Oliver 797-32N Installation Manual

Grand Rapids, Michigan, U.S.A. 49504-5298

USER’S OPERATING AND INSTRUCTION MANUAL

MODELS 797-32N, 797-32NC & 797-48N

BREAD SLICERS

0797S20000-CV2

797-N BREAD SLICER

INDEX

Section Description

SAFETY INSTRUCTIONS -------------------------------------- 0797S20021 --------------------------- 1-1

DESCRIPTION/SPECIFICATIONS --------------------------- 0797S20022---------------------------- 2-1

Description -------------------------------------------------------------------------------------------------- 2-1

Specifications----------------------------------------------------------------------------------------------- 2-1

INSTALLATION INSTRUCTIONS ---------------------------- 0797S20023 --------------------------- 3-1

Removing the Slicer from the Shipping Skid ------------------------------------------------------- 3-1

Installing Optional Casters ------------------------------------------------------------------------------ 3-2

OPERATING INSTRUCTIONS -------------------------------- 0797S20024 --------------------------- 4-1

Adjusting the Gravity Feed Slicer’s Holddown ----------------------------------------------------- 4-1

Adjusting the Slicer for Product Length -------------------------------------------------------------- 4-2

Adjusting the Outfeed Side Guides on a Standard Outfeed Table --------------------------- 4-3

Operating a Gravity Feed Slicer ----------------------------------------------------------------------- 4-4

Operating the Gravity Feed’s Last Loaf Pusher --------------------------------------------------- 4-4

TROUBLESHOOTING ------------------------------------------- 0797S20025 --------------------------- 5-1

The Slicer Will Not Start (Motor is Not Humming) ------------------------------------------------ 5-1

The Slicer Will Not Start (Motor is Humming) ------------------------------------------------------ 5-1

Bread Slices Vary in Thickness ------------------------------------------------------------------------ 5-2

The Blade Frames are Knocking ---------------------------------------------------------------------- 5-2

The Slicer Vibrates Excessively ----------------------------------------------------------------------- 5-2

The Bread is Cutting Slowly or is Being Damaged ----------------------------------------------- 5-2

MAINTENANCE --------------------------------------------------- 0797S20026 --------------------------- 6-1

Cleaning ----------------------------------------------------------------------------------------------------- 6-1

Lubrication -------------------------------------------------------------------------------------------------- 6-1

Removing the Blade Frames --------------------------------------------------------------------------- 6-2

Changing the Blades ------------------------------------------------------------------------------------- 6-6

Tightening the Belt --------------------- ------------------------------------------------------------------- 6-8

Replacing the Belt --------------------- -- ---------------------------------------------------------------- 6-10

Adjusting the Blade Frames When Slices Vary in Thickness -------------------------------- 6-11

Adjusting the Clearance Between the Blade Frames ------------------------------------------ 6-12

RECOMMENDED SPARE PARTS -------------------------- 0797S20027 --------------------------- 7-1

REPLACEMENT PARTS SECTION

MAIN FRAME & ROCKER ------------------------------------- 0797S20028 --------------------------- 8-1

Drawing ------------------------------------------------------------------------------------------------- 8-1

Parts List ----------------------------------------------------------------------------------------------- 8-2

BASE & CASTER ------------------------------------------------- 0797S20029 --------------------------- 9-1

Drawing ------------------------------------------------------------------------------------------------ 9-1

Parts List ----------------------------------------------------------------------------------------------- 9-2

Continued

Rev 9-6-02

Document No. Page No.

0797S20020 0-1

797-N BREAD SLICER

INDEX (Continued)

REPLACEMENT PARTS SECTION (Continued)

Section Description

SLICE PARTS & HOLDDOWN ------------------------------- 0797S20030 -------------------------- 10-1

Drawing ----------------------------------------------------------------------------------------------- 10-1

Parts List ---------------------------------------------------------------------------------------------- 10-2

32 INCH GRAVITY INFEED CHUTE ------------------------ 0797S20031 -------------------------- 11-1

Drawing ----------------------------------------------------------------------------------------------- 11-1

Parts List ---------------------------------------------------------------------------------------------- 11-2

48 INCH GRAVITY INFEED CHUTE ------------------------ 0797S20032 -------------------------- 12-1

Drawing ----------------------------------------------------------------------------------------------- 12-1

Parts List ---------------------------------------------------------------------------------------------- 12-2

32 INCH COMBINATION INFEED CHUTE ---------------- 0797S20058 -------------------------- 13-1

Drawing ----------------------------------------------------------------------------------------------- 13-1

Parts List ---------------------------------------------------------------------------------------------- 13-2

STANDARD OUTFEED ---------------------------------------- 0797S20033 -------------------------- 14-1

Drawing ----------------------------------------------------------------------------------------------- 14-1

Parts List ---------------------------------------------------------------------------------------------- 14-2

DRIVEN PULLEY ------------------------------------------------ 0797S20034 -------------------------- 15-1

Drawing ----------------------------------------------------------------------------------------------- 15-1

Parts List ---------------------------------------------------------------------------------------------- 15-2

SINGLE PHASE ELECTRICAL ------------------------------- 0797S20035 -------------------------- 16-1

Wiring Diagram --------------------------------------------------------------------------------------16-1

Drawing ----------------------------------------------------------------------------------------------- 16-1

Parts Lists -------------------------------------------------------------------------------------------- 16-2

THREE PHASE ELECTRICAL ------------------------------- 0797S20036 ------------------------- 17-1

Wiring Diagram ------------------------------------------------------------------------------------- 17-1

Drawing ----------------------------------------------------------------------------------------------- 17-1

Parts Lists -------------------------------------------------------------------------------------------- 17-2

WARRANTY ---------------------------------------------------- --- GEN 040225

WARRANTY PROCEDURE ----------------------------------- GEN 040226

RETURNED PARTS POLICY -------------------------------- GEN 040227

REV. 3/2/04

Document No. Page No.

0797S20020 0-2

797-N BREAD SLICER

SAFETY INSTRUCTIONS

WARNING

VARIOUS SAFETY DEVICES AND METHODS OF GUARDING HAVE BEEN

PROVIDED ON THIS MACHINE. IT IS ESSENTIAL HOWEVER THAT THE MACHINE

OPERATORS AND MAINTENANCE PERSONNEL OBSERVE THE FOLLOWING

SAFETY PRECAUTIONS. IMPROPER INSTALLATION, MAINTENANCE, OR

OPERATION OF THIS EQUIPMENT COULD CAUSE SERIOUS INJURY OR DEATH.

1. Read this manual before attempting to operate your machine. Never allow an

untrained person to operate or service this machine.

