4 (257 x 364 mm), A4R, 11" x 17", 8

1/2" x 11"

Foldable number of sheets .............1 - 16 (no stapling for 1 sheet)

Maximum number for storage......... 5 or less copies in a set: 30 sets

6 - 10 copies in a set: 20 sets

11 - 16 copies in a set: 10 sets

Paper thickness ..............................60 - 200 g/m2 (only one cover for 81 g/m2 or more)

Punch unit (option)

Available sizes................................A3, B4 (257 x 364 mm), A4, A4R, B5, B5R, A5R, Folio, 11" x 17", 8

1/2" x 14",

8

1/2" x 11", 11" x 8 1/2", 5 1/2" x 8 1/2"

Y104371-8 Service Manual

3H3

1-1-2

1-1-2 Parts names

Figure 1-1-1

9

5

2

1

3

4

7

6

24

22

21

23

20

8

17

19

18

10

16

1312

15

14

11

Finisher

1. Main tray (Tray A)

2. Sub tray (Tray B)

3. Front cover

4. Front cover handle

5. Upper cover

6. Intermediate tray

7. Intermediate tray handle

8. Intermediate tray release lever

9. Lower lever

10. Conveyor knob

11. Coupling section lower guide lever

12. Stapler cartridge A

13. Stapler cartridge B

14. Coupling section upper guide lever

Punch unit (option)

15. Punch unit

16. Punch unit adjustment dial

17. Punch waste box

Centerfold unit (option)

18. Unit release lever

19. Unit transport handle

20. Unit release handle

21. Centerfold unit installation button

22. Conveyor guide lever

23. Storage tray

Multi job tray (option)

24. Job trays No.1 - 5

Service Manual Y104371-8

3H3

1-1-3

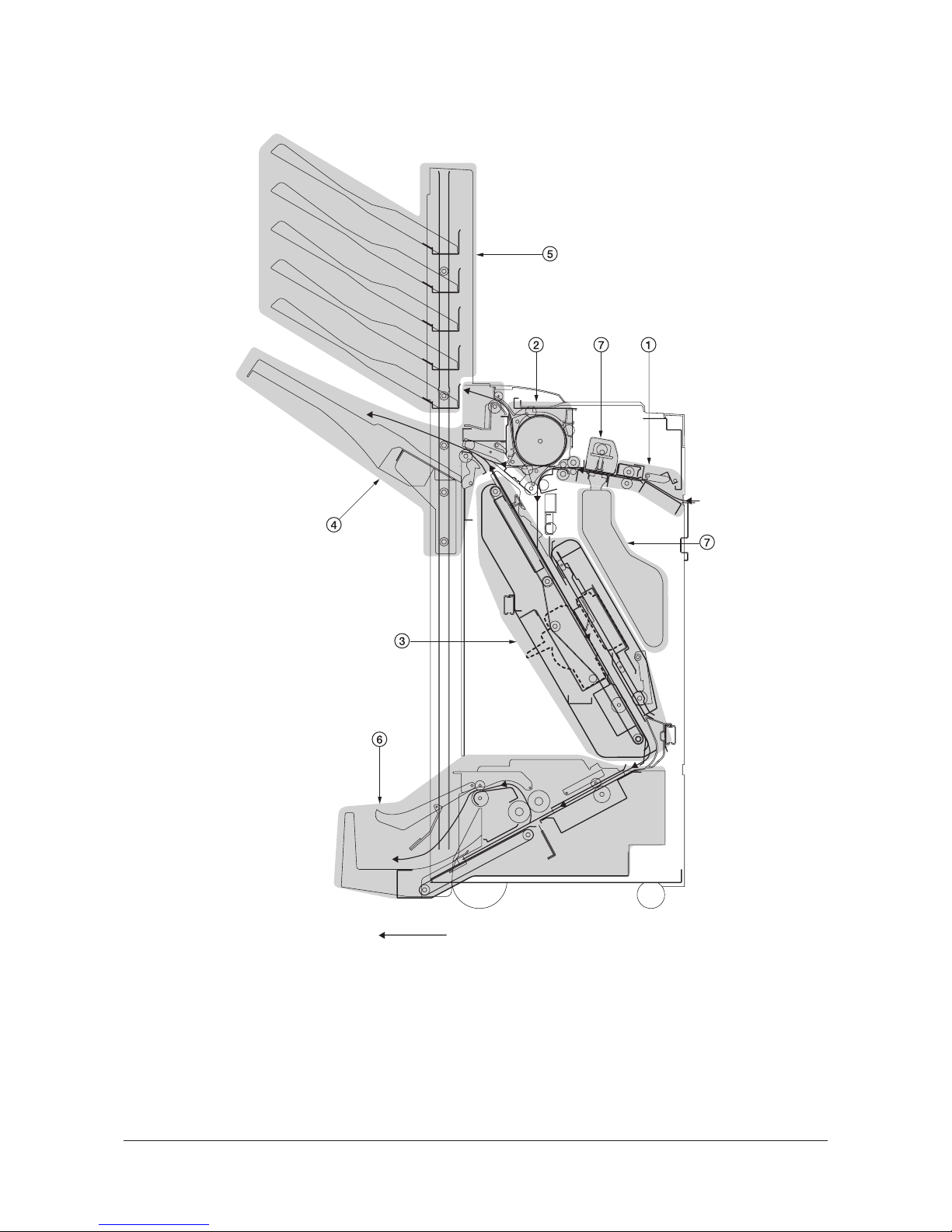

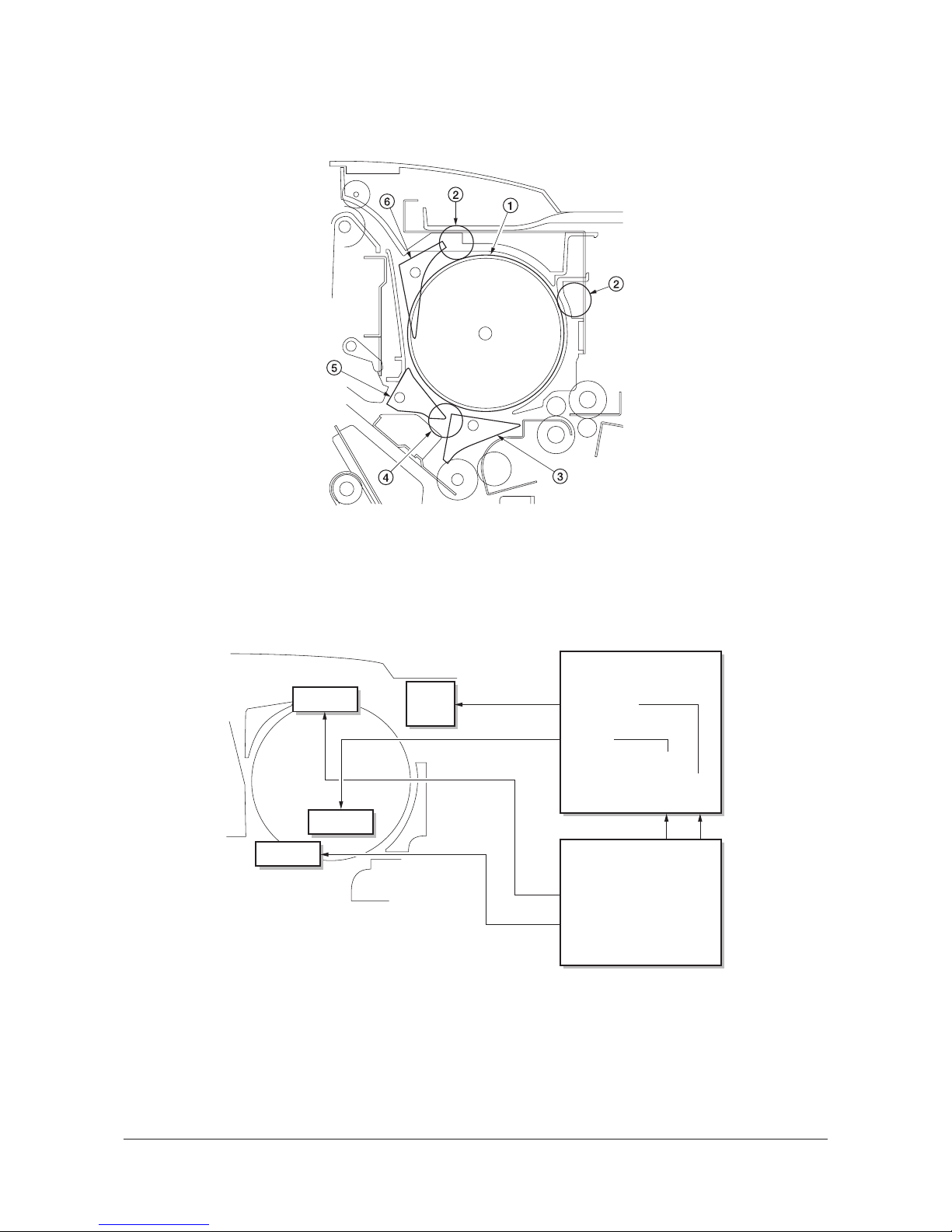

1-1-3 Machine cross sectional view

Figure 1-1-2

Paper path

1. Paper insertion section

2. Feedshift section

3. Intermediate tray section

4. Paper ejection section

5. Multi job tray (option)

6. Centerfold unit (option)

7. Punch unit (option)

Y104371-8 Service Manual

3H3

1-1-4

1-1-4 Machine drive system

(1) Finisher (paper feed and conveying section)

Figure 1-1-3

Viewed from the machine rea

r

1. Paper conveying motor

gear

2. Paper conveying gear Z54/

P50

3. Paper conveying drive belt

4. Paper conveying gear Z48/

P31

5. Drive tension pulley

6. Paper conveying roller pulley 31

7. Intermediate tray drive gear

Z40/P30

8. Drive tension pulley

9. Paper entry motor gear

10. Paper entry gear 25

11. Paddle gear 22

12. Paddle gear 22

13. Siding drum motor gear

14. Drum gear Z50/Z20

15. Drum drive gear 53

16. Drum drive gear 46

17. Movable guide motor gear

18. Idle gear

19. Idle cam gear 75

20. Intermediate tray joint gear

34

21. Drive pulley 20

22. Pulley 16

23. Feed pulley belt

24. Forwarding roller gear

25. Feed pulley drive belt

26. Pulley 16

27. Drive pulley 20

28. Feed pulley belt

29. Forwarding roller gear

30. Paper conveying pulley belt

31. Paper conveying drive pulley 27

32. Upper paper conveying belt

motor gear

33. Intermediate tray drive belt

34. Eject pulley 20

35. Pulley 20

36. Intermediate tray conveying belt

37. Pulley 20

38. Eject pulley 20

39. Intermediate tray drive belt

40. Lower paper conveying belt

motor gear

41. Lower intermediate tray belt

42. Pulley 20

43. Timing belt pulley

44. Pulley 20

45. Eject motor gear

46. Eject gear Z60/Z32

47. Intermediate drive gear 40

48. Intermediate drive gear 40

49. Gear 16T

Service Manual Y104371-8

3H3

1-1-5

(2) Finisher (main tray driving section)

Figure 1-1-4

1. Main tray elevation motor pulley

2. Feed belt

3. Pulley 34

4. Worm gear

5. Gear 50

6. Gear 18

7. Gear 51

8. Pulley 20S

9. Tray drive belt

10. Pulley 20S

11. Gear 26

Y104371-8 Service Manual

3H3

1-1-6

(3) Multi job tray

1. Multi job tray elevation motor pulley

2. Feed belt

3. Pulley 34

4. Worm gear

5. Gear 50

6. Gear 18

7. Gear 51

8. Pulley 20S

9. Tray drive belt

10. Pulley 20S

11. Gear 26

Service Manual Y104371-8

3H3

1-1-7

(4) Centerfold unit

Figure 1-1-5

(5) Punch unit

Figure 1-1-6

1. Main motor pulley

2. Belt 118P2M6

3. Gear 22/40

4. Gear 33/15

5. Gear 51

6. Manual roller gear

(conveyor guide knob)

