Oliver 730 Installation Manual

PRODUCTSV COMPANY

445 - 6TH St. NW, Grand Rapids, Mi 49504 USA

Phone: +1 616 456 7711

®

BAKERY

PRODUCTS BV

Phone: +31 478 640 137

The NetherIand

Spurkt3

USERS OPERATING AND INSTRUCTION

MODEL 730

VERSATILE SLICER

MANUAL

S20000C3

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

oLIyER®

730 Versatile Slicer

olivorproducts.com.

- -.-

INDEX

Section Description

SAFETY INSTRUCTIONS

Electrics-Theory of Operation

Power Failure

Decommissioning Statement

Nameplates List

DESCRI PTION/SPECI FICATIONS

Description

Life Expectancy

Specifications

I NSTALLATION I NSTRUCTIONS

Removing the Slicer from the Shipping Platform

Document No.

0730520002

0730520003

0730520004

Page No.

2-1

2-1

2-1

2-1

3-1

3-1

OPERATING INSTRUCTIONS

TROUBLESHOOTING

0730520005

0730520006

The Slicer Will Not Start (Motor is Not Humming)

The Slicer Will Not Start (Motor is Humming)

The Slicer Does Not Stop Whèn Slicing is Complete

The Slicer Stops Before Slicing Starts or is Complete

Bread Slices Vary in Thickness

The Blade Frames are Knocking

MAINTENANCE

0730520007

Cleaning

Lubrication

Frequency of changing blades

Removing the Blade Frames

Replacing the Blade Frames

Adjusting the Blade Frames When Slices Vary ¡n Thickness

Changing the Blades

Tightening the Belt

Replacing the Belt

Adjusting the Clearance Between the Blade Frames

4-1

5-1

5-1

5-1

5-2

5-2

5-2

5-2

6-1

6-1

6-1

6-1

6-2

6-4

6-5

6-6

6-9

6-10

6-11

RECOMMENDED SPARE PARTS

0730S20001 :

0730520008

7-1

O-1

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

1............

OLiVER®

PRODUCTS 'ti COMPANY

oliverproducts.com

730 Versatile Slicer

INDEX Con't

Section Description

REPLACEMENT PARTS SECTION

ASSEMBLY DRAWING (MECHANICAL PARTS) --0730S20009

Frame Assembly

Blade Frame Assembly

Document No.

Pusher Assembly ----

Holddown Assembly

Covers

Rocker Assembly ------

Driven Pulley Assembly

ELECTRICAL SINGLE PHASE

Wiring Diagram (Single Phase)

Assembly Drawing (Single Phase)

0730520010

Parts List .37kw Motor, 220 yAC, 50 Hertz, I Phase

WARRANTY

GEN 040225

Page No.

8-1

8-1

8-3

8-5

8-8

8-10

8-12

8-14

9-1

.

9-1

9-1

9-2

WARRANTY PROCEDURE

RETURNED PARTS POLICY

Rev. 3/1/04

GEN 040226

GEN 040227

0730S20001

O-2

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

-

PRODUCTS

olive rp rod u cts, corn

: --

COMPANY

V

. :

OL1yER®

SAFETY INSTRUCTIONS

730 Versatile Slicer

VARIOUS SAFETY DEVICES AND METHODS OF GUARDING

PROVIDED ON THIS MACHINE. IT IS ESSENTIAL HOWEVER THAT

OPERATORS AND MAINTENANCE. PERSONNEL 1.)BSERVE THE

SAFETY PRECAUTIONS. IMPROPER INSTALLATION,

OPERATION OF THIS EQUIPMENT COULD CAUSE SERIOUS INJURY

Read this manual before attempting to operate your machine. Never

untrained person to operate or service this machiñe.

Connect the machine to a properly grounded electrica supply that

requirements shown on the electrical specification plate and follow

of local electrical codes.

Disconnect and lockout the.machine from the power sùpplybeforecleaning

servicing.

Check and secure all guards before starting the machine.

Observe all caution and warning labels affixed to the machine.

Use only proper replacement parts.

Do notwear loose fitting clothing or loose hair when working

Shirt tails should be tucked in.

.

MAINTENANCE, OR

near this machine.

HAVE BEEN

FOLLOWING

matches the

all. specifications

.

THE MACHINE

OR DEATH.

allow an

or

Wear proper personal protective safety equipment.

Keep Hands away form the moving parts ofthis machine while

In addition to these general safety instructions, also follow the

instructions given for the different areas f the machine operating

.

I I

Hazardous energy source: Electricity.

DO NOT USE FOR OTHER THAN ORTG1NALLY INTENDED PURPOSE.

0730520002

it isin operation.

more specific safety

instruction manual.

1-1

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

T

OL

. PRODUCTS

oliverproduots.com

COMPANY

730 Versatile Slicer

DO NOT USE FOR OTHER THAN ORIGINALLY INTENDED

Electrics-Theory

of

Operation

Powersupply to machine is: lIme, I neutral, I ground.

Line and neutral are protected individually by fuses.

Motor is protected by thermal overlòad relay attached to contactor.

Motor is started only when

Correct power is supplied to machine

Emergency stop pushbutton released

Thermal overload relay is in reset condition

Fuses are intact and in place

*Sta,i limit switch is activated (contact dosed)

*Sta

pushbutton is momentarily depressed

j! these conditions are met;

lever iñ start position

PURPOSE.

In the event of a power failure motor will only operate after all the abòve

met. Motor will not automatically restart when power is restored.

Motor will operate until

Power supply interrupted

Fuses opened due to short circuit and/or over-current

Thermal overload relay has opened (tripped)

Stop limit switch activated (contact opened) lever in stop position

*Emergency stop pushbutton depressed

.

= requires operator action

0730S20002

jy of the following conditiöns are met.

.

conditions are

1-2

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

OLIVER

PRODUCTS V COMPANY

ollverproducts.com

730 Versatile Slicer

DECOMMISIONING STATEMENT

Please dispose of all materials as suggested in the appropriate

of this manual, and as required by your state and. local regulations.

Remember to always recycle when possible.

MSDS reports at the end

.