2. Connect the machine to a properly grounded electrical supply that matches the

requirements shown on the electrical specification plate and follow all specifications

of local electrical codes.

3. Disconnect and lock-out the machine from the power supply before cleaning or

servicing.

4. Check and secure all guards before starting the machine.

5. Observe all caution and warning labels affixed to the machine.

6. Use only proper replacement parts.

7. Do not wear loose fitting clothing or loose hair when working near this machine.

Shirt tails should be tucked in.

8. Wear proper, personal, protective, safety equipment.

9. Keep Hands away from the moving parts of this machine while it is in operation.

10. In addition to these general safety instructions, please follow the more specific safety

instructions in the rest of this operating instruction manual.

WARNING

DO NOT USE FOR OTHER THAN ORIGINALLY INTENDED PURPOSE.

0797S20021 1-1

THIS PAGE WAS INTENTIONALLY

LEFT BLANK.

GEN020319

797-N BREAD SLICER

DESCRIPTION/SPECIFICATIONS

Description

The Oliver Model 797-N series of Bread Slicers are of a compact, sturdy, time tested

design, which has been used in bakeries worldwide for many years. The machine is

easy to operate, with its gravity fed infeed chute, allowing production slicing of product in

quantities of up to 600 loaves per hour. Speed is of course dependent on condition of

the machine, sharpness of its knives and the texture of the actual product being sliced.

Its design will provide years of efficient, trouble-free operation requiring a minimum of

maintenance.

The Model 797-N series of Bread Slicers are of stainless, plated, and painted steel

construction for easy cleaning and maintenance. Most operators will be able to replace

the knives without the need of a service call.

Oliver Products Company, who has a reputation of serving the Baking Industry for well

over 60 years, backs these slicers.