7. Gear 22

8. Gear 51

9. Gear 19

10. Gear 50/15

11. Gear 16/25

12. Gear 16/25

13. Bypass pulley gear

14. Gear 58

15. Pulley 28

16. Paper drive belt

17. Pulley 28

18. Idle pulley 15

19. Centering plate motor pulley

20. Belt 124

21. Pulley 22

22. Pulley 20

23. Paper conveying belt

24. Pulley 20

25. Blade motor pulley

26. Belt 126P2M6

27. Gear 22/40

28. Gear 33/15

29. Gear 40

30. Gear 22

31. Gear 50

32. Manual roller gear

1. Punch motor gear

2. Idle gear 16/51

3. Drive cum gear 40

Y104371-8 Service Manual

3H3

1-2-1

1-2Installation

1-2-1 Unpacking and installation

Figure 1-2-1 Unpacking (Finisher)

1. Finisher

2. Main tray

3. Sub tray

4. Connecting plate

5. Sponge

6. Pins

7. Nuts

8. M4 x 20 TP tap tight S screws

9. Stapler cartridges

10. Outer case

11. Barcode labels

12. Inner frame

13. Skid

14. Hinge joint

15. Accessory case

16. Bottom cushion sheet

17. Front lower left pad

18. Rear lower left pad

19. Front lower right pad

20. Rear lower right pad

21. Upper pad

22. Machine cover

23. Air cap bag

24. Air cap bag

25. Air cap bag

26. Plastic bag

27. Plastic bag

28. Operation guide

29. Installation guide

30. Spacer

31. Spacer

32. Plastic sheet

33. Clamp

34. M3 x 14 tap tight S screws

35. M4 x 8 tap tight S screws

36. M3 x 10 tap tight S screw

37. Grounding plates A

38. Grounding plates B

Y104371-8 Service Manual

3H3

1-2-2

Removing tapes and spacers

Procedure

1. Remove the plastic sheet.

2. Remove two tapes and spacer.

Figure 1-2-2

3. Remove eight tapes.

Figure 1-2-3

4. Remove four tapes and two spacers.

Figure 1-2-4

Plastic sheet

Ta pe

Ta pe

Spacer

Ta pe

Ta pe s

Ta pe s

Ta pe

Ta pe

Ta pe

Ta pe

Ta pe

Spacers

Service Manual Y104371-8

3H3-2.0

1-2-3

1-2-2 Installing the centerfold unit (option)

• When installing the centerfold unit and multi job tray as a set, first install the centerfold unit and then the multi job

tray.

• Before installing the centerfold unit, press the Power key on the operation panel to off. Make sure that the Power

lamp is off before turning off the main power switch. And then unplug the power cable from the wall outlet.

Turning off the main power switch before pressing the Power key to off may cause damage to the equipped hard

disk.

Procedure

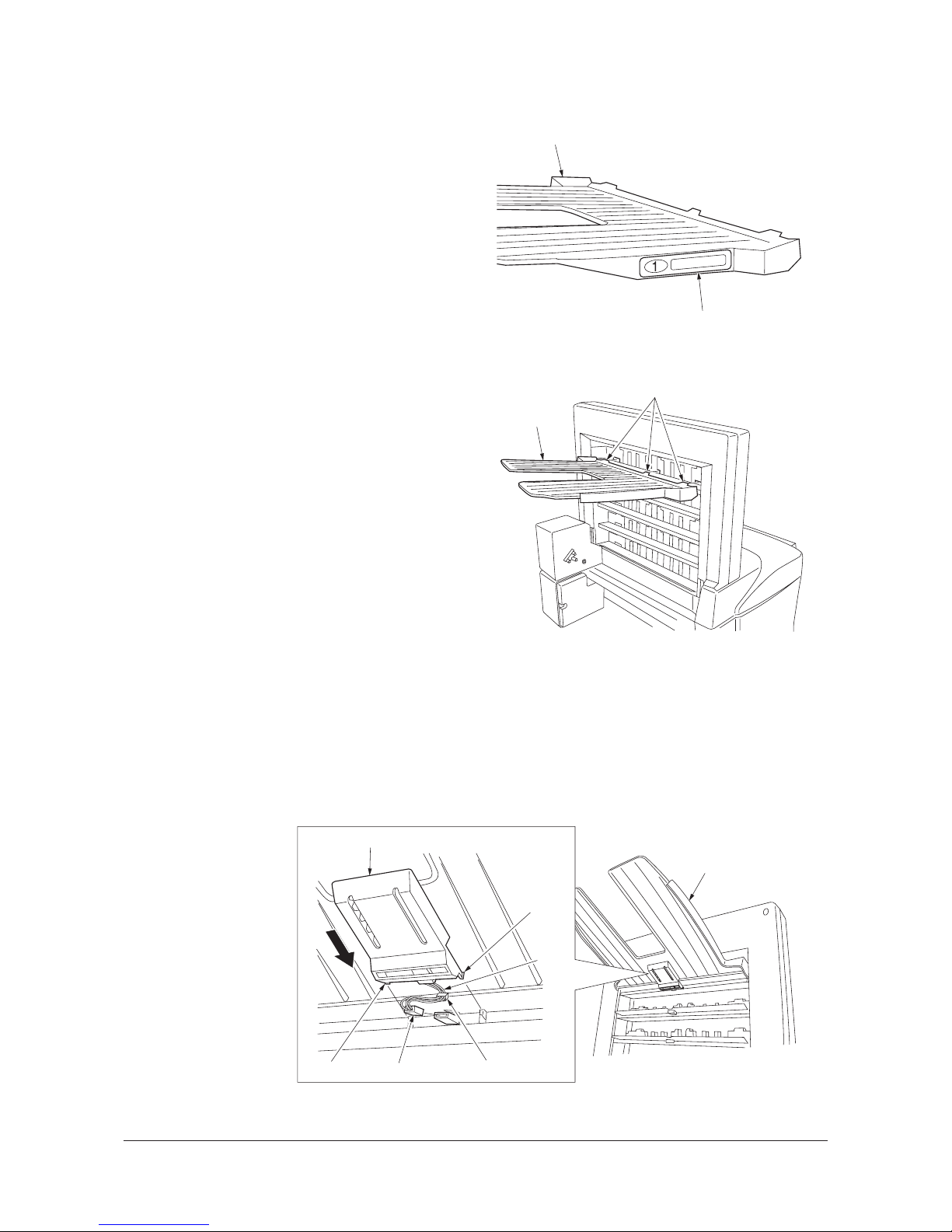

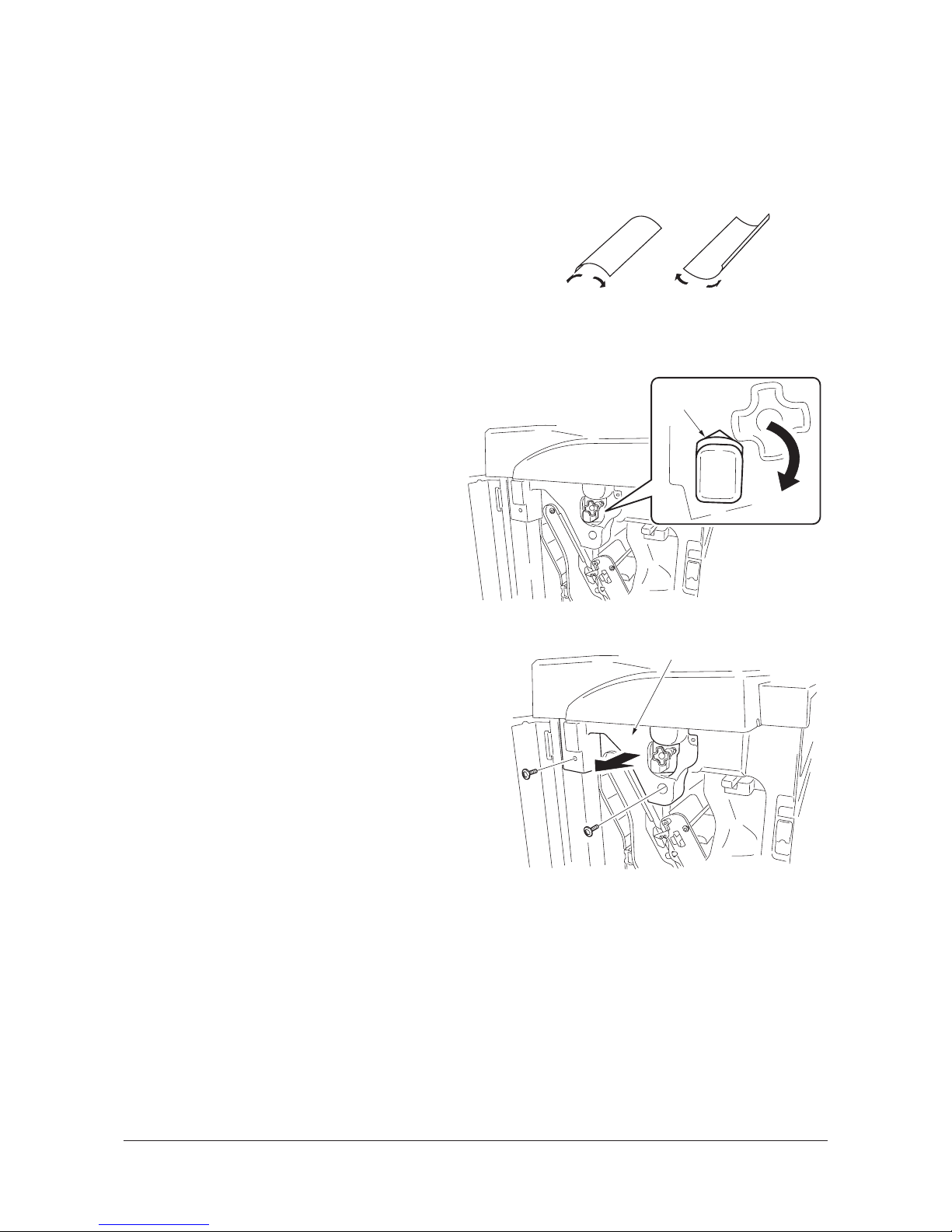

* When unpacking or installing, hold the cen-

terfold unit by a indicated in the illustration.

Do not hold it by b at the center of the unit.

Figure 1-2-5

1. Remove the four screws locking down the

guide plate followed by the plate.

2. Remove the left lower shaft from the finisher

side plate.

Figure 1-2-6

3. Open the front cover. Remove the screw

locking down the retainer followed by the

retainer.

4. While keeping the front cover perpendicular,

detach the cover by raising it vertically in the

direction of the arrow.

Figure 1-2-7

a

a

b

Left lower shaft

Screws

Screws

Guide plate

Front cover

Retaine

r

Screw

Y104371-8 Service Manual

3H3

1-2-4

5. Hook the backstop onto the hook on the

inside of the finisher plate, and install the

two pins from the outside.

6. Attach one end of the small spring to the

backstop and hang the other end over the

hook inside the machine.

Figure 1-2-8

7. Insert the release lever actuating plate from

the front side of the machine into the hole

and fit with two pins. Then, make sure that

the release lever actuating plate slides leftward and rightward.

Figure 1-2-9

8. Attach one end of the small spring to the

release lever actuating plate and hang the

other end over the hook on the side plate.

9. Apply the release lever actuating plate with

TEMP1 or the similar grease in the indicated

area A.

Figure 1-2-10

Backstop

Backstop

Hook

Pins

Small spring

Hook

Hook

Release lever

actuating plate

Release lever

actuating plate

Release lever

actuating plate

Hole

Pin

Pin

Small spring

Hook

Release lever

actuating plate

A

Service Manual Y104371-8

3H3

1-2-5

10. Insert one end of the release pole assembly

into the square bypass hole and the other

end into the hole with the projection, with the

D-cut of the release pole assembly aligned

with the projection.