0730S20002

1-3

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

--

OLIVER®

PRODUCTS

oljverproducts.com

COMPANY

730 Versatile Slicer

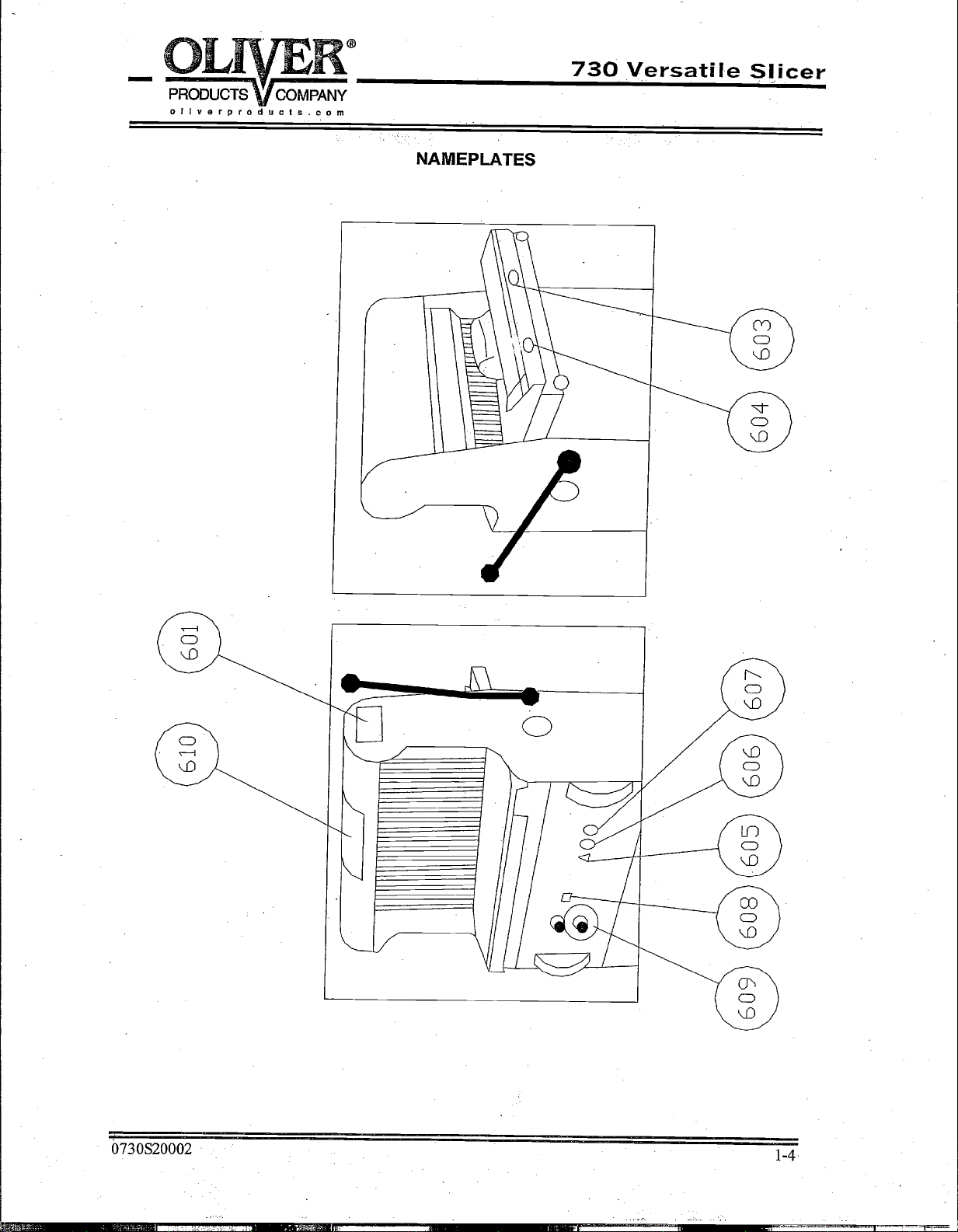

NAMEPLATES

073 0S20002

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

1-4

LflTER®

PRODUCTS

oliverproducts.com

V COMPANY

730 Versatile Slicer

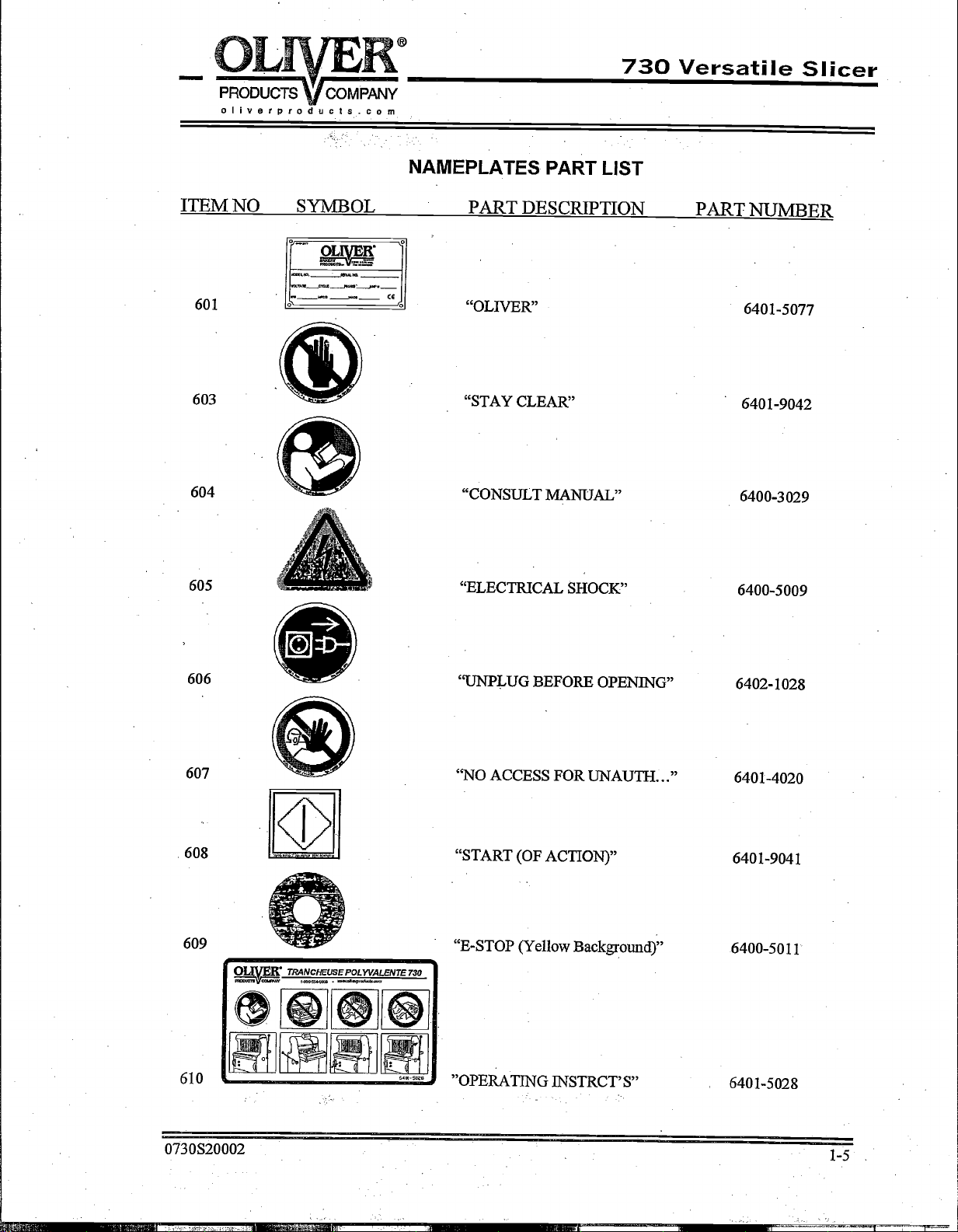

NAMEPLATES PART LIST

ITEM NO

601

603

604

605

SYMBOL

-"

Qk

-".------

PART DESCRIPTION

ce

"OLIVER"

"STAY CLEAR"

.

"CONSULT MANUAL"

"ELECTRICAL SHOCK"

PART NUMBER

6401-5077

.

6401-9042

6400-3029

6400-5009

606

607

608

609

610

OLIyER TRANCHEUSEPOLWALENTE 730

;v

.

1l

"UNPLUG BEFORE OPENiNG"

"NO ACCESS FOR UNAUTH. ."