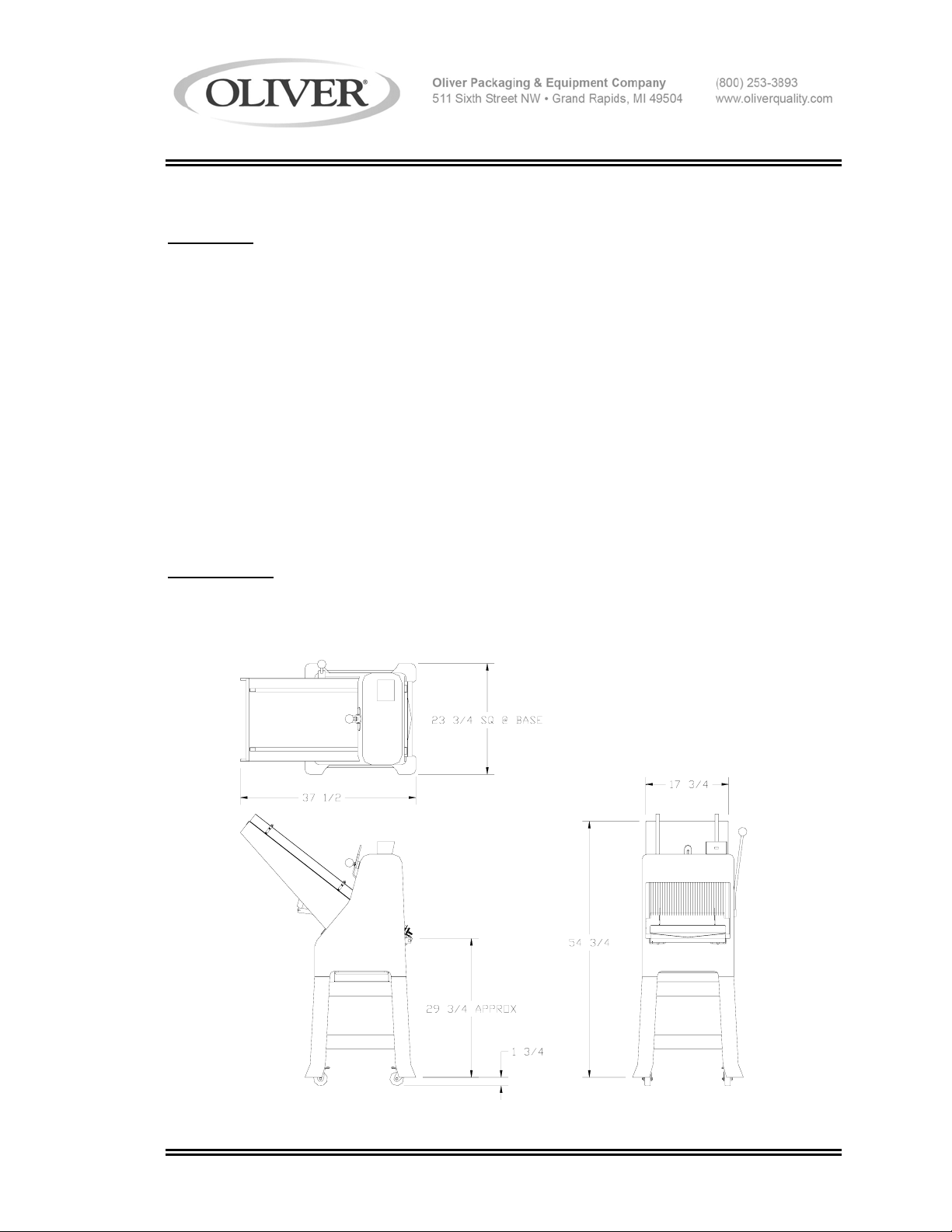

Specifications

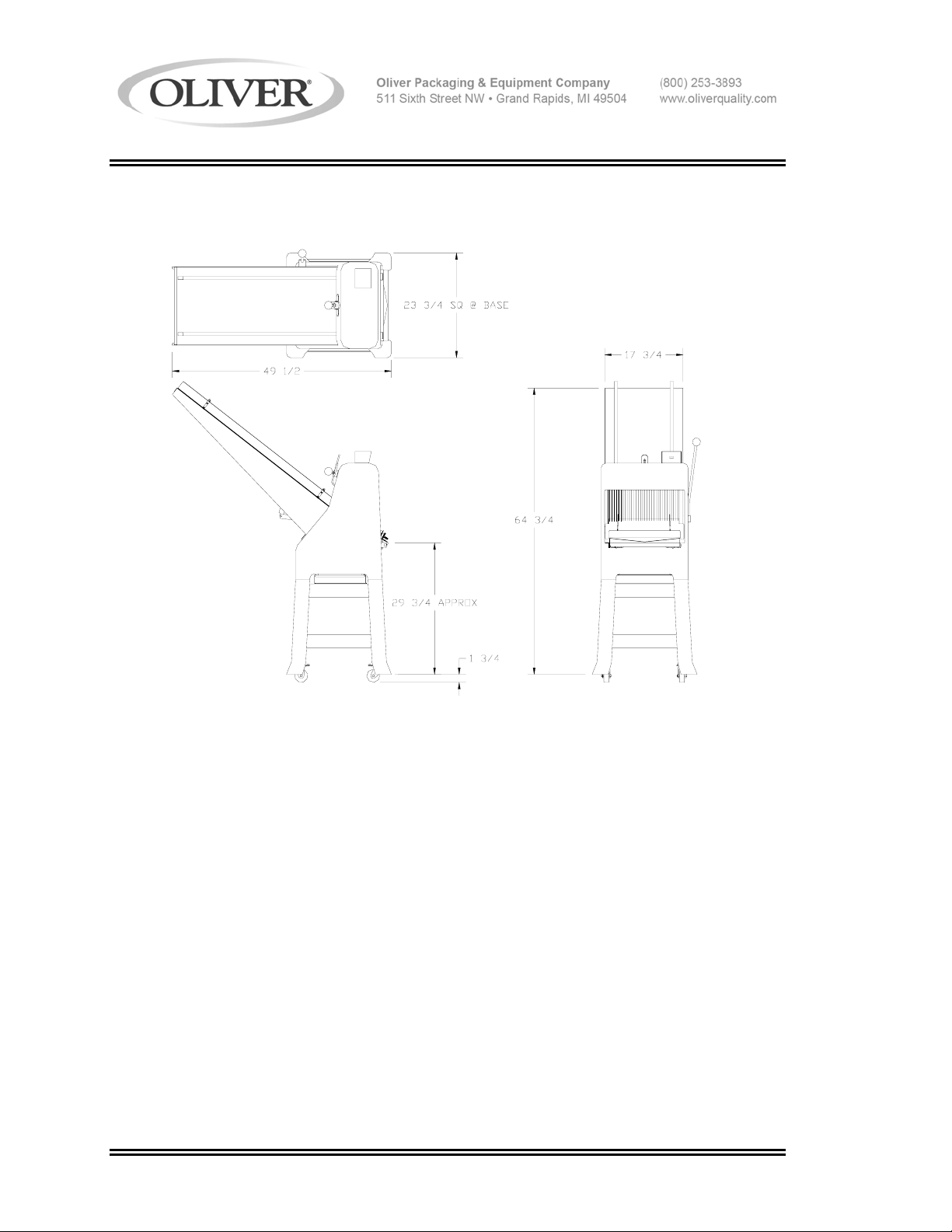

Space Requirements: Models 797-32N, (Shown), & 797-32NC

(All Dimensions are Approximate)

Rev. 9-6-02

0797S20022 2-1

797-N BREAD SLICER

Space Requirements: Models 797-48N

(All Dimensions are Approximate)

Product Capacities:

Up to 16 inches long and in the range of 2 to 5 inches high.

Standard Electrical Options: (Others available at additional cost -- consult factory).

1 phase, 60 hz, 115VAC, 7 Amps.

1 phase, 60 hz, 230VAC, 3.5 Amps.

Standard Slice Spacings, (Models 797-32N & 797-48N)

7/16, 1/2, 9/16 (inches)

Optional Slice Spacings, (Models 797-32N & 797-48N) (At additional cost).

(Specials available -- consult factory).

1/4 (min.), 5/16, 3/8, 5/8, 11/16, 3/4, 13/16, 7/8, 1, 1-1/4 (inches)