11. Insert the end of the release pole assembly

already inserted through the square bypass

hole into the mounting hole.

Figure 1-2-11

12. Fit the medium stop ring onto the release

pole assembly. Then, make sure the release

pole assembly can rotate slightly.

Figure 1-2-12

13. Attach the release handle to the release

pole assembly at the machine front side with

the M4 x 10 TP screw.

Figure 1-2-13

Square

bypass hole

Square

bypass hole

Hole with

the projection

Release pole

assembly

D-cut

Mounting hole

Mounting hole

Medium stop ring

Release pole

assembly

M4 x 10 TP screw

Release handle

Y104371-8 Service Manual

3H3

1-2-6

14. Place the slider on the projections on the finisher rear side-plate and lock down with

three M4 x 8 S tight bind screws.

Insert the M4 x 8 S tight bind screws from

the round holes on the eject side of the finisher.

15. Place the slider on the projections on the finisher front side-plate and lock down with

three M4 x 8 S tight bind screws.

Insert the M4 x 8 S tight bind screws from

the round holes on the eject side of the finisher.

Figure 1-2-14

16. Pull out the intermediate tray of the finisher.

17. Fit the large stop ring onto the unit lock rod.

18. Attach the unit lock hook to the lower guide

stay with the unit lock rod.

Figure 1-2-15

M4 x 8 S tight

bind screws

M4 x 8 S tight

bind screws

Slider

Slider

Projections

Projections

Unit lock rod

Large stop ring

Guide stay

Guide stay

Unit lock hook

Unit lock hook

Intermediate tray

Guide stay

Service Manual Y104371-8

3H3

1-2-7

19. Fit the large stop ring onto the lower part of

the unit lock rod.

20. Hang one end of the large spring over the

hook on the unit lock hook and the other end

over the hook on the guide stay.

21. Insert the intermediate tray of the finisher

and return it to its original position.

Figure 1-2-16

22. Remove the tapes and the cushioning materials provided on the centerfold unit.

Figure 1-2-17

23. Pull the left and right sliders out until they

stop. Attach the centerfold unit on the pins of

the sliders.

Hold the centerfold unit by a indicated in the

illustration. Do not hold it by b at the center

of the unit.

Figure 1-2-18

Large stop ring

Unit lock hook

Hook

Hook

Unit lock rod

Guide stay

Large

spring

Ta pe

Ta pe

Ta pe

Ta pe s

Cushioning

material

a

Centerfold unit

a

b

Slider

Slider

Pin

Pin

Y104371-8 Service Manual

3H3

1-2-8

24. Slide the centerfold unit in the direction of

the arrow.

25. Loosen the two screws and push the

retainer in the direction of the arrow and

retighten the screws.

Figure 1-2-19

26. Fit the left cover and right cover into the

rectangular holes on either side of the center fold unit, and secure each one with the

M4 x 6 TP screw.

Figure 1-2-20

27. Attach the eject tray to the centerfold unit by

inserting the projection of the tray into the

hole inside the unit.

Figure 1-2-21

Centerfold

unit

Screw

Screw

Retainer

Retainer

M4 x 6

TP screw

M4 x 6

TP screw

Left cover

Right cover

Centerfold unit

Projection

Hole

Eject tray

Service Manual Y104371-8

3H3

1-2-9

28. Engage the projection of the douser detecting PI with the cutout on the centerfold unit's

rear side plate, and secure them with a M4 x

8 S tight bind screw.

When inserting the centerfold unit, make

sure that the douser detecting PI does not

come into contact with the finisher's folding

unit sensor.

Figure 1-2-22

29. Push the release lever actuating plate.

30. Push in the centerfold unit until it stops.

Figure 1-2-23

31. Attach the unit transport handle with the M4

x 8 S tight bind screw.

Figure 1-2-24

Douser

detecting PI

M4 x 8 S tight

bind screw

Release lever

actuating plate

Centerfold unit

M4 x 8 S tight

bind screw

Unit transport handle

Y104371-8 Service Manual

3H3

1-2-10

32. After cleaning each area with alcohol, affix

the following labels from label sheet at the

locations shown in the illustration: (C)-1

(G7), (C)-2.

Figure 1-2-25

33. Plug the power cable into a wall outlet and

turn the machine on from the main power

switch.

34. Make a test copy to check that the centerfold unit operates correctly.

35. Adjust the paper folding position (see page

1-5-11.)

20 mm

C -1

C -2

Service Manual Y104371-8

3H3-2.0

1-2-11

1-2-3 Installing the multi job tray (option)

• Hold the frame at the front and back when removing the multi job tray from the box. Supporting the multi job tray

from the bottom can cause deformation of the film affixed to it.

• Before installing the multi job tray, press the Power key on the operation panel to off. Make sure that the Power lamp

is off before turning off the main power switch. And then unplug the power cable from the wall outlet.

Turning off the main power switch before pressing the Power key to off may cause damage to the equipped hard

disk.

• When installing the multi job tray and centerfold unit as a set, first install the centerfold unit and then the multi job

tray.

• Installation should be carried out with the finisher's rear cover removed.

Procedure

1. Remove the two screws locking down the

top cover lid followed by the lid.

2. Open the upper cover and remove the nine

screws locking down the top cover followed

by the top cover.

Figure 1-2-26

3. Remove the four screws locking down the

top cover lid guide followed by the guide.

Figure 1-2-27

Screws

Screws

Screws

Top cover

Upper cover

Top cover lid

Screws

Screws

Top cover lid guide

Y104371-8 Service Manual

3H3

1-2-12

4. Attach the two size detection switches to the

eject stay by inserting the tabs, and lock in

place with one M3 x 5 binding screw each.

5. Connect the 3-pin connector of the size

detection switch to the connector of the finisher.

Figure 1-2-28

6. Attach the bin front guide plate and bin rear

guide plate to the finisher by inserting the

claws on plates into the finisher frame and

lock in place with three M4 x 6 binding

screws each.

Figure 1-2-29

7. Attach the multi job tray to the bin front

guide plate and bin rear guide plate by

inserting the six pulleys at the tray front and

rear into the plates.

Make sure that the shading plate at the rear

of the multi job tray does not make contact

with the sensor.

Figure 1-2-30

M3 x 5

binding screw

Ta b

3-pin connector

Eject stay

Size detection

switch

Bin rear

guide plate

Bin front

guide plate

M4 x 6

binding

screws

M4 x 6

binding screws

Multi job tray

Pulley

Pulleys

Pulleys

Bin front

guide plate

Bin rear

guide plate

Shading

plate

Sensor

Service Manual Y104371-8

3H3

1-2-13

8. Measure the height a against the scale to

make sure that the multi job tray is positioned properly to stay level from front to

rear.

If the height a is not the same at the front

and rear, the multi job tray may not be positioned on a level plane. Install the tray again.

Figure 1-2-31

9. Loosen the two screws.

10. With the retainer slid upward, push in the

gear shaft while holding the bottom of the

multi job tray. Then, lower the multi job tray

by about 30 mm.

Figure 1-2-32

11. Pull out the gear shaft, slide the retainer to

its original position and retighten the two

screws.

Make sure the gear shaft is positioned so

that the retainer will be engaged in groove

on the shaft.

Figure 1-2-33

Bin front

guide plate

Bin rear

guide plate

Multi job tray

a

a

Multi job tray

Screws

Retainer

Gear shaft

Screws

Retainer

Groove

Gear shaft

Y104371-8 Service Manual

3H3

1-2-14

12. Attach the bin guide plate retainer with two

M4 x 6 binding screws.

13. Reattach the top cover with the nine screws

removed in step 2, keeping the upper cover

open halfway to enable proper attaching.

Figure 1-2-34

14. Attach the right cover with four M4 x 8 TP

screws.

Figure 1-2-35

15. Attach the left cover by inserting the two

pegs into the square holes, and lock in place

with two M4 x 8 TP screws.

Figure 1-2-36

Bin guide

plate retainer

M4 x 6

binding screw

M4 x 6

binding screw

M4 x 8

TP screws

M4 x 8

TP screws

Right cover

Left cover

Peg

Peg

M4 x 8

TP screw

M4 x 8

TP screw

Service Manual Y104371-8

3H3

1-2-15

16. Affix a bin No. label to each of the five eject

bins.

Figure 1-2-37

17. Attach the eject bin with the label No.1

affixed at the uppermost shelf of the multi

job tray by inserting the three claws into the

square holes.

Figure 1-2-38

18. Connect the 3-pin connector at the back side of the eject bin.

19. Fit the cable of the 3-pin connector to the inside of the eject bin and lock down with the cable

retainer.

20. Slide the eject bin lid into position and lock in place by inserting the two pegs into the square holes.

Make sure that the cable is tidily fitted and not caught in the eject bin lid.

21. Repeat steps 17 to 20 to attach the other four eject bins.

Attach the eject bins in the order of the bin No. labels so that the bin with the label No.1 is at the

uppermost shelf, No.2 at the second and so forth.

Figure 1-2-39

Eject bin

Bin No. label

Claws

Eject bin

Eject bin

3-pin connector

Cable retainer

Peg

Peg

Cable

Eject bin lid

Y104371-8 Service Manual

3H3

1-2-16

22. Insert the two lugs of the motor front cover

into the rectangular holes, and secure them

with the M4 x 8 TP screw.

Figure 1-2-40

23. Connect the signal cable of the multi job tray

to the finisher connector.

24. Plug the power cable into a wall outlet and

turn the machine on from the main power

switch.

25. Make a test copy and check the multi job

tray performs properly.

Figure 1-2-41

Motor front cover

Lugs

M4 x 8 TP screw

Signal cable

Service Manual Y104371-8

3H3-2.0

1-2-17

1-2-4 Installing the punch unit (option)

• Before installing the punch unit, press the Power key on the operation panel to off. Make sure that the Power lamp is

off before turning off the main power switch. And then unplug the power cable from the wall outlet.

Turning off the main power switch before pressing the Power key to off may cause damage to the equipped hard

disk.

Procedure

1. Remove the five screws, disconnect the

connector, and then remove the rear cover.

2. Open the upper cover.

Figure 1-2-42

3. Remove the two screws, and then remove

the guide plate.

Figure 1-2-43

4. Making sure that frame of the punch unit is in contact with lever of the finisher, insert the punch

unit as far as it will go between the rails that held the guide plate that was removed in step 3.

Figure 1-2-44

Screw

Screw

Screws

Screw

Connector

Rear cover

Screw

Guide plate

Screw

Lever

Punch unit

Frame

Y104371-8 Service Manual

3H3

1-2-18

5. Secure the punch unit with two M4 x 10 tap

tight S screws. Make sure the center of the

right long hole is aligned with the center

guideline.

Figure 1-2-45

6. Connect the 3-pin connector of the solenoid

to the 3-pin connector on the front of the finisher.

7. Close the top cover and open the front

cover.

Figure 1-2-46

8. Slide the guide along the rails on the bottom

of the punch unit so it hooks on the tabs.