"START (OF ACTION)"

"E-STOP (Yellow Background)"

"OPERATING 1NSTRCT'S"

6402-1028

640 1-4020

6401-9041

.6400-5011

6401-5028

0730S20002

1-5

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

OLiVER®

PRODUCTS

oliverproducts.com

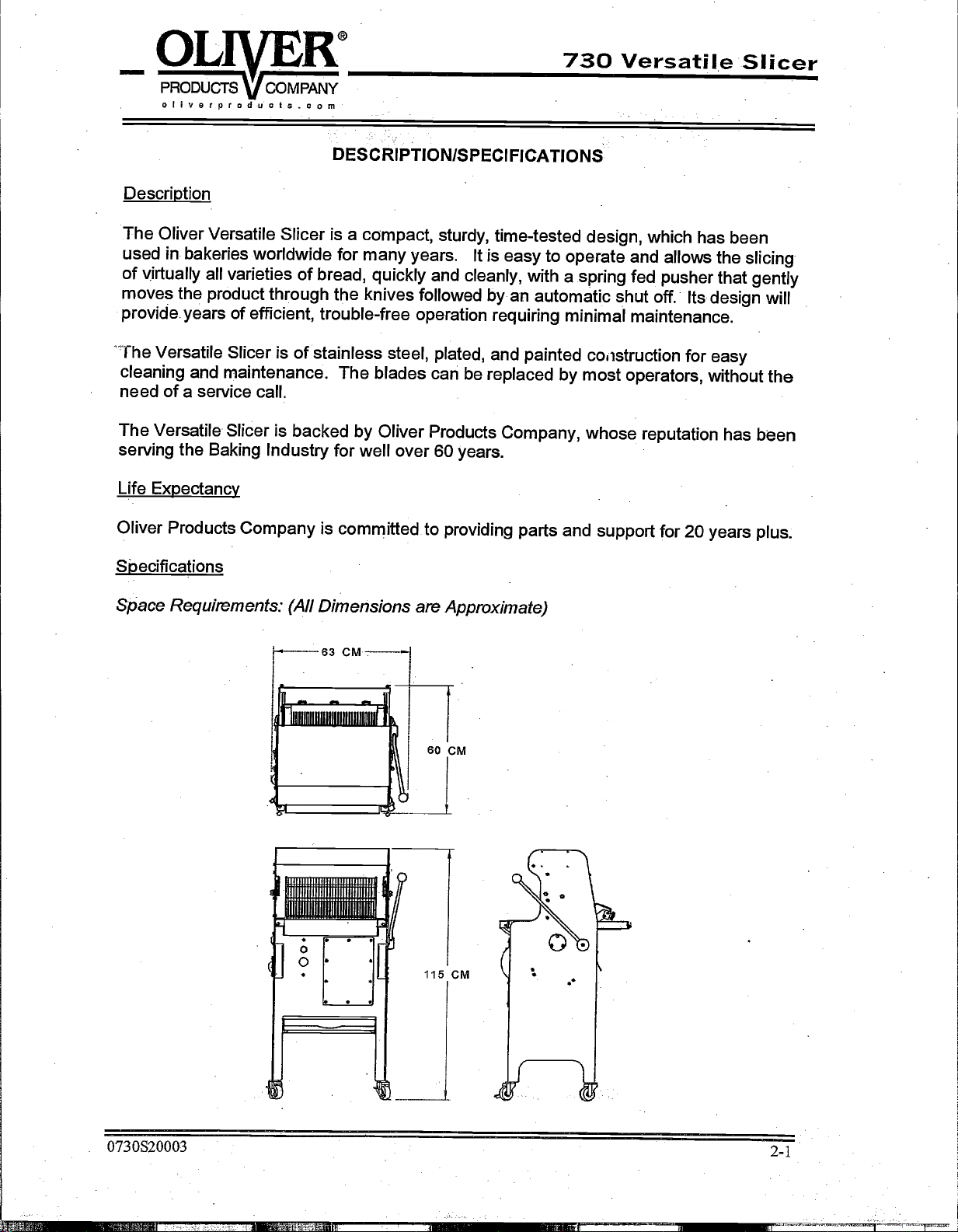

Description

The Oliver Versatile Slicer is a compact, sturdy, time-tested design, which has been

used in bakeries worldwide for many years.

of virtually all varieties of bread, quickly and cleanly, with a spring fed pusher that

moves the product through the knives followed by an automatic shut off. Itsdesign will

provide. years of efficient, trouble-free operation requiring minimal maintenance.

COMPANY

V

DESCRIPTION/SPECIFICATIONS

lt is easy to operate and allows the slicing

730 Versatile Slicer

gently

The Versatile Slicer is of stainless steel, plated, and painted coistruction for

cleaning and maintenance. The blades can be replaced by most operators, without

need of a service call.

The Versatile Slicer is backed by Oliver Products Company, whose reputation has been

serving the Baking Industry for well over 60 years.

Life Expectancy

Oliver Products Company is comrnitted.to providing parts and support for 20

Sbecificatiòns

Space Requirements: (All Dimensions are Approximate)

easy

the

years plus

IIllIII IIIIIIJIIIIIHIlIIIIJU

:!IlIJIJIIIIIIJIIIIIIII1IIIII1IIIJ

iIiliii J JIJIJJIIJJIJJI 1111111 JI

0730S20003

2-1

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

OL

PRODUCTS

oliverproducts corn

Product Capacities:

739 Versatile Slicer

COMPANY

Up to 406mm long, 267mm wide and from 90mm to 152mm

Electrical Options Available:

I phase, 50 hz, 22OVAC, 36 Amps. (.37kw motor)

Others available, cosuIt factory.

Noise Level:

72dba and 83 dbc

Standard Slice Spacings

9.5mm, 11mm, 12mm, 13mm, 14mm, 16mm, 19mm

Optional Slice Spacings (At additional cost)

Others Available consult factory.

high.

Machine Weight (Mass)

113.4kg

Shipping Weight (Mass)

136 kg

CE approved by TÜV america.

0730S20003

.

2-2

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

OL

PRODUCTS V COMPANY

W

oliverproducts.com

INSTALLATION INSTRUCTIONS

THE SLICER IS HEAVY, MUST USE TWO PEOPLE TO LIF

USE PROPER TECHNIQUE WHEN LIFTING.

KEEP BACK STRAIGHT, KNEES BENT, AND LIFT WITH LEGS.

USE GLOVES TO PROTECT HANDS.

Removing the Slicer from the Shipping Platform

730 Versatile Slicer

Lift the slicer off the shipping platform with one person on each side of the slicer.

slicer down on a level floor.

Insure power supply of 22OvoIt, 50hz, single phase.capable of at least I O

available to the machine.

For other electrics, consult féctory.

amps is

Set the

0730S20004

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

.

I: Ut

3-1

OL:

PRODUCTS

ollverproducts.com

COMPANY

V

OPERATING INSTRUCTIONS

730 Versatile Slicer

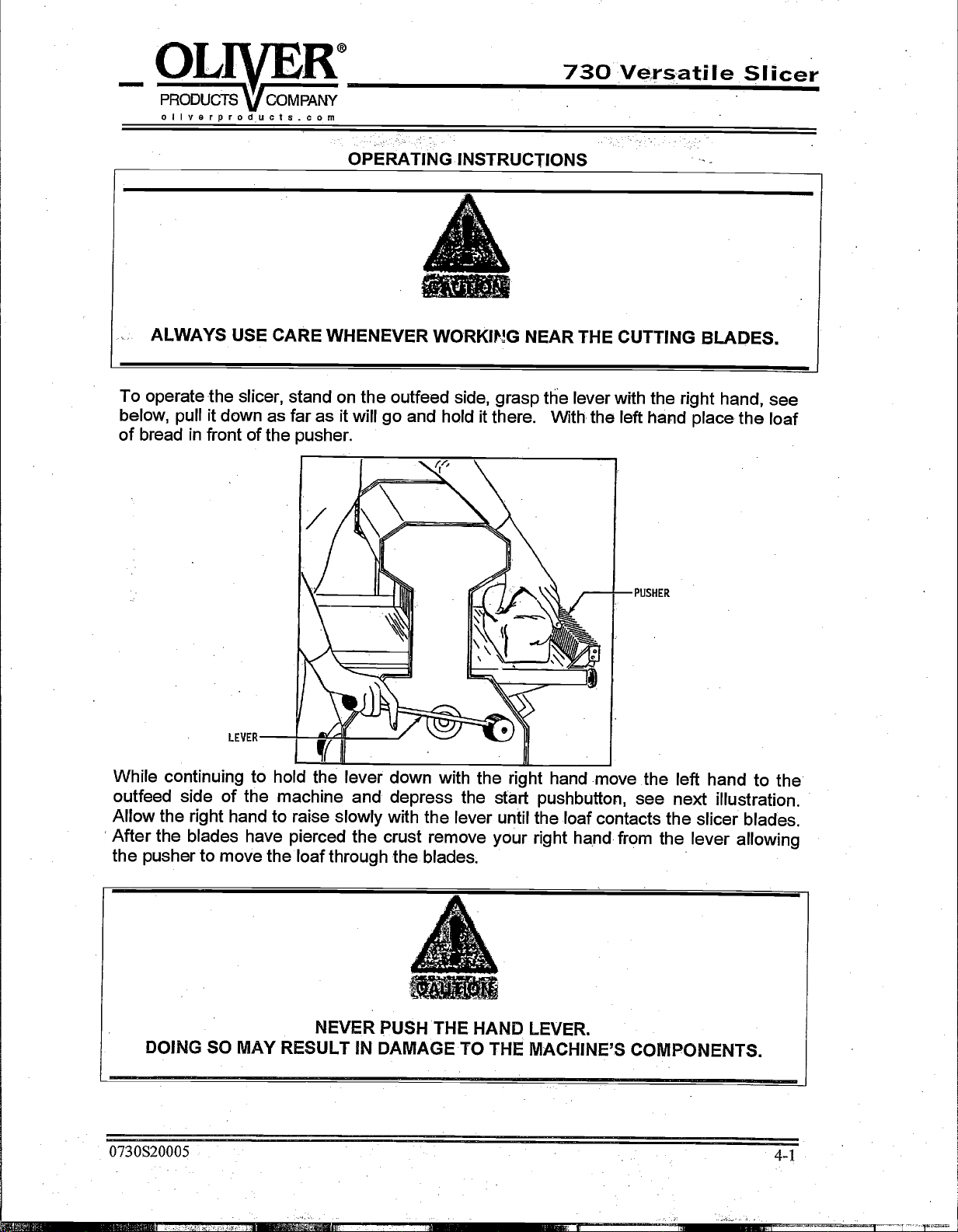

ALWAYS USE CARE WHENEVER WORKI!G NEAR THE CUTTING BLADES.

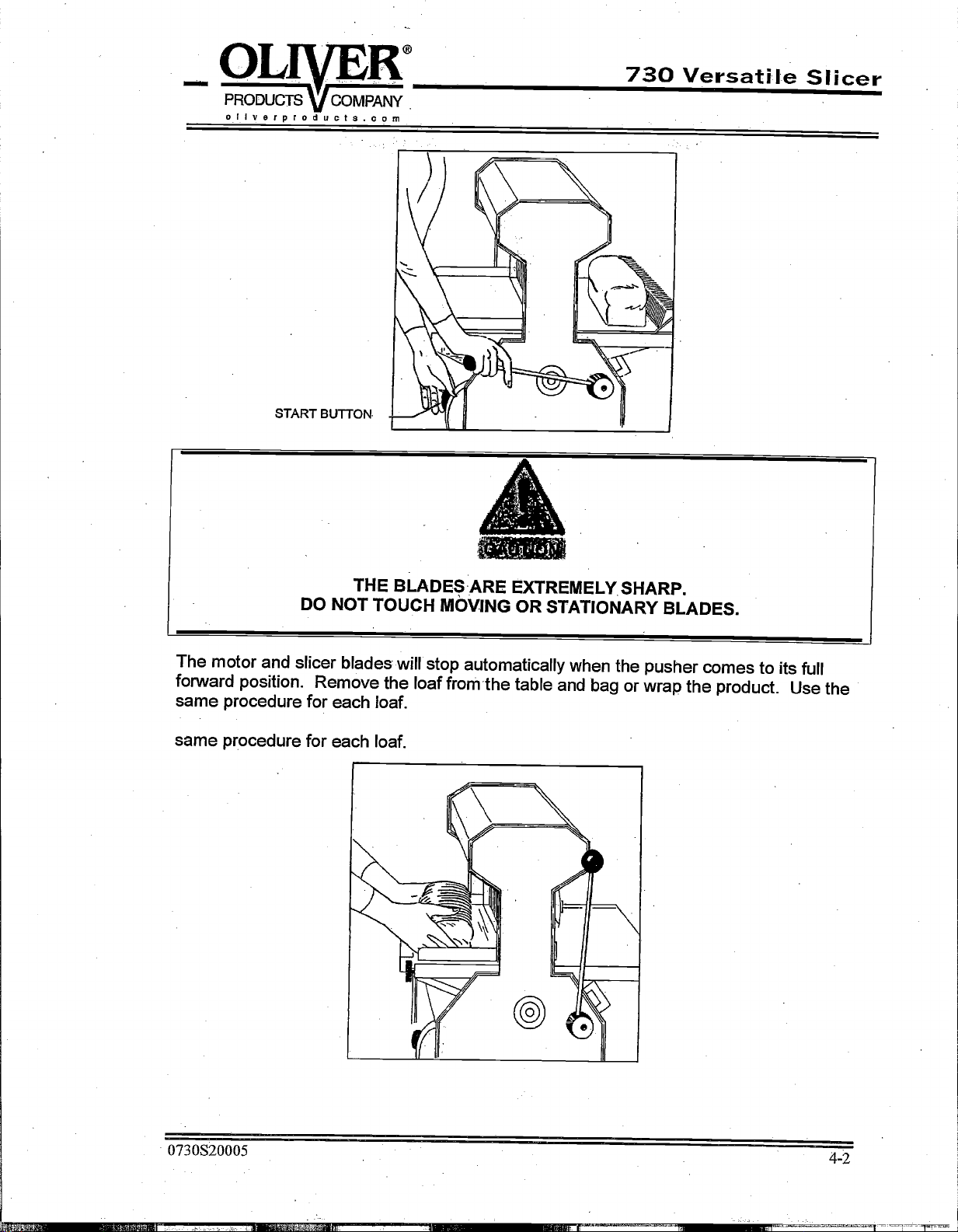

To operate the slicer, stand on the outfeed side, grasp the lever with the right hand,

see

below, pull it down as far as ¡t will go and hold it there. Wth the left hánd place the loaf

of bread in front of the pusher.

PUSHER

LEVER

While continuing to hold the lever down with the right hand move the left hand to the

outfeed side of the machine and depress the sthrt pushbutton, see next illustration.

Allow the right hand to raise slowly with the lever until the loaf contacts the slicer blades

After the blades have pierced the crust remove your right hand from the lever allowing

the pusher to move the loaf through the blades

.

NEVER PUSHTHE HAND LEVER.

DOING SO MAY RESULTIN DAMAGE TO THE MACHINE'S COMPONENTS.

0730S20005

4-1

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

s

f _4_

OL

PRODUCTS

01,1v e r p r o d u c t s .com

START BUTTON

COMPANY

V

730 Versatile Slicer

THE BLADESARE EXTREMELY SHARP.

DO NOT TOUCH MOVING OR STATIONARY BLADES.

The motor and slicer bladeswill stop automatically when the

forward position. Remove the loaf fronithe table and bag

same procedure for each loaf.

same procedure for each loaf.

pusher comes to its full

or wrap the product. Use the

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

o:

PRODUCTS V COMPANY

730 Versatile Slicer.

oliverproduets.com

TROUBLESHOOTING

ALWAYS DISCONNECT THE SLICER FROM THE POWER SUPPLY BEFORE

ATTEMPTING ANY TYPE OF MAINTENANCE TASK, INCLUDING

TROUBLESHOOTING. .

The Slicer Will Not Start (Motor Is Not Humming)

s

The machine is not plugged in.

s

There is no power at the outlet. (Check by plugging in' a small 'working appliance,

like a lamp Check to see if a circuit breaker has tripped

not tripped and the circuit is still riot working havé a qualified

circuit.)

'

'

If the circuit breaker has

Iectriciàn check the

.

There is power at the' outlet but machine still dóes not start. (Have qualified

electrician check machine fuses andor reset thermal overload relay.)

.

The start limit switch is not being made. (Adjust the start limit switch

required to correct the problem.)