Shipping Weight

250 lbs. approximate

Rev. 9-6-31

0797S20022 2-2

797-N BREAD SLICER

INSTALLATION INSTRUCTIONS

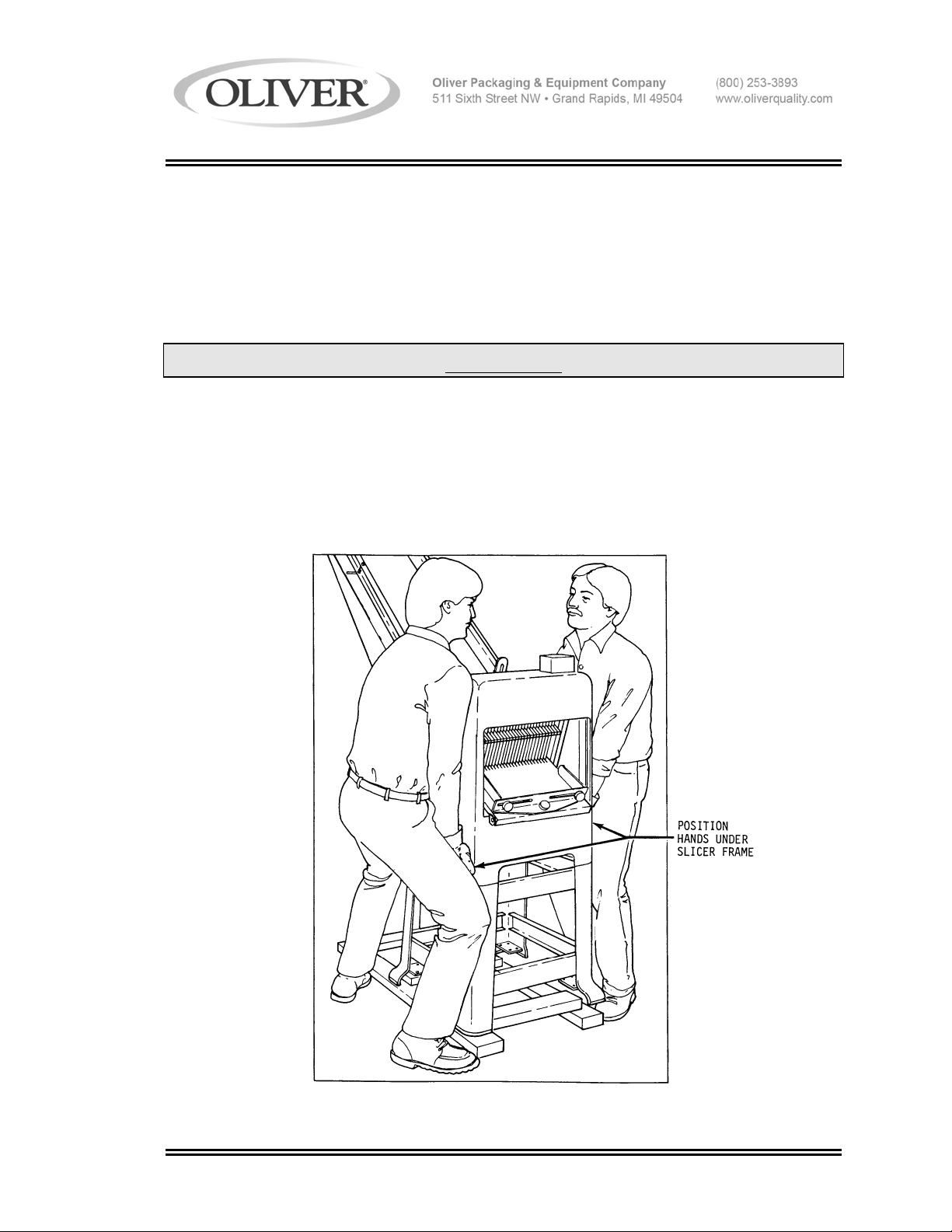

Removing the Slicer from the Shipping Skid

After removing the carton you should find the basic slicer completely assembled and

strapped to the shipping skid. Cut both straps to free the slicer from the skid.

CAUTION

THE SLICER IS HEAVY, USE PROPER TECHNIQUE WHEN LIFTING.

KEEP BACK STRAIGHT, KNEES BENT, AND LIFT WITH LEGS.

USE GLOVES TO PROTECT HANDS.

As shown in the illustration below, lift the slicer off the shipping skid with one person

standing on each side of the slicer. Set the slicer down on a level floor after which it may

be moved to the desired location.

0797S20023 3-1

797-N BREAD SLICER

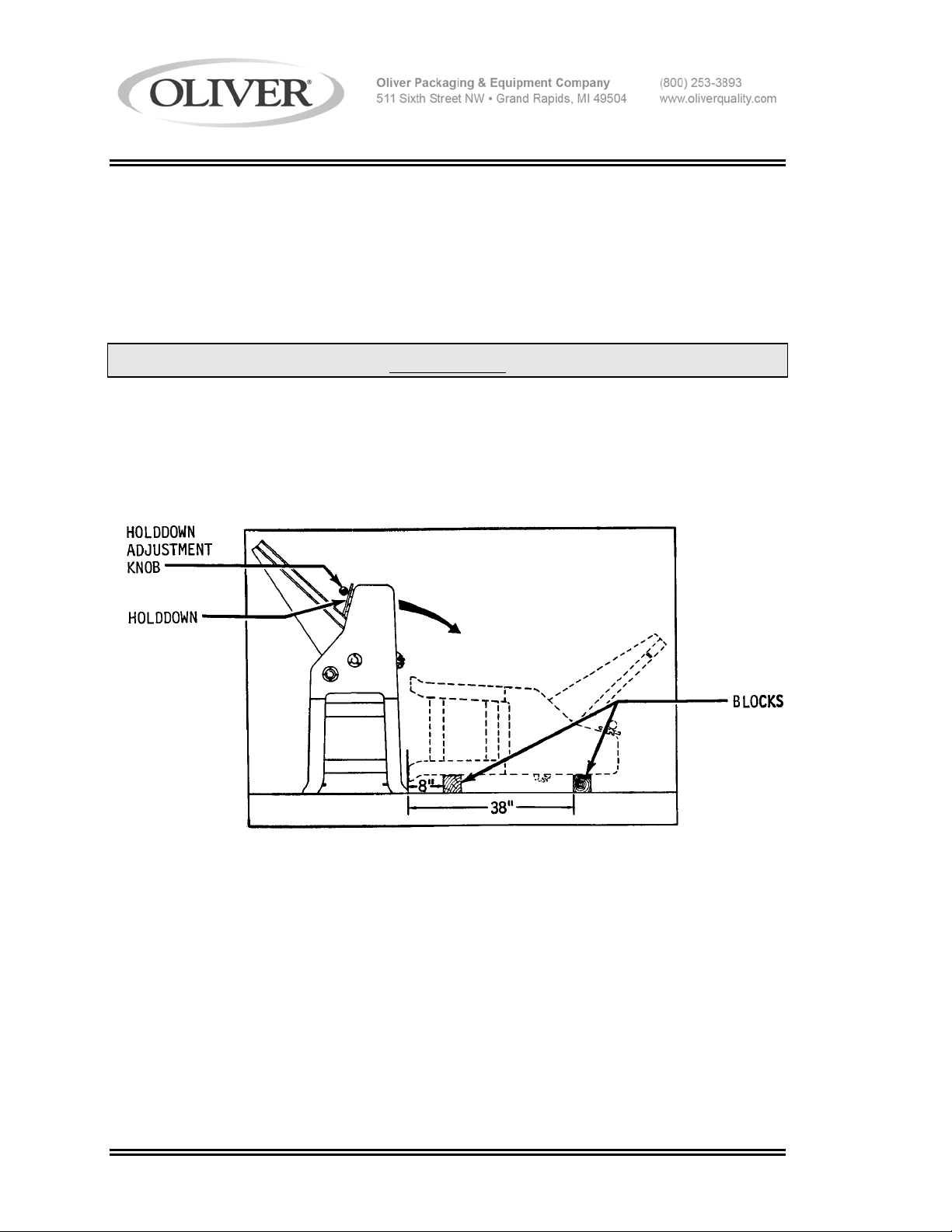

CASTER INSTALLATION INSTRUCTIONS

Place blocks on the floor approximately (8) and (38) inches from the discharge side of

the slicer, see the illustration below. Lower the holddown to its lowest position and

tighten the adjustment knob to prevent the outfeed table from swinging out. With one

person on each side of the slicer, gently lower the slicer onto the blocks.

CAUTION

NEVER ATTEMPT TO LIFT THE SLICER BY ITS INFEED CHUTE

AS DAMAGE TO THE MACHINE MAY RESULT.