9. Pull out the intermediate tray of the finisher.

Figure 1-2-47

Punch unit

M4 x 10 tap

tight S screws

3-pin connector

Guide

Service Manual Y104371-8

3H3

1-2-19

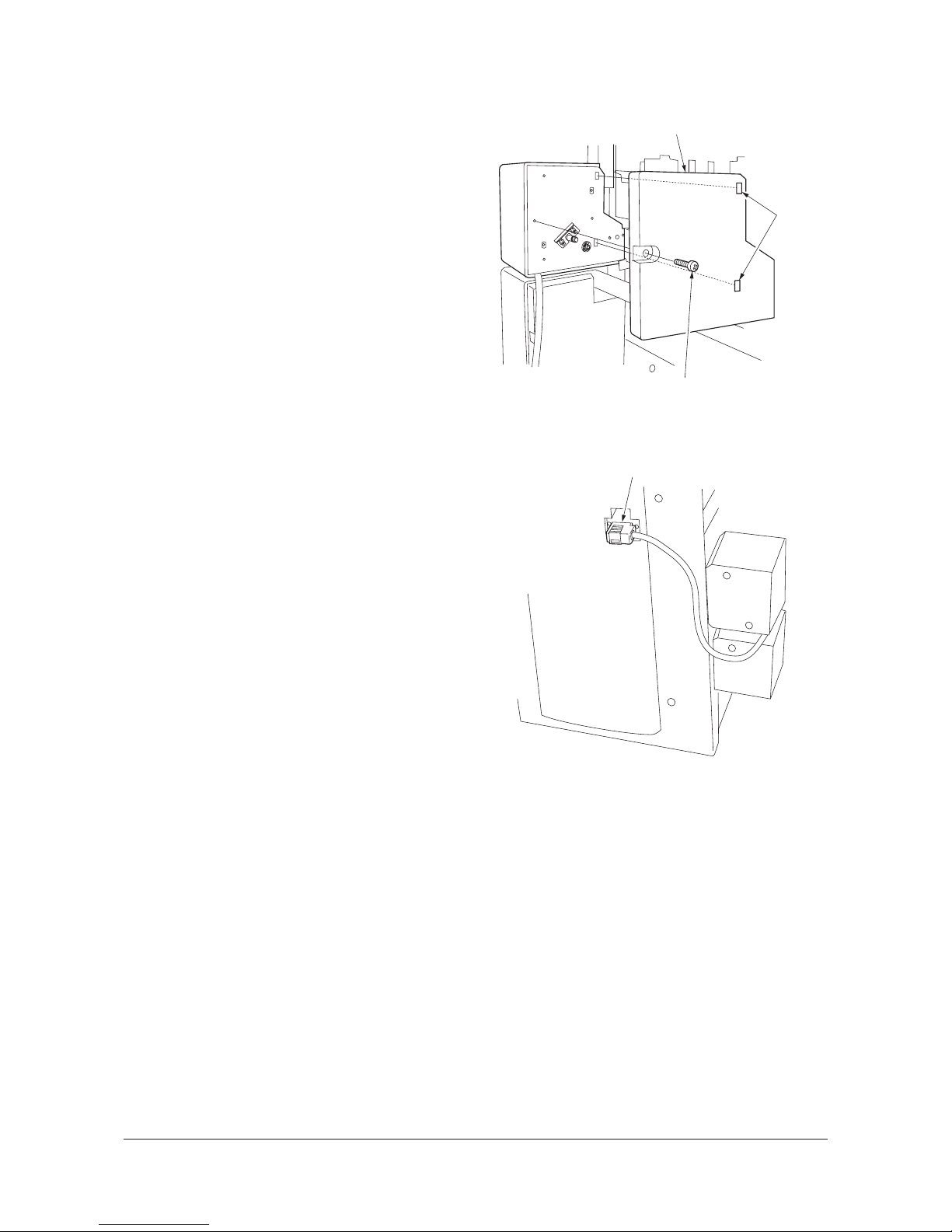

10. Insert the assembly tank holder into the

holes in the side of the finisher, and then

press it downwards to secure it. Next,

secure it further with the screw that was

removed in step 3. Install the screw from the

outside.

11. Connect the 3-pin connector to the 3-pin

connector inside the finisher.

12. Anchor the wires to the frame with a supplied wire saddle.

Figure 1-2-48

13. Insert the intermediate tray of the finisher so

it is back to its original position, and then

install the punch waste box.

14. Close the front cover.

Figure 1-2-49

15. Insert the tab of the punch PWB into the

hole on the back of the finisher, and secure

it with the screw that was removed in step 3.

Figure 1-2-50

Tank holder

Screw

Supplied

wire saddle

3-pin connector

Punch waste box

Intermediate tray

Punch PWB

Screw

Y104371-8 Service Manual

3H3

1-2-20

16. Make the following seven connections.

Top: 2-pin power connector and 2-pin motor connector; 6-pin power connector and 6-pin sensor connector

Center: 4-pin power connector and YC1 of punch PWB; 6-pin power connector and YC3 of punch PWB;

9-pin power connector and YC2 of punch PWB

Bottom: 2-pin power connector and 2-pin finisher power connector; 9-pin power connector and 9-pin finisher

power connector

17. Secure wires at one location with wire saddle.

18. Secure wires with clamp and fix with M4 x 8 tap Tight S screw.

19. Fasten the snap-on band on core A to the hole on the finisher frame.

20. Fasten the snap-on band on core B to the hole on the finisher frame.

21. Refit the rear cover.

Figure 1-2-51

22. Plug the power cable into a wall outlet and

turn the machine on from the main power

switch.

23. Adjust the centering punch-holes (see page

1-5-12).

24. Set margin from the leading edge to punch

holes (see page 1-5-13).

Clamp

M4 x 8 tap

Tight S screw

Wire

saddle

Core A

Core B

6-pin

connector

2-pin

connector

YC1

YC3

YC1

9-pin

connector

2-pin

connector

Service Manual Y104371-8

3H3-2.0

1-2-21

1-2-5 Installing the stopper guide (option)

• Before installing the stopper guide, press the Power key on the operation panel to off. Make sure that the Power

lamp is off before turning off the main power switch. And then unplug the power cable from the wall outlet.

Turning off the main power switch before pressing the Power key to off may cause damage to the equipped hard

disk.

(1) Installing the stopper guide (To the finisher without the multi job tray)

Procedure

1. Secure the stopper assembly to the finisher

sub tray with three screws (M3 × 8 tap tight

P screw).

* The installation position varies from the inch

specification and metric specification. Make

sure to adjust the position for the inch specification to the mark of (I) and the position for

the metric specification to the mark of (C).

Figure 1-2-52

2. After cleaning with rubbing alcohol, affix the

appropriate operation label (Inch or metric)

to the finisher as indicated.

Figure 1-2-53

Stopper assembly

M3 x 8 tap tight P screw

Mark

Installation position

Sub tray

(Metric) (Inch)

5 to 10 mm

5 to 10 mm

Operation label

Y104371-8 Service Manual

3H3-2.0

1-2-22

(2) Installing the stopper guide (To the finisher with the multi job tray)

Procedure

1. Install the stopper to the stopper mount

using stop ring 3.

* Be careful. The stopper hole on the stopper

mount varies from the inch specification and

metric specification.

Figure 1-2-54

2. Push down the main tray of the finisher. (For

the details, refer to step 10 on page 6 of

multi job tray Installation guide.)

3. Hook the guide assembled in step 1 to the

finisher as indicated. Secure it with two M4 ×

8 tap tight S screws. Make sure that the

stopper guide is dropped as indicated.

Figure 1-2-55

Stopper

Stopper mount

Stop ring 3

Stopper hole

(Metric)

Stopper hole

(Inch)

Stopper mount

Stopper guide

M4 x 8 tap tight S screw

Service Manual Y104371-8

3H3-2.0

1-2-23

4. Hold the stopper guide as indicated.

5. Replace the cover removed in step 2.

Figure 1-2-56

6. After cleaning with rubbing alcohol, affix the

appropriate operation label to the finisher as

indicated.

Figure 1-2-57

Stopper guide

5 to 10 mm

5 to 10 mm

Operation label

Y104371-8 Service Manual

3H3

1-3-1

1-3 Maintenance Mode

1-3-1 Maintenance mode

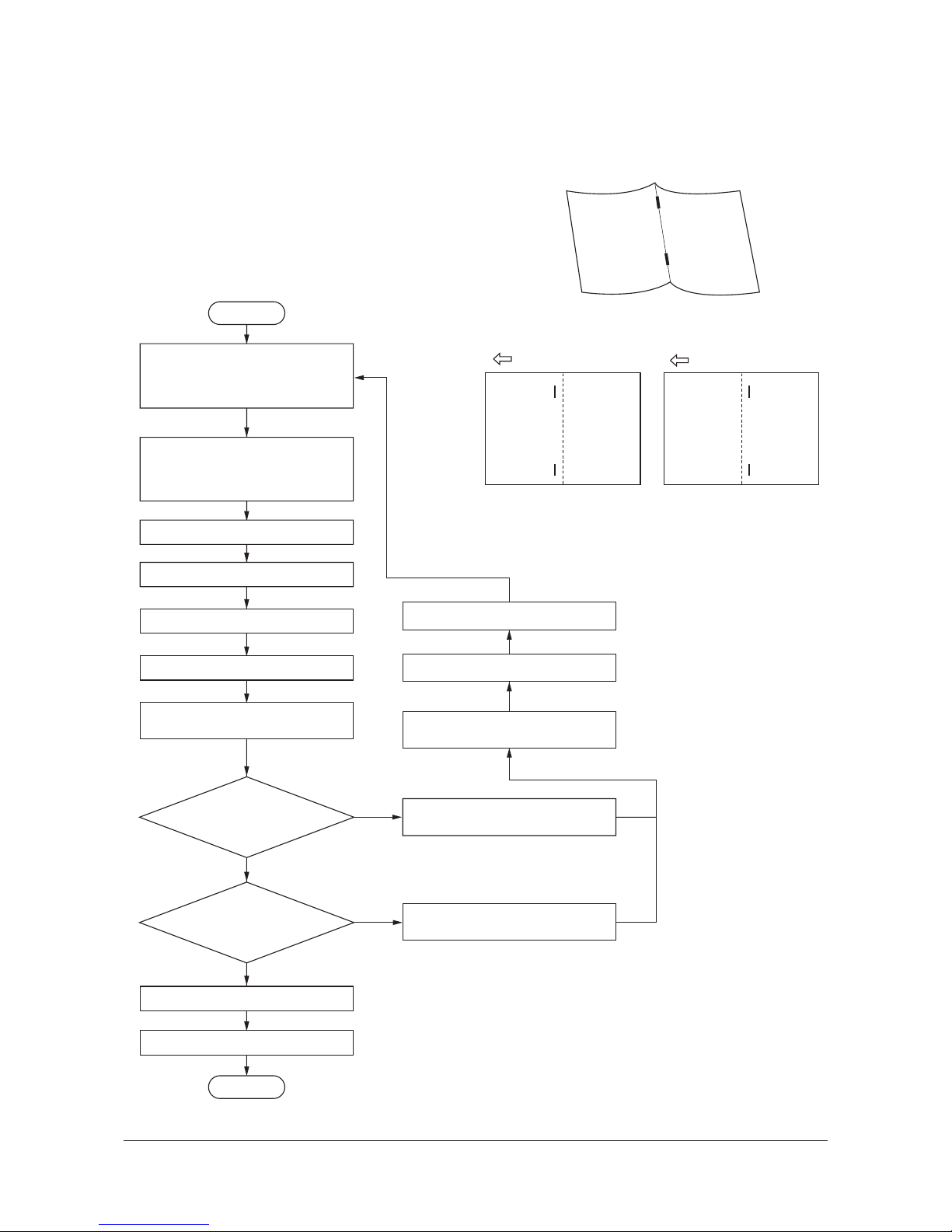

(1) Executing a maintenance item

Enter 10871087 using

the numeric keys.

Enter 001 using the cursor

up/down keys or numeric keys

and press the start key.

Enter the maintenance item

number using the cursor up/down keys

or numeric keys.

The selected maintenance item is run.

Press the stop/clear key.

Press the start key.

Start

End

Maintenance mode is entered.

The maintenance item is

selected.

Maintenance mode is exited.

Repeat the same

maintenance item?

Run another maintenance

item?