The Slicer Will Not Start (Motor Is Humming)

DO NOT ALLOW THE MOTOR TO'HUM WITHOUT STARTING.

' THE MOTOR CAN BE PERMANENTLY DAMAGED BY OVERHEATING.

.

The motor has failed. (Have it checked by a qualified electrician.)

s

The drive system is binding. (Have a qualified service agent check for defective

bearings or other restrictions to free movement.)

screws as

.

There is mechanical interference between other parts ofthe slicer. (Have

service agent evaluate the machine for adjustment or replacement of defective

a qualified

parts)

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

OLiVER®

PRODUCTS V COMPANY

olive rp rod u cts .com

The Slicer Does Not Stop When Slicing is Complete

.

The stop limit switch is not being made. (Adjust the

as necessary.)

730 Versatile Slicer

stop limit switch bracket screws

The Slicer Stops Before Slicing Starts

.

The stop Iimitswitch ¡s being made too soon. (Adjust

screws as necessary.)

Bread Slices Va,y in Thickness

The blade frames are out of adjustment. (See the

manual under "Adjusting the Blade Frames When Slices Vary

to perform this adjustment.)

The Blade Frames Are Knocking

.

The blade frames are out of adjustment. (See the

manual under "Adjusting the Clearance Between the Blade

perform this adjustment.)

or ¡s Complete

"Maintenance" section of this

"Maintenance" section of this

the stop limit switch brackét

in Thickness" on how

Frames" on how to

0730S20006

5 2

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

OLiVE. W

PRODUCTS

oliverproducts.com

ALWAYS DISCONNECT THE SLICER FROM THE POWER SUPPLY BEFORE

Cleaning .

Use a mild detergent solution to clean all exterior surfaces and empty the

daily or more often if necessary Periodically remove both tables and the

and then brush, blow, (if compressed air is available), or wipe all foreign material

COMPANY

V

MAINTENANCE

ATTEMPTING ANY TYPE OF MAINTENANCE TASK.

730 Versatile Slicer

crumb tray

crumb chute

surfaces, especially from moving part.

Lubrication

Once a year, place multipurpose food machinery grease (Fuchs #fmg 387

on each of the pivot points of the plastic links at the top to the blade frames. Also,

lubricate the pusher lever and yoke pivots. All other bearings

or sealed and seldom need attention.

are either grease packed

or equivalent)

from all

Frequency of Changing the Blades

lt is VERY IMPORTANT that you replaceyour blades whenthey

cause lost production, damaged bread, and' may damage yoúr machine. Here is the

schedule we recommend for optimum slicing:

Loaves sliced per day

20 loaves

loo loaves

500 loaves

NEVER OIL OR GREASE THE MOTOR.

Blade change frequency

every 6 months

every 4 months

every month

are dull! Dull blades

.

. .

0730S20007

6-1

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

n-

OLIVER®

PRODUCTS

olive rp ro d u'ct s

COMPANY

co m

730 Versatile Slicer

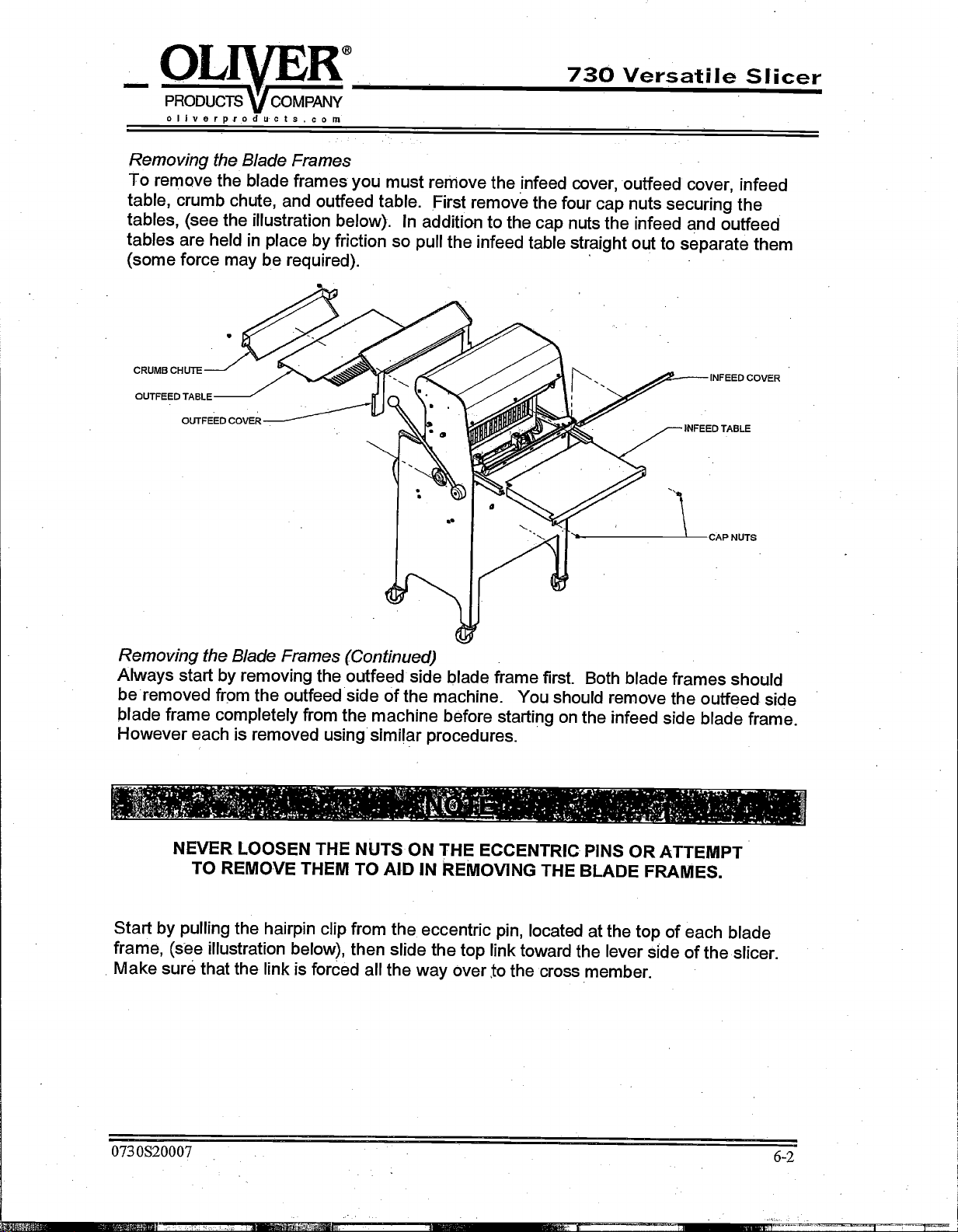

Removing the Blade Frames

To remove the b'ade frames you must remove the infeed

tabte, crumb chute, and outfeed table. First remove the four

cover, outfeed cover, infeed

cap nuts securing the

tables, (see the illustration below). In addition to the cap nuts the infeed and. outfeed

tables are held in place by friction so pull the infeed table straight out to separate

(some force may be required).

.

them

CRUMB CHUTE

OUTFEED TABLE

OUTFEED COVER

INFEED COVER

INFEED TABLE

CAP NUTS

Removing the Blade Frames (Continued)

Always start by removing the outfeed side blade frame first. Both blade frames

beremoved from the outfeed side of the machine. You should

remove the outféed side

should

blade frame completely from the machine before starting on the infeed side blade frame.

However each is removed using similar procedures.

s

NEVER LOOSEN THE NUTSON THE ECCENTRIC PINS OR ATTEMPT

TO REMOVE THEM TO AID IN REMOVING THE BLADE FRAMES.