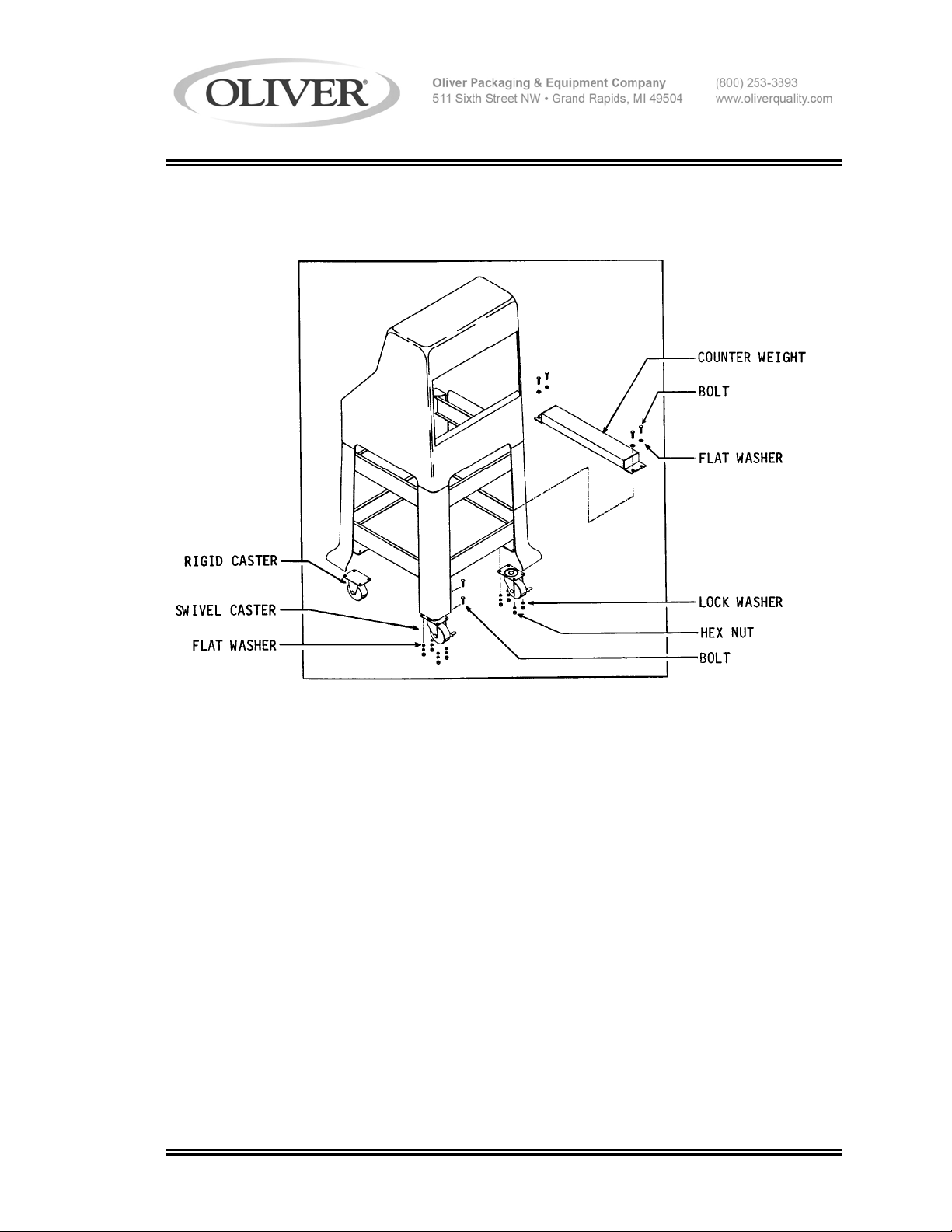

Locate the casters, ¼-inch bolts, lock washers, and nuts in the option package. Install

the casters using the furnished hardware as shown in the figure on the next page tighten

the bolts and nuts securely using two wrenches. Install both locking casters on the

discharge side of the machine. See the next illustration. Set the brakes tightly on both

locking casters, (this will help to keep the wheels from rolling when lifting the slicer back

to its upright position).

Install the two rigid casters in the same manner on the infeed side of the slicer.

Rev. 8/3/04

0797S20023 3-2

797-N BREAD SLICER

On all slicers equipped with either the Power Belt infeed chute option, or a Model 1179S

bagger, a counter weight must be attached to the caster brackets on the right hand side

of the machine, (as viewed from the outfeed side of the slicer). See the above

illustration. This counter weight must not be removed. Use the same hardware used to

secure the weight to attach the casters when both are used. Add additional bolts,

washers and nuts on those caster plate holes not involved with the weight mounted as

shown. Install one rigid caster and one swivel caster on the right hand side of the

machine, (the weight side). Remember, the rigid casters must be installed on the infeed

side of the machine.

Install the remaining two casters as previously described, setting their brakes tightly.

After completing the installation, chock the locked wheels using a 2 x 4 to ensure that

they will not roll or skid when lifting the slicer back to the upright position. Once the

machine is upright release the brakes and roll the slicer to its desired location.

Rev. 8/3/04

0797S20023 3-3

797-N BREAD SLICER

OPERATING INSTRUCTIONS

CAUTION

ALWAYS USE CARE WHENEVER WORKING NEAR THE CUTTING KNIVES.