No

No

Yes

Yes

Y104371-8 Service Manual

3H3

1-3-2

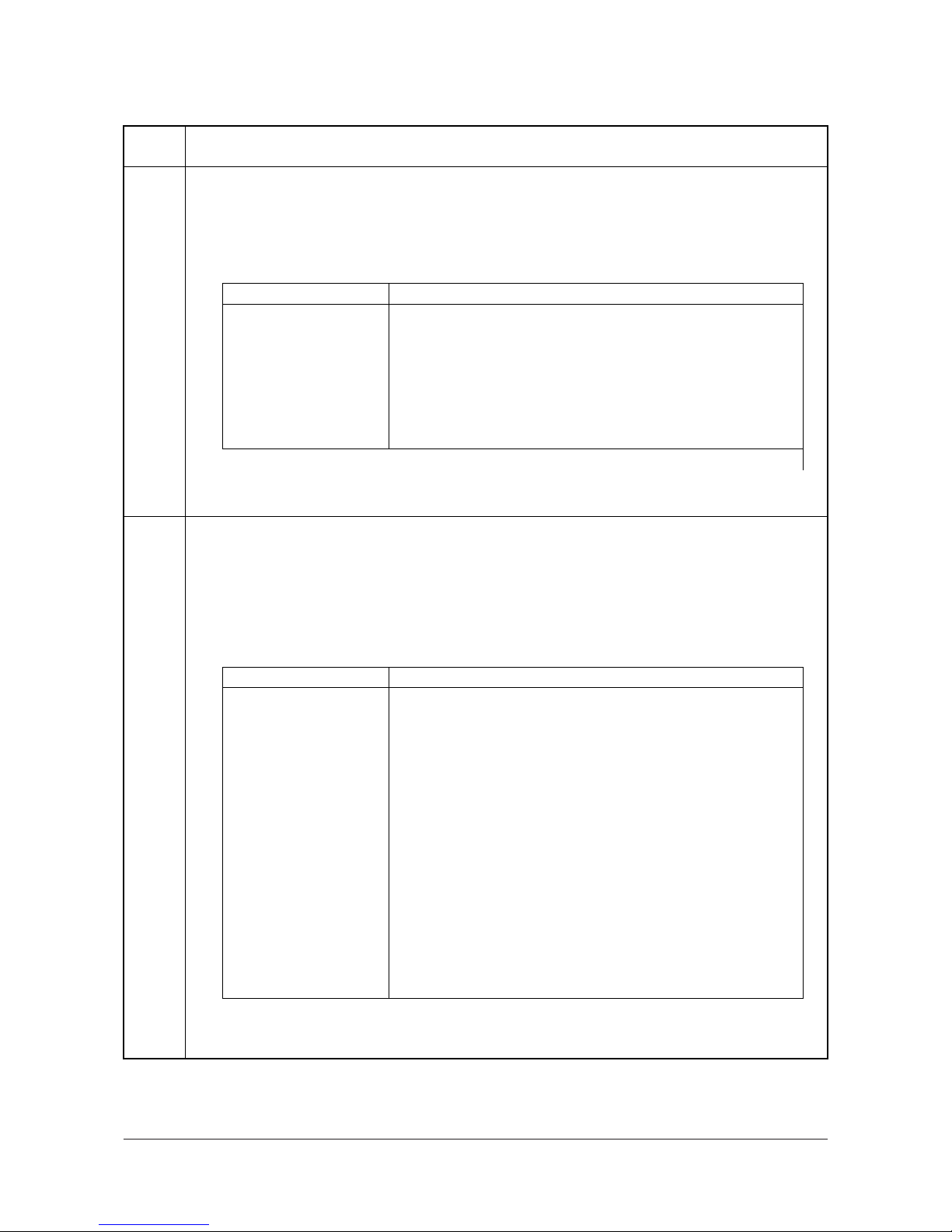

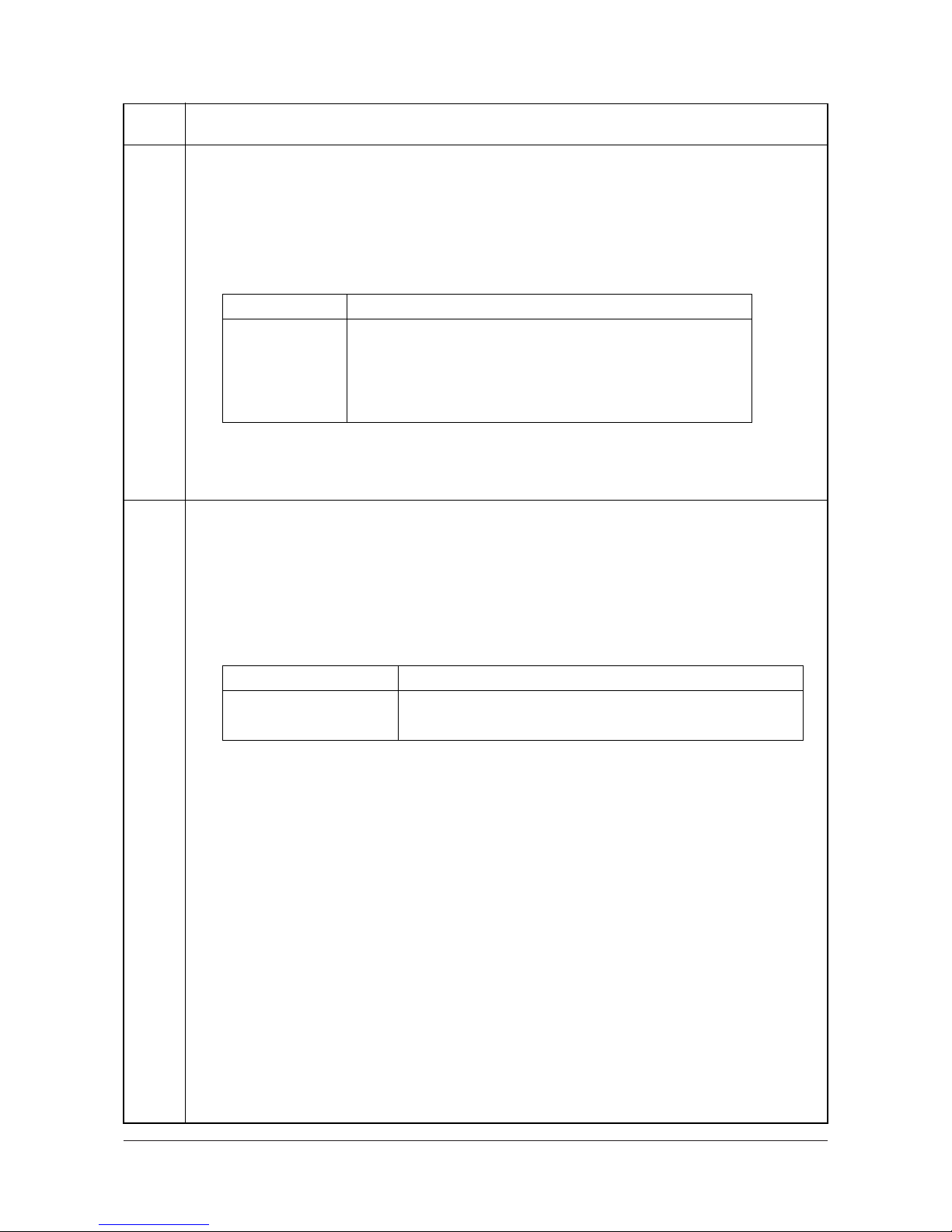

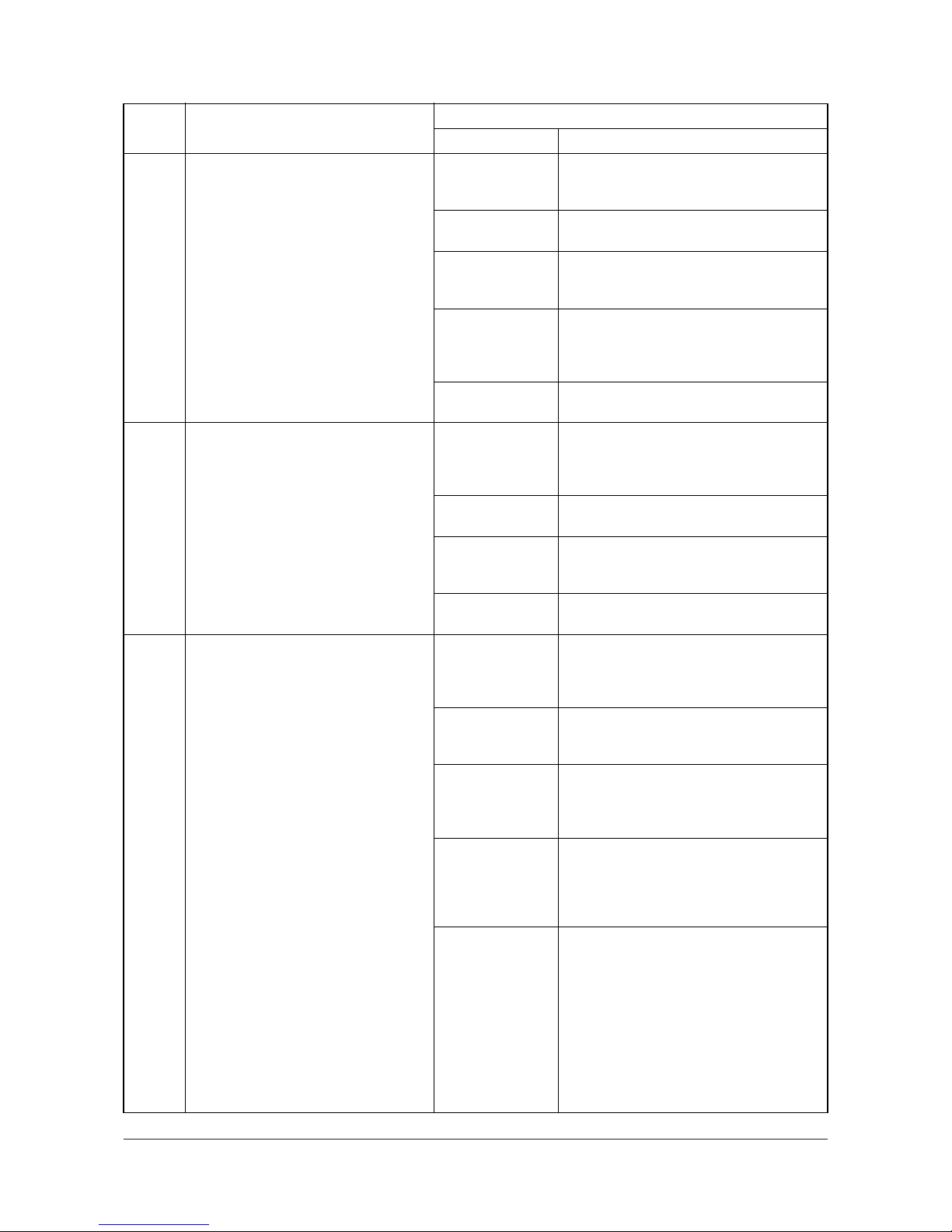

(2) Contents of the maintenance mode items

Maintenance

item No.

Description

U018

Displaying the ROM checksum

Description

Displays the checksum of ROM.

Purpose

To check the checksum.

Method

Press the start key. The ROM checksum is displayed.

Completion

Press the stop/clear key. The screen for selecting a maintenance item No. is displayed.

U019

Displaying the ROM version

Description

Displays the part number for the ROM fitted to each PWB.

Purpose

To check the part number or to decide, based on the last digit of the number, if the newest version of ROM is

installed.

Method

1. Press the start key. The ROM version (the last 6 digits of the part number) is displayed.

2. Change the screen using the * or # keys.

*For the machine.

Completion

Press the stop/clear key. The screen for selecting a maintenance item No. is displayed.

Display Description

MAIN* Main PWB ROM checksum

ENGINE* Engine PWB ROM checksum

SCANNER* Network scanner ROM checksum

LANGUAGE(Stand.)* Standard language ROM checksum

LANGUAGE(Option)* Optional language ROM checksum

DP* DP main PWB ROM checksum

FINISHER Document finisher ROM checksum

*For the machine.