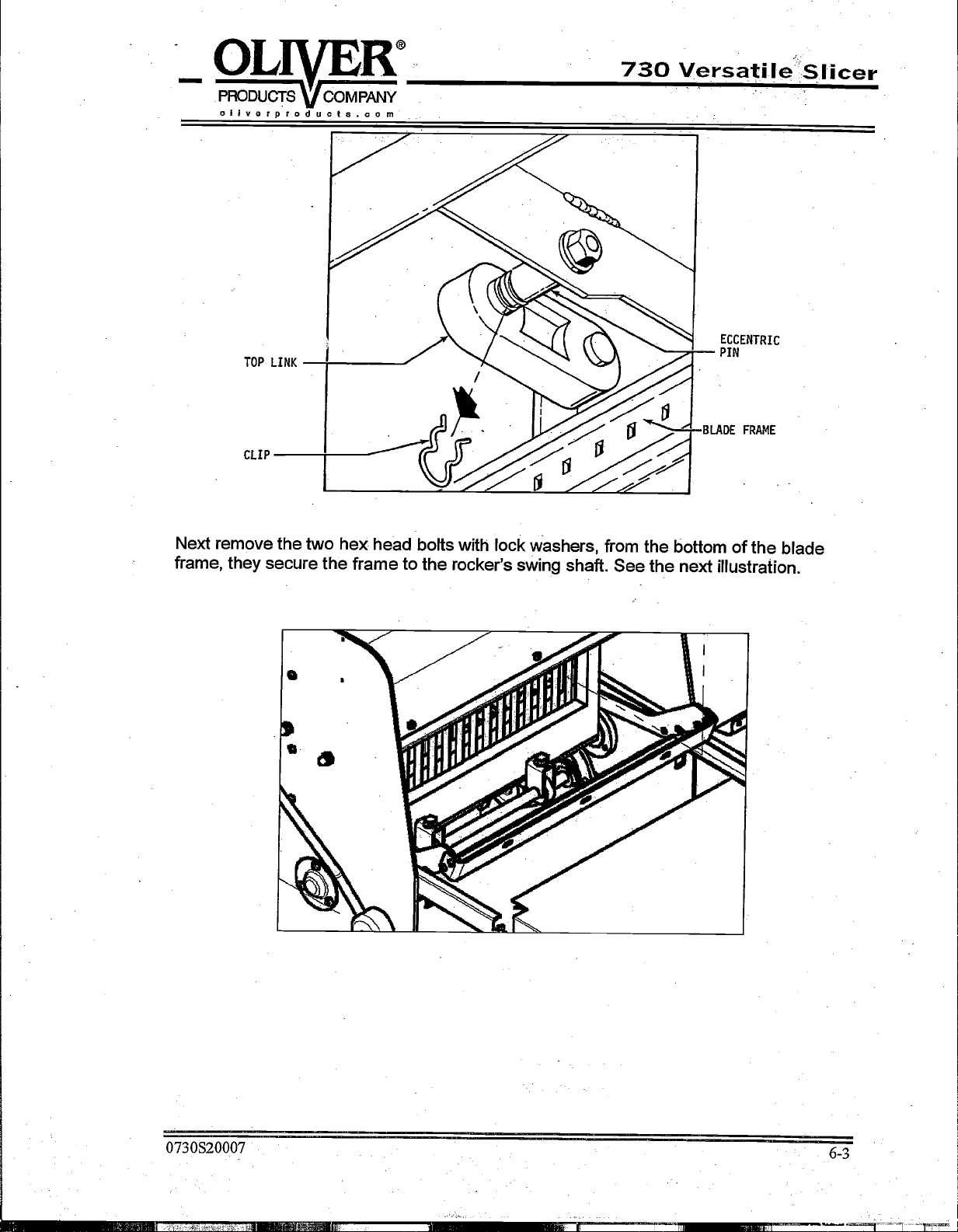

Start by pulling the hairpin clip from the eccentric pin, located at the top of each

frame, (See illustration below, then slide the top link toward the lever sIde

.

Make suré that the link is forced all the way over Ño the cross member.

0730S20007

blade

of the slicer.

6-2

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

OL

PRODUCTS V COMPANY

oHverproducts.com

Top. LINK

CLIP

730 Versatile Slicer

ECCENTRIC

PIN

rr "---BLADE FRAME

>.

Next remove the two hex head bolts with lock washers, from the bottom of the

frame, they secure the frame to the rocker's swing shaft. See the next illustration.

blade

0730S20007

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

6-3

PRODUCTS

o I. Ive r p r o d u c ts .-c orn

COMPANY

V

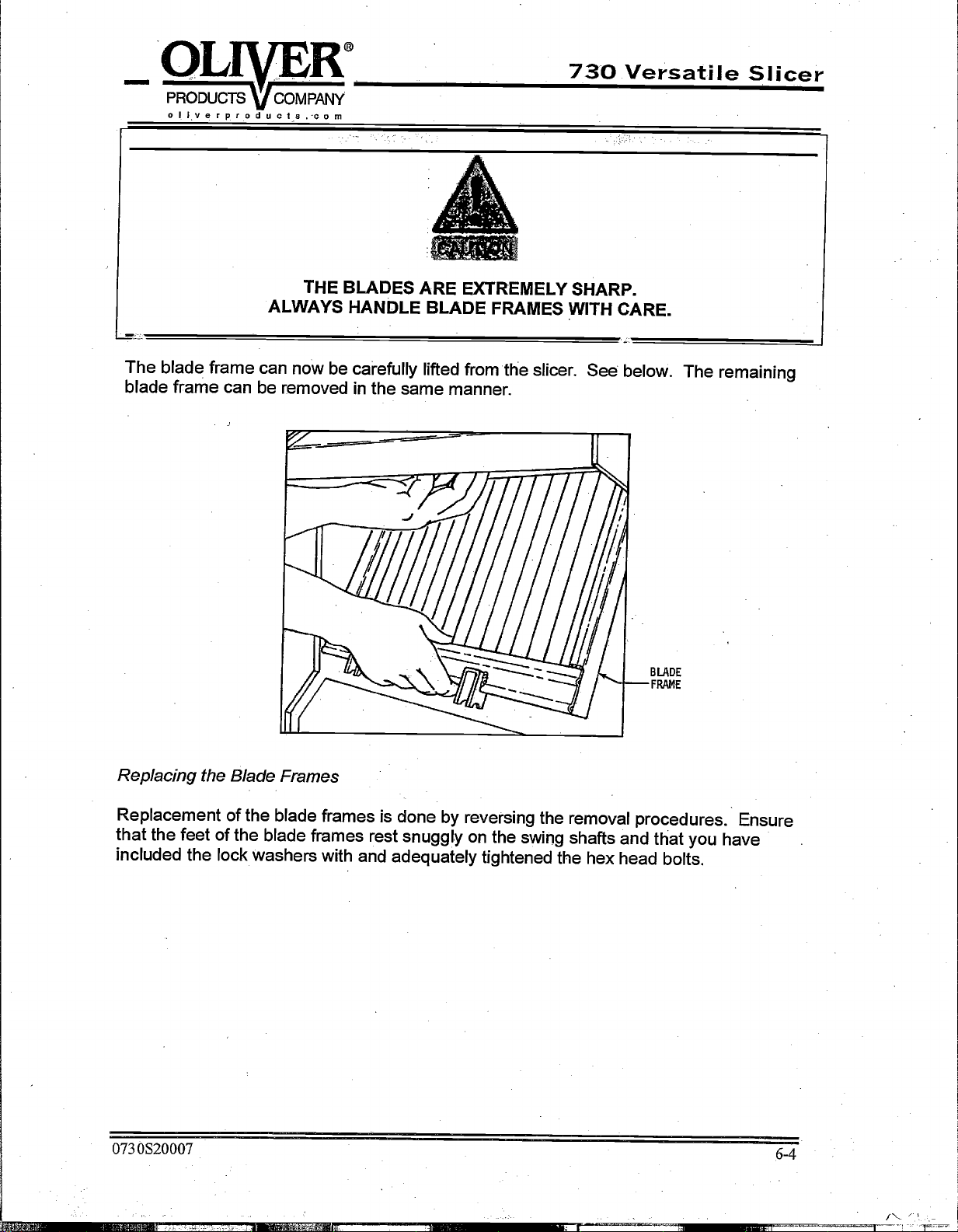

THE BLADES ARE EXTREMELY SHARP.