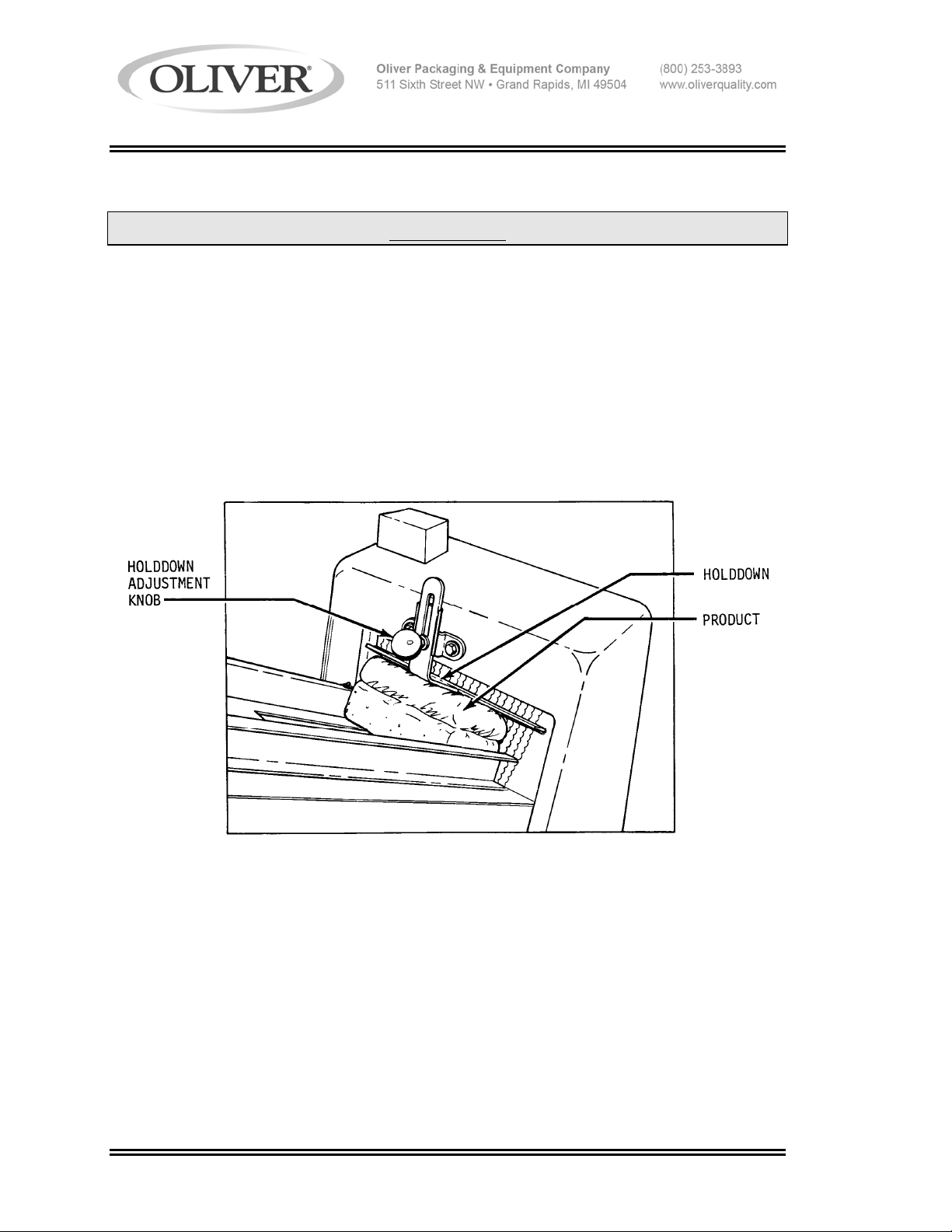

Adjusting the Gravity Feed Slicer’s Holddown, (Models 797-32N & 797-48N)

Loosen the holddown adjustment knob. Adjust the holddown so that the product just

clears the bottom edge of the holddown as it passes through the cutting knives. Tighten

the holddown adjustment knob when the holddown is in the desired location. See the

illustration below. Proper adjustment of the holddown will prevent the product from

jumping as it passes through the cutting knives increasing cutting efficiency.

Rev. 9-6-02

0797S20024 4-1

797-N BREAD SLICER

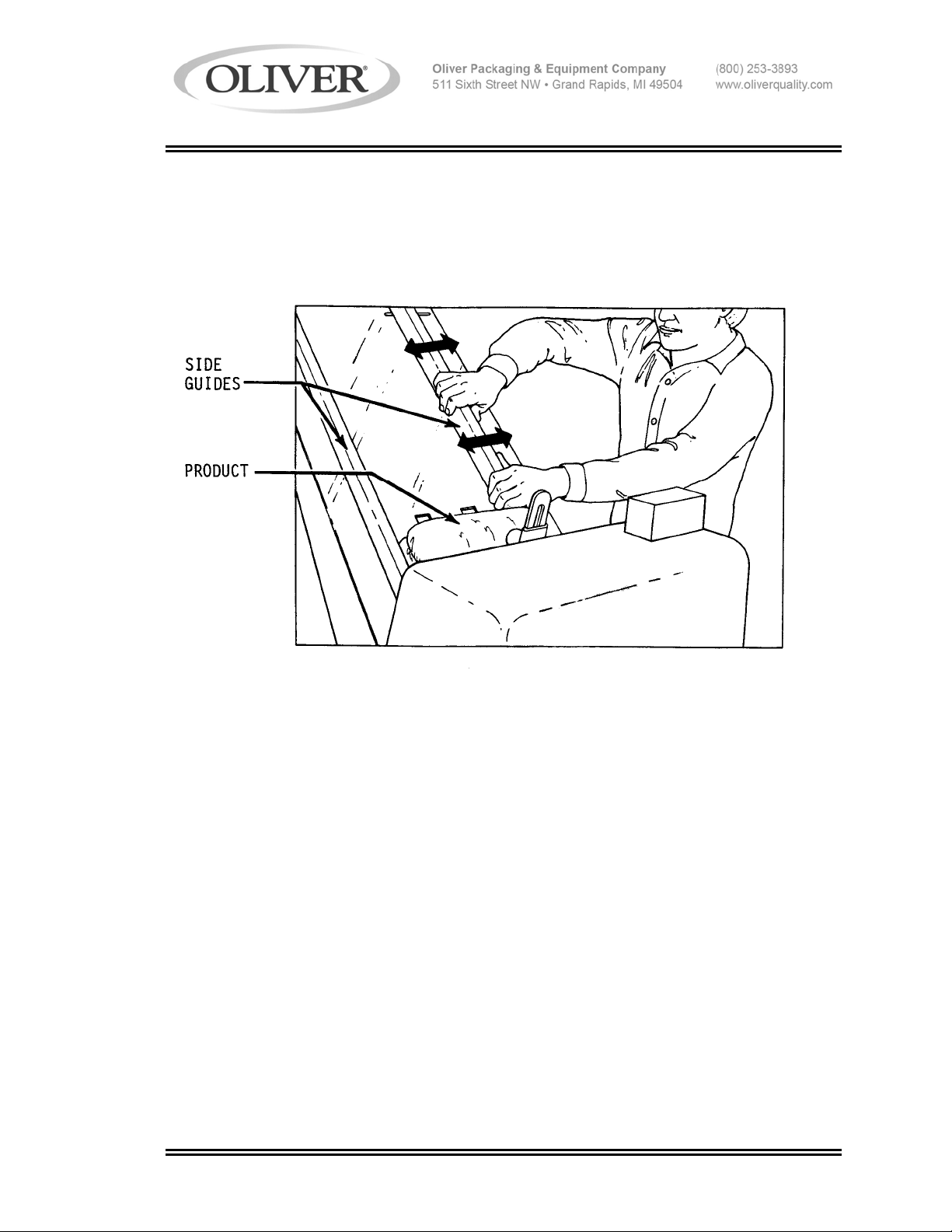

Adjusting the Slicer for Product Length

Using a typical product, adjust the infeed chute side guides by applying hand pressure.

See the next illustration. Set the side guides approximately 1/8 inch wider than the

longest expected product.