Display Description

MAIN* Main PWB ROM IC

ENGINE* Engine PWB ROM IC

SCANNER* Scanner PWB ROM IC

LANGUAGE (Stand.)* Standard language ROM IC

LANGUAGE(Option)* Optional language ROM IC

MAIN BOOT* Main PWB booting

PRINTER* Printer board booting

NETWORK SCANNER* Network scanner ROM IC

DP* DP ROM IC

FINISHER Document finisher main PWB ROM IC

ENGINE BOOT* Engine PWB booting

CASSETTE1* Deck PWB ROM IC

CASSETTE2* Cassette PWB ROM IC

DUPLEX* Duplex PWB ROM IC

SIDE FEEDER* Side feeder main PWB ROM IC

Service Manual Y104371-8

3H3

1-3-3

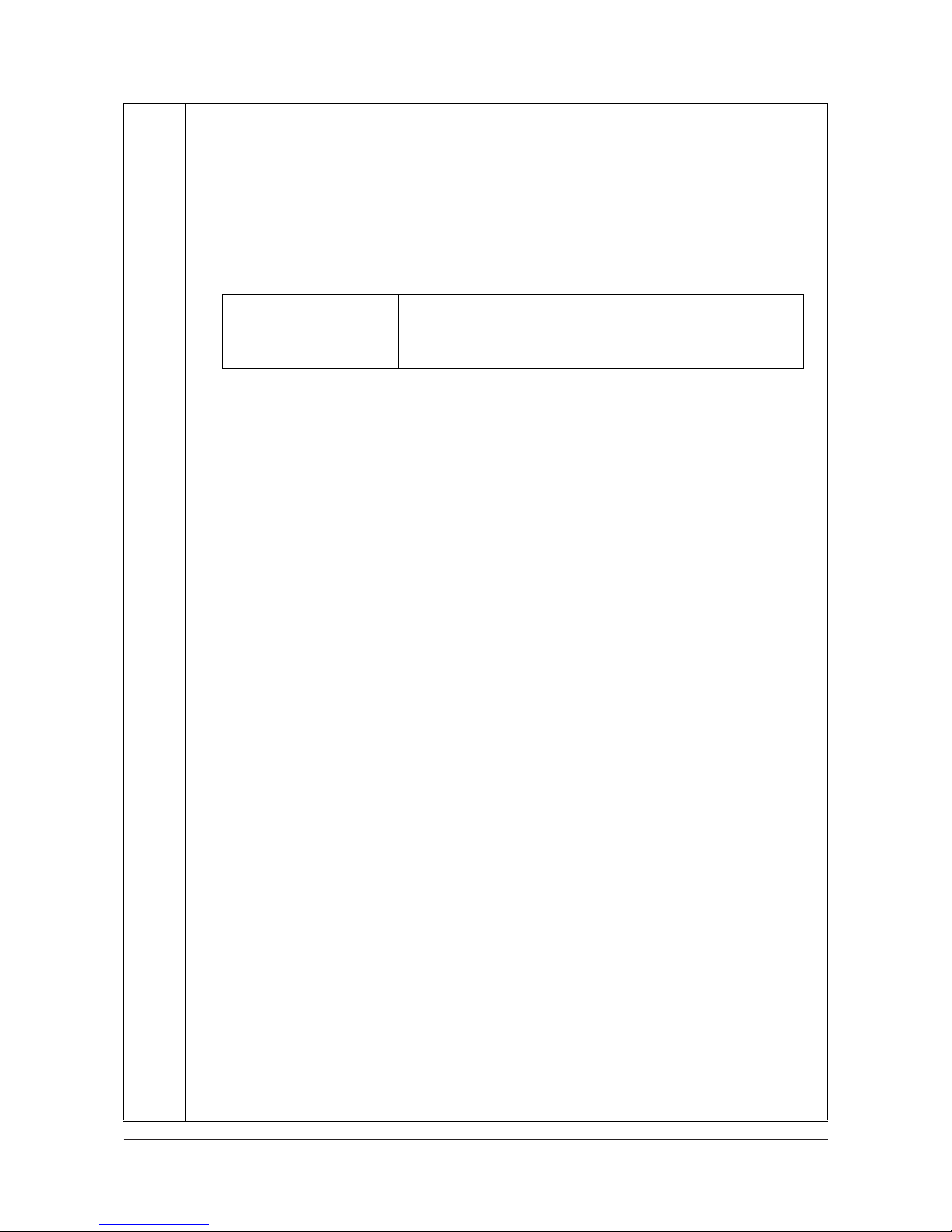

U234

Setting punch destination

Description

Sets the destination of optional punch unit of document finisher.

Purpose

To be set when installing the optional punch unit.

Method

Press the start key. The screen for selecting an item is displayed.

Setting

1. Select the destination.

Initial setting: NOTHING

2. Press the start key. The setting is set.

Completion

Press the stop/clear key. The screen for selecting a maintenance item No. is displayed.

U235

Setting output tray initialize mode

Description

Sets whether or not initialization (shift of eject position to main tray) is performed when auto clear is triggered

if a multi-job tray is installed to an optional finisher.

Purpose

To be set as required according to the user.

Method

Press the start key. The screen for selecting an item is displayed.

Setting

1. Select the item to be set. The selected item is displayed in reverse.

Initial setting: HP ON

2. Press the start key. The setting is set, and the screen for selecting a maintenance item No. is displayed.

Completion

Press the stop/clear key at the screen for selecting an item.

The screen for selecting a maintenance item No. is displayed.

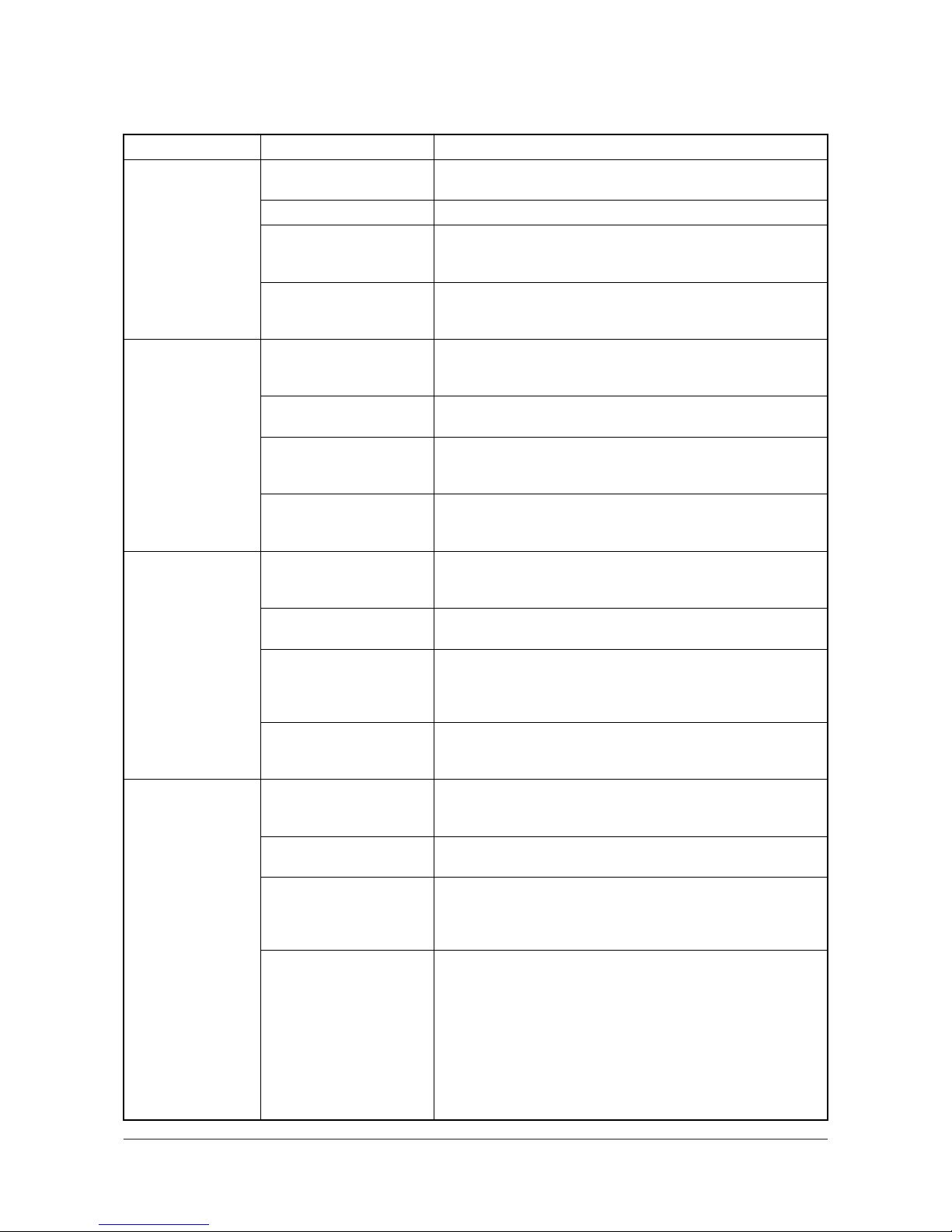

Maintenance

item No.

Description

Display Description

NOTHING Automatic recognization

JAPAN METRIC Metric (Japan) specifications

INCH Inch (North America) specifications

EUROPE METRIC Metric (Europe) specifications

SWEDEN METRIC Metric (North Europe) specifications

Display Description

HP ON Job tray initialization is performed.

HP OFF Job tray initialization is not performed.

Y104371-8 Service Manual

3H3

1-3-4

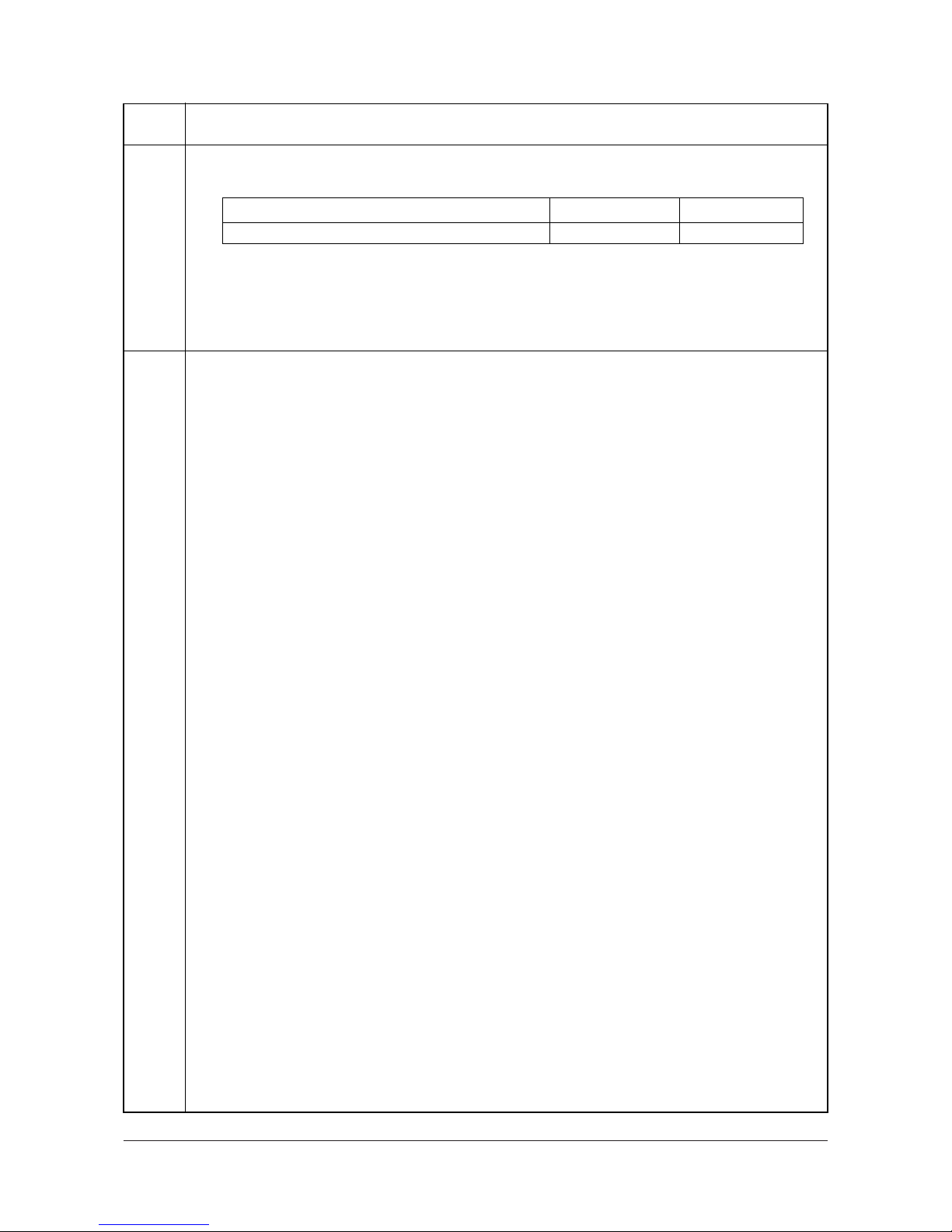

U237

Adjusting finisher stack quantity

Description

Sets the number of sheets of stack on the main tray in the document finisher.