ALWAYS HANÓLE BLADE FRAMES WITH CARE.

730 Versatile Slicer

The blade frame can now be carefully lifted fromthe slicer. See below. The

blade frame can be removed in the same manner.

BLADE

FRANE

Replacing the Blade Frames

Replacement of the blade frames is done by reversing the removal

that the feet of the blade frames rest snuggIy on the swing shafts and that

procedures. Ensure

you have

included the lockwashers with and adequately tightened the hex head bolts.

remaining

0730S20007

6-4

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

OL

PRODUCTS

o I

i V e r p r od u c t s

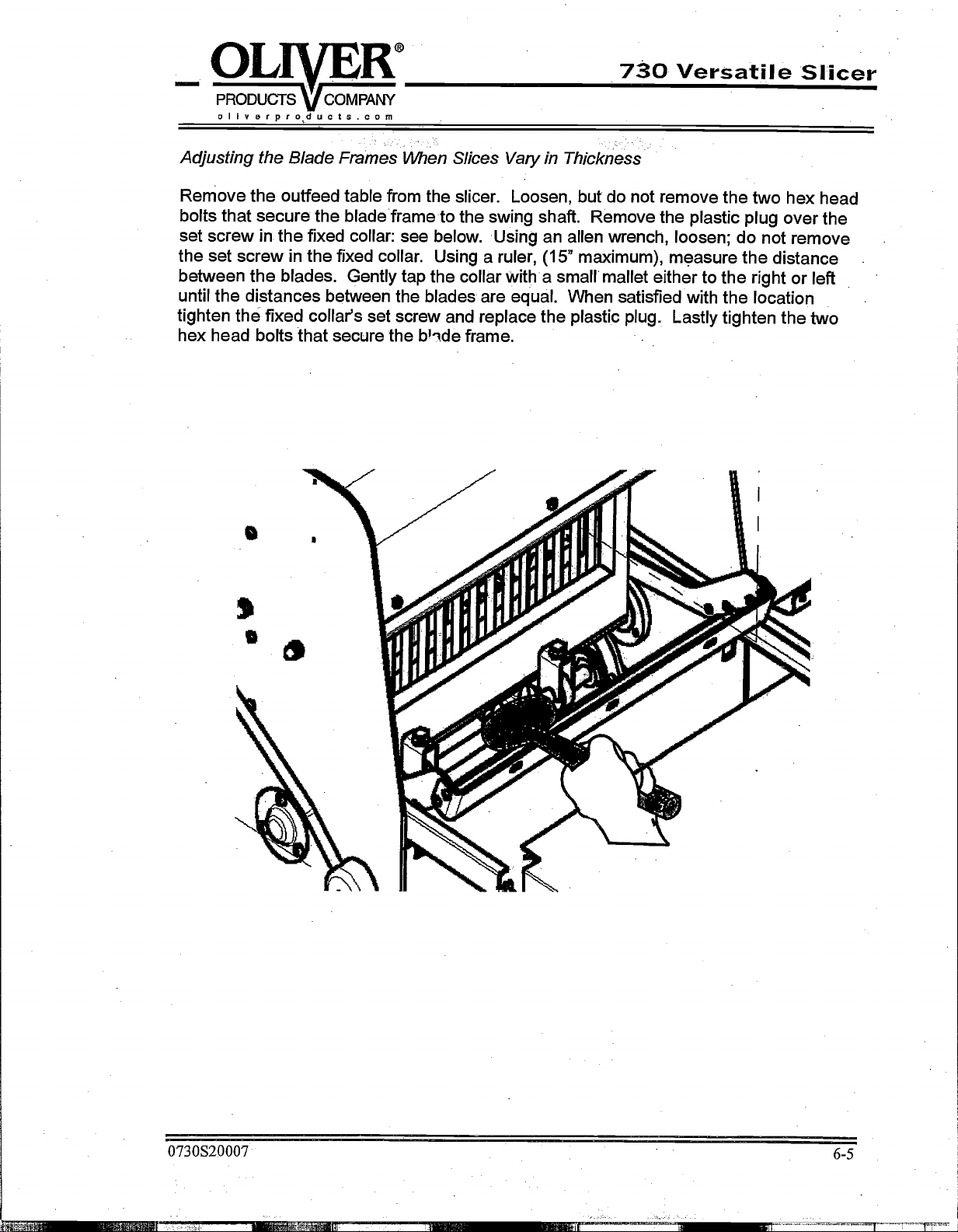

Adjusting the Blade Frames When Slices Vary in Thickness

Remove the outfeed table from the slicer. Loosen, but do not remove the two hex head

bolts that secure the blade frameto the swing shaft. Remove the plastic plug over the

set screw in the fixed collar: see below. Using an allen wrench, loosen; do not remove

the set screw in the fixed collar. Using a ruler, (15" maximum), measure the distance

between the blades. Gently tap the collar with a small mallet either to the right or left

until the distances between the blades are equâl. When satisfied with the location

tighten thé fixed collar's set screw and replace the plastic plug. Lastly tighten the two

hex head bolts that secure the bide frame.

COMPANY

V

. o orn

730 Versatile Slicer

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

PRODUCTS V COMPANY

oliverproduct.com

Changing

the Blades

730 Versatile Slicer

THE BLADES ARE EXTREMELY SHARP. ALWAYS HANDLE THEM WITH

DO NOT INTERCHANGE THE TWO BLADE FRAMES. REPLACE THE

FRAME TO THE SAME SIDE OF THE MACHINE AS IT WAS TAKEN FROM

WHEN CHAINGING BLADES FIRST NOTE THE DIRECTION THE SHARPENED

f EDGESÄ:REFAÒING

FRAME AND DOWNON THE OTHER. DO NOT CHANGE THIS DIRECTION.