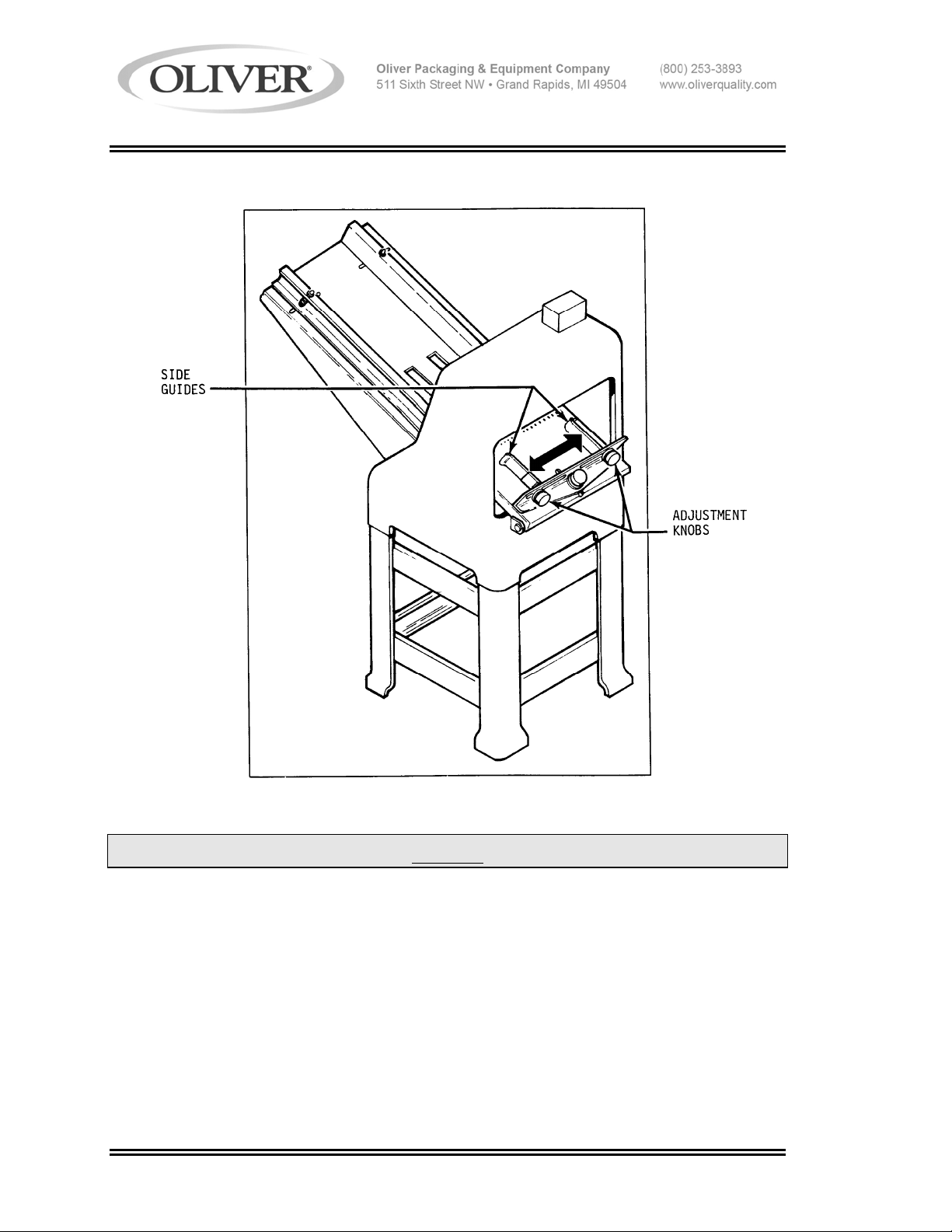

Adjusting the Outfeed Side Guides on a Standard Outfeed Table

Adjust the side guide extensions so that they are approximately 1/4 inch from the cutting

knives. Loosen the outfeed guide adjustment knobs. Adjust the outfeed side guides to

align with the infeed guides. See the illustration, which follows. Once satisfied with the

location re-tighten the side guide adjustment knobs. Proper adjustment of these guides

will keep the end slices from falling over as the product exits the cutting knives.

0797S20024 4-2

797-N BREAD SLICER

NOTE

OPTIONAL OUTFEED TABLE GUIDES ARE ADJUSTED WITH HAND

PRESSURE IN A FASHION SIMILAR TO THAT OF THE INFEED GUIDES.

AS WITH THE STANDARD OUTFEED TABLE ALIGN THE OUTFEED

GUIDES WITH THE INFEED GUIDES.

Operating a Gravity Feed Slicer

Once the slicer has been properly adjusted for product clearance, the infeed chute may

be loaded with the product to be sliced. Flipping the starting switch to the ON position

will begin operation. Remove each sliced product from the discharge table as it is sliced.

0797S20024 4-3

797-N BREAD SLICER

NOTE

THE GRAVITY FEED SLICER’S OPTIMUM OPERATING EFFICIENCY WILL

BE MAINTAINED BY ENSURING THAT THE INFEED CHUTE IS KEPT

FULLY LOADED. THE ACTUAL SPEED OF SLICING IS DEPENDENT ON THE

NUMBER OF PRODUCTS IN POSITION ON THE INFEED CHUTE, SHARPNESS

OF CUTTING KNIVES, AND TEXTURE OF THE PRODUCT.