Purpose

To change the setting when a stack malfunction has occurred.

Method

Press the start key. The screen for selecting an item is displayed.

Setting

1. Change the setting using the cursor up/down keys.

Initial setting: 0

If the preset value is changed to 1, the number of sheets of a stack is limited to 1,500 in modes other

than the staple mode.

2. Press the start key. The setting is set.

Completion

Press the stop/clear key. The screen for selecting a maintenance item No. is displayed.

Maintenance

item No.

Description

Setting Description

0 Stack quantity: 3000 sheets

1 Stack quantity: 1500 sheets

Service Manual Y104371-8

3H3

1-3-5

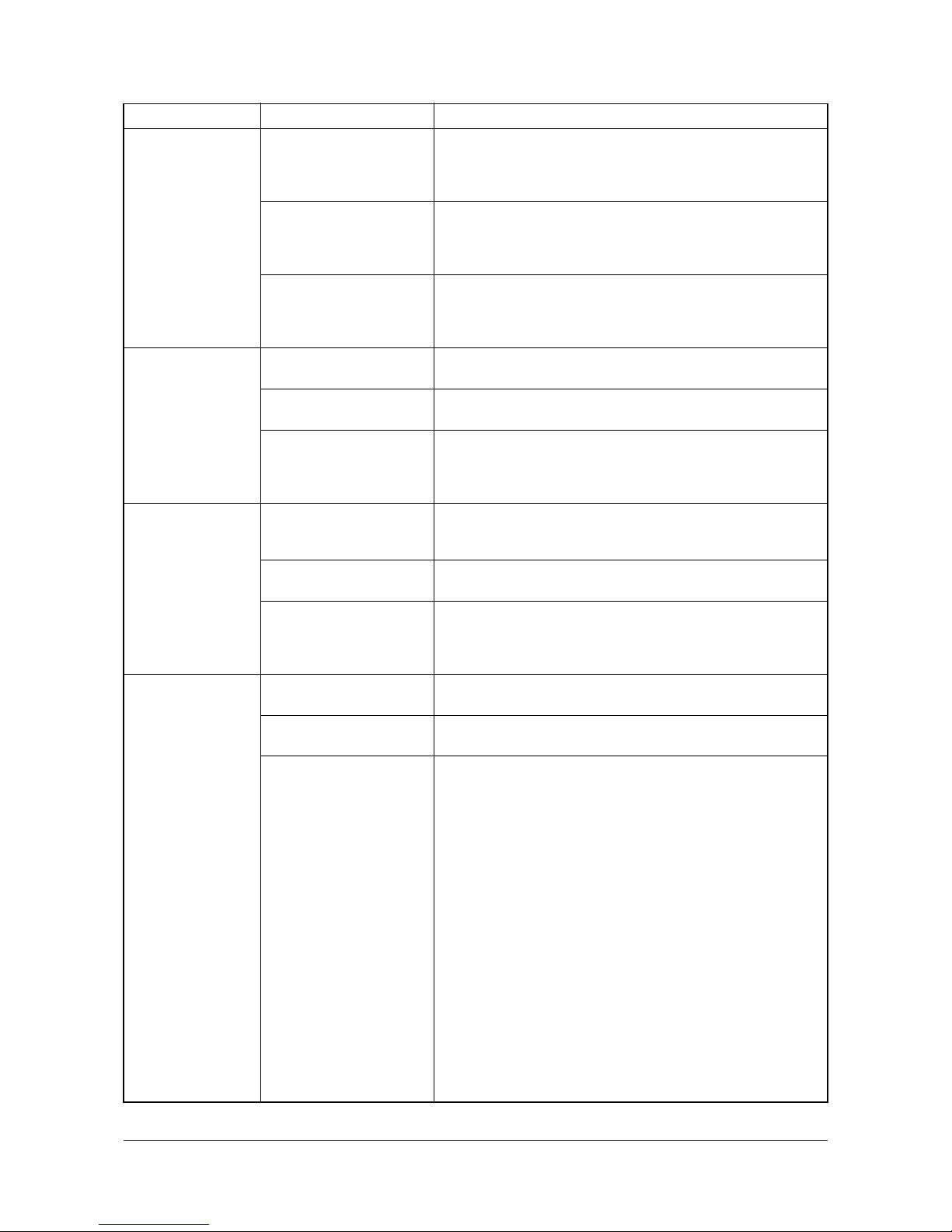

U240

Checking the operation of the finisher

Description

Turns each motor and solenoid of the document finisher ON.

Purpose

To check the operation of each motor and solenoid of the document finisher.

Method

1. Press the start key. The screen for selecting an item is displayed.

2. Select the item to be checked.

Method: Checking the motor and solenoid of the document finisher

1. Select FINISHER on the screen for selecting an item.

2. Select the item to be operated.

Maintenance

item No.

Description

Display Description

FINISHER Motors and solenoids of document finisher

SADDLE Motors and solenoids of centerfold unit

Display Motors and solenoids

FD_IN_MT_H Paper entry motor (PEM) is turned on high speed

FD_IN_MT_M Paper entry motor (PEM) is turned on middle speed

FD_IN_MT_L Paper entry motor (PEM) is turned on low speed

CNV_MT_H Paper conveying motor (PCM) is turned on high speed

CNV_MT_M Paper conveying motor (PCM) is turned on middle speed

CNV_MT_L Paper conveying motor (PCM) is turned on low speed

UP_MT Upper paper conveying belt motor (PCBM-U) is turned on

DOWN_MT Lower paper conveying belt motor (PCBM-L) is turned on

LGR_TEST Front/rear upper side registration guide motor (SRGM-FU/RU) test

operation for 11” x 17” size

A3_TEST Front/rear upper side registration guide motor (SRGM-FU/RU) test

operation for A3 size

WDTH_MT_L Lower side registration guide motor (SRGM-L) is turned on

SLAP_MT_INI Movable guide motor (MGM) is turned on initial driving

SLAP_MT_MOV Movable guide motor (MGM) is turned on

DRM_MT_H Siding drum motor (SDM) is turned high speed

DRM_MT_M Siding drum motor (SDM) is turned middle speed

DRM_MT_L Siding drum motor (SDM) is turned low speed

EJECT_MT_H Eject motor (EJM) is turned on high speed

EJECT_MT_M Eject motor (EJM) is turned on middle speed

EJECT_MT_L Eject motor (EJM) is turned on low speed

MTRAY_MT Main tray elevation motor (MTEM) is turned on

JTRAY_MT Multi job tray elevation motor (MJTEM) is turned on

SOL_A Feedshift solenoid A (FSSOLA) is turned on

SOL_B Feedshift solenoid B (FSSOLB) is turned on

SOL_C Feedshift solenoid C (FSSOLC) is turned on

COLO_SOL Paper forwarding pulley solenoid (PFPSOL) is turned on

LOCK_SOL Lock solenoid (LSOL) is turned on

P_PUT_SOL Paper holder solenoid (PHSOL) is turned on

EJECT_SOL Eject guide solenoid (EGSOL) is turned on

PUNCH_MT Punch motor (PUNM) is turned on

PUNCH_SOL Punch solenoid (PUNSOL) is turned on

Y104371-8 Service Manual

3H3

1-3-6

U240 3. To turn ON a solenoid with the motor driving, press the interrupt key before selecting the solenoid.

The driving motor will start operation, and the selected clutch or the solenoid will remain ON until the

interrupt key is pressed again.

4. To stop motor driving, press the interrupt key again.

5. To return to the screen for selecting an item, press the stop/clear key with the motor stopped.

Method: Checking the motor and solenoid of the centerfold unit

1. Select SADDLE on the screen for selecting an item.

2. Select the item to be operated.

3. To turn ON a solenoid with the motor driving, press the interrupt key before selecting the solenoid.

The driving motor will start operation, and the selected clutch or the solenoid will remain ON until the

interrupt key is pressed again.

4. To stop motor driving, press the interrupt key again.

5. To return to the screen for selecting an item, press the stop/clear key with the motor stopped.

Completion

Press the stop/clear key with the operation stopped. The screen for selecting a maintenance item No. is displayed.

U241

Checking the operation of the switches of the finisher

Description

Displays the status of each switch of the document finisher.

Purpose

To check the operation of each switch of the document finisher.

Method

1. Press the start key. The screen for selecting an item is displayed.

2. Turn each switch ON manually.

When a switch is detected to be in the ON position, the display for that switch will be highlighted.

3. Change the screen using the * or # keys.

Maintenance

item No.

Description

Display Motors and solenoids

SDL_MT_H Main motor (MM) is turned ON high speed

SDL_MT_L Main motor (MM) is turned ON low speed

SDL_BLD_MT Centerfold blade motor (CBLM) is turned ON

SDL_CTR_MT Centering plate motor (CPM) is turned ON

SDL_WDTH_MT Side registration guide motor (SRGM) is turned ON

SDL_SOL Pressure release solenoid (PRSOL) is turned ON

Display Switches

FD_IN_SW Paper entry sensor (PES)

EJT_SW Paper ejection sensor (PEJS)

DRM_SW Sub tray paper ejection sensor (STPES)

M_TRAY_FD_SW Intermediate tray paper conveying sensor (ITPCS)

P_DET_U_SW Upper paper conveying belt home position sensor (PCBHPS-U)

P_DET_D_SW Lower paper conveying belt home position sensor (PCBHPS-L)

PCH_BOX_SW Punch waste box sensor (PWBS)

SLAP_HP_SW Movable guide home position sensor (MGHPS)

P_PUT_SW Paper holder detection sensor (PHDS)

STP_FPIN_SW Front stapler empty sensor (STES-F)

STP_RPIN_SW Rear stapler empty sensor (STES-R)

STP_F_CT_SW Front stapler cartridge sensor (STCS-F)

STP_R_CT_SW Rear stapler cartridge sensor (STCS-R)

STP_F_HP_SW Front stapler home position sensor (STHPS-F)

STP_R_HP_SW Rear stapler home position sensor (STHPS-R)

CRT_F_HP_SW Front clincher home position sensor (CLNHPS-F)

Service Manual Y104371-8

3H3

1-3-7

U241

Completion

Press the stop/clear key. The screen for selecting a maintenance item No. is displayed.

Maintenance

item No.