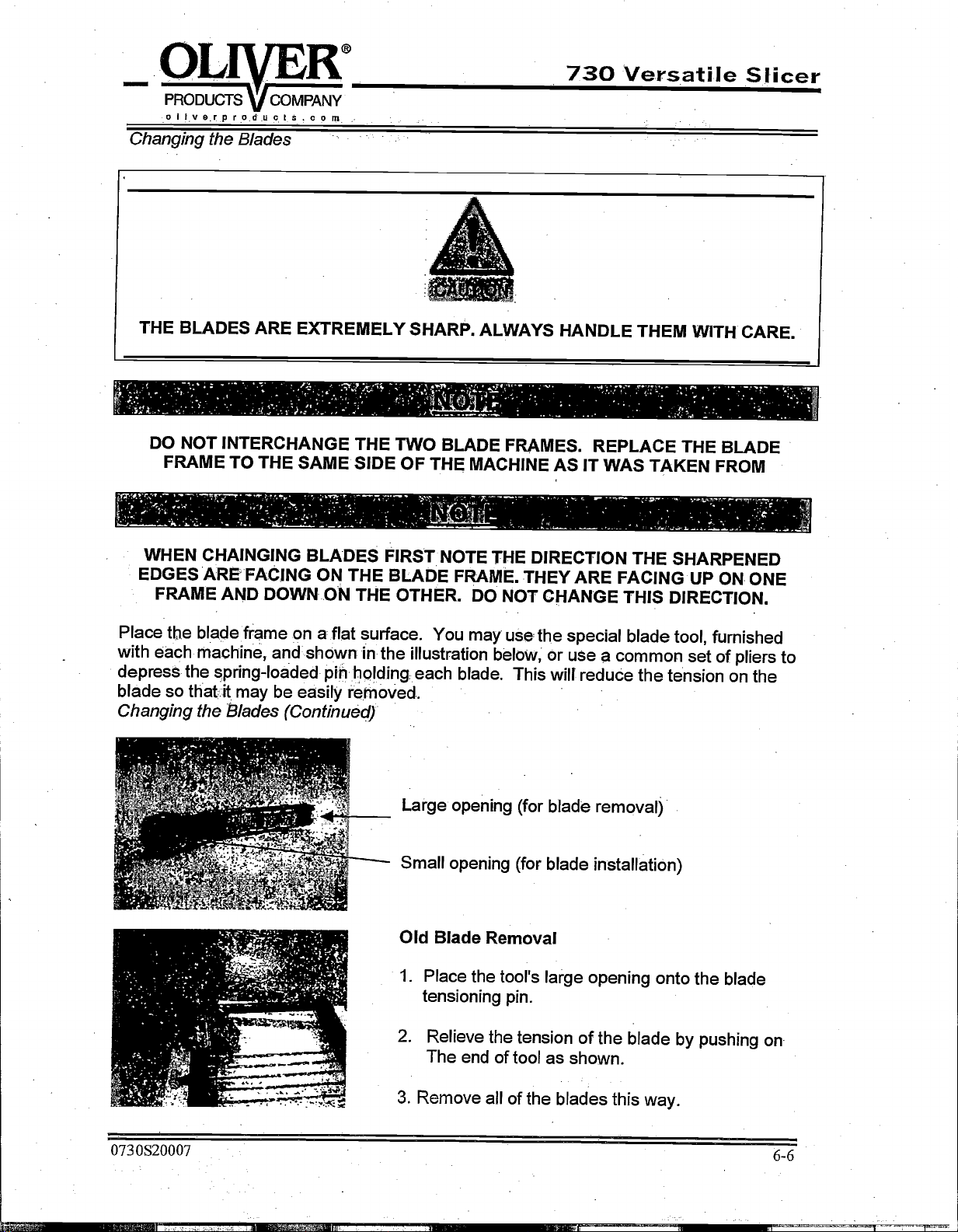

Place the blade frame on a flat surface. You may usethe special blade tool, furnished

with each machine, and shöwn: in the illustration below,'

depress the spring-loaded pin holding each blade This will reduce the tension

blade so that it may be easily removed

Changing the Blades (Continuèd)

ON THE BLADE FRAME. THEYARE FACINGUP ON ONE

or use a common set of pliers to

CARE.

BLADE

on the

Large opening (for blade removal)

Small opening (for blade installätiön)

Old Blade Removal

I.

Place the tool's large opening onto the blade

tensioning pin.

Relieve the tension of the blade by pushing

The end of tool as shown.

on

'$'

Remove all ofthe blades this way.

0730S20007

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

6-6

PRODUCTS

COMPANY

oHverproducts.com

730 Versatile Slicer

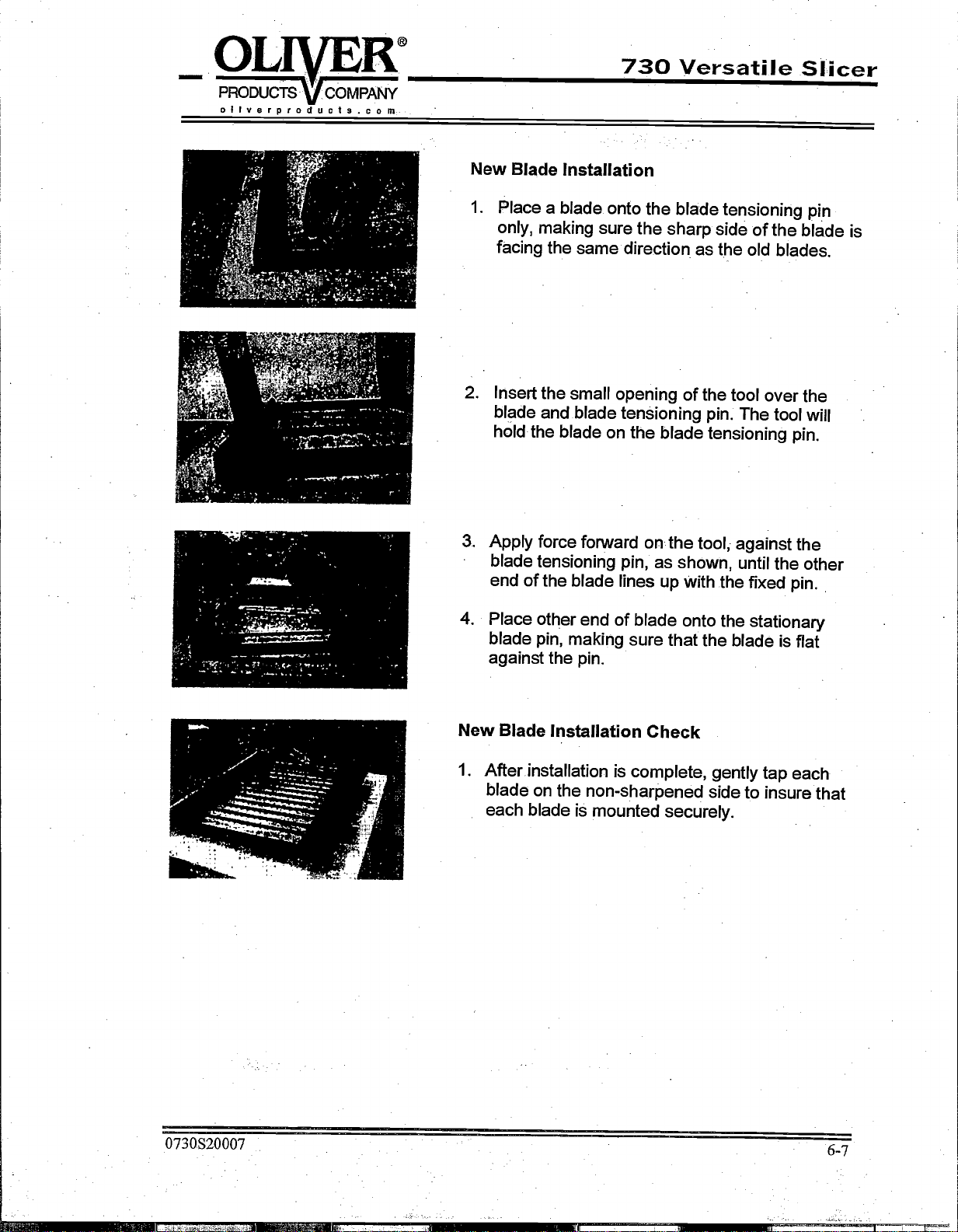

New Blade Installation

I

.

Place a blade. onto the blade tensioning pin

only, making sure the sharp side of the blade is

facing the same direction as the old blades.

Insert the small opening of the tool over the

blade and blade tensioning pin The tOol will

holdthe blade on the blade tensioning pin.

Apply force forward onthe tool, against the

.

blade tensioning pin, as shbwn, until the other

end of the blade lines up with the fixed pin.

Place other end of blade onto the stationary

blade pin, making sure that the blade is flat

against the pin.

New Blade Installation Check

I.

After.installation is complete, gently tap each

blade on the non-sharpened side to insure that

each blade is mounted securely.

0730S20007

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

iJ;Li

.:

j

OLIVER®

PRODUCTS V COMPANY

o I

¡ V e r p r o d u c t

s .

C o m

730 Versatile Slicer

WHEN REPLACING ALL THE BLADES, ALWAYS REMOVE THE CENTER

FIRST AND WORK TOWARD THE ENDS. INSTALL THE NW BLADES

ENDS FIRST AND WORK ALTERNATELY TOWARD THE CENTER.

NEVER PUT BLADE FRAMES IN THE SLICER WITHOUT BLADES.

BLADES

AT THE

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Loading...

Loading...