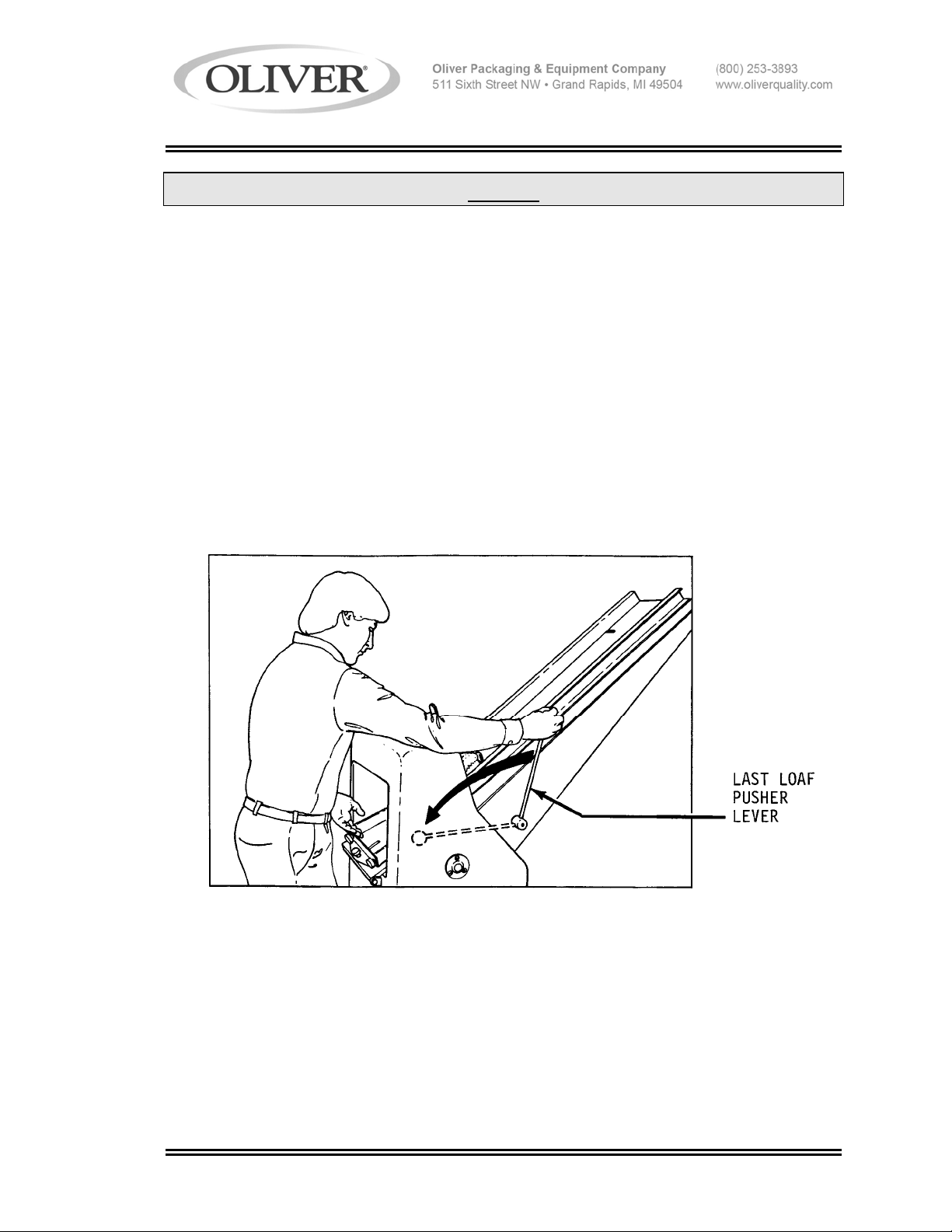

Operating the Gravity Feed’s Last Loaf Pusher, (Models 797-32N & 797-48N)

32 inch and 48 inch gravity feed slicers are equipped with a last loaf pusher to assist in

feeding the last product on the infeed chute through the cutting knives. To operate the

last loaf pusher, slowly pull the last loaf pusher lever toward the discharge side of the

slicer. See the next illustration. Return the lever to the upper position before reloading

the infeed chute.

(Continued)

Rev. 9-6-02

0797S20024 4-4

797-N BREAD SLICER

Operating the Gravity Feed’s Last Loaf Pusher (continued)

CAUTION

THE KNIVES ARE EXTREMELY SHARP.

DO NOT TOUCH MOVING OR STATIONARY KNIVES.

Once the last loaf pusher has fed the product into the cutting knives as far as it can, it

may be necessary to pull the product the rest of the way through the knives by hand.

NOTE

THE MODEL 797-32NC HAS A CENTER MOUNTED

HAND OPERATED THROUGH THE KNIFE PUSHER.

Rev. 9-6-02

0797S20024 4-5

797-N BREAD SLICER

TROUBLESHOOTING

WARNING

ALWAYS DISCONNECT THE SLICER FROM THE POWER SUPPLY BEFORE

ATTEMPTING ANY TYPE OF MAINTENANCE TASK, INCLUDING

TROUBLESHOOTING.

The Slicer Will Not Start (Motor Is Not Humming)

• The machine is not plugged in.

• There is no power at the outlet. (Check by plugging in a small working appliance,

like a lamp. Check to see if a circuit breaker has tripped. If the circuit breaker has

not tripped and the circuit is still not working have a qualified electrician check the

circuit.)

• The motor switch overload has tripped. (To reset push firmly in the direction shown

on the switch nameplate.)

• There are breadcrumbs in the motor starting switch. (Have a qualified electrician

disassemble the switch and clean it.)

• The problem is somewhere in the electrical system of the machine. (Have a qualified

electrician find and repair the problem.)

The Slicer Will Not Start (Motor Is Humming)

CAUTION

DO NOT ALLOW THE MOTOR TO HUM WITHOUT STARTING.

OVERHEATING CAN PERMANENTLY DAMAGE THE MOTOR.

• The motor has failed. (Have it checked by a qualified electrician.)

NOTE

A SPECIAL NON-VENTILATED MOTOR MUST BE USED WITH THIS SLICER.

• The drive system is binding. (Have a qualified service agent check for defective

bearings or other restrictions to free movement.)

0797S20025 5-1

797-N BREAD SLICER

• There is mechanical interference between other parts of the slicer. (Have a qualified

service agent evaluate the machine for adjustment or replacement of defective

parts.)

Bread Slices Vary in Thickness

• The blade frames are out of adjustment. (See the “Maintenance” section of this

manual under “Adjusting the Blade Frames When Slices Vary in Thickness” on how

to correct this problem.)

The Blade Frames Are Knocking

• The blade frames are out of adjustment. (See the “Maintenance” section of this

manual under “Adjusting the Clearance Between the Blade Frames” on how to

perform this adjustment.)

The Slicer Vibrates Excessively

• The drive belt is loose or worn. (See the “Maintenance” section of this manual under

“Tightening the Belt” or “Replacing the Belt” on how to make these corrections.)

• One or more of the bearings on the machine are failing. (Have a qualified service

agent check for defective bearings and replace them as required.)

• The pins, (two eccentrics and two regular), and links at the top of the blade frames

are worn. We suggest that these be replaced together. Mixing worn parts with new

will shorten the life of the replacement parts. Remember, after replacing the pins

and links the clearance between the blade frames must be re-adjusted. (See the

“Maintenance” section of this manual under “Adjusting the Clearance Between the

Blade Frames” on how to perform this adjustment.)

The Bread is Cutting Slowly or is Being Damaged

• The machine’s holddown is either missing or improperly adjusted. (See the

“Maintenance” section of this manual under “Adjusting the Gravity Feed Slicer’s

Holddown” on how to perform this adjustment.)

• The knives of the machine have become worn, (dull). (See the “Maintenance” section

of this manual under “Changing the Cutting Knives”). Most owners can perform this

item of maintenance without calling a service company.

• The blades are not aligned properly. (See the “Maintenance” section of this manual

under “Adjusting the Clearance Between the Blade Frames” on how to perform this

adjustment.)

0797S20025 5-2

Loading...

Loading...