Description

Display Switches

CRT_R_HP_SW Rear clincher home position sensor (CLNHPS-R)

T_OPEN_SW Upper cover switch (UCSW)

F_OPEN_SW Front cover switch (FCSW)

JTRAY_DT_SW Multi job tray position sensor (MJTPS)

JTRAY_P_SW1 Paper detection switch 1 (PDSW1)

JTRAY_P_SW2 Paper detection switch 2 (PDSW2)

JTRAY_P_SW3 Paper detection switch 3 (PDSW3)

JTRAY_P_SW4 Paper detection switch 4 (PDSW4)

JTRAY_P_SW5 Paper detection switch 5 (PDSW5)

JTRAY_ULT_SW Multi job tray upper limit detection sensor (MJTULDS)

JTRAY_P_SW Multi job tray front/rear switches (MJTSW-F/MJTSW-R)

JTRAY_U_SW Multi job tray paper upper surface detection light emitting/intercept-

ing sensors (MJTPUSDLES/MJTPUSDLIS)

MTRAY_U_SW Main tray paper upper surface detection light emitting/intercepting

sensors (MTPUSDLES/MTPUSDLIS)

MTRAY_LM_SW Main tray upper limit detection sensor (MTULDS)

1000_SW Main tray load 1000 detection sensor (MTLDS-10)

1500_SW Main tray load 1500 detection sensor (MTLDS-15)

JTRAY_LLT_SW Multi job tray lower limit detection sensor (MJTLLDS)

3000_SW Main tray load 3000 detection sensors (MTLDS-30)

MTRAY_LLT_SW Main tray lower limit detection sensor (MTLLDS)

N_STP_HP_SW N_STP_CT_SW W_UF_HP_SW Front upper side registration guide home position sensor

(SRGHPS-FU)

W_UR_HP_SW Rear upper side registration guide home position sensor

(SRGHPS-RU)

W_L_HP_SW Lower side registration guide home position sensor (SRGHPS-L)

UP_HP_SW Upper paper sensor (PS-U)

DWN_HP_SW Lower paper sensor (PS-L)

SDL_SET_SW Centerfold unit set switch (CUSSW)

SDL_DET_SW Eject tray detection switch (ETDSW)

SDL_W_HP_SW Side Registration guide home position sensor (SRGHPS)

SDL_S_HP_SW Centering plate home position sensor (CPHPS)

SDL_B_HP_SW Centerfold blade home position sensor (CBLHPS)

SDL_FD_SW Centerfold unit paper entry sensor (CUPES)

SDL_P_SW Eject tray paper detection switch (ETPDSW)

SDL_E_SW Folded edge detection sensor (FEDS)

SDL_T_SW Inside tray detection sensor (ITDS)

Y104371-8 Service Manual

3H3

1-3-8

U248

Setting the paper ejection device

Description

Adjusts the paper stop timing in the punch mode, the booklet stapling position, and the center folding position

for the machine with the document finisher installed. Also, displays and clears the punch-hole scrap count.

Purpose

Adjustment or registration stop timing in punch mode

Adjust if skewed paper conveying occurs or if the copy paper is Z-folded in punch mode.

Adjustment of paper stop timing in the punch mode

To adjust this item when the position of a punch hole is different from the specified one.

Punch-hole scrap count display (clearing)

Used to manually clear the punch-hole scrap count if a message requiring collection of punch-hole scrap is

shown on the touch panel after collection.

Adjustment of booklet stapling position

Adjusts the booklet stapling position in the stitching mode if the position is not proper.

Adjustment of center folding position

Adjusts the center folding position in the stitching mode if the position is not proper.

Setting the punch limit

Sets the maximum number of punches possible in order to be informed of the timing for disposing of waste

punch. Decrease the value when using thick paper frequently.

Start

Press the start key. The screen for selecting an item is displayed.

Setting the registration stop timing in punch mode

1. Select PUNCH REGIST ADJUST on the screen for selecting an item.

2. Change the value using the cursor up/down keys.

If skewed paper conveying occurs (sample 1), increase the preset value. If the copy paper is Z-folded

(sample 2), decrease the preset value.

3. Press the start key. The value is set.

4. To return to the screen for selecting an item, press the stop/clear key.

Maintenance

item No.

Description

Display Description

PUNCH REGIST ADJUST Adjustment of registration stop timing in punch mode

PUNCH POSITION ADJUST Adjustment of the paper stop timing in punch mode

PUNCH COUNT Punch-hole scrap count display

SADDLE STAPLE ADJUST Booklet stapling position adjustment

SADDLE ADJUST Adjustment of center folding position

PUNCH PRESET Punch limit

Description Setting range Default setting

Adjustment of registration stop timing in punch mode -5 to 5 0

Sample 1 Sample 2

Service Manual Y104371-8

3H3

1-3-9

U248

Setting the paper stop timing

1. Select PUNCH POSITION ADJUST on the screen for selecting an item.

2. Change the value using the cursor up/down keys.

If the distance of the position of a punch hole is smaller than the specified value A, increase the preset

value. If the distance is larger than the value A, decrease the preset value.

Changing the value by 1 changes by 1.0 mm.

3. Press the start key. The value is set.

4. To return to the screen for selecting an item, press the stop/clear key.

Displaying the punch-hole scrap count

1. Select PUNCH COUNT on the screen for selecting an item.

2. Change the value using the cursor up/down keys.

Press the reset key to clear the count.

3. Press the start key. The value is set.

4. To return to the screen for selecting an item, press the stop/clear key.

Setting the booklet stapling position

1. Select SADDLE STAPLE ADJUST on the screen for selecting an item.

2. Select the size to be set.

3. Change the setting using the cursor up/down keys.

If the staple position is displaced toward the ejection side (copy sample 1), decrease the preset value.

If the staple position is displaced toward the feeding side (copy sample 2), increase the preset value.

Maintenance

item No.

Description

Description Setting

range

Default

setting

Change in value

per step

Adjustment of the paper stop timing in punch mode -10 to 10 0 0.24 mm

A

Preset value A: 5.5 2mm (inch)

9.5 2mm (metric)

+

-

+

-

Description Setting range Default setting

Punch-hole scrap count

(current number of punching times)

0 to 9999999 -

Display Description Setting

range

Default

setting

Change in value

per step

A4R/8.5 x 11 Adjustment of booklet stapling position for

A4R/8.5 x 11 size

-10 to 10 0 0.55 mm

B4R/8.5 x 14Adjustment of booklet stapling position for

B4R/8.5 x 14 size

-10 to 10 0 0.55 mm

A3R/11 x 17 Adjustment of booklet stapling position for

A3R/11 x 17 size

-10 to 10 0 0.55 mm

Y104371-8 Service Manual

3H3

1-3-10

U248

4. Press the start key. The value is set.

5. To return to the screen for selecting an item, press the stop/clear key.

Setting the center folding position

1. Select SADDLE ADJUST on the screen for selecting an item.

2. Select the size to be set.

3. Change the setting using the cursor up/down keys.

4. Press the start key. The value is set.

5. To return to the screen for selecting an item, press the stop/clear key.

Maintenance

item No.

Description

Copy sample 1 Copy sample 2

Display Description Setting

range

Default

setting

Change

in value

A4R/8.5 x 11 Adjustment of center folding position for

A4R/8.5 x 11 size

-10 to 10 0 0.55 mm

B4R/8.5 x 14 Adjustment of center folding position for

B4R/8.5 x 14 size

-10 to 10 0 0.55 mm

A3R/11 x 17 Adjustment of center folding position for

A3R/11 x 17 size

-10 to 10 0 0.55 mm

Left stapling

Upper side is longer.

Right stapling

Lower side is longer.

Lower side is longer. Upper side is longer.

Adjustment method

Proper

Decrease the

preset value.

Increase the

preset value.

Service Manual Y104371-8

3H3

1-3-11

U248

Setting the punch limit

1. Select PUNCH PRESET on the screen for selecting an item.

2. Change the value using the * or # keys.

The punch limit can be set to any value in increments of 1000.

3. Press the start key. The value is set.

4. To return to the screen for selecting an item, press the stop/clear key.

Completion

To exit this maintenance item without changing the current setting, press the stop/clear key.

The screen for selecting a maintenance item No. is displayed.

U330

Setting the number of sheets to enter stacking mode during sort operation

Description

Sets the number of copies at which copy ejection will be switched from the optional document finisher's sub

tray to its main tray when sorting is turned ON in the setting for the output mode under user simulation.

Purpose

To be set as required according to the number of copies the user makes.

Method

Press the start key. The current setting is displayed.

Setting

1. Change the setting using the cursor up/down keys.

2. Press the start key. The value is set, and the screen for selecting a maintenance item No. is displayed.

Initial setting: 201 (sheets)

Completion

To exit this maintenance item without changing the current setting, press the stop/clear key.

The screen for selecting a maintenance item No. is displayed.

Maintenance

item No.

Description

Description Setting range Default setting

Punch limit (max. number of punches) 0 to 999000 100000

Y104371-8 Service Manual

3H3

1-3-12

U905

Checking/clearing counts by optional devices

Description

Displays or clears the counts of the DP or optional finisher.

Purpose

To check the use of the DP and optional finisher. Also to clear the counts after replacing consumable parts.

Method

1. Press the start key. The screen for selecting an item is displayed.

2. Select the device, the count of which is to be checked. The count of the selected device is displayed.

DP

Finisher

Clearing

1. Select the item to be cleared. The selected item is displayed in reverse.

Select the counts for all, press the reset key.

2. Press the start key. The count is cleared.

To return to the screen for selecting an item, press the stop/clear key.

Completion

Press the stop/clear key at the screen for selecting an item.

The screen for selecting a maintenance item No. is displayed.

Maintenance

item No.

Description

Display Description

ADP Number of single-sided originals that has passed through the DP

RADP Number of double-sided originals that has passed through the DP

Display Description

CP CNT Number of copies that has passed

STAPLE Frequency the stapler has been activated

PUNCH Frequency the punch has been activated

STACK Frequency the stacker has been activated

SADDLE Frequency the center holding has been activated

Service Manual Y104371-8

3H3

1-4-1

1-4 Troubleshooting

1-4-1 Paper misfeed detection

(1) Paper misfeed indication

When a paper jam occurs, the machine immediately stops copying and the operation panel shows a paper misfeed message.

Paper jam counts sorted by the detecting conditions can be checked by maintenance item U903.

To remove paper, open the front cover or upper cover.

To reset the paper misfeed detection, open and close the front cover or upper cover to turn the front cover switch or upper

cover switch off and on, respectively.

Figure 1-4-1

STPES

PES

ITPCS

ITDS

FEDS

PS-L

PEJS

CUPES

Y104371-8 Service Manual

3H3

1-4-2

(2) Paper misfeed detection conditions

Section Jam code Description Conditions

Document

finisher

80 Jam between the finisher

and copier

Paper ejection is not output from the copier to the document

finisher within 15 s of the face-up exit sensor (FUES) turning

off.

81 Paper jam during paper

insertion to the finisher

When the paper entry sensor (PES) does not turn on within

1950 ms of the face-up exit sensor (FUES) of the copier turning off.

82 Paper jam during paper

insertion to the finisher

and paper ejection to the

sub tray

When the sub tray paper ejection sensor (STPES) does not

turn on within 2000 ms of the paper entry sensor (PES) turning

on.

When the paper entry sensor (PES) does not turn off within

1500 ms of its turning on.

83 Paper jam at the siding

drum

When the sub tray paper ejection sensor (STPES) does not

turn off within 1000 ms of its turning on.

84 Paper jam during paper

insertion to the intermediate tray

When the intermediate tray paper conveying sensor (ITPCS)

does not turn on within 1200 ms of the paper entry sensor

(PES) turning on.

When the paper entry sensor (PES) does not turn off within

1500 ms of its turning on.

When the intermediate tray paper conveying sensor (ITPCS)

does not turn on within 2000 ms of the sub tray paper ejection